Aeolian sand foamed soil and application, aeolian sand foamed soil prefabricated block and application and waterproof foundation

A technology of aeolian sand and foamed soil, applied in the field of engineering, can solve problems such as low shear strength, easy loosening and displacement, and lower moisture content in the upper layer, and achieve good mechanical properties, enhanced structural strength, and uniform distribution of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

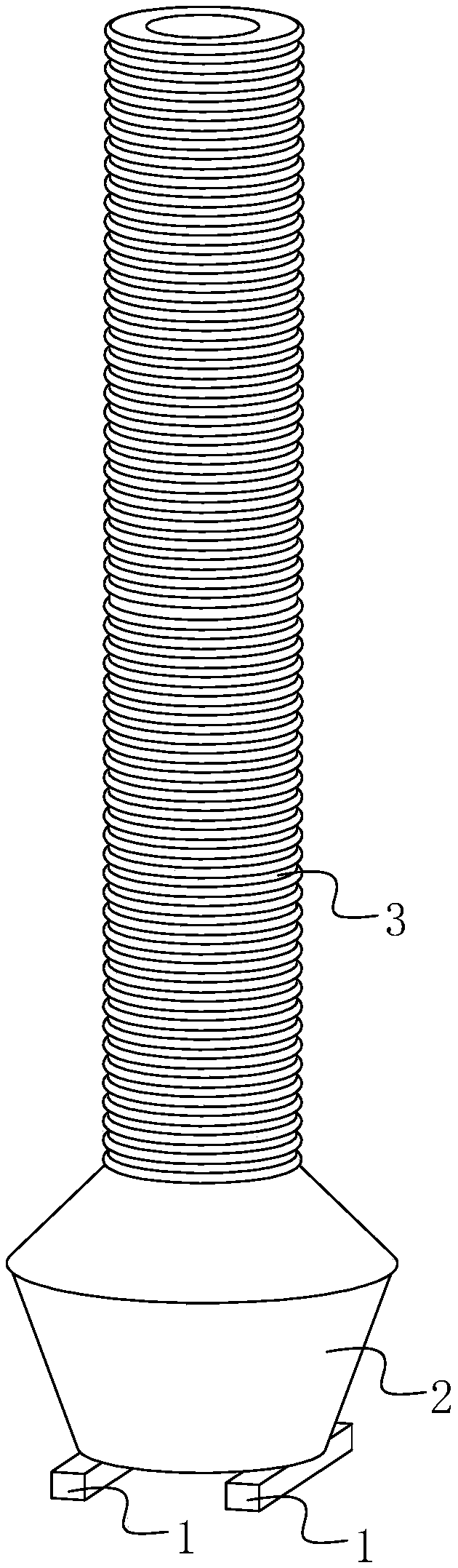

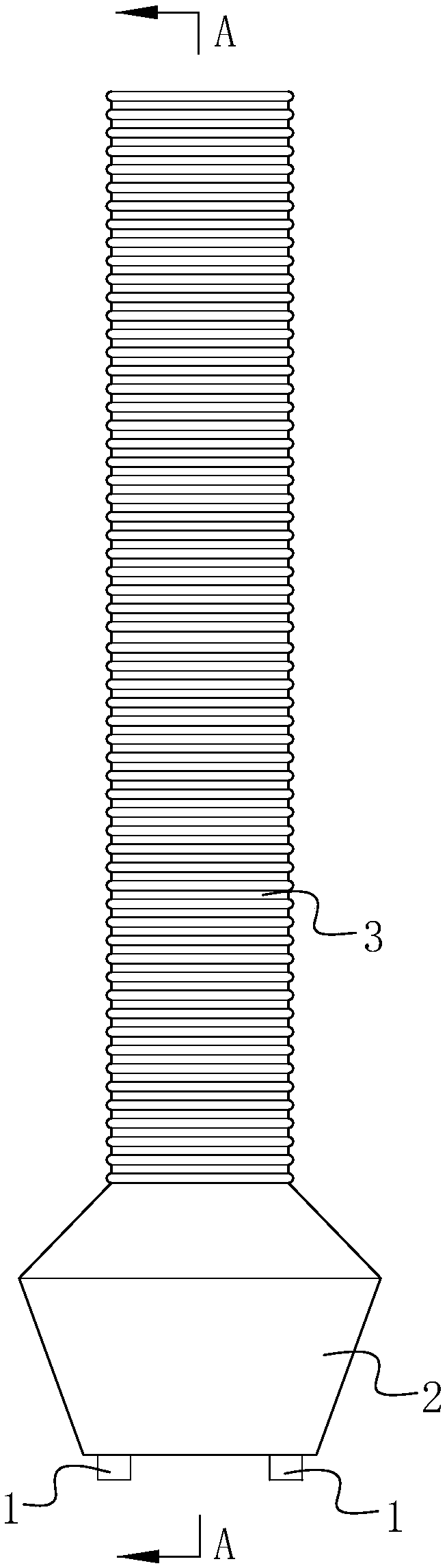

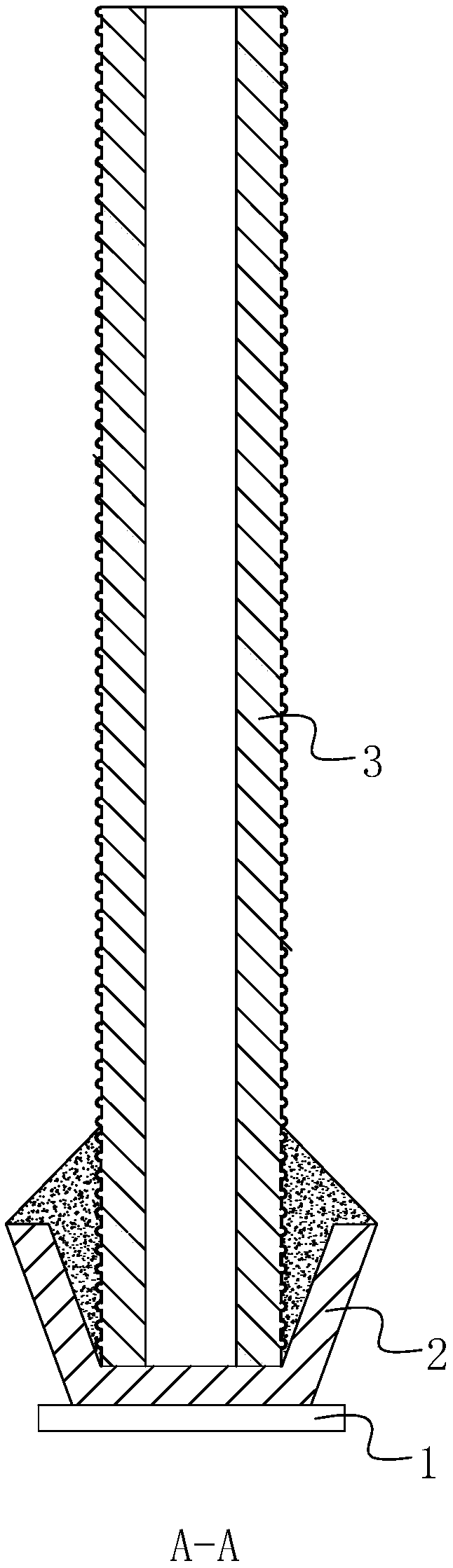

Image

Examples

Embodiment 1

[0041] Preparation of aeolian sofa foam: It is obtained by uniformly mixing the mixture of 250Kg of P.S.A32.5 cement and 250Kg of aeolian sand with the foam made of the solution of 1.81Kg of foaming agent and 180Kg of water.

[0042] Preparation of aeolian sofa foam prefabricated blocks: the above-mentioned aeolian sofa foam soil is made by casting and curing.

Embodiment 2

[0044] Preparation of aeolian sofa foam: It is obtained by uniformly mixing the mixture of 325Kg of P.S.A42.5 cement and 325Kg of aeolian sand with the foam made of the solution of 1.67Kg of foaming agent and 240Kg of water.

[0045] Preparation of aeolian sofa foam prefabricated blocks: the above-mentioned aeolian sofa foam soil is made by casting and curing.

Embodiment 3

[0047] Preparation of aeolian sofa foam: It is obtained by uniformly mixing the mixture of 375Kg of P.S.A32.5 cement and 565Kg of aeolian sand with the foam made of the solution of 1.25Kg of foaming agent and 236Kg of water.

[0048] Preparation of aeolian sofa foam prefabricated blocks: the above-mentioned aeolian sofa foam soil is made by casting and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com