Large-scale direct current electric arc furnace continuous smelting high titanium slag electrode adding device and use method thereof

A DC electric arc furnace and high-titanium slag technology, applied in electric furnace heating, furnace, furnace components and other directions, can solve the problems of complexity, time-consuming electrode addition, labor force, etc., and achieve low electrode consumption, simple and convenient maintenance, and stable arc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The utility model is described in detail below in conjunction with accompanying drawing and specific embodiment.

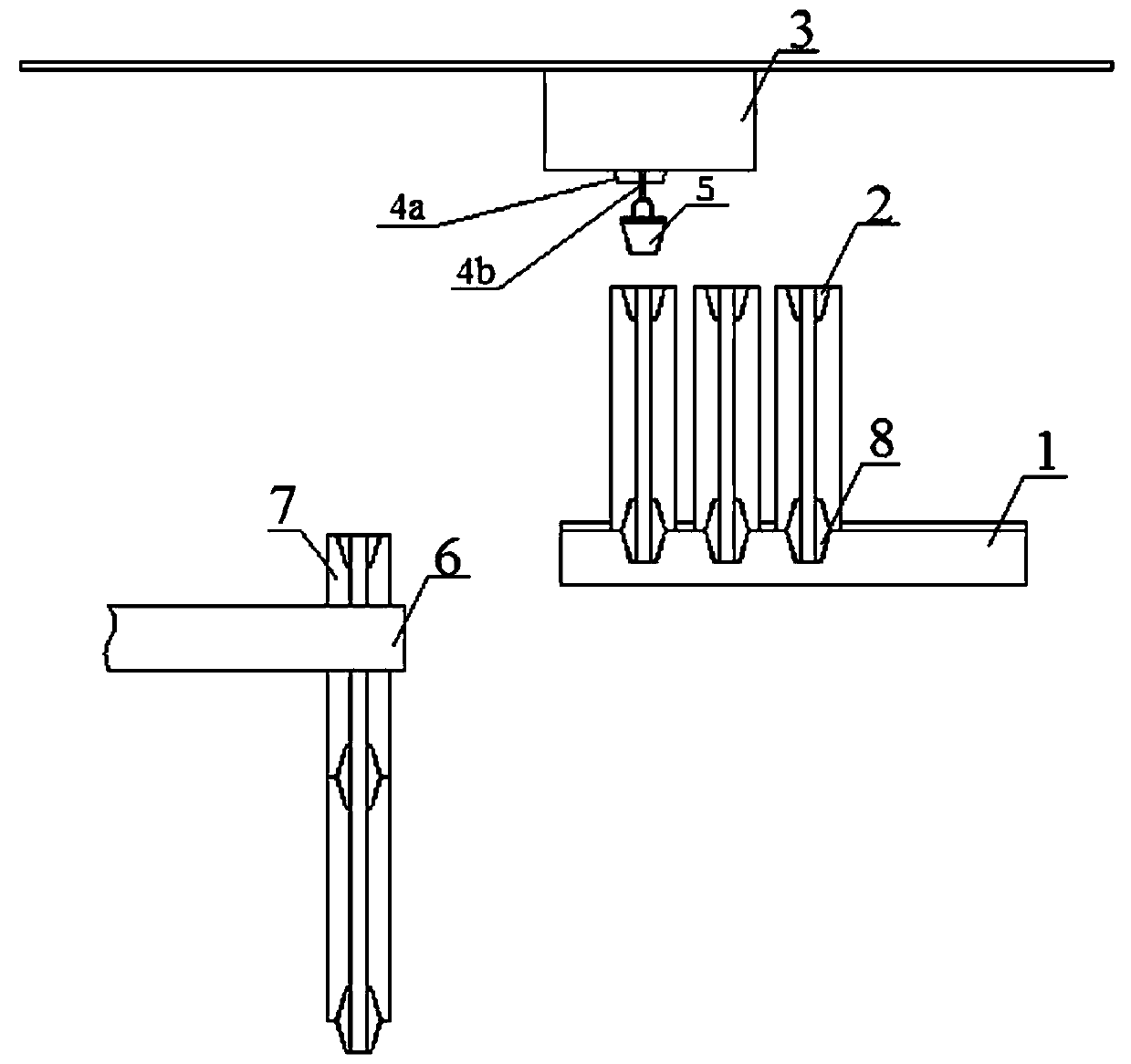

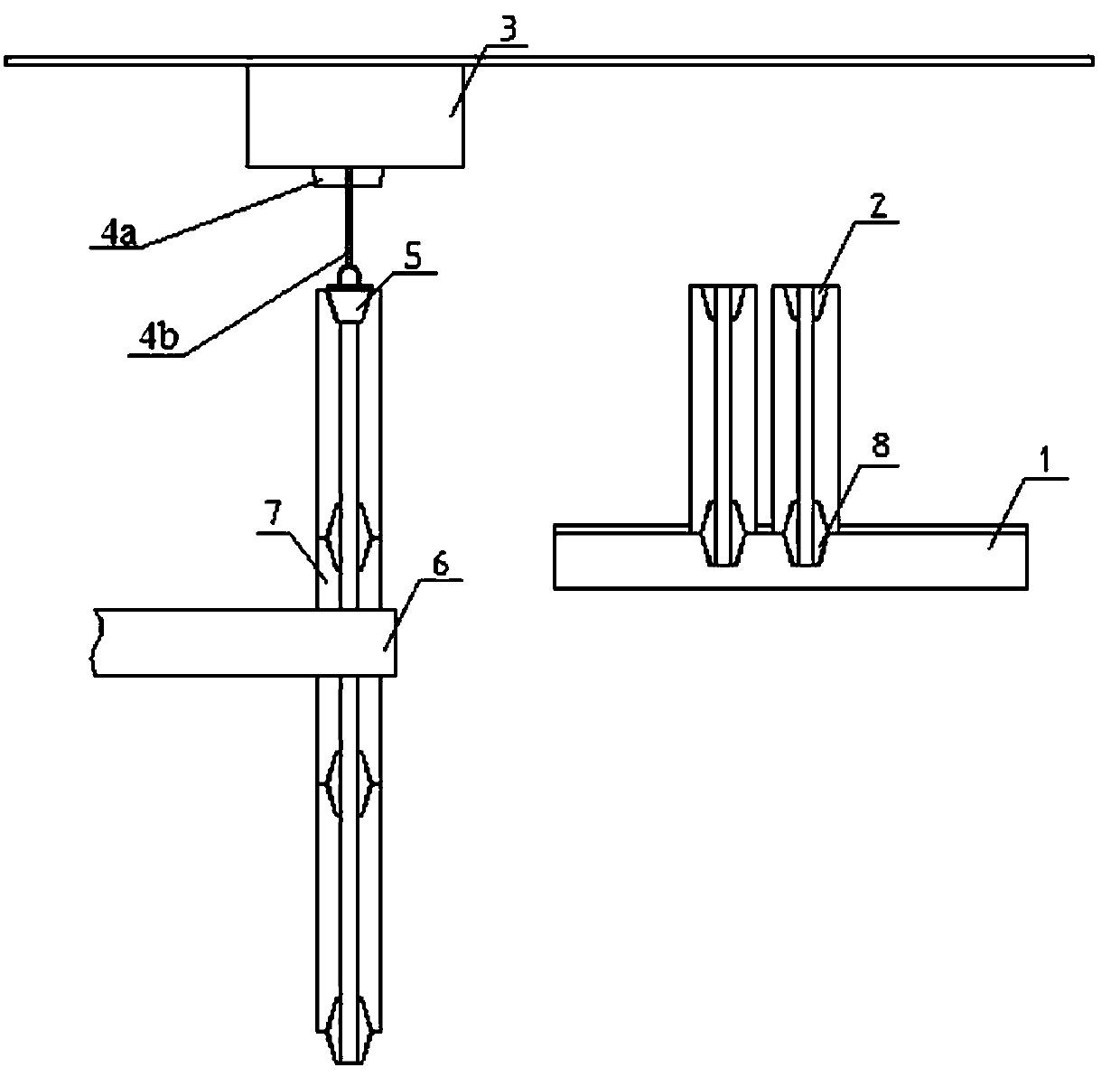

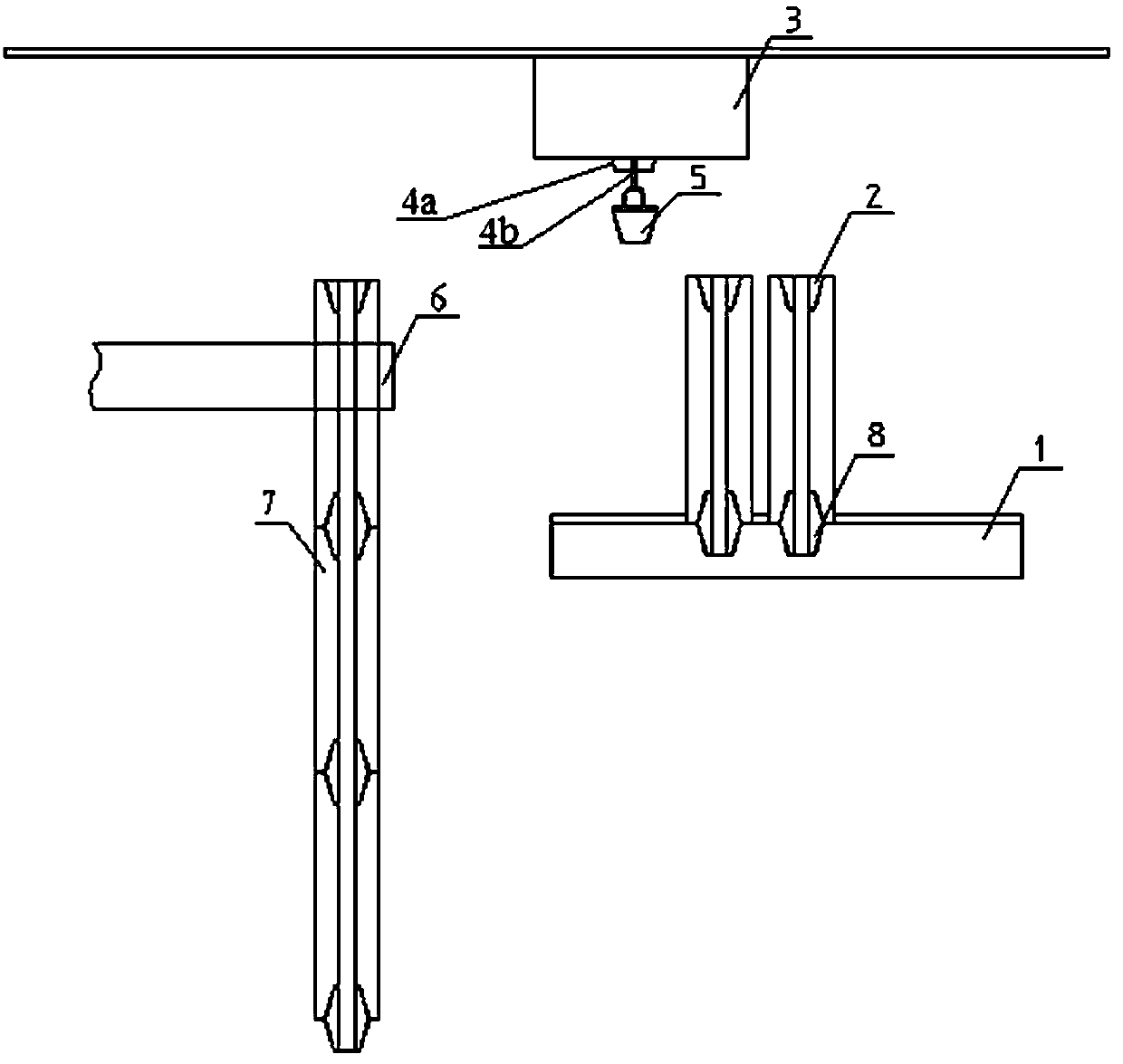

[0014] See figure 1 , figure 2 , image 3 , a large-scale DC electric arc furnace continuous smelting high-titanium slag electrode adding device and its use method, the present invention is characterized in that it includes an electrode trolley 3, an electrode holder 6, and an electrode stand 1, wherein the electrode trolley 3 is rotatably hung on the overhead rail 9, the lifting hydraulic system 4a and the hydraulic rod 4b connected to the lifting hydraulic system 4a are connected to the lower end of the electrode trolley 3, and the electrode head 5 with tapered thread is fixedly connected to the end of the hydraulic rod 4b; the electrode holder 6 is set Below the overhead track 9, it is connected to the vertical track 10 controlled by the electrode arm hydraulic system 11; A draw-in slot 12 matched with the lower end of the new electrode 2 .

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com