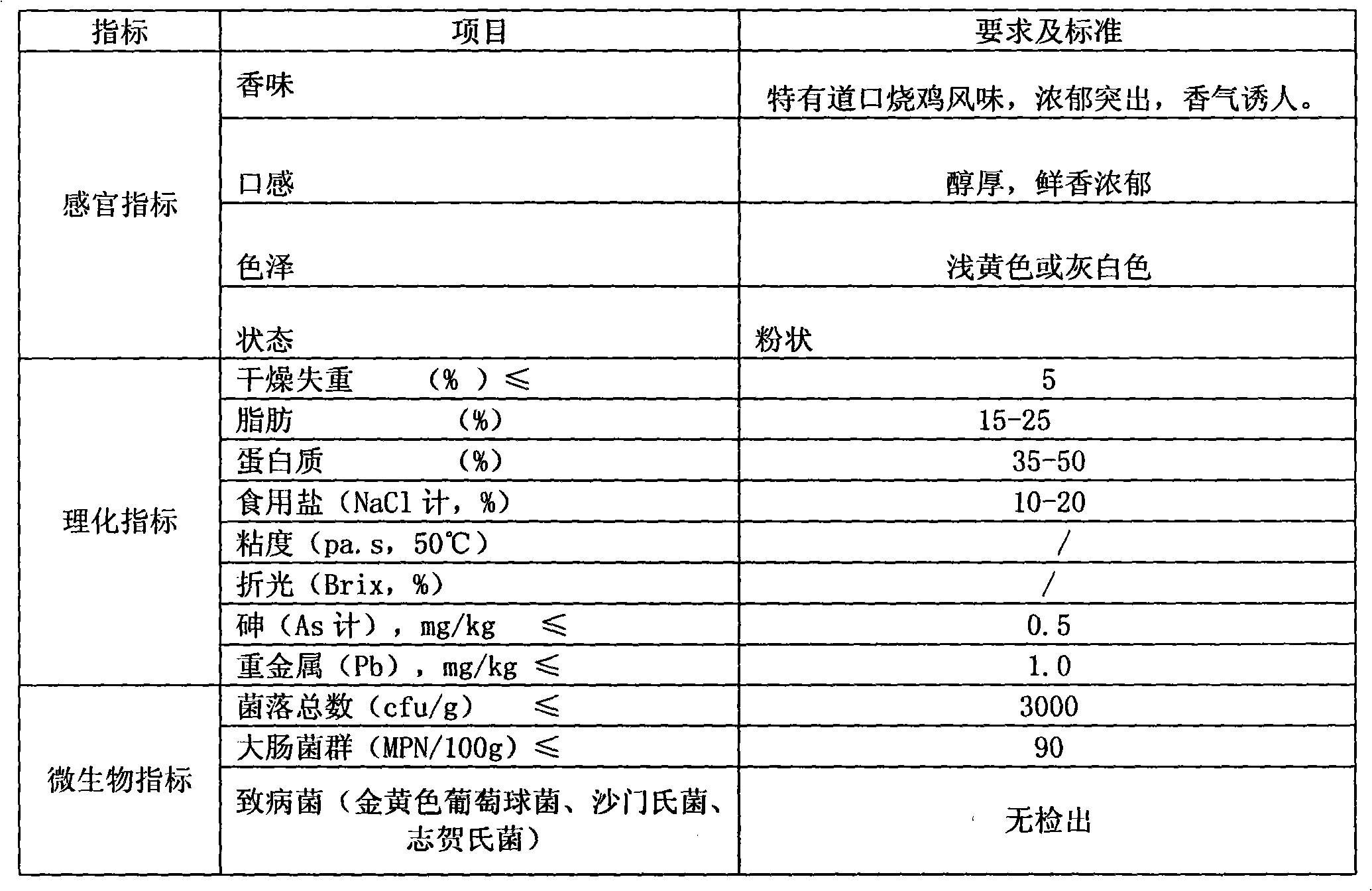

Patents

Literature

250 results about "Roast chicken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roast chicken is chicken prepared as food by roasting whether in a home kitchen, over a fire, or with a rotisserie (rotary spit). Generally, the chicken is roasted with its own fat and juices by circulating the meat during roasting, and therefore, are usually cooked exposed to fire or heat with some type of rotary grill so that the circulation of these fats and juices is as efficient as possible. Roast chicken is a dish that appears in a wide variety of cuisines worldwide.

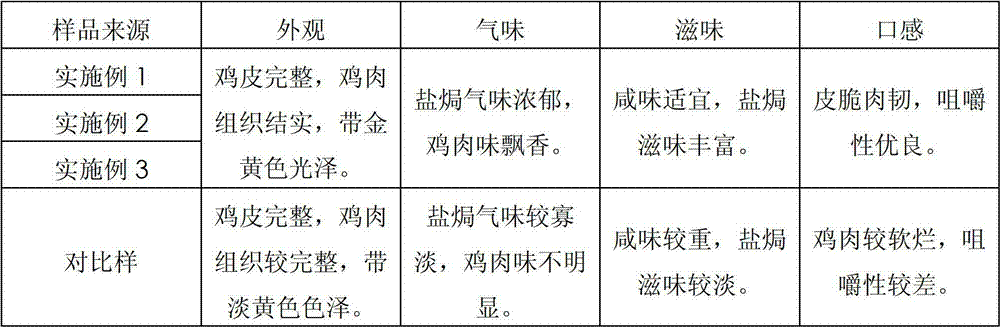

Salt roasted chicken product and preparation method thereof

ActiveCN102178257AReduce surface pressureImprove permeabilityFood preparationRoast chickenSalt content

The invention discloses a salt roasted chicken product and a preparation method thereof. The preparation method comprises the following steps of: (1) salting; (2) precooking; (3) marinating; (4) colouring, carrying out oxidation and protecting colour; (5) roasting a chicken in salt; (6) cutting and reshaping, drying and then cooling, and then packaging with inner package, carrying out microwave sterilization on a packaged and unsealed product, then vacuumizing the sterilized packaging product, and carrying out heat sealing on a package opening to obtain a semi-finished product; and (7) sterilizing the semi-finished product at a high temperature and high pressure, cleaning, and carrying out air drying to obtain the salt roasted chicken product. The salt roasted chicken product discloses by the invention not only can show unique colour, lustre, taste and flavour of the traditional salt roasted chicken product but also is greatly improved, the salt content is greatly reduced, the chicken has crisp taste and elastic and tough meat quality, and the defect that a transparent plastic bag packaging product is easy to fade and oxidize is effectively avoided.

Owner:广东无穷食品集团有限公司

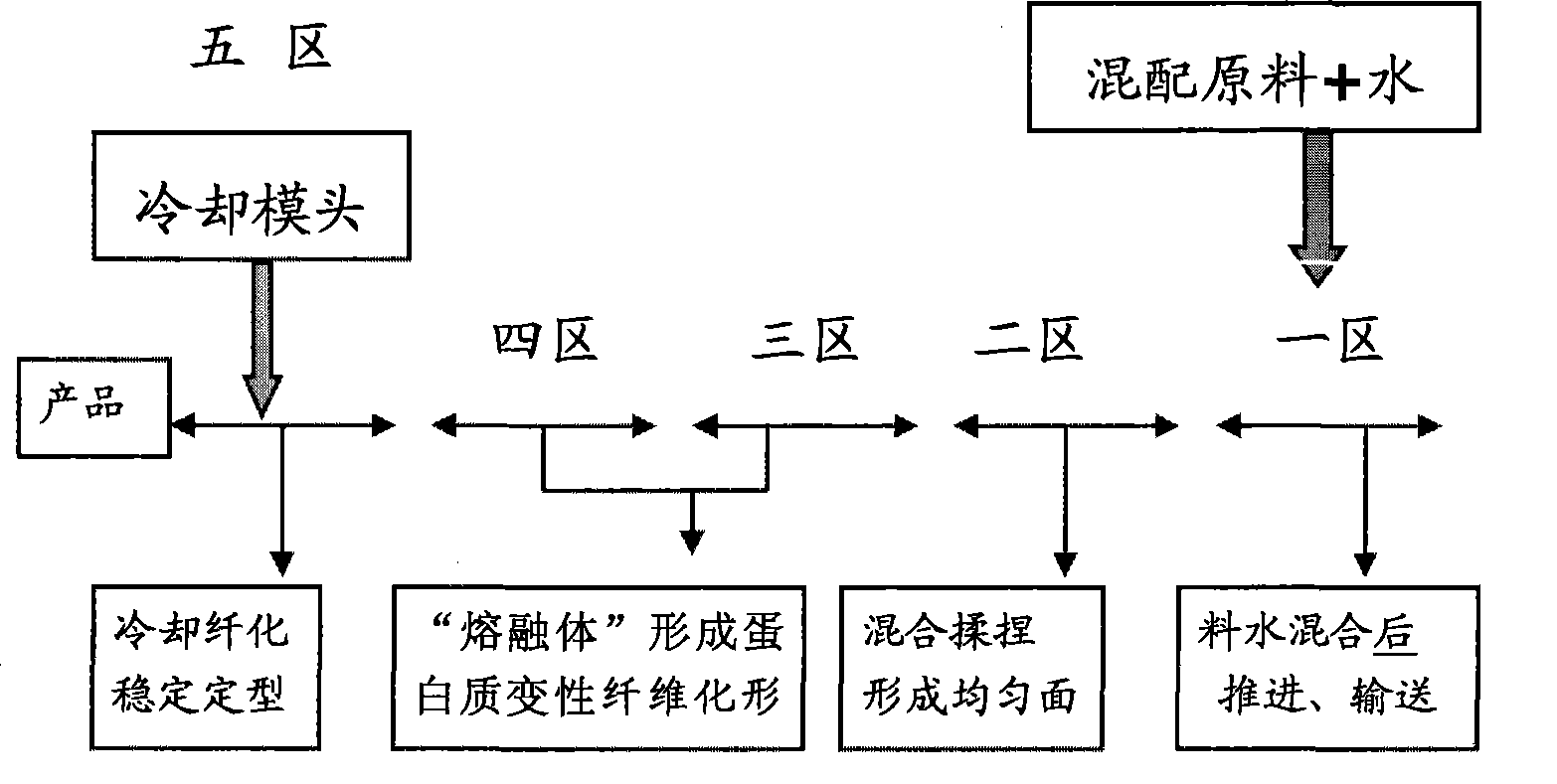

Soy protein texturization meat-imitation product and preparation method thereof

InactiveCN101473966AImprove organizational structureFiber filaments are obviousFood shapingFood preparationRoast chickenFood flavor

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

Process for processing roast chicken

The invention discloses a process for processing a roast chicken. The process comprises the steps of selecting materials, slaughtering, unhairing, eviscerating, injecting, salting, pinning the chicken, shaping, frying the chicken, boiling the chicken and the like. The roast chicken prepared by the process has the characteristics of neatness, no hair, complete body, attractive shape, shiny and glossy surface, soft and tender flesh, delicious taste, strong fragrance, and rotten, deboned, fatty but not greasy flesh. Chewing the bones of the chicken, lingering fragrance exists. The roast chicken is uniform in salinity, is palatable, can be cold or hot food and is suitable for both the elderly and the young.

Owner:宿州市符离集刘老二烧鸡有限公司

Roast chicken and its producing method

The invention discloses a cooked chicken local flavor which includes chicken meat and batching material, the batching material comprises pickled material and sauce material, the pickled material comprises fresh ginger, dahurian angelica root, common fennel fruit, licorice root, anise leaf, sand ginger, white pepper, genkwa ginger, toasted garlic, onion, spiced powder, curry, gourmet powder, white sugar, salt, oyster sauce, bee honey, sesame oil, water, chicken pickling agent.

Owner:BEIJING HAPPY VILLAGE FOOD TECH DEVCO

Preparation method of salt roasted chicken

The invention discloses a preparation method of a salt roasted chicken, comprising the steps of firstly selecting a frozen chicken and unfreezing the frozen chicken in a cold water spraying manner, then placing the chicken in sea salt curing liquid with a mass concentration of 15-25% at normal temperature and normal pressure, after cleaning and draining, placing the chicken in salt roasting liquid to cook for 40-60min, pruning and shaping the salt roasted chicken, drying with hot air at a temperature of 55-65 DEG C for 20-40min and drying with microwaves at a microwave intensity of 300-500W for 1-3min, packaging and carrying out pasteurization on the vacuum packaged salt roasted chicken at a temperature of 75-90 DEG C for 10-50min, and placing the sterilized salt roasted chicken in ice water to carry out rapid cooling for 10-15min so that the salt roasted chicken product is prepared. According to the preparation method, excellent flavor is provided for the salt roasted chicken product and the shelf life can be ensured through special packaging materials while the taste is improved.

Owner:ZHONGKAI UNIV OF AGRI & ENG

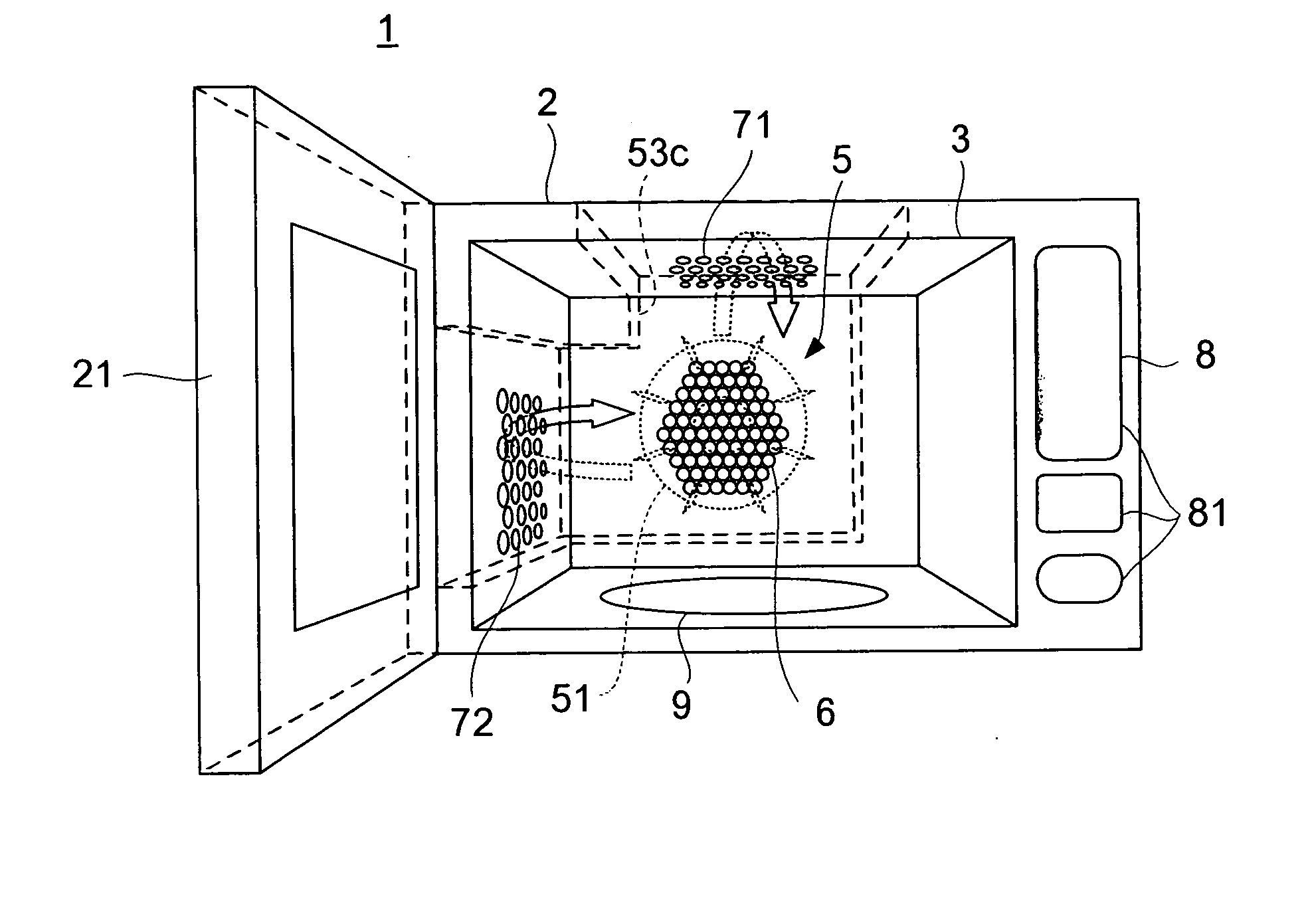

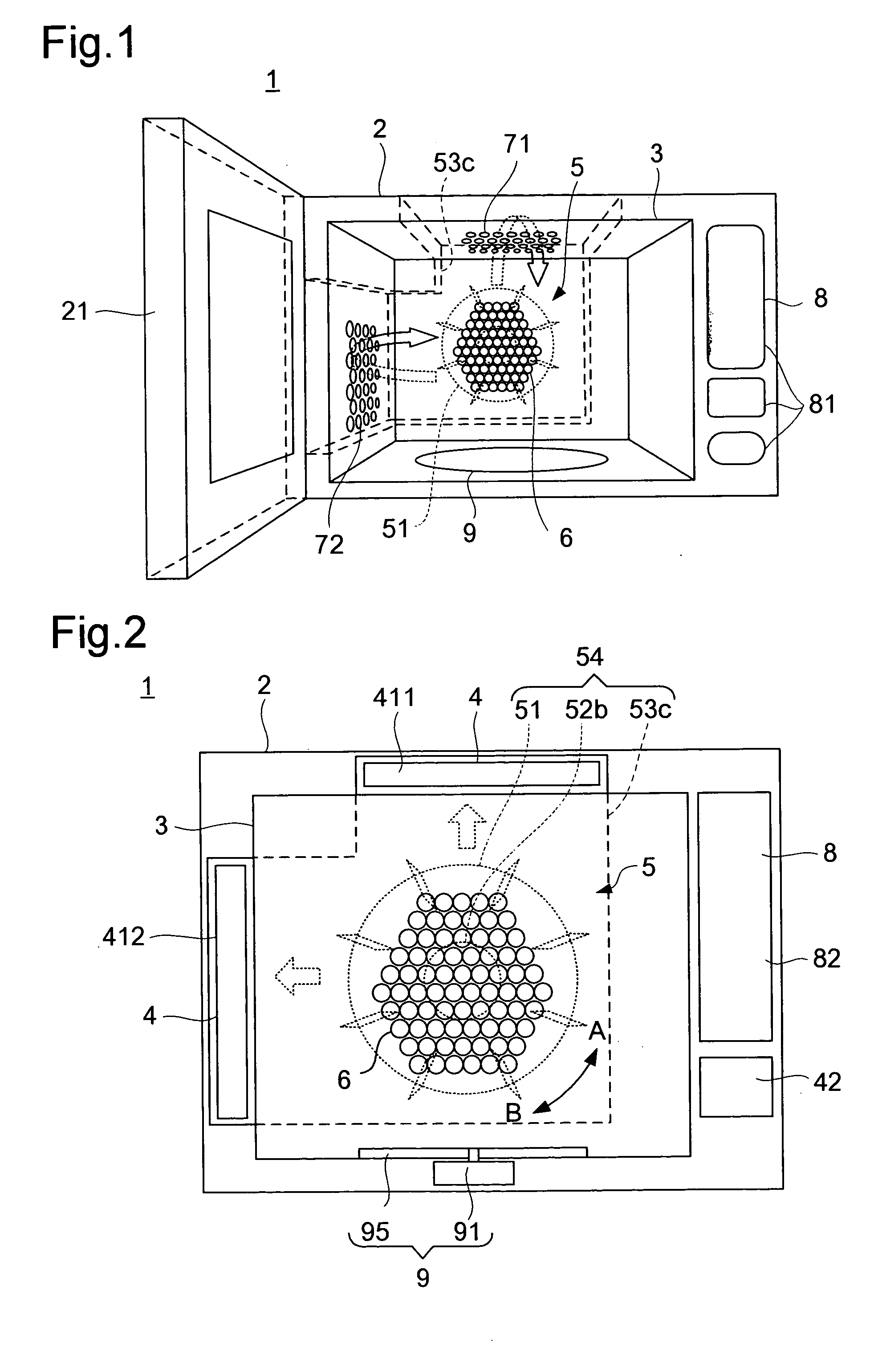

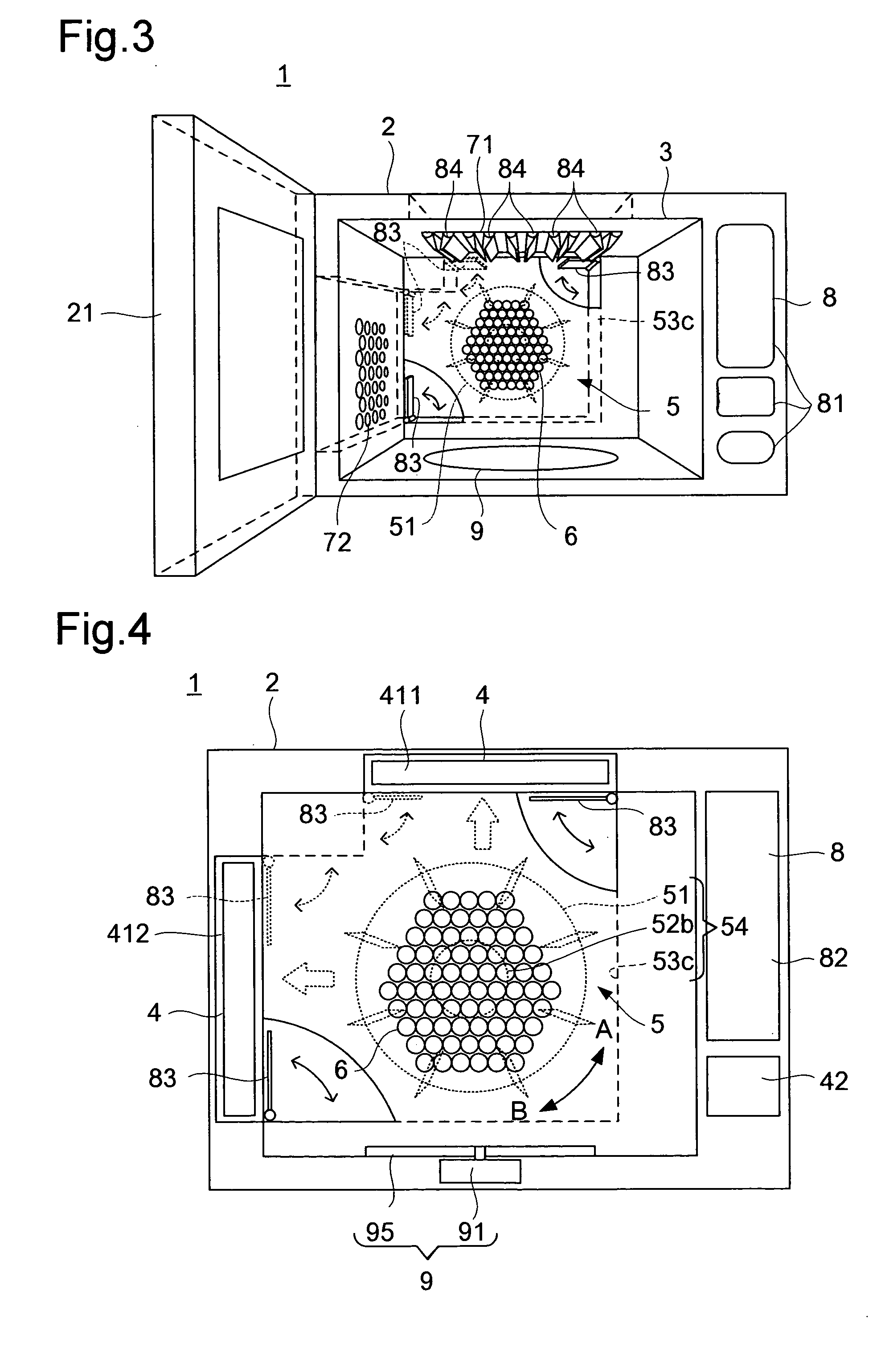

Cooking device

InactiveUS20050005781A1No degradation in cooking performanceImprove cooking resultsAir-treating devicesDomestic stoves or rangesRoast chickenLow speed

A cooking device, wherein, when a roast chicken is selected from a menu displayed on an operating part (81), a centrifugal fan (51) is controlled so as to be rotated in forward direction at a high speed to blow out hot air with a speed of 65 km / h or faster from upper blowout ports (71) and hot air with a speed of 30 km / h or slower from side blowout ports (72) whereby a roast chicken in a heating chamber (3) can be cooked at the high speed and, when a sponge cake is selected from the menu, the centrifugal fan (51) is controlled so as to be rotated in reverse direction at a low speed to blow out hot air with a speed of 30 km / h or slower from the upper blowout ports (71) and hot air with a speed of 40 km / h or slower from the side blowout ports (72) whereby a sponge cake in the heating chamber (3) can be cooked light and fluffy.

Owner:SHARP KK

Baked chicken wing

InactiveCN102038204ARaw materials are cheap and easy to getSimple processFood preparationBiotechnologySpring onion

The invention discloses a baked chicken wing which is prepared from the following raw materials: 180-220 g of chicken wing, 45-55 g of white sugar, 8-12 g of table salt, 4-6 g of pepper, 4-6 g of chicken essence, 4-6 g of cumin, 4-6 g of spring onion, 4-6 g of ginger, 4-6 g of star anise, 18-22 ml of Chinese spirit, 8-12 ml of red wine and 15-25 ml of honey. A preparation process of the roasted chicken wing comprises the following steps: (1) cleaning the chicken wing, removing residual chicken feather, and cutting the chicken wing to obtain 2-5 cuts; (2) adding the auxiliary materials to the chicken wing, and preserving the chicken wing in the cold room of a refrigerator for 2 h; (3) taking out the preserved chicken wing, and placing the preserved chicken wing at the middle layer of a barbeque grill at 200 DEG C for 10 min; and (4) taking out the chicken wing, spreading the honey, and placing the chicken wing again at the middle layer of an oven for 10 min to obtain the baked chicken wing. The raw materials for preparing the baked chicken wing provided by the invention are cheap and easily available, the process is simple and easy to learn, and the prepared baked chicken wing is spicy and tasty and has a unique flavor.

Owner:段红霞

Method for preparing chicken powder by using chicken skeleton and chicken skin

ActiveCN102008061AProduct raw materials are cheap and easy to getEase of industrial productionFood preparationFood industryRoast chicken

The invention discloses a method for preparing chicken powder by using chicken skeleton and chicken skin. The chicken skeleton and the chicken skin are used as raw materials; a Daokou roast chicken formula and a Daokou roast chicken process are adopted; and the chicken powder is prepared by frying, halogenation reaction to produce fragrance, high-pressure low-temperature extraction, separation, concentration, homogenizing and spray drying. The method has low-cost and easily-obtained product raw materials, is convenient for industrialized production, and can be used for scale production; the processes of high-pressure low-temperature extraction, low-temperature vacuum concentration, spry drying and the like adopted during processing the product can well preserve fragrance and flavor of the product and avoid the loss of the fragrance and the flavor; and because the fragrance and the flavor of the product are accepted by customers, the product can be added into food of different saline tastes, the variety of the product is increased, and the product is widely applied in households, catering industry and food industry.

Owner:HENAN YONGDA MEIJI FOOD CO LTD

Potato semi hard biscuit and making method thereof

ActiveCN103891850ASolve rough tasteFast coloringDough treatmentBakery productsSodium bicarbonateCooking & baking

The invention provides a potato semi hard biscuit, and belongs to the technical field of food and processing method thereof. The potato semi hard biscuit mainly resolves the technical problems that an existing coarse cereal biscuit has bed mouth feel, a dim color and a complex making method. According to the technical scheme, potato starch, wheat flour, white granulated sugar, vegetable oil, edible salt, sesame, distarch phosphate, sodium bicarbonate, calcium carbonate, ammonium bicarbonate, ammonium bicarbonate, disodium dihydrogen pyrophosphate, protease, baking chicken powder and water are adopted as raw materials; weighing, mixing, forming, baking and other technologies are conducted. The potato semi hard biscuit has crisp and tasty mouth feel, a bright color, and a simple manufacturing method.

Owner:晋城市古陵山食品有限公司

Method for processing roast chicken with local flavor

The invention relates to a processing method of savory roast chickens, which belongs to the technical field of meat product processing. The processing method comprises the following steps: a. sopping high-pressure permeability is carried out for a slaughtered chicken which is cleaned by a conventional method for 40-60 minutes, the bittern infiltration amount is 1 / 4-1 / 7; b. the chicken is preserved for 3-6 hours; c. the surface moisture of the chicken body is aired; d. sugar solution is made by mixing malt syrup, honey and yellow wine with the conventional dose, and is boiled in a pot; then the chicken body is fully dipped in the sugar solution and decocted for 50-80 seconds; the chicken body with the surface moisture of which is aired is coated with sugar, and then is aired to dry; e. when the temperature in a roaster is rapidly increased to 216-236 DEG C, the aired chicken is quickly put in the roaster for roasting 5-15 minutes at constant temperature; then an air vent of the roaster is opened to decrease the temperature to 175-190 DEG C, the chicken is roasted for 15-60 minutes again; the roaster is turned off, the chicken is stewed in the roaster for 5-15 minutes, therefore, the roast chicken is prepared. Compared with the existing processing method, the processing method of the invention is characterized in that the roast chicken has tender and scented meat, better mouth feeling, unique flavor, long shelf life, possibility of large-scale processing, etc.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Production method for high-chewiness instant roasted chicken wings

The invention discloses a production method for high-chewiness instant roasted chicken wings. The production method comprises the following steps of: unfreezing frozen chicken wings by flowing water or directly selecting fresh chicken wings, residual feathers of which are removed by pulling, washing, and draining for use; soaking the dried chicken wings in a prepared salting solution; draining the chicken wings taken out of the salting solution, and drying the chicken wings to be in a semi-dry state in which the water content of wing roots at a wet basis is 40%-45% by hot wind at the temperature of 80-90 DEG C; roasting the dried chicken wings in a high-temperature oven at the temperature of 165-175 DEG C, overturning once per 5-8 minutes, and stopping the roasting until the water content is 30%-33%; and packaging and sterilizing. The produced instant roasted chicken wing is ready to eat after a package bag is opened, and is red bright and solid in appearance, rich in roast flavor, unique in mouth feel and high in chewiness; the salting solution is high in sugar content and yellow wine content, thereby enabling the instant roasted chicken wing to be sweet and delicious and unique in roast flavor; the water content of the instant roasted chicken wing is controlled to be 30%-33%, thereby enabling the instant roasted chicken wing to be high in chewiness and easier to store.

Owner:SOUTH CHINA UNIV OF TECH +1

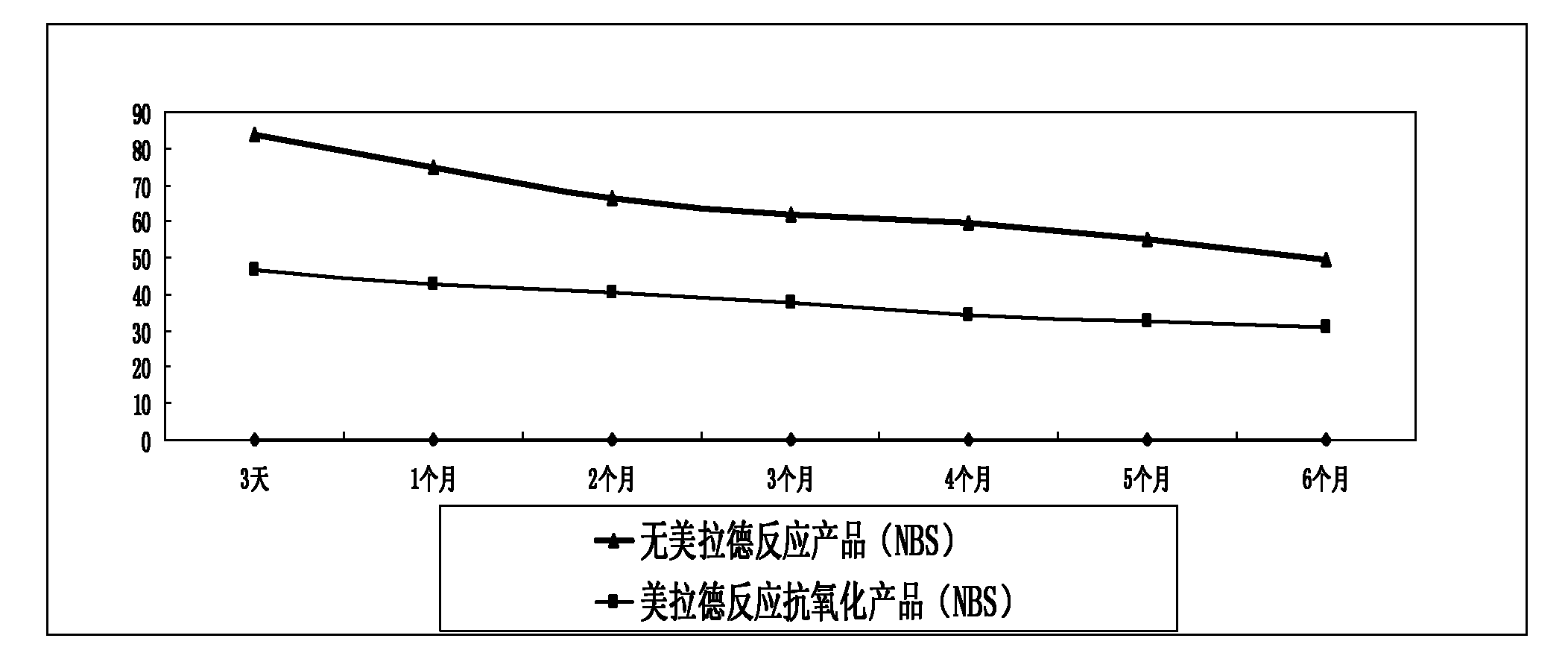

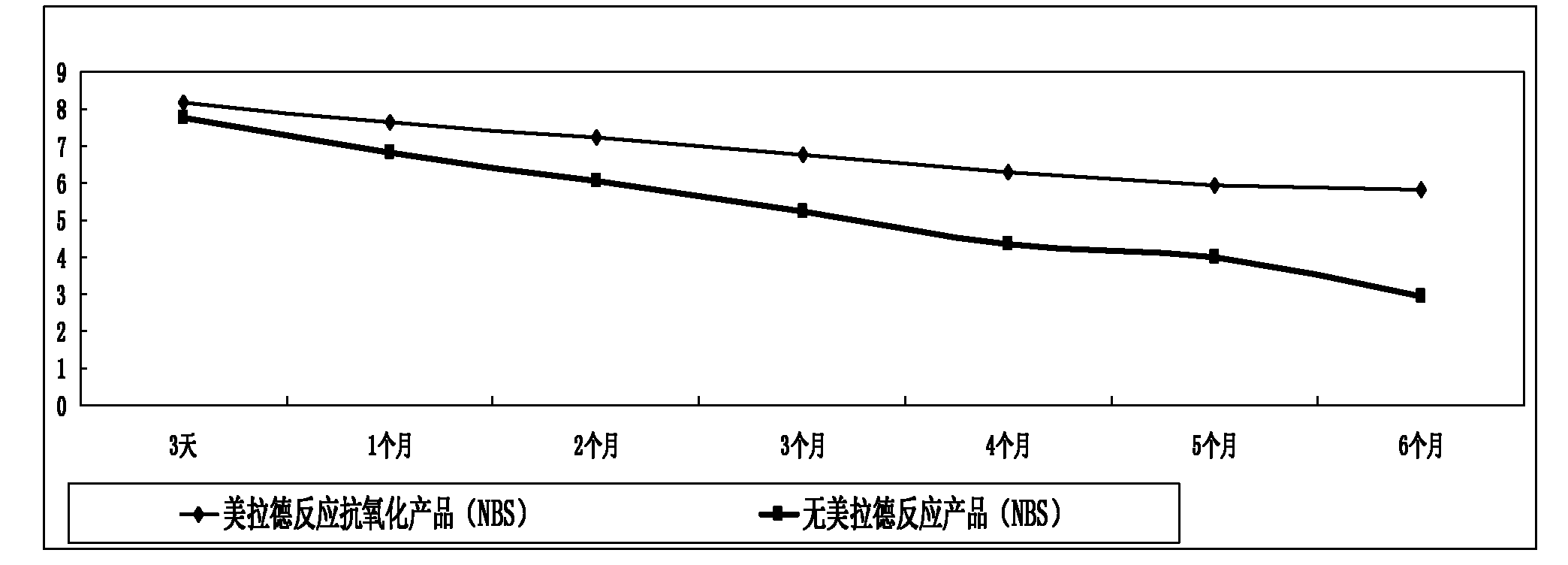

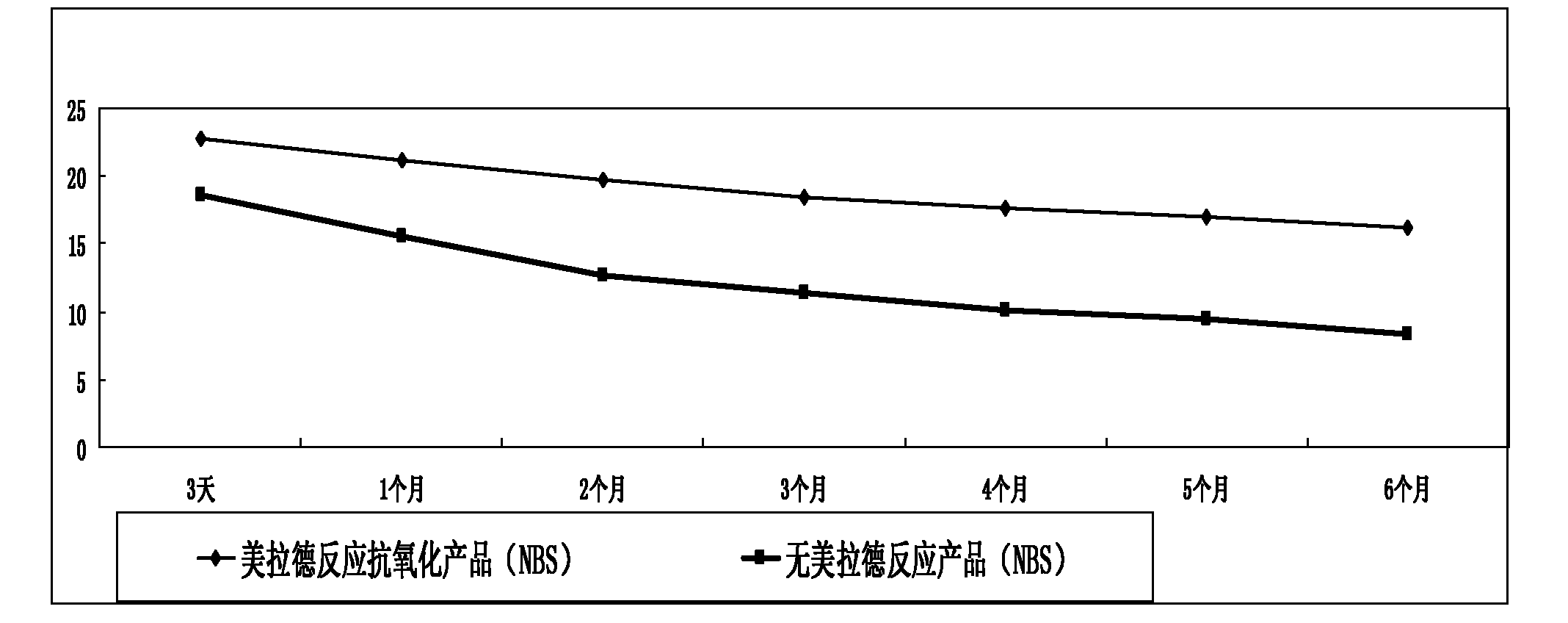

Composition applicable to protecting color of salt roasted chicken and production method for salt roasted chicken with stable color and luster

ActiveCN103783491AGood color protectionColor stableFood preparationOrganic compound food ingredientsRoast chickenPhytic acid

The invention discloses a composition applicable to protecting the color of salt roasted chicken and a production method for the salt roasted chicken with stable color and luster. The composition is composed of following components in parts by mass: 1-25 parts of monascus color, 1-20 parts of tea polyphenol, 100-500 parts of sodium erythorbate, 1-20 parts of phytic acid and 1-200 parts of sodium citrate. The composition for protecting the color is added into marinating liquid for marinating the salt roasted chicken; the produced salt roasted chicken can still keep previous gloss, color and luster after being illuminated for 45 days and the technical difficulty of keeping stable color and luster of a salt roasted chicken product of a salt roasted chicken production technology, particularly a salt roasted chicken production technology using a water roasting method, is overcome; the shelf life of the product is effectively prolonged and the loss of product encounter poor sales, caused by decreasing of the color and the luster, is avoided, so as to lay a good technical foundation for spreading the salt roasted chicken of Guangdong to all parts of the country, even all parts of the world.

Owner:SOUTH CHINA AGRI UNIV

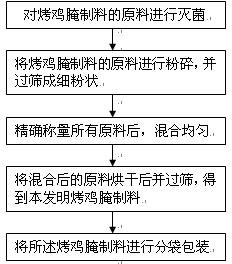

Roast chicken curing material and preparation method thereof

The invention relates to a food condiment and discloses a roast chicken curing material. The roast chicken curing material comprises the following raw materials in percentage by weight: 20-50% of salt, 20-50% of sugar, 1-10% of flavor enhancer, 5-20% of spice, 5-15% of fresh material, 0.1-0.5% of colorant and 10-49% of auxiliary material. The invention also discloses a preparation method for the roast chicken curing material. After the broiler chicken is cured by using the roast chicken curing material disclosed by the invention and roasted, the roast chicken has golden color and attractive flavor and also has crispy skin and tender inside.

Owner:EAST CHINA NORMAL UNIVERSITY +1

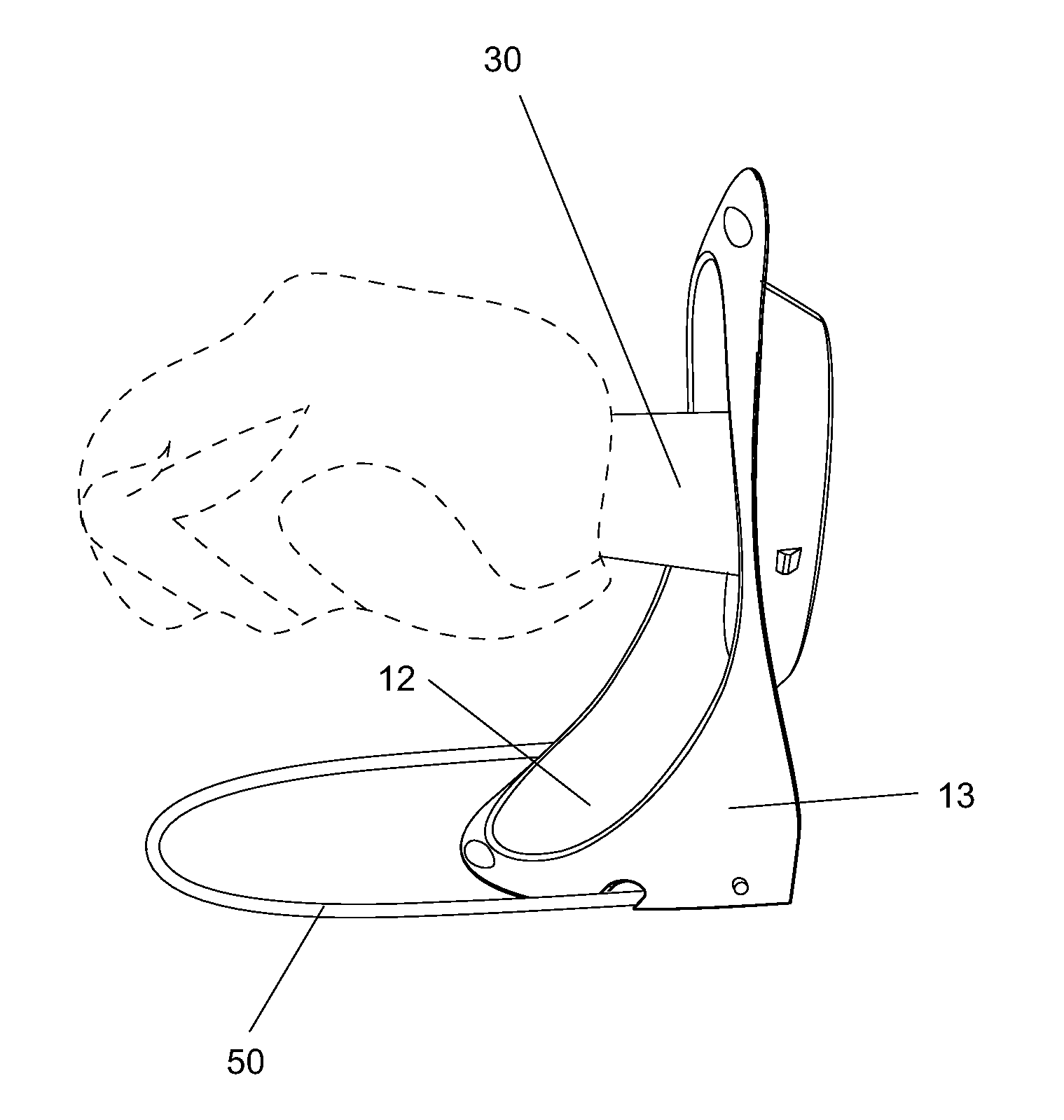

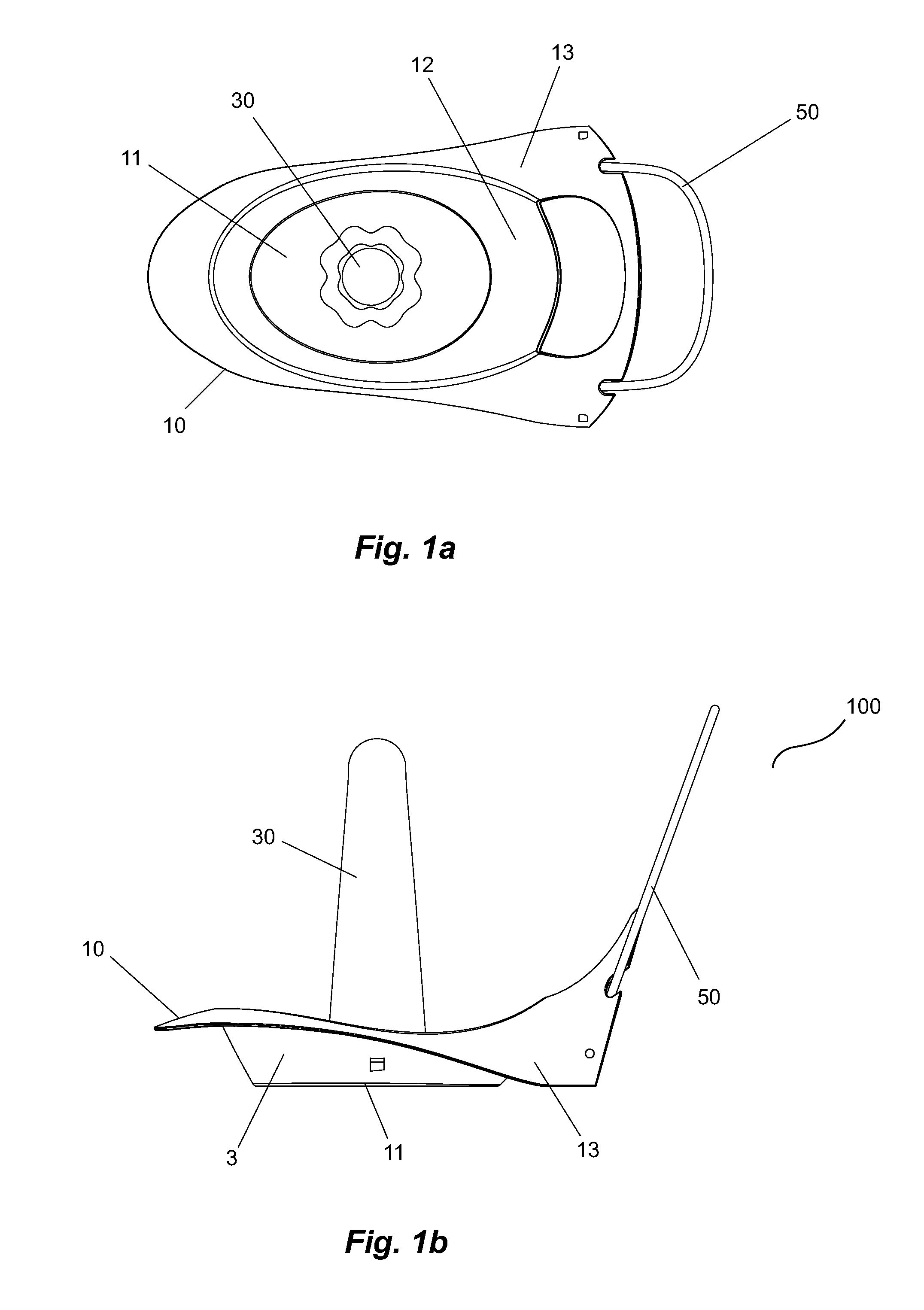

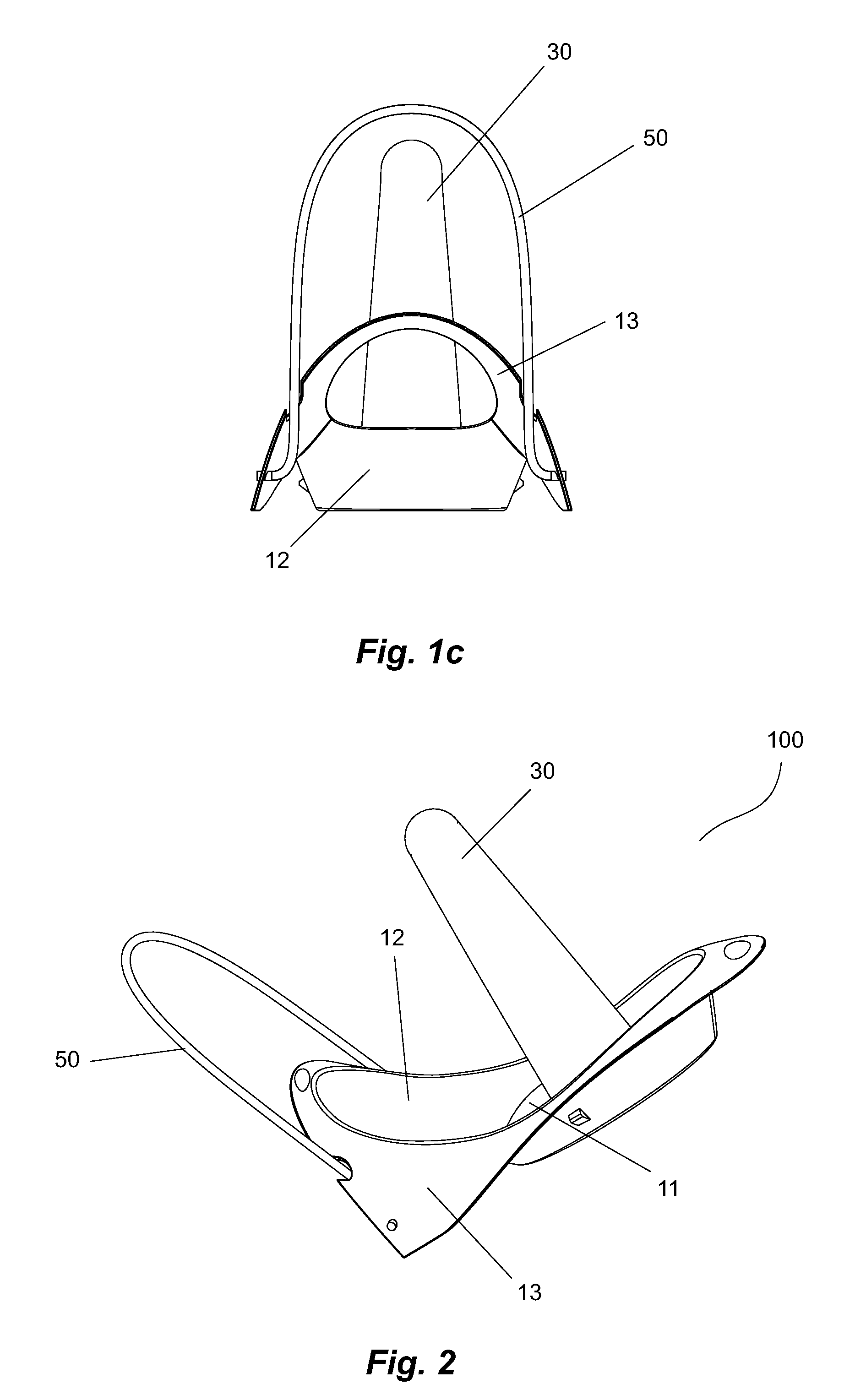

Device For Roasting Fowl

ActiveUS20110209627A1Improve heat transfer performanceSimple configurationCooking vesselsBaking vesselsRoast chickenFowl

A device for roasting fowl includes a base pan shaped to have a first supporting surface and a second supporting surface; an insert extending vertically from the first support surface of the base pan for mounting the fowl; wherein the first supporting surface of the base pan rests in a cooking apparatus to allow for roasting of the fowl in a vertical manner, and the second supporting surface of the base pan rests in the cooking apparatus to allow for roasting of the fowl in a horizontal manner.

Owner:KINGS FLAIR DEV

Mud roasted chicken and making method thereof

The invention relates to mud roasted chicken and a making method thereof. The mud roasted chicken is mainly made by the following steps of: (1) cleaning chicken, namely removing feathers, belly and claws from the chicken of a growth period; (2) filling seasoning, namely filling the mixed seasoning into the belly of the chicken and tightly sewing the chest by using an iron wire; (3) wrapping tinfoil, namely wrapping the filled chicken by using tinfoil; (4) wrapping mud, namely wrapping the chicken body wrapped by the tinfoil by using the unpolluted mud; (5) filling a die, namely filling the mud wrapped chicken into the die; and (6) roasting, namely putting the die filled chicken over open flame or charcoal fire till the chicken is roasted thoroughly. The fragrance of the mud and trace elements such as calcium, phosphorus, iron and the like in the mud permeate into the chicken by roasting, so the mud roasted chicken is fresh, fragrant and delicious, has crisp outside and tender inside, can keep the temperature for long time under the wrapping of the mud, can be eaten when the mud is removed, and keeps fresh.

Owner:陈锡杰

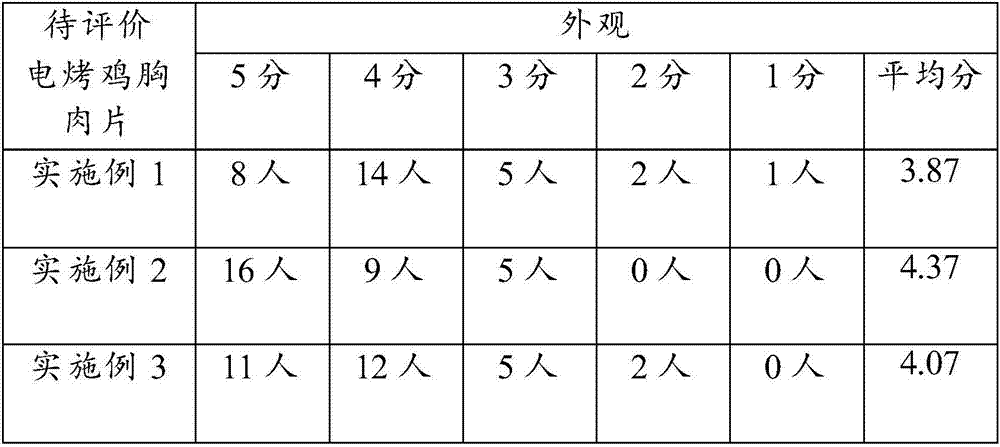

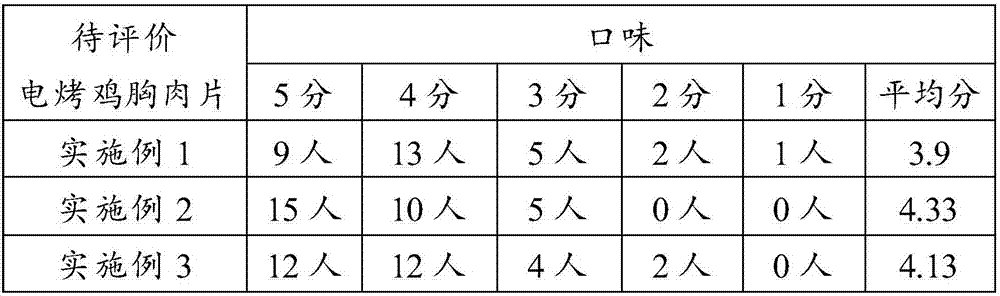

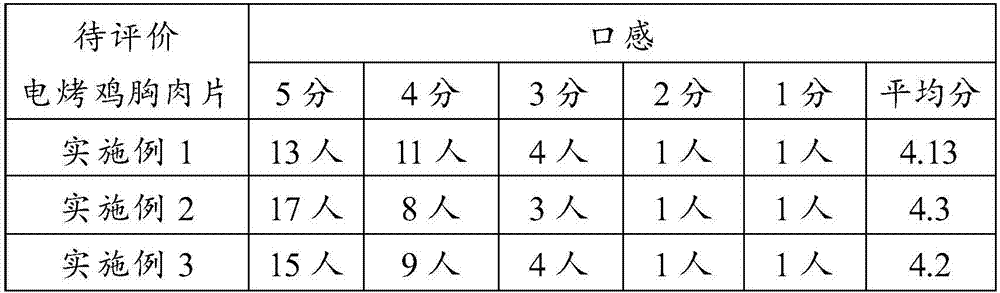

Electrically roasted chicken breast meat suitable for bodybuilding people to eat and preparation method thereof

ActiveCN107125620AFit for consumptionDelicate tasteFood ingredient as mouthfeel improving agentFlavorRoast chicken

The invention provides a preparation method of electrically roasted chicken breast meat suitable for bodybuilding people to eat. The preparation method comprises the following steps: A) mixing and rolling chicken breast meat with seasoning liquid, and then cooking to obtain a semi-finished product; B) dipping the semi-finished product in sauce and sequentially electrically roasting, cooling, packaging, sterilizing and quick freezing to obtain the electrically roasted chicken breast meat suitable for bodybuilding people to eat; the material juice for dipping is prepared from 100 weight parts of water, 7 to 10 weight parts of xylose, 0.5 to 3 weight parts of soy sauce and 1 to 3 weight parts of starch; electrically roasting temperature is 185 to 220 DEG C, the quantity of steam is 70% to 95%, and time is 4 to 10 minutes. The electrically roasted chicken breast meat disclosed by the invention has fine and smooth taste and strong barbecue flavor, and nutritional ingredients of the electrically roasted chicken breast meat are more suitable for bodybuilding people to eat.

Owner:山东优形食品科技有限公司

Condiment and method for bloating roast chicken, roast duck

InactiveCN1593206ABeautiful and fragrantFull of fragranceUnknown materialsFood preparationRoast chickenAdditive ingredient

The invention relates to a condiment for pickling roast chicken and roast duck and method of pickling, wherein the condiment comprises main ingredients and auxiliary materials, the main ingredients comprises iodine salt, white sugar, gourmet powder, yellow rice wine and vinegar, the auxiliary materials include Chinese prickly ash, cassia bark, clove, aniseed, dahurian angelica root, piper nigrum, banksia rose, dried orange peel, and the preparing process consists of cleaning and processing chickens and ducks, and pickling in condiment.

Owner:蓝子花

Preparation method for improving taste of roasted chicken breast product

InactiveCN102150878AGreat tasteGolden and bright appearanceFood preparationRoast chickenSodium bicarbonate

The invention relates to a preparation method for improving taste of a roasted chicken breast product. The method comprises the following steps of: dissolving 1.2 to 1.6 weight percent of salt, 1.2 to 2.0 weight percent of monosodium glutamate, 1.0 to 2.0 weight percent of composite phosphate, carrageenan, seasonings, as well as proper spices, maltose, sodium bicarbonate, polyphenols of green tea and soy protein isolate in deionized water, homogenizing until no residue exists, and cooling the pickling sauce between 0 and 4 DEG C for later use; putting shaped peeled chicken breast in a vacuum tumbler, adding the pickling sauce, and tumbling for 20 to 30 minutes between negative 1 and 4 DEG C under a condition that the vacuum degree is between 0.04 and 0.07MPa; standing, tumbling once again, powdering, and roasting for 4 to 10 minutes in hot air at the temperature between 170 and 190 DEG C; and cooling, individually quick freezing and packaging. The roasted chicken breast product prepared by adopting the method is tender and juicy, and has golden bright appearance.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for making roast chicken with crisp bone

InactiveCN101147600ABeautiful appearanceMuscles and bones are softFood preparationRoast chickenCooked food

The present invention relates to a preparation method of crisp bone roasted chicken, in the concrete, it is a technological process for processing raw chicken or raw duck and making it into cooked food. Said technological process includes the following steps: slaughtering, cleaning, shaping, high-temperature roasting and colouring at normal pressure, high-pressure medium-temperature roasting and curing, exhausting and reducing pressure, taking out and cooling, packaging so as to obtain the invented product.

Owner:王日信

Processing method of salt roasted chicken

ActiveCN103478757AWith tasteBright yellow colorClimate change adaptationFood preparationFlavorRoast chicken

The invention discloses a processing method of salt roasted chicken. The method comprises the following steps: (1) blending marinating liquid, namely adding spices into water, boiling, and adding table salt to prepare the special marinating liquid for processing the salt roasted chicken; (2) preparing broiler chicken, namely adopting a three-pipe killing method to kill live chicken and eviscerating the chicken while keeping the integrity of the broiler chicken; (3) marinating, namely hanging the broiler chicken, heating the marinating liquid in a stainless steel tank, immersing the hung broiler chicken into the marinating liquid for marinating, lifting out the marinated broiler chicken and drying the marinating liquid on the surface of the chicken by blowing; (4) cooling and packaging, namely cooling the salt roasted chicken treated by the step (3) and packaging by a food preservation bag; and (5) storing, namely carrying out low-temperature cold storage on the packaged salt roasted chicken. The salt roasted chicken obtained by a marinating method has bright yellow color and luster, a prominent flavor and moderate salinity, and has the mouth feel, flavor, color and luster of salt roasted chicken produced by a traditional salt roasting method; standardized scale processing can also be realized.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Preparation method of salt roasted chicken product retaining tenderness and unique taste of obsolete chicken

The invention discloses a preparation method of a salt roasted chicken product retaining tenderness and unique taste of obsolete chicken and belongs to the technical field of food processing. The laying ability of laying hens is gradually reduced as the laying hens grow older, and the laying hens are to be obsoleted by a chicken farm two years later and are called as obsolete chickens. According to the preparation method disclosed by the invention, the obsolete chicken is used as a raw material to manufacture the product by the following procedures: tendering treatment, seasoning, phosphate salting, high-temperature cooking, condiment slating, baking, cooling, vacuum packing, high-temperature and high-pressure sterilization and cooling, wherein the final salt roasted chicken product is obtained, wherein the tenderness range of the final product is 1.5-3.5 kg / cm<2>, and the taste value is increased by 70%. The salt roasted chicken product having a unique taste and processed by the method disclosed by the invention has good chicken fiber toughness and tender texture and further has unique salt roasting taste; and the preparation method can be used for shortening and eliminating complex steps of the traditional technique, is suitable for industrial large-scale production on the premise of ensuring the quality, can be used for producing products with long service life and contributing to spreading of the marketing range, and is especially suitable for deep processing, development and utilization of obsolete old bred chickens.

Owner:JIANGNAN UNIV +1

Rose donkey-hid gelatin chicken and preparation method thereof

InactiveCN101416739AIt has the functions of promoting blood circulation, removing stasis, nourishing qi and nourishing bloodWith detoxification and antipyreticFood preparationRoast chickenIllicium verum

The invention discloses a rose and donkey-hide gelatin chicken and preparation method thereof, and especially disclosing the roasted chicken using rose and donkey-hide gelatin glue as main auxiliary materials. The invention adopts chicken as the raw materials, and rose, and donkey-hide gelatin as the main auxiliary materials added with traditional Chinese medicine materials of clove, fructus tsaoko, star anise, pepper and salt as cure and rose sugar paste, and donkey-hide gelatin as colouring material, through curing, scalding, colouring, cooling blank, storing, and roasting. The rose and donkey-hide gelatin have the functions of invigorate blood circulation, transforming stasis, energy invigorating and enriching blood, other traditional Chinese medicine materials have the functions of strengthening mid-energy, invigorating spleen and stomach, Furthermore, the invention is brownish red and bright, thick in rose flavour by colouring and roasting of the rose sugar paste, and is a special food therapy health care product.

Owner:王庆才

Medicated chicken processing method

InactiveCN104982961AControl contentImprove quality stabilityClimate change adaptationNatural extract food ingredientsFlavorRoast chicken

The present invention relates to the technical field of meat product processing and particularly relates to a medicated chicken processing method. The medicated chicken uses killed, feather removed and eviscerated chicken as raw materials, and is processed by tumbling and pickling, cold-air drying, roasting, vacuum packaging and sterilizing. The most important feature of the medicated chicken is the addition of traditional Chinese medicine extract into pickling seasoning during the tumbling and pickling process, which avoids the problems that the traditional nourishing medicated roast chicken processing technology requires preparation of traditional Chinese medicine brine by cooking, which is tedious in processes and not clear in component extraction rates, and the egg white brushing for coloring on chicken before roasting costs a huge manual work, etc. The produced medicated chicken is golden yellow in color and luster, accurate in controlling active ingredients of traditional Chinese medicine, full in flavor of traditional Chinese medicines, and stable in meat quality.

Owner:TENGQIAO FOOD CO LTD

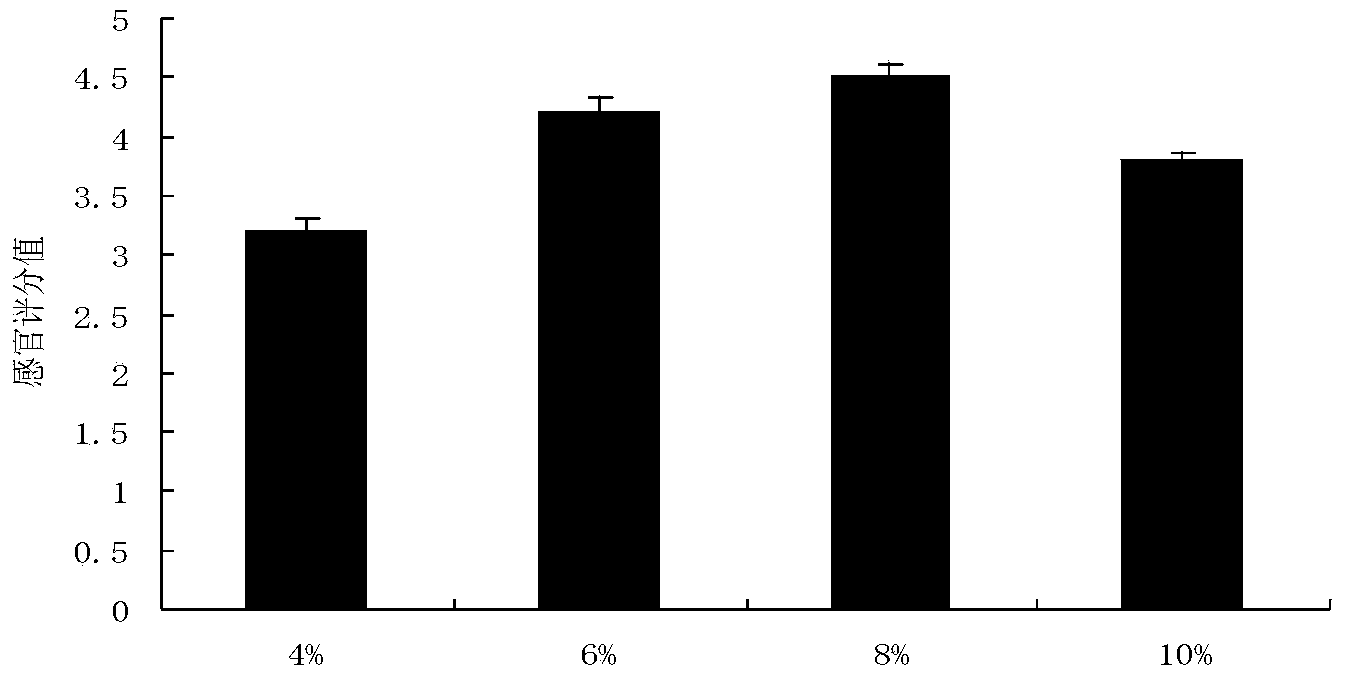

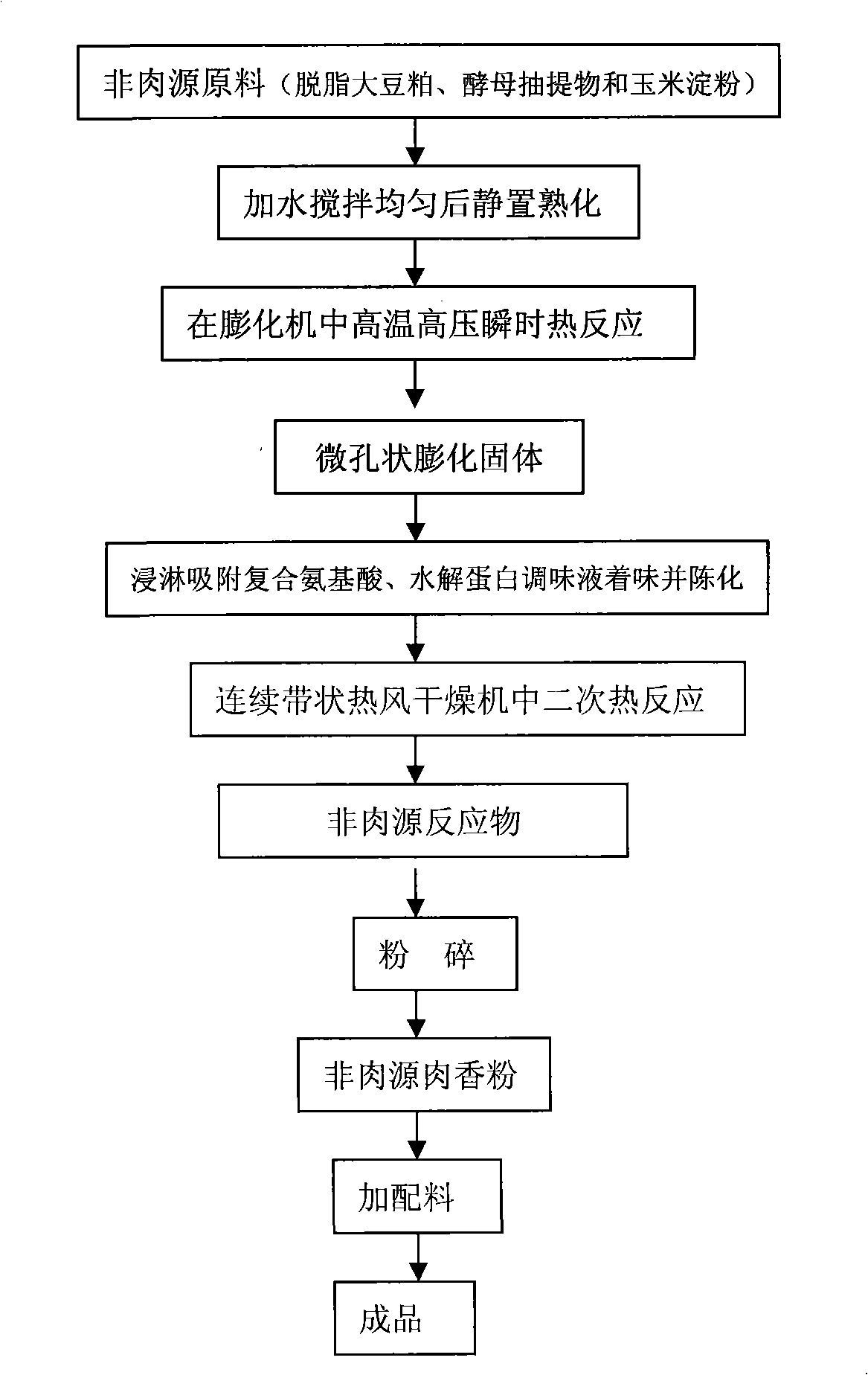

Method for preparing non-meat roast chicken powder and duck powdered meat from degreasing soybean meal

InactiveCN101322544AInhibit productionIncrease production capacityFood preparationRoast chickenAdditive ingredient

The invention relates to a method for preparing non-meat source baked chicken powder and duck powder by using defatted soybean meal, the method can effectively solve the production of the non-meat source baked chicken power and the duck power and meet various needs; the technical proposal for realization is as follows: the non-meat source pure natural raw materials of the defatted soybean meal, yeast extract and corn starch are concentrated, degraded, rearranged and carried out the thermal decomposition reaction in a twin-screw extrusion-expansion machine, a micro-porous expanded solid is obtained, the micro-porous expanded solid is matched with other seasoning liquid and compound amino acid components in a soaking way, the micro-porous expanded solid is sent to a belt dryer by using the continuous way for carrying out the drying, then non-meat source meat flavor powder is prepared, and the non-meat source meat flavor powder is further combined with other components to prepare the baked chicken powder, the duck powder and other seasonings with various flavors; the non-meat source baked chicken powder and duck powder are substitutes of meat source baked chicken power and the duck power, the yield is high, the cost is low, the protein content is high, the aroma and the flavor are thick and vivid, the wide and harmonious meat flavor from the stewing to the barbecuing can be formed, thereby havinggood economic and social benefits.

Owner:河南京华食品科技开发有限公司

Instant roast chicken claw as well as processing method and application thereof

The invention belongs to the field of foodstuff processing technology, and especially relates to an instant roast chicken claw as well as a processing method and an application thereof. The processing method of the instant roast chicken claw comprises the following steps: (1) pickling with brine: the chicken claw is soaked in brine and cleaned; (2) vacuum tumbling: auxiliary materials and the pickled chicken claw are mixed for low temperature vacuum tumbling; (3) drying and boiling: after tumbling, the chicken claw is dried and boiled; (4) roasting: the dried and boiled chicken claw is cooled and roasted; (5) mixing: the roasted chicken claw is cooled, and auxiliary materials are added with fully stirring; and the instant roast chicken claw is obtained. The method has short preparation time, fishy smell of chicken claws are effectively removed, so that the claw meat is elastic and chewable, and the claw is convenient for eating and can be stored at normal temperature for 10 months.

Owner:WUQIONG FOOD

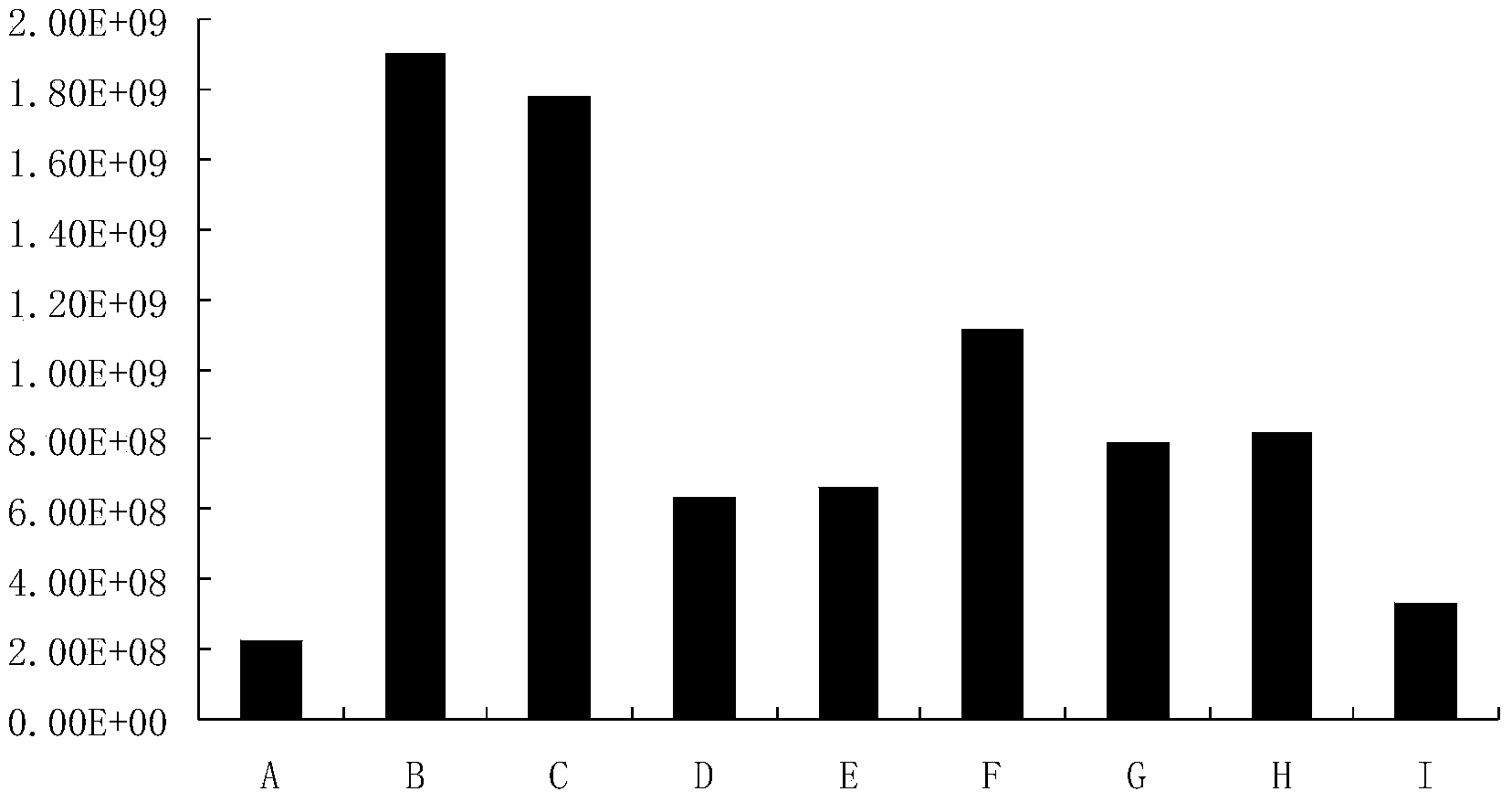

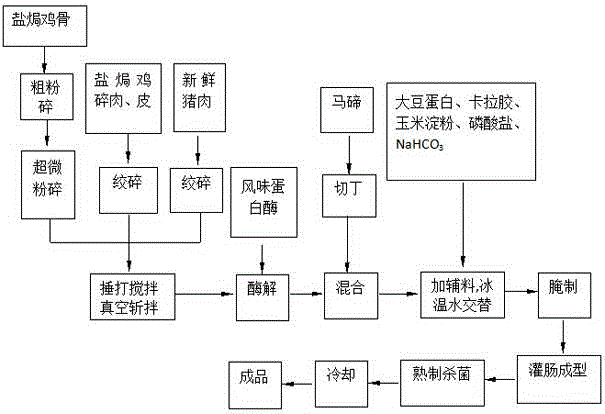

Recombined sausage with salt roasted chicken flavor and preparation method of recombined sausage

ActiveCN104544256AIncrease added valueResolve disposal issuesFood mechanical treatmentFood ingredient as taste affecting agentBiotechnologySodium bicarbonate

The invention discloses a recombined sausage with salt roasted chicken flavor. The recombined sausage comprises a main material, packing and auxiliary materials, wherein the main material comprises the following components in percentage by weight: 5%-30% of bone paste of salt roasted chicken, 30%-60% of salt roasted chicken and / or skin, 8%-45% of fresh pork and 2%-20% of water chestnut; the packing is soybean protein isolate, corn starch or carrageenan; and the auxiliary materials are composite phosphate, sodium bicarbonate, salt and white granulated sugar. Through reasonable formula proportion, and strict control on a preparation process, the prepared recombined sausage with the salt roasted chicken flavor is uniform in mouthfeel, fresh and delicious in taste, abundant in nutrient, and high sensory evaluation, and suitable for being eaten by all people, has special salt flavor and water chestnut taste, and has cool and crisp feeling; no spice or essence except for salt roasted chicken leftover materials is added to the raw materials, so that the recombined sausage has relatively high additional value, and has great significance on environmental protection; and waste is changed into treasures.

Owner:SOUTH CHINA AGRI UNIV

Method for producing chicken roasted in jar

InactiveCN101347248AUnique flavorStrong and long-lasting fragranceFood preparationRoast chickenIllicium verum

The invention relates to the filed of food processing, in particular to a preparation method of a roasted vatted chicken. The method solves the problems that as the chicken is roasted by a roaster, the fresh aroma of the chicken can not last for a long time, the chicken skin is not crisp and the chicken gives a single mouth feeling. The method comprises the steps as follows: (1) a chicken taken as raw material is cut, washed and drained; (2) stacking: salt is daubed inside and outside the chicken body; (3) molding is carried out; (4) a spice bag is placed in the belly of the chicken: the spice is made from nutmeg, tsaoko, cinnamon, star aniseed, and the like; (5) inserting stick is carried out; (6) the surface of the chicken body is daubed with an spice which is made from edible white vinegar and honey; (7) roasting: the chicken is roasted above a charcoal oven in a vat for roasting until the chicken skin is in date red; and the charcoal is made from a fired pear root. The chicken roasted by adopting the method is characterized by unique flavor, strong and lasting aroma, delicious mouth feeling, being crisp outside and tender inside, bright color, attractive appearance and long shelf life, and is suitable for large-scale production. In addition, the more important is that a plurality of nutritional components in the seasoning cause the roasted chicken to have the health care efficacies such as stimulating the appetite and strengthening the spleen, warming yang and dispersing cold, etc.

Owner:齐满贵

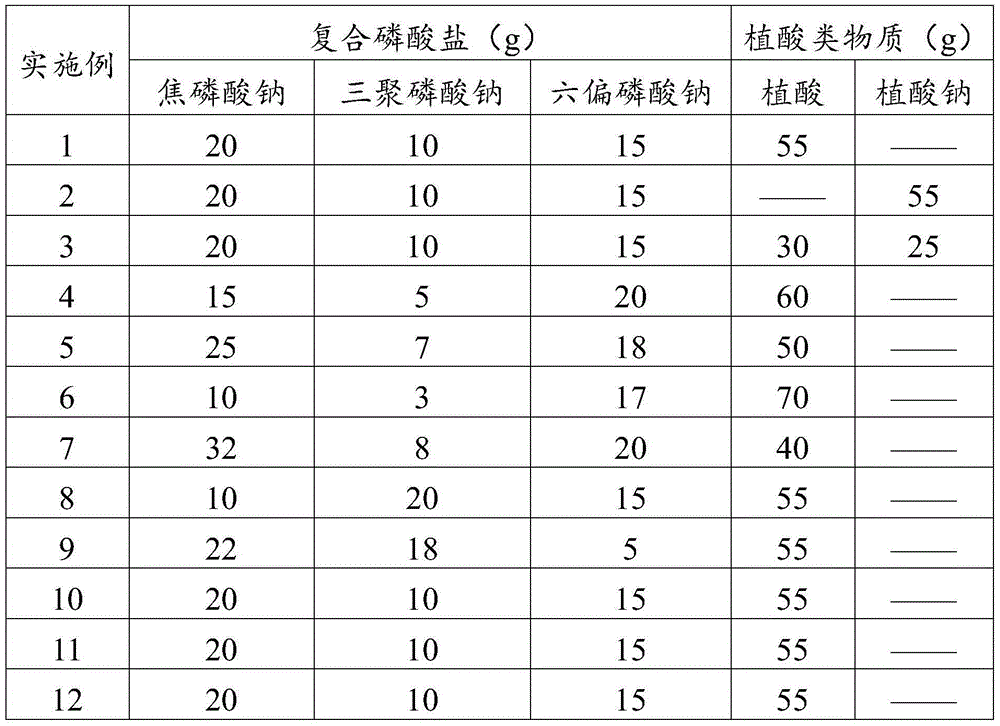

Gardenia yellow pigment color fixative and food dyeing method

ActiveCN103598572AImprove light resistanceImprove high temperature resistanceFood ingredient functionsFood preparationRoast chickenPhosphate

The invention discloses a gardenia yellow pigment color fixative. The color fixative is prepared by uniformly mixing a raw material mixture. The raw material mixture comprises a composite phosphate and a phytic acid type compound. The composite phosphate comprises sodium pyrophosphate, sodium tripolyphosphate and sodium hexametaphosphate. The phytic acid type compound is at least one of phytic acid and sodium phytate. The invention also discloses a food dyeing method. The method includes using a gardenia yellow pigment and the color fixative provided by the invention. When the color fixative is applied for dyeing food by the gardenia yellow pigment, the light resistance and high-temperature resistance of the gardenia yellow pigment can be significantly enhanced. In particular, dyeing effects of bright color, stability, high-temperature resistance and light resistance can be obtained when the gardenia yellow pigment color fixative is applied for dyeing salt-roasted chicken.

Owner:YUNNAN RAINBOW BIO TECH

Electric rice cooker cooking process and application thereof

The invention discloses an electric rice cooker cooking process, comprising an electric rice cooker which is internally provided with a cooker-bottom heating plate, a cooker-body heating wire and a cooker-top heating wire which are controlled by a microcomputer control board, wherein, the bottom of the cooker is also provided with a sensor which is electrically connected with the microcomputer control board; and the microcomputer control board is provided with a salt roasted chicken cooking process which comprises the following steps: A. only the cooker-bottom heating plate is controlled to heat until the sensor finds that the temperature of the bottom of the cooker is K1; B. the cooker-bottom heating plate, the cooker-body heating wire and the cooker-top heating wire heat together, the temperature of the bottom of the cooker is maintained at K2, and the continuous heating time is T1; C. finally, the cooker-bottom heating plate, the cooker-body heating wire and the cooker-top heating wire heat continuously, the temperature of the bottom of the cooker is maintained at K3, and the continuous heating time is T2, wherein, K3 is higher than K2. Accompanying the heating condition of the existing electric cooker, the salt roasted chicken cooking process can control the heating powers, heating temperatures and heating times of the cooker-bottom heating plate, the cooker-body heating wire and the cooker-top heating wire, thereby ensuring that the inner of the cooker liner can achieve the production environment for cooking salt roasted chicken.

Owner:GUANGDONG GALANZ GRP CO LTD

Ready-to-eat and recombined roasted chicken meat with shredded meat and production method therefor

The present invention pertains to the technical field of chicken meat foods and discloses ready-to-eat and recombined roasted chicken meat with shredded meat and a production method therefor. The recombined roasted chicken meat is prepared by the method comprising the following steps of: (1) raw material processing: grinding fresh chicken meat to obtain chicken meat paste; and obtaining the shredded meat by tearing ripen chicken meat; (2) stirring: taking the chicken meat paste, sufficiently stirring the chicken meat paste and added auxiliaries, adding the shredded meat, and stirring the mixture uniformly; and (3) shaping, baking, packaging and sterilizing to obtain the ready-to-eat and recombined roasted chicken meet with shredded meat. According to the preparation method of the ready-to-eat and recombined roasted chicken meat with shredded meat of the present invention, contents of raw materials are changed; the ready-to-eat and recombined roasted chicken meat with shredded meat is prepared by using the chicken meat paste and the shredded chicken meat; and by combining low-temperature and vacuum rolling and kneading, low temperature salting, two-stage medium-high temperature roasting, and back pressure sterilization technologies, use of preservatives and antistaling agents is reduced or even avoided. Different from the conventional soft mouthfeel, the roasted chicken of the present invention provides the tearing feel of pure chicken meat, has the water content that can be controlled to be less than 45%, is high in elasticity and hardness, and has the chewiness greater than 3000g.

Owner:WUQIONG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com