Clamp structure used for parallel face milling of glass mold

A glass mold and face milling technology, which is applied in the field of tooling and fixtures, can solve the problems of difficulty in parallel planes, low processing efficiency, waste of electric energy, etc., meet the requirements of industrialized enlarged production, improve milling efficiency, and reduce operating intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

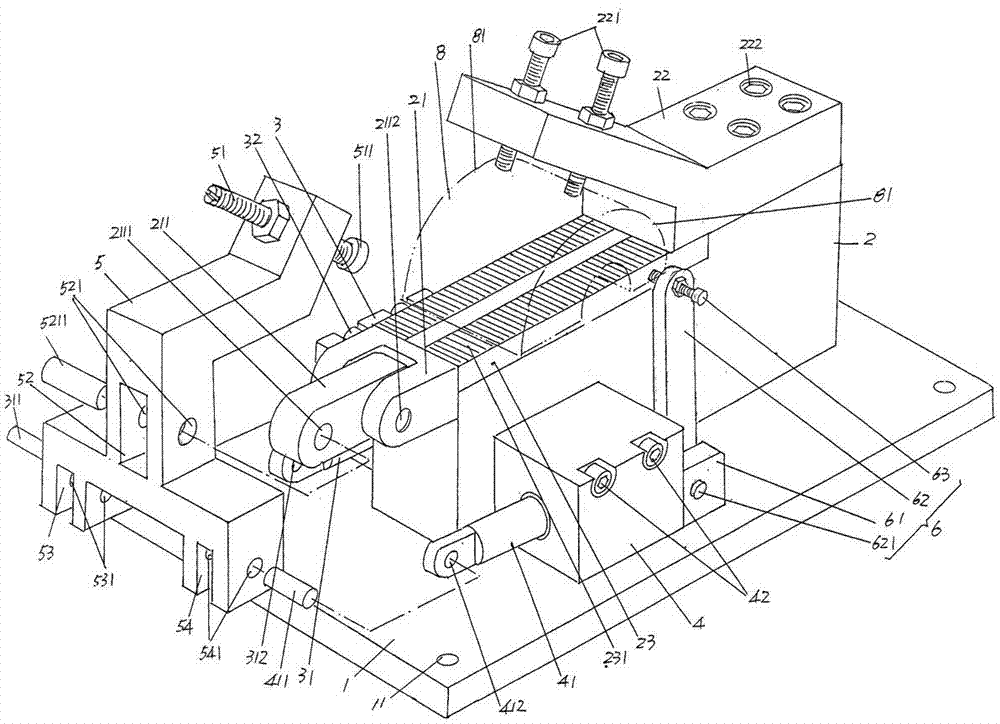

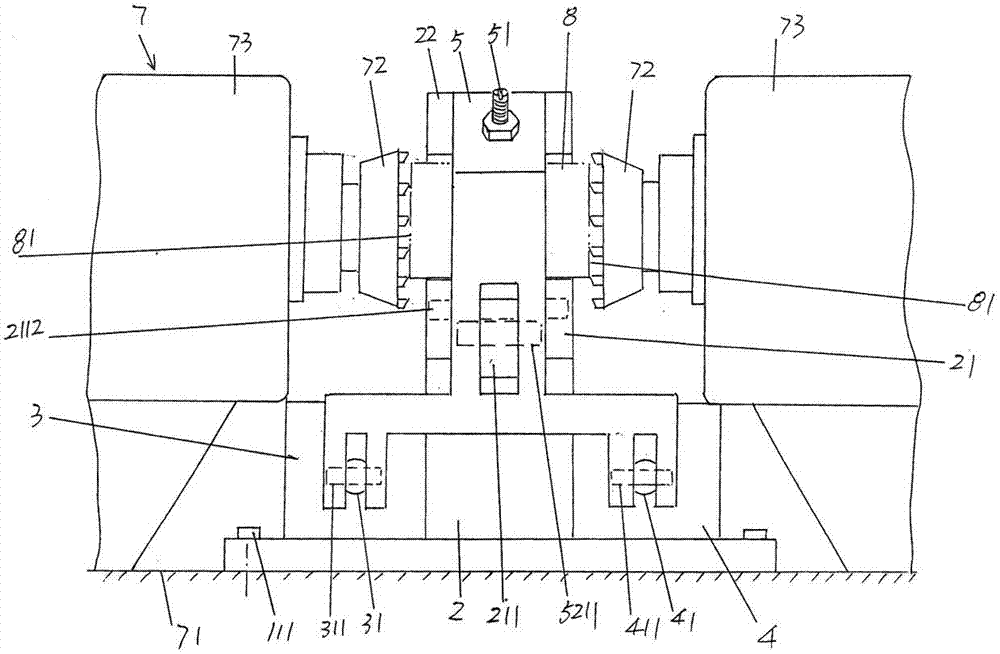

[0022] See figure 1 , a bottom plate 1 with a rectangular shape (cuboid in this embodiment) and made of metal is provided, and a bottom plate installation and fixing hole 11 is provided at each of the four corners of the bottom plate 1, and the bottom plate fixing screw 111 is used for use. Base plate 1 and workbench 71 of milling machine 7 ( figure 2 shown) fixed.

[0023] A pedestal 2 is fixed on the upward side of the bottom plate 1 in use, and a shaft connecting seat 21 is formed on the upper part of one end of the pedestal 2. figure 1 As shown, the connecting seat 21 of the connecting plate protrudes from the end face of the aforementioned one end of the base 2 in a horizontal state, and a connecting plate 211 is pivotally connected to the connecting seat 21 through a pin 2112. The connecting plate The top of the other end of 211 is fixed with a fixed support seat 22, and at the middle part of the base 2 and on the side facing upwards, a glass mold seat plate 23 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com