Patents

Literature

2256 results about "Lanthanum oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum oxide, also known as lanthana, chemical formula La₂O₃, is an inorganic compound containing the rare earth element lanthanum and oxygen. It is used in some ferroelectric materials, as a component of optical materials, and is a feedstock for certain catalysts, among other uses.

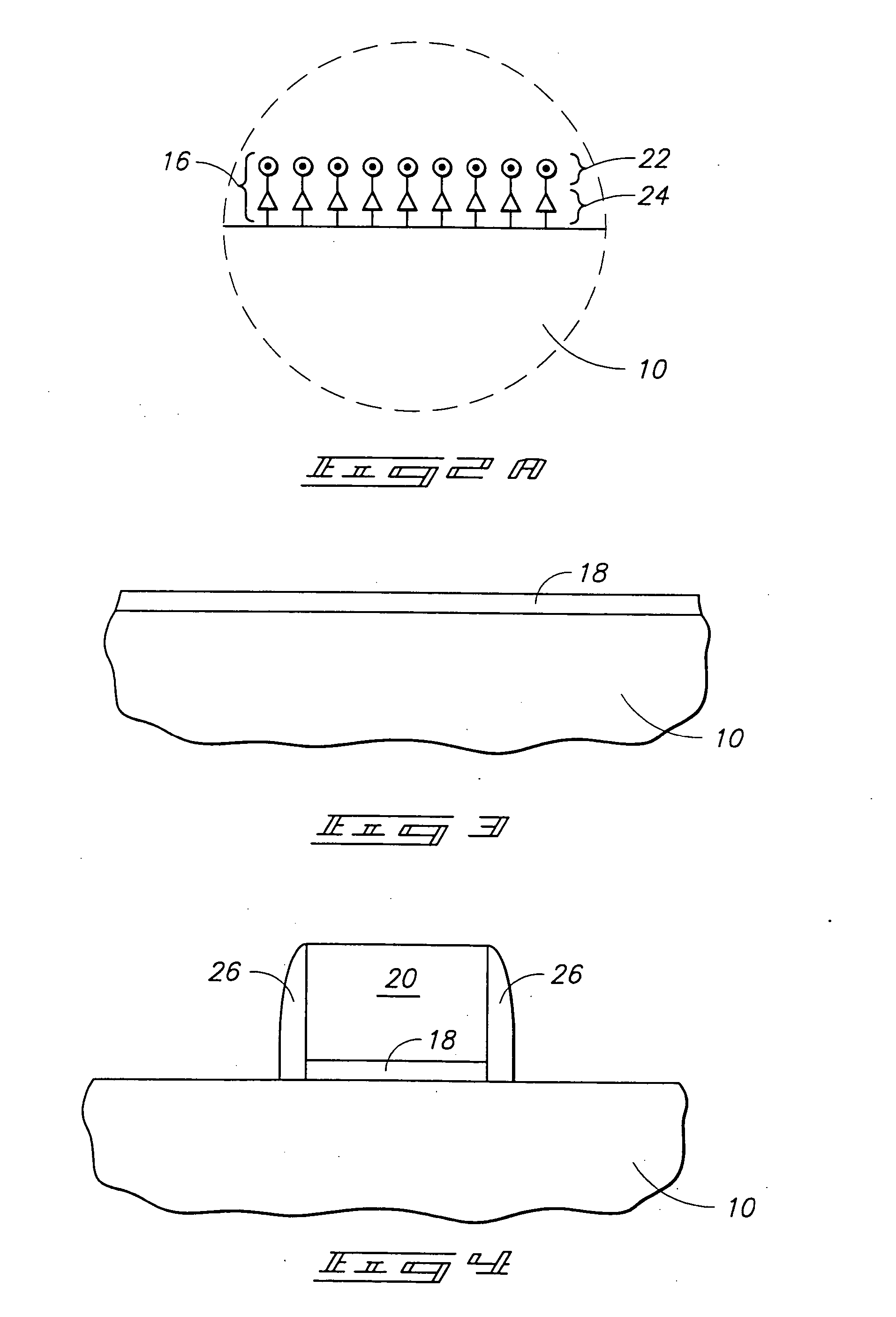

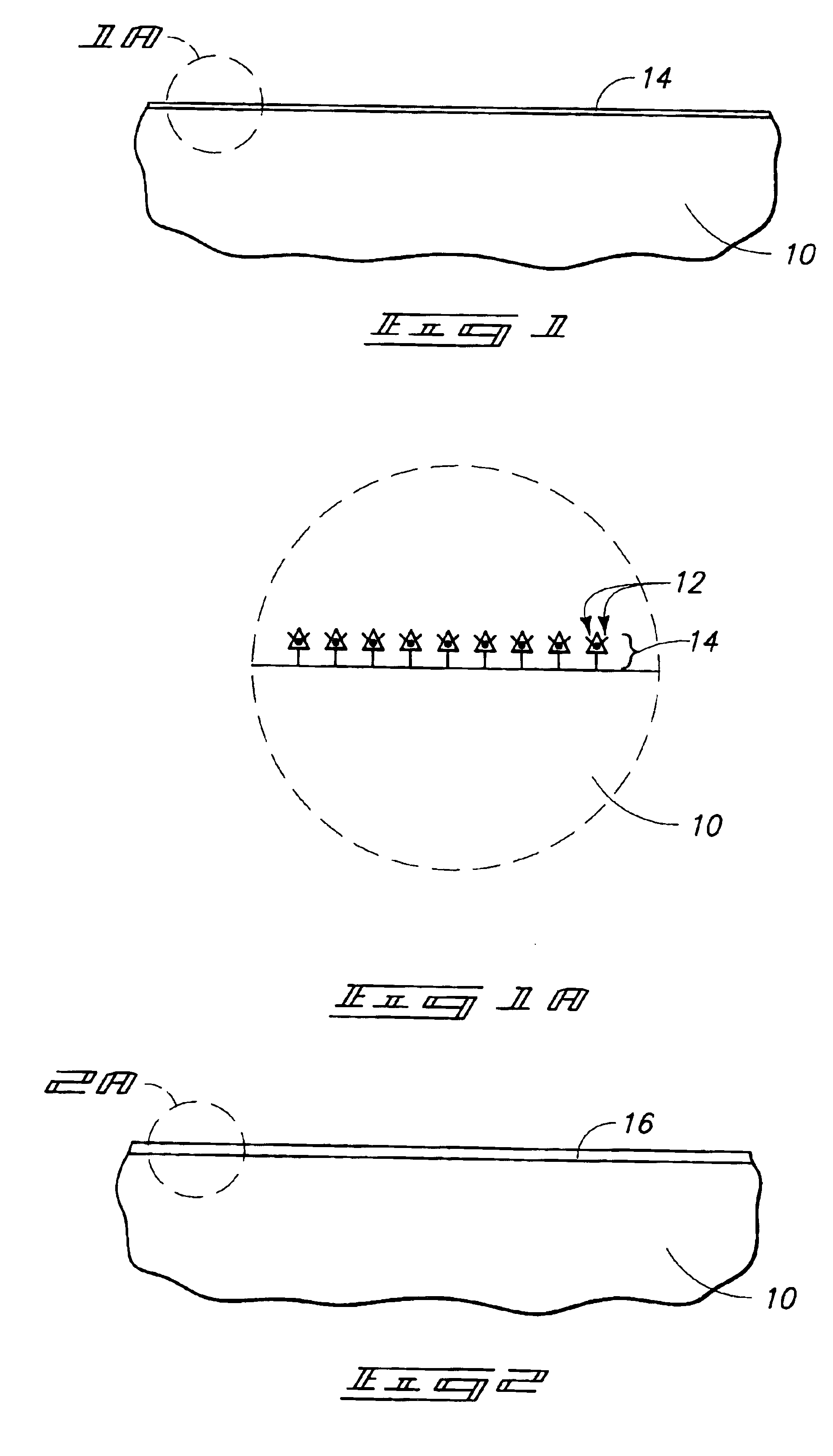

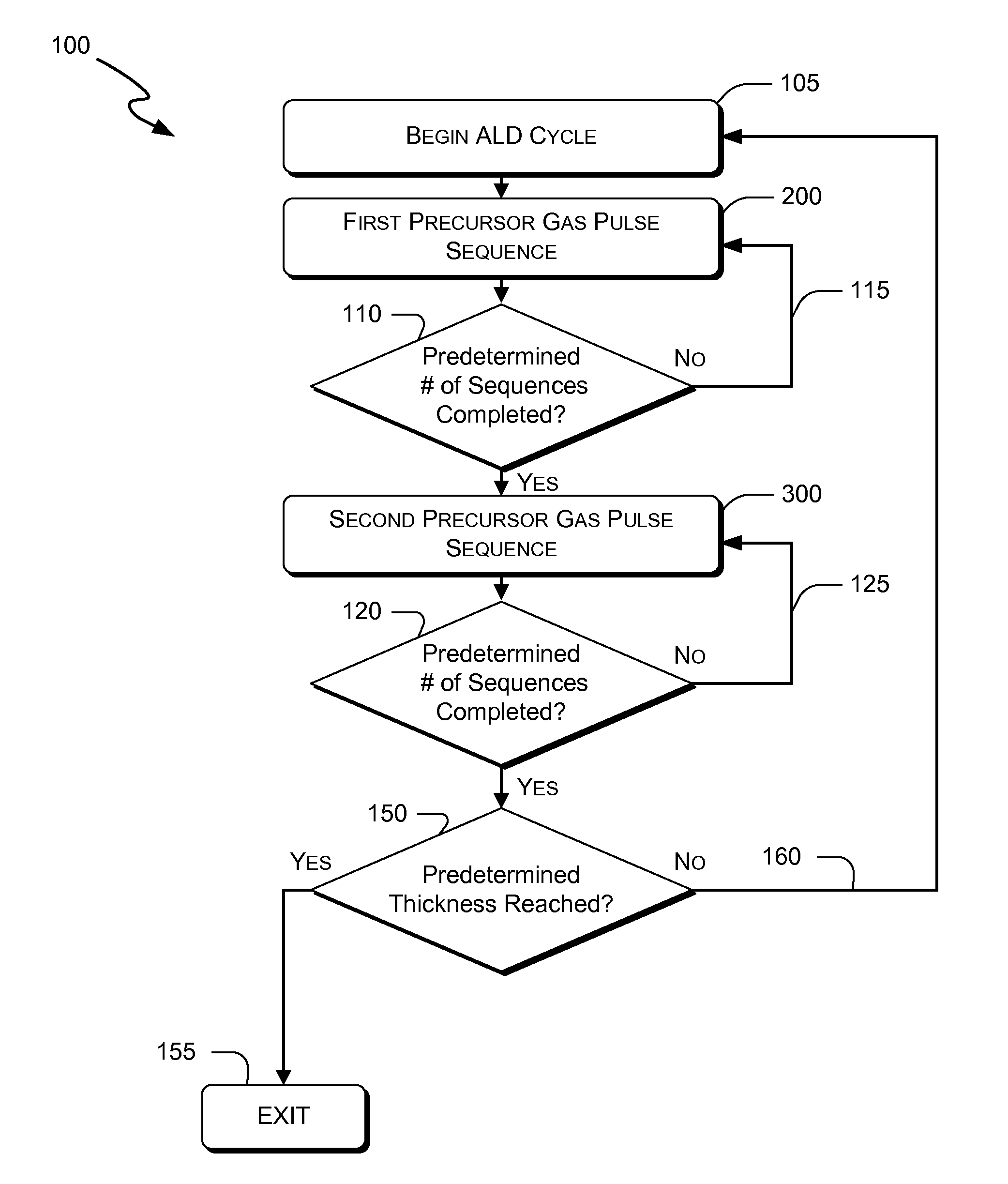

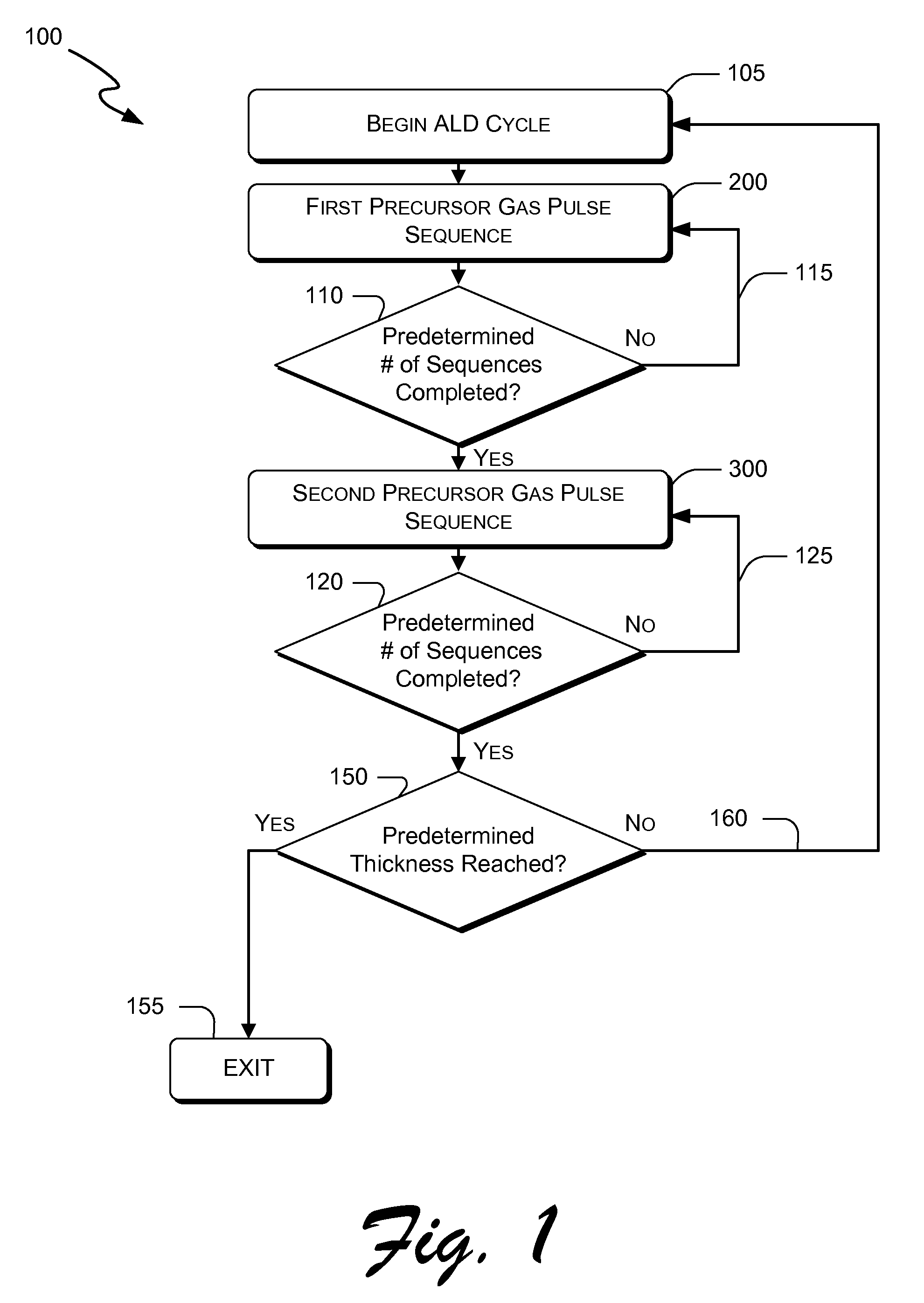

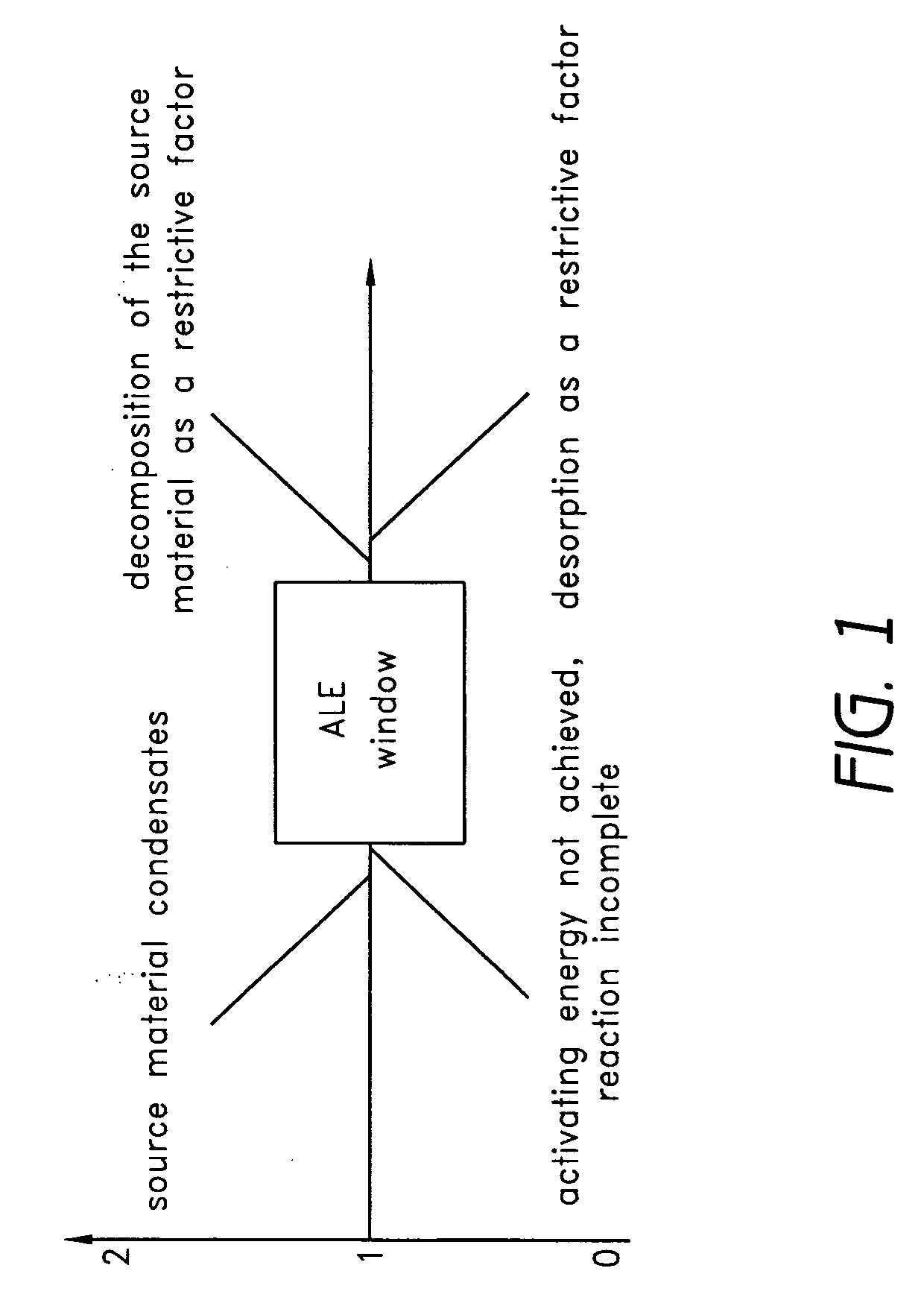

Apparatuses and methods for atomic layer deposition of hafnium-containing high-k dielectric materials

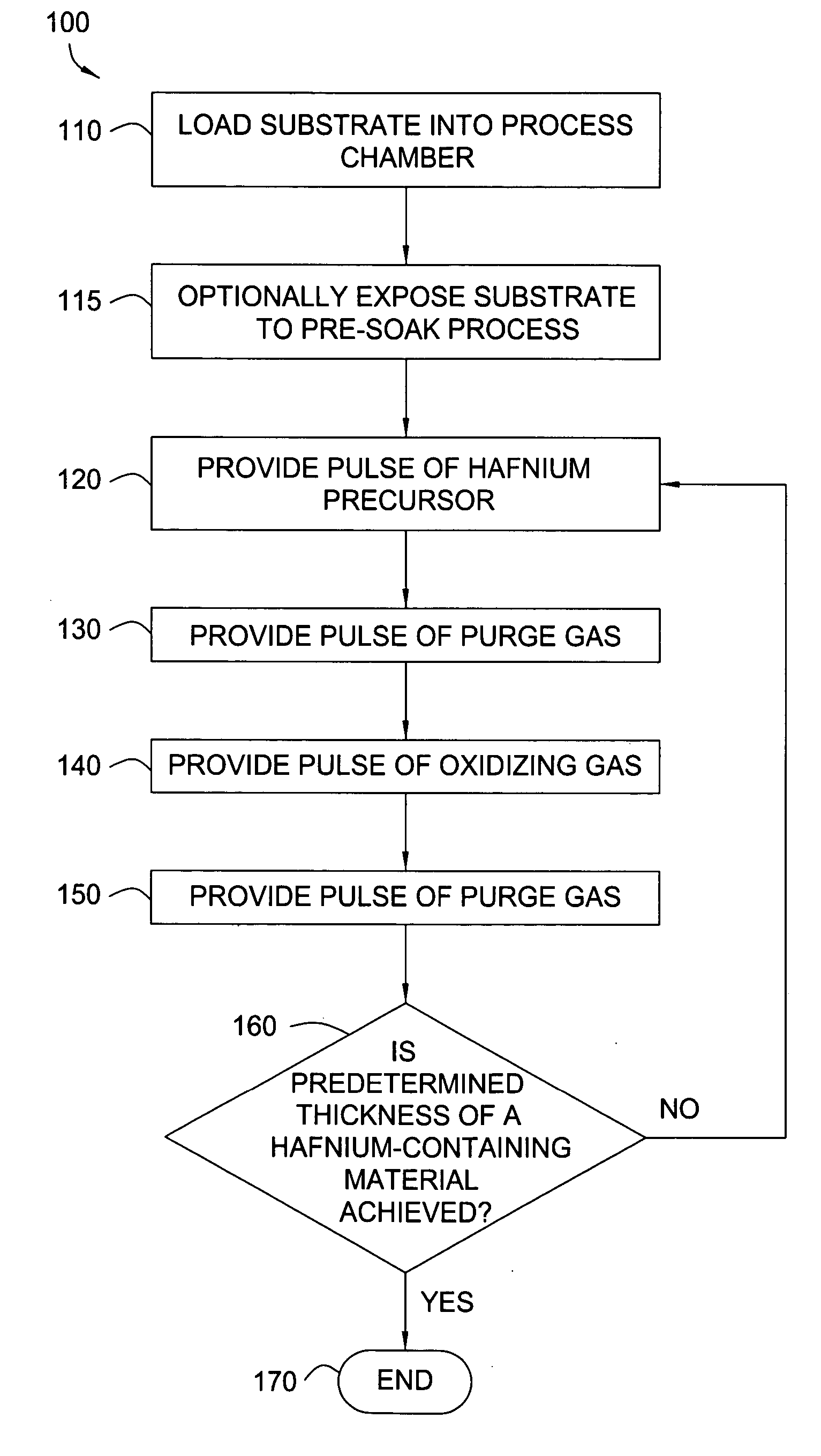

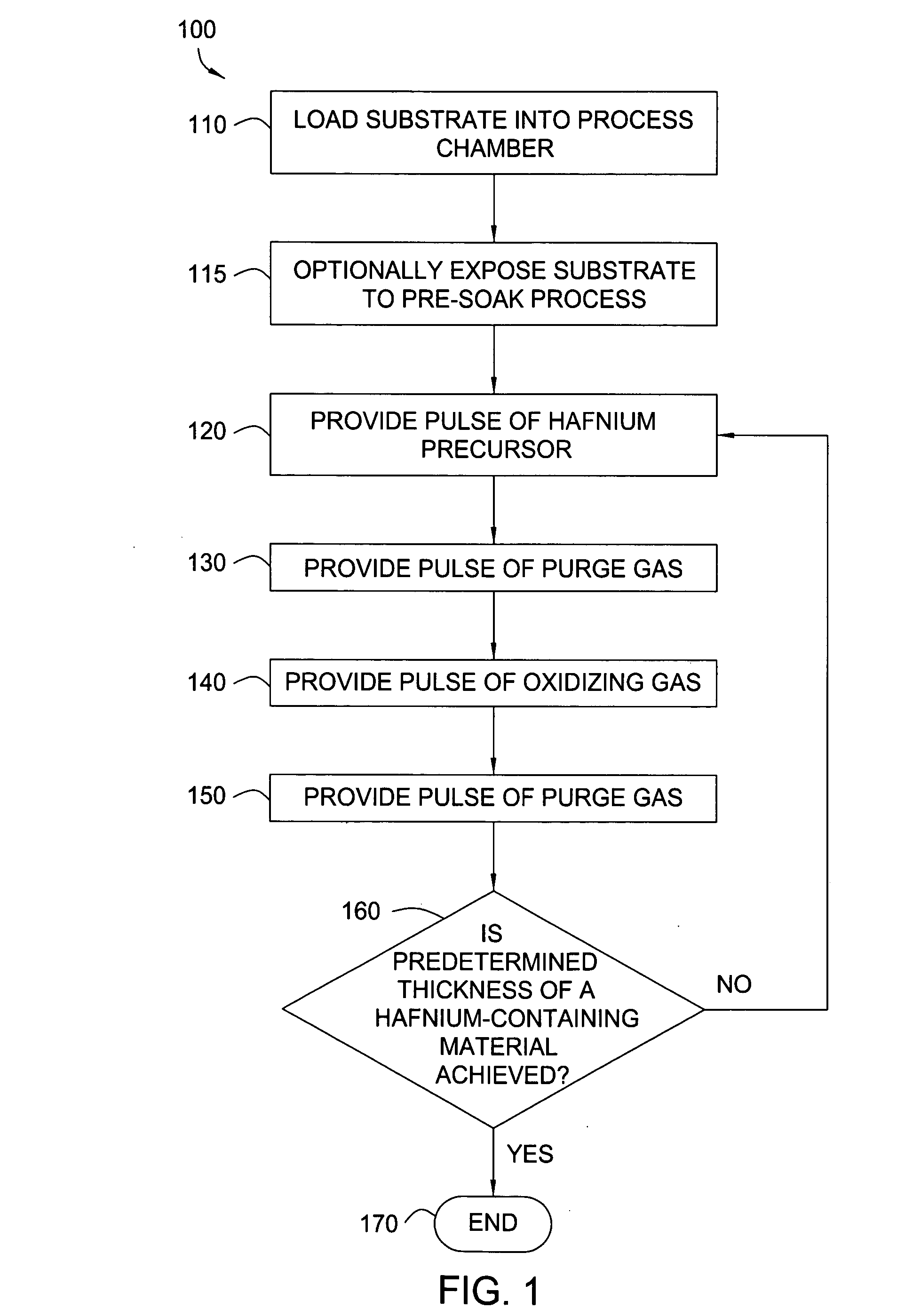

InactiveUS20050271813A1Steam generation heating methodsDecorative surface effectsGas phaseWater vapor

Embodiments of the invention provide methods for depositing dielectric materials on substrates during vapor deposition processes, such as atomic layer deposition (ALD). In one example, a method includes sequentially exposing a substrate to a hafnium precursor and an oxidizing gas to deposit a hafnium oxide material thereon. In another example, a hafnium silicate material is deposited by sequentially exposing a substrate to the oxidizing gas and a process gas containing a hafnium precursor and a silicon precursor. The oxidizing gas usually contains water vapor formed by flowing a hydrogen source gas and an oxygen source gas through a water vapor generator. In another example, a method includes sequentially exposing a substrate to the oxidizing gas and at least one precursor to deposit hafnium oxide, zirconium oxide, lanthanum oxide, tantalum oxide, titanium oxide, aluminum oxide, silicon oxide, aluminates thereof, silicates thereof, derivatives thereof or combinations thereof.

Owner:APPLIED MATERIALS INC

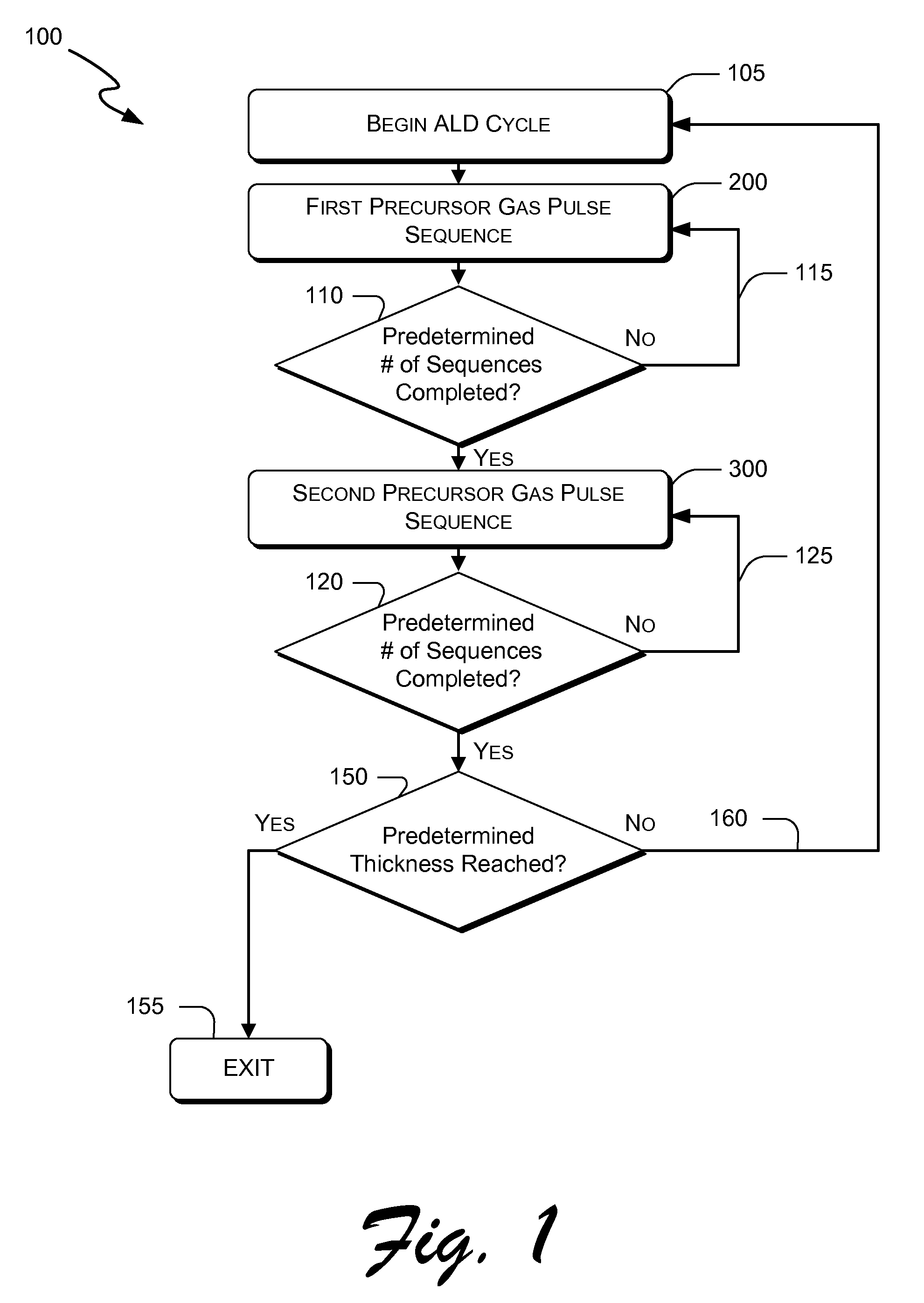

Atomic layer deposition of hafnium lanthanum oxides

There is provided an improved method for depositing thin films using precursors to deposit binary oxides by atomic layer deposition (ALD) techniques. Also disclosed is an ALD method for depositing a high-k dielectric such as hafnium lanthanum oxide (HfLaO) on a substrate. Embodiments of the present invention utilize a combination of ALD precursor elements and cycles to deposit a film with desired physical and electrical characteristics. Electronic components and systems that integrate devices fabricated with methods consistent with the present invention are also disclosed.

Owner:ASM IP HLDG BV

Composite dielectric forming methods and composite dielectrics

InactiveUS20050009370A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricCapacitor

A composite dielectric forming method includes atomic layer depositing alternate layers of hafnium oxide and lanthanum oxide over a substrate. The hafnium oxide can be thermally stable, crystalline hafnium oxide and the lanthanum oxide can be thermally stable, crystalline lanthanum oxide. A transistor may comprise the composite dielectric as a gate dielectric. A capacitor may comprise the composite dielectric as a capacitor dielectric.

Owner:MICRON TECH INC

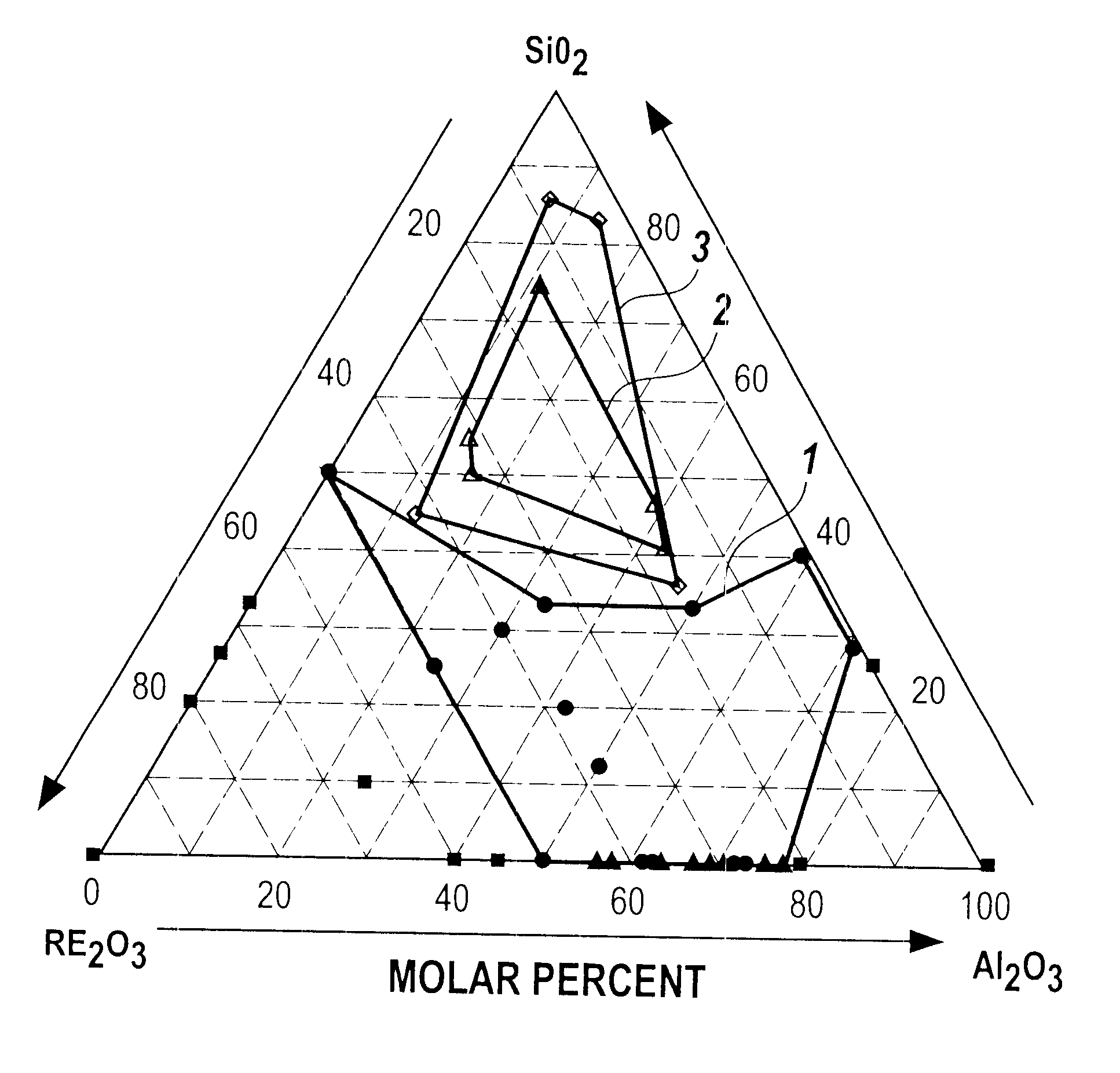

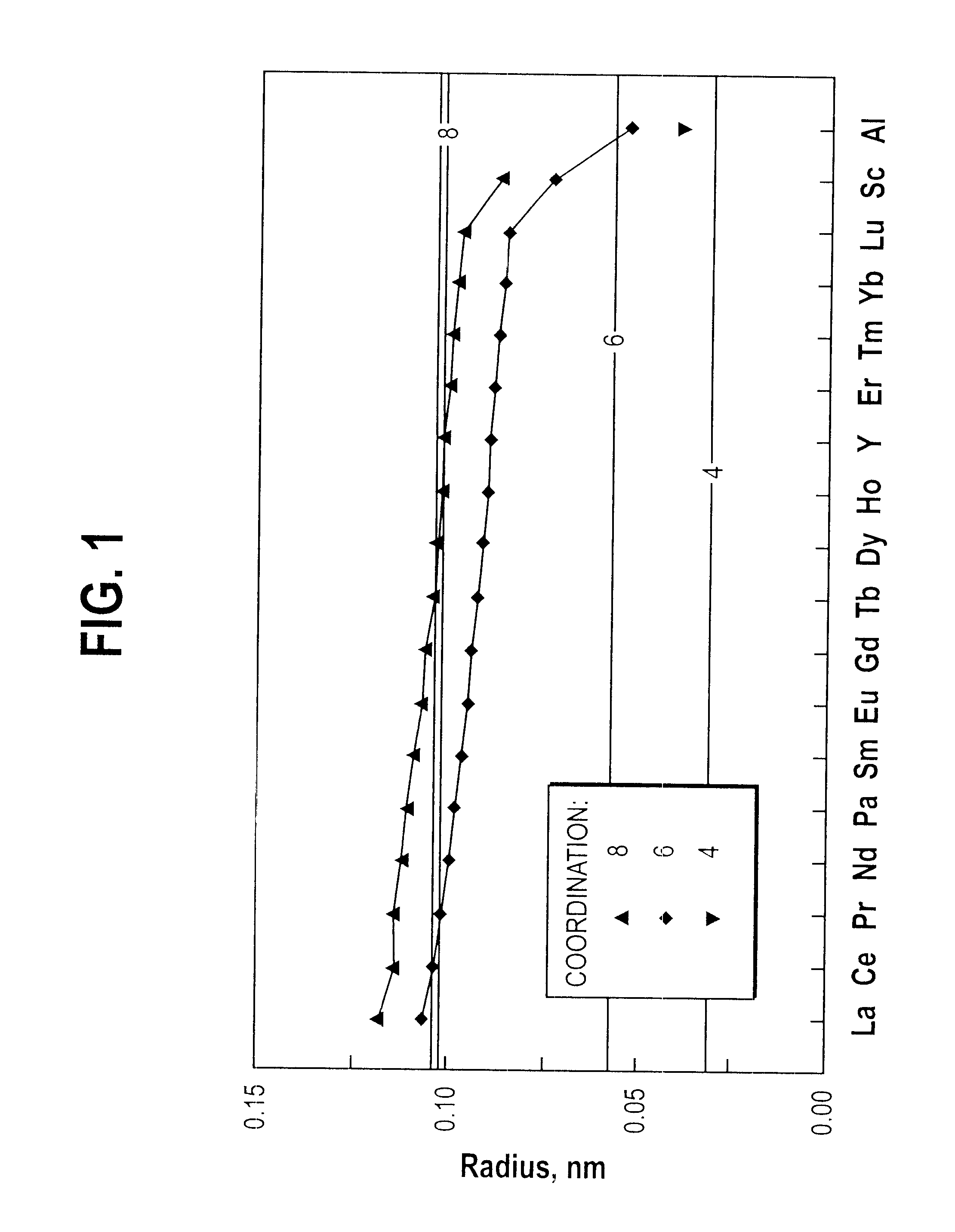

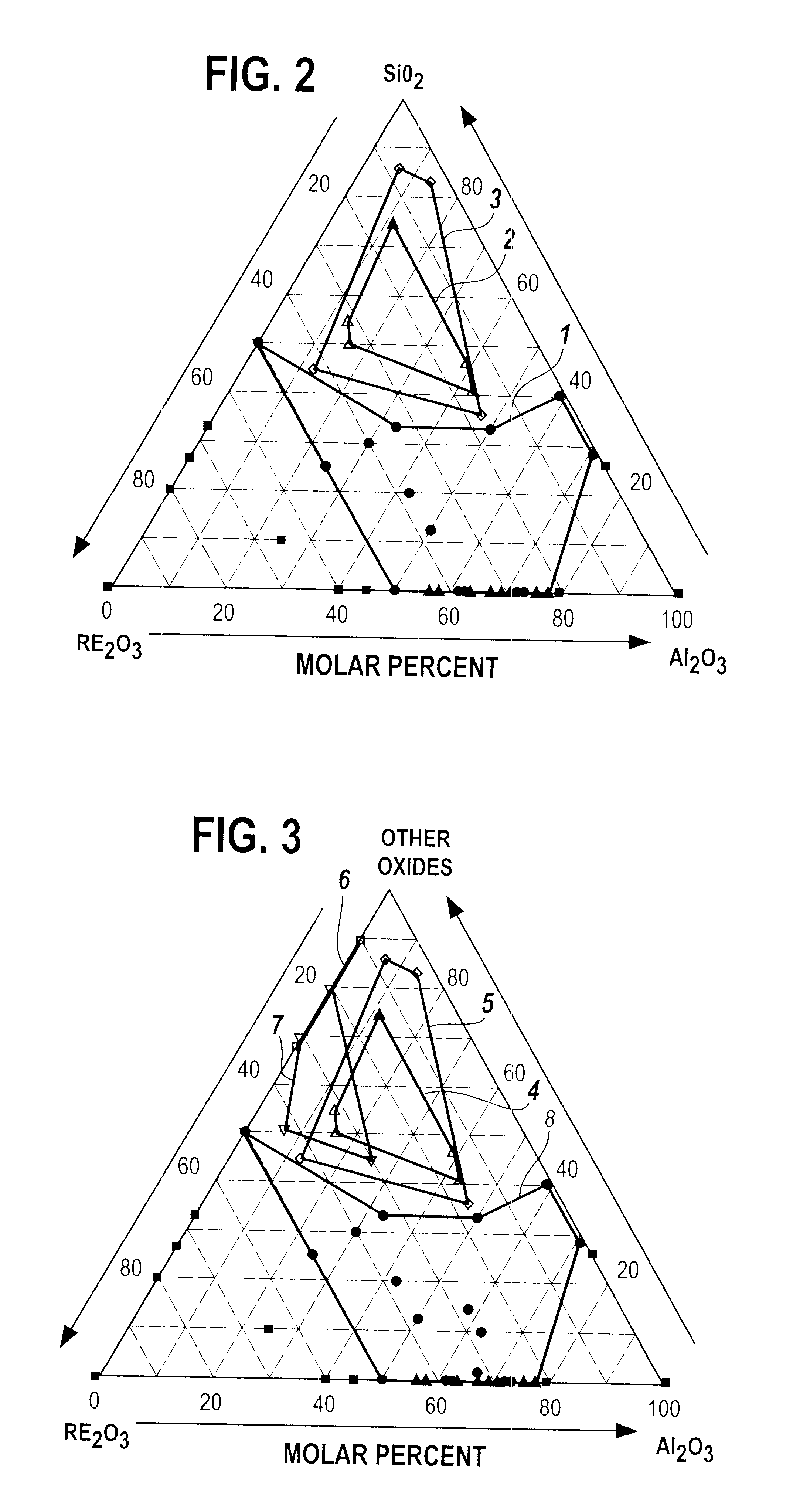

Single phase rare earth oxide-aluminum oxide glasses

A bulk single phase glass comprising 23 molar % to 50 molar % rare earth oxides, RE203, and 50 molar % to 77 molar % aluminum oxide, A12O3 is provided. The glass contains at least 50 molar % of Al2O3+RE2O3 and smaller amounts of oxide glass forming agents and other oxides than are found in prior art glasses. The addition of small amounts of lanthanum oxide, La2O3, prevents phase separation. The single phase glass is useful for optical applications such as lasers and optical amplifiers.

Owner:CONTAINERLESS RES

Composite dielectric forming methods and composite dielectrics

InactiveUS6960538B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricCapacitor

A composite dielectric forming method includes atomic layer depositing alternate layers of hafnium oxide and lanthanum oxide over a substrate. The hafnium oxide can be thermally stable, crystalline hafnium oxide and the lanthanum oxide can be thermally stable, crystalline lanthanum oxide. A transistor may comprise the composite dielectric as a gate dielectric. A capacitor may comprise the composite dielectric as a capacitor dielectric.

Owner:MICRON TECH INC

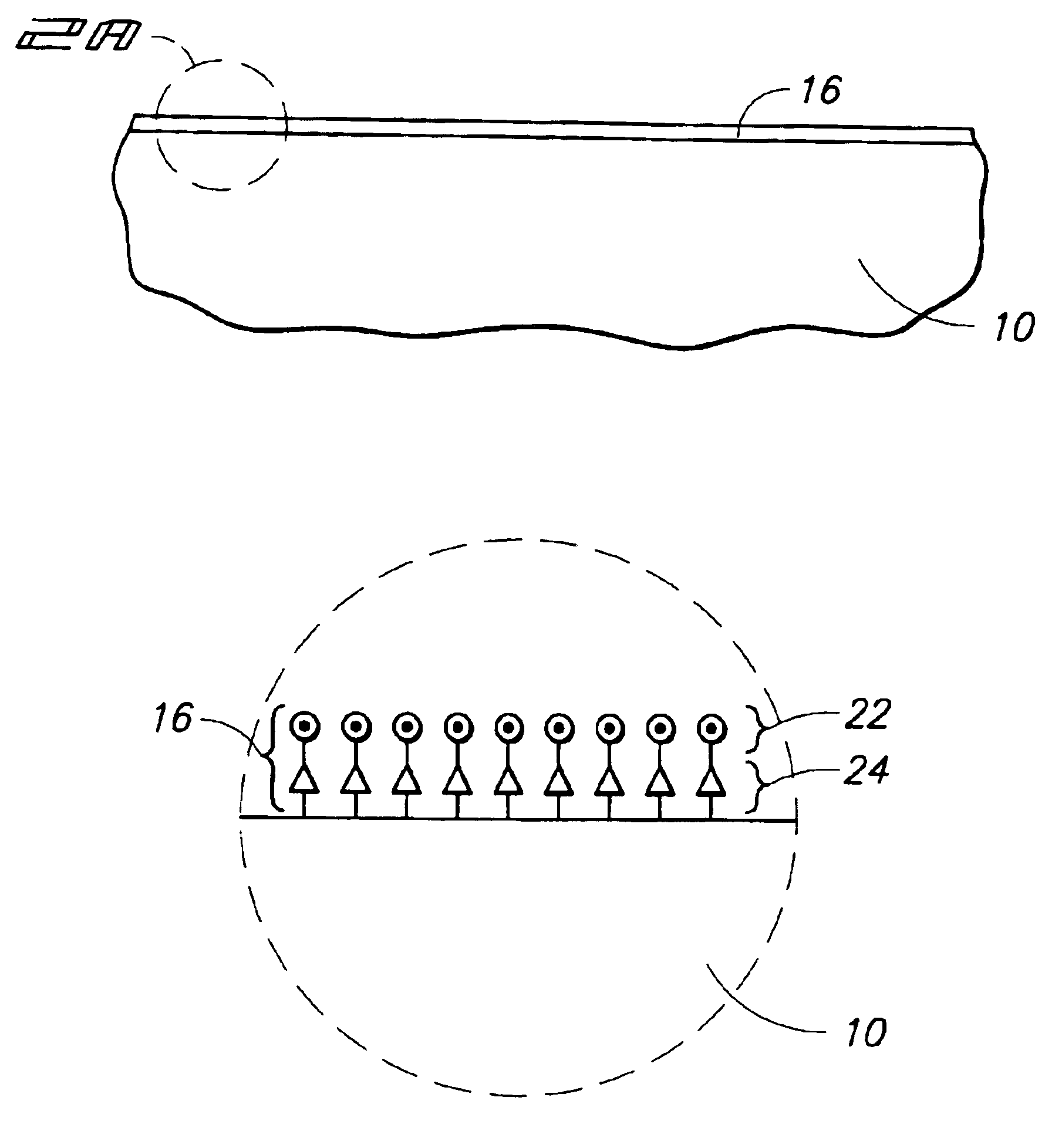

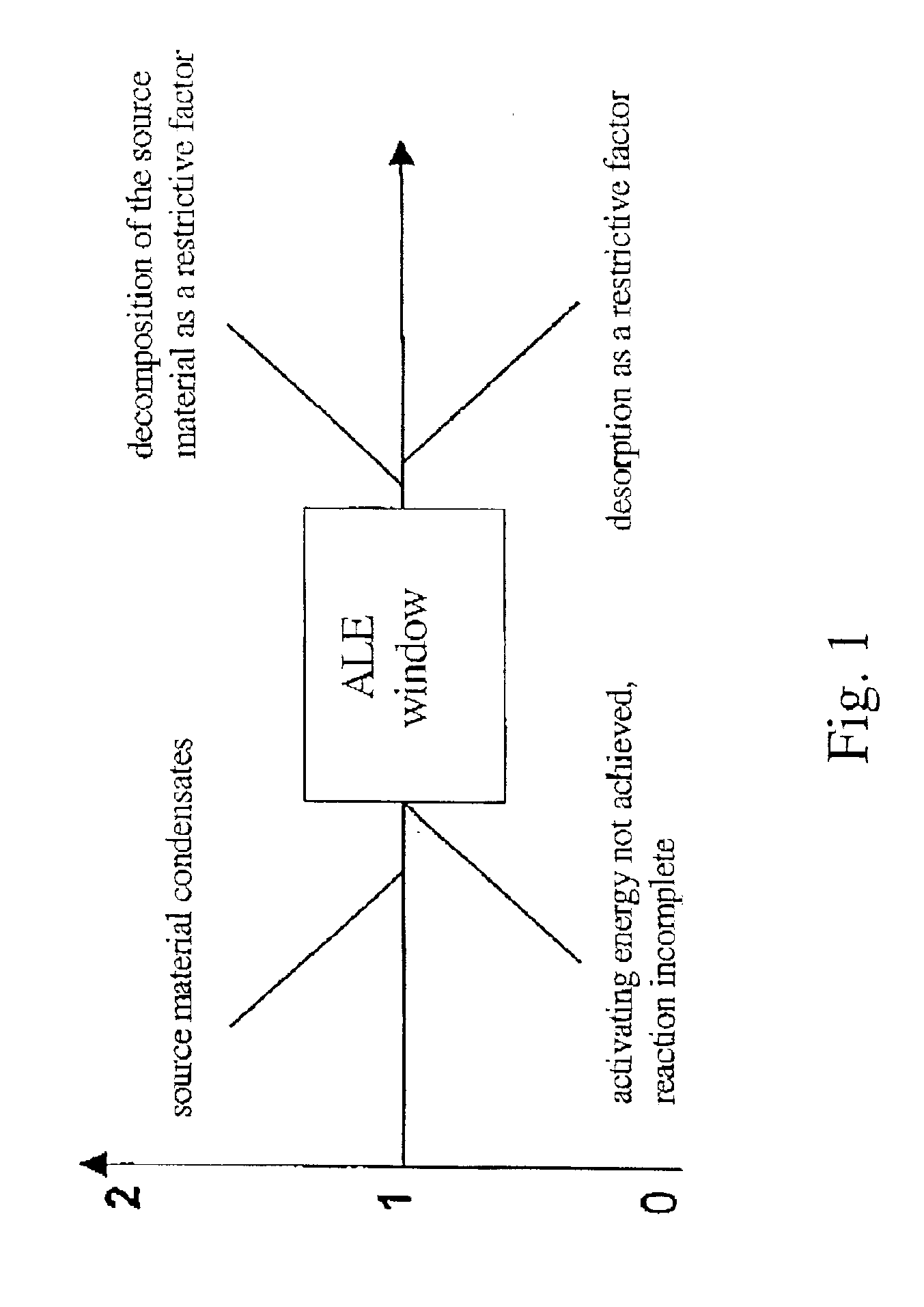

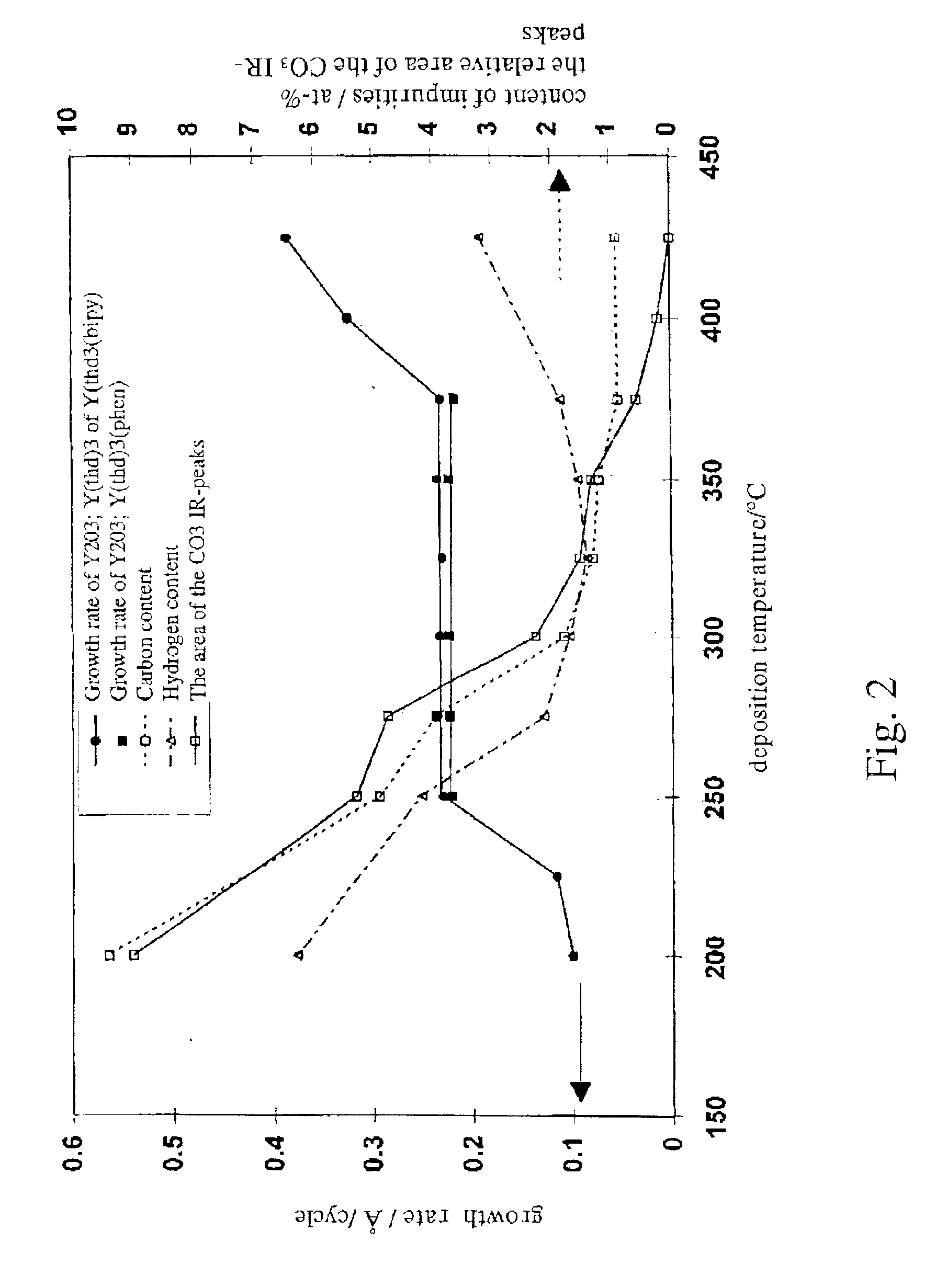

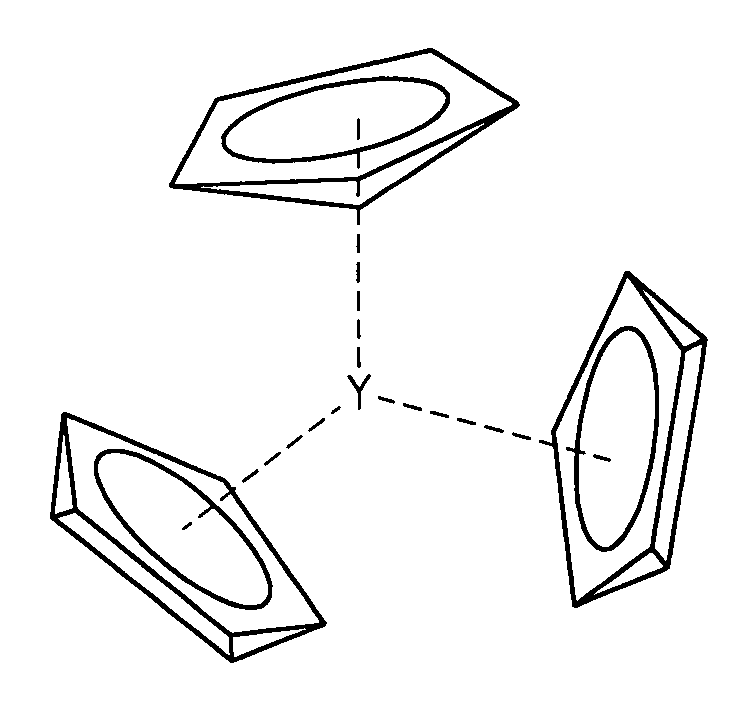

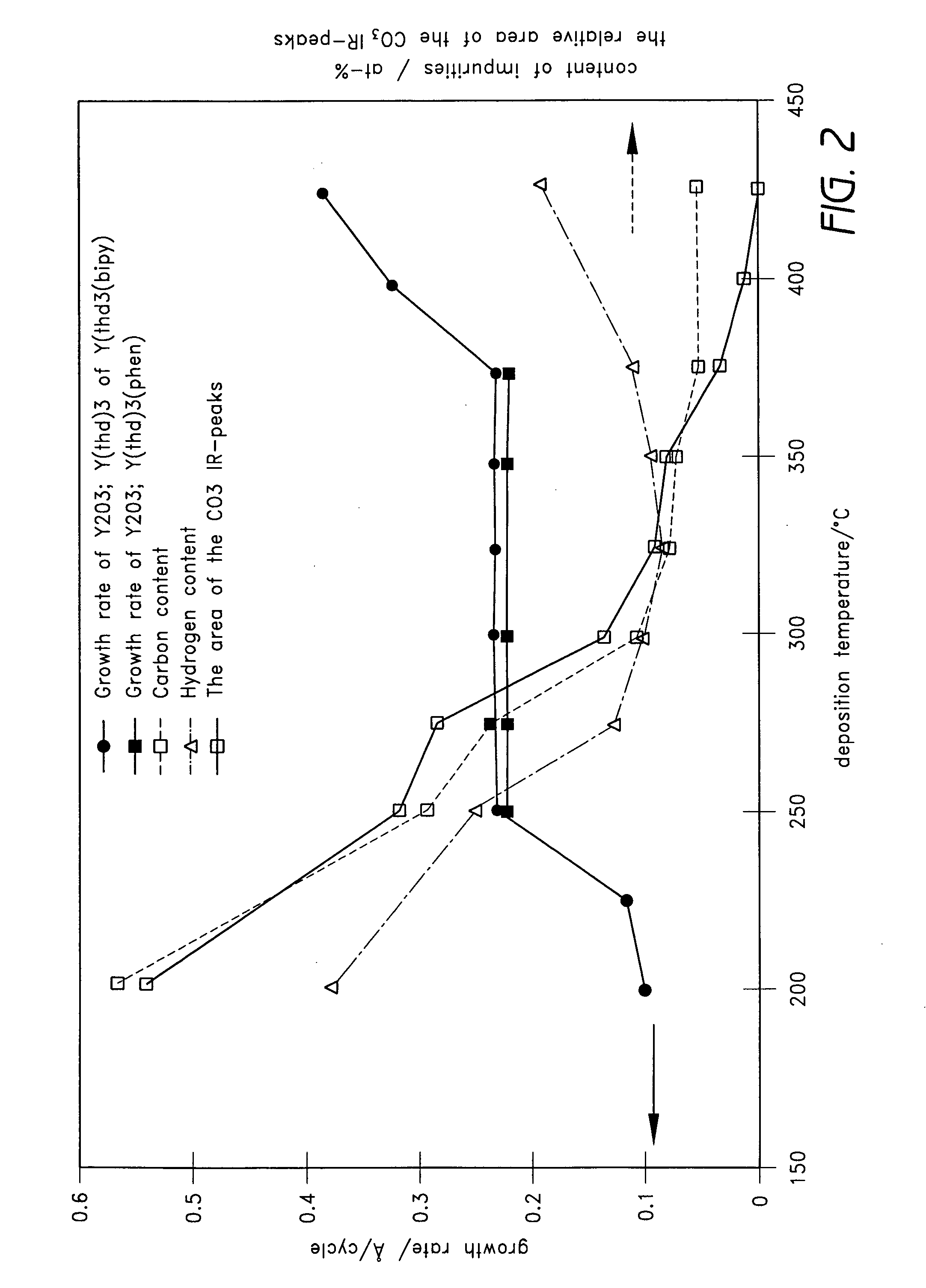

Method of depositing rare earth oxide thin films

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

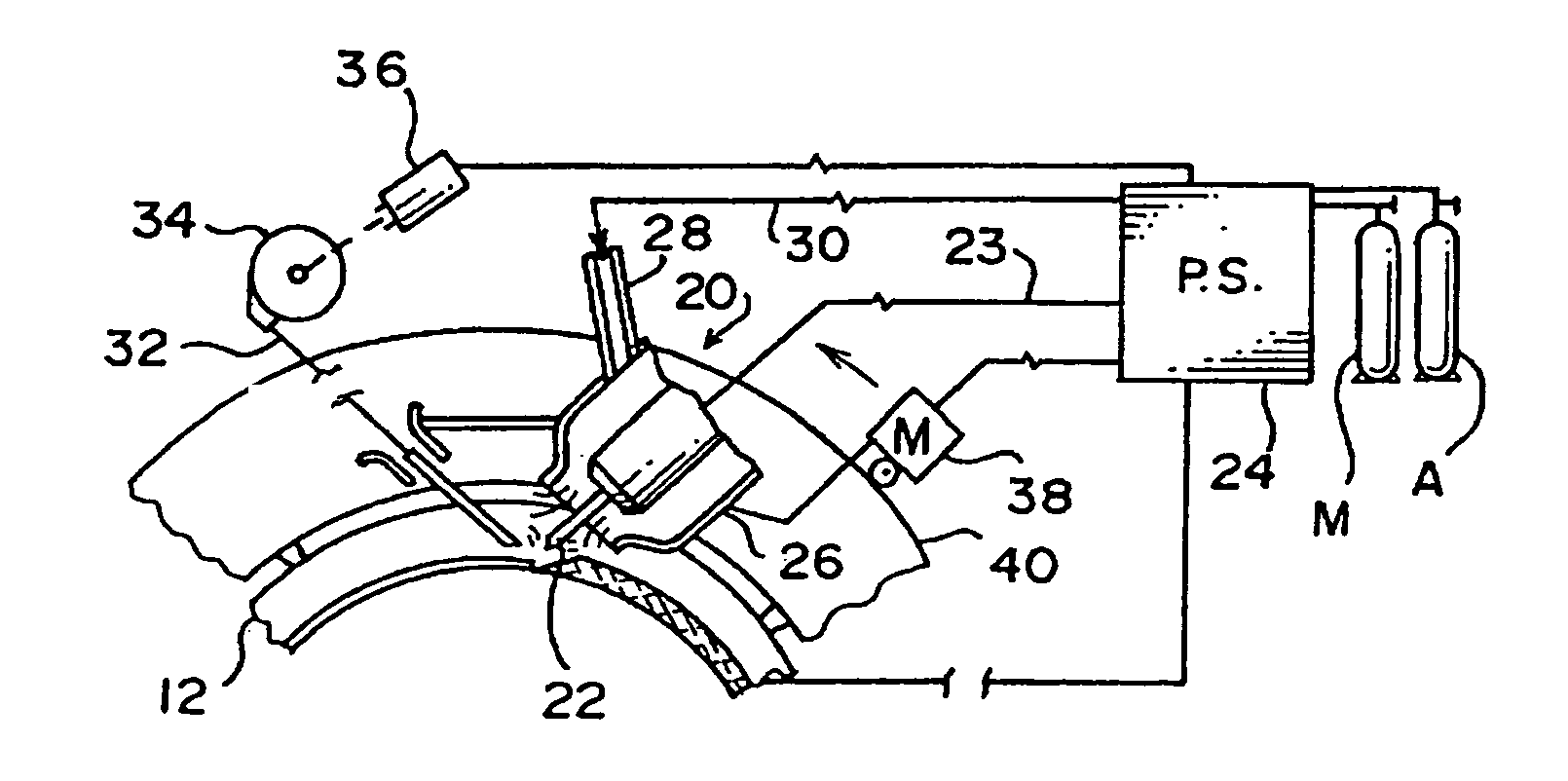

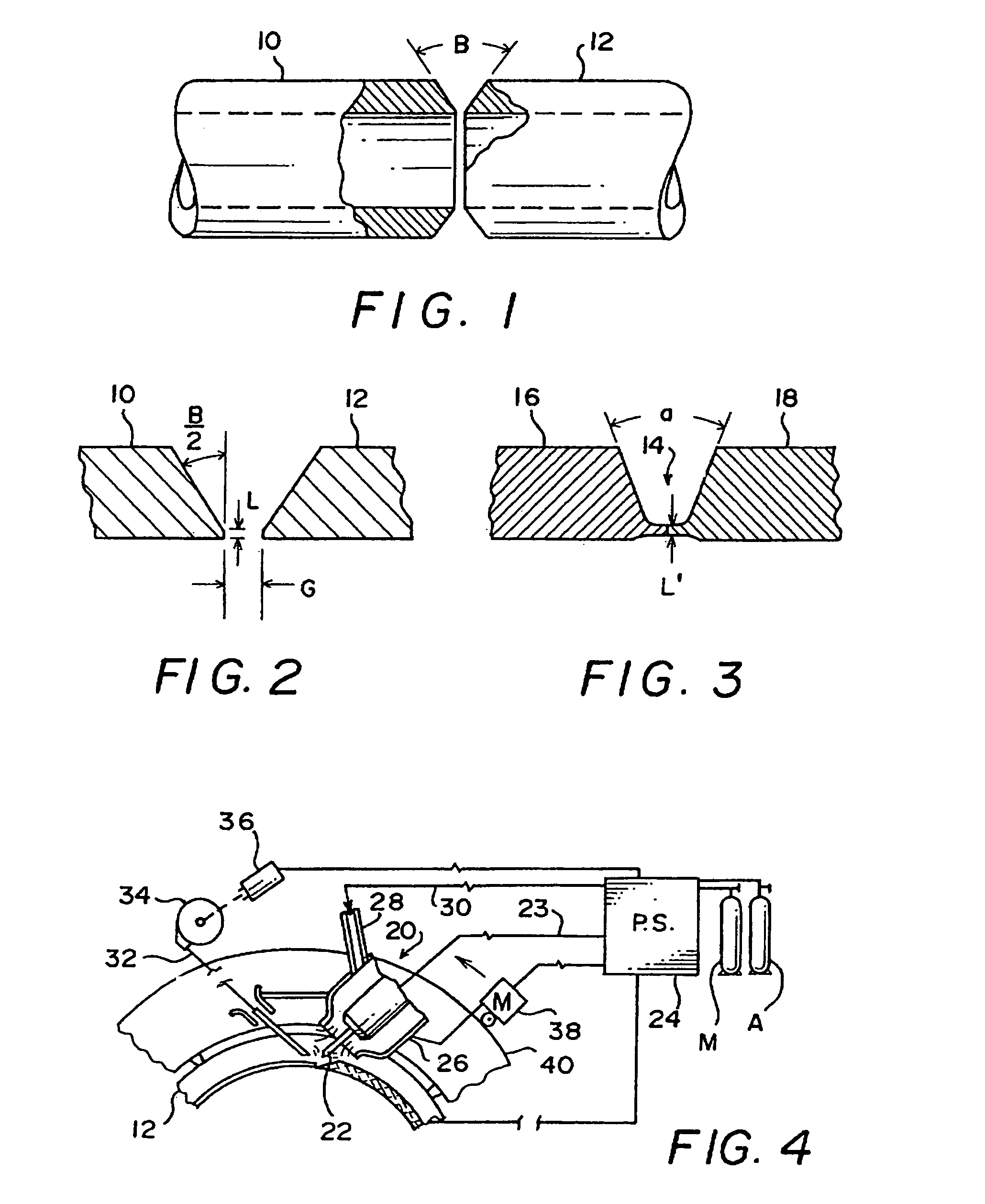

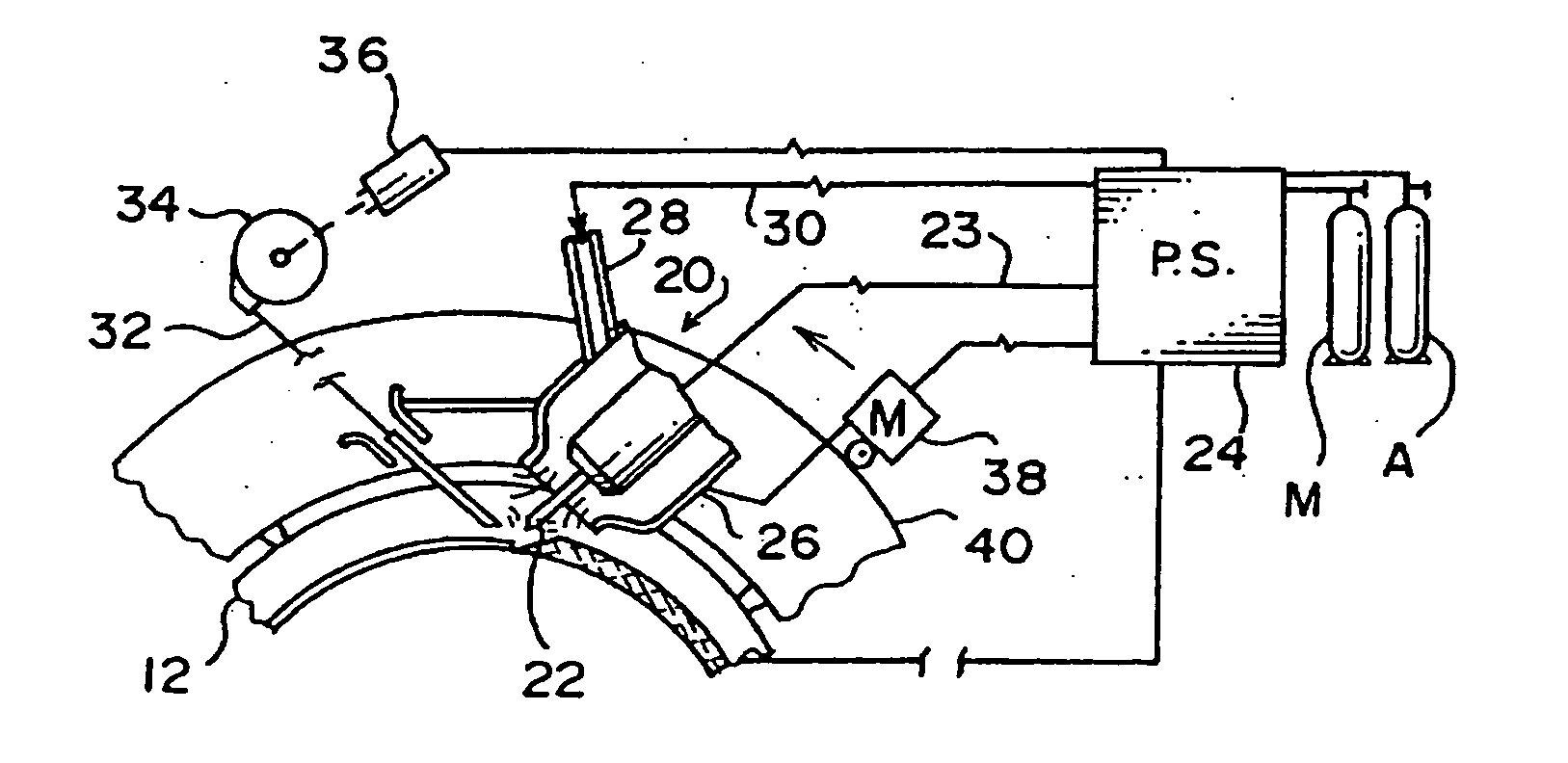

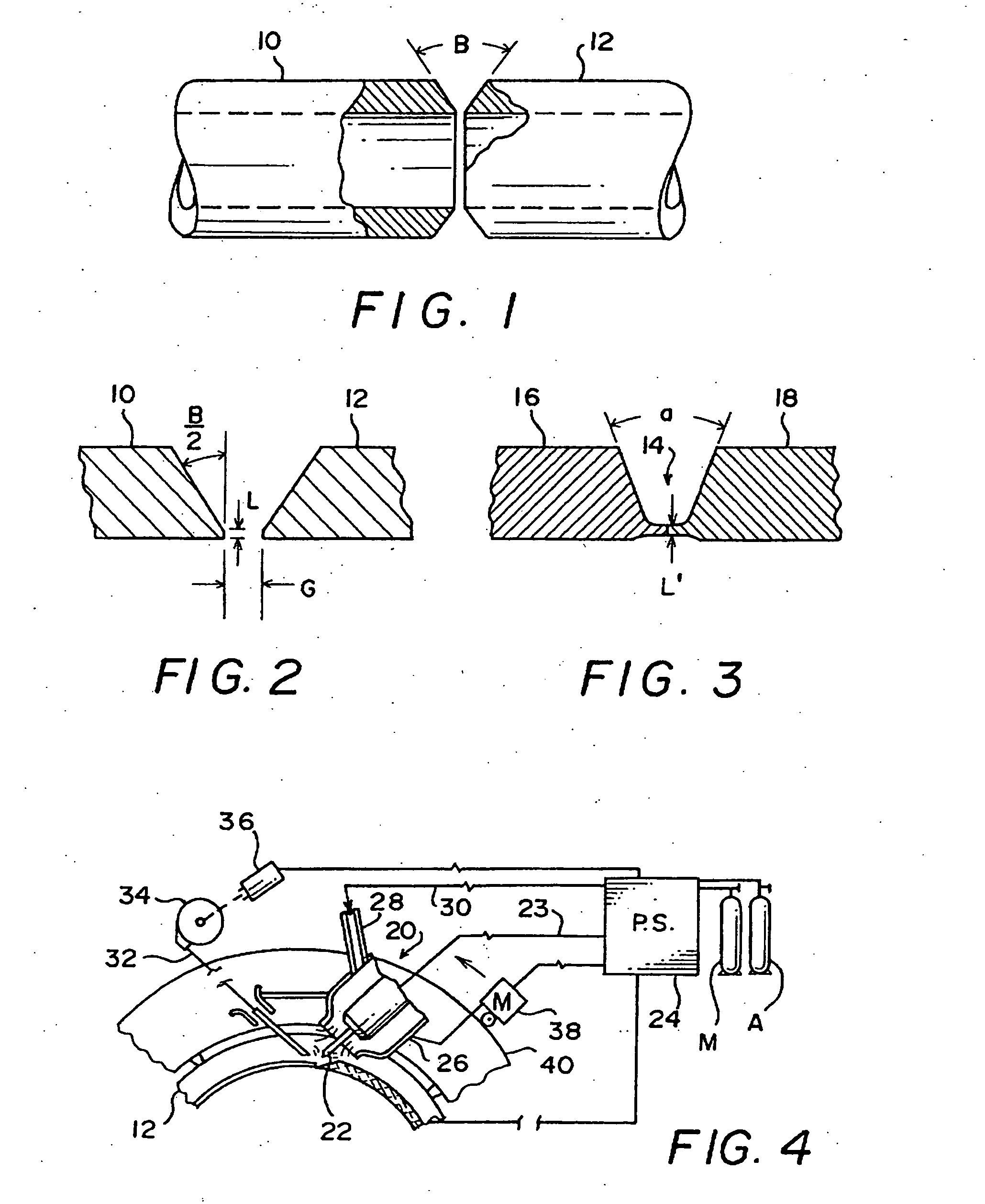

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

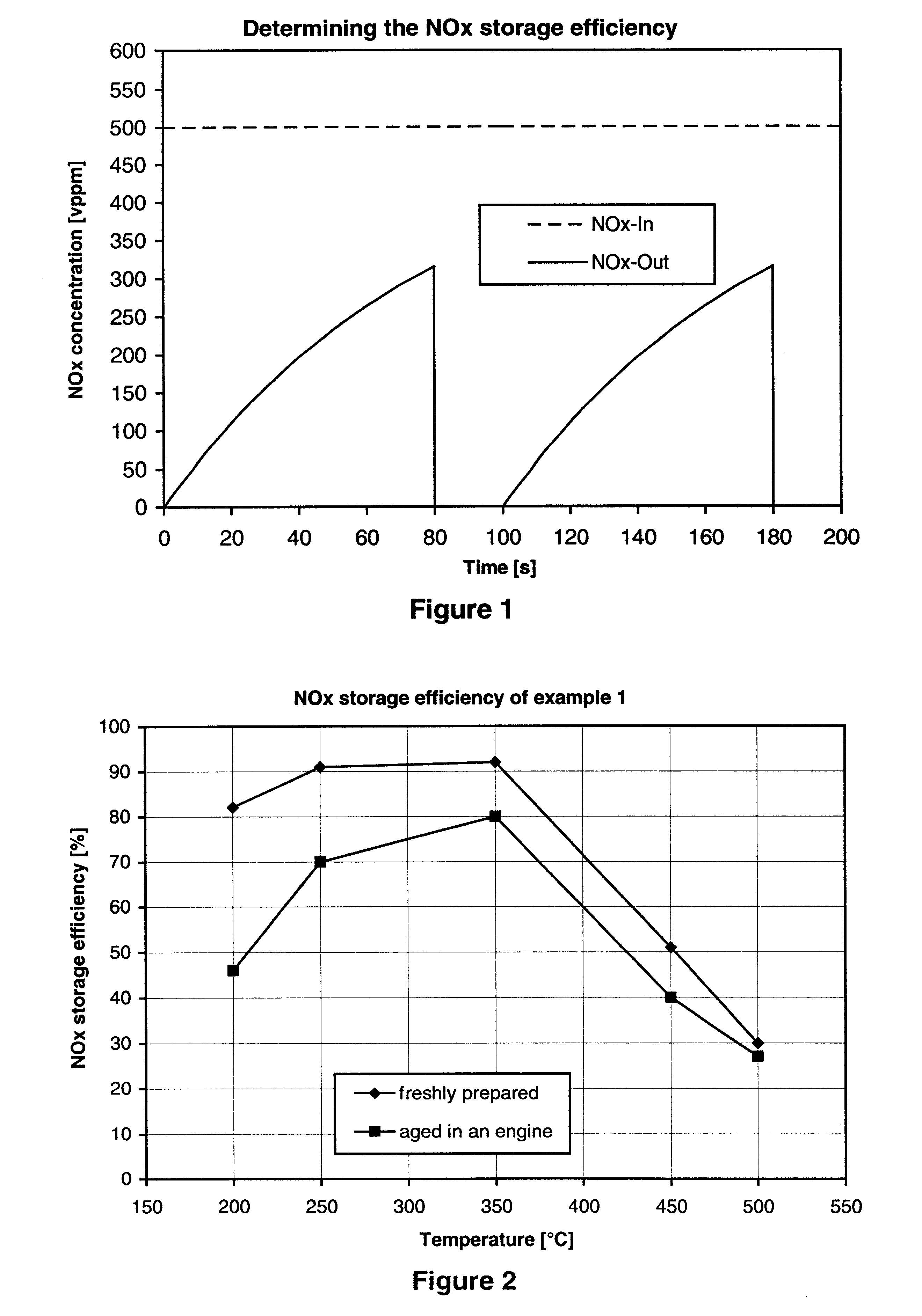

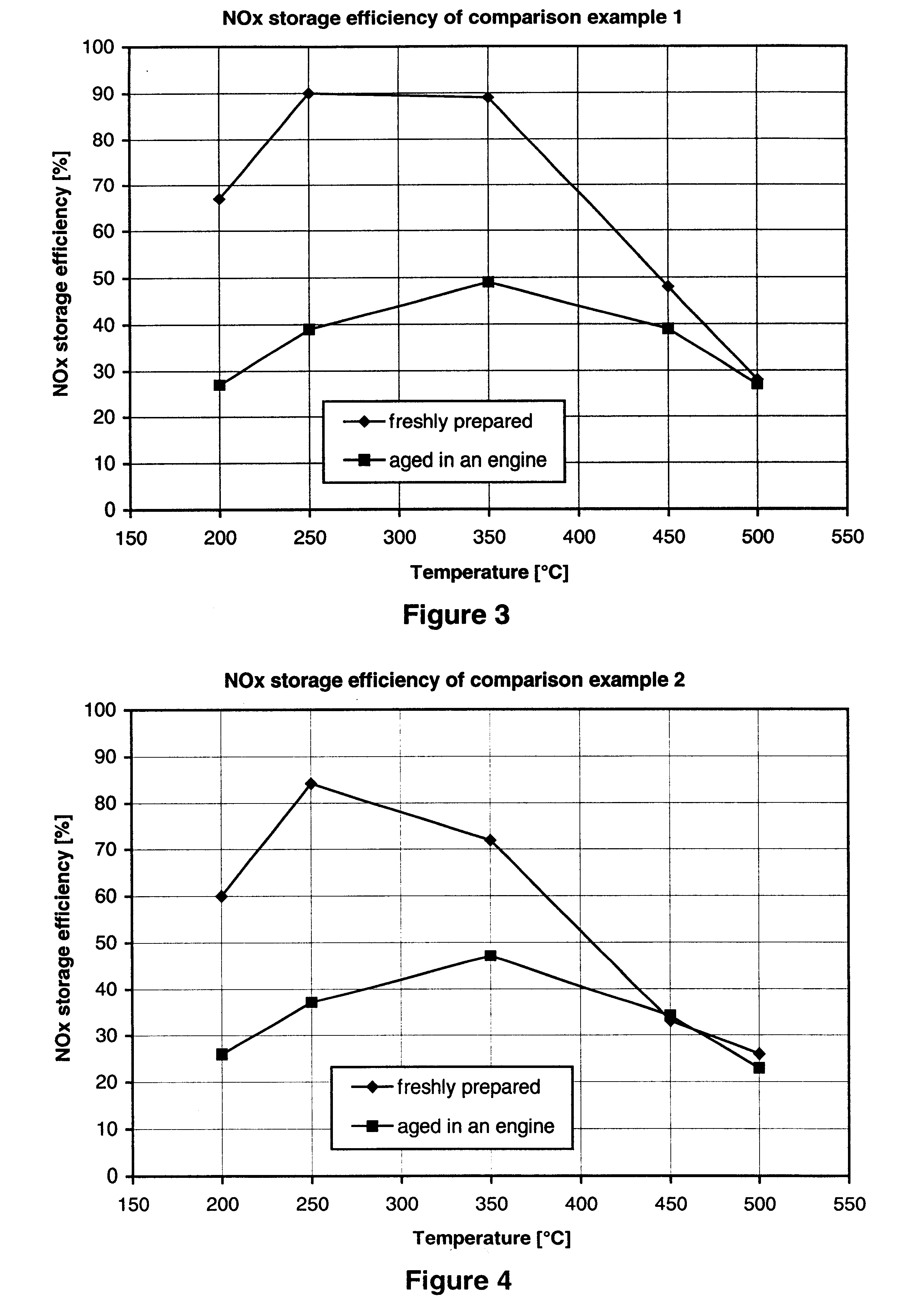

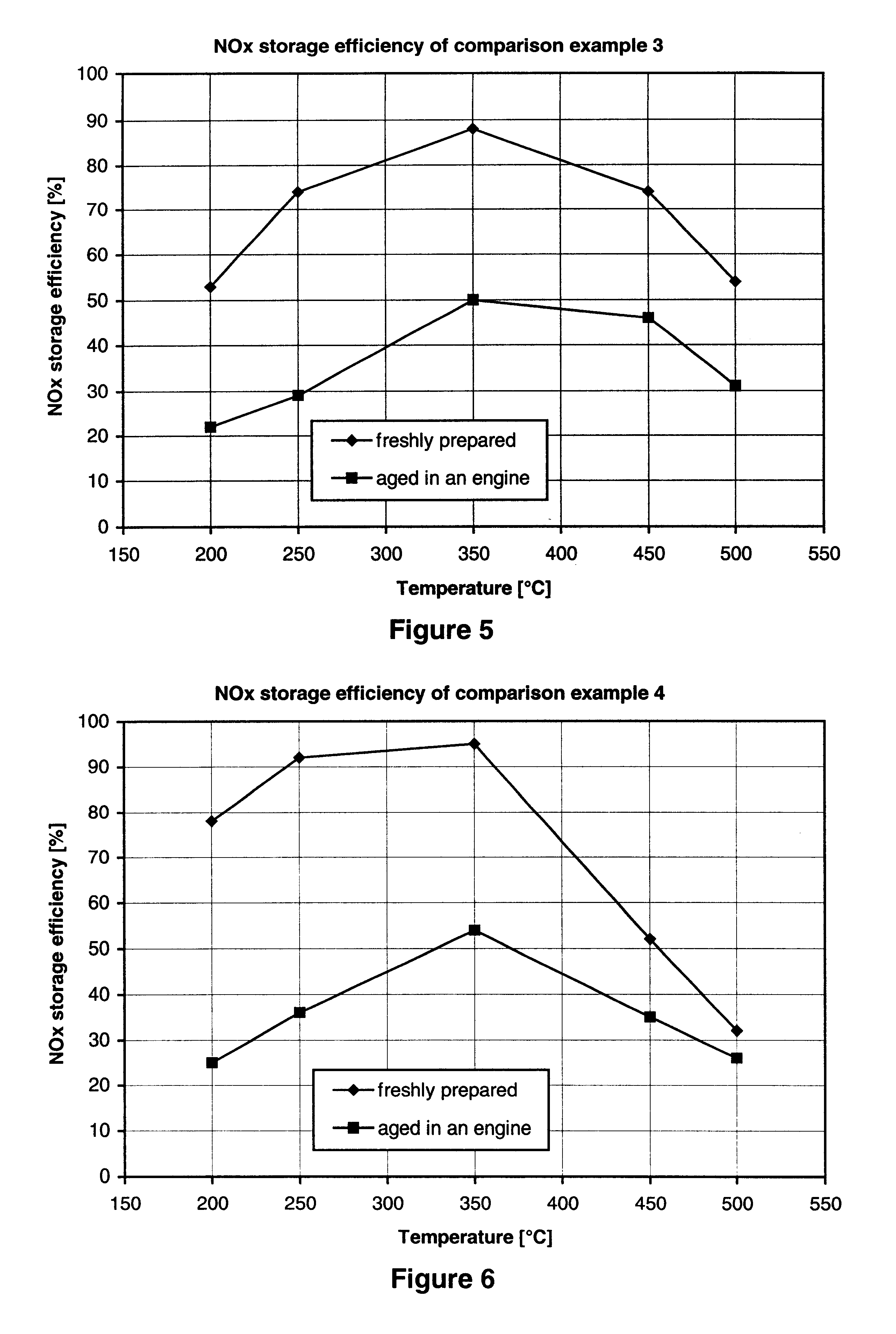

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

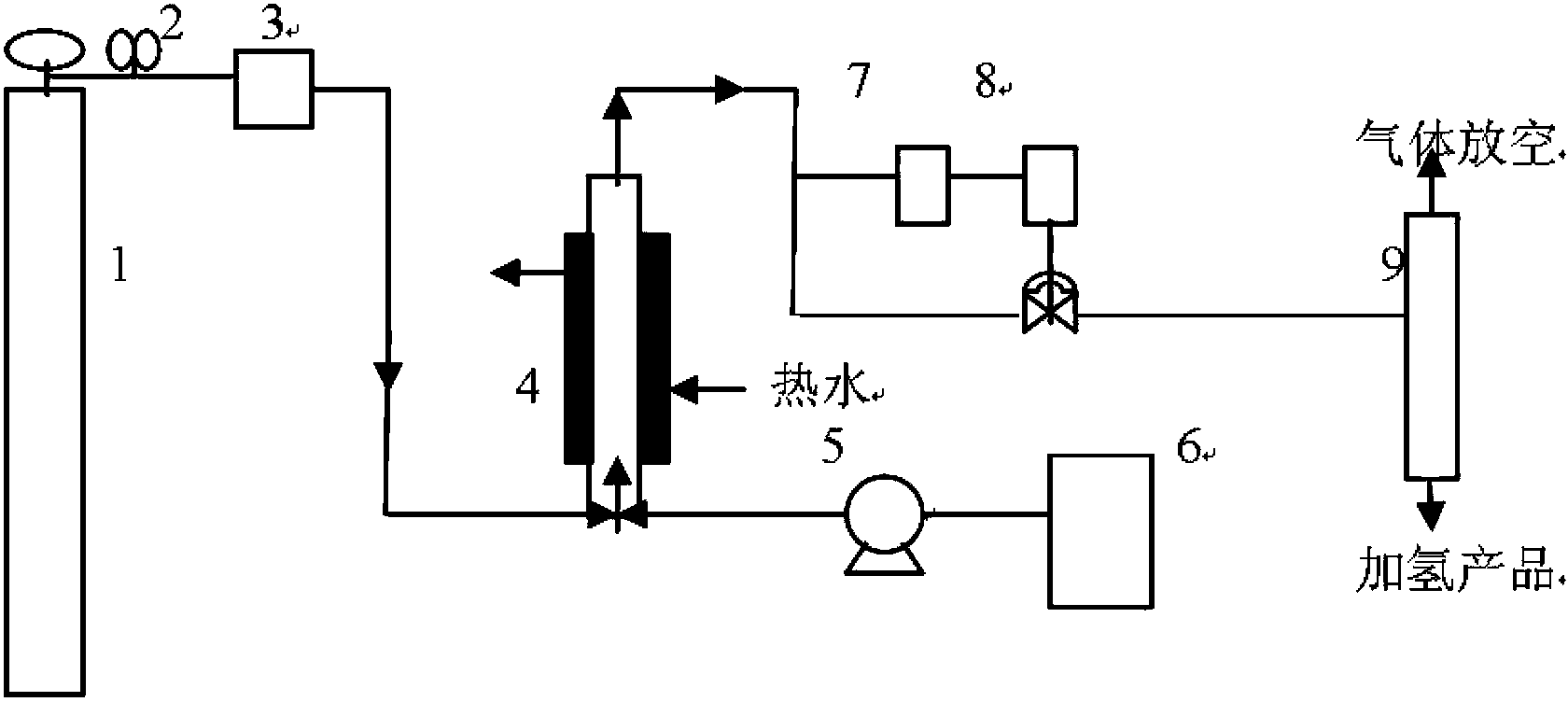

Unsaturated hydrocarbon hydrogenation catalyst, preparation method and applications thereof

ActiveCN102218323ASolve the problem of hydrogenationExpansion of comprehensive utilization channelsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCoalCerium oxide

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst which comprises a carrier, an active component and an additive; the active component is a mixture of nickel oxides and other metal oxides; the additive is at least two out of magnesia oxide, lanthanum oxide and ceria; counted by weight percentage, the unsaturated hydrocarbon hydrogenation catalyst comprises 5-15% of nickel oxides, 1-10% of other metal oxides, 1-10% of additive and remaining quantity of carrier; and the metal oxide is one or more oxides out of molybdenum oxide, cobalt oxide and ferric oxide. The invention also discloses a preparation method and applications of the unsaturated hydrocarbon hydrogenation catalyst. The unsaturated hydrocarbon hydrogenation catalyst has the advantages of high hydrogenation precision, strong side effect resistance, good thermal stability, long service life and the like, can be used for processing tail gas in indirect coal oil production industrial and can be also used for processing unsaturated hydrocarbon in synthesis gas.

Owner:THE NORTHWEST RES INST OF CHEM IND

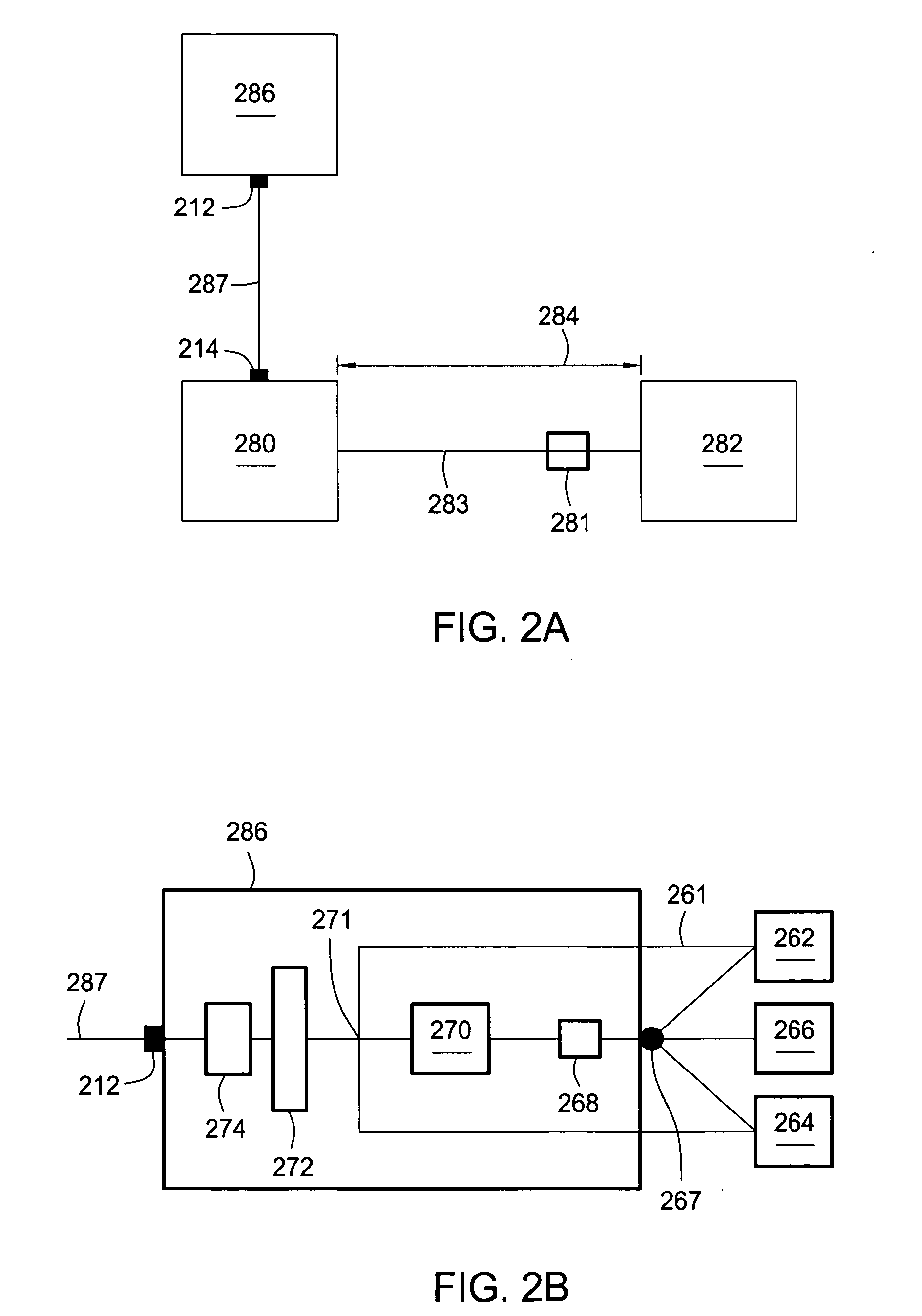

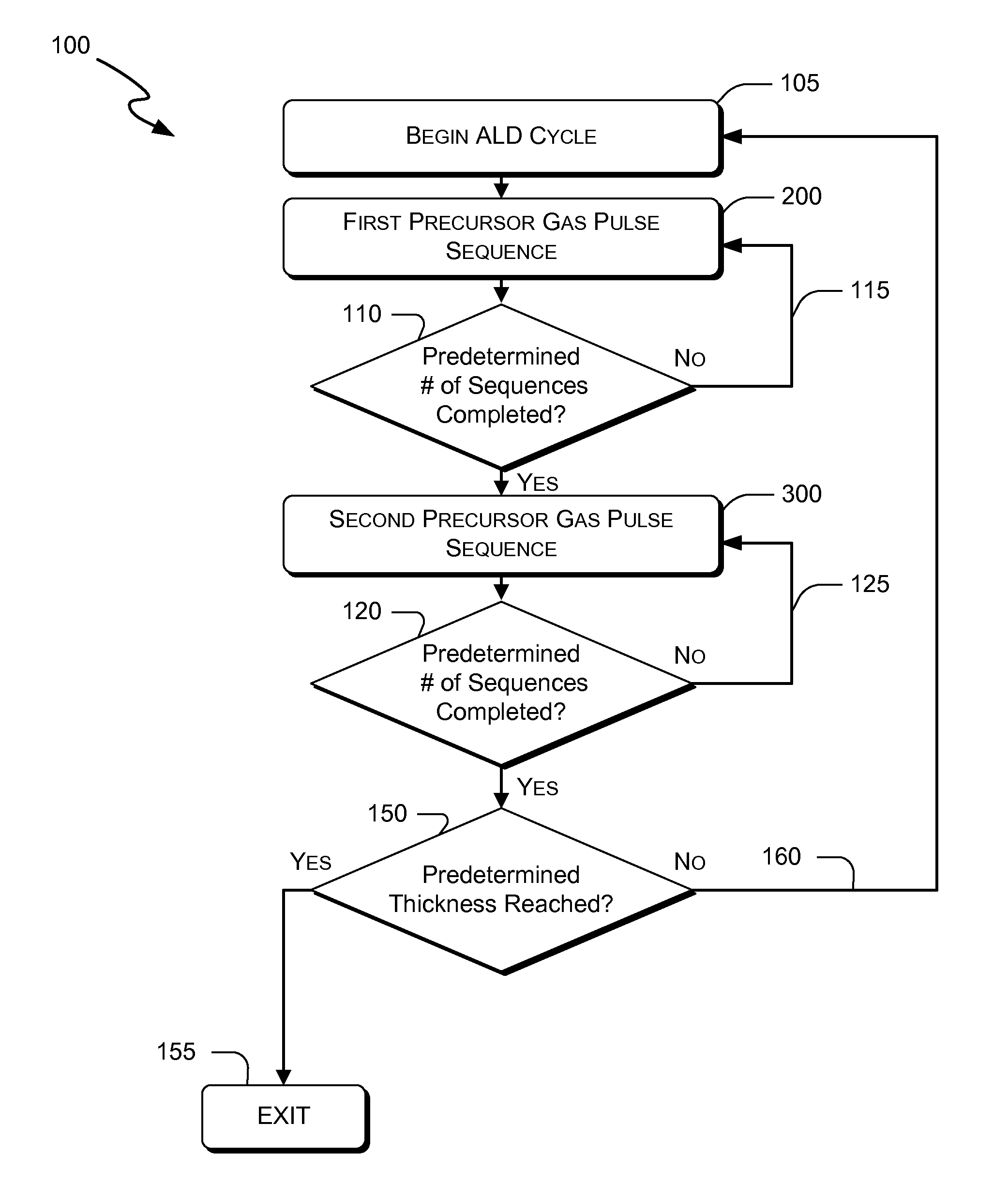

Atomic layer deposition of hafnium lanthanum oxides

ActiveUS20100270626A1Desired characteristicSemiconductor/solid-state device detailsSolid-state devicesDielectricHafnium

There is provided an improved method for depositing thin films using precursors to deposit binary oxides by atomic layer deposition (ALD) techniques. Also disclosed is an ALD method for depositing a high-k dielectric such as hafnium lanthanum oxide (HfLaO) on a substrate. Embodiments of the present invention utilize a combination of ALD precursor elements and cycles to deposit a film with desired physical and electrical characteristics. Electronic components and systems that integrate devices fabricated with methods consistent with the present invention are also disclosed.

Owner:ASM IP HLDG BV

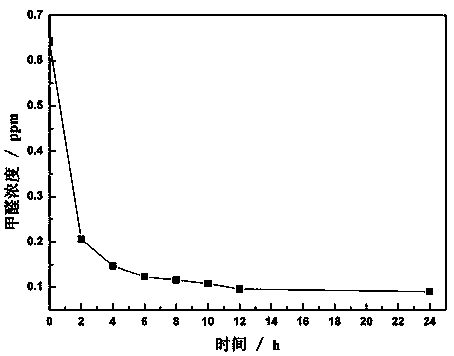

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

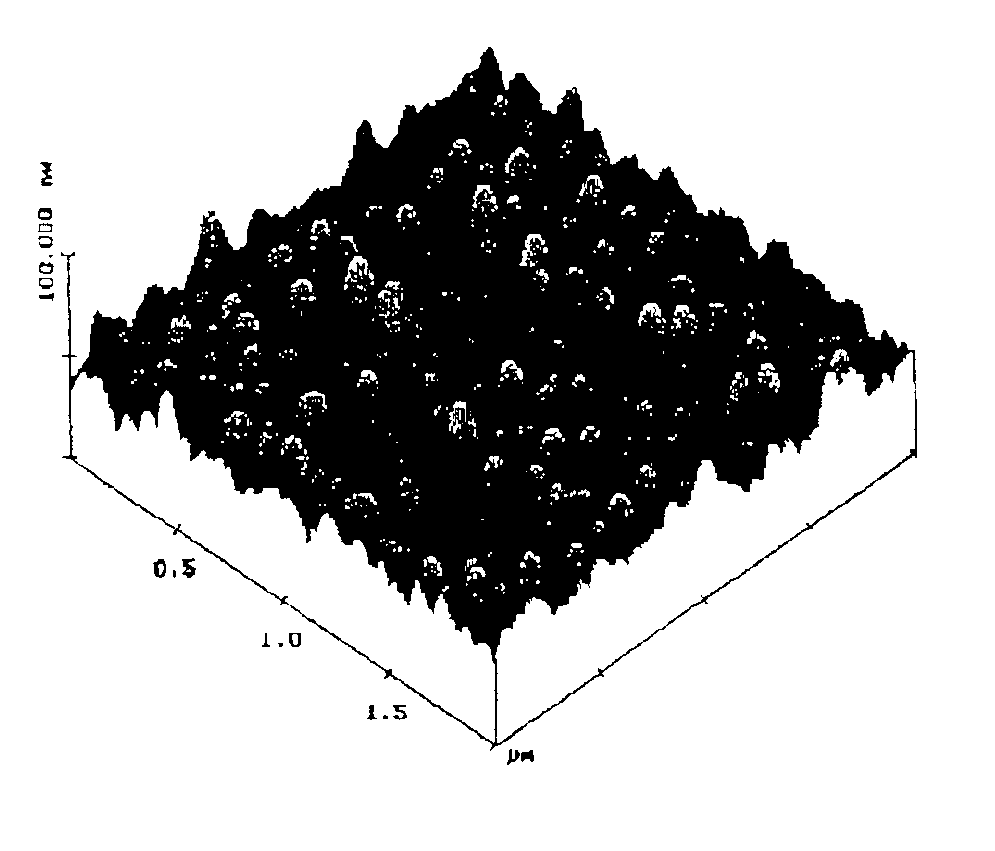

Method of depositing rare earth oxide thin films

InactiveUS20090035949A1Eliminate the problemIncrease probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureMischmetal

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds or rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

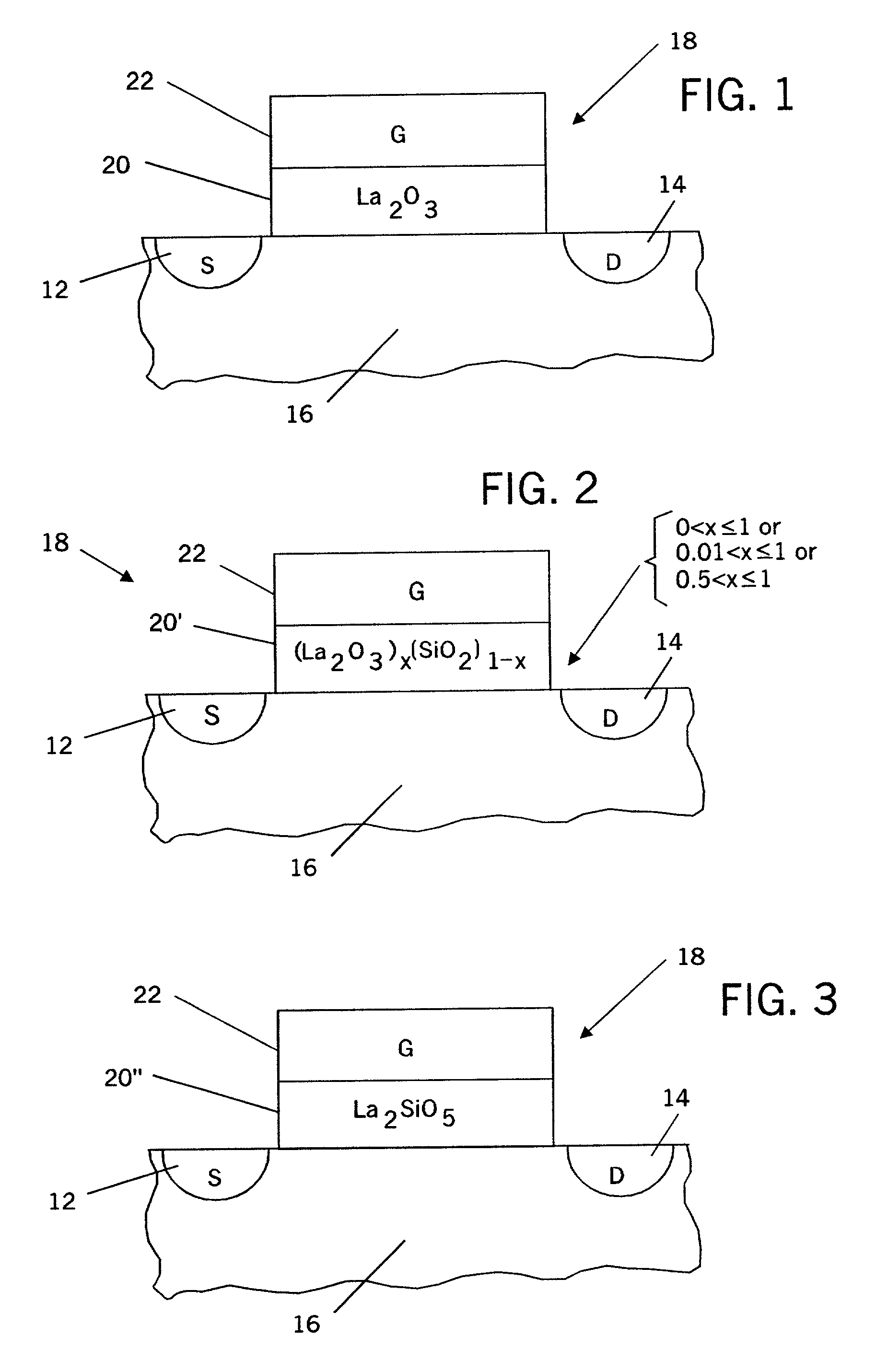

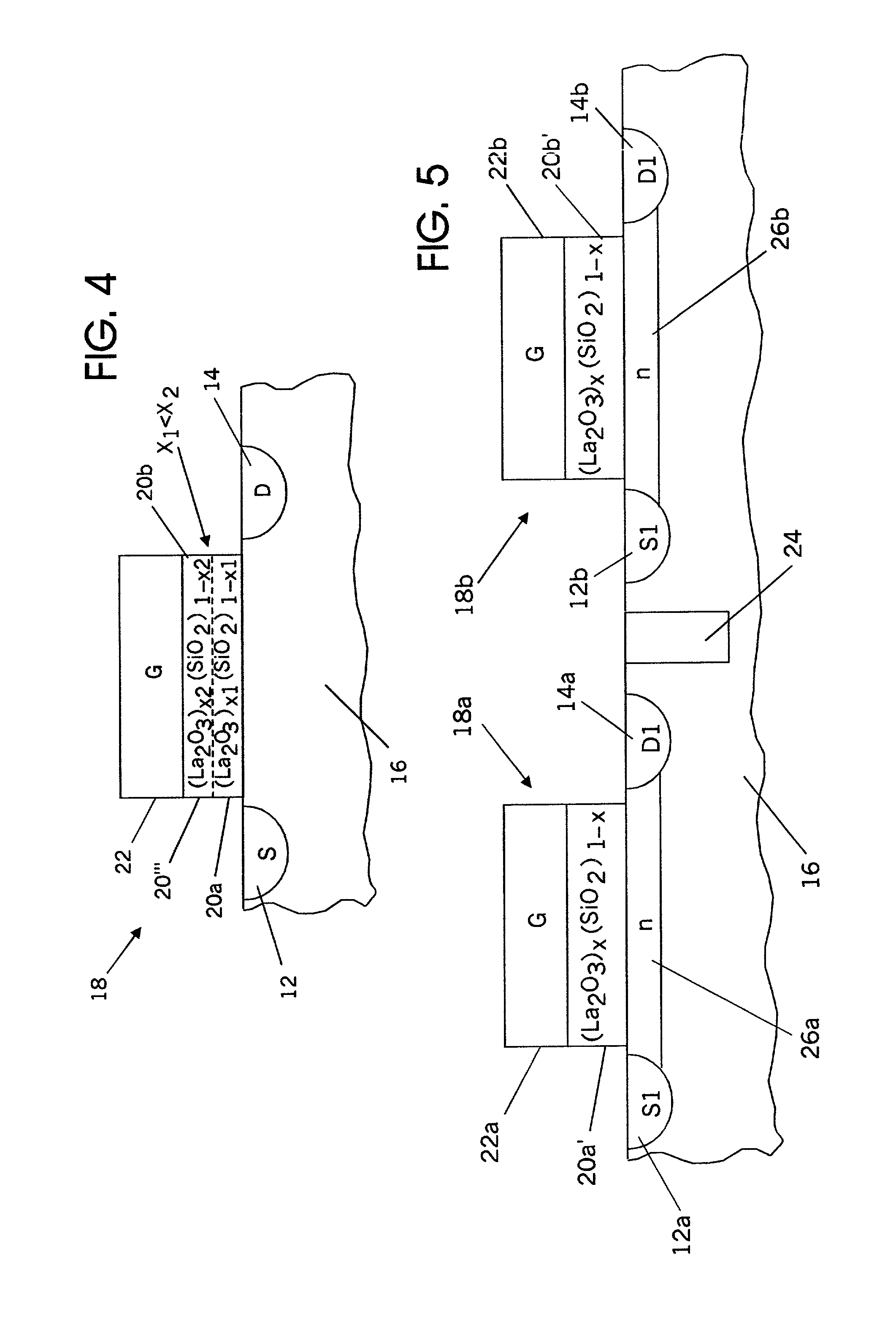

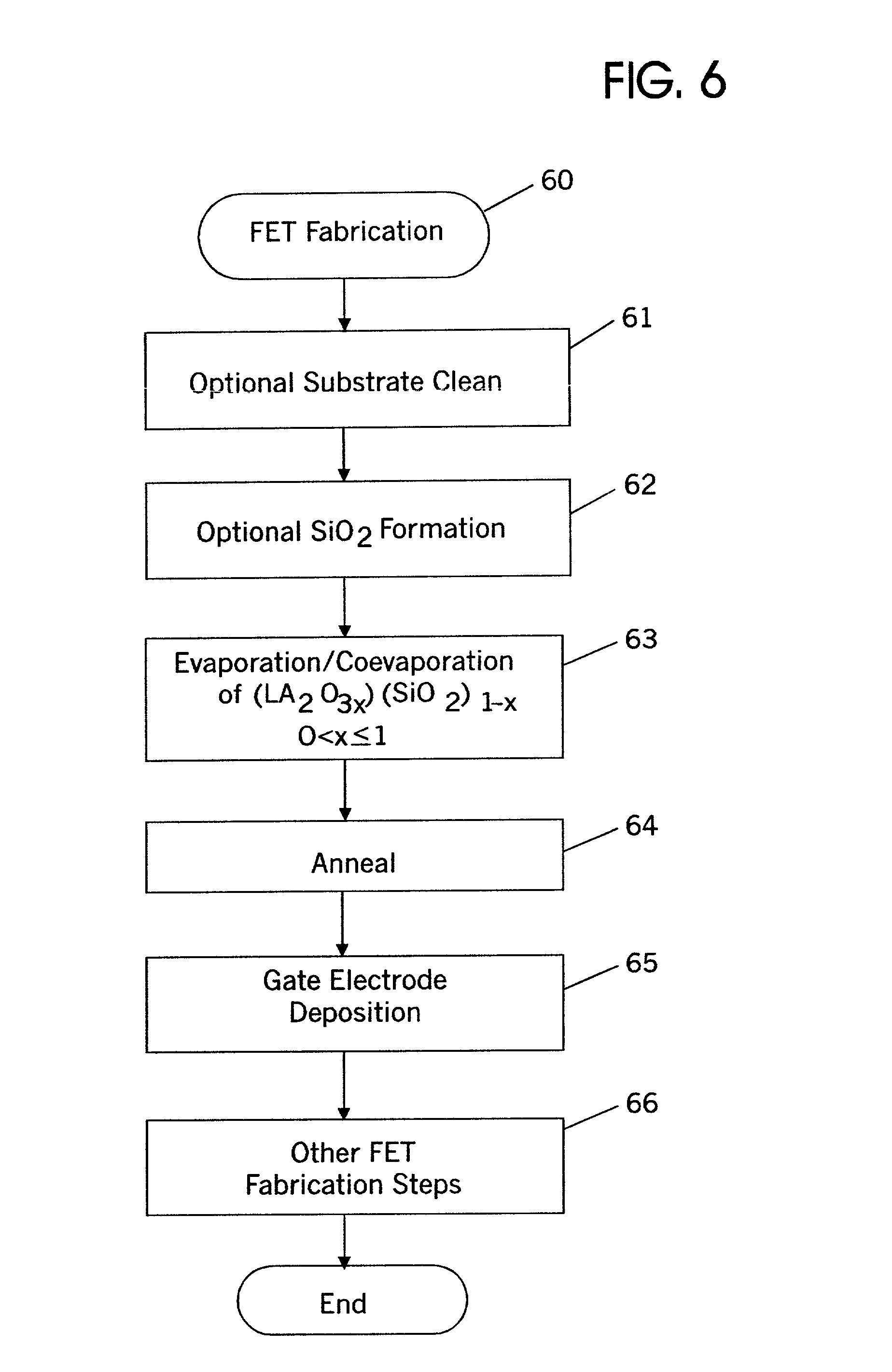

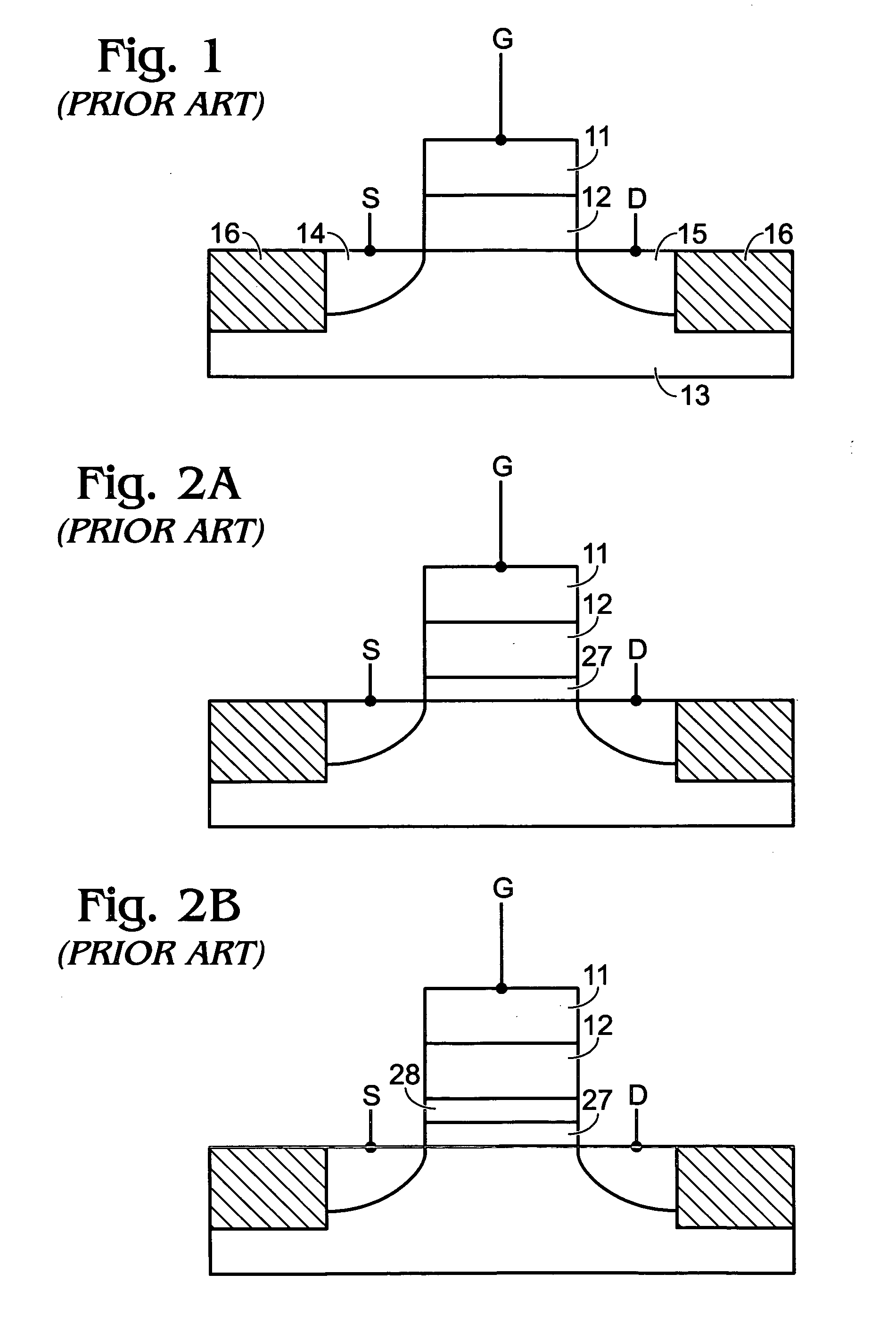

Lanthanum oxide-based gate dielectrics for integrated circuit field effect transistors and methods of fabricating same

Lanthanum oxide-based gate dielectrics are provided for integrated circuit field effect transistors. The gate dielectrics may include lanthanum oxide, preferably amorphous lanthanum oxide and / or an alloy of lanthanum oxide and silicon oxide, such as lanthanum silicate (La.sub.2SiO.sub.5). Lanthanum oxide-based gate dielectrics may be fabricated by evaporating lanthanum on a silicon surface of an integrated circuit substrate. The lanthanum may be evaporated in the presence of oxygen. Lanthanum and silicon may be co-evaporated. An anneal then may be performed. Lanthanum oxide-based dielectrics also may be used for integrated circuit capacitors.

Owner:NORTH CAROLINA STATE UNIV

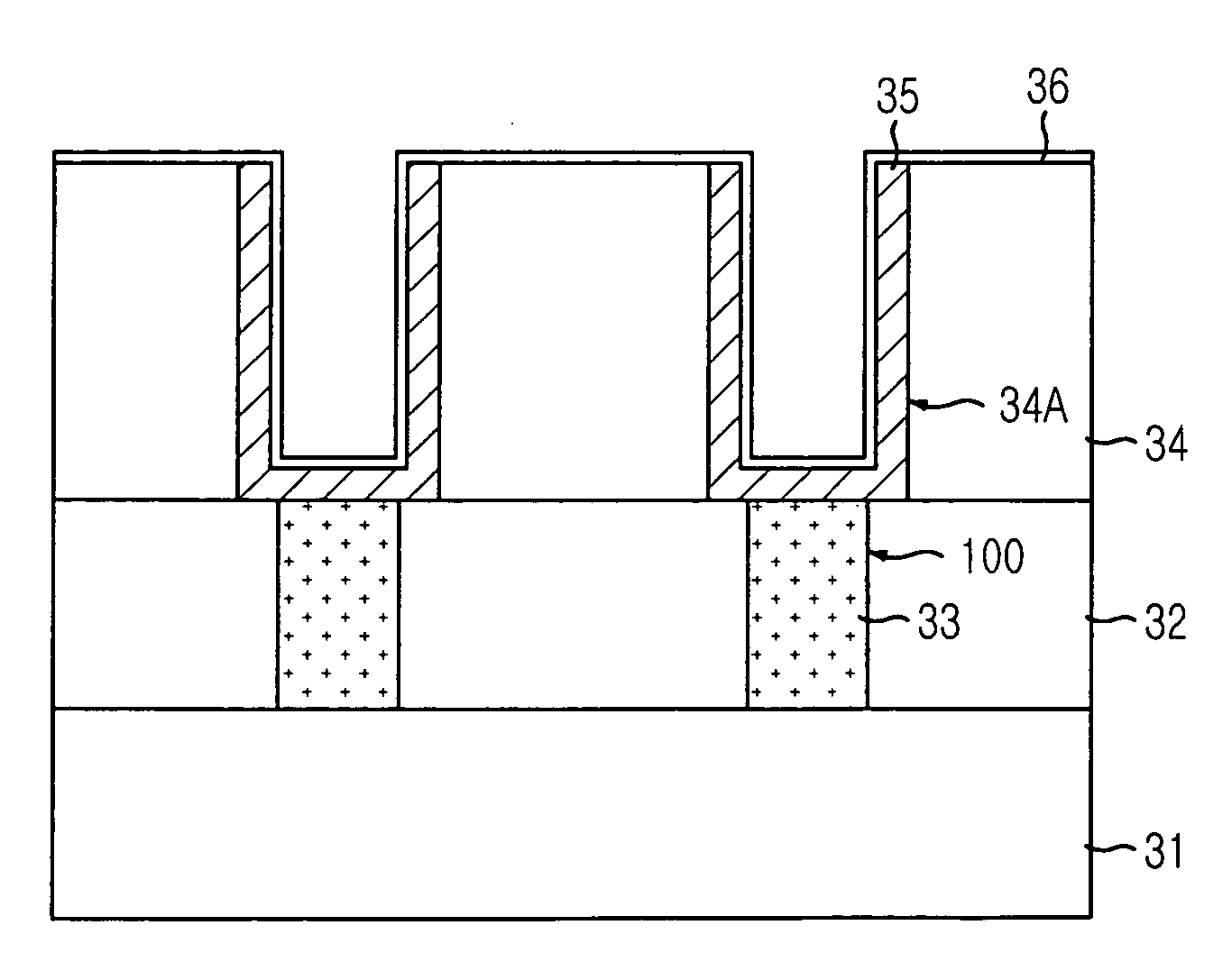

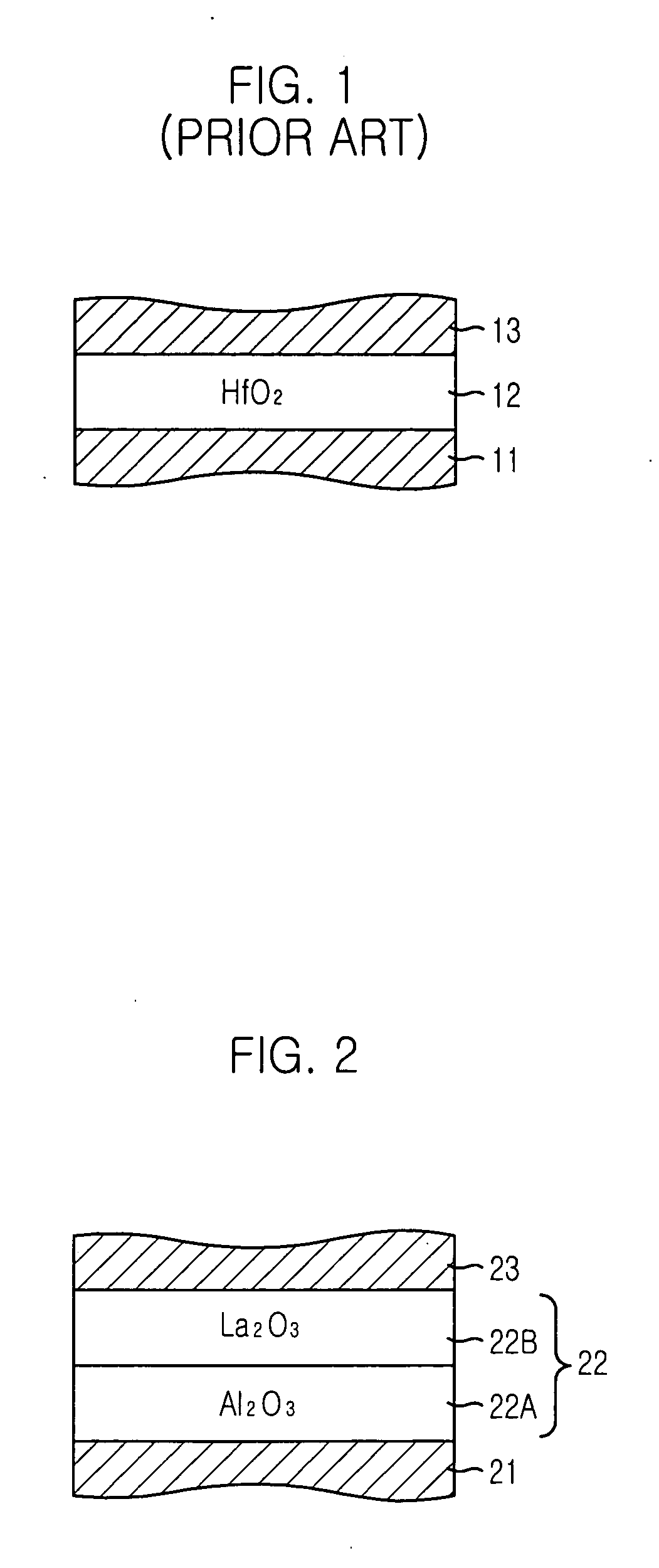

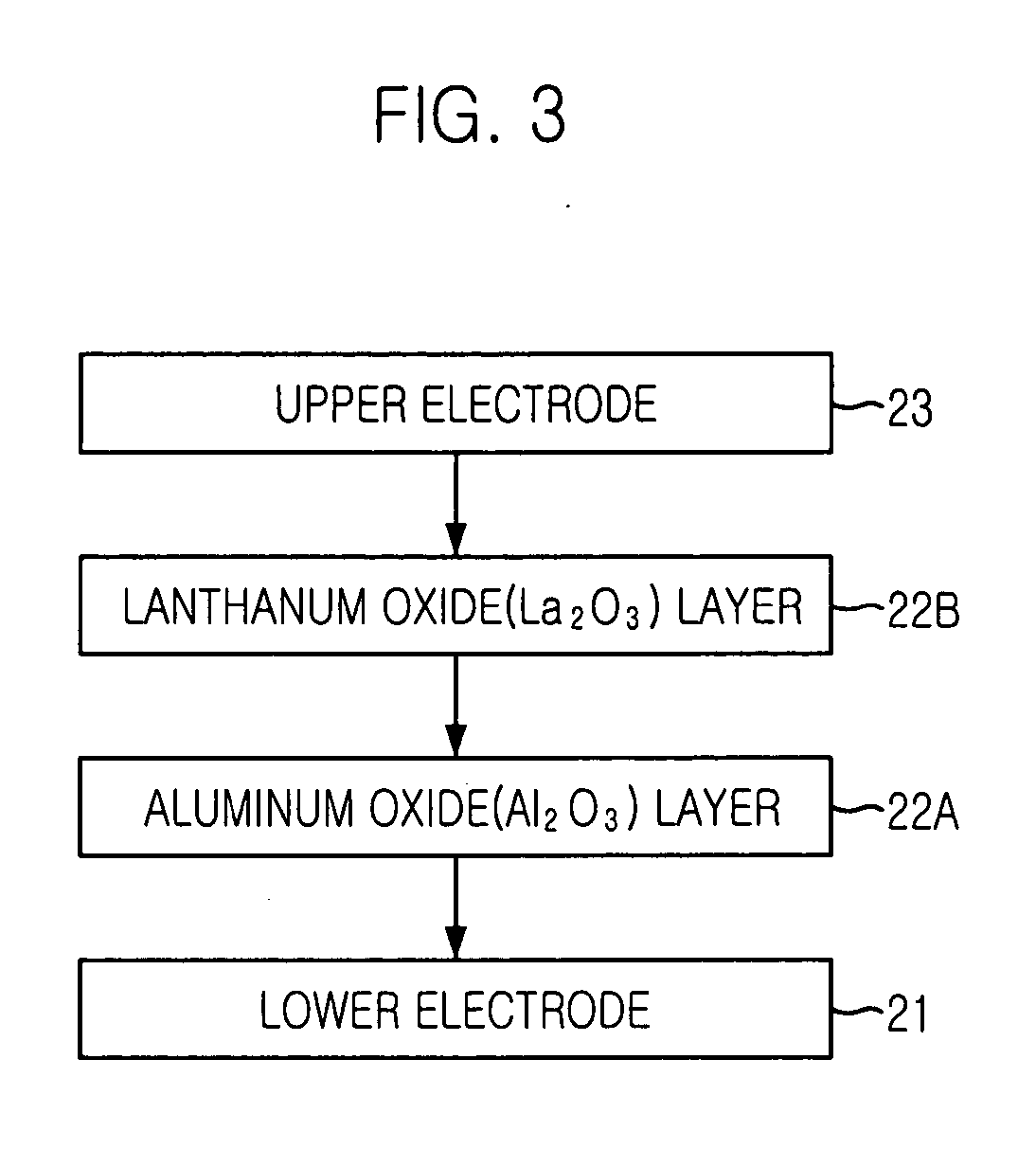

Capacitor with aluminum oxide and lanthanum oxide containing dielectric structure and fabrication method thereof

InactiveUS20050141168A1Reduce equivalent oxide thicknessReduce thicknessFixed capacitor dielectricSolid-state devicesHigh energyDielectric structure

Disclosed is a capacitor with a dielectric structure having an aluminum oxide layer and a lanthanum oxide layer and a fabrication method thereof. The capacitor includes: a lower electrode; a first dielectric layer with a high energy band gap formed on the lower electrode; a second dielectric layer formed on the first dielectric layer, the second dielectric layer with a high dielectric constant, wherein an energy band gap of the second dielectric layer is lower than the energy band gap of the first dielectric layer; and an upper electrode formed on the second dielectric layer.

Owner:SK HYNIX INC

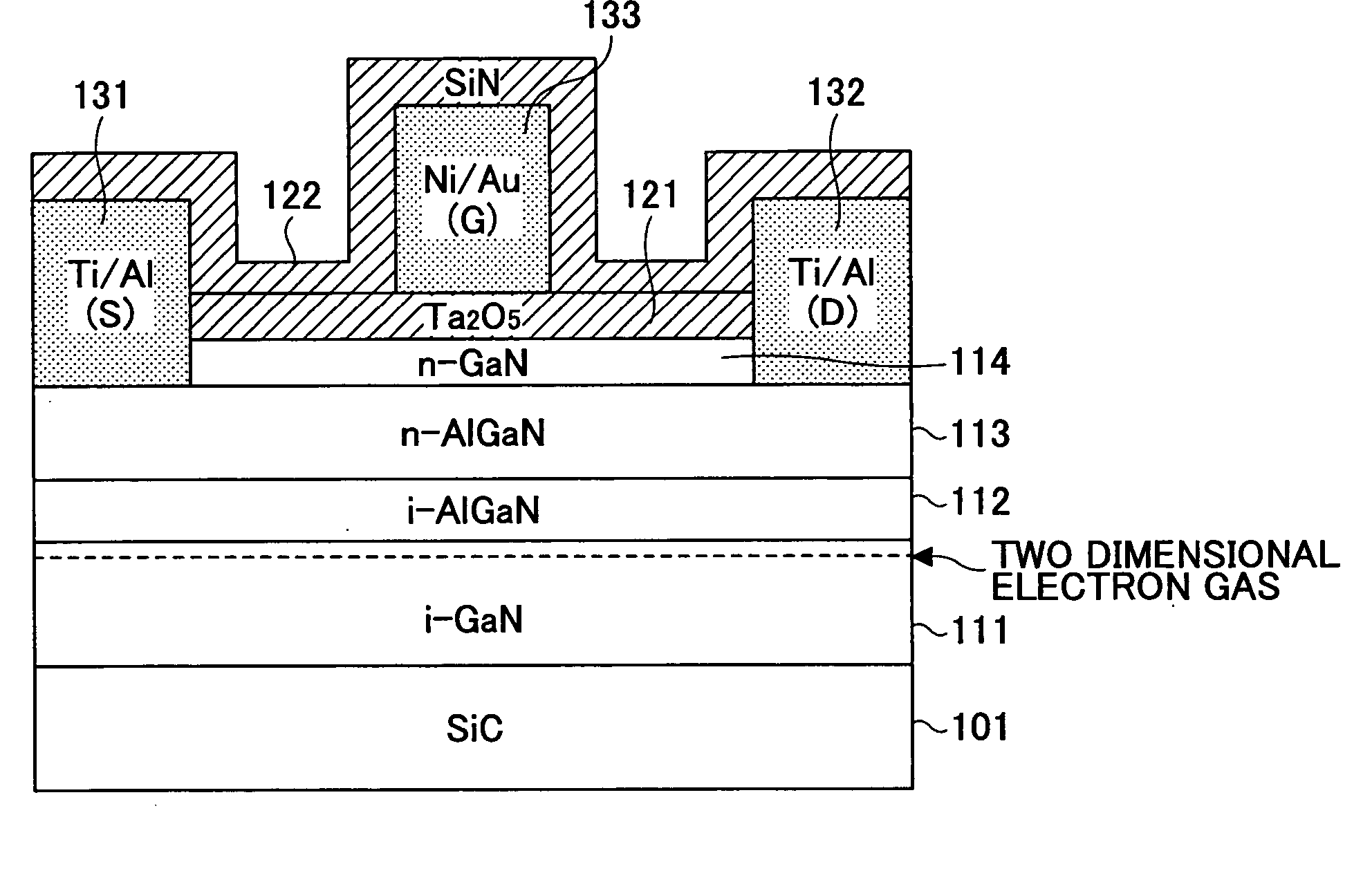

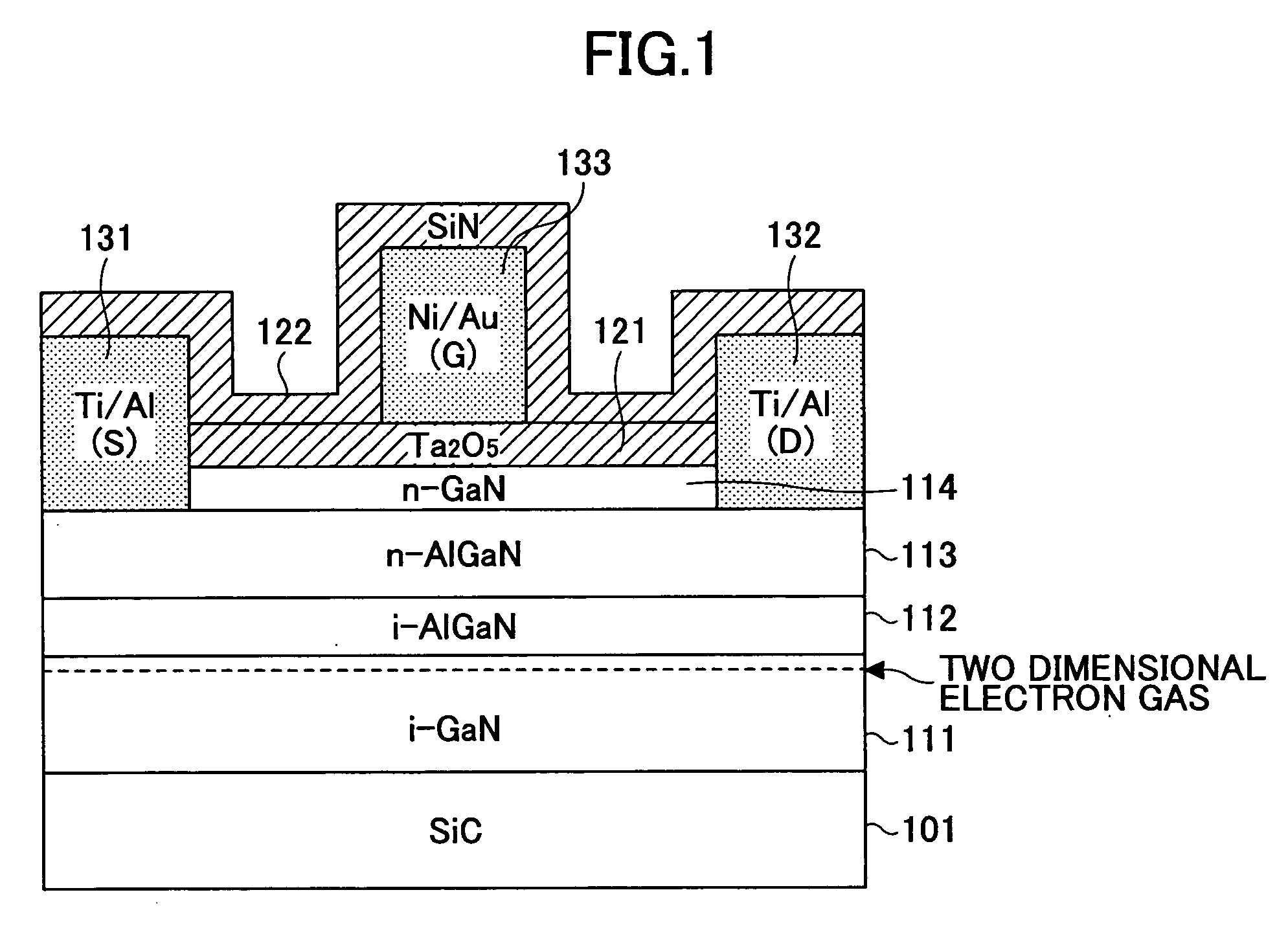

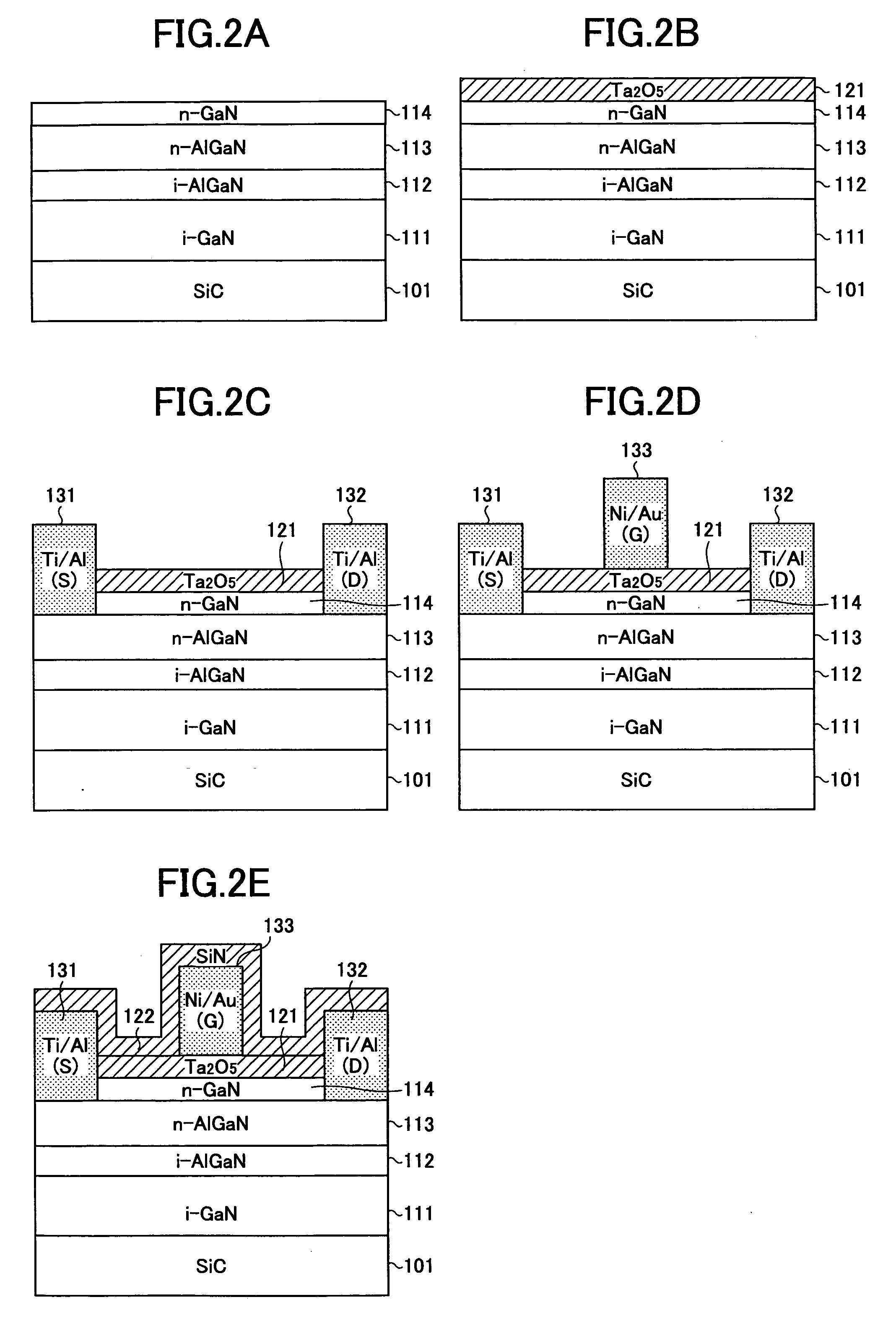

Semiconductor device and production method thereof

InactiveUS20060197107A1Reduce gate leakage currentSimple interfaceSemiconductor devicesGate leakage currentDevice material

A semiconductor device formed from a III-V nitride family semiconductor is disclosed that has a reduced gate leakage current and good interface characteristics between the III-V nitride family semiconductor and a gate insulating film. The semiconductor device includes a semiconductor layer formed from the III-V nitride family semiconductor, a gate insulating film on the semiconductor layer, and a gate electrode on the gate insulating film. The gate insulating film is formed from one of a tantalum oxide, a hafnium oxide, a hafnium aluminum oxide, a lanthanum oxide, and a yttrium oxide.

Owner:FUJITSU LTD

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

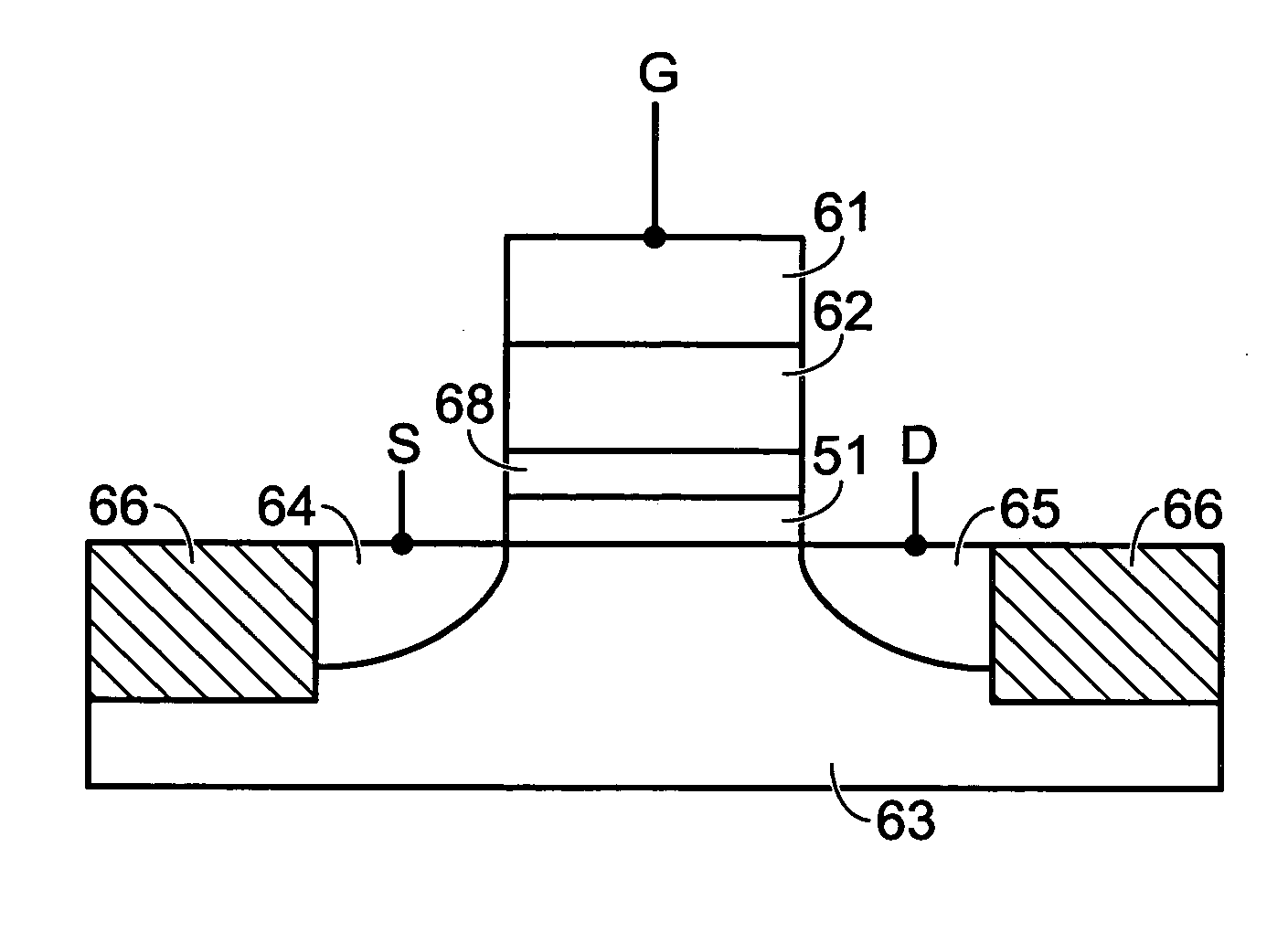

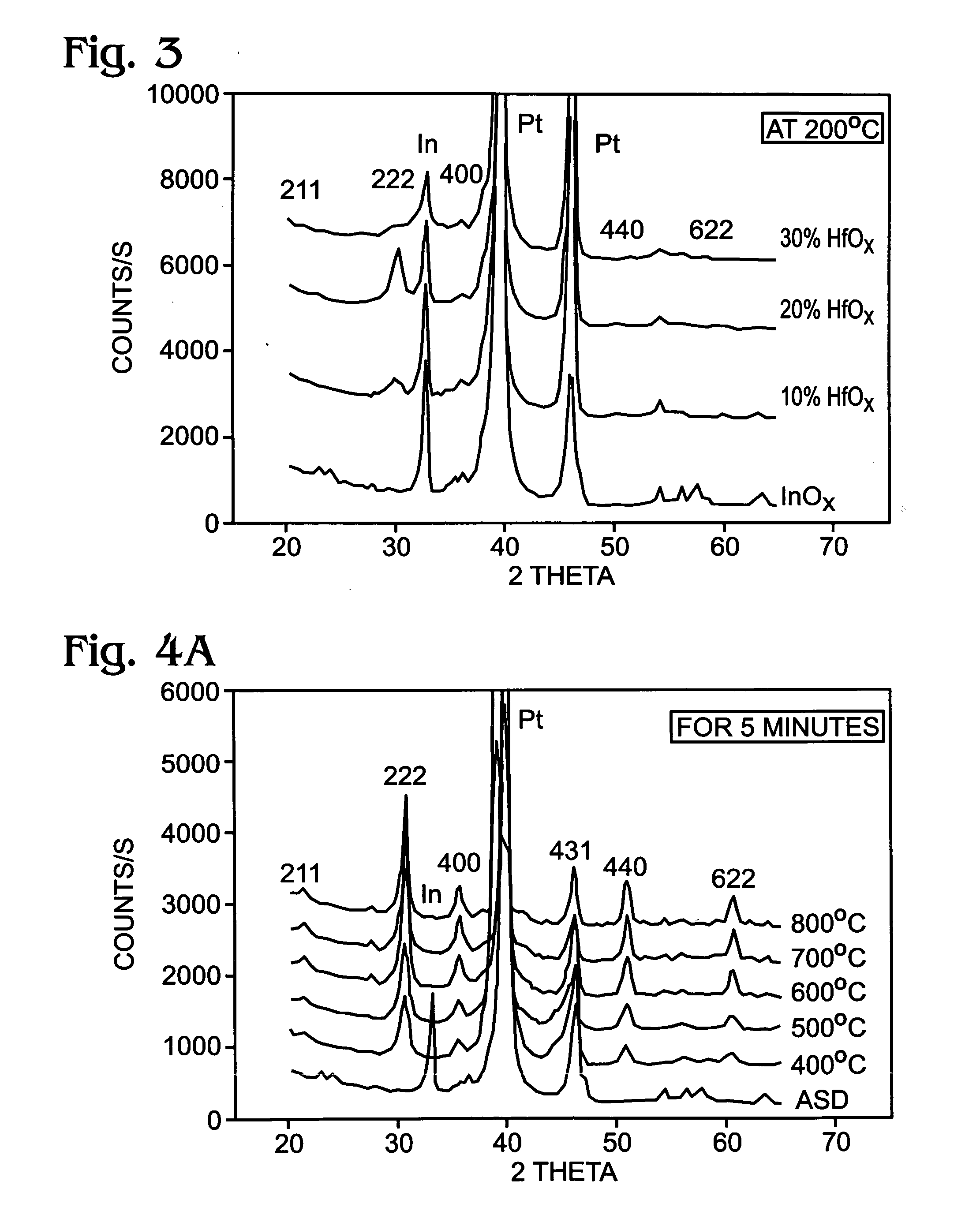

In2O3 thin film resistivity control by doping metal oxide insulator for MFMox device applications

ActiveUS20050151210A1Reduce chargeImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesMemory retentionFilm resistance

The present invention discloses a novel ferroelectric transistor design using a resistive oxide film in place of the gate dielectric. By replacing the gate dielectric with a resistive oxide film, and by optimizing the value of the film resistance, the bottom gate of the ferroelectric layer is electrically connected to the silicon substrate, eliminating the trapped charge effect and resulting in the improvement of the memory retention characteristics. The resistive oxide film is preferably a doped conductive oxide in which a conductive oxide is doped with an impurity species. The doped conductive oxide is most preferred to be In2O3 with the dopant species being hafnium oxide, zirconium oxide, lanthanum oxide, or aluminum oxide.

Owner:SHARP KK

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

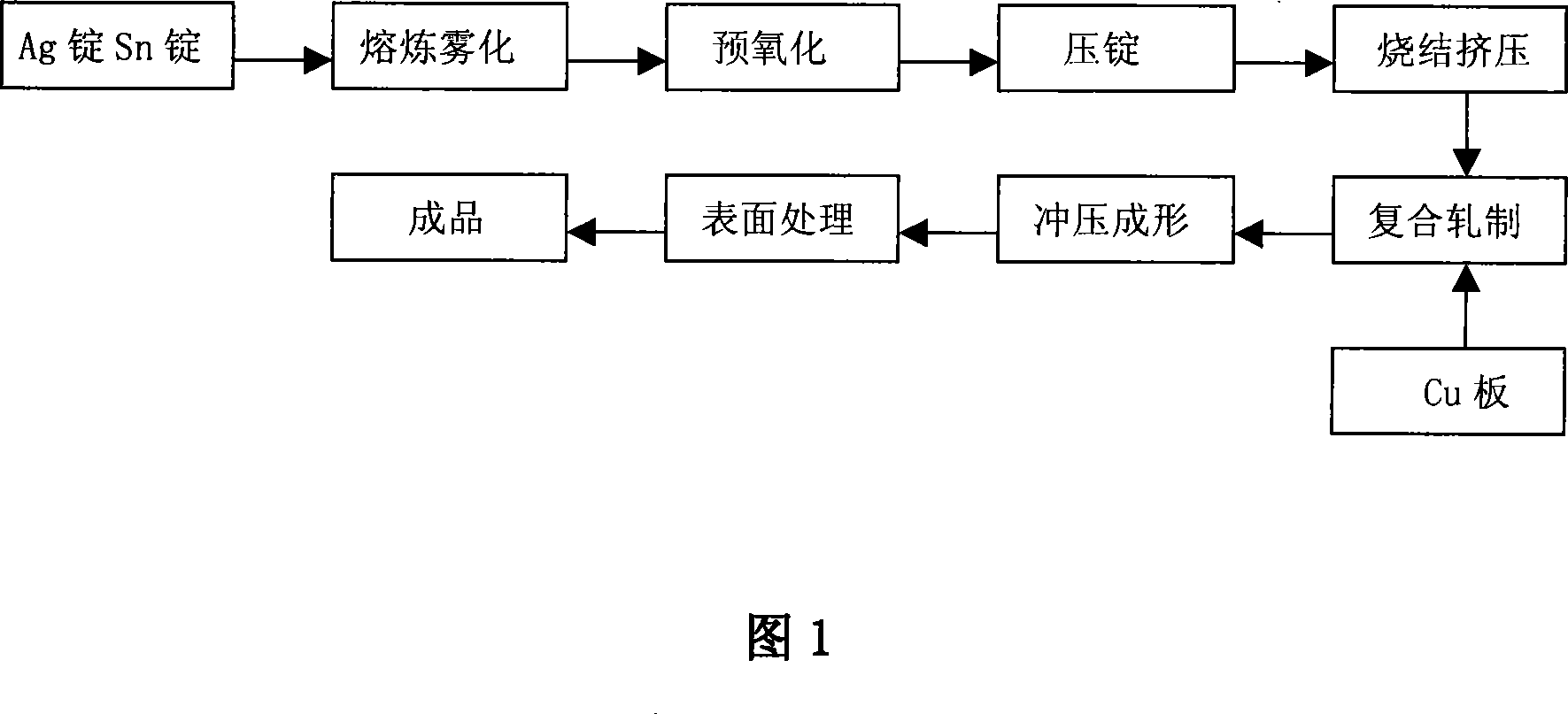

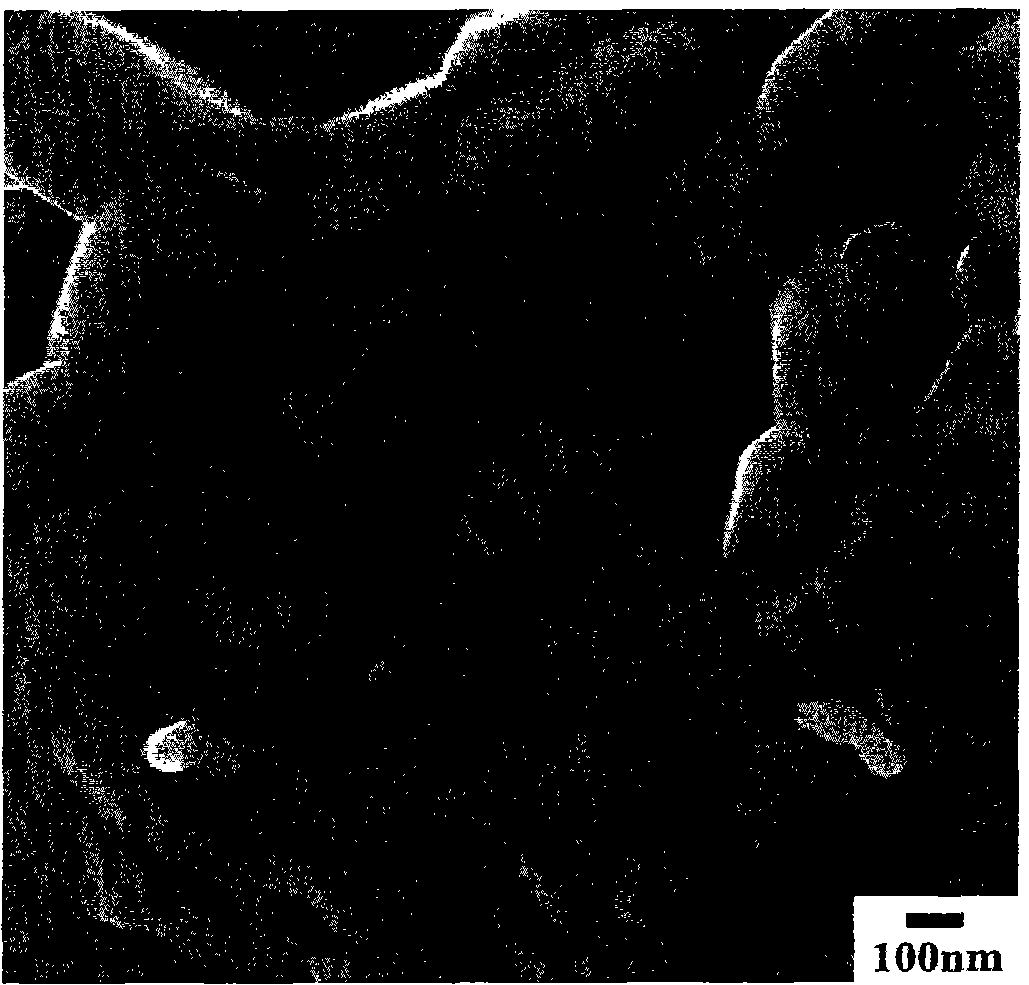

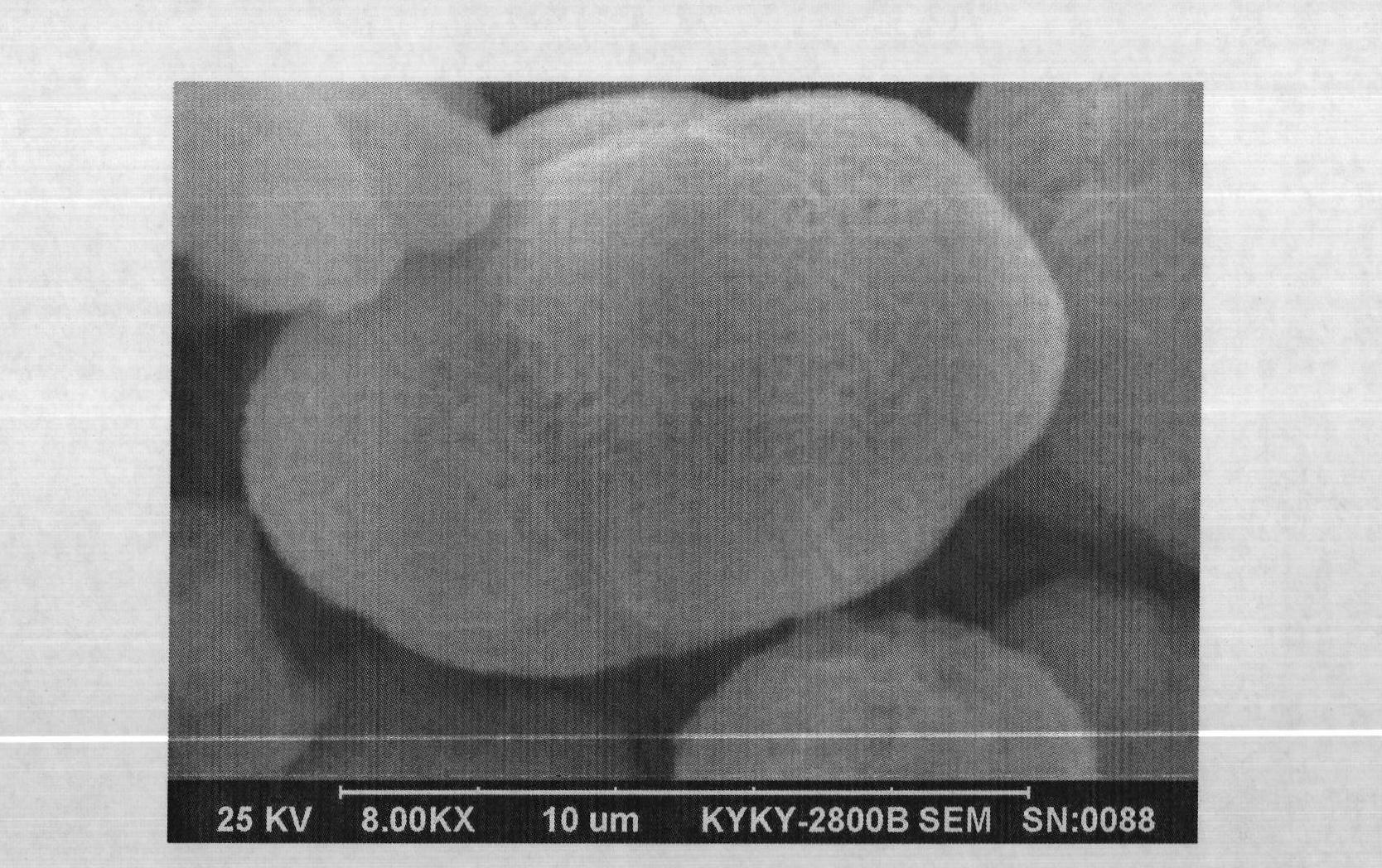

A silver tin/copper oxide compound electrical contact and preparation method

The invention relates to a silver tin oxide / copper compound electrical contact, a working layer of the electrical contact material is composed of silver, tin oxide and mixed rare earth oxide, the weight content of all the components is: 85 percent to 94 percent of Ag, 6 percent to 15 percent of SnO2 and 0.1 percent to 2.0 percent of mixed rare earth oxide, and a welding layer is T2 copper. The weight content of SnO2 is 8 to 12 percent preferentially. The mixed rare earth oxide is a mixture of cerium oxide, lanthanum oxide and yttrium oxide. The preparation method is that the silver and the tin are first mixed according to certain proportion and then are smelted in an intermediate frequency furnace, then high-pressure water atomization equipment is used for carrying out alloy atomization, powder is obtained by drying after the atomization, the powder is screened and arranged in an internal oxidation furnace to carry out the oxidation at certain temperature and oxygen pressure, then billet is obtained by the processing of isostatic cool pressing after the oxidation, after that, a plate is formed by carrying out the sintering and extruding, and finally the finished product is obtained by compound rolling with the copper. The electrical contact is characterized by high conductivity, even and exquisite texture, high bonding strength of the working layer and the welding layer, welding resistance and arc erosion resistance.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Low carbon alkane dehydrogenation catalyst and its preparation method and application

ActiveCN103769079AHigh activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The invention discloses a low carbon alkane dehydrogenation catalyst and its preparation method and application. The low carbon alkane dehydrogenation catalyst uses La-containing alumina as a carrier, and chromium as an active component, taking the weight content of oxides as a reference, the lanthanum oxide content in the final catalyst is 0.1 to 5.0%, the chromium oxide content is 5.0% to 20.0%, and La in the La-containing alumina carrier is introduced in during gelatinizing in the alumina preparation process. The preparation method of the low carbon alkane dehydrogenation catalyst comprises the following steps: preparation of the La-containing Al2O3 carrier and a process of loading active component chromium by an impregnation method. The low carbon alkane dehydrogenation catalyst can be used in production of propylene by dehydrogenation of propane. The low carbon alkane dehydrogenation catalyst prepared by the method does not contain alkaline oxides to avoid strong interaction between the alkaline oxides and the active component, and the activity, stability and propylene selectivity of the low carbon alkane dehydrogenation catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

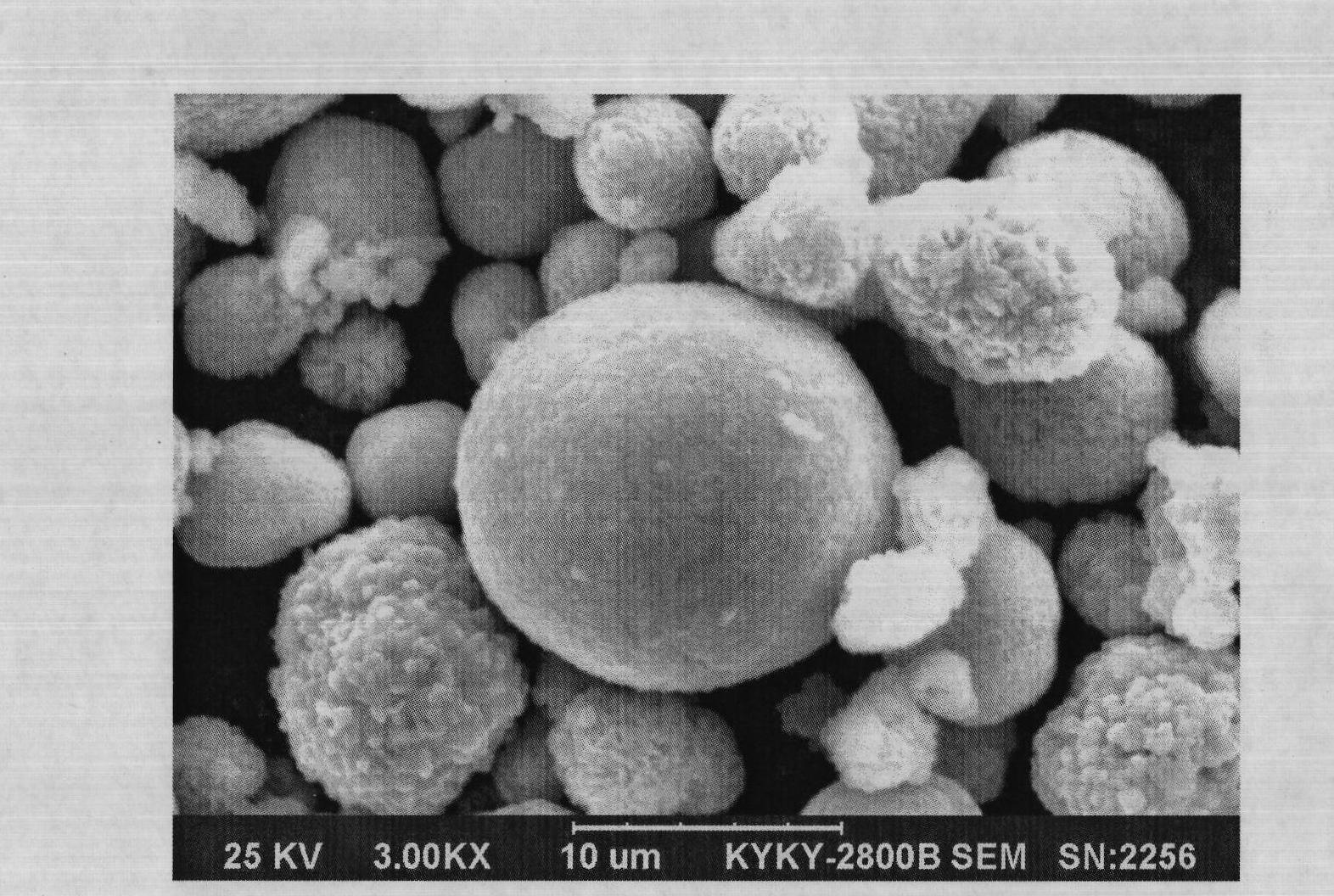

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

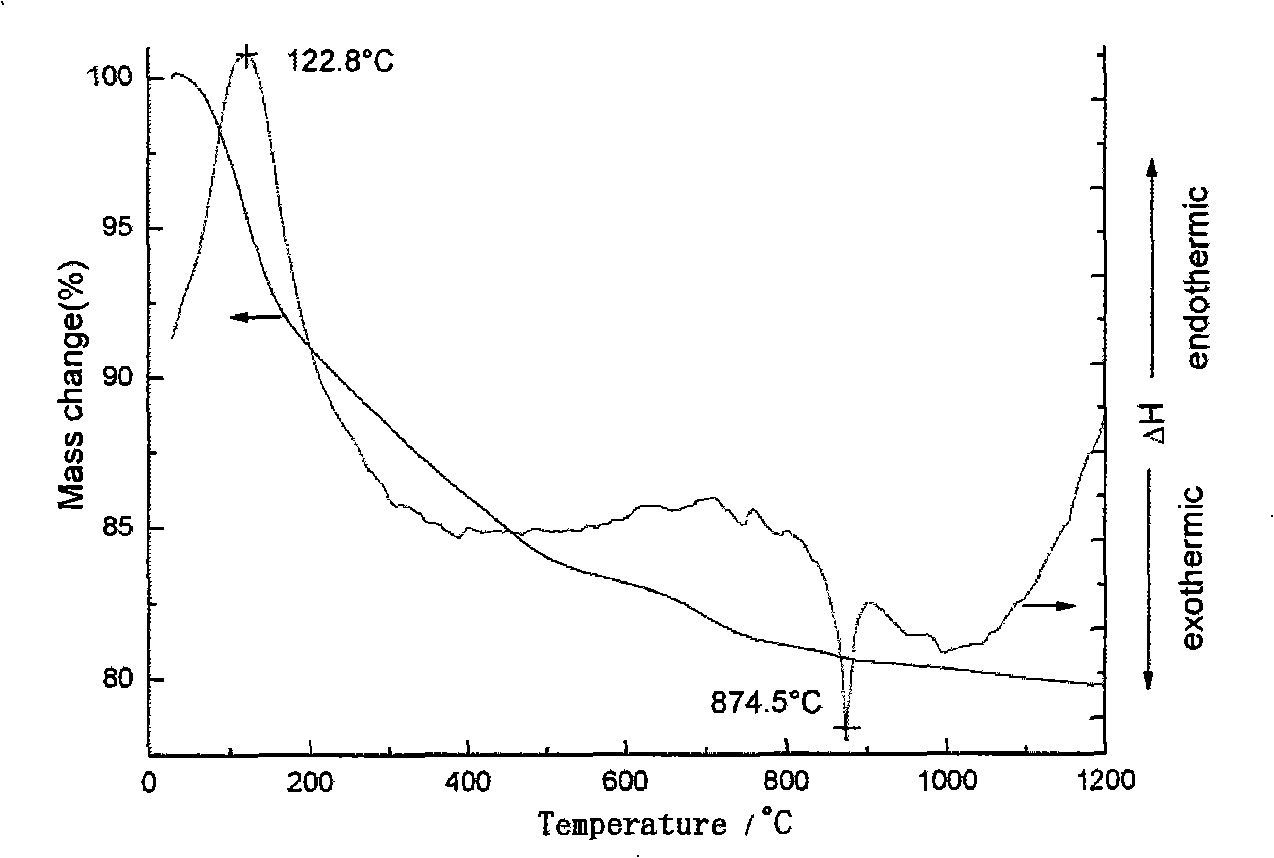

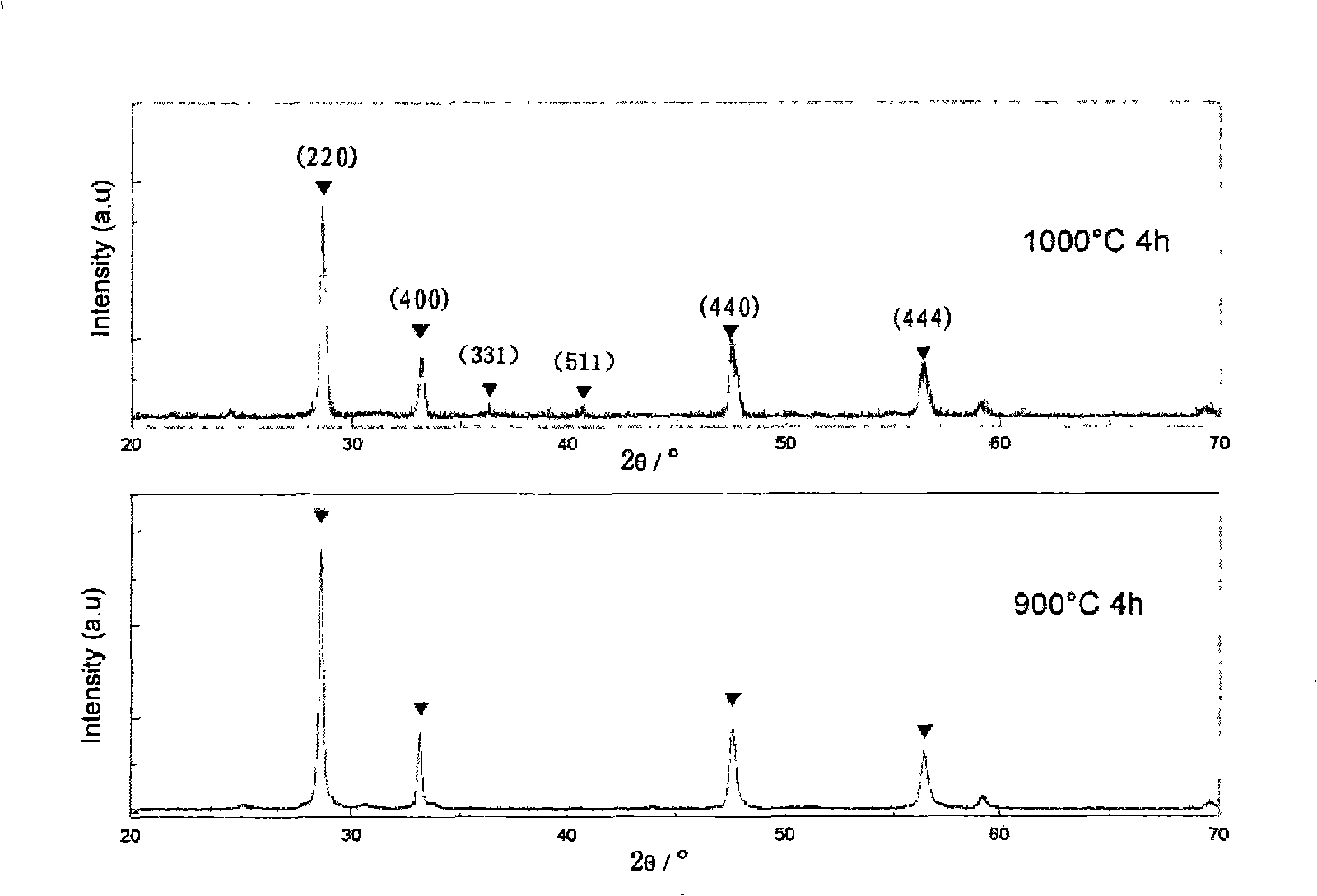

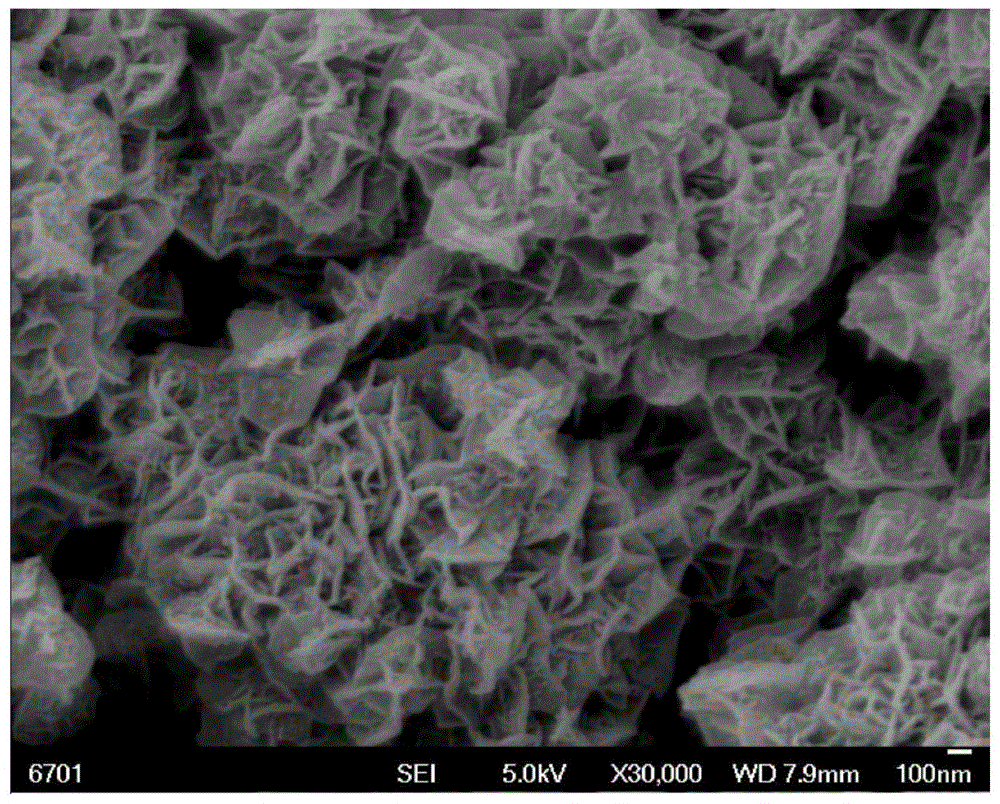

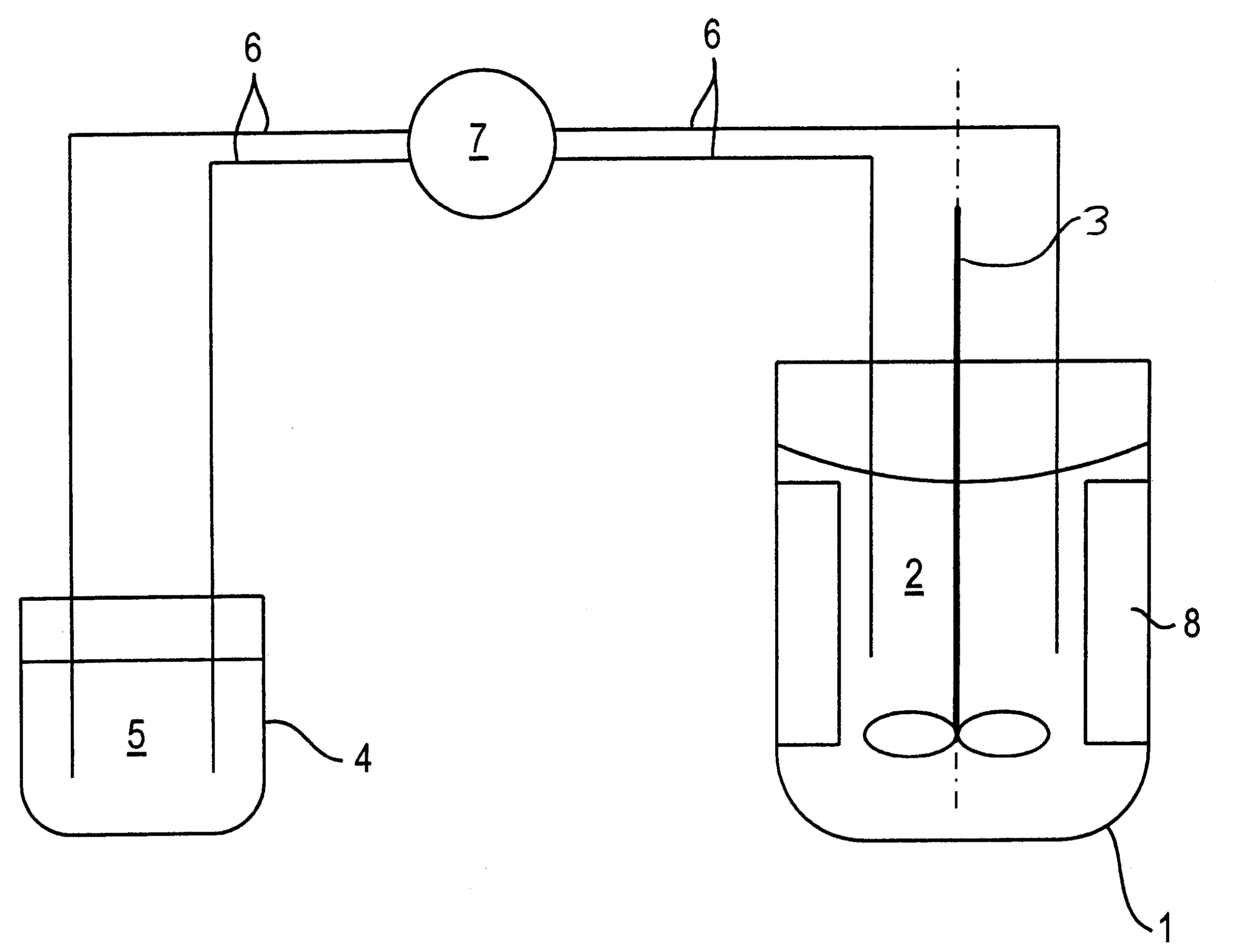

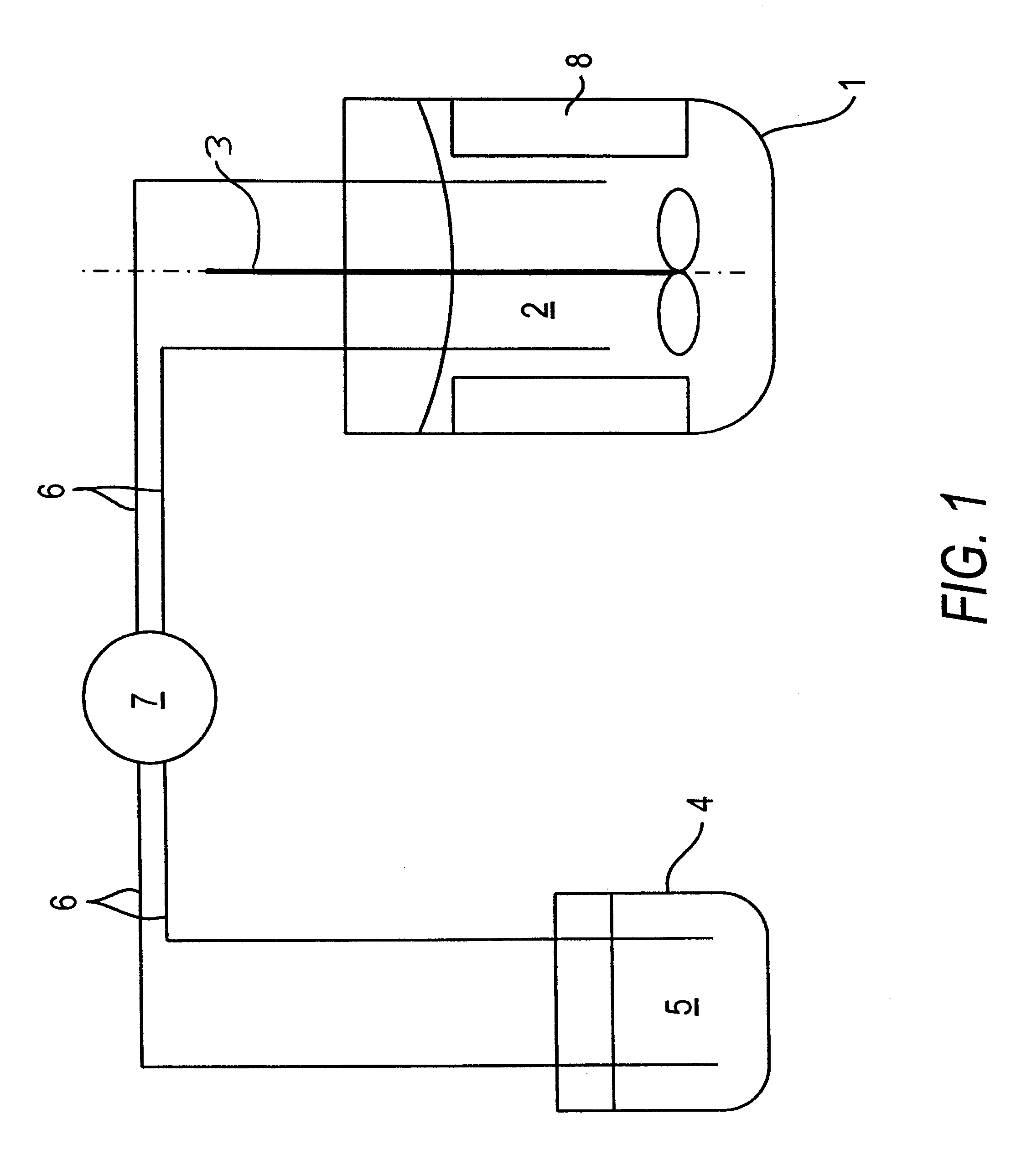

Method for preparing lanthanum zirconate powder

InactiveCN101407336ALow thermal conductivityGood heat insulationZirconium compoundsRare earth metal compoundsSolid reactionPyrochlore

The invention relates to a method for preparing a lanthanum zirconic acid powder, which belongs to the preparation field of ceramic powder used for high temperature heat barrier. The method uses lanthanum oxide or lanthanum soluble salt and zircon salt for respectively preparing the solutions containing La<3+> and Zr<4+>; the two solutions are mixed and dropped into a precipitator (or the precipitator is dropped into the mixing solutions) under continual stirring to obtain precipitate; and the precipitate are washed with a plurality of times, then dried, ground and finally calcined at certain temperature to obtain La2Zr2O7 of defect fluorite structure or pyrochlore constitution. Compared with the existing universal solid reaction process, the method lowers the synthesis temperature by 500-700 DEG C. The heat-insulating property (heat diffusivity) of the obtained power is reduced by about 50 percent compared with YSZ, and reduced by about 40 percent compared with the lanthanum zirconic acid powder obtained by the solid reaction process. The method solves the problems of overhigh heat diffusivity, severe sinter and phase change inefficiency in the existing ceramic materials used for the coating of high temperature heat barrier.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

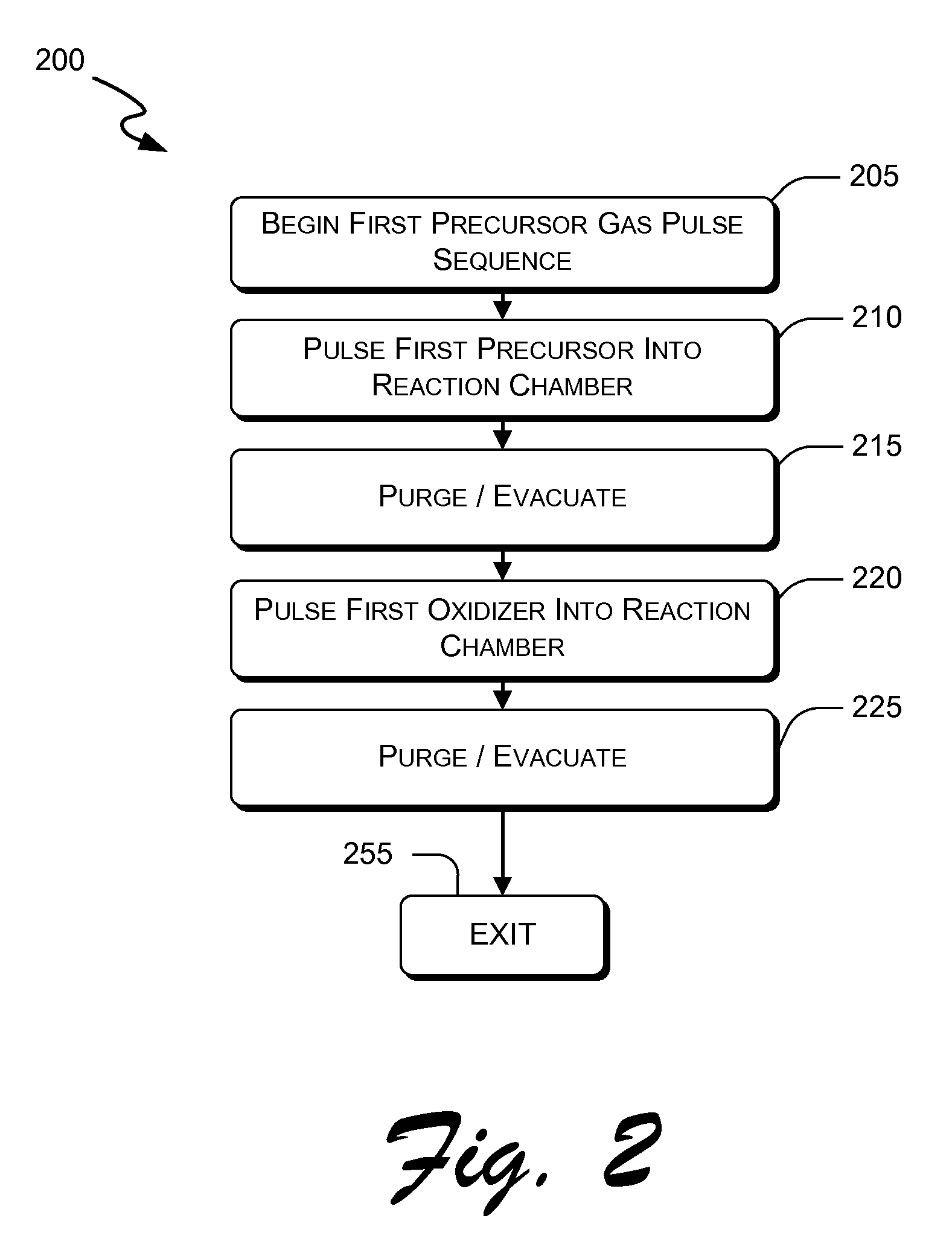

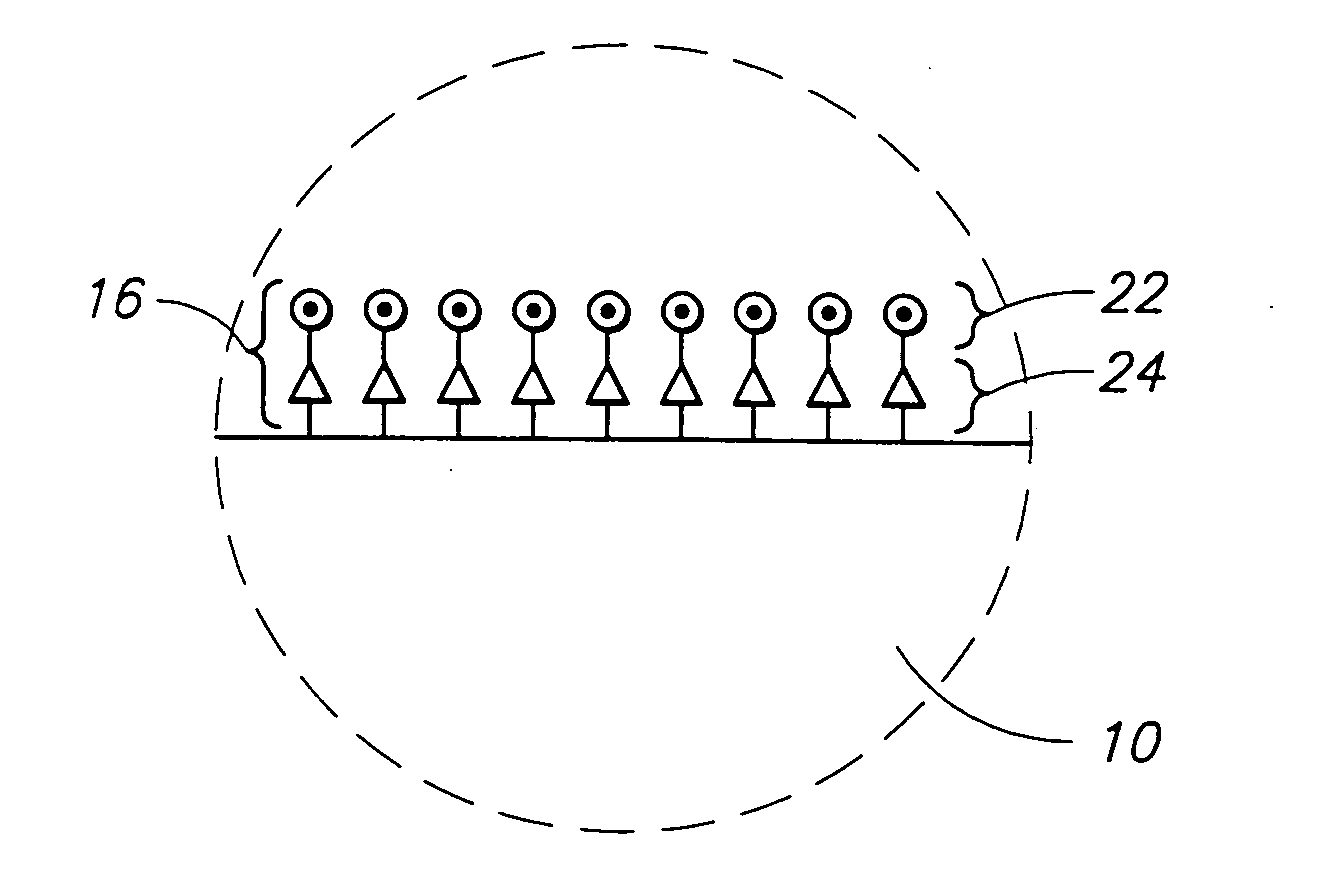

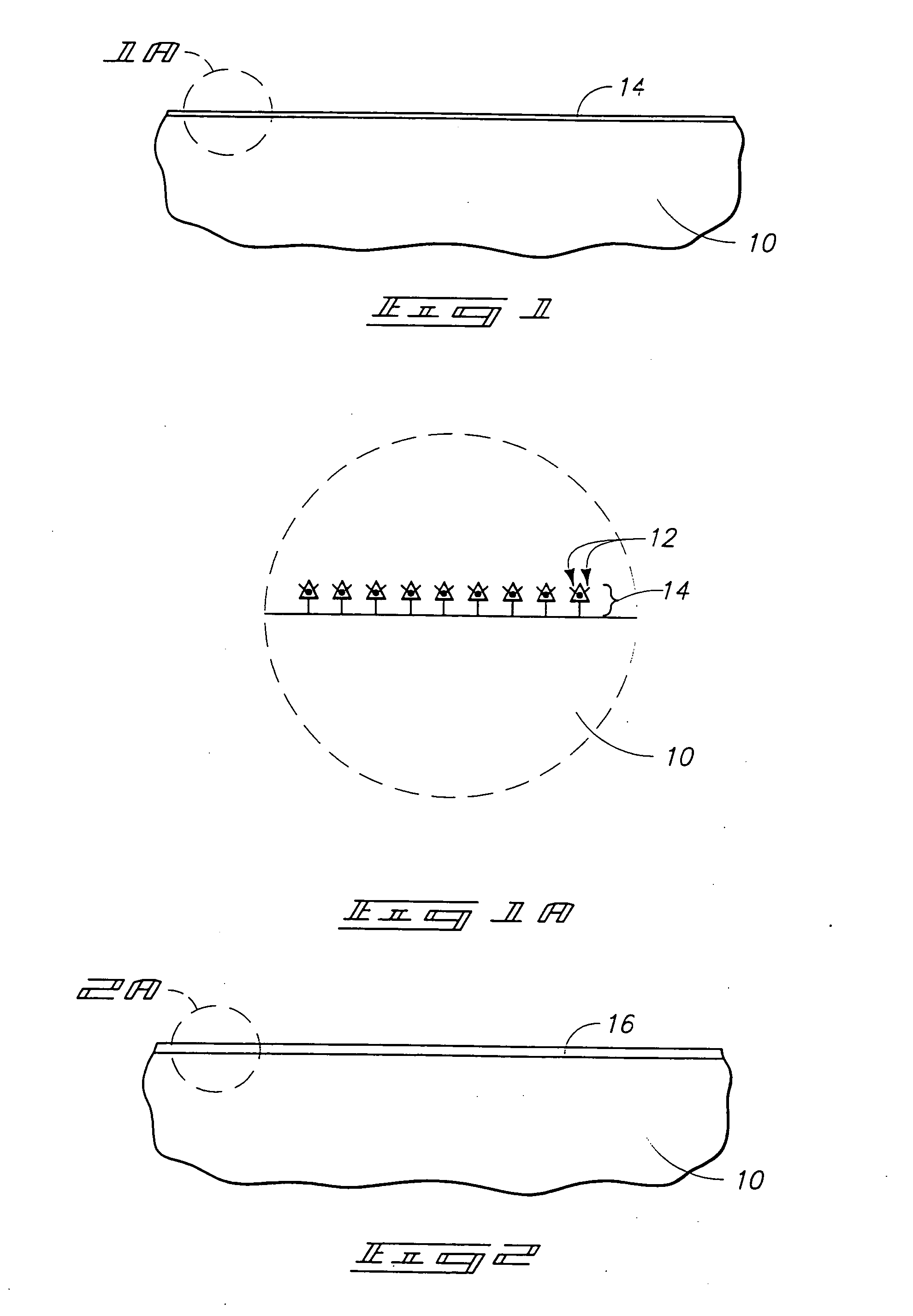

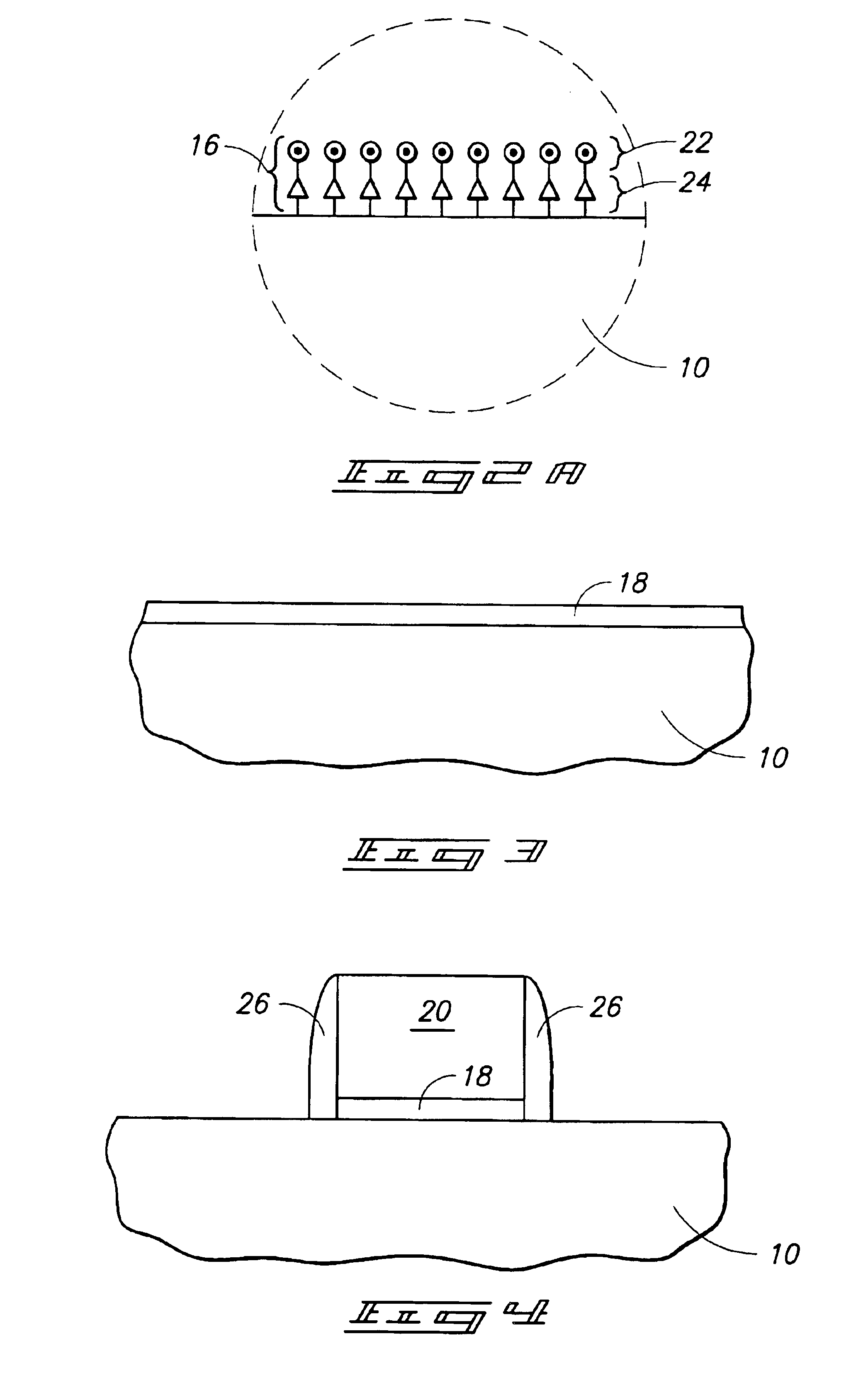

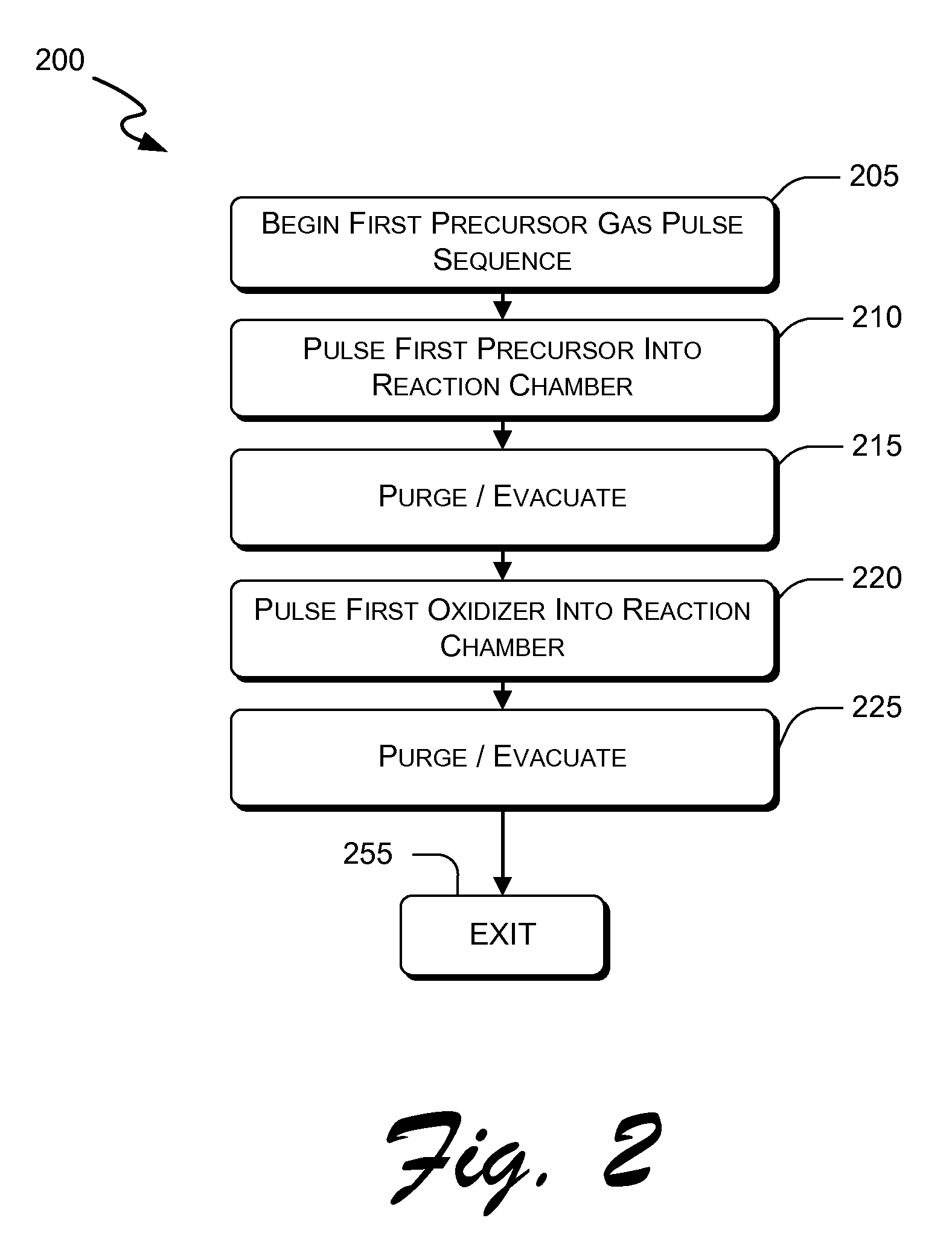

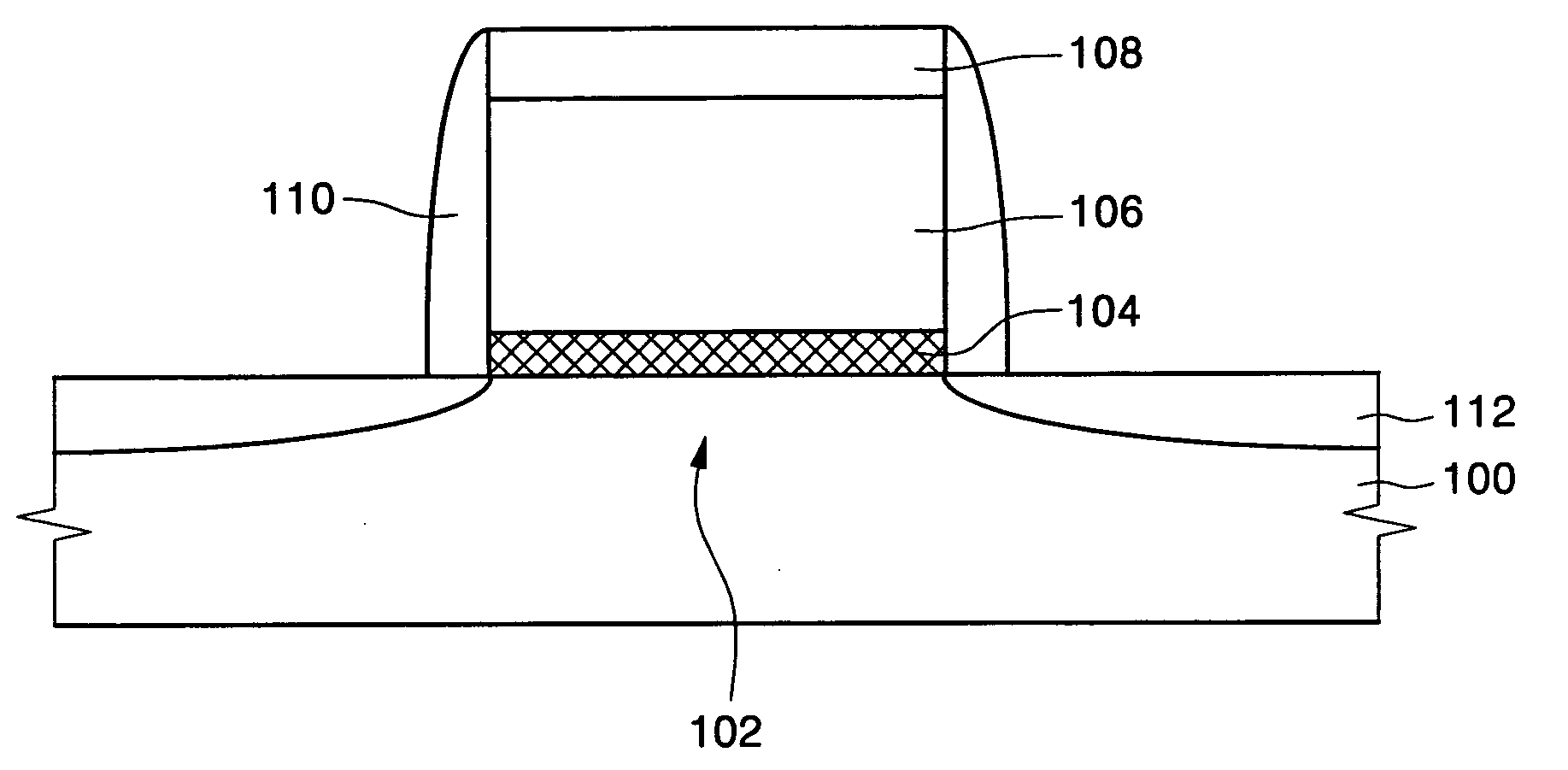

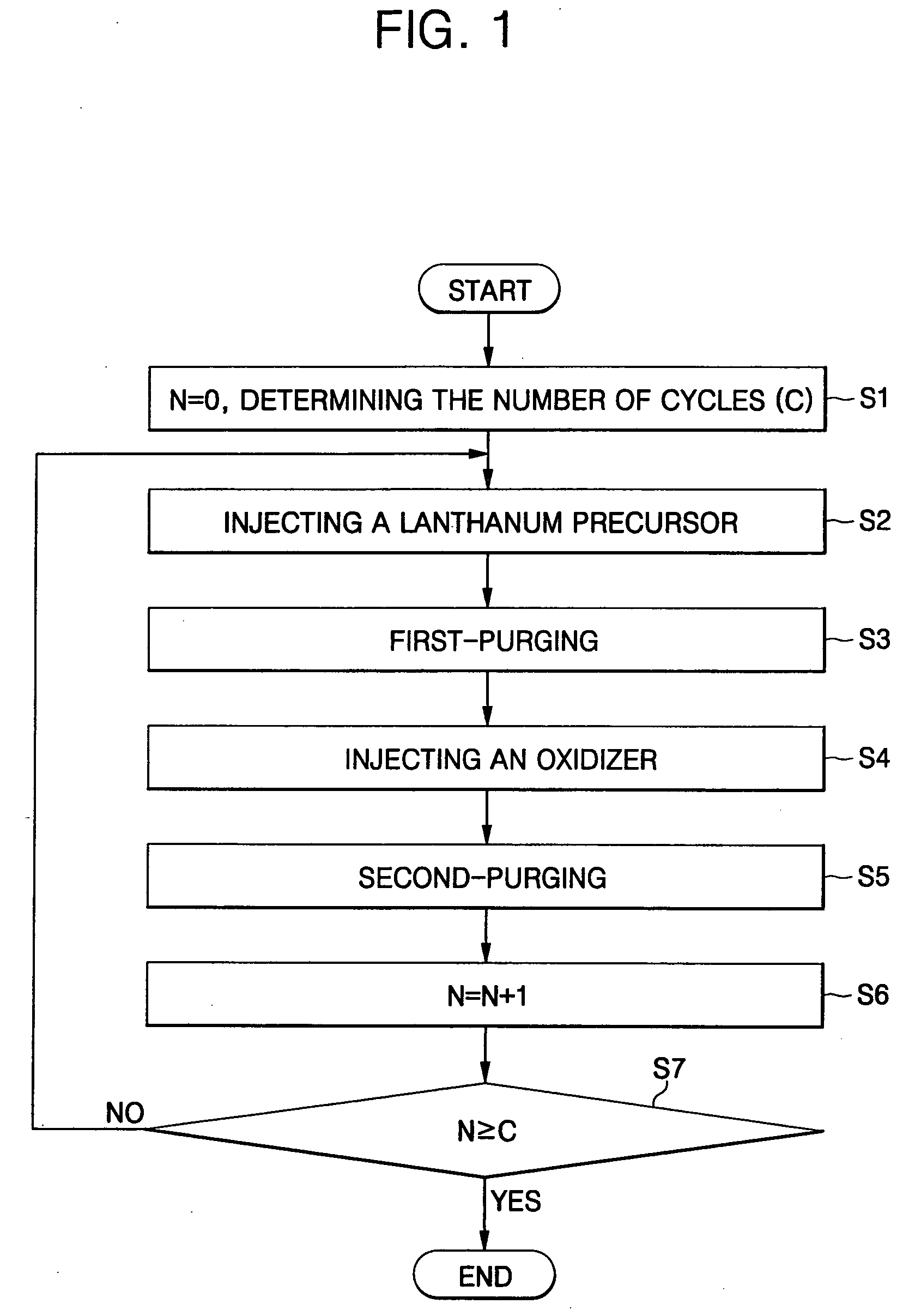

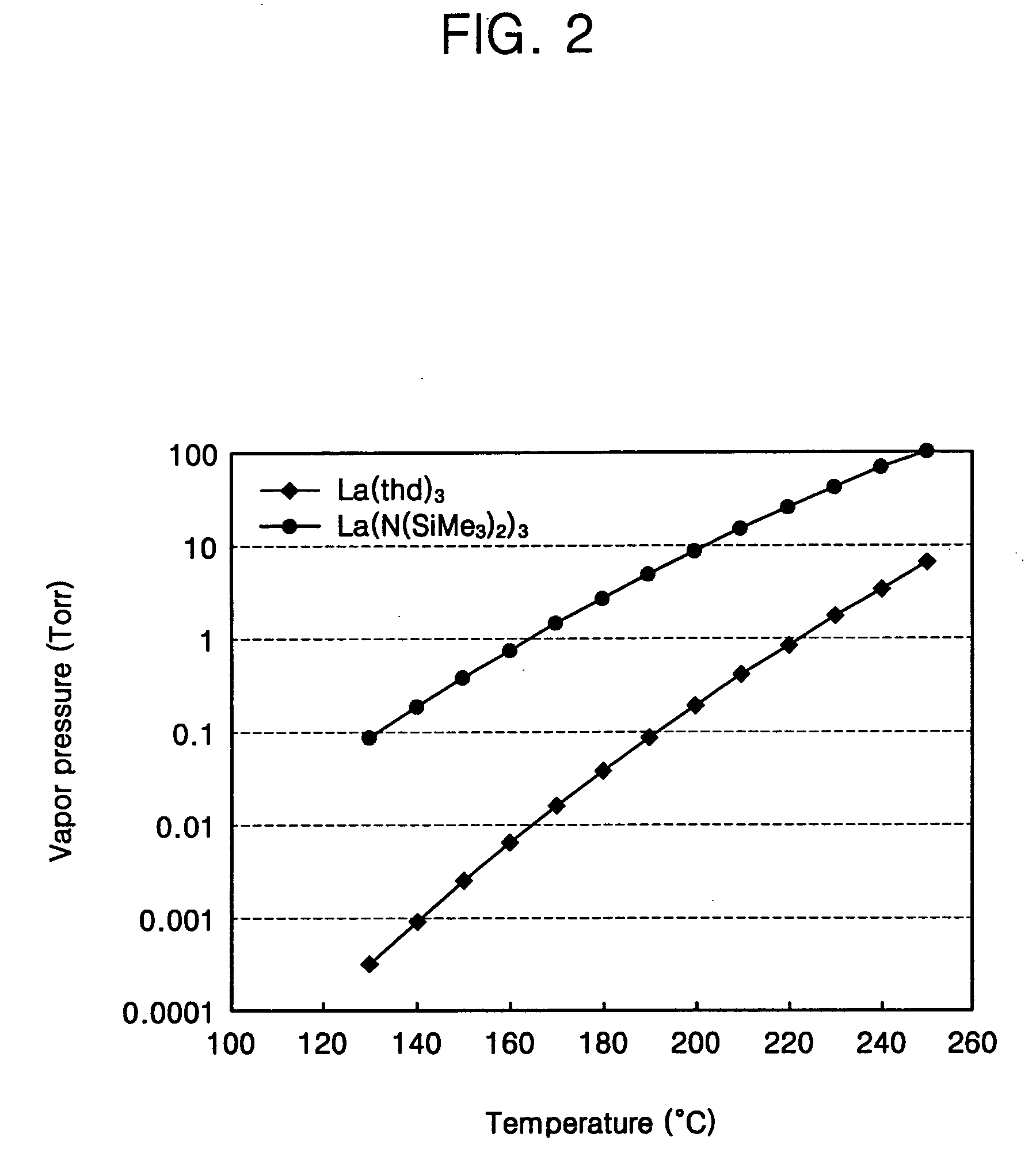

Method of fabricating lanthanum oxide layer and method of fabricating MOSFET and capacitor using the same

ActiveUS20050156256A1Improve productivityMechanical apparatusSemiconductor/solid-state device manufacturingMOSFETTrimethylsilyl

Methods of fabricating a lanthanum oxide layer, and methods of fabricating a MOSFET and / or a capacitor especially adapted for semiconductor applications using such a lanthanum oxide layer are disclosed. The methods include a preliminary step of disposing a semiconductor substrate into a chamber. Tris(bis(trimethylsilyl)amino)Lanthanum as a lanthanum precursor is then injected into the chamber such that the lanthanum precursor is chemisorbed on the semiconductor substrate. Then, after carrying out a first purge of the chamber, at least one oxidizer is injected into the chamber such that the oxidizer is chemisorbed with the lanthanum precursor on the semiconductor substrate. Then, the chamber is purged a second time. The described steps of injecting the lanthanum precursor into the chamber, first-purging the chamber, injecting an oxidizer into the chamber, and second-purging the chamber may be sequentially and repeatedly performed to form a lanthanum oxide layer of a desired thickness having enhanced semiconductor characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

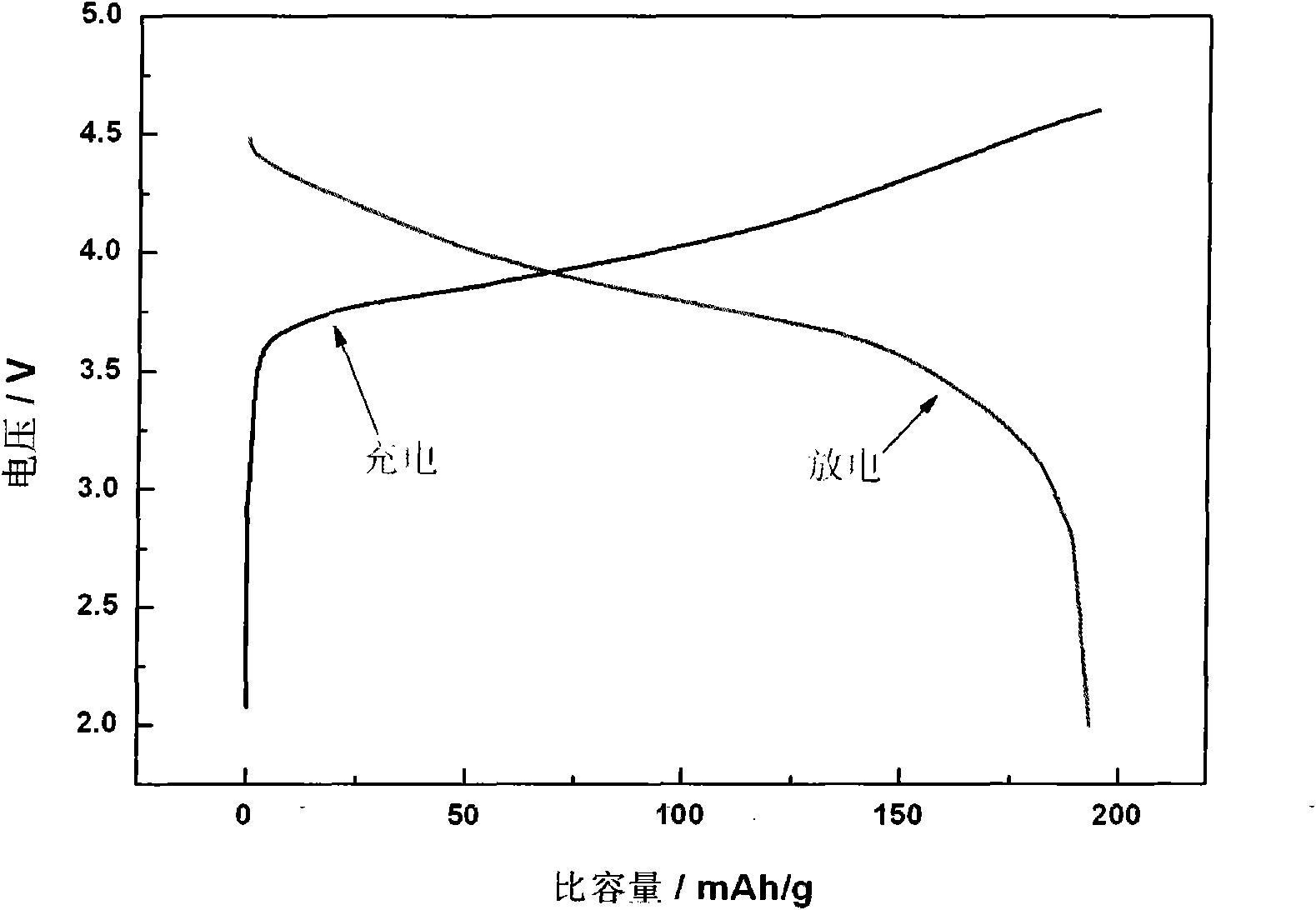

Laminated ternary positive material and preparation method thereof

The invention provides a laminated ternary positive material and a preparation method thereof. The chemical formula of the laminated ternary positive material is aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M, wherein a is more than 0 and less than 1; x is more than 0 and less than 1; y is more than 0 and less than 1; and M is aluminium oxide (Al2O3), titanium dioxide (TiO2), zirconium oxide (ZrO2), lanthanum oxide (La2O3), zinc oxide (ZnO) or magnesium oxide (MgO). The preparation method comprises the following steps of: preparing a precursor mixture; sintering the precursor mixture in a sintering furnace to synthesize a aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 positive material; and performing compounding to obtain the aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M material. The laminated ternary positive material has high energy density, a stable high-voltage charging and discharging structure, a simple preparation process and low production cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Preparation method for self-complement sub-micron crystal alumina ceramic

The invention relates to a preparation method of a low-cost self-reinforced submicron grain alumina ceramic, which belongs to the fine ceramic field. The method comprises the steps of: adopting industrial aluminum hydroxide or boehmite as a raw material, adding fine grain Alpha-alumina and water for ball milling so as to obtain an even slurry; adding water for mixing at a temperature between 70 and 90 DEG C, and adding acid to control the pH value at 2 to 5, so as to form an emulsion; and adding an additive which is a mixture selected from one or more than two of zinc oxide, magnesium oxide, calcium oxide, yttrium oxide, lanthanum oxide, zirconium oxide, boric oxide, ferric oxide, vanadium oxide, silicon oxide or titanium oxide for forming a gel after water is evaporated, and drying the gel and then sintering the gel under high temperature for preparing the self-reinforced submicron grain alumina ceramic containing alumina elongated grains. The ceramic is characterized in that crystal grains have diameters of less than 0.5mu m, and a microstructure contains elongated alumina grains have length-diameter ratios of larger than 5, and has the advantages of high hardness, high toughness and good wear resistance, and can be widely used in ceramic grinding media and the abrasives industry.

Owner:SUZHOU CHUANGYUAN INVESTMENT DEV

Low-temperature sulfur-resistant denitration catalyst and preparation method thereof

InactiveCN105727936AHigh activityImprove sulfur resistanceNitrous oxide captureHeterogenous catalyst chemical elementsCopper oxideManganese oxide

The invention discloses a preparation method of a catalyst for removing NOx in coke oven tail gas through low-temperature sulfur-resistant catalytic reduction.The catalyst is prepared by taking titanium oxide as a carrier, taking one or two of cerium oxide, zirconia oxide and lanthanum oxide as an auxiliary, taking one or more than two of manganese oxide, cobalt oxide, copper oxide and ferric oxide as an active ingredient and adopting a precipitation-deposition method, wherein two or three of TiO2, ZrO2, CeO2, La2O2, MgO, CaO and BaO can be adopted as the carrier.In the low-temperature sulfur-resistant denitration catalyst, the loading quantity of the active ingredient is 5 wt%-20 wt%, and the loading quantity of the auxiliary is 0.5%-5%.According to the preparation method, the active ingredient prepared by achieving precipitation and deposition sodium carbonate and oxidizing and loading the active ingredient manganese dioxide through potassium permanganate is mainly distributed in the surface area of the carrier, and the dosage of the active ingredient can be effectively decreased.The catalyst is high in activity and sulfur poisoning resisting capacity and particularly suitable for catalytic removal of the NOx in the coke oven tail gas, and the denitration effect of the catalyst also can be expanded to the low-temperature denitration process of other tail gases.

Owner:GANSU TIANLANG CHEM TECH CO LTD +1

Catalyst for hyrogenating deoxidating and olefine saturating of Feather synthesizing oil and its mfg. process and application

ActiveCN1597859AImprove hydrogenation activityRefining by selective hydrogenationPtru catalystCopper oxide

The invention is a hydro-deoxidation and alkene-saturation catalyst of Fischer-Tropsch oil product and its components in weight percent: nickel oxide 5.0-18.0%, cobalt oxide 0-11.0%, copper oxide 0-6.0%, iron oxide 0-12.0%, titanium oxide 0-12.0%, lanthanum oxide 0-8.0% and carrier 46.0-85.0%. Its preparing method includes in turn carrier preprocessing and after-processing of supported active component and catalyst. It has higher activity to hydro-deoxidation and alkene saturation of the oil product, especially applied to the hydrofining process of the iron-base paste Fischer-Tropsch oil product with higher content of oxygen-containing compound and alkene.

Owner:SYNFUELS CHINA TECH CO LTD

Oxygen storing material with high thermal stability and a process for preparation and use thereof

An oxygen storing material with high thermal stability is disclosed which contains cerium oxide and at least one stabilizer from the group praseodymium oxide, lanthanum oxide, yttrium oxide and neodymium oxide, wherein the stabilizer(s) and optionally cerium oxide are present in highly dispersed form on the specific surface area of a high surface area support material from the group aluminum oxide, zirconium oxide, titanium oxide, silicon dioxide, cerium oxide and mixed oxides thereof and the oxygen storing material still has a specific surface area of more than 20, preferably more than 30 m2 / g, after calcination in air at 900° C. for a period of 10 hours.

Owner:DMC2 DEGUSSA METALS +1

Denitration catalyst and preparation method thereof

ActiveCN104415780ASimple structureLarge specific surface areaMolecular sieve catalystsDispersed particle separationPtru catalystReaction temperature

The invention discloses a denitration catalyst and a preparation method thereof, the catalyst takes pretreated cordierite honeycomb ceramics as a matrix, a silicon-aluminum coating, a composite coating and an active component are coated on the surface of the matrix, by measuring gross weight of the catalyst, the catalyst contains 80-90wt% of cordierite honeycomb ceramics, 2-9wt% of silicon-aluminium coating, 3-10wt% of composite coating, and 0.01-15wt% of active component, wherein the active component can be Mn and Fe; by measuring gross weight of the silicon-aluminum coating, the silicon-aluminum coating comprises 10-50wt% of silica, and 50-90wt% of alumina; by measuring gross weight of the composite coating, the composite coating contains 40-80wt% of titanium dioxide, 5-35wt% of ZSM-5 molecular sieve, and 10-40wt% of auxiliary agent; wherein the auxiliary agent is selected from one or more of cerium oxide, zirconia or lanthana. The denitration catalyst has the advantages of large coating load capacity, high firmness, good poison-resistance performance and activity, and wide reaction temperature window; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com