Patents

Literature

408 results about "Aeolian sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

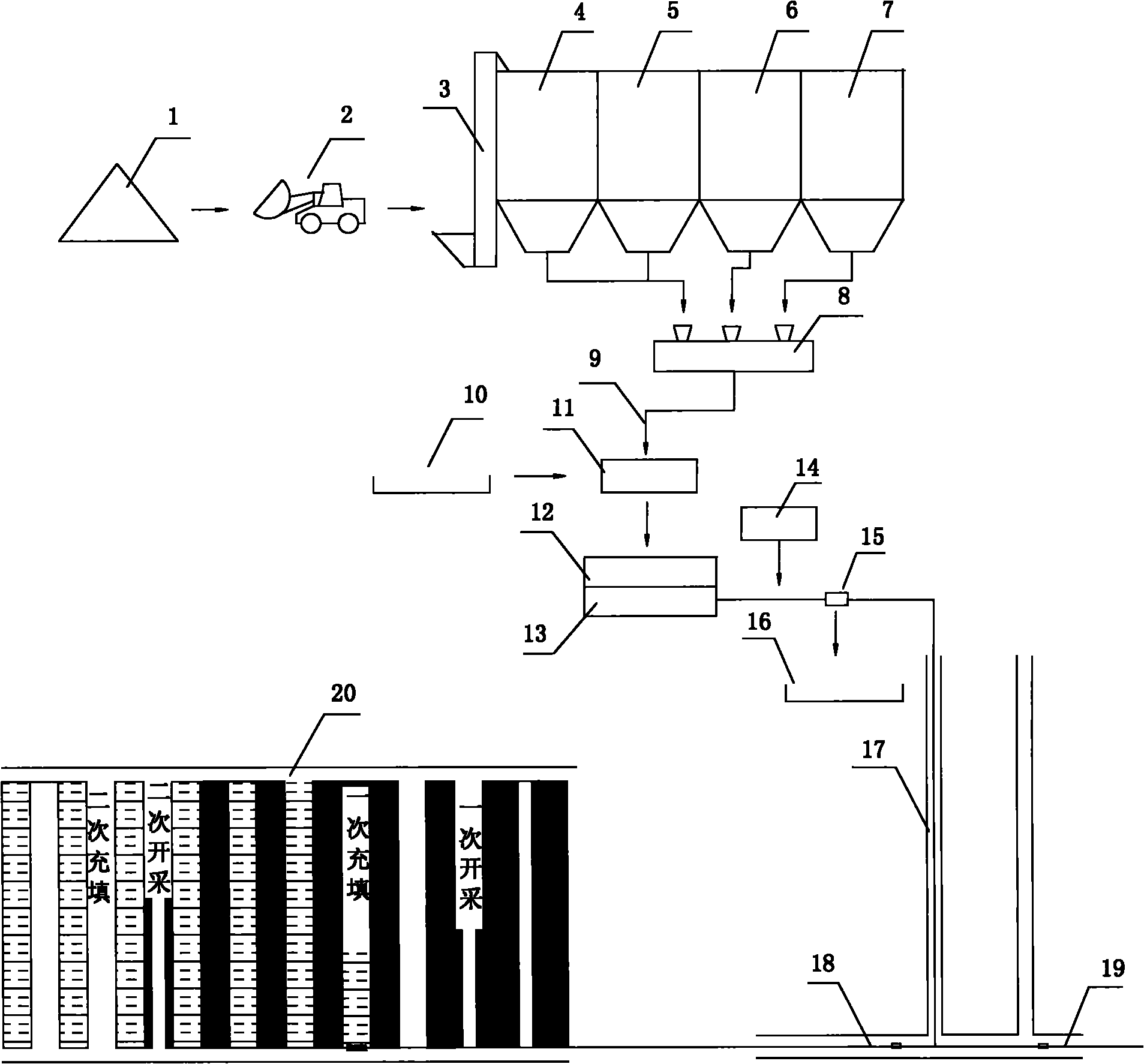

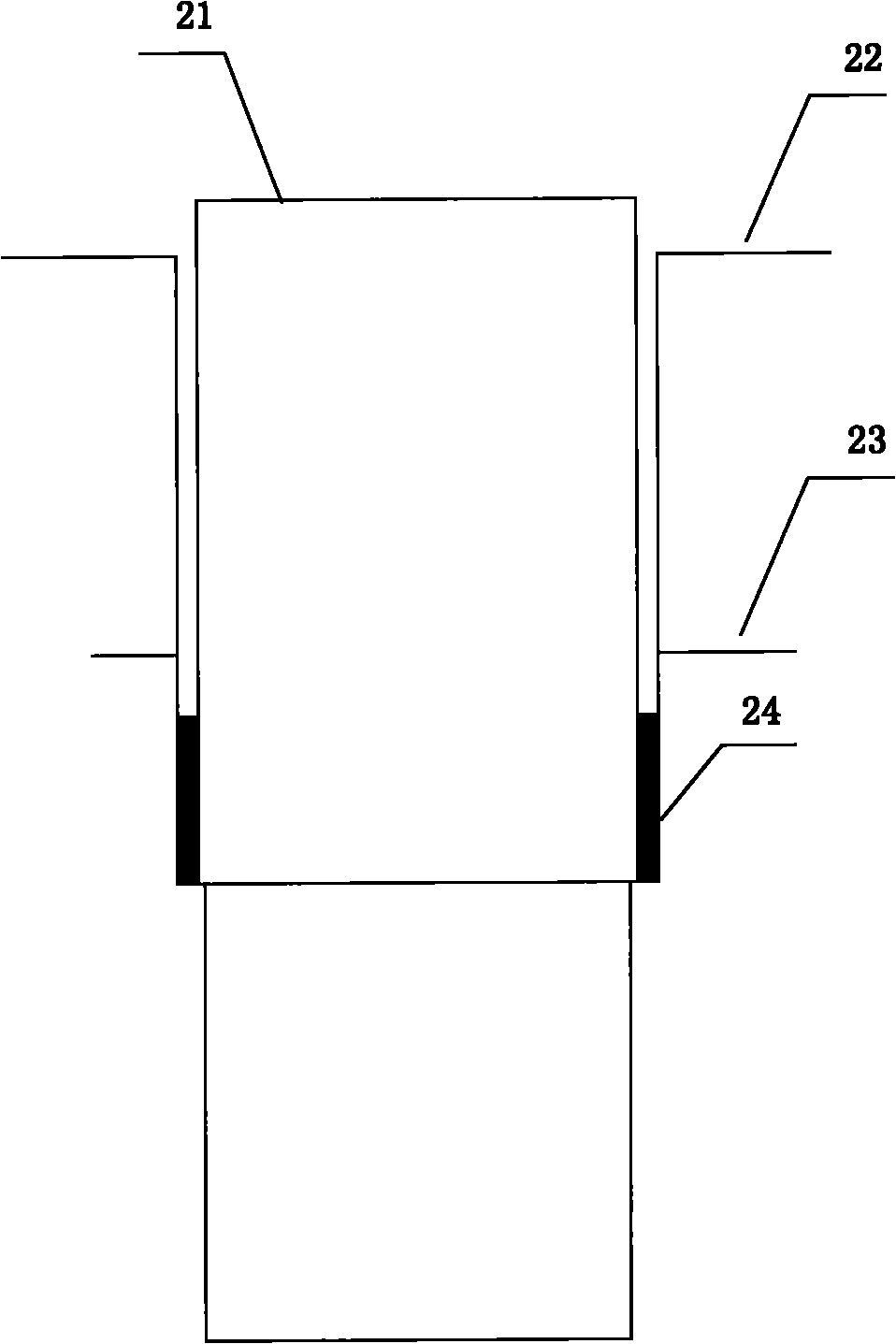

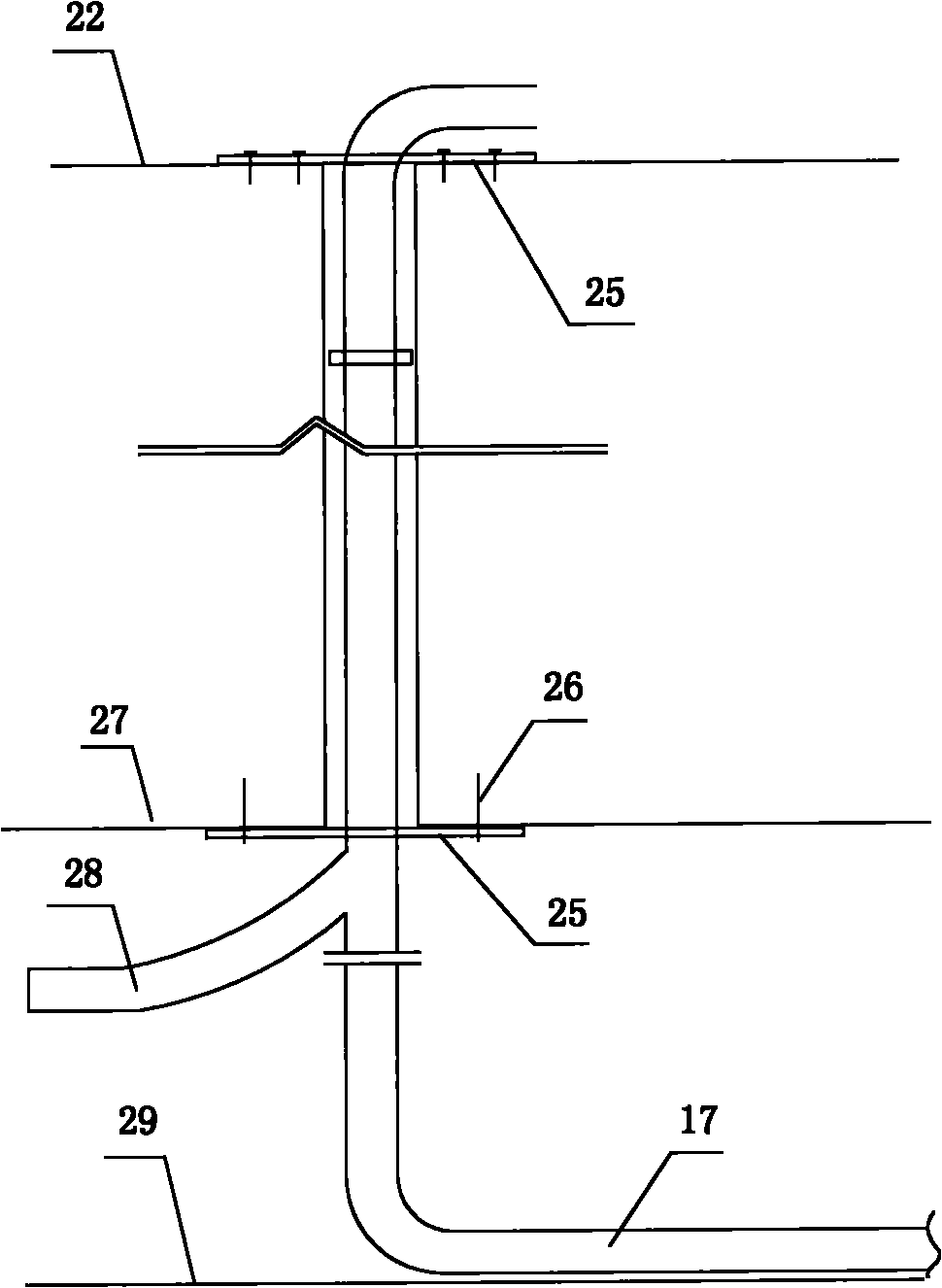

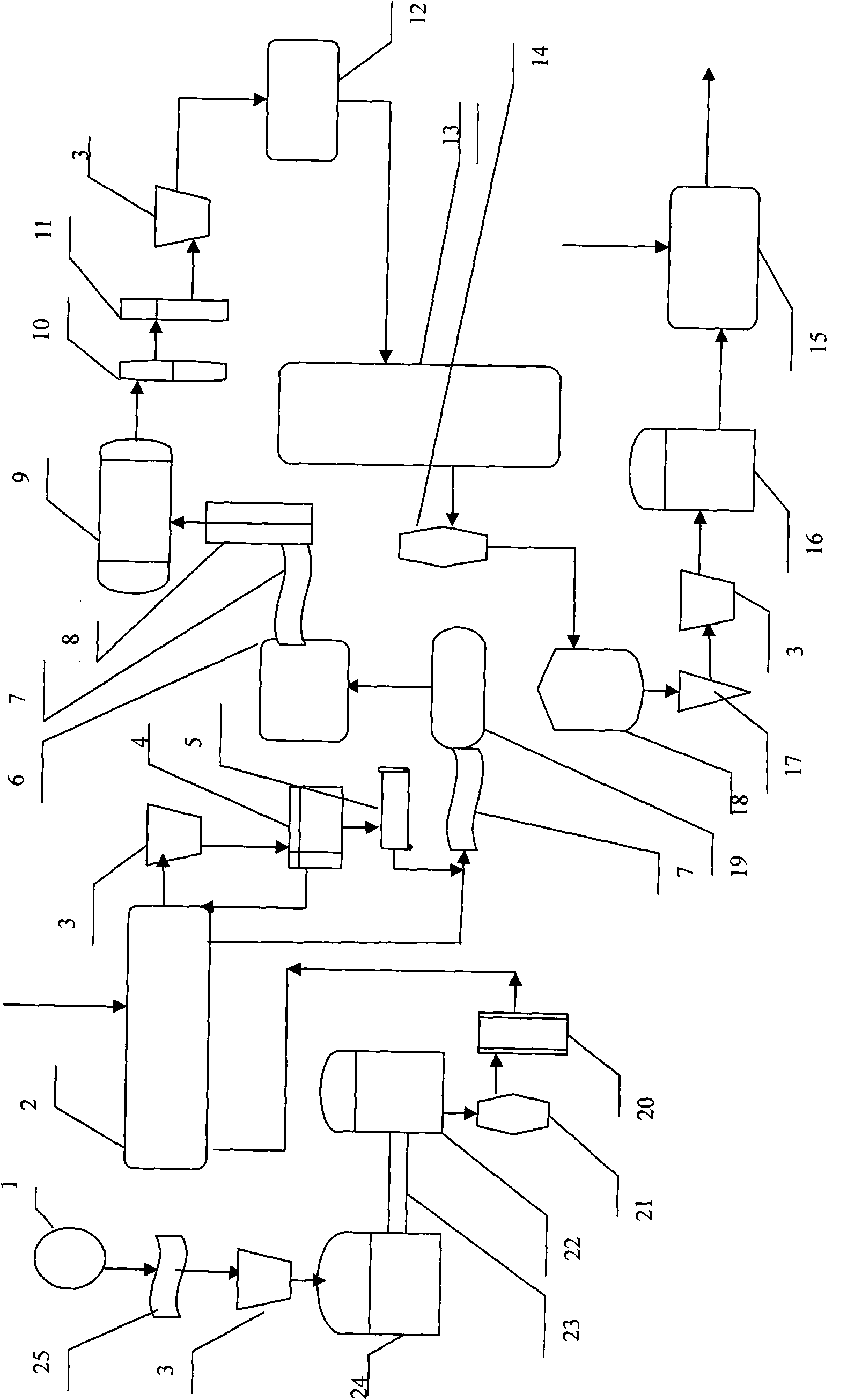

Filling process for recovering coal pillars by filling goaf with paste

The invention provides a filling process for recovering coal pillars by filling a goaf with paste. The filling process comprises three parts: preparing filling paste; conveying the paste via a pipe; and filling the goaf with the paste. The adopted filling paste comprises the following raw materials in percentage by weight: 40%-70% of aeolian sand, 10%-25% of coal ash, 3%-10% of cementing materials, 0.4%-1% of additive and 10%-30% of water. In the filling process, the goaf filling part comprises the procedures of primary filling and secondary filling, wherein, the coal pillars are recovered after primary filling; the whole goaf is fully filled after secondary filling; and roof-contacted supplementary filling is carried out in each filling procedure. The filling process has the advantages that the problems of filling the goaf formed after pillar-support mining and recovering the coal pillars are solved, the mining area environment can be protected more effectively, the increasingly exhausted coal resources are saved, and the filling cost is lowered.

Owner:TIANDI SCI & TECH CO LTD

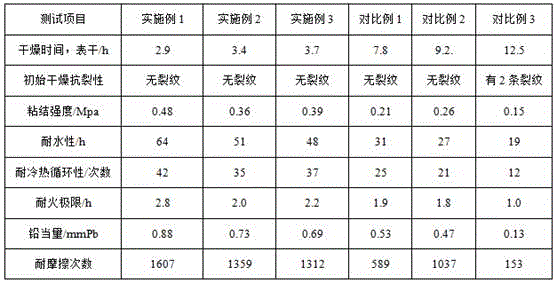

A high-strength anti-seepage concrete

InactiveCN102260059AInhibition of water seepageHigh strengthSolid waste managementUltimate tensile strengthWater reducer

A composition used for high-strength impermeable concrete. The composition contains sand, stone, cement, water reducer, water and reinforced impermeable sand. The reinforced impermeable sand includes aeolian sand and binder covering the surface of the aeolian sand. The reinforced impermeable sand can fill the gap between the sand and the stone, and well combine various components in the composition, and suppress the seepage phenomenon of the molded concrete, thereby greatly improving the strength and impermeability of the concrete.

Owner:BEIJING RECHSAND SCI & TECH GRP

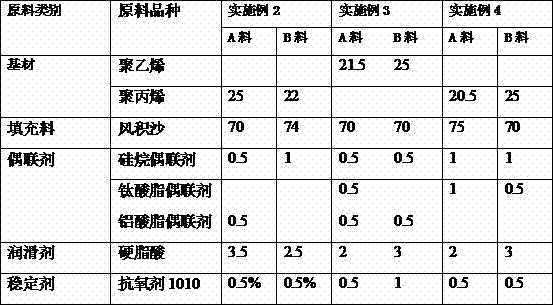

Application of aeolian sand to preparation of synthetic paper

InactiveCN102786731AOvercome the technical difficulty that it cannot be used as a synthetic paper fillerGood moisture permeabilitySynthetic resin layered productsPolymer sciencePolyolefin

The invention discloses the application of aeolian sand to the preparation of synthetic paper. The method of using the aeolian sand to prepare the synthetic paper comprises the following steps: adding a coupling agent into the aeolian sand, dispersing, mixing, grinding the aeolian sand, screening aeolian sand powder, adding a lubricant, a stabilizer and polyolefin resin, mixing, extruding, granulating, carrying out casting molding and calendaring molding, embossing and printing to obtain the wall paper or wrapping paper.

Owner:陶继承 +2

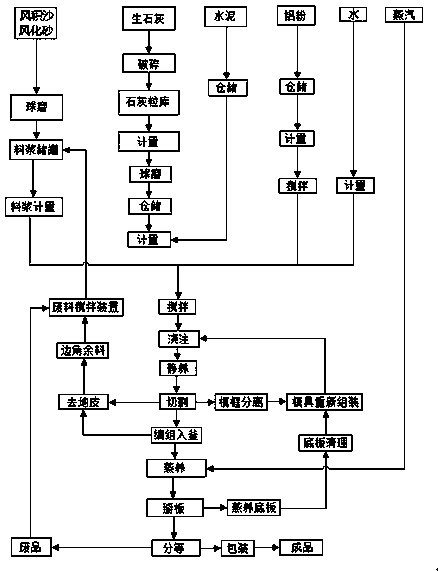

Autoclaved aeolian sand aerated concrete building block and wallboard

The invention provides an autoclaved aeolian sand aerated concrete building block and wallboard which are prepared by the following method: performing ball milling on aeolian sand or weathered sand to obtain slurry with the mass percentage concentration of 50 to 70%; crushing quick lime, grinding into quick lime powder; mixing aluminum powder; according to mass percentage, respectively taking cement, the slurry and the quick lime powder for mixing into a base material, proportionally adding the aluminum powder and gypsum, and stirring evenly to obtain finished product slurry; according to an autoclaved aerated concrete building block production process in the prior art, pouring, curing and cutting to form a green body or a workblank, removing wastes on the green body or the workblank, grouping into a reactor; performing autoclaving and maintaining and other processes, and packaging qualified products to obtain the autoclaved aeolian sand aerated concrete building block or wallboard; collecting produced waste to prepare waste slurry; and adding the waste slurry into the finished product slurry for using again. The concrete building block and wallboard can be prepared into building and environmental protection materials with good performances by comprehensive utilization of the aeolian sand and the weathered sand, and the river sand and ore sand collection and waste of resources can be reduced.

Owner:JINGTAI FUHAI SUNSHINE BUILDING MATERIAL

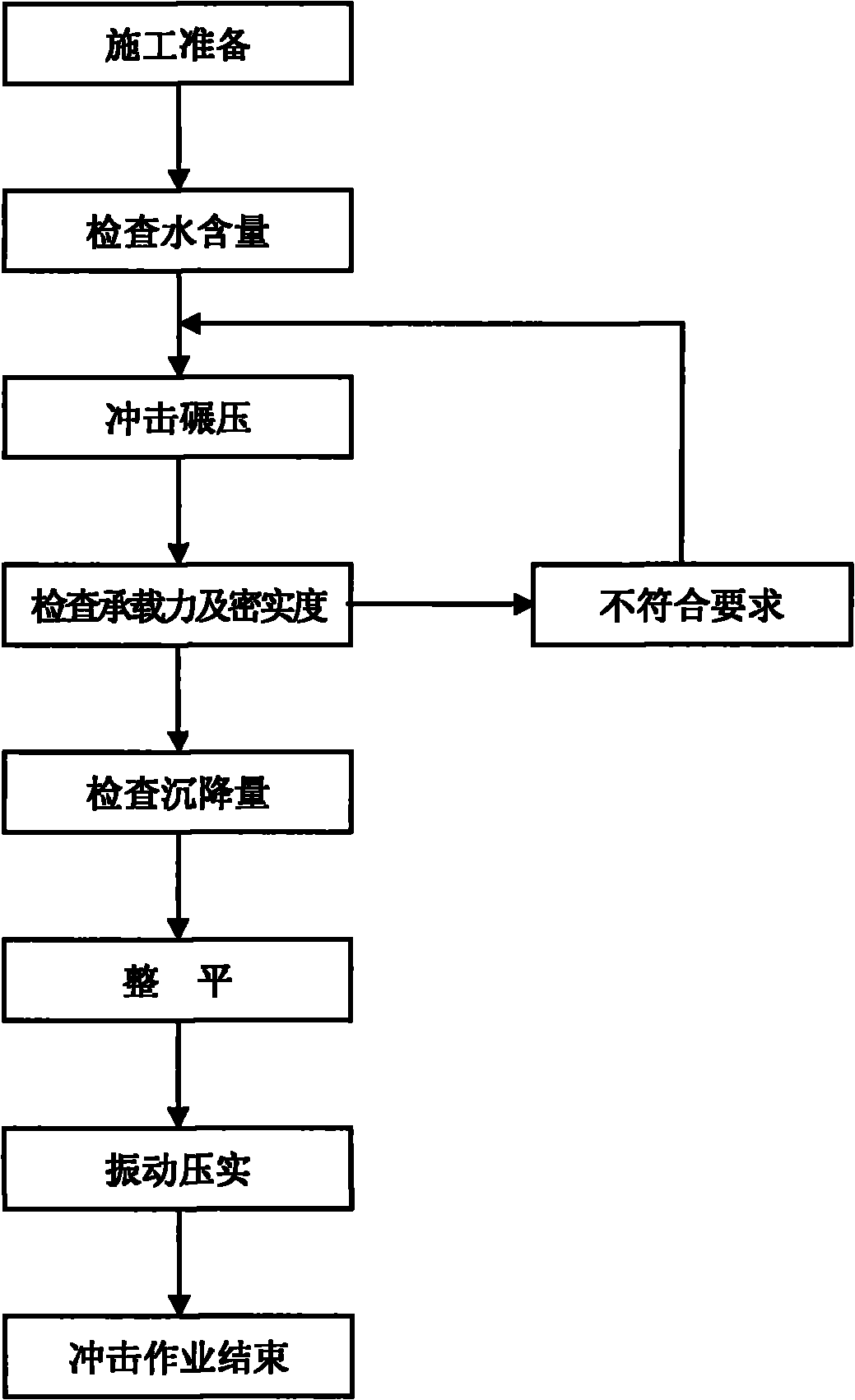

Construction method for processing aeolian sand roadbed base through impacting and grinding

ActiveCN101962928AImpact rolling is easy and fastImpact rolling saves labor and timeRoads maintainenceReplacement methodMoisture

The invention discloses a construction method for processing an aeolian sand roadbed base through impacting and grinding, which is characterized by comprising the following steps of: (1) preparing construction, i.e. carrying out measurement lofting, list clearing and levelling on an impacting and grinding segment; (2) checking moisture content; (3) impacting and grinding the roadbed base, i.e. controlling the longitudinal and horizontal movement of an impact-type road roller by an impact-type compactor which travels at constant speed; (4) checking the bearing capacity and the compactness of the roadbed base, i.e. detecting the compactness of a soil body by adopting two indexes, i.e. a compacting factor and a foundation factor, and using a sand replacement method; (5) checking the settlement amount of the roadbed base; (6) levelling the grinding surface of the roadbed base; and (7) carrying out vibrating compacting on the roadbed base. The invention applies the processing method impacting and grinding a roadbed to the construction of the aeolian sand roadbed base with large post-construction settlement amount caused by difficult compaction of the traditional construction process; and in addition, compared with the traditional processing method, i.e. a replacement method, a heavy-tamping method, and the like, the impacting and grinding method has the advantages of simpleness, convenience, fastness, labor and time saving, engineering cost reduction, and the like.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

Composition used for high strength and impermeable concrete

ActiveUS20130104777A1High strengthImprove impermeabilitySolid waste managementShell moldingHigh intensity

A composition used for high-strength impermeable concrete. The composition contains sand, stone, cement, water reducer, water and reinforced impermeable sand. The reinforced impermeable sand includes aeolian sand and binder covering the surface of the aeolian sand. The reinforced impermeable sand can fill the gap between the sand and the stone, and well combine various components in the composition, and suppress the seepage phenomenon of the molded concrete, thereby greatly improving the strength and impermeability of the concrete.

Owner:BEIJING RECHSAND SCI & TECH GRP

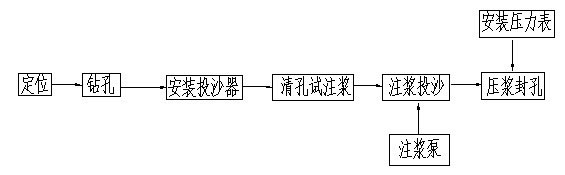

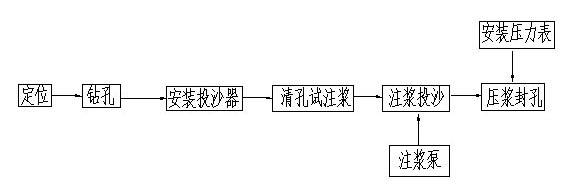

Drilling, grouting and sand-throwing process of ground surface of mined-out region under highway

The invention discloses a drilling, grouting and sand-throwing process of the ground surface of a mined-out region under a highway, comprising a drilling process, a slurry preparation process and a grouting and sand-throwing process, wherein the grouting and sand-throwing process comprises the steps of installing a sand thrower, grouting in a hole cleaning mode, grouting and throwing sand and pressing slurry. The invention combines with the specific geographical condition that a great amount of aeolian sand exists in the construction of highway sections to utilize the aeolian sand as a main material for filling the mined-out region, thereby achieving the purpose of greatly reducing cost.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

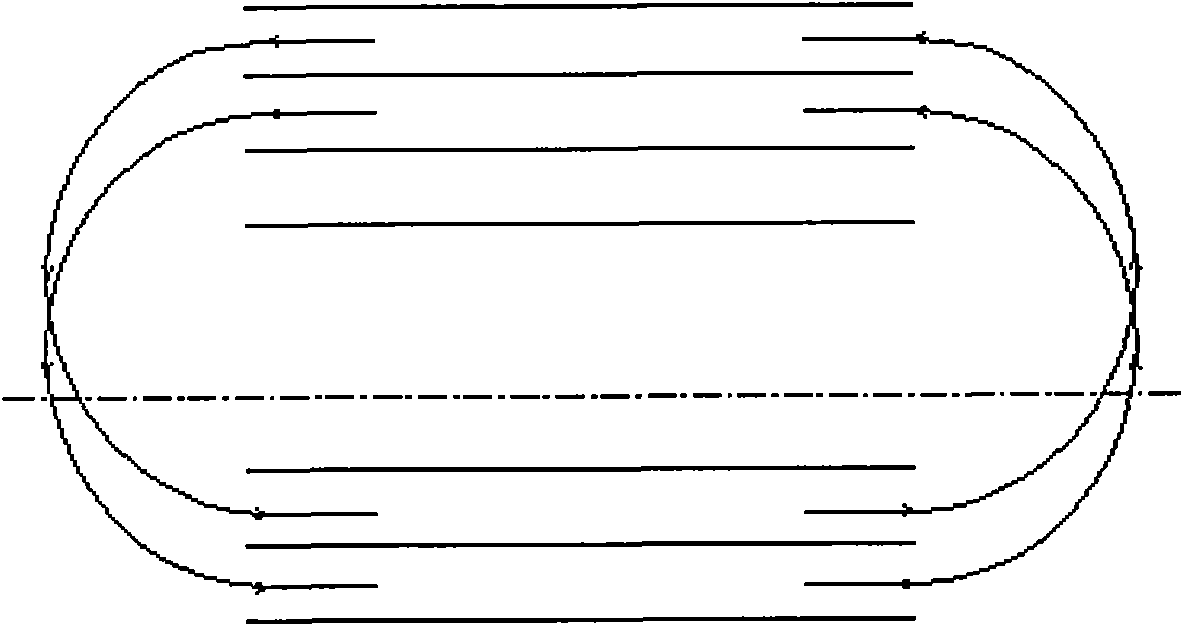

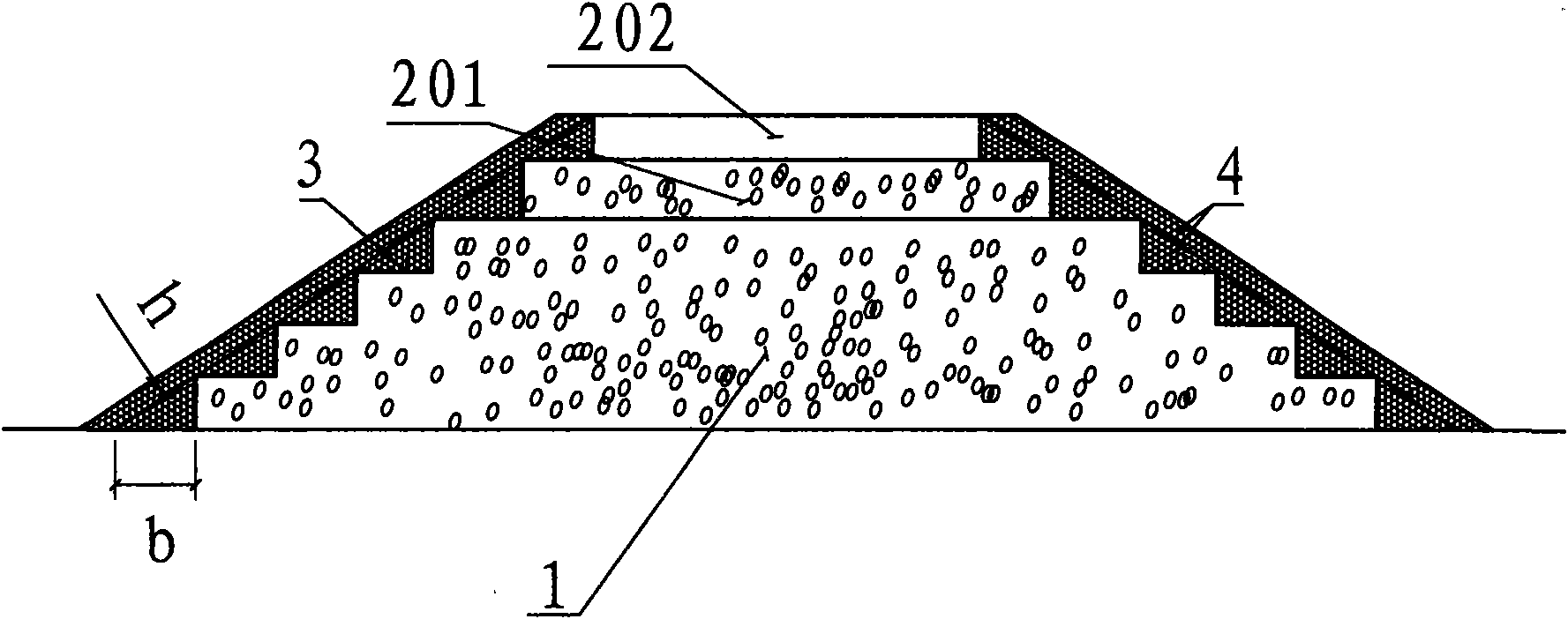

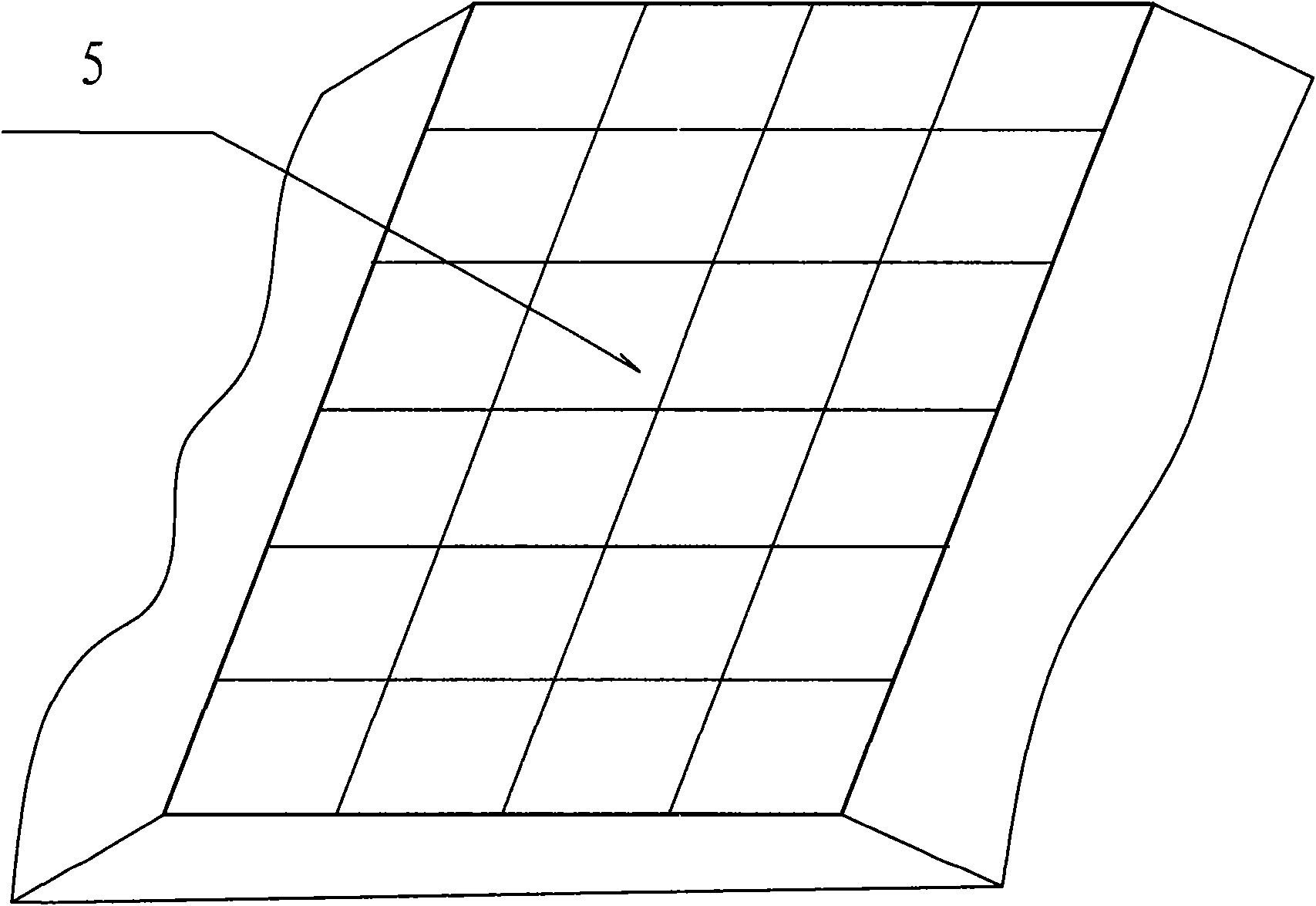

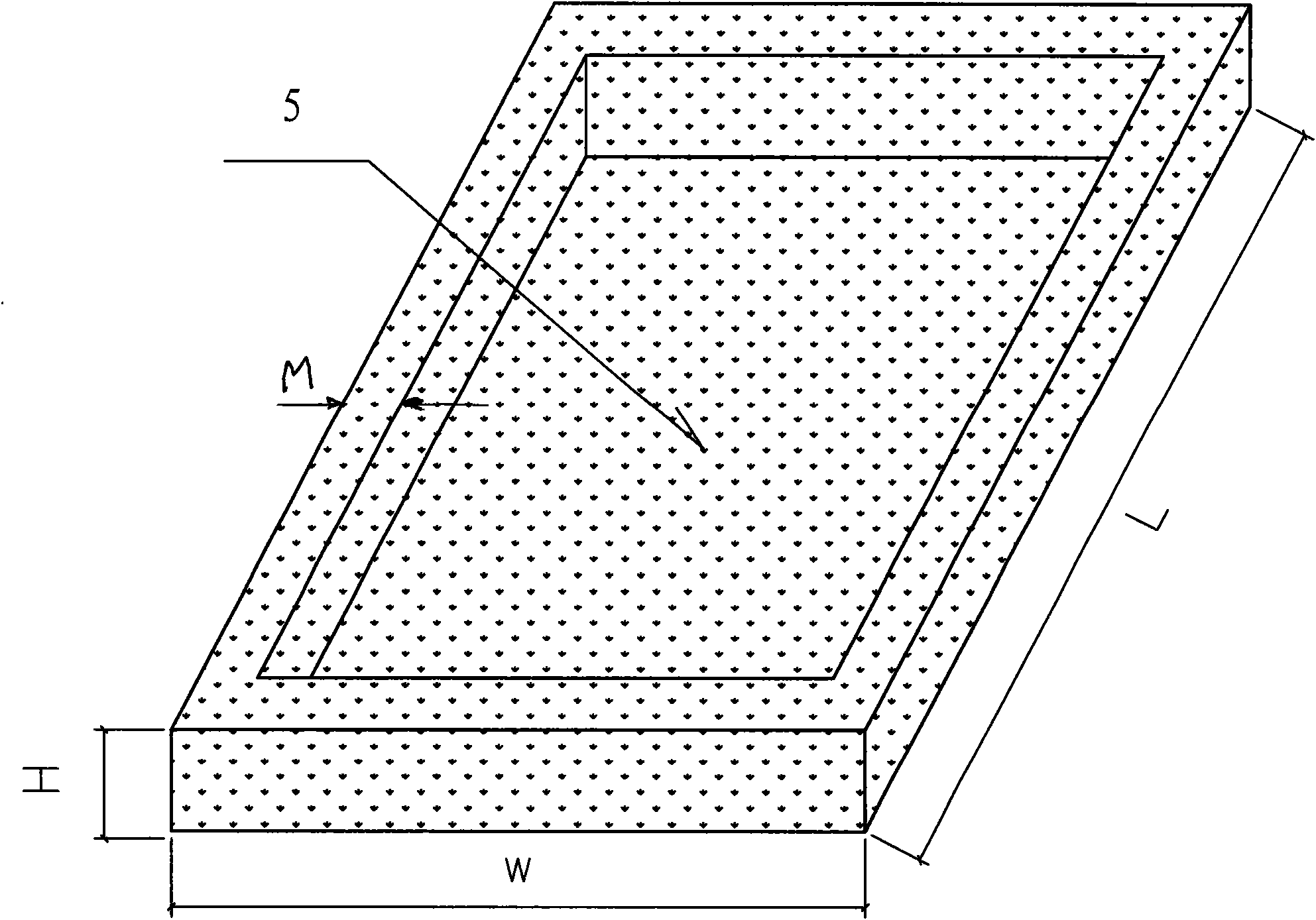

Desert area migratory dune land railway bed construction method

A desert area migratory dune land railway bed construction method includes the steps of: A. leveling and rolling compaction: conducting leveling and rolling compaction on the original ground; and laying pure aeolian sand on the bed ground after rolling compaction; B. arranging a grid coffer: sectioning the pure aeolian sand laid on the bed to make the grid coffer, which is about 10m long, about 5m wide, 0.3m high and 0.3m thick; C. water injection and rolling compaction: injecting water to the coffer by sprinkling irrigation of a sprinkler at the speed of 20m / h, with the water injection rate being 1m and the water sprinkling amount being 10m; when the height of water head steadily reaches 20cm, stopping water injection; after 40-45min of stopping water injection and the thorough permeation of water into sand, conducting rolling compaction; laying the pure aeolian sand on the bed ground after rolling compaction; and repeating the steps of B and C until finishing filling the bed; and D. covering a side slope with clay: after the bed is formed, then digging steps on the embankment slope surface of sand body roads and the slope surface of foundation beds, and sprinkling water on the slope surfaces provided with the steps for moistening; and laying clay on the slope surface to cover the side, wherein the forming thickness of the side slope covered with clay is at least 30cm.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

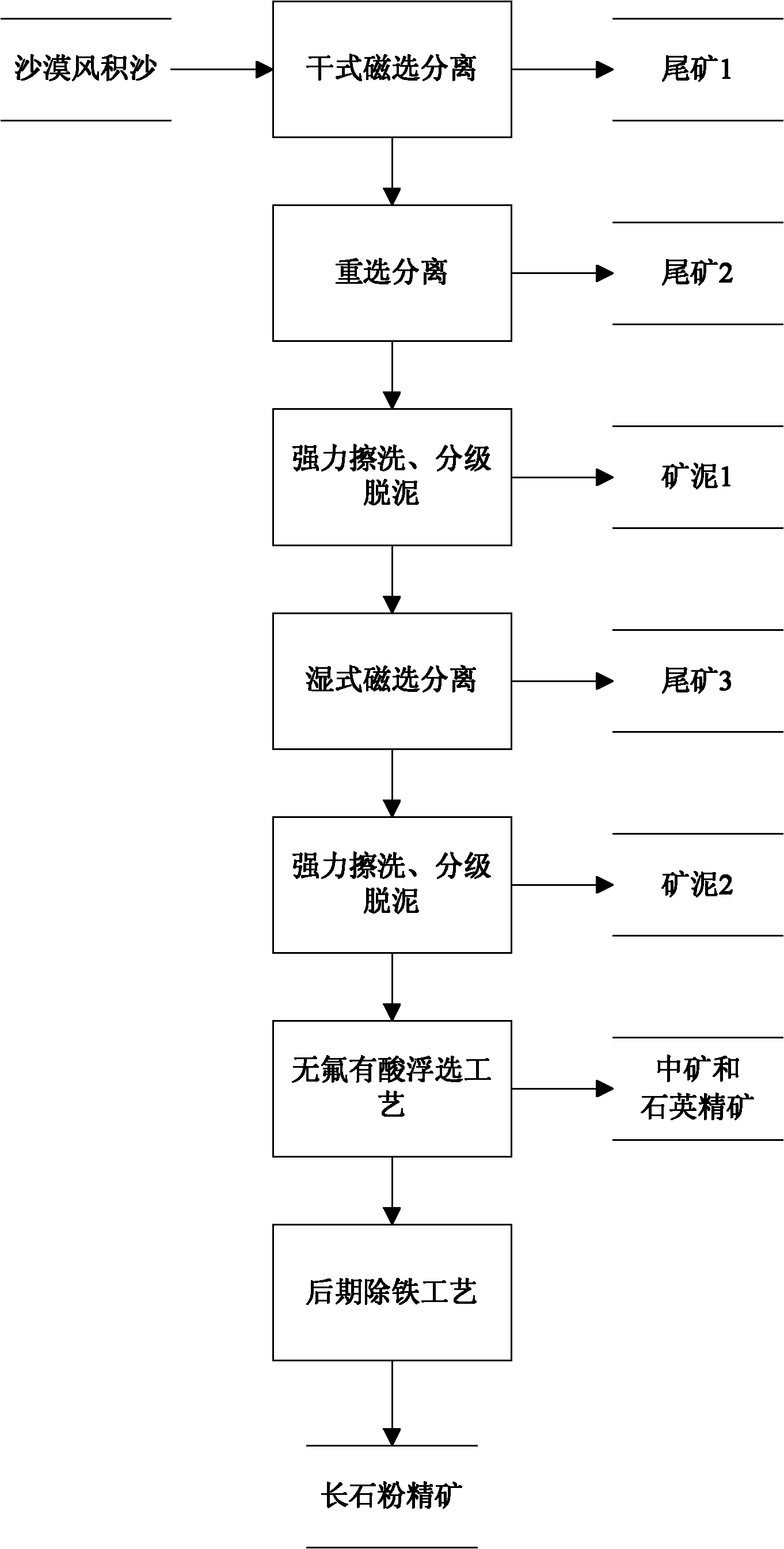

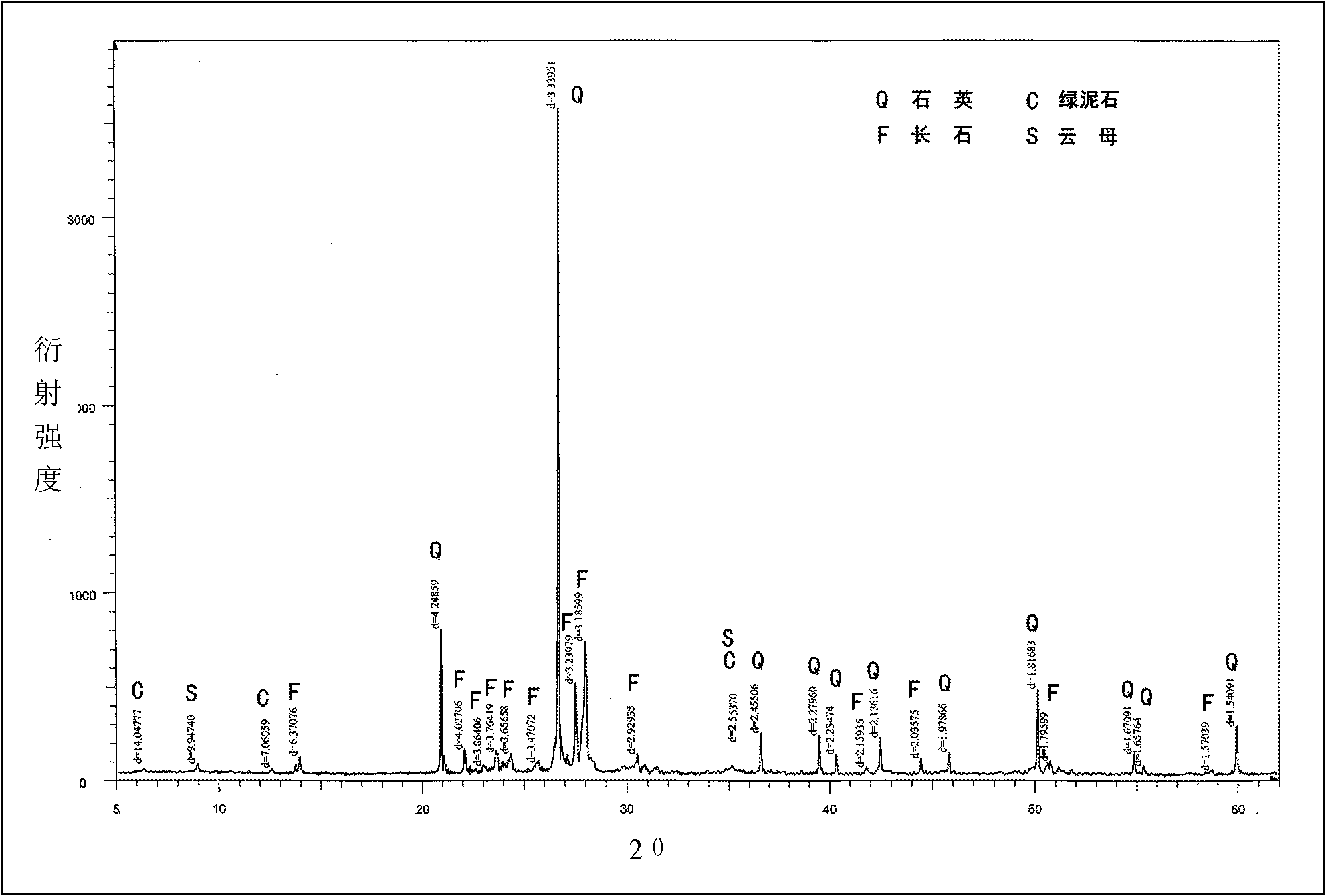

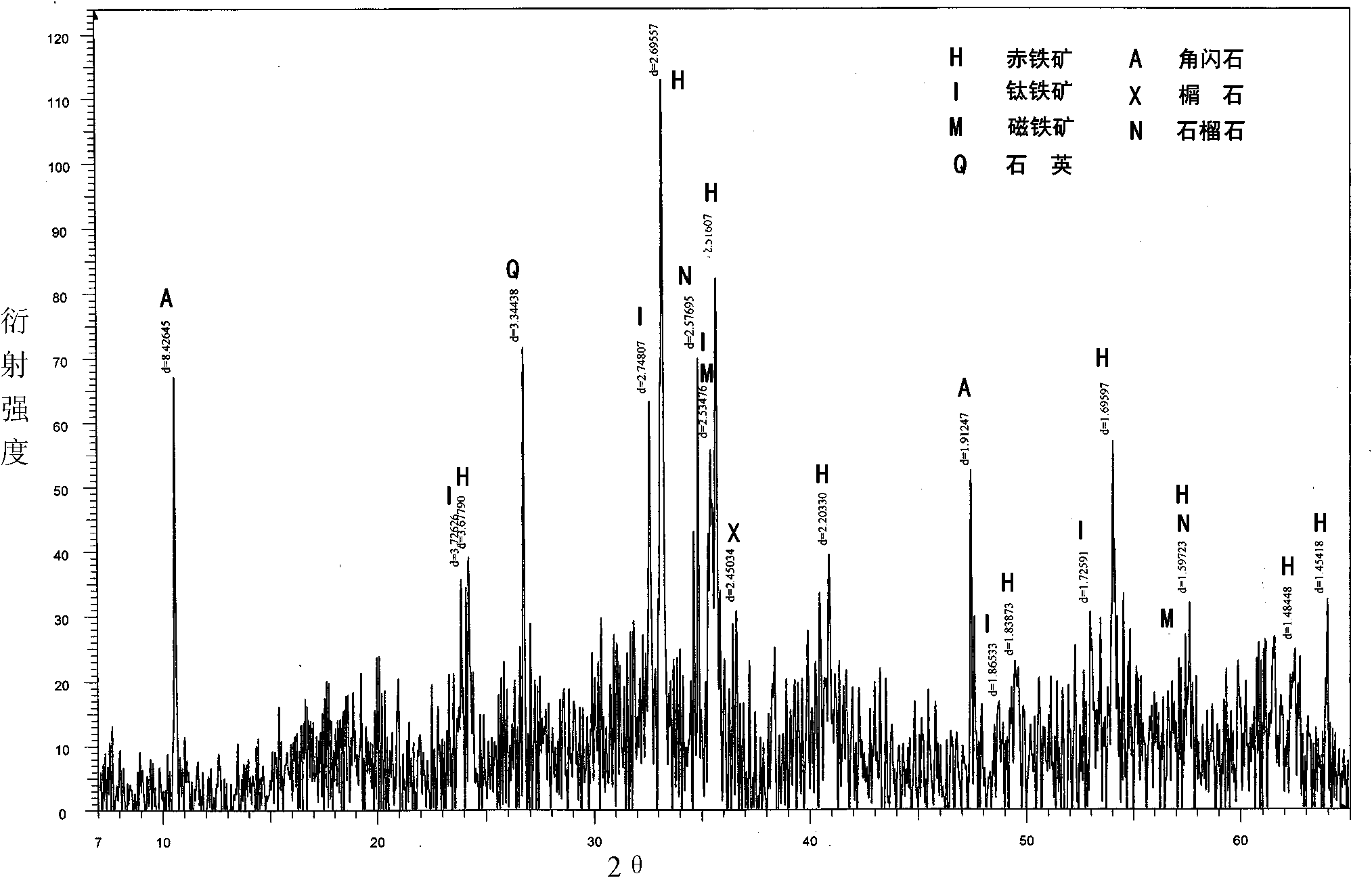

Method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert

ActiveCN101885489AReduce production water consumptionReduce manufacturing costSilicon compoundsIntermediate stageEnergy consumption

The invention belongs to an industrial utilization method of aeolian sand in desert, in particular to a method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert. The method comprises an early-stage ferrum-removal process, a middle-stage feldspar flotation separation process and a later-stage ferrum-removal process. The early-stage ferrum-removal process comprises the following specific steps: firstly, carrying out dry magnetic separation on the aeolian sand in the desert; carrying out reselection and separation on the concentrate obtained after dry magnetic separation; carrying out powerful scrubbing and sizing-desliming on the concentrate obtained after reselection and separation; and carrying out wet magnetic separation to obtain the ferrum-removal concentrate for the middle-stage feldspar flotation separation process, and carrying out the later-stage ferrum-removal process on the feldspar mineral aggregate obtained in the middle-stage feldspar flotation separation process to finally obtain the feldspar powder concentrate. The processes of the invention have the advantages of water conservation, reduced energy consumption and low cost, and can fully utilize the existing aeolian sand resources to produce the high-quality feldspar powder concentrate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

High-strength highly-permeable concrete and method for making the same

InactiveCN101182172AReduce Waterlogging ProblemsSolid waste managementClimate change adaptationChipsealRoad surface

The invention aims at providing a concrete high strength and permeability and a preparation method thereof. The invention adopts the following technical scheme: cement with high strength, a special building material additive and special forming method are used; Aeolian sands in desert or fly ashes produced during the power generation of power plants are used as raw materials to prepare the concrete with high permeability. The used raw materials of the invention respectively are: 40-50 grade of ordinary porland cement; gravels, Aeolian sands in desert and fly ashes with respective particle diameter of 10.0-13.0mm, 5.0-10.0mm and 2.5-5.0mm, the adding ratio of which is selected freely; NNO type water reducing agent and JM-SCA type strengthening agent. The concrete made through the method is provided with good permeability, and the compressive strength can reach to 35MPa above. Passage tiles made through the method can be used to pave roads to greatly reduce hydrops on the surface of the roads. In local areas, sewer pipes even can be reduced or do not have to be paved. For even a heavy rainstorm encountered in 100 years happens, rains can rapidly permeate in soils through the tiles successfully in five minutes, which can be changed into renewable underground water.

Owner:SHENGHONG GRP CO LTD

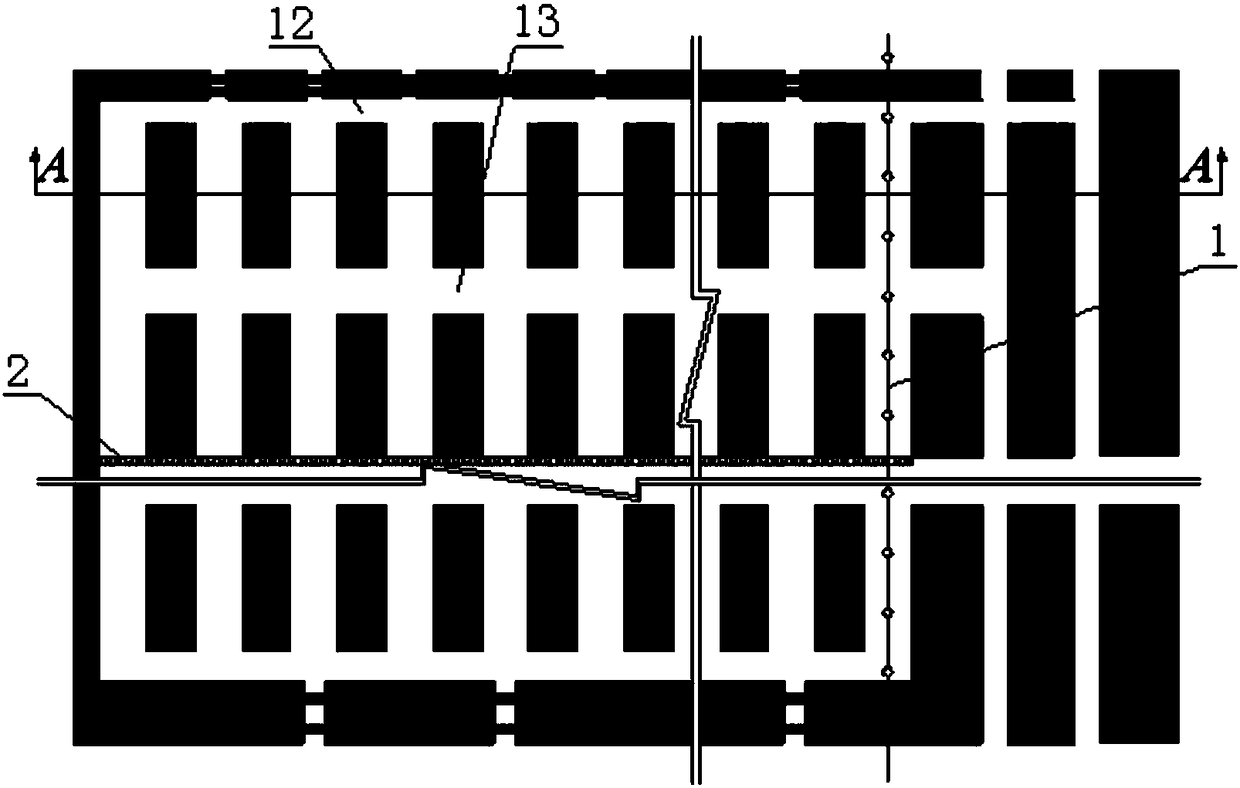

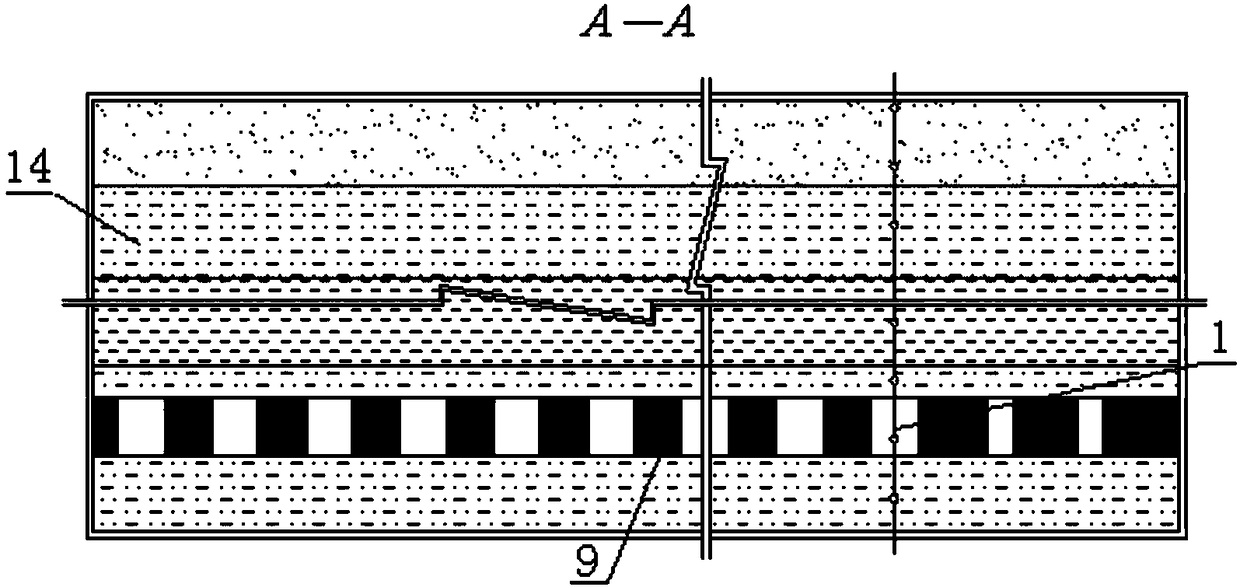

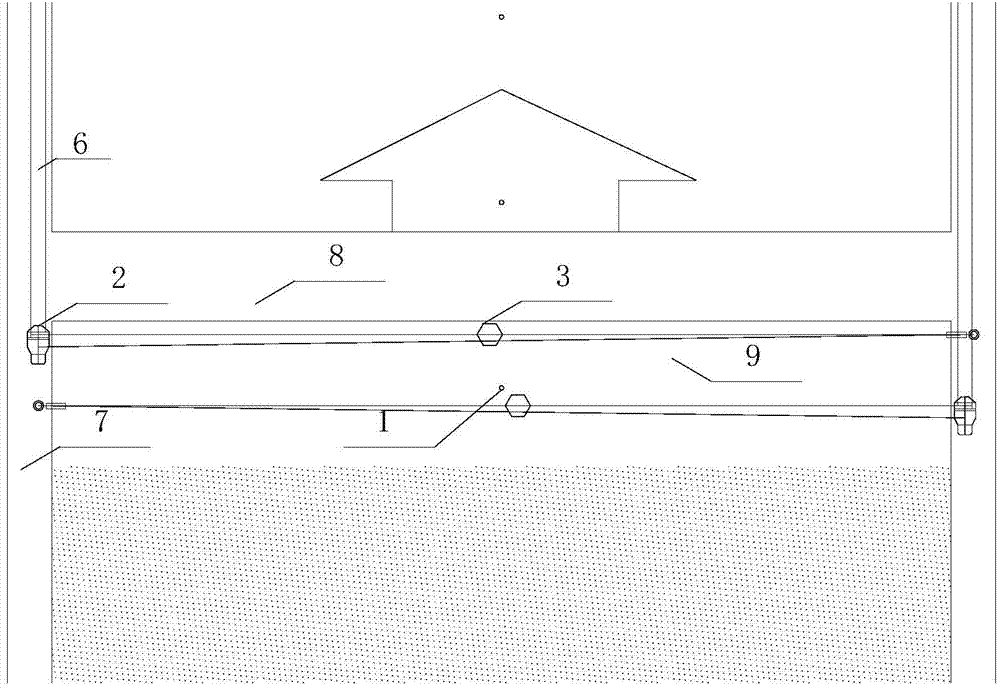

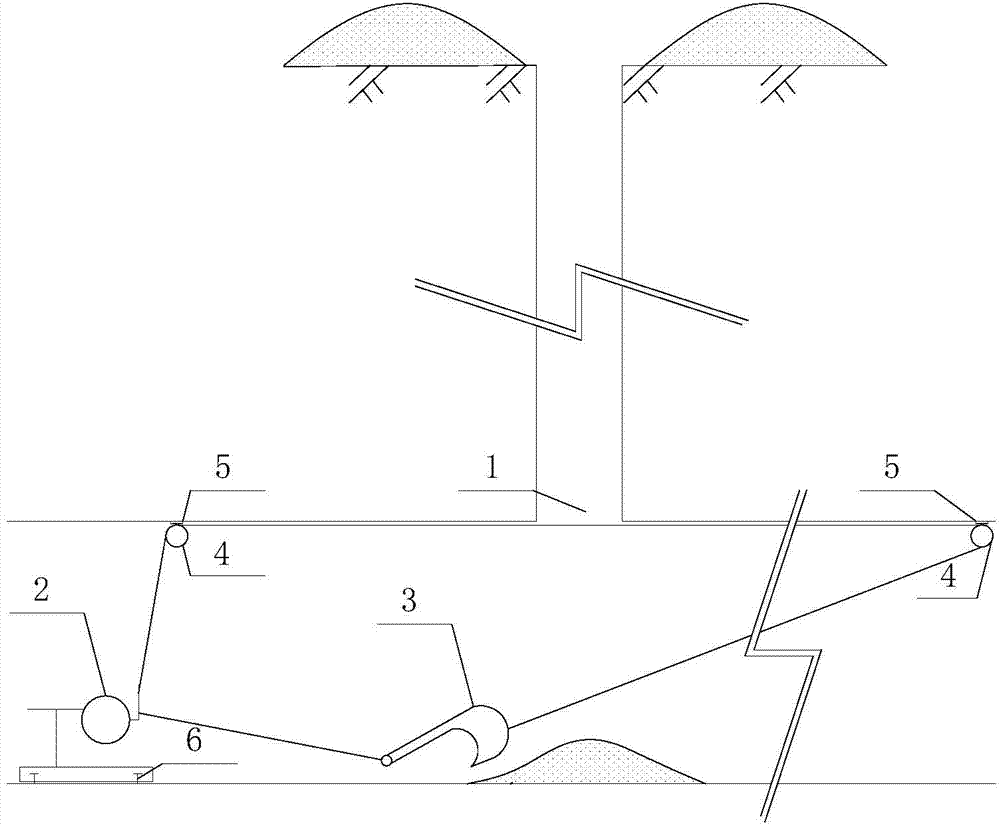

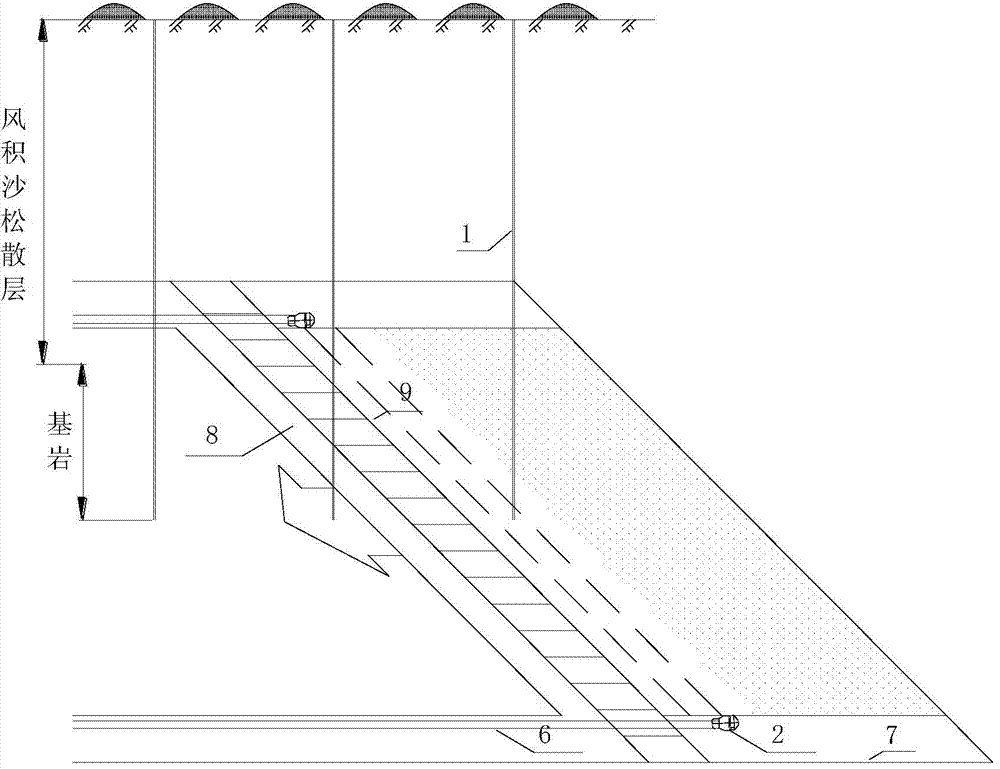

Method for filling mined coal to recover residual coal pillar and controlling stability of waterproof key layer

InactiveCN108087021ARealize recoveryGuaranteed long-term stabilityUnderground miningSurface miningEcological environmentFilling materials

The invention discloses a method for filling mined coal to recover residual coal pillar and controlling the stability of a waterproof key layer. Glue filling and pumping devices are arranged in a tunnel formed by a coal-mined chamber, goafs on the two sides are filled with glue filling materials with aeolian sand as the main part, and the residual coal pillar is recovered after a to-be-filled bodyreaches certain bearing capacity; after the coal pillar is recovered, the goafs are filled with aeolian sand secondarily through a high-speed power throwing machine and a bulldozer. By means of the method, the earth surface natural aeolian sand material can be used to the maximum extent, the overlying waterproof key layer is effectively controlled, and a new technological method is provided for recovering the residual coal pillar in the ecological weak mine area in western China and protecting the ecological environment.

Owner:CHINA UNIV OF MINING & TECH

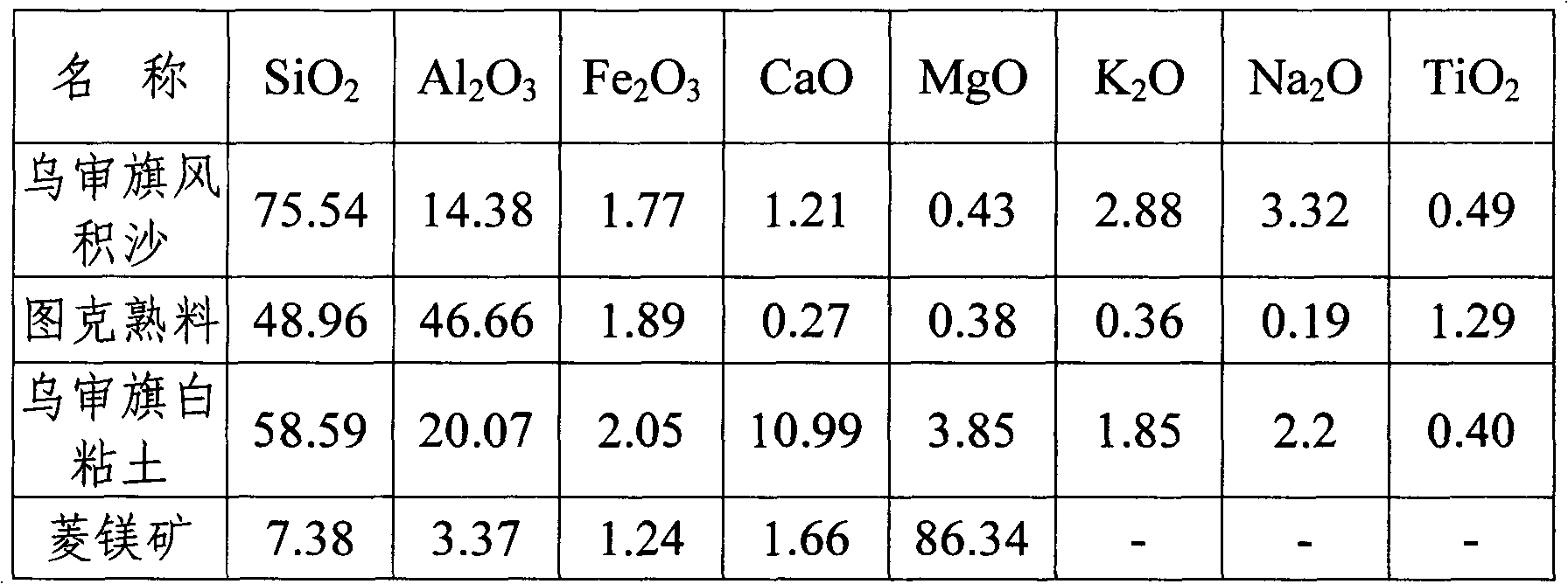

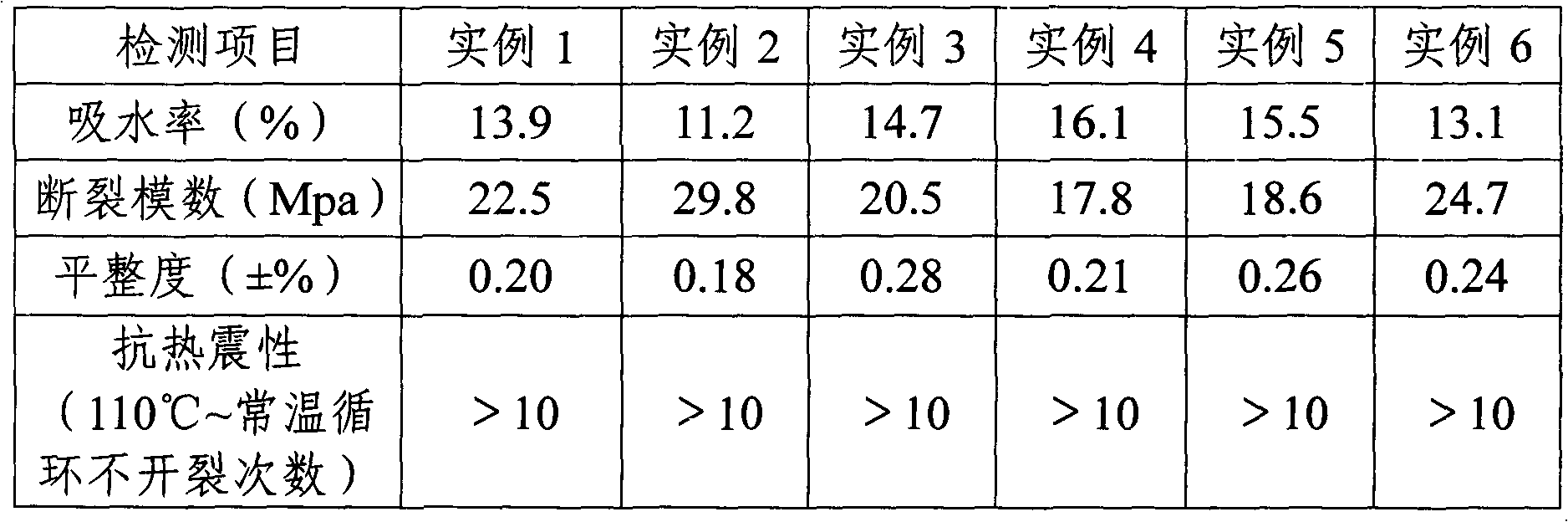

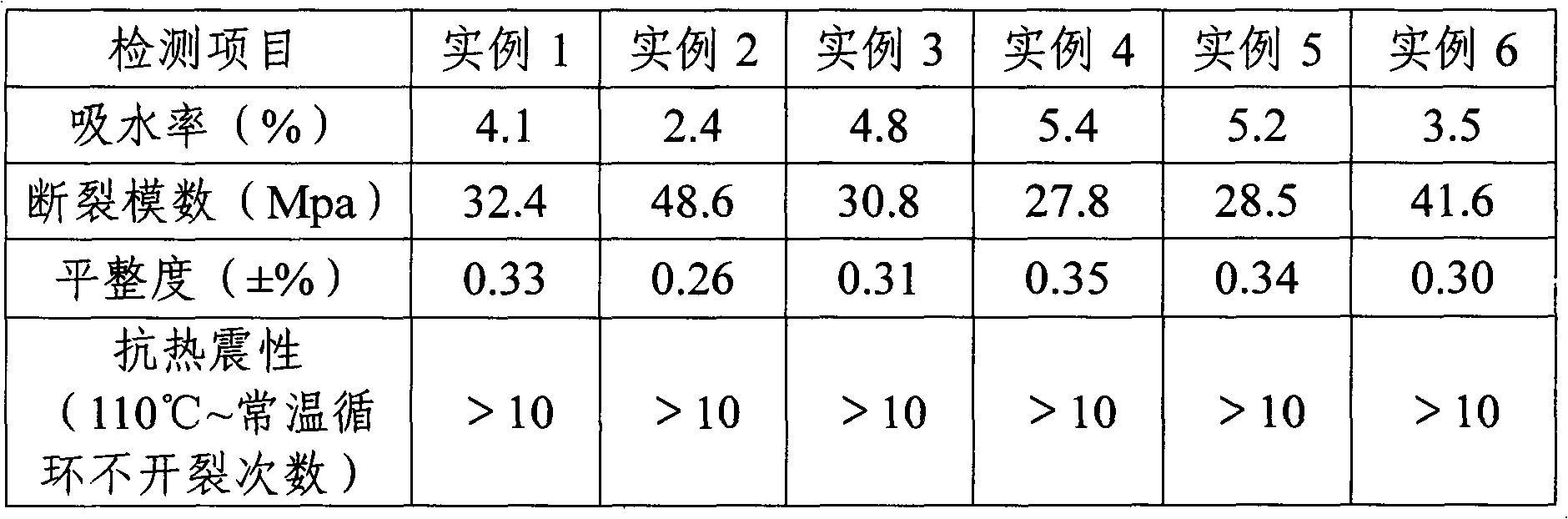

Ceramic brick prepared from aeolian sand

The invention relates to a ceramic brick prepared from aeolian sand. The ceramic brick comprises the following raw materials by weight percent: 50-60% of Uxen aeolian sand. 20-28% of Tuke clinker, 12-20% of Uxen white clay and 2-8% of magnesite. The ceramic product is prepared by the steps of ball milling, smashing, sieving, deironing, forming and firing at the temperature of 1080-1220 DGE C. According to the invention, the aeolian sand enriched in Inner Mongolia is used as a main ceramic-making material, which is beneficial to low-cost desert control and leads the production cost of the ceramic product to be greatly reduced; and the prepared ceramic product has the advantages of excellent quality, small size difference, low water absorption and high strength, and relative indexes reach the requirement of national detection standards.

Owner:马东升

Light Mortar Materials and Method of Use

InactiveUS20120174829A1Avoid hollowingAvoid crackingSolid waste managementCeramicwareHollow coreConstruction aggregate

A lightweight and energy saving mortar consisting of: 30-40% of Ordinary Portland cement; 2-4% of Hydrated lime; 10-20% of lightweight aggregate; 40-50% of heavyweight aggregate; and 1.0% of additive. The lightweight aggregate is a porous inorganic hollow glass material of fineness is smaller than 100 mesh. The heavyweight aggregate is Aeolian sand. During application, the mortar is diluted with water to have a viscosity suitable for mechanical spraying or manual application. The present invention employs a specific lightweight aggregate of porous inorganic hollow glass material to reduce the weight percentage of sand stone so as to decrease the weight of the mortar such that an elastic modulus of the mortar is matched with the lightweight wall object, the heat transmission coefficient is decreased, and the thermal bridge effect is minimized. Hollowing, cracking, and falling off problems are prevented. Heat and sound insulation are improved. Mechanical operation is facilitated.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

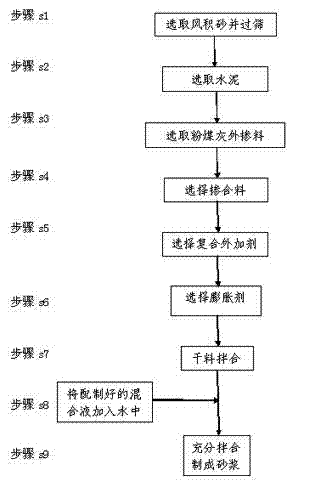

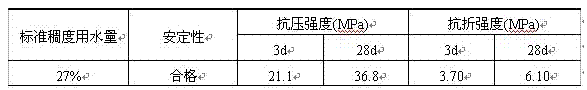

Building mortar prepared by using desert Aeolian sand and preparation method thereof

ActiveCN102199023AProtection securityShorten the construction periodSolid waste managementSoluble glassWater reducer

The invention relates to the technical field of building mortar engineering, in particular to building mortar prepared by using desert Aeolian sand and a preparation method thereof. The building mortar prepared by using the desert Aeolian sand is prepared by using 290kg of Aeolian sand, 72kg of cement, 20kg of fly ash, 1.4kg of water reducing agents, 0.3kg of air entraining agent, 8kg of expanding agents, 62kg of water and 1L of soluble glass through the steps of material selection, blending of dry materials, blending of liquids and preparation of mortar, wherein the soluble glass is measuredin volume, and the unit is liter; and the other materials are measured in weight, and the unit is kilogram. The building mortar prepared by using the desert Aeolian sand and the preparation method thereof have the advantages that the cost performance is higher than that of common river sand; and long-distance transportation is avoided, and thus the construction period is shortened greatly. The invention has great environmental protection significance and important theoretical and practical significance.

Owner:XIAN CHANGQING TECH ENG

Ecological sand plastic composite composition, method for preparing the ecological sand plastic composite, and prepared material

The invention discloses and relates to an ecological sand plastic composite composition, a method for preparing the ecological sand plastic composite, and a prepared material. The composition comprises aeolian sand, a resin and flyash; 100 parts by weight of aeolian sand is taken as a standard, the content of flyash is 12-80 parts by weight, and the content of the resin is 12-80 parts by weight. The disclosed ecological sand plastic composite is chemical in physical and chemical properties, is non-toxic and tasteless, is low in temperature sensitivity, produces wood texture after the surface treatment, is high in biofidelity, can completely or partially replace the conventional wood plastic composite profile and log, and has the properties of secondary processing of sawing, nailing, cutting or fixing through a screw, and a leftover material or a waste product can be recycled, broken, extruded again and set to manufacture a profile product.

Owner:内蒙古仁创沙漠资源利用研究院有限公司

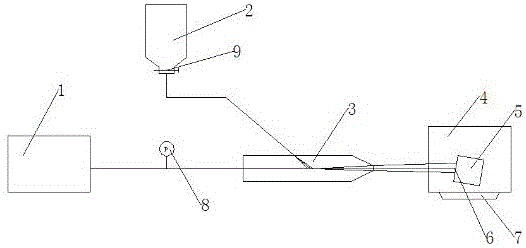

Corrosion experiment and injury evaluation methods of engineering material under wind sand environment

InactiveCN105738235AEasy to controlTotal Damage Assessment StudyInvestigating abrasion/wear resistanceMacroscopic scaleAbrasion (mechanical)

The invention relates to an experiment method and an injury evaluation method of an engineering material and particularly relates to corrosion experiment and injury evaluation methods of the engineering material under a wind sand environment. An experiment system and a method for operating the experiment system are included; the experiment system comprises a wind sand environment simulation system and an erosion room; the injury evaluation method of the engineering material based on a wind sand environment experiment system comprises a weight-loss grading method and a weight-loss rate evaluation method, wherein weight loss is the difference of masses of a test piece before and after an abrasion test, namely deltam=m1-m2; the weight-loss rate is the ratio of the difference of the masses of the test piece before and after the abrasion test to the total mass of sand used in the time period, namely alpha=(deltam / ms*t)*100%=(m1-m2 / ms*t)*100%. The experiment system provided by the invention has the advantages that an actual wind and sand corrosion environment can be really simulated, erosion mechanical parameters are easy to accurately control, a testing period is short and the research cost is low; the experiment and injury evaluation methods explore an erosion abrasion rule and an injury mechanism of the engineering material from macroscopic and microcosmic aspects.

Owner:INNER MONGOLIA UNIV OF TECH

Preparation method of flexible decorative bricks and prepared products

ActiveCN103524073ARich sourcesImprove physicsCovering/liningsCeramic shaping apparatusBrickPolymer science

The invention belongs to the field of building materials and provides a preparation method of flexible decorative bricks. The preparation method comprises the steps of 1) taking desert aeolian sand as a raw material, scrubbing, drying and then screening to obtain raw sand of 20-200 meshes; 2) laminating and coloring the raw sand to obtain color sand with different colors; 3) adding an adhesive, an ultraviolet absorber, a waterproofing agent and a flame retardant into the color sand and uniformly stirring; (4) placing a mixture into a mold frame, molding by rolling, and curing at room temperature. According to the preparation method provided by the invention, the aeolian sand is taken as the raw material, so that the sources are rich and the waste is turned into treasure; a reactive laminating technology is adopted for performing raw sand treatment and coloring, so that the color sand with different specifications and rich colors can be obtained, and a direction is provided for product diversification; a polyurethane type high molecular polymer is adopted for product binding, and the ultraviolet absorber, the waterproofing agent and the flame retardant are used for assistance so as to enable the obtained products to have excellent physical and chemical properties; the products have the advantages of simple process, and can be prepared by molding by rolling and curing at normal temperature, thereby meeting the requirements for mass production.

Owner:BEIJING RECHSAND SCI & TECH GRP

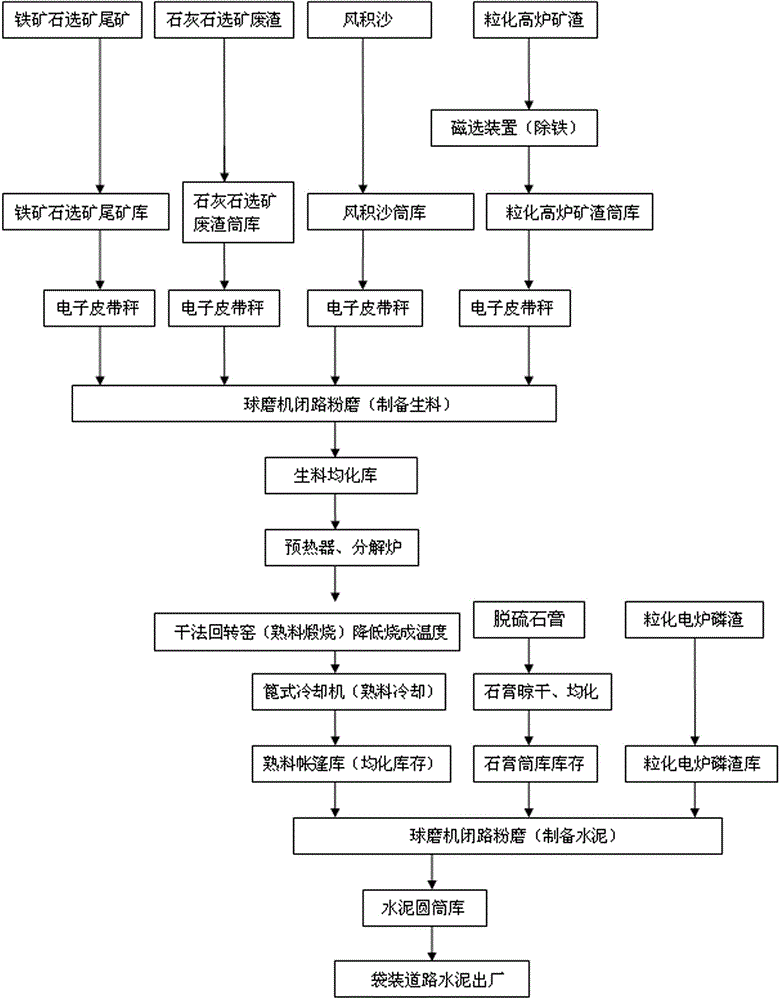

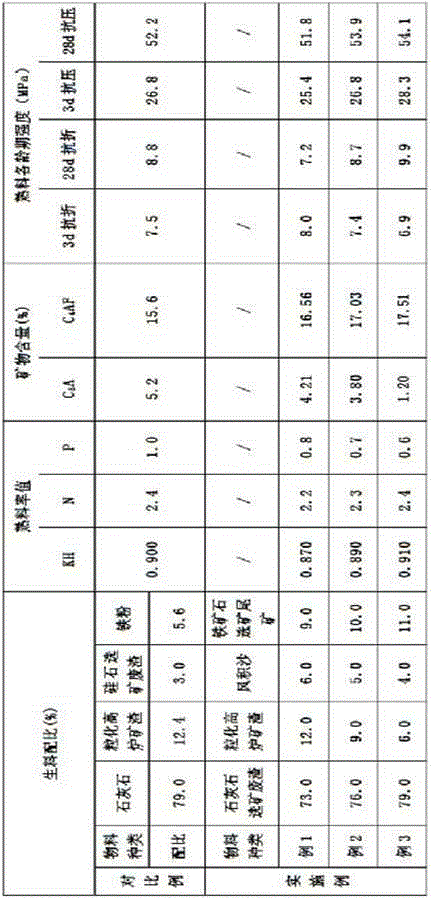

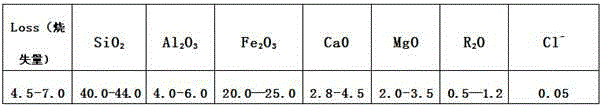

Method for producing portland cement for road by blending iron ore beneficiation tailings in cement

The invention discloses a method for producing portland cement for road by blending iron ore beneficiation tailings in cement, and the method is used for solving the problem that the existing road is low in cement strength. The method comprises the following steps of: A. blending raw materials: 9-11% of iron ore beneficiation tailings, 73-79% of limestone beneficiation waste residue, 4-6% of aeolian sand and 6-12% of granulated blast-furnace slag; B. calcining clinker; and C. blending the cement. According to the method, the iron ore beneficiation tailings, the limestone beneficiation waste residue and the granulated blast-furnace slag are utilized as the raw materials, and desulfurized gypsum and granulated electric furnace phosphorous slag are utilized as accessories, thus saving the consumption of natural raw materials and reducing the cement production cost; the produced portland cement for road is higher in wear resistance and better in air shrinkage, is widely applied to a super highway, an airfield runway and other projects; and the product is good in market prospect and considerable in economic benefit.

Owner:嘉峪关祁连山水泥有限公司

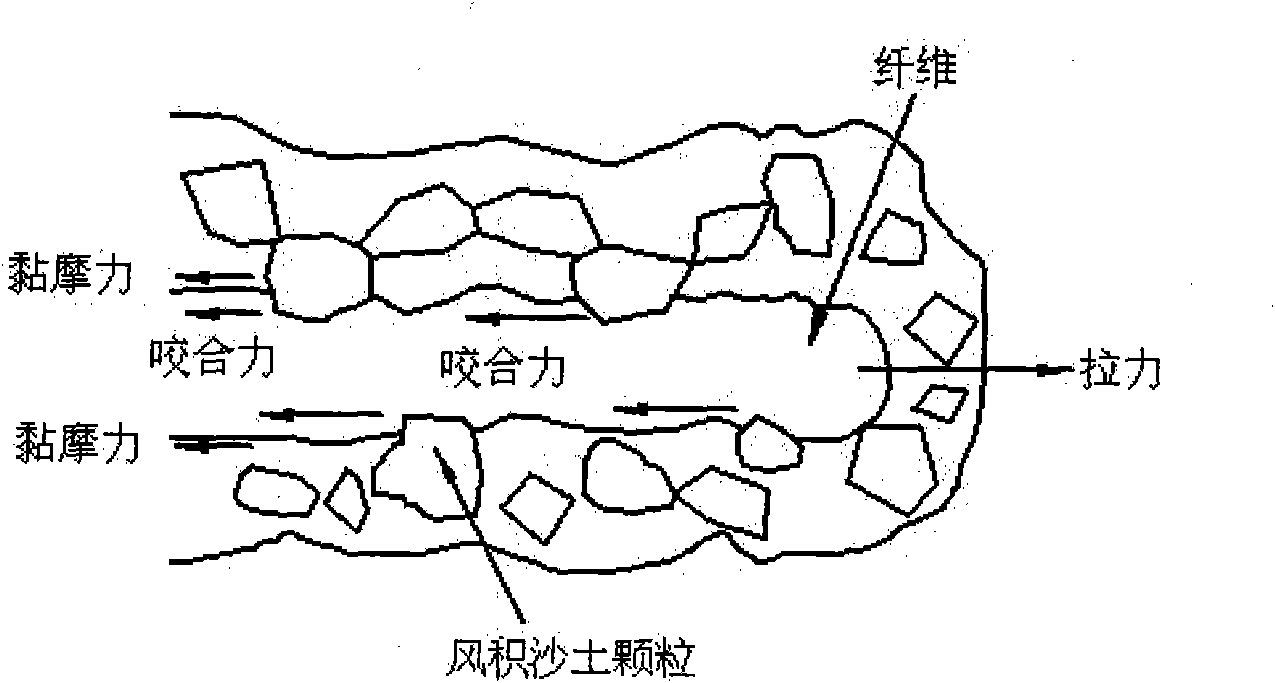

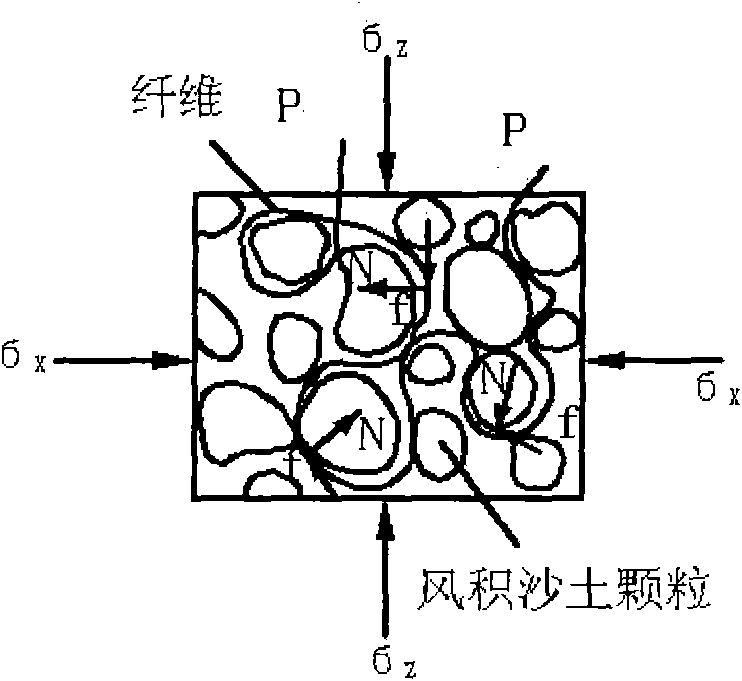

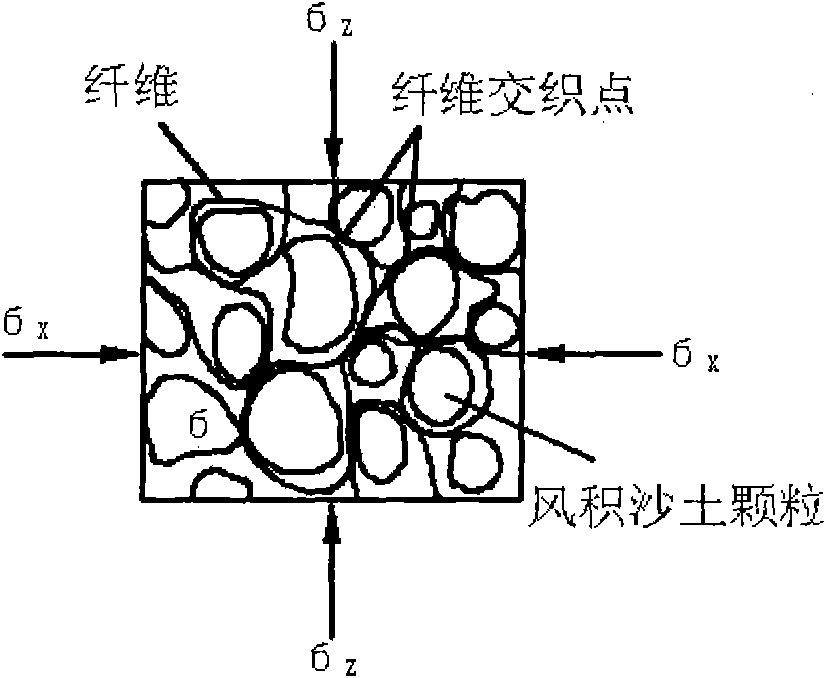

Method for reinforcing aeolian sandy soil by polypropylene fibers

The invention discloses a method for reinforcing aeolian sandy soil by polypropylene fibers. The method comprises the following steps: selecting materials for preparing fiber aeolian sandy soil, wherein the length of the polypropylene fiber is 18mm, the mix ratio of the fiber is 0.3 percent, and the aeolian sandy soil materials are air-dried aeolian sand or aeolian sandy soil (the moisture content accounts for 11.2wt%); according to the proportioning scheme, closely and completely mixing fine TEXSOL with aeolian sandy soil particles by way of spraying, so that a composite three-dimensional spatial structure is formed by the TEXSOL and the aeolian sandy soil; and carrying out mechanical compaction on the composite fiber aeolian sandy soil subjected to spraying, wherein the compaction method and standard of the composite fiber aeolian sandy soil are same as those of common soil, so that the compaction density of the aeolian sandy soil reaches 100 percent of the standard compaction density, and the fiber aeolian sandy soil is compacted closely. By utilizing the method in earth-filled dams, retaining walls and the drainage works of the earth-filled dams, the water stability of the interior of the soil body can be effectively improved, the shearing strength and tensile strength of the soil body can be obviously improved, and the construction process is simple; and because the fiber content of the fiber aeolian sandy soil is very low, the method has the advantages of cheapness and environmental protection.

Owner:HARBIN INST OF TECH

Technology for preparing cement by dry carbide slag method

ActiveCN101560067ASolve the land occupation of stackingSolve processingClinker productionSlagMoisture

The invention relates to a technology for preparing cement by a dry carbide slag method, which comprises the following steps: raw material storage, transportation, mixture, calcinations, grinding, and the like. Dry carbide slag powder with the moisture from 5 percent to 8 percent, which is discharged by a dry acetylene technical generator, is sealed, transported and stored by a pipe chain machine and a bucket lifting machine; stored raw materials and black raw materials ground in a drying process comprise aeolian sand, sulfate slag and lime slag; carbide ash is transported to a dry pipe by an FU chain transporting machine for initially mixing and drying after being automatically matched and ground by a reservoir bottom microcomputer; raw materials with the moisture which is less than 1 percent are collected by a high-efficiency cyclonic collector and are transported to a raw material homogenizing storehouse to mix by gravity; the raw materials are calcined from a three-grade preheater and a decomposing furnace to a rotary kiln; and after the raw materials are cooled, the raw materials, fly ash, carbide ash and citric acid slag are transported to a cement mill to grind after being metered by a speed-regulating constant feed weigher. The technology increases the participation quantity and the economic benefit of the carbide slag, reduces the environmental pollution and the resource waste, can be used by combining the dry acetylene producing technology and the traditional technology and can be singly used.

Owner:天能水泥有限公司

Thin dry powder fire-resistant coating for steel structure

ActiveCN106007582AGood alkali resistanceImprove radiation protection performancePolymer modifiedDimethyl siloxane

The invention discloses a thin dry powder fire-resistant coating for a steel structure. The fire-resistant coating is prepared from, by weight, white cement, titanium dioxide, calcined kaolin, calcium carbonate, polydimethylsiloxane, polymer-modified oxidized graphene, sulfonated polybenzimidazole-modified meso-porous silicon, KH-560 and aeolian sand. The thin dry powder fire-resistant coating for the steel structure has the advantages that the fire resistance is excellent, the adhesive force is high, the wear resistance is good, the weather resistance, the water resistance and the radiation resistance are good, a surface layer of the coating is smooth and fine, and greenness and environmental friendliness are achieved.

Owner:楚雄佑琳生科技有限公司

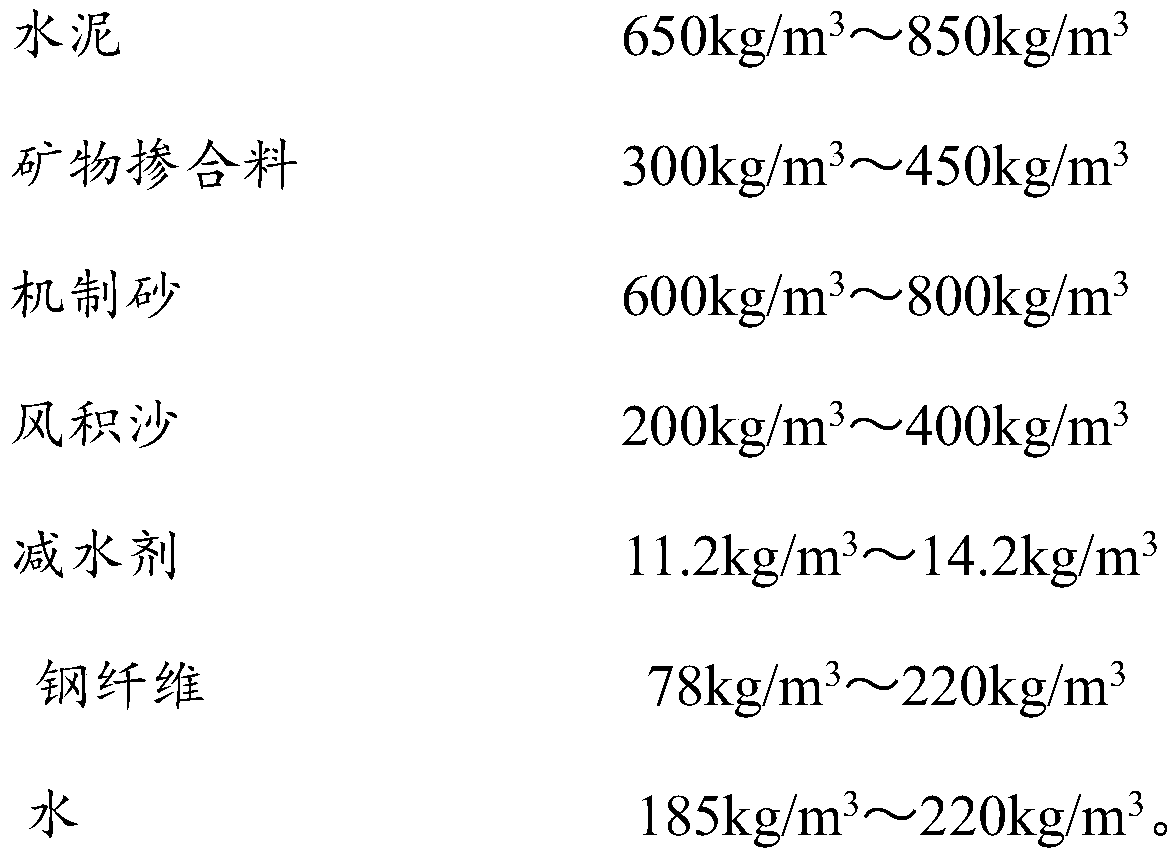

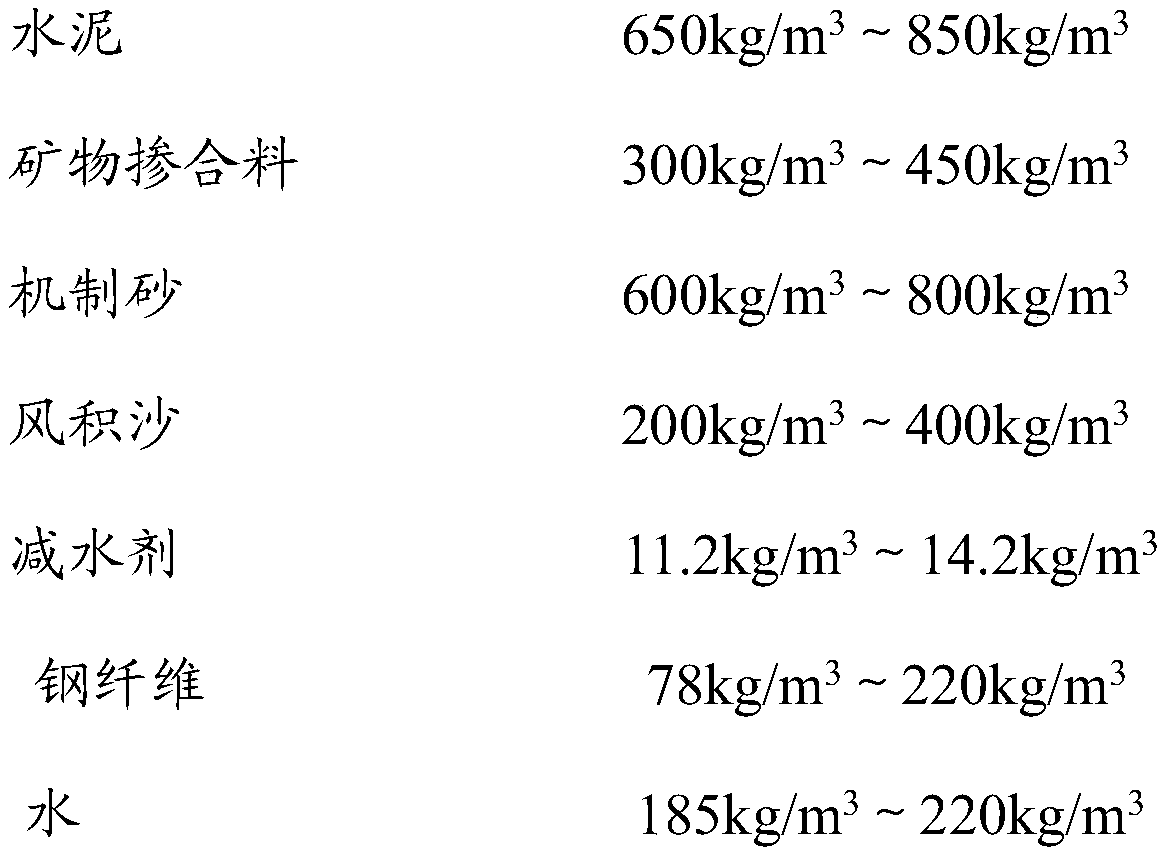

Machine-made sand and aeolian sand co-doped ultra-high performance concrete and preparation method thereof

InactiveCN111533504AImprove performanceSolve the problem of ultra-high performance concrete that is difficult to prepare due to ultra-high performanceSolid waste managementPhysical chemistryWater reducer

The invention relates to machine-made sand and aeolian sand co-doped ultra-high performance concrete and a preparation method thereof. The content per cube of the machine-made sand and aeolian sand co-doped ultra-high performance concrete comprises: 650 to 850 kg / m<3> of cement, 300 to 450 kg / m<3> of a mineral admixture, 600 to 800 kg / m<3> of machine-made sand, 200 to 400 kg / m<3> of aeolian sand,78 to 220 kg / m<3> of steel fiber, 11.2 to 14.2 kg / m<3> of a water reducing agent and 185 to 210 kg / m<3> of water. The machine-made sand and the aeolian sand are adopted to replace natural river sand,the prepared machine-made sand and aeolian sand co-doped ultra-high performance concrete has good working performance, mechanical performance and durability, the problem of shortage of natural river sand resources is solved, local resources are reasonably utilized, and the production cost is reduced.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

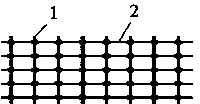

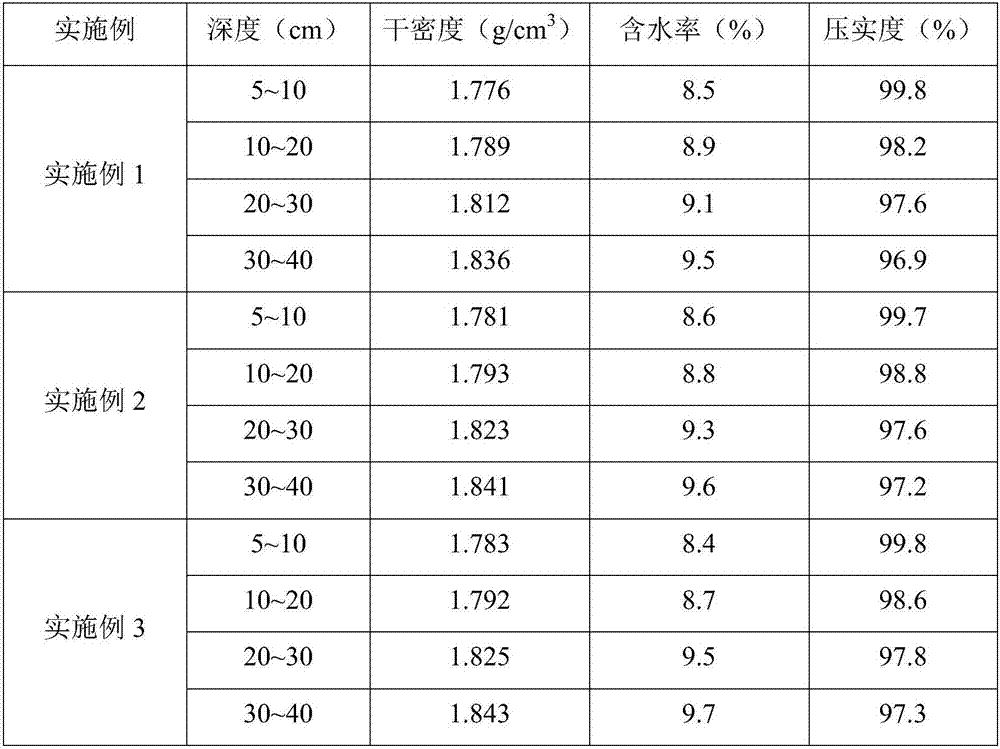

Aeolian sand subgrade construction method

ActiveCN107012755AImprove stabilityImprove reinforcementRoadwaysBuilding constructionsFailure strainEngineering

The invention provides an aeolian sand subgrade construction method. The method comprises the following steps that surveying and setting out are conducted; a base layer is laid; padding is loaded and unloaded; a reinforcing layer is laid; a reinforcing layer is laid on the surface of aeolian sand, wherein the reinforcing layer comprises limestone, polypropylene fibers, loose filling and the balance coal ash; tilling is conducted, specifically, watering is conducted on the reinforcing layer, and tilling is conducted on a subgrade multiple times in the length direction; riffle watering is conducted; rolling compaction is conducted through a bulldozer; rolling compaction is conducted through a road roller; compaction detection is conducted, specifically, the compaction coefficient Kof the compacted aeolian sand is detected in a sand filling mode or a water filling mode; and the step that padding is loaded and unloading to the step that compaction detection is conducted are conducted repeatedly until the subgrade reaches a design elevation, and construction is completed. According to the aeolian sand subgrade construction method provided by the invention, the reinforcing layer is laid on the aeolian sand, the reasonable rolling compaction mode is adopted, the strength of the vibrated and compacted subgrade meets design requirements, the compressive strength is high, the failure strain resistance and tension resistance of the subgrade are greatly improved, and the stability of the subgrade is improved.

Owner:CHINA FOURTH ENG OF CHINA RAILWAY SEVENTH GROUP

Method for preparing cordierite ceramics from desert aeolian sand

The invention discloses a method for preparing cordierite ceramics from desert aeolian sand. According to the method, desert aeolian sand, aluminum oxide, magnesium oxide and cerium oxide are used as raw materials, the raw materials are prepared into powder by wet ball milling, SiO2, Al2O3 and MgO in the mixed powder respectively account for 48-53%, 30-37% and 10-15%, additive amount of the cerium oxide is at most 6%, the mixed powder is granulated and molded under high pressure; the molded blank is sintered for 3-6 hours at high temperature, and then, the cordierite ceramics is obtained. The density of the ceramics synthesized by the method can be 80-95%, bending strength of the ceramics can be 25-45MPa, and coefficient of thermal expansion of the ceramics can be (1.8-3.2)*10<-6> / DEG C.

Owner:INNER MONGOLIA UNIV OF TECH

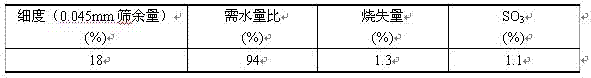

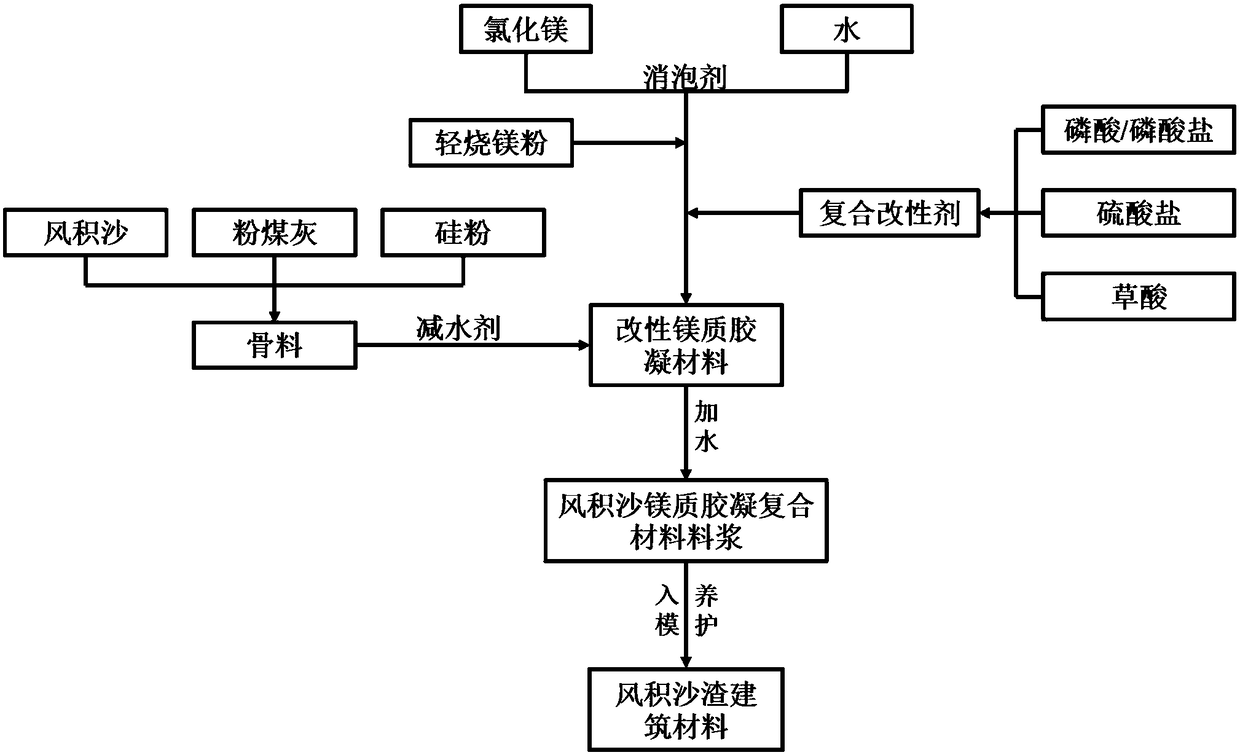

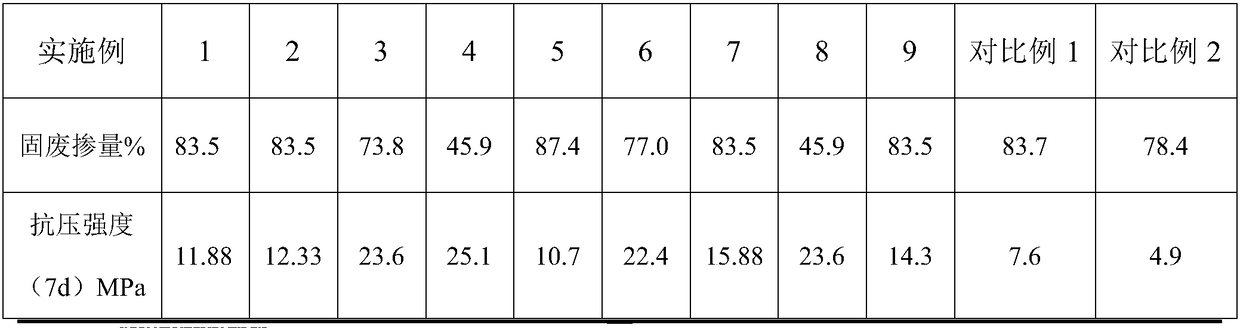

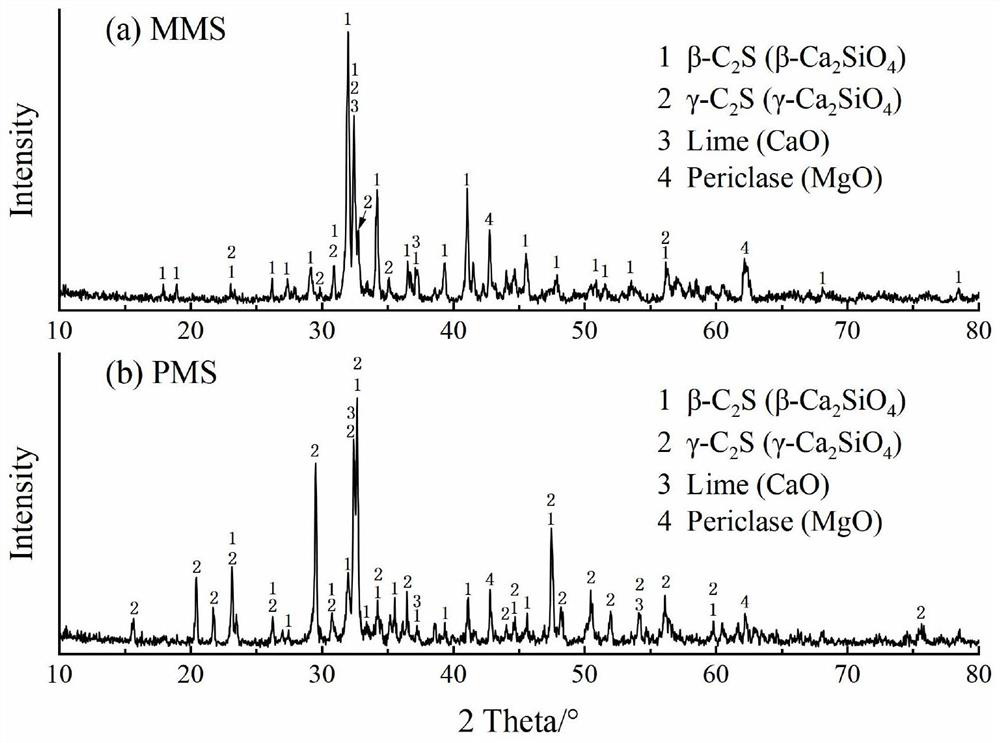

Building material composition containing aeolian sand and preparation method of building material composition

The invention discloses building material composition containing aeolian sand. Raw material powder of a building material comprises components in percentage by mass as follows: 45%-85.5% of aeolian sand, 0-8.5% of fly ash, 0-4% of silica fume, 9.5%-45% of light-burned magnesia, 2.7%-7.1% of magnesium chloride, 0.05%-0.5% of a defoamer, 0-1.5% of a water reducer and 0.15%-4.7% of a composite modifier; the building material is prepared from 100 parts by weight of the raw material powder of the building material and 10-21 parts by weight of water. The aeolian sand doping amount is large, the building material is high in strength and good in toughness, production and blending are easy, special equipment is not needed, the material needs no pretreatment, various forms of building materials areproduced, and production cost and preparation difficulty of the building material containing the aeolian sand are reduced.

Owner:中科镁基(北京)科技有限公司

Low-shrinkage and high-strength concrete material using aeolian sand and gobi gravels as main raw materials and preparation method of low-shrinkage and high-strength concrete material

The invention discloses a low-shrinkage and high-strength concrete material using aeolian sand and gobi gravels as the main raw materials and a preparation method of the low-shrinkage and high-strength concrete material. The low-shrinkage and high-strength concrete material mainly comprises 568.1-604.8 parts of Portland cement, 284.1-302.4 parts of fine sinking beads, 94.7-100.8 parts of silica fume, 589.4-785.7 parts of aeolian sand, 294.6-491.2 parts of gobi gravels, 3.8-20.2 parts of water reducing agent and 161.3-227.3 parts of water. The low-shrinkage and high-strength concrete material and the preparation method thereof have the advantages that the low-shrinkage and high-strength concrete material is simple in preparation process, and the high-strength concrete material which is excellent in various performance such as flowability, strength and long-term stability can be prepared by using a conventional concrete forcing type single horizontal shaft agitator; in addition, the aeolian sand and the gobi gravels which are cheap natural materials rich in reserves are used, the concrete prepared by using the aeolian sand and the gobi gravels to replace materials such as natural river sand and basalt gravels is the inexorable trend of engineering material development, the preparation method is widely applicable to the great northwest region of China, local materials can be utilized, measures can be adjusted according to local conditions, and great economic and social benefits can be achieved.

Owner:SOUTHEAST UNIV

Green super-performance cement-based material with aeolian sand and preparation method of material

The invention discloses a green super-performance cement-based material with aeolian sand and a preparation method of the material. The green super-performance cement-based material mainly consists of550-600 parts of ordinary Portland cement, 250-300 parts of fine sinking beads, 85-100 parts of silicon ash, 750-800 parts of aeolian sand, 25-30 parts of an expanding agent, 180-240 parts of a steelfiber, 18-30 parts of a water reduction agent and 150-195 parts of water. Compared with a conventional super-performance cement-based material, the material comprises the aeolian sand as a raw material, compared with super-performance cement-based materials with quartz sand and river sand as raw materials, the novel green super-performance cement-based material with the aeolian sand can meet identical indexes, in addition, compared with a conventional super-performance cement-based material, the material is relatively good in comprehensive property. Moreover, the invention provides a noel building material, the problems that conventional building materials are in shortage and increasingly serious desertization is caused can be solved, waste resources can be sufficiently utilized, wastes can be turned into wealth, development of the building industry can be promoted, and sustainable development strategies of current society can be met.

Owner:SOUTHEAST UNIV

Method for filling aeolian sand empty field of western desert mining area shallow coal seam

The invention discloses a method for filling an aeolian sand empty field of a western desert mining area shallow coal seam. The method is suitable for a coal face where the self-stabilization performance of a top plate is good and an empty field in a certain size can be formed in the rear portion. According to the method, by means of the small work amount of drilling from the earth surface to the shallow coal seam and the good self-flowing performance of aeolian sand, drilling arrangement is conducted above the empty field formed by mining of the coal face, the aeolian sand is directly injected into the empty field, the empty field is filled in sections before underground periodic weighting, and then the empty field is filled with the aeolian sand. Due to the fact that the coal seam in the west is shallow, an unconsolidated formation above is thick and bed rock is thin, the work amount of drilling is small, cost is low, and the construction period is short. Meanwhile, overburden failures and subsidence can be effectively avoided, water and sand inrush is relieved, and the western mining area environment is improved. The method provides a novel technological approach for green mining of the western desert mining area, production efficiency is high, the number of invested devices is small, and filling cost is low.

Owner:CHINA UNIV OF MINING & TECH

Magnesium-coal cinder based novel paving and mining filling material and preparation method thereof

InactiveCN112851277ALow costRealize the recycling of solid wasteCement productionSlagWaste treatment

The invention discloses a novel magnesium-coal cinder-based paving and mining filling material and a preparation method thereof. The material comprises the following raw materials in percentage by weight: 15-50% of a magnesium-coal cinder-based cementing material, 50-85% of aggregate and 0-5% of an additive, the magnesium-coal cinder-based cementing material is a cementing material formed by adding one or two of fly ash and coal gasification slag into magnesium slag serving as a basic raw material; the aggregate comprises one or a combination of more of construction waste, coal gangue, aeolian sand, slag and desulfurized gypsum; the additive comprises one or a combination of more of a retarder, a water reducing agent, an early strength agent and a drag reducer. The invention provides a new utilization way for solid waste treatment in the coal chemical industry and the magnesium smelting industry, and realizes solid waste recycling.

Owner:西安弗尔绿创矿业科技有限责任公司

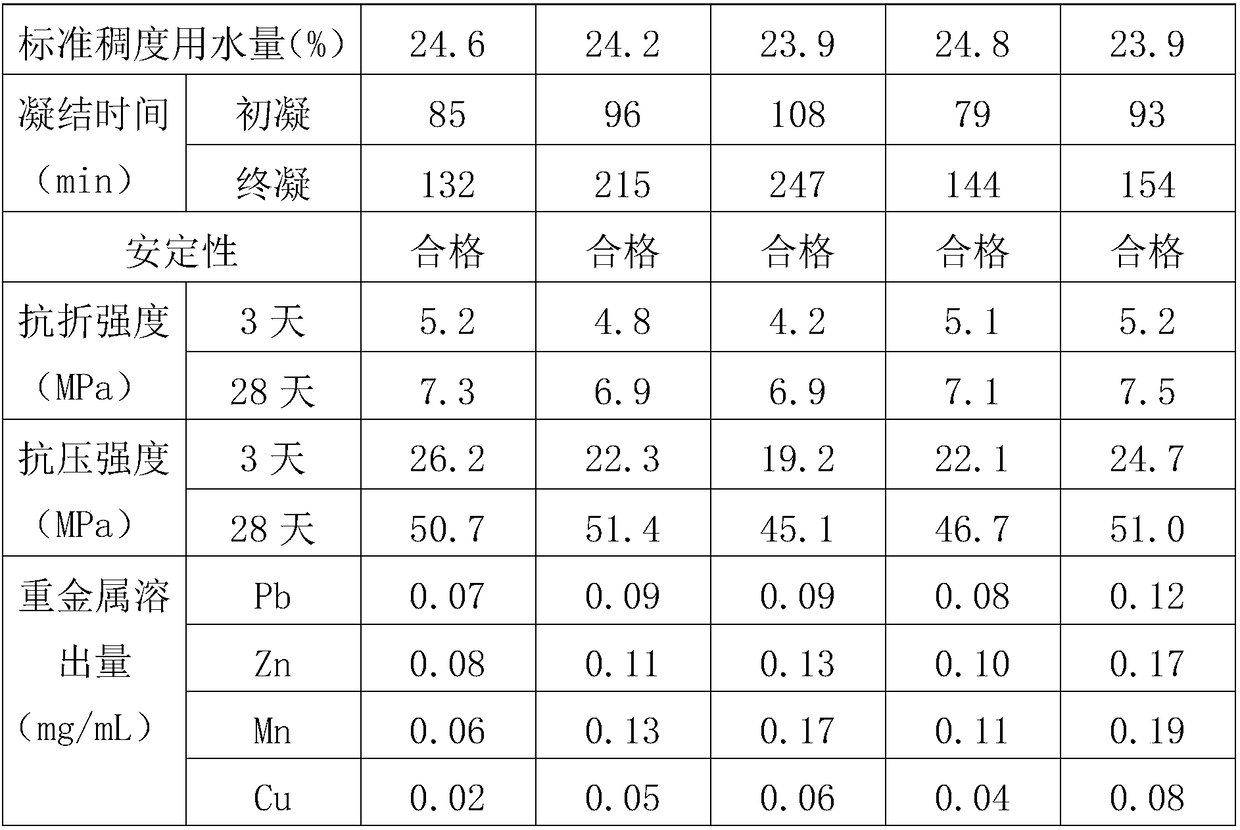

Composite cement and preparation method thereof

InactiveCN108164164AGood physical propertiesHigh strengthCement productionDissolutionToxic industrial waste

The invention relates a composite cement and a preparation method thereof. The composite cement includes: 40-70% of cement clinker; 3-8% of gypsum; 22-53% of waste residue, which is at least one of lead-zinc residue, slag, copper slag and fly ash; 8-22% of a carbonatic raw material; 0-10% of a quartziferous component, which is at least one of lead-zinc tailings, iron tailings, quartz sand and aeolian sand; and 0-4% of an excitation component. Specifically, the composite cement includes at least one of lead-zinc residue and lead-zinc tailings. According to the invention, lead-zinc industrial wastes is applied to preparation of composite cement, and the prepared composite cement has good physical properties and low heavy metal dissolution amount.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com