Semi-automatic stacking method for power battery core

A power battery, semi-automatic technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high assembly adjustment skills, long time-consuming, high operation intensity, etc., to reduce proficiency Requirements, reduce equipment costs, reduce the effect of operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

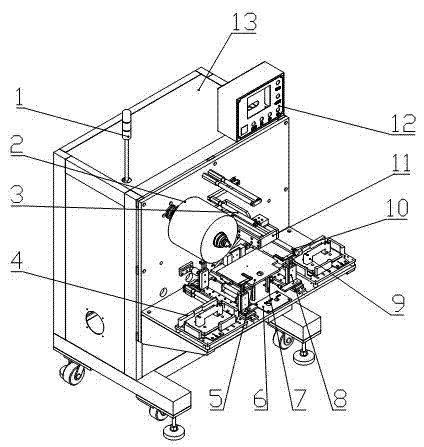

[0090] A semi-automatic lamination method for power battery cells, comprising the following steps:

[0091] 1) Pull and place the base layer diaphragm on the surface of the cell movable plate;

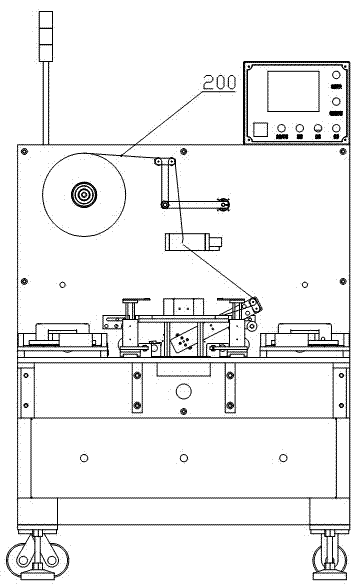

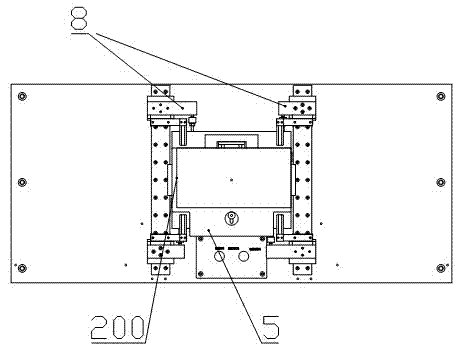

[0092] according to figure 2 Thread the diaphragm 200 as shown, and pull the diaphragm to a suitable position on the cell fixing plate 5 that exceeds the width of the pole piece. On the man-machine interface, select the manual mode, and then turn left on the button plate 6 Knob 601, the left pole clamp 8 moves to clamp the diaphragm, and its clamping state is as follows Figure 4 As shown; same as it, turn the knob 601 on the button plate 6 to the right, the right pole clip 8 moves, and the diaphragm is clamped. Such as Figure 15 shown. After doing the above actions, select the automatic mode on the man-machine interface.

[0093] 2) Lay the first cathode sheet on the surface of the base layer separator;

[0094] Press the button 904 on the left suction cup assembly 9, the suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com