Patents

Literature

94results about How to "Save cooling water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

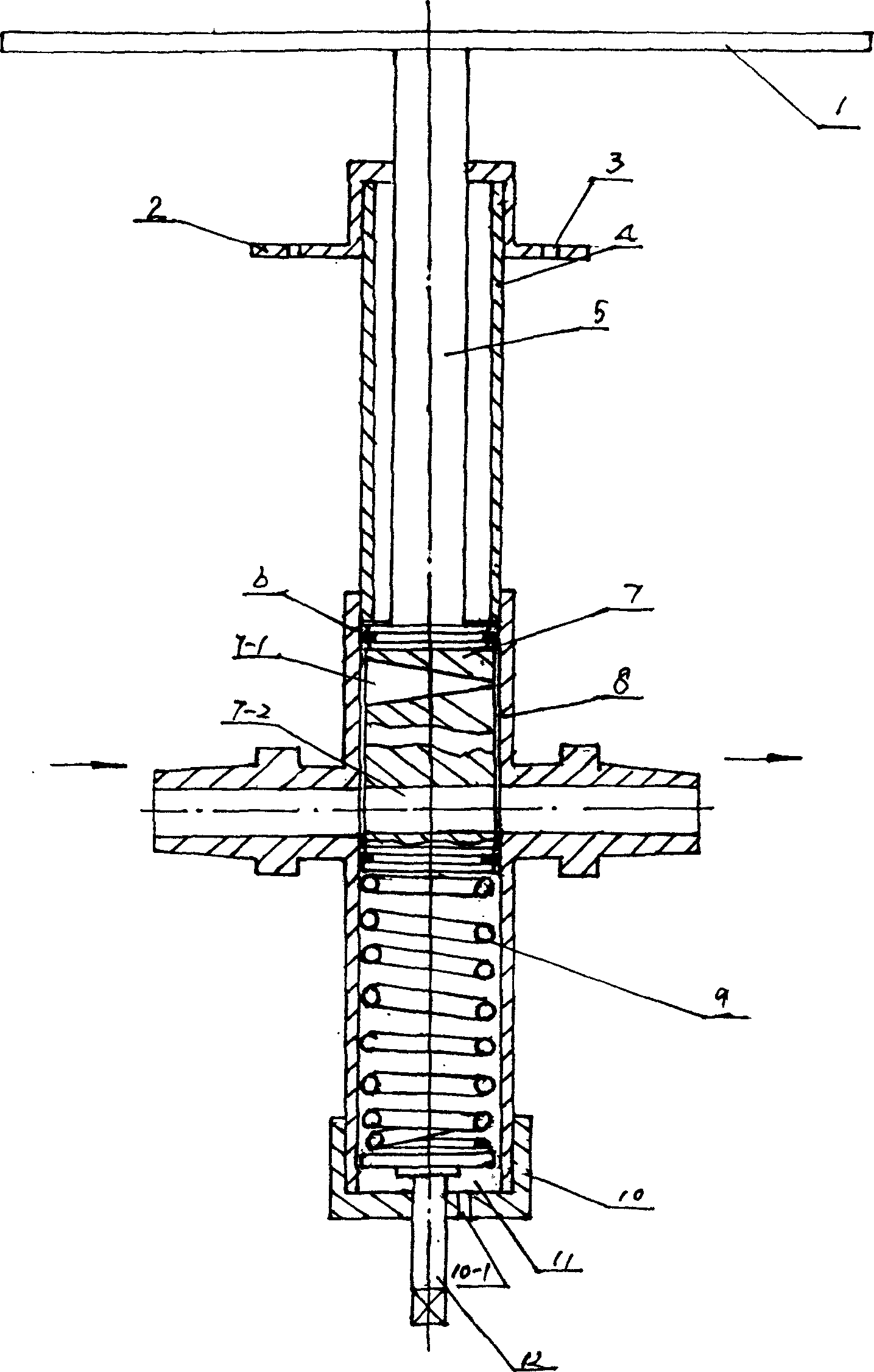

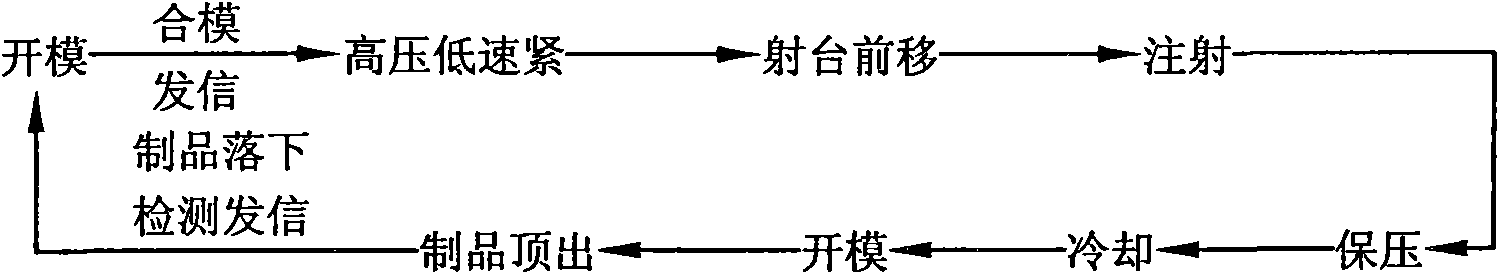

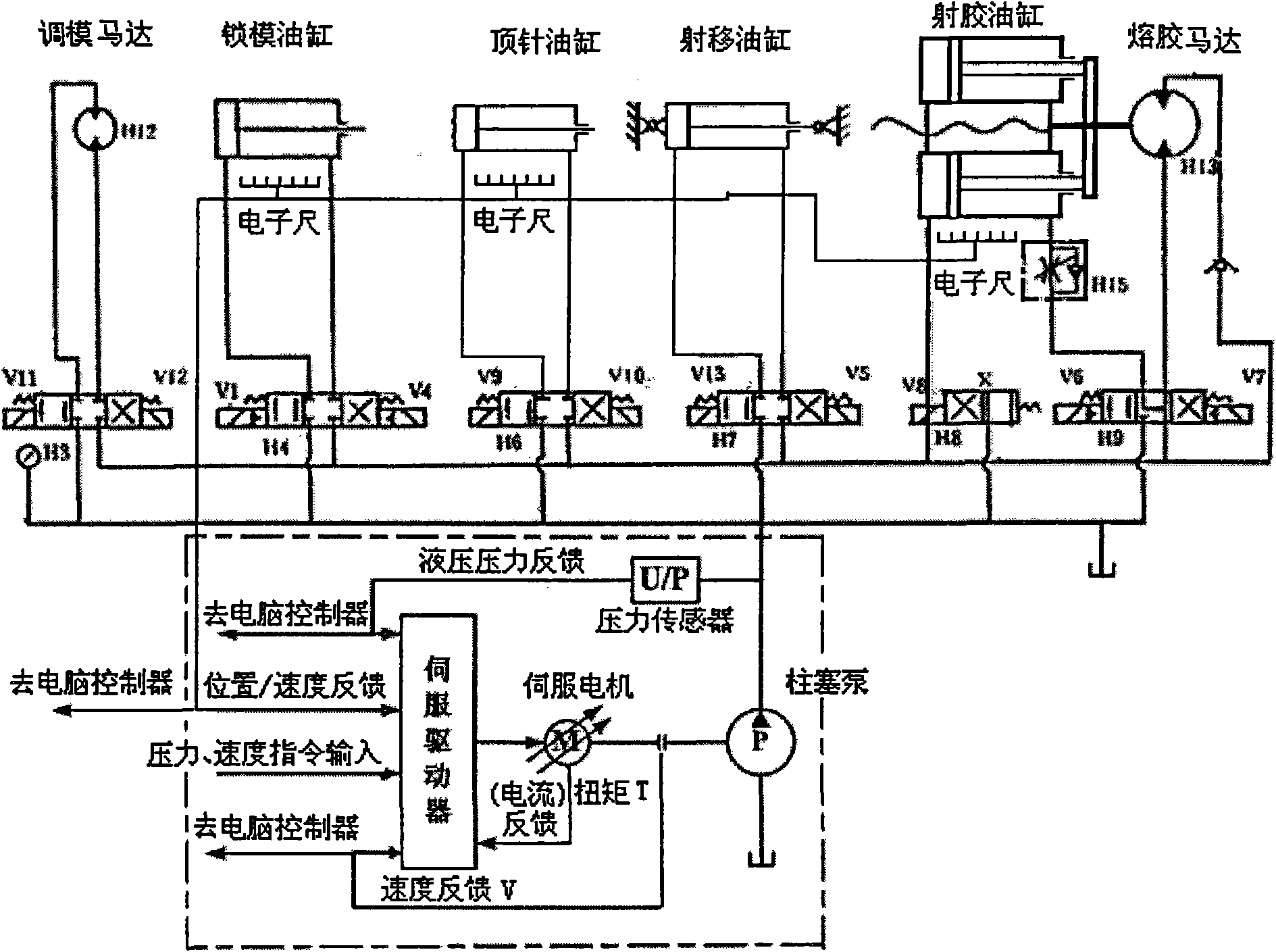

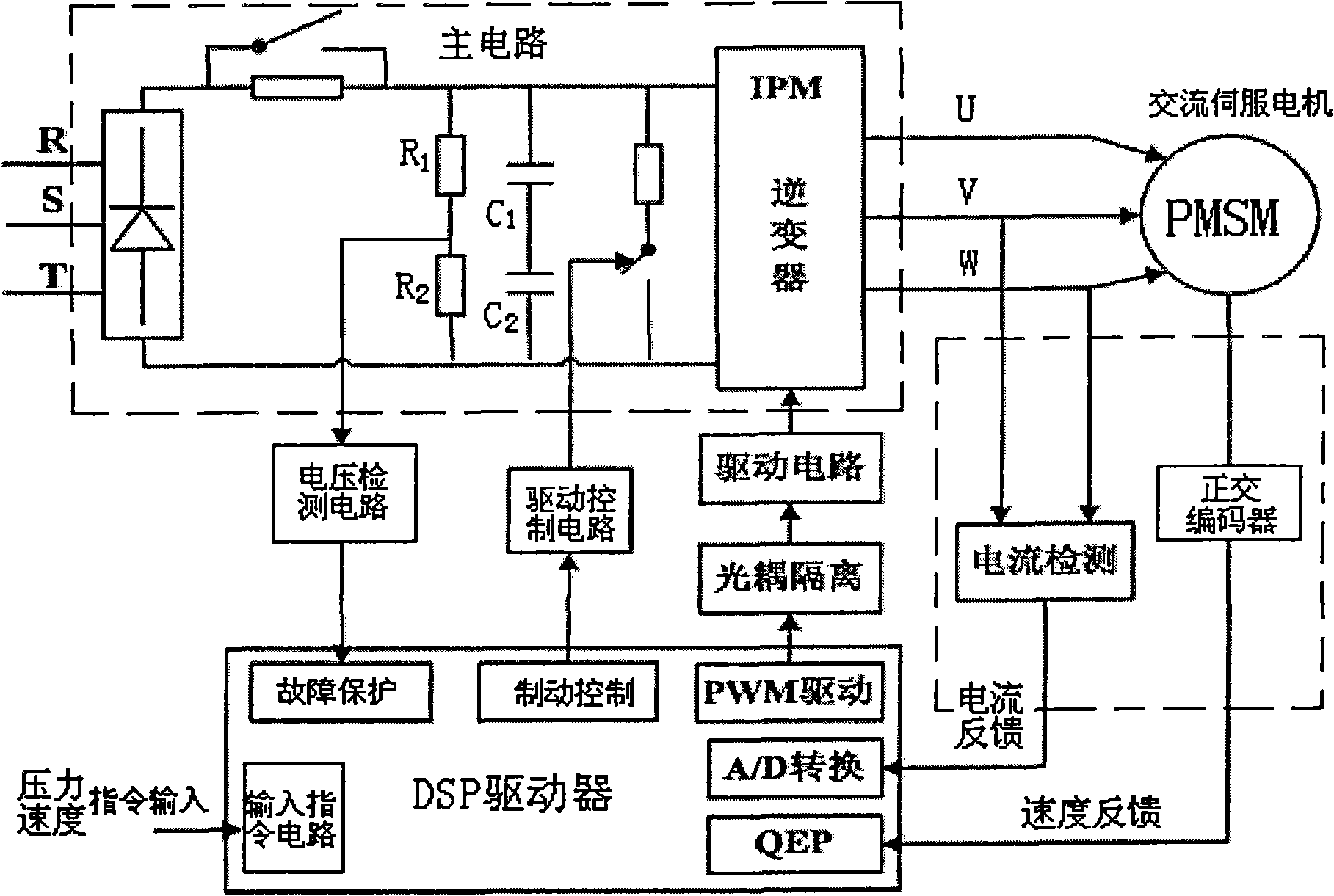

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

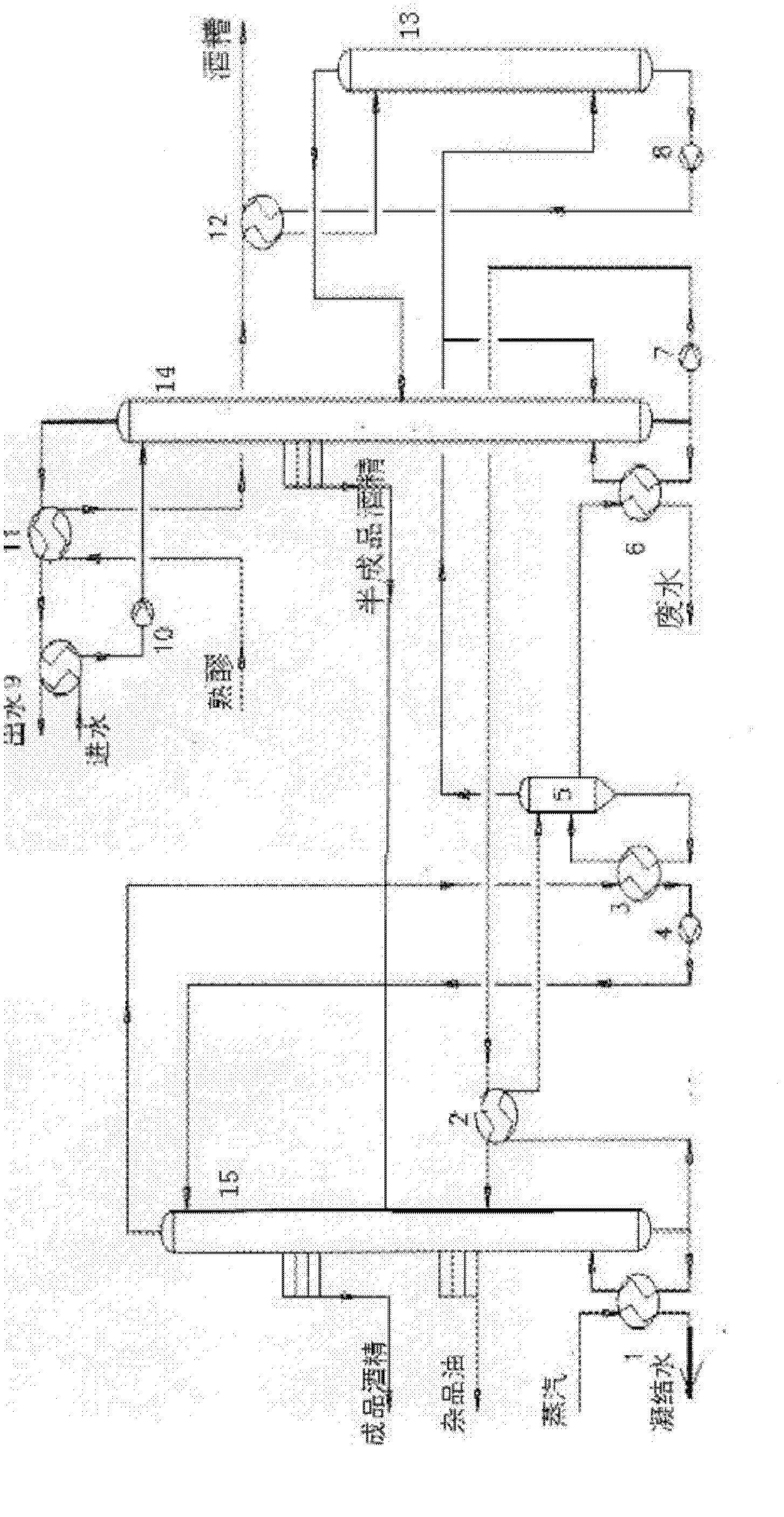

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

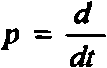

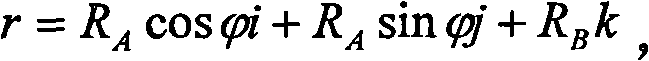

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

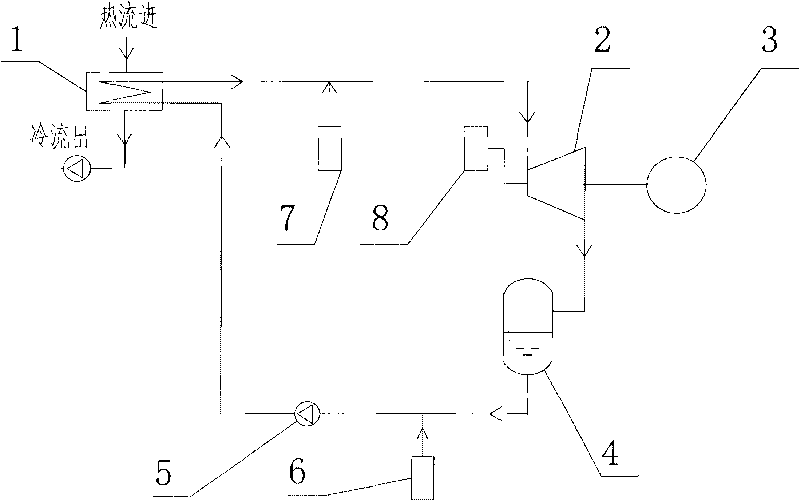

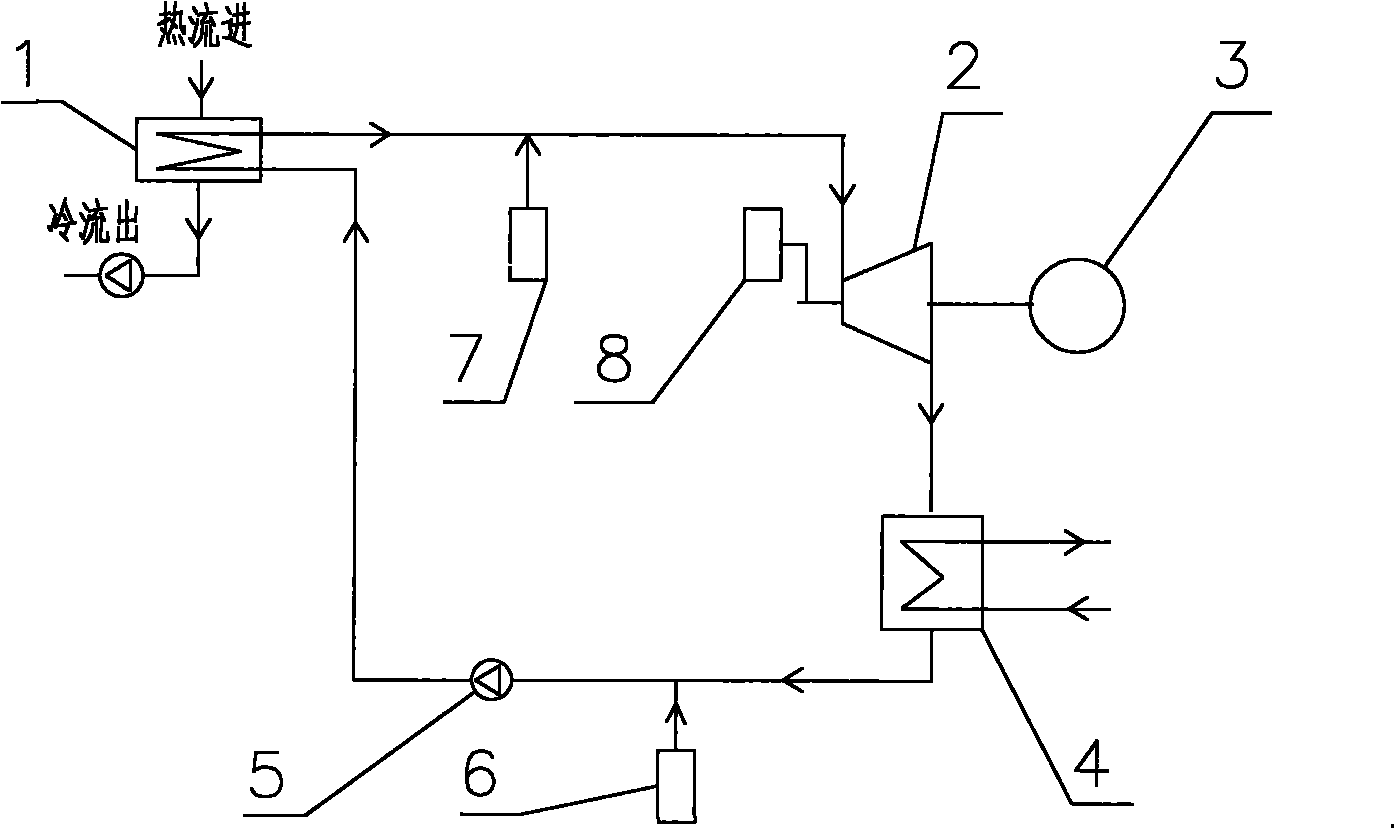

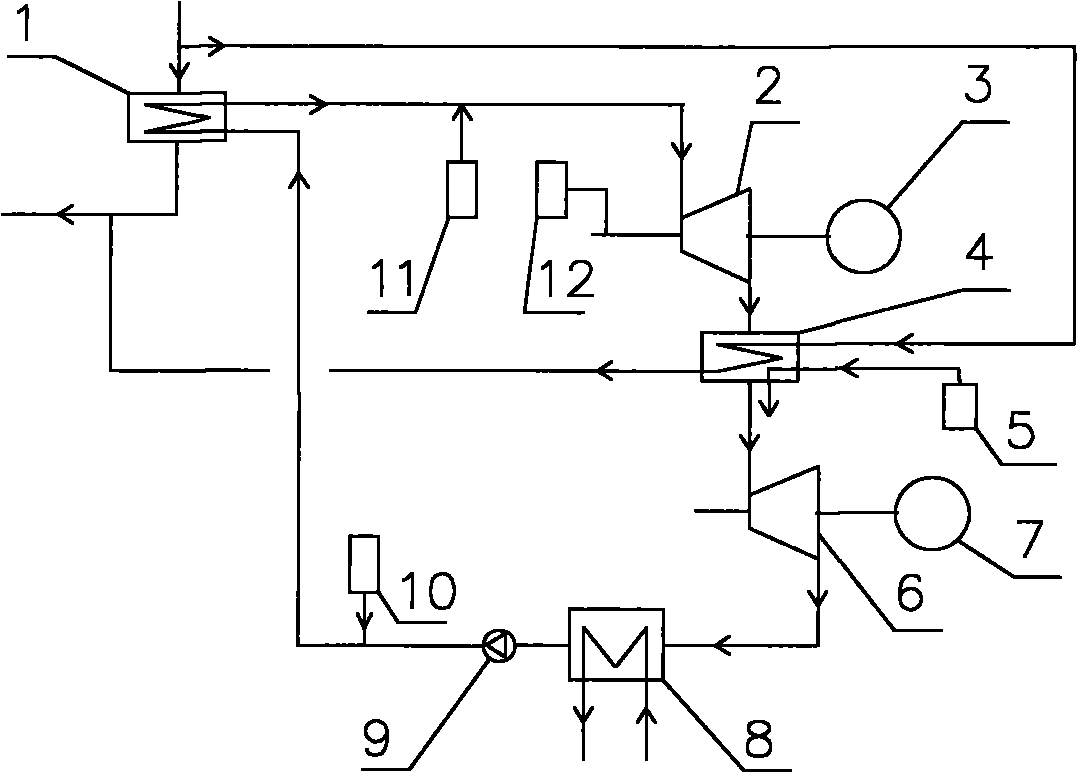

Low-grade heat flow prime motor, power generating system and method thereof

InactiveCN101761368AAlleviate power shortageReduce usageBlade accessoriesSteam engine plantsThermal energyHeat flow

The invention relates to a low-grade heat flow prime motor, a power generating system and a method thereof; the low-grade heat flow prime motor comprises a heat flow boiler unit, an expansion working unit and a pressing unit, after mediums with low boiling point pass through the heat flow boiler unit and exchange heat with the low-grade heat flow, the mediums enter in the expansion working unit to push moving parts to move, and then pressurization is carried out to lead the mediums with low boiling point to flow back to the heat flow boiler unit to form working circulation; the technical proposal provided by the invention is suitable for 30-400 DEG C of temperature range of the heat source, the pressure range is from positive pressure to negative pressure; therefore, the waste heat energy can be fully recovered and utilized, the heat source utilization efficiency is improved, the resources are saved and the environment is protected.

Owner:王世英

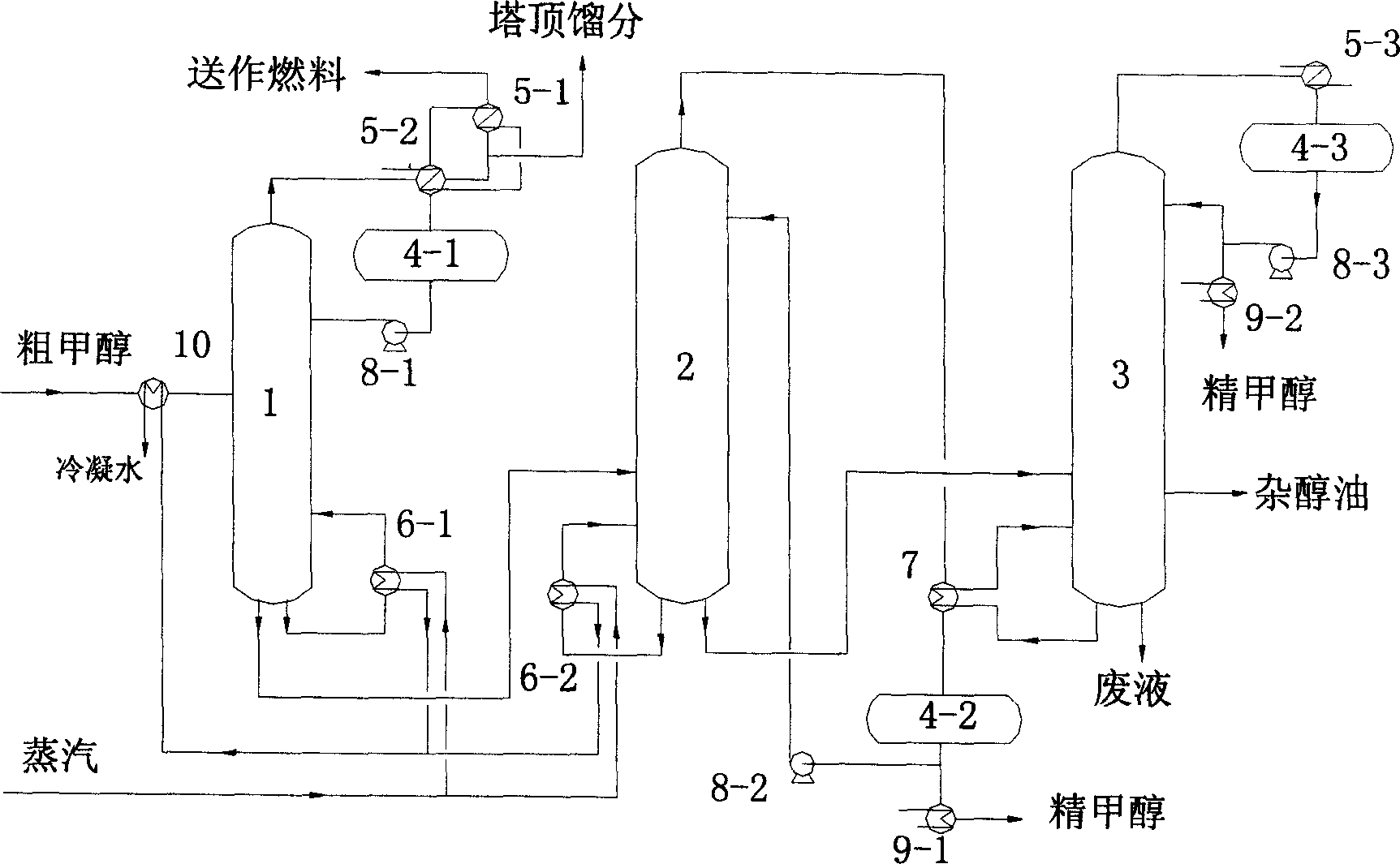

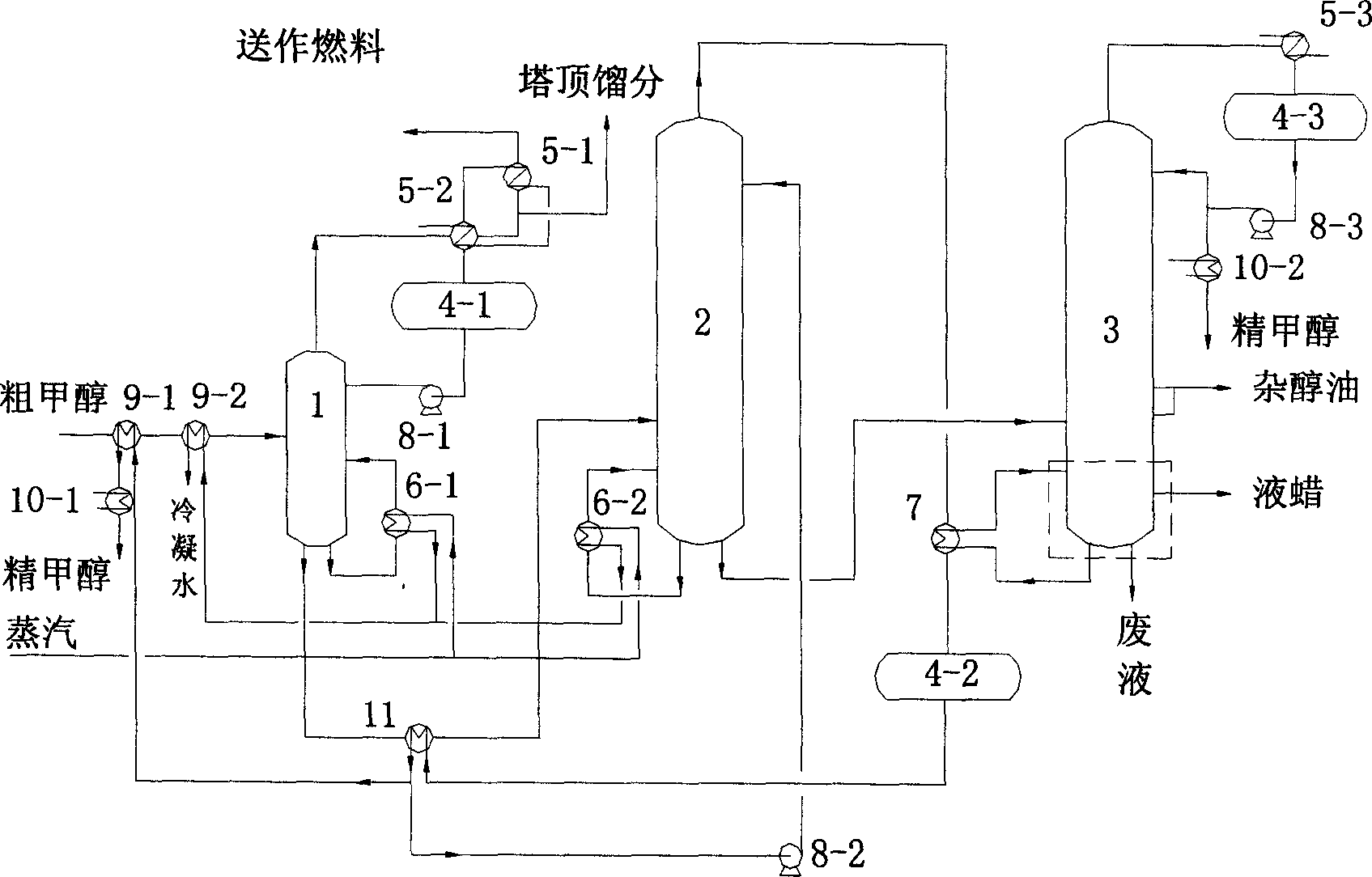

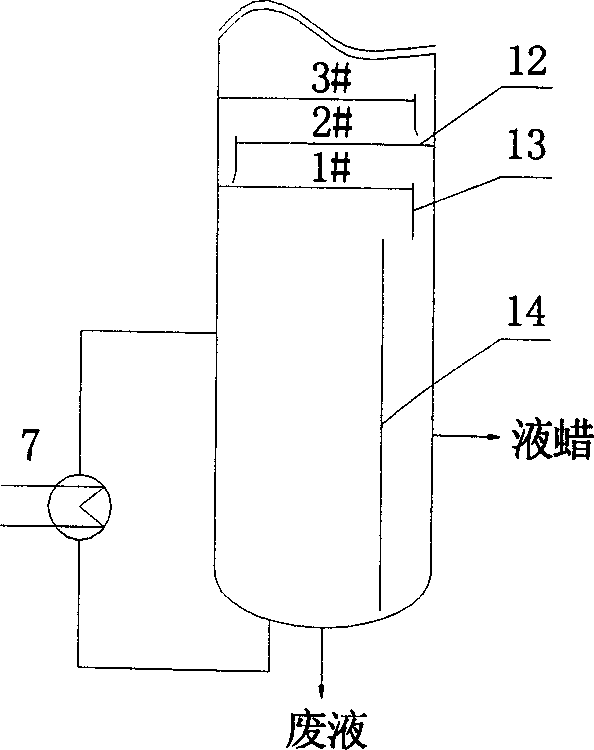

Rectifying tech. and equipment of high purity methanol

ActiveCN1861553ATo achieve the purpose of energy savingImprove product qualityOrganic chemistryReboilerProcess engineering

A rectifying apparatus for preparing high-purity (99.85%) methanol is composed of pre-rectifying tower, pressurizing tower, ordinary-pressure tower, condenser of reflux tank, re-boiler, reflux pump, pre-heater, and cooler. Its process is also disclosed. It features less consumption of energy and cooling water.

Owner:徐州友田生物科技有限公司

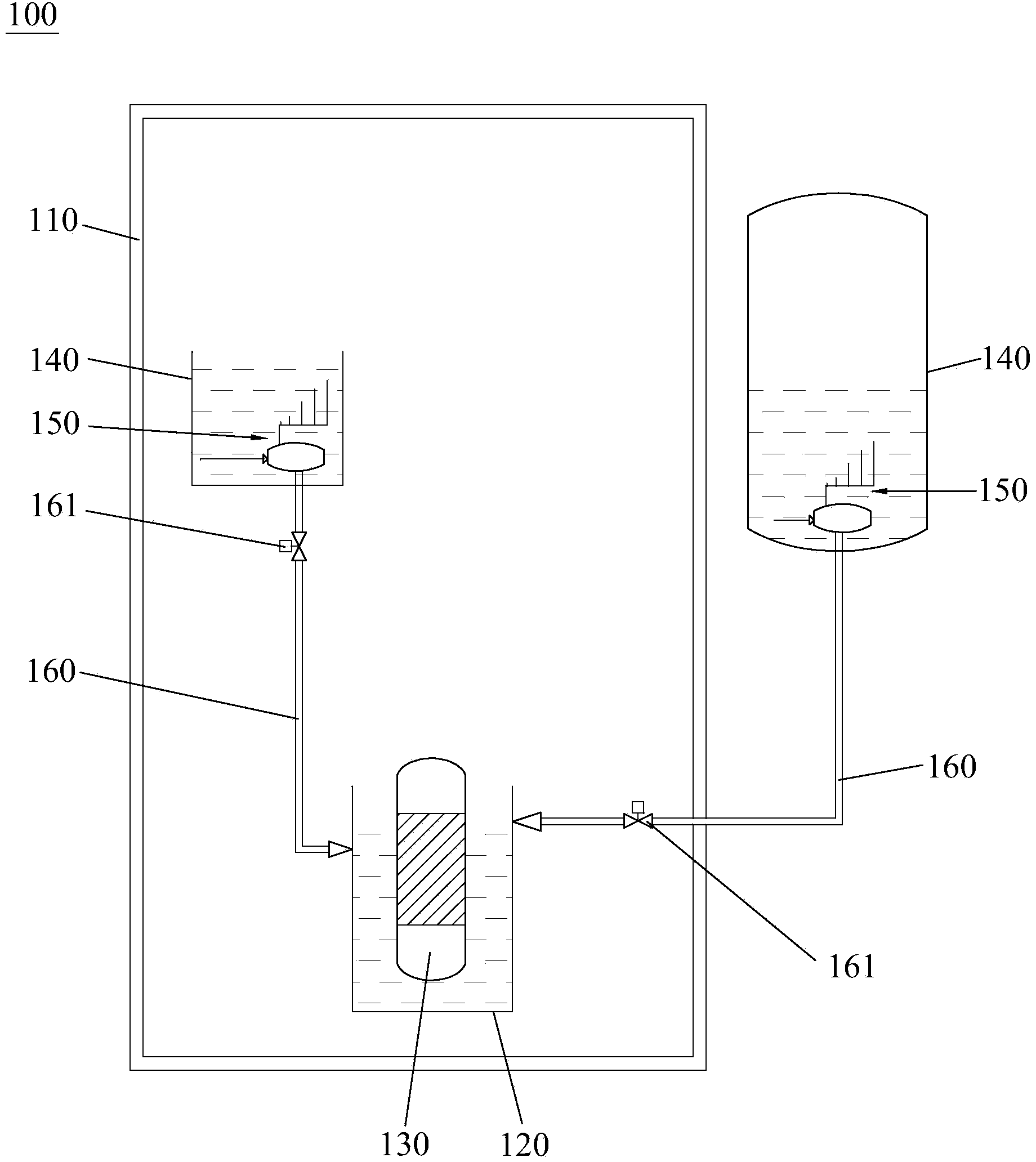

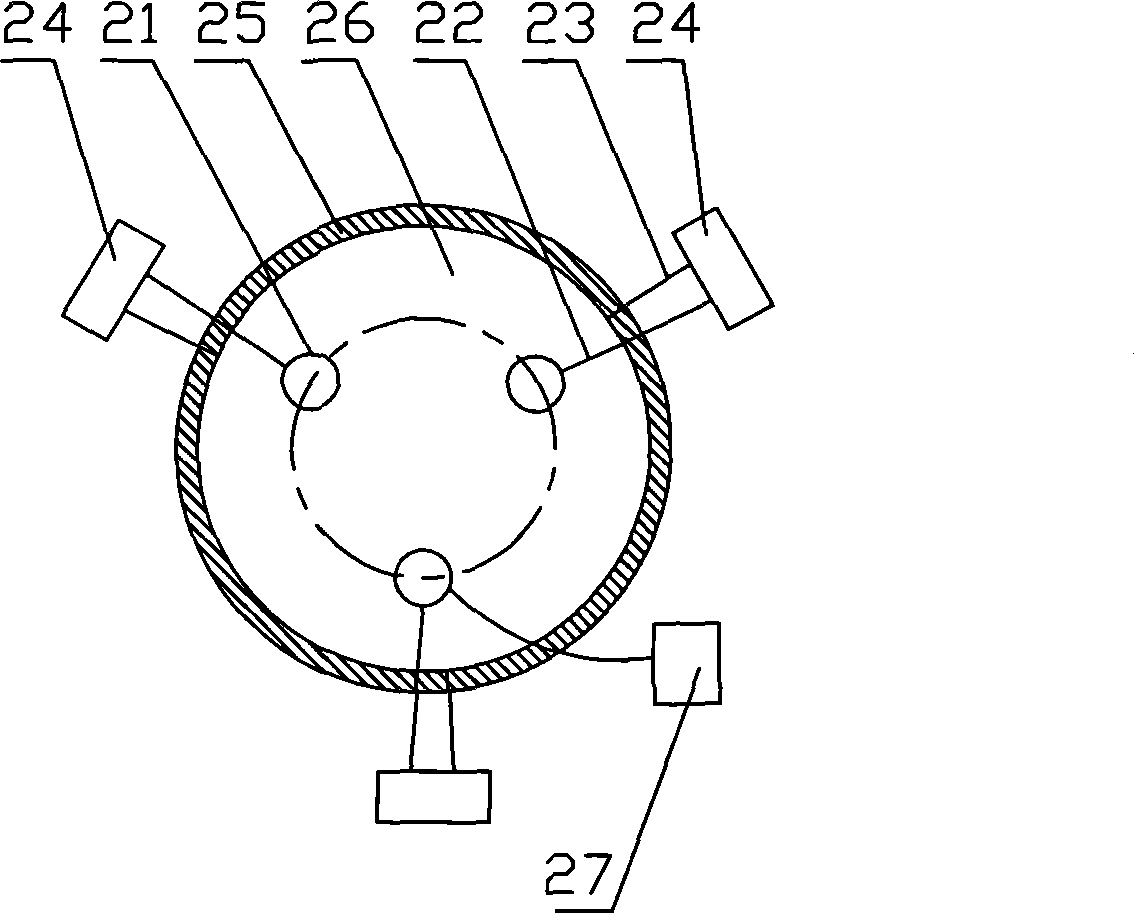

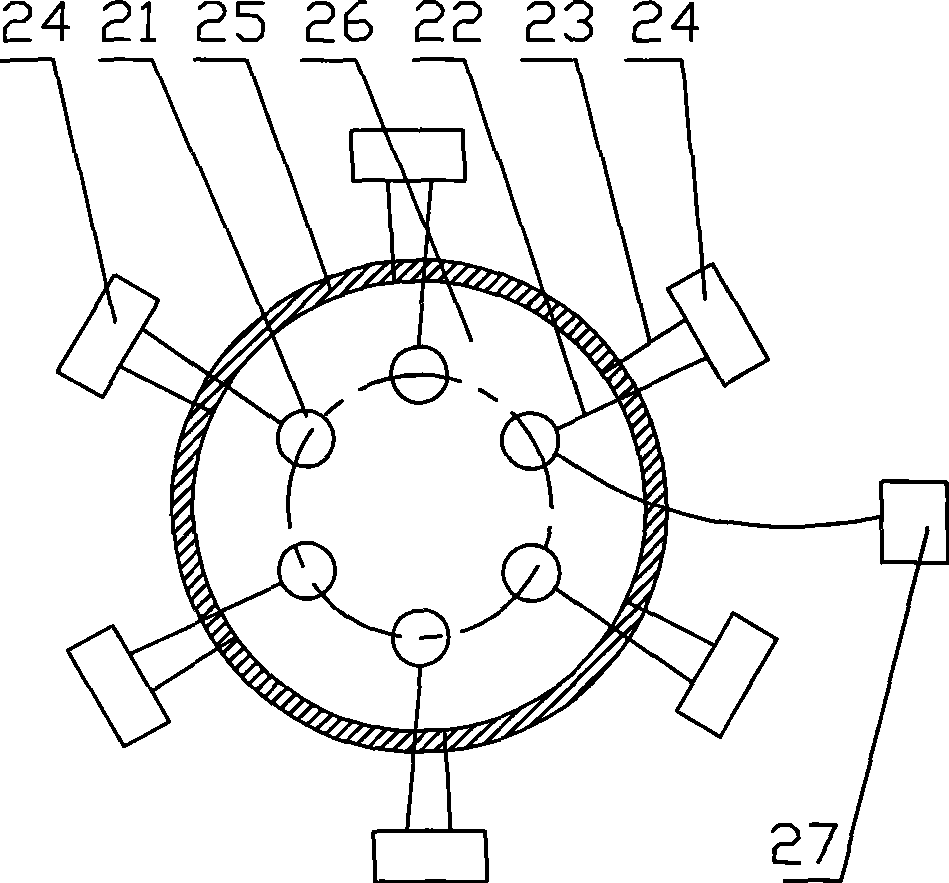

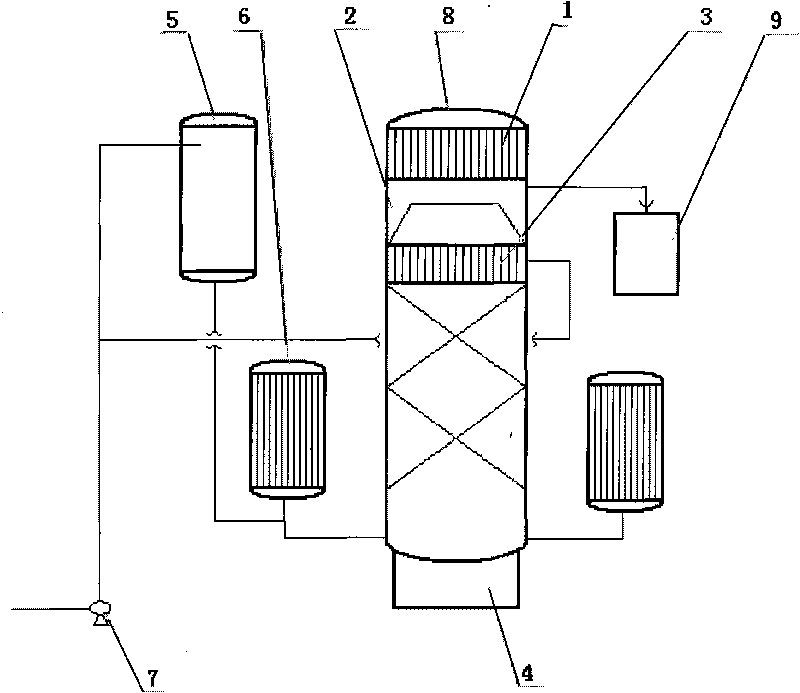

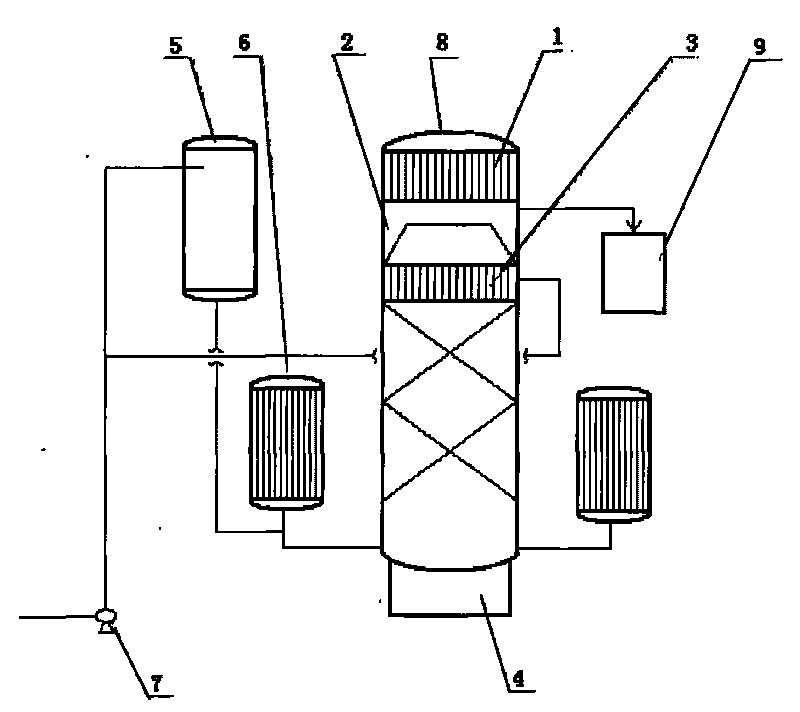

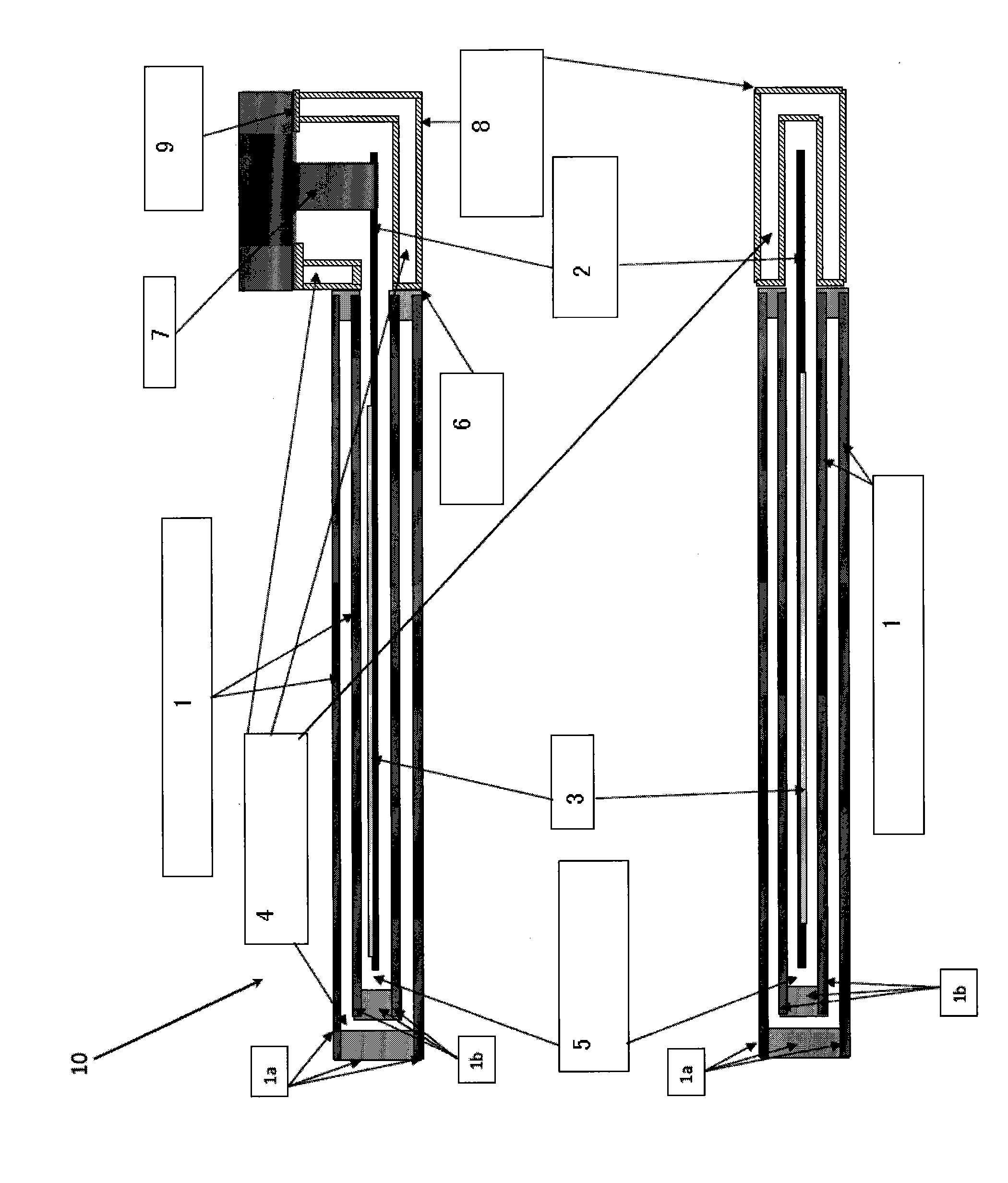

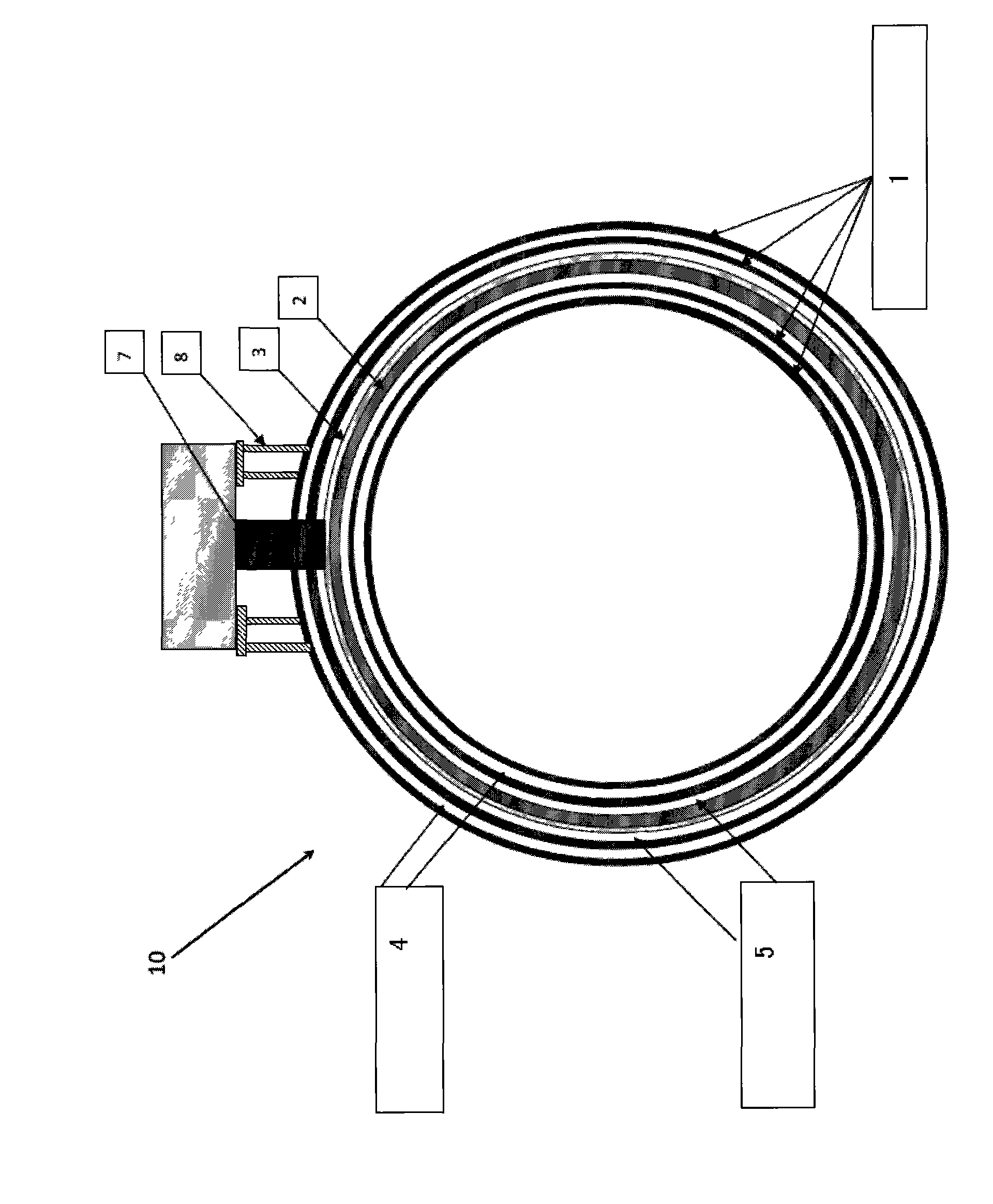

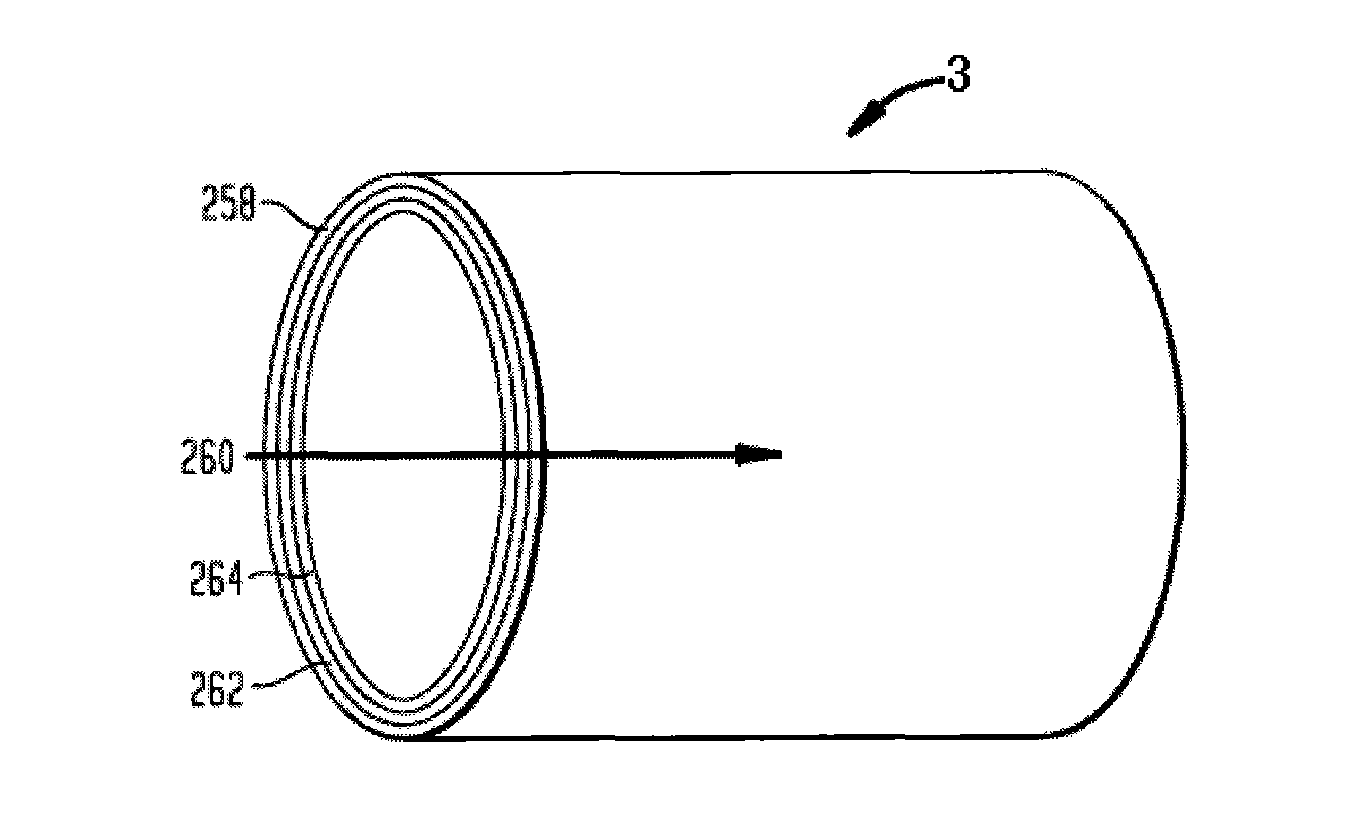

Passive self-flow control water injection system

ActiveCN104112482AAchieve retentionAutomatically adjust intensityNuclear energy generationCooling arrangementInjection pressureFlow resistivity

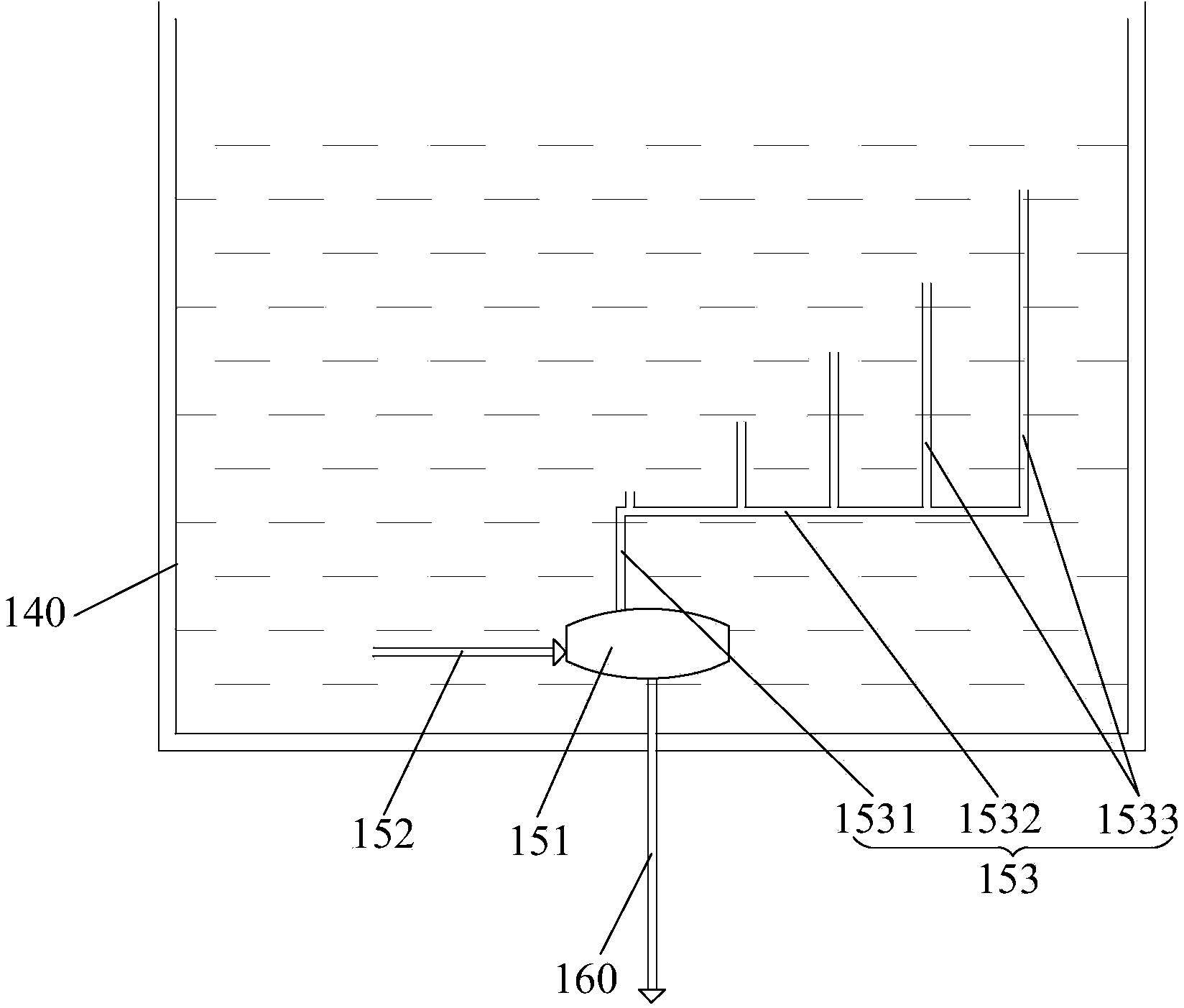

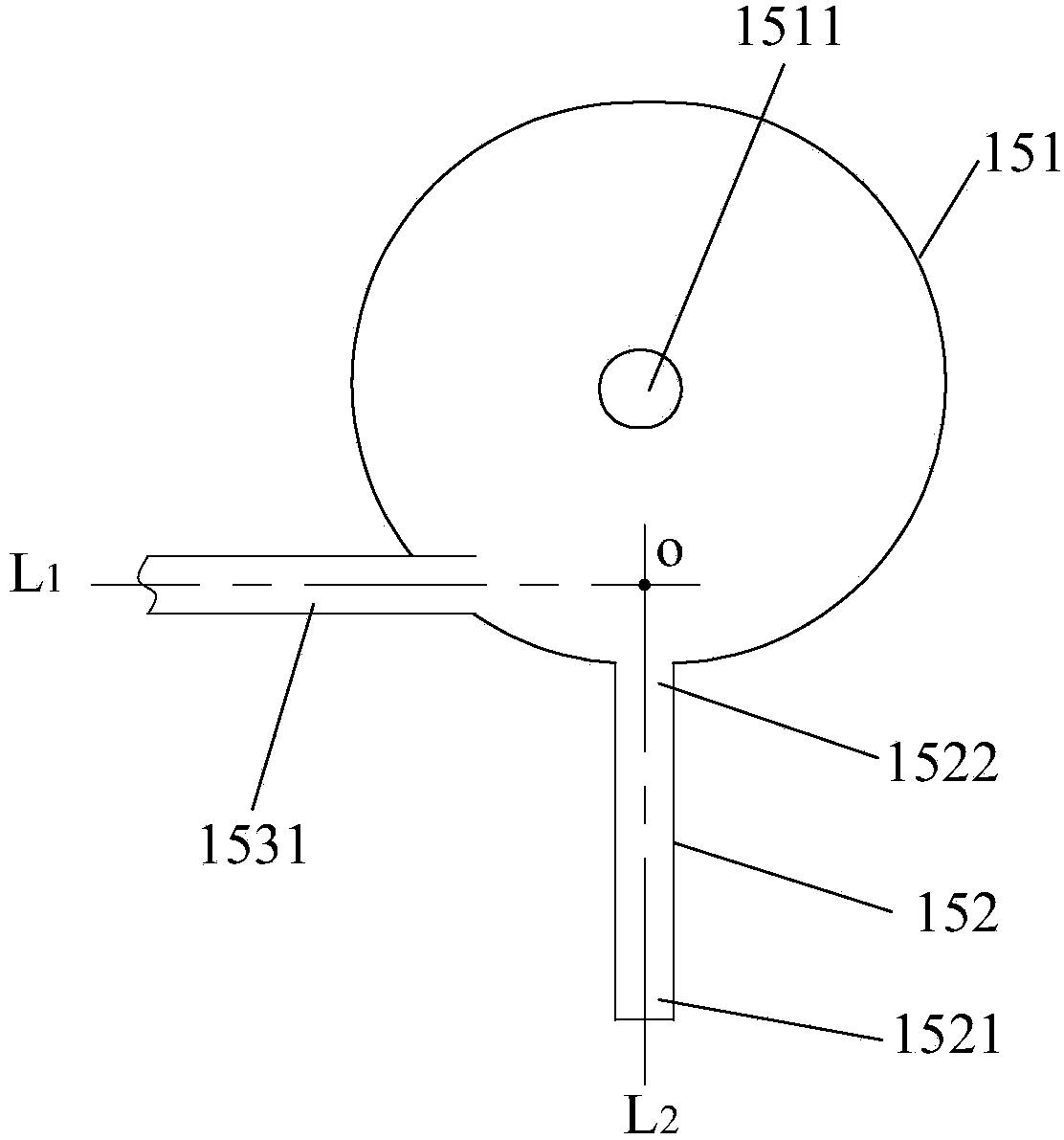

The invention discloses a passive self-flow control water injection system. The passive self-flow control water injection system comprises a safety injection tank, and a self-flow control device which is received in the safety injection tank and communicated with a reactor pit by use of a water outlet pipe; the self-flow control device comprises a volute chamber, and transverse pipe and vertical pipe assemblies; the volute chamber is of a hollow structure and an outlet is formed in the bottom of the volute chamber; the transverse pipe and vertical pipe assemblies are communicated with the hollow structure of the volute chamber, respectively; the positions in which the vertical pipe assemblies are communicated with the volute chamber and the position of the outlet of the volute chamber are arranged so that cooling water in the safety injection tank flows into the hollow structure of the volute chamber via the transverse pipe and the vertical pipe assemblies and then is swirled, and finally flows out via the outlet; the flow in the vertical pipe assembly is reduced as the liquid level in the safety injection tank is reduced, so that the tangential water flow in the volute chamber is gradually reduced; the intensity of vortex in the volute chamber is automatically regulated, and therefore, the flow resistance on an IVR (In-Vessel Retention) injection pipeline is kept relatively consistent with the variation trend of the injection pressure so that relatively stable injection flow in the entire time period can be ensured; besides, the utilization rate of water injected is increased and the passive self-flow control water injection system does not depend on external power.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

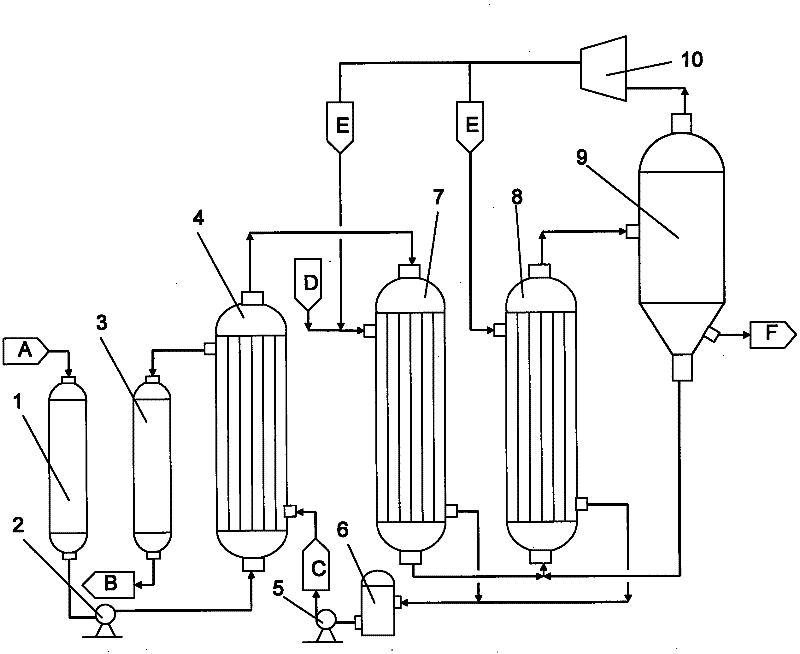

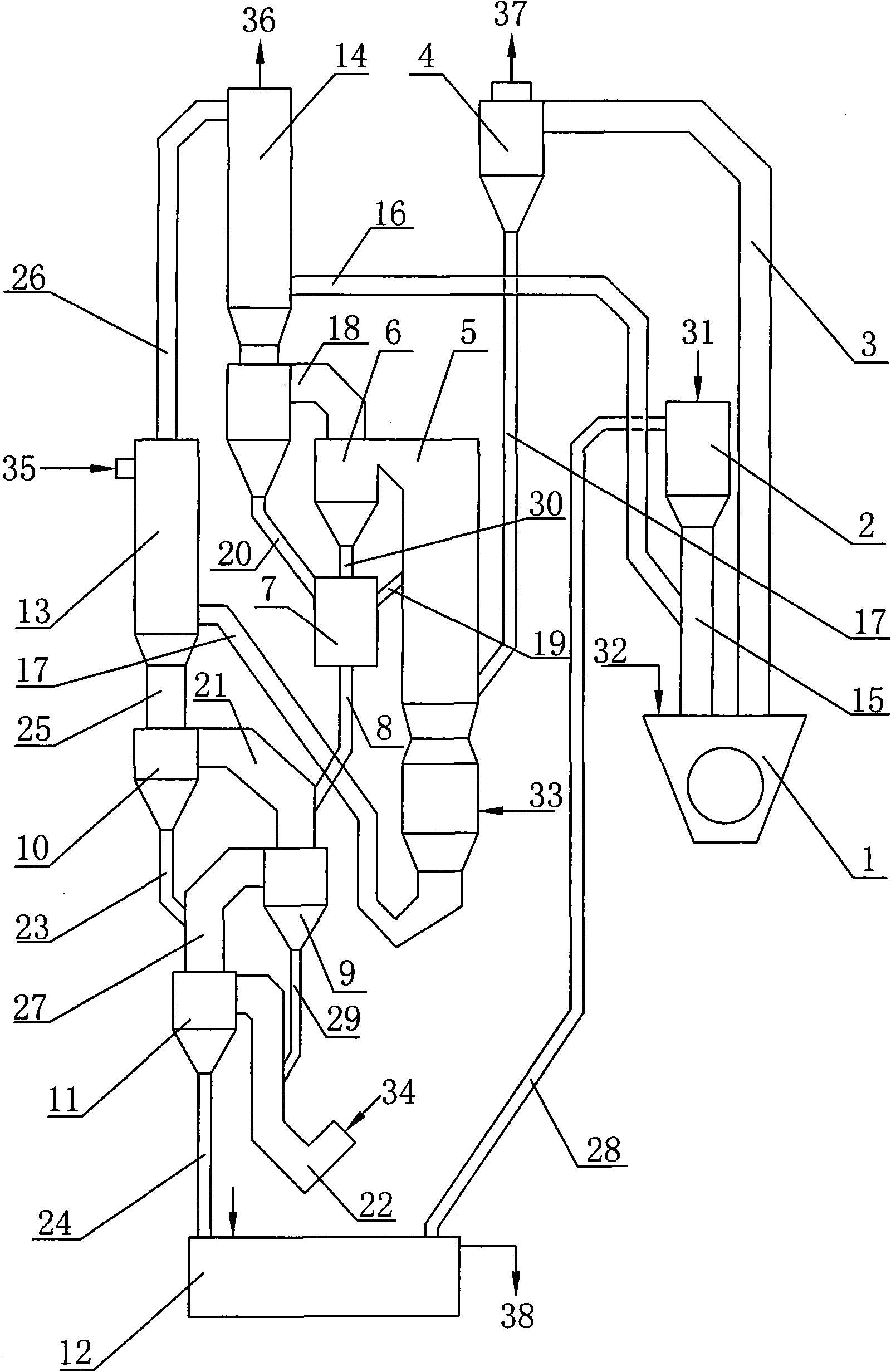

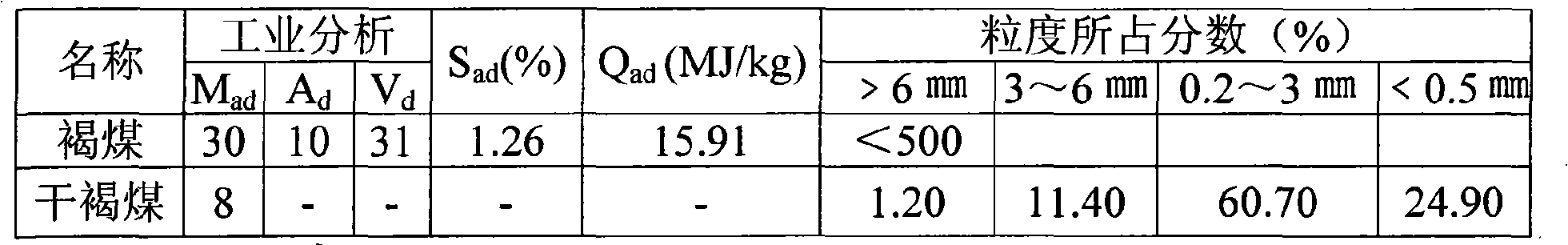

Process for preparing carbocoal, coke tar and coal gas by treating bovey coal by suspending pyrogenation device

ActiveCN101289621ASave spaceIncrease productivityDirect heating destructive distillationHeat carrierGas cooler

The invention relates to a gas heat carrier brown coal suspension pyrolysis device, and adopts the following process: brown coal is fed in a hammer type drier for crushing and drying with the drying temperature lower than 400 DEG C, and then is fed in a suspension pyrolysis oven at 110 to 130 DEG C to generate semicoke and tar gas mixed gas; when separated by a first pyrolysis cyclone separator, the tar gas mixed gas is fed in oil gas cooling gas and is discharged after cooling; semicoke is fed in a detention tank; after pyrolysis reaction and quenching coke through a three-stage quenching coke system, the semicoke is fed in a semicoke cooler and then is fed in a storage yard after cooling; quenching coke gas is fed in an oxygen source heater to cool down oxygen source gas, and then is fed in an oil gas cooler as cooling medium to cool down tar gas mixed gas. Compared with the prior process, the gas heat carrier brown coal suspension pyrolysis device reduces land occupation, investment and labor force, and has uniform thermal transmission, fast speed and high output capacity of tar and coal gas; moreover, the pyrolysis device improves the flammable characteristics of semicoke product and is convenient for safe storage and transportation; in addition, the pyrolysis device has the advantages of lower heat consumption, higher output capacity of semicoke, tar and coal gas and cooling water conservation, etc.

Owner:SHENYANG XINBO IND TECH

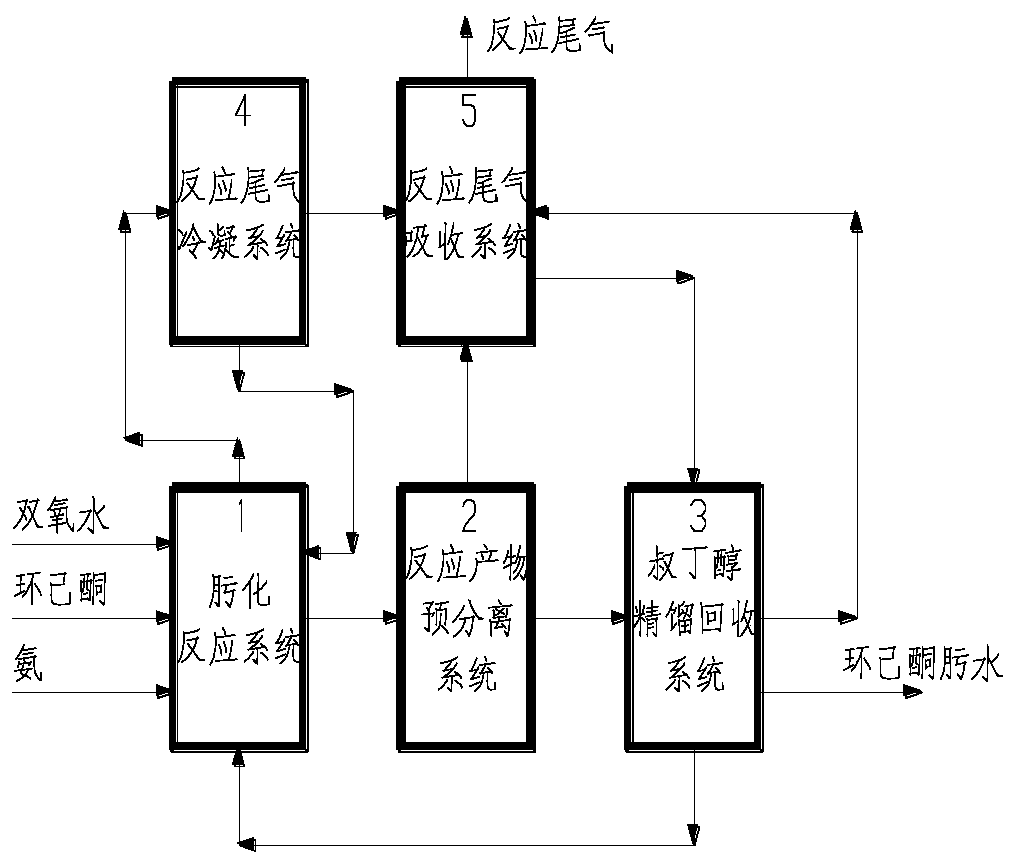

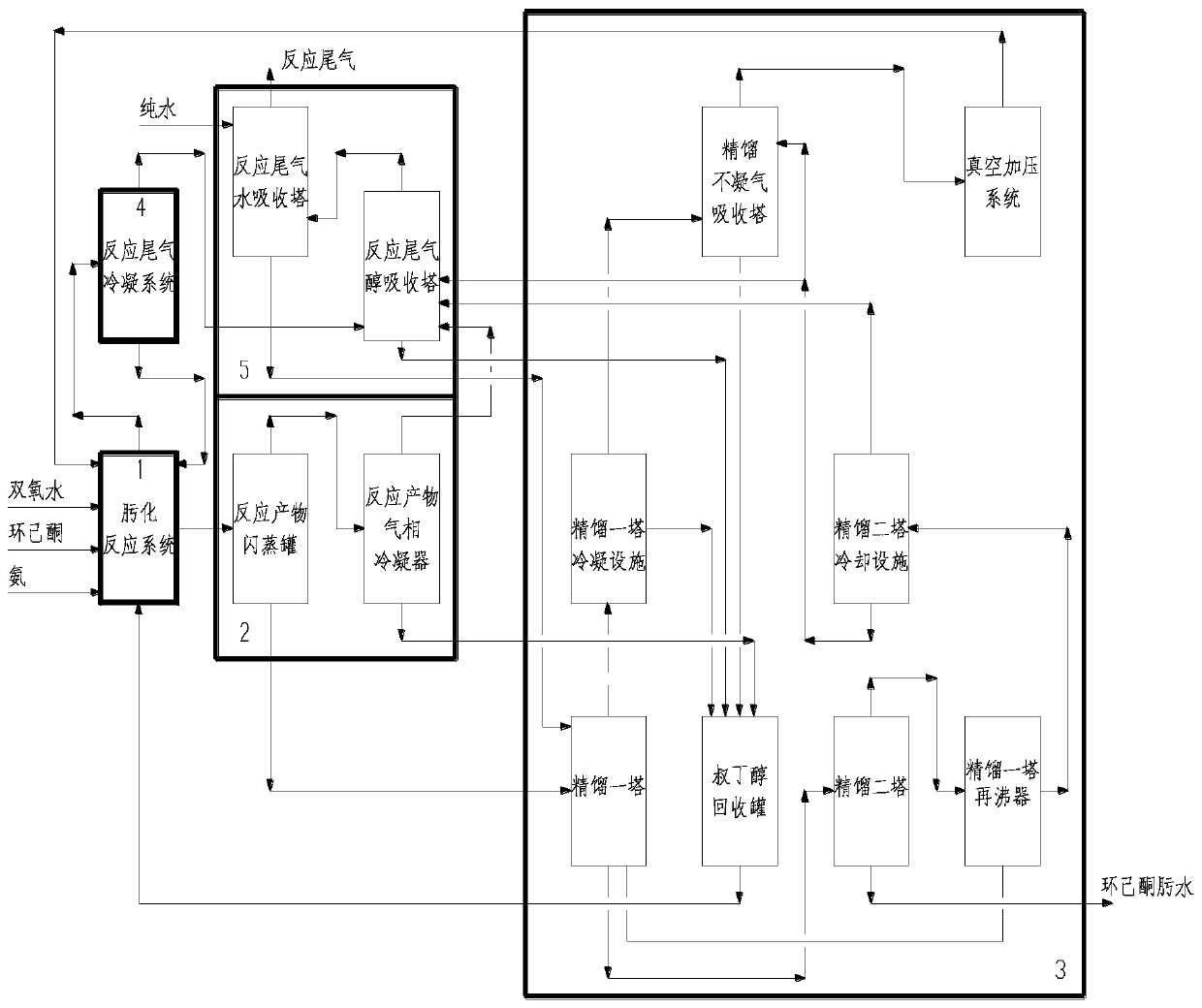

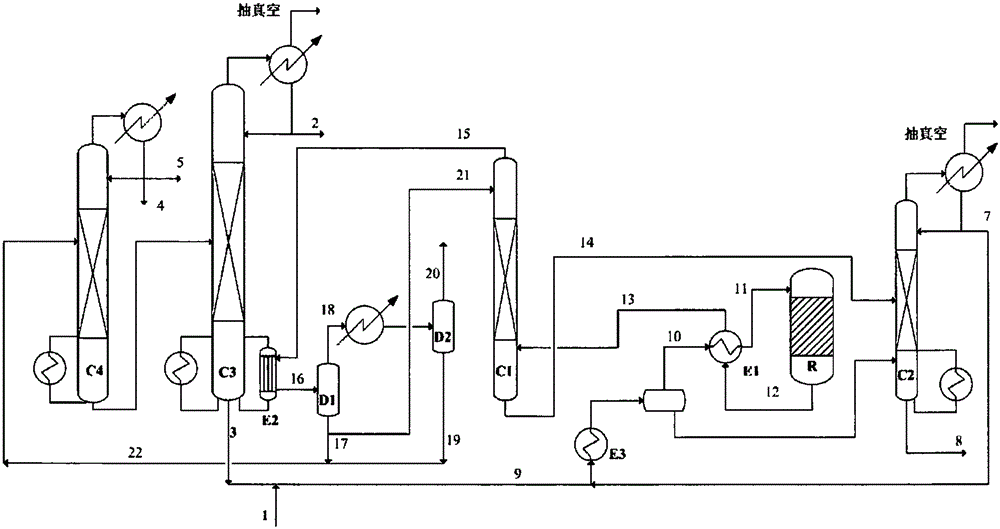

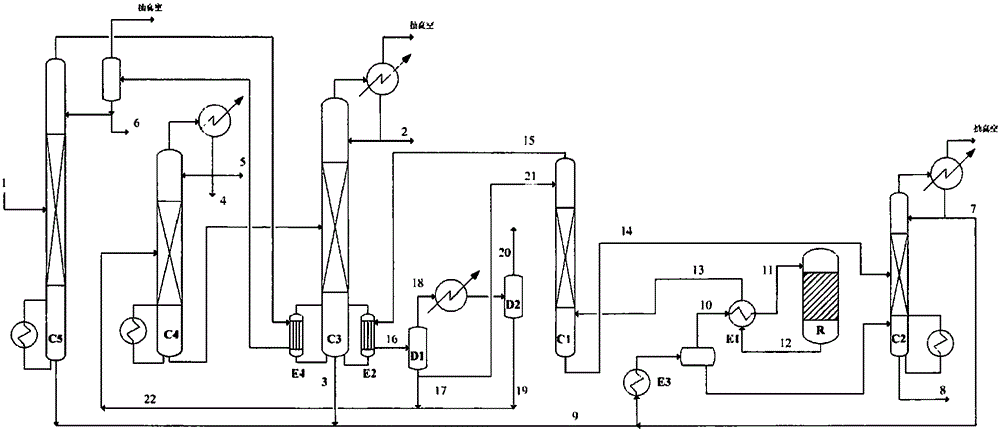

Device and method for recovering ammonia and tert-butyl alcohol in cyclohexanone ammoximation production process

PendingCN111302899AReduce dosageEasy to handleGas treatmentGeneral water supply conservationCyclohexanone oximeChilled water

The invention discloses a device and a method for recovering ammonia and tert-butyl alcohol in a cyclohexanone ammoximation production process. The device consists of an oximation reaction system, a reaction product pre-separation system, a tert-butyl alcohol rectification recovery system, a reaction tail gas condensation system and a reaction tail gas absorption system. According to the invention, the reaction tail gas absorption system adopts two-stage absorption of tert-butyl alcohol and water, so that the desalted water amount for absorption is greatly reduced, the ammonia, tert-butyl alcohol and water amount to the tert-butyl alcohol rectification recovery system are reduced, the water amount in the cyclohexanone-oxime aqueous solution is reduced, and the toluene circulation amount and energy consumption of a downstream cyclohexanone-oxime refining system are favorably reduced; the reaction product pretreatment system is arranged, so that the treatment load of the tert-butyl alcohol rectification recovery system can be reduced, and the condensation effect of the rectification tower I is improved; double-effect rectification is adopted in the rectification recovery system, anda condensation, absorption and vacuum pressurization combined process is adopted in rectification of non-condensable gas, so that the vacuum load and chilled water consumption are reduced; and the steam consumption can be saved by 40-50%, the cooling water consumption can be reduced by 35-50%, the chilled water consumption can be reduced by 10%, the desalted water consumption can be reduced by more than 50%, the treatment load of related facilities can be reduced, and the energy can be saved.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

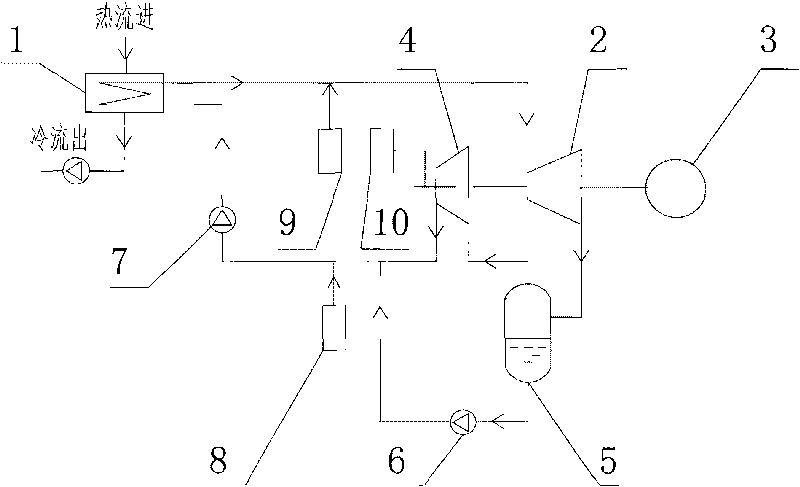

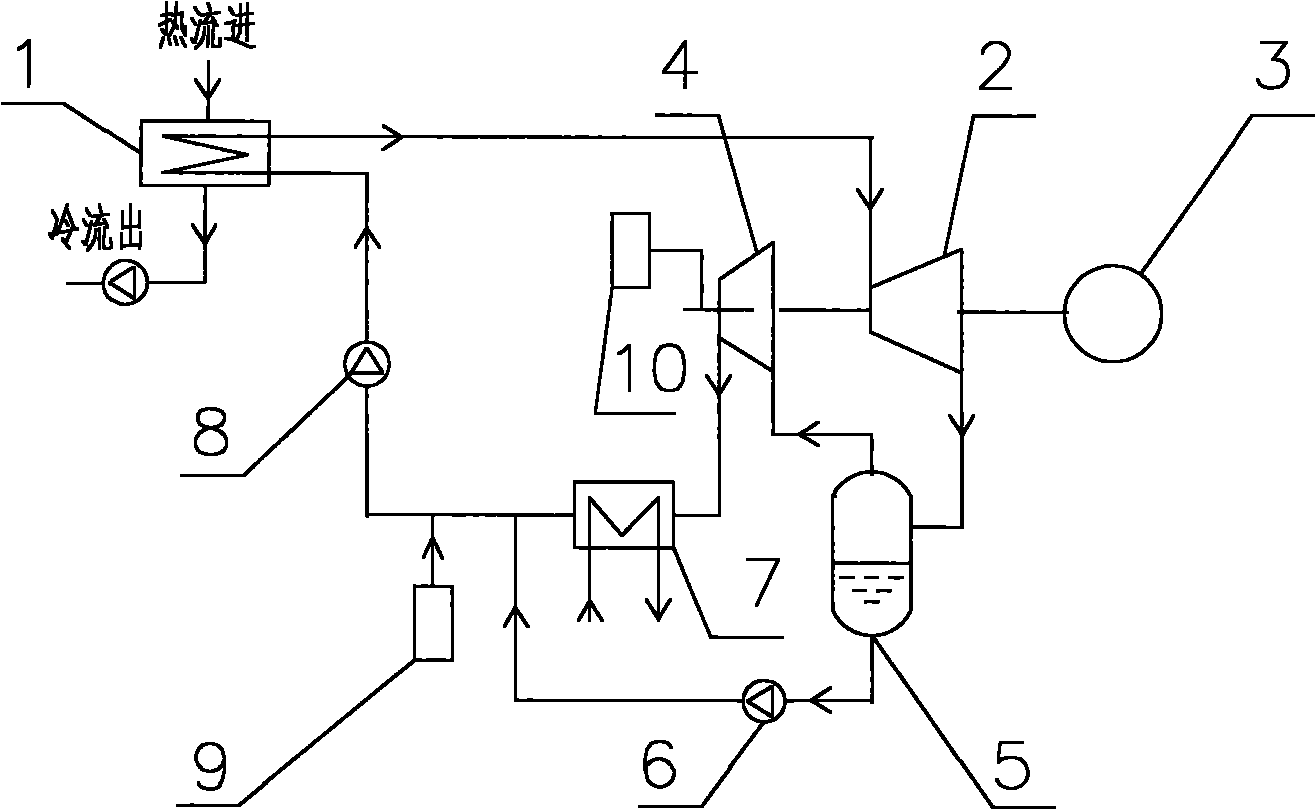

Low-grade heat-flow prime mover, generating system and method thereof

InactiveCN101988397AAlleviate power shortageReduce usageGas turbine plantsSteam engine plantsThermal energyPositive pressure

The invention relates to a low-grade heat-flow prime mover, a generating system and a method thereof. The prime mover comprises the following working units, i.e. a heat-flow boiler unit, an expansion power unit, a liquefying unit and a pressurization unit, wherein the heat-flow boiler unit comprises a heat-flow boiler which uses a low-grade heat flow as a heat source without heat provided by fuel, a medium with a low boiling point is adopted to pass through the working units for working circulation, and the expansion power unit is provided with a power output shaft which drives a generating unit to form a generating system or drive the working unit so as to fully recycle and utilize castoff heat energy, improve the utilization rate of the heat source, save resources and protect the environment. The technical scheme provided by the invention is suitable for a heat source temperature range of 40-200 DEG C and a pressure range from positive pressure to negative pressure.

Owner:王世英

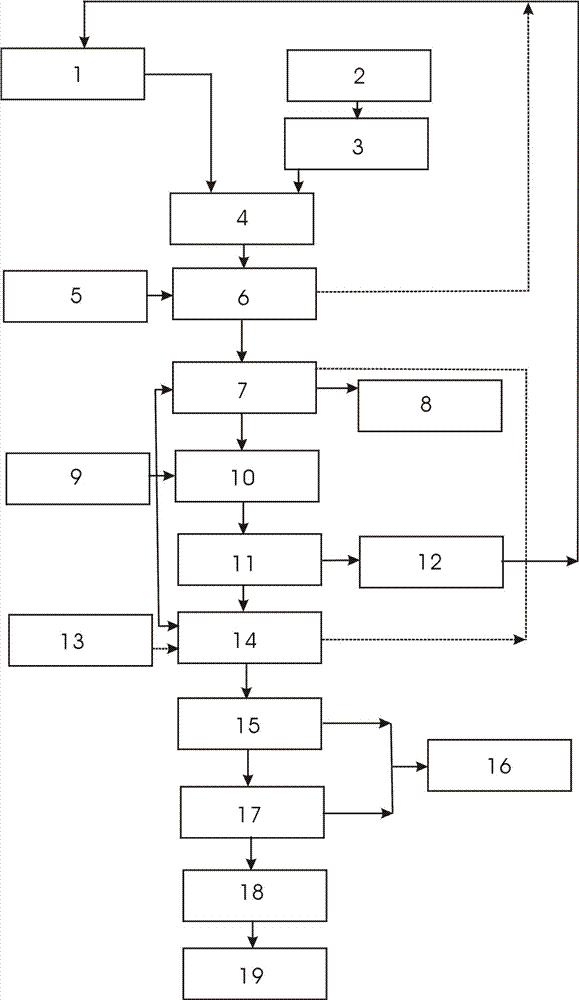

Method for producing high purity 2-hydroxy-3-naphthoic acid

ActiveCN102816063AEasy to handleImprove stabilityCarboxylic compound separation/purificationDistillationCarbonization

Disclosed is a method for producing a high purity 2-hydroxy-3-naphthoic acid. The method includes a 2-naphthol measuring tank, a caustic soda liquid storage tank, a caustic soda liquid measuring tank, a salt forming reaction vessel, carbon dioxide, a carbonization kettle, a resin separation, a resin solid waste, a dilute sulfuric acid, a neutralization, a filter pressing, a filter cake distillation, a 8% sodium hydroxide, a resin adsorption, an acid eduction, a sewage treatment workshop, a centrifugal dewatering, a pneumatic drying and finishing of a high purity 2-hydroxy-3-naphthoic acid product. The caustic soda liquid storage tank is downwards connected to the caustic soda liquid measuring tank, the caustic soda liquid measuring tank is connected to the salt forming reaction vessel, the salt forming reaction vessel is downwards connected to the carbonization kettle, simultaneously the carbon dioxide is connected to the carbonization kettle, 2-naphthol generated by reaction in the carbonization kettle and 2-naphthol obtained by the filter cake distillation are connected to the 2-naphthol measuring tank, the carbonization kettle is downwards connected to the resin separation, and simultaneously the resin separation is upwards connected to an ethyl naphthol feed liquid and the dilute sulfuric acid and downwards connected to the neutralization and the resin solid waste. According to the method, the whole process is simple, the operation and the usage are convenient, the stability is good, and the reliability is high.

Owner:山东世纪阳光科技有限公司

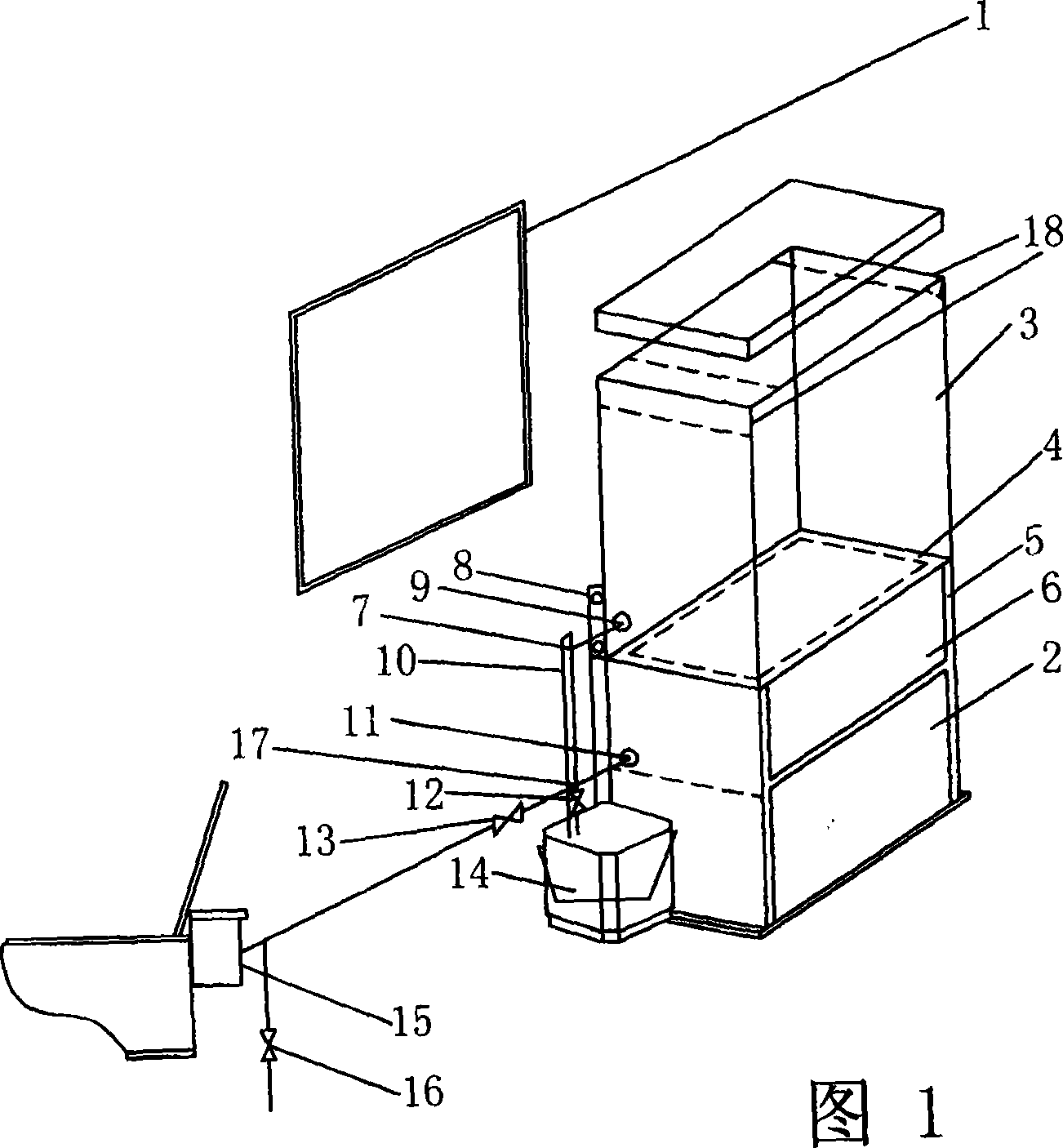

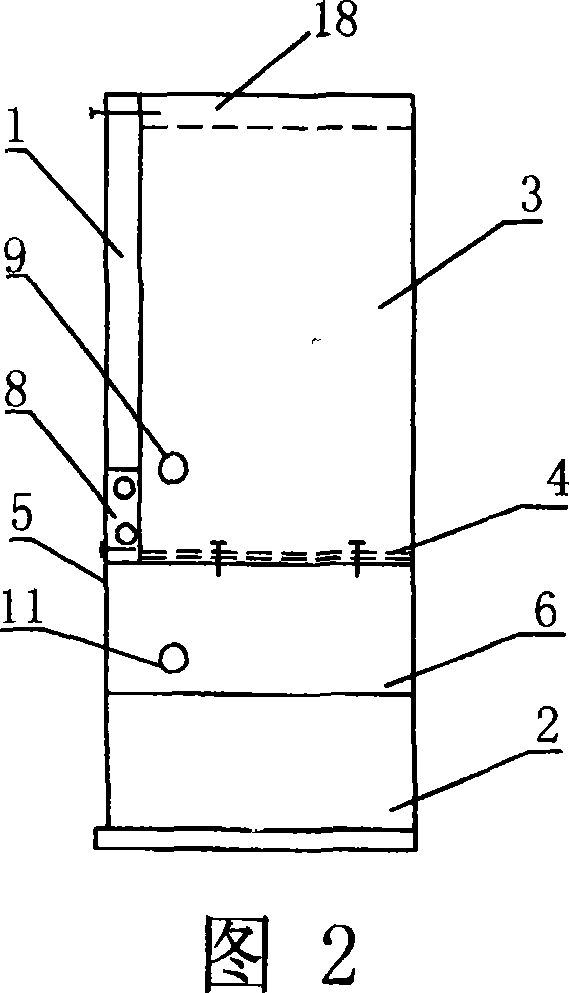

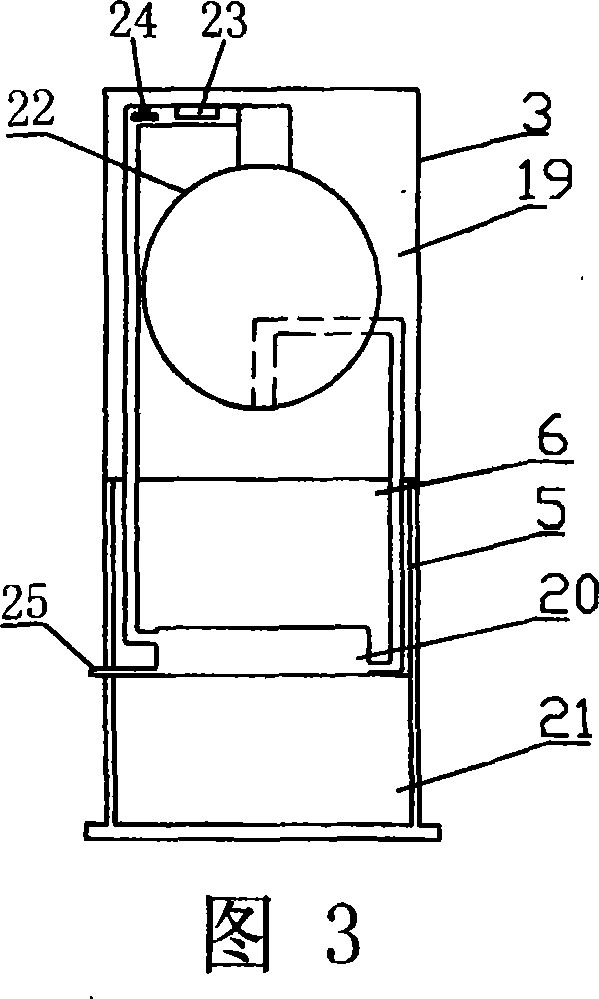

Washing machine drier with condenser set in waste water collecting tank

InactiveCN101050591ASave cooling waterImprove drying efficiencyOther washing machinesWashing machine with receptaclesCisternFlush toilet

The present invention discloses a washing clothes dryer whose condenser is placed in the washing waste water collection tank. It is characterized by that under the forwards door-opening type cylinder washing machine an anti-corrosive and shock-proofing box-type base seat is set, its height exceeds that of flush toilet cistern, a washing waste water collection tank with clothes-drying system condenser is mounted in the upper portion of said box-type base seat interior, said cylinder washing machine and box-type base seat are connected and fixed together by means of fastening components.

Owner:李武

Process waste water discharging free method for the production of furfural

InactiveCN1629151ASave cooling waterReduce the amount of acidOrganic chemistryWater/sewage treatment by heatingChemistryDistillation

The invention discloses a novel method for eliminating waste water discharge during furfural production which comprises, collecting waste liquid exhaust on the distillation tower bottom during furfural production, introducing the waste liquid into a heat exchange pool as cooling liquid, wherein the condensed furfural gas is located in the condensation pipe, heating and condensating the tower bottom waste liquid and charging into the acid trough for furfural production. The invention effectively solve the sewage treatment problem in the furfural production process.

Owner:刘显臣

Sealed submerged arc furnace system

ActiveCN101532781AImprove securityEliminate potential safety hazardsEnergy industryCharge manipulationWaste heat recovery unitElectricity

The invention relates to a sealed submerged arc furnace system, and solves the problems that the existing direct current electrical arc furnace can not be applied to the submerged arc furnace and an alternating current sealed submerged arc furnace, and has high power consumption, large electrode consumption and low safety. The solution is as follows: the sealed submerged arc furnace system comprises a sealed submerged arc furnace, a waste heat recovery device and a waste gas treatment and utilization device; the waste heat recovery device comprises a turbonator and a heat pump; the waste gas treatment and utilization device comprises a waste heat boiler connected with a waste gas outlet of the sealed submerged arc furnace, a waste gas dust removing device connected with a gas outlet of the waste heat boiler and a waste gas reaction device connected with a gas outlet of the waste gas dust removing device; a water inlet of the heat pump is connected with a water outlet of a hollow electrode cooling system and a water outlet of the turbonator; a hot water outlet of the heat pump is connected with the inlet of a heat exchanger of the waste heat boiler; a cold water outlet of the heat pump is connected with a water inlet of the hollow electrode cooling system; and the outlet of the heat exchanger of the waste heat boiler is connected with a steam inlet of the turbonator. The sealed submerged arc furnace system has the advantages of high safety, improvement of product quality and yield and low consumption.

Owner:北京平希节能环保科技有限公司

Compounded edible fungus meat product and processing method thereof

The invention discloses a compounded edible fungus meat product and a processing method thereof. The method comprises the following steps: by taking fresh edible fungi and mauremys mutica as raw materials, firstly carrying out rinsing, color-protecting, slicing, precooking, salting, desalting and the like on the edible fungi so as to prepare a semi-product; carrying out rinsing, fishy smell removing, precooking, bone soup flavoring, cooling, slitting and the like on the mauremys mutica so as to prepare a semi-product; proportionally combining the semi-product of the edible fungi with the semi-product of the mauremys mutica, adding spices, seasonings and auxiliary materials and evenly mixing so as to obtain the compounded edible fungus meat product. The compounded edible fungus meat product has the advantages of being green and natural, reasonable in nutritional matching, excellent in flavor, good in taste, convenient to eat, long in shelf life and the like.

Owner:CHENGDU UNIV +1

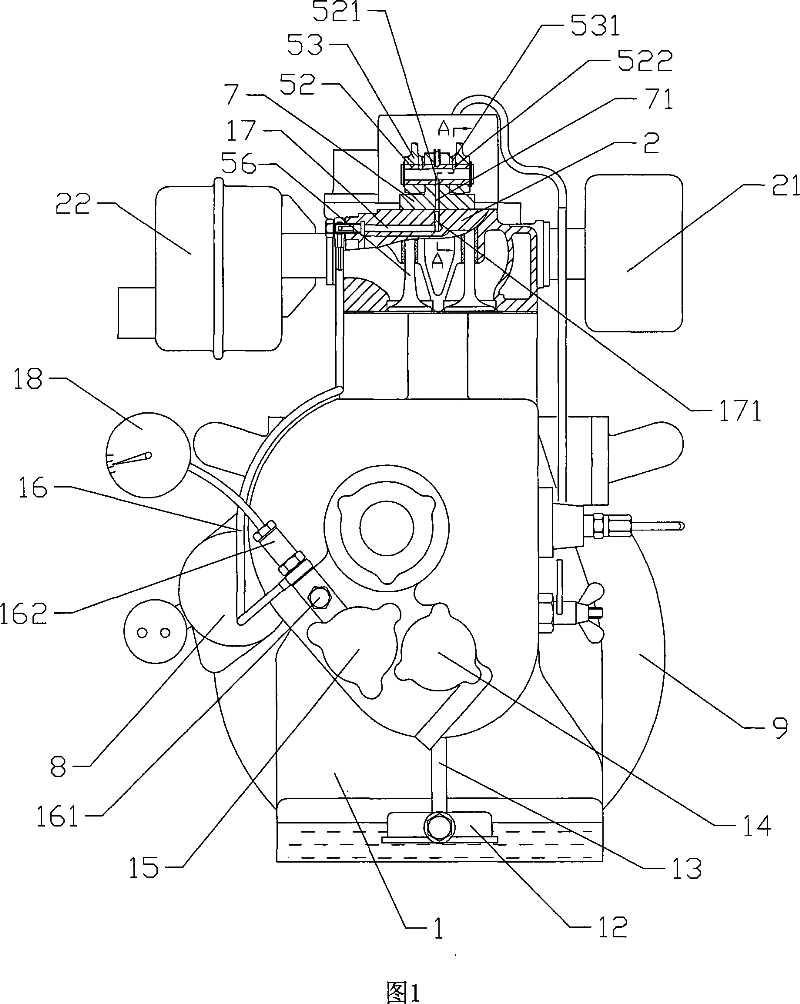

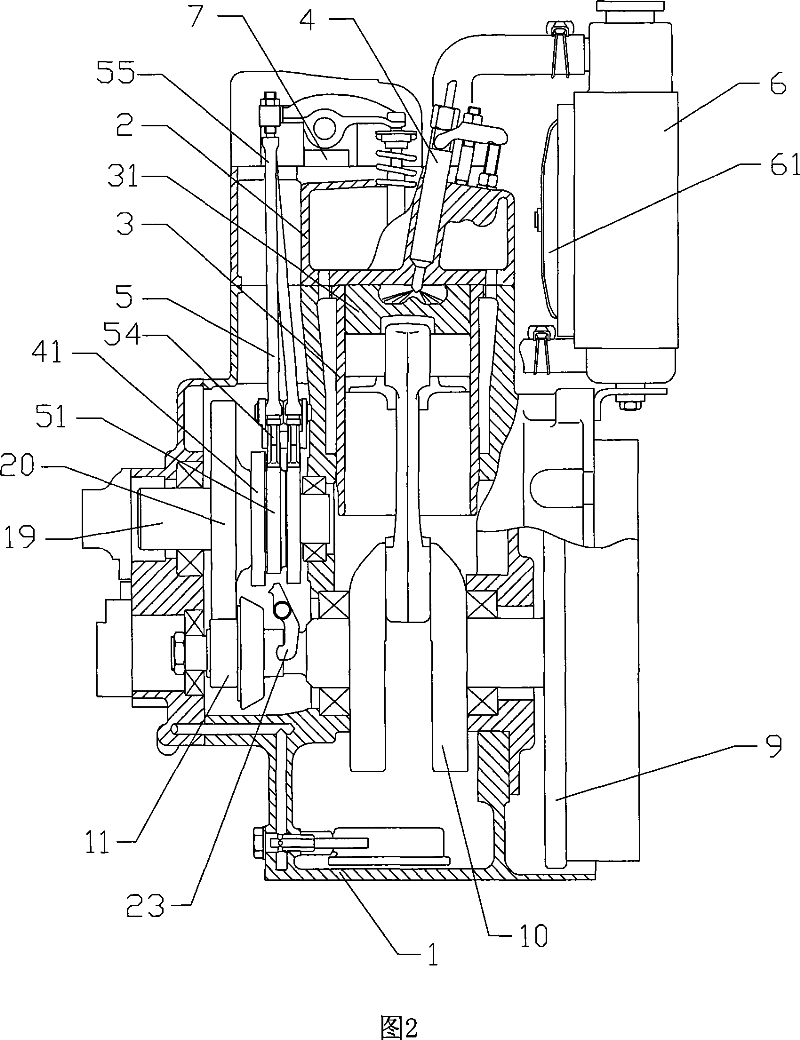

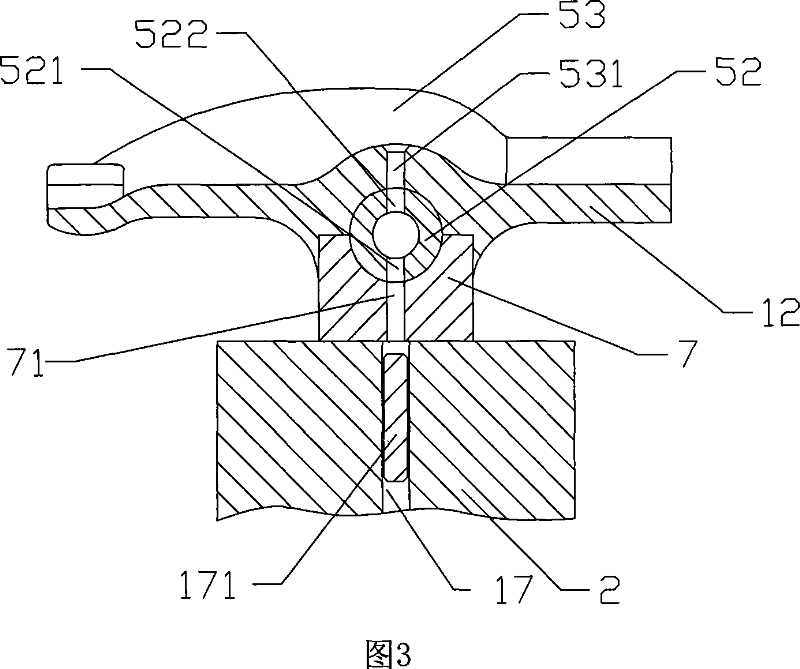

Vertical type single-cylinder diesel engine

InactiveCN101042062AImprove the lubrication effectGet evenlyLubrication of auxillariesCylinder headsGear wheelCrankcase

It relates to a vertical mono cylinder diesel that comprises the crankcase with bottom being able to contain lubricants, air cylinder cap assembly matching with the crankcase, air cylinder assembly, fuel structure matching with the air cylinder assembly, drive structure inside the crankcase, cooling device hang outside with distribution cam set and arm rotating set, the distribution cam set fixed inside the gear chamber of the crankcase, rocking arm set supported on the rocking arm base and fixed on the air cylinder cap assembly, with the drive mechanism composed of serial connected start generator, flywheel gear and crank inside the crankcase, drive arm connecting with the piston inside the ari cylinder assembly, one end of the crank having timing gear, rocking arm shaft of the distribution mechanism having oil inlet and outlet connecting with the inner cavity of the rocking arm shaft, lubricant oil supply mechanism having oil inlet and outlet on the crankcase. It has fixed rotation speed, good in lubrication effect, fine in cooling feature, and light in size.

Owner:GUANGDONG DELUX DIESEL ENGINE

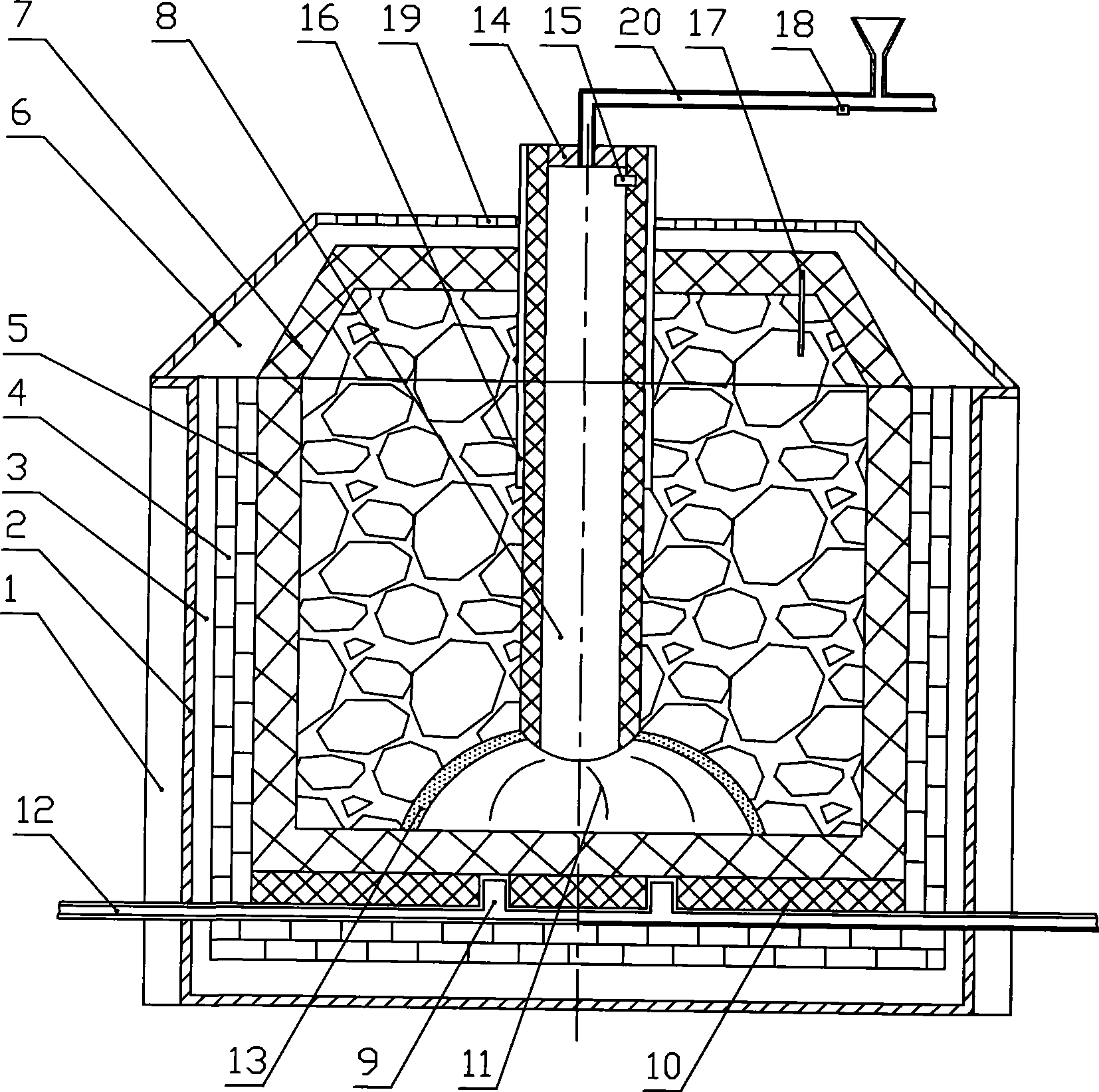

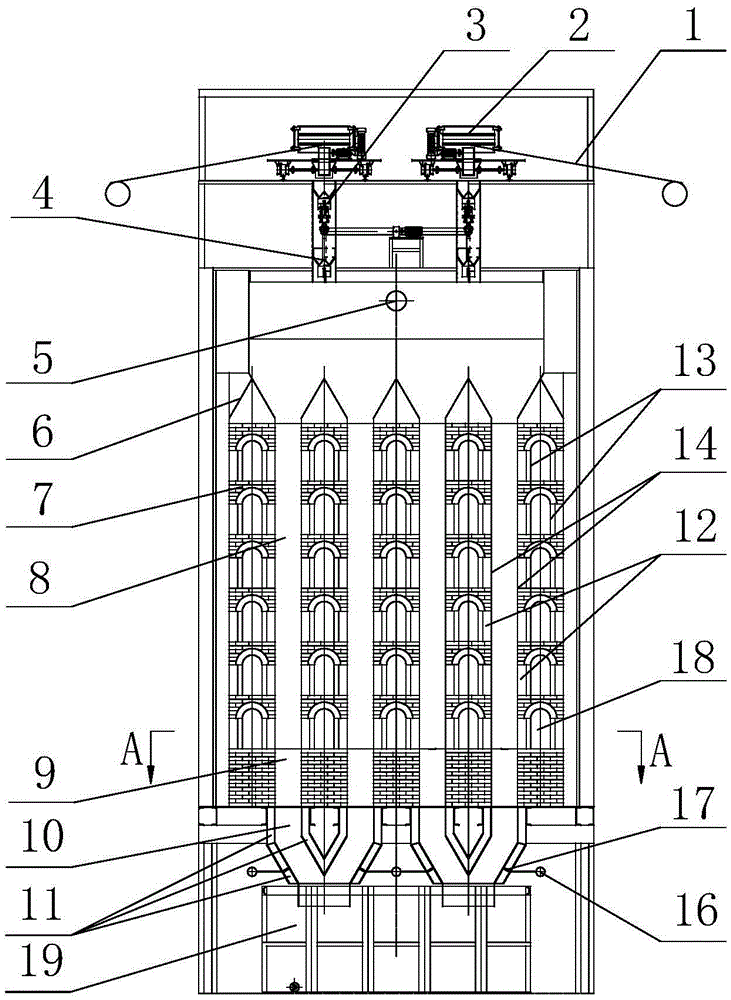

External heat radiation regenerative oil shale dry distillation furnace

ActiveCN105542863AHigh strengthRun smoothlyGasification processes detailsCombustible gas productionCombustion chamberThermal efficiency

The invention relates to an external heat radiation regenerative oil shale dry distillation furnace. The furnace is provided with a plurality rows of alternately arranged dry distillation chambers and combustion chambers; each row of combustion chambers is formed by a plurality layers of independent combustion channels; heat generated by combustion is transferred to oil shale in the dry distillation chambers with heat radiation and heat conduction manners with lattice-wall-structured heat conduction walls. With a gasification section, a cooling section, cooling water jackets and steam nozzle devices on the lower part of the dry distillation furnace, carbon residue in semicoke can be fully recycled, and semicoke and ash residual heat can be recycled. Water gas generated by the reaction of semicoke and steam is used as a medium for bringing out oil shale pyrolysis oil gas, such that outlet gas amount is low, dry distillation gas purity is high, and dry distillation gas heat value is high. The daily processing capacity of the dry distillation furnace can by higher tan 500t, and an oil yield can be higher than 90%. Water and electricity consumptions are low, and an auxiliary recovery system is small. With existing external heat dry distillation technologies, semicoke carbon residue cannot be utilized, thermal efficiency is low, maintenance is difficult, and yield is low. With the dry distillation furnace, the above problems are solved. The dry distillation furnace is especially suitable for water-deficient areas.

Owner:WUHAN UNIV OF SCI & TECH

High-density culture method of clostridium thermocellum

InactiveCN102864089AReduce manufacturing costReduce consumptionBacteriaMicroorganism based processesBiotechnologyCellulose

The invention belongs to the field of microbial fermentation engineering, and specifically relates to a high-density culture method of clostridium thermocellum. The method is characterized in that a GS-2 culture medium is used as an initial culture medium; the fermentation medium is optimized through a multivariate statistical method; and cell concentration of clostridium thermocellum is rapidly and efficiently raised. The invention has the following advantage: the invention provides a fermentation medium for rapid acquisition of large cell concentration of clostridium thermocellum, thus laying the groundwork for subsequent production of cellulosome which has high conversion efficiency of cellulose to bioethanol. Bacterial density of clostridium thermocellum is raised by 6-9 times in comparison with that of the initial culture medium. OD600 under the bottling condition reaches 8.85, and OD600 in a fermentation cylinder reaches 12.7.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

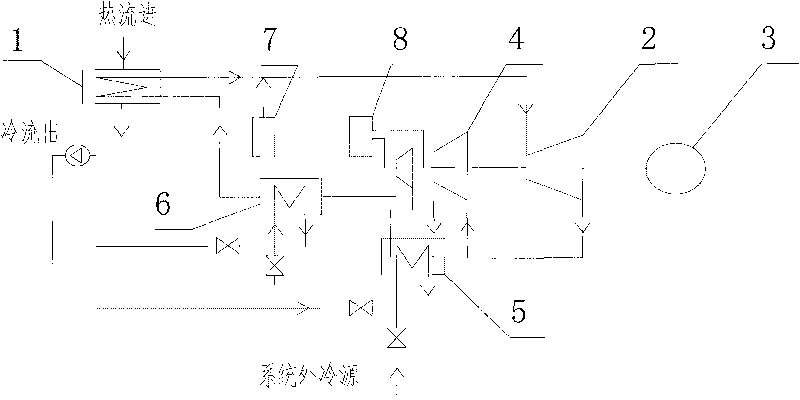

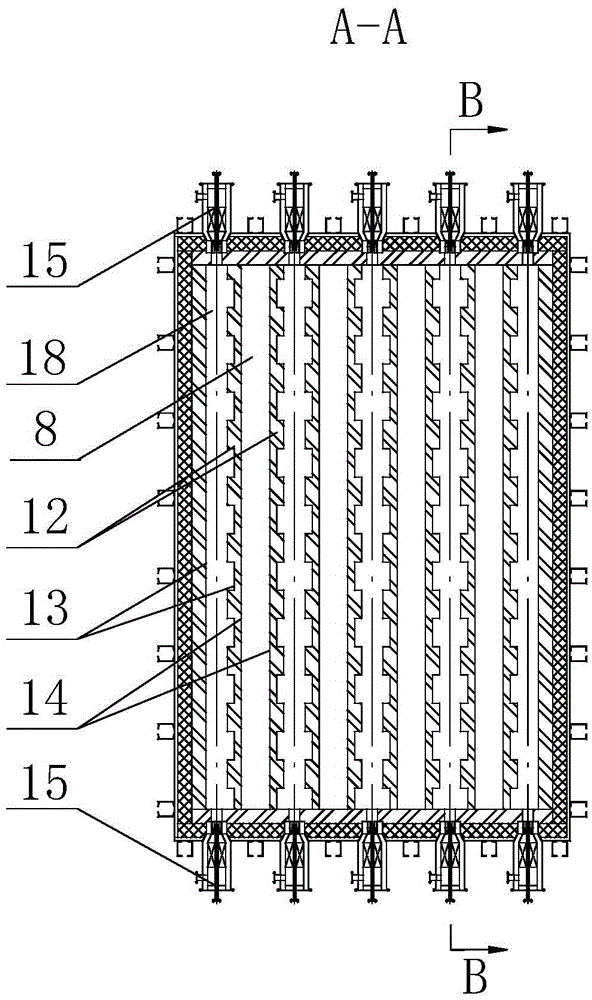

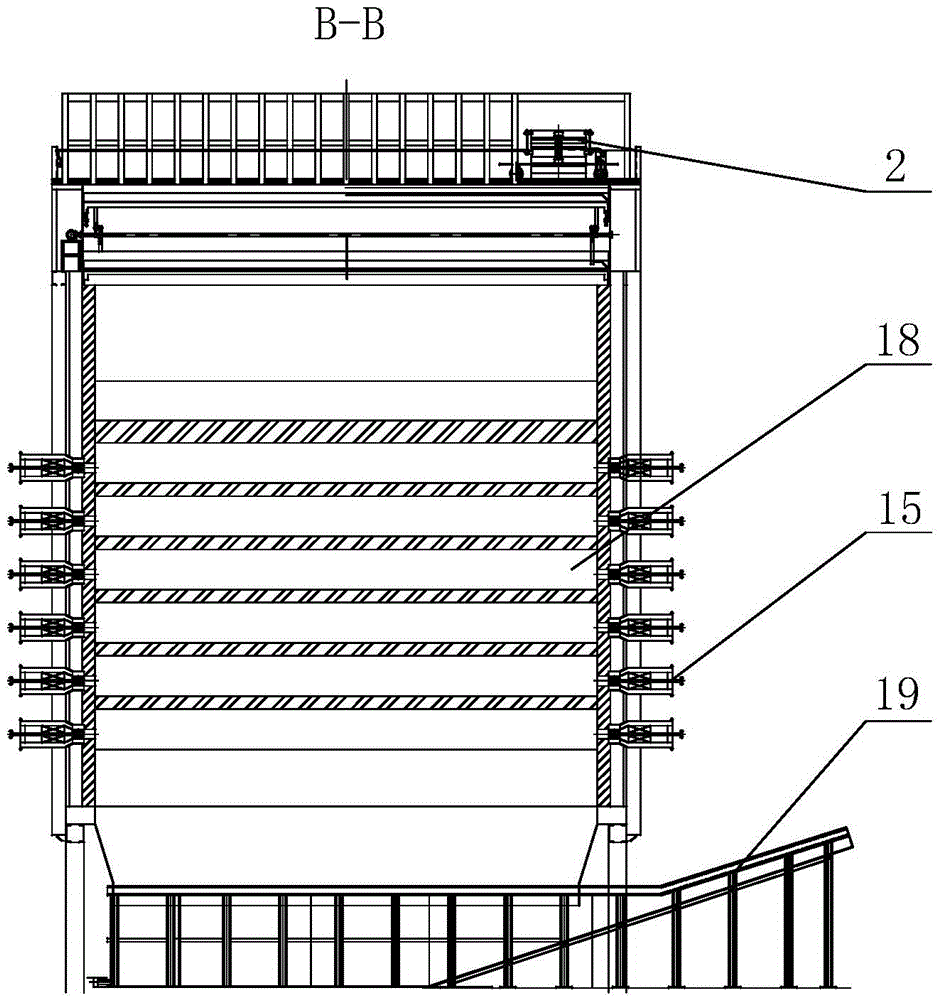

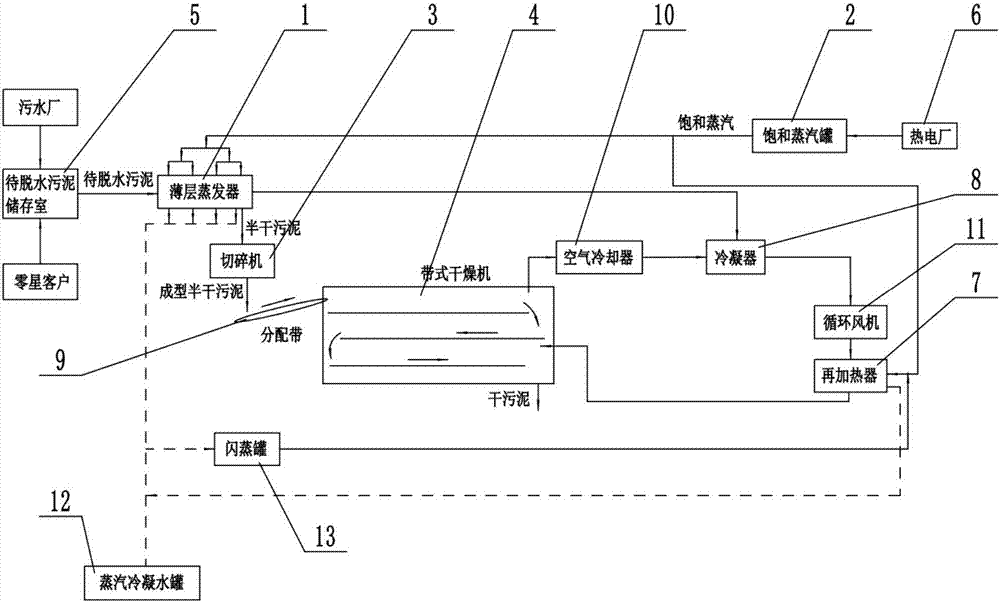

Novel gradient thermal energy recycling system adopting two-section type sludge drying process

PendingCN107098562AReduce supplementationSave cooling waterSludge treatment by de-watering/drying/thickeningSteam generationThermal energySludge

The invention relates to a novel gradient thermal energy recycling system adopting a two-section type sludge drying process. The system comprises a thin-layer evaporator, a flash tank, a reheater, a belt type drier and the like, wherein the sludge input end of the thin-layer evaporator is connected with a dried sludge storage chamber; the saturation flash tank is connected with a thermal power plant; the saturation flash tank is connected with the thin-layer evaporator and the reheater through branch tubes separately; the thin-layer evaporator is connected with an input hole of a condenser; the sludge outlet hole of the thin-layer evaporator is connected with a crushing machine; a waste air outlet of the belt type drier is connected with an air cooler; the output end of the air cooler is connected with another input hole of the condenser; the output hole of the condenser is connected with a circulation fan; the output hole of the circulation fan is connected with the reheater; the reheater is used for conveying secondarily heated air to the belt type drier; and the thin-layer evaporator is connected with a steam condensed water tank through the reheater.

Owner:苏州工业园区中法环境技术有限公司

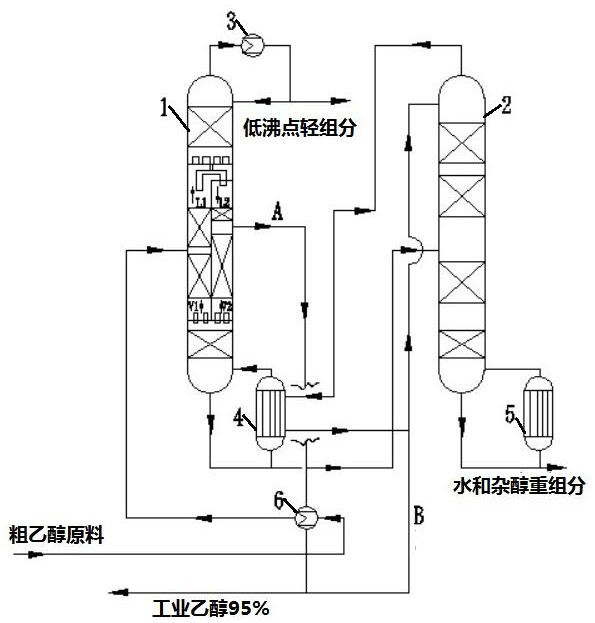

Novel process and device for separating and purifying industrial ethanol

ActiveCN111675601AAchieve separationSave cooling waterOrganic compound preparationDistillation regulation/controlReboilerProcess engineering

The invention provides a novel process and device for separating and purifying industrial ethanol. The industrial ethanol separation and purification device comprises a dividing wall rectifying tower,an ethanol rectifying tower, a dividing wall rectifying tower top condenser, a dividing wall rectifying tower reboiler, an ethanol rectifying tower reboiler and a feeding preheater; crude ethanol rawmaterial liquid exchanges heat with an extracted industrial ethanol product A and then enters the middle part of the left side of the dividing wall rectifying tower; the fraction conditions are controlled, heavy components rich in ethanol, water and fusel are extracted from the bottom of the tower; heavy-component substances at the bottom of the tower enter the ethanol rectifying tower and are separated; an industrial ethanol product B is obtained, part of the prepared industrial ethanol product B flows back to the top of the ethanol rectifying tower, a double-effect coupling rectifying process is adopted, thermal coupling heat exchange is carried out on tower top steam of the ethanol rectifying tower and a tower kettle reboiler of the dividing wall rectifying tower, steam of the tower kettle of the dividing wall rectifying tower is saved, and meanwhile cooling water of the tower top steam of the ethanol rectifying tower is saved.

Owner:雅邦绿色过程与新材料研究院南京有限公司 +1

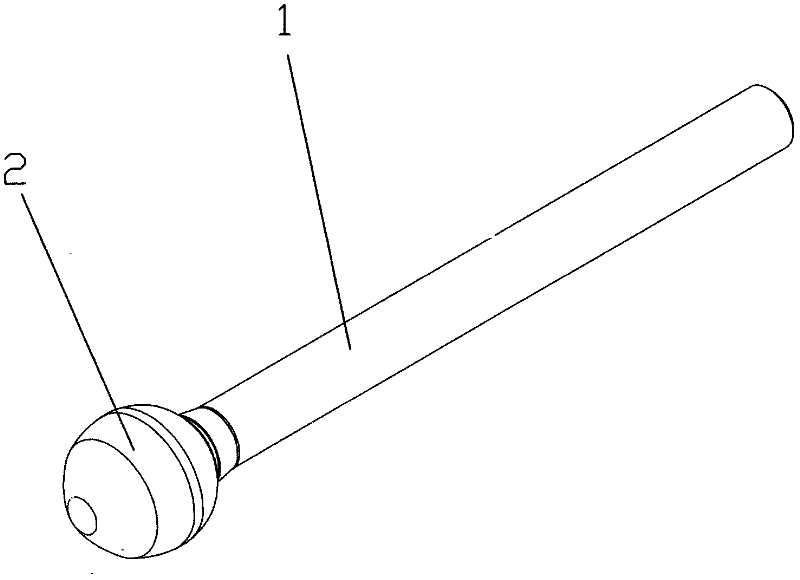

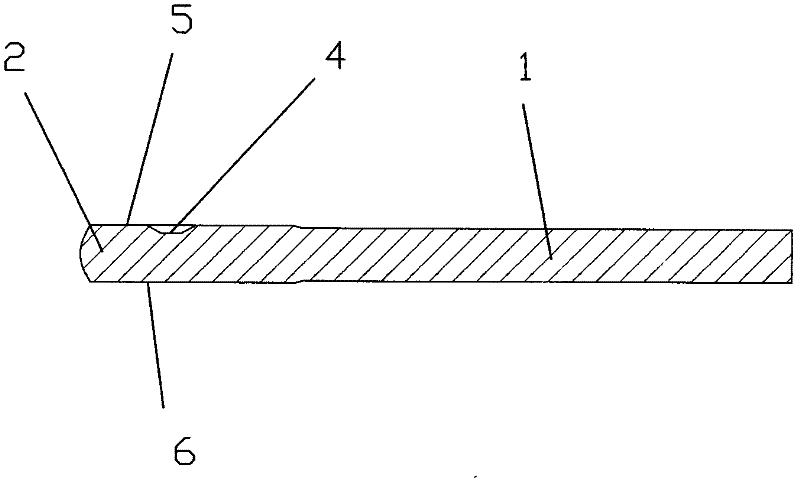

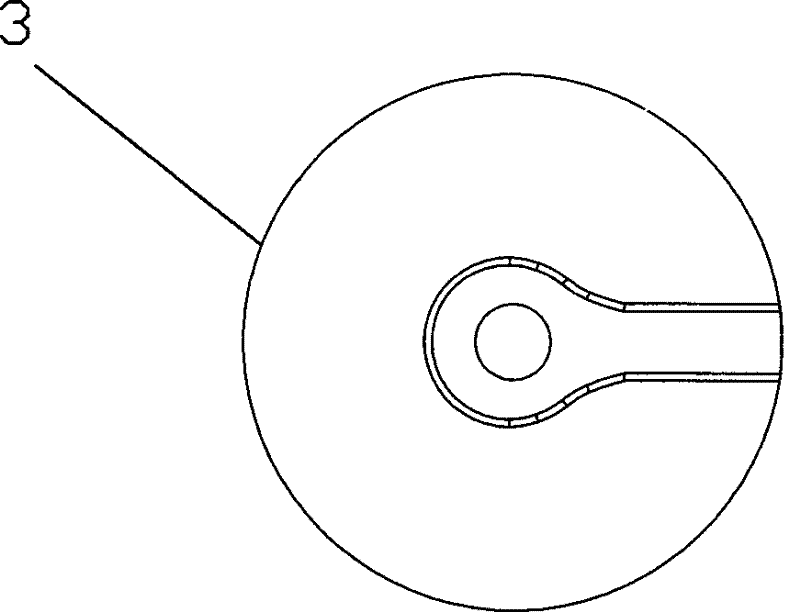

A multi-station cold extrusion molding method for a ratchet handle

The invention relates to a multi-position cold extrusion forming method of a ratchet handle, which belongs to the technical field of ratchet handles, and is characterized by comprising the multi-position cold extrusion processing steps that: one end of a blank is cold extruded into a spherical head through a mould; through cold extrusion, the spherical head is pressed to be flat and a positioninghole is pressed; through cold extrusion, lead holes of an upper end surface and a lower end surface are extruded; through cold extrusion, the outer diameter of the pressed spherical head is enlarged,and the lead holes of the upper end surface and the lower end surface are deepened and enlarged; waste materials in the middle of the lead holes are further pressed to be thinner through cold extrusion, the lead holes are further deepened and enlarged, and the outer diameter of the pressed spherical head is further enlarged; the waste materials in the middle of the lead holes are punched out through cold extrusion, so that the lead holes become counterbores; through cold extrusion, installation positioning holes are extruded, so that the counter bores are enlarged and formed into inner gear holes for processing inner gears; and through cold extrusion, the inner gears which are meshed with ratchets are extruded. The multi-position cold extrusion forming method of the ratchet handle is adopted for processing the ratchet handle, and the blank does not need to be heated, so that energy, power and water are saved, few materials are consumed, and the environment is not polluted.

Owner:JINHUA ZHONGXIN HARDWARE TOOLS

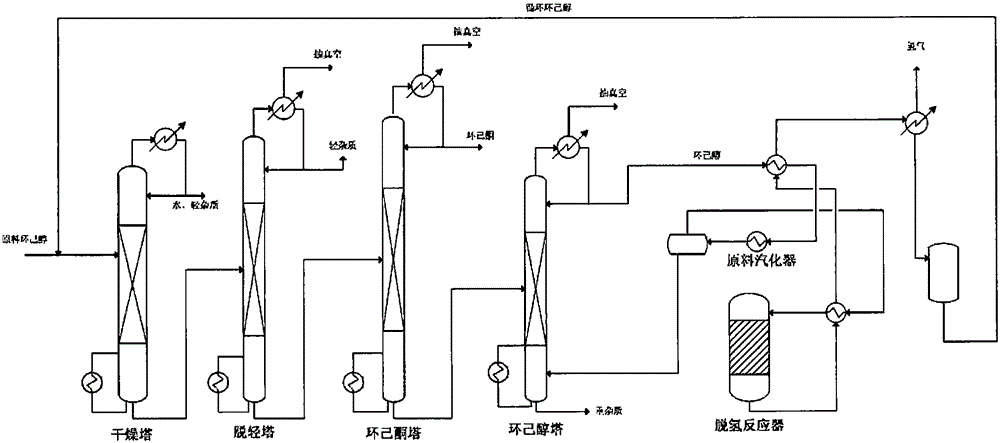

Technological method for producing cyclohexanone through dehydrogenation of cyclohexanol

ActiveCN105218342ASave energyReduce energy consumptionPreparation by dehydrogenationCarbonyl compound preparation by oxidationCyclohexanoneGas phase

A technological method for producing cyclohexanone through dehydrogenation of cyclohexanol comprises procedures including gasification of a raw material, dehydrogenation reaction, gas-liquid separation, cyclohexanone evaporation and the like; the method is characterized in that a gasified and heated cyclohexanol material is contacted with a dehydrogenation catalyst, reaction effluent containing components including hydrogen, cyclohexanone, cyclohexanol, heavy impurities and the like is obtained, and before the hydrogen is separated out, the heavy impurities in the reaction effluent are separated out firstly. According to the method, repeated distillation of the cyclohexanol is reduced, heat contained in a gas-phase reaction product is fully utilized, energy consumption and the cost of production of the cyclohexanone are substantially reduced, and the technique economics of the technology for preparing the cyclohexanone through dehydrogenation of the cyclohexanol is improved.

Owner:李国涛

Rectification energy-saving new process

InactiveCN101745243ASave heatSave cooling waterBiofuelsLiquid hydrocarbon mixture productionThermal energyVegetable oil

The invention discloses a rectification energy-saving new process in the biodiesel production process, and in particular relates to a rectification energy-saving new process which takes vegetable oil as raw material to produce the biodiesel; the rectification energy-saving new process is characterized in that: a heat exchanger is additionally arranged below a discharging plate of a refining tower, the raw material oil is directly conveyed to the heat exchanger in the refining tower by a material pump from a second pot, the raw material oil is pre-heated to 120 DEG C by utilizing the vapor phase waste heat, and then the oil is refined at the lower part of the refining tower, so as to save a great amount of heat energy; in addition, the raw material oil can be used for cooling the vapor-phase refined oil, and a great amount of cooling water can be saved; according to actual measurement in the production, the energy can be saved by 2 percent and water can be saved by 10 percent.

Owner:浙江东江能源科技有限公司

Technology for treating steel-rolling oily sludge by means of steel slag waste heat

The invention discloses a technology for treating steel-rolling oily sludge by means of steel slag waste heat. The technology comprises the following steps that 1, steel slag accounting for more than one third of the volume of a slag pool is loaded in the hot disintegrating slag pool in a paving mode, and the surface temperature of the steel slag is controlled at 500 DEG C or above; 2, the oily sludge generated in steel rolling is transported to a hot disintegrating slag field, poured into the hot disintegrating slag pool and then evenly paved; 3, the steel slag is continuously poured into the slag pool, the high-temperature liquid-state steel slag is poured on the upper portion of the steel-rolling oily sludge which is evenly paved, and a normal hot disintegrating slag technology is implemented after 30 min; 4, after the hot disintegrating slag technology is finished, iron in the steel slag is selected to be utilized according to a normal magnetic separation technology in the steel slag iron selection process.

Owner:新疆互力佳源环保科技有限公司

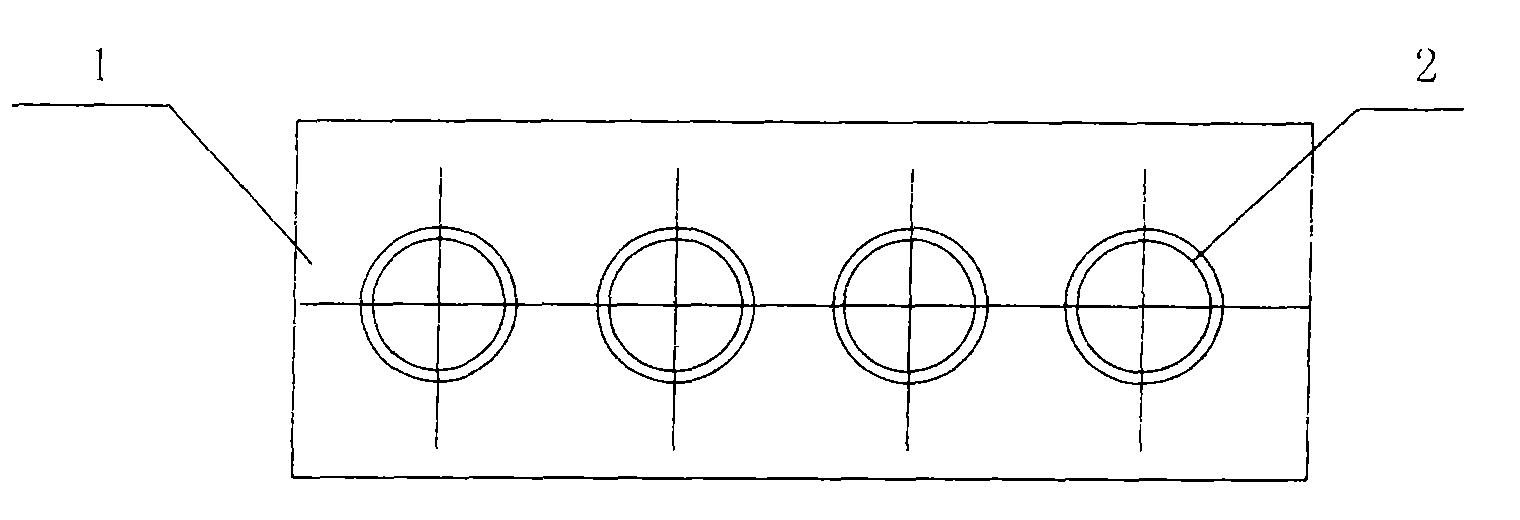

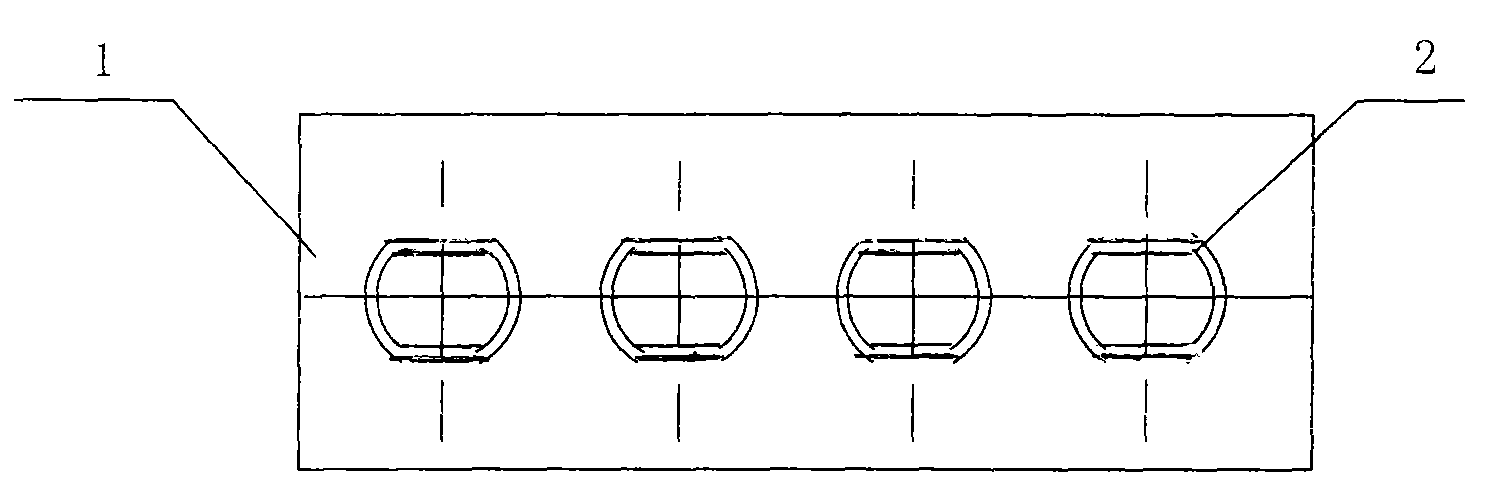

Method for processing cast copper cooling wall of blast furnace

InactiveCN101654718AImprove cooling effectImprove metallurgical bonding strengthCooling devicesBonding strengthCopper

The invention relates to a method for processing a cast copper cooling wall of a blast furnace in the field of metallurgy. The processing method comprises the following steps: firstly, manufacturing acooling tube into a flat tube, then putting into a sand mould and casting. The cast copper cooling wall manufactured by the flat tube has better cooling effect in comparison with the prior circular tube cast copper cooling wall, i.e. the cooling effect of the flat tube can be enhanced by about 14.4% in comparison with the circular tube under the conditions of equal overflowing section, equal flowamount and equal flow rate. Simultaneously, the thickness of the cast copper cooling wall also can be reduced, a large amount of coloured component raw materials are saved, and the manufacturing costof a product is lowered. Furthermore, the metallurgical bonding strength of a tube and a wall body also can be enhanced.

Owner:WUHAN IRON & STEEL (GROUP) CORP

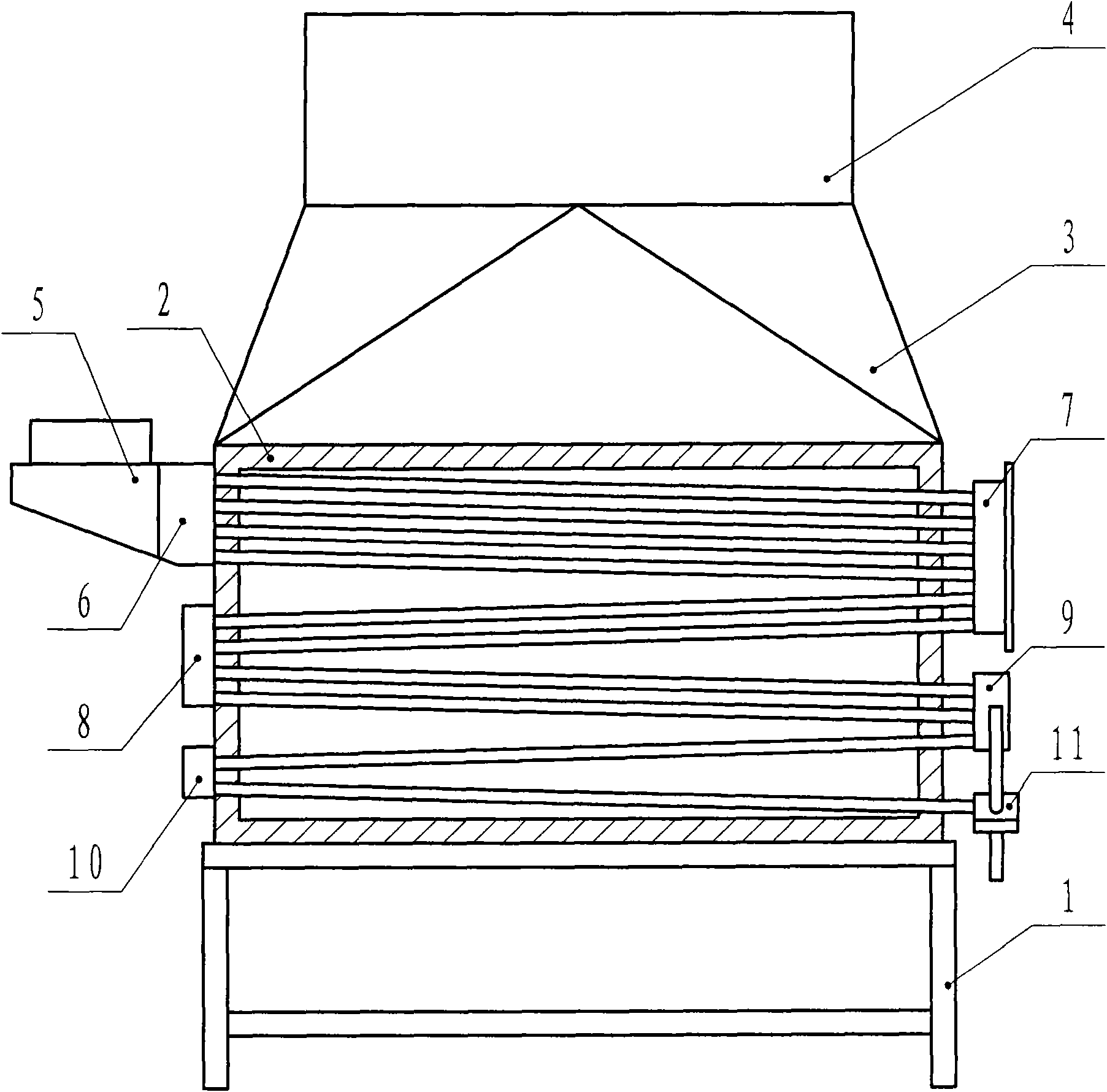

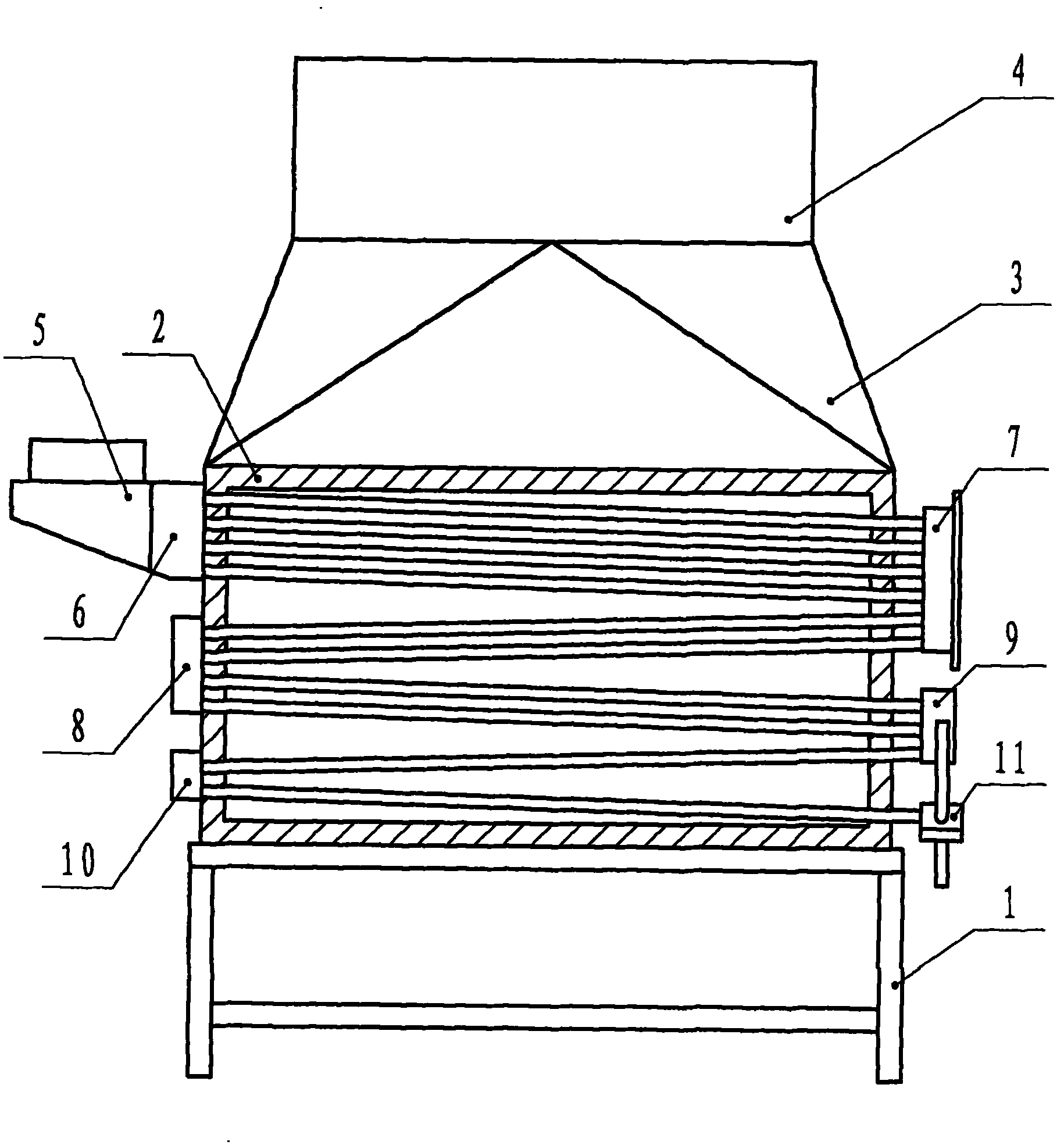

White liquor distilling air cooler

ActiveCN101880621ASave cooling waterLow costAlcoholic beverage preparationWhite liquorAgricultural engineering

The invention relates to a white liquor distilling air cooler which belongs to the technical field of air coolers. The invention aims at providing a white liquor air cooler which can save all cooling water in the white liquor production process. A cooling chamber is arranged on a support, a connection section is arranged on the cooling chamber, an axial flow fan is arranged on the connection section, and a white liquor steam inlet is arranged above one side of the cooling chamber and fixedly connected with the cooling chamber; and a first left channel box is connected with a first right channel box which is connected with a second left channel box, the second left channel box is connected with a second right channel box which is connected with a third left channel box, the third left channel box is connected with a third right channel box, and an outlet is arranged below the third right channel box. The invention is applied in a steam-filling distillation process and can completely substitute the traditional water cooler.

Owner:山西东晟润达热能设备股份有限公司

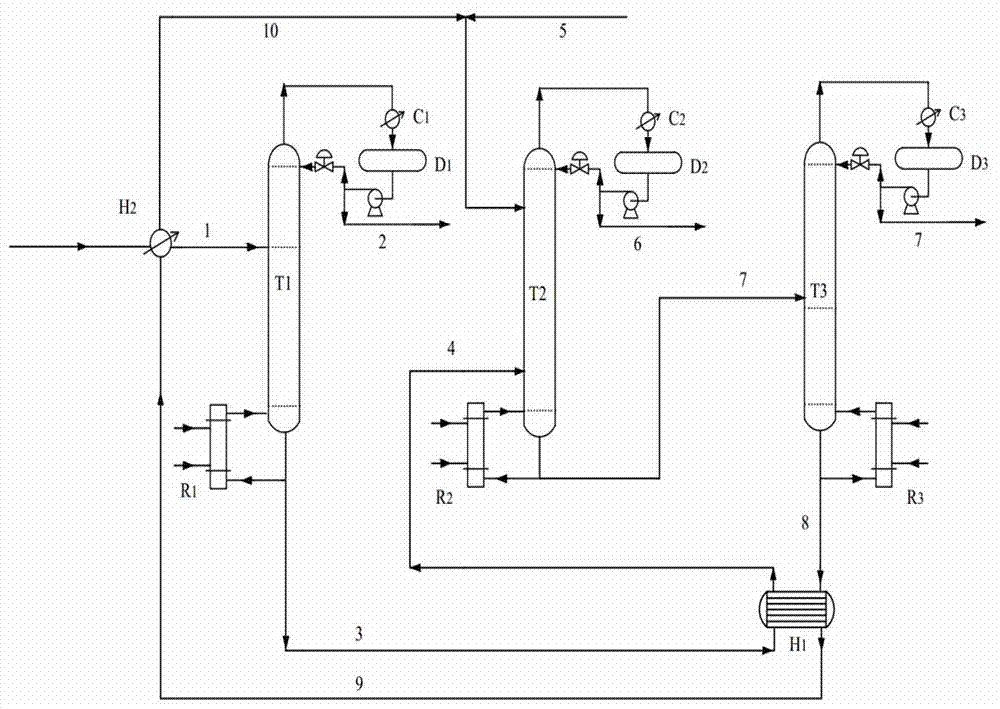

Method of separating acetone-isopropanol-water by three-tower heat-integrated extraction distillation

ActiveCN107473947AEmission complianceSolving intractable puzzlesOxygen-containing compound preparationOrganic compound preparationExtractive distillationEnergy conservation

The invention relates to a method of separating acetone-isopropanol-water by three-tower heat-integrated extraction distillation. A device mainly comprises an acetone tower T1, an isoprpanol tower T2, a solvent recovery tower T3, a heat exchanger H1 and a preheater H2. In the method provided by the invention, a tree-tower distillation way is adopted; acetone which has a lower boiling point is evaporated first; then an isopropanol-water binary azeotrope is separated by extraction distillation; and high-purity acetone and isopropanol are obtained. A second condensation method is used to cool the material flow of a circulating extracting agent, so that high-efficiency used of the material flow is realized; and the heat-integrated way is used to reach a goal of saving energy resources. The method solves the problems of complex process, large energy consumption and low product yield in the prior art, and increases the purity and yield of products.

Owner:青岛三瑞节能环保技术有限公司

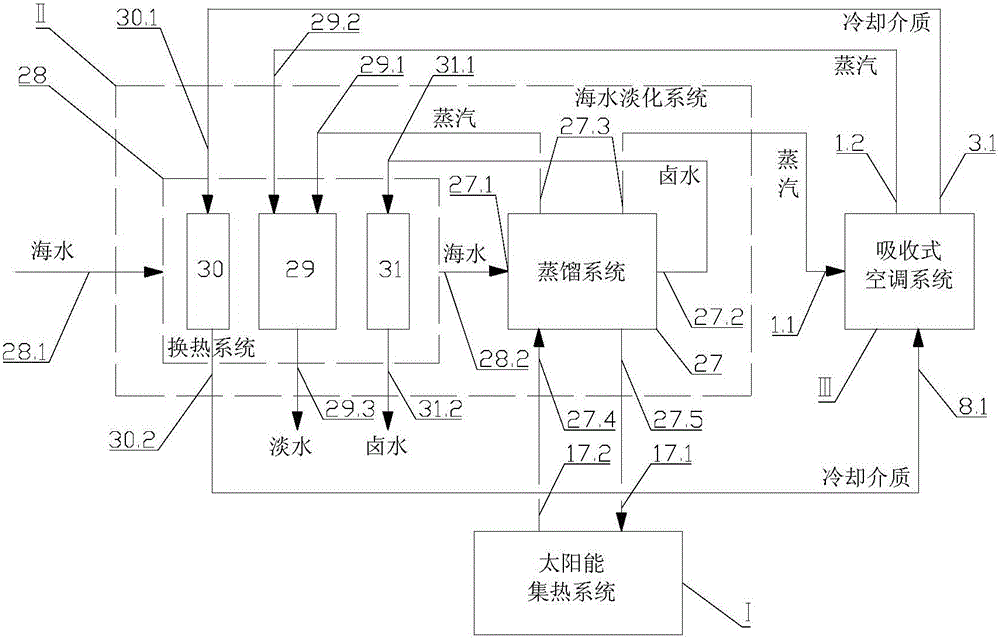

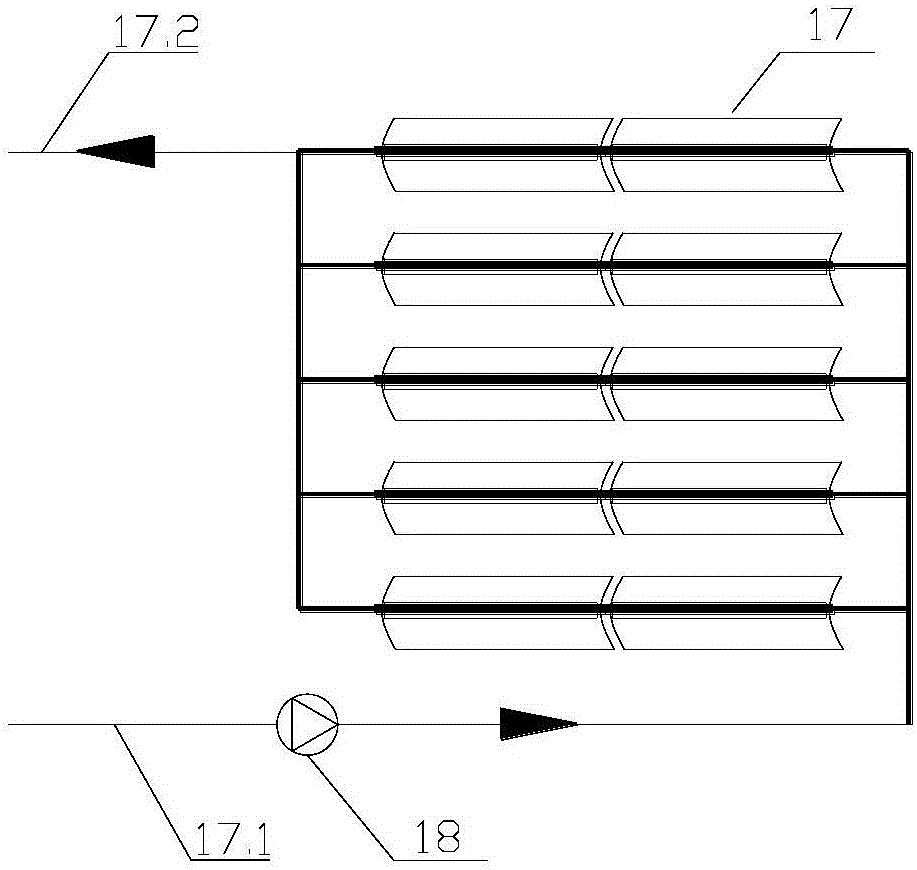

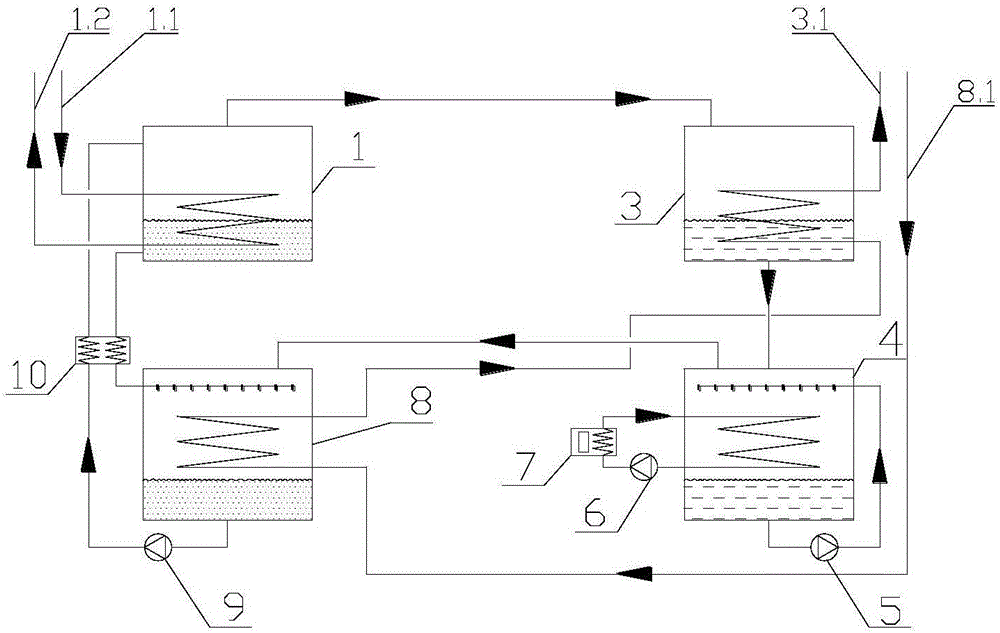

Efficient solar seawater desalination and air conditioner refrigeration combined operation method and system thereof

ActiveCN105923676ASave cooling waterRealize cascade utilizationGeneral water supply conservationSeawater treatmentDistillationCollection system

The invention discloses an efficient solar seawater desalination and air conditioner refrigeration combined operation method and a system thereof. The method comprises a solar heat collection step, a seawater desalination step and an air conditioner refrigeration step; a heat transfer working medium in the solar heat collection step is adopted as a hot source in the seawater desalination step; and distilled steam is adopted as a heat source in the air conditioner refrigeration step, and an air conditioner cooling working medium exchanges heat with seawater and is cooled. The combined operation system comprises a solar heat collection system, a seawater desalination system and an absorption air conditioner system; the seawater desalination system comprises a distillation system and a heat exchange system, and the distillation system heats through the solar heat collection system; the heating steam input port of the absorption air conditioner system is connected with the steam output port of the distillation system, the cooling working medium input port of the absorption air conditioner system is connected with the air conditioner cooling working medium output port of the heat exchange system, and the cooling working medium output port of the absorption air conditioner system is connected with the air conditioner cooling working medium input port of the heat exchange system. The method and the system simultaneously realize seawater desalination and air conditioner refrigeration by using solar energy as a hot source, so the energy utilization efficiency is high.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Sub-cooled superconductor gradient coil module applicable to magnetic resonance imaging

ActiveCN102062844AImprove spatial resolutionReduce lossMagnetic measurementsDiagnostic recording/measuringVacuum pressureResonance

The invention discloses a sub-cooled superconductor gradient coil module applicable to magnetic resonance imaging. The module comprises a vacuum heat-insulating shell, at least one superconductor gradient coil, a heat dissipation element and a port, wherein the vacuum heat-insulating shell comprises a two-layer airtight jacket and can (i) close one high-vacuum space with first vacuum pressure and (ii) close a vacuum space with second vacuum pressure; the at least one superconductor gradient coil is positioned in the vacuum space; the heat dissipation element is positioned in the vacuum space and thermally contacted with the at least one superconductor gradient coil; and the port is at least used for sub-cooling the heat dissipation element. The module has a simple structure, and can improve the performance of a magnetic resonance imager and reduce manufacturing cost and maintenance cost.

Owner:美时医疗技术(上海)有限公司

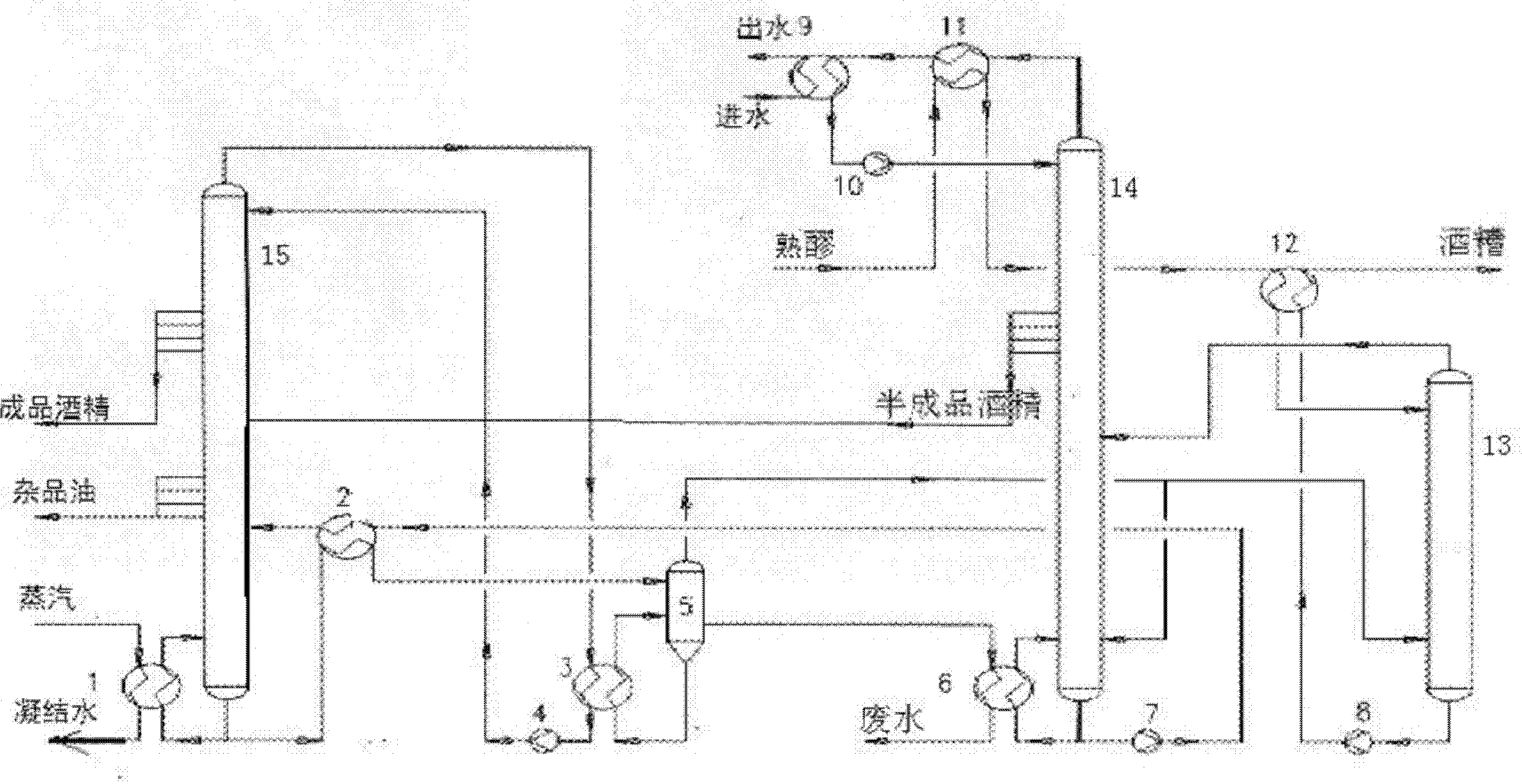

Three-tower energy-saving differential pressure alcohol distillation production system and technological process thereof

InactiveCN102489030AReduce consumptionReduce manufacturing costOrganic compound preparationChemical industryWater savingAlcohol

The invention discloses a three-tower energy-saving differential pressure alcohol distillation production system and a technological process thereof. The three-tower energy-saving differential pressure alcohol distillation production system comprises a two-tower atmospheric distillation system formed by an existing mash tower, an atmospheric rectification tower and accessory equipment, and a pressurization rectification system formed by a pressurization rectification tower and accessory equipment. According to the invention, on the basis of the existing two-tower atmospheric distillation equipment, a pressurization rectification tower is additionally arranged, the operating pressure of the original two-tower is unchanged, the pressurization rectification tower is used for processing dilute alcohol from the bottom of the original atmospheric rectification tower, and the dilute alcohol accounts for 1 / 3 of the total output; and compared with the two-tower atmospheric distillation, the steam is saved by more than 20 percent, the cooling water is saved by more than 30 percent, the steam and water saving effect is obvious, the consumption of steam is greatly reduced, the production cost of enterprises is reduced, and the transformation cost of the enterprises is greatly reduced simultaneously.

Owner:肥城金塔酒精化工设备有限公司

Pressure control valve

A pressure control valve of the invention includes a platform, a spring, a seal ring, a piston, a nut cap, a spring seat, a cross valve body, a strut shell, a dribble capping, a structure adjusting the screw. The cross piston in the cross valve body is disposed with a piston upper bore and a piston lower bore according to upper and lower direction along the entrance of the current. There are seal rings on the two end of the piston and drip holes on the dribble capping. It is convenient for the cooks to operate to make the cooling water adjustable and reduce the production cost to save more than 50% tap water for cooling, so the waste of the water resources is overcome to obtain the win-win of the production and the energy saving.

Owner:胡加江

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com