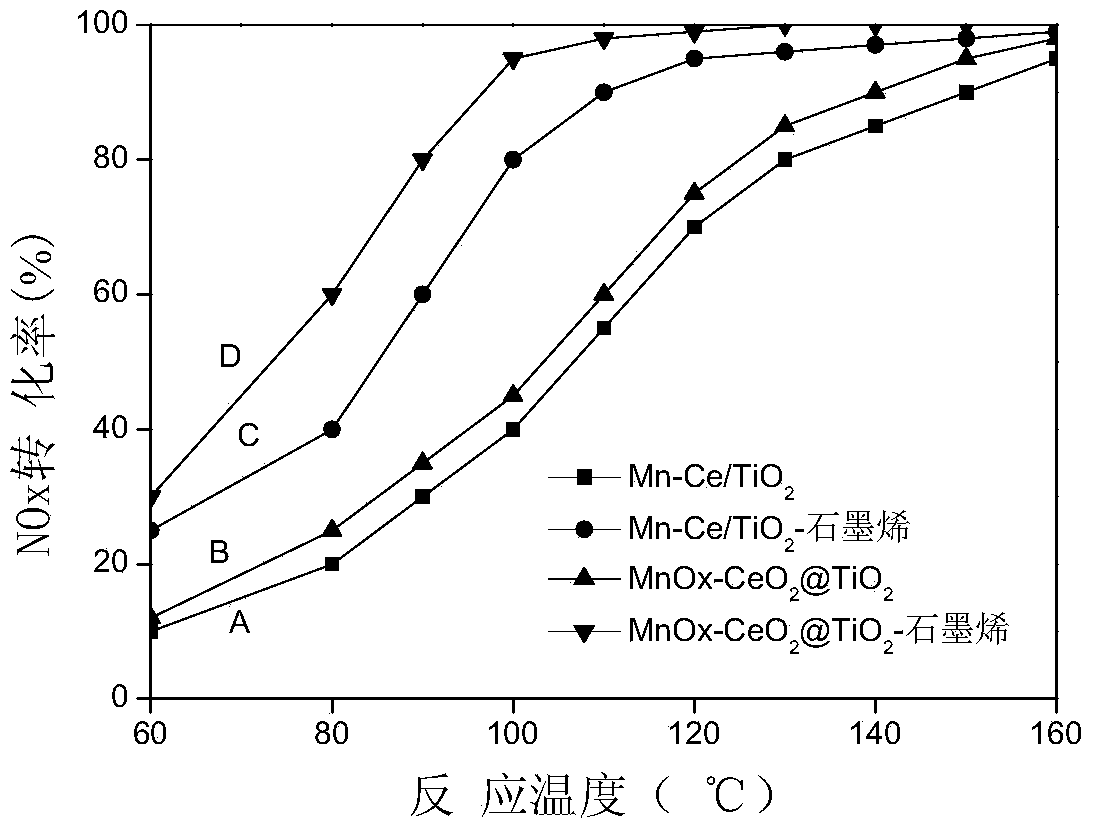

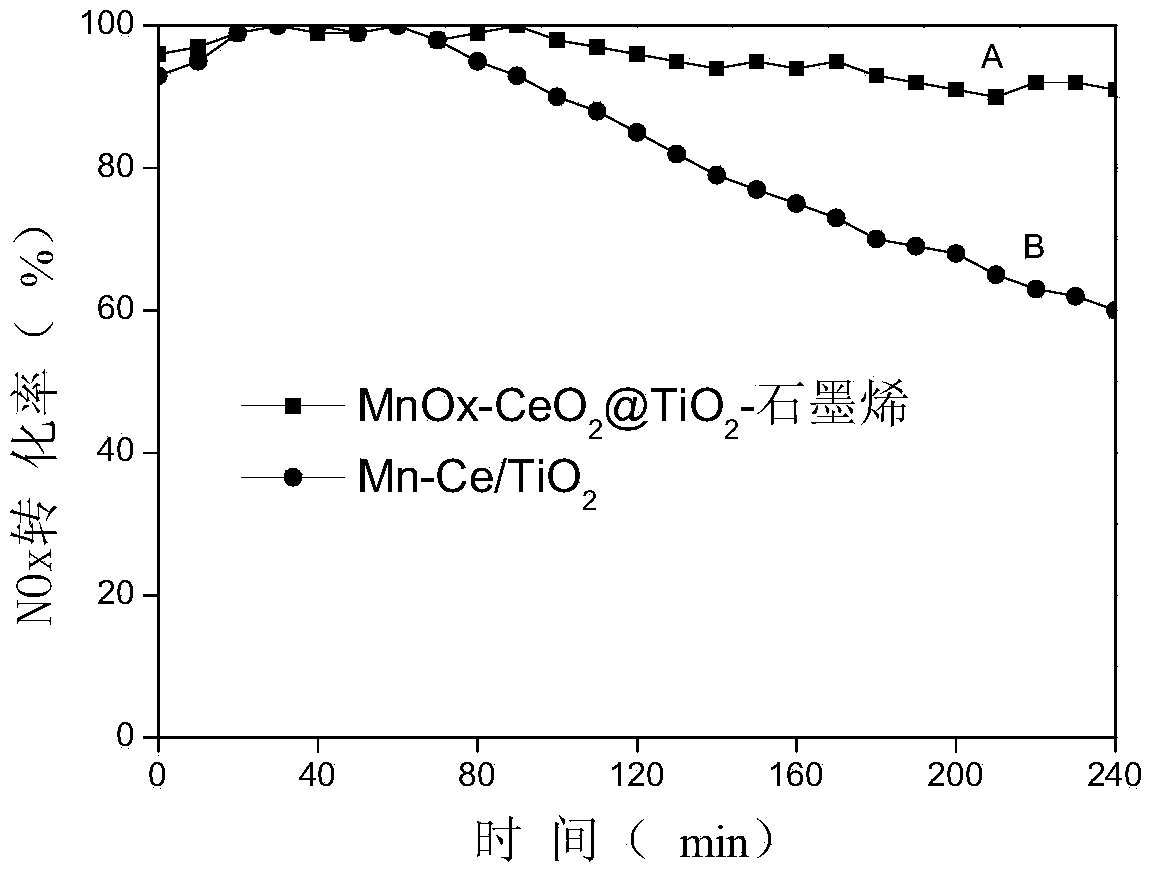

Graphene-loaded titanium-based core-shell-structured low-temperature SCR sulfur-resisting catalyst and preparation method thereof

A core-shell structure, graphene technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve good denitrification activity and selectivity, improve activity and reaction Ability, excellent anti-alkali/alkaline earth metal poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

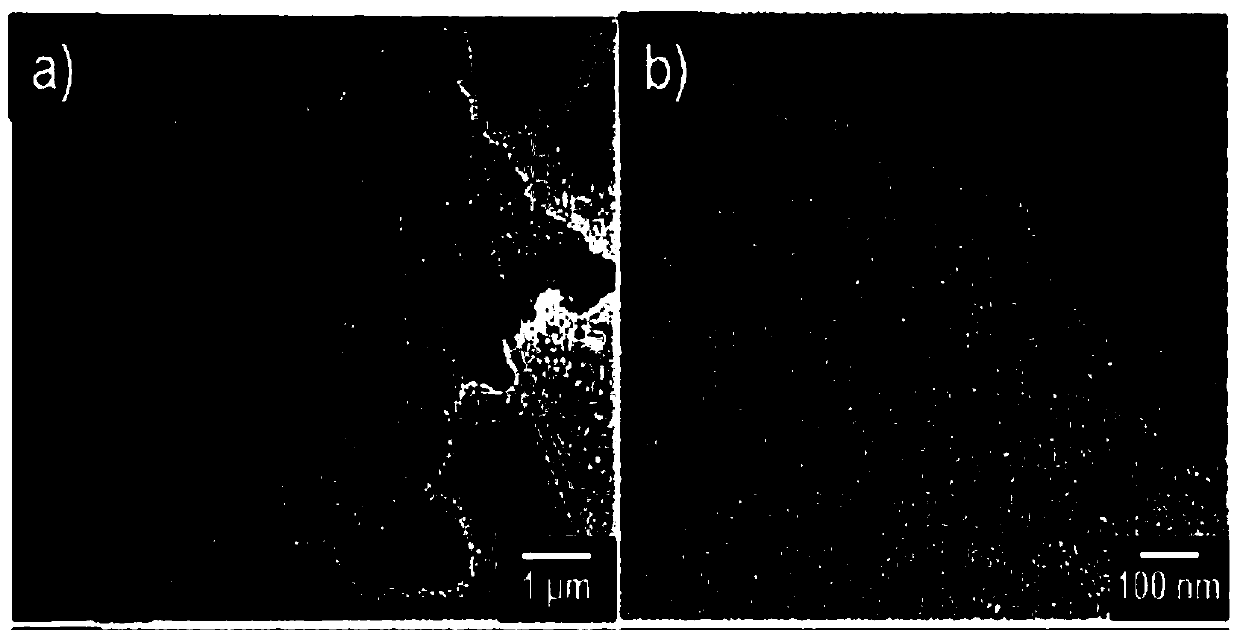

Embodiment 1

[0020] Firstly, MnOx-CeO was prepared by hydrothermal method 2 TiO 2 For the catalyst, the molar ratio of Mn:Ce:Ti is selected to be 0.5:0.7:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, and alternately wash with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in an inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant, and cyclohexane as oil phase, wherein the mass fraction of CTAB was 10%, and the mass fraction of cyclohexane was The fraction is 40%...

Embodiment 2

[0022] Firstly, MnOx-CeO was prepared by hydrothermal method 2 TiO 2 For the catalyst, the molar ratio of Mn:Ce:Ti is selected to be 0.5:0.3:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, wash alternately with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in an inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant, and cyclohexane as oil phase, wherein the mass fraction of CTAB was 15%, cyclohexane The mass fraction of n-pentanol is 20%, and the mass...

Embodiment 3

[0024] Firstly, MnOx-CeO was prepared by hydrothermal method 2 TiO 2 For the catalyst, the Mn:Ce:Ti molar ratio is selected to be 1:1:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, wash alternately with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in an inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant, and cyclohexane as oil phase, in which CTAB mass fraction was 10%, cyclohexane The mass fraction is 30%, and the mass fraction of n-pentanol is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com