Patents

Literature

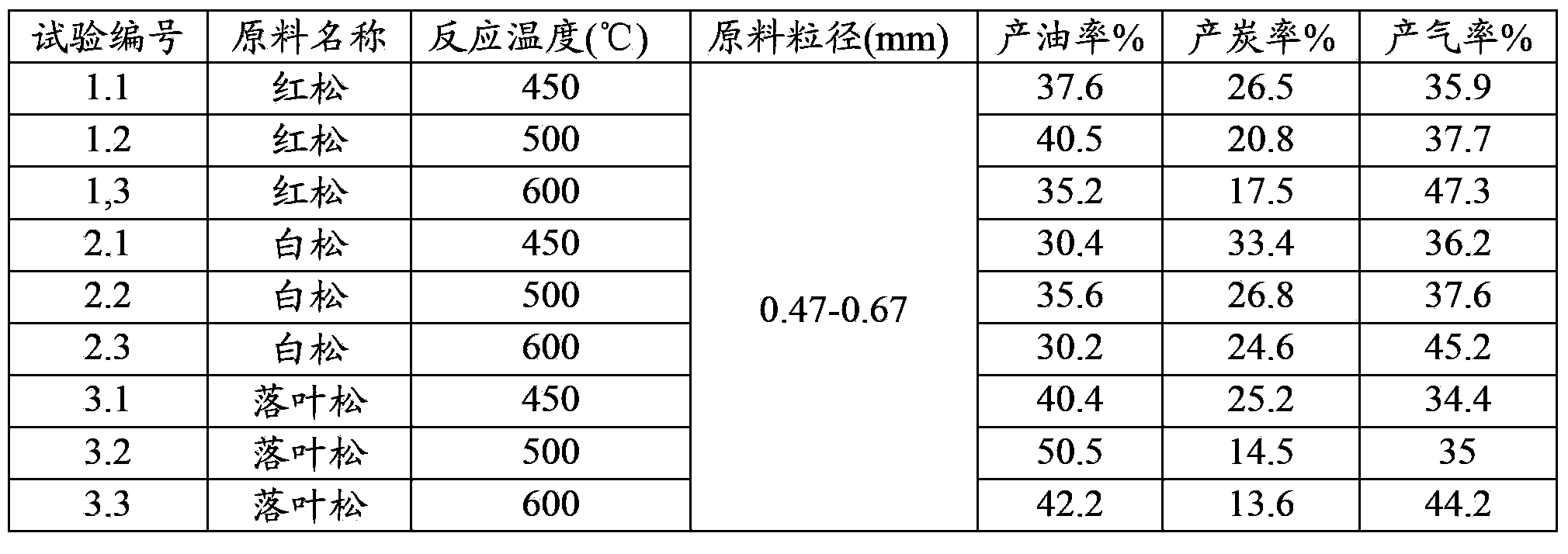

1788 results about "Biomass particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

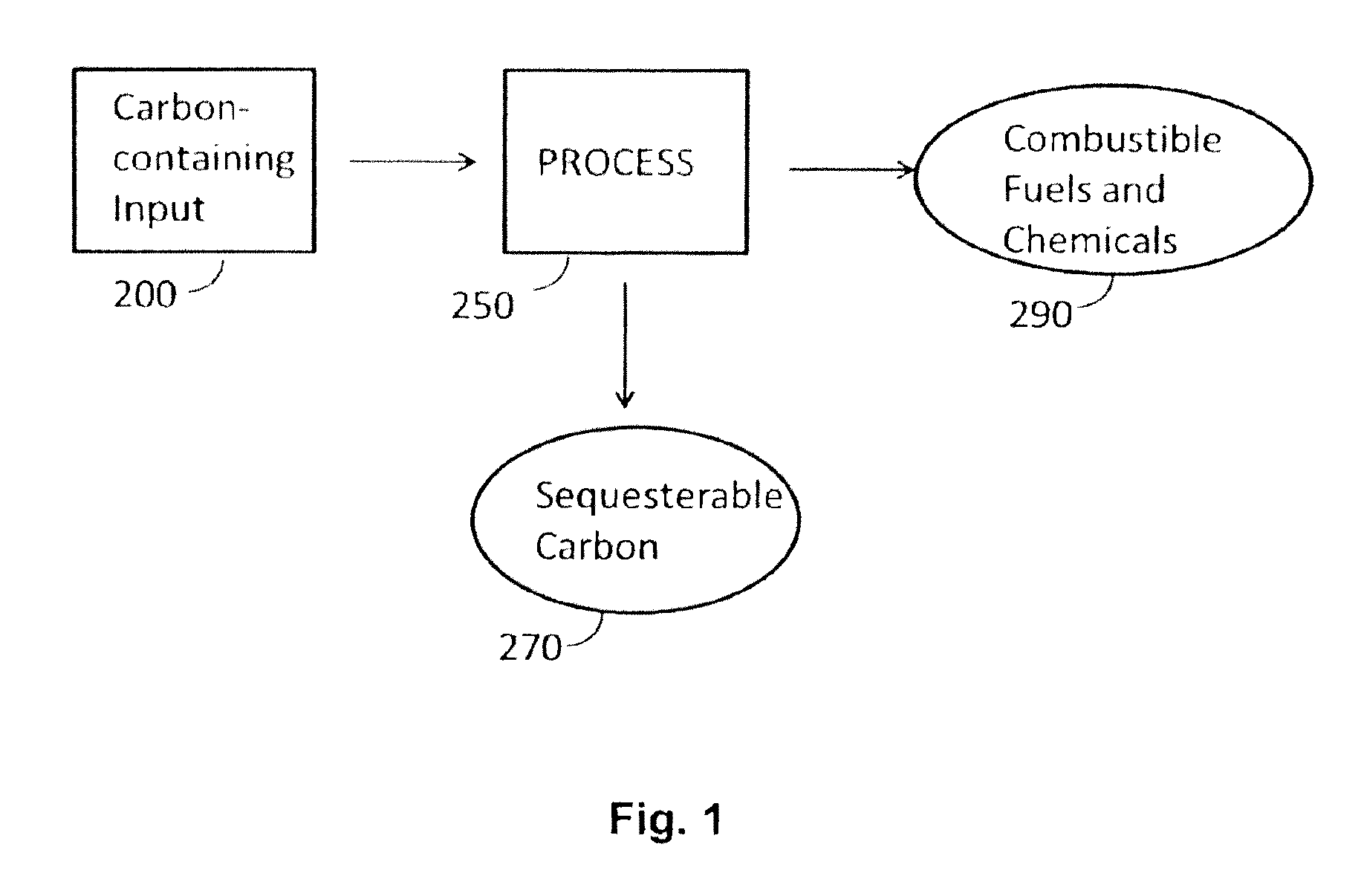

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

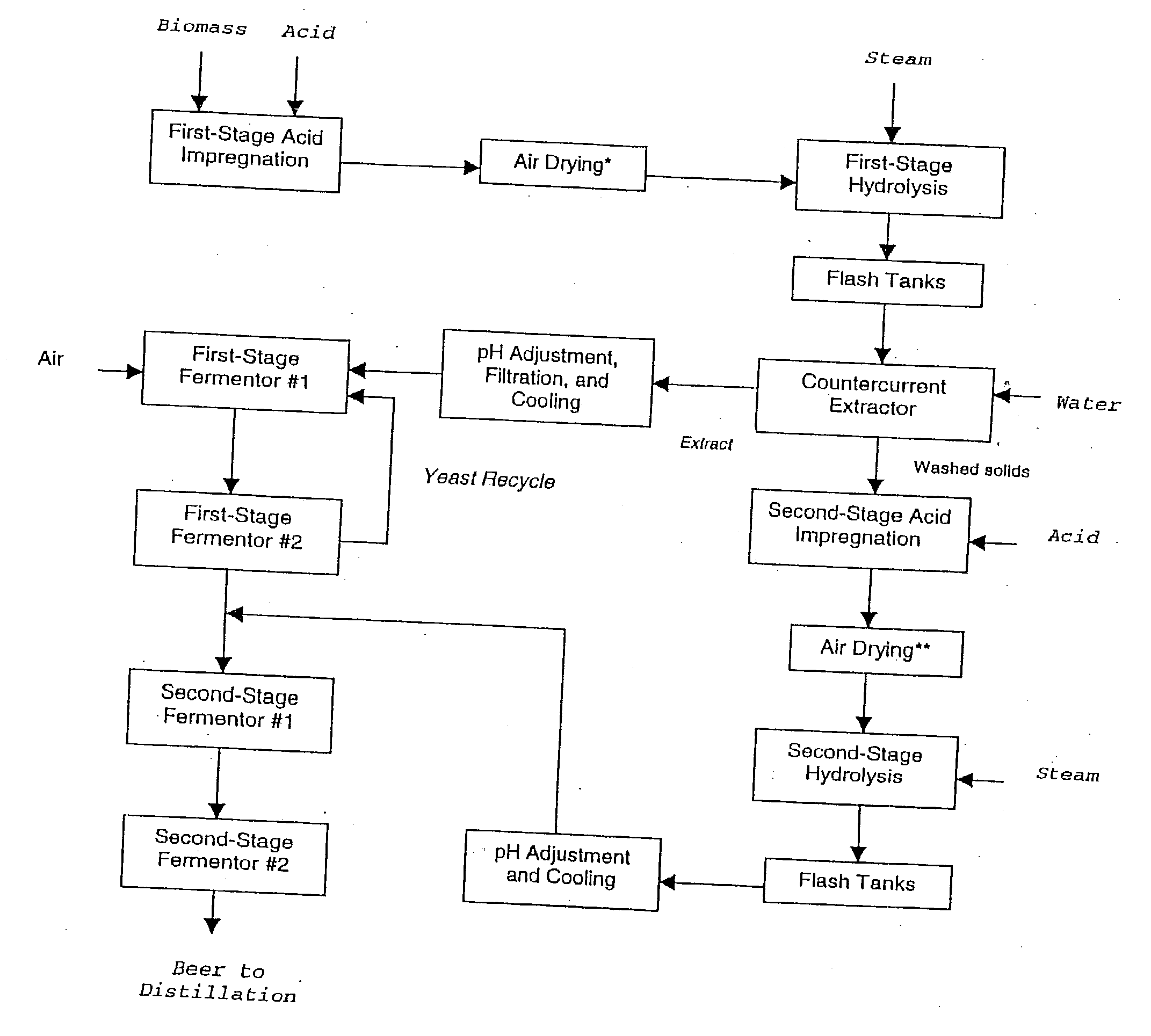

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

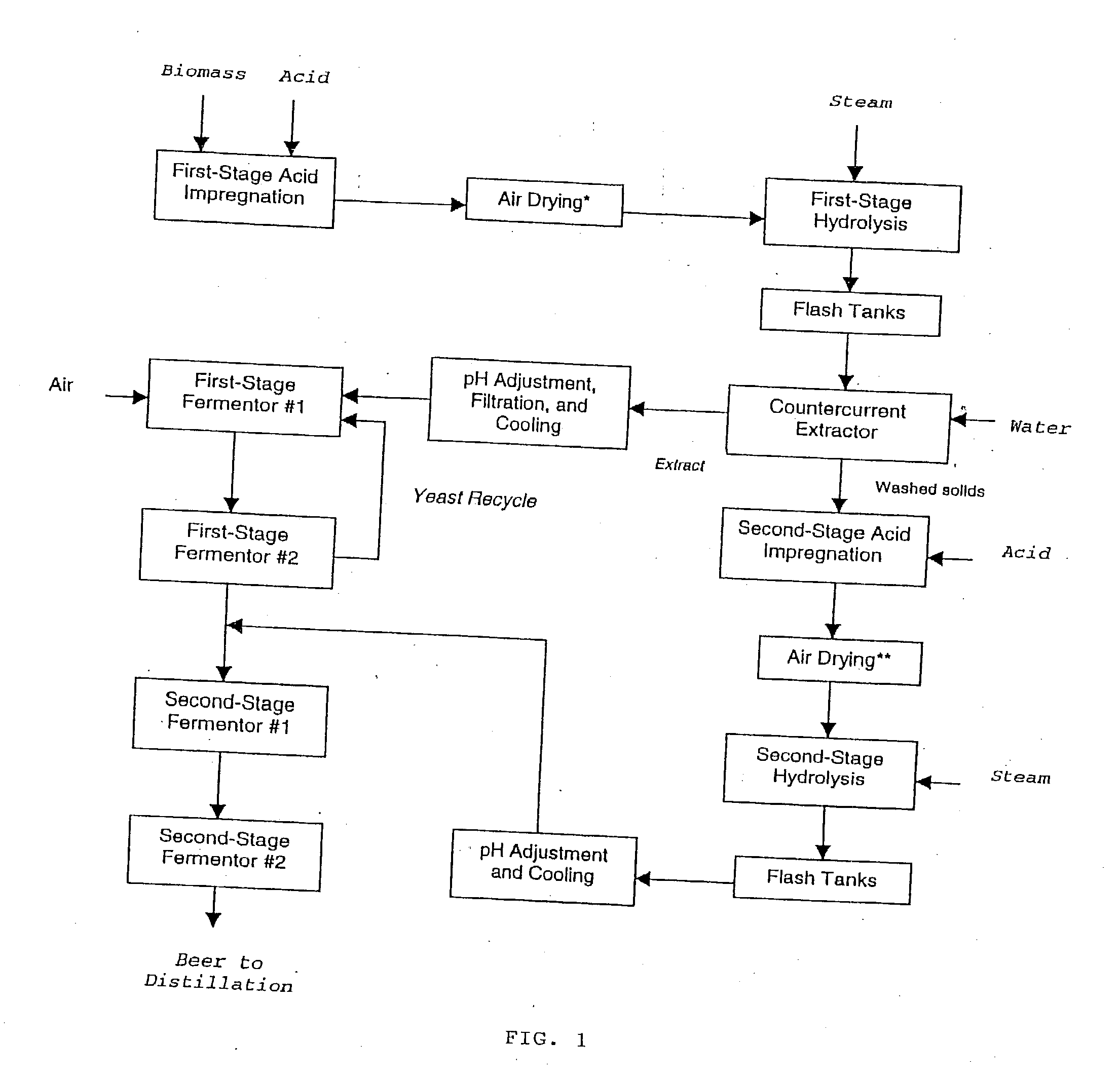

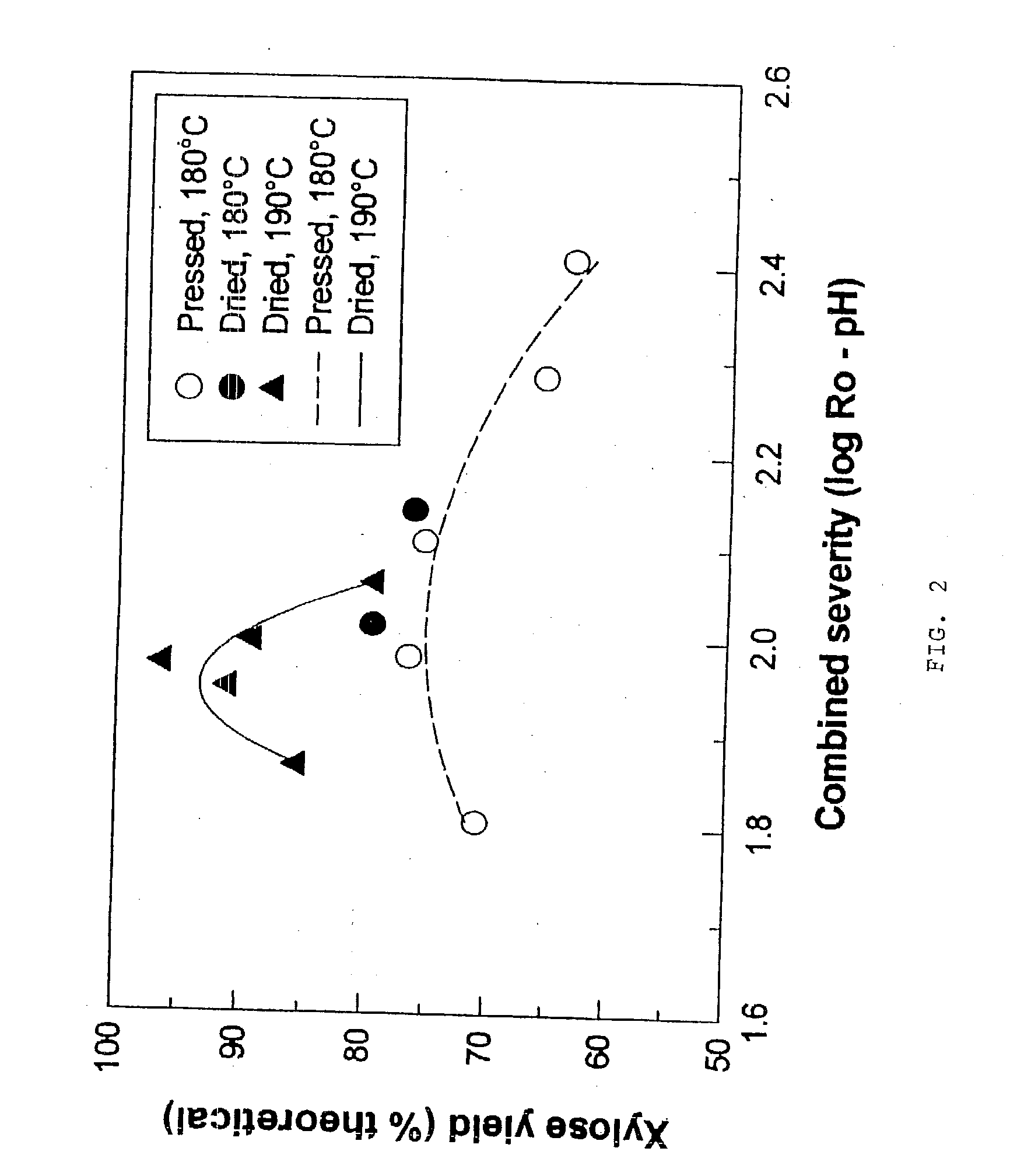

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

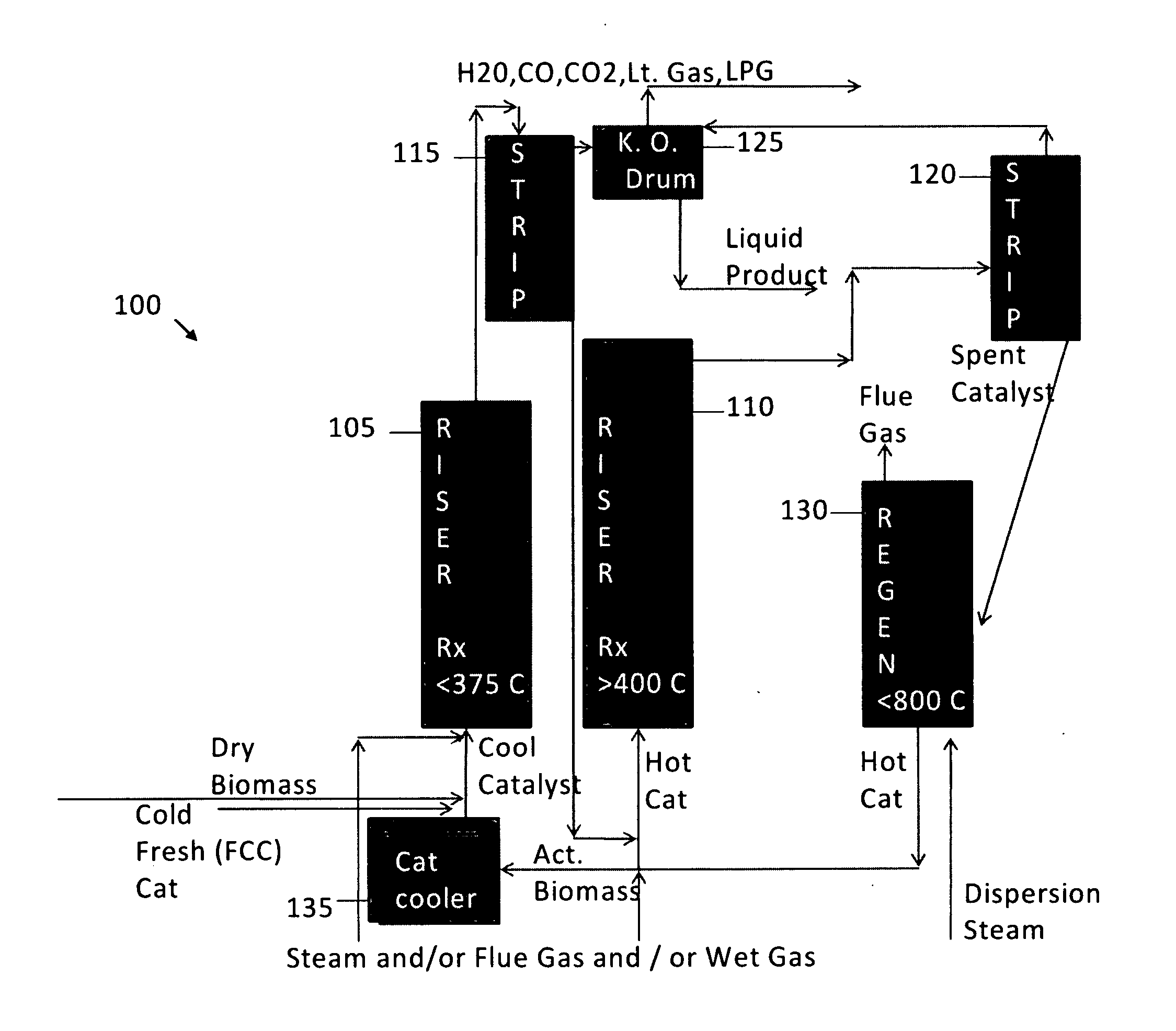

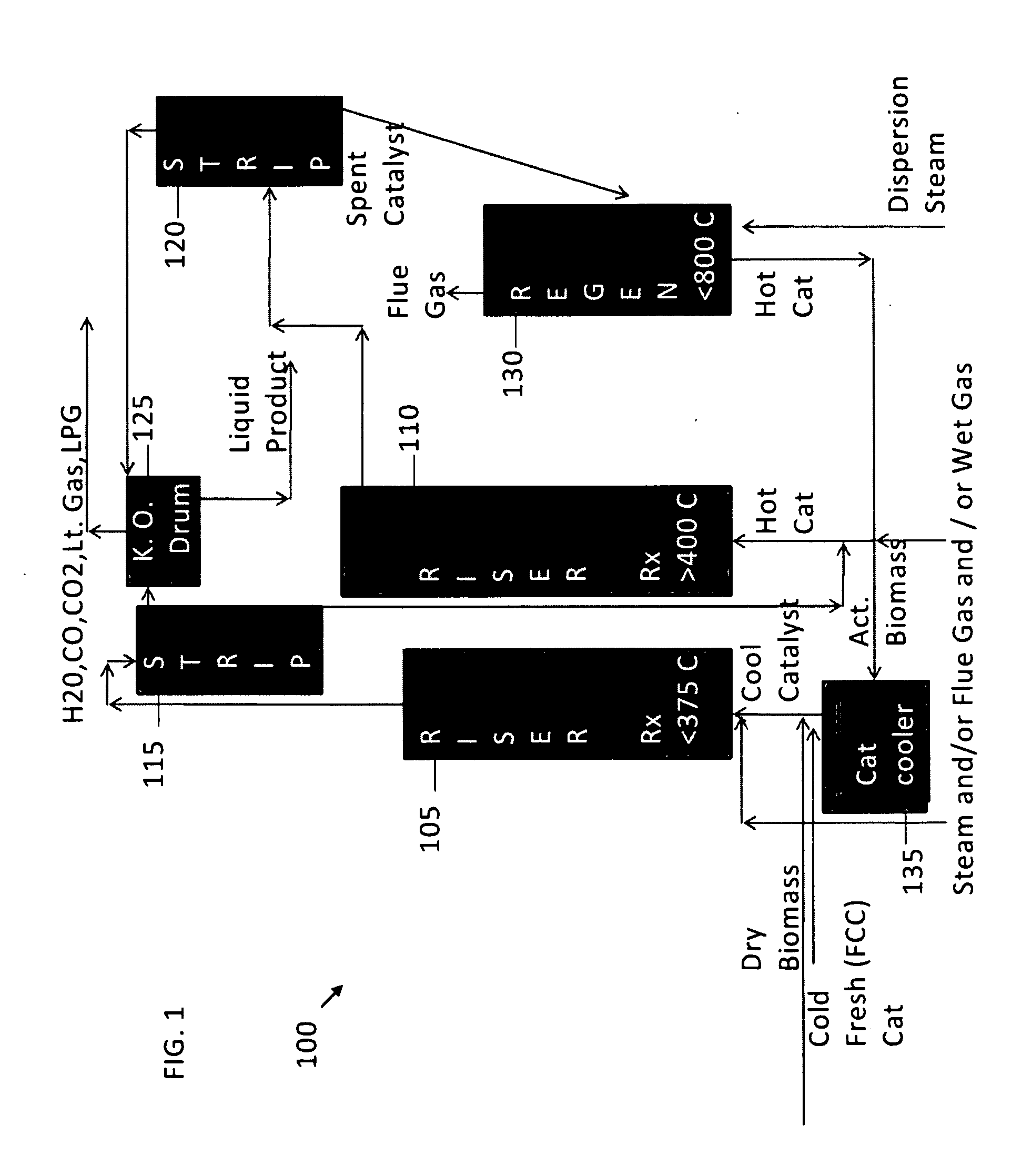

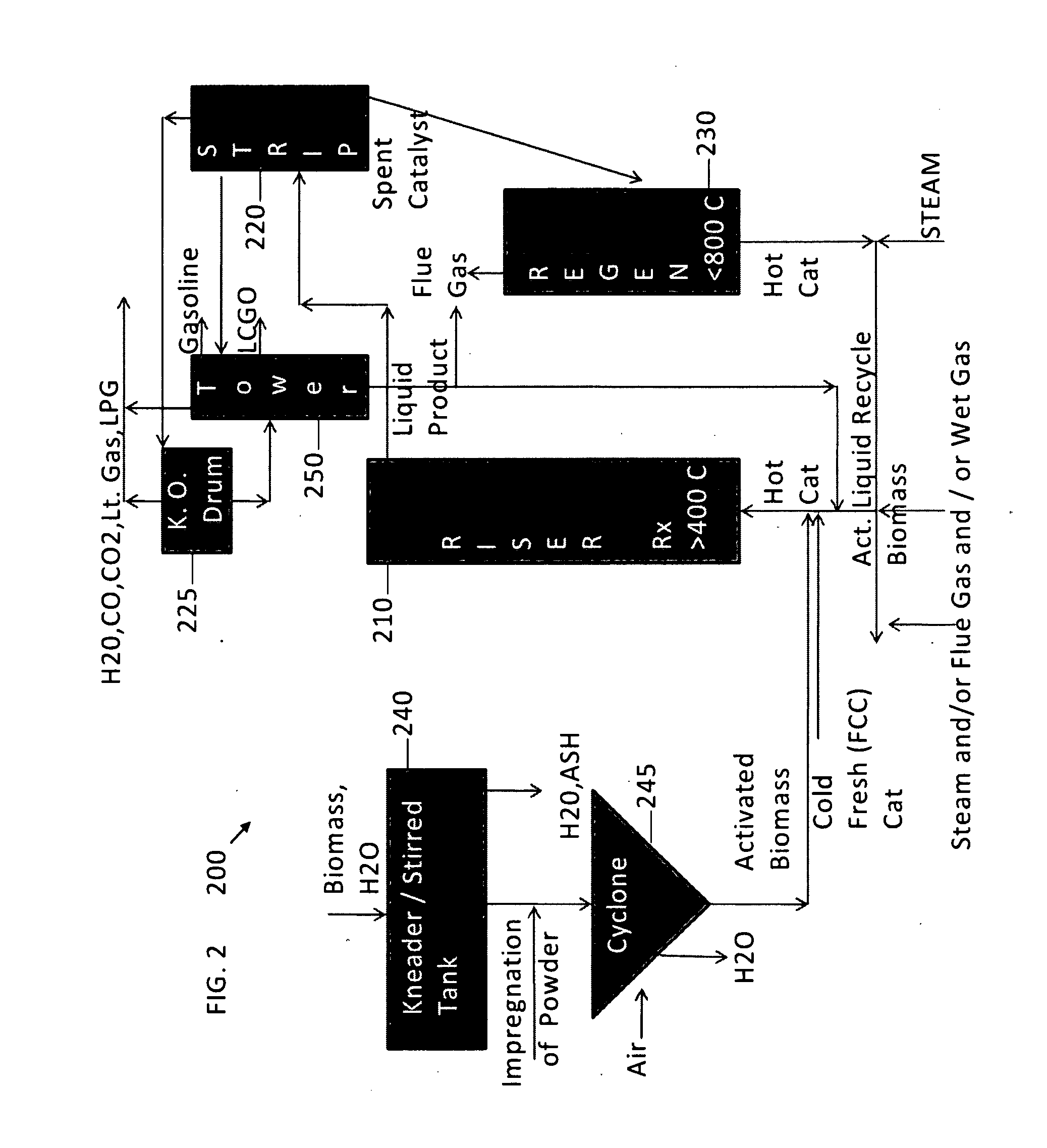

Integrated fcc biomass pyrolysis/upgrading

Owner:PHILLIPS 66 CO

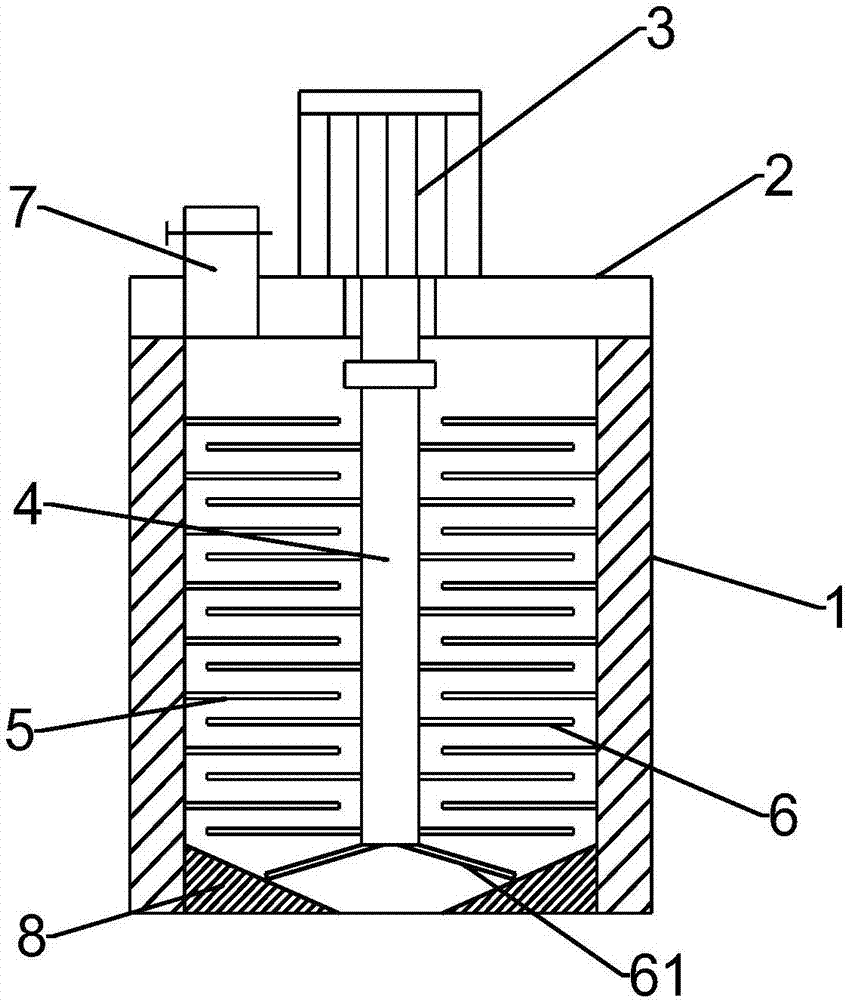

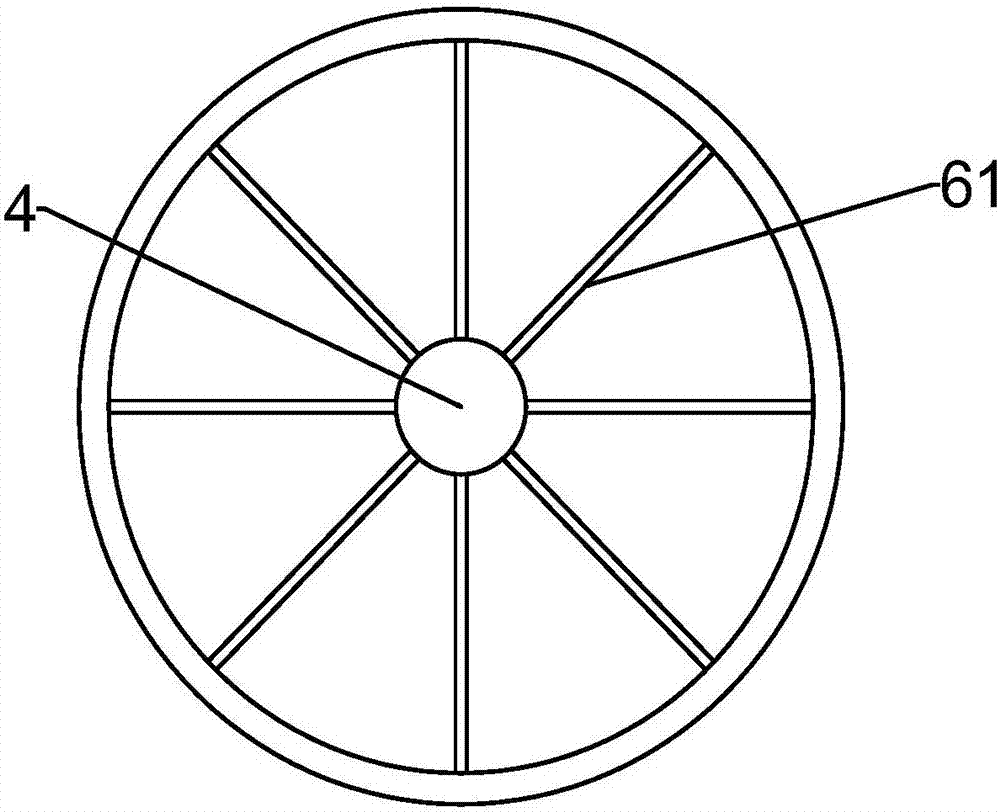

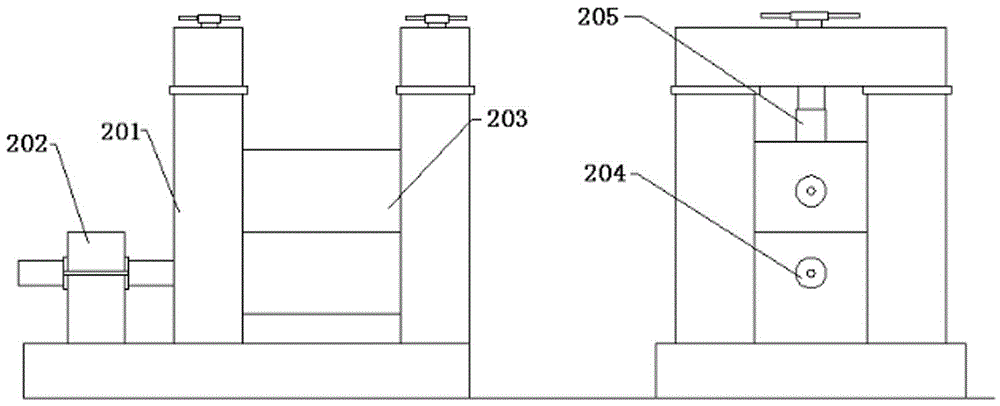

Raw material cleaning and crushing device for biomass pellet fuel

InactiveCN106914318AAvoid incomplete crushingEfficient crushingGrain treatmentsPressesCamWater collection

The invention discloses a raw material cleaning and crushing device for biomass pellet fuel. The device of the invention comprises a crushing tank, a support backing plate, a dehydration chamber, a discharging baffle plate, a dehydration baffle plate, a dehydration push pedal, a water collection chamber, a material collection chamber, a second motor and a cam. The crushing tank is provided with an upper cover, a first motor, a crushing shaft, a fixed blade, a moving blade, a feed pipe, a guide baseboard and a circular cutter group. The support backing plate, the dehydration chamber and the discharging pipe are welded at the lower end of the crushing tank. The discharging baffle plate and a backing plate are movably arranged at the left part of the support backing plate. A sliding groove, a discharge opening, a telescopic rod, the dehydration baffle plate, a push rod and the dehydration push pedal are arranged inside the dehydration chamber. The lower end of the dehydration chamber is provided with the water collection chamber and the material collection chamber. The right wall of the material collection chamber is provided with a movable cover. The upper end of the water collection chamber is equipped with the second motor, a rotating rod, a connecting rod, a support plate, a rotating shaft and the cam. Through the motors for controlling the push rod and the cam, intermittent discharging and automatic extruding-dehydration discharging can be achieved.

Owner:广西众新环保科技有限公司

Carbon-based fertilizer potentiating agent and application thereof

InactiveCN102675001ASimple production processRaw materials are easy to getClimate change adaptationFertilising methodsNitrification inhibitorsPollution

Owner:SHENYANG AGRI UNIV

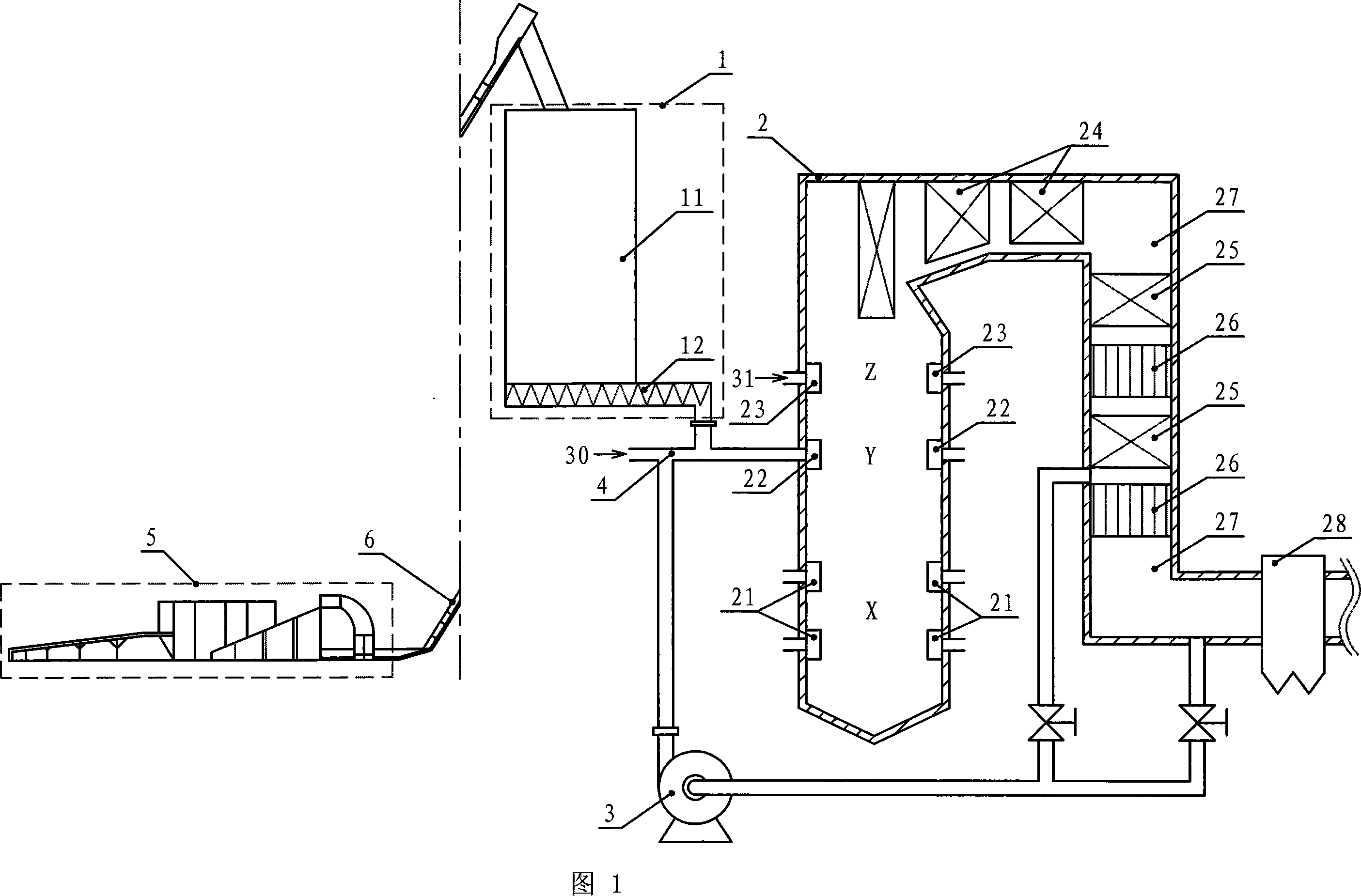

Method and device of denitration utilizing biomass direct burning and re-burning as well as smoke gas recirculating technology

InactiveCN101021316AReduce technical riskLow technical costCombustion apparatusCombustorDirect combustion

The present invention belongs to a denitration method by utilizing biomass direct combustion and secondary combustion and flue gas recirculating process and its equipment, and relates to a coal powder boiler low NOx combustion process and its equipment. The invented method includes the following steps: making coal powder be passed through the combustor of coal powder boiler and fed into main combustion zone to make combustion and form the flue gas containing NOx; utilizing the mixture of once air and recirculating tail portion flue gas to spray biomass particles into secondary combustion reduction zone and make NOx formed in the main combustion zone be reacted and formed into N2; at the same time make the biomass coke ad NOx produce isophase reduction reaction to form Nz; spraying burning air from upper portion of secondary combustion reduction zone to make non-burnt combustible material be burnt up.

Owner:HARBIN INST OF TECH

Preparation and use method of microbial immobilized material for remedying polluted soil

InactiveCN101372688AHigh affinityHigh immobilization efficiencyContaminated soil reclamationOn/in organic carrierHectareIn situ bioremediation

The invention discloses a method for preparing and using a microbial immobilized material for repairing contaminated soil. The method comprises the following steps: (1) after being dried by air, the waste biomass raw material is pulverized or ground into 1-20mm of particles; (2) the biomass particles are carbonized and sterilized at the temperature of 150-450 DEG C and under limited oxygen condition for 0.5-6 hours to prepare a carrier material; (3) the carrier material is put into bacterium suspension for enrichment culture according to the solid-to-liquid ratio of 0.5-2mL / g, then the microbial immobilized material is produced; (4) the produced microbial immobilized material is added to organic contaminated soil according to the proportion of 1-500 tons per hectare soil, 0-30cm of topsoil is ploughed to cause the microbial immobilized material to be mixed evenly in the soil, simultaneously, the contaminated soil is biologically repaired and safe agricultural products are produced. The method has the advantages that the carrier material contains abundant lignin structures, carbon and nutrient elements, which provides more suitable matrix for microbial growth; and the immobilized material has strong affinity, high immobilization efficiency, strong adsorption capacity and good resistance against the pollutants in the environment; and the immobilized material is a soil fertilizer, and is suitable for large-scale in-situ biological repair of the contaminated soil.

Owner:ZHEJIANG UNIV

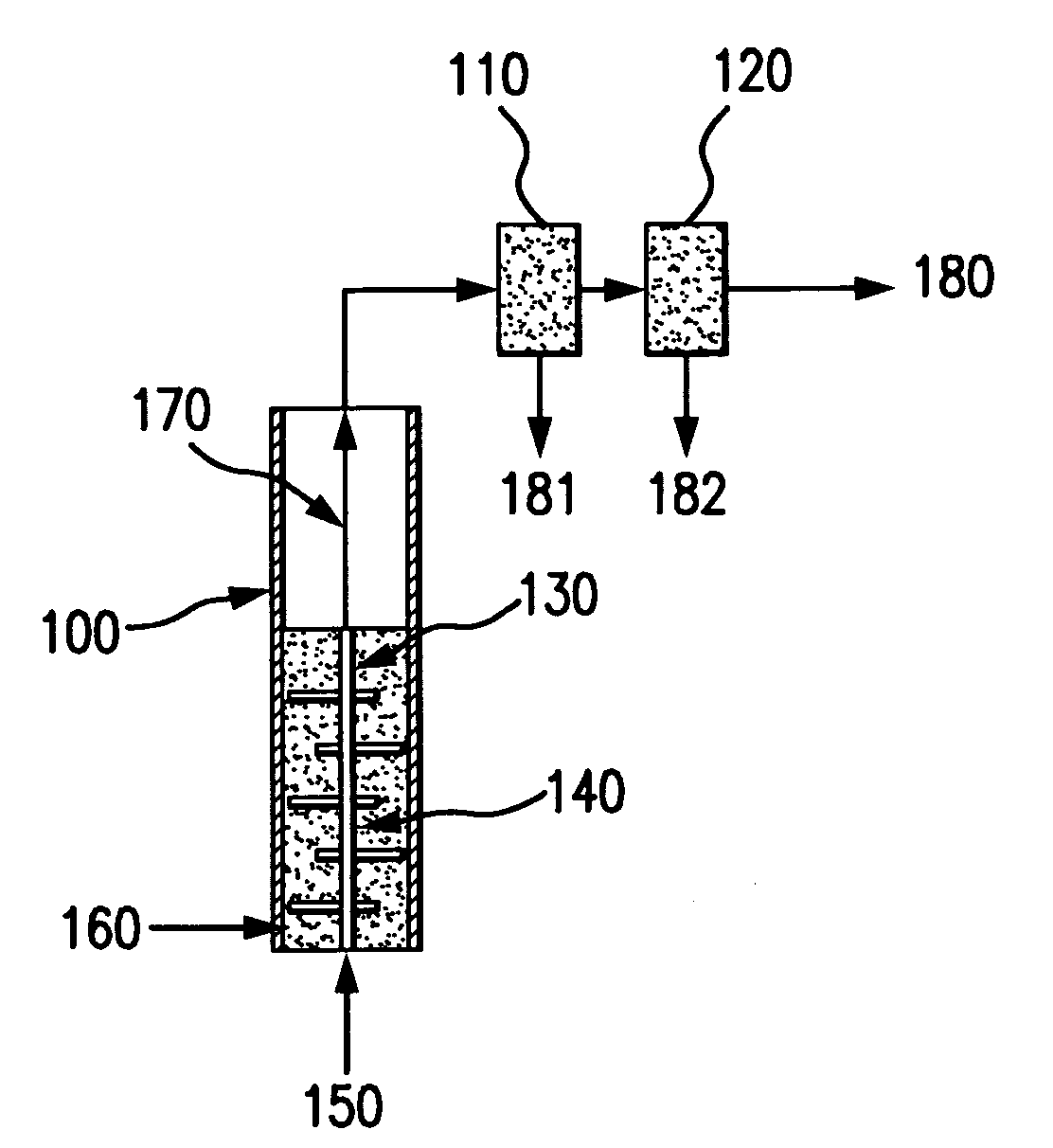

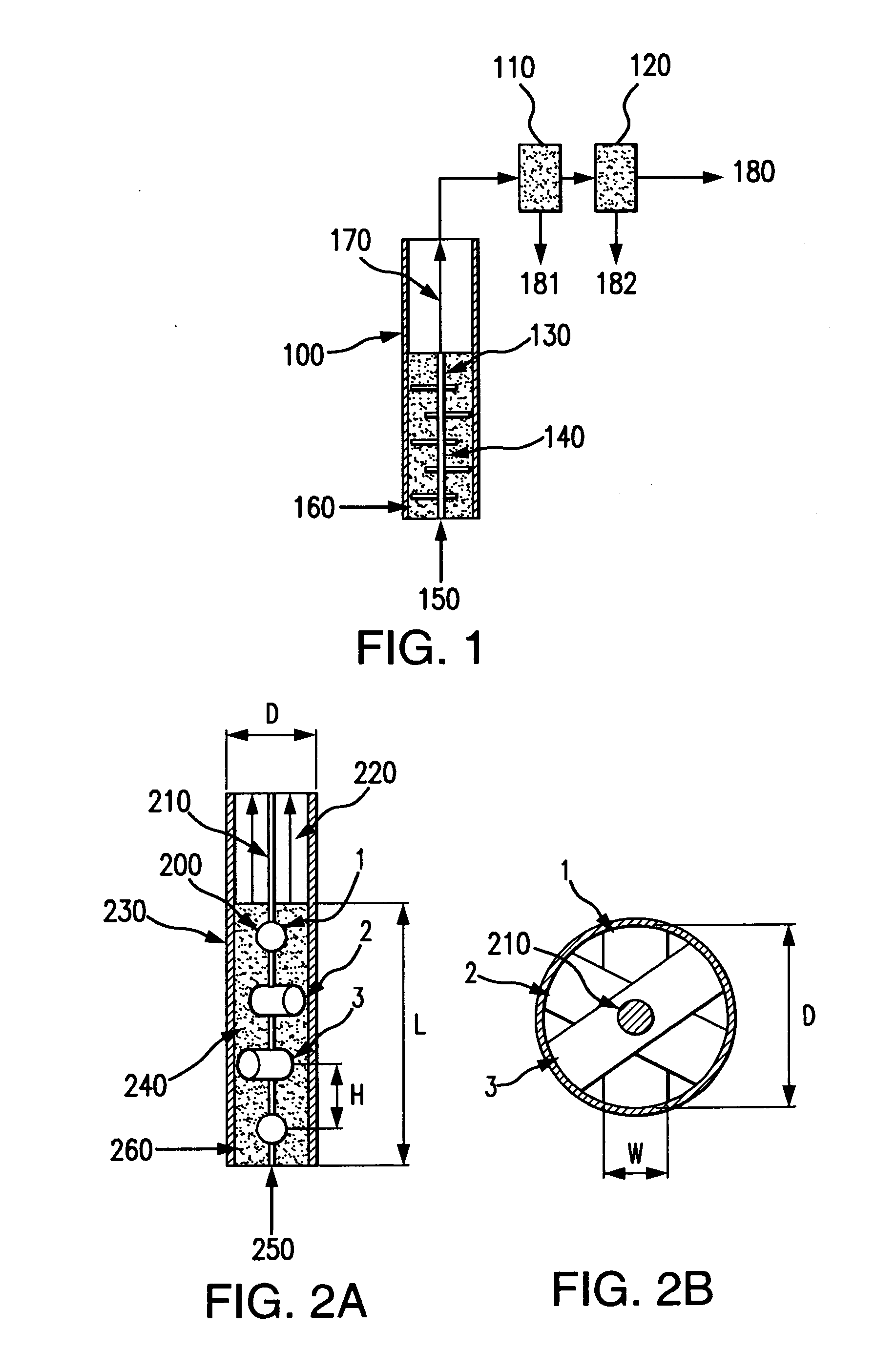

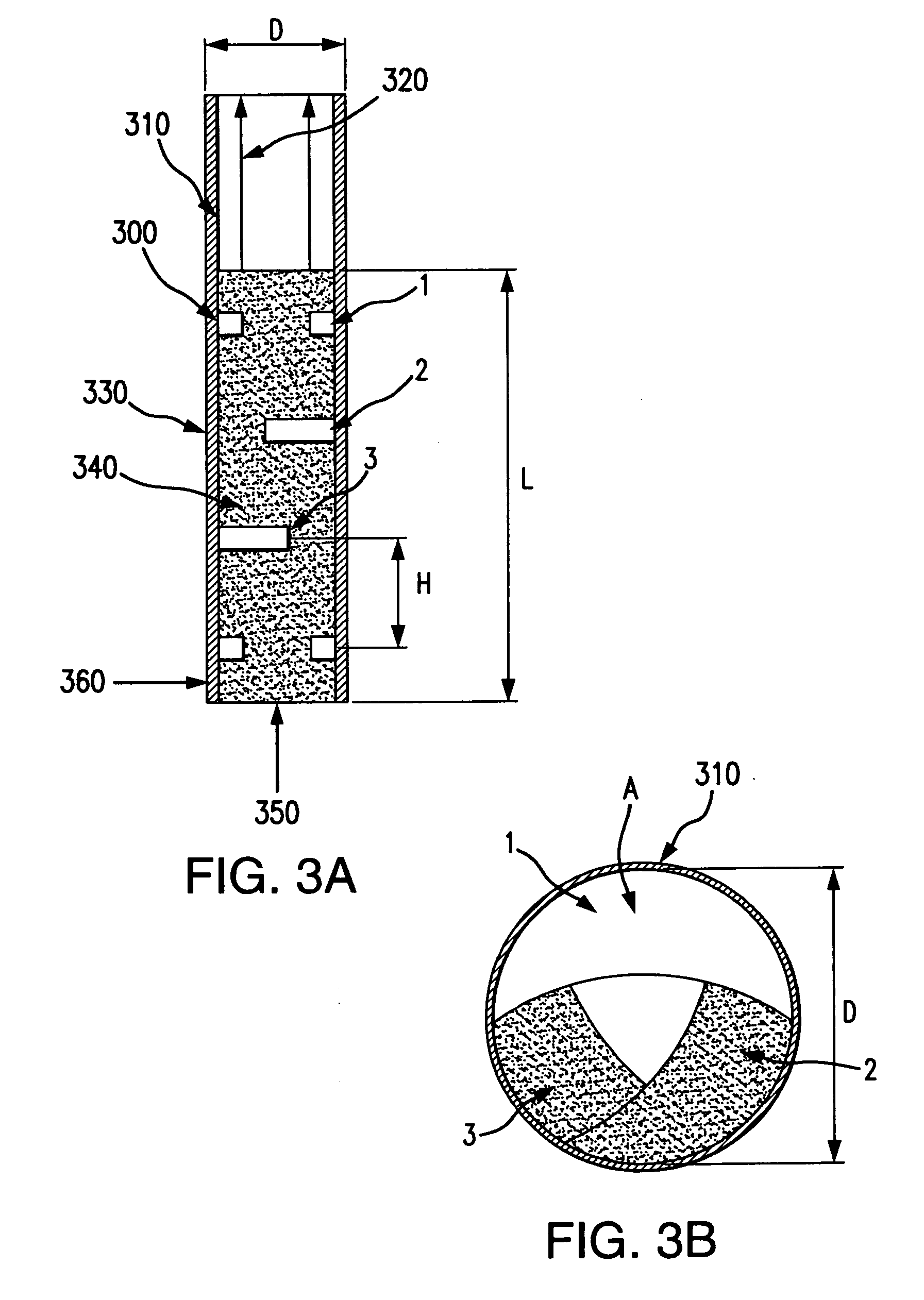

Systems and methods for reactor chemistry and control

InactiveUS20100242354A1Process control/regulationSolar heating energyChemical reactionChemical reactor

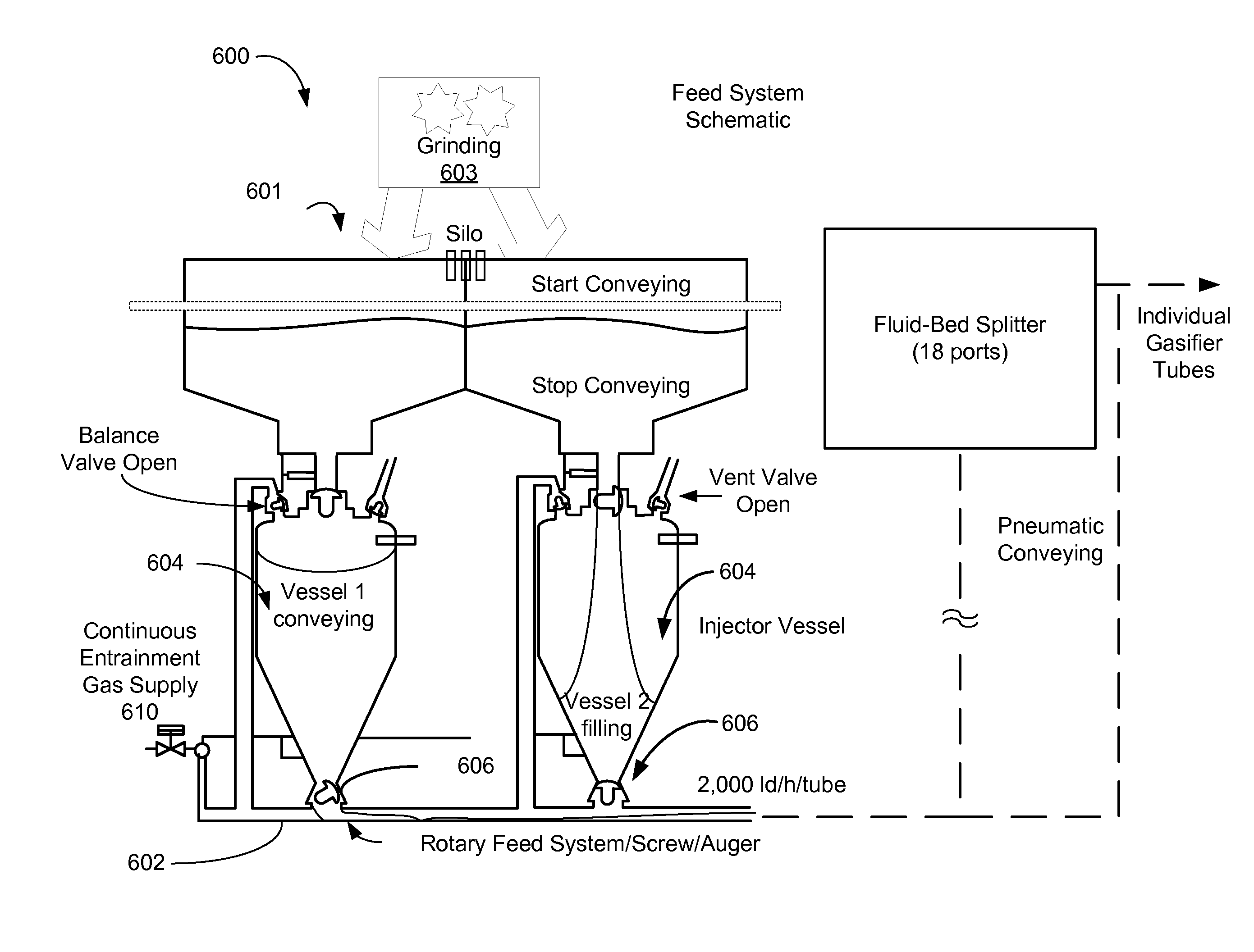

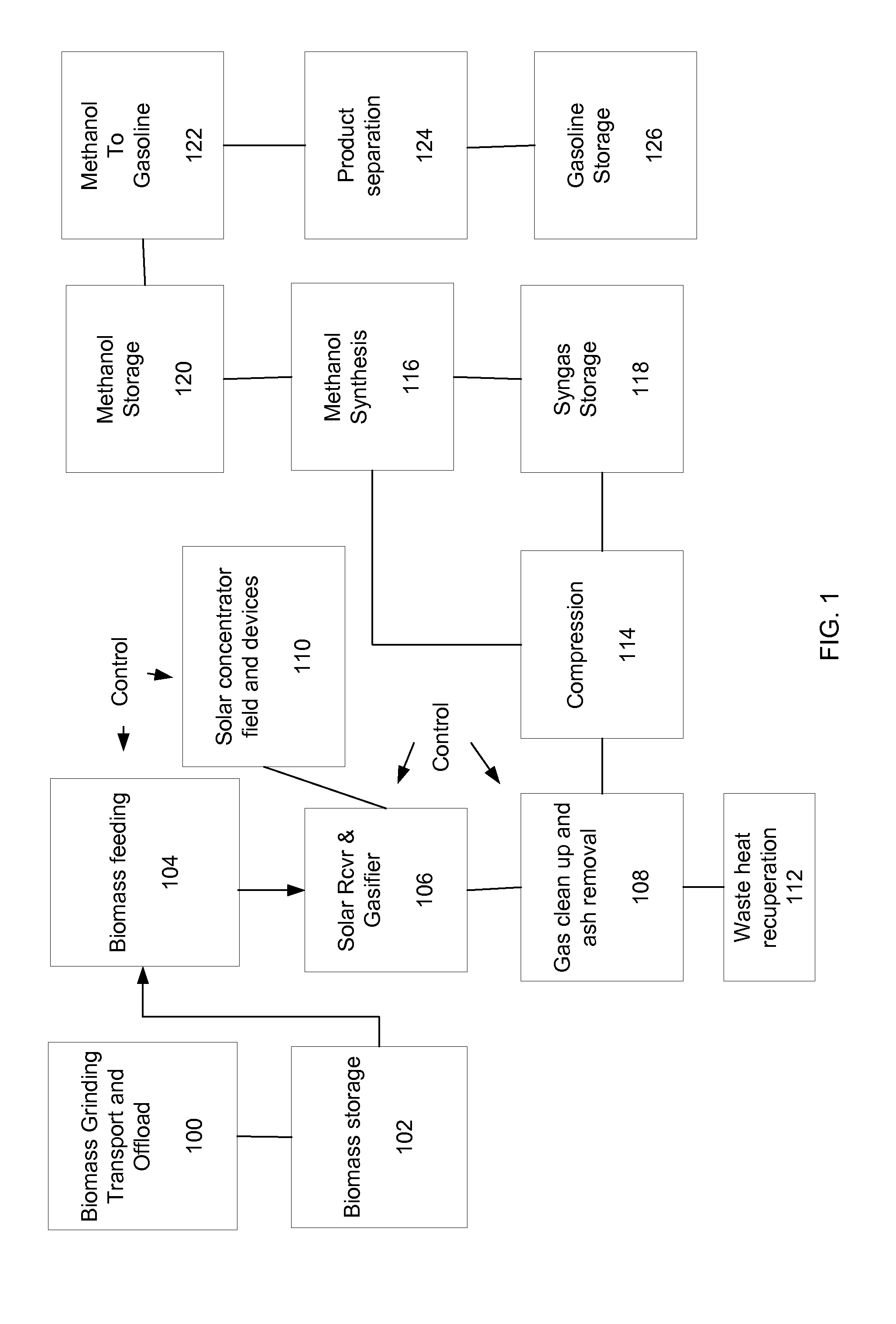

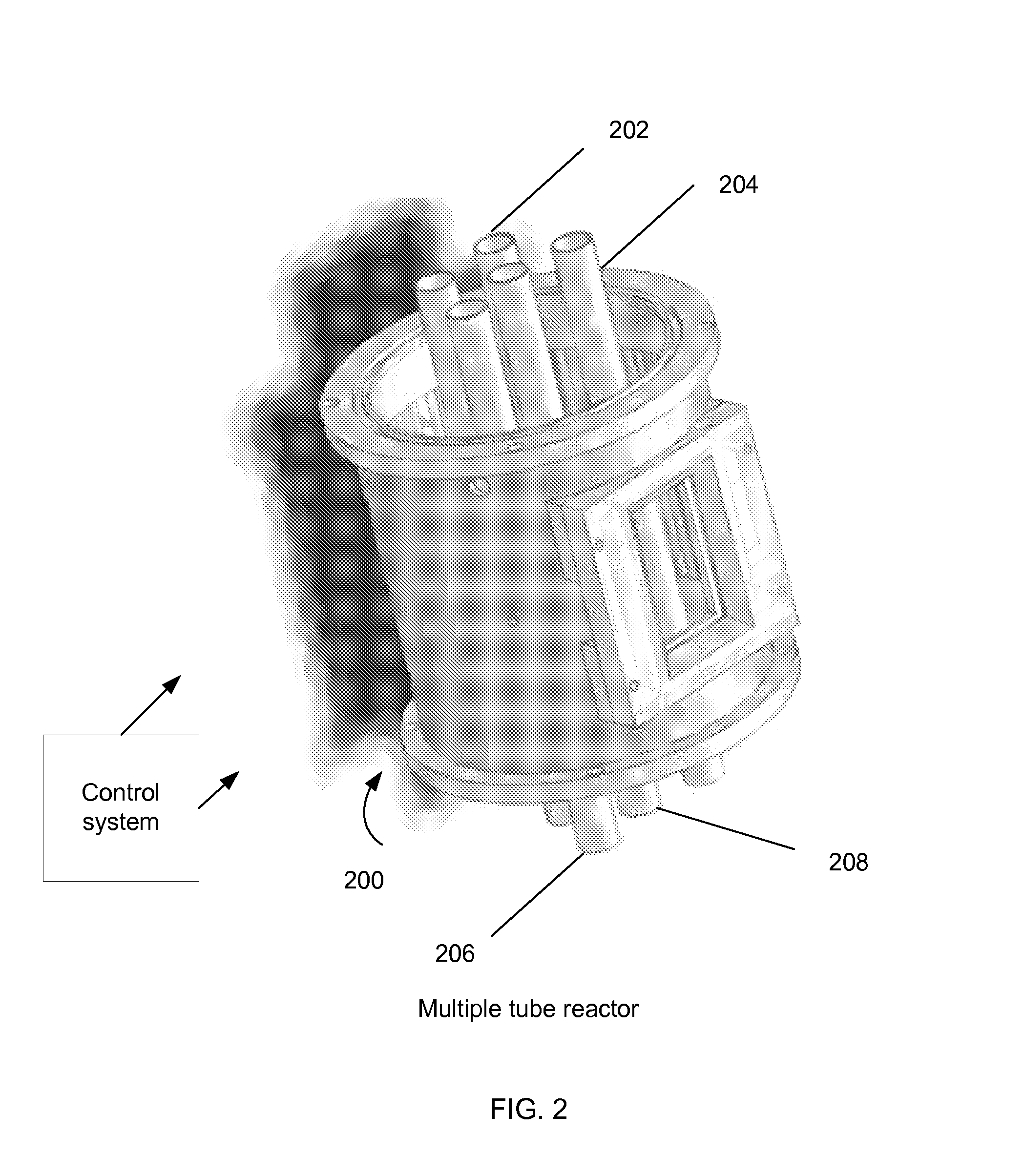

A method, apparatus, and system for a solar-driven chemical plant that manages variations in solar energy are disclosed. Some embodiments include a solar thermal receiver to absorb concentrated solar energy, a solar driven chemical reactor contained within the solar thermal receiver, and an entrained gas biomass feed system that uses an entrainment carrier gas and supplies a variety of biomass sources fed as particles into the solar driven chemical reactor. Inner walls of the solar thermal receiver and the chemical reactor can be made from materials selected to transfer energy. Some embodiments include a control system that may be configured to balance the gasification reaction of biomass particles with the available concentrated solar energy and additional variable parameters including, but not limited to, a fixed range of particle sizes, temperature of the chemical reactor, and residence time of the particles in a reaction zone in the chemical reactor.

Owner:SUNDROP FUELS

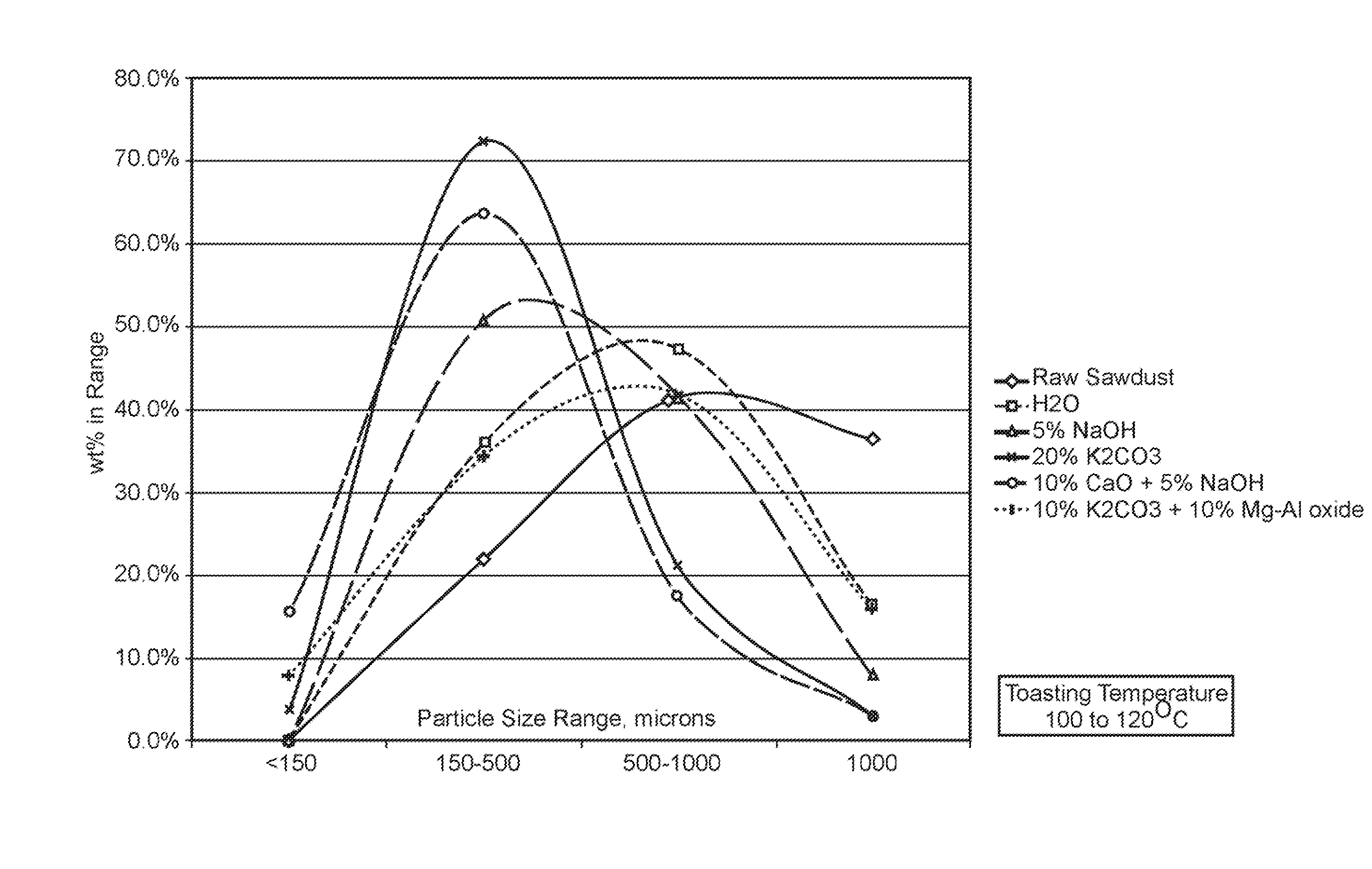

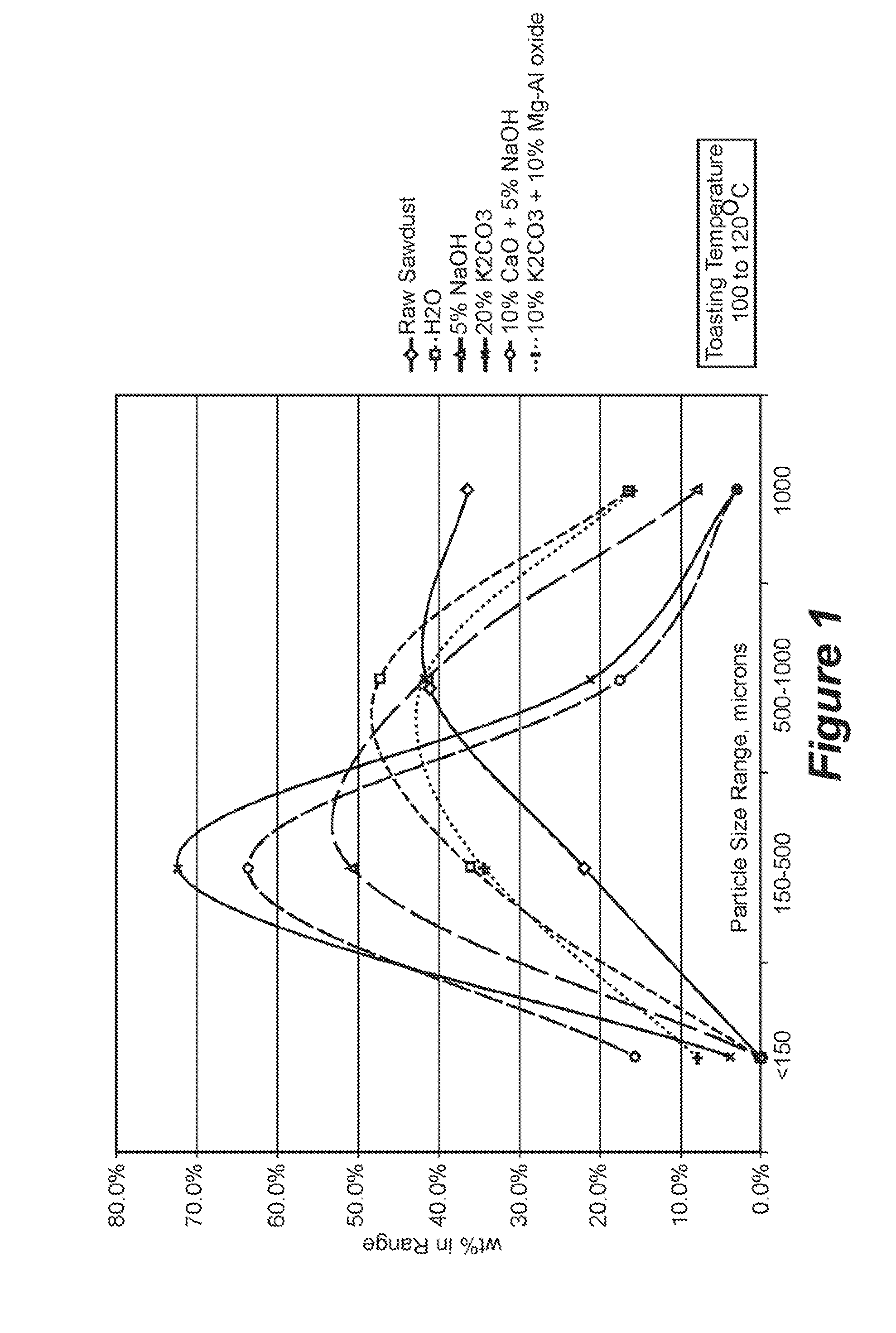

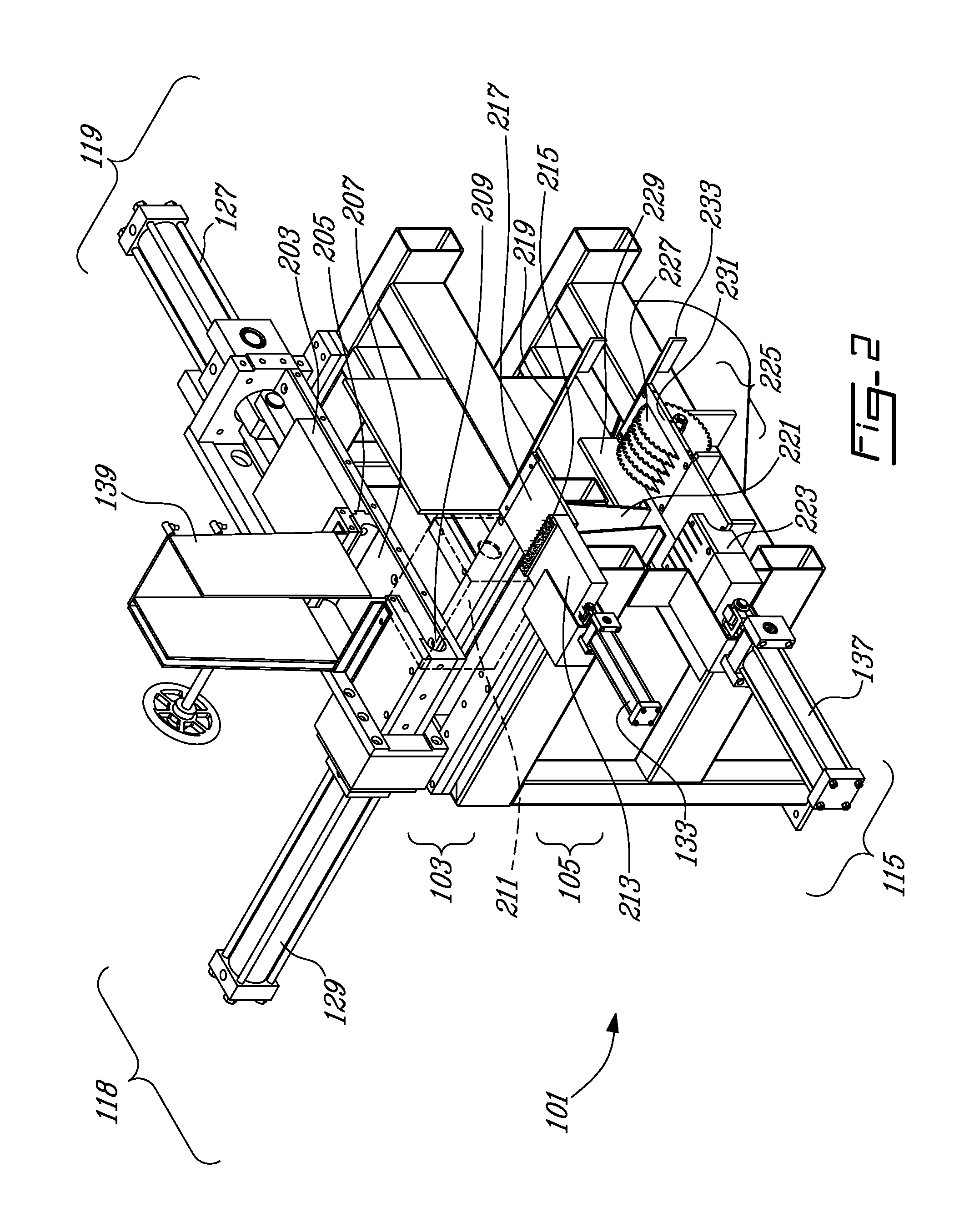

Comminution and densification of biomass particles

A method is disclosed for reducing the mechanical strength of solid biomass material, in particular ligno-cellulosic biomass. The method comprises heating the solid biomass material to a temperature in the range of 105° C. to 200° C. The heat treatment, which is referred to as “toasting”, significantly reduces the mechanical energy required for reducing the particle size of the solid biomass material.The method is particularly suitable as a pretreatment step to a conversion reaction of the solid biomass material.

Owner:MARD INC

Carbon-based ginseng soil conditioner and preparation method thereof

ActiveCN102604645ASimple production processSimple production equipmentOrganic fertilisersSoil-working methodsEcological environmentPhosphate

The invention relates to the field of agricultural chemistry, in particular relates to a carbon-based ginseng soil conditioner and a preparation method thereof. The carbon-based ginseng soil conditioner comprises biomass particle carbon, wood vinegar and an adhesion agent, and further comprises other fertilizers, such as urea, monoammonium phosphate powder, potassium chloride, zinc sulfate, boric fertilizer, manganese sulfate, ammonium molybdate, ferrous sulfate and copper sulfate. The biomass particle carbon is black carbon powder particles (biomass carbon) generated by incompletely combusting biomasses under a low-oxygen condition and has the advantages of stable property, strong adsorptive capacity and good moisture and fertility preservation effects. The soil conditioner prepared from the biomass particle carbon and the wood vinegar can improve the structure of the soil, optimize a soil ecological environment and improve the utilization efficiency of the fertilizer; when production increasing and synergism of ginsengs can be accelerated, the carbon is effectively stored in the soil, so as to realize agricultural emission reduction; and therefore an application prospect is wide.

Owner:SHENYANG AGRI UNIV

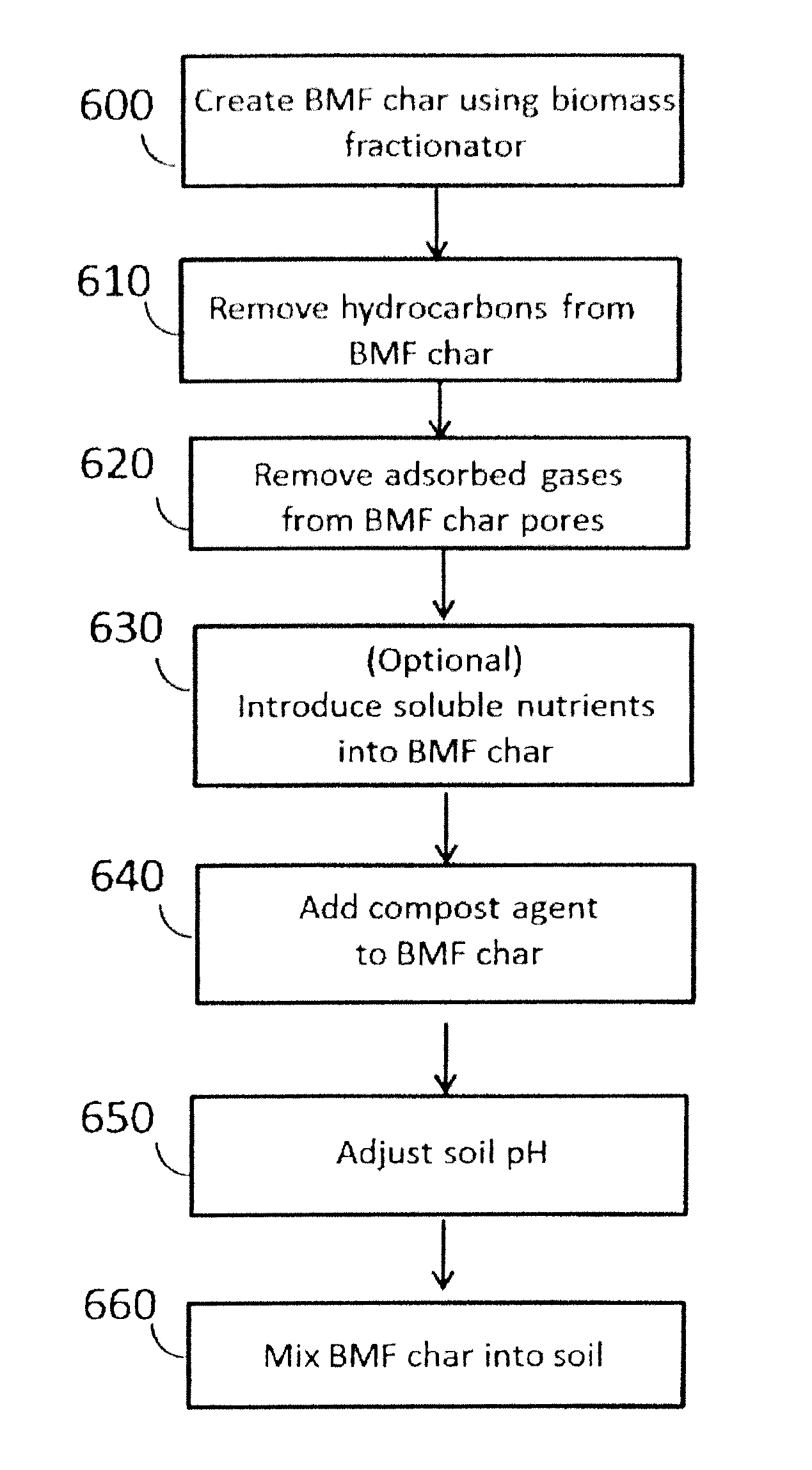

Method for the bioactivation of biochar for use as a soil amendment

A method for the production of an agent for enhancing soil growth is described, comprising: grinding a biomass feedstock to produce ground biomass particles; subjecting the ground biomass particles to a biofractioning process including an auger reactor; selectively collecting at least one volatile component as it is released from the ground biomass particles; collecting a last remaining nonvolatile component comprising BMF char; rendering a surface of the BMF char hydrophilic; exposing the BMF char to microorganisms; and adding the BMF char to soil.

Owner:CARBON TECH HLDG LLC

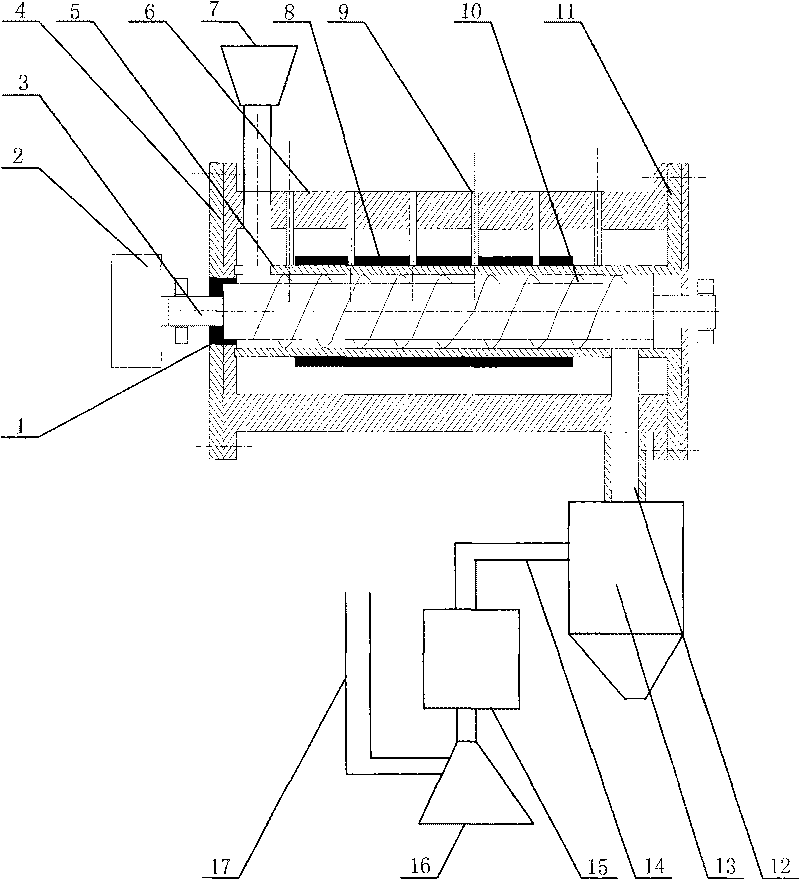

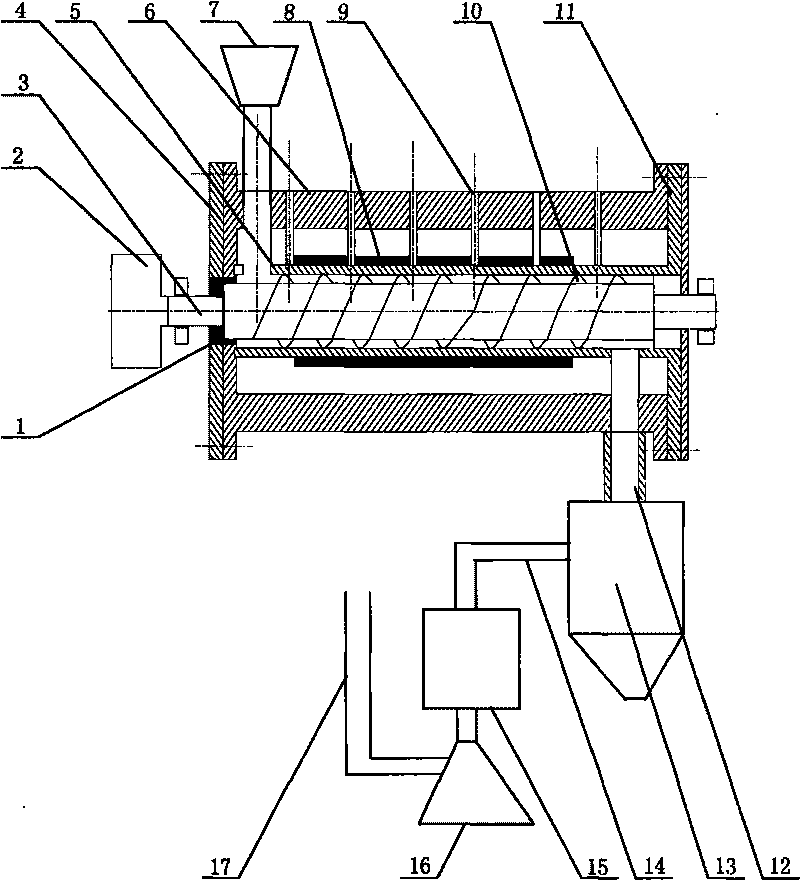

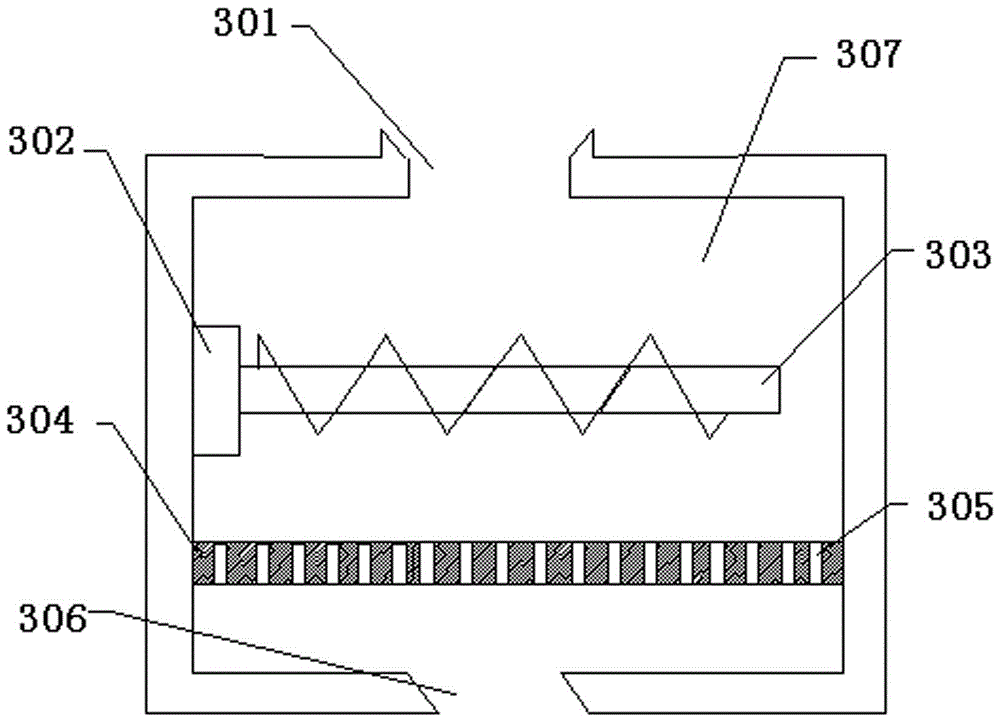

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

Carbon-based controlled-release fertilizer special for potato and preparation method thereof

InactiveCN102173944AGood effect on growth and developmentIncrease profitClimate change adaptationFertilising methodsControlled releaseSoil humus

The invention relates to the field of agricultural chemistry, in particular relates to a carbon-based controlled-release fertilizer special for potato and a preparation method thereof. The environment-friendly efficient carbon-based controlled-release fertilizer special for the potato is a long-acting granular-carbon-based compound fertilizer which is prepared from waste agriculture and forestry biomasses such as corn core, peanut shell, rice shell, edible fungi substrate and the like, wherein the biological granular carbon is black carbon powder granules (carbon black) which is formed by imperfect combustion of biomasses under anaerobic condition and has various features similar to those of soil humus (acid); and the biological granular carbon has strong capabilities of absorbing and retaining nutrition and moisture, can stimulate growth of crops and has good controlled-release effect on NPK, thus the prepared controlled-release fertilizer only needs to be applied once in the full growth and development period of potatoes, has the characteristics of increasing soil fertility, improving soil structure and the like, is efficient and environment-friendly, and has a wide application prospect.

Owner:辽宁金和福农业科技股份有限公司

Charcoal-based rice seedling substrate and preparation method thereof

InactiveCN103772026ASimple production processRaw materials are easy to getCultivating equipmentsSoilless cultivationSulfateDiammonium phosphate

The invention relates to a charcoal-based rice seedling substrate and a preparation method thereof. The charcoal-based rice seedling substrate contains biomass, namely, grain charcoal, grass charcoal and wood vinegar, and can further comprise perlite and other fertilizers such as diammonium phosphate, potassium sulfate, zinc sulfate and monopotassium phosphate. The charcoal-based rice seedling substrate can be widely applied to rice seedling cultivation.

Owner:陈温福

Agricultural and forestry waste carbon-based slow release filter and preparation method thereof

InactiveCN102775236ALow costWidely distributedClimate change adaptationAgriculture gas emission reductionPhosphate ionRelease time

The invention discloses an agricultural and forestry waste carbon-based slow release filter and a preparation method thereof. The preparation method comprises the following steps: crushing agricultural and forestry waste into biomass particles, carrying out pyrolysis to prepare charcoal, dissolving monoammonium phosphate and monopotassium phosphate in water to prepare a saturated water solution of monoammonium phosphate and a saturated water solution of monopotassium phosphate, soaking charcoal prepared in step a in the saturated water solution of monoammonium phosphate and the saturated water solution of monopotassium phosphate so that adsorption capacity of charcoal to phosphate radical ions, ammonium ions and potassium ions is up to 80-90% of balanced adsorption capacity, then taking out charcoal, and drying at the drying temperature of 100-105 DEG C until the moisture content of the slow release filter is less than 5%, thus the agricultural and forestry waste carbon-based slow release filter is obtained. The agricultural and forestry waste carbon-based slow release filter disclosed by the invention is low in cost, long in slow release time and good in slow release effect, can be used for long term and can maintain soil fertility for a long time.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

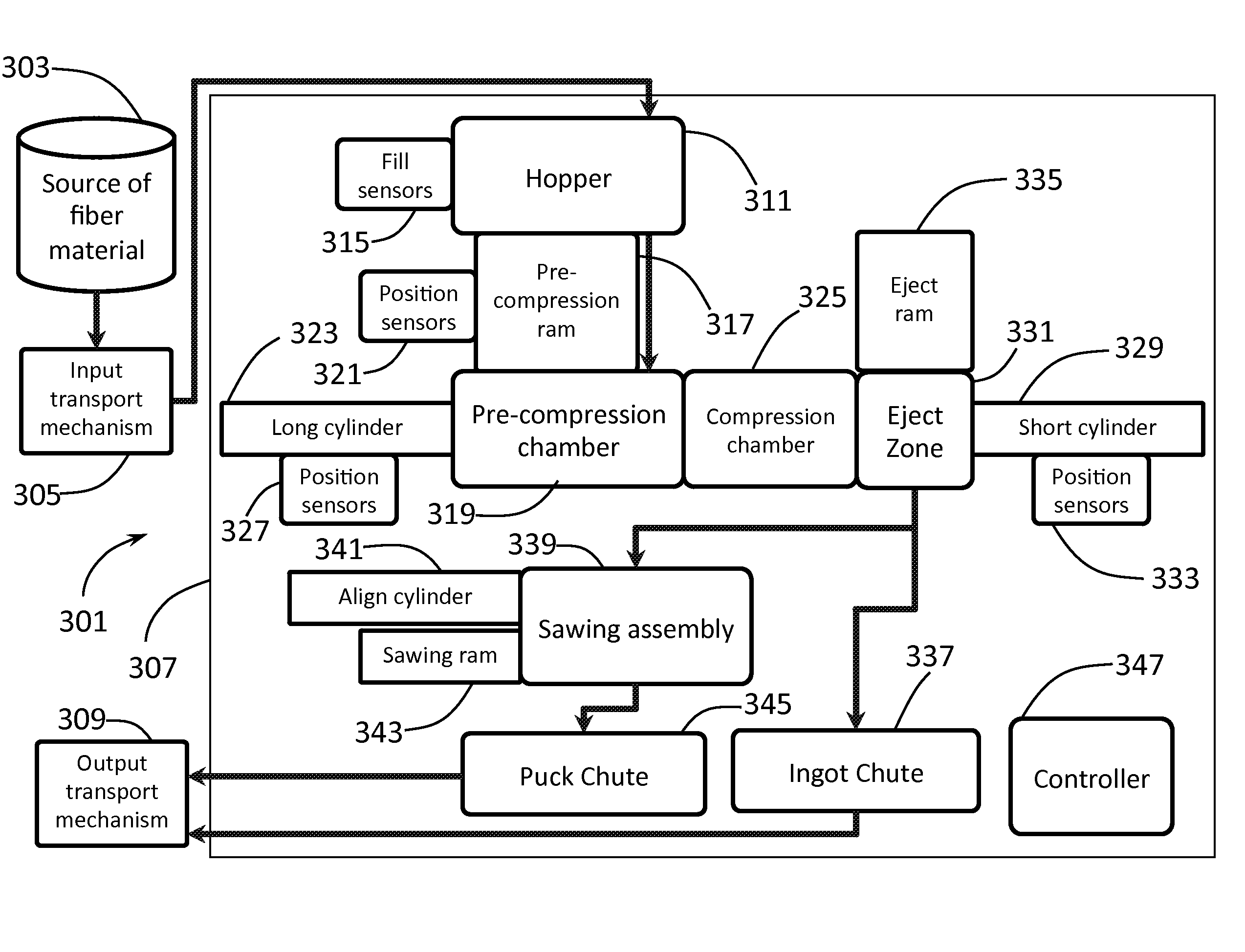

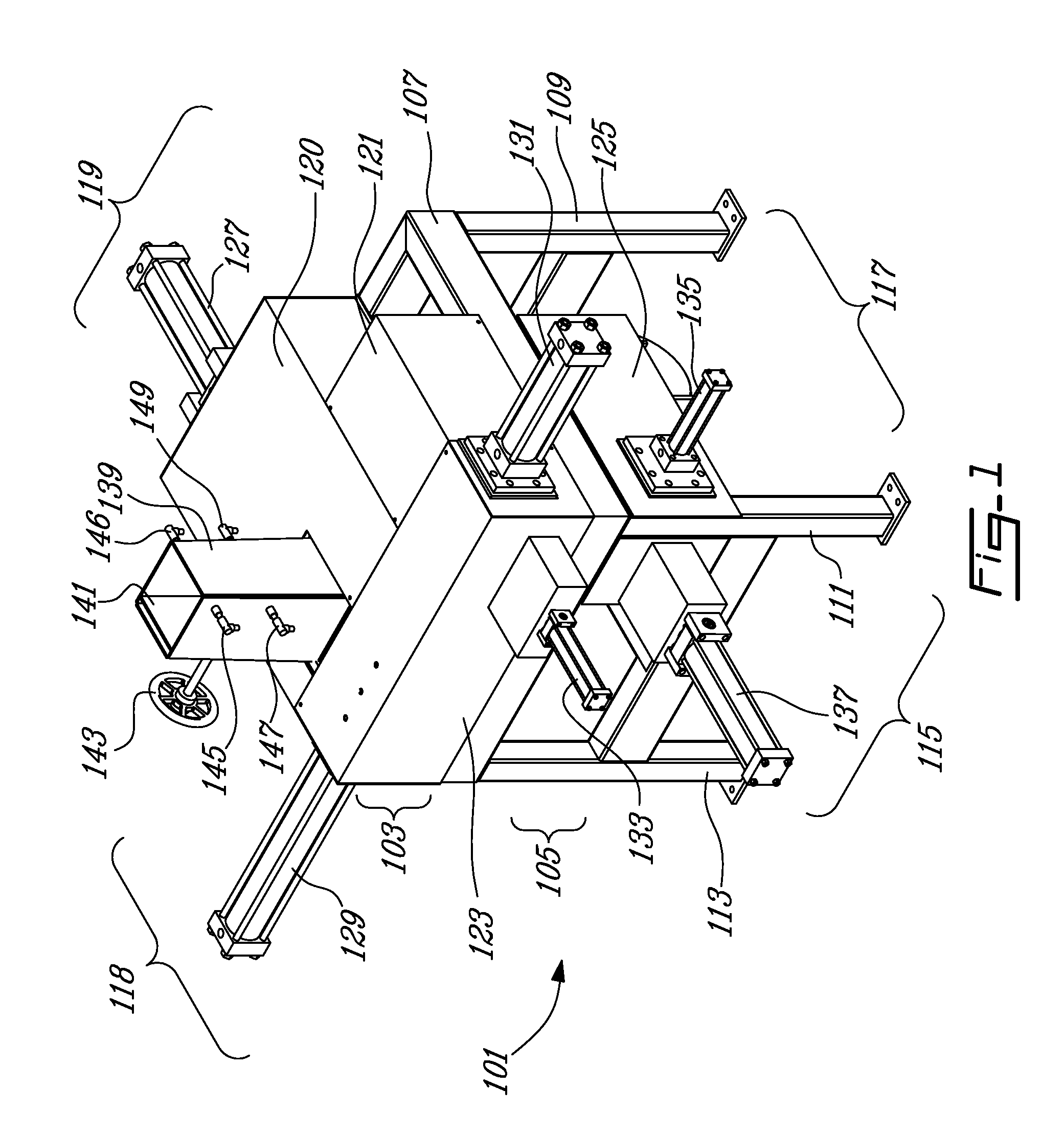

Method and mechanical press system for the generation of densified cylindrical briquettes

InactiveUS8726800B2Promote conversionMinimizes front-end processingBiofuelsSolid fuelsAbutmentBriquette

A method for preparing a pressed article comprises providing a first and a second pressing ram in a compression chamber; supplying biomass particles in the chamber closing the chamber; extending the first pressing ram; displacing the biomass particles with the first pressing ram towards the second pressing ram; detecting abutment of the biomass particles on the second pressing ram; applying pressure to the biomass particles with the first pressing ram and with the second pressing ram detecting a pressure applied to match a predetermined pressure and continuing to extend the first and the second pressing ram until a predetermined time at the matched compression pressure has elapsed; stopping the extension of the second pressing ram when a predetermined extension length is reached; continuing to extend the first pressing ram until a predetermined additional time has elapsed after the stopping; ejecting a pressed article.

Owner:MURRAY DONALD LOUIS +1

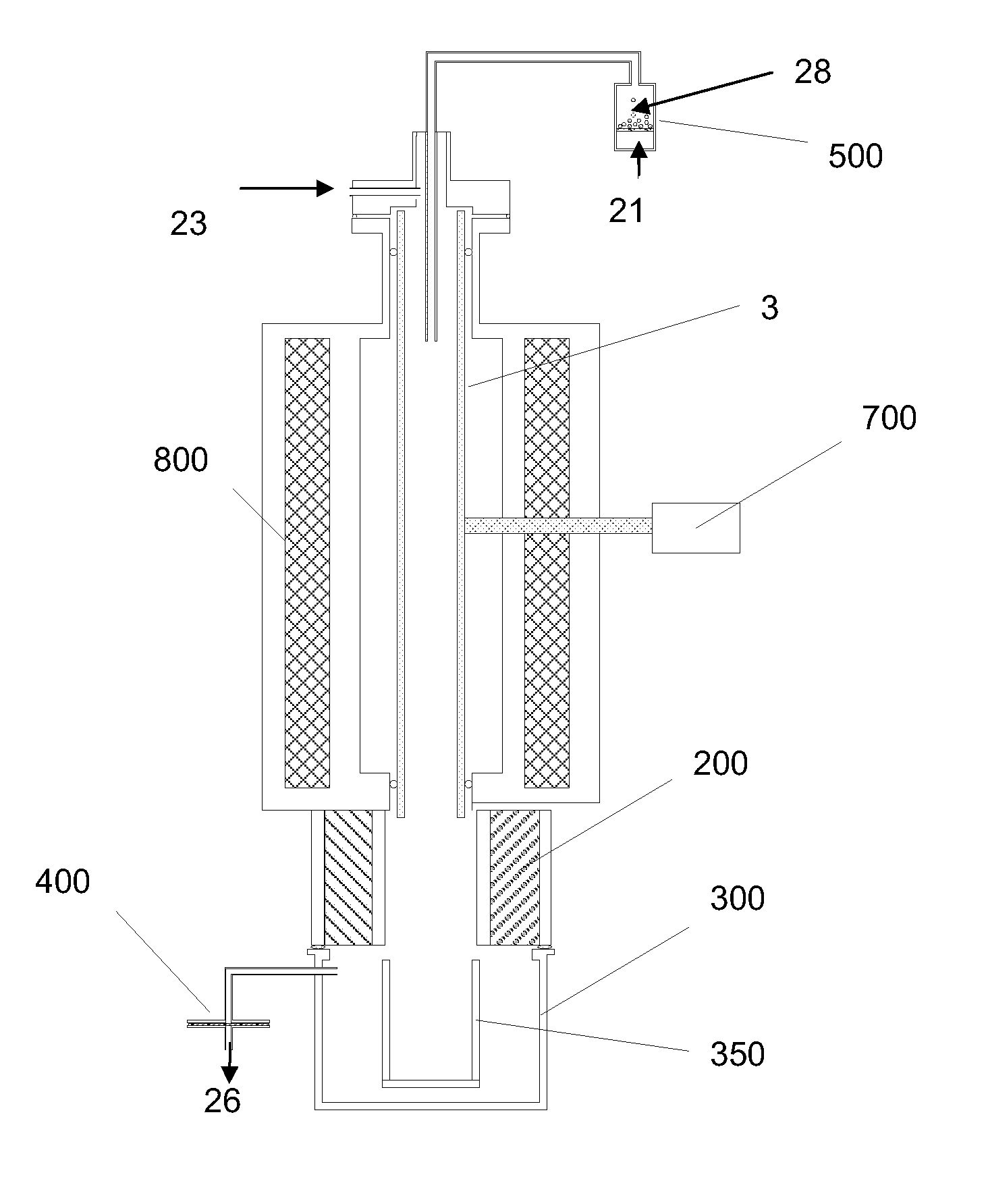

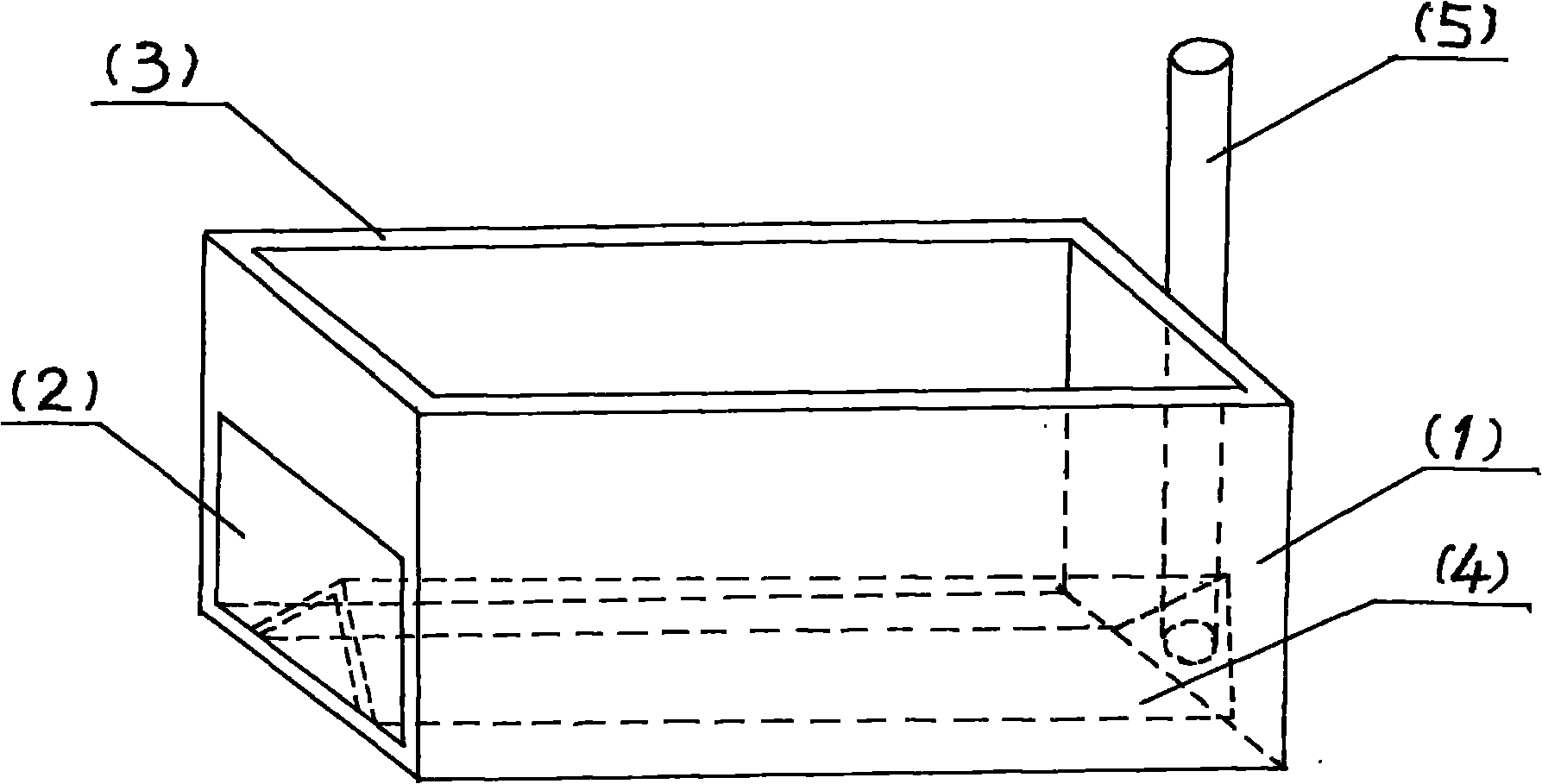

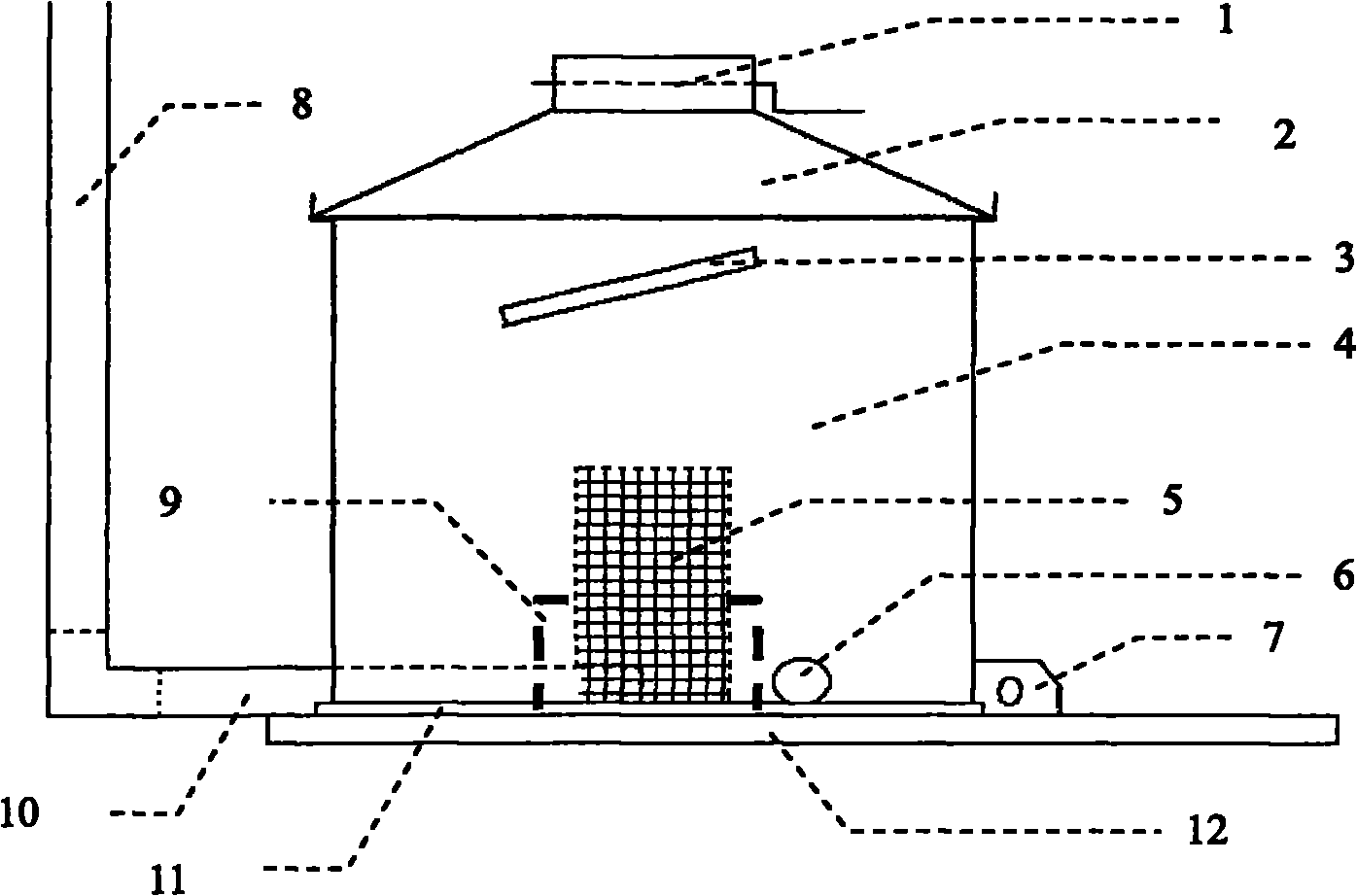

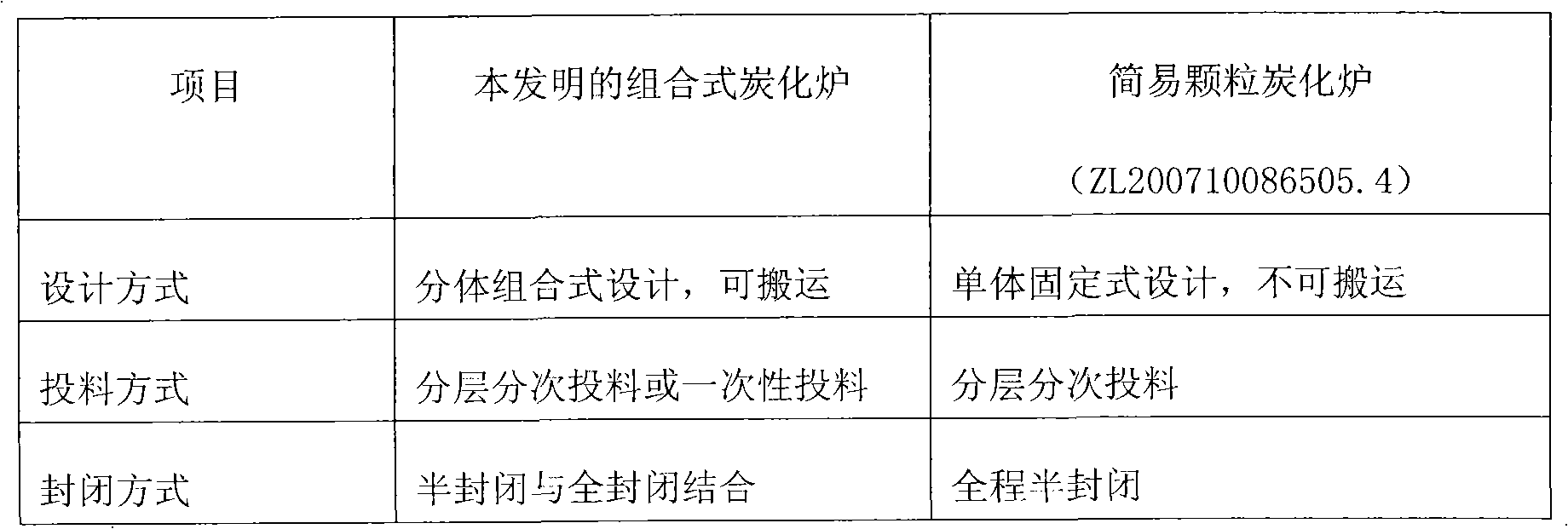

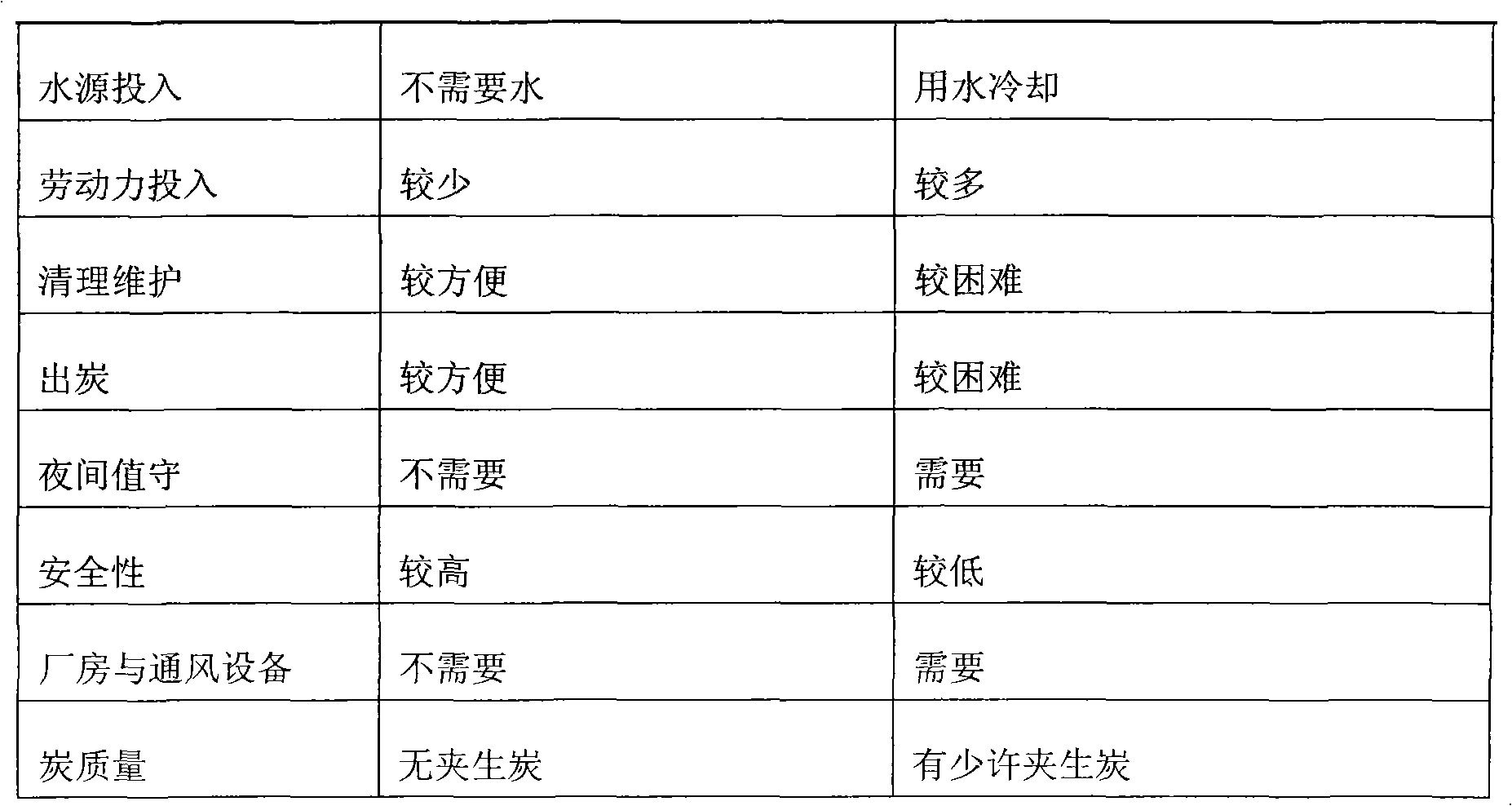

Combined biomass particle carbonization furnace and carbonizing method thereof

The invention relates to the field of agricultural machinery, in particular to a combined carbonization furnace which utilizes agricultural and forestry residue biomass particles to produce biomass carbon particles, and a carbonizing method thereof. The carbonization furnace contains a furnace body, a top cover, a burner, a swing door, a transverse exhaust pipe and a longitudinal exhaust pipe, wherein each component adopts the split-type design and the components are combined for use. The invention also provides a method which uses agricultural and forestry residue biomass as raw material and adopts the carbonization furnace to prepare biochar. The method comprises the following steps: selecting materials, processing the materials, assembling the furnace body, igniting the materials, filling the materials in the furnace, closing the cover, banking, etc. The agricultural and forestry residue biomass refers to corn stalks, corn cobs, peanut hulls, rice hulls, straws, waste edible mushroom medium for production or other wastes.

Owner:沈阳隆泰生物工程有限公司

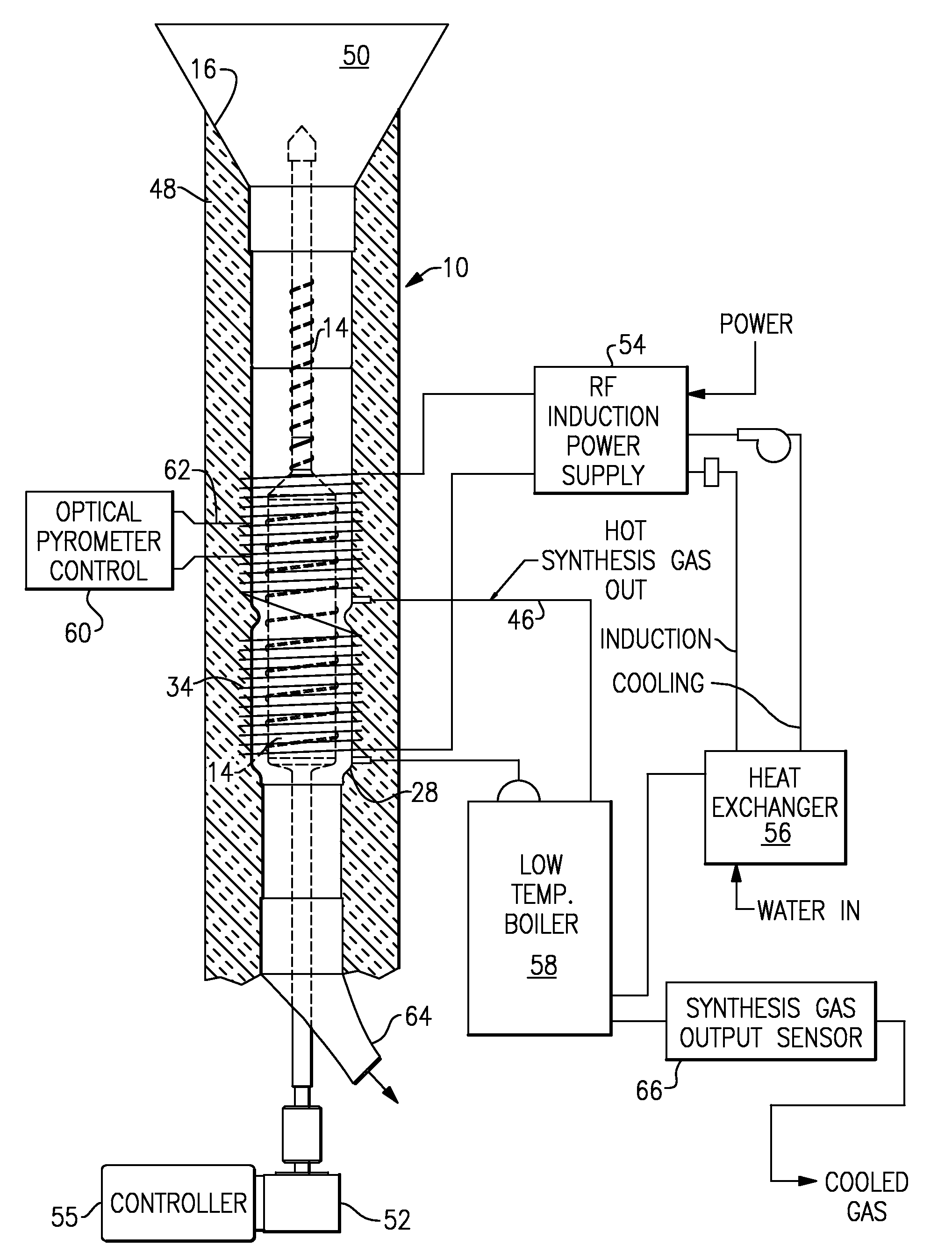

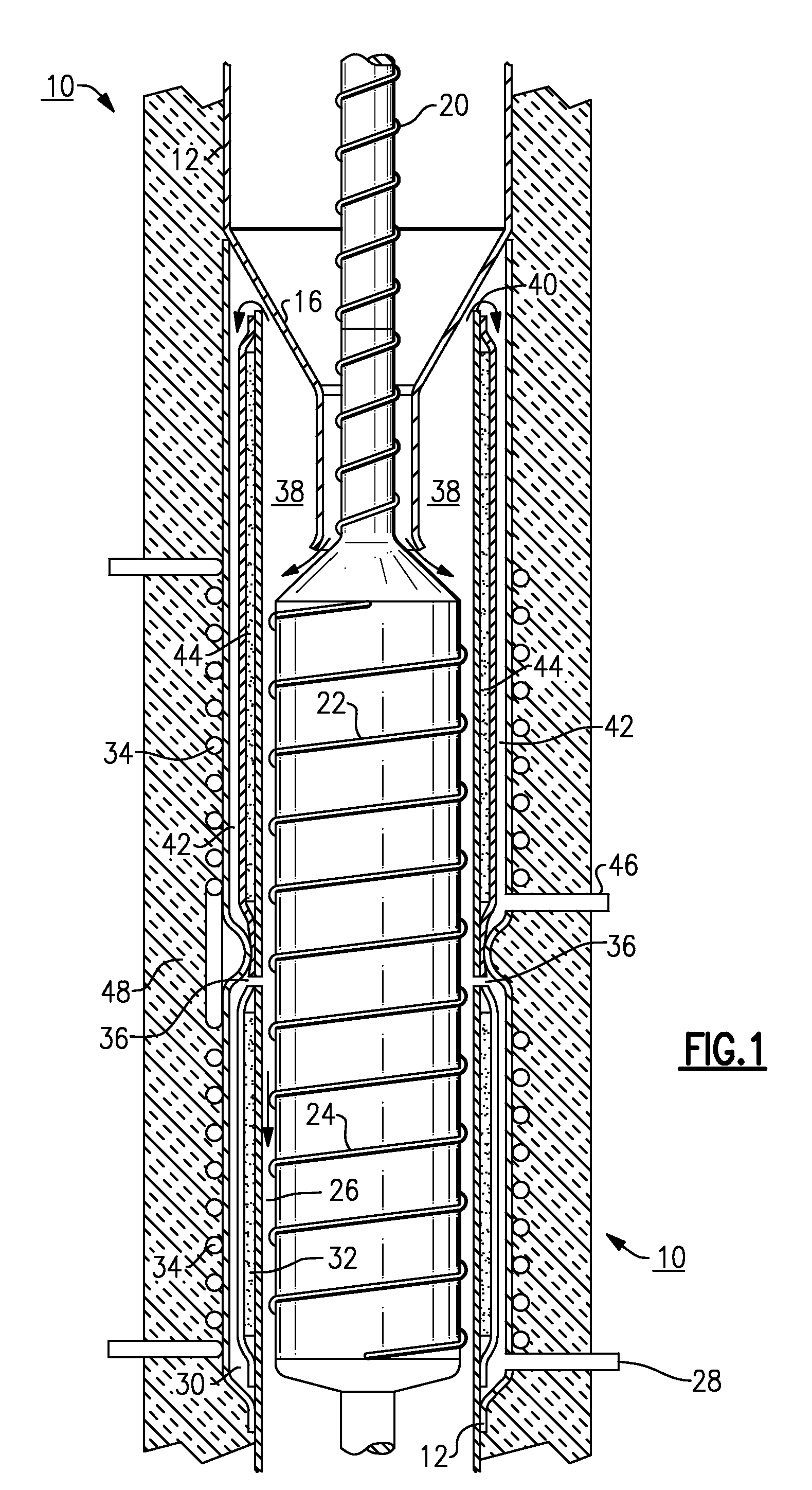

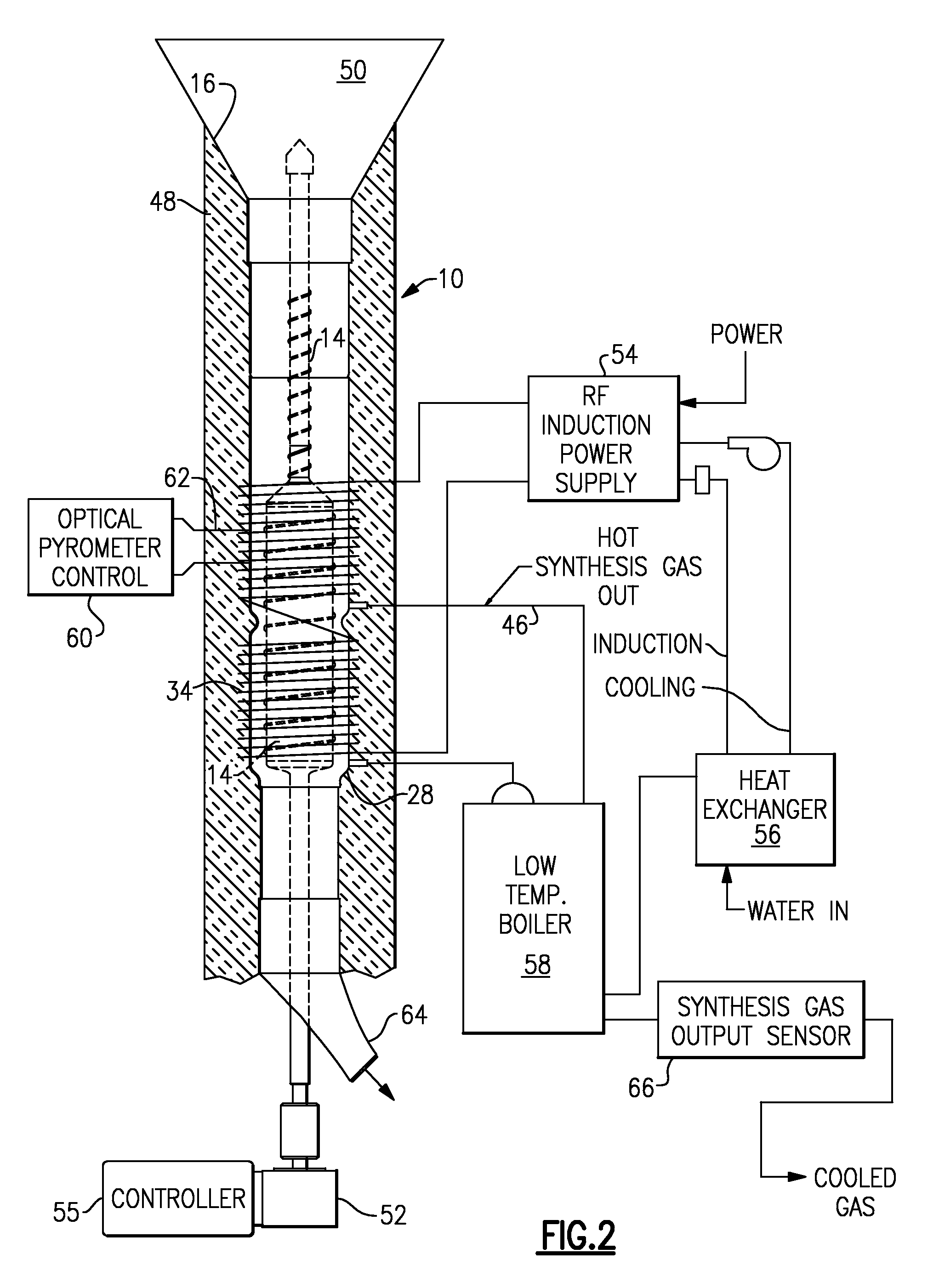

Production of Synthesis Gas from Biomass and Any Organic Matter by Reactive Contact with Superheated Steam

ActiveUS20080171899A1Improve efficiencyConsiderable thermal energySolid waste disposalGasifier mechanical detailsLiquid fuelSuperheated steam

Organic matter, i.e., biomass, fibrous plant matter, organic chemicals or organic waste, or other carbon-based matter is converted to synthesis fuel gas by reactive contact with superheated steam at a temperature of about 200 to 2000 degrees C., typically 500 to 1700 degrees. A reactor has a generally tubular envelope, a rotor within the envelope, and hot reaction spaces disposed annularly within the wall of the tubular envelope. The steam and biomass particles can be heated to the required temperatures by RF induction. The product gases include H2, CO, and CO2 in ratios controlled by a programmable controller. Control of temperature, biomass feed rate and water flow preselects the output synthesis gas mix. The synthesis gas may be processed into portable liquid fuels, or can be used directly in a fuel cell.

Owner:PULKRABEK PETER +1

Biomass particle fuel and preparation method thereof

InactiveCN104927961AQuality improvementImprove qualitySolid fuelsWaste based fuelOrganic matterCow dung

The invention relates to the technical field of biomass fuel, in particular to biomass particle fuel and a preparation method thereof. The biomass particle fuel and the preparation method are characterized in that cow dung, biogas residues, sawdust, yellow mud and corn straw are pre-fermented to change the structure layer of the biomass raw materials and form a compact structure, high-content organic matter is formed, and organic matter components are increased; drainage oil is poured into the organic matter, high-speed stirring is used to allow microscopic biochemical reaction between the drainage oil and the fermented materials, and organic matter mass and quality are increased; the stirred mixture is fermented to further convert the organic matter so as to increase the combustible substances in the organic matter and improve the quality of the organic matter; combustion improver is added and extrusion forming is performed to allow the prepared biomass particle fuel to be good in quality.

Owner:广西稳德福能源科技有限公司

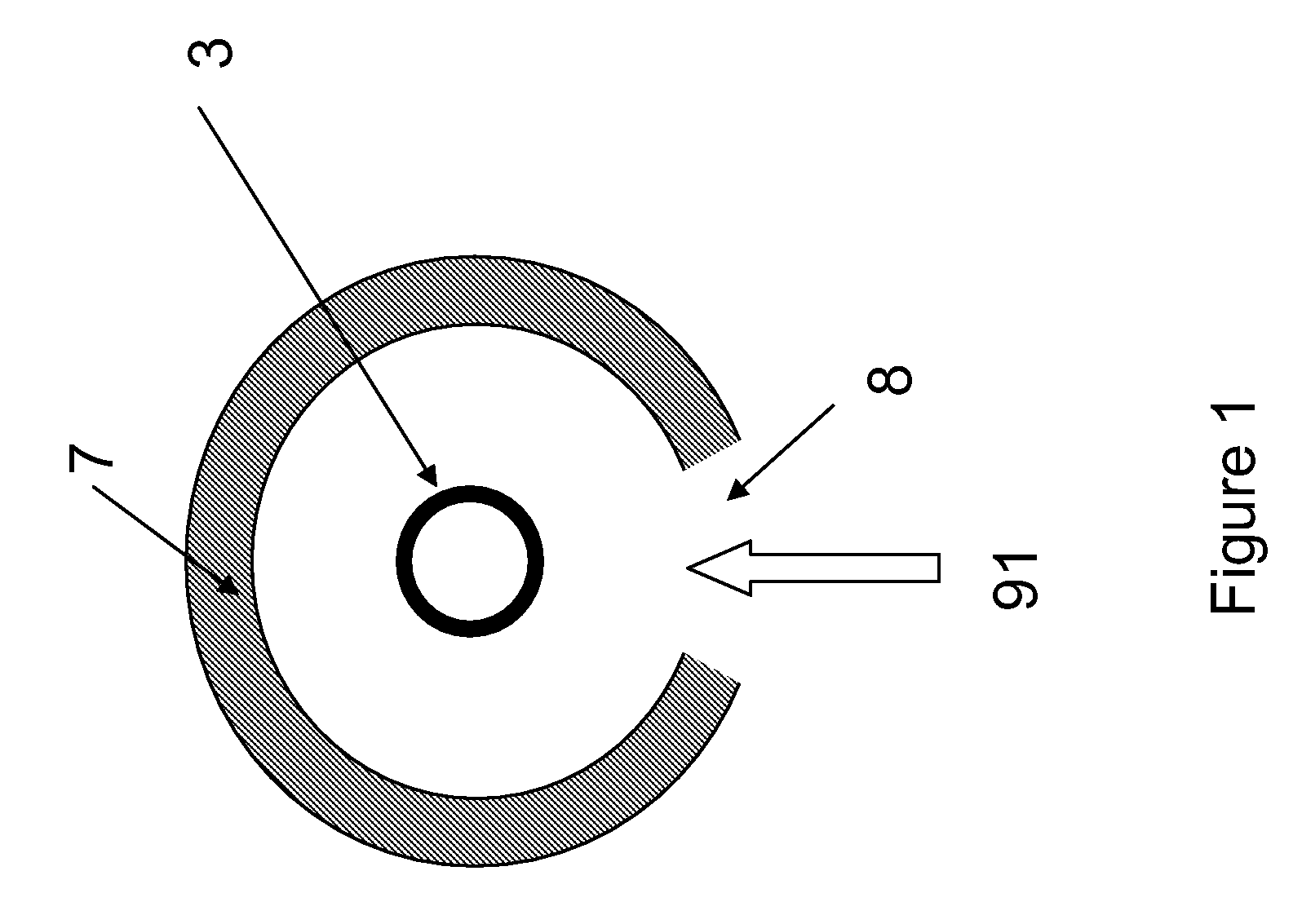

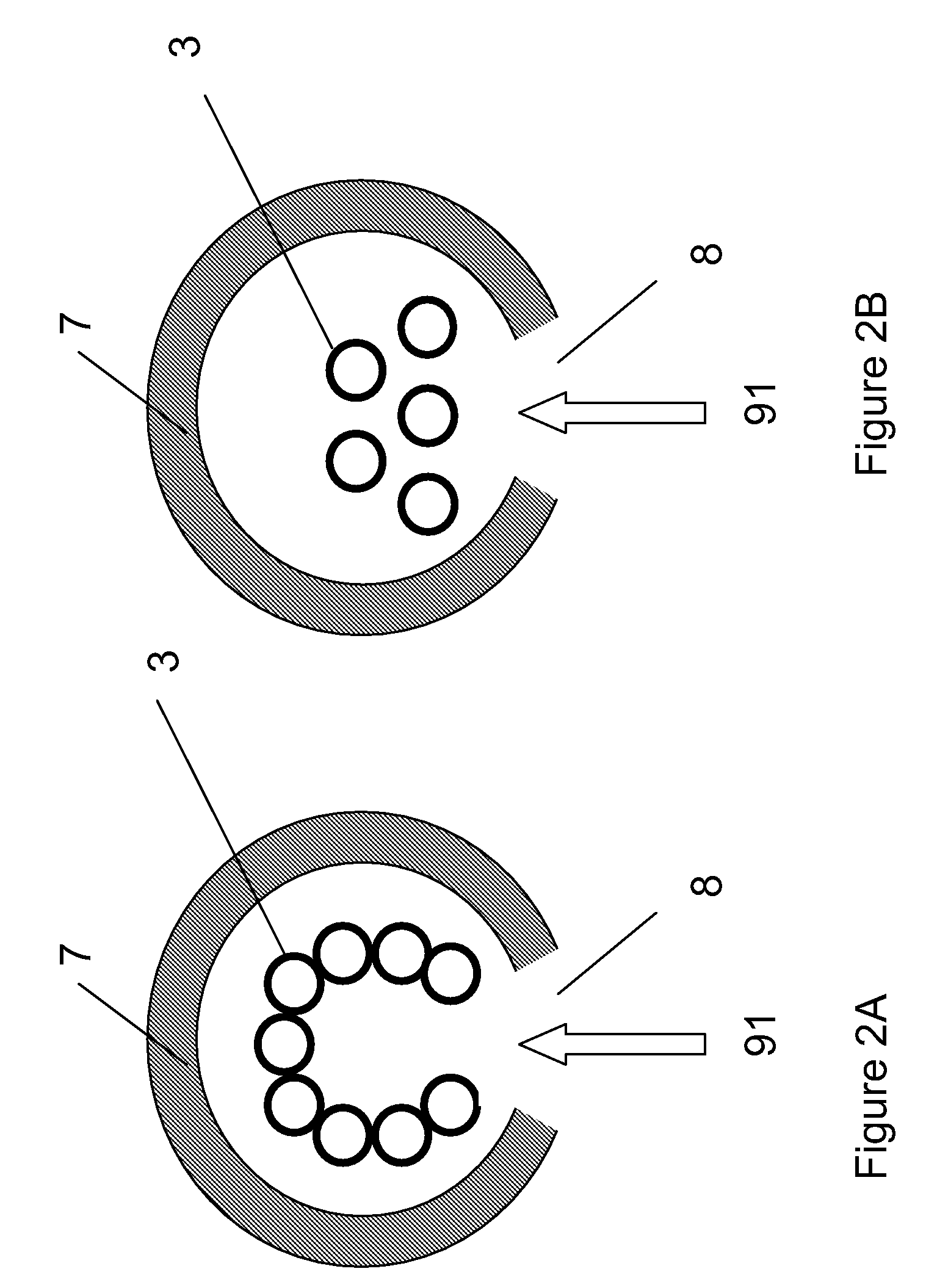

Bubbling bed catalytic hydropyrolysis process utilizing larger catalyst particles and smaller biomass particles featuring an Anti-slugging reactor

This invention relates to a process for thermochemically transforming biomass or other oxygenated feedstocks into high quality liquid hydrocarbon fuels. In particular, a catalytic hydropyrolysis reactor, containing a deep bed of fluidized catalyst particles is utilized to accept particles of biomass or other oxygenated feedstocks that are significantly smaller than the particles of catalyst in the fluidized bed. The reactor features an insert or other structure disposed within the reactor vessel that inhibits slugging of the bed and thereby minimizes attrition of the catalyst. Within the bed, the biomass feedstock is converted into a vapor-phase product, containing hydrocarbon molecules and other process vapors, and an entrained solid char product, which is separated from the vapor stream after the vapor stream has been exhausted from the top of the reactor. When the product vapor stream is cooled to ambient temperatures, a significant proportion of the hydrocarbons in the product vapor stream can be recovered as a liquid stream of hydrophobic hydrocarbons, with properties consistent with those of gasoline, kerosene, and diesel fuel. Separate streams of gasoline, kerosene, and diesel fuel may also be obtained, either via selective condensation of each type of fuel, or via later distillation of the combined hydrocarbon liquid.

Owner:GAS TECH INST

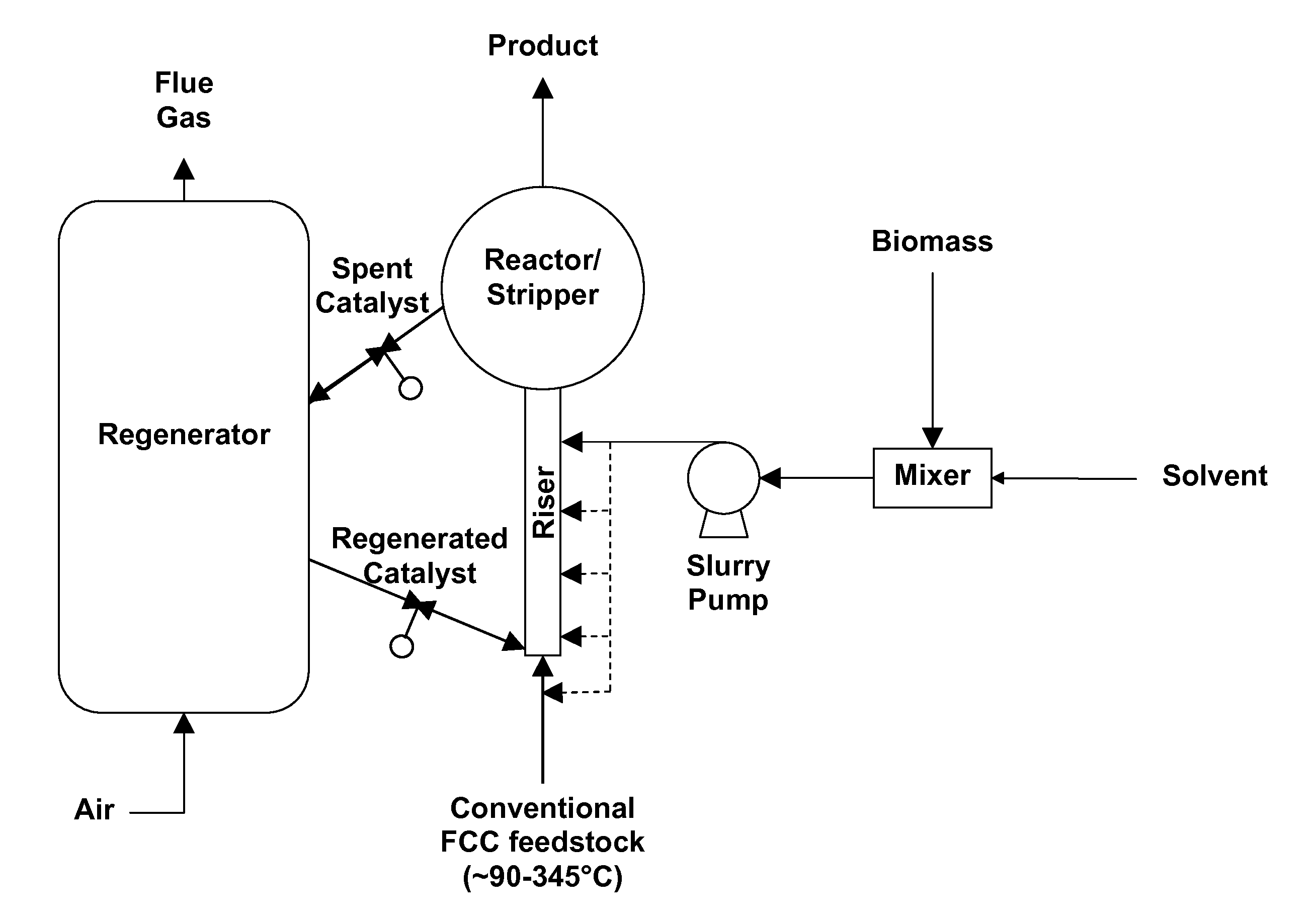

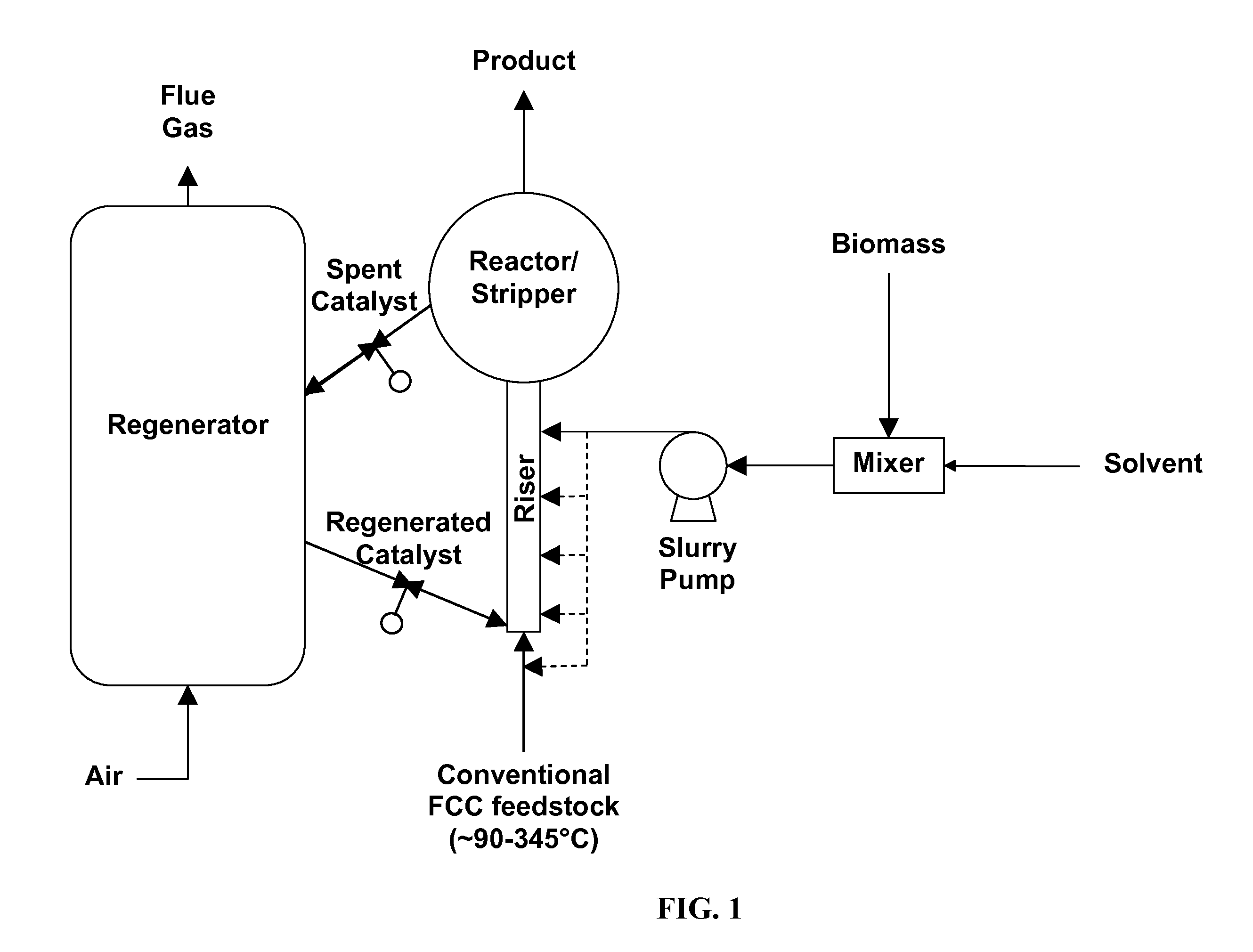

Co-processing solid biomass in a conventional petroleum refining process unit

ActiveUS20120022307A1Reduce degradationReduce energy costsCatalytic crackingOther chemical processesCo-processingPetroleum

Preparing solid biomass particles for catalytic conversion includes agitating solid biomass particles and providing a biomass-catalyst mixture to a conventional petroleum refinery process unit. The biomass-catalyst mixture includes the solid biomass particles and a catalyst. Agitating solid biomass particles includes flowing a gas to provide a velocity to at least a portion of the solid biomass particles sufficient to reduce their sizes. Co-processing a biomass feedstock and a conventional petroleum feedstock includes liquefying at least a portion of a biomass-catalyst mixture and co-processing at least a portion of the liquefied biomass feedstock and a conventional petroleum feedstock in a conventional petroleum refinery process unit. The biomass feedstock includes a plurality of solid biomass particles and a catalyst, which is liquefied to produce a liquefied biomass feedstock.

Owner:MARD INC

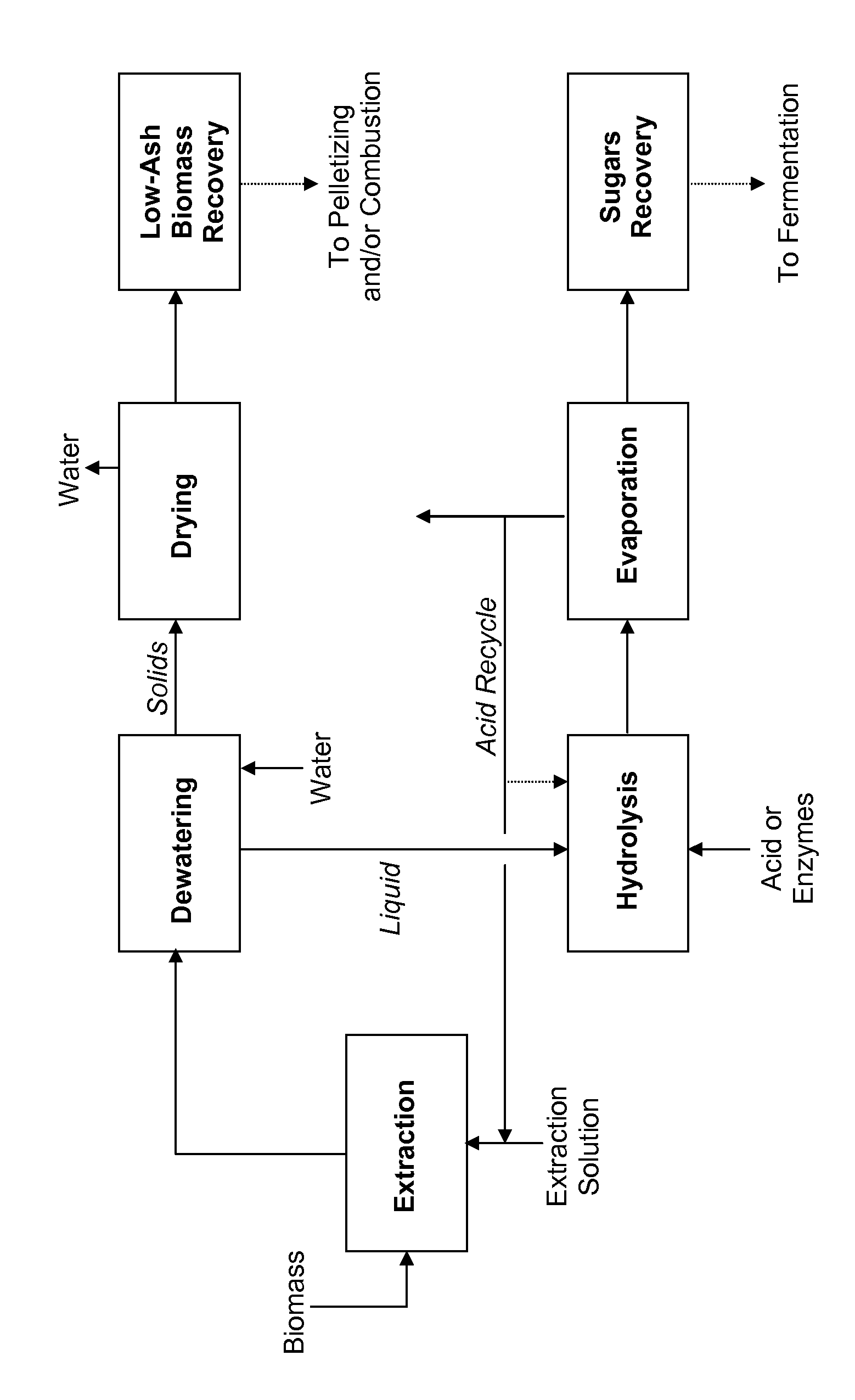

Processes for producing fermentable sugars and low-ash biomass for combustion or pellets

This invention provides processes and apparatus to convert biomass, including wood and agricultural residues, into low-ash biomass pellets for combustion, alone or in combination with another solid fuel. Some embodiments provide processes for producing hemicellulosic sugars and low-ash biomass from cellulosic biomass, comprising providing an aqueous extraction solution with acetic acid; extracting the feedstock to produce an extract liquor containing soluble ash, hemicellulosic oligomers, acetic acid, dissolved lignin, and cellulose-rich solids; dewatering and drying the cellulose-rich, lignin-rich solids to produce a low-ash biomass; hydrolyzing the hemicellulosic oligomers to produce fermentable hemicellulosic sugars, wherein additional acetic acid is generated; removing a vapor stream comprising vaporized acetic acid from the extract; recycling the vapor or its condensate to provide some starting acetic acid for the extraction solution; and recovering fermentable hemicellulosic sugars. The disclosed processes can produce clean power from biomass. Co-products include fermentation products such as ethanol, fertilizers, and lignin.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

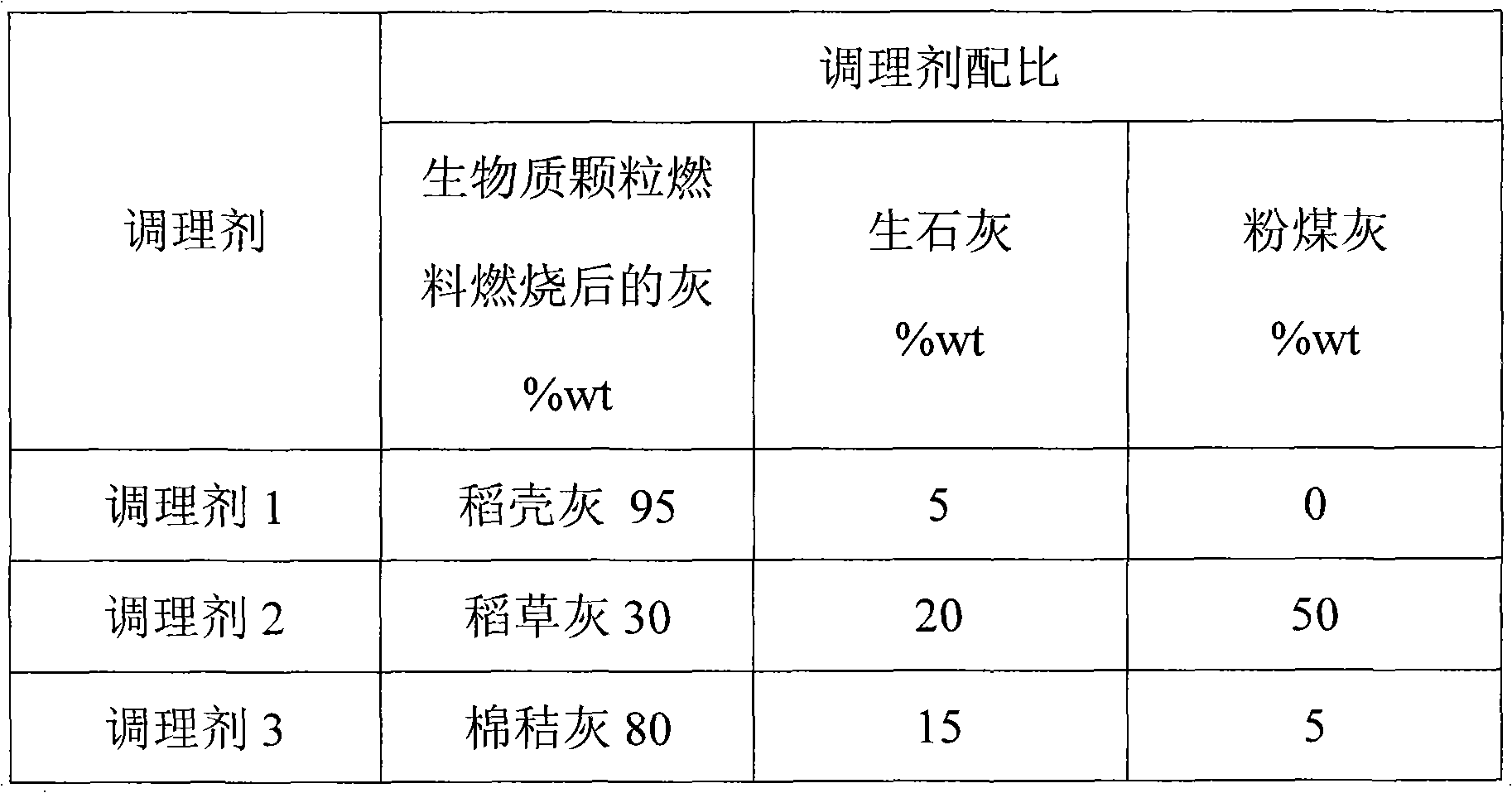

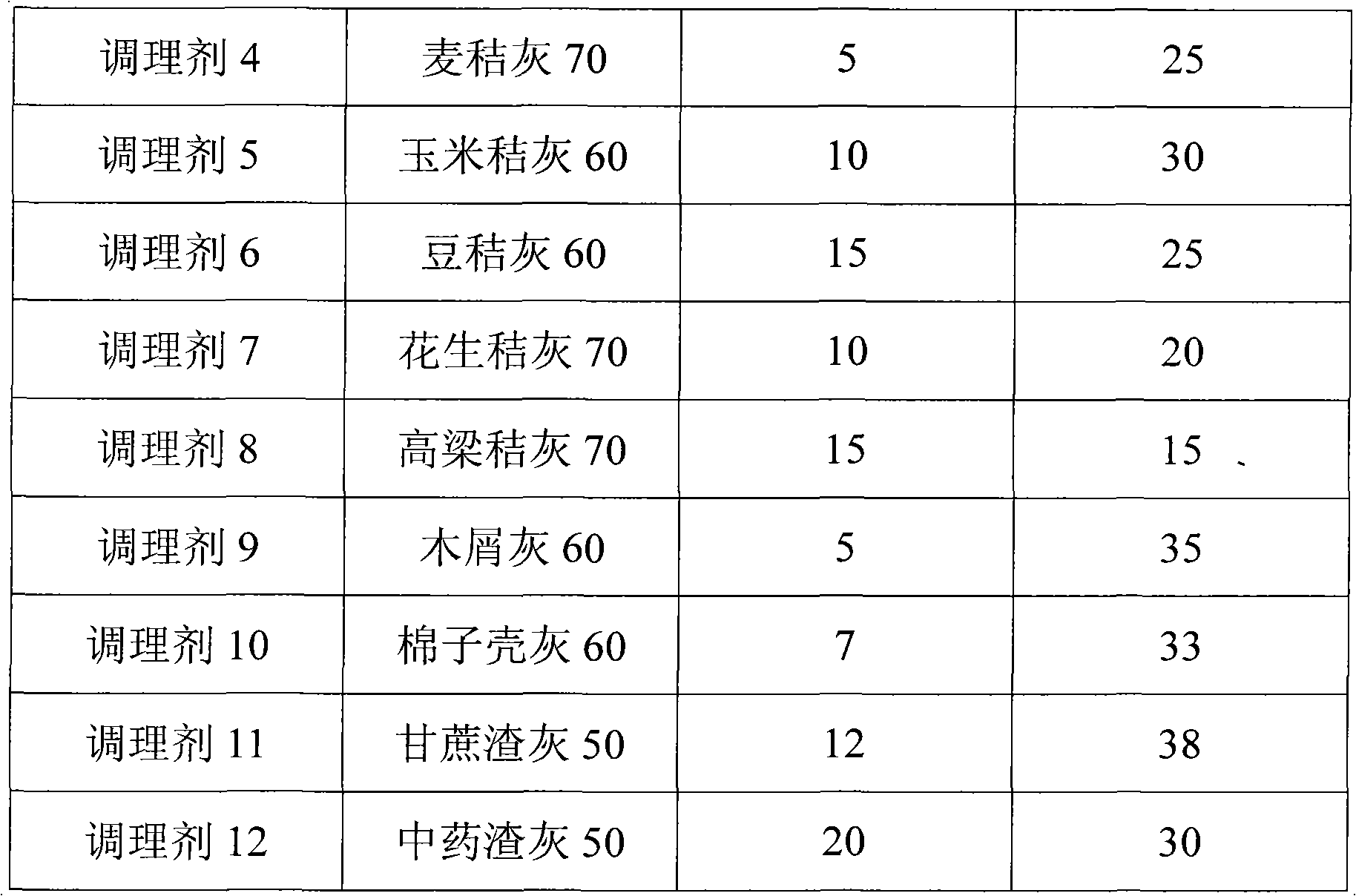

Sludge conditioner and sludge dewatering method thereof

InactiveCN101633549ADestabilizingGood dispersionSludge treatment by de-watering/drying/thickeningPulverized fuel ashMunicipal sewage

The invention belongs to the technical field of municipal sewage sludge treatment, and more particularly relates to a sludge conditioner prepared by ash produced after combustion of biomass pulverized fuel, and a sludge dewatering method thereof. The sludge conditioner is prepared by mixing the raw materials by weight percent: 30-95% of product obtained after the combustion of biomass granule fuel, 5-20% of quicklime powder and 0-50% of pulverized fuel ash. The sludge conditioner is added into water-containing sludge to be evenly stirred and then processed by mechanical dehydration, the water content of sludge mud cake can be reduced to 40-60%, and the sludge specific resistance is reduced to 10<-6>-10<-7>. The invention can solve the problem of deep dehydration of the sludge, and the dehydrated sludge can be used as soil, or raw material for producing clay or building material.

Owner:JIANGHAN UNIVERSITY

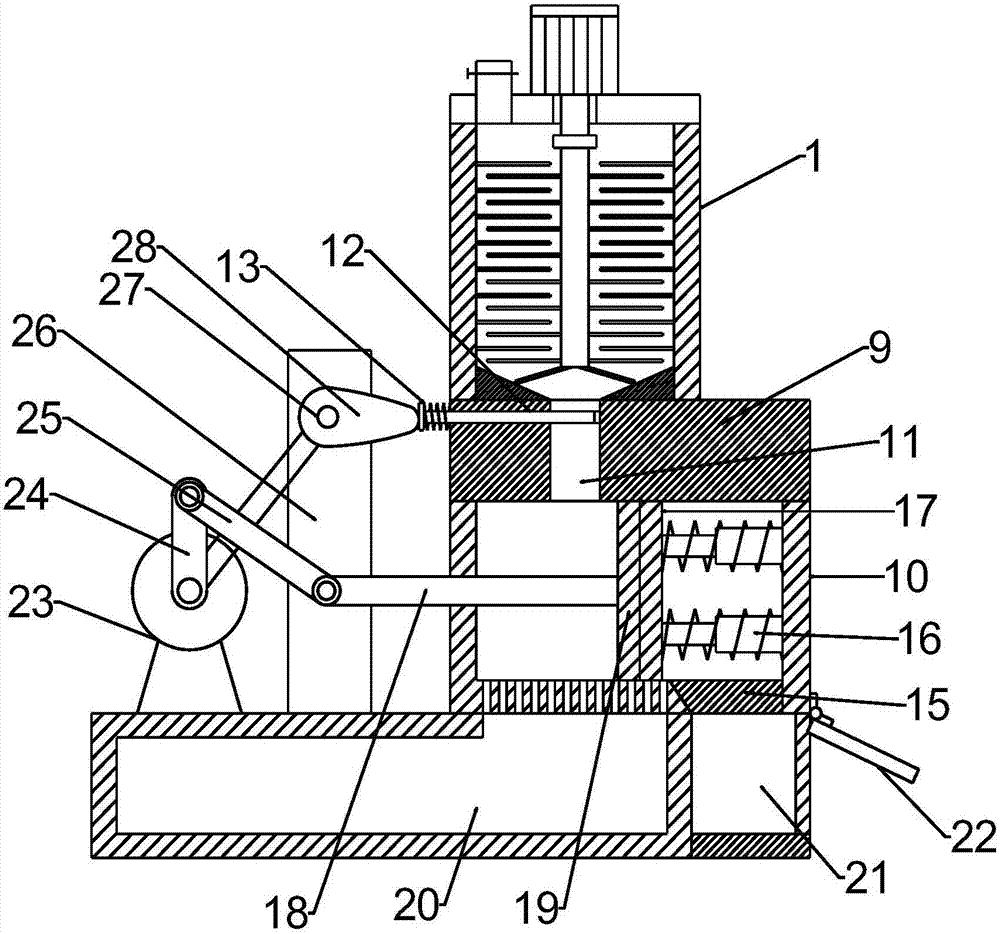

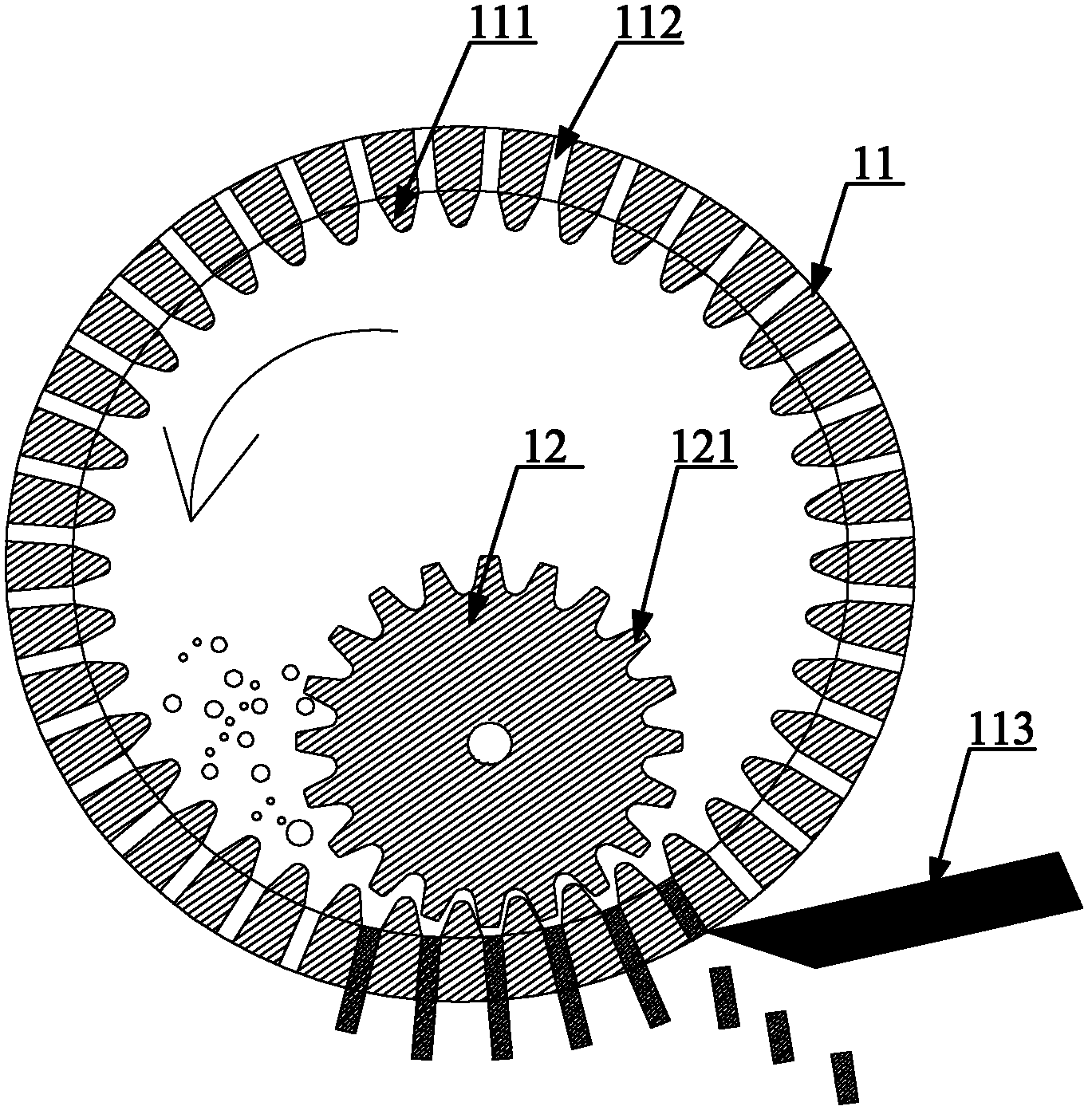

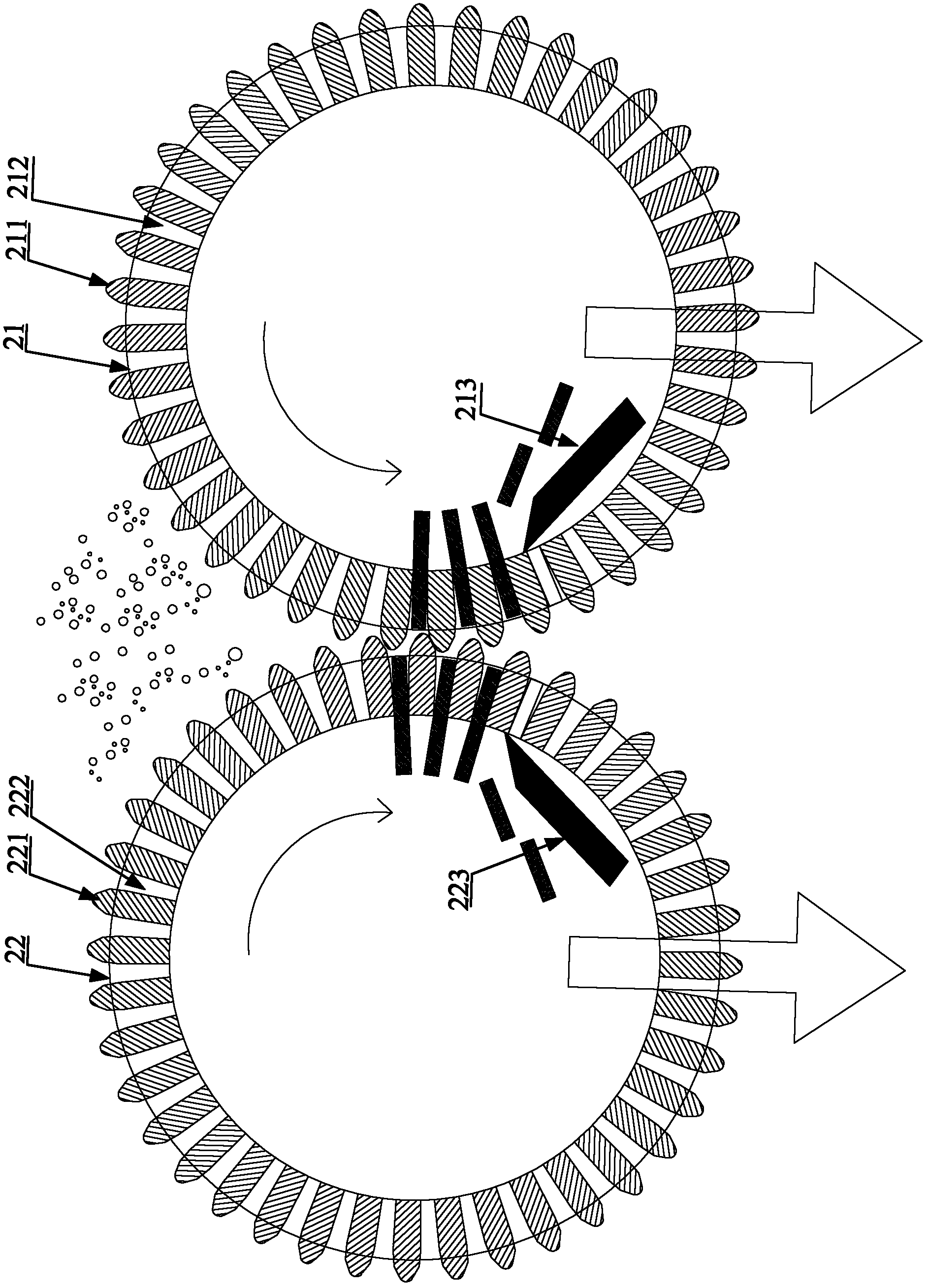

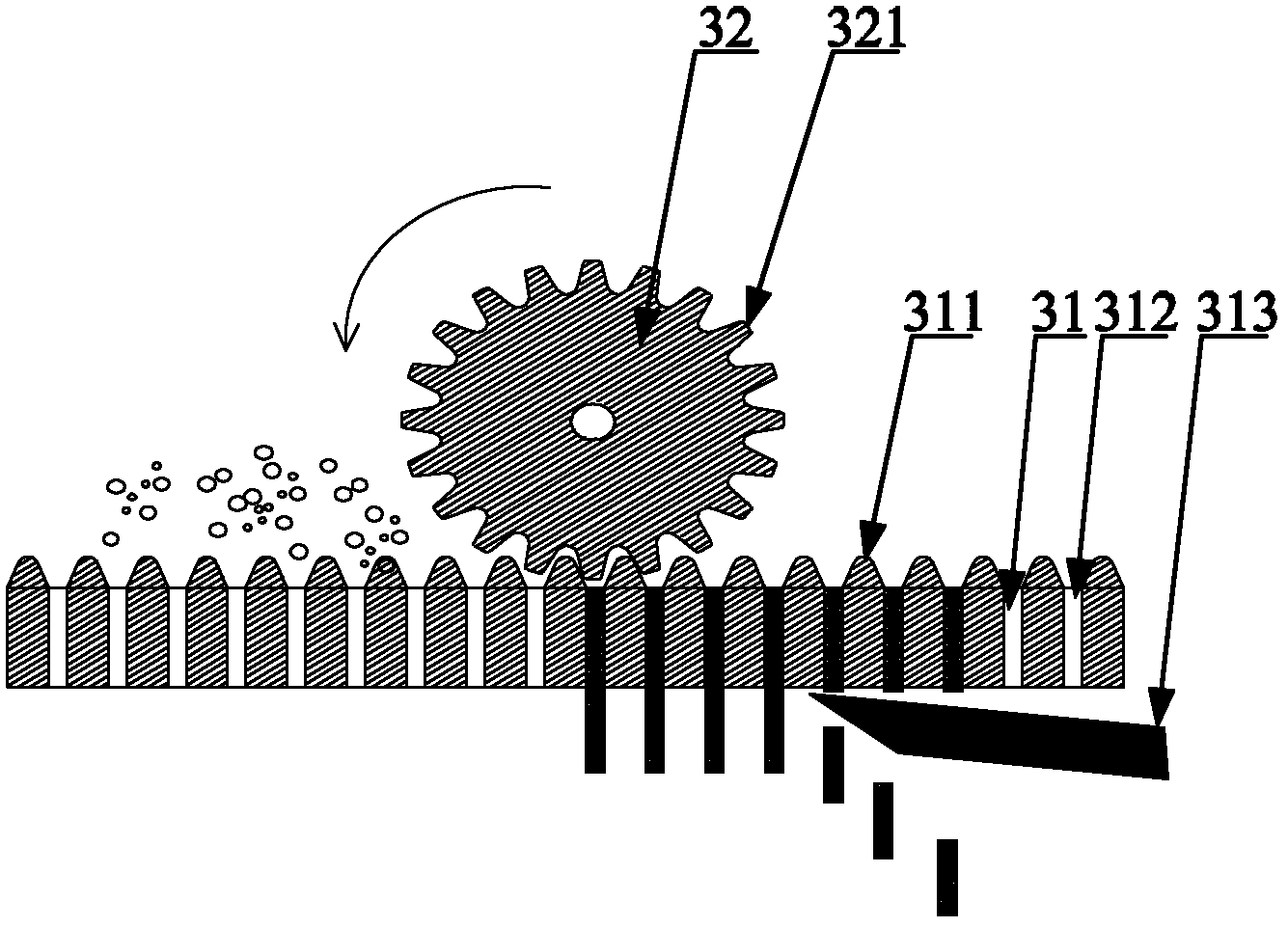

Biomass particle molding module and biomass particle molding machine

InactiveCN102248696AAchieve productionSimple structureGranulation by pressingShaping pressMolding machineEngineering

The invention provides a biomass particle molding module comprising a ring mold and a press roll, wherein particle molding holes are formed on the ring mold; ring mold engaging teeth are arranged on a pressing fit surface of the ring mold; press roll engaging teeth engaged with the ring mold engaging teeth are arranged on a pressing fit surface of the press roll; and the particle molding holes are positioned between the two adjacent ring mold engaging teeth. In the biomass particle molding module provided by the invention, the slipping phenomenon between the ring mold and the press roll in the material extruding process is avoided through the engaging fit between the ring mold engaging teeth and the press roll engaging teeth. The invention also provides a biomass particle molding machine on which the biomass particle molding module is arranged.

Owner:YIWU ANDONG ELECTRICAL APPLIANCES

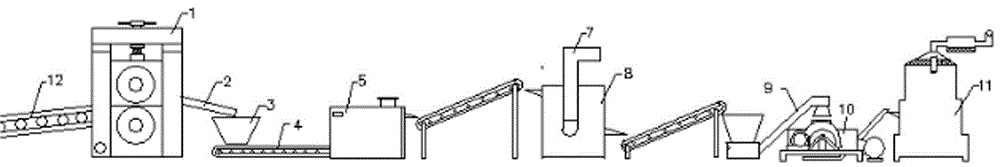

Municipal refuse handling method and equipment

The invention relates to a municipal refuse handling method and equipment. The handling method includes the steps of squeezing for water removal, magnetic separation sorting, first-stage smashing, blasting separation, second-stage smashing, biomass fuel adding, pelletizing and particle burning heating and steam generation or power generation; and the handling equipment comprises a feeding conveying device, a magnetic separation conveying device, a material collecting hopper, a discharging plate, a magnetic separation device, an air blower, a mixing and stirring machine, a refuse water removal roller press, a biomass particle machine, a refuse smashing machine and a smokeless burning device. According to the municipal refuse handling method and equipment, the refuse handling process is simple, a bonding assistant does not need to be added during pelletizing, and manufactured municipal refuse combustible particles are smooth in surface, compact in structure, higher in calorific value, high in drying degree and free of pollution during burning.

Owner:黎汉东

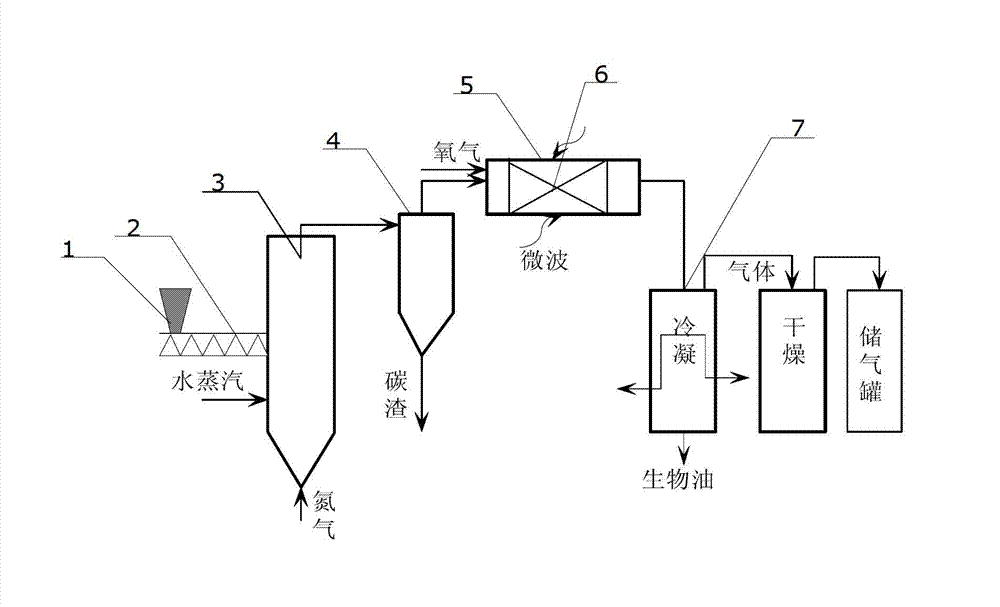

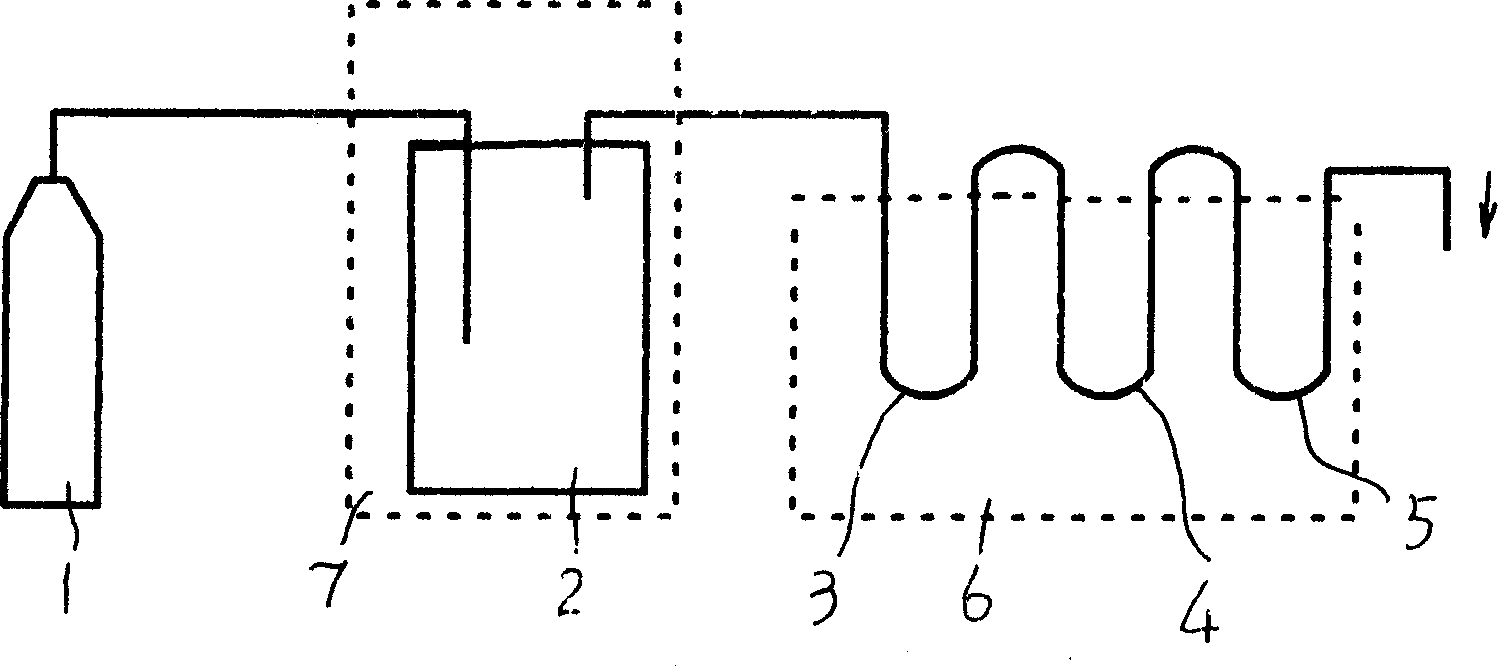

Method for preparing hydrogen-rich synthesis gas via biomass pyrolysis

InactiveCN102963866AReduce gasification cokingReduce energy consumptionHydrogenBiofuelsCatalytic reformingMicrowave

The invention discloses a method for preparing a hydrogen-rich synthesis gas via biomass pyrolysis, comprising the following steps of: by taking biomass particles having a particle size of not greater than 2 mm as raw materials, conveying the biomass particles in a fluidized bed reactor in which the N2 flow of a fluidized bed is 1.0-1.5m<3> / h and the pressure is 0.01-0.08 MPa via a spiral feeder at a speed of 0.005-0.01 t / h; performing pyrolysis at the temperature of 450-550 DEG C; performing catalytic reforming on the surface of a catalyst by the highly-hot vapour generated by the pyrolysis reaction through a microwave catalytic bed; and further transforming biological oil vapour to the synthesis gas, and charging a small amount of oxygen in the microwave catalytic bed to inhibit coking on the surface of the catalyst. According to the invention, energy consumption is reduced, and the transformation rates of hydrogen and biomass are increased by performing a catalytic reforming reaction on a microwave stationary bed via the biological oil vapour after the first-stage fluidized bed pyrolysis.

Owner:ANHUI UNIV OF SCI & TECH

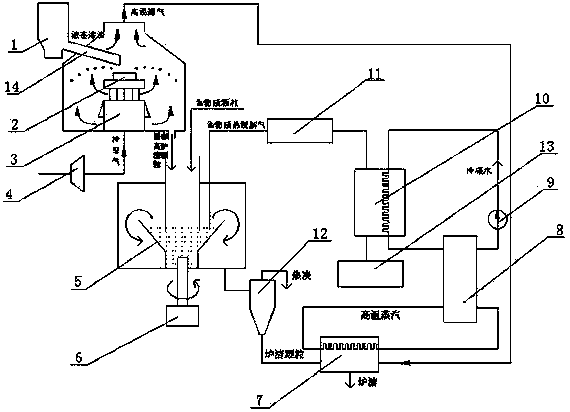

Device and method for preparing biomass oil by using waste heat of blast furnace granulated slag

InactiveCN103396823ARapid coolingRapid lysisDirect heating destructive distillationEnergy inputHeat carrierHeat energy

The invention provides a device and method for preparing biomass oil by using waste heat of blast furnace granulated slag. The method comprises the following steps: granulating blast furnace molten slag into blast furnace granulated slag through a granulator, delivering the blast furnace granulated slag serving as heat carrier particles for preparation of biomass oil into a rotary conical reactor, mixing with biomass particles, performing heat transfer and mass transfer reaction on the mixed particles under the rotation driving action of the reactor to quickly crack and gasify the biomass particles, and cooling the generated condensable gas to obtain the biological oil. The technical scheme of the invention maximally uses a large mount of waste heat contained in the high-temperature granulated slag for preparation of biomass oil, provides 'free' energy for production of biomass energy and can provide sufficient heat energy, and recycling of the waste heat further lowers production cost of biomass liquefaction, so that the main bottleneck constraining industrial production of biomass energy at present is solved, thereby effectively solving the problem that the production cost of biomass fuel is too high, which restricts industrialization of the biomass fuel.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

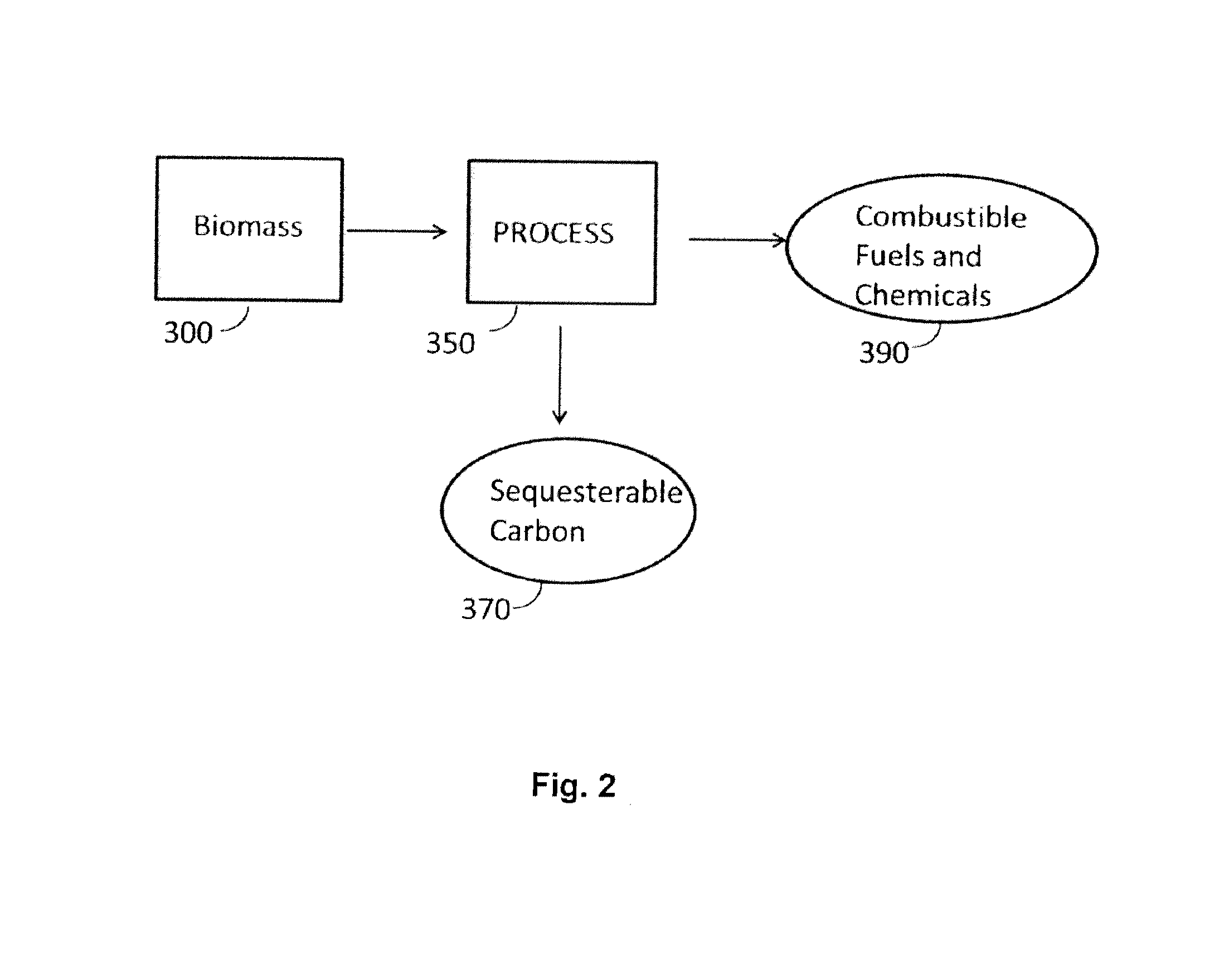

Modification of biomass for efficient conversion to fuels

A process is disclosed for preparing biomass particles for thermolytic or enzymatic conversion whereby the biomass particles baying a moisture content of at least 20% are subjected to flash heating. The flash heating may be preceded by one or more adsorption / desorption cycles with water or steam. A swelling aid may be added during the adsorption part of an adsorption / desorption cycle.

Owner:MARD INC

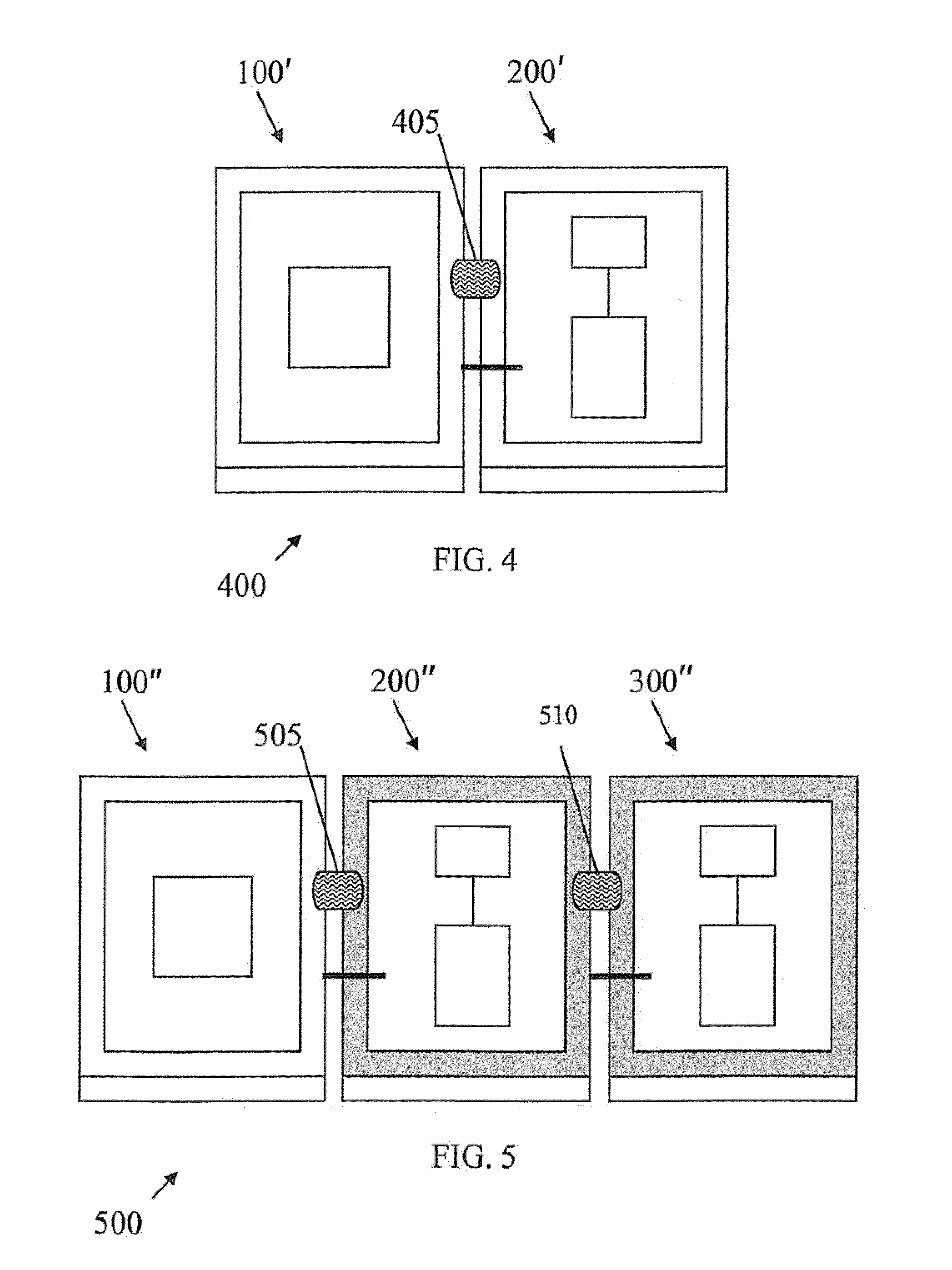

Modular biomass treatment unit

ActiveUS20100281759A1Reduce degradationReduce energy costsCharging-discharging device combinationsBiofuelsSpeciality chemicalsCompound (substance)

A modular biomass treatment unit includes a first module having a pretreater and a first frame for transportation to and operation at a site adjacent to a solid biomass growth source. The pretreater is operable to process solid biomass to produce a plurality of solid biomass particles for conversion into a fuel or specialty chemical. The first frame supports the pretreater during transportation to and operation at the site adjacent to the solid biomass growth source. The modular biomass treatment unit can also include additional modules each comprising a reactor, a separator, and a frame for transportation to and operation at a site such as the site adjacent to the solid biomass growth source.

Owner:MARD INC

Process of preparing rich acetone alcohol biological oil by biomass microwave catalytic pyrolysis

InactiveCN100999676AHighly selective generationImprove use valueOrganic chemistryLiquid hydrocarbon mixture productionCatalytic pyrolysisLiquid product

The microwave catalytic biomass cracking process for preparing biological oil with rich acetone alcohol features using sodium carbonate as catalyst, silicon carbide as microwave absorbing medium, microwave source as heat source for cracking biomass, and ice water mixture for cooling volatile component to obtain biological oil with rich acetone alcohol. By means of the unique temperature effect of microwave in biomass particle and the unique catalyzing effect of sodium carbonate in cracking biomass, the present invention realizes the creation of acetone alcohol in high selectivity. The present invention can obtain liquid product with acetone alcohol content of 30-55 % and raise the utilization value of acetone alcohol greatly. The present invention uses cheap and facile material and catalyst and has greatly shortened reaction period.

Owner:ANHUI UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com