Vertical type single-cylinder diesel engine

A diesel engine and single-cylinder technology, which is applied to cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of many air flow angles, poor lubrication effect, and large cooling airflow resistance, so as to achieve improved lubrication effect, good cooling effect, and advanced The effect of high wind efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

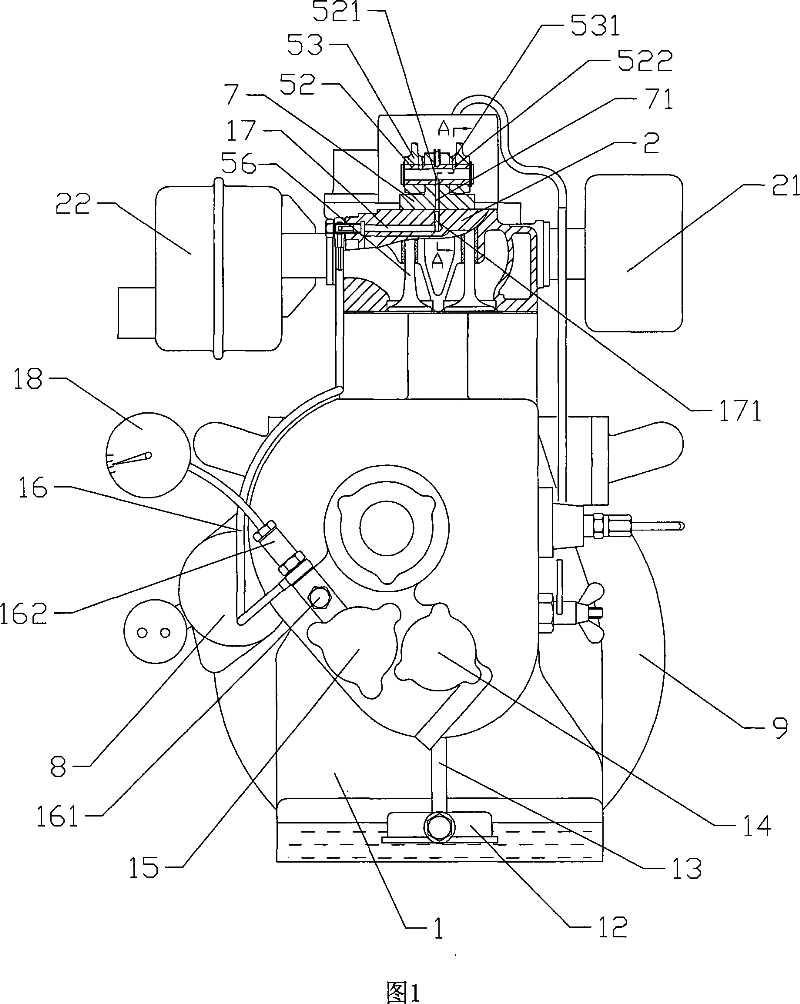

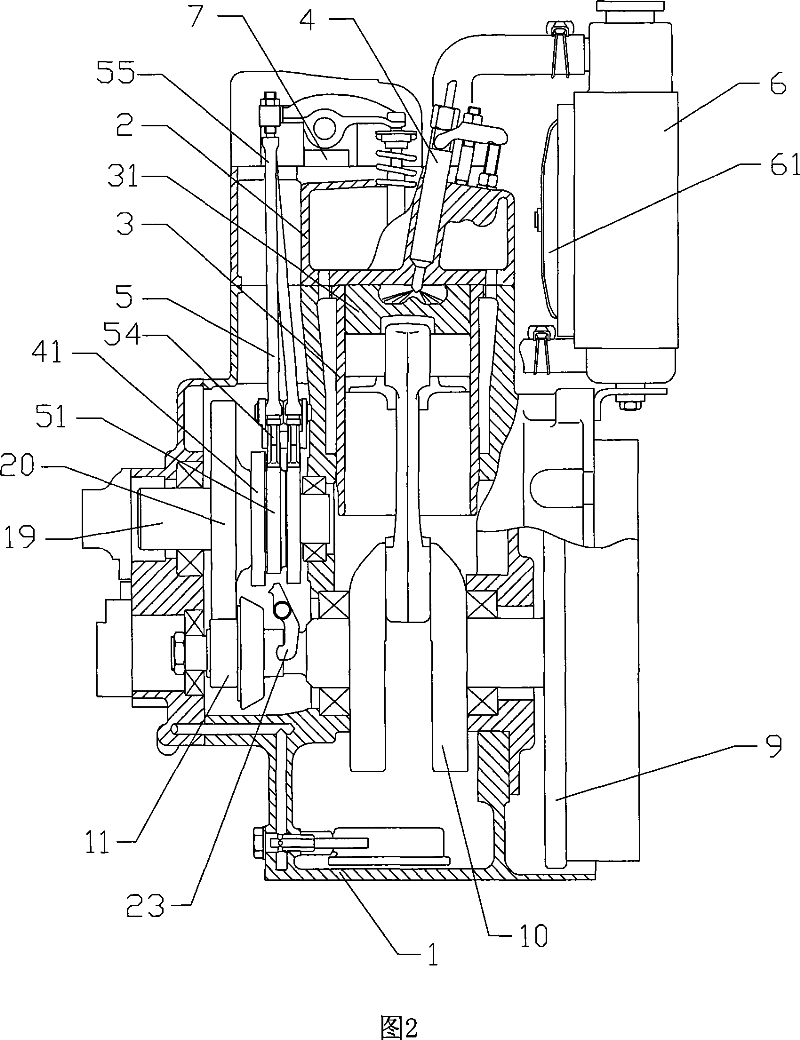

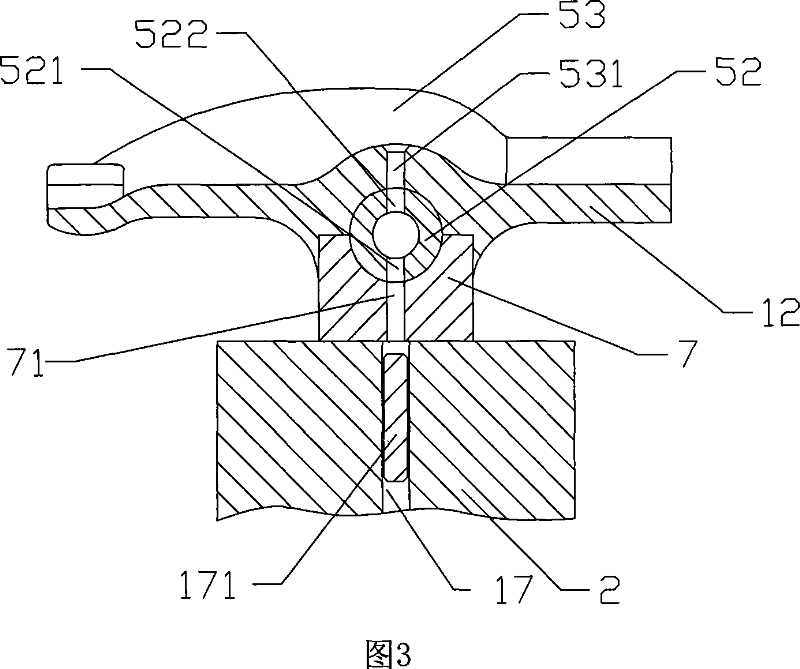

[0018] According to Fig. 1, Fig. 2, Fig. 3 and shown in Fig. 4, the vertical single-cylinder diesel engine of the present invention comprises crankcase 1, cylinder head assembly 2 matched with crankcase 1, cylinder assembly 3, and cylinder assembly The fuel oil mechanism 4 and the gas distribution mechanism 5 are formed into 3. The crankcase 1 is integrally cast, and its bottom can contain lubricating oil. The crankcase 1 is equipped with a transmission mechanism and a cooling device 6 outside. The cooling device 6 A condensing water cooling mechanism is adopted, and in order to overcome the shortcoming that the cooling effect of the existing vertical single-cylinder diesel engine cooling device cannot meet the heat dissipation requirements of the high-speed operation of the machine, an electronic fan 61 is also hung on the cooling device 6 described in the invention, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com