Patents

Literature

58results about How to "Consistent ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorescence immunochromatography device for detecting COVID-19 and using method thereof

InactiveCN111060691AImprove binding efficiencyHigh sensitivityBiological testingImmunoassaysVirologyDisease control

The invention discloses a fluorescence immunochromatography device for detecting a novel coronavirus COVID-19 and a using method of the fluorescence immunochromatography device. The fluorescence immunochromatography device disclosed by the invention is high in sensitivity and strong in specificity, the accuracy is high, the detection sensitivity can reach 10pg / ml, the detection speed is high, theoperation is simple, the device is portable, the requirement for personnel is low, the operation of professionals is not needed, the detection cost is low, the device can be applied to preliminary screening of various places such as hospitals, airports, customs and disease control centers, the detection time (10-15 min) is short, a simpler, more convenient and faster field detection means is provided for suspected patient investigation and asymptomatic infected person screening, and therefore epidemic spreading is prevented as soon as possible.

Owner:SHENZHEN BIOEASY BIOTECHNOLOGY CO LTD

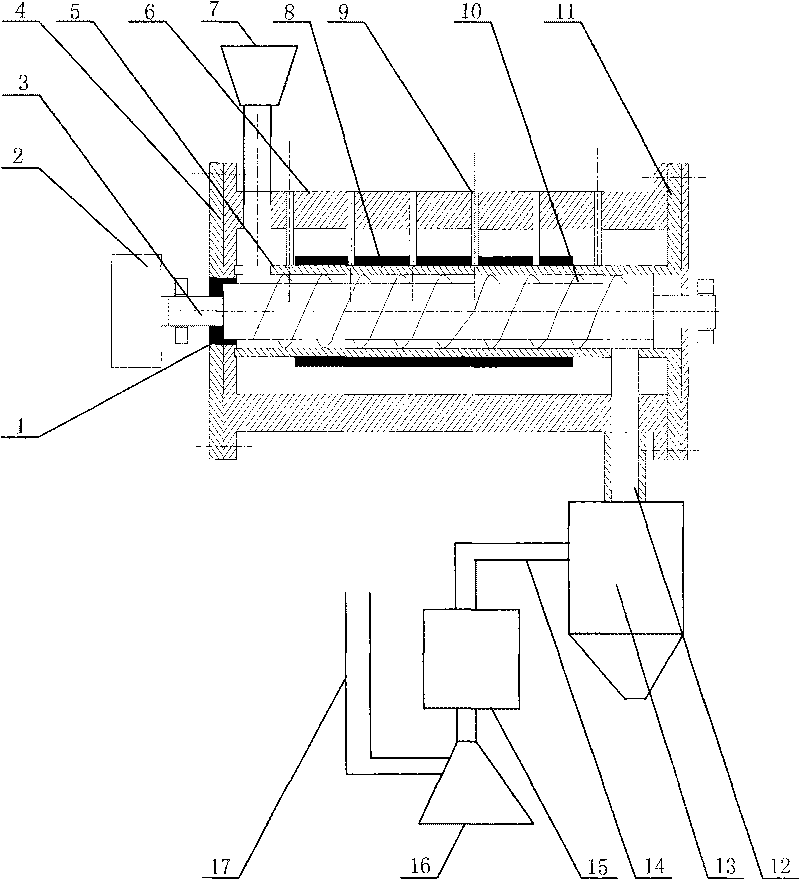

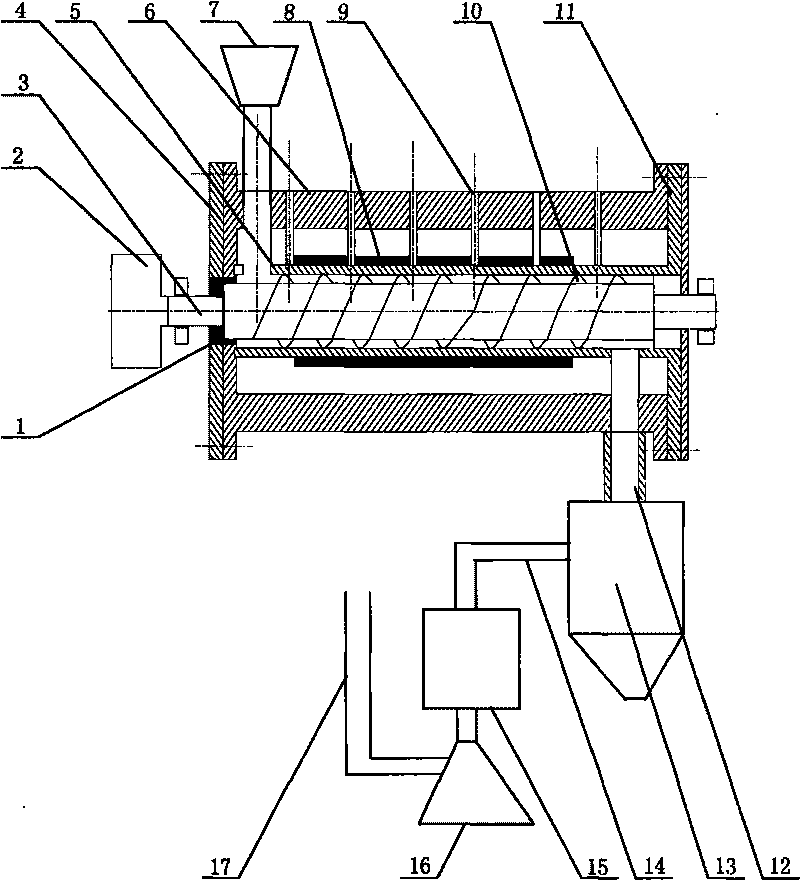

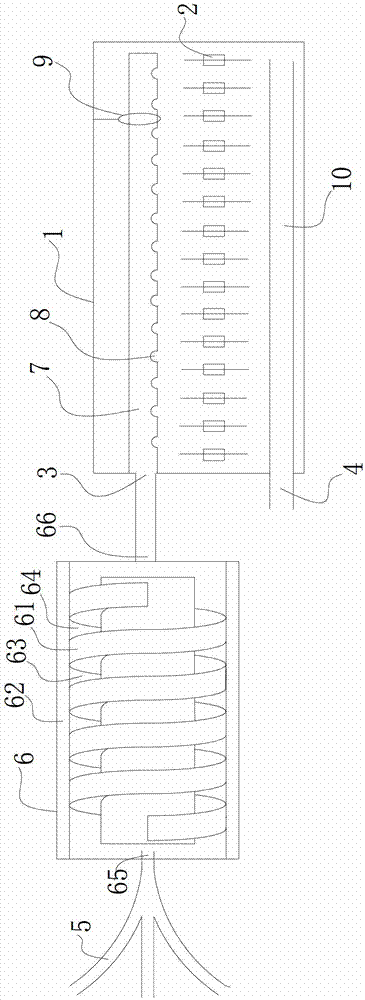

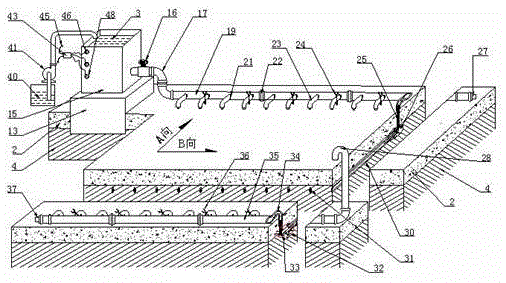

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

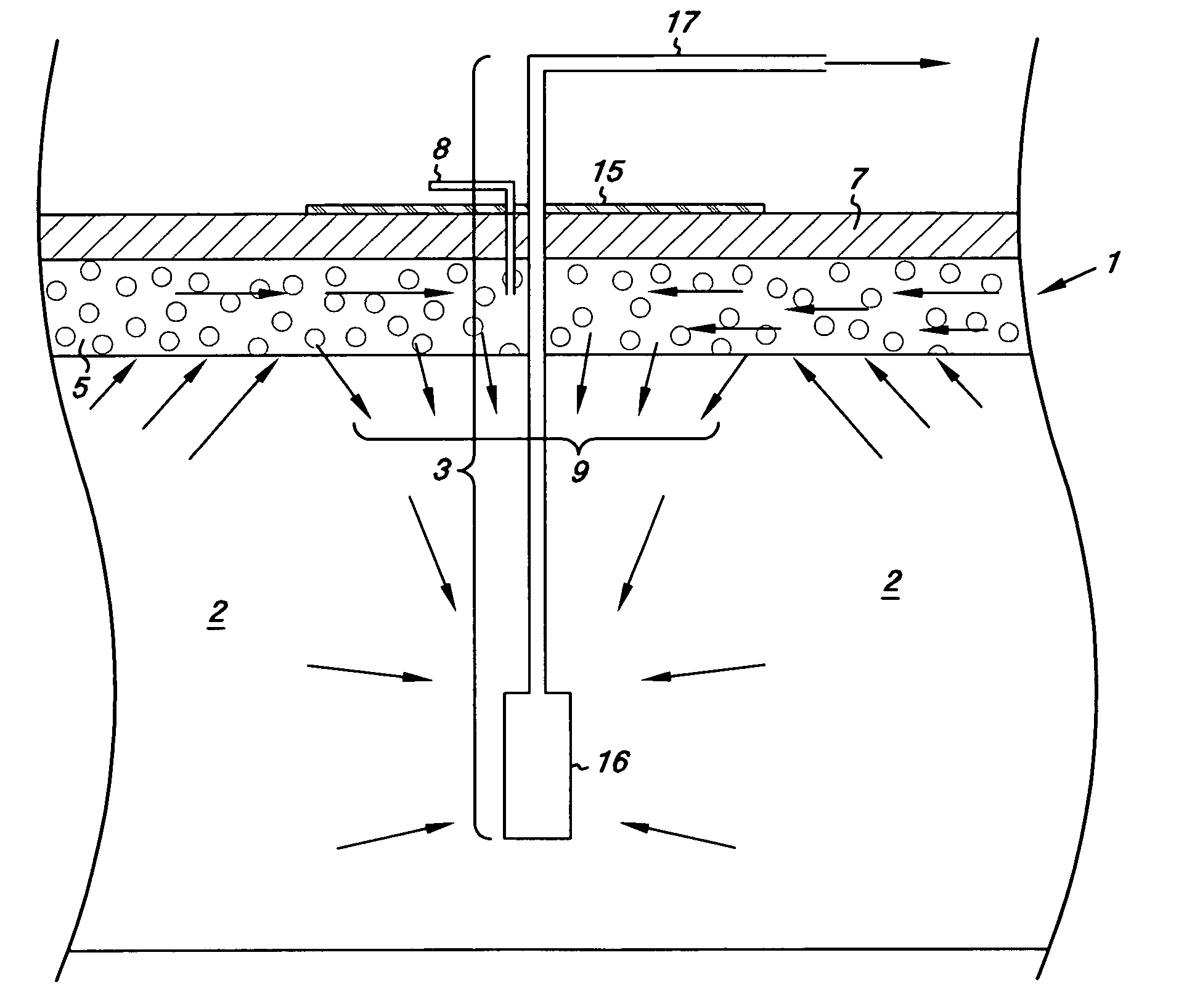

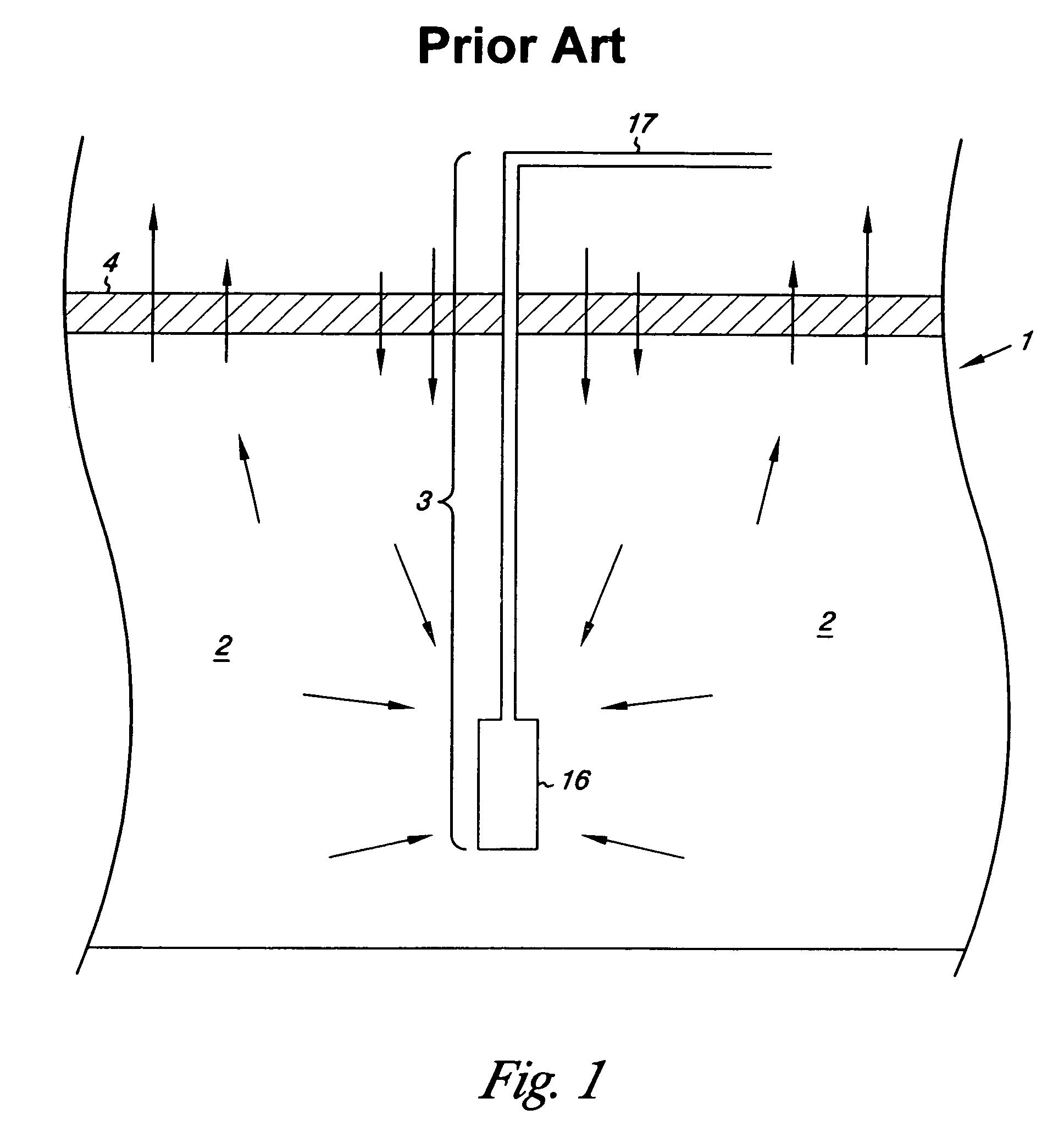

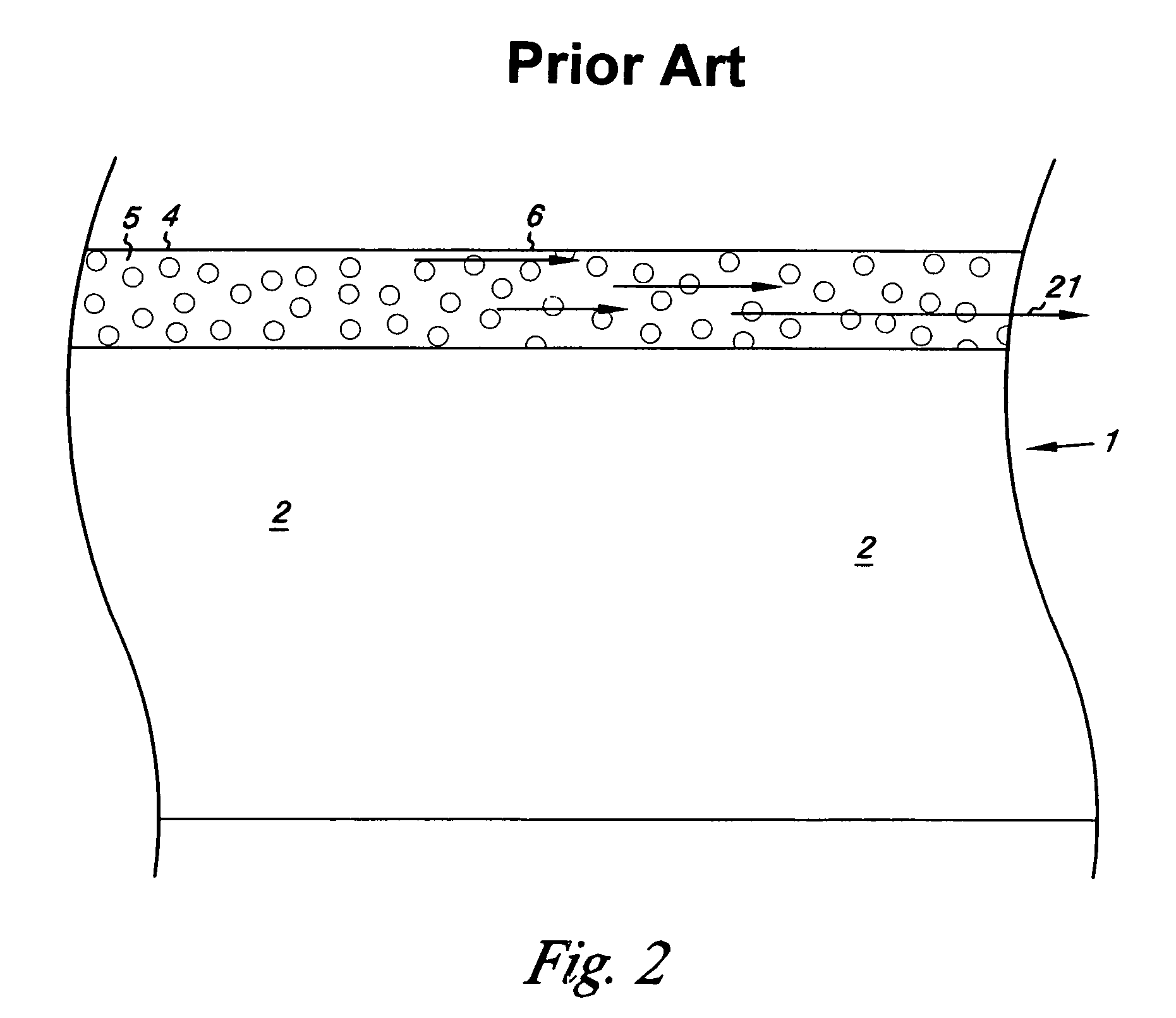

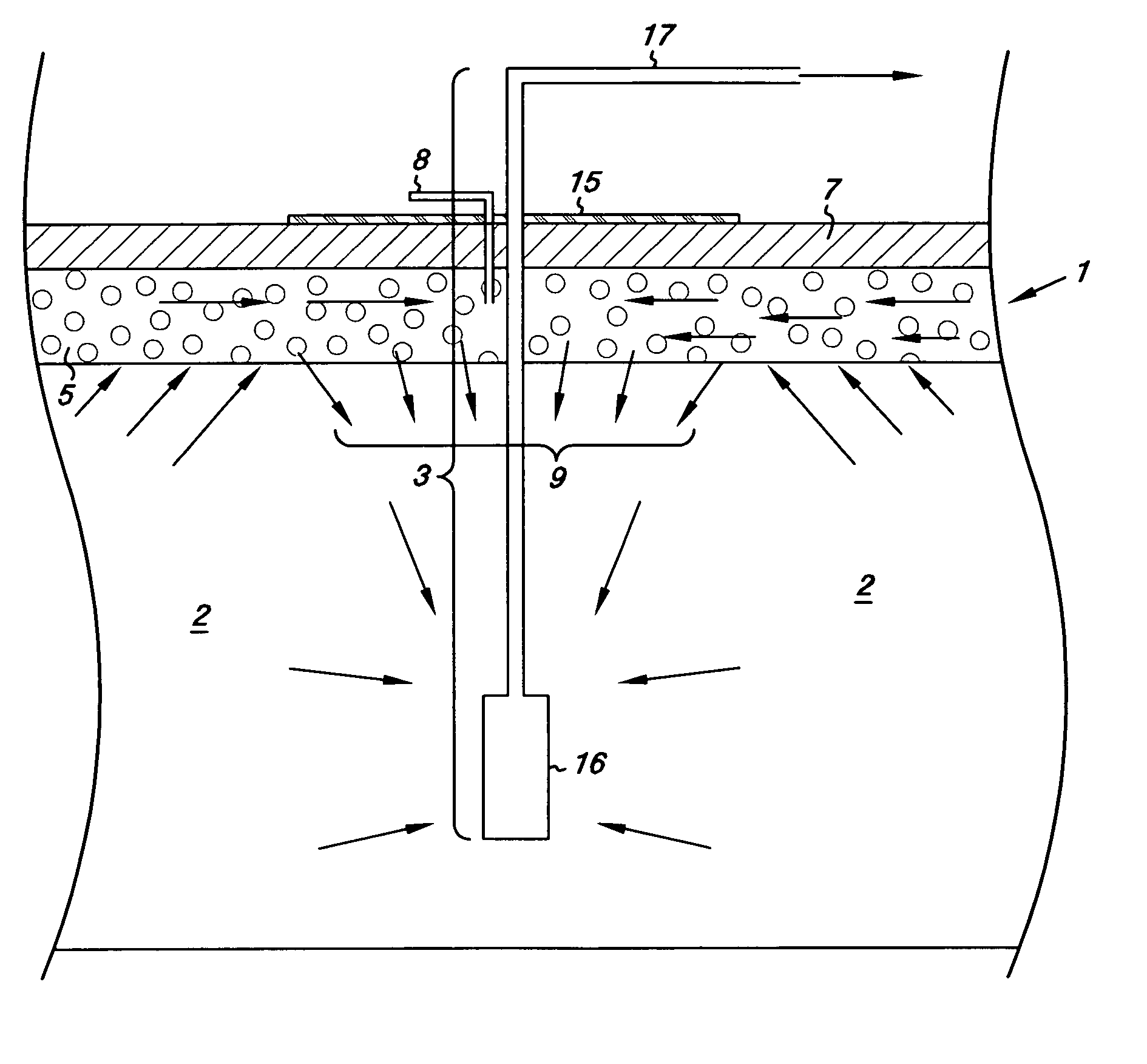

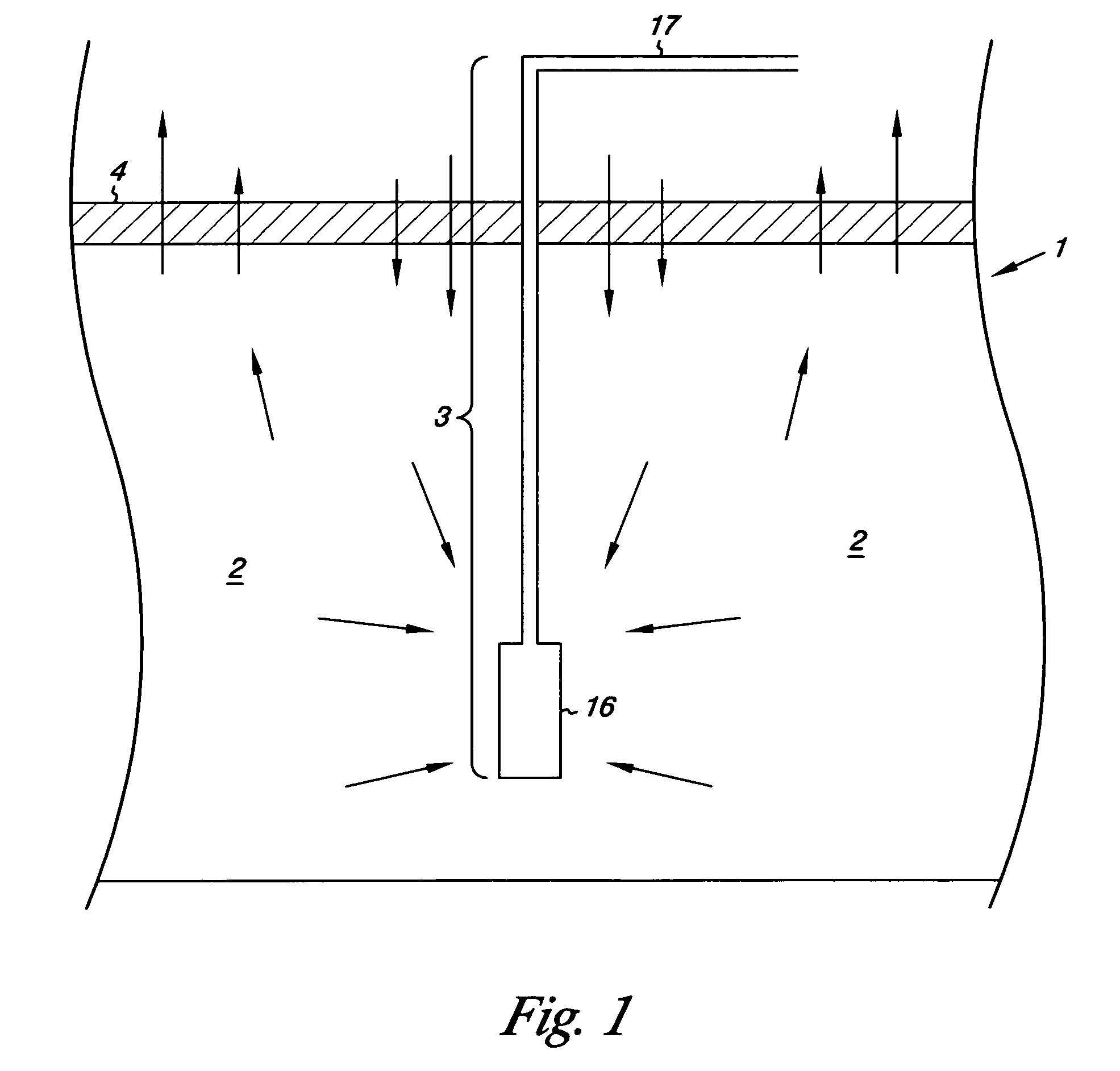

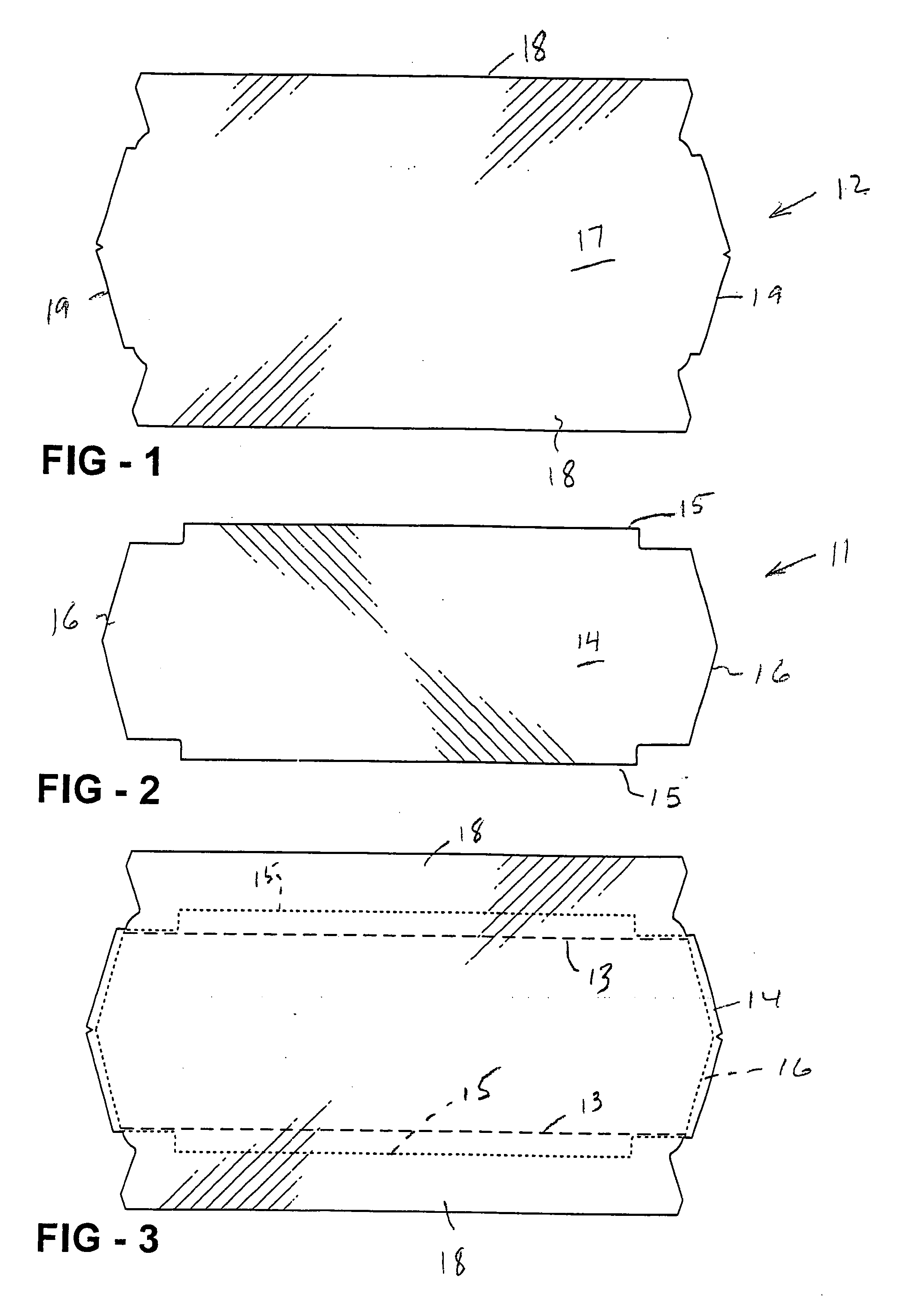

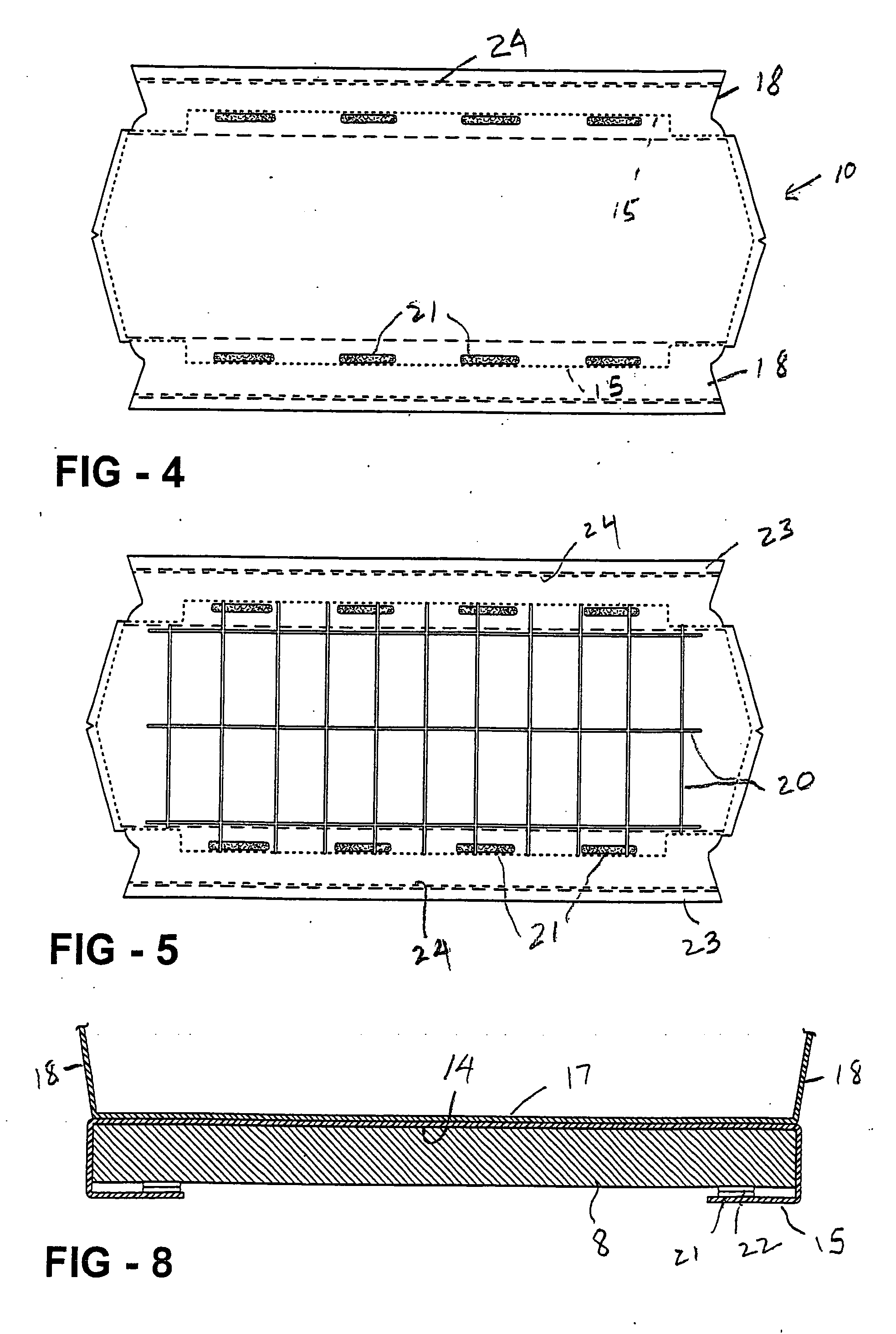

Landfill design and method for improved landfill gas capture

InactiveUS7198433B2Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

Landfill design and method for improved landfill gas capture

InactiveUS20060034664A1Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

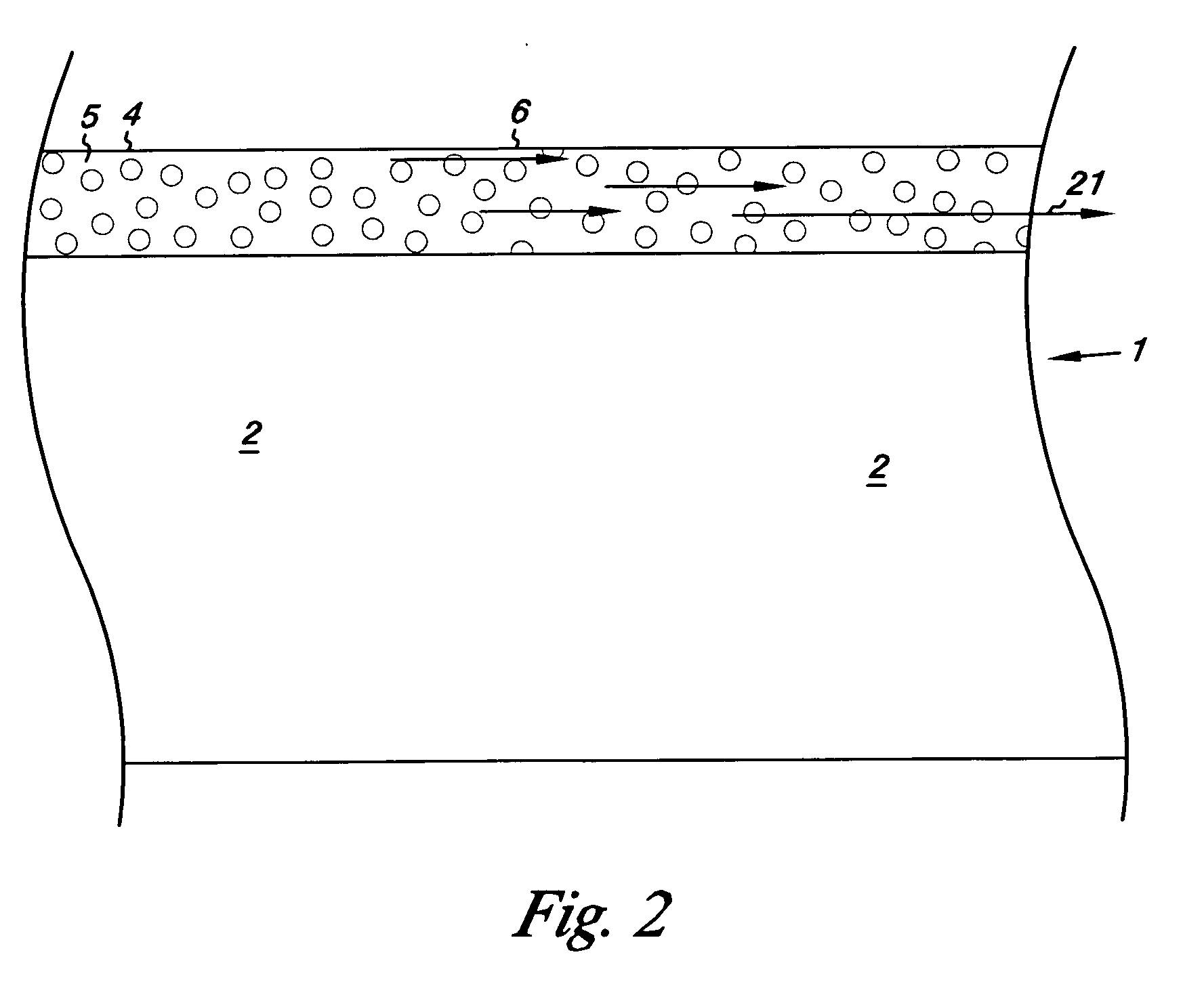

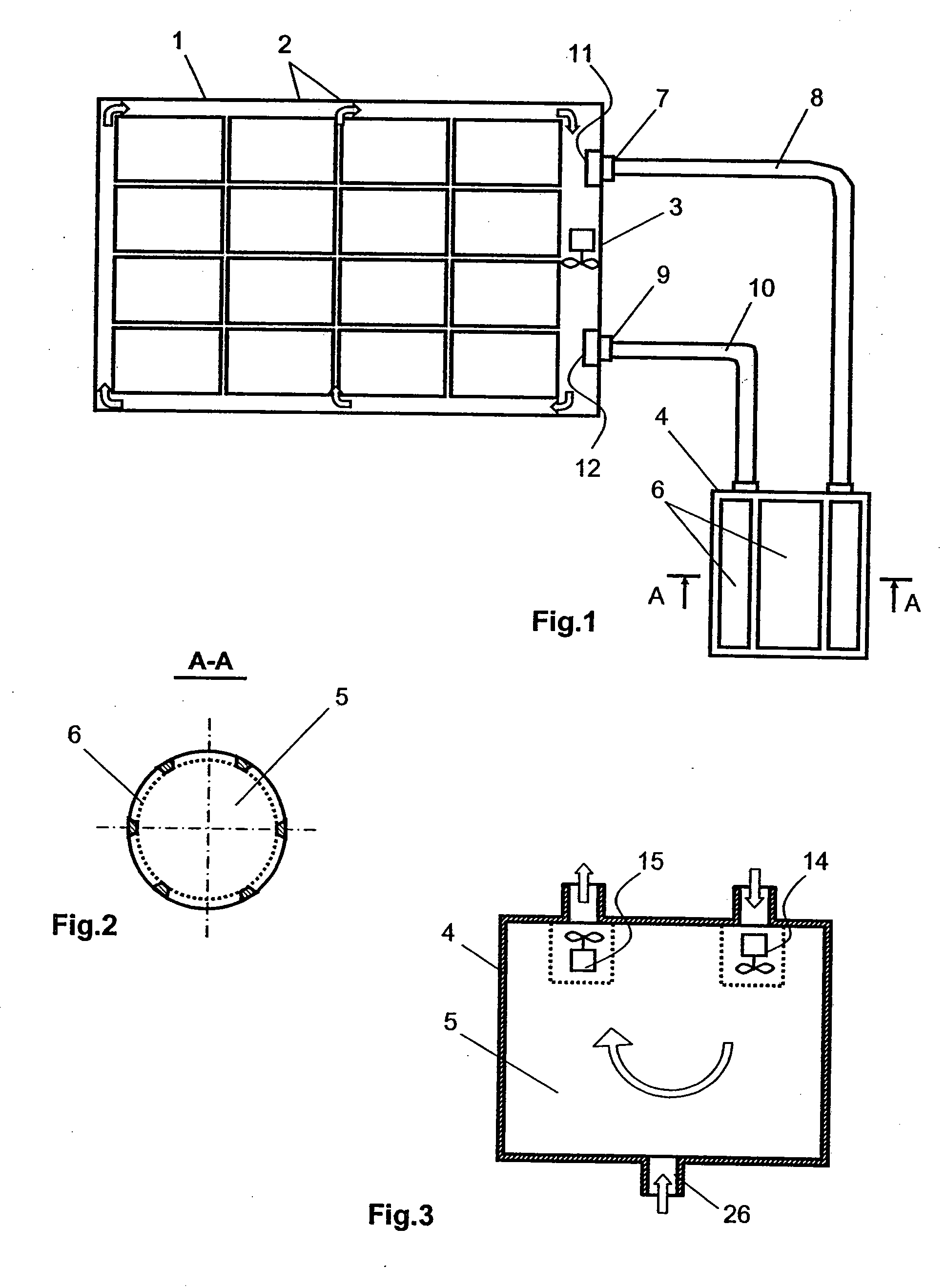

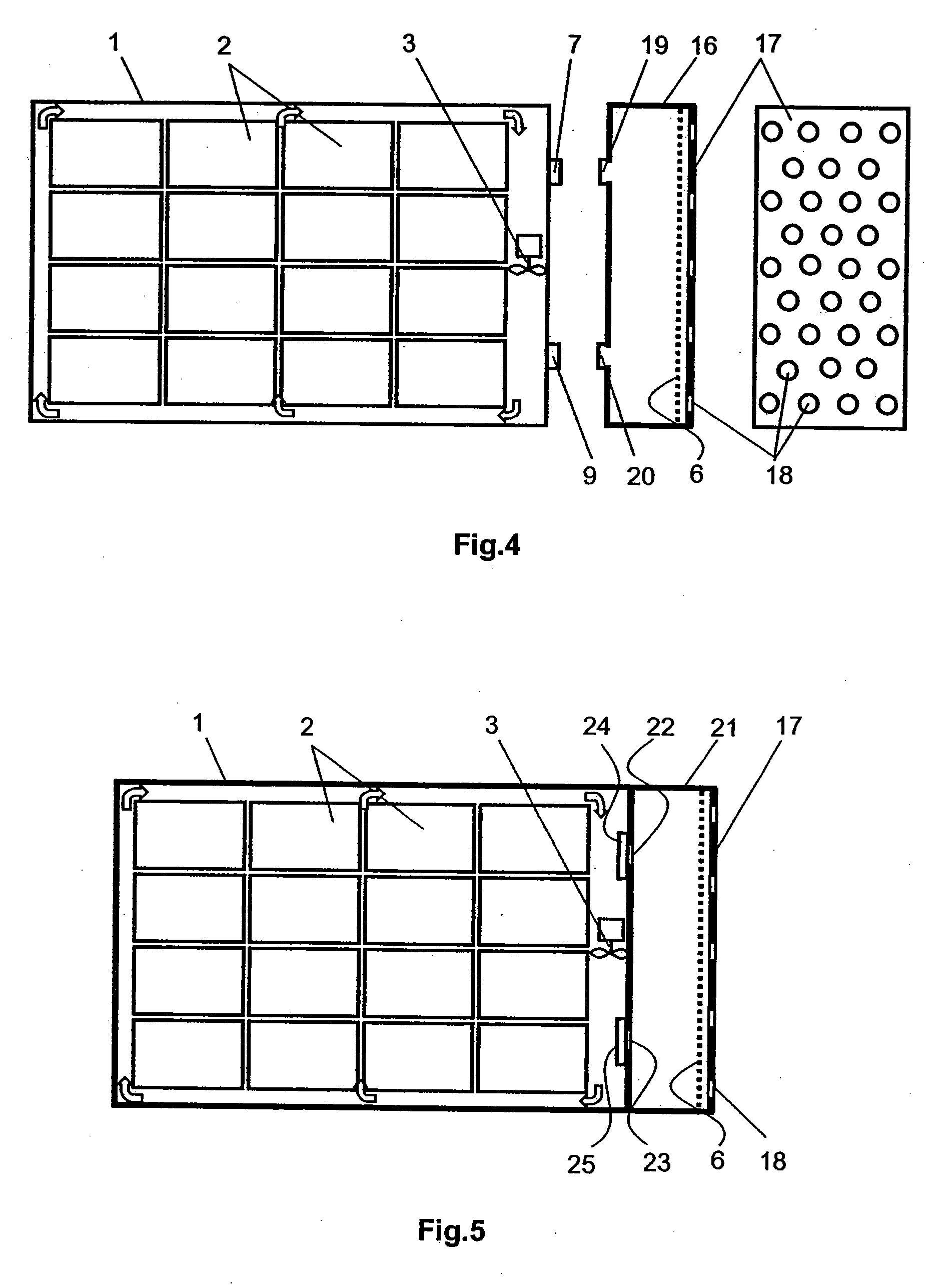

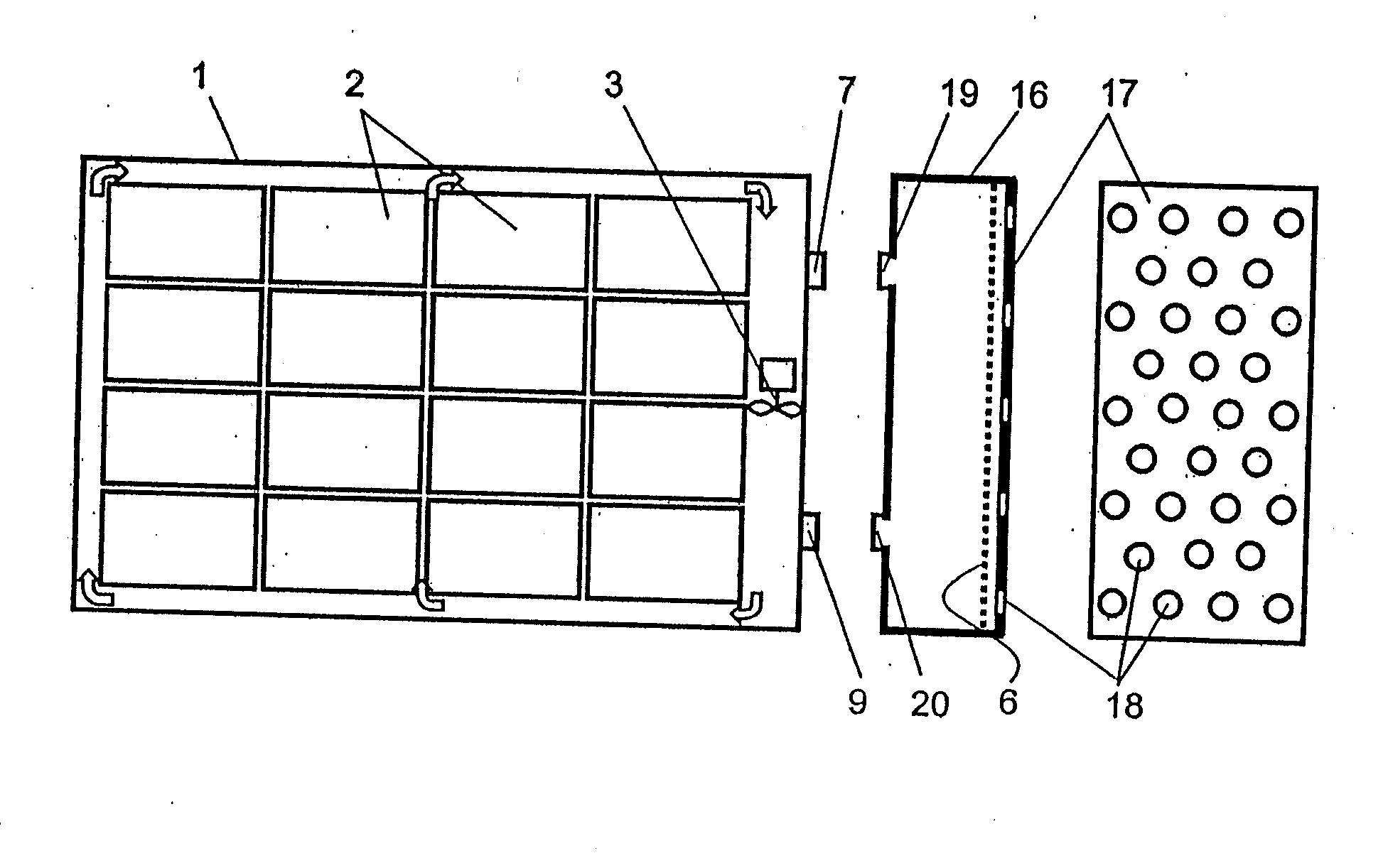

Device for controlling the gas medium inside a container

InactiveUS20070144638A1Simple structureAvoid prematureFruit and vegetables preservationGaseous food ingredientsMembrane configurationAtmosphere

A device for controlling the composition inside a shipping / storage container for produce, such as bananas, is disclosed. Such atmospheric control is particularly important when dealing with the ripening of respiring fruit. The device comprises a chamber surrounded by an outer wall, at least a portion of that wall made up of a selectively gas-permeable membrane which is in communication with the outside atmosphere. The chamber also includes at least two channels which are connected to the container: one which transmits gas form the chamber to the container, and one which transmits gas from the container to the chamber.

Owner:CHIQUITA BRANDS LLC

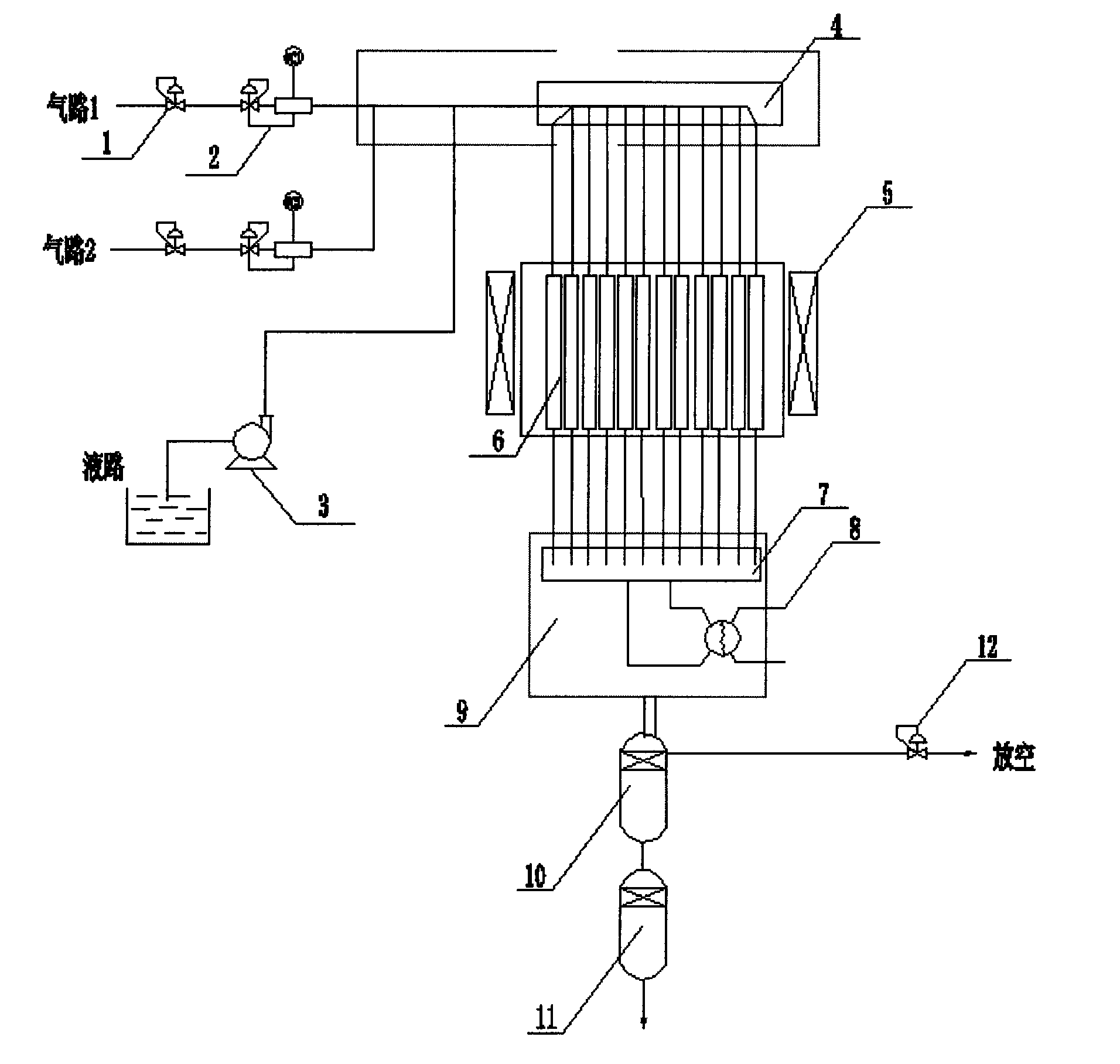

A multi-channel differential reaction device

ActiveCN102266742AImprove efficiencyImprove the level ofComponent separationChemical/physical/physico-chemical processesAutomatic controlGas phase

The invention discloses a multi-channel differential reaction device, and belongs to catalyst analysis and evaluation reaction device. The multi-channel differential reaction device comprises four systems of a gas-liquid charging system of (1)-(3), a multi-channel reactor system of (4)-(6), an automatic control system (7) and an on-line analysis system (8). The multi-channel differential reaction device adopts a high pressure distributor (4) to distribute a raw material into reaction tubes (6) of all channels. Temperatures of the all reaction tubes (6) are controlled unitedly by a heating furnace (5). The multi-channel differential reaction device is provided with the automatic control system (7) and the on-line analysis system (8) and can satisfy that in a reaction process, at any time, reaction products in all channel reaction tubes can be taken out on line simultaneously, are placed respectively in corresponding quantitative rings and are analyzed orderly through use of a gas chromatography. The catalyst analysis and evaluation reaction device can evaluate a catalyst rapidly and also evaluate and screen multiple catalysts simultaneously under a condition thus saves time spent on research and exploitation of a novel catalyst.

Owner:TIANJIN GOLDEN EAGLE TECH

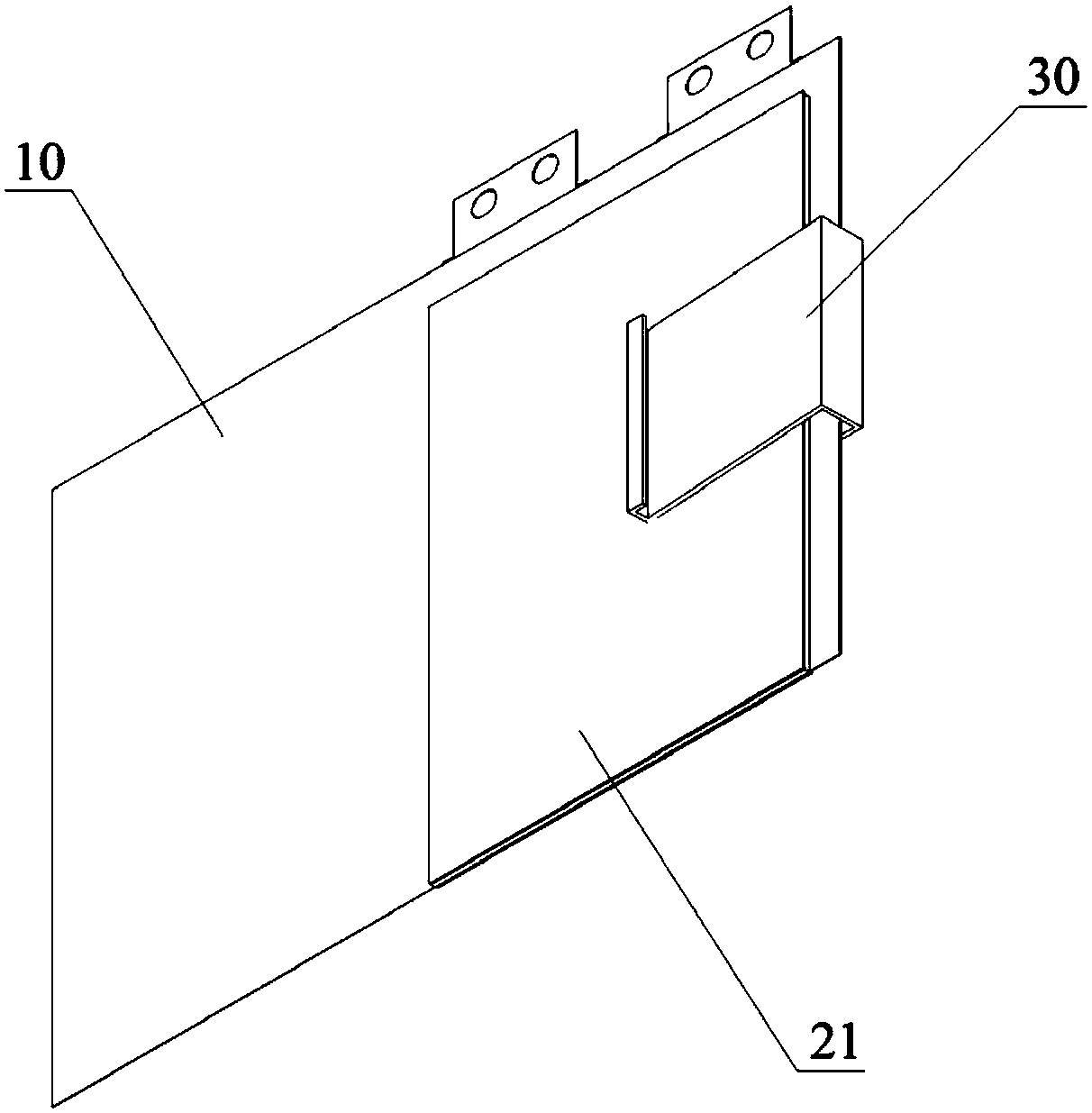

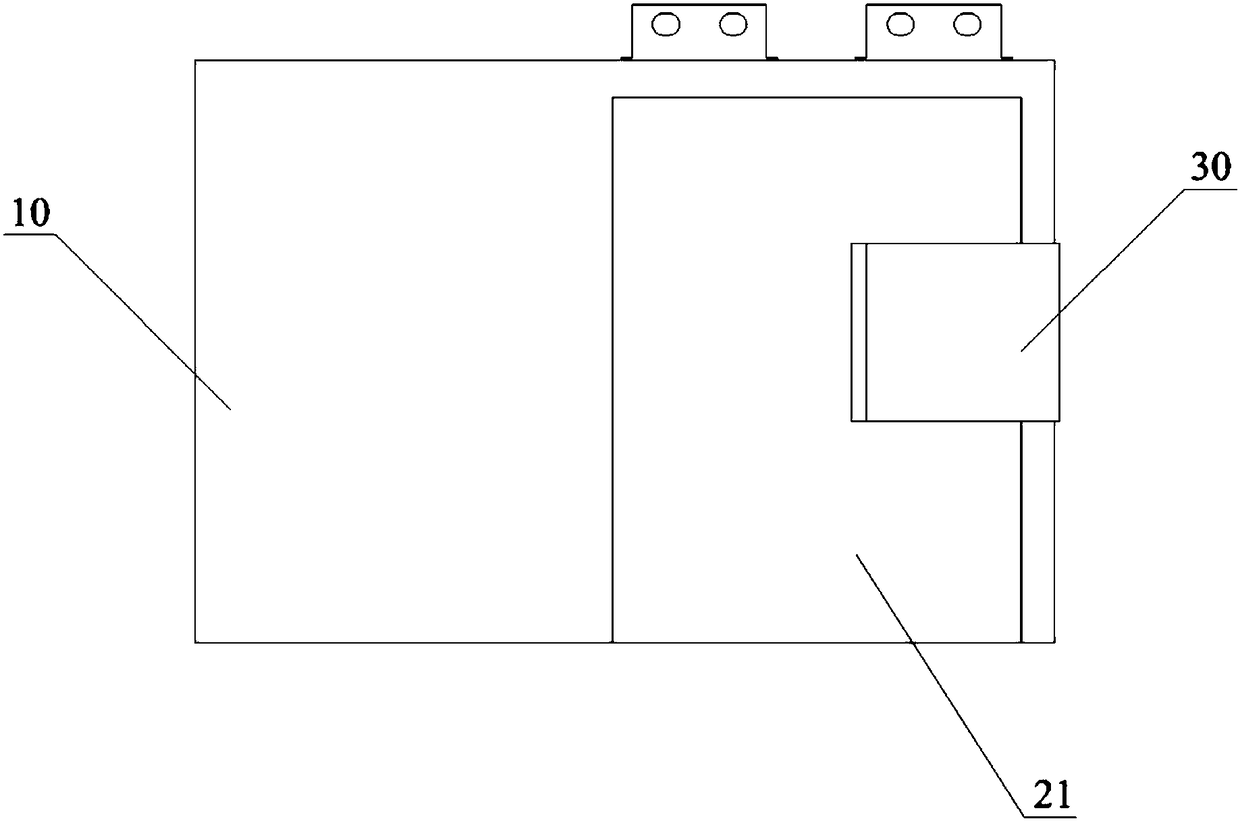

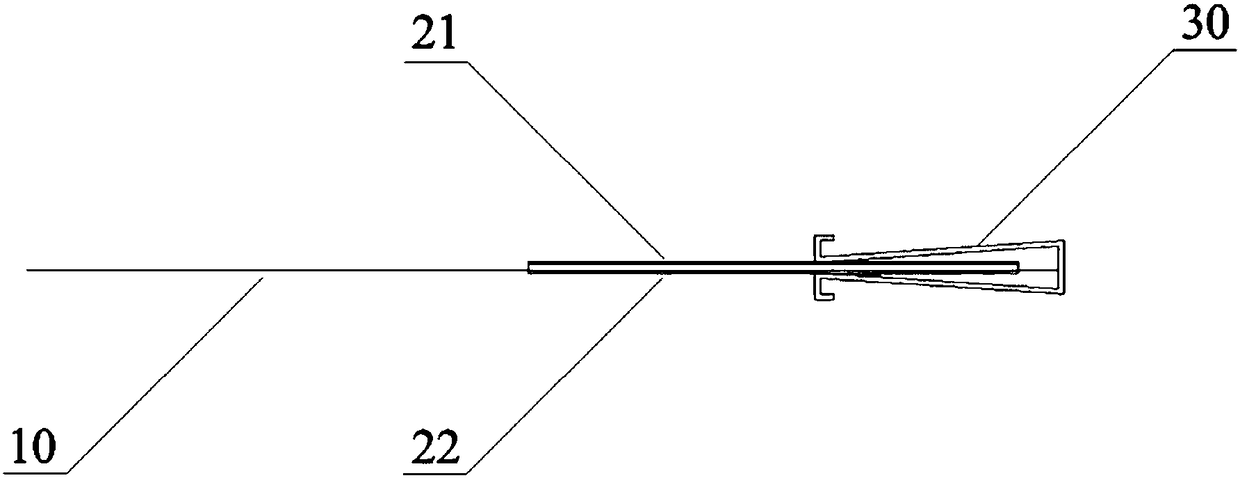

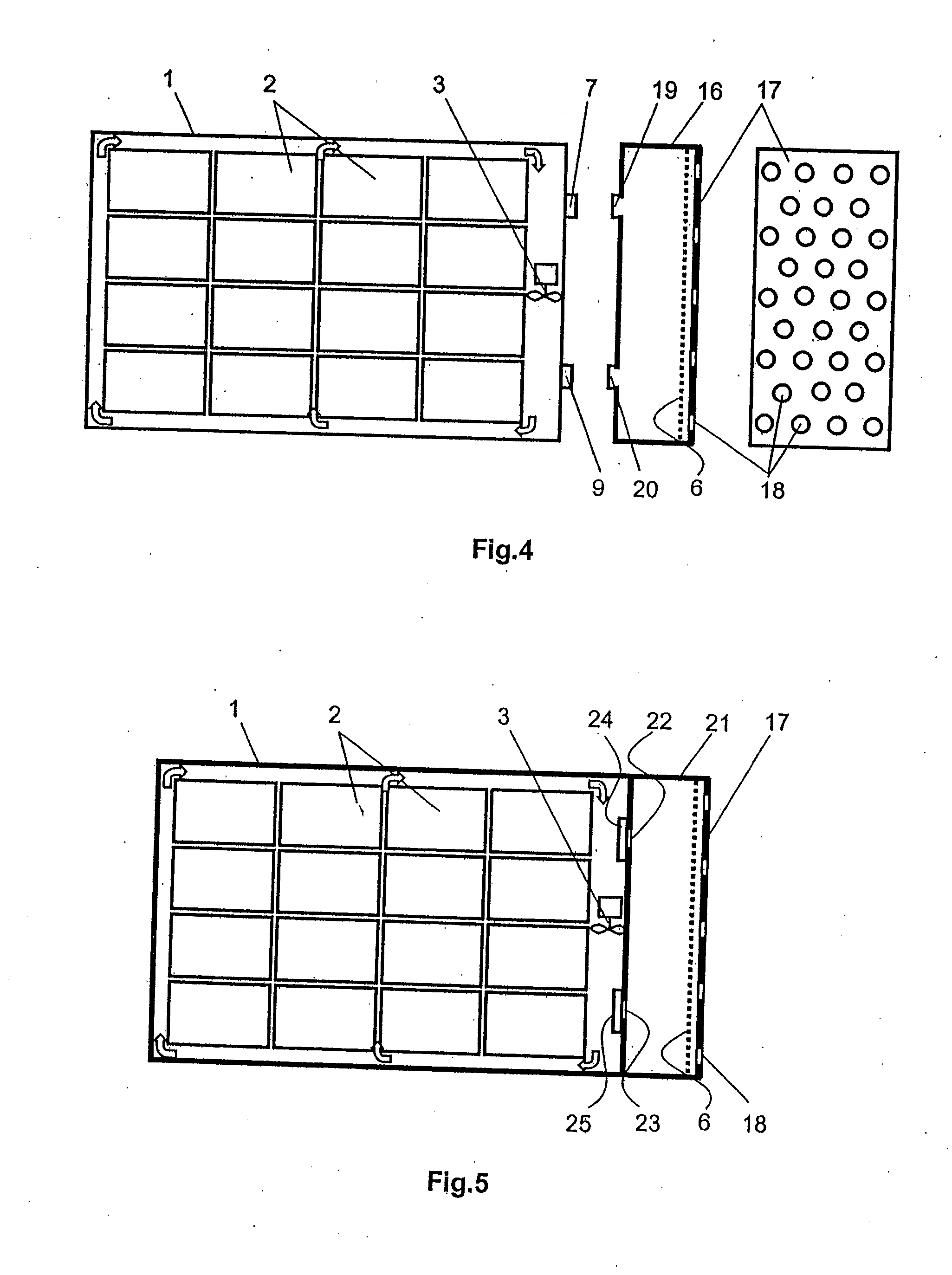

Formation method capable of prolonging cycle life of soft package power battery, battery formation clamp, applications and soft package power battery

PendingCN108306062AImprove cycle lifeFormation method to improve cycle lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPower batteryElectrical battery

The invention provides a formation method capable of prolonging the cycle life of a soft package power battery, a battery formation clamp, applications and the soft package power battery and relates to the technical field of soft package power batteries. The formation method comprises the steps of adopting multi-echelon vacuum standing and vacuum sealing treatment on the battery subject to liquidinjection, putting the vacuum sealed battery into the battery formation clamp for carrying out the steps of aging, precharge treatment and standing, wherein an immersion method of echelon vacuum standing is adopted after liquid injection, so that the absorption rate of an electrolyte can be reduced and the drainage time is shortened; pressure standing is adopted in the aging process, so that infiltration of the electrolyte can be fuller under certain pressure; and the battery formation clamp is adopted for precharge treatment, so that a positive plate and a negative plate of the battery can bein close contact, the formed SEI film is consistent in components, and the surface thickness is uniform and stable. The invention further provides the battery formation clamp. The clamp is simple instructure, convenient to use and suitable for industrial production.

Owner:BEIJING NAT BATTERY TECH

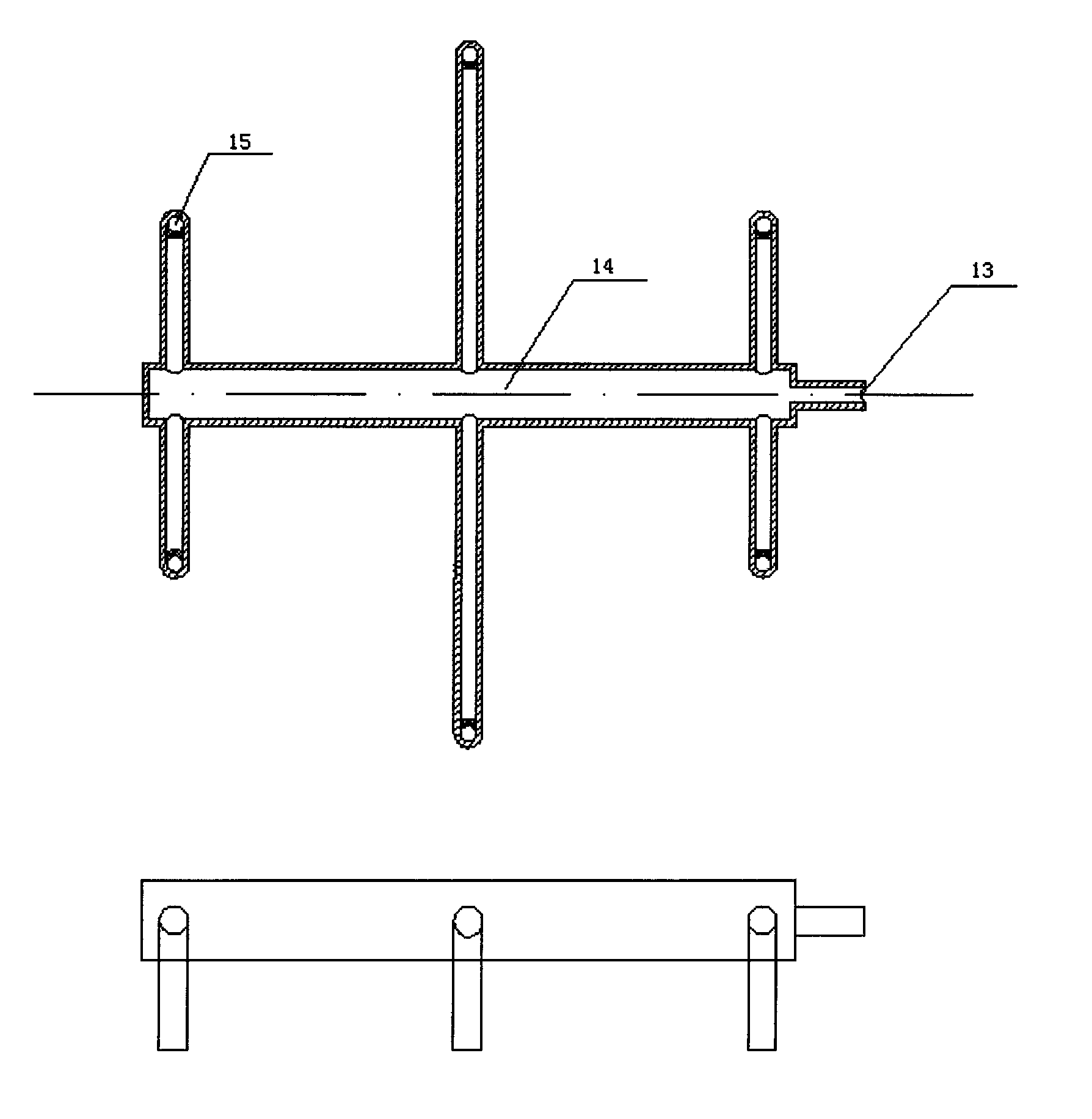

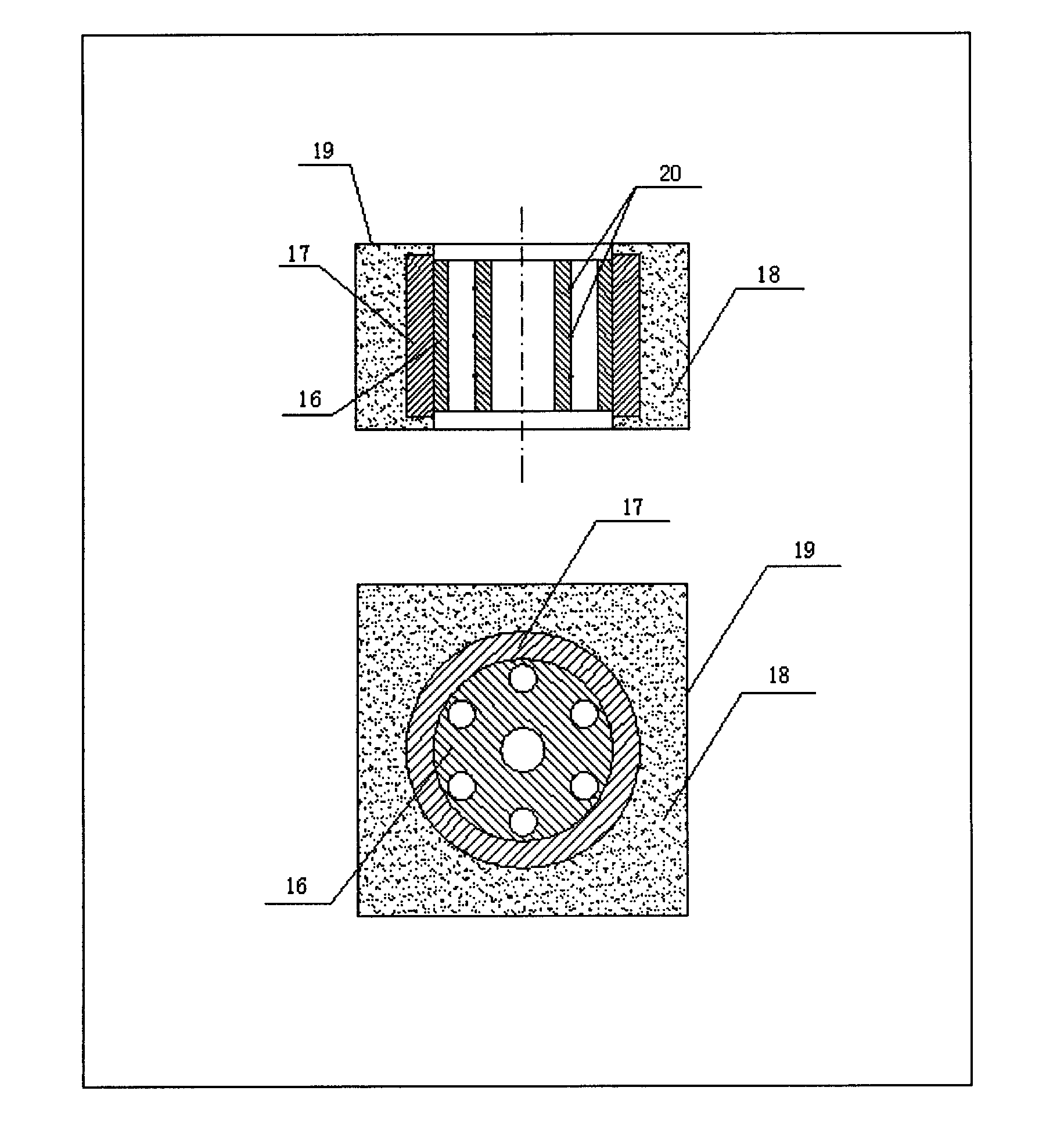

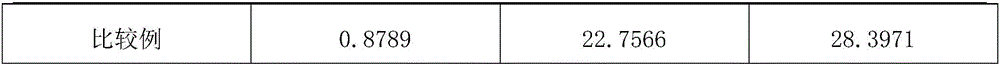

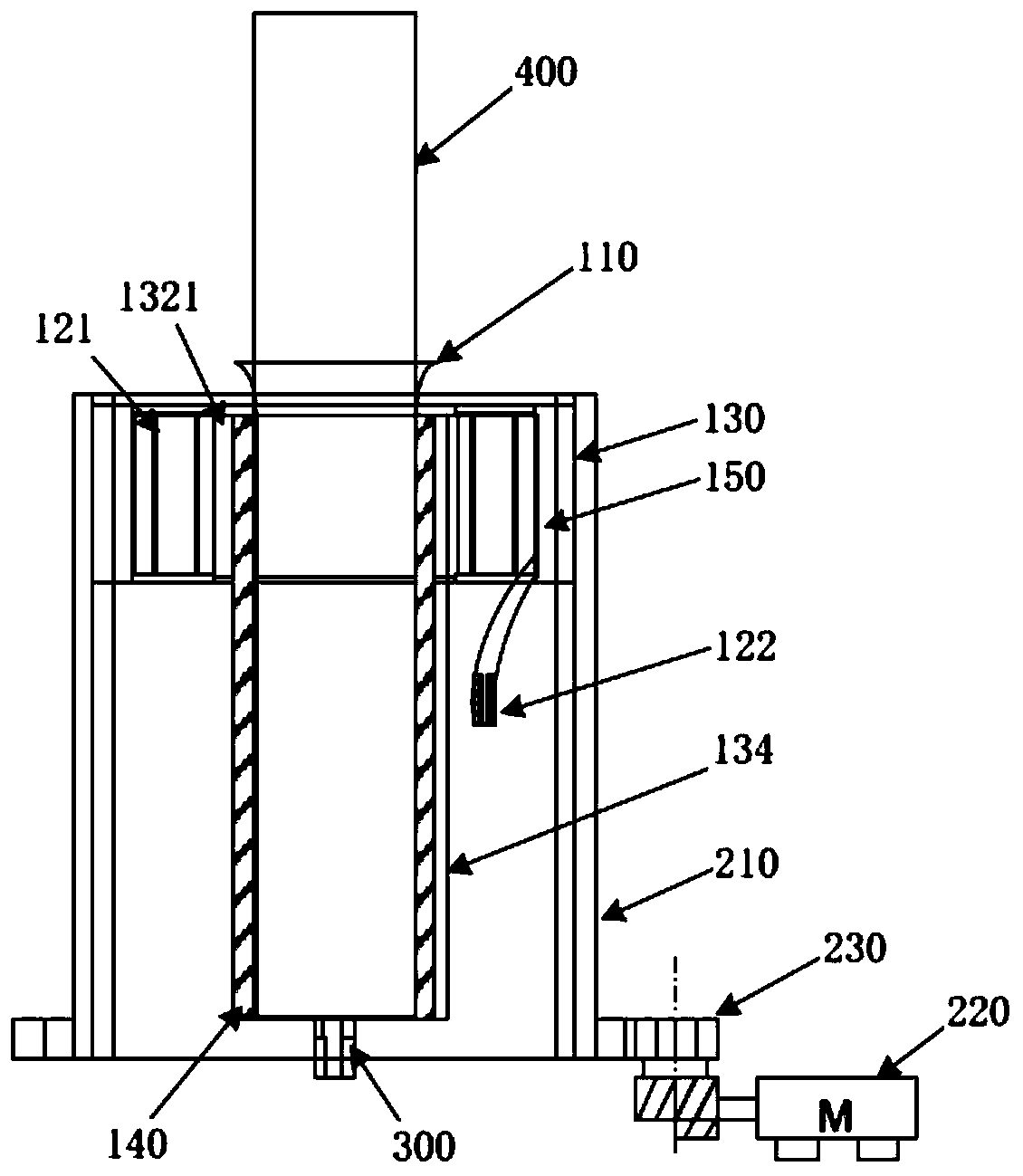

Silicon nitride film preparation device

InactiveCN102732852AConsistent ingredientsConsistent film thicknessChemical vapor deposition coatingMetallurgyCrystalline silicon

The invention provides a silicon nitride film preparation device, which can evenly mix gases of various manufacture procedures. The silicon nitride film preparation device comprises a vacuum deposition chamber, wherein a plurality of plasma reactors are arranged in the vacuum deposition chamber; the vacuum deposition chamber is provided with a gas inlet and a bleeding point; the air inlet is connected with a gas mixing device; the gas mixing device is provided with an inlet and an outlet; the inlet is connected with a plurality of air inlet pipes used for introducing in manufacture procedure gas; and the outlet is communicated with the air inlet of the vacuum deposition chamber. Firstly, the gases of various manufacture procedures are mixed by the gas mixing device; after the gases are evenly mixed, the gases are introduced into the vacuum deposition chamber to react; therefore, the components and the component concentrations of various gases in the vacuum deposition chamber are same; the component and the membrane thickness of silicon nitride deposited on the surfaces of wafers on different positions in the vacuum deposition chamber tend to be similar; and the product quality can be greatly improved. The silicon nitride film preparation device disclosed by the invention is suitable for popularizing and applying in the crystalline silicon solar energy production equipment field.

Owner:LESHAN TOPRAYCELL

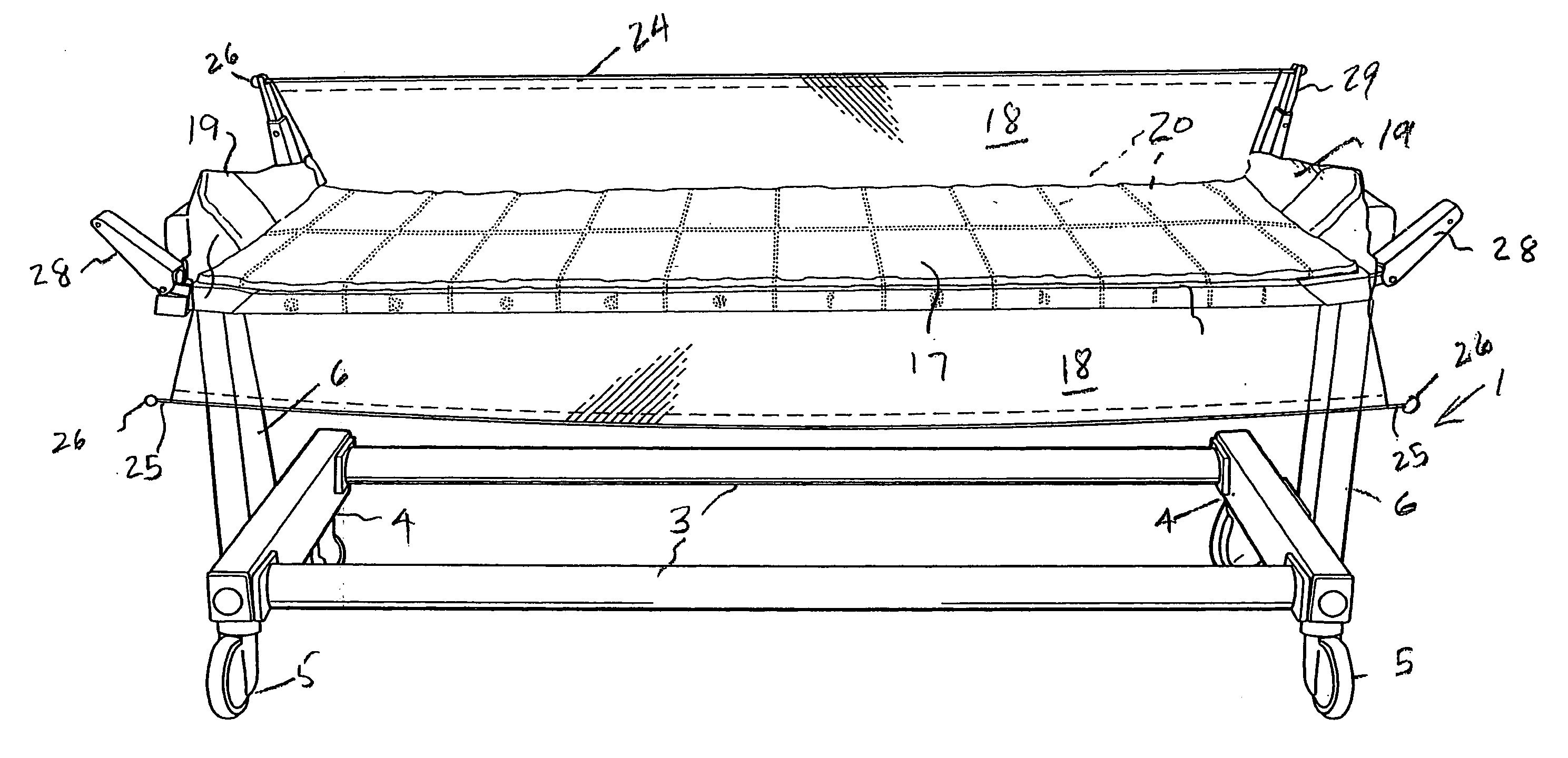

Protective cover and patient security apparatus

A sheet assembly adapted to occupy a position beneath a patient and an upper surface of a patient support. The assembly has overlying upper and lower pliable sheets formed of a material of low density gradient and having central sections from which upper and lower flaps extend laterally. The lower flaps may be secured to the patient support and the upper flaps may be elevated to and maintained at a level above that of the upper surface of the patient support, thereby providing a safeguard against the patient's falling off the support surface.

Owner:TIDI CFI PROD

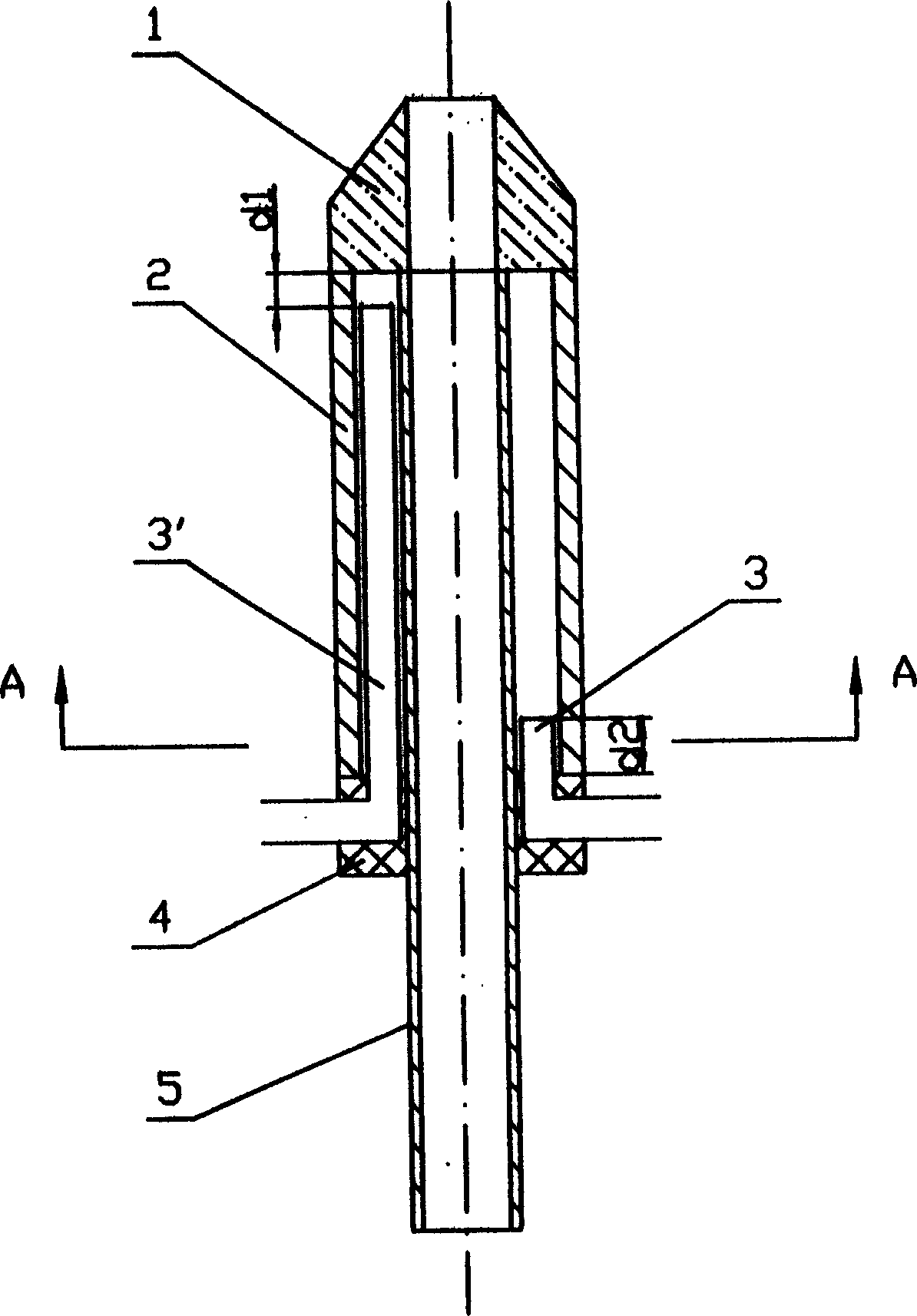

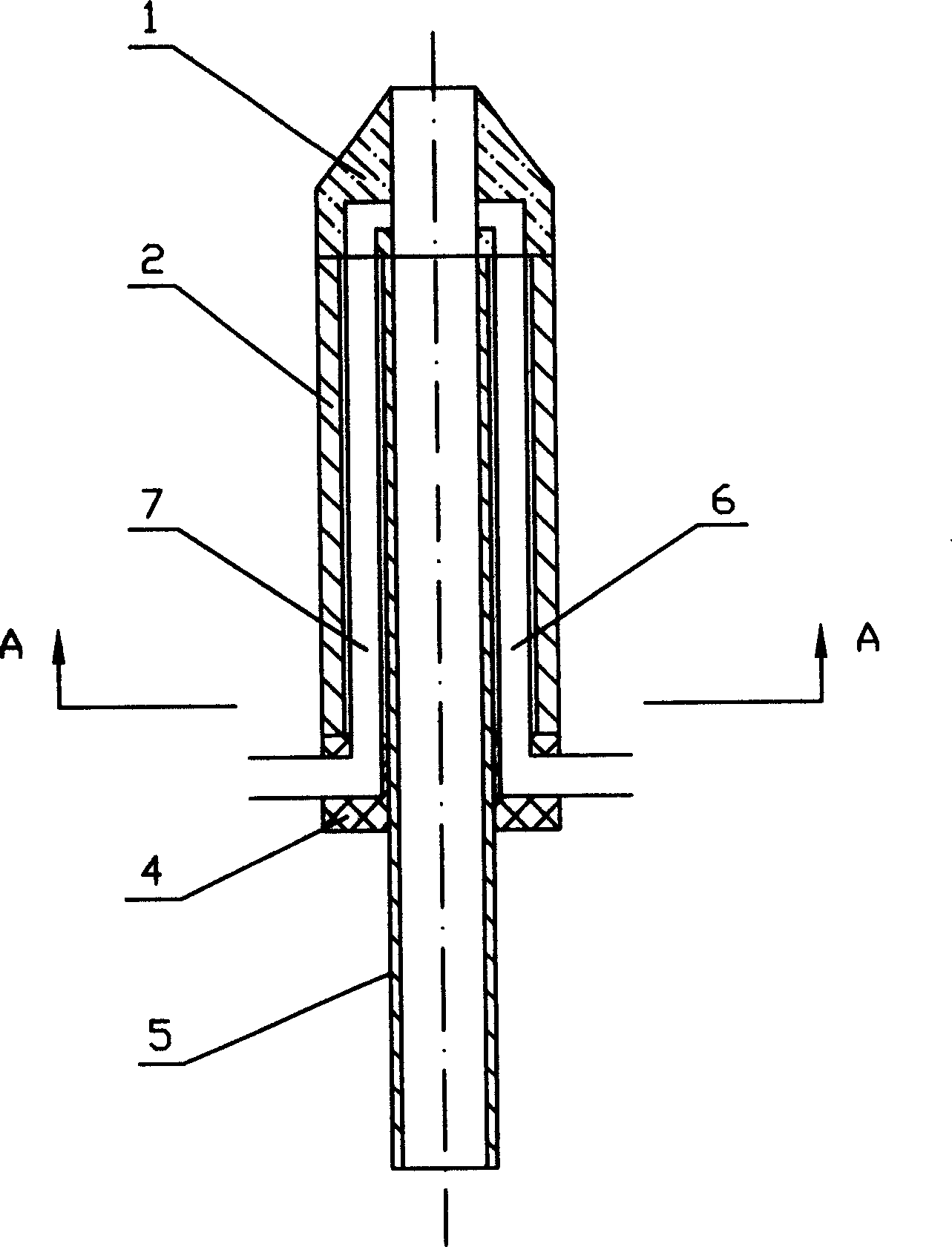

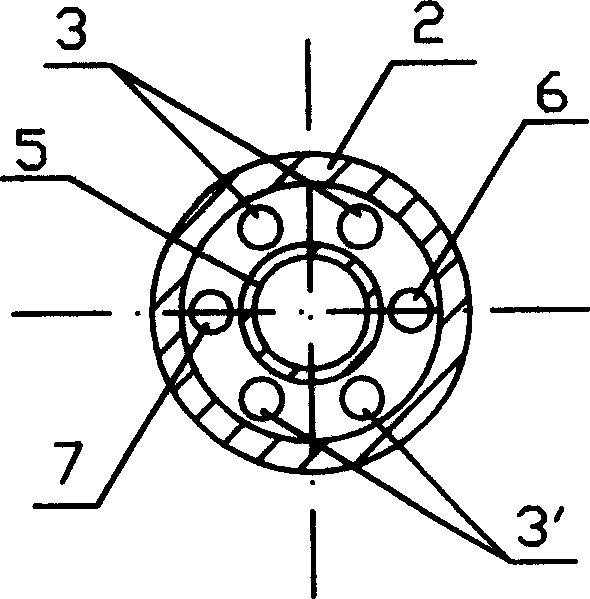

Superfine particles sampling device

InactiveCN1570590AImprove cooling effectReduce the temperaturePreparing sample for investigationEngineeringParticle sampling

This invention discloses a sampling device for ultrafine grain and its tip is located on the upper edge of central sampling tube while outer tube covers the central tube. There fixes inflow and outflow tubes for cooling between the layers, and the tip of the inflow tube is located in the end portion of central sampling tube and that of the outflow tube is located in the upper portion. There locate two diluting tube between outer tube and central sampling tube and their air vent is symmetrically located on the tube tip. The tip, central sampling tube and outer tube form a sealing cavity. The invention can dilute the gas of high temperature to ensure effective sampling and prevent the sample from reaction in the tube. This invention is especially suitable for the sampling of ultrafine grain with high temperature environments such as metallurgy furnace,industrial furnace, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

Rare earth nickel magnesium intermediate alloy for hydrogen storage alloy and preparation method of rare earth nickel magnesium intermediate alloy

The invention relates to a rare earth nickel magnesium intermediate alloy for a hydrogen storage alloy, which comprises the following compositions in percentage by mass: 40-65 percent of Mg, 30-55 percent of Ni, 1-5 percent of RE, 0-0.5 percent of Fe, 0-1.5 percent of Si, 0-2.5 percent of Al, 0-0.5 percent of Zn, 0-0.5 percent of Cu, 0-0.1 percent of Cr, 0-0.5 percent of Mn, 0-0.5 percent of Ti, and 0-0.5 percent of Ca, wherein the RE comprises 0-100 percent of Y, 0-50 percent of La, and 0-50 percent of Ce. A preparation method comprises the following steps of: material processing, compounding, loading, vacuumizing, gas shielding, power transmitting, melting, stirring, secondary feeding, halting, stirring and pouring. The rare earth nickel magnesium intermediate alloy for the hydrogen storage alloy has stable components, and is suitable for being added into hydrogen storage materials.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

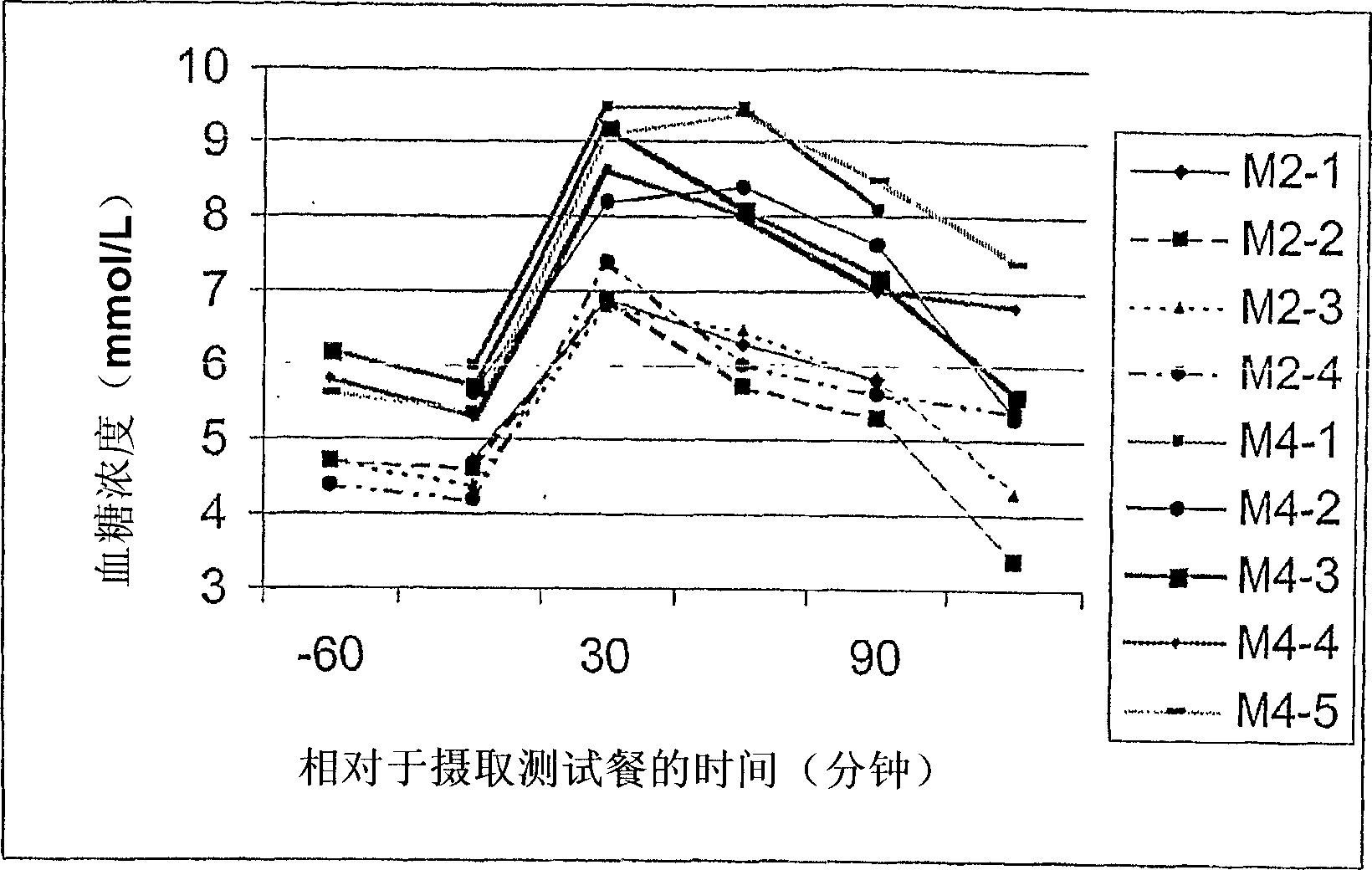

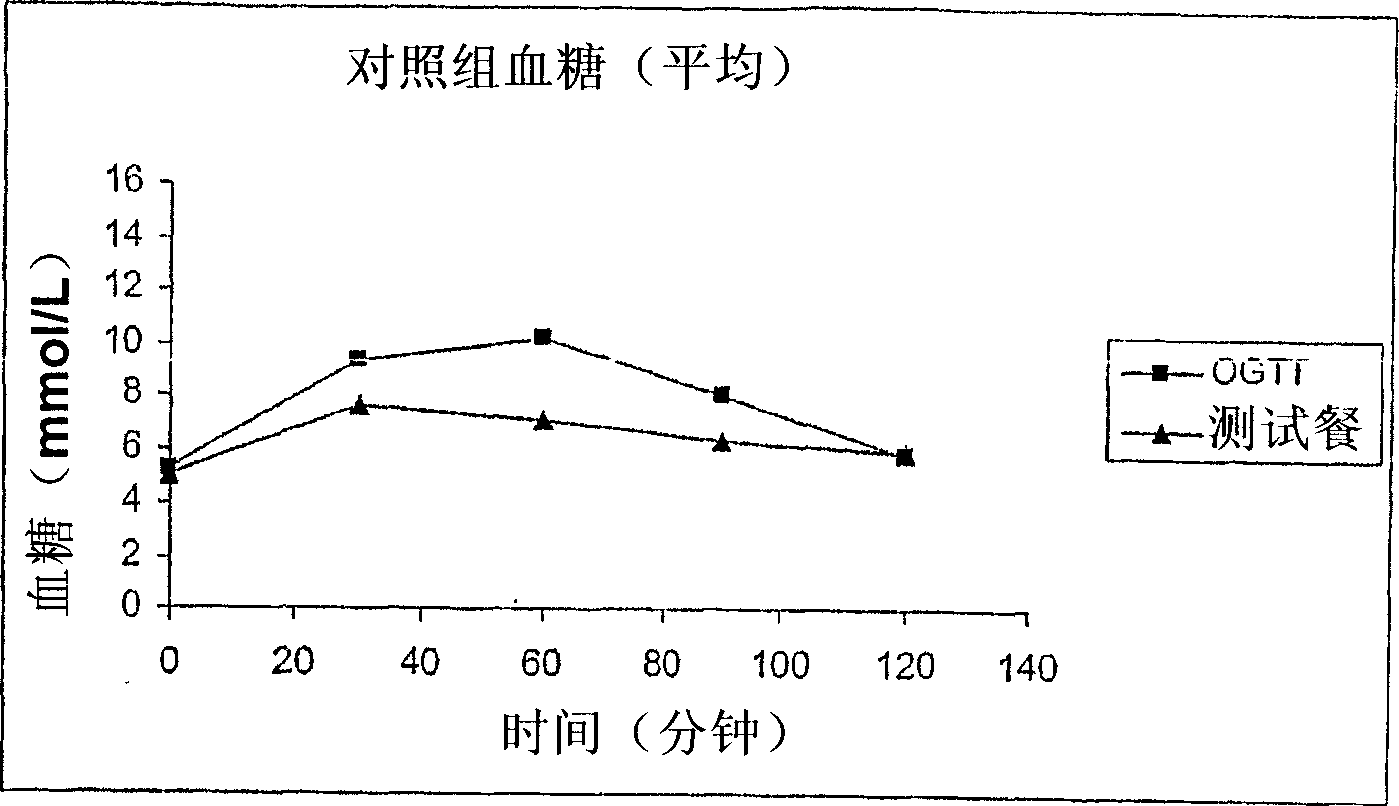

Diagnostic composition for diabetes type-2 and impaired glucose tolerance, and methods of use

InactiveCN1836167AConsistent ingredientsCompounds screening/testingDisease diagnosisDiagnostic testMonosaccharide metabolism

Owner:CEAPRO

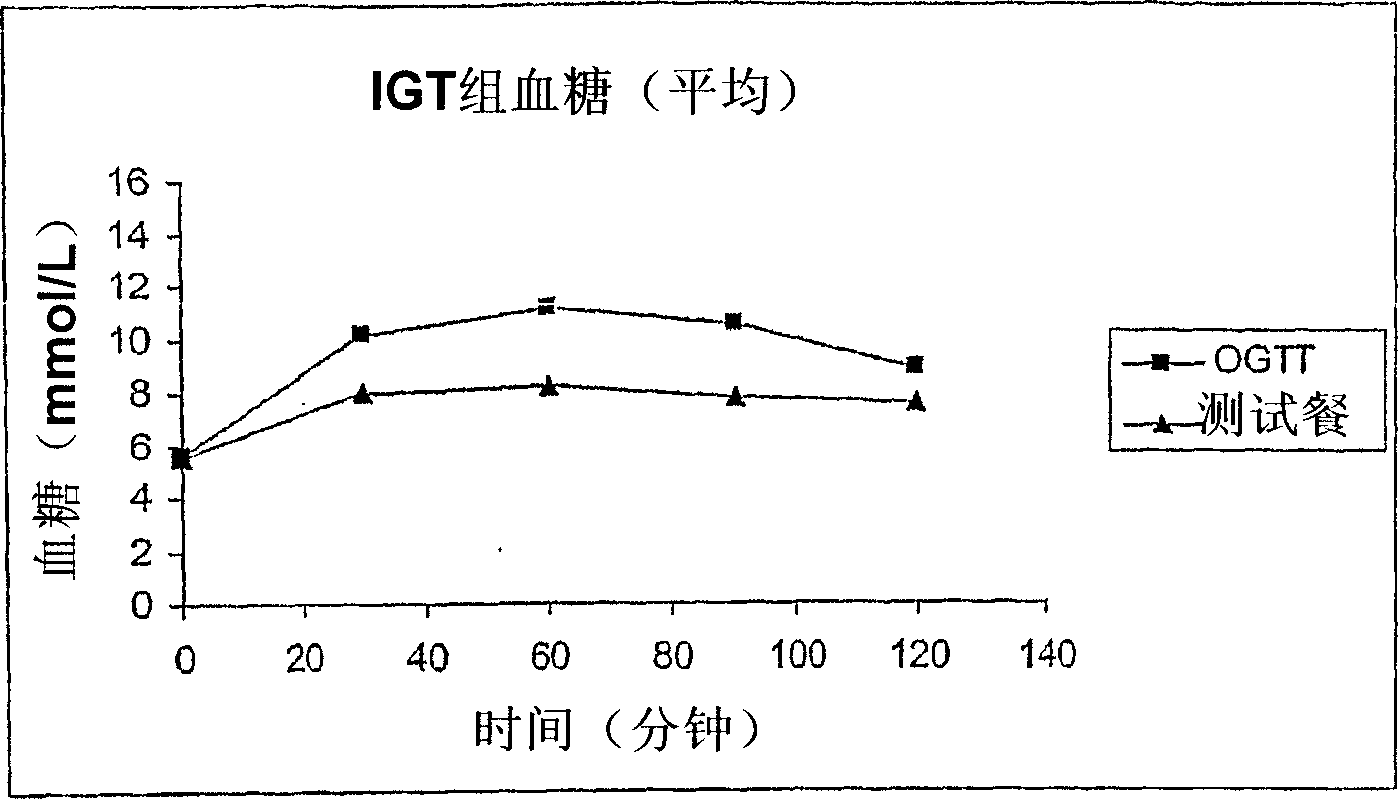

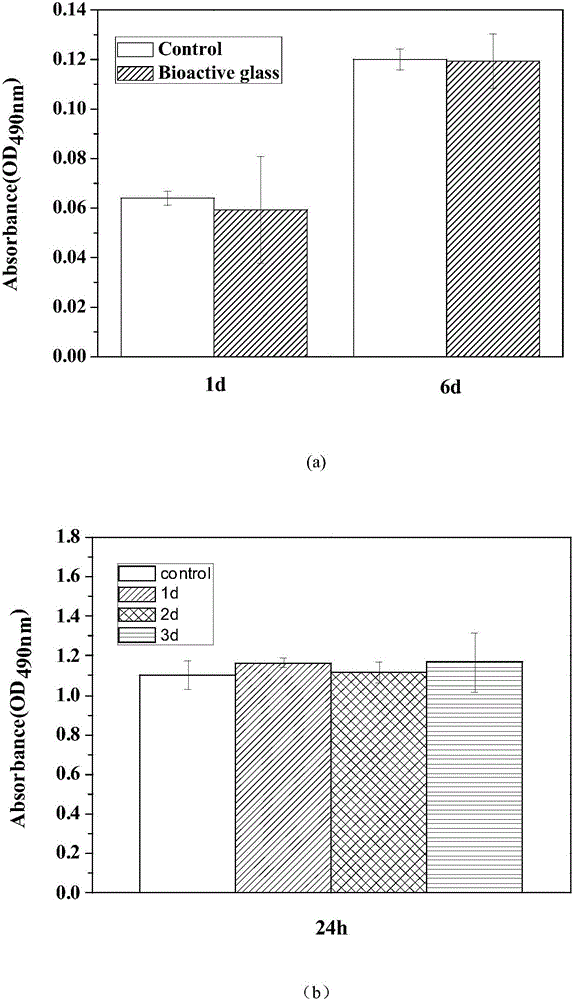

Regenerative medical material and preparation method and application thereof

InactiveCN106421889AGrowth inhibitionPromote repairCosmetic preparationsToilet preparationsInositol HexakisphosphateNetwork structure

The invention provides a regenerative medical material for promoting soft or hard tissue repair and a preparation method and application thereof. The regenerative medical material has a three-dimensional network structure and is a composite material prepared from inorganic matter and organic matter, wherein the mass ratio of the inorganic matter to the organic matter is 2:1 to 4:1. Based on the total mass of the inorganic matter, the inorganic matter contains 12-38% of SiO2, 3-5% of Na2O, 15-29% of CaO, 10-32.5% of P2O5, 1-5% of inositol hexaphosphate, 1-5% of inositol hexaphosphoric acidand the balance impurities, and the content of the impurities is 0.5% or below. Based on the total mass of the organic matter, the organic matter contains 30-60% of carboxymethyl chitosan and 30-60% of sodium hyaluronate. The regenerative medical material has the composition and the properties suitable a human body and has the key effect on the aspects of cell repair and bonding, cell proliferation and promotion of hair follicle growth.

Owner:胡方

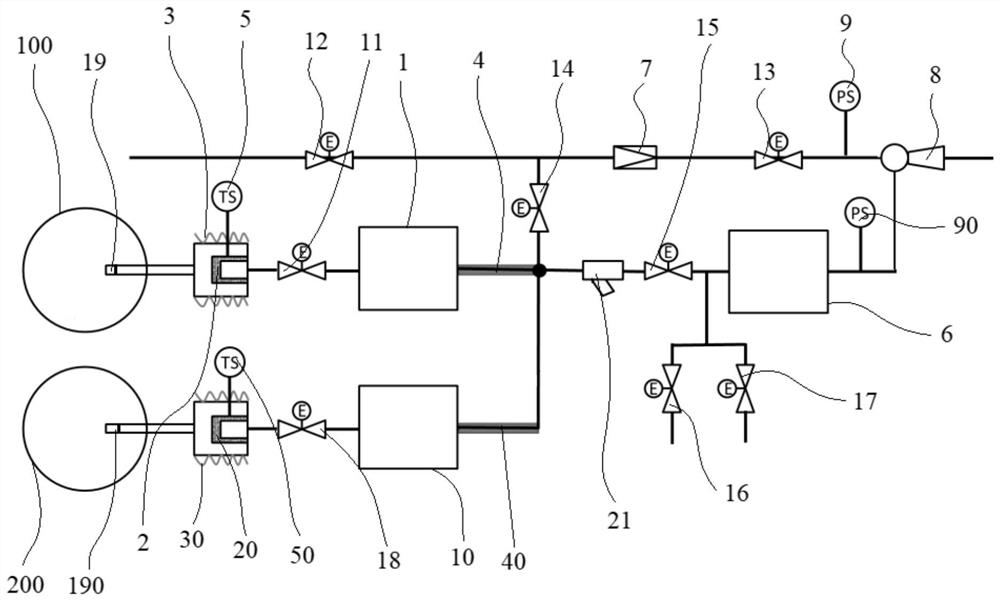

Ship exhaust emission monitoring system and control method thereof

PendingCN113267392AConcentration parameters are accurateImprove detection accuracyAnalysing gaseous mixturesPreparing sample for investigationAutomotive engineeringExhaust fumes

The invention discloses a ship exhaust emission monitoring system and a control method thereof, relates to the technical field of ship exhaust emission, and the system and the control method are used for solving the problem of low detection precision of an exhaust emission detection system in a ship in the prior art. The ship exhaust emission monitoring system comprises a sampling module, a processing module and a concentration detection module which are connected in sequence, wherein the sampling module collects gaseous pollutants discharged by a ship, the processing module processes the gaseous pollutants, the dew point temperature of the gaseous pollutants is lower than a preset dew point temperature so as to obtain to-be-detected gas, and the concentration detection module detects concentration parameters of various gases in the to-be-detected gas. The ship exhaust emission monitoring system and the control method thereof are used for detecting the exhaust emission condition of the ship.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

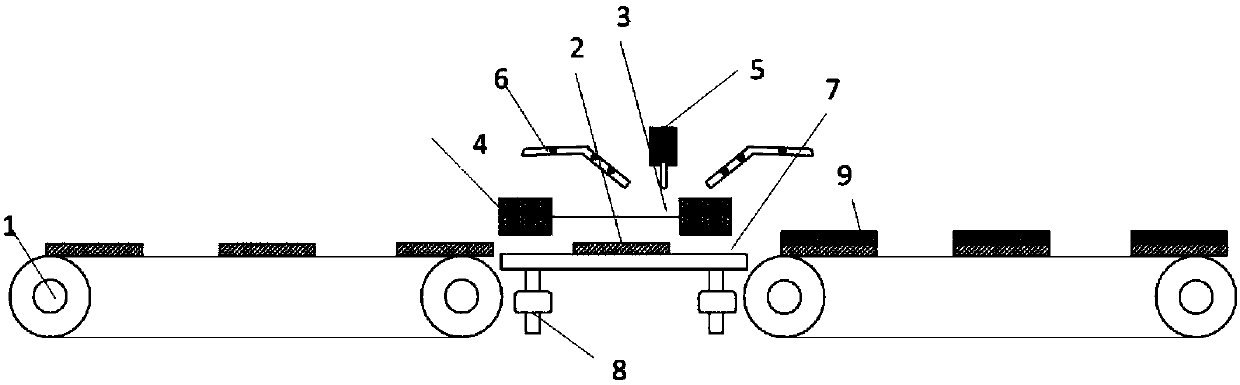

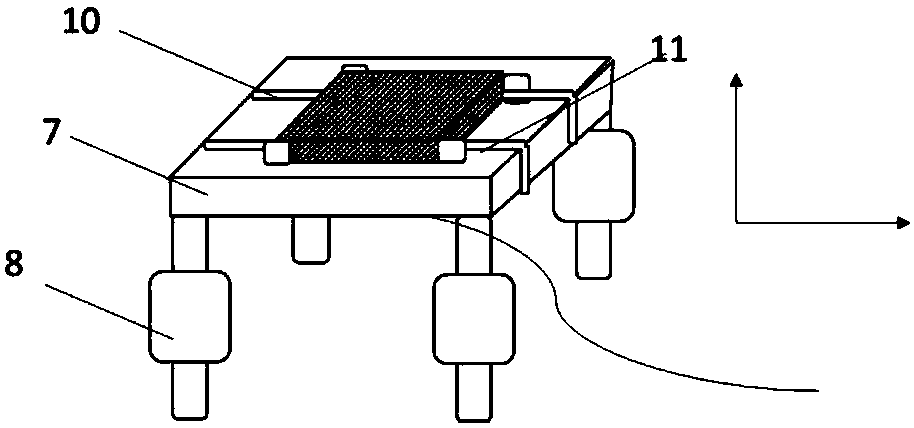

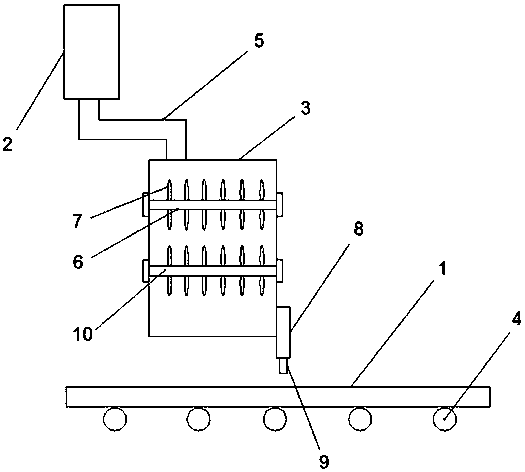

Fully automatic printer for aluminum base plate

PendingCN107757083AWith automatic feedingWith automatic positioning calibrationScreen printersScreen printingScreen printingThermal insulation

The invention provides a four-column-type fully automatic printer for an aluminum base plate, and the four-column-type fully automatic printer comprises an automatic material inlet system, an automatic printing system and an automatic material outlet system. The automatic material inlet system conveys the aluminum plate through a conveyor belt; the automatic printing system comprises a printing screen plate, screen frames, a scraper, spray mouths, a workbench and automatic lifting columns, and the automatic printing system prints heat-conducting and insulating glue on the aluminum plate evenly; the material outlet system conveys the aluminum plate with the surface being printed a dense uniform insulation layer through the conveyor belt for the output; in a silk-screen printing system, theworkbench is supported by four automatic lifting columns, the surface of the workbench is provided with horizontal sliding electric guide rails in a paved manner, and the silk-screen printing system further comprises height sensors, a scraper moving rod and a rotating head; and the rotating head connects the scraper moving rod and the scraper, the height sensors are installed under the screen frames, and the workbench, the scraper moving rod, the spray mouths, positioning sensors and the height sensors are all connected with a general control platform and are controlled. The four-column-type fully automatic printer for the aluminum base plate has the characteristics of automatic material feeding, automatic positioning calibration, automatic printing and high production capacity.

Owner:乾乐欣展新材料技术(上海)有限公司

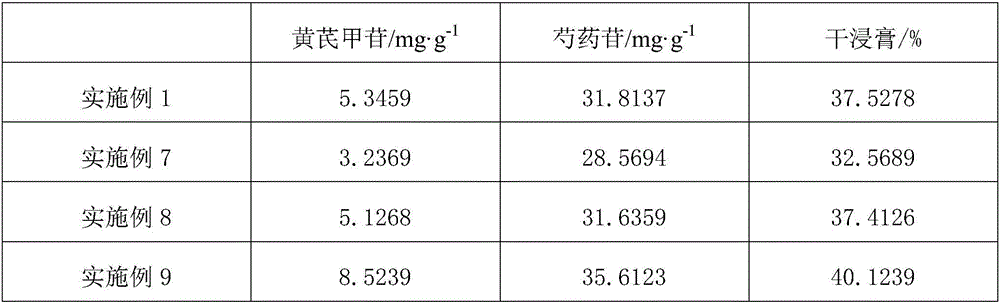

Granular preparation prepared by concentrating decoction of fresh traditional Chinese medicines and preparation method of granular preparation prepared by concentrating decoction of fresh traditional Chinese medicines

InactiveCN106265531AHigh active ingredientHazard reductionGranular deliveryPlant ingredientsMedicinal herbsPesticide residue

The invention belongs to the technical field of traditional Chinese medicine and particularly relates to a granular preparation prepared by concentrating a decoction of fresh traditional Chinese medicines and a preparation method of the granular preparation prepared by concentrating the decoction of the fresh traditional Chinese medicines. The preparation method includes weighing all fresh traditional Chinese medicine materials prior to pretreatment, blending and adding water into the blended fresh traditional Chinese medicine materials for low-temperature extraction and filtration so as to obtain an extracting solution and decoction dregs; concentrating the extracting solution into liquid extract, drying the decoction dregs, grinding the dried decoction dregs into fine powder, stirring and mixing the liquid extract with the fine decoction dreg powder or part of fine decoction dreg powder uniformly, and carrying out freeze drying so as to obtain the granular preparation. The granular preparation and the preparation method thereof have the advantages that on one hand, the problem that the traditional Chinese medicine materials are prone to mildewing and deteriorating is avoided, and on the other hand, the problems of hazardous substance pesticide residues, excessive heavy metal, processing pollution residues or the like in the dried traditional Chinese medicine materials are solved; biological activity is improved, so that efficacy is enhanced.

Owner:北京心颐和创新国际中医药医疗技术研究院(有限合伙)

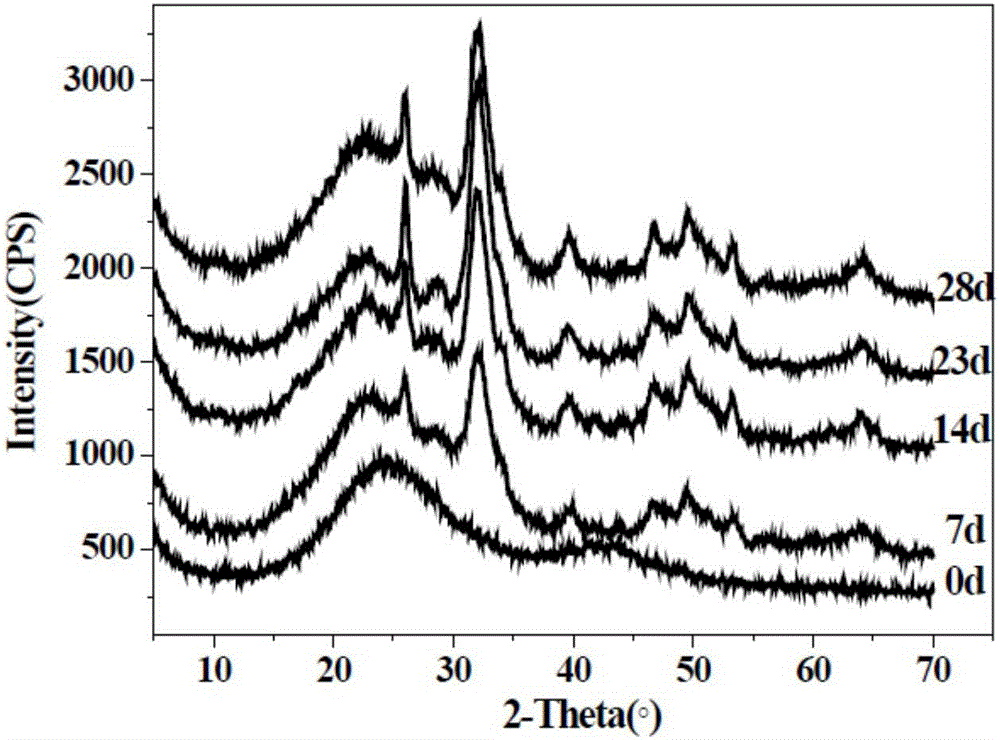

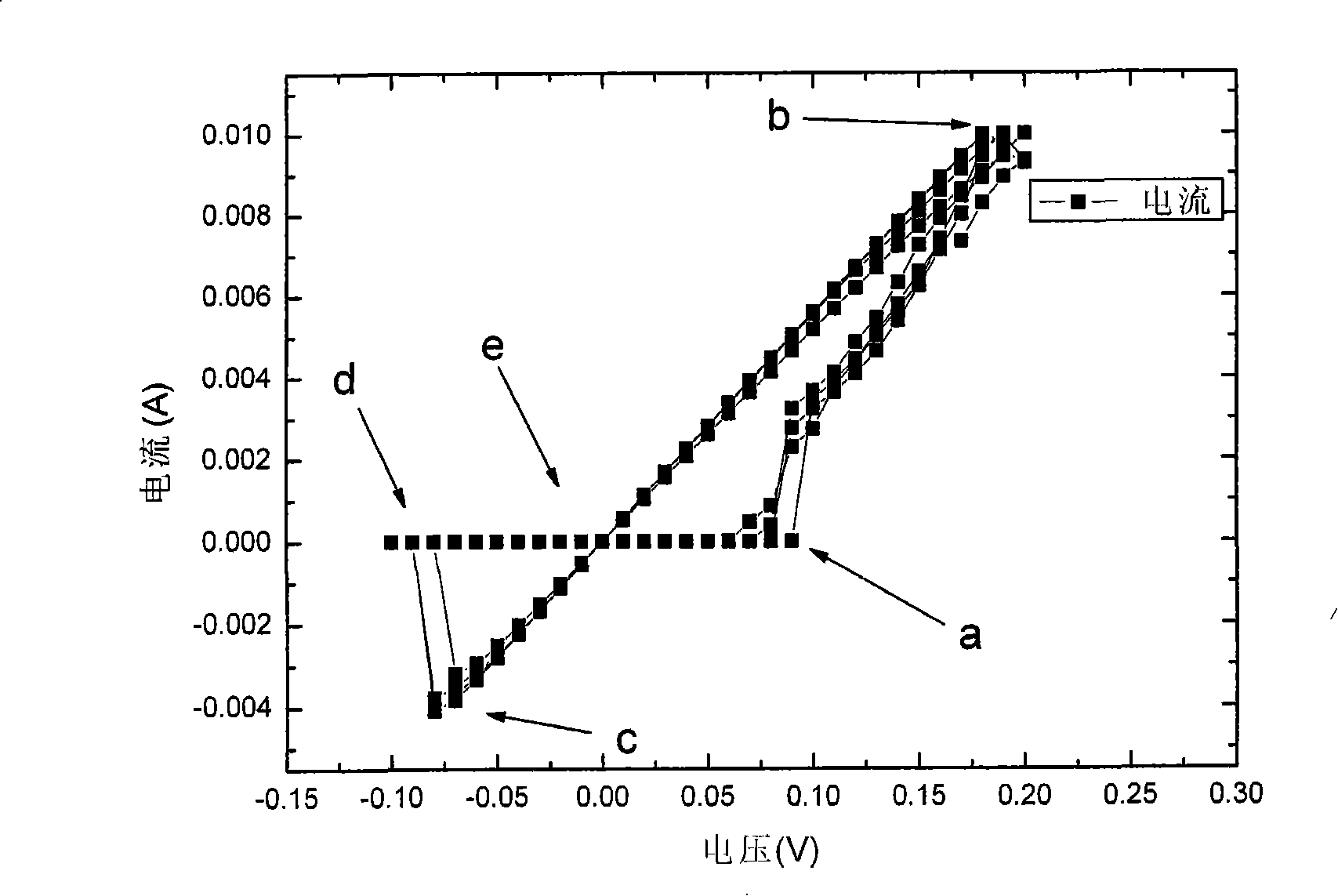

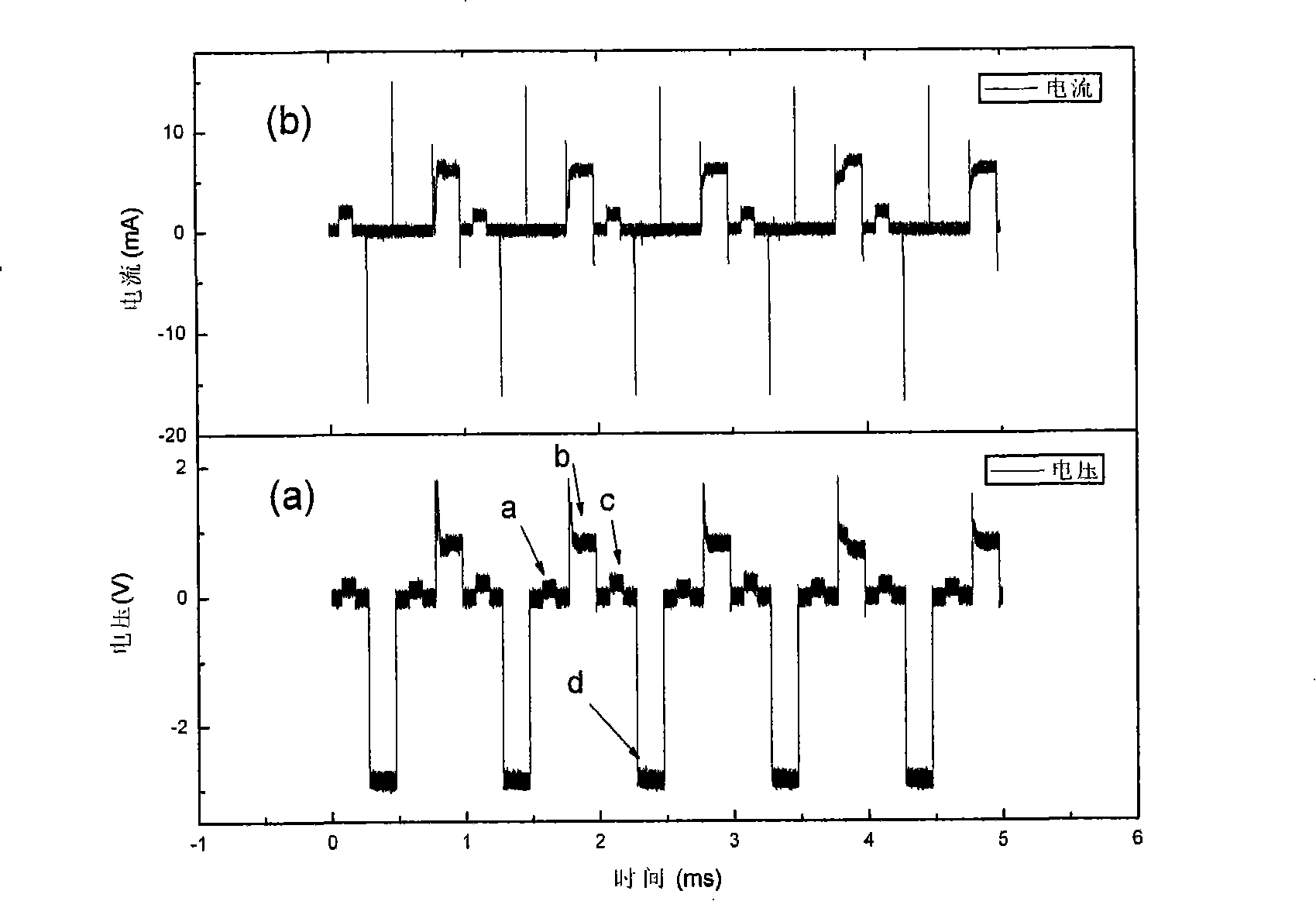

Electrolyte thin film (AgI)x(AgPO3)1-x based on amorphous solid and its preparing method

InactiveCN101222019ASimple structureFast read and writeElectrical apparatusVacuum evaporation coatingHigh densityAmorphous silicon

The invention discloses a novel memory material - an amorphous solid electrolyte membrane (AgI) x (AgPO3)1-x, which is utilized to prepare a nonvolatile memorizer and can be used for an integrated circuit like information storage and other varieties. The amorphous solid electrolyte membrane (AgI) x (AgPO3)1-x of the invention is characterized in that: the (AgI) x (AgPO3)1-x is a solid electrolyte membrane material, has ionic conductivity, can be reversibly converted into electronic conductivity under certain conditions and takes the structure of an amorphous material under room temperature, and the nonvolatile memorizer with small size, high density and stable performance can be prepared by utilization of the membrane. The invention provides a preparation method for the amorphous solid electrolyte membrane (AgI) x (AgPO3)1-x, comprising the following steps: AgI, AgNO3 and (NH4)2HPO4 with adequate mixture ratio are melted and then fabricated into glass target materials, and then the amorphous solid electrolyte membrane is prepared by utilization of a laser pulse sedimentation method.

Owner:NANJING UNIV

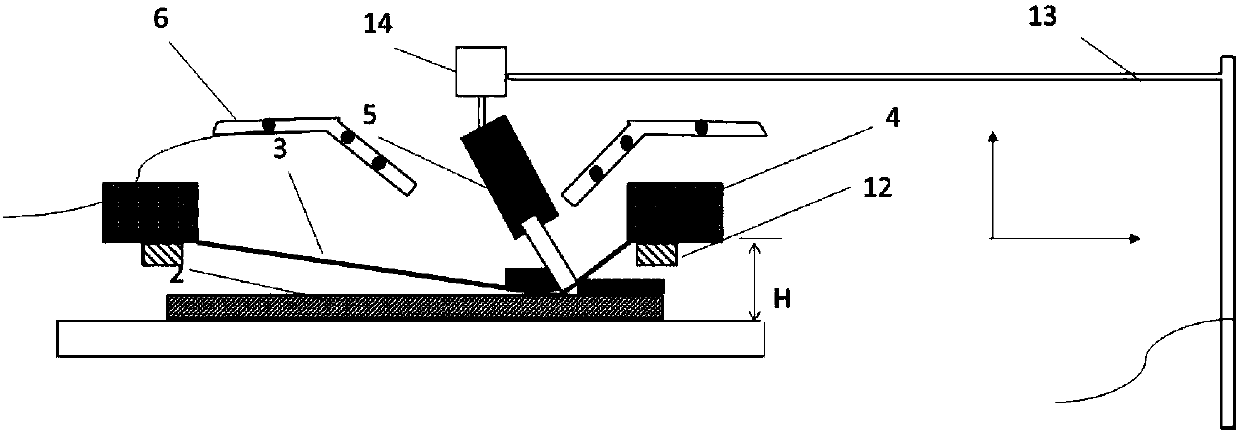

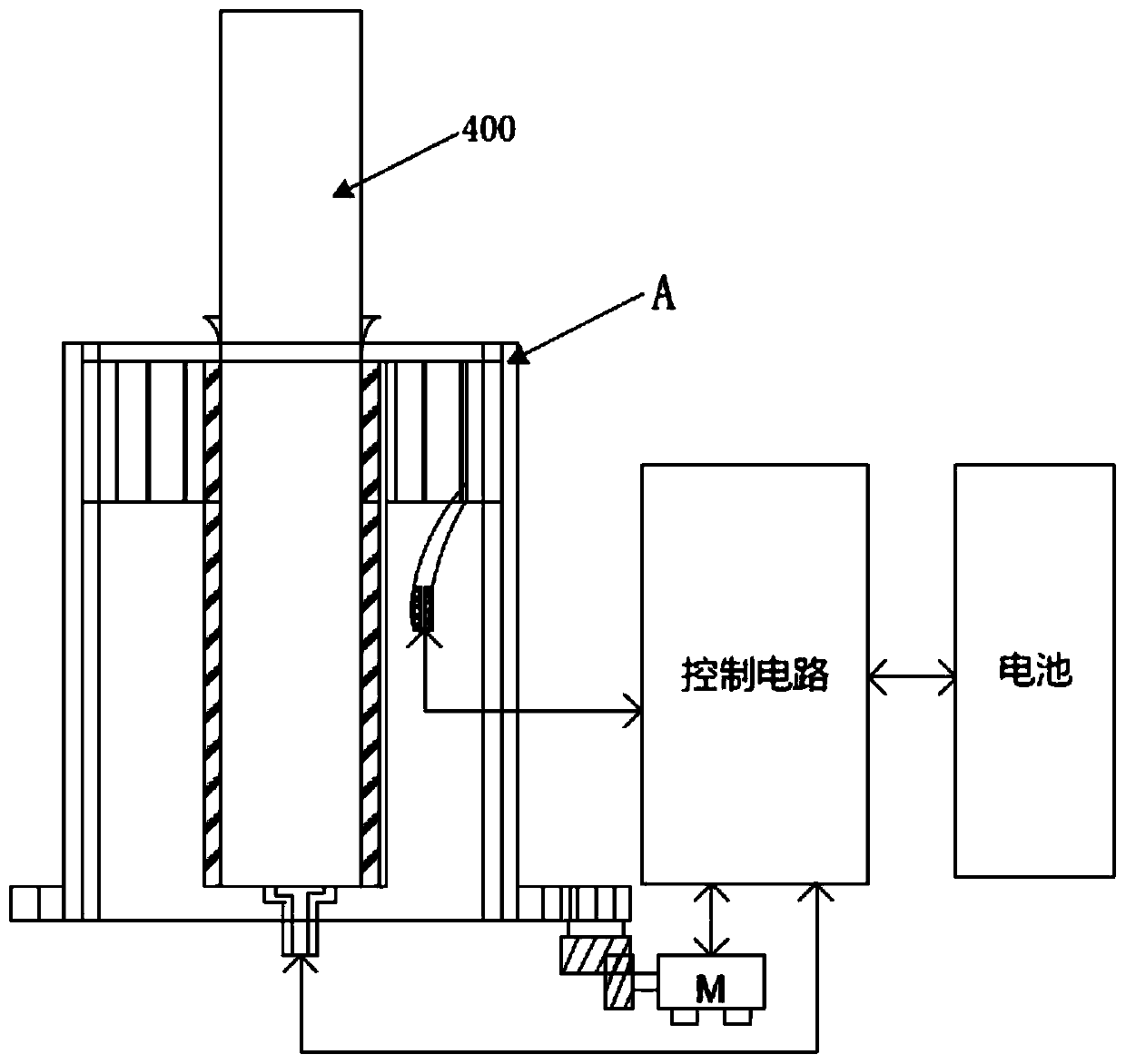

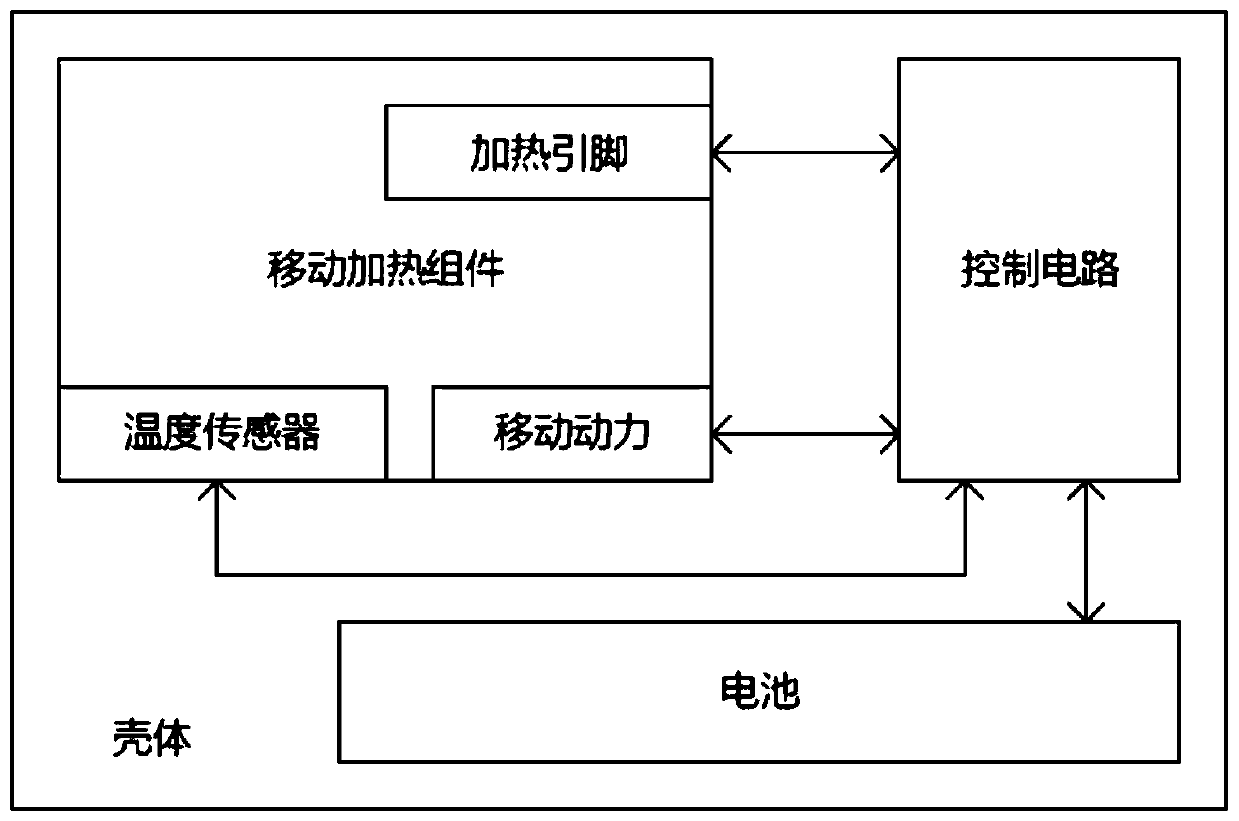

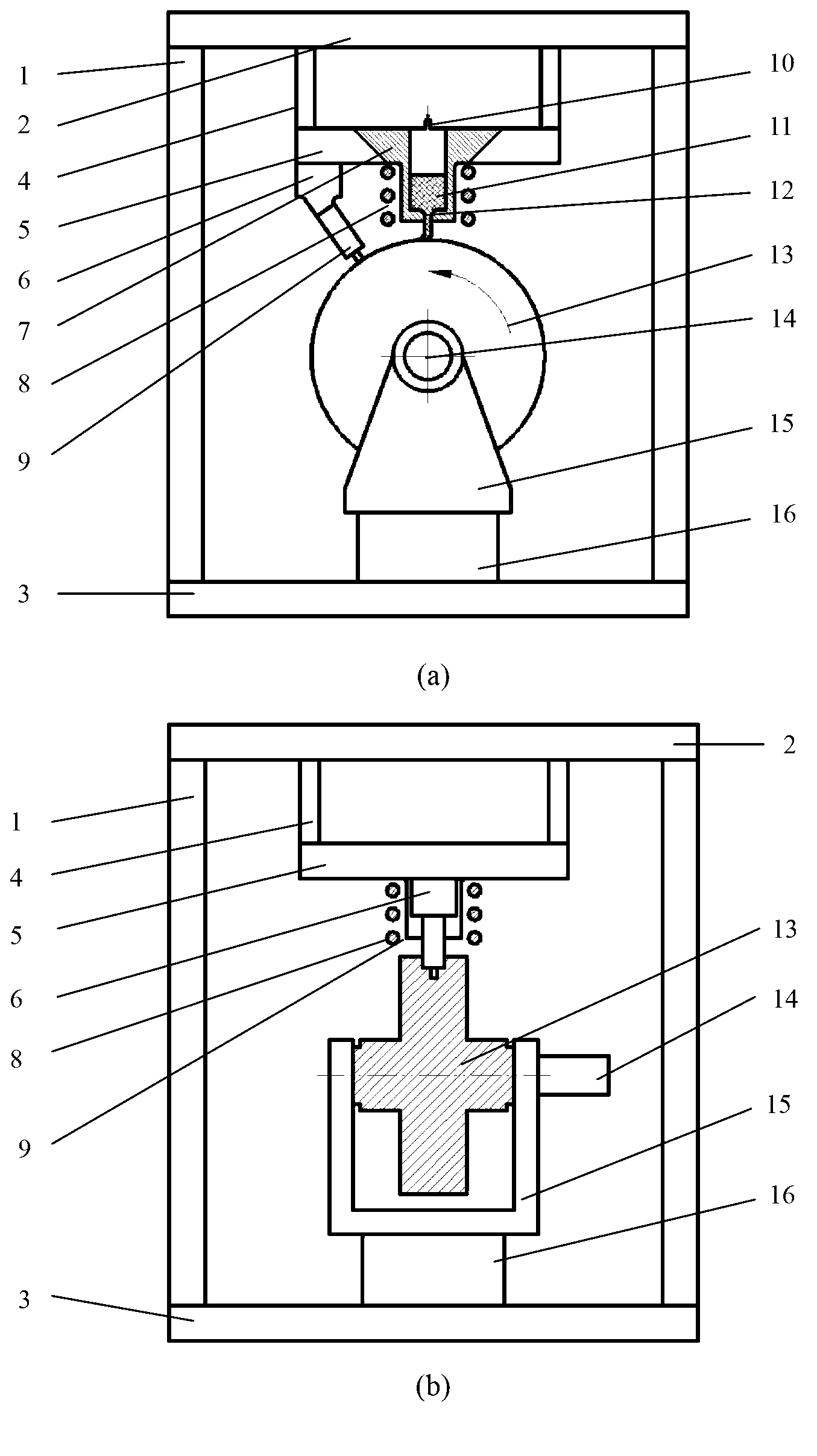

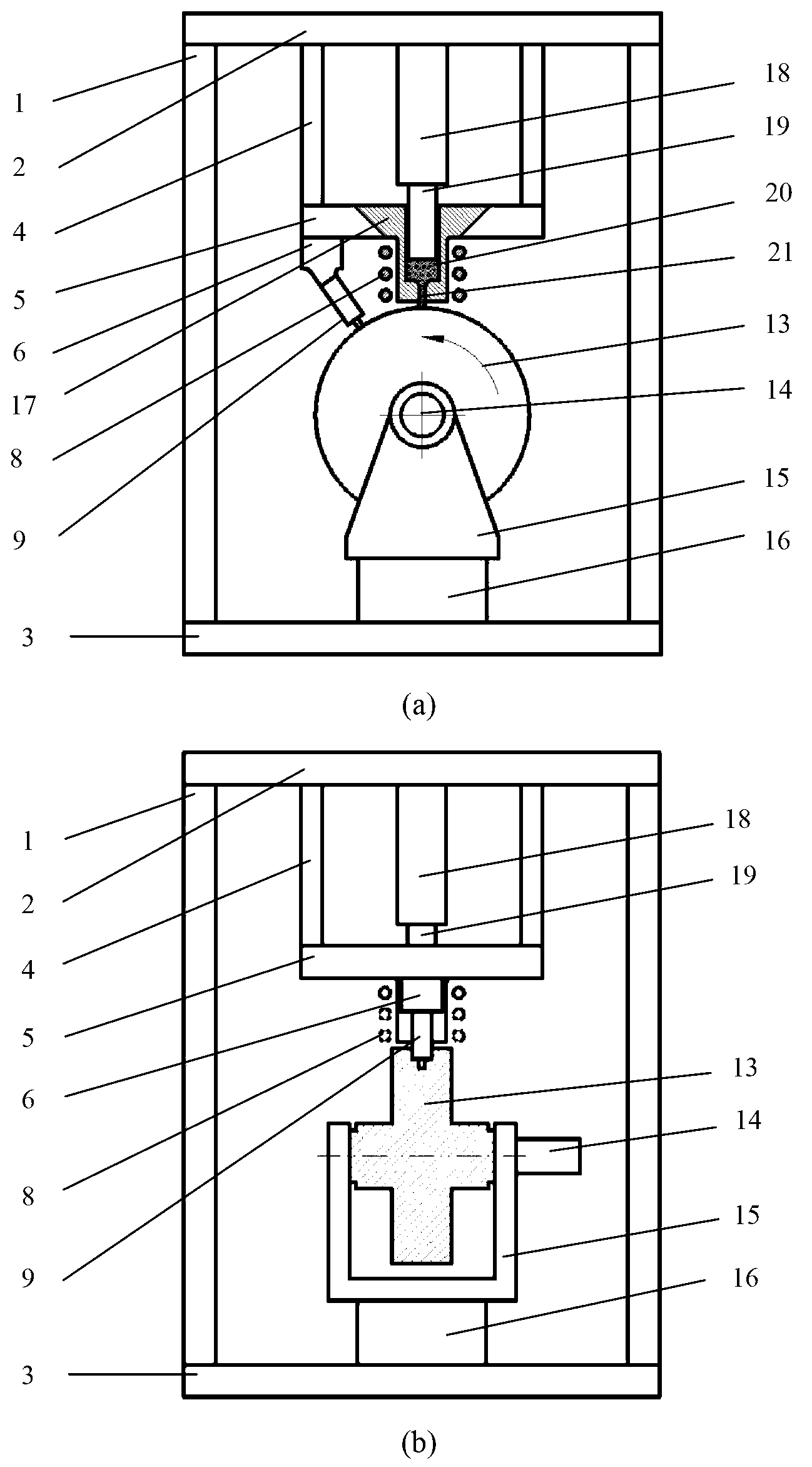

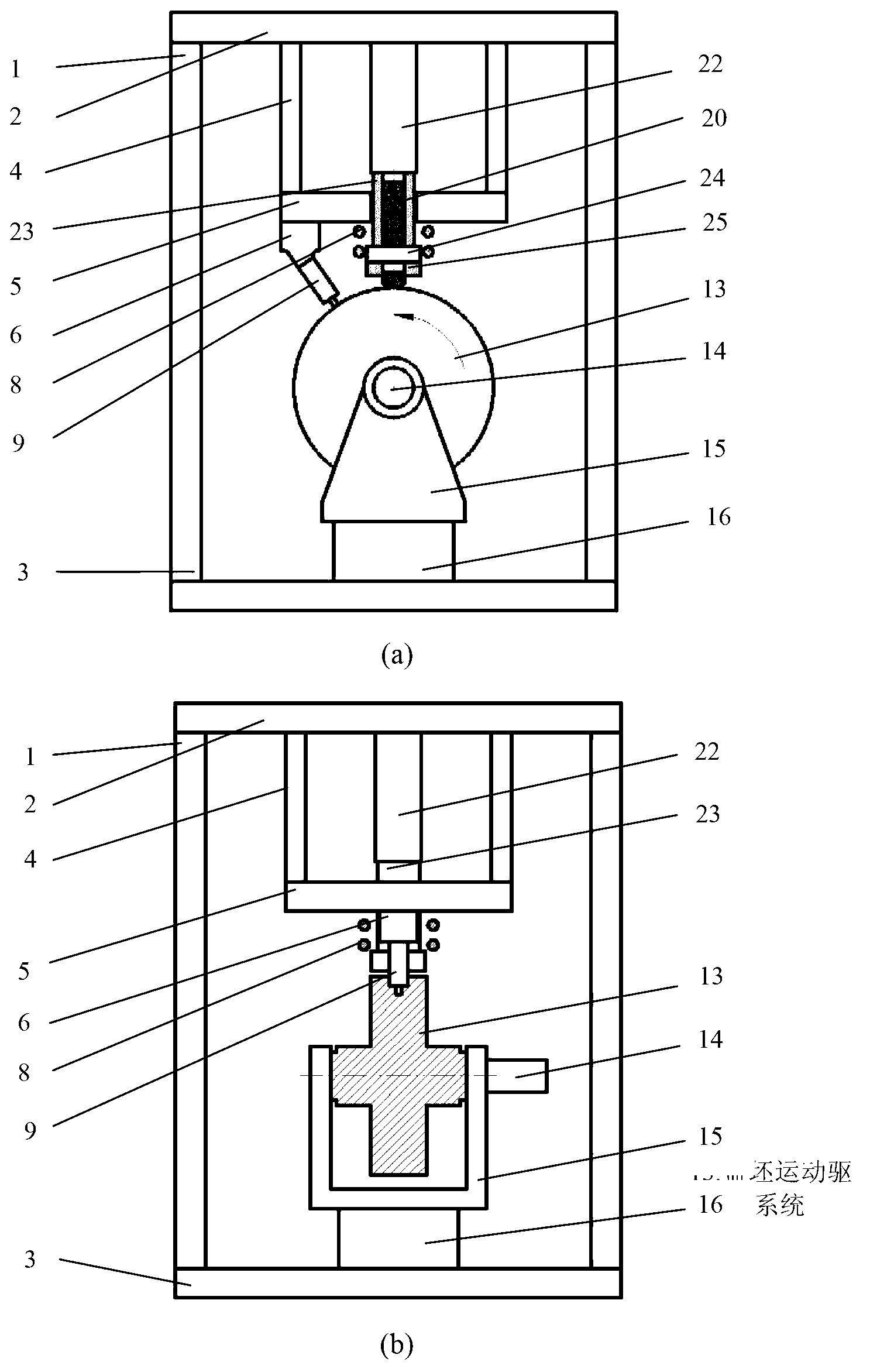

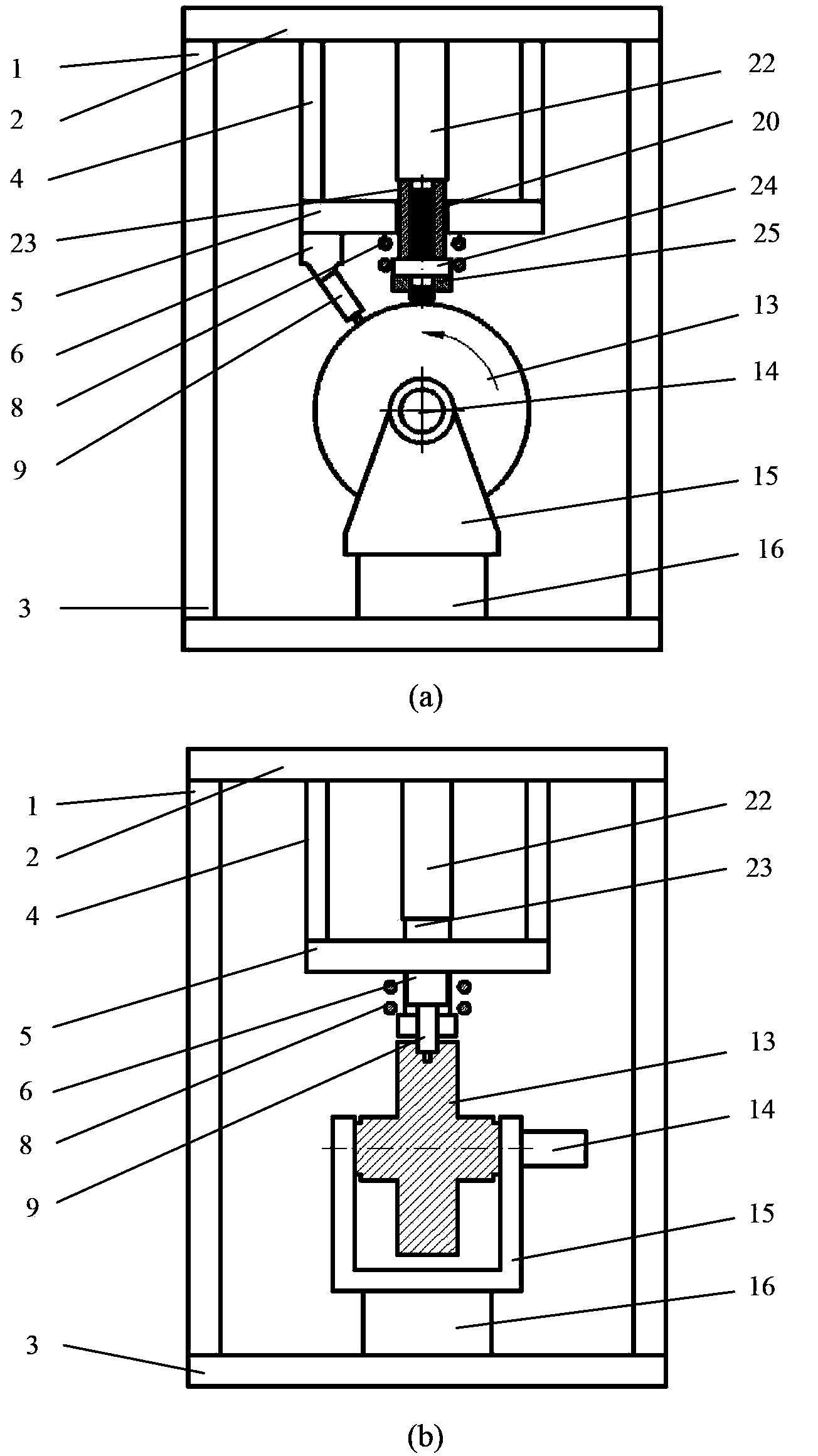

Movable heating assembly, aerosol generating device and implementation method thereof

The invention discloses an aerosol generating device, a movable heating assembly in the aerosol generating device and a method for generating aerosol, and belongs to the technical field of aerosol heating. The movable heating assembly comprises a heating assembly unit for heating aaerosol generating base material product and a movable assembly unit for driving the heating assembly unit to move / rotate, and the heating assembly unit and the movable assembly unit are both connected with a control circuit in the aerosol generating device; the method comprises the steps of defining a starting pointand an ending point, starting heating from the starting point, moving / rotating, ending heating and the like. The aerosol generating base material product is heated in a movable heating mode, the purpose of fully utilizing the aerosol to generate the base material product is achieved, meanwhile, the components of the generated aerosol are kept consistent, and the aerosol generating effect is improved.

Owner:COMBETTER TECH CO LTD

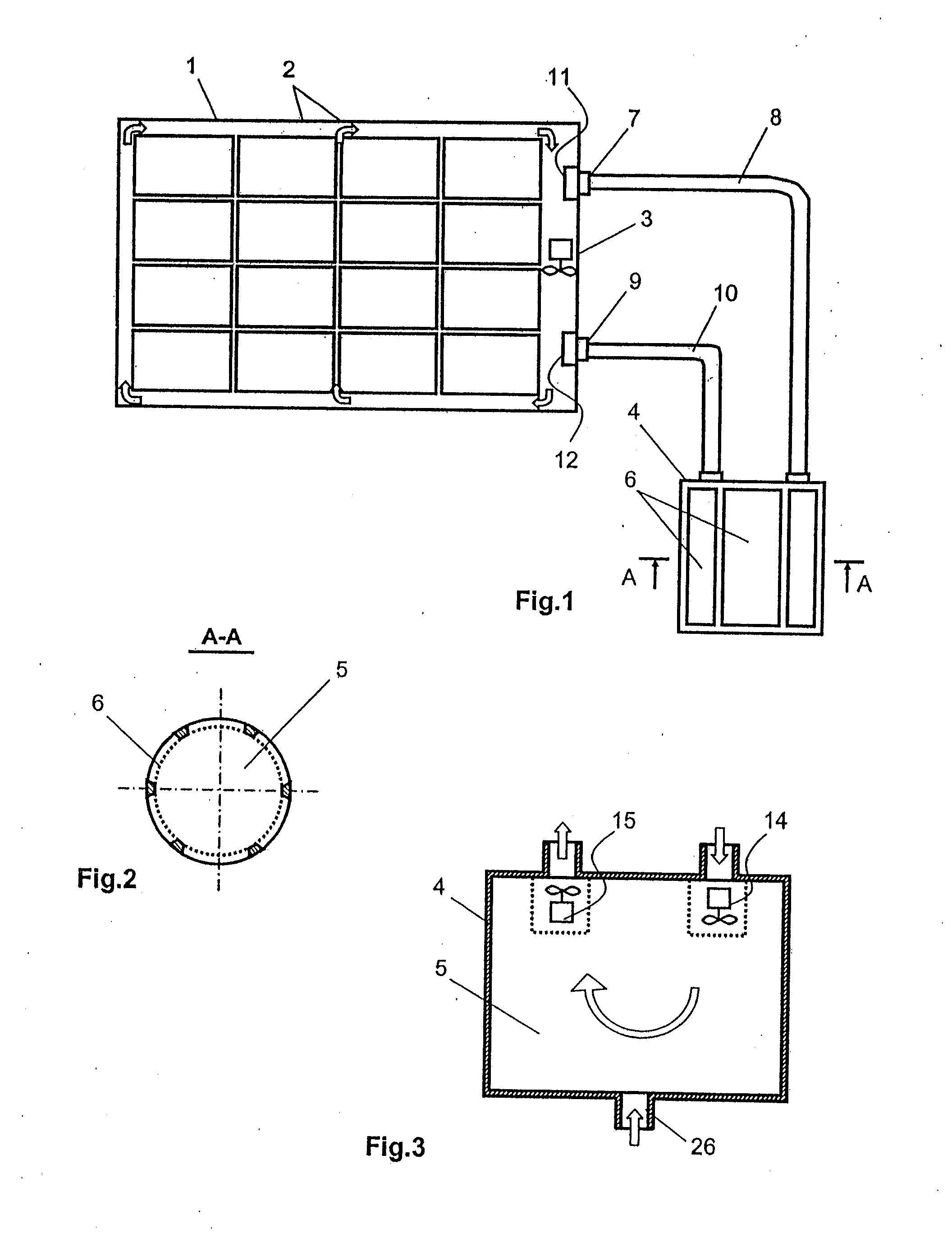

Irrigation system with inorganic micro-irrigation pipes and capable of saving water

InactiveCN105123440AGuaranteed pressureSame pressureClimate change adaptationWatering devicesWater sourceWater saving irrigation

An irrigation system with inorganic micro-irrigation pipes and capable of saving water comprises a water supply system, a distributed water pipe and a gas collecting pipe, the water supply system is arranged on the portion, closes to a water source, of a land to be irrigated, the distributed water pipe and the gas collecting pipe are arranged on the two paralleled edges of the land to be irrigated respectively, the distributed water pipe is provided with multiple distributed water heads which are connected with water-guide pipes respectively, the gas collecting pipe is provided with gas-guide pipes of which the number is equal to that of the water-guide pipes, and the multiple rows of inorganic micro-irrigation pipes which are distributed at equal intervals are arranged between the distributed water pipe and the gas collecting pipe. According to the irrigation system with the inorganic micro-irrigation pipes and capable of saving the water, equal irrigation can be conducted on different crops, and appropriate irrigation can be conducted on the crops in different growing period; the water saving effect is equivalent to that of trace quantity irrigation and moistube irrigation, and the water is saved by 60% to 80% of that of drop irrigation.

Owner:LUOYANG NORMAL UNIV

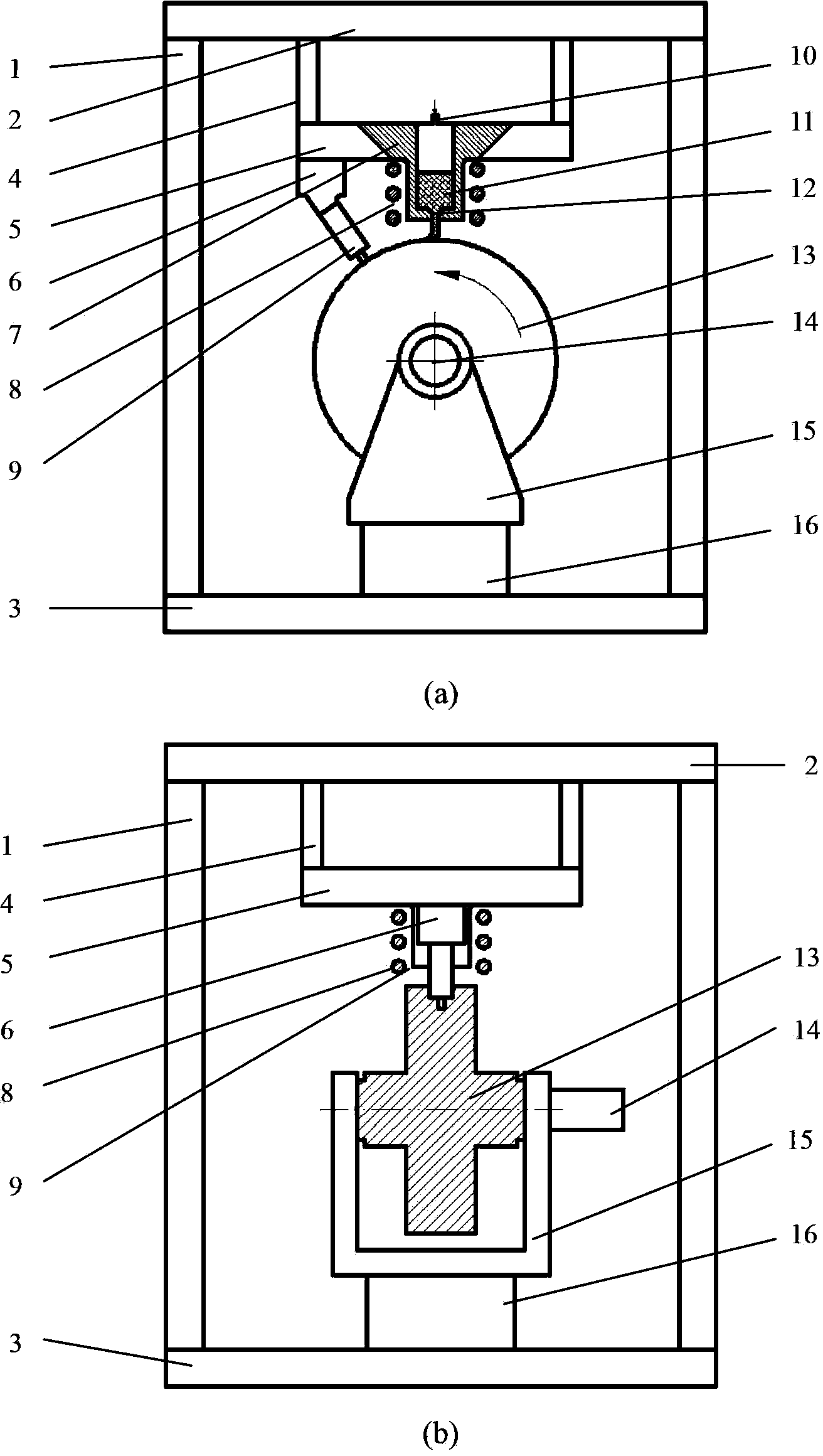

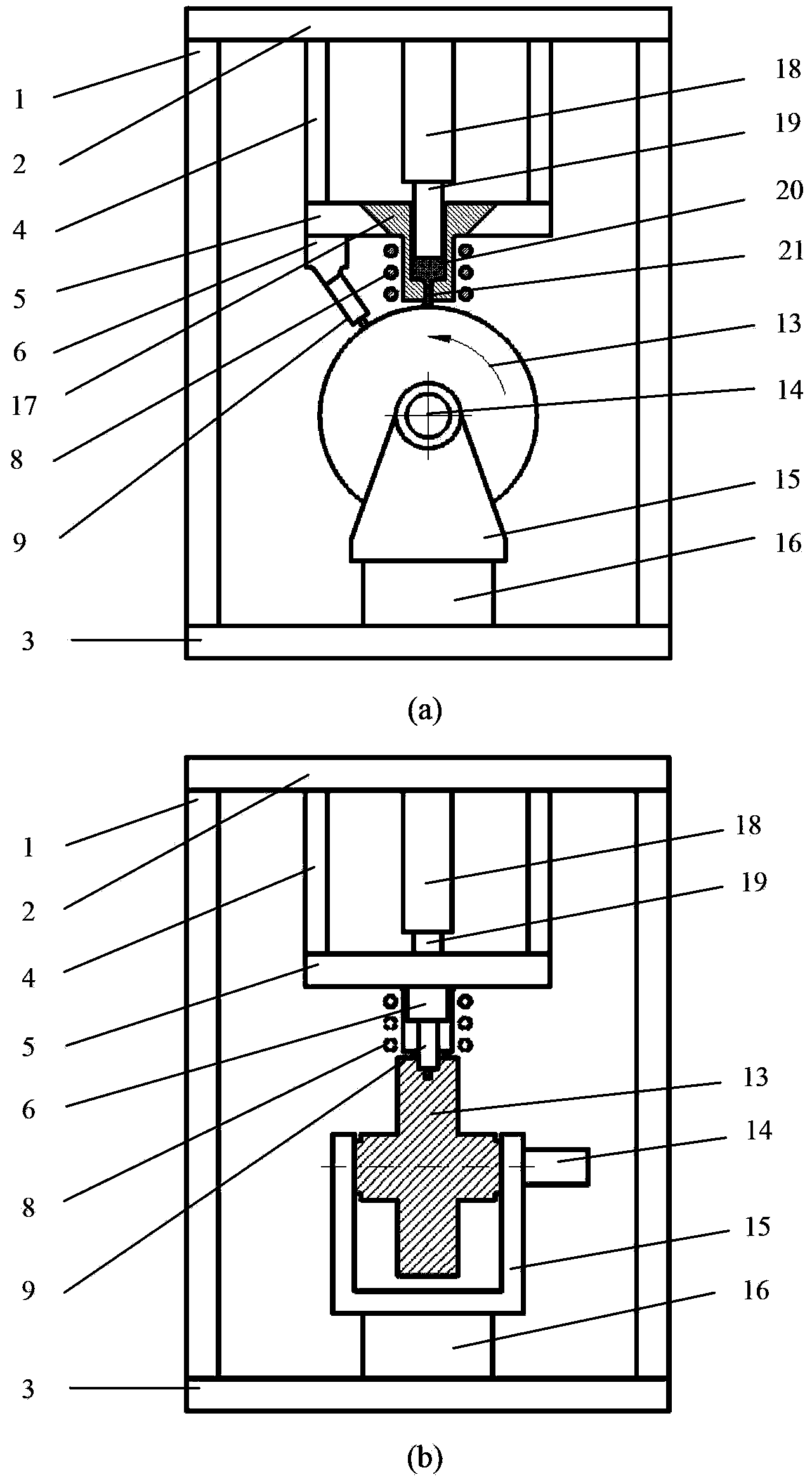

Coating and forming method for disk-type parts

The invention belongs to the manufacturing technology of disk blanks made of titanium alloy and high temperature alloy, and relates to a coating and forming method for disk-type parts. According to the invention, an air compressor disk or a turbine disk is prepared with titanium alloy and high temperature alloy according to a layer-by-layer coating / thermal machining method which is low in raw material requirements, high in efficiency, low in cost, uniform in tissues of prepared parts, and high in performance of the prepared parts. The method is suitable for preparing various disk-type or ring-type parts made of titanium alloy and high temperature alloy used in the aerospace industry.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Coating and forming method for disk-type parts

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

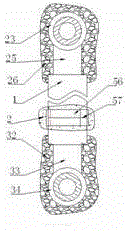

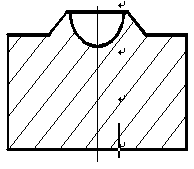

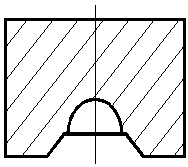

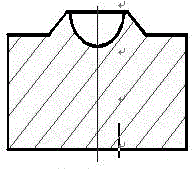

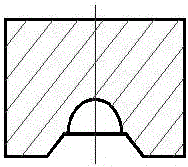

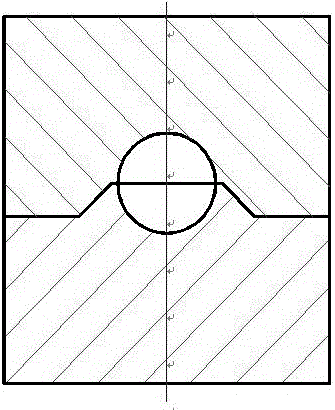

A kind of manufacturing method of metal hollow microsphere

The invention provides a manufacturing method of a metal hollow microsphere. The manufacturing method is characterized in that a diamond tool is used to machine inner semispherical faces and an interface on the end face of a metal bar, each inner semispherical face is polished into a mirror face through the inner semispherical face grinding technology, using material diffusion to connect the two inner semispherical faces under a vacuum, high-temperature and high-pressure environment, using the diamond turning technology to machine a first outer semispherical face, using a clamp special for the outer semispherical face to clamp and machine a second outer semispherical face, using the four-axis sphere grinding technology to grind the whole outer spherical face, using CT to detect the wall thickness and the wall thickness evenness of the sphere, performing correction until the wall thickness and the wall thickness evenness satisfy requirements, and polishing into mirror faces to obtain the metal hollow microsphere. The manufacturing method has the advantages that the outer diameter phi of the metal hollow microsphere manufactured by the method is 1-10mm, and the wall thickness of the metal hollow microsphere is 100-200 micrometers; the machining of the inner semispherical faces of the metal hollow microsphere is achieved; automatic centering of the connection of the two inner semispherical faces is achieved; connection of two semispherical faces is achieved, and component consistency of the metal hollow microsphere is guaranteed.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

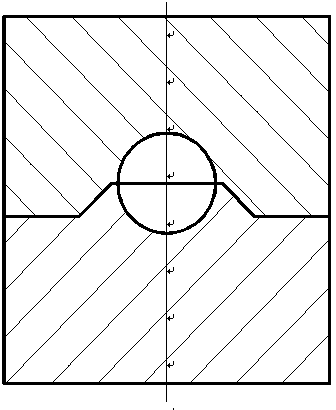

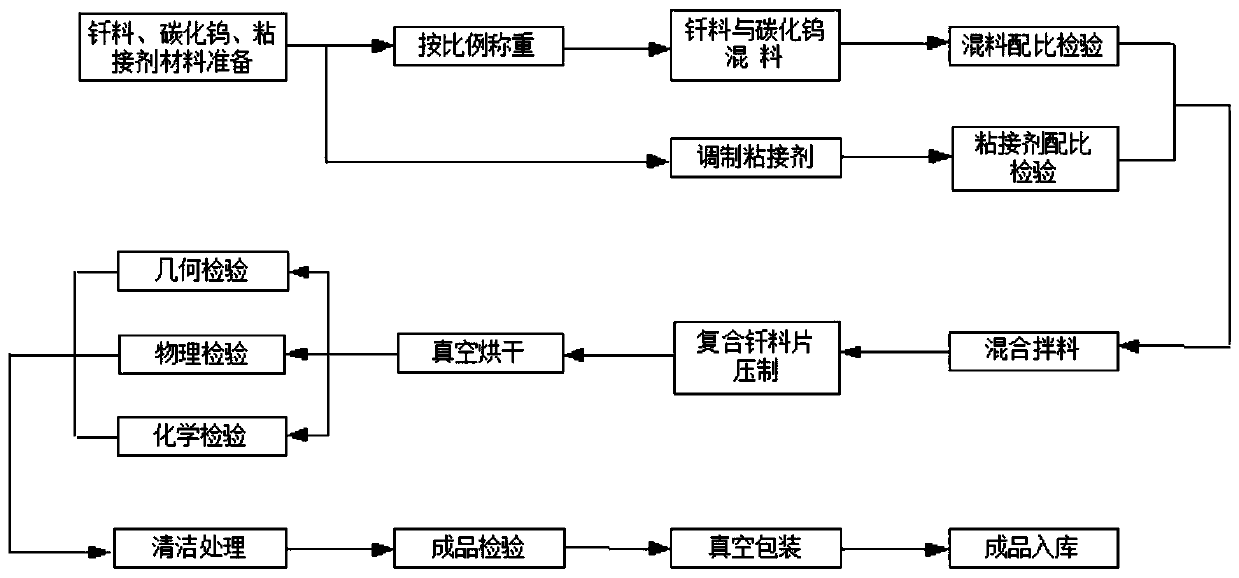

Flaky composite brazing filler metal, preparation method and application thereof and method for welding blades by adopting flaky composite brazing filler metal

ActiveCN110293331AGuaranteed SolderabilityPrevent oxidationWelding/cutting media/materialsSoldering mediaAdhesiveProduct processing

The invention discloses a flaky composite brazing filler metal, a preparation method and application thereof and a method for welding blades by adopting the flaky composite brazing filler metal. The flaky composite brazing filler metal with certain strength is prepared by stirring tungsten carbide, a brazing filler metal and an adhesive into mixed powder according to a specified proportion, pressing into sheets, and then stably solidifying; the flaky composite brazing filler metal is consistent in specification and size, the cladding amount on each blade can be guaranteed to be consistent, sothat the stability and quality of product processing are greatly improved; and as a solid flaky body, flaky composite brazing filler metal sheets are available on demand, with no need of deploying a pasty composite brazing filler metal on site, the working efficiency of preparation before welding the blades can be greatly improved. The flaky composite brazing filler metal sheets are melted throughthe cooperation of automatic equipment, so that the welding cladding quality is influenced by pollution caused by manual operation on cladding materials is avoided, and the high-efficiency automationof welding is realized.

Owner:AECC AVIATION POWER CO LTD

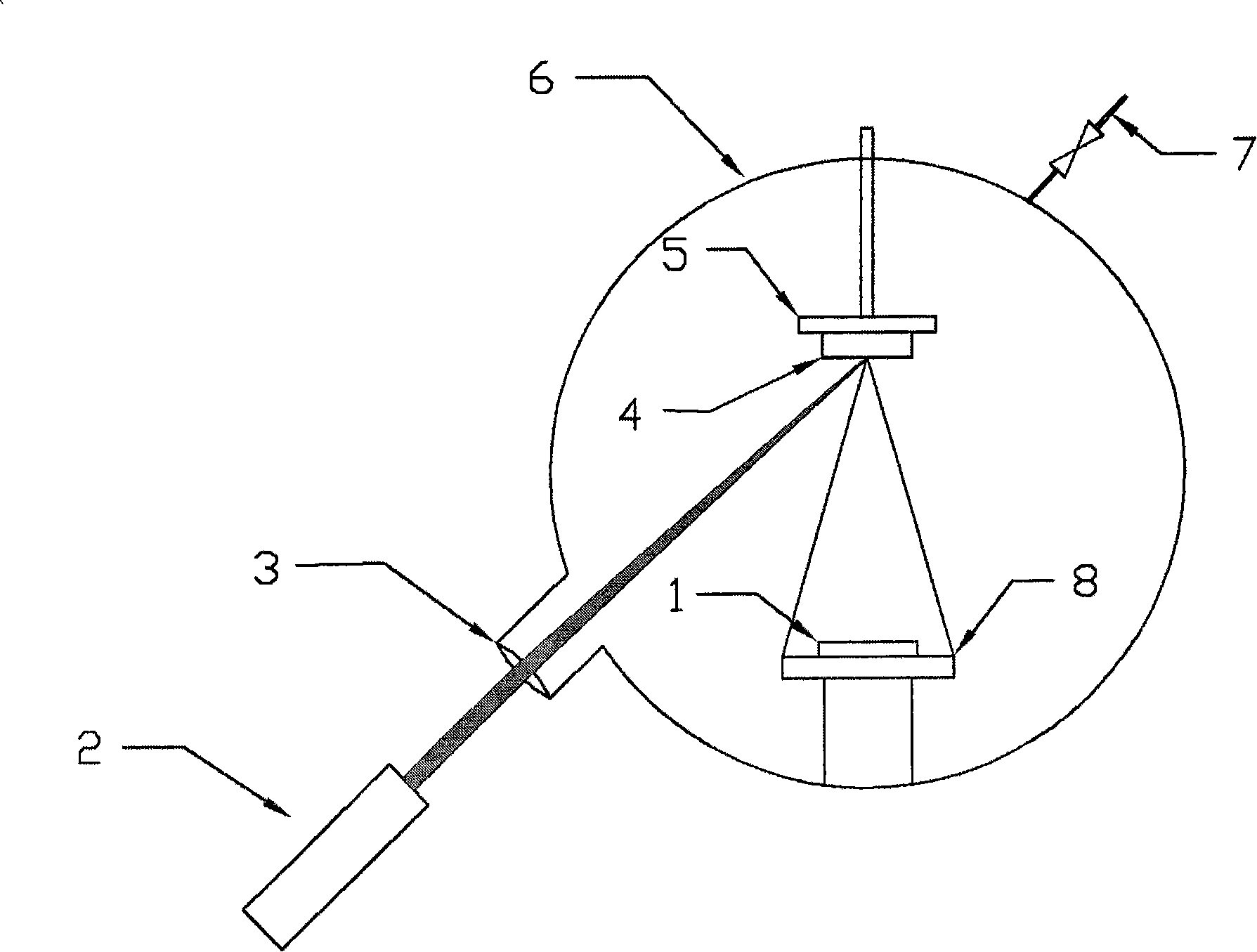

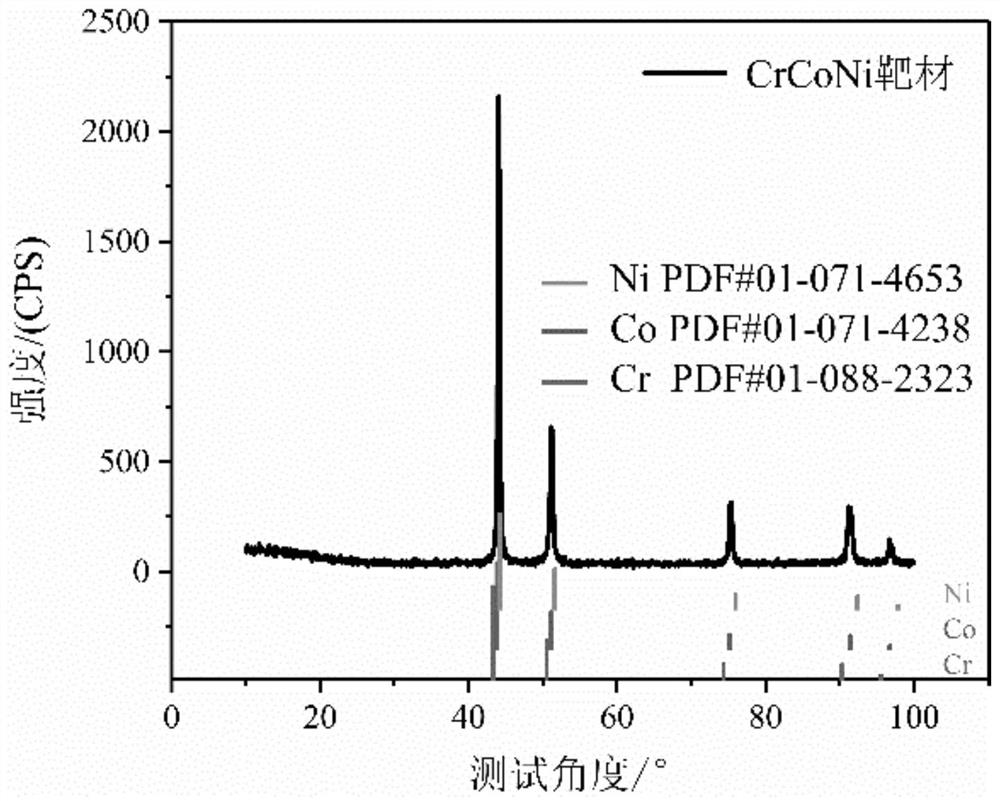

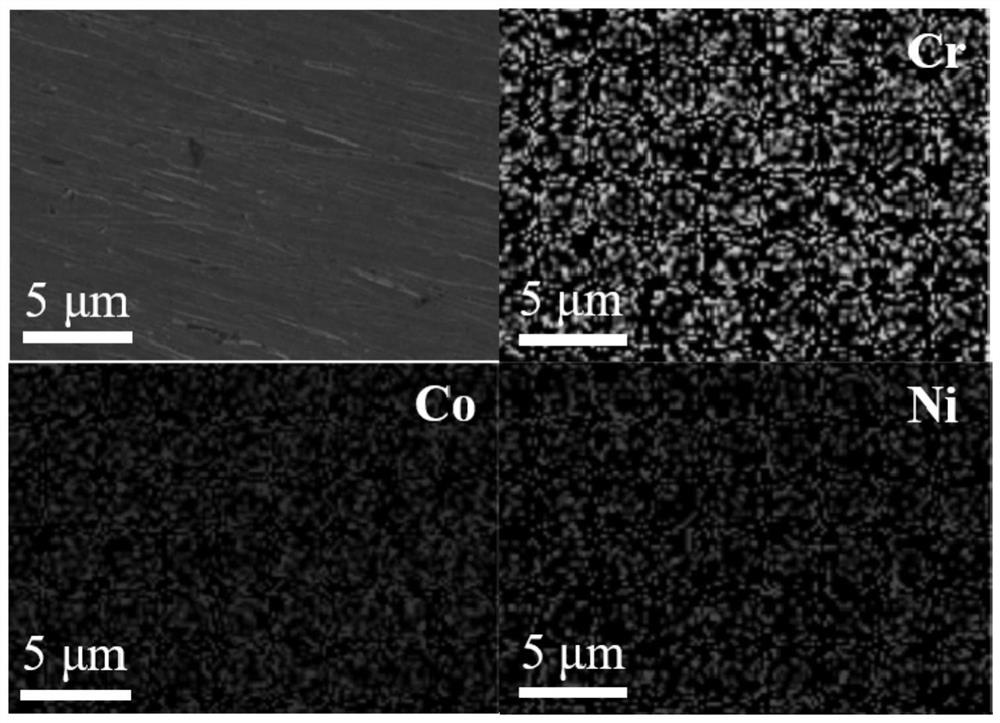

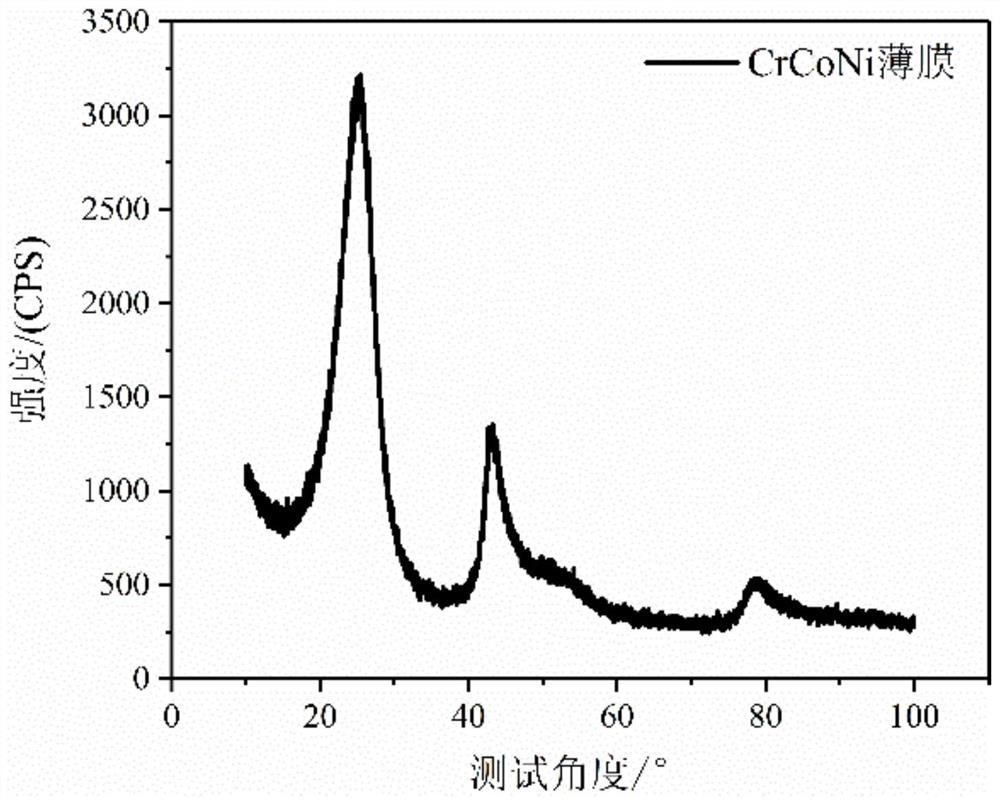

Amorphous CrCoNi alloy film loaded Pt methanol oxidation composite electrode and preparation method thereof

ActiveCN114045465AImprove mechanical stabilityConsistent ingredientsCell electrodesVacuum evaporation coatingPtru catalystComposite electrode

The invention discloses an amorphous CrCoNi alloy film loaded Pt methanol oxidation composite electrode and a preparation method thereof, and the preparation method comprises the following steps: carrying out mechanical polishing, washing and drying on a glassy carbon sheet to prepare a pretreated glassy carbon sheet, i.e., a substrate; respectively fixing a CrCoNi alloy target material and a Pt target material on a target holder of a pulse laser deposition instrument, fixing the target holder on a target disc of a vacuum deposition chamber, placing a substrate holder in the vacuum deposition chamber, and adjusting the distance between the target material and the substrate; vacuumizing the vacuum deposition chamber, then carrying out pre-sputtering, and then depositing CrCoNi alloy; subjecting the Pt target material to the position of the original CrCoNi alloy target material, carrying out pre-sputtering, and then depositing Pt; and after deposition is finished, adjusting the pressure of the vacuum deposition chamber to atmospheric pressure, taking the substrate out, and preparing the amorphous CrCoNi alloy film loaded Pt methanol oxidation composite electrode. The film catalyst of the composite electrode has better catalytic activity and better stability and durability.

Owner:CHENGDU UNIV

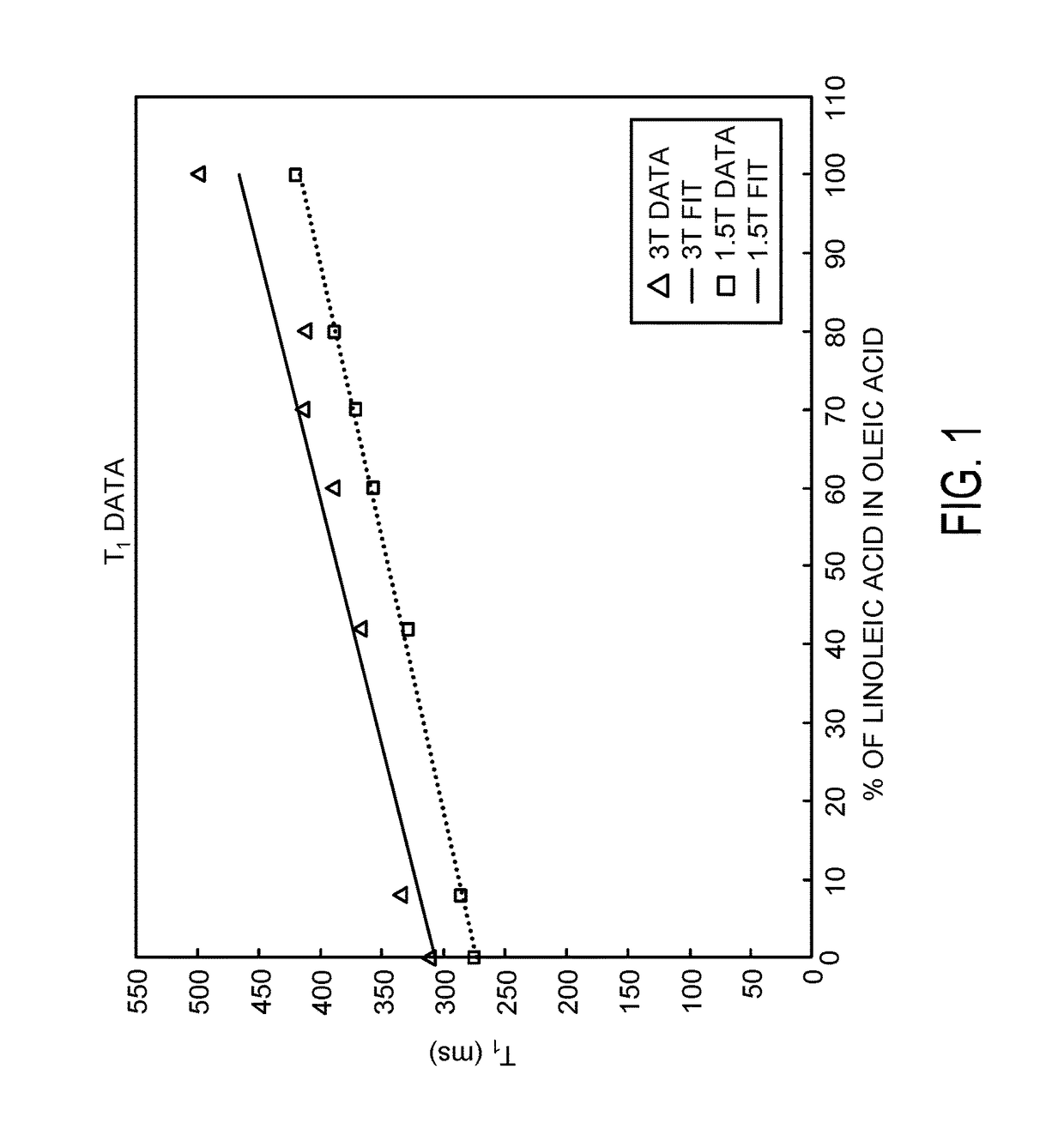

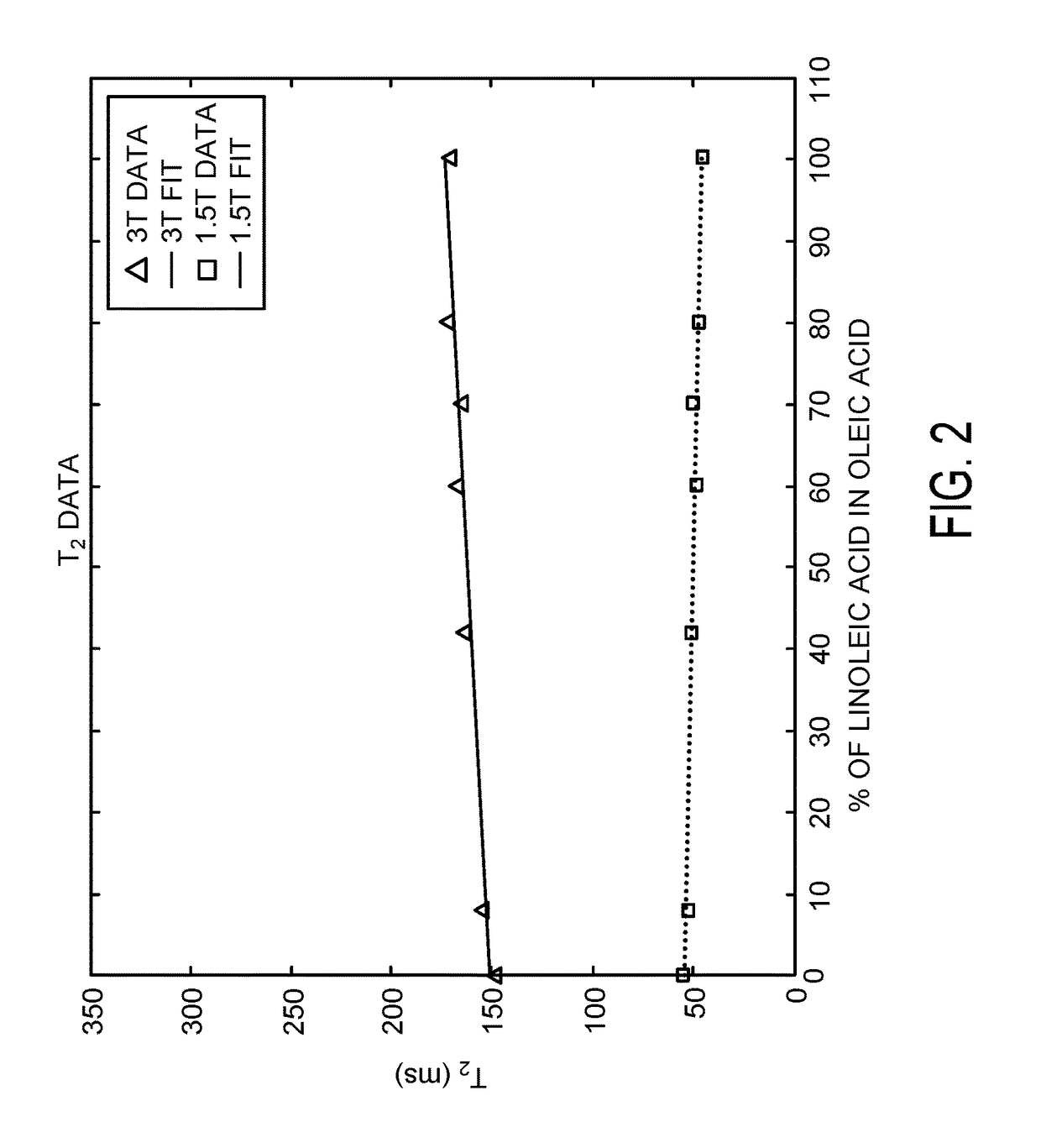

Novel Compositions that Mimic Adipose Tissue in MRI

InactiveUS20170293011A1Consistent ingredientsNMR/MRI constrast preparationsPharmaceutical non-active ingredientsMagnetic susceptibilityFat suppression

Provided herein are adipose mimic compositions for use in MRI. The compositions of the invention mimic the MRI properties of human adipose tissue, including T1 relaxation kinetics, T2 relaxation kinetics, magnetic susceptibility, and chemical shift artifact. The compositions of the invention are readily manufactured from inexpensive materials. The compositions of the invention may be used in MRI system calibration or for implementing image correction techniques such as fat suppression.

Owner:QALIBREMD INC

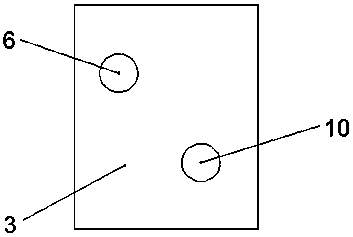

Improved fruit wine filling machine

The invention discloses an improved fruit wine filling machine, which comprises a conveyer belt, a mixing tank, and a filling tank, the filling tank is arranged over the conveyer belt, the mixing tankis arranged above the filling tank and is communicated with the filling tank through a pipeline, an upper horizontal agitating shaft and a lower horizontal agitating shaft are arranged in the fillingtank, the upper horizontal agitating shaft and the lower horizontal agitating shaft are respectively arranged on the left and the right in the filling tank, a plurality of impellers are arranged on each of the upper horizontal agitating shaft and the lower horizontal agitating shaft, a guide tube is arranged on the side of the filling tank, and a nozzle is arranged at the lower end of the guide tube. The design of the improved fruit wine filling machine is reasonable, the structure is simple, mixture in the filling tank can circularly flow under the agitating function of the upper horizontalagitating shaft and the lower horizontal agitating shaft, consequently, ingredients of all the parts are uniform, the ununiformity of the ingredients of filled product is prevented, and the quality ofthe product is improved.

Owner:江阴市一品酿酒有限公司

Device for controlling the gas medium inside a container

InactiveUS20140220203A1Simple structureAvoid prematureFruit and vegetables preservationGaseous food ingredientsRipeningEngineering

A device for controlling the composition inside a shipping / storage container for produce, such as bananas, is disclosed. Such atmospheric control is particularly important when dealing with the ripening of respiring fruit. The device comprises a chamber surrounded by an outer wall, at least a portion of that wall made up of a selectively gas-permeable membrane which is in communication with the outside atmosphere. The chamber also includes at least two channels which are connected to the container: one which transmits gas form the chamber to the container, and one which transmits gas from the container to the chamber.

Owner:CHIQUITA

Manufacturing method of metal hollow microsphere

The invention provides a manufacturing method of a metal hollow microsphere. The manufacturing method is characterized in that a diamond tool is used to machine inner semispherical faces and an interface on the end face of a metal bar, each inner semispherical face is polished into a mirror face through the inner semispherical face grinding technology, using material diffusion to connect the two inner semispherical faces under a vacuum, high-temperature and high-pressure environment, using the diamond turning technology to machine a first outer semispherical face, using a clamp special for the outer semispherical face to clamp and machine a second outer semispherical face, using the four-axis sphere grinding technology to grind the whole outer spherical face, using CT to detect the wall thickness and the wall thickness evenness of the sphere, performing correction until the wall thickness and the wall thickness evenness satisfy requirements, and polishing into mirror faces to obtain the metal hollow microsphere. The manufacturing method has the advantages that the outer diameter phi of the metal hollow microsphere manufactured by the method is 1-10mm, and the wall thickness of the metal hollow microsphere is 100-200 micrometers; the machining of the inner semispherical faces of the metal hollow microsphere is achieved; automatic centering of the connection of the two inner semispherical faces is achieved; connection of two semispherical faces is achieved, and component consistency of the metal hollow microsphere is guaranteed.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

TPR shoe surface modification technology

The invention discloses a TPR shoe surface modification technology. The modification technology comprises the following steps of (1) a TPR shoe surface processing step, in which a TPR specific processing agent is employed to clean the external surface of the shoe and soften the external surface, and the shoe external surface is dried for 10 to 20 minutes, (2) a priming paint spraying step, in which a paint spraying device is employed to spray priming paint to the TPR shoe to form a flat priming paint plane on the external of the TPR shoe, and then the shoe sprayed with the priming paint is dried by 10 to 20 minutes at the temperature of 60 to 70 DEG C, (3) a metal spraying step, in which a spraying device is employed to spray an imitating metal layer on the priming paint, and then the imitating metal layer is dried for 5 to 10 minutes at the temperature of 60 to 70 DEG C, and (4) a spraying device is employed to spray a layer of surface paint on the external surface of the imitating metal layer and then the shoe is dried. The modified shot can be achieved at last. The priming paint is composed of the following components according to weight by parts: 100 parts of base main resin, 10 to 30 parts of hardener, 30 to 80 parts of diluents and 1 to 10 parts of binding agents; and the surface paint is formed by the following components according to weight by parts: 100 parts of surface main resin, 30 to 50 parts of hardener, 50 to 80 parts of diluents and proper pigment. The TPR shoe surface modification technology is characterized by great decorating effect.

Owner:晋江国盛新材料科技有限公司

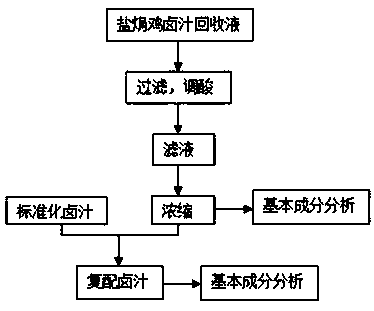

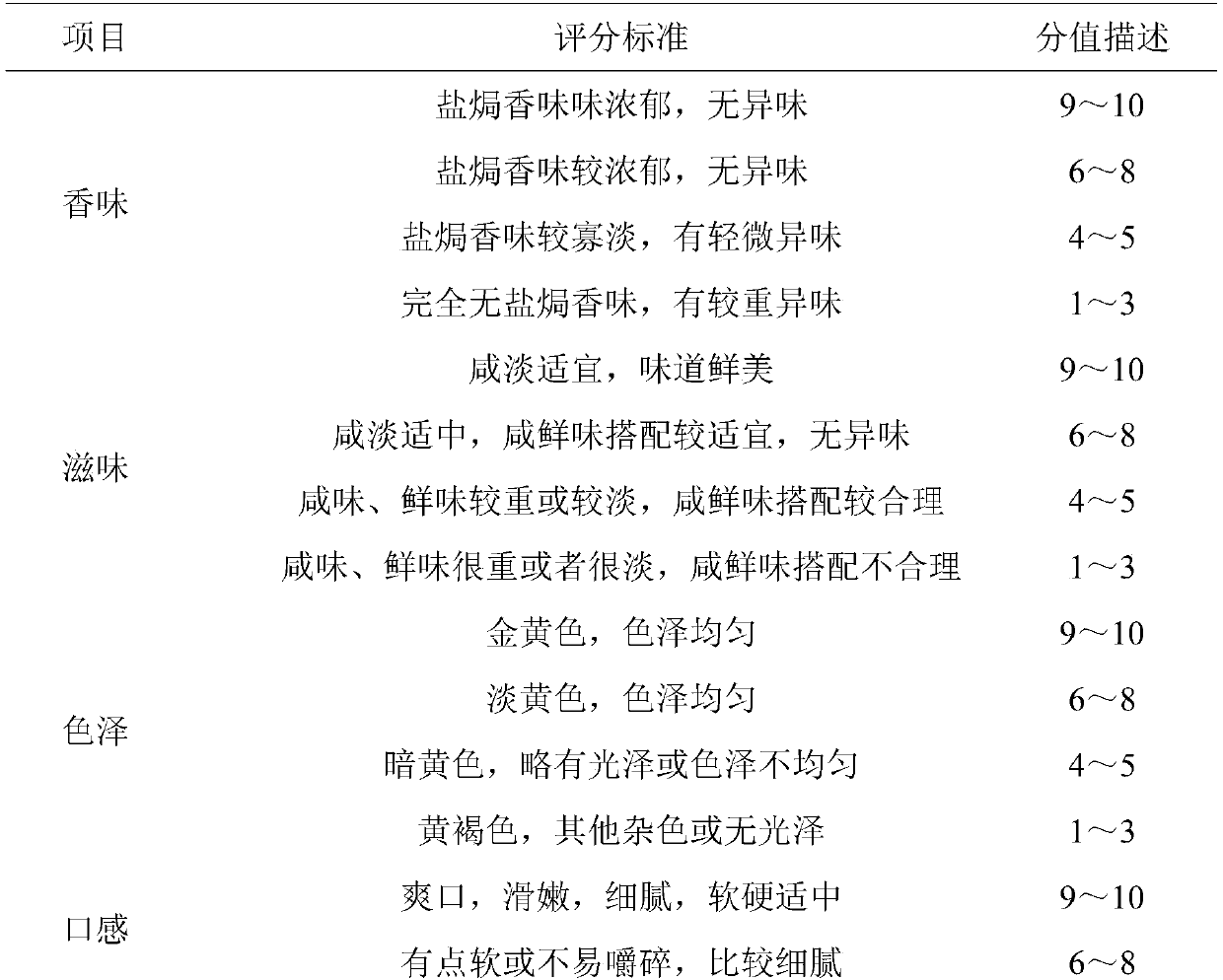

Preparation method of salt roasted chicken compound marinade

PendingCN109511902AKeep alive functionKeep the flavorClimate change adaptationFood ingredient as taste affecting agentRoast chickenFunctional activity

The invention discloses a preparation method of salt roasted chicken compound marinade. The preparation method comprises the steps that marinated salt roasted chicken marinade is filtered, subjected to pH value conditioning and concentration, so that concentrated marinade is obtained; and the concentrated marinade and newly prepared salt roasted chicken marinade are compounded, and the salt roasted chicken compound marinade can be obtained. According to the preparation method, concentration and compounding are conducted on the salt roasted chicken marinade which is marinated for many times, the problem that the marinade is hard to recycle and reuse in a production process is solved, the nutrient value and volume loss of the marinade is reduced at the same time, and the nutrient value and the functional activity of the marinade are increased; in addition, the problem of environmental pollution caused by waste marinade can be effectively relieved. The compound marinade has a variety types of free amino acid, is rich in taste and high in nutrient value, a standardized marinade formula is provided, stable quality of products in different batches is ensured, experimental evidences and technical support are provided for achieving standarized and industrialized production of the products, and the preparation method can be popularized and applied widely.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com