Patents

Literature

1166results about How to "Reduce operating intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

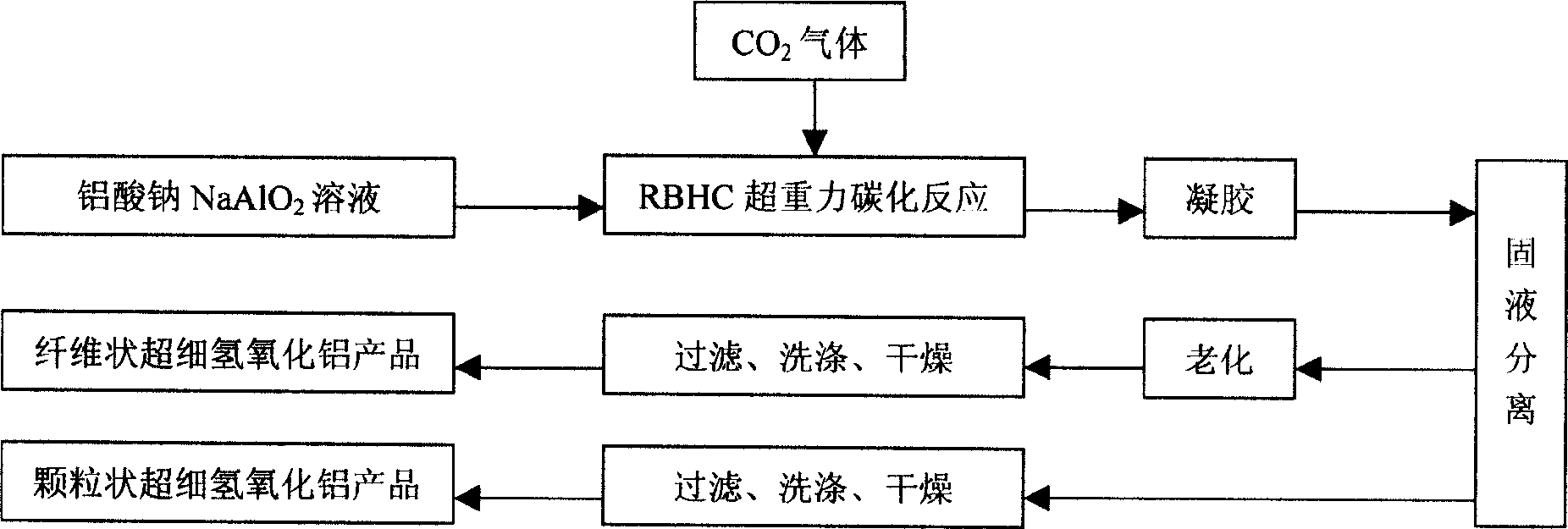

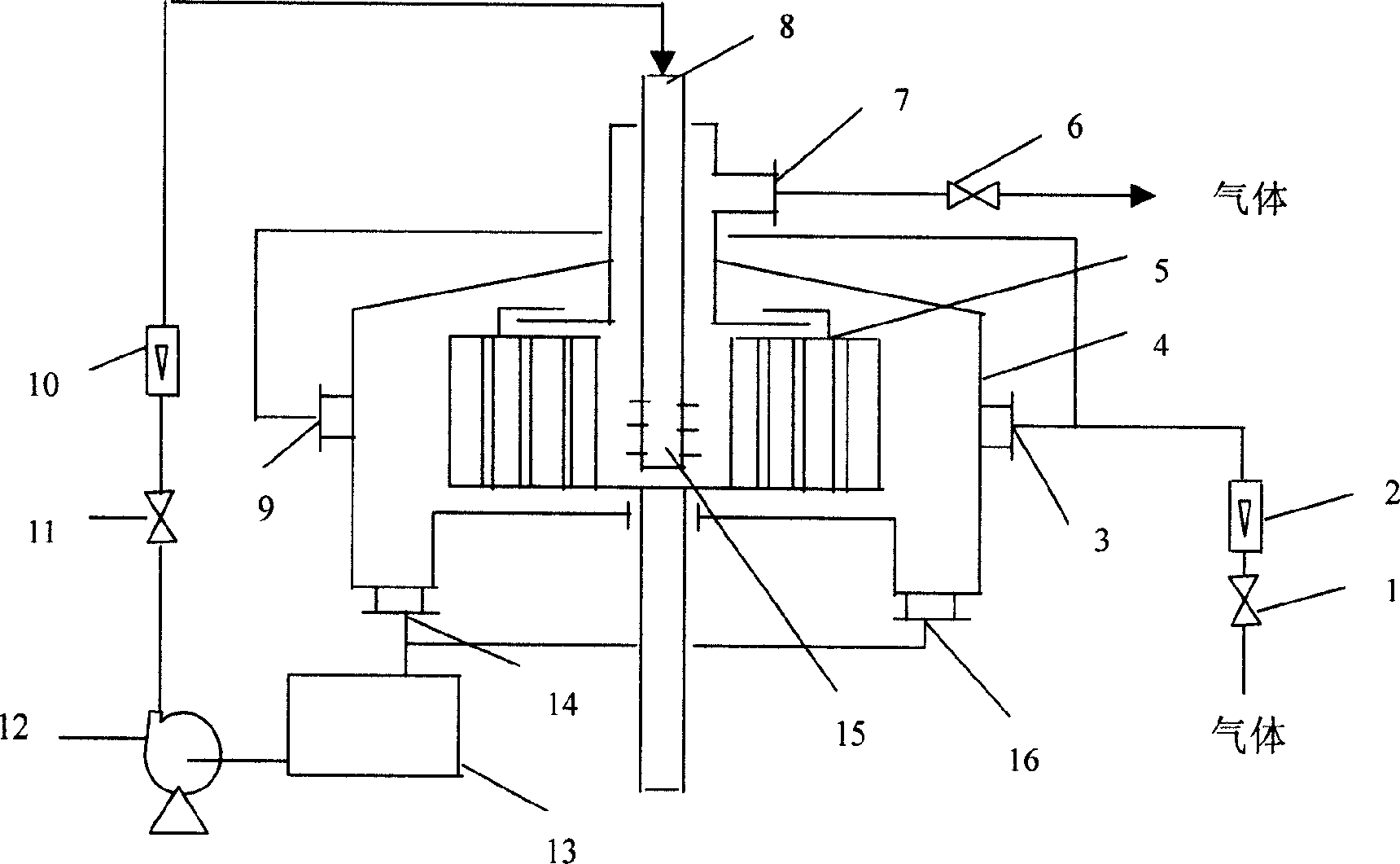

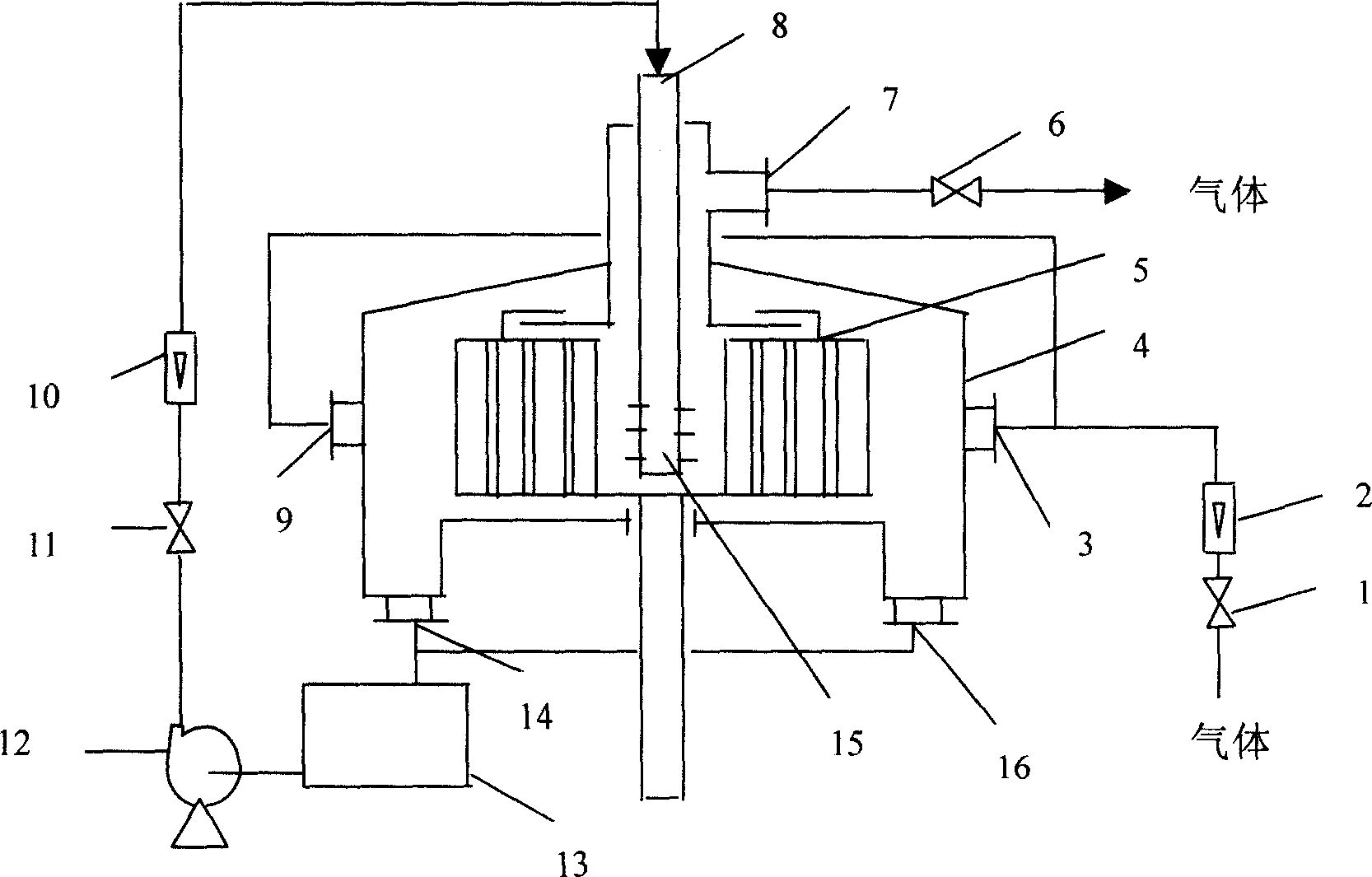

Preparation method of ultrafine aluminium hydroxide

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

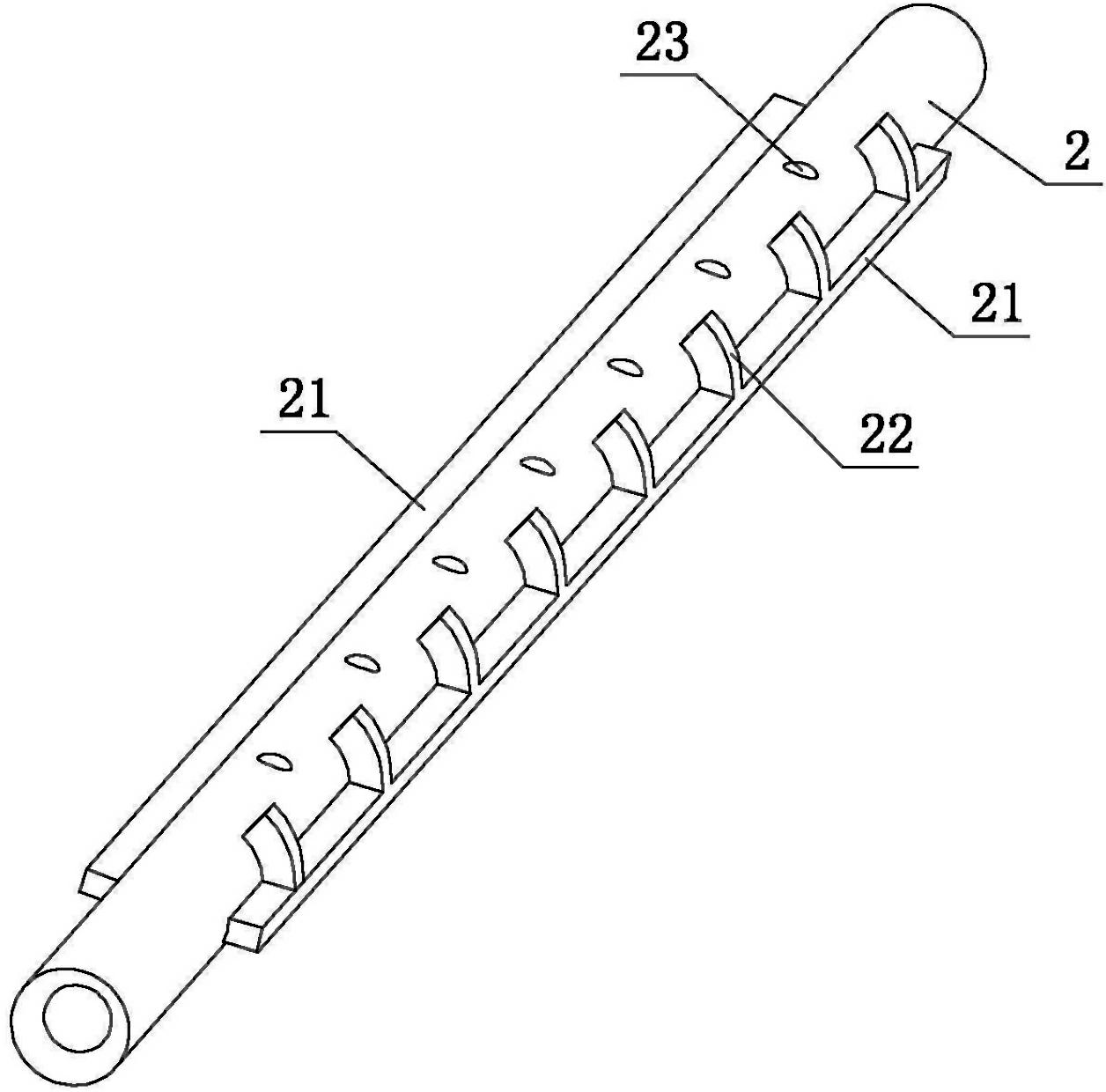

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

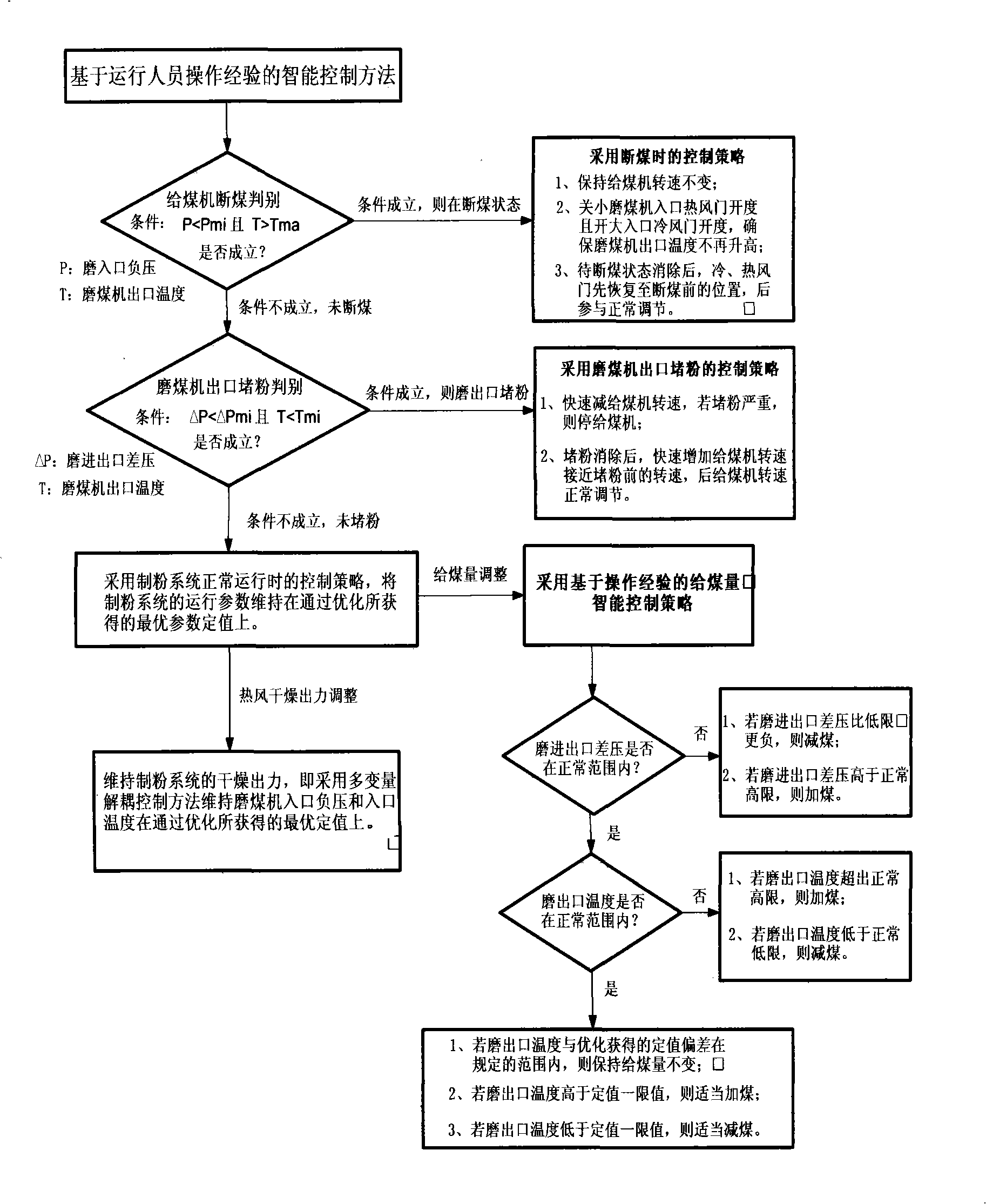

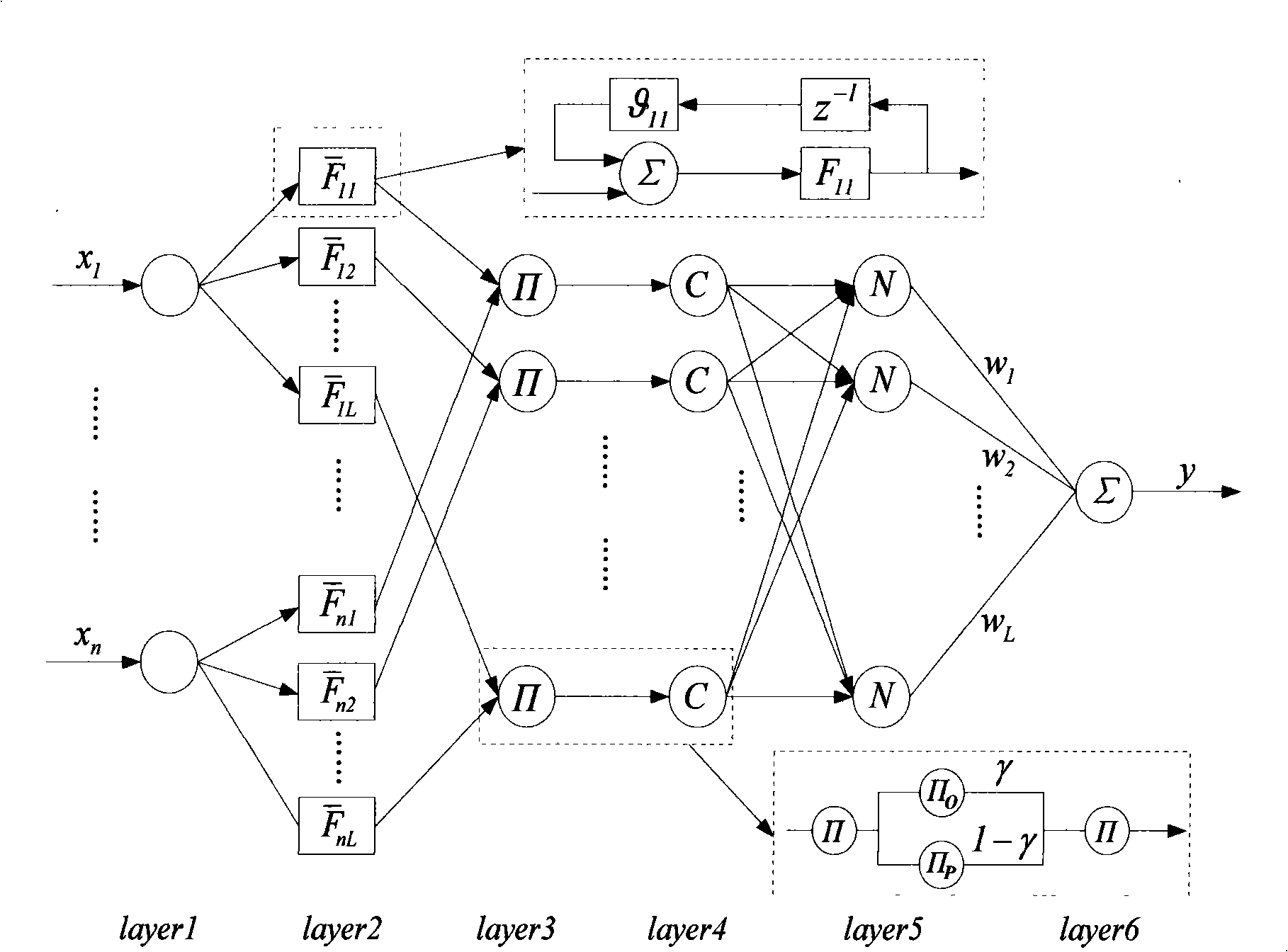

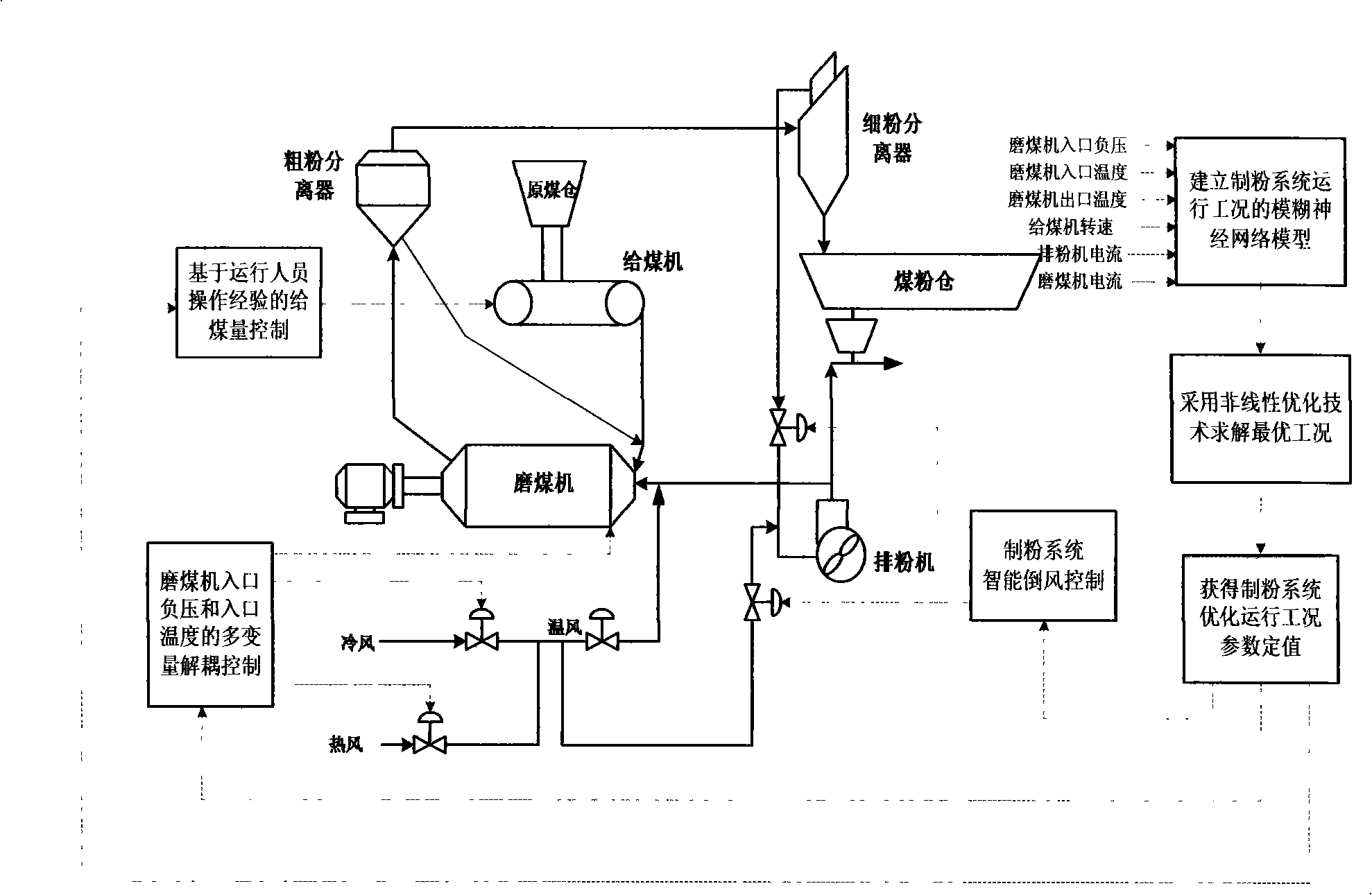

Operation optimizing and energy-saving control method for intermediate storage iron shot mill flour milling system

The invention relates to a method for the optimization of operation and control of energy conservation for a reserve ball-grinding powder system. Firstly, a non-linear neural network model about the consumption of powder of a powder-making system and operating parameters is established through collecting the service data of the powder-making system, then the negative pressure and the temperature at the entrance of a coal mill and the temperature at the outlet of the coal mill are obtained through the non-linear optimization with restricted conditions as a set value for controlling the system, wherein, the negative pressure, the temperature at the entrance and the outlet lead to lower consumption of powder; the entire optimized controlling of the powder-making system is carried out through the intelligent control of rotation of the coal mill and multivariable decoupling control of parameters at the entrance of the coal mill based on the operating experience as well as an intelligent down draft control technology, so as to ensure that the powder-making system strictly runs at an optimal condition and effectively reduces the powder consumption. The method provided by the invention can effectively inhibit the fluctuations of a primary air pressure in the on / off process of the powder-making system, put an end to serious accidents such as flameout in a boiler caused by down draft and effectively reduce the operating intensity for the staff.

Owner:SOUTHEAST UNIV

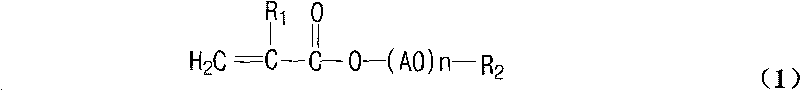

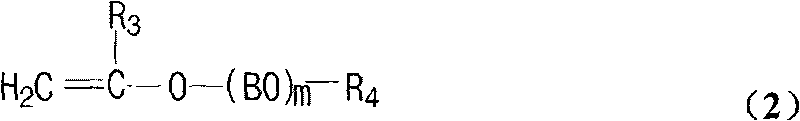

Water-plastic retaining polycarboxylic acid water reducer and method for preparing same

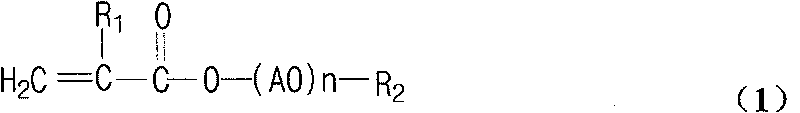

The invention provides water-plastic retaining polycarboxylic acid water reducer and a method for preparing same, belonging to the technical field of the cement dispersant. The water-plastic retaining polycarboxylic acid water reducer is characterized by being prepared in nature through copolymerizing a big water-plastic retaining monomer and a small water-plastic retaining monomer, wherein the big water-plastic retaining monomer is prepared by mixing a big ester monomer with a small ester monomer. Prepared from the big water-plastic retaining monomer, the water-plastic retaining polycarboxylic acid water reducer can well retain the water and the plastic of concrete which is prepared through stirring different cement and different aggregate, and the ubiquitous problems of the segregation due to water bleeding and the quick slump loss are effectively solved. The water is used as solvent for the polymerization reaction, which is good for the industrial production and ensures the safe and environmental-friendly production process.

Owner:山东华伟银凯建材科技股份有限公司

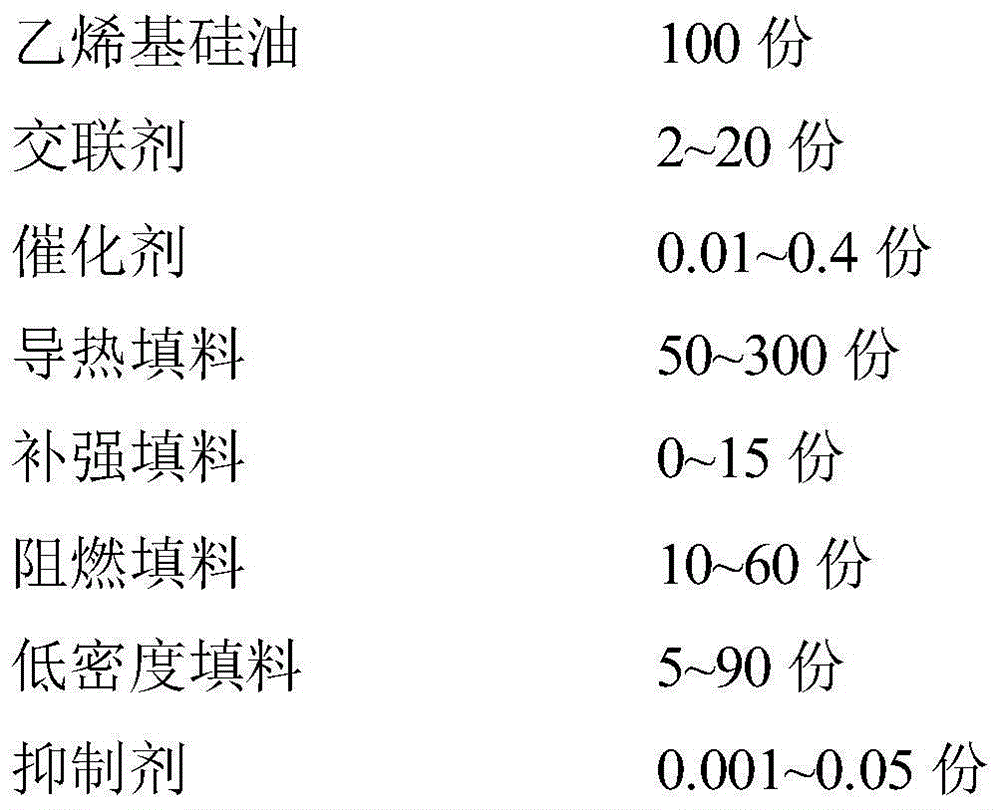

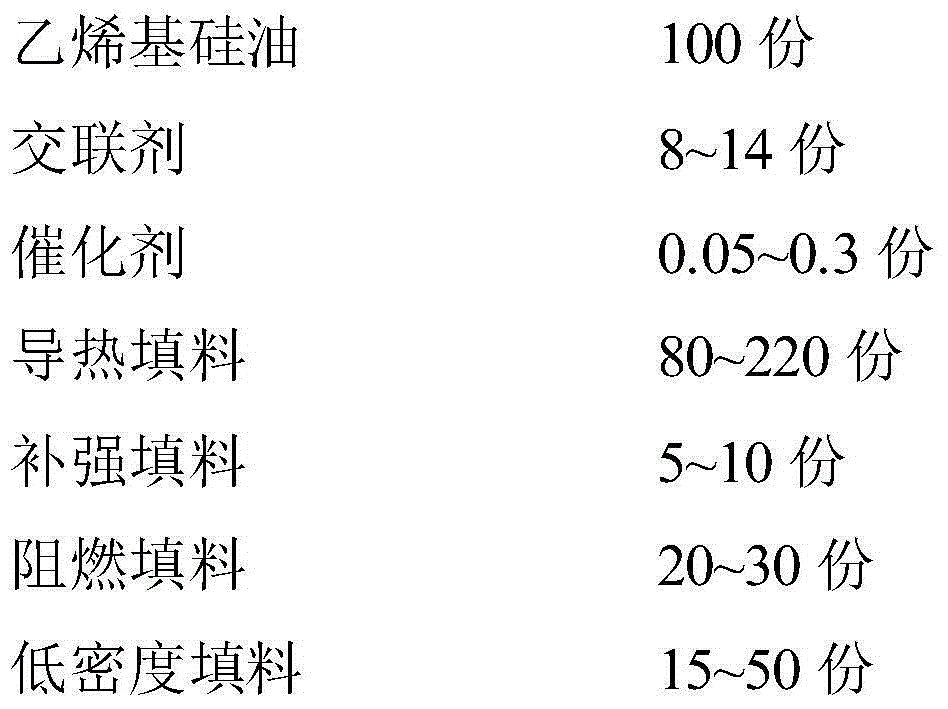

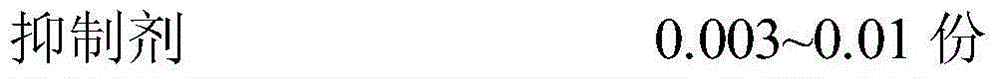

Low density heat conduction pouring sealant and preparation method thereof

InactiveCN104861661ALow densityImprove flame retardant performanceDensity reductionMaterials preparation

The invention discloses a low density heat conduction pouring sealant which comprises 100 parts of vinyl silicone oil, 2-20 parts of cross-linking agent, 0.01-0.4 parts of catalyst, 50-300 parts of heat conduction filler, 0-15 parts of reinforcing filler, 10-60 parts of inflaming retarding filler, 5-90 parts of low density filler and 0.001-0.05 part of inhibitor. The sealant has good heat conduction performance, excellent inflaming retarding performance and dynamic performance and low density. Compared with common heat conduction pouring sealant, the sealant achieves the effect that the density is reduced by about 40%, and has wide application prospect in the field of electronic devices, electric automobiles and the like. A preparation method of the low density heat conduction pouring sealant is further provided. The method includes three steps of base material preparation, preparation of a component A and a component B and preparation of the low-density heat conduction pouring sealant. The preparation method is simple in process, short in production period, low in workload and very suitable for industrial large-scale production. The equipment is conventional equipment.

Owner:浙江中天东方氟硅材料股份有限公司

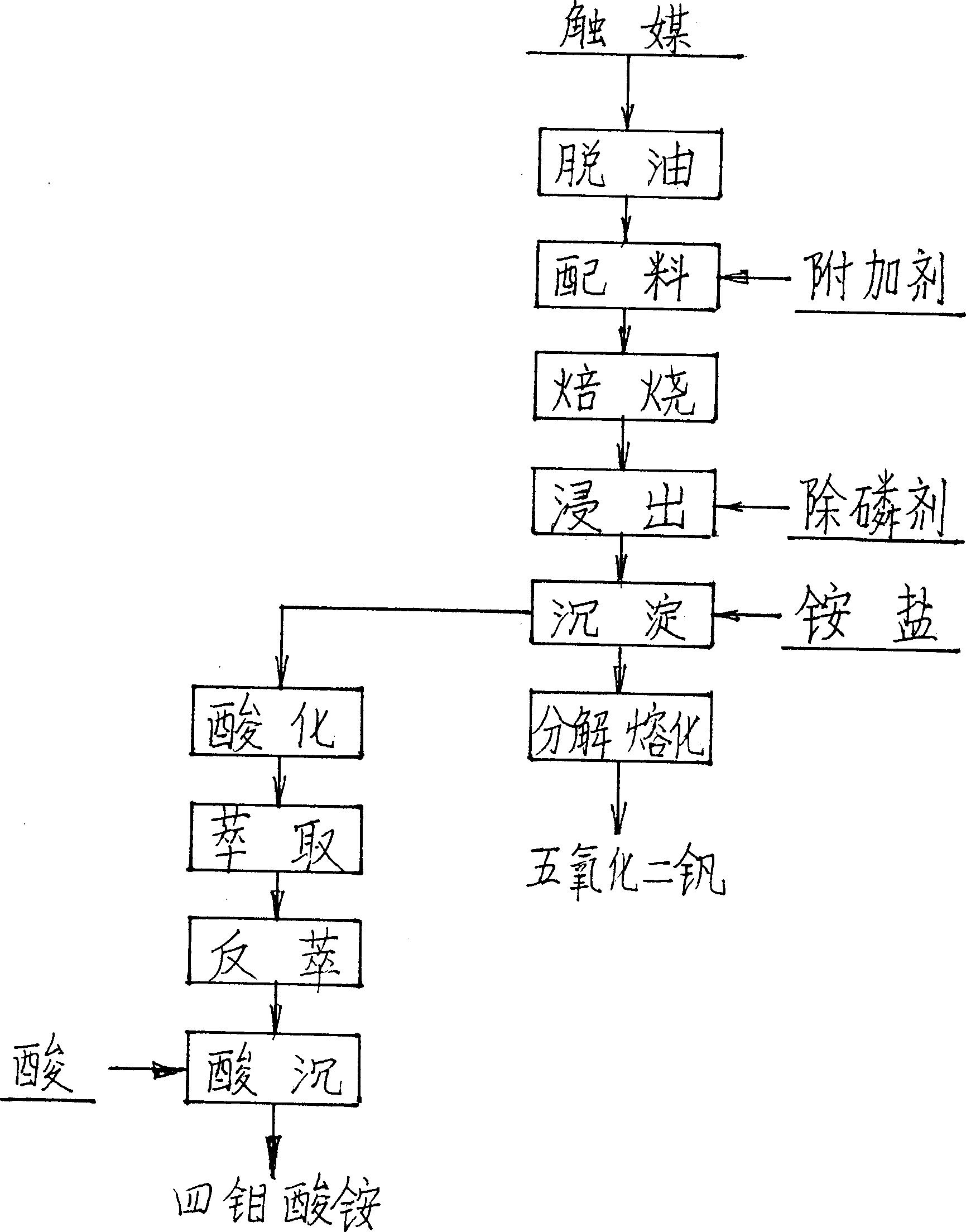

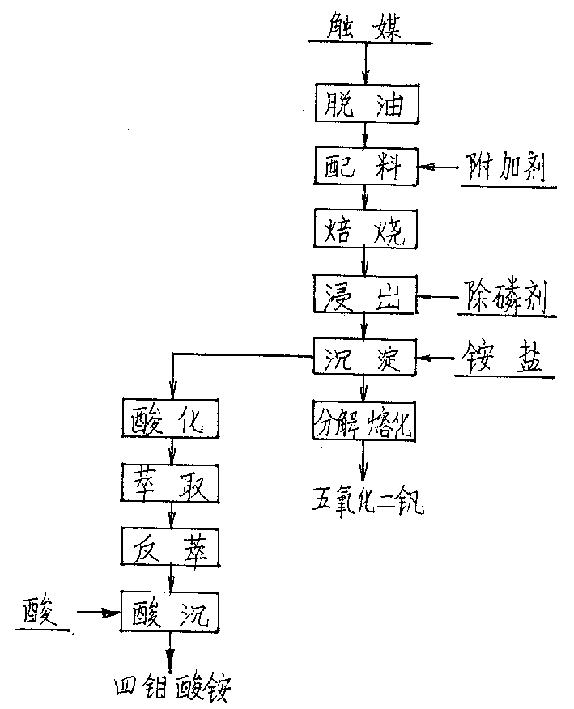

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

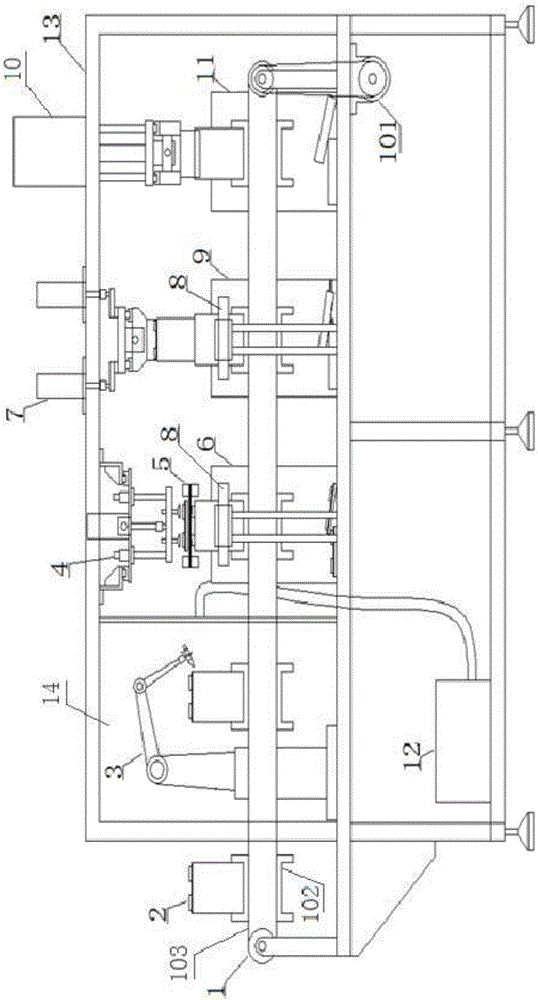

Lithium ion battery automatic dismantling device

ActiveCN106058357ANo deviationTimely recyclingWaste accumulators reclaimingBattery recyclingElectrical batteryEngineering

The invention provides a lithium ion battery automatic dismantling device comprising a frame and a circulation carrier for transferring a waste battery; the frame bottom located at one side of the circulation carrier is successively fixedly provided with a cover plate recycling box, an electric core recycling box, and an outer shell recycling box; the bottom of the frame is successively fixedly provided with a cutting manipulator for annular cutting of a waste battery shell body and two outer shell clamping mechanisms for clamping and fixing the waste battery shell body along the running direction of the circulation carrier; the top of the frame is successively erected with a cover plate recycling mechanism for clamping a waste battery cover plate, an electric core taking-out mechanism for clamping a waste battery electric core, and an outer shell transfer mechanism for clamping the waste battery shell body along the running direction of the circulation carrier; the cover plate recycling mechanism and the electric core taking-out mechanism are respectively located at the top ends of the two outer shell clamping mechanisms; an electrode ear cutting mechanism for cutting a waste battery electrode ear is arranged between the cover plate recycling mechanism and the outer shell clamping mechanism. The automation degree is improved, the work efficiency is increased, and the intensity of work is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

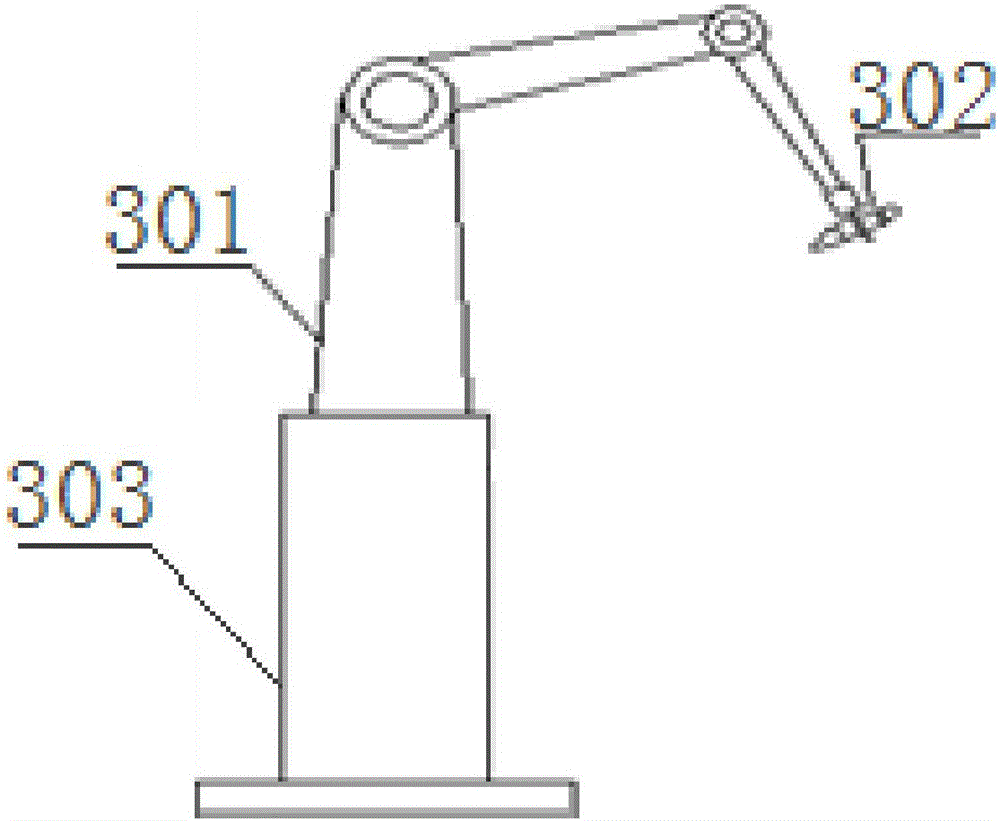

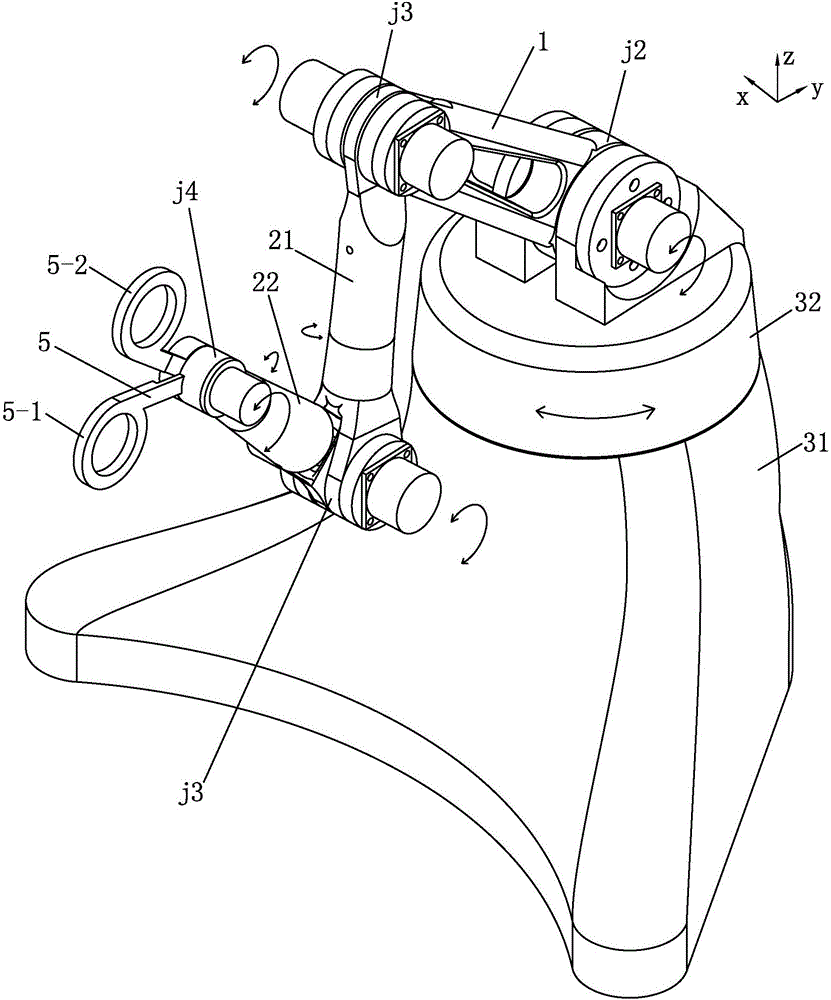

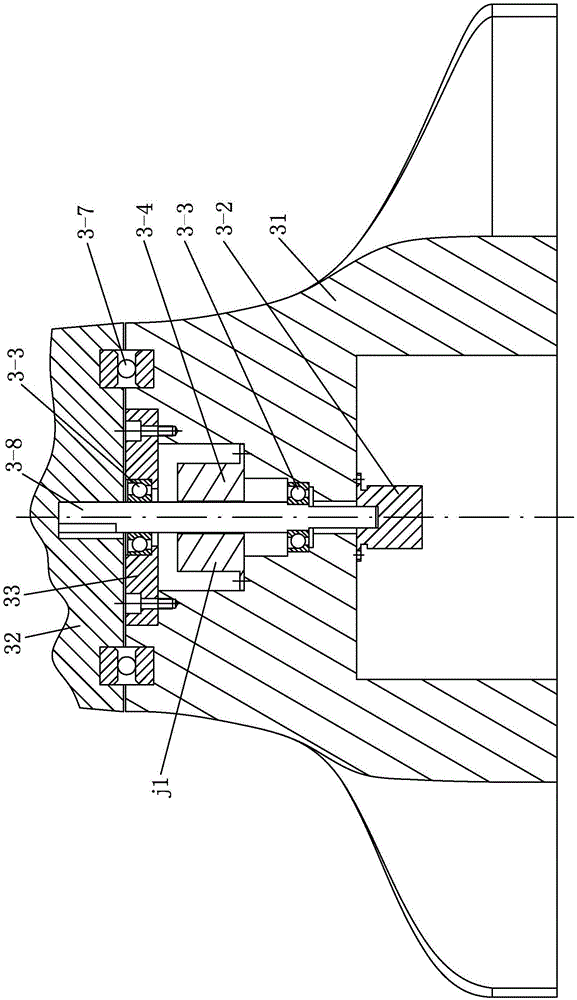

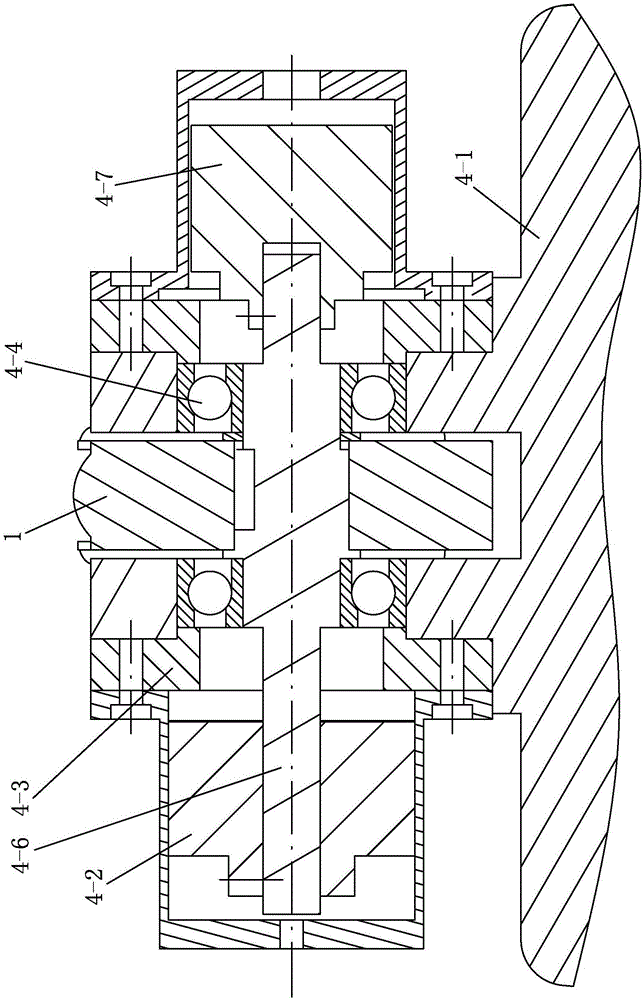

Minimally invasive surgery robot 7-degree freedom operation master manipulator

ActiveCN106667583AReduce operating intensityAvoid misuseSurgical robotsLess invasive surgeryIndex finger

The invention discloses a minimally invasive surgery robot 7-degree freedom operation master manipulator, and relates to a minimally invasive surgery robot; the operation master manipulator is used for solving the problems of complex structure and bad flexibility and university of the manipulator of the minimally invasive surgery robot. The master manipulator comprises a substrate, a turntable arranged on the substrate and rotated around a z axis, a link rod connected with the turntable and rotated around the x axis, a 1# self-rotating link rod connected with the link rod an rotated around the x axis, a 2# self-rotating link rod connected with the 1# self-rotating link rod and rotated around the x axis, and a clamping mechanism connected with the 2# self-rotating link rod; the clamping mechanism comprises a thumb part and an index finger part which are rotated face to face.

Owner:吉林省金博弘智能科技有限责任公司

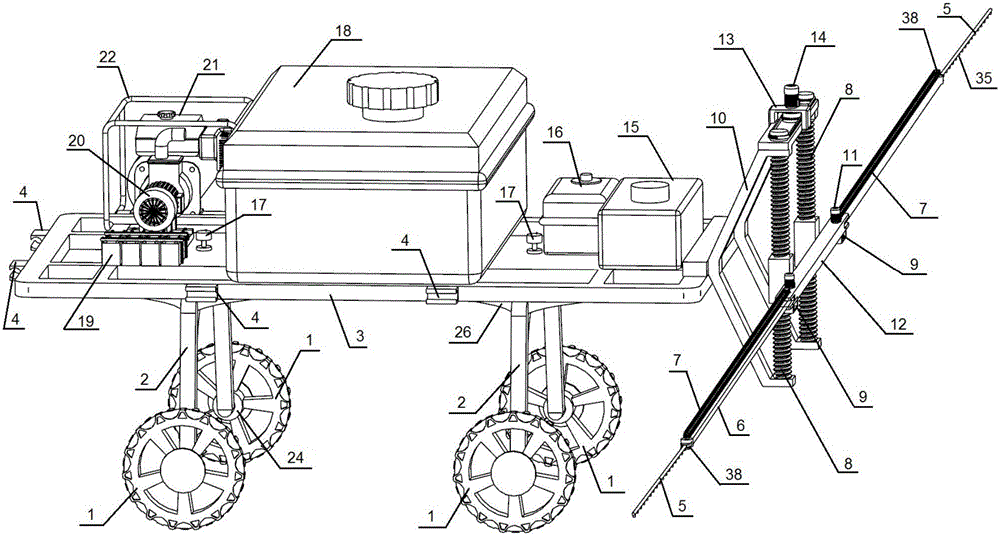

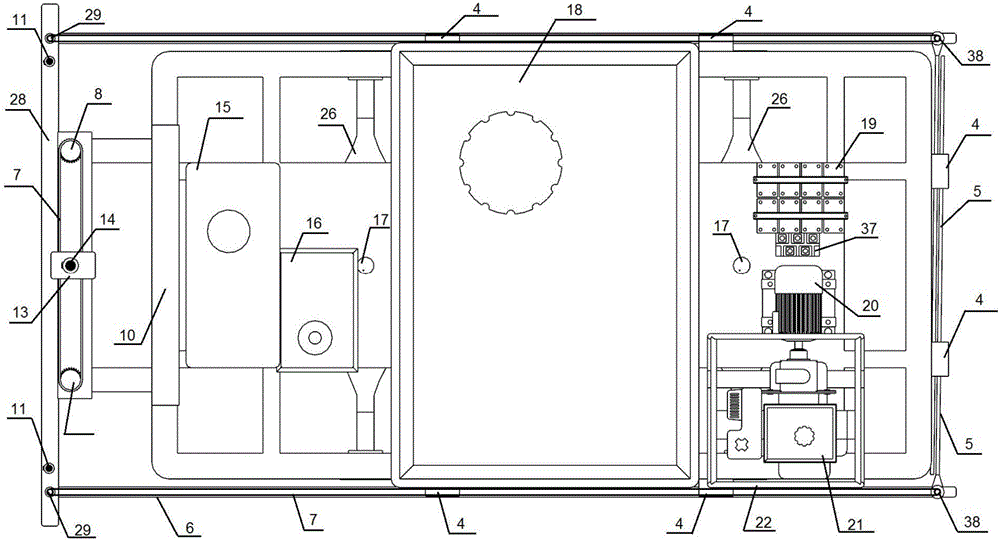

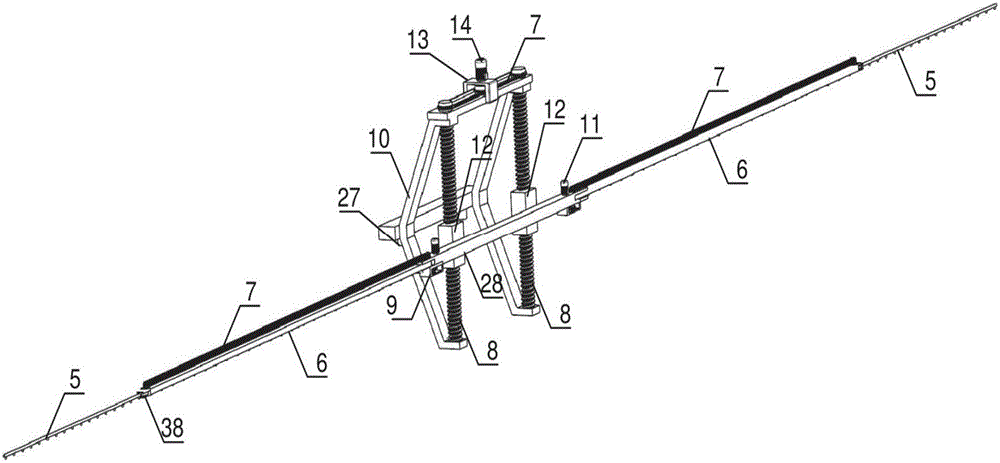

Multi-ground-clearance self-steering intelligent sprayer and control method

ActiveCN106719539AReduce weightImprove space utilizationInsect catchers and killersElectric machineryTurning frames

The invention discloses a multi-ground-clearance self-steering intelligent sprayer and a control method. The sprayer comprises a vehicle platform, two self-steering traveling mechanisms, a controllable lifting spraying device, a gasoline power generation and supply device and a control device, and each self-steering traveling mechanism is connected with the vehicle platform by adopting a rotation structure; the controllable lifting spraying device is fixed at the tail of the vehicle platform and comprises a sprayer lifting mechanism, a spraying rod device and a drug mixing device, the spraying rod device is arranged on the sprayer lifting mechanism and connected with the drug mixing device, and a spraying rod can move up and down along with traction of the sprayer lifting mechanism; the drug mixing device is fixed in the middle of the vehicle platform and provides drug to spraying equipment for spraying, the gasoline power generation and supply device is fixed on the front portion of the vehicle platform and serves as a stable voltage power source of the equipment, and the control device is connected with driving equipment, a control motor and multiple sensors. Four hub motors are controlled by the control device to realize self-steering of wheels at differential speeds, and the sprayer is high in control accuracy and small in turning radius.

Owner:JIANGSU UNIV

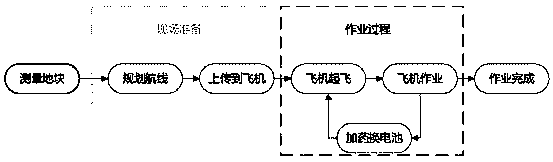

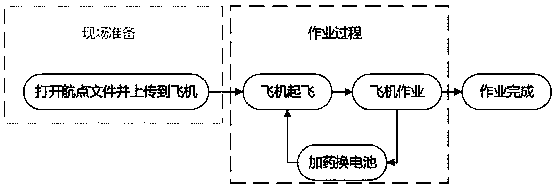

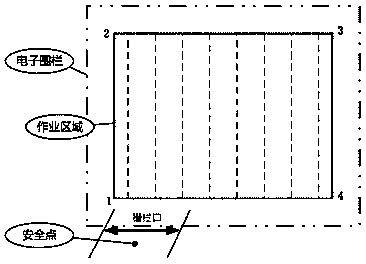

Autonomous-flight unmanned aerial vehicle system and control method thereof

ActiveCN107688354AImprove work efficiencyReal-time power monitoringPosition/course control in three dimensionsFly controlData acquisition

An autonomous-flight unmanned aerial vehicle system comprises a master controller and ground station equipment. The master controller comprises a data acquisition module, a data processing module anda communication module. Flight control and flight management functional requirements of unmanned aerial vehicles in different models can be realized through correction of an internal procedure and a peripheral circuit of the master controller. The system is characterized in that the ground station equipment is responsible for configuration parameter and flight route planning electronic fence setupand navigation mode configuration of each single unmanned aerial vehicle, and the master controller realizes autonomous flight including autonomous obstacle avoidance and breakpoint endurance of theunmanned aerial vehicles according to waypoint files, flight parameters and safety parameters generated by the ground station equipment.

Owner:BEIJING BOYING TONGHANG TECH CO LTD

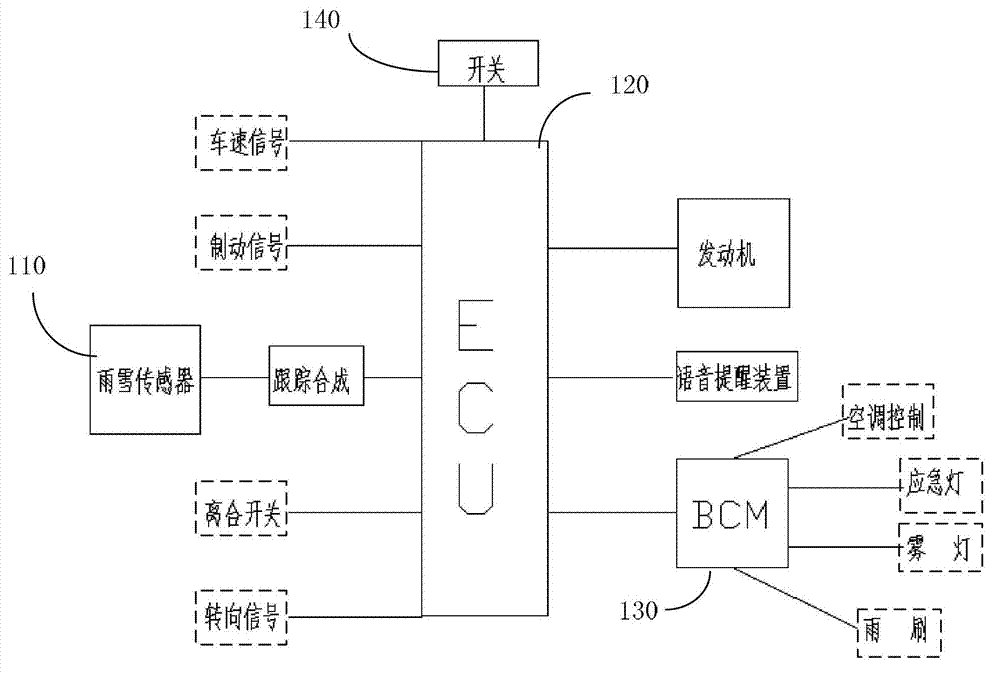

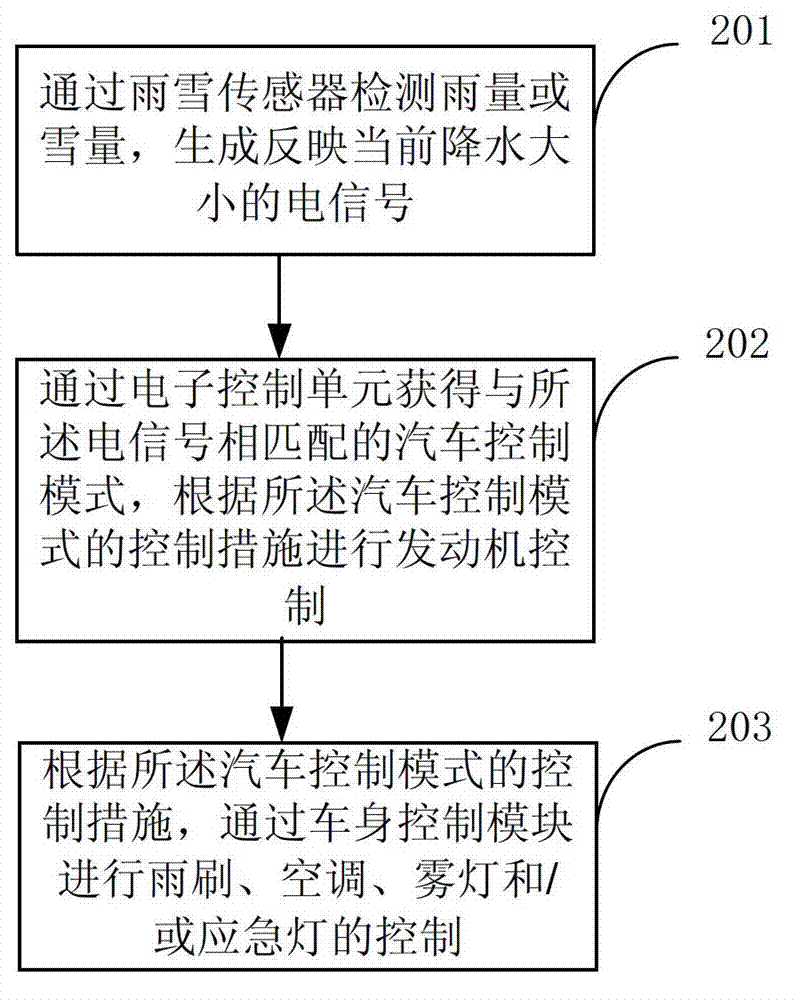

Aided driving system on rain or snow days and aided driving method

ActiveCN102866695AReduce operating intensityImprove driving safetyEngine controllersMachines/enginesDriving safetyControl measure

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

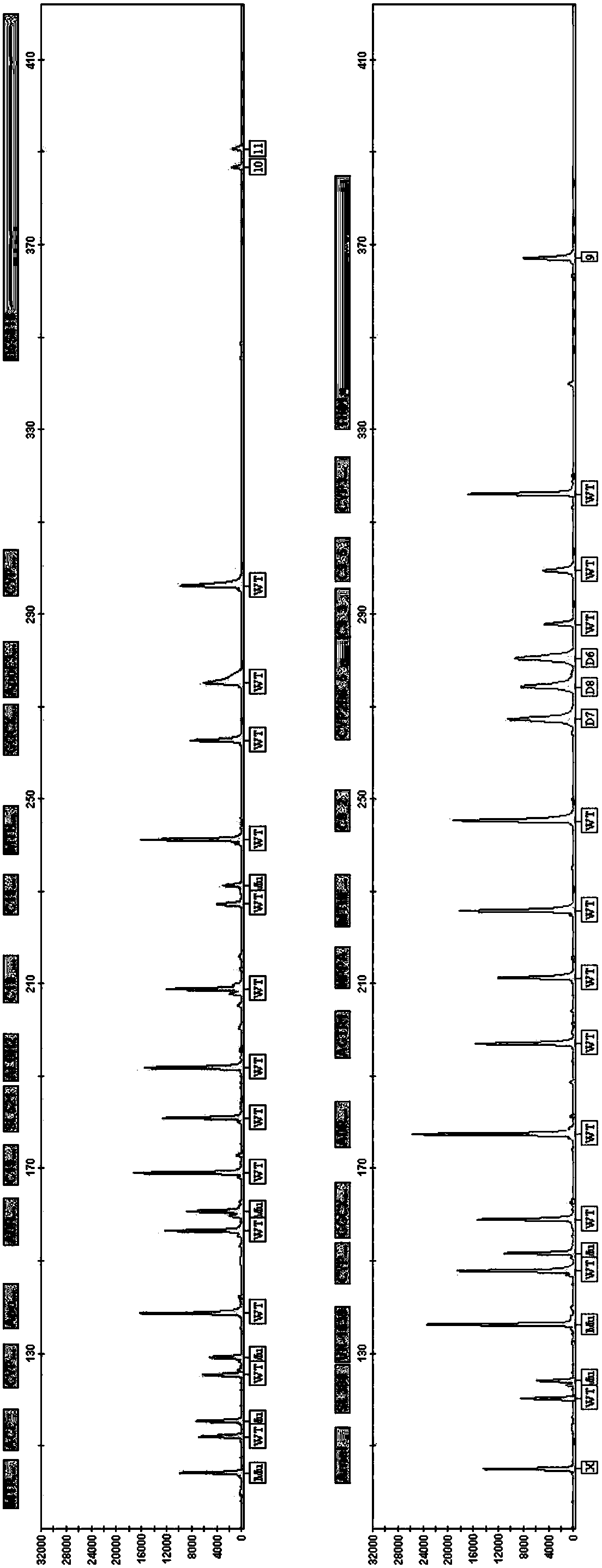

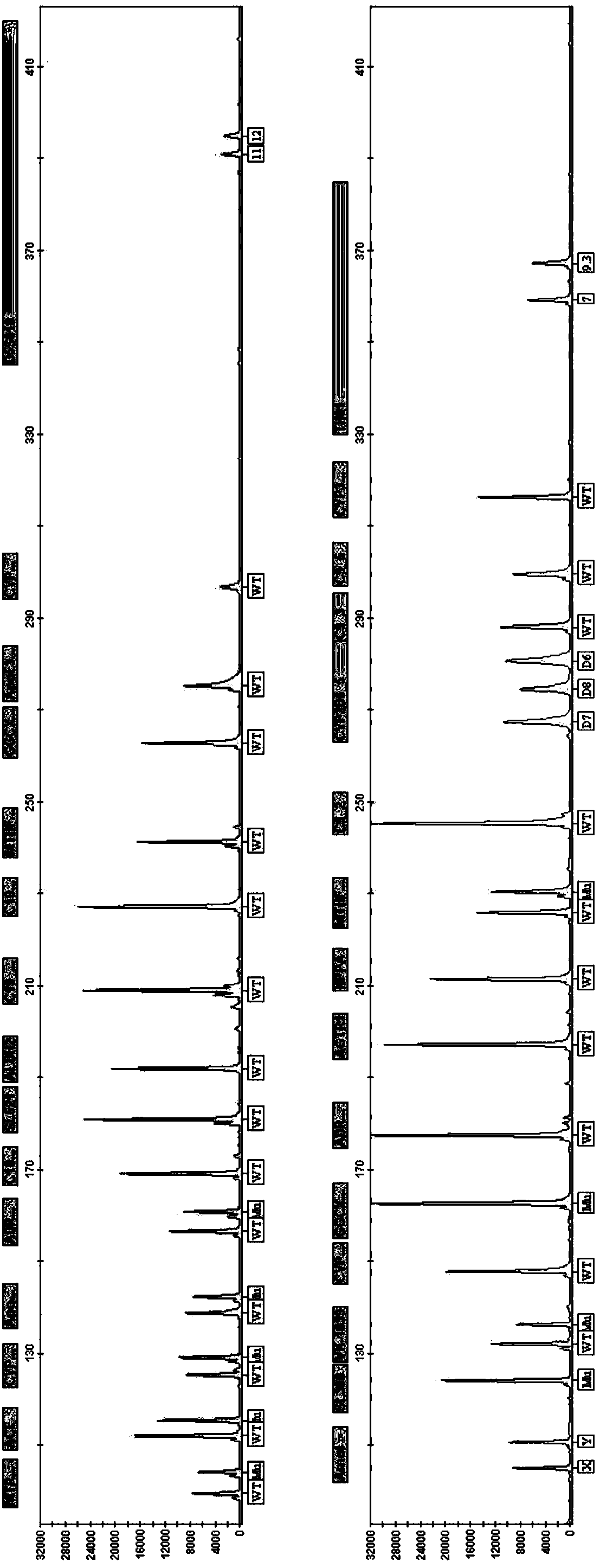

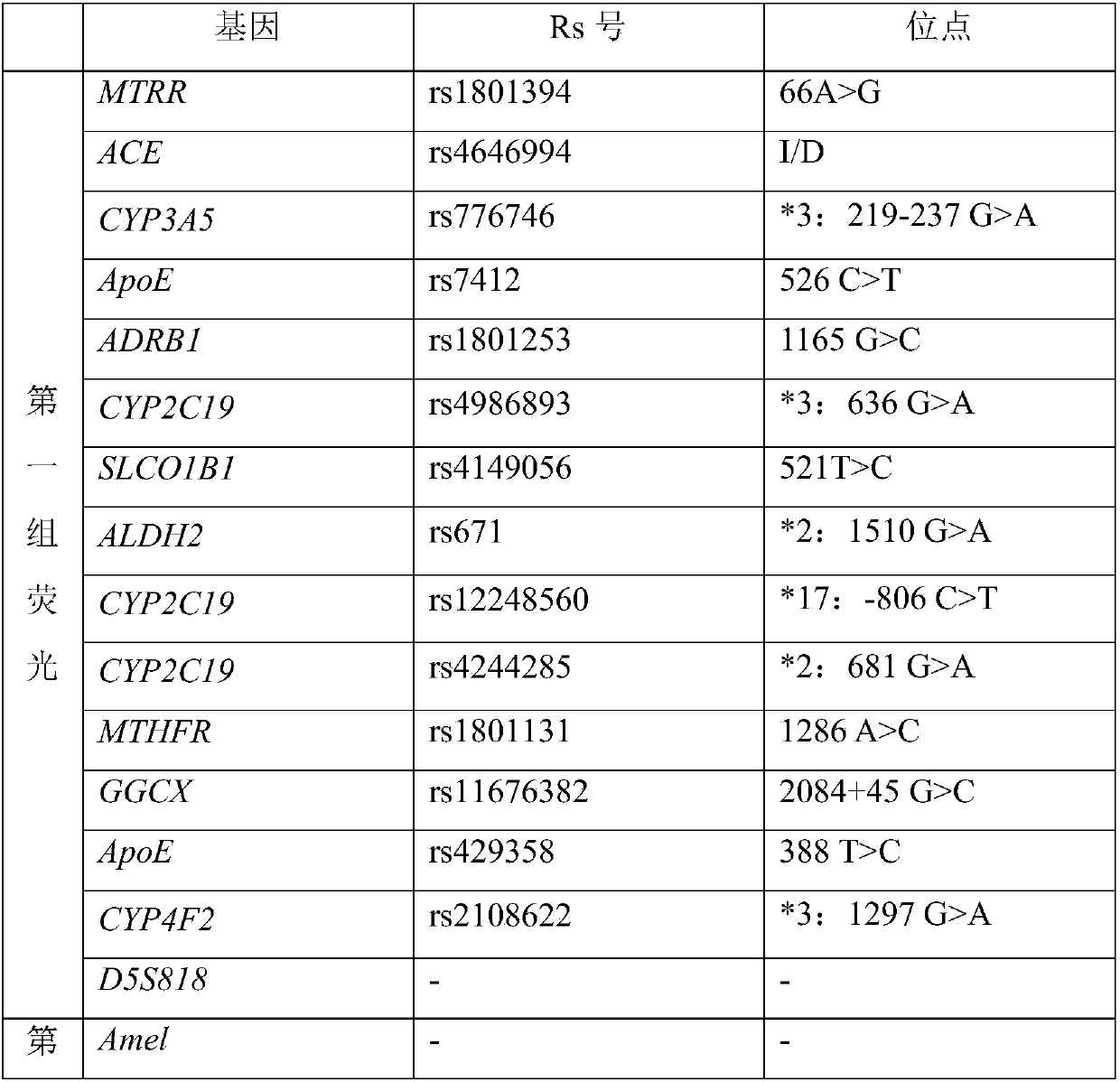

Polymorphism detection system and kit for gene relevant to personalized medication for cardiovascular disease

ActiveCN107641645AReduce operating intensityReduce testing costsMicrobiological testing/measurementDNA/RNA fragmentationDeoxyuridine TriphosphatePersonalization

The invention discloses a polymorphism detection system and a kit for a gene relevant to personalized medication for a cardiovascular disease. The system relates to a quantitive fluorescent PCR (Polymerase Chain Reaction) amplification (Quantitive Fluorescent PCR, QF-PCR) technique and a capillary electrophoresis detection technique. The system has the characteristics that 1, through the multiplePCR, the amplification of 27 polymorphic sites of 17 genes is realized in a one-tube manner; 2, the reference can be provided for the use of common medicines of an antihypertensive drug, an antiplatelet drug, oral anticoagulant drug, a blood lipid regulation drug and the like by a detection result; 3, the system can be used for realizing the direct amplification of blood and blood card, and is used for avoiding the step of extracting DNA (Deoxyribonucleic Acid); 4,the system can be used for integrating a UDG-dUTP (Uracil DNA Glycosylase-Deoxyuridine Triphosphate) pollution prevention measure,and can be used for effectively preventing a product from being polluted. The polymorphism detection system and the kit have the advantages of being complete in detection site coverage, high in specificity, high in sensitivity, high in reliability, simple and convenient to operate, high in practicability and low in cost, and has large-batch detection ability.

Owner:BEIJING MICROREAD GENE TECH

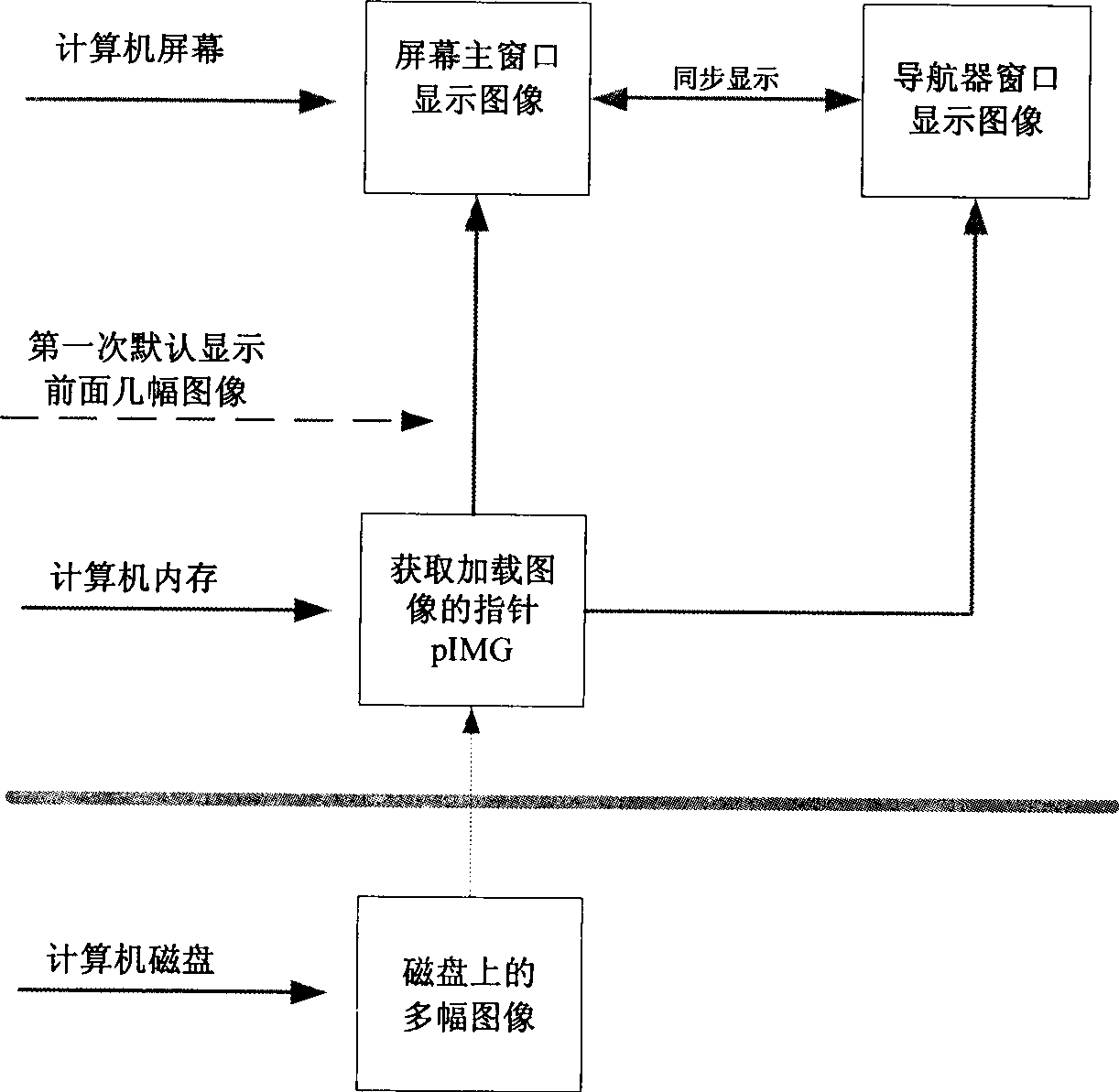

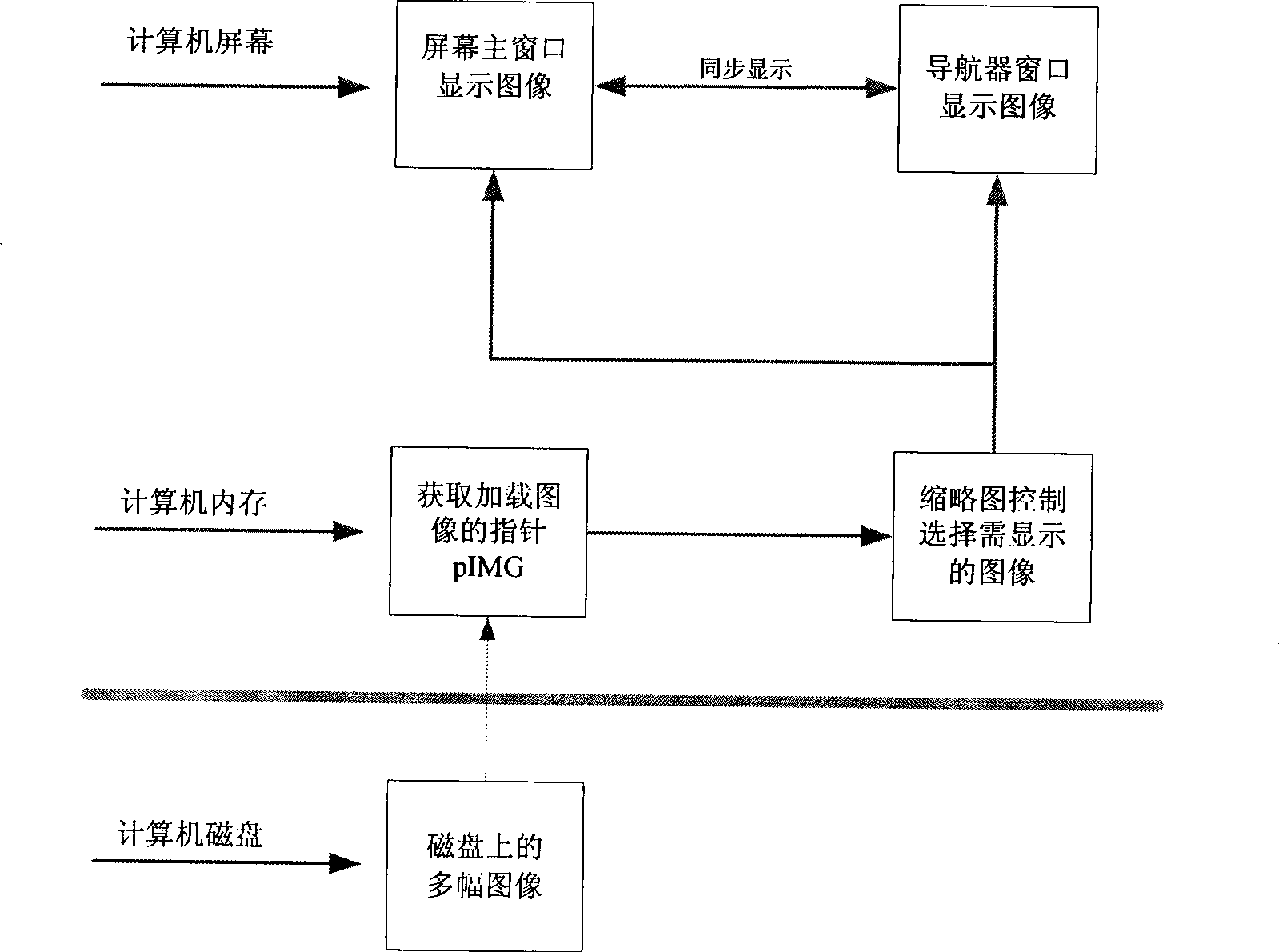

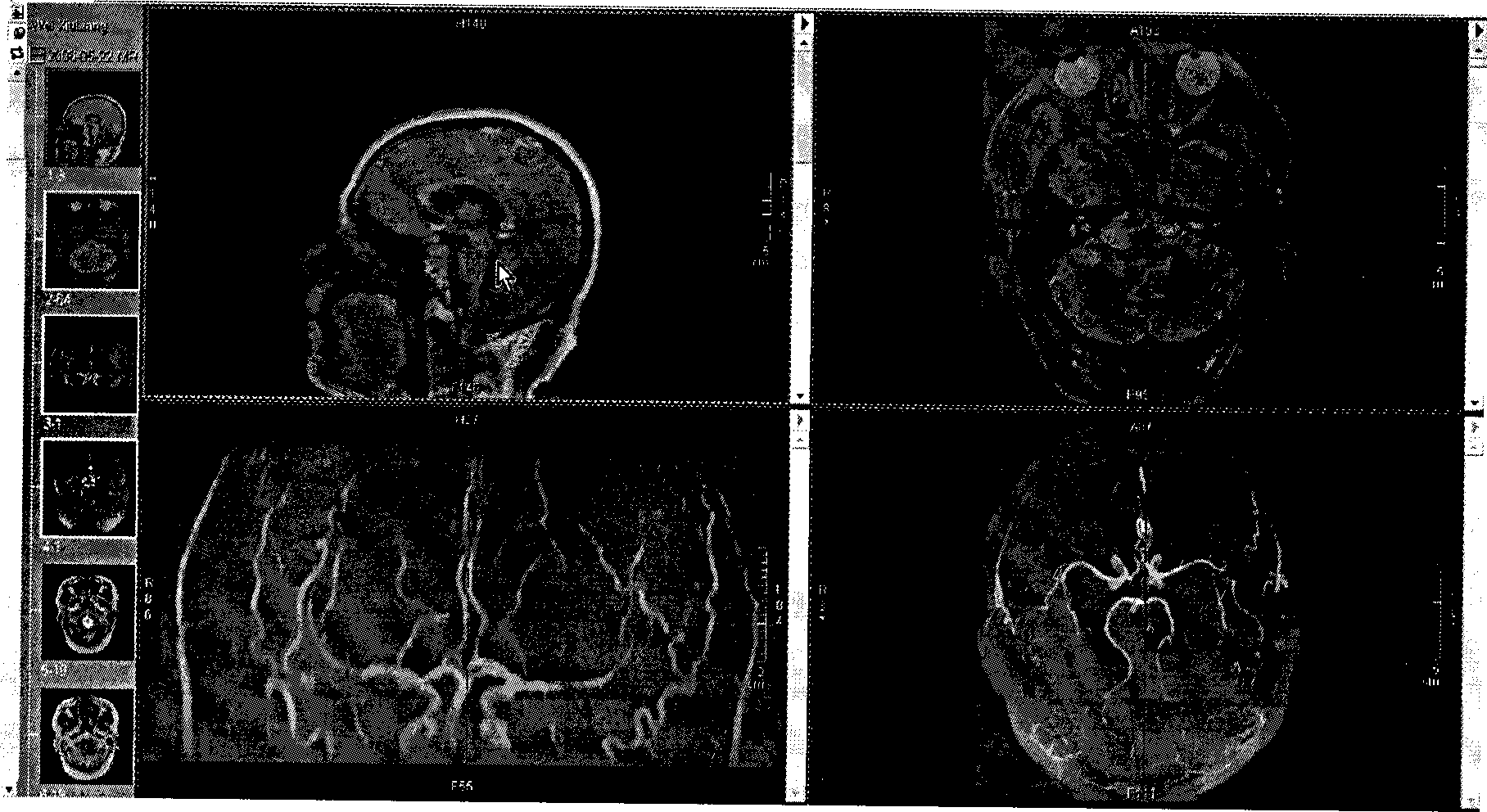

Medical image system pathfinder implementing method based on thumbnail

ActiveCN101398742AWeakening rangeReduce the difficulty of operationDiagnosticsSurgeryThumbnailImaging data

The invention discloses a realizing method for a medical image system omniselector based on thumbnails, which includes the steps of: A1, loading the image data from a memorizer into an EMS memory and recording the addresses of each image; A2, building a main display window, displaying at least one image in the display window and storing an image pointer pointing at the image; A3, building a thumbnail display window, compressing each image according to the addresses and a certain proportion and then displaying each image in the thumbnail display window; A4, building an omniselector display window at the edge of the thumbnail display window, compressing the image in the main display window according to the image pointer and the size of the omniselector display window and then displaying the image in the main display window in the omniselector display window.

Owner:LANWON TECH

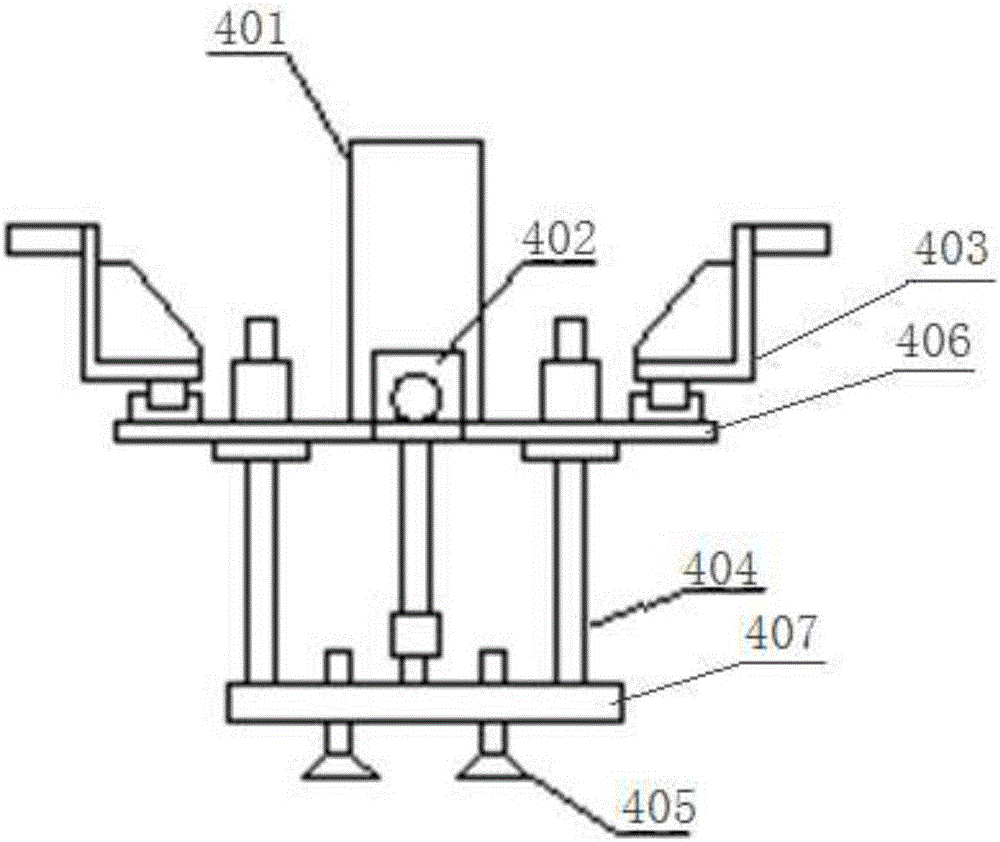

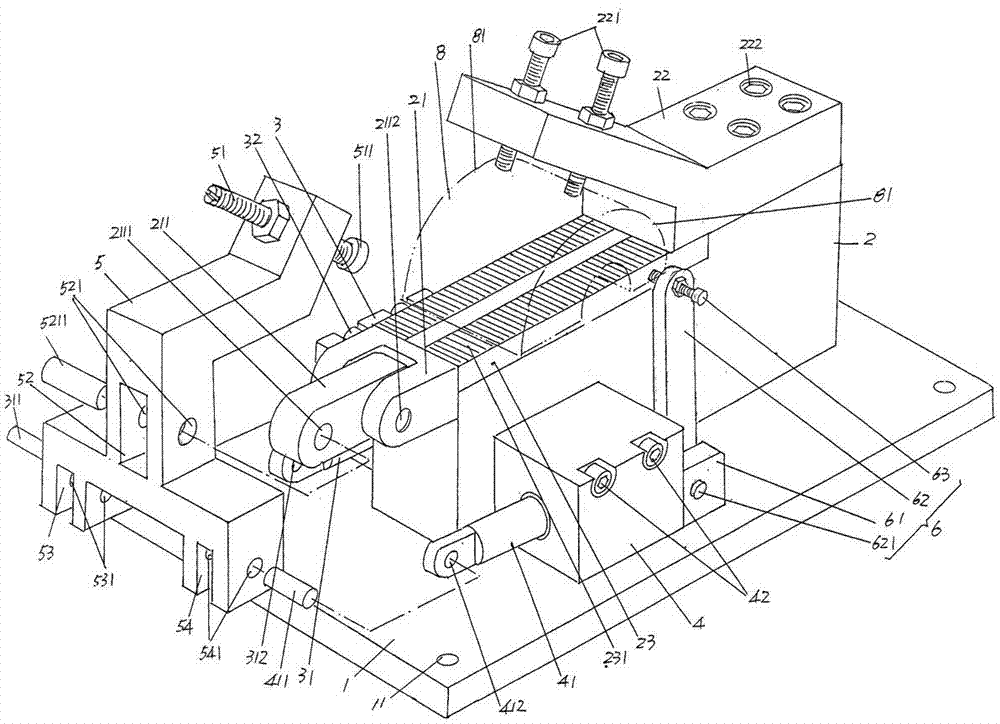

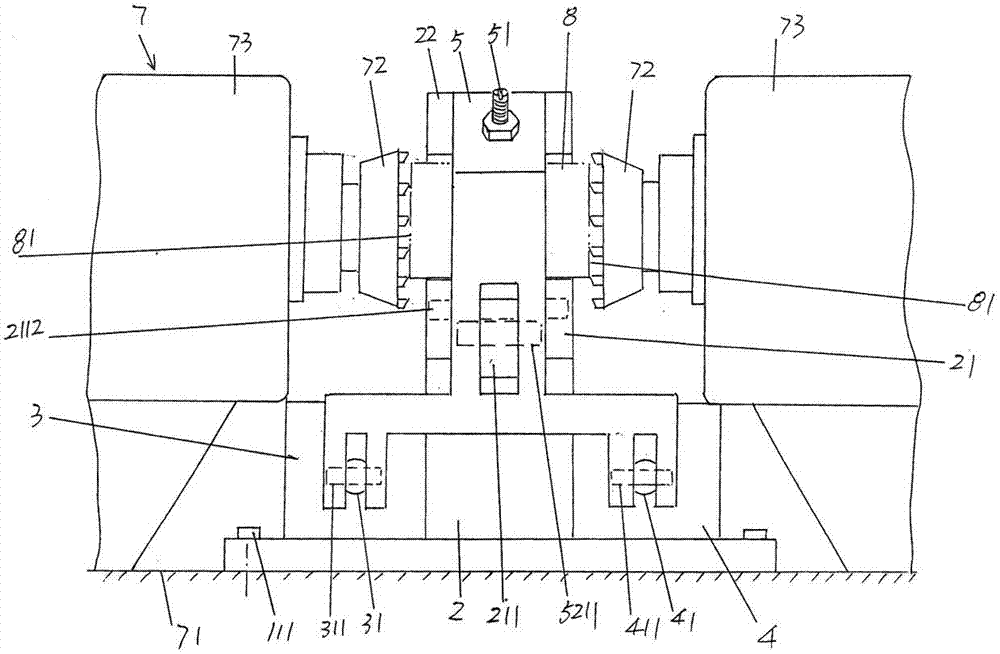

Clamp structure used for parallel face milling of glass mold

ActiveCN103273350BGuaranteed parallelismImprove milling efficiencyPositioning apparatusMetal-working holdersFixed bearingEngineering

The invention provides a clamp structure used for parallel face milling of a glass mold, and belongs to the technical field of tool clamps used for manufacture of the glass mold. The clamp structure comprises a bottom plate, a base, a first action cylinder, a second action cylinder, and a movable bearing base. The base is fixed on the upward side of the bottom plate, a connection shaft plate connecting base is formed on the upper portion of one end of the base, a fixed bearing base is fixed on the upper portion of the other end of the base, and a glass mold base plate is fixed in the middle of the base. The first action cylinder and the second action cylinder are located on two sides of the base respectively and fixed on the base. The upper portion of the movable bearing base corresponds to the fixed bearing base, the middle of the movable bearing base is connected with the connection shaft plate connecting base, one end of the lower portion of the movable bearing base is connected with the first action cylinder, the other end of the lower portion of the movable bearing base is connected with the second action cylinder, the upper portion of the movable bearing base corresponds to the upper portion of one end of the glass mold base plate in a vacant state, and the fixed bearing base faces one end of the movable bearing base and corresponds to the upper portion of the other end of the glass mold base plate. Milling efficiency is high, industrialization widened production requirements are met, operation intensity of workers is reduced, the parallelism of parallel faces of the glass mold can be guaranteed, and energy-saving effects are ideal.

Owner:ORI MOLD TECH SUZHOU

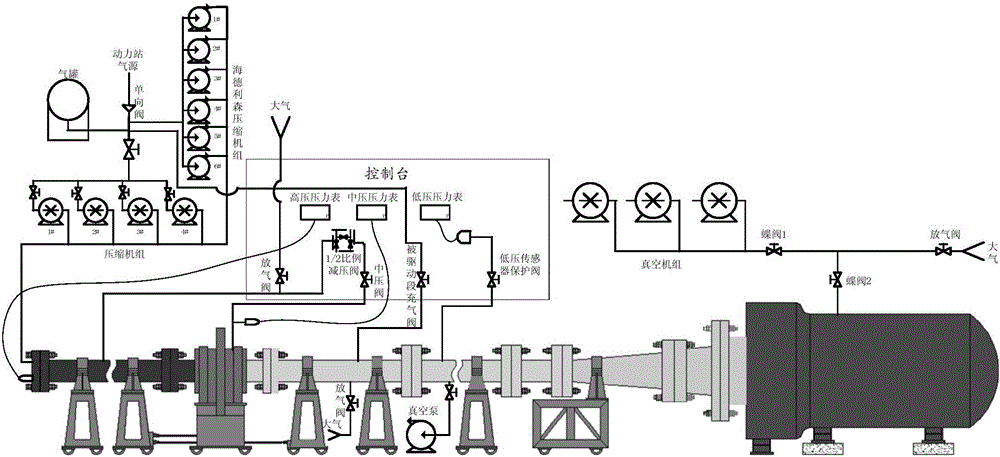

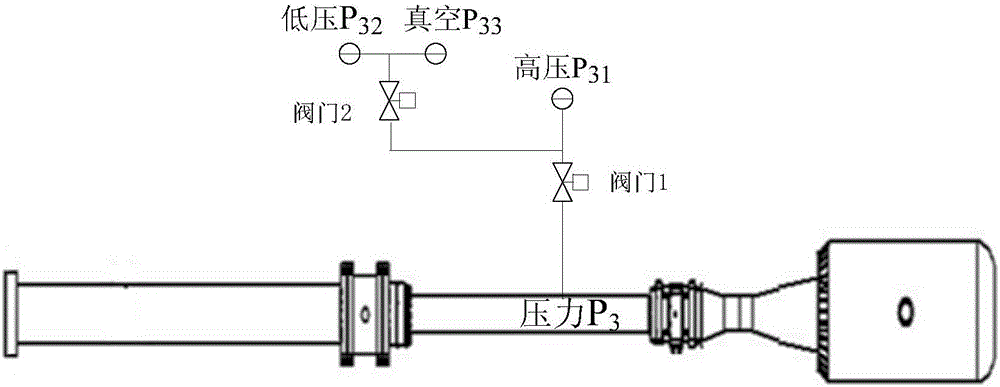

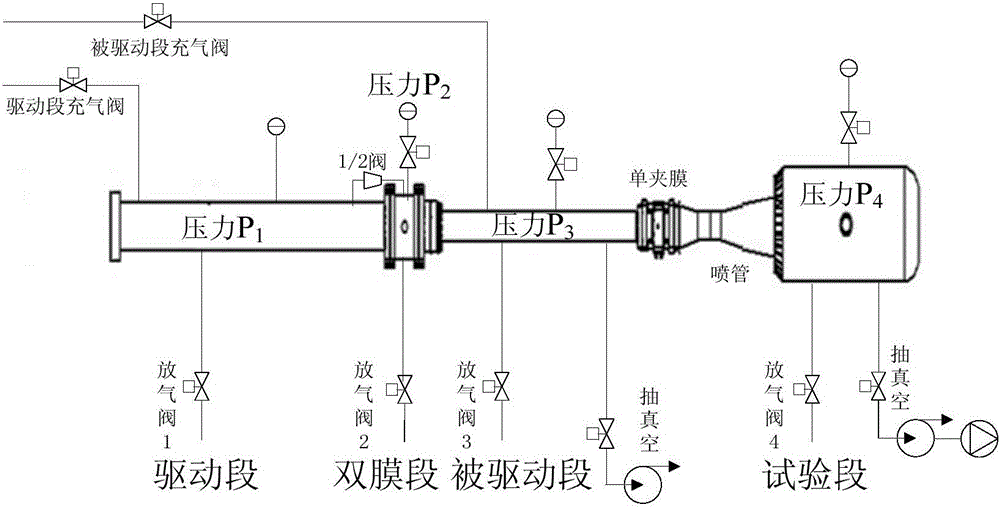

Pulse wind tunnel operation control system and pulse wind tunnel operation control method

ActiveCN106840582AEnsure the safety of personnel operationHigh repeatabilityAerodynamic testingAutomatic controlAutomotive engineering

The invention relates to a pulse wind tunnel operation control system and pulse wind tunnel operation control method. The system comprises a PLC module, a driving section inflation valve, a driving section deflation valve, a driving section pressure sensor, a 1 / 2 valve, a double film section deflation valve, a double film section pressure sensor, a driven section inflation valve, a driven section deflation valve, a driven section pressure measuring module, a driven section vacuum pumping valve, a test section deflation valve, a test section vacuum pumping valve, a test section pressure sensor and a vacuum machine tool; the PLC module achieves automatic control in a wind tunnel test process, a distributed control mode is adopted, all operation is completed in a test control room, there is need to enter a field for work, a high pressure air source is isolated, and the personnel operation safety is guaranteed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

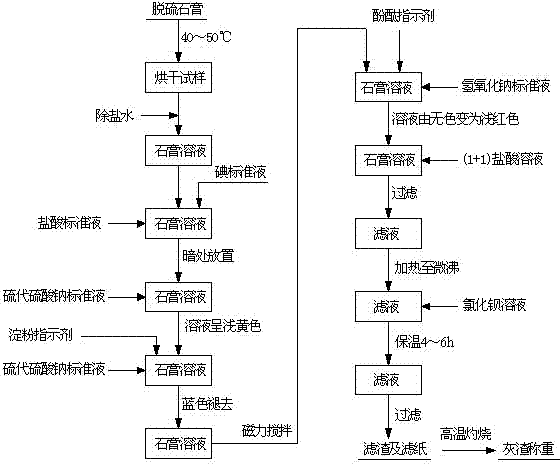

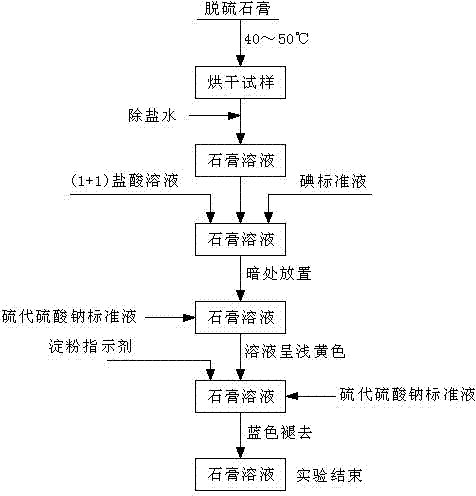

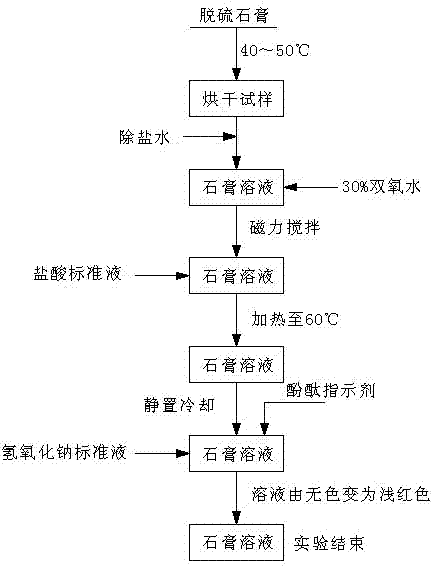

Process for continuously and rapidly determining components in desulfurization gypsum

ActiveCN102331422AReduce typesReduce dosageWeighing by removing componentChemical analysis using titrationIodometric methodPhysical chemistry

The invention which relates to a process or continuously and rapidly determining components in desulfurization gypsum belongs to the field of chemical detection. The process adopts iodometry, a back titration method with sodium hydroxide and a gravimetric method with barium sulfate in sequence to determine. The process of the invention has the advantages of reasonable design of test steps, easy and laborsaving operation, low cost, less pollution, high accuracy and less test workload.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

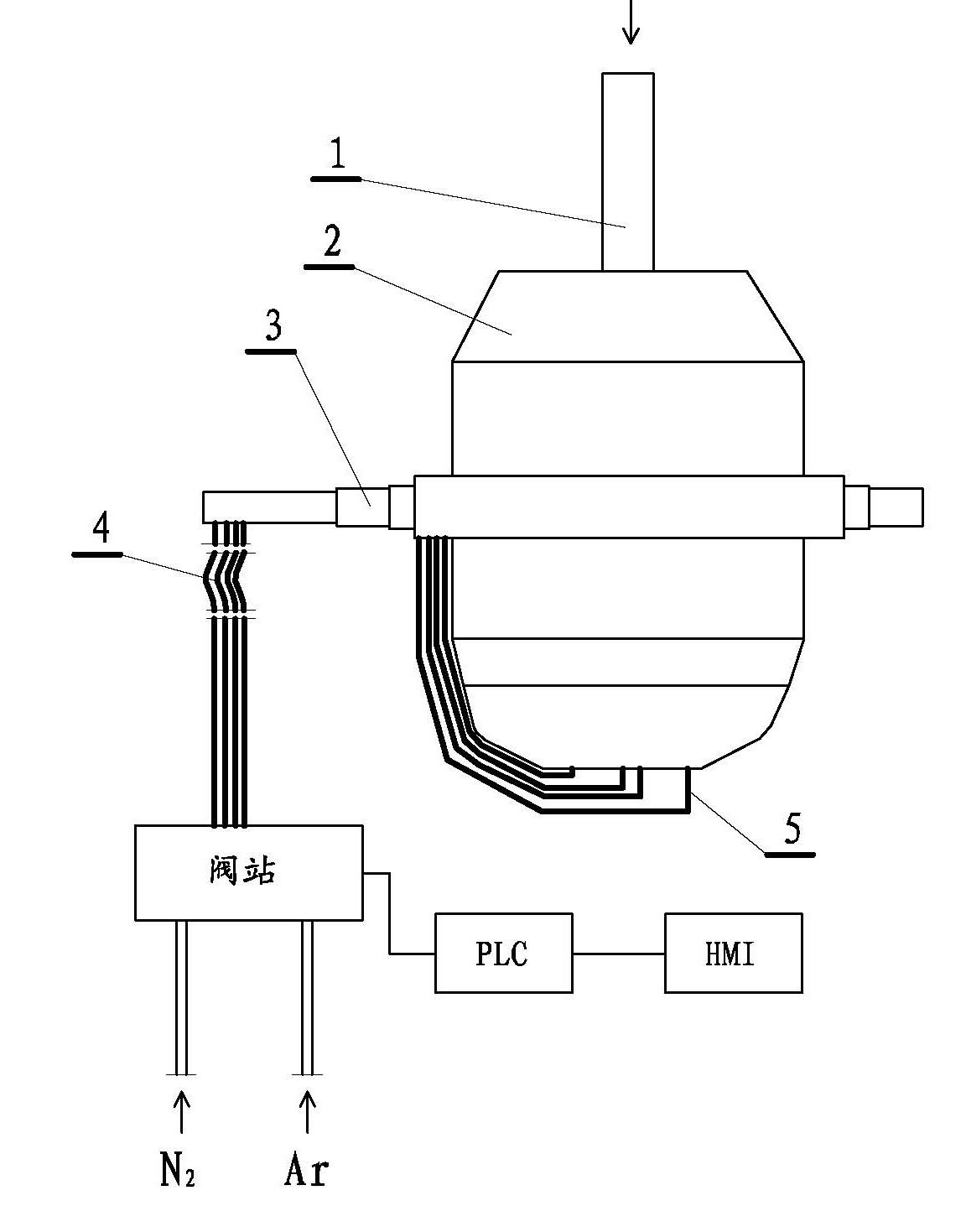

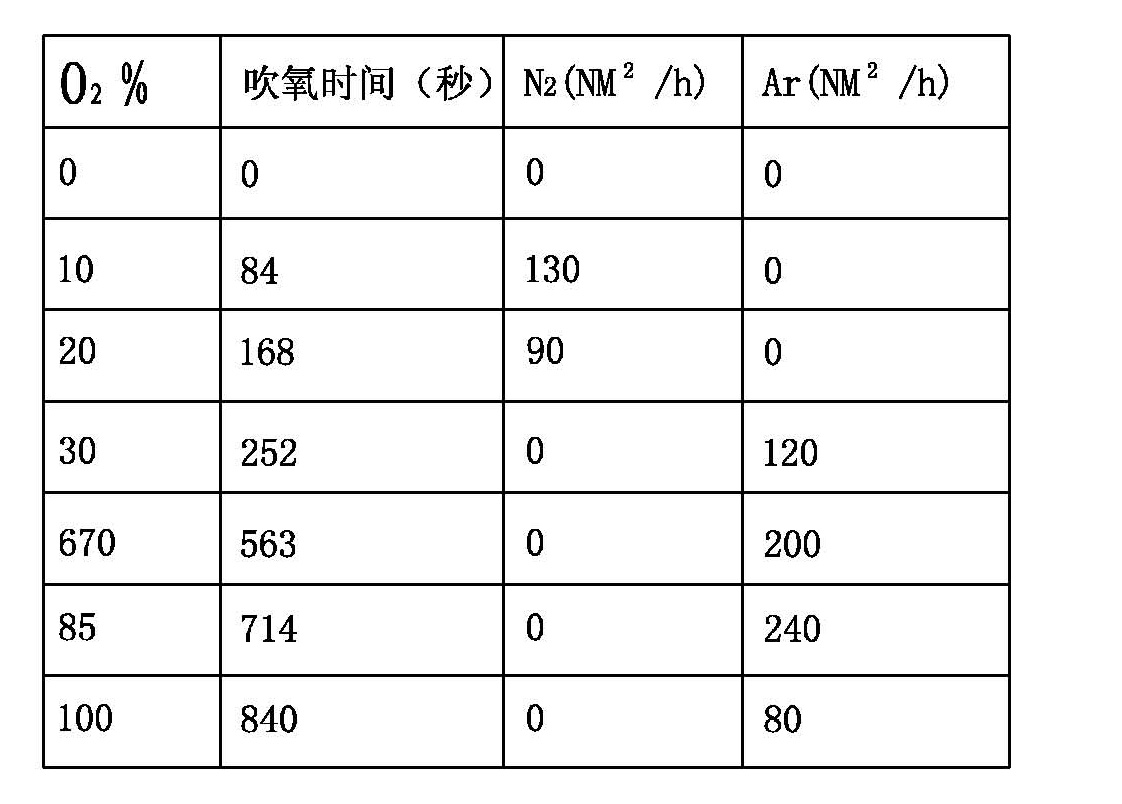

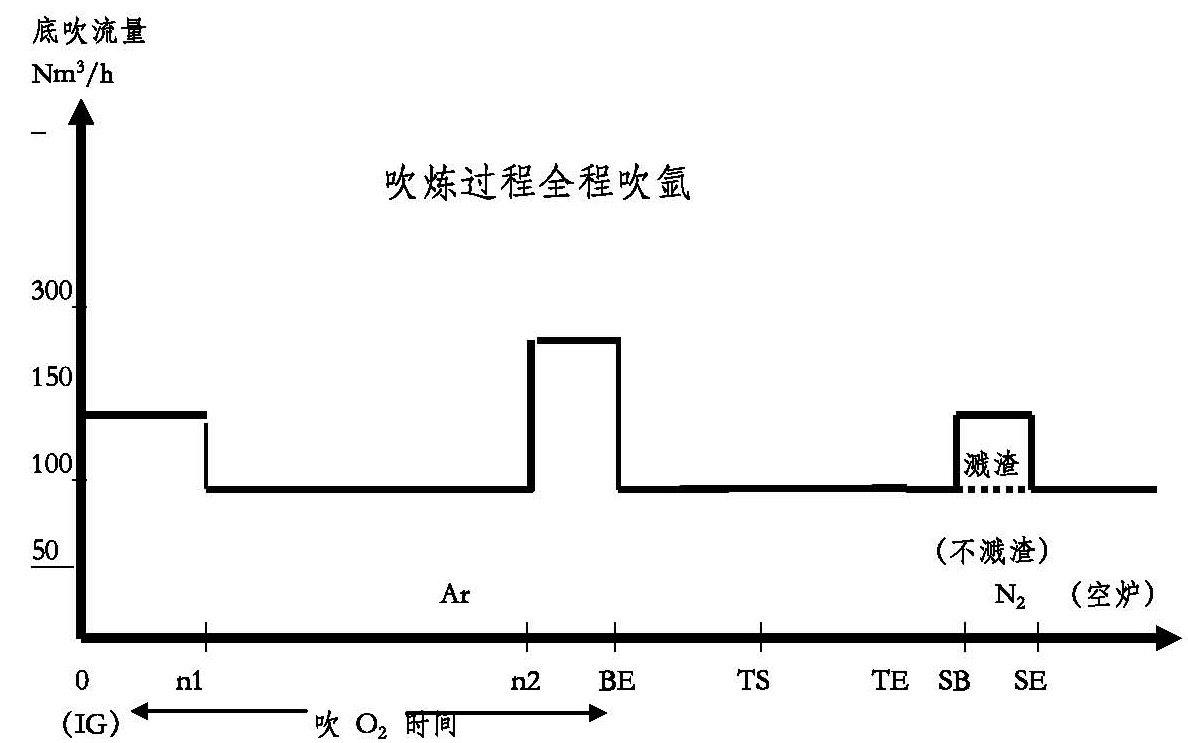

Method for automatic bottom blowing control of converter

InactiveCN102041346AQuality improvementShorten blowing timeManufacturing convertersHuman–machine interfaceSmelting process

The invention relates to a method for the automatic bottom blowing control of a converter. Hardware adopted by the method in the invention comprises a converter with a combined blowing function, a valve station for supplying argon and nitrogen and a PLC (programmable logic controller) with an HMI (human machine interface), wherein the PLC controls the valve station and stores a plurality of bottom blowing models. The method comprises the followings steps: selecting a bottom blowing model; confirming; loading a flow set value; transmitting the flow set value; and monitoring smelting process. According to different nitrogen contents and carbon contents of a target steel type, 9 models are combined in the invention, production operation personnel select a corresponding model code only according to a steel type to be smelted, and the parameter and the curve data of the model are automatically downloaded to the PLC. Thus, in the invention, the phenomenon that production operation personnel continuously and manually adjust valve opening in the conventional production step is reduced, thus the operation intensity is lightened. The PLC automatically switches nitrogen and argon, controls stable intake pressure and adjustable branch pipe flow, has high control precision and strong degree of automation and lowers production cost.

Owner:BEIJING JIANLONG HEAVY IND GROUP

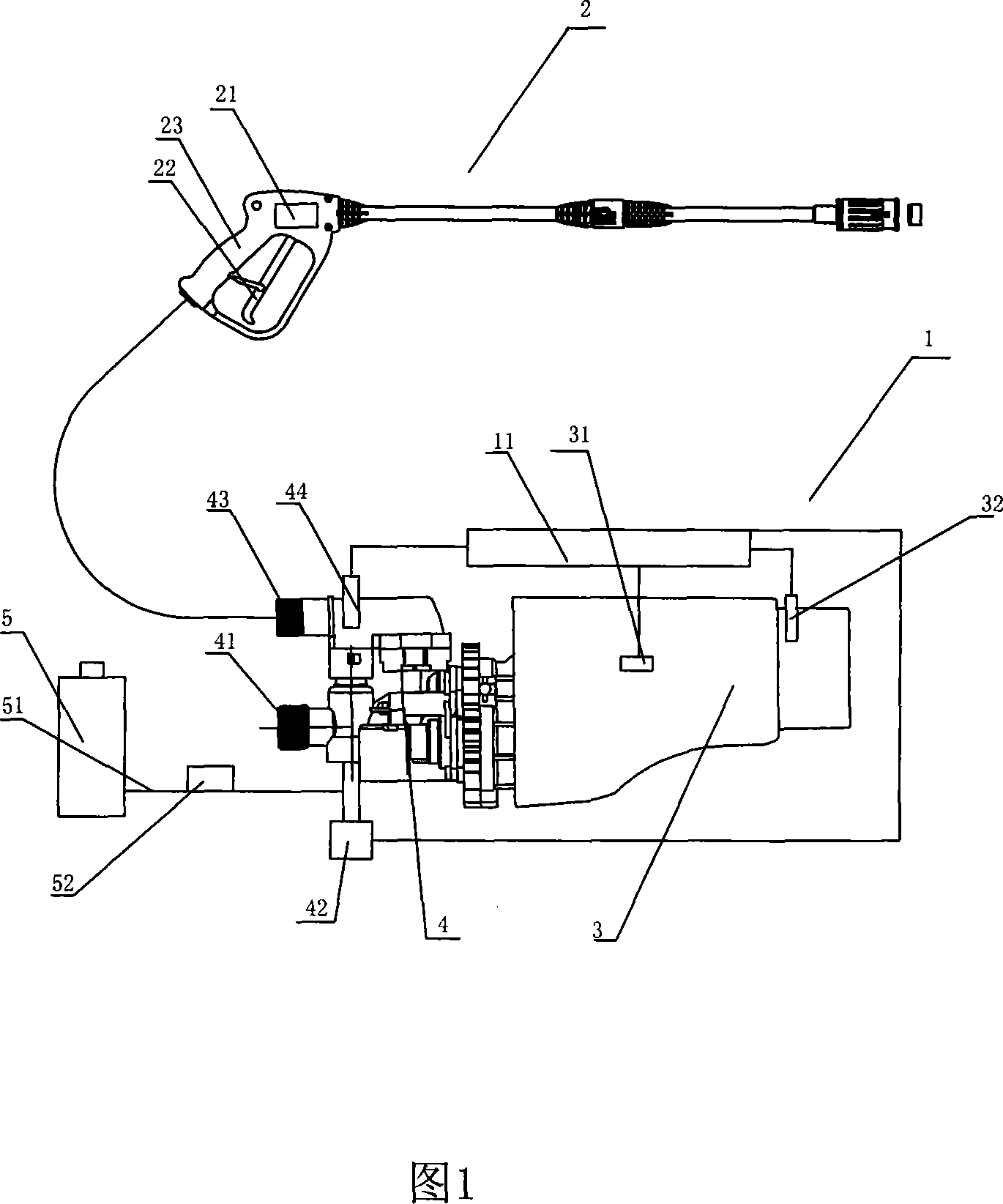

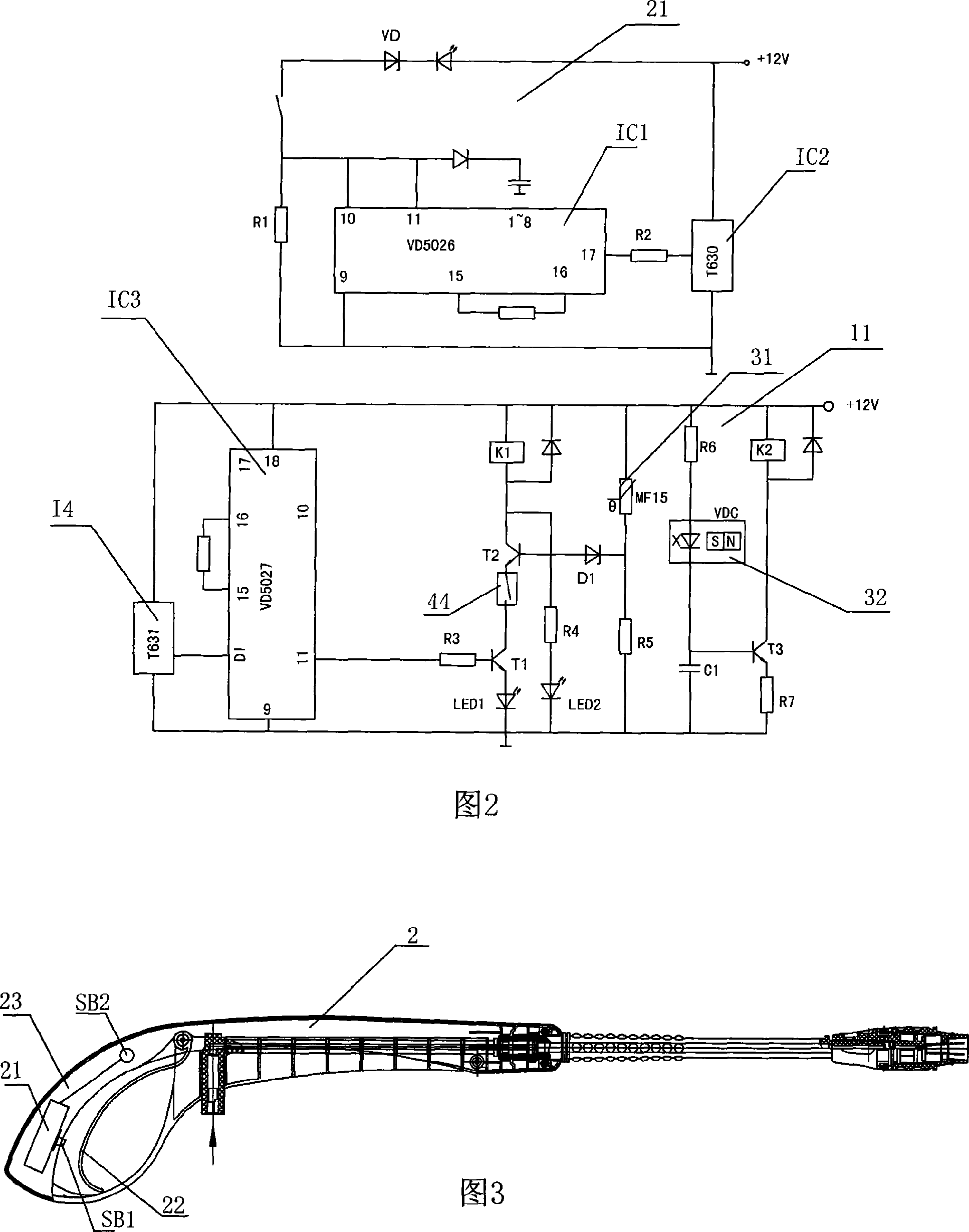

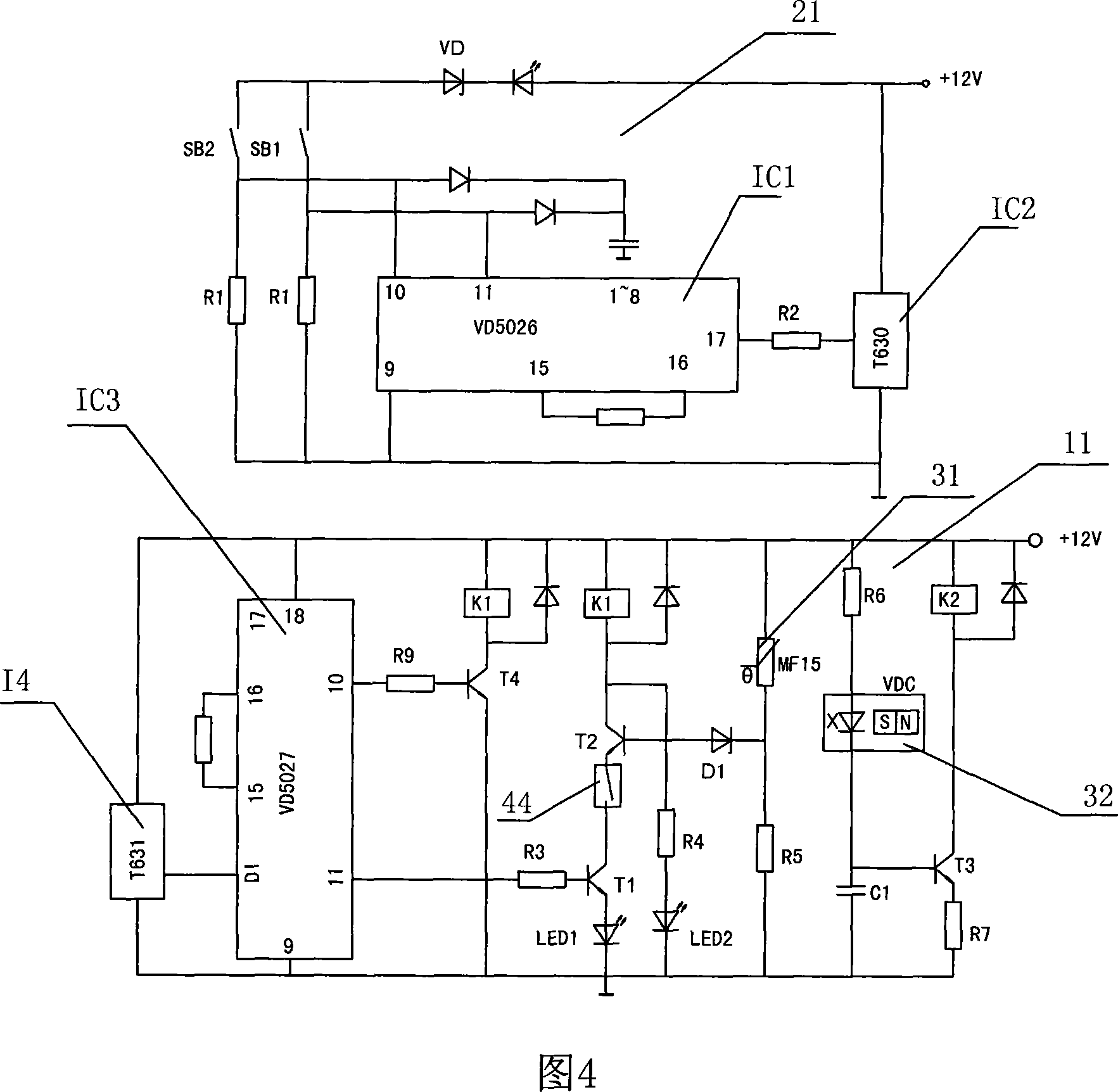

High pressure cleaning machine and operation method of the cleaning machine

InactiveCN101134199ARealize closed-loop controlSolution to short lifeElectric signal transmission systemsThermometers using electric/magnetic elementsElectricitySolenoid valve

The high pressure cleaning machine includes one main machine and one cleaning gun. The main machine includes one motor with one power relay switch, one high pressure pump with one water inlet pipe connected to the external water source and one water outlet pipe connected to the cleaning gun, and one detergent container with detergent pipe with switch unit and communicated to the water inlet pipe. The cleaning gun has one signal emitter with one first button corresponding to the trigger in the cleaning gun, and the main machine has corresponding signal receiving control device, water inlet solenoid valve on the water inlet pipe, temperature sensor and speed sensor on the motor, and pressure sensor on the water outlet pipe. All the sensors, the power relay switch and the water inlet solenoid valve are connected to the signal receiving control device, and the high pressure cleaning machine has the features of high safety, long service life, low cost and high reliability.

Owner:胡松海

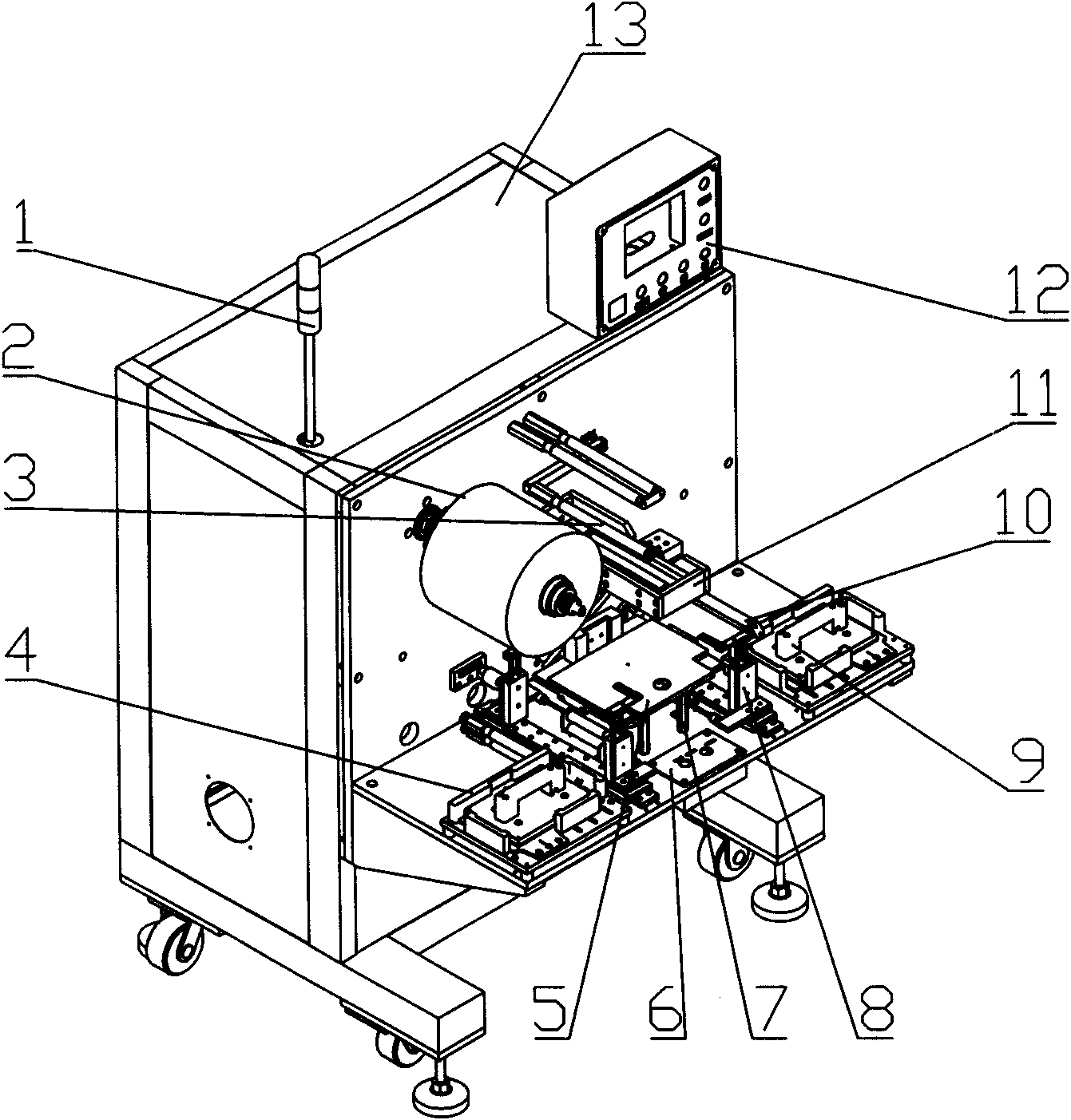

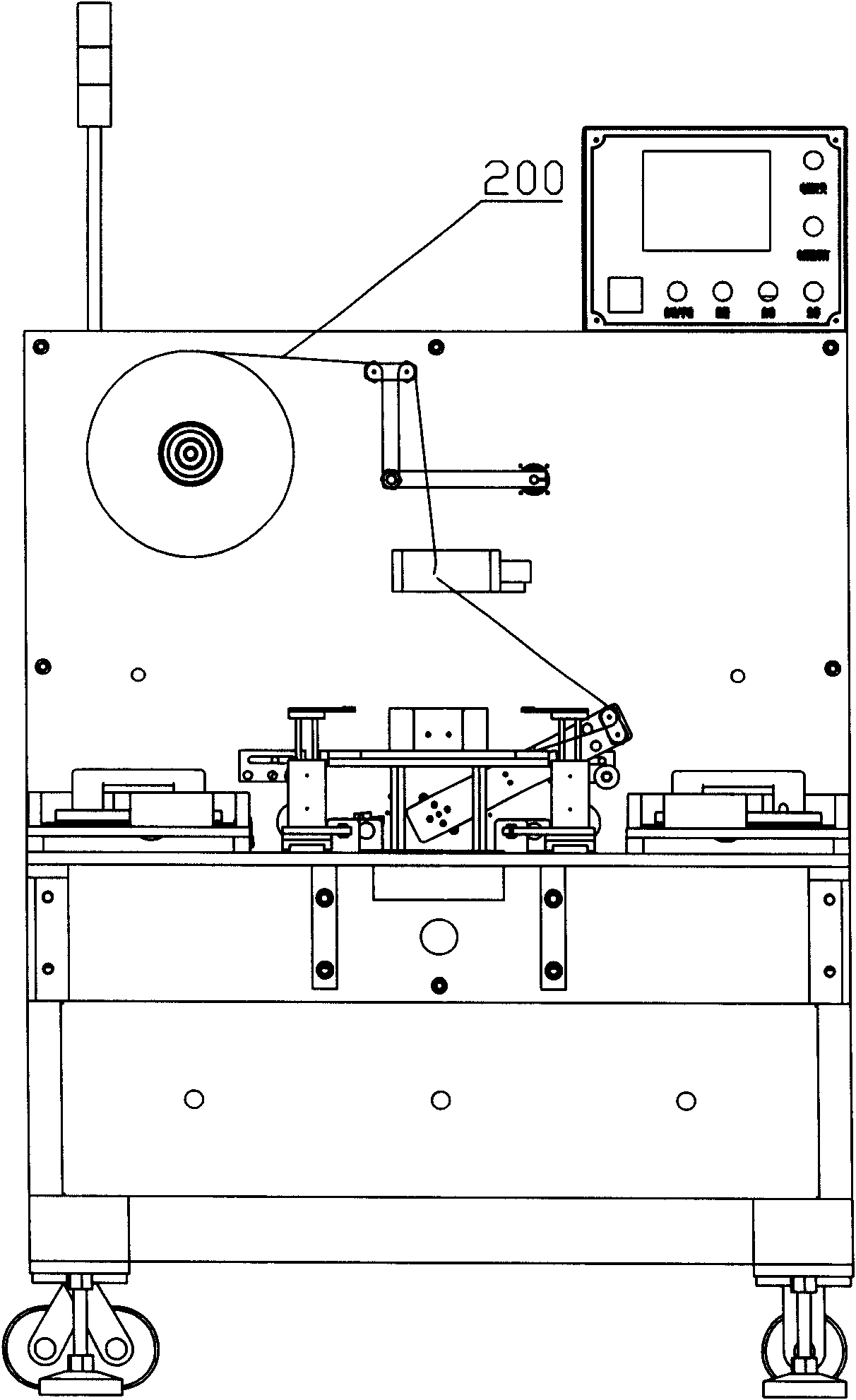

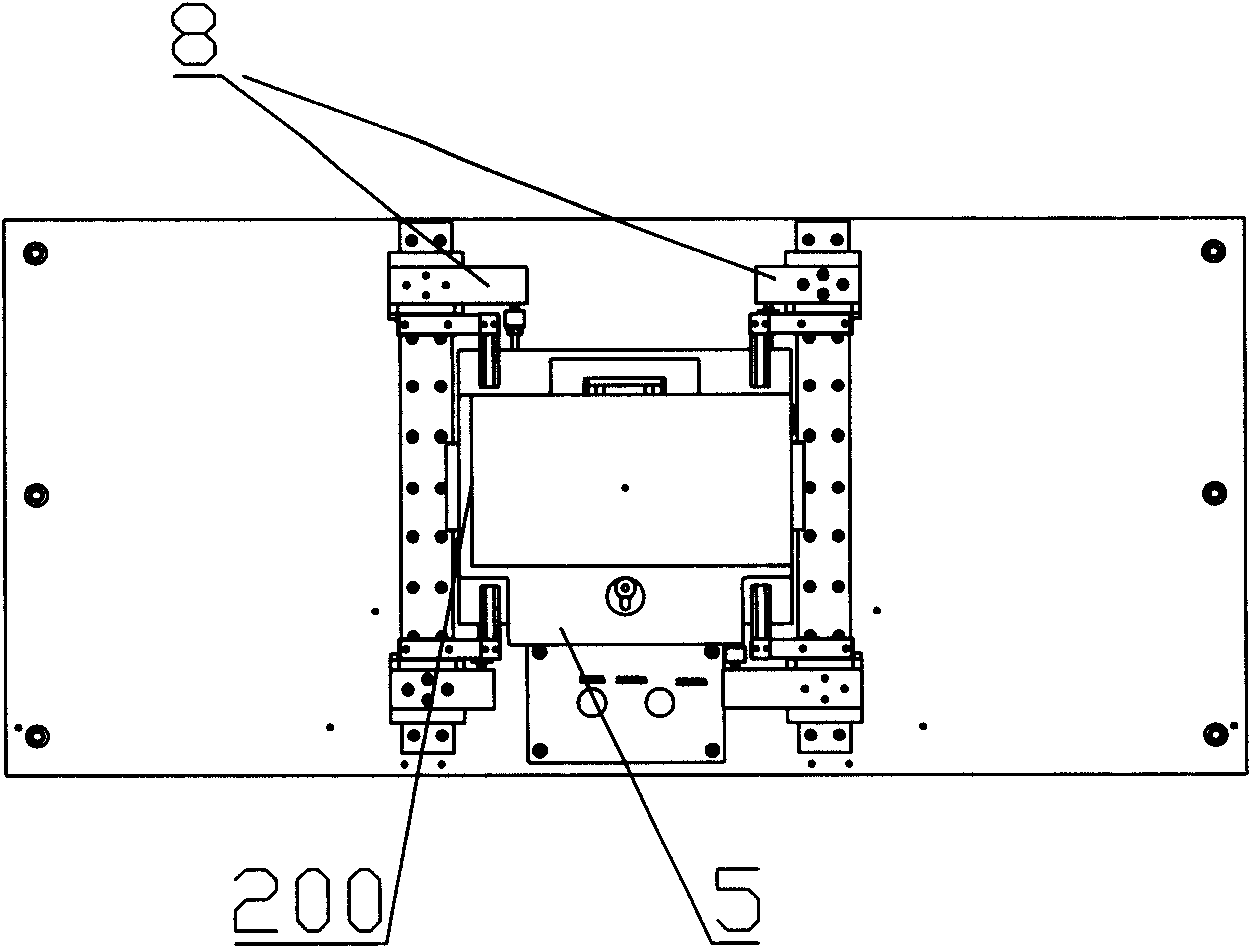

Semi-automatic laminating method of electrical core of power battery and laminating equipment thereof

ActiveCN101685887ALow costGuaranteed positioning accuracyFinal product manufactureSecondary cellsPower batterySemi automatic

The invention relates to a semi-automatic laminating method of an electrical core of a power battery and laminating equipment thereof. The method comprises the following steps: (1) stretching a diaphragm on the base layer; (2) laminating a first cathode piece; (3) winding a diaphragm on the first layer; (4) laminating a first anode piece; (5) winding a diaphragm on the second layer; (6) cyclicallyoperating step (2) to step (5) until the numbers of the laminated pieces and the wound diaphragms reach the set numbers of pieces and layers; and (7) taking out the laminated electrical core, whereinstep (3) and step (5) are carried out in an automatic mode, and other steps are carried out in a manual mode. A diaphragm winding component of the equipment controls a servo motor through a pedal switch, and controls the positioning of a diaphragm winding roller through a photoelectricity eye sensitive film; manual sucking discs at the left side and the right side suck pole pieces in a cathode piece box and an anode piece box at the left side and the right side by the vacuum generated by a vacuum valve through a vacuum sucking plate, and the pole pieces are laminated on the surfaces of the diaphragms which are wound to finish laminating; and then, the diaphragm winding component winds to the same side to automatically wind the diaphragms on the surfaces of the pole pieces. The invention can enable the diaphragms to be basically controlled in constant tension, relieve the operating strength, is convenient for replacing models and reduces the equipment cost.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

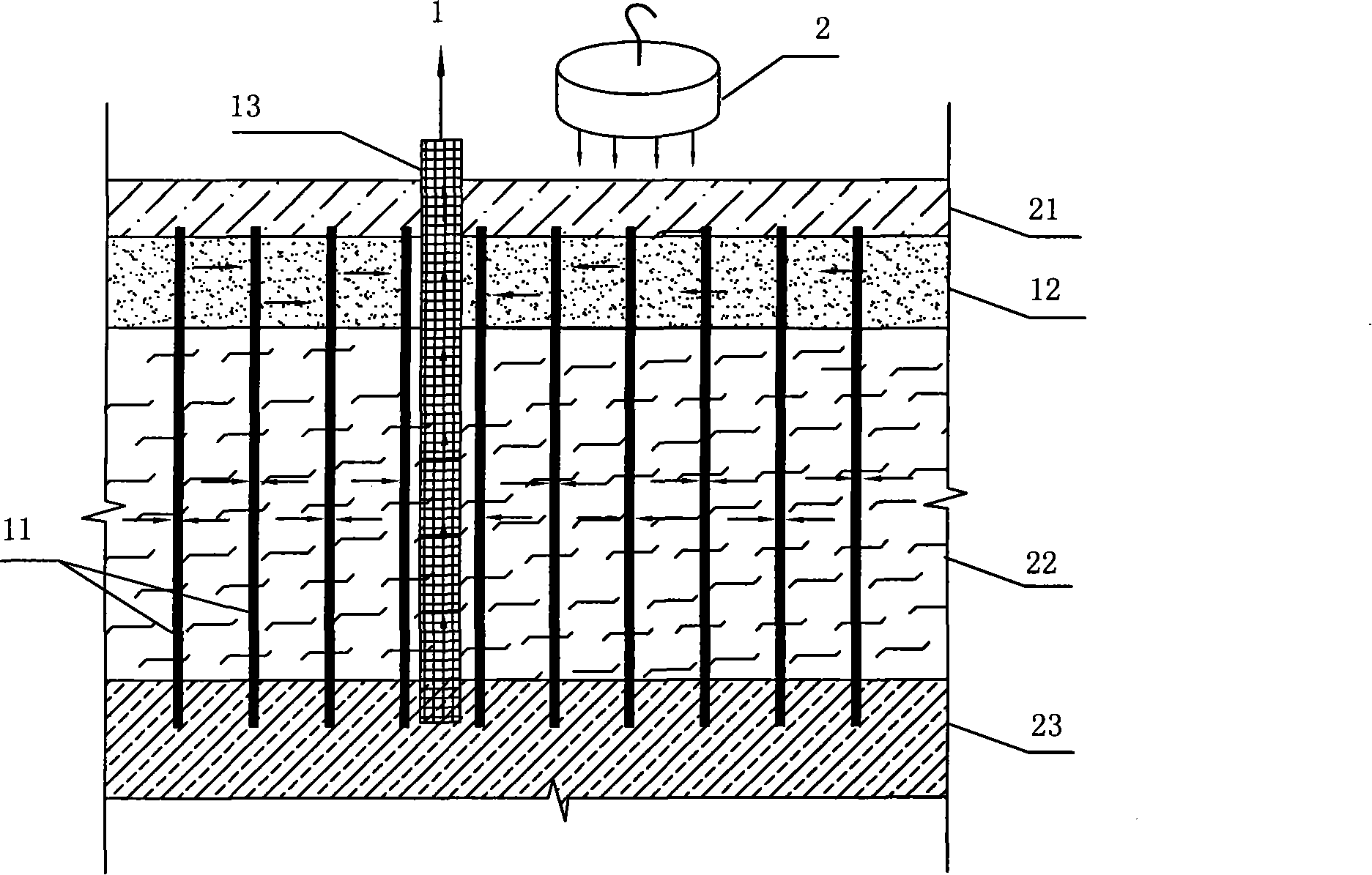

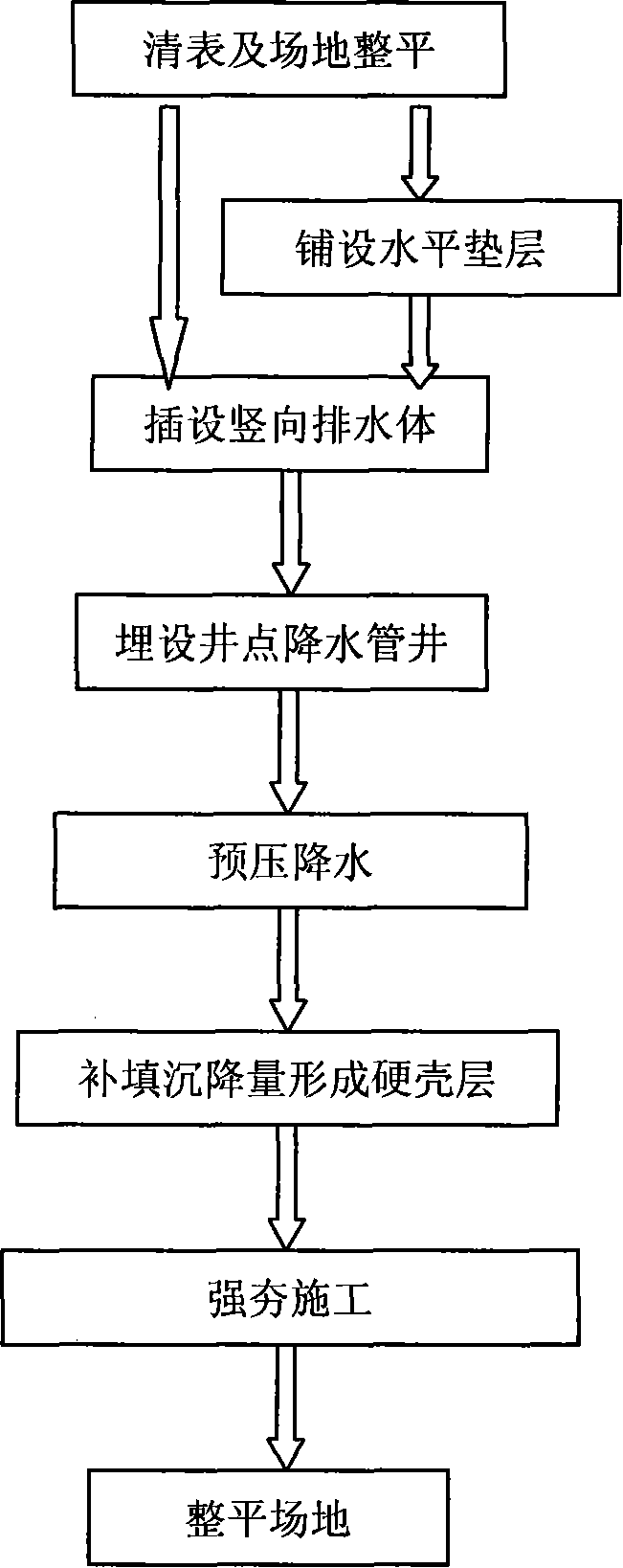

Precipitation prepressing association motivation induration deep densification method

ActiveCN101250868AIncrease the permeability coefficientAdd additional pressureSoil preservationSoil sciencePermeability coefficient

The invention discloses a deep strengthening method of dewatering reinforcement combined dynamic consolidation, which comprises the following steps: V1ing: a vertical drainage body is arranged in a strengthened foundation. V2ing, soft soil foundation is done with the dewatering reinforcement. V3ing, after a deep soil body below 8 meter of the ground surface of the strengthened foundation is acted by the dewatering reinforcement, the consolidation degree is above to 75 percent, and then the consolidation construction is done. The invention combines a dewatering reinforcement method and a dynamic consolidation method to be applied to strengthen the deep soil body of the soft soil foundation, particularly the permeability coefficient is not less than 10-6cm / s, and the water content of the soil body before the dynamic consolidation is not higher than a strengthened soft soil foundation which is 20 percent of the best water content. The foundation reinforcement effect is obvious, the construction period is capable of being reduced 1 / 3-2 / 3 as a whole, the construction cost is greatly reduced, the cost is saved (compared with a vacuum preloading method, the treatment cost in each square meter is reduced by 30-50 percent ), because the operating intensity is small, the demand for equipment is not high, and the deep strengthening method is suitable for popularization and application.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

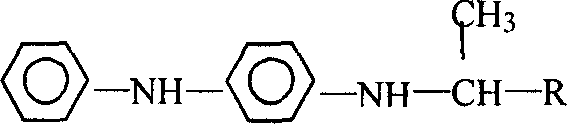

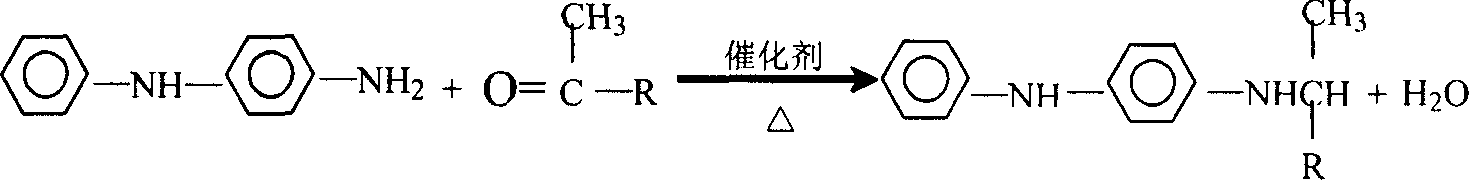

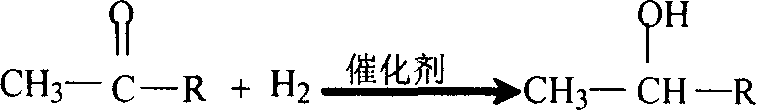

Condensating reductive alkylation catalyst, preparation method and uses thereof

ActiveCN101204658AAppropriate areaAvoid wastingPreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsWater useOrganic acid

The invention provides a condensation reductive alkylation catalyst and preparation method and use thereof. The catalyst pertains to copper-based catalyst, and is prepared by coprecipitation method with acid or salt thereof as precipitator. The preparation method is energy saving and environment friendly for including no impurity natrium, which avoids environmental protection problem existing in catalysis preparation technology with traditional precipitation method and reduces washing water use. The specific surface area of the catalyst is 30.0 to 75.0m<2> / g and pore volume 0.08 to 0.15ml / g. The catalyst can be used in condensation technology of RT Base and aliphatic ketone to inhibit an unnecessary side reaction in production of anti-aging agent 4010NA and 4020, especially to a reaction of aliphatic ketone alkylation regent hydrogenated to corresponding mellow.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

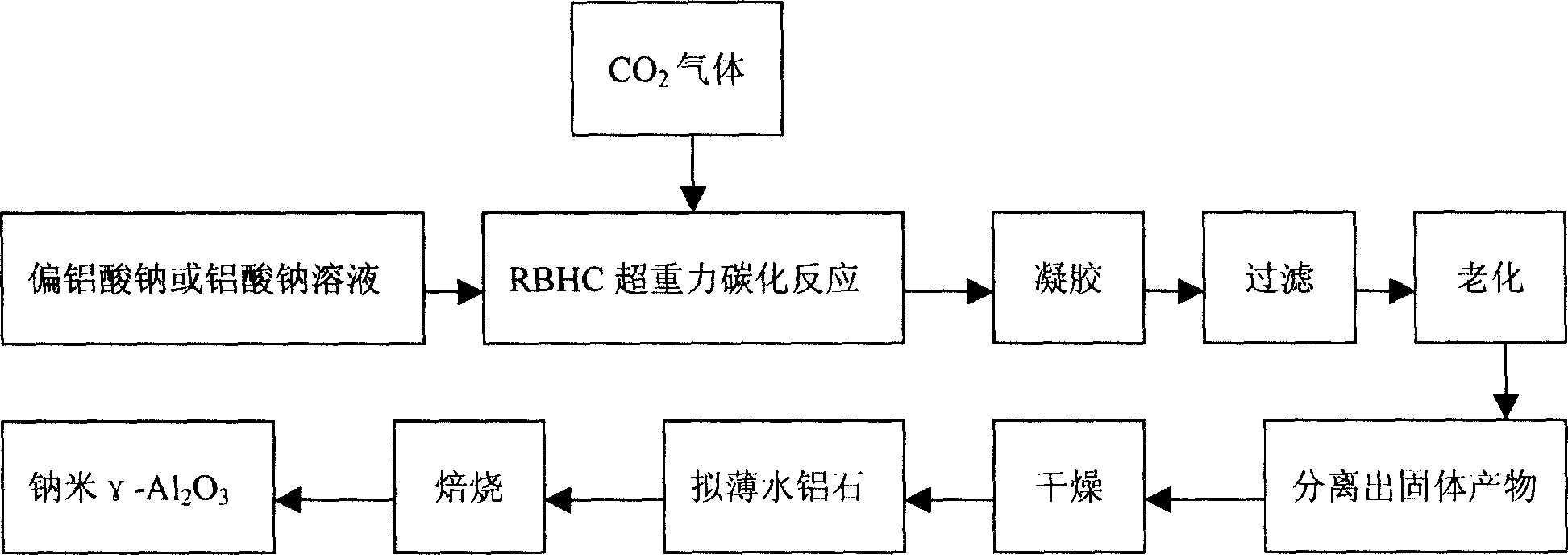

Preparation method of ultrafine active aluminium oxide

InactiveCN1752005ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateNanofiber

A process for preparing superfine active alumina includes such steps as carbonifying reaction between the solution of sodium metaaluminate (or aluminate) and the gas containing CO2 in gravitation condition to obtain alpha-AlO(OH) gel, filtering, ageing, separating solid, drying and calcining. Said product has high pore volume, large specific surface area and large average pore diameter, and can be used to prepare reforming catalyst and hydrocracking catalyst.

Owner:XIANGTAN UNIV

Water-soluble self-emulsifying coupled modified silicone oil composite and application in pickling, tanning and dyeing of leather making

InactiveCN101629218AEasy to controlFooling the processTanning treatmentPre-tanning chemical treatmentAfter treatmentPollutant emissions

The invention is water-soluble self-emulsifying coupled modified silicone oil composite and an application in pickling, tanning and dyeing of leather, which is characterized in that the water-soluble self-emulsifying coupled silicone oil composite after modification is adopted to carry out oil pretanning, tanning, softening, dyeing and setting treatment on pickled skins of animals in a revolving drum. The crust leather to be coated has the advantages of plumpness, softness, no loose grain, good elasticity, good foaming sense and velvet silicon sense after treatment. By adopting the composite and the application method thereof to carry out oil pretanning, tanning, softening, dyeing and setting treatment, the quality of finished leather can be improved and stabilized, the production cost isreduced, the workshop sections such as wet blue pickling and degreasing, chrome retanning, alkali extraction overnight, neutralization and the like in the traditional leather making technique can be completely canceled, and the usage amounts of dye, fatliquor, stuffing and the like can be reduced, water washing is avoided by twice, thus saving more than 40% of water, shortening more than one third of the production period, reducing more than half of subsequent milling time, greatly stabilizing and simplifying the technique procedures, being easy to control the leather quality, and obviously reducing pollutant discharge in the traditional leather-making workshop sections of tanning, pretanning and dyeing water yard and lowering energy consumption such as water, electricity, manpower and the like.

Owner:CHENGDU KAITE ORGANOSILICON NEW MATERIALS TECH

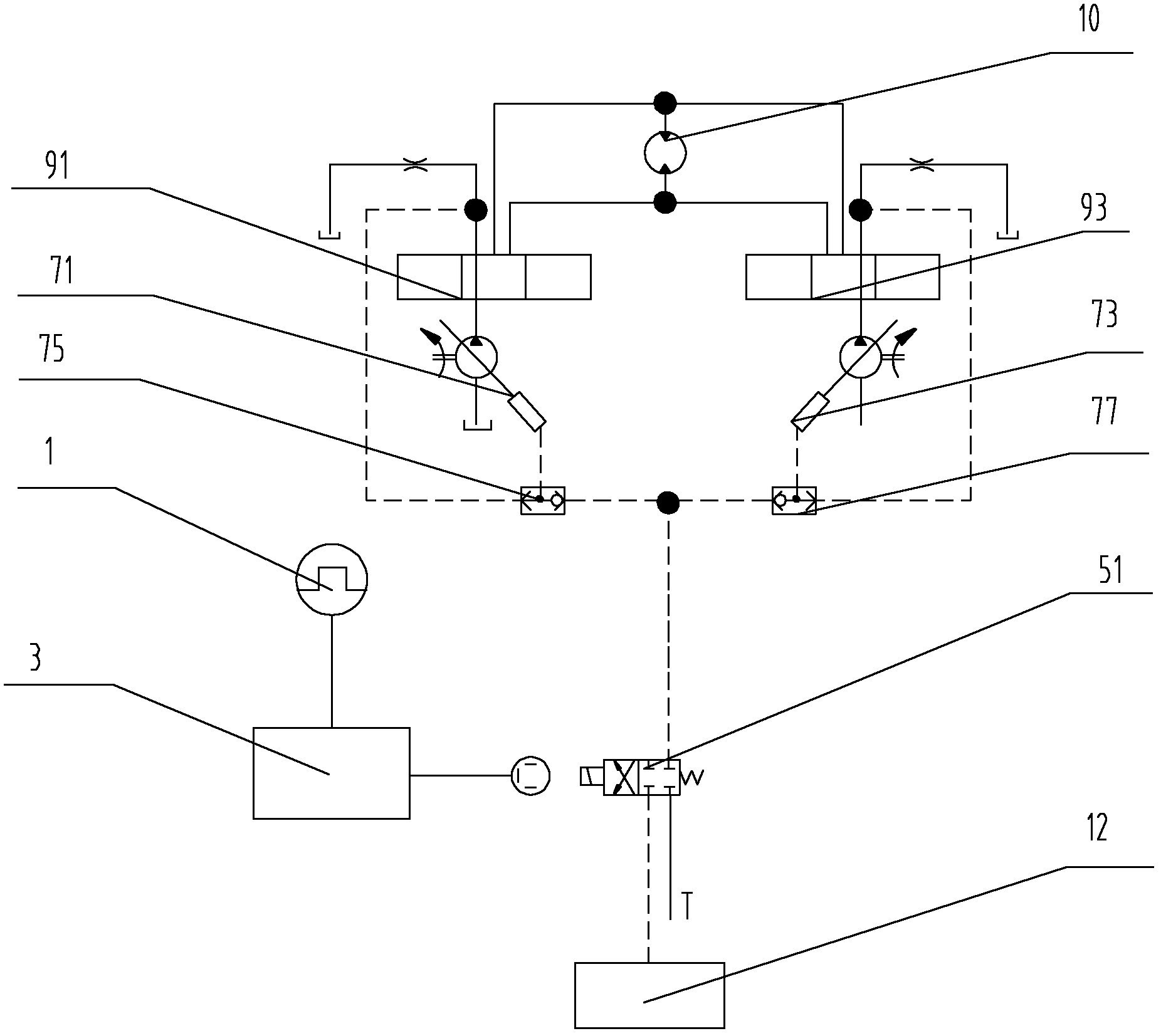

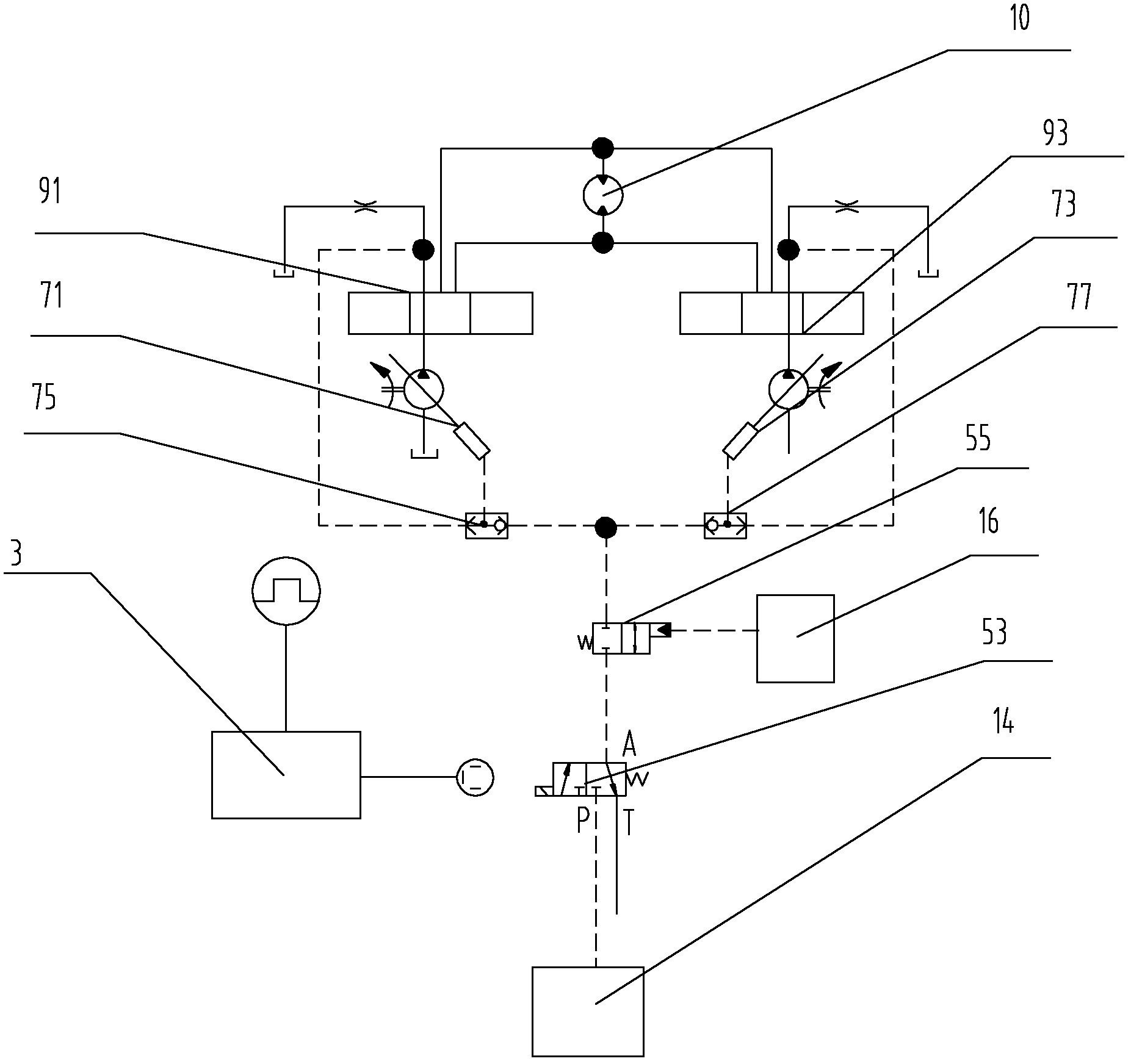

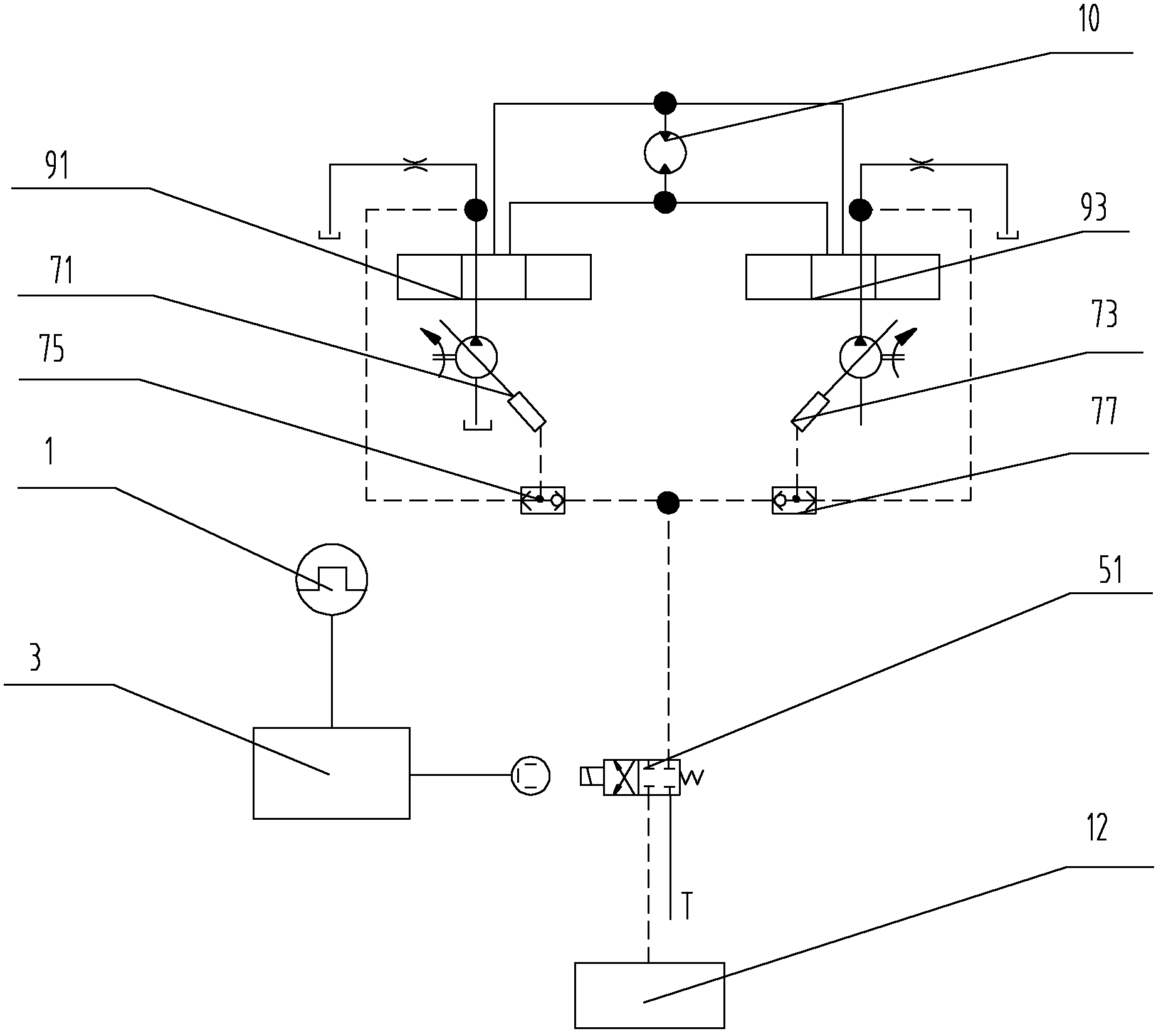

Rotary drilling rig and main winch placing down speed control device thereof

InactiveCN102424336AExtended service lifeImprove machine reliabilityDrilling rodsConstructionsNegative feedbackEngineering

The invention provides a rotary drilling rig and a main winch placing down speed control device thereof, wherein the main winch placing down speed control device comprises a sensor, a controller and a reverse valve device, the sensor is used for sensing the relative distance between a drill rod and a power head buffer device in real time and sending triggering signals when the relative distance equals to the preset distance, the controller is used for sending voltage signals to the reverse valve device after receiving the triggering signals, an oil supply opening of a main pump negative feedback opening is connected with the main pump negative feedback opening through the reverse valve device, and the oil supply opening supplies oil to the main pump negative feedback opening when the reverse valve device receives the voltage signals and the main winch is in the placing down state. The negative feedback pressure of a main pump can be controlled, and the discharge capacity of the main pump is changed, so the main winch placing down speed can be effectively decelerated in the drill rod placing down process, the severe collision between the drill rod and a power head is avoided, the service life of the power head is prolonged, and the whole machine reliability is improved.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Method for filling nickel-based alloy in glass die cavity with cast iron alloy as base matrix

InactiveCN102248358AEasy maintenanceExtended service lifePlasma welding apparatusAlloyUltimate tensile strength

The invention discloses a method for filling a nickel-based alloy in a glass die cavity with a cast iron alloy as a base matrix, belonging to the technical field of glass dies and comprising the following steps of die cavity pre-processing, preheating, treating before welding, welding, annealing and finish processing. The invention has the advantages that the cast iron alloy is taken as the base matrix of the glass die, thus the method has low cost, abundant raw materials, moderate heat conductivity, convenience for maintenance of the die and no limitation from the produced glass products; a plasma welder is adopted; a plasma arc is used as a heat source, the temperature is high and the heat is centralized, and a micro molten pool is formed on the surface of a workpiece, so that a welding layer is metallurgically bonded with a matrix, the combined strength of the welding layer is high and the welded welding layer is not easy to fall off; by using the plasma welder to operate, the automatic streamline operation can be formed, the requirement for industrial production enlargement is met, welding powder is saved, the productivity is improved and the operation strength of workers is reduced; in addition, the service life of the die can be prolonged and the requirement for high machine speed is met.

Owner:CHANGSHU JIANHUA MOLD TECH

Hair-protection and hair-removing composition of organosilicon and enzyme and method for hair-protection and hair-removing animal skin by the same

InactiveCN1928123AReduce operating intensityReduce dosagePre-tanning chemical treatmentHair rootsHair falling

One kind of hair-keeping and eliminating silicone-enzyme composition and the method of using the composition in treating animal hide are disclosed. The composition consists of water soluble silicone polymer and coarse enzyme preparation. When the composition is used in treating leather, the leather is first rolled in a roller with the composition to loosen the hair root without hair falling, and then coated with the composition and piled to depilate completely, with the hair being recovered. The depilating process with the composition is simple, and can obtain high quality leather.

Owner:禾瑞(漳州)助剂有限公司

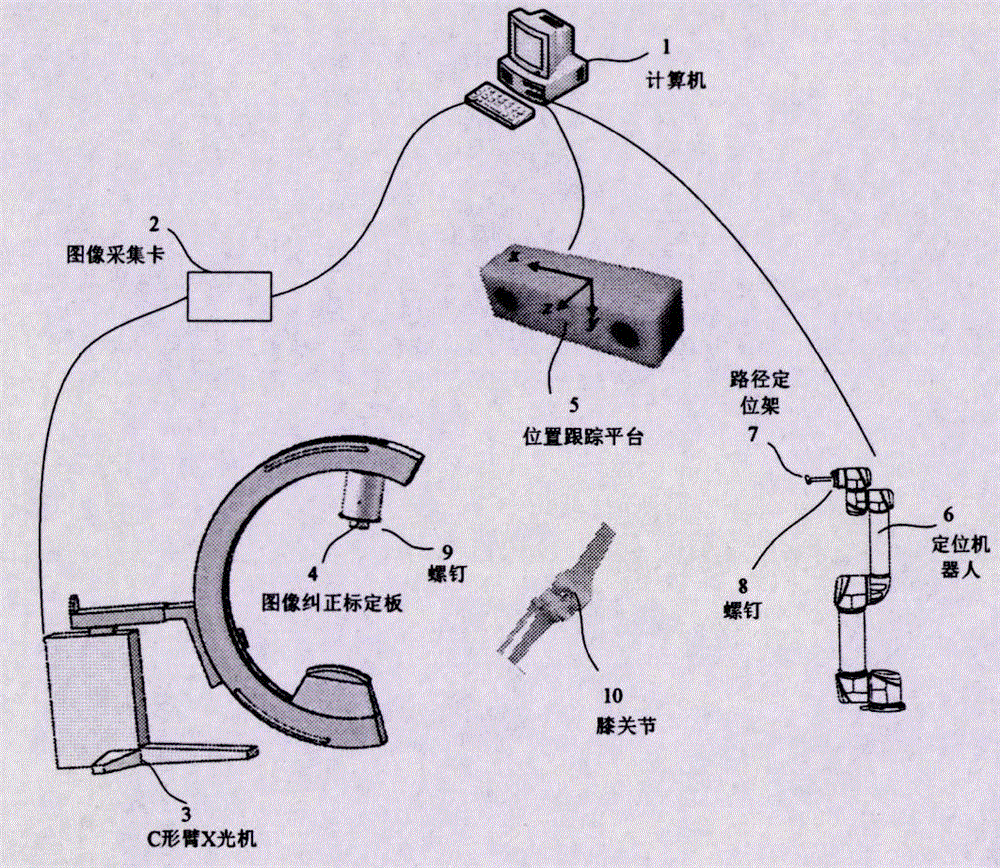

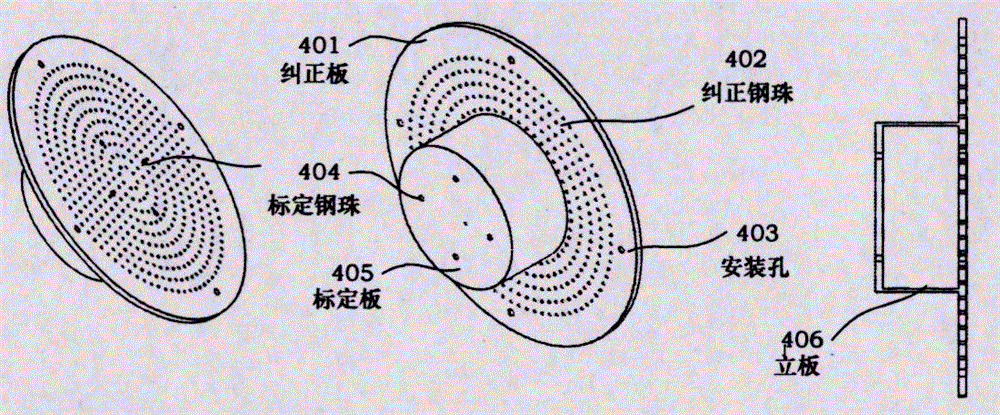

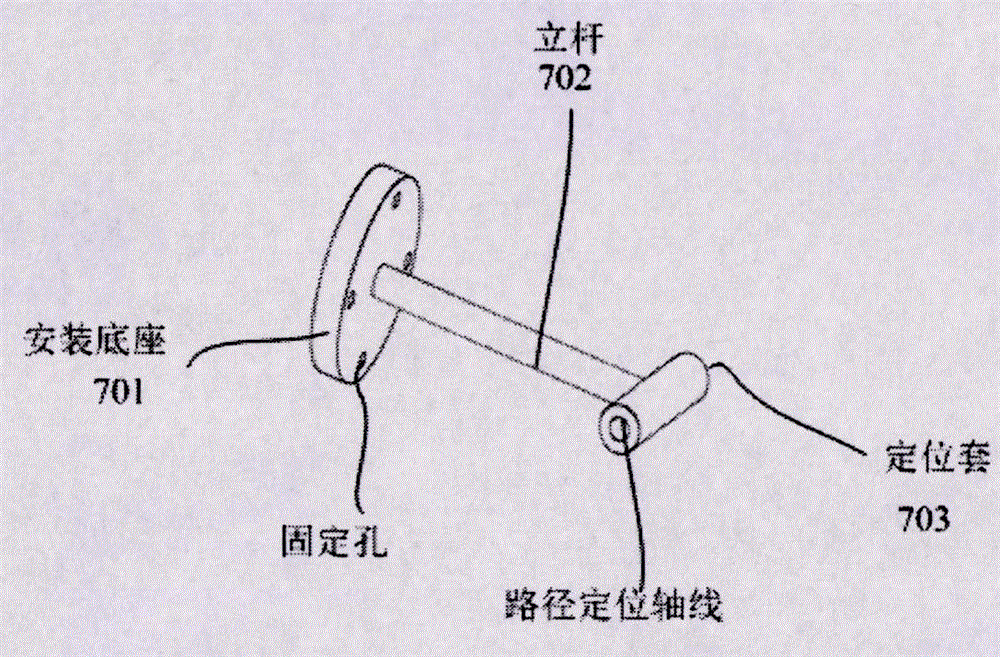

Anterior cruciate ligament stopping location and ligament tunnel location device combining with preoperative 3D planning information

InactiveCN106420054AReduce operating intensityImprove surgical precisionSurgical navigation systemsComputer-aided planning/modellingPosterior cruciate ligamentX-ray

The invention relates to the field of medical science, and particularly relates to an anterior cruciate ligament stopping location and ligament tunnel location device combining with preoperative 3D planning information. The device comprises hardware such as a C-type arm X-ray machine, a gama correction calibration board, an image capturing card, a positioning robot, a path positioning rack, a position trailing platform, and a computer as well as software such as a 3D planning module and a 2D positioning and navigation module which are stored in the computer. The 3D planning module makes use of preoperative 3D image data of knee joints of a patient, assists a doctor in finishing personalized surgical planning, and projecting a 3D environmental message to a 2D navigation message along a specific projection direction. The 2D positioning and navigation module makes use of a 2D medical image in surgical space collected by the hardware as well as location information of various trailing objects and combines the 2D navigation message to construct a navigation environment to control the hardware such as the positioning robot and the path positioning rack to finish an accurate operation path positioning. The anterior cruciate ligament stopping location and ligament tunnel location device can assist the doctor in finishing the precise and personalized operation of anterior cruciate ligament stopping location and ligament tunnel location, thus lowering operative difficulties and enhancing operative treatment efficacy.

Owner:胡磊 +2

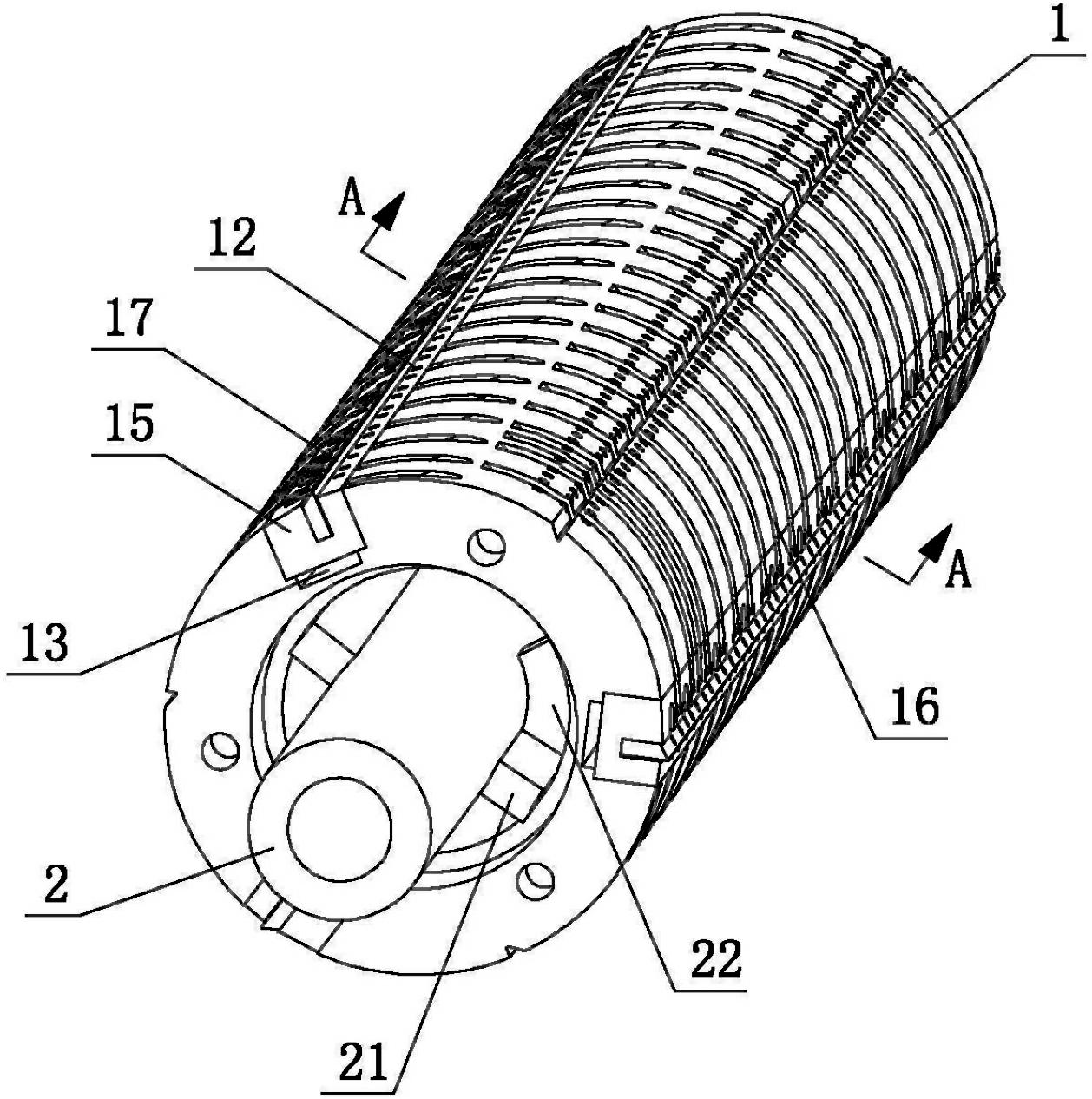

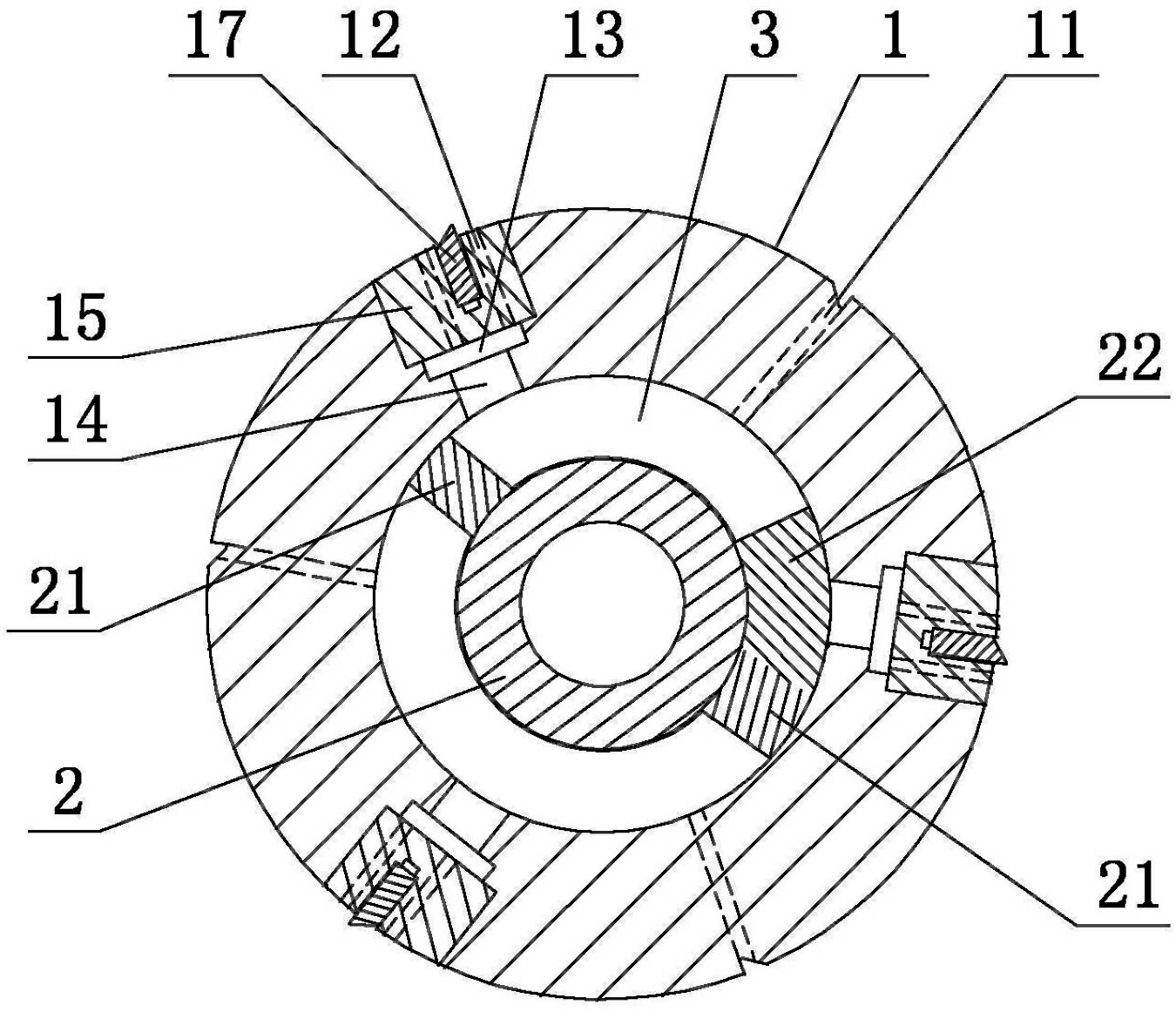

Folding roller of folding machine used for folding continuous sheets

A folding roller of a folding machine used for folding continuous sheets comprises a fixed mandrel and roller body sleeved on the mandrel and rotating around the mandrel, wherein the roller body is a tube body with a hollow cavity. By adopting the structure of the folding roller formed by combination of the hollow roller body and the mandrel, a stable and constant-pressure vacuum cavity smartly formed in the roller body and defined by the upper surface of the mandrel, two separating ribs and the inner cavity surface of the roller body is communicated with external extraction equipment, so that multiple airflow channels do not need to be processed, the problem of communicating with the air due to periodic communication of the airflow channel and an air ring inlet is solved when rotating with the vacuum roller, and the power of the external extraction equipment is effectively reduced. The production cost is effectively lowered, the purpose of energy conservation and emission reduction is achieved, the air ring structure with high processing difficulty is saved on the basis of ensuring the tidiness and conformity of the processed finished products, the production efficiency of the paper processing is effectively improved, and the operation difficulty and strength of the worker are reduced.

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

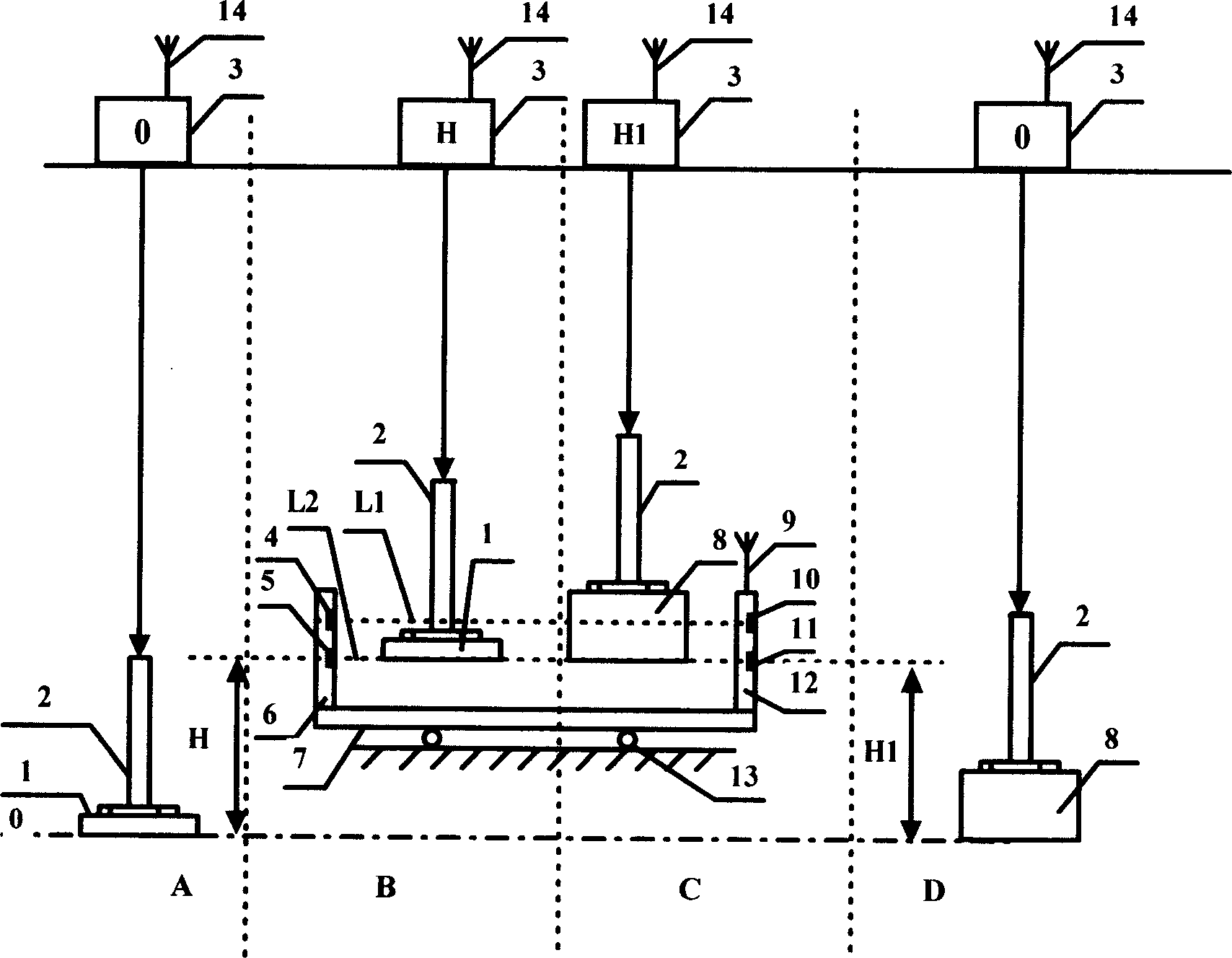

Anode horizontal height-finding system with radio comparing base as platform

InactiveCN1740743AImprove work efficiencyAvoid measurement errorsTransmission systemsUsing optical meansElectrolysisRadio reception

The horizontal height-measuring system includes the following several portions: aluminium electrolytic overhead traveling crane, old anode and new anode. It is characterized by also including the portions of wireless comparison base platform which can be moved on the ground surface, background controller and foreground controller. Said invention also provides the concrete action of the above-mentioned every portion and working principle of said system. Said system adopts the optical measurement techniques of laser, etc., so that its measurement accuracy is high.

Owner:ZHONGCHENGWEIYE CONTROL TECH NANNING CITY

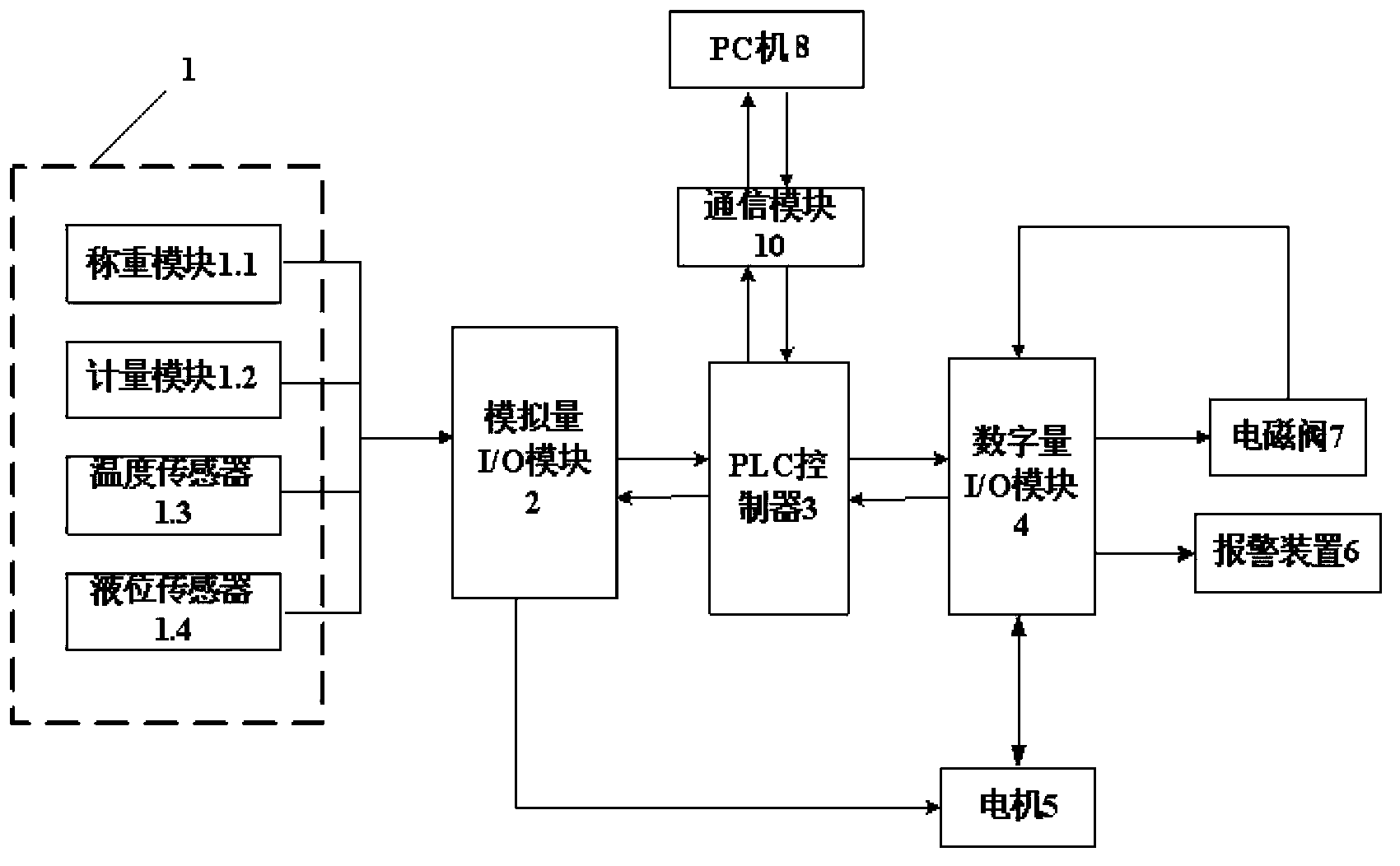

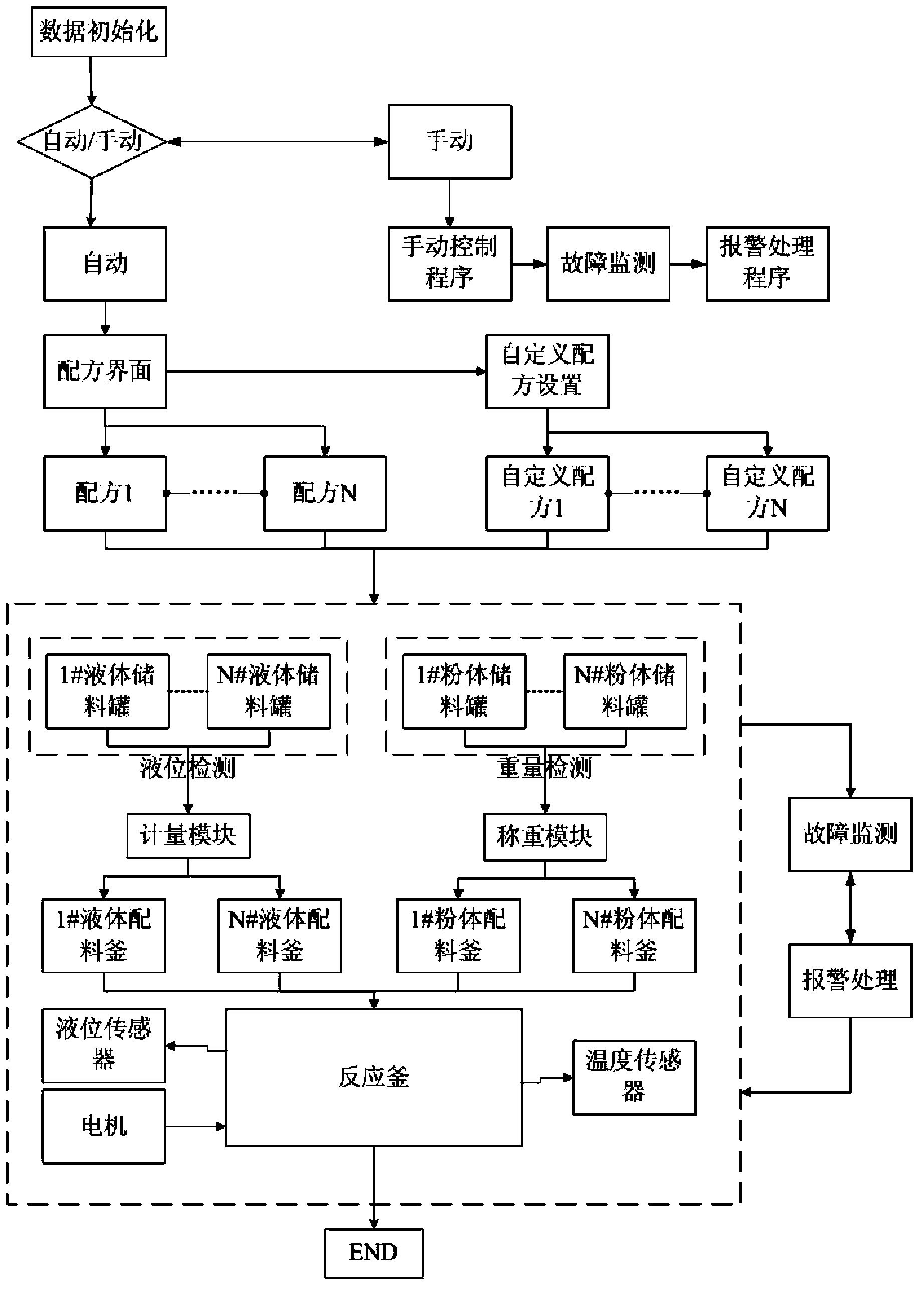

DCS control system for material processing

InactiveCN103823416AReduce operating intensity and number of peopleReduce manufacturing costTotal factory controlProgramme total factory controlAutomatic processingProgrammable logic controller

The invention provides a DCS control system for material processing. The system comprises a diaphragm pump arranged on a material storage tank and a motor used for starting material processing, an electromagnetic valve is arranged on the diaphragm pump, and a detection module is arranged inside the material storage tank. The detection module is in interactive connection with a PLC via an analog I / O module, the programmable logic controller is in interactive connection with a digital I / O module, the digital I / O module controls operation of the diaphragm pump through the electromagnetic valve, the output end of the electromagnetic valve is connected with the input end of the digital I / O module, and the output ends of the analog I / O module and the digital I / O module are both connected with the motor. According to the DCS control system for material processing provided by the invention, material weighing, material feeding, and the temperature, liquid level and the like inside the material storage tank in the process of material stirring, dispersing or grinding can be automatically and remotely controlled, a processing device can be automatically started or stopped, the purpose of automatic processing is achieved, the cost is saved, and the product quality is improved.

Owner:ANHUI LAND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com