Steering gear

A steering mechanism, longitudinal technology, applied in steering mechanism, power steering mechanism, electric steering mechanism, etc., can solve the problems of complex assembly, undesired mobility of rolling bearings, weakening of bearing sleeves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

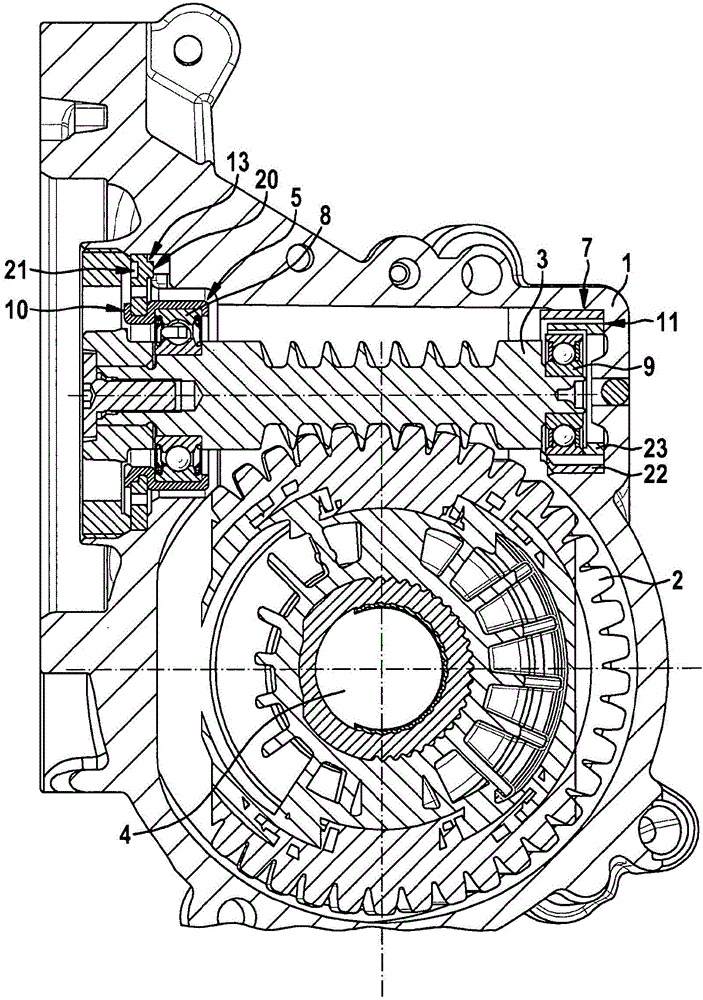

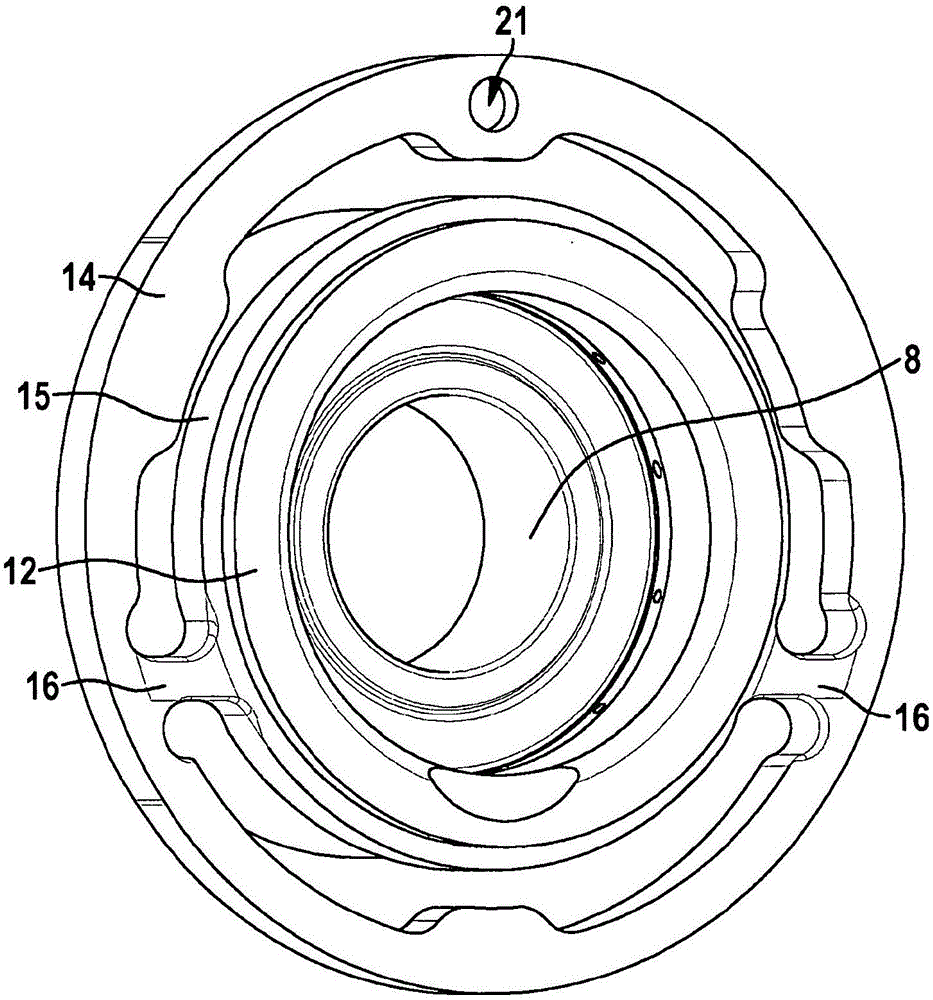

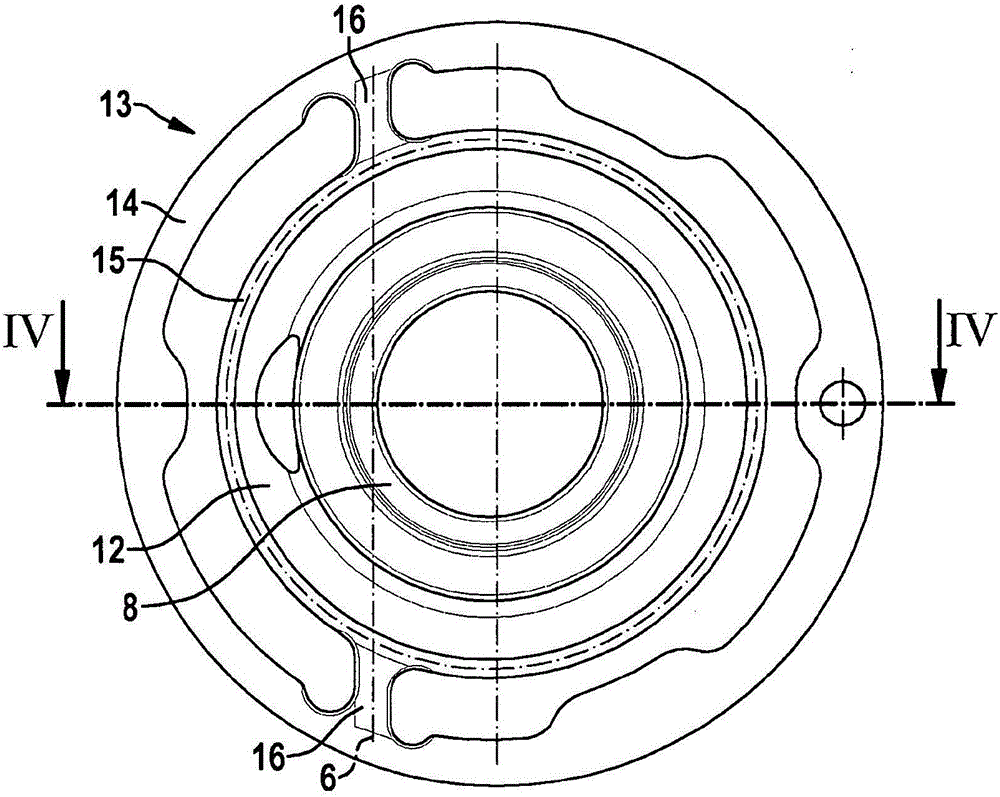

[0027] figure 1 The essential components of an embodiment of the steering mechanism according to the invention are shown. The steering mechanism comprises a housing 1 in which a gear 2 and a pinion meshing with the gear 2 are supported. The pinion and the pinion shaft 3 including the pinion are integrally formed in the form of a worm.

[0028] The gear 2 is securely fastened to the steering column 4 or to the output shaft of the steering mechanism of the motor vehicle.

[0029] The pinion shaft 3 has a drive-side end via which it is connectable to the output shaft of a drive (not shown), for example an electric motor. In the region of this drive-side end, the pinion shaft 3 is supported in the housing 1 by means of a first bearing. This bearing is designed as a fixed bearing 5 which essentially does not allow a translation of the pinion shaft 3 relative to the housing 1 , but allows a deflection about the pivot axis 6 .

[0030] This deflection causes a deflection of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com