Patents

Literature

102 results about "Dc arc furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

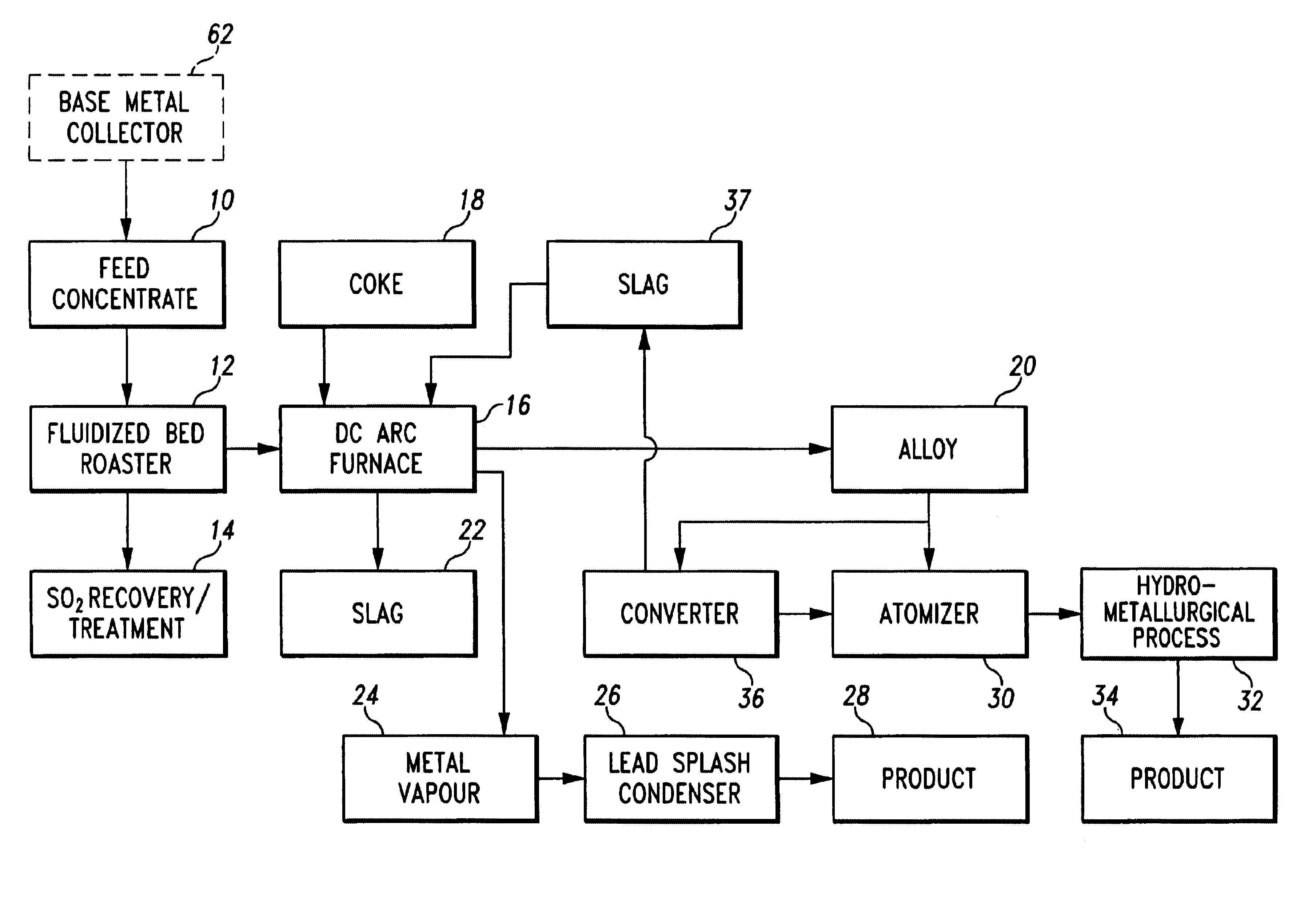

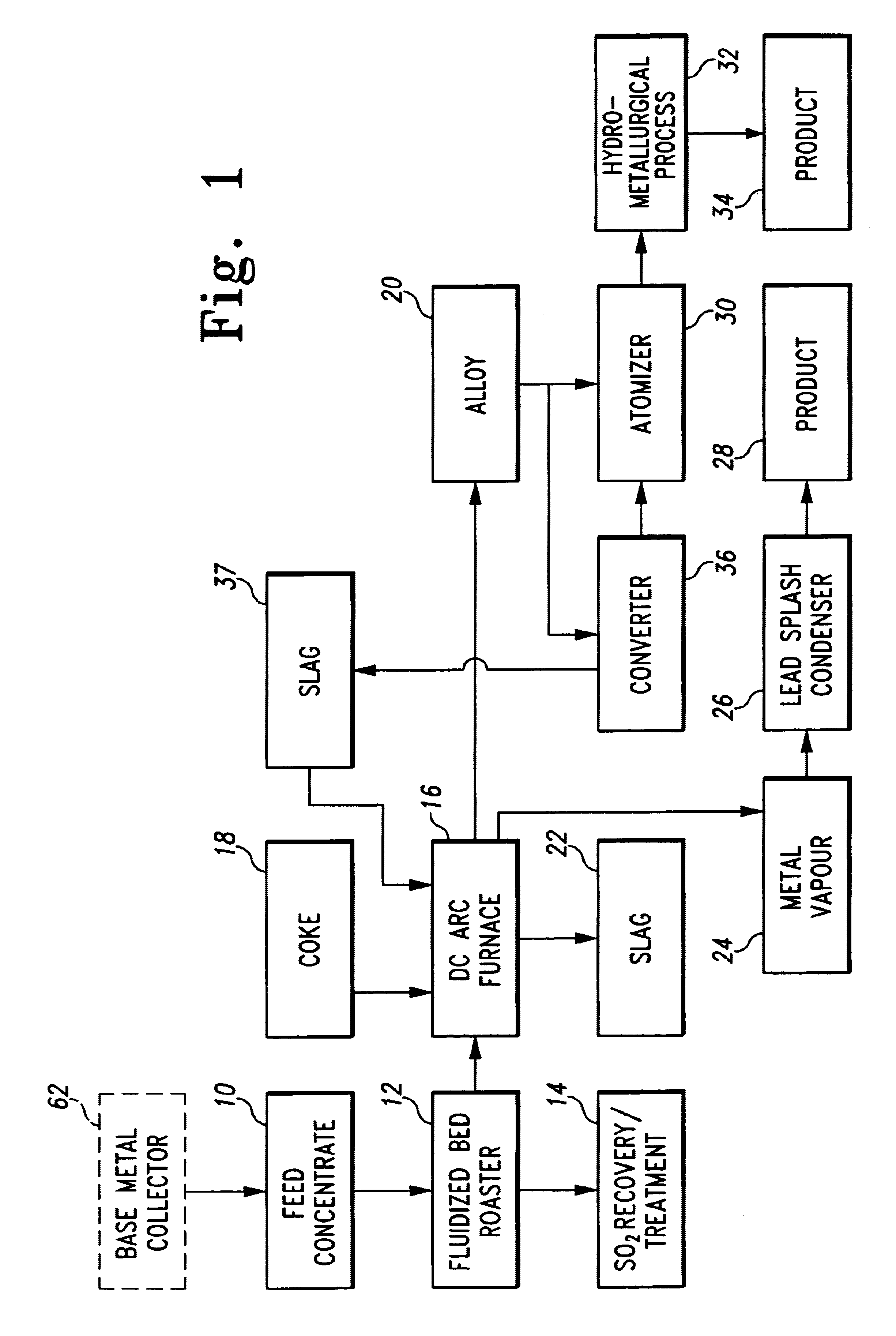

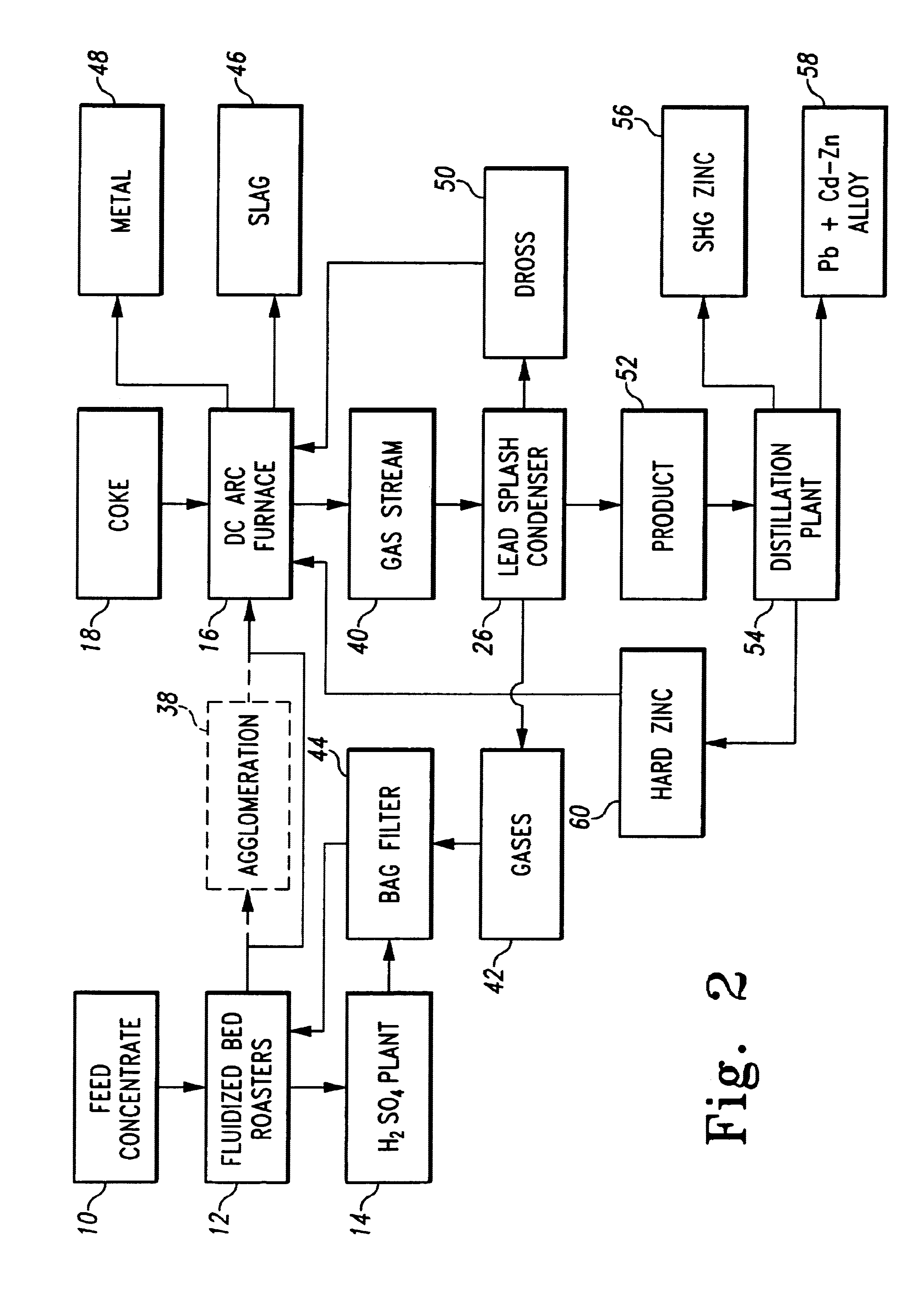

Treatment of metal sulphide concentrates by roasting and electrically stabilized open-arc furnace smelt reduction

InactiveUS6699302B1Improved arc stabilityIncreased energy lossProcess efficiency improvementElectric furnaceDc arc furnaceMetallic sulfide

A process for treating a metal sulphide concentrate which includes the steps of: a) roasting the concentrate to reduce the sulphide content of the concentrate, to a negligible value and b) melting the concentrate, under reducing conditions, in an electrically stabilized open-arc furnace, in particular a DC arc furnace.

Owner:MINTEK

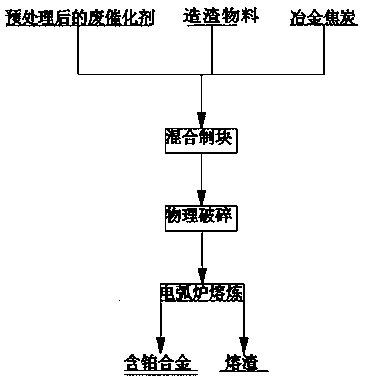

Method for recovering precious metal platinum in car dead catalyst through pyrogenic process

InactiveCN108441647AAchieve recyclabilityAvoiding Insufficient Capture ProblemsProcess efficiency improvementGlass ballDc arc furnace

The invention discloses a method for recovering precious metal platinum in a car dead catalyst through a pyrogenic process. The method comprises the steps that (1) the car dead catalyst is pretreated,and then the car dead catalyst is sealed for standby application; (2) the car dead catalyst obtained in the step (1) is evenly mixed with a carbon reducing agent, a trapping agent and a slagging material according to a certain percentage to prepare blocky mixtures; (3) the mixtures obtained in the step (2) are broken to be placed into a direct current electric arc furnace for high-temperature smelting to obtain melted liquid; and (4) upper-layer slag liquid of the melted liquid obtained in the step (3) is poured out to prepare glassy state or wee glass balls, and a lower-layer precious metalplatinum containing alloy is naturally cooled at room temperature. The method is suitable for high-grade materials, can be used for recovering precious metal platinum from low-grade materials, the process is simple, and the period is short.

Owner:NORTHEASTERN UNIV +1

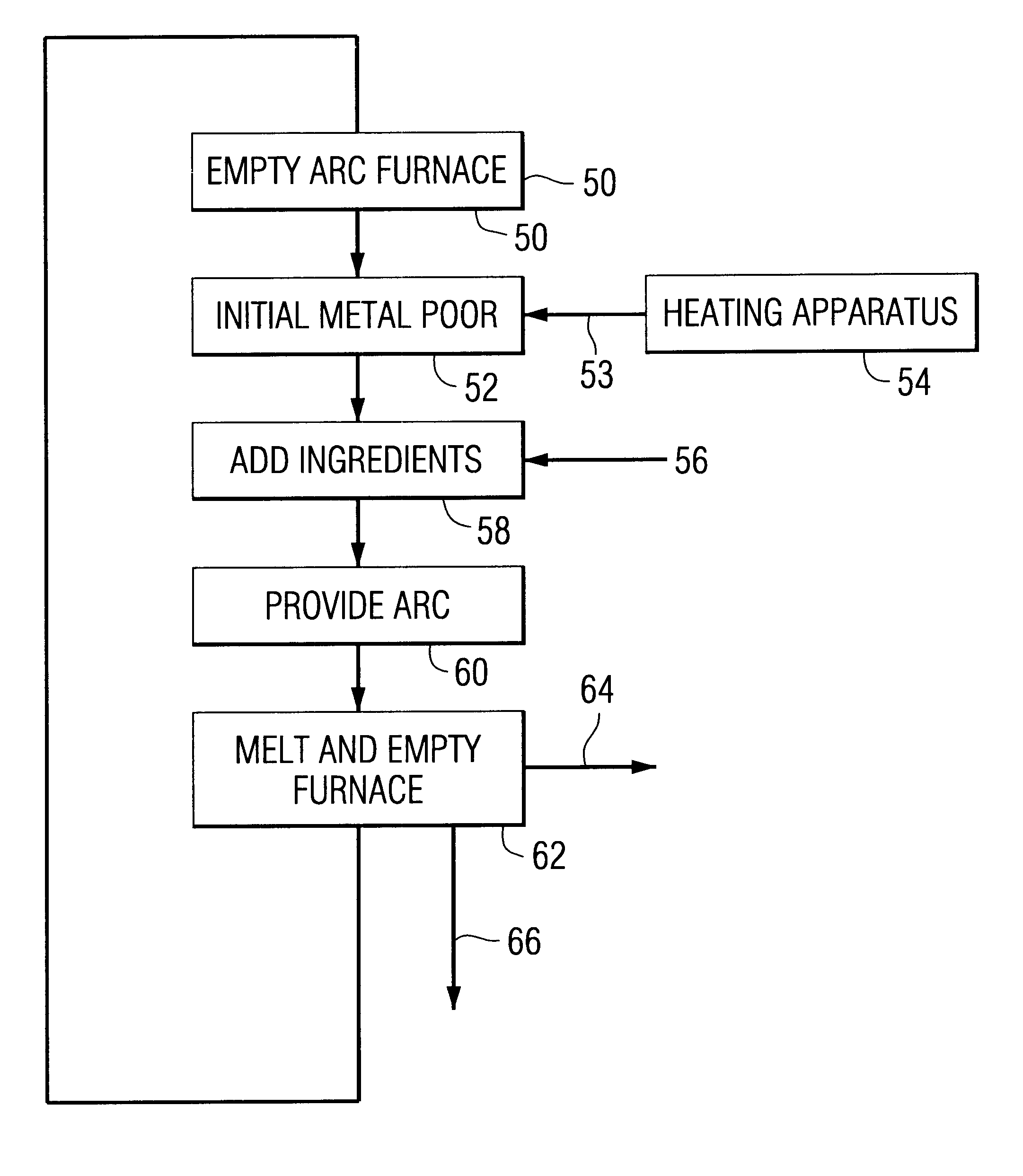

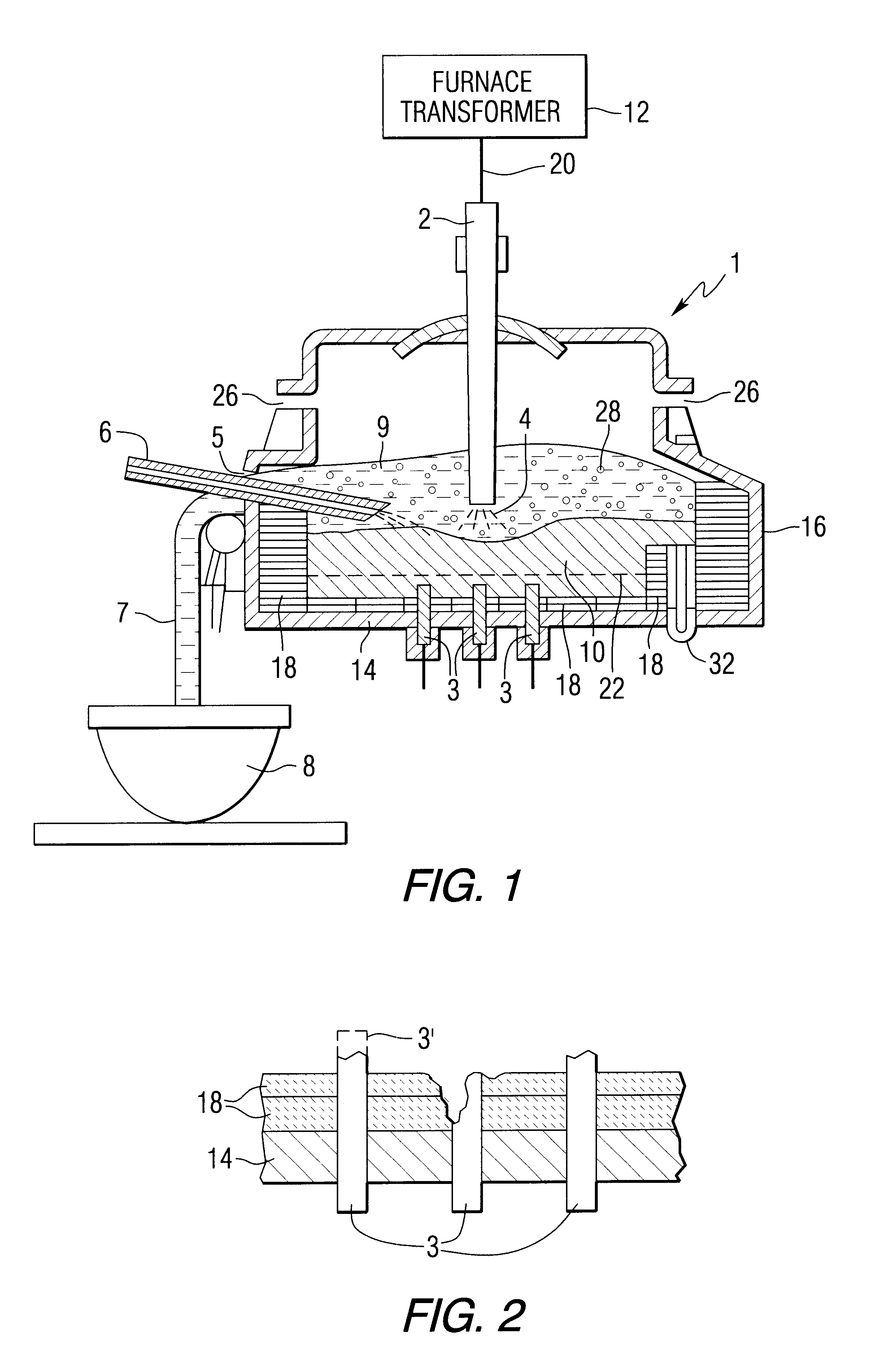

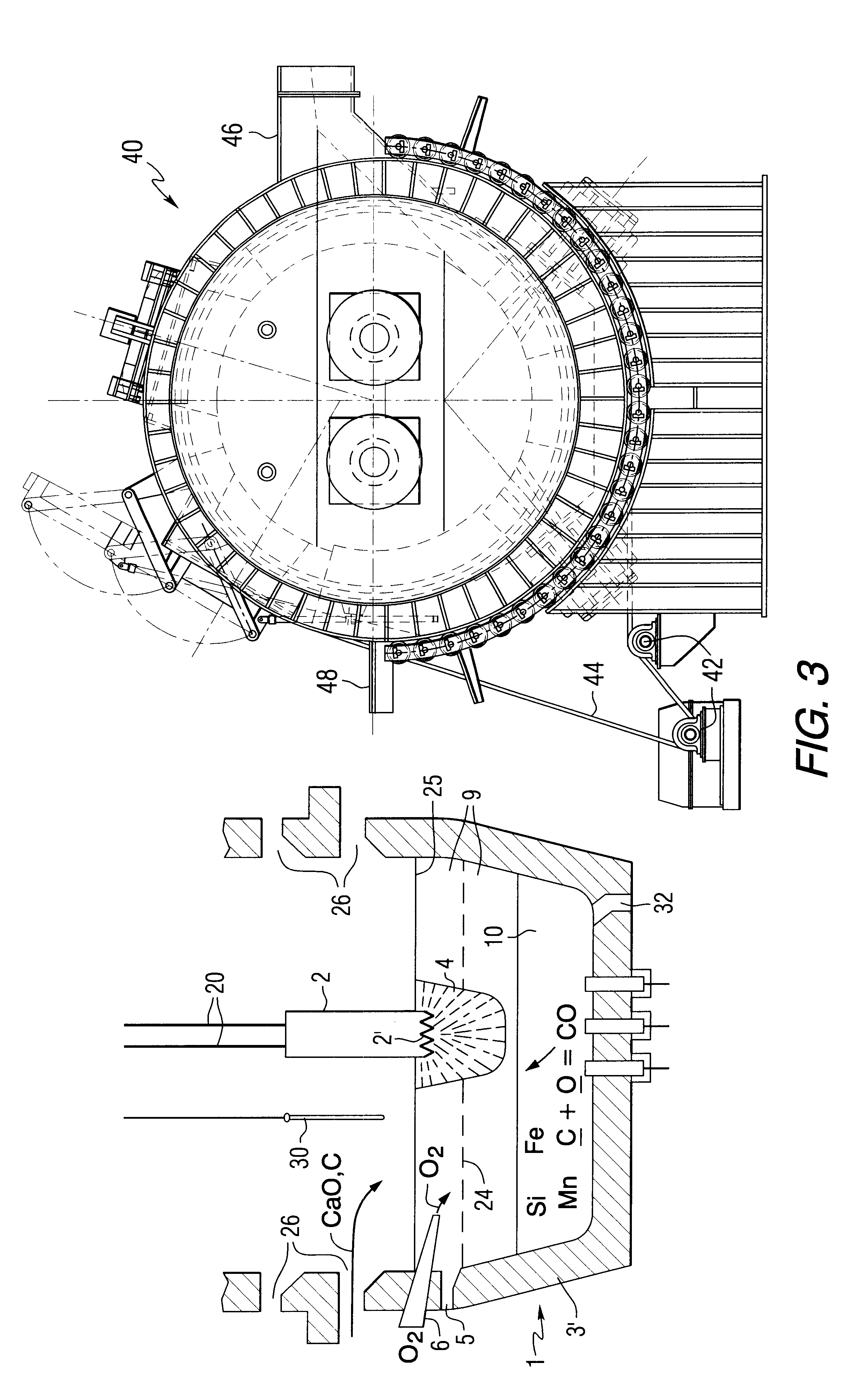

Method to protect the anode bottoms in batch DC electric arc furnace steel production

A batch process for an electric arc furnace (1) to manufacture steel (10) includes the steps of providing an empty furnace having a bottom (14) and sides (16) and electrodes (2, 3); adding molten metal to the empty furnace; adding other necessary ingredients through charge openings (26); applying current to provide an arc (4) and supplying oxygen through an oxygen lance (6) to react and melt the contents of the furnace and form a top slag (9) and bottom molten metal / steel (10); and stopping the reaction and pouring out all the slag through a slag tap (5) and molten metal tap (32) to provide an empty furnace for the next batch run.

Owner:D L SCHROEDER & ASSOCS

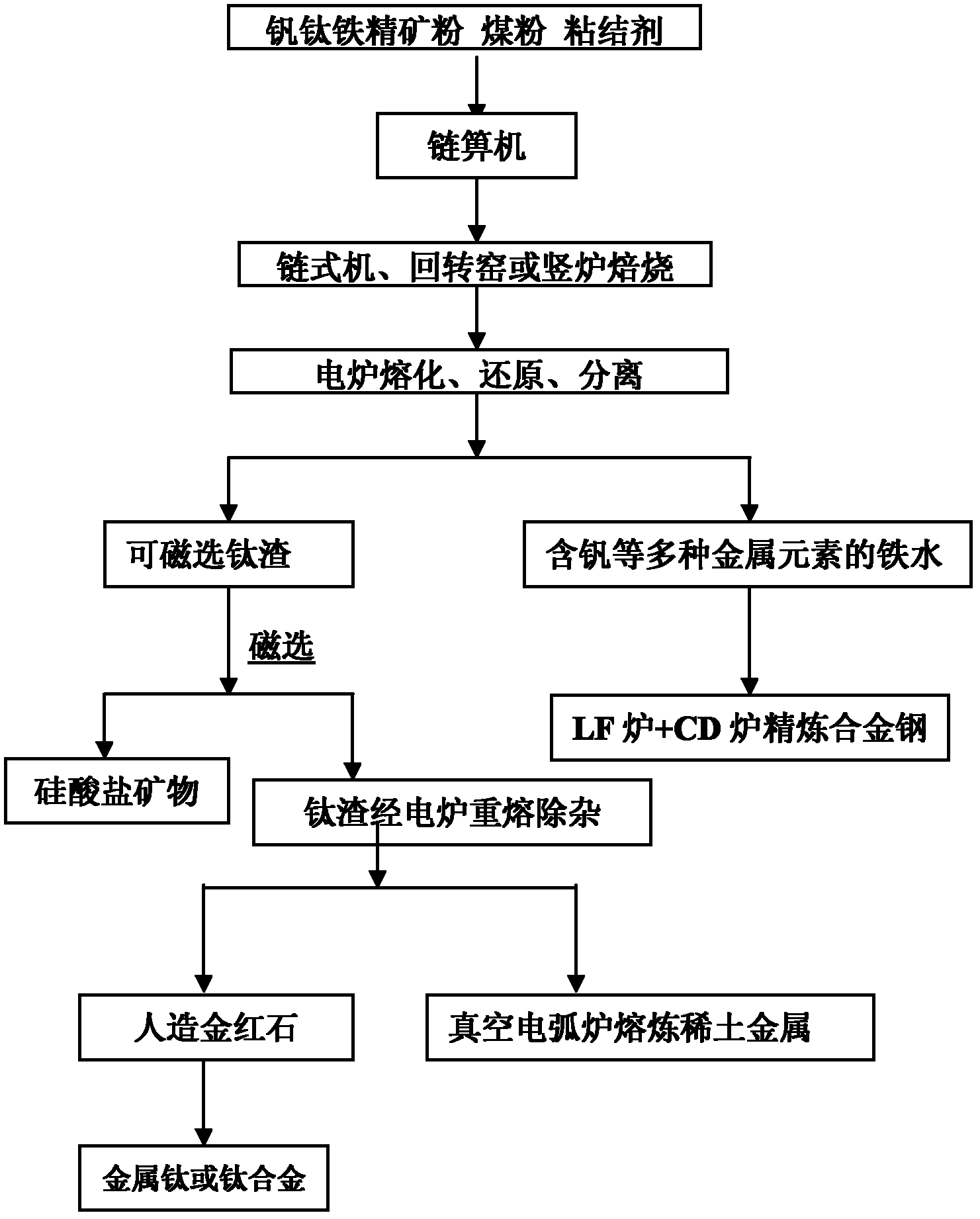

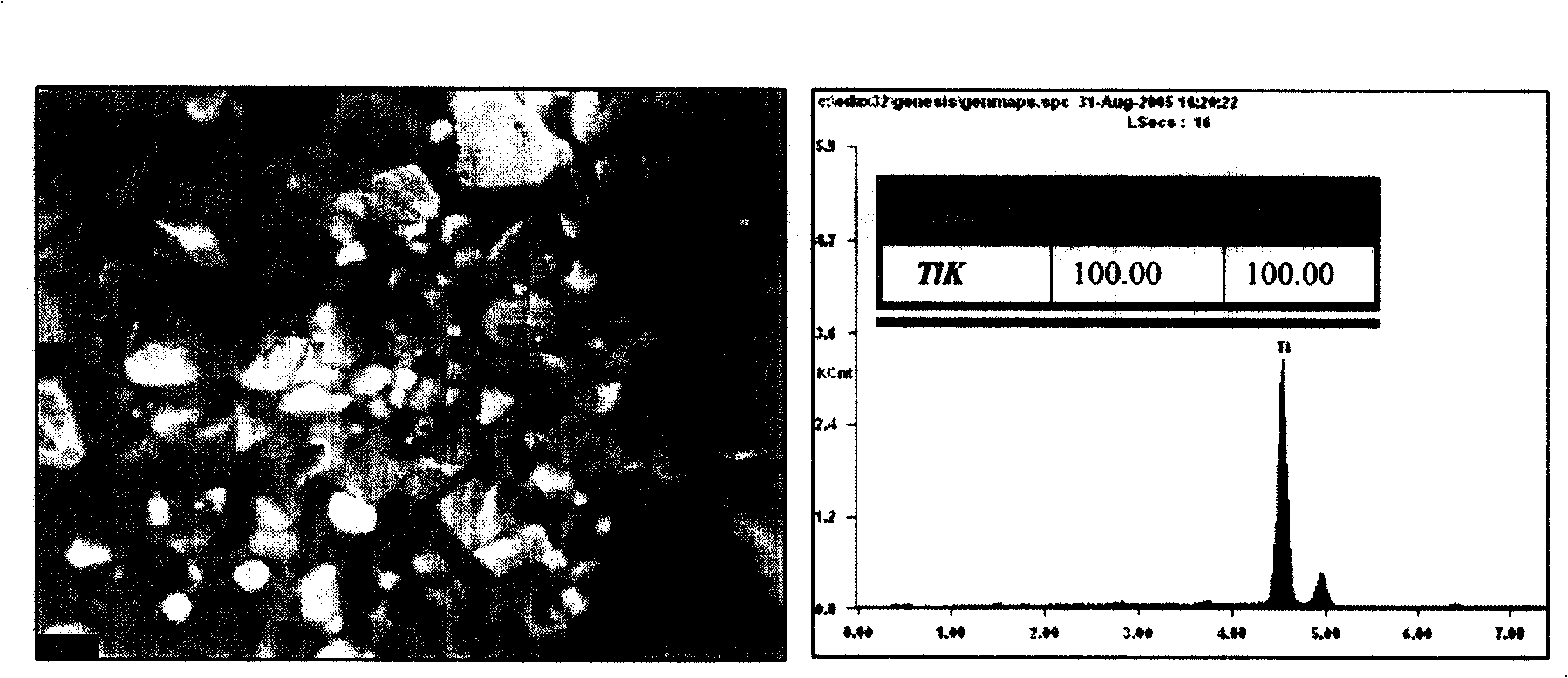

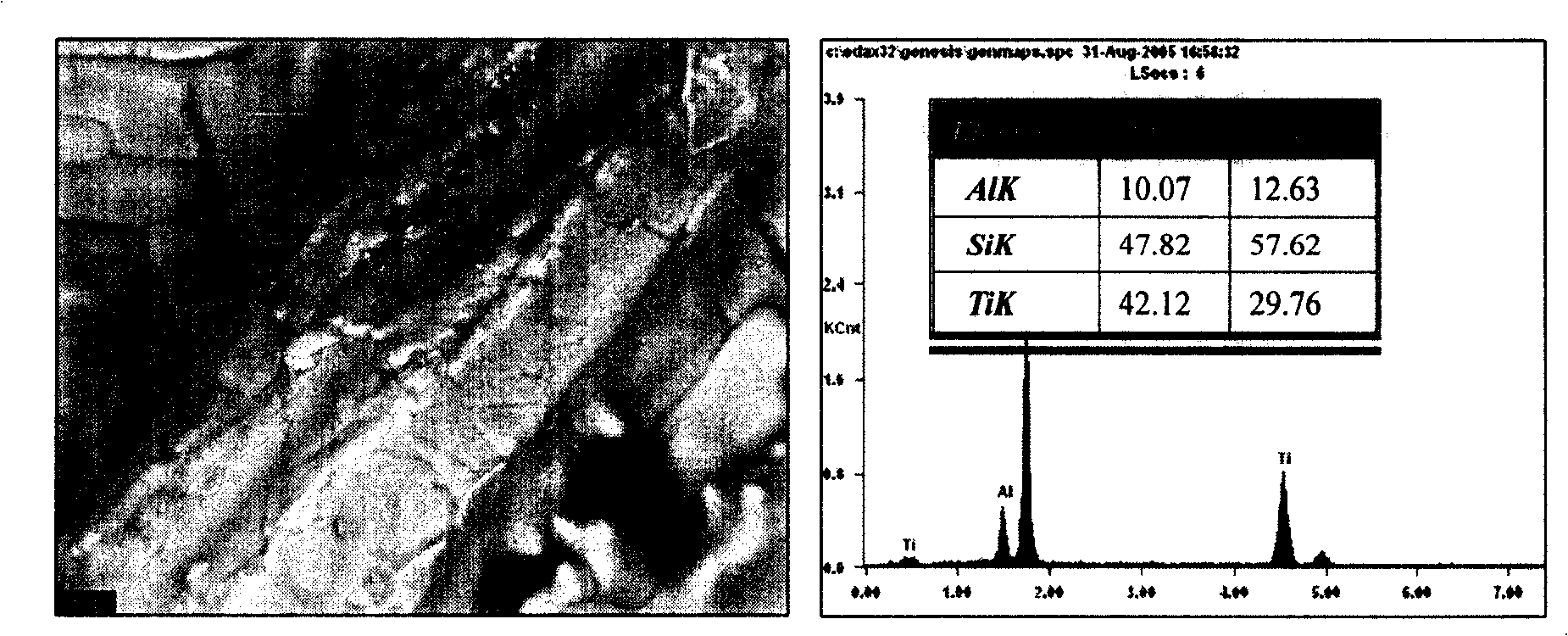

Method for selecting and smelting titanium from vanadium titanomagnetite at low temperature

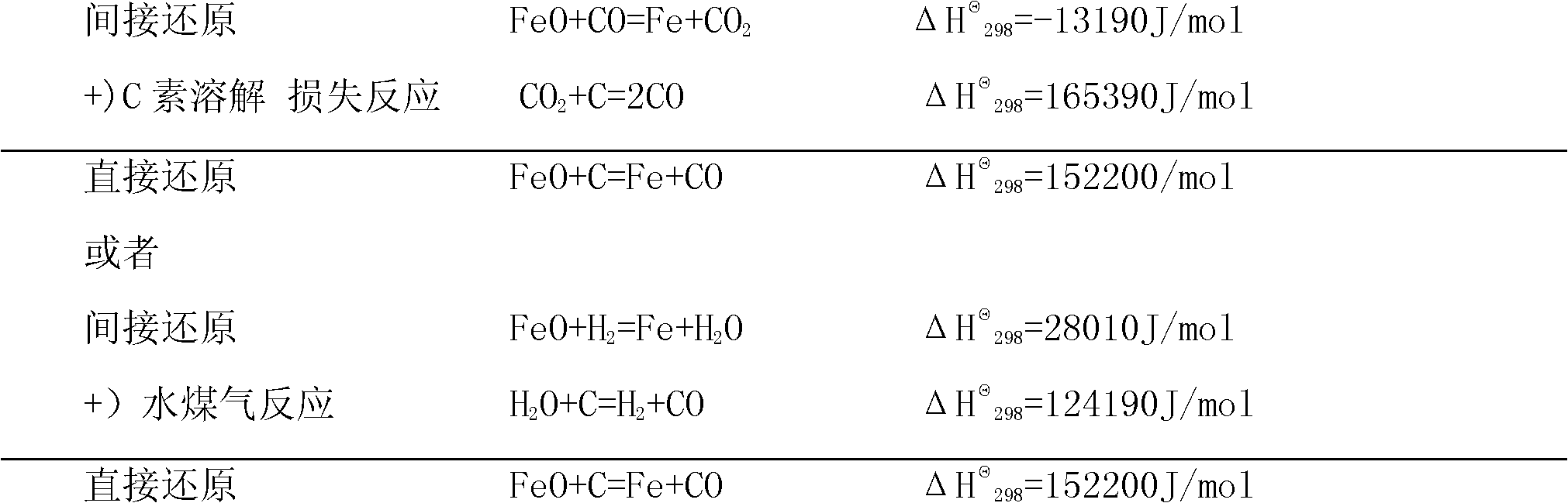

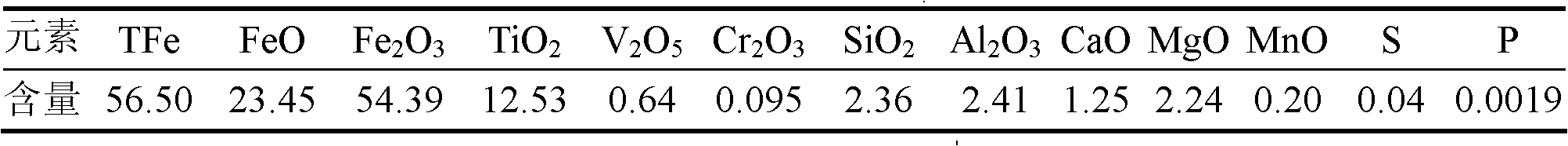

InactiveCN102352423AQuick restoreIncrease magnetic susceptibilityProcess efficiency improvementElectric furnaceDc arc furnaceTitanium metal

The invention relates to a method for selecting and smelting titanium from vanadium titanomagnetite at low temperature, belonging to the technical field of metallurgy. The method comprises the following steps: 1) roasting at the low temperature of 500-1100 DEG C; 2) adding a solid reductant to the roasted product, carrying out reduction smelting at 1100-1300 DEG C, and separating slag and iron torespectively obtain molten iron and titanium slag; carrying out magnetic separation on the titanium slag to remove impurities, thereby obtaining the titanium-rich material; and 4) adding required metal oxide concentrate into a direct-current arc furnace, and directly alloying the molten iron to obtain alloy steel. The smelting method provided by the invention is a brand new smelting method, and changes the existing iron ore selection into titanium ore selection; the pellet is molten and reduced by roasting at low temperature, and the separated molten iron facilitates the addition of ores withdeficient metal elements so as to directly smelt the alloy steel; the titanium slag is subjected to magnetic separation to obtain the titanium-rich material, and the titanium-rich material is furthersmelted to obtain the titanium alloy or titanium metal; and the smelting slag can be used as the raw material for smelting rare earth metals so as to sufficiently and respectively utilize the elements in the ores in one step.

Owner:攀枝花慧泰金属新材料有限公司

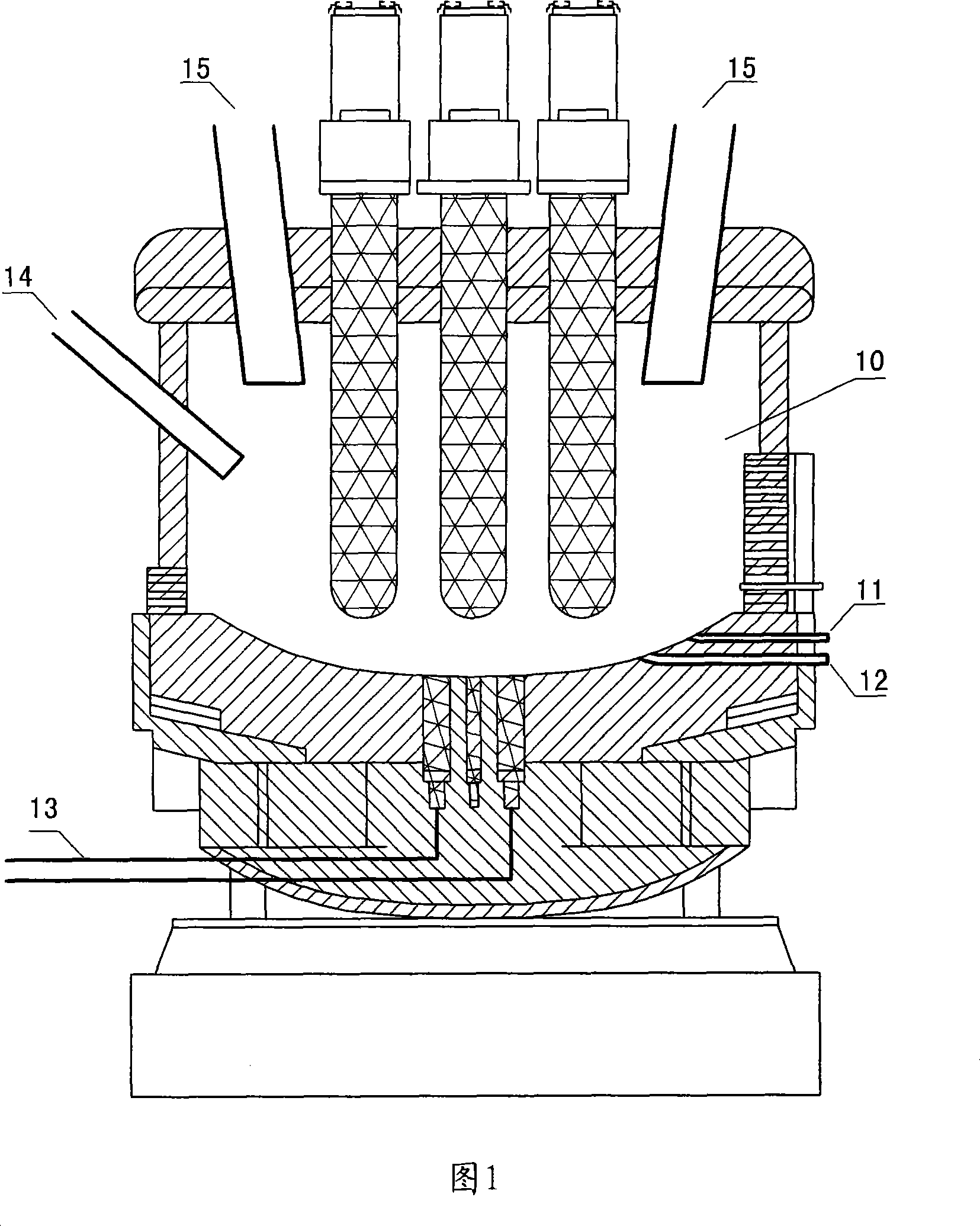

Arc furnace

InactiveCN101029794AMelting is achieved quicklyAchieve meltingLighting and heating apparatusComing outDc arc furnace

This invention discloses a kind of electric-arc furnace in order to make it work continuously and smelt quickly, primely satisfy the demand of low-grade smelt, or large quantity of slag, or the iron-bearing material having the special request in discharging slag. It includes molten pool (10) formed by the stove body and the electrode inserted into molten pool (10). The body of the furnace is sealed, and the feed head (15) inserted into molten pool (10) is installed at the top of it. There are a slag hole (11) and a taphole extending and coming out of the furnace at the bottom of the molten pool (10). Power transformer and the volume of the molten pool (10) are in a ratio of 1-1.5 MVA / t.

Owner:PANZHIHUA IRON AND STEEL

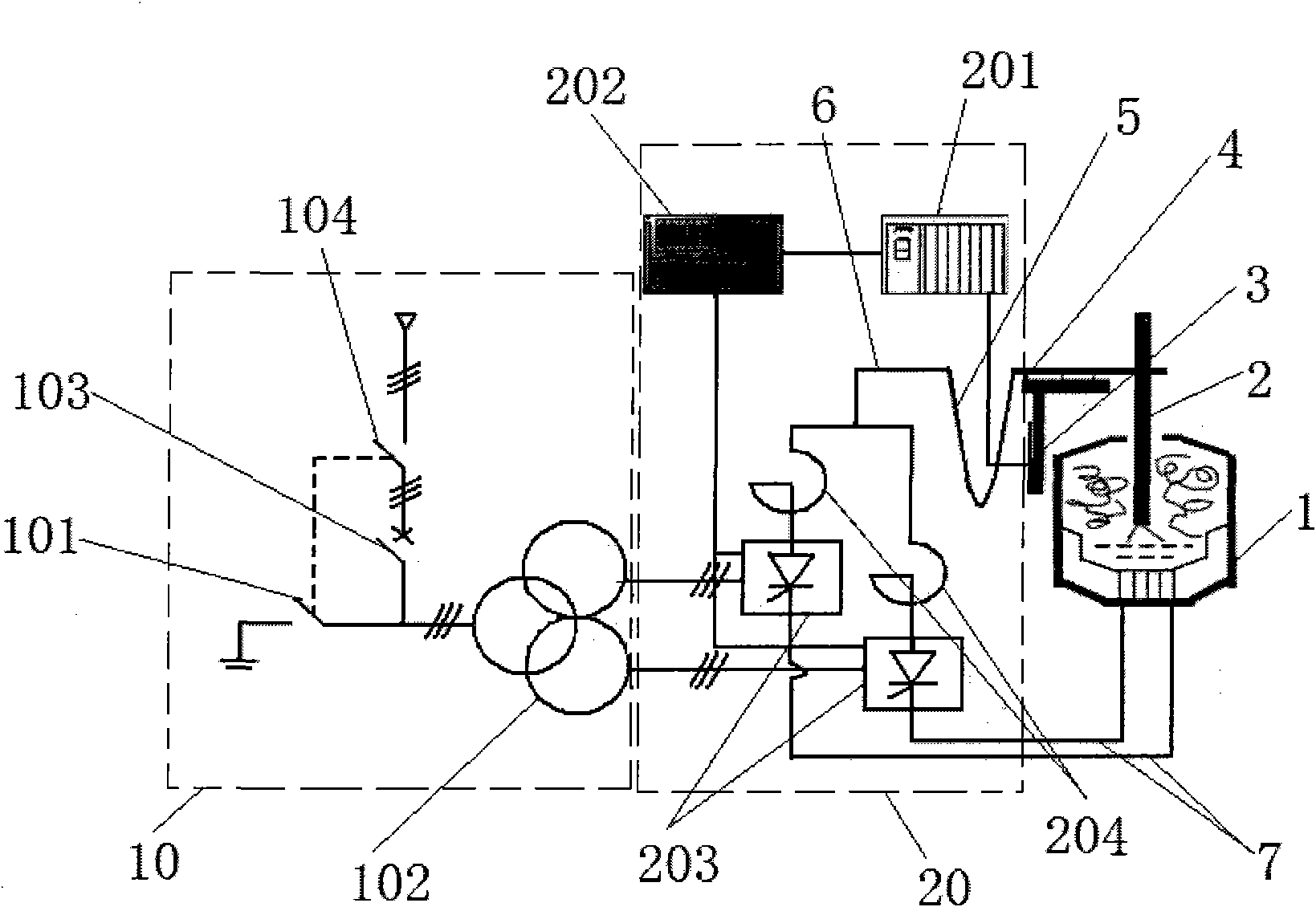

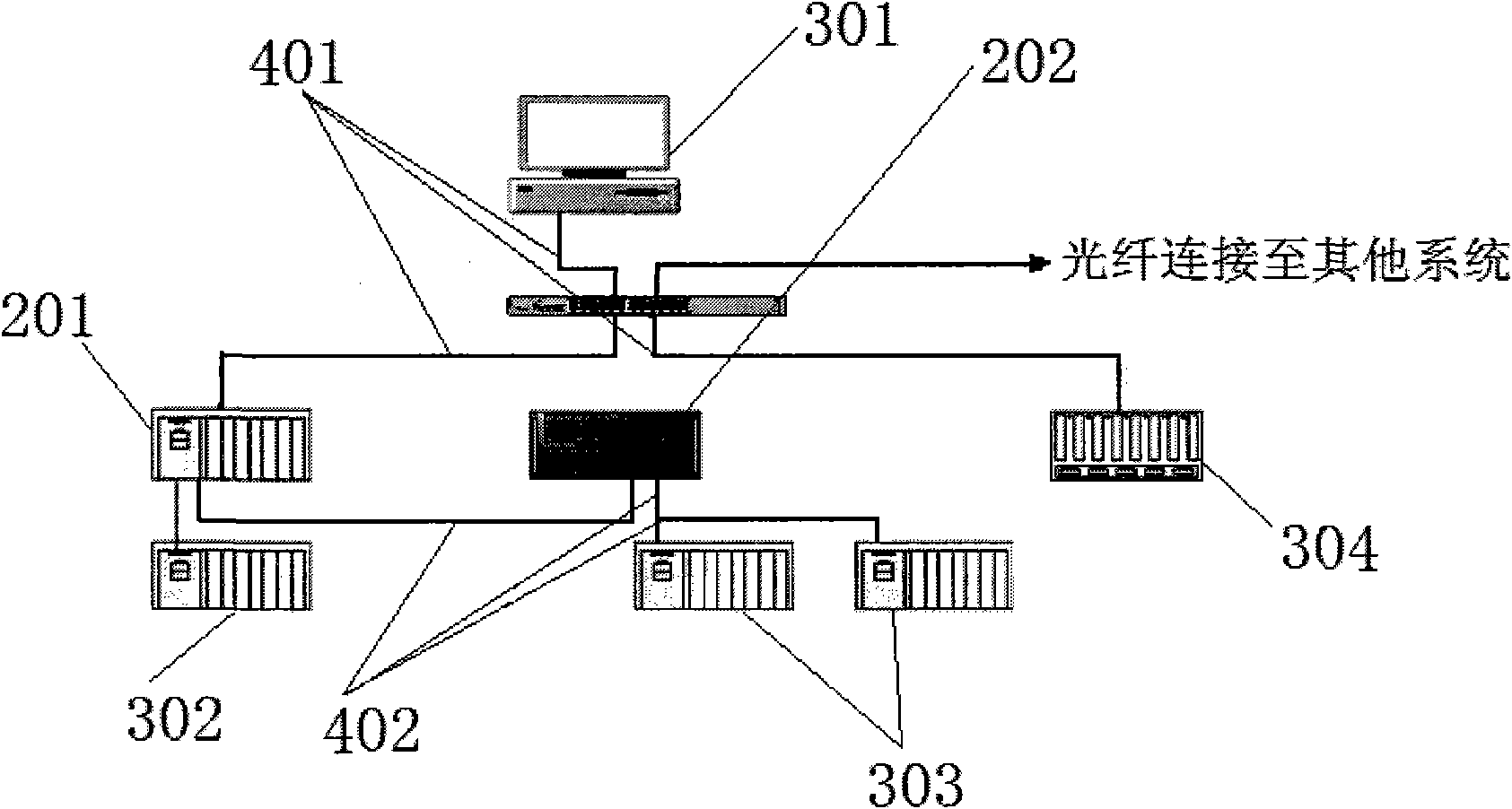

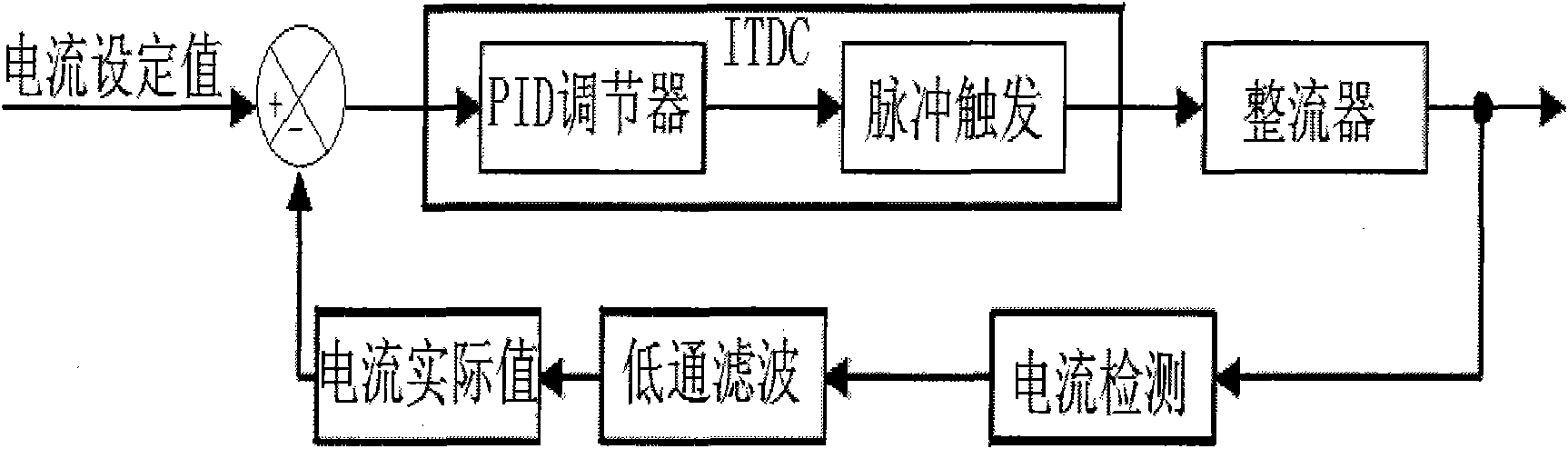

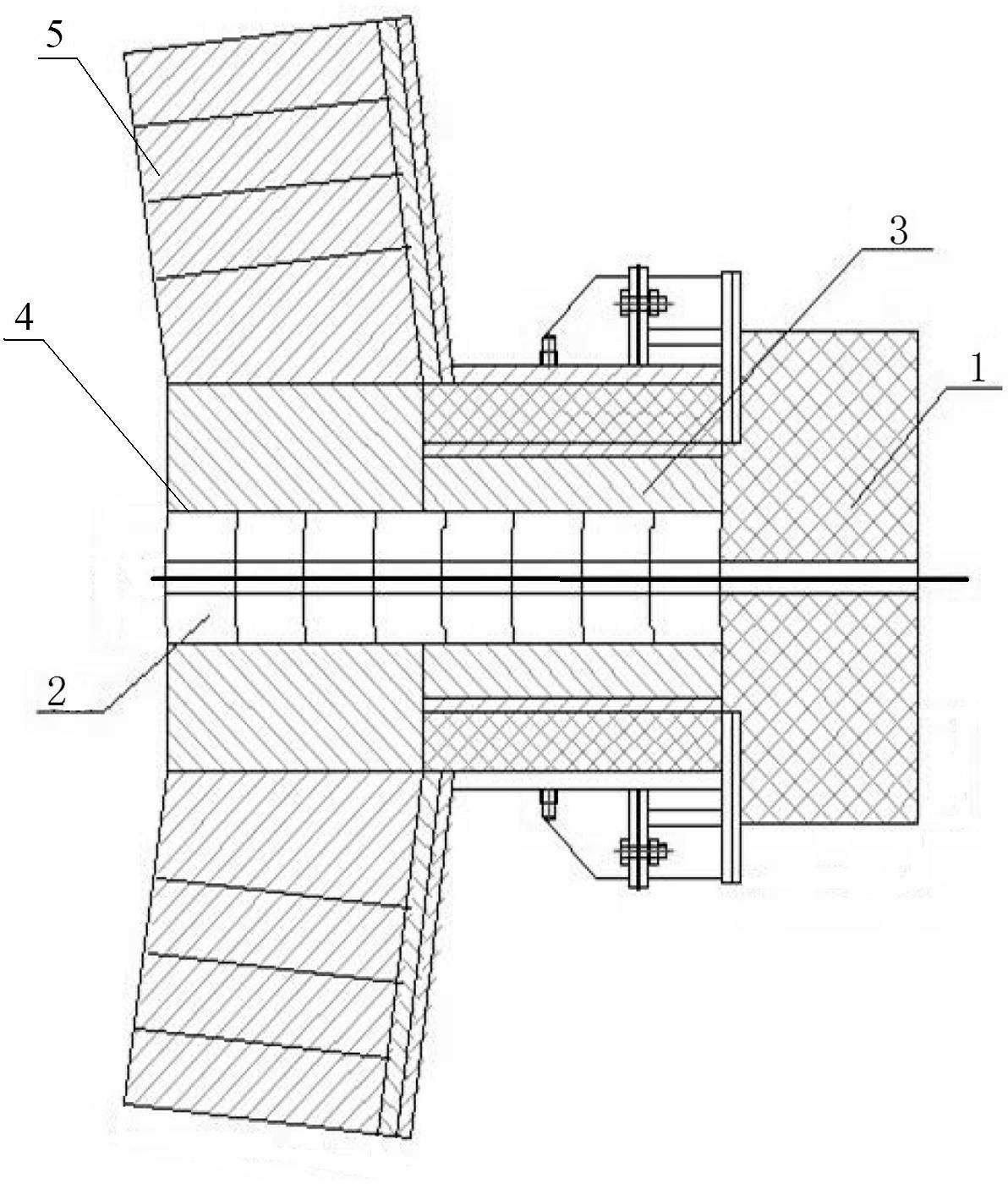

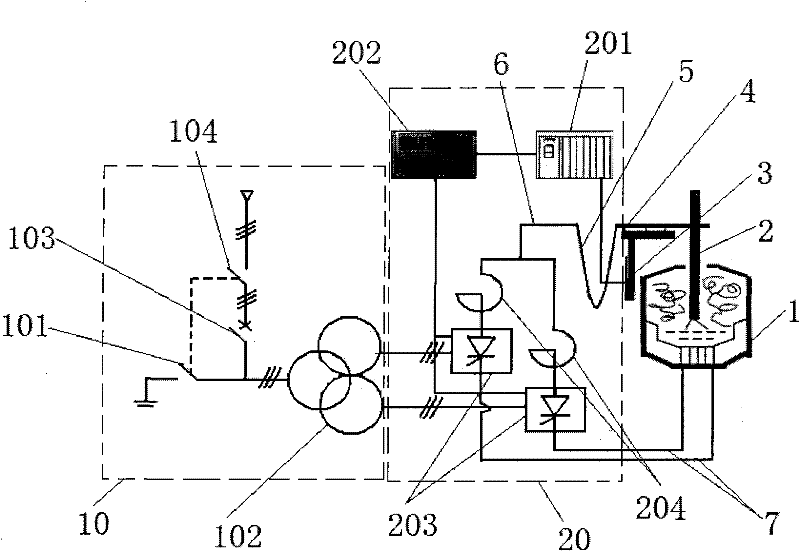

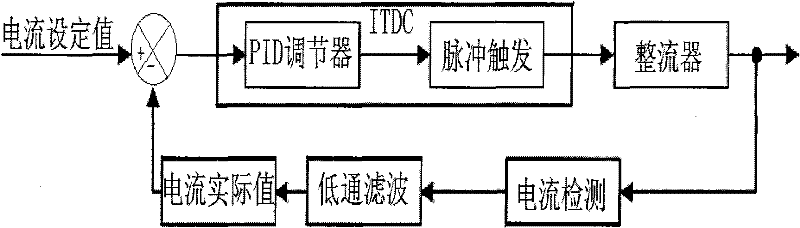

Automatic regulating device of DC electric arc furnace electrode and control method thereof

ActiveCN101782321AEasy to controlControl System Control RealizationElectric heating for furnacesDc arc furnaceEngineering

The invention discloses an automatic regulating device of a DC electric arc furnace electrode and a control method thereof, which comprise an electric arc furnace, a lifting cylinder, a contact tube, an graphite electrode, an arc voltage and current regulating control system and a main power supply loop, wherein the external side of the electric arc furnace is provided with the lifting cylinder, the top of the lifting cylinder is provided with the contact tube, the tail end of the contact tube is provided with the graphite electrode which is erected into the interior of the electric arc furnace, and the arc voltage and current regulating control system is connected with the contact tube, the lifting cylinder and the electric furnace and is simultaneously connected with the main power supply loop. In the invention, the arc voltage and current regulating control system controls a hydraulic proportional valve to control the up-and-down motion of the graphite electrode so as to change the distance between the electrode and the steel liquid level, so the arc length can be controlled to realize the purpose of controlling the arc voltage; a rectifier control system controls the size of the trigger angle Alpha of a rectifier thyristor so as to realize the purpose of controlling the arc current; and the invention has high control accuracy, safety and reliability, and can timely and accurately control the size of the arc voltage and the arc current.

Owner:上海金自天正信息技术有限公司

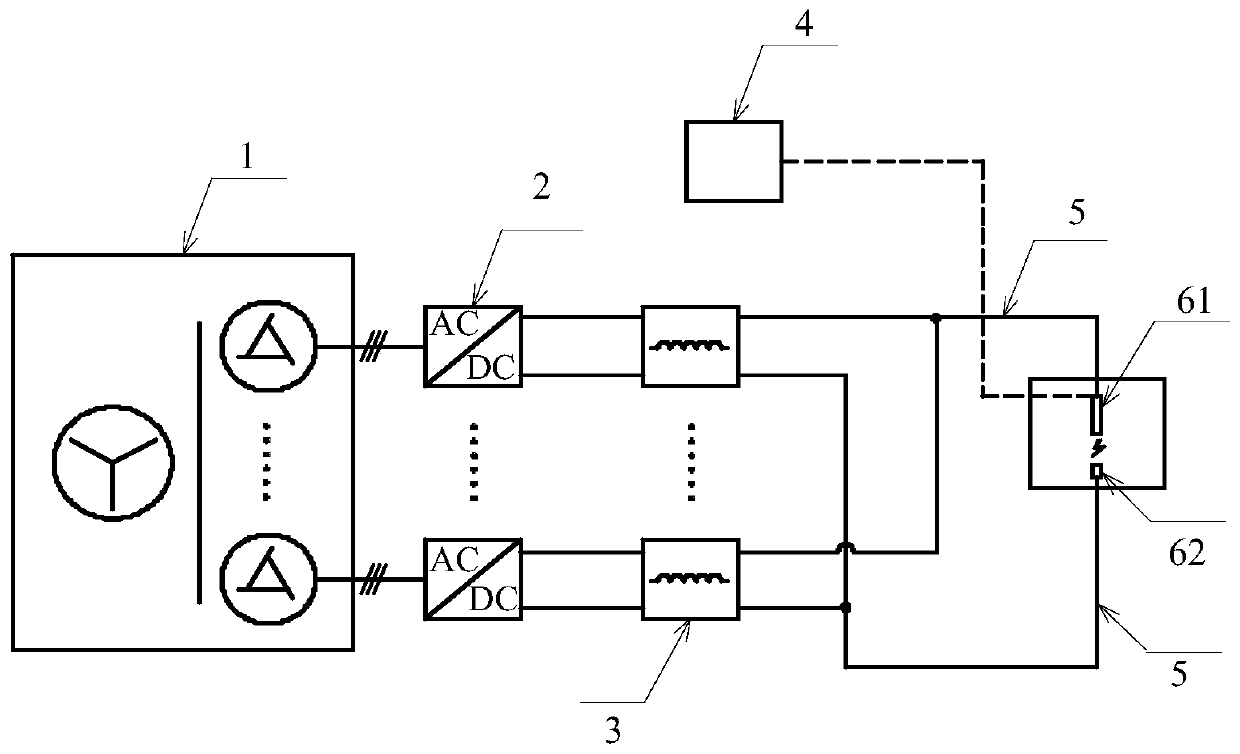

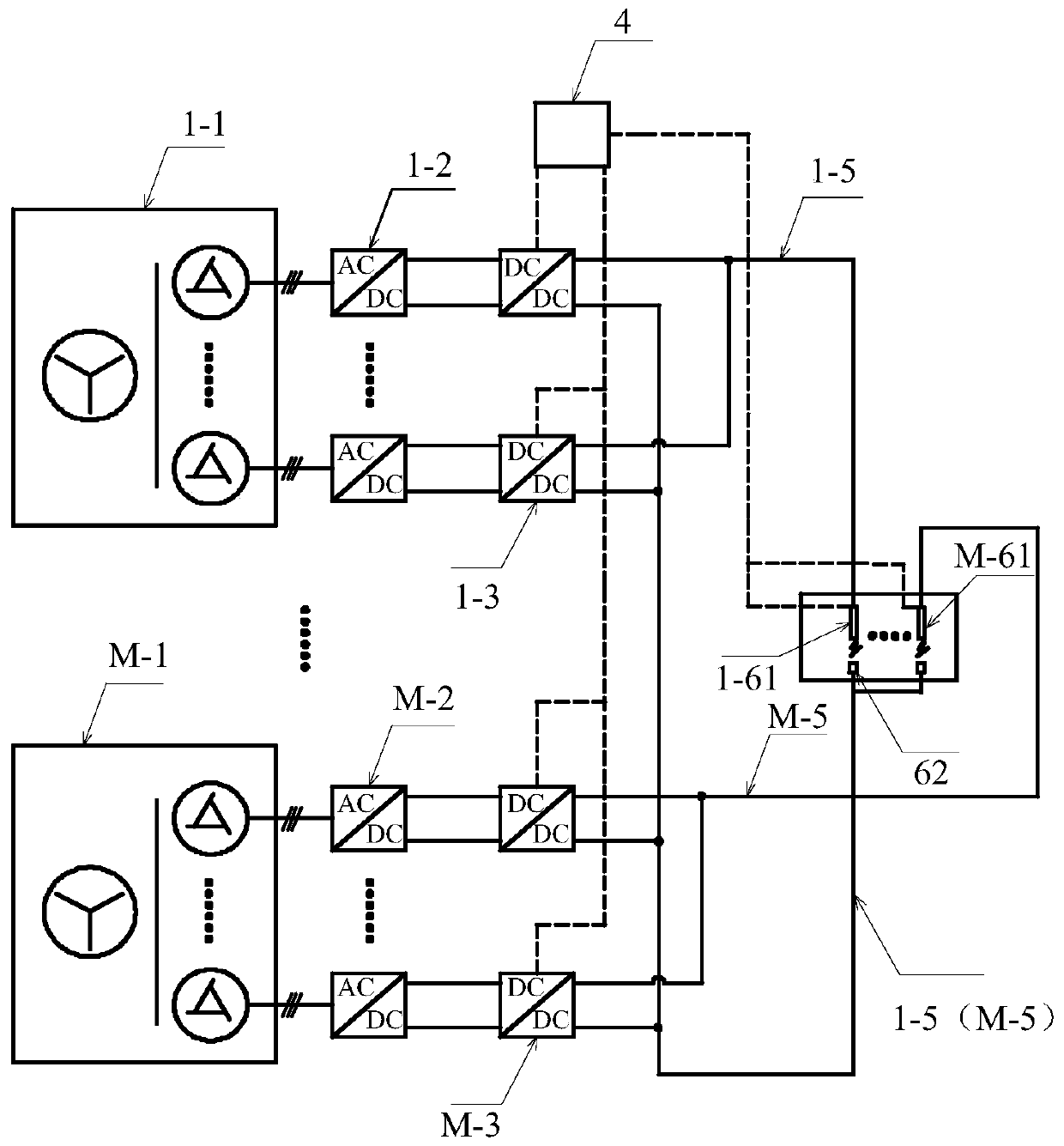

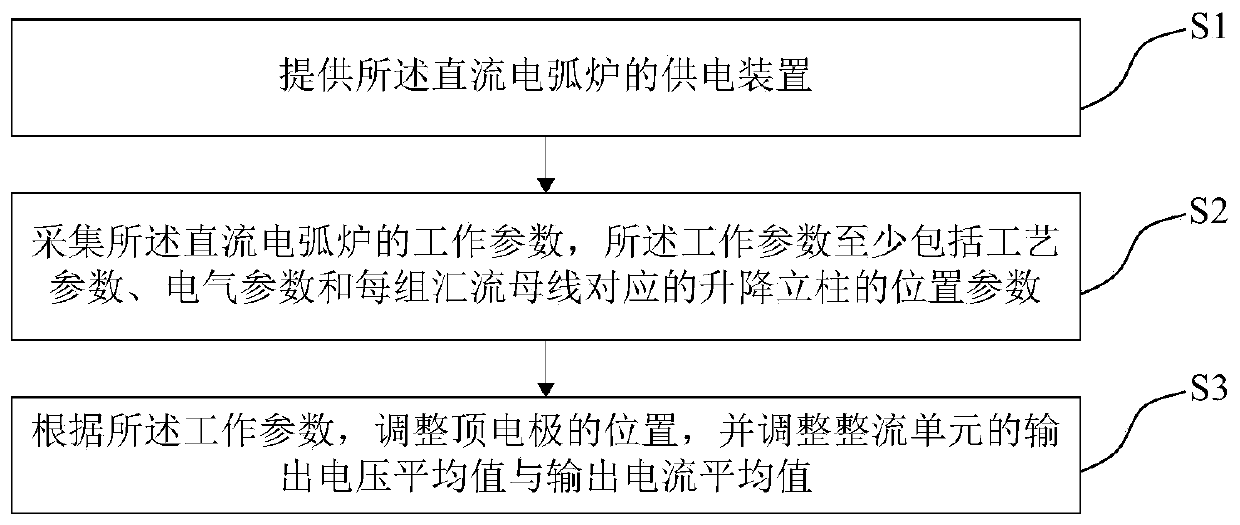

Power supply device and method of DC electric-arc furnace

InactiveCN110247562AMeet supply current requirementsStable high currentAc-dc conversion without reversalElectric discharge heatingDc arc furnaceThermodynamics

The invention provides a power supply device and a power supply method of a DC electric arc furnace. The power supply device comprises a rectification phase-shifting transformer, a rectification unit and a regulator. Through the structural design of a plurality of branches and a plurality of rectification units at the output end of the rectification phase-shifting transformer; and the outputs of the plurality of rectification units are connected in parallel and then are connected to a power supply short network of the DC electric arc furnace through a bus bar, a current output topological structure is formed, stable large current can be provided for one electrode set, power can be supplied to the multiple electrode sets through the multiple current output topological structures, and then the larger power supply current requirement of the DC electric arc furnace can be met. The regulator judges and regulates the position of the top electrode according to the real-time working parameters, so that the lifting mechanism of the top electrode can stably exert the function of stabilizing electric arc combustion for a long time. Meanwhile, the regulator regulates the output voltage and the output current of the rectifying unit according to the feedback of the real-time working parameters, and stable electric energy is provided for the DC electric arc furnace.

Owner:CISDI ENG CO LTD +1

Technology for manufacturing high-quality titanium slag through three-section method

InactiveCN105463186ASimple processReduce calcium and magnesium contentProcess efficiency improvementDc arc furnaceMicrowave

The invention discloses a technology for manufacturing high-quality titanium slag through a three-section method. The technology includes the steps of titanium slag modifying, pressurizing acid leaching and pelleting; high-calcium-magnesium and low-grade titanium slag raw materials are subjected to ball grinding to -200 meshes, evenly mixed with a modifying agent, enter a rotary kiln to be roasted and then filtered and washed to obtain filter slag; the obtained filter slag is put into a pressurizing kettle to be subjected to pressurizing acid leaching, the filter slag is washed, filtered, dried and roasted after being discharged out of the kettle, and fine-grain titanium slag is obtained; and the obtained fine-grain titanium slag and a bonding agent are mixed evenly and put into a pelletizer for pelleting, microwave drying is conducted, and the high-quality titanium slag is obtained. The technology is simple in process, titanium slag smelting smoke of a large airtight direct-current electric arc furnace can be comprehensively utilized, and the prepared high-quality titanium slag is low in calcium and magnesium content and can be used as the raw material of a boiling chlorination process. Meanwhile, adaptability to titanium slag raw materials is high, and the technology can be suitable for titanium slag with the content of TiO2 being 35%-70%.

Owner:KUNMING METALLURGY INST

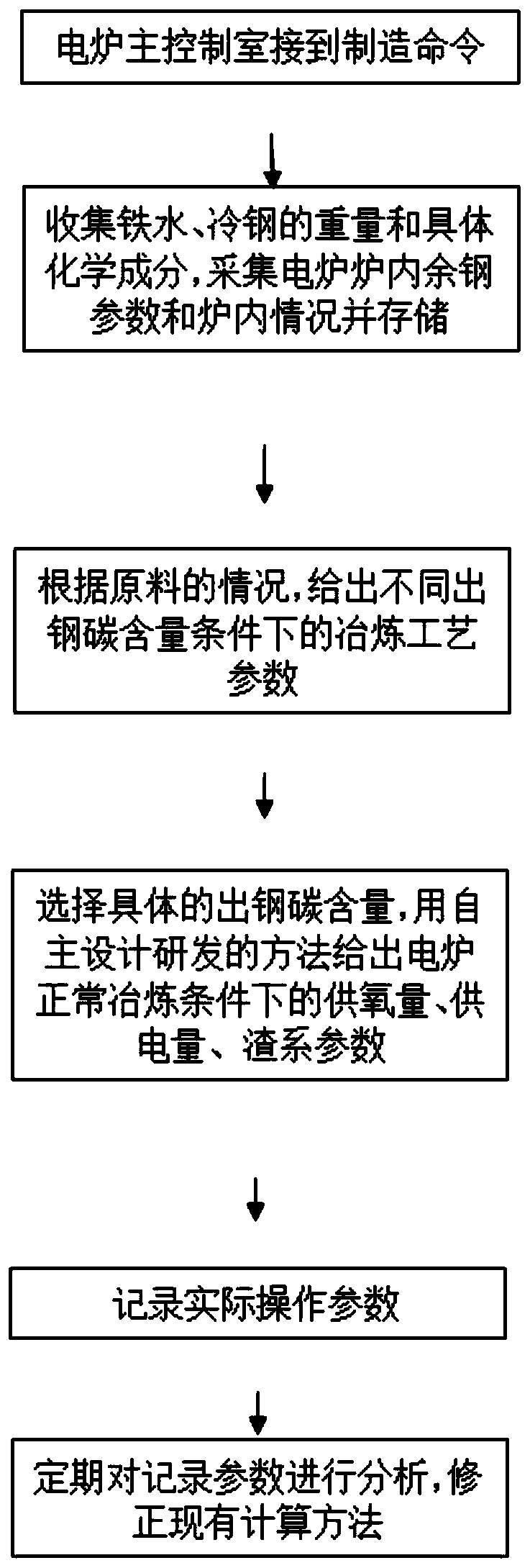

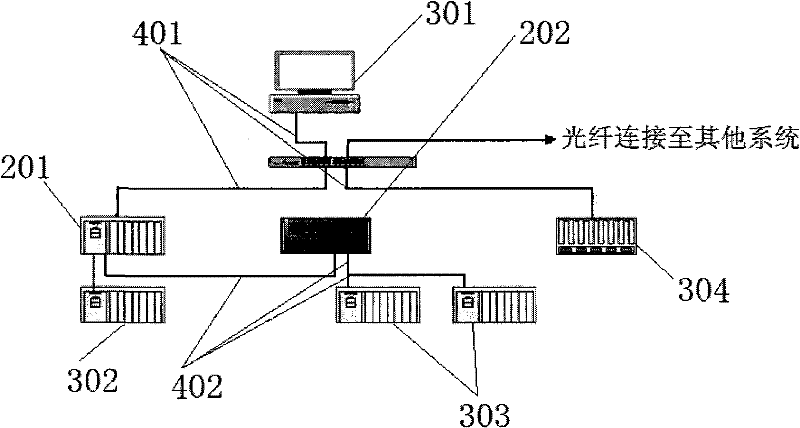

Prediction system and prediction method for tapping carbon component of 100t direct-current electric arc furnace

ActiveCN110322057ASimple processImprove quality controlSteel manufacturing process aspectsForecastingDc arc furnaceData acquisition

The invention relates to a prediction system and a prediction method for tapping carbon components of a 100t direct-current electric arc furnace. The prediction system comprises a data acquisition module, a data storage module, a data analysis module and an operation guidance module, the prediction method comprises the following steps: the data acquisition module acquires main raw material data offurnace smelting; the data storage module is used for storing the acquired data and establishing a database; the data analysis module performs analysis and comparison according to the data provided by the database, and proposes oxygen supply and power supply parameters under different tapping carbon content conditions; and the operation guidance module gives an oxygen supply intensity value and apower supply operation curve according to the data provided by the analysis module and in combination with operation rules and tapping carbon requirements. According to the method, a large amount ofdata is collected in the field production process, database resources are used for supporting accurate logic analysis and judgment, and operation process parameters for different tapping carbon components are deduced according to specific steel grade carbon component requirements.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

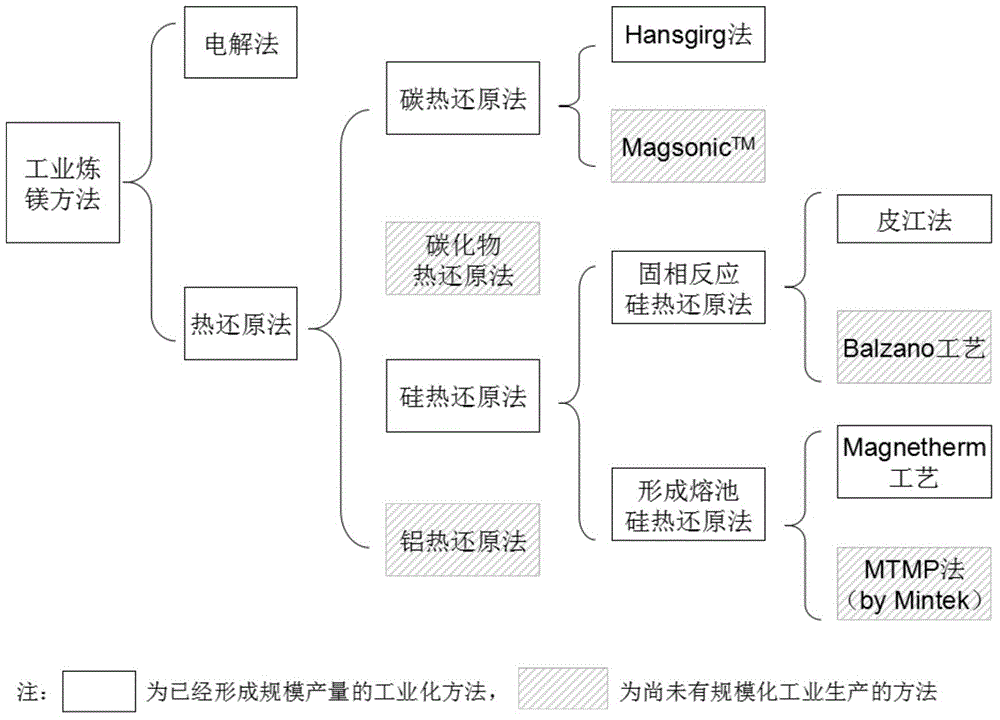

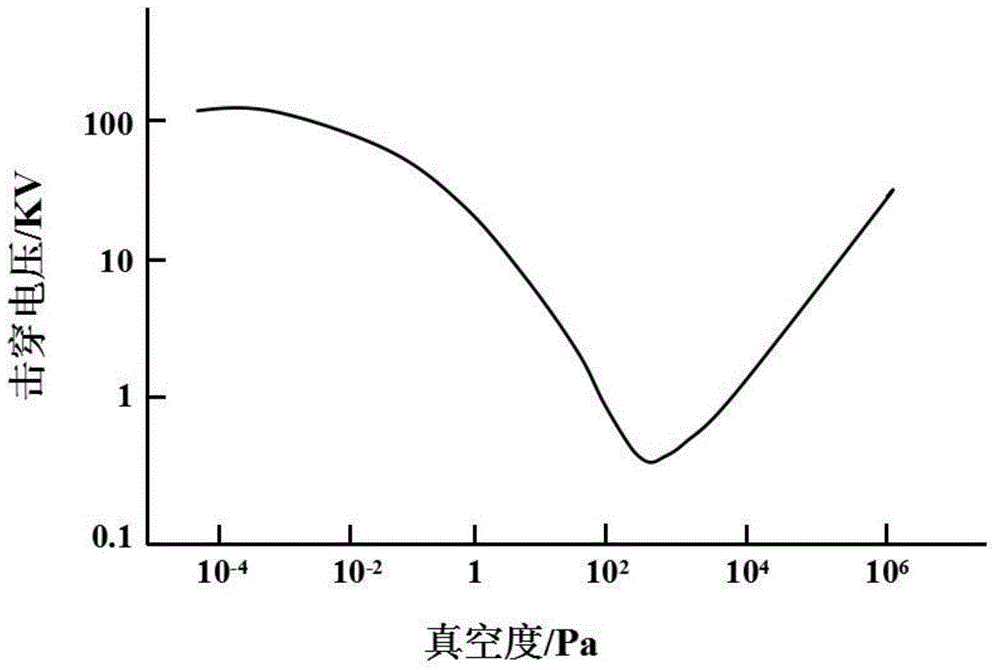

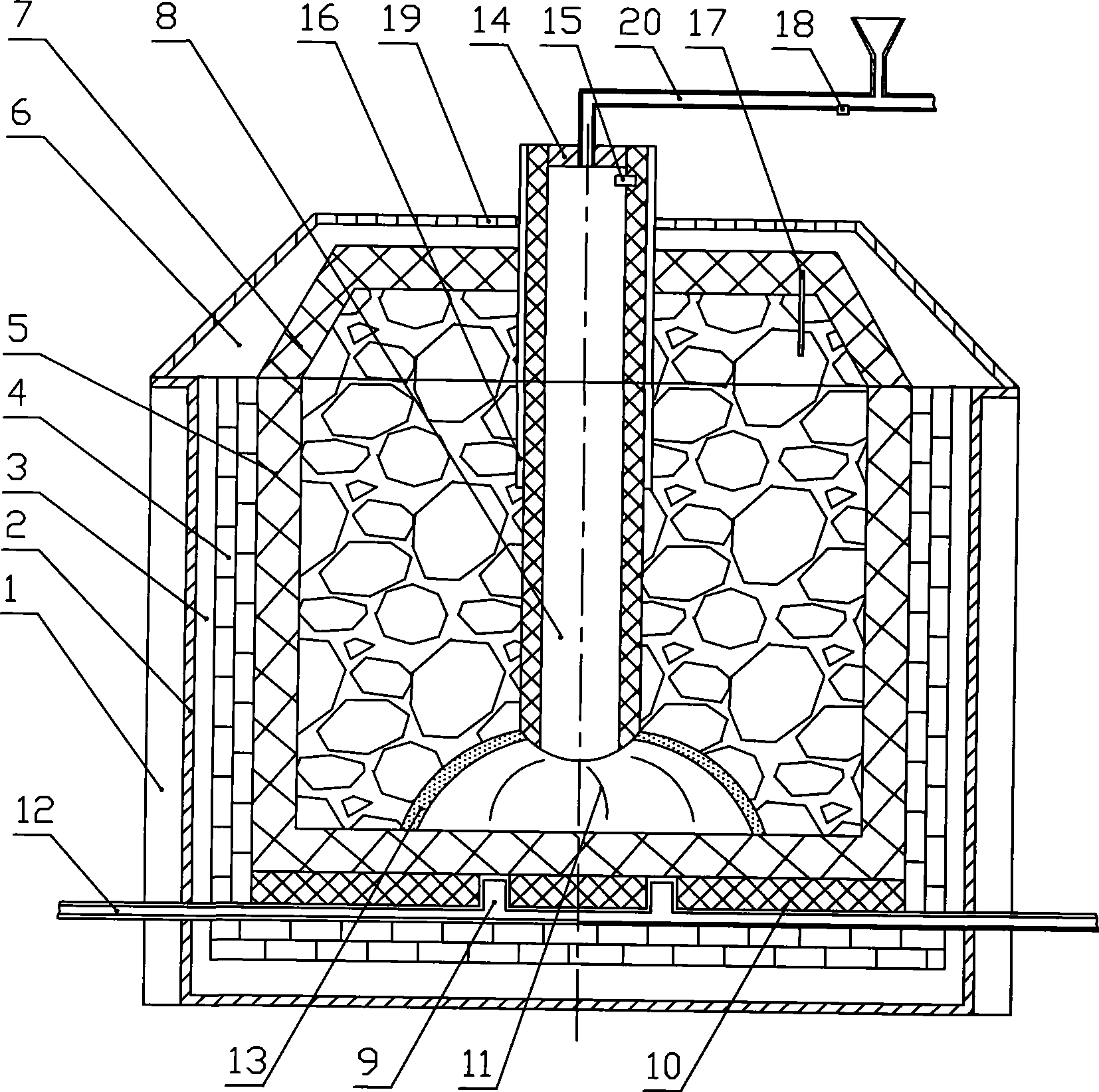

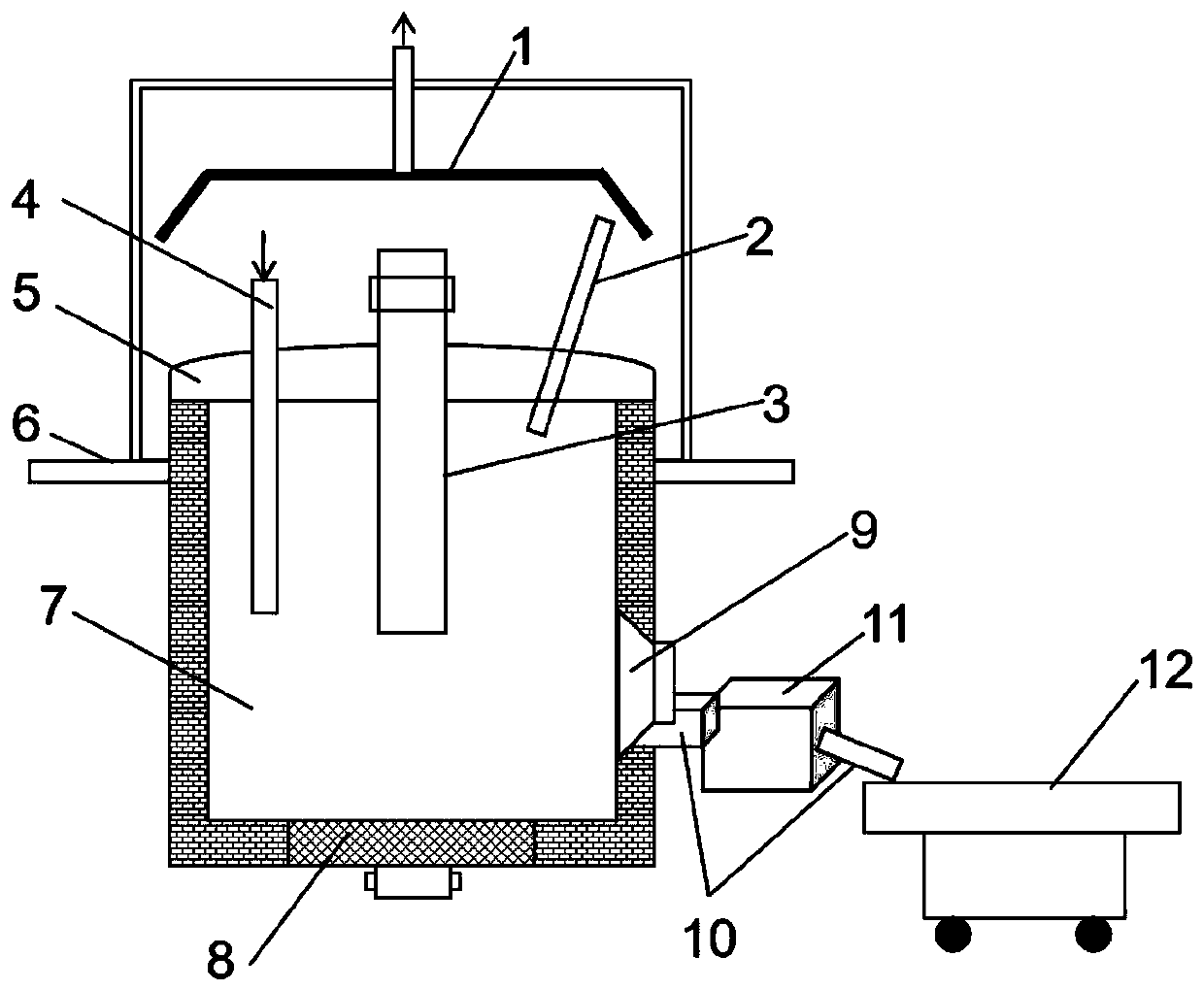

Vacuum electrothermal magnesium smelting apparatus with protector

ActiveCN104651636AReduce adverse effectsImprove securityProcess efficiency improvementDc arc furnaceThermal insulation

The invention relates to a vacuum electrothermal magnesium smelting apparatus with a protector, belonging to the technical field of nonferrous metal magnesium extraction metallurgy. The apparatus comprises an electric-heating vacuum electric furnace, wherein the lower part is provided with a liquid outlet, and the upper part is provided with a liquid injection port, a feed port and a magnesium vapor outlet; the magnesium vapor outlet is communicated to a magnesium vapor condensing chamber through a sealed thermal-insulation pipeline, and then connected to a vacuum pump; the liquid outlet of the vacuum electric furnace is positioned inside a vacuum deslagging chamber; and the vacuum electric furnace and vacuum deslagging chamber are arranged inside an argon protective chamber. The vacuum magnesium smelting reactor (especially hollow cathode direct-current arc furnace) by using electricity as the heat source has high electrothermal power, is suitable for large-scale production, and greatly enhances the productive capacity of metal magnesium. The peripheral argon protective barrier can prevent air from leaking into the magnesium smelting furnace, which can cause severe safety production accidents, thereby greatly enhancing the safety of the magnesium smelting production device. The vacuum electrothermal magnesium smelting apparatus implements continuous production, greatly enhances the single-furnace magnesium yield, and obtains the original metal magnesium with lower impurity content.

Owner:牛强

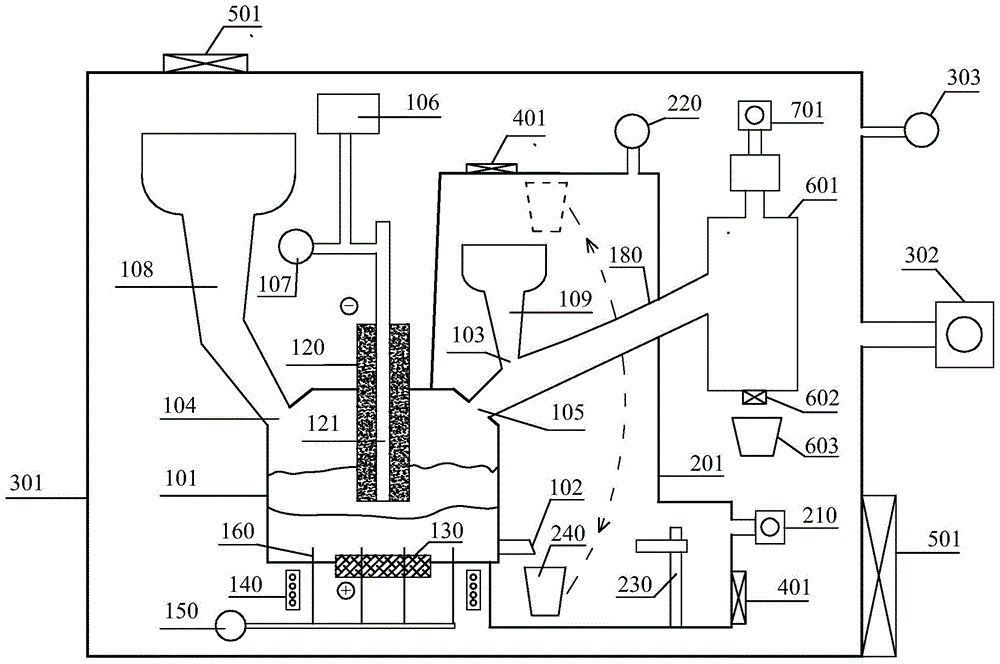

Sealed submerged arc furnace system

ActiveCN101532781AImprove securityEliminate potential safety hazardsEnergy industryCharge manipulationWaste heat recovery unitElectricity

The invention relates to a sealed submerged arc furnace system, and solves the problems that the existing direct current electrical arc furnace can not be applied to the submerged arc furnace and an alternating current sealed submerged arc furnace, and has high power consumption, large electrode consumption and low safety. The solution is as follows: the sealed submerged arc furnace system comprises a sealed submerged arc furnace, a waste heat recovery device and a waste gas treatment and utilization device; the waste heat recovery device comprises a turbonator and a heat pump; the waste gas treatment and utilization device comprises a waste heat boiler connected with a waste gas outlet of the sealed submerged arc furnace, a waste gas dust removing device connected with a gas outlet of the waste heat boiler and a waste gas reaction device connected with a gas outlet of the waste gas dust removing device; a water inlet of the heat pump is connected with a water outlet of a hollow electrode cooling system and a water outlet of the turbonator; a hot water outlet of the heat pump is connected with the inlet of a heat exchanger of the waste heat boiler; a cold water outlet of the heat pump is connected with a water inlet of the hollow electrode cooling system; and the outlet of the heat exchanger of the waste heat boiler is connected with a steam inlet of the turbonator. The sealed submerged arc furnace system has the advantages of high safety, improvement of product quality and yield and low consumption.

Owner:北京平希节能环保科技有限公司

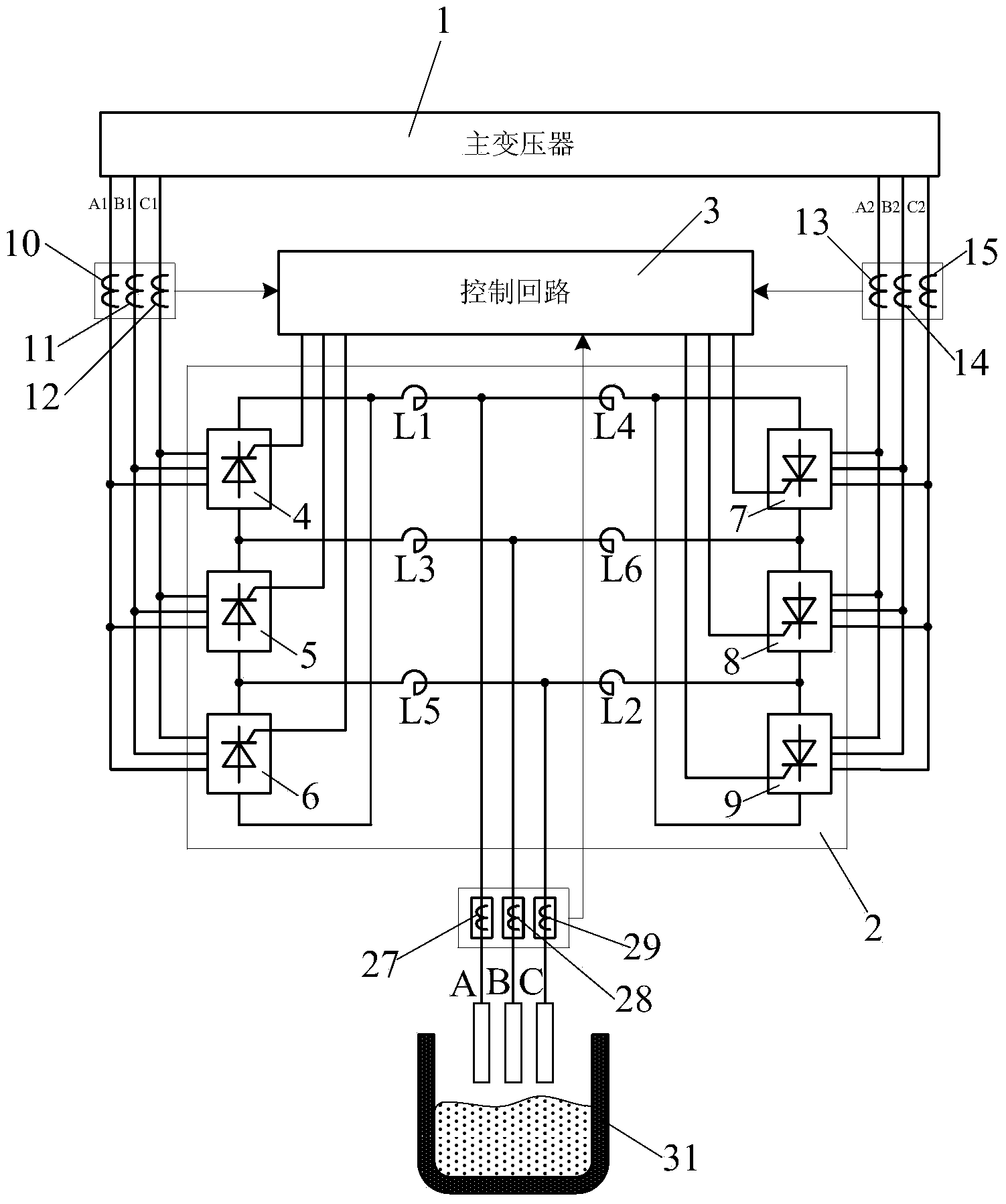

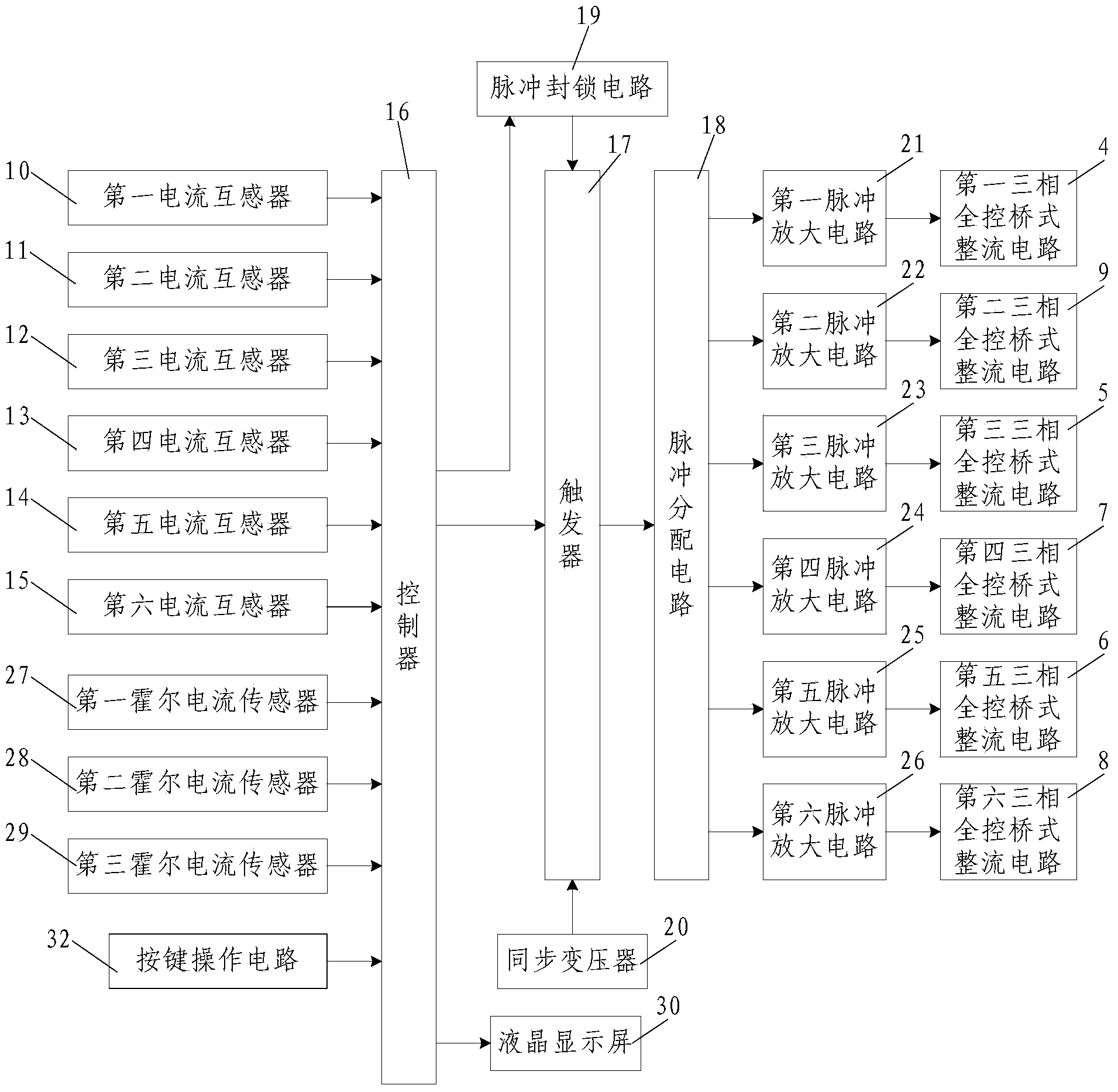

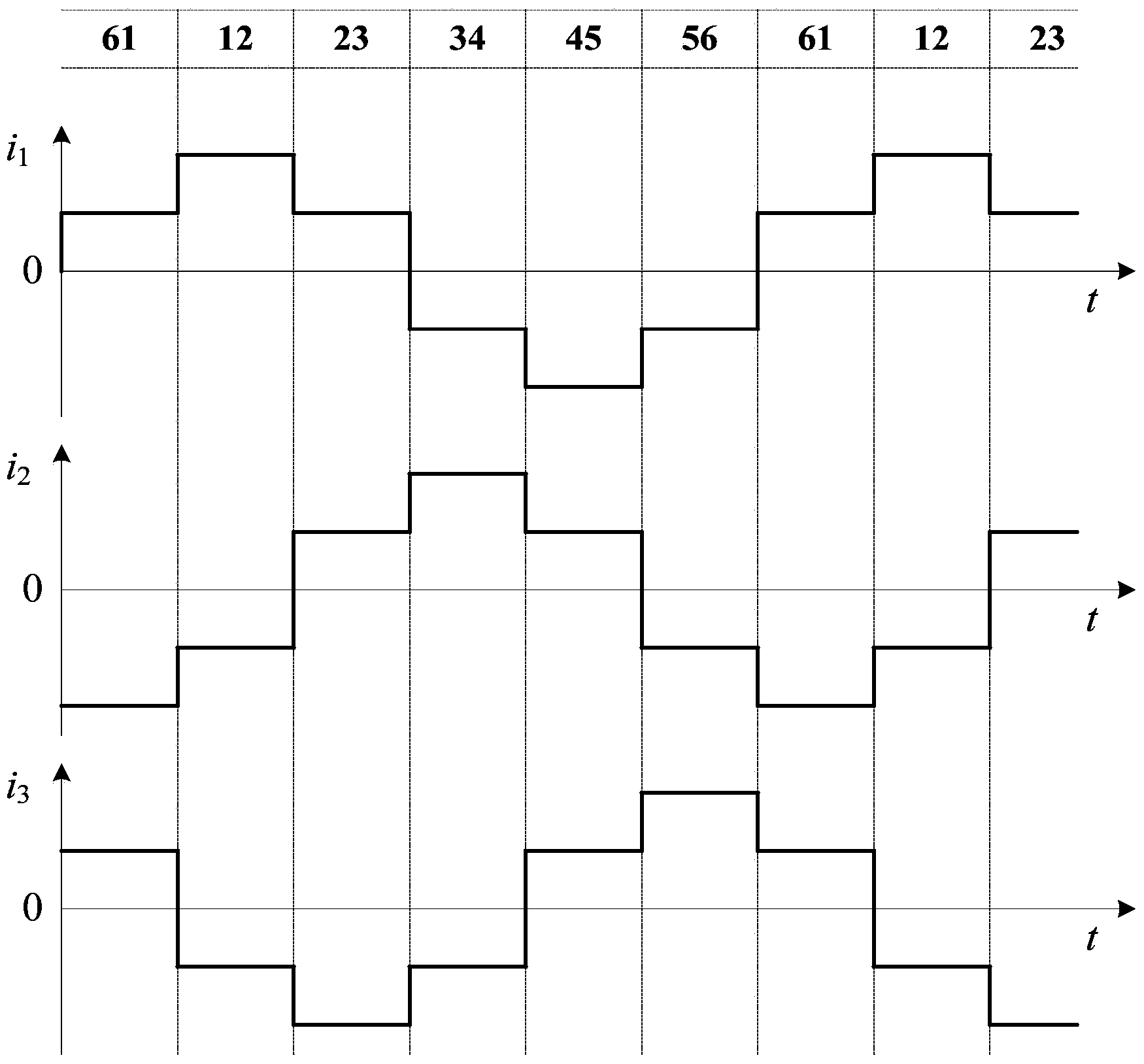

Three-phase controllable polar direct-current electric arc furnace power supply device

ActiveCN103840685ASimple structureNovel and reasonable designEfficient power electronics conversionAc-dc conversionDc arc furnaceElectrical polarity

The invention discloses a three-phase controllable polar direct-current electric arc furnace power supply device which comprises a main transformer, a main loop and a control loop. Secondary side windings of the main transformer comprise a first winding and a second winding. The main loop comprises a first three-phase fully-controlled bridge rectifier circuit, a third three-phase fully-controlled bridge rectifier circuit, a fifth three-phase fully-controlled bridge rectifier circuit, a second three-phase fully-controlled bridge rectifier circuit, a fourth three-phase fully-controlled bridge rectifier circuit and a sixth three-phase fully-controlled bridge rectifier circuit, wherein the first three-phase fully-controlled bridge rectifier circuit, the third three-phase fully-controlled bridge rectifier circuit and the fifth three-phase fully-controlled bridge rectifier circuit are connected with the first winding, and the second three-phase fully-controlled bridge rectifier circuit, the fourth three-phase fully-controlled bridge rectifier circuit and the sixth three-phase fully-controlled bridge rectifier circuit are connected with the second winding. The control loop comprises six current transformers, a trigger, a pulse distribution circuit, a pulse inhibition circuit, a synchronous transformer and six pulse amplifying circuits. The three-phase controllable polar direct-current electric arc furnace power supply device is simple in structure, convenient to use and operate and capable of accelerating the melting speed of a direct-current electric arc furnace, reduces heat shut-down, improves heat efficiency, prolongs the service life of a furnace body of the direct-current electric arc furnace, and is high in practicability and convenient to popularize and use.

Owner:高辉

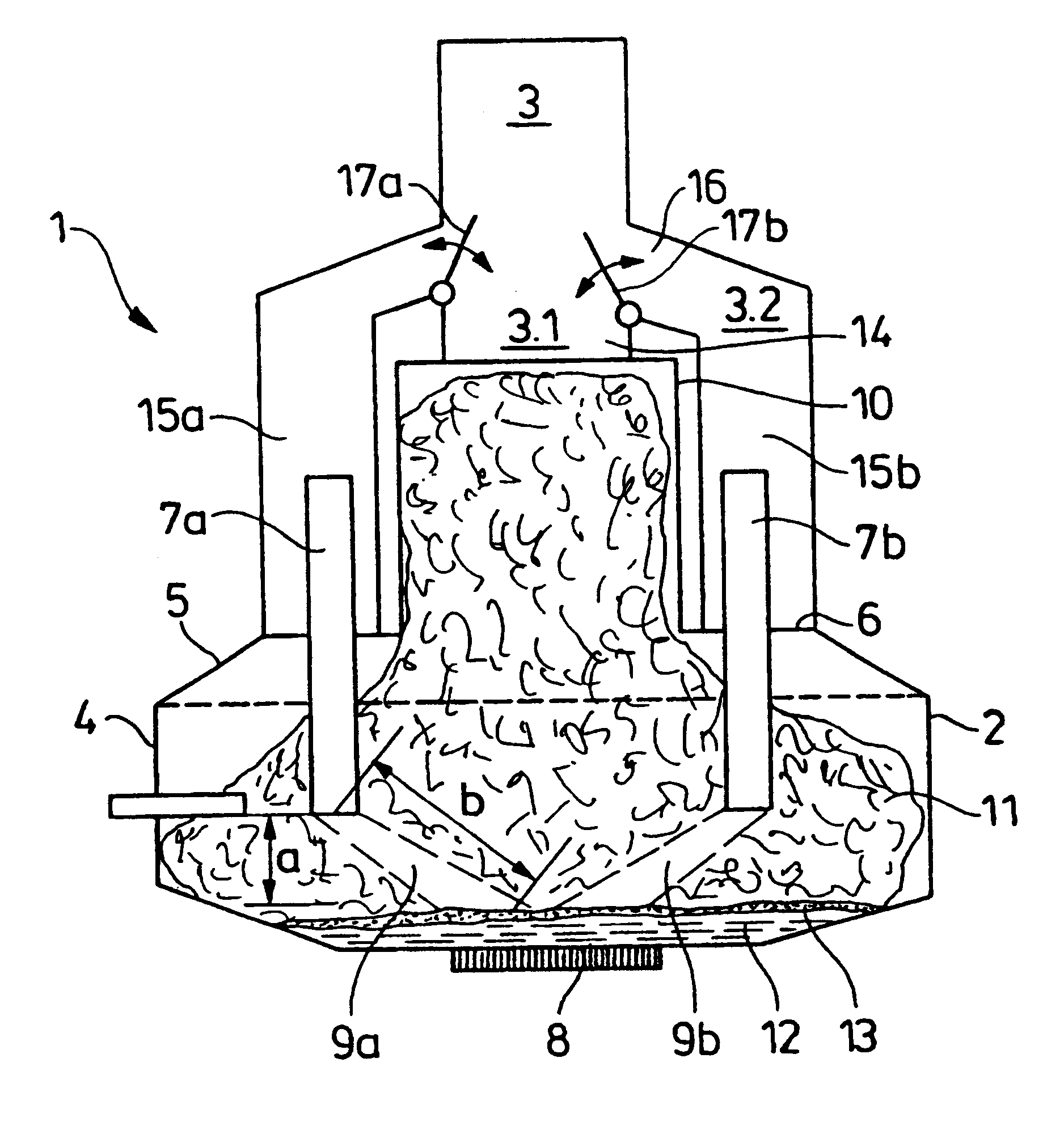

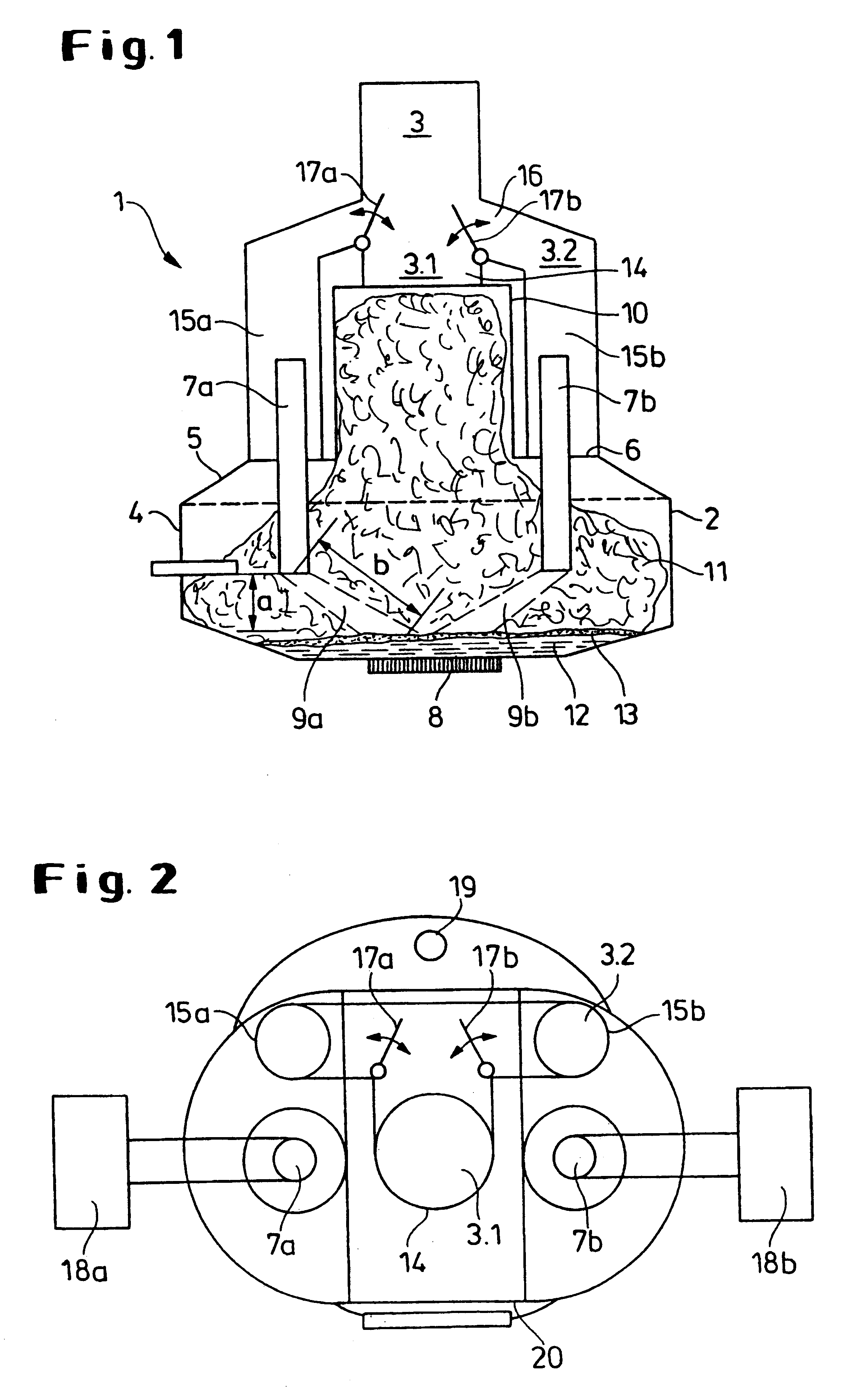

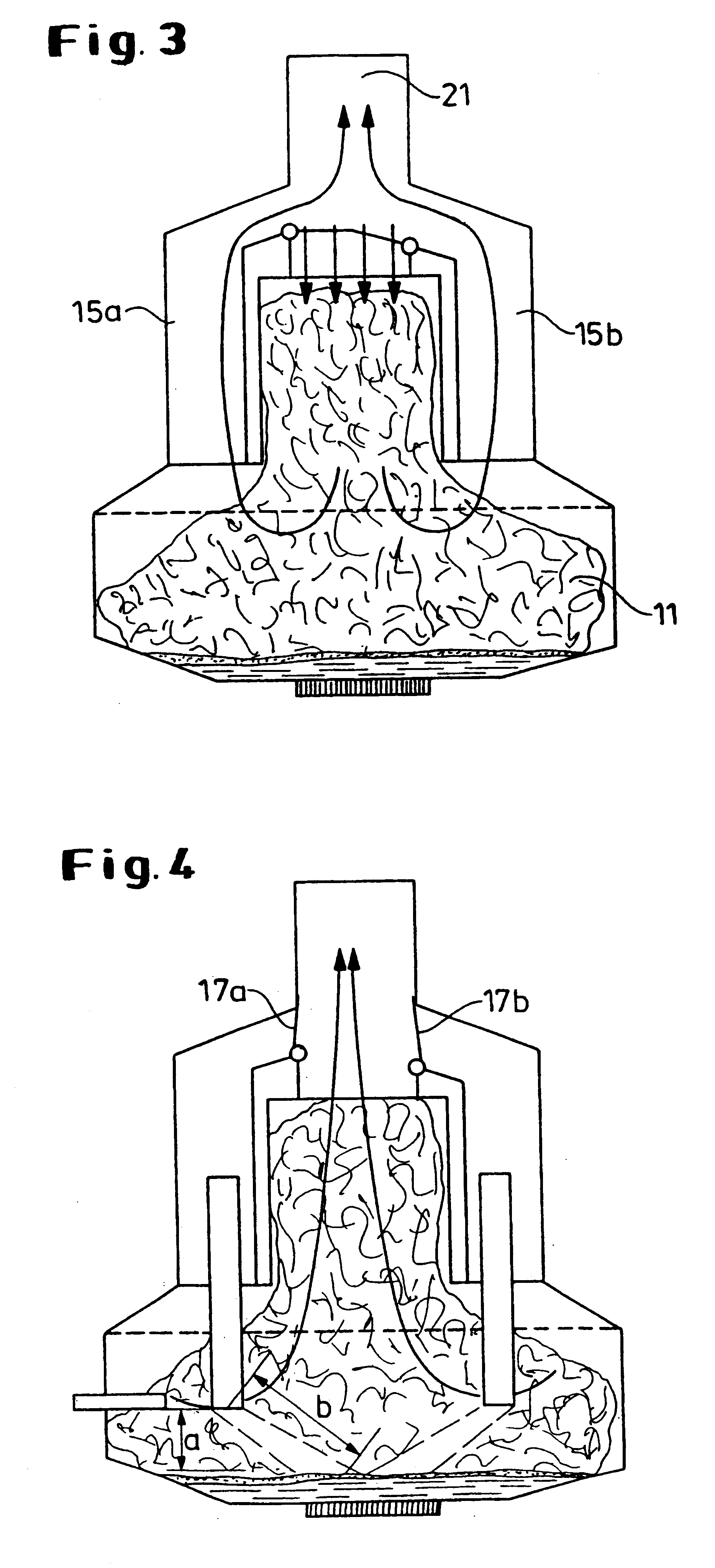

Direct-current arc furnace comprising a centric charging shaft for producing steel and a method therefor

InactiveUS6490312B1High-capacity melting processQuick cutElectric discharge heatingCharge manipulationDc arc furnaceSmelting process

A direct-current arc furnace for producing steel has a smelting vessel with electrodes, tapping openings for the molten mass and slag, and a device for a direct removal of exhaust gases. The smelting vessel is extended upwardly by a central shaft for introducing melt-down material into the vessel. The extension of the central shaft forms a melt-down material column. A shaft suction device is provided as an extension of the shaft for removal of the exhaust gases during the smelting process. Adjacent to the shaft openings are provided in the upper part of the smelting vessel for receiving a vessel suction device for dust and / or gases resulting during the charging process of the melt-down material. The shaft suction device and the vessel suction device are connected to a common device and switching elements are provided for actuating only one suction device and / or adjusting a combination of the exhaust gas flows dependent on the charging and smelting process.

Owner:SMS SCHLOEMANN SIEMAG AG

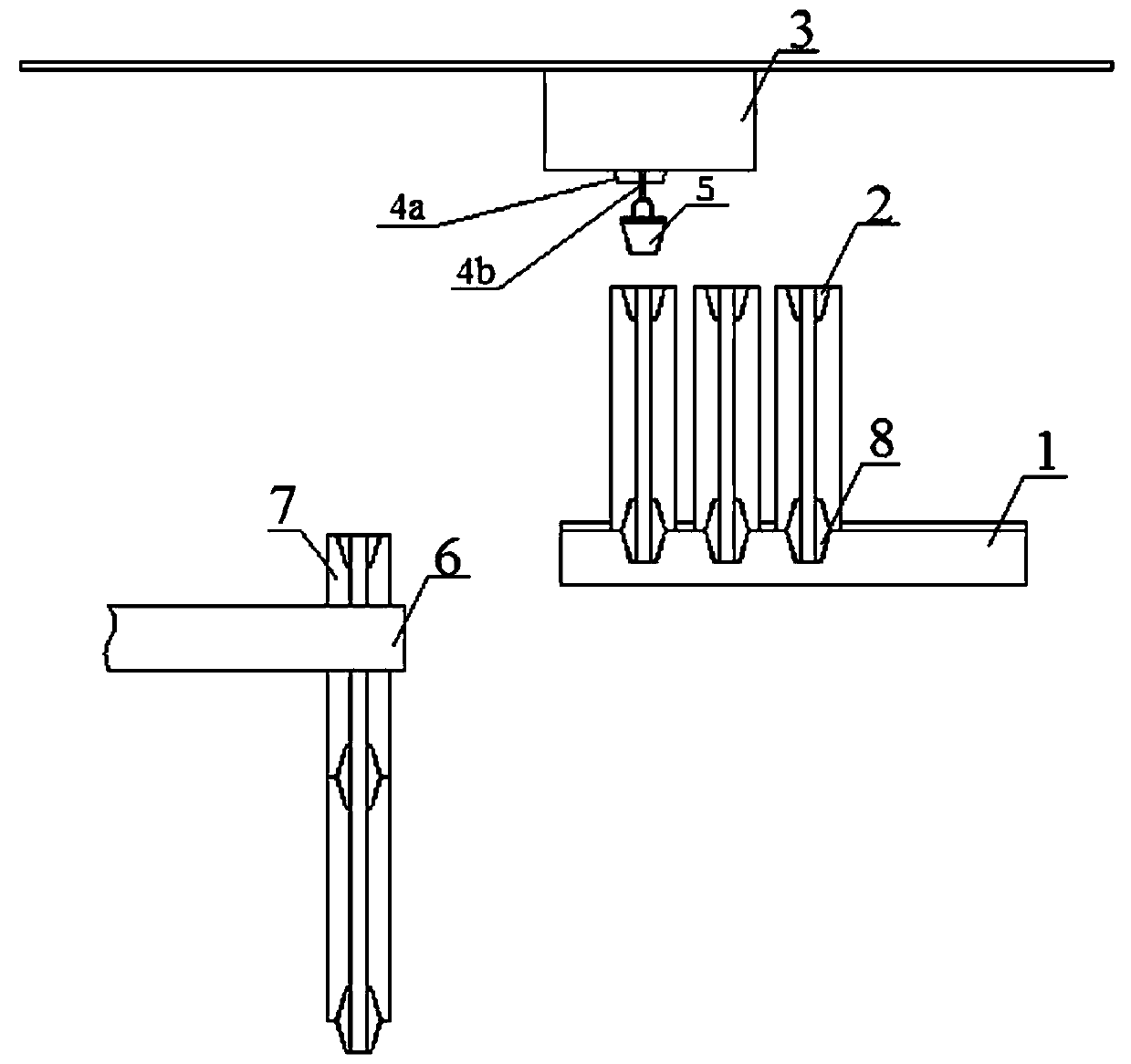

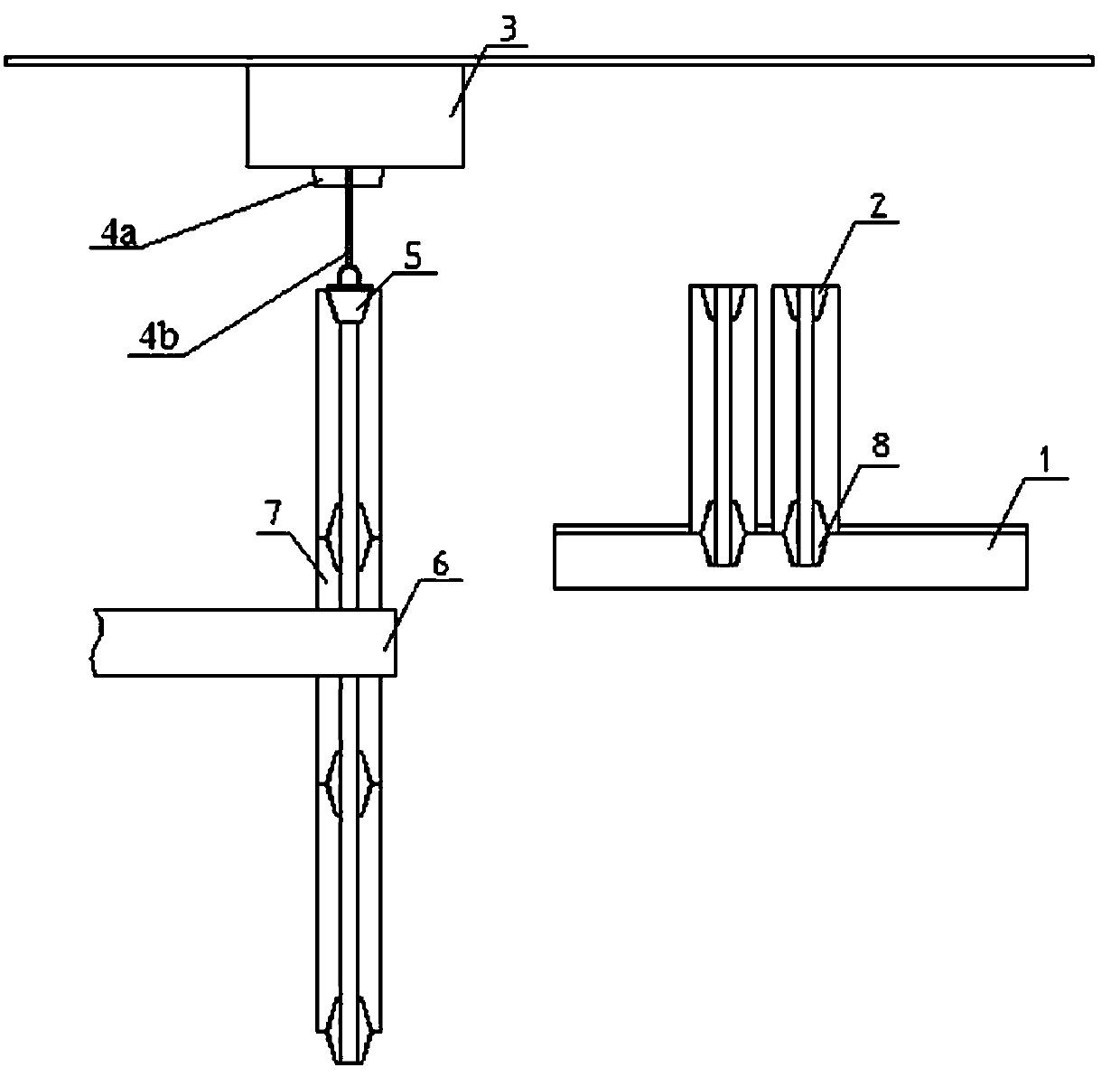

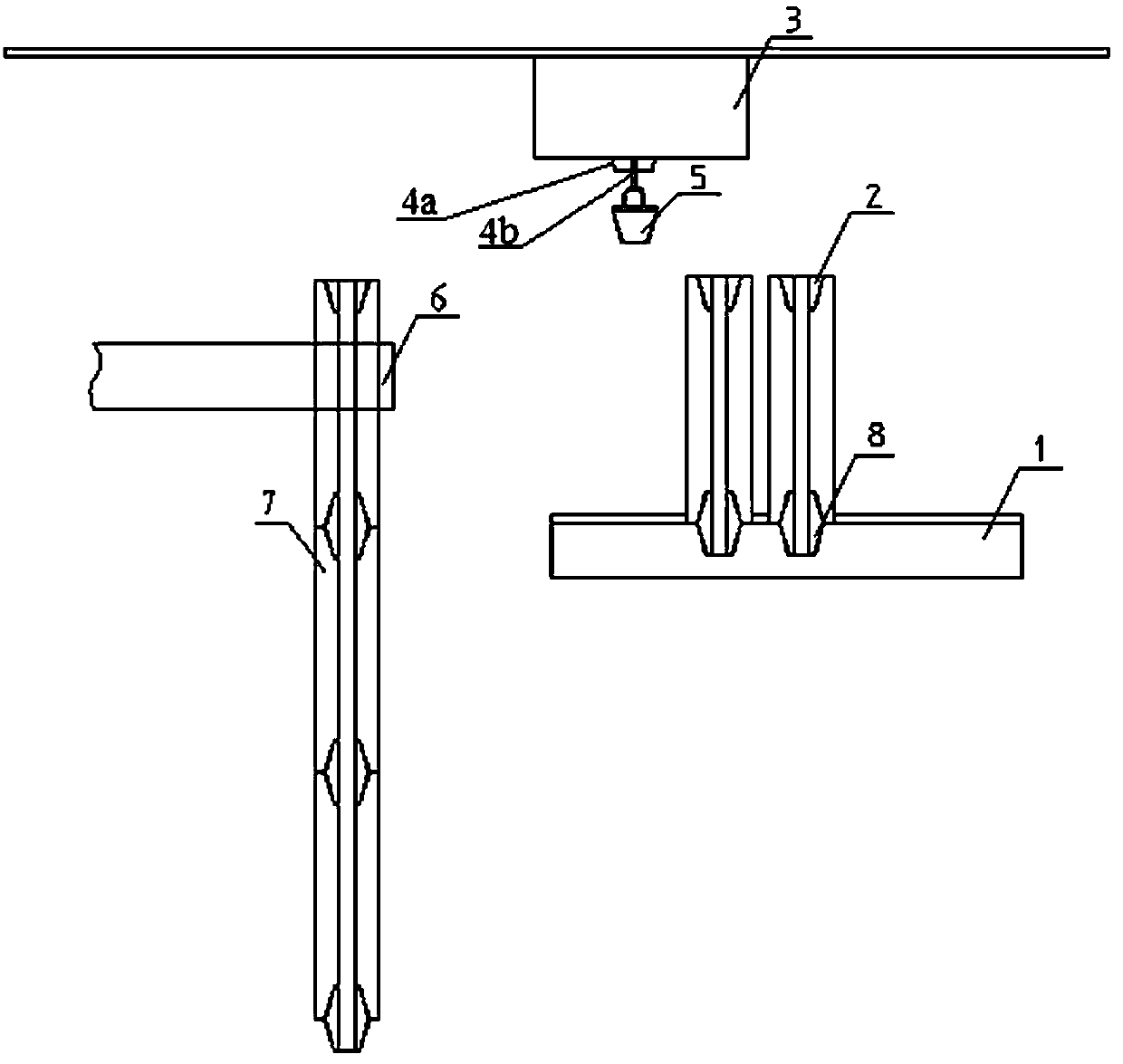

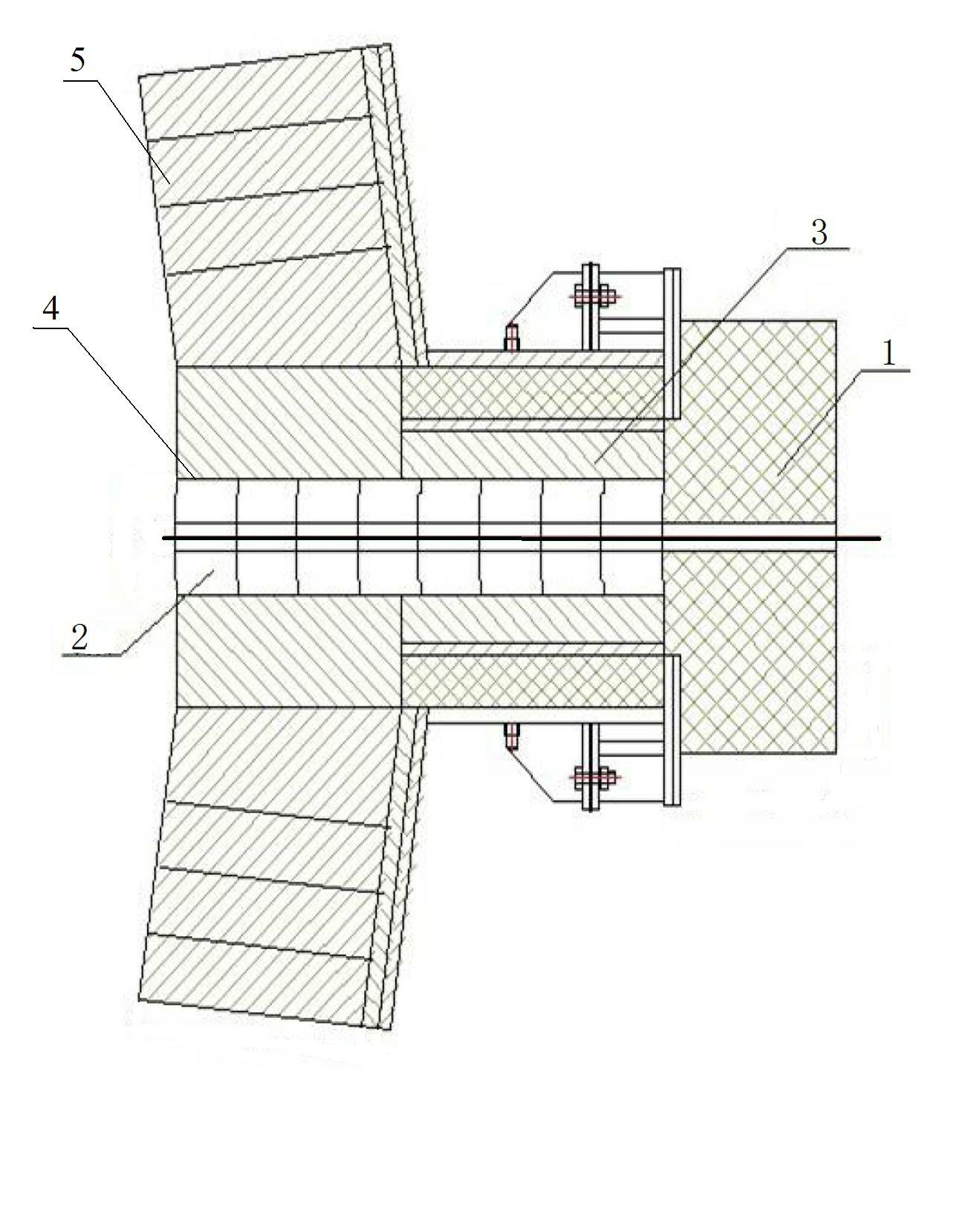

Large-scale direct current electric arc furnace continuous smelting high titanium slag electrode adding device and use method thereof

ActiveCN103727799AShort timeImprove efficiencyElectric heating for furnacesDc arc furnaceSmelting process

The invention discloses a large-scale direct current electric arc furnace continuous smelting high titanium slag electrode adding device and a use method thereof. The electrode adding device comprises an electrode trolley (3), an electrode holder (6) and an electrode base frame (1), wherein the electrode trolley (3) is connected with a lifting hydraulic system and a hydraulic rod, the electrode holder (6) is controlled by an electrode arm hydraulic system (11), and the electrode base frame (1) is provided with a clamping groove. The device takes the purpose of continuous smelting as the main, the energy utilization rate is high, power consumption of slag per ton is low, electrode consumption is low, waste slag, waste water and waste gas pollution does not exist, and the device belongs to an environmentally friendly production industry. In the smelting process, due to continuous smelting and continuous production, efficient and safe electrode adding working is required, the invention provides the method for efficiently and safely adding electrodes for a high titanium slag smelting large-scale direct current seal electric furnace, the electrode adding working is safely and efficiently completed, and an important role in stabilizing the high titanium slag smelting process is played.

Owner:武定国钛金属有限公司

Bottom electrode of direct current arc furnace

InactiveCN104154738AImprove high temperature resistanceAccelerated corrosionLighting and heating apparatusDc arc furnaceBrick

The invention provides a bottom electrode of a direct current arc furnace, and belongs to the field of arc furnaces. The bottom electrode of the direct current arc furnace comprises a furnace bottom fire resistant material, a graphite protection sleeve and a plurality of conductive metal rods. One face of the graphite protection sleeve is provided with blind holes with the number being larger than or equal to that of the conductive metal rods, the upper ends of the conductive metal rods are in clearance fit with the blind holes of the graphite protection sleeve, the lower ends of the conductive metal rods are inserted into the furnace bottom fire resistant material through ramming, the fire resistant material is made to cover the upper surface of the graphite protection sleeve, and the upper surface of the fire resistant material is covered with a magnesia carbon brick layer. According to the bottom electrode of the direct current arc furnace, three layers of protection are provided for the conductive metal rods, the first layer is the magnesia carbon brick layer at the upmost portion, the second layer is the furnace bottom fire resistant material containing carbon powder and magnesia, the third layer is the graphite protection sleeve, erosion resistance and high-temperature resistance of a bottom electrode structure of the direct current arc furnace to molten liquid are improved, and service life of the bottom electrode is effectively prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

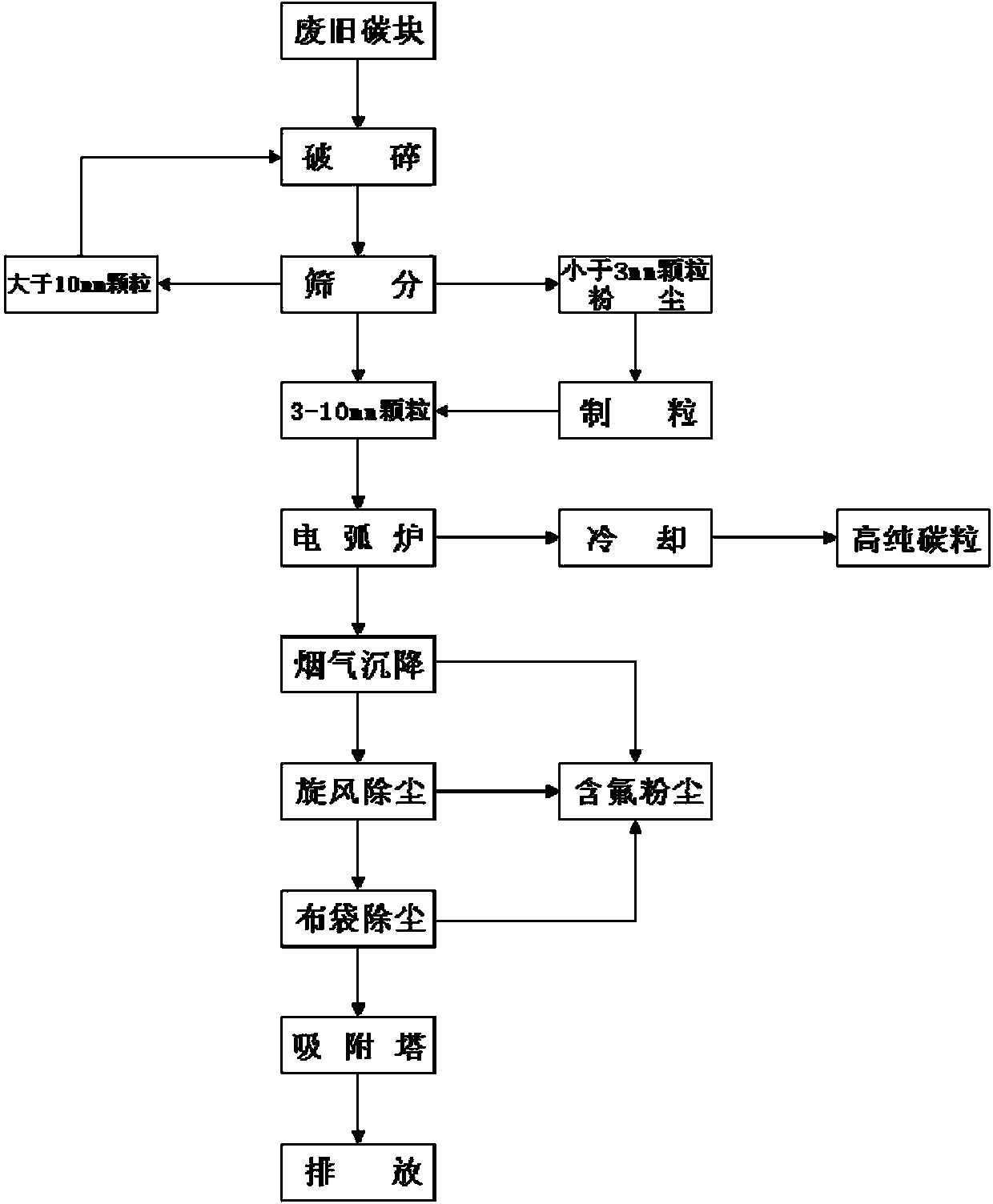

Method for producing high-purity carbon granules from waste carbon blocks in arc furnace

ActiveCN103754861AHigh calorific valueImprove conductivityCarbon preparation/purificationDc arc furnaceLarge Calorie

The invention discloses a method for producing high-purity carbon granules from waste carbon blocks in an arc furnace, which comprises the steps of pretreatment, preparation and after-treatment, and specifically comprises the following steps: crushing the raw material waste carbon blocks, and screening to obtain waste carbon block granules; and adding the obtained carbon block granules into a direct-current arc furnace, electrifying to start arc, taking out, and cooling to obtain the target substance high-purity carbon granules, wherein fume generated by combustion enters a dust collecting system to be collected and recycled. The method has the advantages of simple technique and obvious environmental benefit, and uses waste in urgent need of treatment as the raw material; the whole production procedure adopts a dry process, and thus, does not generate wastewater; various resources are completely recycled, no that no waste is generated; and the gas is completely collected and purified, and thus, the environmental pressure is low. The fixed carbon content can reach 99% above, the ash content is less than 1%, the total sulfur is less than 0.5%, and the low heat value on air dry basis is greater than 8000 calories / g; and the high-purity carbon granules with the graphitization degree of higher than 80% have favorable electric conductivity,, favorable thermal conductivity, high stability and high heating value, and thus, are a favorable raw material for various graphite products and metallurgical industry.

Owner:云南蓝天铝业环保科技有限公司

Method for producing alloy through processing slag of autothermal furnace with direct current electric arc furnace

InactiveCN111778408AReduce consumptionLow failure rateProcess efficiency improvementDc arc furnaceSlag

The invention discloses a method for producing an alloy through processing slag of an autothermal furnace with a direct current electric arc furnace, and relates to a comprehensive processing method of nickel copper smelting slag. The method for producing the alloy through processing slag of the autothermal furnace with the direct current electric arc furnace is characterized in that a process ofthe method is to uniformly mix the slag of the autothermal furnace, reducing agent and calcic flux, then, perform reduction smelting at the direct current electric arc furnace, automatically layer reduction products according to different specific gravity, and respectively discharge a liquid metal and tailings, wherein the liquid metal is a copper nickel alloy. The method provided by the inventioncan fully use molten hot slag of the autothermal furnace, also can process stacked cold slag, can realize efficient synchronous separation and recycling of nickel and copper metals by adjusting amount of the reducing agent, the flux and reducing time, can solve problems of too much stockpiling of the slag and environment pollution, can optimize a technological process and simultaneously can effectively improve operation technology economic indicators of a system.

Owner:JINCHUAN GROUP LIMITED

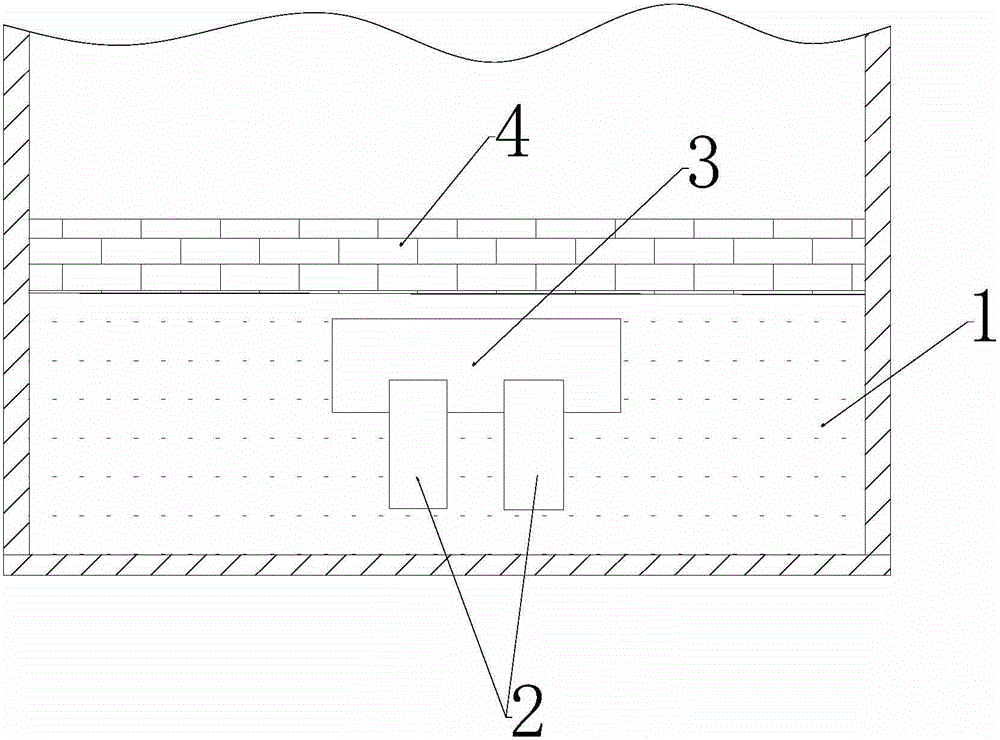

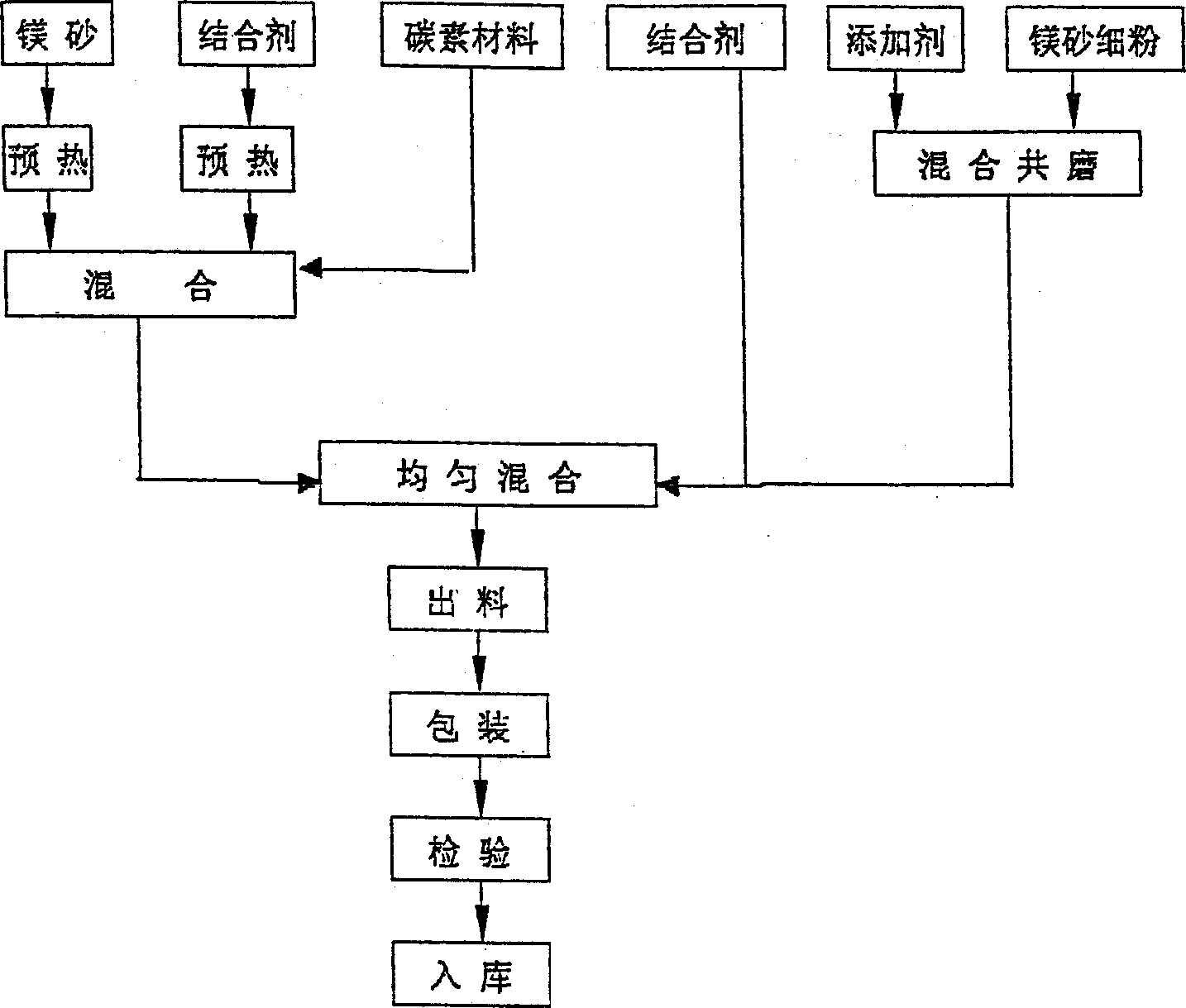

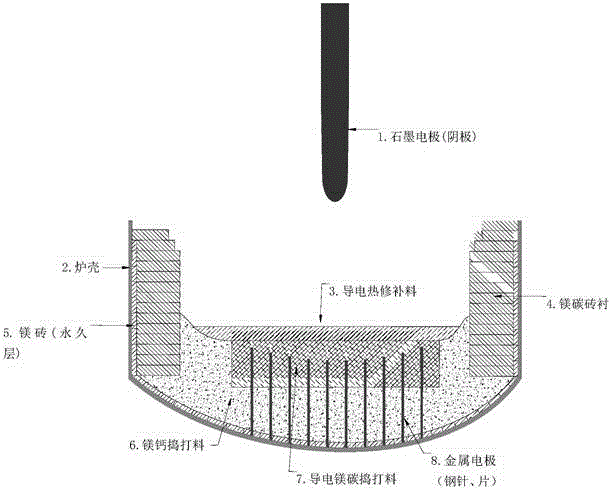

Electrically conductive hot-patch material for DC arc furnace and its preparing process

InactiveCN1363532AStrong corrosion resistanceGood resistance to rapid cooling and heatingLighting and heating apparatusDc arc furnaceRefractory

An electrically conductive hot patch material for DC arc furnace contains MgO (81-85%), CaO (1-2%) SiO2 (0.5-1.5%), Fe2O3 (0.5-1.0%), Al2O3 (0.2-1%), C (5-10%) and Mg+Al (2-3%), and is prepared through choosing electric melting magnesium sand and carbon material, crushing, sieving, adding binder and additive, and mixing. Its advantages include low cost, high flowability, electric conductivity andanticorrosion nature, and long service life.

Owner:宋景尧

Method for directly transmitting power to bake large-scale direct current electric arc furnace

The invention discloses a method for directly transmitting power to bake a large-scale direct current electric arc furnace. Conductive refractory materials with the thickness of 50-100mm are laid on a newly-built furnace bottom, a conductive carbon block is laid in the center of the furnace bottom, and is higher than 1m, iron blocks of 50-100t are placed around the carbon block and are fully laid on the whole furnace bottom, temperature thermocouples are placed in a cavity in the furnace, a discharge outlet and the furnace bottom so as to measure furnace baking temperature, an electrode is powered to conduct arc ignition, an electric arc is arranged between a furnace top electrode and the conductive carbon block at the furnace bottom, according to the temperature rising speed inside the furnace, the transmission power, the position of the electric arc and the length of the electric arc are adjusted, and the temperature rising speed conforms to the requirement of the fireproof brick baked furnace. When the electric arc is lower than 0.7m, the iron blocks are added in the furnace to melt the iron blocks so as to form a molten pool, and the temperature rising speed of the furnace bottom is controlled. After furnace baking is finished, materials can be continuously put into the furnace to begin smelting, and according to the method, fuel and fuel gas cost is saved, and the cost for furnace baking is reduced.

Owner:龙佰武定钛业有限公司 +1

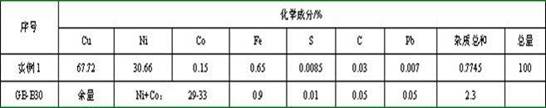

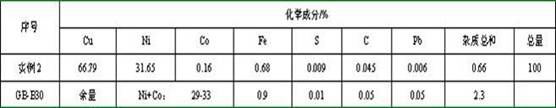

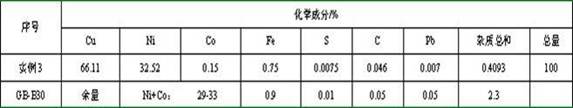

Preparation method for producing cupronickel B30 raw material from copper-nickel slag

InactiveCN113293306AMaximize utilizationQuick cashProcess efficiency improvementDc arc furnaceCupronickel

The invention discloses a preparation method for producing a cupronickel B30 raw material from copper-nickel slag. A direct current electric arc furnace is adopted for smelting, a fluxing agent and a reducing agent are added into a copper-nickel slag nonferrous smelting intermediate material to produce a copper-nickel alloy, a qualified raw material for preparing the cupronickel B30 is produced through refining and impurity removal, and chemical components of the qualified raw material meet the requirement of GB / T5231-2012 for processing cupronickel B30 chemical components. According to the method, the problems of valuable metal loss, energy loss and the like are solved, and meanwhile, the cupronickel B30 alloy can be industrially applied more widely. The direct-current electric arc furnace is adopted for reduction smelting and slagging, the copper-nickel alloy is subjected to refining and impurity removal treatment to produce the raw materials meeting the requirement for producing the cupronickel B30 alloy, the method is short in process, low in energy consumption and high in recovery rate, the cost for producing the copper-nickel alloy can be greatly reduced, and the method is a novel technology for comprehensively developing and utilizing nonferrous smelting slag and developing the low-cost preparation of the cupronickel B30 alloy. The cupronickel B30 alloy has important significance in wider industrial application in the fields of shipbuilding, electric power, chemical engineering and the like.

Owner:金川镍钴研究设计院有限责任公司 +1

Method for changing refractory brick at tapping hole of direct current electric arc furnace

The invention discloses a method for changing a refractory brick at a tapping hole of a direct current electric arc furnace. The method comprises the following steps of: (1) stopping feeding a material into the furnace and preserving heat; (2) discharging molten iron above the tapping hole; (3) clearing the outermost casting material of the tapping hole; (4) stopping the furnace; (5) detaching the damaged refractory brick; (6) building a new refractory material; and (7) starting the furnace to recover production. According to the method, the damaged refractory brick at the tapping hole is discovered by observation and analysis, the furnace is stopped after a large amount of molten iron higher than the tapping hole is discharged, the damaged refractory brick is detached, and the refractory brick is newly built. Compared with a common changing method, the method has the advantages that: the slag in the furnace does not need to be emptied, the repair time is relatively short, the changing method is simple and convenient and the like, and the method is relatively practical in the field of metallurgy.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Direct current electric arc furnace bottom electrode structure and application thereof

InactiveCN106091671AGuaranteed lengthCharge composition/stateElectric furnaceSteelmakingDc arc furnace

The invention relates to a direct current electric arc furnace bottom electrode structure. A bottom electrode structure is a composite bottom anode structure. The bottom electrode structure comprises a plurality of metal conduction elements vertically installed at the furnace bottom at intervals. The intervals between the metal conduction elements are filled with fireproof materials. The lower portions of the intervals are filled with non-conduction fireproof materials. The upper portions of the intervals are filled with first conduction fireproof materials. A layer of second conduction fireproof material is laid on the top of each metal conduction element. The second conduction fireproof materials are used for heat repairing. The invention further relates to application of the direct current electric arc furnace bottom electrode structure. By adoption of the conduction fireproof materials, a metal bottom anode is changed into a composite bottom anode in which metal and the conduction fireproof materials are combined, a metal bottom anode which cannot be repaired is changed into a bottom anode capable of being subjected to cold state repairing and heat state repairing, and therefore the service life of the bottom anode is greatly prolonged, the operation rate of steelmaking of an electric furnace is increased, the steelmaking cost is reduced, and the equipment utilization rate is increased.

Owner:上海彭浦特种耐火材料厂有限公司 +2

Method of preparing titanium and titanium alloy using titanium containing furnace clinker

A process for preparing Ti metal from the Ti contained slags includes such steps as proportionally mixing said slags with C, Al, Fe and Mg, stirring, and smelting for thermal reducing in plasma furnace, DC arc furnace or AC arc furnace. Its advantage is high output rate.

Owner:WUHAN UNIV OF SCI & TECH

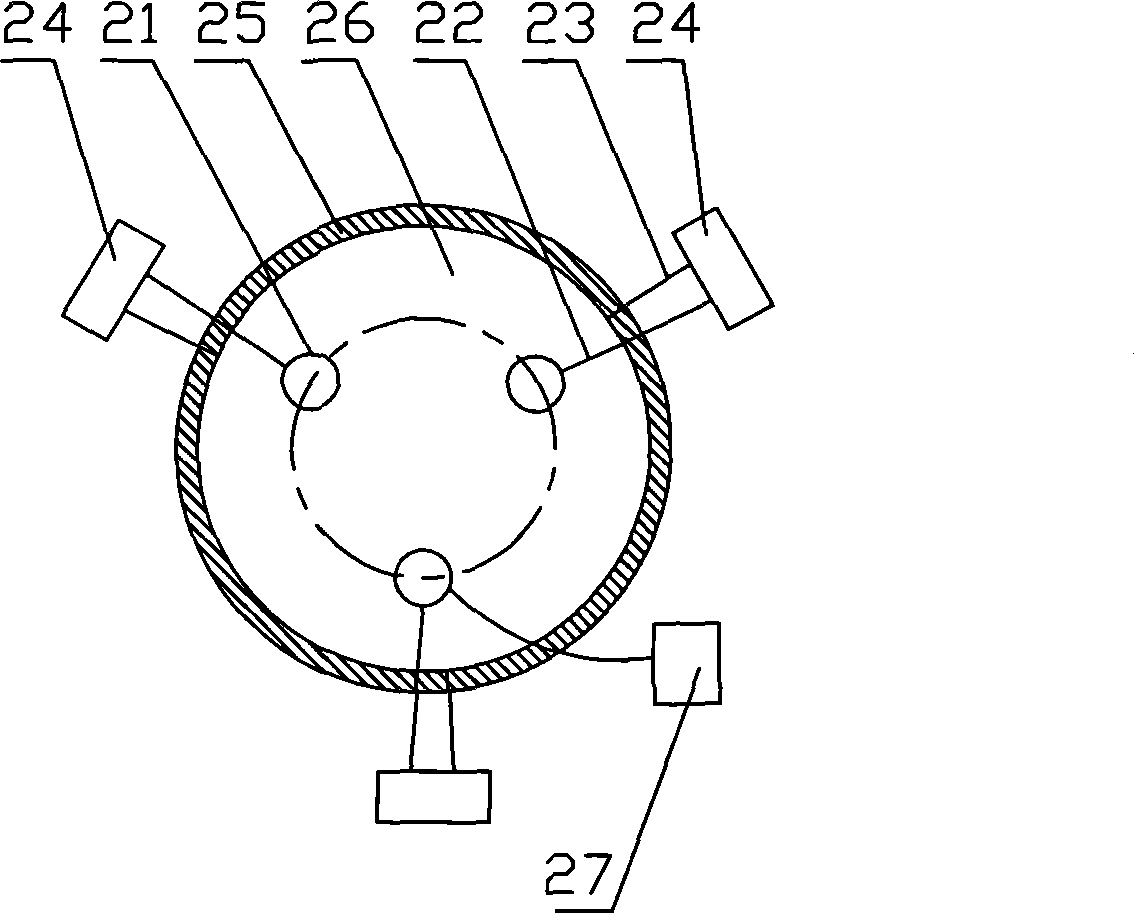

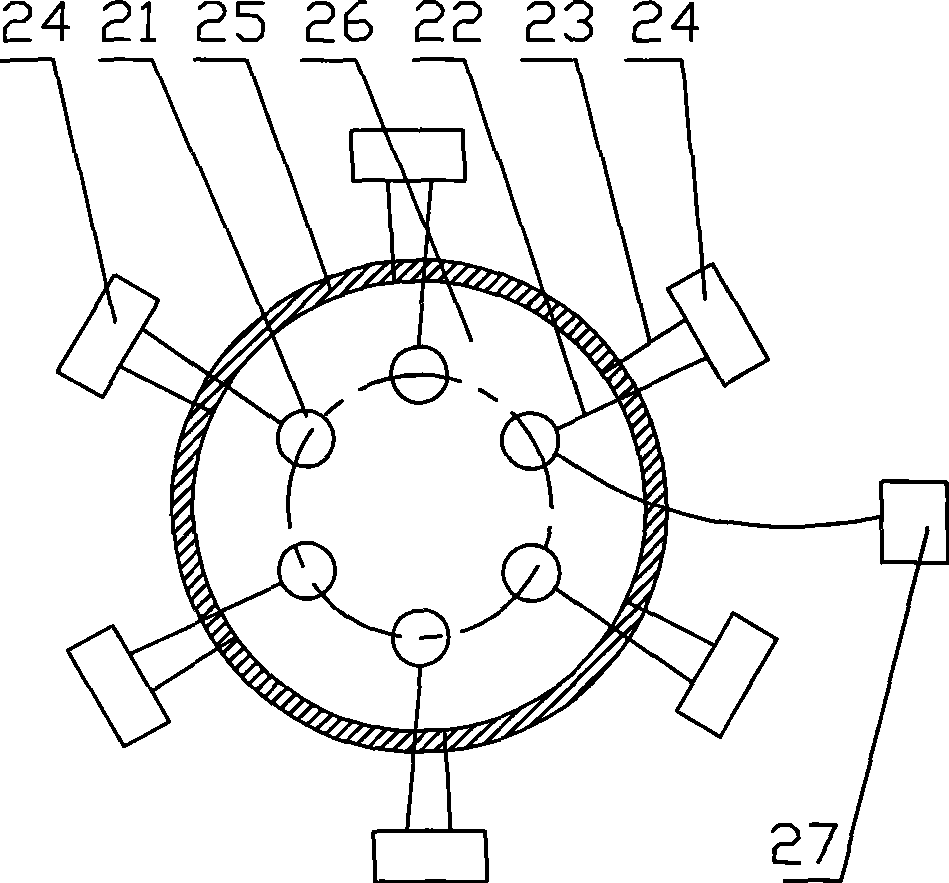

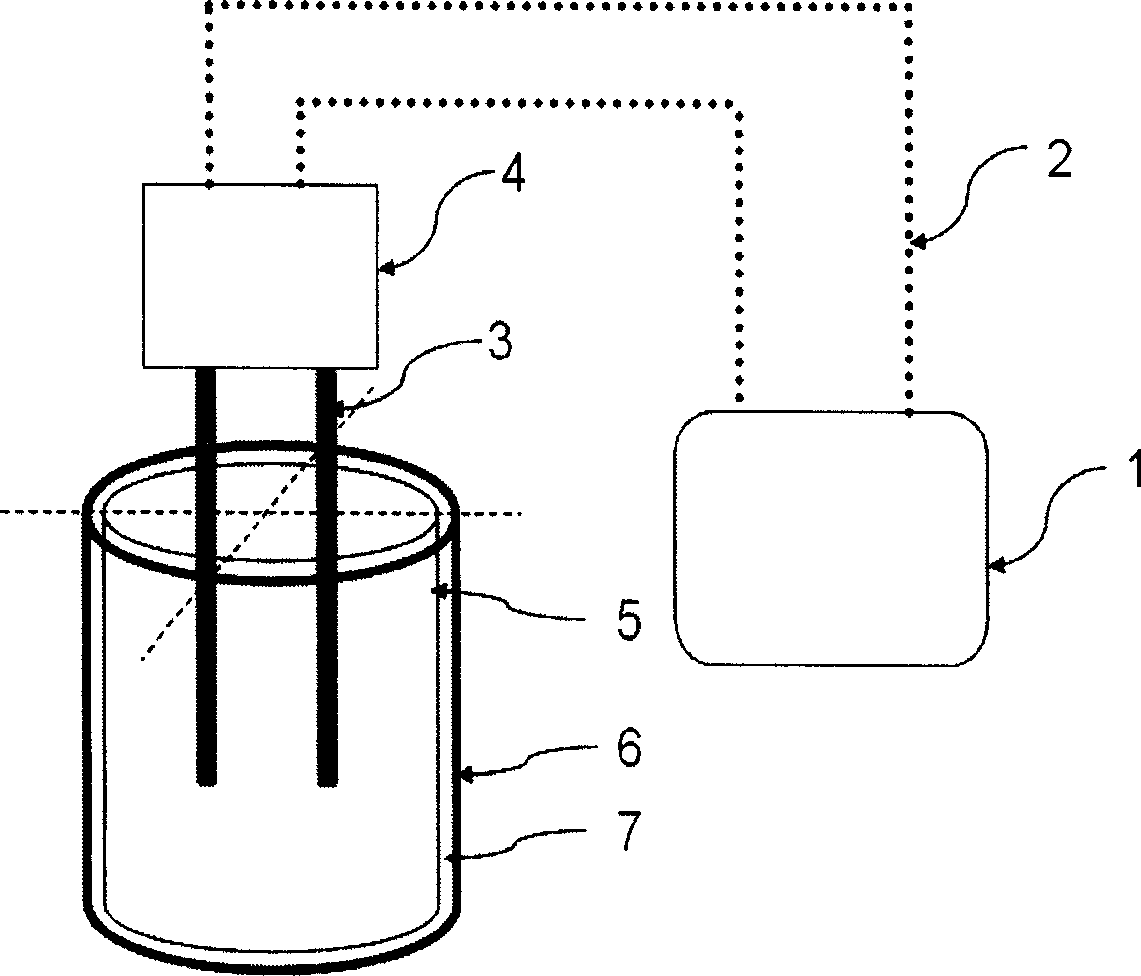

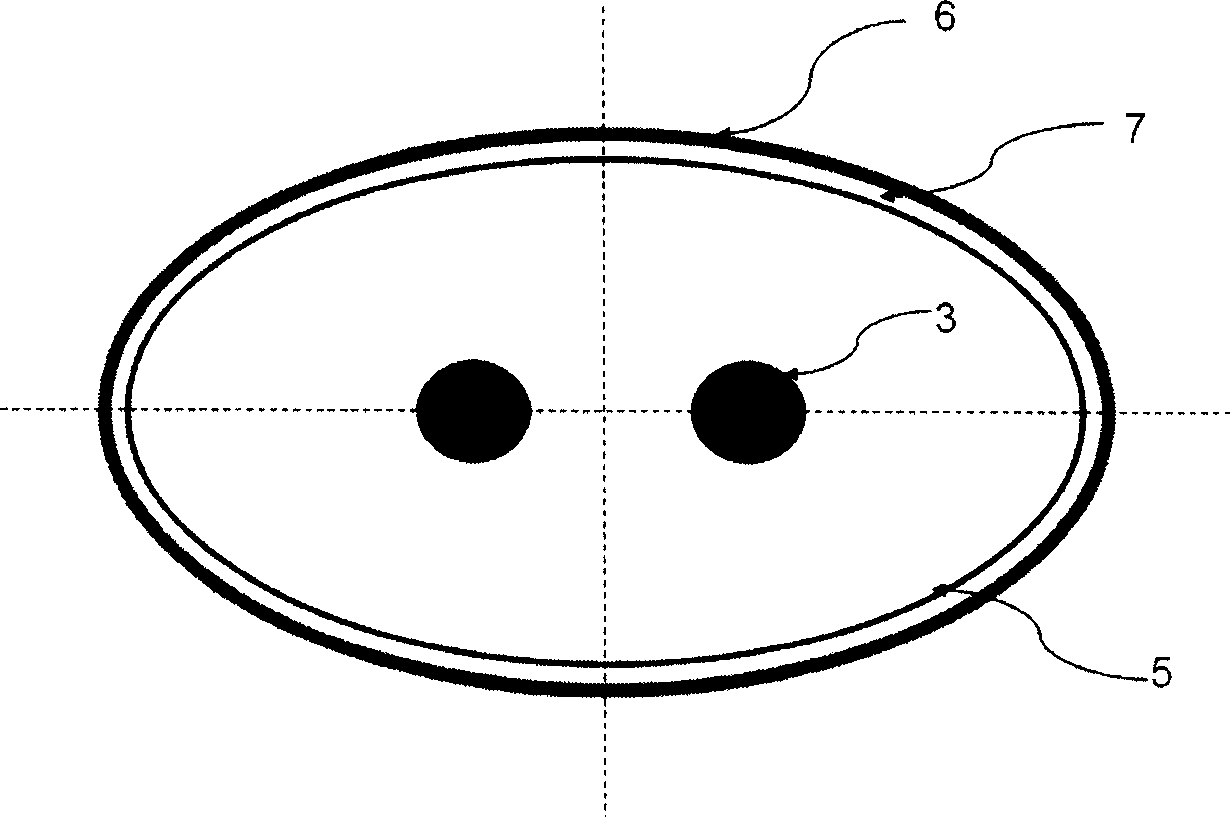

Direct-current arc furnace for preparing magnesium oxide single-crystal

InactiveCN1721588AReduce consumptionReduce shockAfter-treatment apparatusElectric heating for furnacesDc arc furnaceSingle crystal

The present invention belongs to the field of crystal preparing equipment technology, relates to electrical smelting equipment for preparing magnesia monocrystal, and is especially one magnesia monocrystal preparing DC arc furnace. The arc furnace features the furnace shell structure of double layer elliptic cylinder with air gap; the arc heating system comprising DC smelting power supply, electrode elevating unit and two vertical graphite electrodes; and the vertical furnace body structure. The present invention has greatly raised magnesia monocrystal yield and quality, less impact to the power network and raised electric energy utilization rate. In addition, the present invention is also suitable for producing other kinds of high temperature crystal.

Owner:LIAONING ZHONGDA SUPERCONDUCTING MATERIAL

Automatic regulating device of DC electric arc furnace electrode and control method thereof

ActiveCN101782321BEasy to controlControl System Control RealizationElectric heating for furnacesDc arc furnaceEngineering

The invention discloses an automatic regulating device of a DC electric arc furnace electrode and a control method thereof, which comprise an electric arc furnace, a lifting cylinder, a contact tube, an graphite electrode, an arc voltage and current regulating control system and a main power supply loop, wherein the external side of the electric arc furnace is provided with the lifting cylinder, the top of the lifting cylinder is provided with the contact tube, the tail end of the contact tube is provided with the graphite electrode which is erected into the interior of the electric arc furnace, and the arc voltage and current regulating control system is connected with the contact tube, the lifting cylinder and the electric furnace and is simultaneously connected with the main power supply loop. In the invention, the arc voltage and current regulating control system controls a hydraulic proportional valve to control the up-and-down motion of the graphite electrode so as to change thedistance between the electrode and the steel liquid level, so the arc length can be controlled to realize the purpose of controlling the arc voltage; a rectifier control system controls the size of the trigger angle Alpha of a rectifier thyristor so as to realize the purpose of controlling the arc current; and the invention has high control accuracy, safety and reliability, and can timely and accurately control the size of the arc voltage and the arc current.

Owner:上海金自天正信息技术有限公司

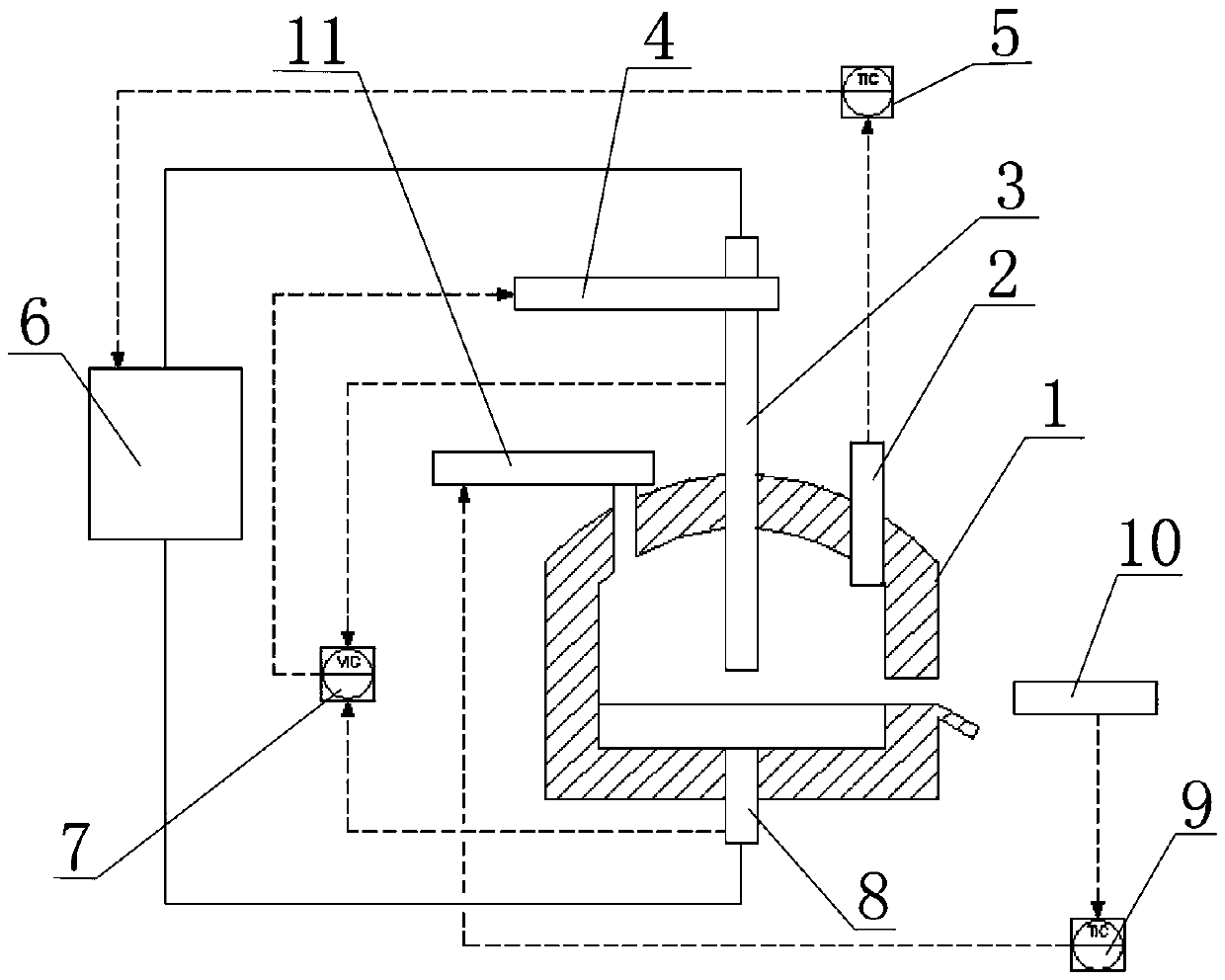

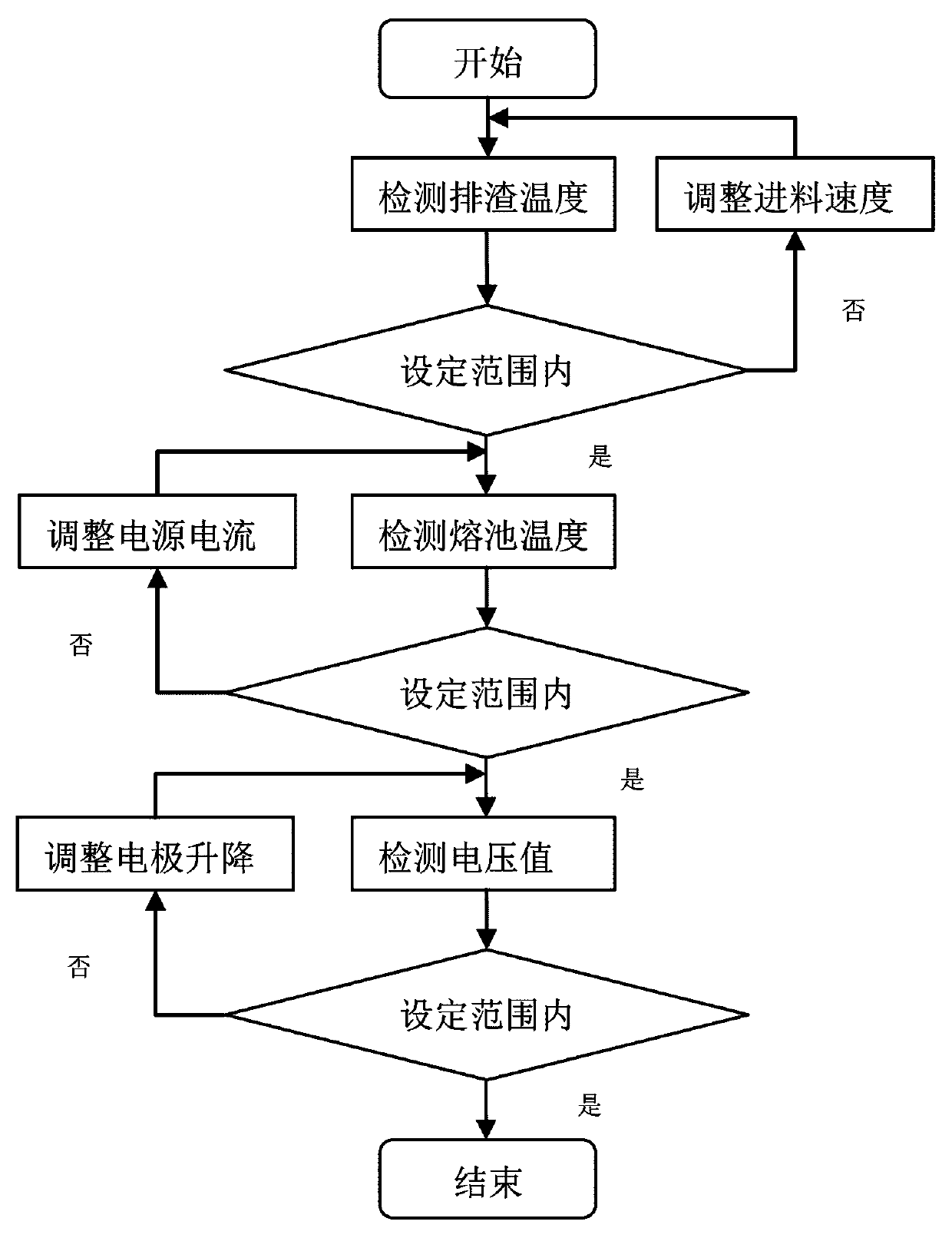

Automatic control system and automatic control method of direct current electric arc furnace

ActiveCN110285667AAvoid cross influenceRealize automatic controlLighting and heating apparatusFurnace temperatureInfrared

The invention discloses an automatic control system and an automatic control method of a direct current electric arc furnace. The automatic control system of the direct current electric arc furnace comprises a direct current electric arc furnace body, an in-furnace infrared temperature measuring device, a cathode electrode, an electrode lifting device, an in-furnace temperature control sensor, an electrical power device, a voltage control sensor, an anode electrode, a discharge temperature control sensor, a discharge infrared temperature measuring device and a feed control device. The automatic control method of the direct current electric arc furnace includes: collecting voltage values between the cathode electrode and the anode electrode in the direct current electric arc furnace body, and calculating difference values between the voltage values and a preset voltage value so as to control the electrode lifting device to rise and fall for adjusting the voltage values; collecting in-furnace temperature, and calculating different values between the in-furnace temperature and preset temperature so as to control current magnitude of a direct current power source; collecting temperature of material flowing out of a discharge port, and calculating difference values between the temperature of the material and preset temperature so as to control feed amount. The automatic control system and the automatic control method of the direct current electric arc furnace use different control parameters for amending voltage, electric arc, feeding speed and the like, avoid cross influence of the above factors, and achieve full automatic control for the direct current electric arc furnace.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

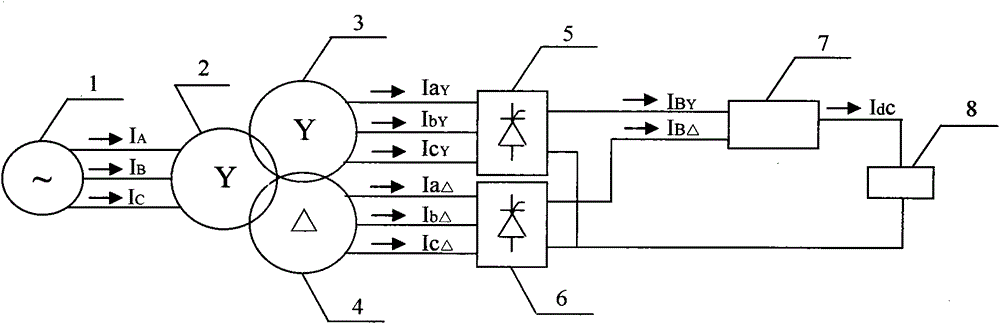

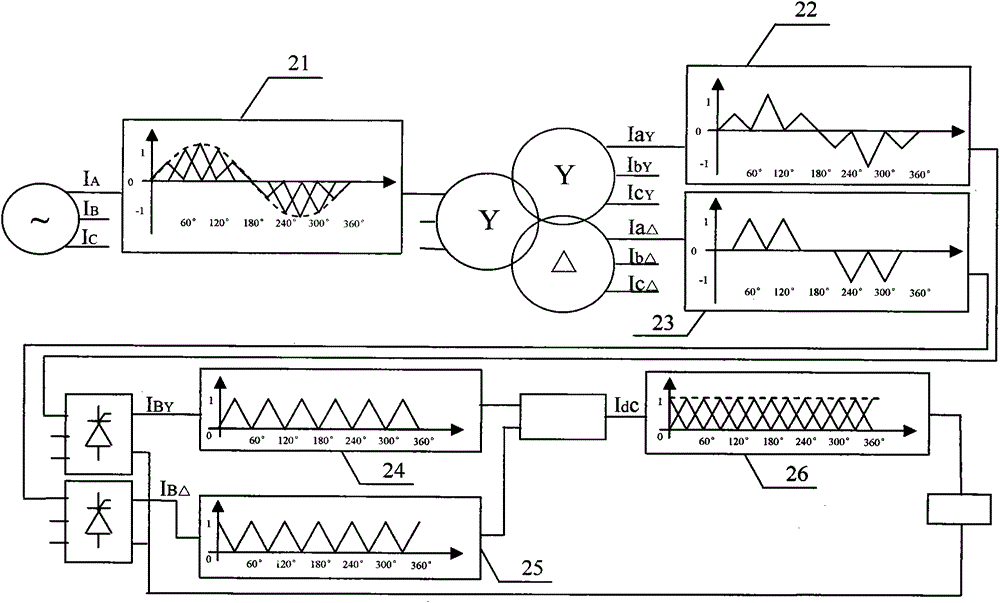

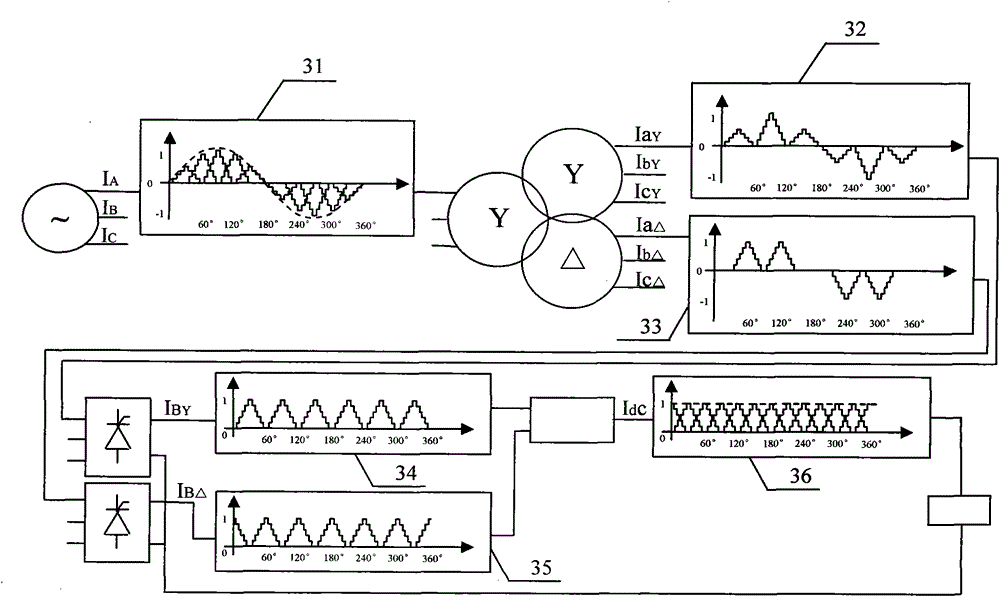

High-performance direct-current power supply implementation method of direct-current electric arc furnace

The invention provides a high-performance direct-current power supply implementation method of a direct-current electric arc furnace, belongs to an electric direct-current power supply and direct-current electric arc furnace melting technique and aims to develop an AC ( alternating current) / DC (direct current) converter with low harmonic wave, high power factor and adjustability of direct-current voltage and current in a large range. The high-performance direct-current power supply implementation method is characterized in that a high-performance direct-current power supply comprising a phase-shifting transformer, a twelve-pulse-wave converter bridge formed by two completely identical thyristor six-pulse-wave converter bridges (5) and (6) and a multi-level direct-current current control and synthesis unit (7) adopts an asymmetric current control strategy to control current waveforms of two three-phase converter bridges through the multi-level direct-current current control and synthesis unit (7) according to specific conversion rules of a formula (1) and a formula (2), so that three-phase alternating-current input current of the converter is sine-wave current, and a direct-current power supply has the characteristics of low harmonic wave, high power factor and continuous adjustability of direct-current side voltage and currents in a large range and can be used for a high-performance direct-current power supply system of newly-built and improved direct-current electric arc furnaces.

Owner:BEIJING KDHY SCI & TECH DEV LTD

Treatment method for converting sulfur-containing blister copper furnace slag through Kaldo furnace

InactiveCN111778407AReduce pollutionReduce manufacturing costProcess efficiency improvementDc arc furnaceSlag

The invention discloses a treatment method for converting sulfur-containing blister copper furnace slag through a Kaldo furnace, and relates to a comprehensive treatment method for recycling valuablemetals from nickel-copper smelting slag. The method is characterized in that the Kaldo furnace slag is treated through a direct-current electric arc furnace; and the method comprises the following steps of carrying out reduction smelting on furnace slag generated by converting sulfur-containing crude copper in a Kaldo furnace in the direct-current electric arc furnace to obtain liquid copper-nickel alloy and tailings. According to the treatment method, a direct-current electric arc furnace process is adopted, and a reducing agent and a calcium flux are added for reduction smelting, so that thecopper-nickel alloy is obtained, meanwhile, the production cost is reduced, the environmental pollution is reduced, and the production efficiency is improved. The high-grade copper-nickel alloy is prepared through smelting, the atomized copper-nickel alloy is subjected to wet treatment, or the copper-nickel alloy is used as an intermediate material to produce a cupronickel product after impurityremoval, so that the technological process control is greatly optimized, and the operation technical and economic indexes of a system are effectively improved.

Owner:JINCHUAN GROUP LIMITED

Hardening and tempering heat preserving furnace for microcrystalline glass production

PendingCN111574026ASmall footprintFew supporting facilitiesGlass furnace apparatusElectric furnaceDc arc furnaceHeat conservation

The invention discloses a hardening and tempering heat preservation furnace for microcrystalline glass production. The furnace is used for microcrystalline glass and microcrystalline stone production.The hardening and tempering heat preservation furnace is a direct-current electric arc furnace and comprises a smoke hood, a burdening and conveying device, a first direct-current electrode, a top blowing stirring device, a water cooling furnace cover, a furnace body, a second direct-current electrode, a flow control device and a heat preservation flow channel, wherein the heat preservation furnace is provided with the first direct-current electrode and the second direct-current electrode which are matched with each other and can generate electric arcs to heat the furnace charge; the flow control device used for controlling the flow of furnace charge and the heat preservation flow channel used for transporting and discharging the furnace charge are arranged at a discharge port of the furnace body; the top blowing stirring device used for blowing gas is further installed on a cover body of the water cooling furnace cover; and the smoke hood is arranged above the furnace body and can beused for collecting smoke and reducing energy loss. The hardening and tempering heat preservation furnace is a direct-current electric arc furnace which is small in occupied area, convenient to operate, capable of achieving real continuous production, capable of saving energy and capable of enabling materials to be evenly mixed.

Owner:JIAOCHENG YIWANG FERROALLOY

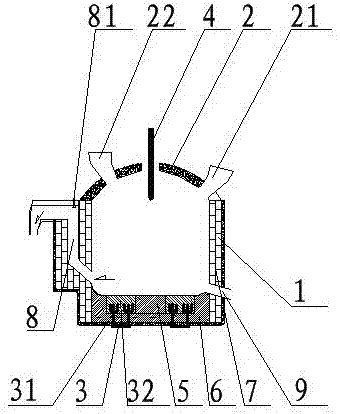

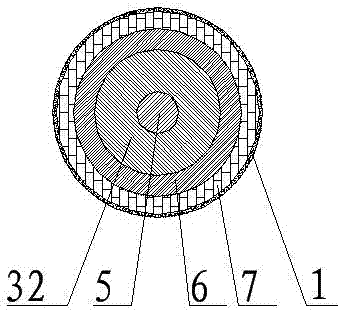

Direct-current electrical arc furnace

The invention discloses a direct-current electrical arc furnace which is mainly composed of two parts of a furnace body (1) and a furnace cover (2). The furnace body (1) is of a cylindrical structure, and annular electrodes (3) are arranged at the bottom of the furnace body (1); and each annular electrode (3) is composed of two parts of a metal electrode (31) and a fire-resistant electrode (32). The direct-current electrical arc furnace is adopted to smelt quartz stone, basalt, blast furnace slag, dolomite, limestone and the like, the characteristics of low energy consumption, no pollution, and easy operation are achieved, meanwhile, process operation of furnace bottom slag overflow is adopted, scour over refractory materials of the electrical arc furnace in feeding is reduced, the continuous service life of the refractory materials is guaranteed, and electrode cores for insulation are arranged in the middles of the annular electrodes at the furnace bottom, so that the defect of electrode core scorching of the furnace bottom of a traditional direct-current electrical arc furnace is eliminated.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com