Patents

Literature

231results about How to "Consistent concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

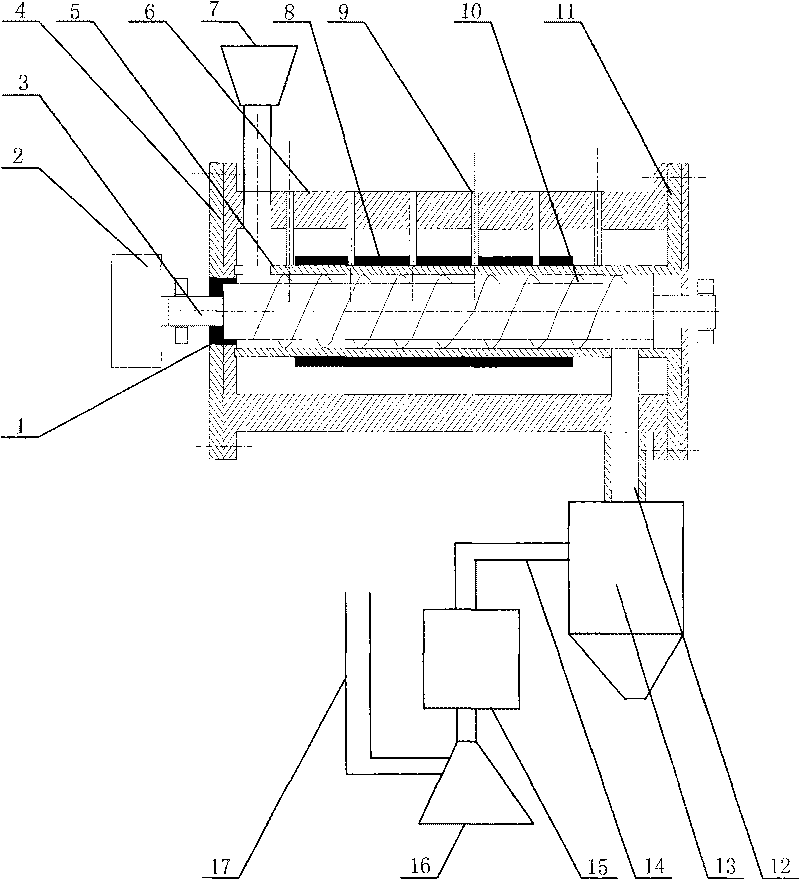

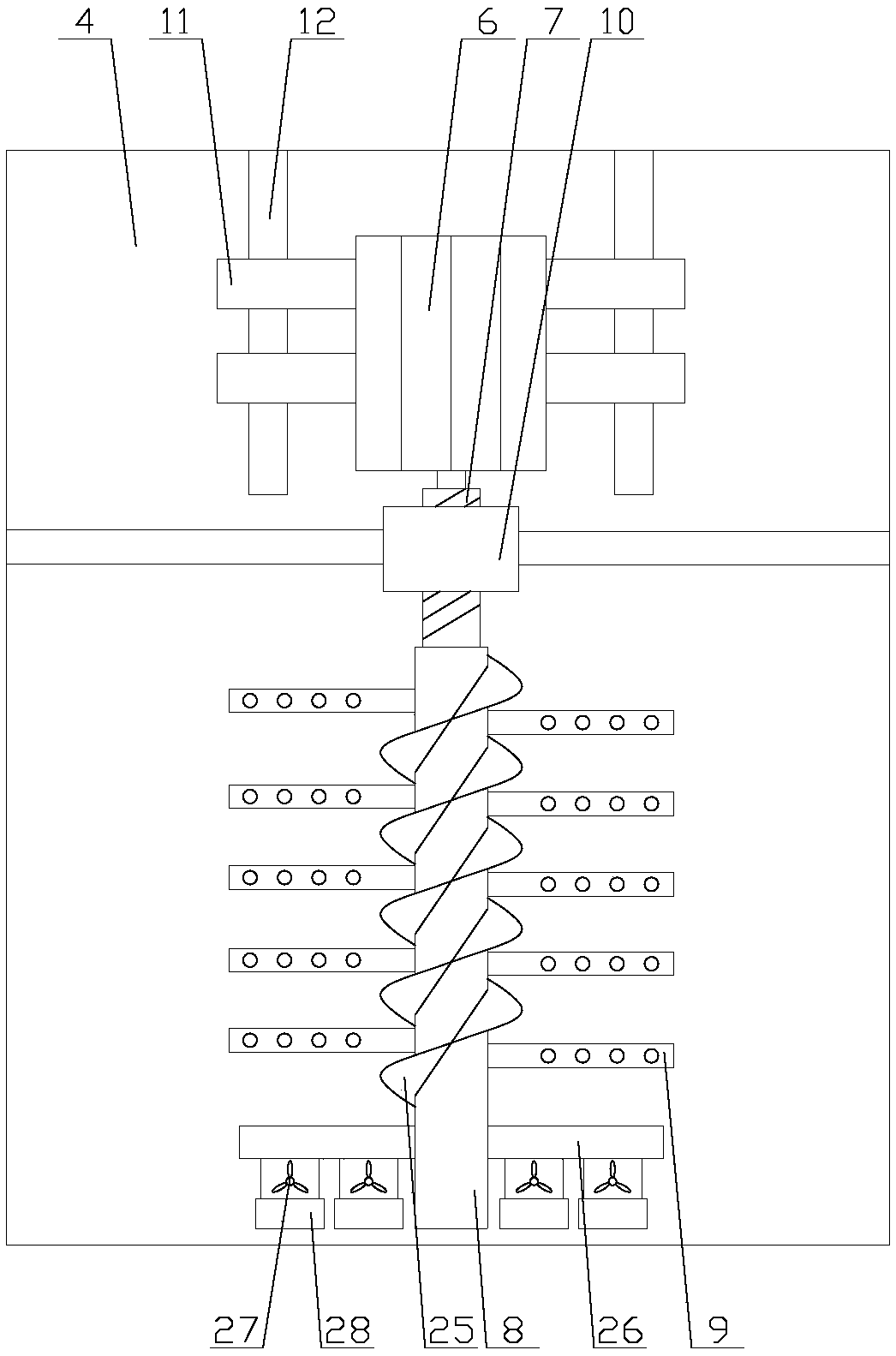

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

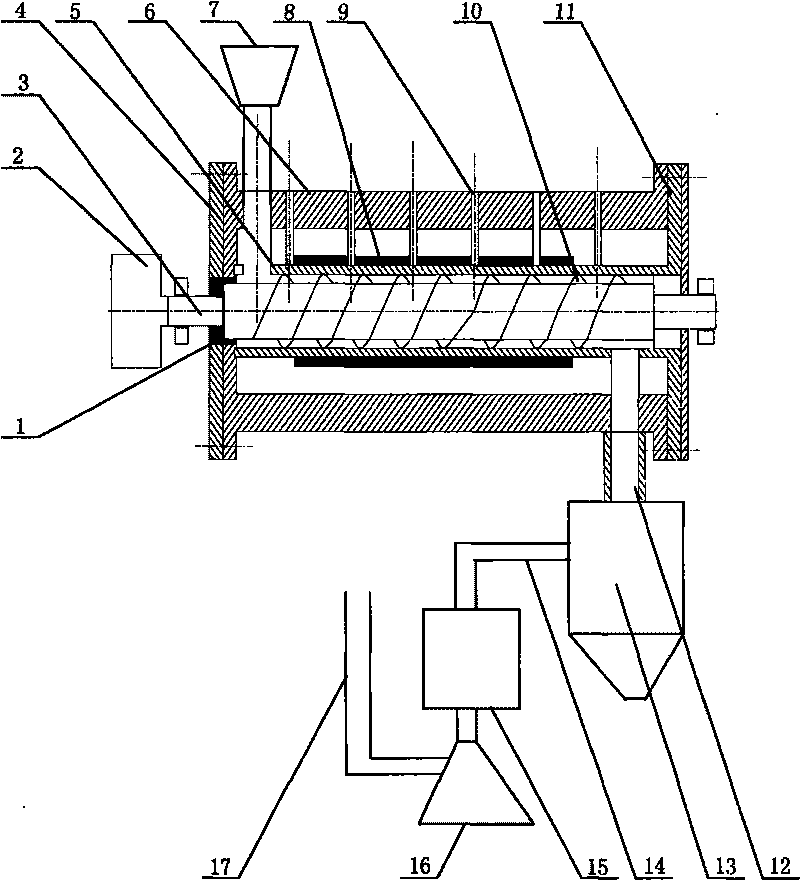

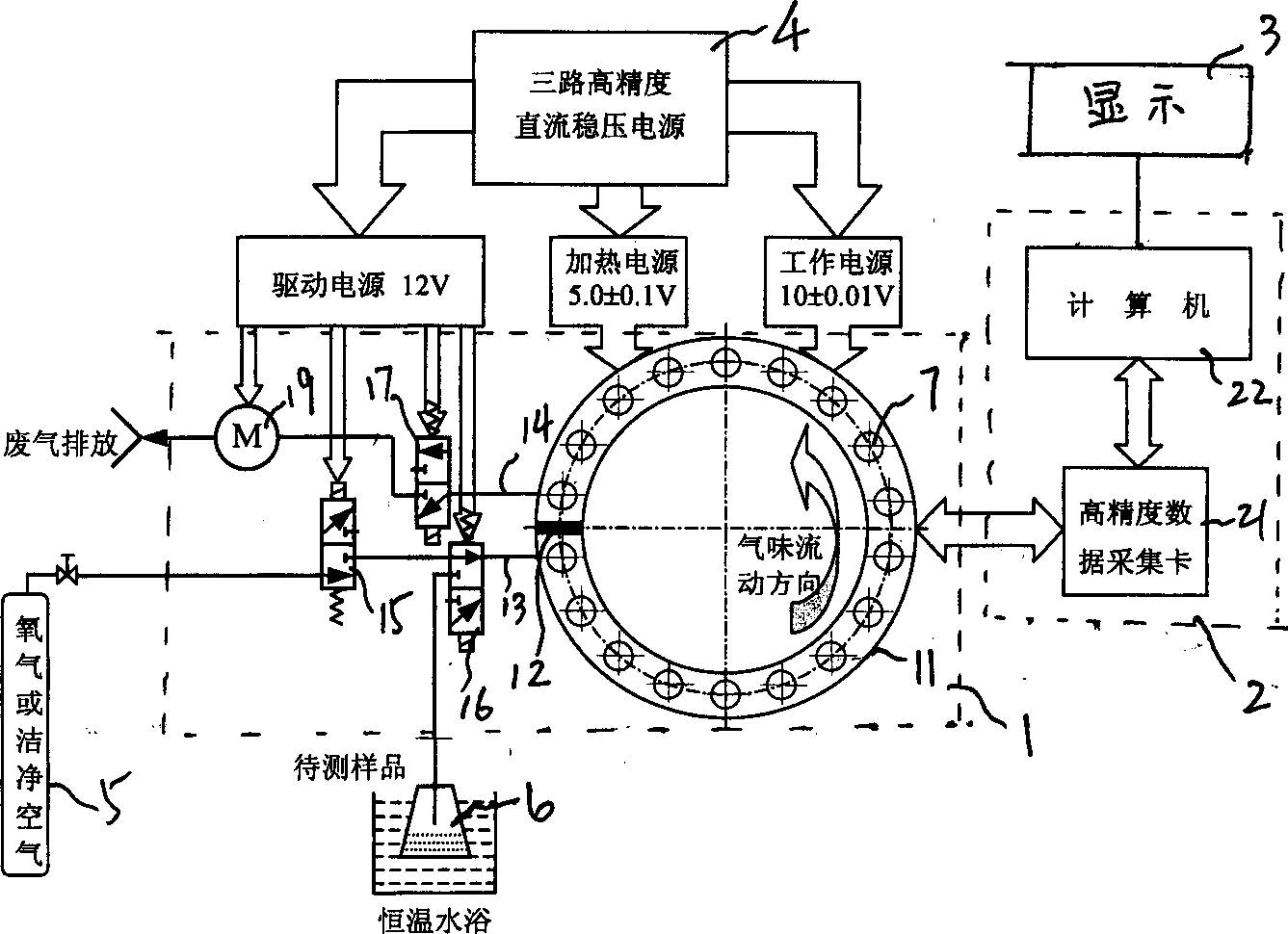

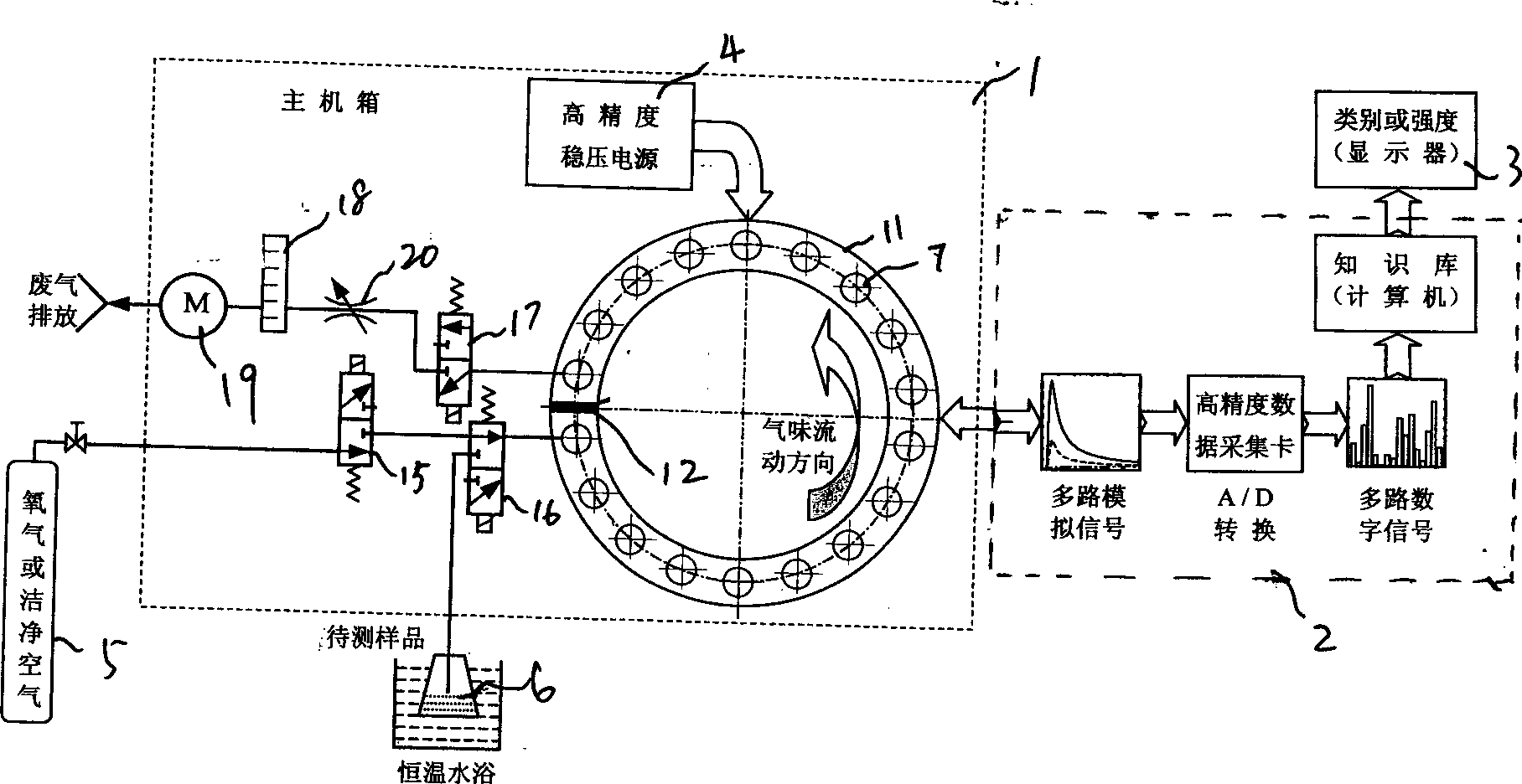

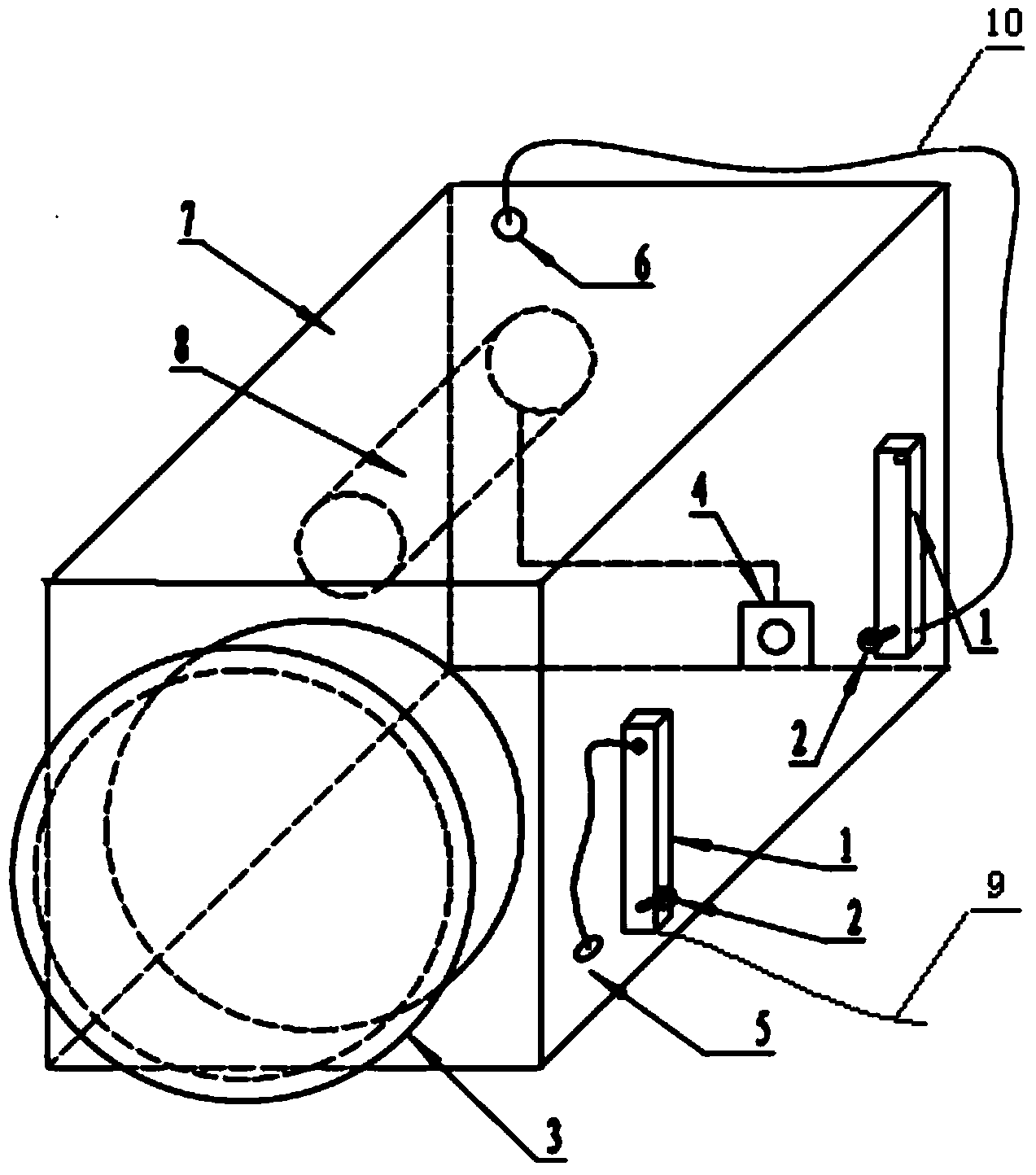

Olfactory simulator and its olfactory simulation testing method

InactiveCN1367381AConcentration did not decreaseSmall volumeMaterial resistanceGas detectorDisplay device

The present invention relates to an olfactory simulation device and its olfactory simulation testing method. Said device is formed from main machine box, computer processing portion, display portion and power supply circuit, and said method includes the following steps: a). the odor to be tested can be sucked into ring testing box by means of miniature diaphragm pump, said gas can be quickly passed through sensing membrane surface of every sensor, then discharged from outlet; b). every response produced by every gas sensor when the gas is passed through every sensor can be collected into datacollecting card, passed through A / D converter to obtain a multidimensional response signal; and c). said signal is processed by computer so as to can obtain the type of odor to be tested, integral intensity and its simple component composition, and can be displayed.

Owner:SHANGHAI HUIBI INTELLIGENCE SCI & TECH

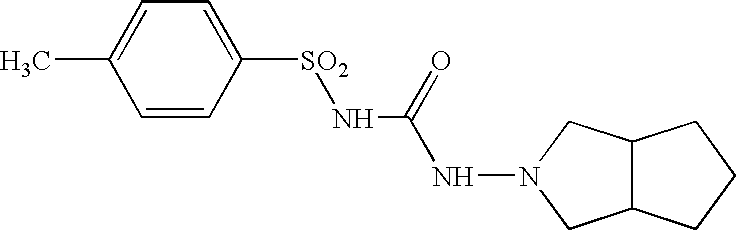

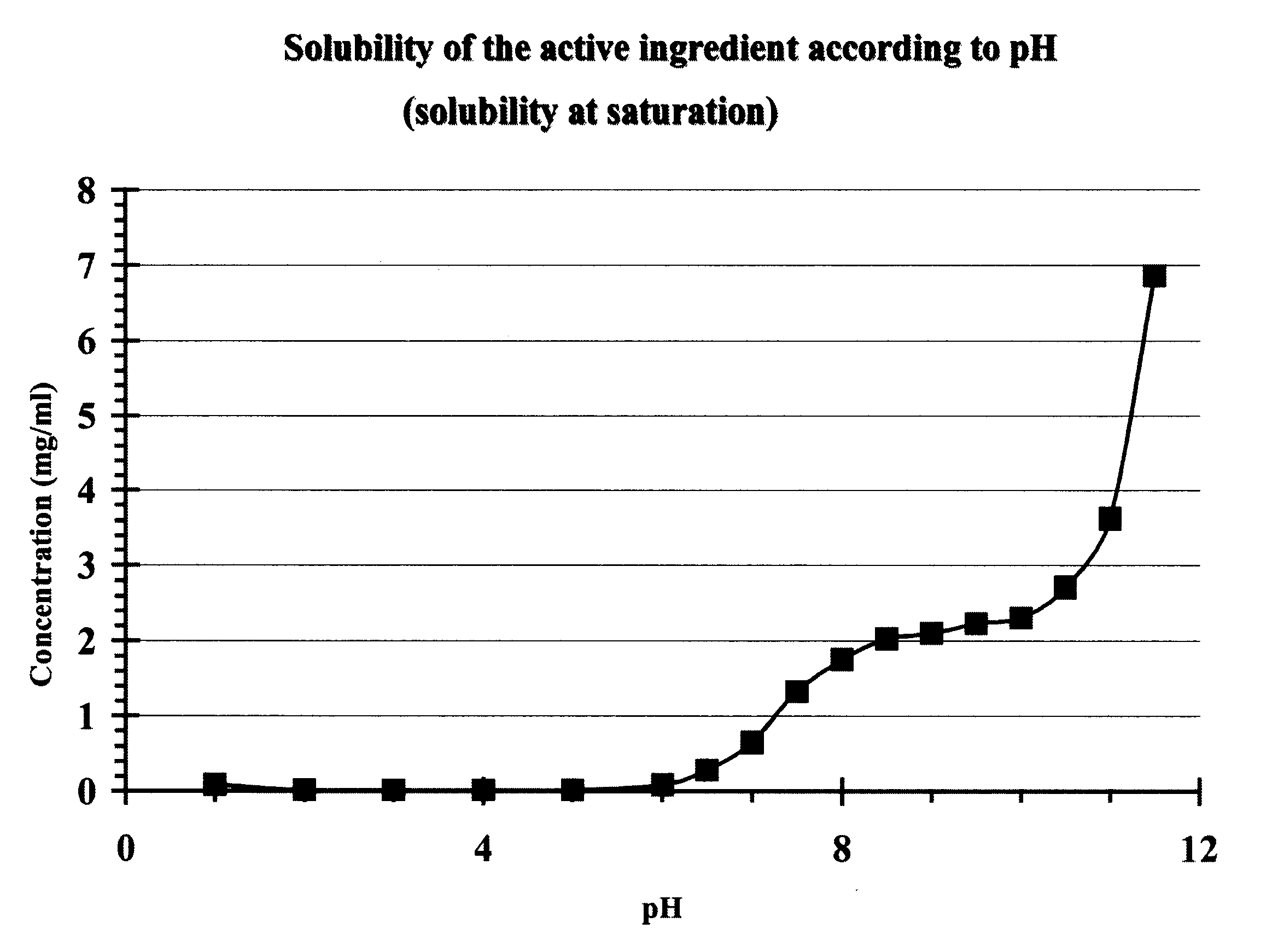

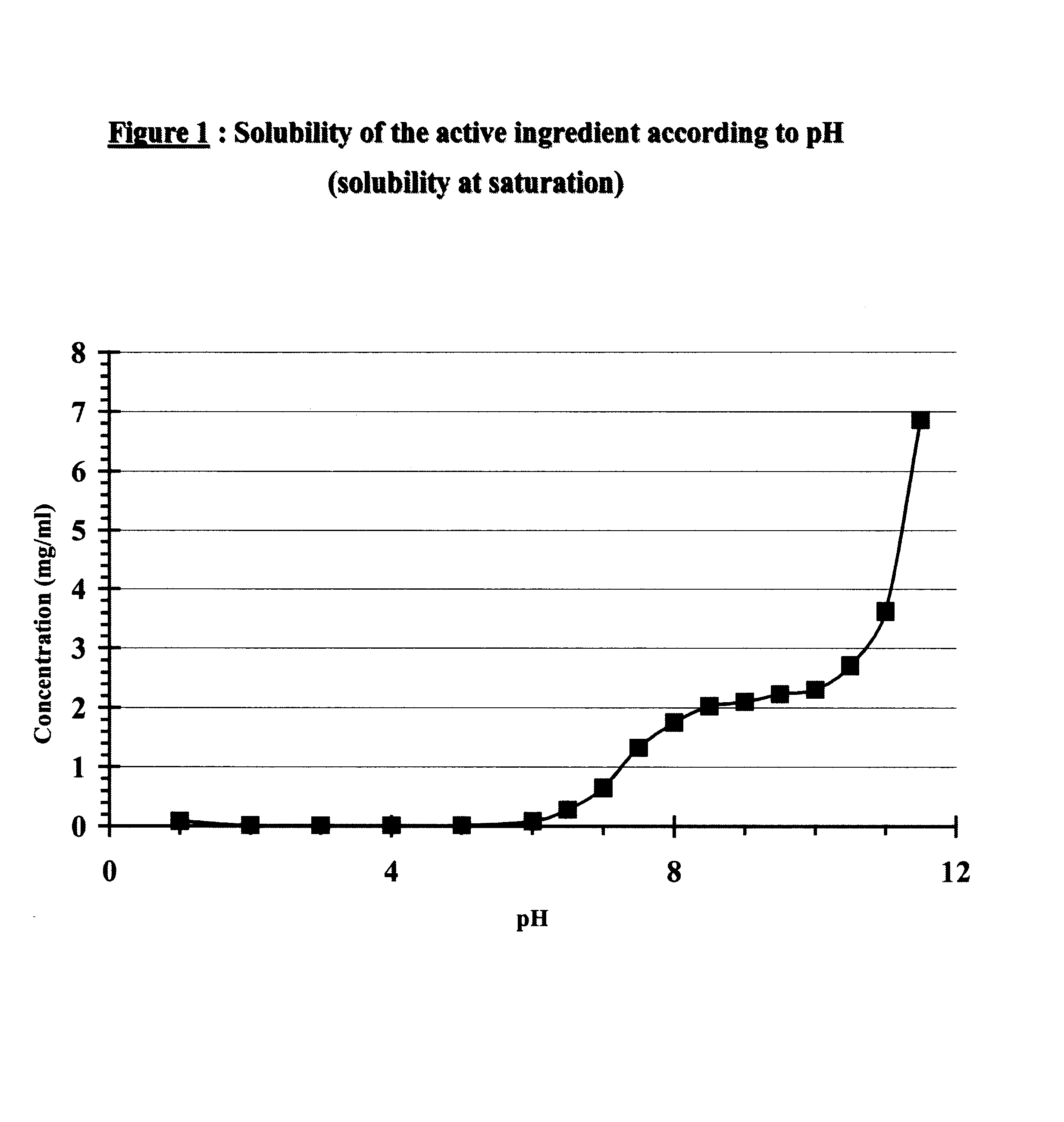

Core tablet for controlled release of gliclazide after oral administration

InactiveUS6733782B1Facilitated releaseIncrease concentrationPowder deliveryMetabolism disorderControlled releaseOral medication

The invention relates to a matrix tablet for the prolonged release of gliclazide which ensures continuous and consistent release of the active ingredient after administration by the oral route, the release being insensitive to variations in the pH of the dissolution medium.

Owner:LES LAB SERVIER

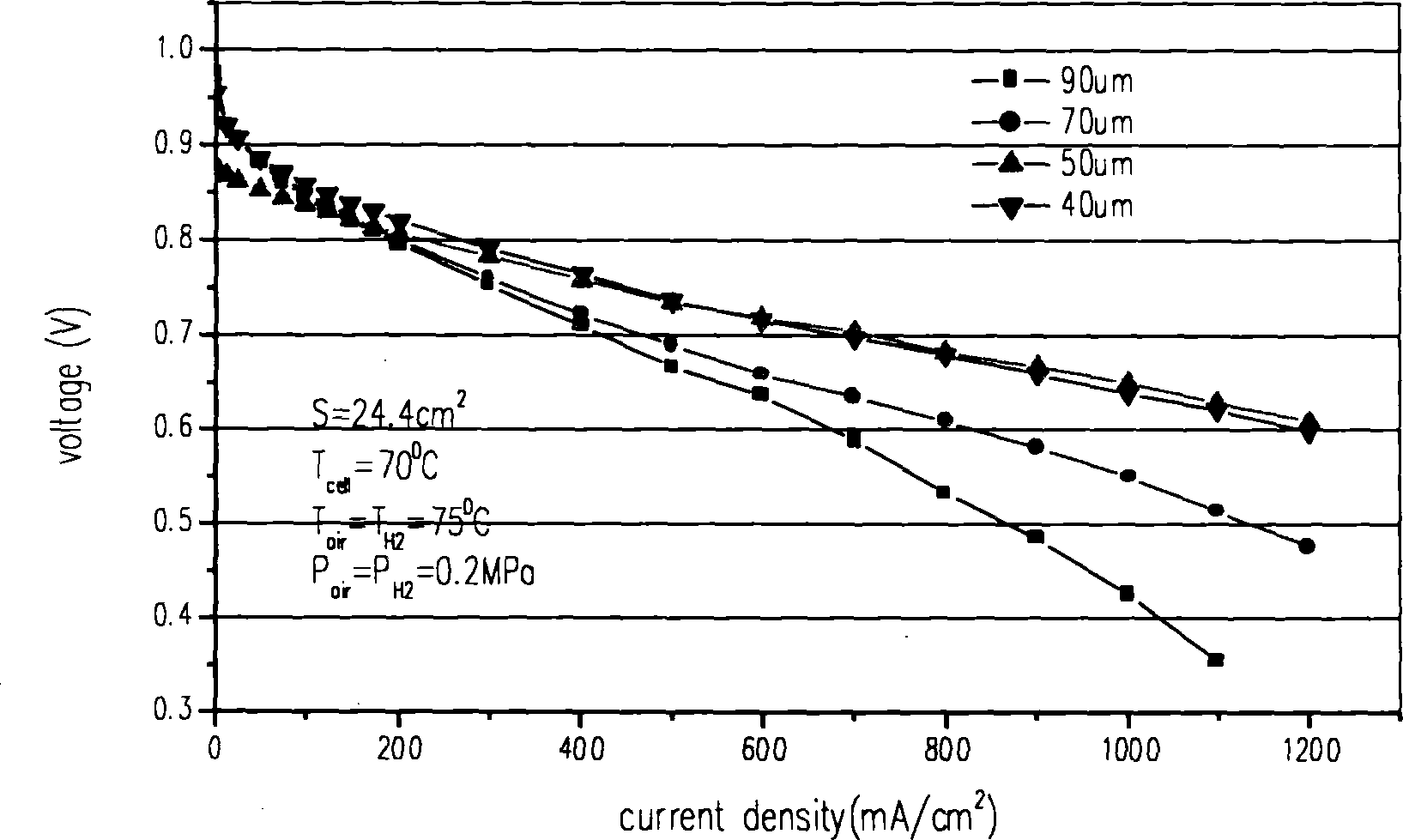

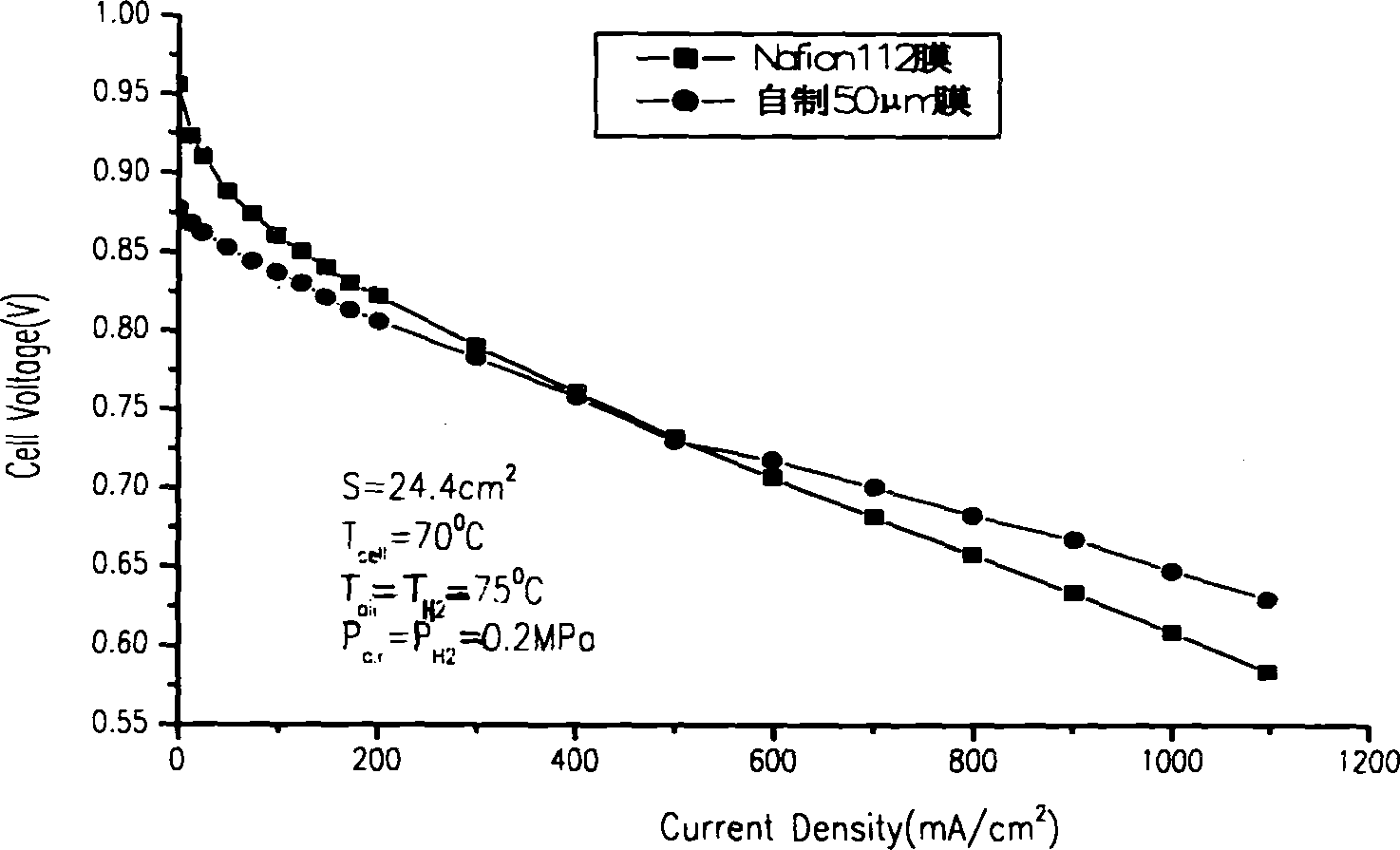

Process for preparing perfluorinated sulfonic resin solution by using waste ion exchange membrane in chlor-alkali industry

The invention discloses a method for preparing perfluoro sulfonic resin with abandoned ion exchange membrane in alkali-chloride industry, comprising following steps: swelling said abandoned ion with lower alcohol, emulsifying it with emulsion machine to resin particle, adding alcohol / water solvent and resin particle into autoclave, dissolving resin particle under high temperature and pressure and protection of nitrogen; getting solid mixture of perfluoro sulfonic resin and solution, separating with solid-liquid separation method and getting perfluoro sulfonic resin solution and solid perfluoro sulfonic resin. The resin solution is characterized by transparent, low content of foreign matter, high purity, similar property to that of Nafion EW 1100 solution, usage in field of mending ionic membrane pinhole and other mechanical damage, preparation of fuel battery proton exchange membrane and stereoscopic electrode and chemical catalysis.

Owner:SUNRISE POWER CO LTD

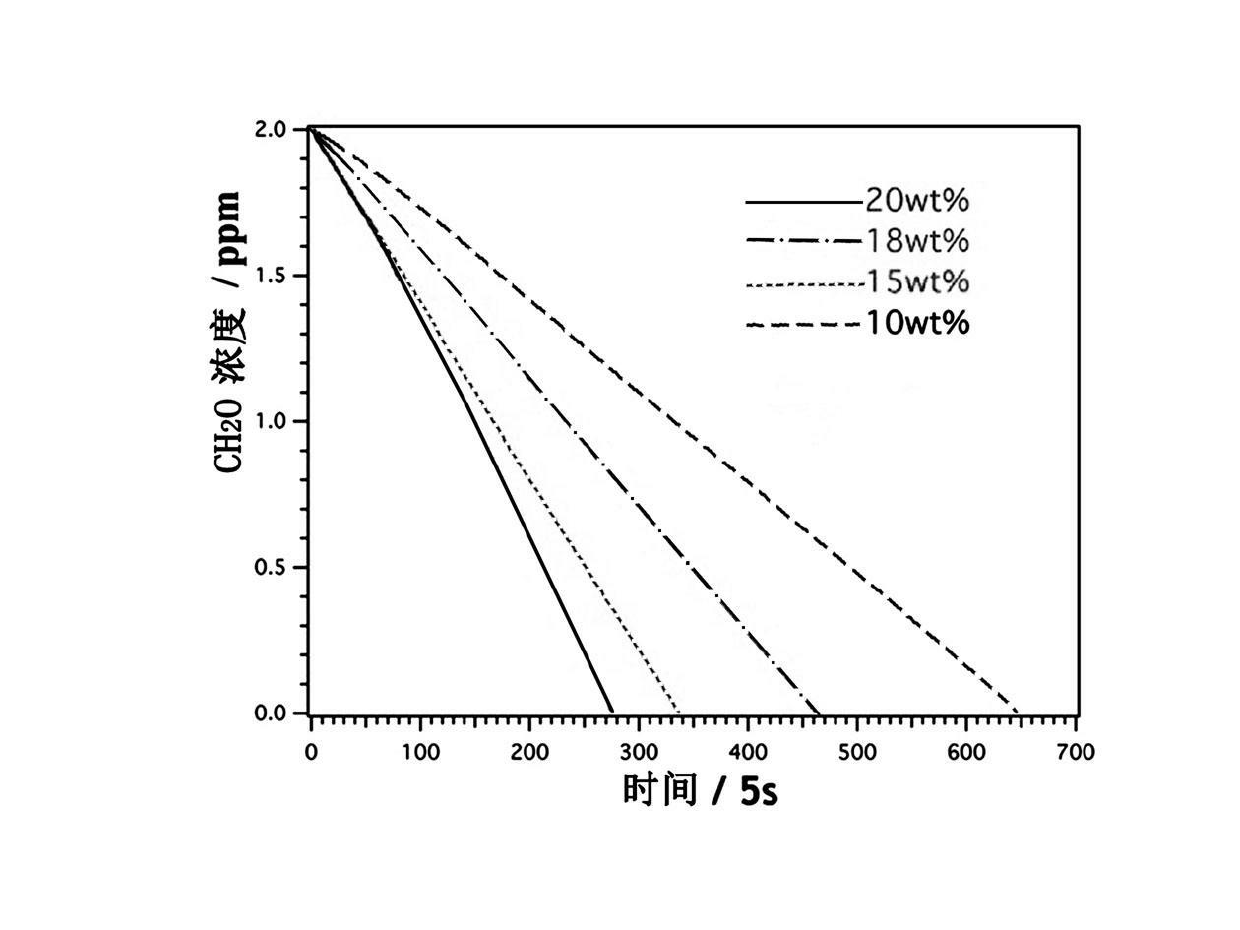

Detection apparatus and detection method for photocatalyzed gas degradation rate

InactiveCN102590439AEasy to viewEasy to installChemical analysis using catalysisPhase detectorGas detector

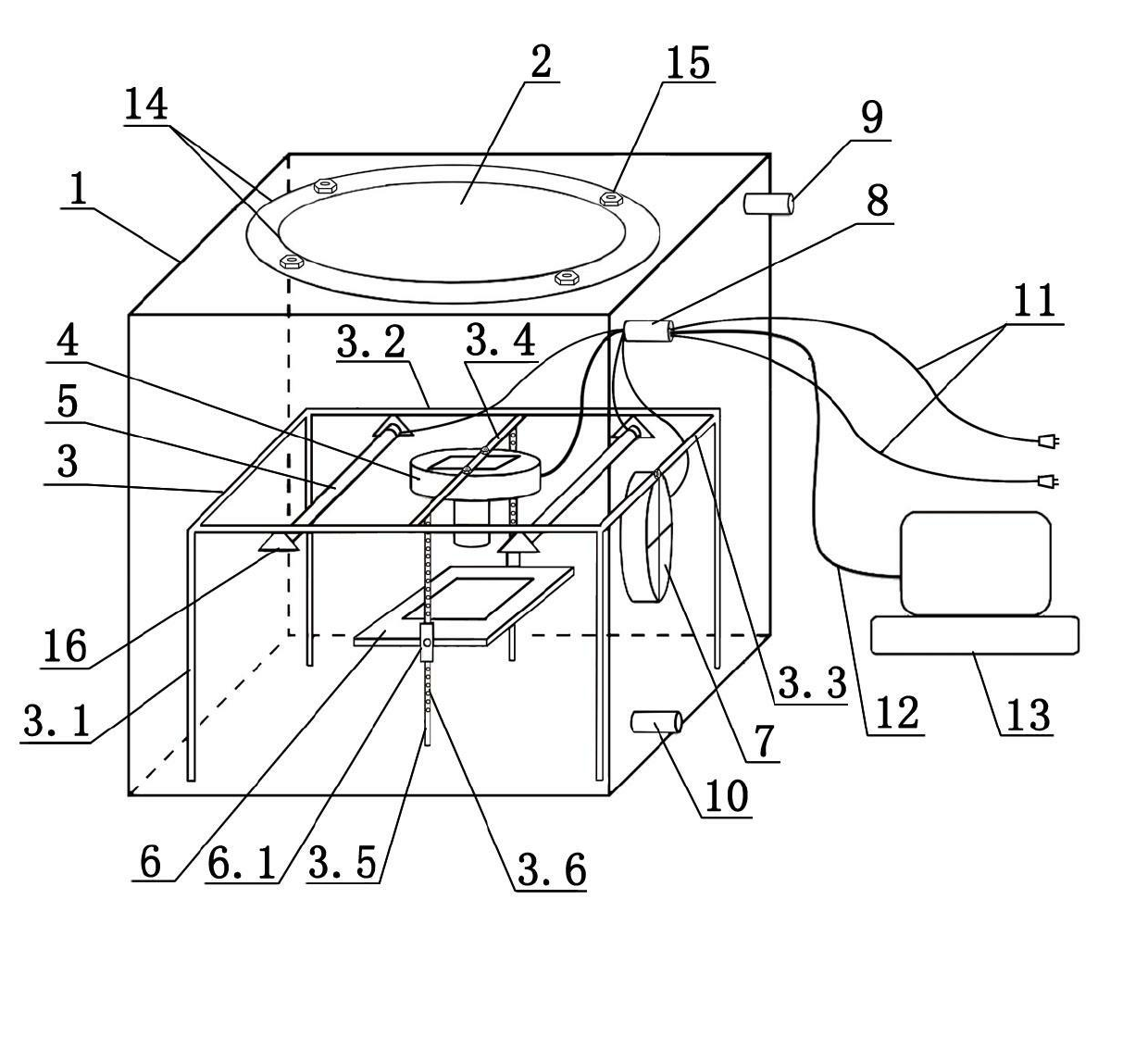

The invention provides a detection apparatus and a detection method for a photocatalyzed gas degradation rate. The apparatus comprises a completely sealed detection box; the top of the detection box is provided with an openable transparent box cover, the side wall of the detection box is provided with a self-sealing cable interface, an inlet valve and an air pressure balancing valve, a multifunctional rack is arranged in the detection box, a gas detector and ultraviolet lamps are fixed on the top of the multifunctional rack, an elevating sample bench is slidably connected onto the multifunctional rack below the gas detector, a convection blower is fixed at one side of the multifunctional rack, and the gas detector is connected with a computer arranged out of the detection box through a transmission cable passing through the self-sealing cable interface. The photocatalyzed gas degradation detection apparatus and the method provided in the invention have the advantages of a broad detection scope, high detection precision, good repeatability of results and capacity of obtaining a continuous smooth variation curve of gas content and time, are applicable to detection of gas degradation under photocatalysis and can accurately and conveniently evaluate degradation capability of photocatalyst products to gas.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

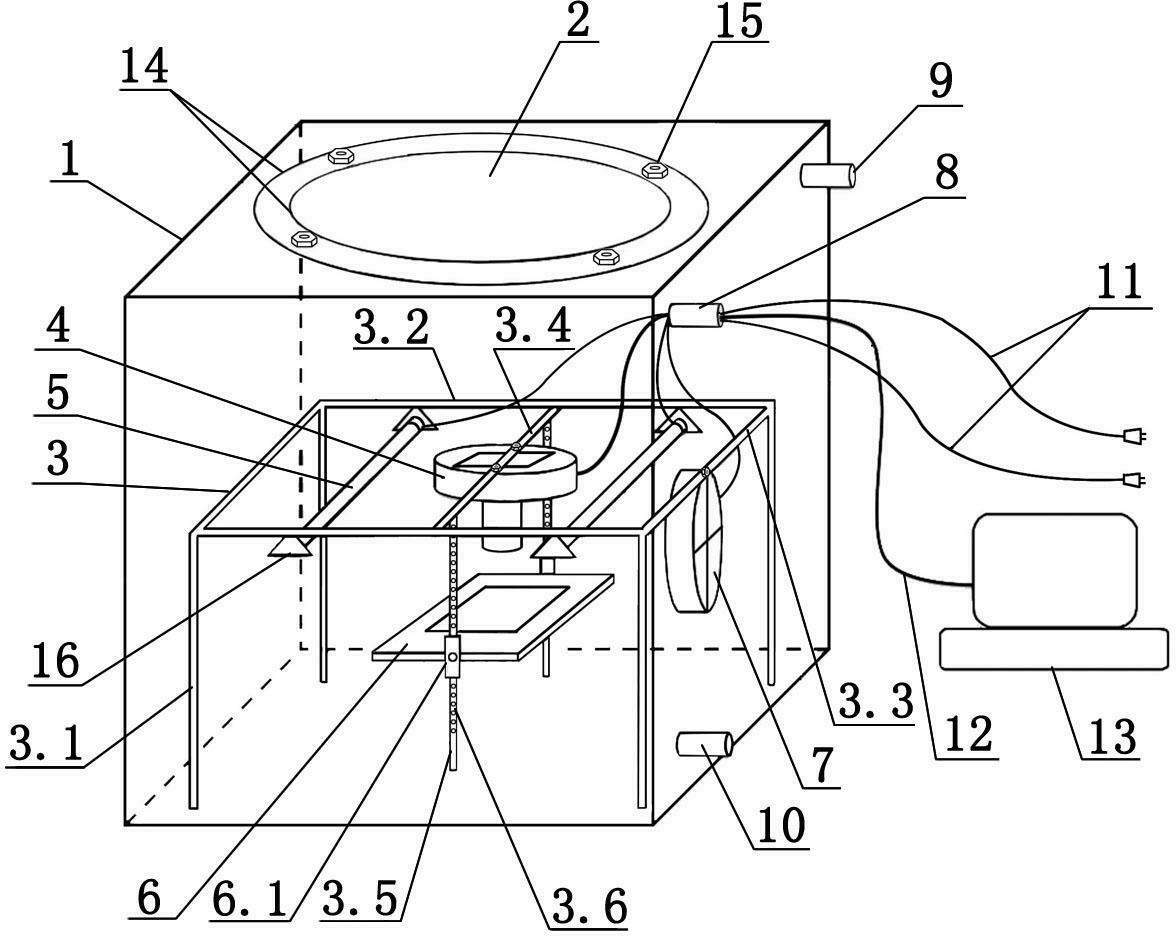

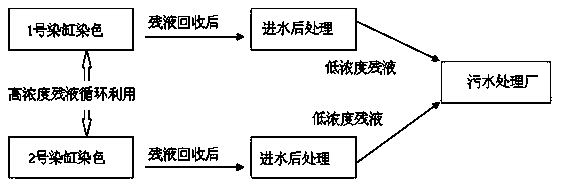

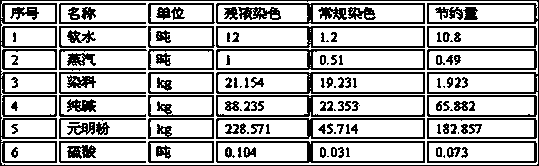

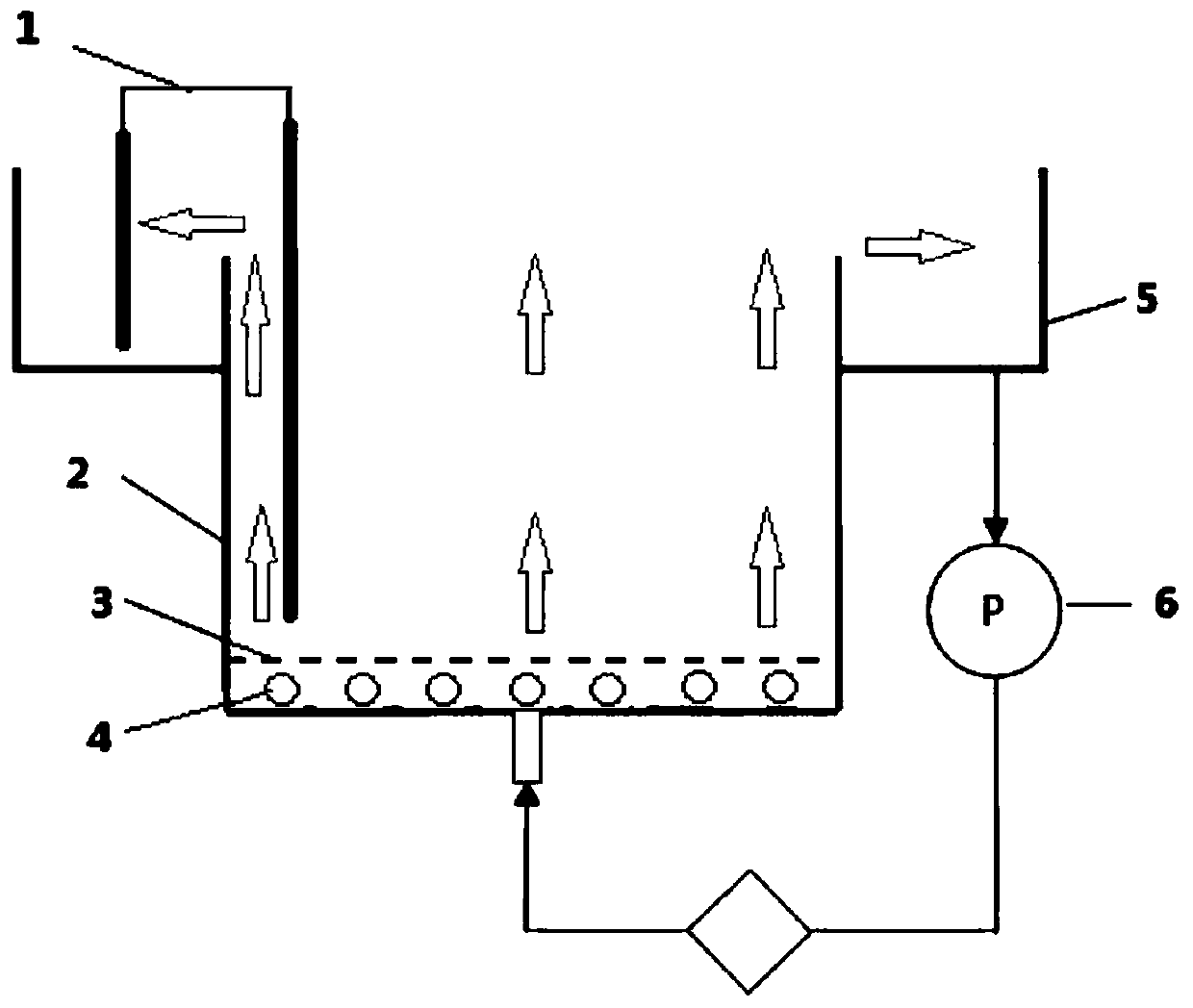

Residual liquid dyeing process of cheese

ActiveCN103741526AReduce consumptionEmission reductionTextile treatment machine arrangementsDyeing processYarnPulp and paper industry

The invention provides a residual liquid dyeing process of cheese in order to reduce the dye consumption for cheese dyeing. The residual liquid dyeing process is characterized in that a dye vat No.1 and a dye vat No.2 are connected through a pump, after yarns in the dye vat No.1 are dyed for the first time, a dyeing solution is pumped into the dye vat No.2, and after the yarns in the dye vat No.2 are dyed, the dyeing solution is returned to the dye vat No.1 to dye undyed yarns; the dyeing solution is recycled for dyeing between the dye vat No.1 and the dye vat No.2 according to the method; and after the dyeing solution is exhausted each time, a post-processing stage is entered, the dyed yarns are taken out after the post-processing is completed, and the undyed yarns are hung to wait for the import of the dyeing solution. According to the residual liquid dyeing process disclosed by the invention, the water consumption and sewage discharge are reduced from the source, resource consumption and environment pollution are reduced, and the cyclic utilization of resources and clean production are realized.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

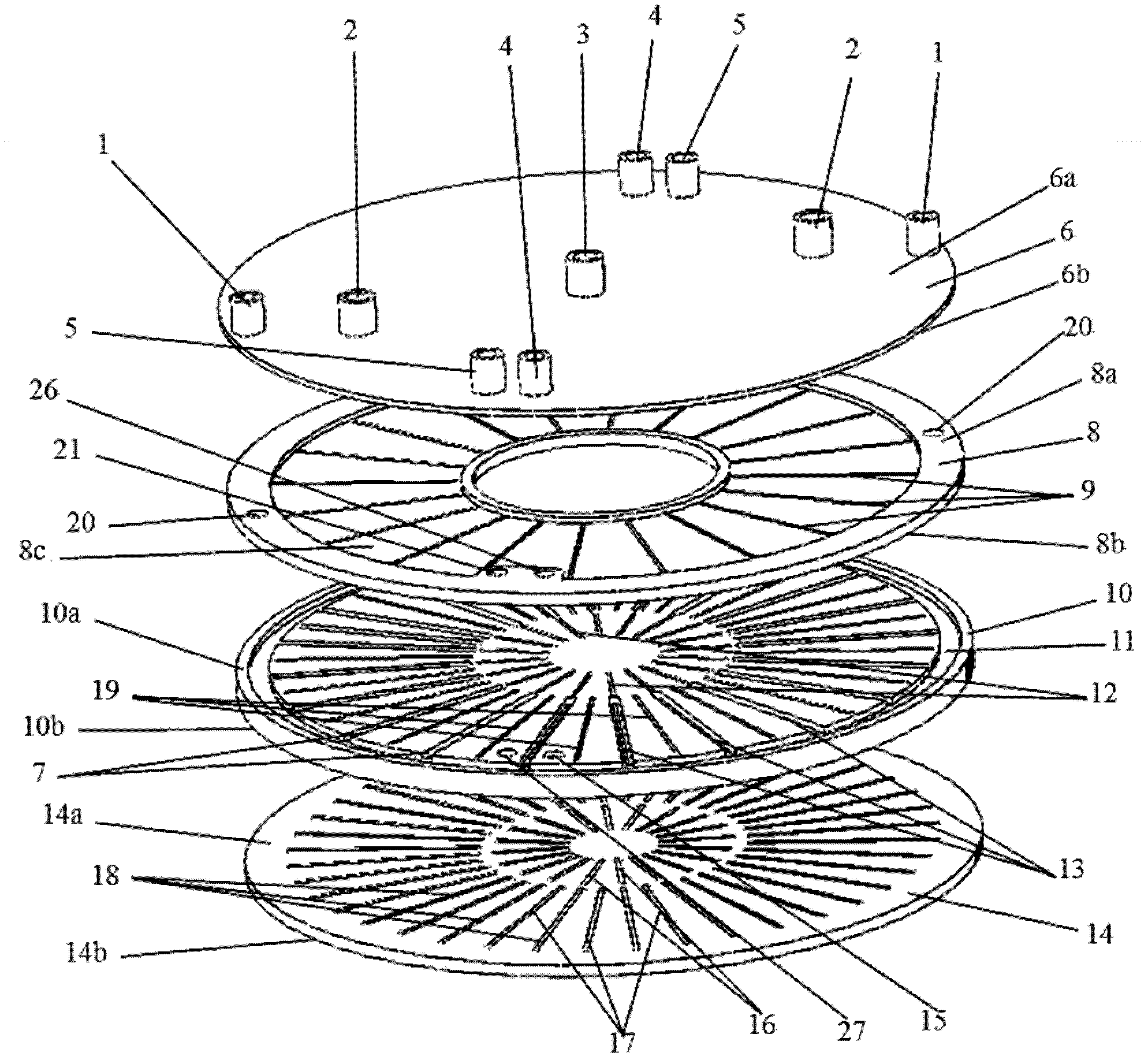

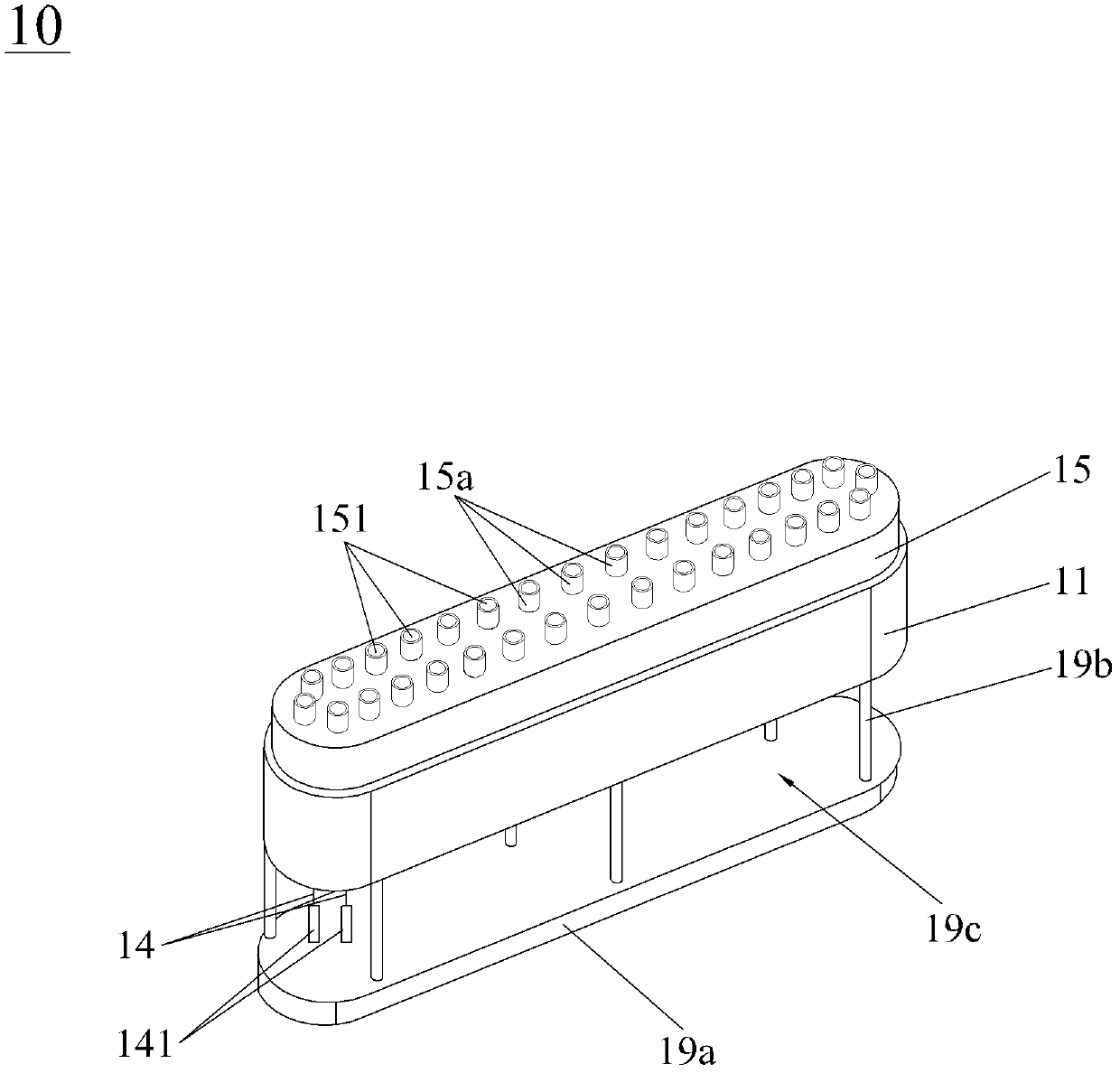

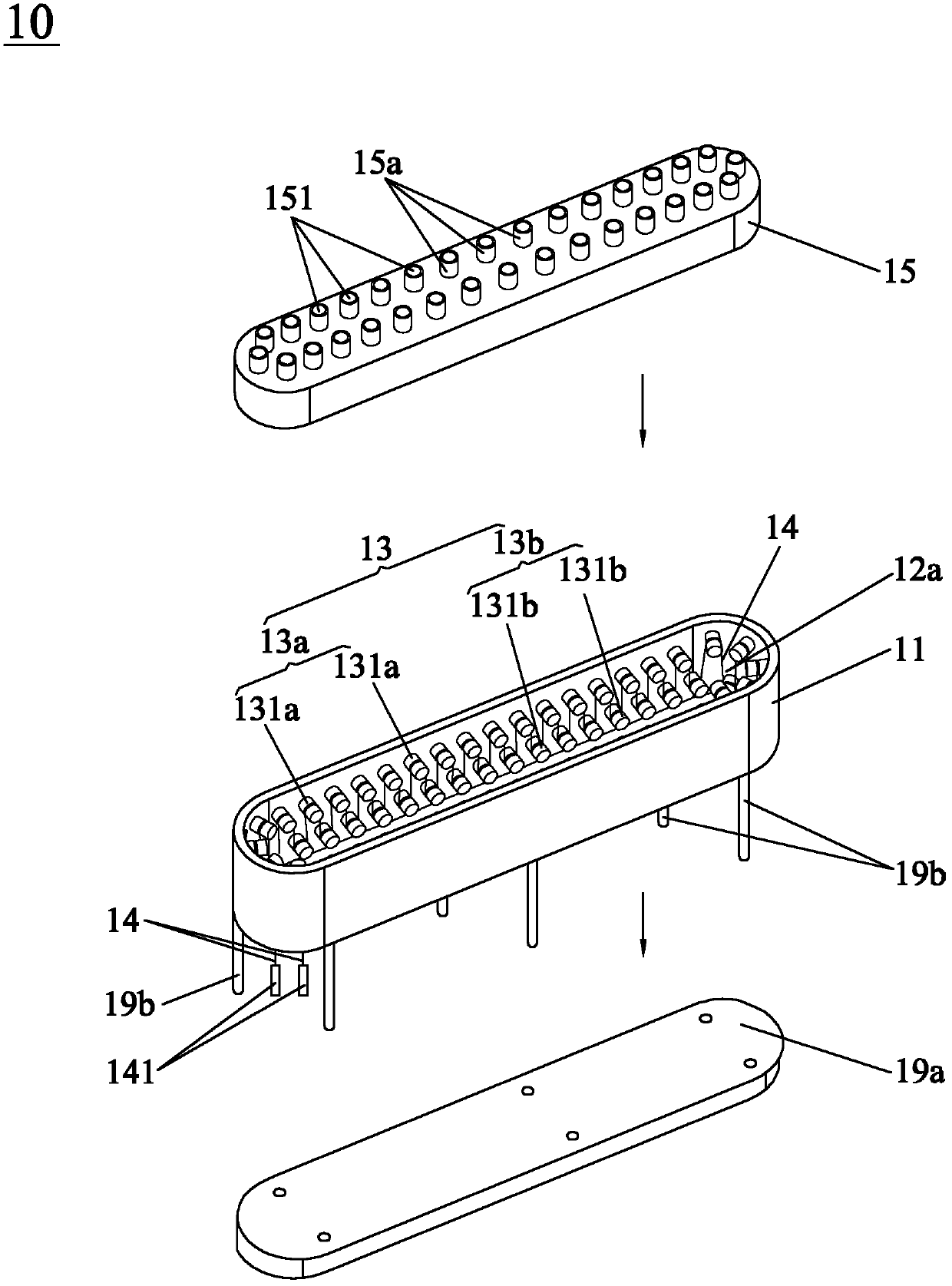

Inclined entering gas spray header applied to metal organic chemical vapor deposition reactor

ActiveCN102534563ASolve the problem of exhaustionAvoid the disadvantage that it is not easy to form a stable laminar flowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

Provided is an inclined entering gas spray header applied to a metal organic chemical vapor deposition reactor, comprising a gas jet tray arranged above the reaction chamber, a gas connecting board arranged above the gas jet tray, and at least two laminated gas distribution boards arranged between the gas connecting board and the gas jet tray, wherein the gas connecting board is provided with a plurality of gas interfaces and cooling liquid interfaces; the gas distribution boards and the gas jet tray are provided with a plurality of mutually isolated gas channels; and the gas channels include a first forebody gas channel, a second forebody gas channel, and the carrier gas channel which are communicated to the corresponding gas interfaces as well as a cooling liquid channel communicated to the cooling liquid interface. The inclined entering gas spray header overcomes the reactant exhaustion along the airflow direction of a horizontal reactor and avoids the defect of uneasiness of forming a stable layer flow in a vertical reactor.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

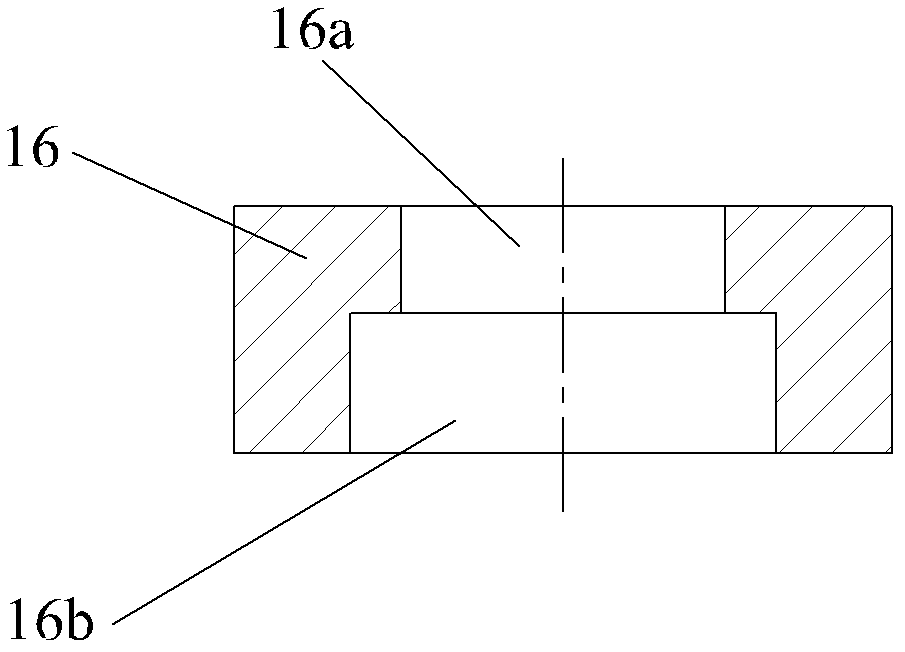

Linear evaporation source device and precise evaporation rate control evaporating unit with same

InactiveCN102703866AConsistent concentrationUniformity Coating ControlVacuum evaporation coatingSputtering coatingEngineeringPoint source

The invention provides a linear evaporation source device for evaporating an evaporation source in a vacuum. The linear evaporation source device comprises a body, an insulating sleeve component, a heating wire and an evaporating cover. The body is provided with a containing trough with an upward opening. The insulating sleeve component is fixed inside the containing trough and comprises a first horizontal insulating sleeve row. The first horizontal insulating sleeve row comprises a plurality of first insulating sleeves projecting at intervals inside the containing trough at the same height. The heating wire is sequentially wound on the first insulating sleeves, and both ends of the heating wire are connected with an external power source electrically. The evaporating cover covers the body and forms a heating cavity with the containing trough. The evaporating cover is provided with holding sockets in one-to-one correspondence to the first insulating sleeves. The holding sockets penetrate through the evaporating cover to form evaporating holes. The linear evaporation source device is capable of forming a plurality of independent evaporation point sources, concentration of evaporated material is evener at any position, and accordingly excellent conditions are created for even coating of a substrate. In addition, the invention further discloses a precise evaporation rate control evaporating unit.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

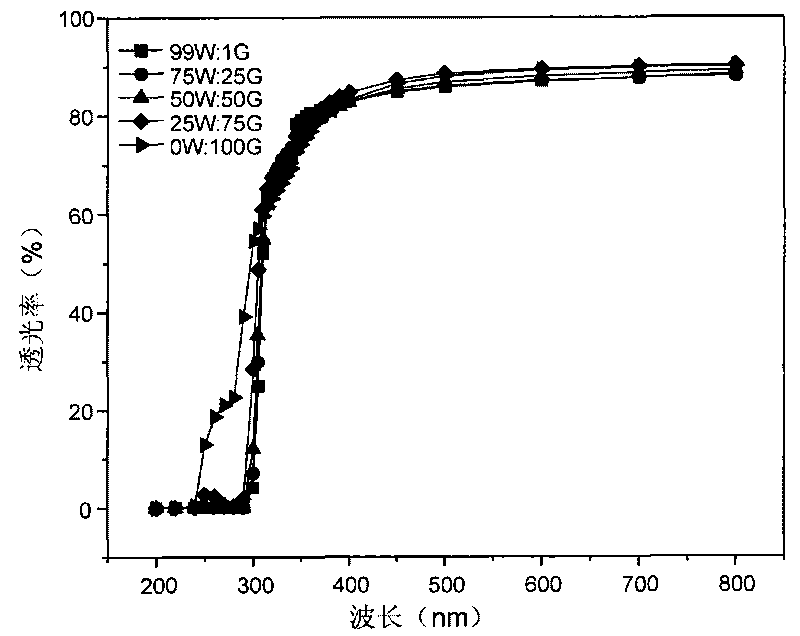

Whey protein/gelatin edible compound film and preparation method thereof

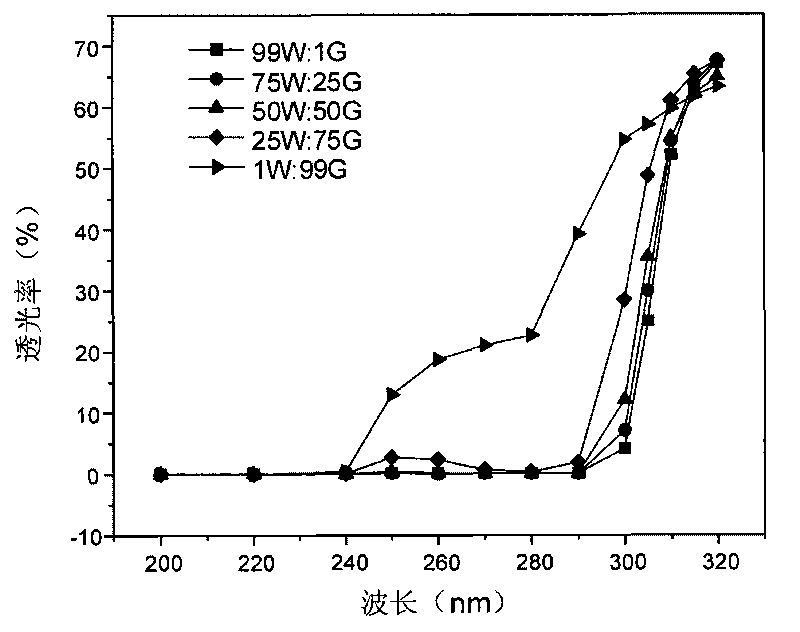

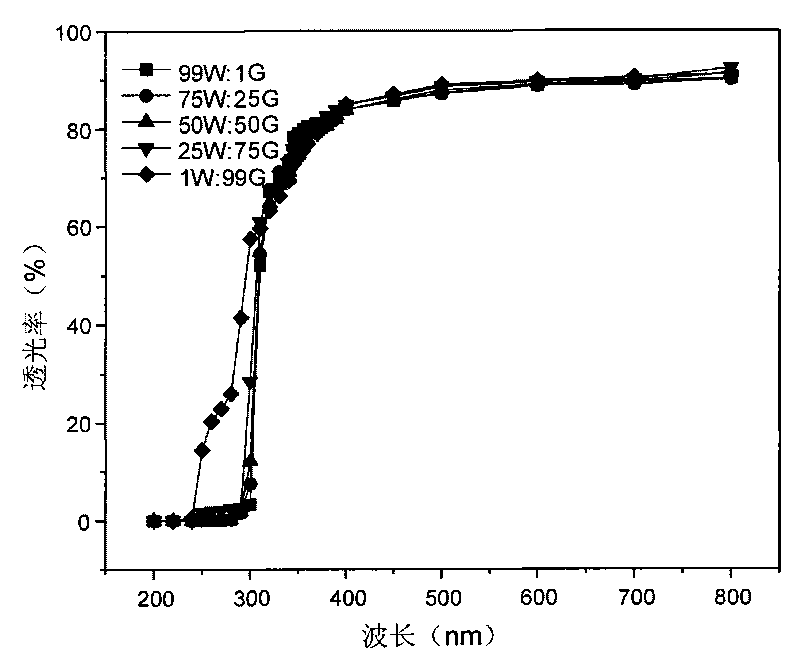

InactiveCN101746557AConsistent concentrationLow costFlexible coversWrappersNutritive valuesWhey protein

The invention discloses a whey protein / gelatin edible compound film which belongs to the field of food-packaging materials. The compound film is made from whey protein solution and gelatin solution which are added with plasticizer and blended, wherein the weight ratio between whey protein and gelatin is 1-99:99-1. The thickness of the edible compound film is 80 Mu m to 110 Mu m. The weight percentage concentration of the whey protein solution is 8 percent to 10 percent, and the weight percentage concentration of the gelatin solution is 8 percent to 10 percent. The invention also discloses a preparation method for the compound film. The compound film has a high nutritive value and is cheap, and the mechanical properties of the film can be controlled by regulating the compound proportion of whey protein and gelatin in order to adapt to packages for different purposes.

Owner:CHINA AGRI UNIV

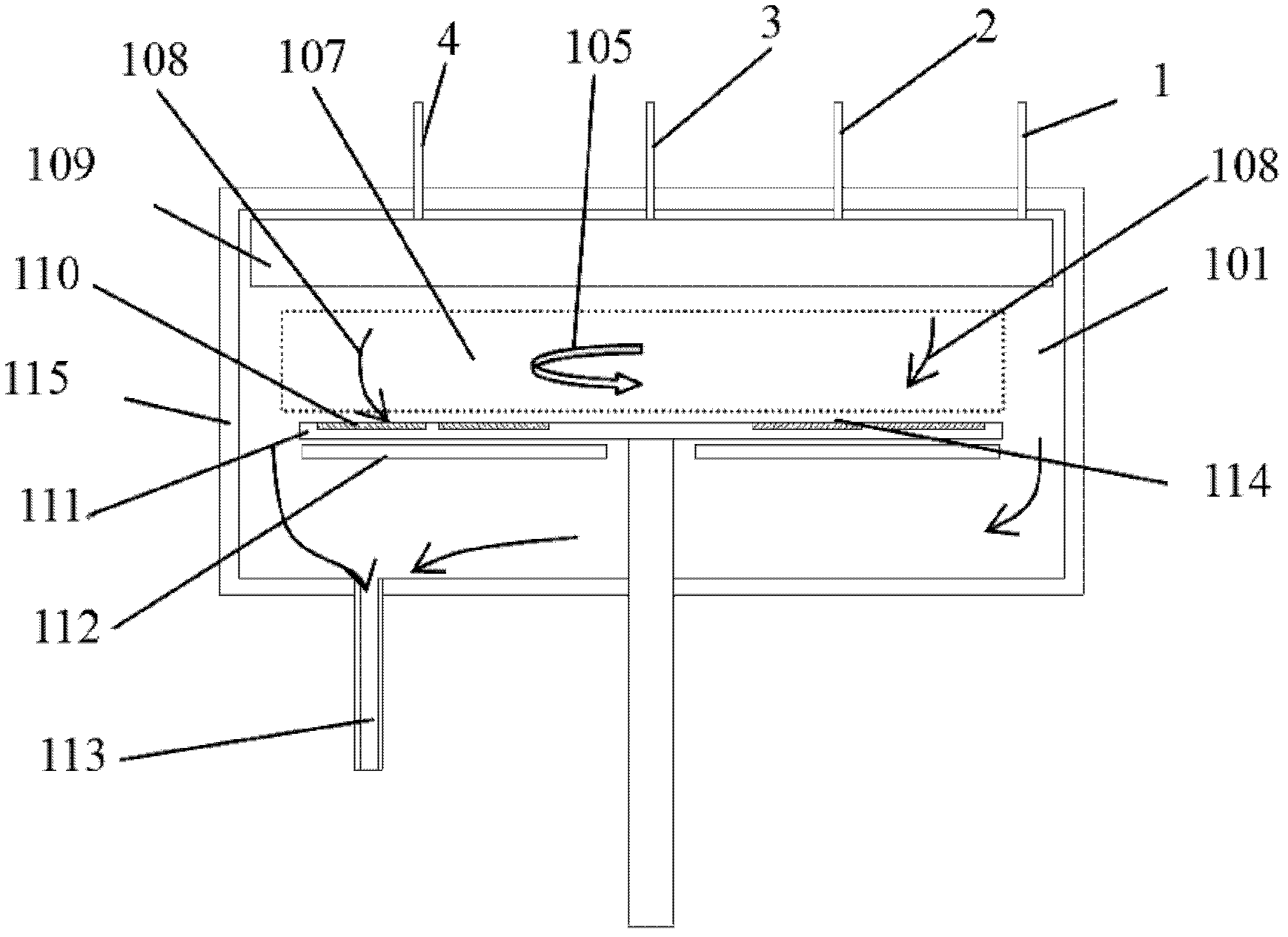

Cold bleaching device for open-width knitted fabrics

InactiveCN101818423AGuaranteed wrinkle-freeGood open width stateTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersOxygenControl circuit

The invention discloses a cold bleaching device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a immersion / padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the immersion / padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the immersion / padding liquid device and the wet supported cloth conveying device are the devices capable of forming, during the use thereof, supported conveyance for wet fabrics; during the use, the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the immersion / padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and can also be flatly rolled onto a cloth roller in the form of big batch which can be rotated, thus the fabrics, after being immersed in cold-bleaching liquid, can be completely piled up under movable state, thereby ensuring the consistent effect of cold batch oxygen bleaching.

Owner:蔡宗义

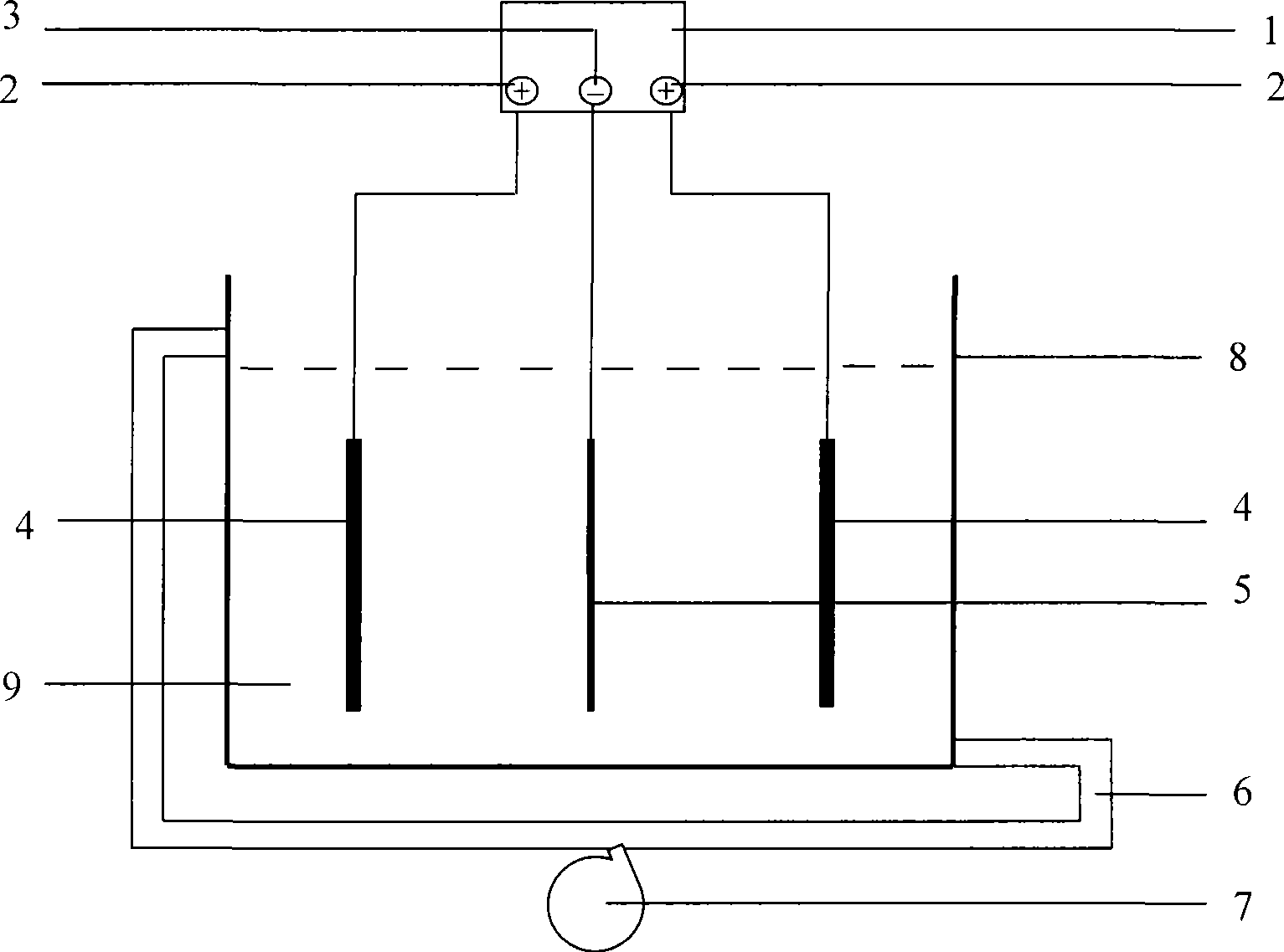

Method for electroplating metal on surface of stephanoporate metal product

The invention provides a method for electroplating metal on a porous metal product surface, which comprises: the porous metal product surface is subjected to surface chemical treatment for oil and surface oxide removal, and cleaned by purified water repeatedly; a suction filter pump and an ultrasonic generator are started to lead the flow speed of electroplate liquid to be 15 to 50L / min and the ultrasonic frequency to be 20 to 40kHz; and the cleaned porous metal product is placed between two platinized and titanized mesh anodes which are arranged in an electrolytic bath provided with the ultrasonic generator side by side for electroplating. The method adopts a suction filter method when electroplating to lead the electroplate liquid to pass through the porous metal product at a certain flow speed; ultrasonic vibration is adopted to accelerate the migration of ions in the pores, so as to lead the concentration of cations in the pores to be consistent with that in the electroplate liquid; and plating layers on the inner surface and the outer surface of the pores of the porous metal product are uniform when electroplating.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

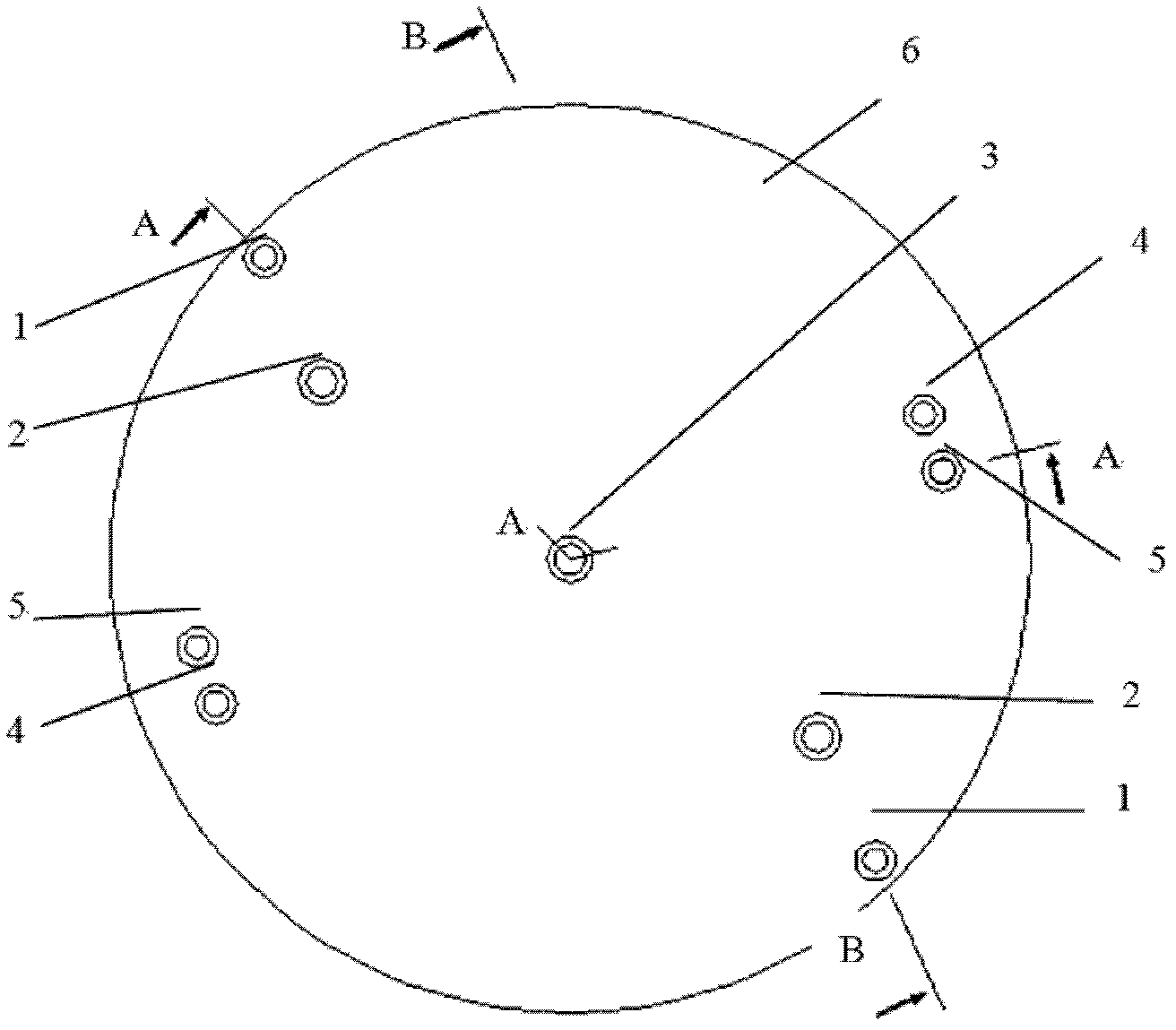

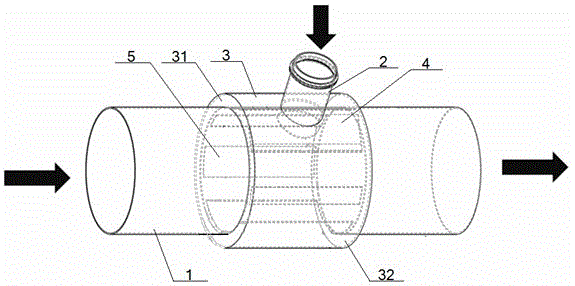

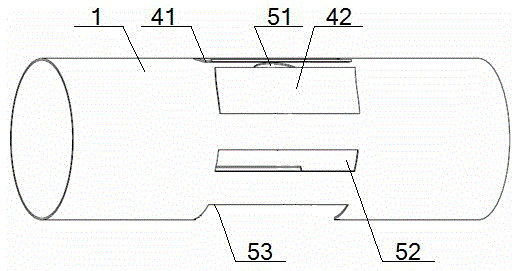

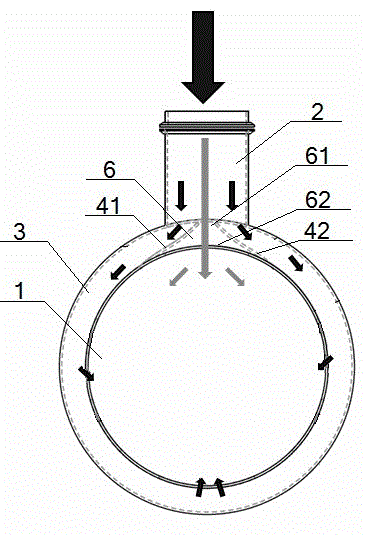

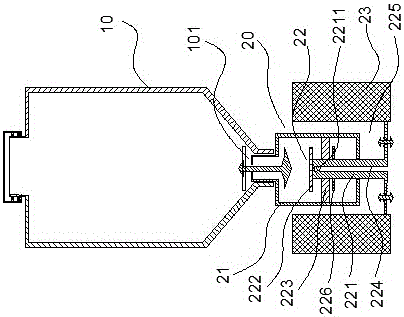

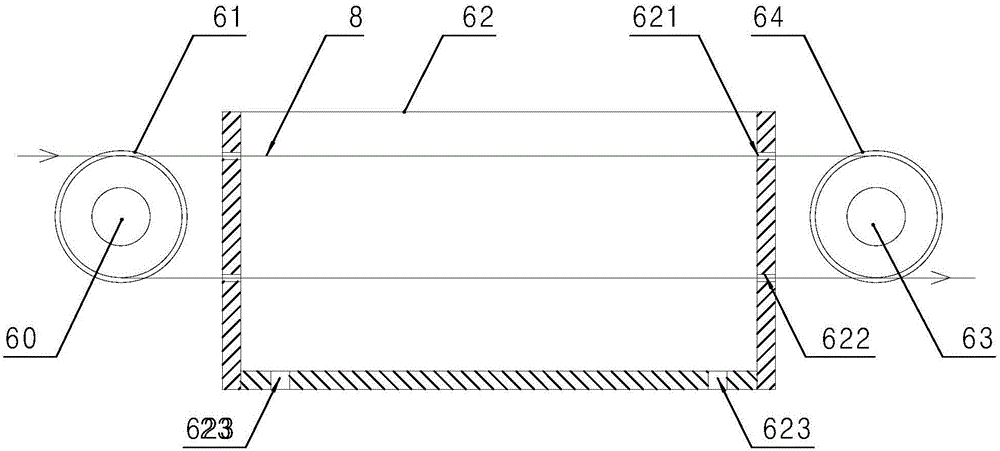

Mixing device for vehicle engine exhaust gas recirculation (EGR)

ActiveCN102748169AImprove stabilityConsistent concentrationInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesEngineering

The invention discloses a mixing device for a vehicle engine exhaust gas recirculation (EGR). The mixing device comprises a gas inlet pipe, an exhaust gas pipe, a flow guide shell and an exhaust gas flow guide device, wherein the exhaust gas flow guide device comprises a first flow guide plate, a second flow guide plate, a front exhaust gas passage, a lateral exhaust gas passage and a back exhaust gas passage; one end of the first flow guide plate and one end of the second flow guide plate are connected with the outer wall of the gas inlet pipe, and the other ends of the first flow guide plate and the second flow guide plate are connected with the inner wall of the flow guide shell; a small cavity port of the gas inlet cavity between the first flow guide plate and the second flow guide plate is communicated with the exhaust gas pipe, and a large cavity port of the gas inlet cavity is opposite to the front exhaust gas passage; a part of the gas inlet pipe opposite to the front exhaust gas passage is provided with the back exhaust gas passage; the lateral exhaust gas passage is formed between the front exhaust gas passage and the back exhaust gas passage; the front exhaust gas passage is smaller than the lateral exhaust gas passage; and the lateral exhaust gas passage is smaller than the back exhaust gas passage. According to the mixing device, the uniformity of mixing of exhaust gas and inlet gas can be improved, the stability of operation of an engine is enhanced, the gas inlet pressure loss is small, the structure is simple, and the manufacturing is convenient.

Owner:DONGFENG MOTOR CORP HUBEI

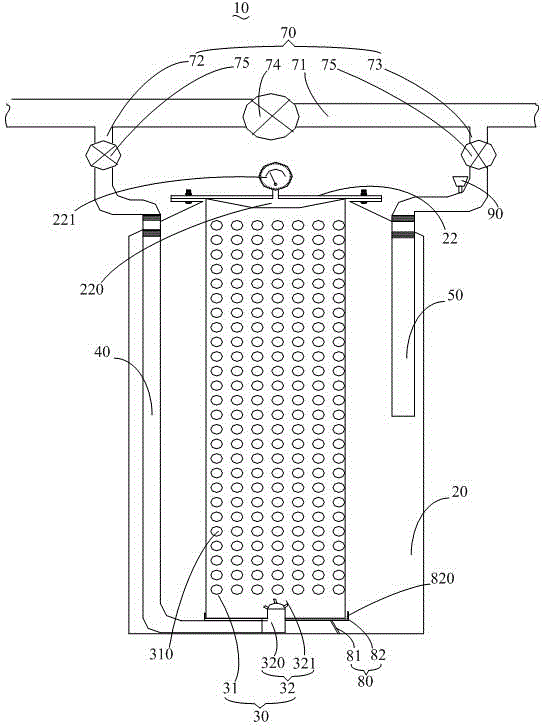

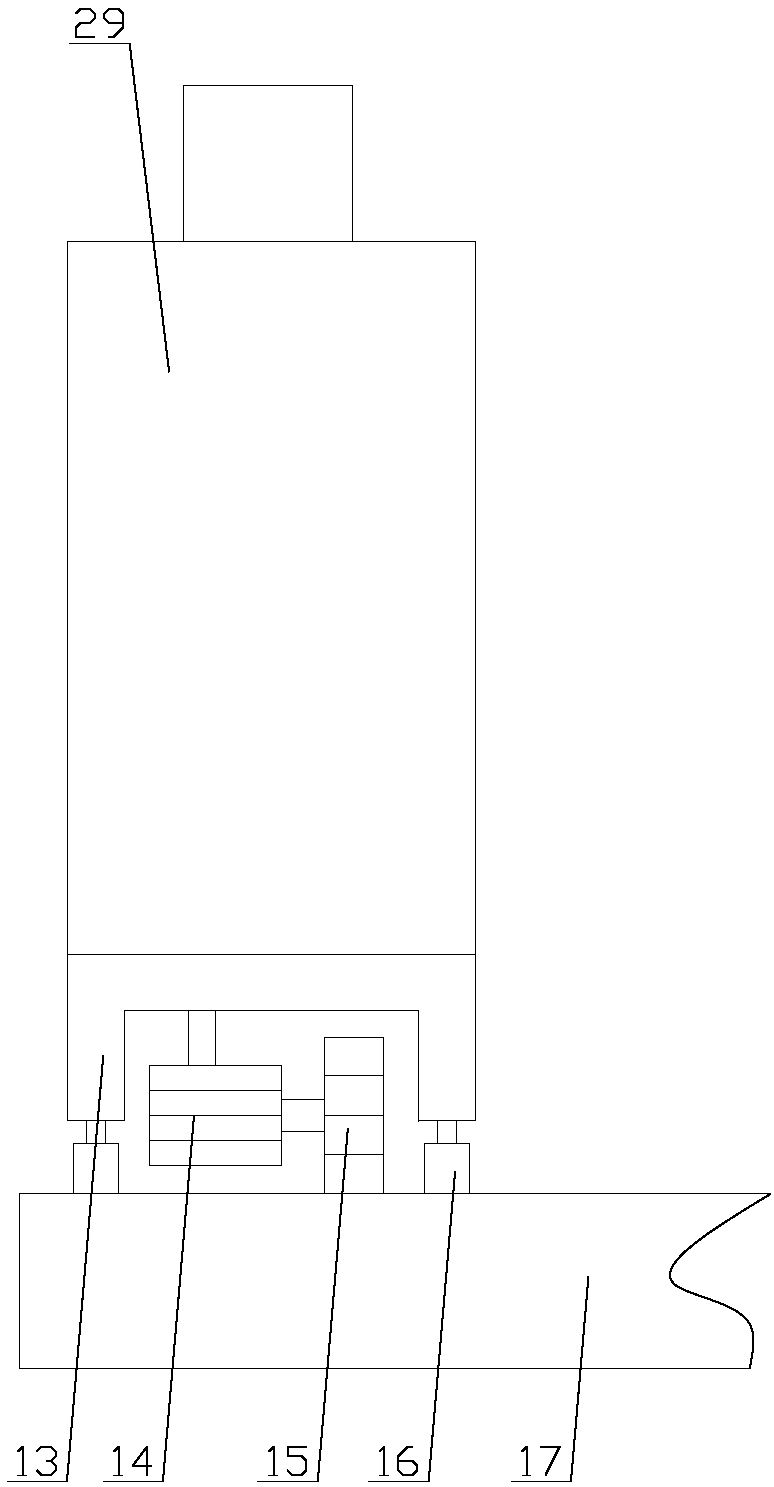

Water-fertilizer all-in-one machine

InactiveCN104541731AImpact forceConsistent concentrationPressurised distribution of liquid fertiliserWater flowEngineering

The invention discloses a water-fertilizer all-in-one machine, which comprises a tank body, a vortex stirring and filtering device, a water inlet pipeline and a fertilizer solution discharge pipeline, wherein the vortex stirring and filtering device is fixedly arranged in the tank body, and comprises an accommodating part and a flow directional jet device; a fertilizer solution discharge hole is formed in the lateral wall of the accommodating part; the flow directional jet device is fixedly arranged on the bottom of the accommodating part; a flow inlet end of the flow directional jet device is connected with the water inlet pipeline; a flow outlet end of the flow directional jet device is located in an accommodating space of the accommodating part; and the flow output end of the flow directional jet device is not vertical or parallel to the lateral wall of the accommodating part, so that water jet from the flow output end of the flow directional jet device reaches the lateral wall of the accommodating part at a preset angle and generates vortex under the action of the lateral wall of the accommodating part to dissolve the fertilizer contained in the accommodating part.

Owner:张江龙

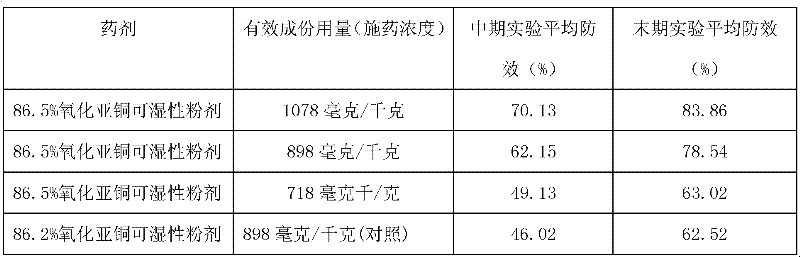

A kind of high-concentration protective fungicide and preparation method thereof

The invention provides a high-concentration protective fungicide and a preparation method thereof. The fungicide is composed of cuprous oxide, fillers and additives in a certain proportion, and is prepared by mixing, fluidized-bed jet crushing and remixing to obtain a high-concentration fungicide. Cuprous oxide bactericide, the fineness can reach 1200 mesh, the suspension rate is over 95%, it can make the particles of the active ingredients evenly suspended in the liquid medicine for a long time, so that the medicine sprayed before and after the spraying process The concentration of the solution is kept consistent, and it is evenly deposited on the target, so that the drug effect can be better exerted, and the bactericidal effect is good.

Owner:天津市绿亨化工有限公司

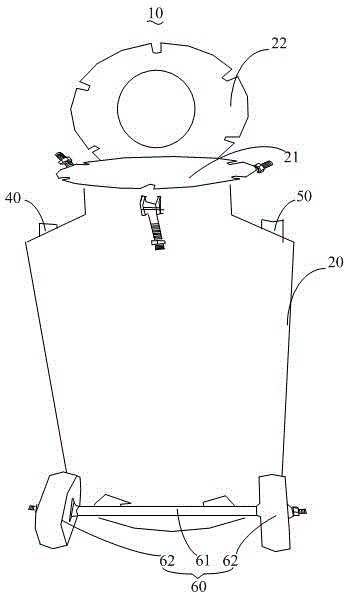

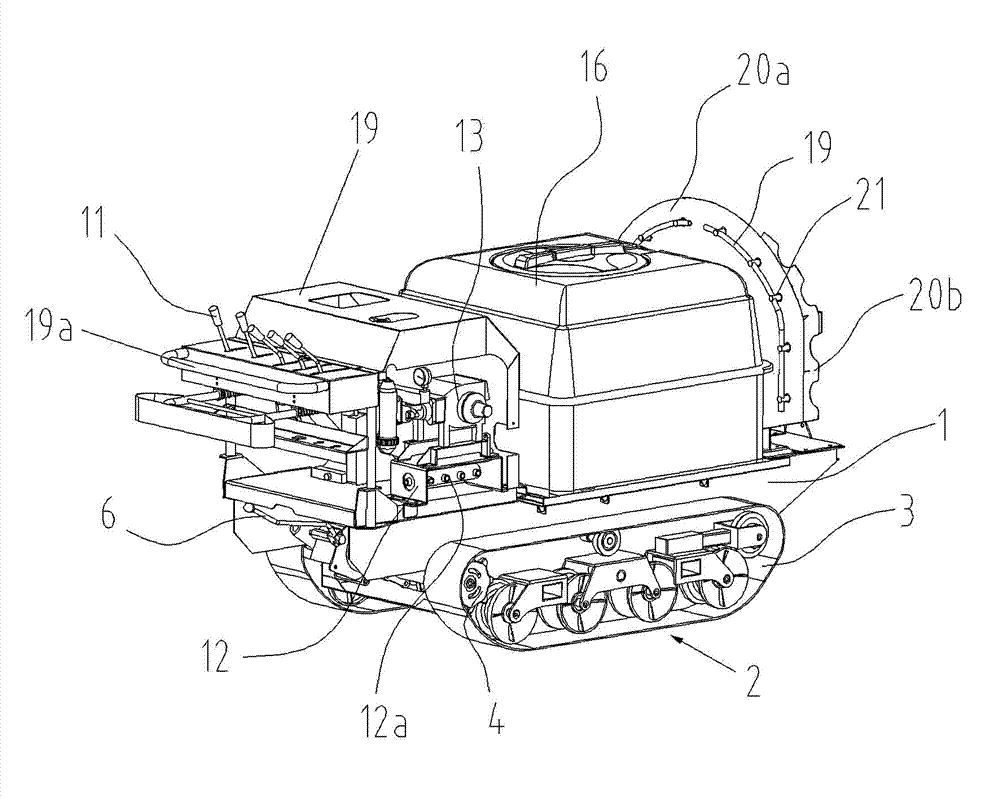

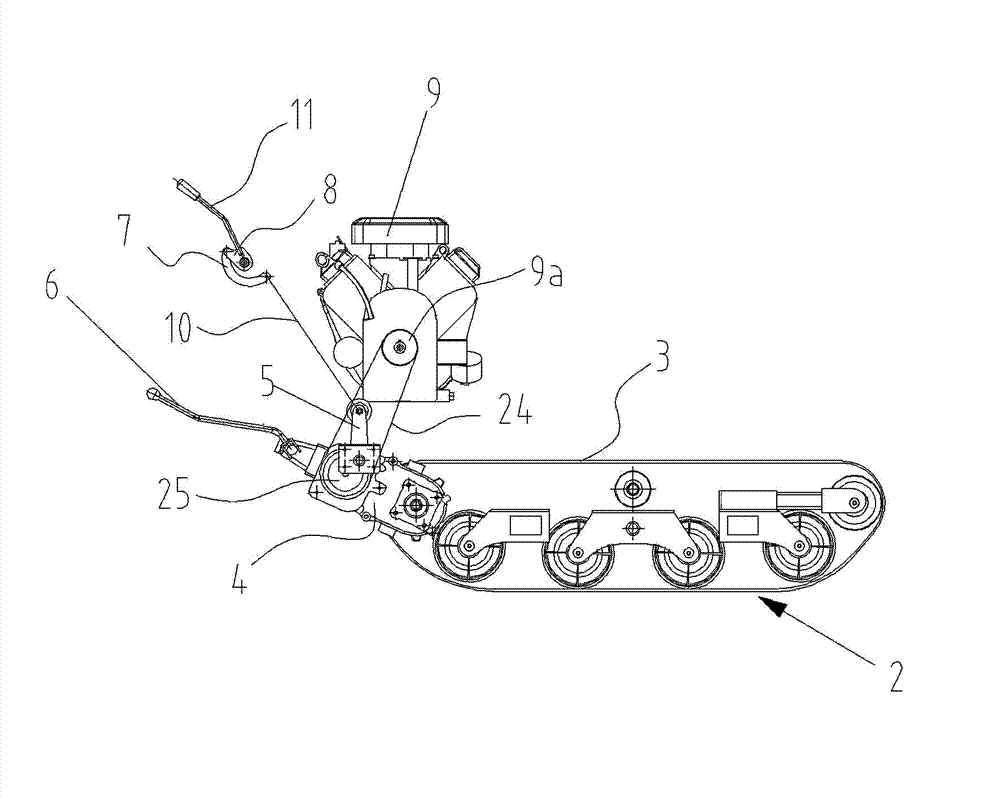

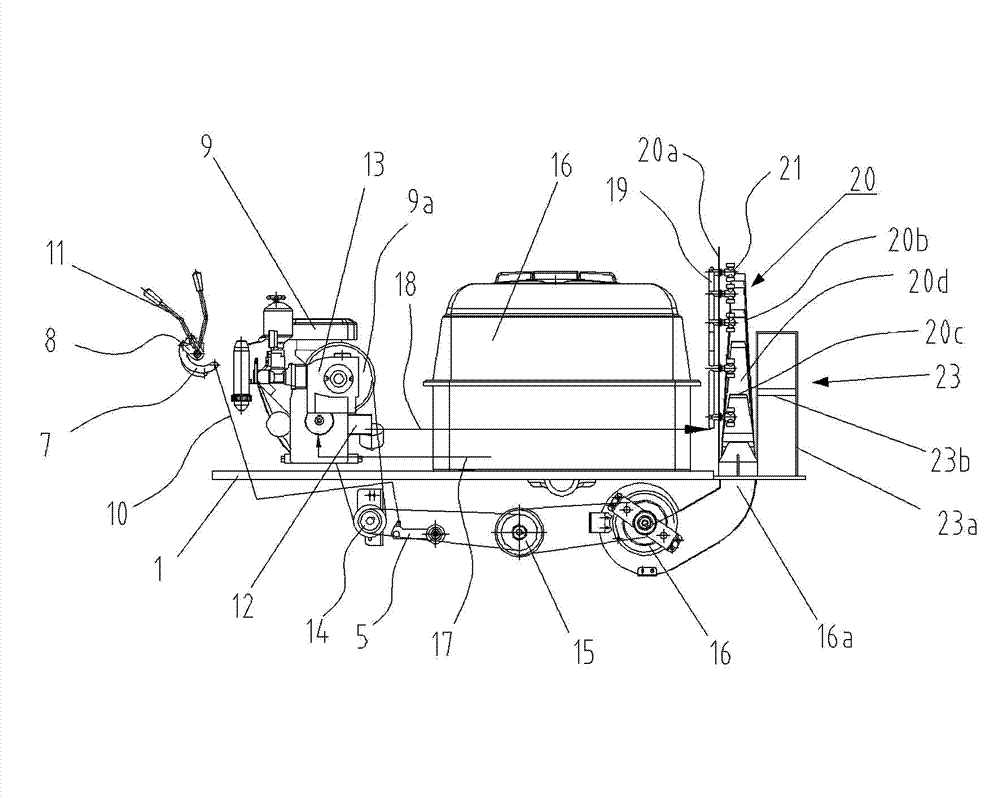

Self-walking type spraying vehicle

InactiveCN103039422AEasy to assemble and disassembleConsistent concentrationInsect catchers and killersFixed frameEngineering

The invention relates to a self-walking type spraying vehicle which comprises a frame (1), a track running mechanism (2) and a draught fan (16) are connected with the lower portion of the frame (1); the upper portion of the frame (1) is provided with a motor (9), a distributor (12), a pesticide case(16), a spraying plate (20) and a pipeline fixing frame (23), wherein a pesticide pump (13) which is connected with the motor (9) is connected with the distributor (12), the distributor (12) is communicated with an arc-shaped spraying rod (19) and a spraying gun which are arranged on the spraying plate (20) through a pipeline, and a spraying gun pipeline winds on the pesticide pump (13). The draught fan (16) is connected with the motor (9) through a transmission mechanism and an air outlet of the draught fan (16) is connected with the spraying plate (20). The self-walking type spraying vehicle has the advantages of being convenient to operate, low in working strength, high in working efficiency, large in output volume of the pesticide pump by utilizing a triplet type plunger pump, stable and reliable in working, large in pesticide case capability and long in spraying time.

Owner:ANHUI JIANGHUAI HEAVY IND MACHINERY

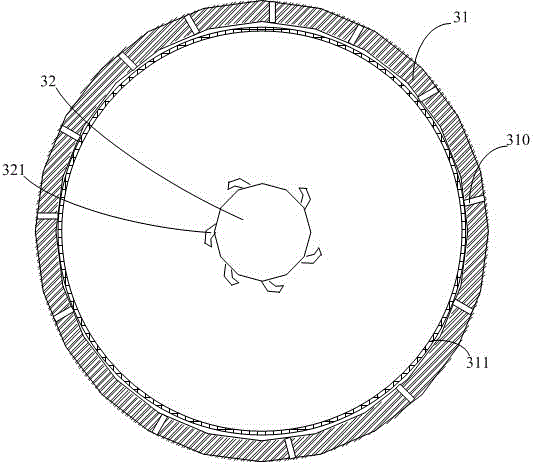

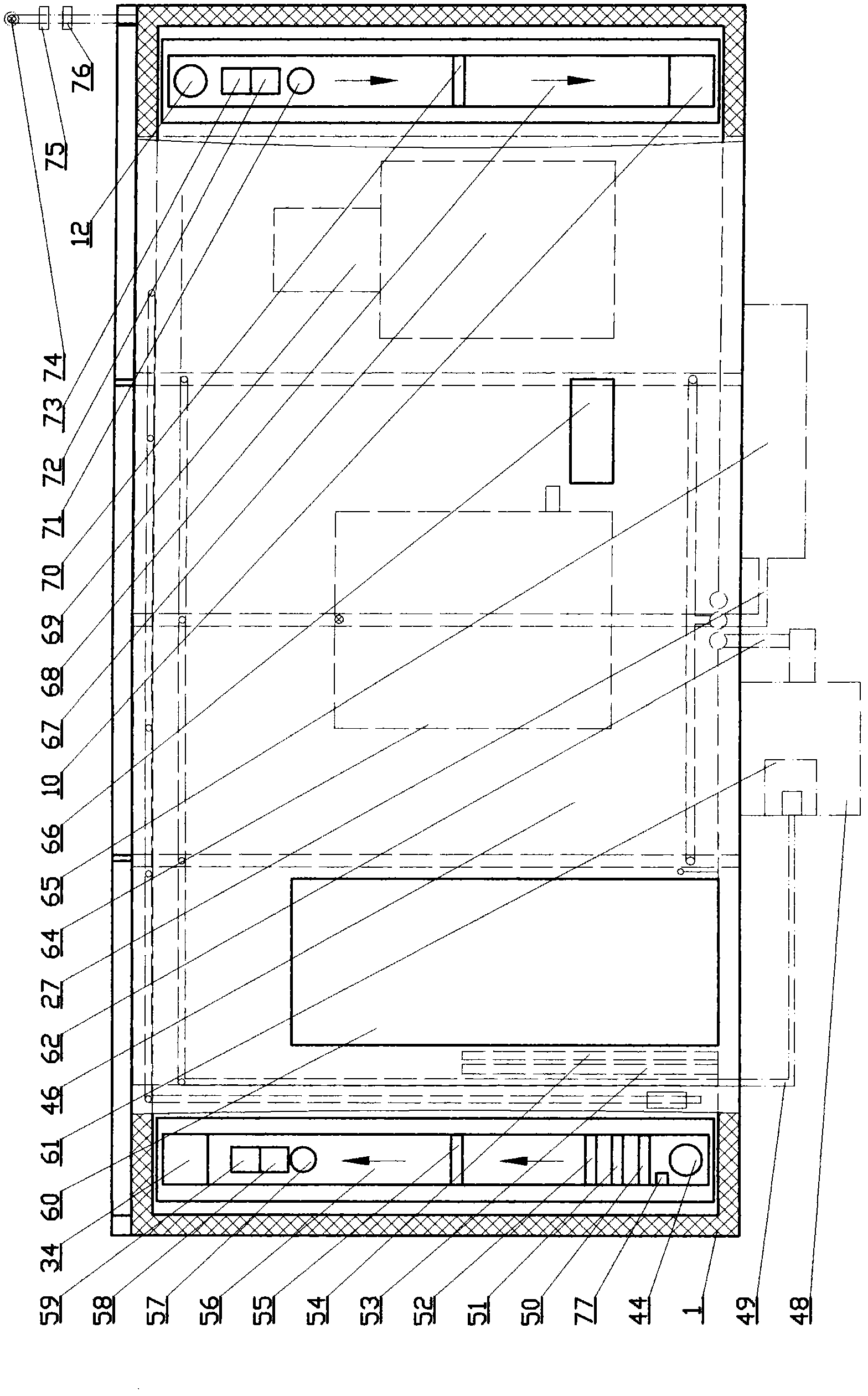

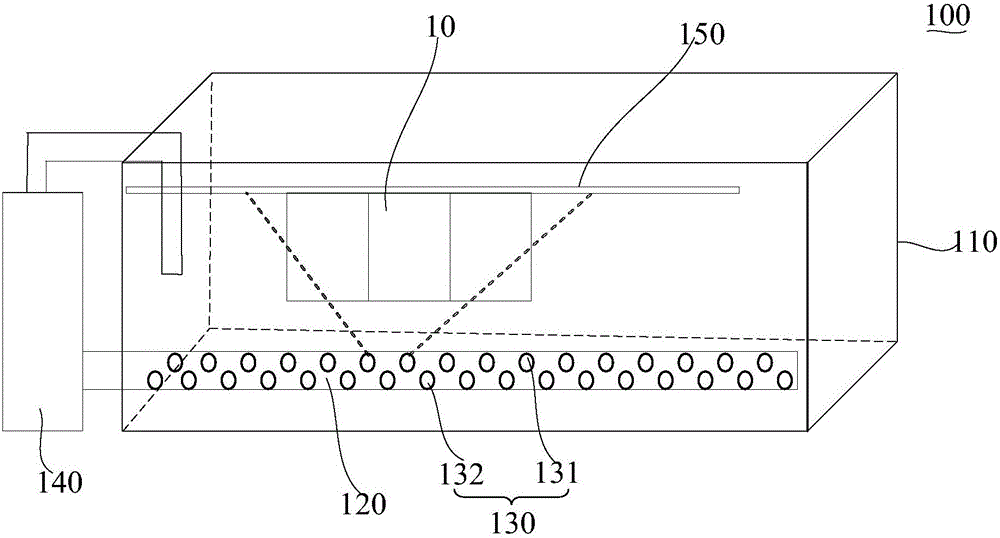

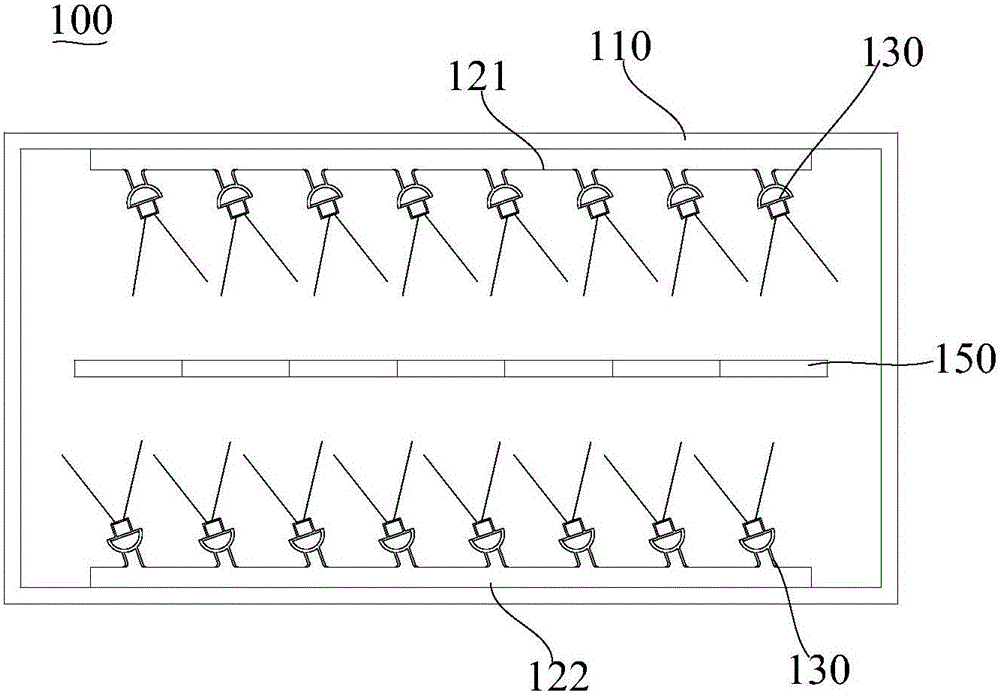

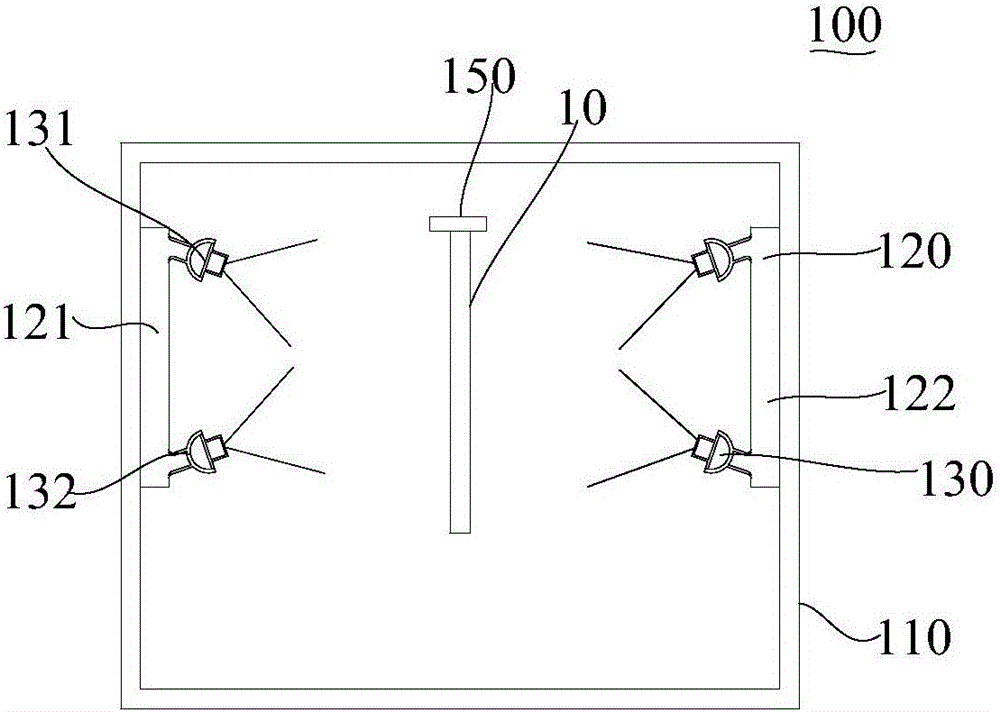

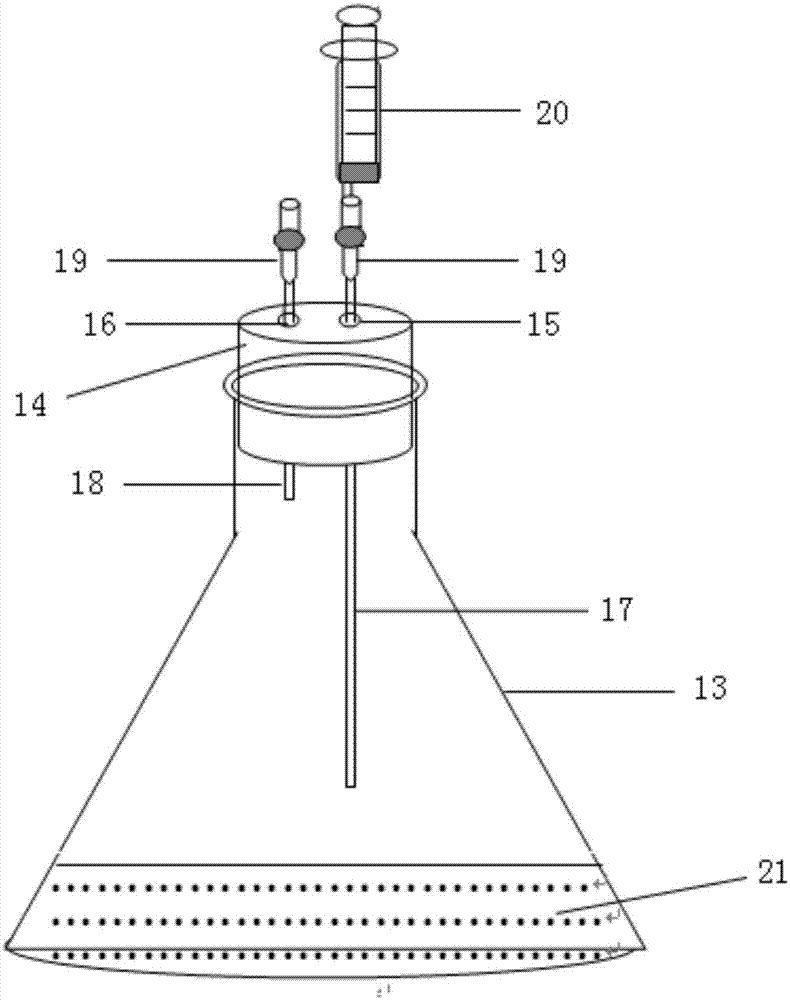

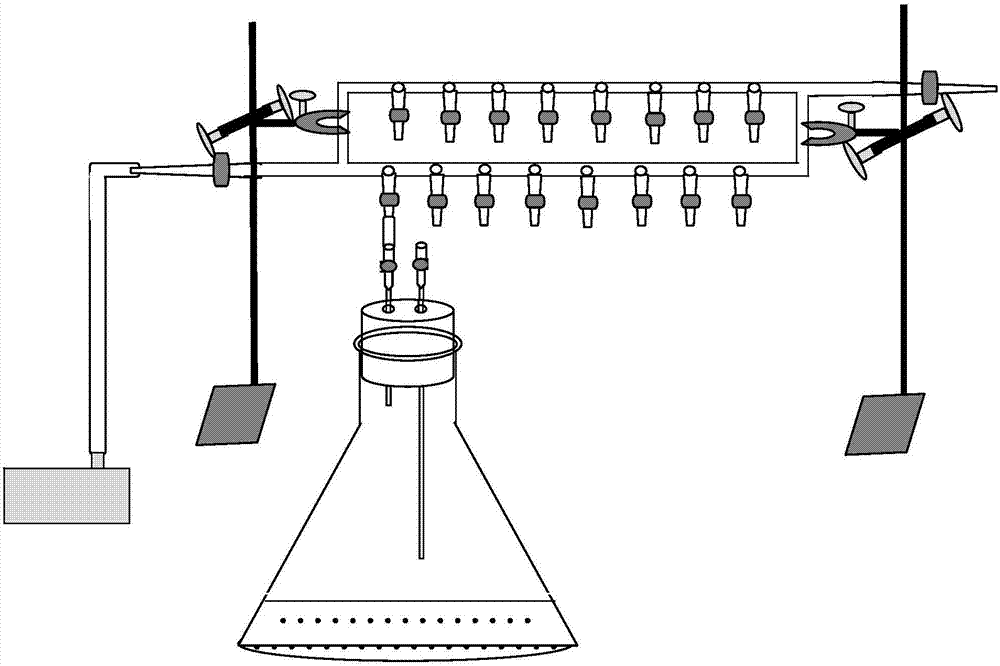

Microalgae culture reactor

InactiveCN104109631AAvoid pollutionSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsCulture environmentMutant

The invention relates to the technical field of biology, particularly a microalgae culture reactor capable of setting different concentration CO2 culture environments, which comprises a culture box, an ultraviolet lamp tube, a gas inlet pipe and a gas outlet pipe, wherein the box body of the culture box is a transparent box body; the lower side of the front end of culture box is provided with a gas inlet; the upper side of the back end of the culture box is provided with a gas outlet; the gas inlet pipe and gas outlet pipe respectively connected with the gas inlet and gas outlet of the culture box are respectively provided with a gas flowmeter and a valve; a CO2 gas analyzer for detecting carbon dioxide concentration at the gas inlet and gas outlet is arranged outside the culture box; the gas inlet and gas outlet of the culture box are respectively provided with a gas filter unit; and a humidification system is arranged in the culture box. A plurality of culture box can be arranged in parallel. By setting different concentration CO2 culture environments to screen the wild type microalgae or corresponding mutants, the complete reactor is simple in structure and convenient to operate.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

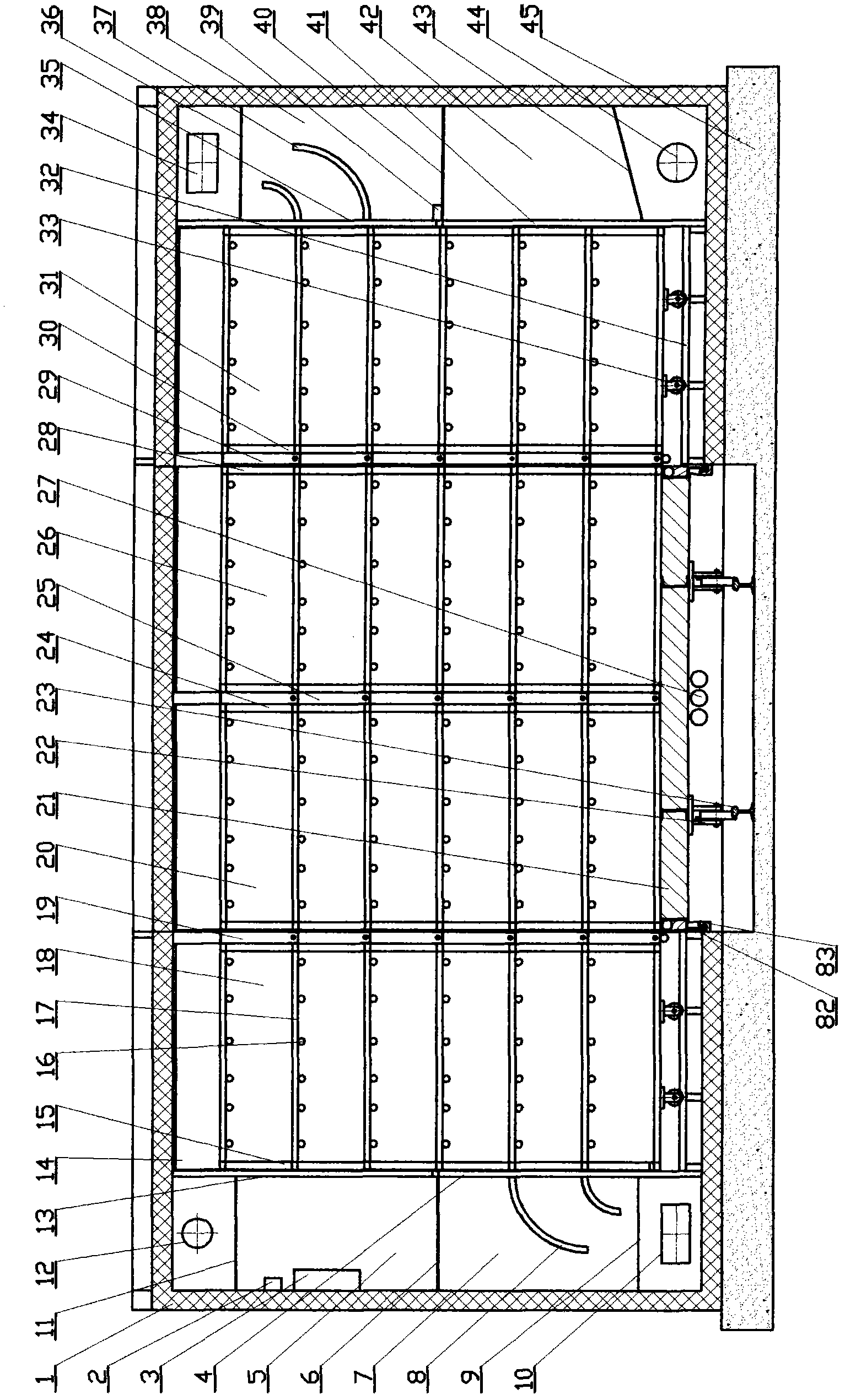

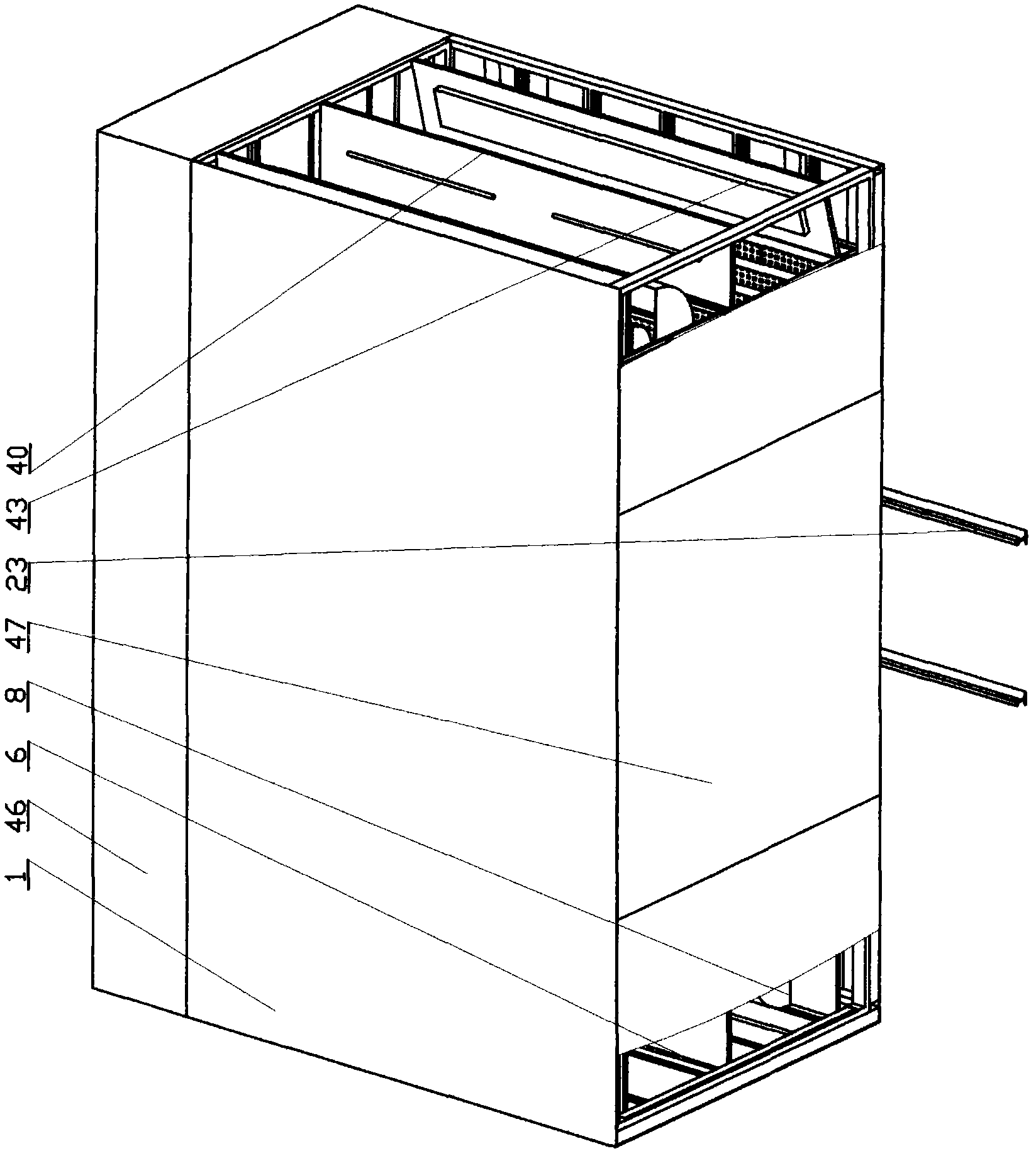

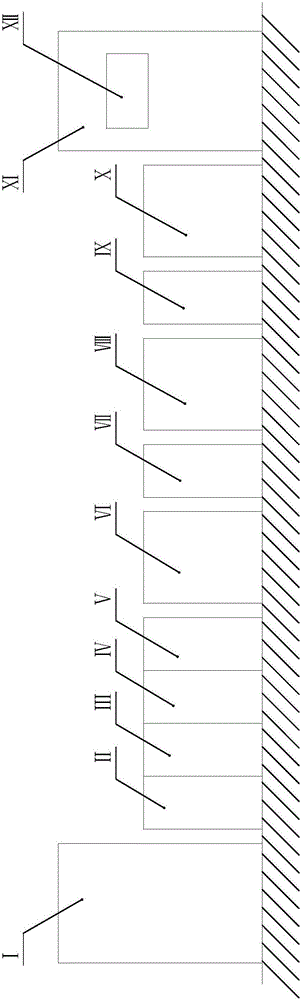

Full-numerical-control track-type seeding culturing device

InactiveCN102550329ALess investment in equipmentReduce use costClimate change adaptationGreenhouse cultivationLight sourceSeedling

The invention discloses a full-numerical-control track-type seeding culturing device and relates to the technical field of facility agricultural planting. The device comprises a box body 1, a base 45, a control assembly, a seeding culturing system and an environment adjusting system, wherein the seeding culturing system comprises a seeding culturing rack, a track trolley 21, a track 23, a seedingculturing lamp 16 and an automatic nutrient solution supplying assembly; and the environment adjusting system comprises an air duct 68, an air delivery channel 56, a draught fan 70, a blower 55 and the like. The indoor temperature and humidity can be ensured to be consistent with concentrations of O2 and CO2, the requirements of a young seeding on light source intensity at different culturing periods can be met, the device investment is small, the use cost is low, the operation is convenient, and the device is a multi-layer seeding culturing facility which is fully sealed indoors or outdoors,can be used for culturing seedlings of vegetables, fruits, tobaccos, flowers and trees, and also can be used for culturing seedlings of food crops.

Owner:吴小平

Closestool automatic cleaning mechanism

The invention belongs to the technical field of a cleaning device, and particularly relates to a closestool automatic cleaning mechanism. The closestool automatic cleaning mechanism comprises a tank body, wherein the tank body is matched with a closestool to be used and is used for containing cleaning agents; the bottom of the tank body is provided with a flow guide opening; the flow guide opening is connected with a control structure for controlling the cleaning agent from flowing into the closestool through a one-way valve; the control structure comprises a cylinder body for temporarily storing a small number of cleaning agents, a control body for controlling the cleaning agents in the cylinder body to enter the closestool and a gravity time delay body connected with the control body; the gravity time delay body controls the on-off state of the control body. By using the water outlet of the closestool water tank, the fixed amount of cleaning agents are filled; by using the water inlet of the water tank, the fixed amount of cleaning agents are fed into the water tank; new cleaning agents are added for each time of water inlet; along with the slow addition of the water inlet, the diffusion effect of the cleaning agent in the water is good; the concentration of the cleaning agents in a water solution always maintain the consistency; the cleaning effect is better.

Owner:湖州创星智能科技有限公司

Technique for BOE corrosion

ActiveCN110600374ACorrosion achievedImprove consistencySemiconductor/solid-state device manufacturingLiquid surfacesSilicon

The invention discloses a technique for BOE corrosion. The technique comprises the following steps: enabling a silicon wafer to move up and down in acid liquor to reduce bubble quantity clung to the silicon wafer in the corrosion process in the etching process of photoetching technology, entirely taking out the a rack from the liquid surface for 1S so that the bubbles clung to the silicon wafer are easy to break through the quick change of the pressure, and finally the silicon wafer is placed in the acid liquor to continuously move up and down for circular corrosion for 12min, thereby realizing the corrosion on the silicon wafer. The silicon wafer is corroded through a BOE corrosion trough, so that the corrosion liquor can circularly flow to maintain the consistent concentration of the corrosion liquor at various locations in the trough in the corrosion process; and meanwhile, the flowing corrosion liquor can completely or mostly remove the bubbles clung to the silicon wafer, the silicon wafer corrosion consistency is improved, and the influence on the corrosion effect by the bubbles produced in the corrosion process is reduced.

Owner:富芯微电子有限公司

Frozen drink containing kudzu-vine root and preparation method thereof

The invention provides a frozen drink containing kudzu-vine root and a preparation method thereof. Based on the total weight of the frozen drink, the frozen drink comprises the following compositions: 1 to 4 percent of candied kudzu-vine root block and 5 to 20 percent of candied kudzu-vine root water, wherein the candied kudzu-vine root block and the candied kudzu-vine root water are prepared by the following method: performing candied treatment on a kudzu-vine root raw material, namely mixing 10 to 30 weight portions of fresh kudzu-vine root raw material or equal amount of dry kudzu-vine raw material, 10 to 20 weight portions of sugar and 30 to 40 weight portions of water for the candied treatment; filtering to obtain the candied kudzu-vine root block and filtrate; and adjusting the weight of the filtrate to 40 to 60 weight portions to obtain the candied kudzu-vine root water. The method performs high-temperature candied treatment on the kudzu-vine root, effectively applies the kudzu-vine root to the production of the frozen drink, and makes the prepared frozen drink have nutrition and good flavor and mouthfeel through a reasonable formula and a proper process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

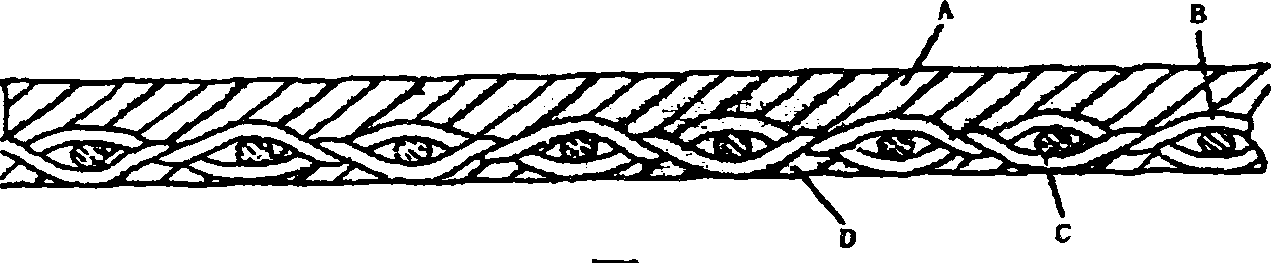

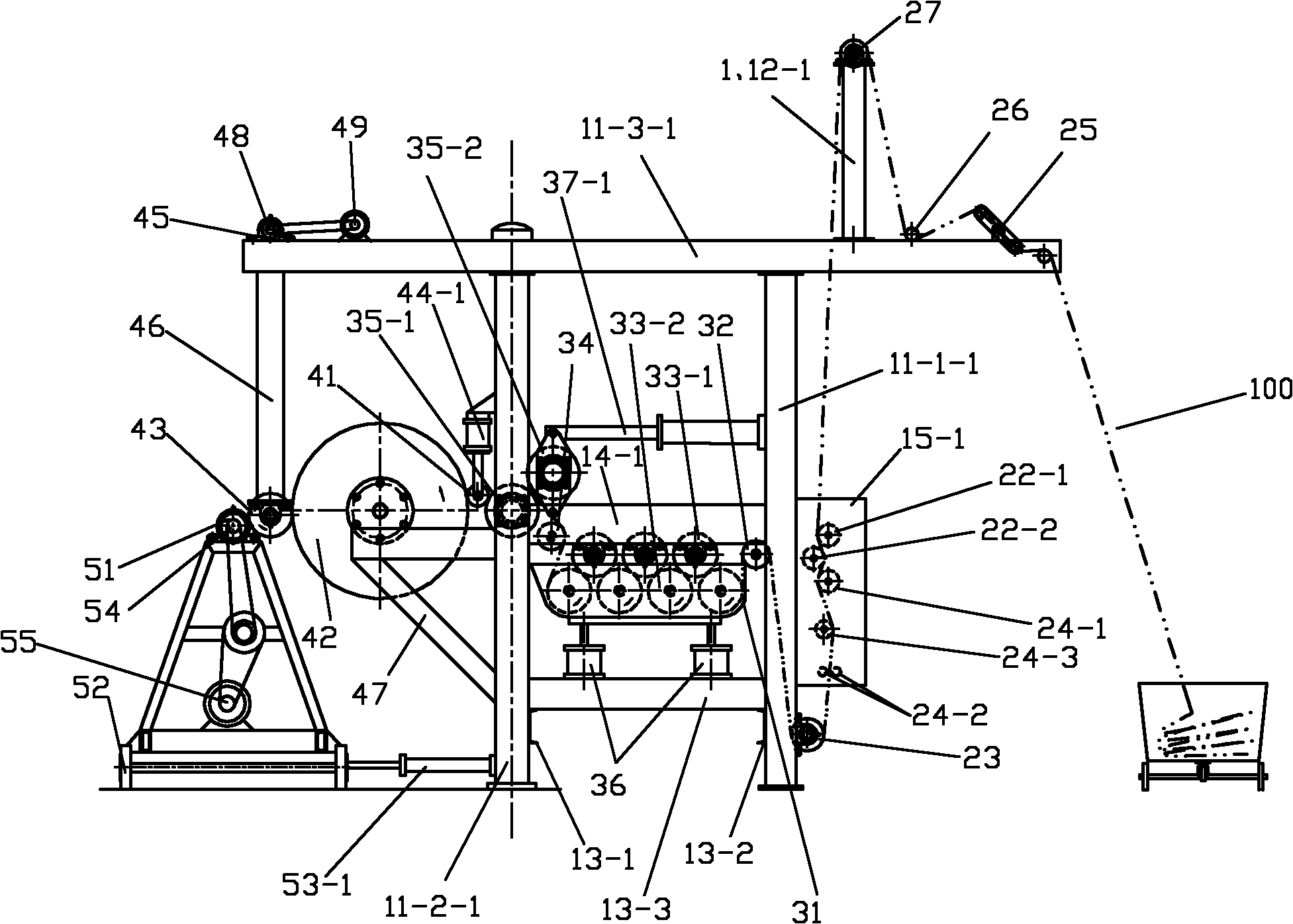

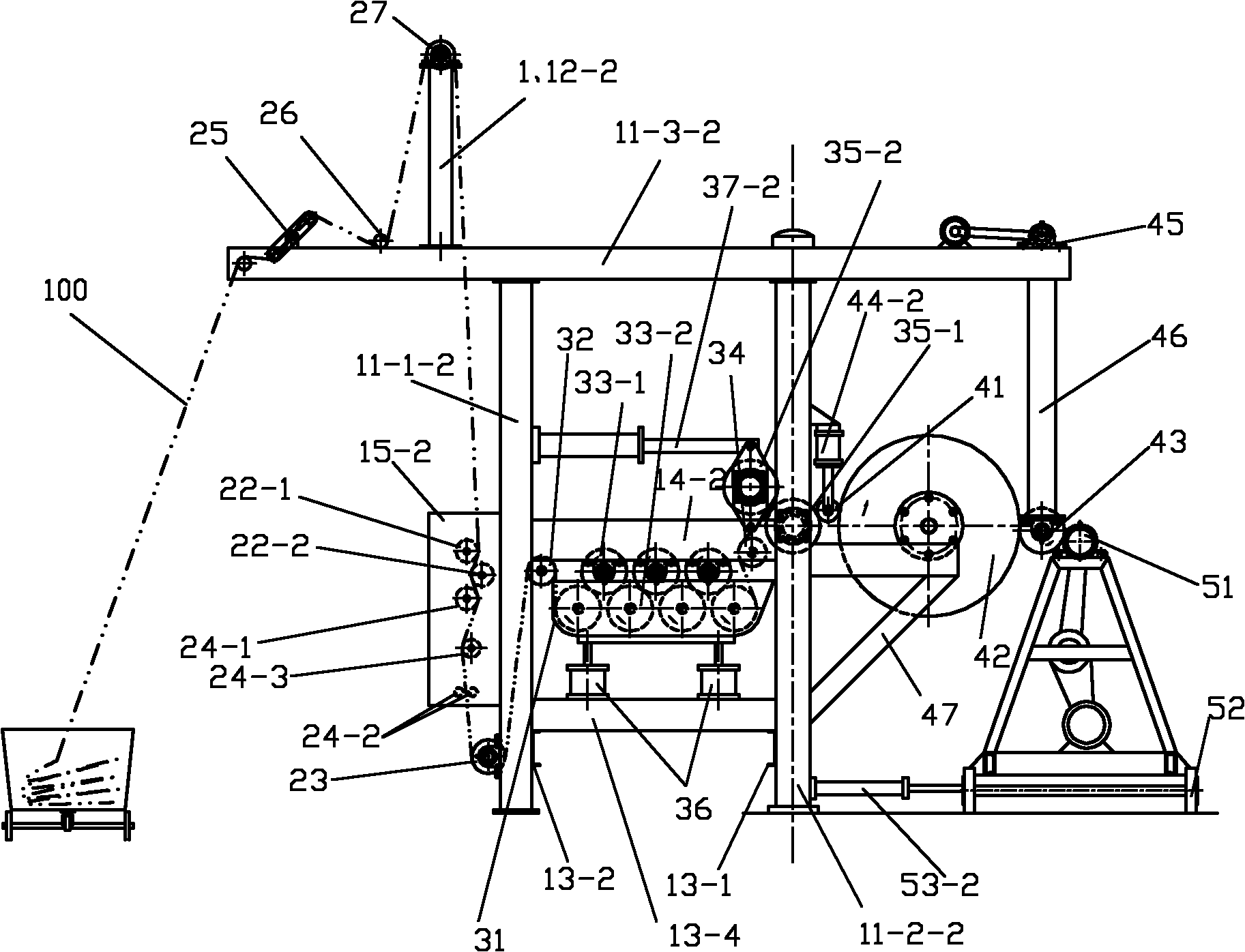

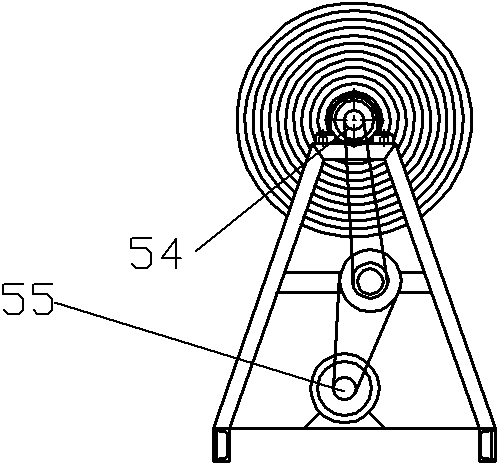

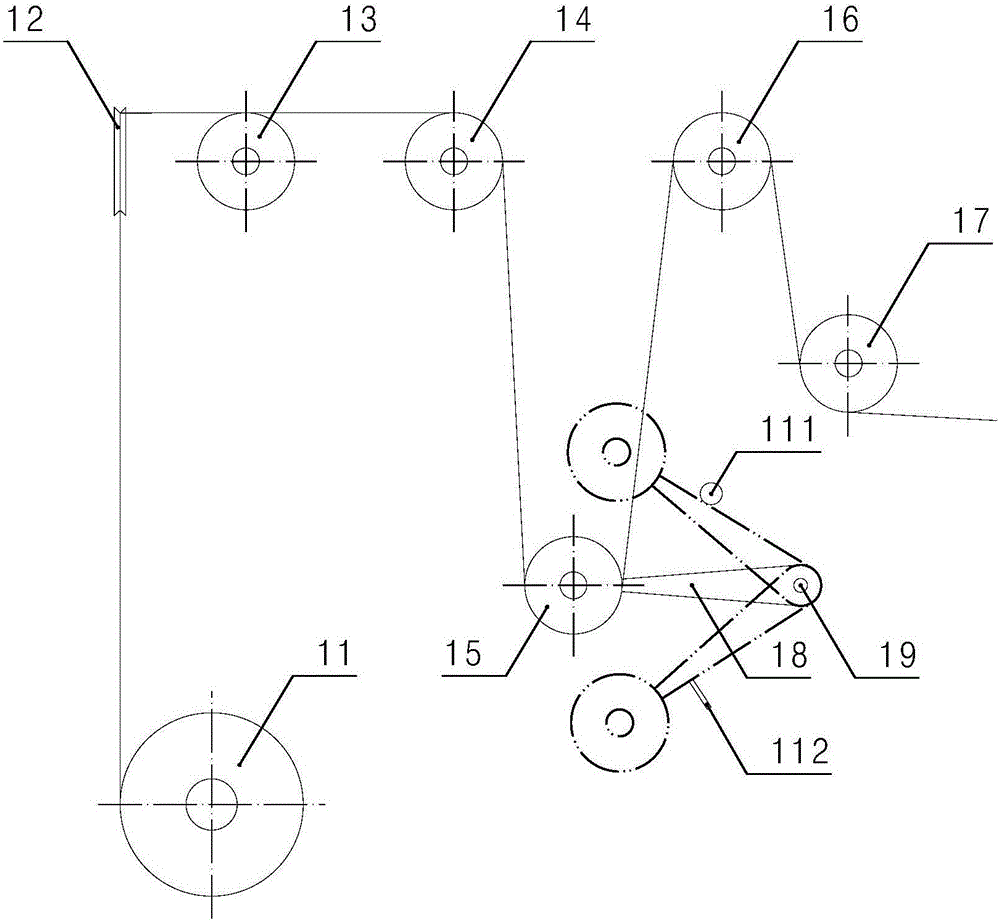

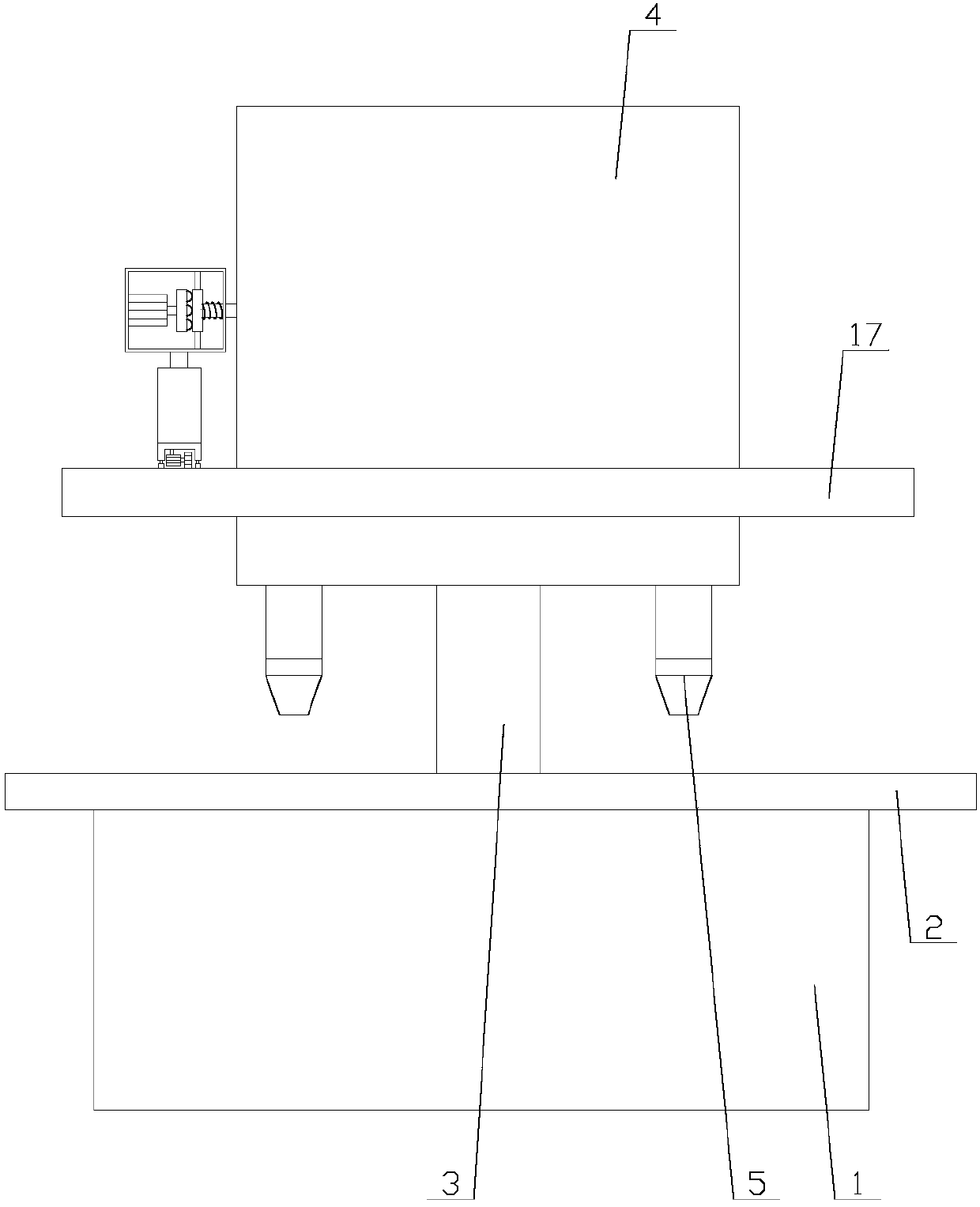

Diamond wire saw production line

ActiveCN106011981AEnough time to stayIncrease travel speedElectrolysis componentsElectrolytic coatingsProduction lineWire speed

The invention discloses a diamond wire saw production line capable of ensuring enough sanding time for a metal wire and improving the moving speed of the metal wire. The production line comprises a wire placing device, an alkali washing device, a before-acid water washing device, a acid washing device, a before-sanding water washing device, a sanding device, an after-sanding washing device, a sand consolidating device, an after-sand-consolidation water washing device, a drying device and a wire taking device which are disposed successively along the moving direction of the metal wire used for electro-plating diamond micro powder. The sanding device comprises a sanding tank; at least one liquid inlet is disposed on the bottom or the lower part of the sanding tank; both sides of the sanding tank are respectively provided with a tumbling barrel; the pair of tumbling barrels are disposed parallelly and horizontally; a plurality of wire grooves are formed on the tumbling barrels; and an upper and a lower wire passing hole are formed on the sanding tank at the sides near the corresponding tumbling barrels. Compared with the traditional diamond wire saw production lines, the wire speed of the production line disclosed by the invention is improved by more than 5 times.

Owner:ZHANGJIAGANG SHUNCHEN MACHINERY CO LTD

Electroplating bath

The invention relates to an electroplating bath for electroplating a to-be-plated board. The electroplating bath comprises a bath body for containing electroplating liquid, a plurality of guide tubes and a plurality of nozzles. The to-be-plated board is accommodated by the bath body. The guide tubes are arranged on the two sides of the bath body. The nozzles are arranged on the guide tubes and arranged in rows along the guide tubes. The electroplating liquid flows in the guide tubes and is sprayed out through the nozzles. The outflow direction of each row of nozzles faces the to-be-plated board. The included angle between the outflow direction of the nozzles and the to-be-plated board ranges from 40 degrees to 50 degrees. The electroplating liquid in the electroplating bath is sprayed around the to-be-plated board; the electroplating liquid around the to-be-plated board is evenly and quickly supplemented; the temperature, concentration, pH value and the like of the electroplating liquid around the to-be-plated board are kept consistent; other chemical compositions are evenly scattered, so that the thickness of an electroplating layer deposited on the board face of the to-be-plated board is kept consistent; and the purpose of reducing the production cost is achieved.

Owner:迈瑞凯电子科技(天津)有限公司

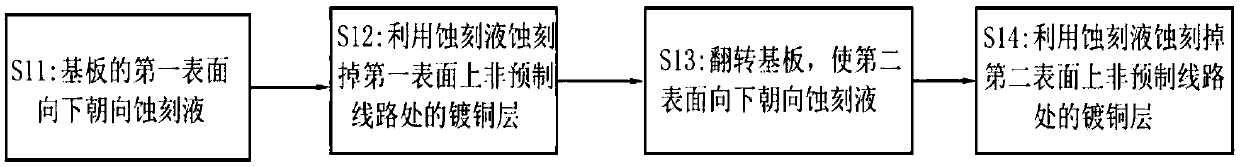

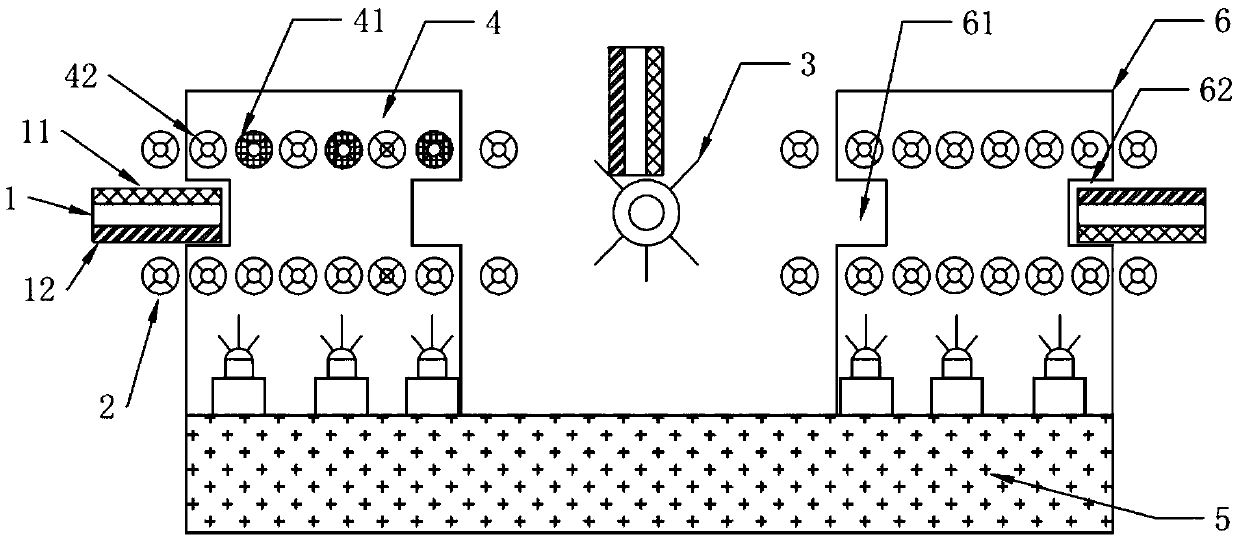

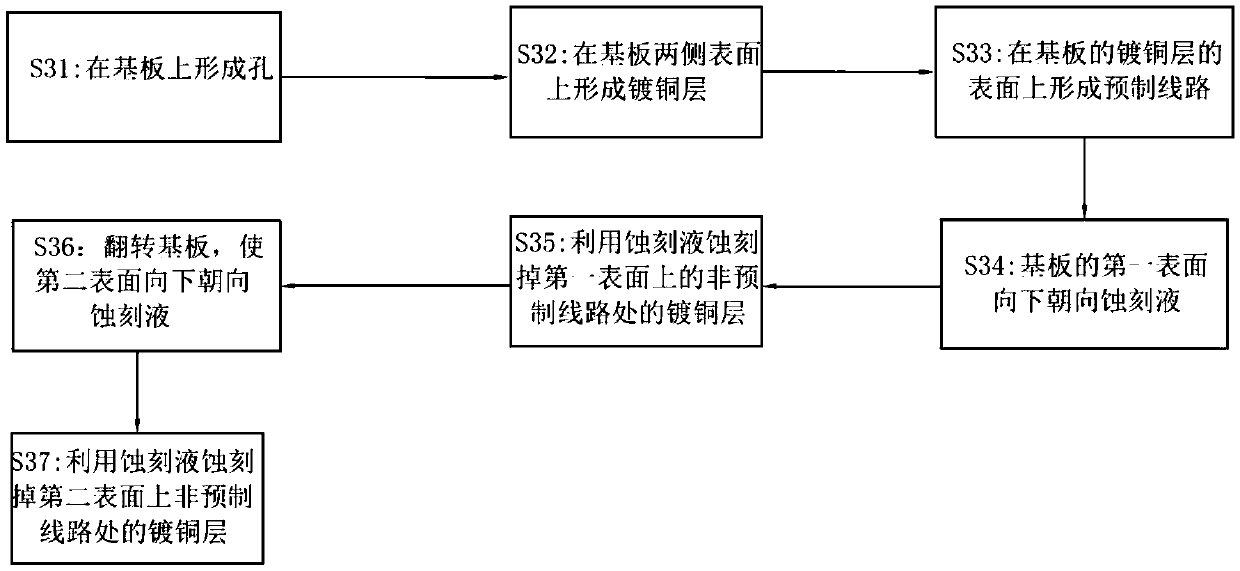

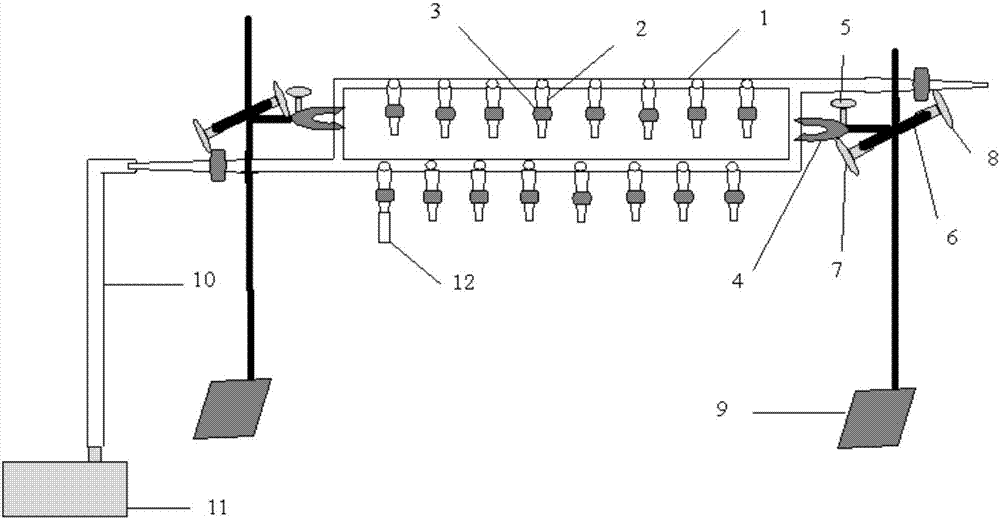

Etching method, etching system and preparation method of PCB

InactiveCN105517352AEtching speed is fastIncrease the areaInsulating layers/substrates workingChemistryEtching

The invention discloses an etching method, etching system and preparation method of a PCB. The etching method includes the following steps that: the first surface of a substrate is arranged downwards to face an etching solution, and the etching solution etches the first surface; the substrate is turned over, so that the second surface of the substrate which is opposite to the first surface, is arranged downwards to face the etching solution; and the etching solution etches the second surface. The etching system includes a conveying device used for supporting a substrate and can driving the substrate to move, at least one spray device used for spraying an etching solution to the to-be-etched surfaces to the substrate, and a turnover device used for turning over the substrate so as to make the to-be-etched surfaces of the substrate face the spray device. According to the preparation method of a PCB, the above PCB etching method or PCB etching system are adopted to etch two side surfaces of a substrate. The two side surfaces of the substrate are etched in twice, a certain to-be-etched surface faces downwards each time, and therefore, the etching solution will not be deposited on any surface of the substrate, and prefabricated lines at the two side surfaces of the substrate, which are formed by etching, can be identical.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

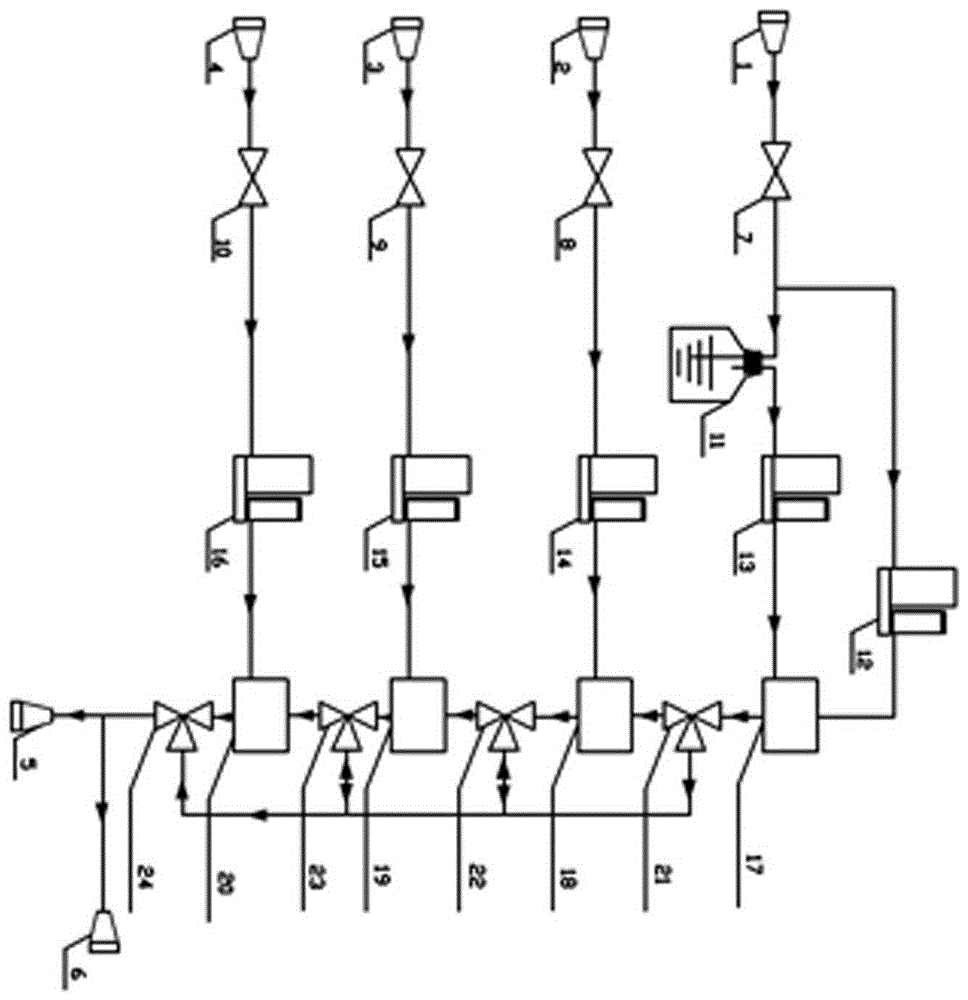

Method for testing greenhouse gas emission of indoor culture soil

ActiveCN106932241ASimple structureEasy to manufactureWithdrawing sample devicesPreparing sample for investigationEngineeringGas exchange

The invention relates to a method for testing greenhouse gas emission of indoor culture soil. The method is implemented by using a gas exchange and culture gas production integral device; the gas exchange culture gas production integral device comprises a gas exchange device and a culture gas production device which is connected with the gas exchange device; the testing method comprises steps of opened culture of soil, gas exchange, sealed culture and gas collection. By adopting the method, the influence of gases generated from the soil at an early stage upon sealed culture gas emission is eliminated, sealed culture at normal pressure is achieved, meanwhile the problem that a target gas is absorbed by negative pressure in sampling is overcome, in addition, culture and gas collection of multiple culture flasks can be completed at one time, the initiation culture concentration is accordant, and the working efficiency is high.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

SF6 decomposition product multi-component dynamic gas preparation method

InactiveCN106092676AConsistent concentrationGuaranteed accuracyPreparing sample for investigationGas analyser calibrationDecompositionProduct gas

The invention relates to an SF6 decomposition product multi-component dynamic gas preparation method. The method realizes gas mixing preparation through a mass flow mix technology, and comprises the following steps: inputting a standard sample gas and a background gas, dynamically preparing a dry background gas source and a wet background gas source, dynamically preparing dry SF6 decomposition product multi-components gas with different concentrations, and dynamically preparing SF6 decomposition product multi-component gas with different humidity values. The SF6 decomposition product multi-component dynamic gas preparation method can simulate the decomposition product concentration of onsite gas to dynamically prepare decomposition product standard mixed gas with different concentrations, verifies an SF6 decomposition product instrument, has the advantages of high convenience, fastness, and easiness in operation, and greatly improves the gas preparation working efficiency in the dynamic preparation process; and single-component and multi-component standard gases prepared in the invention are difficultly influenced by the temperature and pressure change of environment, and the practical concentration of the prepared gas is same to an ideal gas concentration, sot eh precision of the prepared gas is guaranteed.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Energy-saving type filling machine with uniform filling based on internet of things

InactiveCN108033043AEvenly filledPrevent precipitationRotary stirring mixersLiquid materialThe InternetProcess engineering

The invention relates to an energy-saving type filling machine with uniform filling based on the internet of things. The energy-saving type filling machine comprises a machine base, a filling table, amain shaft, a storage barrel, a filling valve, a mixing mechanism and a vibration mechanism, wherein the mixing mechanism comprises a mixing assembly and a lifting assembly, and the vibration mechanism comprises a steering assembly and a vibration assembly. According to the energy-saving type filling machine with uniform filling based on the internet of things, raw materials are periodically mixed by the mixing mechanism, so that the raw materials are prevented from depositing in a filling process, a certain degree of uniformity of the raw materials can be kept all the time, the consistent concentration of filled products is guaranteed, and the uniform filling of the raw materials is realized; in addition, when the filling of the raw materials in the storage barrel is nearly finished, thestorage barrel is vibrated by the vibration mechanism, so that the raw materials attached to the inner wall of the storage barrel drop down, filling can be realized by virtue of the filling valve, the waste of the raw materials is avoided, and the raw material input cost of an enterprise is reduced.

Owner:FUJIAN PINPAI PACKAGING

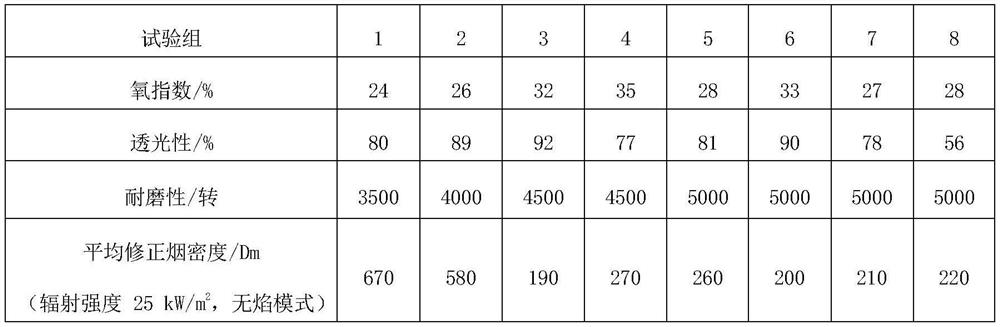

Preparation method of high-flame-retardant smoke-suppression LVT floor wear-resistant layer

InactiveCN111761772AGuaranteed uniformityIncrease concentrationFlat articlesFlooring insulationsPolymer sciencePlasticizer

The invention discloses a preparation method of a high-flame-retardant smoke-suppression LVT floor wear-resistant layer. The preparation method comprises the following steps of: (1) taking the following production raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 0-40 parts of a plasticizer, 0-50 parts of a flame retardant, 0-8.0 parts of a smoke suppression agent, 1.0-6.0 parts of a stabilizer and 0.5-3.0 parts of a processing aid; and (2) mixing the production raw materials, performing internal mixing, performing open milling, calendering, cooling, drawing and discharging to obtain the high-flame-retardant smoke-suppression LVT floor wear-resistant layer. According to the LVT floor wear-resistant layer prepared by the method disclosed by the invention, the wear-resistant layer has excellent flame-retardant smoke-suppression performance by reasonably proportioning the components of the plasticizer, the flame retardant and the smoke suppression agent; and by controlling the mixing, internal mixing and other parameters, the light transmittance and flexibility of the wear-resistant layer are greatly improved, the pattern of a color film can be displayed to thegreatest degree when the wear-resistant layer is applied to the LVT floor, the pattern diversity of the LVT floor is reflected, and the wear-resistant layer can be applied to ships, rail transit and other places with relatively strict operating requirements.

Owner:宜宾天亿新材料科技有限公司 +1

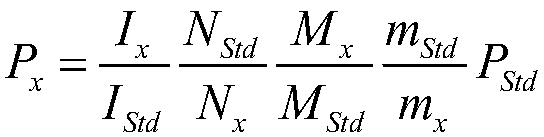

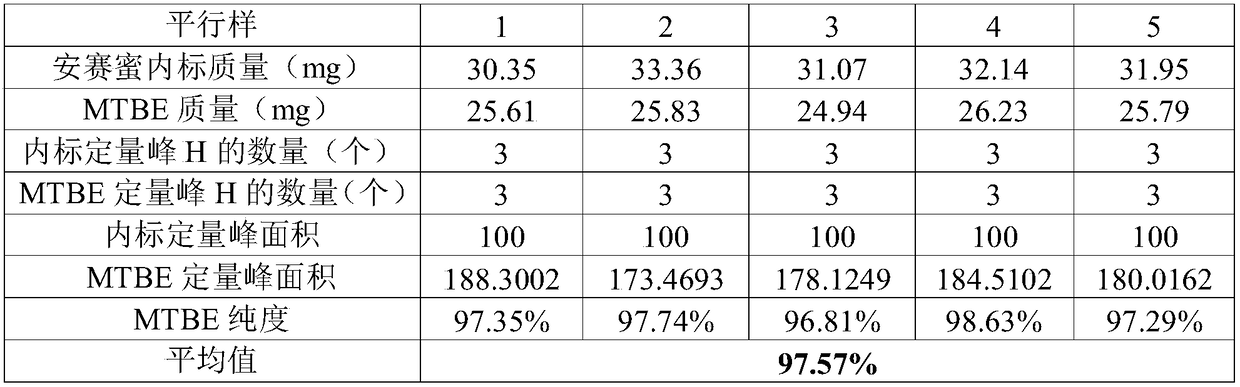

Method for accurately measuring purity of volatile substances by adopting quantitative HNMR

ActiveCN108827998AAccurately Measure PuritySolve the difficulties in the application of quantitative nuclear magnetic resonance technologyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceHydrogen

The invention discloses a method for accurately measuring the purity of volatile substances by adopting quantitative HNMR (Hydrogen Nuclear Magnetic Resonance). The method comprises the following steps: (1), taking a volatile substance as a to-be-detected target sample; (2), taking high-purity solvent standard substance with metrological traceability as an interior label; (3), accurately weighingthe target sample and the interior label in a sealed sample bottle through an air-tight needle and a high-precision balance, and dissolving in deuterated solvent to prepare solution; and (4), after mixing uniformly, transferring the solution into a sealed nuclear magnetic tube through the air-tight needle to perform HNMR measurement. The method can effectively solve the problem that the measurement result is not accurate due to weighing deviation caused by sample volatilization. The method provided by the invention has the characteristics that the degree of accuracy is high and the result cantrace to the source of SI, and the like, and the method can be applied to scientific researches such as high-accuracy analysis and detection and standard substance valuing.

Owner:NAT INST OF METROLOGY CHINA

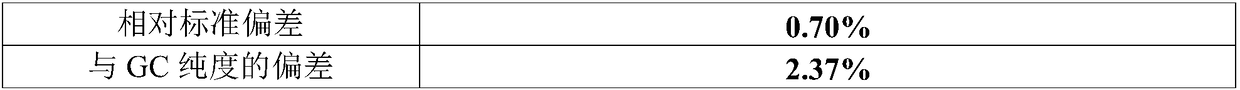

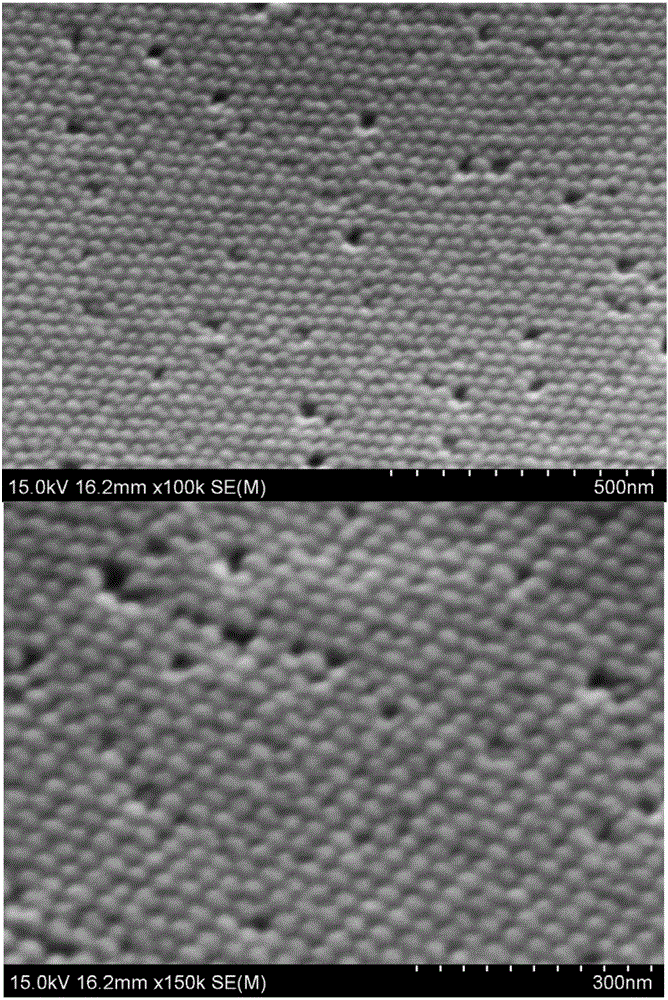

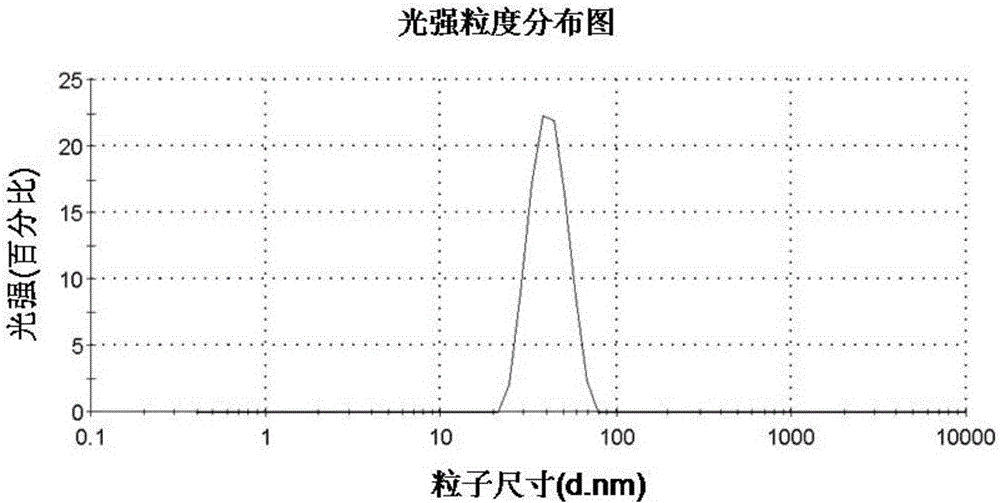

Method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis

The invention relates to a method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis. The method includes the following steps that 1, silica powder is added into an inorganic alkali solution, the mass ratio of the silica powder to water is controlled to be 1:8-15, and a reaction is conducted to obtain a silica sol mother solution with the pH of 9.5-10.5; 2, an organic alkali solution is added into the silica sol mother solution, a reaction is conducted at 70-90 DEG C to increase the particle diameter, and the system pH value in the reaction process is controlled to be 9.5-10.5; 3, after the reaction is finished, unreacted solid impurities in reaction liquid are removed, the product is concentrated to needed concentration, and then the monodisperse large-particle-diameter silica sol is obtained. According to the difference of the relative use quantities and proportions of two kinds of catalysts added in two steps and the difference of the particle diameters, activities and use quantities of the selected silica powder, the monodisperse large-particle-diameter silica sol with the mean particle diameter ranging from 20 nm to 100 nm or so is prepared.

Owner:SHANDONG YINFENG NANOMETER NEW MATERIAL CO LTD

Method for preparing nanometer magnesium hydroxide from phosphorus ore magnesium removal waste liquor

InactiveCN106745106APrevent leakageConsistent concentrationNanotechnologyMagnesium hydroxideFlue gasPhosphorite

The invention discloses a method for preparing nanometer magnesium hydroxide from phosphorus ore magnesium removal waste liquor. The method specifically includes subjecting ammonia gas and the phosphorus ore magnesium removal waste liquor to further neutralizing and edulcorating reaction in a submerged circulating impinging stream reactor, and performing solid-liquid separation after the reaction so as to obtain mother liquor; adding a dispersant into the mother liquor, and continuing to feed the ammonia gas for magnesium precipitation reaction so as to reach a pH value of 10-11; performing solid-liquid separation, washing and drying after the reaction so as to obtain nanometer magnesium hydroxide powder. The nanometer magnesium hydroxide prepared by the method has the purity up to 98%, is small in particle size and regular in shape and can be widely applied to the fields of fire retardants and flue gas desulfurizing agents, and secondary utilization of resources is achieved effectively.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com