Liquid-distributing device for falling-film evaporator

A falling-film evaporator and liquid distribution technology, which is applied to heat exchanger shells, lighting and heating equipment, heat exchange equipment, etc., can solve the problem of high processing accuracy requirements, save space and investment costs, and improve heat transfer. coefficient, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

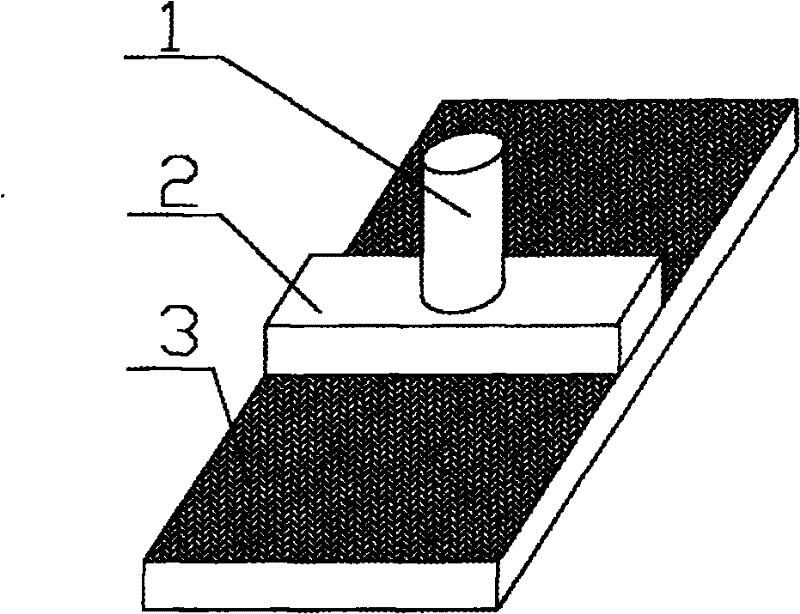

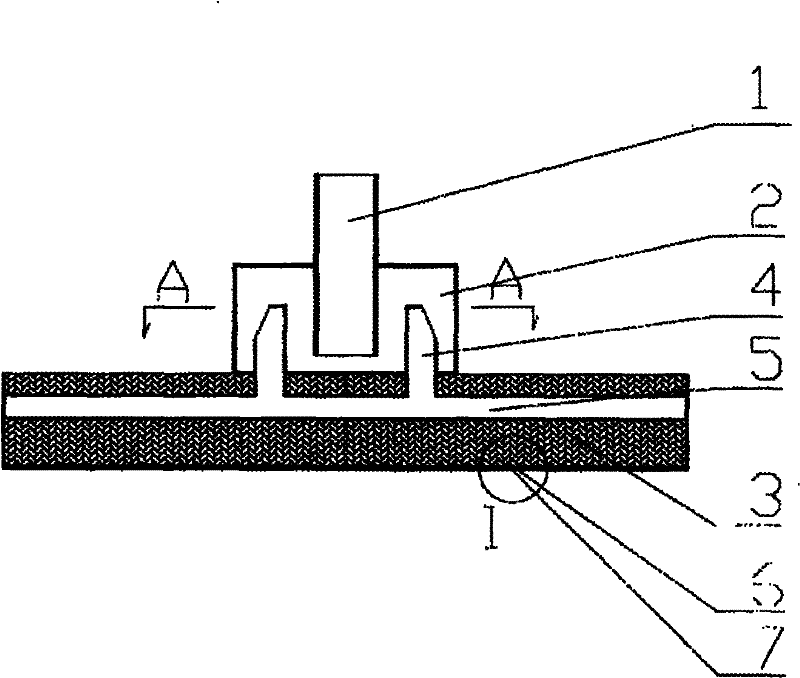

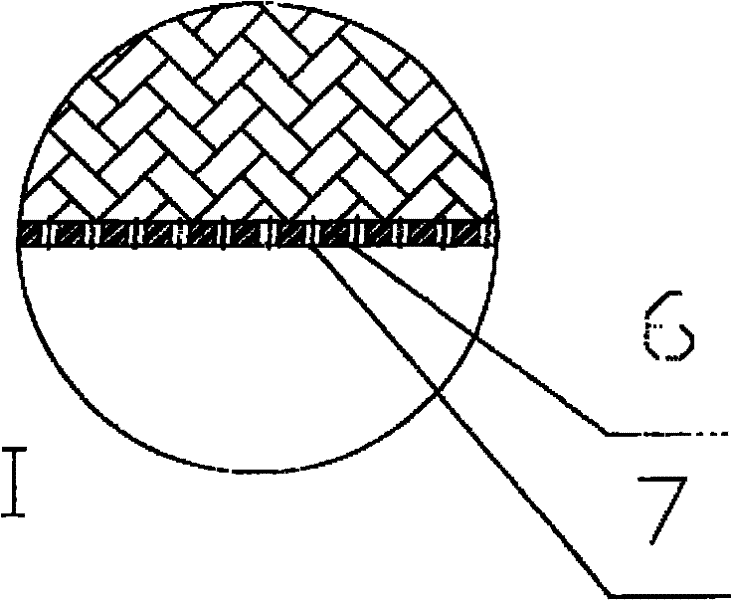

[0028] The structure of its liquid distribution device is as follows: figure 1 , 2 As shown, the liquid inlet pipe 1 is connected to the diversion tank 2, the diversion tank 2 is connected to the diversion pipe 4, the diversion pipe 4 is connected to the porous liquid distribution pipe 5, and the porous liquid distribution pipe 5 is placed in the stuffing tank 3. like image 3 The bottom plate 6 of the porous packing tank 3 shown has a plurality of liquid distribution holes 7 .

[0029] like figure 1 , 2 As shown, the diameter of the liquid inlet pipe 1 is 50 mm, and it passes vertically downward through the center of the top cover of the split pool 2, and the distance between the nozzle and the bottom plate of the split pool is 15 mm. The liquid inlet pipe 1 and the top cover of the split flow pool 2 are welded and sealed to each other.

[0030] like figure 1 , 2 As shown, the shape of the shunt pool 2 is a cuboid with a length of 360mm, a width of 150mm and a depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com