Preparation method of fire prevention and extinguishing material for coal mine

A fire prevention and coal mine technology, applied in the field of flame retardant materials, can solve the problems of poor fire prevention effect and easy cracking, and achieve the effects of fire extinguishing, strong water retention and prevention of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

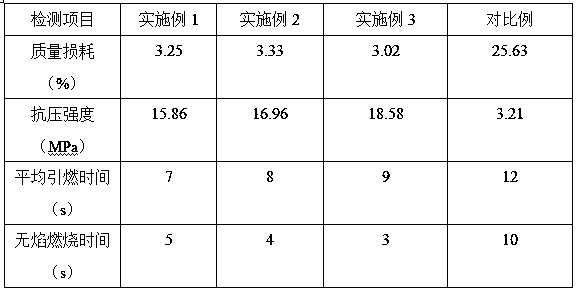

Embodiment 1

[0040] Take chitosan, ammonium persulfate, mixed solution, and 1% acetic acid solution by volume fraction, mix chitosan and 1% acetic acid solution by volume fraction, and stir to obtain reaction solution A, and add mixed liquid, and stirred at constant temperature to obtain the reaction solution B. Add ammonium persulfate to the reaction solution B and continue to stir for 10 minutes to obtain the reactant; take the reactant, sodium montmorillonite, acrylic acid, water glass, N, N' - Methylenebisacrylamide, deionized water, mix the reactants with deionized water, and disperse ultrasonically to obtain a dispersion, add acrylic acid, N, N'-methylenebisacrylamide, sodium base The montmorillonite and water glass are stirred and reacted to obtain the semi-finished product; the semi-finished product is washed with deionized water for 3 times, and the pH value is adjusted, and the precipitate is obtained by filtration. The precipitate is washed and dried, cooled to room temperature, ...

Embodiment 2

[0042] Take chitosan, ammonium persulfate, mixed solution, and 1% acetic acid solution by volume fraction, mix chitosan and 1% acetic acid solution by volume fraction, and stir to obtain reaction solution A, and add mixed liquid, and stirred at constant temperature to obtain the reaction solution B. Add ammonium persulfate to the reaction solution B and continue to stir for 13 minutes to obtain the reactant; take the reactant, sodium montmorillonite, acrylic acid, water glass, N, N' - Methylenebisacrylamide, deionized water, mix the reactants with deionized water, and disperse ultrasonically to obtain a dispersion, add acrylic acid, N, N'-methylenebisacrylamide, sodium base The montmorillonite and water glass are stirred and reacted to obtain the semi-finished product; the semi-finished product is washed with deionized water 4 times, and the pH value is adjusted, and the precipitate is obtained by filtration. The precipitate is washed and dried, cooled to room temperature, and ...

Embodiment 3

[0044] Take chitosan, ammonium persulfate, mixed solution, and 1% acetic acid solution by volume fraction, mix chitosan and 1% acetic acid solution by volume fraction, and stir to obtain reaction solution A, and add mixed solution, constant temperature stirring treatment, that is, the reaction solution B, ammonium persulfate was added to the reaction solution B, and continued to stir for 15 minutes to obtain the reactant; take the reactant, sodium montmorillonite, acrylic acid, water glass, N, N' - Methylenebisacrylamide, deionized water, mix the reactants with deionized water, and disperse ultrasonically to obtain a dispersion, add acrylic acid, N, N'-methylenebisacrylamide, sodium base The montmorillonite and water glass are stirred and reacted to obtain the semi-finished product; the semi-finished product is washed with deionized water for 5 times, and the pH value is adjusted, and the precipitate is obtained by filtration. The precipitate is washed and dried, cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com