Rubber track and chain wheel suitable for rubber track and core iron for rubber track

A technology of rubber track and sprocket, which is applied in the field of rubber track and sprocket, so-called rubber track, which can solve the problems of insufficient consideration of the situation from the roller to the driving protrusion, the degradation of the appearance quality of the rubber track, and the decrease of the guiding function. Achieve surface pressure reduction, achieve durability, and reduce surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. Embodiments of the first invention and the second invention described above will be described in order.

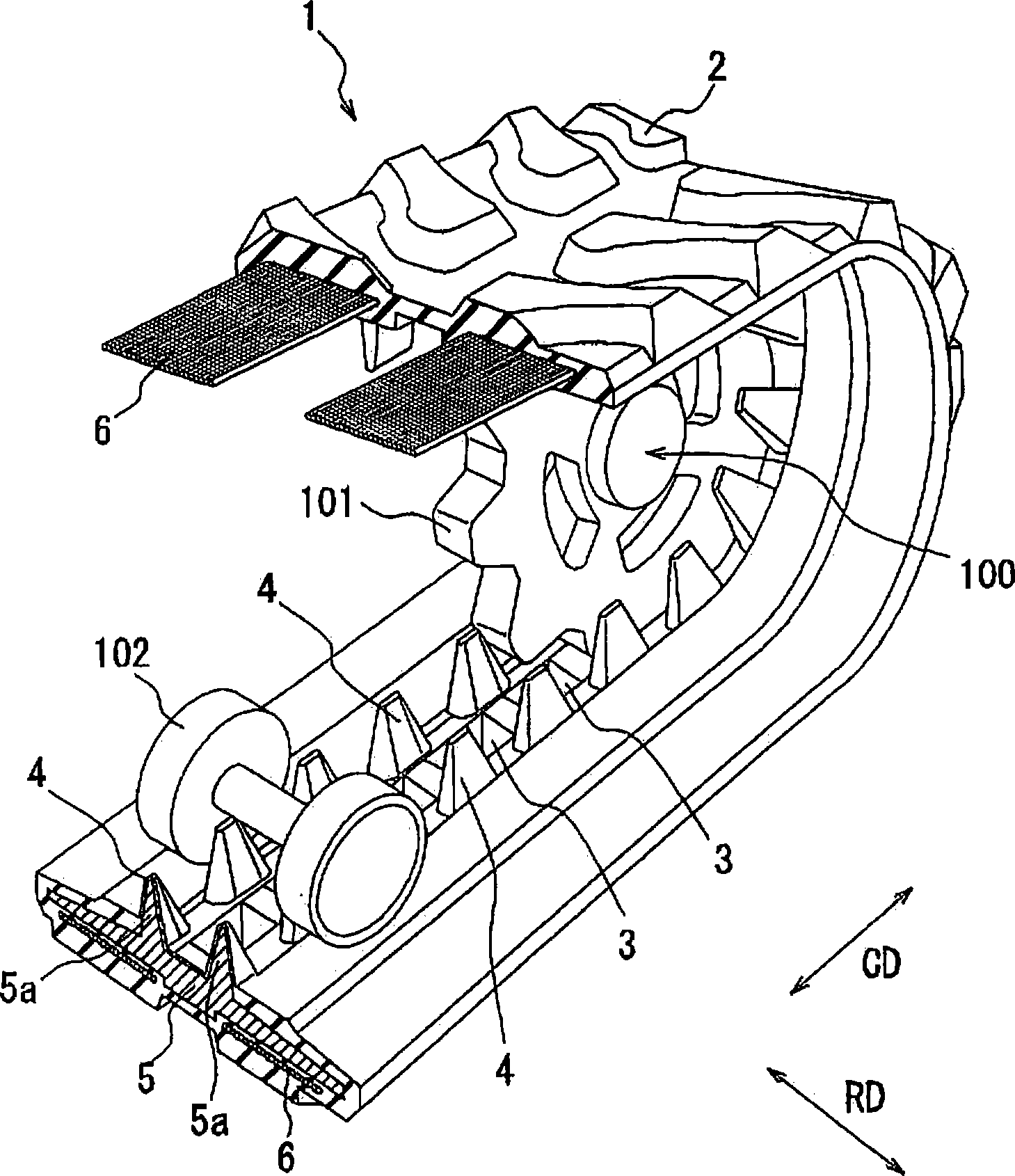

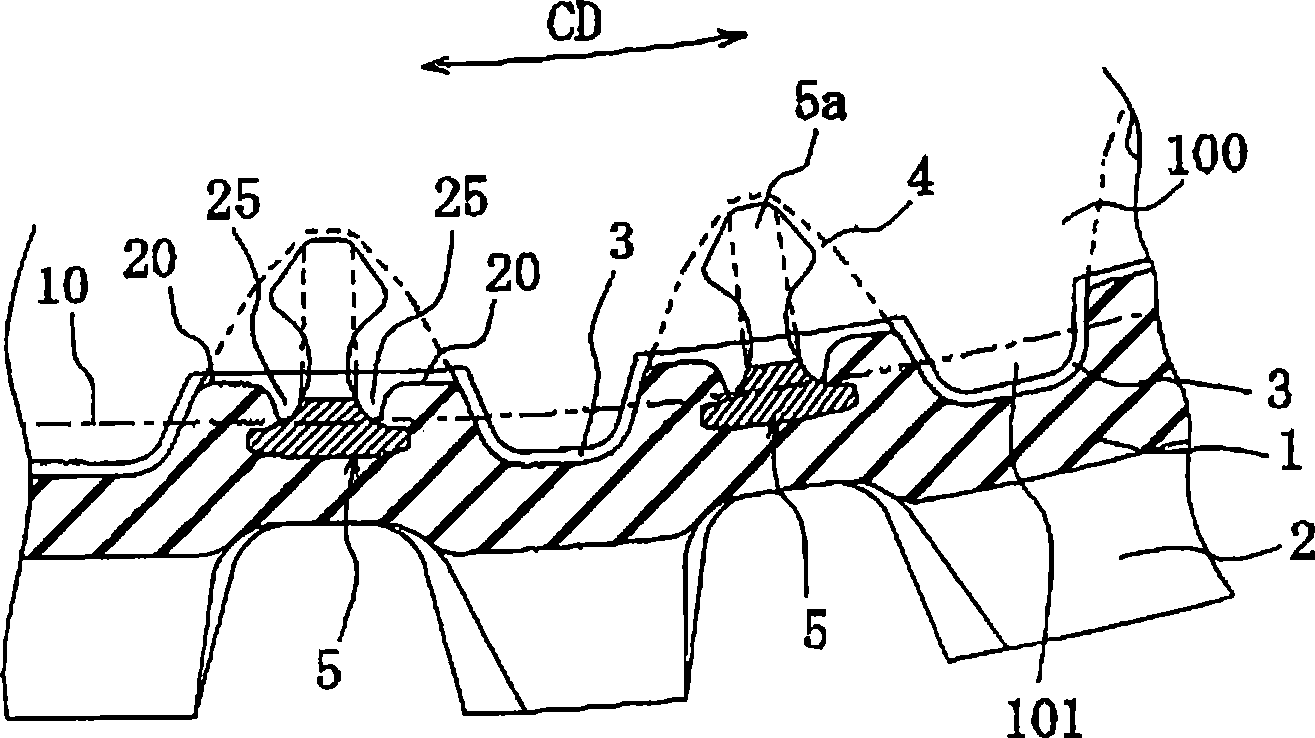

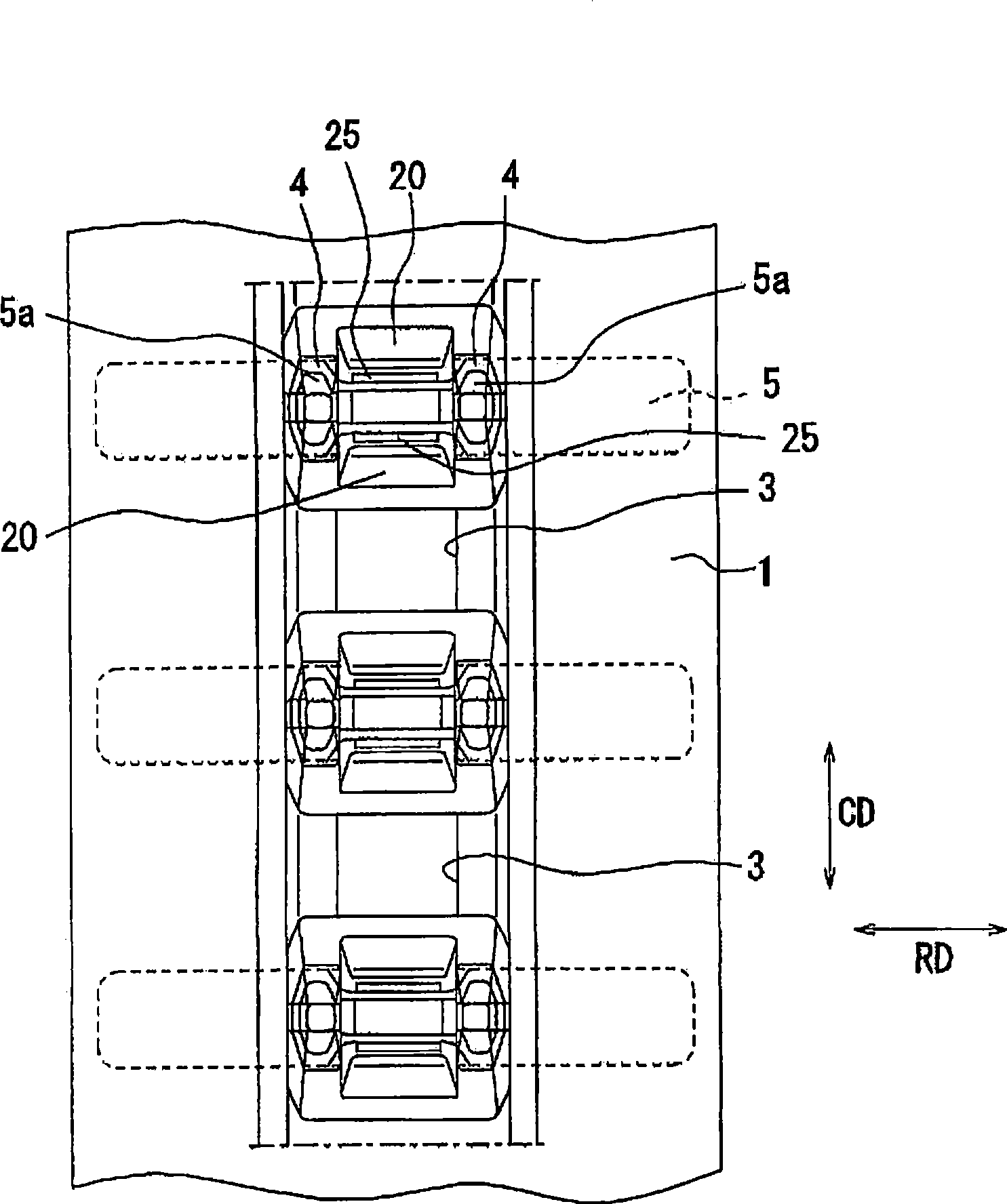

[0049] figure 1 It is a perspective view which shows part of the rubber crawler in embodiment of 1st invention. Should figure 1 The sprockets that transmit the driving force (rotational force) to the rubber track are also illustrated accordingly.

[0050] figure 1 The rubber crawler 1 is a so-called inner peripheral drive type rubber crawler, which has a tooth portion 2 acting on the road surface on its outer peripheral surface side, and a drive card for transmitting the driving force to the rubber crawler itself is formed on its inner peripheral surface side. Hebu. The driving engaging part includes: the following hard engaging members buried in the circumferential direction of the rubber crawler 1 at a constant pitch; and recesses 3 respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com