Low-dimensional nano-structured iron vanadate denitration catalyst, and preparation method and application thereof

A denitration catalyst and low-dimensional nanotechnology are applied in the field of low-dimensional nanostructured iron vanadate catalyst and its preparation, which can solve the problems of sharp reduction of forests, marine pollution, solid waste pollution, etc., achieve N2 selective sulfur resistance, improve Catalytic efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

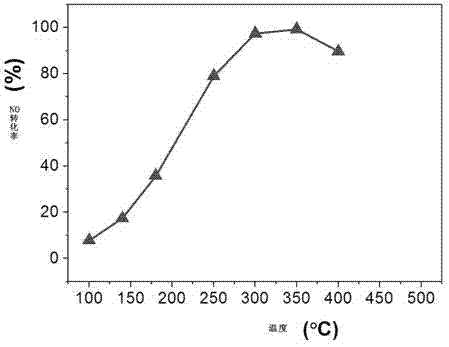

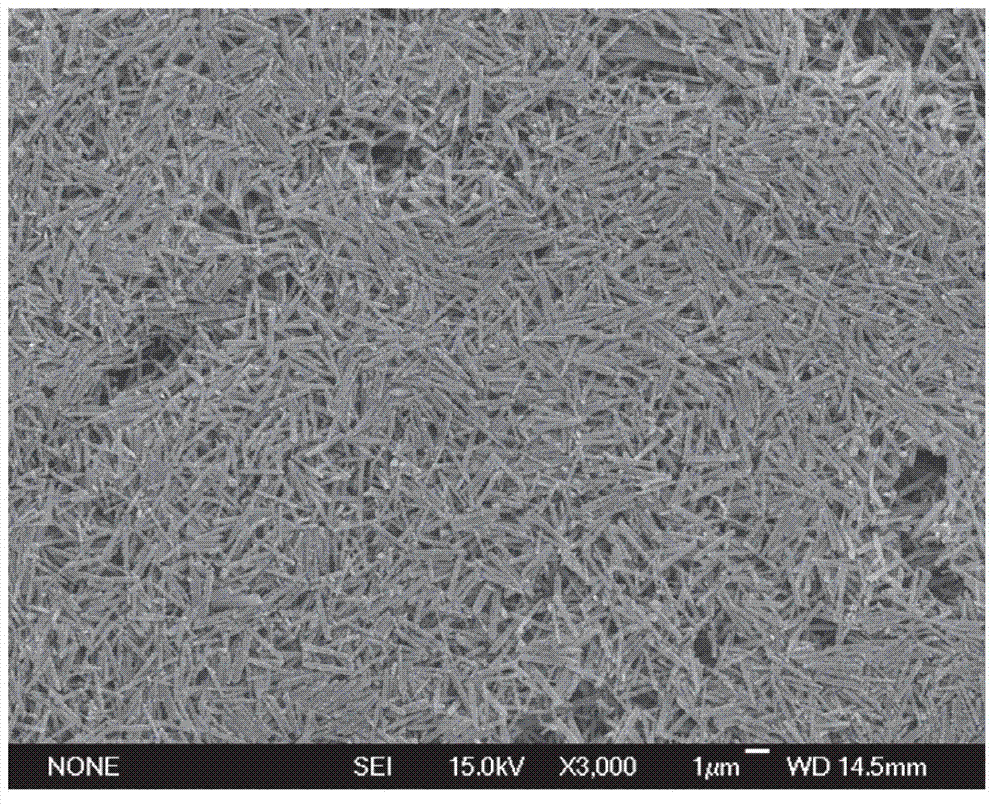

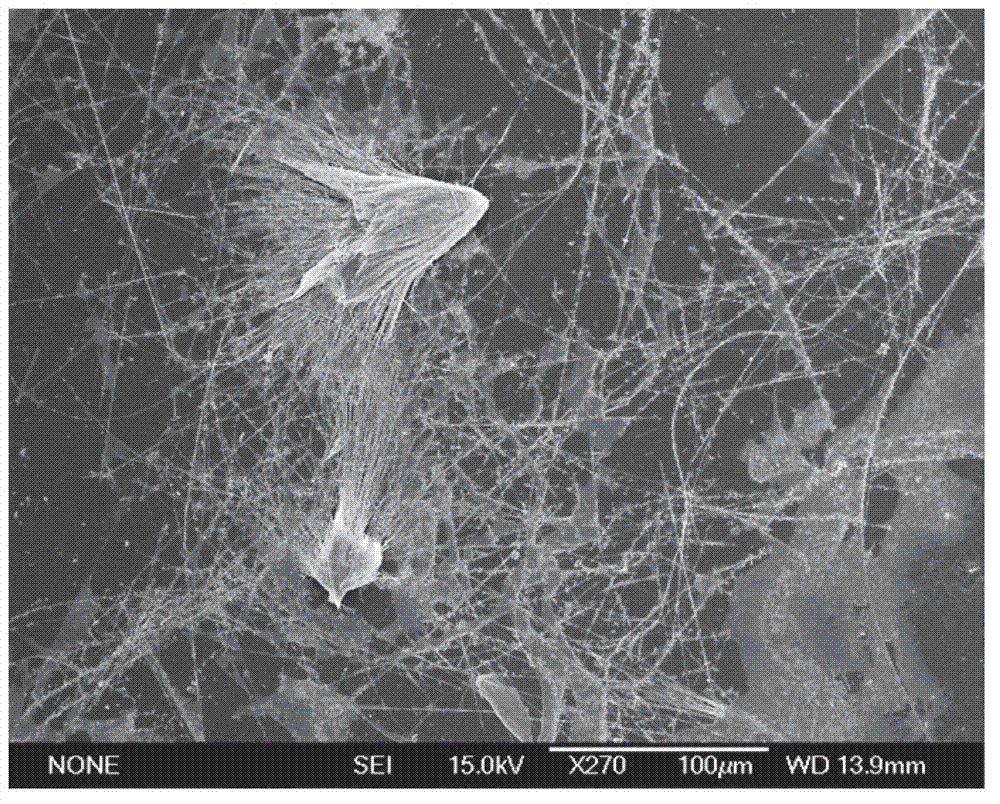

[0039] see Figure 1 to Figure 5 , the present invention provides a low-dimensional nano-structure iron vanadate denitration catalyst, which is one of the iron vanadate structures of nanorods, nanowires or nanosheets.

[0040] The iron vanadate with a nanorod structure has a diameter of 50-300 nm and a length of 1-5 μm; the iron vanadate with a nanowire structure has a diameter of 50-300 nm and a length of 10-500 μm; the vanadate with a nanosheet structure Iron, 0.5-5μm long, 0.5-5μm wide, 50-100nm thick.

[0041] The low-dimensional nano-structure iron vanadate denitration catalyst is made of the following components: metavanadate, nitric acid, iron salt, ammonia, and surfactant, and its molar ratio is: metavanadate 1.0: Nitric acid 10.0: iron salt 0.5-1.0: ammonia water 0.1-4.0: surfactant 0.0-4.0.

[0042] Wherein the metavanadate is one of ammonium metavanadate, sodium metavanadate or potassium metavanadate; the iron salt is one of ferric nitrate, ferric chloride or ferr...

Embodiment 2

[0055] see figure 1 , the low-dimensional nanostructure ferric vanadate denitration catalyst provided in this example and its preparation method and application, its structure, components and steps are the same as in Example 1, the difference is:

[0056] The low-dimensional nanostructure iron vanadate denitration catalyst is specifically a nanorod structure, which is made of metavanadate, nitric acid, iron salt, and ammonia water. The molar ratio of metavanadate, nitric acid, iron salt, and ammonia water is It is 1.0:10.0:0.8:3.

[0057] The metavanadate is ammonium metavanadate.

[0058] The iron salt is iron nitrate.

[0059] The preparation method of the above-mentioned low-dimensional nanorod structure iron vanadate denitration catalyst comprises the following steps:

[0060] (1) prepare each raw material component according to following mol ratio: the mol ratio of metavanadate, nitric acid, iron salt, ammoniacal liquor is 1.0: 10.0: 0.8: 3;

[0061] (2) Configure iro...

Embodiment 3

[0066] The low-dimensional nanostructure ferric vanadate denitration catalyst provided in this example and its preparation method and application, its structure, components and steps are the same as those of Examples 1 and 2, the difference is:

[0067] This embodiment provides a low-dimensional nanorod structure iron vanadate denitration catalyst, which is made of metavanadate, nitric acid, iron salt, and ammonia water, and the molar ratio of metavanadate, nitric acid, iron salt, and ammonia water is 1.0:10.0:1:0.1.

[0068] The metavanadate is sodium metavanadate.

[0069] The iron salt is ferric chloride.

[0070] The method for preparing the above-mentioned low-dimensional nanorod structure iron vanadate denitration catalyst comprises the following steps:

[0071] (1) The mol ratio of metavanadate, nitric acid, iron salt, ammoniacal liquor is 1.0: 10.0: 1: 0.1, prepare each component according to above-mentioned mol ratio:

[0072] (2) Configure iron salt solution: diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com