Patents

Literature

172results about How to "Meet the requirements of industrial scale-up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

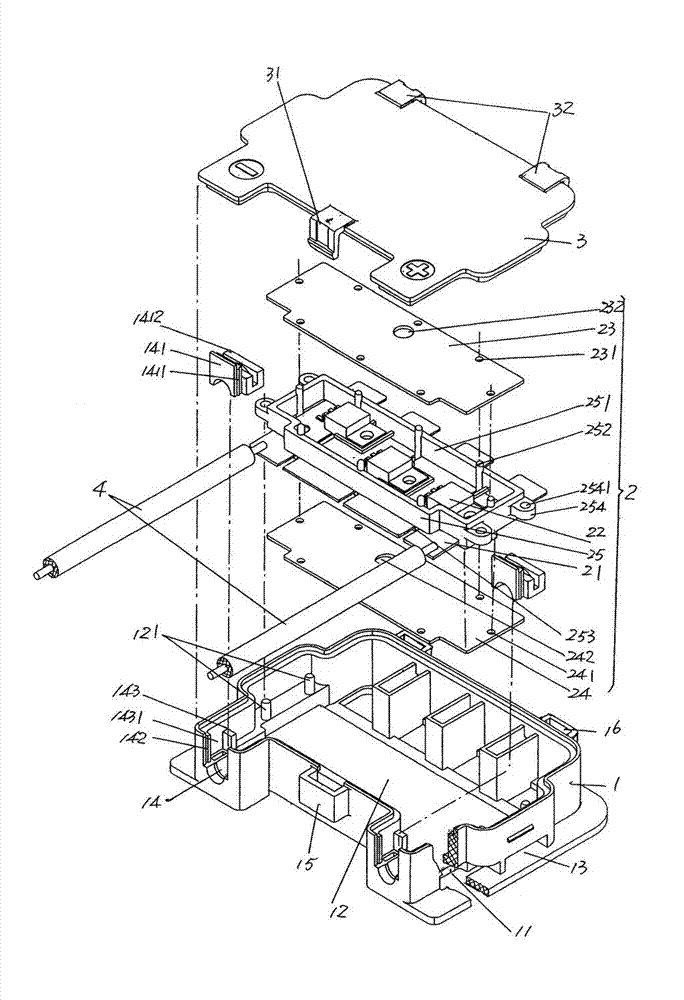

Power-dissipation-free and energy-saving type start protector of single phase AC motor

InactiveCN104734570AReduce volumeSmall footprintSingle-phase induction motor startersEmergency protective circuit arrangementsRefrigeration compressorEngineering

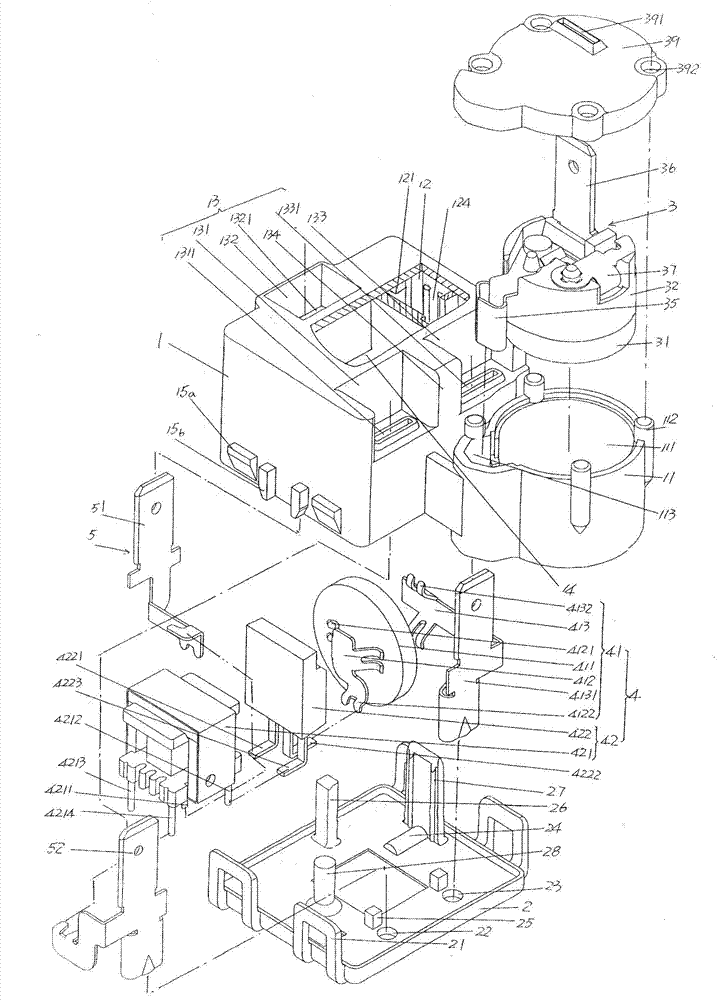

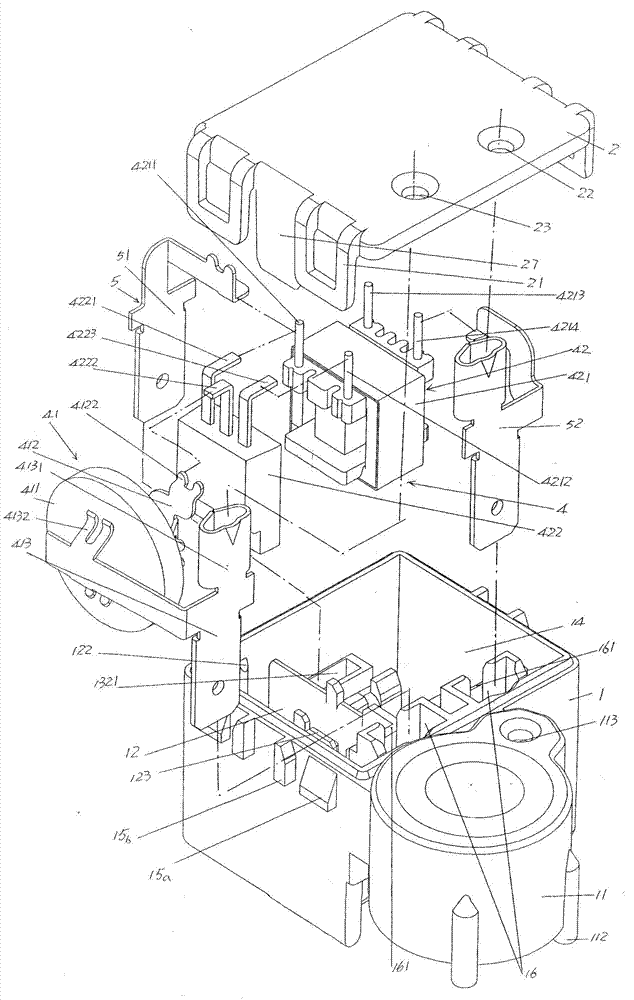

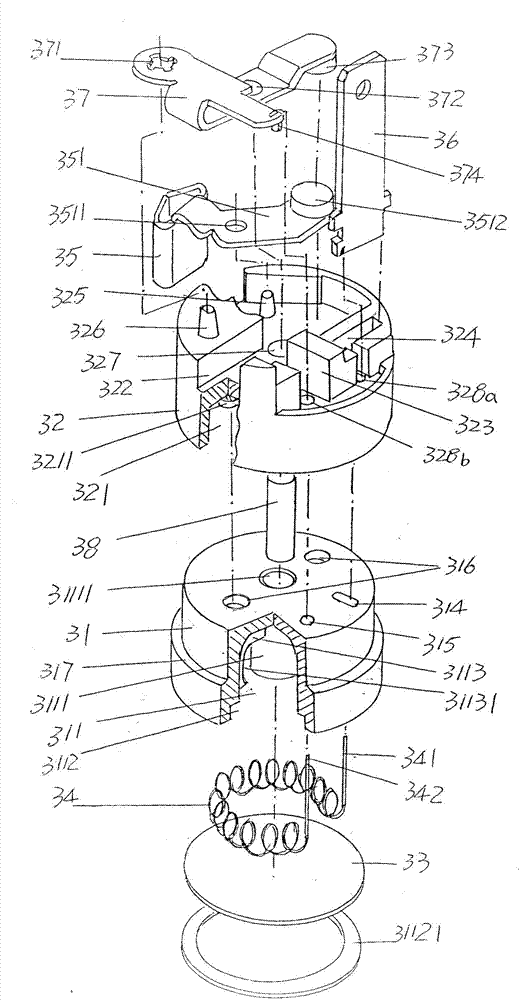

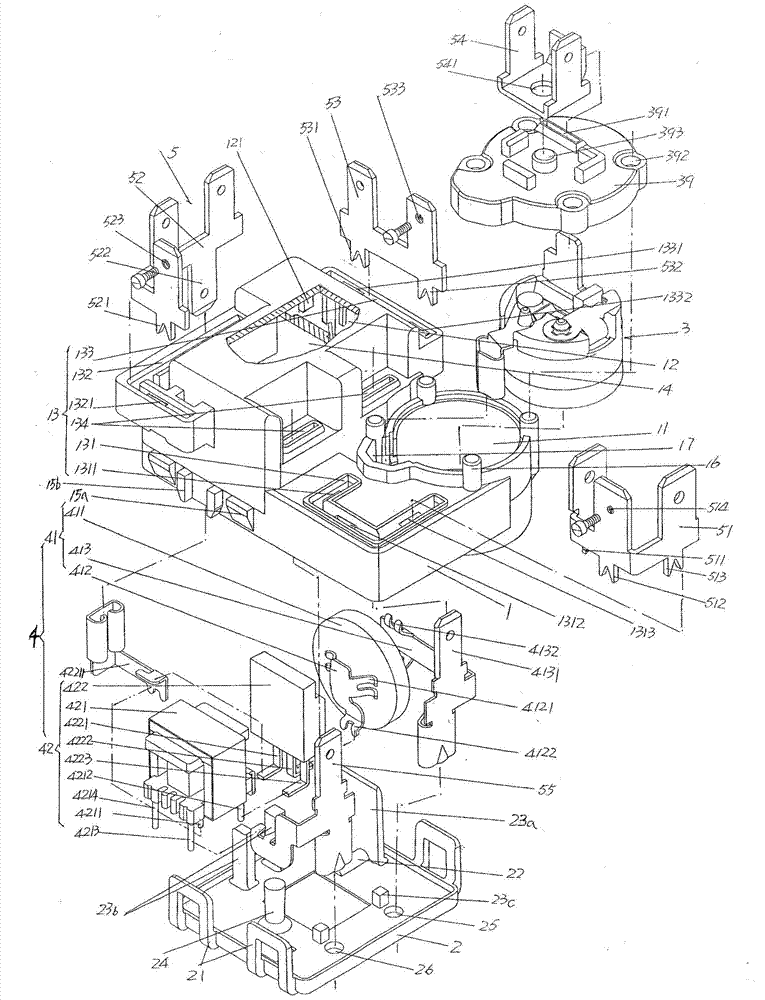

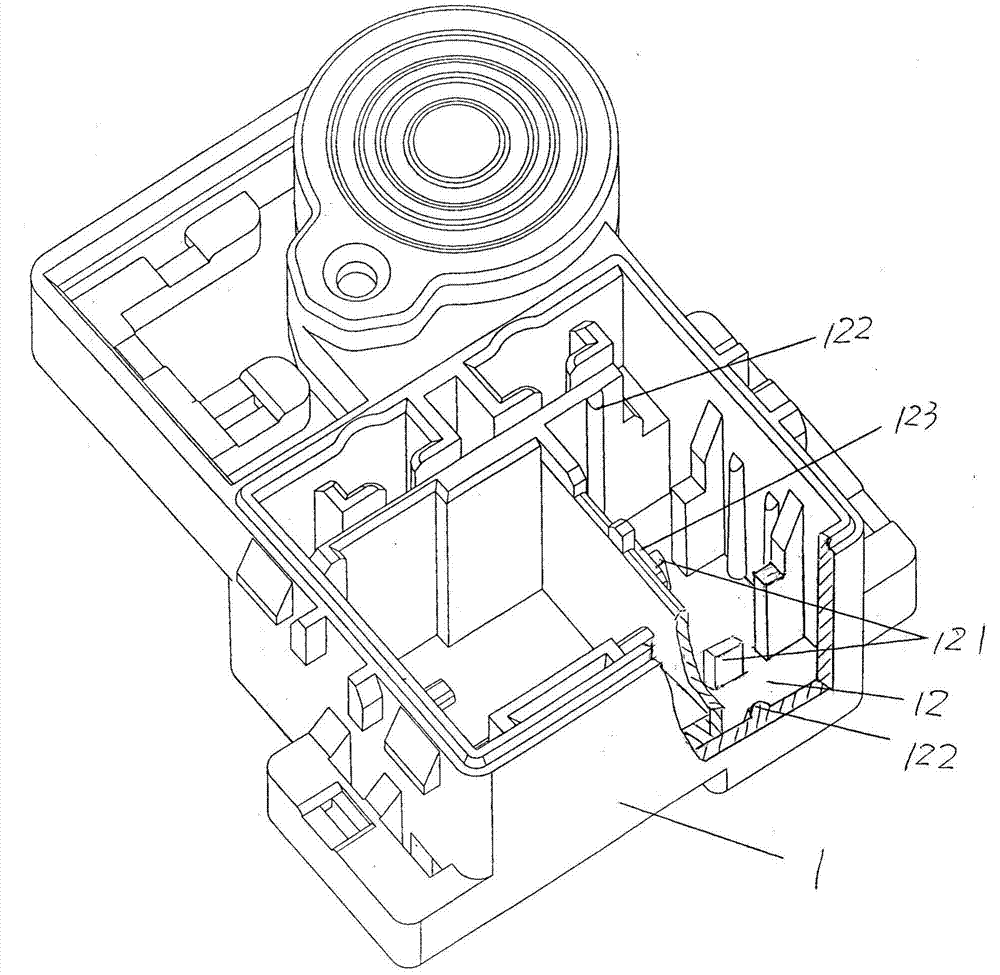

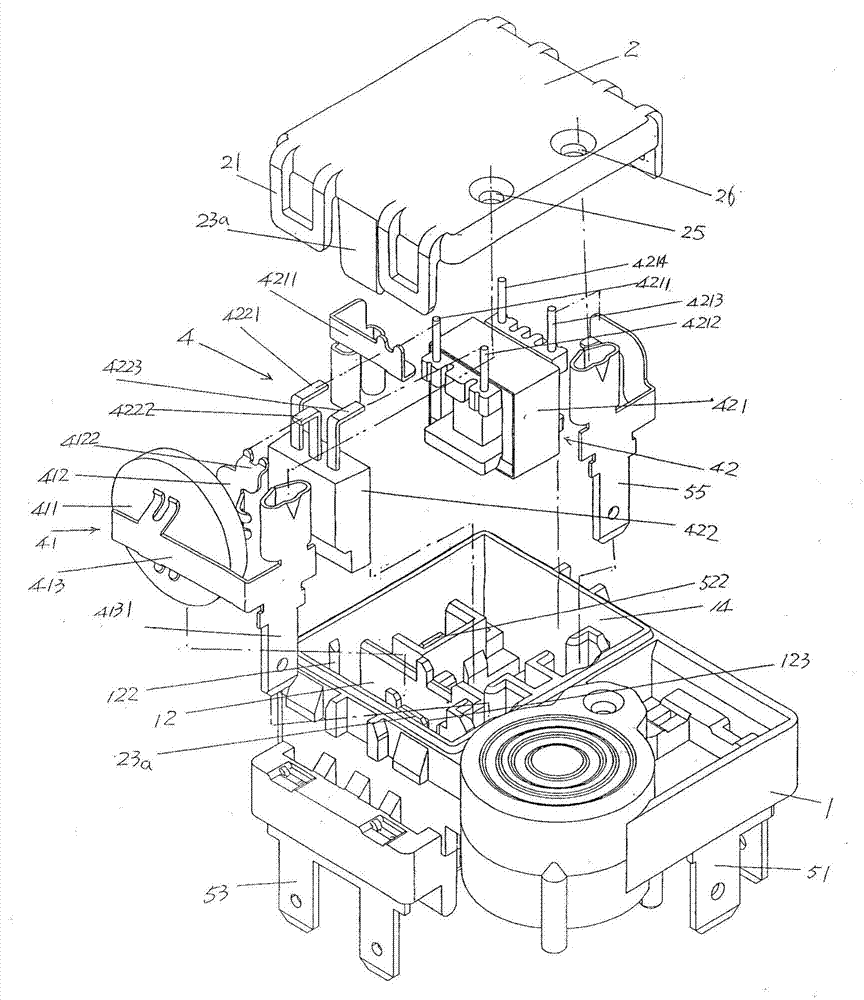

The invention provides a power-dissipation-free and energy-saving type start protector of a single phase AC motor and belongs to the technical field of refrigeration compressors. The power-dissipation-free and energy-saving type start protector comprises a shell, a shell cover, an overload protector, a power-dissipation-free starter and an external terminal mechanism. The shell is provided with an overload protector seat, a power-dissipation-free starter accommodation cavity, an external terminal mechanism cavity and a start controller accommodation cavity. The shell cover is provided with a first three-terminal jack and a second three-terminal jack. The overload protector is arranged in an overload protector accommodation cavity. The power-dissipation-free starter comprises a power-dissipation-free starter body and a start controller. The external terminal mechanism is matched with the external terminal mechanism cavity. The start protector is characterized in that the external terminal mechanism cavity comprises a first insertion cavity, a second insertion cavity and a third insertion cavity, the second insertion cavity is formed in the left side of the shell, and the bottom wall of the second insertion cavity is provided with a second shell insertion groove; the first insertion cavity and the third insertion cavity are formed in the right side of the shell, a first shell insertion groove is formed in the bottom wall of the first insertion cavity, and a third shell insertion groove is formed in the bottom wall of the third insertion cavity; the external terminal mechanism comprises a first insertion piece and a second insertion piece, the first insertion piece is matched with the second shell insertion groove in an inserted mode, and the second insertion piece is matched with the first shell insertion groove in an inserted mode.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

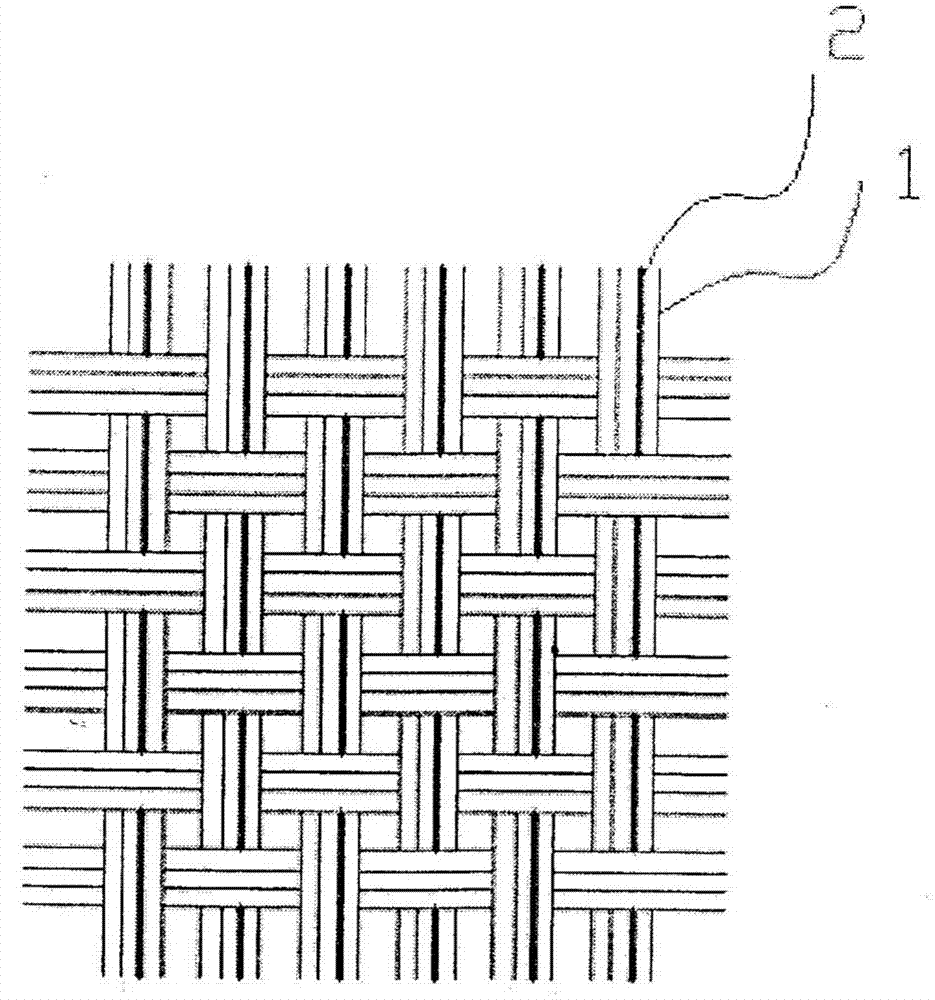

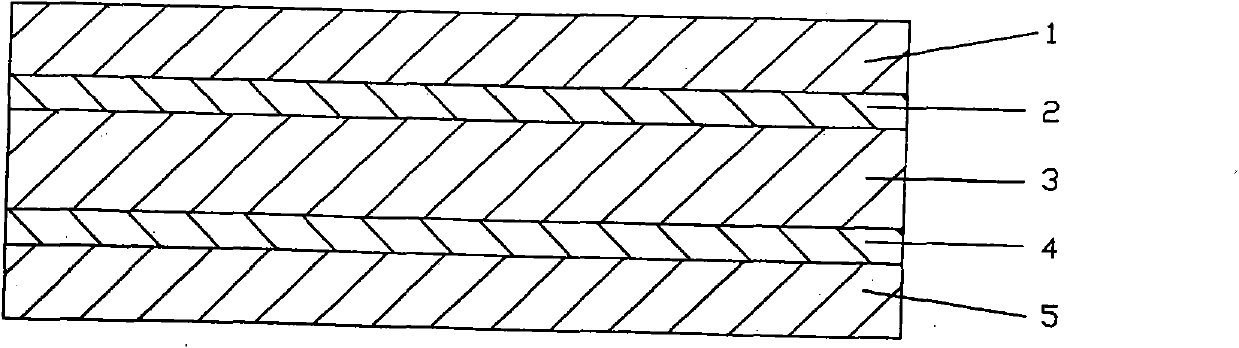

Permanent flame-retardant multifunctional fabric and making method thereof

ActiveCN104499161AImprove flame retardant propertiesReduce investmentWoven fabricsYarnPolymer scienceNatural fiber

The invention discloses permanent flame-retardant multifunctional fabric and a making method thereof and belongs to the technical field of protecting fabric and processing thereof. The permanent flame-retardant multifunctional fabric is formed by interweaving warp yarn and weft yarn. The permanent flame-retardant multifunctional fabric is characterized in that a raw material by which each of the warp yarn and the weft yarn is made is a mixture of high-temperature-resistant natural flame-retardant fibers and natural fibers or regenerated cellulose fibers, the high-temperature-resistant natural flame-retardant fibers account for 40-90% of the fabric, the natural fibers or the regenerated cellulose fibers account for 8-58% of the fabric, and antistatic filaments are woven in the warp yarn at intervals and account for 1-3% of the fabric. The permanent flame-retardant multifunctional fabric can permanently maintain ideal flame-retardant characteristics which do not decline with passage of time or increase of washing times, demonstrates high environment friendliness, breathability and wearing comfortability and has safety, and excellent antistatic performance can be guaranteed lastingly; processes are simplified, so that the above advantages of the fabric can be demonstrated comprehensively.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Energy-saving type power-consumption-free single-phase alternating current motor starting protector with structure improvement

InactiveCN104734428AReduce volumeSmall footprintStructural associationSupports/enclosures/casingsRefrigeration compressorCapacitance

The invention discloses an energy-saving type power-consumption-free single-phase alternating current motor starting protector with structure improvement, and belongs to the technical field of refrigeration compressors. The energy-saving type power-consumption-free single-phase alternating current motor starting protector comprises a shell body, a shell cover, an overload protector, a power-consumption-free starter and an externally connected terminal mechanism, wherein an overload protector containing cavity, a power-consumption-free starter containing cavity, an externally connected terminal mechanism insertion cavity and a starting controller containing cavity are defined by the shell body; the shell cover is matched with the shell body; the overload protector is arranged in the overload protector containing cavity; the power-consumption-free starter comprises a power-consumption-free starter body and a starting controller; the externally connected terminal mechanism is matched with the externally connected terminal mechanism insertion cavity in an inserting mode. The energy-saving type power-consumption-free single-phase alternating current motor starting protector is characterized in that externally connected terminal mechanism insertion cavity comprises a first insertion sheet cavity, a second insertion sheet cavity, a third insertion sheet cavity and a fourth insertion sheet cavity. The externally connected terminal mechanism comprises a first insertion sheet, a second insertion sheet, a third insertion sheet, a fourth insertion sheet and a fifth insertion sheet. The first insertion sheet is matched with the first insertion sheet cavity in an inserting mode, the second insertion sheet is matched with the second insertion sheet cavity in an inserting mode, the third insertion sheet is matched with the third insertion sheet cavity in an inserting mode, the fifth insertion sheet is matched with the fourth insertion sheet cavity in an inserting mode, the fourth insertion sheet is in electrical connection with the overload protector, and the first insertion sheet and the third insertion sheet serve as transfer terminals to be connected with an externally connected power source and a capacitor.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

Preparation method for chlorotrifluoropropylene

InactiveCN101168494AAvoid it happening againLow reaction temperaturePreparation by halogen replacementChemical industryDichloropropaneHydrogen fluoride

A monochloro-fluoropropene preparation belongs to the intermediate preparation technical field of coolant, foaming agent and fluorine compounds, which comprises that under catalyst condition, the telomeric reaction on chloromethane and chloroalkene is processed to prepare pentachloro-propane, which is fluorinated with hydrogen fluoride via the catalysis of composite catalyst to prepare trifluoro-dichloropropane, and hydrogen chloride is removed via the alkali alcohol liquid catalysis to obtain monochloro-fluoropropene as final product. The invention has the advantages that the preparation fluorinates pentachloro-propane into trifluoro-dichloropropane, to remove hydrogen chloride to obtain monochloro-fluoropropene, thereby avoiding azeotropic material and sub isomer generated in the fluorination from pentachloro-propane to monochloro-fluoropropene, while the whole process has low reaction temperature to save energy, and the monochloro-fluoropropene product has reach 99.0-99.6% purity and 80.70-88.05% yield, to meet industrial batch production.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS

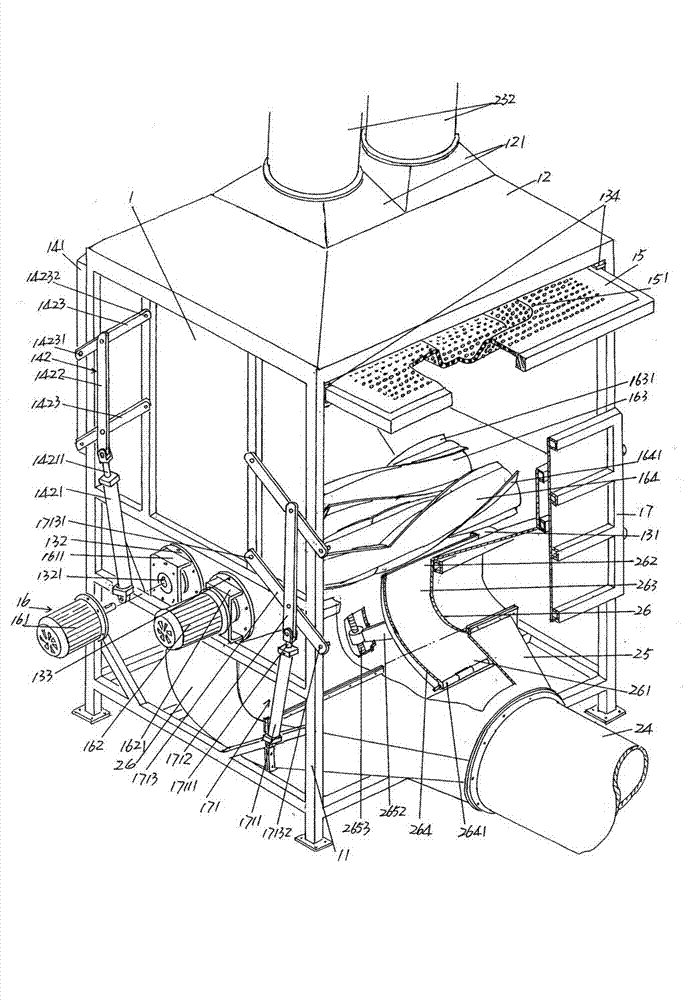

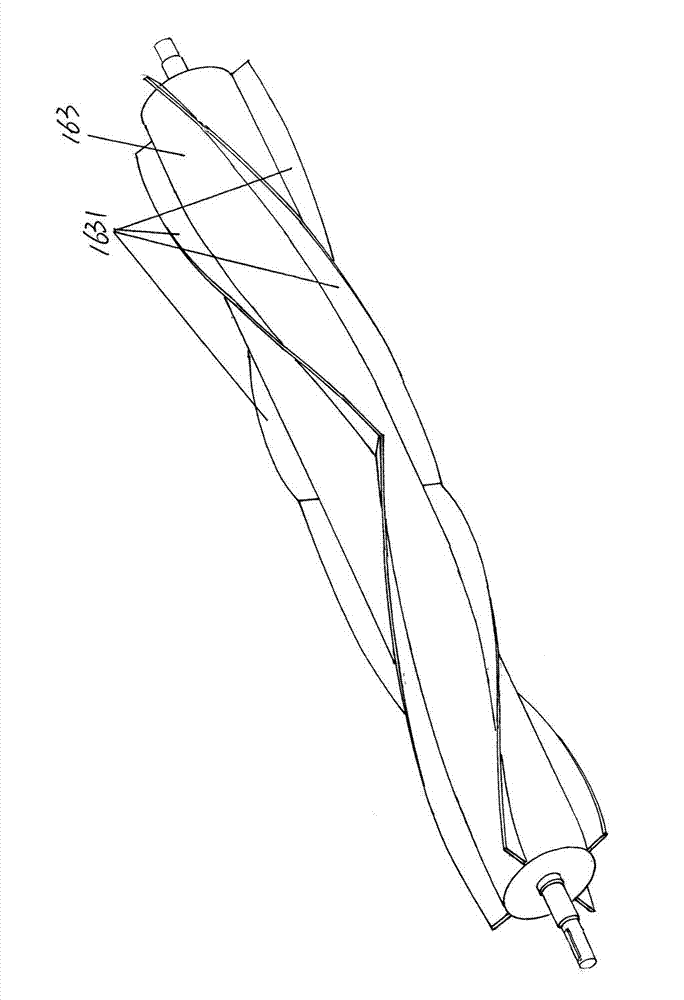

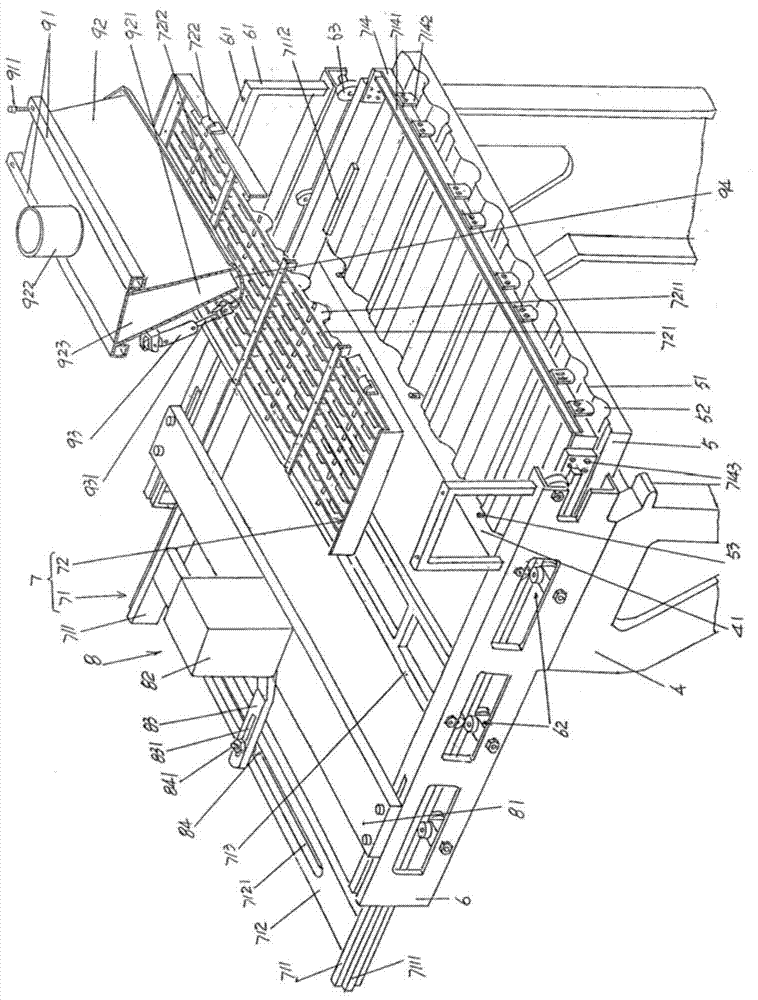

Automotive upholstery pre-shaping machine adopting air filling method

The invention provides an automotive upholstery pre-shaping machine adopting an air filling method, belonging to the technical field of automotive upholstery production devices. The automotive upholstery pre-shaping machine adopting the air filling method comprises a pre-shaping box, an airflow circulation mechanism, a fiber weighing and measuring mechanism, a fiber conveying mechanism and a hot air generation mechanism, wherein a box cover is formed on the top part of the pre-shaping box; an aspiration pipe adapting port is connected with the top of the box cover in a matching way; a box chamber opening / closing mechanism is arranged on one side of the pre-shaping box; a pre-shaping mould is arranged on the top of a box chamber; an aspiration hole is opened in the pre-shaping mould; a fiber feeding mechanism is arranged on the bottom of the pre-shaping box; the hot air generation mechanism is connected with the airflow circulation mechanism by a pipeline; and the airflow circulation mechanism comprises a working motor, a fan, an aspiration pipe, an air supply pipe, a connection cotton box and a cotton guide box. The automotive upholstery pre-shaping machine adopting the air filling method has the advantages that the quality of automotive upholsteries which are pressed and shaped by subsequent pressing processes can be reliably guaranteed, the overall structure is simple, and the labor intensity is decreased for workers; the processing efficiency is high and the energy is saved; and in addition, fibers with a low melting point are vitrified, so that the prototypes of the automotive upholsteries are formed.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

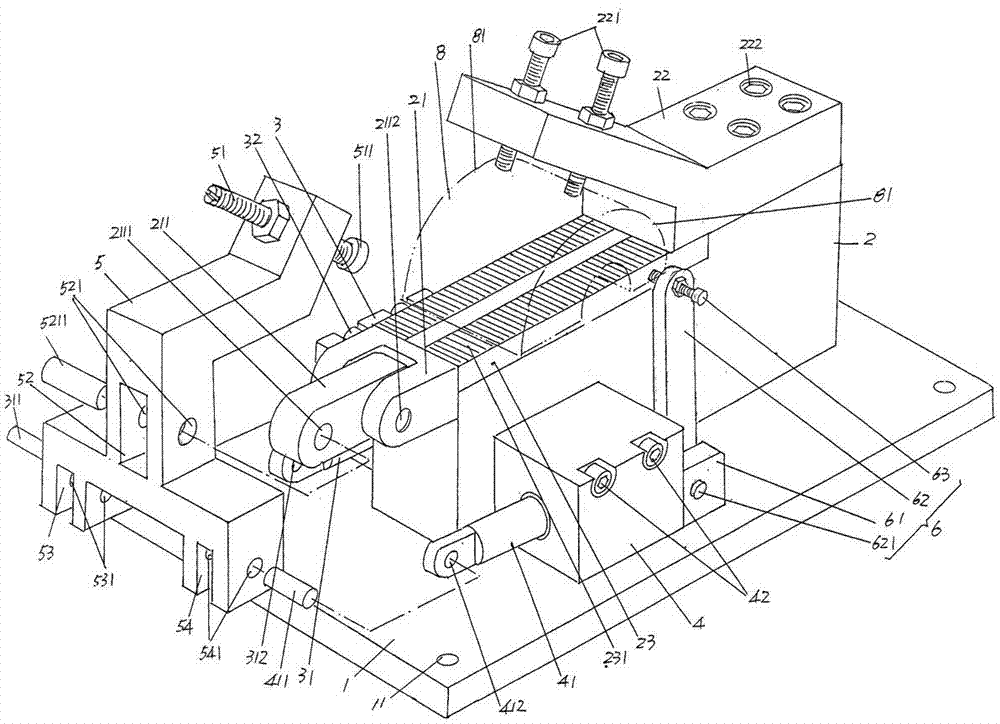

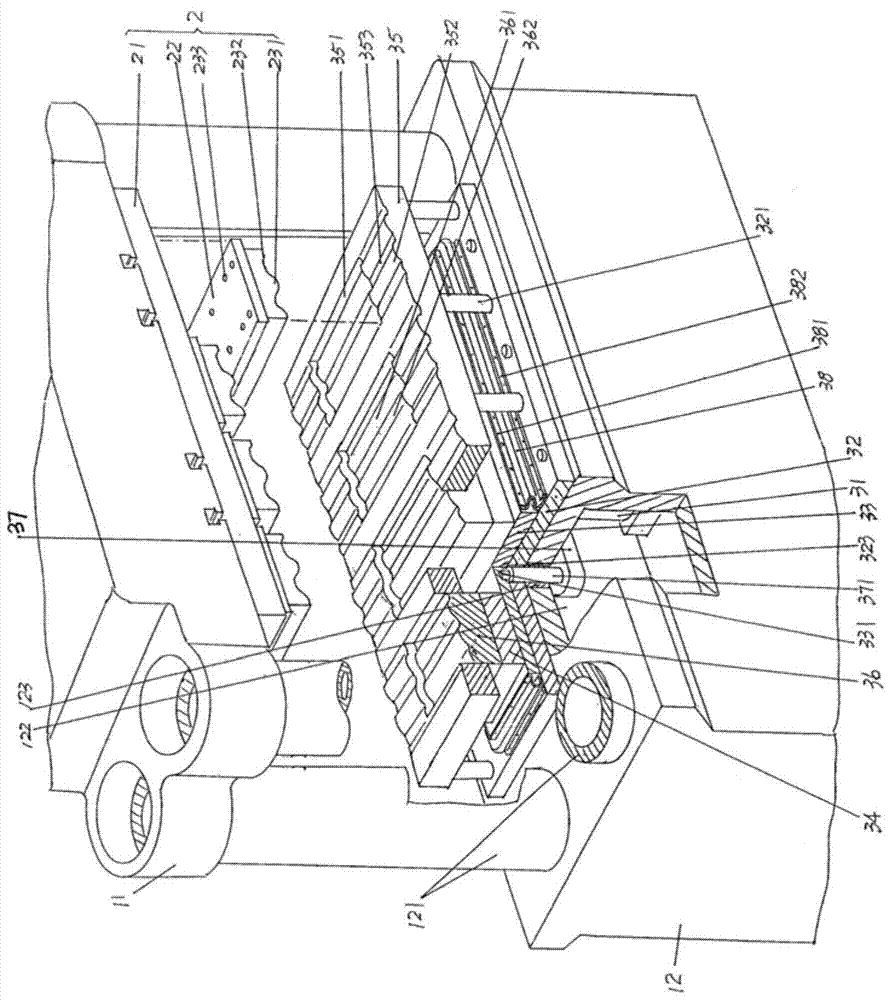

Clamp structure used for parallel face milling of glass mold

ActiveCN103273350BGuaranteed parallelismImprove milling efficiencyPositioning apparatusMetal-working holdersFixed bearingEngineering

The invention provides a clamp structure used for parallel face milling of a glass mold, and belongs to the technical field of tool clamps used for manufacture of the glass mold. The clamp structure comprises a bottom plate, a base, a first action cylinder, a second action cylinder, and a movable bearing base. The base is fixed on the upward side of the bottom plate, a connection shaft plate connecting base is formed on the upper portion of one end of the base, a fixed bearing base is fixed on the upper portion of the other end of the base, and a glass mold base plate is fixed in the middle of the base. The first action cylinder and the second action cylinder are located on two sides of the base respectively and fixed on the base. The upper portion of the movable bearing base corresponds to the fixed bearing base, the middle of the movable bearing base is connected with the connection shaft plate connecting base, one end of the lower portion of the movable bearing base is connected with the first action cylinder, the other end of the lower portion of the movable bearing base is connected with the second action cylinder, the upper portion of the movable bearing base corresponds to the upper portion of one end of the glass mold base plate in a vacant state, and the fixed bearing base faces one end of the movable bearing base and corresponds to the upper portion of the other end of the glass mold base plate. Milling efficiency is high, industrialization widened production requirements are met, operation intensity of workers is reduced, the parallelism of parallel faces of the glass mold can be guaranteed, and energy-saving effects are ideal.

Owner:ORI MOLD TECH SUZHOU

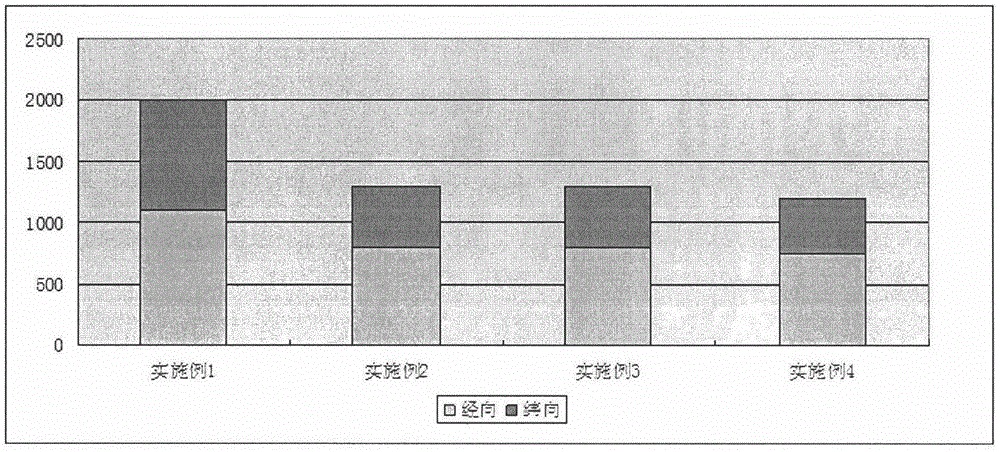

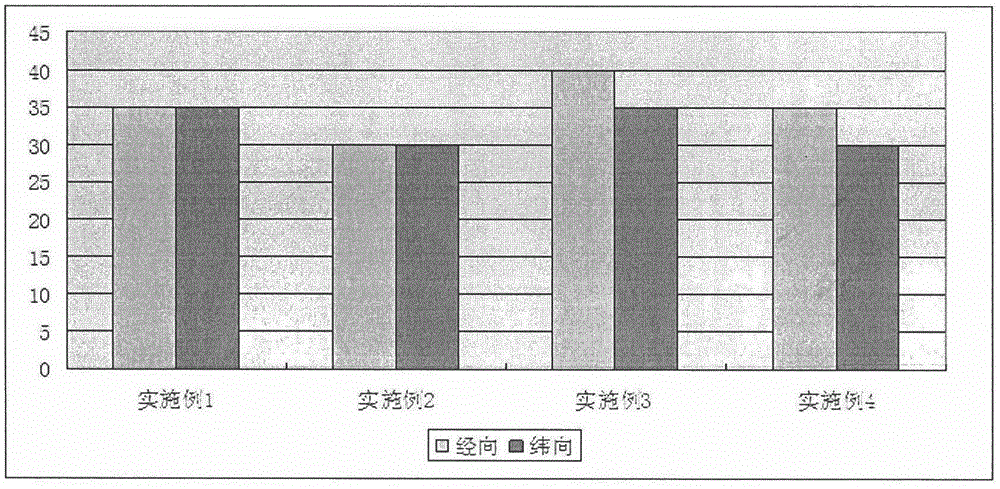

Glass fiber flame retardant silica gel cloth and preparation method thereof

The invention relates to glass fiber flame retardant silica gel cloth and a preparation method thereof, belonging to the technical field of gluing glass fiber products. The glass fiber flame retardant silica gel cloth comprises glass fiber cloth and a corrosion resistant flame retardant layer, wherein the corrosion resistant flame retardant layer is combined to at least one side surface of the glass fiber cloth and comprises the following raw materials in parts by weight: 60-70 parts of mixing silicon rubber, 25-30 parts of flame retardant agent, 2-5 parts of pigment and 0.1-0.5 part of vulcanizing agent. In the technical scheme, because the glass fiber cloth is used as a base material, and the corrosion resistant flame retardant layer formed by the mixing silicon rubber, the flame retardant agent, the pigment and the vulcanizing agent is combined to one side or both sides of the glass longitudinal fiber cloth, the glass fiber flame retardant silica gel cloth can be suitable for being used as a flexible connecting element, can achieve the ideal effects of high-temperature resistance, corrosion resistance and flame retardancy and also has excellent longitudinal and transverse tearing resistant strength; and the provided preparation method has simple and short process step and undemanding process and equipment requirement, not only can guarantee the comprehensive embodiment of the technical effect of the glass fiber flame retardant silica gel cloth but also can meet the industrialized amplification production requirement.

Owner:常熟市嘉诚织造有限公司

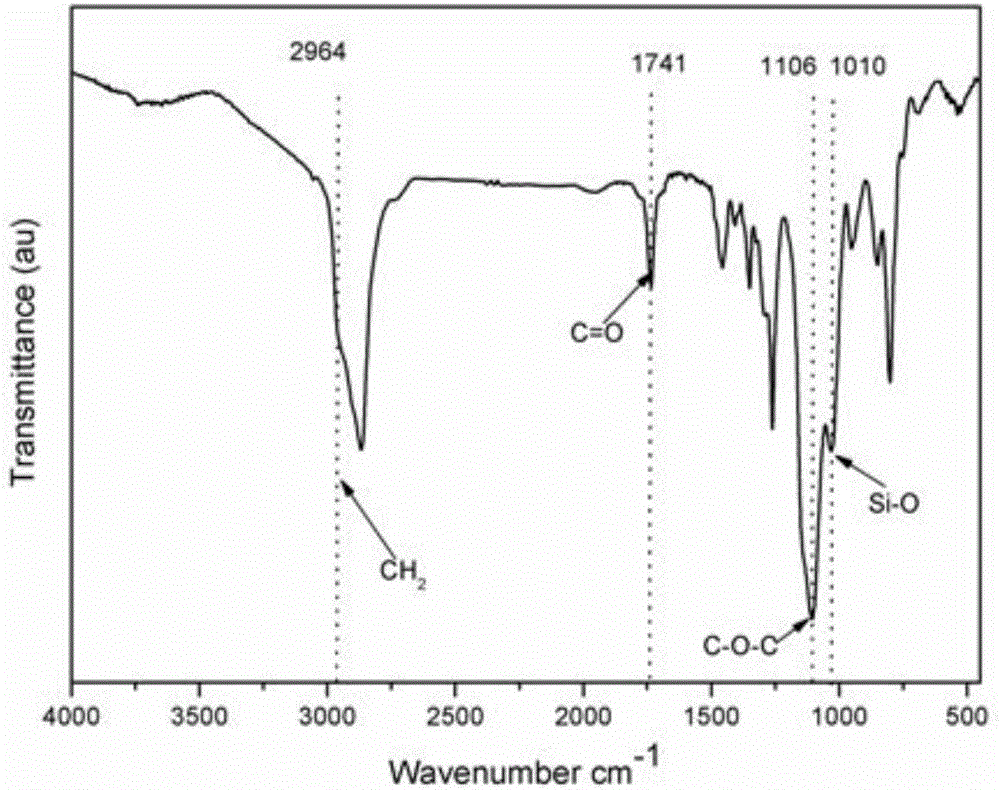

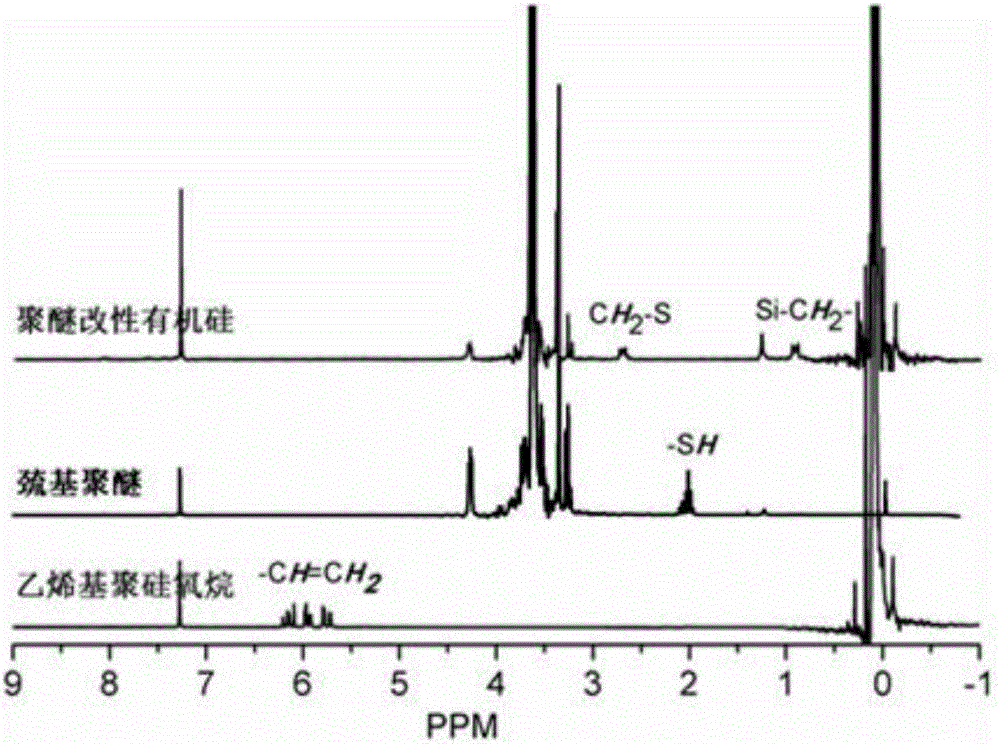

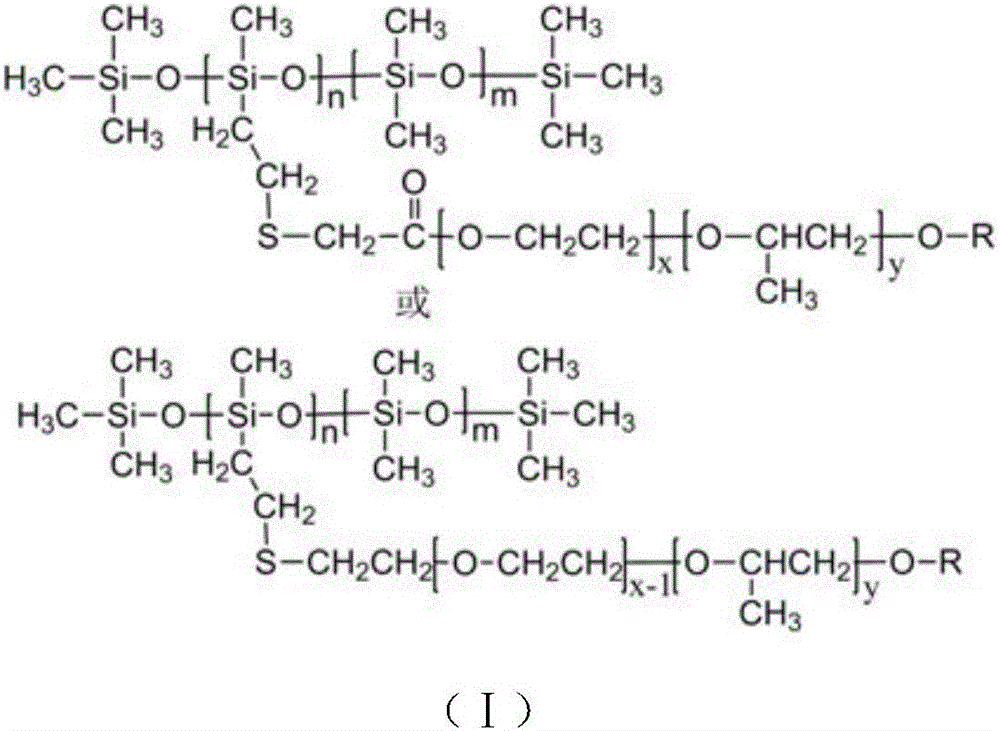

Organosilicon surfactant and thiol-ene click chemistry process preparation method thereof

InactiveCN105713204AShort reaction timeReduce manufacturing costTransportation and packagingMixingEvaporationClick chemistry

Provided are an organosilicon surfactant and a thiol-ene click chemistry process preparation method thereof. The organosilicon surfactant is of a structure shown in a formula (I) (shown in the description), wherein the m and the n are integers, the sum of the m and the n is greater than 20 but is smaller than 100, the x is 10-100, the y is 0-80, the x and the y are integers, and the R is C1-10 straight-chain or heterogeneous long-chain alkyl or alkyl phenyl. The preparation method comprises the steps that thiol polyether and vinyl polysiloxane serve as raw materials and are dissolved in a benign solvent, a light initiator is added under stirring for reaction, the reaction materials are subjected to vacuum rotary evaporation at the temperature of 25-45 DEG C to remove the solvent after the reaction is completed, then vacuum drying is performed at the temperature of 30-60 DEG C for 2-48 hour to obtain the organosilicon surfactant having structural characteristics shown in the formula (I). Precious metal catalysts (such as a metal platinum catalyst) used for synthesis of organosilicon surfactants in the prior art are abandoned, and environmental protection and safety and widening of the product application field are guaranteed.

Owner:SOUTHEAST UNIV

Method for manufacturing steel pipe for bearing ring

InactiveCN102626723AAvoid wastingMeet technical requirementsFurnace typesHeat treatment furnacesHeat conservationContinuous annealing

The invention discloses a method for manufacturing a steel pipe for a bearing ring, belonging to the technical field of manufacturing of steel pipes. The method comprises the following steps of: perforating a bearing steel bar material in a heated state, and quickly cooling after perforation to obtain a pierced billet; introducing the pierced billet into an annealing furnace for annealing to obtain an annealed pierced billet; introducing the annealed pierced billet into a cold rolling mill for performing cold rolling to obtain a cold-rolled pipe blank; introducing the cold-rolled pipe blank into the annealing furnace for performing relief annealing to obtain a stress-relieved pipe blank; washing the stress-relieved pipe blank with acid, and phosphorizing treatment to obtain a pipe blank to be subjected to cold drawing; performing cold drawing on the pipe blank to be subjected to cold drawing, and controlling the cold drawing extension multiple to obtain a cold-drawn pipe; and introducing the cold-drawn pipe into a continuous annealing furnace for performing finished product thermal treatment, controlling the thermal treatment temperature and heat preserving time of a finished product, cooling along with the furnace after heat preservation is completed, and discharging to obtain the steel pipe for the bearing ring. The method has the advantages that: the technical requirements of the bearing ring manufactured with a cold rolling process can be met; and the method has simple process steps, and can meet the requirement of industrial mass production.

Owner:常熟市旋力轴承钢管有限公司

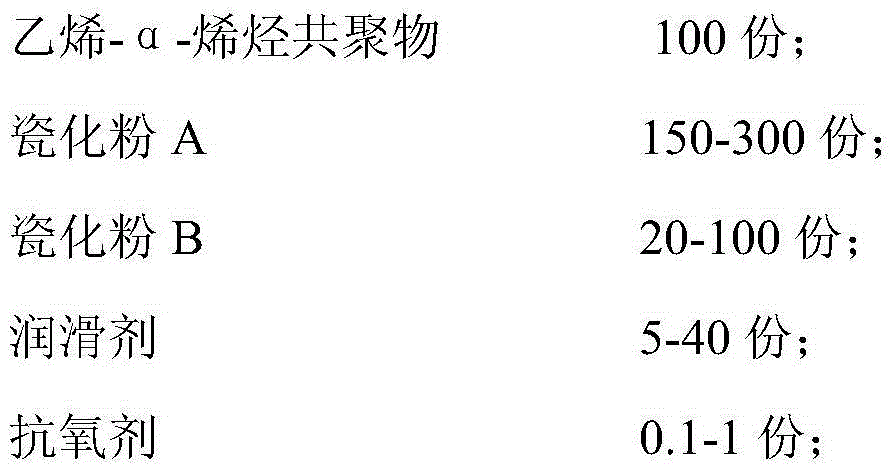

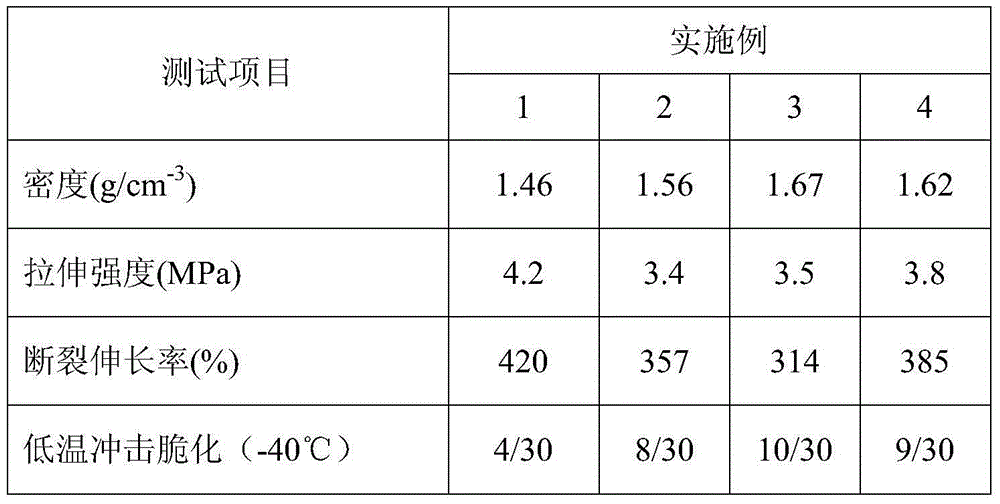

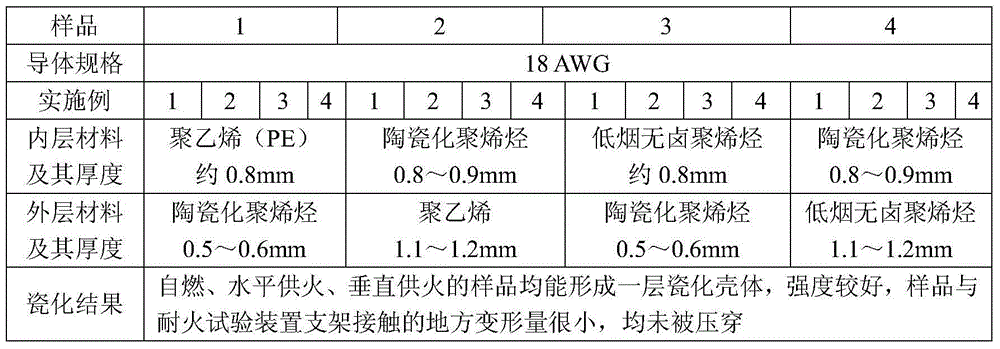

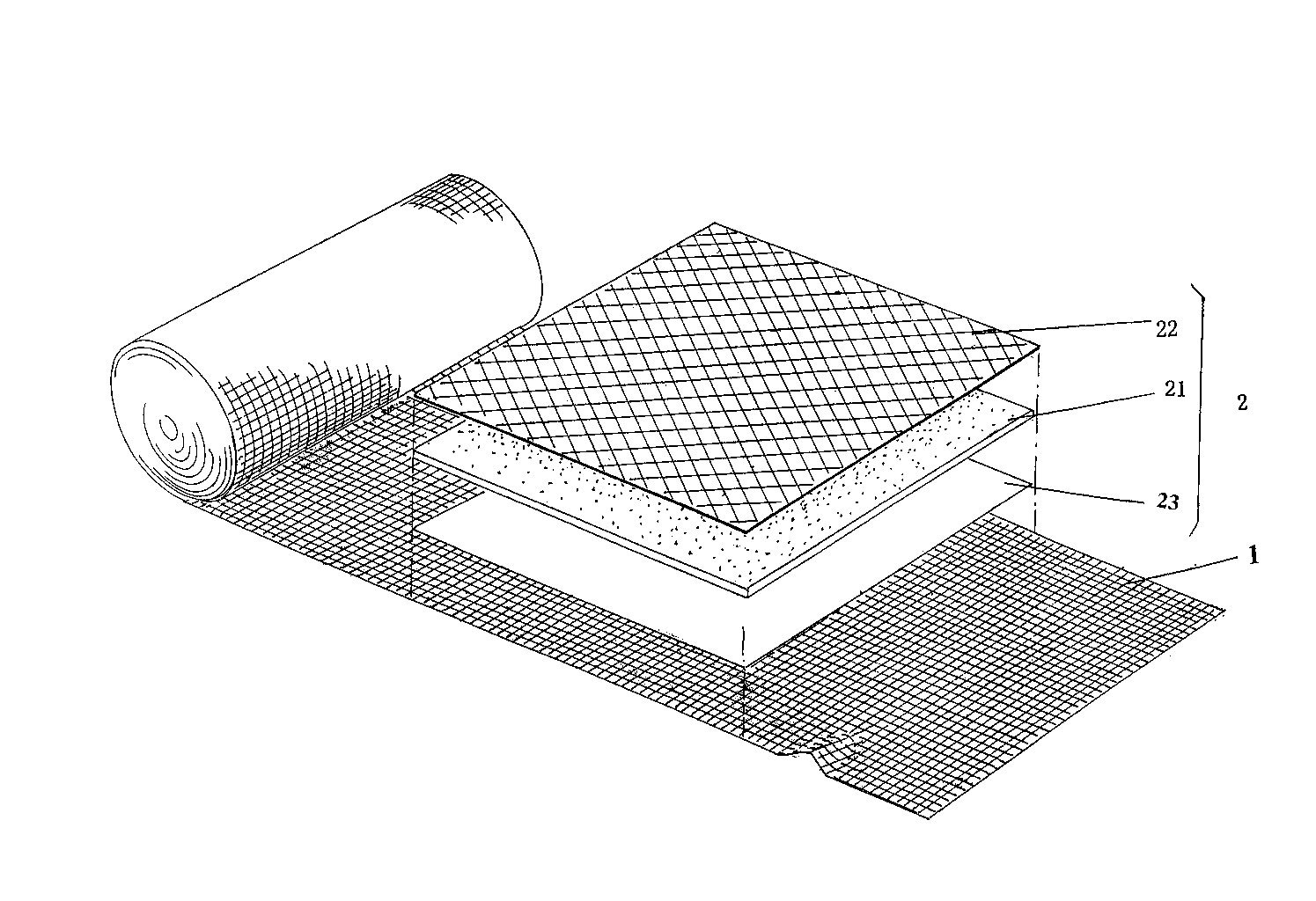

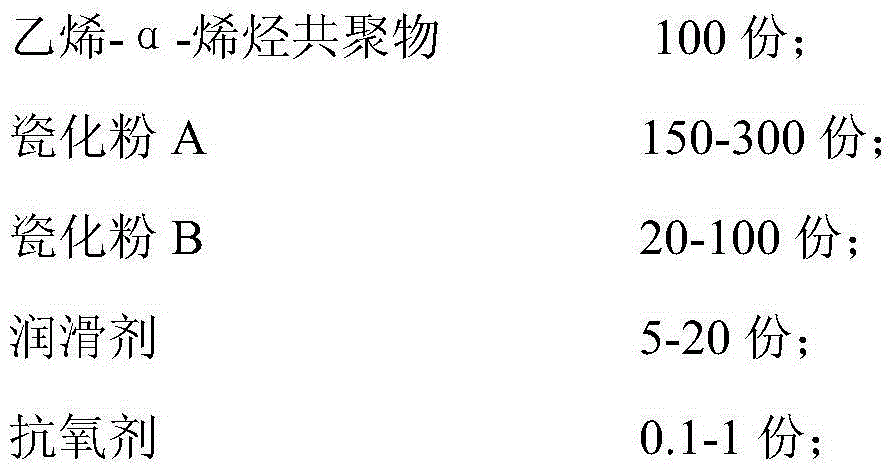

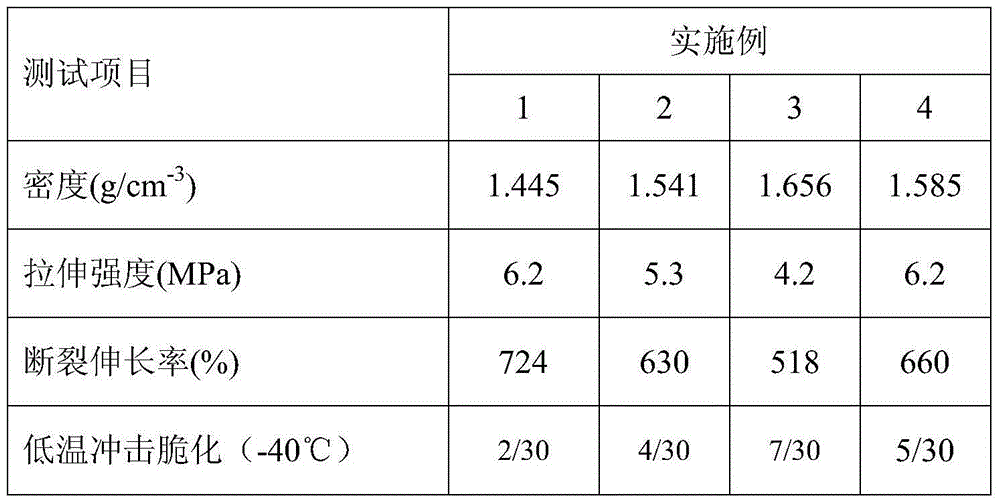

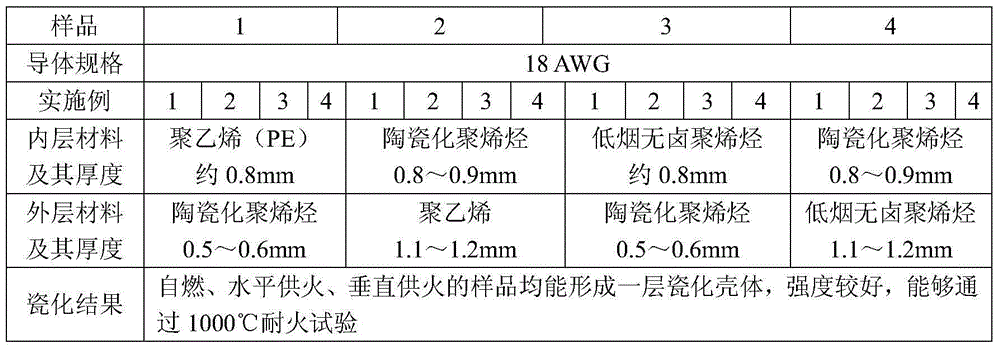

Ceramized polyolefin material and preparation method thereof

InactiveCN104558804AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 150-300 parts of ceramized powder A, 20-100 parts of ceramized powder B, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP. The ceramized polyolefin material is reasonable in raw material and proportion, capable of ensuring normal operation of a route, good in flexibility, simple in process and low in cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Foliar blocking and controlling agent capable of reducing cadmium contamination of brown rice, and preparation method and application thereof

InactiveCN105837308AIncrease added valueInhibit migrationCalcareous fertilisersFertilising methodsSilicon dioxidePlant growth

The invention provides a foliar blocking and controlling agent capable of reducing cadmium contamination of brown rice, and a preparation method and application thereof, belonging to the technical field of foliar sprinkling fertilizer for crops. The preparation method comprises the following steps: adding, on the basis of each liter of water, 200 to 230 g of silicon dioxide, 60 to 80 g of potassium oxide, 8 to 15 g of calcium oxide, 1 to 2 g of selenium, less than 2 g of adding elements and 1 to 2 g of a plant growth regulator into a container equipped with a stirring device; carrying out uniform mixing under stirring; controlling stirring time and speed; and the discharging the obtained mixture and carrying out so as to obtain the foliar blocking and controlling agent capable of reducing cadmium contamination of brown rice. The application of the foliar blocking and controlling agent comprises a first step of diluting the foliar blocking and controlling agent with water and a second step of sprinkling the diluted agent on the leaves of rice in stages. The foliar blocking and controlling agent inhibits migration of cadmium ions, guarantees ideal cadmium reduction effect on brown rice, realizes the dual effects of cadmium blocking and nutrient absorption of plants, enables the yield of paddy rice per mu to increase by 6% or above, is beneficial for prolongation of the life span of human beings and increases the added value of rice; the preparation method is simple and has no strict requirements on essential factors; and the application method is convenient and efficient.

Owner:陈金虎

Colored glaze ceramic tile, production method of colored glaze ceramic tile, and forming device using production method

ActiveCN103538141AReduce weightImprove viewing effectRoof covering using tiles/slatesFeeding arrangmentsWeather resistanceCeramic tiles

The invention relates to a colored glaze ceramic tile, a production method of the colored glaze ceramic tile, and a forming device using the production method and belongs to the field of building roof materials. The colored glaze ceramic tile comprises a tile body and a surface colored glaze layer. The surface colored glaze layer is attached to the tile body and faces out when in use. The tile body is made with, by weight, 25-40% of clay, 10-20% of quartz sand, 5-15% of auxiliary material, 30-45% of flux, and 0.15-0.5% of additive. The colored glaze ceramic tile, the production method and the forming device have the advantages that materials are selected and matched reasonably, the weight of the obtained colored glaze ceramic tile is evidently lower than that of clay or cement tiles, storage and transportation cost can be saved, and the tile is good in strength and weather resistance and water resistance; energy can be saved, and the requirements for industrial enlarged production are met; the surface colored glaze layer can be reliably attached to the tile body, and the appearance of the colored glaze tile can be improved; the finally obtained colored glaze ceramic tile can be even in thickness and density.

Owner:常熟大象建陶有限公司

Processing method of 2Cr13 rectangular pipe

InactiveCN102489944AReduce production passesShort processFurnace typesHeat treatment furnacesMartensitic stainless steelMaterials science

The invention provides a processing method of a 2Cr13 rectangular pipe, belonging to the field of the processing technology of the martensite stainless steel pipes. The processing method comprises the following steps: preparing materials; heating; punching a hole; annealing; pickling; lubricating; cold-rolling; hammering; cold-drawing and final-annealing; and finishing. The technical scheme provided by the invention only needs one or two passes of cold rolling and twice cold drawings, thus reducing three production passes relative to the production passes in the prior art, further obviously shortening the process flow and having outstanding energy-saving effect; and as the production passes are obviously reduced, the processing method provided by the invention can improve the rolling yield by 8-10 % relative to the rolling yield in the prior art, thus meeting the requirement of the industrial large-scale production.

Owner:CHANGSHUSMLESS STEEL TUBE

Method for filling nickel-based alloy in glass die cavity with cast iron alloy as base matrix

InactiveCN102248358AEasy maintenanceExtended service lifePlasma welding apparatusAlloyUltimate tensile strength

The invention discloses a method for filling a nickel-based alloy in a glass die cavity with a cast iron alloy as a base matrix, belonging to the technical field of glass dies and comprising the following steps of die cavity pre-processing, preheating, treating before welding, welding, annealing and finish processing. The invention has the advantages that the cast iron alloy is taken as the base matrix of the glass die, thus the method has low cost, abundant raw materials, moderate heat conductivity, convenience for maintenance of the die and no limitation from the produced glass products; a plasma welder is adopted; a plasma arc is used as a heat source, the temperature is high and the heat is centralized, and a micro molten pool is formed on the surface of a workpiece, so that a welding layer is metallurgically bonded with a matrix, the combined strength of the welding layer is high and the welded welding layer is not easy to fall off; by using the plasma welder to operate, the automatic streamline operation can be formed, the requirement for industrial production enlargement is met, welding powder is saved, the productivity is improved and the operation strength of workers is reduced; in addition, the service life of the die can be prolonged and the requirement for high machine speed is met.

Owner:CHANGSHU JIANHUA MOLD TECH

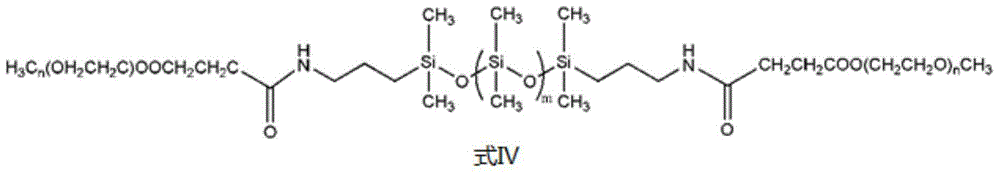

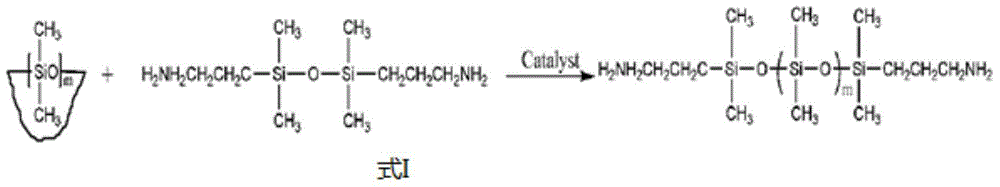

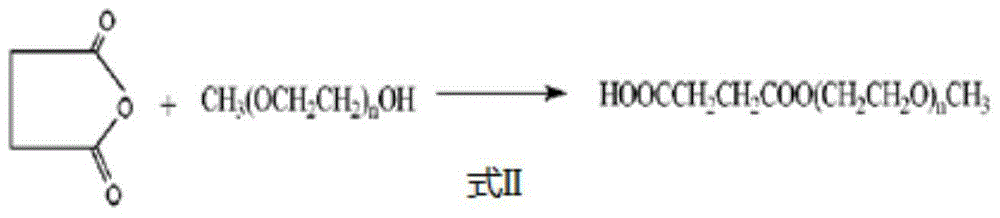

Bola type polyether-modified organosilicon surfactant and preparation method thereof

ActiveCN104645877AImprove surface activityGuarantee environmental safetyTransportation and packagingMixingAlcoholPolyethylene glycol

The invention discloses a Bola type polyether-modified organosilicon surfactant and a preparation method thereof. A general structural formula of the organosilicon surfactant is as shown in the specification, wherein m is an integer of 1-200; and n is an integer of 8-40. The preparation method comprises the following steps: (1) with cyclosiloxane and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane as raw materials, preparing bis-aminopropyl-terminated modified polysiloxane in the presence of a catalyst; (2) enabling succinic anhydride to react with methoxy polyethylene glycol to obtain succinic acid mono polyethylene glycol monomethyl ether ester; and (3) enabling the bis-aminopropyl modified polysiloxane to react with the succinic acid mono polyethylene glycol monomethyl ether ester under the condition of lower alcohol as a solvent, so as to obtain the Bola type polyether-modified organosilicon surfactant. According to the preparation method disclosed by the invention, a catalyst, chloroplatinic acid, used by synthesis of an organosilicon surfactant in the prior art is abandoned to ensure environmental protection and safety; and in addition, the method disclosed by the invention is simple but not fussy in preparation technology and low in preparation cost, and can meet the requirements of industrialized enlarged production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

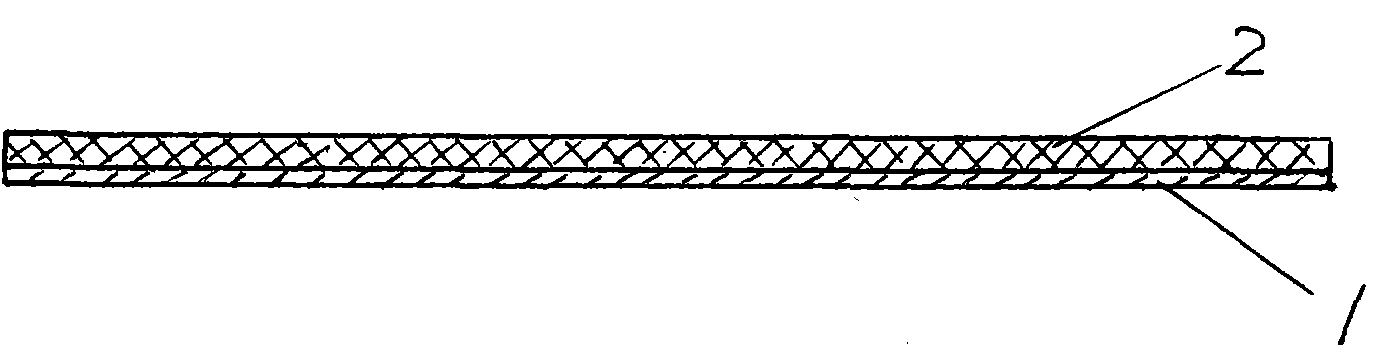

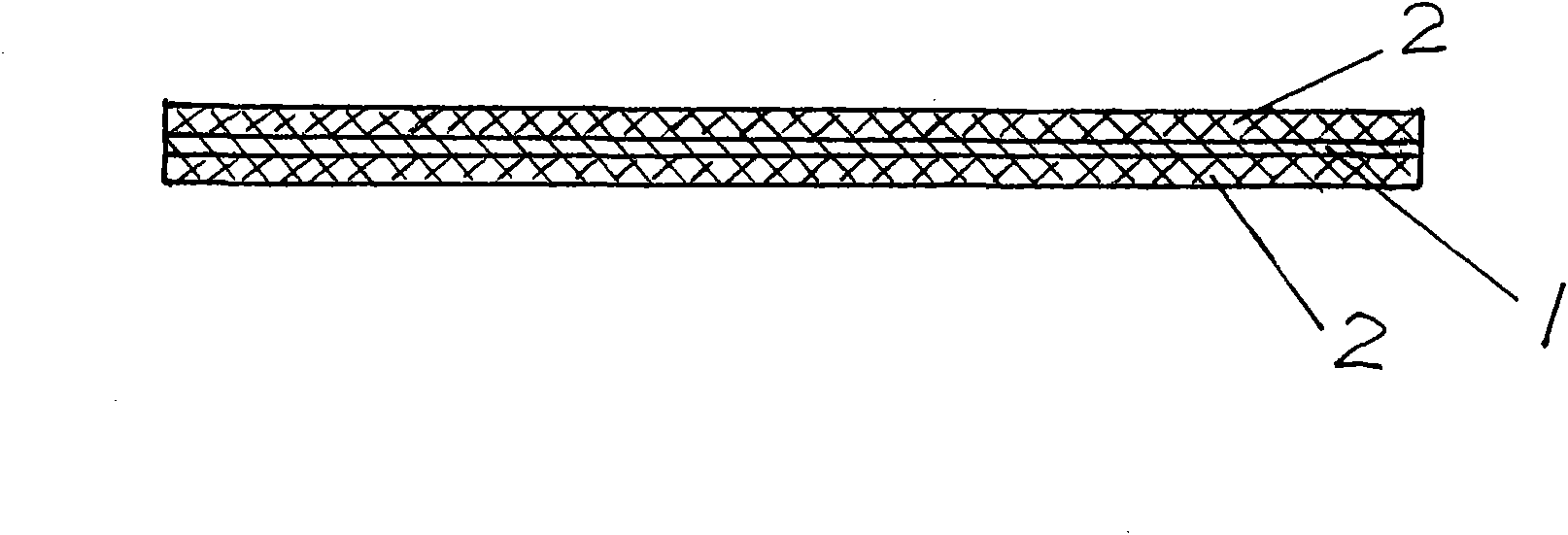

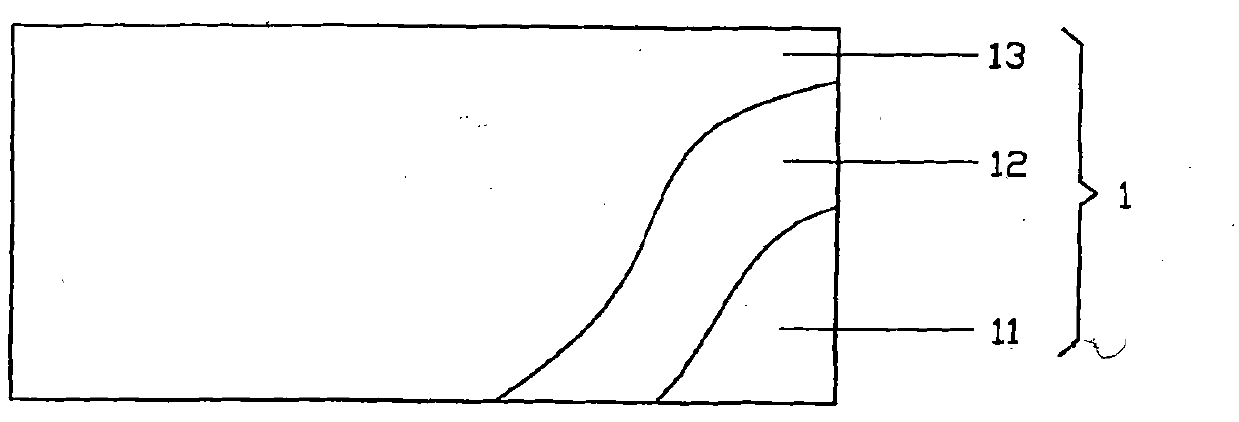

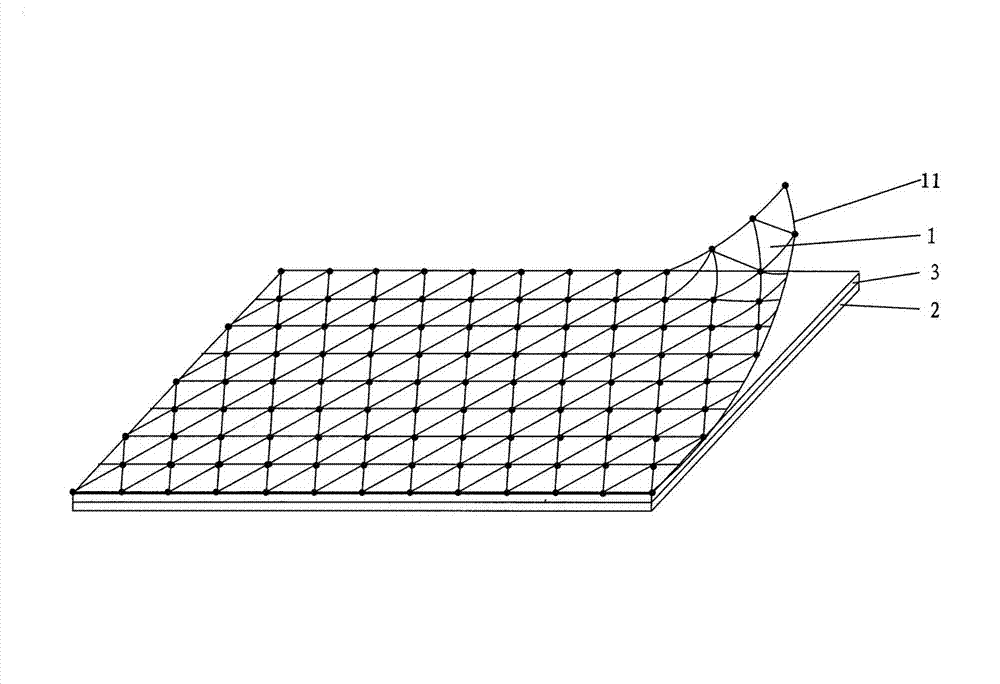

Insulating back plate for solar photovoltaic component

InactiveCN101992572AGood compatibilityImprove barrier propertiesSynthetic resin layered productsPhotovoltaic energy generationPolyolefinWater vapor

The invention discloses an insulating back plate for a solar photovoltaic component and belongs to the technical field of solar photovoltaic cells. The solar photovoltaic component comprises a weather-resistant layer, an electric insulating layer and a thermal bonding layer, wherein the electric insulating layer is positioned between the weather-resistant layer and the thermal bonding layer; the weather-resistant layer is made from a mixture of polyvinylidene fluoride, acrylic resin and an inorganic material; the electric insulating layer is made from polyethylene glycol terephthalate and poly2,6-naphthalate or polyamide; and the thermal bonding layer is made from polyolefin. In the technical scheme, because the weather-resistant layer made from the polyvinylidene fluoride and the inorganic material in the prior art is modified into the weather-resistant layer made from the polyvinylidene fluoride, the acrylic resin and the inorganic material, and the acrylic resin and the polyvinylidene fluoride have high compatibility, the water vapor barrier effect and the ultraviolet resistance are enhanced and the service life of the solar photovoltaic component is guaranteed. Because the materials of the provided scheme are readily available and the cost of the insulating back plate is low, the insulating back plate can get away from the dependence on import and meets the requirement of industrialized mass production.

Owner:CHANGSHU TOP SOLAR MATERIAL

Lubricating oil for cold reduction of tubes and preparation method thereof

ActiveCN103215112AEasy to cleanImprove antioxidant capacityLubricant compositionVegetable oilActive agent

The invention discloses lubricating oil for cold reduction of tubes and a preparation method thereof, belonging to the field of water-soluble lubricating oil and a preparation technology thereof. The lubricating oil is composed of the following raw materials in parts by weight: 25-65 parts of base oil, 25-75 parts of chlorinated paraffin, 0.2-3 parts of vegetable oil, 2-25 parts of surfactant, 1-5 parts of antioxidant and 2-6 parts of antirust agent. The preparation method comprises the following steps of: firstly adding 25-65 parts of base oil and 25-75 parts of chlorinated paraffin into a container with a stirring device and a heating device, and stirring in a heating state; adding 0.2-3 parts of vegetable oil, 1-5 parts of antioxidant and 2-6 parts of antirust agent, and continuously heating and stirring; adding 2-25 parts of surfactant, and heating and stirring; and cooling and discharging to obtain a finished product. The lubricating oil disclosed by the invention is harmless to environment and has excellent extreme-pressure abrasion resistance; and the process flow is simple, and the technological requirements are not harsh, thus the need for industrial production amplification can be met.

Owner:SUZHOU MEIBEIER IND OIL

Improved 40CrNiMo steel and preparation method thereof

The invention relates to improved 40CrNiMo steel and a preparation method thereof, and belongs to the technical field of alloy steel. The improved 40CrNiMo steel comprises the following chemical elements in percentage by weight: 0.37 to 0.45 percent of C, 1.65 to 1.85 percent of Cr, 0.45 to 0.65 percent of Ni, 0.15 to 0.25 percent of Mo, 0.90 to 1.20 percent of Mn, 0.40 to 0.55 percent of Si, 0.0025 to 0.0045 percent of B, 0.22 to 0.28 percent of N, 0.007 to 0.012 percent of Ca, 0.002 to 0.005 percent of Mg, 0.03 to 0.06 percent of Nb, 0.04 to 0.08 percent of Ti, 0.02 to 0.06 percent of RE, less than or equal to 0.015 percent of S, less than or equal to 0.025 percent of P, less than or equal to 0.0008 percent of Al and the balance of Fe. The invention has the advantages that: the improved 40CrNiMo steel has low nickel content, so that cost can be reduced; the steel has a fine structure, the number of impurities is obviously reduced, and the impurities have a small size and are uniformly distributed, so that the performance of the steel is obviously improved; and a few process steps are performed in the preparation method, so that energy is saved, and the requirement of industrial scale-up production is met.

Owner:江苏环立板带轧辊有限公司

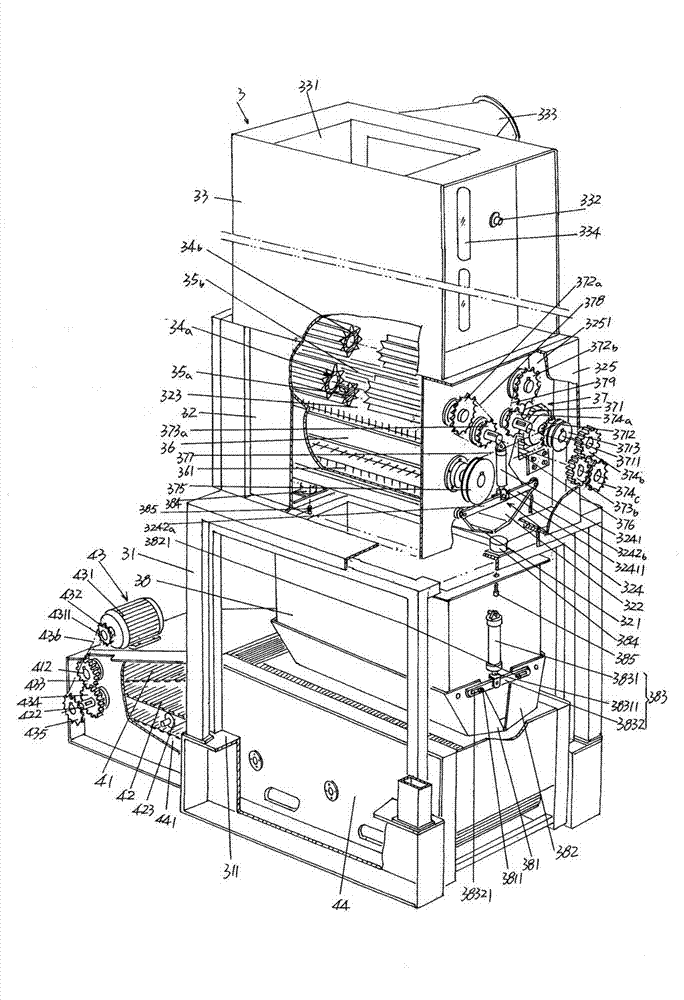

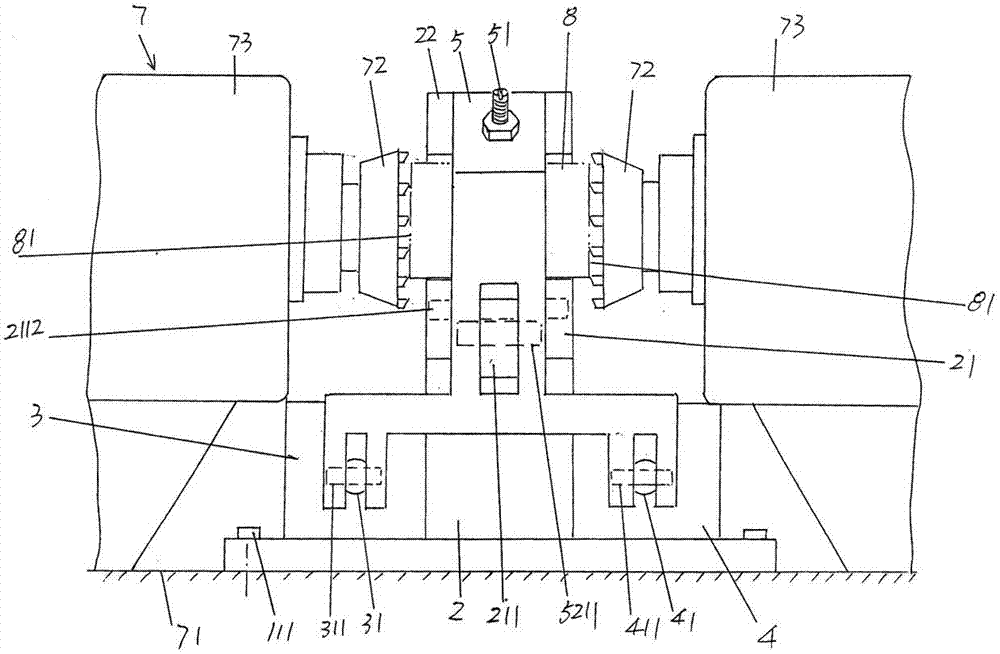

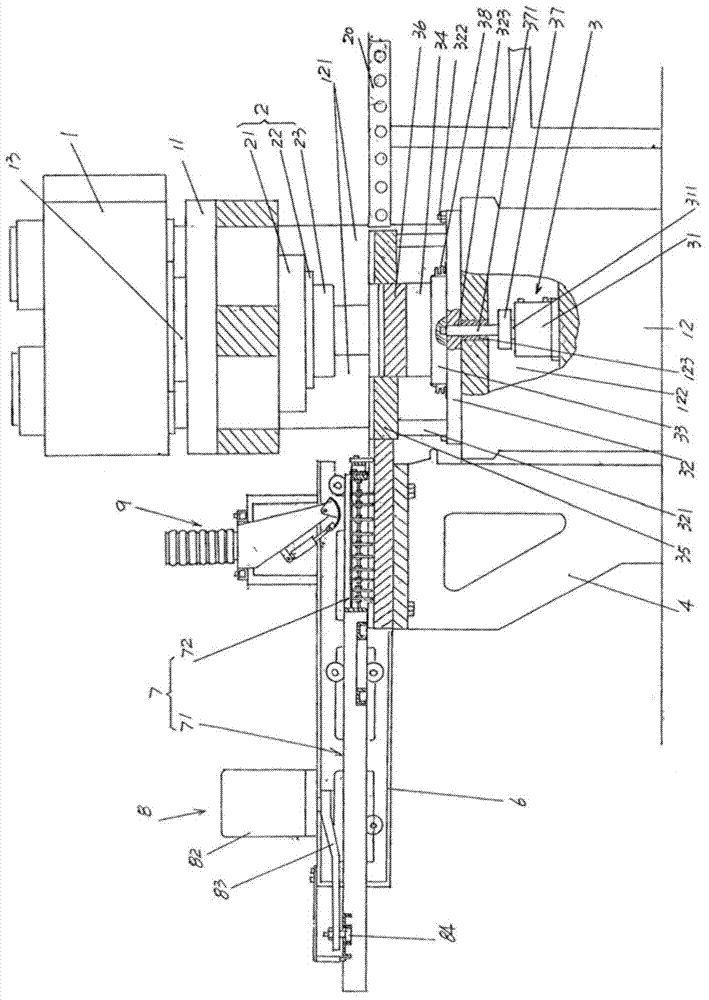

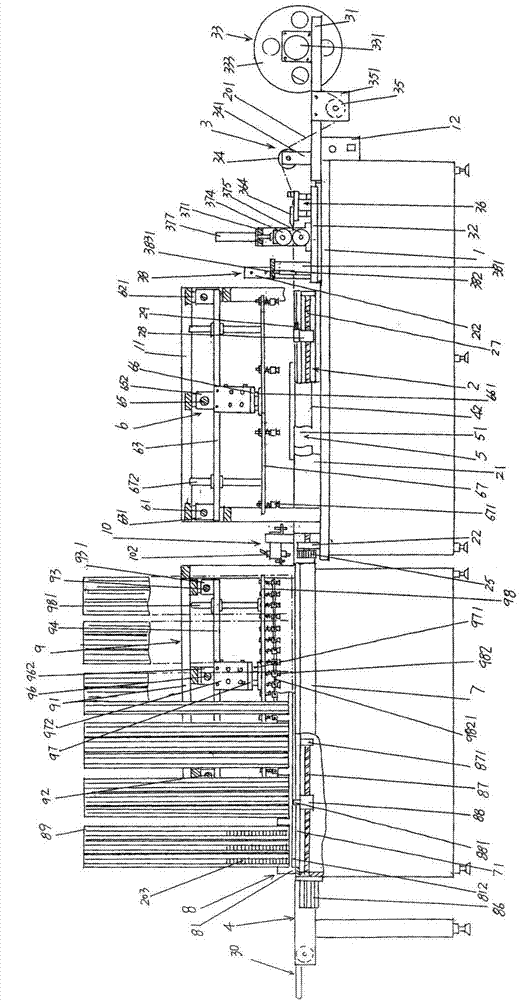

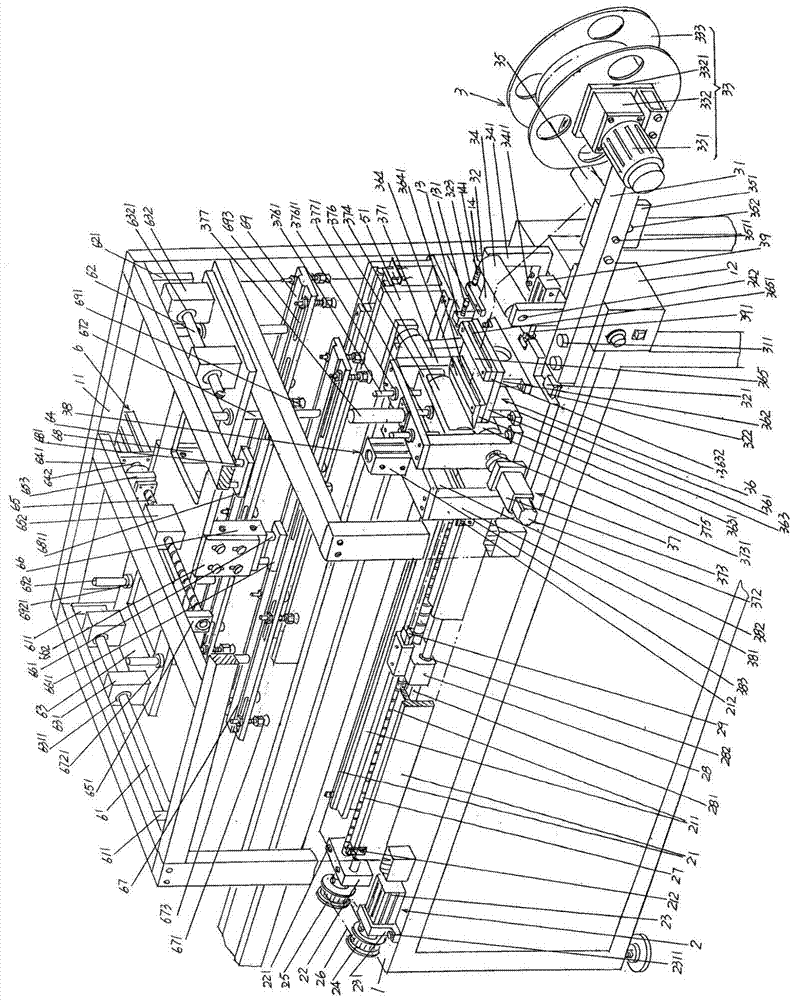

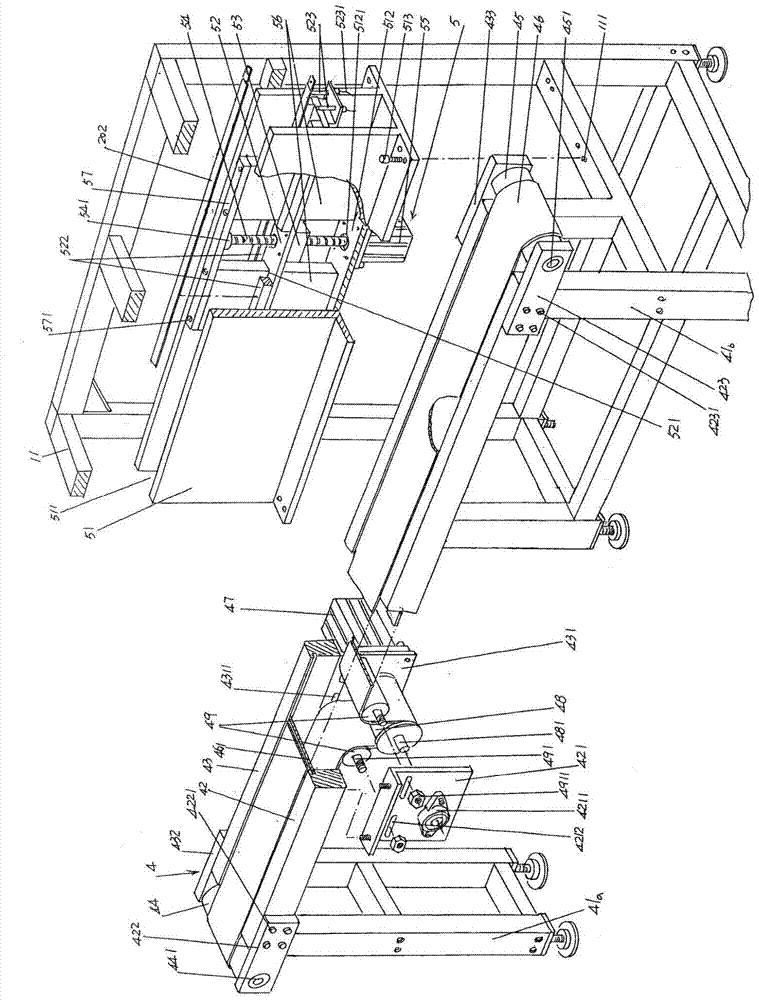

Automatic assembly device of heater PTC heating core

ActiveCN103878584AMeet the requirements of industrial scale-up productionReduce work intensityAssembly machinesTransfer mechanismAutomation

The invention discloses an automatic assembly device of a heater PTC heating core and belongs to the technical field of automation machines. The automatic assembly device comprises an insulating film strip conveying working table and a PTC element conveying working table. An insulating film strip traction mechanism is arranged on the insulating film strip conveying working table. An insulating film strip conveying mechanism is arranged on the insulating film strip conveying working table. A conveying belt mechanism is arranged on a floor, and an electrode slice feeding mechanism is arranged on the rear side of a working table rack. A film strip and electrode slice transferring mechanism is arranged on the working table rack. A PTC element feeding mechanism is arranged on the PTC element conveying working table. A PTC element transferring mechanism is arranged on the rear side of the conveying belt mechanism. An adhesive spraying mechanism is arranged on the conveying belt mechanism. Labor input is reduced, and assembly efficiency is improved; operation intensity is relieved; quality is guaranteed; the insulating film strip, electrode slices and the surface electrode layers of a PTC element can not be stained or damaged; mutual reliable combination between the PTC element and the electrode slices can be guaranteed.

Owner:浙江西塘实业有限公司

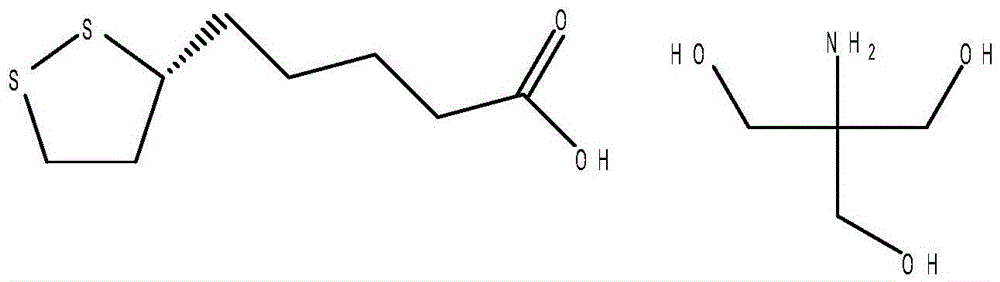

Preparation method of R-lipoic acid tromethamine salt

InactiveCN105622571AEmission reductionReduce process stepsOrganic chemistryOrganic solventFiltration

The invention discloses a preparation method of R-lipoic acid tromethamine salt and belongs to the field of organic medicinal chemistry. The method includes the steps that (S)-6,8-dichloro ethyl caprylate and sulphur are put into a reaction vessel, the temperature is raised, a cyclization reaction is carried out, the temperature is preserved, extraction is carried out with a first organic solvent, concentration is carried out, and cyclization liquid is obtained; then, a hydrolysis reaction is carried out, cooling is carried out, and hydrolysis liquid is obtained; a second organic solvent is added into the hydrolysis liquid, the pH value is regulated, extraction is carried out, an obtained organic layer is washed with water to be neutral, the second organic solvent is removed at reduced pressure, and an initial product is obtained; mixed liquor is added into the initial product, the temperature is raised, a first filter aid is added, stirring adsorption is carried out, filtration is carried out, and light yellow liquid is obtained; cooling is carried out to separate out crystals, and R-lipoic acid is obtained; R-lipoic acid is dissolved, trihydroxymethyl aminomethane is added, the temperature is raised for solution, a second filter aid is added for filtration, and light yellow liquid is obtained; cooling is carried out to separate out crystals, centrifugal drying is carried out, and the finished product is obtained. According to the method, few steps are needed, efficiency is high, energy is saved, and waste discharge is reduced.

Owner:SUZHOU FUSHILAI PHARMA CO LTD

Manufacturing method of composite medical non-woven fabric absorbent pads

The invention relates to a manufacturing method of composite medical non-woven fabric absorbent pads and belongs to the field of preparation of medical dressing. The manufacturing method includes steps of feeding medical non-toxic polyethylene particles into a screw extruder to fuse and extrude, forming a film through curtain coating, rolling to form anti-adhesive holes, cooling and winding to obtain a medical non-toxic polyethylene film used as an anti-adhesive layer; subjecting blended fibers blended by viscose fibers and high-absorbent fibers to opening by an opener, carding by a carding machine, lapping by a lapping machine and needling by a needle machine, and obtaining non-woven fabric used as a liquid absorbent layer; feeding polyurethane particles into the screw extruder to fuse and extrude, and forming a film by curtain coating, cooling and winding to obtain a polyurethane film used as a waterproof breathable layer; subjecting the anti-adhesive layer and one surface of the liquid absorbent layer to thermal compositing, and subjecting the waterproof breathable layer and the other surface of the liquid absorbent layer to thermal compositing to obtain a composite medical non-woven fabric absorbent pad. The manufacturing method of the composite medical non-woven fabric absorbent pads has the advantages that liquid absorbent quantity is high, leakage to the outside is prevented, contact area of the skin can be remarkably decreased, handling time of medical staff can be shortened, and technical steps are few.

Owner:SUZHOU EMY MEDICAL SUPPLIES

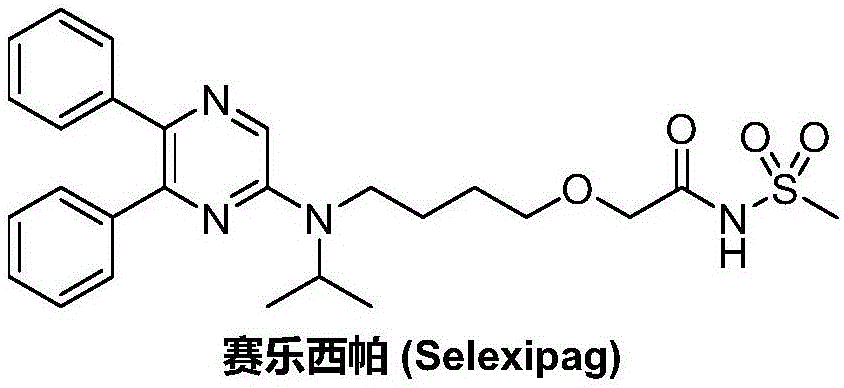

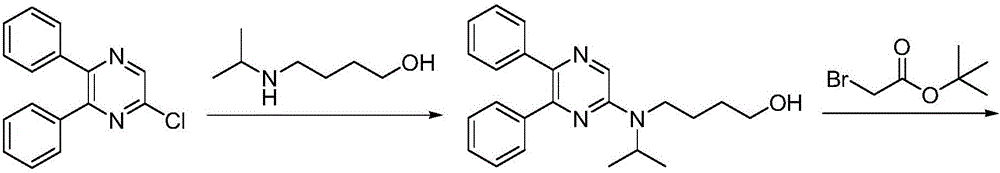

Synthetic method of selexipag

The invention discloses a synthetic method of selexipag. According to the method, 4-[(t-butyloxycarboryl)(isopropyl) amino]-1-butanol and tert-butyl bromoacetate are subjected to a condensation reaction, and obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] tert-butyl acetate is subjected to a hydrolysis reaction under an alkaline reaction; obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] acetic acid and methanesulfonamide are subjected to a condensation reaction; obtained 2-[4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide is subjected to a deprotection reaction under an acid condition, obtained 2-[4-(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide and 5-chloro-2,3-diphenyl pyrazine are subjected to a substitution reaction, and the finished product selexipag is obtained. The method has a reasonable and concise process route and is environment-friendly and suitable for industrial production, the operation is simplified, and the cost is relatively low.

Owner:湖南欧亚药业有限公司

Natural L-alpha-glycero-phosphatidylcholine preparation method

InactiveCN102875592AShort process stepsSave resourcesPhosphatide foodstuff compositionsChemistryCationic exchange

The invention belongs to the technical field of natural drug isolation and purification and relates to a natural L-alpha-glycero-phosphatidylcholine preparation method. The method includes: using acid liquor for soaking macroporous cation exchange resin, draining the acid liquor, washing with water, soaking with alkali liquor, washing with water, soaking with acid liquor again, washing with deionized water and using low-carbon alcohol for replacement; adding powder phospholipid into the low-carbon alcohol, alkalifying for reaction, leaching, washing with the low-carbon alcohol, adjusting pH to be alkalescent, decomposing, condensing, cooling, transferring into a separating funnel, standing, and separating out a lower-layer low-carbon alcohol phase; packing the powder phospholipid and the alcohol-phase resin, adsorbing alcoholysis mixed solution, washing the resin with low-carbon alcohol to remove impurities; and eluting the resin with pure water; and decolorizing with decolorizing agent, decomposing and condensing to obtain a finished product. The natural L-alpha-glycero-phosphatidylcholine preparation method has the advantages that process steps are simple, and industrial production requirements are met; resources are saved and cost is reduced; and the total yield of the finished product reaches 65.47-86.08%, the external standard content is more than 99%, and the optical purity is up to 99%.

Owner:SUZHOU FUSHILAI PHARMA CO LTD

Machining method of abnormal tubular product for lift control switch

InactiveCN102632102ASimple processMeet the requirements of industrial scale-up productionLubricationMachining process

The invention provides a machining method of an abnormal tubular product for a lift control switch and belongs to the technical field of machining of the abnormal tubular product. The machining process comprises the following steps of: sawing and cutting a steel circular rod to obtain a circular rod blank; conveying the circular rod blank into a heating furnace to be heated; perforating the circular rod blank on a perforating machine; hammering one end of a perforated tubular billet into a circular head; leading the tubular billet into an acid washing tank to be washed with an acid, and then washing the tubular billet with clean water, and washing by high-pressure water; leading the tubular billet which is subjected to the acid washing into a phosphorization tank to carry out phosphorization treatment and then washing with the clean water; leading a phosphorized tubular billet into a lubricating tank to carry out lubrication treatment; carrying out primary cold-drawing deformation and secondary cold-drawing deformation on the tubular billet on a cold-drawing machine; conveying a circular tube subjected to the cold drawing into a fuel gas type continuous annealing furnace to be continuously annealed; after changing the head of the annealed circular tube, carrying out cold-drawing abnormal deformation; and straightening an initial blank of the abnormal tube and cutting end heads at two ends to obtain the finished abnormal tubular product for the lift control switch. The machining method of the abnormal tubular product for the lift control switch has the advantages of simple process flow, capability of meeting the requirements of industrial amplification production, light weight and ideal material-saving effect.

Owner:CHANGSHUSMLESS STEEL TUBE

Hemostasis bandaid and preparation method thereof

InactiveCN103169570AGood anti-adhesionWith hemostasisTourniquetsWoven fabricsNonwoven fabricSURGICAL DRESSINGS

The invention provides a hemostasis bandaid and a preparation method of the hemostasis bandaid, and belongs to the field of surgical dressing. The hemostasis bandaid comprises a bandaid body and a wound treating pad. The wound treating pad is combined on one side surface of one end of the length direction of the bandaid body, and a transition distance is reserved between the wound treating pad and the end portion of the end with the wound treating pad. The hemostasis bandaid is characterized in that the hemostasis bandaid is formed by alginic acid fiber non-woven fabrics, an anti-adhesion thin film and a polyurethane breathable thin film, the anti-adhesion thin film is combined on one side, facing the wound of a patient, of the alginic acid fiber non-woven fabrics in a using state. The polyurethane breathable thin film is combined on the side, facing the bandaid body, of the alginic acid fiber non-woven fabrics, and the bandaid body is medical absorbent gauze. The hemostasis bandaid not only has good effects of liquid imbibition and seepage resistance, but also has excellent effects of hemostasis, antibiosis, healing promotion and pain relieving to the wound, can avoid blindness, avoid waste and reduce treatment cost of the patient, cannot cause adhesion to the wound, and can meet requirements of expanding production of industrialization.

Owner:SUZHOU EMY MEDICAL SUPPLIES

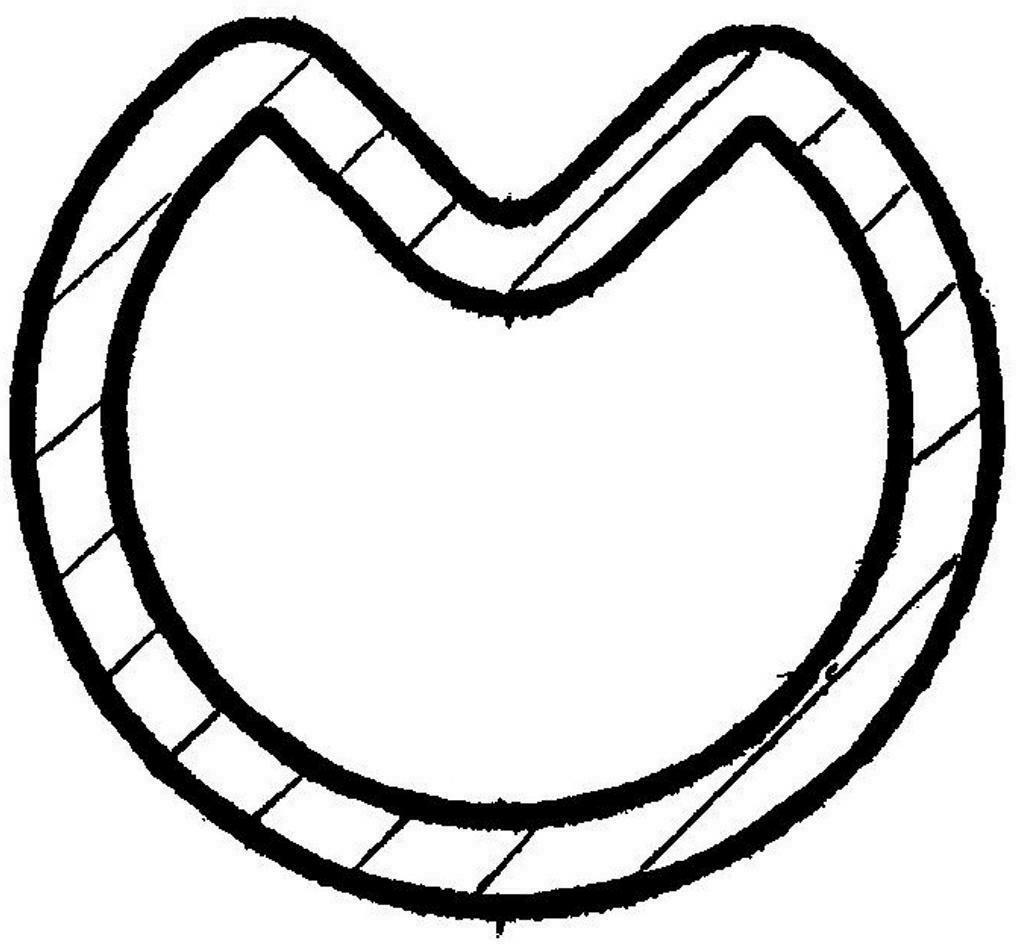

Ceramic polyolefin cable material and preparation method thereof

InactiveCN104558806AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramic polyolefin cable material and a preparation method thereof, and belongs to the technical field of a wire / cable material. The ceramic polyolefin cable material consists of the following raw material components in parts by weight: 100 parts of an ethylene-alpha-olefine copolymer, 150-300 parts of ceramic powder A, 20-100 parts of ceramic powder B, 5-20 parts of a lubricant and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefine copolymer is a mixture of ethylene and any one or more of alpha-propylene, alpha-butylene, alpha-hexylene and alpha-octylene copolymers according to any proportions by weight; the ceramic powder A is any one or any combinations of lamellar inorganic powder, fibrous inorganic powder and acicular inorganic powder; the ceramic powder B is at least one of borax, ammonium borate, zinc borate, boron frit, low-melting-point phosphate glass powder, low-melting-point borate glass powder and low-melting-point silicate glass powder; and the antioxidant is at least one of 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Connecting box for solar photovoltaic module

InactiveCN102856409AMeet application requirementsMeet the requirements of industrial scale-up productionSemiconductor/solid-state device detailsSolid-state devicesSolar cellHeat sink

The invention discloses a connecting box for a solar photovoltaic module, and belongs to the technical field of solar cell modules. The connecting box comprises a box body, a protecting mechanism and a box cover, a suspended cavity is formed in the box body, the protecting mechanism is arranged in a protecting mechanism cavity of the box body, the box cover is used for fittingly covering the box body, and the protecting mechanism comprises a group of electric connecting plates, a group of bypass diodes, an upper radiating plate and a lower radiating plate. The connecting box is characterized in that the protecting mechanism further comprises a module support, the electric connecting plates are combined on the side of the module support facing the protecting mechanism cavity and arrayed along the length direction of the side of the module support at intervals, each bypass electrode in the group of bypass diodes in a module support cavity of the module support is connected with the corresponding two adjacent electric connecting plates, the upper radiating plate fittingly covers the side of the module support facing the box cover, the lower radiating plate fittingly covers the side of the module support facing the protecting mechanism cavity, and the module support cavity is sheltered by mutual matching of the upper radiating plate and the lower radiating plate. The connecting box for the solar photovoltaic module has the advantages that application requirements on the high-power bypass diodes are met, the connecting box is convenient to manufacture and quick in assembly, and requirements on industrial large-scale production can be met.

Owner:CHANGSHU TOP SOLAR MATERIAL

Multifunctional inherent-flame-retardant viscose blended yarn, fabric and yarn preparation method

InactiveCN105483890ALow fabric costCost-effectiveWoven fabricsYarnTemperature resistanceElectric arc

The invention provides multifunctional inherent-flame-retardant viscose blended yarn, fabric and a yarn preparation method. The viscose blended yarn comprises 50wt%-80wt% of flame-retardant viscose fibers, 20wt%-50wt% of aromatic polyamide fibers and 0-5wt% of antistatic fibers. The multifunctional inherent-flame-retardant viscose blended yarn has the multiple advantages of electric arc resistance, high temperature resistance, heat insulation, comfort, breathability and the like; the fabric is low in cost, high in cost performance and excellent in protective performance and has the performance of high fiber strength, tearing resistance, excellent wear resistance, good flame retardance, high-temperature resistance, heat insulation and the like. Therefore, the industrial enlarged production requirement is sufficiently met, and personal safety of a worker can be sufficiently guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

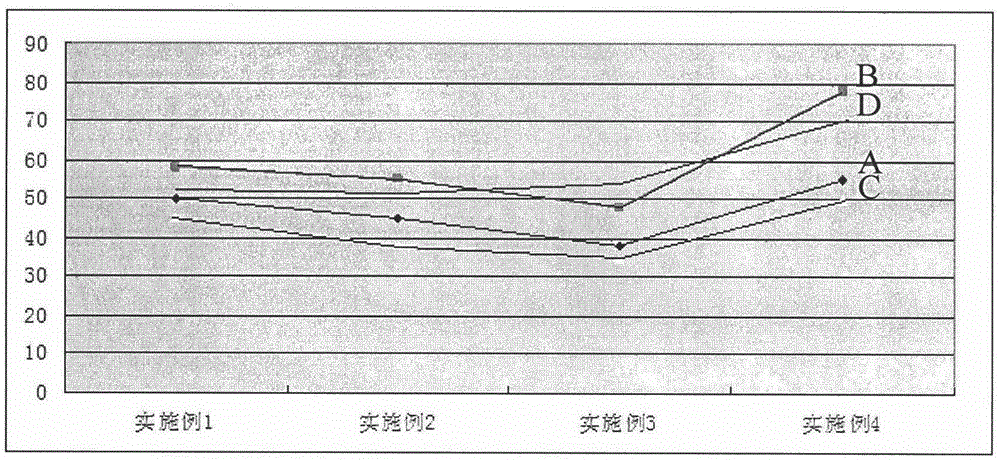

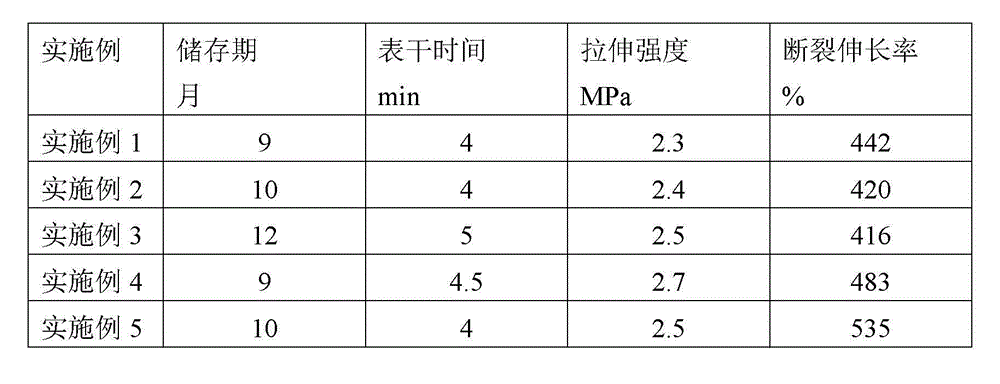

Dealcoholization type cured organosilicone sealant and preparation method thereof

InactiveCN103146339AImprove adaptabilityImprove curing speedAdhesivesAging resistanceUltimate tensile strength

The invention discloses a dealcoholization type cured organosilicone sealant and a preparation method thereof and belongs to the technical field of high polymer materials. The dealcoholization type cured organosilicone sealant consists of the following raw materials in parts by weight: 100 parts of 107 silicon oil, 10-200 parts of reinforcement filler, 0.1-1 part of silane coupling agent, 0.01-0.5 part of catalyst and 5-7 parts of cross-linking agent. The dealcoholization type cured organosilicone sealant has the advantages that sizing depth is 5mm, and the sealant can be cured within 24 hours, so that the sealant has excellent curing speed; because the tensile strength and the elongation at break can respectively reach 2MPa and 200-500 percent, the sealant has excellent mechanical properties; because the sealant is not yellowed within 1000 hours at the temperature of 150 DEG C and is not cracked, the sealant has outstanding ageing resistance; because the storage time can be 9-12 months long, the sealant has ideal stability; the sealant can be suitable for sealing a solar module frame; and because the provided preparation method is simple in process steps and the process requirements are not strict, the industrial large-scale production requirements can be met.

Owner:西卡(江苏)工业材料有限公司

Method for preparing DTY (drawn textured yarn) polyester super-bright flat yarn by POY (polyester pre-oriented yarn) polyester yarn

InactiveCN102534898AThe process steps are simpleSoft touchTextiles and paperPolyesterPolymer chemistry

The invention discloses a method for preparing a DTY (drawn textured yarn) polyester super-bright flat yarn by a POY (polyester pre-oriented yarn) polyester yarn, belonging to the field of knitting / spinning raw material processing technologies. According to the method, the POY yarn is rolled after passing through a first roller, an upper heating box, a cooling plate, a false twister, a second roller, a lower heating box and a third roller, and then the DTY polyester super-bright flat yarn is obtained, wherenin the linear velocity of the first roller is 410-450m / min; the linear velocity of the second roller is 690-720m / min; a temperature of the upper heating box is 193-196 DEG C; and a temperature of the lower heating box is 135-145 DEG C. The method has the advantages that the processing steps are simple and the industrial large-scale production can be satisfied; and as the linear velocities of the first and second rollers as well as the temperatures of the upper and lower heating boxes are selected reasonably, fleece-faced fabrics processed from the obtained DTY polyester super-bright flat yarn has smooth and soft handfeel as well as fluffy and vivid texture, which is markedly superior to that of the prior art.

Owner:江苏东方阳光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com