Permanent flame-retardant multifunctional fabric and making method thereof

A multi-functional, fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the secondary hazards of burns to the wearer, have no flame retardant effect, lose environmental protection and safety, and reduce equipment and manpower investment , Excellent antistatic performance, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

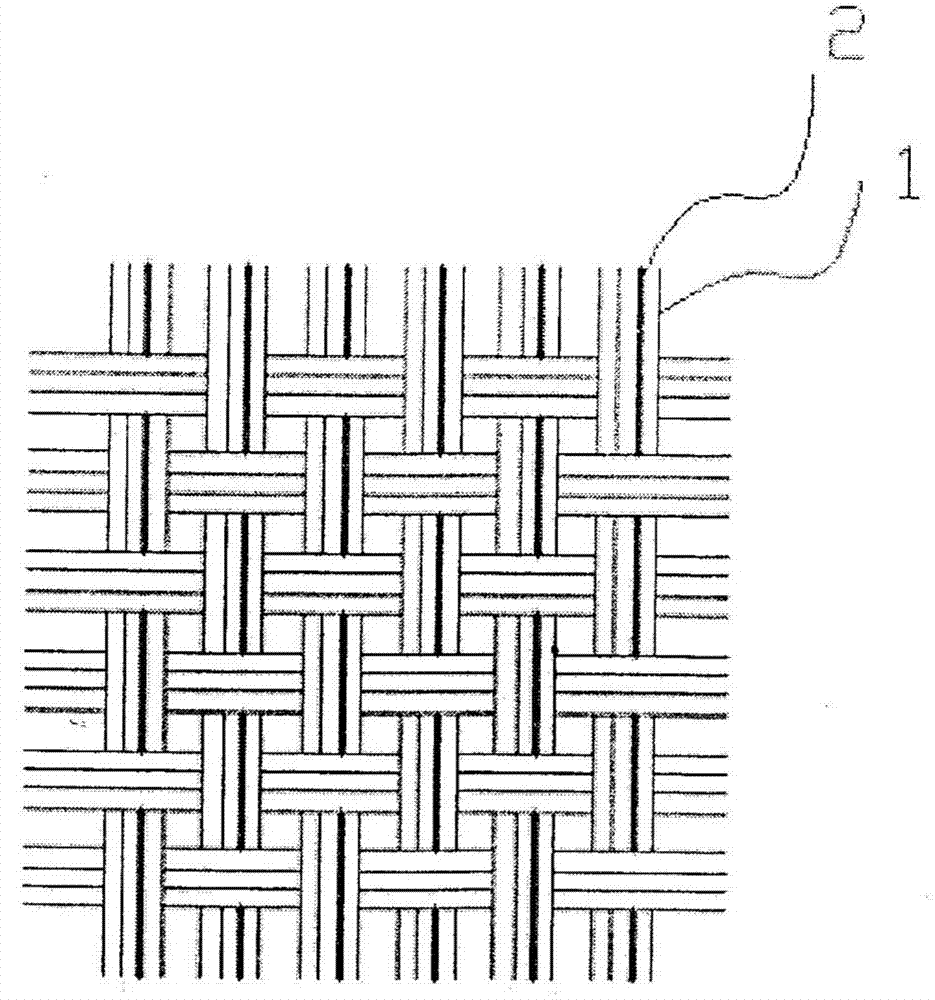

[0027] figure 2 The weave structure of the permanent flame retardant multifunctional fabric shown is given by figure 1 shown in figure 2 In , reference numeral 1 denotes warp yarns and weft yarns, and reference numeral 2 denotes antistatic filaments woven into warp yarns.

[0028] above by figure 2 The preparation method of the shown permanent flame-retardant multifunctional fabric comprises the following steps:

[0029] A) Raw material selection, select high temperature resistant intrinsic flame retardant fibers mixed with natural fibers as raw materials for warp and weft, and select antistatic filaments for weaving into warp in a spaced state, in this embodiment , the aforesaid high-temperature-resistant essential flame-retardant fiber is a synthetic organic fiber, the synthetic organic fiber is aramid 1313, and the mass percentage of aramid 1313 in the fabric is 40%, the aforesaid natural fiber is cotton fiber, and the cotton fiber The percentage by mass in the fabri...

Embodiment 2

[0033] A) Raw material selection, select high temperature resistant intrinsic flame retardant fiber mixed with regenerated fiber as the raw material of warp and weft, and select antistatic filaments for weaving into warp at intervals, in this embodiment , the above-mentioned high temperature resistant essential flame retardant fiber is a synthetic organic fiber, the synthetic organic fiber is aramid 1313 and aramid 1414, the mass percentage of aramid 1313 in the fabric is 70%, and the mass percentage of aramid 1414 in the fabric is The mass percentage is 7%, the regenerated fiber is a mixed fiber of viscose fiber and bamboo fiber, and the mass percentage in the fabric is 10%, and the antistatic filament is a metal substance added in the spinning process ( Metallic substances such as copper sulfide) polyester filaments; the mass percentage of the polyester filaments in the fabric is 3%;

[0034] B) Spinning, first make a clear cotton blended sliver from the blended fibers of ar...

Embodiment 3

[0037] A) Raw material selection, select high temperature resistant intrinsic flame retardant fibers mixed with natural fibers as raw materials for warp and weft, and select antistatic filaments for weaving into warp in a spaced state, in this embodiment , the above-mentioned high temperature resistant essential flame retardant fiber is a synthetic organic fiber, the synthetic organic fiber is aramid 1313, polyimide and polyphenylene sulfide, wherein: aramid 1313, polyimide and polyphenylene sulfide are in The mass percentages in the fabric are 40%, 5% and 10% respectively, the natural fiber is wool fiber, the mass percentage of wool fiber in the fabric is 44%, and the antistatic filament is added in the spinning process. The acrylic filament of carbon black; The mass percentage that this acrylic filament accounts for in the fabric is 1%;

[0038] B) Spinning, first make the mixed fiber of aramid 1313 fiber, polyimide fiber, polyphenylene sulfide fiber and wool fiber obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com