Patents

Literature

2559 results about "Fixed bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

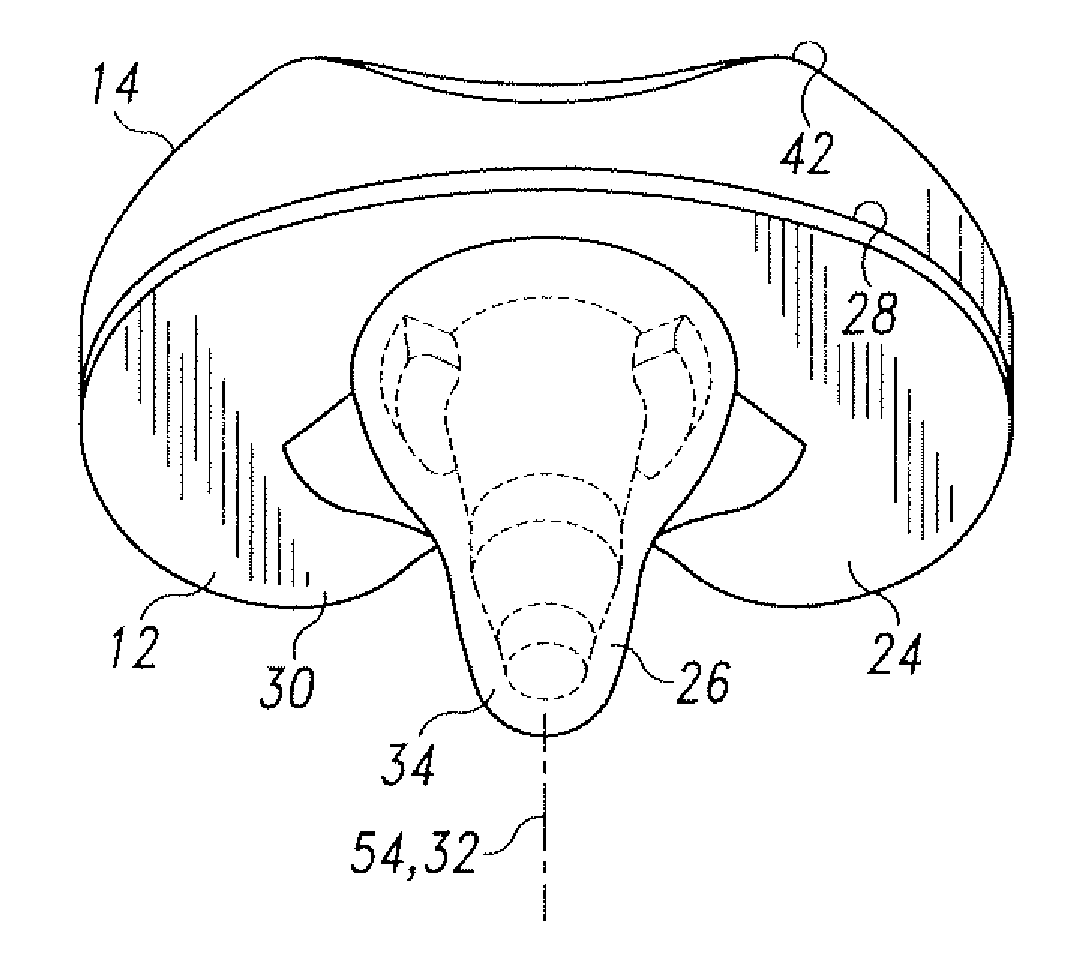

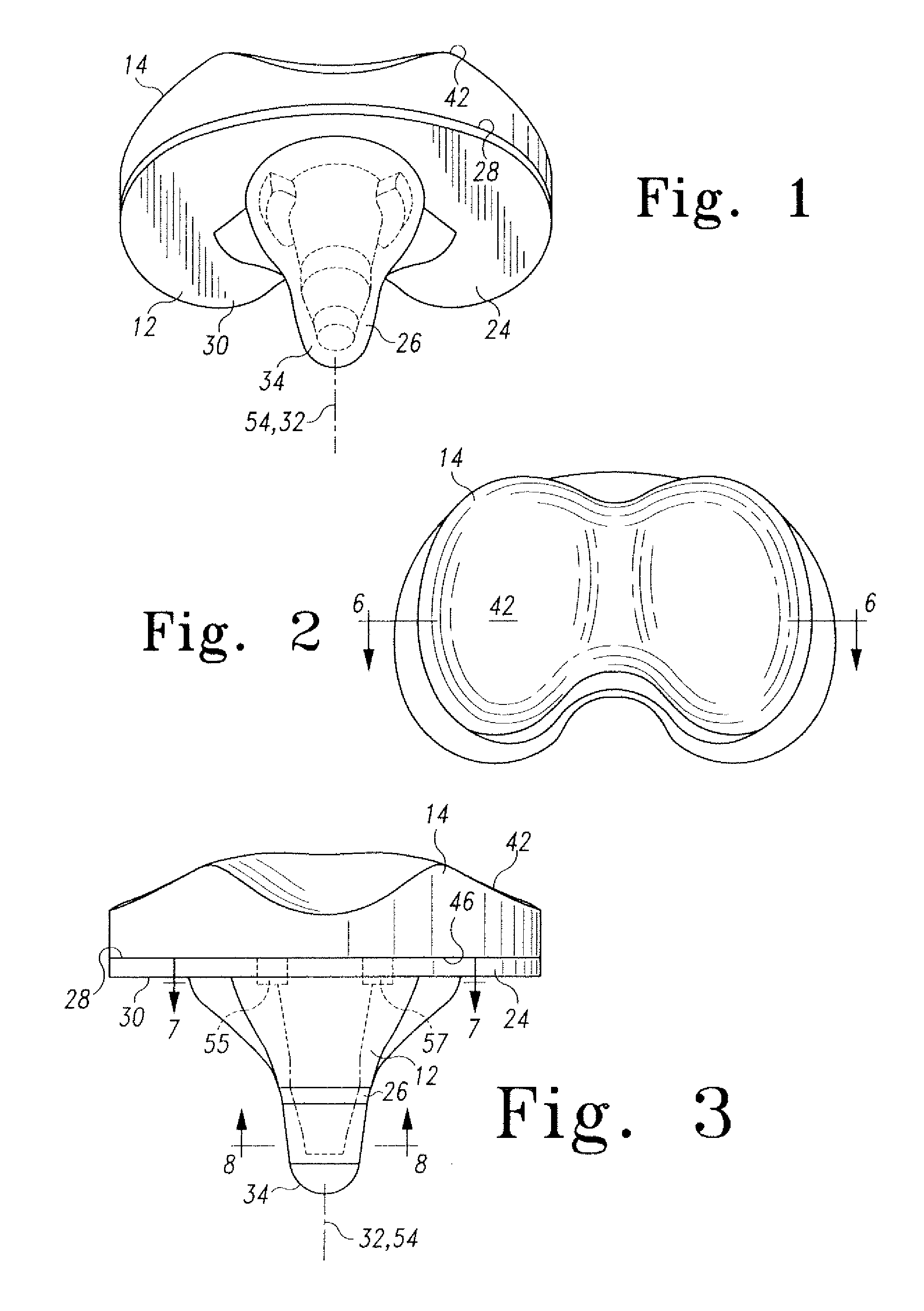

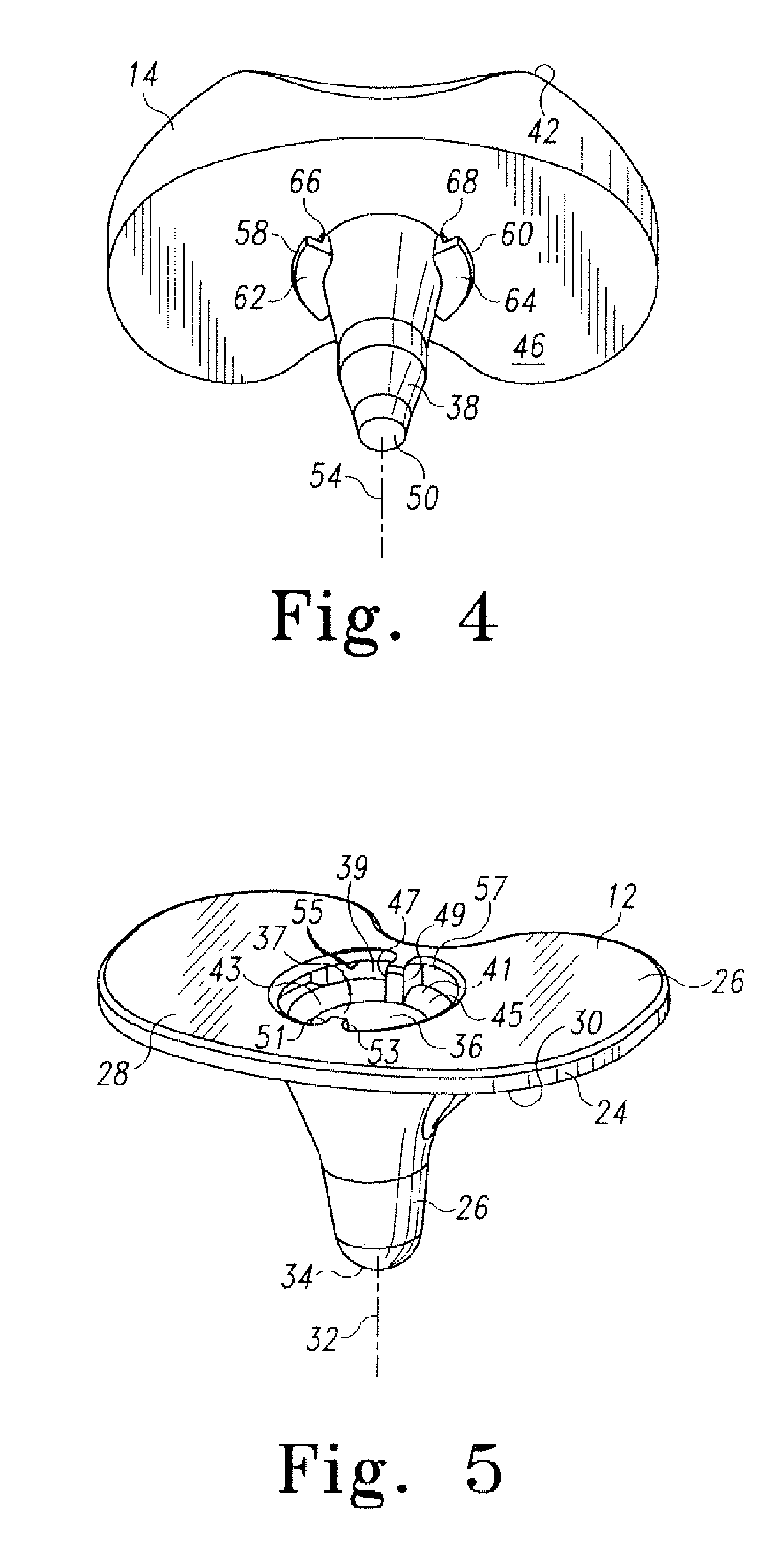

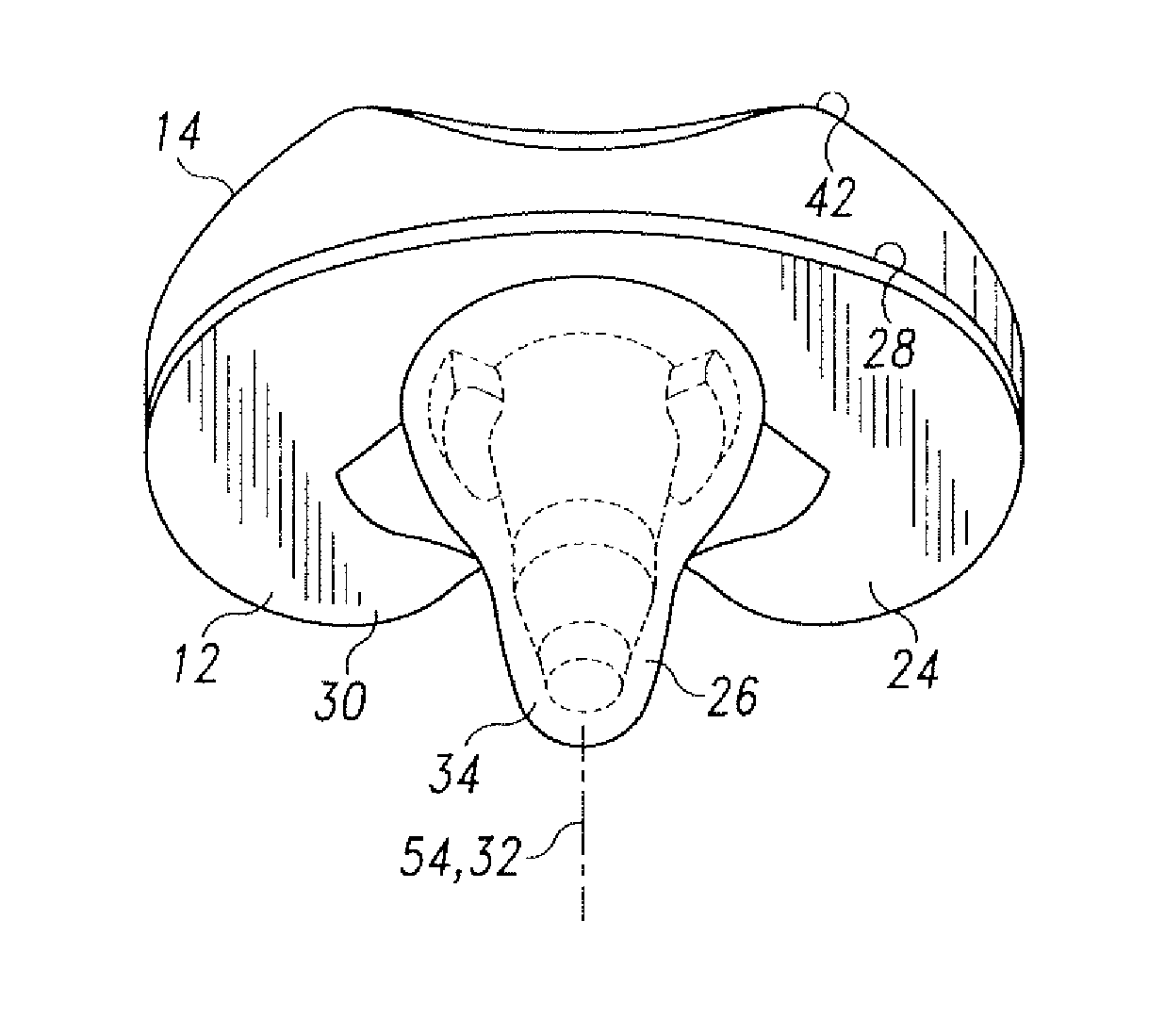

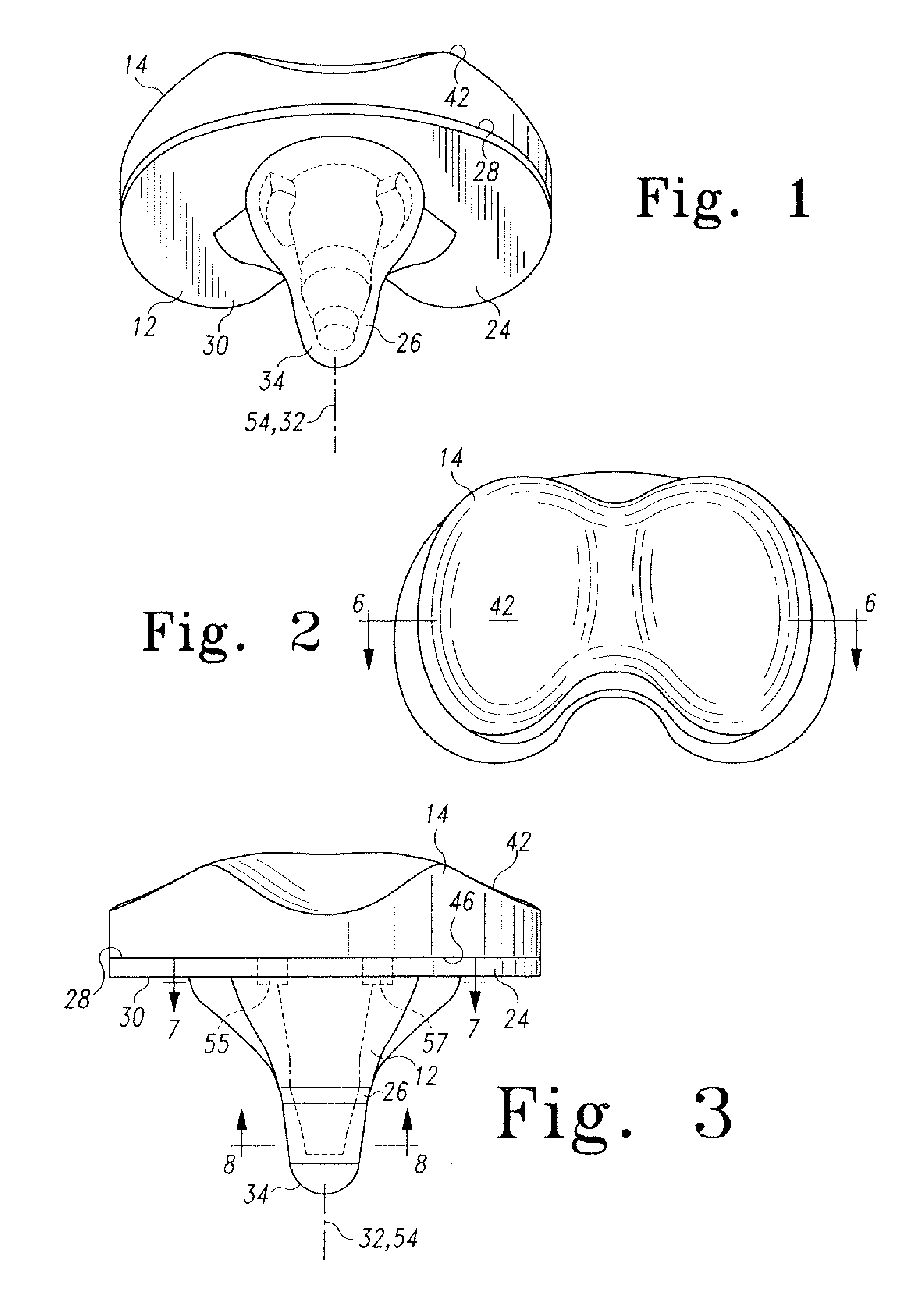

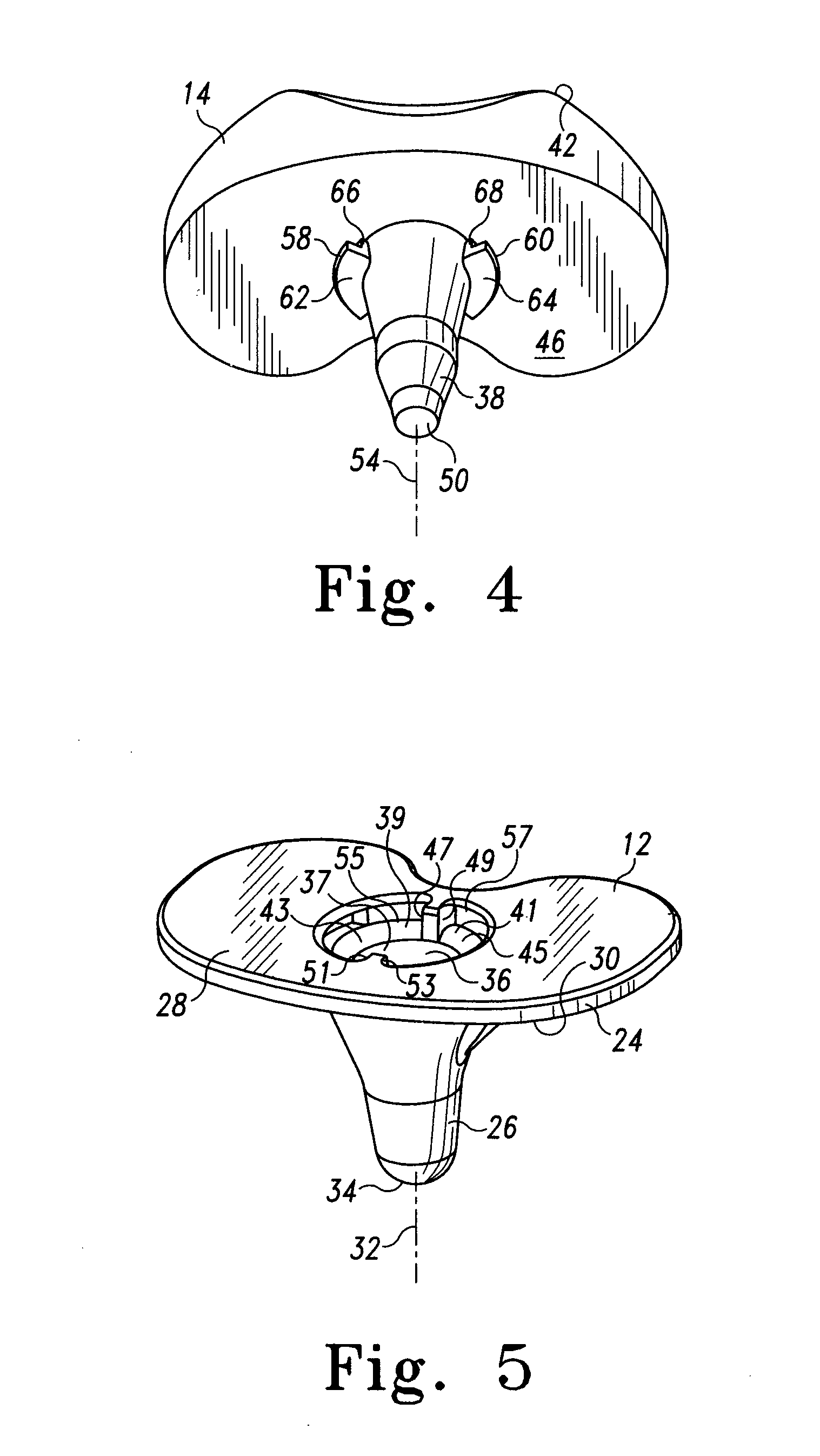

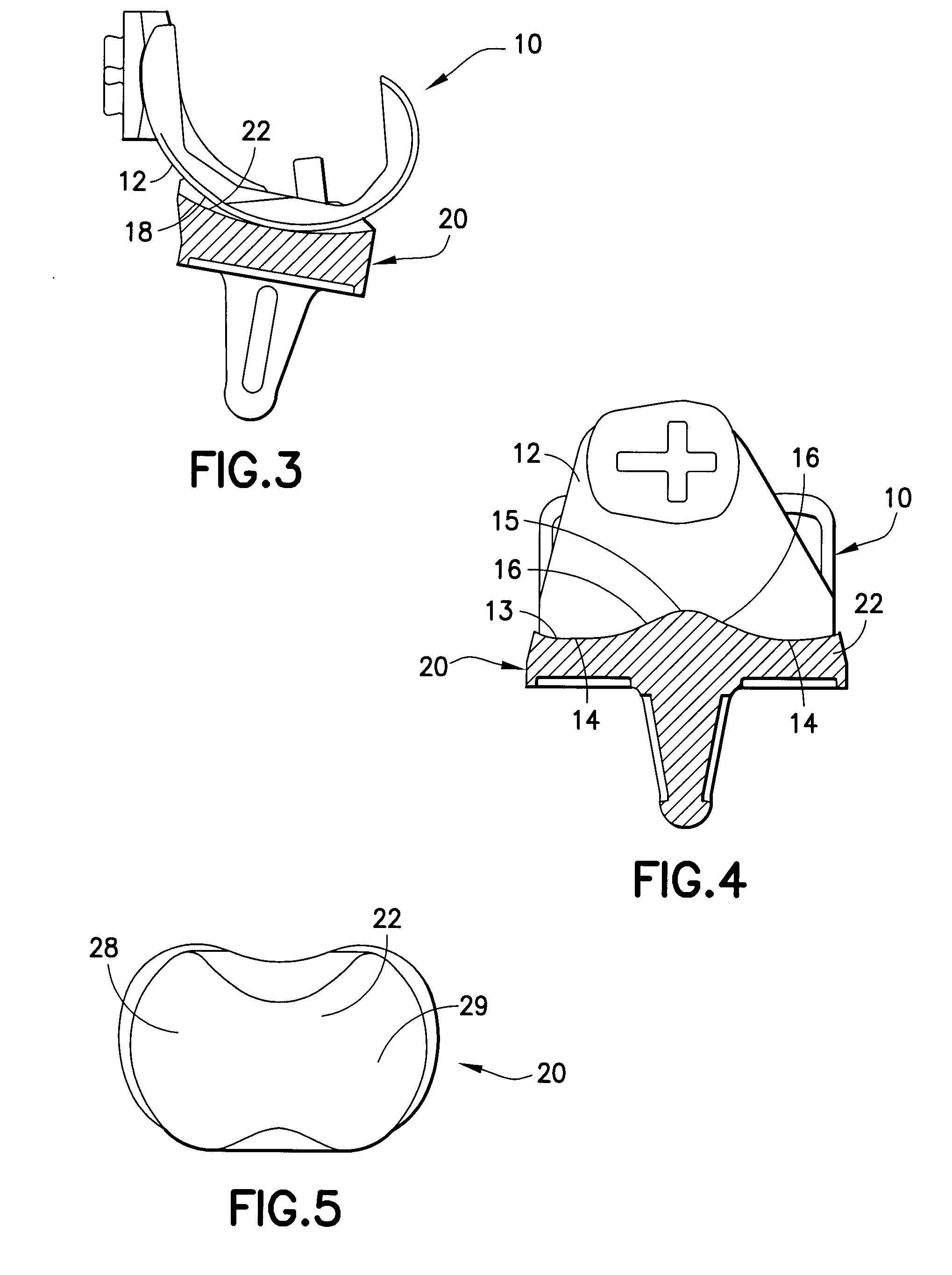

Ankle prosthesis

A fixed-bearing ankle prosthesis may include tibial and talar components whose articulating surfaces directly contact one another. The tibial component defines medial and lateral concave condylar facets separated by a convex central portion. The talar component includes medial and lateral convex condyles separated by a concave central portion. The condyles each have a single radius of curvature in a medial-lateral plane such that each condyle has a circular-arc cross-section continuously extending from the respective medial or lateral edge of the talar component to the concave central portion. The medial-lateral radii of the condyles are smaller than corresponding radii of the condylar facets.

Owner:UNIV OF IOWA RES FOUND

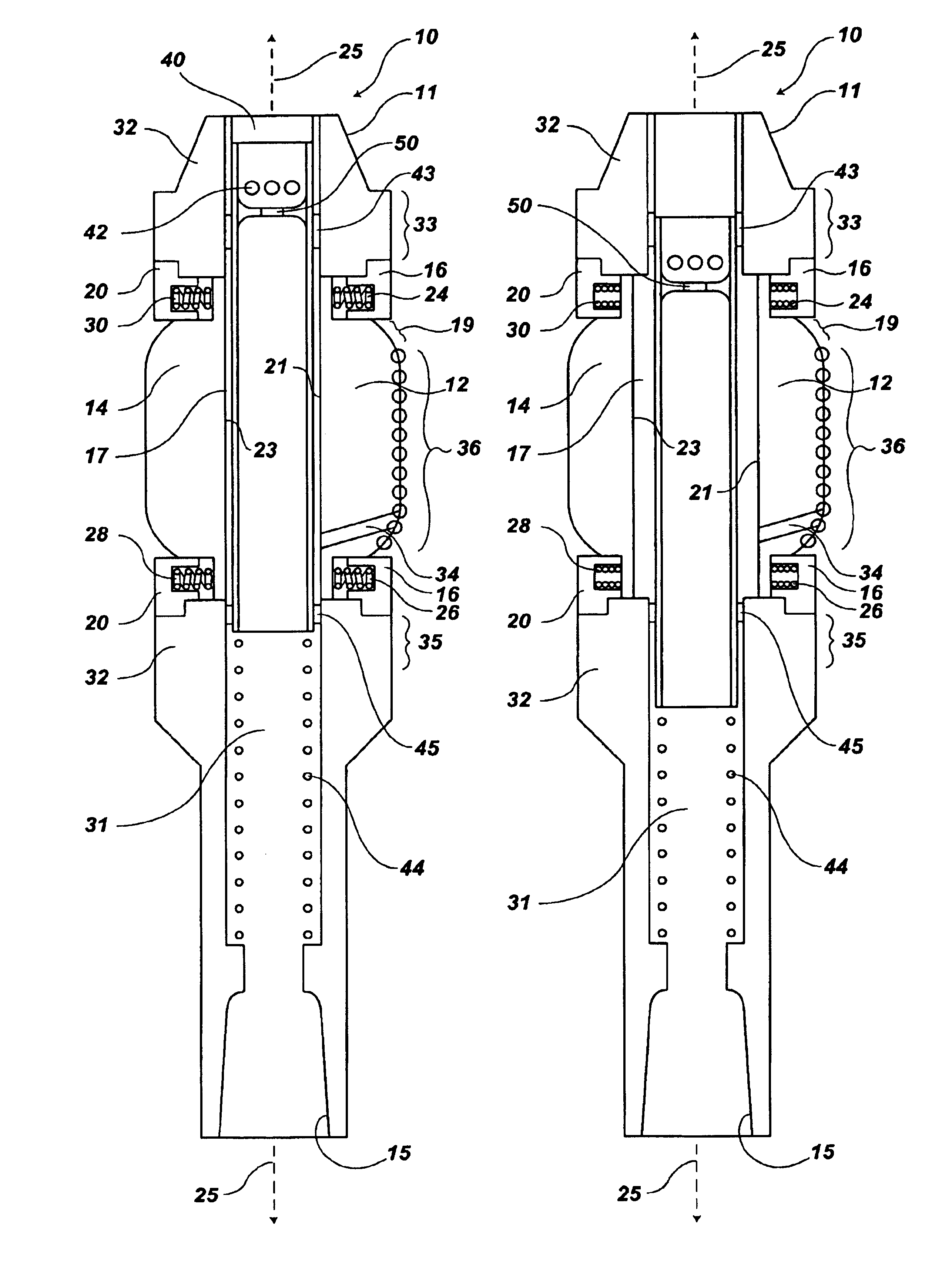

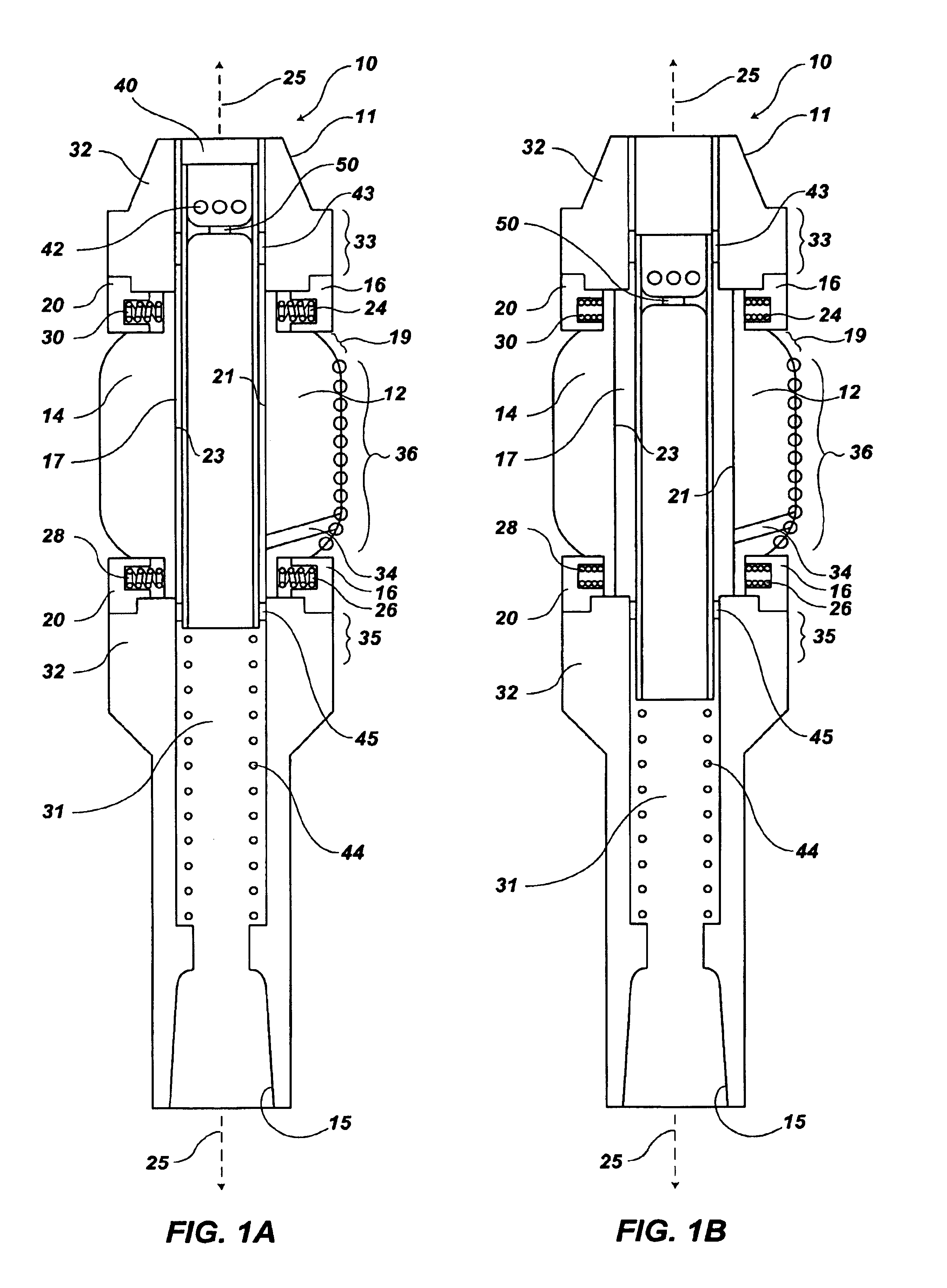

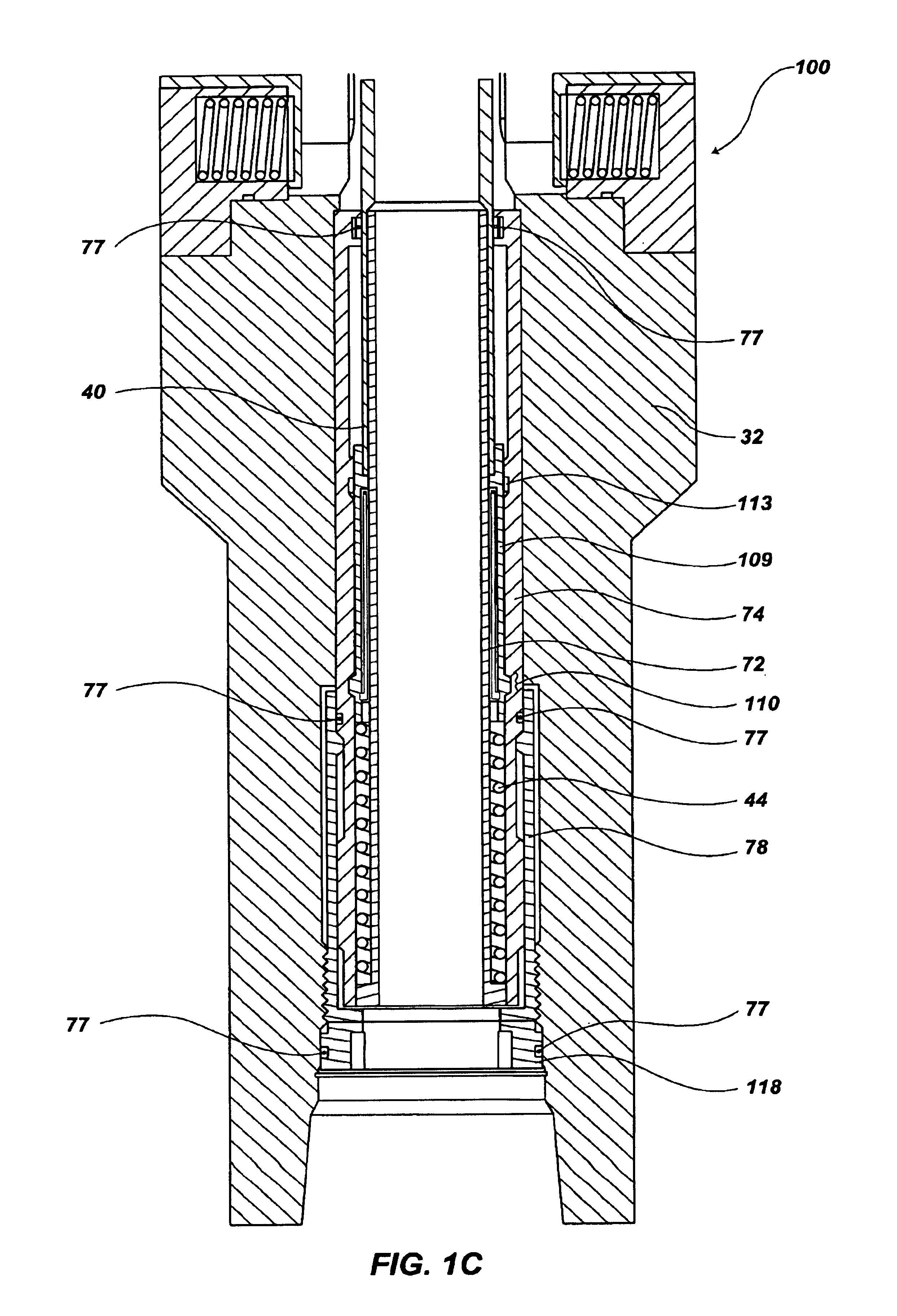

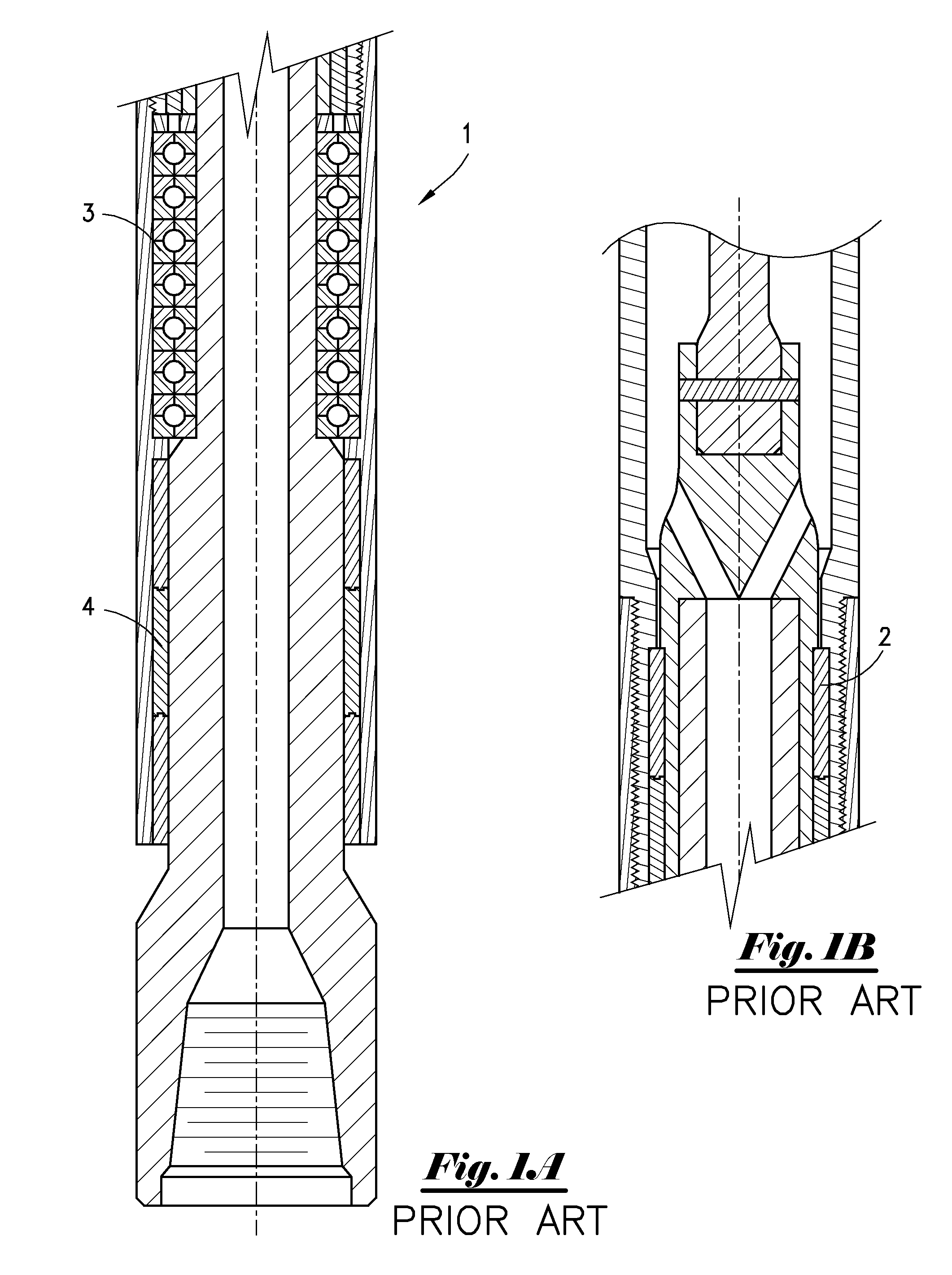

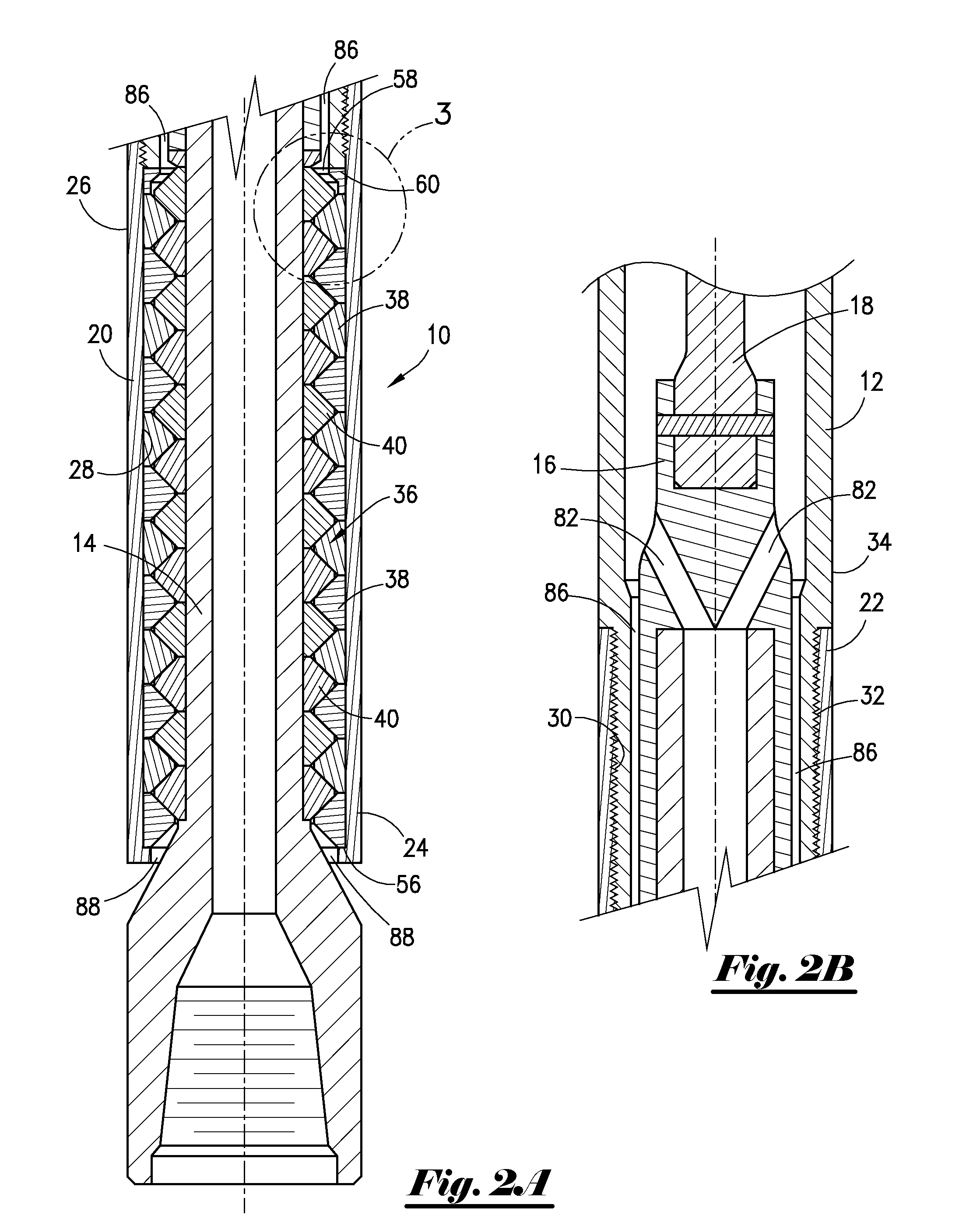

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

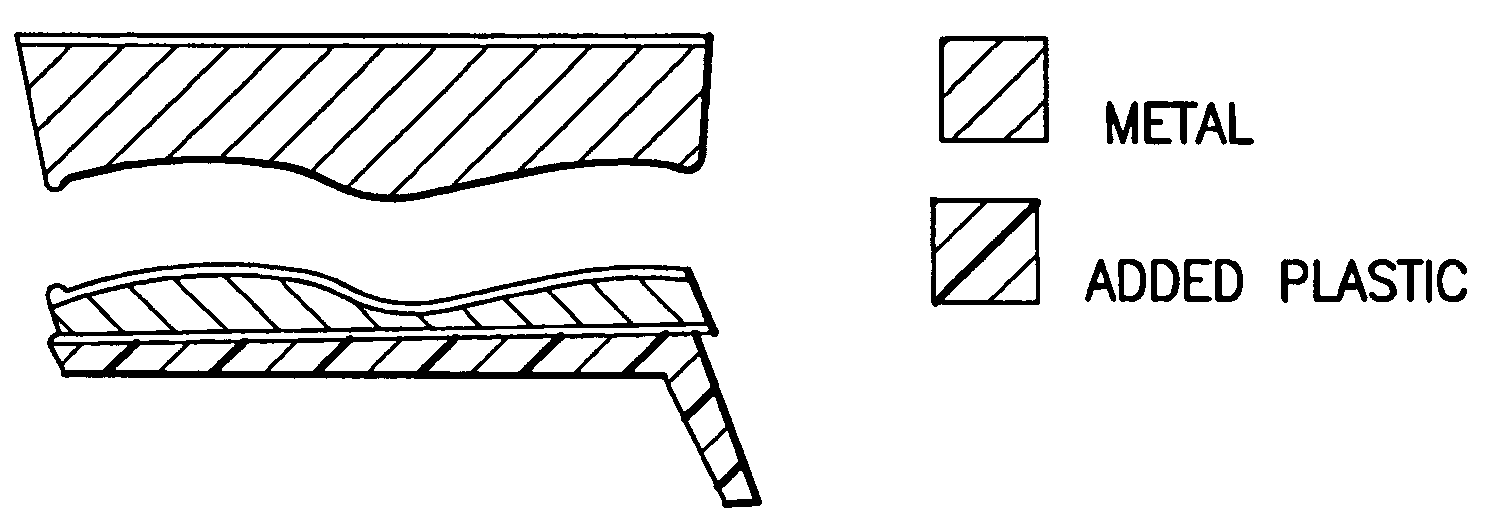

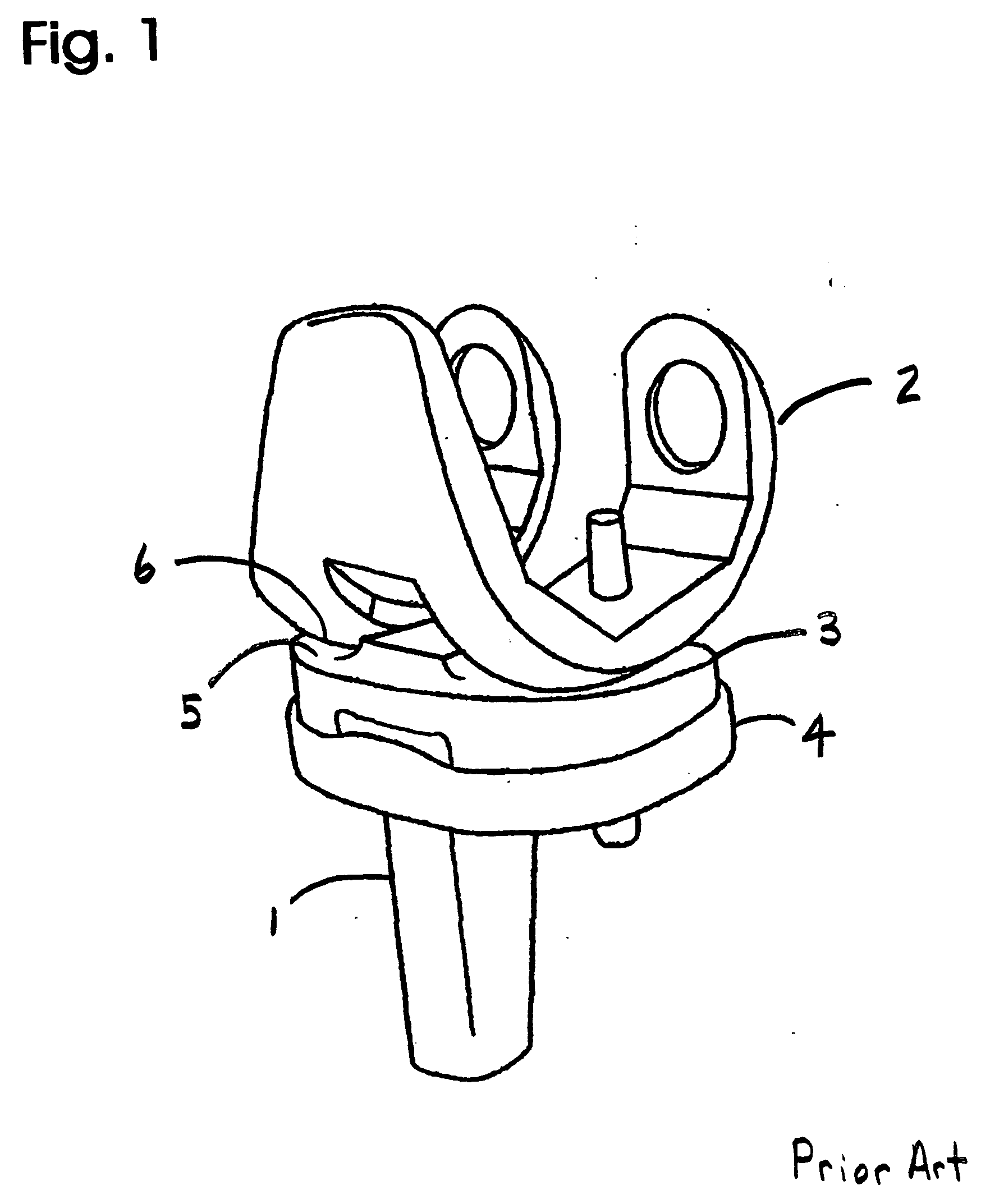

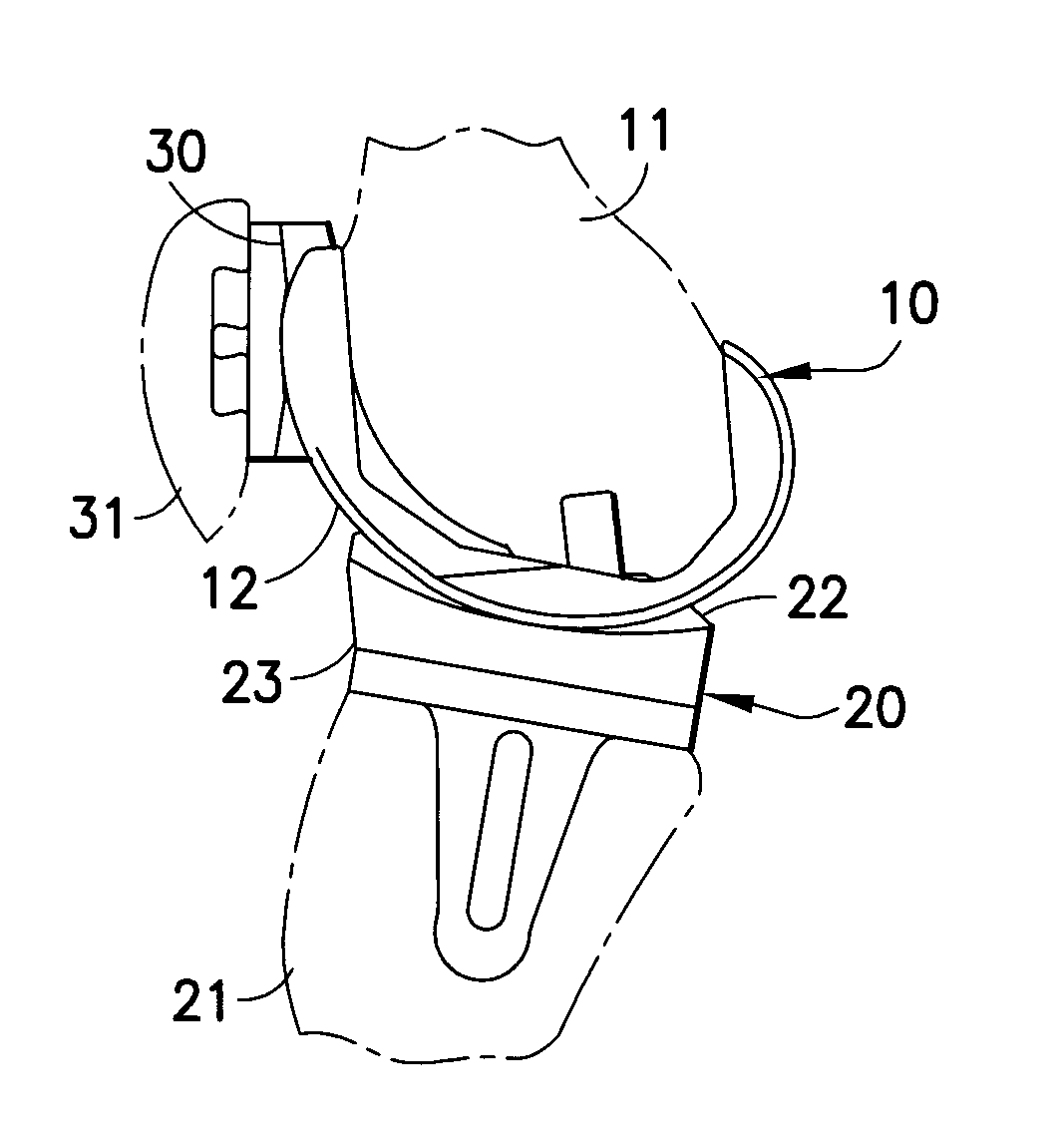

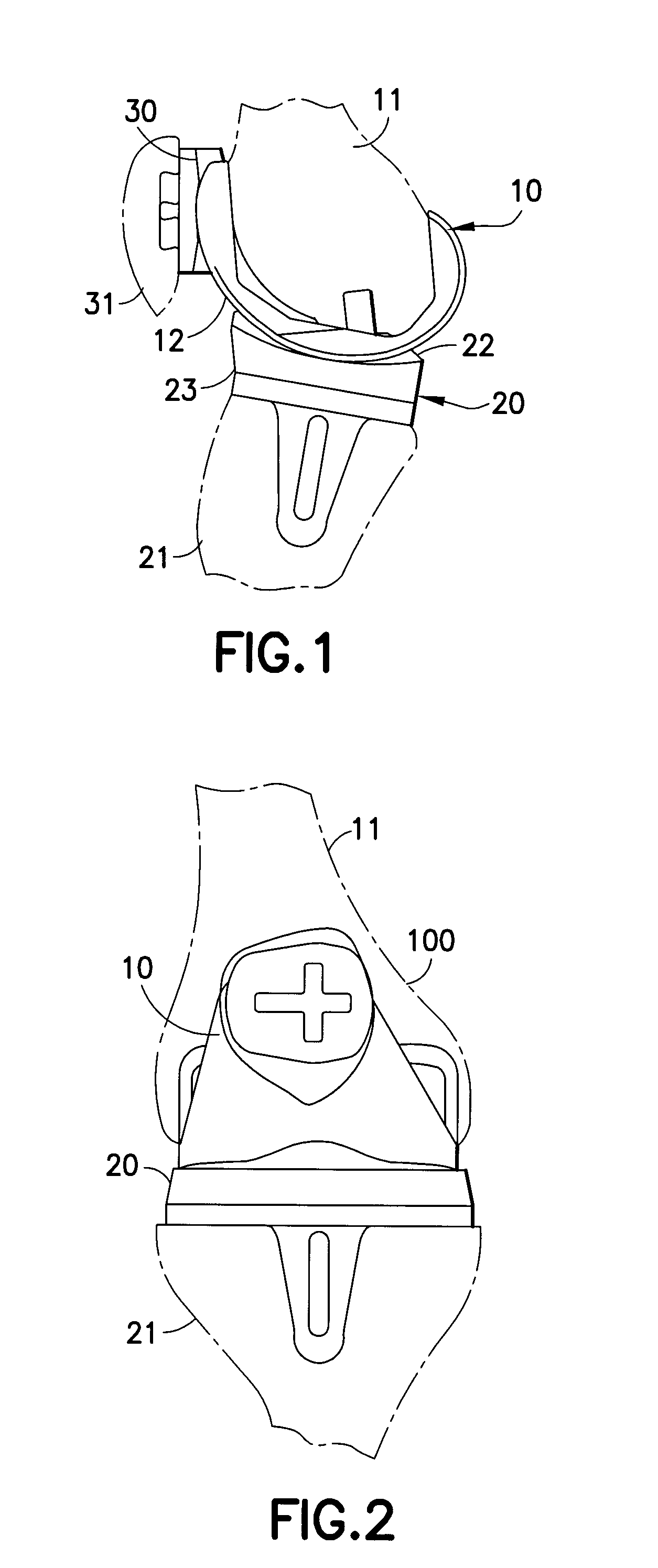

Physiological total knee implant

The present invention generally comprises a fixed bearing prosthesis and a mobile bearing prosthesis. The fixed bearing prosthesis comprises a tibial component, a femoral component and a meniscal component and addressees the loss of congruency during deep knee flexion and the possible direct, repetitive contact of the tibial and femoral components. The tibial component of the fixed bearing prosthesis includes a tibial platform having an anterior and posterior edge. The meniscal component of the fixed bearing prosthesis includes a posterior ridge overlapping the posterior edge of the tibial platform that prevents metal-to-metal contact during deep knee flexion. The mobile bearing prosthesis comprises generally a tibial component, a femoral component and a meniscal component addresses the lack of conformity to natural biomechanical movement. The tibial component comprises a tibial platform having a curved rail system designed to mimic the asymmetrical rotation of femoral rollback while simultaneously providing sufficient anterior-posterior translation.

Owner:TARABICHI SAMIH

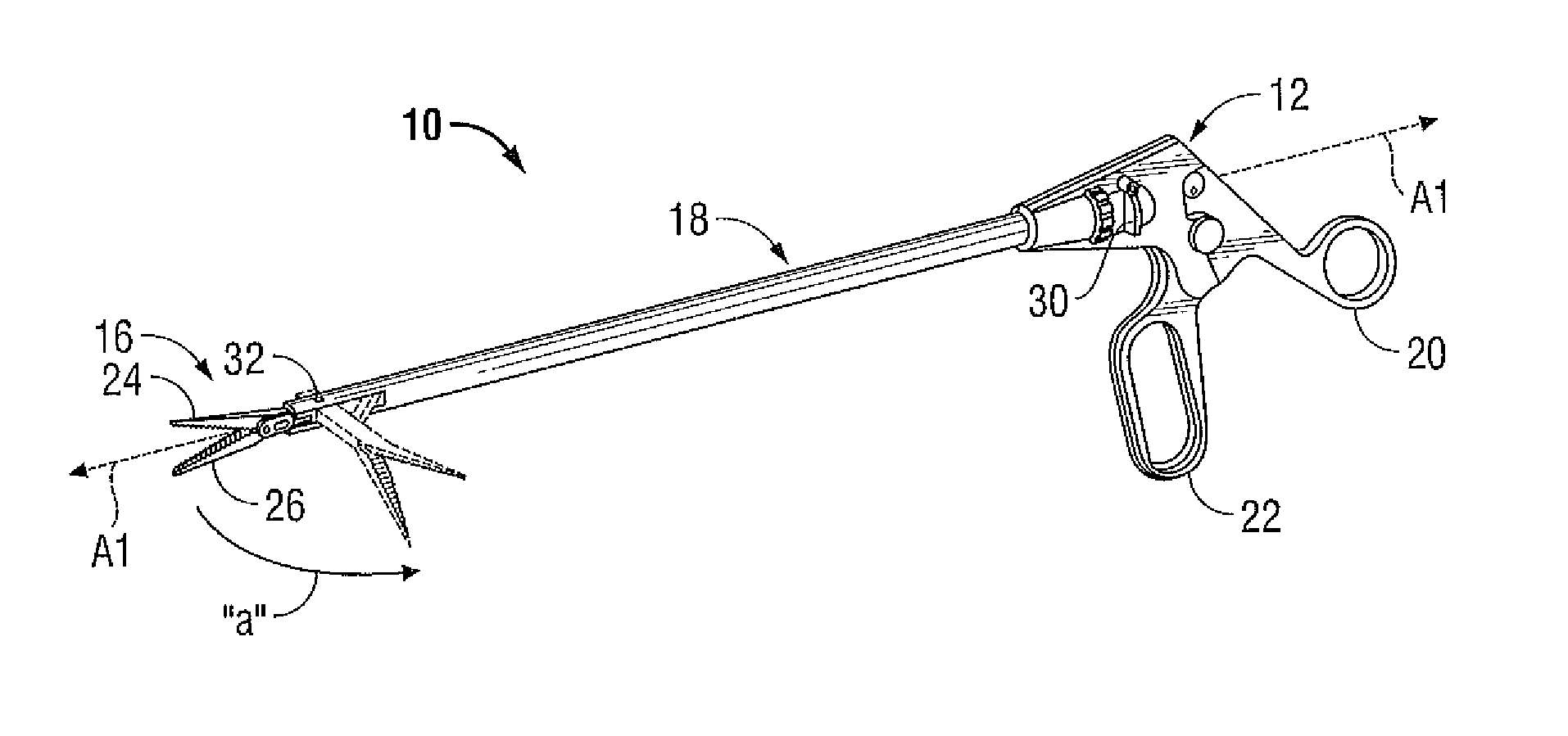

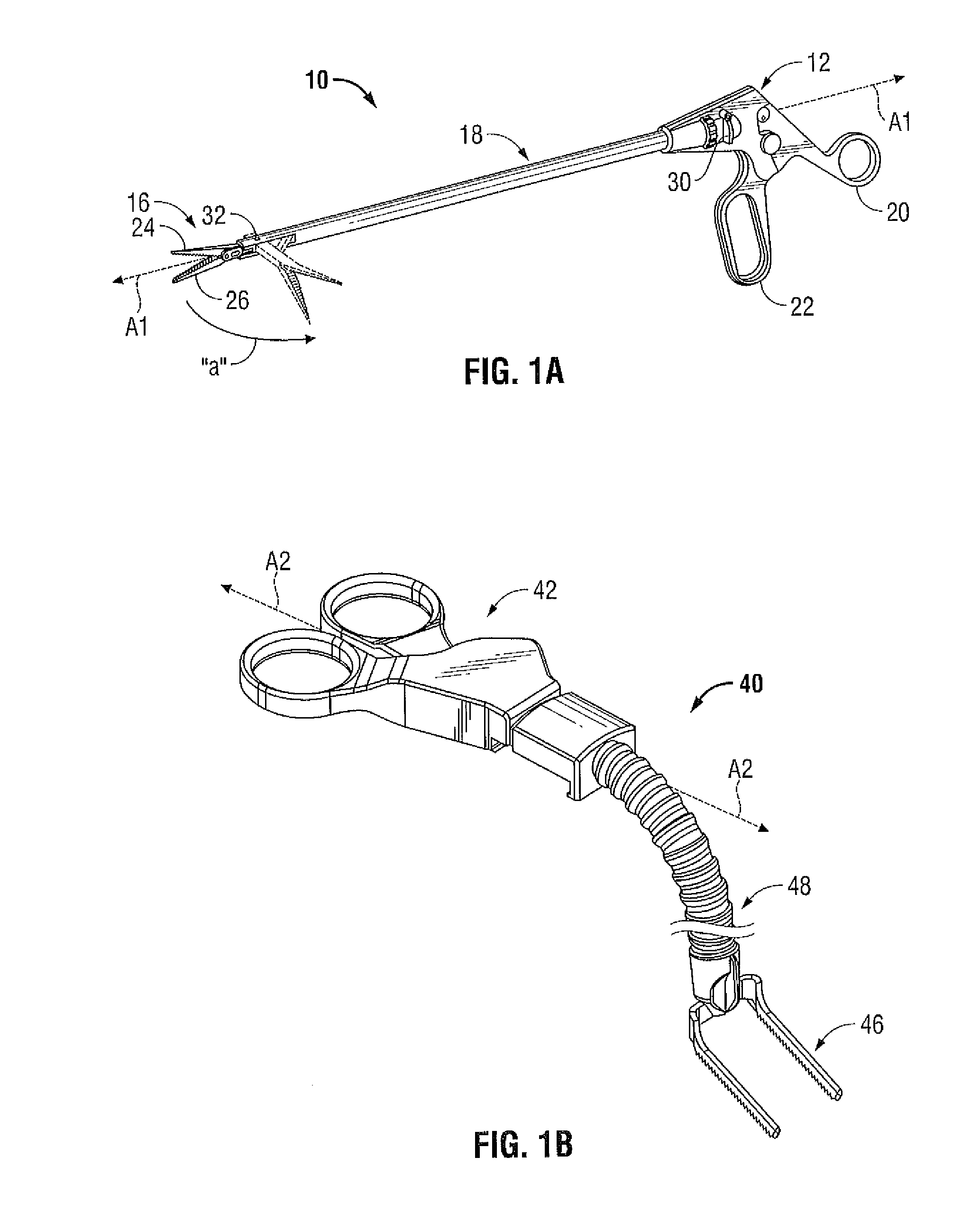

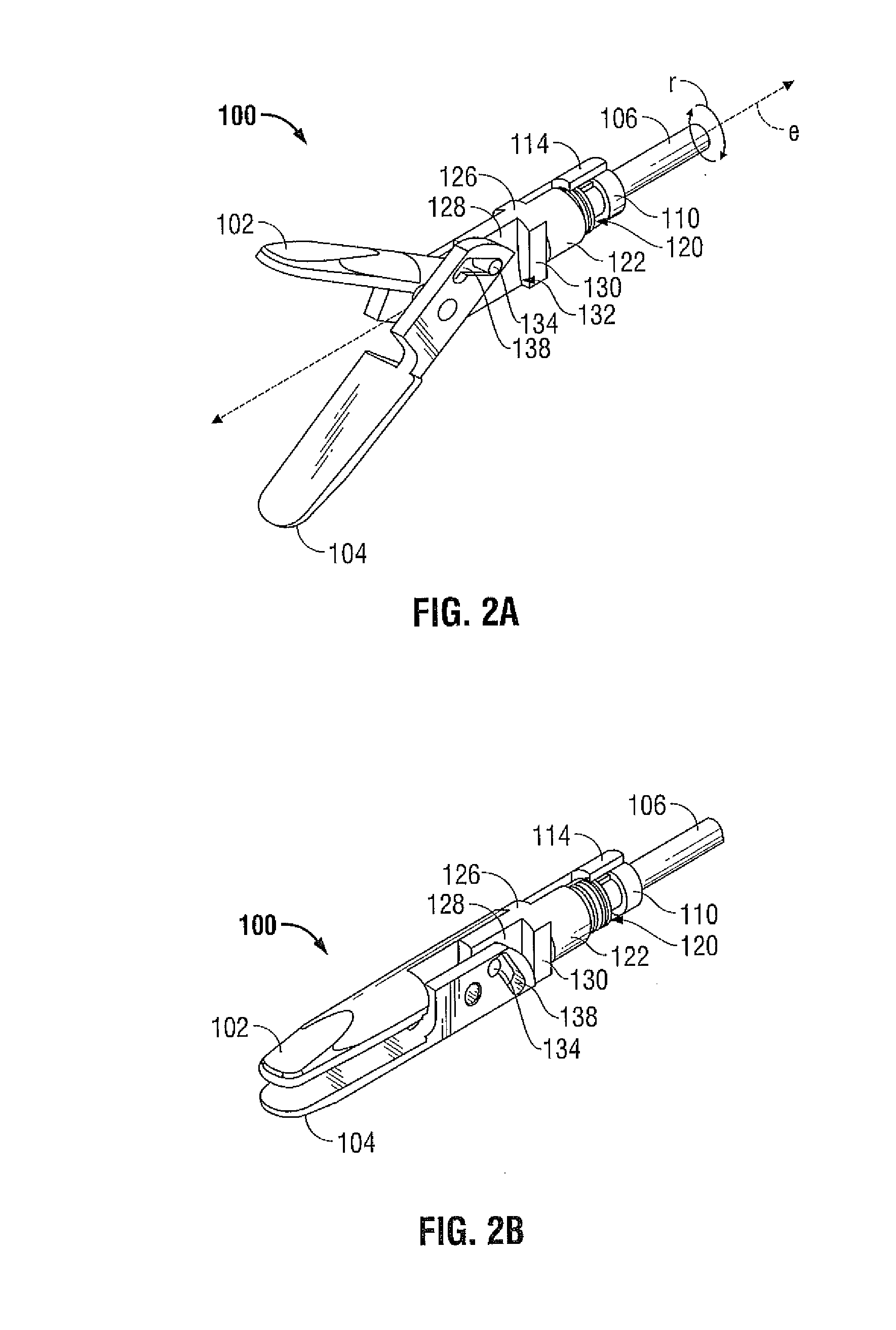

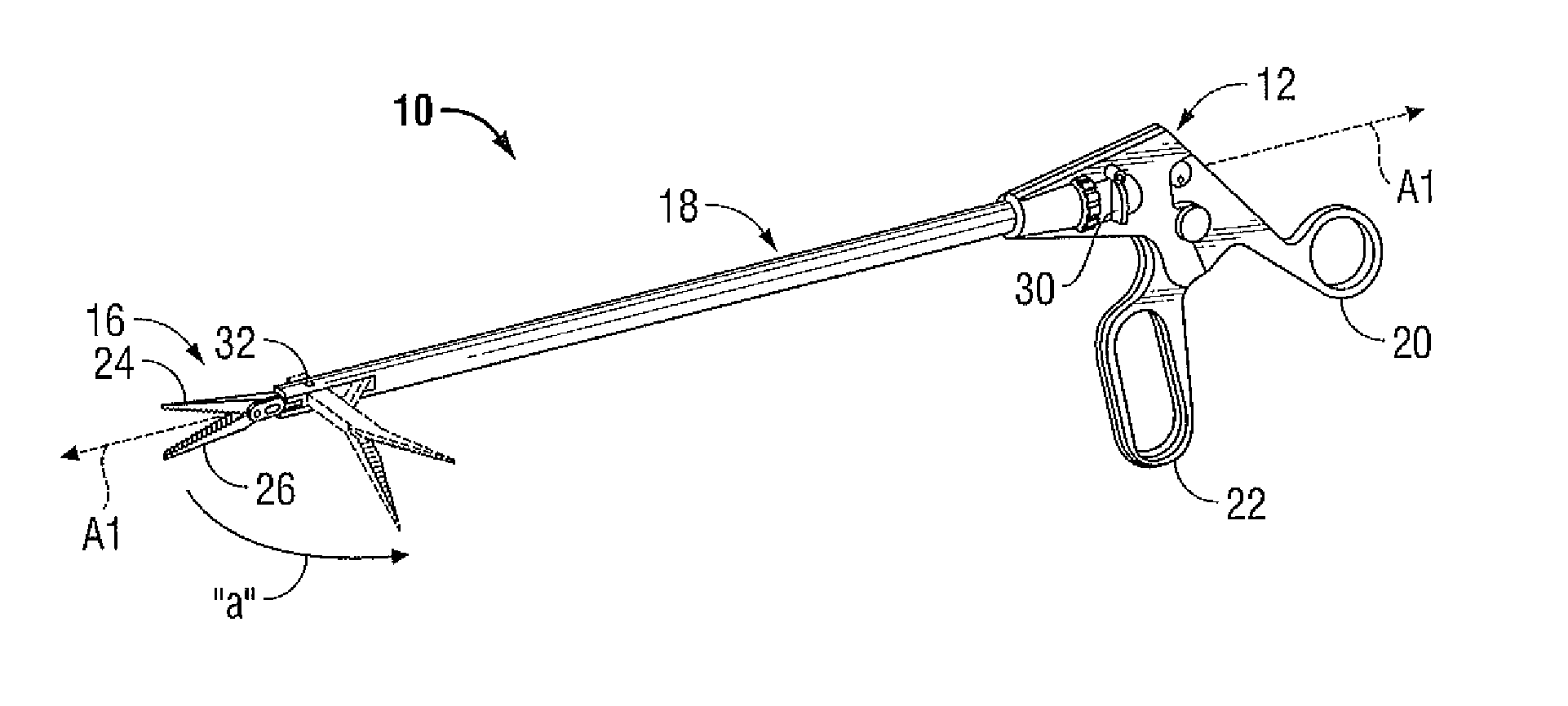

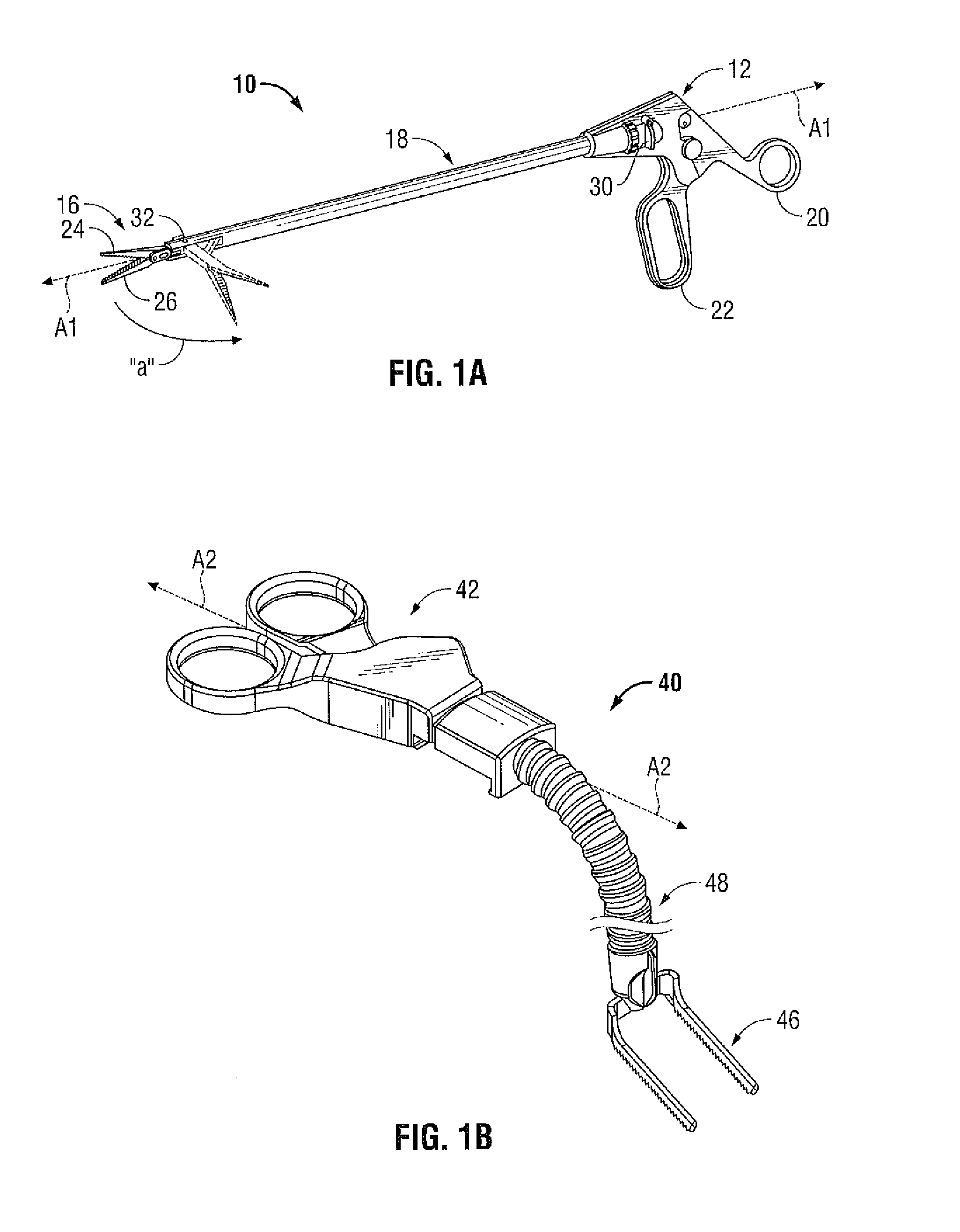

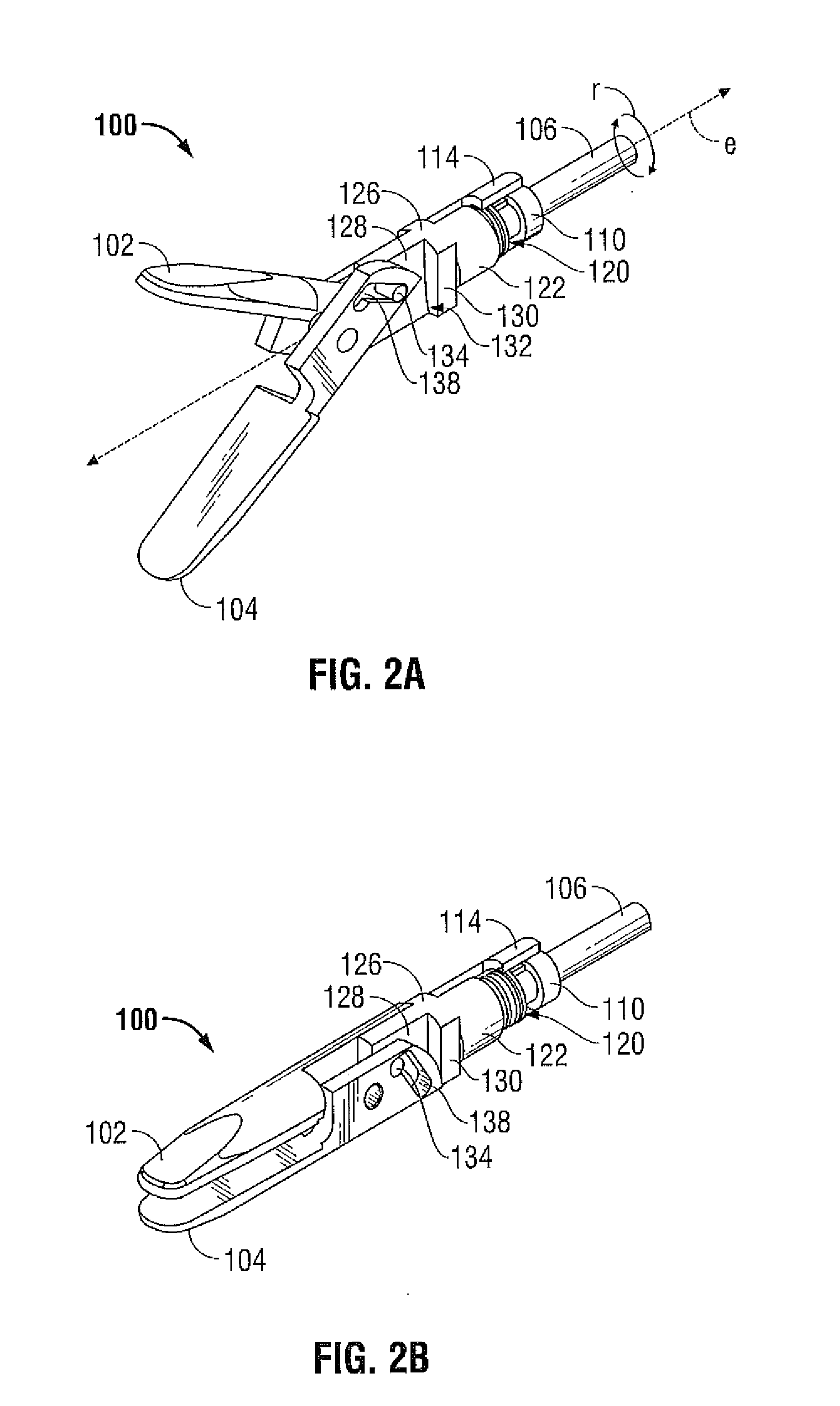

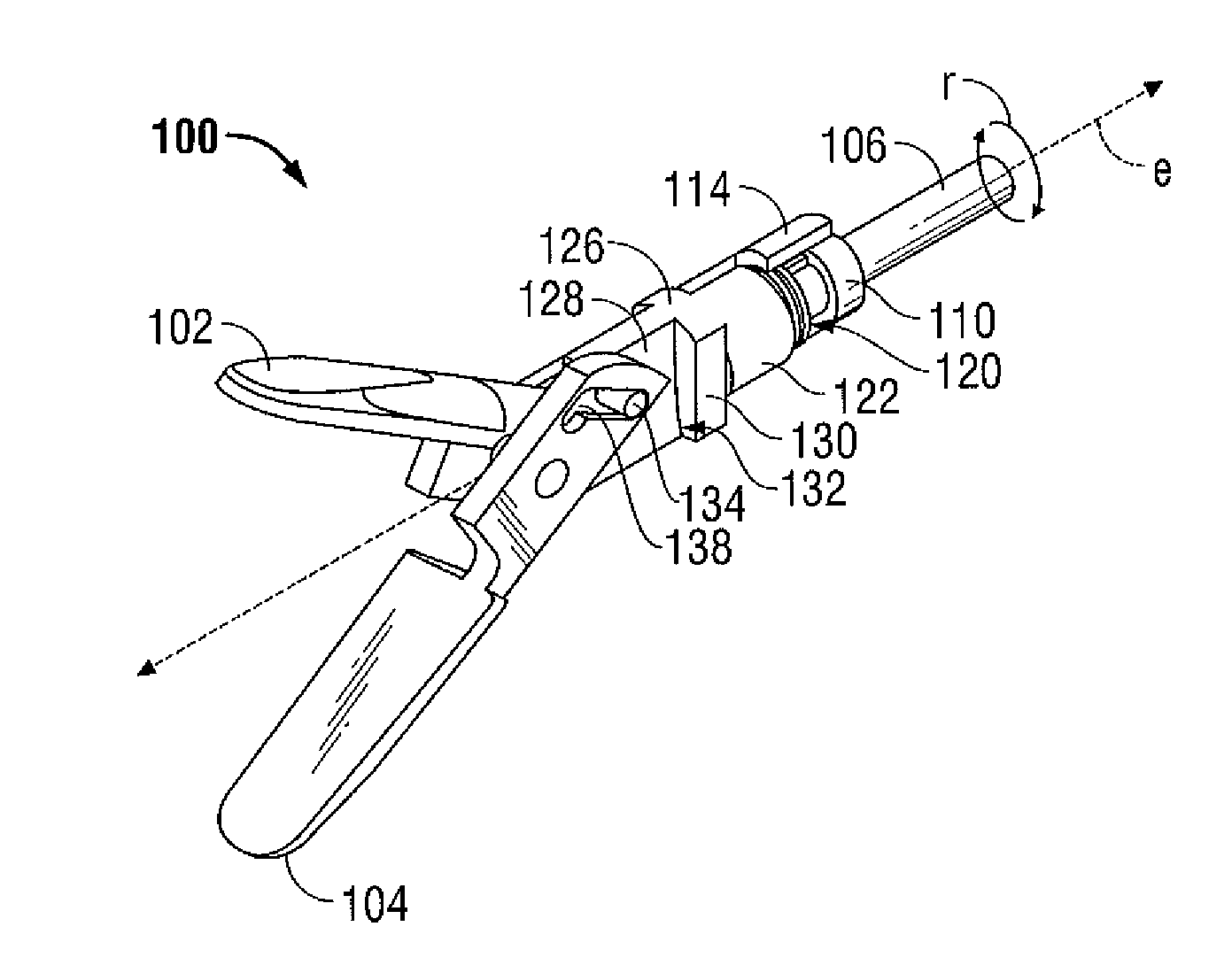

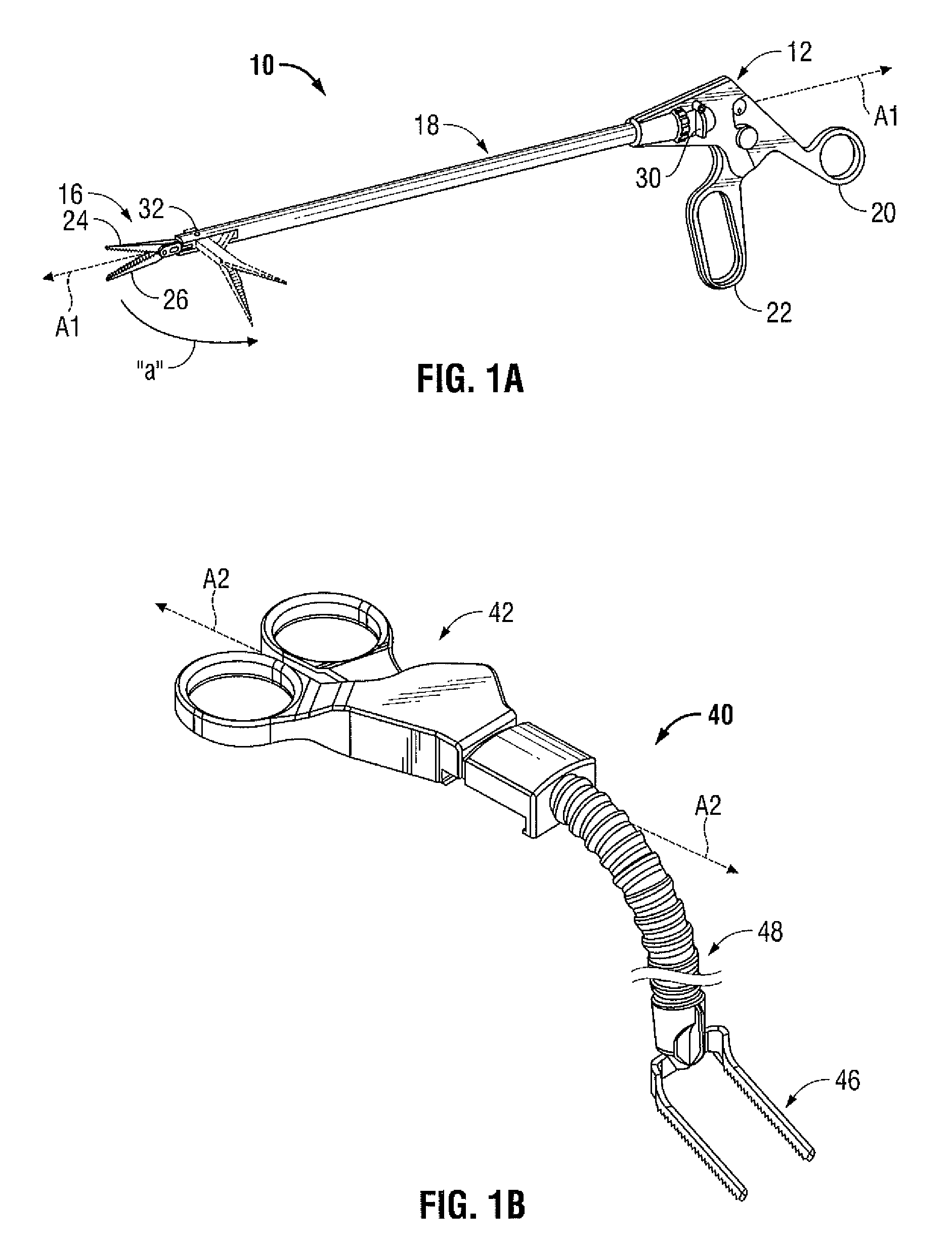

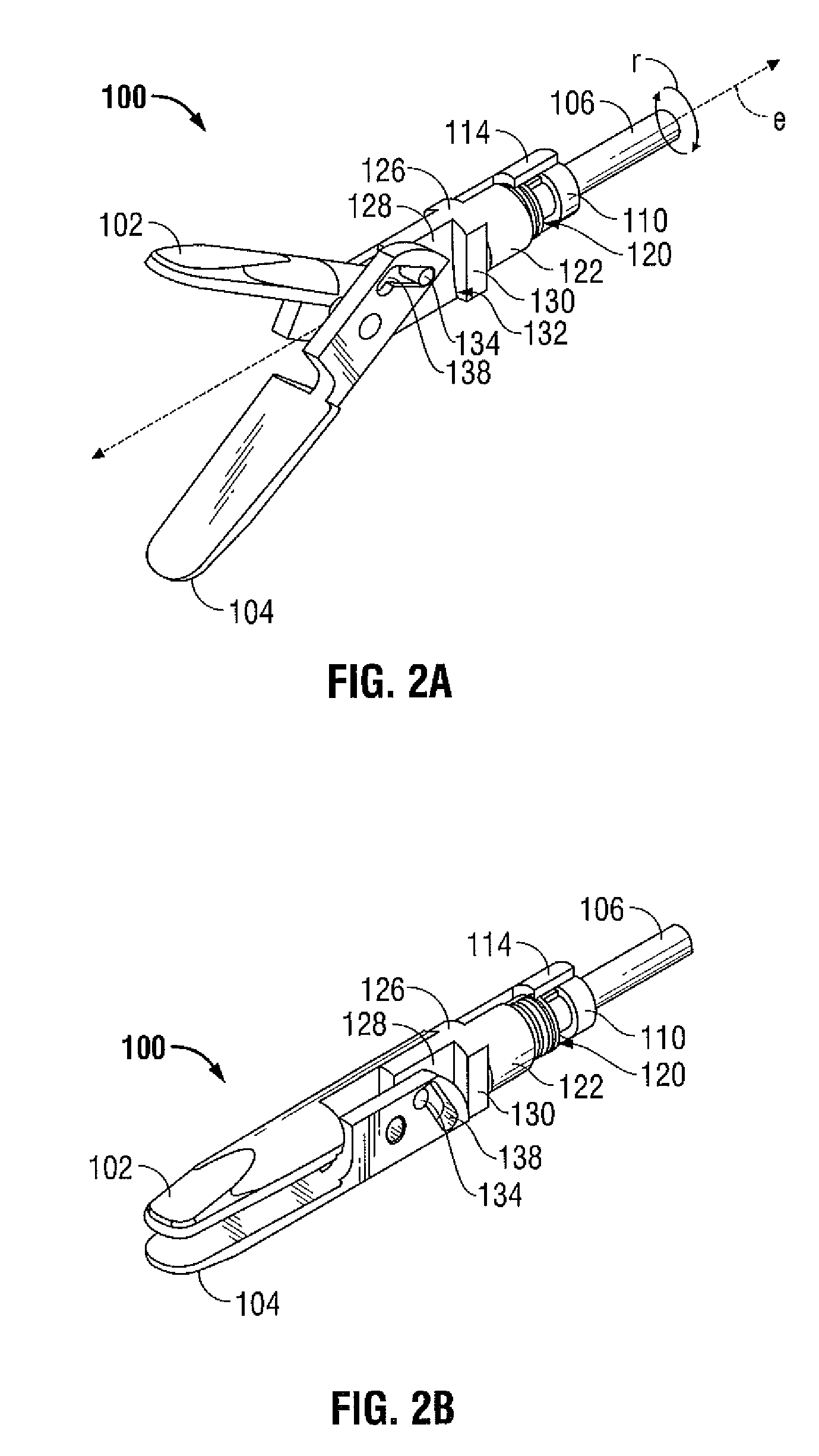

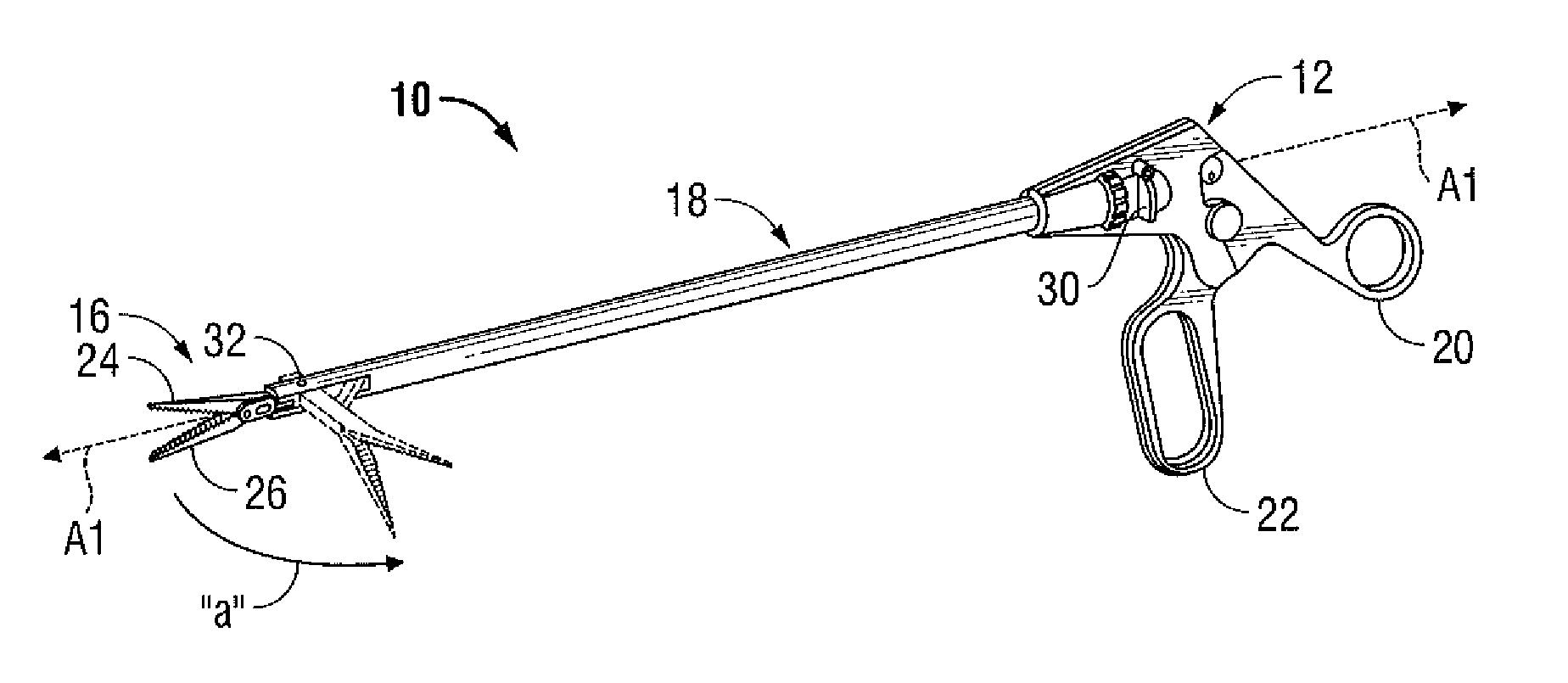

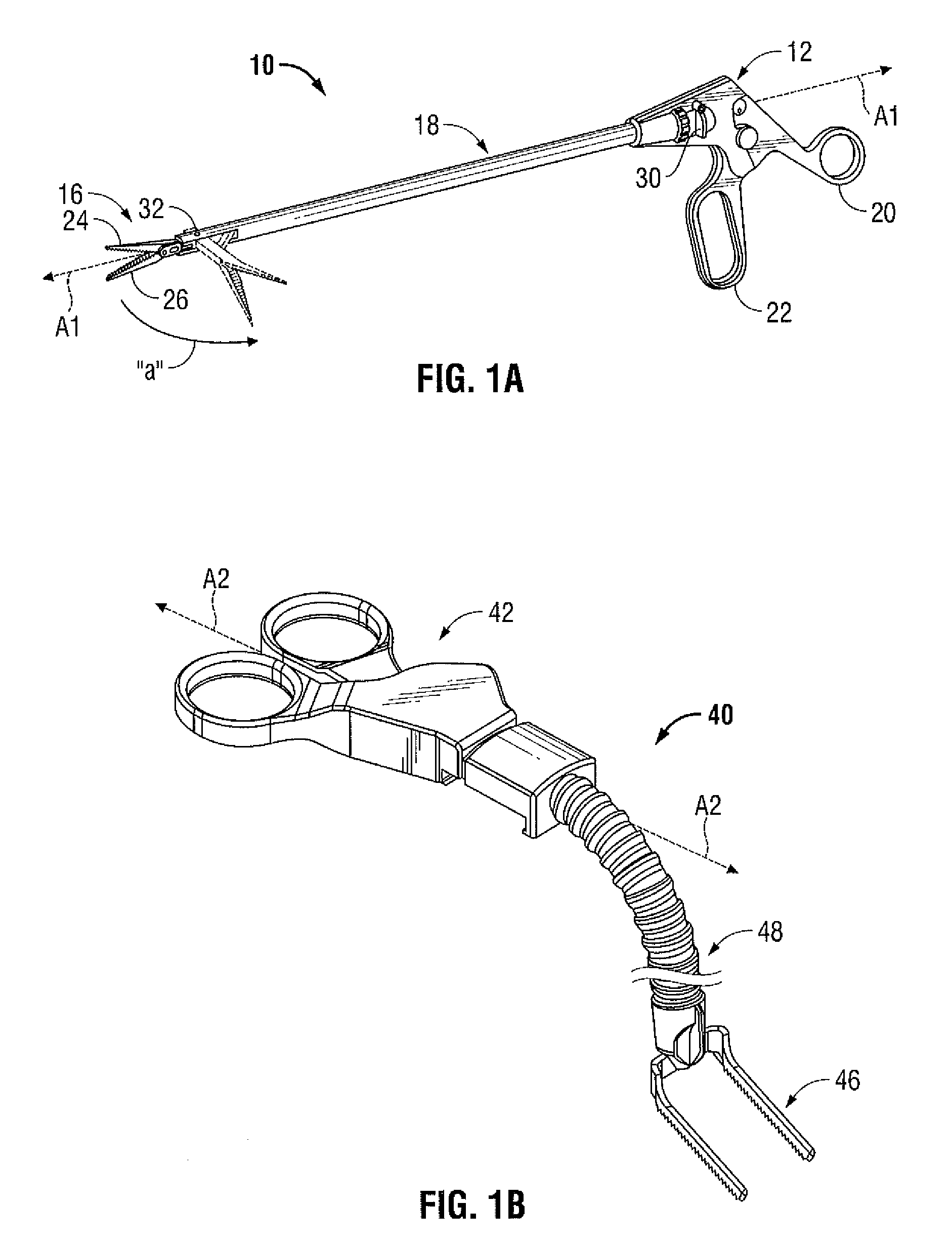

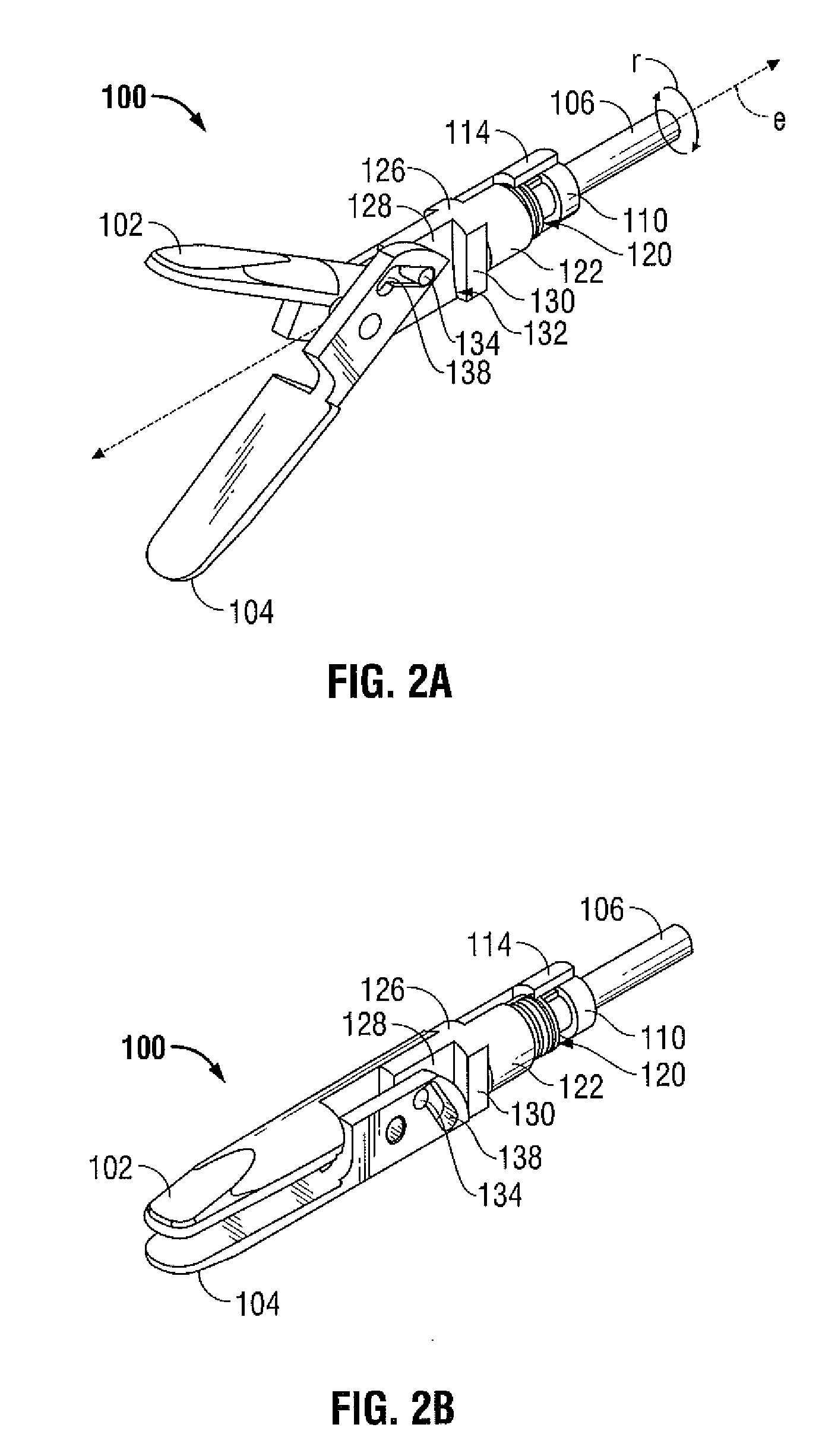

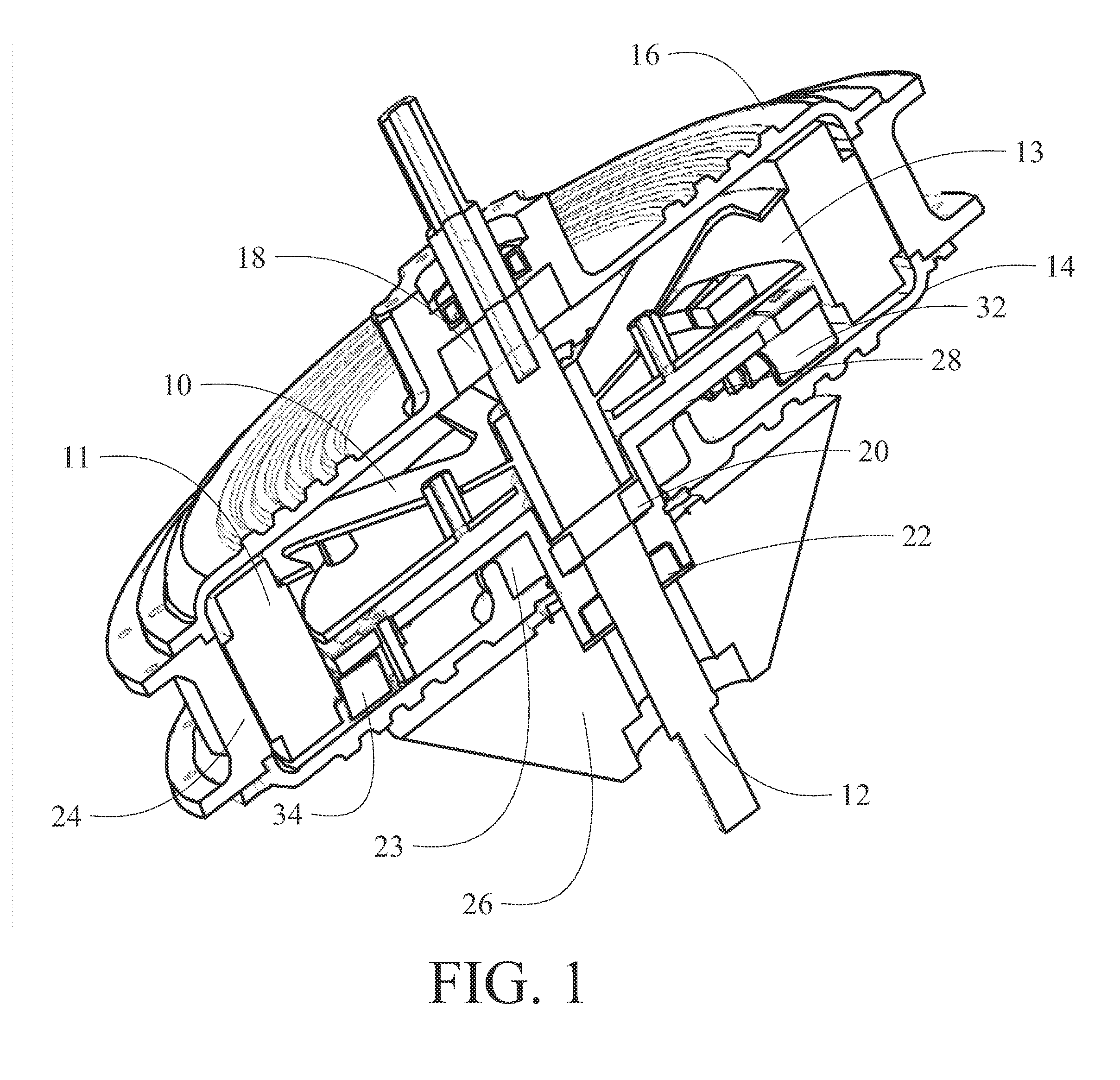

Method of Transferring Pressure in an Articulating Surgical Instrument

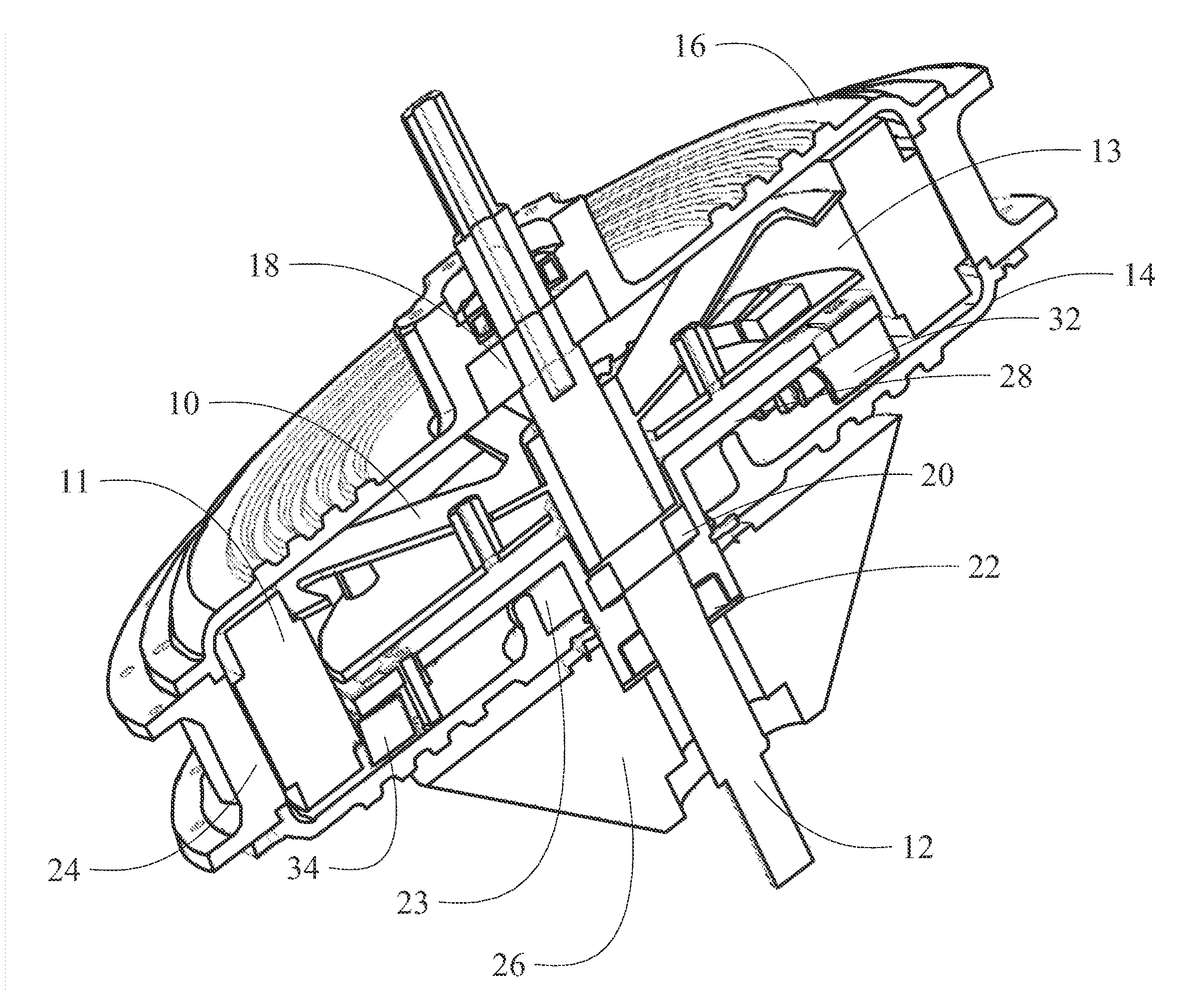

An end effector for a surgical instrument includes a fixed bearing member with mounting surfaces for attachment to a distal end of the surgical instrument. At least one jaw member of the end effector is configured to move relative to an opposing jaw member between open and closed configurations, and a force transfer member is configured for longitudinal motion with respect to the fixed bearing member. The end effector also includes a reactive member that has a pivot boss about which the at least one jaw member rotates, and is coupled between the fixed bearing member and the at least one jaw member. The force transfer member applies a longitudinal force to the at least one jaw member at some lateral distance from the pivot boss to urge the at least one jaw member to move between the open and closed configurations.

Owner:TYCO HEALTHCARE GRP LP

Modular fixed and mobile bearing prosthesis system

A knee prosthetic system includes a femoral component, a fixed tibial bearing component, a mobile tibial bearing component and an integrated or common tibial base component. The same tibial base component can be used with either the fixed tibial bearing component or the mobile tibial bearing component. The fixed bearing component and tibial base component have mating anti-rotation features. One embodiment of the mobile bearing component does not engage the anti-rotation feature of the tibial base component. Another embodiment engages the anti-rotation feature to allow for limited rotation.

Owner:DEPUY (IRELAND) LTD

Method of Transferring Pressure in an Articulating Surgical Instrument

An end effector for a surgical instrument includes a fixed bearing member with mounting surfaces for attachment to a distal end of the surgical instrument. At least one jaw member of the end effector is configured to move relative to an opposing jaw member between open and closed configurations, and a force transfer member is configured for longitudinal motion with respect to the fixed bearing member. The force transfer member includes a pivot channel therein. The end effector also includes a reactive member coupled between the fixed bearing member and the at least one jaw member. The reactive member is constructed from a thin strip of conformable material and extends through the pivot channel such that relative longitudinal motion between the fixed bearing member and the force transfer member causes the reactive member to flex and the at least one jaw member to move relative to the opposing jaw.

Owner:TYCO HEALTHCARE GRP LP

Method of transferring pressure in an articulating surgical instrument

An end effector for a surgical instrument includes a fixed bearing member, having an end effector axis defined therethrough, with mounting surfaces for attachment to a distal end of the surgical instrument. An input shaft is configured for rotational motion relative to the fixed bearing member about the end effector axis and a force transfer member is coupled to the input shaft such that rotary motion of the input shaft generates longitudinal motion in the force transfer member. At least one jaw member couples to the force transfer member such that longitudinal motion of the force transfer member results in the jaw member moving between an open and a closed configuration relative to an opposing jaw member.

Owner:TYCO HEALTHCARE GRP LP

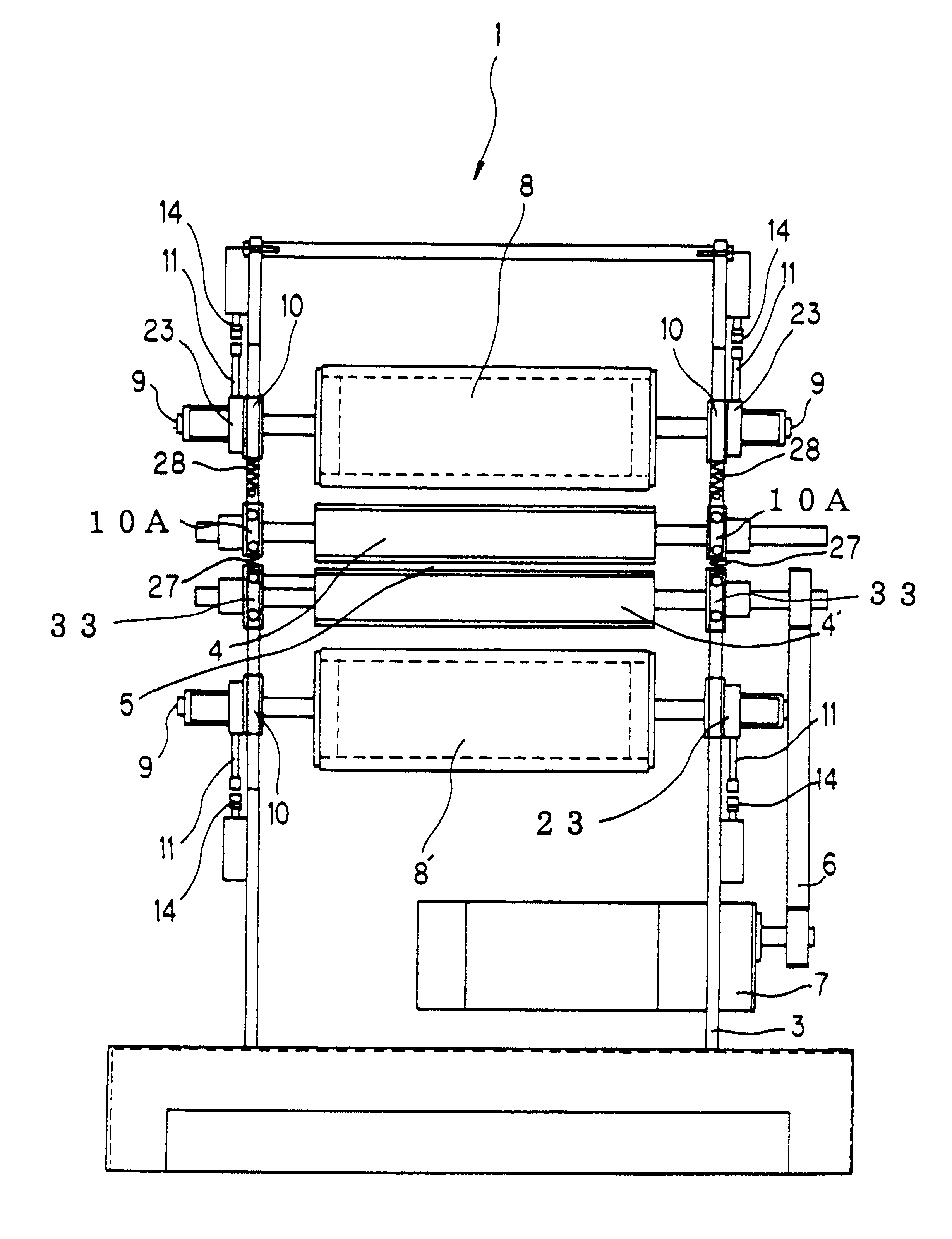

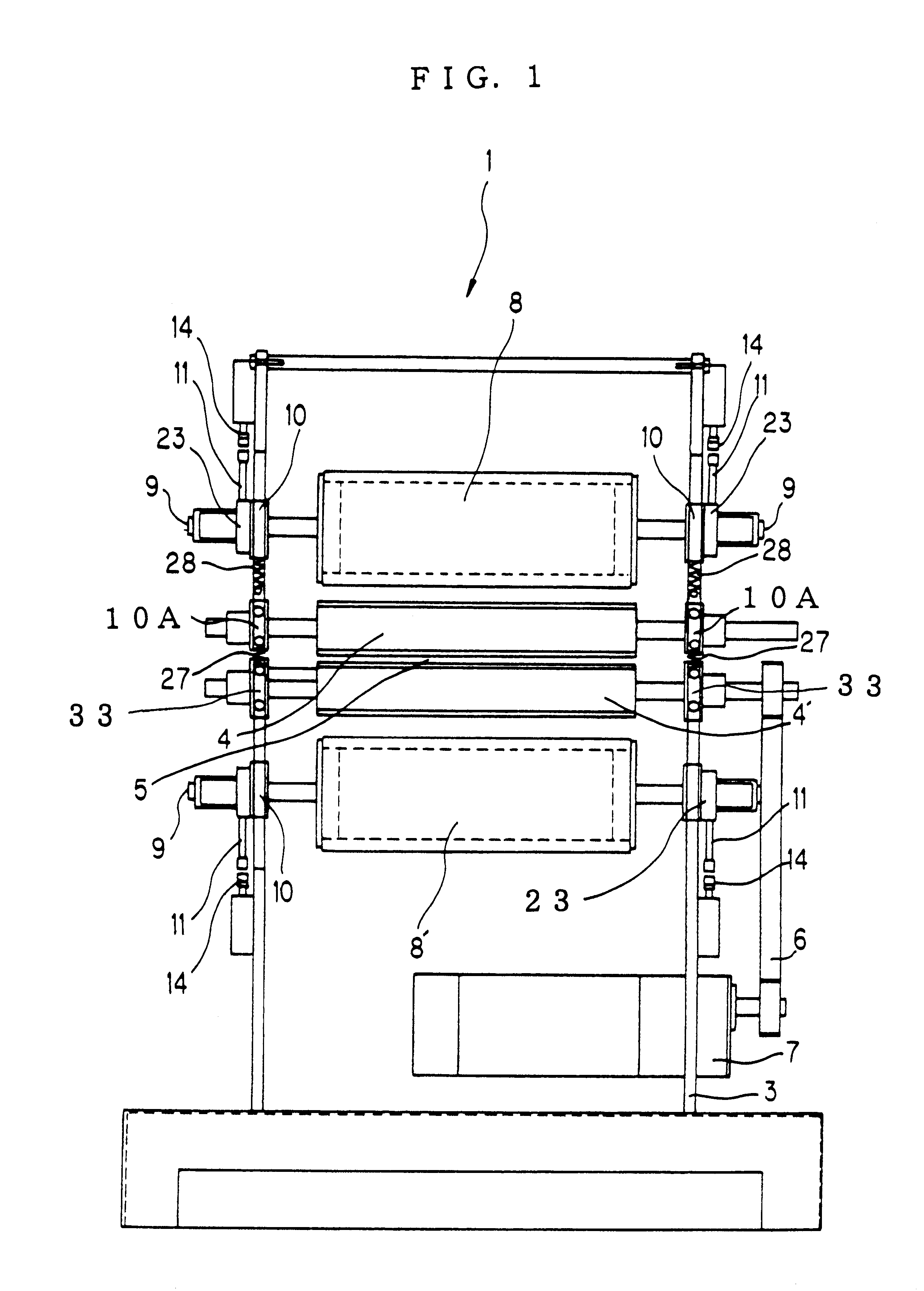

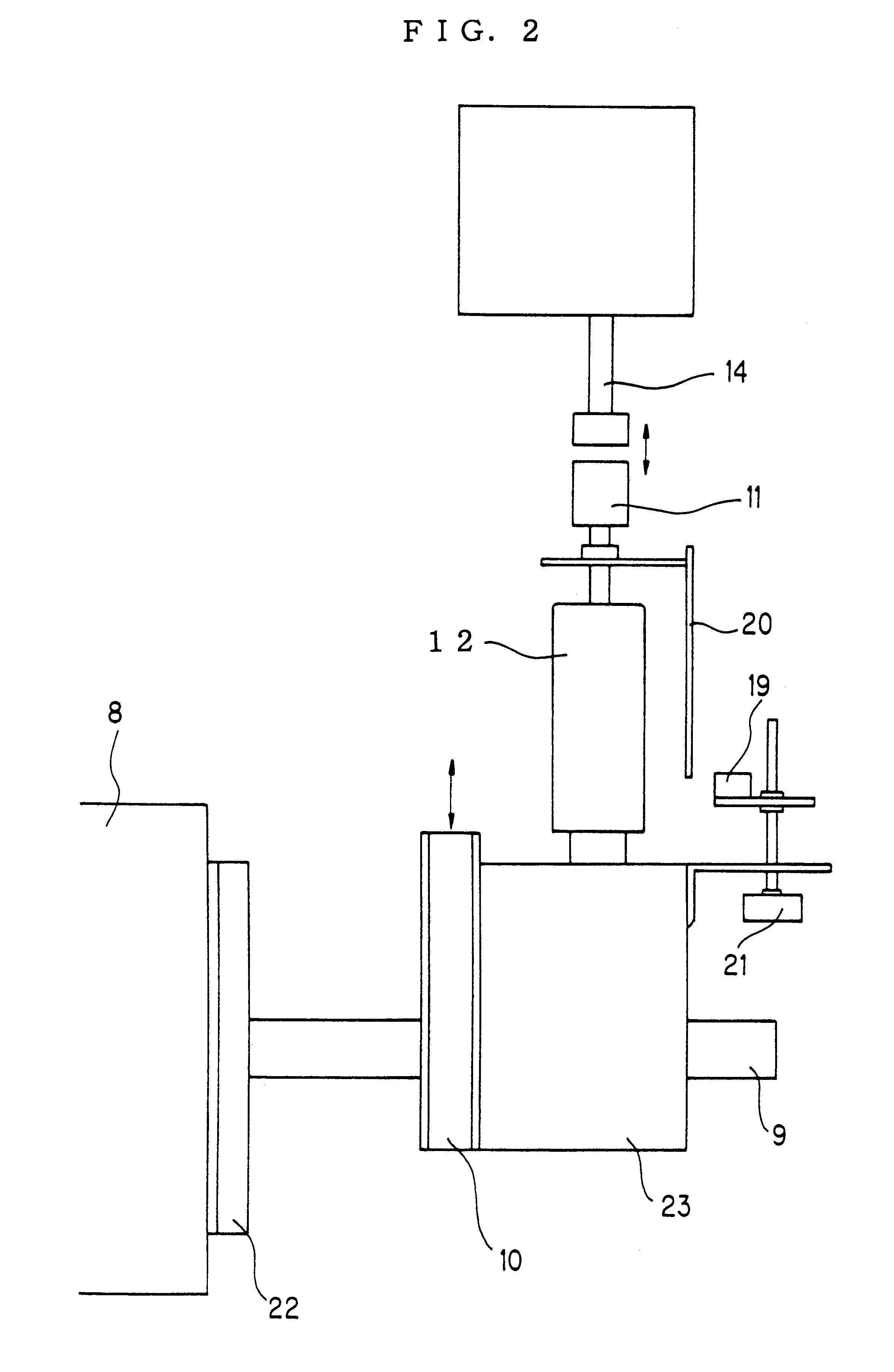

Substrate or sheet surface cleaning apparatus

InactiveUS6237176B1Efficient captureEfficient removalLiquid processingCarpet cleanersFixed bearingSurface cleaning

A substrate or sheet surface cleaning apparatus is provided with at least one tacky rubber roller and at least one adhesive tape roll which is brought into close contact with the tacky rubber roller. The roller and roll are rotatably supported at opposite ends of their shafts by bearings which are slidable in a vertical direction. Pressed rods are arranged integrally on the slidable bearings for the roll. By urging the pressed rods with pressing rods driven by d.c. motors via gear trains while controlling the d.c. motors by a position sensor, the pressure between the roll and the roller and the pressure between the roller and the substrate or sheet are optimized so that dirt or particles can be efficiently removed from an opposing surface of the substrate or sheet. Another substrate or sheet surface cleaning apparatus is provided two tacky rubber rollers arranged in an up-and-down parallel relationship and two adhesive tape rolls arranged above the upper roller and below the lower roller, respectively. Position adjusters with one or more springs disposed therein are arranged between slidable bearings supporting the upper roller and fixed bearings supporting the lower roller to correct tilting, if any, of the upper roller.

Owner:RAYON IND

Method of Transferring Pressure in an Articulating Surgical Instrument

An end effector for a surgical instrument includes a fixed bearing member, having an end effector axis defined therethrough, with mounting surfaces for attachment to a distal end of the surgical instrument. An input shaft is configured for rotational motion relative to the fixed bearing member about the end effector axis and a force transfer member is coupled to the input shaft such that rotary motion of the input shaft generates longitudinal motion in the force transfer member. At least one jaw member couples to the force transfer member such that longitudinal motion of the force transfer member results in the jaw member moving between an open and a closed configuration relative to an opposing jaw member.

Owner:TYCO HEALTHCARE GRP LP

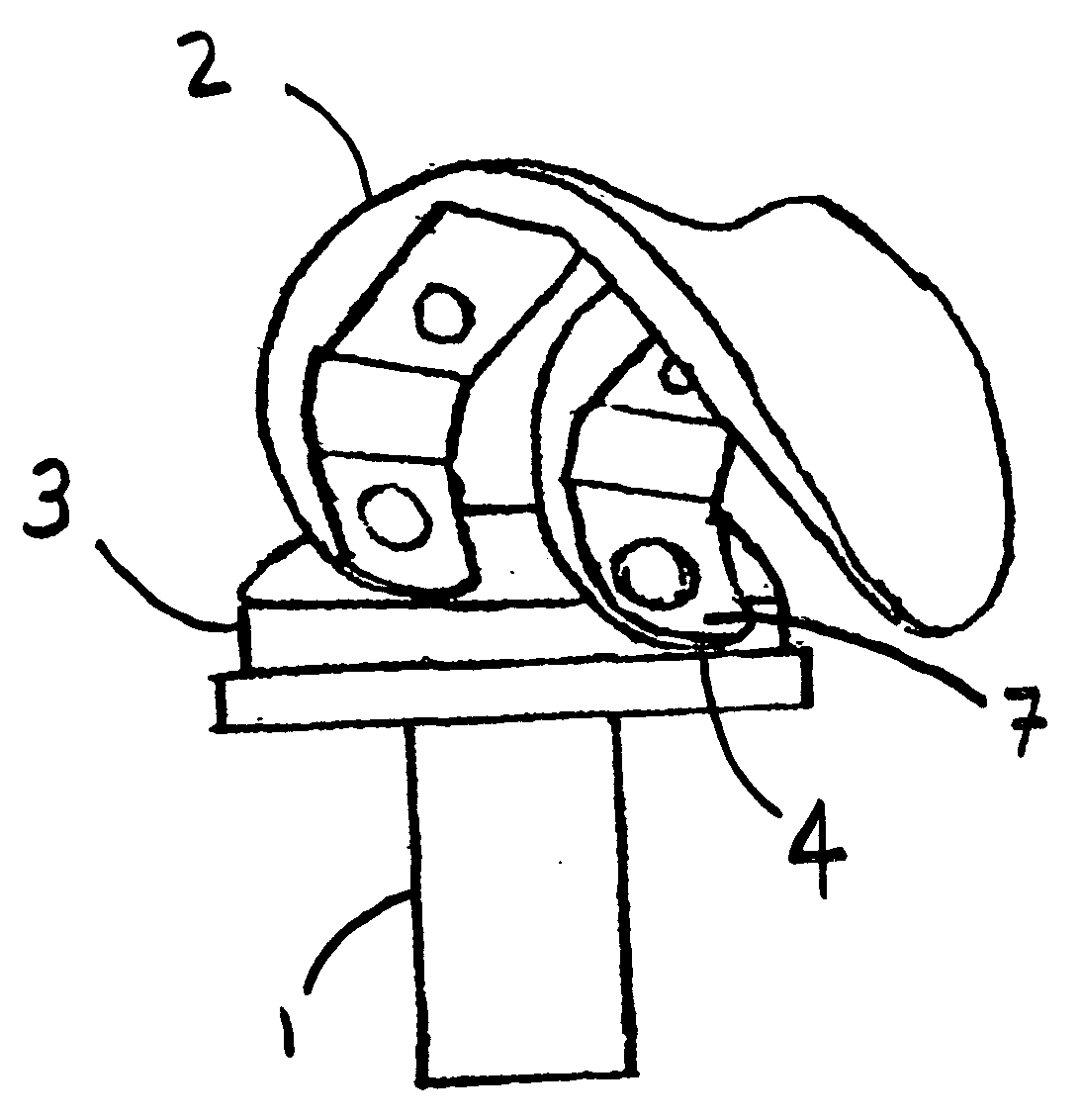

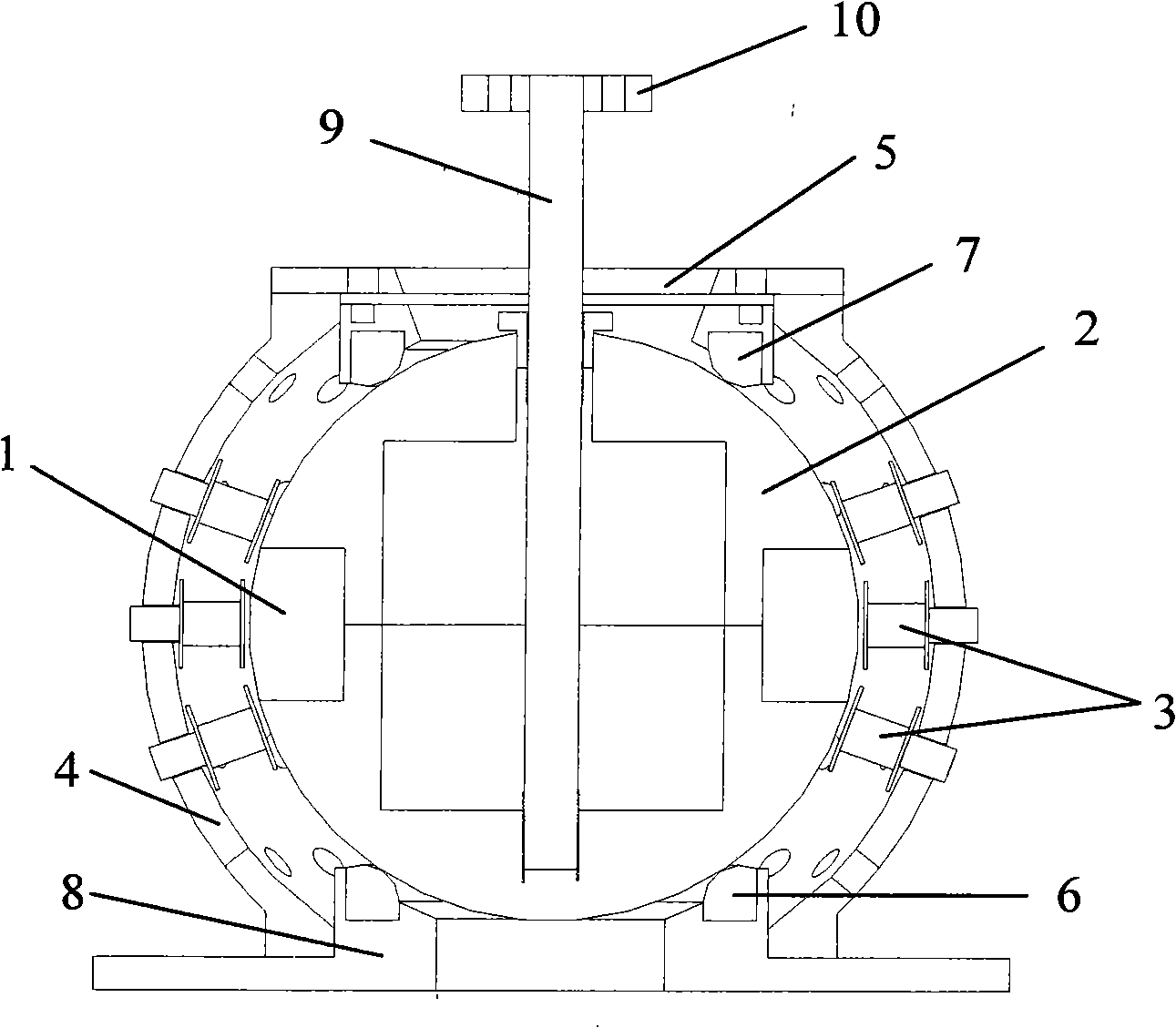

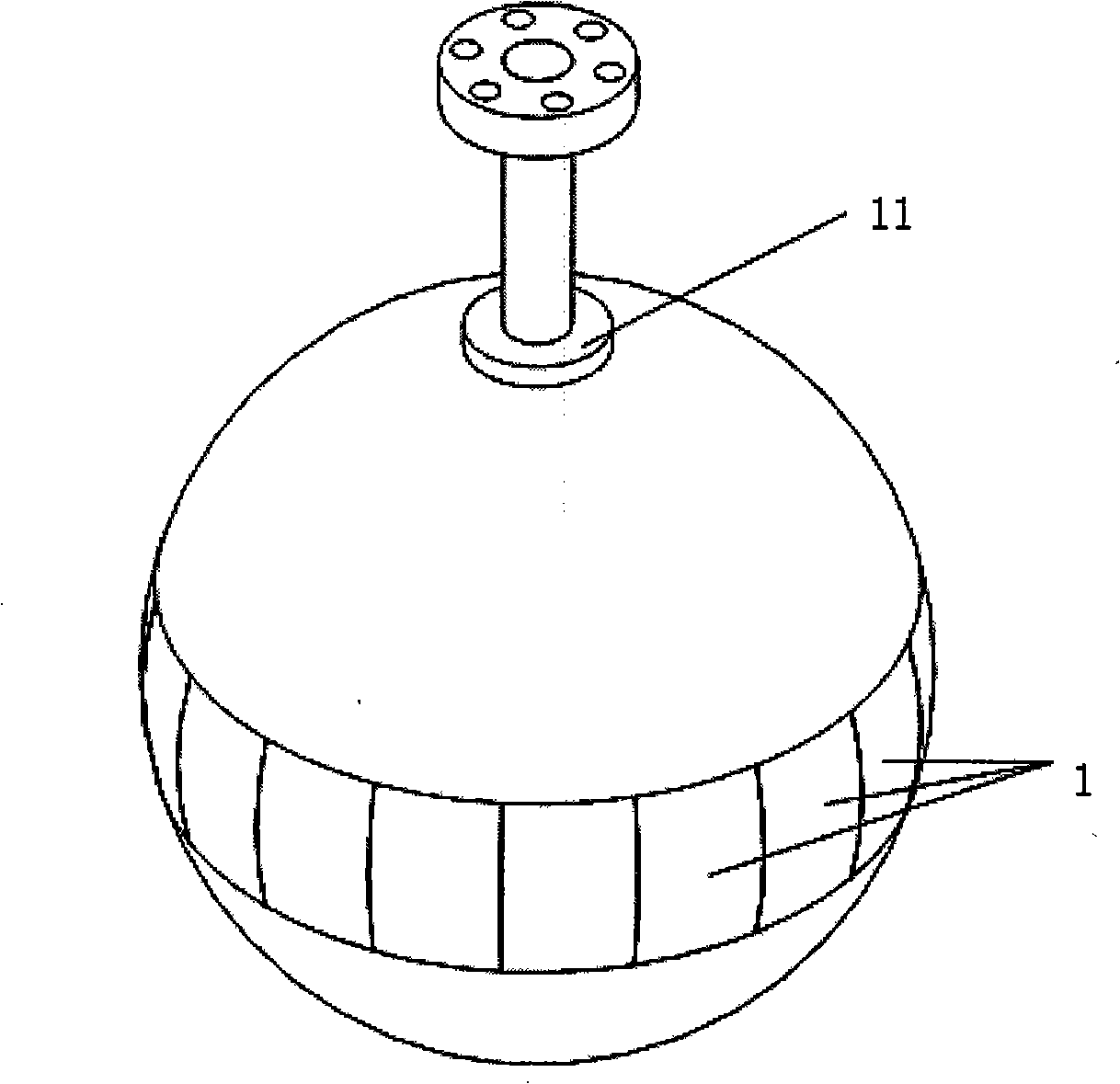

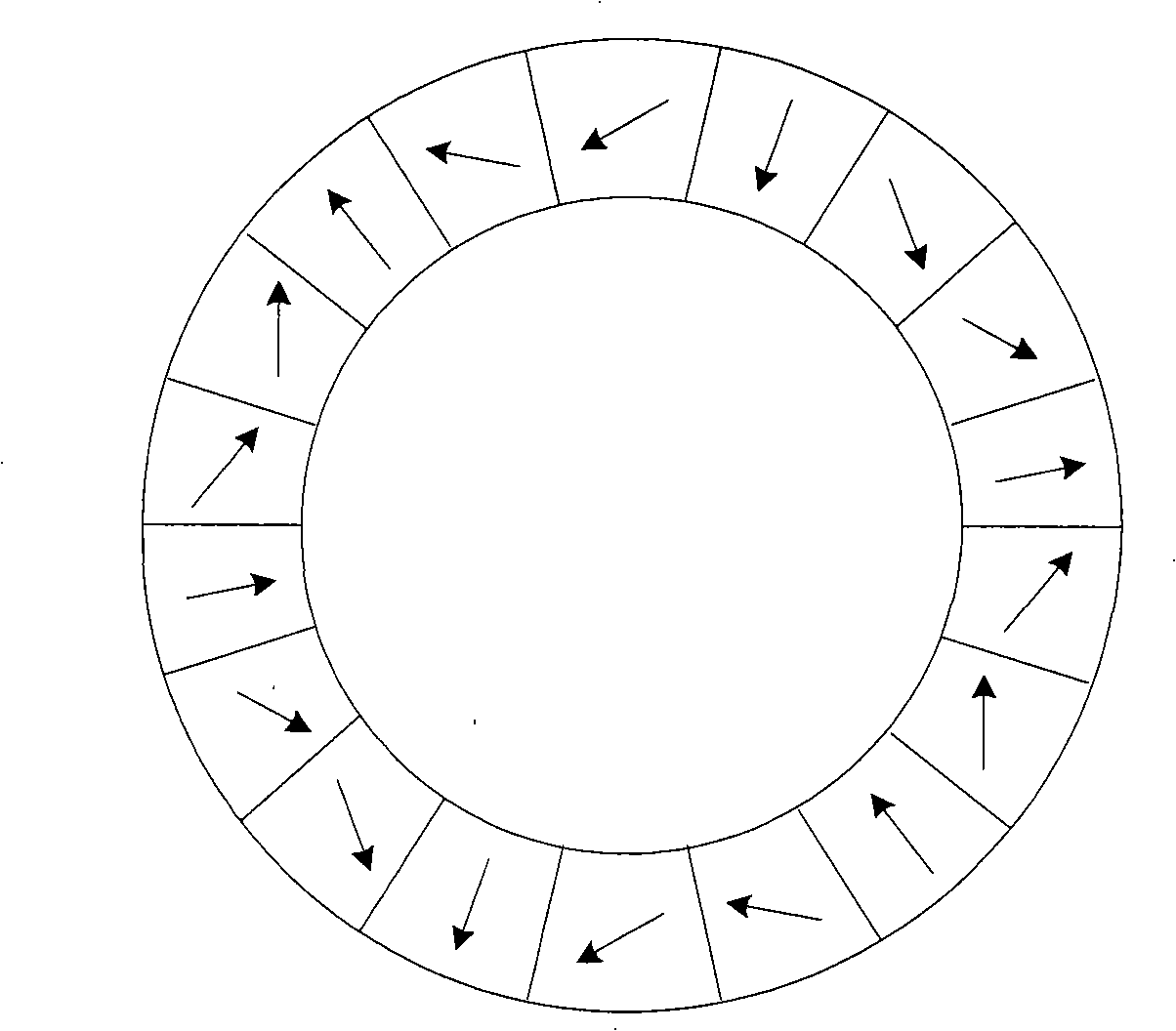

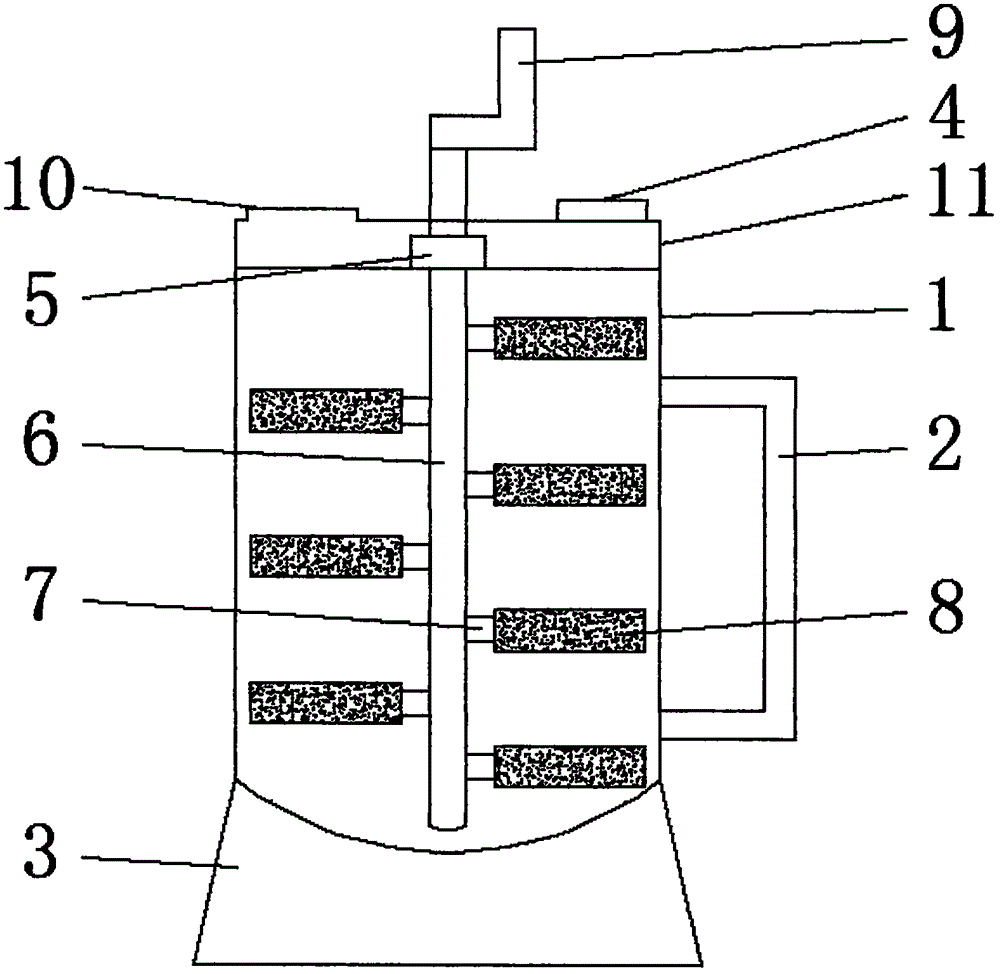

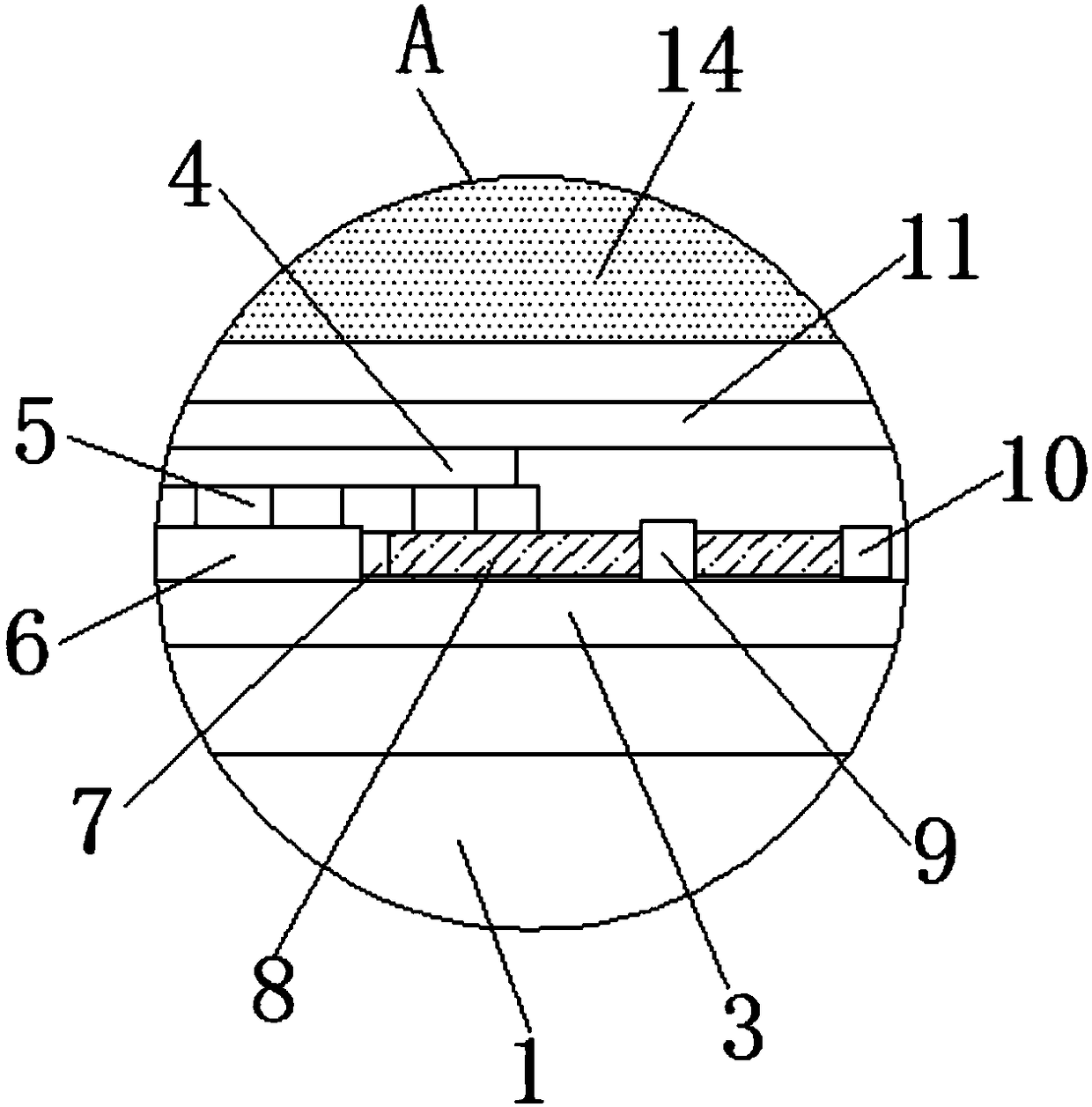

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

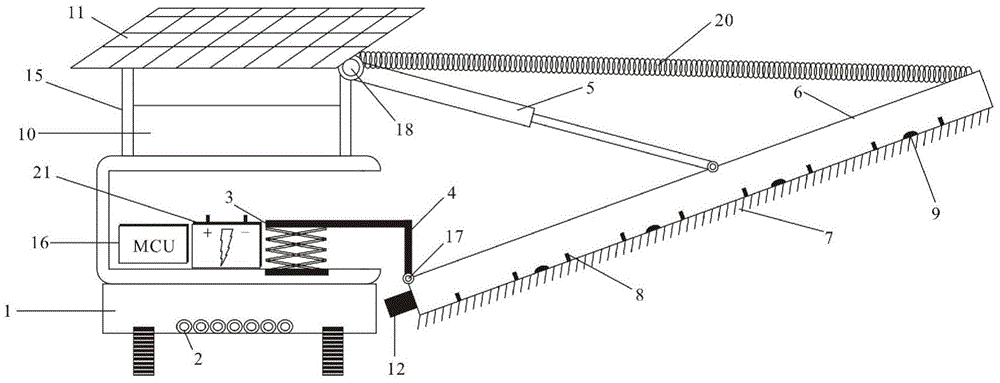

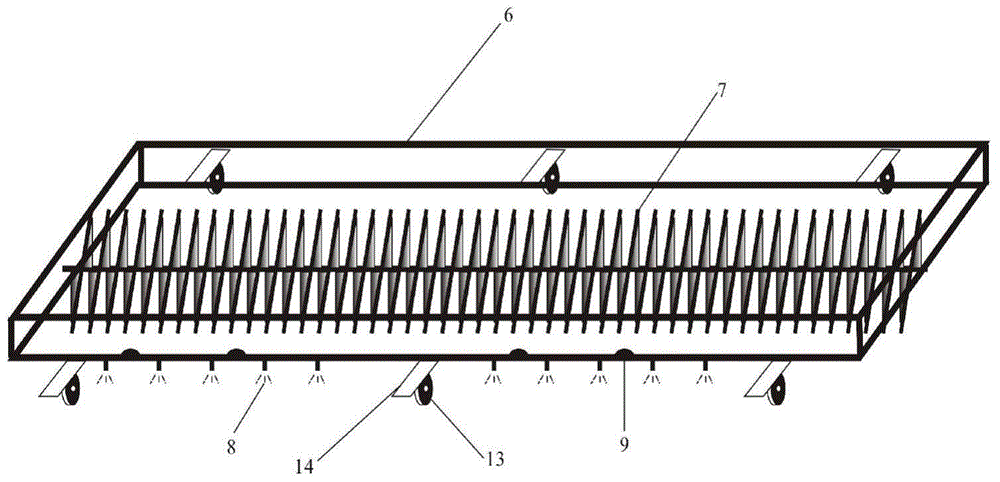

Self-navigation full-automatic cleaning device for photovoltaic cell panel

InactiveCN103599907AReduce labor intensityImprove work efficiencyCleaning using toolsCleaning using liquidsFixed bearingCells panel

The invention discloses a self-navigation full-automatic cleaning device for a photovoltaic cell panel. The device has the full-automatic functions of automatically navigating travelling, automatically regulating a cleaning state, automatically selecting a cleaning mode and automatically charging an accumulator. The load-bearing trolley of the device realizes the automatic travelling function of a fixed route by utilizing a self-navigation sensing system and detecting characteristic markers previously placed on site; the lifting platform, telescopic link, brush roller bracket and fixed bearing of the device can completely substitute for the design of a mechanical arm to realize the automatic real-time control of the angle height of the brush roller bracket and realize the function of automatically regulating the cleaning state according to pressure sensing data; a photoelectric sensing system can feed back the dust dirty degree of the surface of the photovoltaic cell panel in real time so as to regulate the travelling speed of the load-bearing trolley and the rotation speed of a brush roller and determine whether a water spray cleaning mode is adopted or not. The self-navigation full-automatic cleaning device disclosed by the invention is simple in structure, can not only save the cost, but also increase the cleaning efficiency, and is very suitable for large-area popularization and usage.

Owner:邵俊松 +1

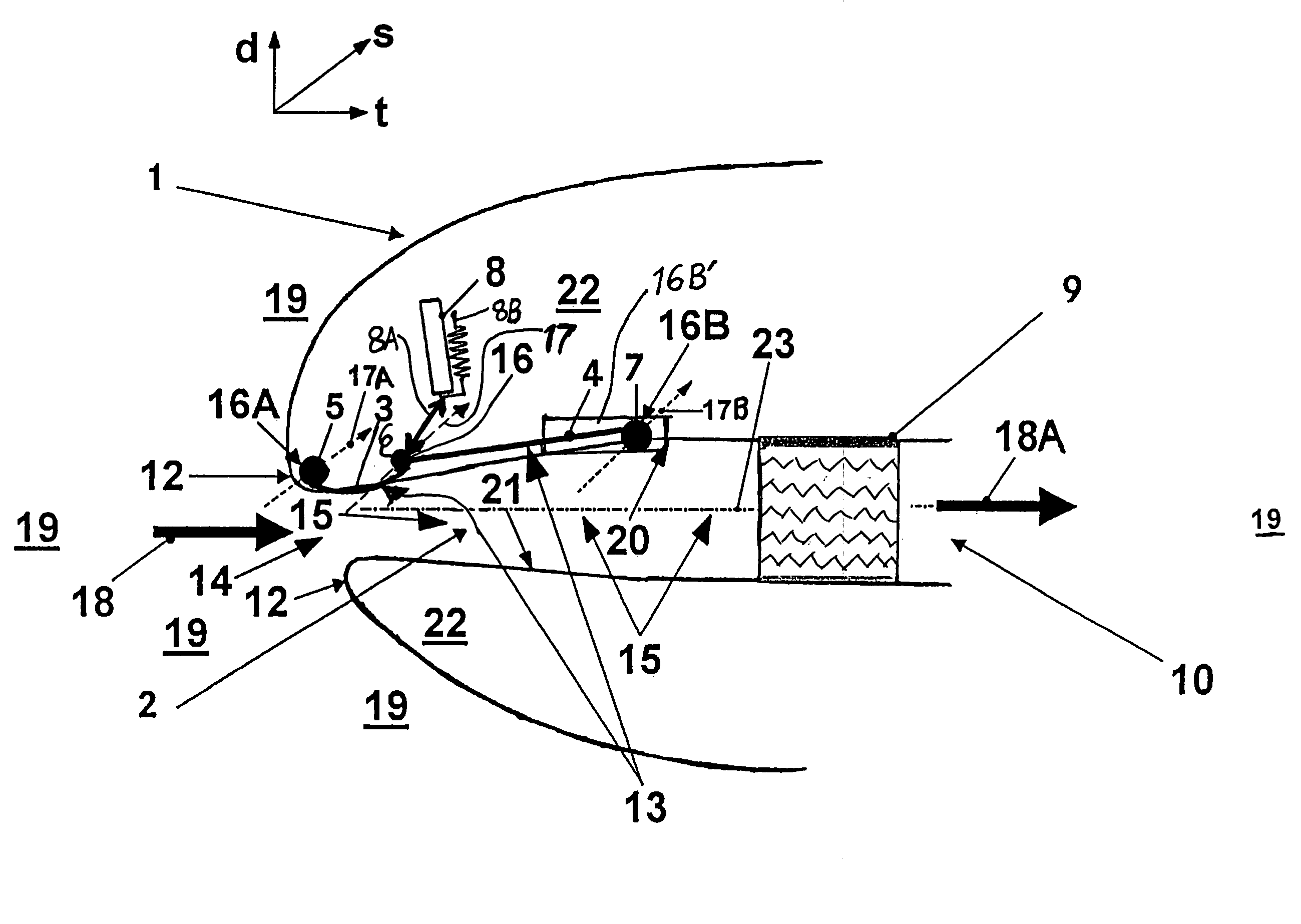

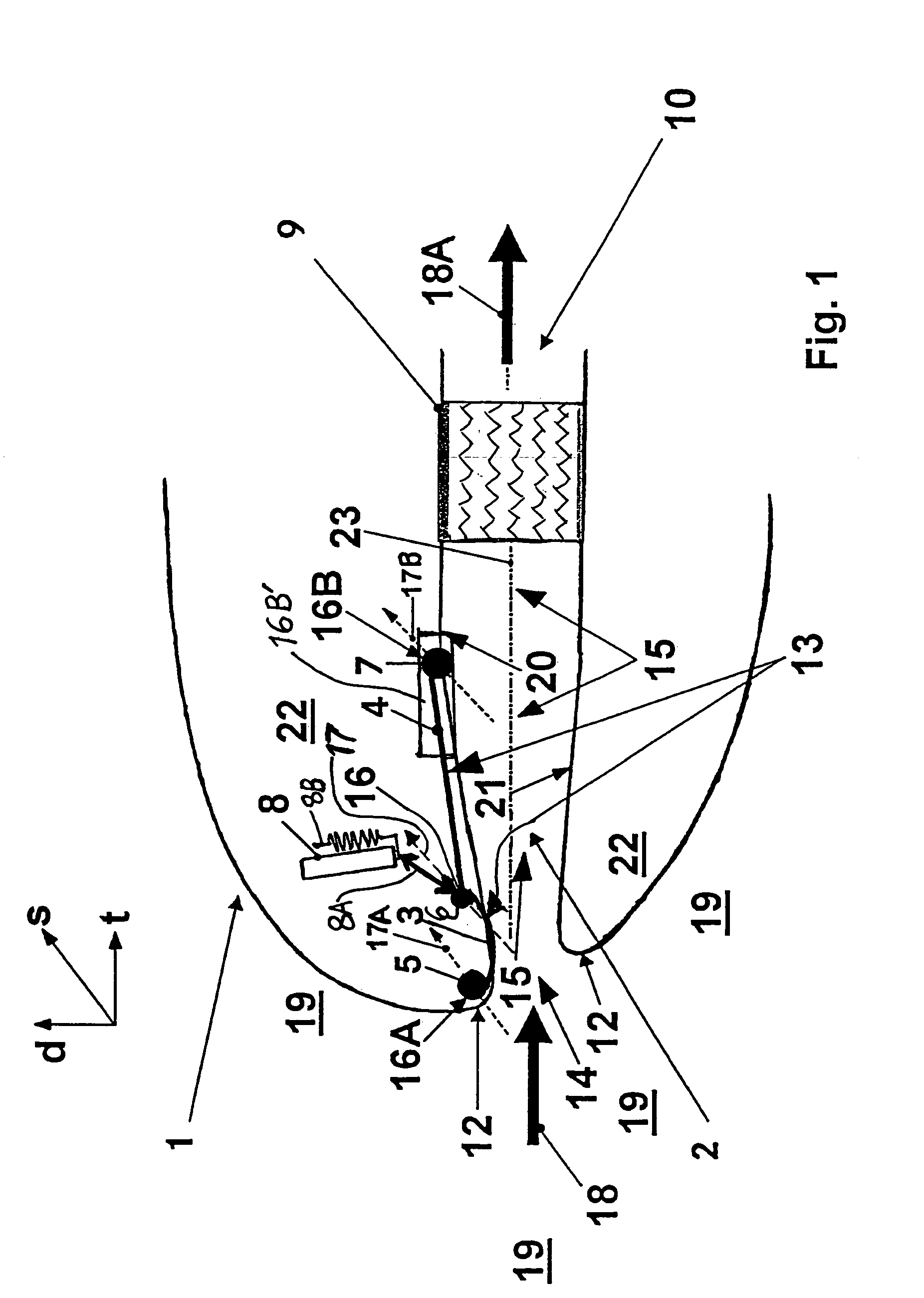

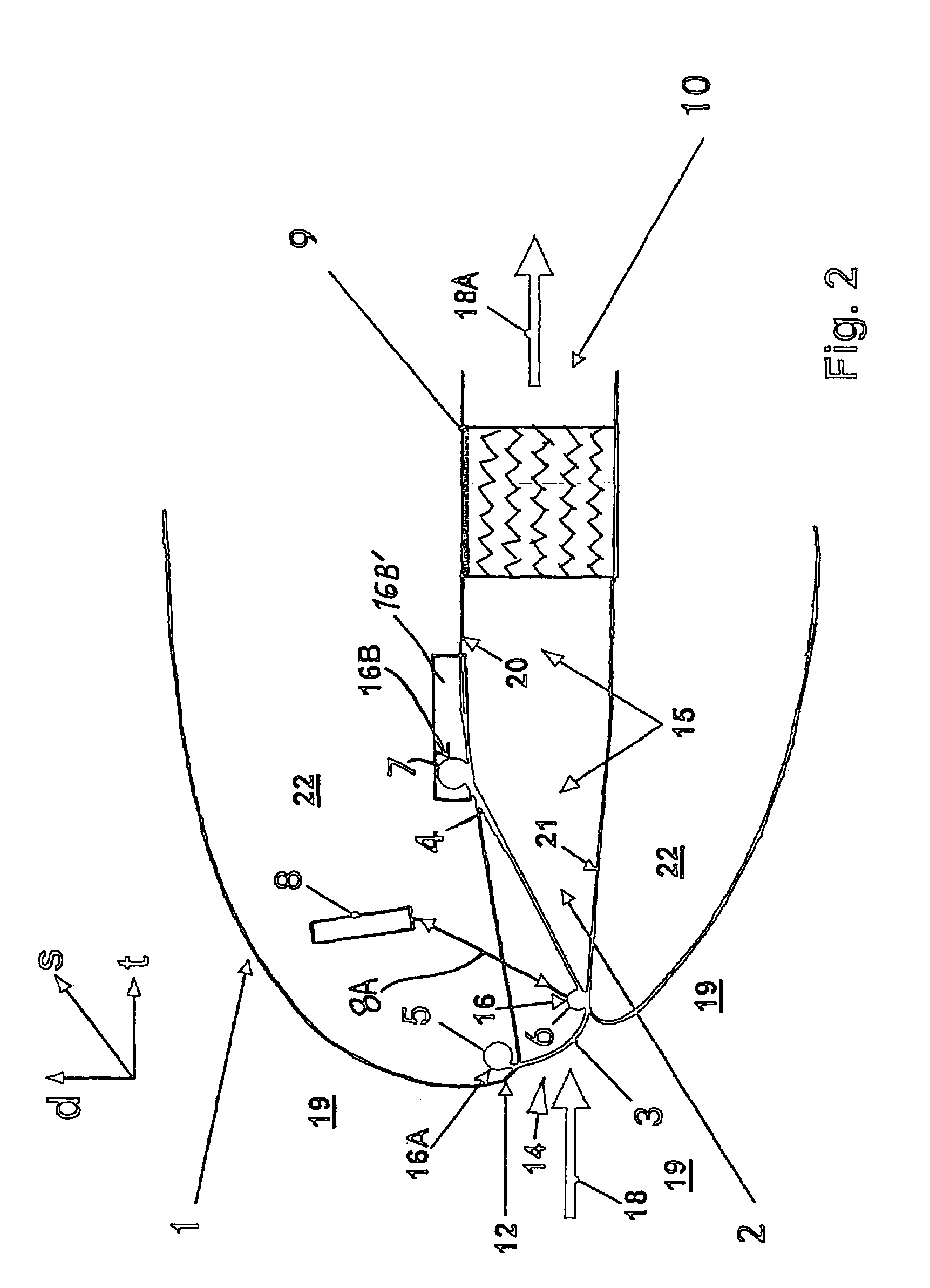

Aircraft ram air inlet with multi-member closure flap

InactiveUS7222819B1Reduce air resistanceEffective controlAir-treatment apparatus arrangementsWeight reductionFixed bearingLeading edge

A ram air inlet includes a channel with an intake in a wing leading edge, front and rear flaps arranged in the channel for selectively closing or opening the channel, and an actuator connected to the flaps. A front end of the front flap is pivotably connected by a fixed bearing to an aircraft structure adjacent the intake. A rear end of the rear flap is moveably and pivotably mounted to the aircraft structure via a movable bearing arrangement, e.g. a pivot bearing linearly movable in guide tracks, or a flexible lever connected to a fixed pivot bearing, or a swinging bearing pivotably connected to a fixed bearing. The opposite ends of the flaps are pivotably connected to each other by a third bearing. The actuator drives the third bearing to pivot the front flap between opened and closed positions, while the rear flap pivots and moves in the wing chord and / or thickness directions.

Owner:AIRBUS OPERATIONS GMBH

Modular fixed and mobile bearing prosthesis system

A knee prosthetic system includes a femoral component, a fixed tibial bearing component, a mobile tibial bearing component and an integrated or common tibial base component. The same tibial base component can be used with either the fixed tibial bearing component or the mobile tibial bearing component. The fixed bearing component and tibial base component have mating anti-rotation features. One embodiment of the mobile bearing component does not engage the anti-rotation feature of the tibial base component. Another embodiment engages the anti-rotation feature to allow for limited rotation.

Owner:DEPUY (IRELAND) LTD

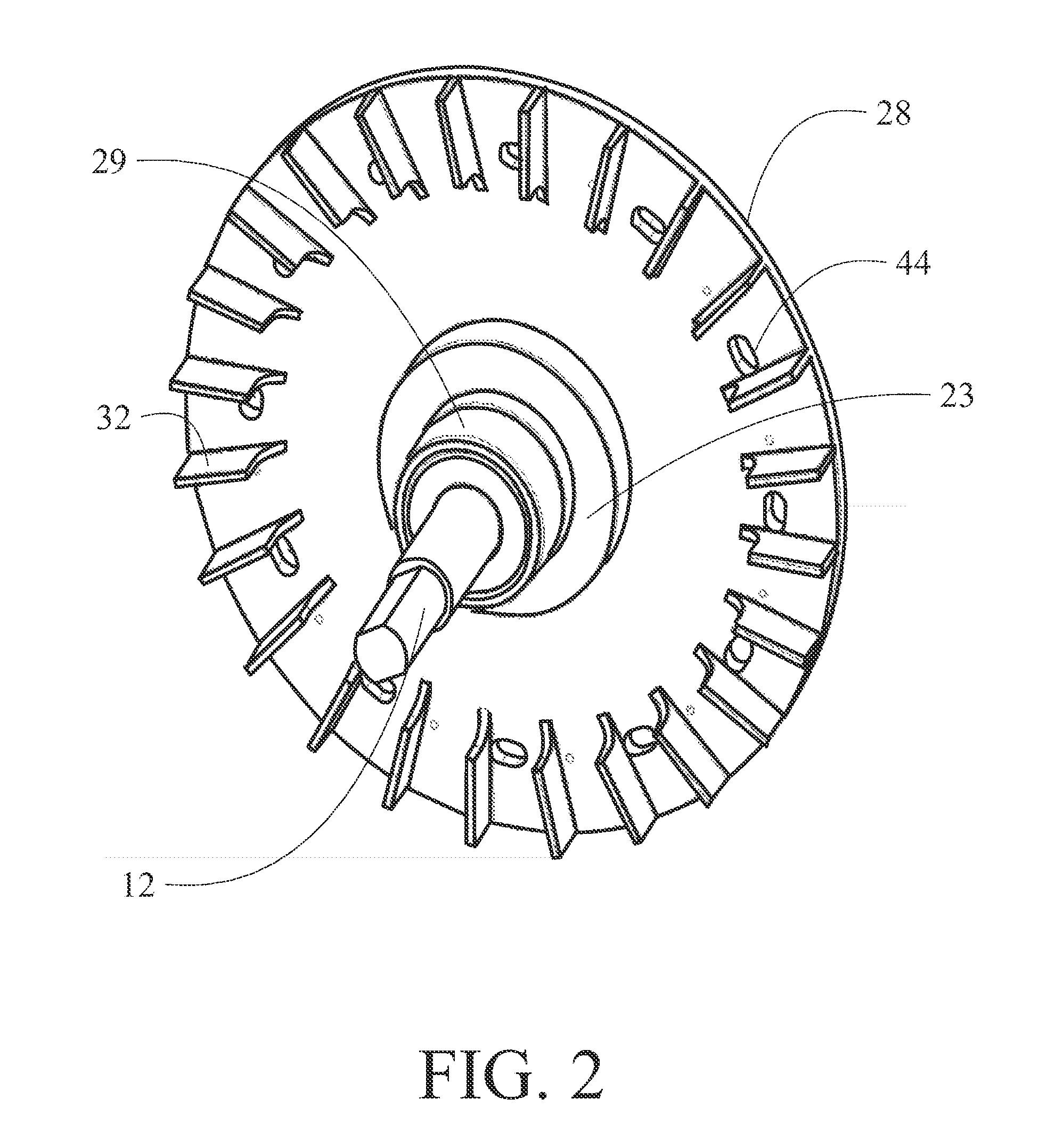

Electronic bike integrated supplemental motor system

An integrated supplemental motor system for e-bikes incorporates a motor stator carried by a fixed axle with a torroidal cavity surrounding the axle. A motor rotor for interaction with the stator is supported by a motor casing rotatable on a plurality of bearings carried by the fixed axle. A torque member is concentrically carried within the torroidal cavity and has a first attachment engaged to a gear cluster for force input and a second resilient attachment for engagement to the motor casing. The torque member is urged by the gear cluster from a first no force position resiliently through a range of motion to a second maximum force position. A first element connected to the torque member has a set of first signal generation interfaces and a second element connected to the motor case has an equal set of second signal generation interfaces. The first and second signal generation interfaces are spaced in relation to the range of motion of the torque member. A sensor detects the consecutive first and second signal generation interfaces. A controller connected to the sensor receives a speed input and an effort input and provides a stator actuation current proportional to the spacing of the detected first and second signal generation interfaces.

Owner:RUBEN MURRAY

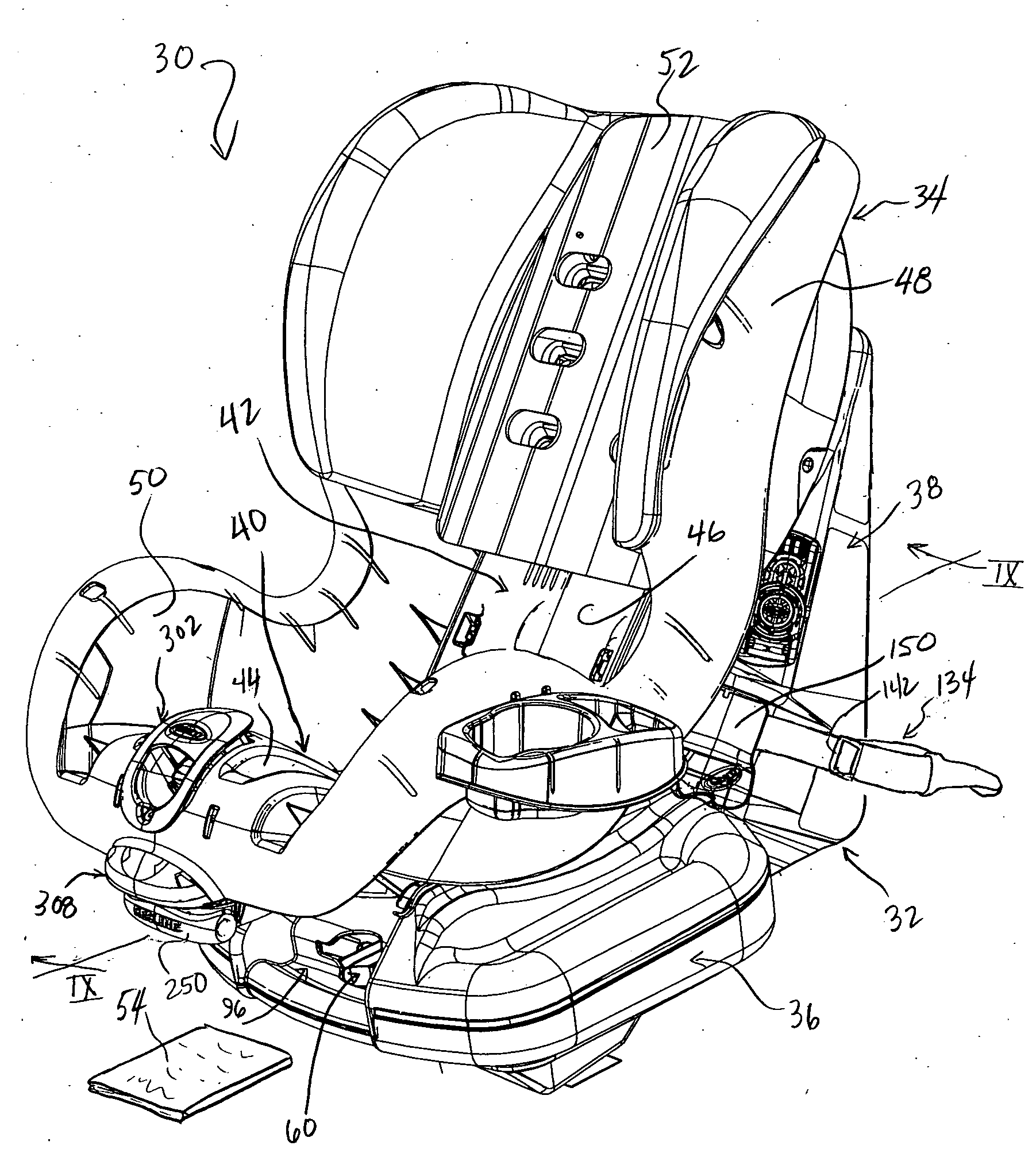

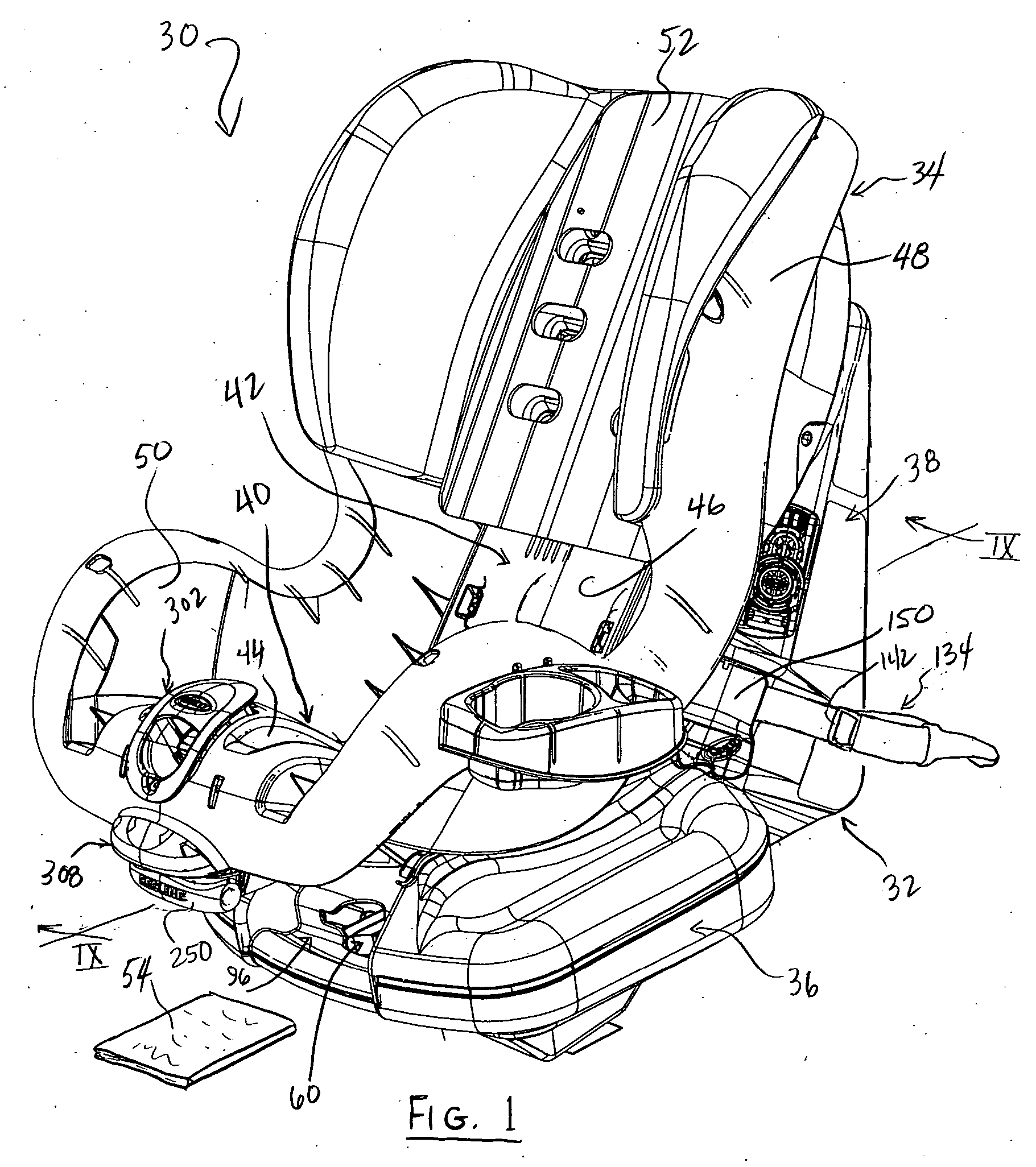

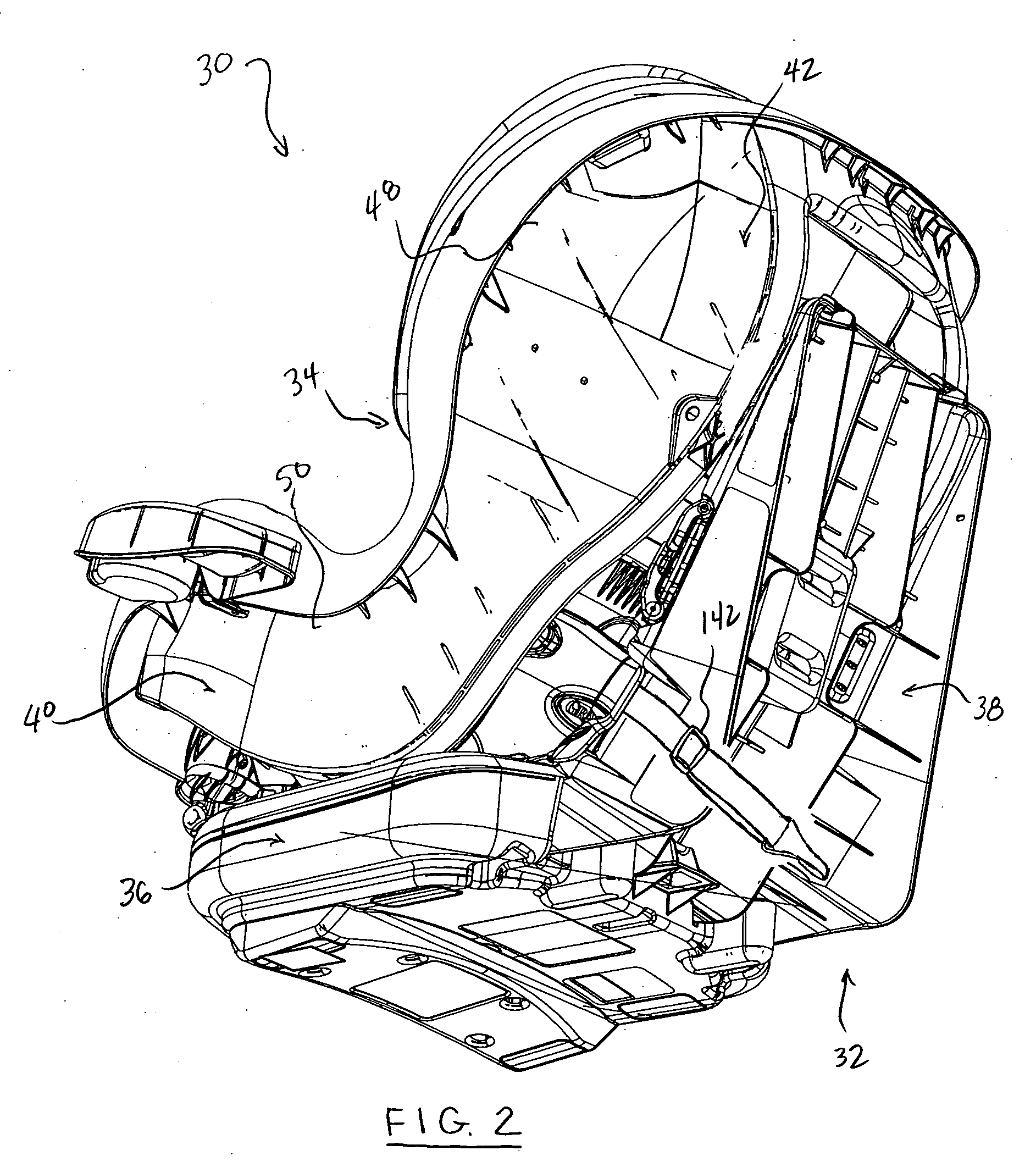

Child vehicle safety seat

A car seat has a support base configured to test on a dedicated seat of a vehicle when installed. The car seat also has a seat shell coupled to the support base that defines a seating surface of the car seat. The seating surface has a seat bottom portion that terminates at a front end of the seat shell. The seat shell is adjustable to a plurality of selectable seat recline orientations relative to the support base. A recline lever is mounted under the seat shell and is movable between a latch position and a release position. A handle on one end of the recline lever is positioned below and projects forward of the front end of the seat shell. The handle is movable upward to move the recline lever to the release position. A shroud projects forward from the front end of the seat shell and is positioned above and spaced from the handle. A top side of the shroud is positioned to act as a fixed bearing surface for grasping and moving the handle upward toward the shroud.

Owner:GRACO CHILDRENS PROD INC

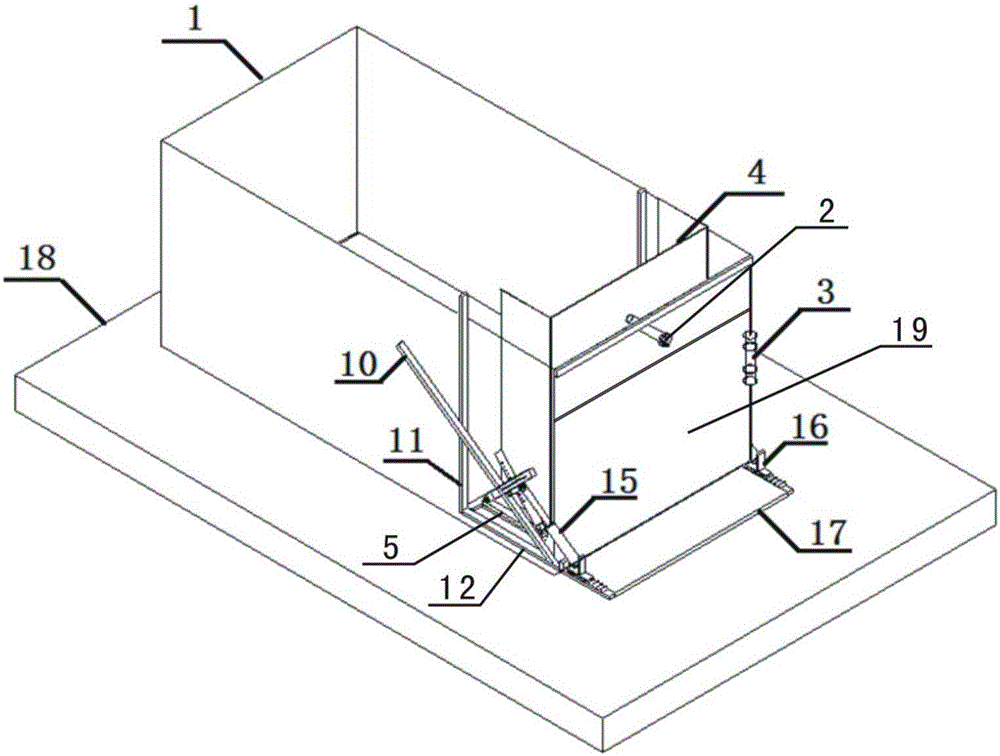

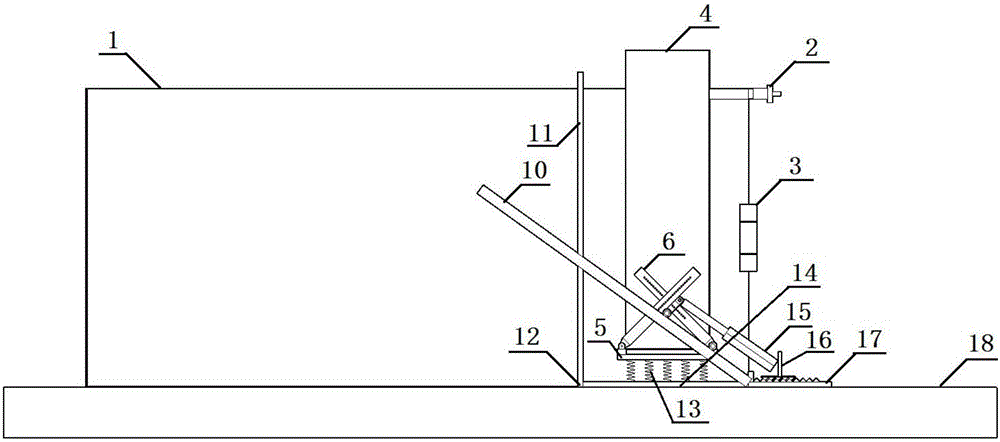

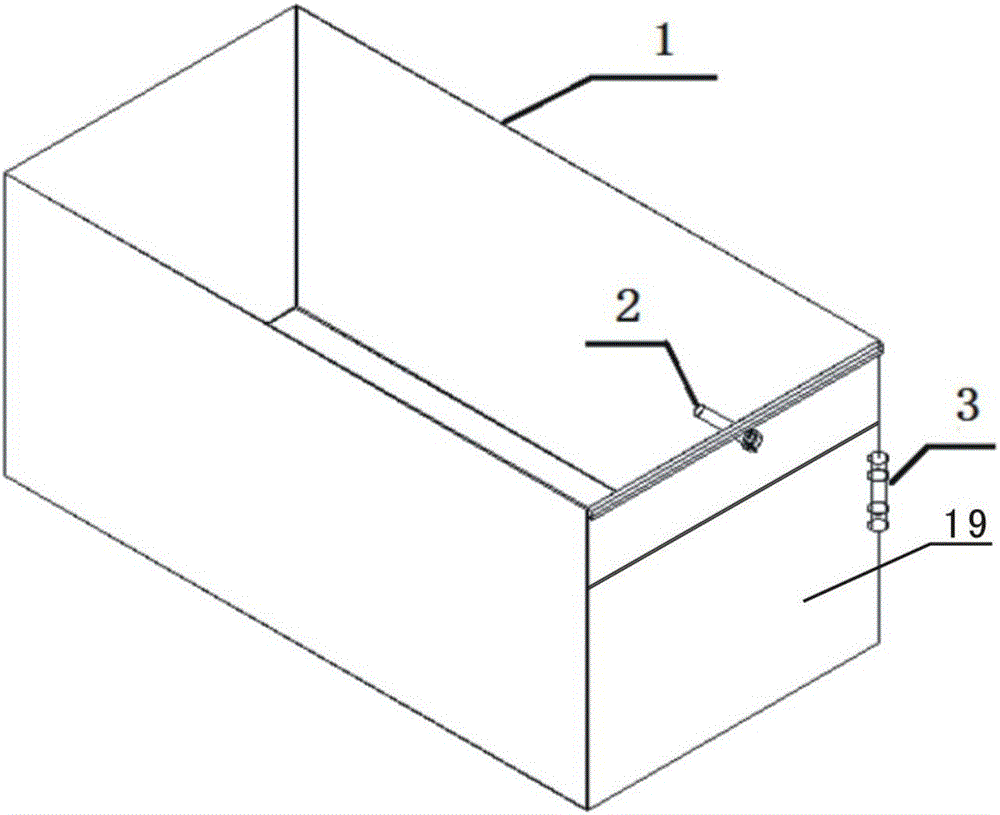

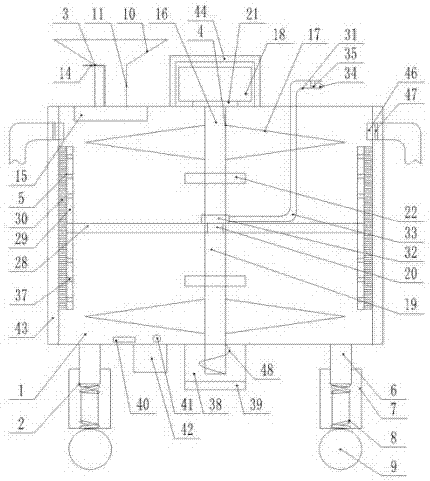

Test device for simulating tunnel seismic response under fault movements and test methods

InactiveCN106226808ANo excessive displacementGuaranteed continuous misalignmentSeismologyMaterial strength using steady shearing forcesFixed bearingMobile bearing

The invention discloses a test device for simulating a tunnel seismic response under fault movements, which comprises a vibration table, a model test box, a guide rail underframe, a guide rail, a calibrated rod, a spring matrix, a spring mounting plate, a load-bearing bottom plate, an adjustment connecting rod, a fixed bearing, a mobile bearing, a lifting drawer, a jack base and a hydraulic jack. The invention further discloses two test method adopted by the test device for simulating the tunnel seismic response under the fault movements, and the two methods are respectively used for normal fault simulation and reverse fault simulation. A dynamic response of a seismic action in a condition that a fault movement force acts on a tunnel model can be realized by adopting the test device disclosed by the invention, the fault movement force is provided by the hydraulic jack, faults with any inclination angle can be simulated, and the spring matrix can ensure continuous dynamic movements of a hanging side soil body when the vibration table is in operation, so that stress of the tunnel model is enabled to be more consistent with actual situations, the authenticity and the precision of a test result are significantly improved, and research on anti-seismic and shock absorption design of a fault crossing tunnel is facilitated.

Owner:SOUTHWEST JIAOTONG UNIV

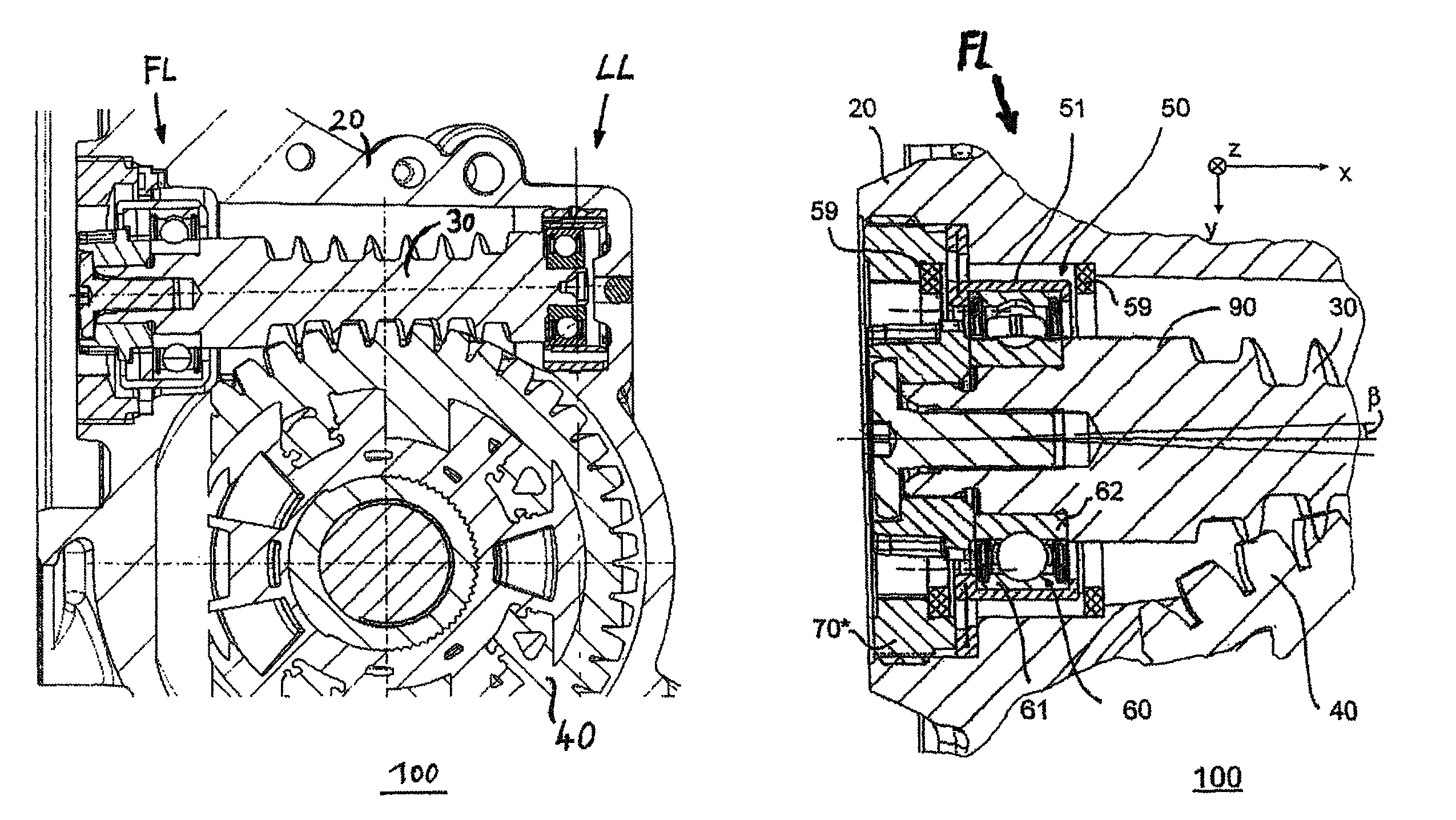

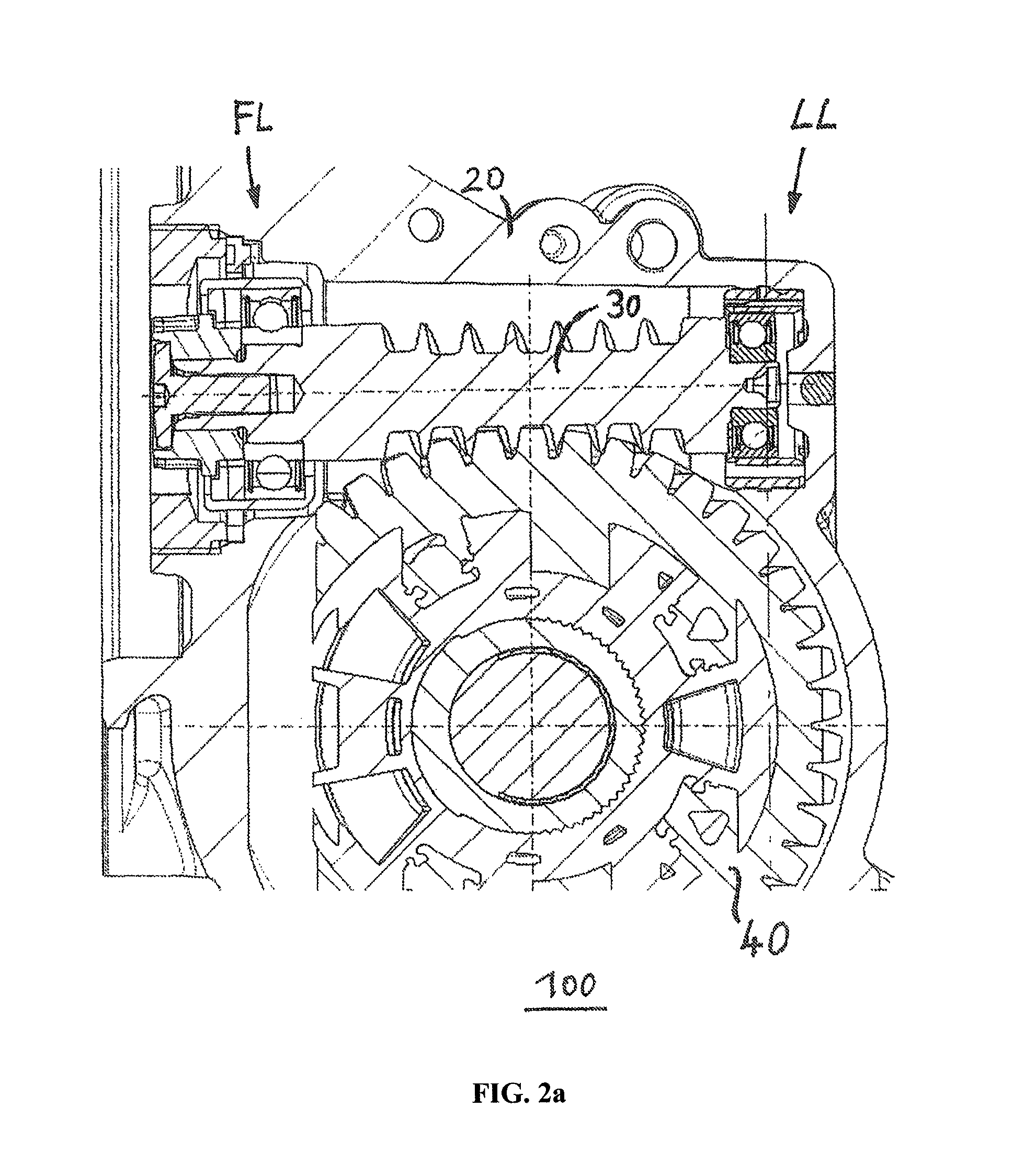

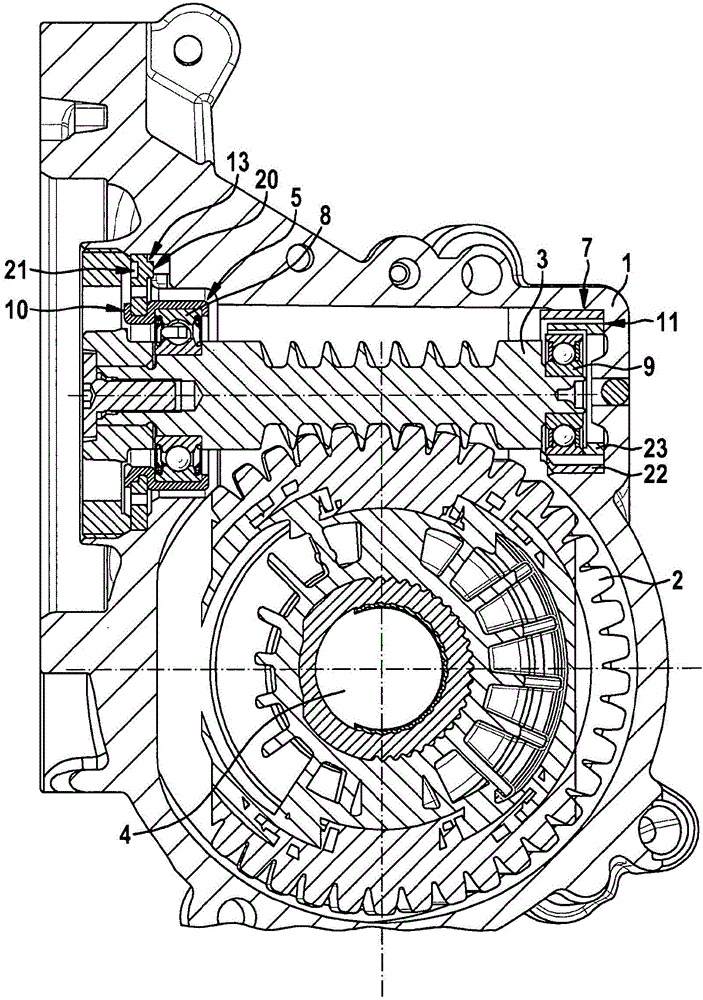

Steering gear having a fixed bearing and a floating bearing for a screw pinion

ActiveUS8667858B2Reduce noiseDefinable elasticityRolling contact bearingsShaftsFixed bearingGear wheel

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

Flow machine with rotor and stator

A flow machine with rotor and stator in axial structure in flow-oriented terms, at least in sections, having moving blades at the rotor and housing-fixed guide vanes, whereby the latter are arranged as at least one guide vane ring with an inner and an outer cover band. The at least one guide vane ring is implemented as self-bearing component part having a closed reinforcement at the inner cover band that reinforces the component part to resist jamming axial deformation, comprises a segmented outer cover band and is positioned in the housing over at least three cover band segments with bearing units that respectively allow radial relative movements. An air guide shell that guides a cooling air stream along the inside of the housing and is provided with openings for the housing-fixed bearing elements of the at least one guide vane ring is arranged between the housing and the outer cover band of the at least one guide vane ring.

Owner:DU BRO PRODS

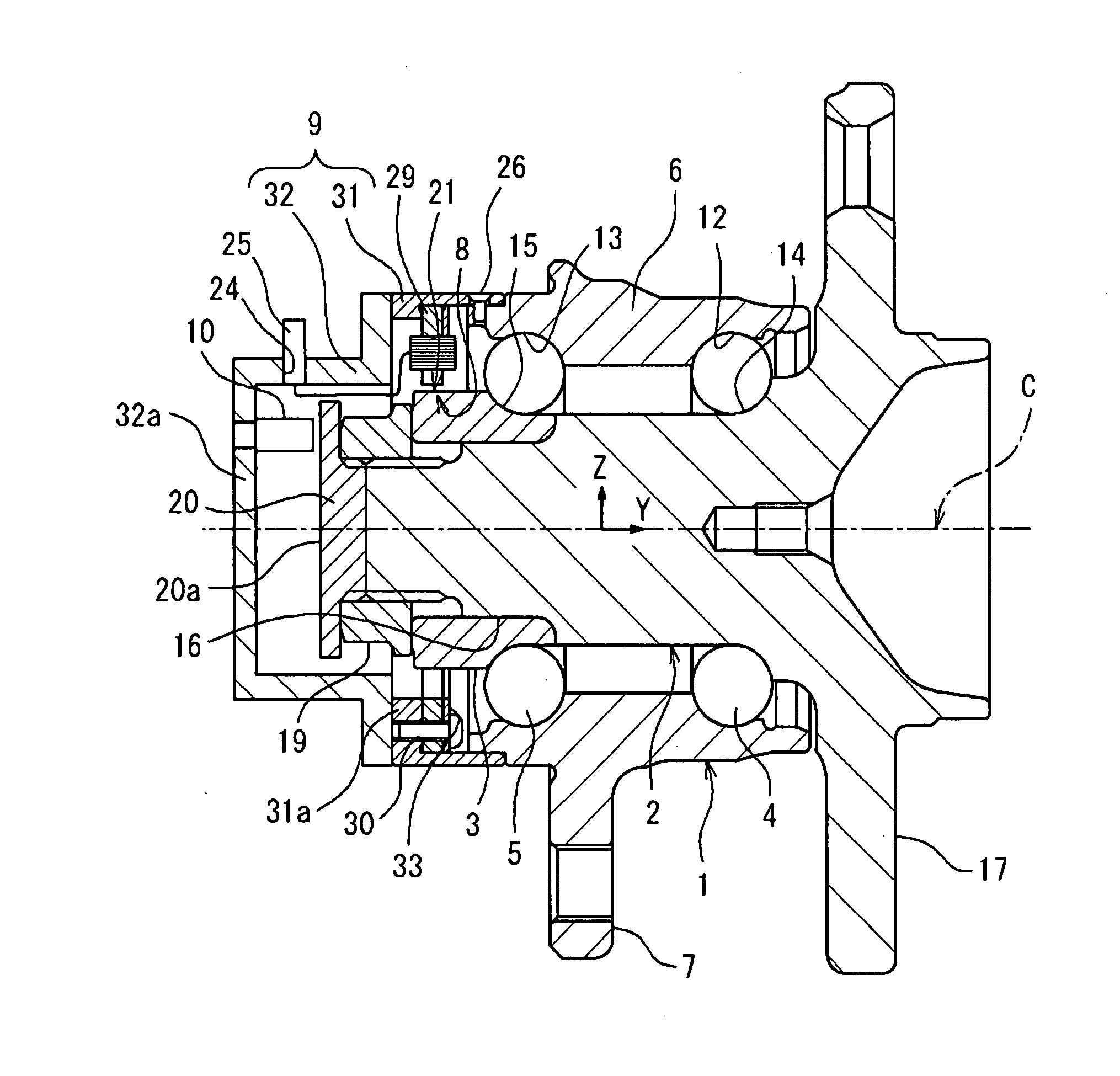

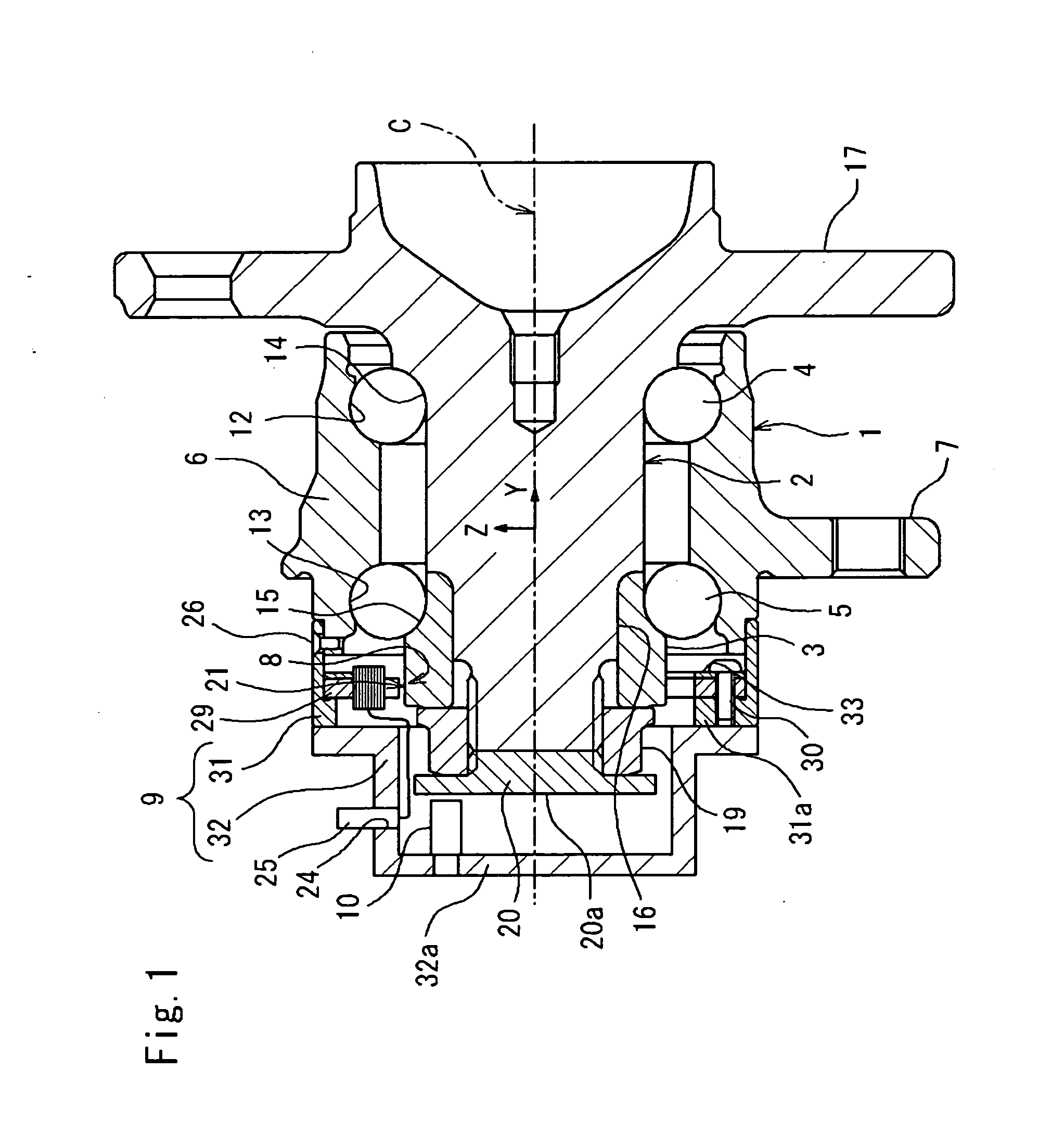

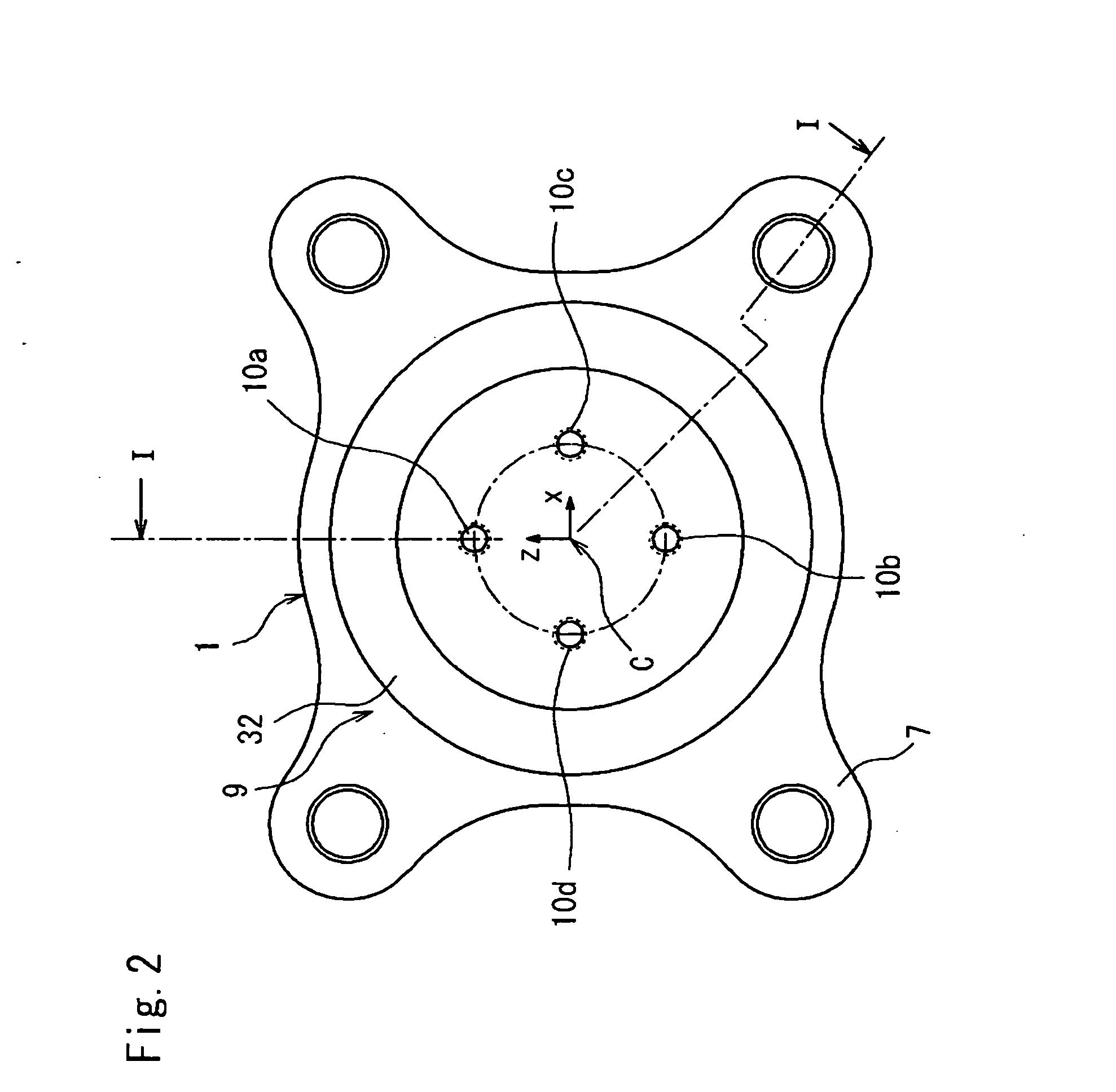

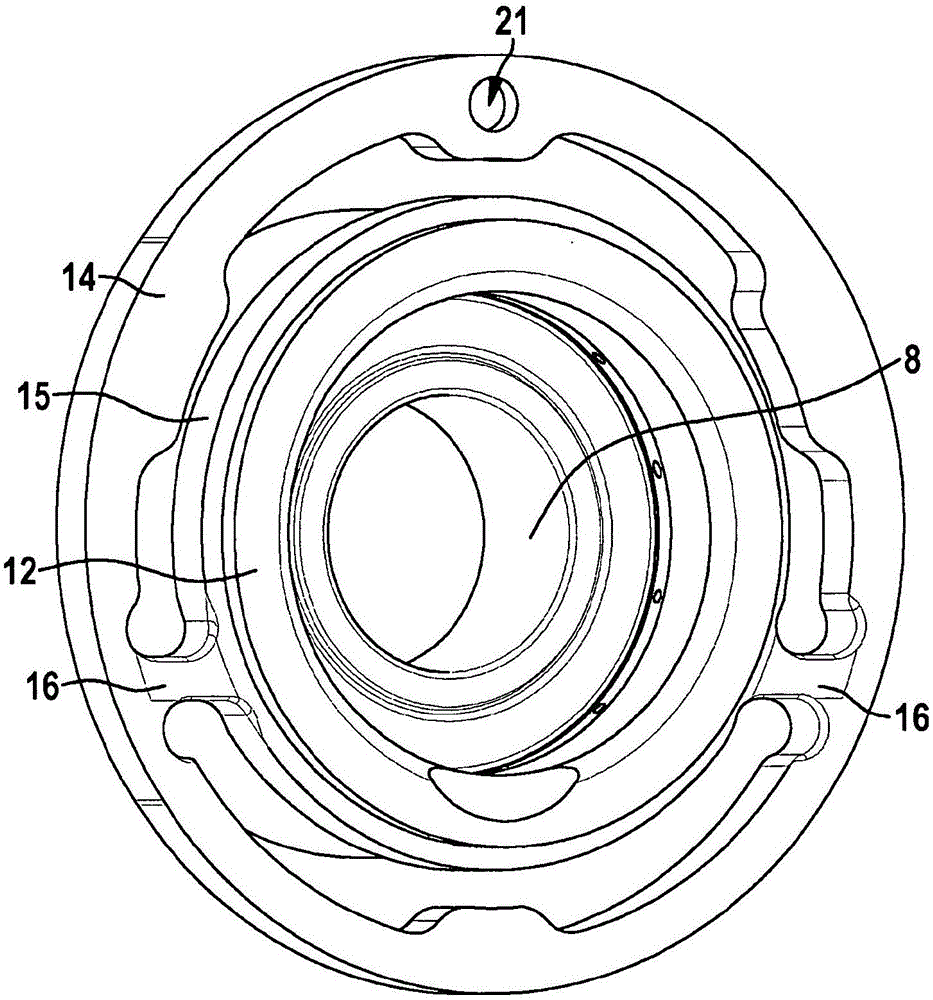

Sensor-equipped rolling bearing assembly

InactiveUS20070058892A1Easy to assembleImprove generalityRolling contact bearingsBearing assemblyFixed bearingRolling-element bearing

A sensor-equipped rolling bearing assembly includes: a cylindrical fixed bearing ring fixed to a vehicle body; a rotary bearing ring rotatably inserted through the fixed bearing ring and having a wheel-mounting portion on an outboard side thereof; and plural rows of rolling elements rollably interposed between these bearing rings. The bearing assembly is provided with a case member having plural displacement sensors which are circumferentially arranged at predetermined space intervals and which detect gaps between themselves and an outside surface of an inboard end of the rotary bearing ring. The case member is mounted to the inboard end of the fixed bearing ring.

Owner:JTEKT CORP

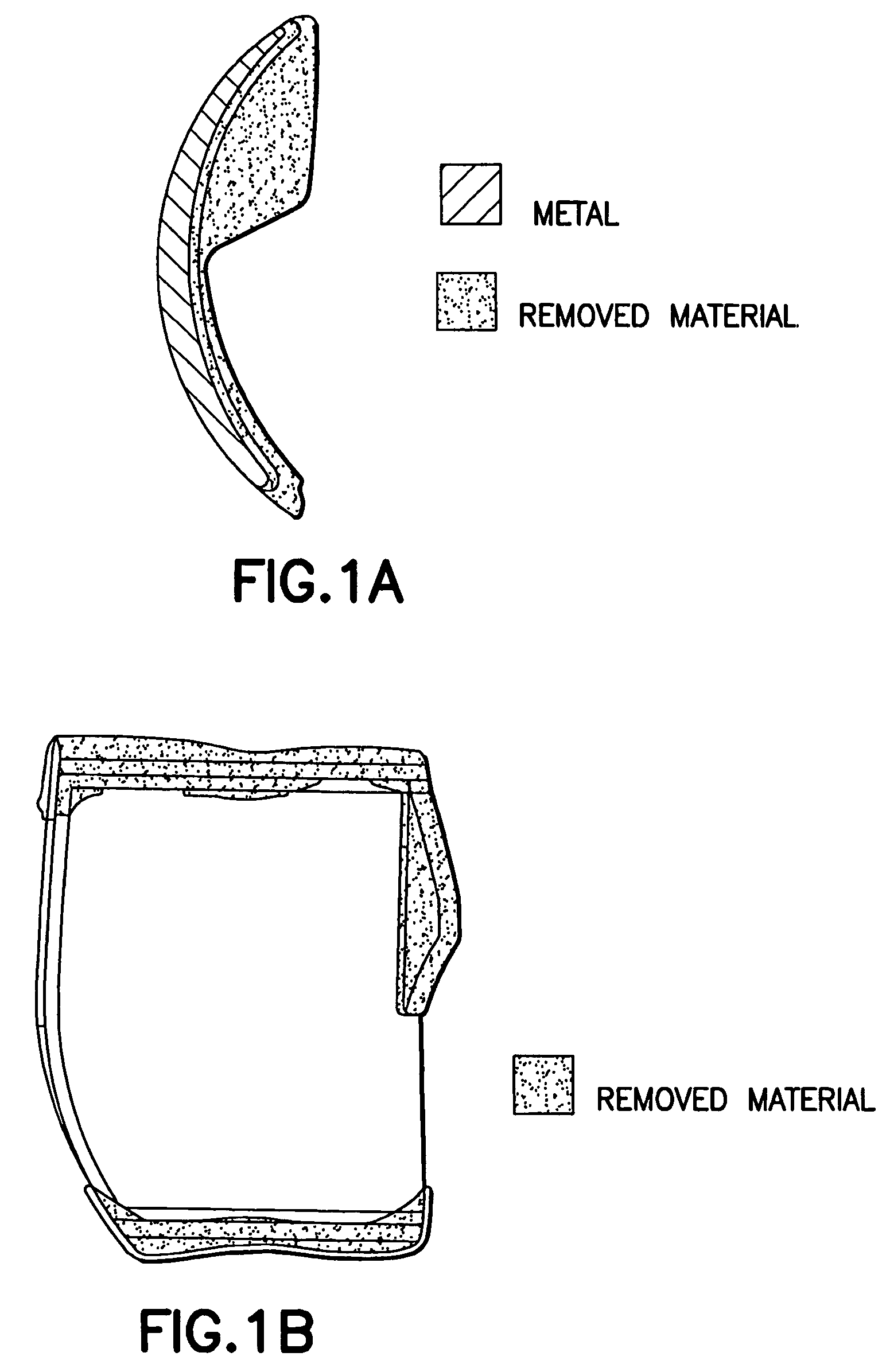

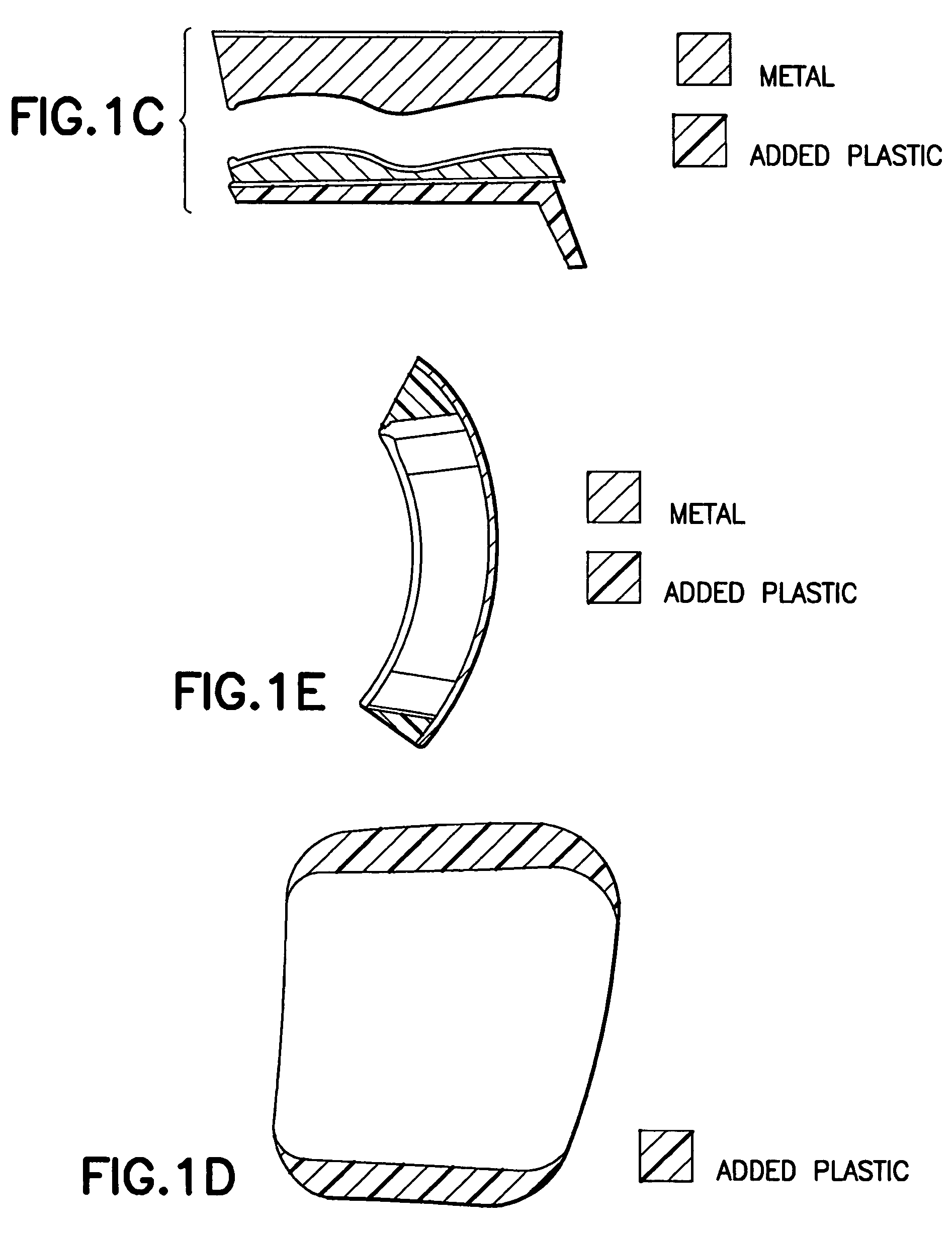

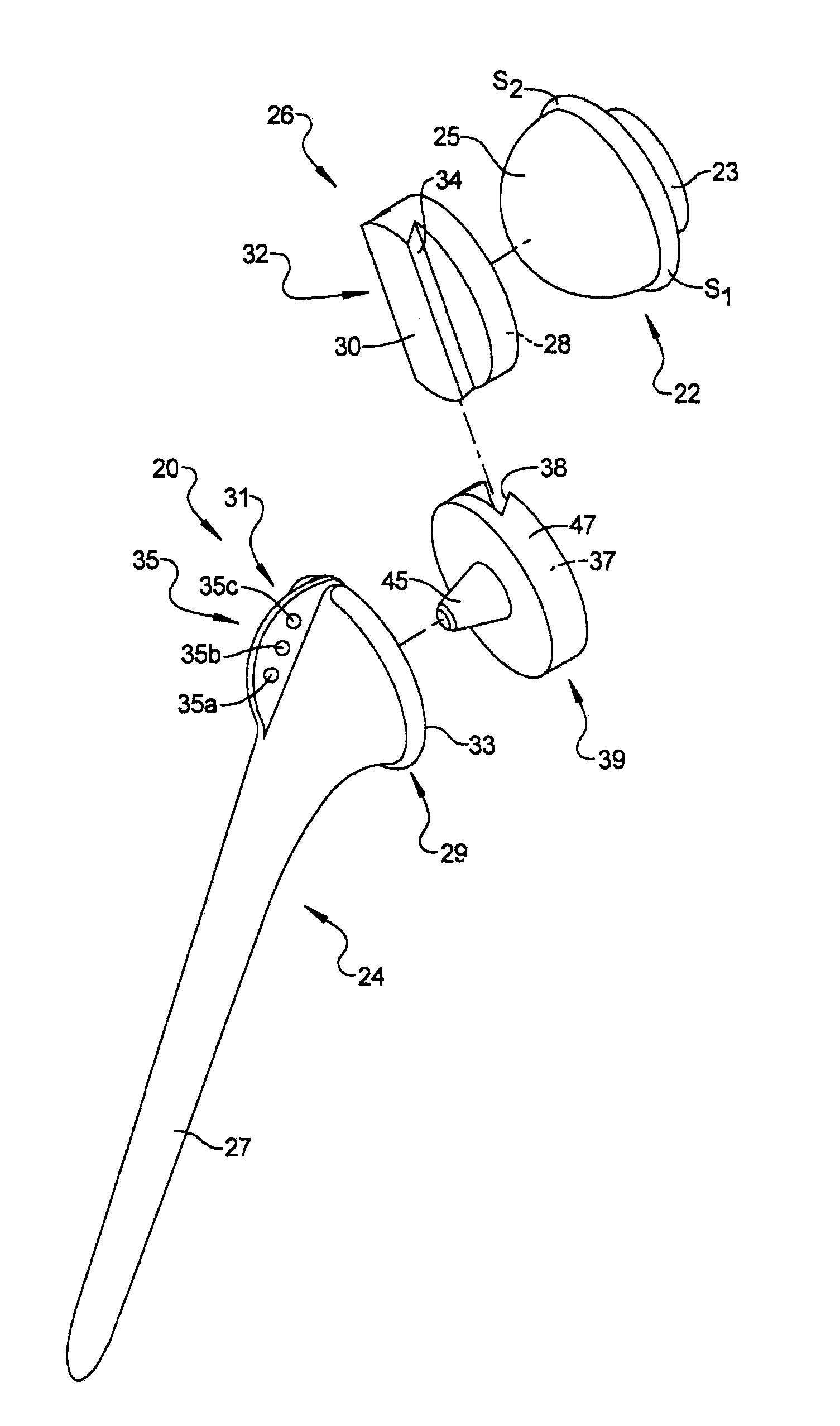

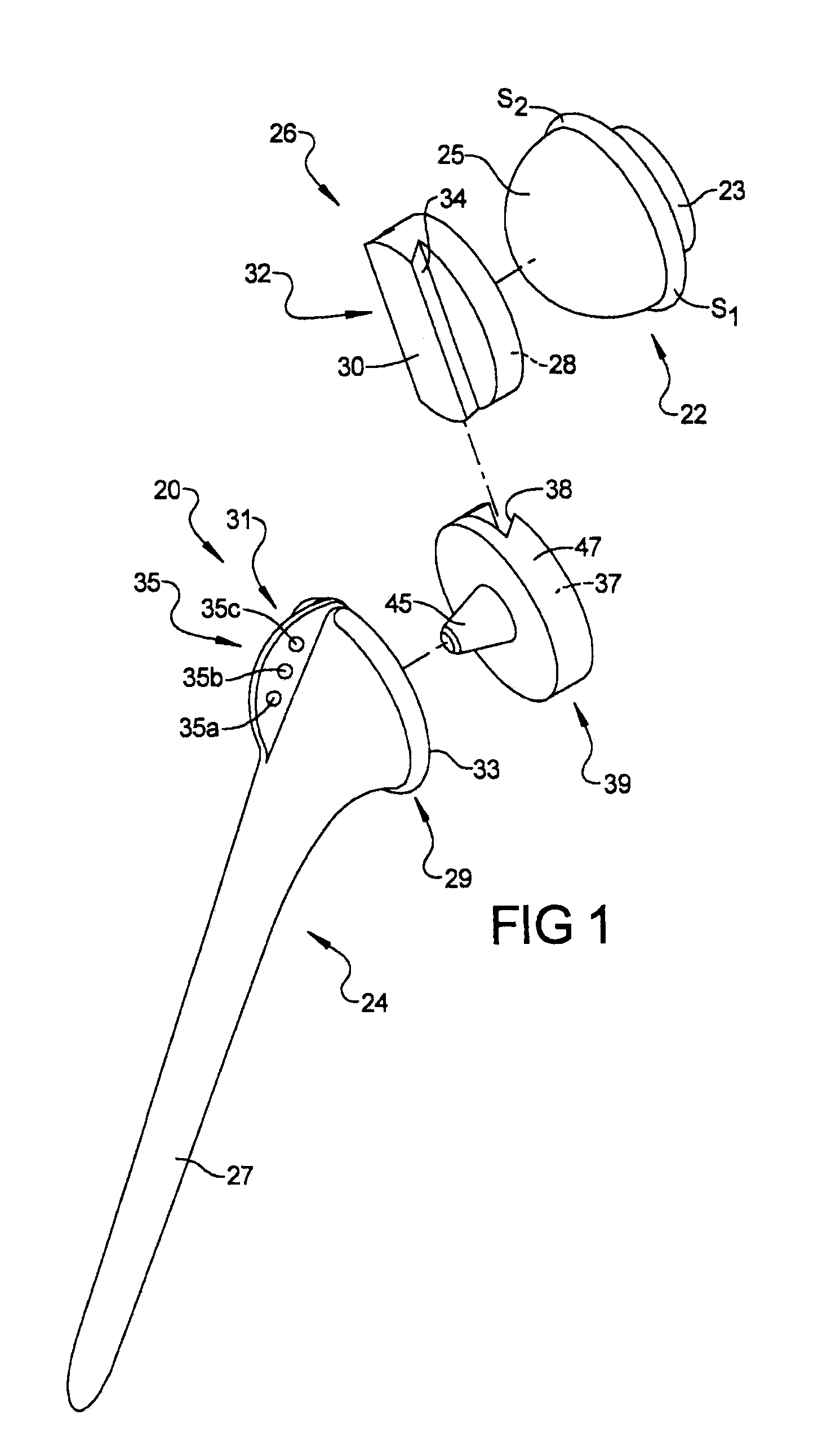

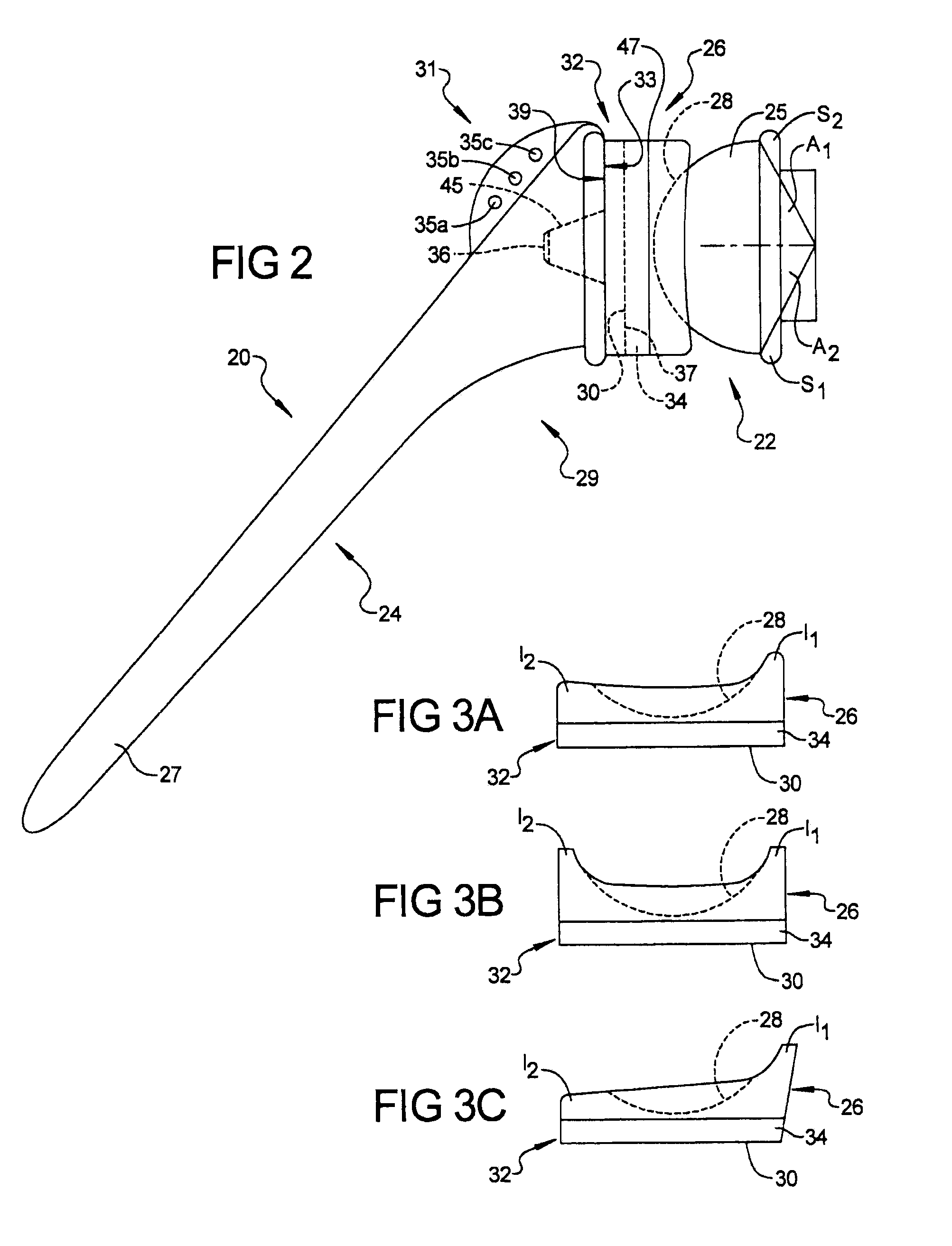

Fixed bearing joint endoprosthesis with combined congruent - incongruent prosthetic articulations

InactiveUS20100241237A1Limited degreeHeavy loadFinger jointsAnkle jointsFixed bearingJoint component

An orthopedic joint replacement has first and second joint components that can be placed in load-bearing articulation with one another. The first joint component has first and second convex spherical condylar segments defining first and second radii. The second joint component has a spherical first concave condylar segment with a radius equal to the radius of the first convex spherical condylar segment. The second joint component also has a non-spherical second concave condylar segment. The first convex spherical condylar segment of the first joint component is in congruent contact with the first spherical concave condylar segment of the second joint component. The second spherical convex condylar segment of the first joint component is in line contact with the non-spherical concave condylar segment of the second joint component.

Owner:BUECHEL PAPPAS TRUST

Hand-cranking type fruit cleaning device

The invention provides a hand-cranking type fruit cleaning device which comprises a washing container, a fixed base, a second handle, a fixed bearing, a rotating shaft, a rubber bar, bristles and a cover. A first handle is installed on the outer wall of the right side of the washing container. The bottom of the washing container is fixed to the fixed base. The cover is arranged on the top of the washing container. The fixed bearing is installed in the middle in the cover. The rotating shaft penetrates through the fixed bearing and is installed on the cover. The rubber bar is installed at the position, at the lower end of the cover, of the rotating shaft and provided with the bristles. A cranking handle is installed at the position, at the upper end of the cover, of the rotating shaft. By using the rotating shaft, the rubber bar, the bristles and the cranking handle in cooperation, fruits can be cleaned manually; due to the rubber bar, it can be avoided that a rubber bar is too hard and damages fruits; due to the bristles, fruits can be cleaned more thoroughly, cleaning efficiency is greatly improved, and convenience is brought to people for use.

Owner:王本

Steering gear

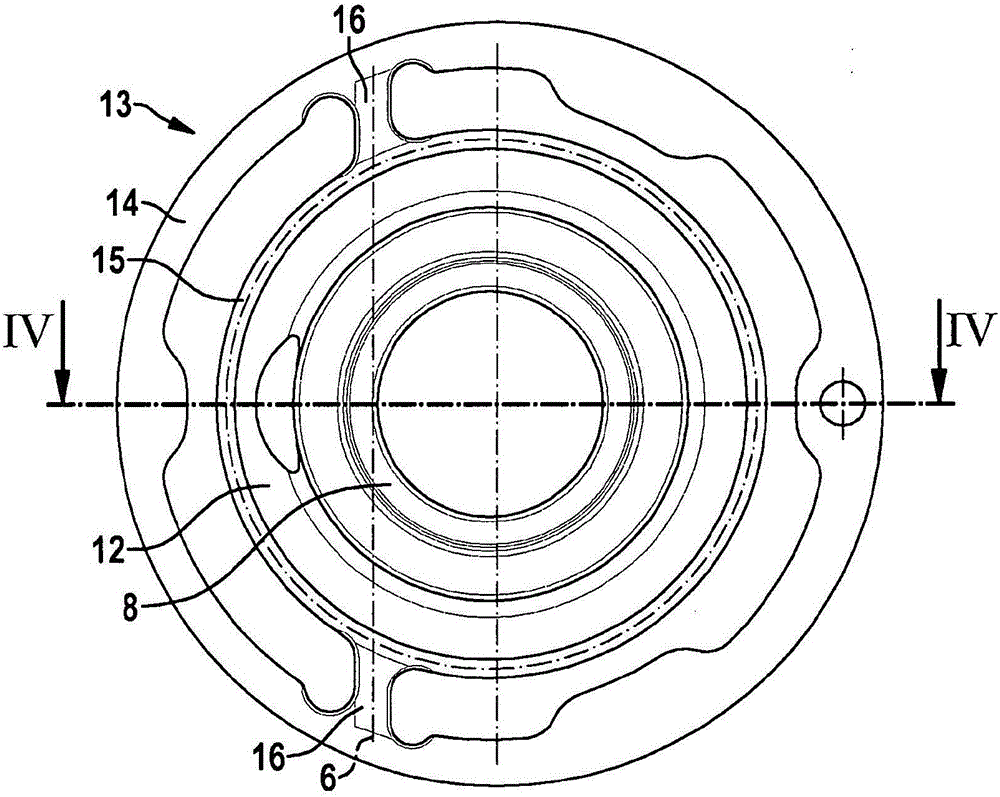

The invention relates to a solid bearing (5) for a steering gear comprising a swivel, which solid bearing comprises an inner bearing shell provided for accommodating a pinion shaft (3) of the steering gear, and an outer bearing shell, which is accommodated in a bearing bushing (12), and comprising a swivel ring (13) having an outer ring (14) and an inner ring (15), which rings are pivotally connected via one or more torsion webs(16), wherein the outer ring (14) is provided for bearing the solid bearing (5) in a housing (1) of the steering gear, characterized in that the inner ring (15) of the pivot ring (13) is mounted and axially fixed on the outer side on the bearing bushing (12).

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

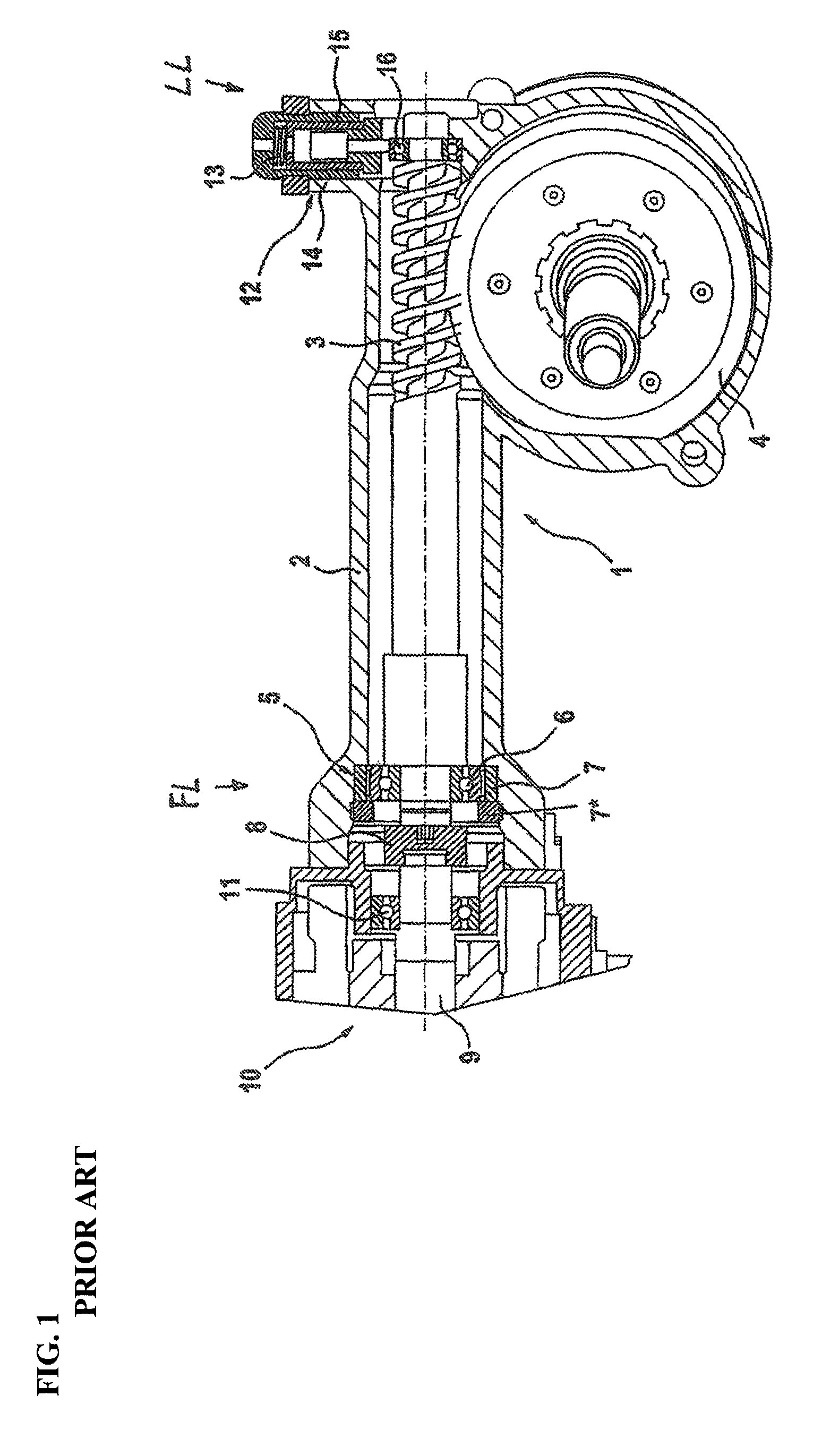

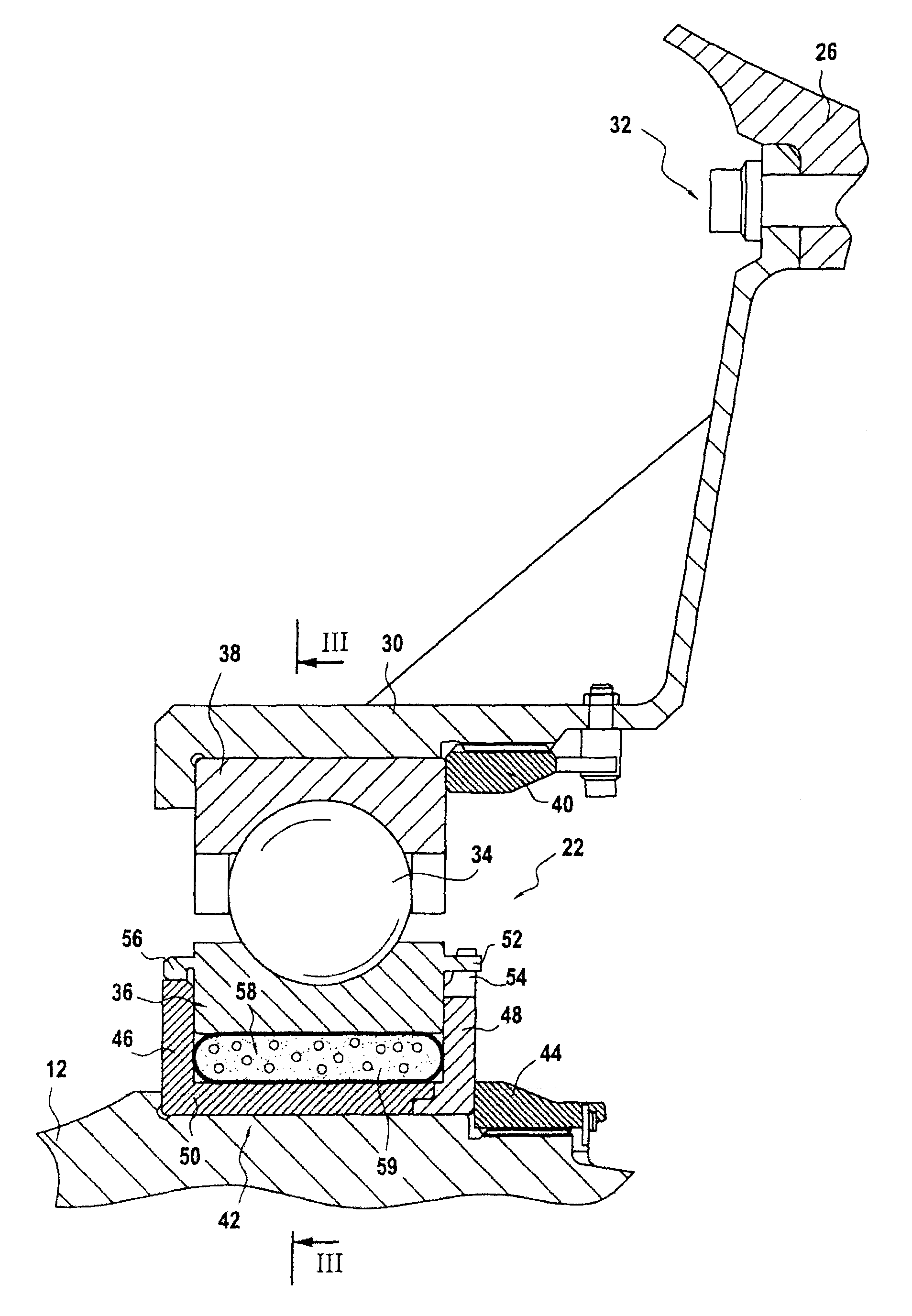

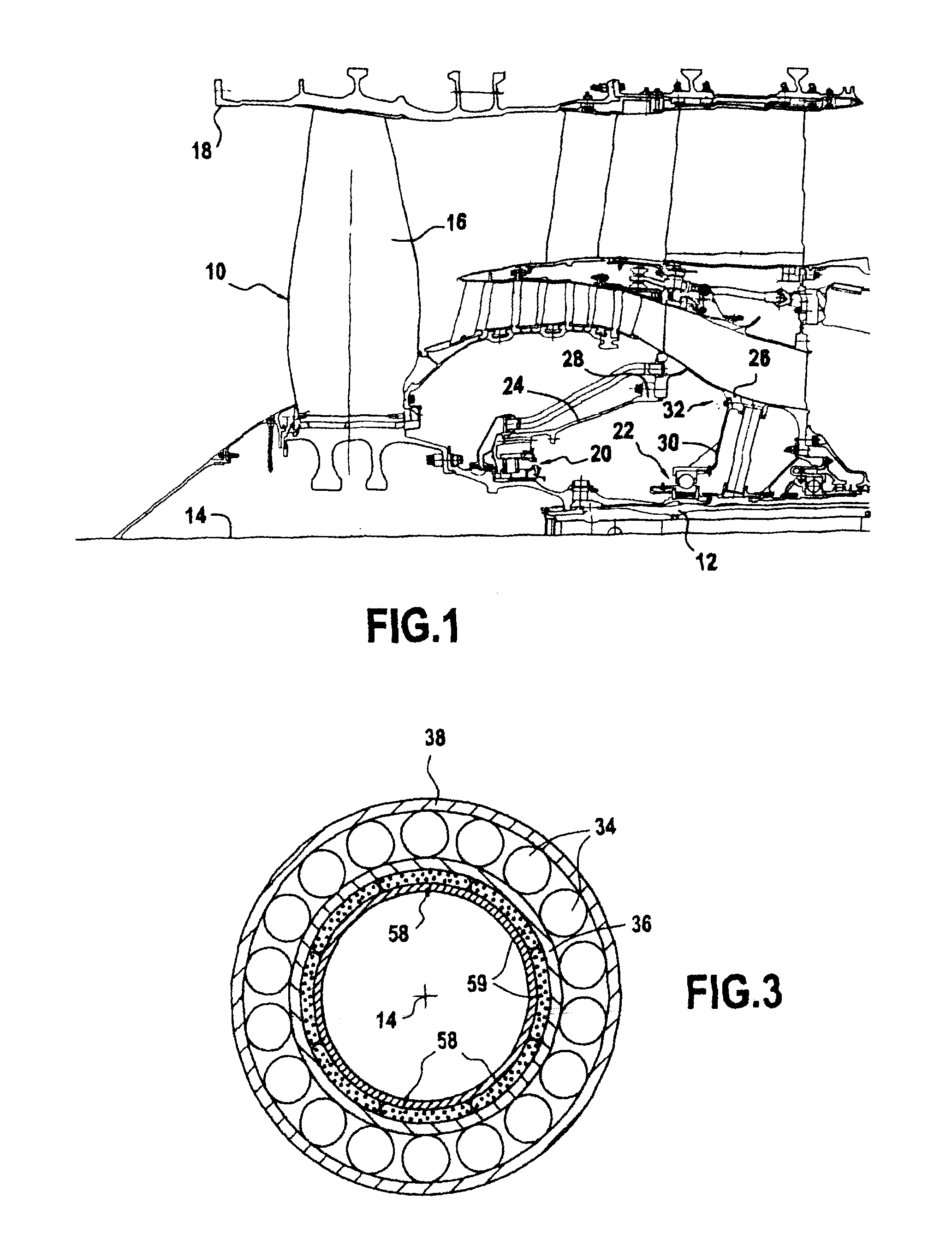

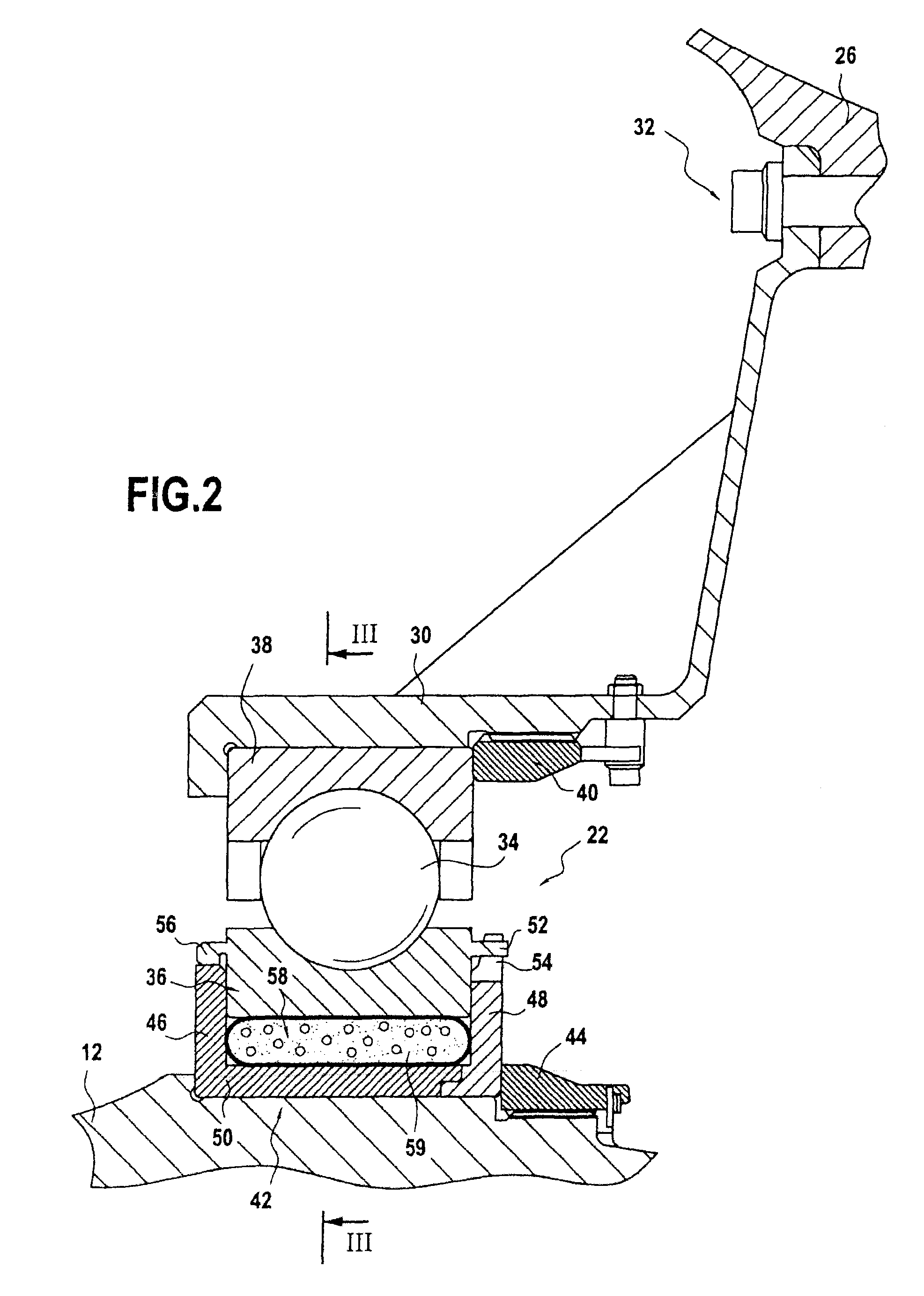

Uncoupling system for an aircraft turbojet engine rotary shaft

A decoupling system for a rotary shaft of an aircraft turbojet, the decoupling system including: a rolling bearing including rolling elements inserted between a first ring fastened to a stationary bearing support and a second ring mounted in a mounting chamber fastened to a rotary shaft; a transmission mechanism transmitting rotary torque from the rotary shaft to the second ring; a mechanism allowing the second ring to move radially relative to the mounting chamber when a static force associated with an unbalance affecting the rotary shaft exceeds a predetermined threshold; and a plurality of leaktight flexible bags interposed between the second ring and the mounting chamber and each including a heterogeneous structure including a porous capillary solid matrix and an associated liquid relative to which the matrix is lyophobic.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

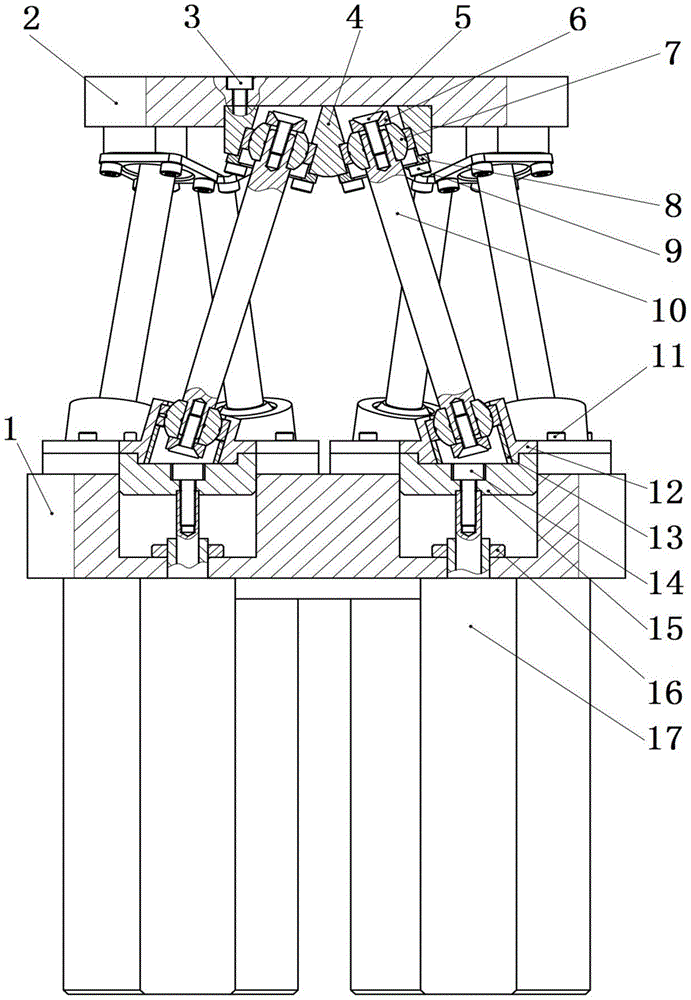

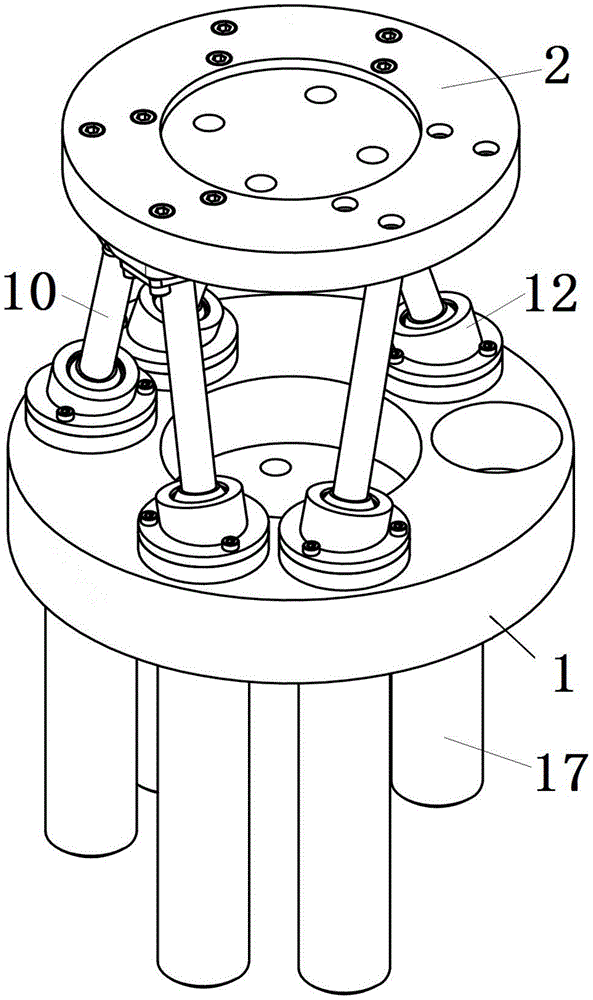

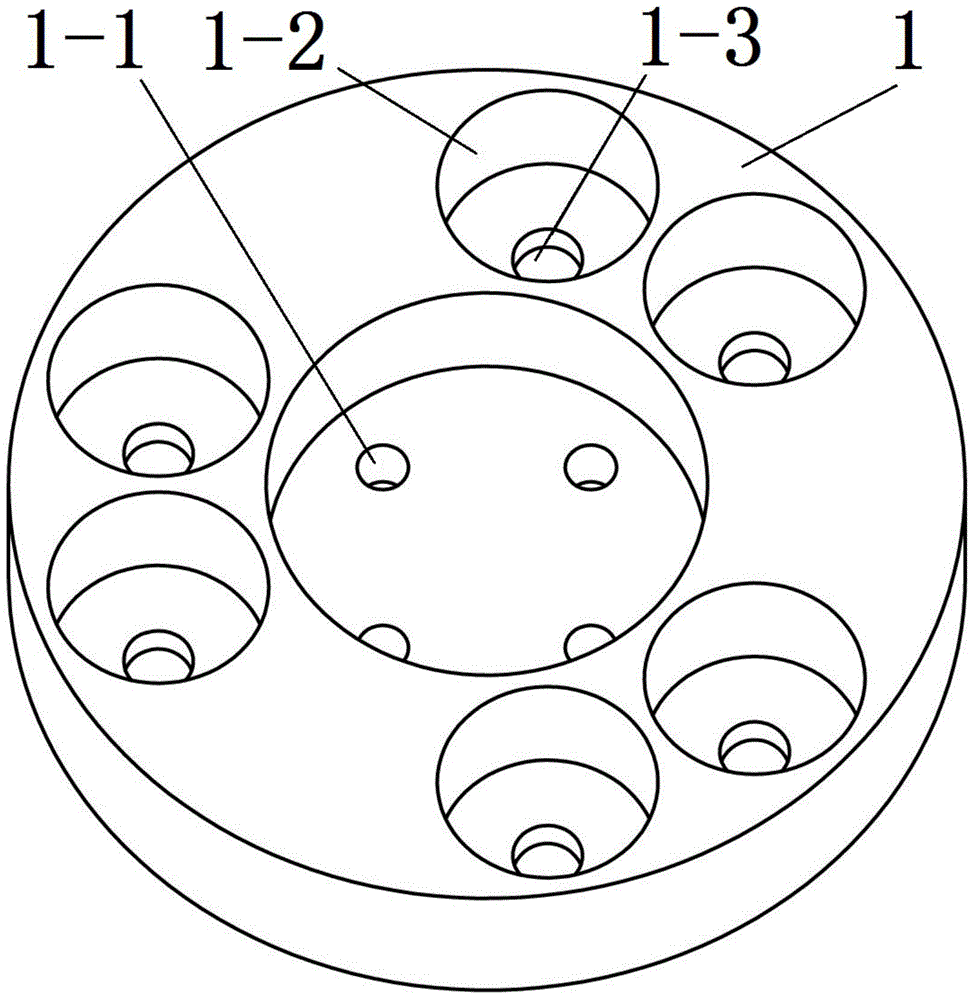

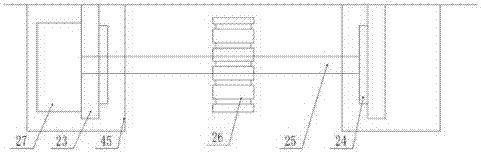

Six-degree-of-freedom parallel micro platform

InactiveCN104002299ASolve sizeSolve the accuracy problemProgramme-controlled manipulatorFixed bearingActuator

The invention discloses a six-degree-of-freedom parallel micro platform which comprises a fixed platform body and a movable platform body. The lower surface of the movable platform body is evenly provided with three sets of fixing bearing bases, and each fixing bearing base is connected with the fixed platform body downwards in a transmission mode through two branch chains, namely, the three sets of the bearing bases and six branch chains are arranged between the fixed platform body and the movable platform body. According to the six-degree-of-freedom parallel micro platform, the fixed platform body is fixed to the installation end face at the tail end of a macro robot through a micro platform installation hole, a tail end actuator is fixed to the movable platform body through a gripper installation hole in the movable platform body, the size is small, the weight is low, rigidity and precision are high, six-degree-of-freedom precise trimming of space postures of a workpiece in the assembly process is achieved, and the aim of precise assembly is achieved.

Owner:XIAN UNIV OF TECH

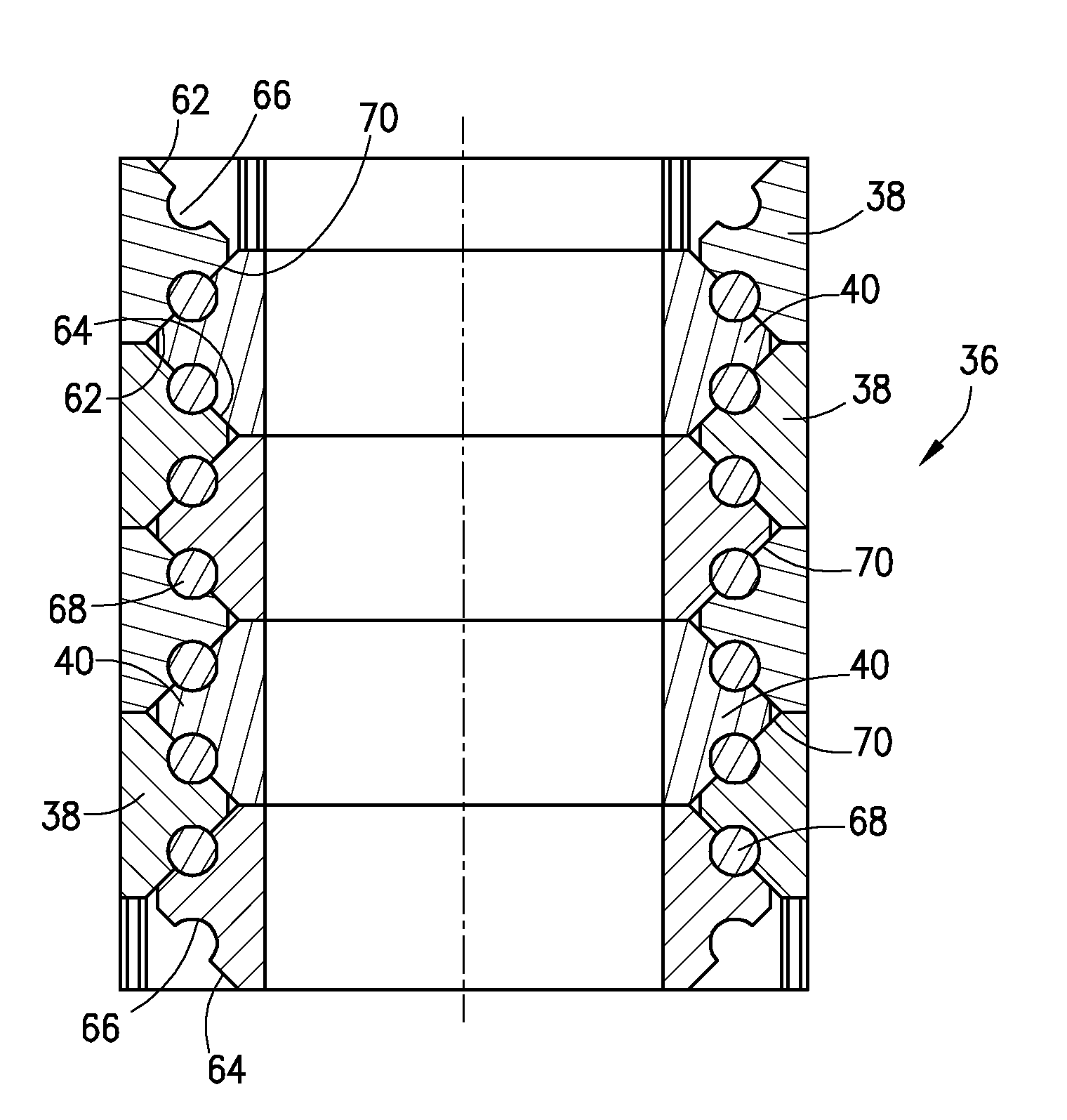

Mud Motor Bearing Assembly and Method

ActiveUS20130299243A1Cheap constructionInexpensive to constructShaftsBearing componentsMud motorEngineering

A mud motor bearing assembly for use in drilling a hydrocarbon well. The bearing assembly includes a bearing section containing stationary bearing rigs and rotating bearing rings in stacked arrangement. The bearing rings have wedge-shaped projections. The wedge-shaped projections of two adjacent stationary bearing rings form a recess to accommodate the projection of a rotating bearing ring in sliding engagement. The bearing assembly is capable of bearing both radial and axial loads.

Owner:RIVAL DOWNHOLE TOOLS LC

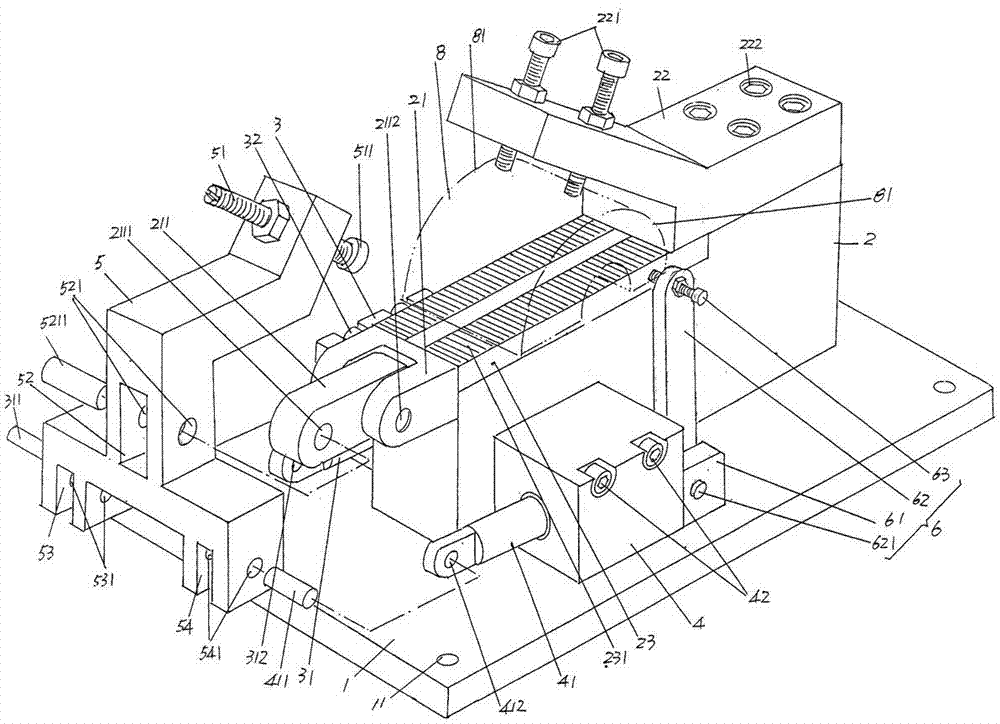

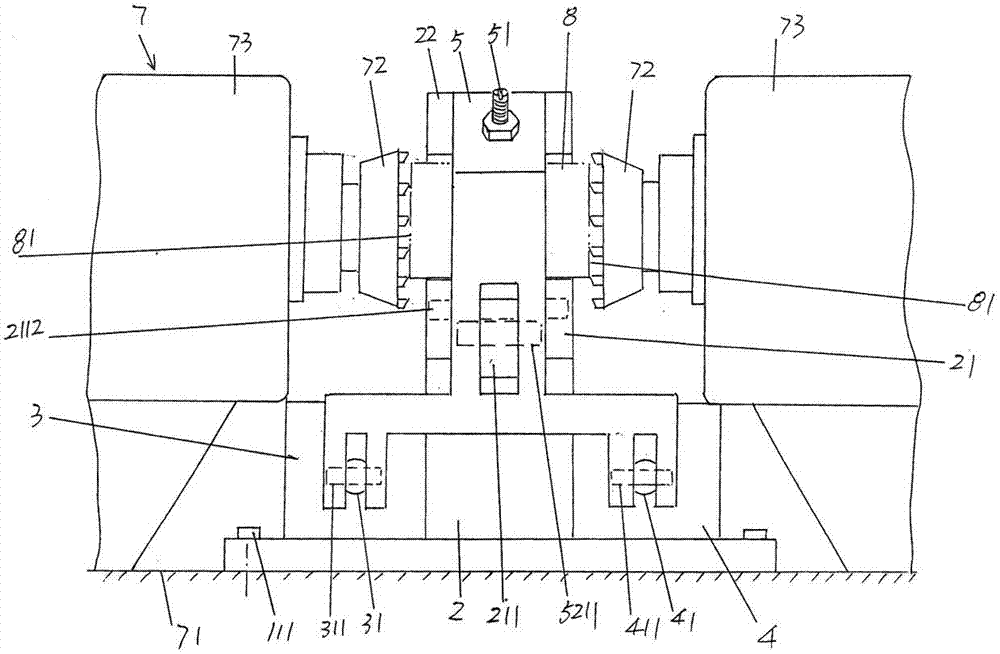

Clamp structure used for parallel face milling of glass mold

ActiveCN103273350BGuaranteed parallelismImprove milling efficiencyPositioning apparatusMetal-working holdersFixed bearingEngineering

The invention provides a clamp structure used for parallel face milling of a glass mold, and belongs to the technical field of tool clamps used for manufacture of the glass mold. The clamp structure comprises a bottom plate, a base, a first action cylinder, a second action cylinder, and a movable bearing base. The base is fixed on the upward side of the bottom plate, a connection shaft plate connecting base is formed on the upper portion of one end of the base, a fixed bearing base is fixed on the upper portion of the other end of the base, and a glass mold base plate is fixed in the middle of the base. The first action cylinder and the second action cylinder are located on two sides of the base respectively and fixed on the base. The upper portion of the movable bearing base corresponds to the fixed bearing base, the middle of the movable bearing base is connected with the connection shaft plate connecting base, one end of the lower portion of the movable bearing base is connected with the first action cylinder, the other end of the lower portion of the movable bearing base is connected with the second action cylinder, the upper portion of the movable bearing base corresponds to the upper portion of one end of the glass mold base plate in a vacant state, and the fixed bearing base faces one end of the movable bearing base and corresponds to the upper portion of the other end of the glass mold base plate. Milling efficiency is high, industrialization widened production requirements are met, operation intensity of workers is reduced, the parallelism of parallel faces of the glass mold can be guaranteed, and energy-saving effects are ideal.

Owner:ORI MOLD TECH SUZHOU

Humeral Implant Having A Floating Bearing

A shoulder can include a fixed bearing having a generally spherical articulating surface configured to be coupled to a glenoid. The implant can also include a floating bearing member defining a first spherical bearing surface and a second planar articulating bearing surface. The implant can include a stem defining a stem planar bearing surface coupled to the second planar articulating bearing surface. The second planar articulating bearing surface can cooperate with the stem planar bearing surface to enable the floating bearing to translate relative to the stem.

Owner:BIOMET MFG CORP

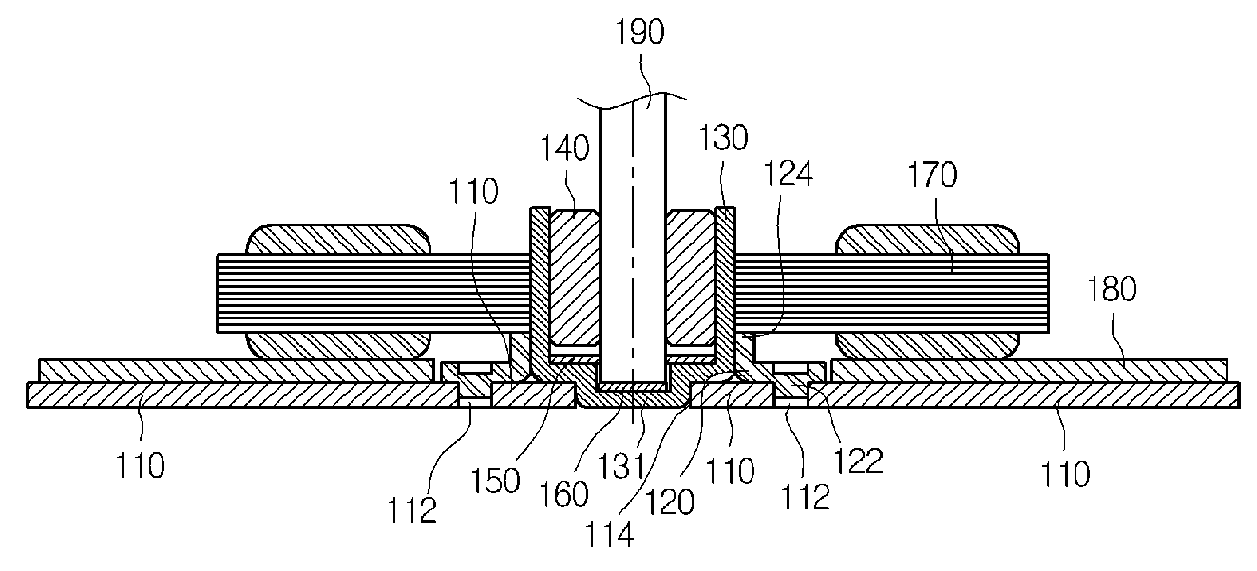

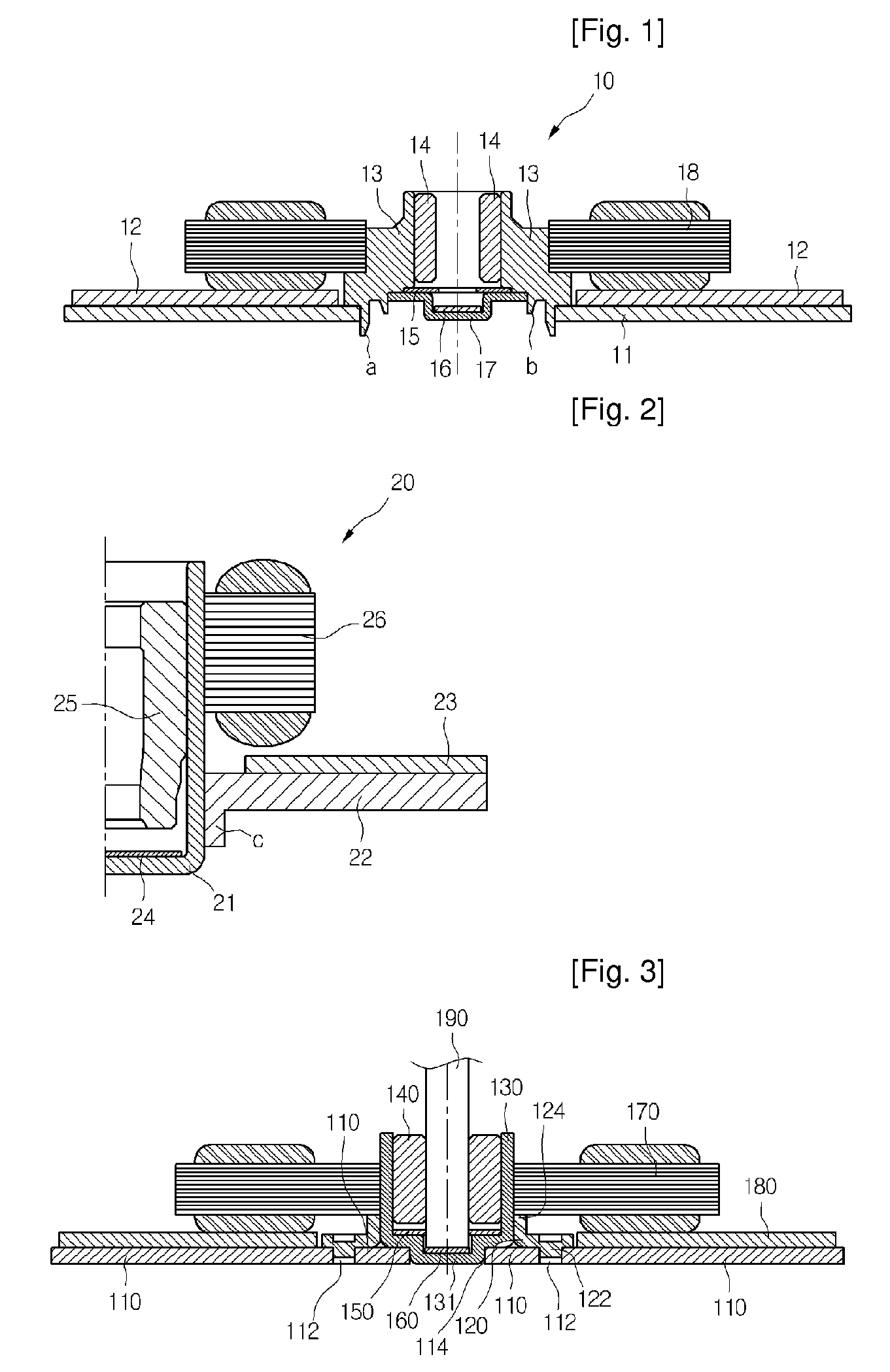

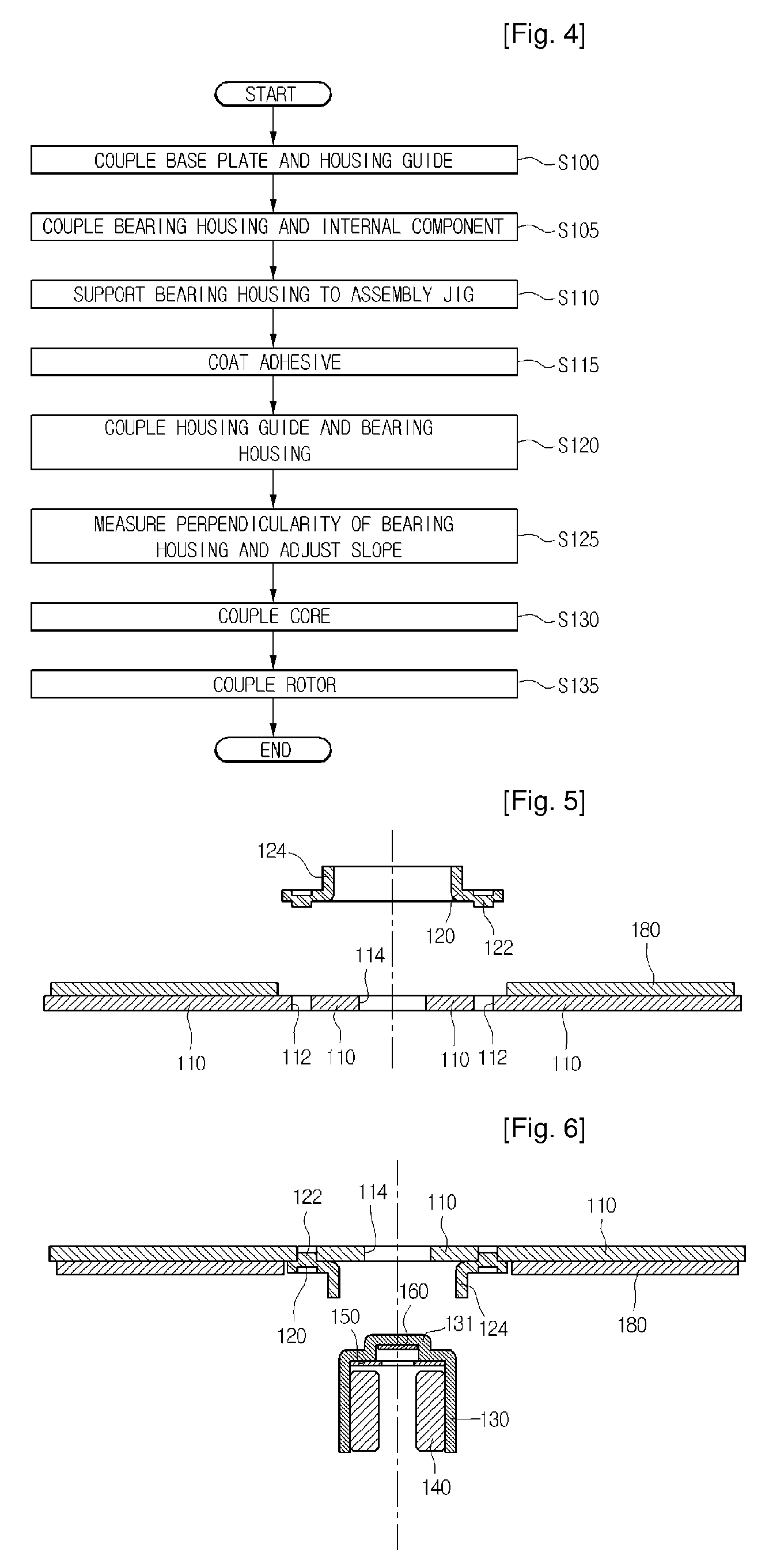

Spindle Motor and Fabricating Method Thereof

InactiveUS20080169709A1Avoid componentsAvoid defectsAssociation with control/drive circuitsWater closetsFixed bearingEngineering

A spindle motor, obtaining more accurate shaft perpendicularity and more convenient assembling process, is disclosed, the spindle motor includes: a rotor; a bearing housing into which the rotor is inserted; a base plate fixing the bearing housing; a housing guide fixed to the base plate, the housing guide having at least one vertical portion guiding an outer surface of the bearing housing; a printed circuit board mounted on the base plate; and a stator coupled to an outer surface of the bearing housing and supplied with power from the printed circuit board.

Owner:HITACHI LG DATA STORAGE KOREA

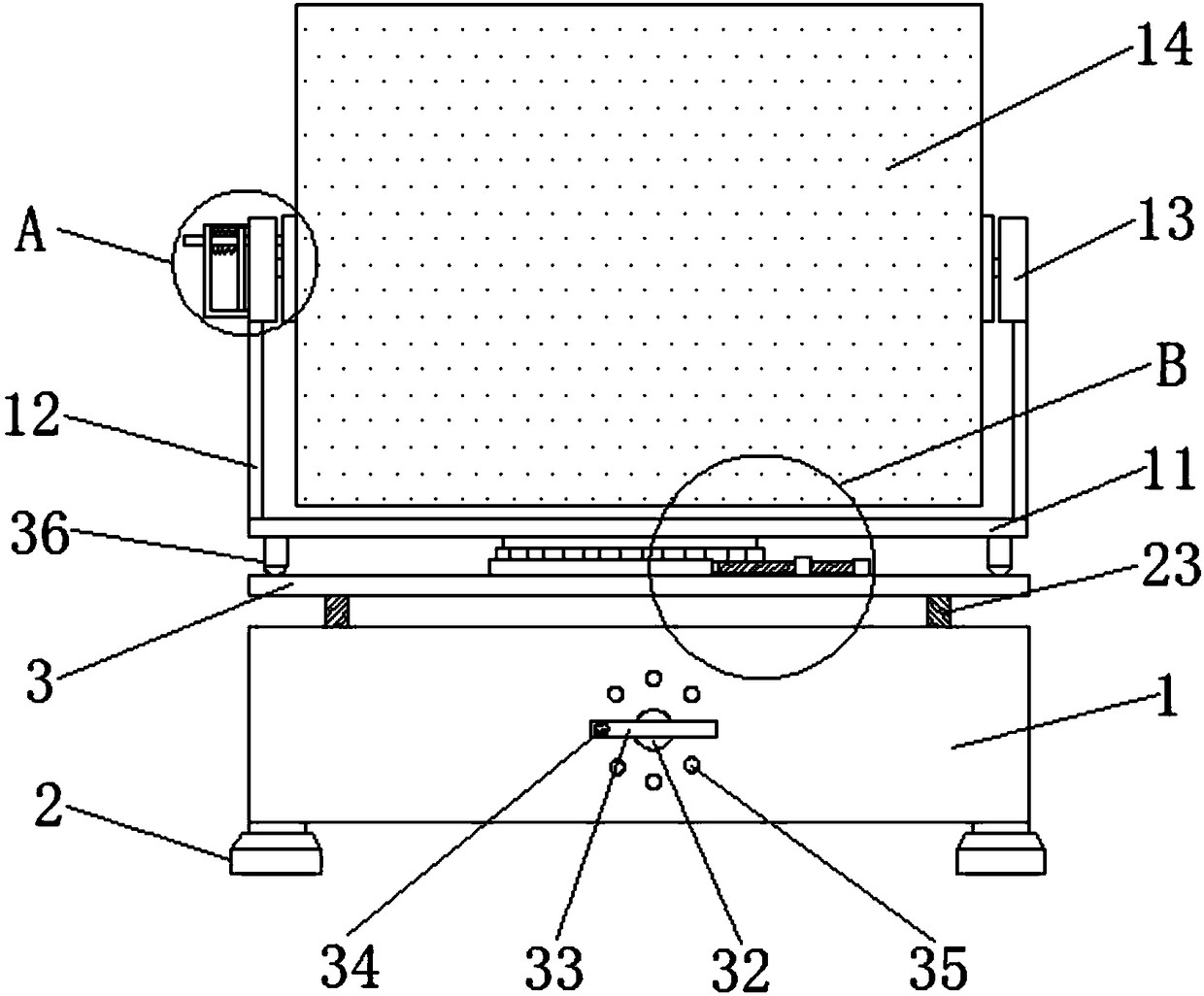

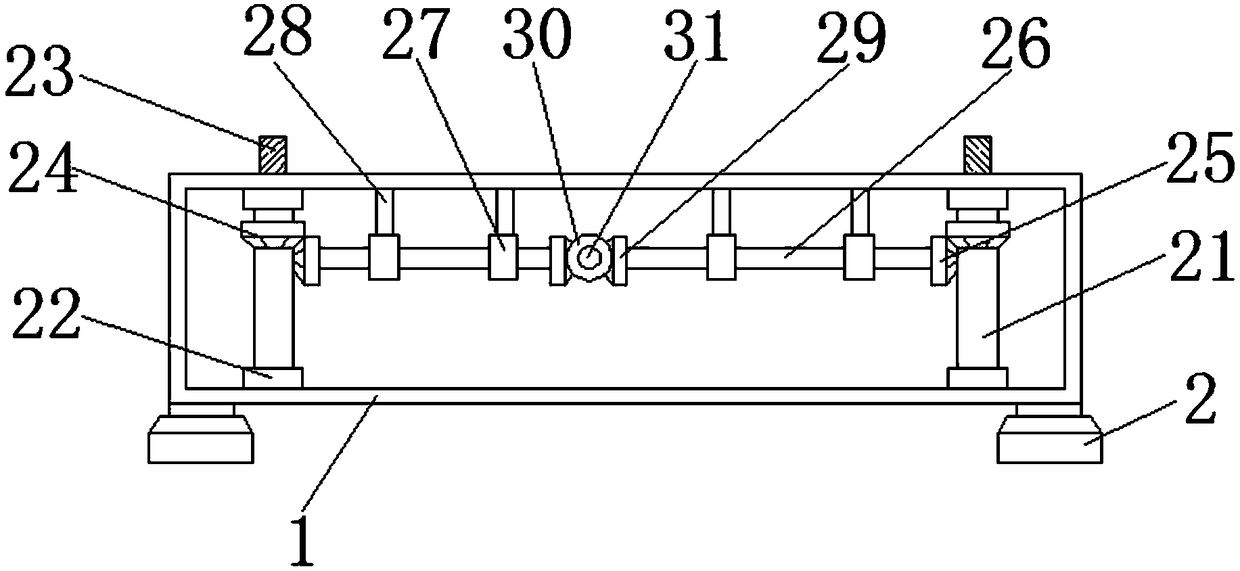

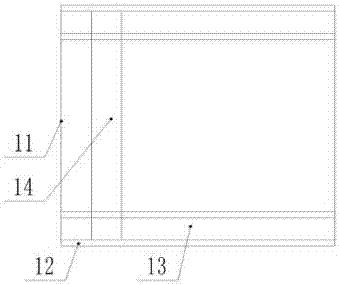

Display capable of adjusting screen angle for computer network equipment

The invention provides a display capable of adjusting the screen angle for computer network equipment and relates to the field of displays. The display capable of adjusting the screen angle for the computer network equipment comprises a box body. Pad feet are fixedly mounted at the bottom of the box body; a bottom plate is arranged above the box body; the top of the bottom plate is movably connected with the bottom of a connecting plate through a fixing bearing; and a display screen body is arranged above the connecting plate. According to the display capable of adjusting the screen angle forthe computer network equipment, a handle 10 is rotated to drive rotation of a transverse screw 8, and thus the transverse screw 8 rotates inside a transverse screw cylinder 9; the transverse screw 8 horizontally moves inside the transverse screw cylinder 9 while rotating, and accordingly a rack 6 is driven to horizontal move to enable an outer gear 5 engaged with the rack 6 to rotate; and an outerring of a fixing bearing 4 is driven to rotate, so that the horizontal angle of a display screen body 14 above the fixing bearing 4 is rotated, the display screen body is adjusted to a suitable angle, and watching of a user is better facilitated.

Owner:HUANGHE S & T COLLEGE

Powder mixing and stirring equipment for hydraulic engineering construction

ActiveCN107570042AImprove the mixing effectFast deliveryRotary stirring mixersHollow article cleaningCushioningFixed bearing

The invention discloses powder mixing and stirring equipment for hydraulic engineering construction. The powder mixing and stirring equipment comprises a basic rectangular stirring tank, wherein cushioning devices are arranged at the lower end of the basic rectangular stirring tank; a feeding device is arranged at the upper end of the basic rectangular stirring tank; a stirring device and a cleaning device are arranged in an inner cavity of the basic rectangular stirring tank; the feeding device consists of a feeding funnel, a feeding cylinder, guide rails, a sliding chute and a material controlling plate; the stirring device consists of a crushing device, rotating shafts, stirring paddles, a rotating motor I, a screw rod, a nut and the cleaning device; the screw rod is separately connected with the rotating shafts at the upper end and the lower end through couplings II; the crushing device consists of fixed supports, fixed bearings, a rolling shaft, a crushing frame and a rotating motor II; the cleaning device consists of a hollow support, brush handles, scraping hairbrushes and a water inlet device; the water inlet device consists of a circular water inlet pipe, an L-shaped waterinlet cylinder, a water inlet pipe and a water suction pump; a discharging cylinder is arranged at the lower end of the basic rectangular stirring tank; a manual switch valve is arranged on the innerwall of the discharging cylinder. The powder mixing and stirring equipment disclosed by the invention has the advantages of simple structure and high practicality.

Owner:山东龙程矿业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com