Patents

Literature

228results about How to "Low proficiency requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

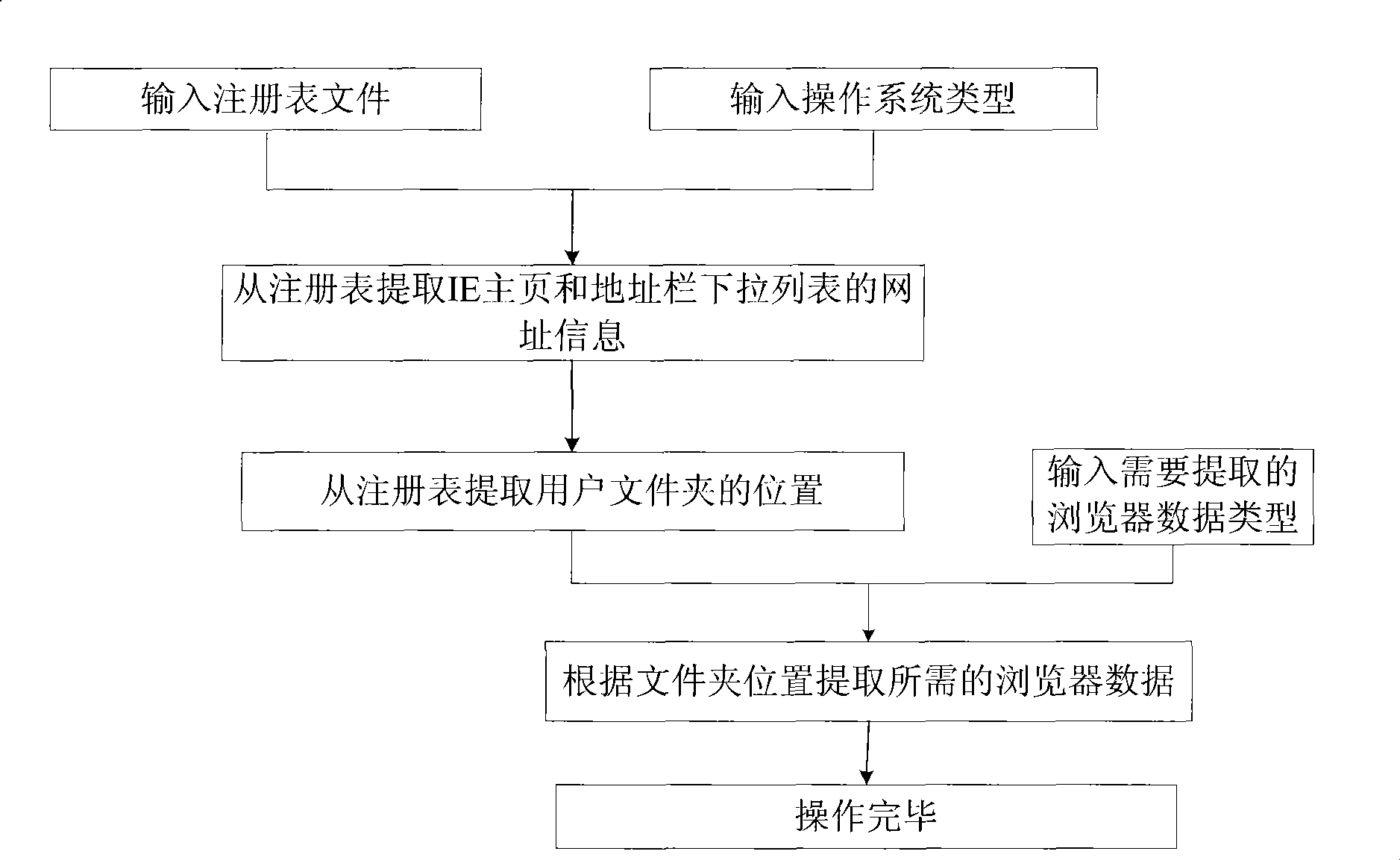

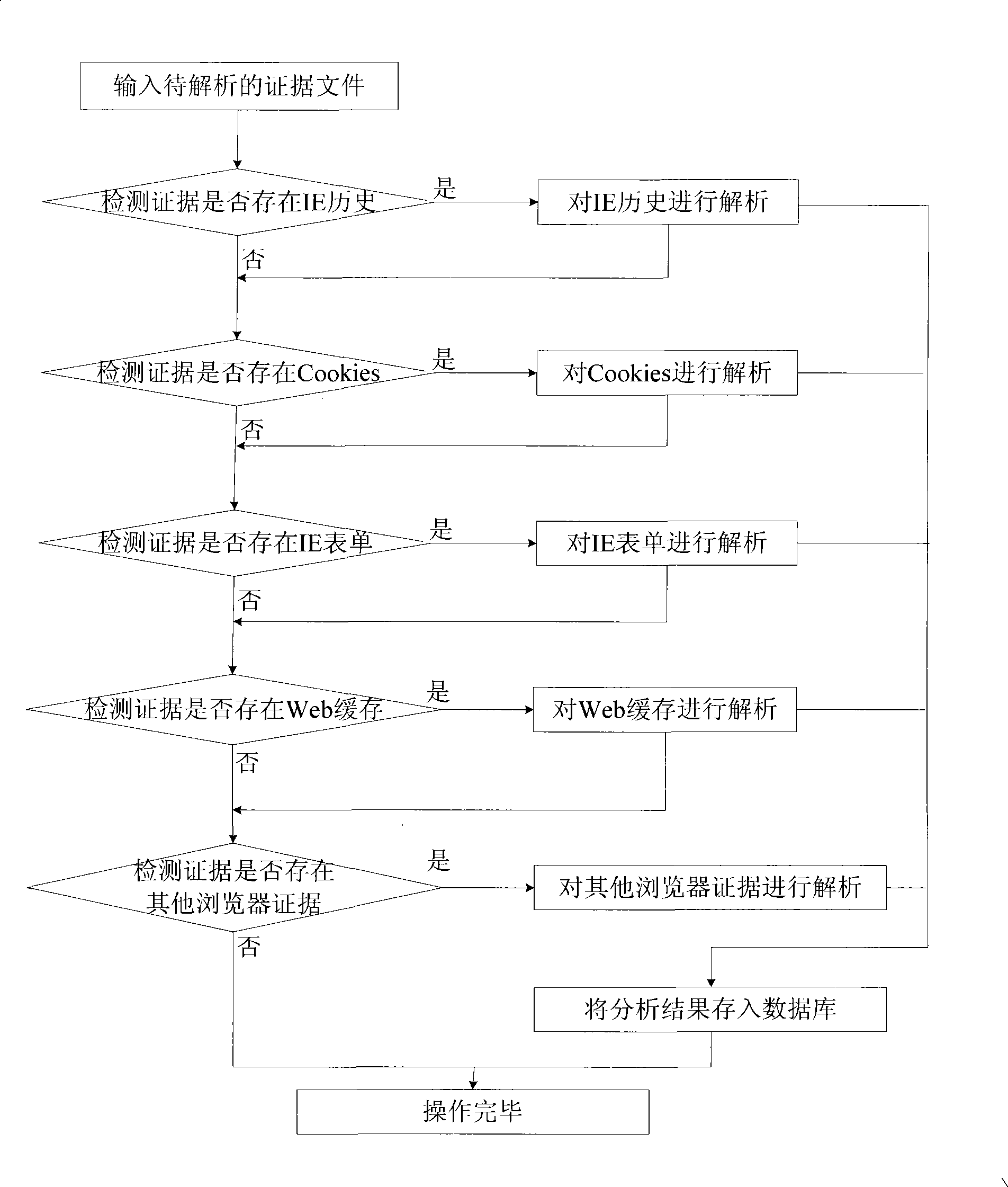

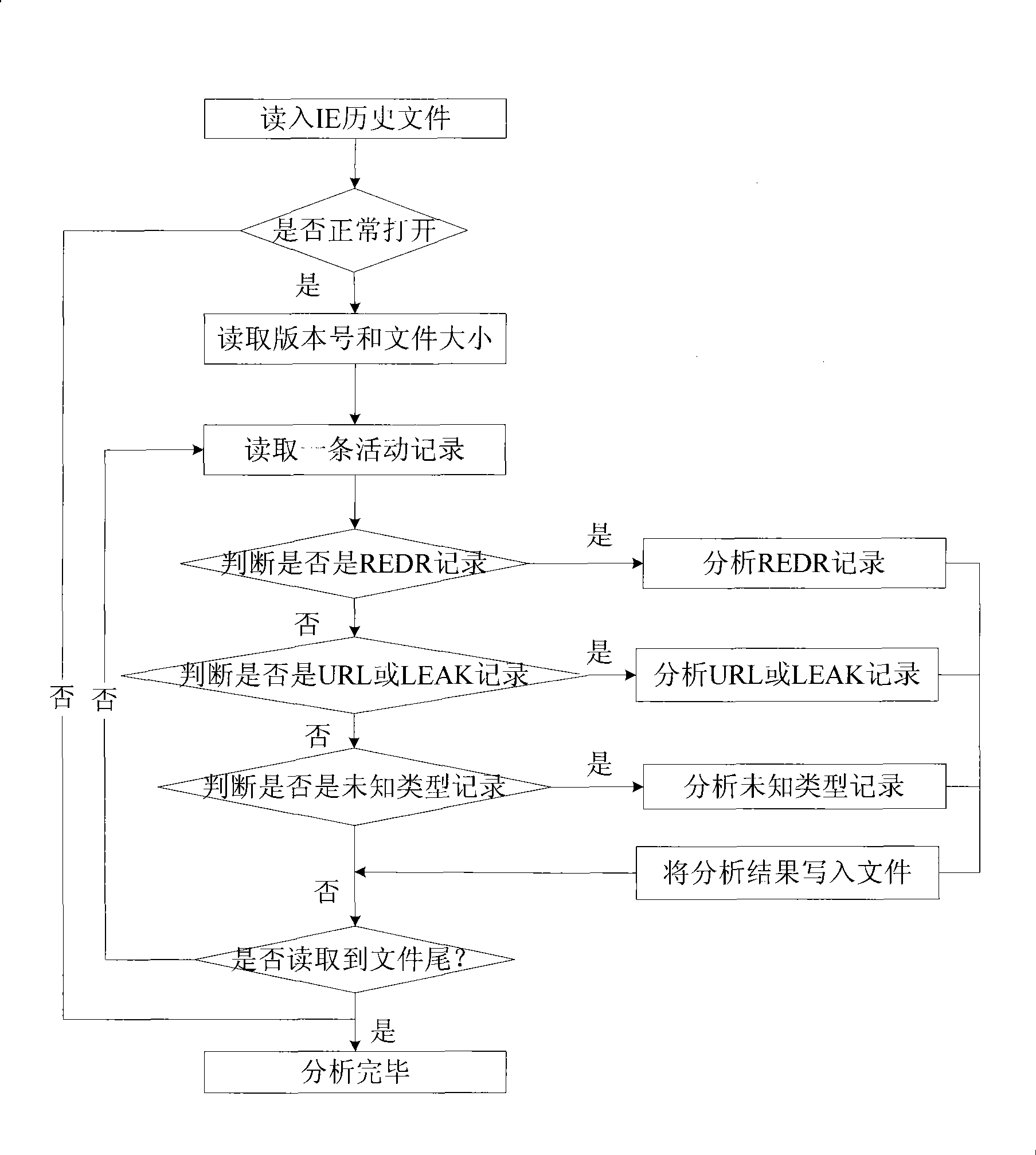

Evidence obtaining method for Web browser caching data

InactiveCN101369276AEasy to viewRefining the browsing pathSpecial data processing applicationsVisit timeWeb browser

The invention relates to an evidence-taking method of Web browser buffer memory data. In the method of the prior art, it is difficult to acquire click operation of the web and information which is acquired by users. The method comprises: inputting a Web browser data file and searched sensitive key words; resolving and pretreating an evidentiary document; conforming each record and other associated Web evidence into a Web object using Web browse record as a main line; selecting special Web object as a root node, constructing a Web tree according to link reference and web visit time between webs, construct a web evidence forest; performing intelligent search on the forest though input key words, obtaining relative web object; performing content analysis on relative Web object and Web tree; generating a Web evidence-taking report for the user to browse. The method of the invention is high in efficiency, strong in intelligibility and low in requirement on proficiency of investigators.

Owner:HANGZHOU DIANZI UNIV

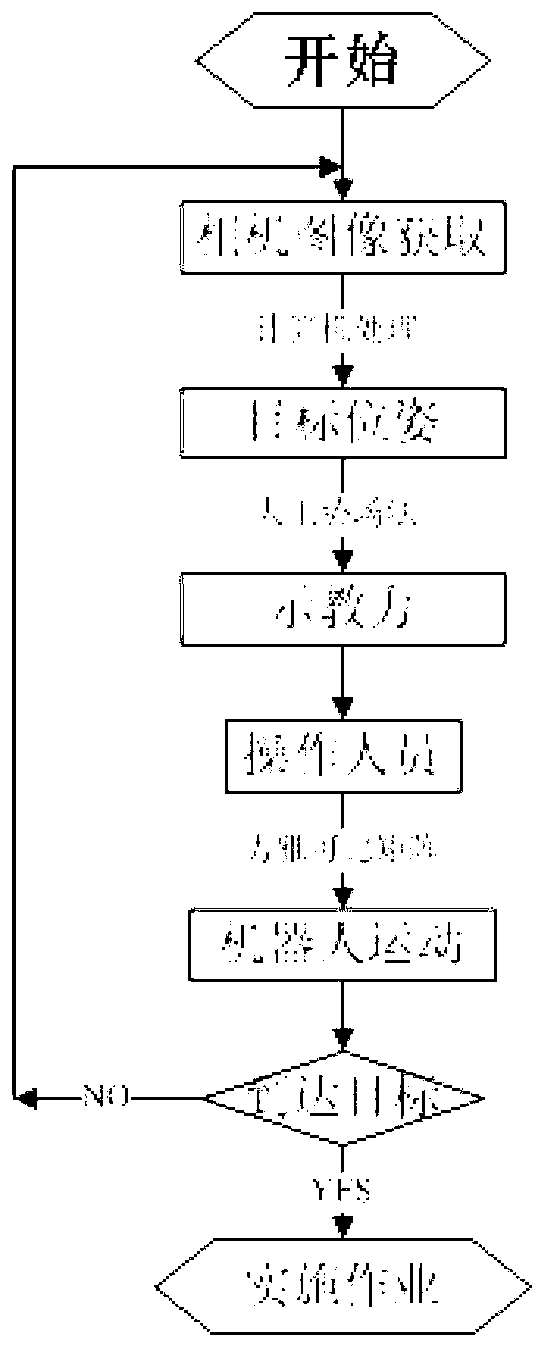

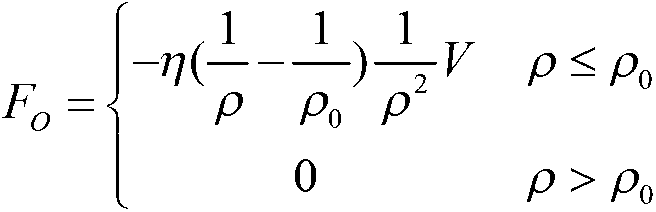

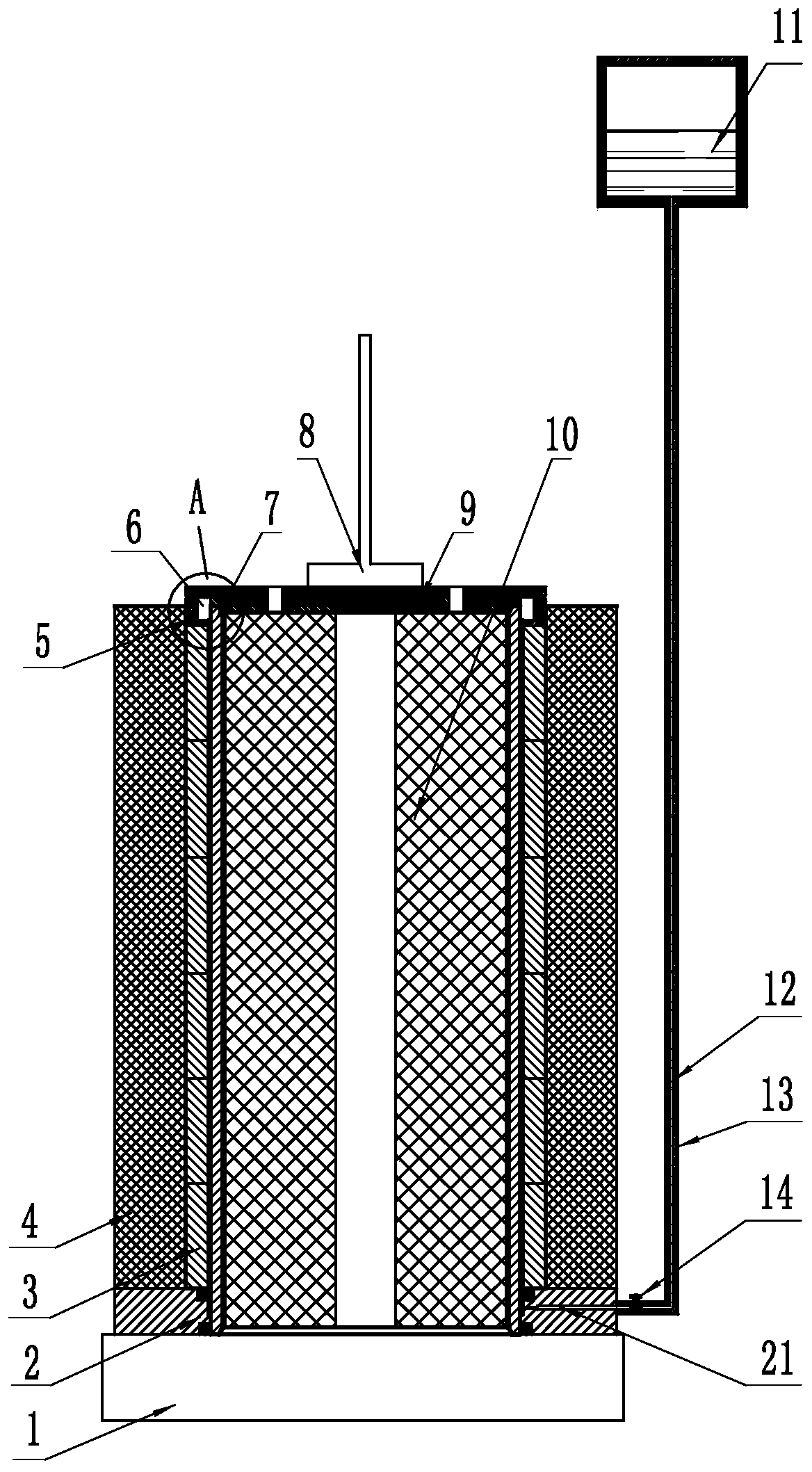

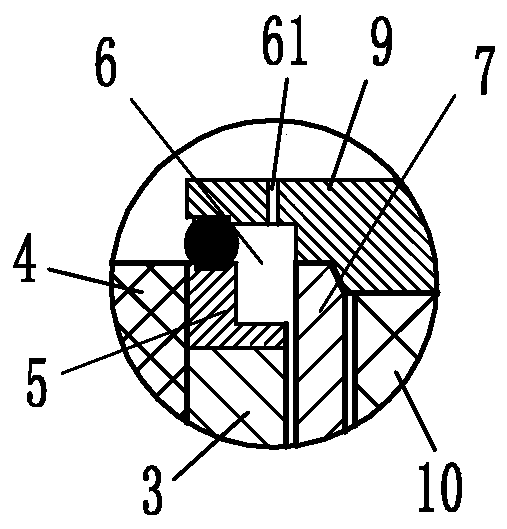

Kinesthesis teaching control method based on vision sense for remote control of robot

InactiveCN103105851ARealize kinesthetic teachingImprove work efficiencyVehicle position/course/altitude controlPosition/direction controlRobotic systemsRemote control

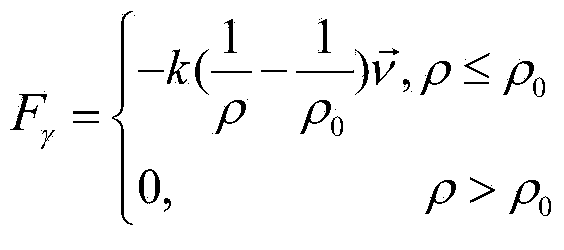

The invention provides a kinesthesis teaching control method based on vision sense for remote control of a robot. The steps comprises the steps of using stereoscopic vision technology to identify an onsite operation object and a background environment (an obstacle) and extract space information; constructing virtual attraction of the operation object to the robot by using the pose relation of the operation object and the tail end of the robot calculated through vision identification as a parameter; constructing the obstacle repulsive force exerted by the robot by using the distance of the tail end of the robot and the background environment (the obstacle) along the speed direction of the robot as a parameter; combining the virtual attraction of the operation object, the obstacle visual repulsive force and the real acting force of the robot when the robot clamps objects into the teaching force of the robot; and through the jacobian matrix between a main end system and a sub end system, feeding back the teaching force to an operation handle, and therefore kinesthesis teaching to an operator is achieved. The kinesthesis teaching control method can effectively improve the intellectuality, the safety and easy handling of a main robot system and a sub robot system.

Owner:JILIN UNIV

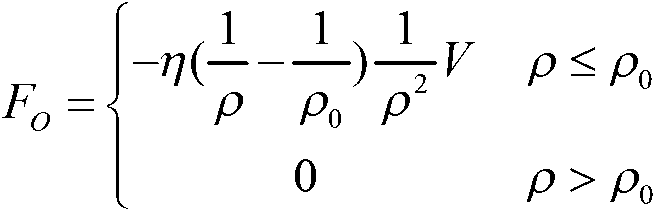

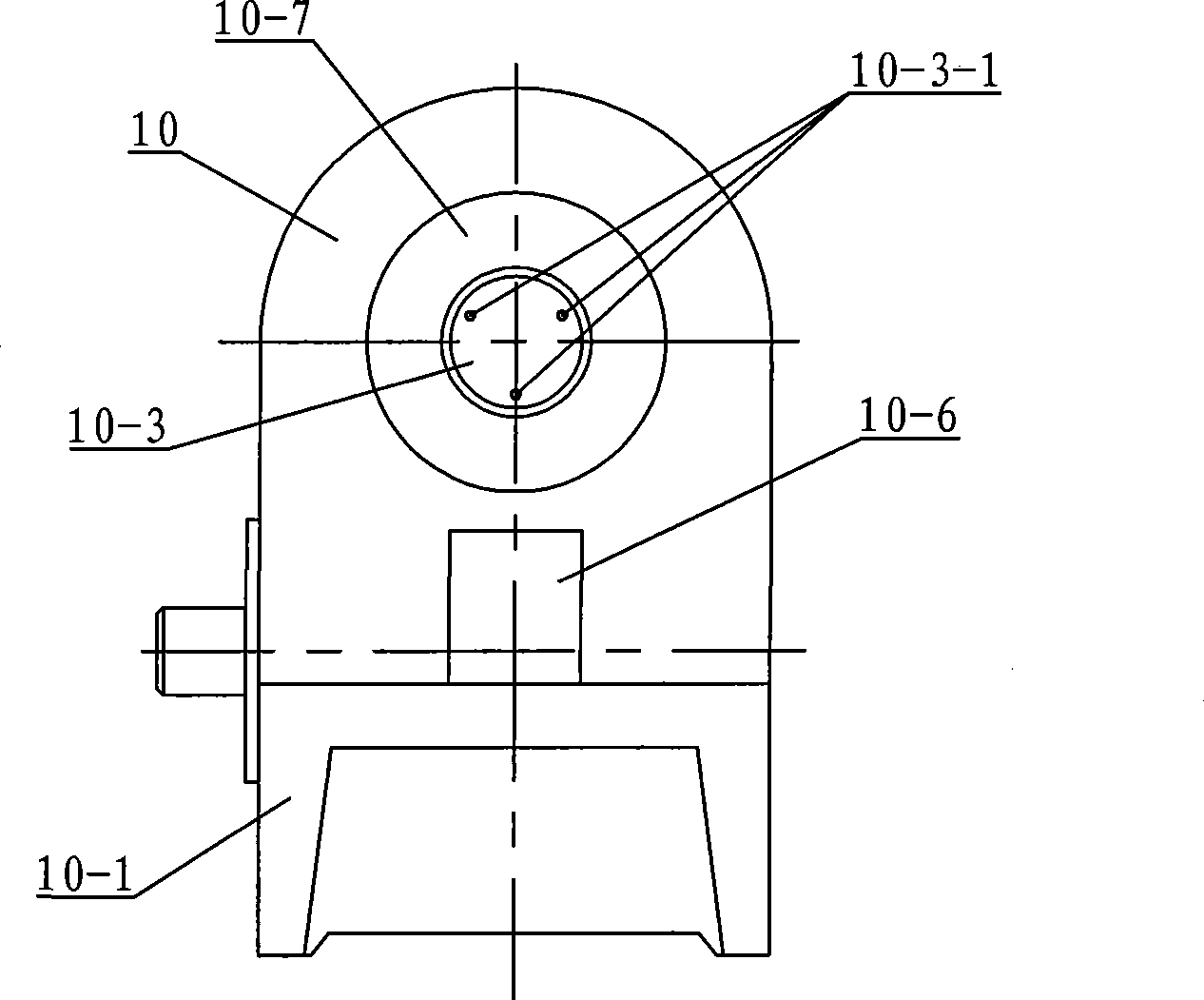

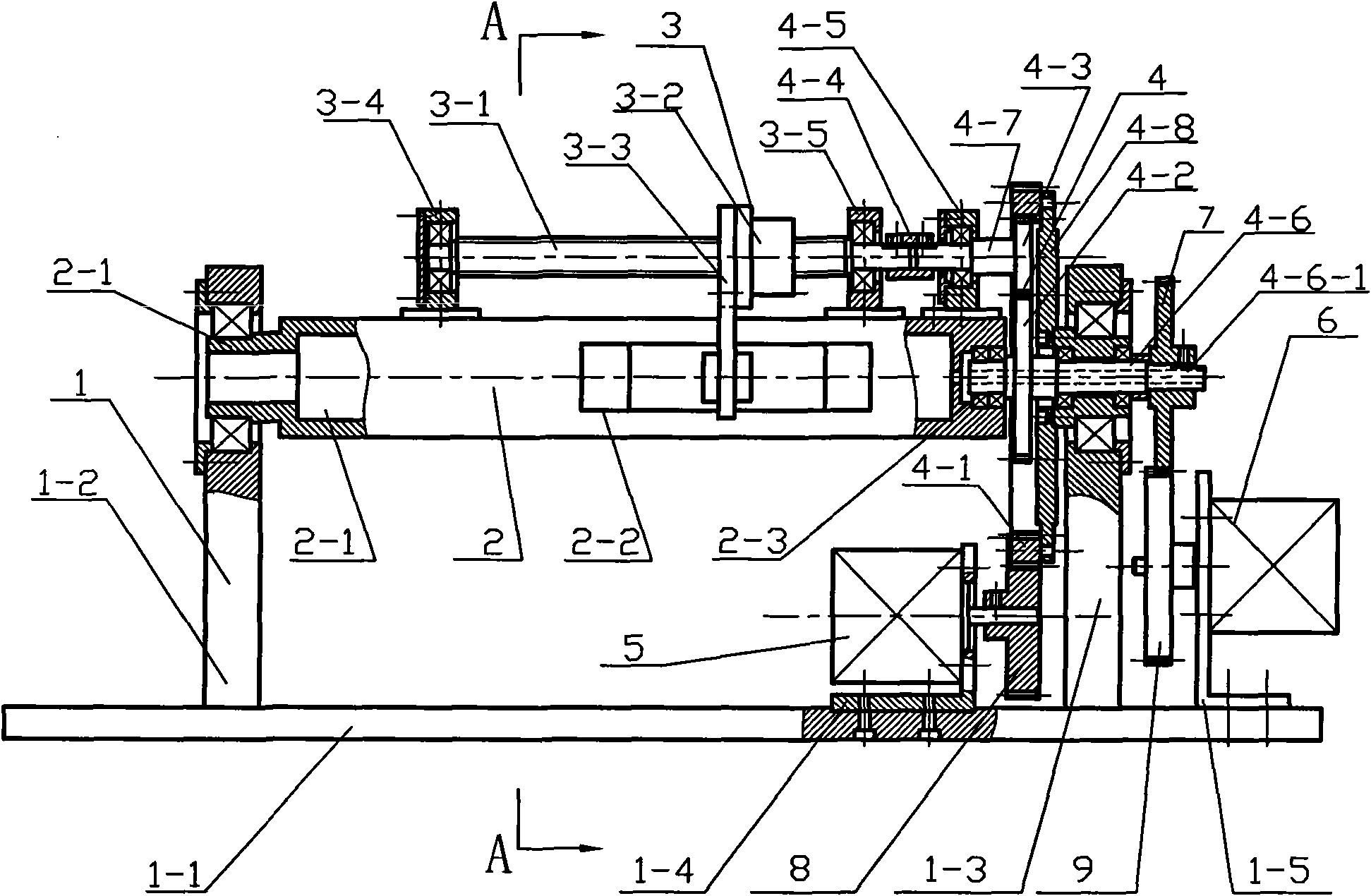

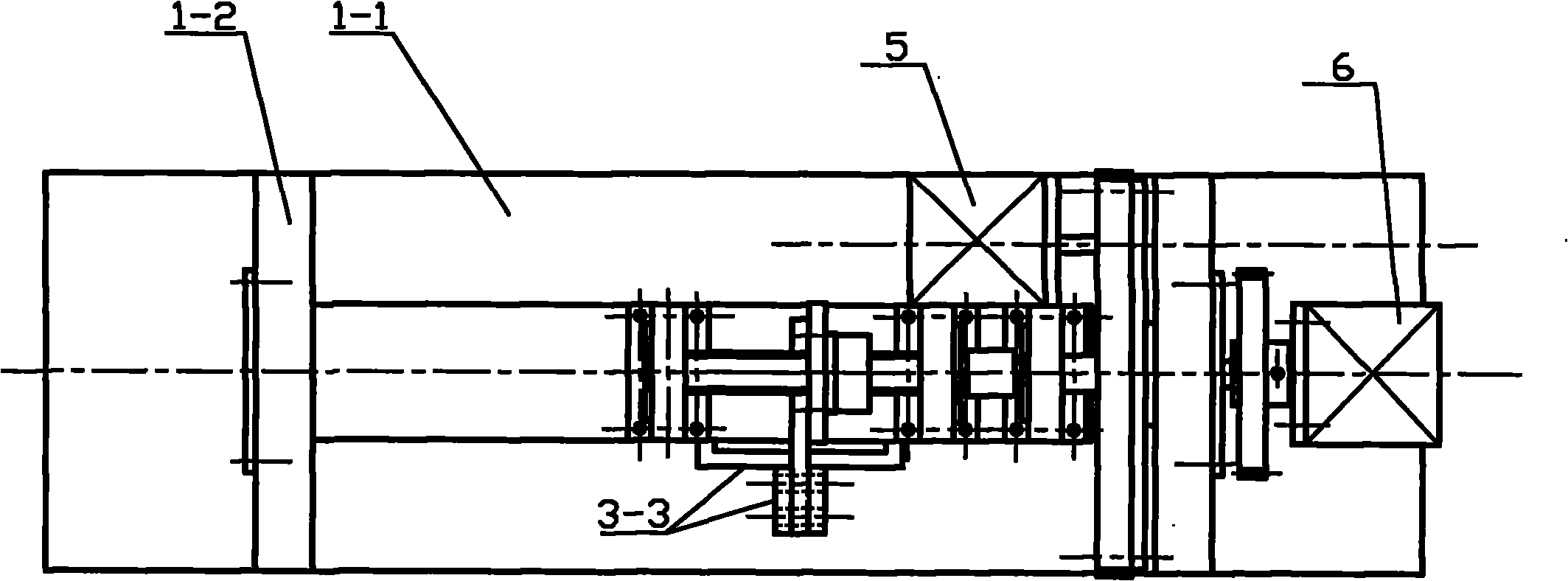

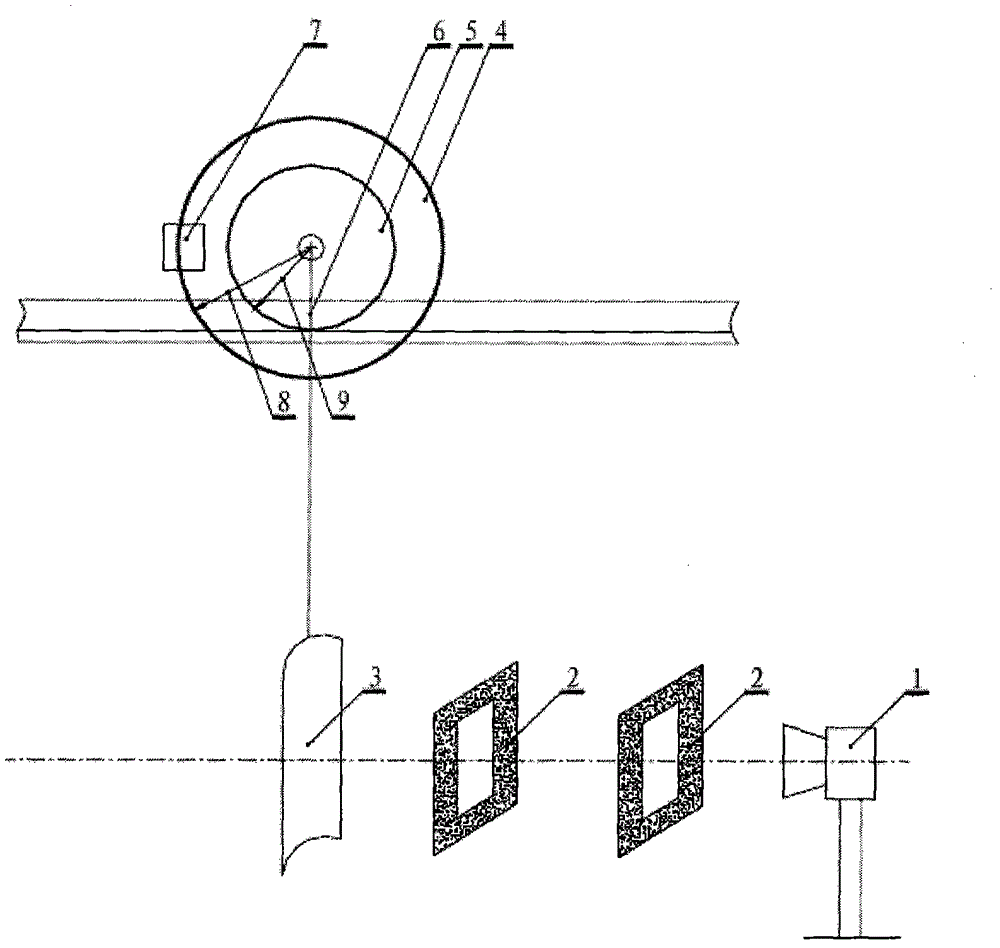

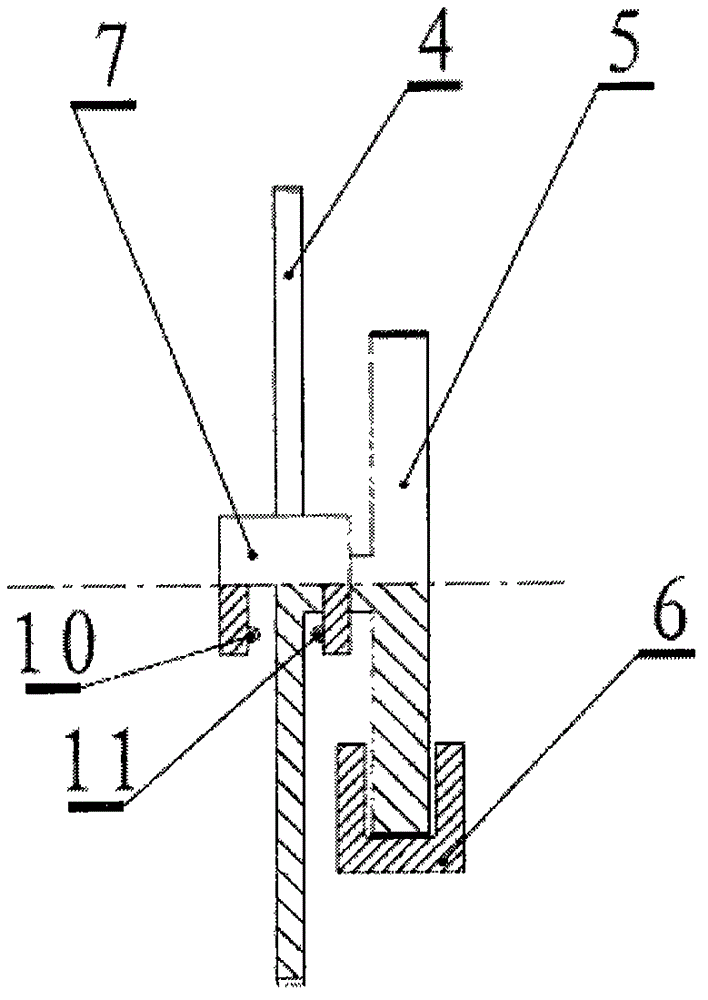

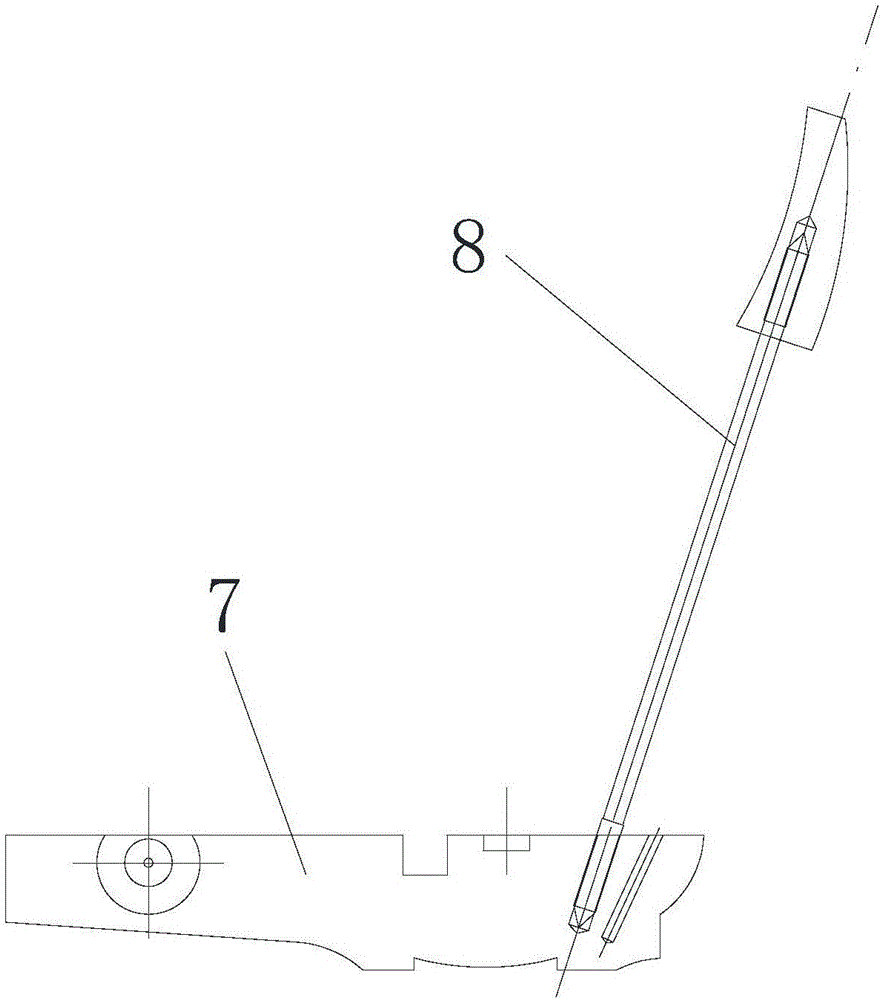

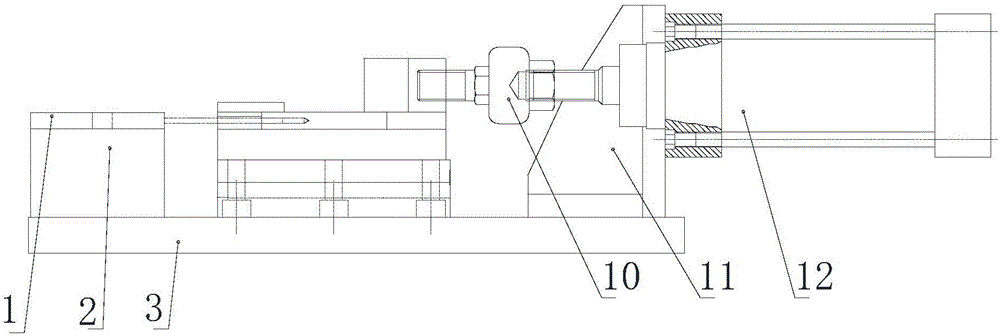

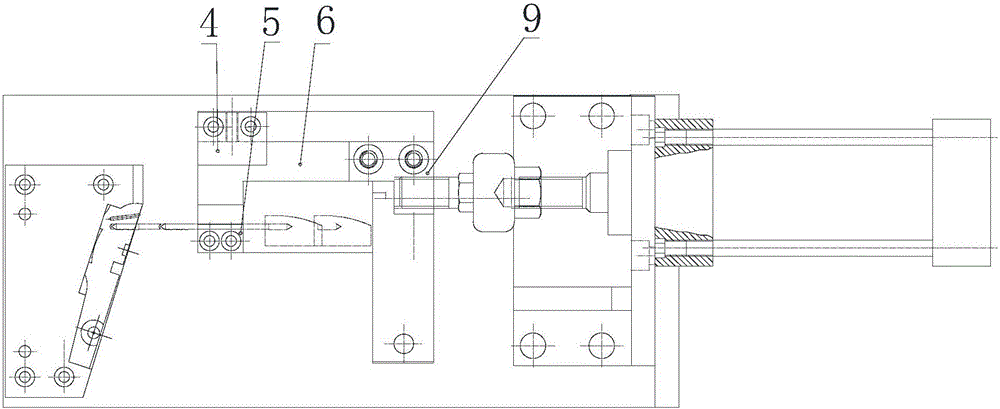

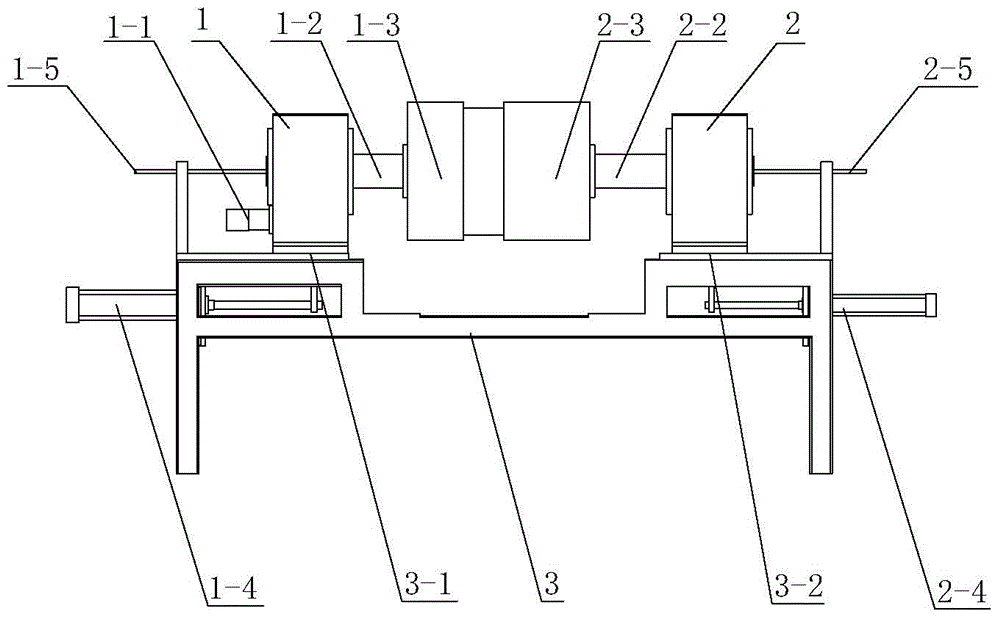

Automatic intervention device of catheter

A conduit automatic intervention device relates to a conduit delivery mechanism. The conduit automatic intervention device solves the problems that the existing continuous mode delivery mechanism has difficult force feedback and has slippage; the motor of a batch-type delivery mechanism needs frequently positive inverted alternation. Two holding jaw fixed rails are symmetrically arranged on the outside of a first fixed rail and a second fixed rail. A dovetail at the lower end of a first double rack is matched with a dovetail groove of the first fixed rail. The dovetail at the lower end of a second double rack is matched with the dovetail groove of the second fixed tail. A first half gear and a second half gear are respectively arranged on a shaft, the two ends of which are articulated with the two holding jaw fixed rails. A first holding jaw mechanism is fixedly arranged on a first connection plate and a second holding jaw mechanism is fixedly arranged on a second connection plate. The centre line of a catheter sheath is superposed with the axle center of the first holding jaw mechanism and the second holding jaw mechanism. The axle center of a tunnel body of a tube replacing mechanism is superposed with the axle center of the first holding jaw mechanism and the second holding jaw mechanism. The conduit automatic intervention device realizes the continuous delivery of the conduit and avoids the frequency starting of the motor.

Owner:HARBIN INST OF TECH

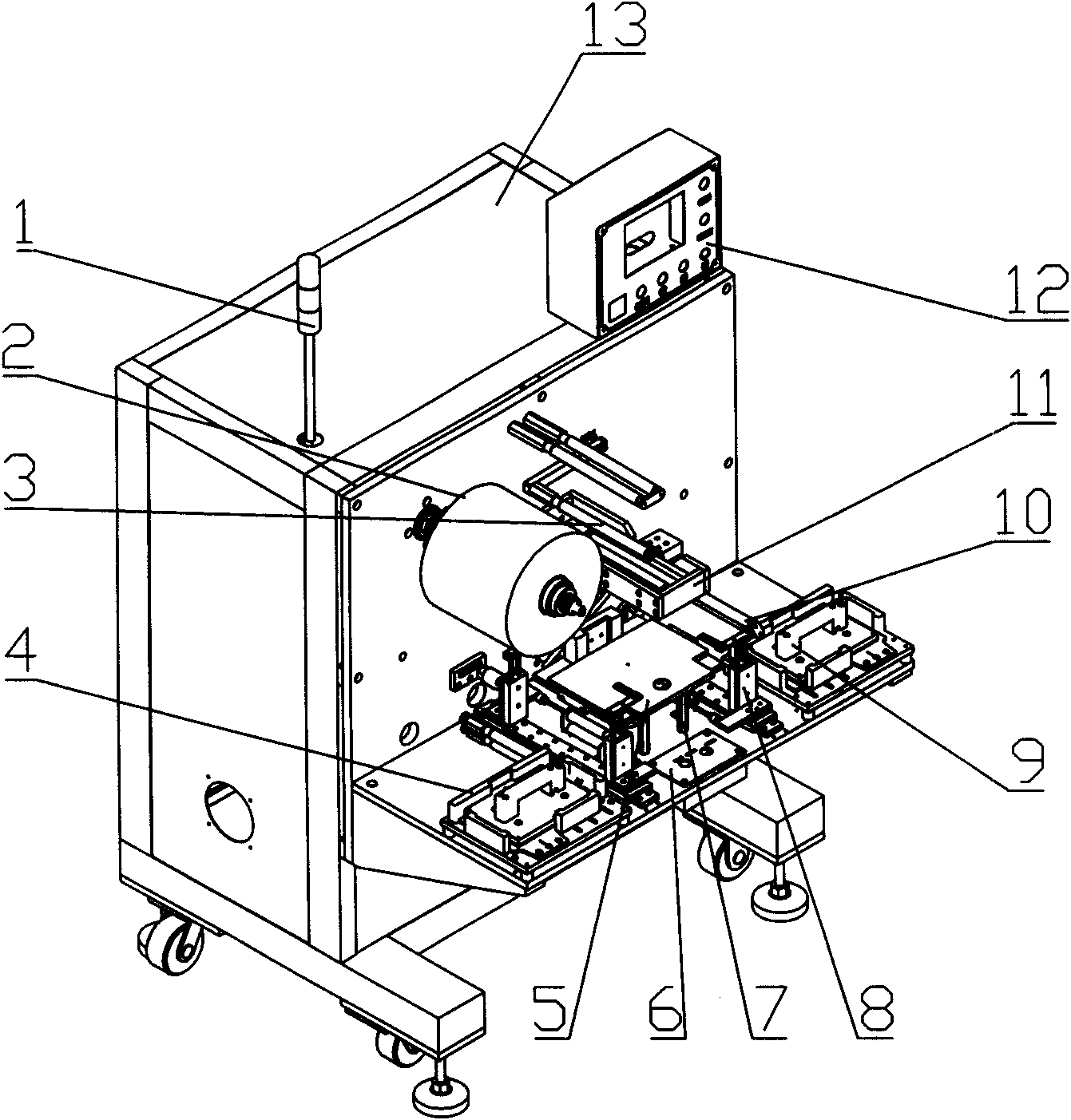

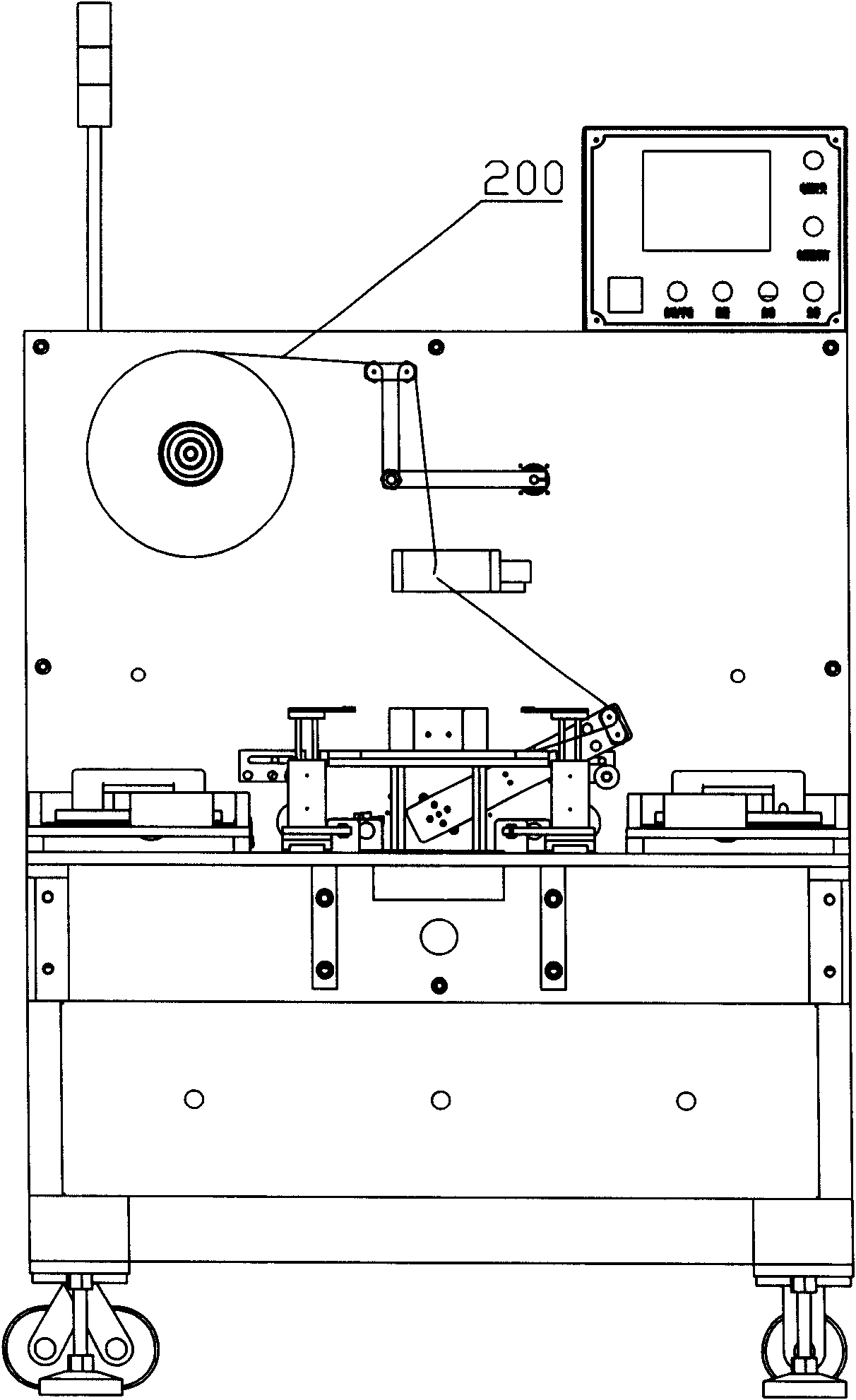

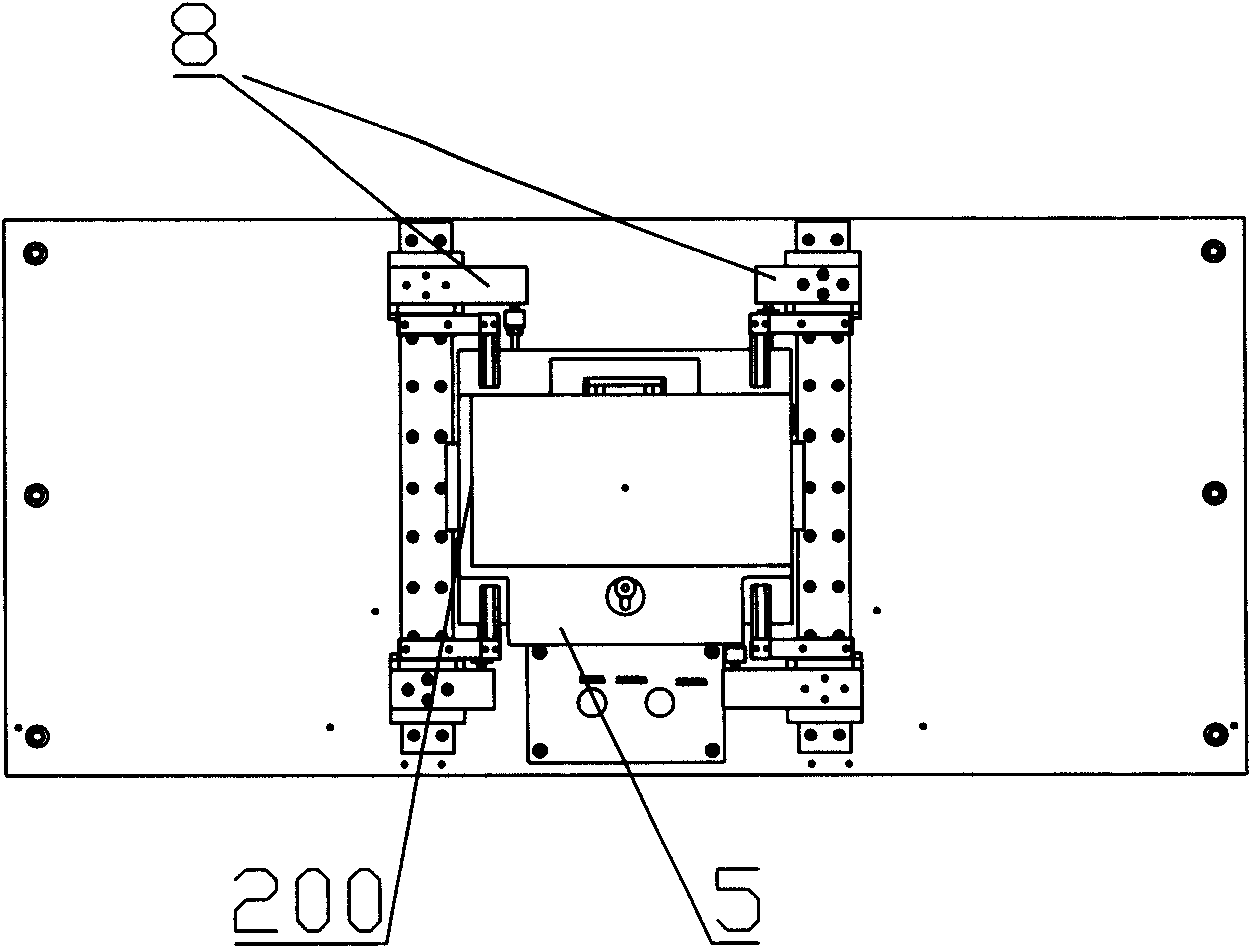

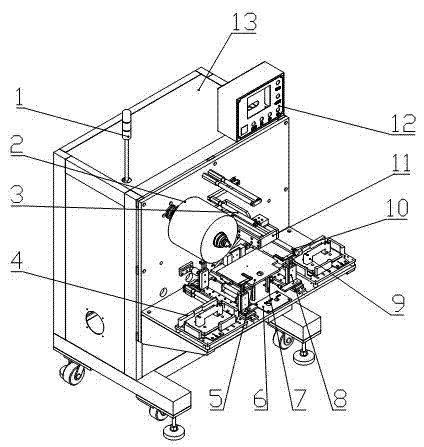

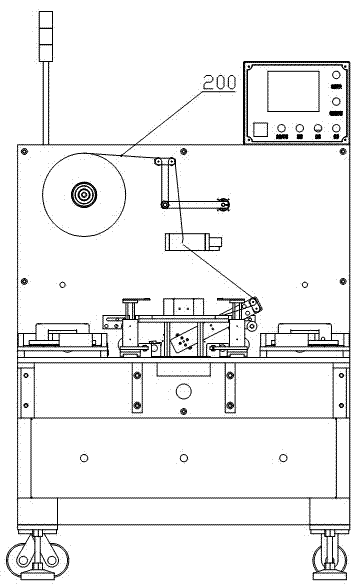

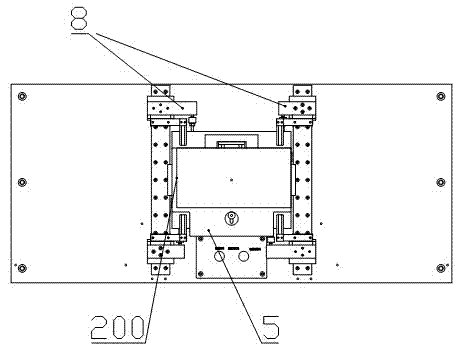

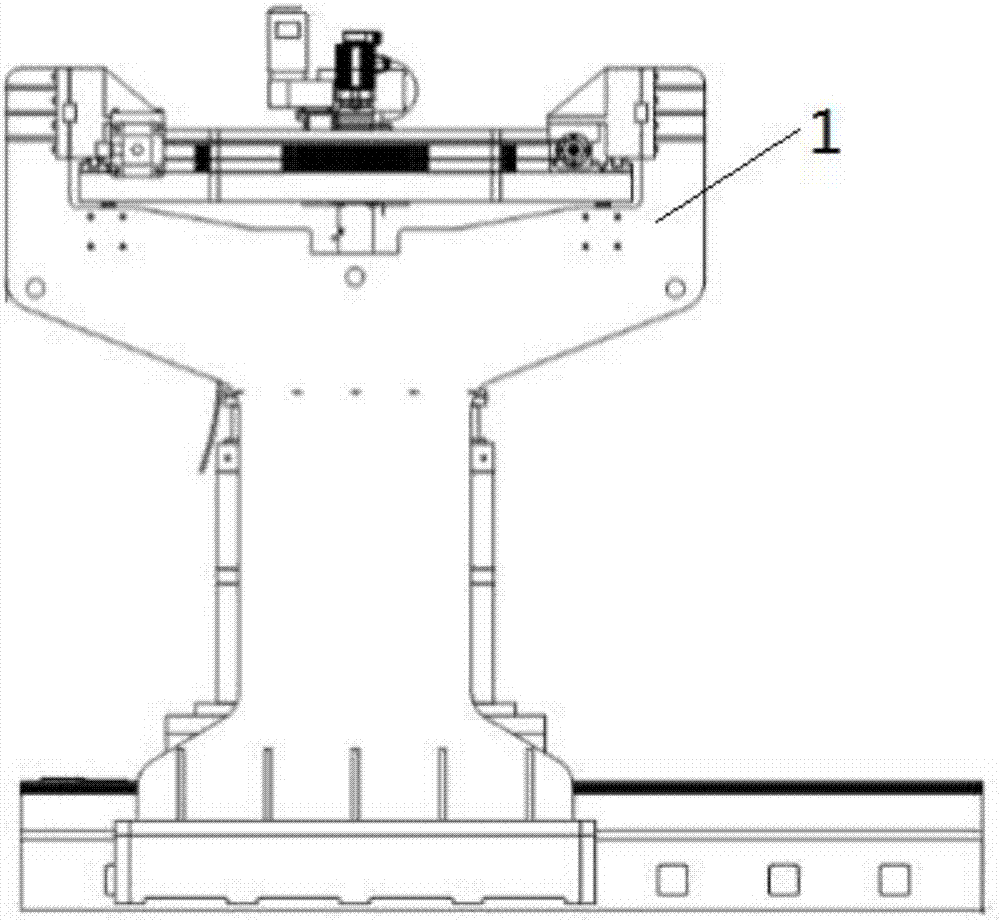

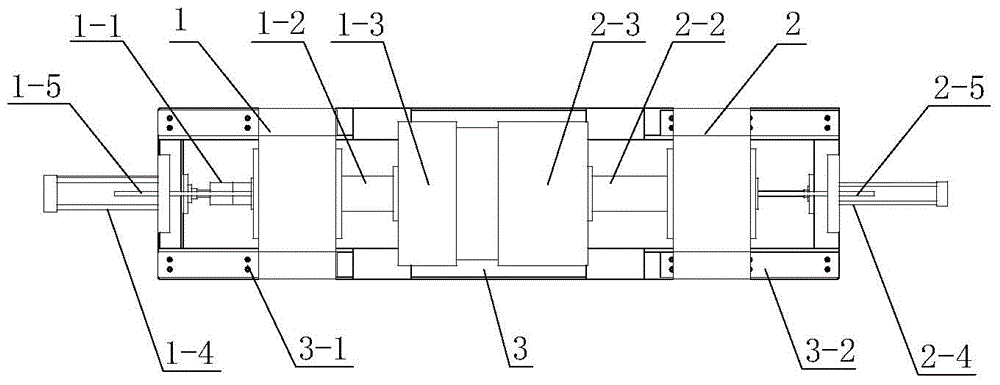

Semi-automatic laminating method of electrical core of power battery and laminating equipment thereof

ActiveCN101685887ALow costGuaranteed positioning accuracyFinal product manufactureSecondary cellsPower batterySemi automatic

The invention relates to a semi-automatic laminating method of an electrical core of a power battery and laminating equipment thereof. The method comprises the following steps: (1) stretching a diaphragm on the base layer; (2) laminating a first cathode piece; (3) winding a diaphragm on the first layer; (4) laminating a first anode piece; (5) winding a diaphragm on the second layer; (6) cyclicallyoperating step (2) to step (5) until the numbers of the laminated pieces and the wound diaphragms reach the set numbers of pieces and layers; and (7) taking out the laminated electrical core, whereinstep (3) and step (5) are carried out in an automatic mode, and other steps are carried out in a manual mode. A diaphragm winding component of the equipment controls a servo motor through a pedal switch, and controls the positioning of a diaphragm winding roller through a photoelectricity eye sensitive film; manual sucking discs at the left side and the right side suck pole pieces in a cathode piece box and an anode piece box at the left side and the right side by the vacuum generated by a vacuum valve through a vacuum sucking plate, and the pole pieces are laminated on the surfaces of the diaphragms which are wound to finish laminating; and then, the diaphragm winding component winds to the same side to automatically wind the diaphragms on the surfaces of the pole pieces. The invention can enable the diaphragms to be basically controlled in constant tension, relieve the operating strength, is convenient for replacing models and reduces the equipment cost.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Intelligent transformer station relay protection testing system and method and realization method

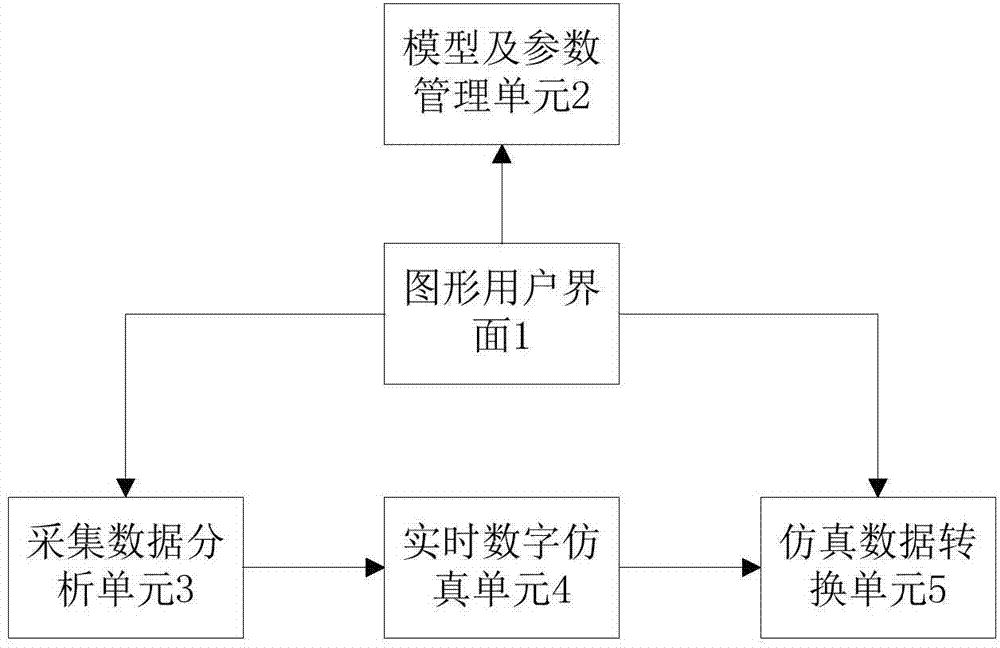

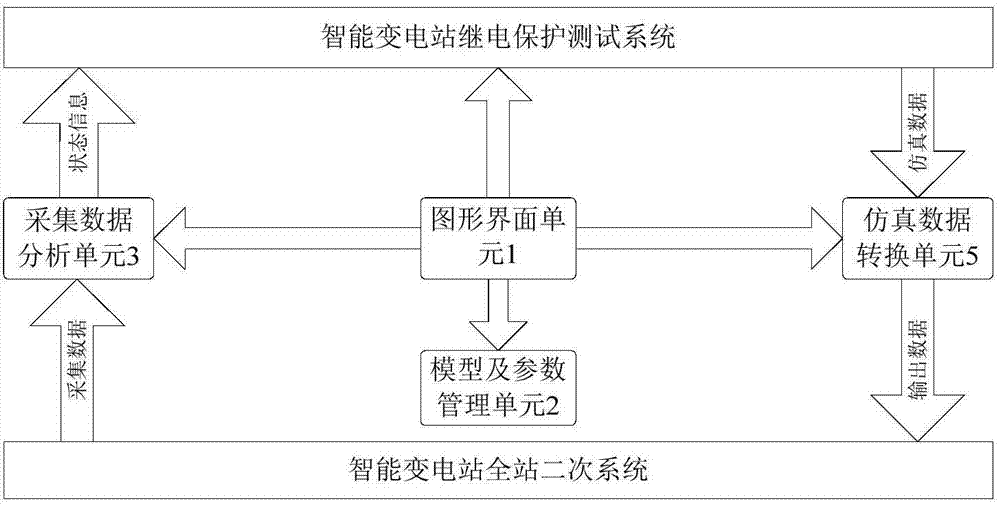

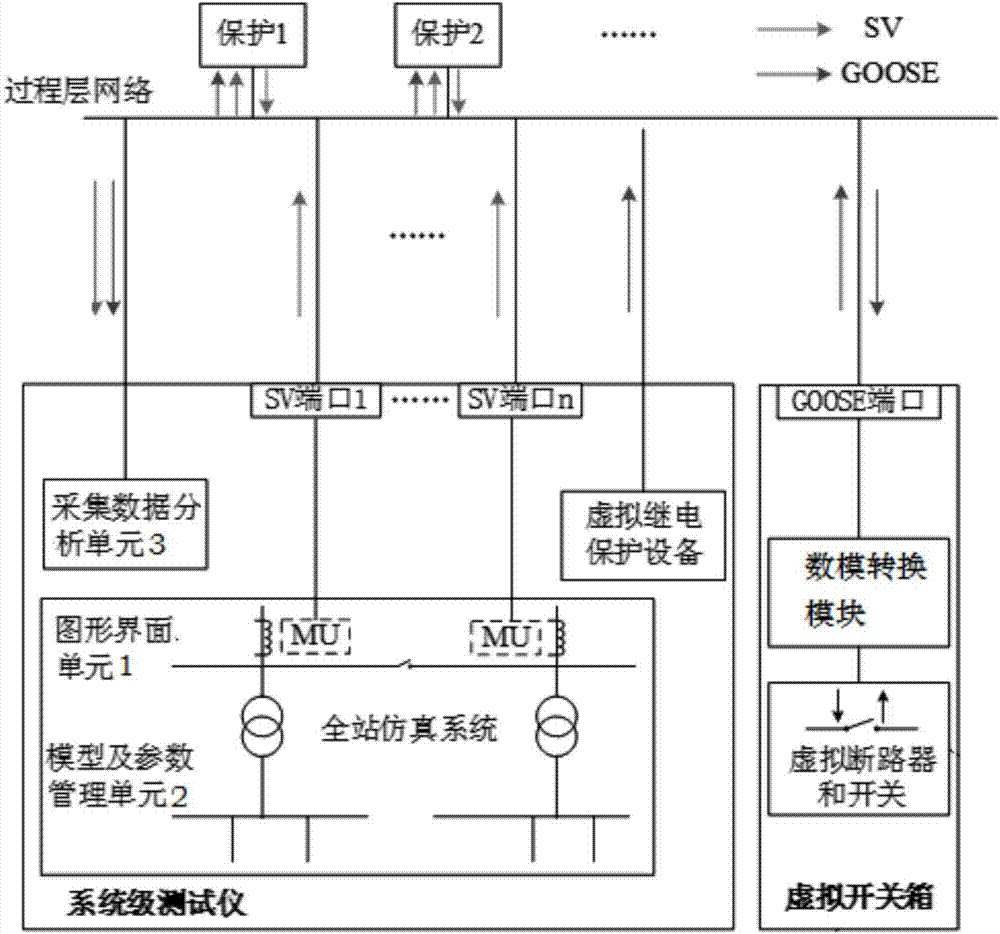

ActiveCN104749466ALow level of professionalism requiredLow proficiency requirementElectrical testingGraphicsManagement unit

The invention provides an intelligent transformer station relay protection testing system and method and a realization method. The testing system comprises a graph user interface, a model and parameter management unit, a collected data analysis unit, a realtime digital simulation unit and a simulated data conversion unit, the model and parameter management unit is connected with a graph interface unit, the collected data analysis unit is connected with the graph interface unit and used for analyzing collected data, converting the collected data into a format needed by corresponding state information in a model and transmitting the collected data to the realtime digital simulation unit, and the simulated data conversion unit is connected with the graph interface unit and the realtime digital simulation unit respectively. The intelligent transformer station relay protection testing system and method and the realization method have the advantages that construction period is short, cost is lowered, requirements on professional level and proficiency of testing personnel are low, and configuration and wiring errors in the process of intelligent transformer station relay protecting site assembly can be avoided.

Owner:广州穗华能源科技有限公司

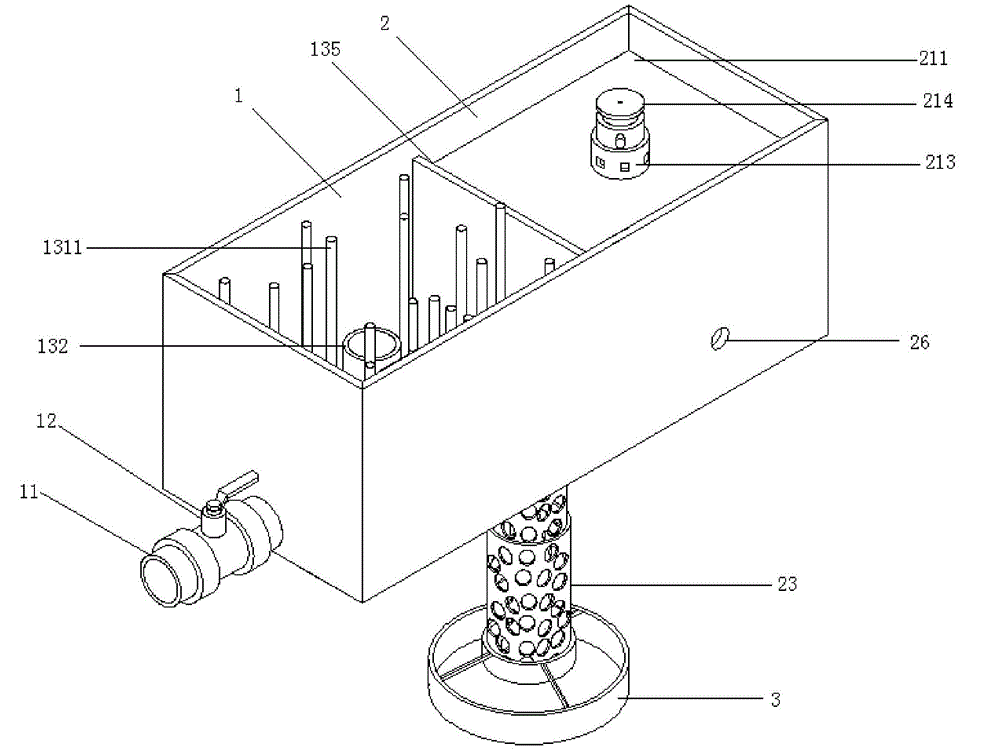

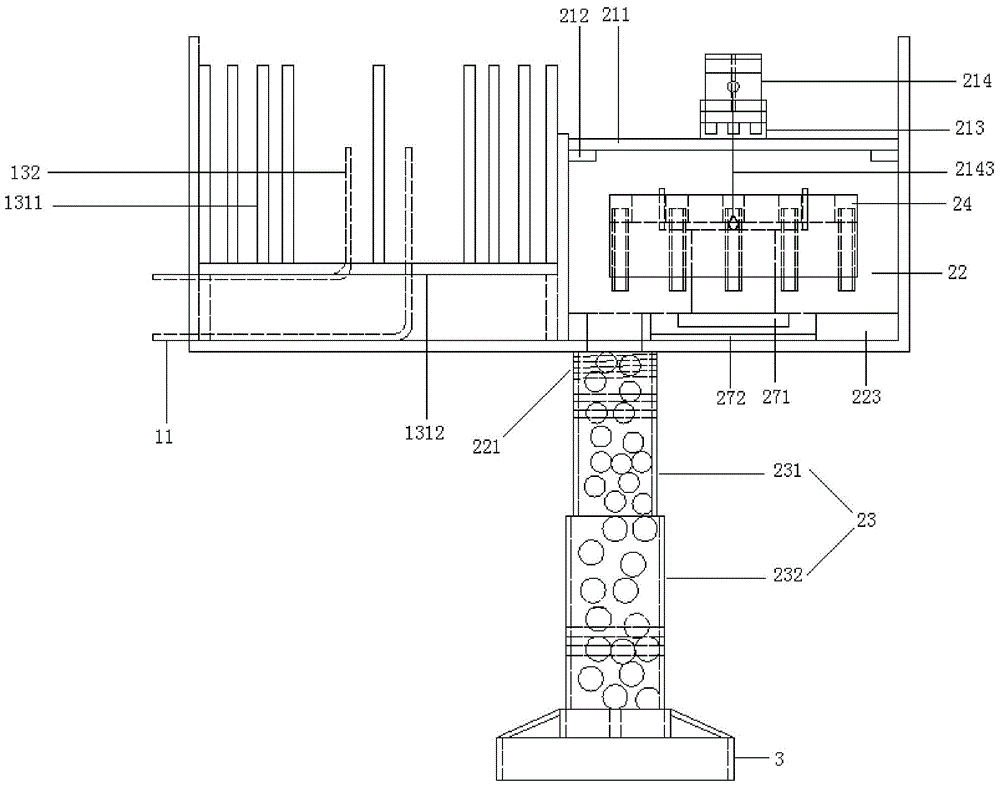

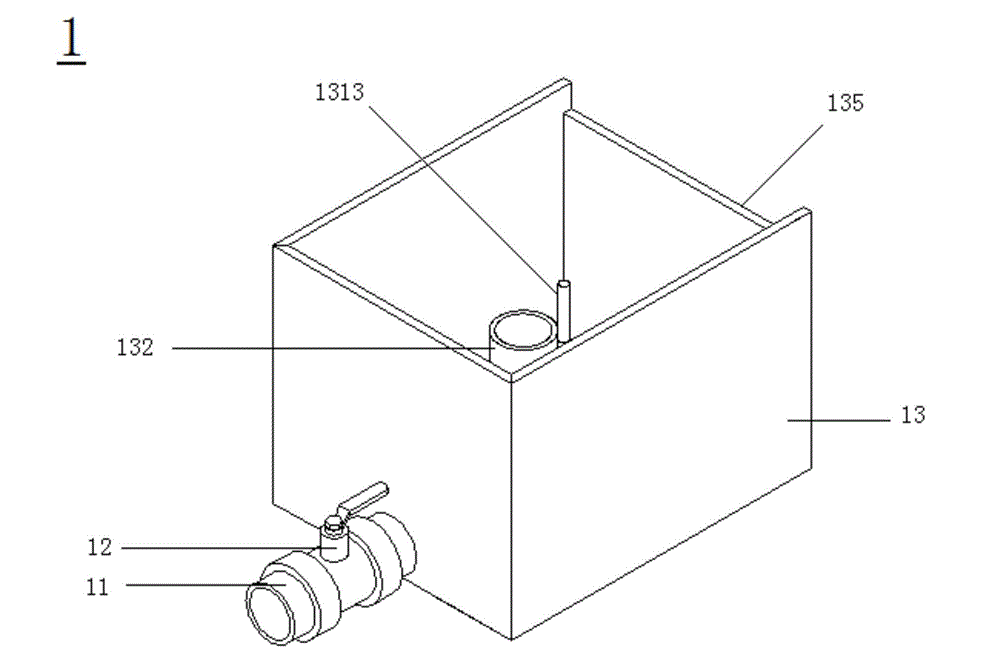

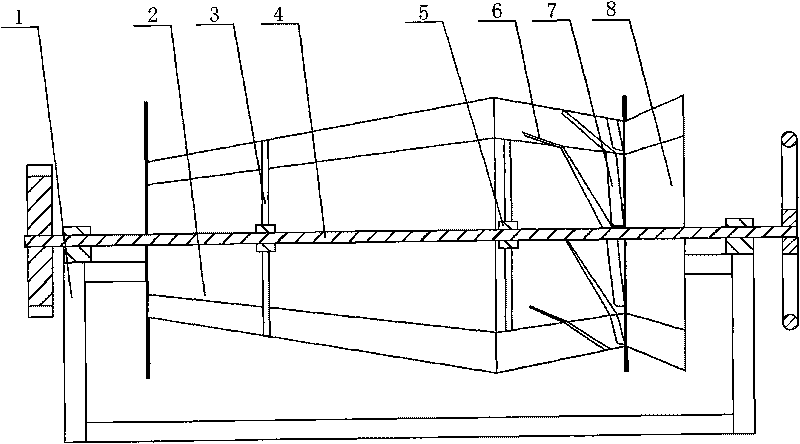

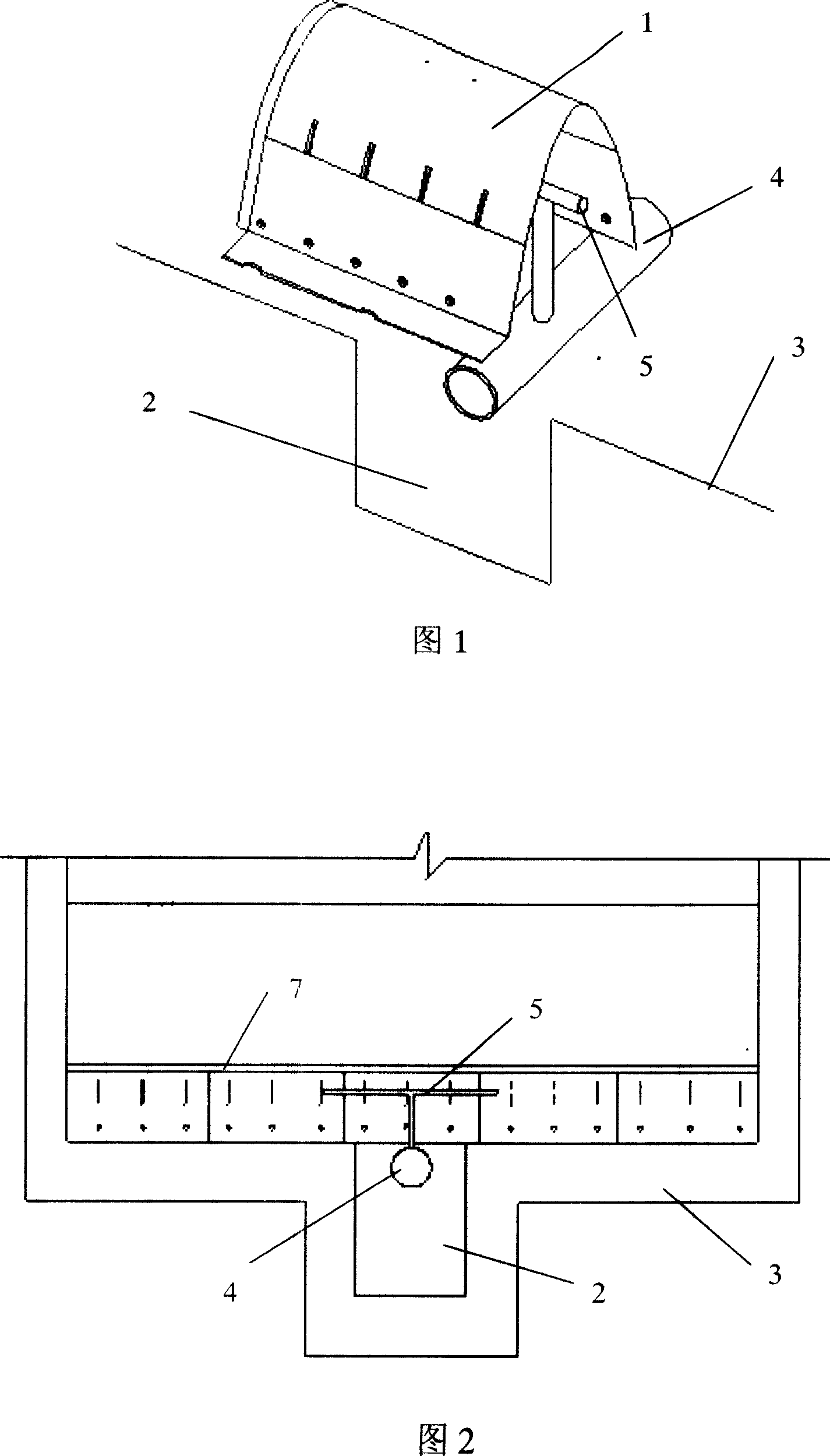

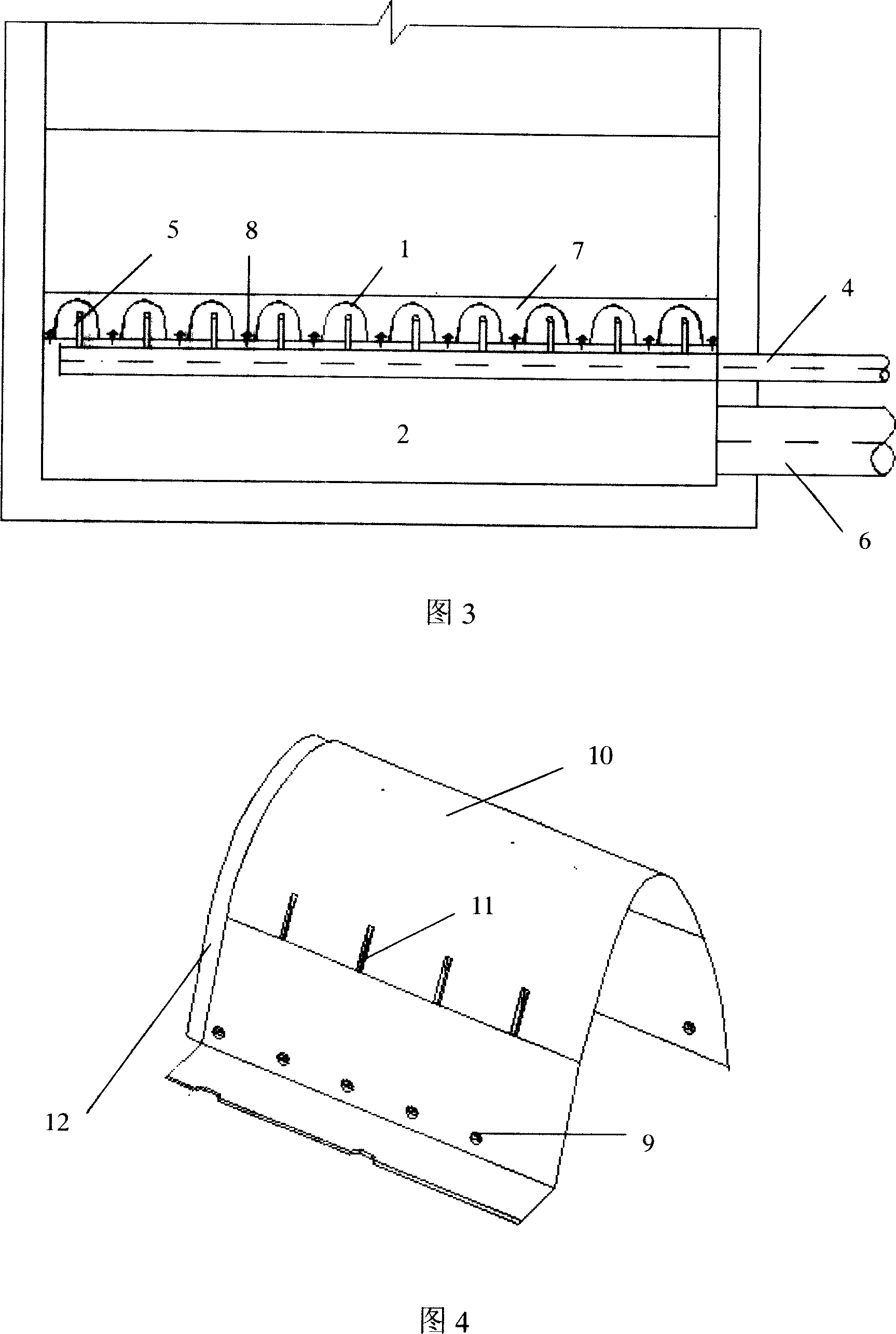

Liquid-distributing device for falling-film evaporator

ActiveCN102410773AReduce resistanceIncrease resistanceHeat exchanger casingsRefrigerant distributionEngineering

The invention relates to a liquid-distributing device for a falling-film evaporator used for a refrigerating system. The liquid-distributing device comprises a liquid inlet pipe, a flow branching pool, a flow-guiding pipe, a porous liquid-distributing pipe and a packing tank, wherein the liquid inlet pipe is connected with the flow branching pool; the flow branching pool is connected with the flow-guiding pipe; the flow-guiding pipe is connected with the porous liquid-distributing pipe; the porous liquid-distributing pipe is arranged in the packing tank; and a plurality of liquid-distributingholes are formed on a base plate of the packing tank. The evenness of refrigerating fluid distribution is promoted by the liquid-distributing device provided by the invention, thereby being capable of evenly distributing refrigerating fluid along a radial direction and a length direction of a heat exchange pipe bundle, avoiding the generation of a local drying phenomenon, reducing a demand on horizontality during a mounting process of a refrigerating machine set, efficiently promoting a coefficient of heat transfer of the falling-film evaporator, saving space and capitalized cost, and achieving higher applicability.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

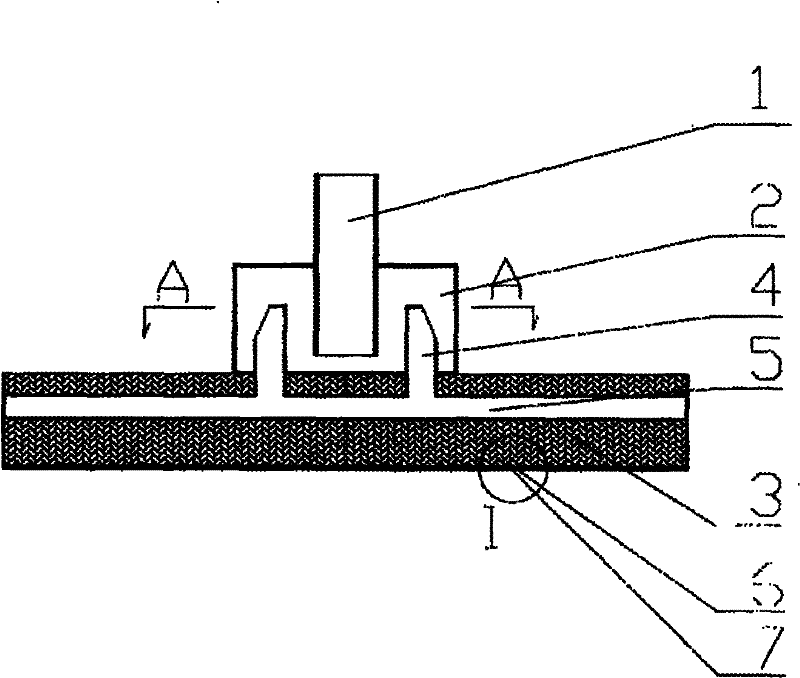

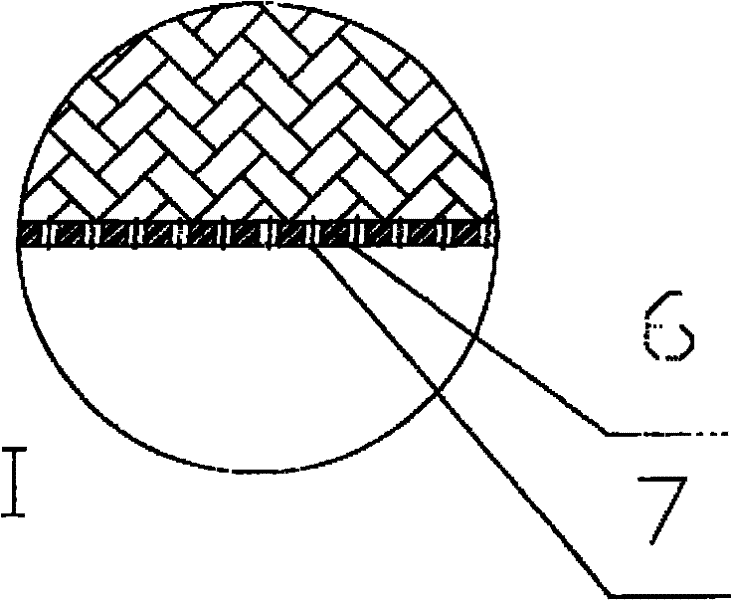

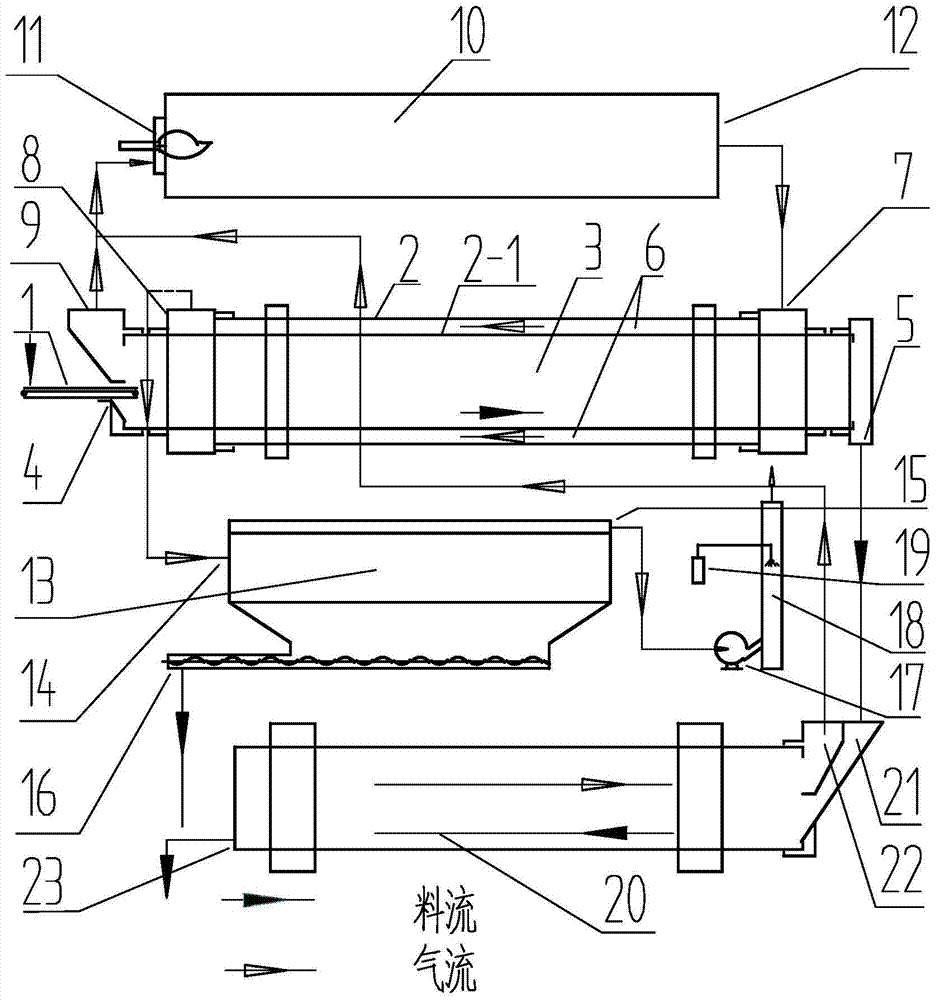

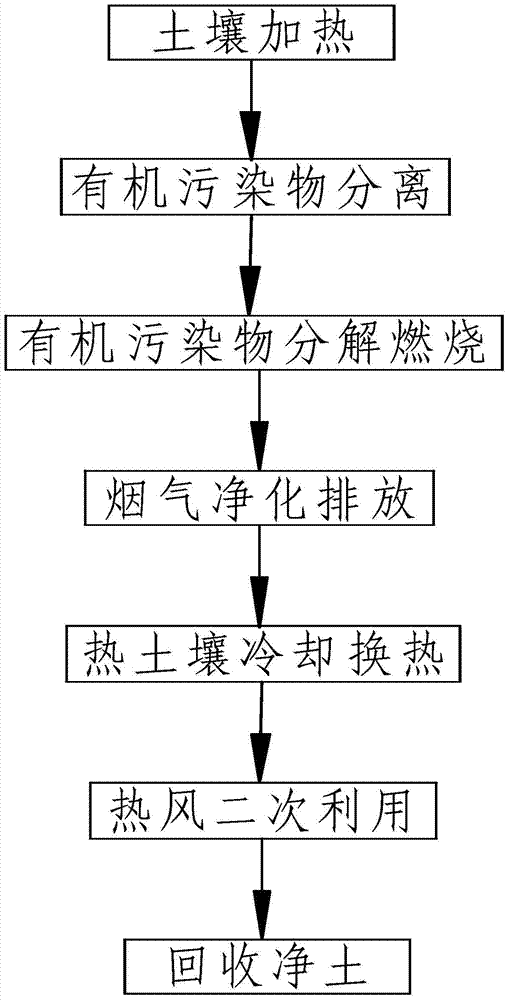

Organically-polluted soil remediation method

ActiveCN103495598AAchieve the purpose of repairPrevent leakageContaminated soil reclamationDesorptionEngineering

The invention discloses an organically-polluted soil remediation method which refers to a conveyer, a rotary kiln, a roasting furnace wall, a roasting chamber, a material inlet, a material outlet, a heating channel, a heating channel heat inlet, a heating channel heat outlet, a polluting gas outlet, a combustion furnace, a combustion furnace gas inlet, a combustion furnace heat outlet, a bag deduster, a bag deduster air inlet, a bag deduster smoke outlet, a soil particle outlet, an exhaust fan, a chimney, a deacidification device, a cooler, a cooler feed port, a cooler hot air outlet and a cooler discharge port. Since indirect heating desorption is adopted, hot air and soil are not in direct contact, energy consumption is low, desorption efficiency is high, and the soil can be thoroughly remedied; separated organic pollutants enter the combustion furnace to be completely combusted and decomposed by enriched oxygen, as a result, exhausted air quantity is small, secondary pollution is not caused, energy is saved, efficiency is improved, and investment is low.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

Binding method of rotary target material

InactiveCN110804726AReduce labor intensityLow proficiency requirementVacuum evaporation coatingSputtering coatingIndiumTitanium

The invention relates to a binding method of a rotary target material. The method includes the steps of performing roughening treatment on a target material and a titanium pipe, performing metallization treatment on the target material and the titanium pipe correspondingly, evenly coating the target material and the titanium pipe with a layer of scaling powder, assembling the target material and the titanium pipe, starting a heating device, removing an indium liquid oxidized film from an indium groove, switching on an indium pipeline valve so that indium liquid can slowly fulfill a whole weldjoint and an indium pool from the bottom, starting to perform segmented cooling on the target material, and finally cooling to the room temperature so as to complete the binding process of the whole target material. By means of the binding mode of the whole target material, the binding work of multiple segments of the target material can be simply and efficiently completed. The binding method hasthe advantages that no high-temperature assembling is needed, the assembling time is not strictly controlled, the automation level is high, the requirements for the labor intensity of workers and theproficiency of operation of personnel are not high, and the welding rate and welding quality are quite high.

Owner:GUANGXI CRYSTAL UNION PHOTOELECTRIC MATERIALS CO LTD

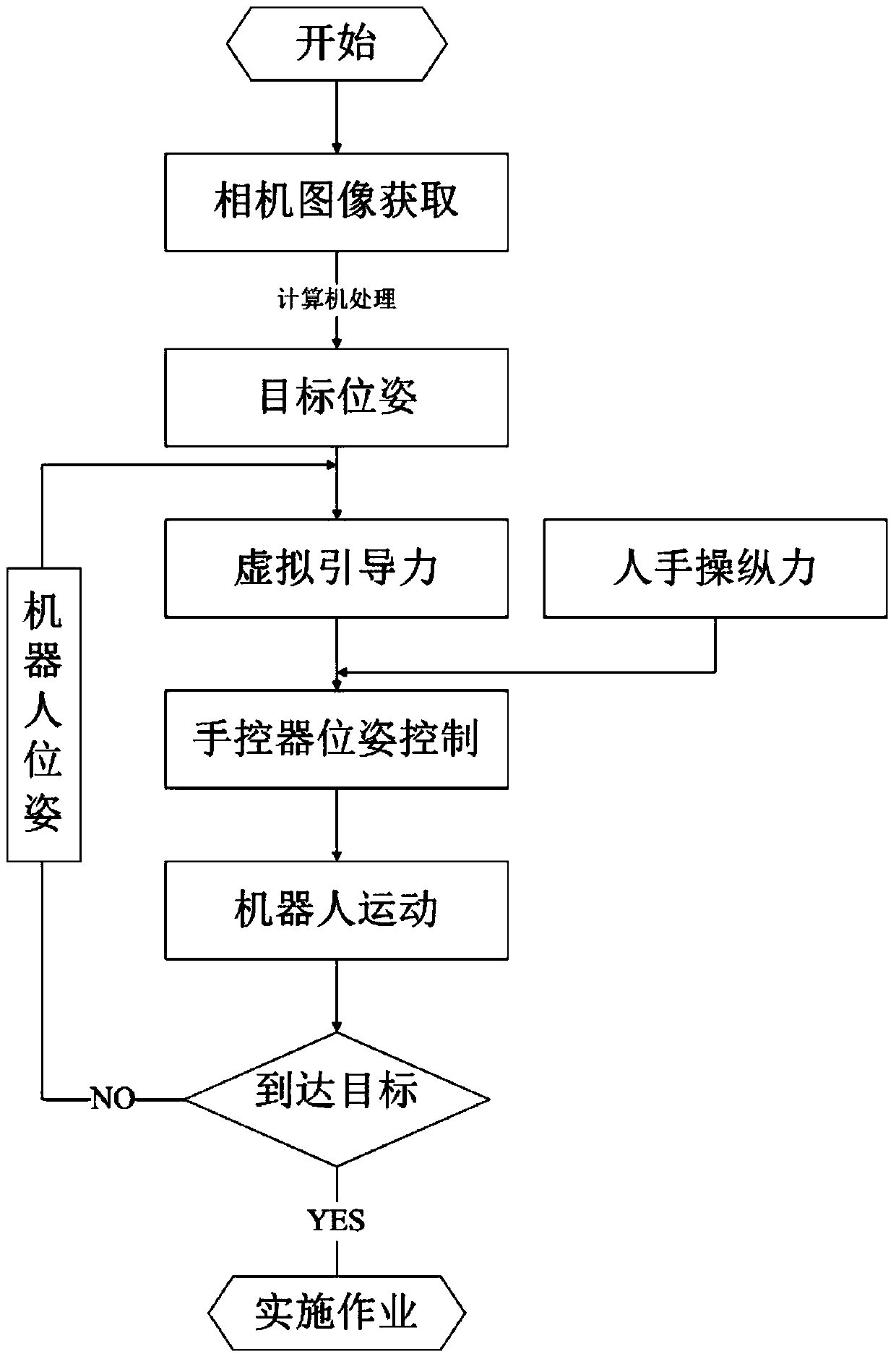

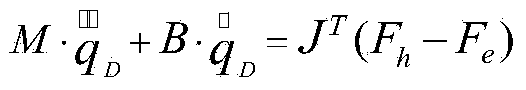

Robot hand controller shared control method based on force fusion

InactiveCN103991077ALow proficiency requirementImplement navigationManipulatorPID controllerHuman intelligence

The invention provides a hand controller shared control method based on force fusion. The method includes the steps that first, a target object serves as guidance, an operator manipulates a hand controller by human hands to control a robot to move through intelligent decision of the operator; meanwhile, operation scene image data are acquired through a stereoscopic vision technology, a three-dimensional environment is reconstructed in real time, virtual guiding force for making the robot approach a target independently is constructed with the target object as the guidance, the hand controller is guided through the virtual force to control the robot to move, the operating force of the operator and the virtual guiding force of the target object are fused, the hand controller and motion of the robot are controlled through the fused force, and thus the robot can approach the target object under the joint action of machine intelligence and human intelligence, and the operation process is completed. Through the robot hand controller shared control method based on force fusion, human intelligence and machine intelligence can be effectively combined, and safe and fast operation is guaranteed.

Owner:JILIN UNIV

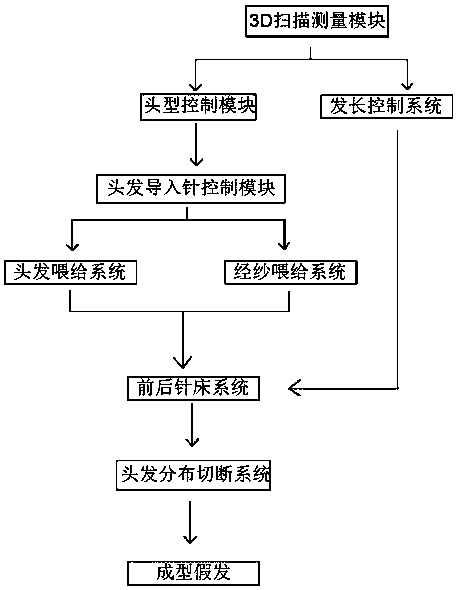

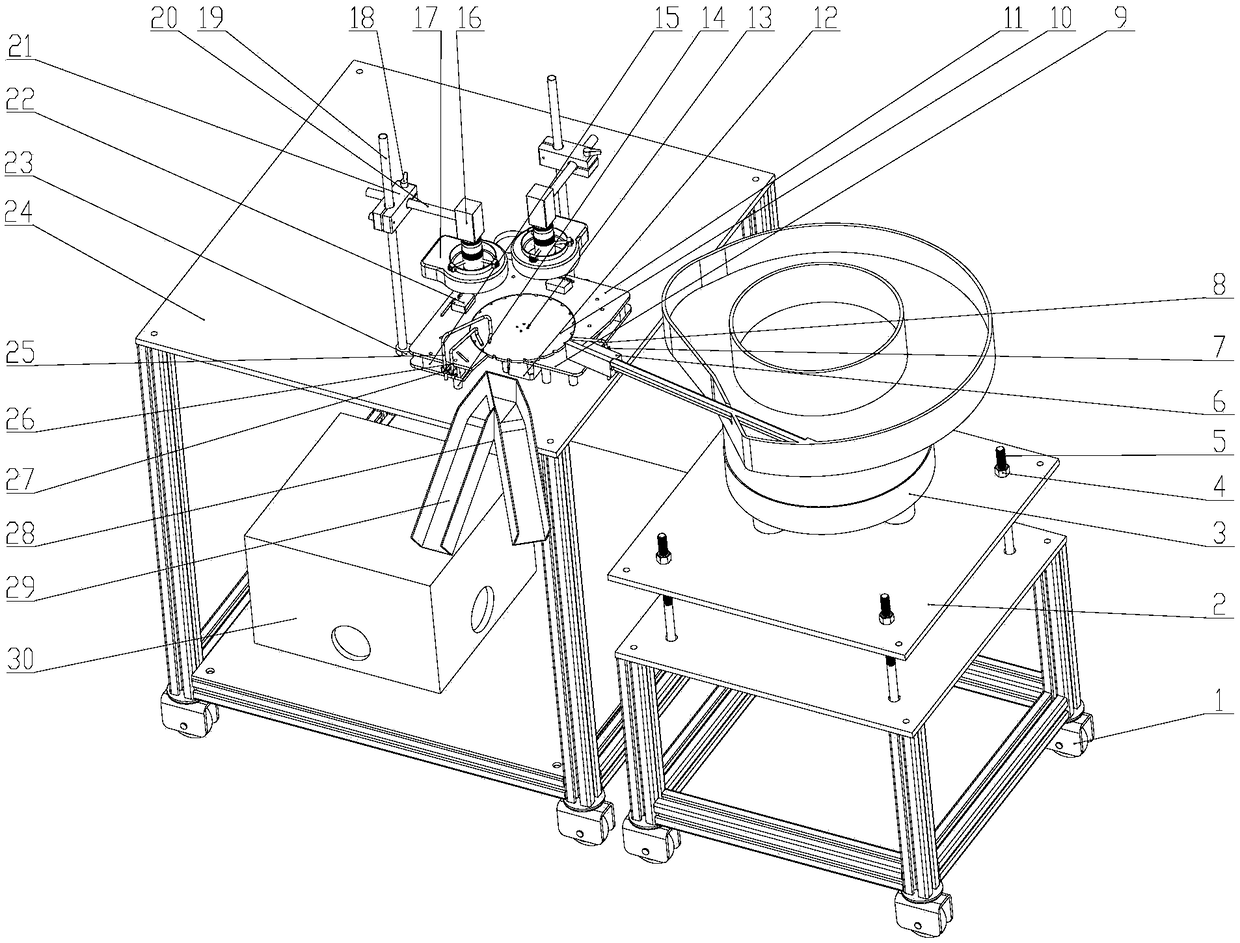

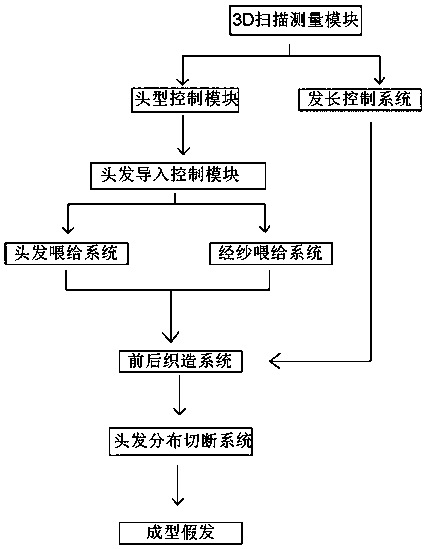

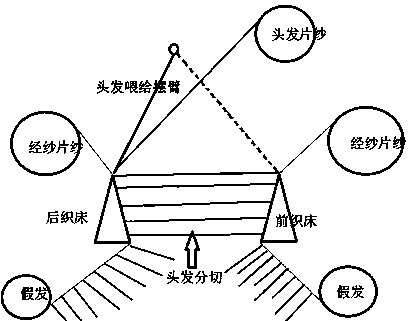

Intelligent 3D wig preparation method and equipment

The invention relates to the technical field of wig preparation, in particular to an intelligent 3D wig preparation method and equipment. The equipment comprises a 3D scanning measurement module, a head type control module, a hair length control module, a hair distribution cutting system, a warp feeding system, a hair feeding system, a hair introduction needle control module, and a front and rearneedle bed system. The equipment combines 3D scanning measurement and manual parameter input, so that a customer can freely select the needed wig model, and the free choice right of the customer is increased; meanwhile, the equipment adopts a semi-automatic control system, the number of workers required is greatly reduced, the requirements for proficiency and quality of the workers are reduced, and the problems of low processing efficiency and high labor costs are solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

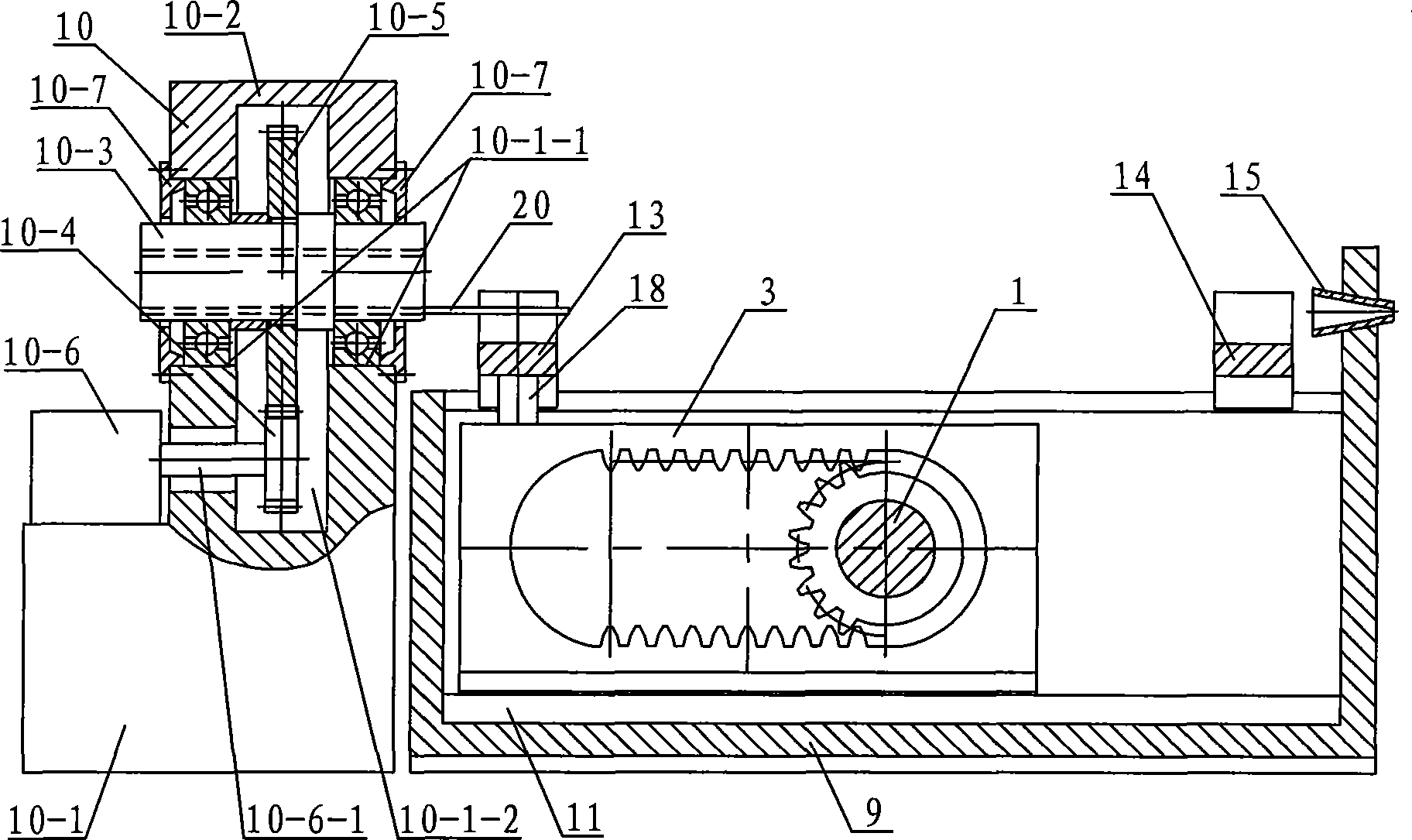

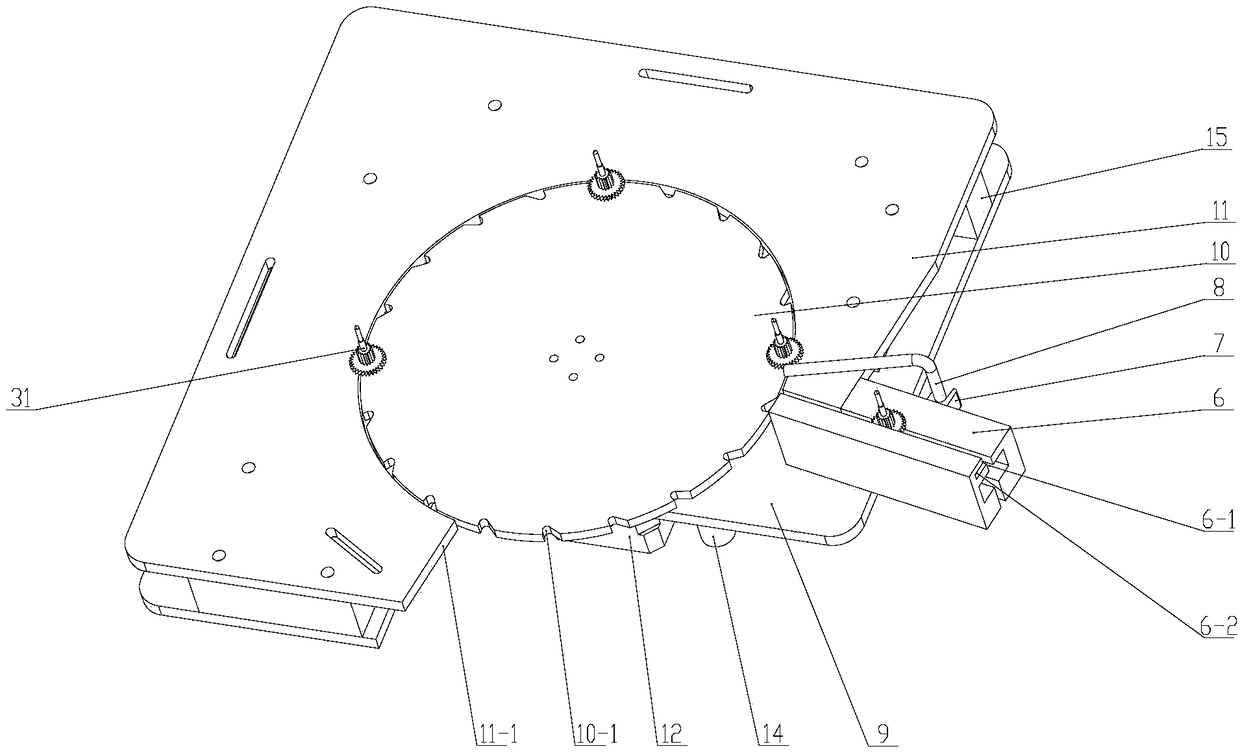

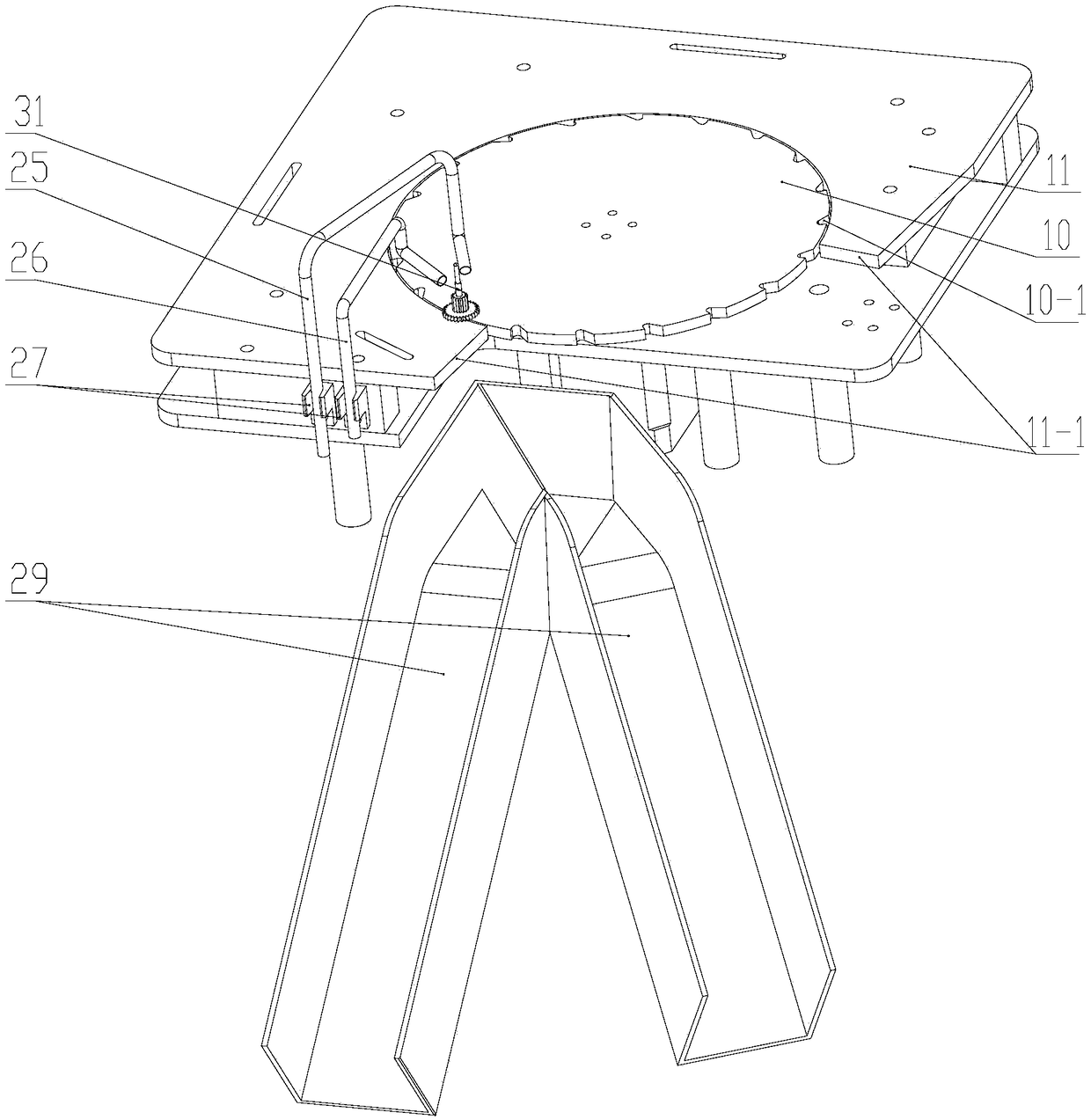

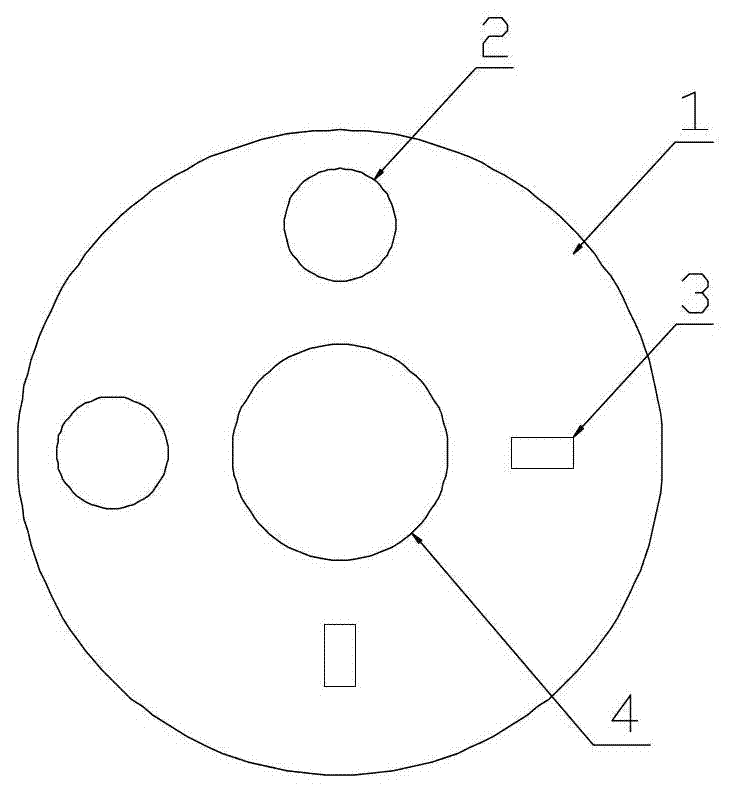

Appearance defect detection apparatus for small-modulus gear with shaft

InactiveCN108387590ALow technical requirementsLow proficiency requirementOptically investigating flaws/contaminationSortingCircular discVisual perception

The invention relates to an appearance defect detection apparatus for a small-modulus gear with a shaft. The appearance defect detection apparatus comprises a gear transferring disc mechanism, a gearfeeding mechanism, a visual detection mechanism and a gear removal mechanism, wherein the gear feeding mechanism, the visual detection mechanism and the gear removal mechanism are circumferentially distributed around the gear transferring disc mechanism, the gear feeding mechanism enables the gear with the shaft to enter the gear transferring disc mechanism in a state that the axial direction is in the vertical direction, the gear with the shaft is transferred by the gear transferring disc mechanism to successively pass through the visual detection mechanism and the gear removal mechanism, andthe gear removal mechanism sorts and blanks the gear with the shaft according to a gear shape visual detection result of the visual detection mechanism. Compared with the prior art, by adopting an automatic feeding way, a visual detection way and an automatic removal way, the appearance defect detection apparatus is high in accuracy, low in power consumption, capable of solving the problems thatthe gear detection efficiency is low, and one set of devices is suitable for detecting a product and the like, capable of realizing the rapid and automatic detection, and widely applicable to the appearance defect detection of various small-modulus gears with the shaft.

Owner:FUZHOU UNIV

Water-flow air-breathing oxygenation and purification integrated energy-saving apparatus

The invention discloses a water-flow air-breathing oxygenation and purification integrated energy-saving apparatus which mainly includes a purification system and an oxygenation system. By means of the water-flow air-breathing oxygenation and purification integrated energy-saving apparatus, a method, in which water purification and oxygenation are separated, generally employed for feeding aquarium fish in household at present is changed. An oxygenation pump is removed and functions of oxygenation and purification can be achieved just by connecting a proper water pump to the apparatus. The water-flow air-breathing oxygenation and purification integrated energy-saving apparatus allows full contact between water and pumped air so that dissolved oxygen in water can satisfy survival demand of the aquarium fish in a certain amount. The water-flow air-breathing oxygenation and purification integrated energy-saving apparatus can reduce electricity consumption and electromagnetic pollution, can achieve water filtration, can provide required environment for subsistence and reproduction of nitrifying bacteria and can maintain water in a fish tank to be clear easily.

Owner:EAST CHINA NORMAL UNIV

Semi-automatic stacking method for power battery core

ActiveCN102201598ALow costGuaranteed positioning accuracyFinal product manufactureElectrolyte accumulators manufacturePower batterySemi automatic

The invention relates to a semi-automatic stacking method and device for a power battery core. The semi-automatic stacking method comprises the following steps: (a) arranging a substrate-layer diaphragm; (2) stacking a first cathode plate; (3) winding a first diaphragm; (4) stacking a first anode plate; (5) winding a second diaphragm; (6) repeating the steps from the steps (2) to the step (5) to reach the preset numbers of plates and layers; (7) taking out the laminated core, wherein the step (3) and the step (5) are performed automatically and other steps are performed manually. A diaphragm winding part of the device controls a servo motor through a foot switch; a photoelectric eye photosensitive sheet is used for controlling the location of a diaphragm winding roller; left and right manual suckers can suck electrode plates in cathode plate box and a anode plate box which are arranged on the left and right sides respectively through a vacuum suction plate on the basis of vacuum generated by a vacuum valve; and then the electrode plates are stacked on the surface with wound diaphragms, thus, the plate stacking is finished; and the diaphragm winding part rotates to the same side toautomatically wind diaphragms on the surface of the electrode plates. The method can control the diaphragm under basically constant tension, thereby reducing the operation intensity, facilitating model replacement and lowering the device cost.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

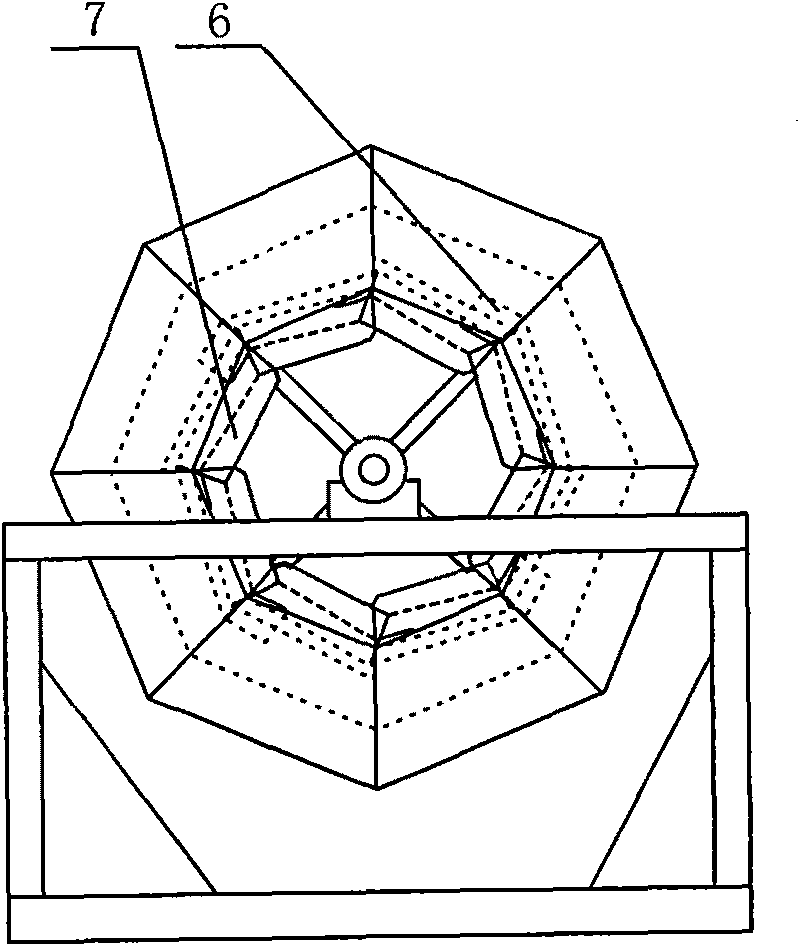

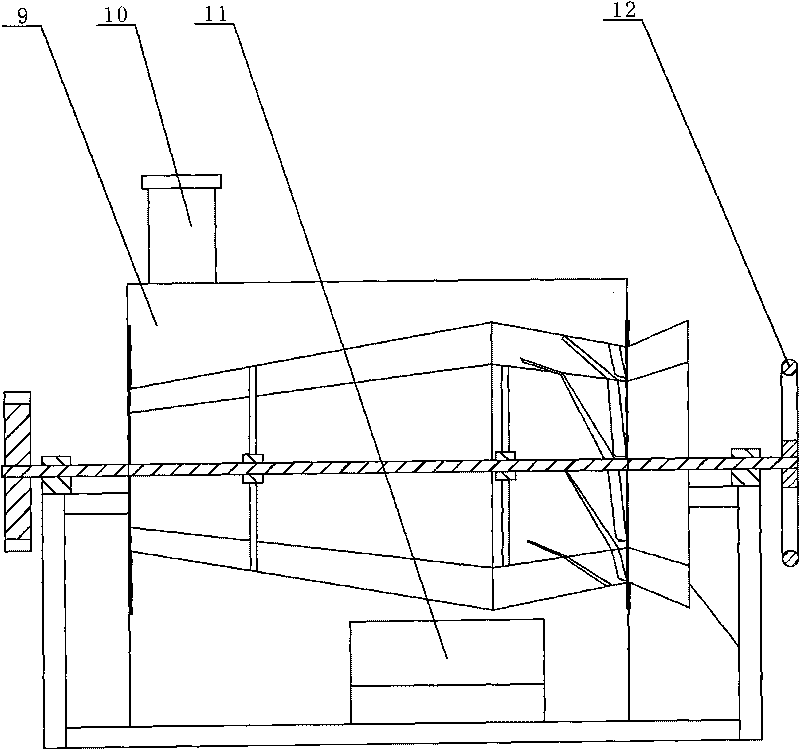

Novel roasting machine

InactiveCN101690608AEasy dischargeAvoid breakingPre-extraction tea treatmentFood treatmentHearthEngineering

The invention provides a novel roasting machine, particularly relates to the mechanical field of food processing. The mode that a revolving shaft is connected with a heating barrel through a connecting piece and a support bar is adopted, therefore the heating barrel can be made into a pyramid shape, the middle of which is raised and two ends are shrunk, and the section is octagon, thus being favor for materials to be fried fully in the heating barrel. The lower part of the raised part in the middle is used for providing with a hearth, and the thickness of materials accumulating at this part is thicker in the frying process, thus being beneficial to using heating power fully. An improved guide vane and a mixing vane not only enable the materials to be fully fried, but also can realize that materials are not clamped, the materials can not be dropped out in positive rotation, and the materials can be discharged out rapidly in reversed rotation. The heating barrel can be driven to rotate by a prime motor through a transmission gear, and further can rotate through being controlled by a hand wheel. The invention has the advantages of flexible and convenient operation, low requirement on proficiency level of the operation personnel, high fuel utilization efficiency and high production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

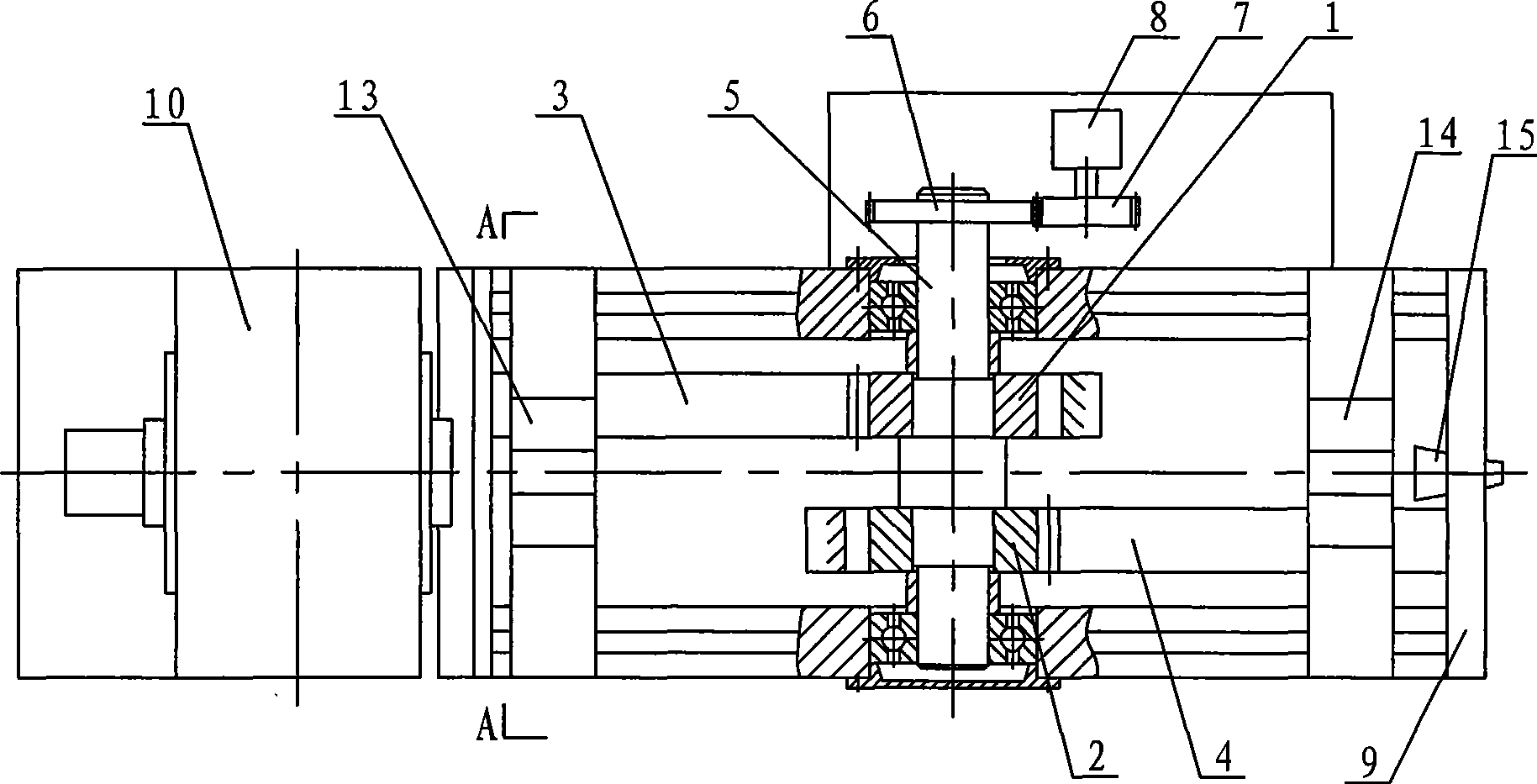

Operation device of radio frequency electrode ablation catheter handle

InactiveCN101785705AReasonable arrangementOvercome the tangle problemDiagnosticsSurgical instruments for heatingRf ablationCoupling

The invention provides an operation device of a radio frequency electrode ablation catheter handle, which relates to an operation device of a catheter handle. The invention solves the problems that in the catheter intervene type operation, the intervene process of the radio frequency electrode ablation catheter needs the manual operation of a doctor, so the operation difficulty is great, the precision is not easy to control, and the doctor can not avoid the radiation. An outer sun wheel is arranged on an inner sun wheel shaft through an outer sun wheel connecting disc, a planetary wheel is arranged between the outer sun wheel and an inner sun wheel, outer teeth of the planetary wheel are respectively engaged with inner teeth of the outer sun wheel and outer teeth of the inner sun wheel, a ball nut is arranged on a lead screw, the other end of the planetary wheel shaft is connected with one end of the lead screw through a sleeve barrel shaft coupler, and a slide button clamping and grasping element of the catheter handle is fixed on the ball nut. The invention controls the rotation of the radio frequency electrode ablation catheter handle and the slide of the slide button on the handle through a differential planetary wheel system mechanism, the deflection rotation of the far end of the catheter connected with the handle is further realized, the operation and the control are accurate and convenient, and in addition, the operation is easy.

Owner:HARBIN INST OF TECH

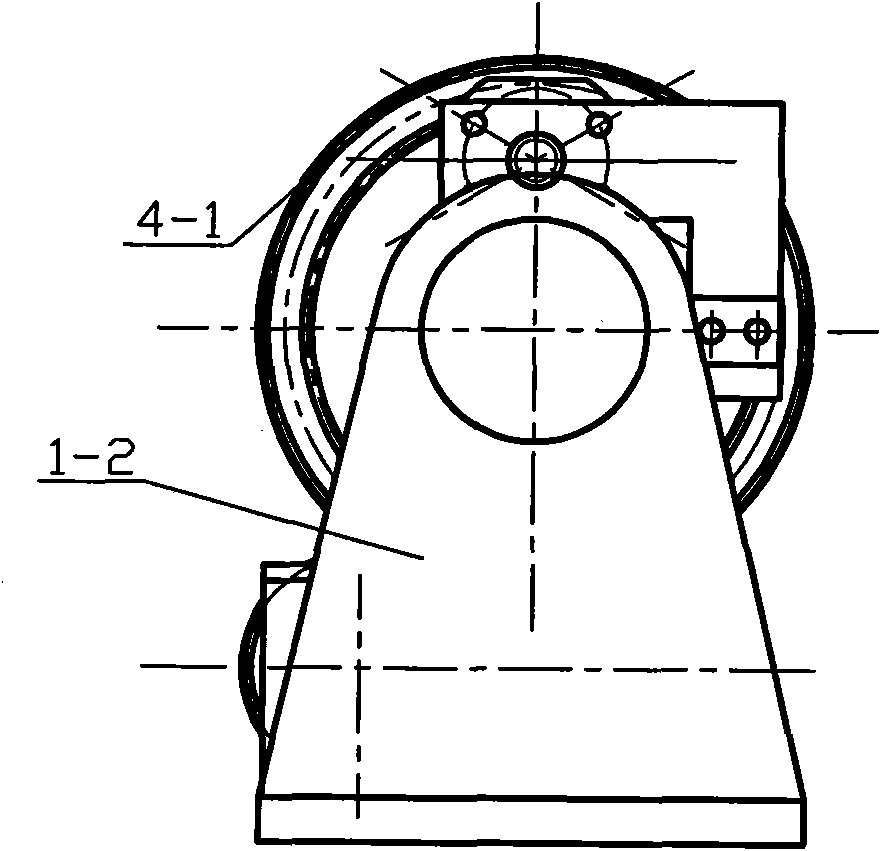

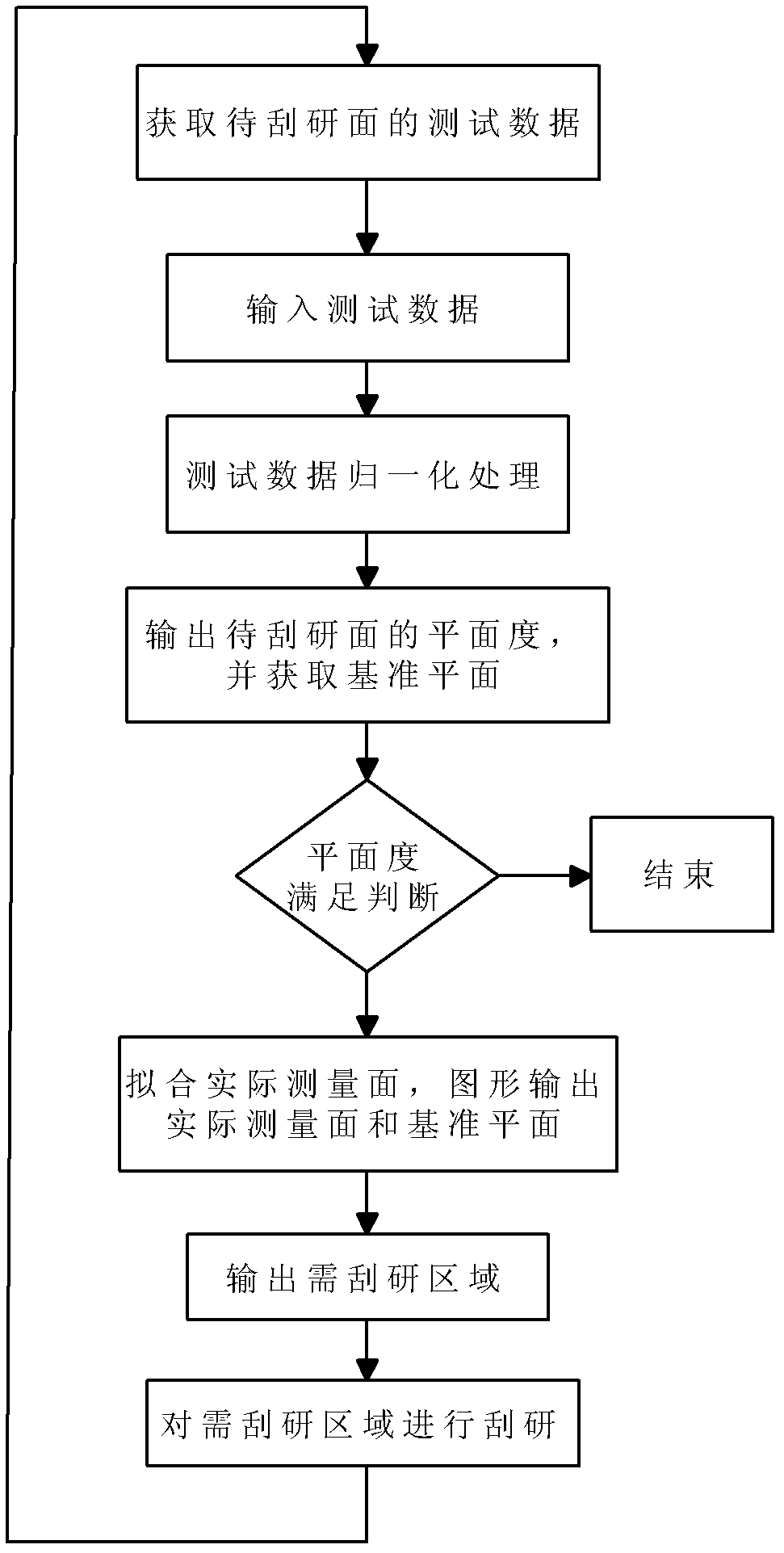

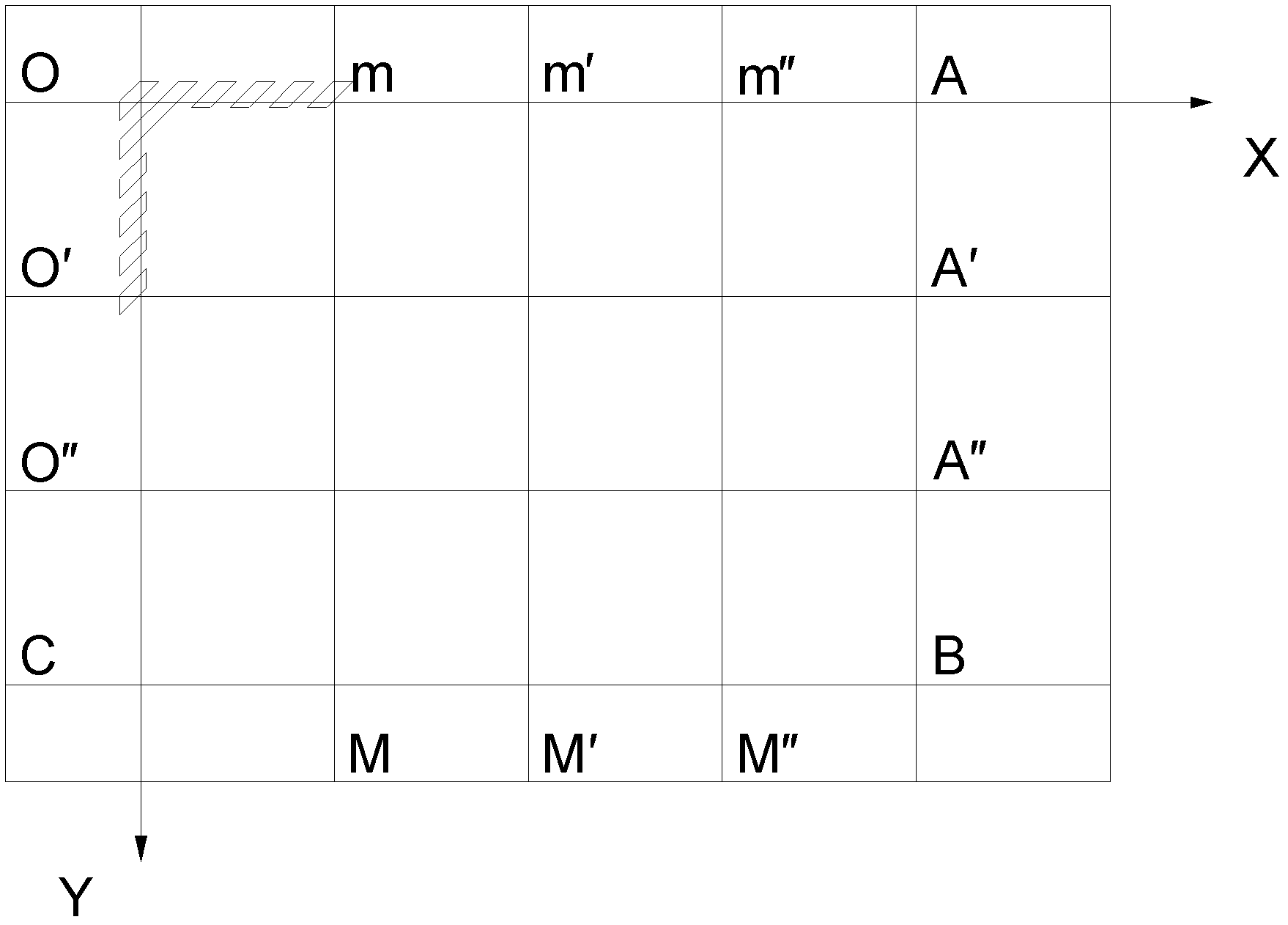

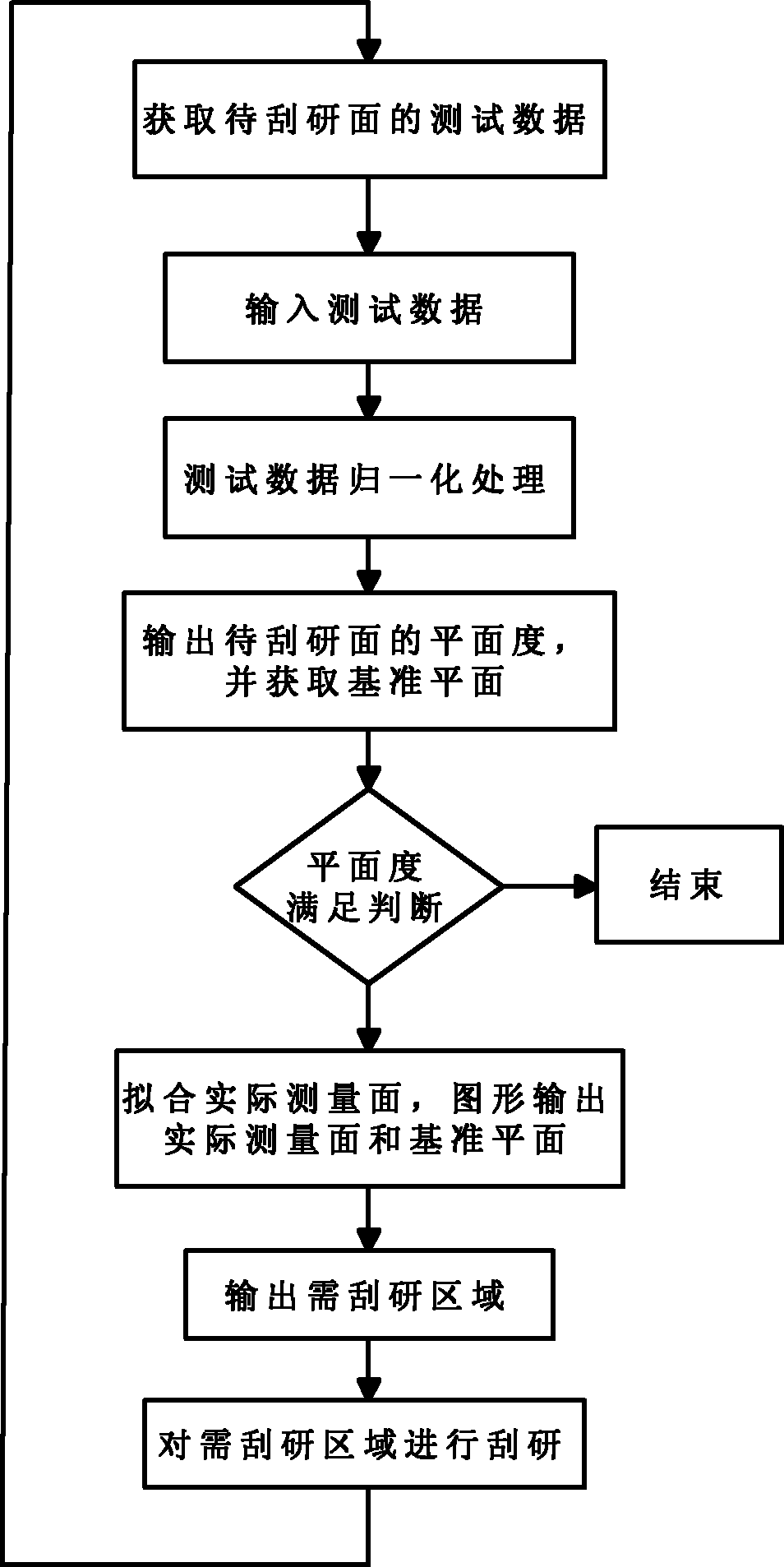

Plane scraping method based on flatness measurement

InactiveCN102632456ALow proficiency requirementShorten the timeGrinding feed controlGrinding machinesGraphicsMechanical engineering

The invention discloses a plane scraping method based on flatness measurement. The plane scraping method includes acquiring a plurality of points on a surface to be scraped at first; computing the flatness of the surface to be scraped by a visualized software capable of processing and fitting data; then judging whether the surface needs to be scraped or not according to the flatness of the surface to be scraped; fitting a graph of the surface to be scraped and a graph of a reference surface of the surface to be scraped according to the multiple points on the surface to be scraped if the surface needs to be scraped; outputting regions which are higher than the reference surface and are required to be scraped on the surface to be scraped; and scraping the outputted regions required to be scraped by an operator by the aid of a scraping plate. Accordingly, only the portions, higher than the reference surface, on the surface to be scraped need to be scraped, most of areas of the surface to be scraped do not need to be scraped, scraping time is saved, scraping pertinence is improved, scraping efficiency is also enhanced, and requirements on proficiency of the scraping operator are lowered.

Owner:SUZHOU JIANG YUAN PRECISION MACHINERY +1

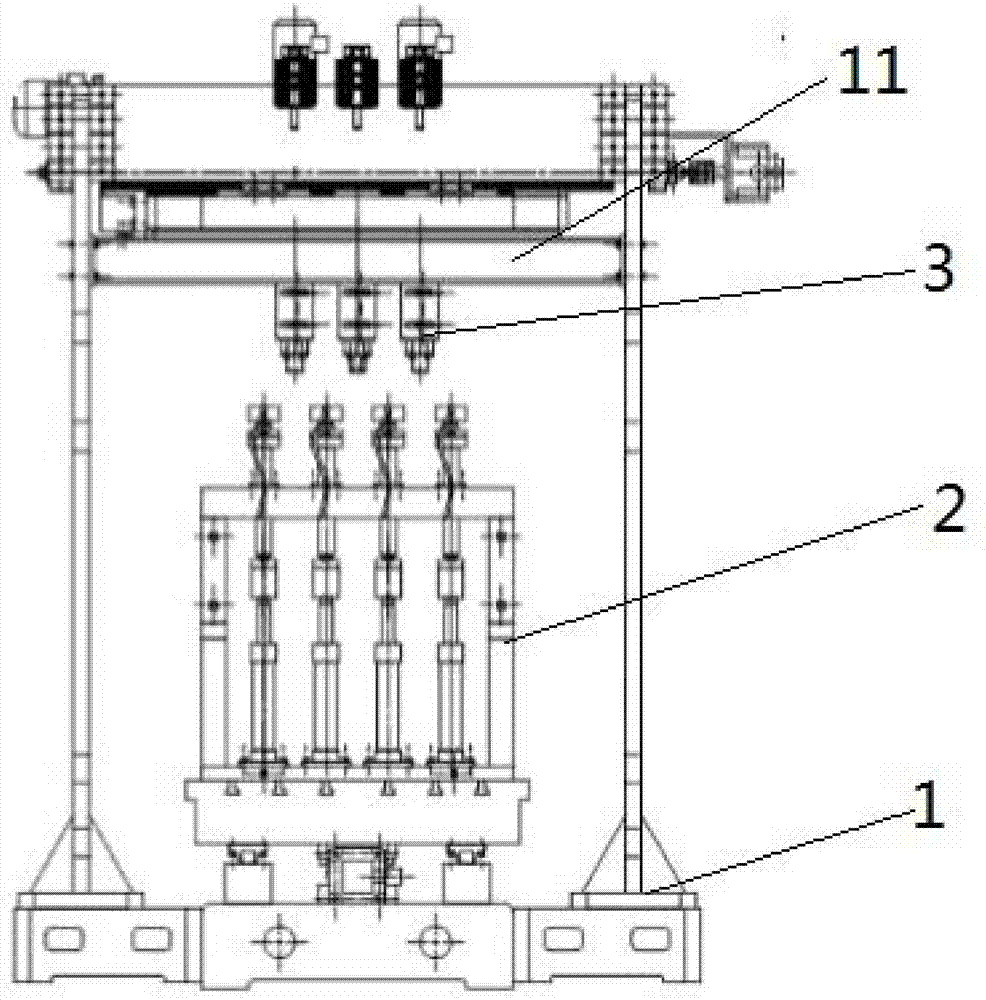

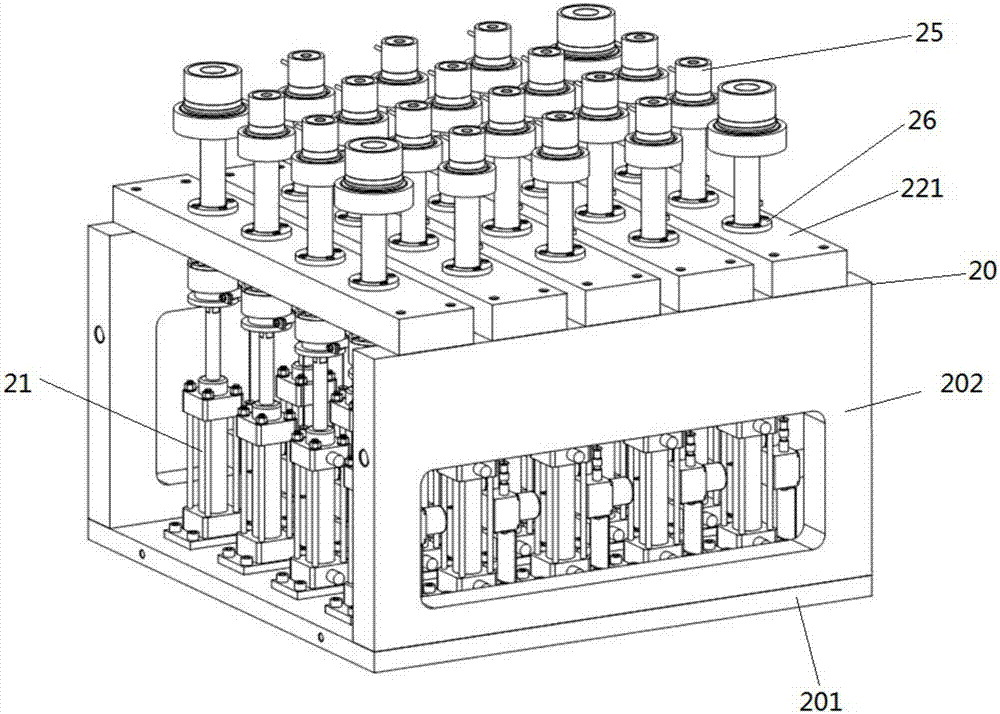

Complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and forming method

InactiveCN107052096AImprove processing qualityLow proficiency requirementMetal-working feeding devicesPositioning devicesEngineeringOperability

The invention belongs to the technical field of complex curved-surface steel sheet forming and discloses complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and a forming method. The forming equipment comprises a forming machine tool body, a supporting and adsorption device for performing step-by-step progressive machining and forming on a metal sheet and a tool pressing head set. The supporting and adsorption device comprises a supporting frame, adsorption components for adsorbing the metal sheet and supporting components for adjusting displacement of the adsorption components. The complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment is adopted for the forming method. The method comprises the following steps that a machined piece is divided into a plurality of segments, and the tool pressing head set and the supporting and adsorption device act on the two sides of all segments of the machined piece correspondingly in sequence in a progressive manner. By means of the complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and the forming method, the metal sheet of multiple shapes can be machined, the structure is stable and reliable, operability is high, machining efficiency is higher, the requirement for the skilled degree of operation workers is low, and the quality of a finished product is high.

Owner:SHENZHEN INST OF ADVANCED TECH

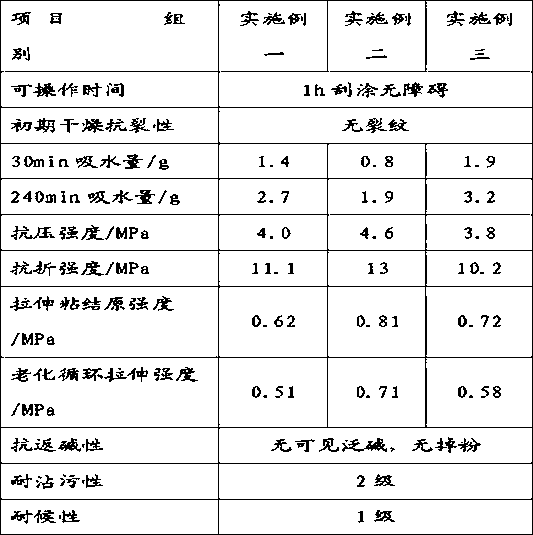

Facing mortar

The invention discloses a facing mortar, which comprises a glue powder, a thickening agent and a quartz sand, and the facing mortar comprises the following components by mass percent respectively: glue powder 8-10%, thickening agent 0.05-0.1% and quartz sand 65-91%. The invention has the advantages that the facing mortar of the present invention does not contain cement, thereby the whiskering risk is avoided, and the aberration is smaller than that of the cement based facing mortar, and the production and construction control are simple and convenient, and after 2 min of stirring at 450r / min by the mixer, the product can be used, and the construction mode is diversified, and the construction time is substantially shortened, and the requirements of construction environment and worker skill degree are lower than those of the cement based facing mortar. In addition, compared with the traditional cement facing mortar, the facing mortar of the present invention does not contain toxic substances, and the volatility is extremely low, and the product has the advantages of nontoxic side-effects of construction worker and user, moreover the compressive strength and flexural intensity are better than those of the traditional facing mortar.

Owner:北京宝辰联合科技股份有限公司

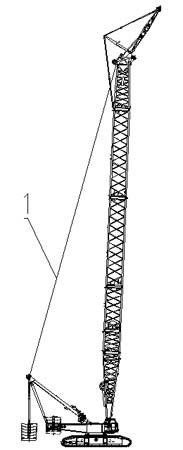

Crane, positioning system and positioning method for hoisting operation of crane and storage medium

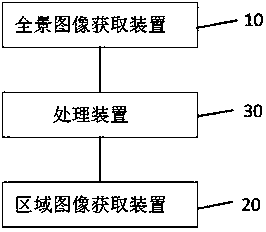

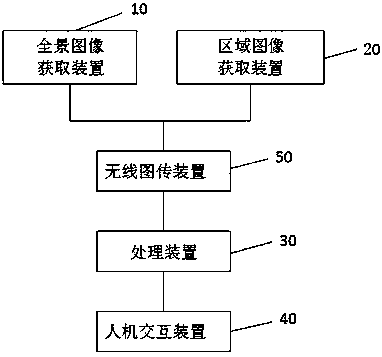

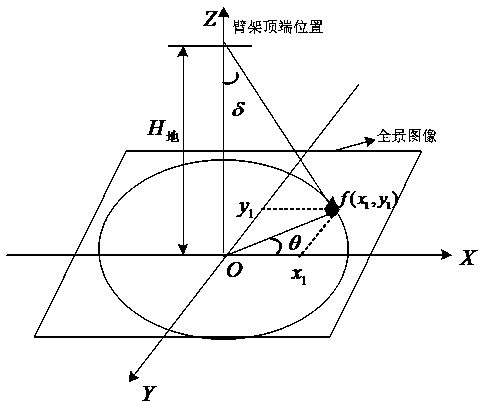

PendingCN111487610AAutomatic control movementAchieve full coverageLoad-engaging elementsRadio wave reradiation/reflectionAutomatic controlPanorama

The invention relates to the field of automatic control of cranes, and discloses a crane, a positioning system and a positioning method for the hoisting operation of the crane, and a storage medium. The positioning system comprises a panoramic image acquisition device arranged on an arm support of the crane and configured to acquire a panoramic image in a predetermined operation area; a regional image acquisition device which is arranged on the arm support; a processing device which is configured to determine an initial target position of an operation target according to the first position ofthe operation target in the panoramic image; when it is determined that the arm support of the crane moves to a preset spatial distance range of the initial target position, acquiring a regional imageof the position where the operation target is located through the regional image acquisition device with the focal length adjusted; and determining an accurate target position of the operation targetaccording to the second position of the operation target in the region image. Therefore, the full coverage and accurate positioning of a crane hoisting operation scene can be realized, the operationintensity and proficiency of operators are reduced, and the working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

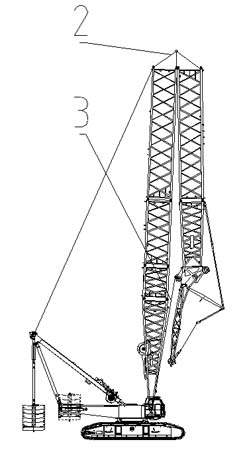

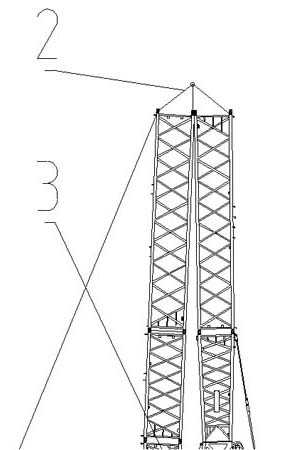

Method for lowering gravity center of crane arm support

InactiveCN101898729ALower center of gravityLow proficiency requirementCranesGravity centerRoad surface

The invention provides a method for lowering a gravity center of a crane arm support, comprising the following steps: connecting a crane pulling plate connected at the top end of the arm support to one arm section of the arm support; folding the arm support from the arm section; utilizing a bracket to connect the folded two arm supports into a whole; and finally utilizing a digging rope to vertically connect the folded arm support to the crane. The method for lowering the gravity center of the crane arm support of the invention has simple operation, effectively lowers the gravity center of the whole arm support of a crawler crane in the travelling process and improves the balanced capacity thereof, thereby effectively preventing the crane from tipping in the travelling process and lowering the requirements of the crane on travelling pavement levelness.

Owner:SHANGHAI SANY TECH

Large resistance gas distribution, medium resistance water distribution system and device for water gas back flush of filter tank

InactiveCN1962021ALow proficiency requirementImprove uniformityLoose filtering material filtersGravity filtersLow demandDistribution system

The invention relates to a system used to wash the filter pool, which will distribute gas in large resistance and distribute water in middle resistance, wherein it comprises a water distribute groove at the bottom of filter pool, a water gas distribute arc device, a gas inlet tube, and a T-shape gas distribute tube; the middle of pool bottom has a concave water distribute groove; the gas inlet tube is in the water distribute groove to extend to the end of groove; the water gas distribute arc device comprise several arc tubes mounted on the bottom and span the water distribute groove; under each row of arc tubes, the gas inlet tube is connected to one T-shaped gas distribute tube; the transverse tube of said T-shape gas distribute tube is at the upper part of arc tube. The invention has standard elements, simple installment, and low demand on the horizontal level of pool bottom. The whole installment only needs 1-2 weeks.

Owner:SHENZHEN QINGQUAN WATER IND CO LTD

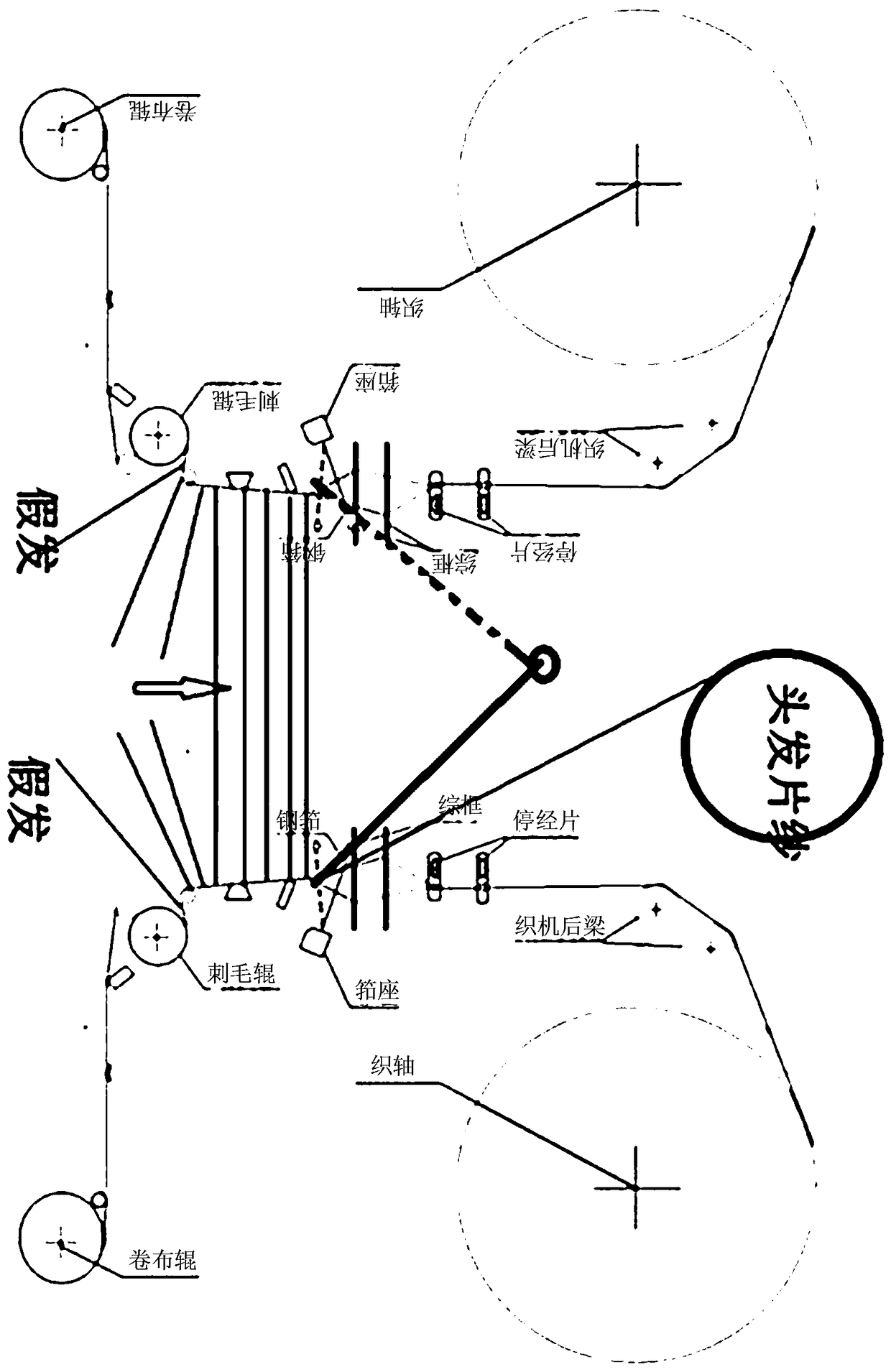

Preparation method of three-dimensional woven hair net

InactiveCN108505181AIncreased freedom of choiceReduce in quantityWigsPattern making devicesAutomatic controlAutomatic train control

The invention relates to the technical field of wig preparation, in particular to a preparation method of a three-dimensional woven hair net. According to the method, a 3D scanning measurement module,a head shape control module, a hair length control module, a hair distribution cutting module, a warp feeding system, a hair feeding system, a hair guide control module and a front-rear weaving system are involved. The preparation method combines 3D scanning measurement and manual parameter input and allows a client to freely select a required wig model, and the free selection right of the clientis enlarged; meanwhile, a self-automatic control system is adopted for the method, the number of required workers is greatly reduced, the requirements for proficiency and quality of the workers are lowered, and the problems of low processing efficiency and high labor cost are solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

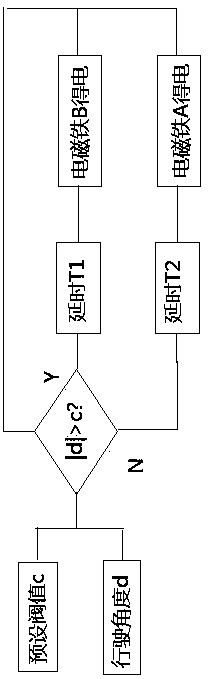

Automatic control device of agricultural machinery plow and control method

InactiveCN104914882ATroubleshooting Difficulty Using ControlsEasy to useControl using feedbackAutomatic controlAgricultural engineering

The invention provides an automatic control device of an agricultural machinery plow and a control method. The automatic control device of the agricultural machinery plow comprises a signal monitoring module, a programmable controller, a hydraulic dive module and a plow execution module; the programmable controller drives a plow in the plow execution module through the hydraulic drive module to implement deep plowing, steering and obstacle crossing actions and the like; and the signal monitoring module is used to monitor a plow state and a tractor running state and to feed the plow state and the tractor running state to the programmable controller. The automatic control method for the agricultural machinery plow comprises a plow steering automation control and plow obstacle crossing automation control. The problem that the traditional agricultural machinery has a plow using control difficulty is effectively solved, the facts that the agricultural machinery plow automatically completes deep plowing control, steering control and obstacle crossing control are achieved, use is simple, and a requirement for a driver's degree of proficiency and driver's labor intensity are greatly reduced.

Owner:HUNAN WANGDA TECH

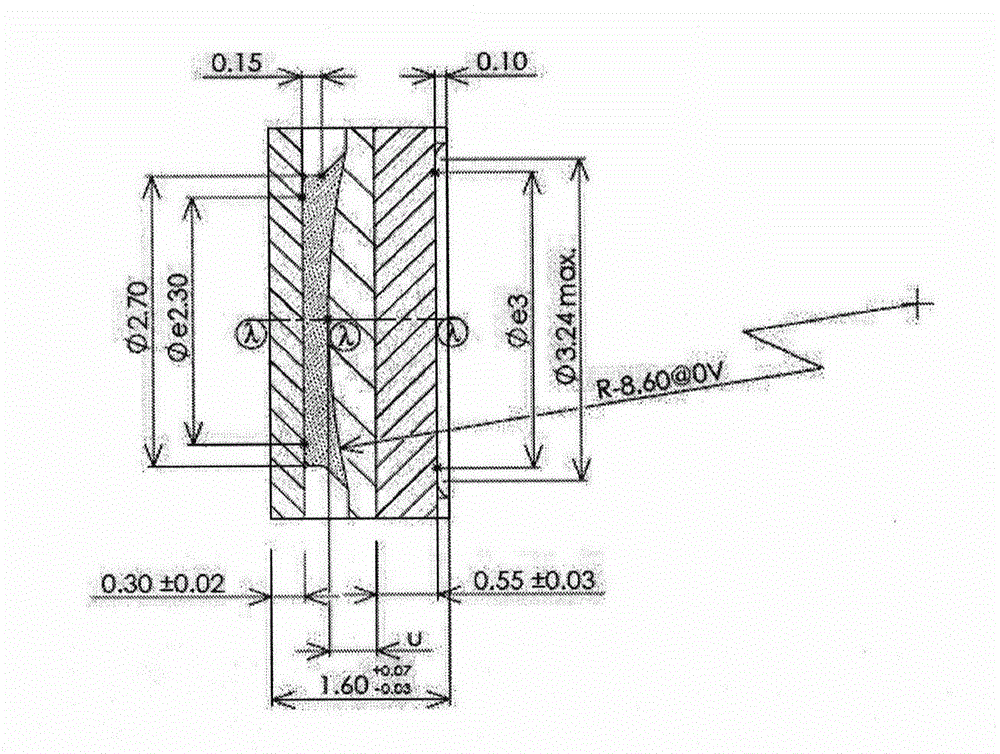

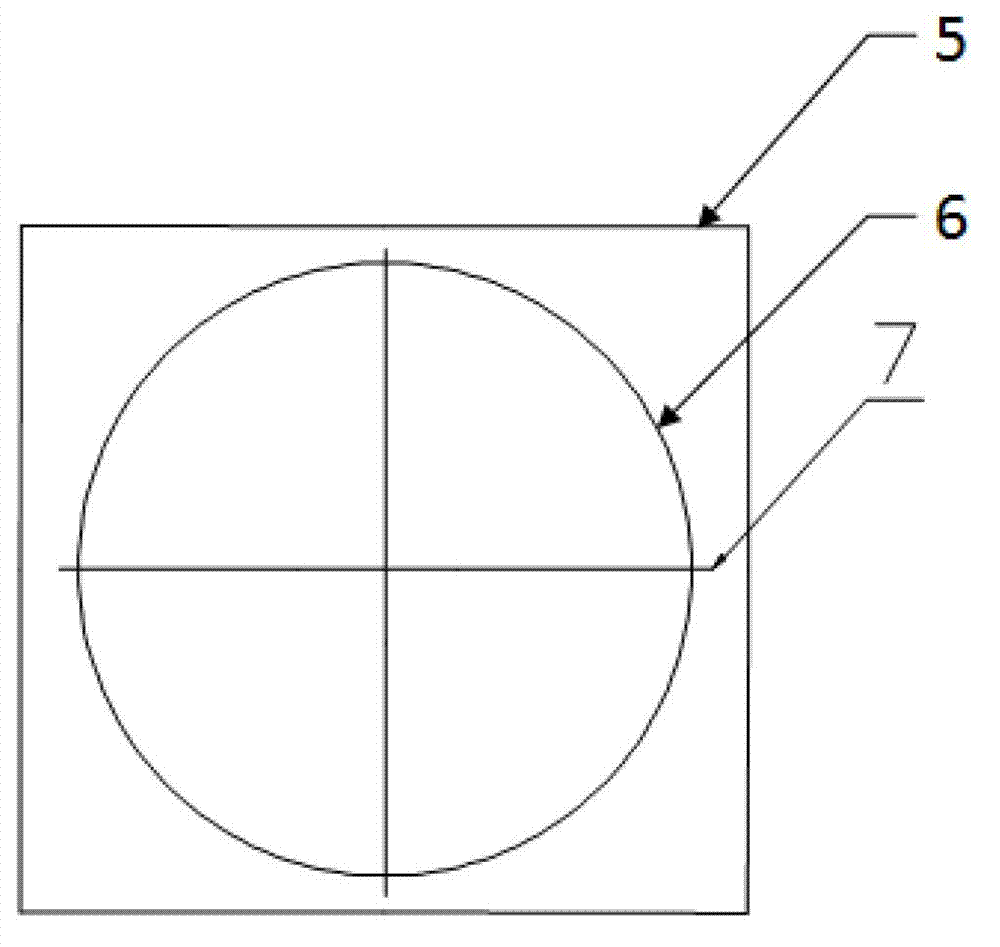

Radar liquidometer calibration device

InactiveCN105987743ALow proficiency requirementLittle effect on reflection efficiencyTesting/calibration apparatusGratingImage resolution

The invention relates to a radar liquidometer calibration device. The radar liquidometer calibration device is simple in structure, is easy to operate, is low in demand for the levelness of guide rails, and is high in resolution. The radar liquidometer calibration device includes a horizontal guide rail; the horizontal guide rail is provided with a sliding base; a metal radar wave reflection plate is hanged under the base and is used for reflecting radar wave emitted by a radar liquidometer; the base is provided with a displacement sensing disc which can synchronously rotate while the base moves on the horizontal guide rail; the displacement sensing disc is coaxially connected to a raster sensing disc; 360 gaps are evenly formed in the perimeter of the raster sensing disc; and the base is provided with a displacement pulse conversion device which is corresponding to the gaps of the e raster sensing disc.

Owner:SHENZHEN EXSAF ELECTRONICS CO LTD

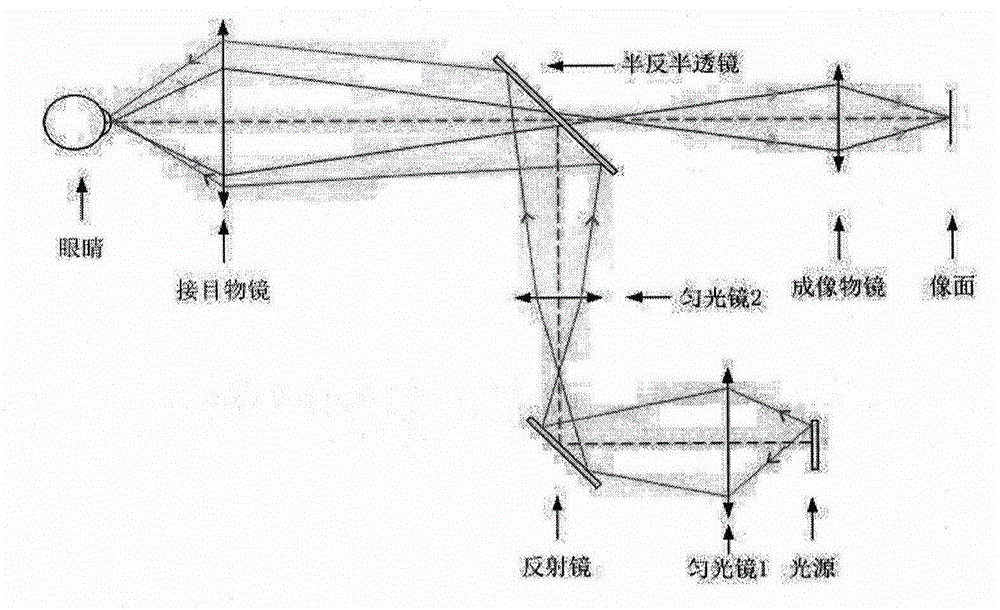

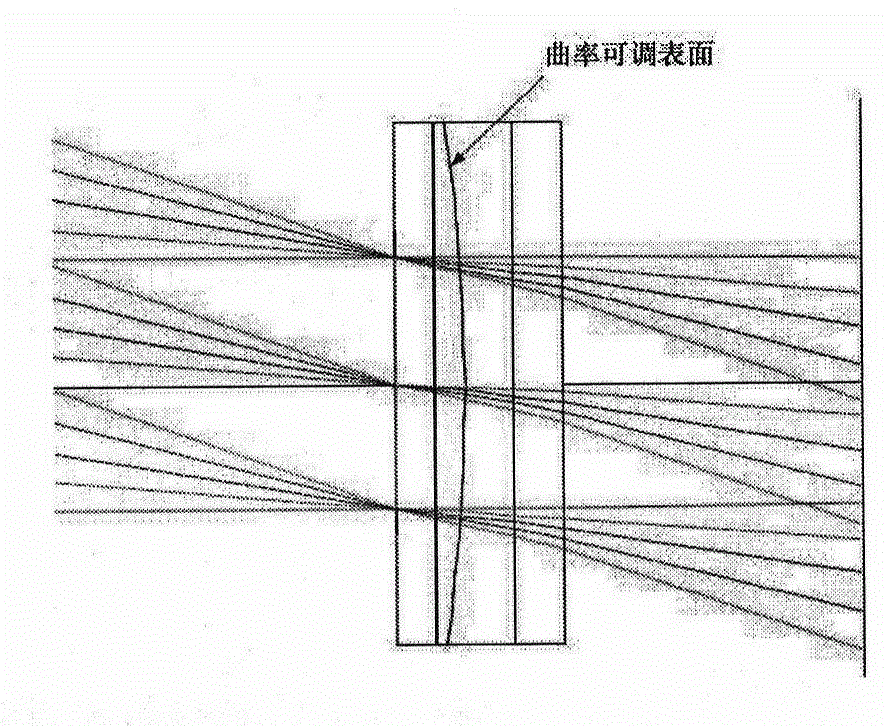

Focus-adjustable retina camera imaging system based on liquid lens

InactiveCN104856643AAchieve clear imagingLow proficiency requirementOthalmoscopesVisibilityLighting system

The invention provides a focus-adjustable retina camera imaging system based on a liquid lens, which comprises an imaging system and an illuminating system, wherein the imaging system comprises an aperture diaphragm, an eye object lens, a spectroscope, an imaging object lens, the liquid lens and an image plane; the components are connected by the respective sequences that the eye object lens, the spectroscope, the imaging object lens and the liquid lens are in sequence disposed behind the aperture diaphragm, and the liquid lens is disposed between the imaging object lens and the image plane. The invention designs the imaging system based on a mechanical focus-adjusting manner, wherein the liquid variable-focus lens is introduced into the imaging system and surface curvature of the liquid lens can be changed continuously by adjusting voltage in order to realize clean human eye imaging with different visibilities. The focus-adjusting manner only needs to adopt a focus-fixed mechanical structure form, has a simple mechanical structure, reduces requirements for proficiency of an operator, and can realize more accurate adjustment by continuously changing the surface curvature of the lens.

Owner:宁波奉化科创科技服务有限公司

Device and method for feeding wood support rod into linking rod

ActiveCN106425412AAutomate operationIncrease productivityMetal working apparatusEngineeringRejection rate

The invention relates to a device for feeding a wood support rod into a linking rod. The device comprises a base, a linking rod positioning mechanism and a wood support jacking mechanism, wherein the linking rod positioning mechanism is mounted on the base; the wood support jacking mechanism comprises a translation driving mechanism, a translation guide mechanism, a mounting plate, a movable pressing block, a clamping positioning block and a back surface positioning block; the clamping positioning block and the back surface positioning block are fixedly arranged on the mounting plate; one end of the movable pressing block is fixedly arranged on the mounting plate through a rotating pin; the other end of the movable pressing block is positioned between the clamping positioning block and the back surface positioning block; the translation driving mechanism is connected with the movable pressing block to drive the movable pressing block to rotate between the clamping positioning block and the back surface positioning block, a drive the mounting plate to translate on the base through the translation guide mechanism; the wood support rod is clamped between the movable pressing block and the clamping positioning block. The invention further relates to a method for feeding the wood support rod into the linking rod. The device and the method have the advantages of being high in production efficiency, low in rejection rate and precise in positioning, and belongs to the technical field of piano component processing equipment.

Owner:PEARL RIVER PIANO GROUP

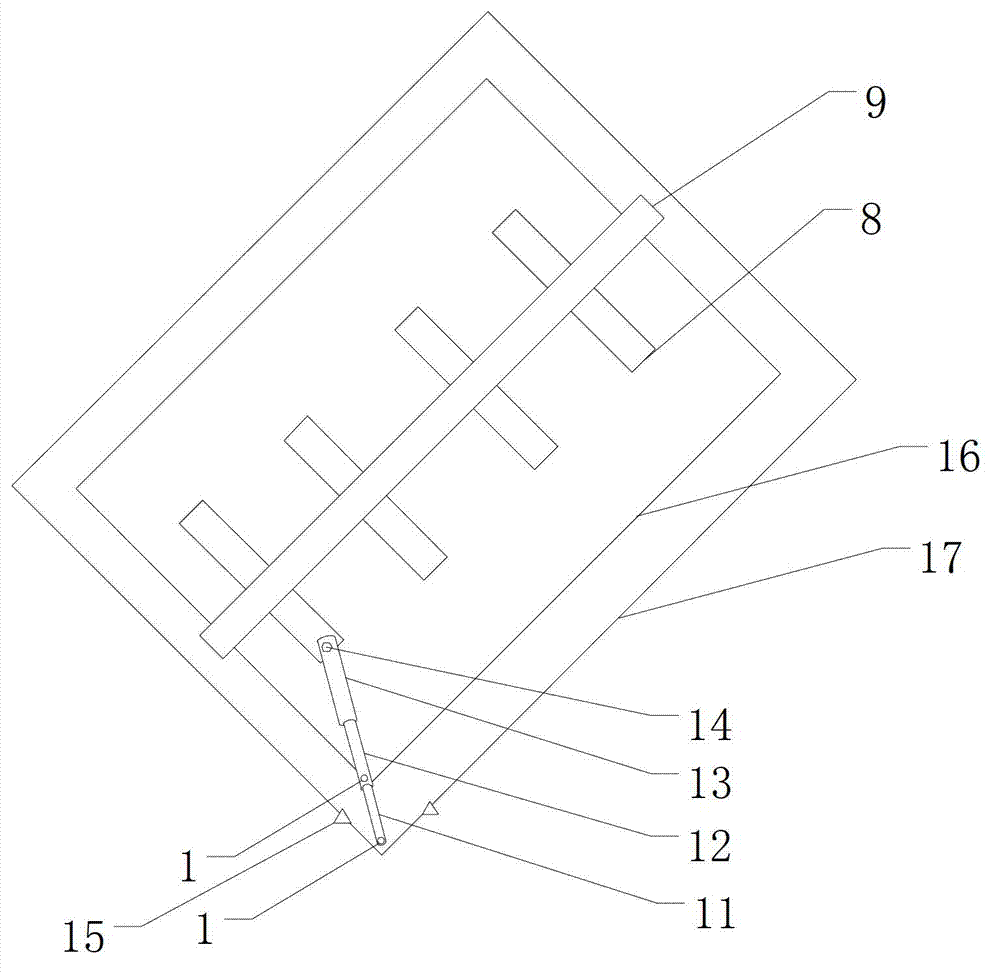

Stacking system and stacking method for steel plate

ActiveCN103043535AImprove stabilityImprove securityStacking articlesLoad-engaging elementsStructural engineeringMiddle line

The invention relates to a stacking system and a stacking method for a steel plate. The stacking system comprises illumination subsystems, view indication subsystems, camera subsystems, a display subsystem, a position indicating point and a telescopic link, wherein integrated base bodies are arranged on a second section of telescopic tube and a first section of telescopic tube of the telescopic link respectively; and each integrated base body is provided with the illumination subsystems, the view indication subsystems and the camera subsystem. The stacking method comprises the steps: 1) the distance between the camera subsystem on the second section of telescopic tube of the telescopic link and a cross beam middle line of an electromagnetic lifter is half of the width of the lifted steel plate; 2) positions of a travelling crane and a lifting tool of the electromagnetic lifter are observed and adjusted through a cruciform goal aiming baseline, corner parts of the steel plate are superposed with a right angle of the cruciform goal aiming baseline; and 3) the steel plate is lifted and moved to above a target stacking zone, a right angle of the position indicating point is superposed with the right angle of the cruciform goal aiming baseline, and the steel plate is laid down. With the adoption of the system, planar accurate positioning of the steel plate during the stacking course can be realized, and the stacking efficiency and stacking quality are improved.

Owner:LAIWU IRON & STEEL GRP

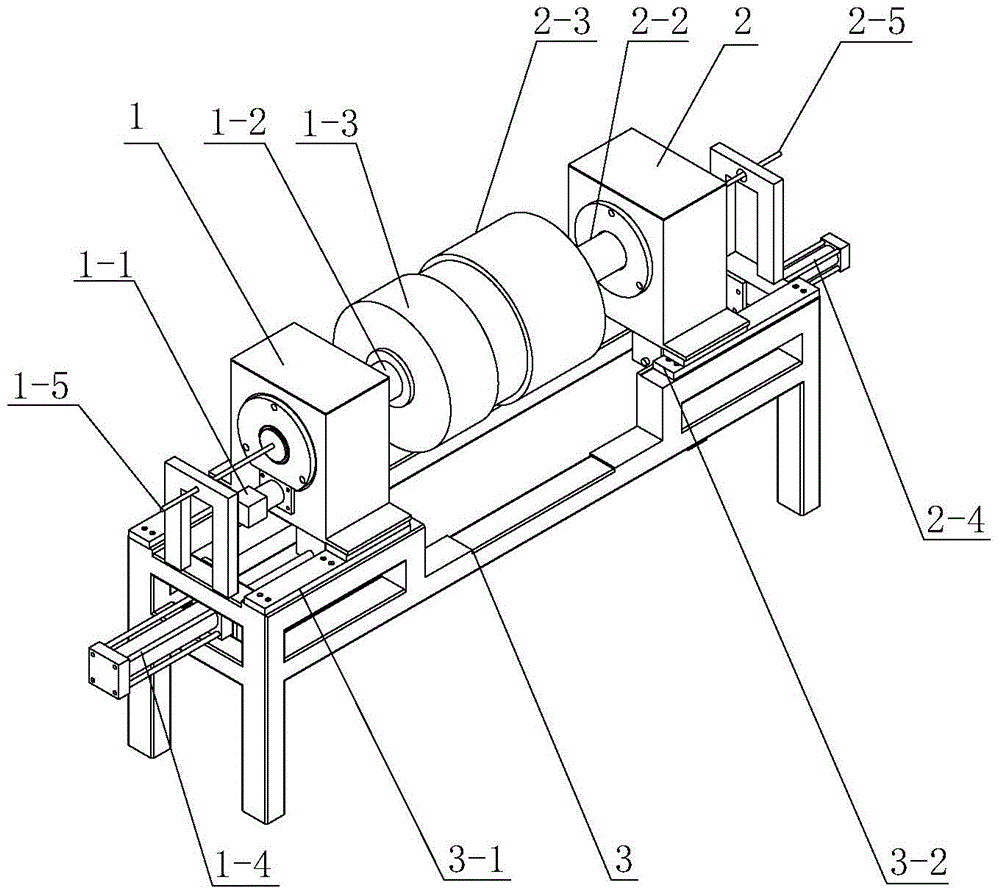

Gas filling bottle welding rotating device and working method thereof

ActiveCN104084668AIncrease productivityFast manufacturingWelding/cutting auxillary devicesElectrode supporting devicesProduct gasEngineering

The invention discloses a gas filling bottle welding rotating device and a working method thereof. The device comprises a machine frame, a driving rotating body, a driven rotating body, clamping sleeves and a motor and the like, wherein the driving rotating body and the driven rotating body can move relatively, and the clamping sleeves are installed on the driving rotating body and the driven rotating body. The working method of the gas filling bottle welding rotating device comprises the steps of feeding, clamping, rotation and blanking and the like. The gas filling bottle welding rotating device can greatly improve gas filling bottle production efficiency and reduce manpower resource investment.

Owner:无锡市迪索数控焊接设备有限公司

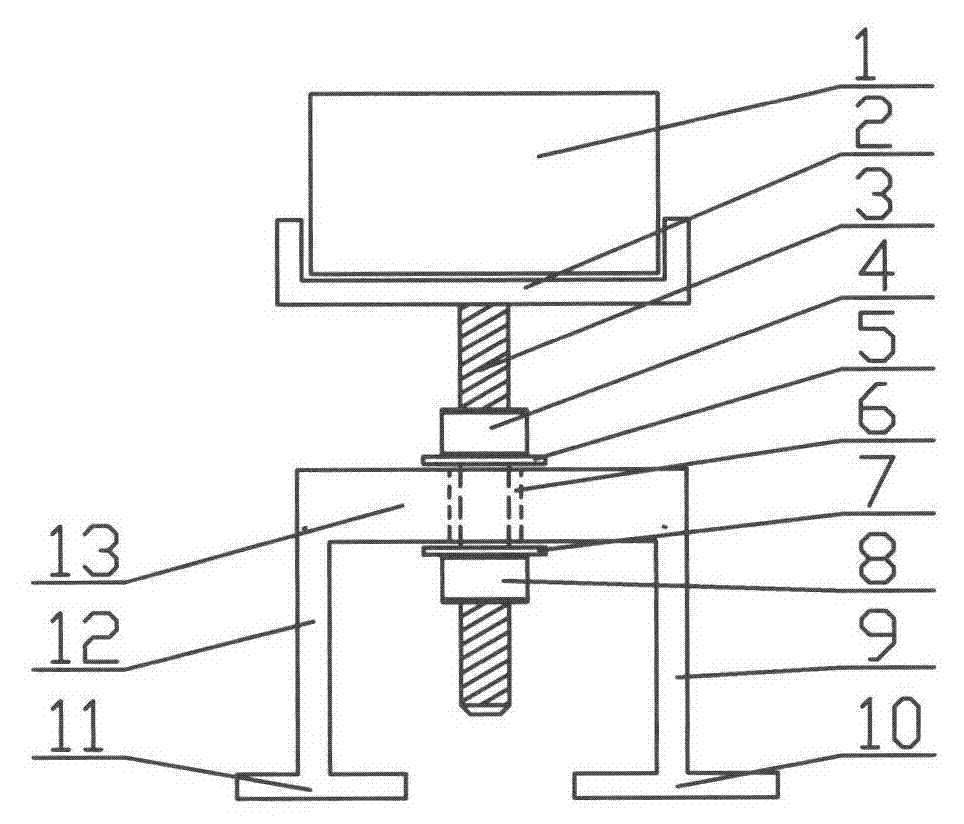

Self-adjustment supporting structure

The invention relates to a supporting adjustment device, in particular to a self-adjustment supporting structure. The self-adjustment supporting structure comprises a keel, a supporting plate, a bolt rod, a first adjustment nut, a first gasket, a bolt through hole, a second gasket, a second adjustment nut, a first vertical rod, a first support, a second support, a second vertical rod and a transverse rod, wherein threads are formed on the outer surface of the bolt rod; one end of the bolt rod is fixedly connected with the center of the bottom of the supporting plate, and the other end of the bolt rod penetrates through the first adjustment nut, the first gasket, the bolt through hole, the second gasket and the second adjustment nut in sequence. The self-adjustment supporting structure has the advantages that contact between a wall body and a terrace is separated, so that the levelness of the keel can be conveniently and quickly adjusted; the self-adjustment supporting structure is easy to manufacture, mount and operate.

Owner:杨芳芳

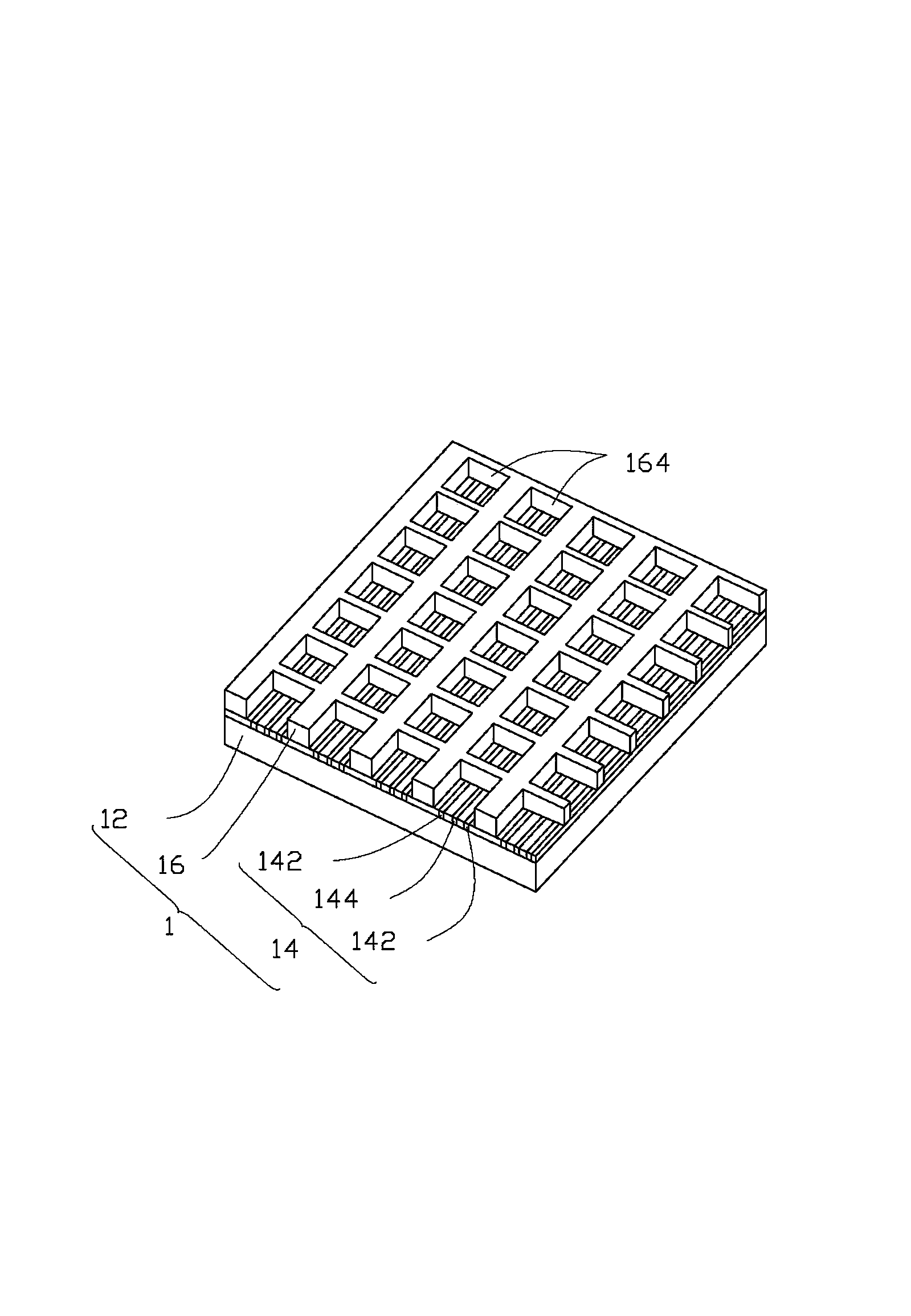

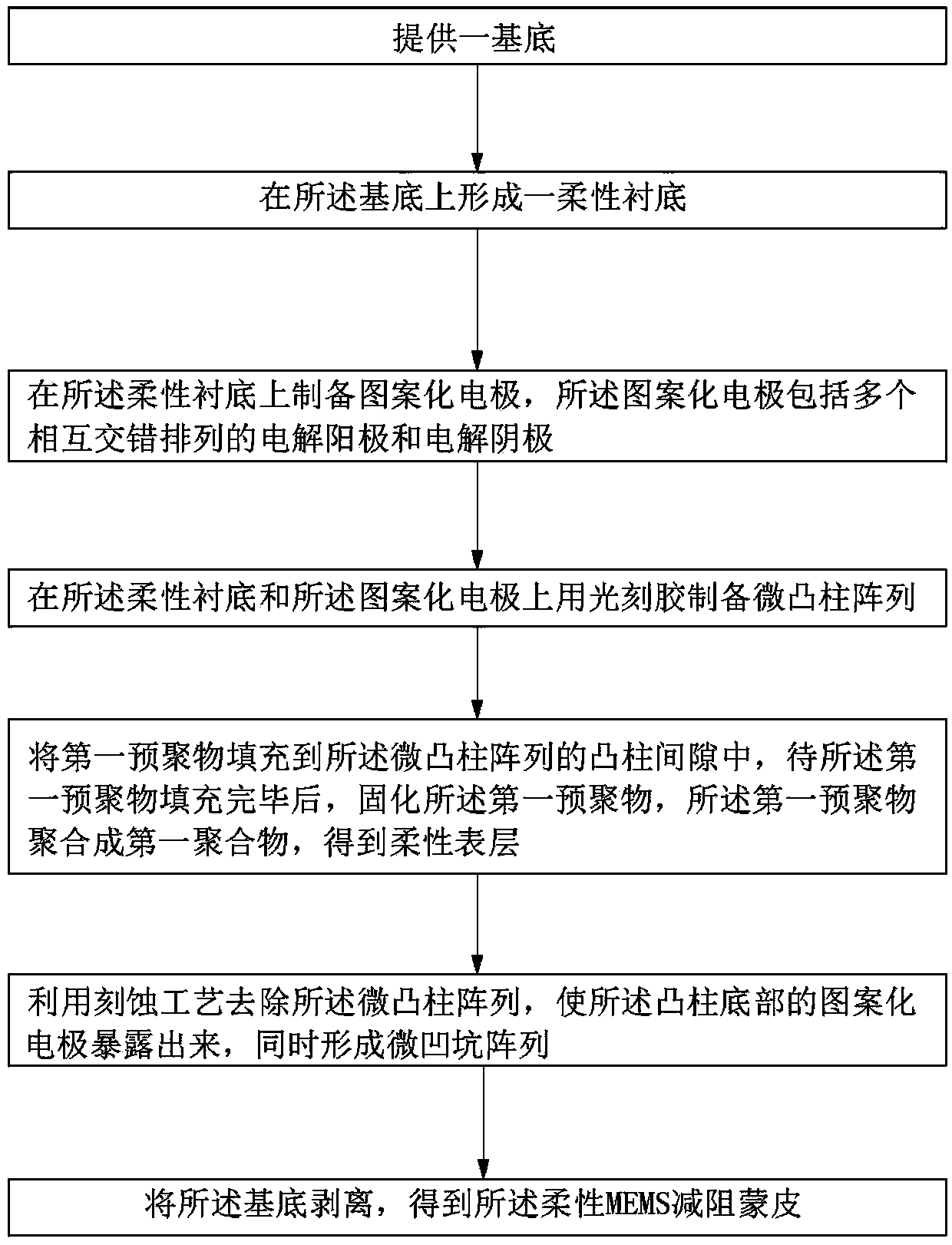

Preparation method of flexible anti-drag skin of micro-electromechanical system (MEMS)

InactiveCN103754819ALow proficiency requirementImprove yieldDecorative surface effectsChemical vapor deposition coatingElectrolysisSurface layer

The invention discloses a preparation method of a flexible anti-drag skin of a micro-electromechanical system (MEMS). The method comprises the following steps: providing a substrate; forming a flexible substrate on the base; preparing a patterned electrode on the flexible substrate, wherein the patterned electrode comprises a plurality of electrolytic anodes and electrolytic cathodes, which are arranged in a staggered manner; preparing micro convex column arrays on the flexible substrate and the patterned electrode by using a photoresist; filling first pre-polymer into a convex column gap of the micro convex column arrays; solidifying the first pre-polymer after the first pre-polymer is filled; polymerizing into a first polymer from the first pre-polymer, so as to obtain a flexible surface layer; removing the micro convex column arrays by using an etching technology, so that the patterned electrode at the bottom of the convex column is exposed, and meanwhile, a micro-concave pit array is formed; stripping the base, so as to obtain the flexible anti-drag skin of the MEMS.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com