Biomass spiral pyrolysis device and pyrolysis process

A biomass and pyrolysis technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of restricting the promotion of pyrolysis technology and low added value, and achieve the effects of convenient storage and transportation, controllable components, and easy extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

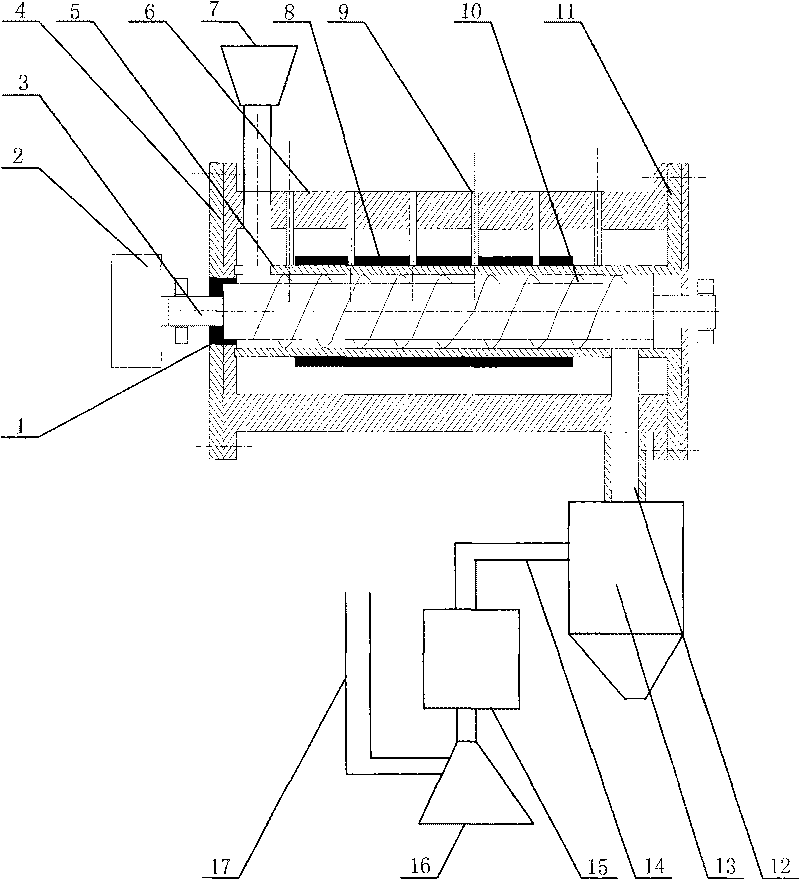

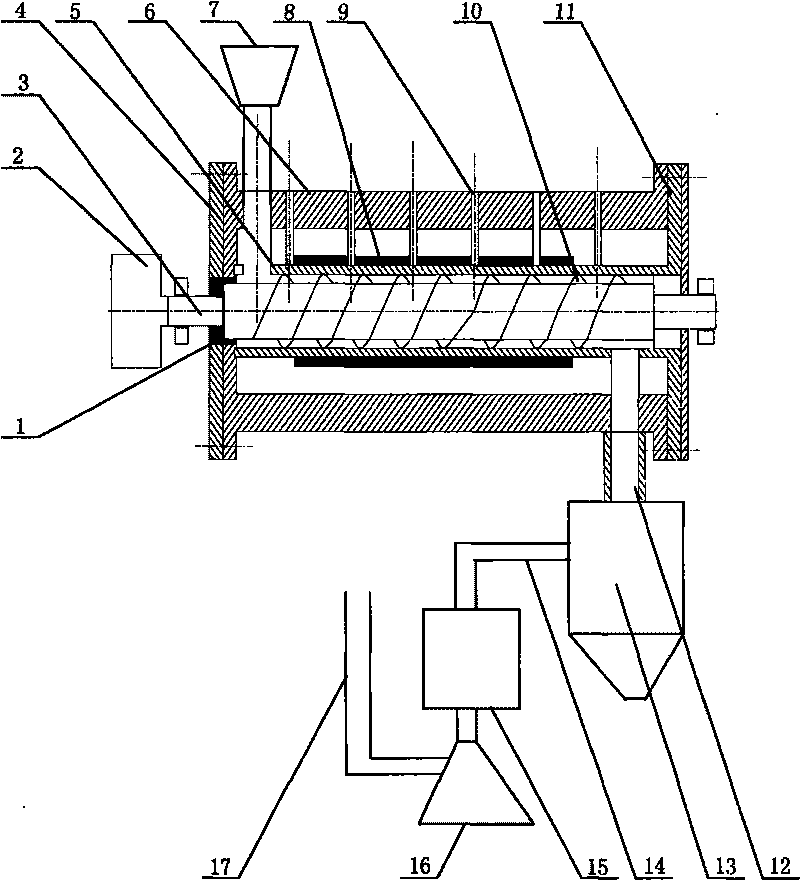

[0030] see figure 1 One end of the cylinder body 5 of the garden cylindrical reactor is flange-shaped, and the two ends of the outer sleeve 6 that plays a role in heat insulation are also flange-shaped, and the cylinder body 5 and the outer sleeve 6 are nested together, adding The upper, left, and right end covers 4, 11 and the threaded connectors form a whole. There is a large enough gap between the inner wall of the outer sleeve 6 and the outer wall of the cylinder body 5. Four electric heating plates 8 are arranged in this gap and surrounded by on the outer wall of the barrel 5. The electric heating plate is a 4×1KW electric heating plate with adjustable power, which is controlled by four thermocouples 9 respectively. After reaching the set temperature, the heating power is automatically reduced, so the reaction temperature in the reactor can be effectively controlled at a certain temperature. range (500-550°C). Four thermocouples independently control four heating plates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com