Biomass particle fuel forming machine

A biomass pellet and molding machine technology, which is used in material molding presses, presses, manufacturing tools, etc., can solve the problems of short service life, inability to achieve extruded materials, and great influence on output and pellet quality. Reduce production cost, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

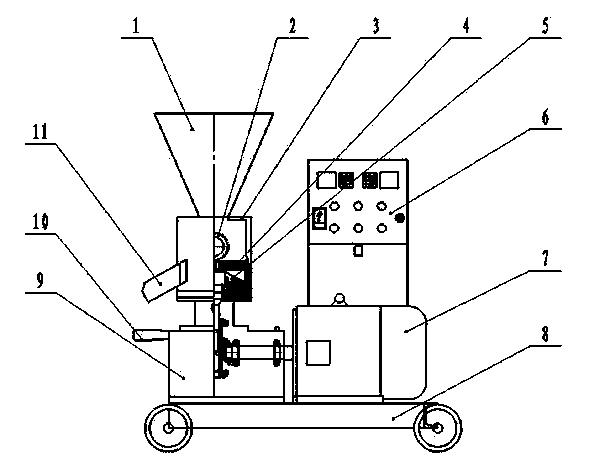

[0016] Such as figure 1 As shown, it is a schematic diagram of the overall structure of this embodiment, including a frame 8, a motor 7 is installed on the frame 8, an electric control cabinet 6 is installed on the motor 7, the motor 7 is connected with the gearbox 9, and the speed change pull rod 10 is located at the speed change On the box 9, a hopper 1 is provided above the pressing roller 2, and the flat die 4 is self-locked and positioned at the bottom of the material chamber 3, and the pressing roller 2 is installed above the flat die 4, and a discharge tray 5 is provided below the flat die 4. A material outlet 11 is provided below the material chamber 3 .

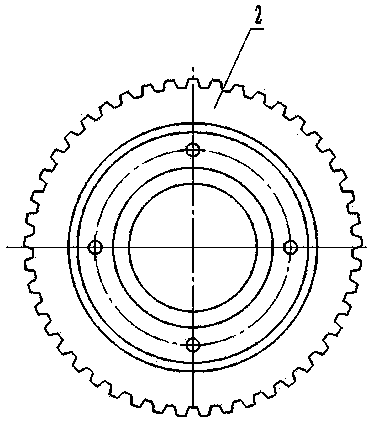

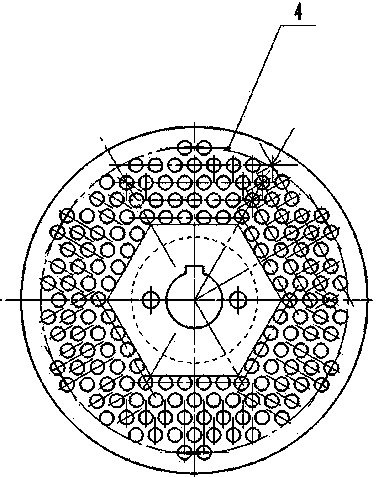

[0017] Such as figure 2 and image 3 As shown, it is a front view and a top view of the pressing roller of this embodiment, and the pressing roller 2 is provided with a pyramid-shaped rolling block 12, which can increase the friction force and realize extrusion feeding more effectively.

[0018] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com