Low-temperature sulfur-resistant denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of increasing pore volume and specific surface area, short service life, and low sulfur resistance performance , to achieve the effect of easy reaction, simple and easy preparation method and good sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

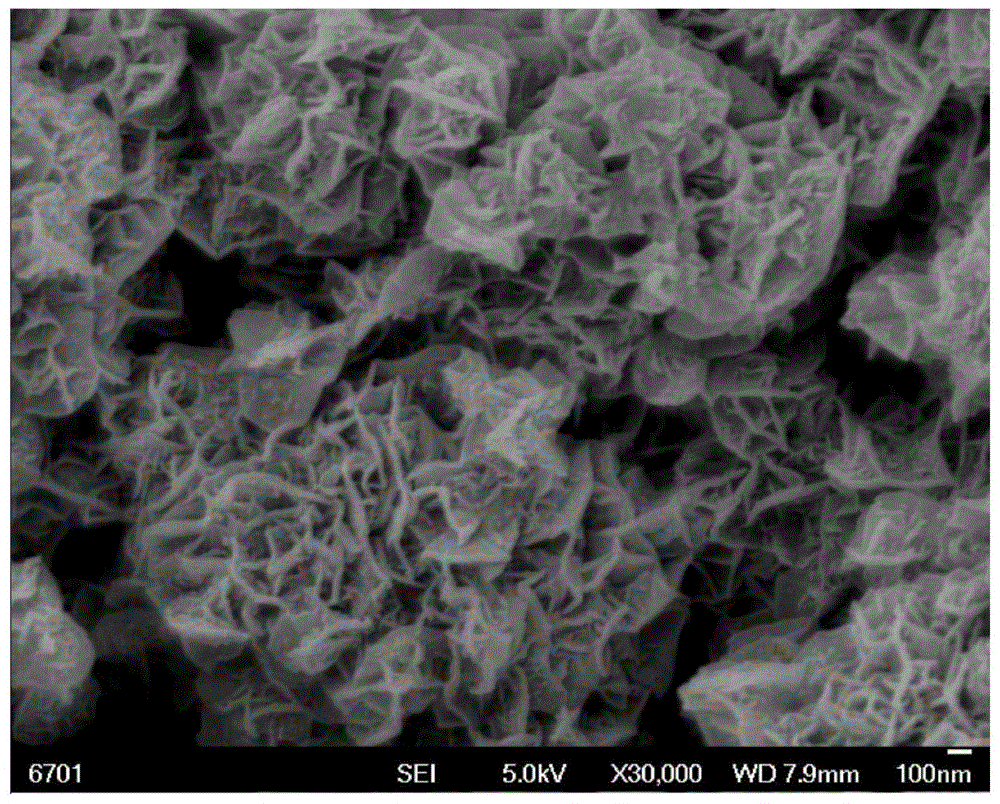

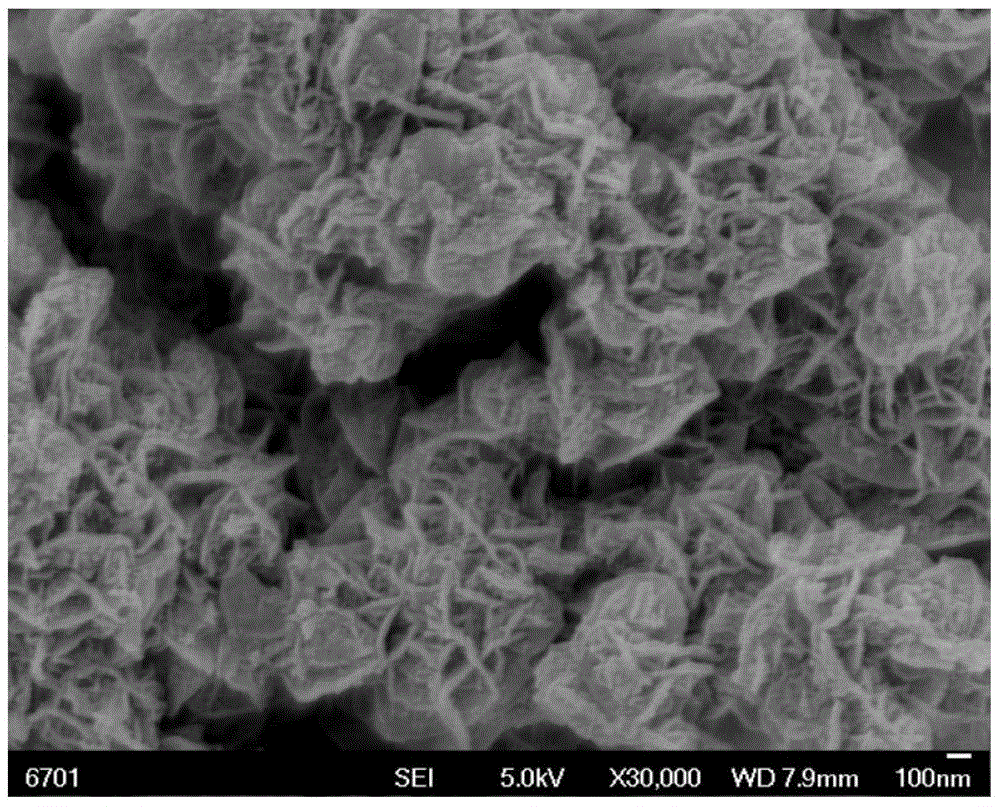

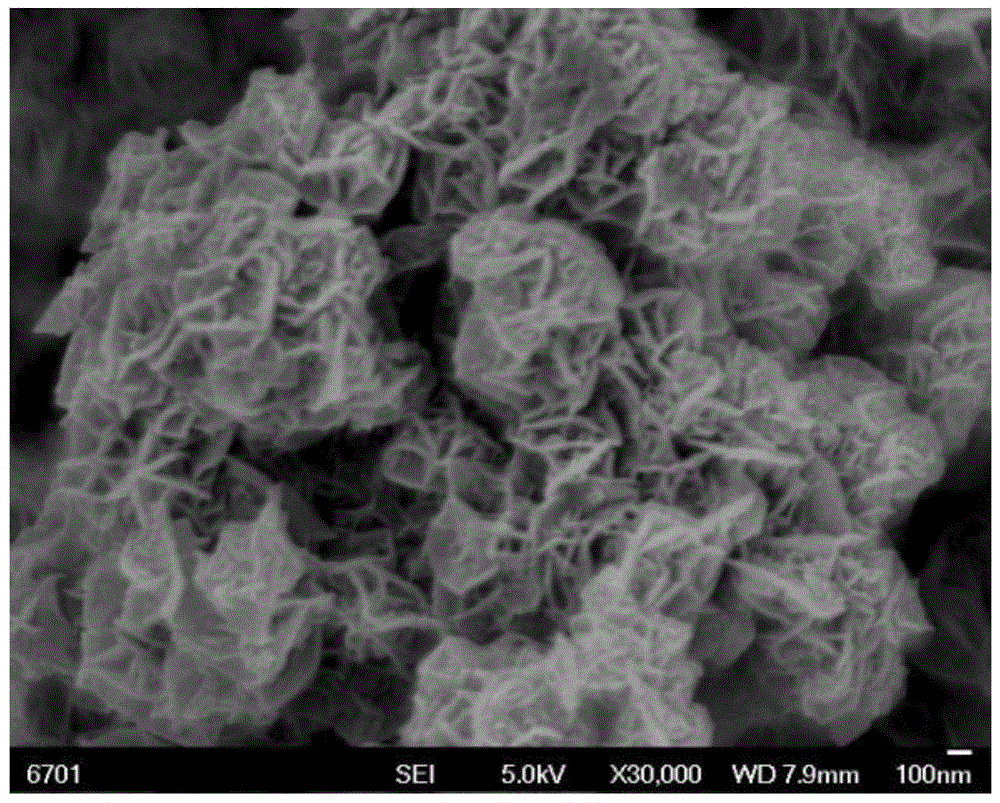

Image

Examples

Embodiment 1

[0029] A low-temperature sulfur-resistant denitrification catalyst is characterized in that it mainly consists of the following components in mass percentages: 5% of active components, 0.5% of additives, and the balance of catalytic carriers.

[0030] The carrier can be TiO 2 and ZrO 2 .

[0031] The active component is manganese oxide.

[0032] The auxiliary agent is cerium oxide.

[0033] A method for preparing a low-temperature sulfur-resistant denitrification catalyst, comprising the following method steps,

[0034] (1) Catalyst powder preparation: at room temperature, the molar ratio of titanium tetrachloride to sodium carbonate is 1:3, and titanium tetrachloride is slowly added to a sodium carbonate solution with a mass fraction of 5% under stirring conditions to control carbonic acid The concentration of the sodium solution makes the end point pH value of the mixed solution 9; 2+ : Ti = 1: 4, add to the above system, after fully stirring, the final pH value of the ...

Embodiment 2

[0042] A low-temperature sulfur-resistant denitrification catalyst is characterized in that it mainly consists of the following components in mass percentages: 20% of active components, 5% of additives, and the balance of catalytic carriers.

[0043] The carrier can be CeO 2 , La 2 o 3 , MgO.

[0044] The active component is cobalt oxide.

[0045] The auxiliary agent is zirconia.

[0046] A method for preparing a low-temperature sulfur-resistant denitrification catalyst, comprising the following method steps,

[0047] (3) Catalyst powder preparation: at room temperature, the molar ratio of titanium tetrachloride to sodium carbonate is 1:5; titanium tetrachloride is slowly added to a sodium carbonate solution with a mass fraction of 20% under stirring conditions to control carbonic acid The concentration of the sodium solution is such that the pH value of the mixed solution at the end point is 10; 2+ : Ti=1:20, add to the above system, after fully stirring, the final pH v...

Embodiment 3

[0055] A low-temperature sulfur-resistant denitrification catalyst is characterized in that it is mainly composed of the following components in mass percentages: 10% of active components, 2.5% of additives, and the balance of catalytic carriers.

[0056] The carrier can be on BaO.

[0057] The active components are cobalt oxide and iron oxide.

[0058] The auxiliary agent is lanthanum oxide.

[0059] A method for preparing a low-temperature sulfur-resistant denitrification catalyst, comprising the following method steps,

[0060] (1) Catalyst powder preparation: at room temperature, the molar ratio of titanium tetrachloride to sodium carbonate is 1:4; titanium tetrachloride is slowly added to a sodium carbonate solution with a mass fraction of 10% under stirring conditions to control carbonic acid The concentration of the sodium solution makes the end point pH of the mixed solution 9.5; 2+ : Ti=1:16, add to the above system, after fully stirring, the final pH value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com