Patents

Literature

36results about How to "Good self-flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

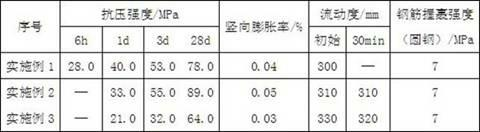

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Contraction-free cement grout material

The invention relates to the field of cement grout materials, in particular relating to a property-adjustable functional contraction-free cement grout material. The contraction-free cement grout comprises the following components in percentage by weight: 30.0%-6.0% of gelled material, 0%-5.0% of anhydrite, 4.0%-6.0% of expanding agent, 0.6%-1.5% of water reducing agent, 0%-0.09% of coagulant, 0%-2% of shrinkage agent, 0%-0.06% of thickener and 40.0%-65.0% of aggregate. The grout material has the advantages of good self-flowability, no sedimentation, no bleeding, minimum inflation and no obvious contraction phenomenon; the property of the grout material can be adjusted at random according to the requirement of a building, thus the grout material is wide in adaptability, low in cost, flexible to operate and convenient to use; and the grout material can be suitable for aid repair engineering with a high strength requirement at early period, can be used for a common grout material with a general requirement, and also can be used for a superfluid grout material with large flowability.

Owner:浙江五龙新材股份有限公司

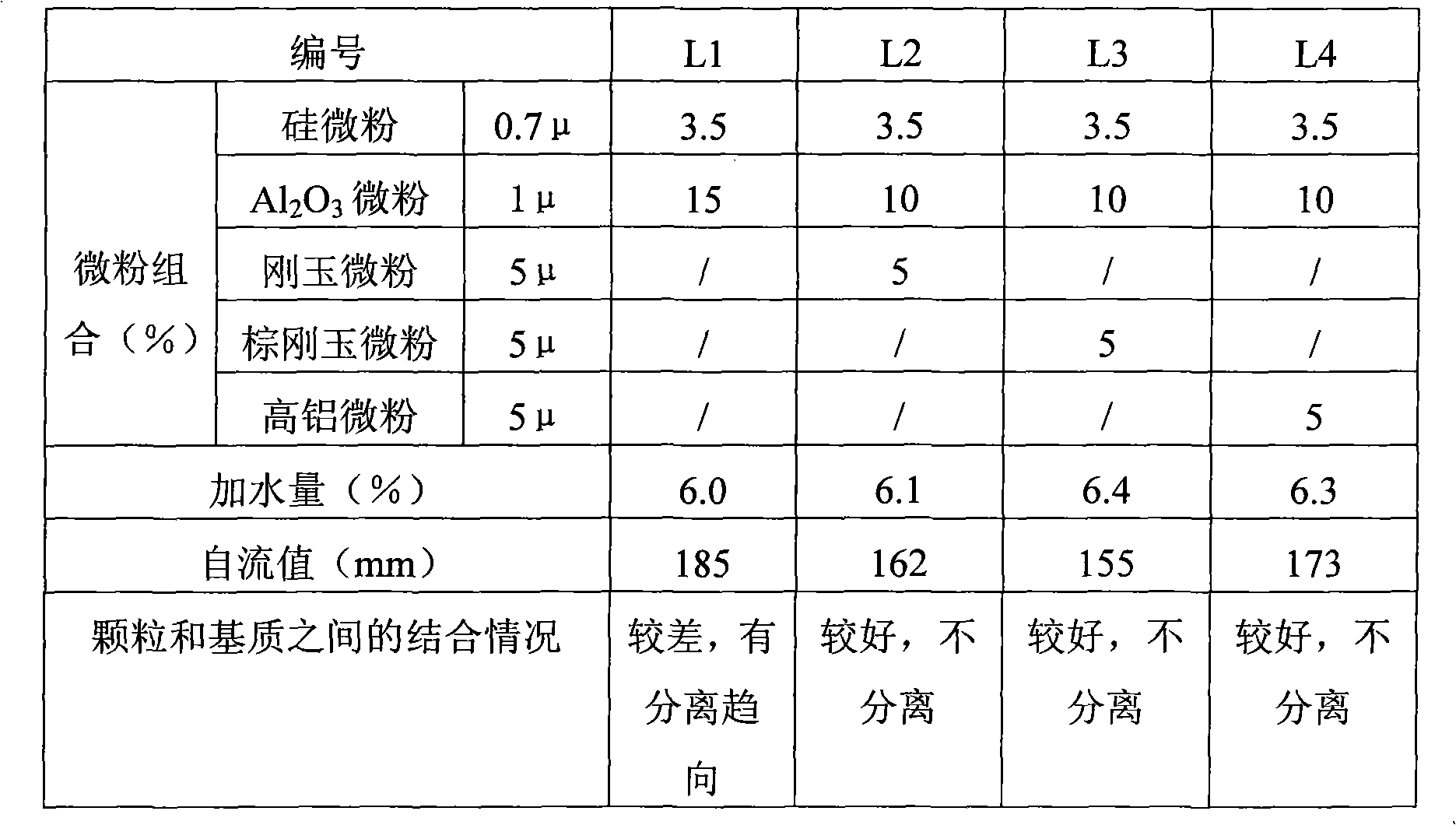

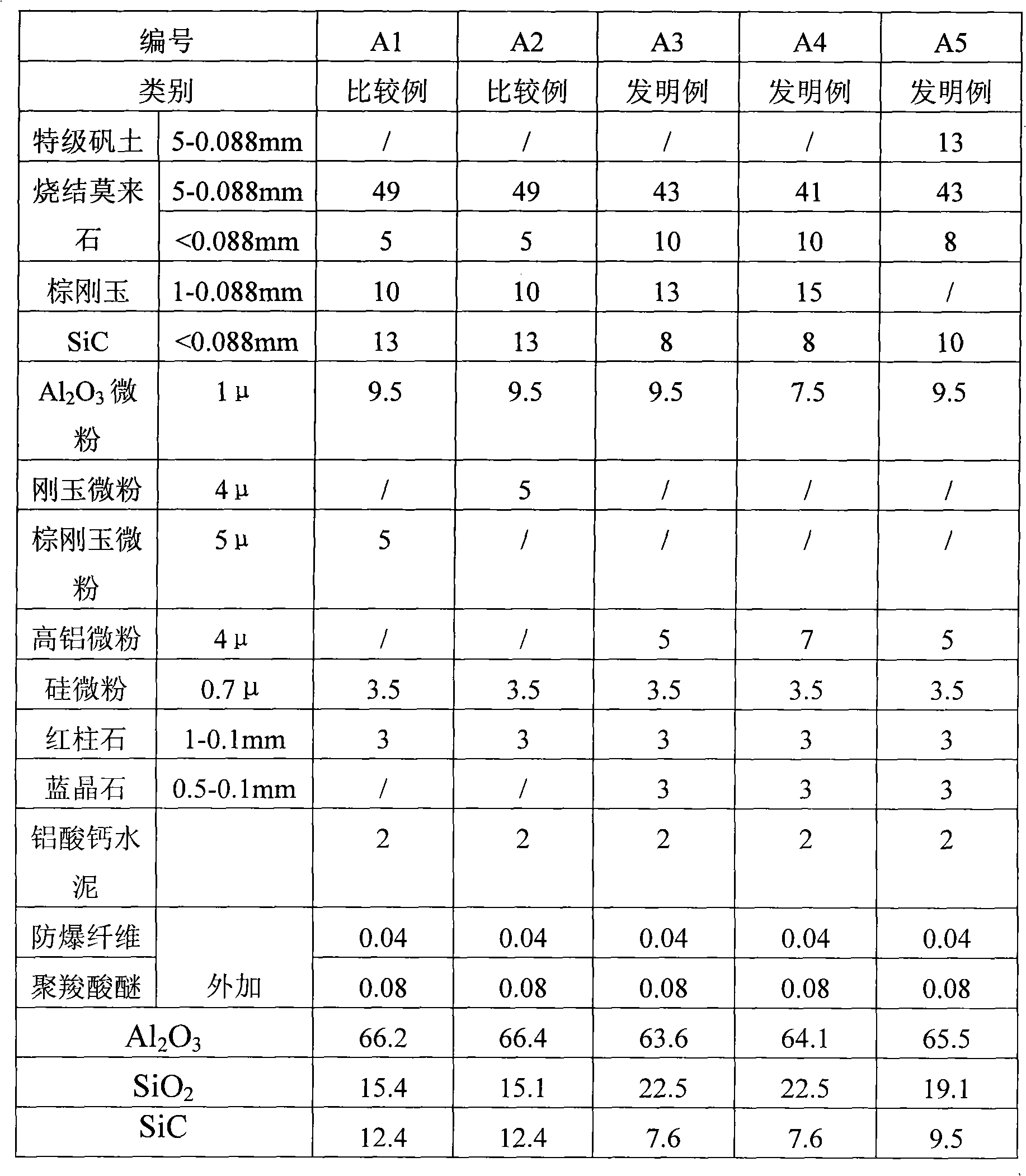

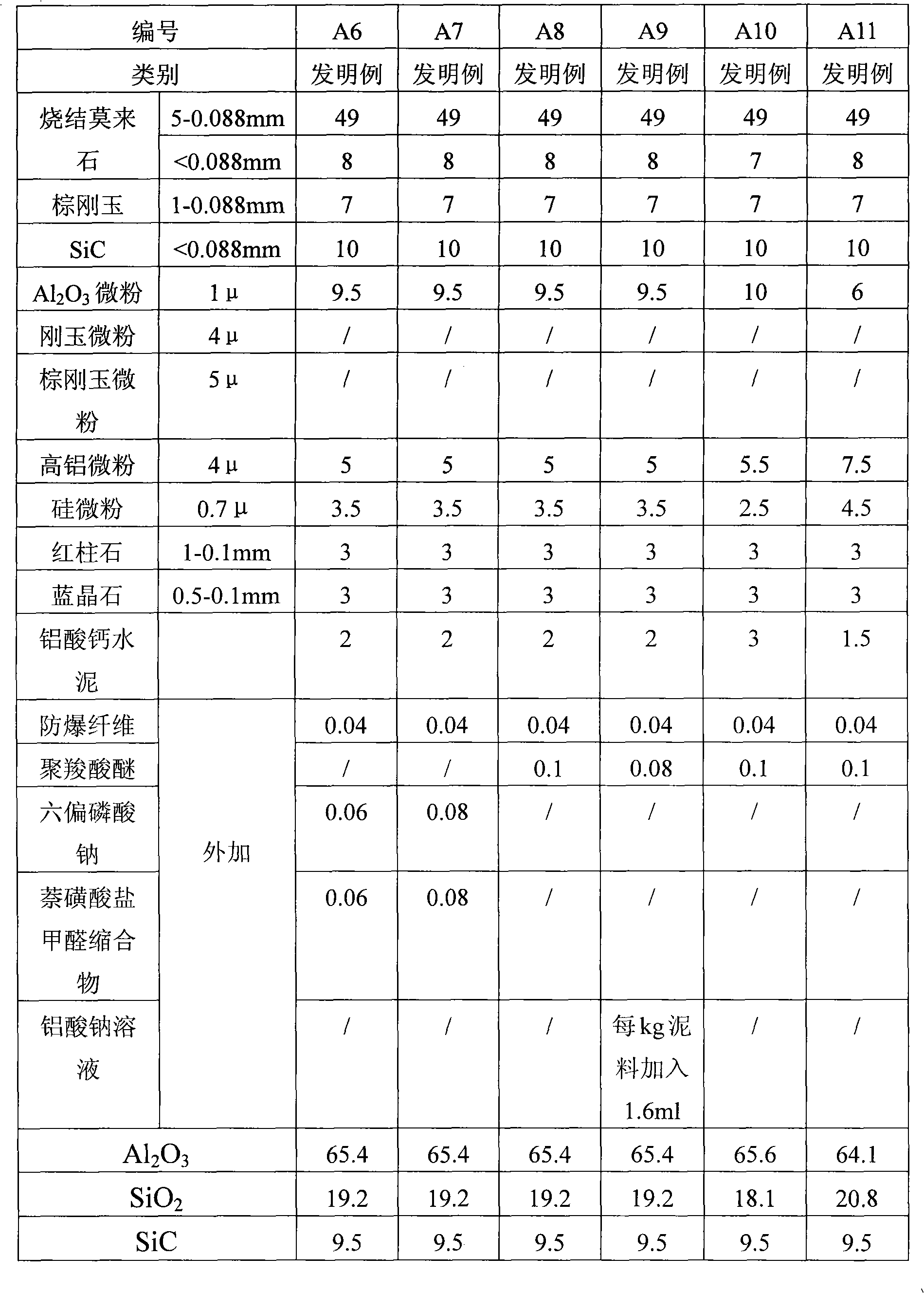

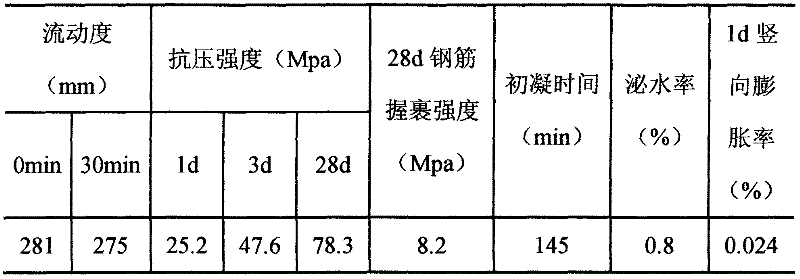

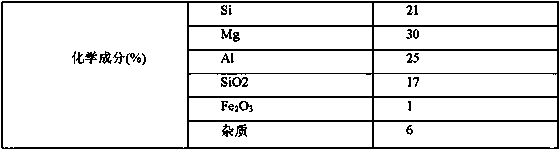

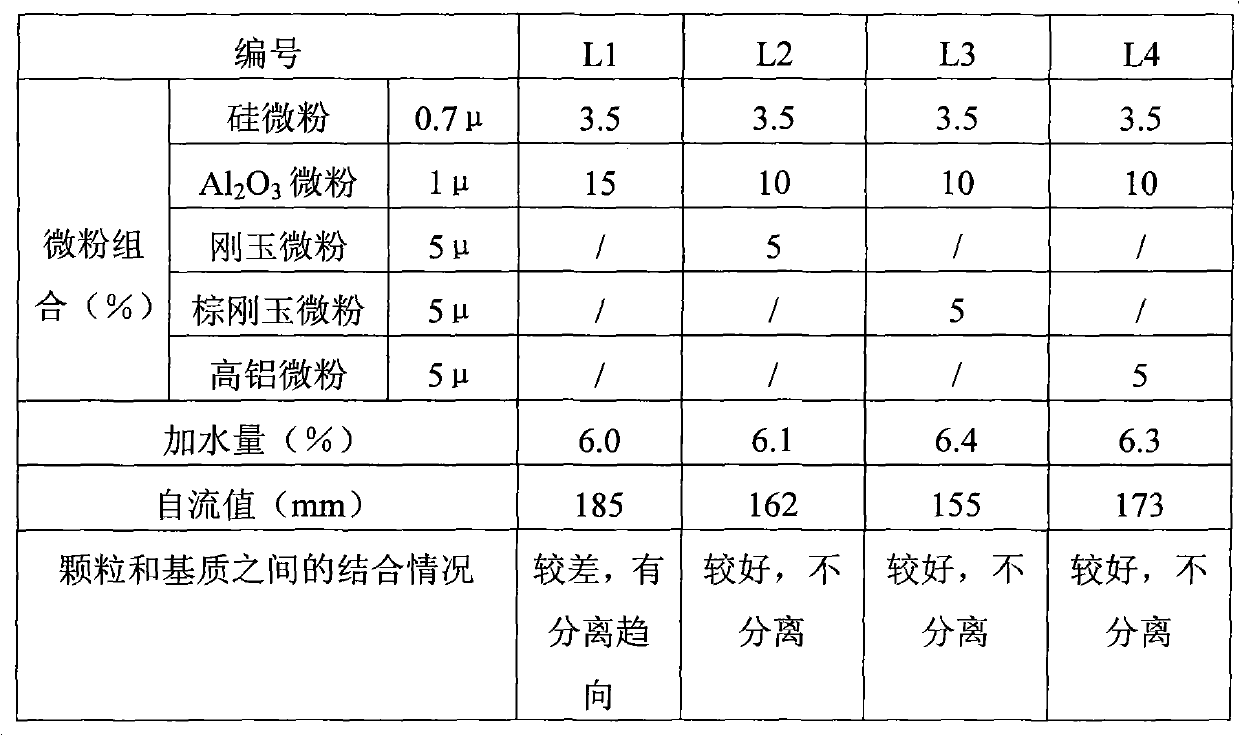

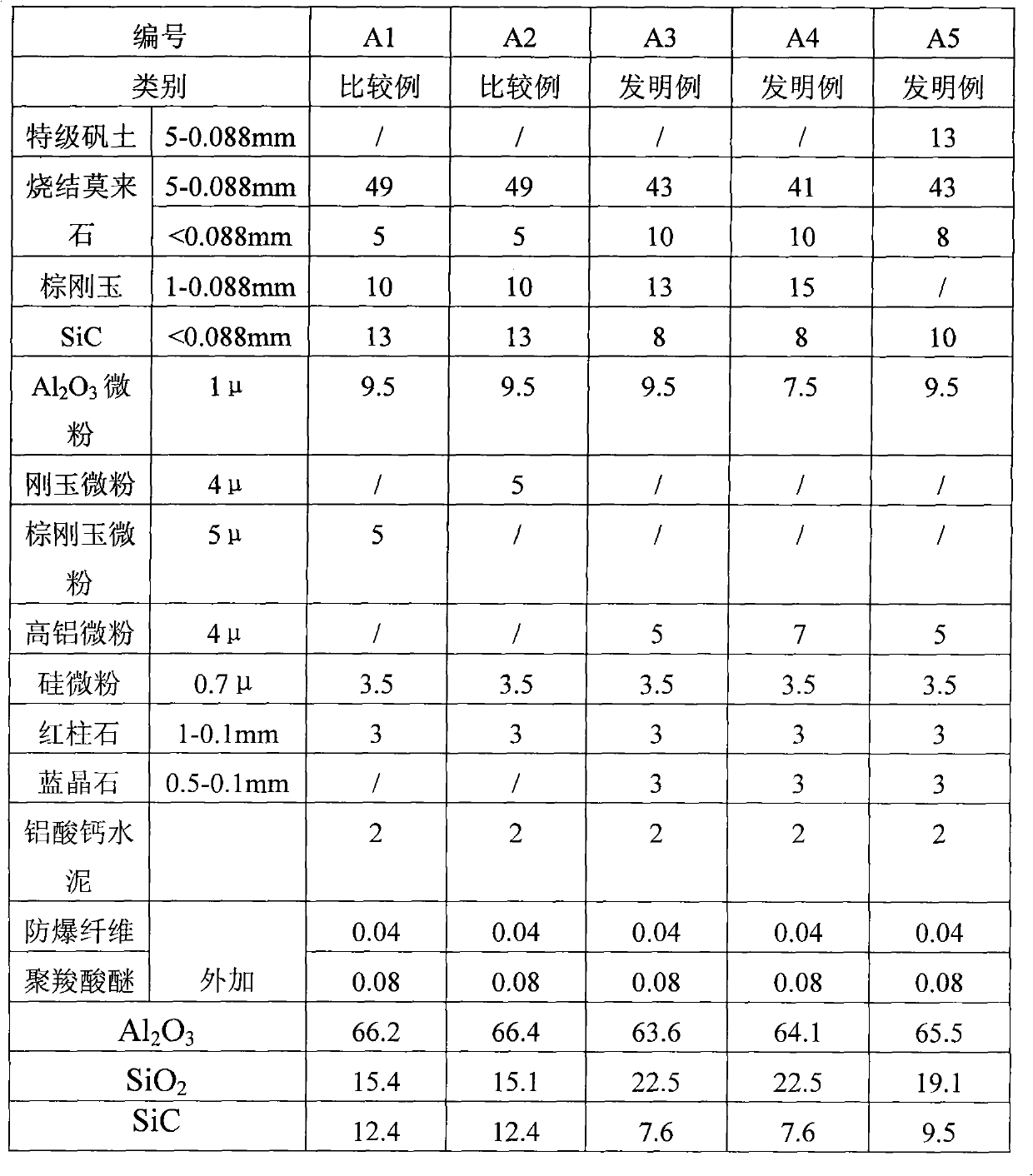

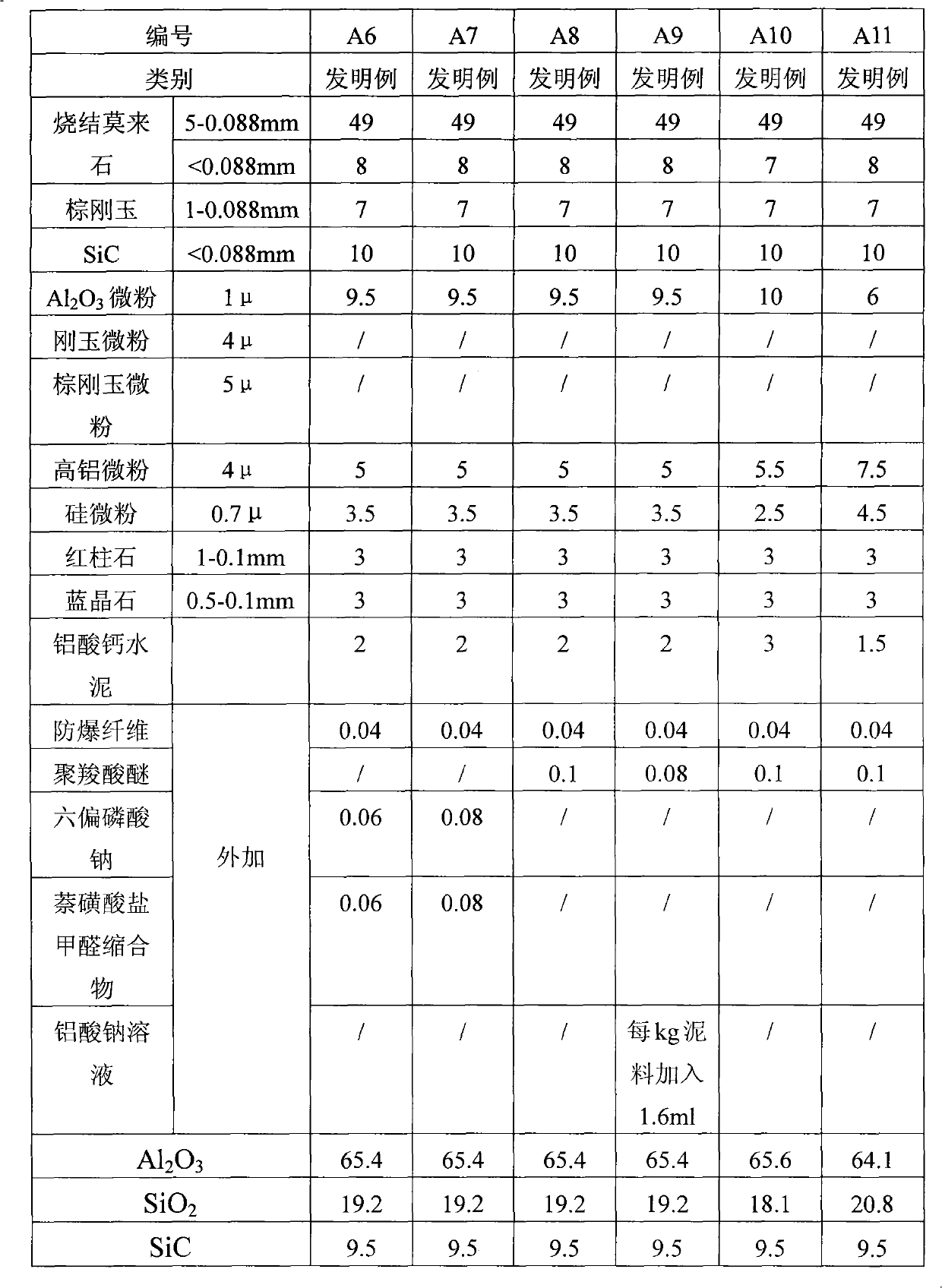

Al2O3-SiO2-SiC-based jet material for foundry ladle

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Owner:BAOSHAN IRON & STEEL CO LTD

Cement-based shrinkage-free grouting mortar

The invention discloses a cement-based shrinkage-free grouting mortar which is characterized by comprising the following components in percentage by weight: 35%-42% of silicate cement, 5%-12% of aluminate cement, 6%-10% of gypsum, 40%-50% of aggregate, 0.8%-1.4% of high-efficiency water reducing agent, 0.05%-0.2% of coagulation-regulating agent, 0.4%-1.0% of defoamer and 1%-3% of bleeding resisting agent. The cement-based shrinkage-free grouting mortar is a gelled material which is prepared from the silicate cement, the aluminate cement and the gypsum and has stable performance, and the flow degree, coagulation time and expansion rate of the grouting mortar can be regulated according to the requirement of a user. After mixed with water, the grouting mortar has a good self-flowing property, no sedimentation and no bleeding; the grouting mortar has the characteristics of plastic micro-expansion property, no gap, high early strength, no contracted later strength, good durability, impermeability, freezing resistance and vibration resistance, low material price and wide raw material sources; and the grouting mortar is flexible to operate and is simple to use.

Owner:JIANGSU MINGHE GRP

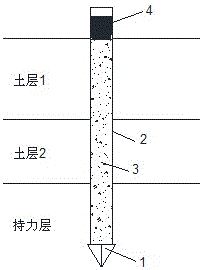

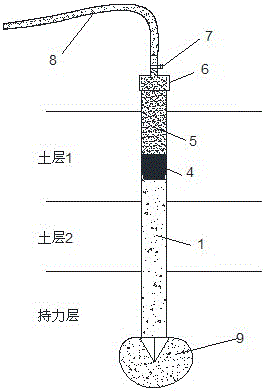

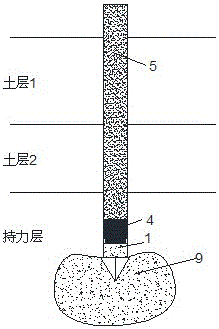

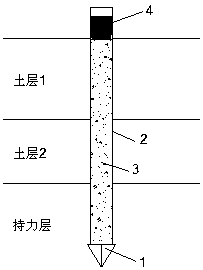

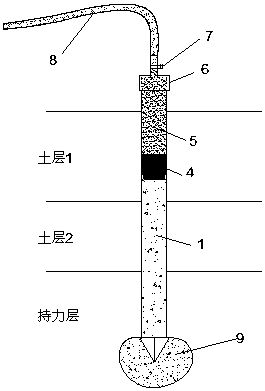

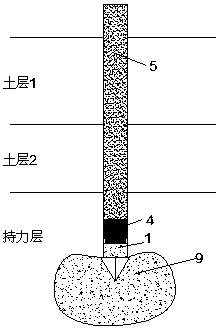

Miniature steel pipe pile and grouting reinforcement method

ActiveCN106013098AGuaranteed StrengthGood self-flowBulkheads/pilesSoil preservationCement pasteSoil horizon

The invention provides a miniature steel pipe pile and a grouting reinforcement method. The miniature steel pipe pile comprises a steel pipe pile body; a pile tip sealing plate is connected to the lowermost end of the steel pipe pile body and provided with a grout discharge hole communicating with the inner side of the steel pipe pile body and a soil layer on the periphery of a pile tip; reinforcement treatment is conducted on a soil layer under the pile tip through two times of grouting; the characteristics of being good in automatic flow performance, quick in hardening, early in strengthening, free of shrinkage, slight in expansion and the like of grouting materials are utilized, the bearing capacity of a foundation can be improved quickly and effectively, and accordingly the bearing capacity of the pile tip is improved; and mixing of cement paste and the grouting materials is effectively prevented through a rubber plug in an inverted circular truncated cone shape, and the strength of the grouting materials at the pile tip is ensured.

Owner:HUAIHAI INST OF TECH

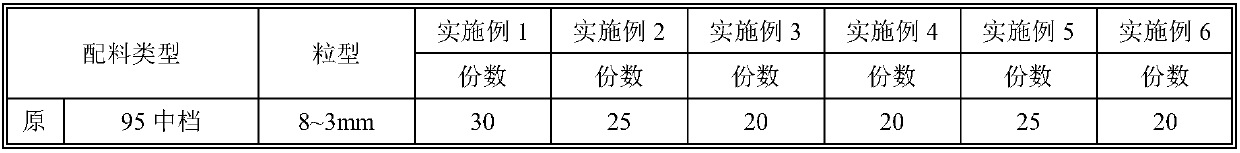

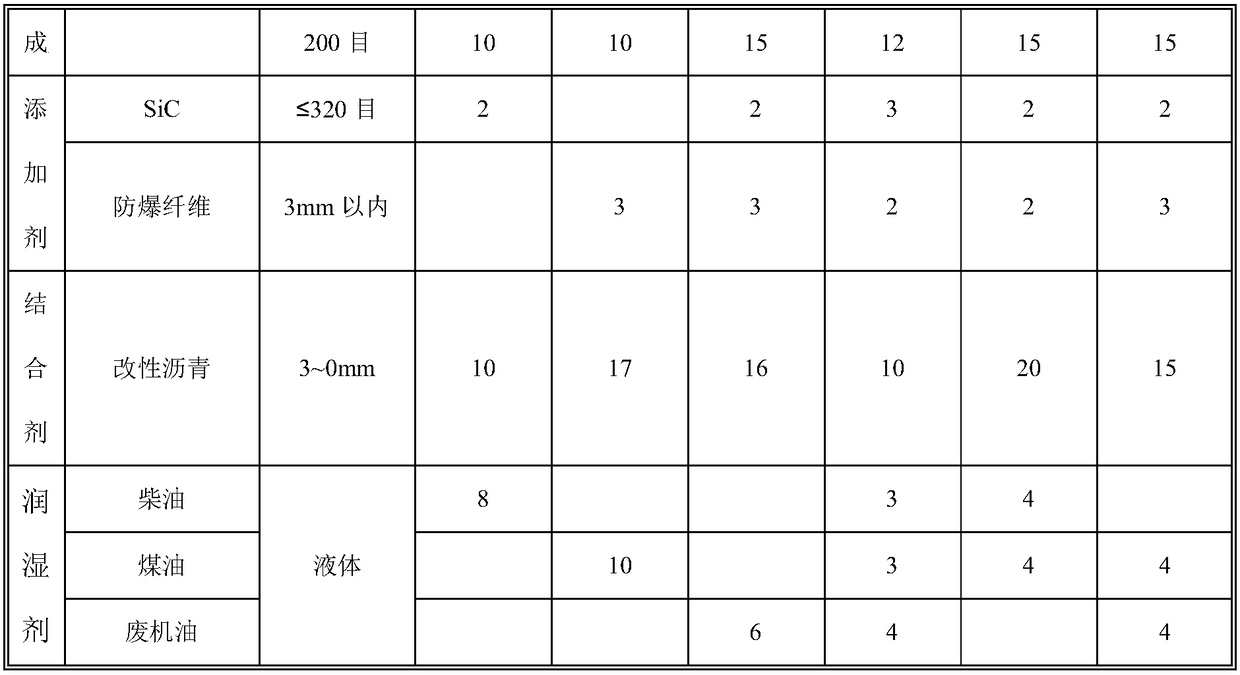

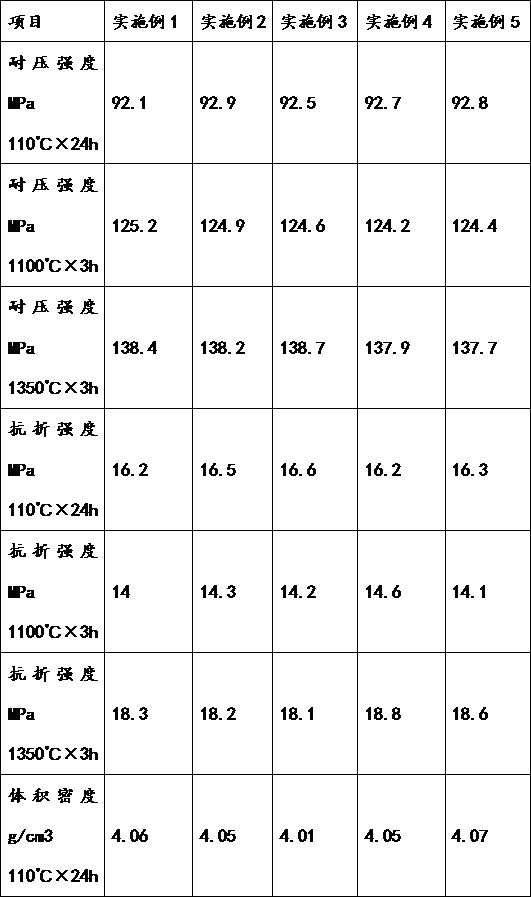

Fettling material for converter as well as preparation and using methods thereof

InactiveCN107793163AResolution timeSolve the pollution of the environmentManufacturing convertersThermal stateEconomic benefits

The invention provides a fettling material for a converter as well as preparation and using methods thereof. The fettling material is prepared from the following raw materials in parts by weight: 60 to 95 parts of magnesia, 10 to 20 parts of a binding agent, 2 to 5 parts of additives and 6 to 10 parts of wetting agents, wherein the binding agent is a mixture of asphalt and silica fume. Compared with the prior art, the fettling material for the converter has the beneficial effects that the fettling material for the converter as well as the preparation and using methods thereof disclosed by theinvention have good self-flow property, thermal-state strength, erosion resistance and thermal shock property; the hardening time of the fettling material is short, the maintenance time of furnace shutdown of the converter can be effectively reduced, the operation efficiency is improved, and the binding of the fettling material and a working lining of the converter is good so as to prevent stripping of the fettling material in a using process, and environmental pollution is reduced. The fettling material for the converter as well as the preparation and using methods of the fettling material disclosed by the invention have significant meanings on energy conservation and consumption reduction, environmental protection and increment of economic benefits.

Owner:海城利尔麦格西塔材料有限公司 +1

Single-iron notch blast furnace main channel self-flow repairing material

The invention discloses a single-iron notch blast furnace main channel self-flow repairing material which comprises the following components by mass ratio: 40-50 parts of brown corundum or compact corundum, 18-25 parts of silicon carbide superfine powder, 12-15 parts of white corundum, 4-6 parts of alpha-Al2O3, 1-3 parts of silica micropowder, 1-2 parts of paraffin, 4.8-5.6 parts of ball pitch, 3-5 parts of silicon metal, 1-2 parts of ethylene glycol, 0.2-0.3 part of chromic oxide, 0.5-0.8 part of boron nitride, 0.2-0.3 part of zirconium oxide, 1.5-2.5 parts of compound additive and 0.3-0.5 part of composite explosion-proof agent. The single-iron notch blast furnace main channel self-flow repairing material is good in self-flow performance and high in permeability, can be used for greatlyimproving the repairing effect, and is very convenient in repairing operation; when the repairing material is used in a repairing technology, a construction tool is not needed in the operation, and the material is only needed to be placed at the corresponding position to be repaired without vibration; and the good self-flow function of the material can be used for repairing, so that the construction safety is improved, and the labor intensity of workers can be lightened.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

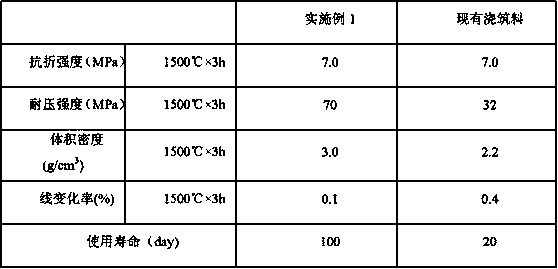

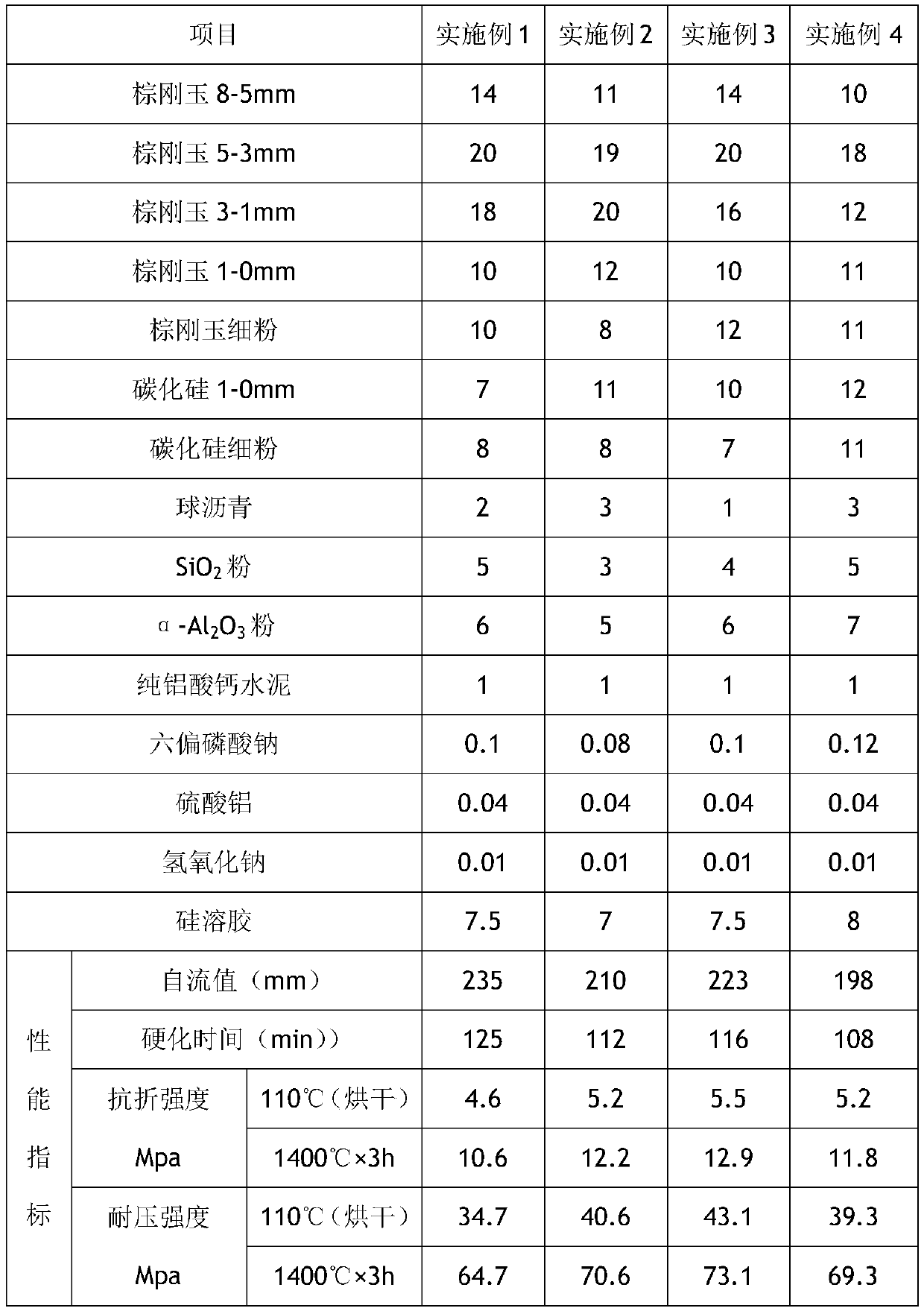

High-strength self-flow type explosionproof refractory castable

The invention relates to the field of refractory materials and specifically relates to high-strength self-flow type explosionproof refractory castable. The high-strength self-flow type explosionproofrefractory castable disclosed by the invention is prepared from the following ingredients in mass percent: 6% to 15% of brown fused alumina with the particle diameter as 0 to 1 mm, 10% to 20% of brownfused alumina with the particle diameter as 1 to 3 mm, 15% to 30% of brown fused alumina with the particle diameter as 3 to 5 mm, 5% to 10% of SiC particle with the particle diameter as 0 to 1 mm, 3%to 5% of SiO2 micropowder, 3% to 7% of SiC fine powder, 8% to 18% of white fused alumina powder, 3% to 6% of alpha-Al2O3 micropowder and 3% to 8% of pure calcium aluminate cement. According to the high-strength self-flow type explosionproof refractory castable disclosed by the invention, the brown fused alumina raw materials with different particle diameters are utilized as the main materials, sothat compact performance and compression strength are enhanced; furthermore, cost is reduced; by means of adding polypropylene fiber composite metal aluminum powder, oxidation resistance is achieved;meanwhile, toughness of the castable is enhanced, shock resistance and explosionproof performance are improved, and self-flow performance is better.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Joint refractory material for heat exchange of converter bottom and construction method

ActiveCN108439958ASatisfy the requirement of service life of 1000~2000 furnacesEnsure safe productionAlcoholRefractory

The invention discloses a joint refractory material for heat exchange of the converter bottom and a preparation method and a construction method of the joint refractory material. The joint refractorymaterial is prepared from a first constituent part and a second constituent part, wherein the first constituent part comprises following components in percentage by weight: 63wt%-85wt% of magnesia, 0-10wt% of asphalt, 0-10wt% of graphite and 2wt%-17wt% of metal powder; the second constituent part is prepared from resin accounting for 5wt%-15wt% of weight of the first constituent part, alcohol substances accounting for 5wt%-15wt% of weight of the first constituent part and a curing agent accounting for 0.5wt%-1.5wt% of weight of the first constituent part. The joint refractory material can meetthe requirement of 1000-2000 furnaces of service life when the converter bottom is replaced in new furnace campaign and medium term of furnace campaign and guarantees normal and safe production of aconverter.

Owner:SHOUGANG CORPORATION

Ladle brick cup hot repairing material and preparation method thereof

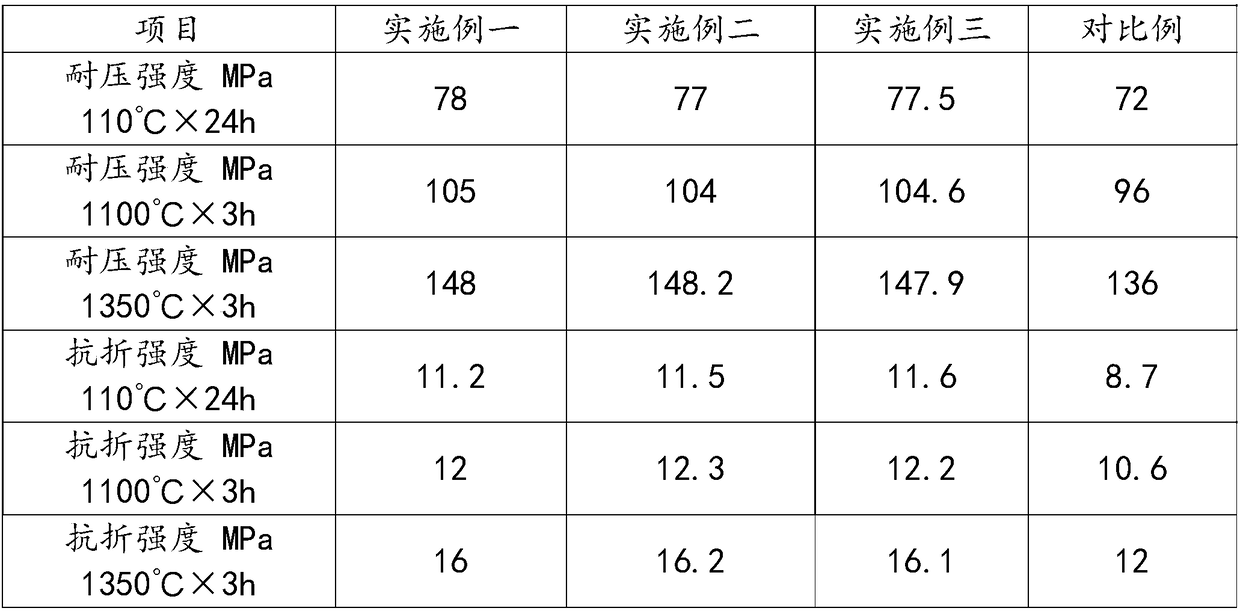

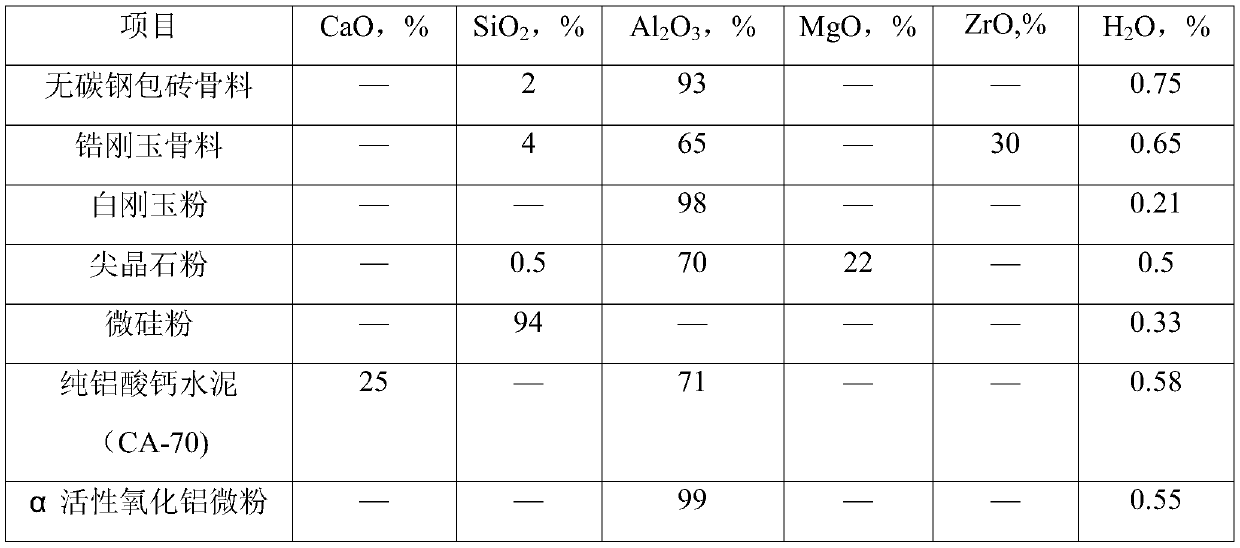

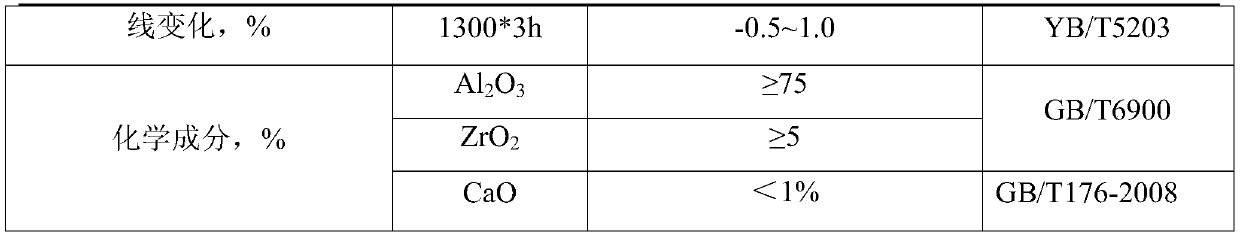

The invention belongs to the technical field of steelmaking ladle refractory materials, and particularly relates to a ladle brick cup hot repairing material and a preparation method thereof. The ladlebrick cup hot repairing material is provided to solve the problems that a ventilation seat and a nozzle brick cup are prone to being corroded and damaged and the service life is shorter than that ofother ladle brick cups. The ladle brick cup hot repairing material is prepared from 39-43 wt% of carbon-free ladle brick particles, 19-23 wt% of fused alumina zirconia particles, 15-20 wt% of white corundum powder, 8-10 wt% of fine spinel powder, 8-10 wt% of alpha-alumina micro-powder, 0.5-1 wt% of silicon dust powder, 2-3 wt% of pure calcium aluminate cement, 0.1 wt% of a high-efficiency water reducing agent and 0.05-0.1 wt% of an explosion-proof fiber. The hot repairing material has the advantages of good self-flowing performance, excellent sintering performance, small linear change rate, good air permeability, certain medium and high temperature breaking strength and slag corrosion resistance, can effectively solve the phenomenon that the service life of the steel ladle brick cup blockis inconsistent with the service life of refractory materials at other parts and reduce the minor repair frequency and the labor intensity of workers, and has great practical significance.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

Pit patching material for converter

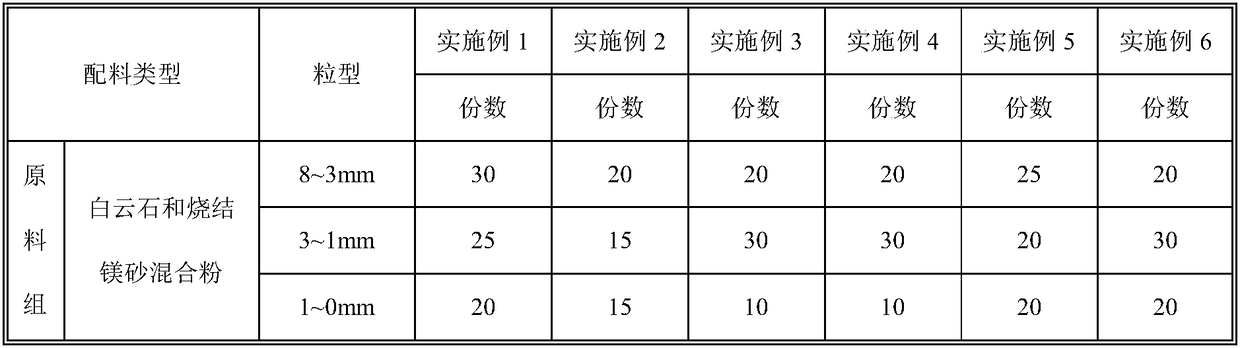

The invention relates to a pit patching material for a converter, wherein the pit patching material comprises the following raw materials by weight: 60-85 parts of the mixed powder of dolomite and sintered magnesia, 10-20 parts of modified asphalt, 2-5 parts of an additive, and 6-10 parts of a wetting agent, and a ratio of the dolomite to the sintered magnesia in the mixed powder is 1:(1-2). According to the present invention, the pit patching material has advantages of good self-flowing property, hot strength, corrosion resistance, thermal shock resistance and short hardening time so as to reduce the blowing-out maintenance time of the converter and improve the working efficiency; and the pit patching material and the converter working line are well adhered so as to prevent the pit patching material from peeling off during the use.

Owner:海城利尔麦格西塔材料有限公司

Environment-friendly water-based large fabric for converter fettling

The invention relates to an environment-friendly water-based large fabric for converter fettling. The fabric comprises the following components in parts by weight: 80-90 parts of magnesia, 6-10 partsof binding agent, 0.5-1 part of slaked lime and 0.5-1 part of bentonite. The preparation method comprises the steps: adding water into the supplementary material, stirring to form porridge, pouring the stirred material into a position needing to be repaired in the converter, burning for 15-25 minutes at 800-1350 DEG C, and finishing the repair when the supplementary material is large and the surface material turns red. Compared with a common converter large-area fettling material, the sintering time is shortened by about 30 minutes; during sintering, no smoke, no odor and no harmful volatile matter exist, and no harm is caused to human bodies and the environment; and during sintering, gunning operation can be carried out so that the steelmaking efficiency is improved.

Owner:鞍山赛诺新材料有限公司

Anti-cracking refractory castable for kiln and preparation method of anti-cracking refractory castable

The invention belongs to the field of refractory materials, and particularly relates to an anti-cracking refractory castable for a kiln and a preparation method of the anti-cracking refractory castable. The anti-cracking refractory castable for the kiln is prepared from the following raw materials in parts by weight: 30 to 50 parts of aluminum oxide ceramic whiskers, 5 to 10 parts of silicon carbide whiskers, 3 to 5 parts of aluminum carbide whiskers, 8 to 18 parts of silicon oxide whiskers, 4 to 6 parts of basalt fibers, 0.2 to 0.4 part of sodium tripolyphosphate, 1 to 2 parts of polydimethylsiloxane, 3 to 8 parts of aluminum silicate cement and 20 to 40 parts of deionized water. According to the anti-cracking refractory castable for the kiln, the refractory materials with different average diameters are adopted as main materials, the compression strength of the anti-cracking refractory castable for the kiln can be improved while the compactness is enhanced, the toughness of the castable is enhanced by adding the basalt fibers, and the shock resistance and the explosion-proof performance are improved.

Owner:成都欧乐启新材料科技有限公司

Repair material for steel ladle and preparation method thereof

The invention discloses a repair material for a steel ladle and a preparation method thereof, and relates to the repair material for the steel ladle. The repair material for the steel ladle is prepared from the following components in percentage by mass: 75 to 90 percent of corundum and / or alumina particles and fine powder, 0 to 5 percent of activated alumina micro-powder, 2 to 9 percent of magnesia, 1 to 4 percent of sepiolite and 0 to 5 percent of an additive; the preparation method of the repair material for the steel ladle comprises the following steps: weighing and bagging the corundum and / or alumina fine powder, the activated alumina micro-powder, fine magnesia powder, the sepiolite, silicon micro-powder and the additive according to the requirement of a formula; checking the weight,and adding the components into a material mixing machine; after the materials are mixed, fixing single weight, and bagging the materials for later use; adding a fine powder homogenizing material andfibrous sepiolite into a mixing machine according to the requirement of the formula; adding magnesia and corundum particles less than or equal to 1 mm, stirring, and then adding the corundum or alumina particles of 3 to 1 mm and 5 to 3 mm, stirring and discharging a material, and sealing and packaging a finished product by using plastics. The repair material can be directly used without adding water and stirring, has high construction performance, and is used for repairing refractory materials, such as a steel ladle breathable pocket brick, a nozzle pocket brick and a steel ladle brick, in a thermal state.

Owner:洛阳利尔功能材料有限公司

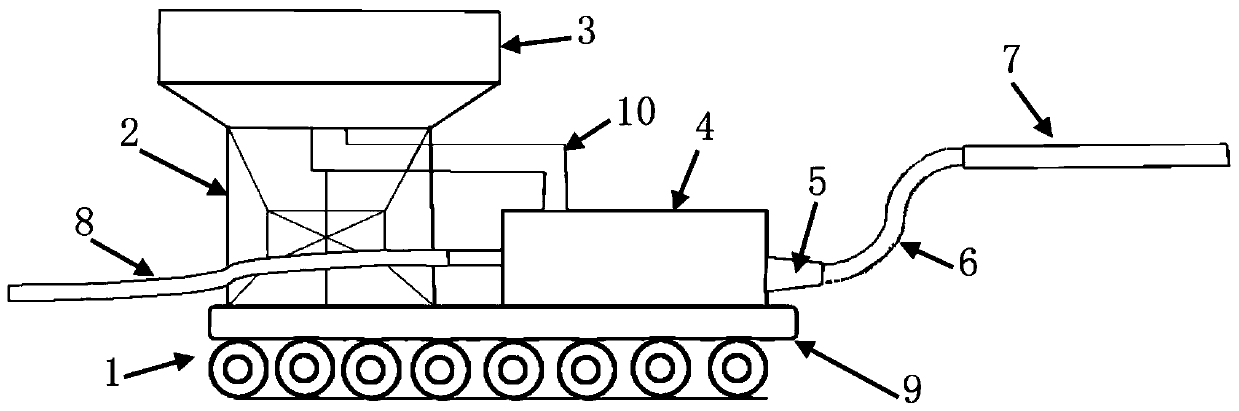

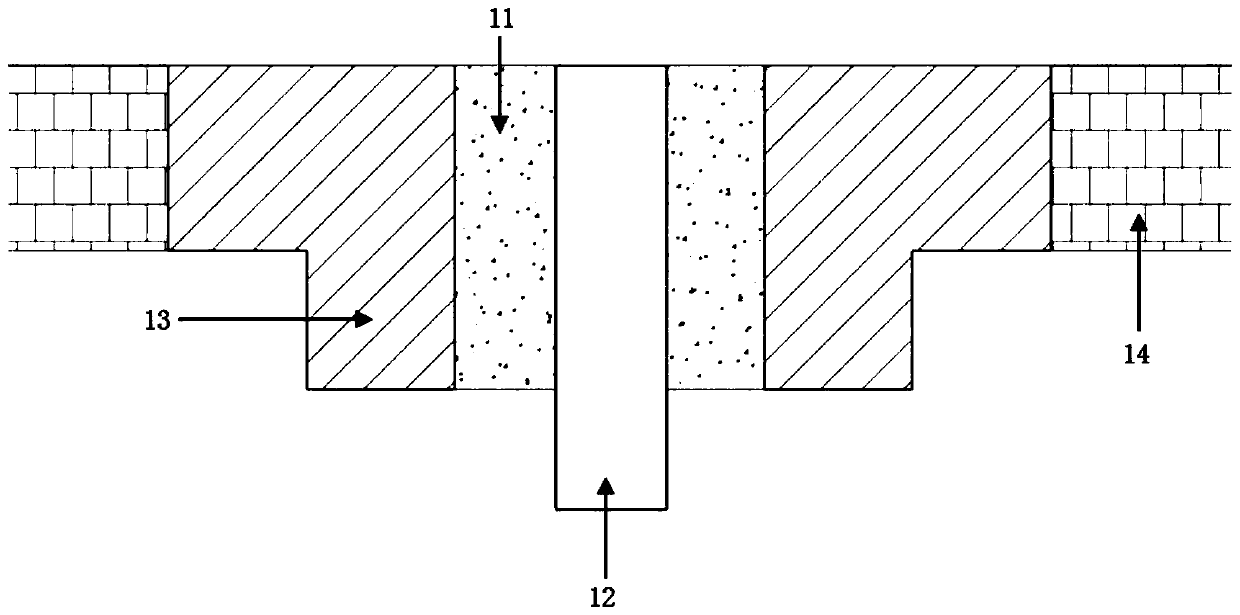

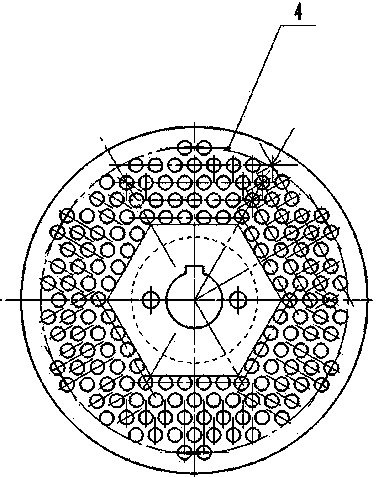

Converter steel-tapping hole pumping and casting repair equipment and casting repair method

The invention provides converter steel-tapping hole pumping and casting repair equipment and a casting repair method, and belongs to the technical fields of construction of fireresistant artesian casting material construction and equipment. The converter steel-tapping hole pumping and casting repair equipment is characterized in that a support frame is fixed to a delivery platform, wherein a material storing device is fixed to the support frame, and is connected with a feed opening of a pumping device through a conveying device, a discharge opening of the pumping device communicates with a heat insulating chute through a discharge pipe, and a material conveying device and the pumping device are both fixed to the delivery platform; and a high pressure gas source also communicates with the material conveying device through a high pressure gas pipe. Through hot-state artesian performance of a casting material, the casting material can be conveyed into a converter through a heat insulatingchute, and cast into tiny cracks between the periphery of casing pipe bricks and steel-tapping hole big bricks, and surplus heat of a backup lining brick is used for sintering. In the artesian process of the casting material, a liquid binder is added, wherein the casting machine is a magnesium artesian casting material, and main raw materials are sintered magnesia and fused magnesia. Efficient dispersing agents of explosion-proof fiber and polyocarboxy acid are added, and silicon dioxide micro powder, graphite or carbon black powder are compounded.

Owner:北京联合荣大工程材料股份有限公司

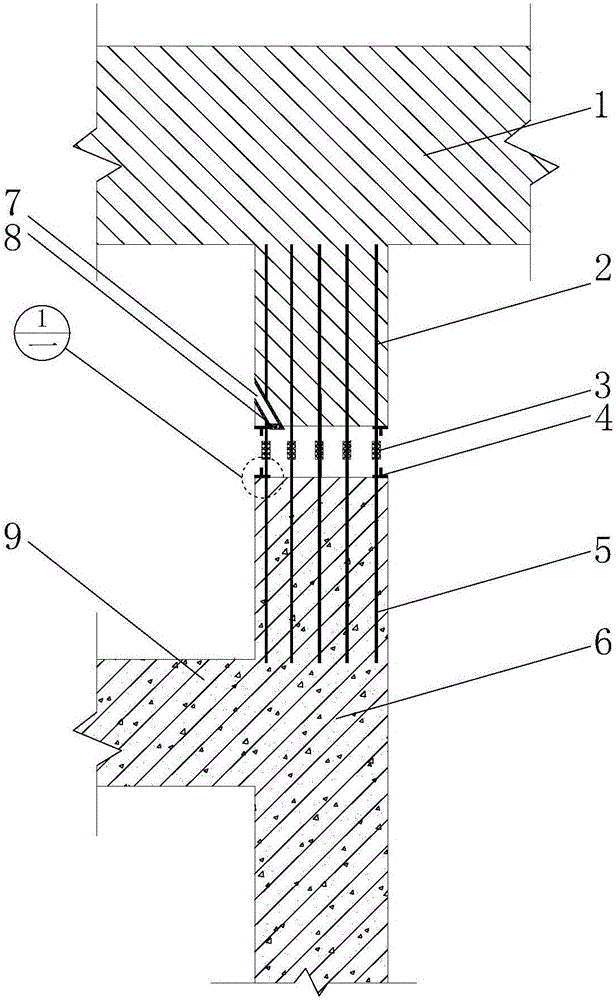

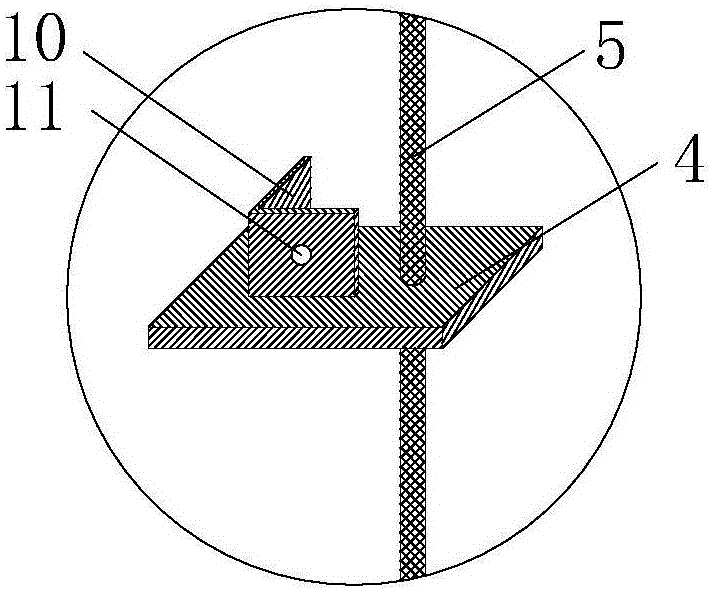

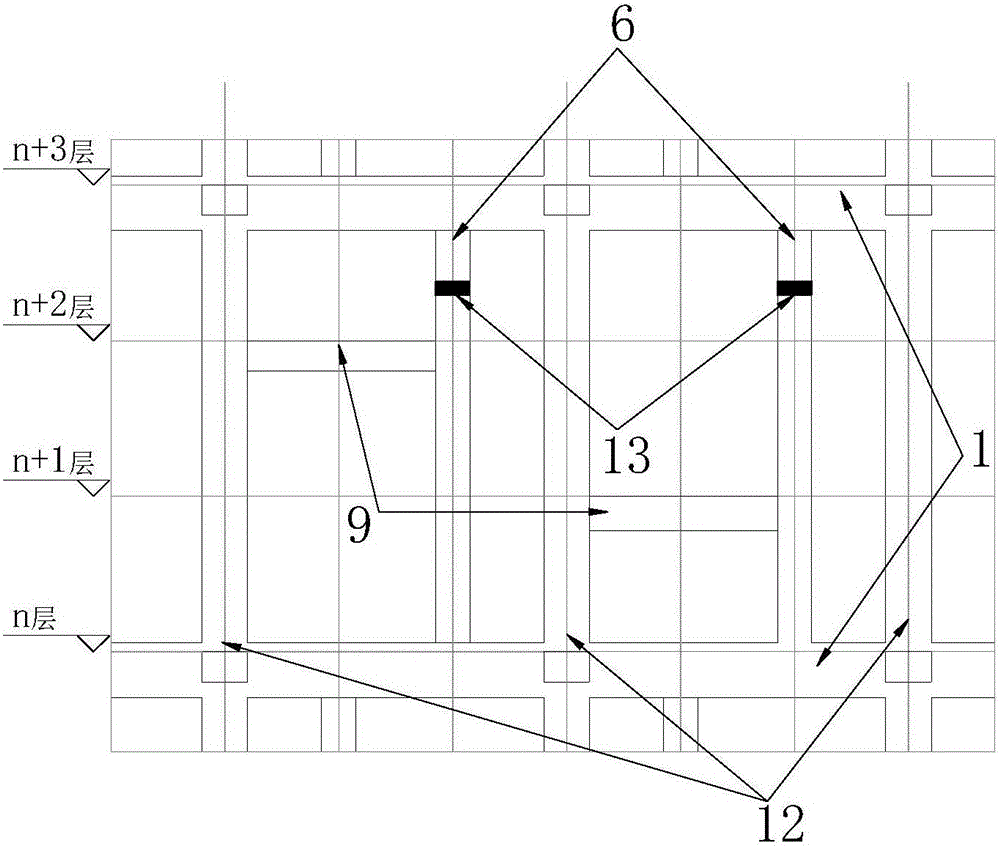

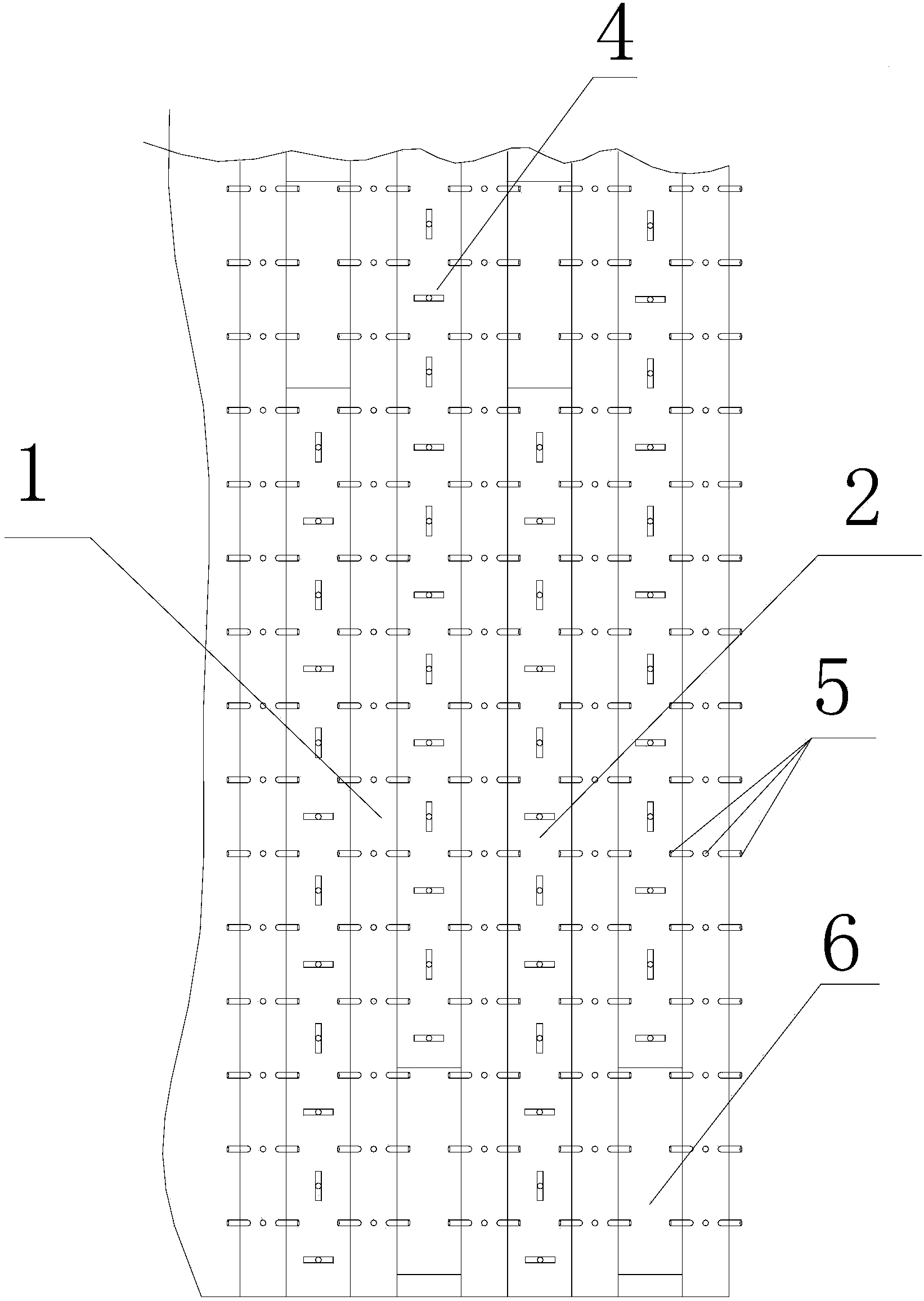

Sub-frame post-cast joint with external permanent aluminum plate outer mold

ActiveCN105951987AGood self-flowTightly boundForms/shuttering/falseworksBuilding reinforcementsRebar

The invention relates to a sub-frame post-cast joint with an external permanent aluminum plate outer mold. The sub-frame post-cast joint mainly comprises a sub-frame column, steel bar connection sleeves, aluminum plate connectors, an external aluminum plate, a prefabricated grouting material opening, a steel screen and connecting bolts. The post-cast joint is arranged on the sub-frame column to separate the sub-frame column into two parts. The aluminum plate connectors are welded to the upper reinforcing steel bars and the lower reinforcing steel bars of the sub-frame column, and the upper reinforcing steel bars and the lower reinforcing steel bars are connected through the steel bar connection sleeves. The prefabricated grouting material opening is welded in one upper reinforcing steel bar of the sub-frame column. The external aluminum plate is fixedly connected with the aluminum plate connectors through the connecting bolts and self-fixed in an enclosed manner through anchoring screws. Grouting material fills the space formed by the external aluminum plate and the steel screen in an enclosed manner. A leveling concrete layer is arranged outside the external aluminum plate. The sub-frame post-cast joint has the advantages that a main structure and a sub-structure are completely disconnected first to allow the main frame to subside sufficiently and allow a sub-frame to be unstressed, and structure safety is guaranteed. The invention further provides a construction method of the sub-frame post-cast joint.

Owner:浙江新曙光建设有限公司

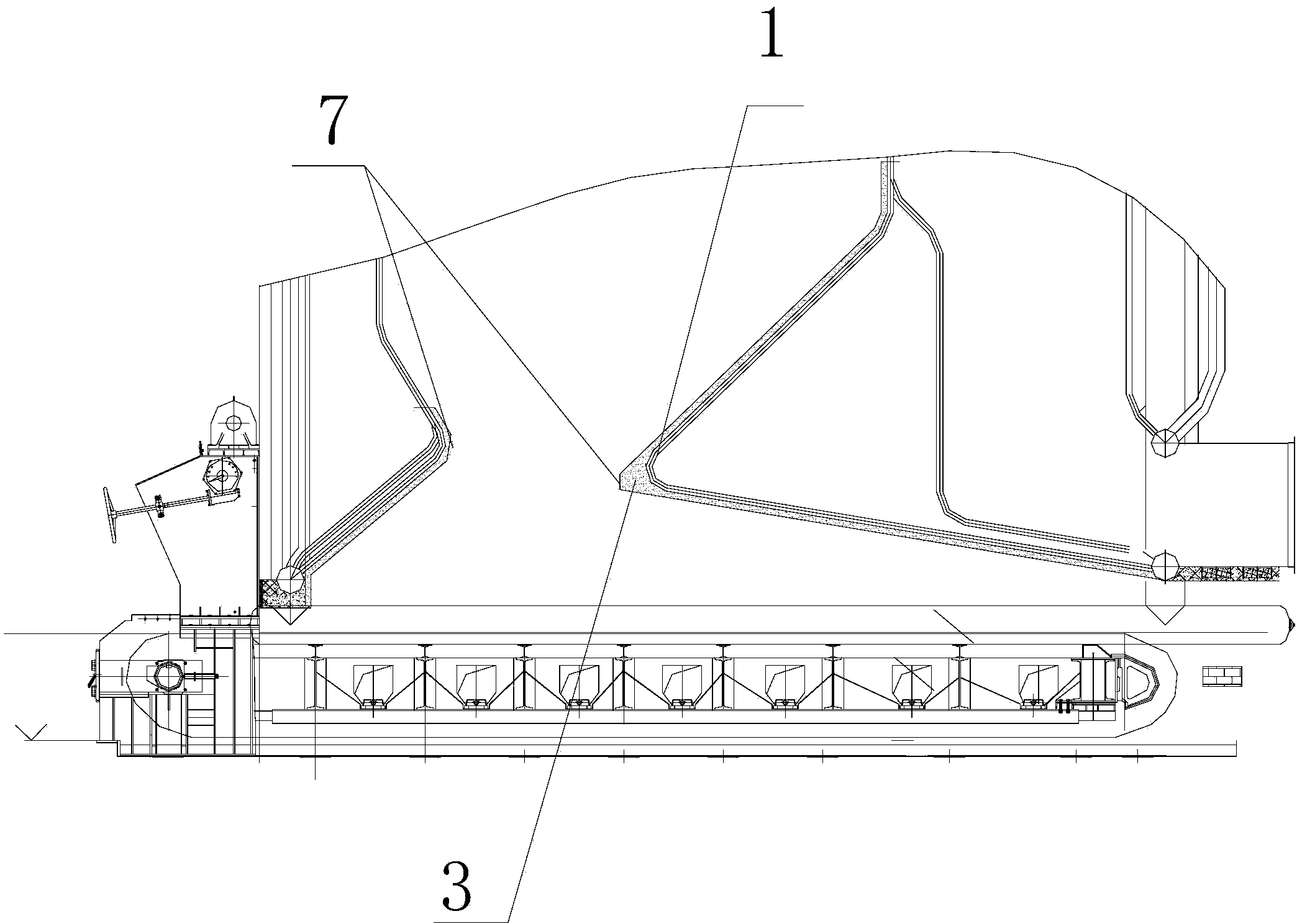

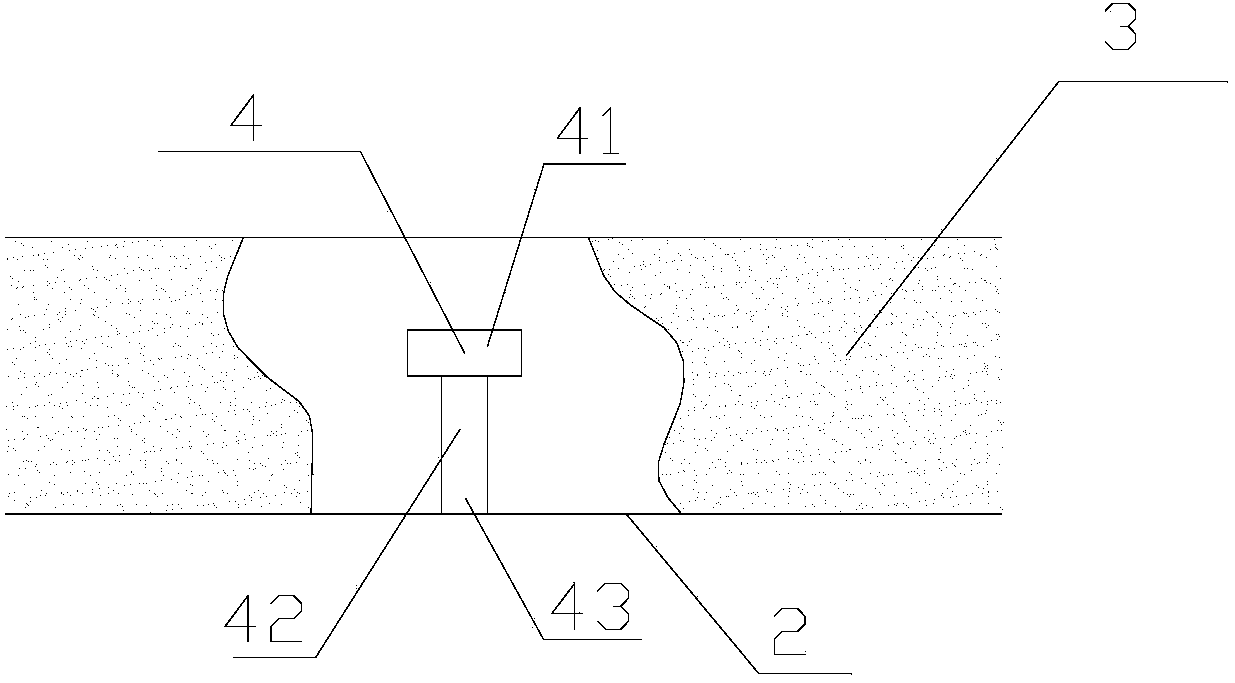

Membrane wall type front-rear arch for large-sized coal-fired boiler

The invention discloses a membrane wall type front-rear arch for a large-sized coal-fired boiler, which comprises a plurality of boiler front-rear arch tube bundles; two adjacent tube bundles are fixedly connected through a steel plate; sides, close to the boiler furnace, of the tube bundles and the steel plates are covered with casting layers; a plurality of T-shaped dowels are arranged in the casting layers; the T-shaped dowels comprise nail heads and nail caps; the nail heads are fixedly connected onto the steel plates. The front-rear arch can prevent the casting layers from irregular fracturing and falling at a high temperature effectively, and can improve the thermal efficiency of the boiler.

Owner:BEIJING YINGXIANG BORI REFRACTORIES TECH CO LTD

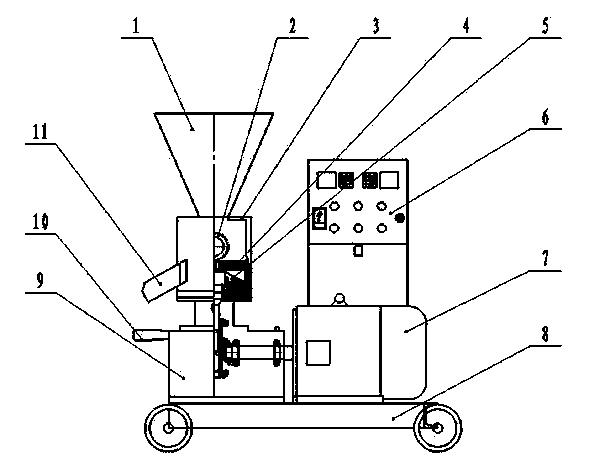

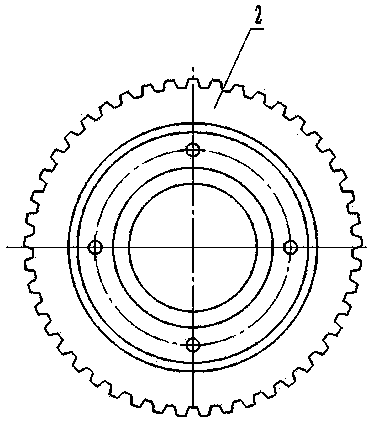

Biomass particle fuel forming machine

The invention relates to a biomass particle fuel forming machine and belongs to the technical field of biomass energy forming equipment. The biomass particle fuel forming machine comprises a press roll 2 and a flat die 4. A pyramid type roll block 12 is formed on the surface of the press roll 2. The flat die 4 is provided with a die hole wedge feed area 13 and a shape keeping section 14. The biomass particle fuel forming machine has the advantages that the flat die can be used forwardly and reversely, service life of the flat is prolonged, the pyramid type roll block disposed on the surface of the press roll increases frictional force, extrusion feed is achieved effectively, production cost is lowered effectively, the biomass particle fuel forming machine is simple in structure, small in floor space, low in noise and dual-power, and the formed particles are high in hardness, smooth in surface, and good in self-flowability.

Owner:武乡县小金牛微型耕作机有限责任公司

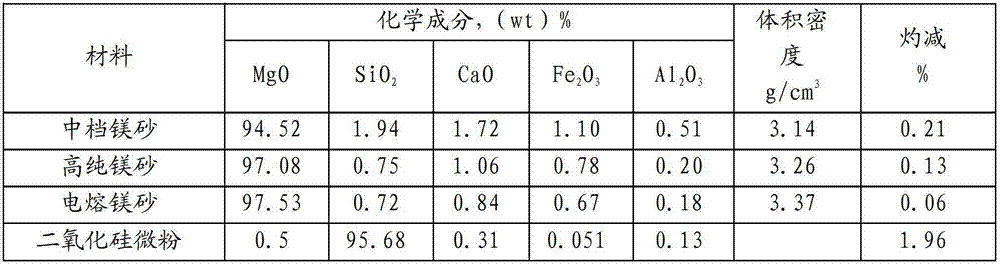

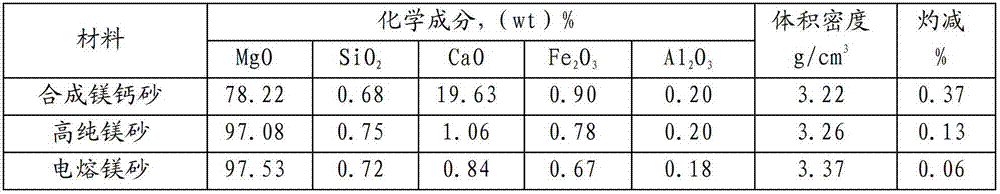

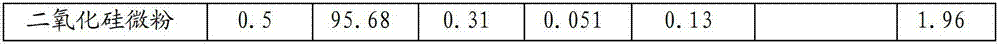

Large-area self-flow material for water-based revolving furnace and preparation method thereof

The invention relates to a large-area self-flow material for a water-based revolving furnace and a preparation method thereof. The large-area self-flow material comprises the following components in parts by weight: 60-88 parts of magnesium oxide MgO, 6-18 parts of silicon dioxide SiO2, 0.5-15 parts of calcium oxide CaO, 0-0.5 part of a retarding agent and 0.1-0.5 part of a water reducing agent, wherein a liquid bonding agent is increased by 5-6 parts by weight during stirring; and the flow value (self-flow) is 240-320 millimeters. The preparation method comprises the following steps of: adding sodium citrate, sodium tartrate, boric acid and the like into magnesite, forsterite, synthetic magnesium-calcium sand, dolomite and silicon fine powder serving as major raw materials, and premixing uniformly to form a scattered dry uniform aggregate; before use, adding 5-6 percent of liquid bonding agent; stirring into a fluid plastic state by using a forced stirrer; loading into a hopper for putting into a furnace; and rapidly shaking a furnace body till a material flows to positions required to be repaired naturally, wherein the sintering time is 15 minutes per 1-2 tons of materials.

Owner:北京联合荣大工程材料股份有限公司

Single-iron notch blast furnace main channel self-flow repairing material

Owner:CHANGXING MINGTIAN FURNACE CHARGE

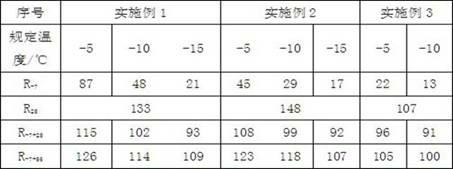

dry grout

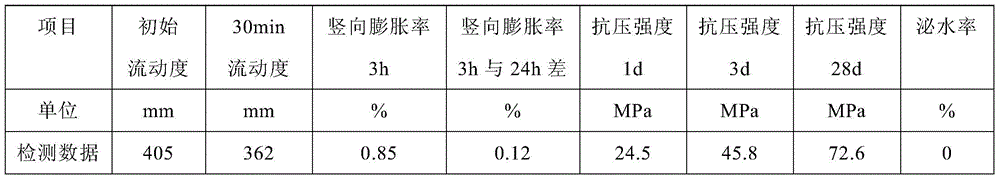

The invention relates to a dry grouting material, which comprises the following components: 300-400 parts by weight of Portland cement, 5-10 parts by weight of aluminate cement, 500-600 parts by weight of quartz sand, CSA expansion The agent is 5-8 parts by weight, the lithium carbonate is 0.05-0.10 parts by weight, the calcium formate is 0.5-1.0 parts by weight, and the polycarboxylate superplasticizer is 1-2 parts by weight. The dry grouting material of the present invention is easy to operate, and only needs to be added with water and stirred evenly at the construction site. It has good fluidity, high strength, good early strength performance, and is non-corrosive to steel bars.

Owner:NANJING SUBAO ENERGY SAVING TECH

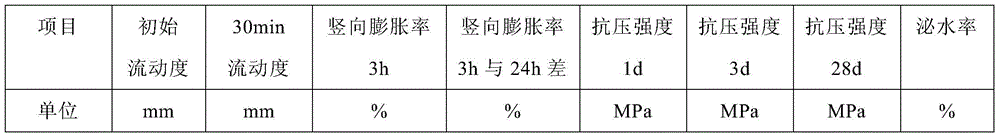

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

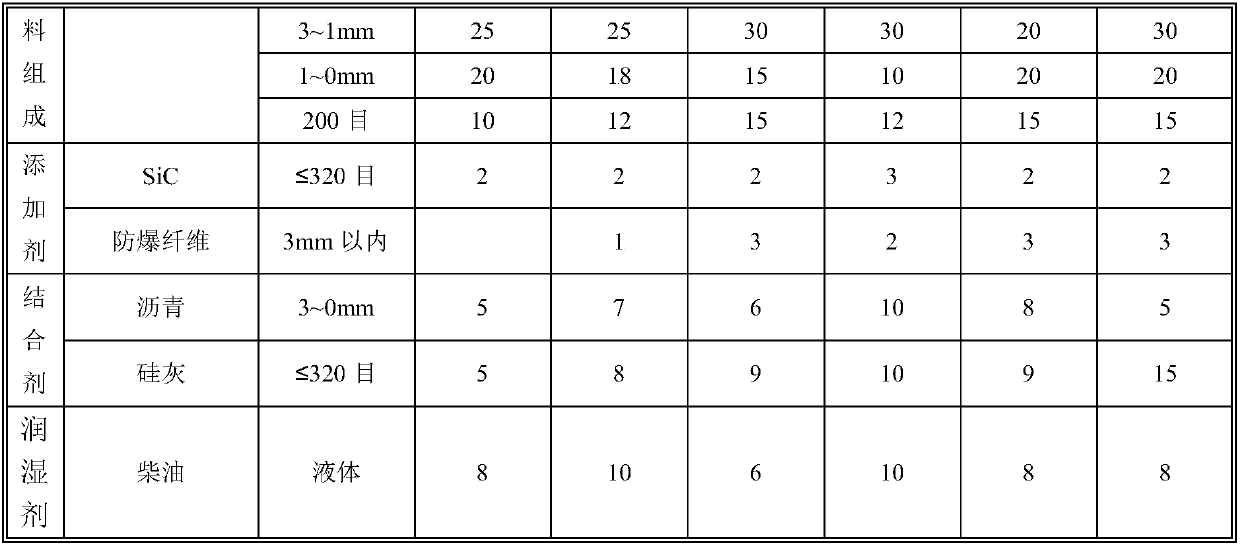

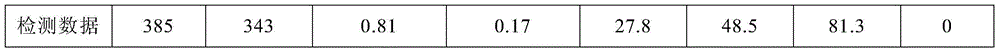

High-density high-strength alumina self-flow castable

ActiveCN102126867BContinuous and reasonable particle size distributionReduce the amount of water addedAluminateHigh density

The invention provides a high-density high-strength alumina self-flow castable. The alumina self-flow castable with good fluidity, high density, high strength and high refractoriness is prepared from alumina raw material, alpha-Al2O3 micro powder, aluminate cement and other external additives by reasonably mixing the raw materials with different size fractions according to the theory of granularity, especially by optimizing the size fraction proportion and addition amounts of medium and small particles (less than or equal to 3mm) and substrate fine powder.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Bismuth reverberatory retaining wall castable for smelting

The invention belongs to the technical field of refractory materials, and in particular relates to a bismuth reverberatory retaining wall castable for smelting. The bismuth reverberatory retaining wall castable for smelting is prepared from the following raw materials in parts by weight: 50 to 60 parts of a first component and 40 to 50 parts of a second component, wherein the first component is prepared from the following raw materials in parts by weight: 34 to 42 parts of spinel, 15 to 23 parts of aluminum metal, 17 to 21 parts of silicon metal, and 38 to 40 parts of pink fused alumina; the second component is prepared from the following raw materials in parts by weight: 15 to 25 parts of a suspending agent and 75 to 85 parts of a binder. The bismuth reverberatory retaining wall castablefor smelting is resistant to high temperature and corrosion, long in service life, and environmentally friendly.

Owner:HENAN HUAXI FURNACE REFRACTORY

Micro-steel pipe pile and grouting reinforcement method

ActiveCN106013098BGuaranteed StrengthGood self-flowBulkheads/pilesSoil preservationCement pasteUltimate tensile strength

The invention provides a miniature steel pipe pile and a grouting reinforcement method. The miniature steel pipe pile comprises a steel pipe pile body; a pile tip sealing plate is connected to the lowermost end of the steel pipe pile body and provided with a grout discharge hole communicating with the inner side of the steel pipe pile body and a soil layer on the periphery of a pile tip; reinforcement treatment is conducted on a soil layer under the pile tip through two times of grouting; the characteristics of being good in automatic flow performance, quick in hardening, early in strengthening, free of shrinkage, slight in expansion and the like of grouting materials are utilized, the bearing capacity of a foundation can be improved quickly and effectively, and accordingly the bearing capacity of the pile tip is improved; and mixing of cement paste and the grouting materials is effectively prevented through a rubber plug in an inverted circular truncated cone shape, and the strength of the grouting materials at the pile tip is ensured.

Owner:HUAIHAI INST OF TECH

A joint refractory material and construction method for heat replacement of converter bottom

ActiveCN108439958BSatisfy the requirement of service life of 1000~2000 furnacesEnsure safe productionRefractoryProcess engineering

The invention discloses a joint refractory material for heat replacement of the furnace bottom of a converter, a configuration method and a construction method thereof. Wherein, the joint refractory material is configured by a first component and a second component, and the first component by weight percentage is: magnesia 63-85wt%, asphalt 3-10wt%, graphite 4-10wt% %, metal powder 2-17wt%; the second component includes 5-15wt% resin, 5-15wt% alcohol and 0.5-1.5wt% curing agent based on the weight of the first component. The invention can meet the requirements of the life span of 1000-2000 furnaces when the bottom of the converter is replaced in the new furnace service or in the mid-term of the furnace service, and ensures the normal and safe production of the converter.

Owner:SHOUGANG CORPORATION

Al2O3-SiO2-SiC-based jet material for foundry ladle

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Owner:BAOSHAN IRON & STEEL CO LTD

Rapid-hardening blast furnace hearth repair material and preparation method thereof

The invention discloses a rapidly-hardened blast furnace hearth repair material, which comprises a solid material, an admixture and a binding agent, wherein the solid material contains corundum particles and / or fine powder, silicon carbide particles and / or fine powder, a carbon additive and composite superfine powder, and the admixture includes a dispersant and a coagulation accelerator. The invention further discloses a preparation method of the rapidly-hardened blast furnace hearth repair material. The repair material belongs to a downgrade flow type and rapidly-hardened type, can be pumped and poured by clinging to a hearth carbon brick formwork, a pouring body and carbon bricks are closely attached, the construction is rapid and simple and convenient, the repair material is rapidly hardened, the construction period can be effectively shortened by 25%, the structure integrity of the repaired hearth is good, no brick joint exists, and the compactness is high.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Reinforcement grouting material

The invention provides a reinforcement grouting material which comprises the following raw materials in parts by mass: 500-600 parts of sulphate aluminum cement, 20-45 parts of mineral powder, 20-50 parts of silica fume, 50-80 parts of expanding agent, 250-350 parts of quartz sand, 4-6 parts of polycarboxylic acid early-strength type water reducer, 2-5 parts of tartaric acid, 0.5-2.5 parts of basalt fiber, 1-3 parts of defoaming agent and 0.5-2 parts of lithium carbonate.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

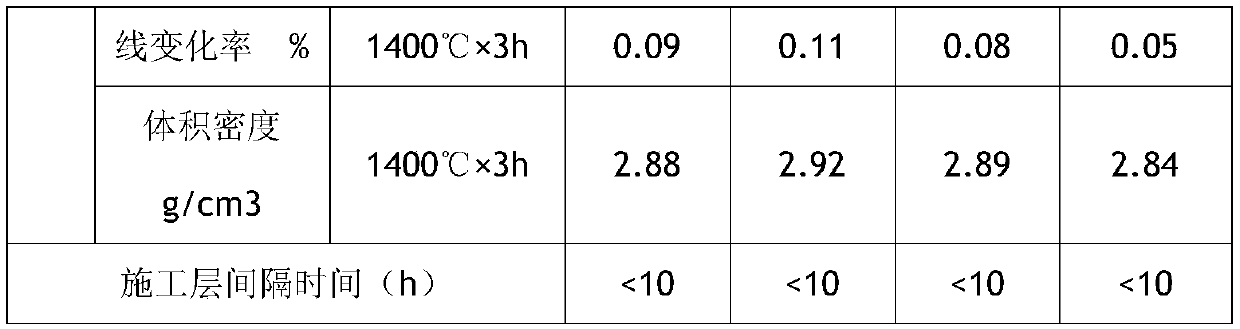

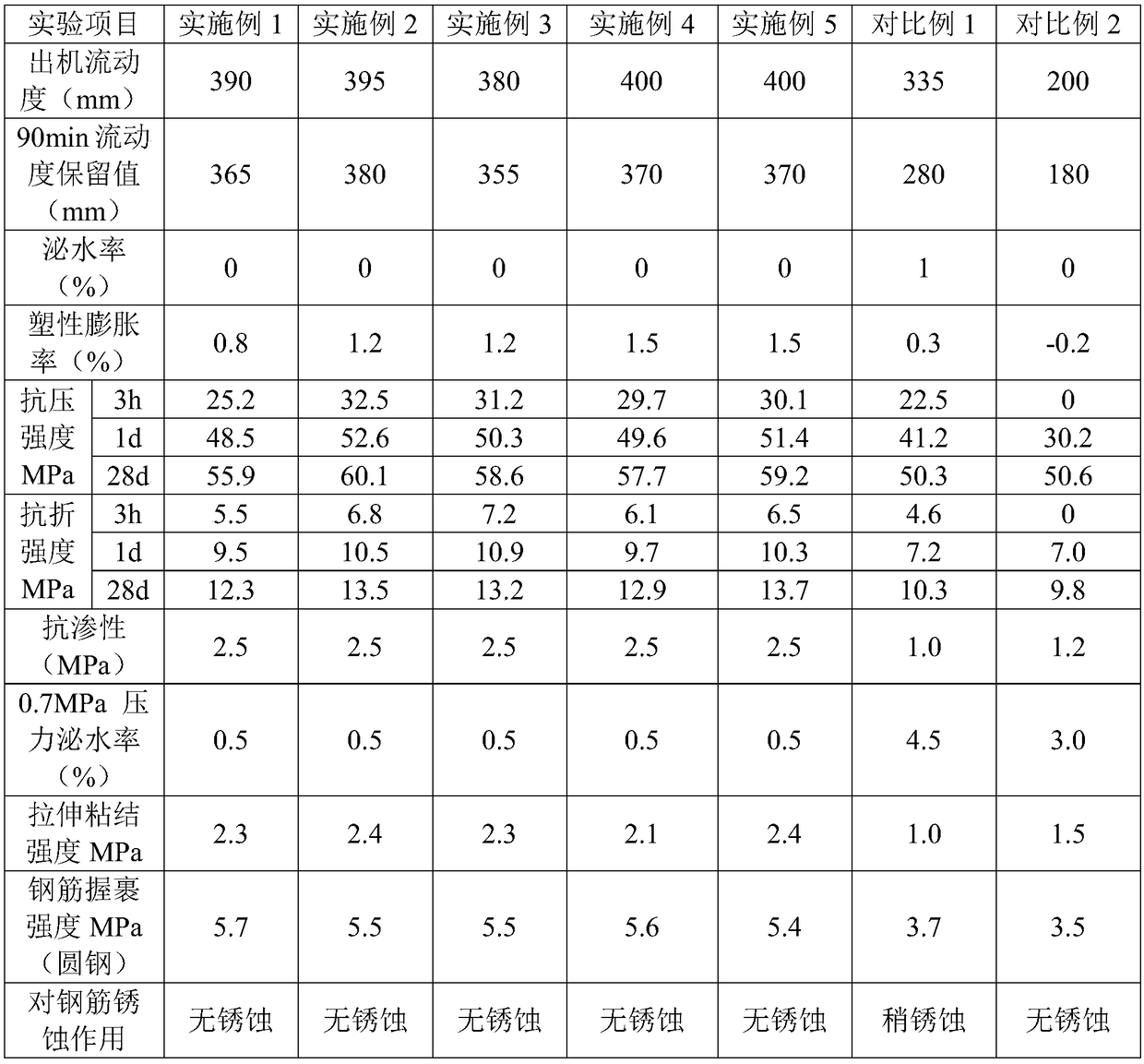

A kind of high-throw steel pipe self-compacting concrete and preparation process thereof

ActiveCN113277799BGood self-flowImprove liquiditySolid waste managementSlagArchitectural engineering

The application relates to the technical field of concrete, and specifically discloses a high-throw steel pipe self-compacting concrete and a preparation process thereof. The high-throw steel pipe self-compacting concrete is mainly composed of the following raw materials by weight: 750-900 parts of coarse aggregate, 700-850 parts of fine aggregate, 350-450 parts of cement, 50-80 parts of fly ash, and 90- parts of slag powder 120 parts, 150-170 parts of water, 6-10 parts of water reducing agent, 35-45 parts of swelling agent, 20-35 parts of modifier; modifier includes N-2-(aminoethyl)-3-aminopropyl trimethoxysilane, and expansion agents include light-burned magnesium oxide. The high-throw steel pipe self-compacting concrete of the present application can be used for construction of high-rise buildings, bridges, etc., and has the advantages of good fluidity and few micro-cracks.

Owner:北京建工一建工程建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com