Patents

Literature

352results about How to "Increase injection pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

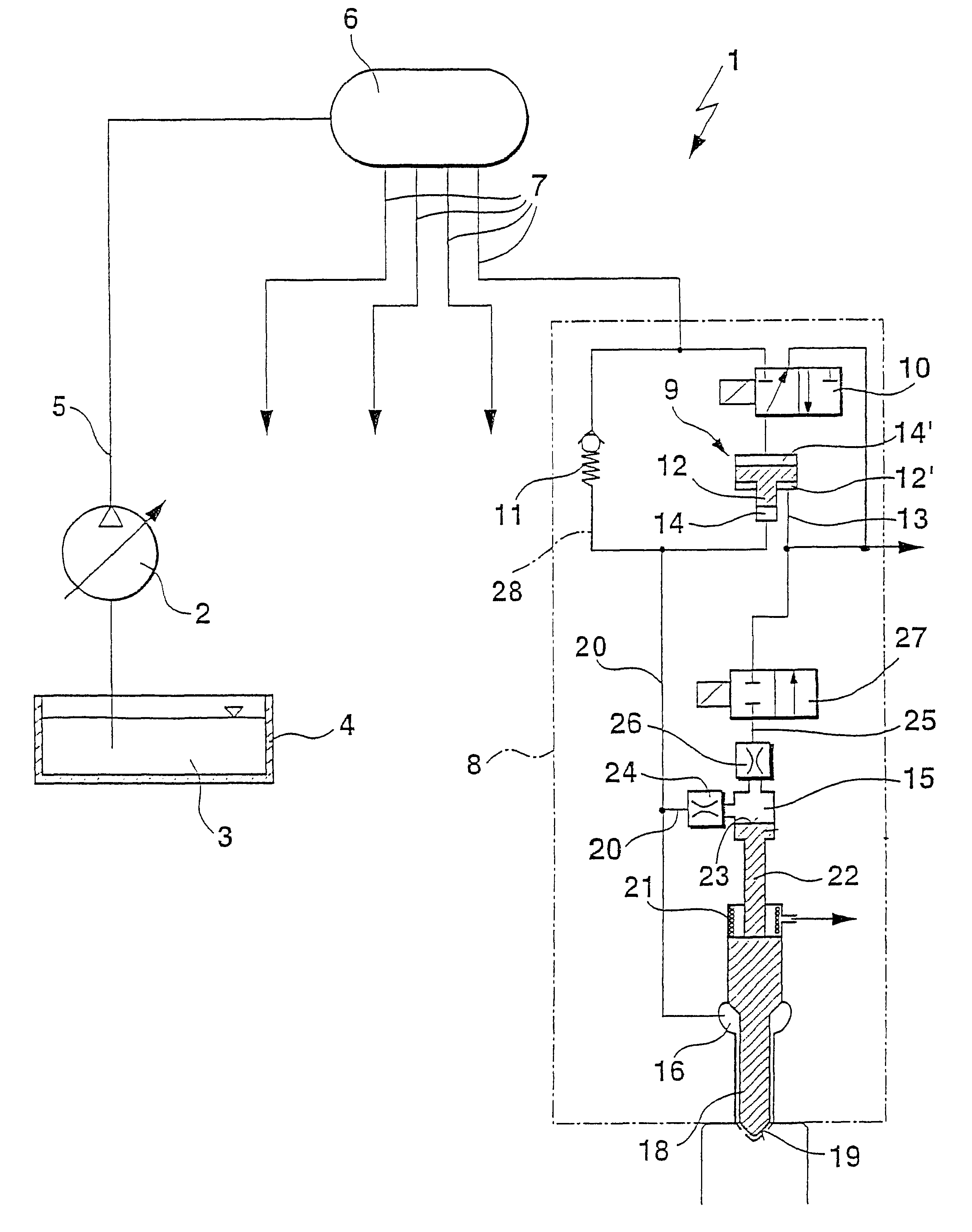

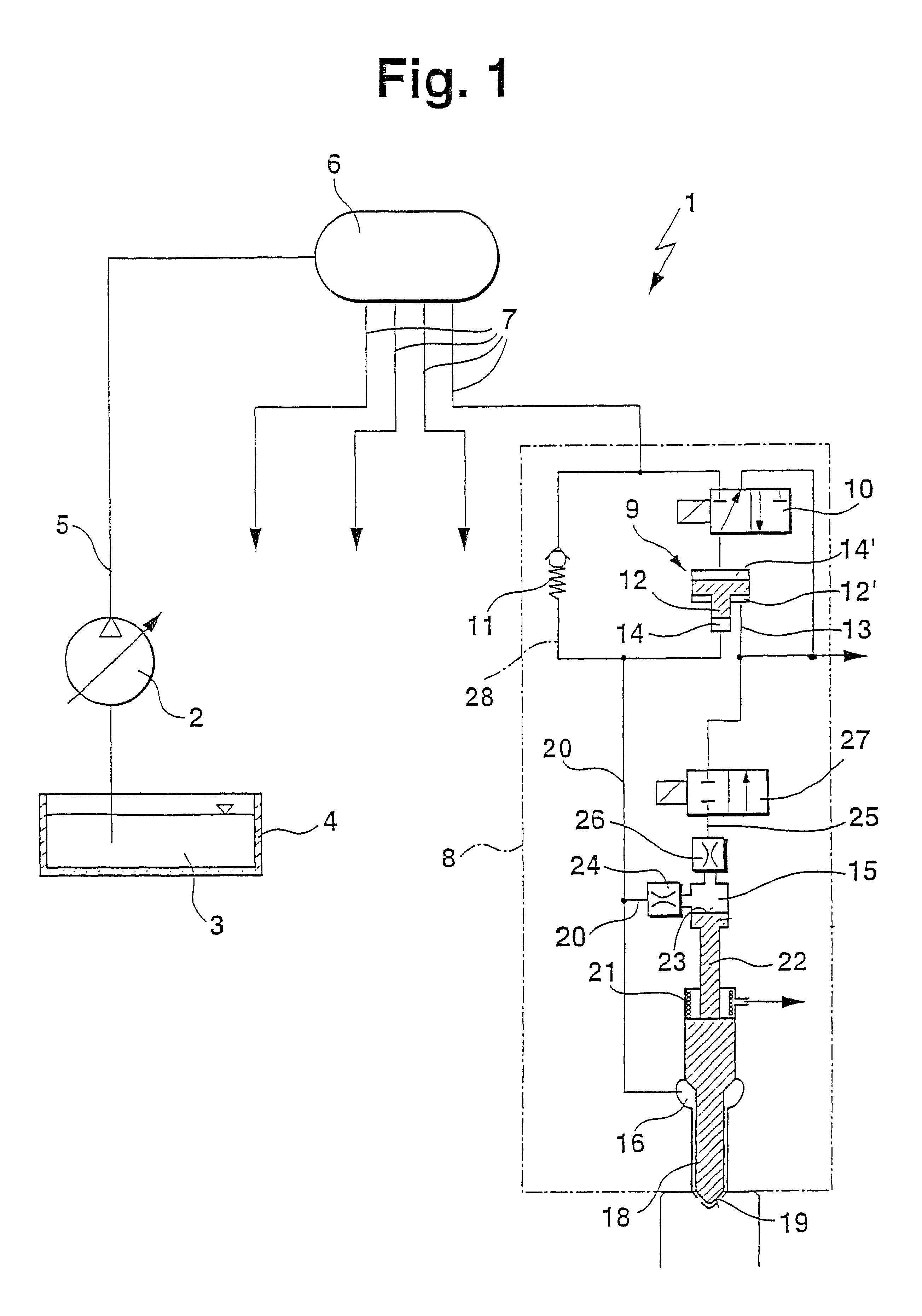

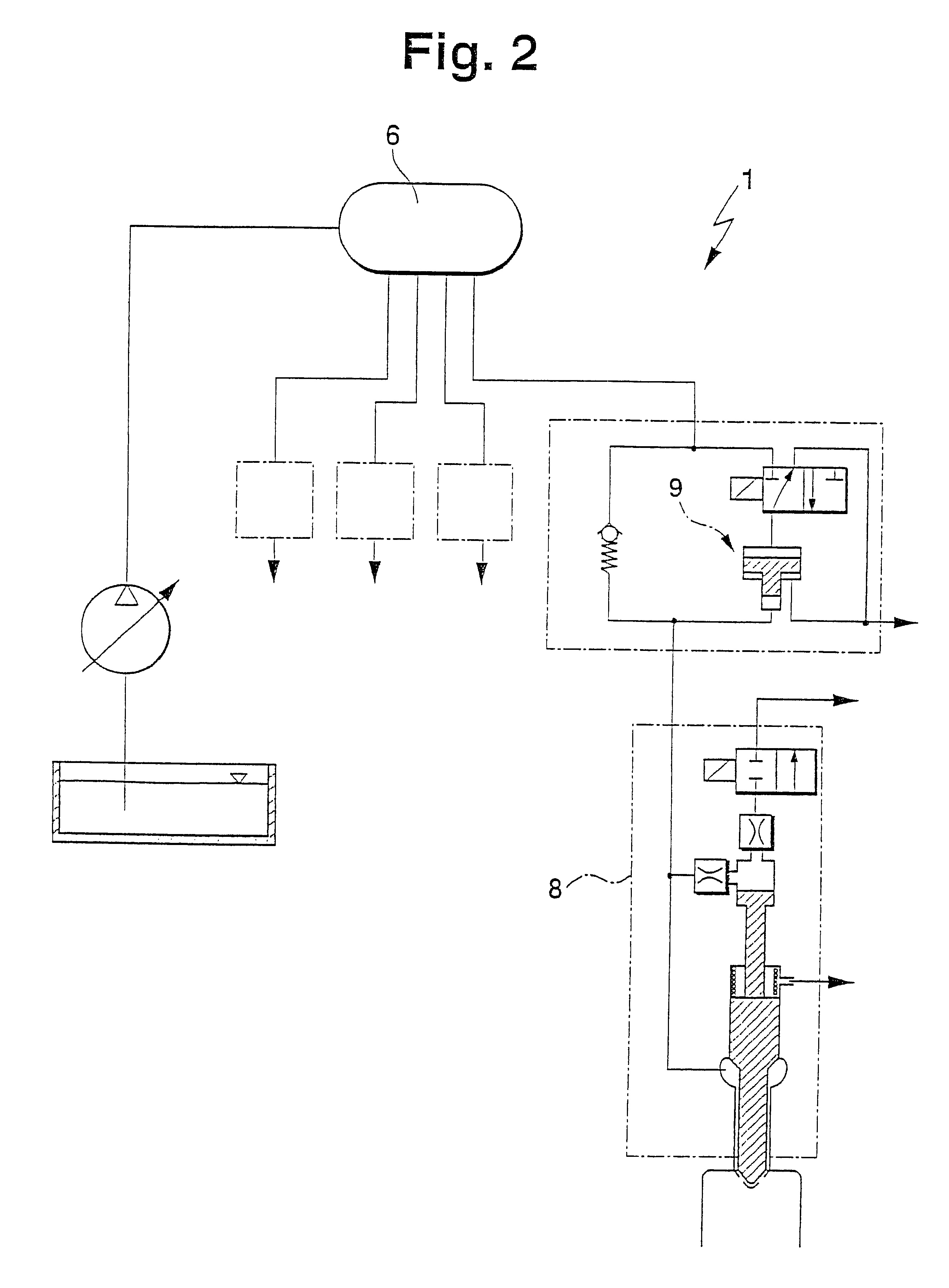

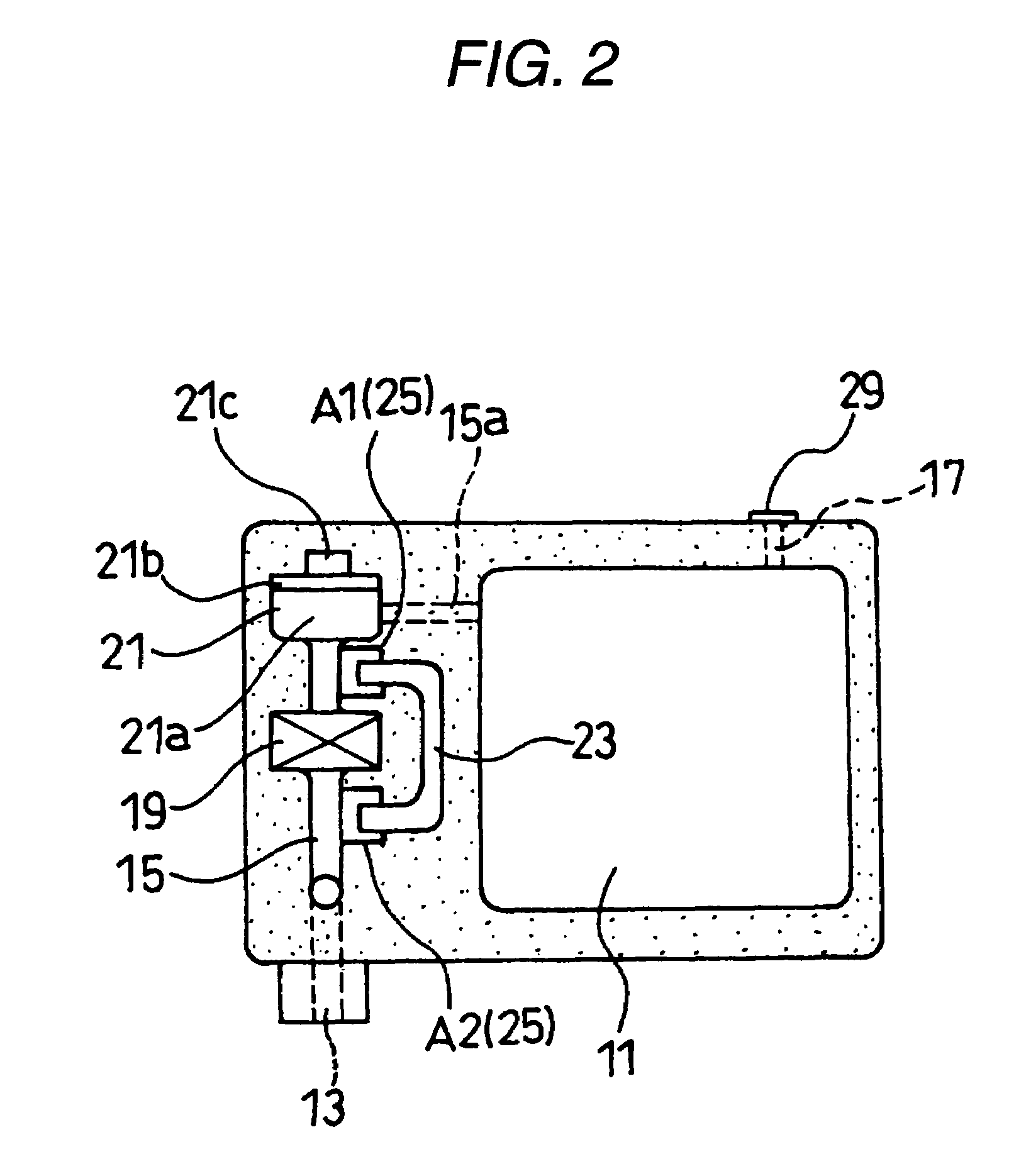

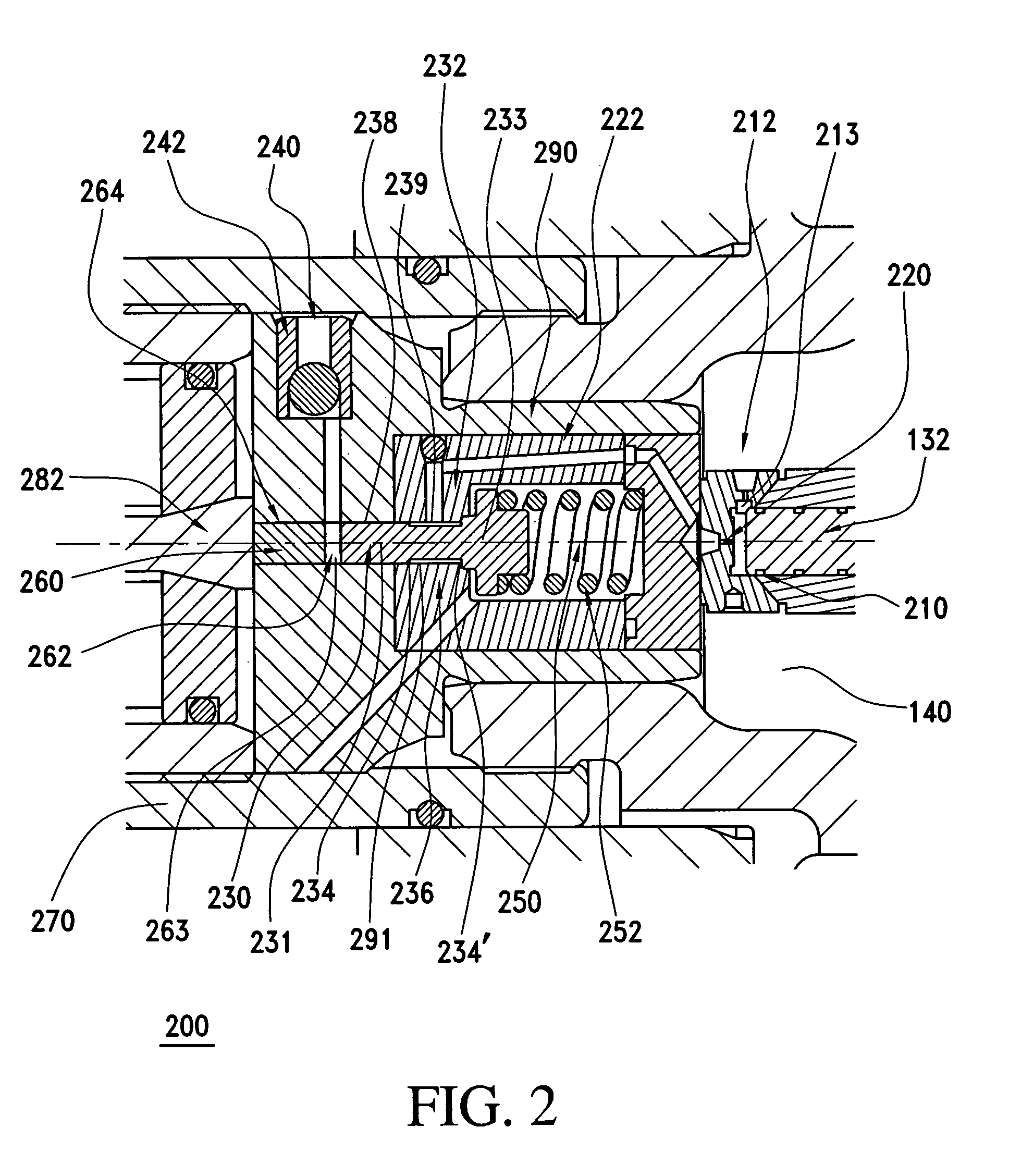

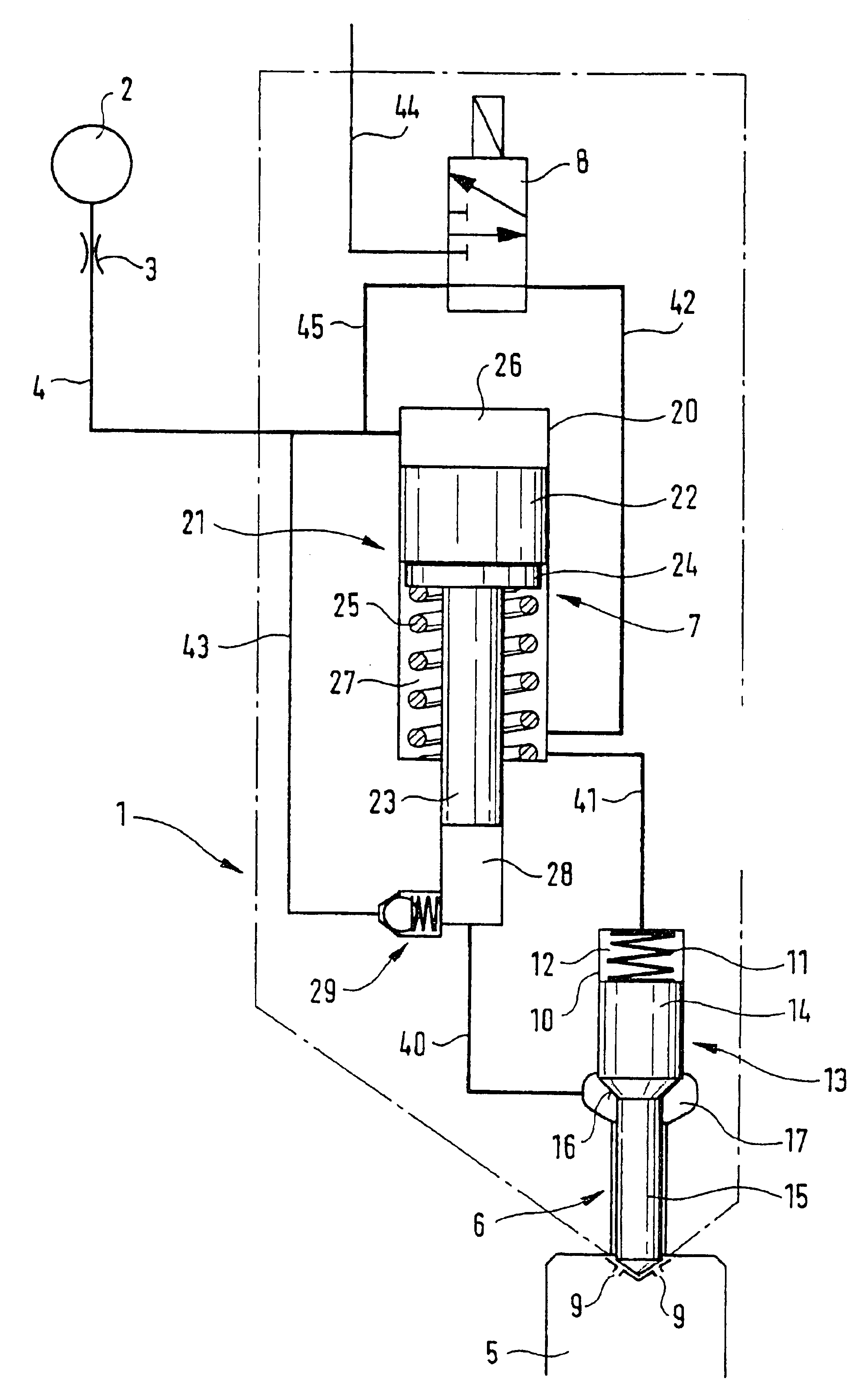

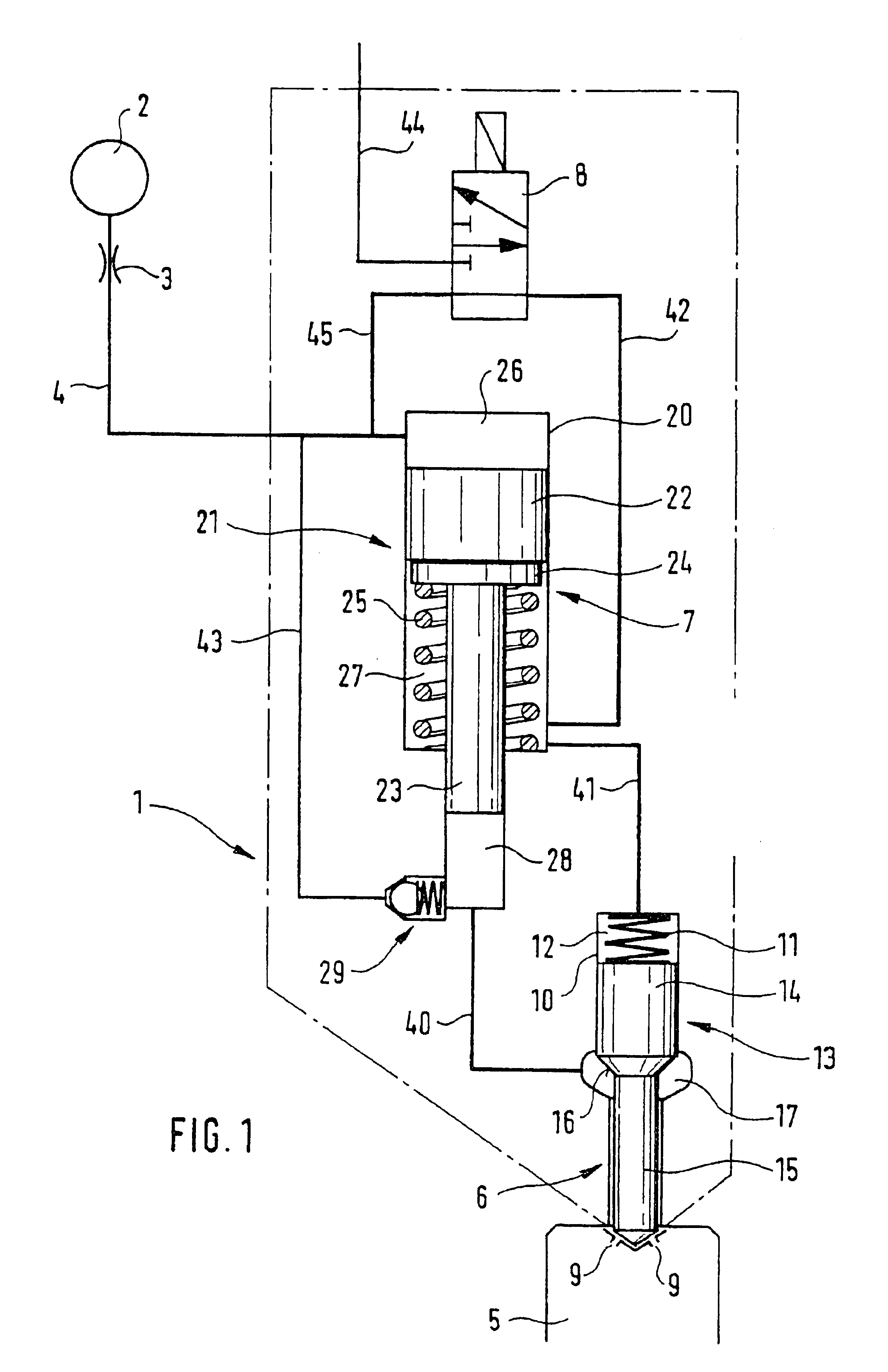

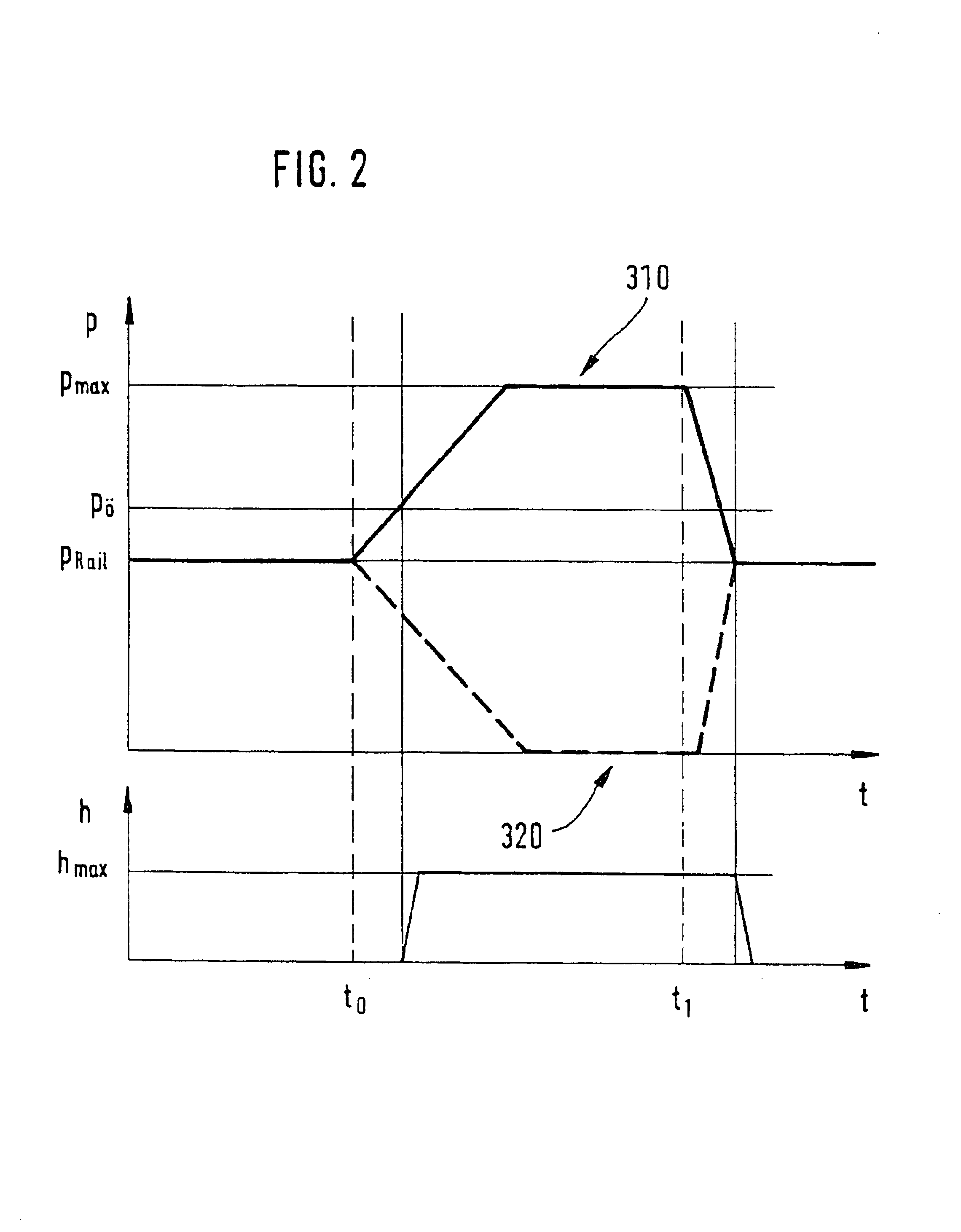

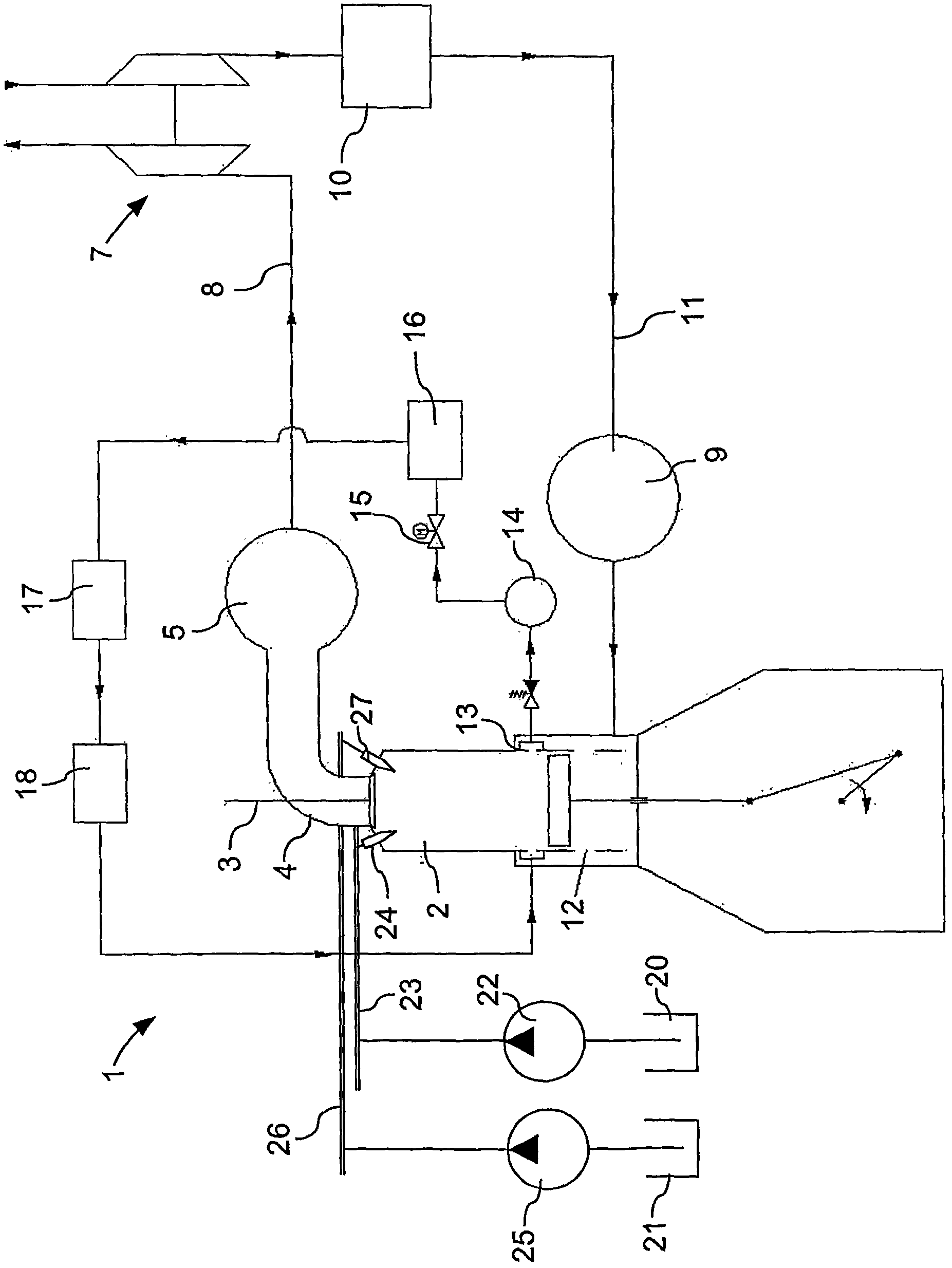

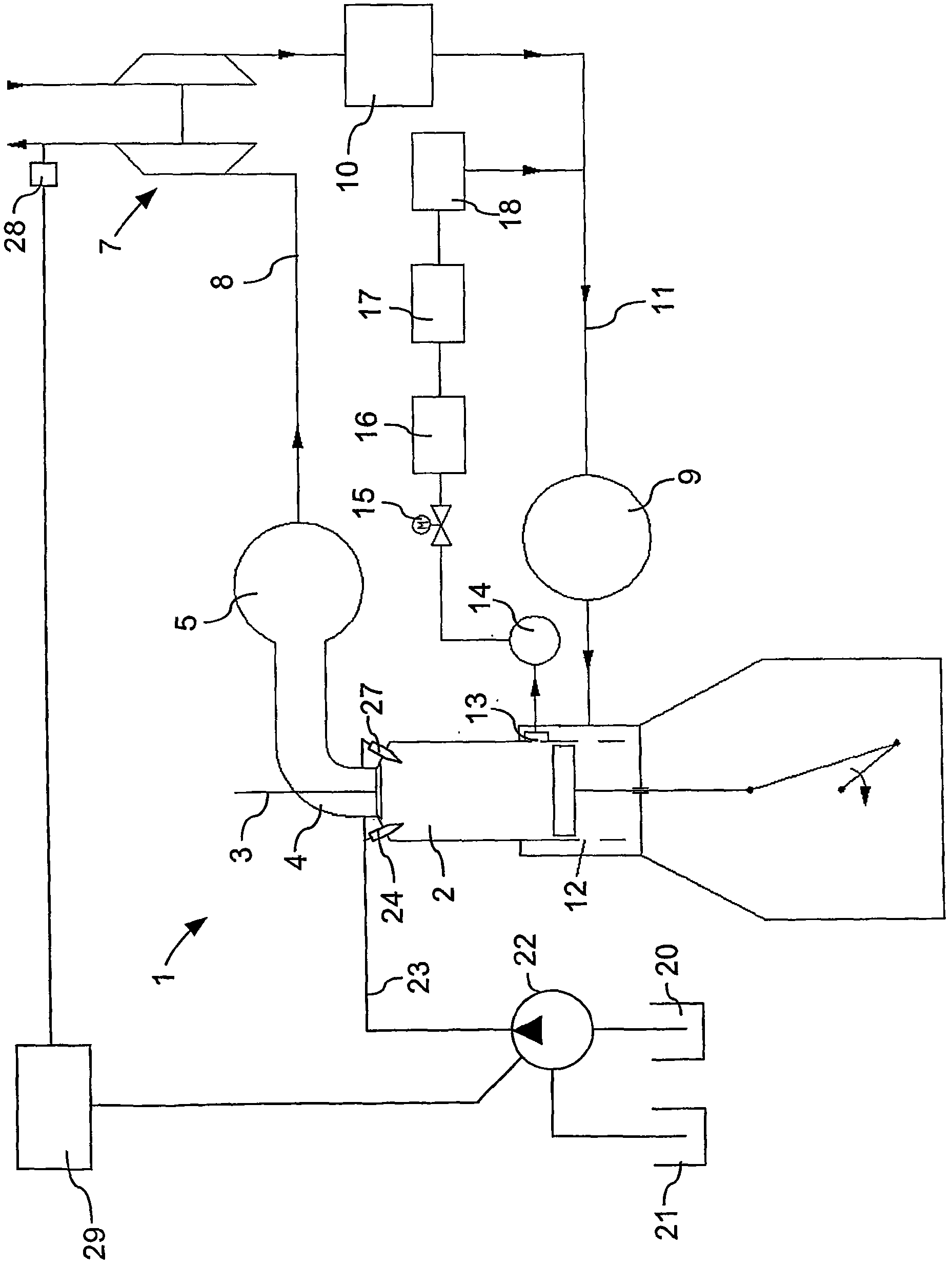

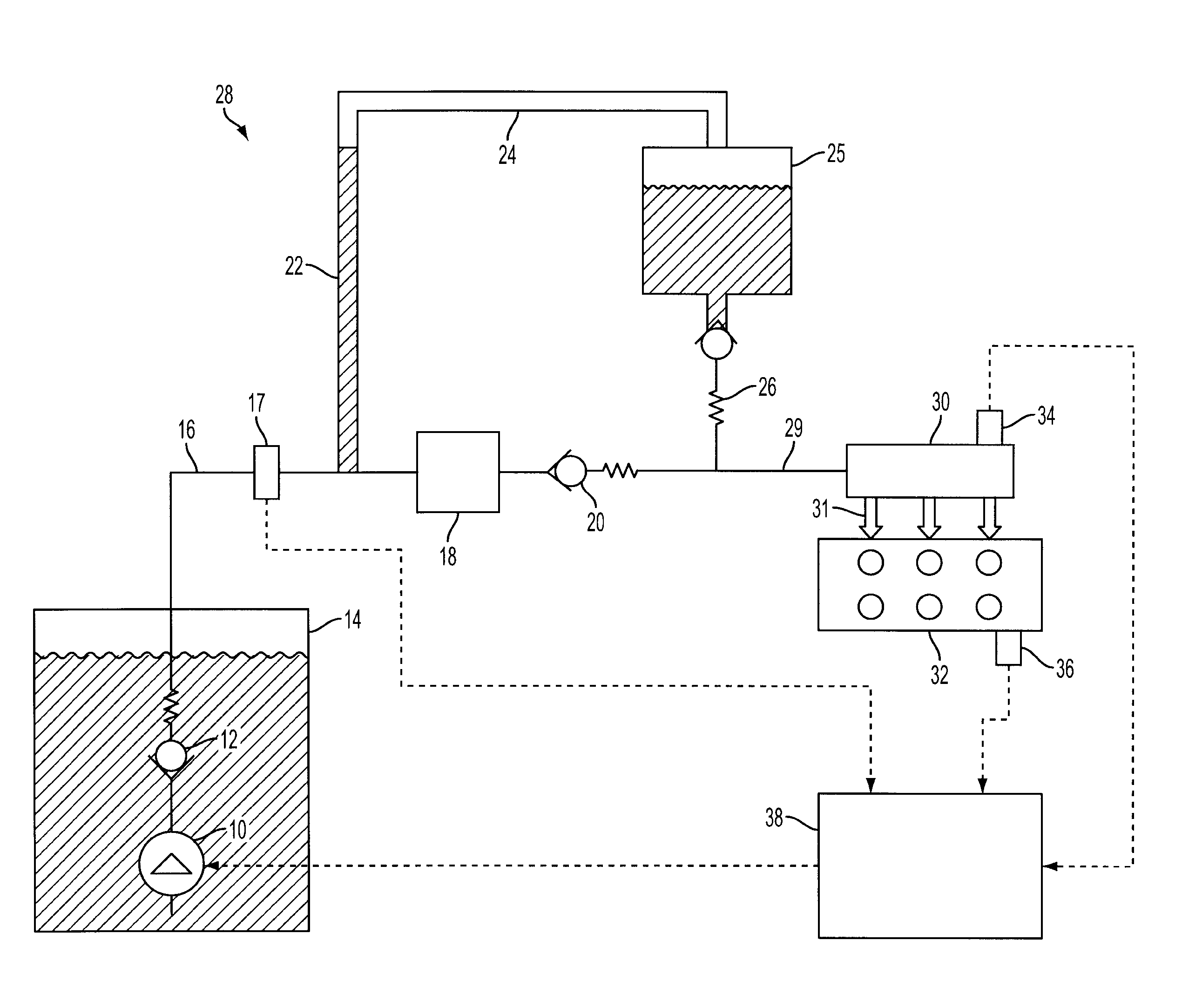

Fuel injection system which uses a pressure step-up unit

InactiveUS6453875B1Increase flexibilityIncrease injection pressureFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesEngineeringPiston

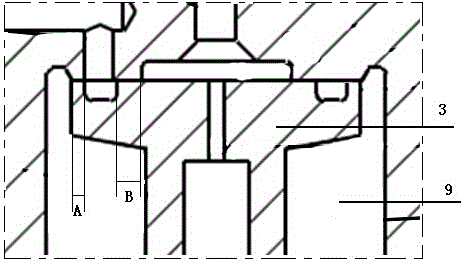

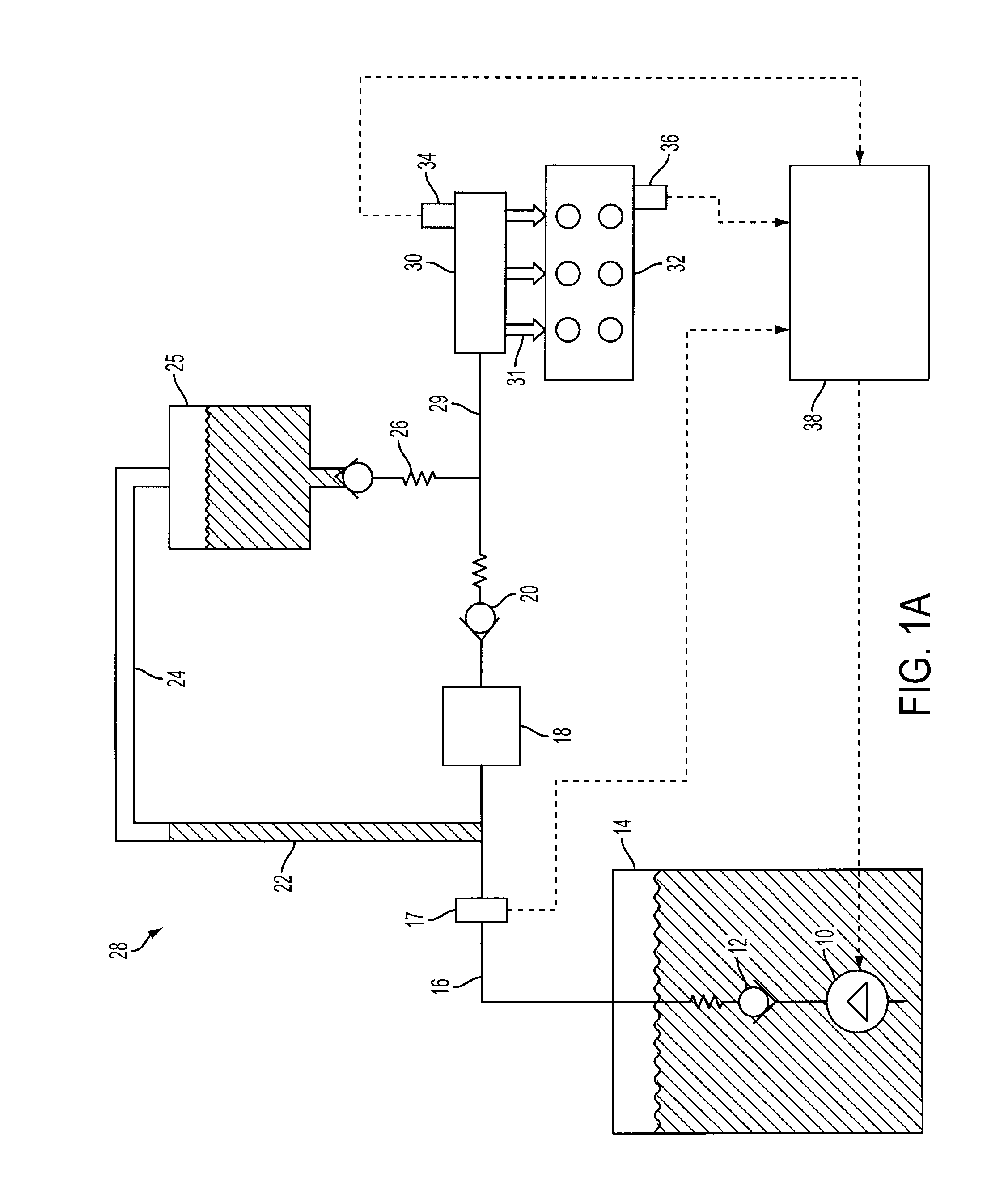

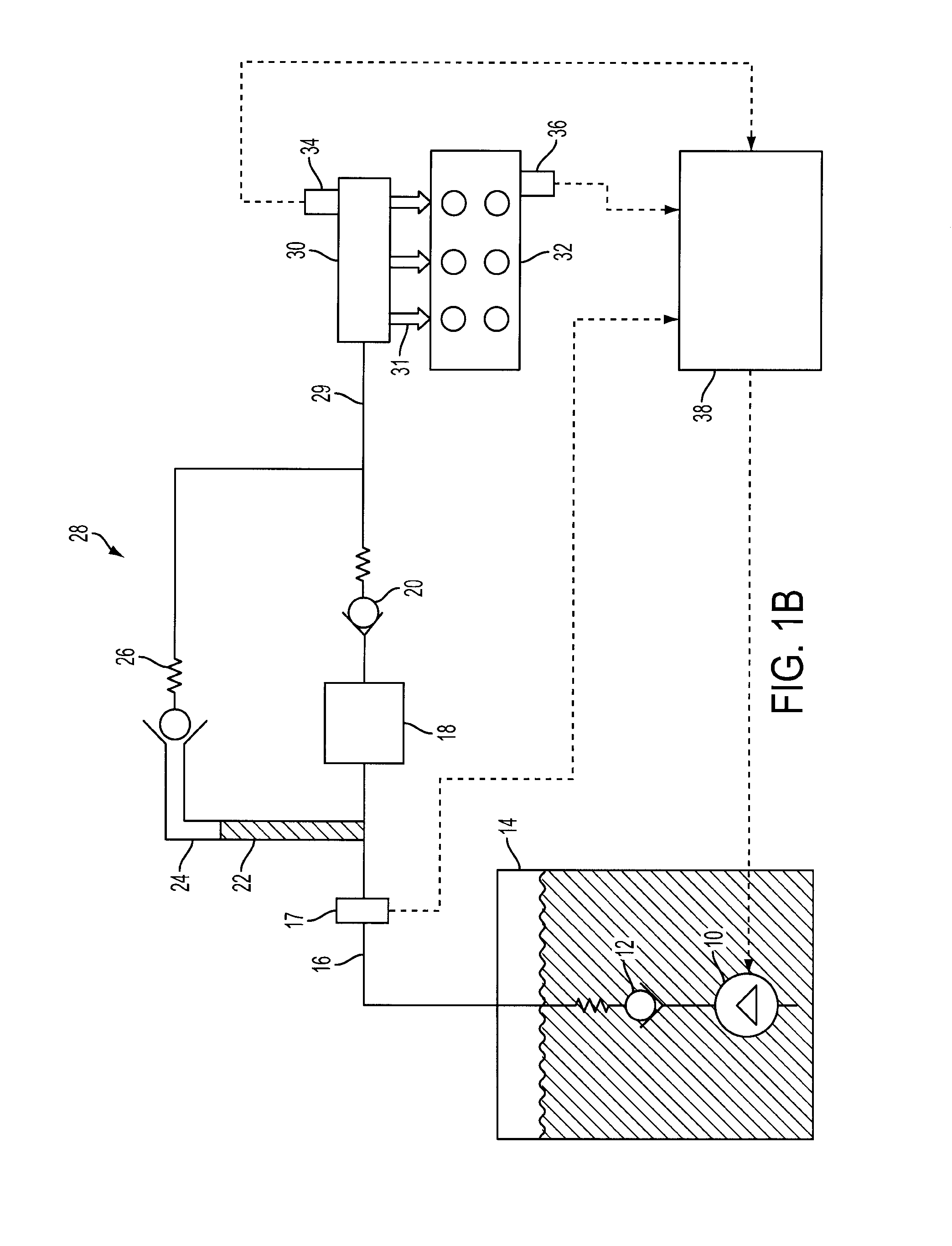

A fuel injection system has a pressure step-up unit, disposed between a pressure storage chamber and a nozzle chamber, whose pressure chamber communicates with the nozzle chamber via a pressure line. A bypass line connected to the pressure storage chamber is also provided. The bypass line communicates directly with the pressure line. The bypass line can be used for pressure injection and is disposed parallel to the pressure chamber, so that the bypass line is open regardless of the motion and position of a displaceable piston element in the pressure step-up unit. This enhances the flexibility of injection.

Owner:ROBERT BOSCH GMBH

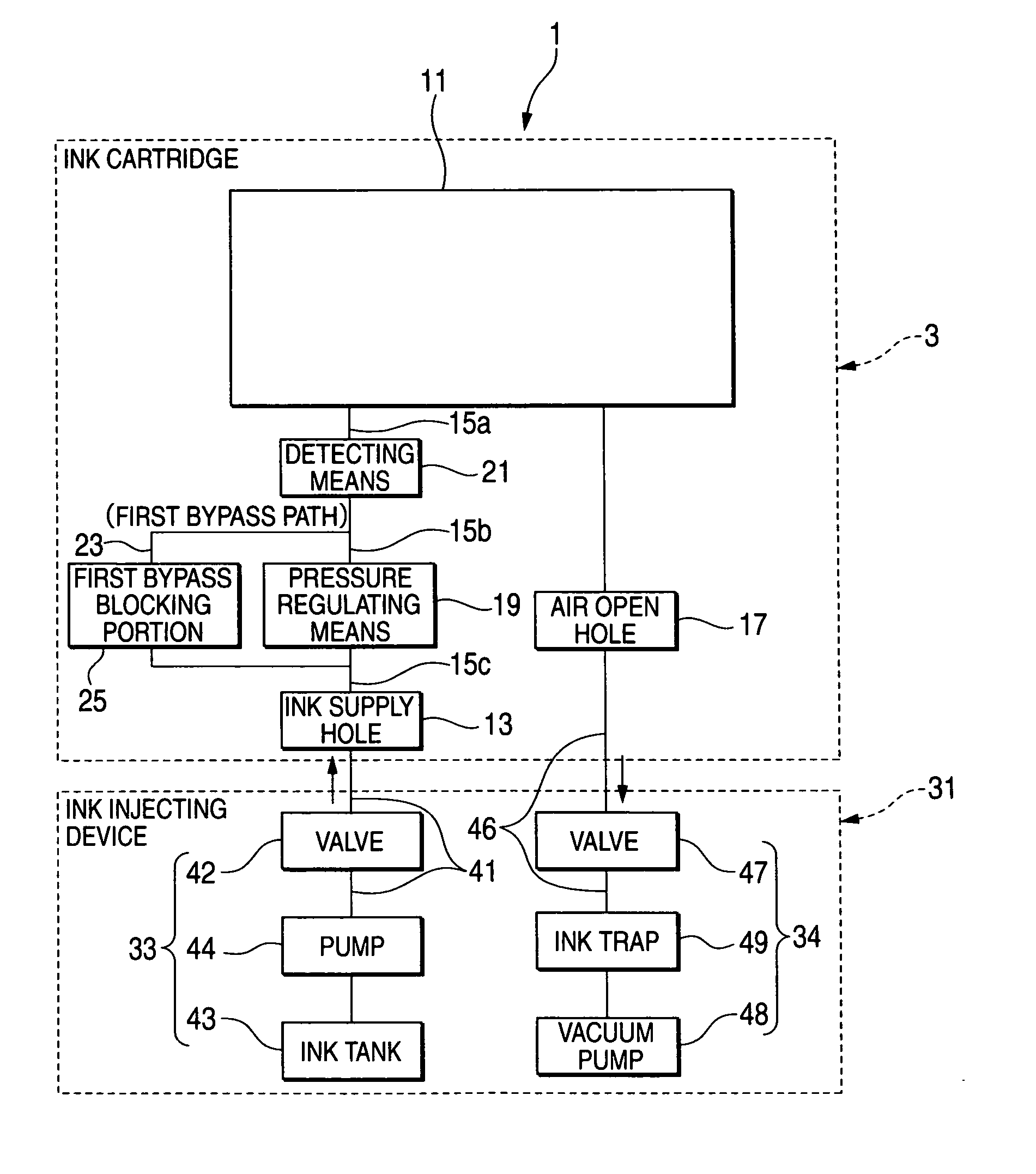

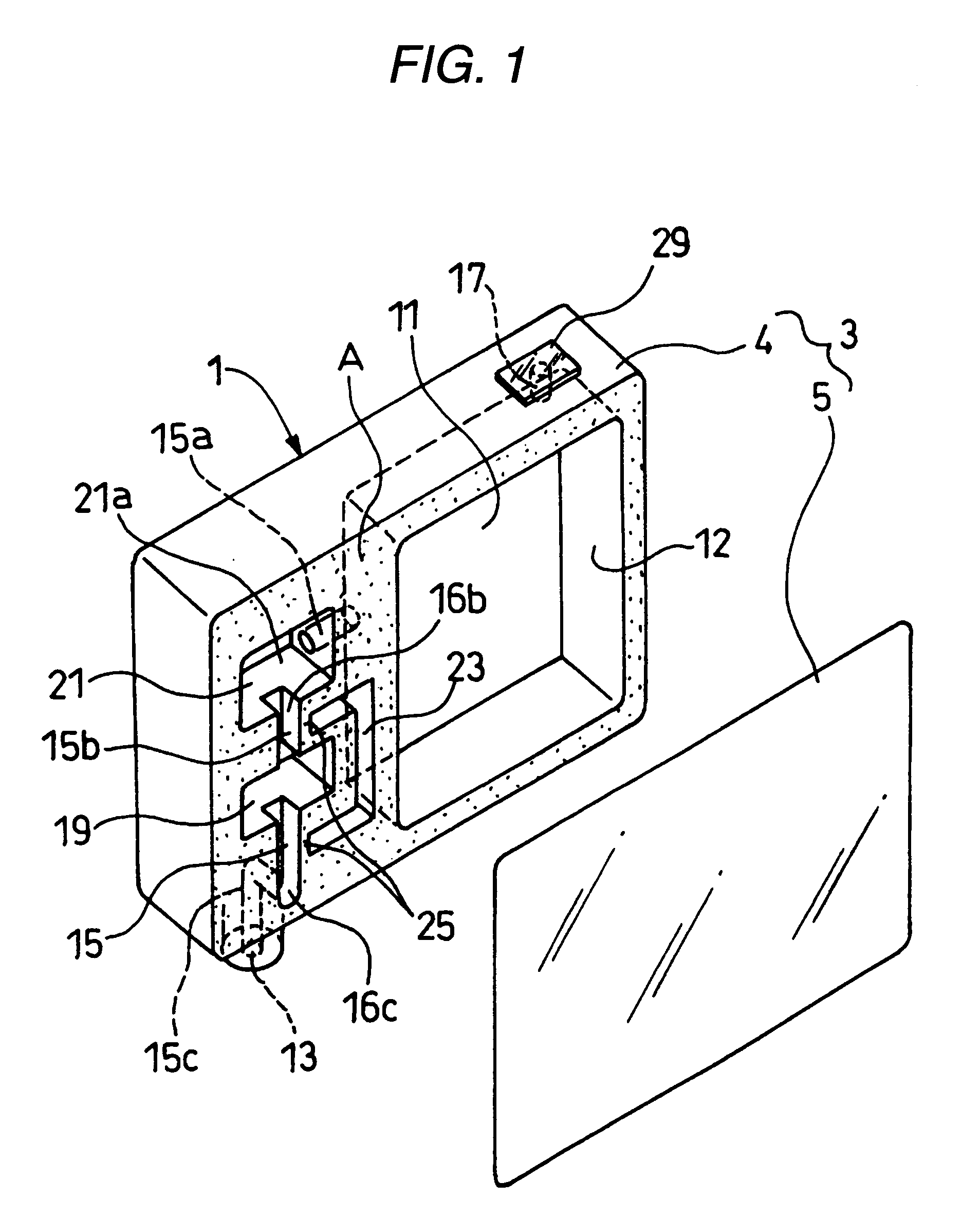

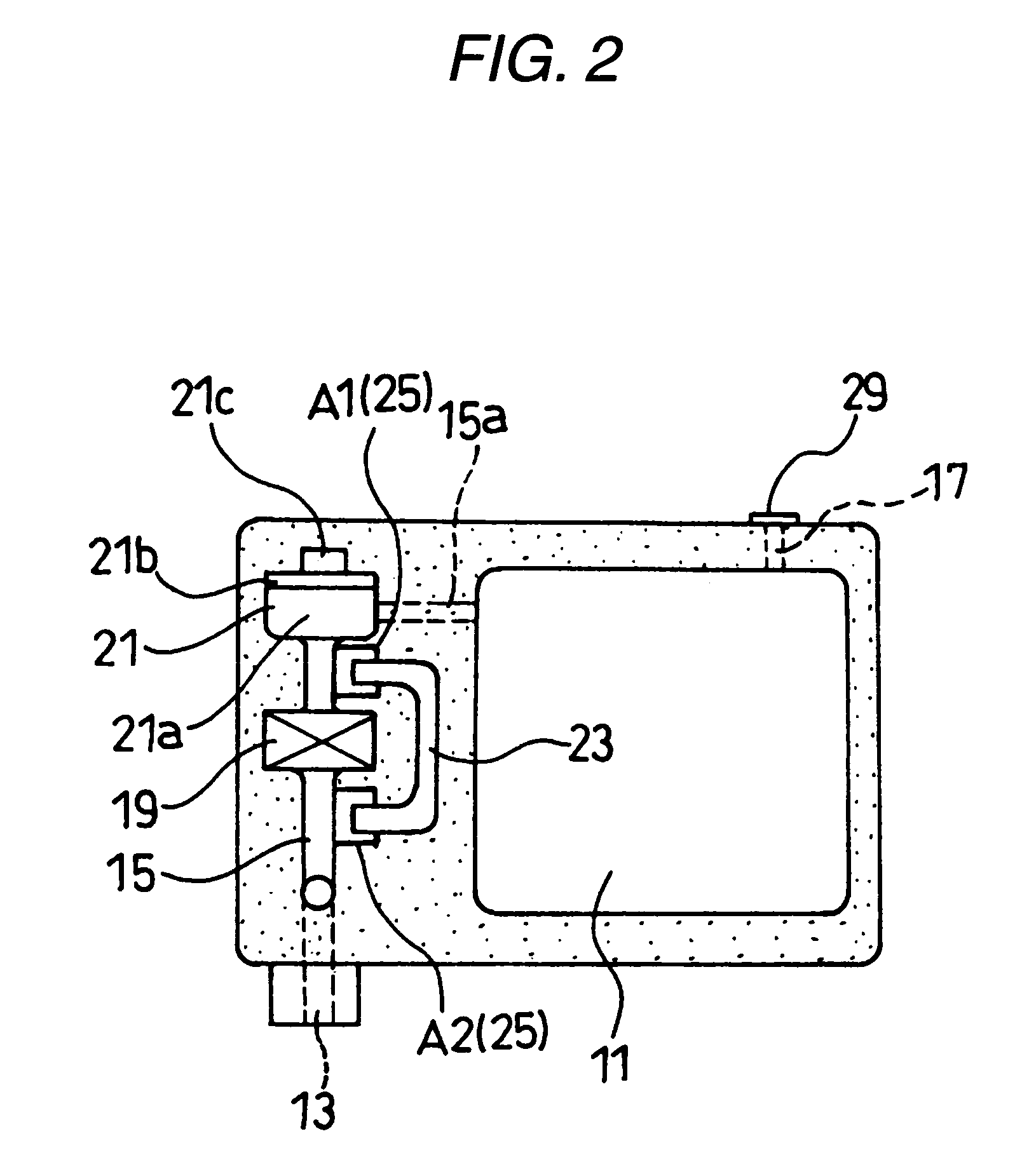

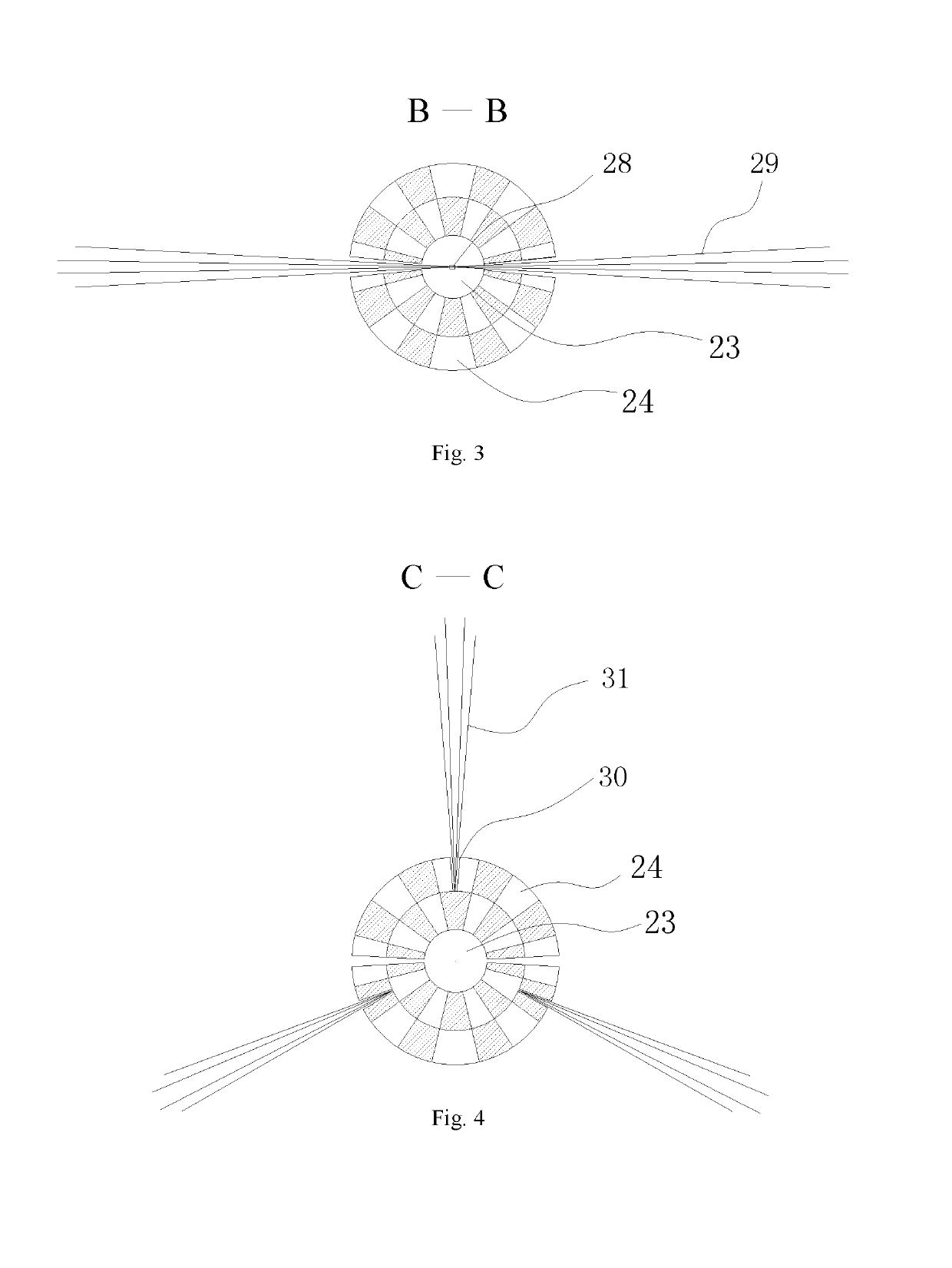

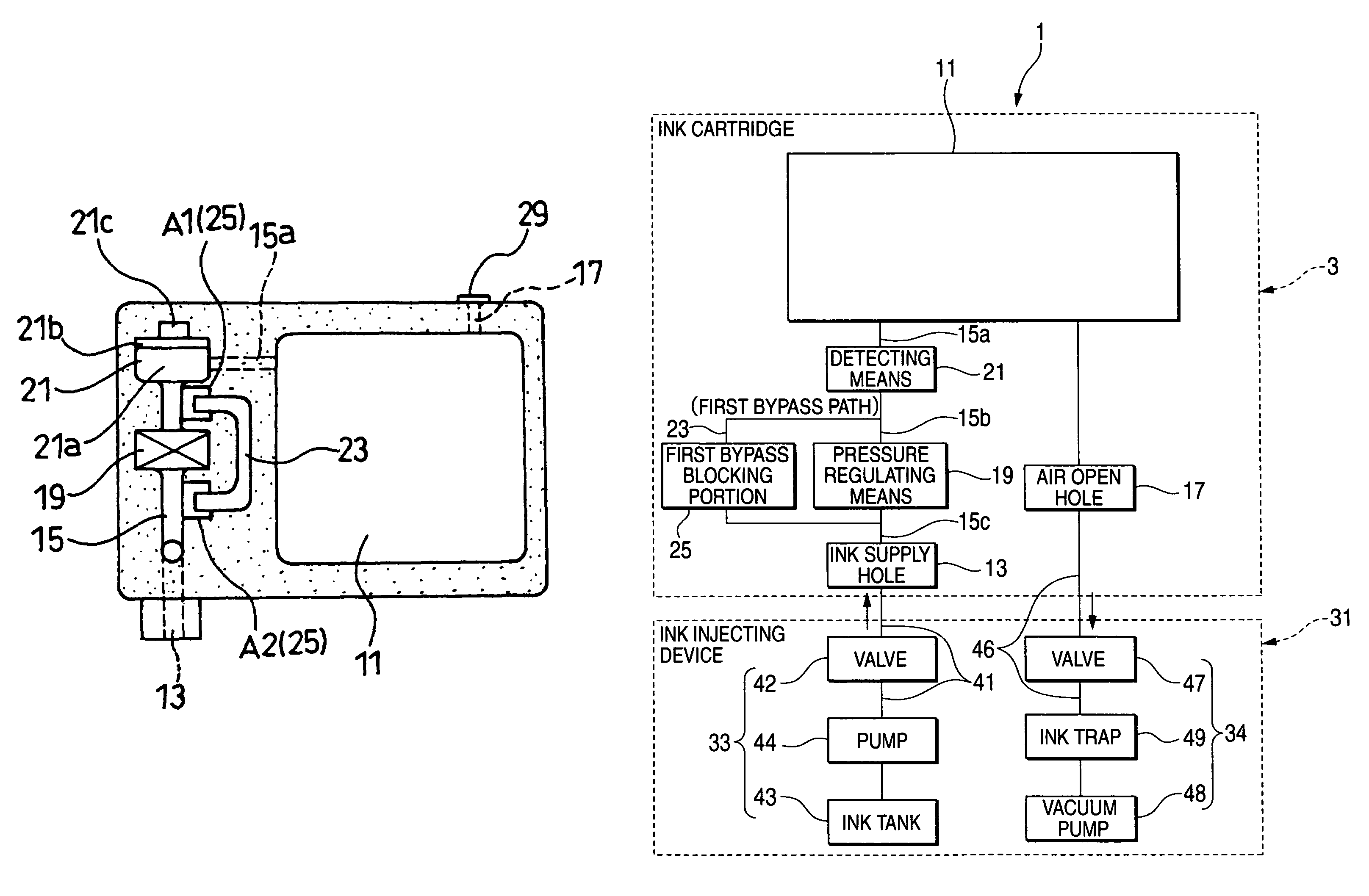

Liquid container and liquid filling method

A liquid container includes: a container body attachable to a container attachment portion of an apparatus side; a liquid chamber, provided in the container body, for accommodating a liquid therein; a liquid supply hole connectable to a liquid receiving portion of the apparatus side; a liquid leading path for leading the liquid stored in the liquid chamber to the liquid supply hole; an air open hole for introducing outside air into the liquid chamber as the liquid in the liquid chamber is consumed; pressure regulating means, provided in a portion of the liquid leading path, for regulating a pressure of the liquid to be supplied to the liquid receiving portion through the liquid supply hole and hindering a reverse flow of the liquid from the liquid supply hole to the liquid chamber; a first bypass path for causing first and second liquid leading passages of the liquid leading path, provided respectively before and after the pressure regulating means, to communicate with each other; and a first bypass blocking portion capable of blocking the bypass path.

Owner:SEIKO EPSON CORP

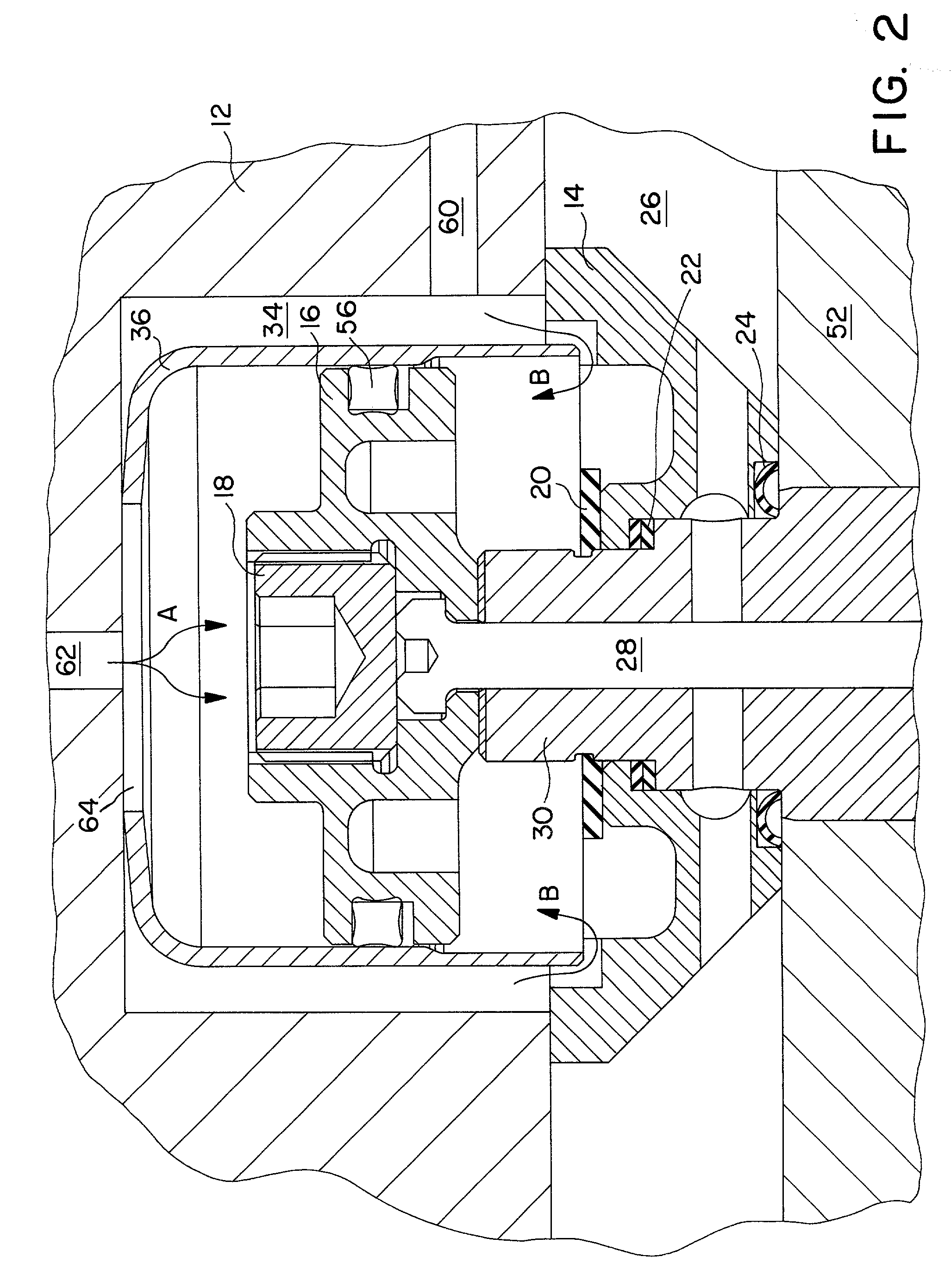

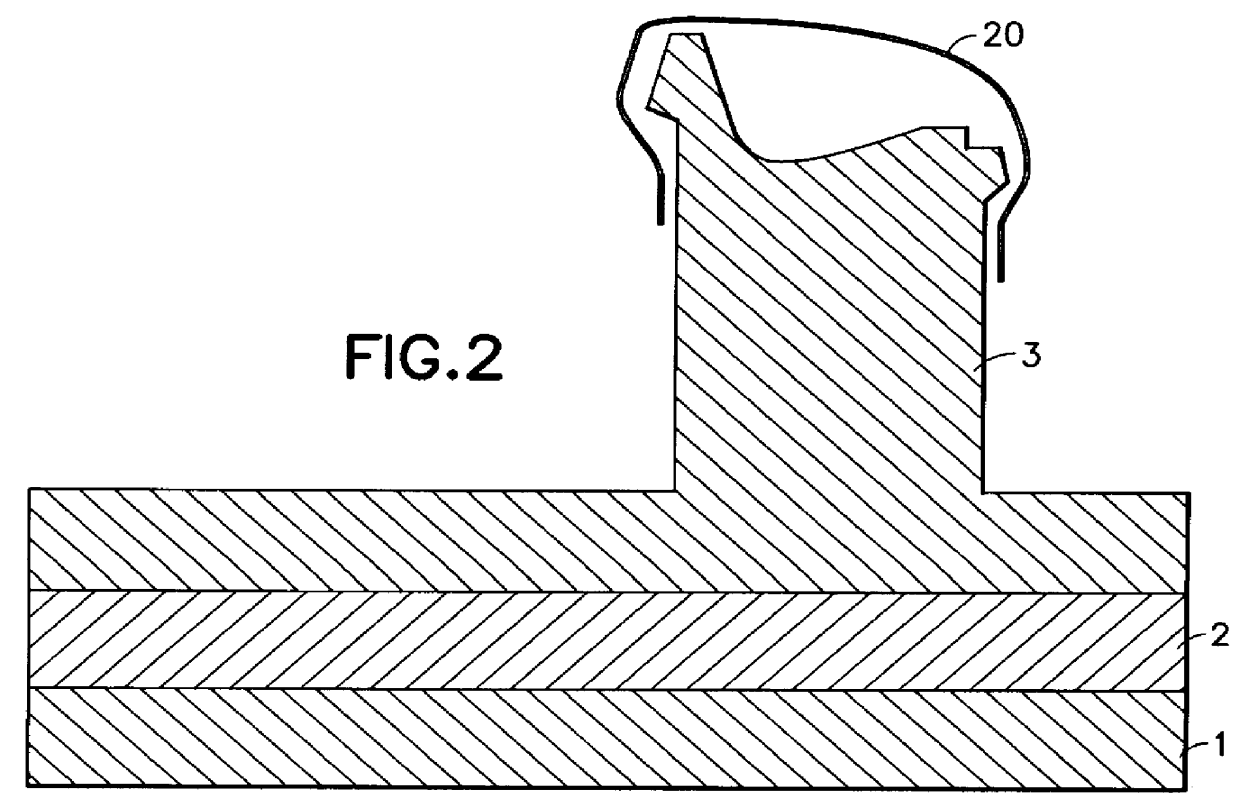

Injection molding nozzle

InactiveUS20030143298A1Reduce maintenance costsReduce waste costsConfectionerySweetmeatsEngineeringInjection molding machine

An injection molding nozzle is provided having a first sealing member to substantially eliminate the leakage of molten material from around the injection nozzle. A second sealing member is configured to substantially reduce the leakage of a pressurized fluid, such as air, which may be used to open and close a valve stem associated with the injection nozzle.

Owner:HUSKY INJECTION MOLDING SYST LTD

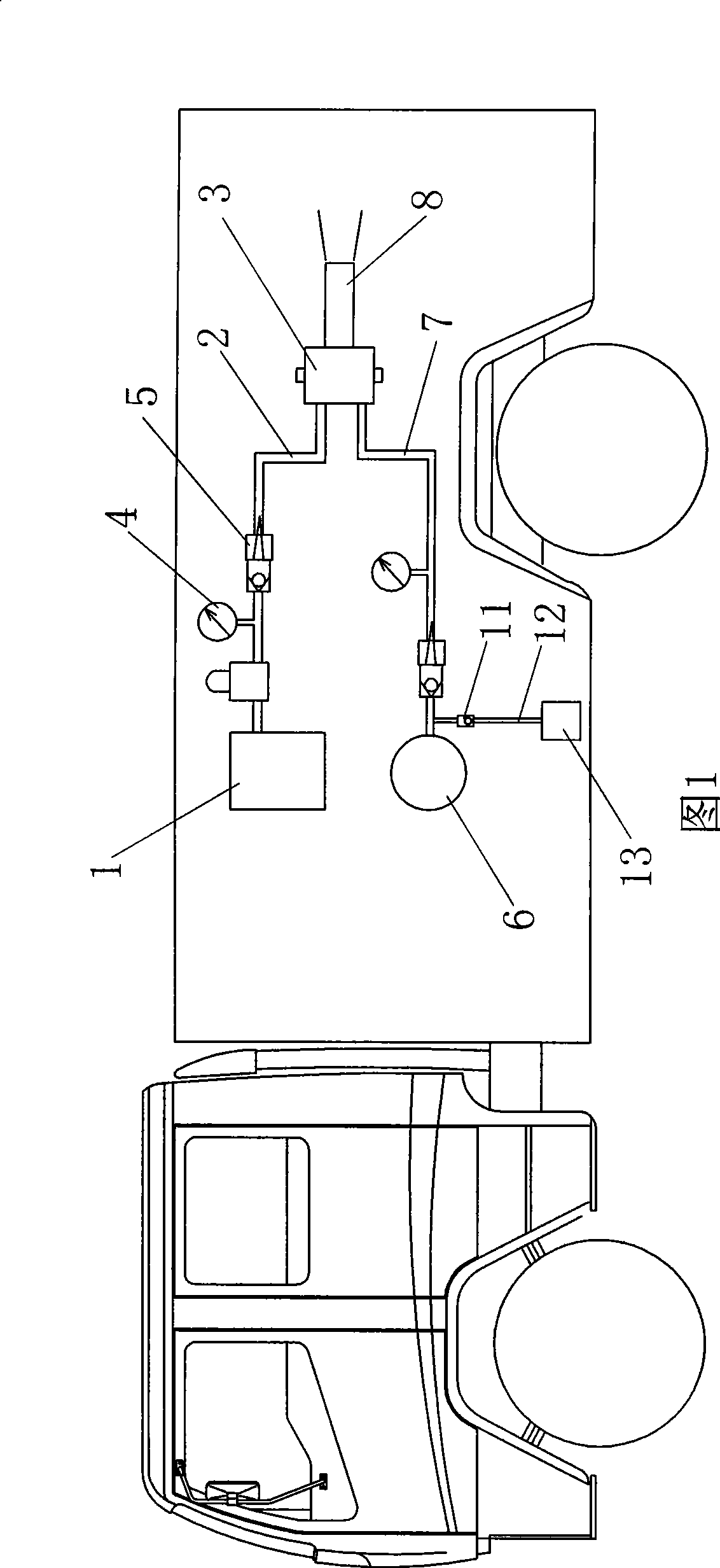

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

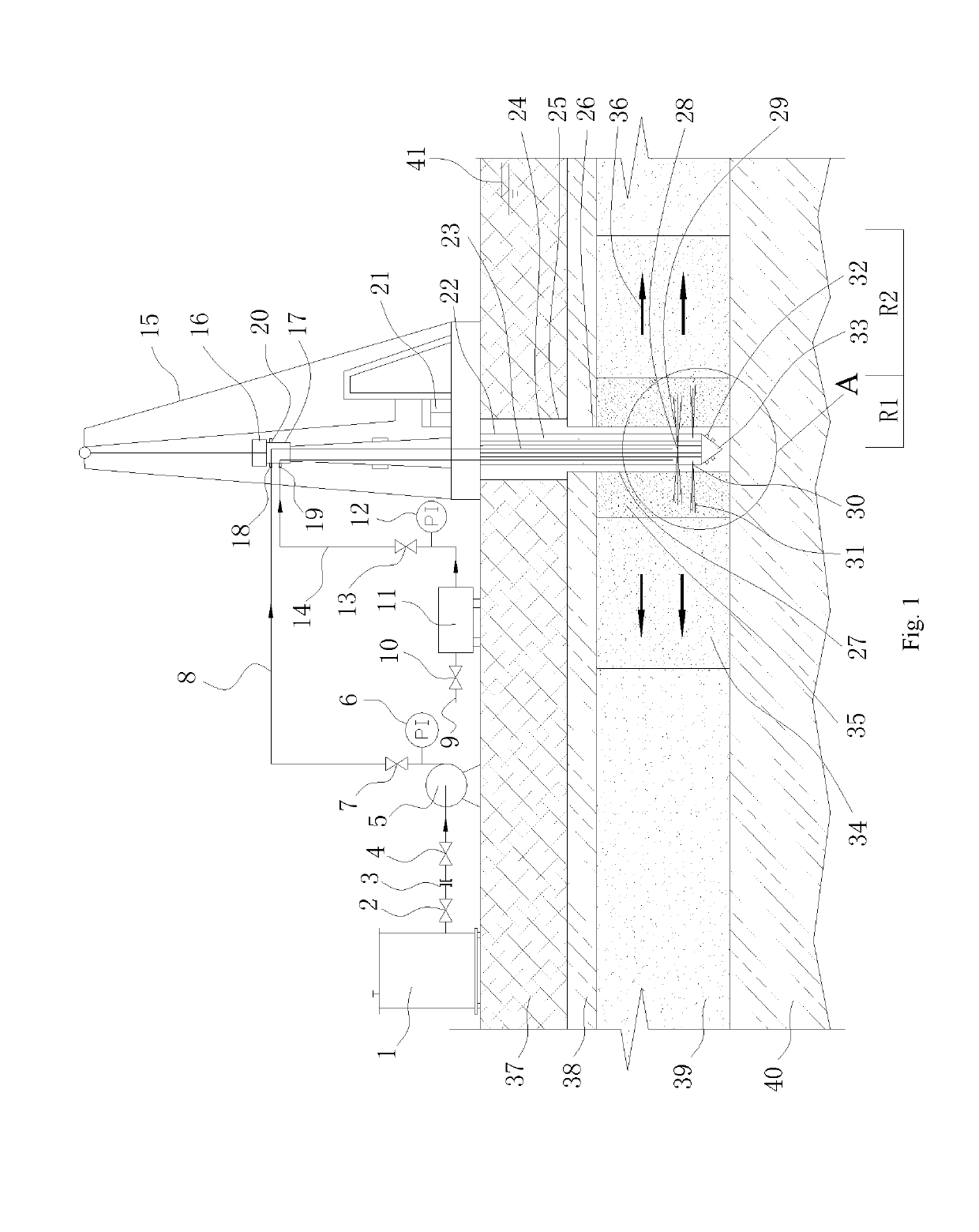

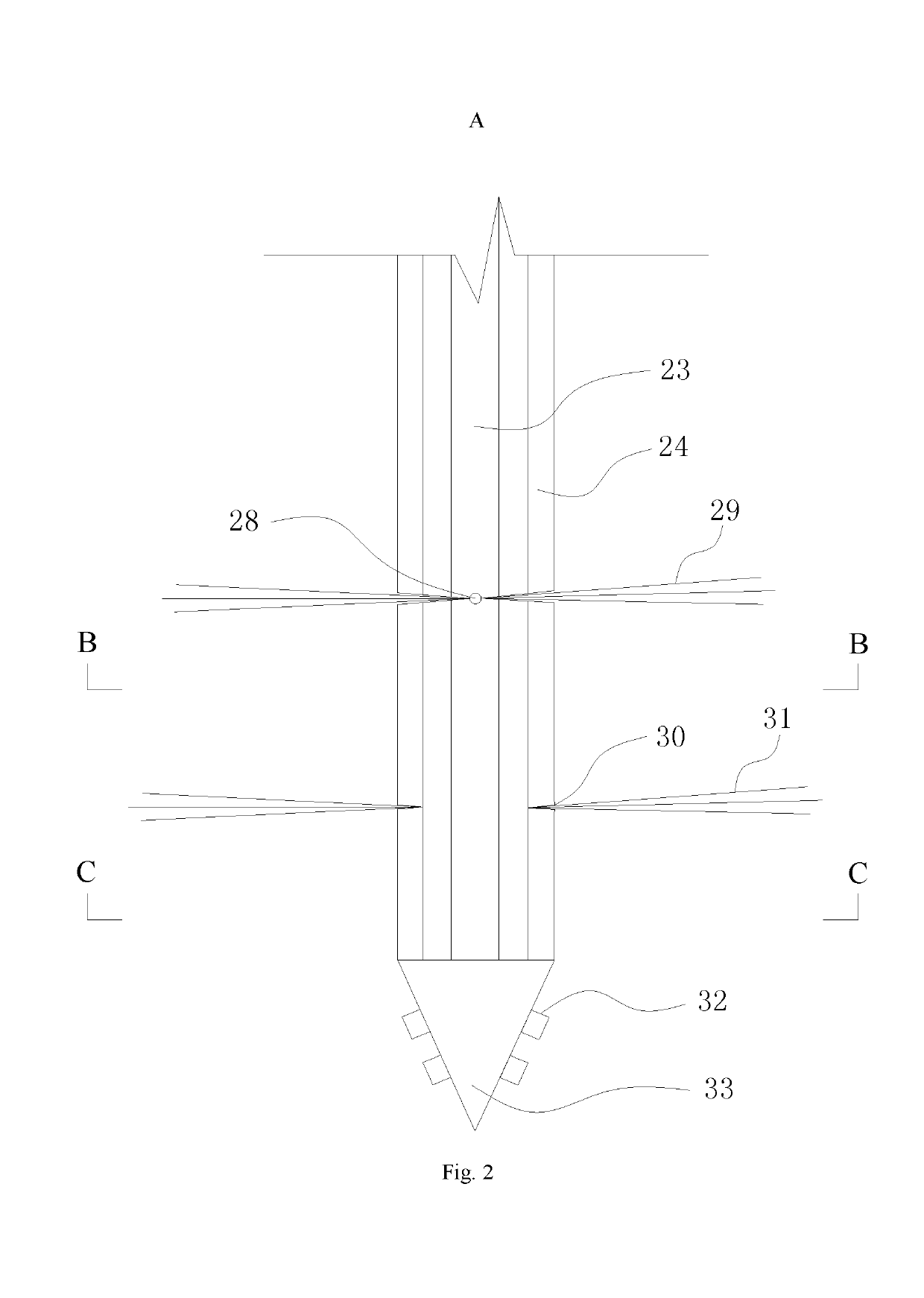

In-situ injection of soil and groundwater - high pressure rotary jet grouting in-situ remediation system and method

ActiveUS20190145190A1Efficient constructionDestroying bearing capacityDrilling rodsContaminated soil reclamationPipe waterAir compressor

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Enhancement of transfection of DNA into the liver

InactiveUS7211248B2High expressionFacilitating transfectionBiocideOrganic active ingredientsTransfectionDNA

A method for transfection of DNA or RNA encoding apo A1 into the liver to regulate lipid metabolism comprises injection of a solution containing the DNA or RNA gene into the liver in combination with gas microbubbles or microspheres and using ultrasound to induce the transfection of the DNA or RNA in the liver.

Owner:SONOGENE

Method of raising oil deposil erude petroleum recovery ratio

A method for increasing the recovering rate of crude oil includes preparing the mixed solution from polyacrylamide, foaming agent and water, and proportionally filling said mixed solution and gas or N2 in the water injecting well alternatively by the alternative period of 20 days.

Owner:中国石化胜利油田有限公司地质科学研究院

Liquid container and liquid filling method

A liquid container includes: a container body attachable to a container attachment portion of an apparatus side; a liquid chamber, provided in the container body, for accommodating a liquid therein; a liquid supply hole connectable to a liquid receiving portion of the apparatus side; a liquid leading path for leading the liquid stored in the liquid chamber to the liquid supply hole; an air open hole for introducing outside air into the liquid chamber as the liquid in the liquid chamber is consumed; pressure regulating means, provided in a portion of the liquid leading path, for regulating a pressure of the liquid to be supplied to the liquid receiving portion through the liquid supply hole and hindering a reverse flow of the liquid from the liquid supply hole to the liquid chamber; a first bypass path for causing first and second liquid leading passages of the liquid leading path, provided respectively before and after the pressure regulating means, to communicate with each other; and a first bypass blocking portion capable of blocking the bypass path.

Owner:SEIKO EPSON CORP

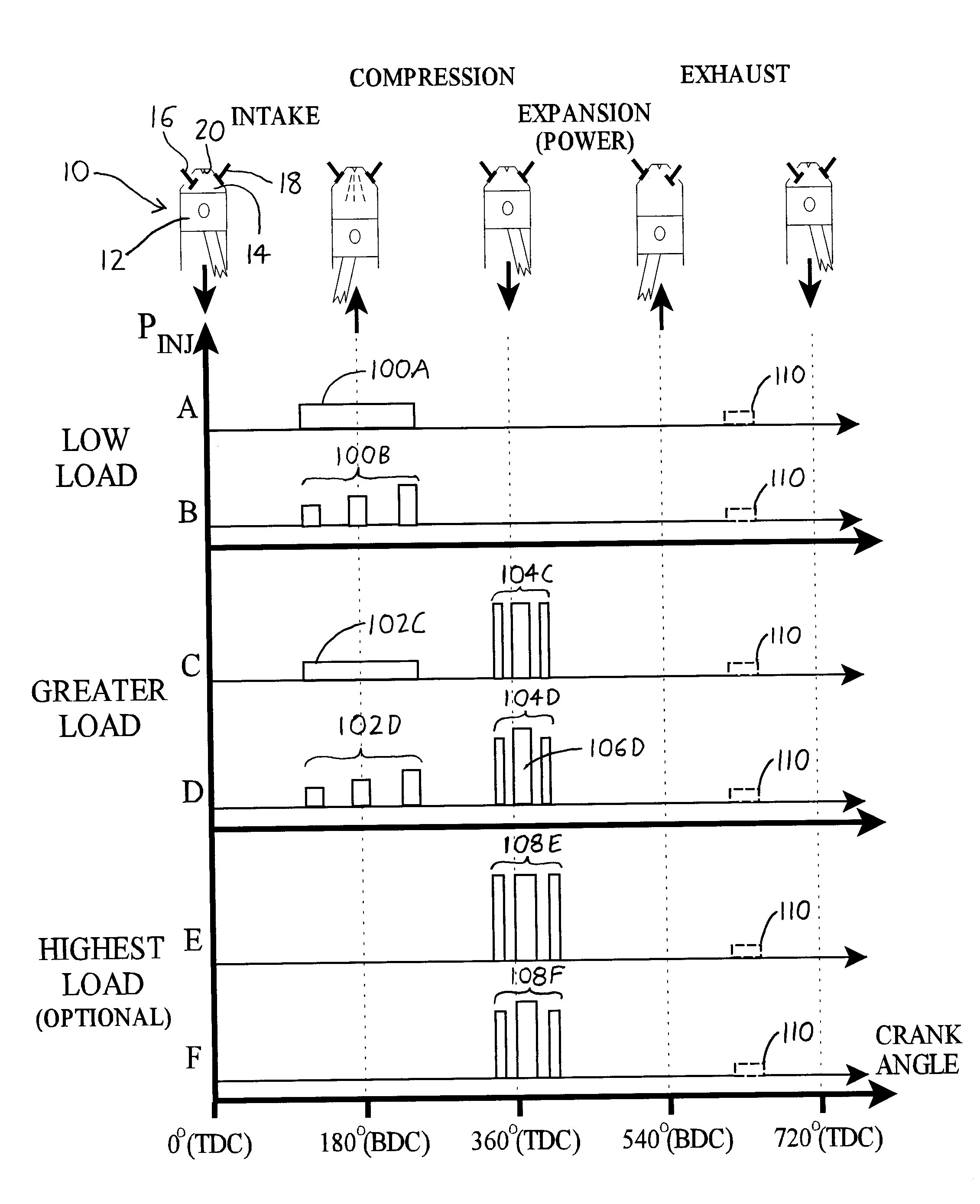

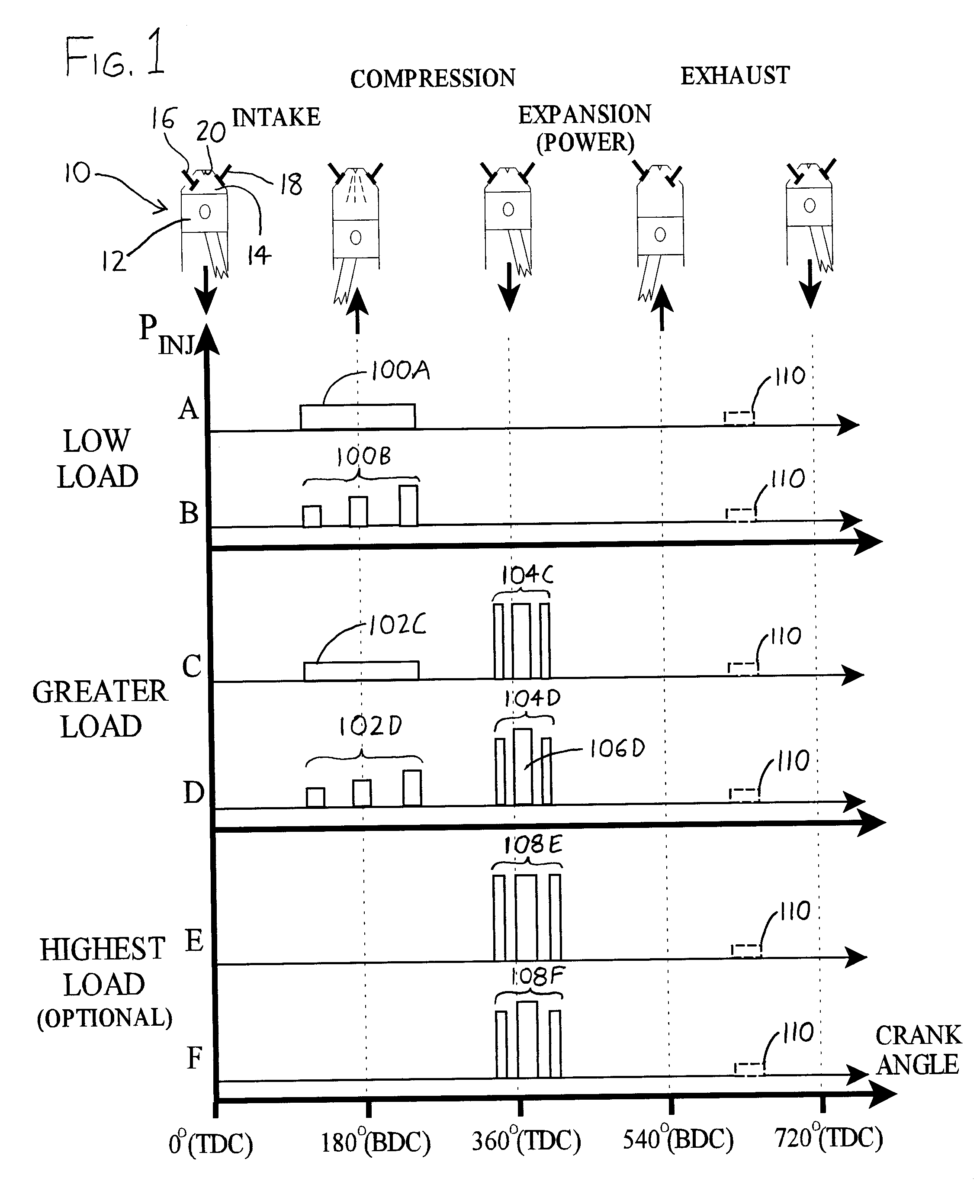

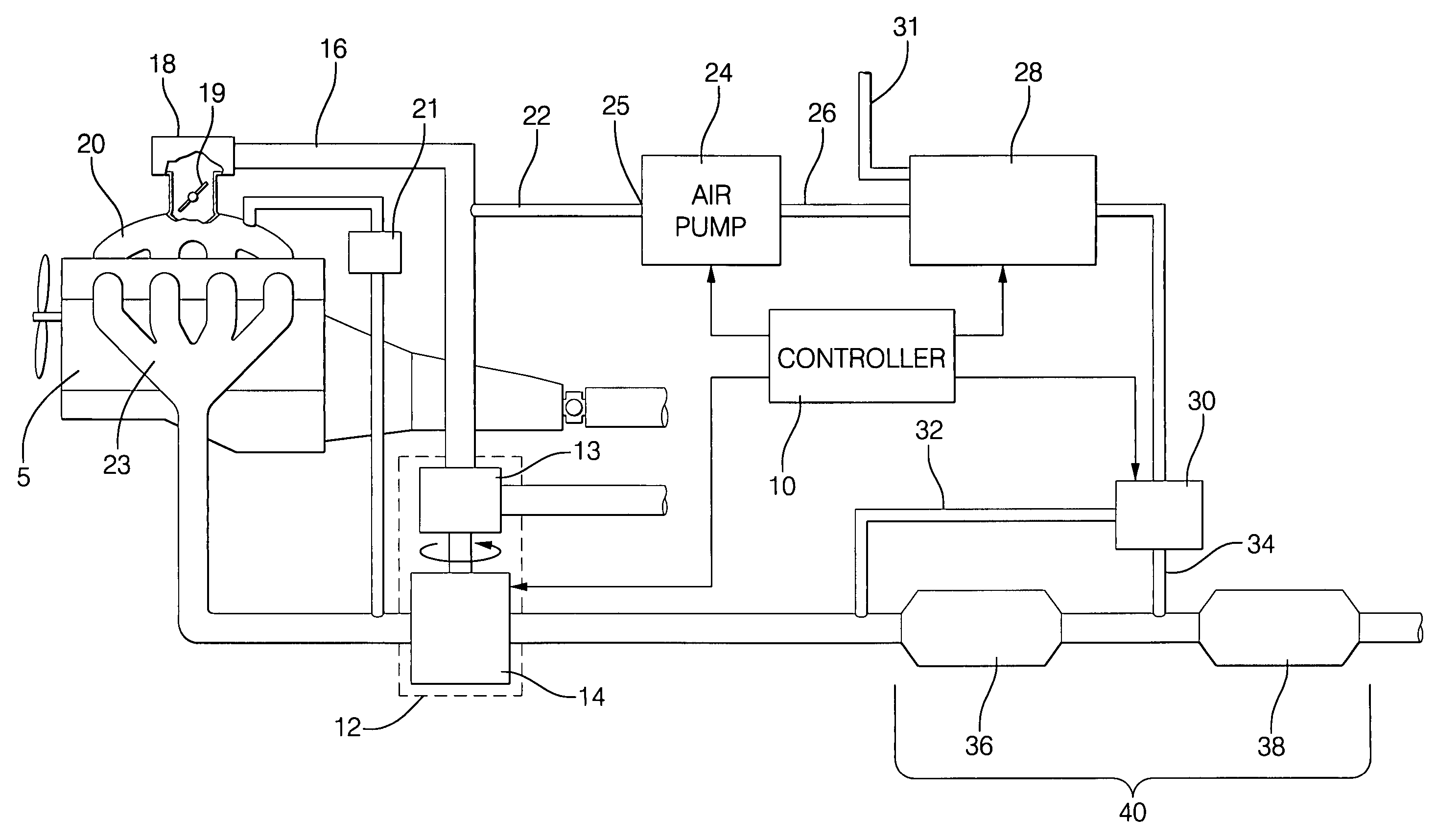

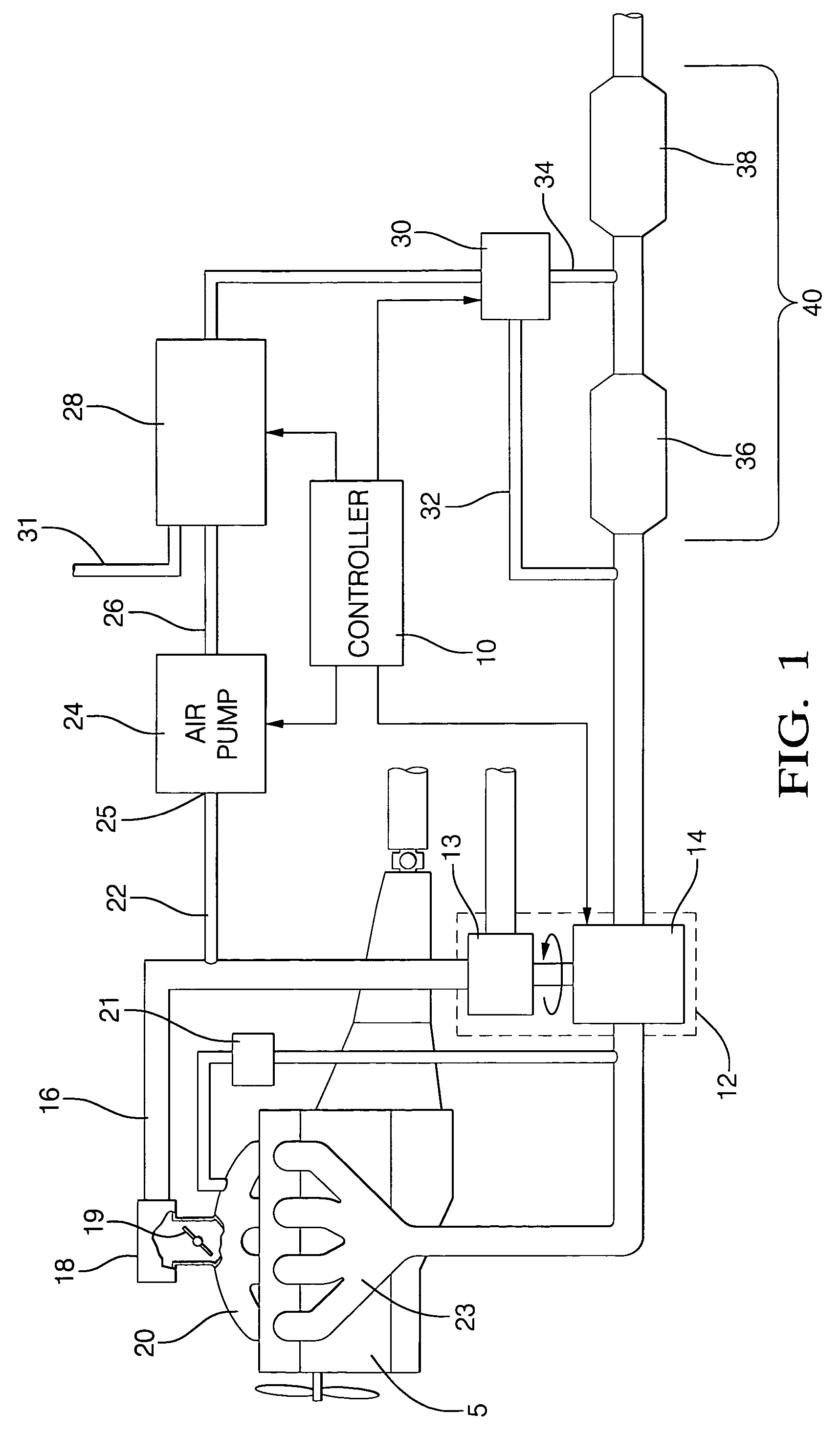

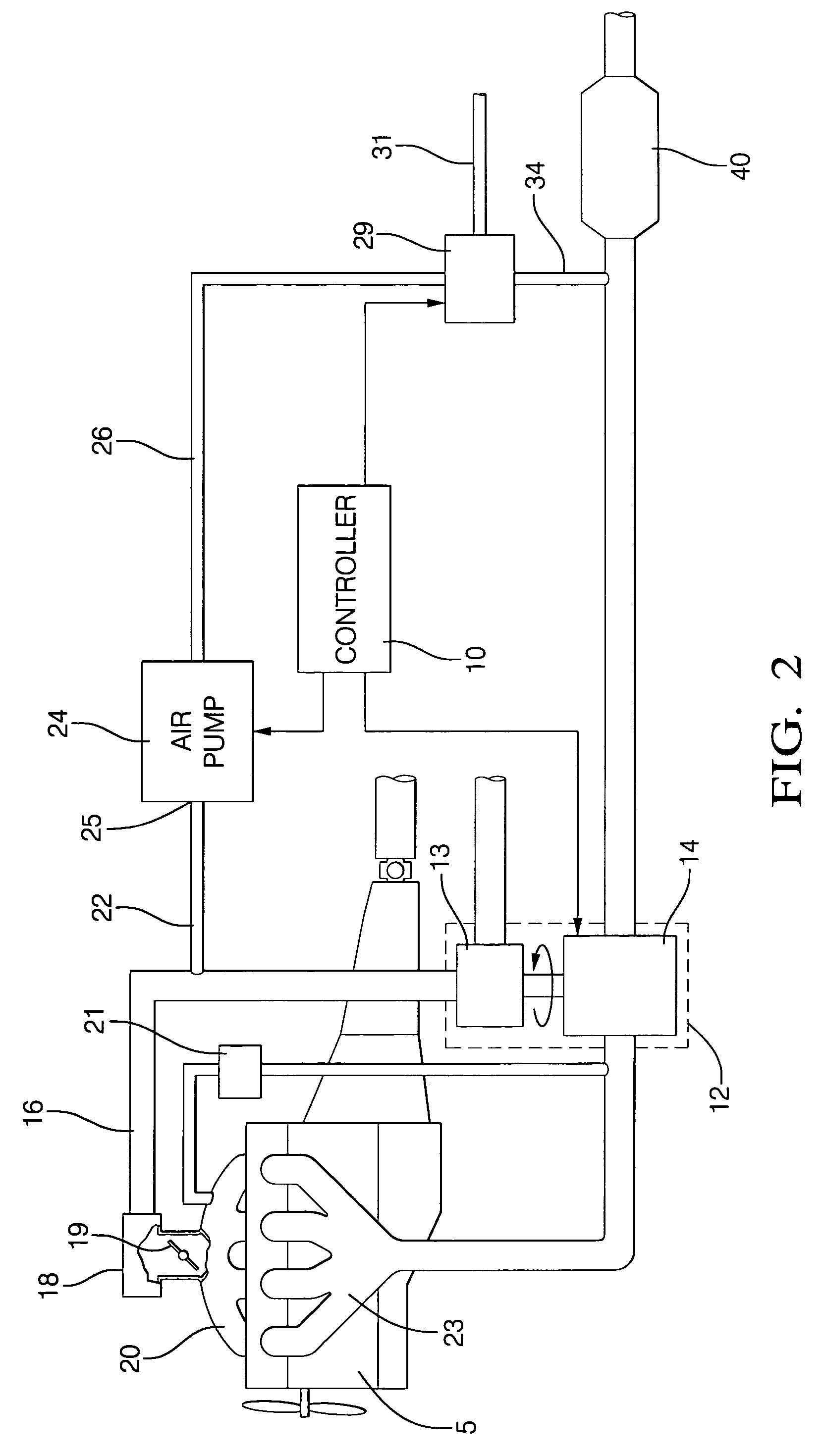

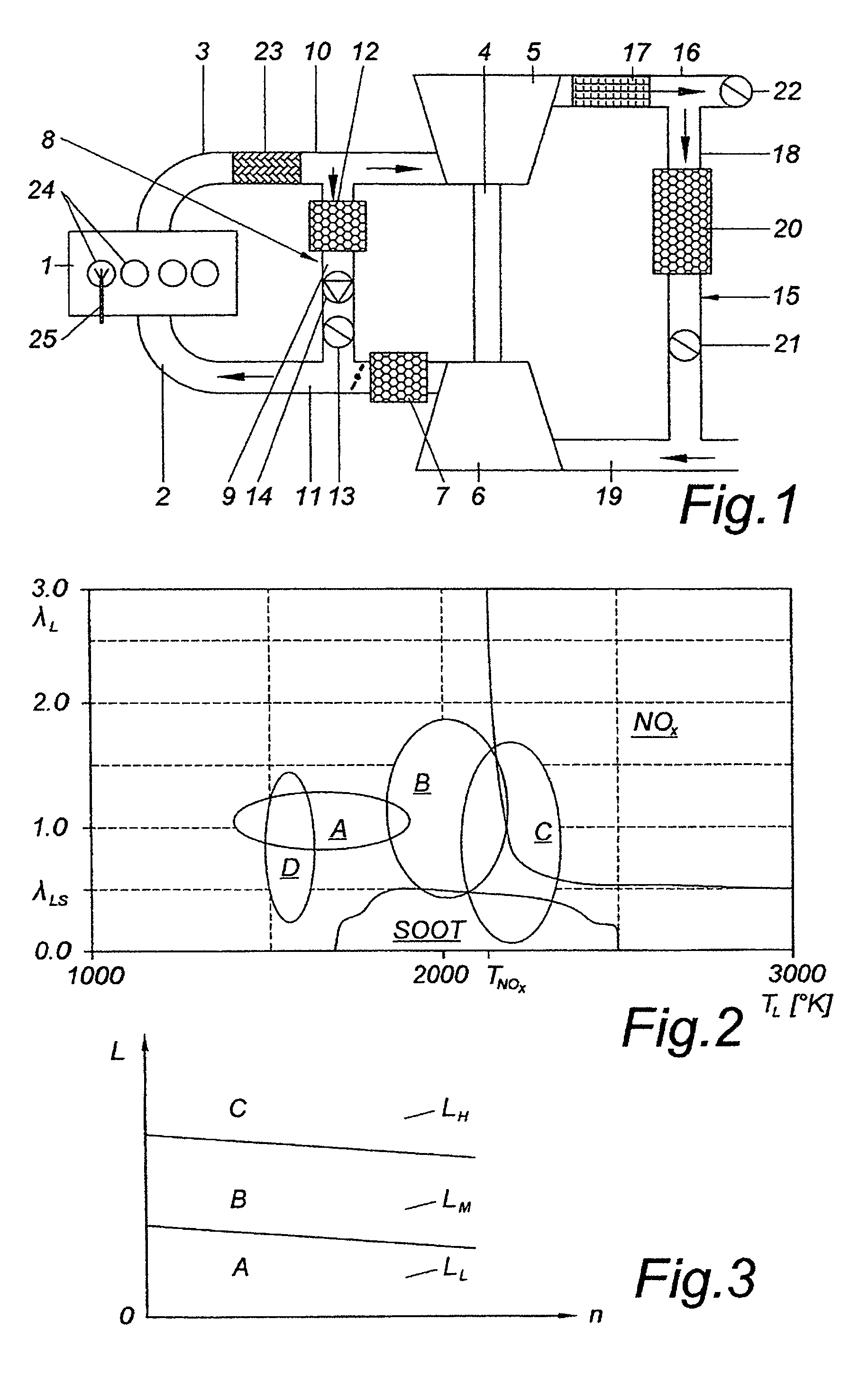

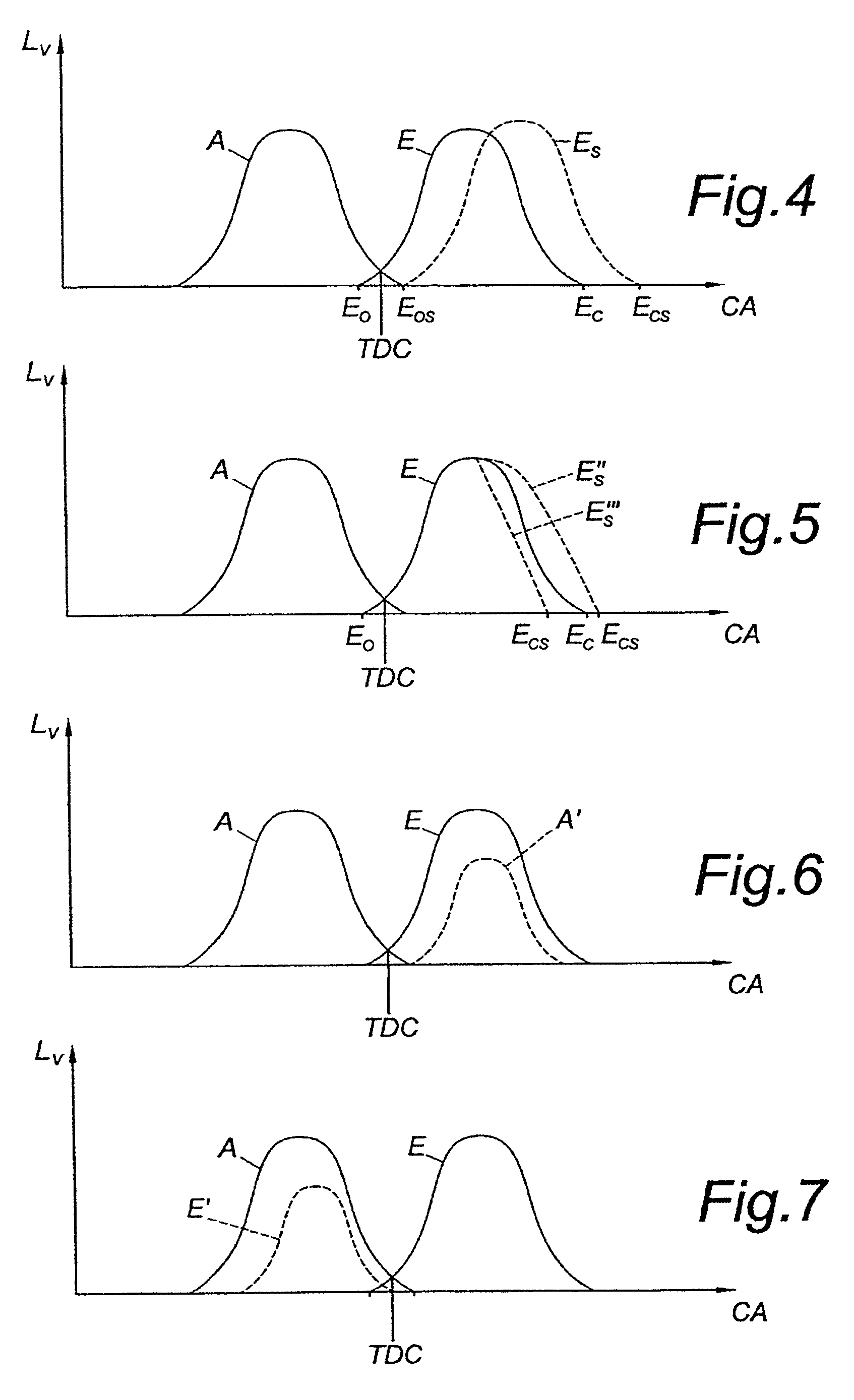

Adaptive engine injection for emissions reduction

ActiveUS7464690B1Avoiding potentially damaging rapid chamber pressure increasesHigh power outputElectrical controlInternal combustion piston enginesInjection pressureTop dead center

Owner:WISCONSIN ALUMNI RES FOUND

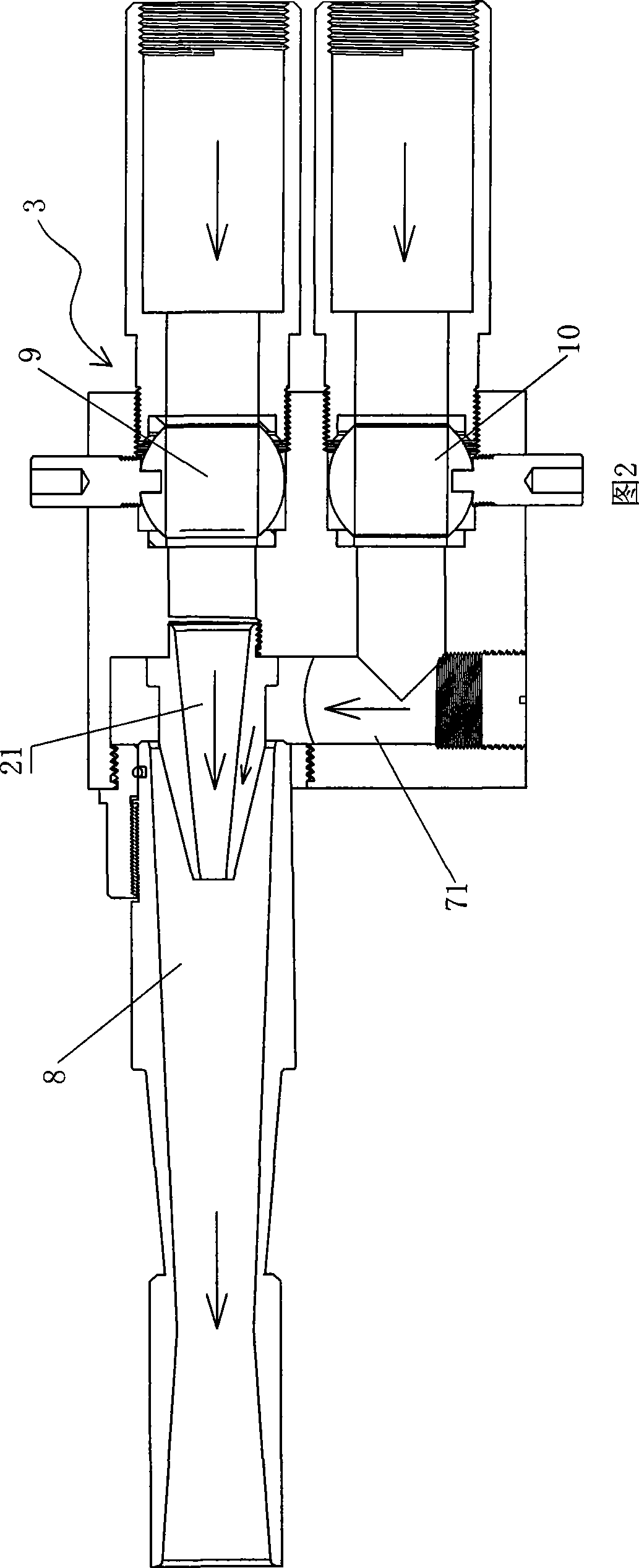

Vehicle mounted superfine spray fire extinguishing device

InactiveCN101371943AImprove fire extinguishing efficiencyIncrease injection pressureFire rescuePipingTransmission system

The present invention discloses a vehicle-bone superfine water fog fire extinguishing device which is characterized by using a fire engine as a carrier and being provided with a water-air double-pipeline transmission system; the air pipeline comprises an air compressor and a pressure air pipeline which transmits high pressure air; the water pipeline comprises a pump and a pressure water pipeline which is communicated with a pump outlet and transmits high pressure water; the pressure air pipeline is joined up with the pressure water pipeline in a spray device; the high pressure water is cut by the high pressure air in the spray device and then is sprayed out as superfine water fog by a spray cylinder; and the fire extinguishing effect is far higher than fog water or water mist. The internal shape of the spray cylinder from an inlet to an outlet is the shape from convergent to spread and is accorded with the aeronautical dynamics and the fluid mechanics theory better, and the spray cylinder can maximize the ray range of the sprayed superfine water fog, so as to meet the requirement of remote fire extinguishing.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

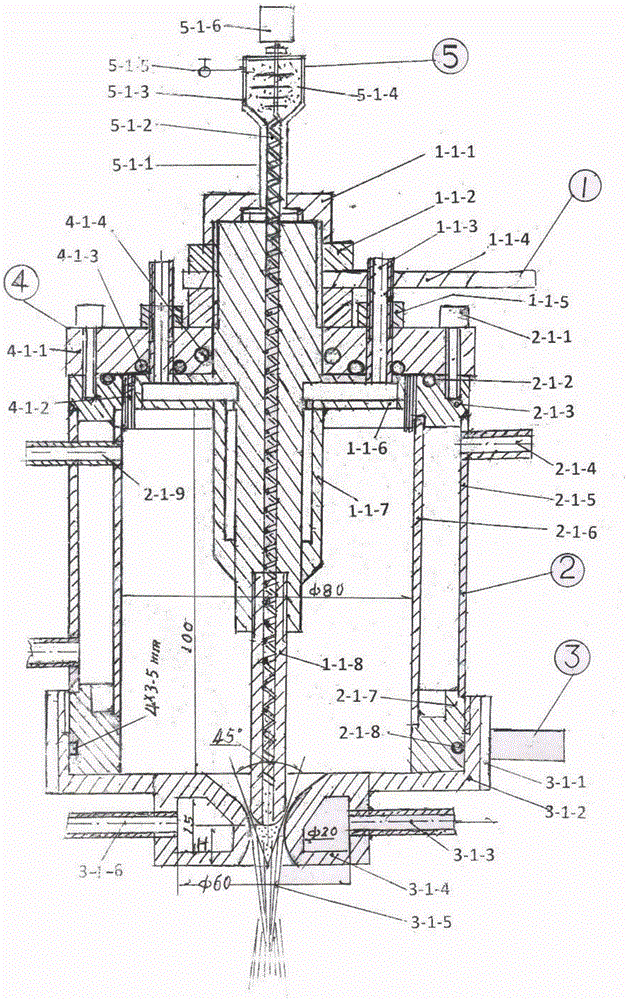

Direct-current argon arc plasma powder spray gun and manufacturing method

ActiveCN105755421AExpand the field of technology applicationImprove stabilityMolten spray coatingMetallurgyPlasma heating

The invention discloses a direct-current argon arc plasma powder spray gun and a manufacturing method and belongs to the field of flame spraying equipment and technology of metal powder and metal ceramic powder.Two novel technologies including a hollow tungsten cathode outer surface annular arcing direct-current plasma heating method and an axial powder feeding mechanism penetrating the core of an argon arc are adopted, and position matching of a negative voltage pressure of the electric arc and the powder feeding mechanism is utilized, so that stability of the spray gun during long-time working is improved, and uniformity in heating temperature of metal powder particles, uniformity in spray speed and stability of spray layer quality are guaranteed.In addition, due to structural changing of a gun body, technology application field of the gun is expanded obviously, and the gun is expected to make a beneficial contribution to development of high technology in the future.

Owner:UNIV OF SCI & TECH BEIJING

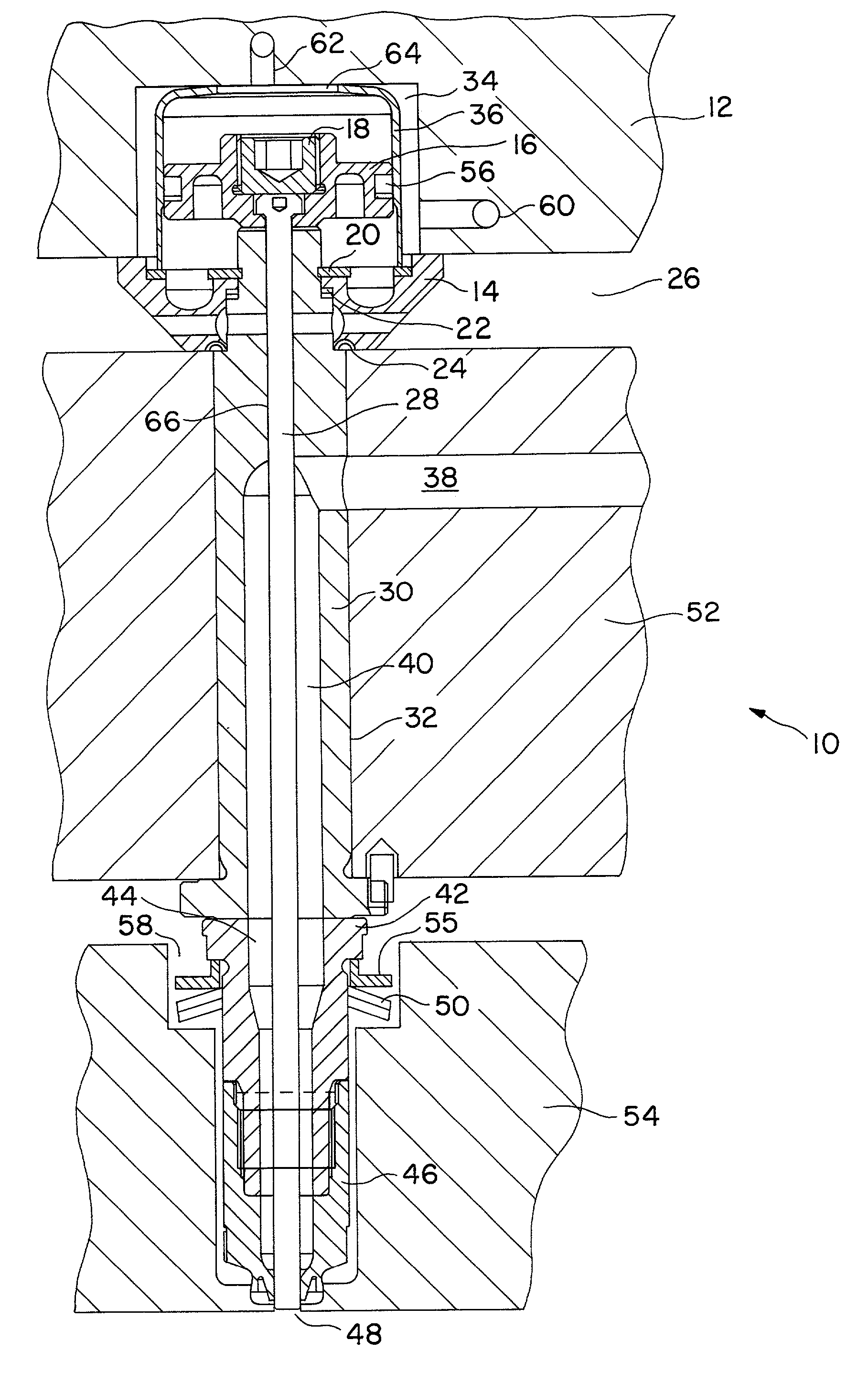

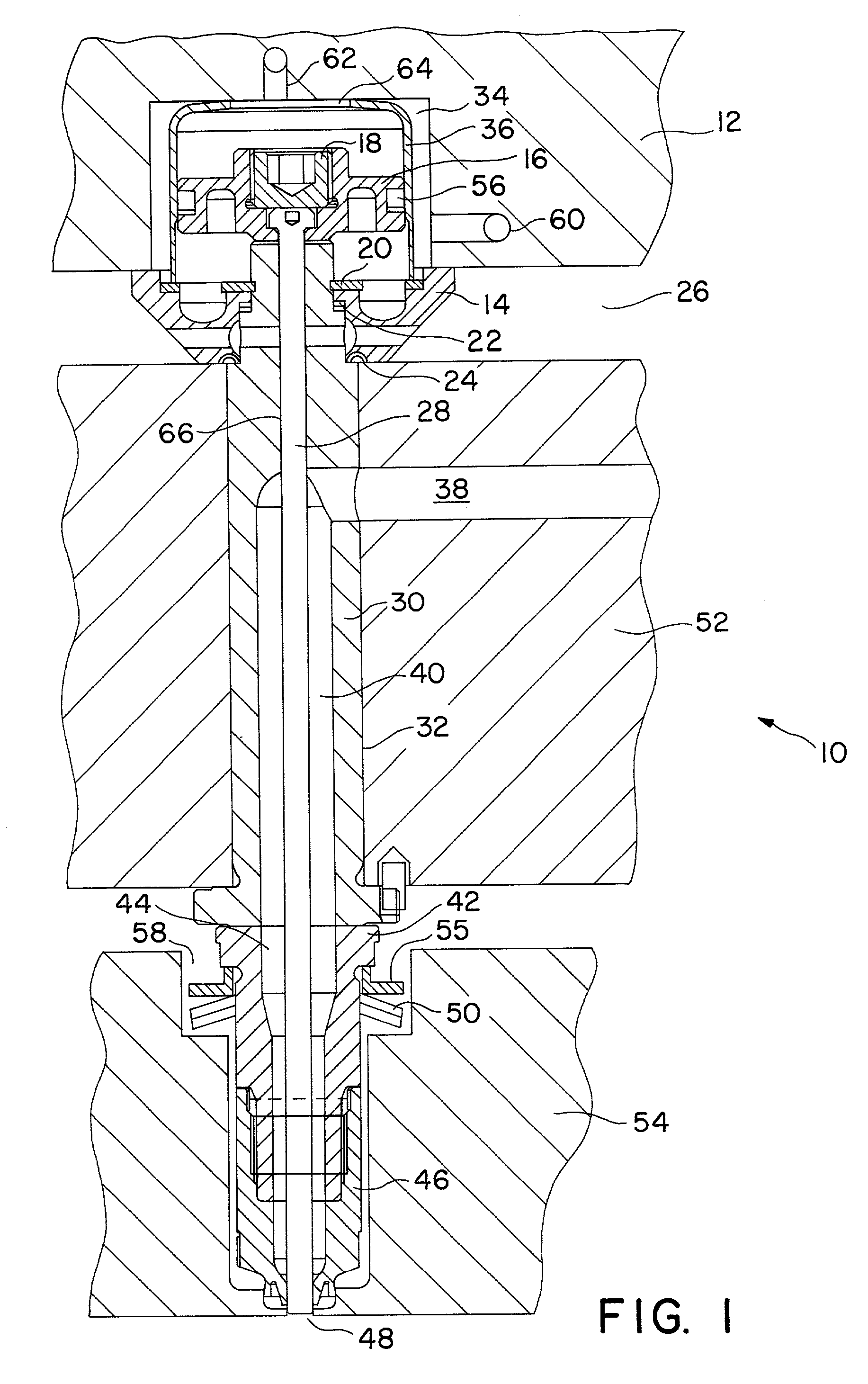

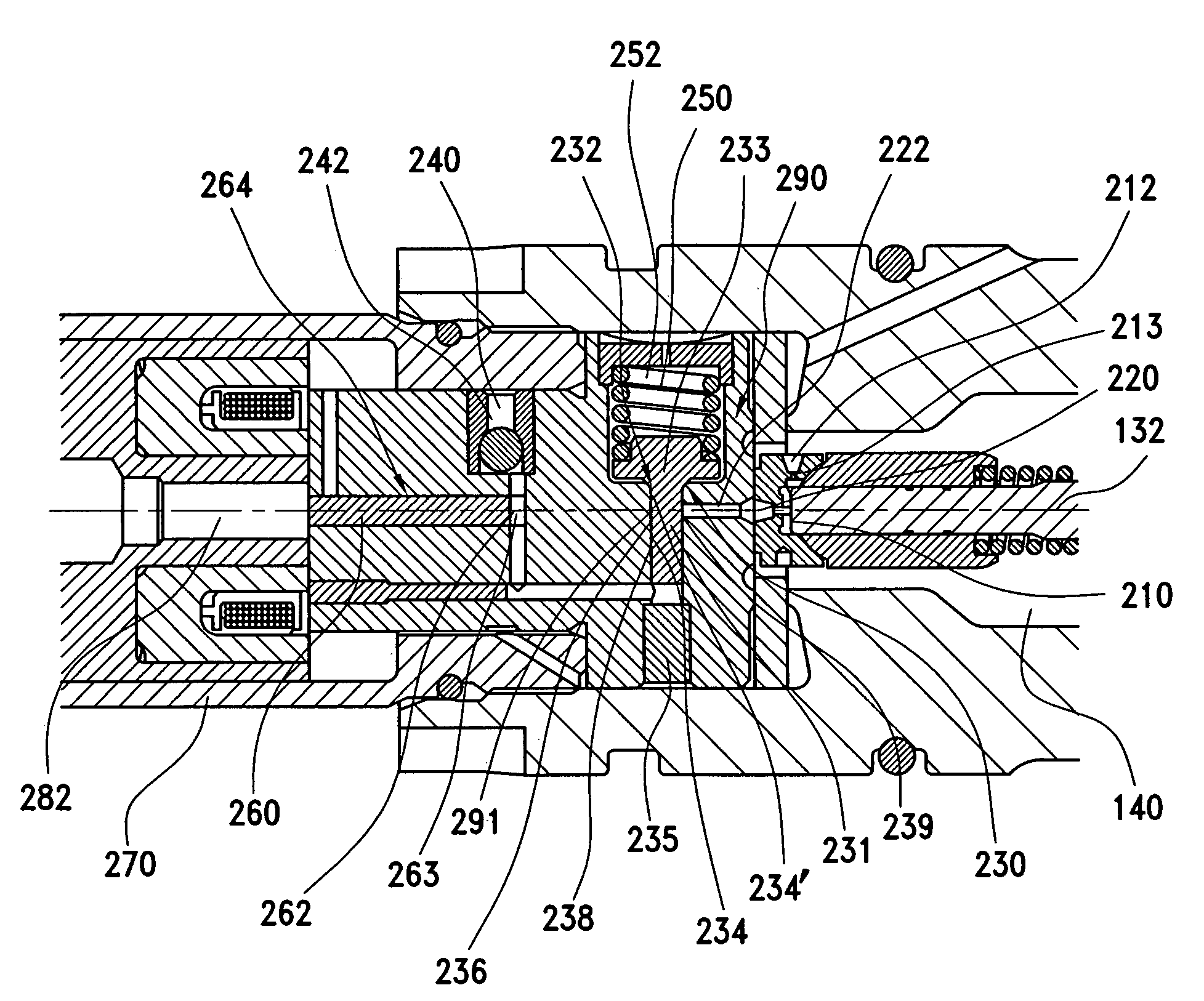

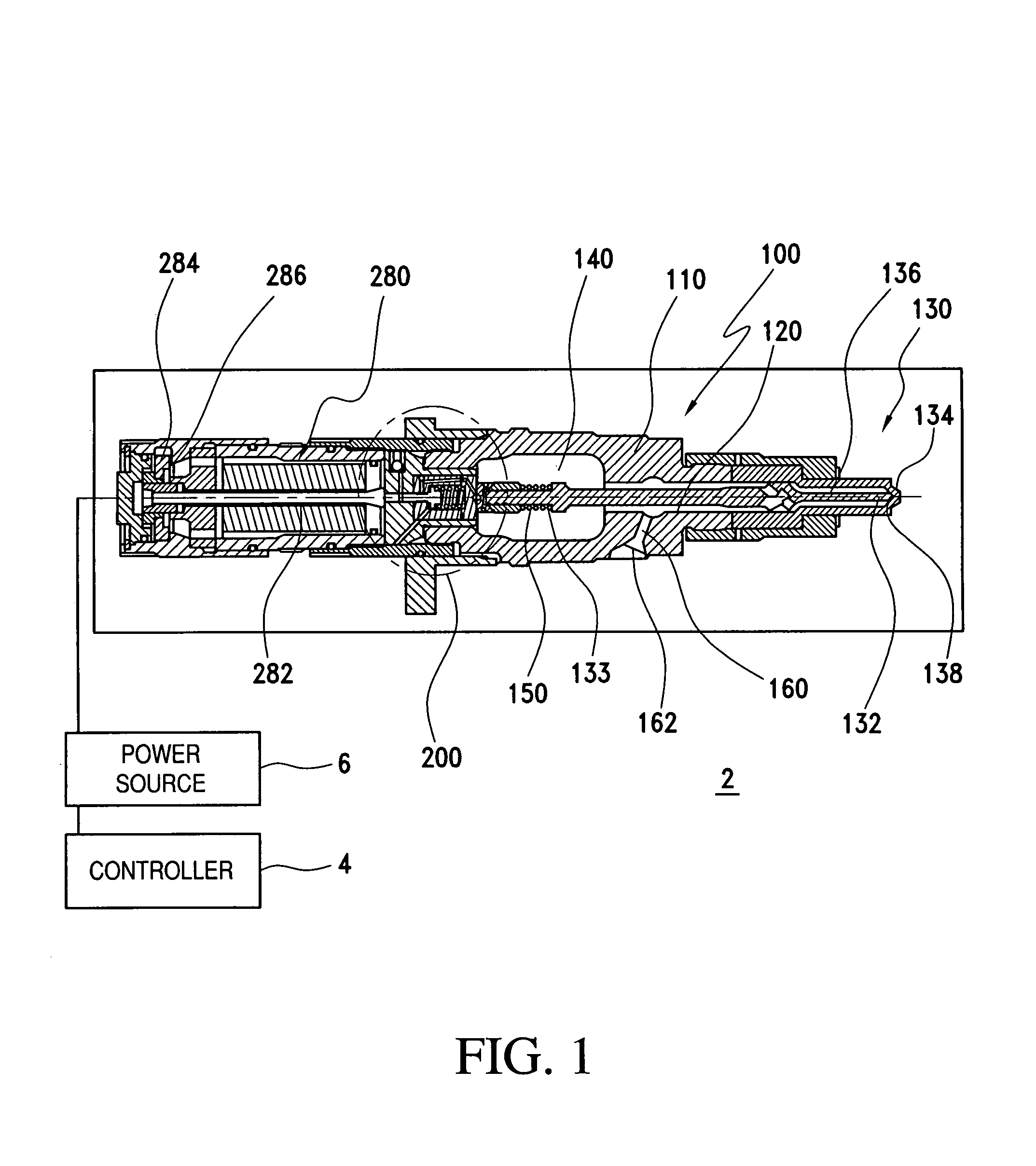

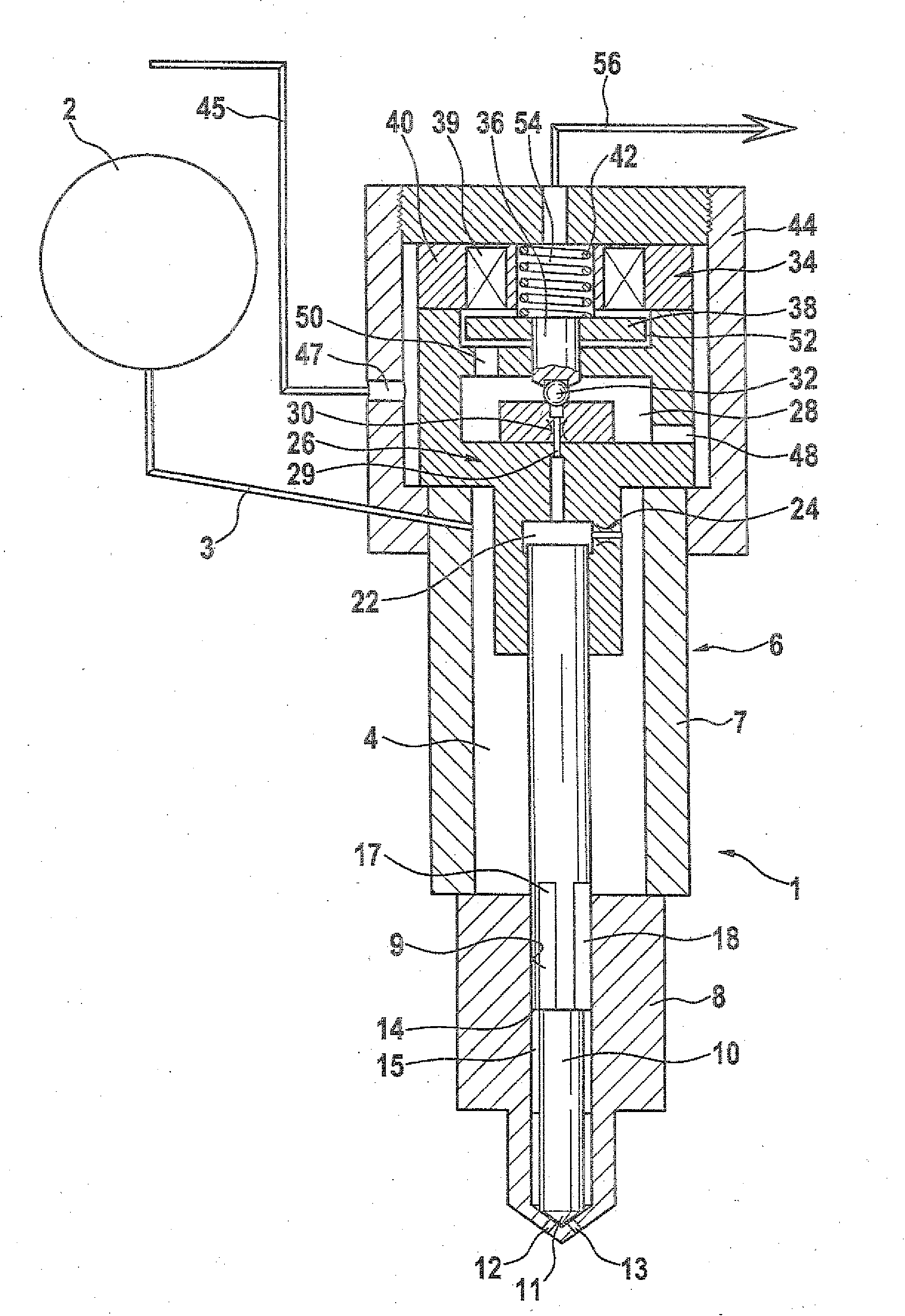

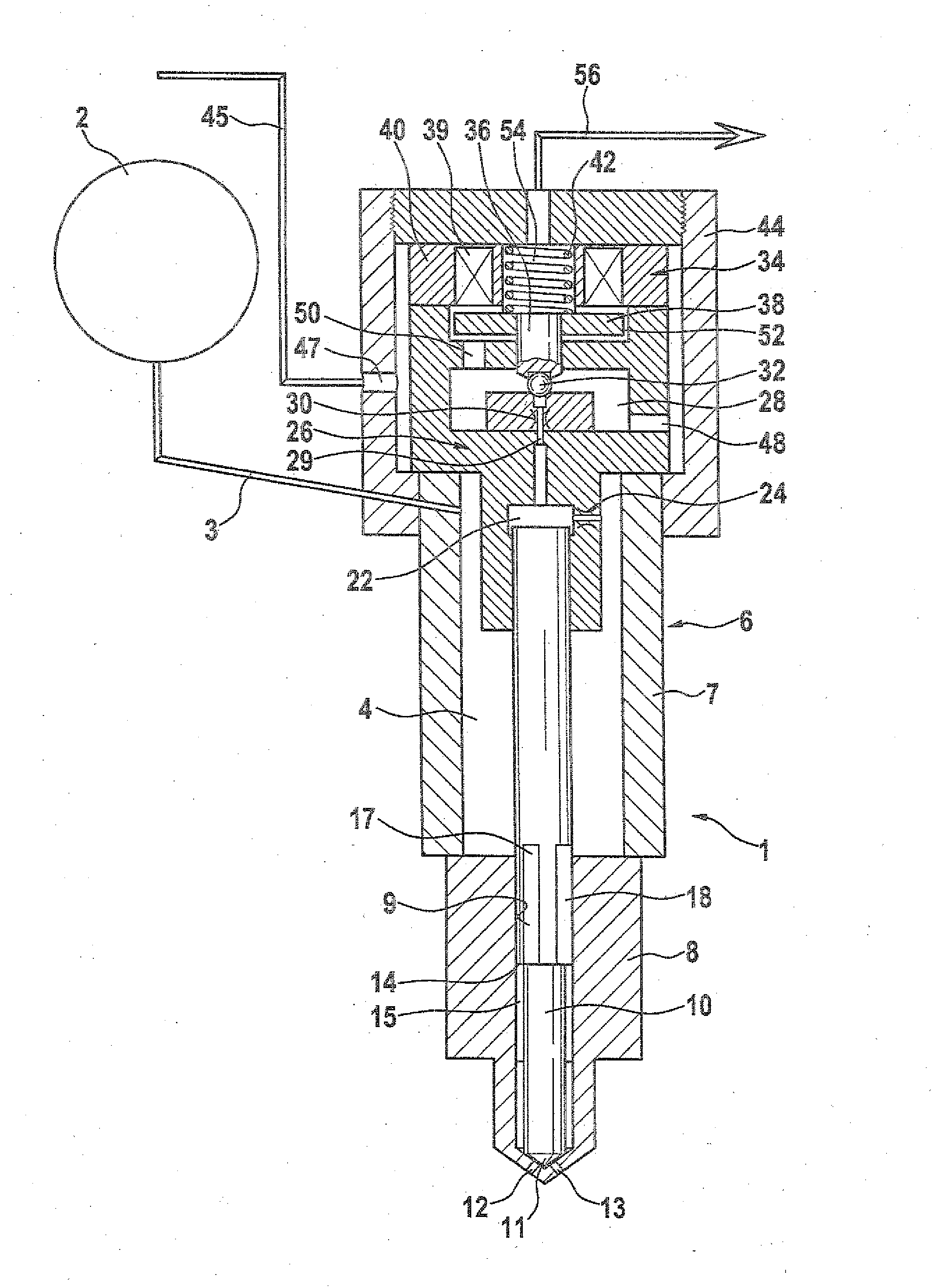

Fuel injector with pressure balancing valve

InactiveUS7353806B2Reduce exhaust emissionsImprove fuel economyMovable spraying apparatusSpray nozzlesCombustion chamberEngineering

A fuel injector device, for injecting fuel into a combustion chamber of an internal combustion engine, has a nozzle valve and nozzle valve control assembly adapted to use a control valve and high pressure fuel in the fuel injector in order to actuate movement of the nozzle valve between an open position to inject fuel and a closed position to terminate fuel injection. The nozzle valve control assembly employs a pressure balancing control valve so that the fuel pressure exerts a zero net force on the control valve in a dimension along which the control valve moves. Thus, the actuation occurs independently of the fuel pressure. In addition, the actuator is operably connected to the control valve by at least a hydraulic linkage, where the hydraulic linkage compensates for changes in the actuator and the injector body due to changes in temperature.

Owner:CUMMINS INC

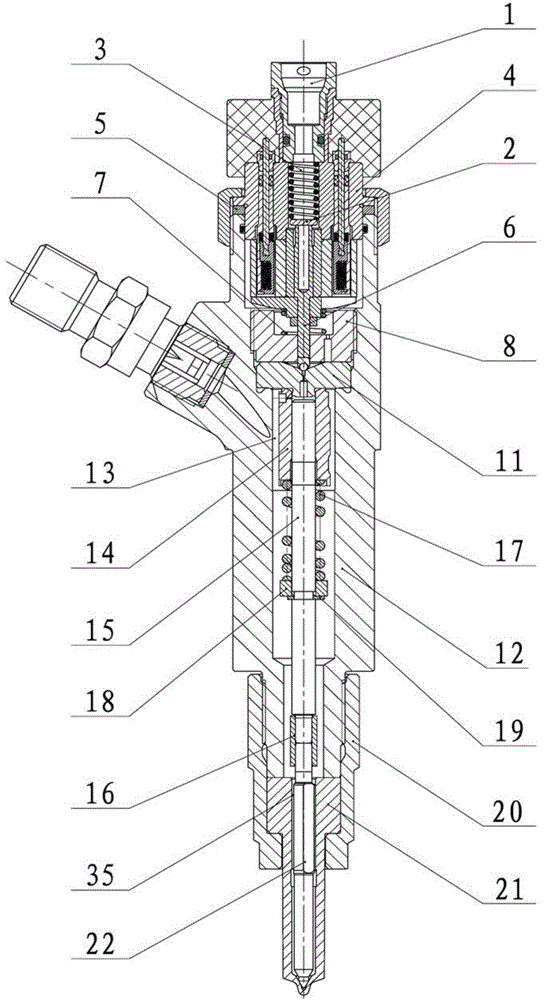

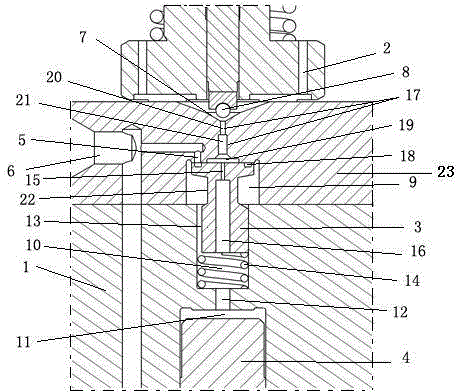

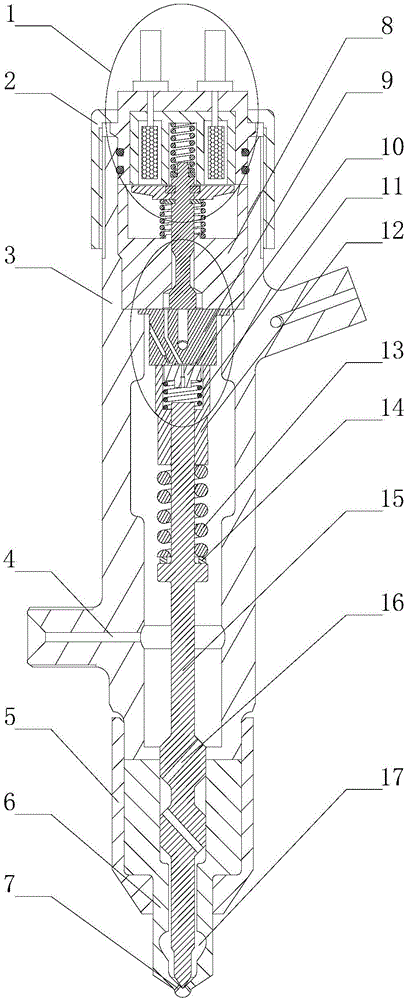

Middle hole pressure storage static leakage-free oil sprayer

ActiveCN104314725ASimple structureImprove sealingFuel injection apparatusMachines/enginesSolenoid valvePlunger

The invention discloses a middle hole pressure storage static leakage-free oil sprayer, comprising a high speed solenoid valve, a locking screw sleeve, a tapered surface ball valve type switch valve, a control plunger and barrel assembly, an oil sprayer spring, a spring seat, an opening check ring, an oil sprayer body, an oil sprayer assembly and an oil nozzle locking cap; the tapered surface ball valve type switch valve is arranged in a concave cavity in the upper end of the oil sprayer body; the upper end of the oil sprayer body is connected with the high speed solenoid valve by a locking nut; the lower end of the oil sprayer body is connected with the oil nozzle assembly by the oil nozzle locking cap; the control pole plunger and barrel assembly is arranged in a central hole formed along the axis of the oil sprayer body; the central hole of the oil sprayer body and the control pole plunger and barrel assembly form a middle hole pressure storage cavity. The oil sprayer is simple in structure, low in machining cost and convenient to mount, so the production efficiency and product percent of pass are improved.

Owner:钧风电控科技(大连)有限责任公司

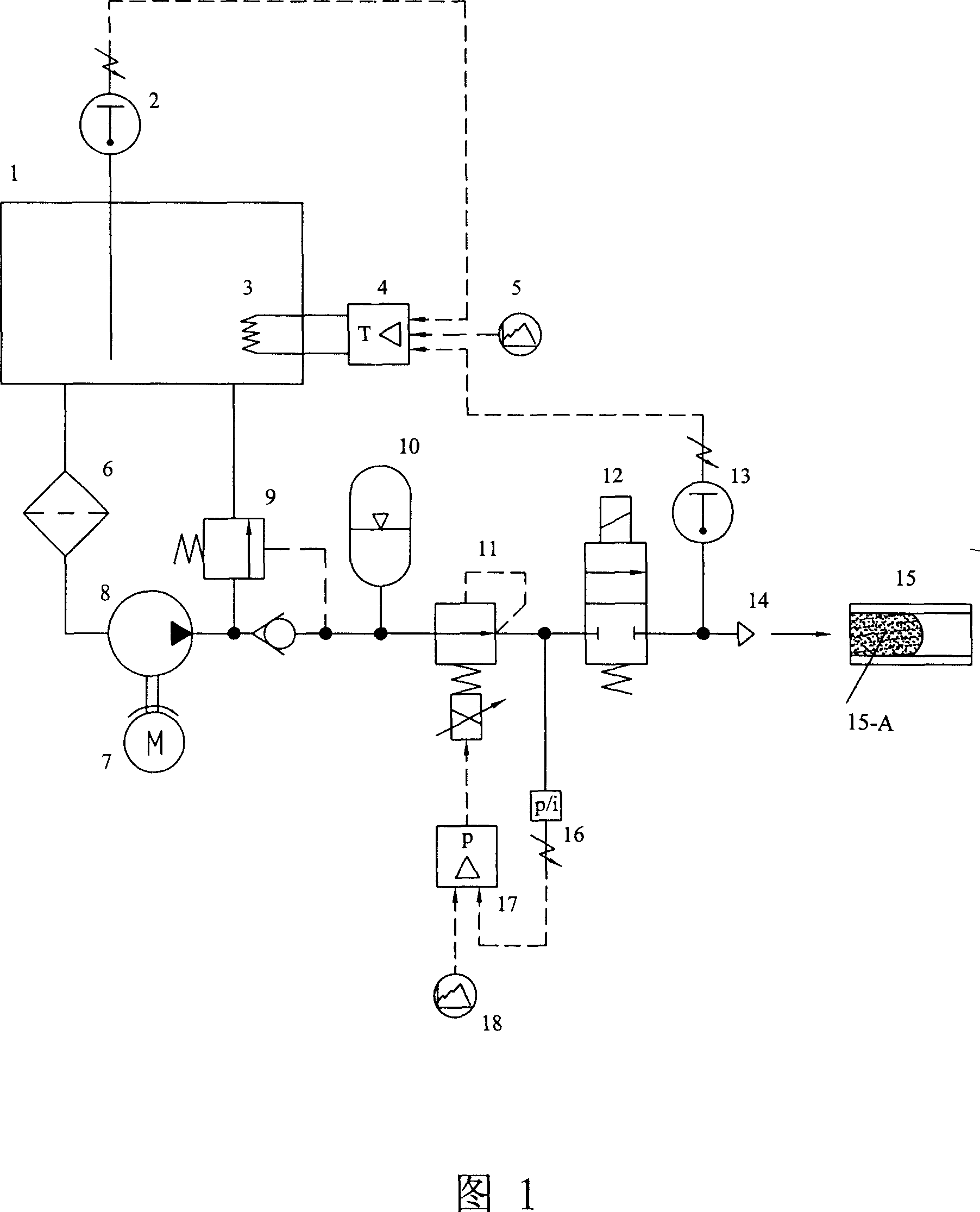

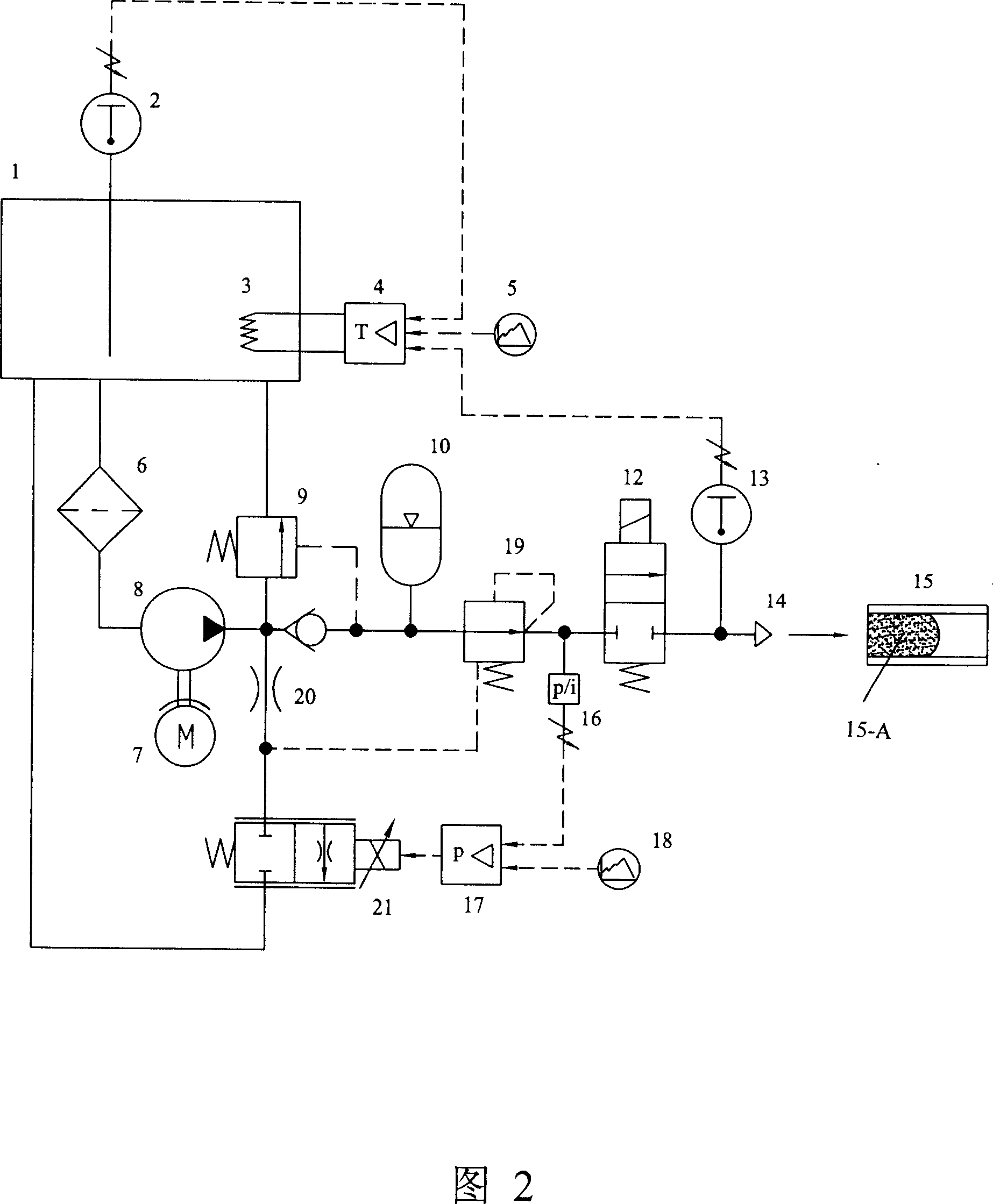

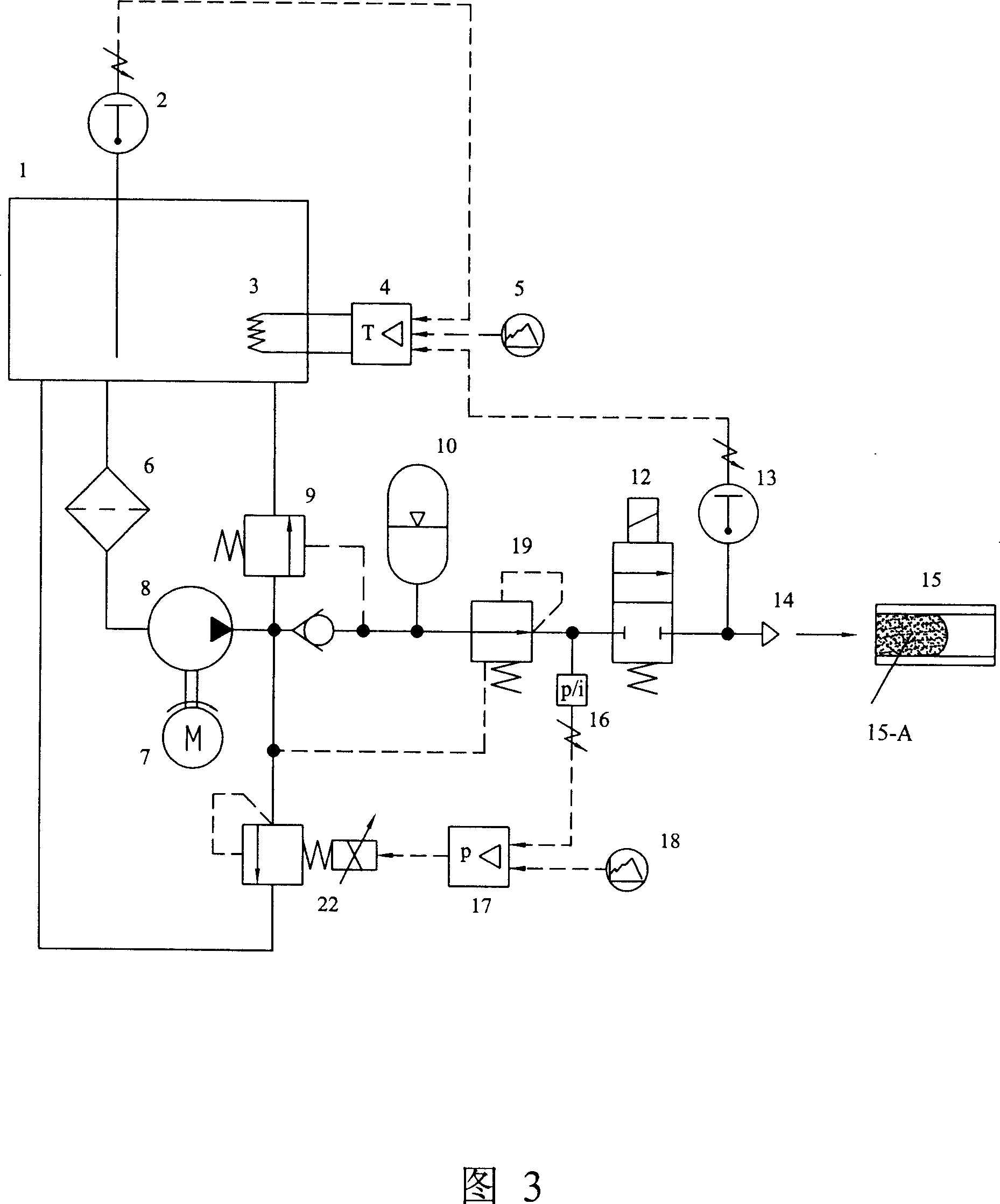

Water moulding water-fluid pressure ratio system

The present invention discloses a water auxiliary moulding water hydraulic proportion system. It is characterized by that in the outlet of water hydraulic pump driven by motor are successively connected a pressure control valve, a reversal valve and nozzle, between the pressure control valve and reversal valve a booster can be used for implementing pressurization, between the pressure control valve and water hydraulic pump an accumulator can be connected for saving energy, the pressure sensor can be used for feeding back the pressure to pressure controller so as to form closed-loop control, the pressure controller can be used for receiving injection pressure instruction signal given out by computer to control pressure control value and further control injection pressure, the temperature sensor can be used for feeding back the temperature of temperature-controlled water tank and the temperature of injection water to the water temperature controller, the water temperature controller can be used for controlling heater closed-loop to regulate water temperature, the temperature produced by water hydraulic proportion system and injection water controlled by pressure can be injected into the plastic melt in the mould cavity by means of nozzle so as to implement water auxiliary injection moulding of hollow plastic product.

Owner:ZHEJIANG UNIV

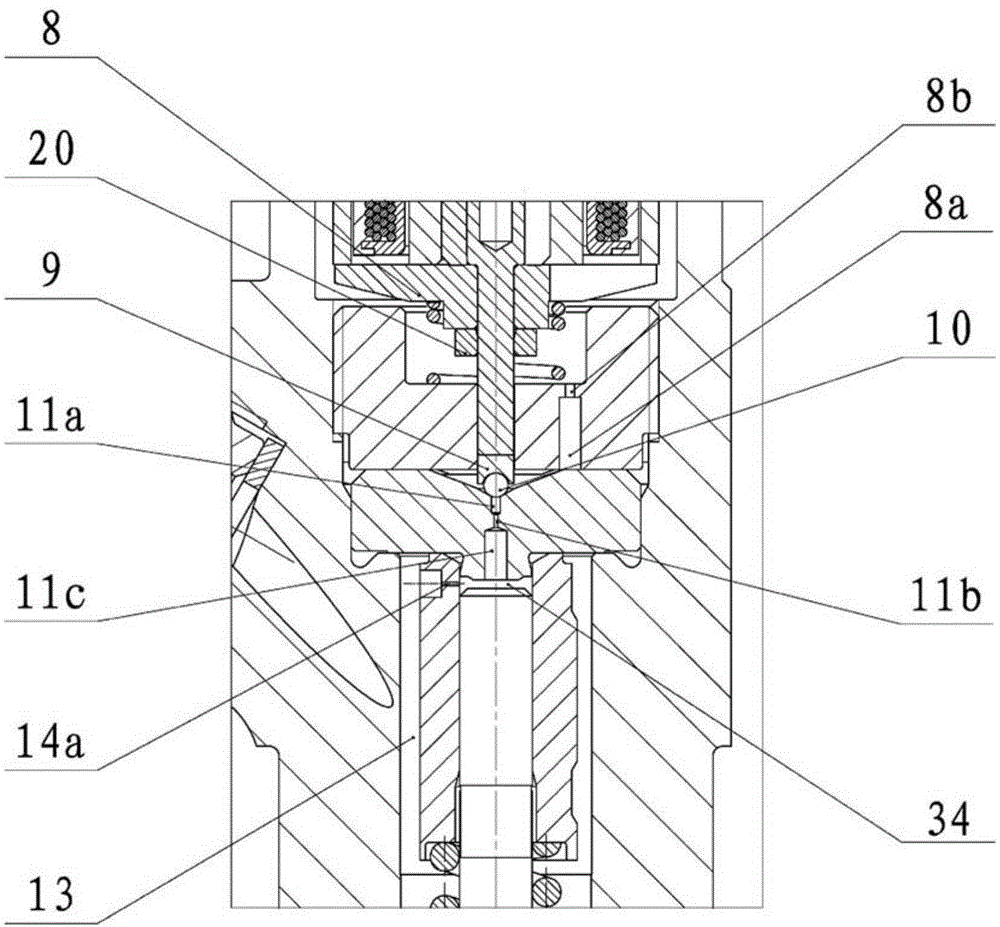

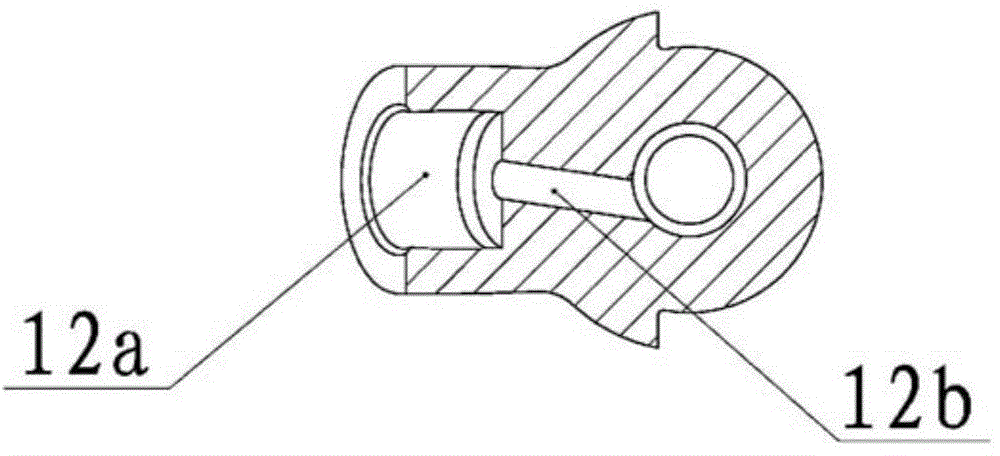

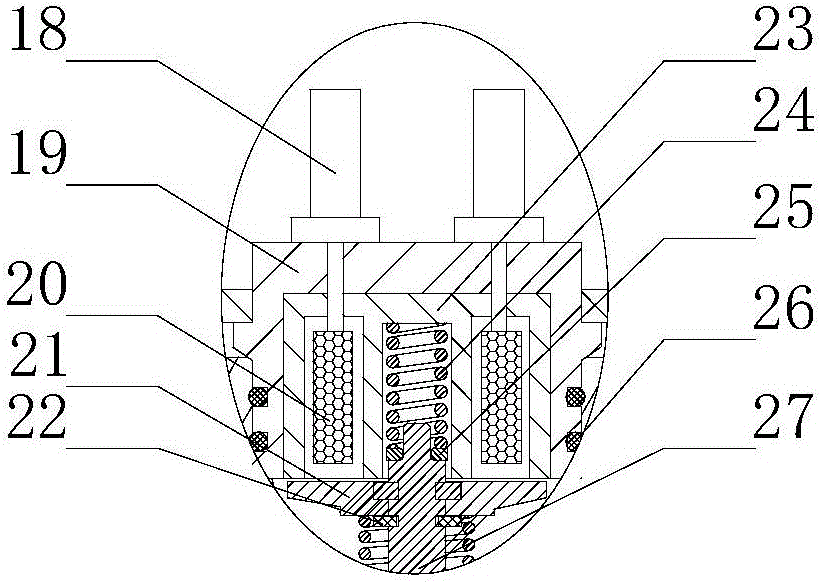

Novel common-rail oil injector

ActiveCN104481767AGuaranteed stabilityImprove reliabilityFuel injection apparatusMachines/enginesCommon railControl valves

The invention discloses a novel common-rail oil injector, which comprises an oil injector shell body. A pore plate is arranged at the upper end of the oil injector shell body. A control valve seat is mounted at the upper end of the pore plate. A low-pressure oil duct is installed inside the control valve seat. Oil cavities are installed inside the oil injector shell body and the pore plate. The oil cavities are respectively communicated with a high-pressure oil duct and the low-pressure oil duct. The high-pressure oil duct is connected with an oil inlet. A sealing surface and a switching valve are arranged between the low-pressure oil duct and the oil cavities. Compared with the prior art, the novel common-rail oil injector has the advantages that when injecting oil, the communication process of the high-pressure oil duct and the low-pressure oil duct is short, the high-pressure fuel entering a control cavity will be cut off, the oil return amount is greatly reduced, the oil injection efficiency of the novel common-rail oil injector is increased, the oil temperature rising of the oil injector is reduced, the working stability of the novel common-rail oil injector is ensured, the reliability of the novel common-rail oil injector is improved, also the energy consumption of a flushing pump is reduced, and the novel common-rail oil injector creates conditions for pressure injection of the common-rail system.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

Method and apparatus for delivery of supplemental material to an exhaust gas feedstream with supplemental air assistance

ActiveUS7409823B2Increase injection pressureIncrease in sizeCombination devicesNon-fuel substance addition to fuelHydrogenTurbocharger

Owner:DELPHI TECH IP LTD

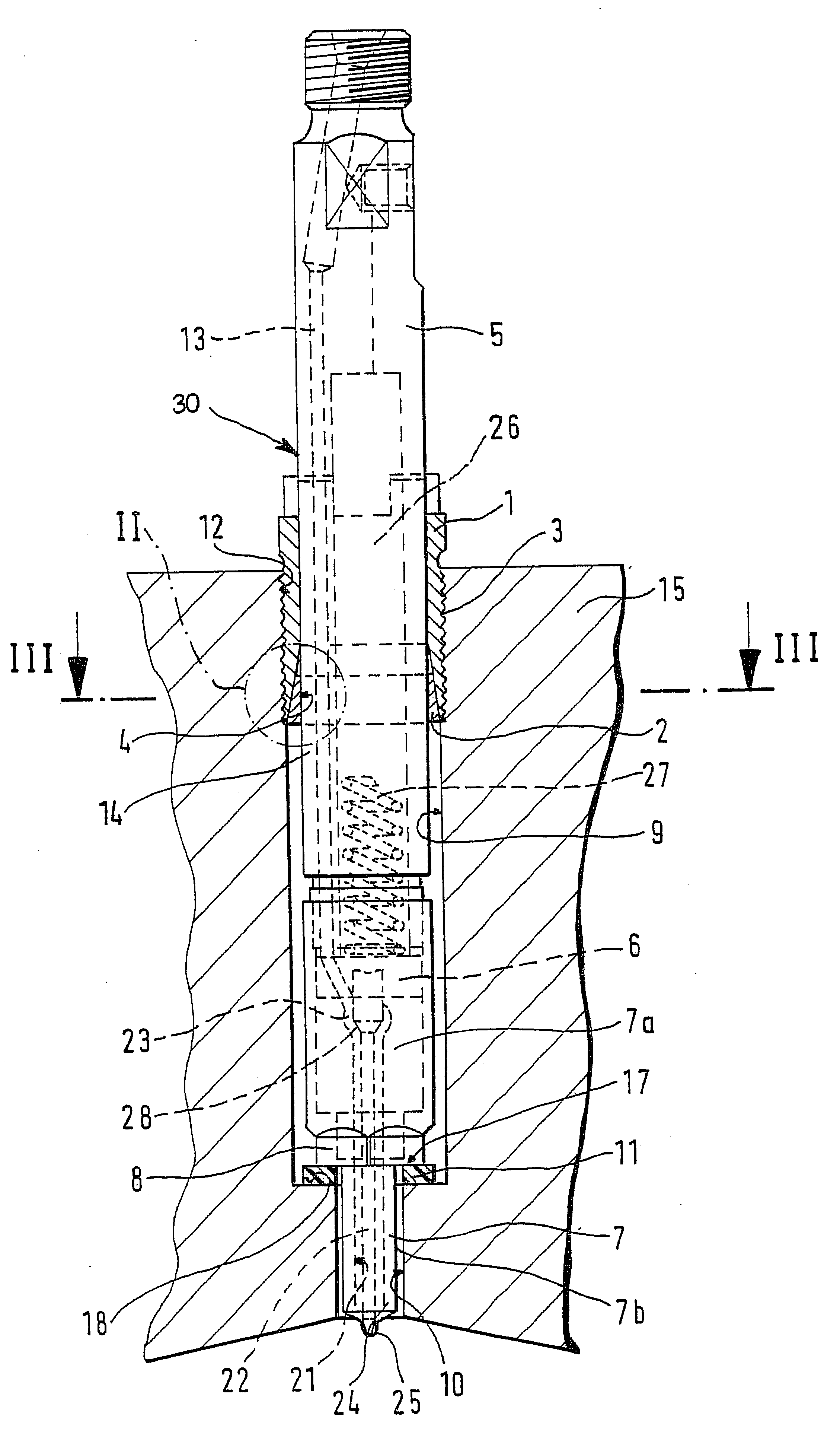

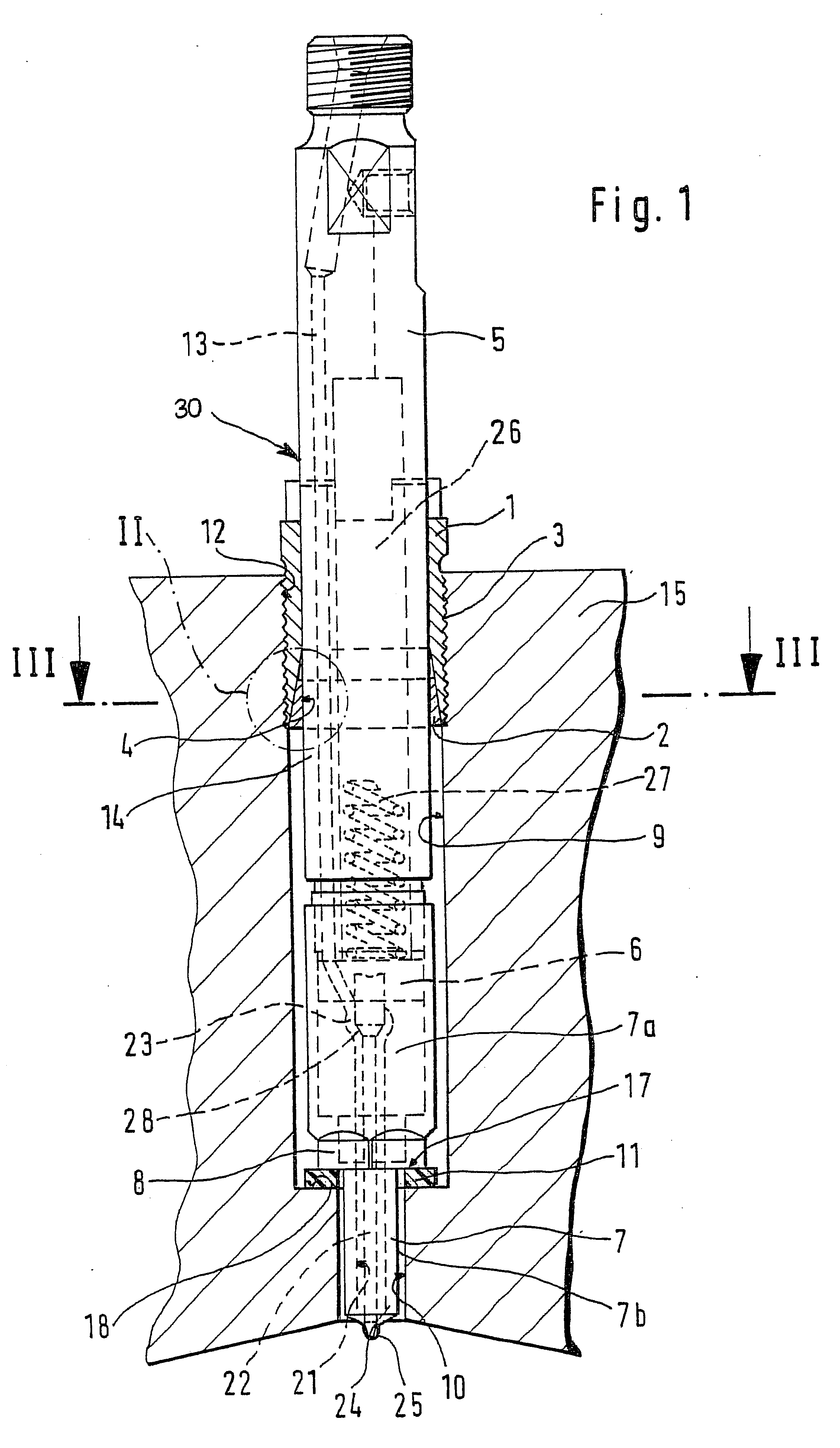

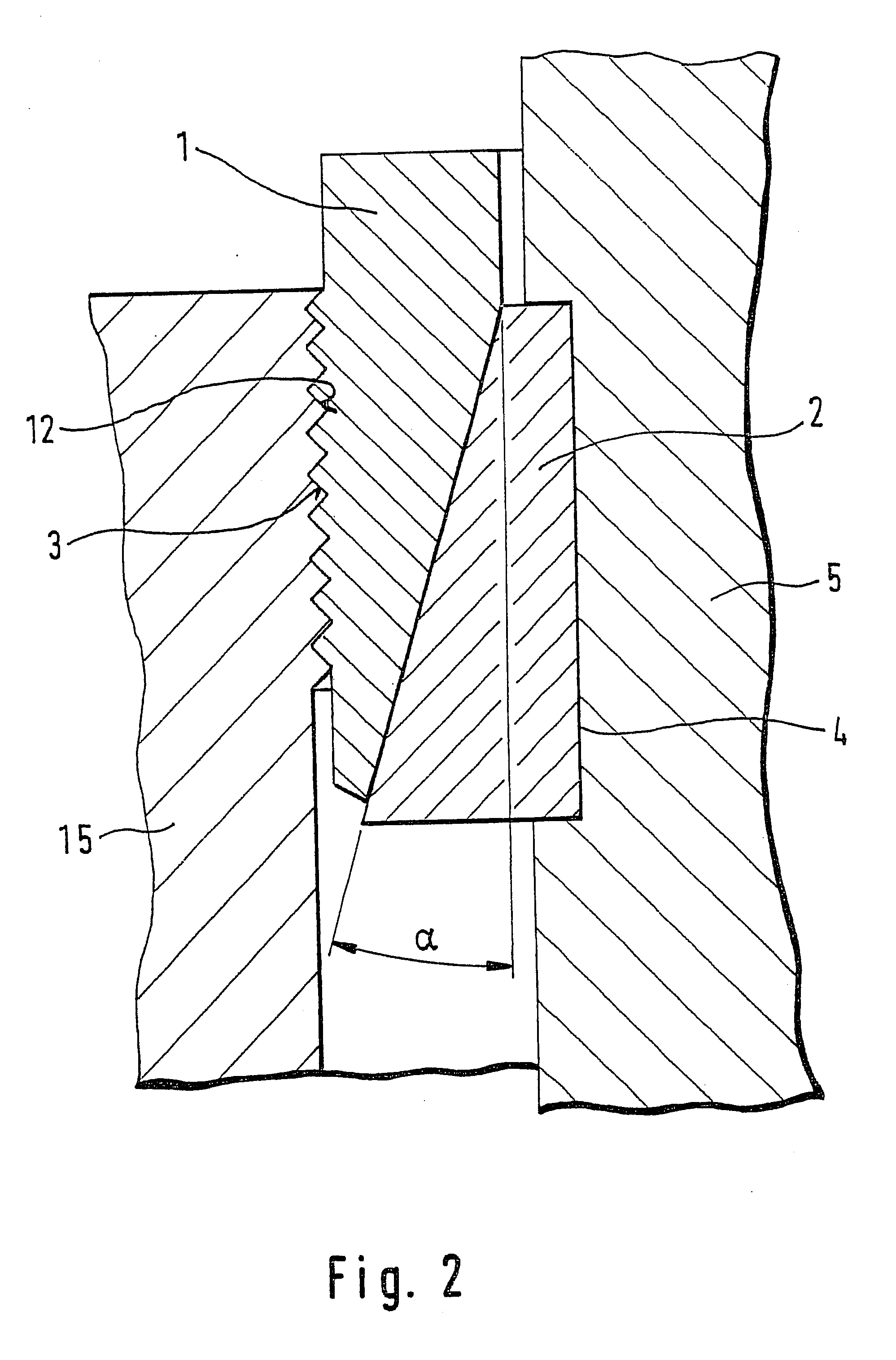

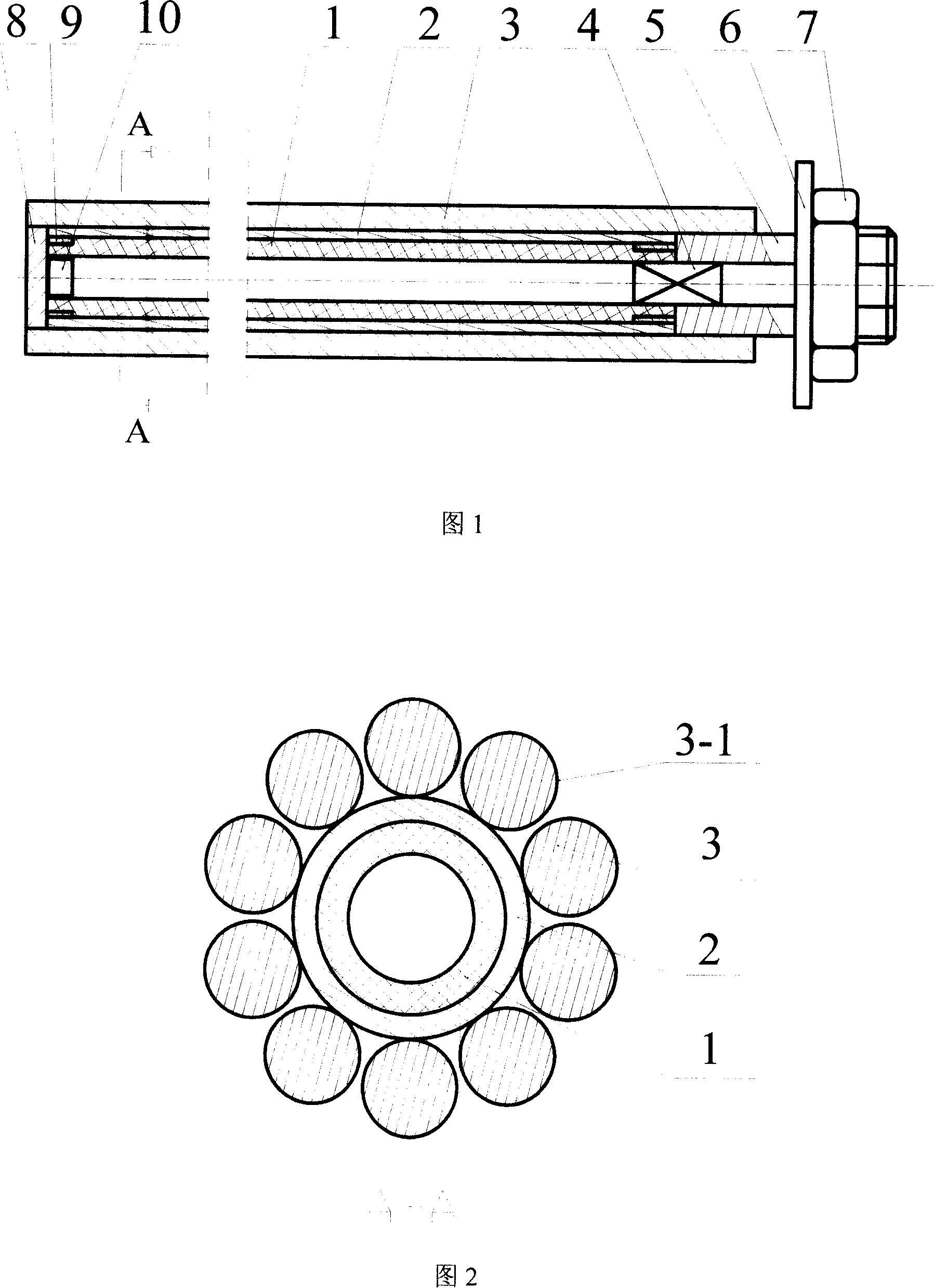

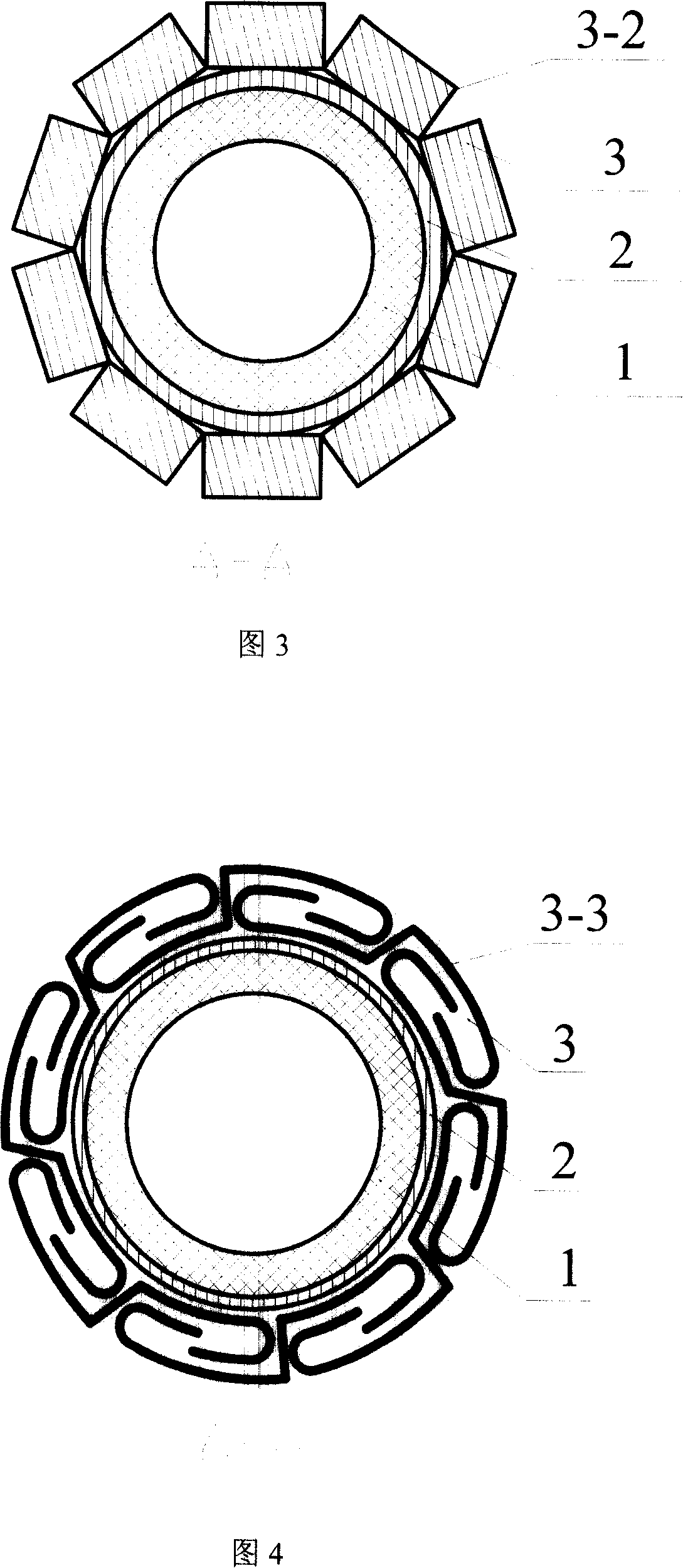

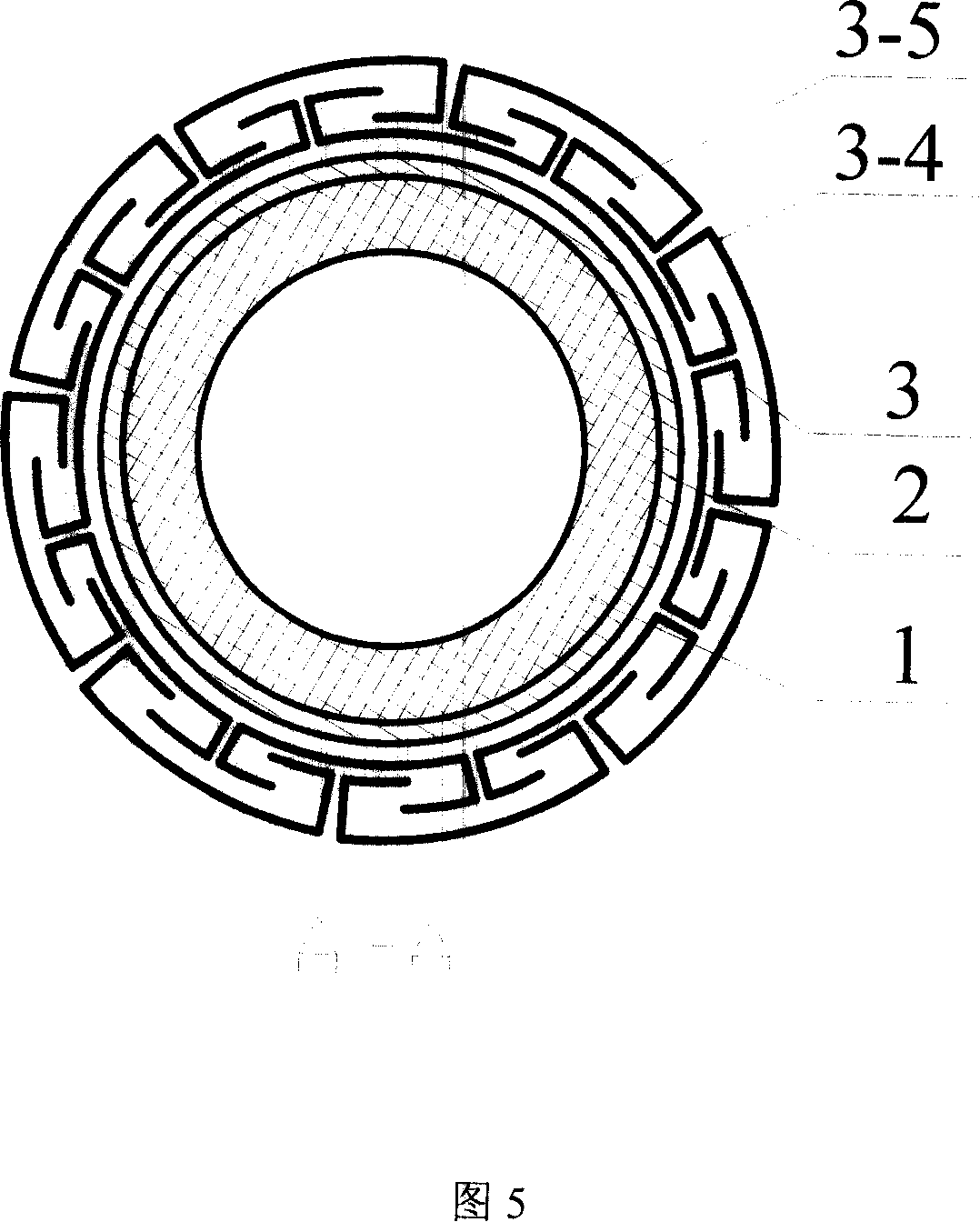

Fuel injection valve for internal combustion engines

InactiveUS6499468B1Increase injection pressureReduce surface pressureFuel injection apparatusMachines/enginesCombustion chamberHigh surface

A fuel injection valve for internal combustion engines, having an associated valve body, wherein the valve body is inserted into the receiving bore of the housing of an internal combustion engine and-by means of a clamping element, which is screwed into an internal thread embodied at the end of the receiving bore remote from the combustion chamber, and a support element disposed in an annular groove-is clamped with an annular shoulder embodied on the valve body against a contact surface embodied in the bore. The inner circumference surface of the clamping element and the outer circumference of the support element are conically embodied so that the axial movement of the clamping element when it is screwed in, exerts a radial force on the support element as a result of which it is pressed with its cylindrical inner circumference surface into the annular groove and as a result, a high axial force can be transmitted to the valve body without high surface pressures occurring as a result.

Owner:ROBERT BOSCH GMBH

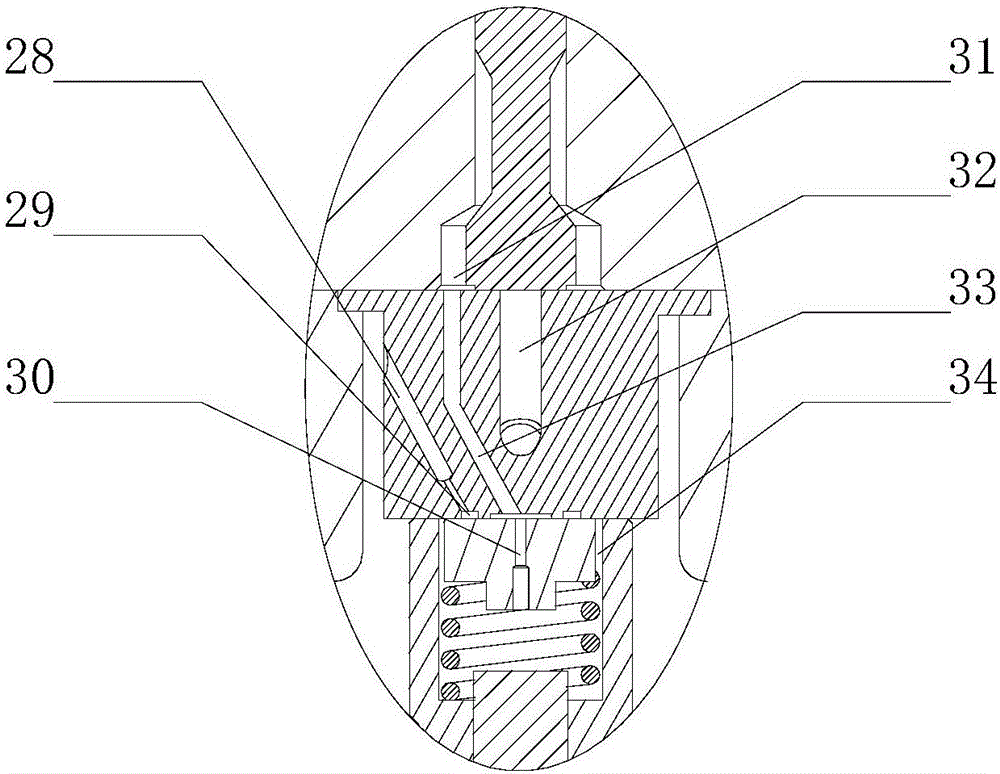

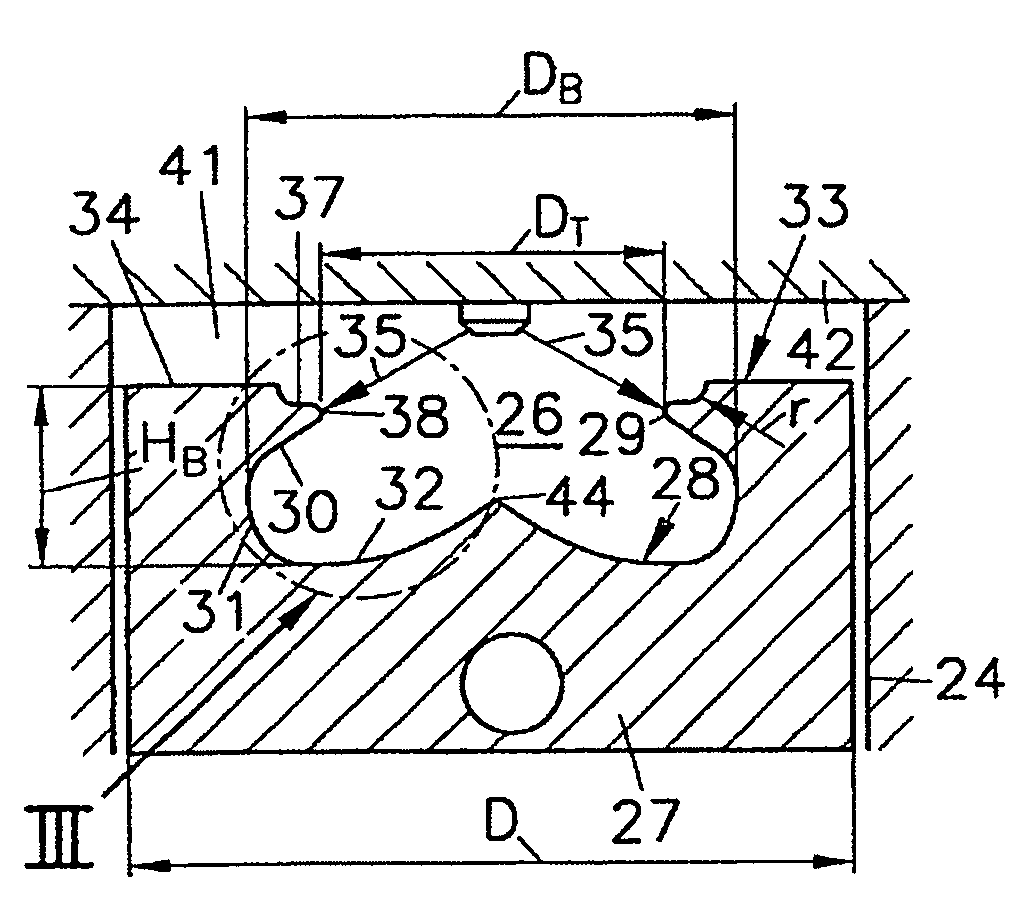

Long needle valve hole plate type electronic control oil atomizer without static leakage

InactiveCN106762291AAchieve no static leaksReduce lossFuel injection apparatusMachines/enginesCommon railCoupling

The invention aims at providing a long needle valve hole plate type electronic control oil atomizer without static leakage. The long needle valve hole plate type electronic control oil atomizer comprises an electromagnetic valve assembly, an oil atomizer body, a nozzle, a long needle valve, a limiting sleeve, a control plate, a middle block and an electromagnetic valve seat. An oil cavity is designed in the oil atomizer body, the interior of the oil cavity is completely filled with high-pressure fuel oil, the upper end and the lower end of a needle valve coupling piece are in the high-pressure environment, the pressure difference of the upper end and the lower end is close to zero, fuel oil leakage of the electronic control oil atomizer due to a fit clearance of inner coupling pieces is avoided, static leakage of the fuel oil is avoided, power consumption of an oil pump is reduced, the device working stability is improved, and the oil atomization character is improved. The control plate is designed in a control cavity, in the early stage of oil releasing of the control cavity, the control plate closes an annular oil inlet amount hole in the middle block, the dynamic fuel oil leakage amount generated during actual work of the electronic control oil atomizer can be effectively reduced, accordingly, fuel oil losses are reduced, and the oil atomization pressure of a common rail pipe is effectively increased.

Owner:HARBIN ENG UNIV

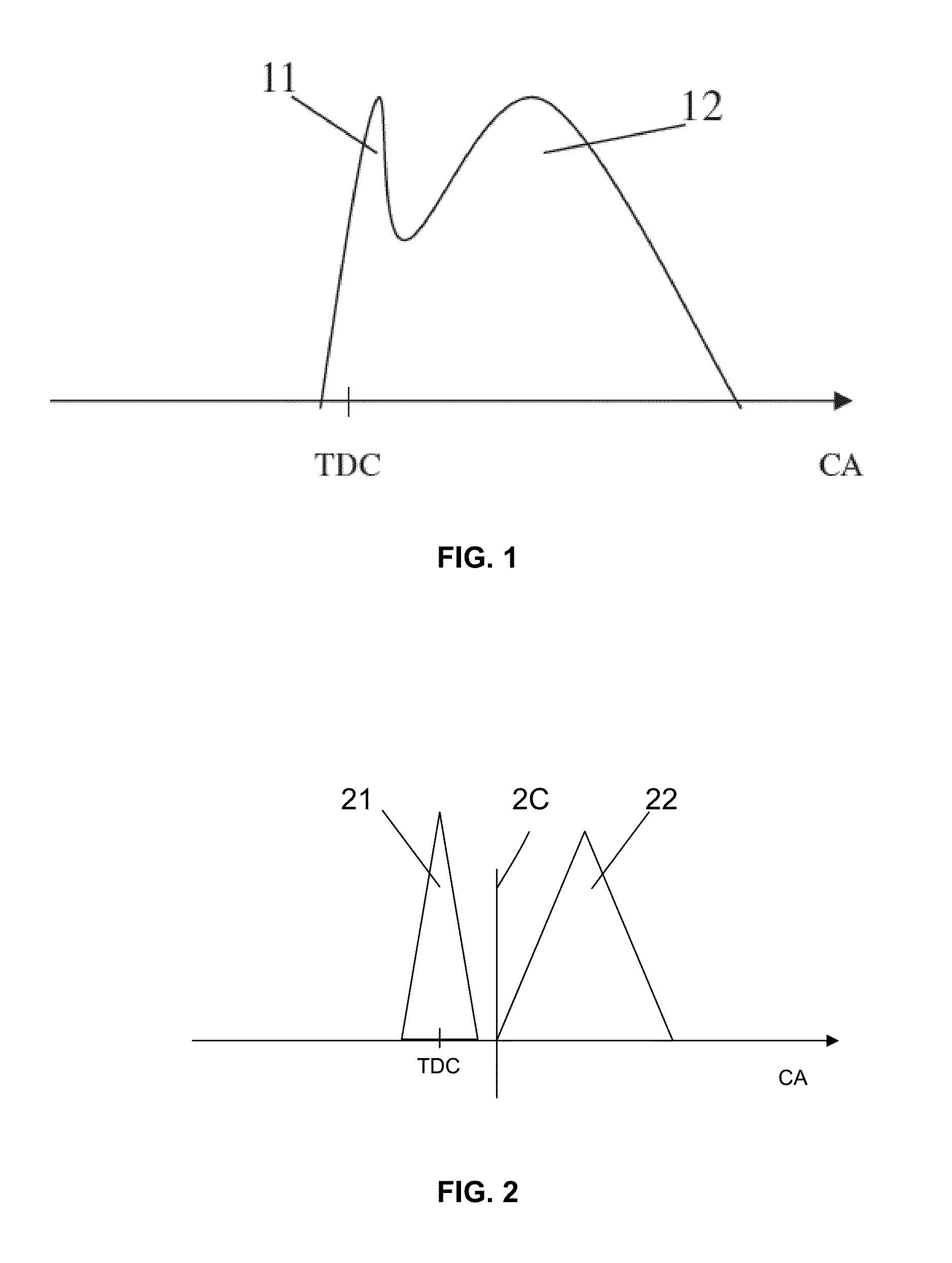

Method for operating an internal combustion engine

InactiveUS7415963B2Shorten injection timeEasy to igniteElectrical controlInternal combustion piston enginesNitrogen oxidesInternal combustion engine

The invention relates to a direct-injection internal combustion engine that is operated in a first operating range associated with the low part load, with largely homogeneous combustion of the mixture and subsequent injection. Said internal combustion engine is operated in a second operating range associated with the middle part load, with low-temperature combustion of the mixture. In this way, minimum nitrogen oxide and soot emissions and a high degree of efficiency can be achieved both in the lower part load region and up to the full load region.

Owner:AVL LIST GMBH

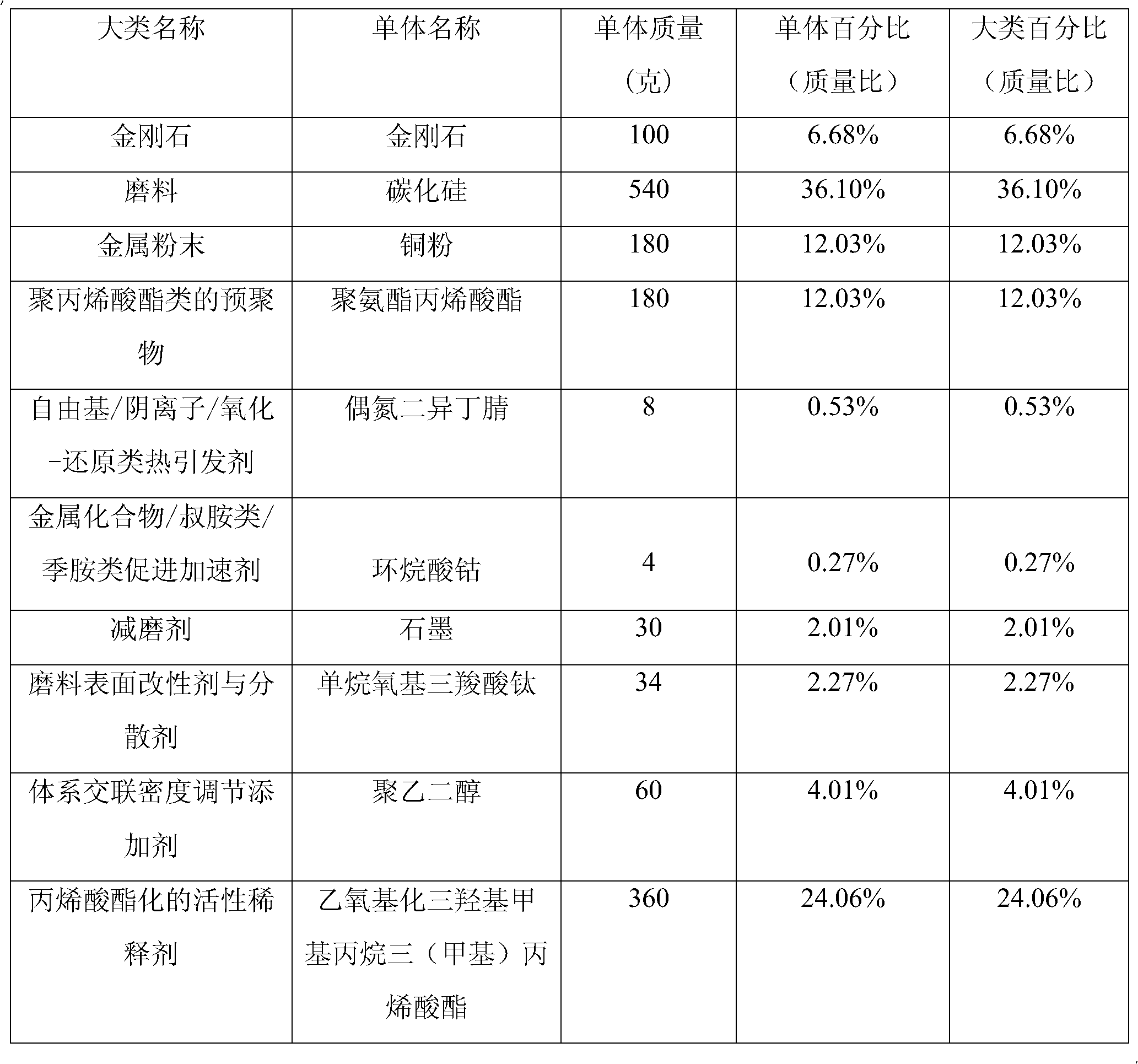

Thermosetting resin grinding pad and preparation method thereof

InactiveCN102632453AHigh densityHigh hardnessGrinding devicesLapping toolsReactive diluentMetal powder

The embodiment of the invention discloses a thermosetting resin grinding pad and a preparation method thereof. The thermosetting resin grinding pad comprises a diamond, a grinding material and a resin base body and contains the following components in percentage by mass of: 4 to 7 percent of diamond with the particle size being between 40 and 50 microns, 9 to 40 percent of grinding material with the particle size being between 20 and 70 microns, 10 to 55 percent of metal powder with the particle size being between 20 and 70 microns, 10 to 60 percent of polyacrylic prepolymer, 0.1 to 1 percent of radical / anion / oxidation-reduction thermal initiator, 0 to 0.7 percent of metal compound / tertiary amine / quaternary amine promote accelerator, 0.5 to 5 percent of antifriction composition, 0 to 4 percent of grinding material surface modifier and dispersing agent, 0 to 20 percent of system crosslinking density adjustment additive and 5 to 40 percent of acyclic acid esterification reactive diluent. According to the thermosetting resin grinding pad, the density, the mechanical strength and the abrasion resistance of the thermosetting resin grinding pad are improved.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

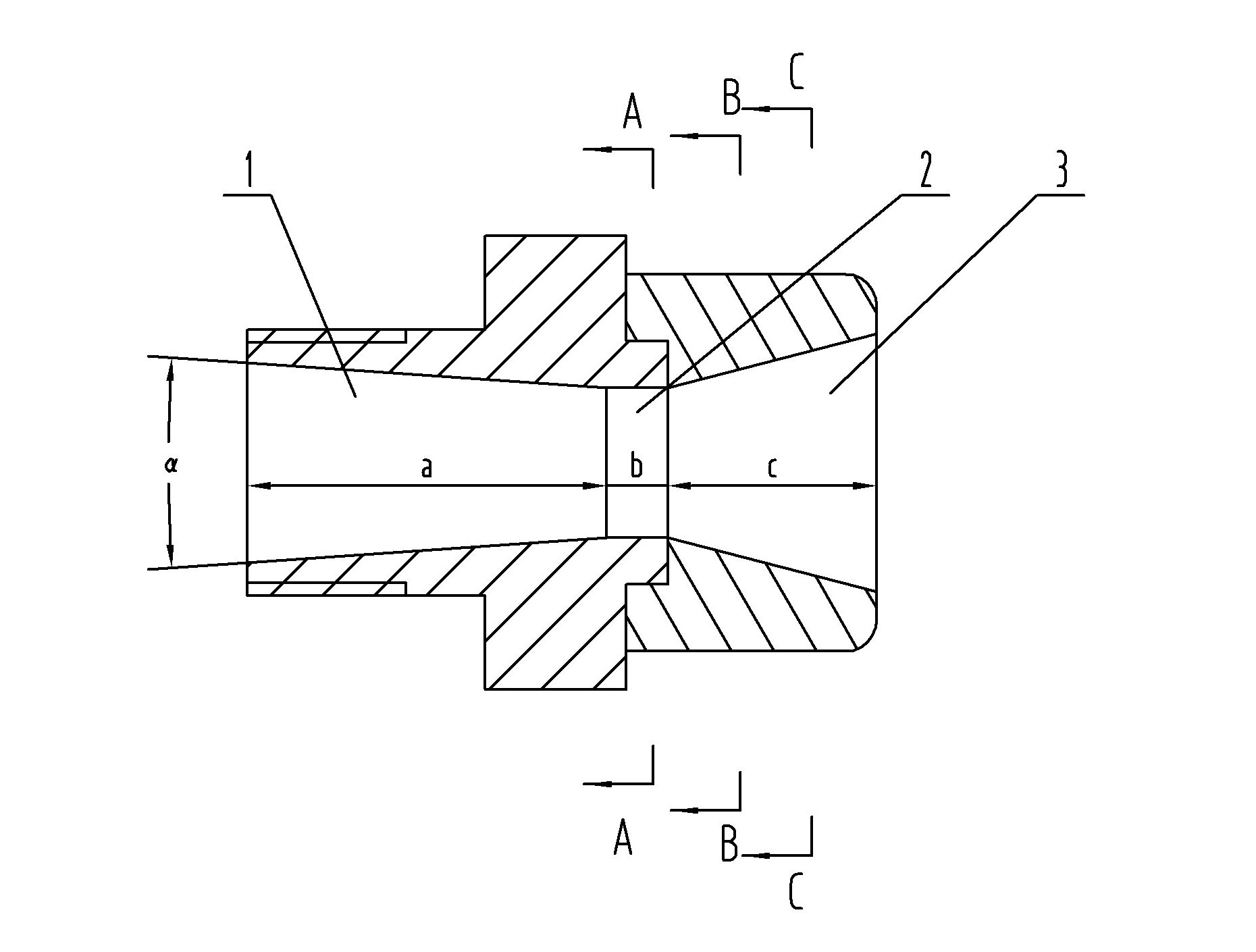

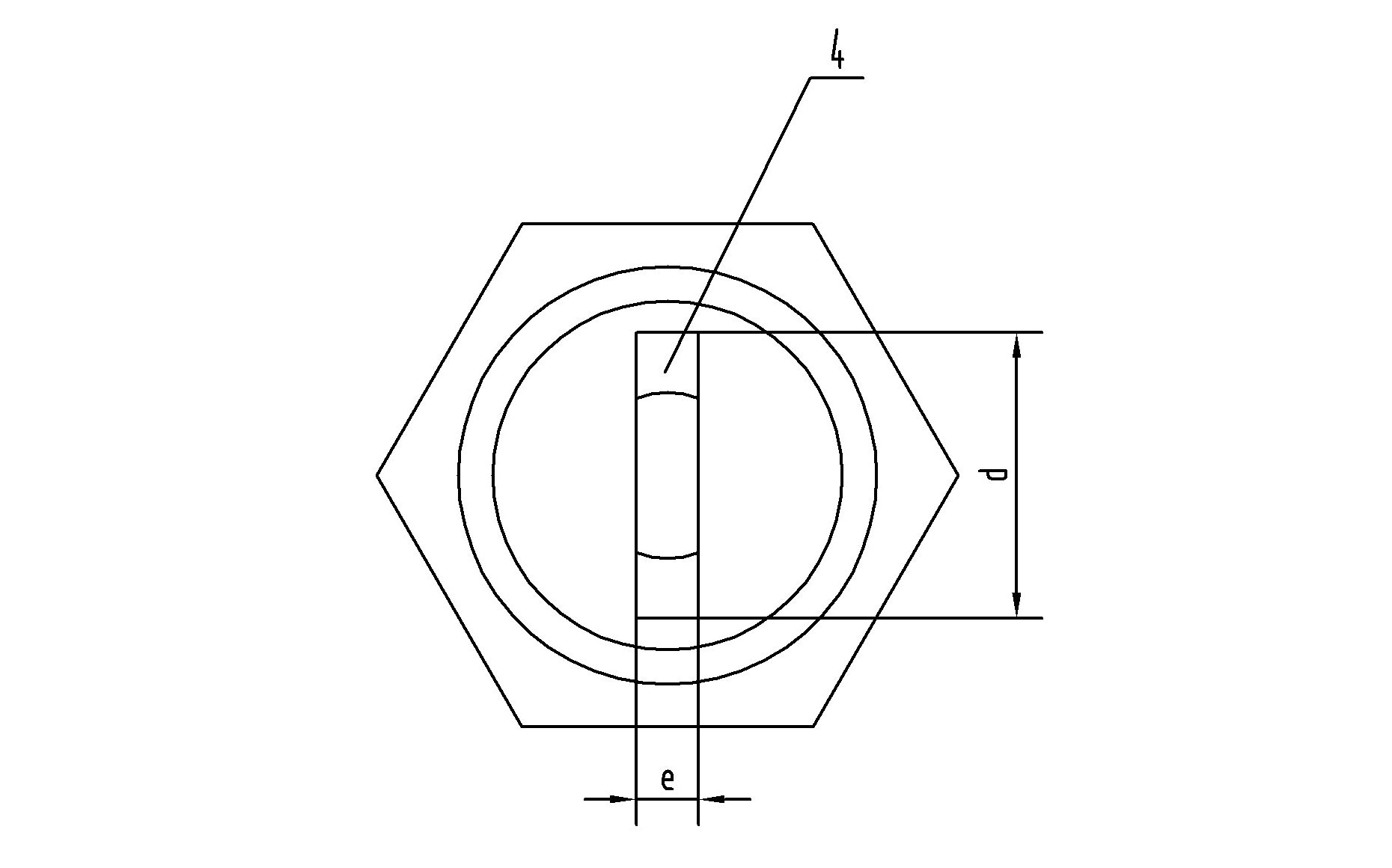

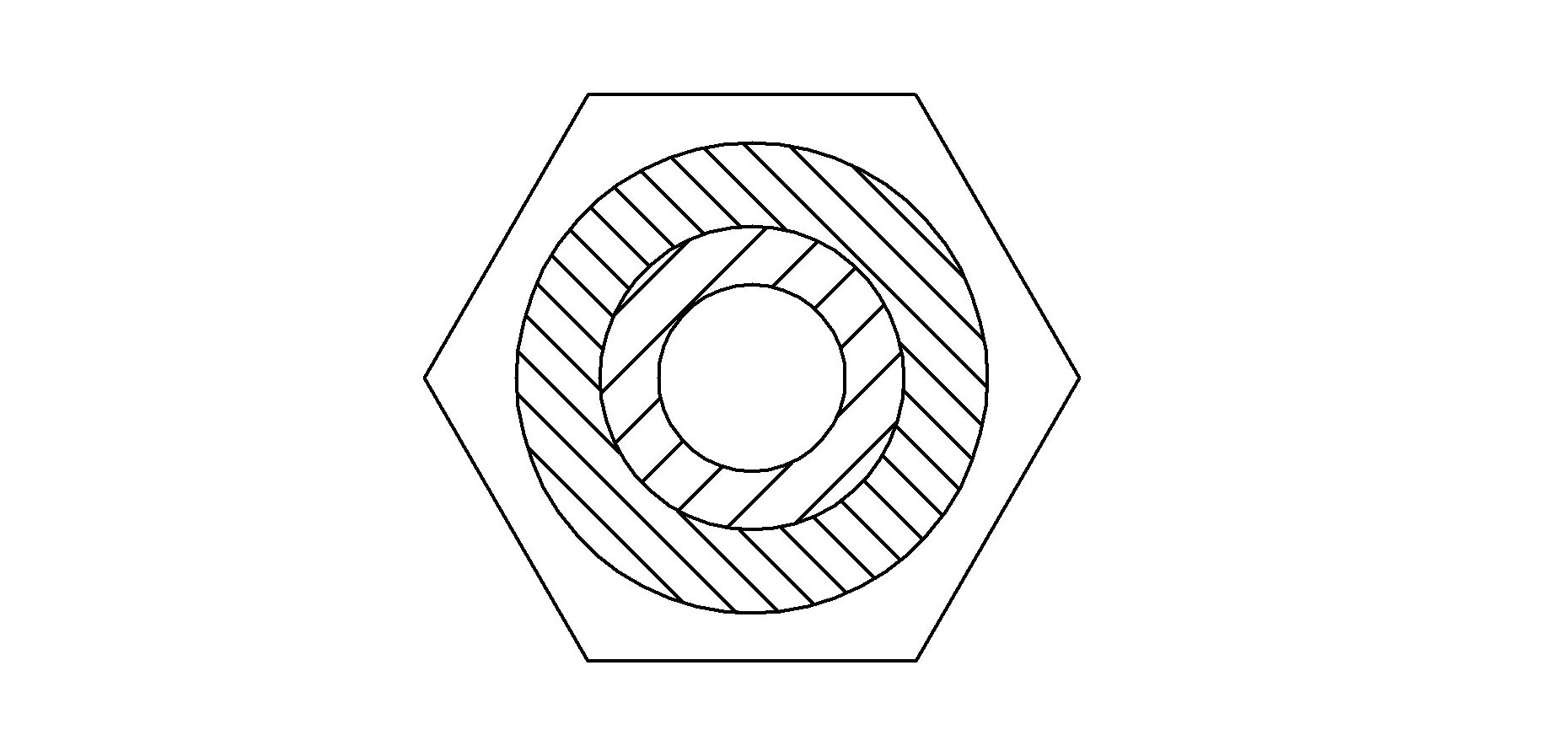

Flat jet flow nozzle and special coating machine

ActiveCN102535823AIncrease output resistanceImprove compactnessSpray nozzlesBuilding constructionsEconomic benefitsPipe

The invention belongs to the technical field of building machinery, and particularly relates to a flat jet flow nozzle and a special coating machine which are used for coating various materials on surfaces of the inner wall and the outer wall of a building. The flat jet flow nozzle comprises a shrinkage pipe section, a throat pipe section and a diffuse pipe section from left to right in sequence, the shrinkage pipe section is in a hollow cone shape, the cone angle alpha is in a range being greater than or equal to 30 degrees and less than or equal to 120 degrees, the length of the shrinkage pipe section a is in a range being greater than or equal to 8mm and less than or equal to 30mm, the throat pipe section is in a hollow cylinder shape, the length of the throat pipe section b is in a range being greater than or equal to 1mm and less than or equal to 4mm, an inner cavity of the diffuse pipe section is a flat hole which is formed in a way that the tail of an inner cavity of the throat pipe section gradually transits to the end surface of the tail end of the nozzle, the length of the diffuse pipe section c is in a range being greater than or equal to 3mm and less than or equal to 12mm, the height of the flat hole d is in a range being greater than or equal to 3mm and less than or equal to 12mm, and the width of the flat hole e is in a range being greater than or equal to 1.5mm and less than or equal to 6mm. In the nozzle and the coating machine which are provided by the invention, the coating effect is uniform and smooth, the bonding degree of the materials and a wall body is high, the compactness of the materials is high, the coating efficiency is high, the coating quality is ensured, and further the special coating machine is wide in application range, obvious in economic benefit, and is beneficial to popularization and application.

Owner:河南恒睿机械制造有限公司

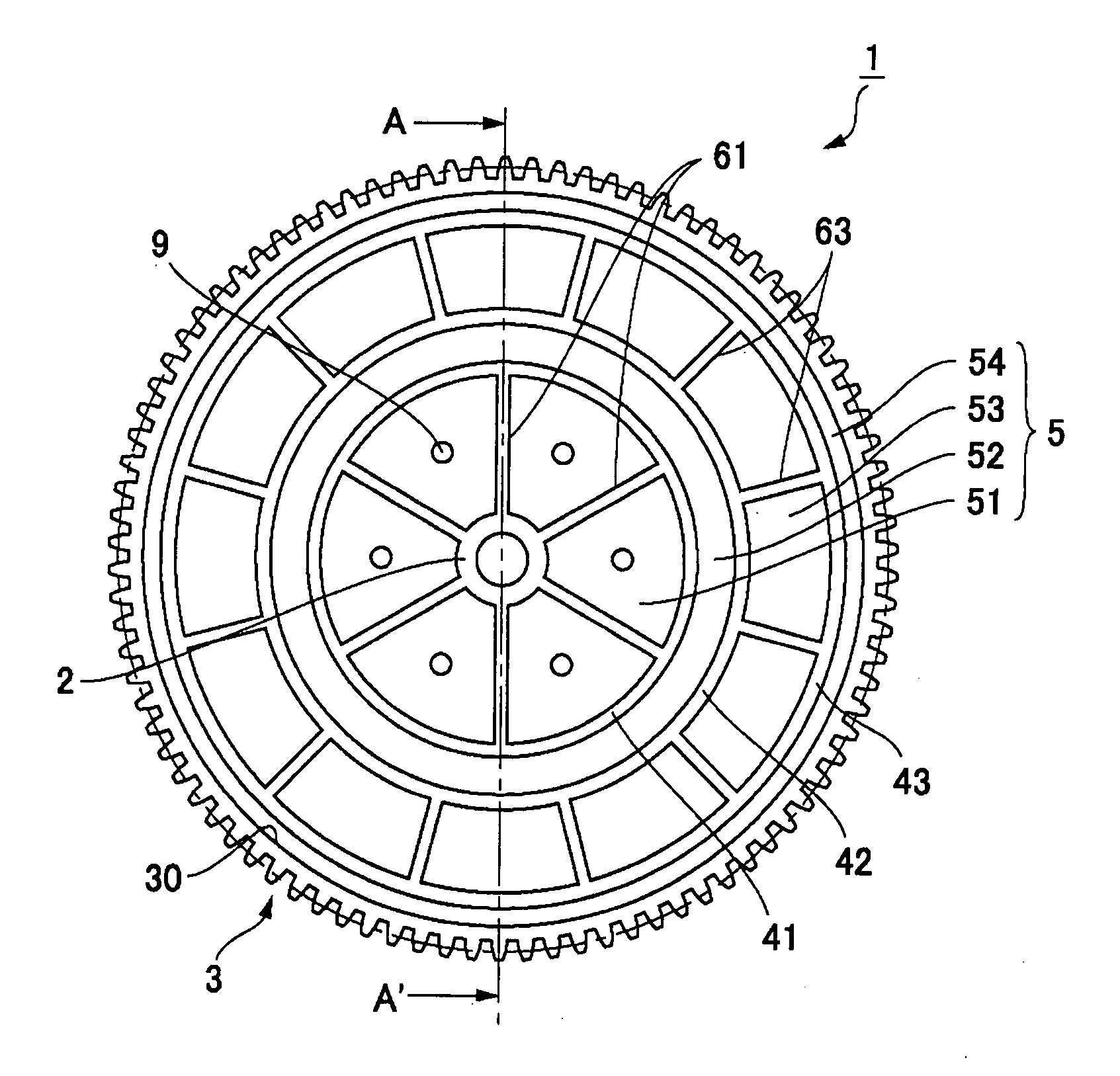

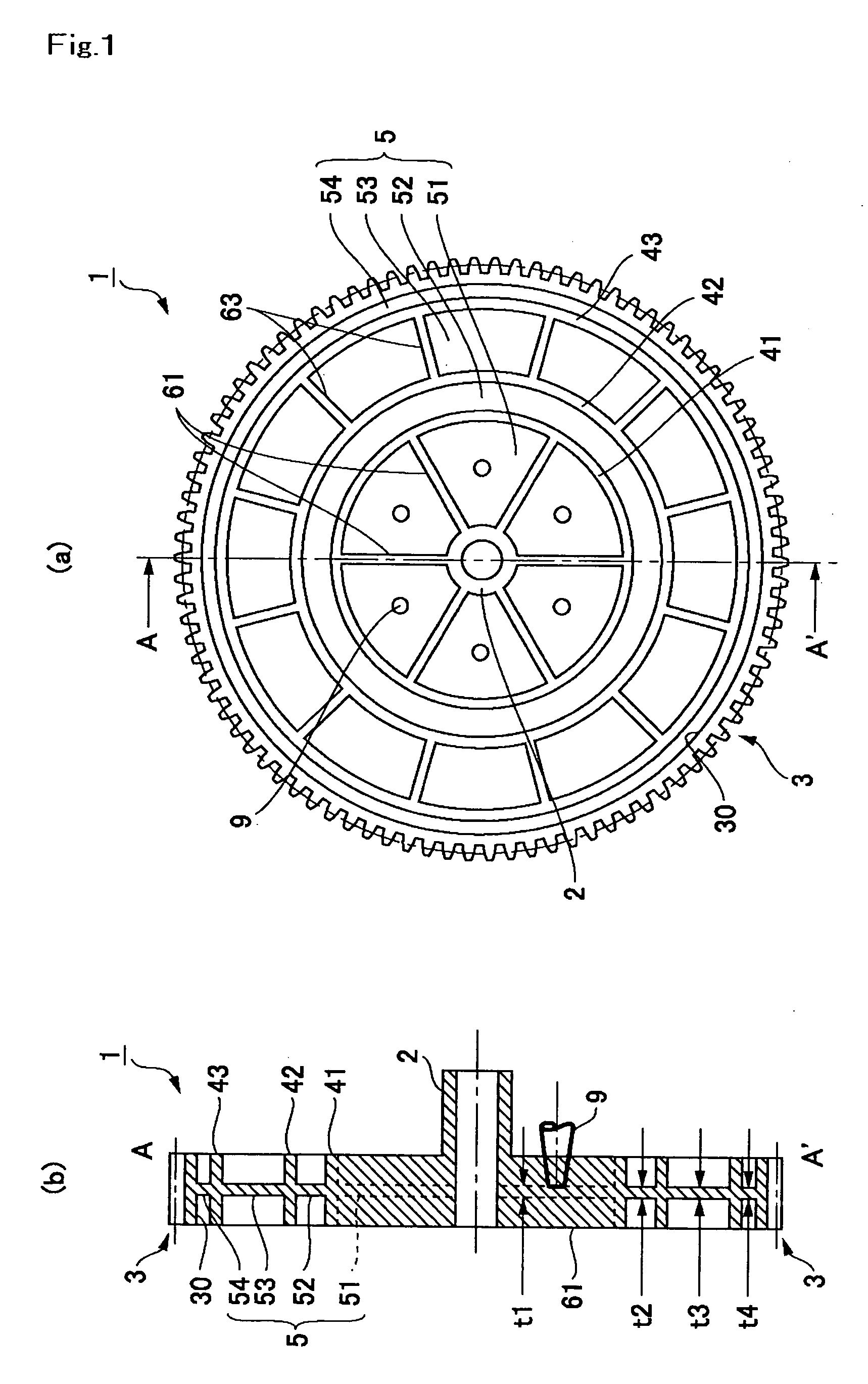

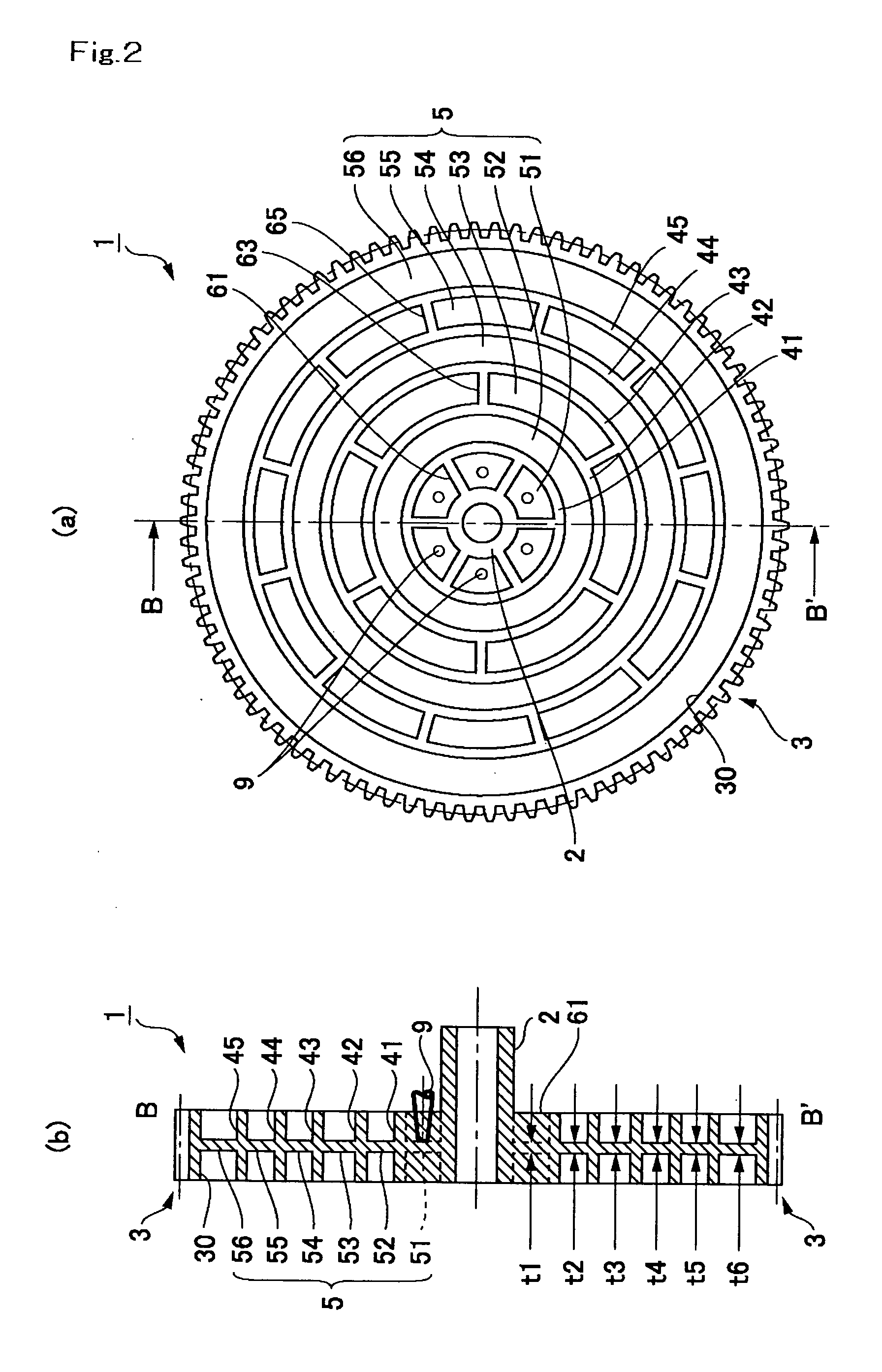

Plastic gear

InactiveUS20060053917A1Good transferabilityIncrease injection pressureToothed gearingsGearing elementsEngineeringTooth part

A plastic gear includes a teeth part formed on its outer periphery, a web formed on the inner side of the teeth part and a plurality of ring-shaped rims concentrically formed such that the web is divided into a plurality of ring-shaped webs in a concentrically circular shape. The plurality of ring-shaped webs includes two or more ring-shaped webs without rib which has no ribs connecting adjacent ring-shaped rims on an outer peripheral side other than the ring-shaped web to which gates for resin molding are to be disposed at the time of resin molding.

Owner:NISSHIN KOKI KK

Fuel injection device

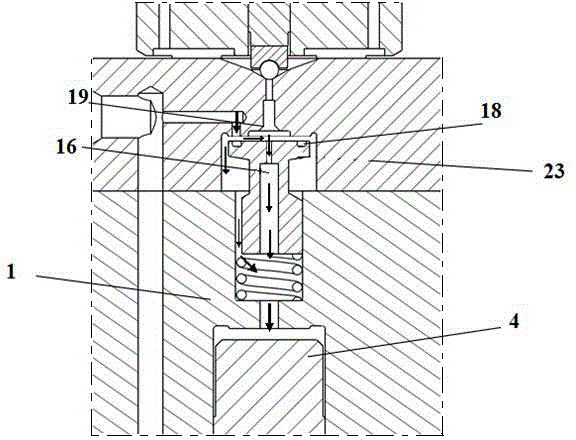

InactiveUS6880527B2Low pressure boosting ratioHighly dynamic pressure buildupFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesCombustionEngineering

A fuel injection system for internal combustion engines includes an injector supplied from a high-pressure fuel source and with a pressure booster device, in which the closing piston can be acted upon by fuel pressure to attain a force exerted on the closing piston in the closing direction, and in which the closing pressure chamber and the return chamber of the pressure booster device are formed by a common closing pressure return chamber, and all the portions of the closing pressure return chamber communicate with one another permanently for exchanging fuel, so that despite a low pressure boost by the pressure booster device, a relatively low injection opening pressure is attainable.

Owner:ROBERT BOSCH GMBH

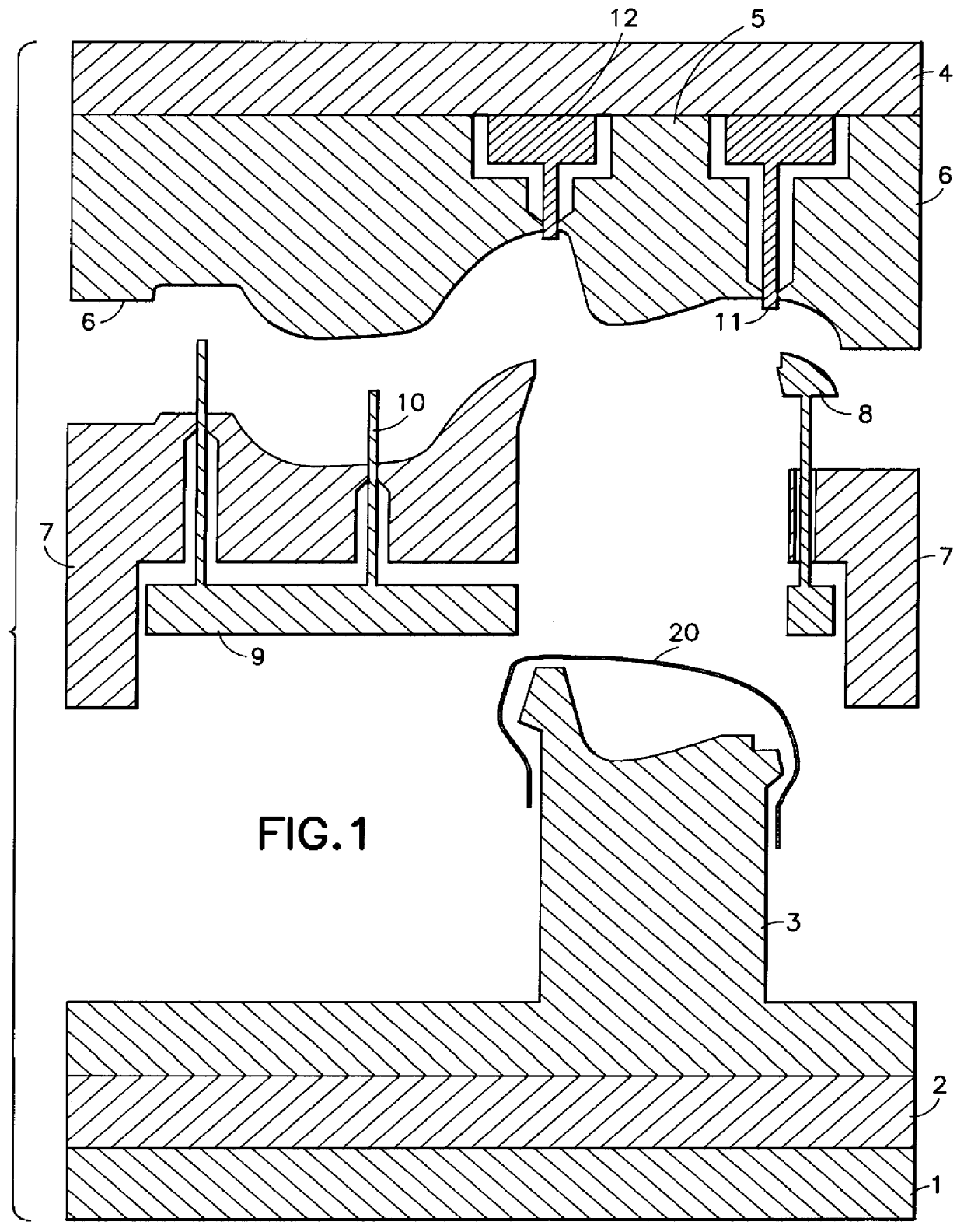

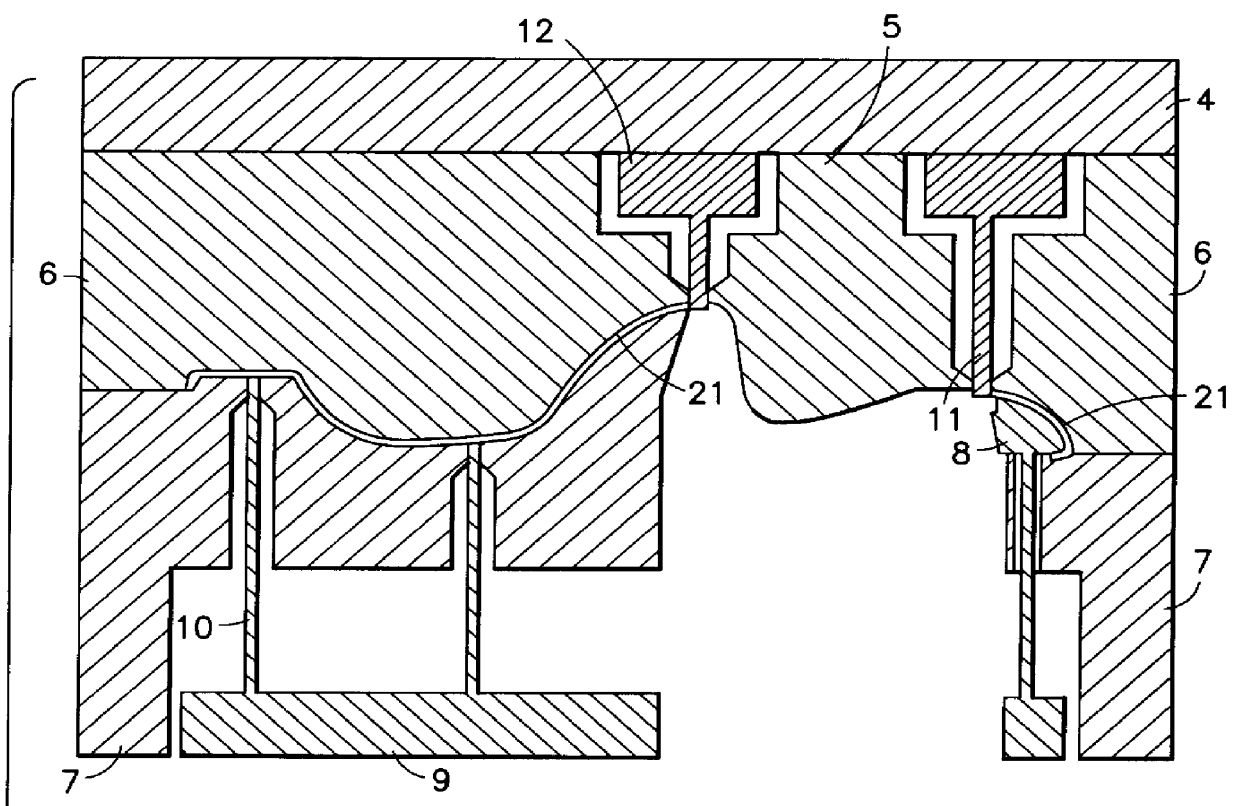

Process for including a decoration, particularly a textile decoration, in a piece of plastic material

InactiveUS6054087ASatisfactory bondingIncrease injection pressureMouldsConfectioneryPlastic materialsEngineering

A decorative sheet including a decoration and a process for forming the sheet are disclosed. This process comprises the following steps: using a mold consisting of at least two parts, at least one part of which is formed of at least two elements, at least one element (5) corresponding to the medallion and at least one other element (6) corresponding to the periphery of the piece, around the medallion; placing the decorative sheet (20) on the element corresponding to the medallion and closing the mold; within the cavity of the mold, isolating the space (23) located below the decorative sheet from the peripheral space (21); injecting plastic material in succession into the spaces thus isolated; and ejecting the piece obtained.

Owner:CENTRE DETUDE ET DE RECHERCHE POUR LAUTOMOBILE (CERA)

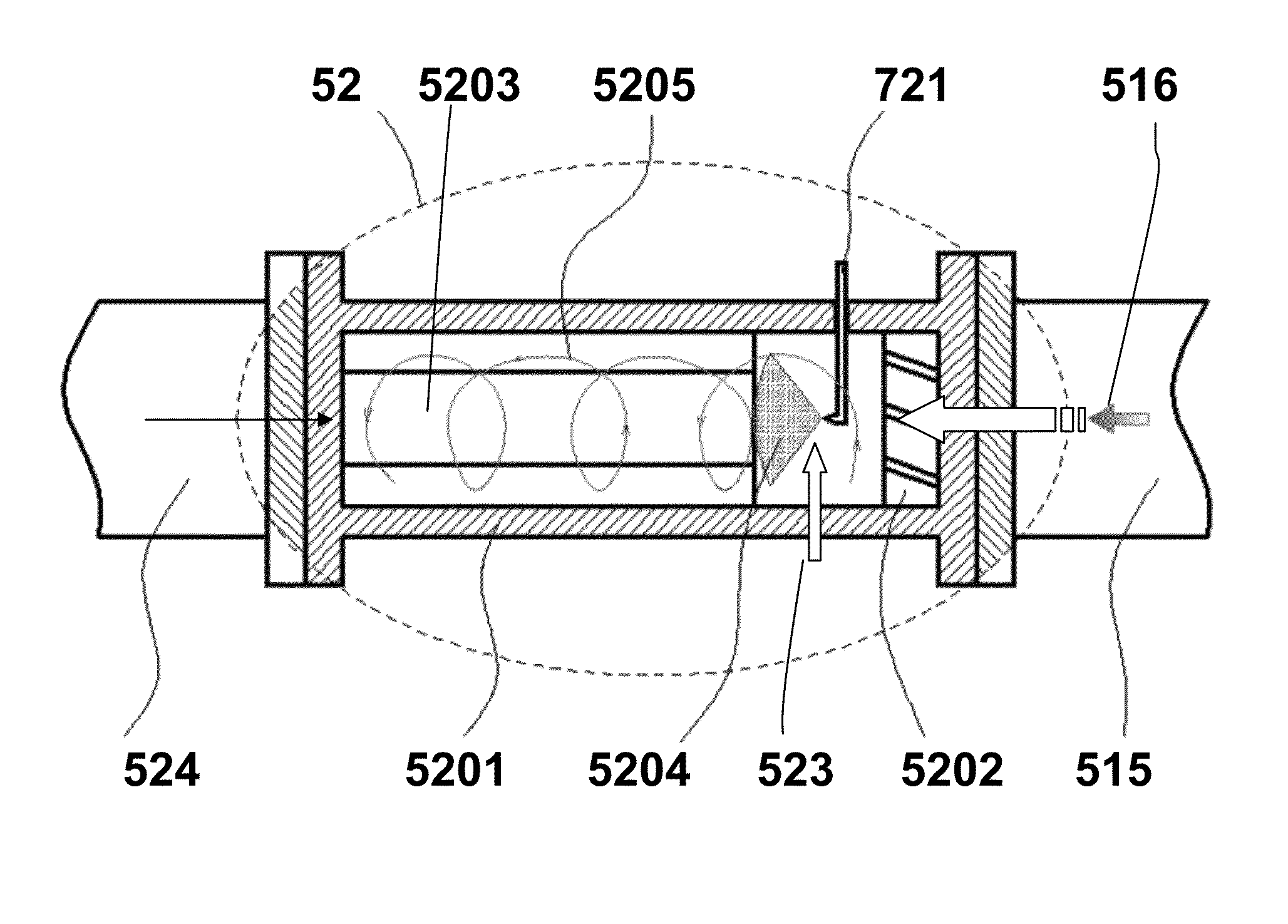

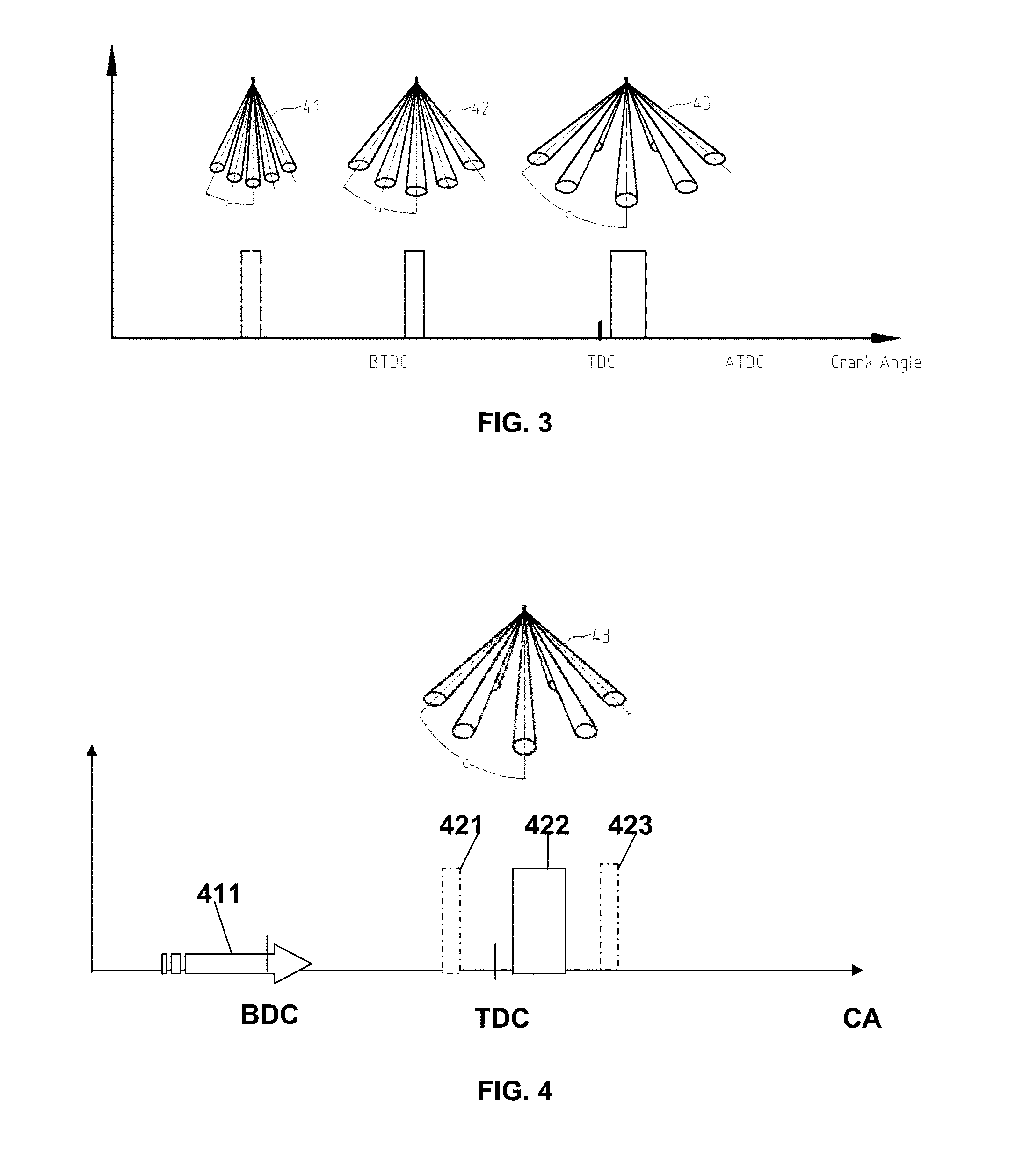

Mixed-Mode Combustion Methods Enabled by Fuel Reformers and Engines Using the Same

InactiveUS20150136047A1Emission reductionReduce fuel consumptionElectrical controlInternal combustion piston enginesCombustion chamberEngineering

Disclosed here is an adaptive mixed-mode combustion method, which is mainly for internal combustion engines, either compression ignition or spark ignition, or mixed-mode engines using both compression ignition and spark ignition. The combustion method is composed of steps of partially charging fuel reformates through intake ports, or charging fuels with high ignition temperature through intake ports, wherein it has adaptive means to introduce fuels into combustion chamber space through both intake port fuel charge and direct fuel injections, based on engine loads and speeds, to produce a separate twin triangular heat release curves to effectively reduce emissions and fuel consumptions. A combustion engine using the disclosed combustion method is also provided. A corresponding method and fuel reformer of using exhaust energy for fuel reforming is also disclosed. Also disclosed is a rotating fuel reformer, comprising a rotating catalyst block to accelerate the fuel reforming rate and reduce the reformer weight and catalyst usage. The reformer also has devices to pressurize and atomize fuel through centrifugal forces.

Owner:HOU DEYANG

Expansion anchor rod

InactiveCN101126321ARigid AnchorIncrease anchoring forceExcavationsAnchoring boltsFiberWear resistant

The invention relates to the technical field of a support facility for the rock, earth and mining engineering, in particular to an expansion anchor rod. The expansion material of the anchor rod adopts a high-elasticity high molecular material, or a compound intensified material made of the steel wire or fibrous material and the high-elasticity and high molecular material or the thin corrugated metal sheet. The expansion body of the anchor rod has a hollow structure; the hollow part is a pressure cavity for injection, one end of the cavity is sealed and an introduction valve and a tube orifice anchor head are closely arranged at the other end ; an expansive force transfer layer is sleeved around the outer edge of the expansion body of the anchor rod and an anchor layer is sleeved around the outer edge of the expansive force transfer layer to form the expansion anchor rod. The expansion anchor rod additionally has the advantages of the rigid anchor rod on the base of keeping the application effect of the flexible injection bolt. The anchoring force is reliable and is easy to be adjusted, supplement and reclaimed; the creep resistance is strong and the anchoring effect is not affected if the geotechnical or the hole wall has honeycombed crack or collapse of artifices; also, the anchor rod is high in strength, low in cost, wear-resistant and is easy to be processed and manufactured.

Owner:SHANDONG UNIV

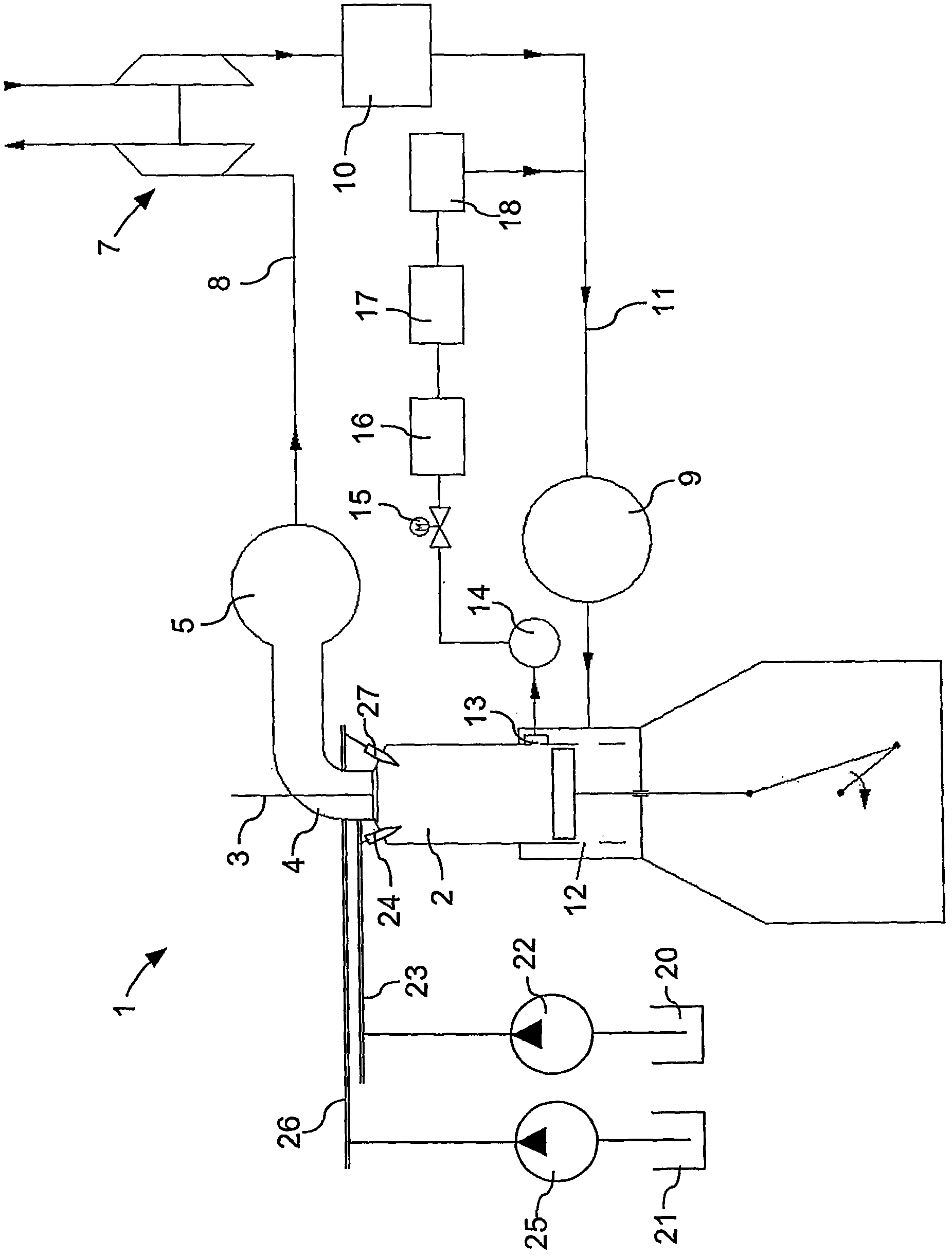

A Large Turbocharged Two-Stroke Diesel Engine With Exhaust- Or Combustion Gas Recirculation And Method For Reducing Nox And Soot Emissions

ActiveCN102341589AIncrease injection pressureAvoid formingElectrical controlNon-fuel substance addition to fuelExhaust gas recirculationTwo-stroke diesel engine

A large two-stroke turbocharged diesel engine of the crosshead type provided with an exhaust gas recirculation system and with a fuel injection system that can, selectively add water to the fuel flow to thereby increase the mass flow through the injection nozzles under particular operating conditions, e.g. at high exhaust gas recirculation rates. The increased mass flow through the injection nozzles improves the entrainment of the fresh charge into the high-speed of the fuel spray and thereby increases the fuel / air mixing and brings the combustion towards the lean side and hence counteracts soot formation.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

Fuel injector

InactiveUS20100102143A1Increase injection pressureReduce in quantityCombustion-air/fuel-air treatmentSpray nozzlesLine tubingCombustion chamber

The invention relates to a fuel injector comprising an injector housing having a pressure chamber from which fuel subjected to a high pressure is injected into a combustion chamber of an internal combustion engine when the pressure in a control chamber expands into a pressure relief chamber by a control valve device. The aim of the invention is to create a fuel injector which has a long service life even though subjected to high pressures. To this end, the injector includes a low-pressure supply line which is connected to a low-pressure return line by a purge path extending through the pressure relief chamber.

Owner:ROBERT BOSCH GMBH

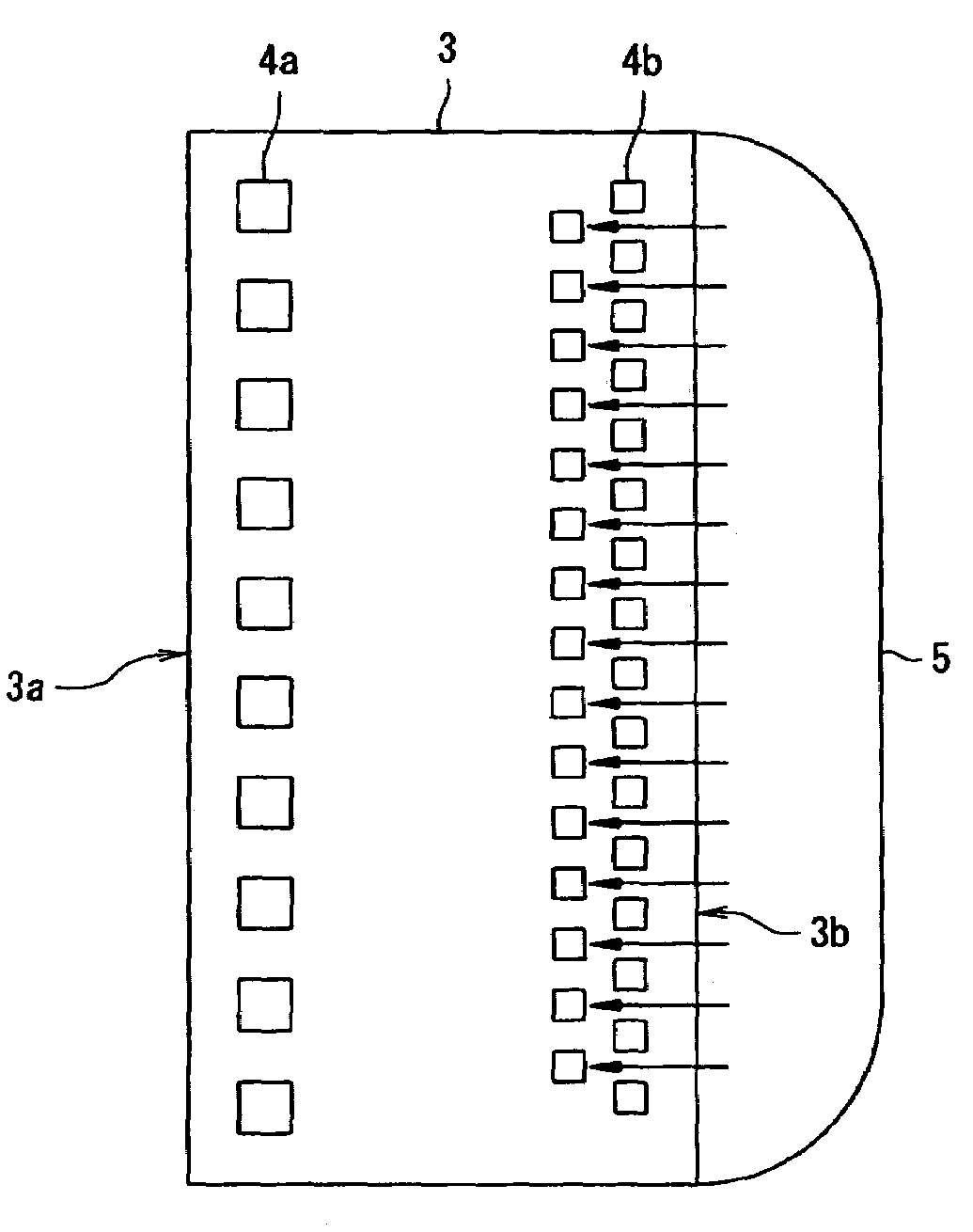

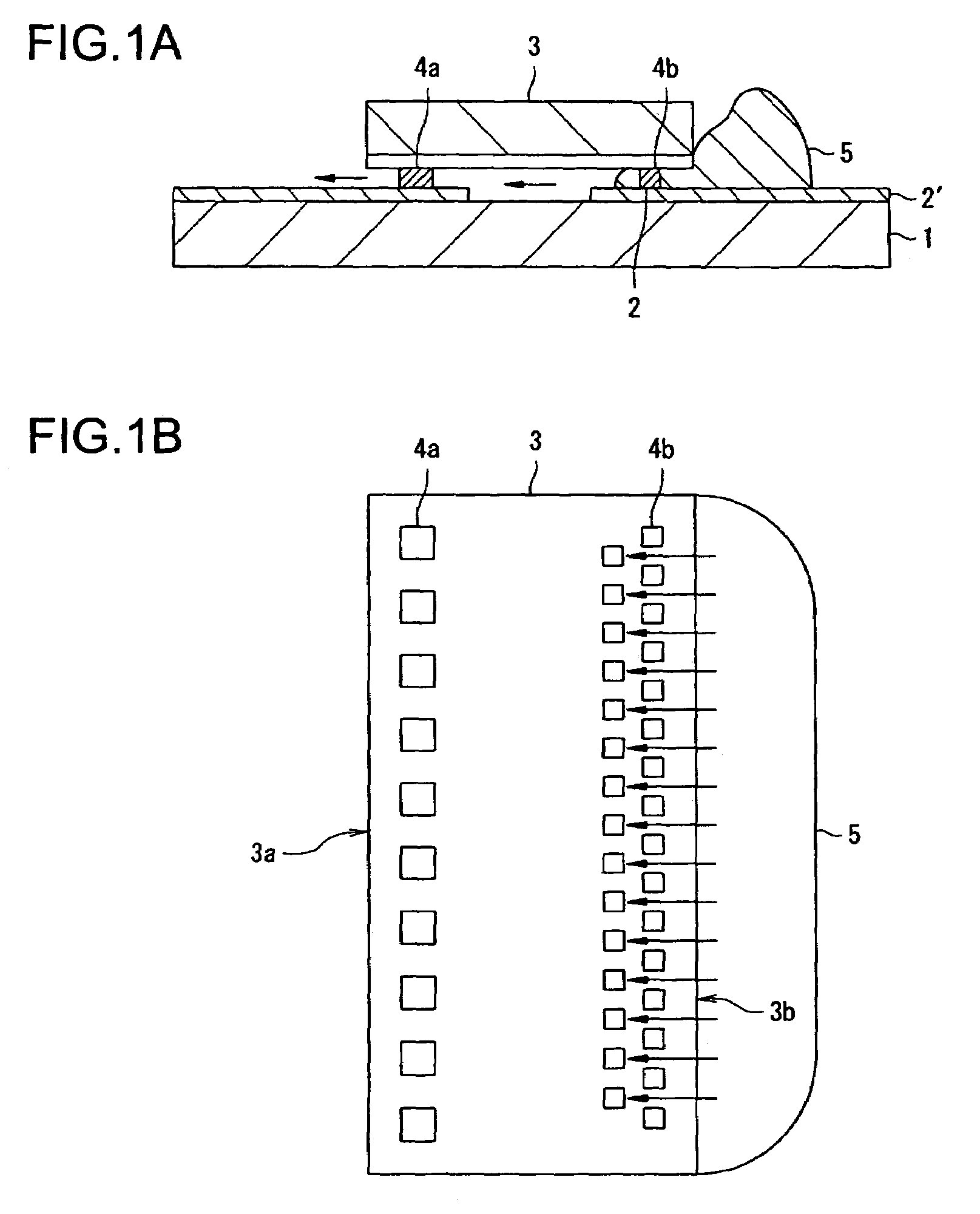

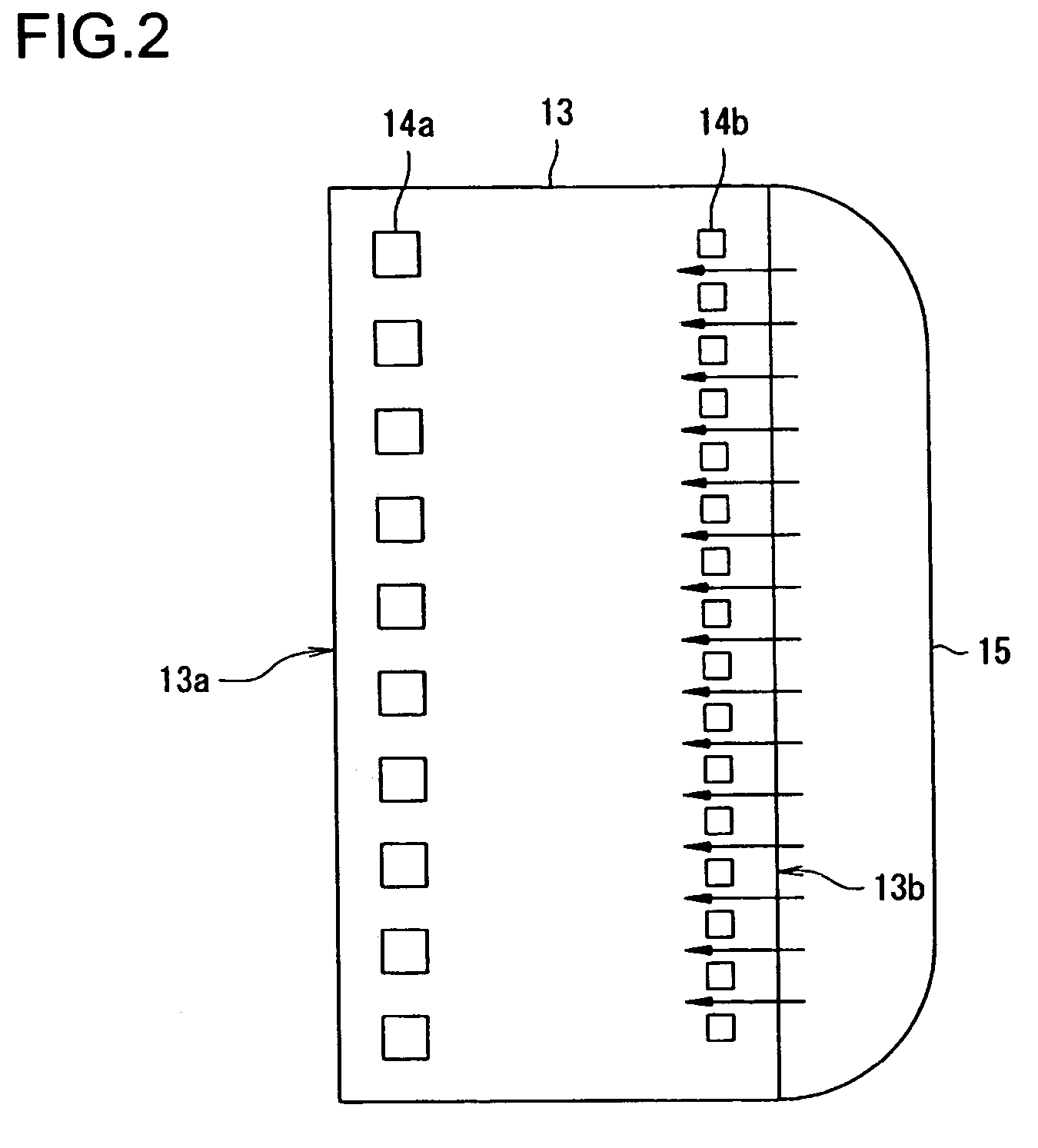

Manufacturing method of semiconductor device, including differently spaced bump electrode arrays

ActiveUS7144758B2InhibitionWithout increasing complex and laborious handling in manufacturing processesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

First bump electrodes are arrayed in a straight line along a first side of a semiconductor chip. Second bump electrodes are more narrowly arrayed in a zigzag arrangement along a second side of the chip. By carrying out an injection of a sealing resin from the second side on which the second bump electrodes are arrayed, a surface of the semiconductor chip that is subjected to face-down mounting on a film substrate is sealed.

Owner:SEIKO EPSON CORP

Direct Injection Fuel System with Reservoir

InactiveUS20090107461A1Improved fuel pressure riseImprove efficiencyElectrical controlInternal combustion piston enginesFuel tankCooling down

A method of operating a fuel delivery system for an internal combustion engine is described. The system may include a plurality of direct cylinder injectors, a fuel rail upstream of the injectors, a first pump, and a second pump coupled downstream of the first pump and to the fuel rail. The method may include, after or during engine shutdown, and during a fuel system cool down, activating the first pump; and varying the activation of the first pump responsive to temperature to maintain a higher pressure for high temperatures. Alternatively, in some examples, the system may include a reservoir in a bypass around the second pump, the bypass having a valve downstream of the fuel reservoir, where the valve is positioned vertically above the second pump and the fuel reservoir is positioned vertically above the valve. The fuel reservoir may be sized to hold a sufficient amount of fuel in the bypass to allow fuel to migrate from the bypass to the fuel rail during engine cool down.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com