Vanadium-phosphorus-zirconium-titanium composite oxide catalyst for synthesising acrylic acid (ester) as well as preparation method and application of vanadium-phosphorus-zirconium-titanium composite oxide catalyst

A technology of composite oxides and catalysts, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, and catalysts for physical/chemical processes. Stability, excellent conversion rate, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

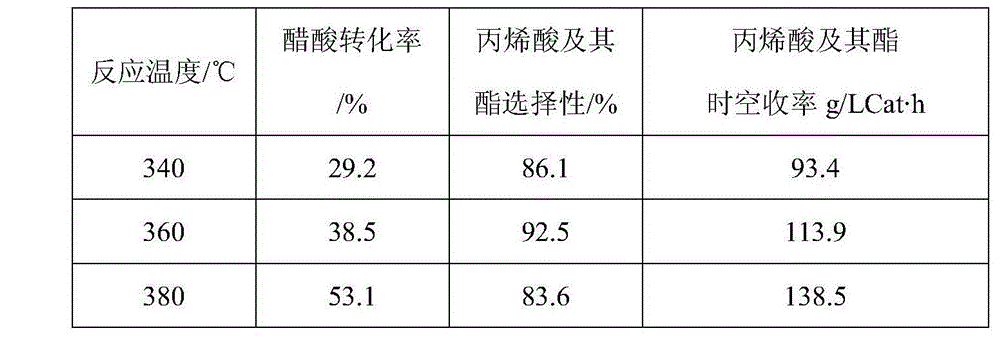

Image

Examples

Embodiment 1

[0028] (1) Carrier modification: Titanium dioxide is used as the carrier, and B and Ce oxides are used as modification aids.

[0029] Take boric acid 2.3g (accounting for 3% of carrier weight in boron oxide), cerium nitrate hexahydrate 4.3g (accounting for 4% of carrier weight in cerium oxide) adds deionized water 35g preparation solution, then weighs 40gTiO 2The powder was added to the prepared solution, soaked at room temperature for 4 hours, then dried at 100°C for 5 hours, and then put into a muffle furnace and roasted at 500°C for 4 hours to obtain a modified carrier.

[0030] (2) Preparation of vanadium phosphorus zirconium titanium composite sol

[0031] Take 42.5g of butyl titanate, dissolve it in 80ml of absolute ethanol, add a small amount of deionized water and glacial acetic acid, then weigh 7.1g of zirconium nitrate and add it, stir evenly to obtain a titanium-zirconium sol, and then take 100ml of 8mol / L Phosphoric acid solution was slowly added to the mixed sol,...

Embodiment 2

[0034] (1) Carrier modification: HZSM-5 is used as the carrier, and B, Ce, and La oxides are used as modification aids.

[0035] Take boric acid 1.9g (accounting for 3% of carrier weight in boron oxide), 3.5g of cerium nitrate hexahydrate (accounting for 4% of carrier weight in cerium oxide), lanthanum nitrate 1.9g (accounting for lanthanum oxide, accounting for 2% of the total weight of the carrier) plus 30 g of deionized water to prepare a solution, then weigh 32 g of HZSM-5 molecular sieve powder, add it to the prepared solution, soak it at room temperature for 4 hours, then dry it at 100 ° C for 5 hours, and then put it into the muffle Calcined in a furnace at 500°C for 4h to obtain a modified carrier.

[0036] (2) Preparation of vanadium phosphorus zirconium titanium composite sol

[0037] Take 70.8g of butyl titanate, dissolve it in 120ml of absolute ethanol, add a small amount of deionized water and glacial acetic acid, then weigh 28.3g of zirconium nitrate and add it,...

Embodiment 3

[0040] (1) Carrier modification: TiO 2 , SiO 2 as the carrier, Al, Ce, La oxides as modification aids.

[0041] Take by weighing aluminum nitrate 15.4g (in terms of aluminum oxide, account for 6% of the weight of the carrier), 4.4g of cerium nitrate hexahydrate (in terms of cerium oxide, account for 5% of the weight of the carrier), 1.9g of lanthanum nitrate (in terms of lanthanum oxide, Accounting for 2% of the total weight of the carrier) add 40g of deionized water to prepare the solution, then weigh 20gTiO 2 and 10gSiO 2 The powder was added to the prepared solution, soaked at room temperature for 4 hours, then dried at 100°C for 5 hours, and then put into a muffle furnace and roasted at 500°C for 4 hours to obtain a modified carrier.

[0042] (2) Preparation of vanadium phosphorus zirconium titanium composite sol

[0043] Take 81.6g of butyl titanate, dissolve it in 120ml of absolute ethanol, add a small amount of deionized water and glacial acetic acid, then weigh 47....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com