Patents

Literature

304results about How to "Reduce surface pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Load relieving wound dressing

An improved load relieving dressing for transferring pressure away from a wound on a foot of a patient. The dressing having a wound opening formed through the dressing for surrounding a wound site. The dressing having an external shape which substantially conforms to the shape of the pressure distribution on the foot during load bearing. A first layer of the dressing interfacing with and cushioning a foot during load bearing. The first layer is of a material sufficient to limit pressure increases at the wound opening and within said dressing adjacent the wound opening. An off-loading layer is engaged with said first layer, and is of a material sufficiently thick and firm to reduce pressure at the wound site.

Owner:DIAPEDIA

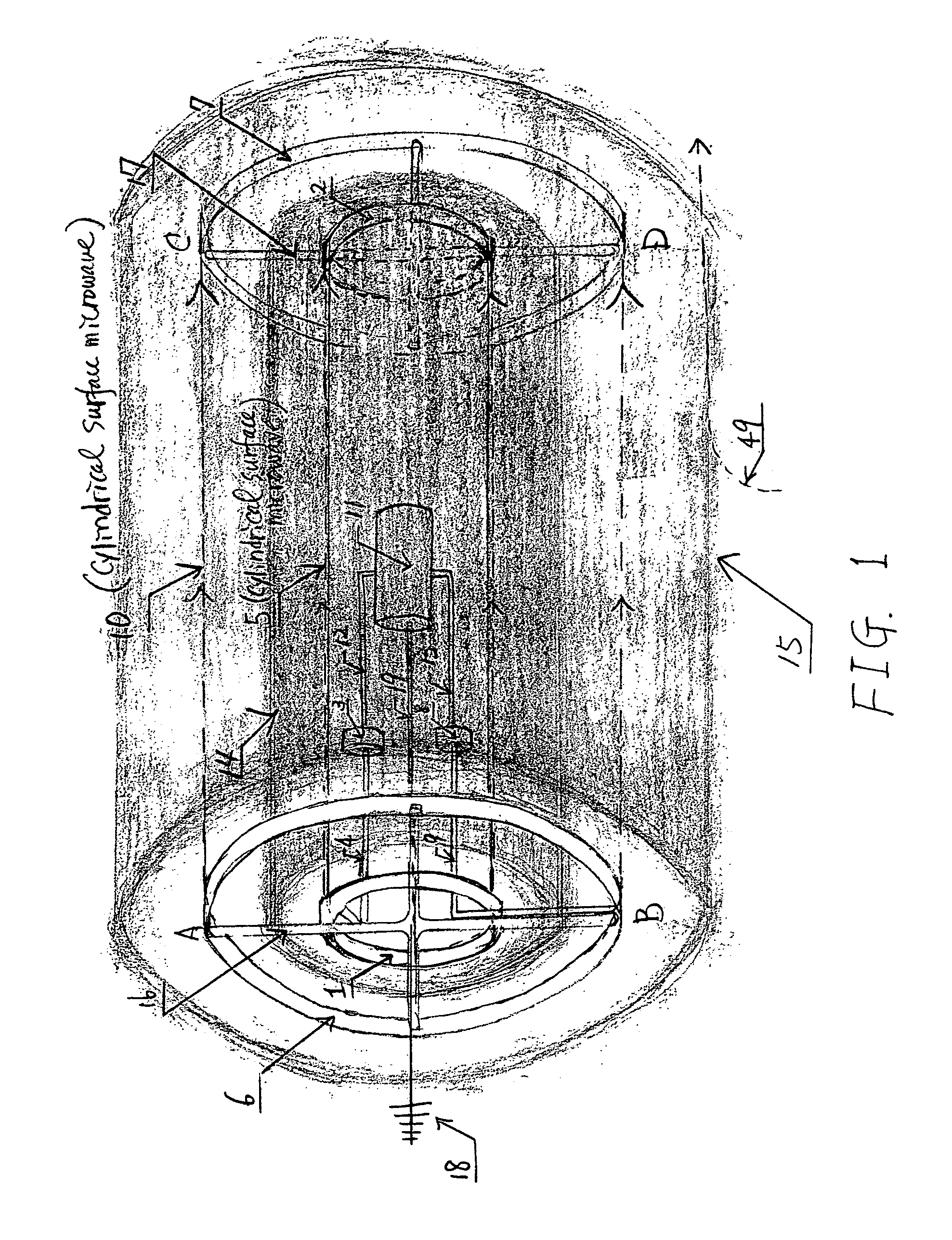

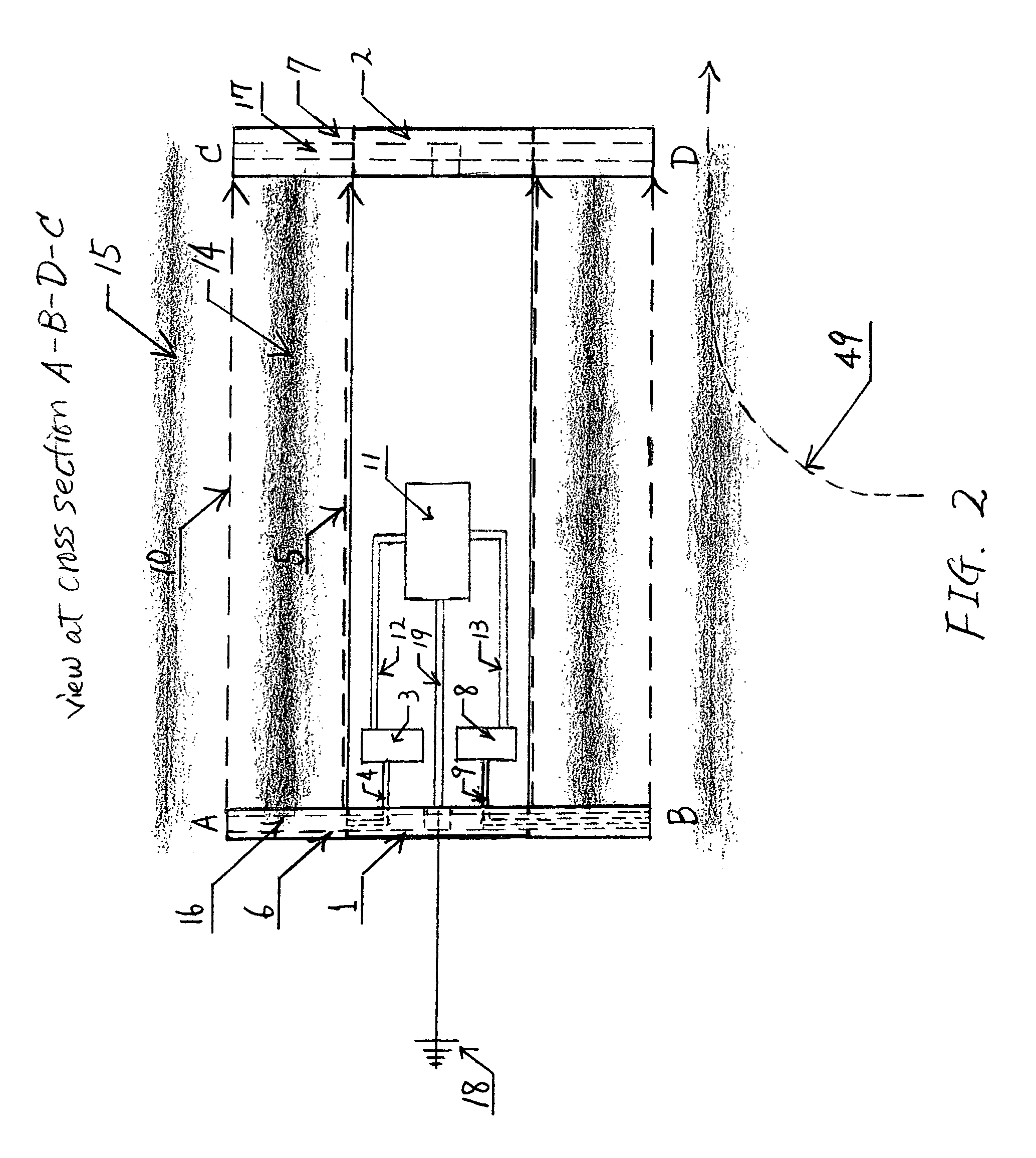

Pseudo surface microwave produced plasma shielding system

ActiveUS7255062B1Increase the magnetic field strengthSuppress DiffuseElectric discharge tubesElectric arc lampsPlasma densityCombustion chamber

A pseudo surface microwave produced plasma shielding system is a simple device that creates a prescribed plasma environment with a prescribed plasma density gradient, and protects an object surrounded by this environment as a shield. Pseudo surface microwaves interacting with an artificial intelligence equipped on board are used to create and to adjust this plasma environment for a particular application. This plasma environment provides potential capabilities of military applications of the plasma in the system. Examples of military applications include a stealth system from RADAR and SONAR, a protection system from WMD, and a weapon system to generate and launch plasmoids as a plasma gun. The scope of this invention extends to commercial applications of this plasma shielding system as a conditioned and controlled flow field, for example, a boundary layer and turbulence control system, and a lift control system to improve flight performance and flight economy of aircrafts. It further extends to develop a concept of a new type of engine using this plasma shielding system as a heating method alternative to the conventional combustion method that uses petroleum based fuel in the combustion chamber of an engine.

Owner:HIGMAN KUMIKO I

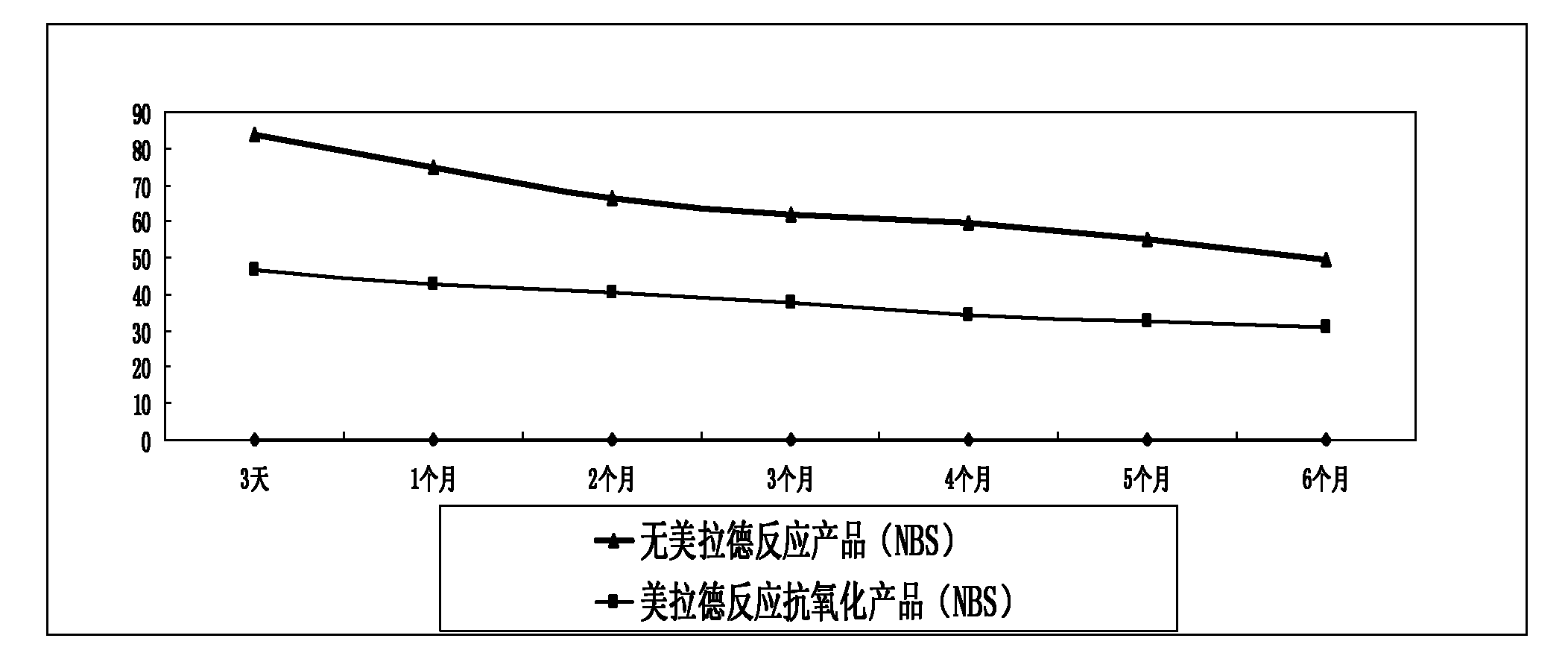

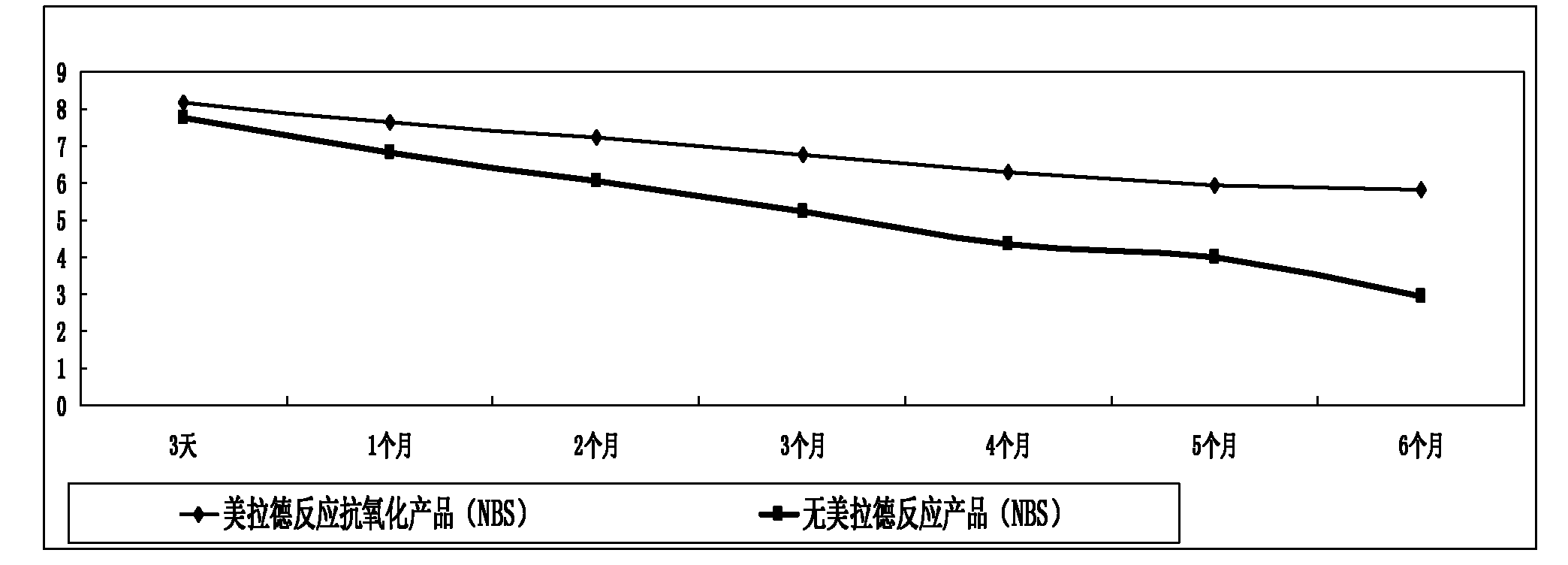

Salt roasted chicken product and preparation method thereof

ActiveCN102178257AReduce surface pressureImprove permeabilityFood preparationRoast chickenSalt content

The invention discloses a salt roasted chicken product and a preparation method thereof. The preparation method comprises the following steps of: (1) salting; (2) precooking; (3) marinating; (4) colouring, carrying out oxidation and protecting colour; (5) roasting a chicken in salt; (6) cutting and reshaping, drying and then cooling, and then packaging with inner package, carrying out microwave sterilization on a packaged and unsealed product, then vacuumizing the sterilized packaging product, and carrying out heat sealing on a package opening to obtain a semi-finished product; and (7) sterilizing the semi-finished product at a high temperature and high pressure, cleaning, and carrying out air drying to obtain the salt roasted chicken product. The salt roasted chicken product discloses by the invention not only can show unique colour, lustre, taste and flavour of the traditional salt roasted chicken product but also is greatly improved, the salt content is greatly reduced, the chicken has crisp taste and elastic and tough meat quality, and the defect that a transparent plastic bag packaging product is easy to fade and oxidize is effectively avoided.

Owner:广东无穷食品集团有限公司

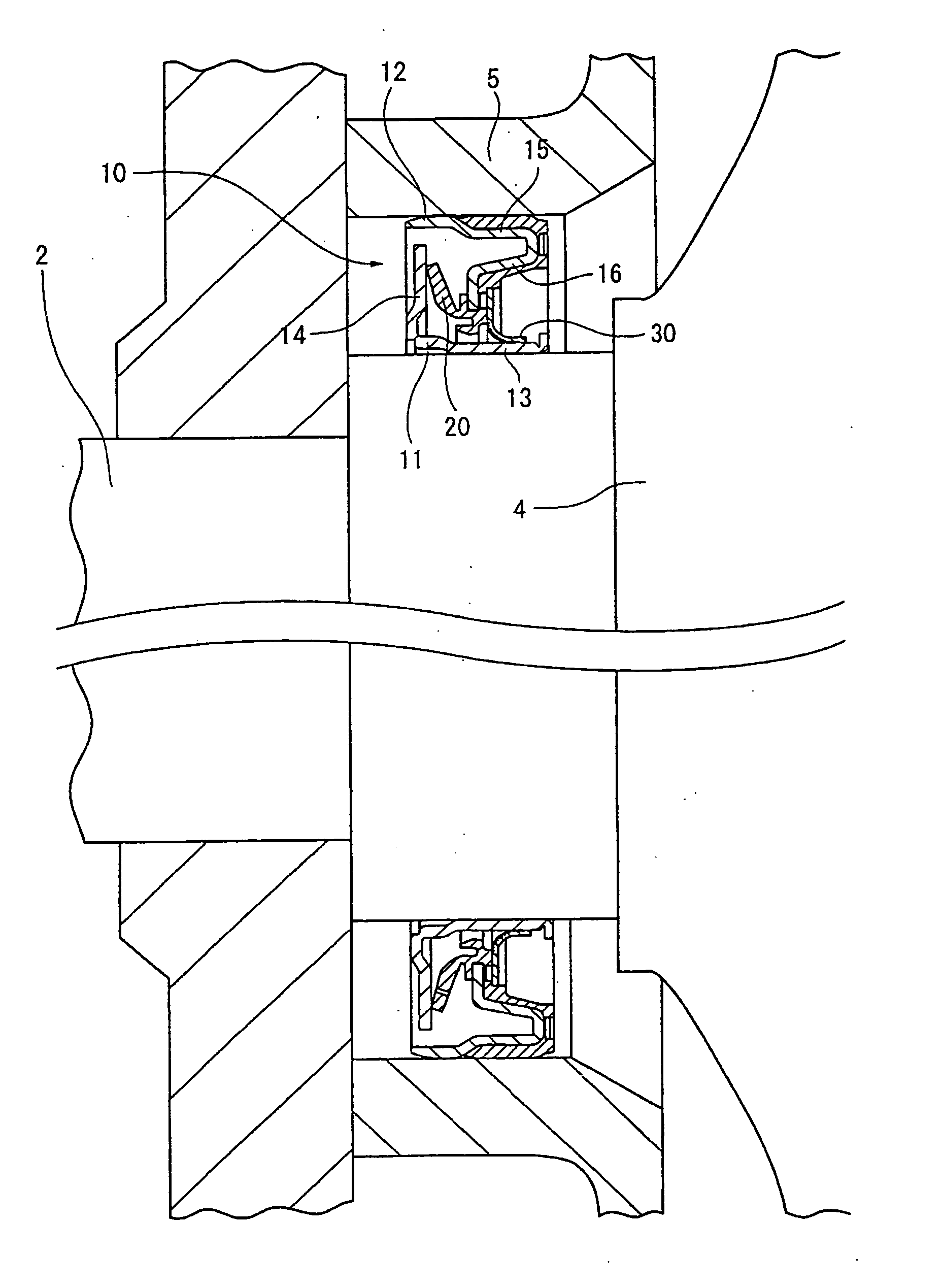

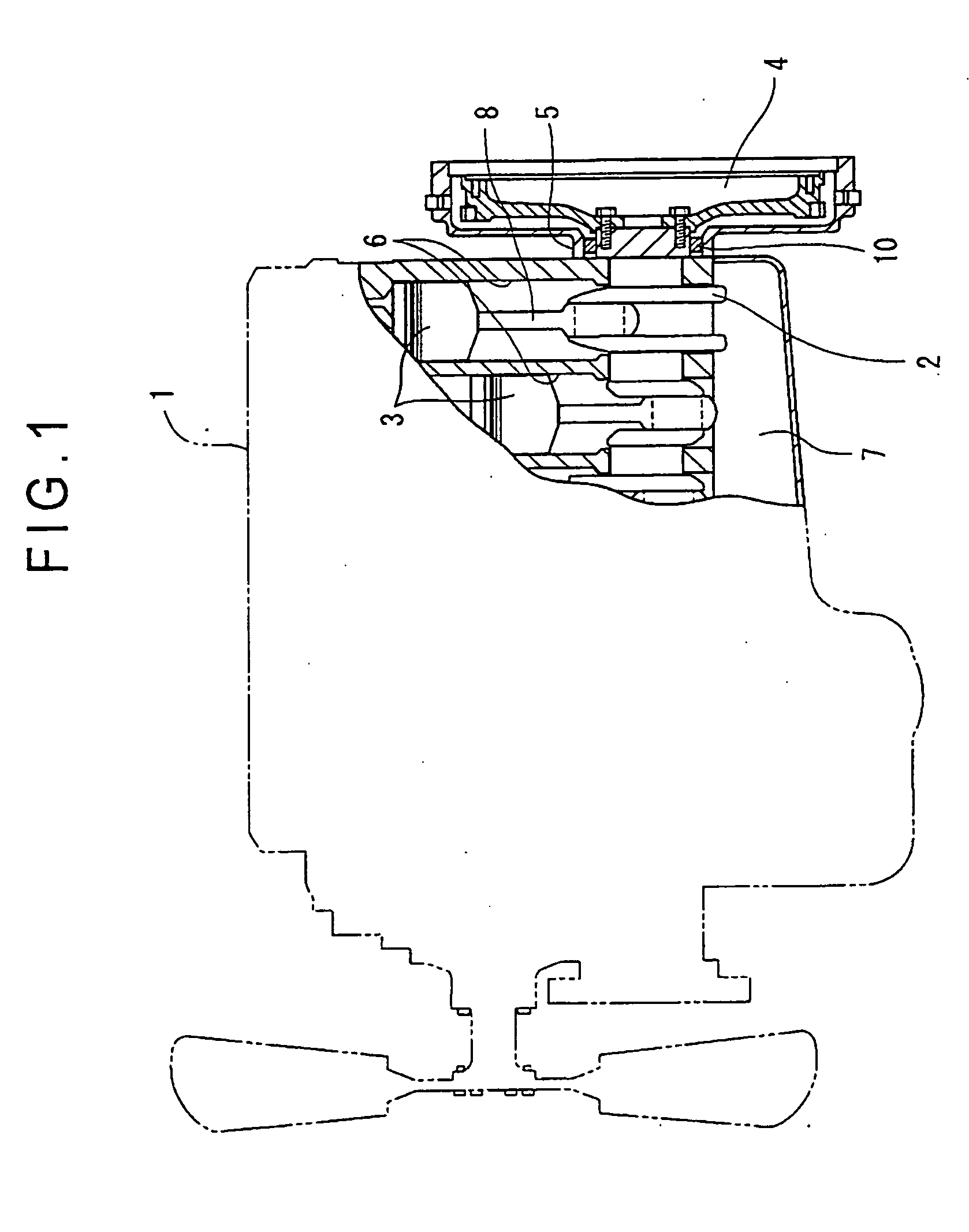

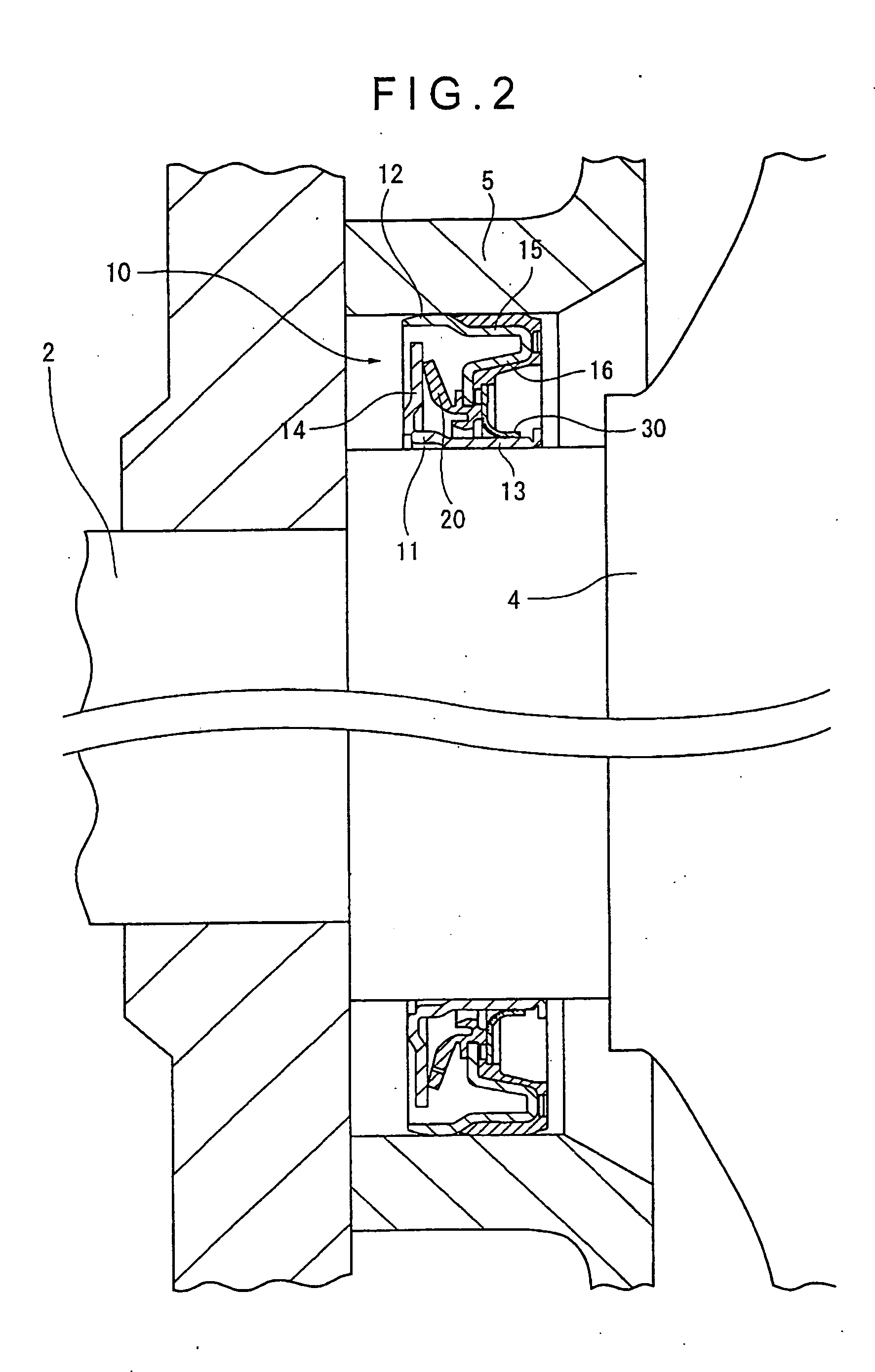

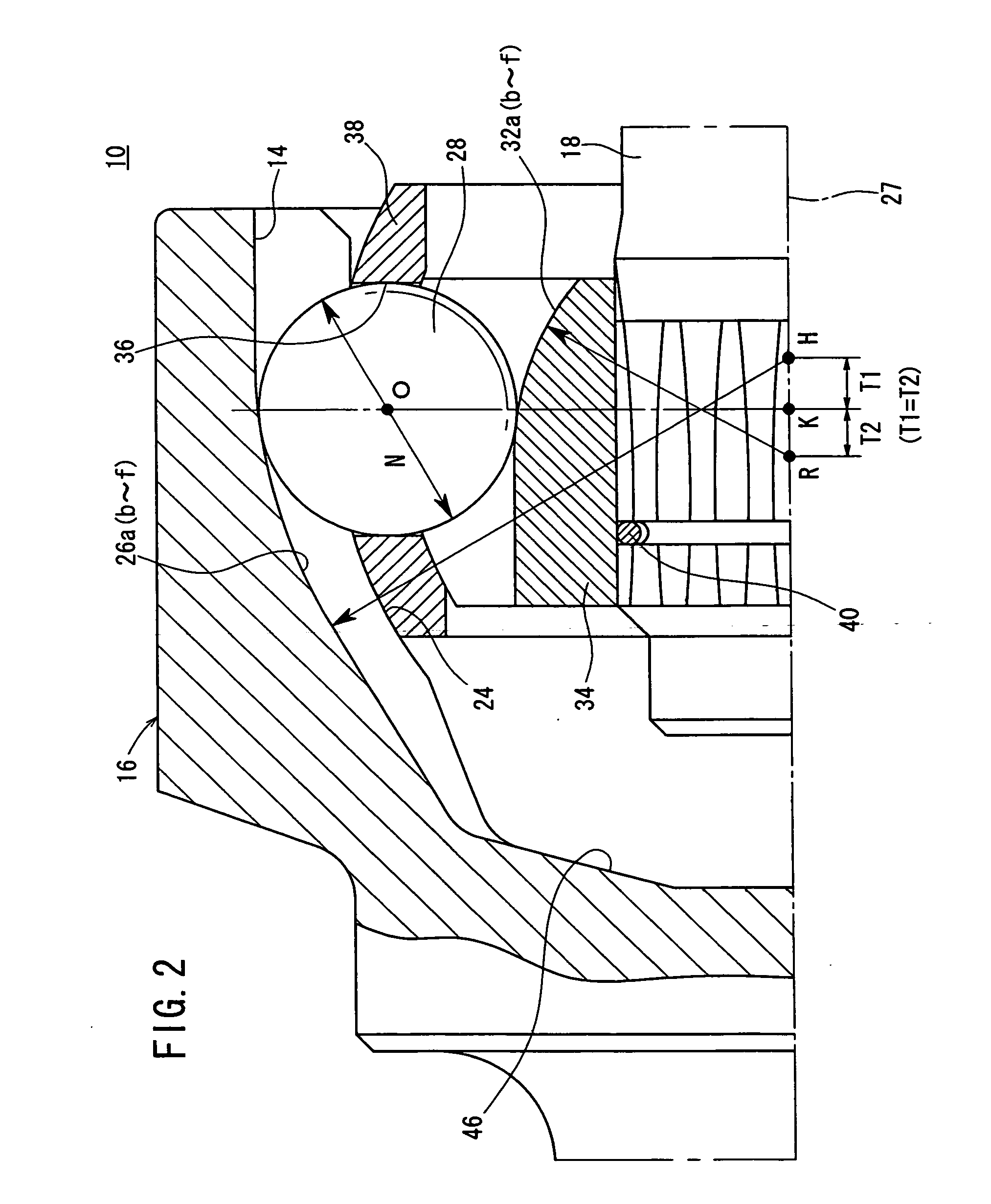

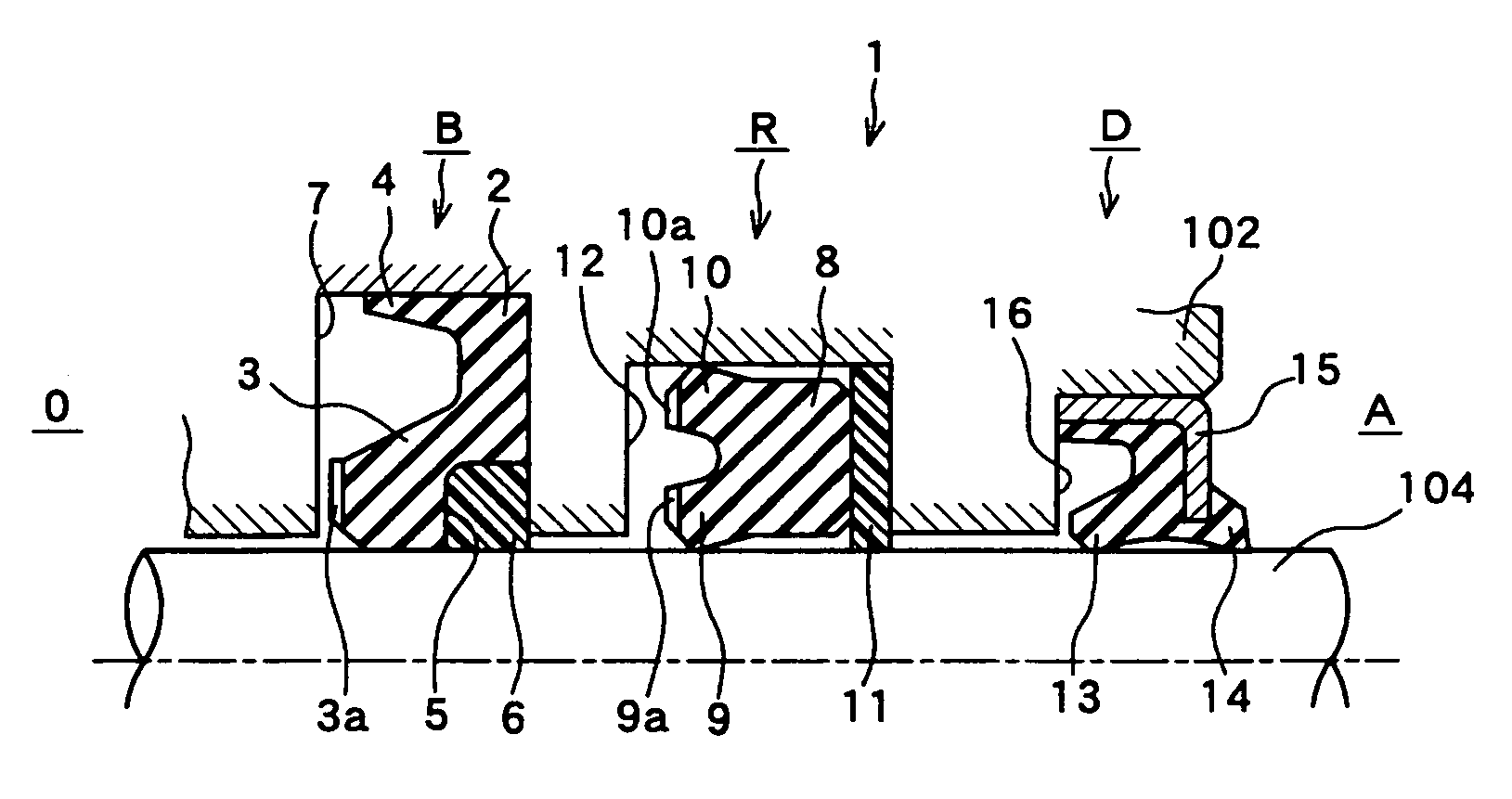

Oil seal

An oil seal (10) includes a first seal (20) for sealing an engine (1) side and a second seal (30) for sealing a flywheel (4) side. The first seal (20) is an axial seal abutted on an inner ring (11) from the direction along the axial direction of a crank shaft (2). The second seal (30) is a radial seal abutted on the inner ring (11) from the direction along the radial direction of the crank shaft (2). A communication hole (25) is provided on the second seal (30), thereby preventing a space (40) surrounded by the first seal (20), the second seal (30) and the inner ring (11) from the occurrence of the negative pressure.

Owner:KOMATSU LTD

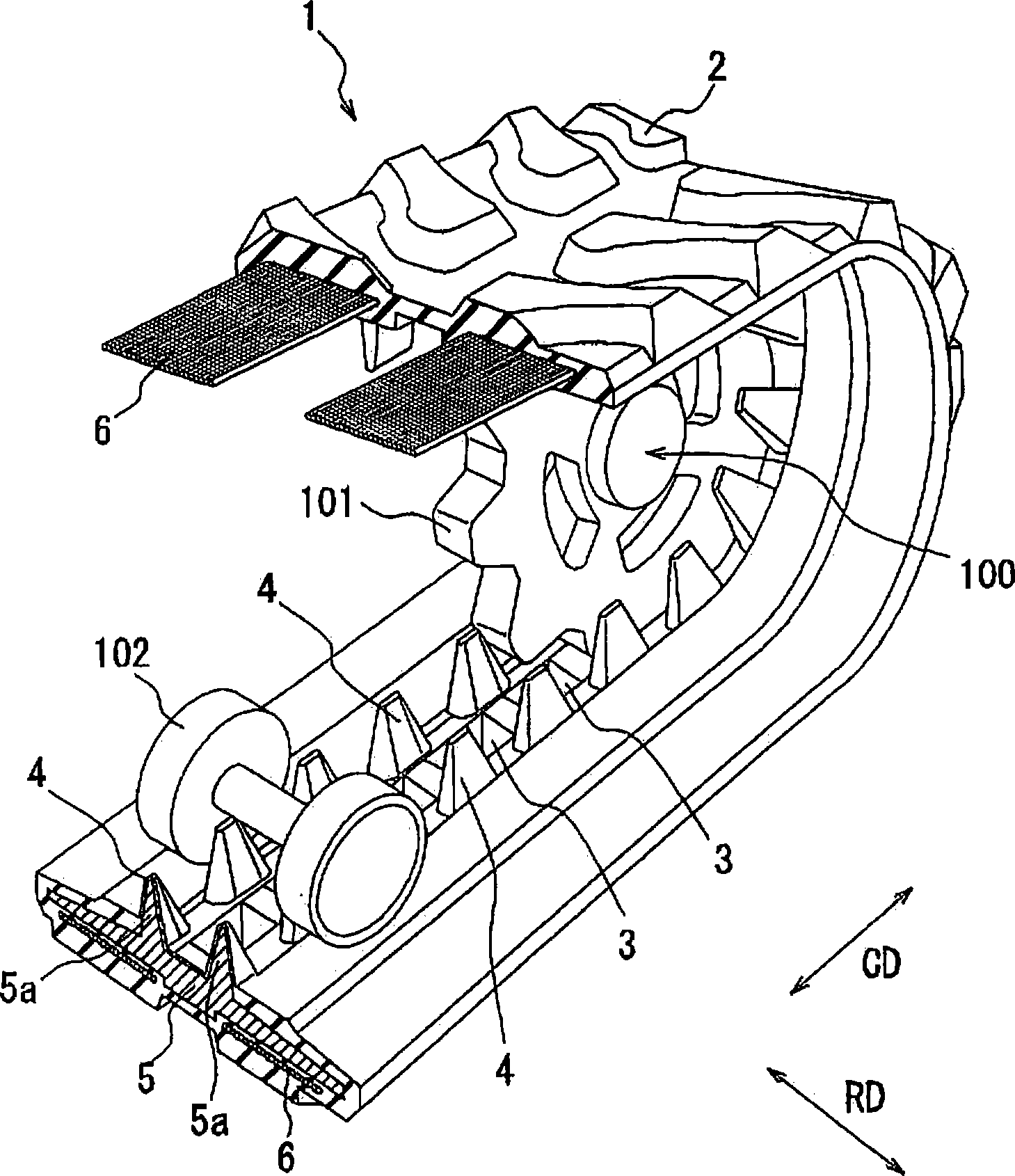

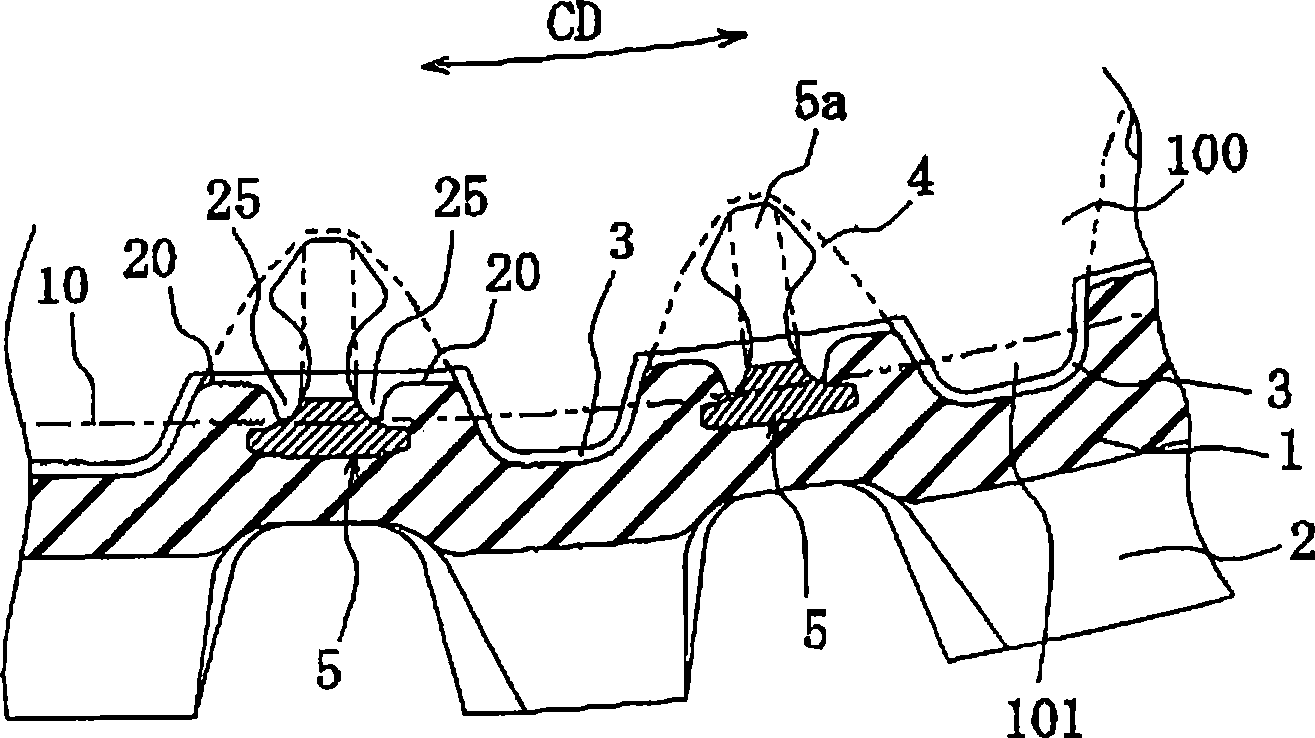

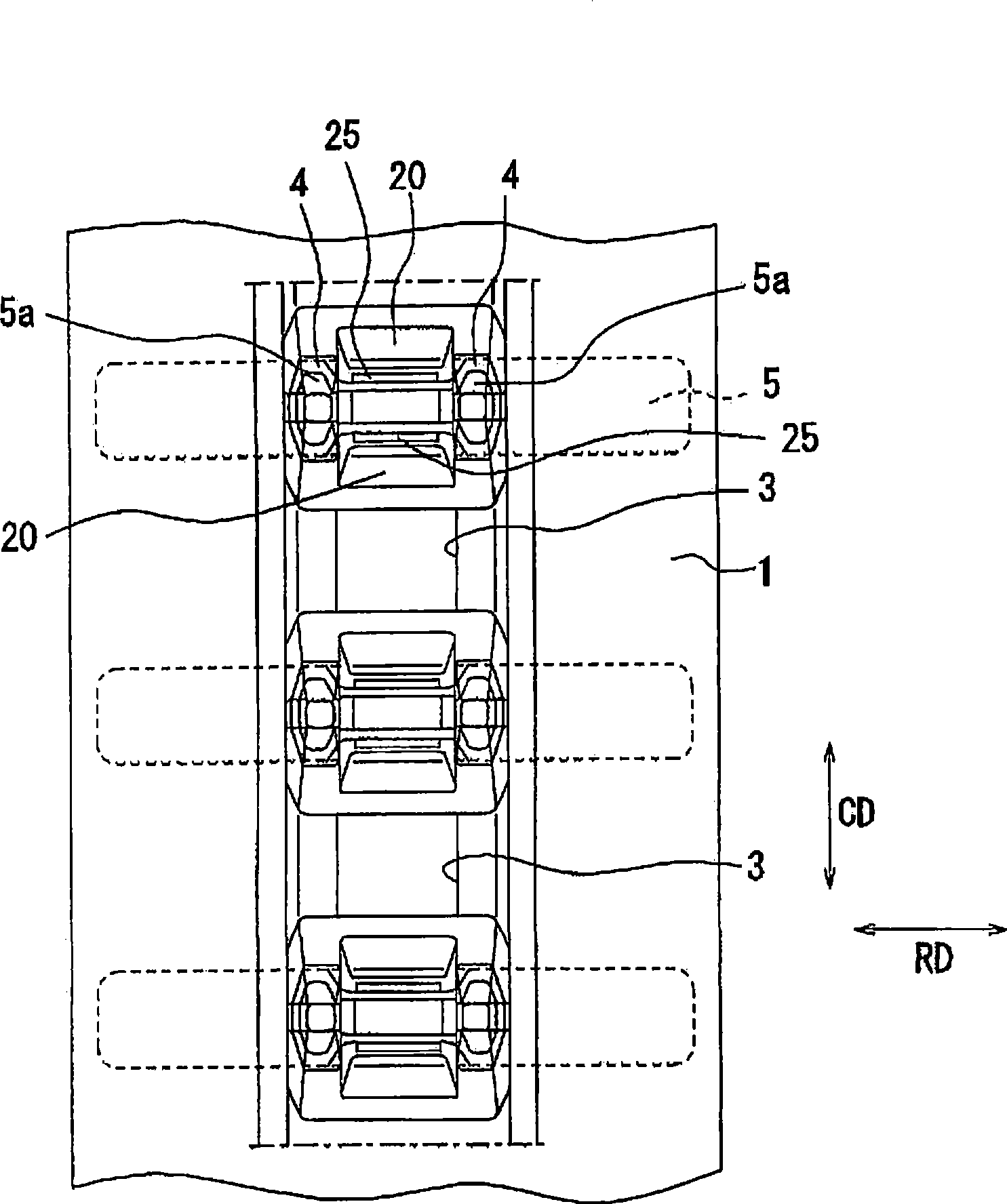

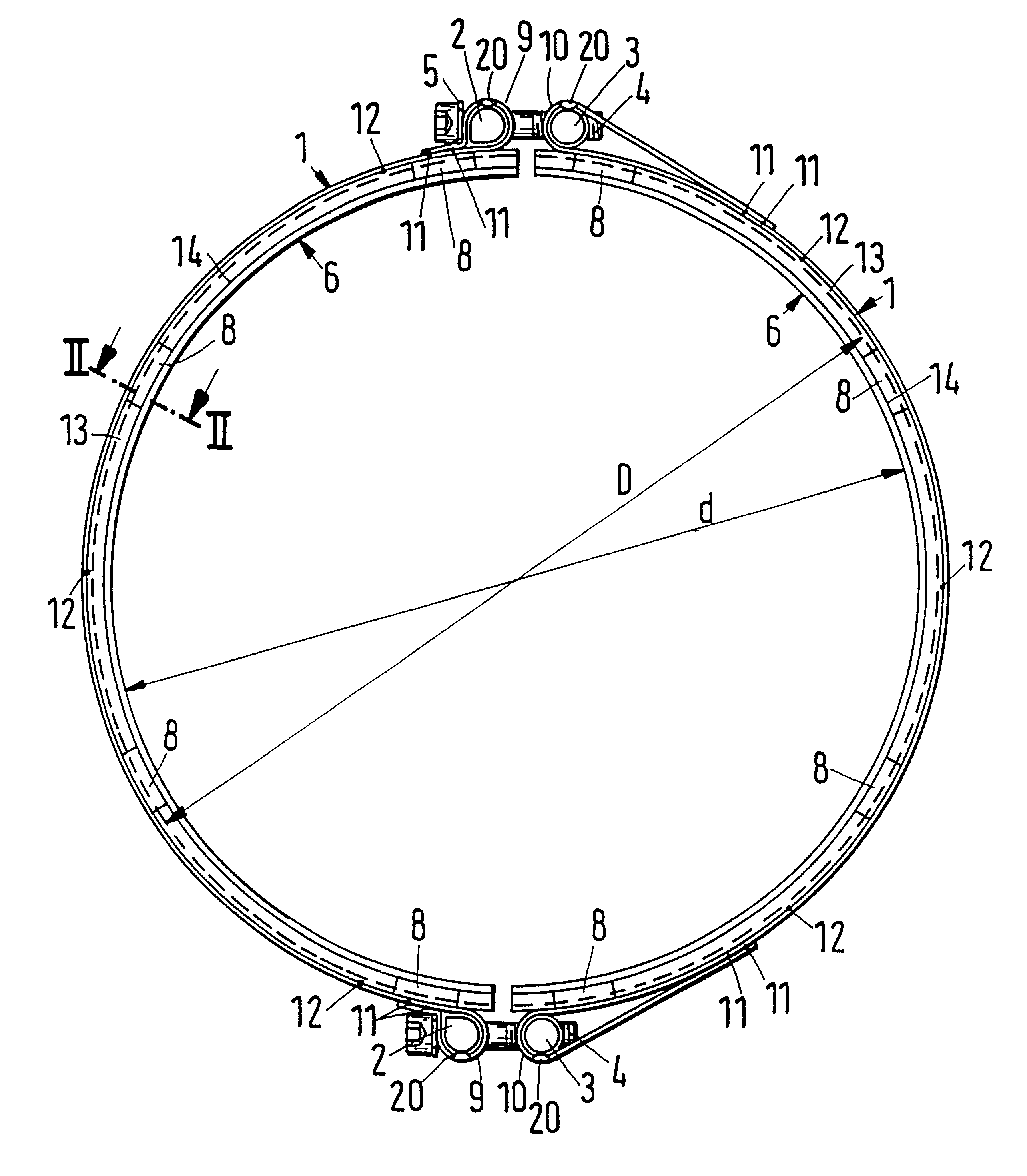

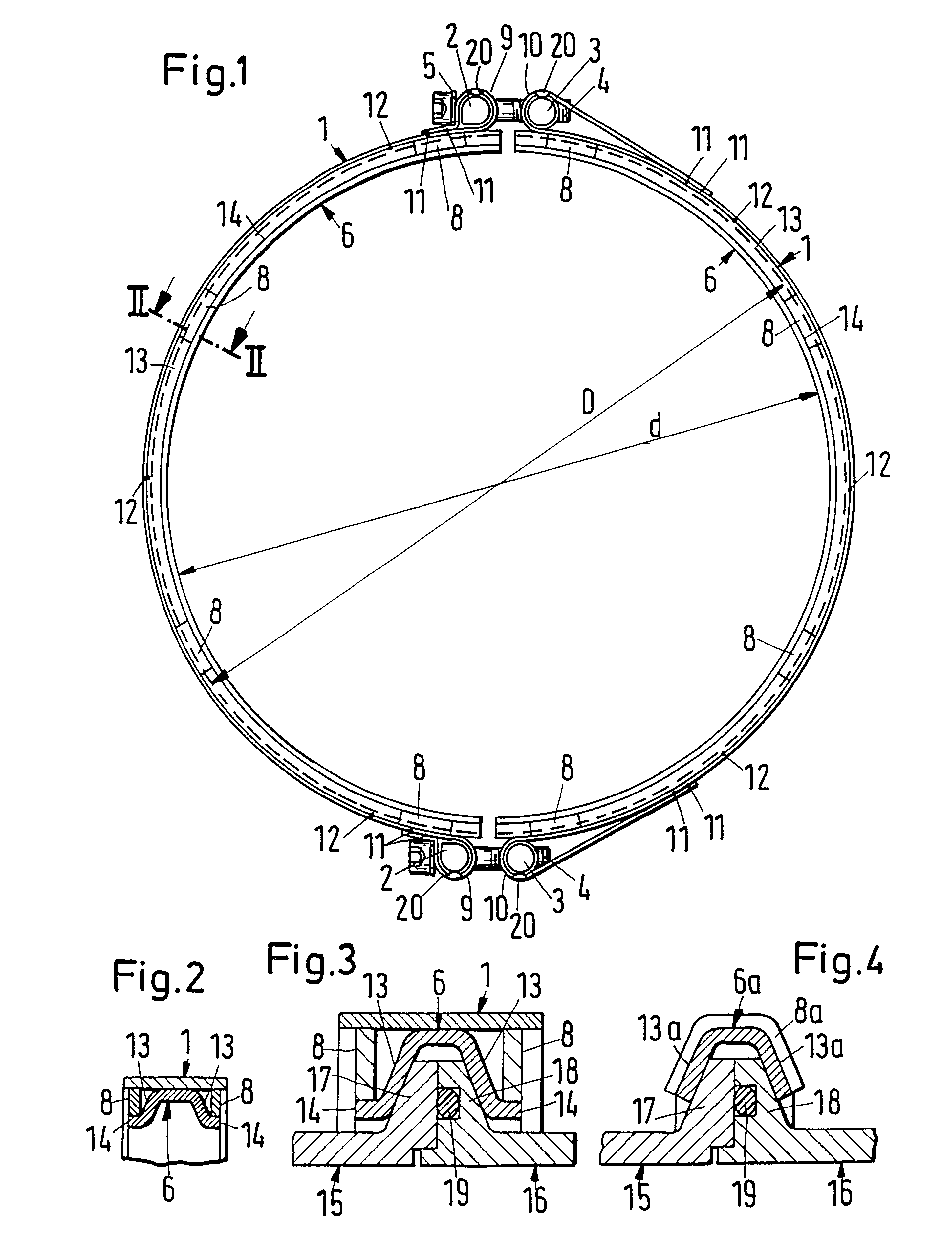

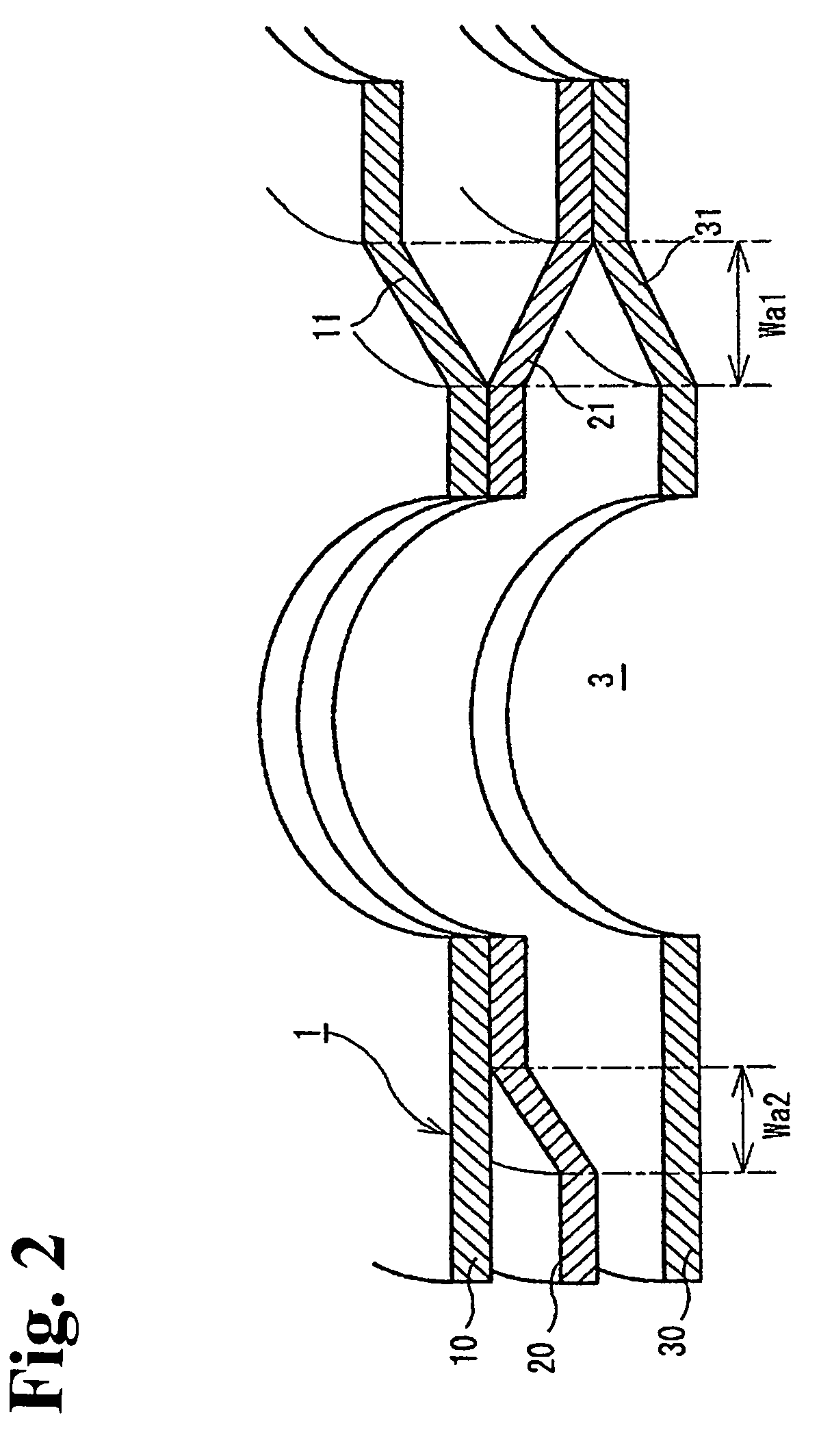

Rubber track and chain wheel suitable for rubber track and core iron for rubber track

The invention provides a rubber track, a chain wheel suitable for the rubber track, and a core rod for the rubber track. The outer peripheral face of the rubber track (1) is provided with a projecting part (2), and the inner peripheral face is provided with a driving clamping part for transferring a driving force which is transferred through clamping of the chain wheel (100) and the driving clamping part, wherein the driving clamping part comprises hard clamping components (5) embedded in the circumferential direction of the rubber track by a certain pitch, and a concave part (3) arranged among the clamping components (5) to receive a tooth part of the chain wheel. According to the rubber track, the tooth part of the chain wheel is clamped with the concave part between the hard clamping components; therefore, compared with the prior condition that the tooth part is abutted with a driving protrusion projecting on the inner peripheral face, damage can be inhibited. Moreover, the shape of the concave part is properly changed to increase the area blocking with the tooth part, so as to reduce surface pressure.

Owner:BRIDGESTONE CORP

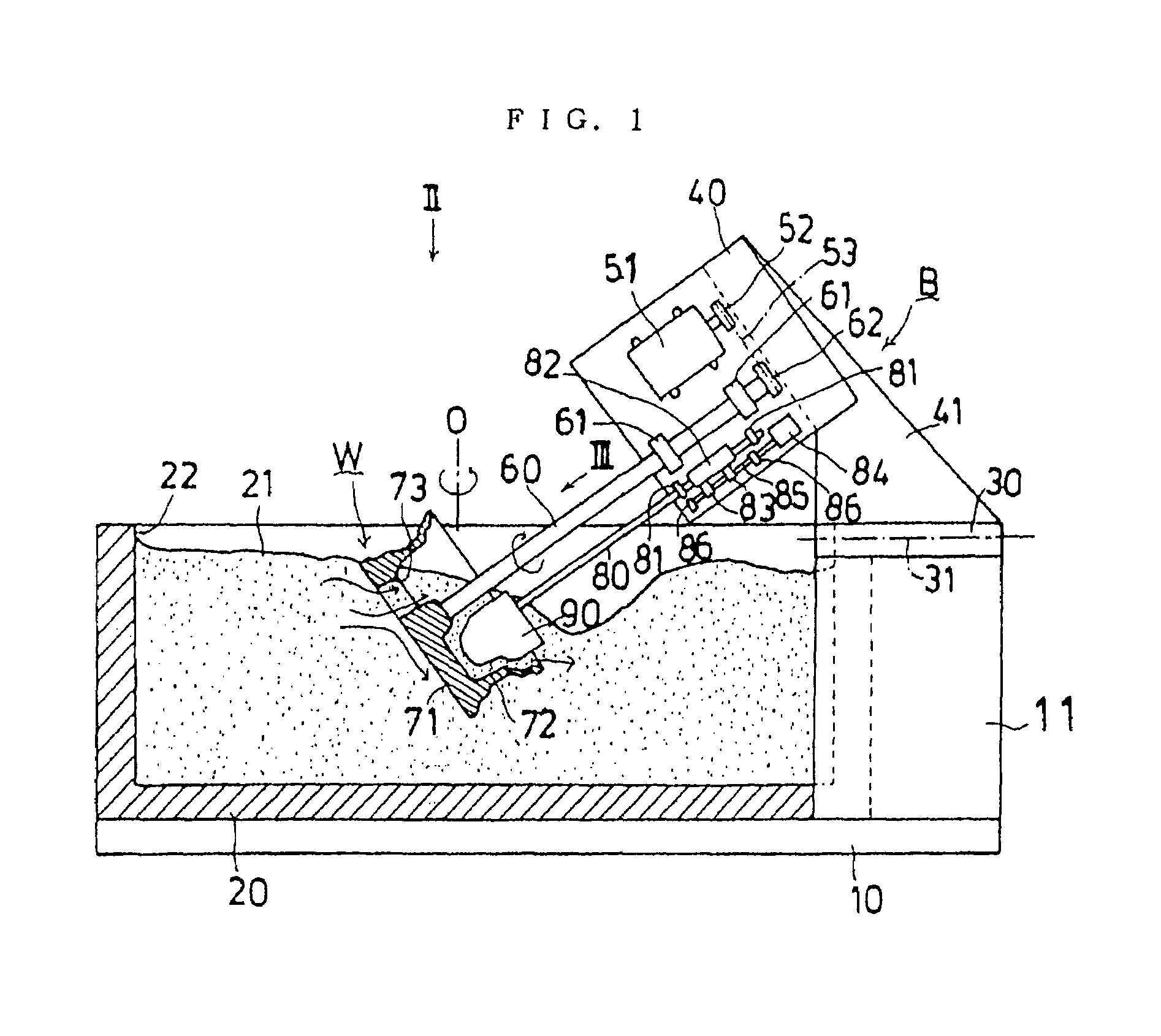

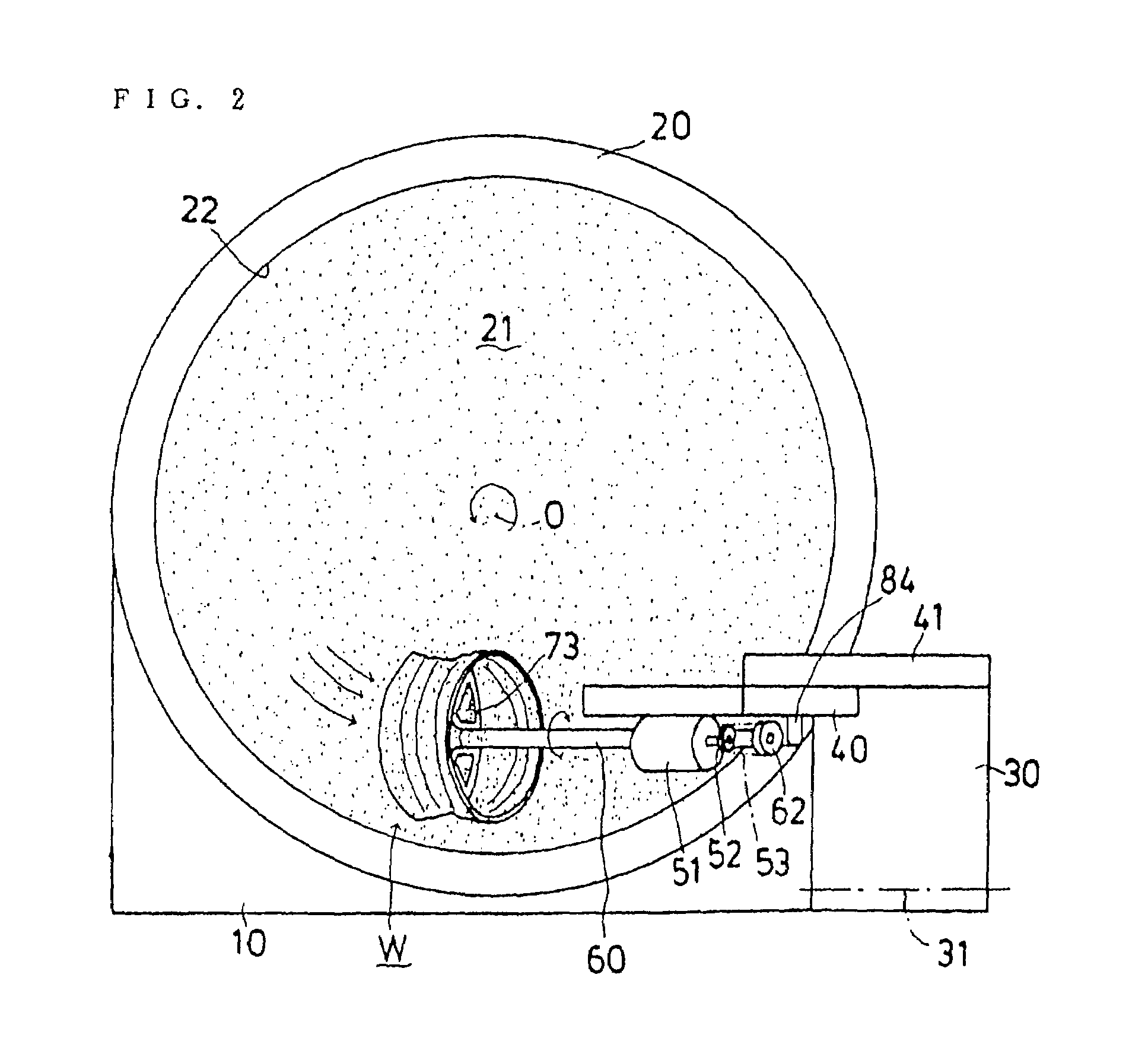

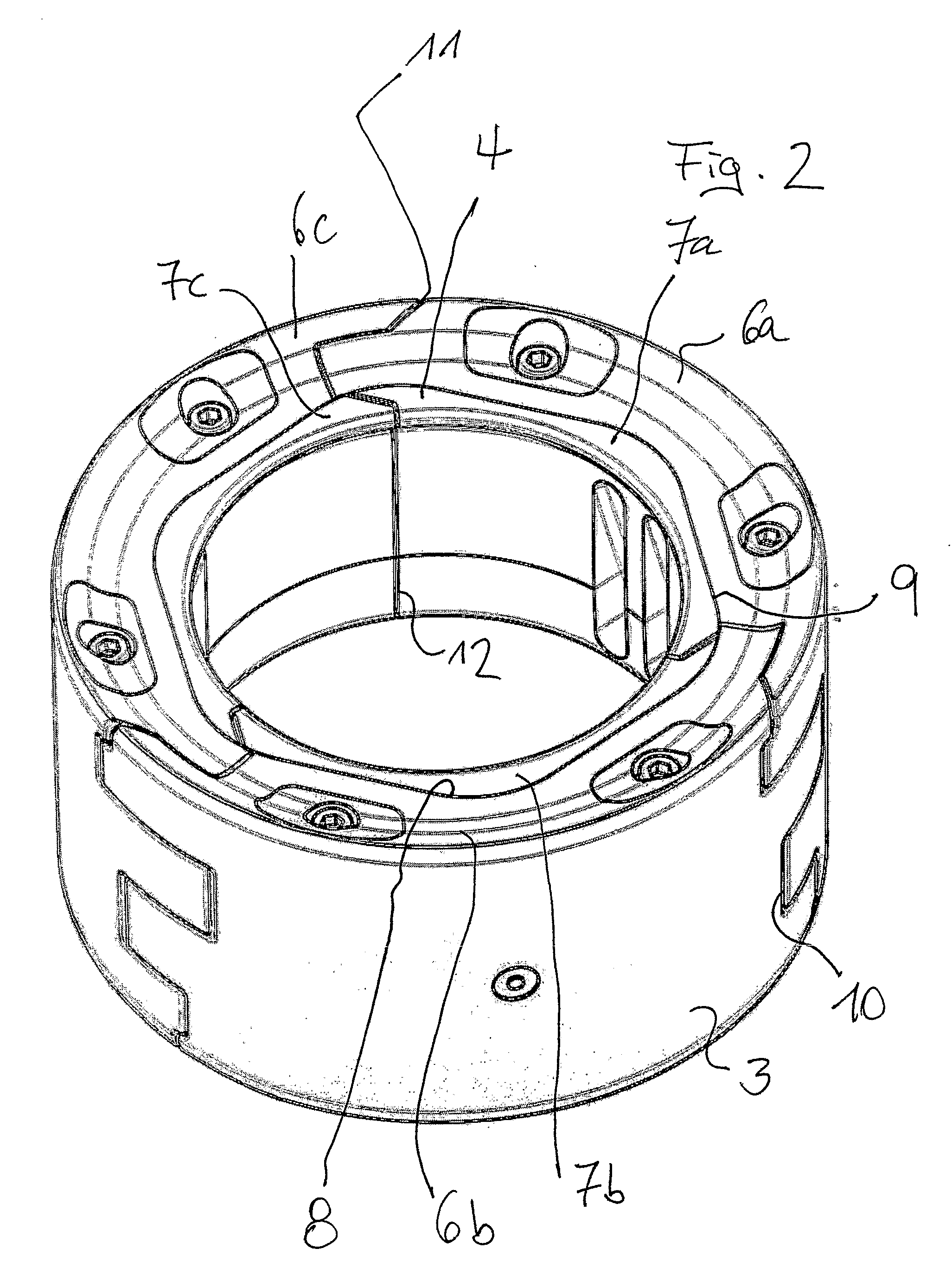

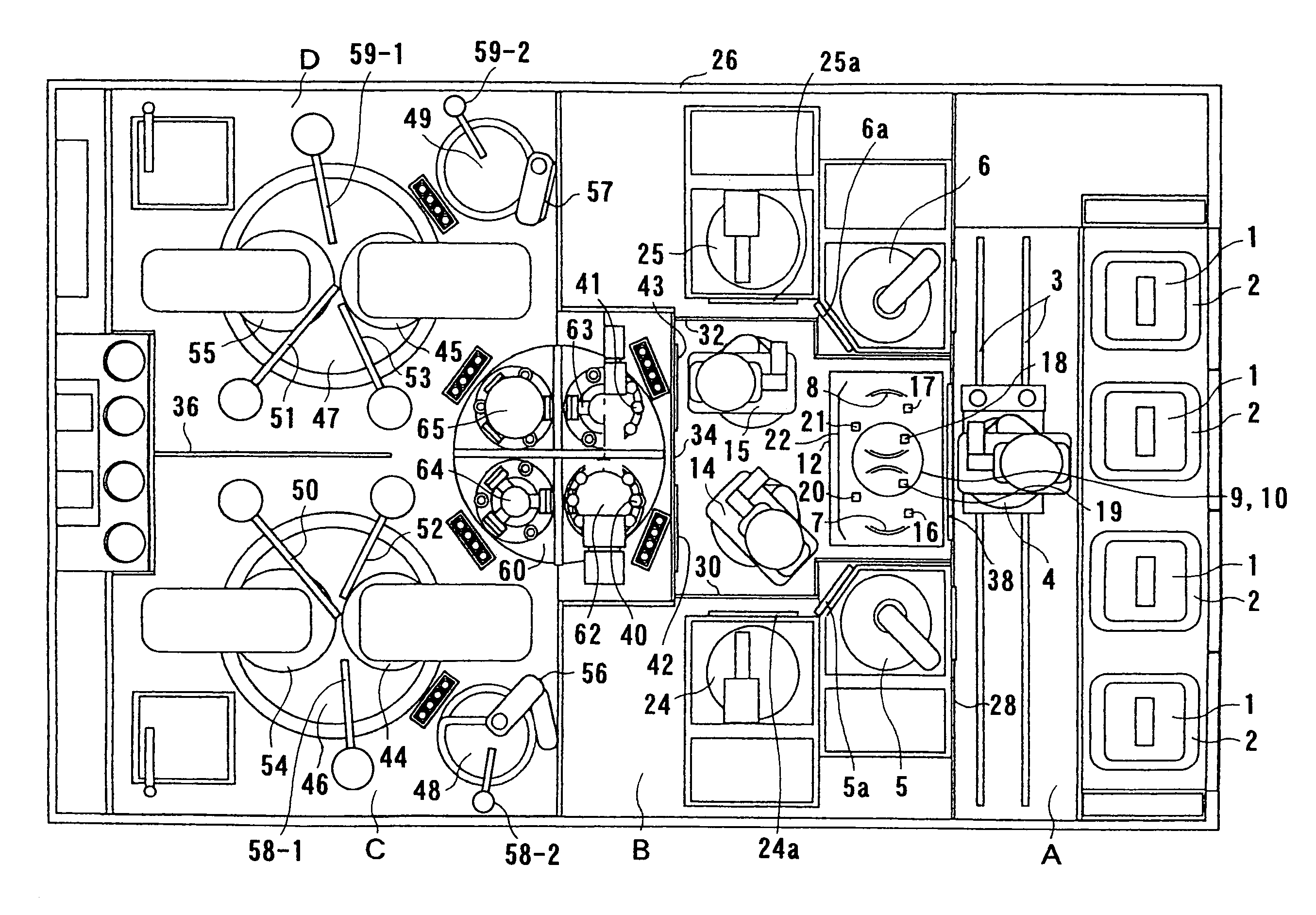

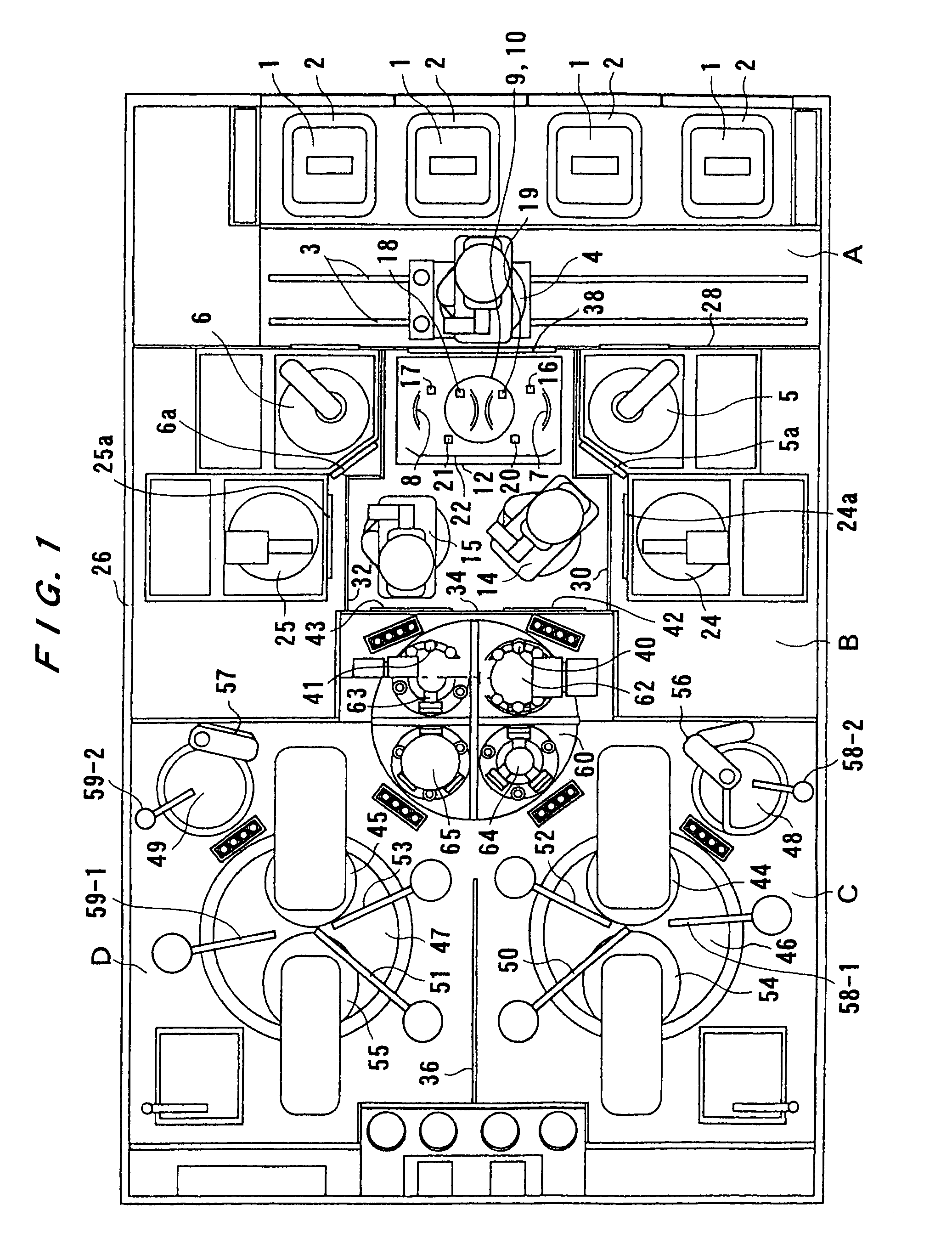

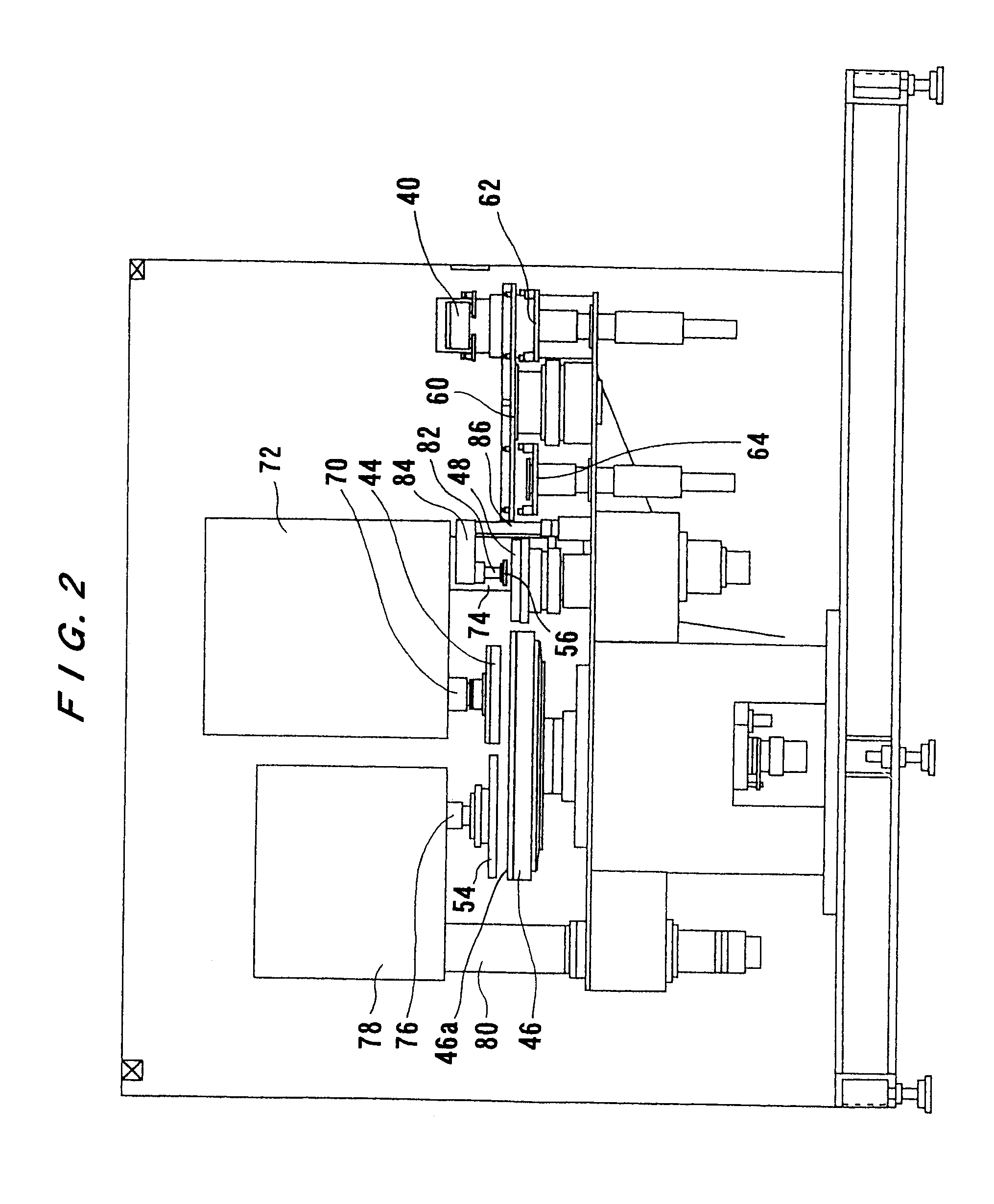

Barrel polishing device

InactiveUS6962522B1Reduce surface pressureIncrease surface pressureEdge grinding machinesPolishing machinesEngineeringMechanical engineering

A barrel polishing device for polishing a workpiece having a relatively complicated shape such as a vehicle wheel. The barrel polishing device comprises a polishing medium storage tank for storing polishing media, a base, a workpiece supporting shaft mounted on the base, and a workpiece detachably mounted on a tip part of the workpiece supporting shaft, the polishing media stored in the polishing medium storage tank being flowed by an appropriate means, and the workpiece supporting shaft being disposed so that a front side of the workpiece opposes the flow of the polishing media, the workpiece supporting shaft being rotated about an axis thereof, and a baffle member being placed in the vicinity of a back side of the workpiece.

Owner:BBF YAMATE

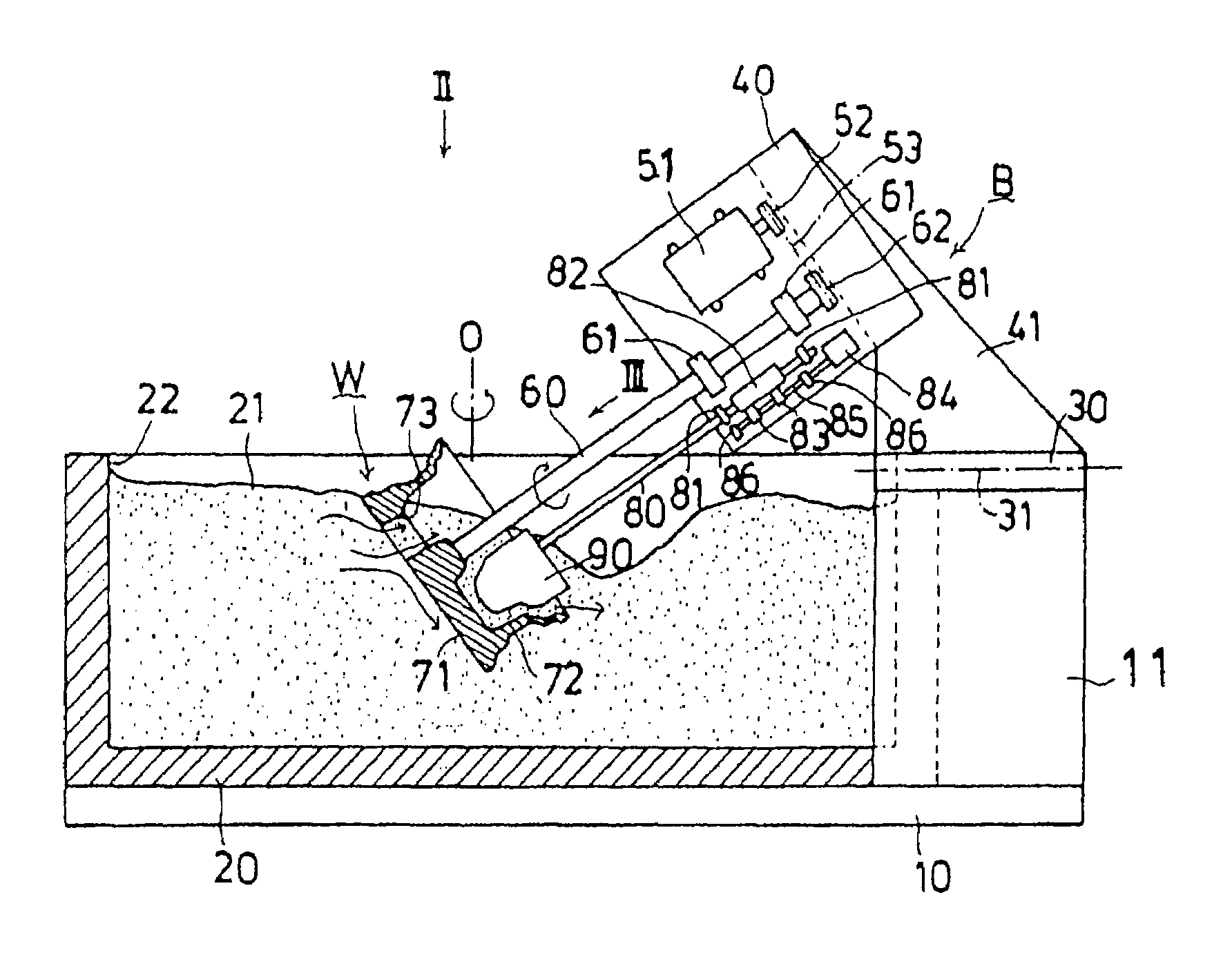

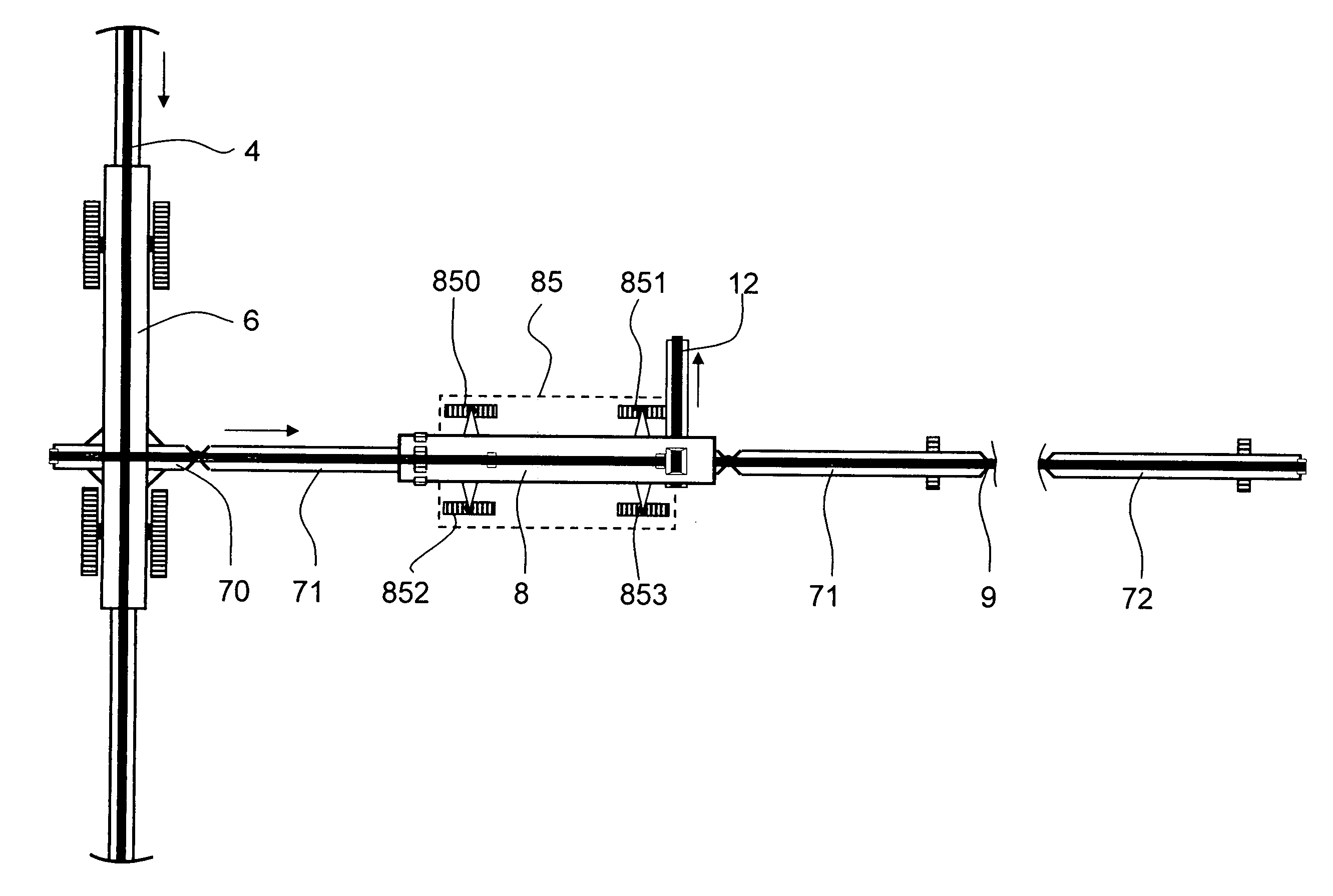

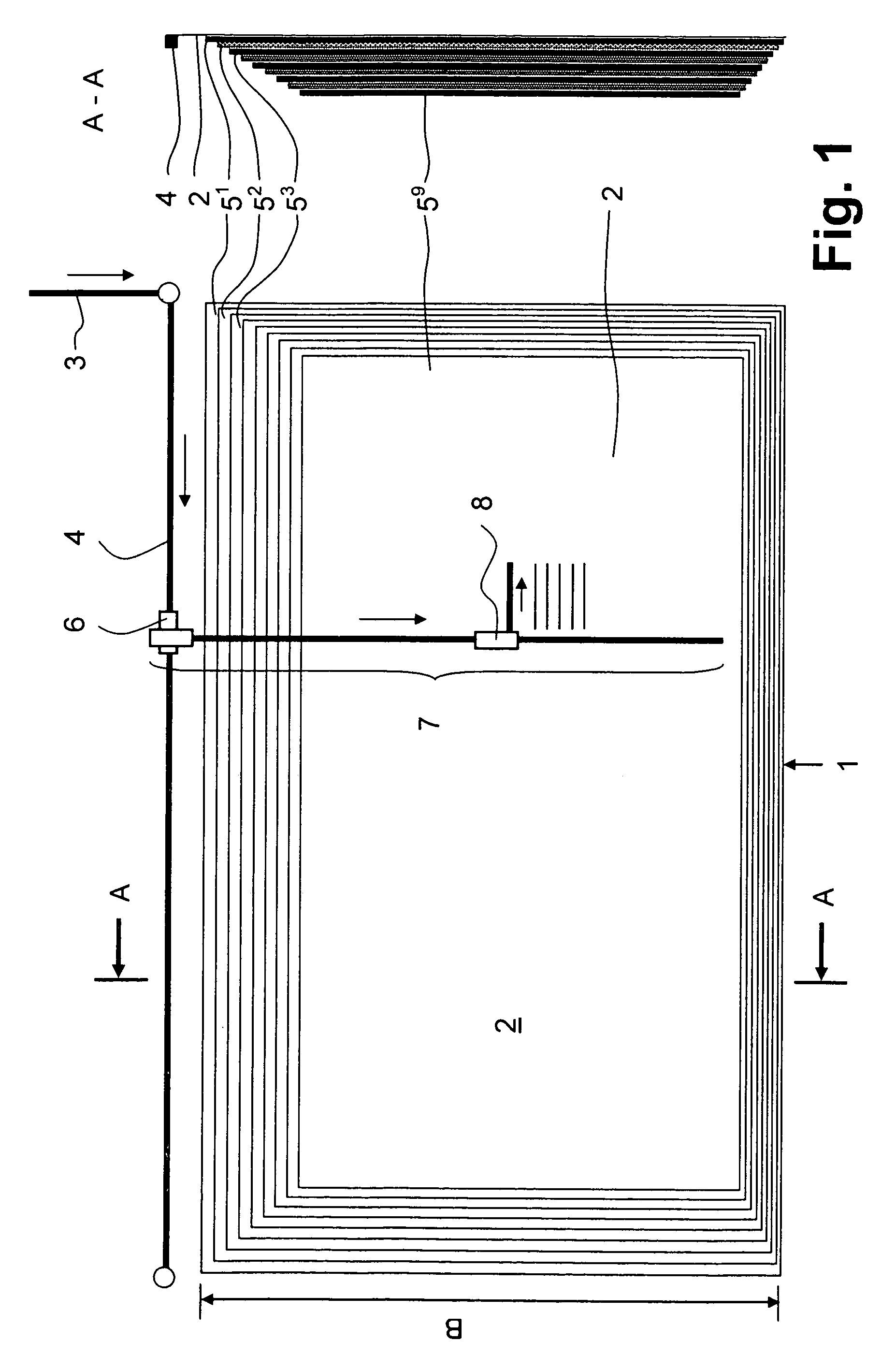

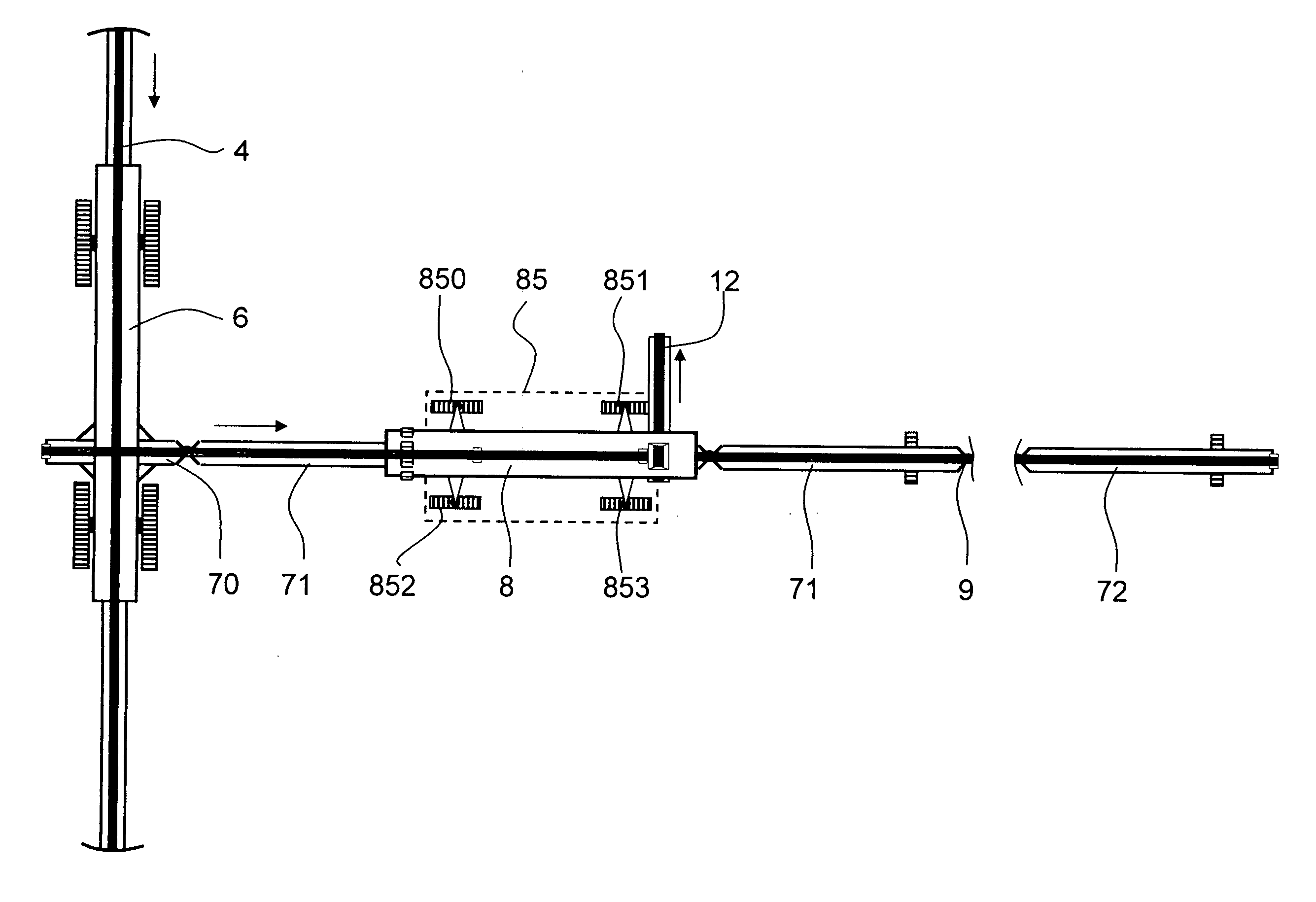

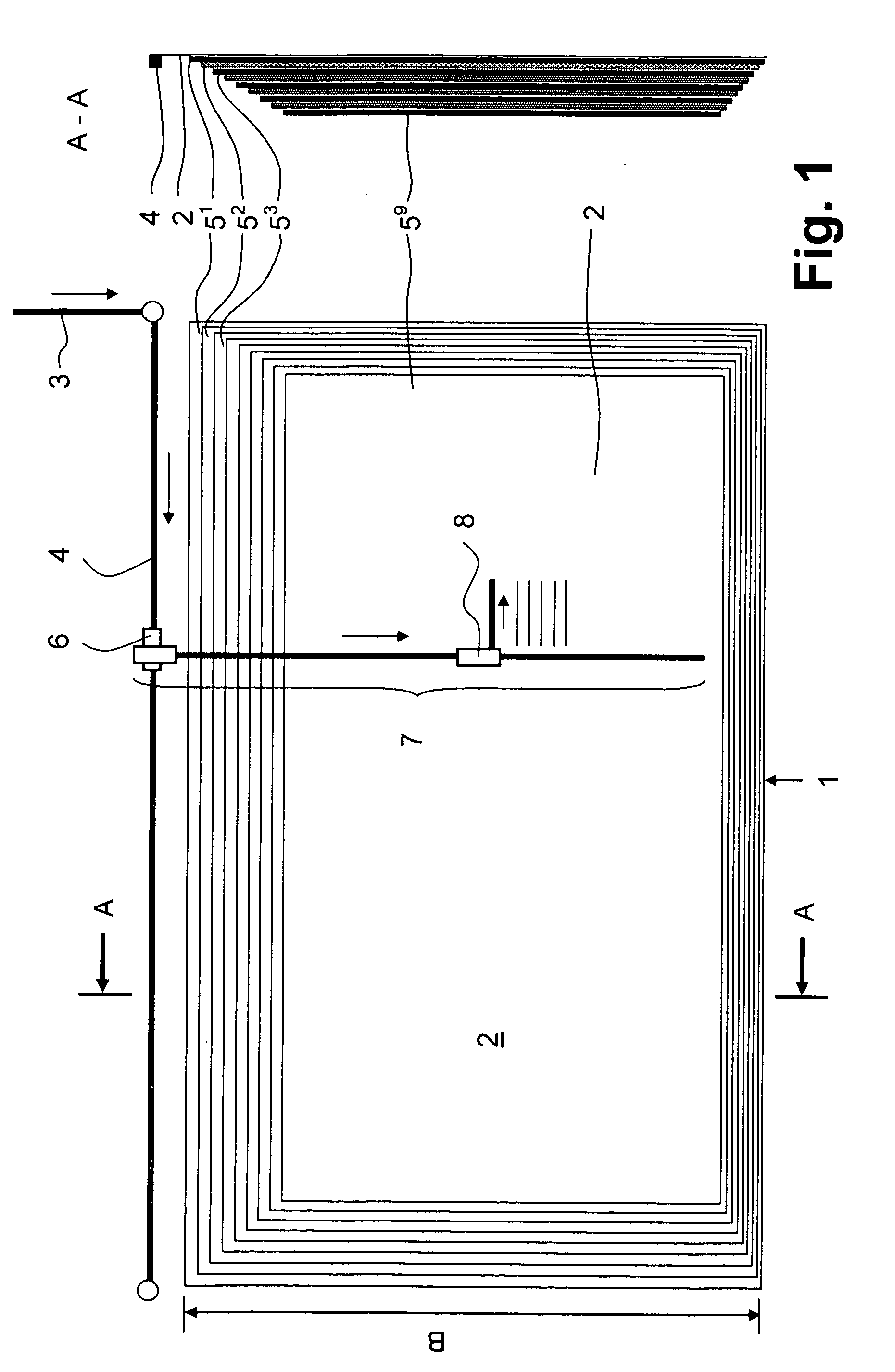

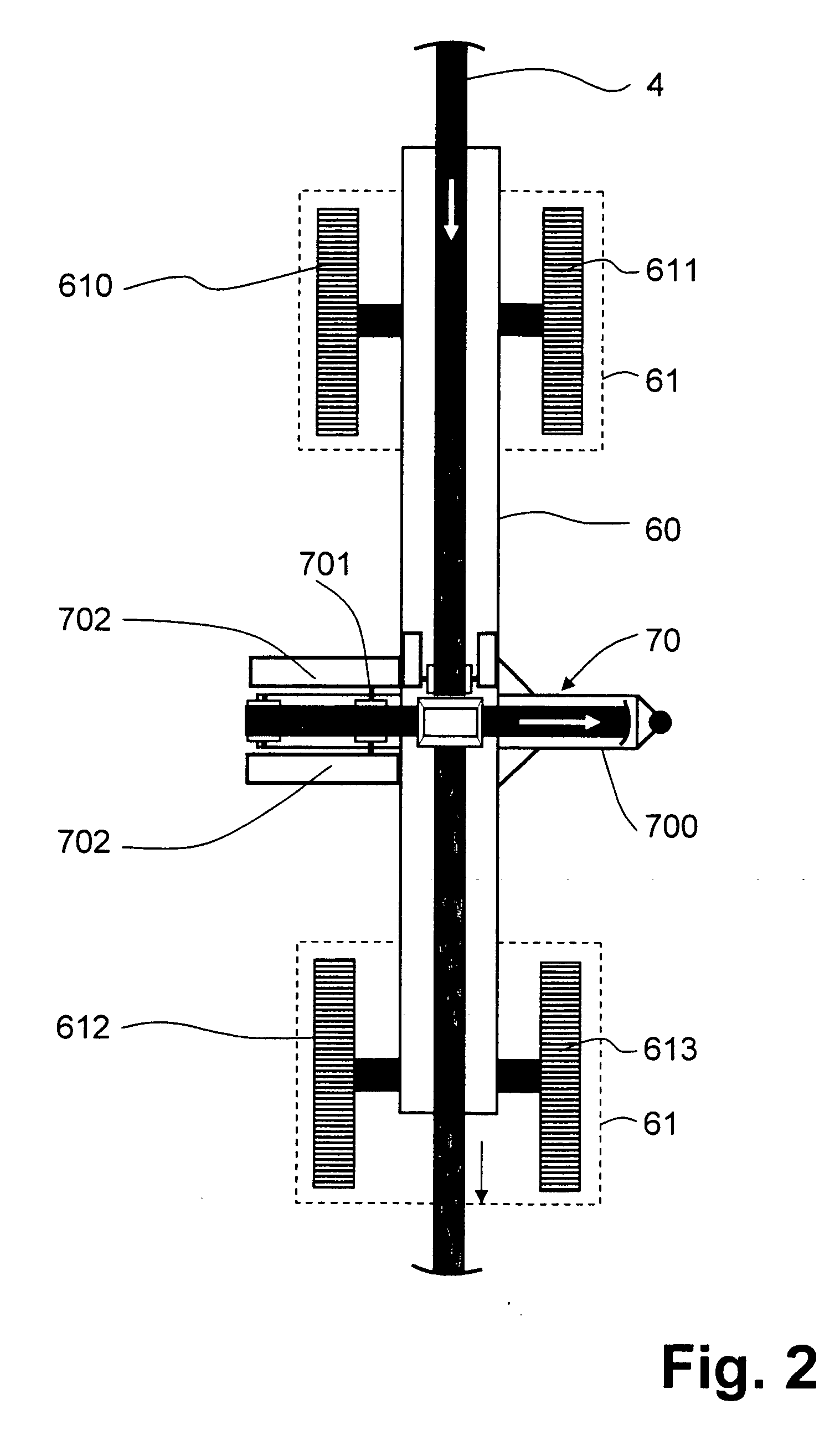

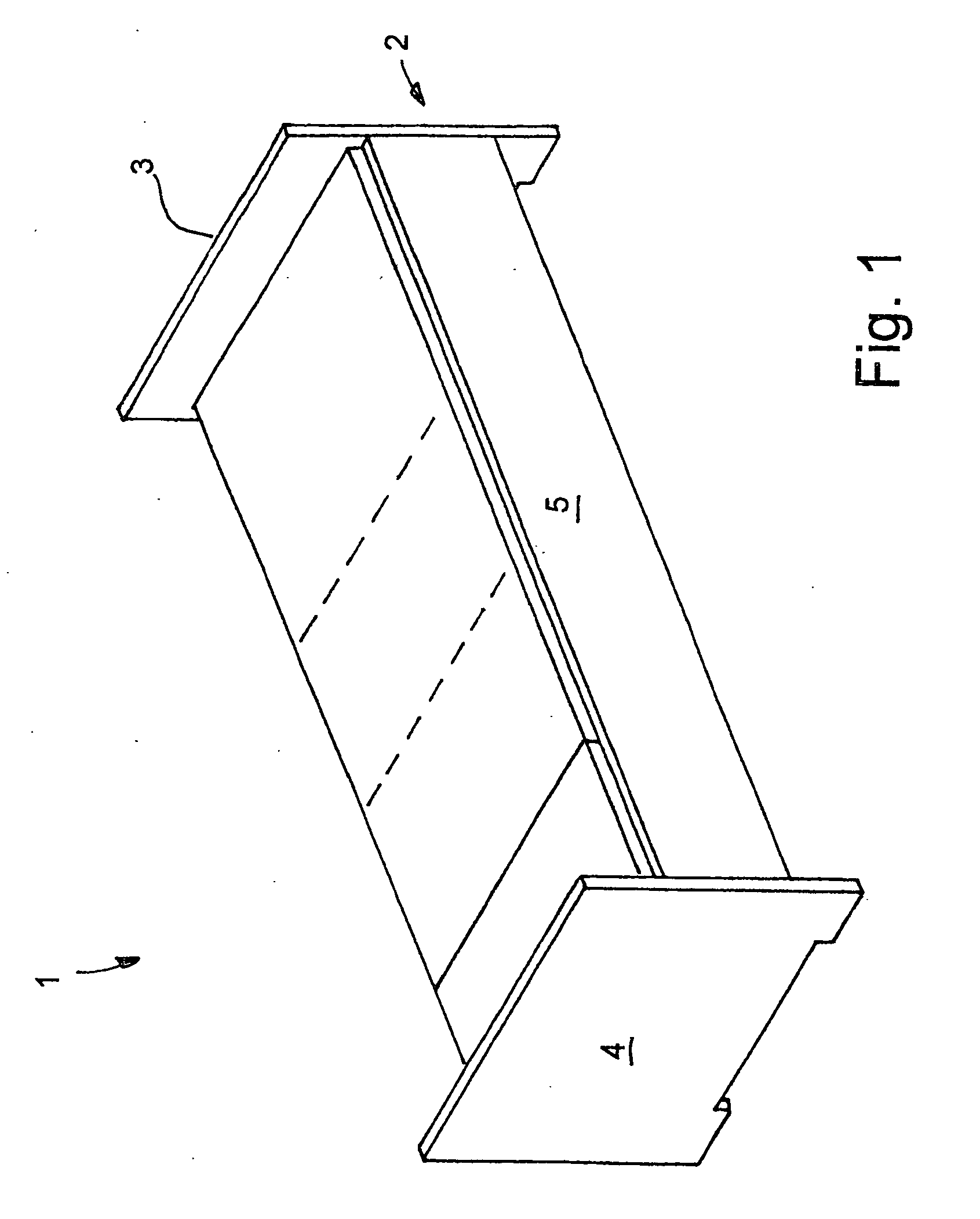

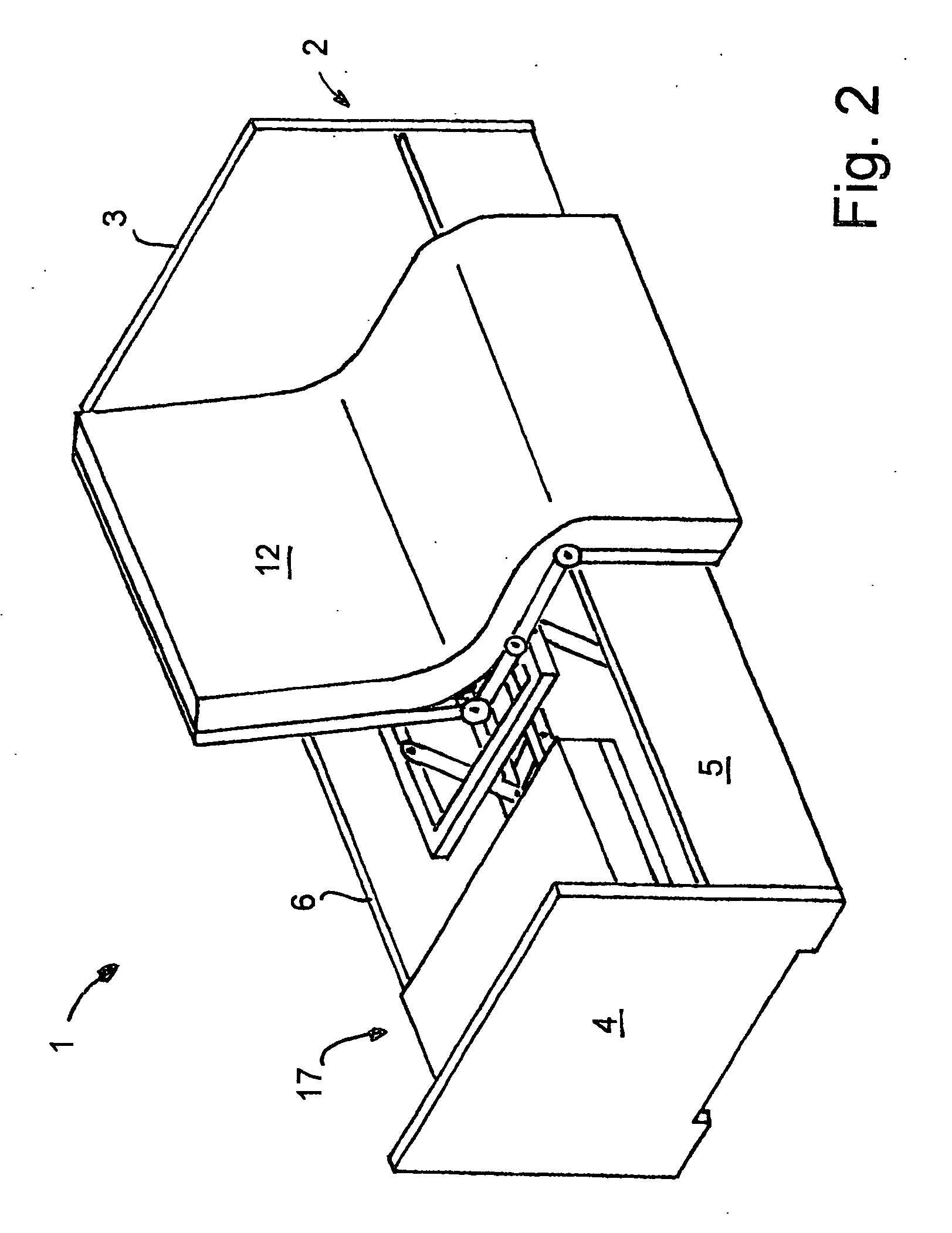

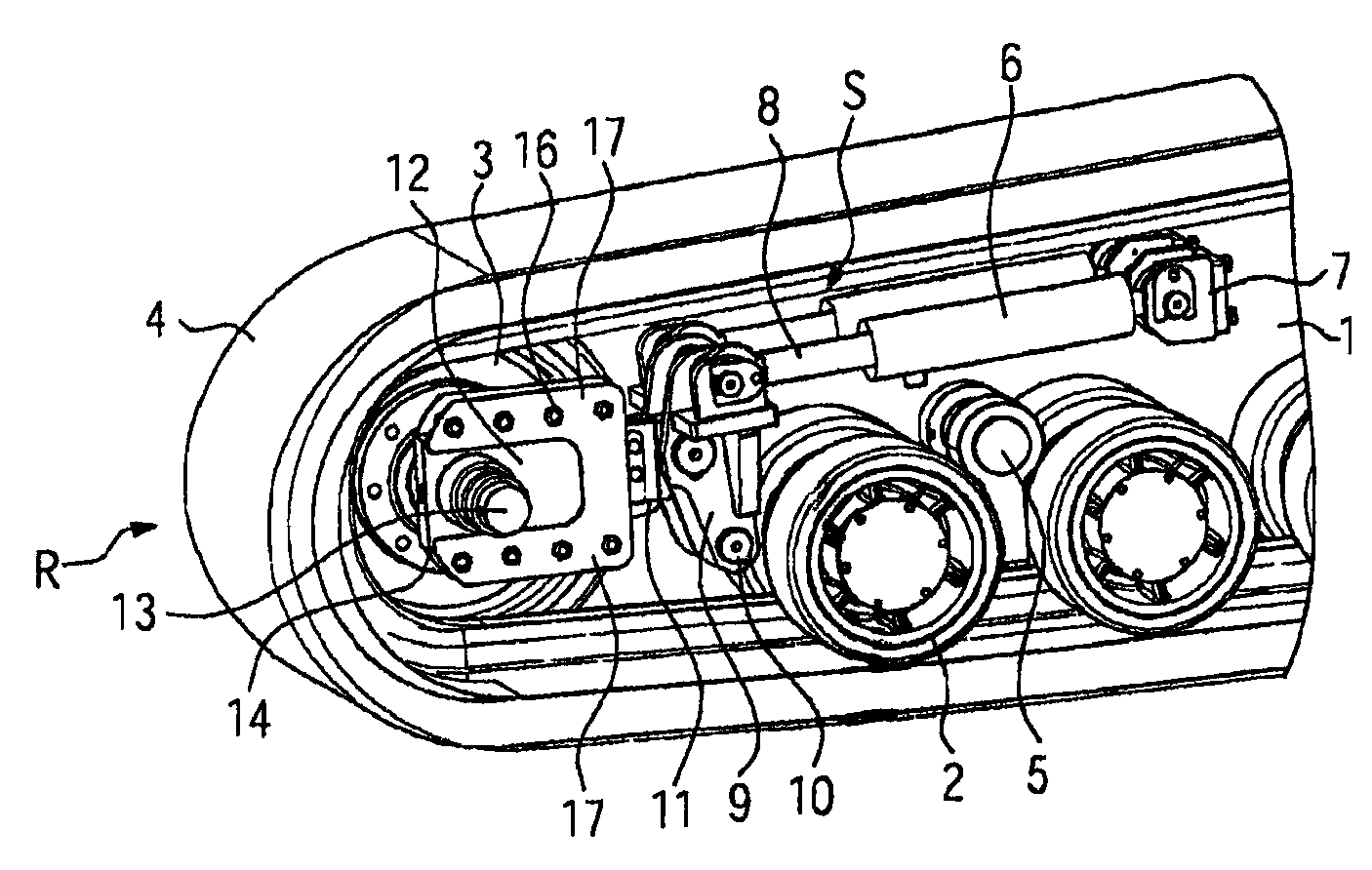

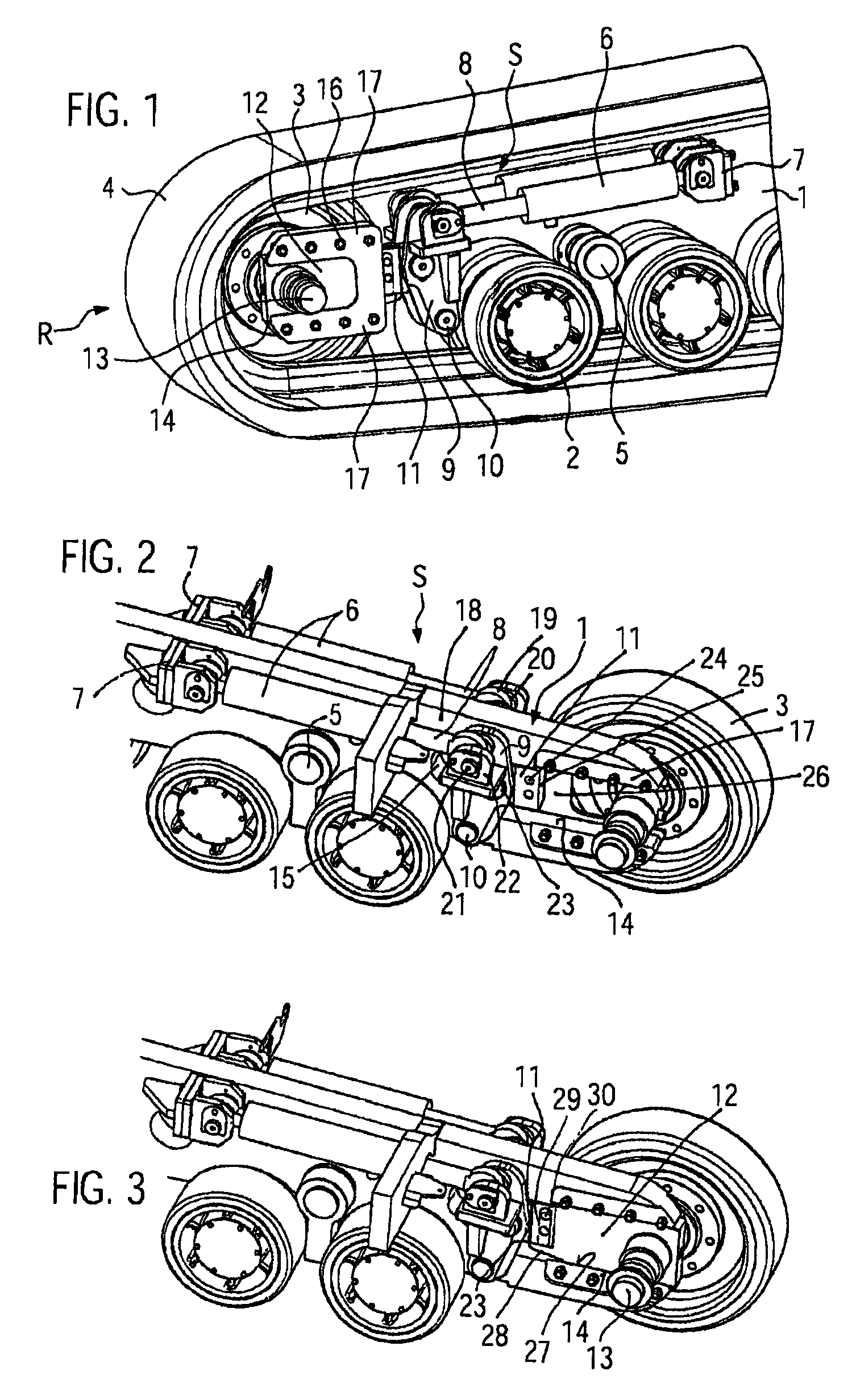

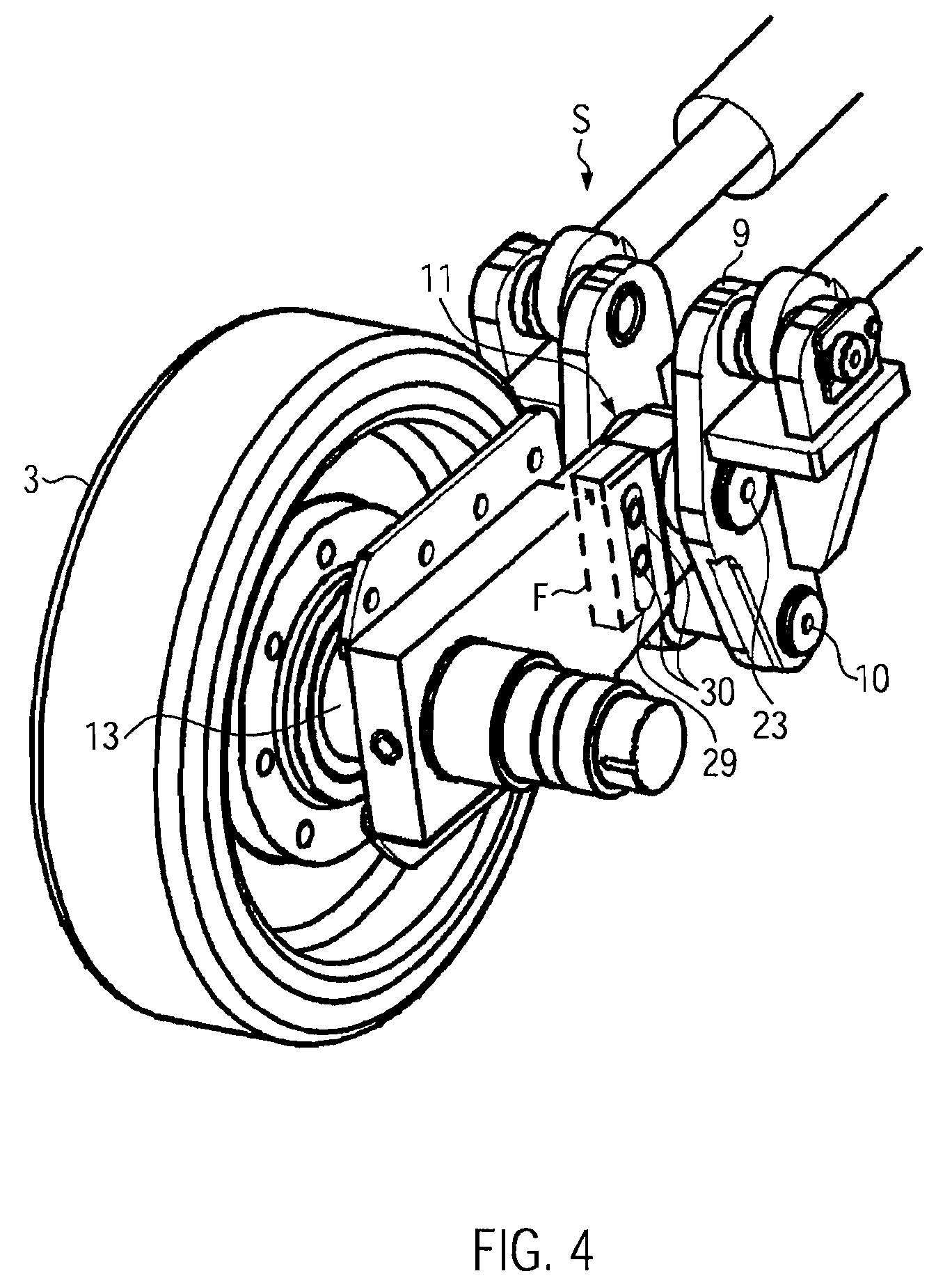

Movable belt conveyor system

ActiveUS7191888B2Reduce weightUsed economicallyUnderground miningSoil-shifting machines/dredgersSurface pressureCopper

A movable belt conveyor system for a leach pad for use for sulfidic copper ore, where favorable conditions are to be generated for leaching out the copper by a slight compaction of the ore piled up into a dump for the microbiological leaching technology. The movable belt conveyor system of a length of up to several km is composed of a plurality of smaller belt segments, comprising a tail segment (70), standard segments (711-n) and a head segment (72), as well as a traveling tripper (8). To prevent the loading by these individual components from being excessively compacted by the weight of the device during multiple travel over the dump during the moving process, the belt drives with the driving drum are accommodated in the tail element (70), which is supported on the soil next to the leach pad. In addition, the traveling tripper (8) is designed as an independent unit with the belt drums, additional belt drives and the belt-tensioning means, which unit is autarchically displaceable on a caterpillar-type moving gear (85) of its own. Due to the moving of the belt on the caterpillar-type moving gears of the standard segments (711-n), on the head segment (72) and on the traveling tripper (8) as well as due to the absorption of the weight of the tail segment (70) by the transfer carriage (6), the surface pressure acting locally on the dump is reduced and the compaction of the ore on the dump due to being traveled over by the belt conveyor system remains low. Traveling over with a moving device, which frequently happens with the use of a moving caterpillar, is eliminated.

Owner:MAN TAKRAF FORDERTECHN

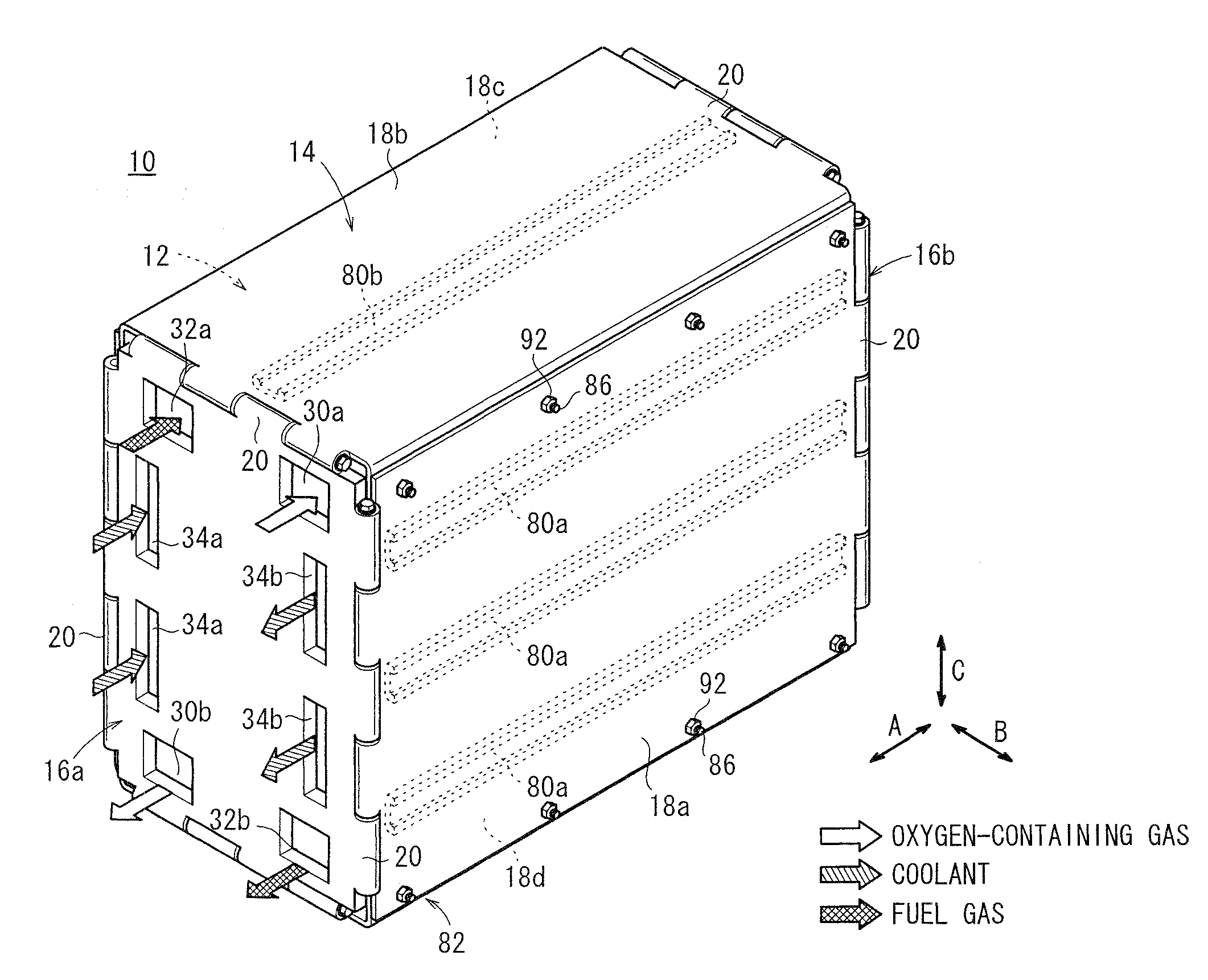

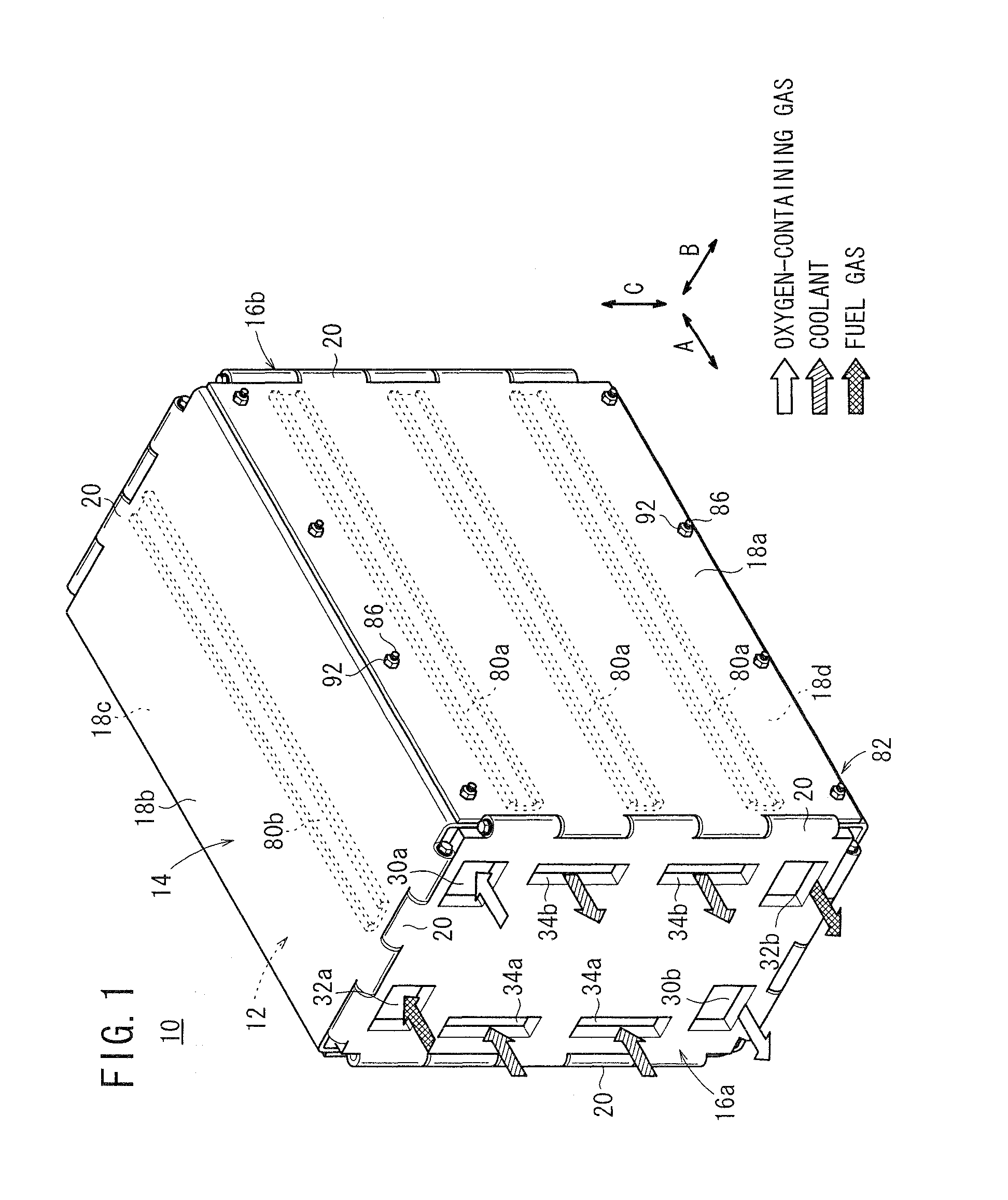

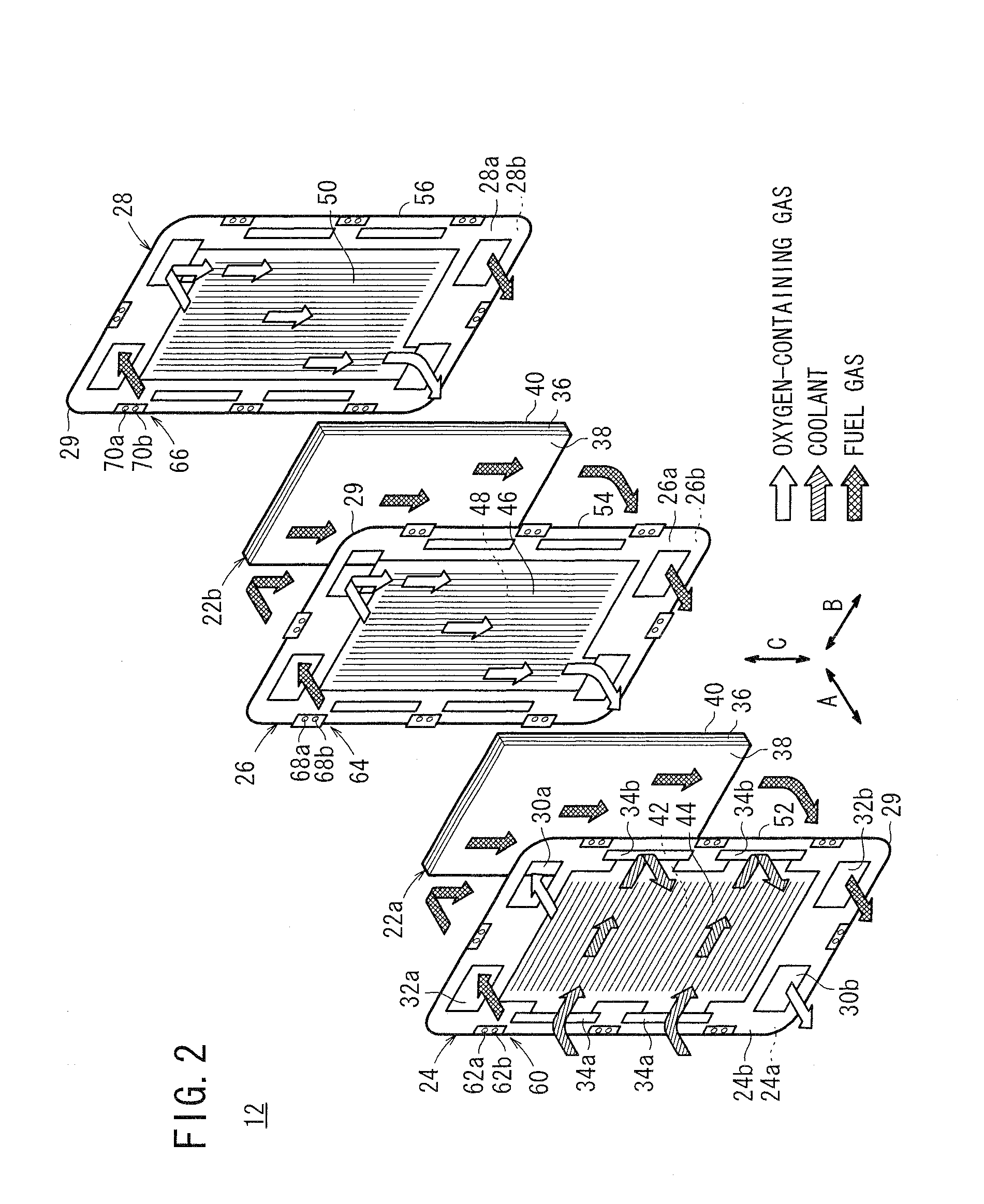

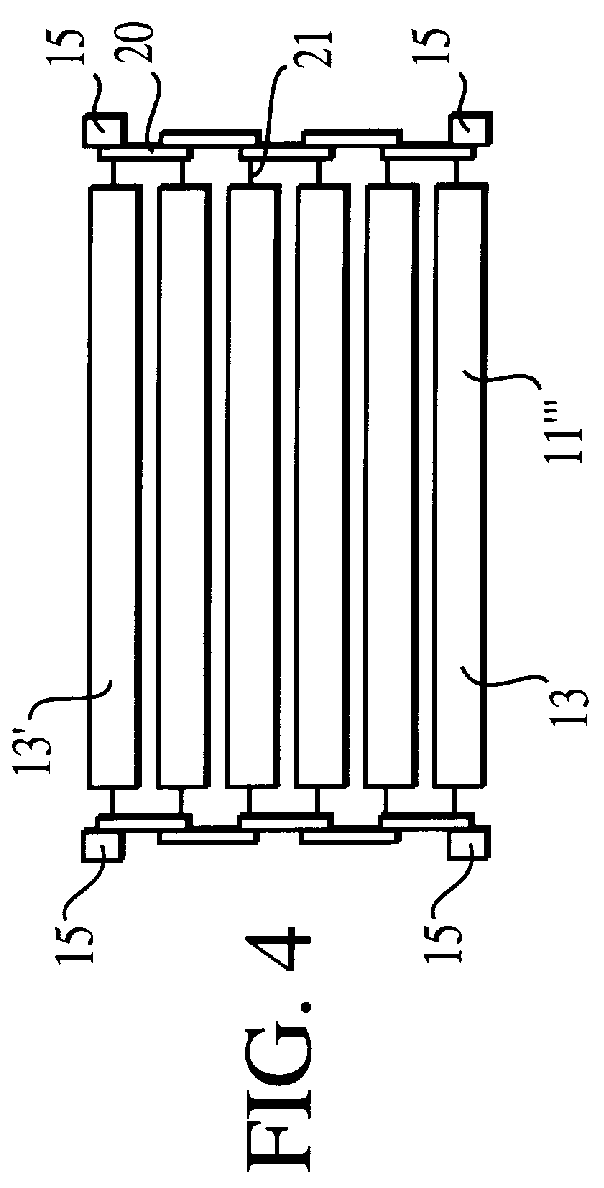

Fuel cell stack

InactiveUS20080305368A1Avoid lateral displacementSmall sizeFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell stack includes a load receiver provided at an outer end of a fuel cell unit, a guide receiver provided in a box, and a pressure receiver provided in at least one corner in the box. The guide receiver abuts against the load receiver for receiving the external load. The pressure receiver protrudes toward the fuel cell unit. The pressure receiver abuts against a corner of the fuel cell unit for receiving the load. The pressure receiver has a resin receiver, and the resin receiver abuts against a curved portion of the fuel cell unit for supporting the fuel cell unit.

Owner:HONDA MOTOR CO LTD

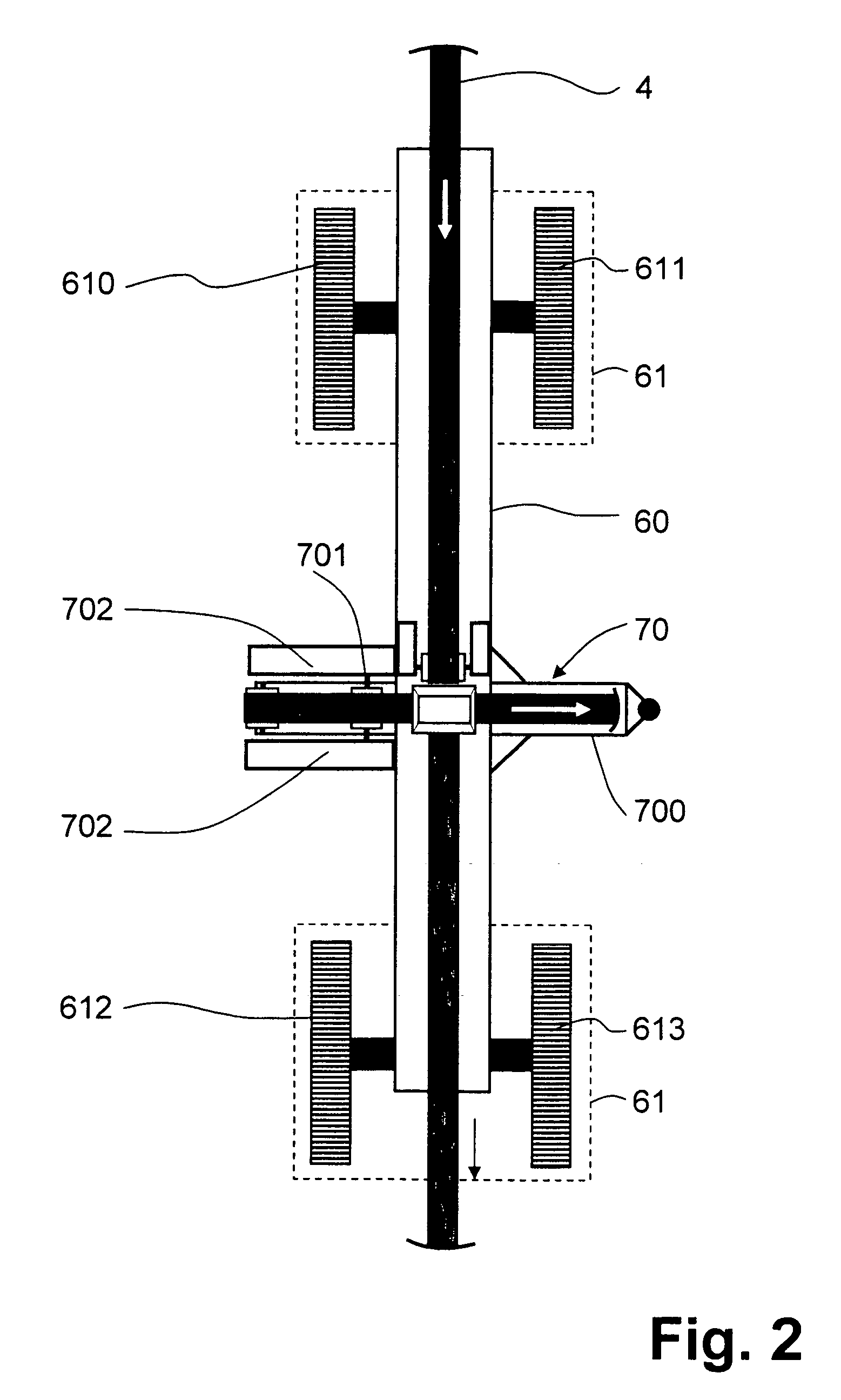

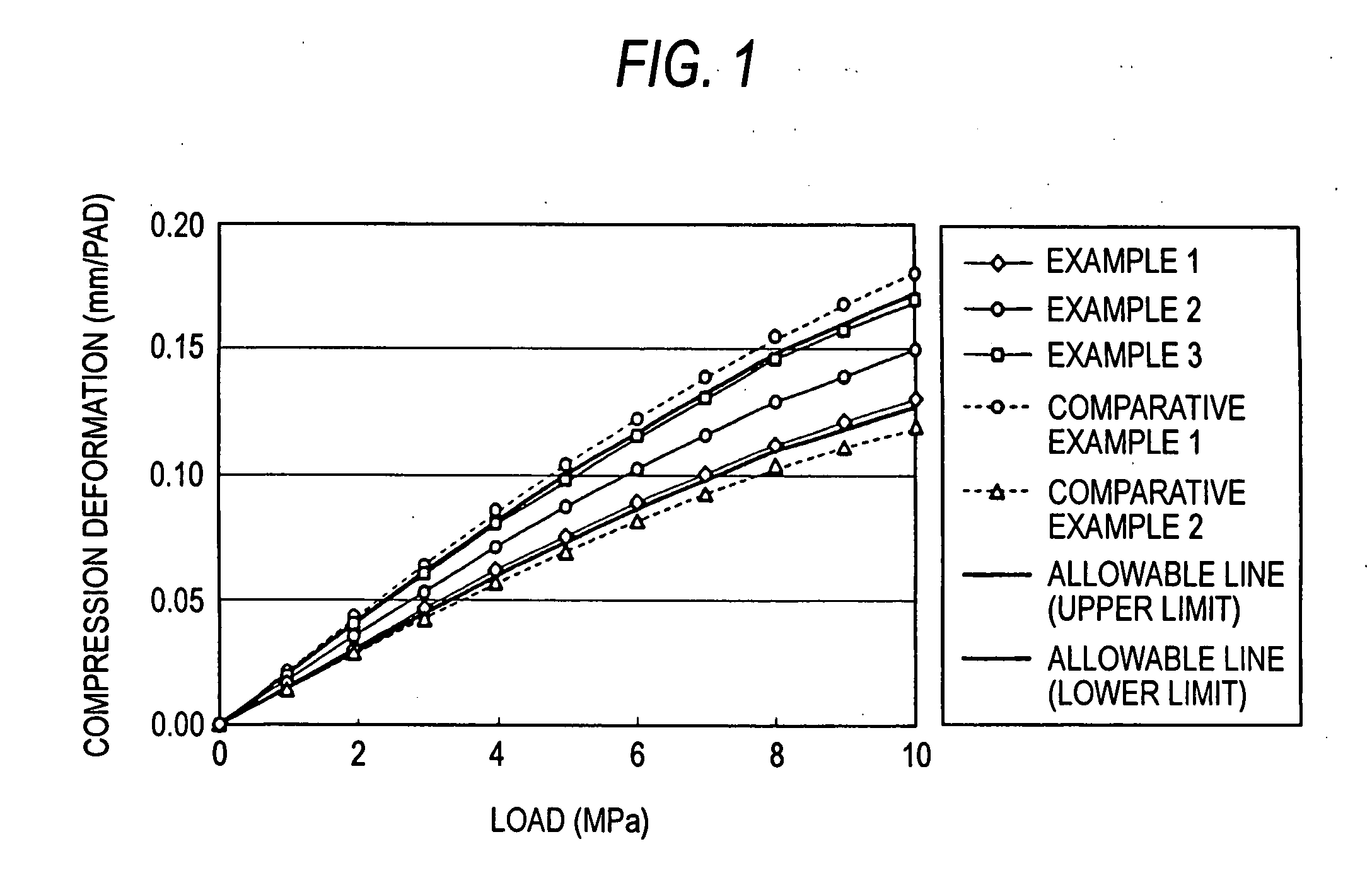

Movable belt conveyor system

ActiveUS20070039802A1Reduce weightUsed economicallyUnderground miningSoil-shifting machines/dredgersEngineeringSurface pressure

A movable belt conveyor system for a leach pad for use for sulfidic copper ore, where favorable conditions are to be generated for leaching out the copper by a slight compaction of the ore piled up into a dump for the microbiological leaching technology. The movable belt conveyor system of a length of up to several km is composed of a plurality of smaller belt segments, comprising a tail segment (70), standard segments (711-n) and a head segment (72), as well as a traveling tripper (8). To prevent the loading by these individual components from being excessively compacted by the weight of the device during multiple travel over the dump during the moving process, the belt drives with the driving drum are accommodated in the tail element (70), which is supported on the soil next to the leach pad. In addition, the traveling tripper (8) is designed as an independent unit with the belt drums, additional belt drives and the belt-tensioning means, which unit is autarchically displaceable on a caterpillar-type moving gear (85) of its own. Due to the moving of the belt on the caterpillar-type moving gears of the standard segments (711-n), on the head segment (72) and on the traveling tripper (8) as well as due to the absorption of the weight of the tail segment (70) by the transfer carriage (6), the surface pressure acting locally on the dump is reduced and the compaction of the ore on the dump due to being traveled over by the belt conveyor system remains low. Traveling over with a moving device, which frequently happens with the use of a moving caterpillar, is eliminated.

Owner:MAN TAKRAF FORDERTECHN

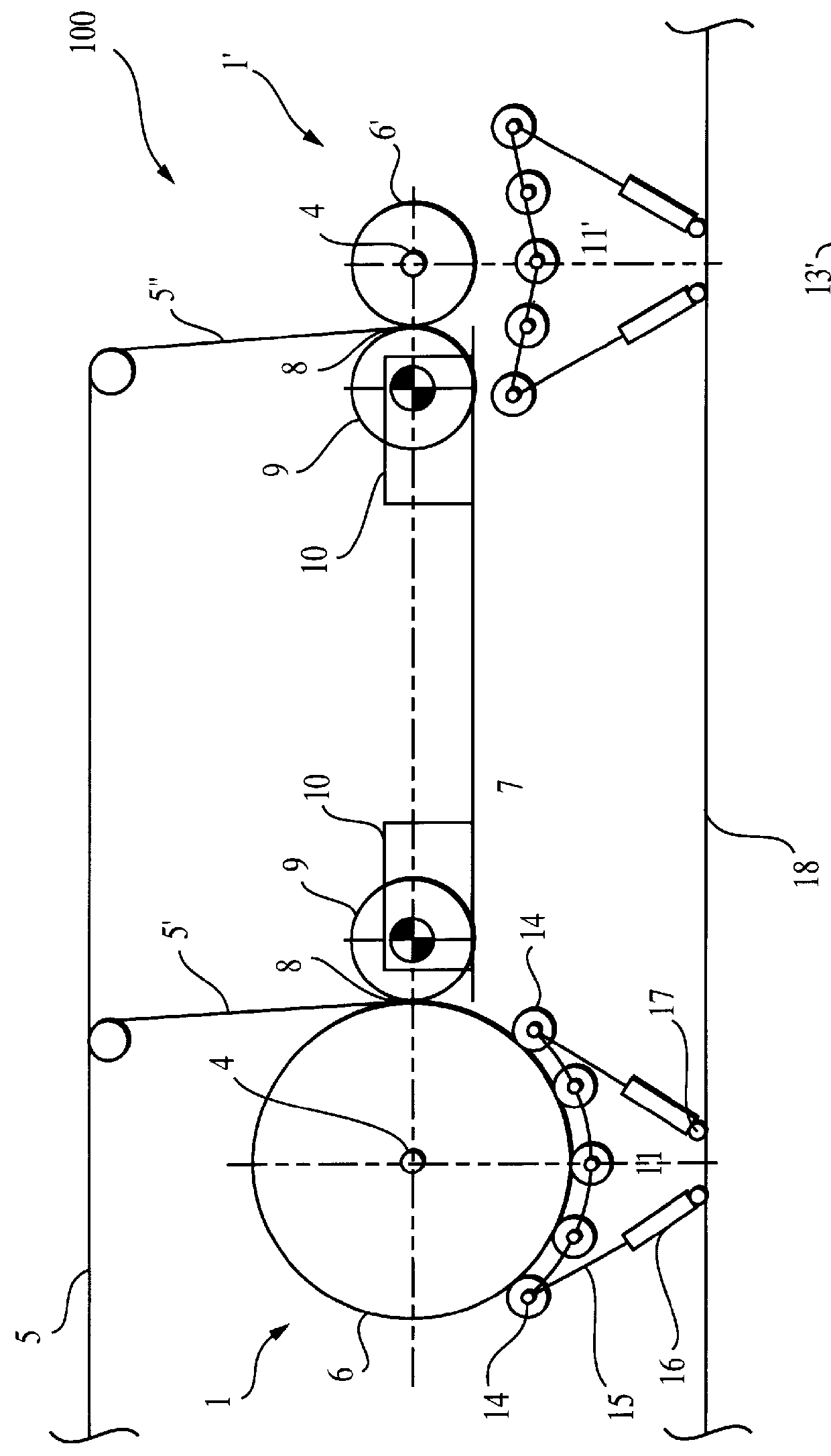

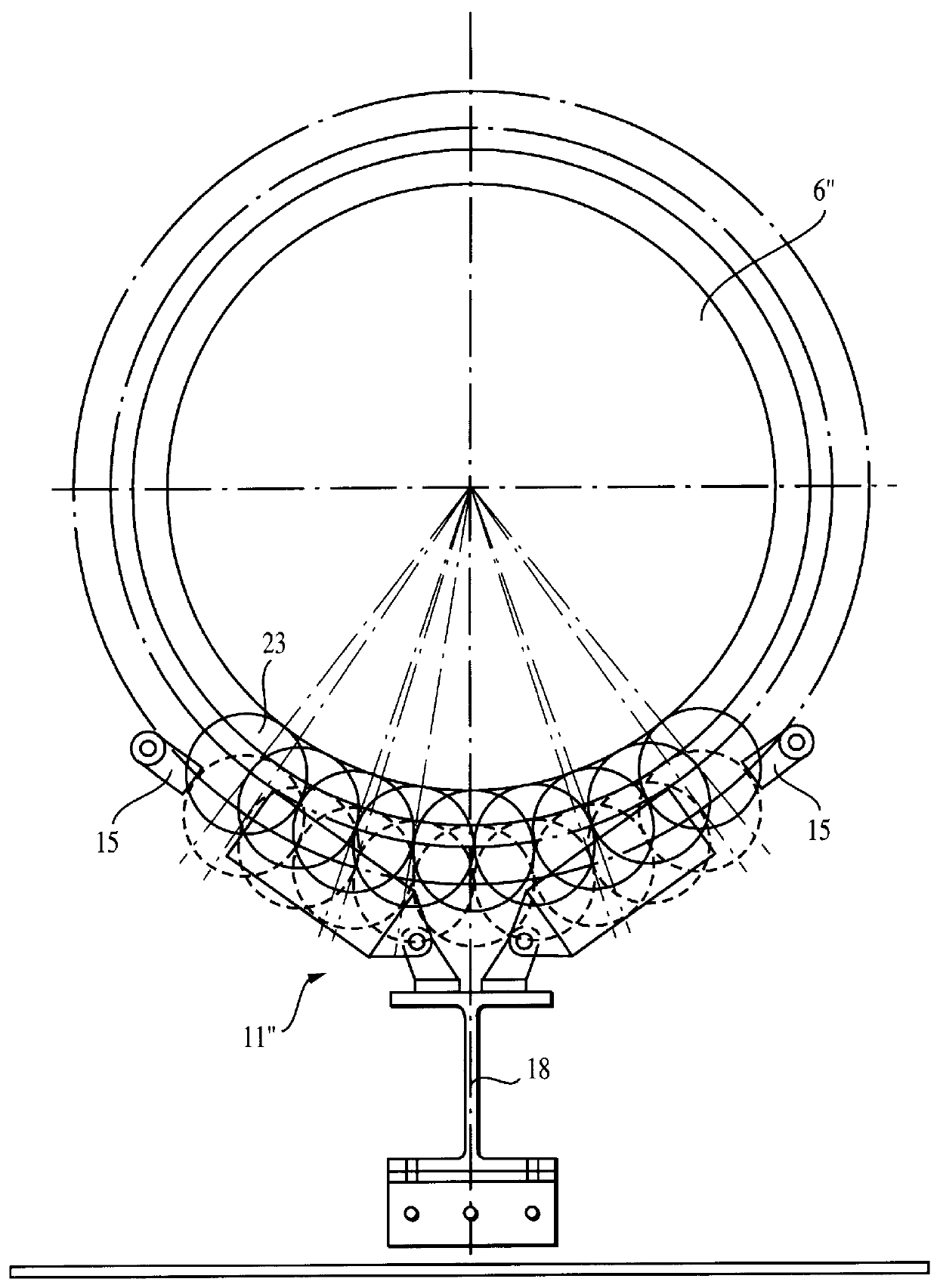

Winding device including a support device and winding process

Apparatus and process for at least one of winding a material web onto and unwinding a material web off of a winding roll. The apparatus includes a winding roll and a support device, adapted to be positioned against a circumferential portion of the winding roll, that includes a plurality of rotational axes arranged substantially parallel to each other and substantially parallel to a winding axis of the winding roll and a plurality of rotatable rollers arranged on the plurality of rotational axes. The plurality of rotational axes are swivelably coupled to one another substantially perpendicularly to the rotational axes. The process includes turning the winding roll, horizontally tensioning a support device formed as one of a belt and chain, upon attaining a predefined roll diameter, supporting a circumference of the winding roll from below with the support device, and vertically moving ends of the support device at a rate of speed less than approximately a rate of change of diameter of the winding roll.

Owner:VOITH PAPER GMBH

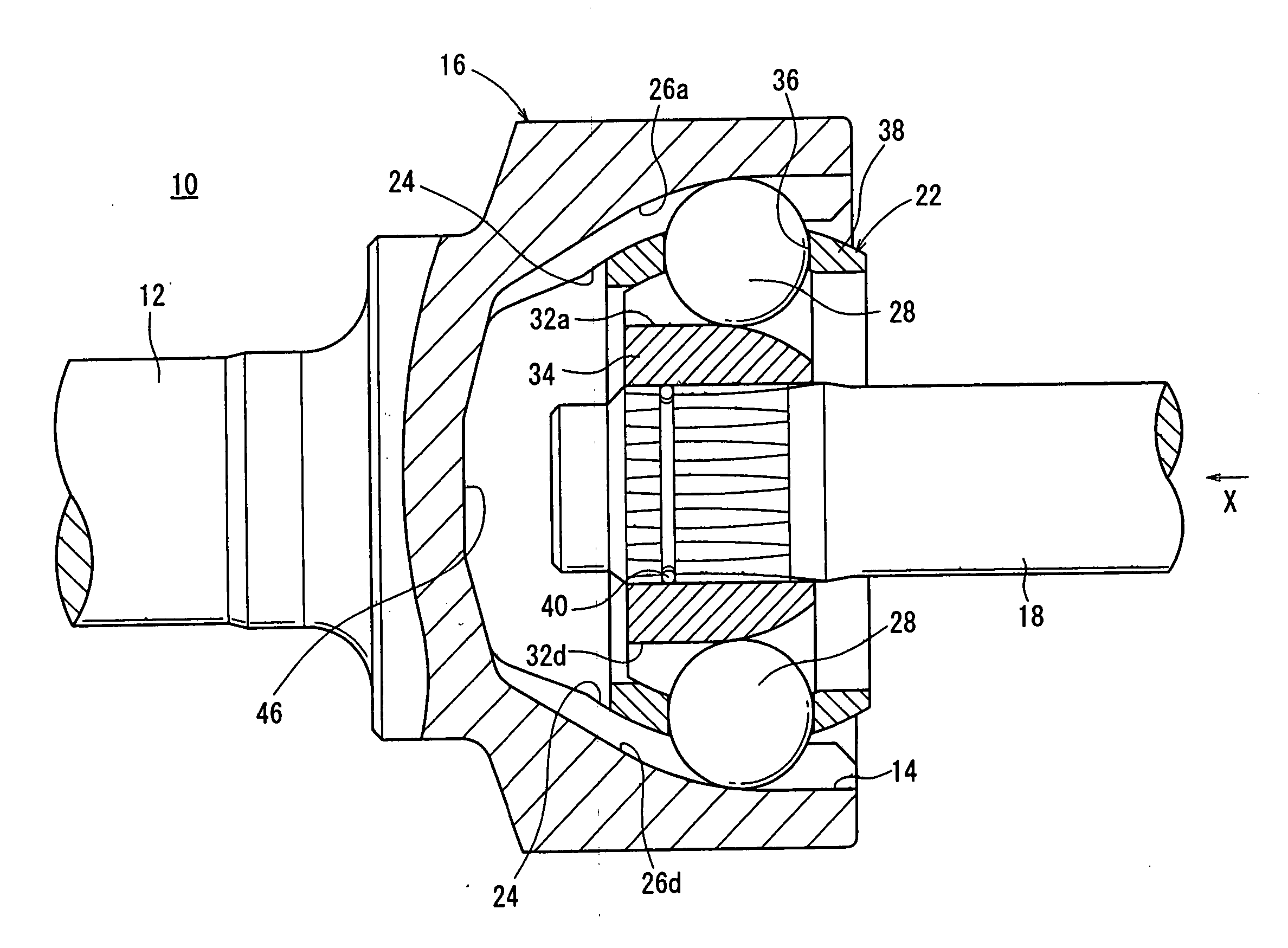

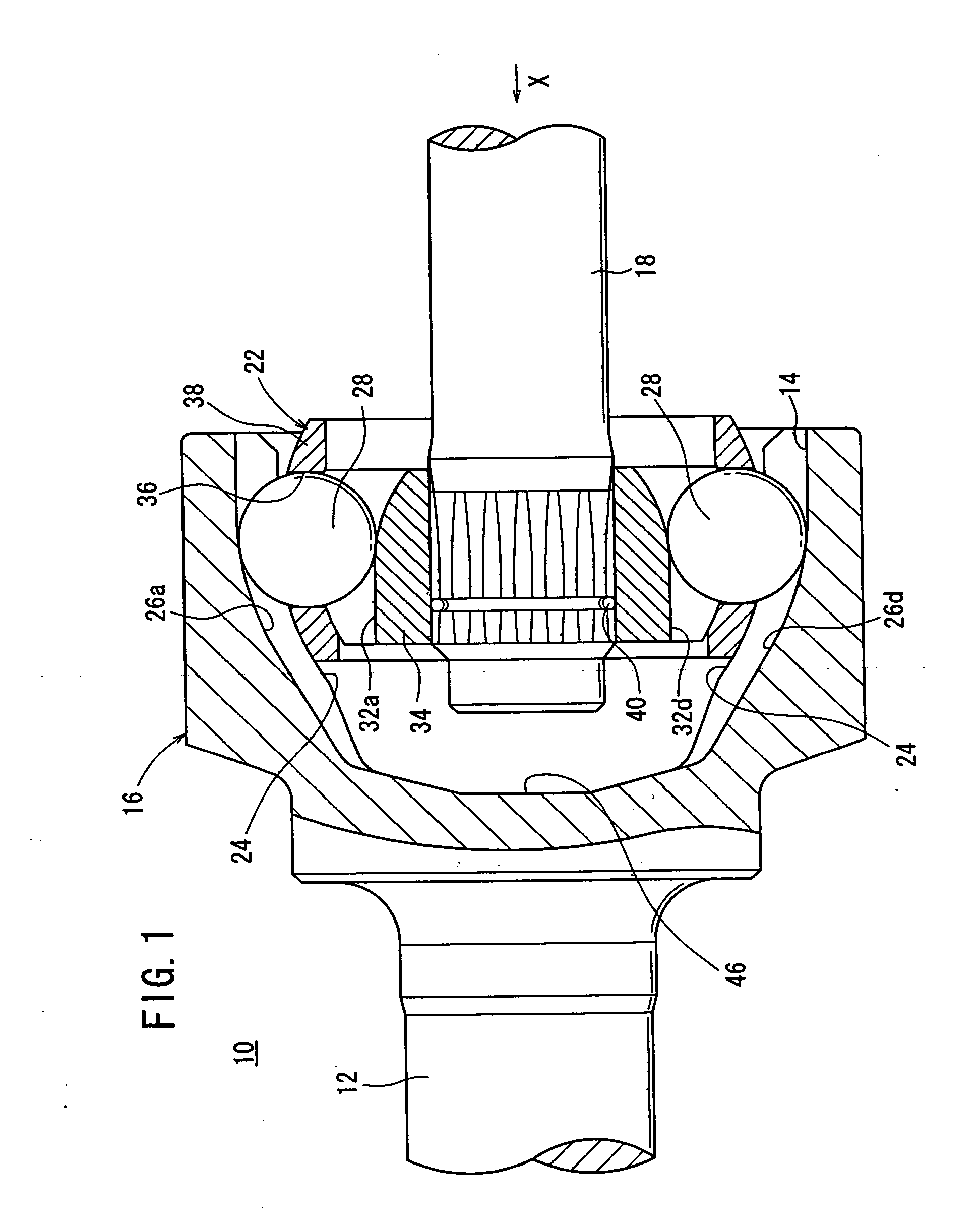

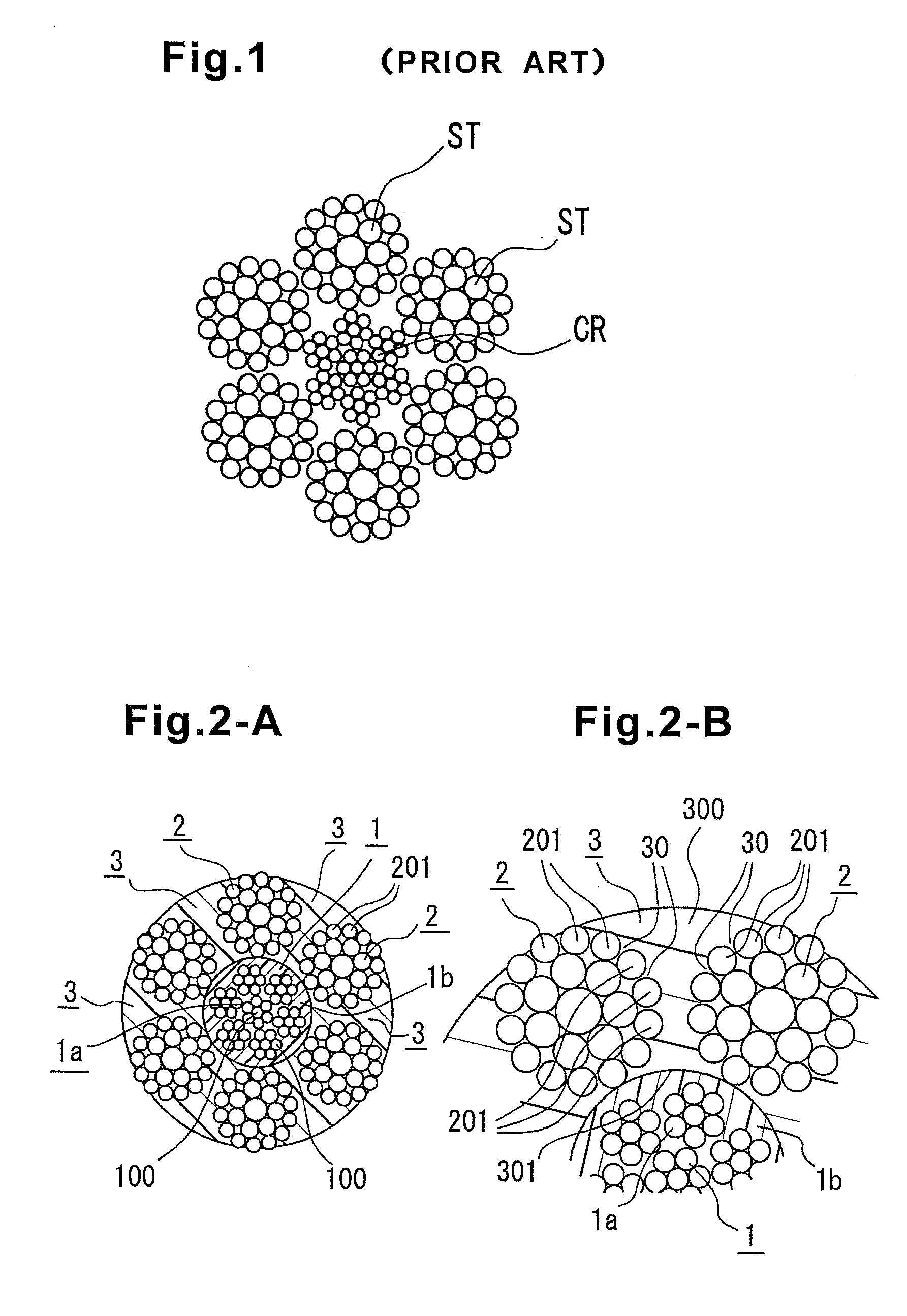

Constant velocity joint

InactiveUS20070161428A1Increased durabilityReduce surface pressureYielding couplingRotary machine partsConstant-velocity jointEllipse

Lateral cross-sections of first guiding grooves provided in the inner wall surface of an outer cup are formed in a circular arc shape for one point contact with balls, and lateral cross-sections of second guiding grooves provided in the outer wall surface of an inner ring are formed in an elliptic arc shape for two-point contact with the balls. The diameter of a ball and an offset amount between a first and a second groove is set to satisfy the expression of 0.12≦V≦0.14 with V being the ratio of the two values.

Owner:HONDA MOTOR CO LTD

Profile clamp and method for manufacturing a profile clamp

InactiveUS6383315B1High hardnessHigh strengthFlanged jointsExhaust apparatusCarrying capacityThermal expansion

A steel profile clamp is used to join flanged component parts. The profile clamp has at least partially conical side walls that are bent radially inwardly. The profile clamp has welding joints to maintain the shape of the clamp. The steel is martensitic for increased load-carrying capacity of the joint. The steel material, in an ambient temperature range of 20° C. to 750° C., has a coefficient of thermal expansion that is at least 0.3x10-6 m / m° C. lower than that of the coefficient of thermal expansion of a ferritic casting material. The method for manufacturing the profile clamp includes prequenching and tempering the material of the profile clamp when it is in the form of a strip. After forming and welding the profile clamp, the weld is subject to induction tempering.

Owner:ABB (SCHWEIZ) AG

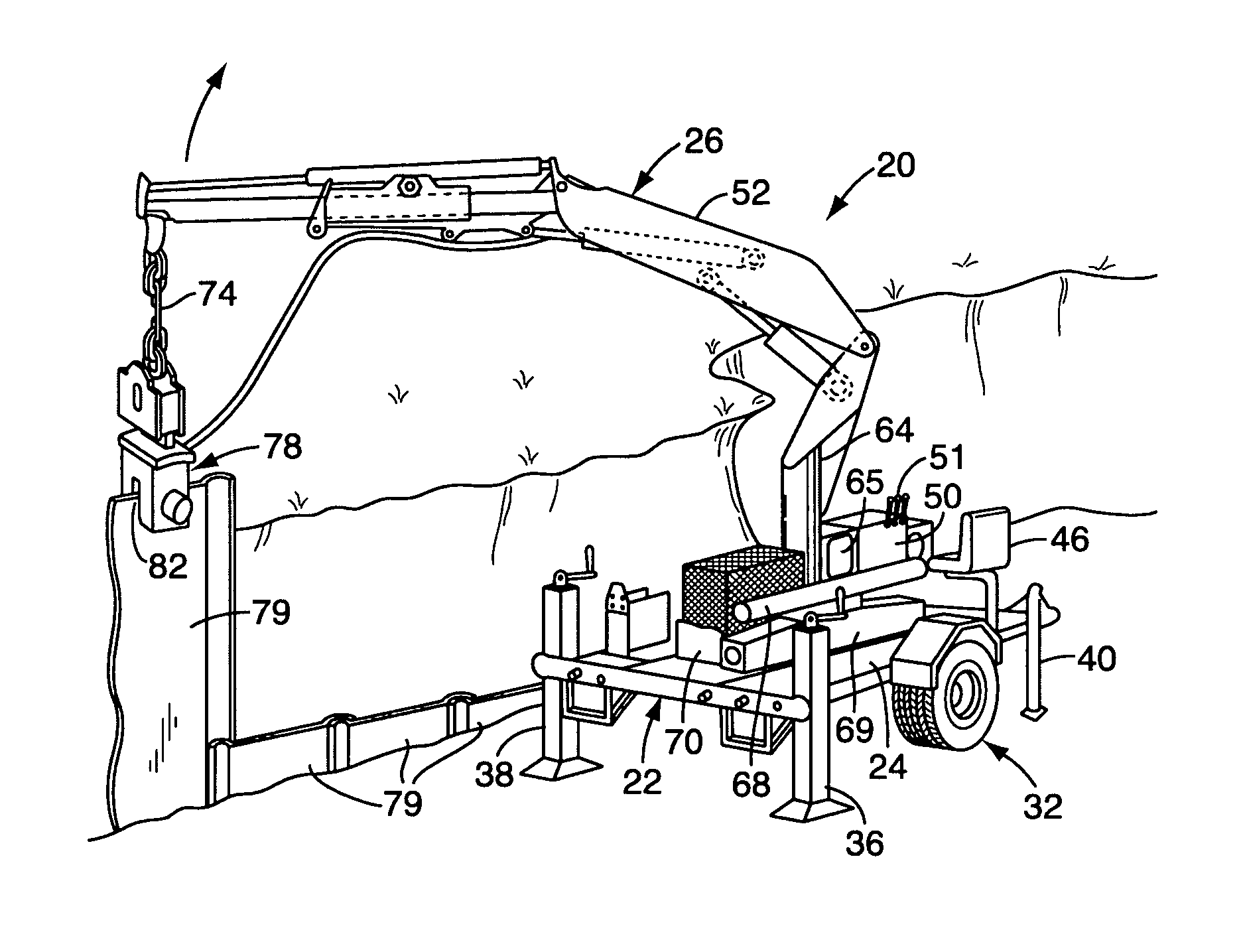

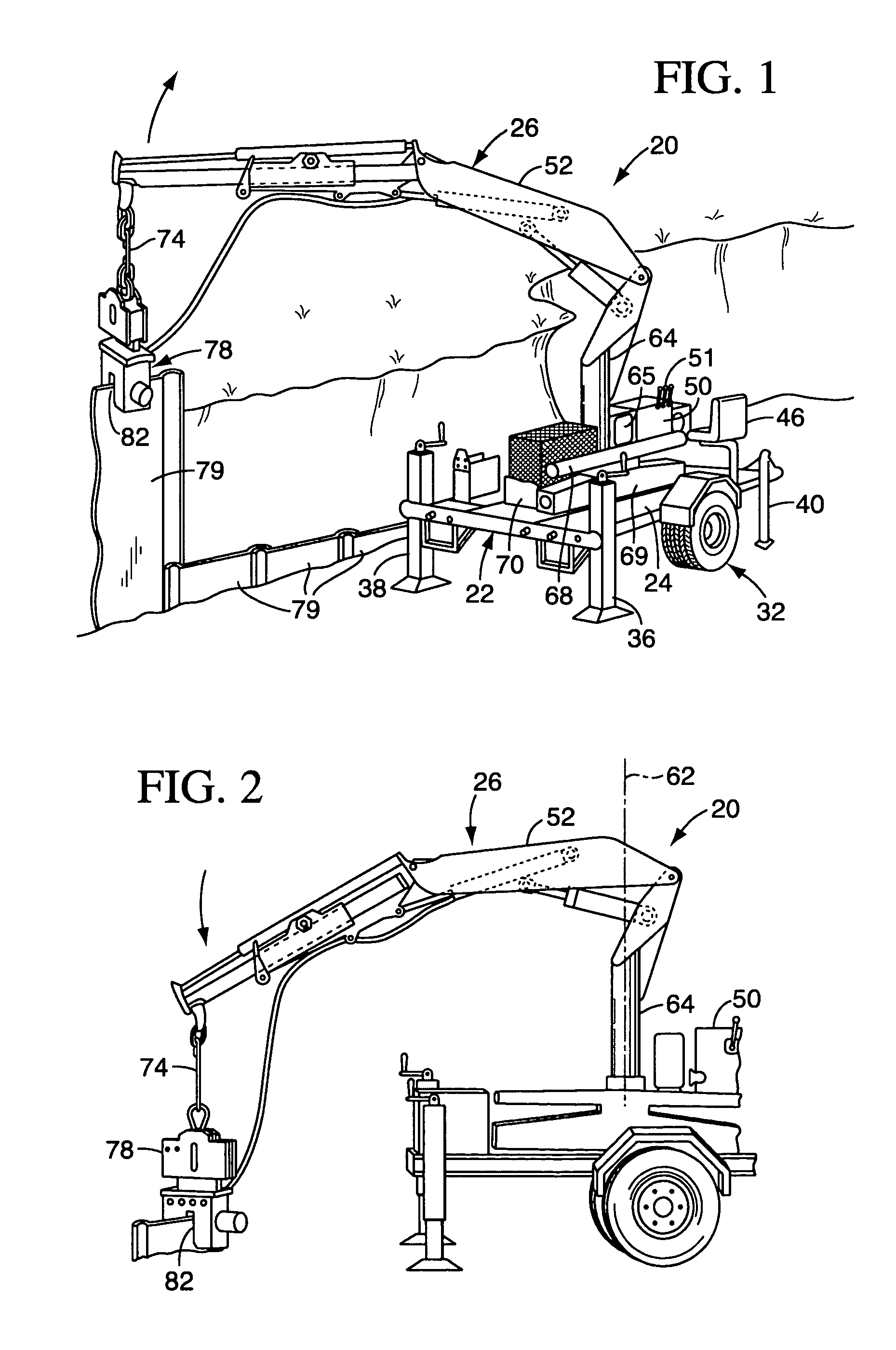

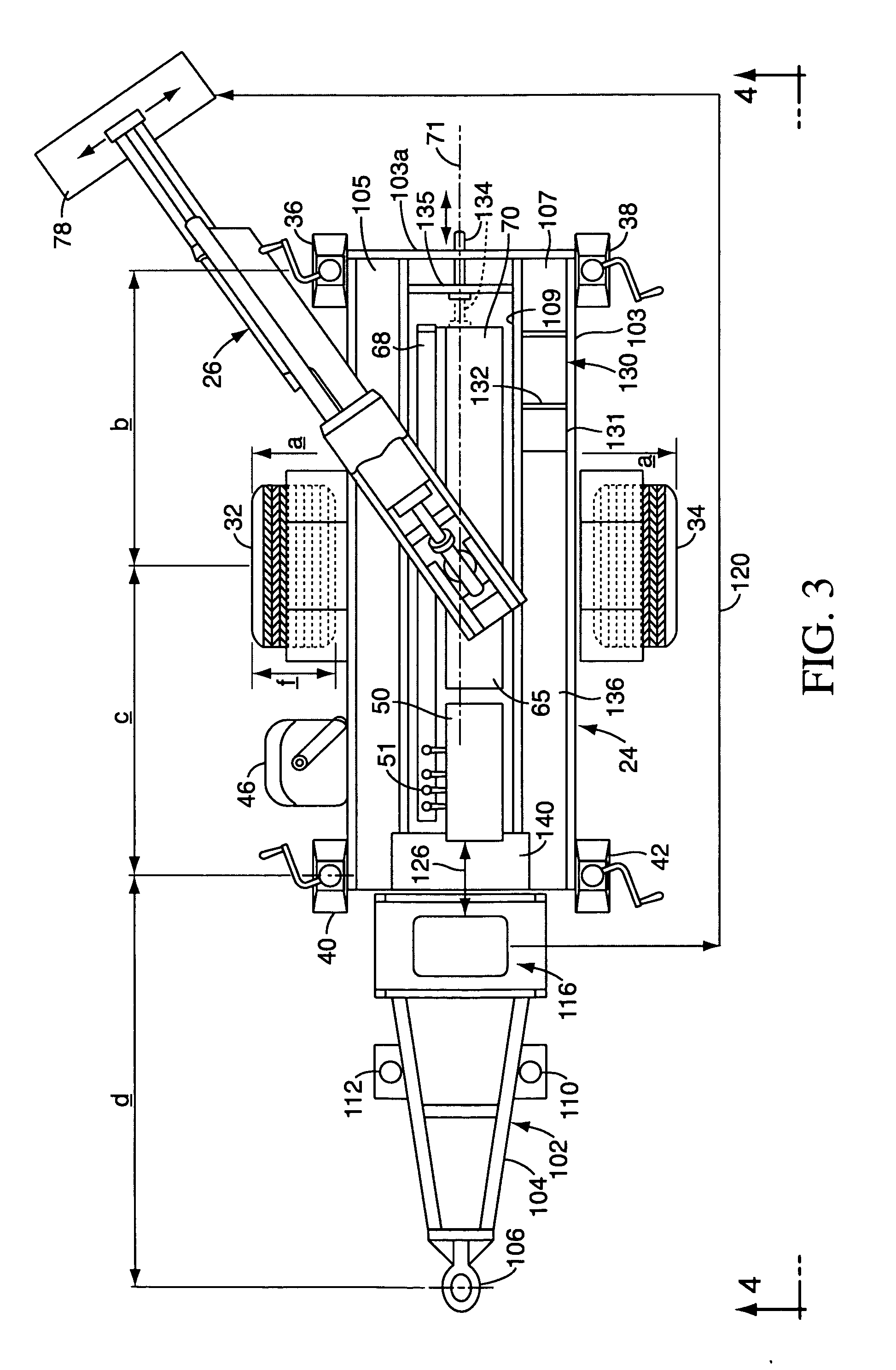

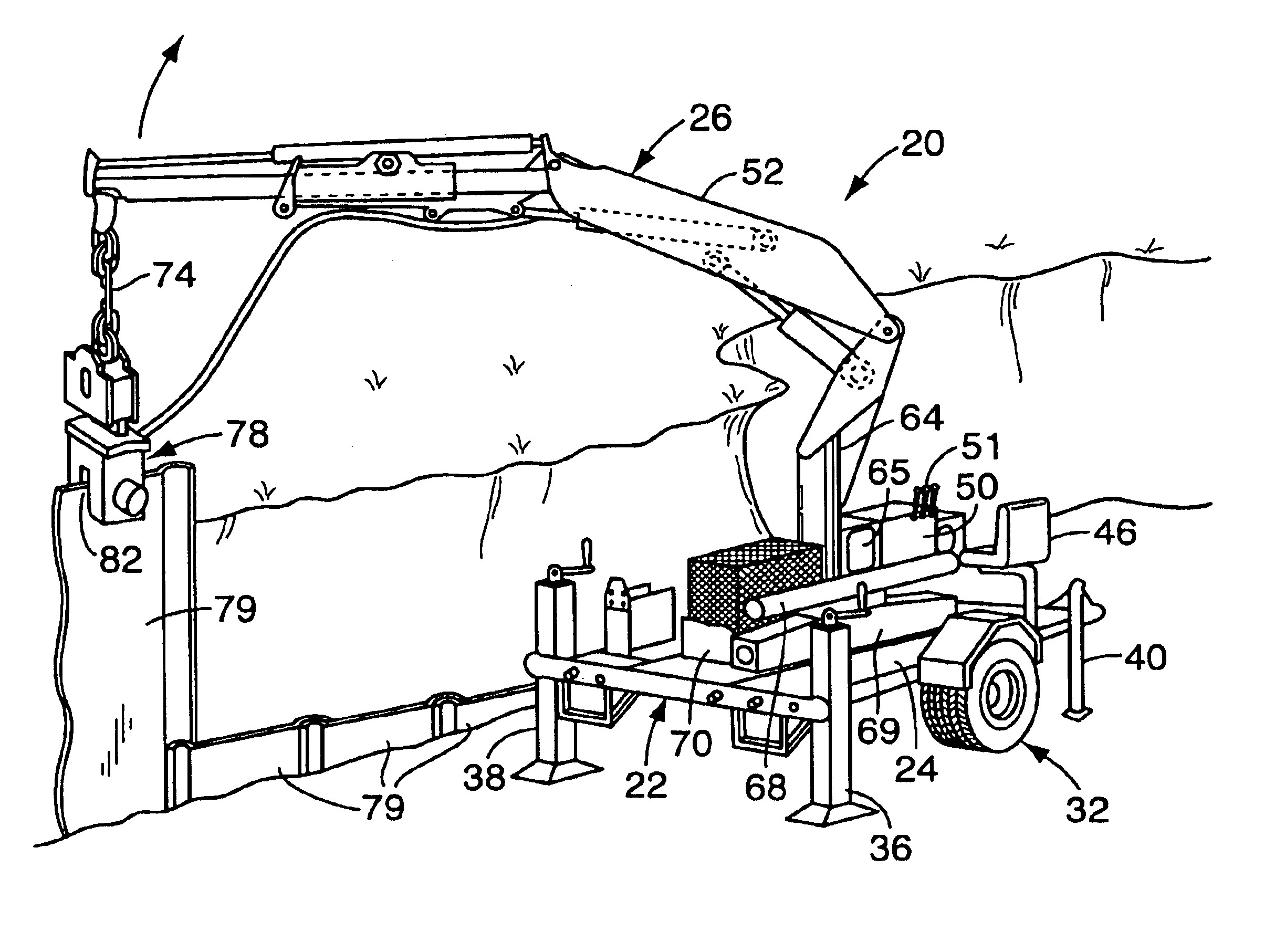

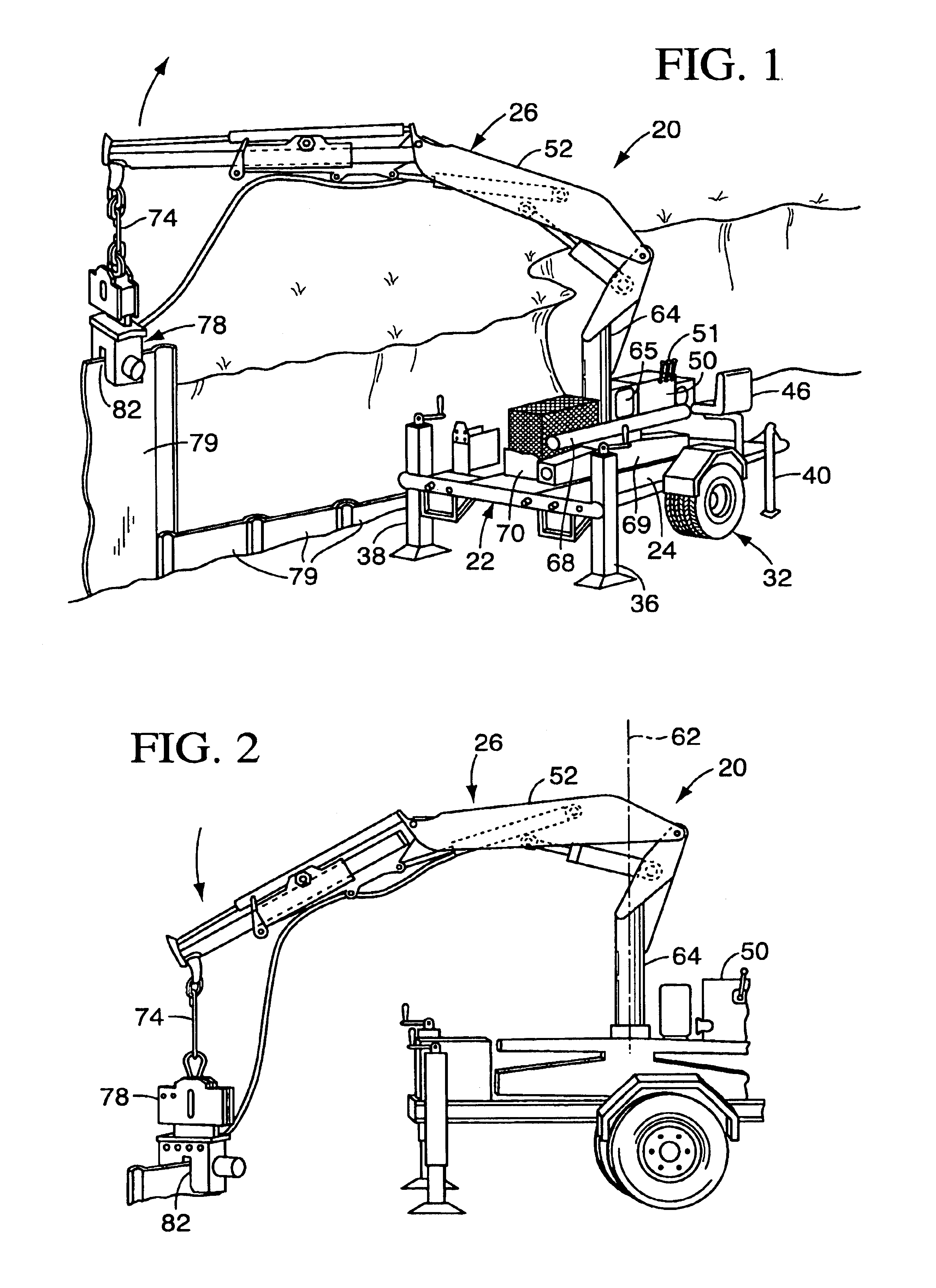

Trailer-mounted crane apparatus

InactiveUS20050220597A1Reduce surface pressureLight weightRefuse receptaclesLoading/unloading vehicle arrangmentDriver/operatorMarine engineering

A trailer-mounted crane apparatus includes a trailer supported from a ground surface on at least two wheels. A hydraulically operated crane arm is mounted to the trailer and is extendable outwardly. A crane hydraulic power unit is mounted to the trailer and supplies pressurized hydraulic fluid to the crane arm. A vibrational sheet piling driver can be supported by the crane arm. A vibrational hydraulic power unit for supplying power to the driver is mounted on the trailer. A control panel for the crane hydraulic power unit and the vibrational driver hydraulic power unit, and an associated operator's seat, are also mounted on the trailer. The crane apparatus includes wide tires for reducing the surface pressure under the apparatus. This allows the apparatus to be transported across and used on delicate surfaces such as golf course greens and other groomed surfaces.

Owner:BURKETT DARRYL S

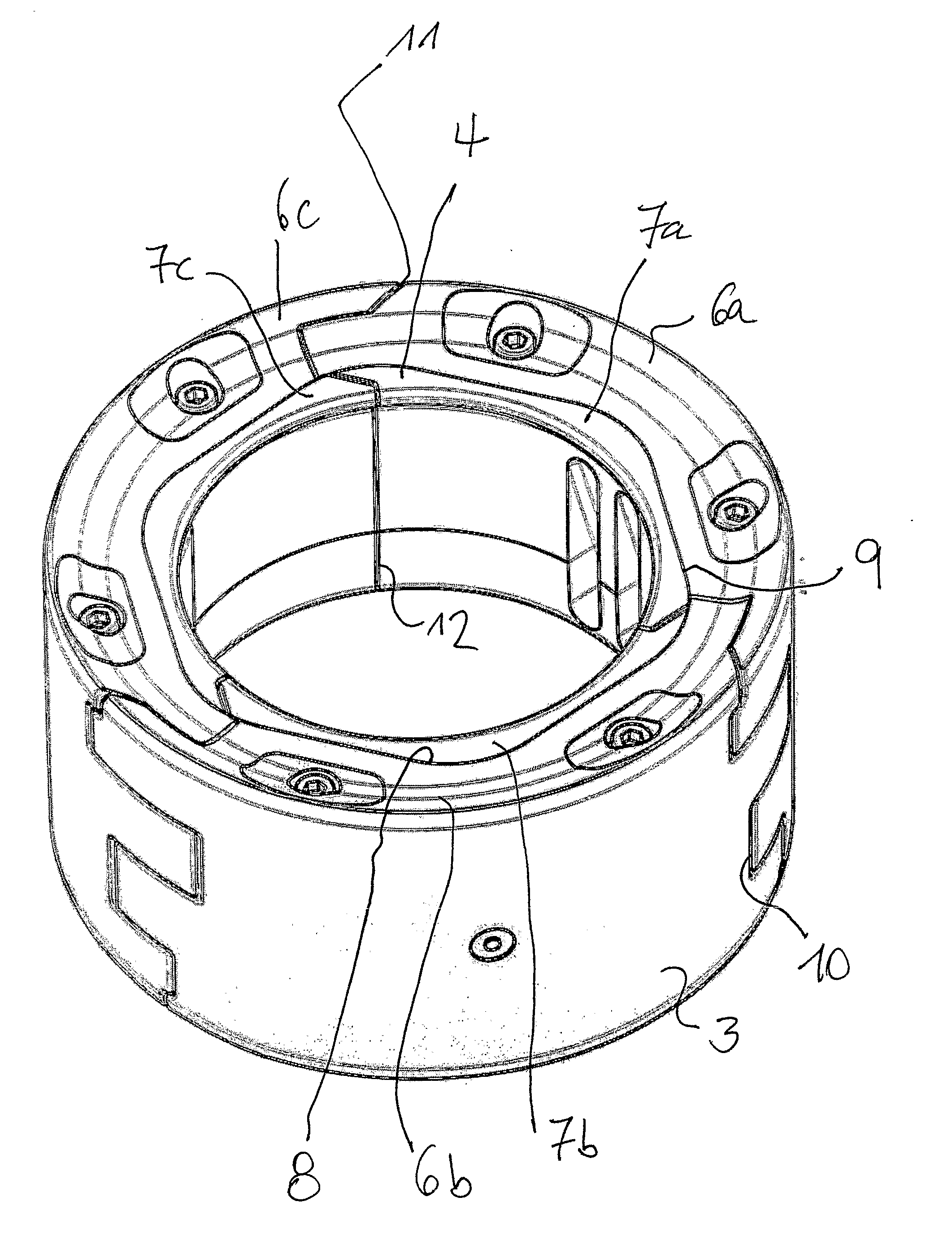

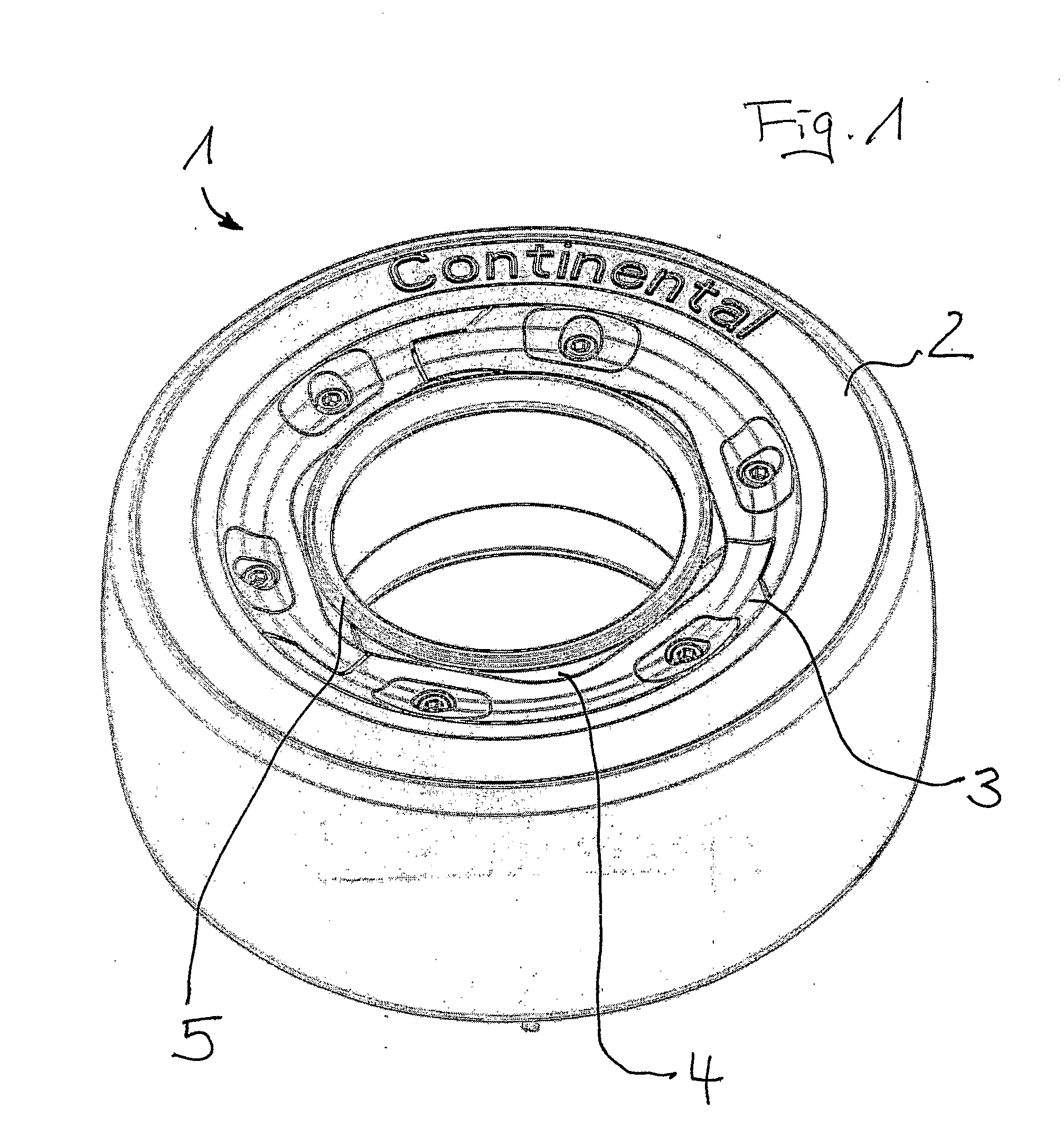

Vehicle Wheel Comprising A Wheel Rim And Rubber Tire

InactiveUS20070240800A1Laborious and lengthy handling is avoidedEasy to installWithout separate inflatable insertsRimsEngineeringMechanical engineering

A vehicle wheel with a wheel rim and a solid tire positioned on the wheel rim. The vehicle wheel has an annular upper shell having a first wedge-shaped surface and composed of at least two upper segments. Further, the vehicle wheel includes an annular lower shell composed of lower segments and having an outer circumference having a second wedge-shaped surface. Moreover, the second wedge-shaped surface is structured and arranged in a diametrically opposed manner to the first wedge-shaped surface. Additionally, the annular lower shell is arranged on the rim, the annular lower shell is arranged against the annular upper shell, and the annular upper shell is connected to the solid tire.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

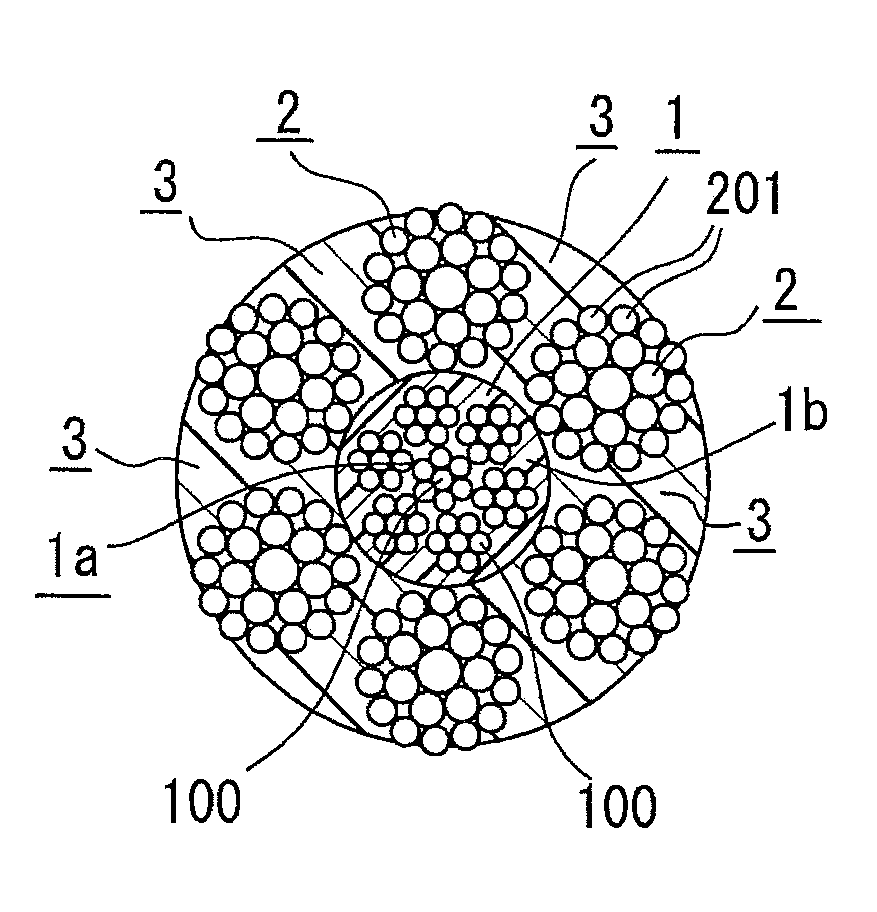

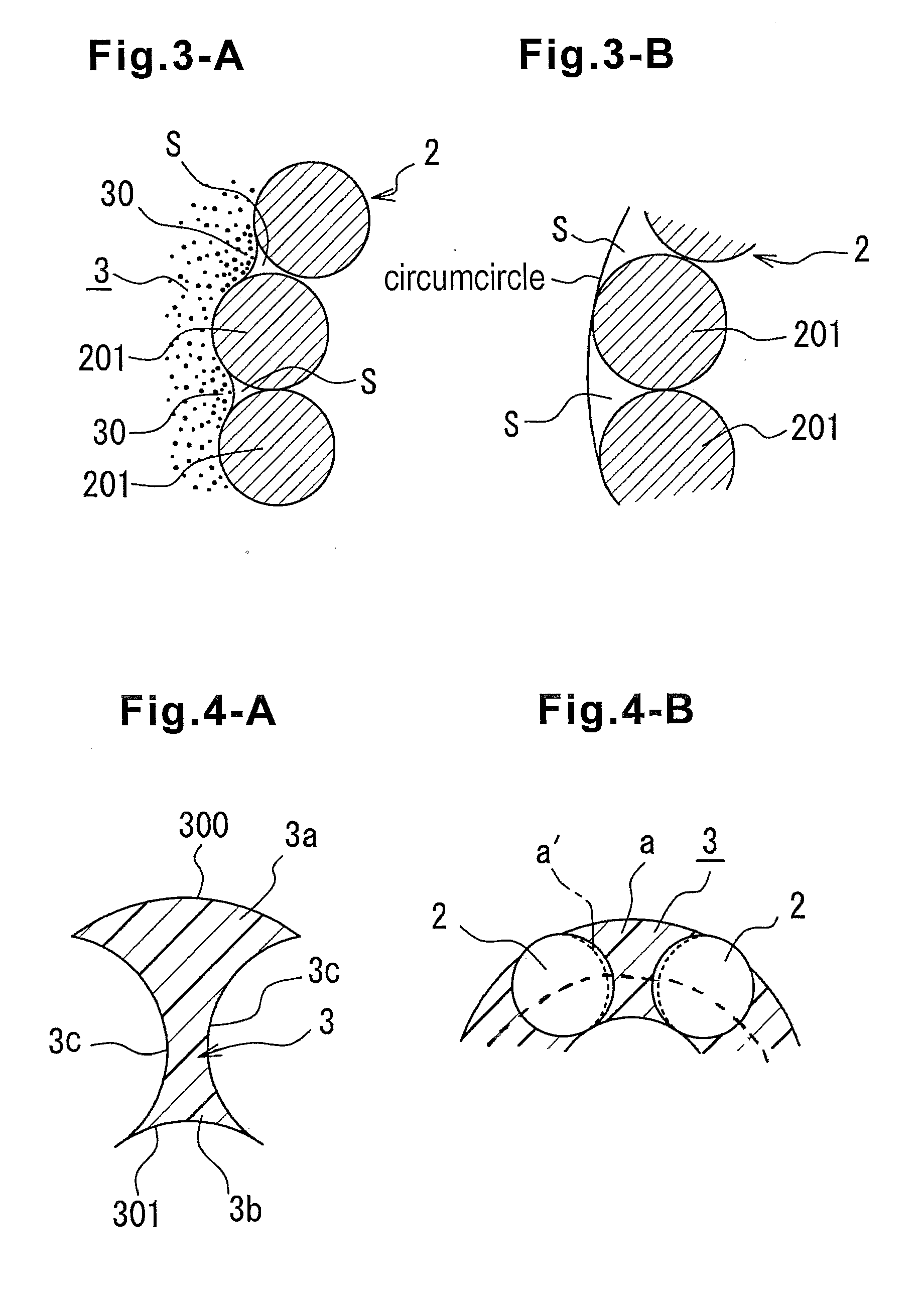

Wire rope for running wire

ActiveUS20080236130A1Improve fatigue lifeReduce disconnectionFilament/thread formingRope making machinesWire rodEngineering

In a rope of a type of filling a resin constituting other member between strands, there is provided a wire rope for a running wire capable of promoting fatigue life by reducing a wire breakage at a point of being contacted to a core rope by precisely constraining a movement of a wire and reducing an elongation.A rope having a core rope and a plurality of pieces of side strands arranged at an outer periphery thereof and twisted together, and a resinous spacer interposed between the side strands, in which the core rope includes a rope main body and a resin coating layer outwardly surrounding the core rope main body, the core rope main body and the side strand are separated by the resin coating layer, and the resin spacer is provided with a contour in correspondence with an outer layer wire of the side strand and invades between the wires.

Owner:TOKYO ROPE MFG

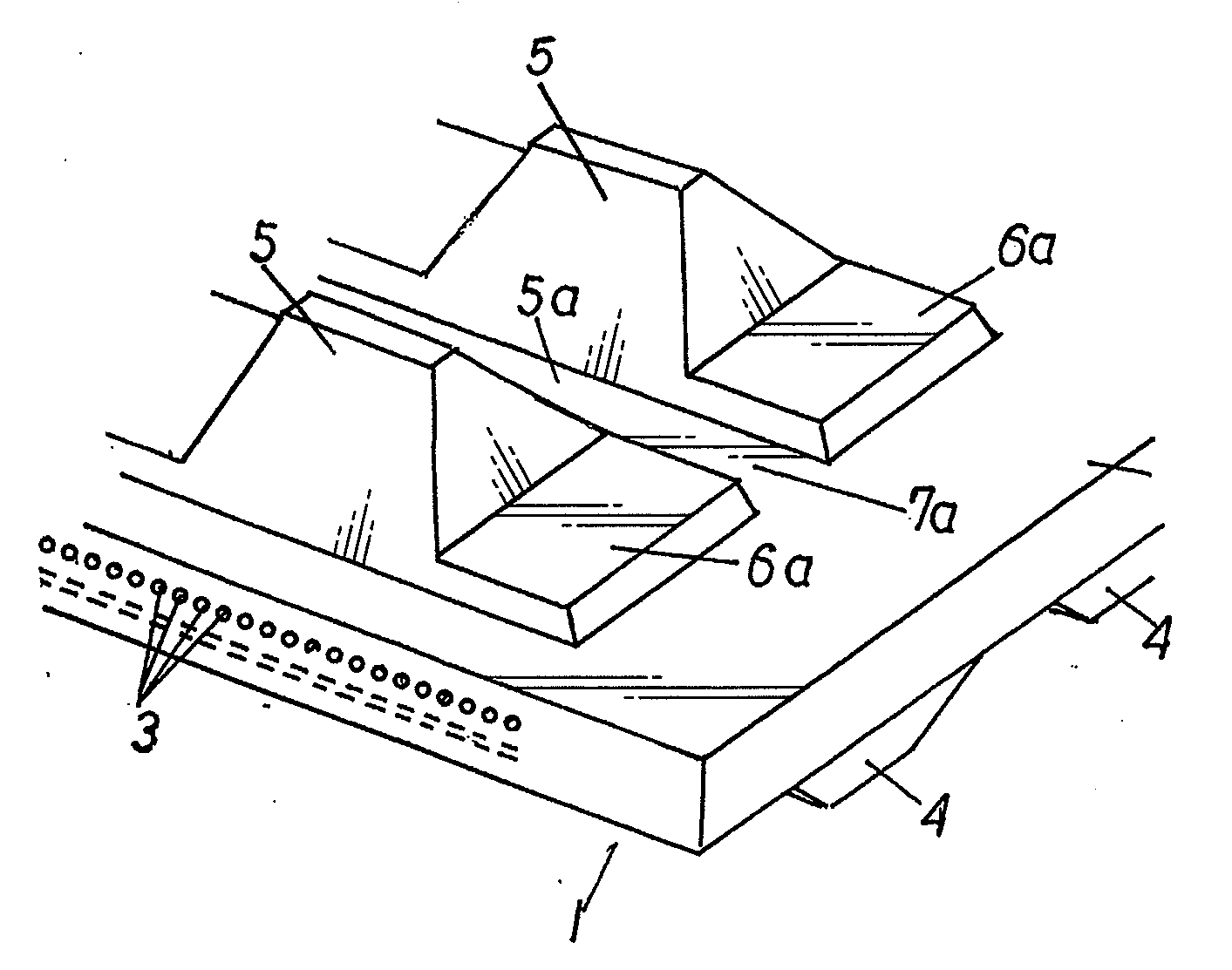

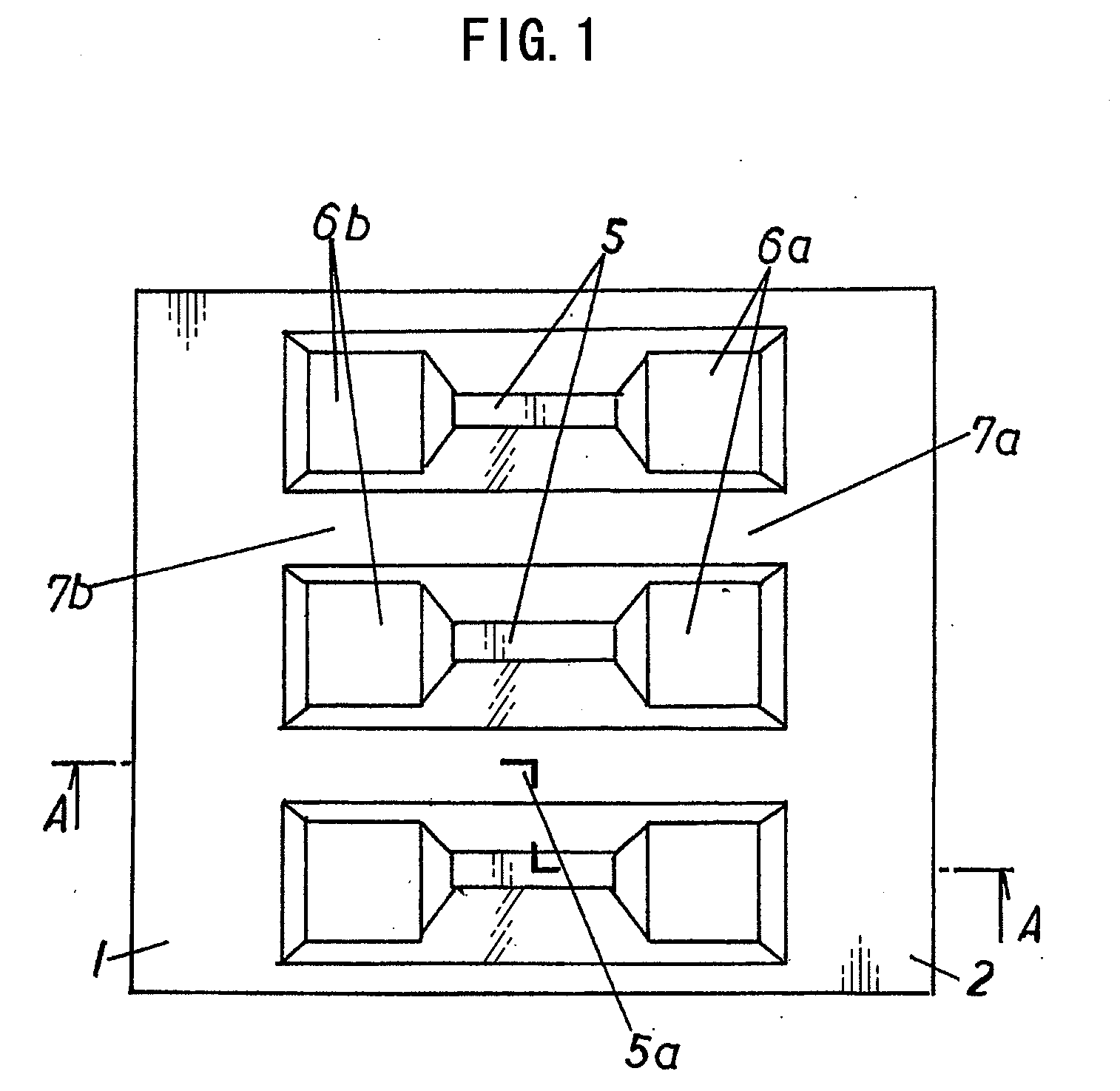

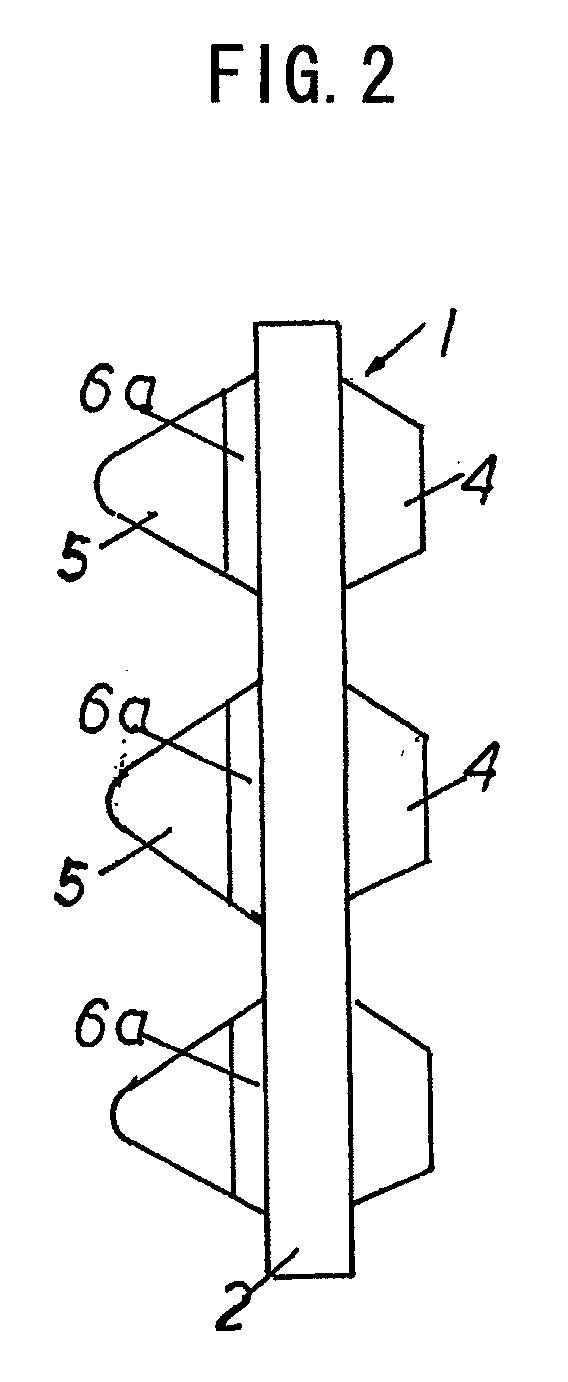

Coreless rubber crawler and traveling device

InactiveUS20090195062A1Reduce surface pressureLarge deformationConveyorsDriving beltsElastomerEngineering

The present invention provides a rubber crawler in which tooth skipping does not occur even if a large load acts on a rubber protrusion (5), and in which surface pressure on the rubber protrusion (5) is reduced. The coreless rubber crawler includes an endless rubber elastic body, a tensile material (3) buried in the longitudinal direction thereof, a rubber lug (4) formed at an outer circumferential surface of the rubber elastic body, and rubber protrusions (5) further formed at an inner circumferential surface of the rubber elastic body at a constant pitch in the longitudinal direction thereof, wherein raised step portions (6a) are formed to the right and left of the rubber protrusions (5) in the width direction of the rubber crawler, and a linear groove (7a) is formed between raised step portions that are adjacent to each other in the longitudinal direction of the rubber crawler so as to be continuous to base portions of the rubber protrusions when the rubber elastic body is seen in side view.

Owner:BRIDGESTONE CORP

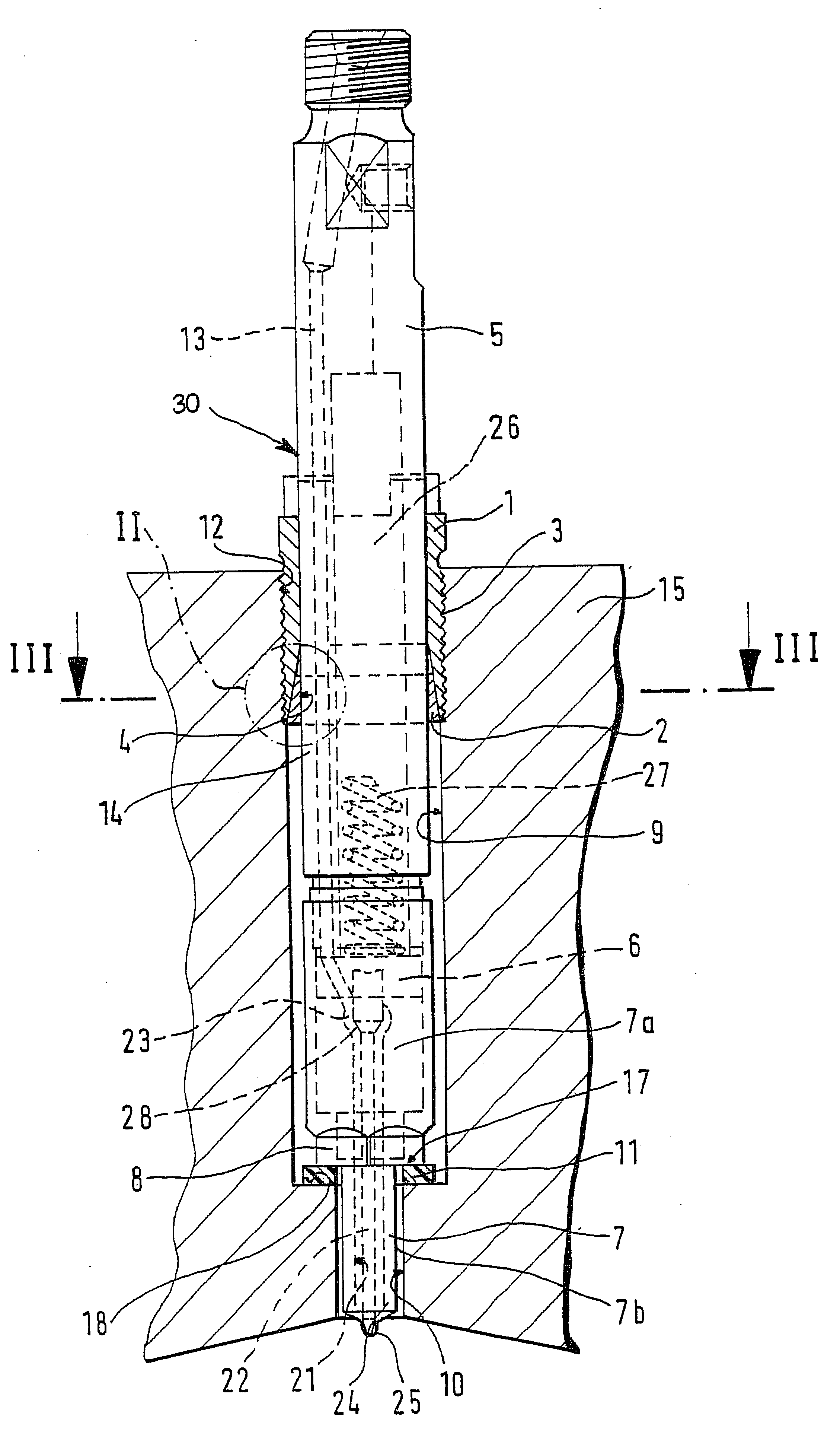

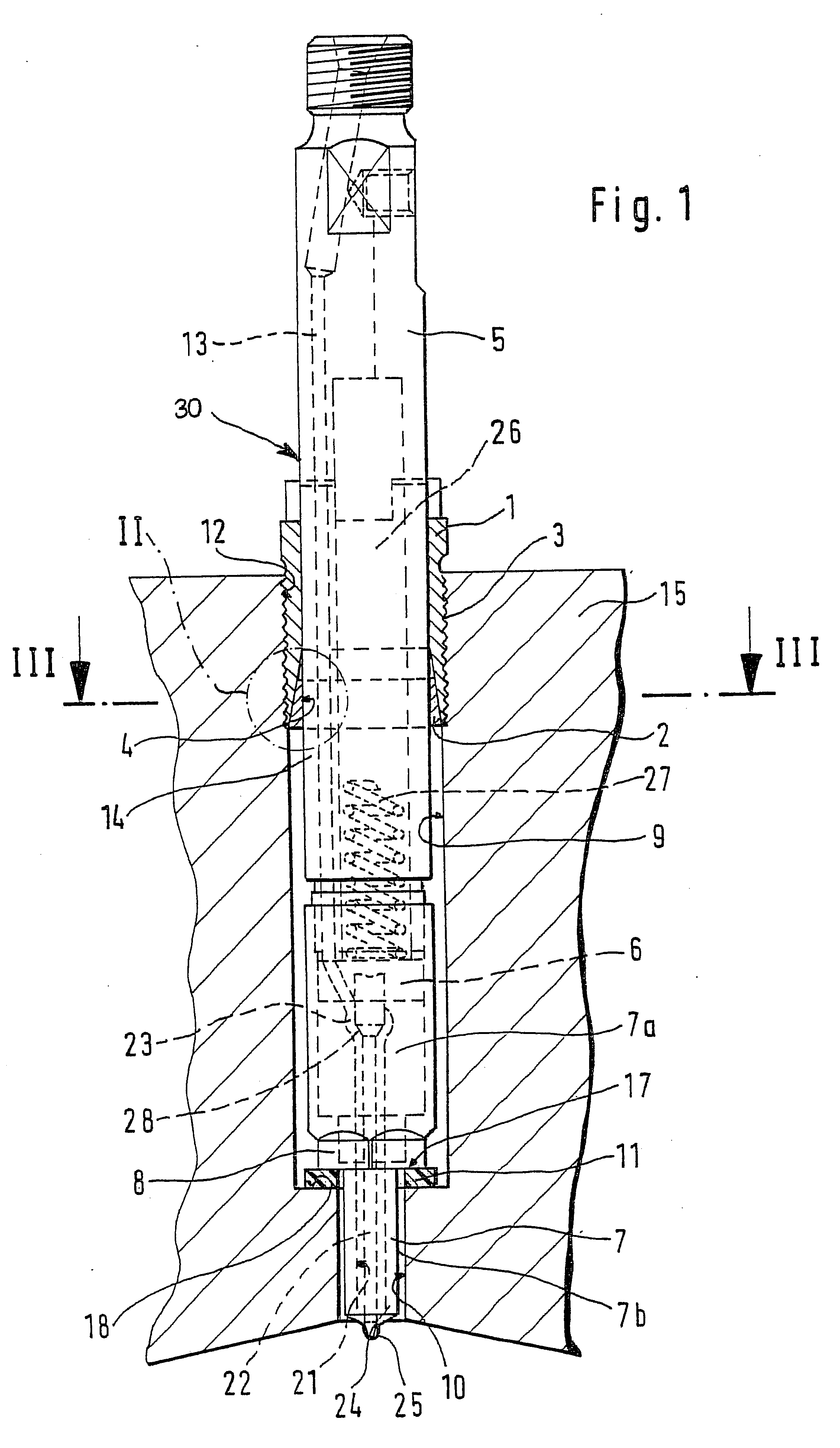

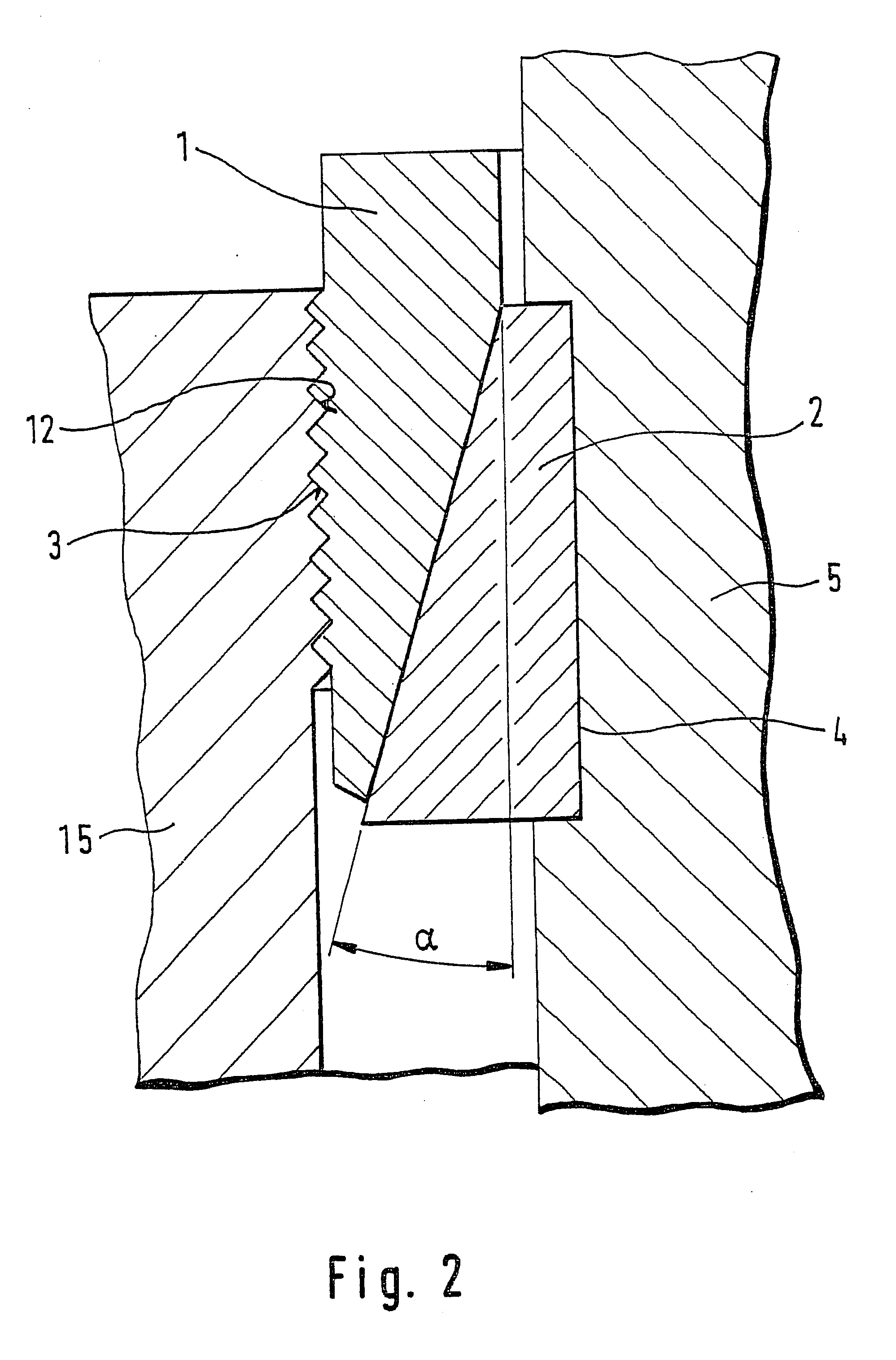

Fuel injection valve for internal combustion engines

InactiveUS6499468B1Increase injection pressureReduce surface pressureFuel injection apparatusMachines/enginesCombustion chamberHigh surface

A fuel injection valve for internal combustion engines, having an associated valve body, wherein the valve body is inserted into the receiving bore of the housing of an internal combustion engine and-by means of a clamping element, which is screwed into an internal thread embodied at the end of the receiving bore remote from the combustion chamber, and a support element disposed in an annular groove-is clamped with an annular shoulder embodied on the valve body against a contact surface embodied in the bore. The inner circumference surface of the clamping element and the outer circumference of the support element are conically embodied so that the axial movement of the clamping element when it is screwed in, exerts a radial force on the support element as a result of which it is pressed with its cylindrical inner circumference surface into the annular groove and as a result, a high axial force can be transmitted to the valve body without high surface pressures occurring as a result.

Owner:ROBERT BOSCH GMBH

Method and device for polishing

InactiveUS7108579B2Low polishing rateReduce rateGrinding drivesSemiconductor/solid-state device manufacturingSurface-active agentsSliding contact

The present invention relates to a polishing method for polishing a workpiece by pressing the workpiece, to be polished, against a fixed abrasive and bringing the workpiece into sliding contact with the fixed abrasive. The polishing method includes a first step of polishing the workpiece while supplying a polishing liquid which contains an anionic surface-active agent and does not contain abrasive particles, and a second step of polishing the workpiece while supplying a polishing liquid which contains a cationic surface-active agent and does not contain abrasive particles.

Owner:EBARA CORP

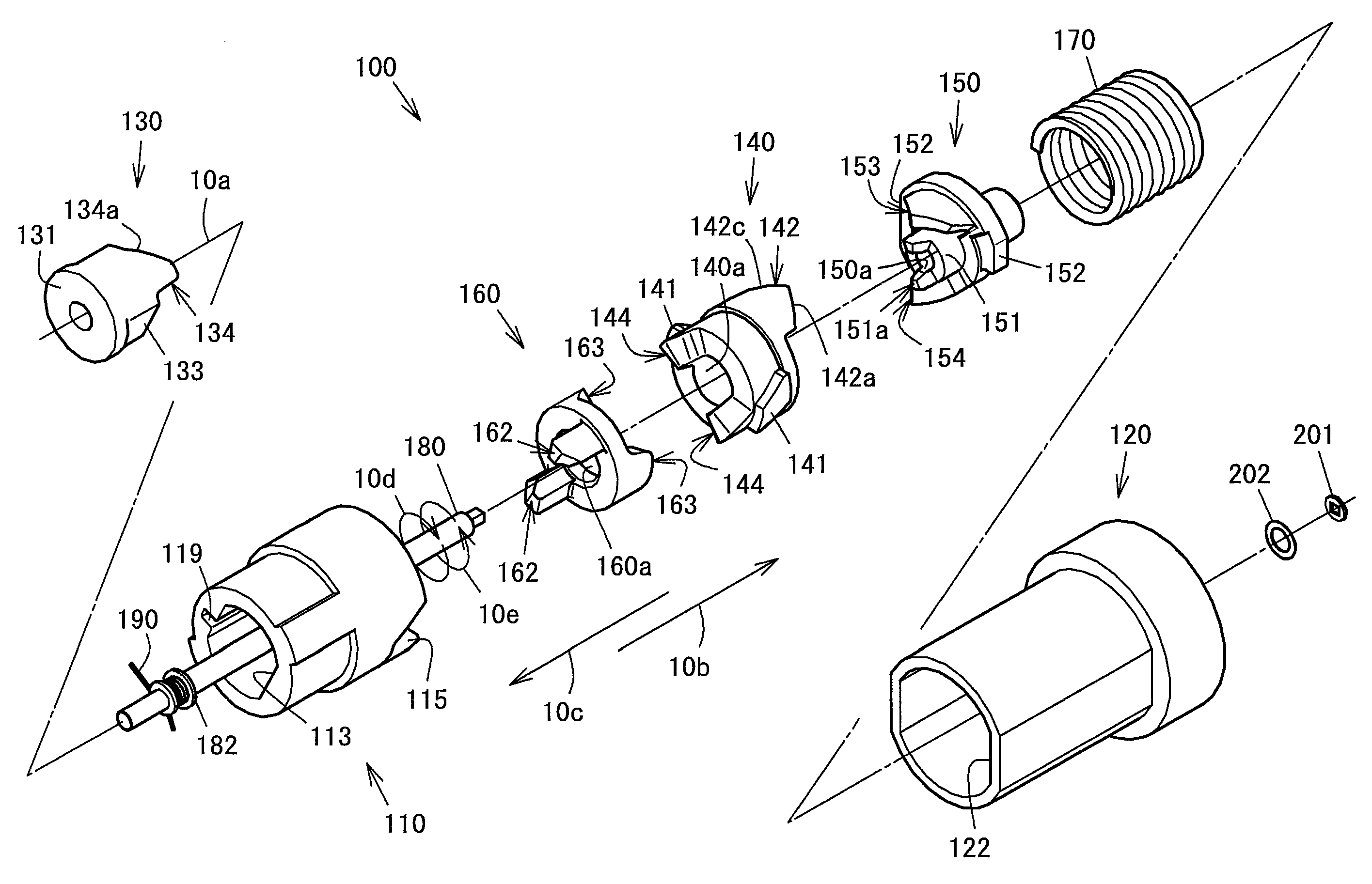

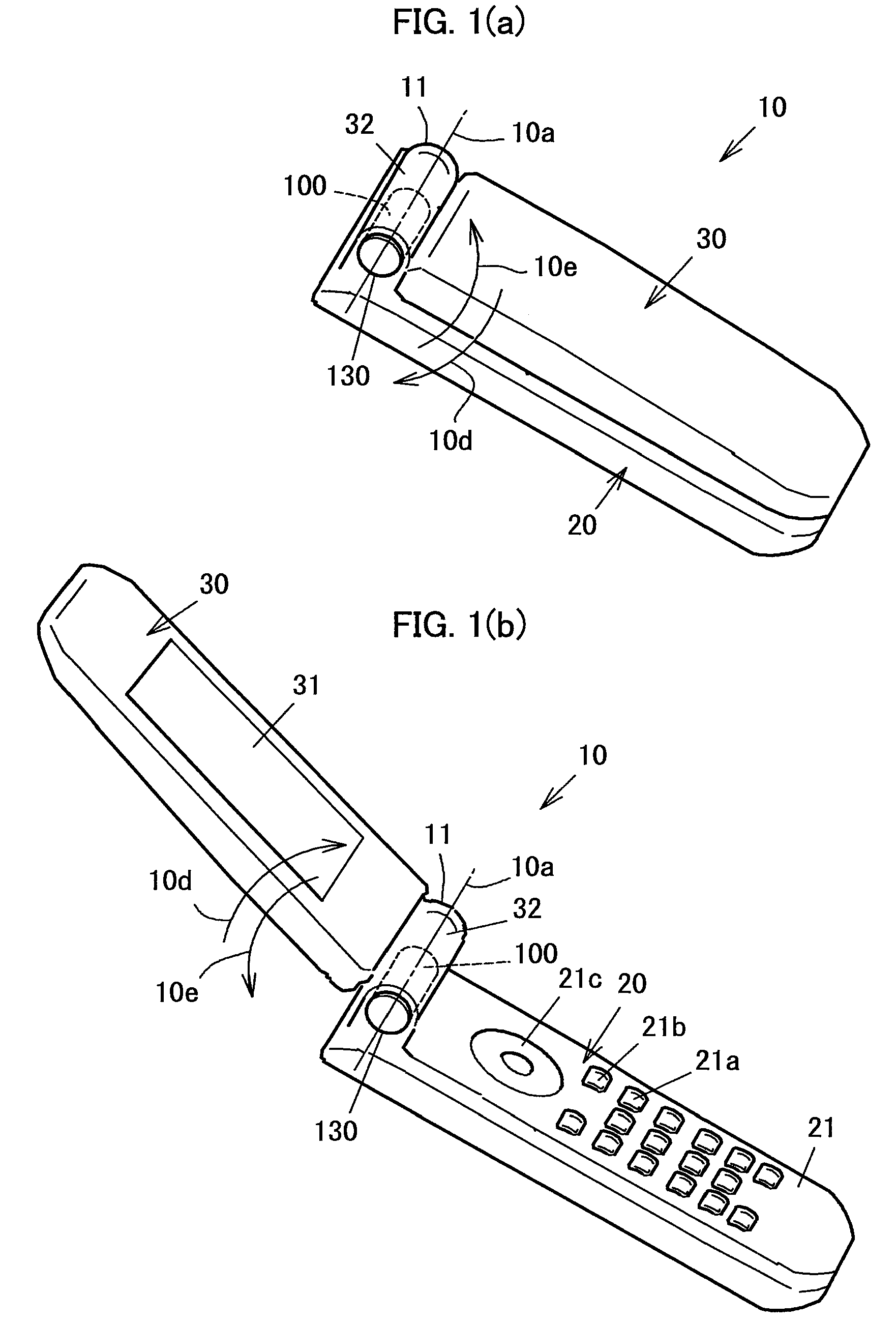

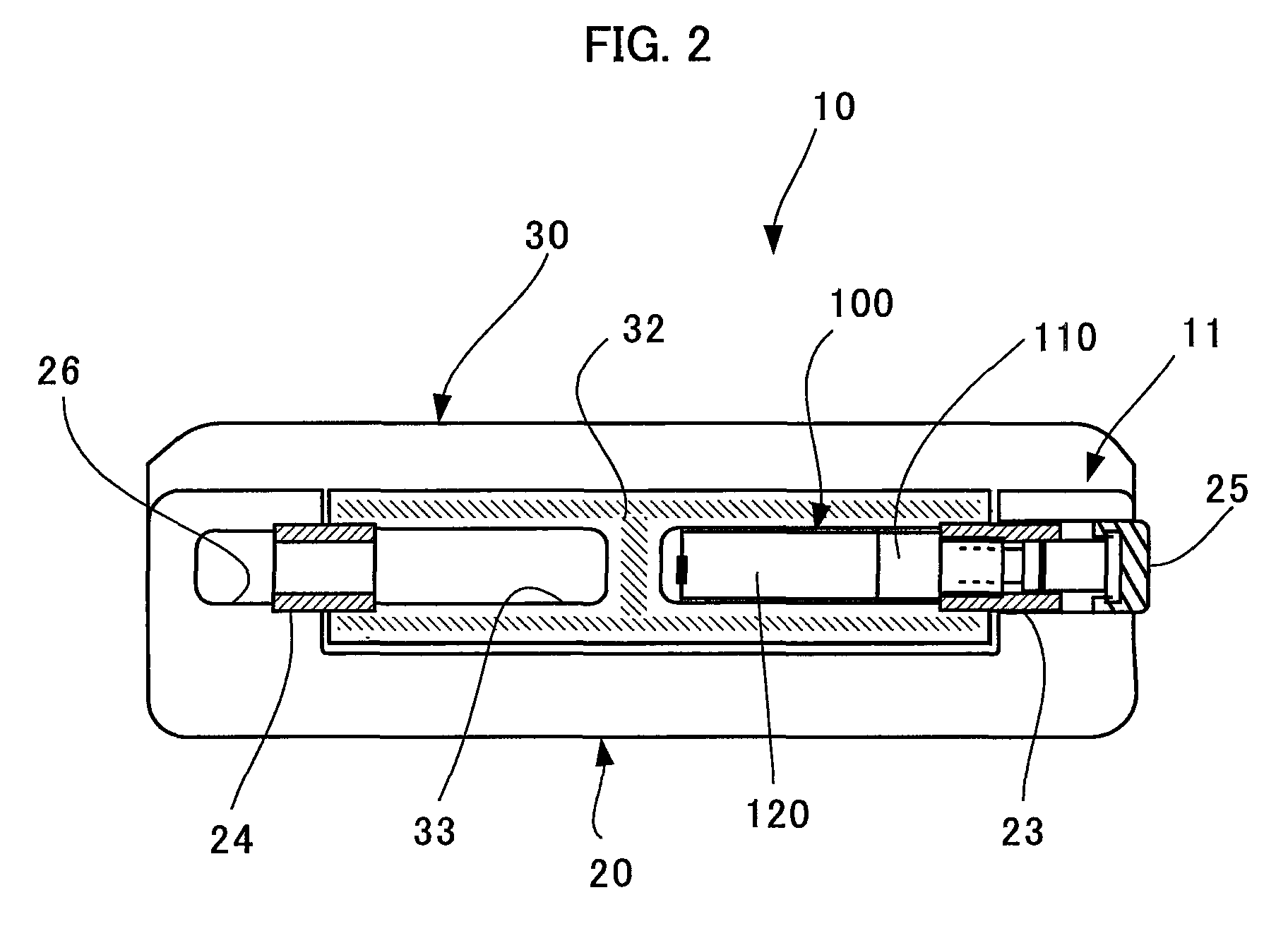

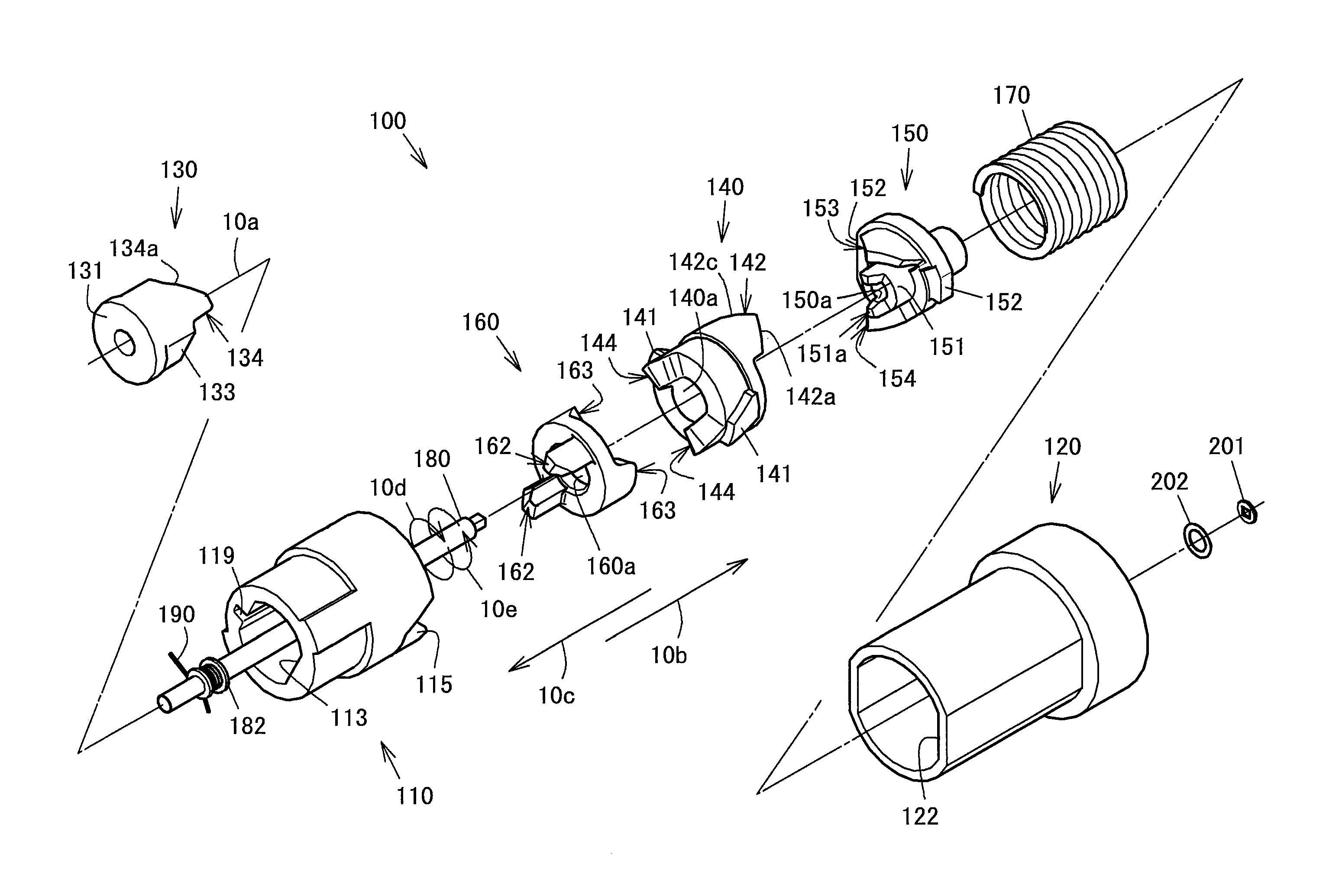

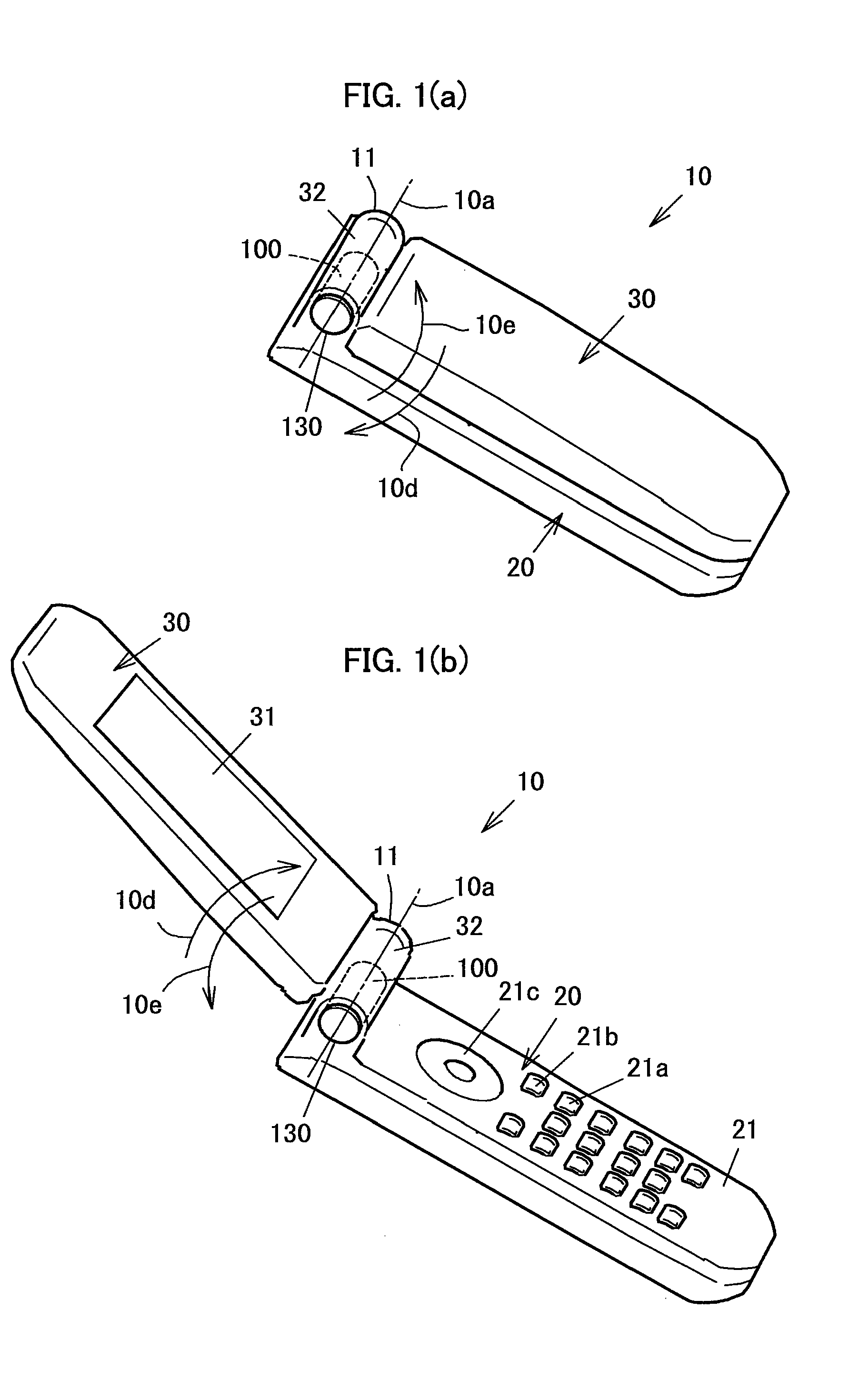

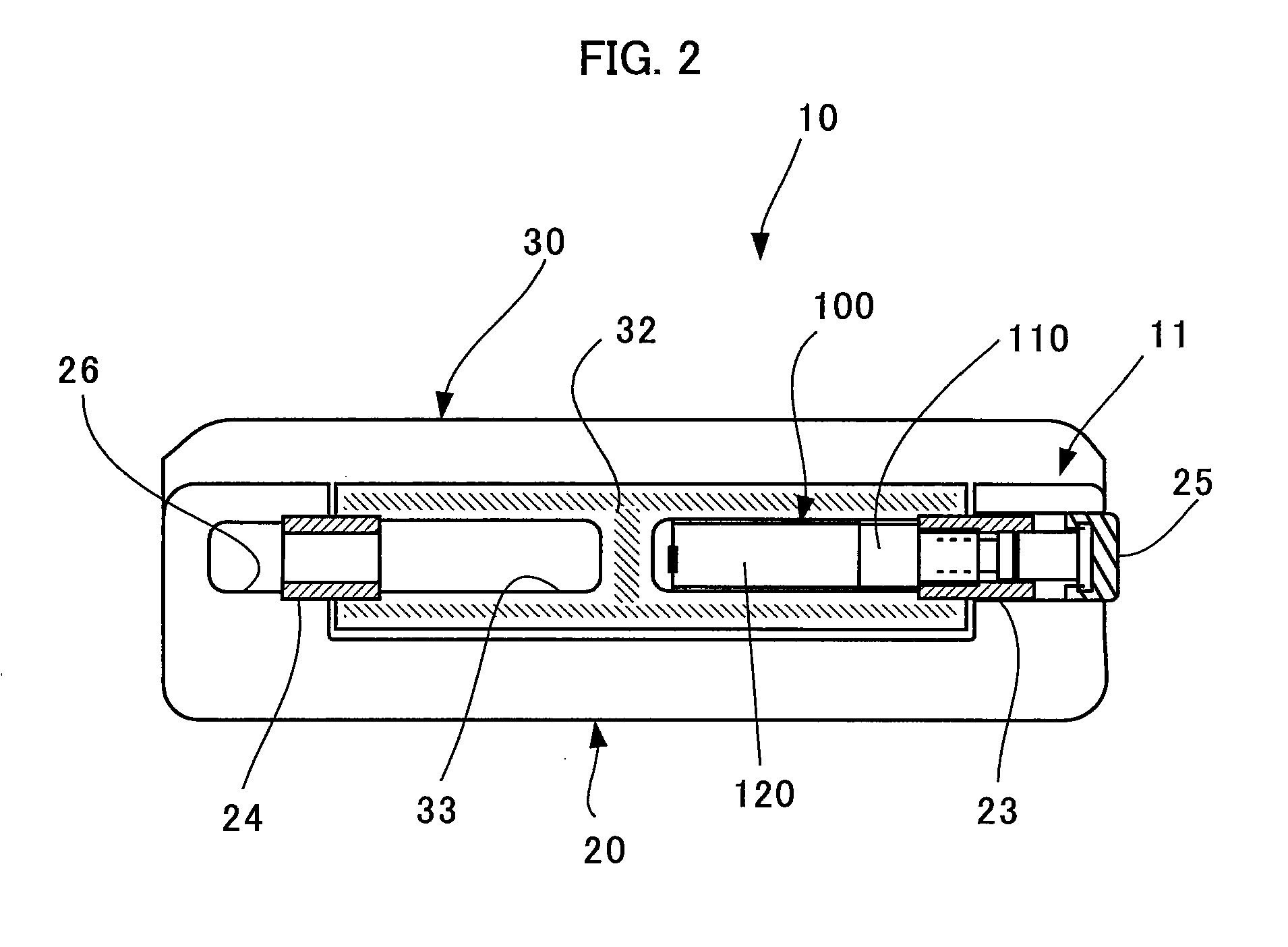

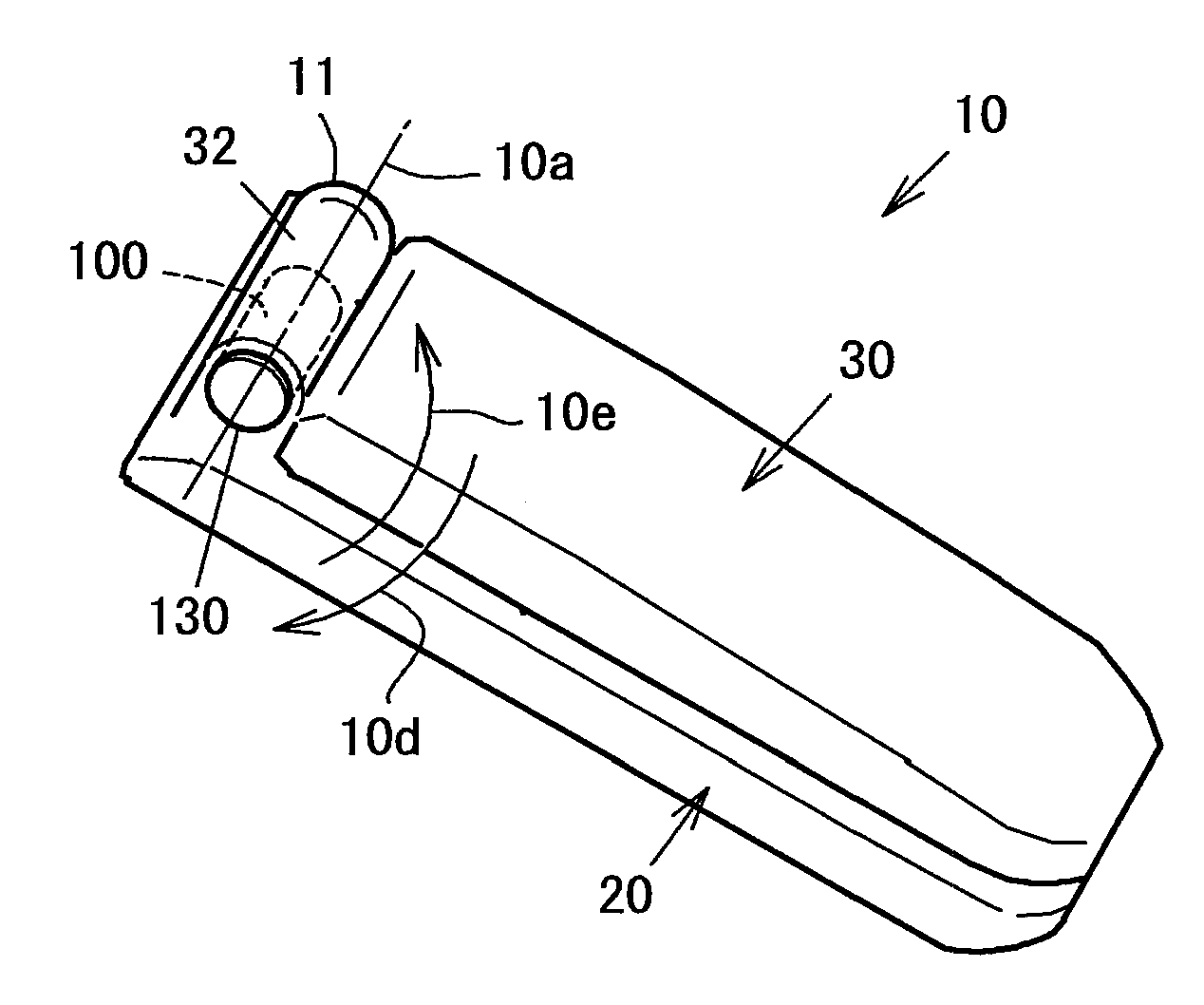

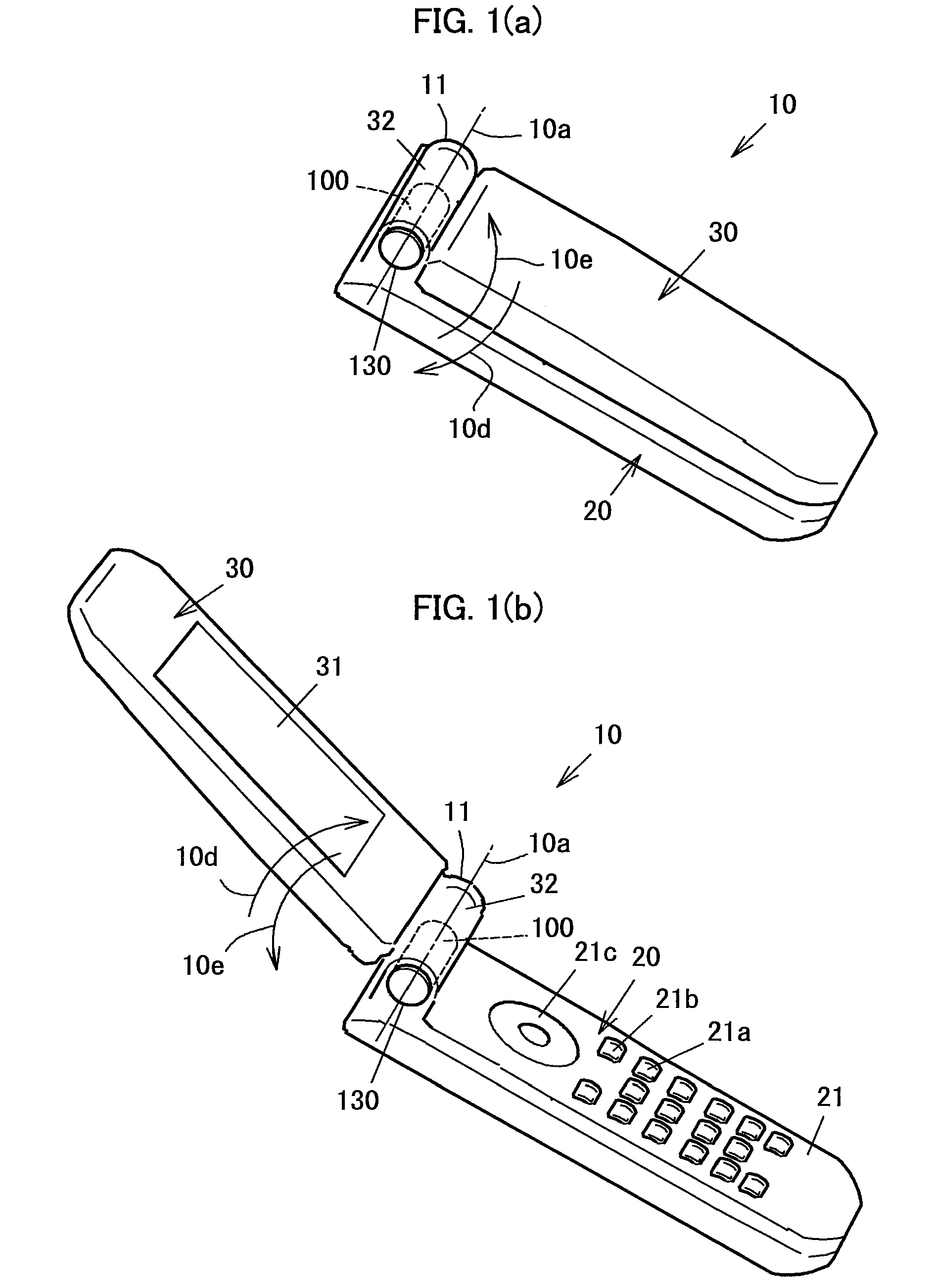

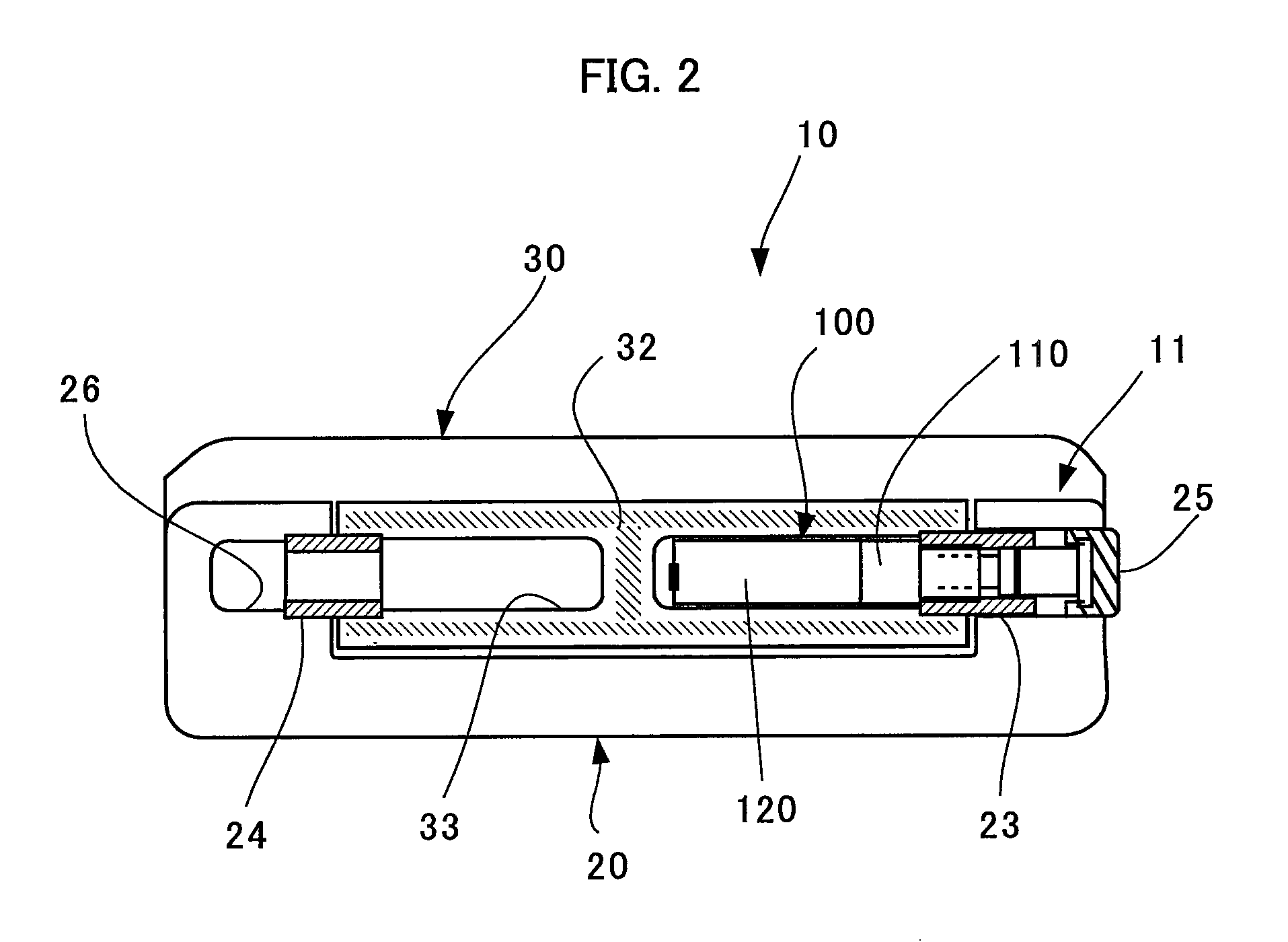

Opening/closing device and mobile device using the same

InactiveUS7974666B2Low costSmall sizeInterconnection arrangementsSubstation equipmentEngineeringGuiding center

It is an object of the present invention to provide an opening / closing hinge device which can be produced simple in construction and inexpensive in production by reducing the number of the parts forming part of the mobile device and to provide a mobile device small in size, reduced in cost and sufficiently reliable in the hinged members. The second member is rotated with respect to the first member toward the opening operation direction through the movable cam (150) by the urging force of the urging means (170) when the operation cam (130) is displaced in the predetermined operation direction by the external operation force. The fixed guide member (110) has inclined guide portions (115) each inclined at an advance angle in a predetermined inclination direction with respect to the surface perpendicular to the guide center axis to have the second rotation cam (140) rotated around the guide center axis in response to the displacement of the second rotation cam (140) along the guide center axis. The second rotation cam (140) being driven to rotate by the inclined guide portions (115) under a pressing force from the movable cam (150) to have its engagement state with the movable cam (150) changed and to have the urging direction of the second member by the urging means (170) changed when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the operation starting position.

Owner:PANASONIC CORP

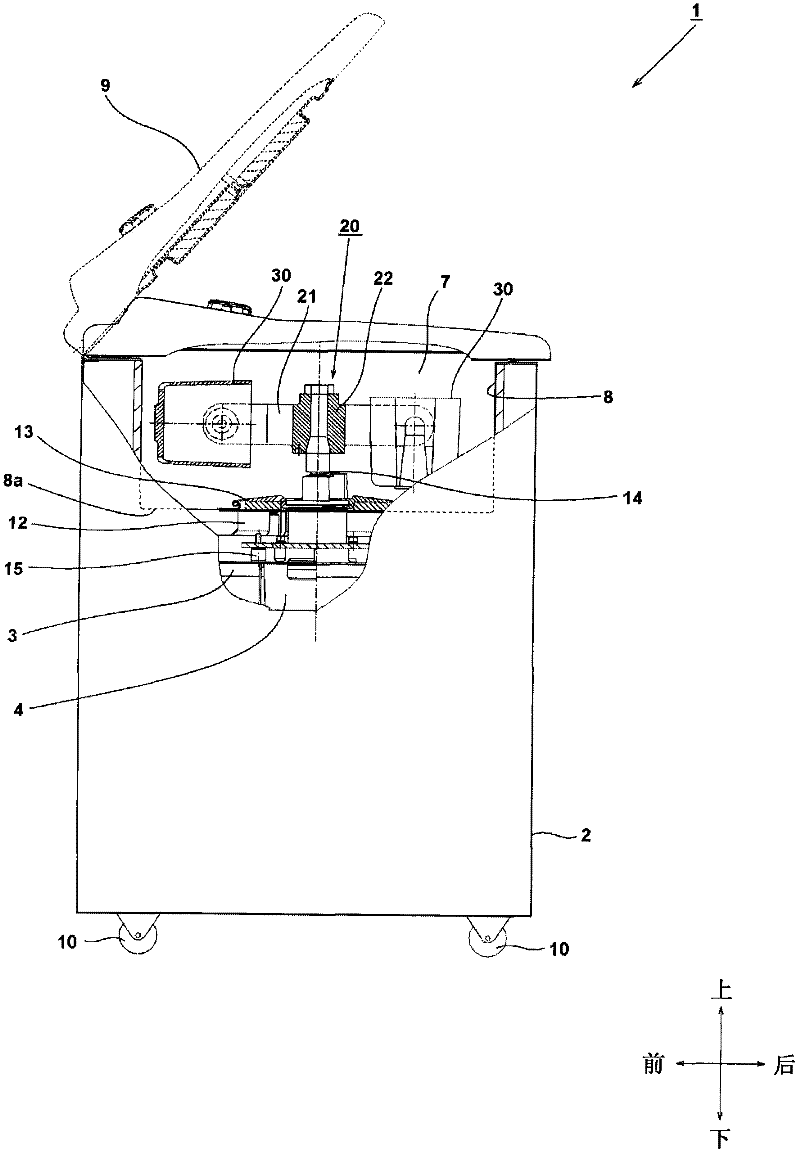

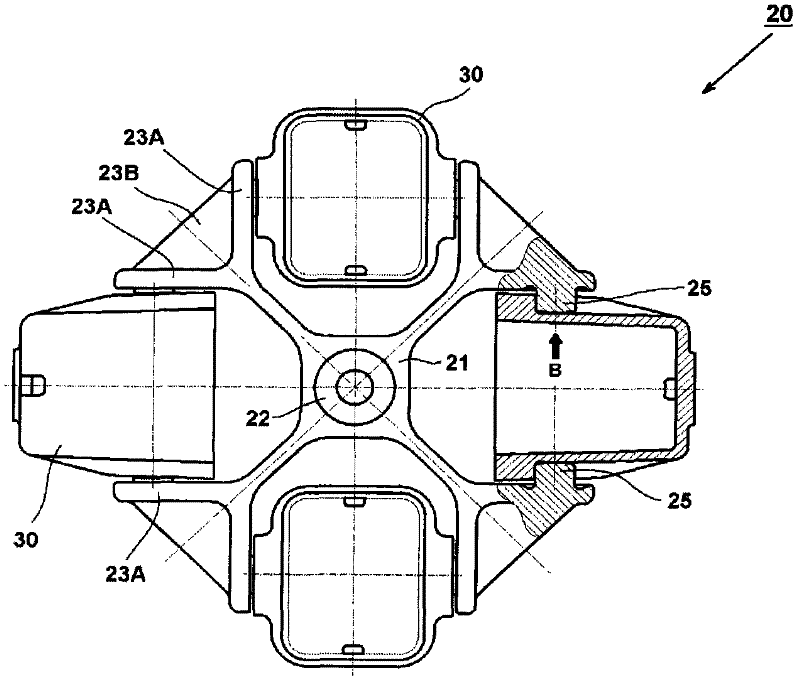

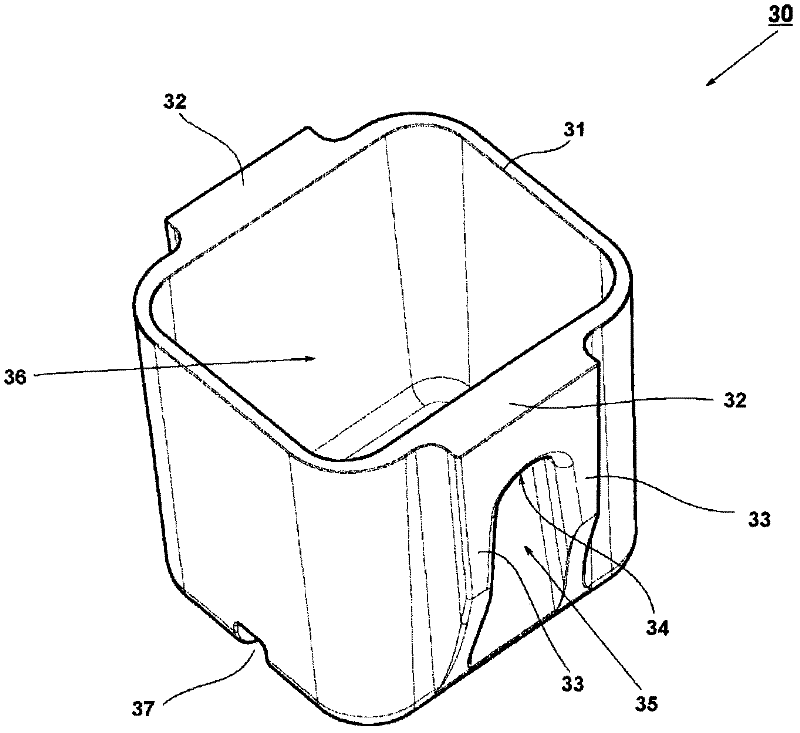

Siwing-bucket-rotor for centrifugal separator, and centrifugal separator

ActiveCN102463195ASmooth swingReduce frictional resistanceCentrifugesEngineeringMechanical engineering

The invention provides a siwing-bucket-rotor for a centrifugal separator. The sliding resistance of hanging buckets during swinging is inhibited so that poor rotation is eliminated. The siwing-bucket-rotor for a centrifugal separator comprises a rotor body. The rotor body is equipped with a plurality of arms, a plurality of hanging buckets and holding pins. The arms extend from the inner rim to the outer rim. The hanging buckets of the same shape are held on the corresponding arms in a swinging manner for holding samples. The holding pins are arranged on the arms in a way that the pins extend toward the tangential direction of the rotary direction of the rotor body and, are used for holding the hanging buckets in a swinging manner. Two clamping portions supported by the holding pins are arranged on the hanging buckets, and are supported by holding pin shafts. The sliding surfaces of holding pins are configured in a way that the axial width of a contact area when the hanging buckets stop swinging and the axial width of the contact area when the hanging buckets swing to a horizontal position through centrifugal separation operation are not fixed. For instance, the axial width of the contact area when the hanging buckets are static is smaller than the axial width of the contact area when the hanging buckets are rotating.

Owner:EPPENDORF HIMAC TECH CO LTD

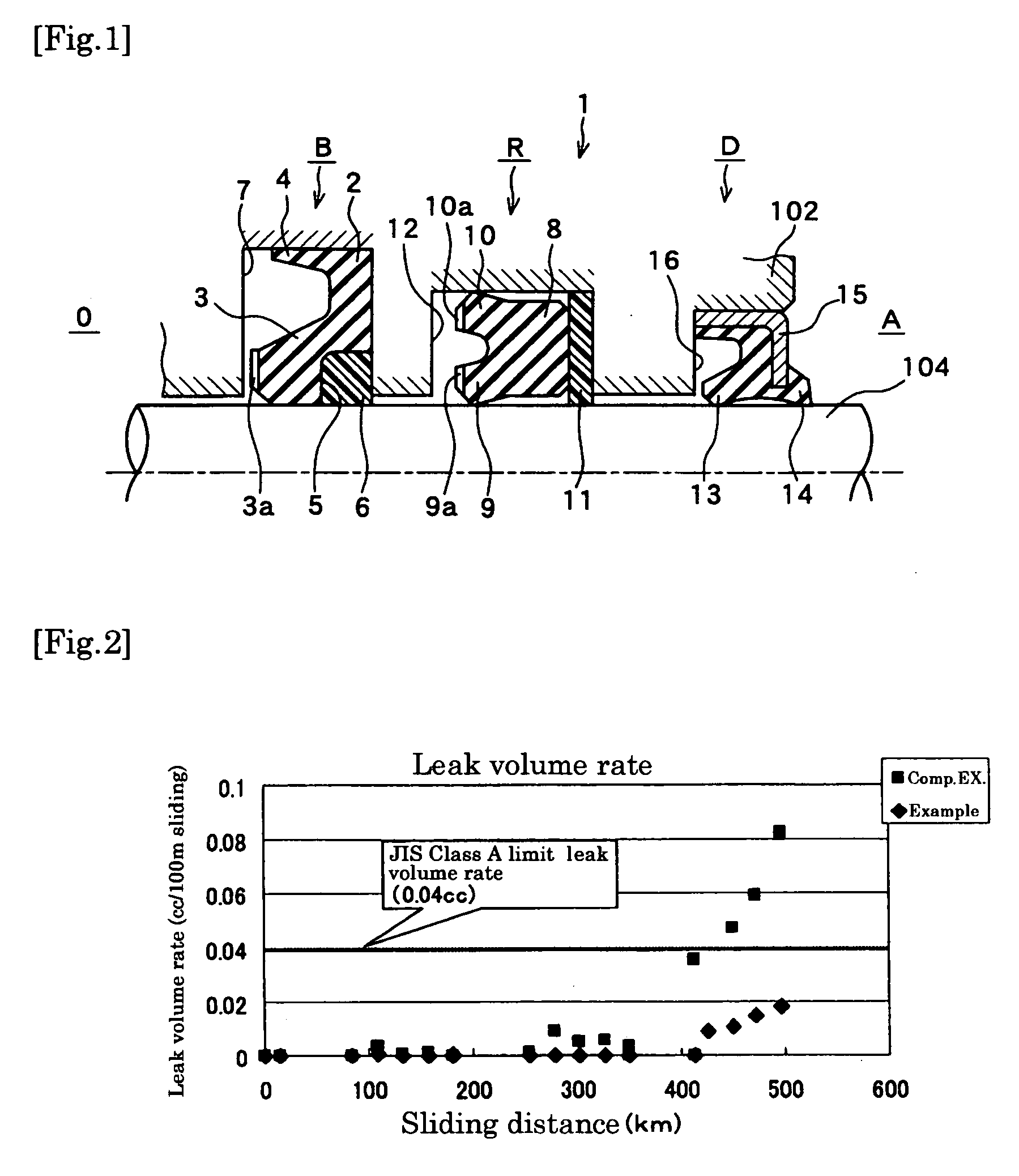

Rod Sealing System

ActiveUS20090166984A1High heat resistanceHigh compression set characteristicEngine sealsPiston ringsPolymer scienceReciprocating motion

In a rod sealing system, which comprises a buffer ring, a rod seal, and a dust seal, provided successively in this order from a fluid hydraulic side toward the outside in an annular clearance between two members in reciprocating motion, the buffer ring is made up of a thermoplastic polyurethane molding product obtained by subjecting a thermoplastic polyurethane molding product prepared by reaction of (A) a high molecular weight polycarbonatediol having a number average molecular weight Mn of 500-6,000, (B) an aromatic diisocyanate, and (C) a low molecular weight diol as a chain elongation agent in an NCO / OH ratio of 0.95-1.20, to heat treatment under conditions that a glass transition point (Tg) of hard phases becomes 170° C. or higher, preferably 170-230° C., and an endothermic peak area (ΔH) at Tg becomes 5 J / g or more, by differential scanning calorimetry. The buffer ring made up of the thermoplastic polyurethane molding product has a distinguished heat resistance capable of withstanding the service environmental temperature, particularly maximum 120° C., compression set characteristics, follow-up to eccentricity, etc.

Owner:UNIMATEC CO LTD +1

Opening/Closing Device and Mobile Device Using the Same

InactiveUS20100024165A1Smooth transferring operationReliable engagementSubstation equipmentHingesSurface pressureEngineering

It is an object of the present invention to provide an opening / closing device which can be produced simple in construction and reduce the surface pressure of its cam portions, and a mobile phone which can be reduced in cost and sufficiently reliable in the hinged members by using the opening / closing device. In the opening / closing device operable to rotate the second member (30) with respect to the first member (20) hingedly connected the second member (30) in an opening operation direction by operating first and second rotation cams (160, 140), and a movable cam (150) held in engagement with the second rotation cam (140) in response to the displacement of the operation cam (130), the second rotation cam (140) and the movable cam (150) have a plurality of kinds of end cam portions ((142, 153), (143, 154)) formed thereon at different radiuses (r1, r2) from the guide center axis (110c) in opposing relationship with each other, the urging direction of the urging means (170) to the second member (30) is changed by the end cam portions ((142, 153), (143, 154)) when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the predetermined operation starting position.

Owner:PANASONIC CORP

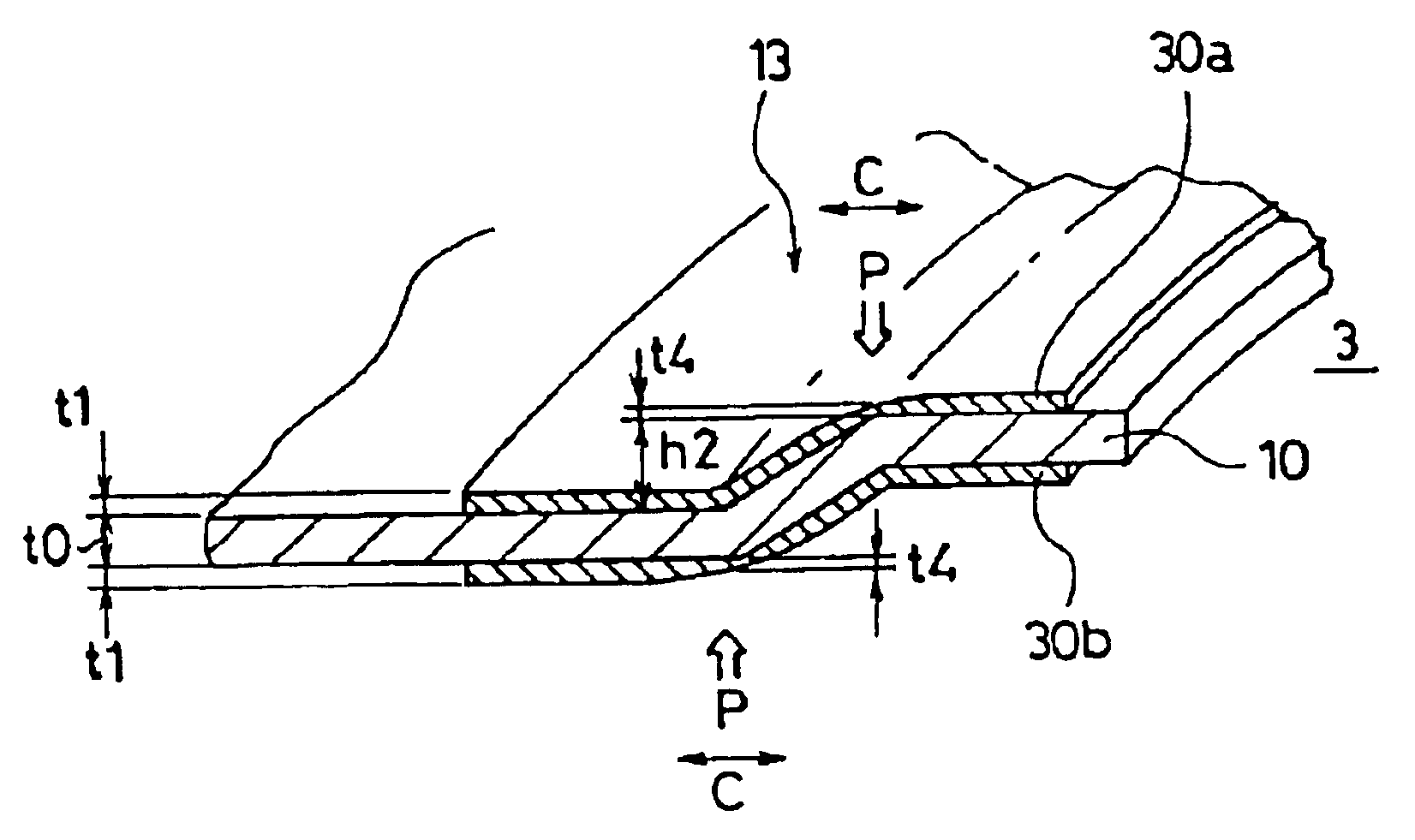

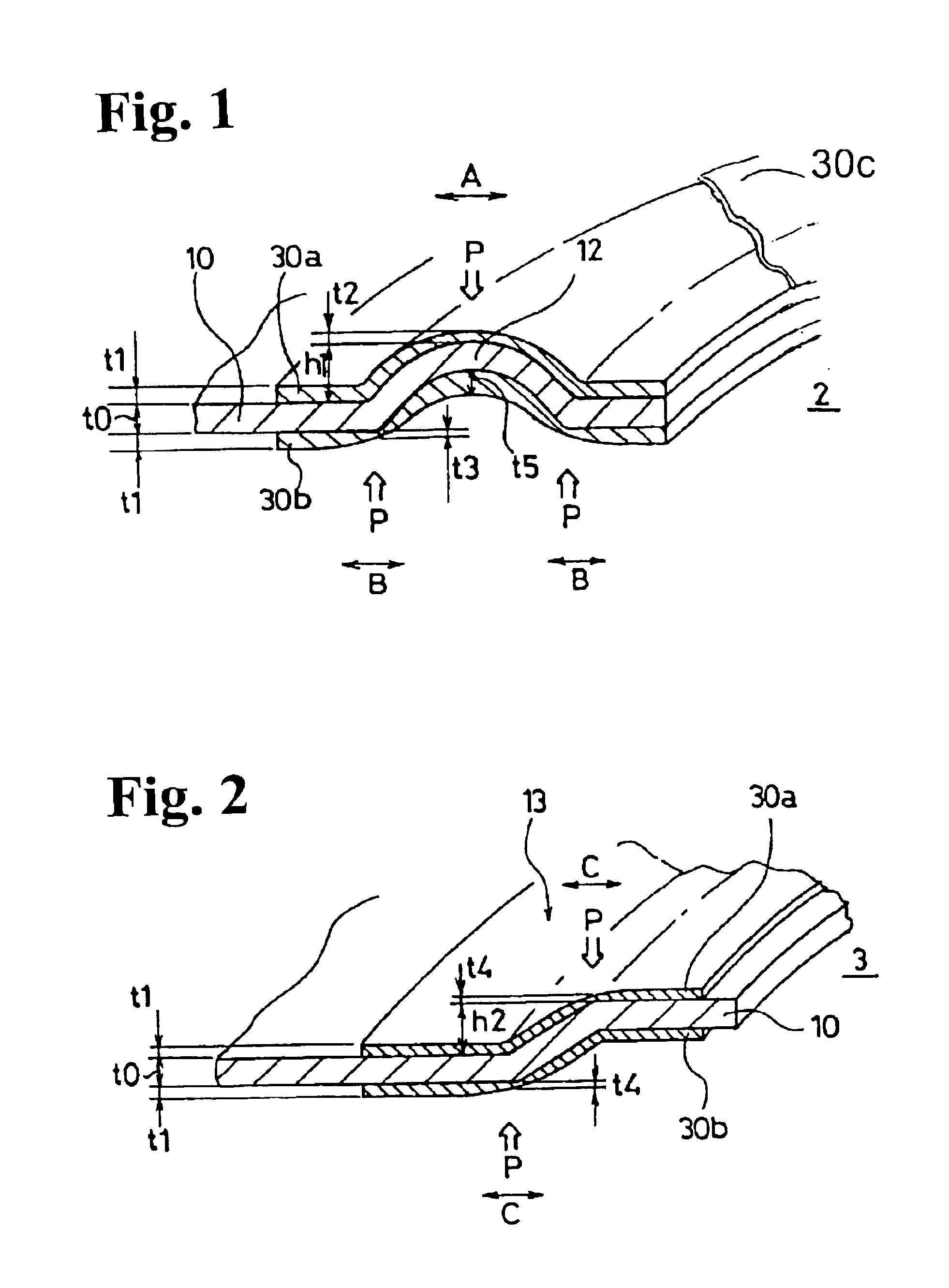

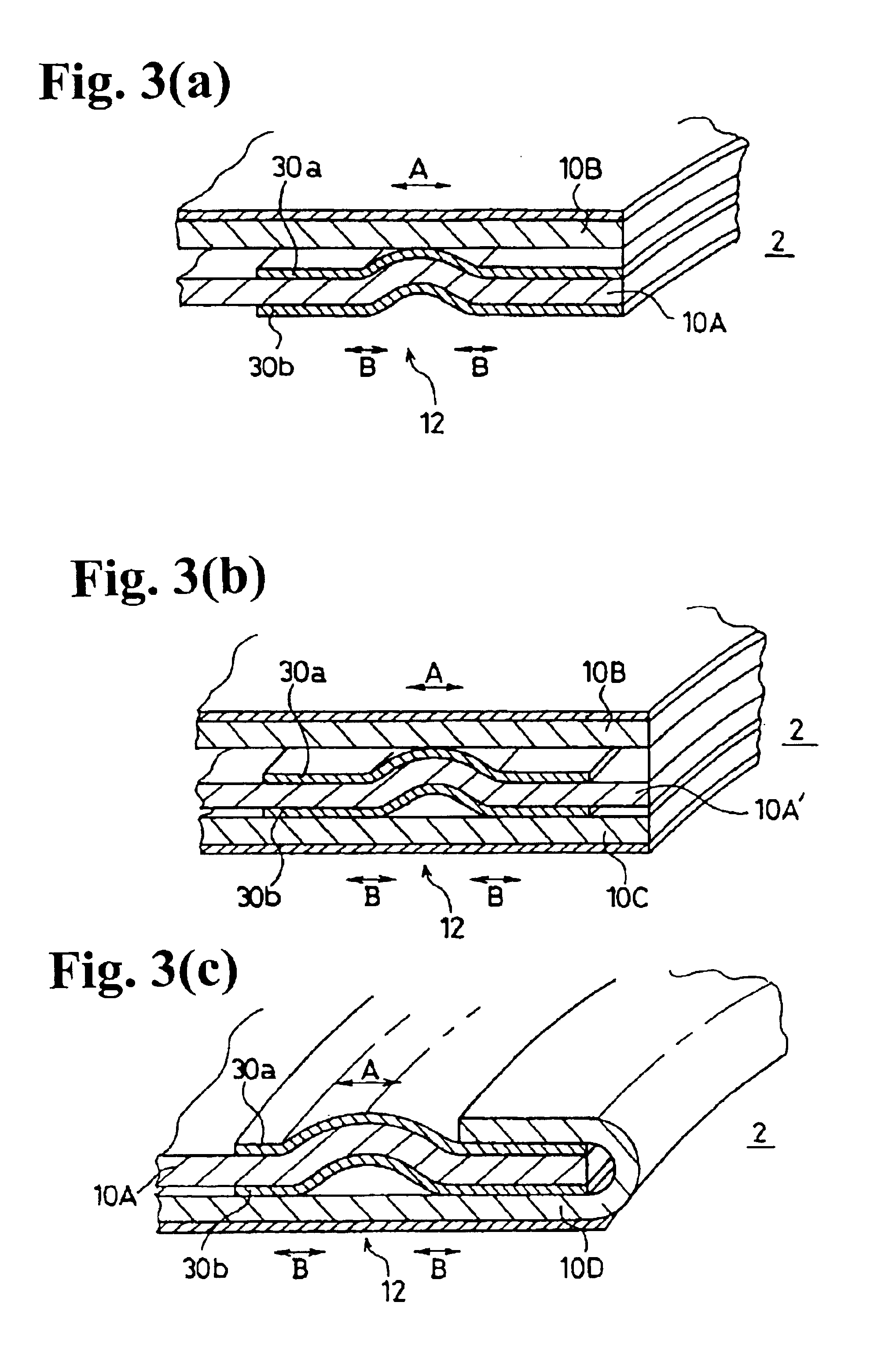

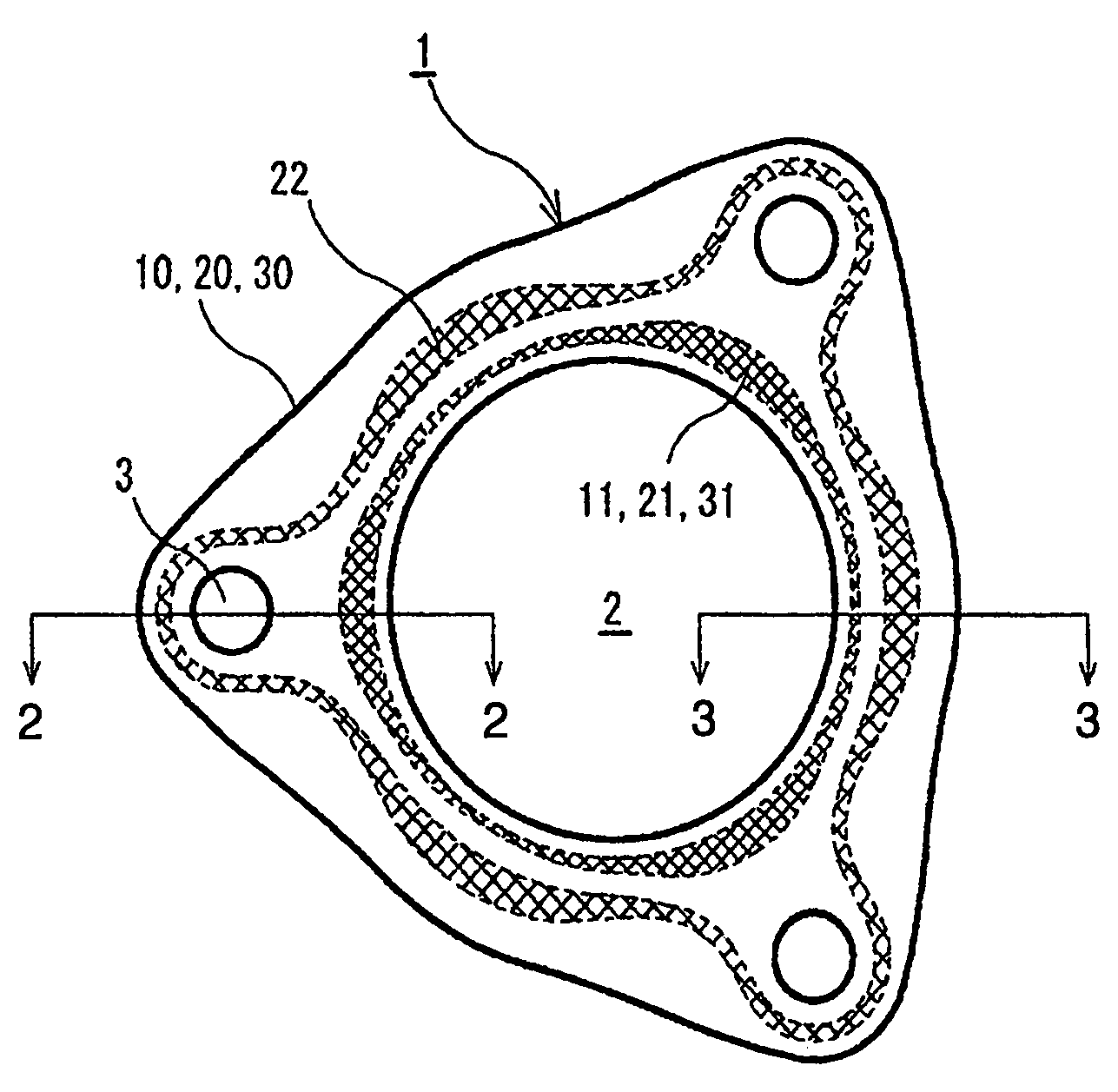

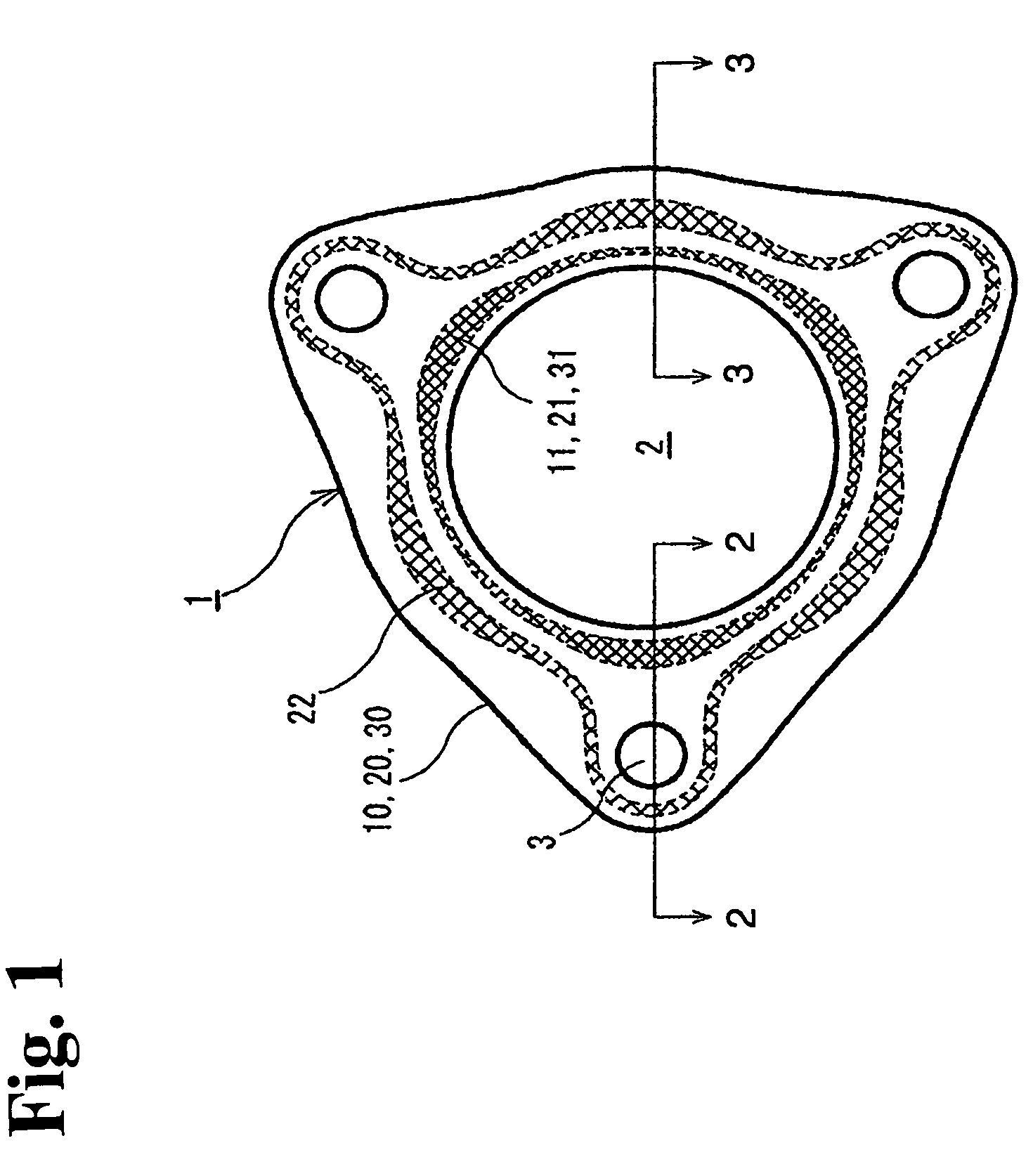

Metal gasket with partial coating

InactiveUS6893023B2Good effectImprove sealingEngine sealsSealing arrangements for enginesSurface pressureMetal

A metal gasket is formed of a metal base plate for sealing between two members. The metal gasket has a bead around a cylinder bore and a bead around a fluid hole. The coatings are applied on both surfaces of the beads, respectively. When the metal gasket is tightened, strong sealing surface pressures are locally generated at sealing line portions. The thicknesses of the coatings at the sealing line portions are formed to be thinner than those of the other portions.

Owner:ISHIKAWA GASKET CO LTD

Trailer-mounted crane apparatus

InactiveUS6966448B1Reduce contact pressureUsed for stabilizationLoading/unloading vehicle arrangmentCranesGolf course turfMarine engineering

A trailer-mounted crane apparatus includes a trailer supported from a ground surface on at least two wheels. A hydraulically operated crane arm is mounted to the trailer and is extendable outwardly. A crane hydraulic power unit is mounted to the trailer and supplies pressurized hydraulic fluid to the crane arm. A vibrational sheet piling driver can be supported by the crane arm. A vibrational hydraulic power unit for supplying power to the driver is mounted on the trailer. A control panel for the crane hydraulic power unit and the vibrational driver hydraulic power unit, and an associated operator's seat, are also mounted on the trailer. The crane apparatus includes wide tires for reducing the surface pressure under the apparatus. This allows the apparatus to be transported across and used on delicate surfaces such as golf course greens and other groomed surfaces.

Owner:BURKETT DARRYL SCOTT

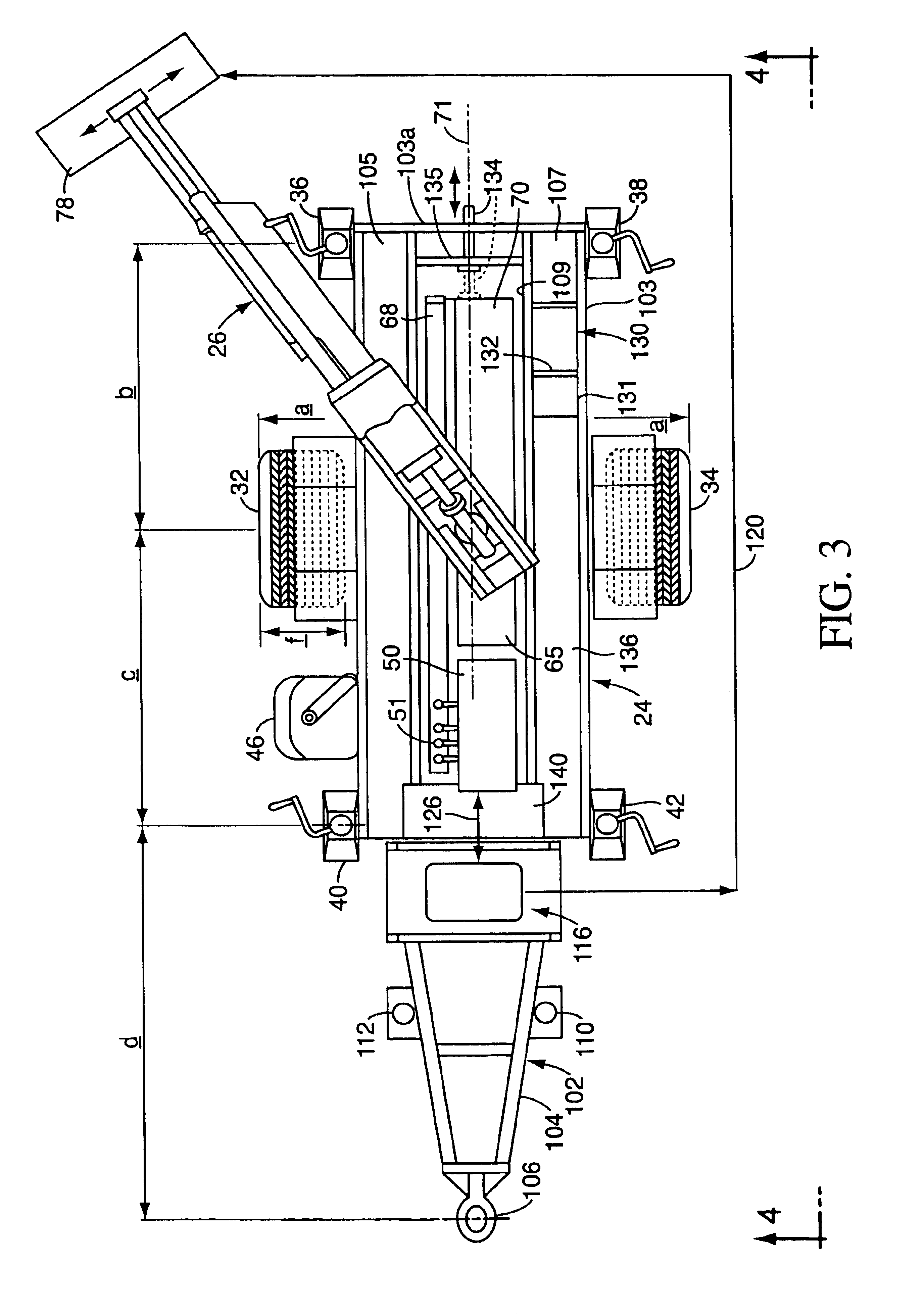

Friction material

InactiveUS20070287768A1Brake feeling can be improvedFeel goodFriction liningFriction modifierMaterials science

Anon-asbestos friction material is provided with a fibrous base material, a friction modifier, and a binder, wherein a partially graphitized coke is blended in a ratio of 0.5 vol % to 2.5 vol %. By blending the partially graphitized coke, compression strain of the friction material is adjusted so as to improve brake feeling without deteriorating friction properties.

Owner:AKEBONO BRAKE IND CO LTD

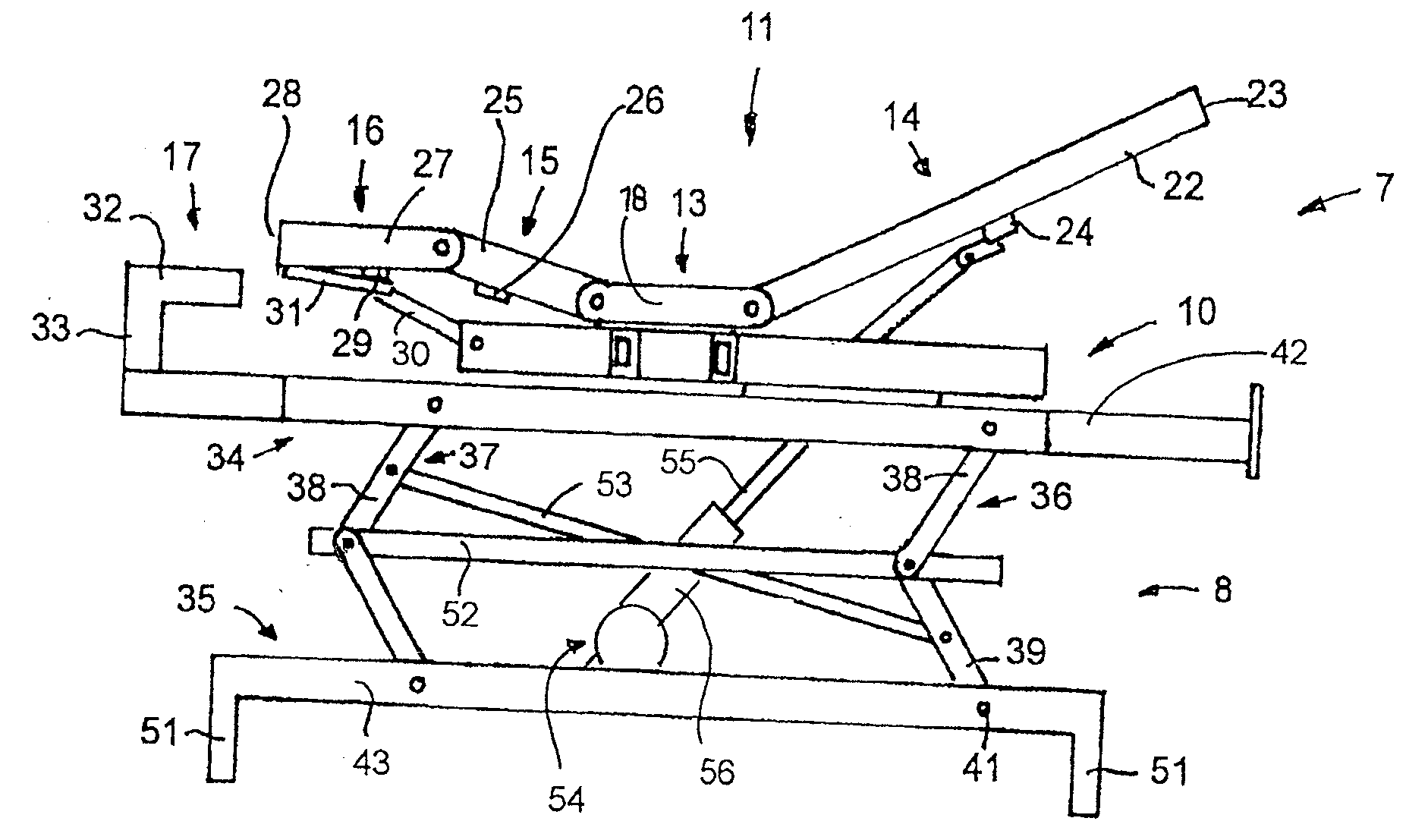

Hospital bed having a locally reinforced frame

InactiveUS20100017965A1Simple wayReduce loadNursing bedsRigid tablesMechanical engineeringHospital bed

A hospital bed having longitudinal rails, between which levers are supported. The levers are fixed on an axle tube that extends between the two longitudinal rails. The longitudinal rails are locally reinforced with respect to their wall thickness on the side situated adjacent to the axle tube by means of reinforcing plates welded thereto. A round rod extends through through-holes in the two longitudinal rails and the axle tube. For this purpose, the longitudinal rails are provided with through-holes that extend through the reinforcing plate.

Owner:BARTHELT HANS PETER

Metal gasket

ActiveUS8186690B2Reduce surface pressureReduce resistanceEngine sealsSealing arrangements for enginesEngineeringMetal

A metal gasket includes at least one structural plate having a sealing bore and bolt holes located around the seal bore. An inner bead is formed on the at least one structural plate to surround the sealing bore. The inner bead has first neighboring portions near the bolt holes and first outer portions outside the first neighboring portions. The first neighboring portion has a compression resistance smaller than that of the first outer portion. An outer bead is formed on the at least one structural plate to surround the inner bead such that the bolt holes are located inside thereof. The outer bead has second neighboring portions near the bolt holes and second outer portions outside the second neighboring portions. The second neighboring portion has a compression resistance greater than that of the second outer portion.

Owner:ISHIKAWA GASKET CO LTD

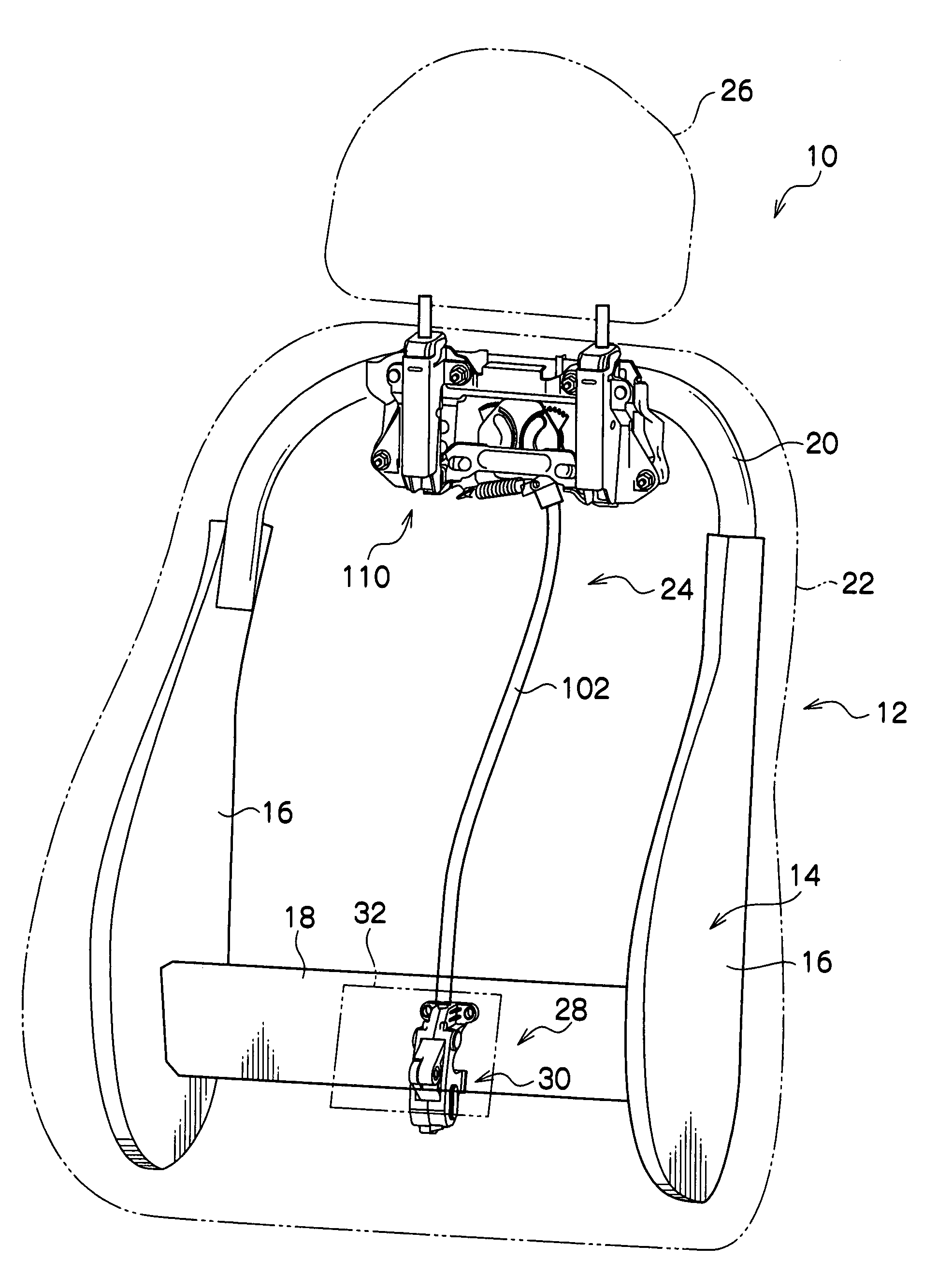

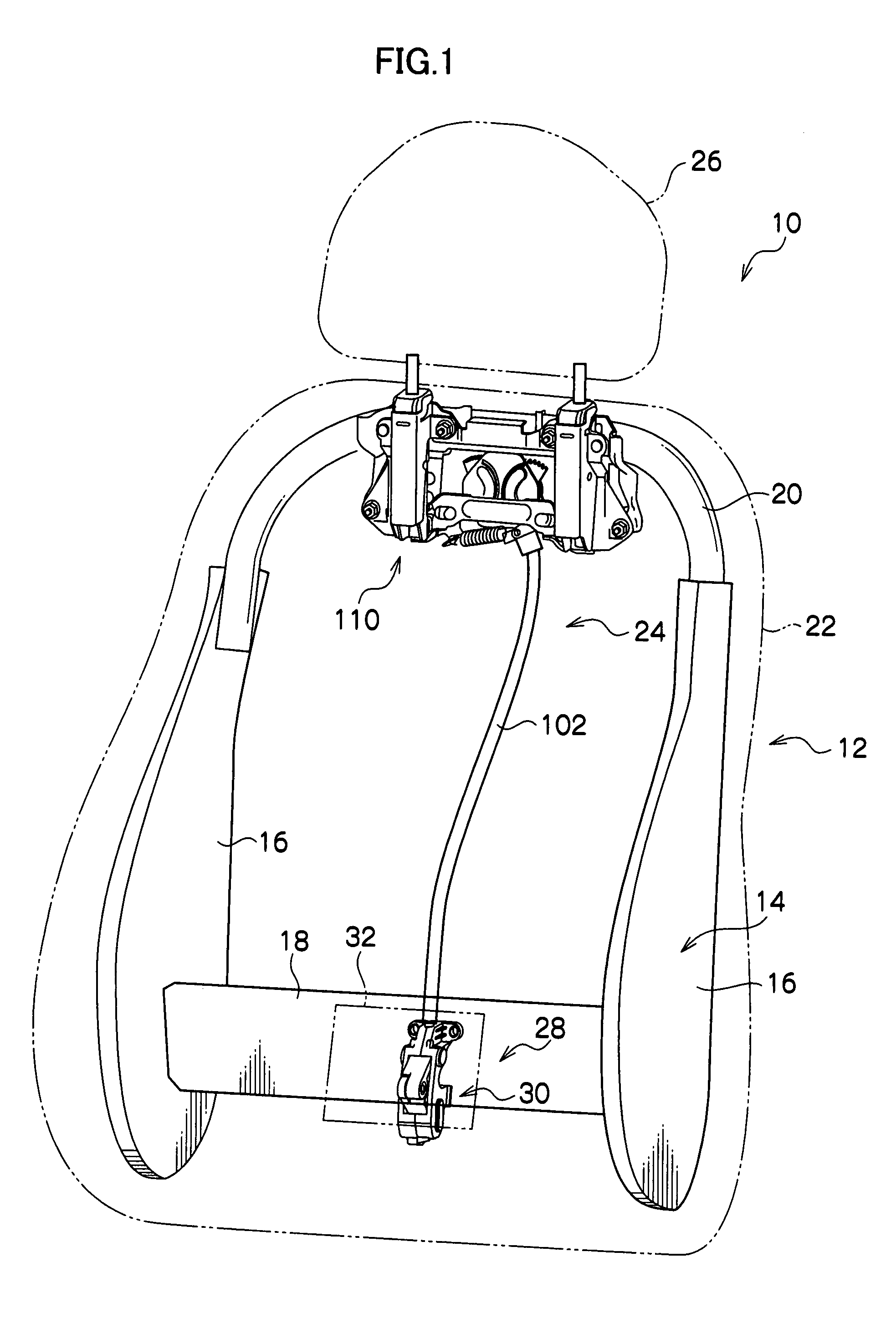

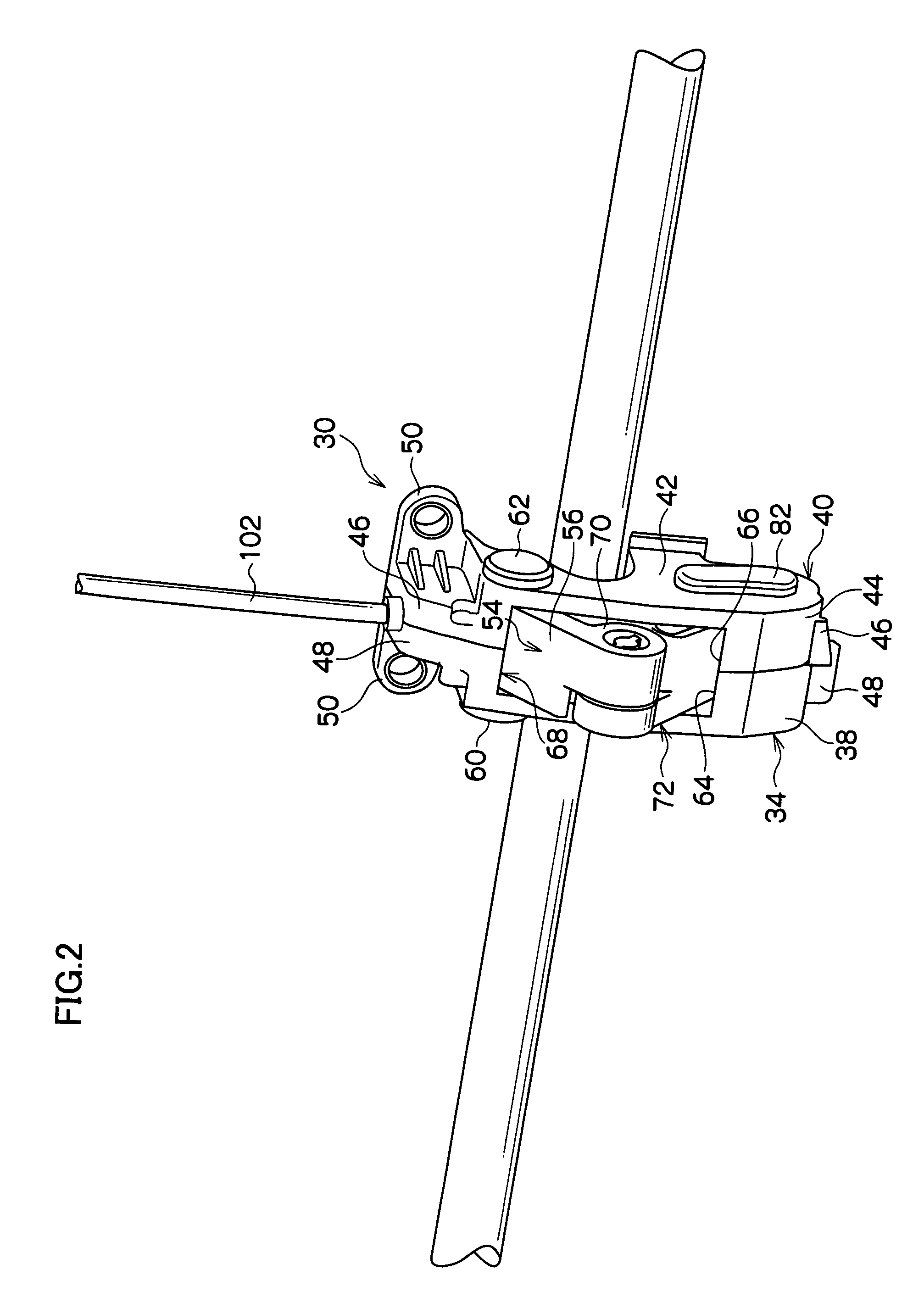

Vehicle seat

ActiveUS7673938B2Displacement of the headrest displaces toward the front is ensuredReduce surface pressureVehicle seatsOperating chairsEngineeringMechanical engineering

Owner:NHK SPRING CO LTD +1

Crawler track

Owner:JOSEPH VOEGELE AG

Opening/closing device and mobile device using the same

InactiveUS20090280874A1Smooth transferring operationEasy to participateSubstation equipmentHingesRotational axisGuiding center

It is an object of the present invention to provide an opening / closing hinge device which can be produced simple in construction and inexpensive in production by reducing the number of the parts forming part of the mobile device and to provide a mobile device small in size, reduced in cost and sufficiently reliable in the hinged members. The second member is rotated with respect to the first member toward the opening operation direction through the movable cam (150) by the urging force of the urging means (170) when the operation cam (130) is displaced in the predetermined operation direction by the external operation force. The fixed guide member (110) has inclined guide portions (115) each inclined at an advance angle in a predetermined inclination direction with respect to the surface perpendicular to the guide center axis to have the second rotation cam (140) rotated around the guide center axis in response to the displacement of the second rotation cam (140) along the guide center axis. The second rotation cam (140) being driven to rotate by the inclined guide portions (115) under a pressing force from the movable cam (150) to have its engagement state with the movable cam (150) changed and to have the urging direction of the second member by the urging means (170) changed when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the operation starting position.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com