Patents

Literature

559results about How to "Improve sulfur resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

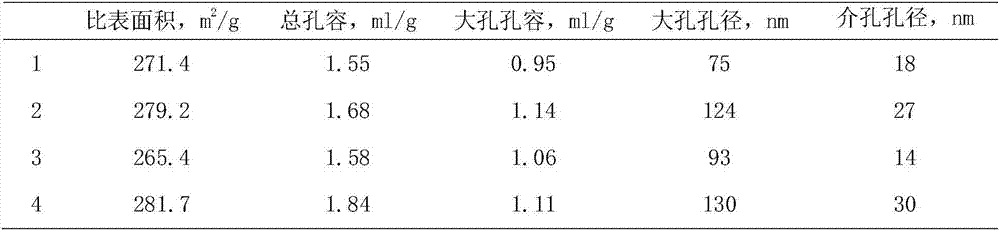

Preparation method for composite oxide carrier

ActiveCN102451765AGood dispersionLarge specific surface areaCatalyst carriersRefining to eliminate hetero atomsAluminium hydroxideAqueous solution

The present invention discloses a preparation method for a composite oxide carrier. According to the method of the present invention, a composite oxide dry glue is prepared by the following steps, wherein the steps comprise: firstly preparing an aluminum hydroxide wet filter cake and an aqueous solution containing an IVB group metal complex; adding the wet filter cake to the complex solution, andstrongly stirring; carrying out filtering and drying to obtain the composite oxide dry glue. With the composite oxide dry glue prepared by the method, most of the IVB group metal oxide can be distributed on the surface of aluminum oxide so as to reduce the influence on the pore structure of the aluminum oxide, improve the assistant catalysis effect of the IVB group metal oxide, and improve the pore structure and the surface performance of the composite oxide carrier. In addition, with the present invention, the sulfurization performance of the catalyst adopting the composite oxide carrier as the carrier can be improved, and the loaded active metal is easy to reduce.

Owner:CHINA PETROLEUM & CHEM CORP +1

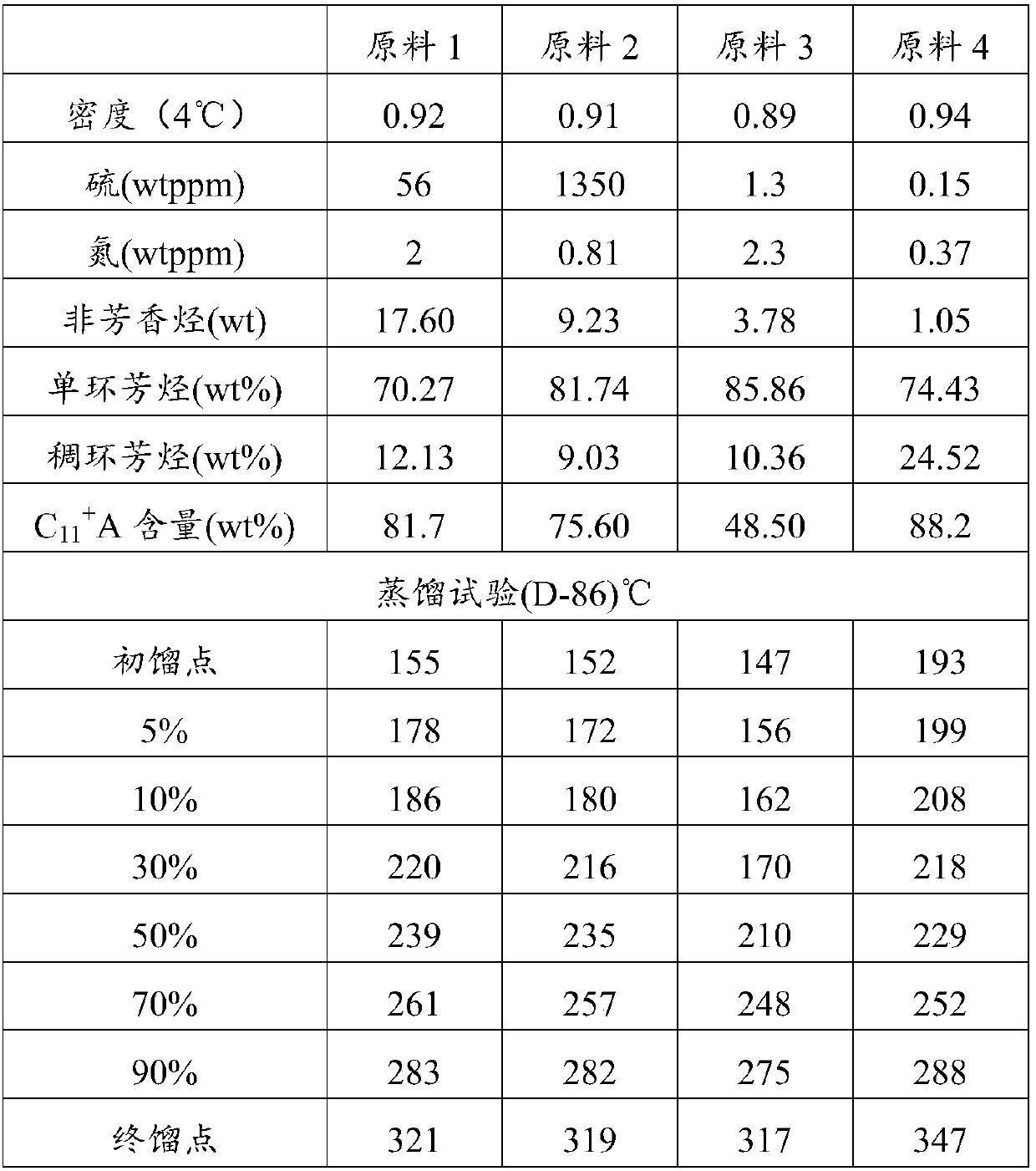

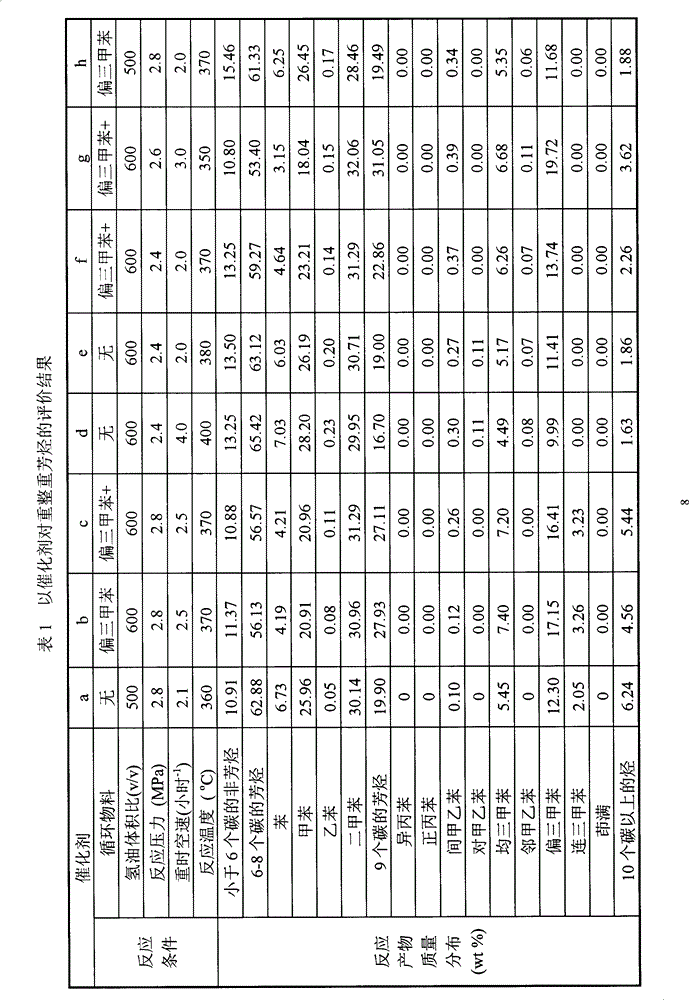

Catalyst and process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock

InactiveUS20090023968A1Large acid densityModerate activityMolecular sieve catalystsCatalyst activation/preparationPolycyclic aromatic hydrocarbonAlkane

The present invention provides a catalyst comprising metallic Pt and / or Pd supported on a binder-free zeolite for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock, wherein the amount of metallic Pt and / or Pd is of 0.01-0.8 wt %, preferably 0.01-0.5 wt % on the basis of the total weight of the catalyst, and the binder-free zeolite is selected from the group consisting of mordenite, beta zeolite, Y zeolite, ZSM-5, ZSM-11 and composite or cocrystal zeolite thereof. The present invention also provides a process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock using said catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

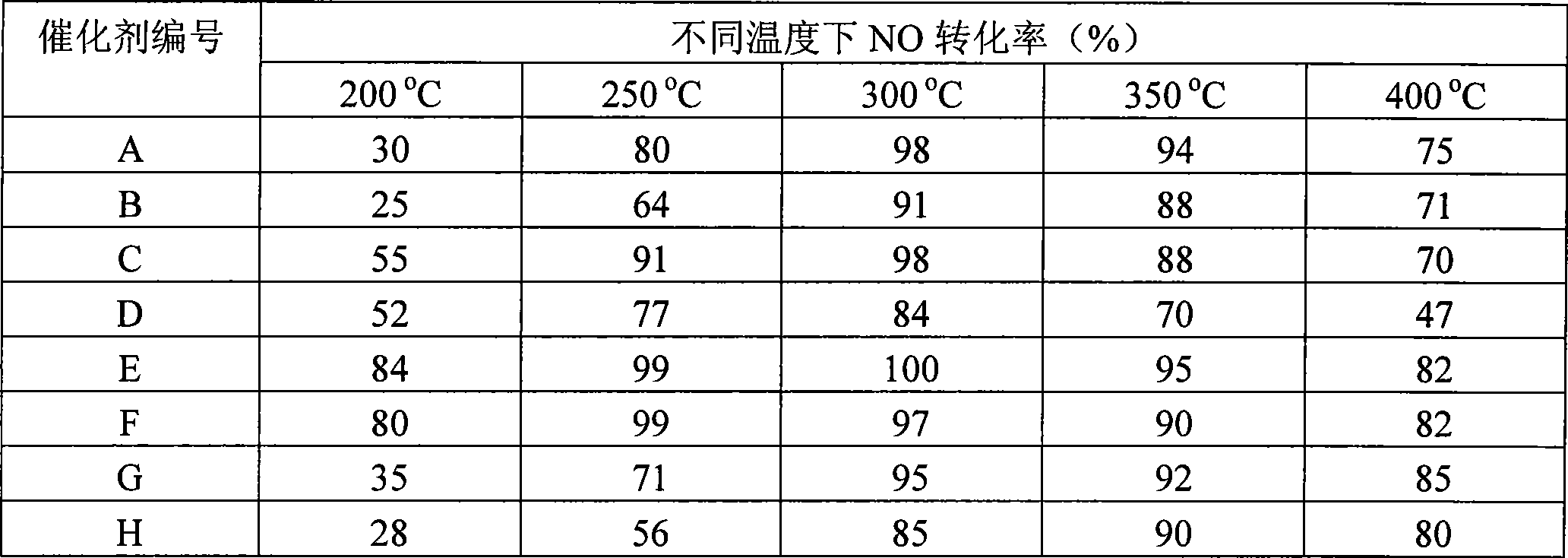

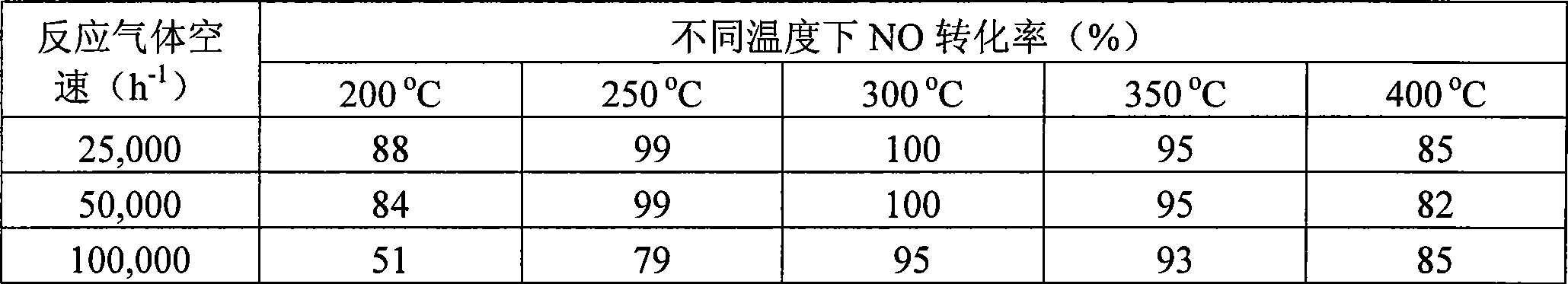

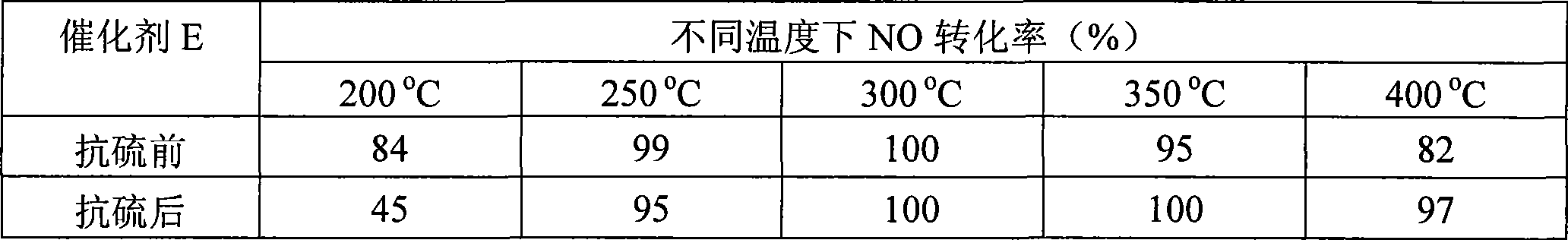

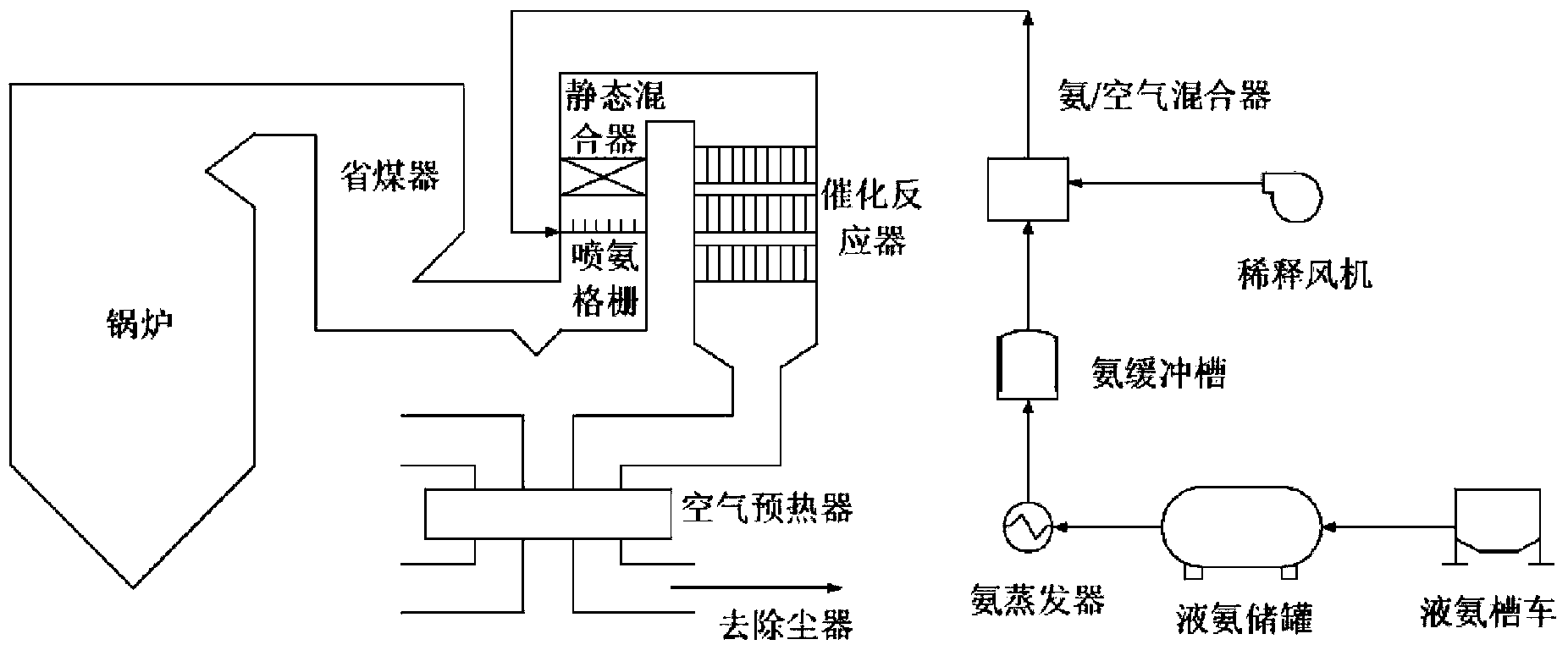

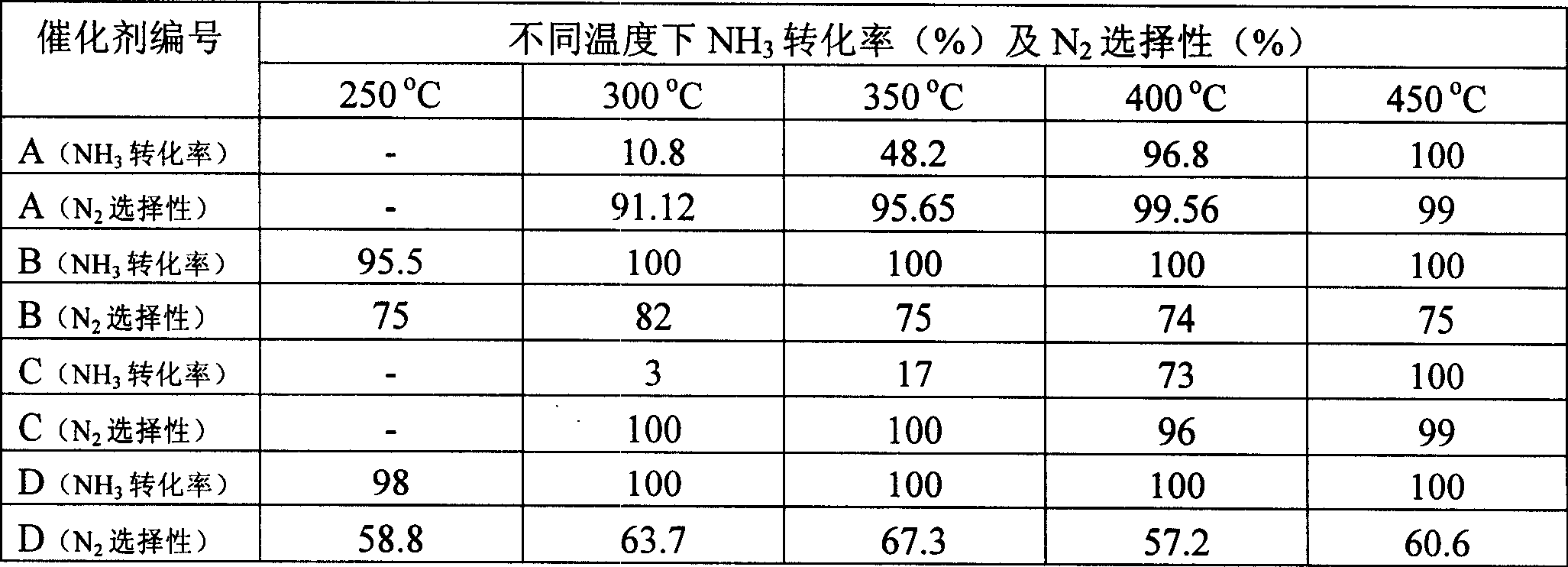

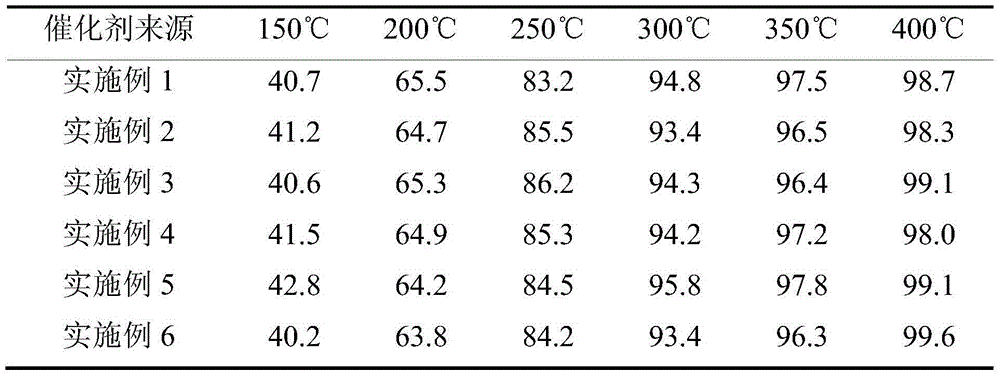

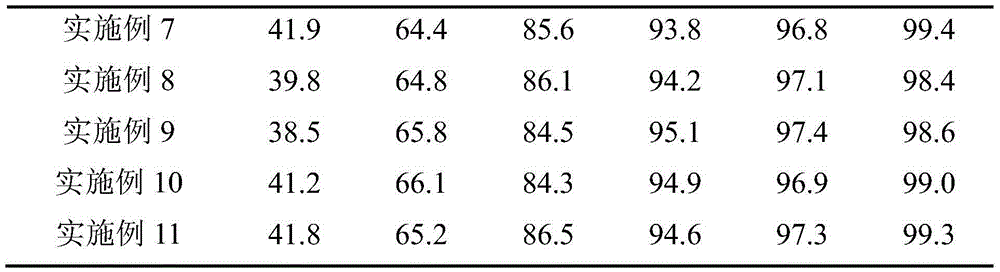

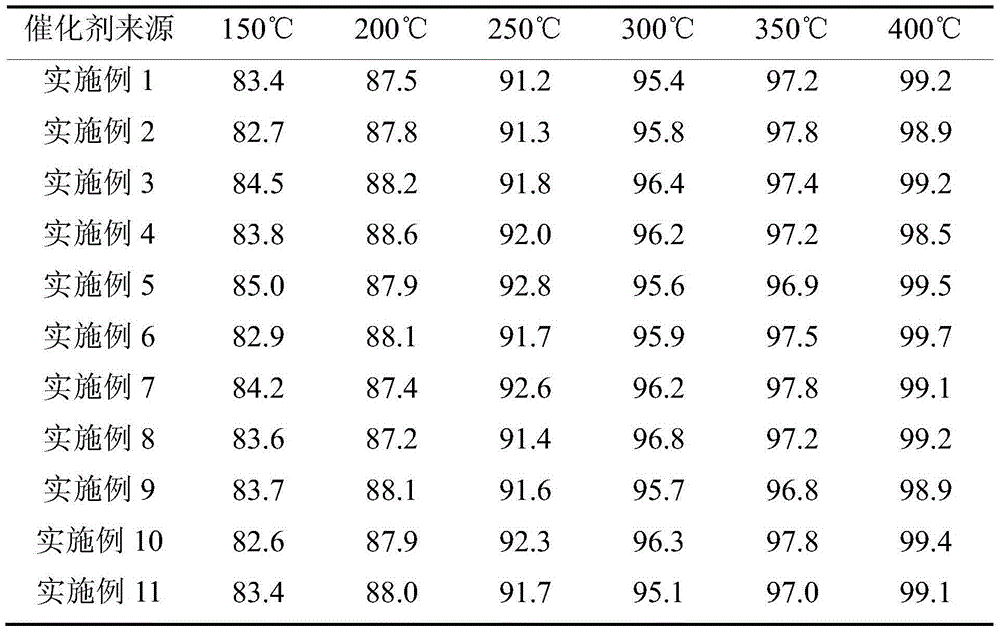

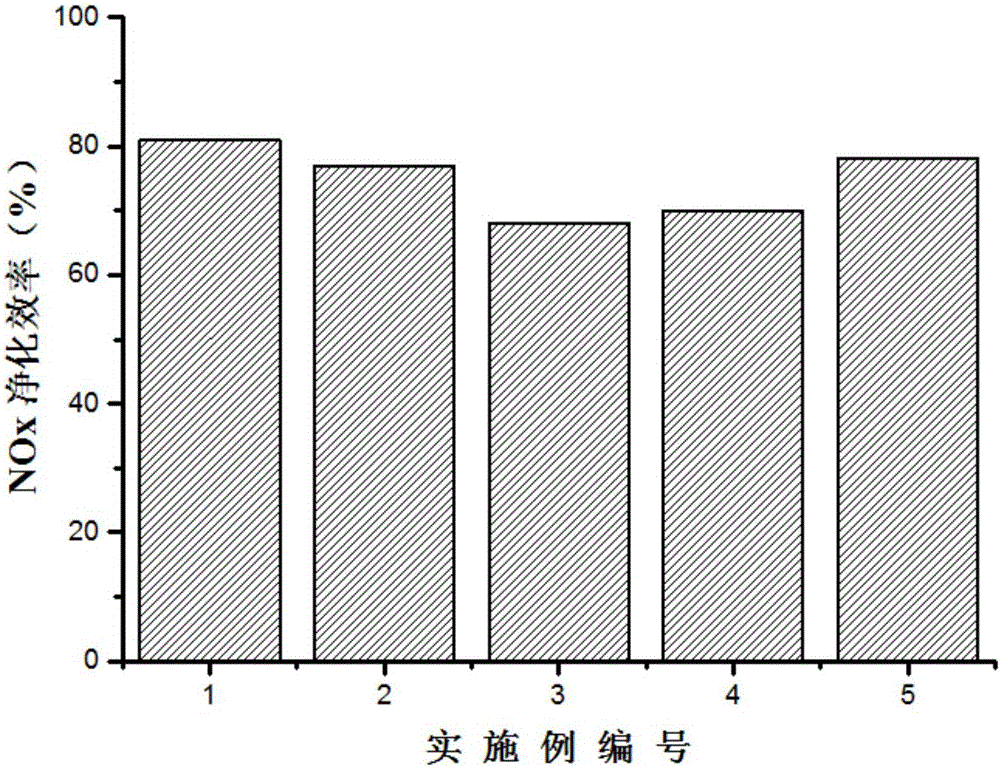

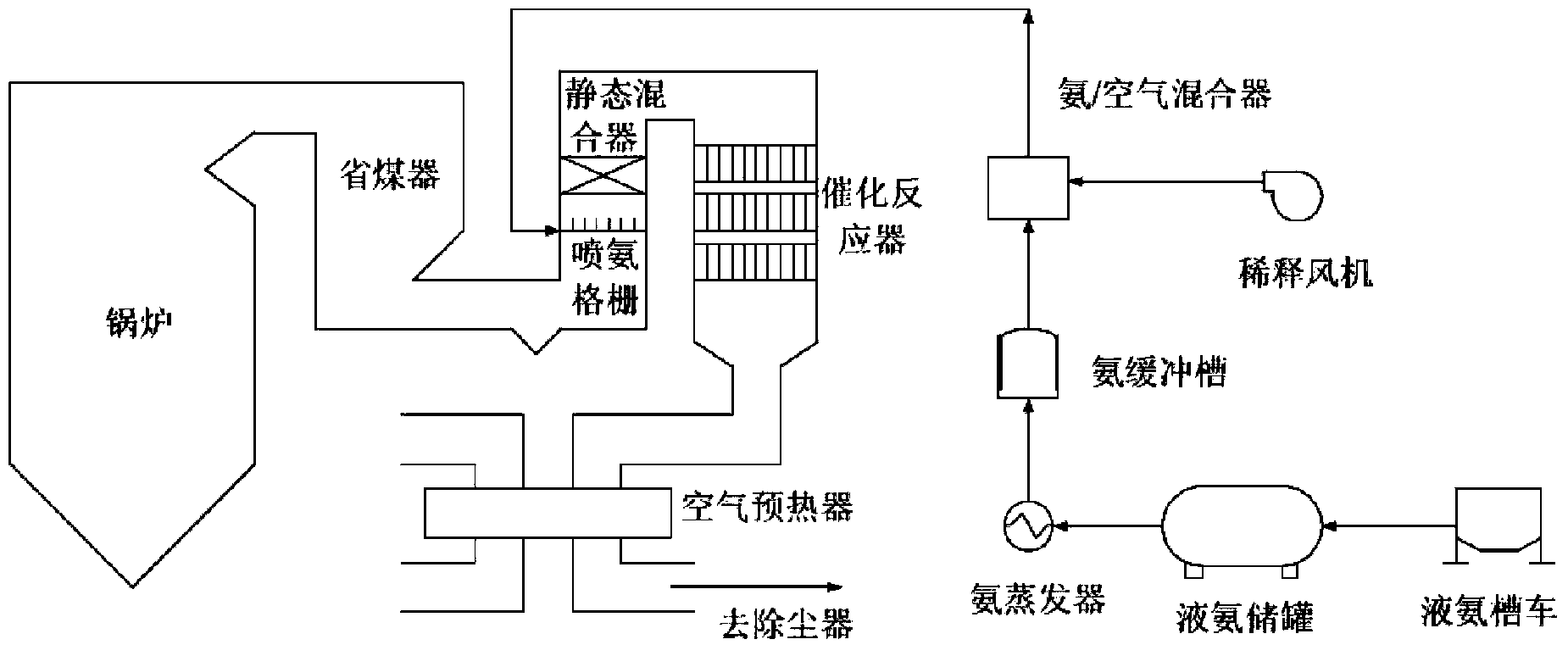

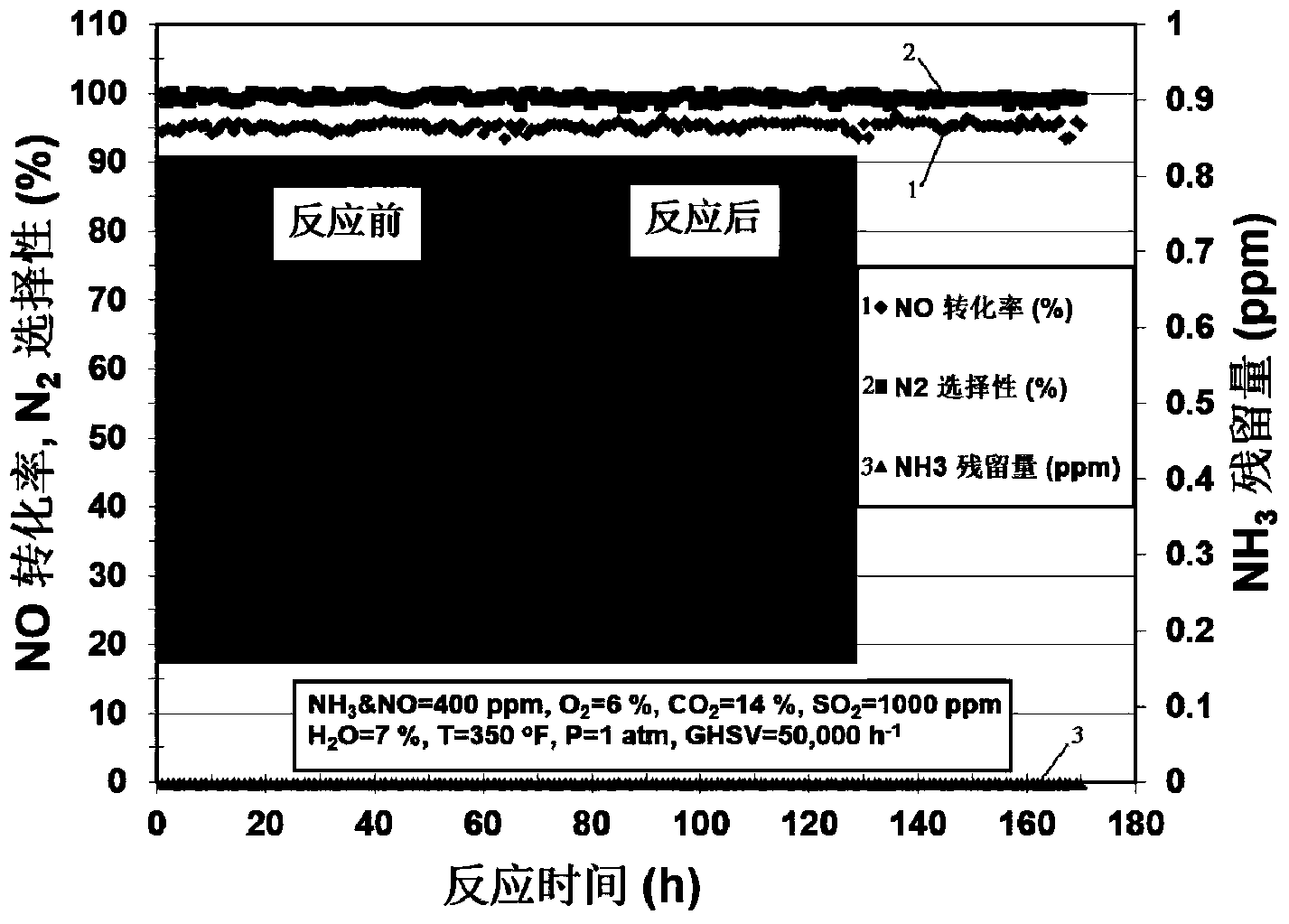

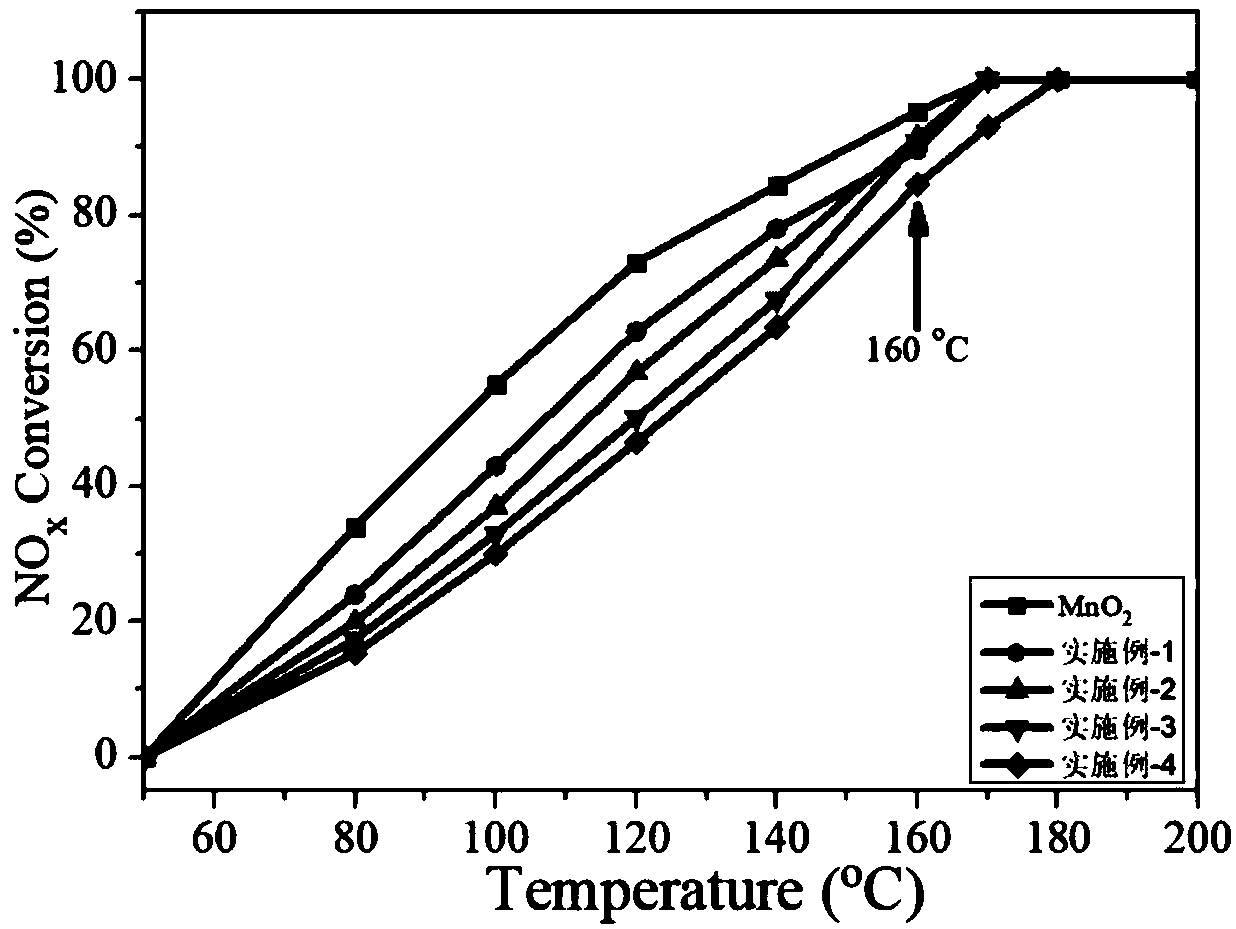

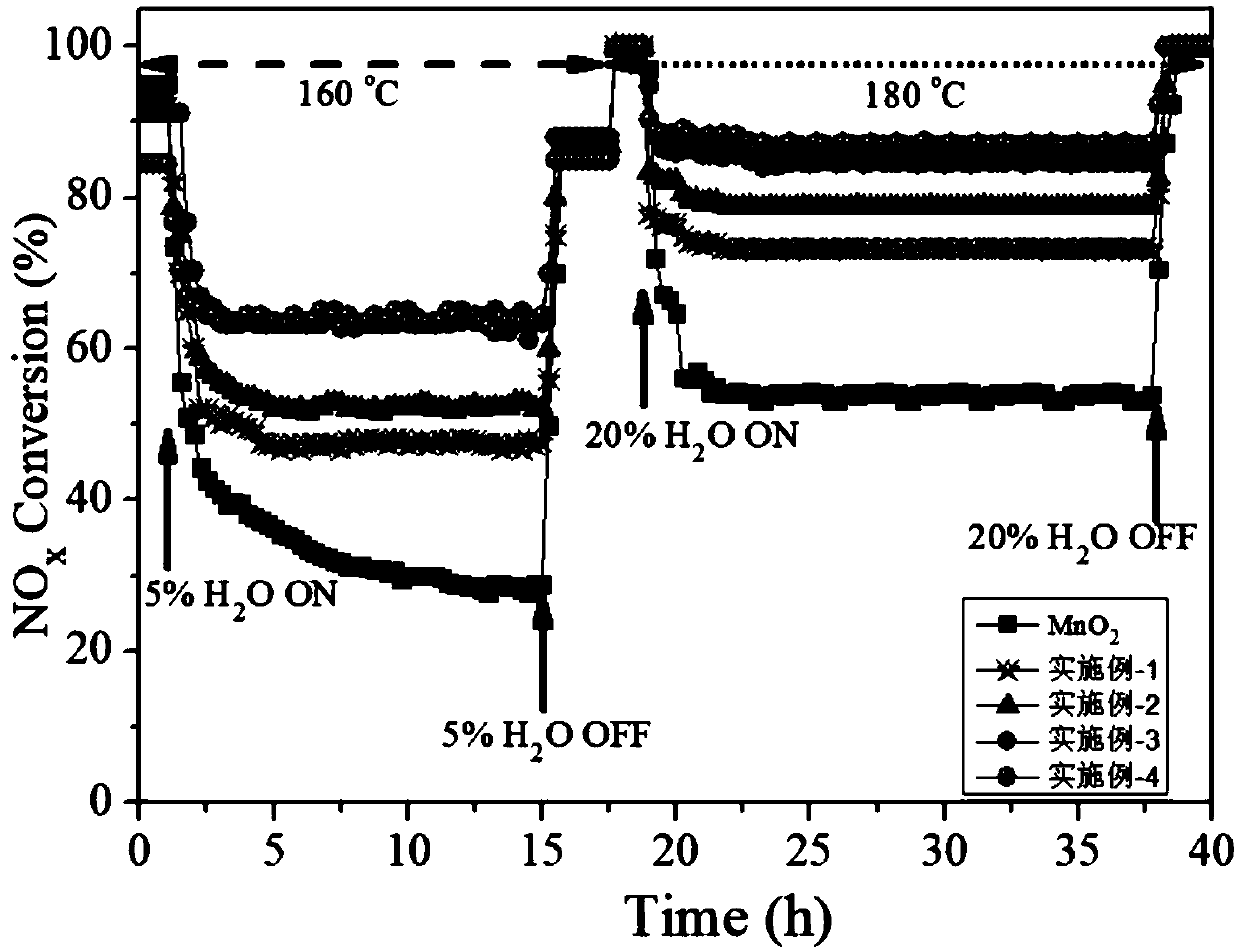

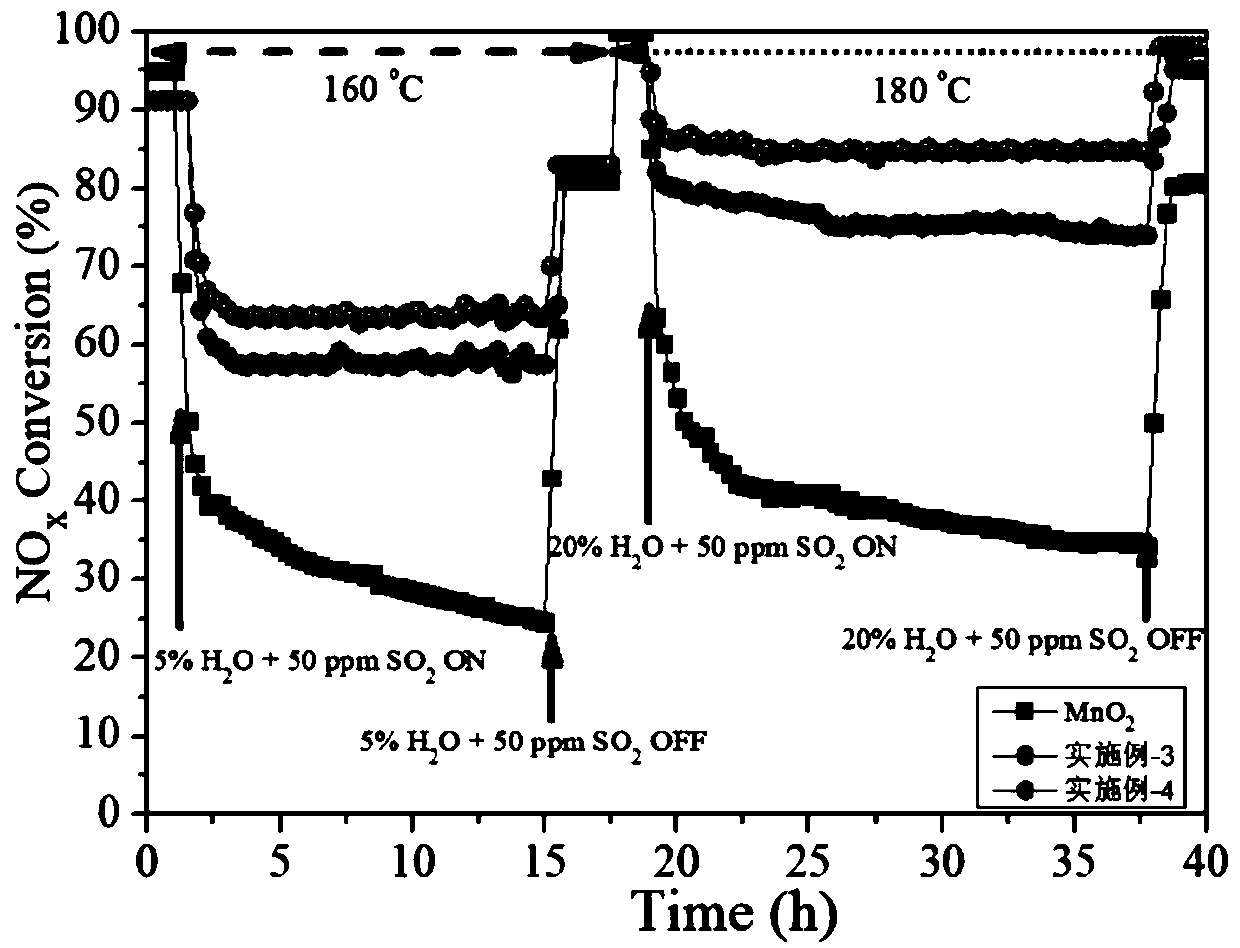

Low-temperature sulfur-resistant denitration catalyst and preparation method thereof

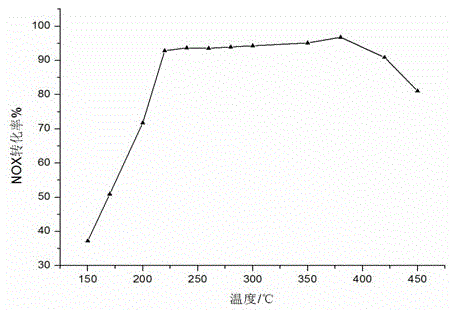

InactiveCN105727936AHigh activityImprove sulfur resistanceNitrous oxide captureHeterogenous catalyst chemical elementsCopper oxideManganese oxide

The invention discloses a preparation method of a catalyst for removing NOx in coke oven tail gas through low-temperature sulfur-resistant catalytic reduction.The catalyst is prepared by taking titanium oxide as a carrier, taking one or two of cerium oxide, zirconia oxide and lanthanum oxide as an auxiliary, taking one or more than two of manganese oxide, cobalt oxide, copper oxide and ferric oxide as an active ingredient and adopting a precipitation-deposition method, wherein two or three of TiO2, ZrO2, CeO2, La2O2, MgO, CaO and BaO can be adopted as the carrier.In the low-temperature sulfur-resistant denitration catalyst, the loading quantity of the active ingredient is 5 wt%-20 wt%, and the loading quantity of the auxiliary is 0.5%-5%.According to the preparation method, the active ingredient prepared by achieving precipitation and deposition sodium carbonate and oxidizing and loading the active ingredient manganese dioxide through potassium permanganate is mainly distributed in the surface area of the carrier, and the dosage of the active ingredient can be effectively decreased.The catalyst is high in activity and sulfur poisoning resisting capacity and particularly suitable for catalytic removal of the NOx in the coke oven tail gas, and the denitration effect of the catalyst also can be expanded to the low-temperature denitration process of other tail gases.

Owner:GANSU TIANLANG CHEM TECH CO LTD +1

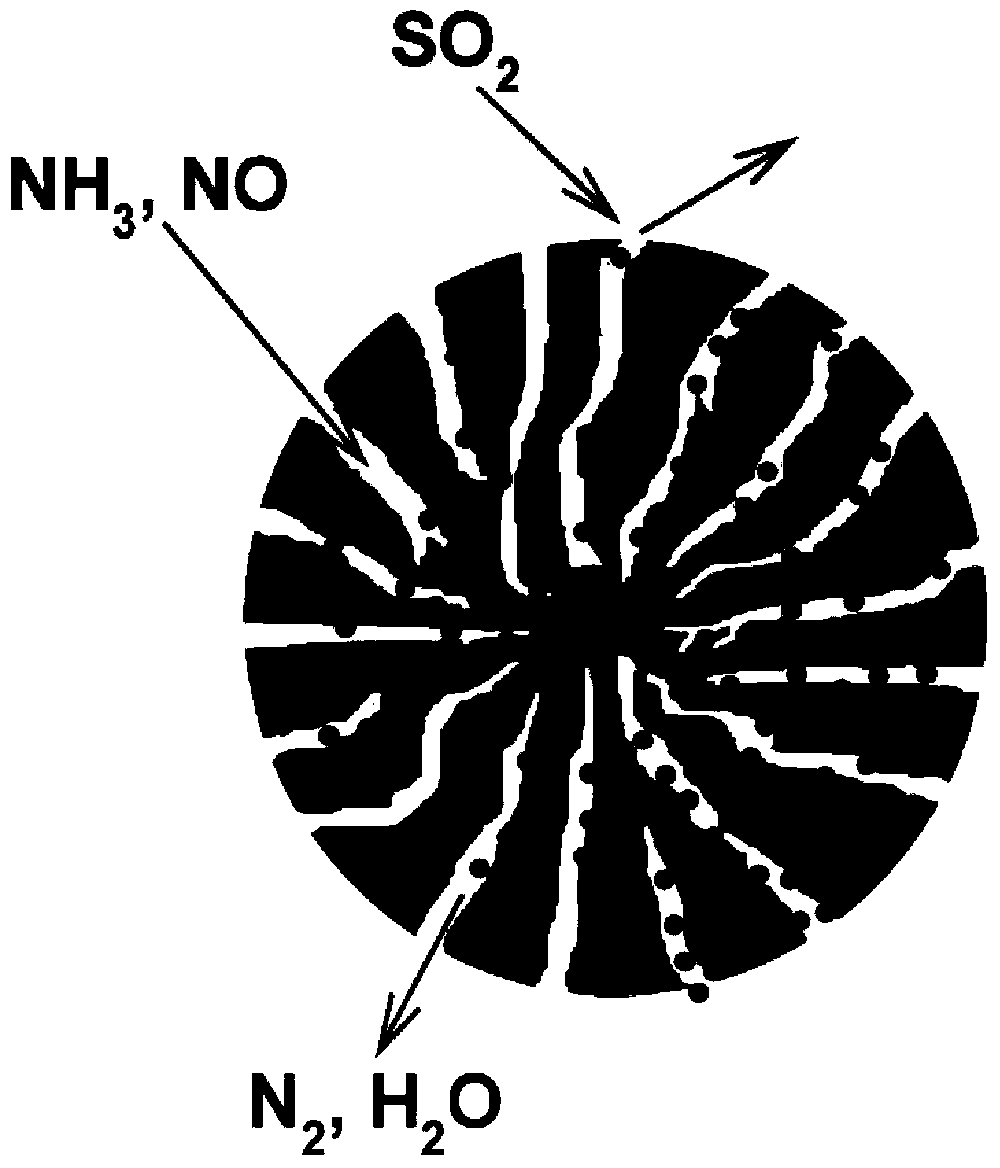

Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

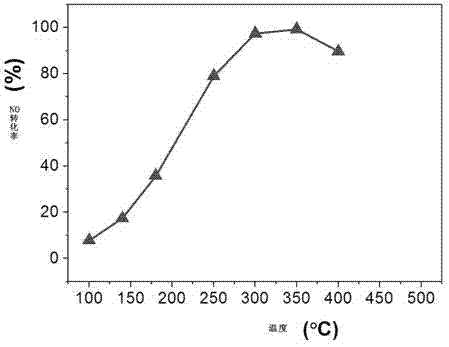

ActiveCN101380578ALow priceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideHigh activity

The invention relates to a catalyst of selective reduction of nitrogen oxide by ammonia, which mainly solves the existing problems that the commonly used NH3-SCR catalyst system is toxic to environment and human body, the anti-SO2 poisoning ability of the catalyst system is poor in the reference and the catalyst system can not adapt to the conditions of high space velocity. The invention adopts cheap and non-toxic raw materials to prepare a Fe-Ti oxide catalyst with high activity, selectivity, stability and anti-S2 poisoning ability by the simple and practicable co-precipitation method, which can better solve the existing technical problems. If the catalyst is loaded on honeycomb ceramics after being made into pulp, the catalyst is hopeful to be put into practical application of flue gas denitrification of coal-fired power plants.

Owner:江西中科鸿虔新材料有限公司

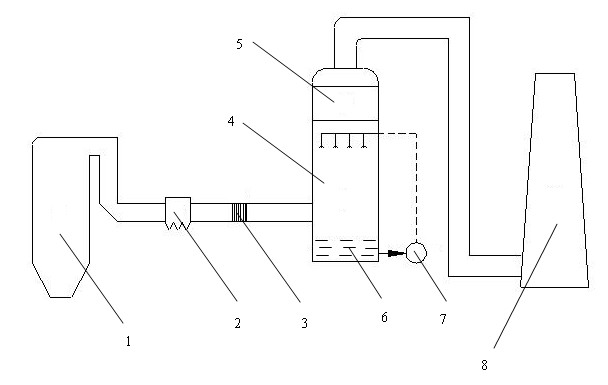

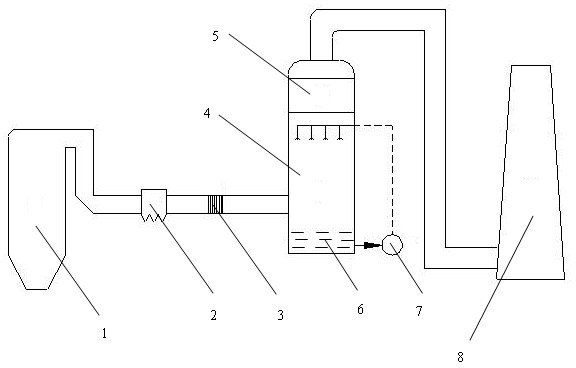

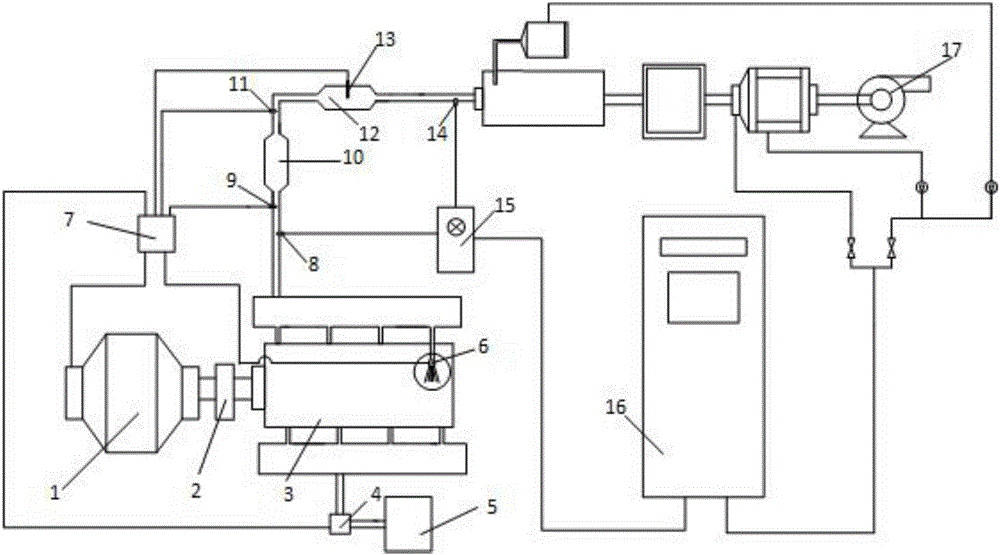

Method and system for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation

ActiveCN102527205AAvoid preparationImprove safety and economyDispersed particle separationEnvironmental chemistryDust control

The invention discloses a method for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation. The method is characterized by comprising the following steps of: (1) arranging a catalytic reactor in a dust-removed smoke duct, wherein a catalyst for promoting oxidizing reaction of NO and HgO is filled in the catalytic reactor; (2) allowing the dust-removed smoke to pass through the catalytic reactor, wherein under catalysis of the catalyst, the reaction speed of the NO, the HgO and O2 is increased and the NO and the HgO are oxidized into NO2 and Hg<2+>; and (3) introducing the smoke subjected to catalytic oxidation into an absorber with an absorption solution, wherein the absorption solution is used for absorbing NO2, Hg<2+> and SO2 from the smoke. The invention also discloses a system applicable to the method. According to the method and the system, the sulfur, the niter and the mercury are removed from the smoke; external oxidant is not required to be added; preparation, transportation and storage of strong oxidant are avoided; operating cost is reduced; and economy and safety of the system are improved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

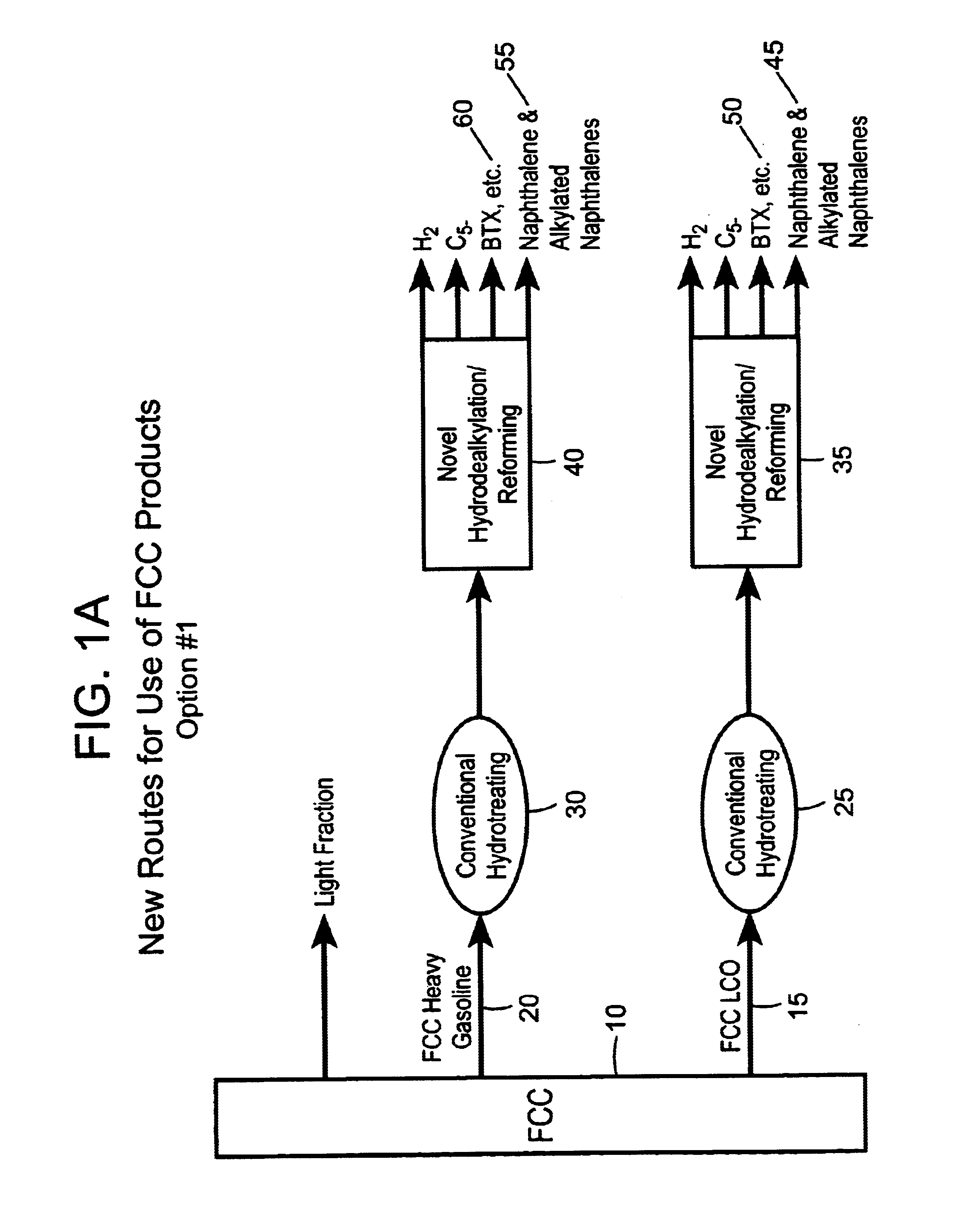

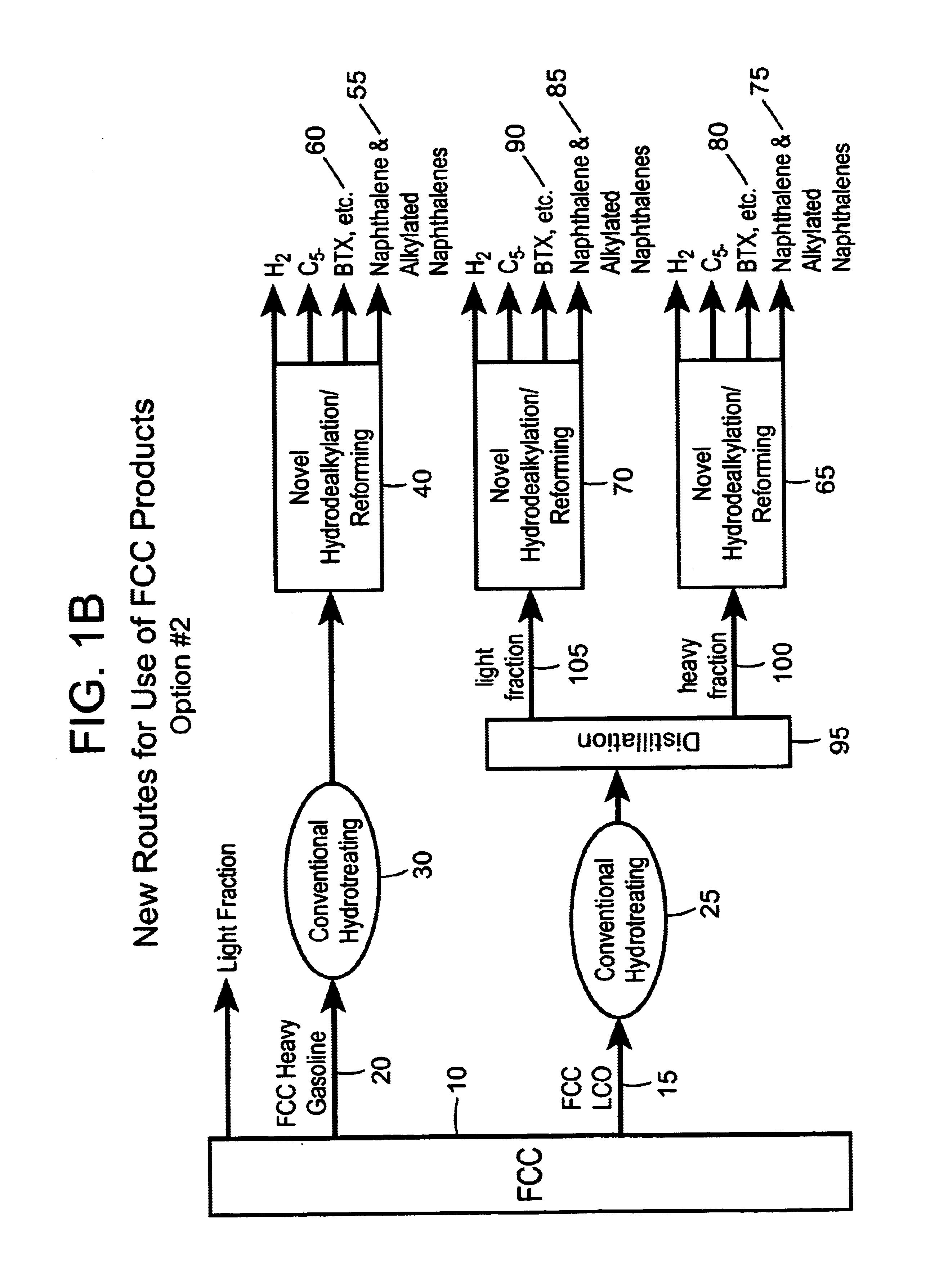

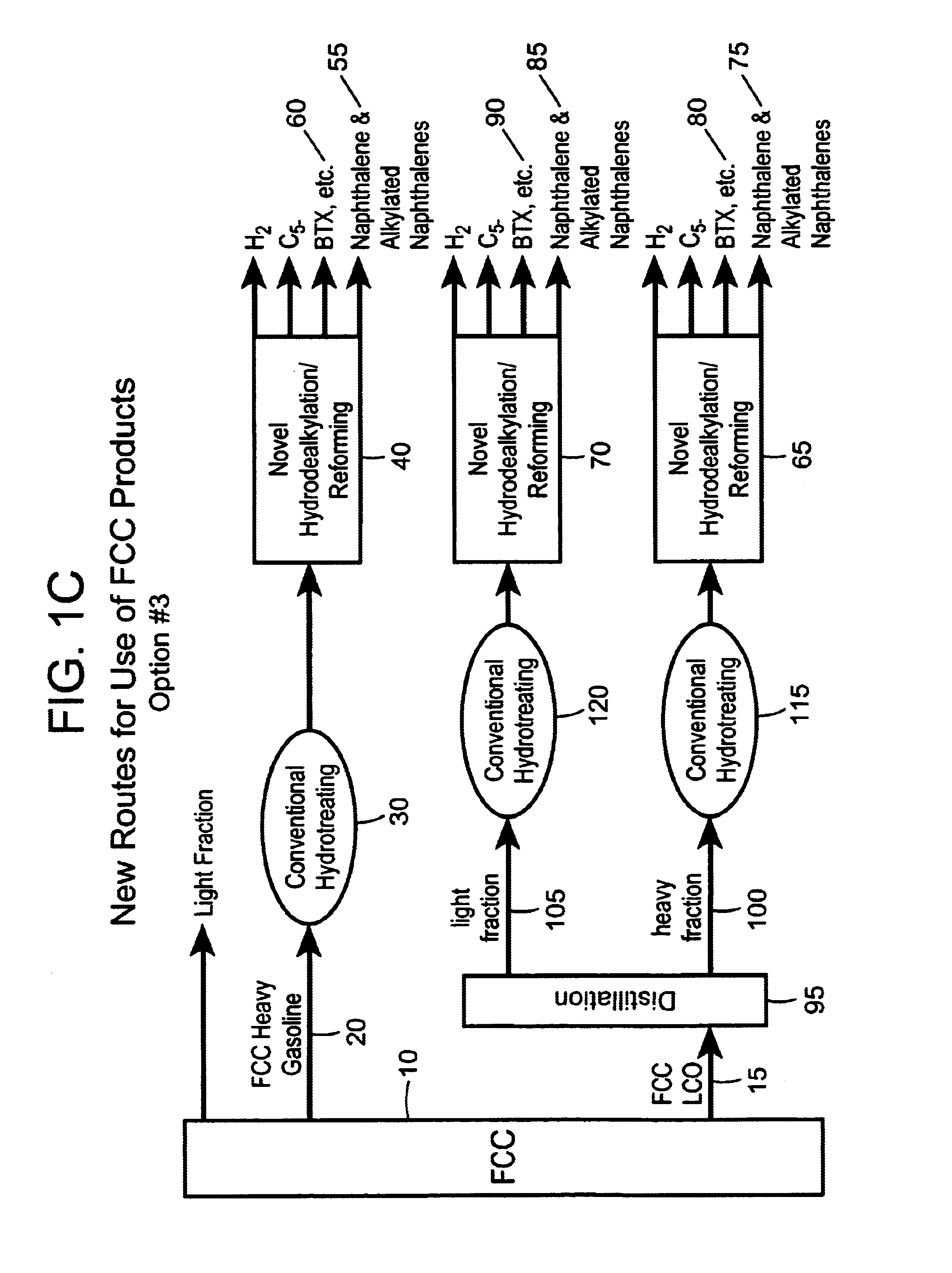

Process for converting heavy hydrocarbon feeds to high octane gasoline, BTX and other valuable aromatics

InactiveUS6900365B2High yieldOutstanding propertyCatalytic naphtha reformingHydrocarbonsMolecular sieveDehydrogenation

A catalytic hydrodealkylation / reforming process which comprises contacting a heavy hydrocarbon feedstream under catalytic hydrodealkylation / reforming conditions with a composition comprising borosilicate molecular sieves having a pore size greater than about 5.0 Angstroms and a Constraint Index smaller than about 1.0; further containing a hydrogenation / dehydrogenation component; wherein at least a portion of the heavy hydrocarbon feedstream is converted to a product comprising benzene, toluene, xylenes and ethylbenzene.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Low-temperature sulfur-resistant denitration catalyst and preparing method thereof

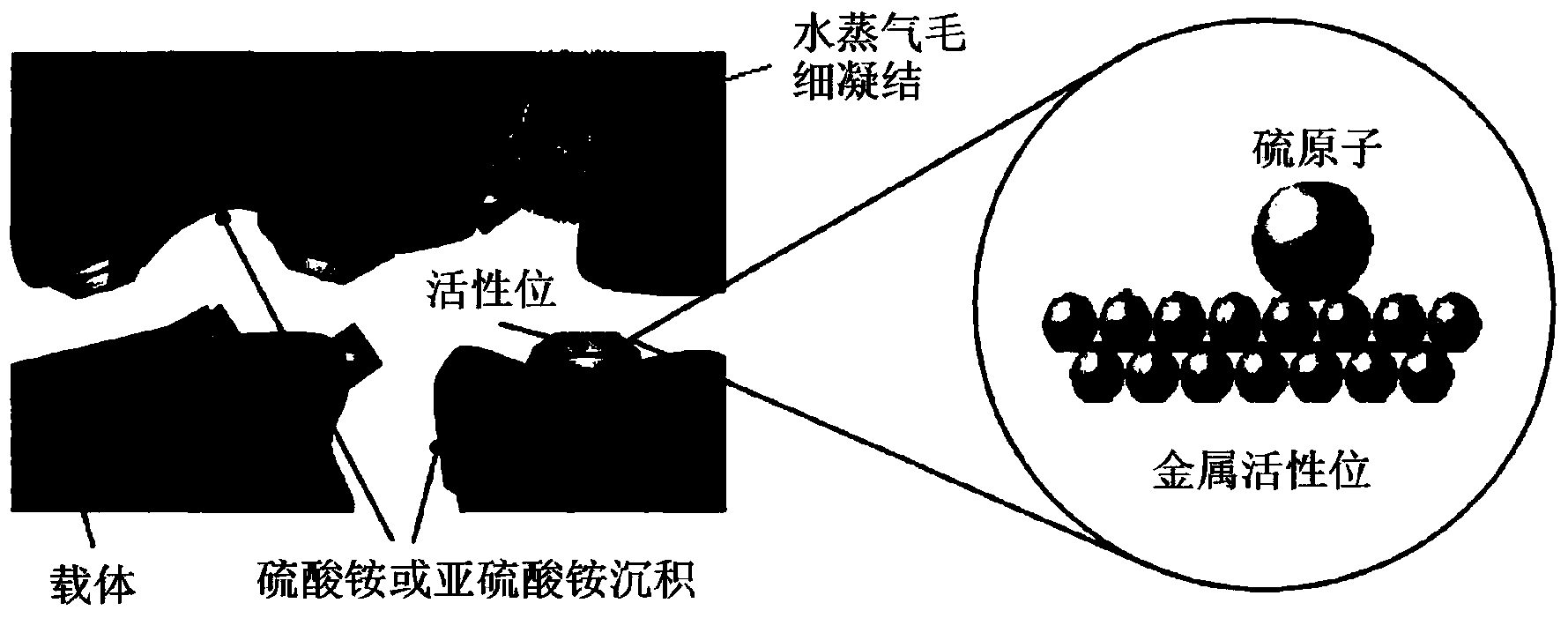

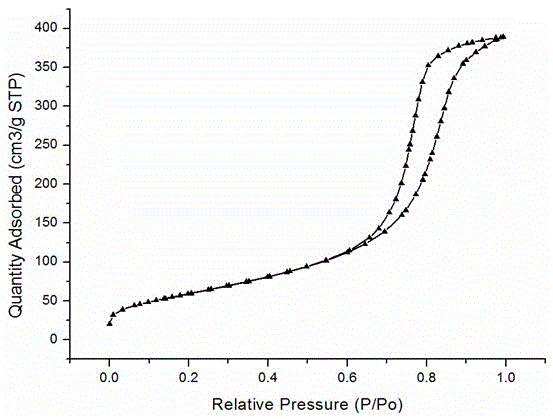

ActiveCN104056658AStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationCapillary condensationMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

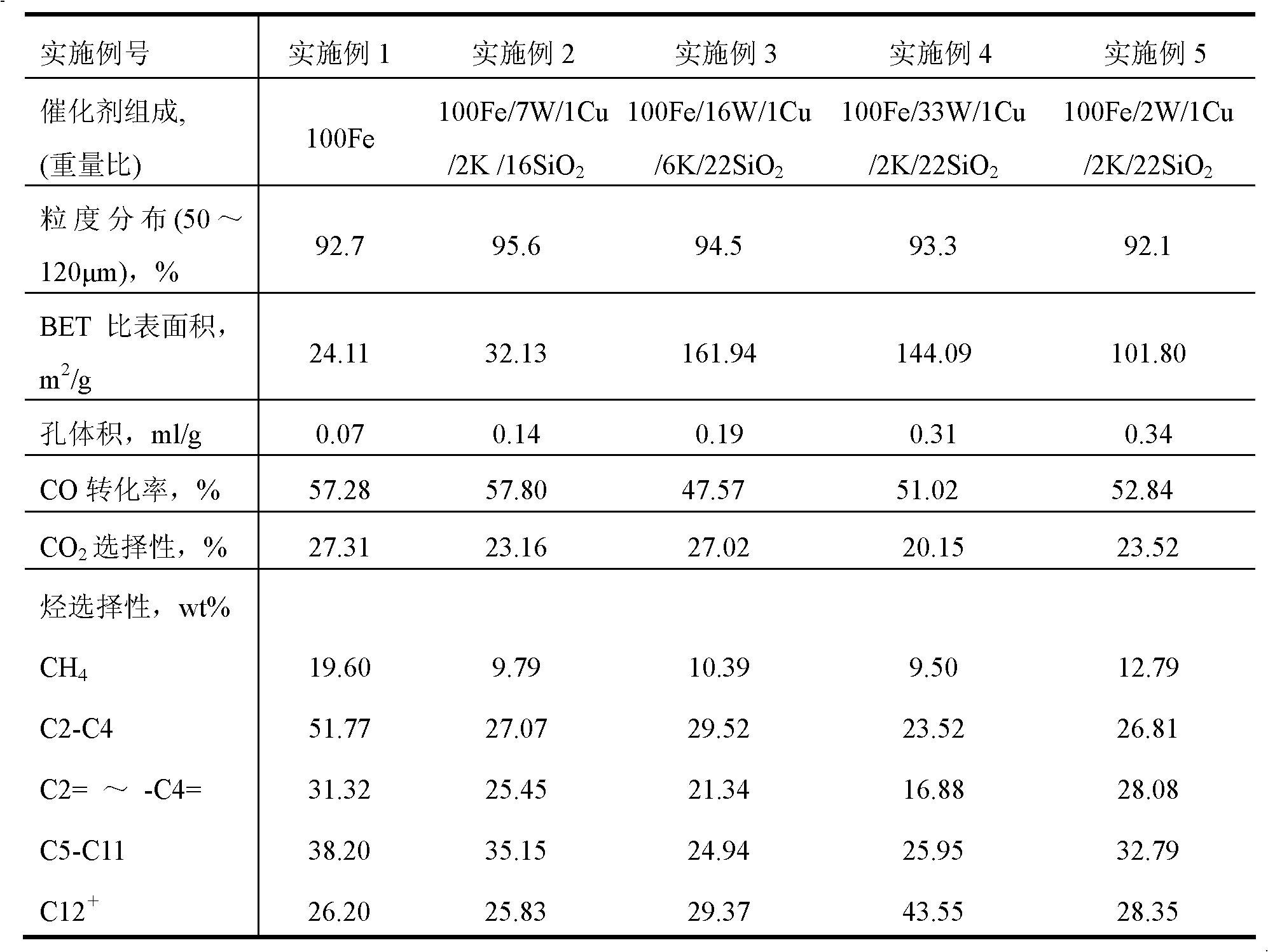

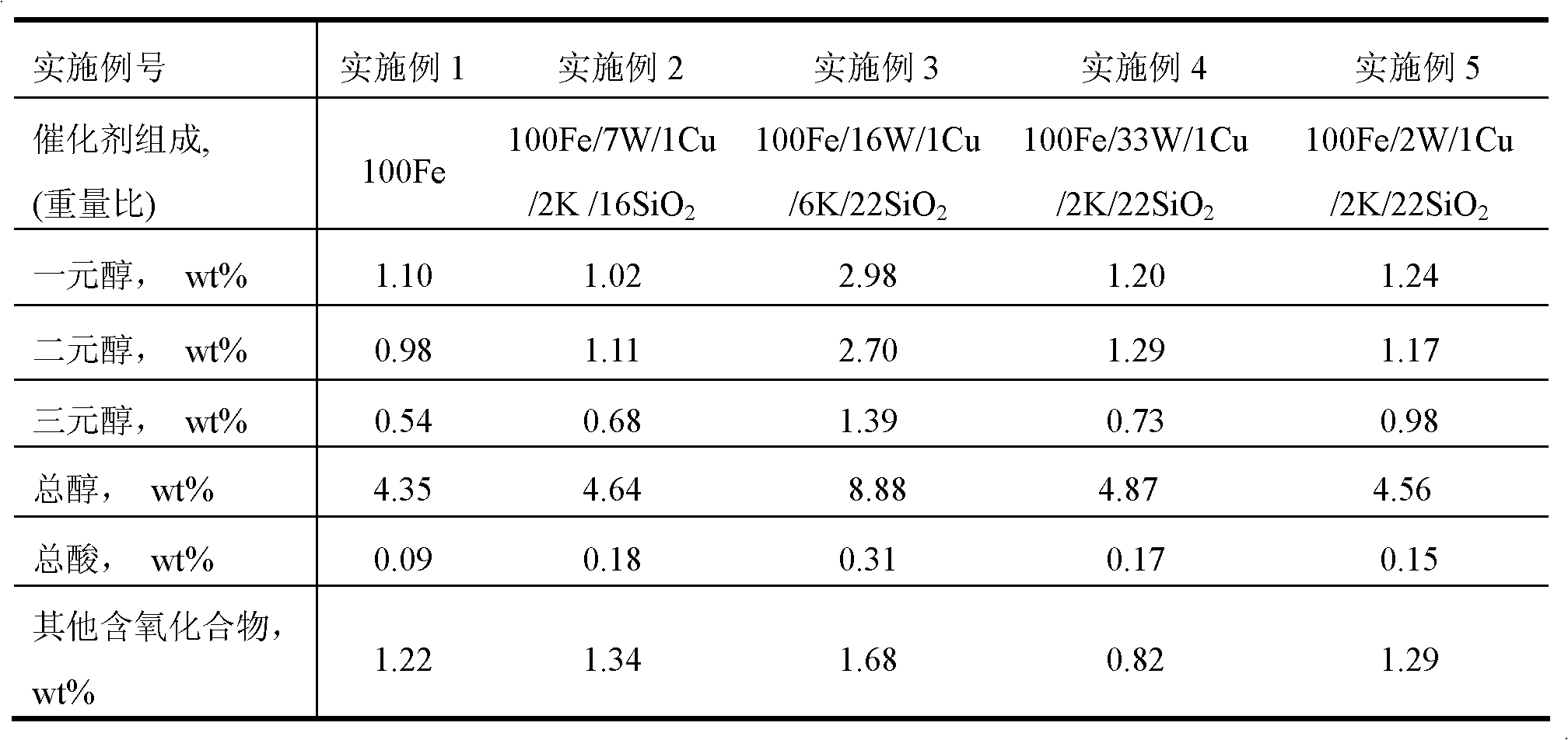

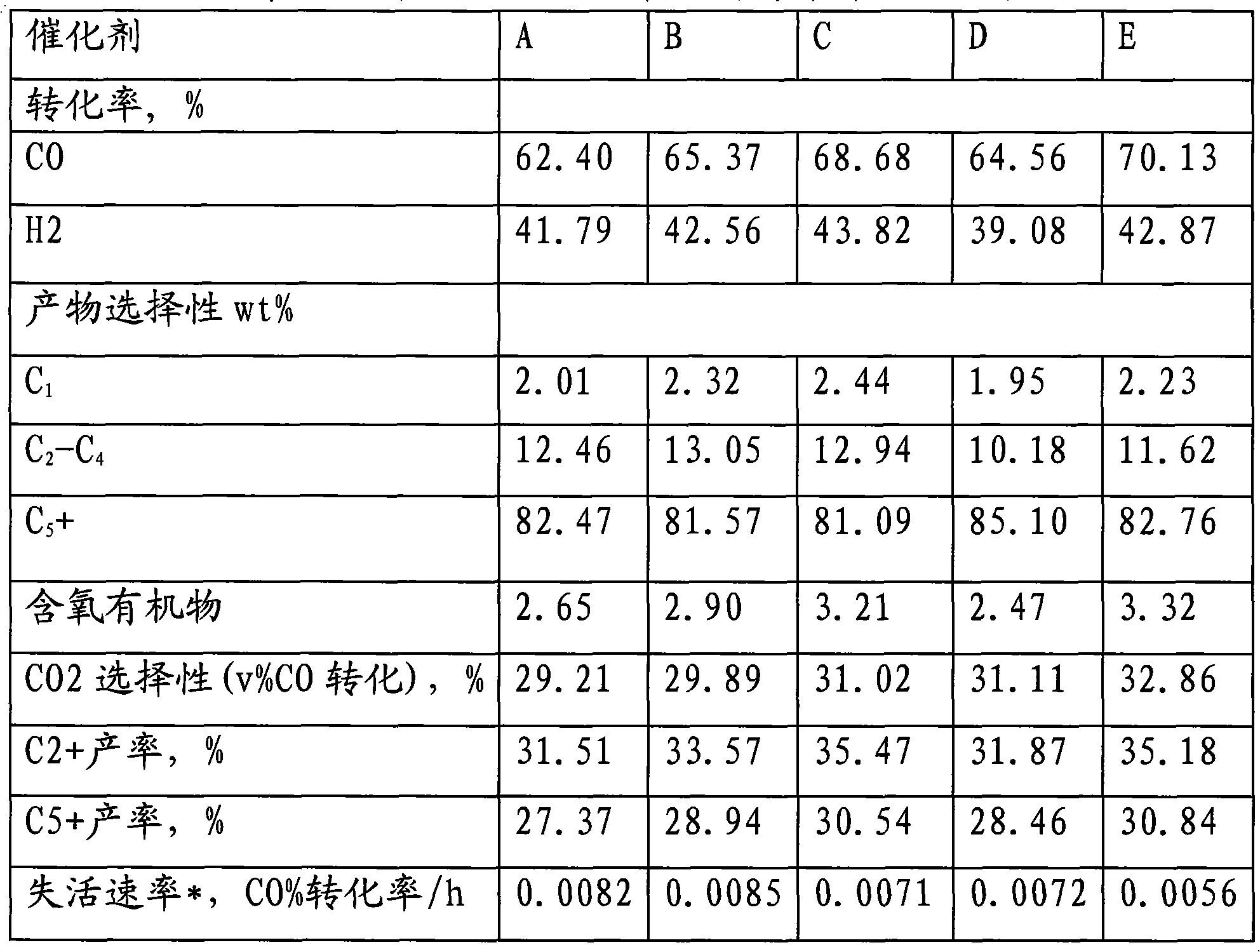

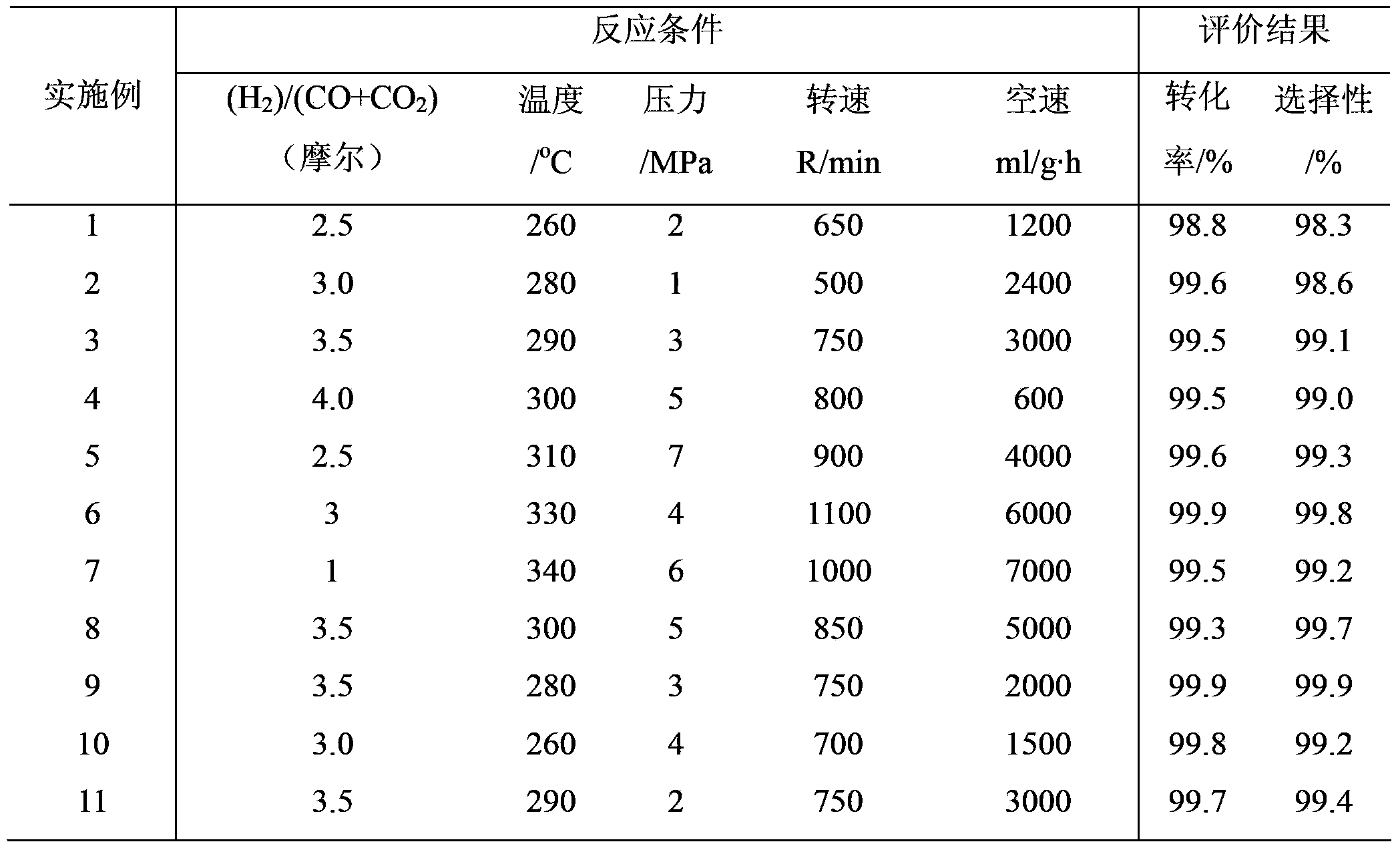

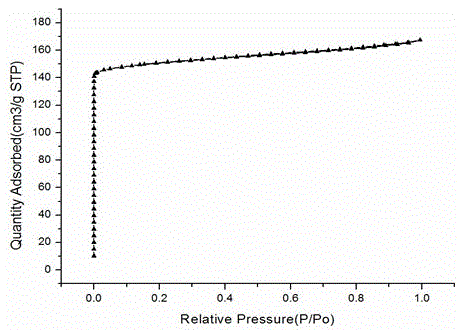

Fischer-Tropsch synthesis catalyst, its preparation method and application thereof

InactiveCN102728379AImproved stability of synthetic activityImprove sulfur resistanceLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationOxygen

The invention relates to a Fischer-Tropsch synthesis catalyst, its preparation method and an application thereof. The catalyst comprises the following main components: Fe, a metal auxiliary component W, a Cu auxiliary agent, an alkaline auxiliary agent selected from Li, Na, K, Mg, Ca, Rb and Cs, and a structural promoter which contains at least one ingredient or any combination selected from SiO2, active carbon, Al2O3, ZrO2 and TiO2. The specific surface area of the catalyst provided by the invention is usually 50-240 m<2> / g. The catalyst can be prepared by a sol-gel method, a coprecipitation method, an immersion method or any combination of the above preparation methods, but preferably by a parallel flow precipitation method. The catalyst provided by the invention can be used in high selectivity production of hydrocarbons, oxygen-containing compounds and the like through Fischer-Tropsch synthesis of synthetic gas. its reaction activity and stability are obviously improved. And selectivity of light olefins in the Fischer-Tropsch synthesis product hydrocarbon is obviously raised.

Owner:SYNFUELS CHINA TECH CO LTD

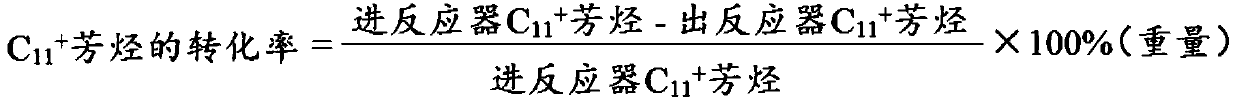

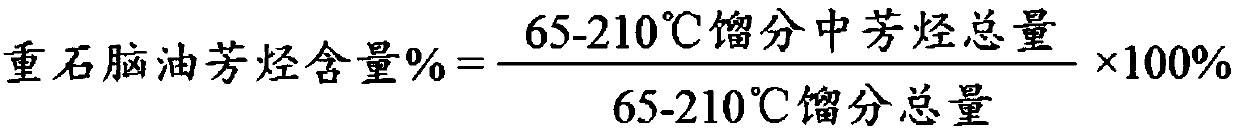

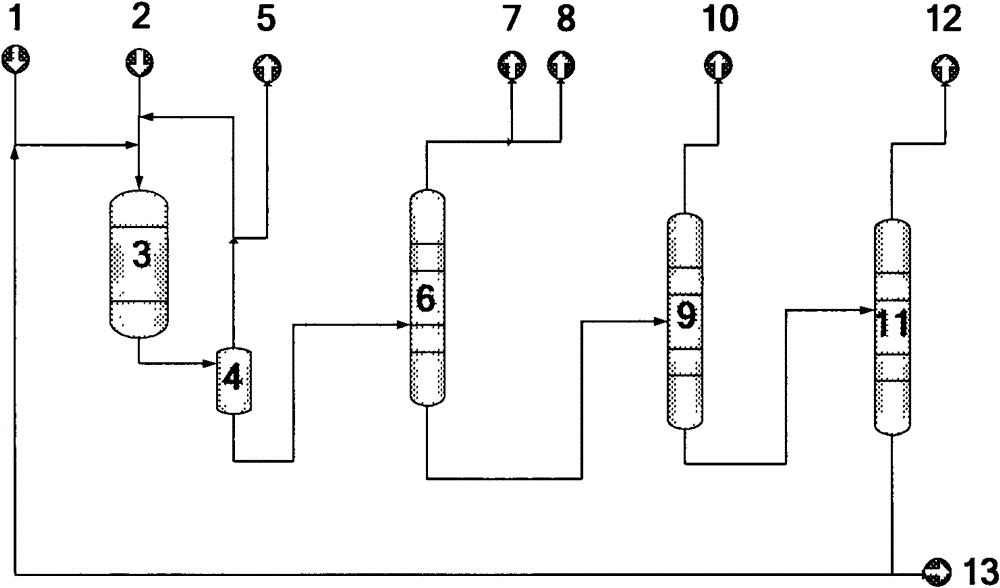

Catalyst and applications in C11<+> heavy aromatic hydrocarbon lightening reactions

ActiveCN110180581AStrong anti-coking abilityGuaranteed uptimeMolecular sieve catalystsMolecular sieve catalystMetallic sulfideAromatic hydrocarbon

The invention relates to a catalyst and applications in C11<+> heavy aromatic hydrocarbon lightening reactions, wherein the catalyst comprises, by weight, a) 5-80 parts of solid acid zeolite, b) 0.05-8 parts of a Group VIII metal, c) 3-25 parts of a Group VIB metal oxide, d) 0.1-2 parts of a Group VIB metal sulfide, and e) 20-95 parts of a binder. According to the present invention, the catalyst can be used for producing light aromatic hydrocarbons from full-distillate C11<+> poor-quality heavy aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

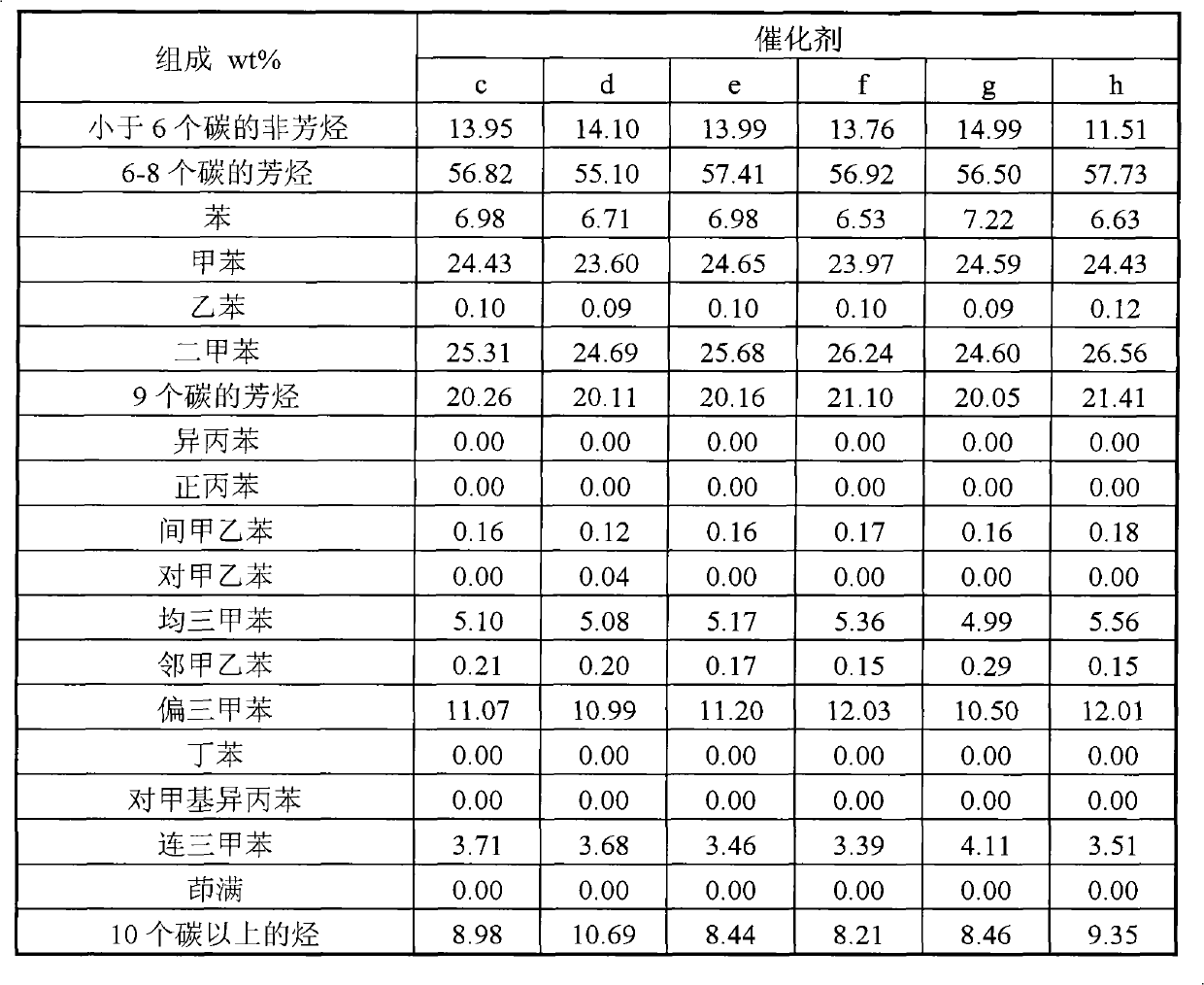

Method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746092AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionHydrogenBoiling point

The invention relates to a method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low added value of the heavy aromatic hydrocarbons, and complex flow, low product purity, low yield and the like in separation of 1,3,5-trimethylbenzene monomers from the heavy aromatic hydrocarbons. According to the method, hydrogen type binder-free ten-membered ring zeolite loading 0.005-0.5% by mass of Pt or Pd is adopted as a catalyst, hydrogen and the heavy aromatic hydrocarbons which are raw materials undergo hydrocracking treatment, and 1,2,4-trimethylbenzene and heavy aromatic hydrocarbons having boiling points greater than the boiling point of the 1,2,4-trimethylbenzene in products are returned to a reactor, so BTX aromatic hydrocarbon yield increase and 1,3,5-trimethylbenzene separation production are realized. The method well solves the problems, and can be used for the industrial production for yield increases of the BTX (benzene, toluene and xylol) aromatic hydrocarbon and the 1,3,5-trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

PtX-Fe-ZSM-5 molecular sieve catalyst for ammine selective catalytic oxidation

InactiveCN101417237ASimple preparation processEasy to operateMolecular sieve catalystsDispersed particle separationIonIon exchange

The invention provides a NH3 selective oxidation catalyst; the NH3 is selectively catalytically oxidated as N2 and H2O without pollution. The catalyst mainly solves the problems that the oxidation catalyst which is applied to elimination industries and traffic and the like and generates the NH3 pollution has bad low-temperature activity, low selectivity and poor anti-sulfur performance. The catalyst firstly prepares Fe-ZSM-5 molecular sieve catalyst with large specific area by a secondary ion exchanging method; subsequently, trace noble metal Pt is loaded on the Fe-ZSM-5 so as to prepare the Ptx-Fe-ZSM-5 catalyst; and the oxidation catalyst has high activity, N2 selectivity, good stability and anti-SO2 poisoning performance, and excellently solving the technical problem of the prior art. If the catalyst is prepared into slurry and loaded on honeycomb ceramics, the NH3 pollution in the practical industrial tailings can be expected to be removed; furthermore, the catalyst can be used as postpositive oxidation catalyst in the tailings disposal system of diesel engine so as to prevent the pollution caused by the leakage of NH3 in the NH3-SCR catalytic system.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

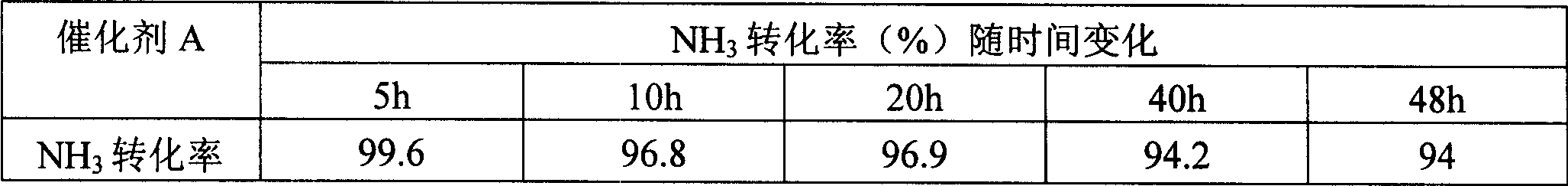

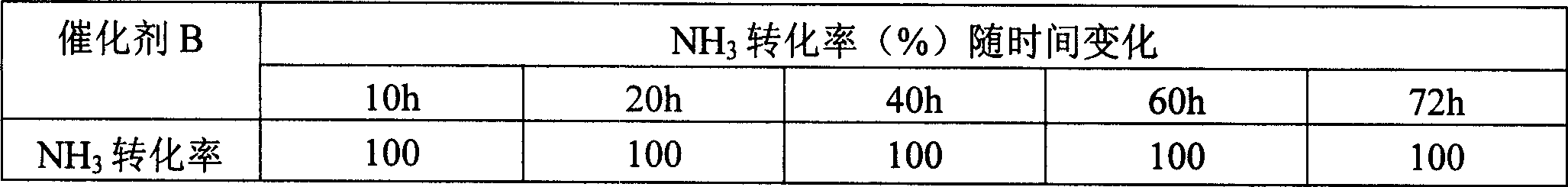

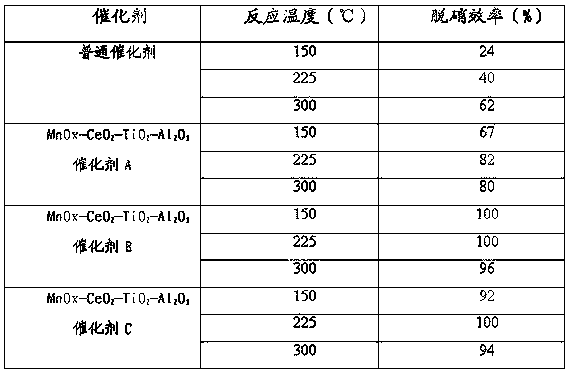

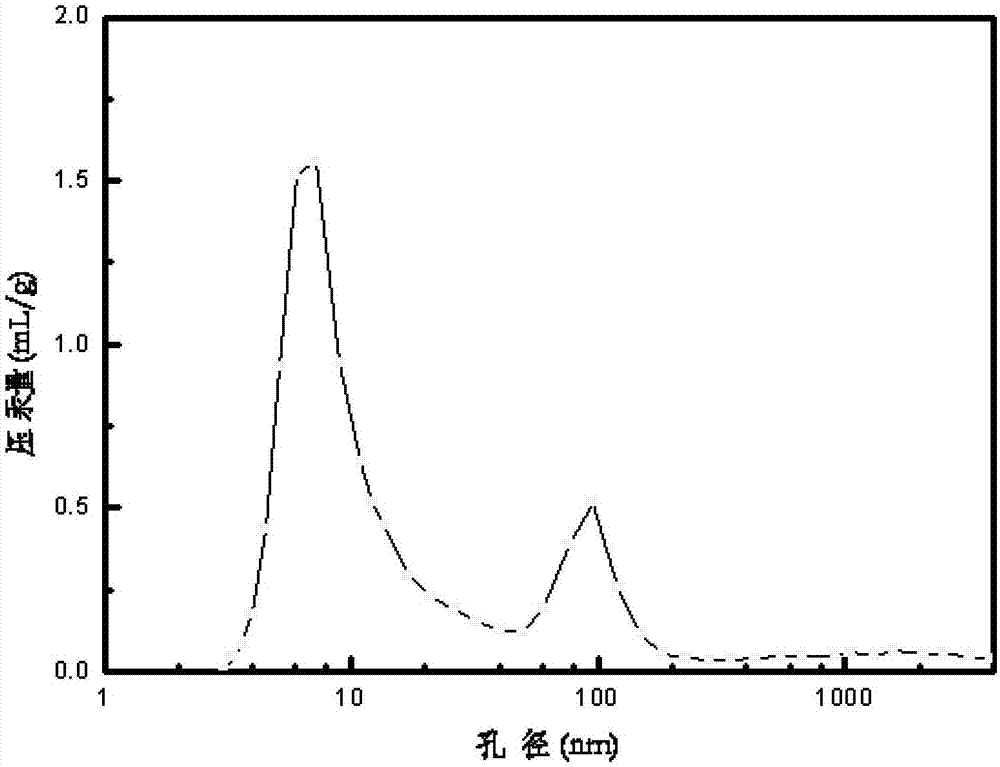

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for selective hydrogenation through cracking of C5-C9 distillate

InactiveCN107159283AAperture size adjustableGood adhesive performancePhysical/chemical process catalystsRefining by selective hydrogenationPtru catalystHydrogenation reaction

The present invention relates to a method for selective hydrogenation through cracking of a C5-C9 distillate. According to the method, the catalyst comprises an alumina carrier having a macroporous structure and metal active components comprising nickel and tungsten and supported on the carrier, the nickel oxide content is 12-22 wt% based on the total weight of the catalyst, the tungsten oxide is 1.5-8 wt% based on the total weight of the catalyst, and the hydrogenation reaction process conditions are that the reaction inlet temperature is 40-55 DEG C, the reaction pressure is 2.0-3.5 MPa, the hydrogen oil volume ratio is 60-150, and the liquid volume space velocity is 3.0-5.5 h<-1>. According to the present invention, the catalyst has characteristics of good glue capacity, strong arsenic resistance, strong sulfur resistance, strong coking inhibition and low temperature activity; and the method provides strong adaptability for the cracking gasoline raw materials having different arsenic contents and different sulfur contents.

Owner:QINZHOU UNIV

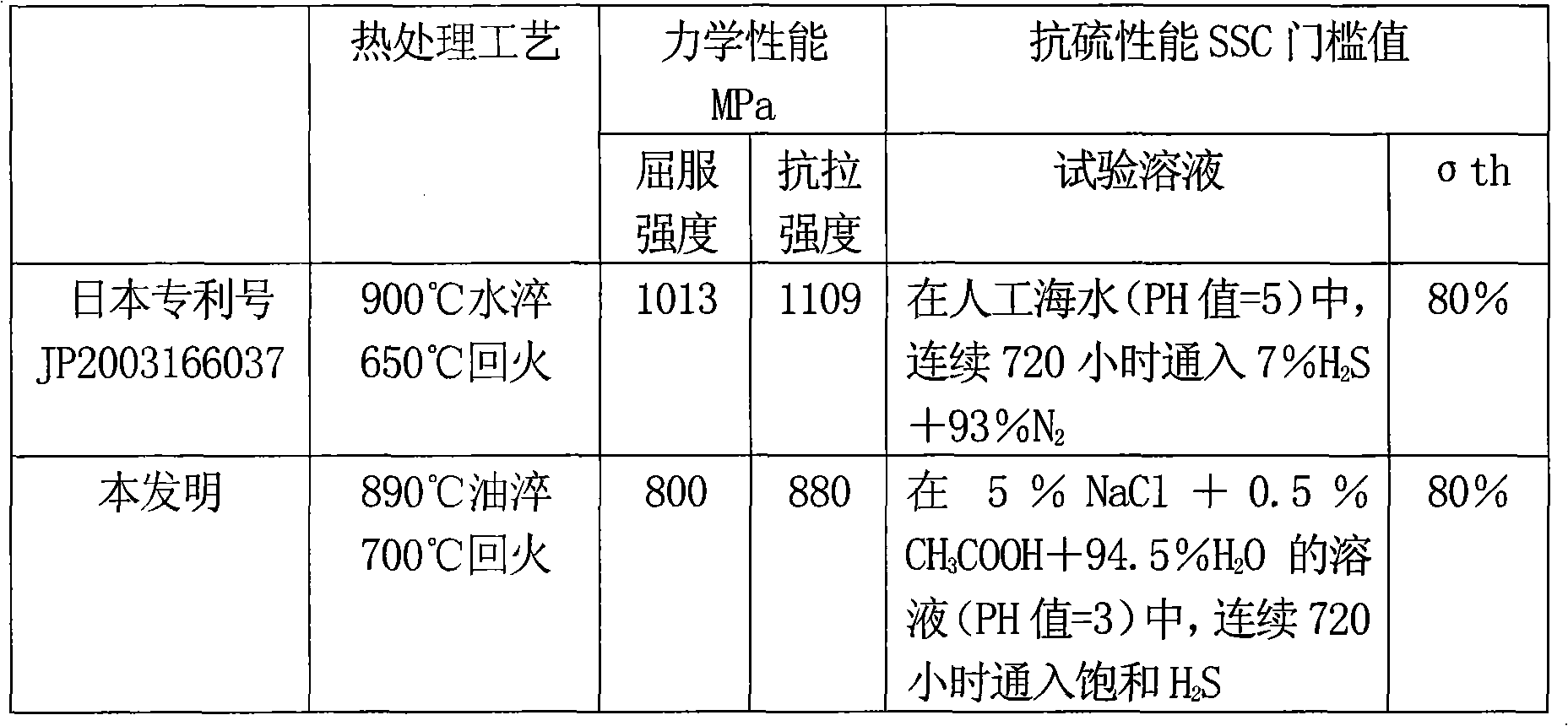

H2S-corrosion-resistant tool joint for petroleum drill pipe and hot treatment method thereof

ActiveCN101275207AImprove hardenabilityGuaranteed full hardeningDrilling rodsFurnace typesHydrogenSulfur

Owner:BAOSHAN IRON & STEEL CO LTD

Rare earth hydroxide catalyst for moderate/low temperature carbonyl sulfur hydrolysis and preparation method thereof

InactiveCN1593751AHigh activity at medium and low temperatureGreat operating flexibilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCarbonyl groupLow activity

The invention relates to a kind of rare-earth hydroxide catalyst with medium-low carbonyl sulfur hydrolysis and its manufacturing method. The catalyst of the invention is rare earth hydroxide, and chemical molecular formulas of it are: Re(OH)3, on which Re is stood for La, Pr, Nd, Sm, Eu, Gd. Compared with the existing COS hydrolysis catalyst, the catalyst of the invention has the advantages of \ high medium-low activity, great operating elasticity, excellent resistibility of oxygen and sulfur, simple manufacturing method and so on. When the concentration of oxygen in virgin gas is less than 2%, the catalyst activity has no influence; furthermore, when the virgin gas contains oxygen and hydrogen sulfide at the same time, the influence of catalyst activity can be neglected.

Owner:TONGJI UNIV

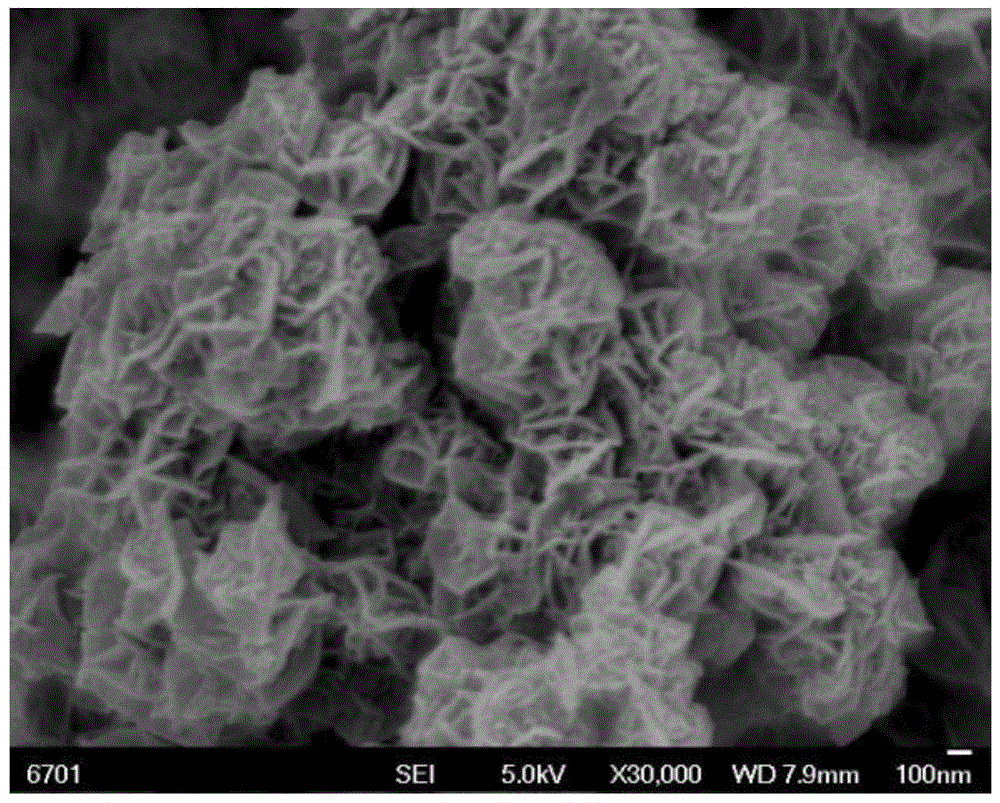

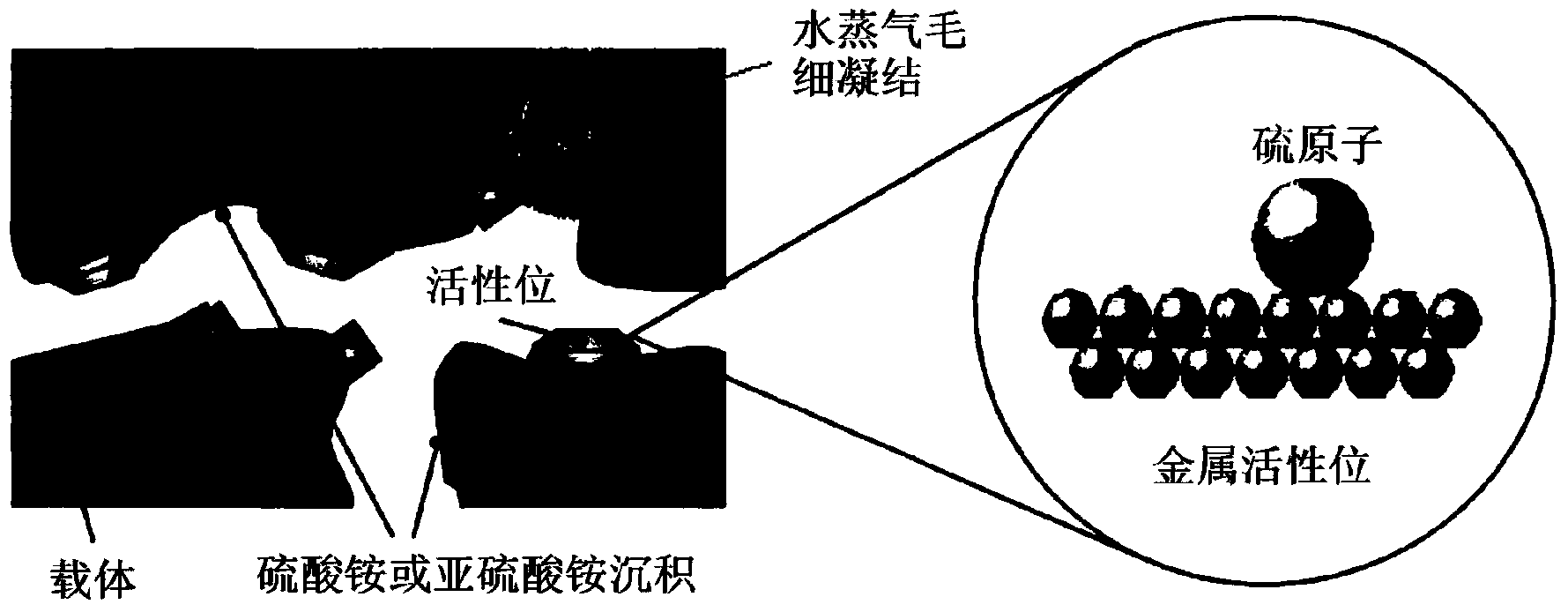

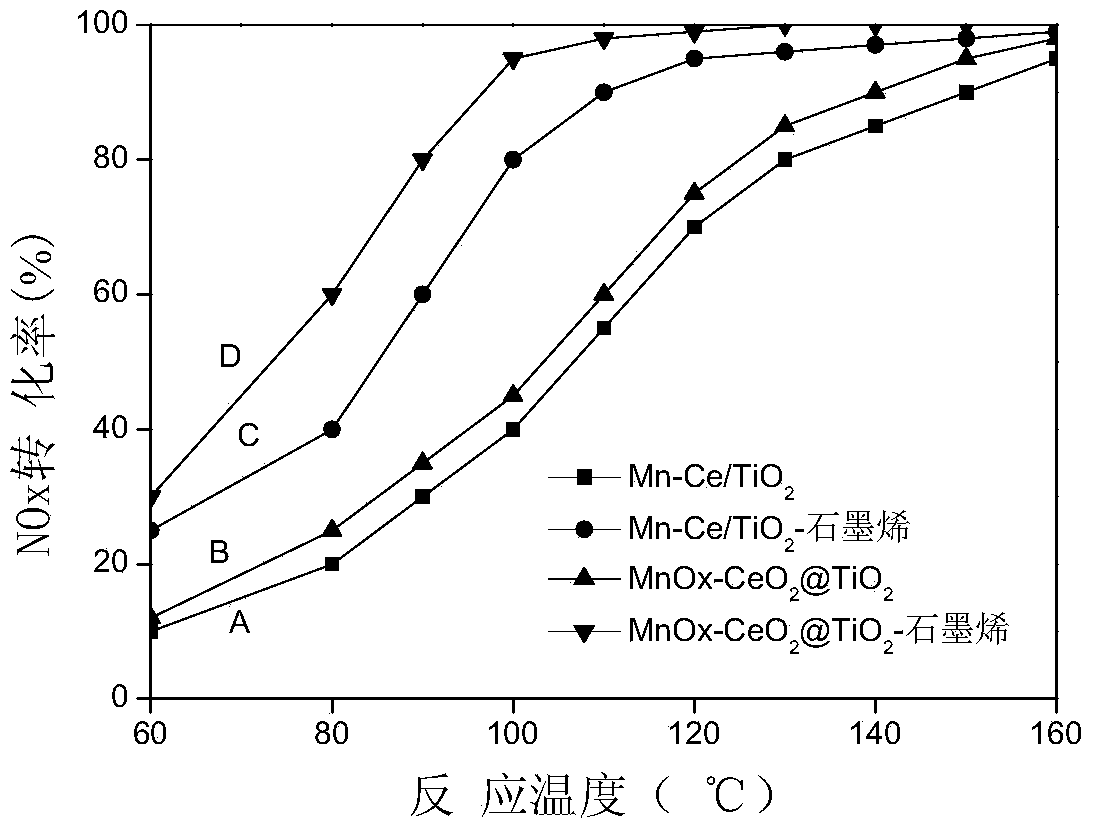

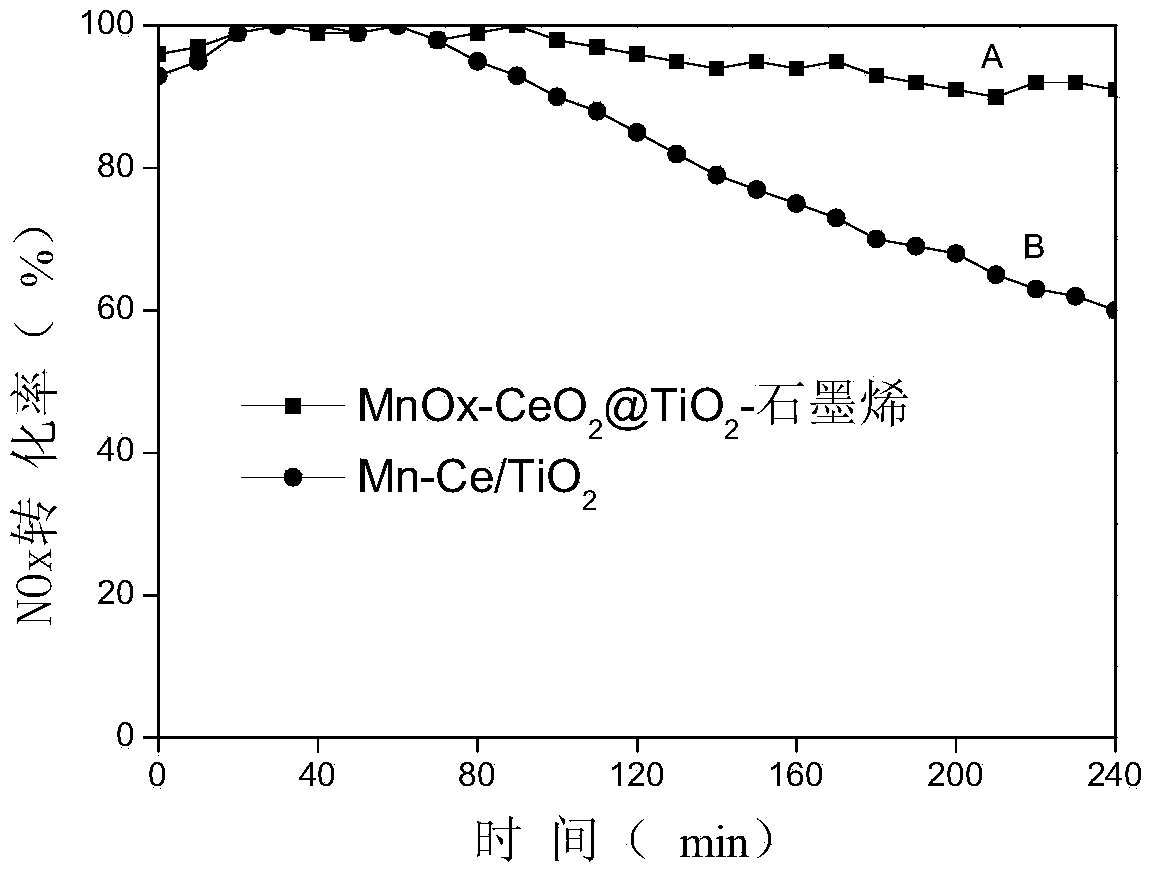

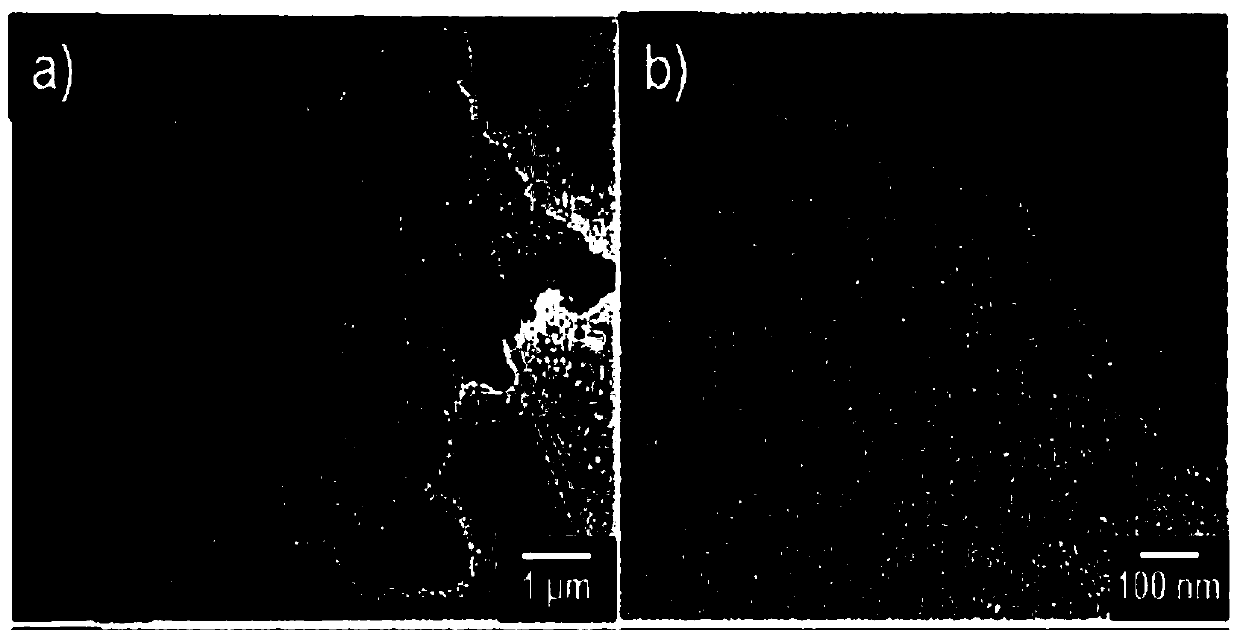

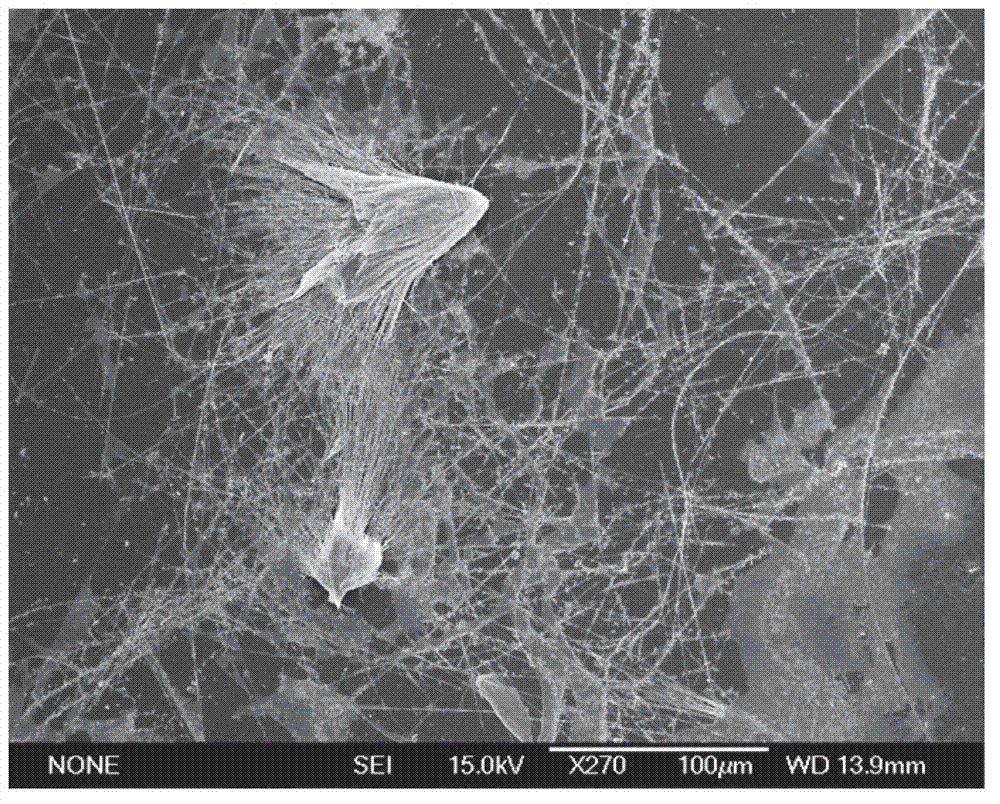

Graphene-loaded titanium-based core-shell-structured low-temperature SCR sulfur-resisting catalyst and preparation method thereof

ActiveCN104190409AReduce the probability of exposureReduce depositionMaterial nanotechnologyDispersed particle separationPtru catalystGraphene

The invention provides a graphene-loaded titanium-based core-shell-structured low-temperature SCR sulfur-resisting catalyst and a preparation method thereof. The preparation method of the graphene-loaded titanium-based core-shell-structured catalyst comprises the following steps: firstly forming a compound core-shell structure MnOx-CeO2@TiO2 by taking a nano particle MnOx-CeO2 as a core and TiO2 as a shell, and compounding the MnOx-CeO2@TiO2 with graphene, wherein the size range of the catalyst is within a range of about 20nm-200nm and the mol ratio of Mn to Ce to Ti in the core-shell structure MnOx-CeO2@TiO2 is (0.05-1) to (0.05-1) to 1; and the mass ratio of a graphene carrier to the nano core-shell structure MnOx-CeO2@TiO2 is (0.01-0.6) to 1. According to the invention, the graphene-loaded titanium-based core-shell structure is constructed for the first time and the active center of the catalyst is protected through special physicochemical properties of the core-shell catalyst and the accumulation of ammonium sulfate is reduced by virtue of graphene, so that the sulfur-resisting capability of a low-temperature denitration catalyst is enhanced.

Owner:NANJING NORMAL UNIVERSITY

Application of metal oxide modified CePO4 catalyst to collaborative denitration and demercuration

InactiveCN104888602AEasy to operateRaw materials are readily availablePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses application of a metal oxide modified CePO4 catalyst to collaborative denitration and demercuration. The application includes introducing medium-high temperature flue gas containing elemental mercury and nitrogen oxide into a catalyst loaded catalytic apparatus. Specifically, the main component of the catalyst is cerium phosphate, and the modification component is at least one of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum and tin metal oxides. The temperature of the medium-high temperature flue gas is 250-420DEG C. According to the application of the metal oxide modified CePO4 catalyst to collaborative denitration and demercuration, the oxidation efficiency to null valence mercury in high temperature flue gas is high, the NO is the flue gas can promote and enhance the catalytic efficiency of the catalyst, and the practicability is strong. In addition, the catalyst has good medium-high temperature SCR activity and anti-sulfur and waterproof performance.

Owner:ZHEJIANG UNIV

Catalyst for catalytic combustion of VOCs and preparation method thereof

PendingCN110614101AHigh activityGood mass and heat transferHeterogenous catalyst chemical elementsDispersed particle separationAlkaline earth metalRare earth

The invention discloses a catalyst for catalytic combustion of VOCs and a preparation method of the catalyst. Cordierite honeycomb ceramic or a porous metal material is used as a carrier, the carrieris coated with a nano coating material, precious metal compound transition metal is used as an active component, compound rare earth oxide is used as a catalyst aid, and a solid solution prepared froman alkaline earth metal compound and main group metal oxide is used as a carrier modifier; the carrier and the active component are coated through an automatic production line; the catalyst has advantages of high substrate bonding force, high adhesive force between the active component and the carrier after high-temperature roasting, difficult shedding, high activity, good thermal stability, goodsulfur resistance and long service lifetime, is a broad-spectrum VOC oxidation catalyst, can be used for catalytic combustion treatment of VOCs in the industries of spraying, printing, electronics and the like, and is suitable for CO and RCO catalytic combustion devices.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

Catalyst based on modified molecular sieve and hydrotalcite derived oxides and applied to diesel engine, preparation and application

ActiveCN106582794ASimple manufacturing processHigh oxygen storage performanceNitrous oxide captureGas treatmentHeat stabilityCordierite

The invention discloses a catalyst based on a modified molecular sieve and hydrotalcite derived oxides and applied to a diesel engine. The catalyst adopts the Co modified ZSM-5 molecular sieve as a main catalyst, a CeO2-ZrO2 solid solution as a cocatalyst, adopts multi-metal modified hydrotalcite derived composite oxides and gamma-Al2O3 as coating base materials and adopts cordierite honeycomb ceramic as a catalyst support. A preparation technology comprises steps as follows: determination of the use quantity of the raw materials of the catalyst; preparation of the Co modified ZSM-5 molecular sieve and the multi-metal modified hydrotalcite derived composite oxides; preparation and coating of coating slurry. The catalyst can efficiently catalyze adsorption-reductive purification reaction of NOx in exhaust gas. By means of the synergistic effect of four metallic oxides, NOx adsorption performance and heat stability of the hydrotalcite derived oxides are improved. Meanwhile, a precious metal main catalyst is replaced with the Co modified ZSM-5 molecular sieve, so that the cost of the raw materials is reduced, and sulfur resistance and heat stability of the catalyst are improved.

Owner:TIANJIN UNIV

Low-temperature sulphur-resisting denitration catalyst and preparation method thereof

ActiveCN104069852AStrong water resistanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCapillary condensationOpen framework

The invention discloses a low-temperature sulphur-resisting denitration catalyst and preparation method thereof. The catalyst is formed by mixing the following components in weight percent: 1-15% of active site and 85-99% of a carbon-base carrier, wherein the active site is formed by mixing one or several of Ag2O, K2O, BaO, SnO2, Bi2O3 or PbO improved vanadium-base alloy oxides. The preparation method comprises the steps of mixing the active site and the carbon-base carrier to prepare the low-temperature sulphur-resisting denitration catalyst. Since the surface hydrophobic treatment is performed on the catalyst prepared by the invention, the situation that water molecules in the flue gas adhere to an open-framework structure of the catalyst to form capillary condensation or form sulfuric acid or ammonium sulfite with adsorbed NH3 and SO2 or SO3 to inactivate the catalyst is avoided.

Owner:XIAN SINO GREEN HI TECH CO LTD

Iron catalyst containing cobalt auxiliary agent for Fischer-Tropsch synthesis reaction and preparation method thereof

ActiveCN101602000AImprove responseGood dispersionHydrocarbon from carbon oxidesCatalyst activation/preparationSulfurCobalt

The invention discloses an iron catalyst containing a cobalt auxiliary agent for a Fischer-Tropsch synthesis reaction and a preparation method thereof. The catalyst comprises Fe, Cu, K, Co and SiO2 in a weight ratio of 100:(0.1-10):(0.1-10):(0.01-5):(5-30). The iron catalyst containing the cobalt auxiliary agent has higher specific surface area, CO transforming activity, sintering resistance and sulfur resistance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Oil well tube resisting stress corrosion of H2S and manufacture method thereof

ActiveCN1924068AImprove hardenabilityHigh strengthDrilling rodsFurnace typesUltimate tensile strengthImpurity

The invention discloses a hydrogen sulfide resistance stress corrosion oil sleeve, which comprises the following parts: 0.20-0.32% C, 0.1-0.5% Si, 0.4-1.0% Mn, 0.1-0.8% Cr, 0.5-1.2% Mo, 0.01-1.10% V, 0.01-0.10% Nb, not more than 0.015% P, not more than 0.010% S and Fe and inevitable impurity. The preparing method comprises the following steps: proceeding arc electric melting and external fine melting; deairing in the vacuum; proceeding calcium disposal; casting to form round mould; rolling to form seamless steel pipe; tempering to do heat disposal; quenching between 820 and 1000 deg.c; insulating for over 30min; quenching inner and outer steel pipe simultaneously; setting flashback temperature over 650 deg.c; insulating for over 60min; proceeding air cooling; making heat aligning temperature over 480 deg.c; preparing oil pipe or sleeve through fault finding and pipe manufacturing.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving water resistance and sulfur resistance of manganese-based low-temperature SCR denitration catalyst

PendingCN109529948AImprove water resistanceImprove sulfur resistanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroethyleneDopant

The invention relates to a method for improving water resistance and sulfur resistance of a manganese-based low-temperature SCR denitration catalyst, which belongs to the technical field of a water-resistant sulfur-resistant catalyst. The hydrophobic polytetrafluoroethylene is used as a coating or a dopant, is simply dispersed in a reaction vessel containing anhydrous ethanol, and then is mixed with the manganese-based catalyst, and steps of filtering, drying and calcining are carried out to obtain the manganese-based low-temperature SCR denitration catalyst. The method of the invention has the advantages of simple process, low cost, no toxicity and no pollution, and can prepare the manganese-based low-temperature SCR catalyst with excellent water and sulfur resistance.

Owner:BEIJING UNIV OF TECH

Sulfur tolerant catalyst suitable for slurry bed methanation, its preparation method and application

InactiveCN103357418AWell mixedSmaller granularity andGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsHigh selectivityActive component

The invention relates to a sulfur tolerant catalyst suitable for slurry bed methanation. The catalyst adopts the main metal W as an active component, and on the basis the assistant metal W1 is added as an auxiliary agent, and the catalyst carrier is M. The catalyst is composed of, by mass: 2-40% of W, 0.5-35% of W1, and 50-97.5% of the carrier M. The sulfur tolerant catalyst provided in the invention has the advantages of high catalytic activity, long service life and high selectivity.

Owner:SEDIN ENG +1

High-energy-ball-milling-method SCR molecular sieve catalyst and preparation method thereof

ActiveCN105413738ASimple preparation processImprove conversion efficiencyMolecular sieve catalystsCatalyst activation/preparationHigh energyCopper oxide

The invention relates to a composite oxide iron-based molecular sieve SCR catalyst and a preparation method thereof. The composite oxide iron-based molecular sieve SCR catalyst is characterized in that the preparation method comprises the following steps: uniformly mixing copper oxide, iron oxide and co-catalyst metal oxide materials with molecular sieves by using a high energy ball milling method; adding an active component guiding-in agent and a surface dispersant to carry out impregnation; and ball-milling, drying, grinding and calcining to obtain the composite oxide iron-based molecular sieve SCR catalyst. The composite oxide iron-based molecular sieve SCR catalyst is used for catalytically purifying NOx in motor vehicle exhaust. The preparation process of the catalyst is simplified, the high energy ball milling method is adopted, the active component guiding-in agent and the surface dispersant are added so that metal active components are uniformly distributed in molecular sieve holes and on surfaces of the molecular sieve holes, during calcining, the metal oxide has abundant valence states, and the NOx conversion efficiency is high; and by the added co-catalyst metallic compound, sulfur resistance is improved, meanwhile, the co-catalyst metallic compound can also serve as an active component, NO-to-NO2 conversion is strengthened, the activity of the SCR catalyst is improved remarkably, and the actual application value is high.

Owner:CHINA FIRST AUTOMOBILE

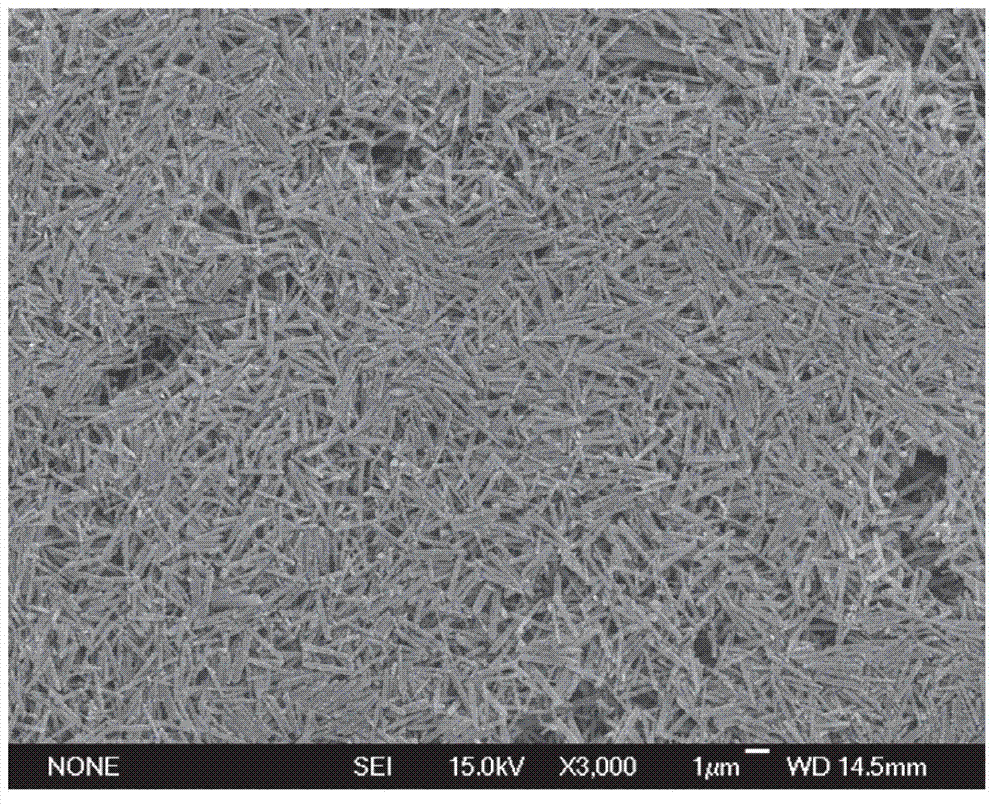

Low-dimensional nano-structured iron vanadate denitration catalyst, and preparation method and application thereof

ActiveCN103316685AHigh activityHigh selectivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIron saltsNanowire

The invention discloses a low-dimensional nano-structured iron vanadate denitration catalyst which is characterized in that the iron vanadate has a nano-rod or nano-wire or nano-sheet structure. The catalyst is prepared by using meta-vanadate, nitric acid, iron salt and ammonia water with a molar ratio of 1.0:10.0:0.5-1.0:0.1-4.0:0.0-4.0. The invention also discloses a preparation method and an application of the low-dimensional nano-structured iron vanadate denitration catalyst. According to the invention, advantages of a vanadium-based catalyst, an iron-based catalyst, and the low-dimensional nano structure are combined. Excellent activity, selectivity, thermal stability, and SO2 intoxication resistance are provided. The catalyst can be used in removing of nitrogen oxides in various flue gases.

Owner:SHANGHAI UNIV

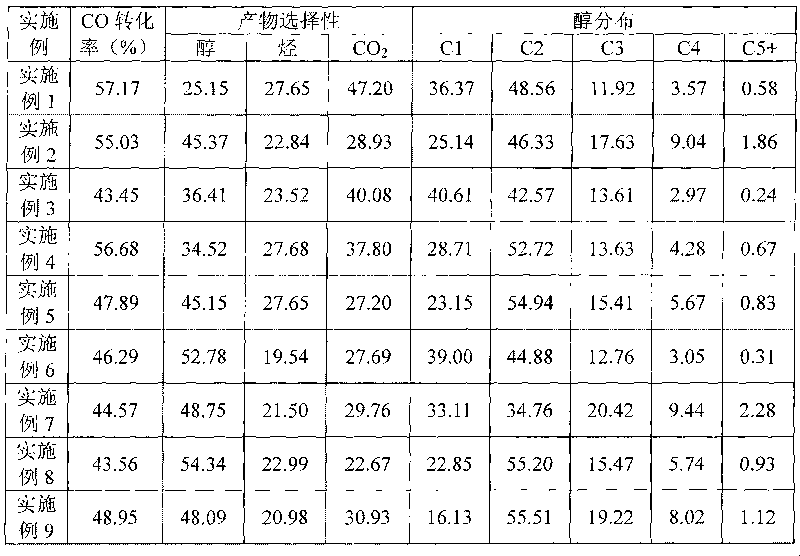

Sulfur-tolerant low-carbon alcohol catalyst and preparing method and application thereof

ActiveCN101733135AEasy to manufactureLess harshOrganic compound preparationHydroxy compound preparationAlcoholActive component

The invention relates to sulfur-tolerant low-carbon alcohol catalyst which has the expression of MC-M1-M2. The sulfur-tolerant low-carbon alcohol catalyst takes the M metal carbide as the active component, and M1 metal element and M2 metal element are added to the M metal carbide so as to be used as the auxiliary agents. The molar ratio of the M1 to the M2 to the M is 0.01-0.5:0.1-1:1. The M is one or some of the Mo, the W and the V, the M1 is one or some of the Fe, the Co, the Ni, the Cr, the Mn, the La, the Y and the Ce, and the M2 is one or some of the K, the Na, the Be and the Mg. The sulfur-tolerant low-carbon alcohol catalyst has the advantages of good sulfur tolerance, good stability and high activity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

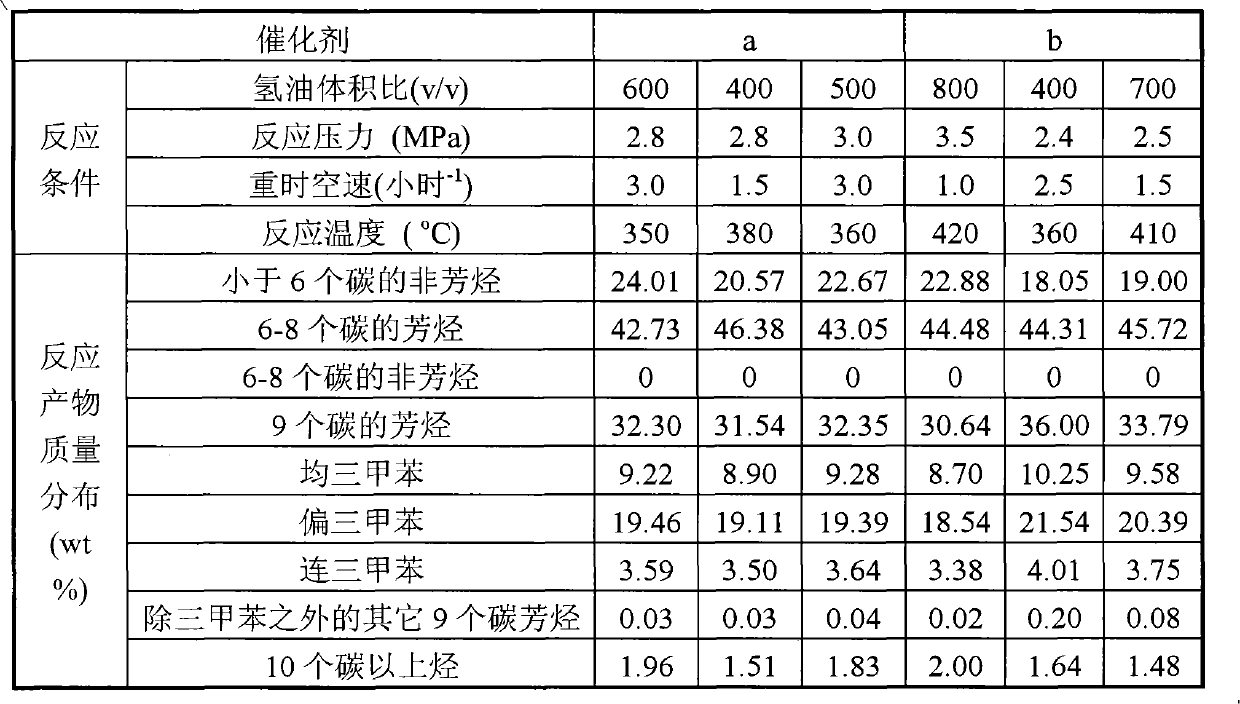

Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746093AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionBenzeneHydrogen

The invention relates to a method for the increase production of BTX aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low heavy aromatic hydrocarbon added value and high cost for separating and producing trimethylbenzene monomers in the heavy aromatic hydrocarbons containing methylethylbenzene, propylbenzene and butylbenzene. The method comprises a step that the heavy aromatic hydrocarbons are subjected to a hydrocracking reaction through adopting Pt / Pd-loaded hydrogen type binder-free ten-membered ring zeolite as a catalyst under reaction conditions comprising that the reaction temperature is 320-450DEG C, the reaction pressure is 2.0-4.0Mpa, the hydrocarbons raw material weight hourly space velocity is 1.0-4.0h<-1> and the hydrogen / hydrocarbon raw material ratio by mole is 3-10:1. The method well solves the problems through above technical scheme, and can be applied to the industrial production of the BTX aromatic hydrocarbons and the trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

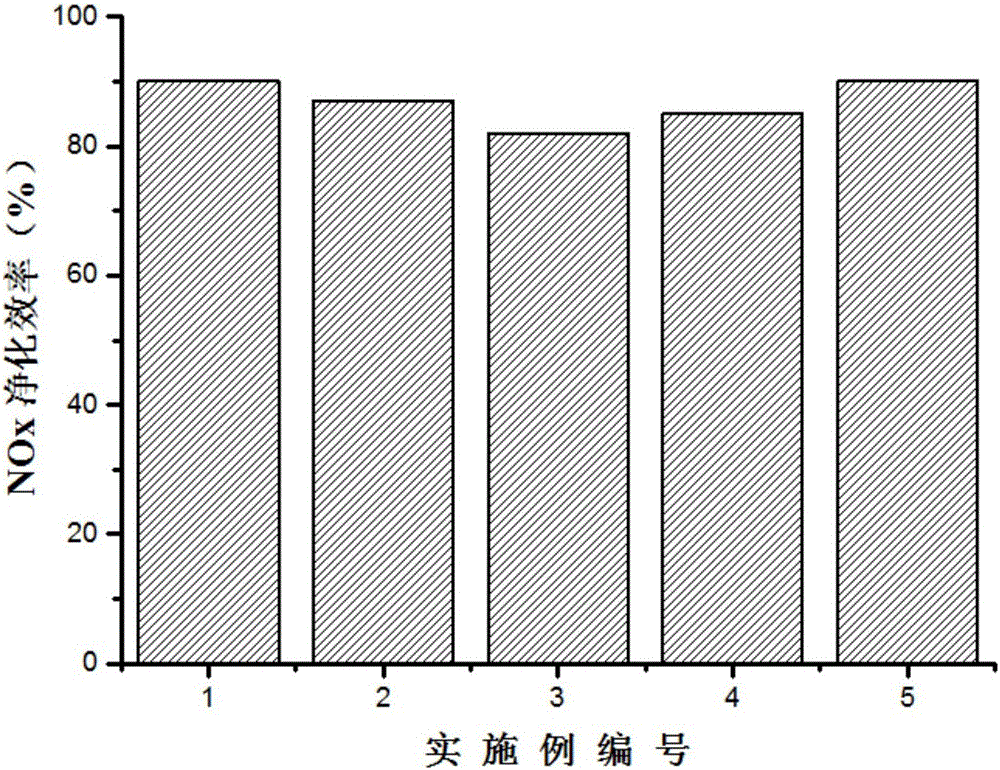

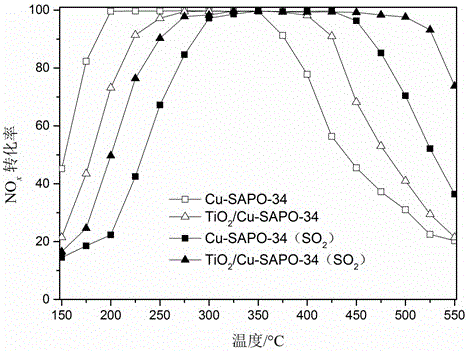

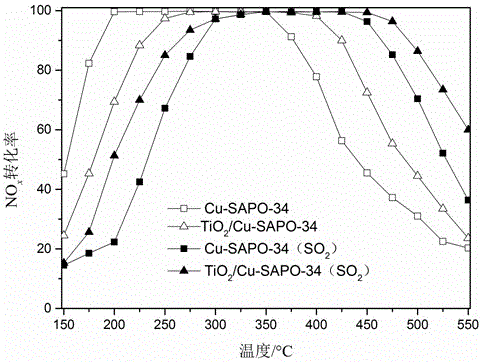

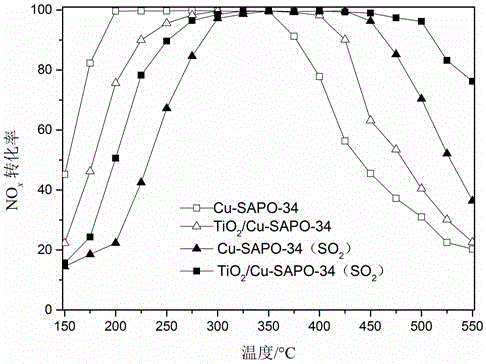

Preparation method of low-temperature NH3-SCR sulfur-resistant denitration catalyst

InactiveCN105944755AImprove purification efficiencyImprove sulfur resistanceMolecular sieve catalystsDispersed particle separationTitanium tetraisopropoxideSulfur

The invention discloses a preparation method of a low-temperature NH3-SCR sulfur-resistant denitration catalyst. The preparation method is characterized in that titanium tetrachloride, titanium(IV) isopropoxide, isopropyl titanate and butyl titanate are used as the titanium sources of the sulfur-resistant denitration catalyst, and a chemical vapor deposition method or aqueous phase method to precipitate a TiO2 sulfur-resistant layer on the surface of a Cu-SAPO-34 catalyst or wrap the surface of the Cu-SAPO-34 catalyst with the TiO2 sulfur-resistant layer so as to form a TiO2 / Cu-SAPO-34 compound catalyst. The prepared catalyst keeps the low-temperature high-activity feature of the Cu-SAPO-34 catalyst and adopts the TiO2 sulfur-resistant layer to evidently enhance of the sulfur resistance. At 300-500 DEG C, SO2 (100-500ppm) is fed into a reaction system, and the conversion rate of NOx in the NH3-SCR reaction is above 80%. Compared with a common catalyst, the compound catalyst is wider in temperature operation window, excellent in low-temperature activity and high in sulfur resistance.

Owner:KUNMING UNIV OF SCI & TECH

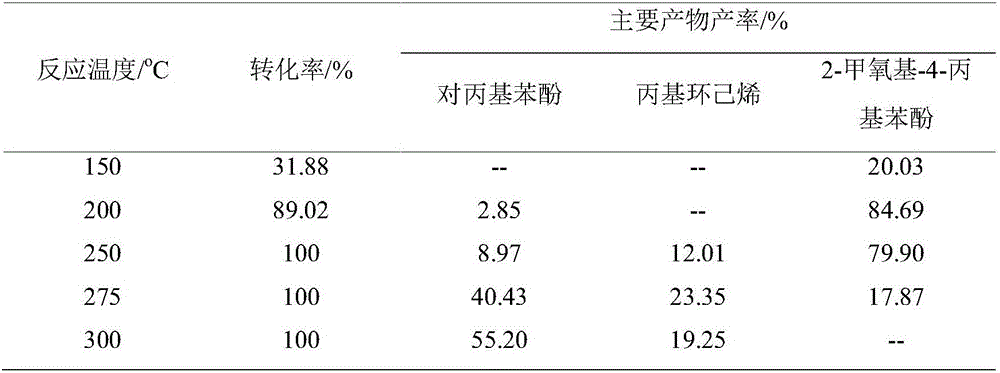

Molybdenum sulfide catalyst and preparation thereof, and applications of molybdenum sulfide catalyst in hydrogenation degradation of aromatic phenol and ether compounds

InactiveCN106238075ALow priceEasy to preparePhysical/chemical process catalystsOrganic compound preparationActivated carbonIridium

The invention discloses a molybdenum sulfide catalyst and a preparation method thereof, and applications of the molybdenum sulfide catalyst in high-added value aromatic fine chemical product production reactions through hydrogenation degradation of aromatic phenol and ether compounds. According to the molybdenum sulfide catalyst I, molybdenum sulfide is adopted as a main active component, one or a plurality of materials selected from nickel, cobalt, iron, copper, platinum, ruthenium, rhodium, palladium, lanthanum, osmium, iridium and the like can be added as a second metal component, the components can be supported on one carrier selected from active carbon (AC), carbon black (VB), carbon fiber (CF), graphene, carbon nano-tubes (CT), a mesoporous carbon material, gamma-alumina (gamma-Al2O3), silica (SiO2), zirconia (ZrO2), titania (TiO 2), a silicon-aluminum molecular sieve and a phosphorous-aluminum molecular sieve, and the catalyst is used for the catalytic hydrogenation degradation reaction of aromatic phenol and ether compounds. According to the present invention, with the catalyst, the aromatic phenol and ether compounds can be catalytically converted into the high-added value aromatic chemical products having the aromatic structure at the temperature of 150-350 DEG C under the initial hydrogen gas pressure of 1-6 MPa in the high-efficiency, high-selectivity and high-yield manner.

Owner:TIANJIN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com