Sealed submerged arc furnace system

A closed ore and hot furnace technology, applied in furnace, crucible furnace, electric furnace heating, etc., can solve the problems of high power consumption of AC closed submerged arc furnace, unusable DC electric arc furnace, and large environmental pollution, so as to achieve good ventilation and eliminate Potential safety hazards and high power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

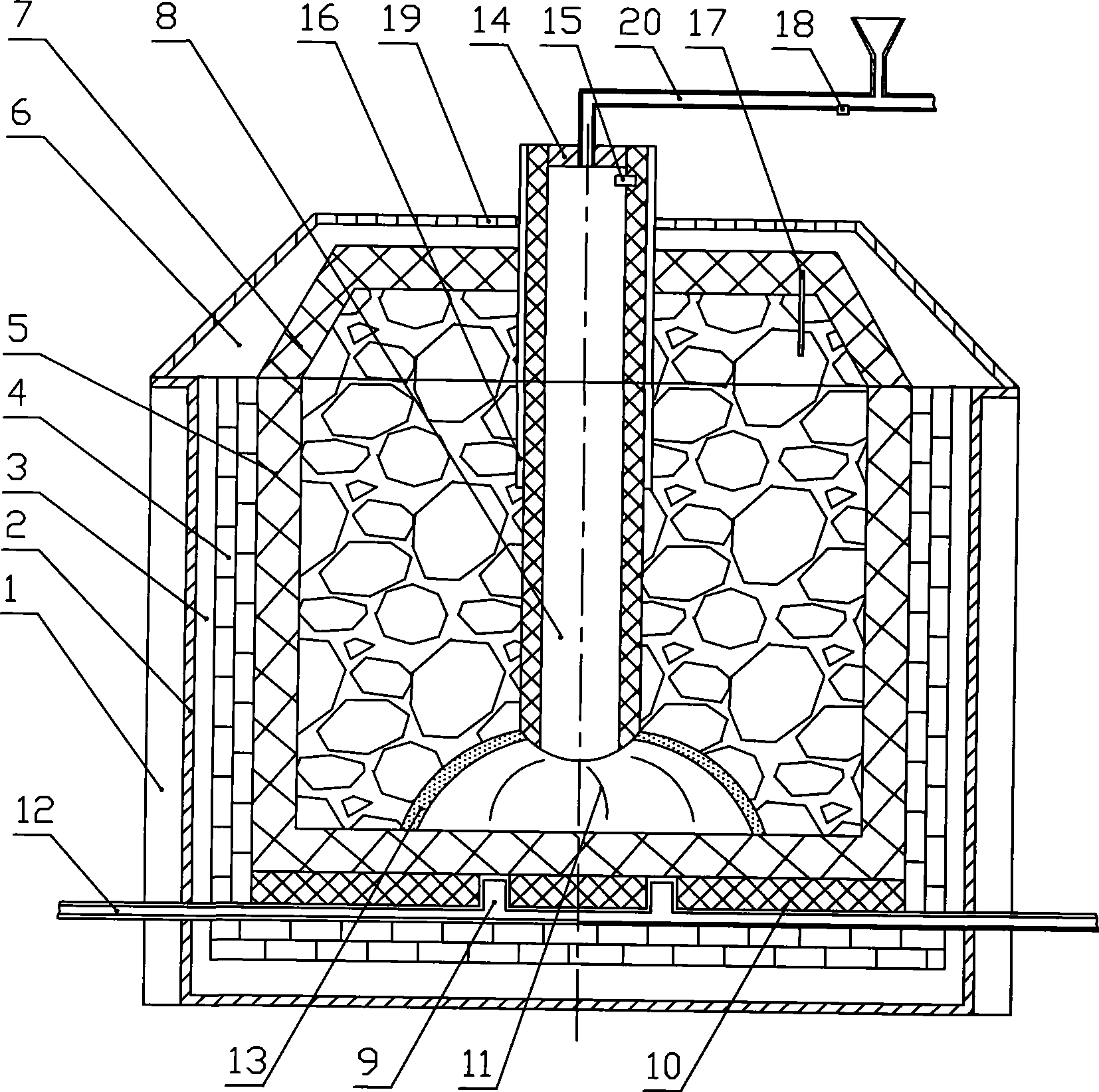

[0034] The invention belongs to large-scale equipment in the smelting industry, and is a submerged-arc type particularly suitable for large-scale smelting and production of high-quality calcium carbide (chemical raw material products), ferroalloy (steelmaking and casting raw material), yellow phosphorus (chemical raw material) and other products. electric arc furnace.

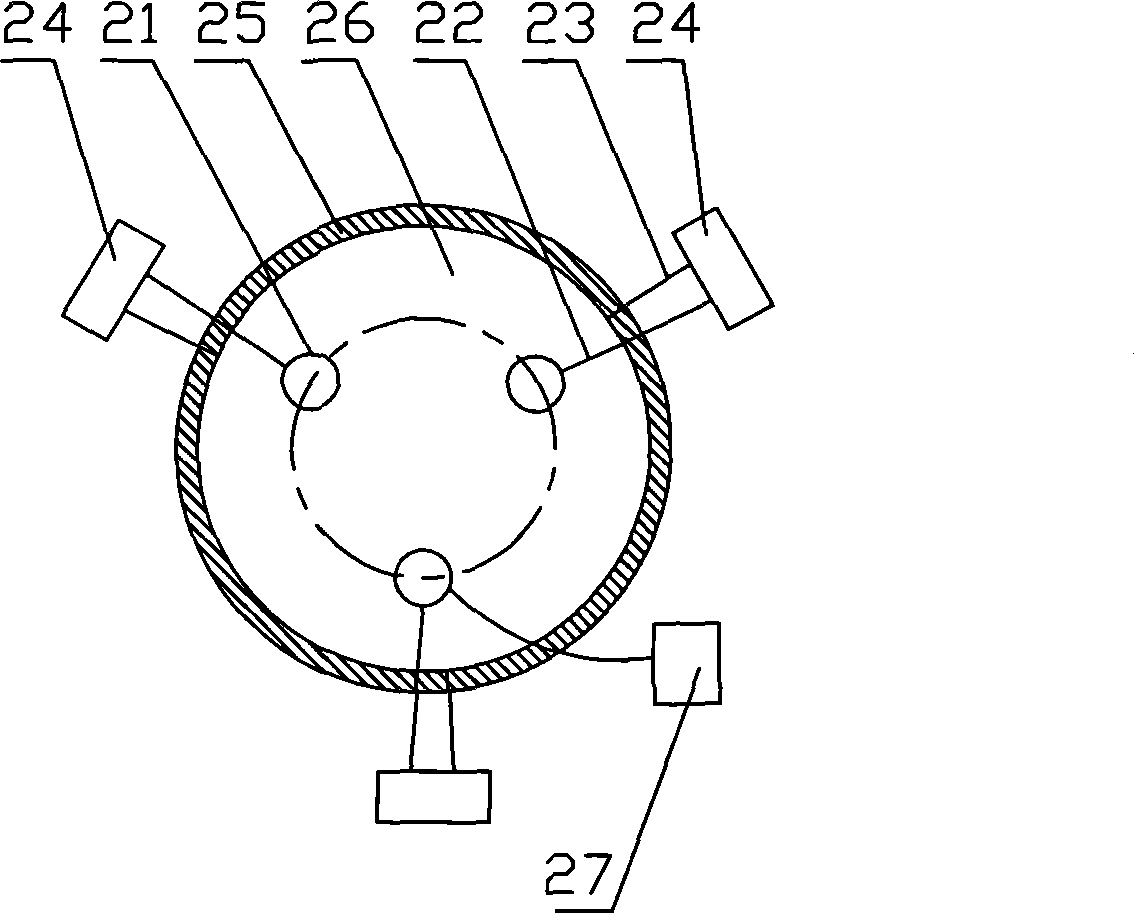

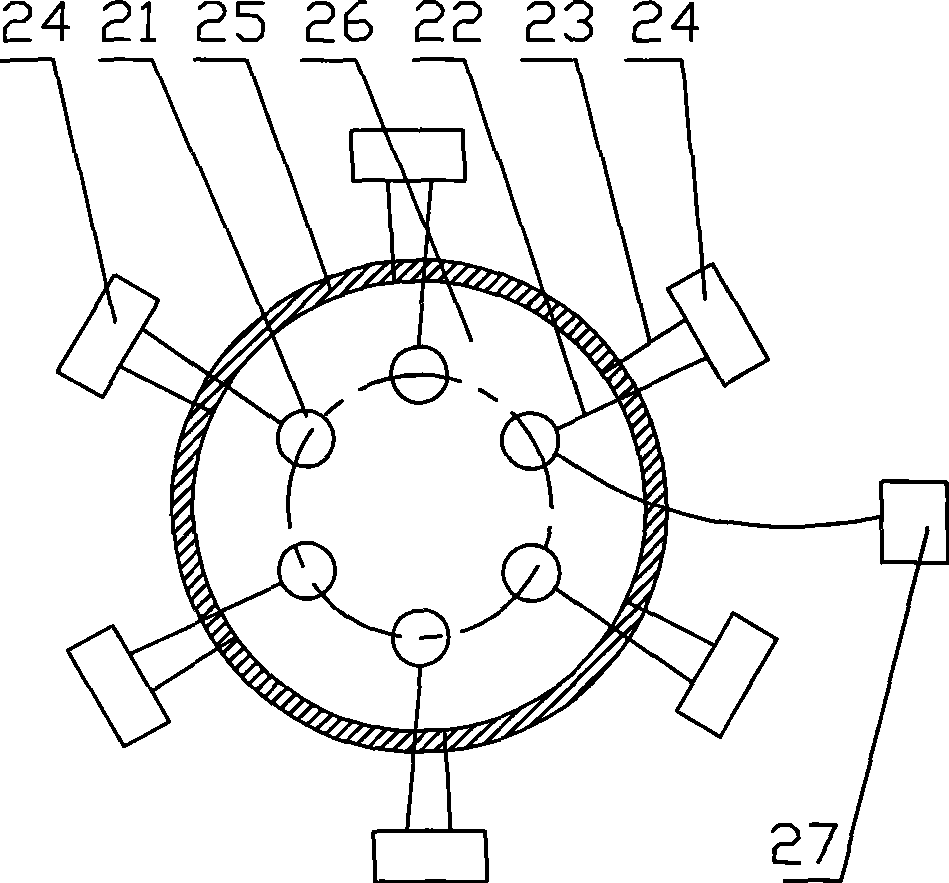

[0035] figure 1 and figure 2 It is a schematic diagram of the electrode distribution of the submerged arc furnace in the system of the present invention, wherein 21 is a hollow electrode; 22 is a cathode water-cooled cable in the short network; 23 is an anode water-cooled cable in the short network; 24 is a direct current including a transformer and a rectifier circuit Power supply; 25 is the furnace wall; 26 is the common anode which is also the bottom of the submerged arc furnace; 27 is the automatic control system, which is equipped with on each electrode to control the lifting of the electrodes to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com