Method for filling aeolian sand empty field of western desert mining area shallow coal seam

A technology of aeolian sand and empty field, which is used in filling materials, mining equipment, earth-moving drilling, etc. to achieve the effect of thin bedrock, low filling cost and environmental improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

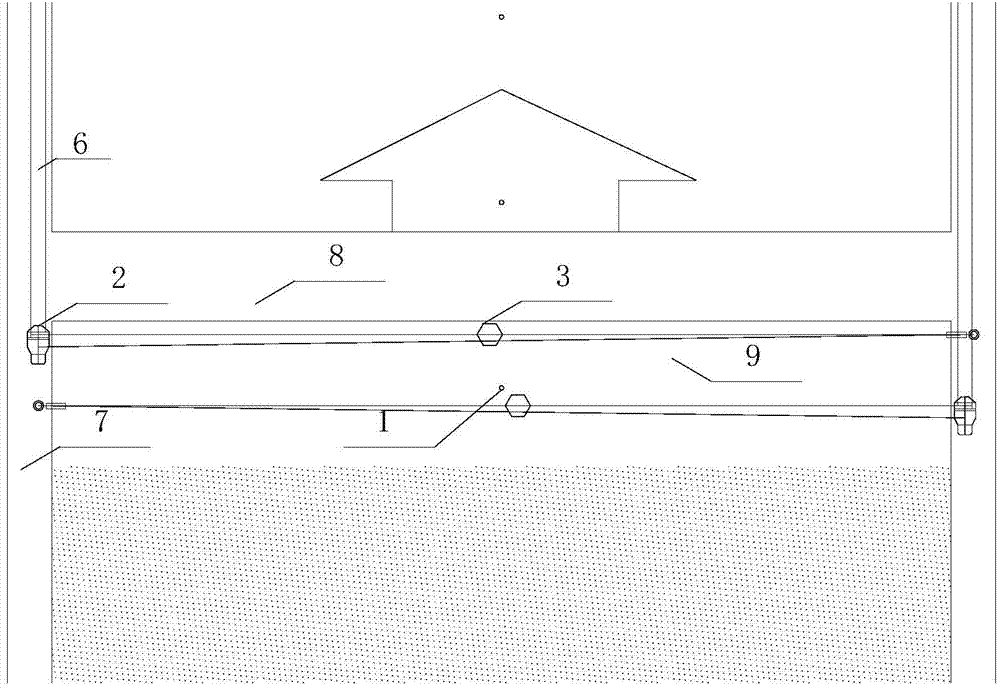

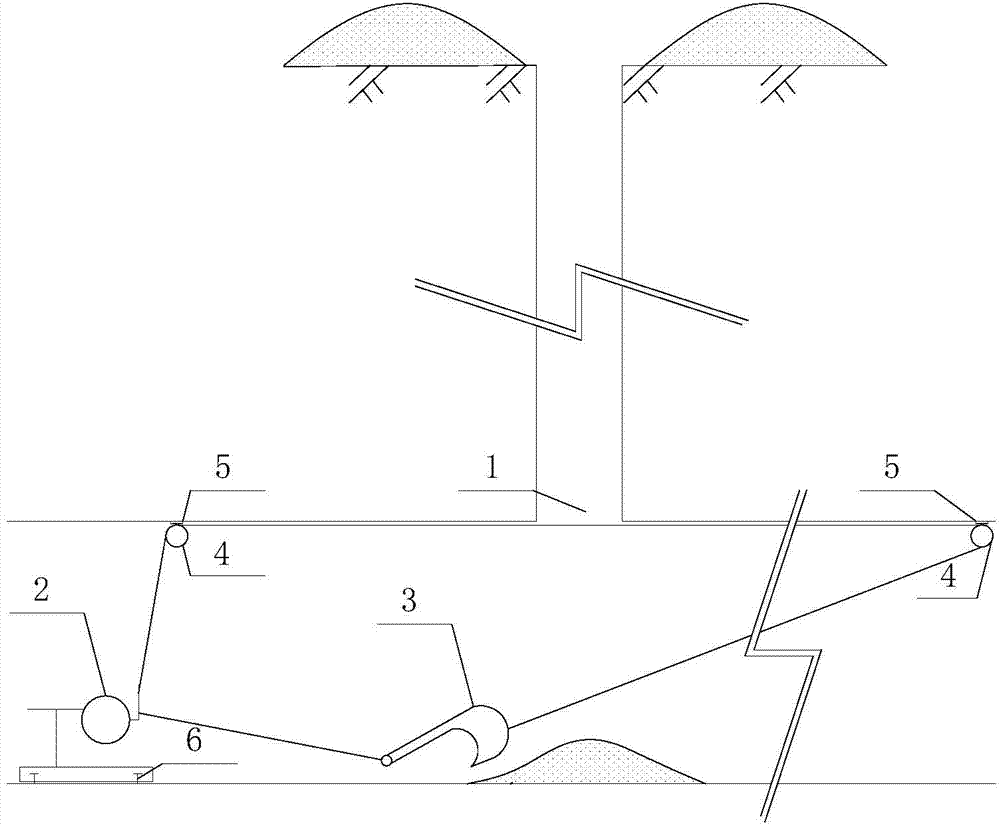

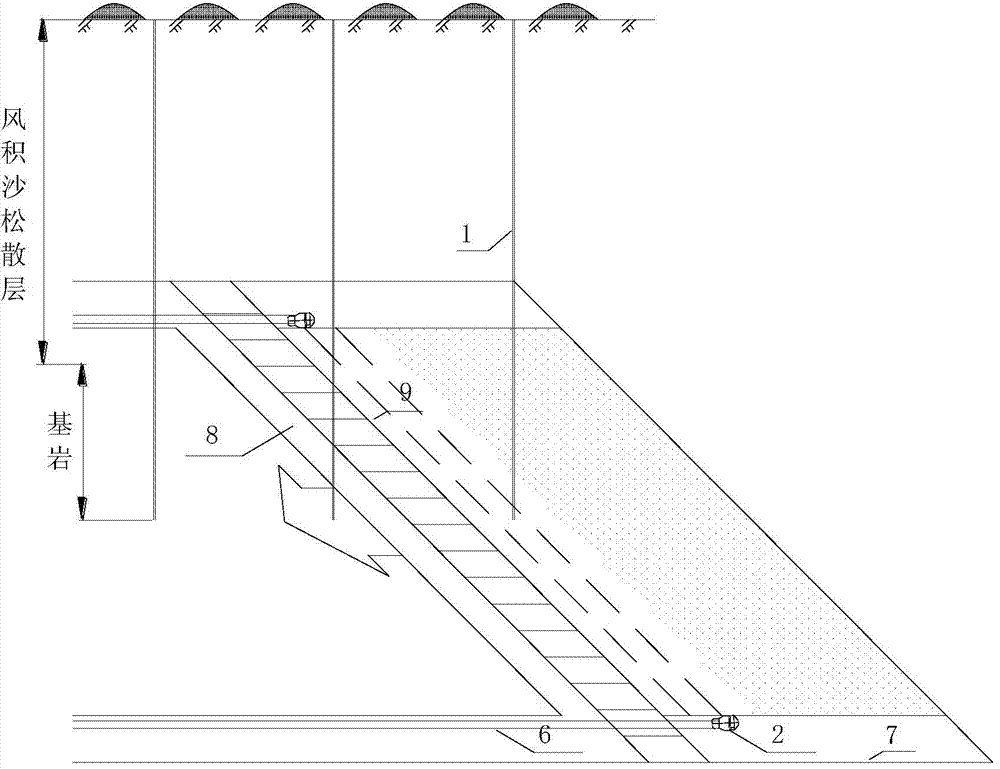

[0039] (1) The buried depth of a mine in the west is about 65m, the loose layer of aeolian sand is about 45m thick, the bedrock is about 20m thick, and the coal bulk density γ is 1.3t / m 3 . The length L of the designed coal mining face 8 is 90m, and the mining height H is 5.2m. The self-stabilization performance of the open field roof is better. The average periodic pressure step distance is 15m, and the row spacing of the quicksand well is 15m, arranged according to 1-1, and a movable shuttle-type leveling system mainly based on a sand raking winch is arranged.

[0040] (2) Arrange a sand raking winch 2 in the gob-side roadway 7 on both sides of the coal mining face 8, and the volume of the raking bucket 3 is V 0 =1.2m 3 , the total number of rake buckets 3 n is 2, the rope capacity of the winch is 100m, and the average working speed of rake buckets 3 is v t is 1.2m / s, the daily flattened filling operation time is 0.5d, the coal mining operation time is 0.5d, and the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com