Patents

Literature

158results about How to "Save investment cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Somatosensory interactive broadcasting guide system and method based on free viewpoints

InactiveCN102307309AHave full autonomyIndependentInput/output for user-computer interactionCharacter and pattern recognitionSomatosensory systemMulti camera

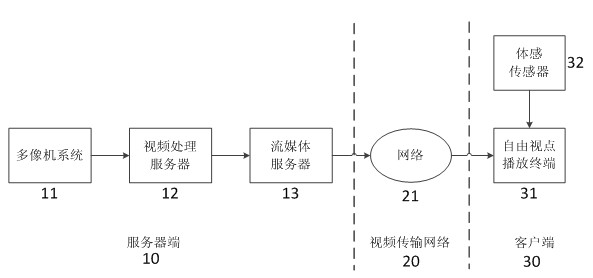

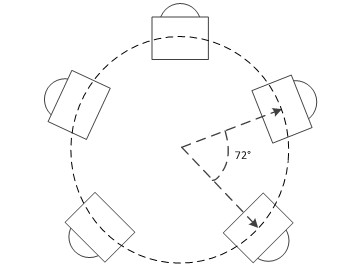

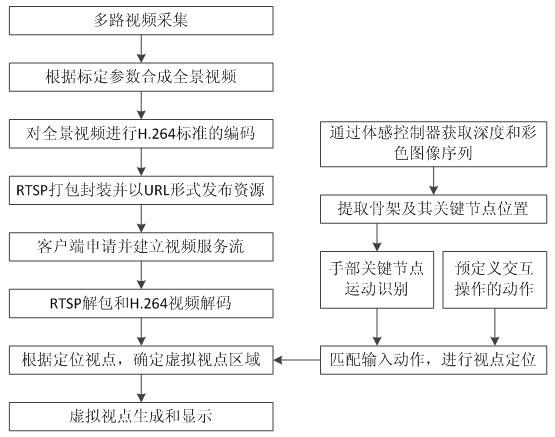

The invention relates to a somatosensory interactive broadcasting guide system and method based on free viewpoints. The system comprises a server side, a video transmission network and a client side, wherein, the server side comprises a multi-camera system, a video processing server and a streaming media server which are used for completing multi-channel video capture, panoramic video synthesis, H.264 encoding and RTSP (real time streaming protocol) streaming media service; the video transmission network is a local area network (LAN) or wide area network (WAN) based on a TCP / IP (transmission control protocol / Internet protocol); and the client side comprises a free viewpoint playing terminal and a somatosensory sensor, wherein, the free viewpoint playing terminal comprises functional modules which are used for completing video streaming media receiving and decoding, gesture recognition based on a somatosensory controller, free viewpoint generation and other tasks. The somatosensory interactive broadcasting guide system and method have the beneficial effects that by combining multi-channel video into panoramic video, software and hardware investment and technical cost can be saved by directly utilizing the currently mature video coding and streaming media transmission technology, and meanwhile panoramic seamless roaming at 360 degrees and free viewpoint switchover can be really realized.

Owner:HANGZHOU DIANZI UNIV

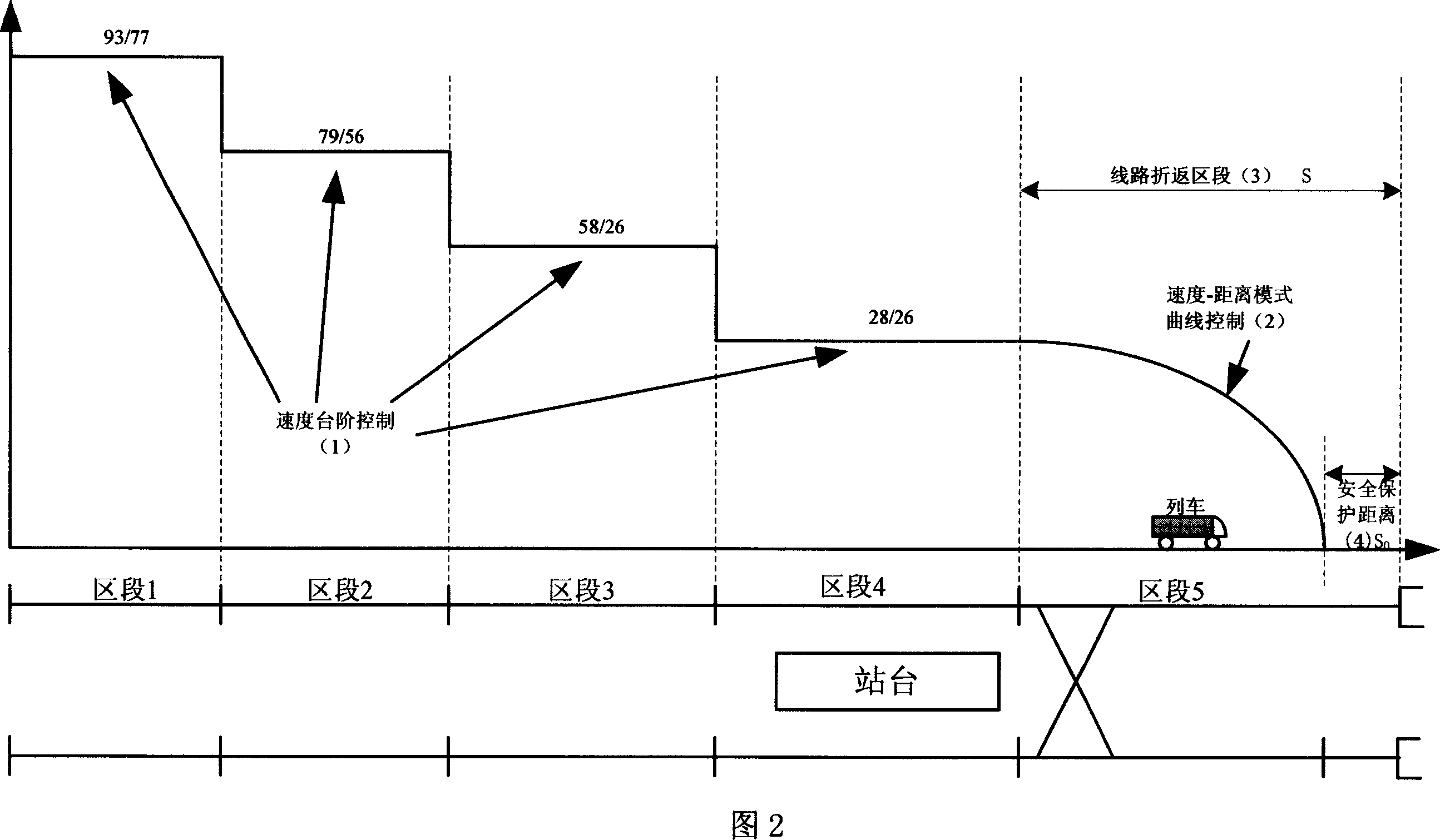

Universal automatic protection (ATP) vehicle-mounted system for train and its mode control method

InactiveCN101007537AReduce workloadIncrease flexibilityVehicle route interaction devicesDigital signal processingAutomatic control

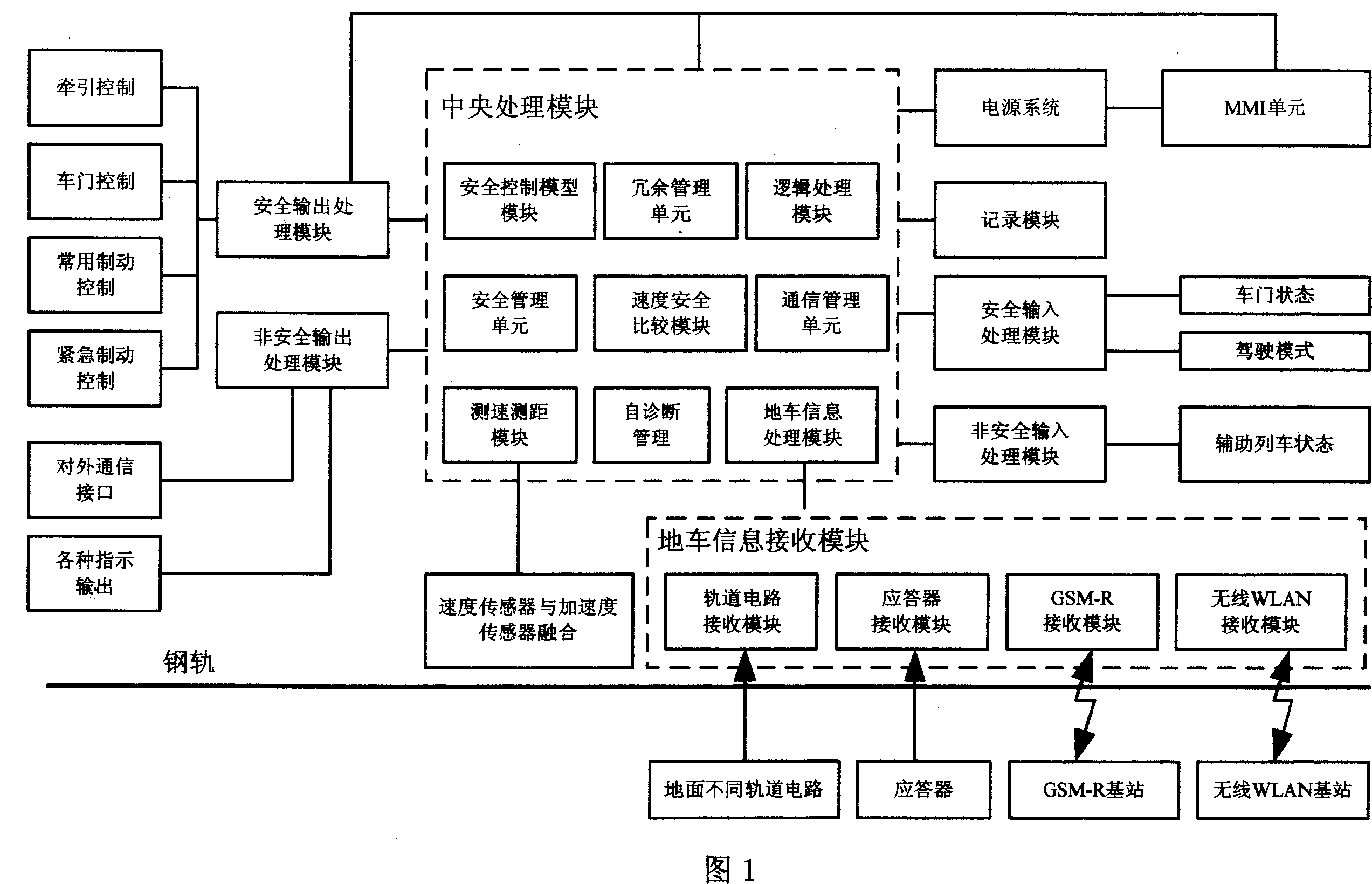

A universal Automatic Train Protection ATP vehicle mounted system and mode control method. The invention mainly uses digital signal processing and safe redundant control technology, designs a safe Protection Automatic control system which can receive many varieties of ground vehicles information transmission modus, realize the combination of the train speed steps control and the first-order speed-distance model curve and realize the generalization of vehicle automatic protection system vehicle mounted equipments. And the ground vehicles information transmission modus consists of analog and digital track circuit, responder, GSM-R transmission, 2.4GHz wireless transmission, etc. the safe protect control is the safe braking model control using the combination of speed steps and first-order speed-distance model curve. The system mainly consists of power module, ground vehicles information transmission reception module, central processing module, recording module and man-machine interface MMI module, etc. The beneficial result is getting a solving program for users on the base of reducing construction costs and intercommunicating transport operation.

Owner:BEIJING JIAOTONG UNIV

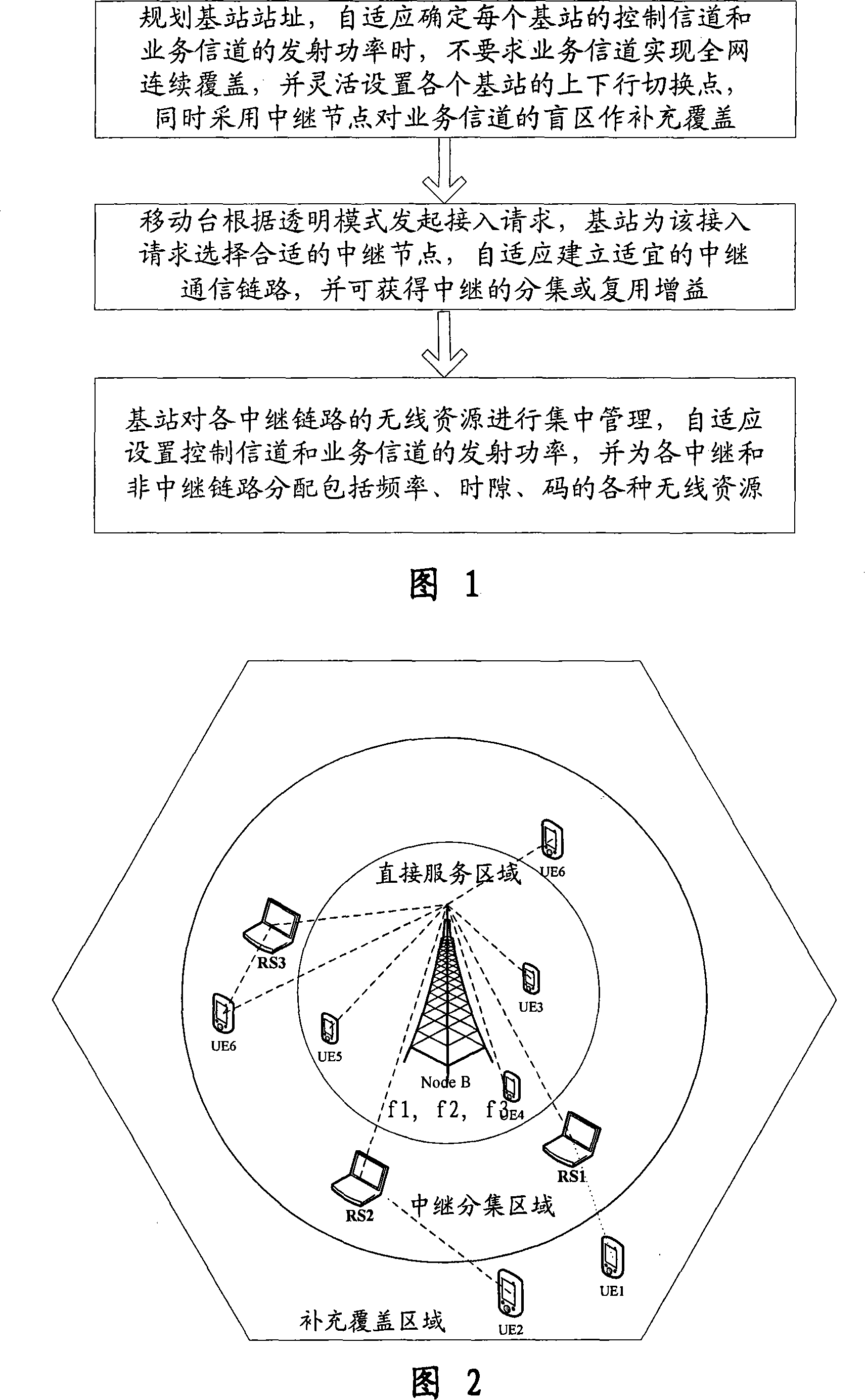

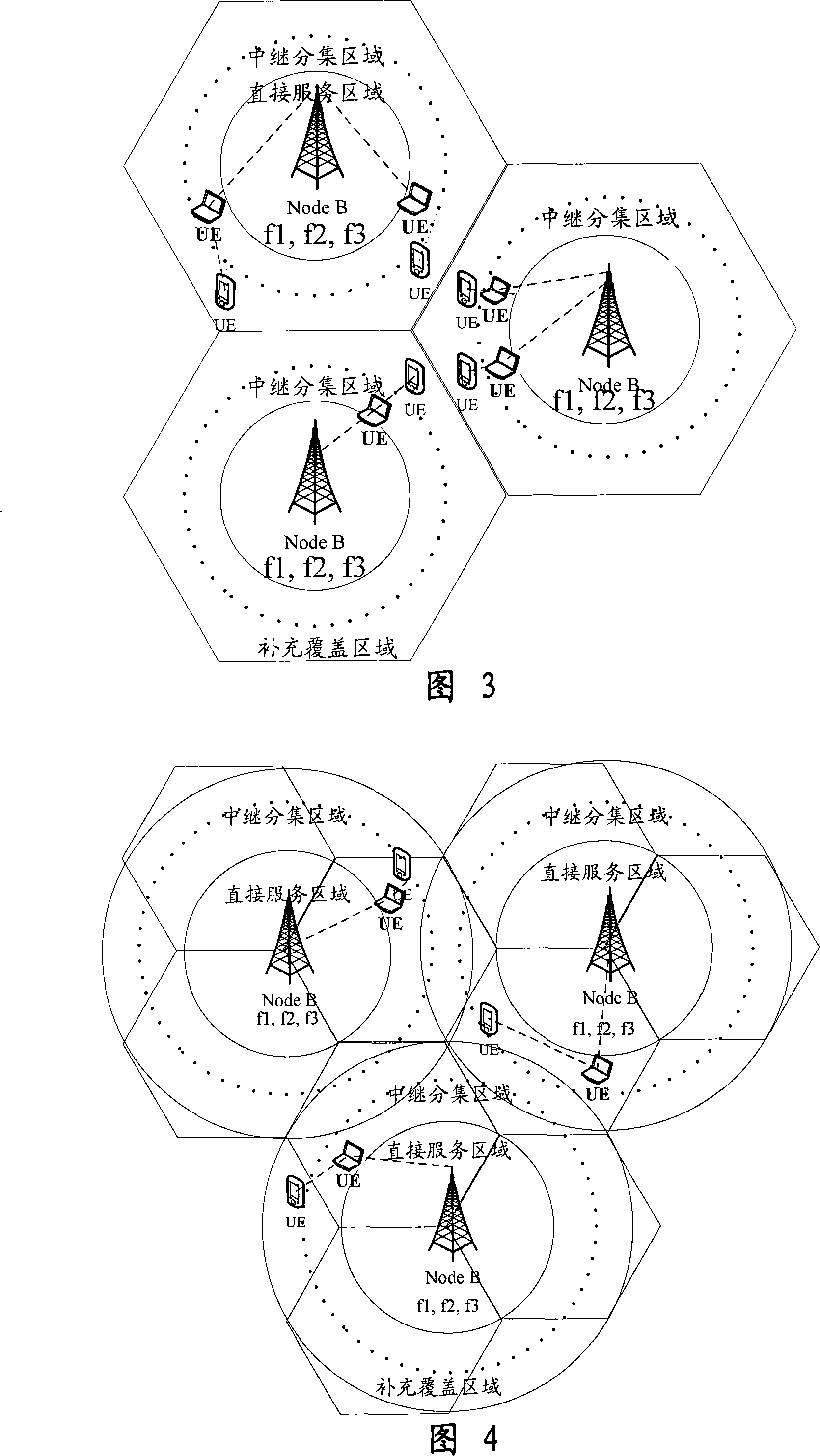

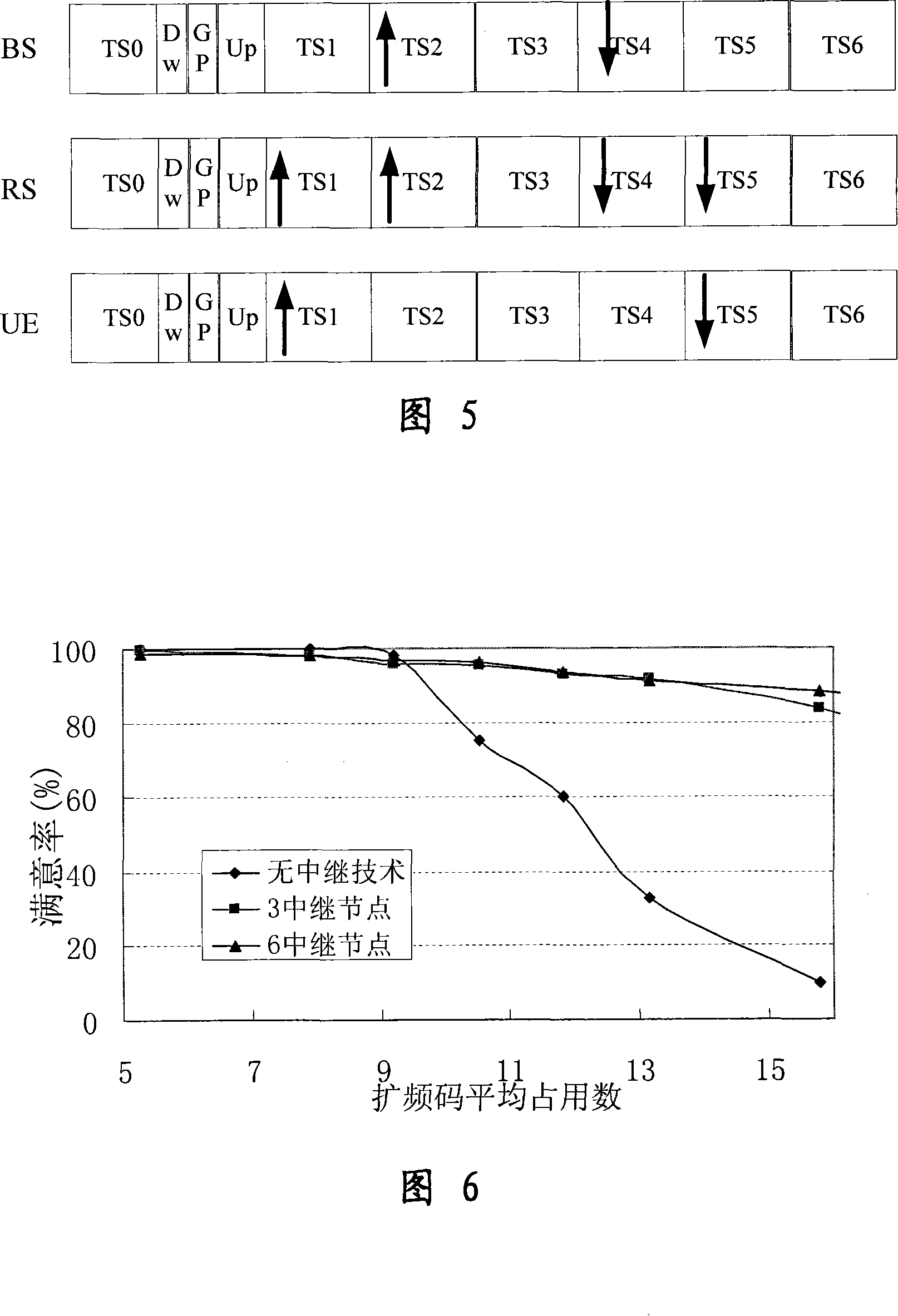

Multi-frequency point TD-SCDMA group network and communication implementing method based on relaying technology

InactiveCN101132601AReduce the difficulty of planning and layoutMinor changesPower managementTransmission control/equalisingSystem capacityTD-SCDMA

This invention relates to realizing method for multi-point TD-SCDMA netwroking and comunication including: 1, programming addresses of base stations, determining the emission power of control channel and service channel of each station adaptively and setting up-and down-line switch points flexibly and carrying out supplement cover to blind regions of service channels with relay nodes, 2, a mobile station initiates an access request according a transparent mode and the base station selects a suitable relay node for it to set up a communication link adaptively and get diversity and multiplex gain of the relay, 3, the base station manages radio resources of relay links in concentration to set emission power of the control channel and service channels and distribute radio resources of frequency, time slot and codes to relay and non-relay links.

Owner:COMBA TELECOM SYST CHINA LTD

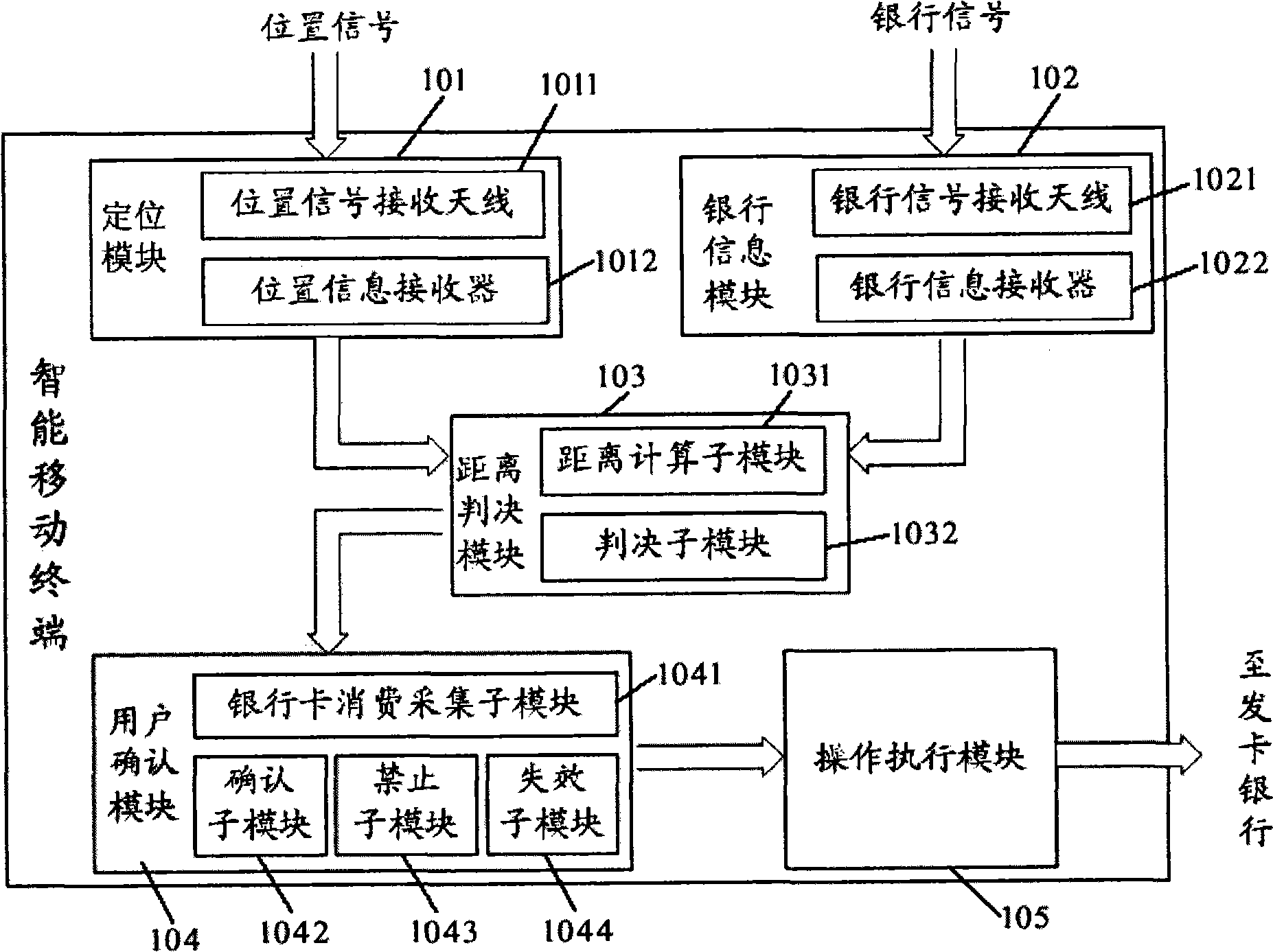

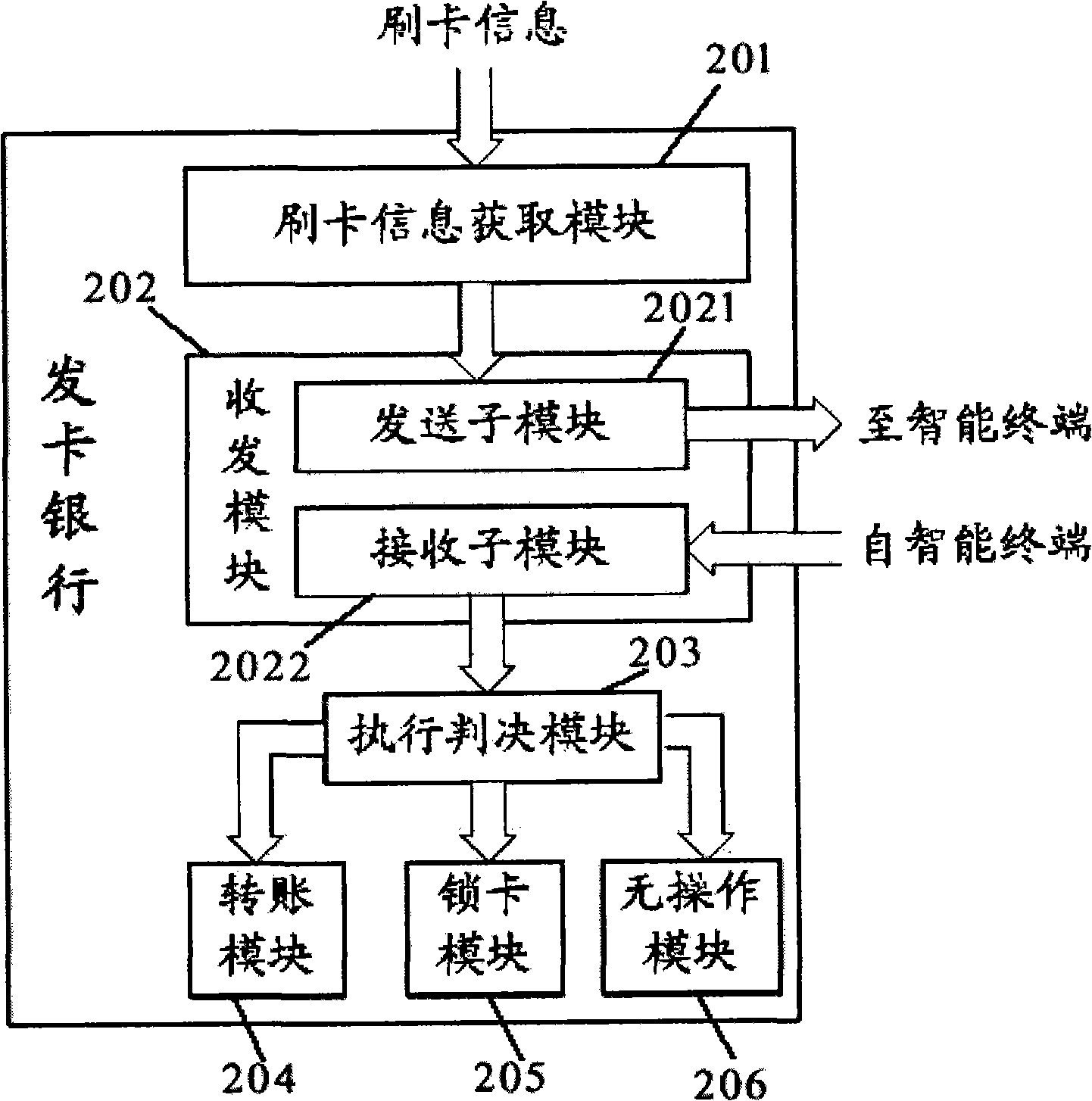

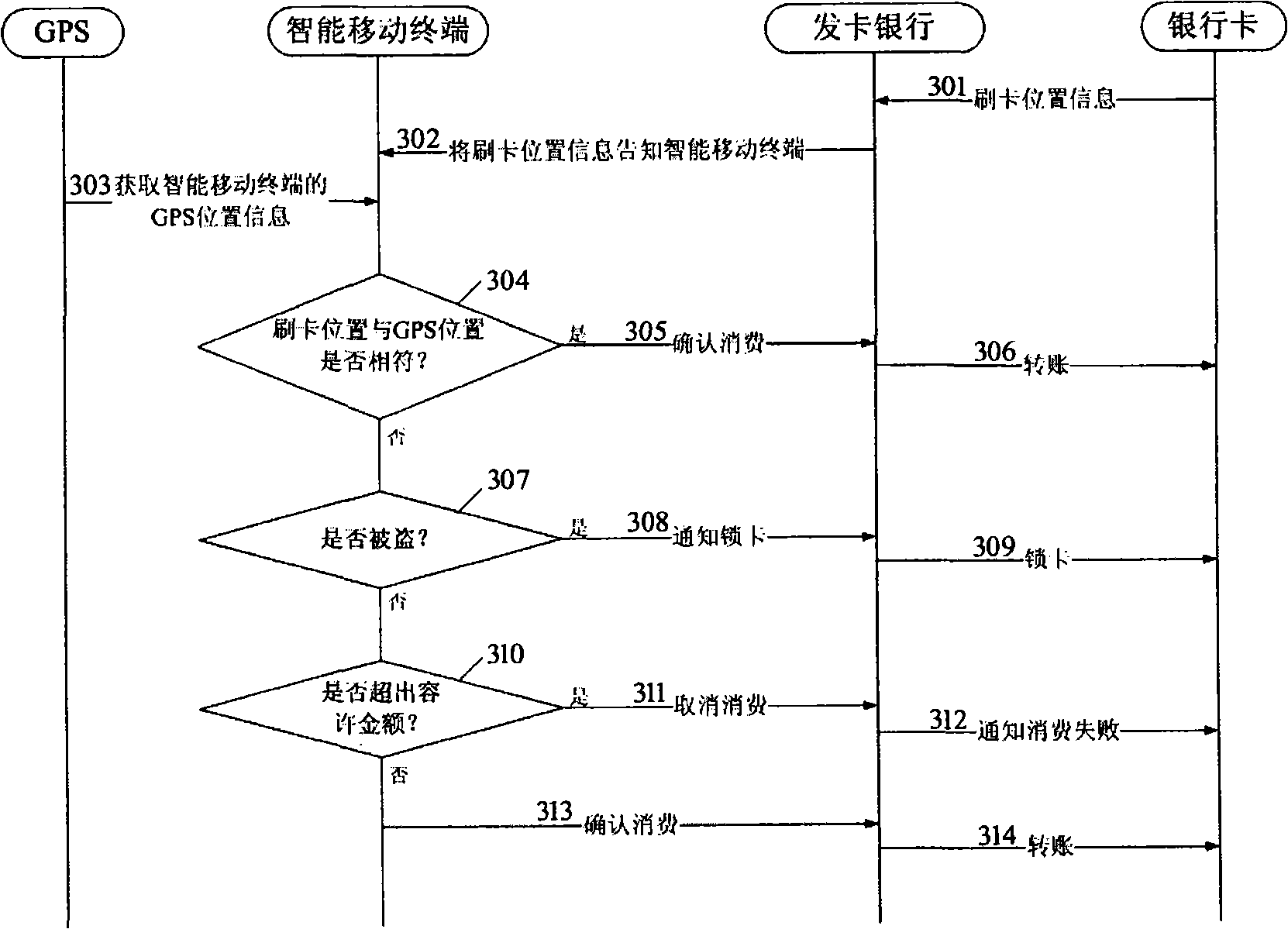

Method and equipment for preventing finance card from brushing deceptively

InactiveCN101303781APrevent theftWide coverageBeacon systems using radio wavesPosition fixationIssuing bankPunching

The invention discloses a method and a device for preventing the unauthorized use of a fiscal card; after a user stamps a card on the card punching terminal of a financial system, the value of the distance between an intelligent mobile terminal device of the fiscal card owner and the current card punching terminal is obtained. The value of the distance can be determined through the positioning information about the intelligent mobile terminal device and information about the position of the current card punching terminal provided by a bank. The obtained distance value is then compared with a predefined distance value; if the value of the distance between the intelligent mobile terminal device and the current card punching terminal is smaller than the predefined distance value, then the financial system automatically performs a remit account, and the consumption transaction is succeeded; if the value of the distance between the intelligent mobile terminal device and the current card punching terminal is larger than the predefined distance value, then the issuing bank takes further measures after taking the advice from the fiscal card owner. The scheme of the invention further enhances the safety of using the fiscal card.

Owner:BEIJING UNIV OF POSTS & TELECOMM

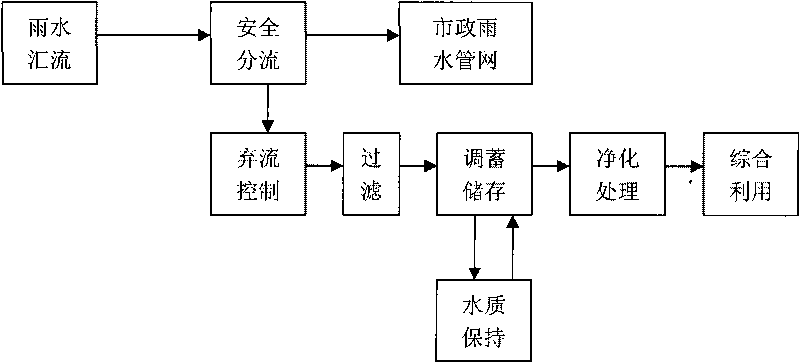

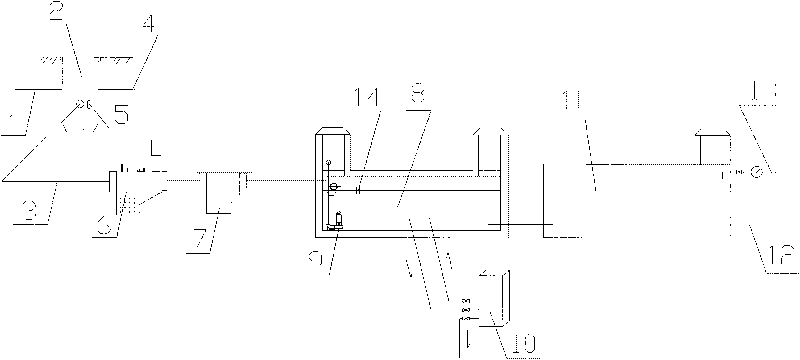

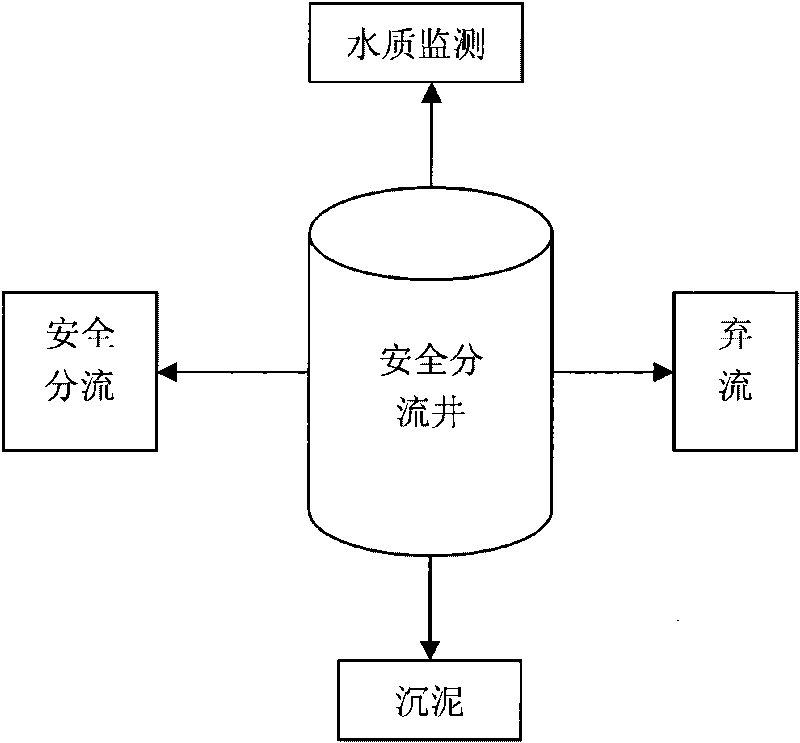

Rain and flood utilization system

InactiveCN101736774ADrainage safetyEnsure normal drainageGeneral water supply conservationSewage drainingEcological environmentFiltration

Owner:北京科净源科技股份有限公司

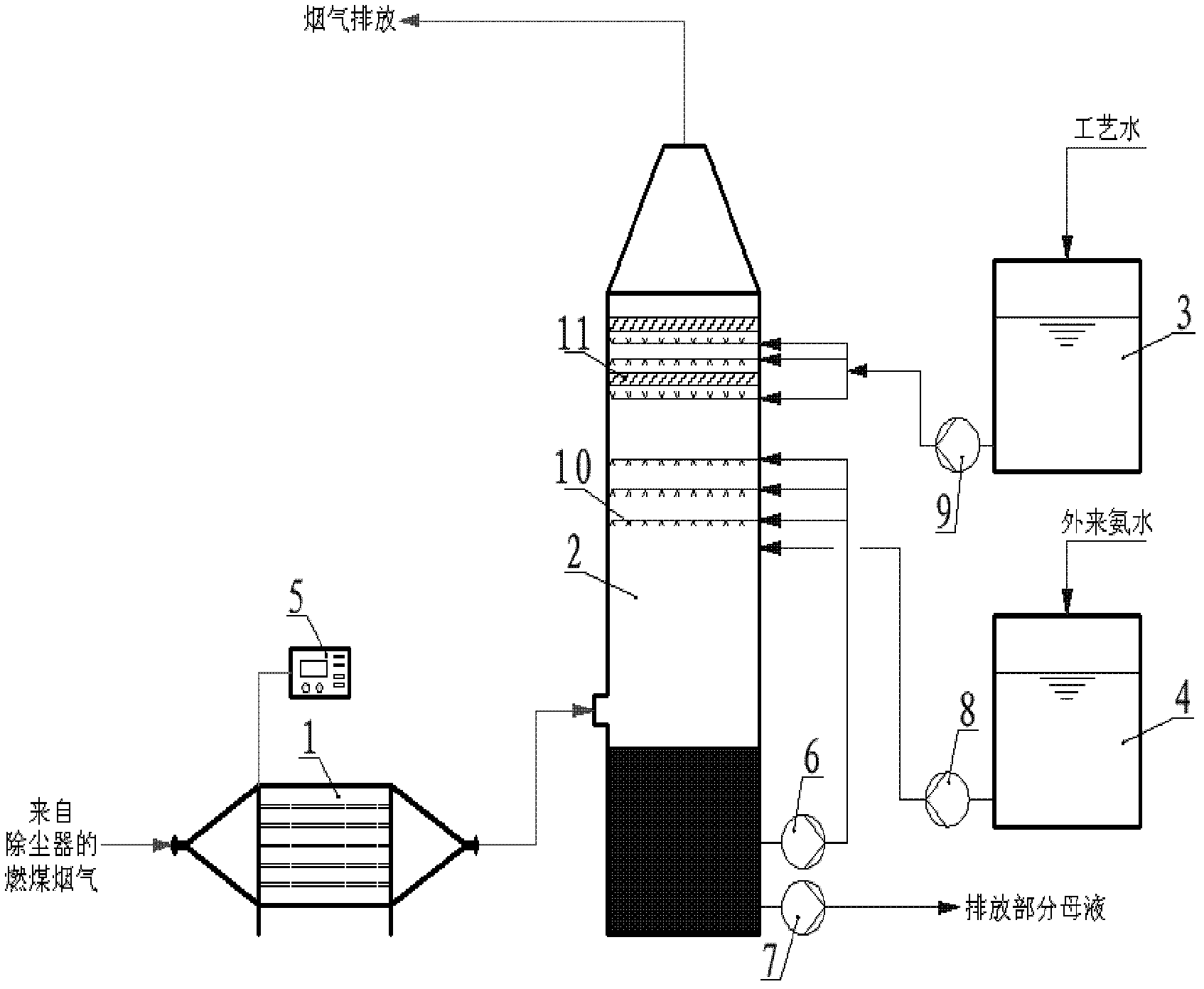

Synchronous denitration process based on wet ammonia process flue gas desulfurization

InactiveCN104226095ALow investment costLow running costDispersed particle separationAmmonium sulfatesSulfateFlue gas

The invention discloses a synchronous denitration process based on wet ammonia process flue gas desulfurization. The problems such as high operating cost and equipment investment cost, complex process and high energy consumption existing in an existing process are solved. According to the technical scheme, the process comprises the following steps: pressurizing flue gas, feeding the flue gas into a concentrating tower, allowing the flue gas to contact and react with a concentrated solution in the tower, feeding the flue gas out of the concentrating tower into an absorption tower to contact and react with absorption liquid in the tower, feeding a small amount of reacted concentrated solution at the bottom of the concentrating tower into an ammonium sulfate crystallization system, and adding a complexing agent EDTA-Fe (II) or adding EDTA-Na salt and ferrous sulfate according to a molar ratio of 1:1 into the absorption liquid in the absorption tower, so that the concentration of the EDTA-Fe (II &III) in the absorption liquid is 0.015-0.05mol / L; and feeding a small amount of absorption liquid in the absorption tower into the concentrating tower to be mixed with the concentrated solution. The synchronous denitration process disclosed by the invention has the advantages of simplicity, low operating cost and equipment investment, capacity of performing high-efficiency synchronous desulfurization and denitration and low energy consumption.

Owner:WUHAN WUTUO TECH +2

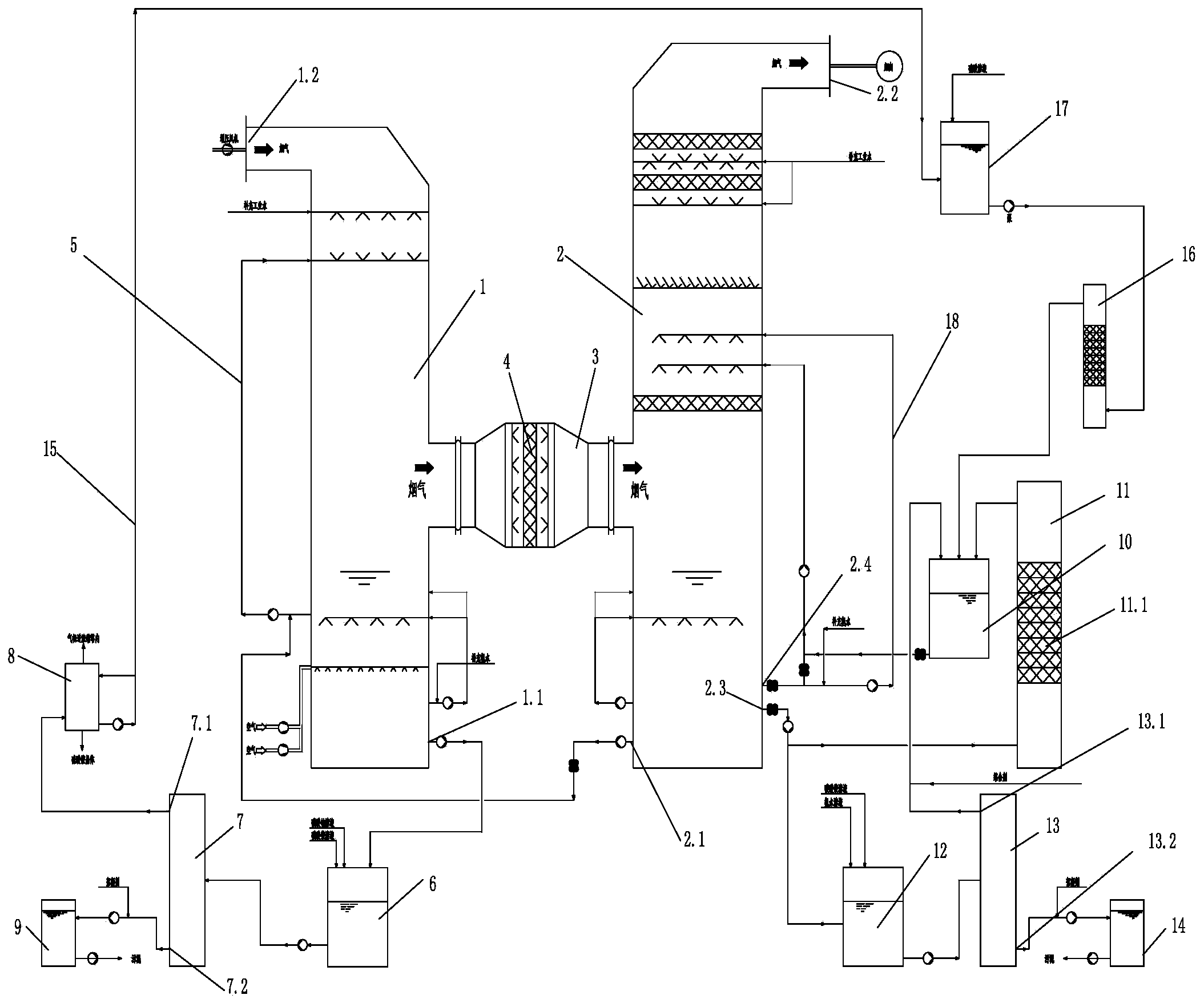

Coal-fired flue gas desulphurization denitration process and desulphurization denitration device thereof

InactiveCN102500207AImprove absorption rateHigh removal rateAmmonium nitratesDispersed particle separationLow temperature plasmaChemistry

The invention discloses a coal-fired flue gas simultaneous desulphurization denitration process by low temperature plasma oxidation combined with ammonia-method wet absorption; the process comprises two processes of low temperature plasma oxidation and ammonia-method wet absorption; coal-fired flue gas to be treated is firstly introduced into a low temperature plasma reactor through a flue, and thus 40%-50% of NO in the flue gas is oxidized into NO2; the conditioned flue gas is introduced into a simultaneous desulphurization denitration spray tower, and fully contacts ammonia water absorption liquid so as to remove SO2 and NOx in the flue gas and discharge the flue gas; the absorption liquid at the bottom of the simultaneous desulphurization denitration spray tower is delivered into a spray layer again for recycle through an absorption liquid circulating pump; ammonia water in an ammonia water groove is supplied continuously to the spray tower through an ammonia water pump; and a part of mother liquor is discharged through a mother liquor transfer pump. The process of the invention is applicable to the simultaneous desulphurization denitration treatment of coal-fired flue gas, and the device of the invention has the advantages of good pollutant removing effect, simple equipment, less land occupation, convenient operation, and convenience for management.

Owner:SOUTHEAST UNIV

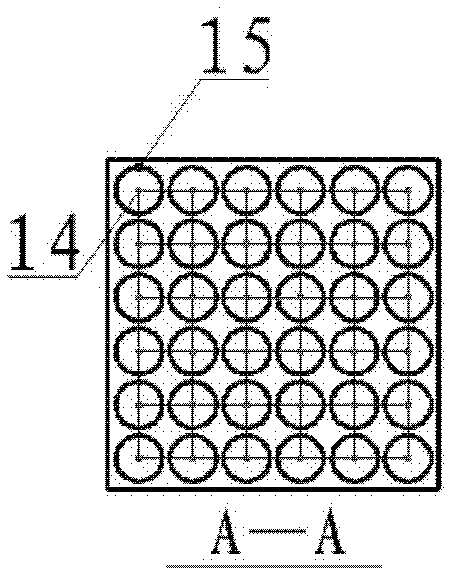

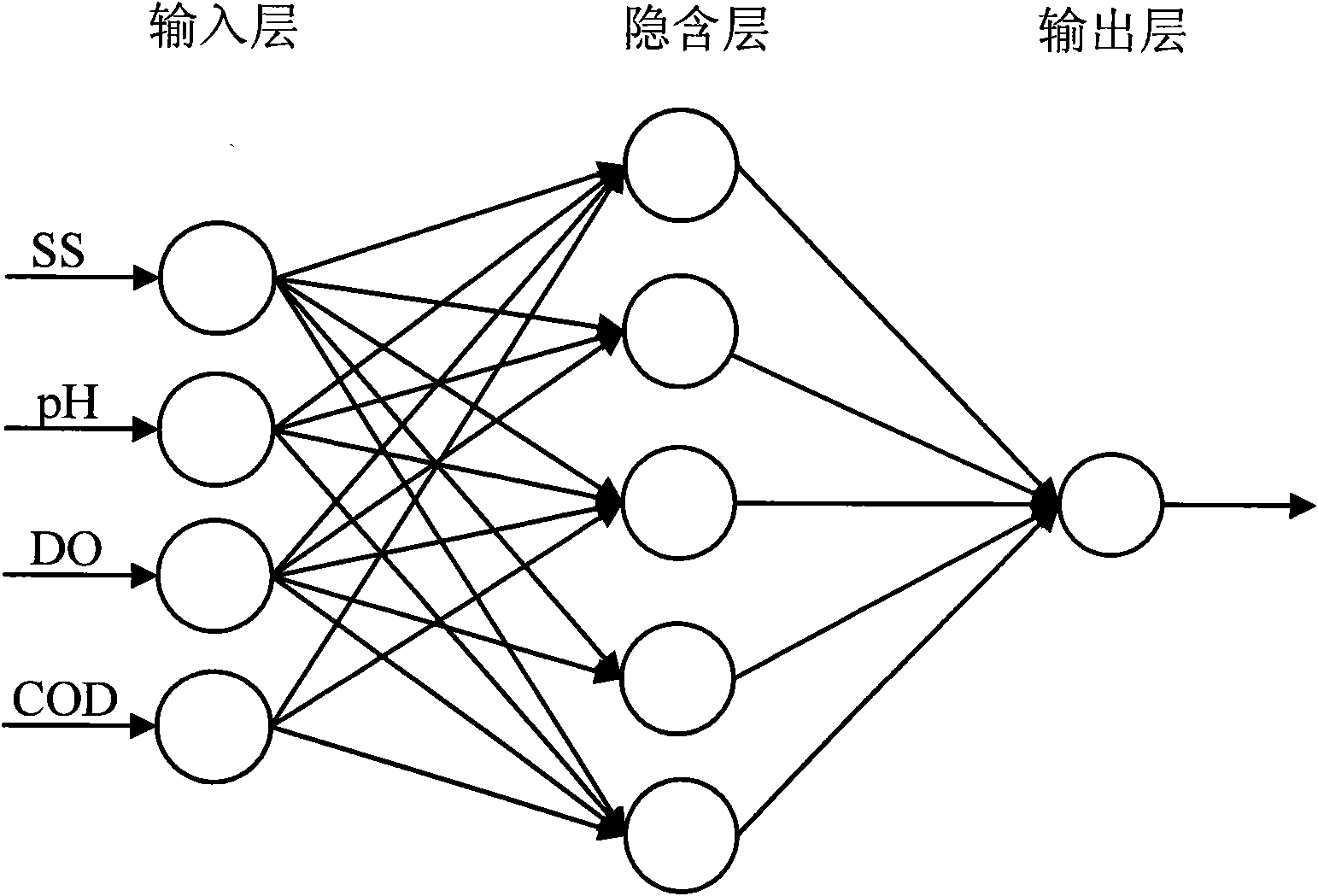

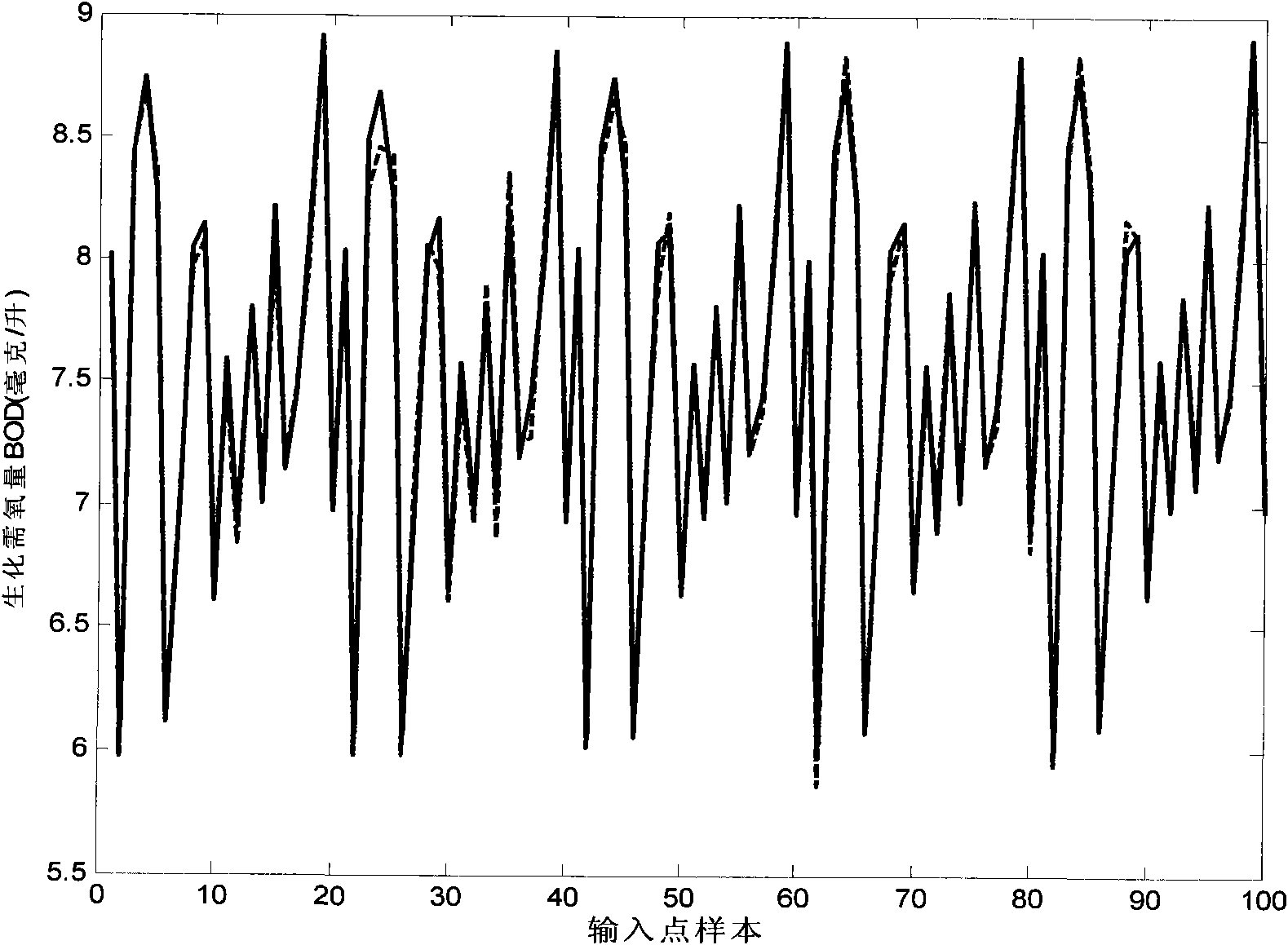

Biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network

ActiveCN101957356AGuaranteed uptimeSave investment costBiological neural network modelsTesting waterMathematical modelWater quality

The invention discloses a biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network, belonging to the technical field of detection. The sewage processing process has severe production condition and serious random disturbance, has the characteristics of strong nonlinearity, large time varying and serious lag and is hard to build a precise mathematical model by mechanism analysis. The invention utilizes the liveness function of an RBF neuron to judge the activeness of the neuron, and divides the neuron with strong activeness; then, joint strength between the hidden layer neuron and the output layer neuron of an RBF neuron network is analyzed by calculating a mutual information dependency function so as to revise the neural network structureaccording to the mutual information intensity; and finally, the parameter of the neural network is adjusted until the network structure satisfies the requirement on processing information. The invention improves the quality and the efficiency of sewage processing, lowers sewage processing cost and provides in-time water quality and relevant parameter monitoring for realizing closed loop control for the sewage processing process so as to accelerate sewage treatment plants to efficiently and stably operate.

Owner:BEIJING UNIV OF TECH

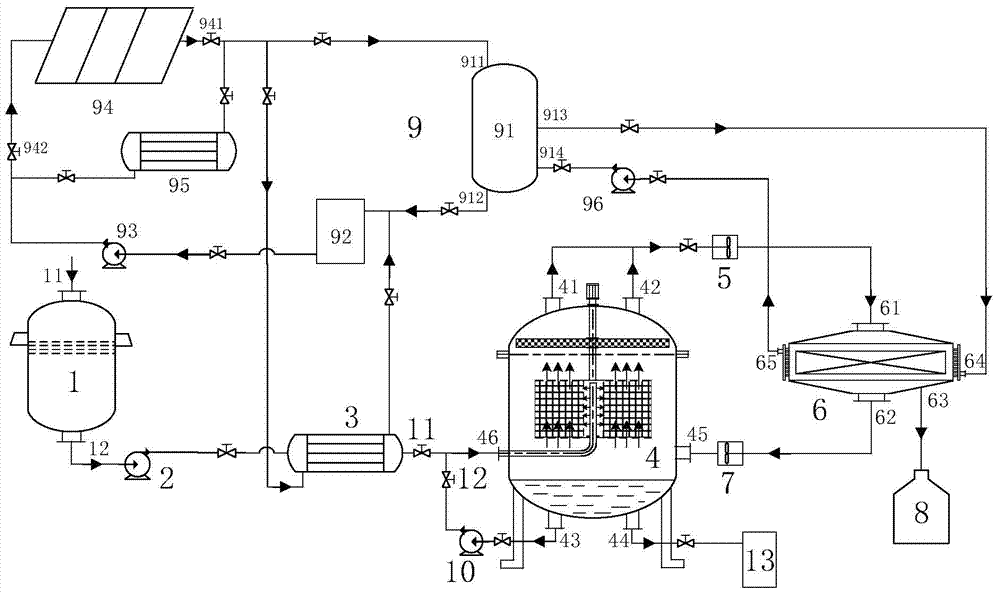

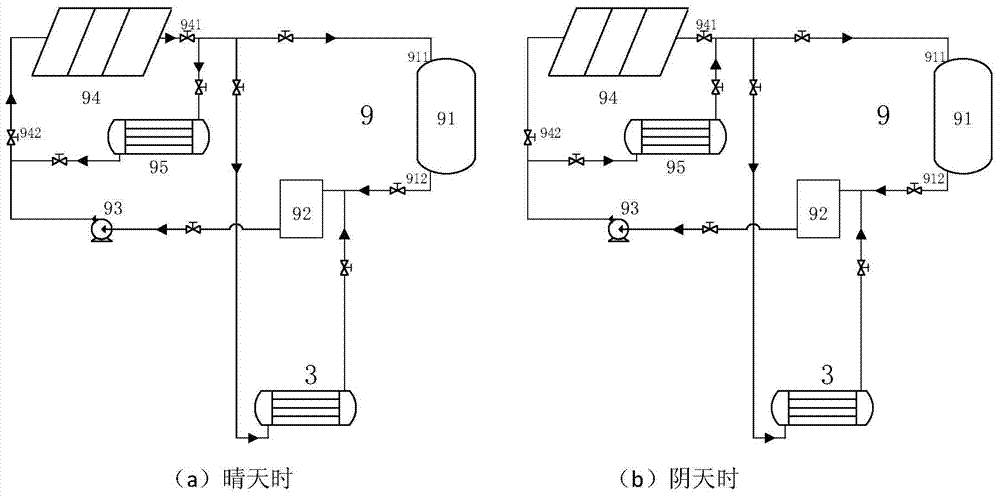

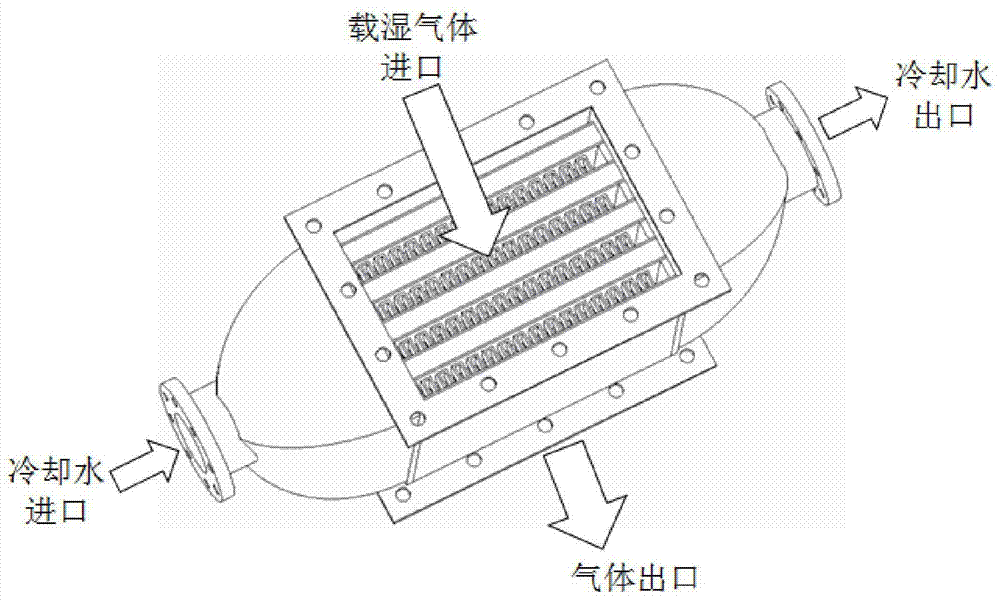

Solar-powered waste water evaporation system

ActiveCN104118918AGuaranteed uptimeImprove absorption efficiencyGeneral water supply conservationWater/sewage treatmentWater desalinationLithium bromide

The invention discloses a solar-powered waste water evaporation system. The energy source used by the system is mainly solar energy. Hot water generated by a solar heat collector pre-heats waste water; by means of a wet-carrying capacity of a gas, steam is carried after being contacted with pre-heated waste water in an evaporation chamber; the wet-carrying gas is condensed in a surface air cooler by cooling water generated by a solar-powered lithium bromide refrigerator, and the dehumidified gas further enters the evaporation chamber to carry wet circularly. The system disclosed by the invention needs not to consume steam, so that the system is remarkable in energy conservation. The system can realize low-temperature evaporation and can be widely applied to the industries of petrochemical engineering, foods, light industry, pharmacy, sewage treatment, sea water desalination and the like.

Owner:NANJING UNIV OF TECH

Device and method for cleaning, activating or pre-treating workpieces by blasting carbon dioxide snow

ActiveCN101124065AMixed Effects FavorableImprove stabilityBlast gunsCarbon compoundsPhysical chemistryEnvironmental engineering

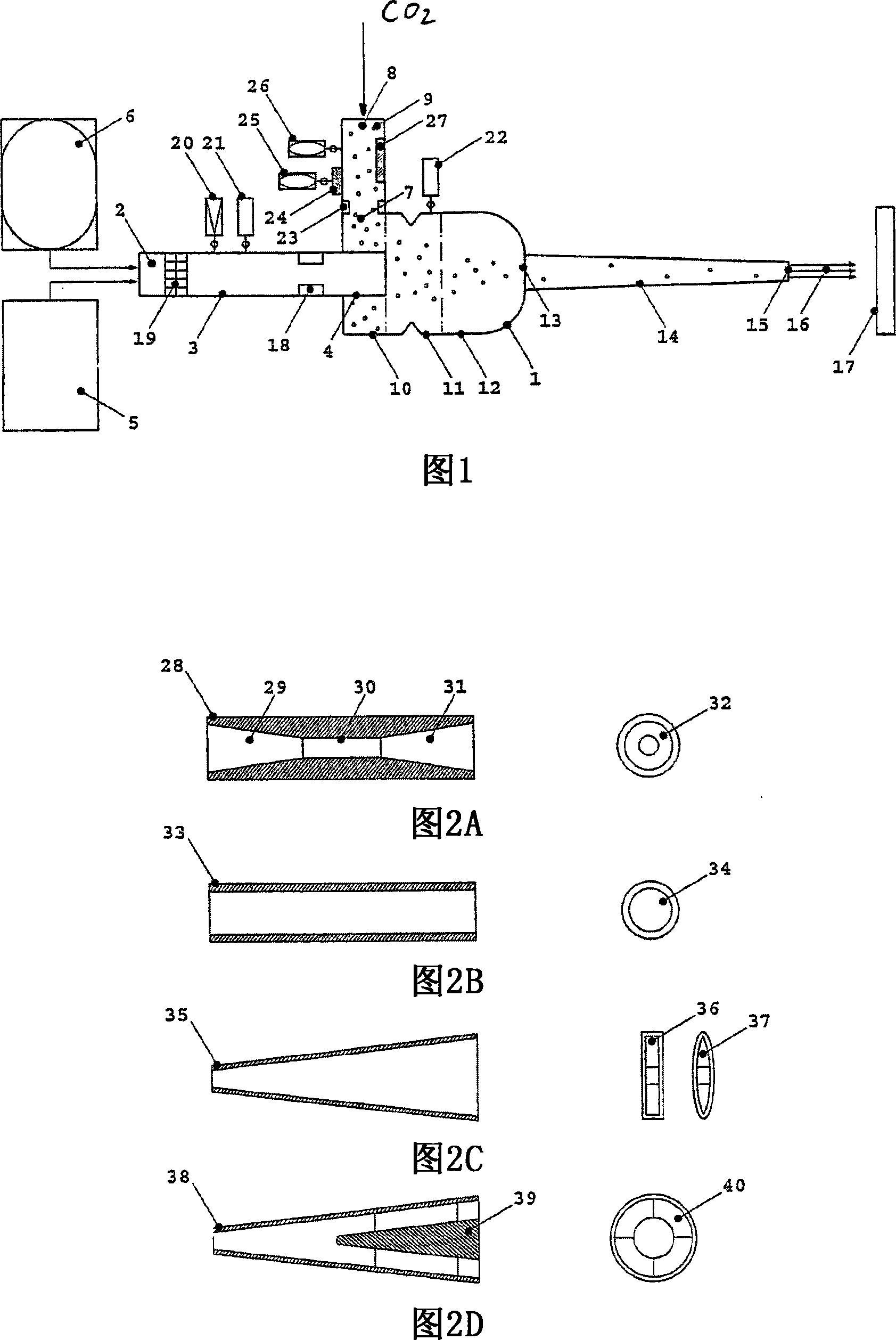

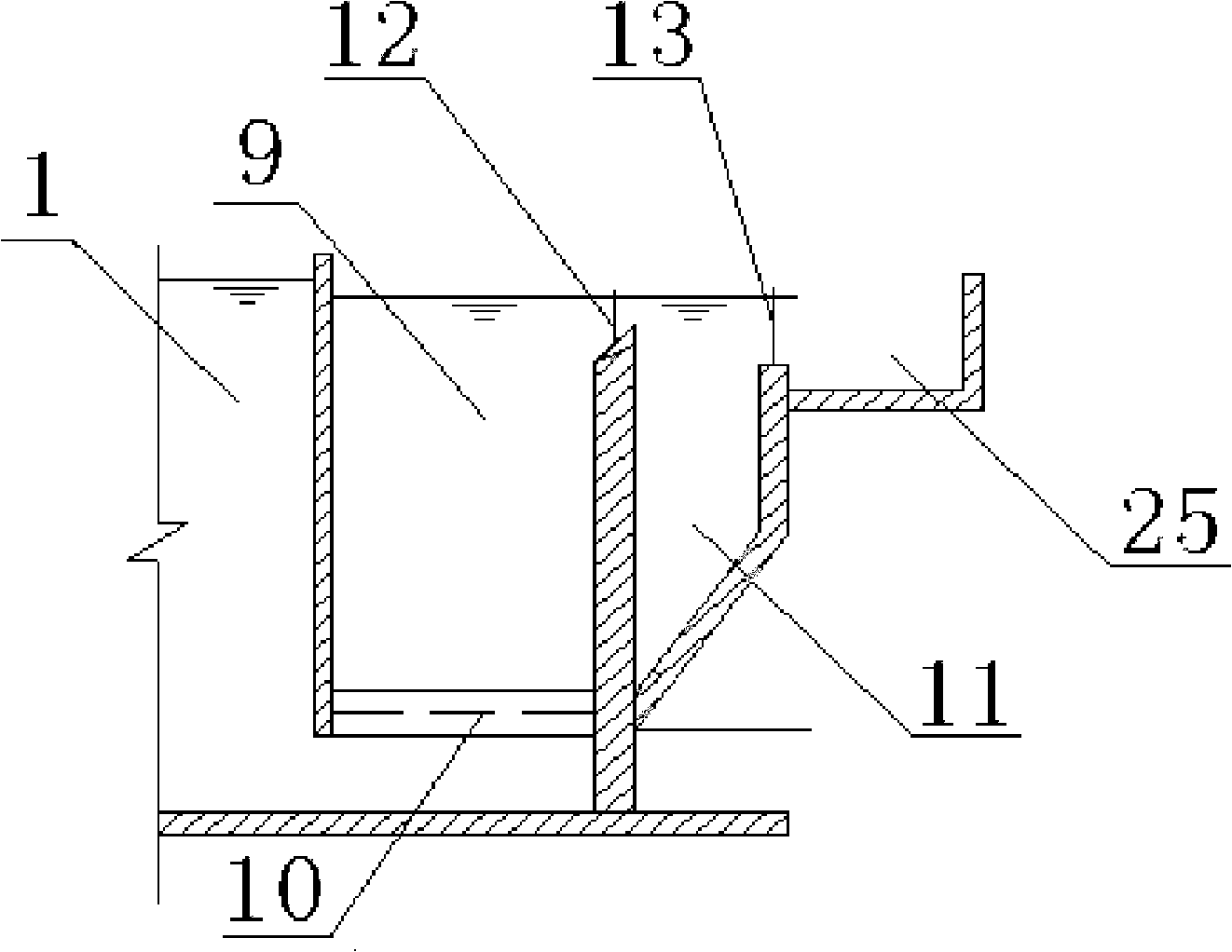

The invention relates to a device and method for cleaning, activating or pre-treating workpieces by blasting a carbon dioxide snow which is produced from pressurised CO2-containing fluids and at least one type of carrying compressed gas and is accelerated by means of a discharge nozzle (14), wherein a two-phase carbon dioxide mixture of a carbon dioxide gas and carbon dioxide particles is produced in an agglomeration chamber (8) by agglomerating and compressing carbon dioxide snow crystals which are radially added to the carrying gas in a multistage mixing chamber (10, 11, 12) comprising a central jet pipe (4), around which the carbon dioxide mixture circulates and which is used for supplying said carrying gas in such a manner that a high-energy turbulent gas flow for processing a workpiece is obtainable.

Owner:CRYOSNOW GMBH

Integrated oxidation ditch, construction and operation method

InactiveCN101269882AImprove settlement performanceIncrease concentrationTreatment with aerobic and anaerobic processesSewageSmall footprint

The invention discloses an integrated oxidation ditch and a construction and operation method thereof. The construction and operation method has the technical proposal that the integrated oxidation ditch is divided into an anoxic zone, an anaerobic zone and an aerobic zone, which are communicated mutually, the anoxic zone and the anaerobic zone are arranged at one end of the integrated oxidation ditch in common, the aerobic zone is arranged at the other end of the integrated oxidation ditch, and a water-retaining wall is arranged at the middle part of each zone to cause each zone to be formed a single annular channel, water inlet pipes used for feeding water by the division point way are arranged at the anoxic zone and the anaerobic zone, an aeration device is arranged in a circulation channel at one side of the aerobic zone communicated with the anoxic zone, and a mud-water separation device used for the mud-water separation and the water emission is built on the side wall of the aerobic zone for the water emission. The aeration device is started, and the sewage passes through the anoxic zone, the anaerobic zone, the aerobic zone, and the mud-water separation device in sequence, so the dephosphorization and the denitrification as well as the decarbonization treatments of the sewage are realized. The integrated oxidation ditch has the advantages of simple structure, lower cost, small occupation area, and good sewage treatment effect, and can particularly and effectively perform the dephosphorization and the denitrification simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU +1

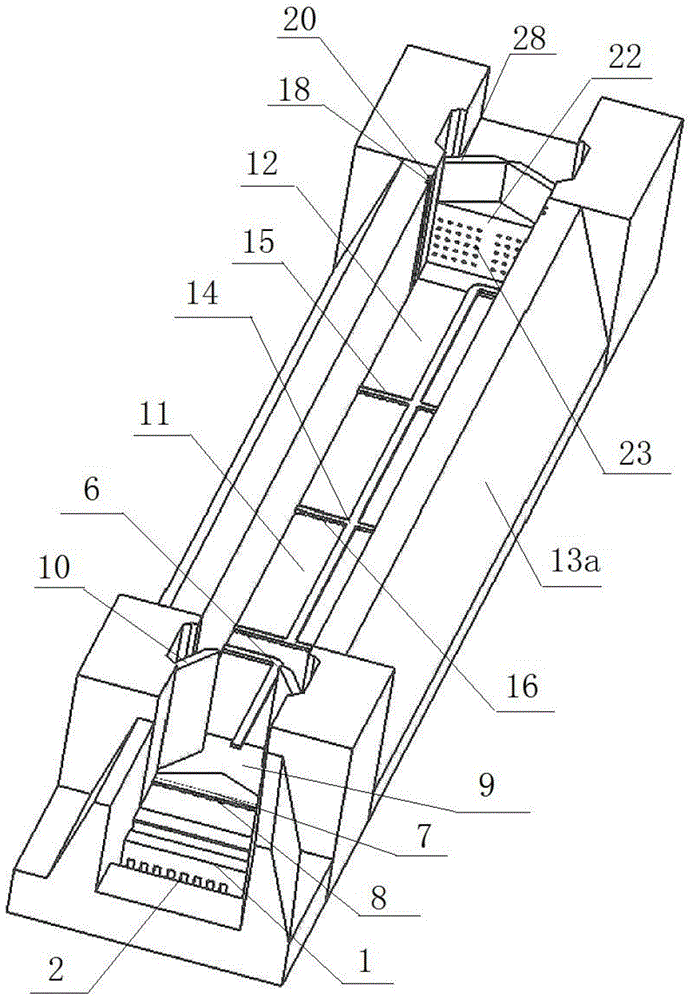

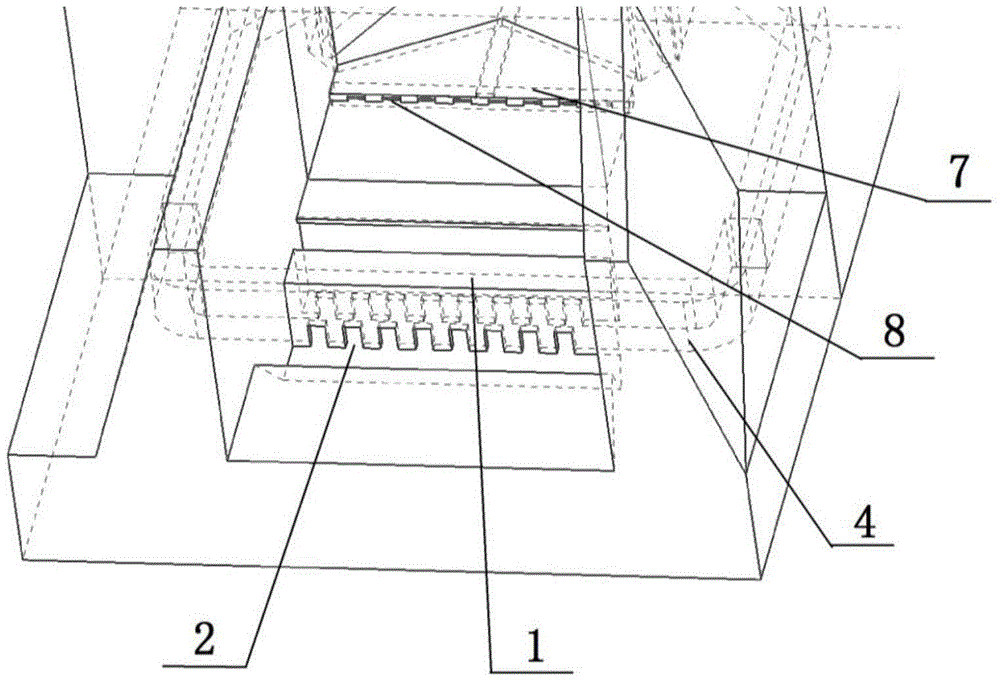

Fish-passing type lock and fish-passing method

ActiveCN104594320ADoes not affect the structure layoutDoes not affect navigational safetyBarrages/weirsDry-docksEngineeringPoint of entry

The invention discloses a fish-passing type lock and a fish-passing method. The fish-passing type lock comprises a fish collecting and water replenishing gallery system with the inlet end located in an upstream approach channel and the outlet end located in a downstream approach channel, a fish luring and water replenishing gallery system with the inlet end located in the upstream approach channel and the outlet end located in a lock chamber, an upper lock head water replenishing gallery system with the inlet end located in the upstream approach channel and the outlet end located in an upper lock head curtain wall, and a fish blocking system comprising a fish blocking electric grid and a fish blocking net. On a lock of a navigable river built flood retarding project and a lock of a new flood retarding project, the fish-passing type lock can be used for greatly saving the project investment in building fish-passing facilities and guaranteeing the ecological balance of rivers.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

MTP (methanol to propylene) device and novel separation process thereof

ActiveCN105503492AReduce lossLess solvent absorptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseSolvent

The invention relates to an MTP (methanol to propylene) separation device and a novel separation process adopted by the MTP device. The novel separation process comprises the steps that quenched reaction gas is pressurized by a compressor and undergoes washing and alkali wash treatment on a third compression section, a gas phase at the outlet of a fourth compression section goes to a depropanizer and a liquid phase goes to a debutanizer, water phases of separating tanks among the sections of the compressor return to a quench tower, and a hydrocarbon phase is sent to a separating tank at the outlet of the fourth compression section after being pressurized; the materials ejected from the debutanizer go to the depropanizer and the materials discharged from tower reactors enter a dehexanizer; a deethanizer compressor is arranged between a deethanizer and an oil absorption tower, the oil absorption tower adopts recycle propane or C4 as an absorbing solvent, fuel gas excluding C2 is obtained at the tower tops, the materials discharged from the tower reactors go to a stripping tower to recover the propane or C4 solvent, and the materials ejected from the stripping tower go to an ethylene rectification tower, thus obtaining the byproduct ethylene. The novel separation process has the effects that the process flow can be effectively optimized; the energy consumption of systems, the pipeline corrosion and the cost of investment can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

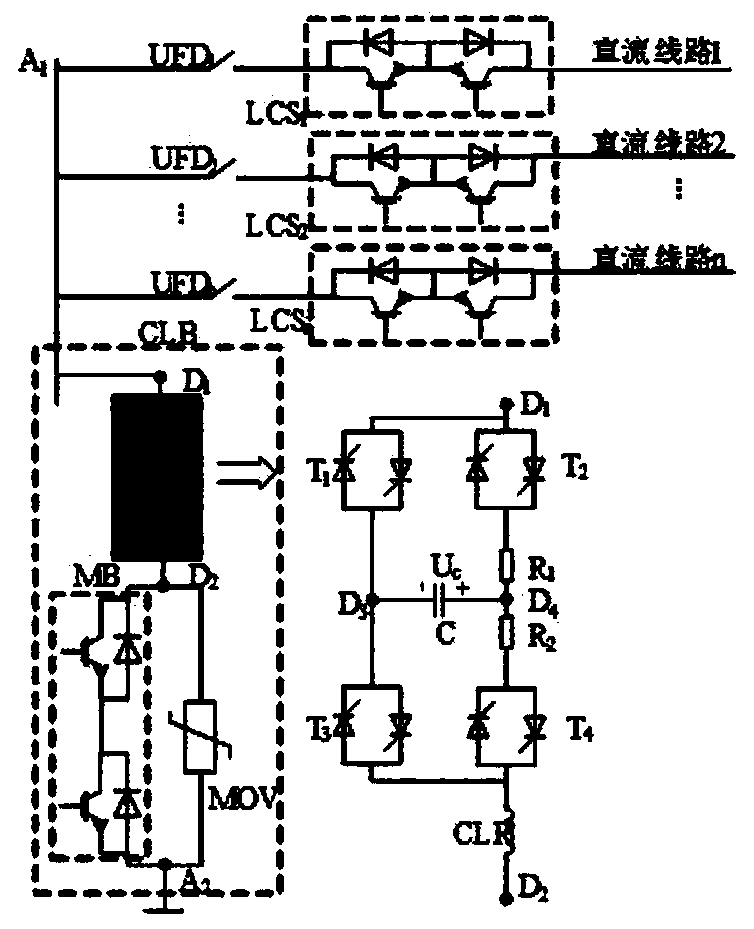

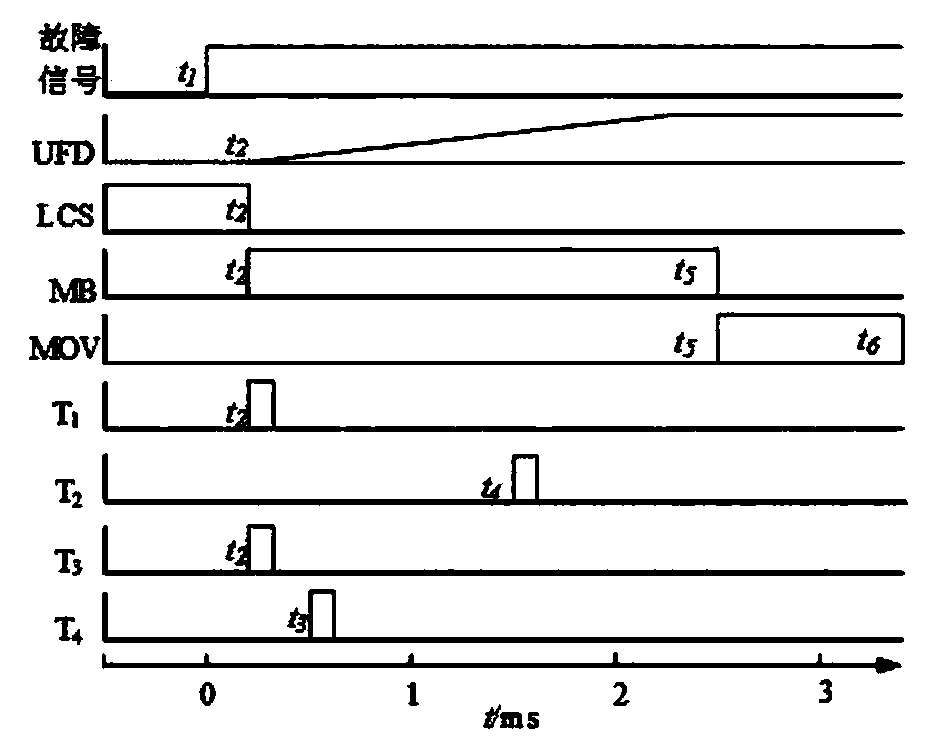

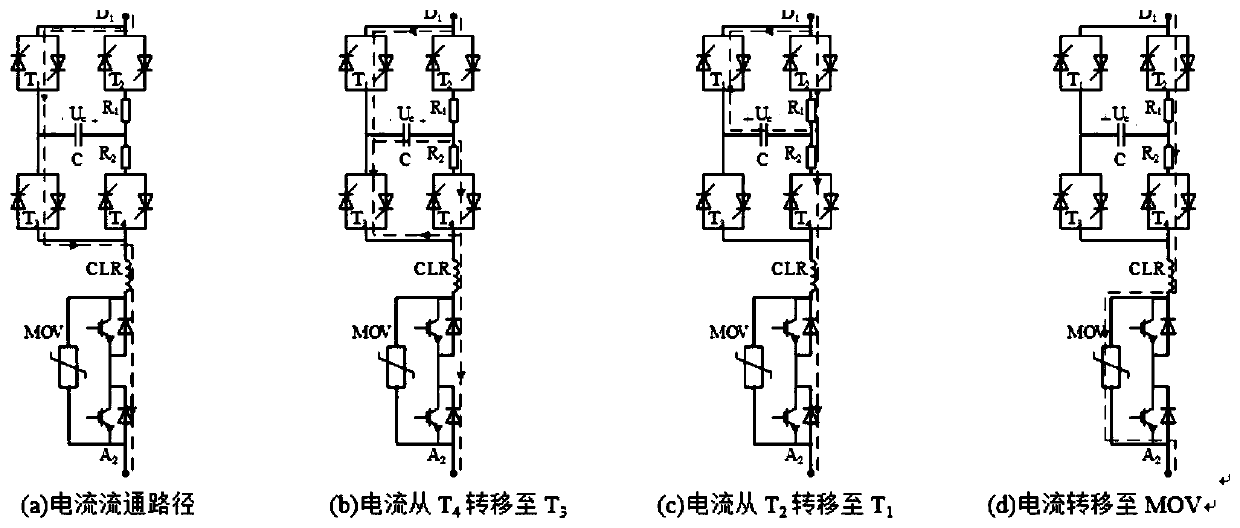

Combined current-limiting type direct-current circuit breaker for direct-current power grid

InactiveCN110970875ASave investment costSave floor spaceEmergency protective circuit arrangementsDC - Direct currentDc circuit breaker

The invention discloses a combined current-limiting direct-current circuit breaker for a direct-current power grid. The combined current-limiting direct-current circuit breaker comprises a current-carrying transfer branch and a current-limiting blocking branch; the current-carrying transfer branch is formed by connecting an ultra-fast mechanical switch and a load converter switch in series, one end of the current-carrying transfer branch is connected with a direct-current bus of a direct-current power grid, and the other end of the current-carrying transfer branch is connected to the direct-current power transmission line of the direct-current power grid in series; the current-limiting blocking branch comprises a current-limiting branch, a main circuit breaker branch and an energy absorption branch, one end of the main circuit breaker branch and one end of the energy absorption branch are connected in series with one end of the current-limiting branch after the main circuit breaker branch and the energy absorption branch are connected in parallel, and the other end of the current-limiting branch is connected to a potential point A1; and the other end of the main circuit breaker branch and the other end of the energy absorption branch are connected with a potential point A2 after the main circuit breaker branch and the energy absorption branch are connected in parallel. According to the invention, an expensive cutoff assembly can be separated from the circuit breaker for sharing, and the investment cost and the occupied area can be effectively reduced. A thyristor in the current-limiting blocking branch can share voltage to ground, and a charging resistor and a current-limiting inductor can effectively reduce the acceleration of a fault current and reduce the breaking current of the circuit breaker.

Owner:SICHUAN UNIV

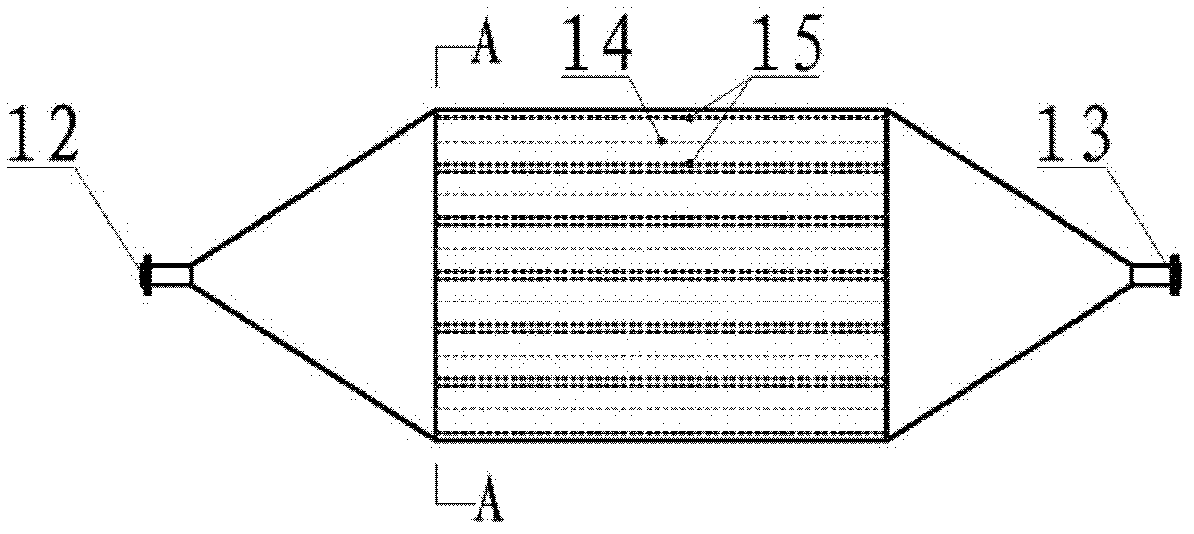

Liquid-distributing device for falling-film evaporator

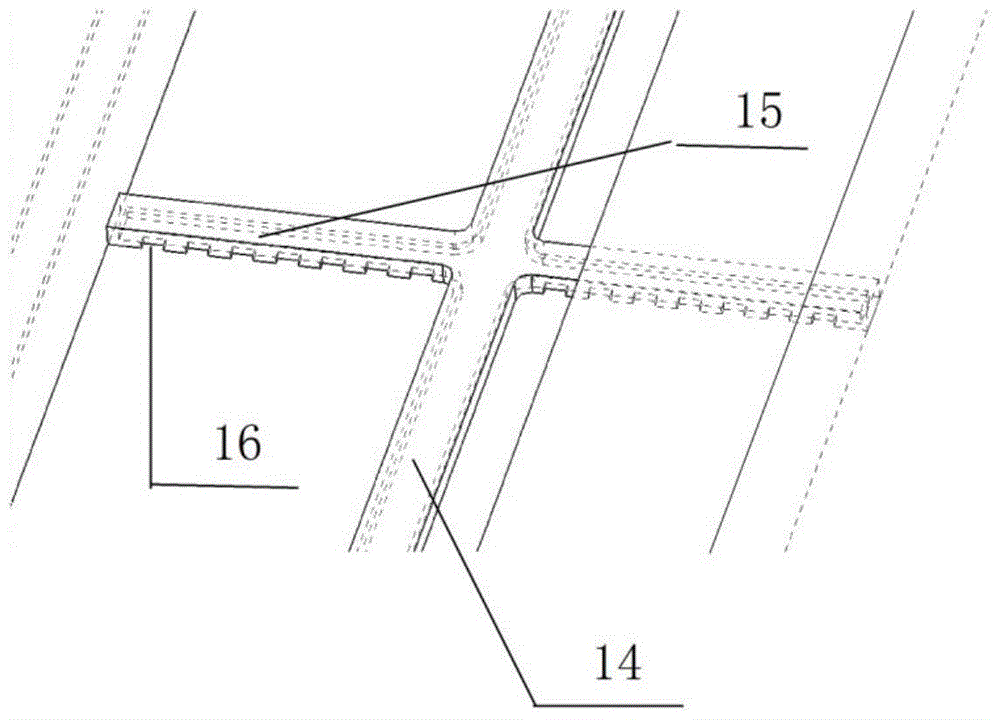

ActiveCN102410773AReduce resistanceIncrease resistanceHeat exchanger casingsRefrigerant distributionEngineering

The invention relates to a liquid-distributing device for a falling-film evaporator used for a refrigerating system. The liquid-distributing device comprises a liquid inlet pipe, a flow branching pool, a flow-guiding pipe, a porous liquid-distributing pipe and a packing tank, wherein the liquid inlet pipe is connected with the flow branching pool; the flow branching pool is connected with the flow-guiding pipe; the flow-guiding pipe is connected with the porous liquid-distributing pipe; the porous liquid-distributing pipe is arranged in the packing tank; and a plurality of liquid-distributingholes are formed on a base plate of the packing tank. The evenness of refrigerating fluid distribution is promoted by the liquid-distributing device provided by the invention, thereby being capable of evenly distributing refrigerating fluid along a radial direction and a length direction of a heat exchange pipe bundle, avoiding the generation of a local drying phenomenon, reducing a demand on horizontality during a mounting process of a refrigerating machine set, efficiently promoting a coefficient of heat transfer of the falling-film evaporator, saving space and capitalized cost, and achieving higher applicability.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

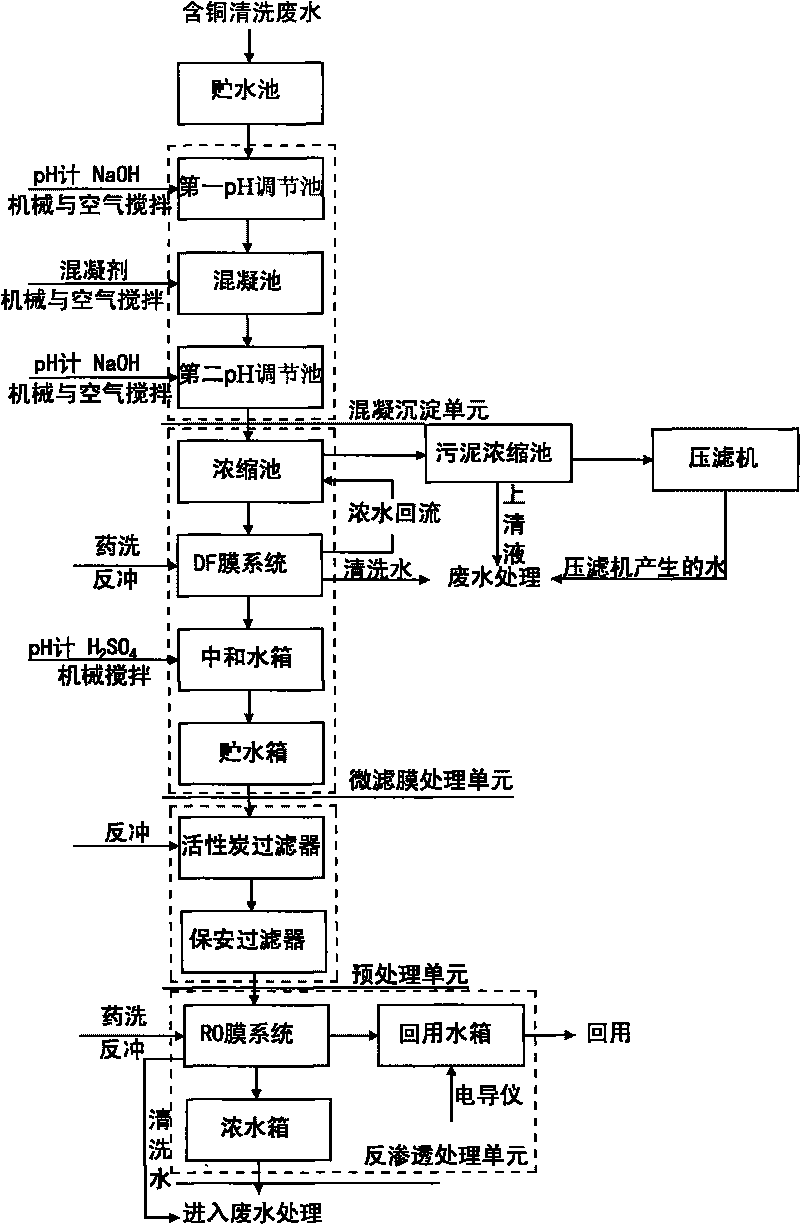

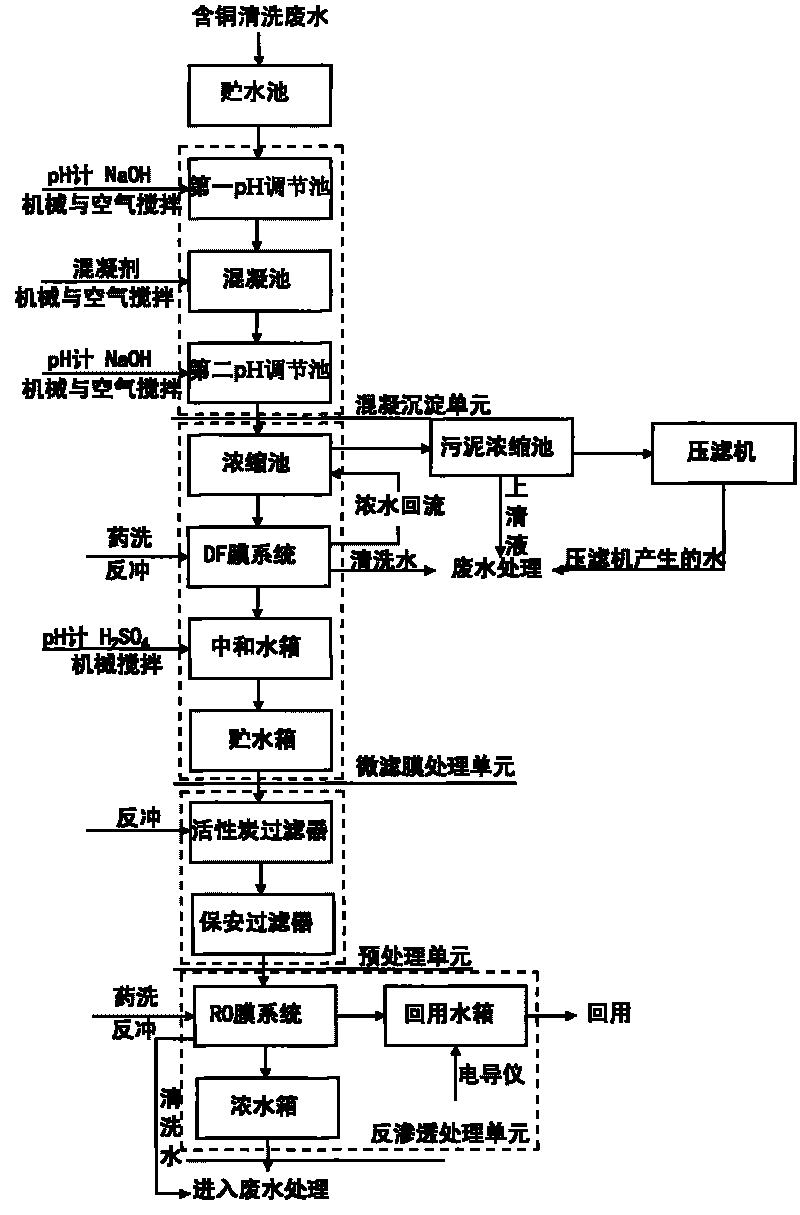

Electronic electroplating wastewater recycling advanced treatment technology

InactiveCN101734815AImprove coagulation and sedimentation effectAvoid easy cloggingWaste water treatment from metallurgical processMultistage water/sewage treatmentMembrane technologyReverse osmosis

The invention relates to an electronic electroplating wastewater recycling advanced treatment technology. The technology uses a large amount of rinse-wastewater with heavy metals in the production process of the electronic electroplating industry as the main object, adopts a combined technology of pH adjustment-microfiltration membrane treatment-pretreatment-reverse osmosis membrane treatment, is mainly characterized by the joint application of DF membrane technology and RO membrane technology and can achieve the aim of reusing wastewater and reducing the emission of heavy metals; and the reuse water reaches the production demand of process water, thus saving the fresh water consumption of the industry, effectively reducing the production cost of the industry, solving the pollution problem of heavy metals, increasing the clean production level of the electronic electroplating industry and having remarkable social environmental and economic benefits.

Owner:苏州市环境工程有限责任公司

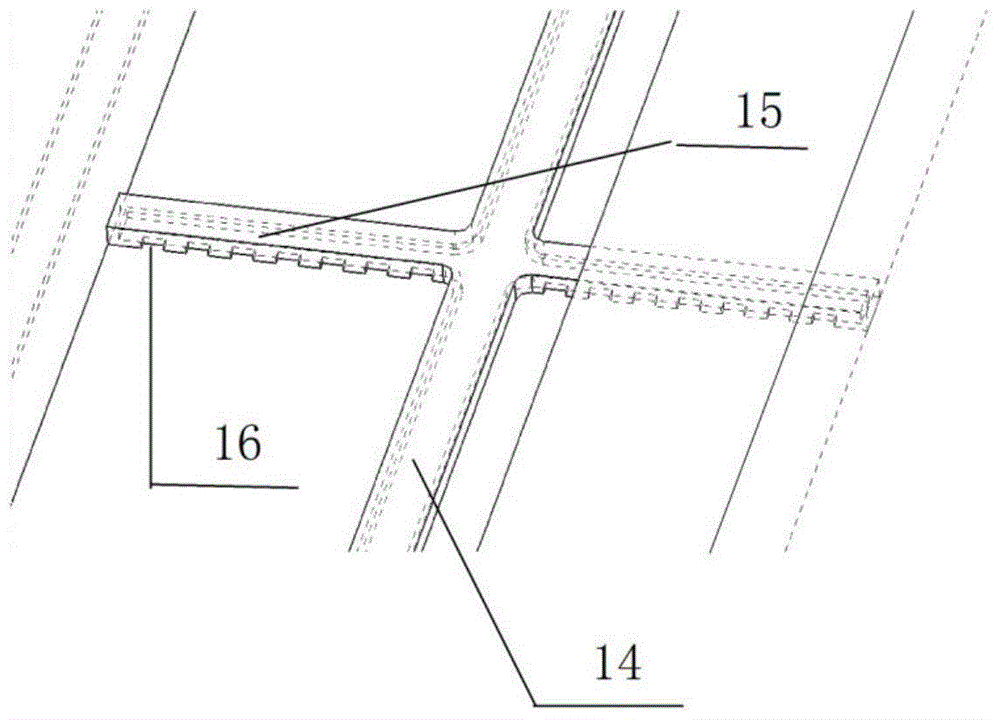

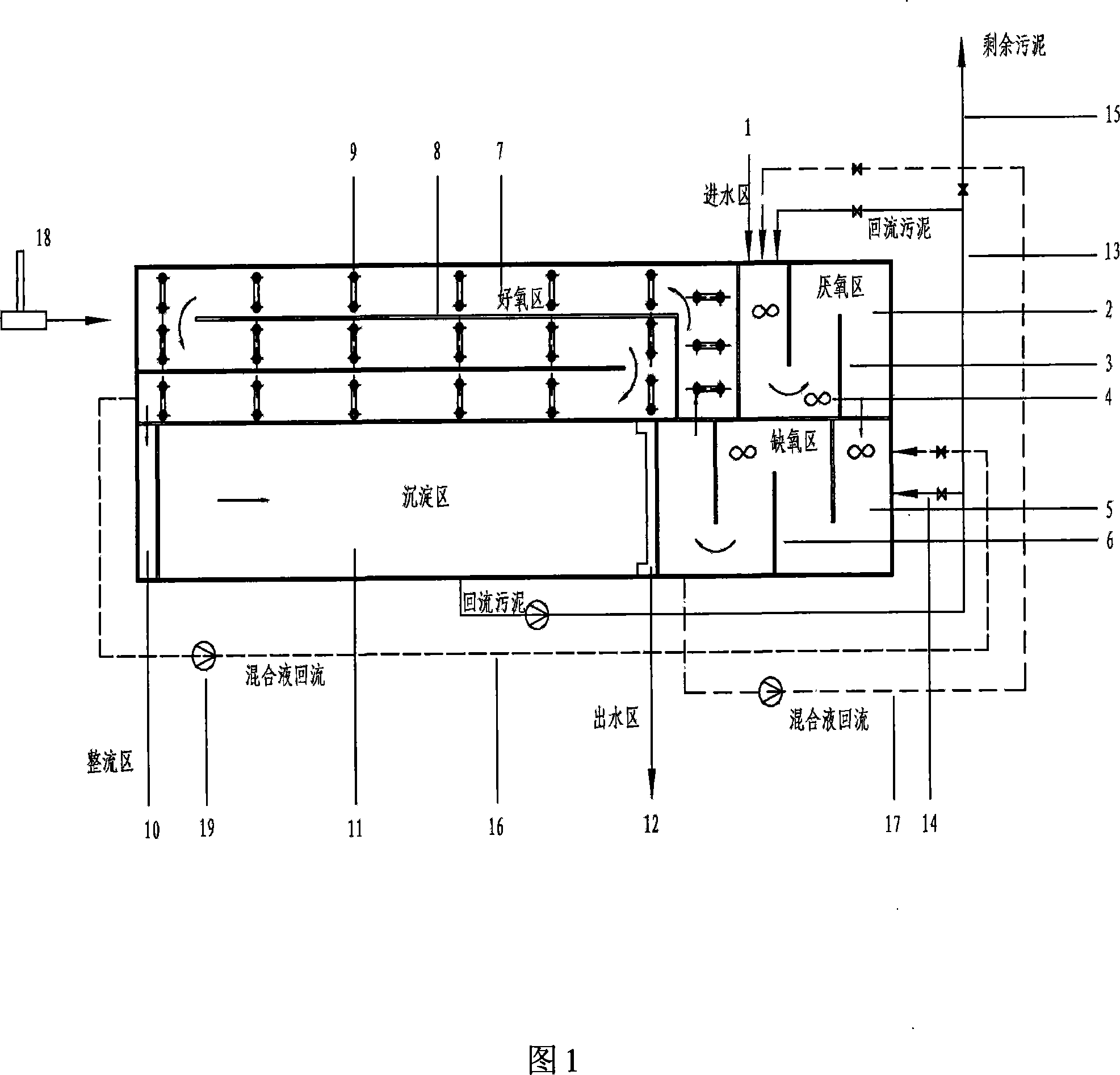

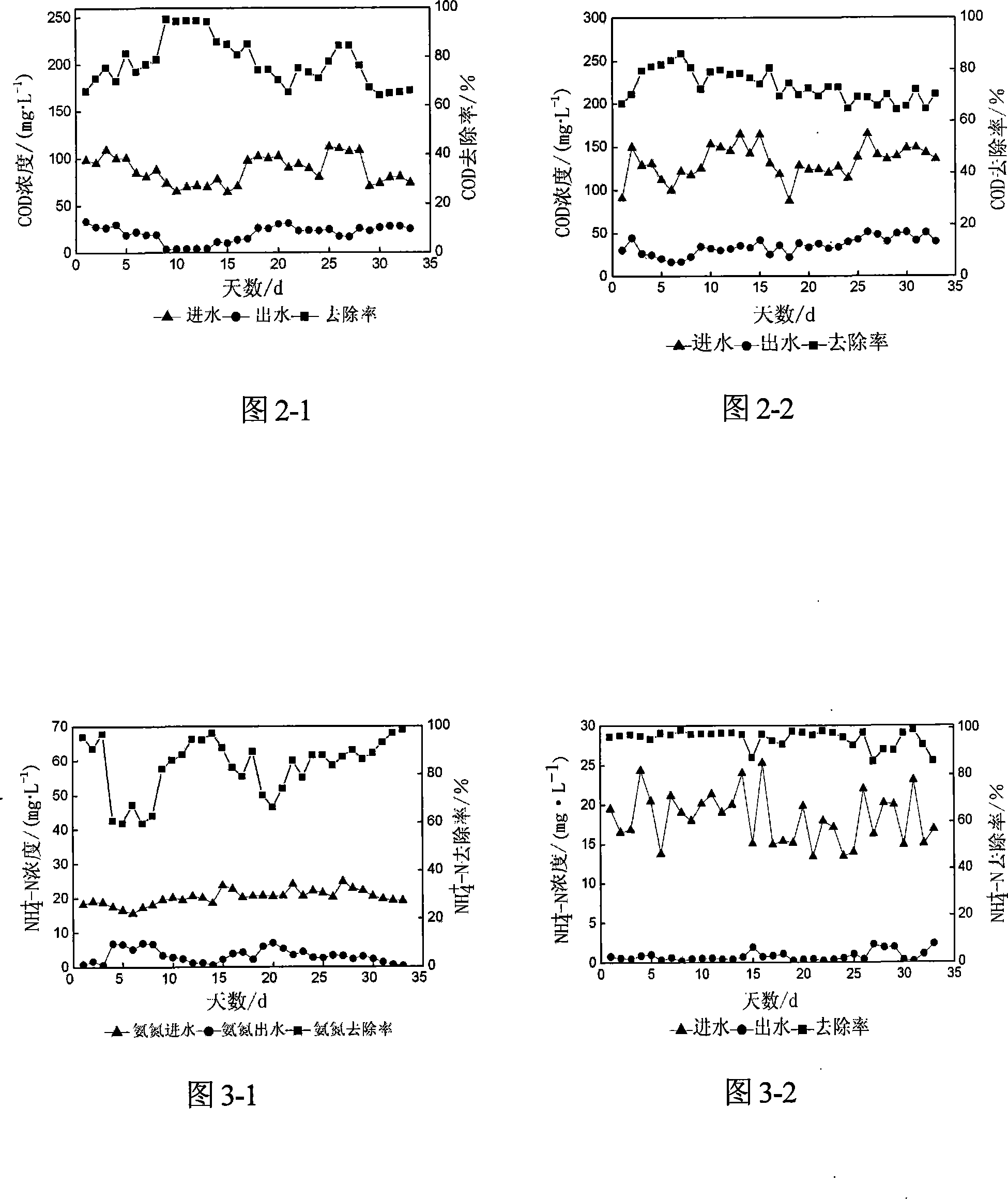

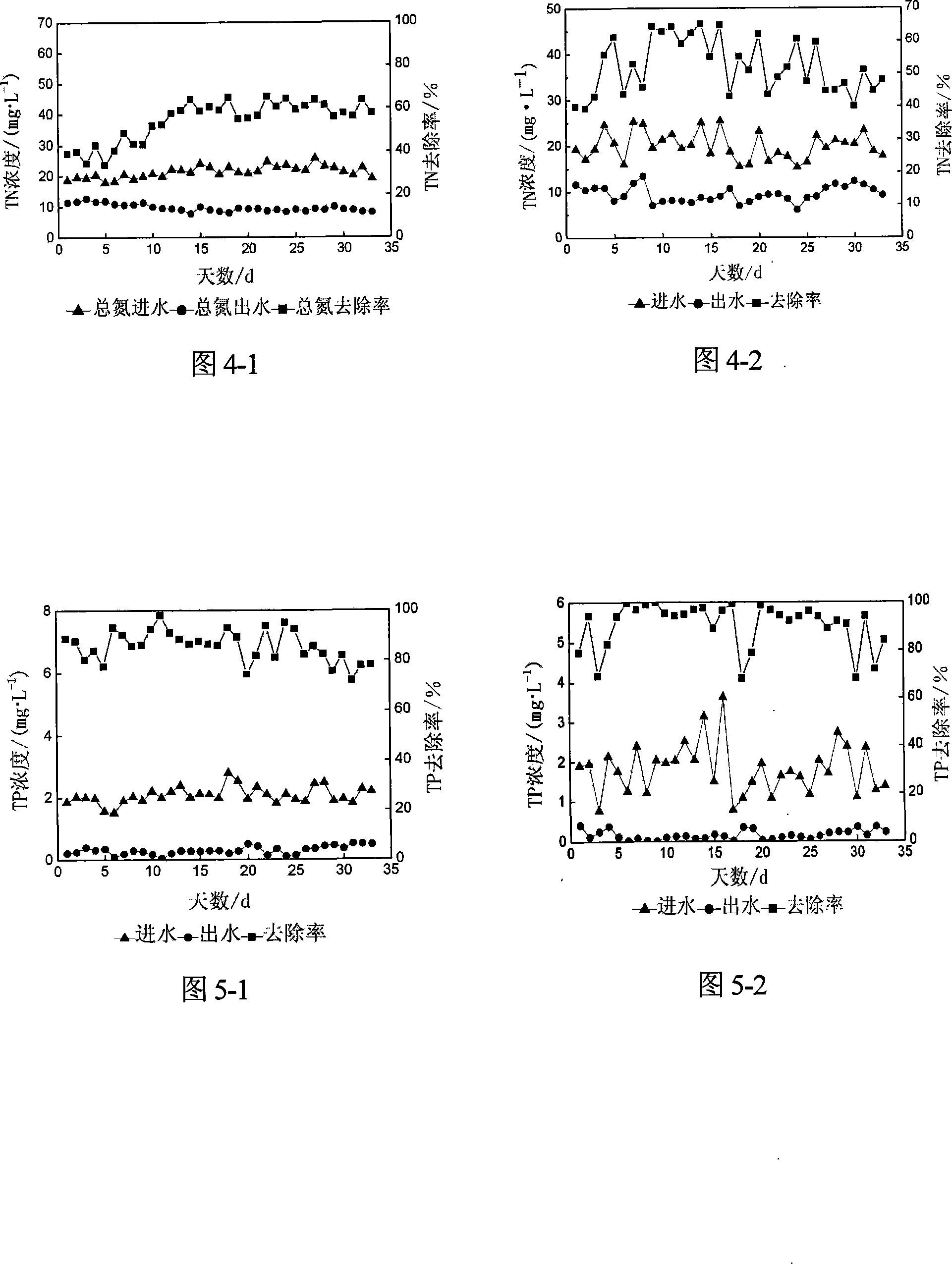

Integral combined process treatment reactor for city sewage

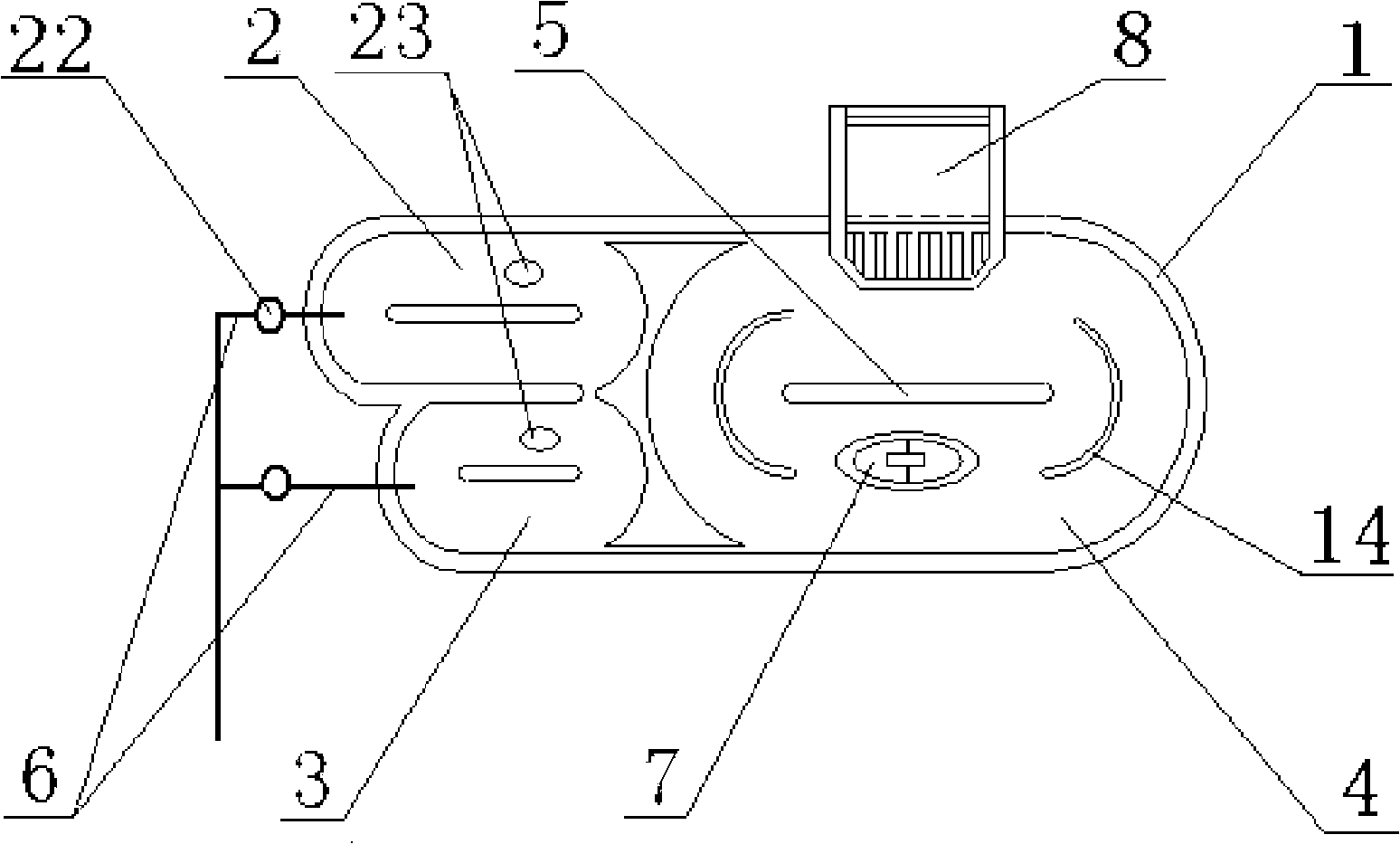

InactiveCN101205100AFlexible operationGood removal effectTreatment with aerobic and anaerobic processesNitrogenMunicipal sewage

The invention discloses a reactor of integrative combination technique for treating city sewage.The reactor comprises an anaerobic zone (2), a hypoxia zone (5), an aerobic zone (7) and a precipitate zone (11); one of sludge return tube (13) and another sludge return tube (14) which are provided with valves are connected with the anaerobic zone (2) and the hypoxia zone (5) from the precipitate zone (11) respectively; one of mixture return pipe (16) and another mixture return pipe (17) which are provided with valves are connected to front of the hypoxia zone (5) and the anaerobic zone (2) from end of the aerobic zone (7) and end of the hypoxia zone (5) respectively.The invention runs two sewage treatment techniques alternatively in the integrative reactor, by arranging an anaerobic pool, a hypoxia pool and an aerobic pool in the integrative reactor, nitrogen and phosphorus removal can be realized efficiently and economically.And under requirements of different conditions, the two techniques are alternatively run and technology resource is integrated, which can realize high-efficient and economical life sewage treatment function.

Owner:SOUTH CHINA UNIV OF TECH

Preparation process of cigar coat and cigar sleeve with tobacco leaf texture

InactiveCN104480774AStrong three-dimensional senseRich texturePaper coatingCoatingsFiberNicotiana tabacum

The invention provides a preparation process of a cigar coat and a cigar sleeve with a tobacco leaf texture, wherein the preparation process comprises the following steps: making a tobacco raw material into a tobacco extract; adding a combustion improver, a humectant and a tobacco colorant into the tobacco extract, and thus obtaining a tobacco coating liquid; shoving the tobacco raw material to obtain a tobacco pulp; pulping an externally-added commodity wood pulp fiber, to obtain an externally-added fiber pulp; mixing the tobacco pulp into the externally-added fiber pulp; adding calcium carbonate into the mixed pulp; adding one or more of a bagasse crude fiber, a tobacco stem crude fiber and a corn stigma crude fiber into the mixed pulp, to obtain a pre-papermaking pulp; papermaking the pre-papermaking pulp into a paper base; applying the tobacco coating liquid onto the paper base, and thus obtaining the cigar coat and the cigar sleeve with the tobacco leaf texture. The cigar coat and the cigar sleeve prepared by the process have the advantages of strong three-dimensional sense of tendons and vessels, natural and smooth lines, diverse texture, low cost, and quite strong practicality.

Owner:HUBEI CHINA TOBACCO IND +1

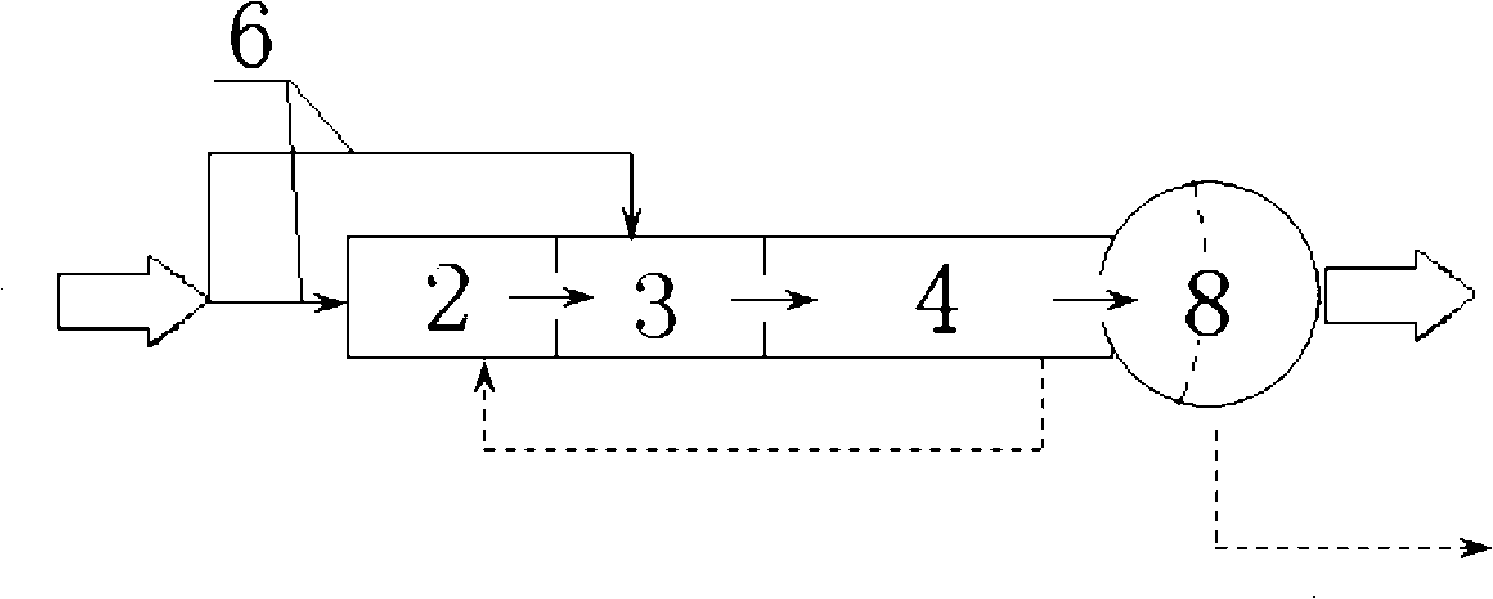

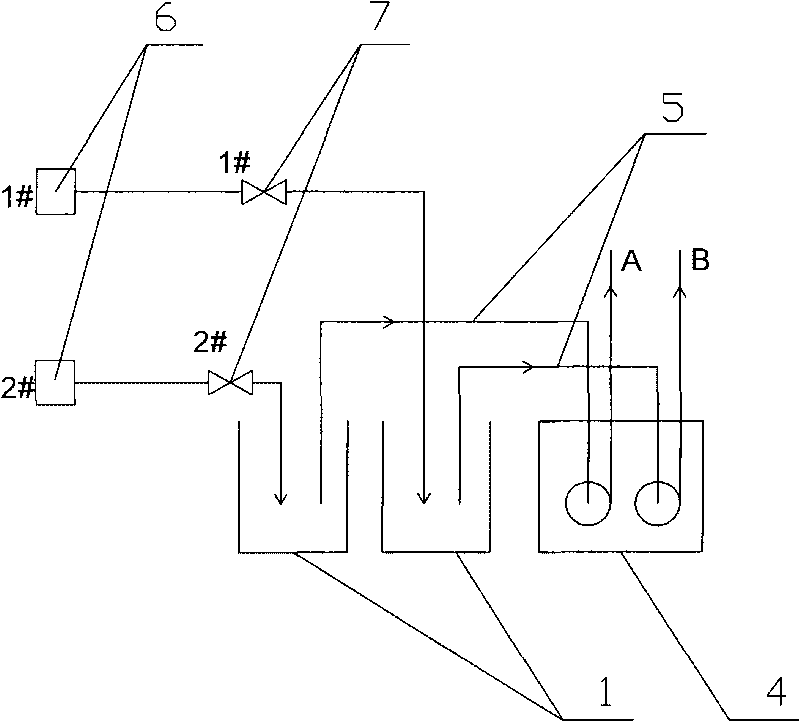

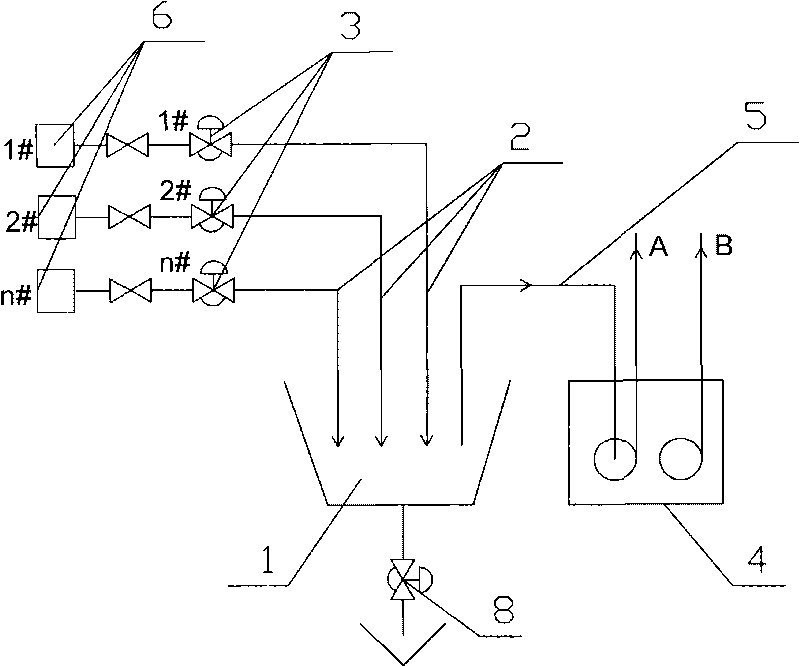

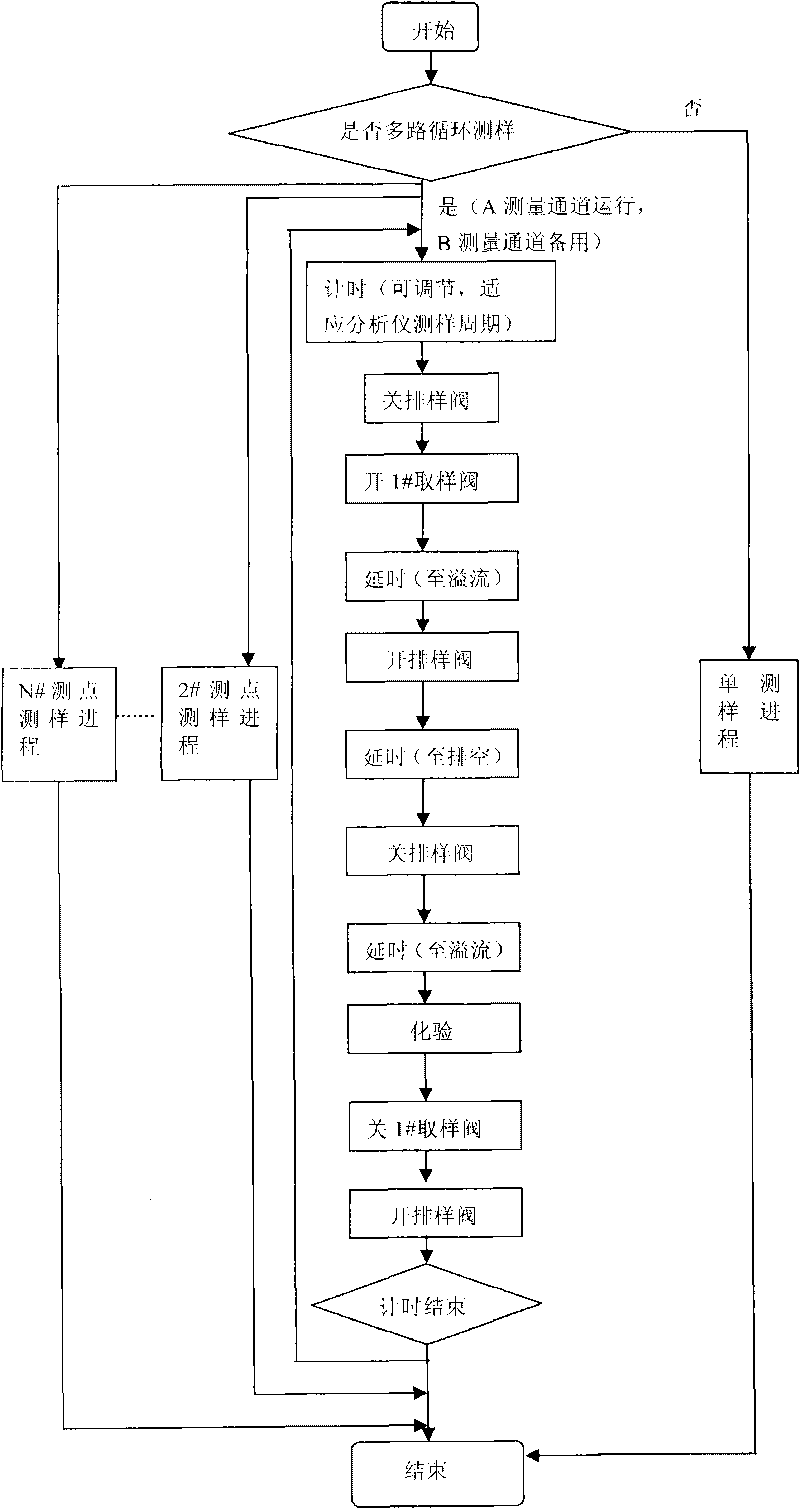

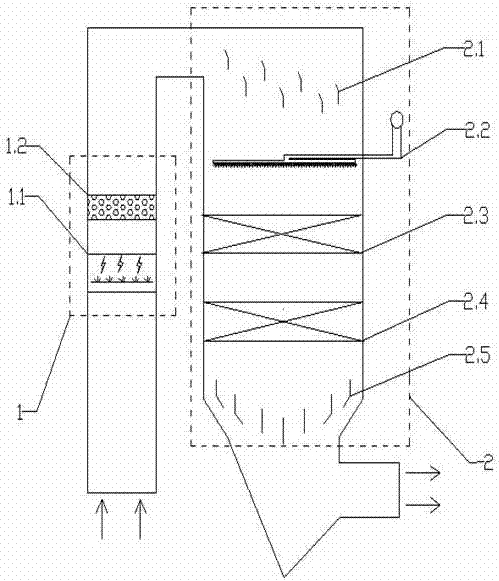

Sampling device for analyzer and sampling analysis and control method

InactiveCN101701883ASave investment costSave maintenance costWithdrawing sample devicesTesting waterAutomatic controlComputer science

The invention provides a sampling device for an analyzer and a sampling analysis and control method. The sampling device for the analyzer comprises a sampling tank and a sampling pipeline, wherein the sampling pipeline comprises a plurality of paths of branch pipelines which are independently connected into the sampling tank, and each branch pipeline in the sampling pipeline is respectively provided with a sampling valve connected with a controller; and a sample discharging valve which is connected into a liquid discharging pipeline is arranged at the bottom of the sampling tank. The sampling analysis and control method corresponding to the sampling device for the analyzer automatically controls the switches of the sampling valve and the sample discharging valve through the controller according to the preset sequence and time to achieve the purpose of sampling measurement of a plurality of process point parameters by using one analyzer and one sampling tank, thereby effectively reducing investment cost, maintenance cost and production energy consumption.

Owner:湖南骏泰新材料科技有限责任公司

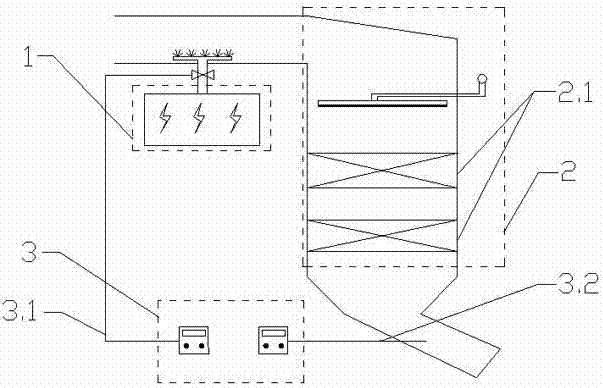

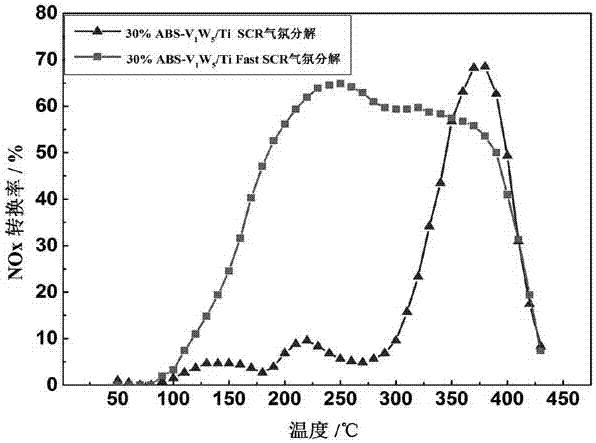

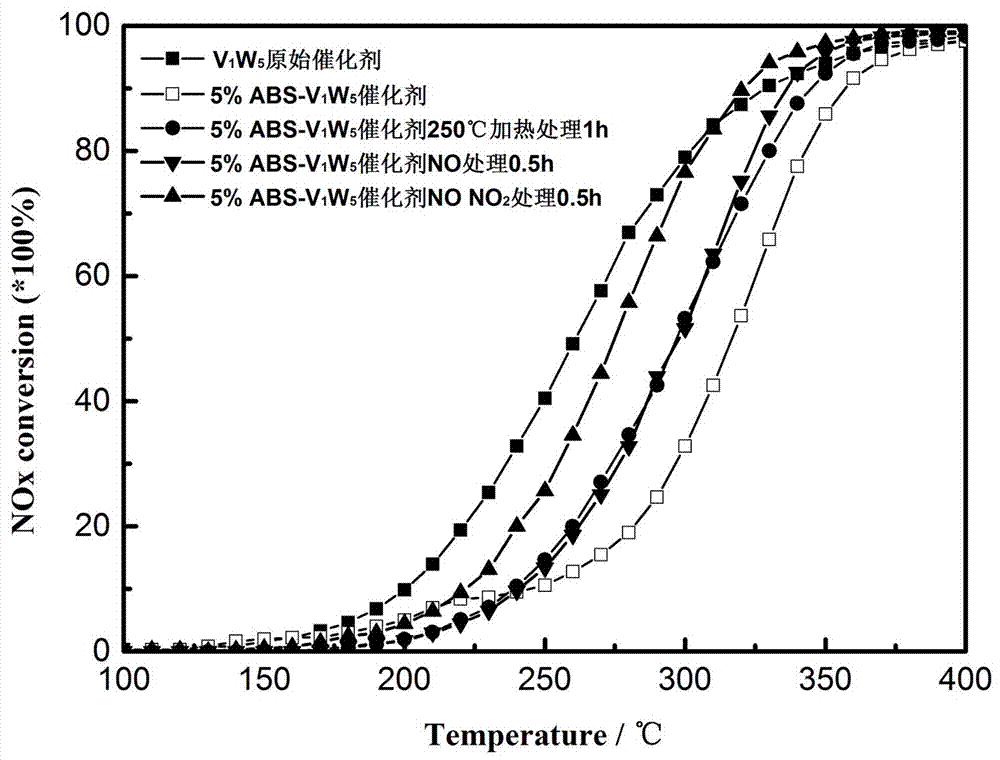

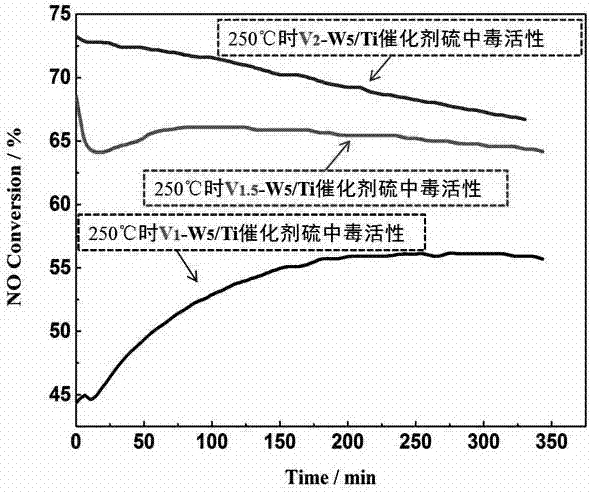

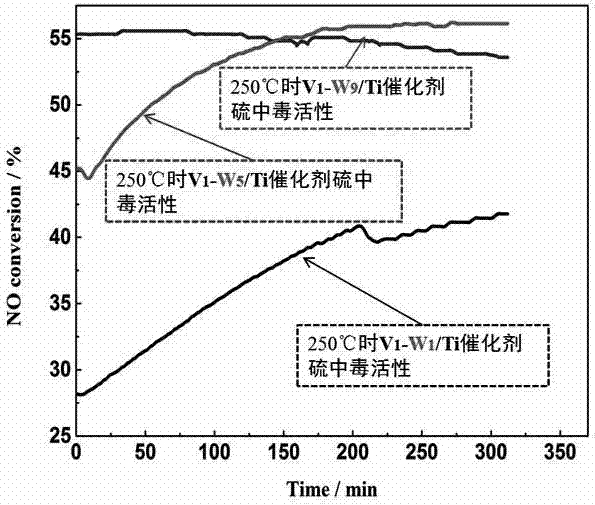

Efficient medium and low temperature sulfur-containing flue gas denitration device and method based on Fast SCR reaction

InactiveCN107051203AReduce heating linksAvoiding Sulfur Poisoning ProblemsDispersed particle separationFlue gasReaction temperature

The invention discloses an efficient medium and low temperature sulfur-containing flue gas denitration device and method based on Fast SCR reaction, and the sulfur-containing flue gas denitration device and method can be used in a utility boiler and flues on the tail portions of various industrial furnace. The sulfur-containing flue gas denitration device comprises an oxidization module used for oxidizing NO and an SCR reaction module used or denitration, part of NO in flue gas is converted into NO2 through the oxidization module and then enters the SCR reaction module, and pre-oxidized flue gas and sprayed NH3 are mixed and enter a selective catalytic reduction layer to conduct rapid SCR reaction. The catalytic reduction layer is made of a low-vanadium loaded vanadium, tungsten and titanium cellular catalyst, and the reaction temperature is 200-350 DEG C. The denitration system has efficient sulfur poisoning resistance and greatly promotes denitration efficiency of the flue gas low-temperature section, it is verified through experiments that under the low-temperature sulfur-containing flue gas atmosphere at the temperature of 250 DEG C, the system has the obvious denitration effect, and the efficiency can reach 90% or more and is kept stable.

Owner:CHONGQING UNIV

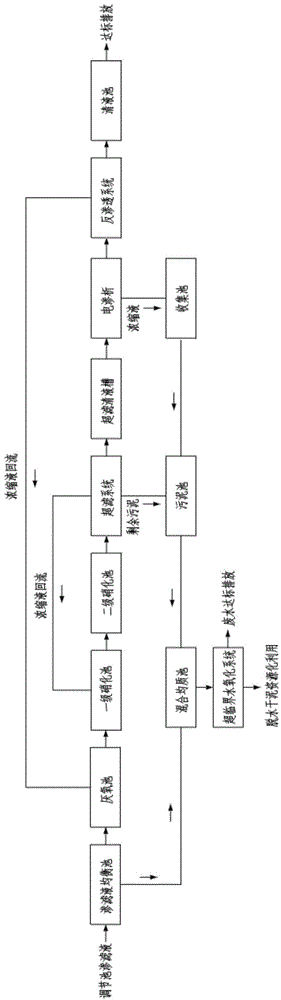

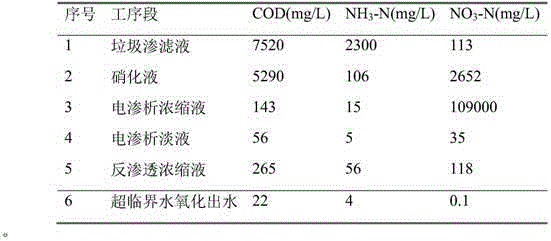

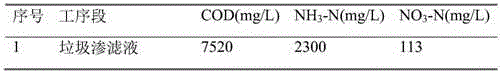

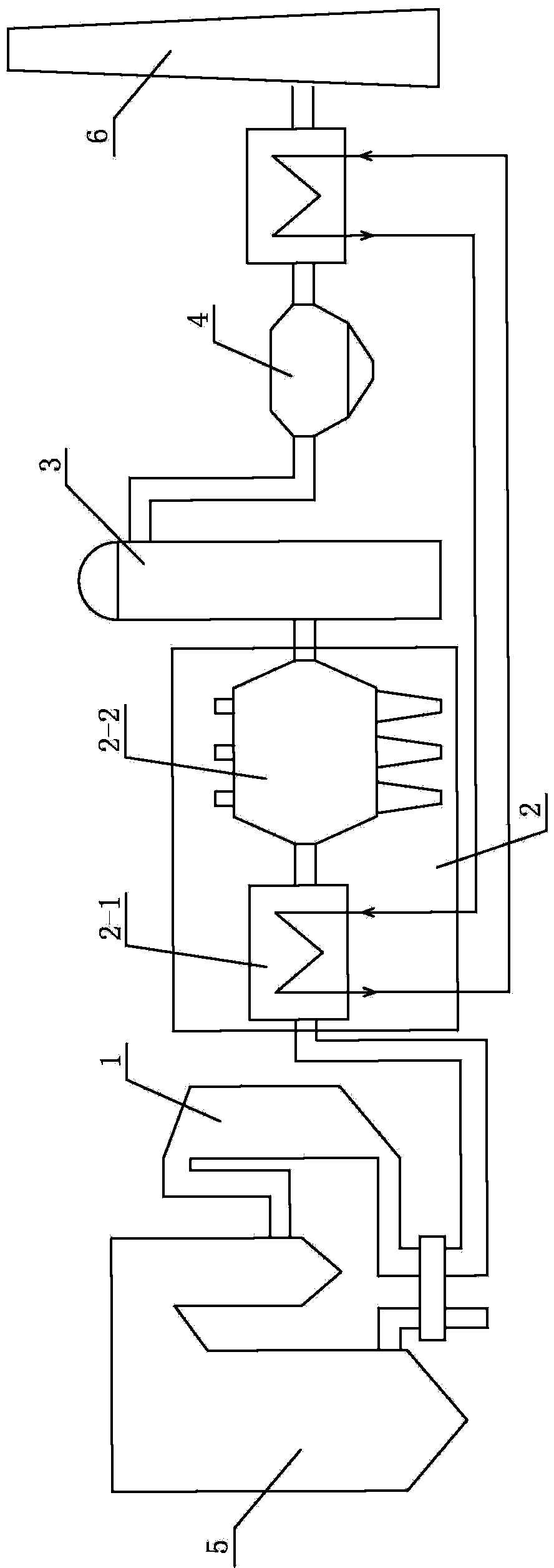

Treatment method of garbage leachate

ActiveCN104787982ADehydration lowers moisture contentAchieve reductionMultistage water/sewage treatmentFresh water organismUltrafiltration

The invention discloses a treatment method of garbage leachate. The treatment method comprises the following steps: leachate in a garbage regulation pool is introduced into a leachate equalization pool; one part of effluent in the leachate equalization pool flows through an anaerobic pool to degrade organic pollutants, then enters a primary nitrification pool and a secondary nitrification pool in sequence to degrade organic pollutants and nitrify ammonia, and then enter an ultrafiltration system to obtain an ultrafiltration concentrated solution; the ultrafiltration concentrated solution flows back to the primary nitrification pool; ultrafiltration freshwater enters an ultrafiltration clear liquid tank, is introduced into an electrodialysis system to concentrate inorganic salt, and then enters a reverse osmosis system; a reverse osmosis concentrate flows back to the anaerobic pool to further degrade organic pollutants, and the reverse osmosis freshwater is discharged in compliance with the standards; meanwhile, the other part of the effluent in the leachate equalization pool is fully mixed with sludge generated by the ultrafiltration system and concentrated solution generated by the electrodialysis system in a mixing and homogenizing pool, and then enters a supercritical water oxidation system; the effluent is discharged in compliance with the standards; the generated concentrated solution is subjected to resource utilization after centrifugal dewatering. The treatment method treats a waste with another waste, and realizes the reduction and recycling of sludge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Integrated system for efficiently and synergistically removing multiple pollutants

ActiveCN103994456AImprove removal efficiencyImprove compatibilityLighting and heating apparatusAtmospheric pollutionDust collector

The invention relates to an integrated system for efficiently and synergistically removing multiple pollutants. The integrated system reduces discharge values of smoke, SO2, NOx, mercury, SO3 and other main smoke pollutants to achieve the discharge standard of a fuel gas unit. According to the technical scheme, the system comprises an SCR reactor, low-temperature dust removing equipment, a desulfurizing absorption tower and a wet-type electrostatic dust collector, wherein the inlet of the SCR reactor is connected with a smoke outlet through a tail smoke channel of a boiler improved through low-nitrogen combustion, and SCR denitration catalysts are modified catalysts capable of improving oxidation susceptibility of zero-valent mercury; the inlet of the low-temperature dust removing equipment is connected with the outlet of the SCR reactor to be used for removing dust and SO3; the inlet of the desulfurizing absorption tower is connected with the outlet of the low-temperature dust removing equipment to be used for desulfuration and dust removal; the inlet of the wet-type electrostatic dust collector is connected with the outlet of the desulfurizing absorption tower, and the outlet of the wet-type electrostatic dust collector is connected to a chimney through warming equipment to be used for removing the dust, gypsum fogdrops, the mercury and SO3. The integrated system is used for the technical field of atmospheric pollution prevention.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

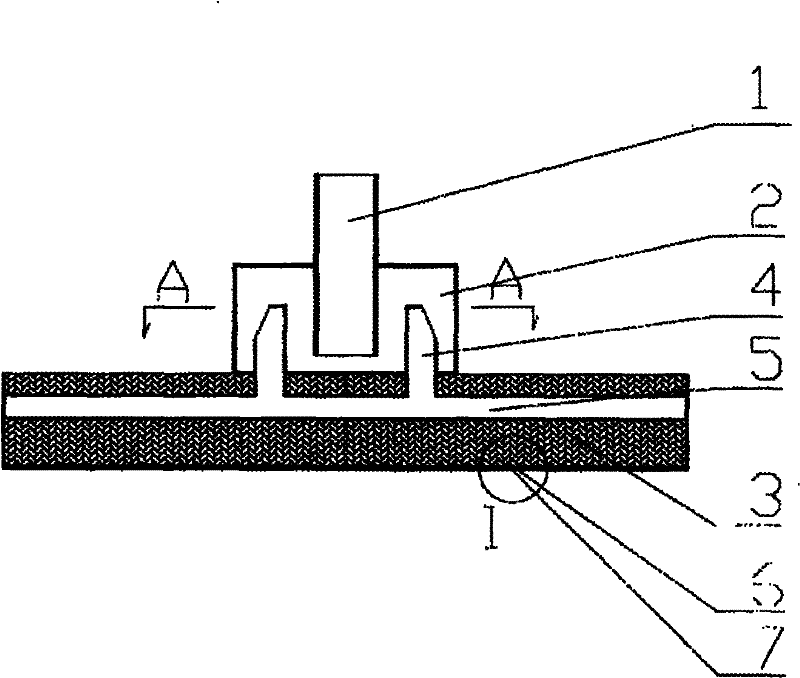

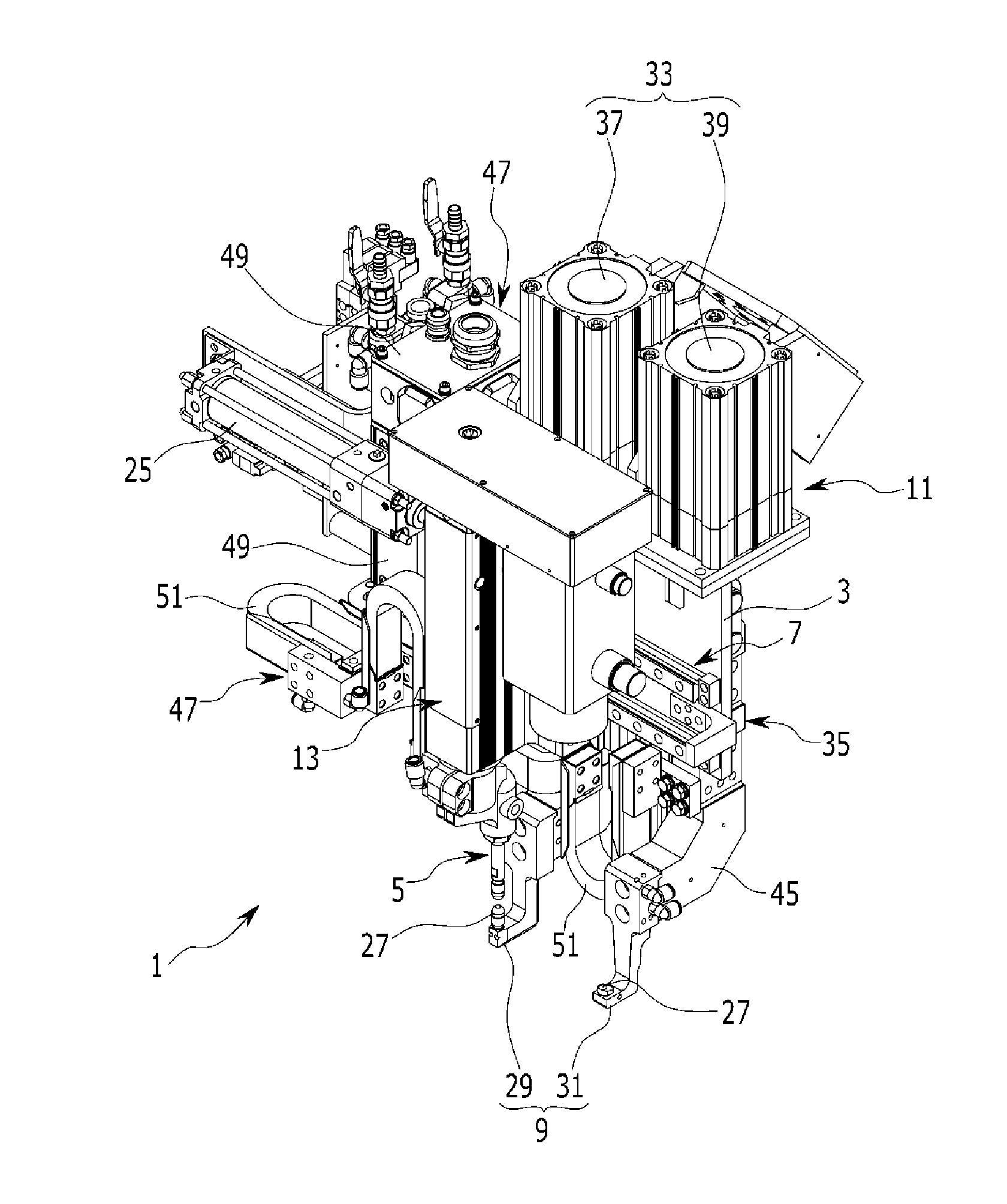

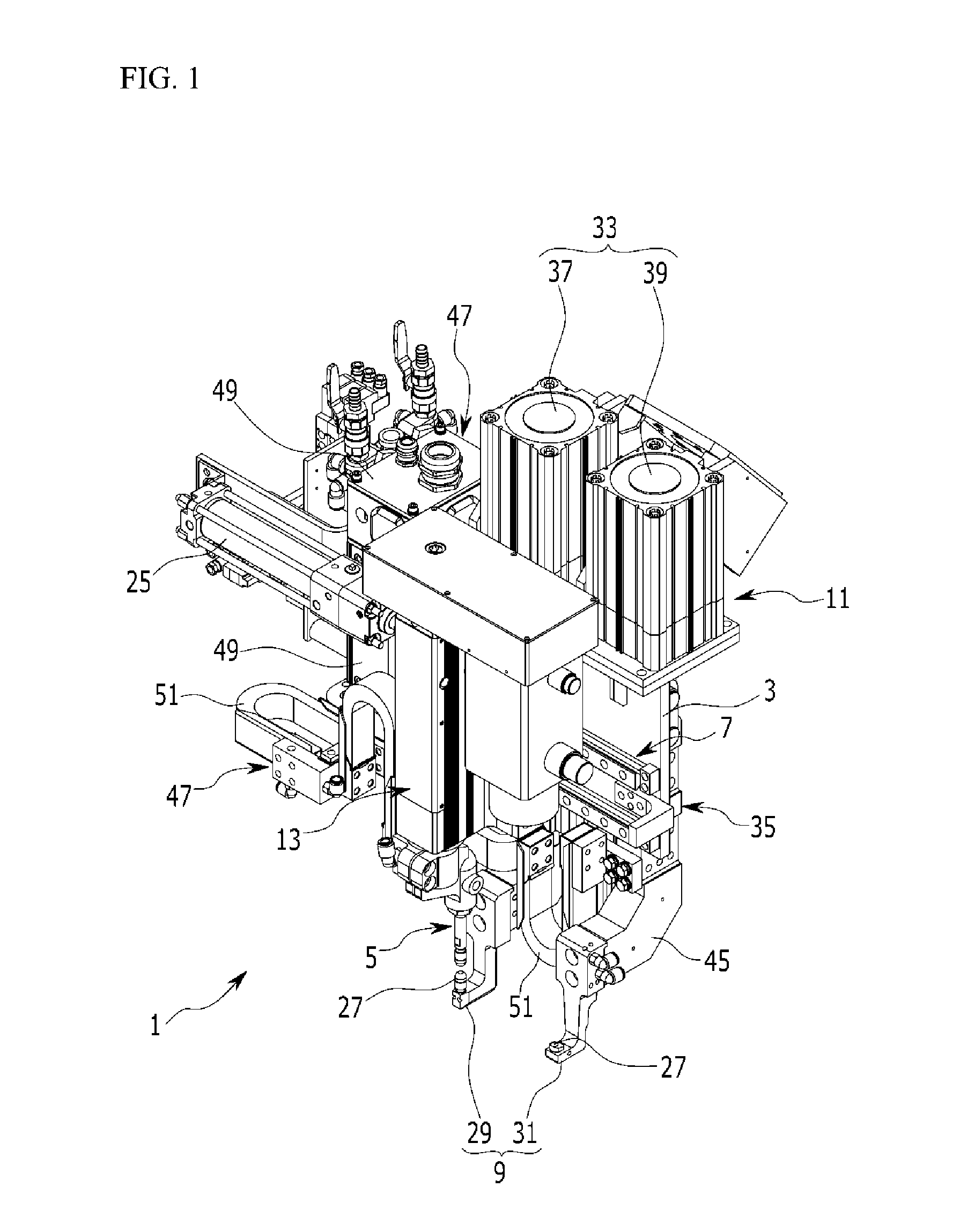

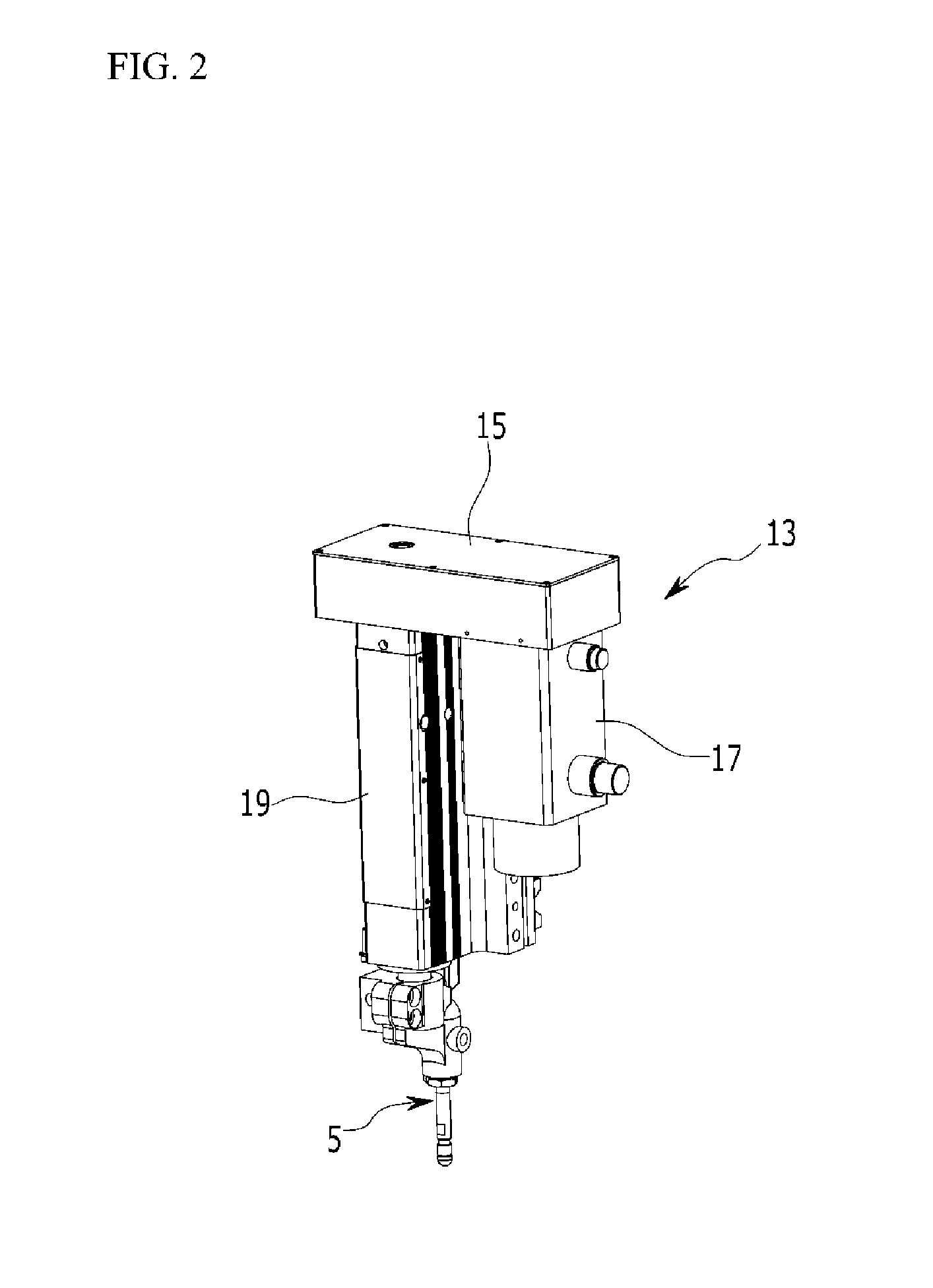

Spot welding apparatus

ActiveUS20150183049A1Improve productivity and flexibility and efficiencySave investment costResistance electrode holdersVehicle componentsEngineeringReciprocating motion

A spot welding apparatus is provided that includes a fixation panel mounted on an arm of a robot. An upper welding gun is vertically installed on a front of the fixation panel, reciprocatesvertically through a pressing unit and moves horizontally toward the fixation panel. A left and right moving unitis installed between the fixation panel and the pressing unit to move the upper welding gun horizontally. Further, two or more lower welding guns are horizontally disposed to correspond to the upper welding gun, and an upper and lower moving unit are installed on the fixation panel to reciprocate the lower welding gun vertically.

Owner:HYUNDAI MOTOR CO LTD

Method for preparing nanoscale pesticide preparation by means of silicon dioxide aerogel

InactiveCN105360115AImprove performanceReduce precipitationBiocideAnimal repellantsNanoparticleDrug carrier

The invention discloses a method for preparing a nanoscale pesticide preparation by means of silicon dioxide aerogel, belongs to the technical field of pesticides, and particularly relates to the application of silicon dioxide aerogel serving as a novel carrier of a pesticide processing aid. According to the technical scheme, when the silicon dioxide aerogel is used for nanocrystallized preparation processing of a slightly soluble technical material as a carrier, the technical material is dissolved in a solvent or broken, the silicon dioxide aerogel is loaded with liquid containing the solvent through adsorption or mixed with the broken technical material so as to form a nanoparticle drug carrier system with the diameter smaller than 100 nm, water is added to the nanoparticle drug carrier system, stirring or emulsification is conducted for homogenous dispersion, the solvent and water are removed through drying, and then a nanoscale pesticide is obtained. The method has the advantages that environment friendliness is realized, and the gap in the carrier material for nanoscale pesticides at home and abroad is filled.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

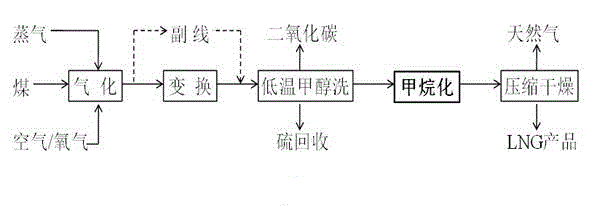

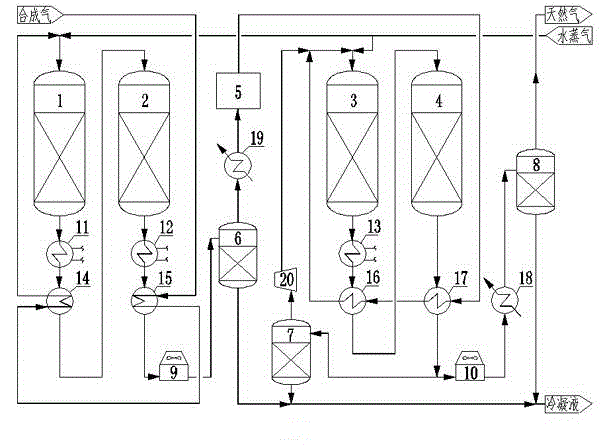

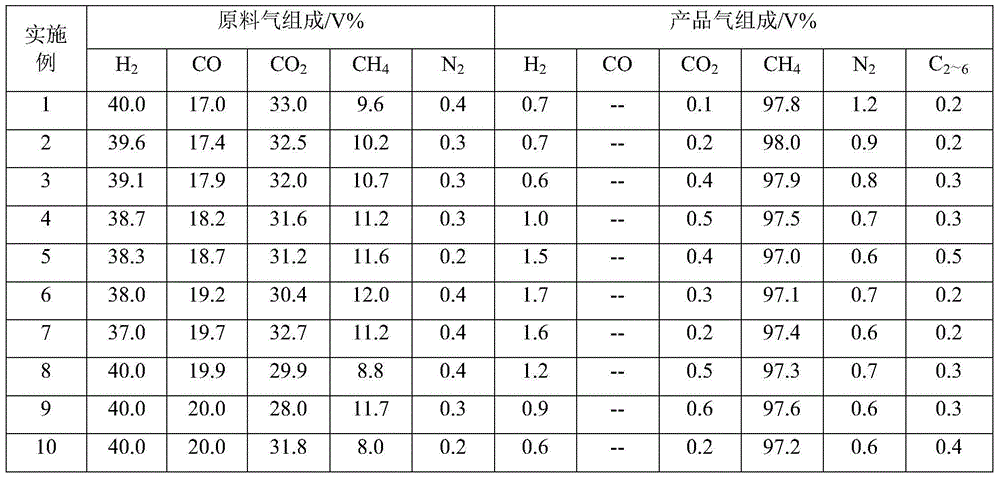

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

ActiveCN104164262AWith characteristicsHave made significant progressGaseous fuelsMethanationWater vapor

The invention provides a process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas. The process is characterized in that the synthesis gas enters sulphur-tolerant methanation reactors I and II in sequence, and the mixed gas of the synthesis gas and water vapor enters a rectisol system so as to remove the impurities such as CO2, H2S and the like in the gas after undergoing sulphur-tolerant shift and sulphur-tolerant methanation reaction on a molybdenum-based bifunctional catalyst and then undergoes methanation reaction in methanation reactors I and II in sequence under the action of Ni-based methanation catalysts, thus obtaining the natural gas product. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

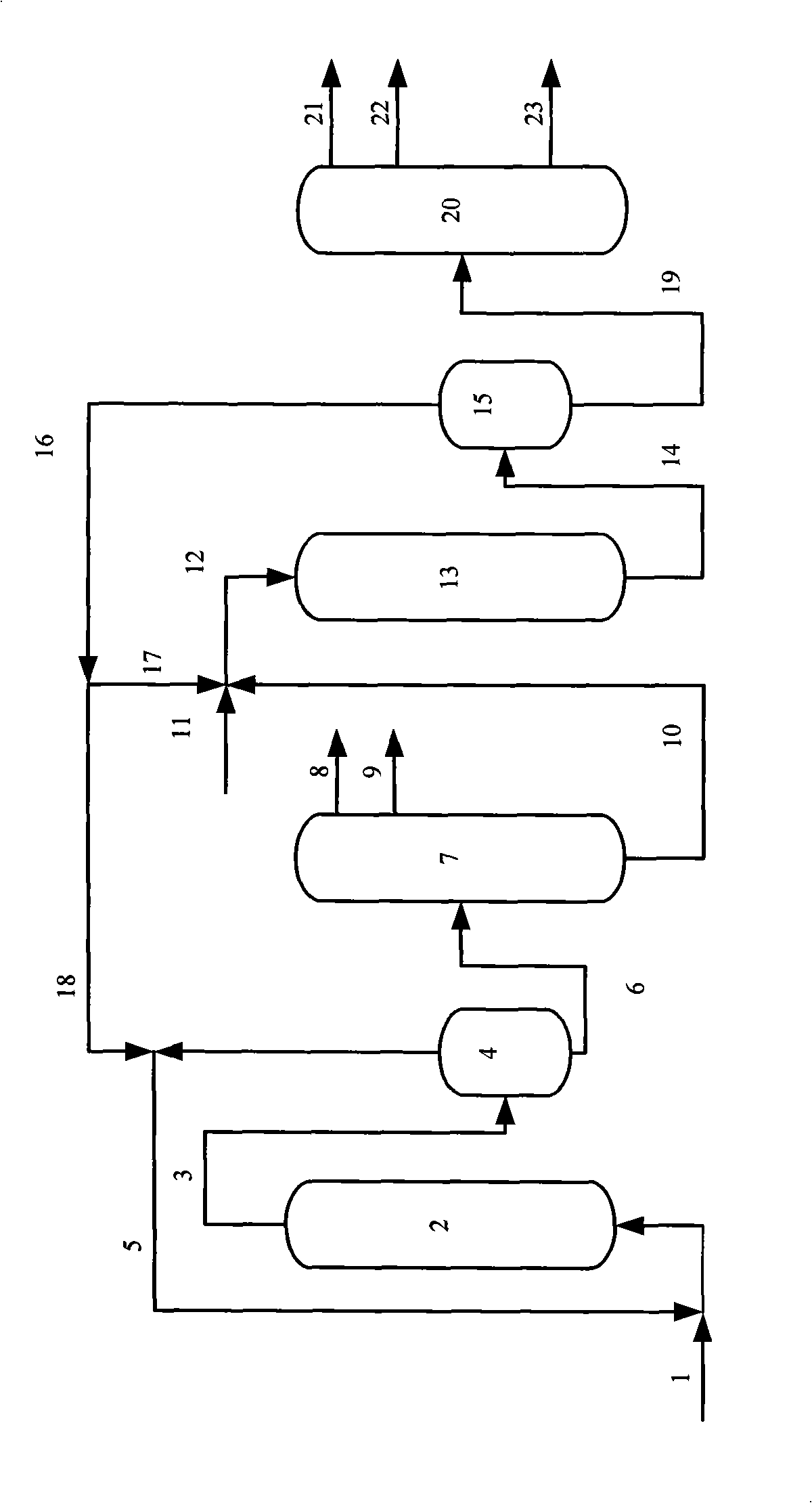

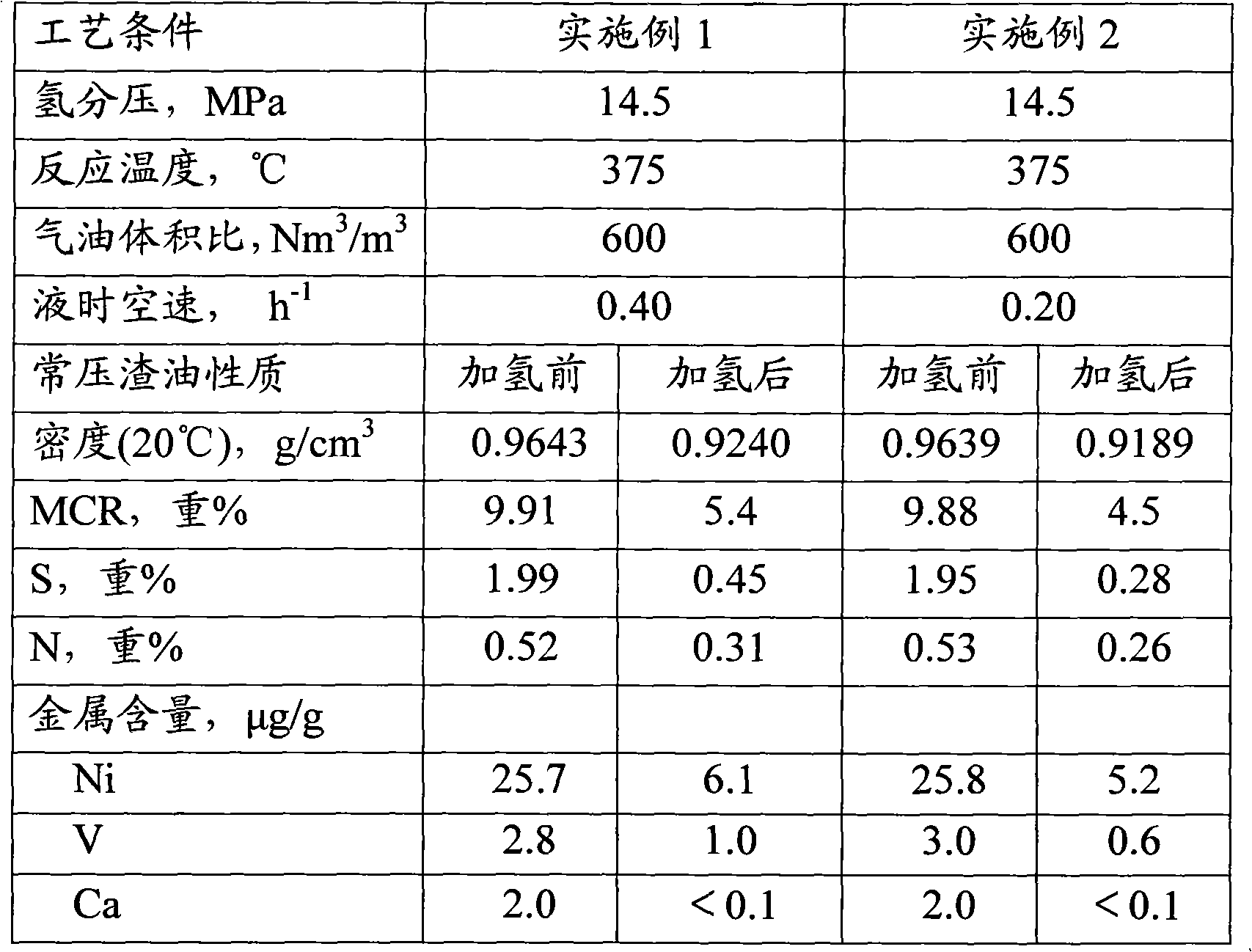

Hydrotreating method of high-acid and high-calcium crude oil

ActiveCN101684414ALow costReduce hydrogen consumptionRefining to eliminate hetero atomsNaphthaHydrogenation reaction

The invention relates to a hydrotreating method of high-acid and high-calcium crude oil. The high-acid and high-calcium crude oil carries out hydrogenation reaction in a crude oil hydrogenation reaction area; obtained hydrogenation crude oil enters a normal-pressure tower and is fractionated to obtain normal-pressure naphtha, normal-pressure diesel and normal-pressure residue oil, wherein the normal-pressure residue oil and hydrogen gas enter a residue oil hydrogenation reaction area together to carry out the hydrogenation reaction; and reaction products are separated to obtain hydrogenationnaphtha, hydrogenation diesel and hydrogenation residue oil, wherein the hydrogenation residue oil is qualified catalytic cracking feeds. Through the method, after the high-acid and high-calcium crude oil is in hydrotreatment in the crude oil hydrogenation reaction area, acid materials and calcium in the crude oil can be efficiently removed, and therefore, corrosion of the acid materials to the normal-pressure tower can be avoided, and increase of pressure drop of a residue oil hydrogenation catalyst bed caused by calcium deposition can be avoided, and long-period safety operation of the normal-pressure tower and a residue oil hydrogenation reactor can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

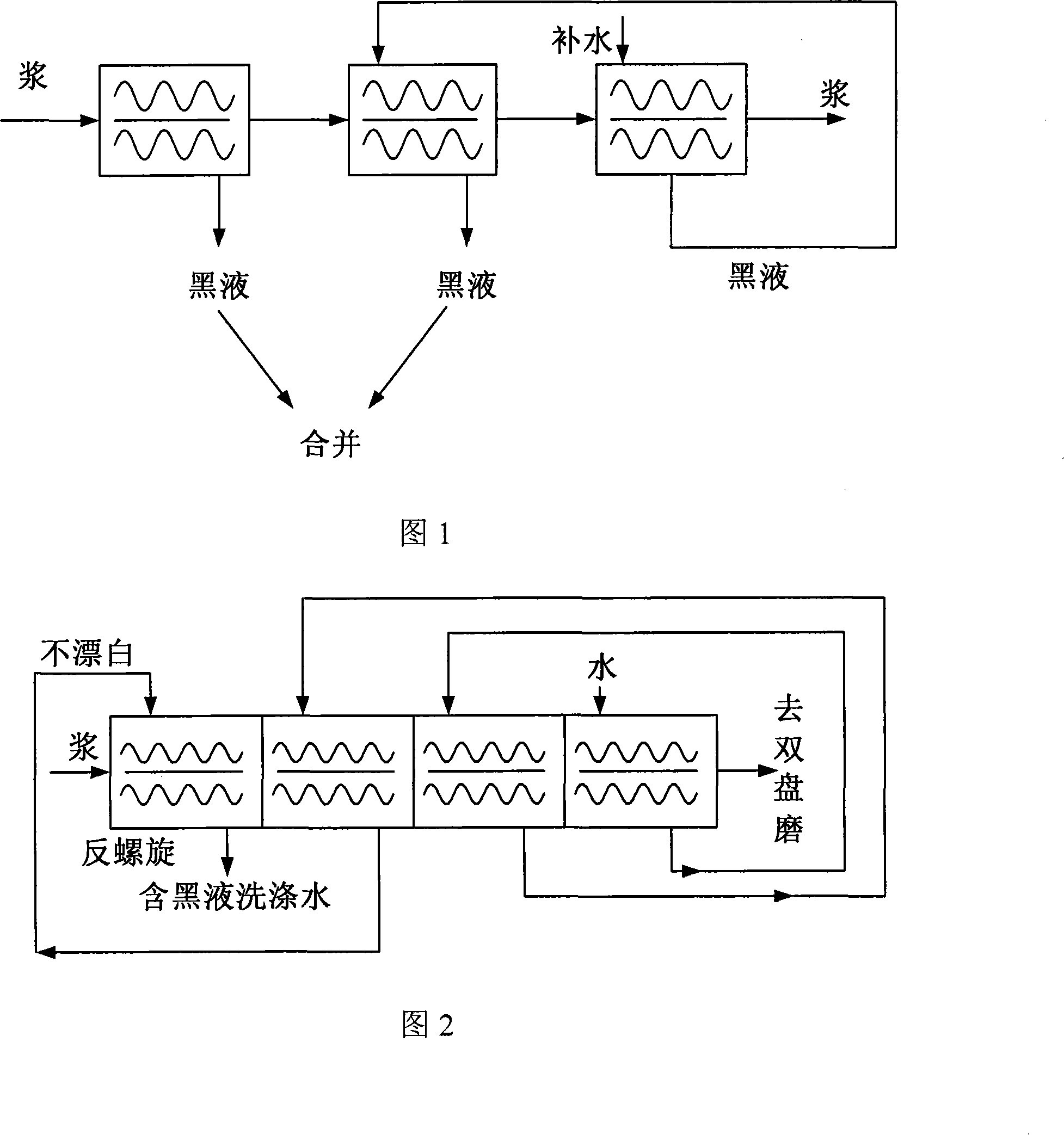

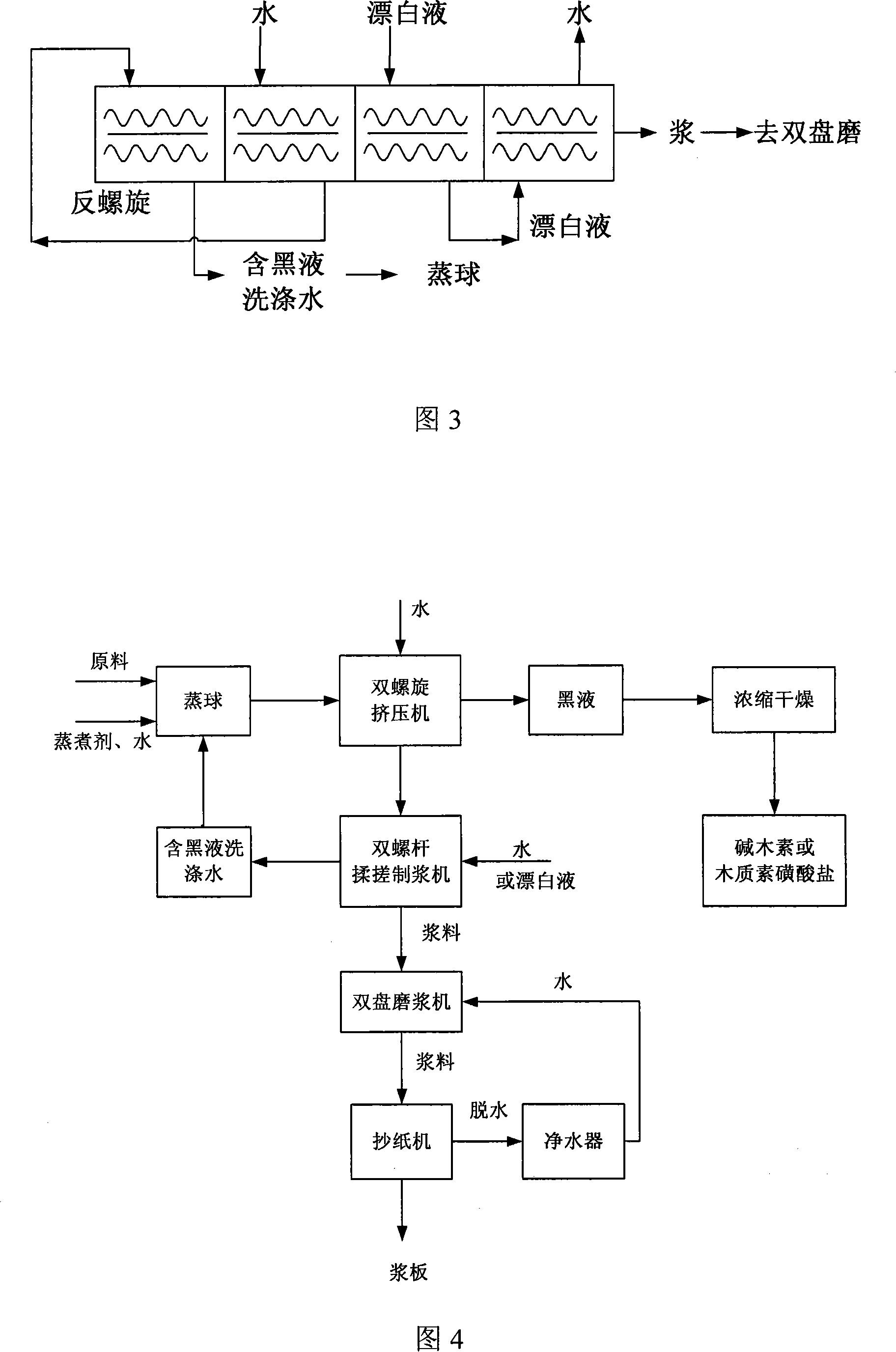

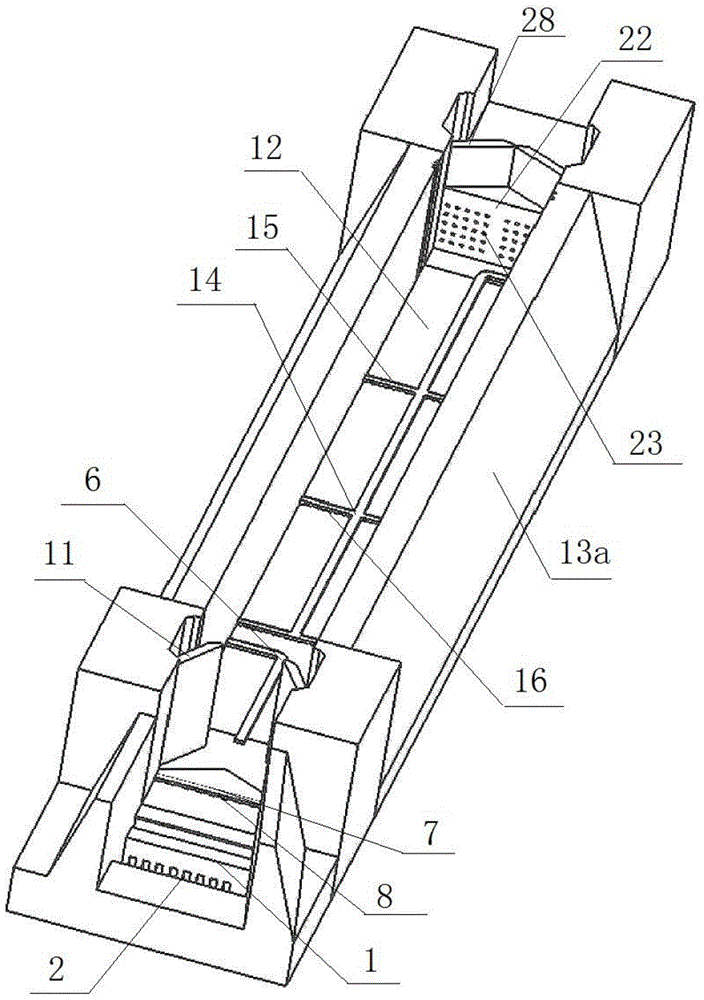

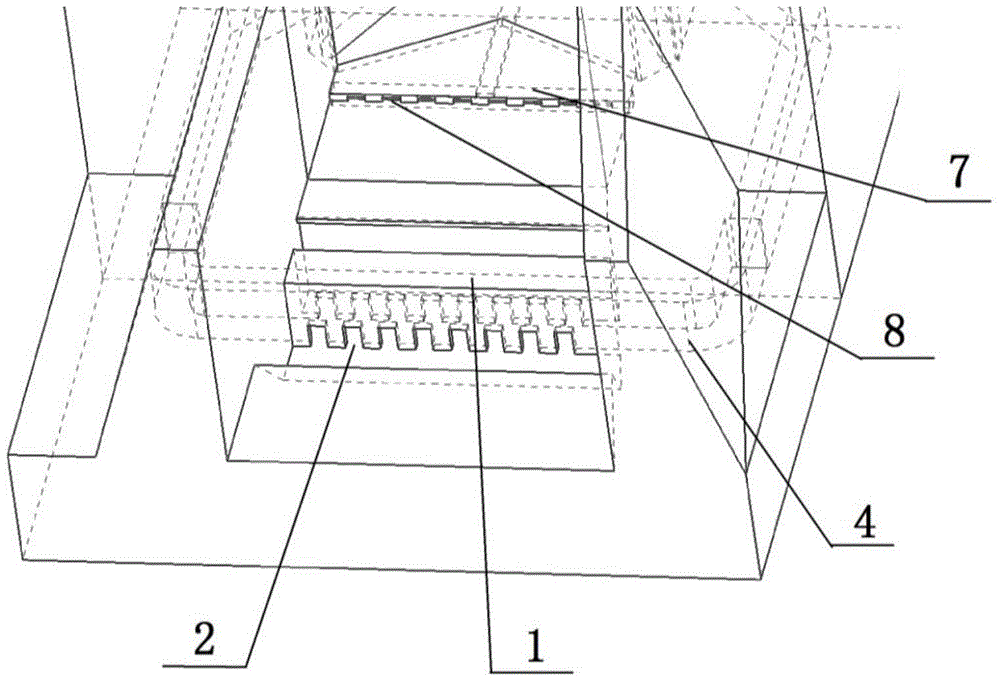

Pulping method with zero discharge of sewage water

InactiveCN101220565AHigh extraction rateLess investmentPulp liquor regenerationWashing/displacing pulp-treating liquorsPolyesterBlack liquor

The invention discloses a pulp making method for discharging sewage thoroughly which includes the following steps: pulping material, steam cooking agent and catalyst are mixed evenly and put into a spherical digester and the mixture is cooked by steam; the cooked material is squeezed by passing through a plurality of twin-screw extruders connected in series so as to extract black liquid and obtain the pulp material, and the black liquid obtained from the last twin-screw extruder is squeezed sequentially after returning to the former twin-screw extruder, while the black liquid obtained from a first and a second twin-screw extruders is merged straightly, and the merged black liquid is concentrated and dried to obtain alkali lignin and or lignosulfonate; the pulp material is delivered into a twin-screw rubbing and kneading pulper, the polyester washing is carried out in multiple-section series while the pulp is grinded, or the polyester washing is carried out in multiple-section series and bleached in multiple-section series, the washing water is returned to the washing process in the former section, and finally the residuary black liquid is obtained, that is the washing water coming from the first washing process; then, the residuary black liquid is returned to the pulping material or the spherical digester; the pulp material is refined in a dual-disk refining machine by adding water, then a pulp plate is made after the refined pulp material enters a paper machine. Meanwhile, the removed water circulates to the dual-disk refining machine or other processes needing the water by the pure water treatment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fish collecting and fish luring system and fish collecting and fish luring method of fish-passing type lock

ActiveCN104594321ADoes not affect the structure layoutDoes not affect navigational safetyBarrages/weirsDry-docksEngineeringFish owl

The invention discloses a fish collecting and fish luring system and a fish collecting and fish luring method of a fish-passing type lock. The fish collecting and fish luring system comprises a drainage cross gallery positioned inside a downstream approach channel, a fish collecting and water replenishing gallery system with the inlet end in an upstream approach channel and the outlet end in the downstream approach channel, and a fish luring and water replenishing gallery system with the inlet end in the upstream approach channel and the outlet end in a lock chamber. On a lock of a navigable river built flood retarding project and a lock of a new flood retarding project, the fish collecting and fish luring system of the fish-passing type lock can be used for gathering migrating fishes on the downstream side in the lock.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

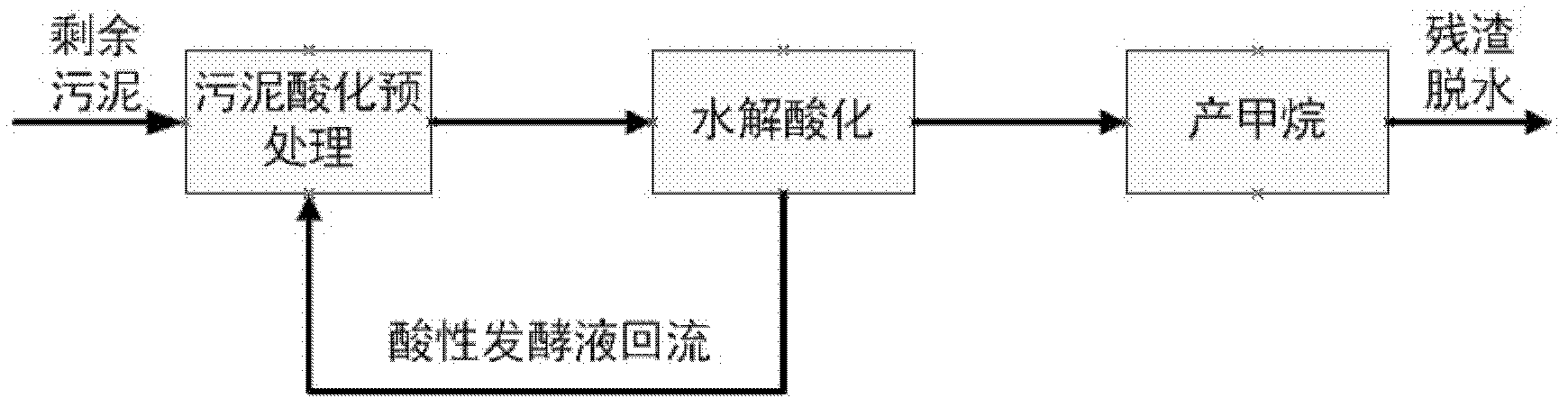

Method for treating sludge through refluxing of acidified fermentation liquor and application of method

InactiveCN102531311AIncrease productionReduce pretreatment costsWaste based fuelBiological sludge treatmentMethane productionPre treatment

The invention discloses a method for treating sludge through the refluxing of acidified fermentation liquor and application of the method. The method comprises the following steps of: performing hydrolytic acidification on the sludge, refluxing the acidified fermentation liquor of the sludge, performing acidification pretreatment on the sludge, and performing hydrolytic acidification fermentation on the pretreated sludge and producing methane by using a product. The sludge is subjected to acidification pretreatment by using the fermentation liquor of the sludge, so that the time required by anaerobic digestion is shortened, the gas yield is improved, and the operating cost is reduced.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com