Patents

Literature

97results about How to "Efficient Flame Retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

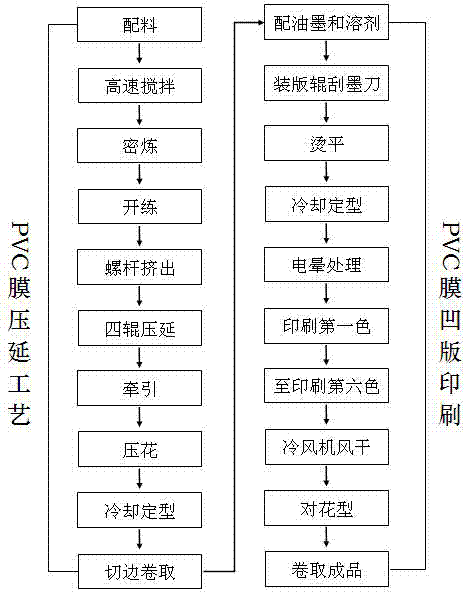

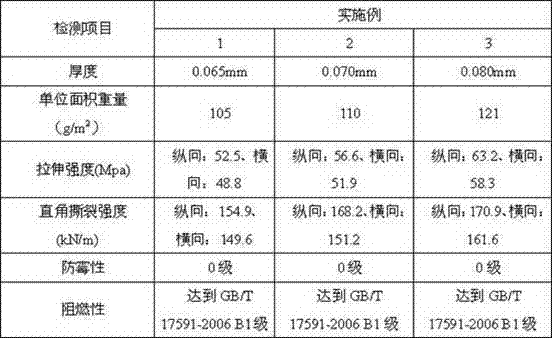

Semi-rigid PVC (polyvinyl chloride) decorative membrane

The invention relates to a semi-rigid PVC (polyvinyl chloride) decorative membrane. The semi-rigid PVC decorative membrane comprises the following main raw materials in parts by weight: 100 parts of PVC resin powder, 18-23 parts of plasticizer, 3-5 parts of stabilizer, 25-35 parts of calcium carbonate, 4-6 parts of flame retardant, 6-9 parts of titanium white, 2-4 parts of soybean oil and 0.1-0.3 part of mold preventive; and the semi-rigid PVC decorative membrane is prepared through a calendering stage and an intaglio printing stage. The product provided by the invention is thin and semi-rigid, can not bubble in case of being laminated with glass and other materials, and can prevent broken glass from splashing and falling when the glass is broken; the addition of the flame retardant and the mold preventive endows the product with high-efficiency flame-retardant and mold-resistant properties, and the flame-retardant property and the mold-resistant property can be respectively up to B1 level and 0 level; and the product has long color retention time and long service life, and can soften bright light, partition space, enhance privacy and create a mild atmosphere.

Owner:ZHEJIANG BOTAI PLASTIC

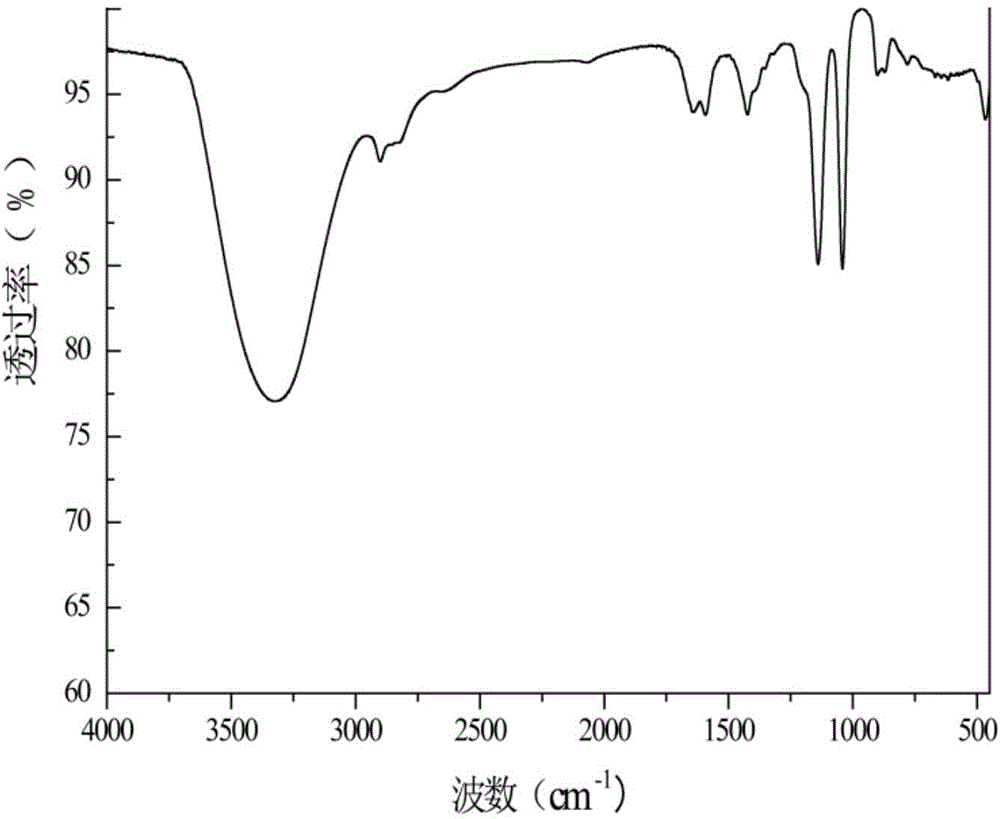

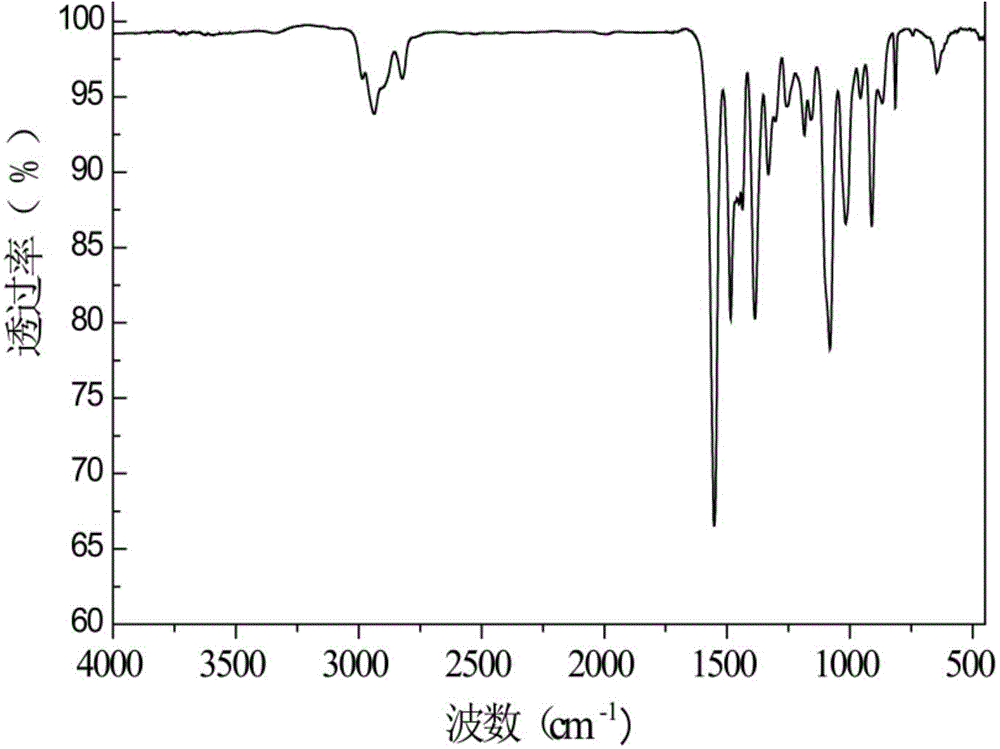

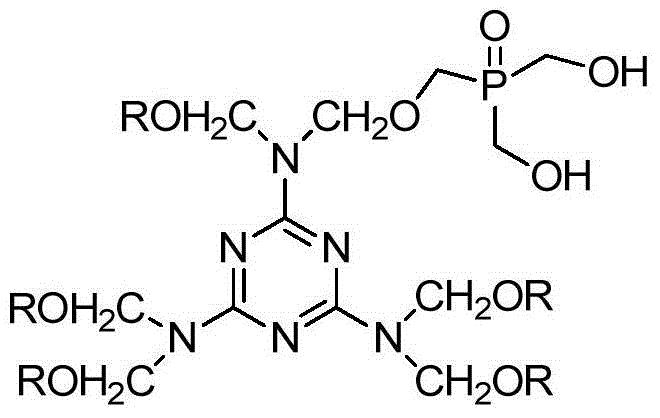

Phosphorus-nitrogen synergistic flame-retardant polyalcohol and preparation method thereof

InactiveCN103980313AEfficient Flame RetardancyAvoid the weakness of easy hydrolysisGroup 5/15 element organic compoundsDistillationPhosphine oxide

The invention discloses phosphorus-nitrogen synergistic flame-retardant polyalcohol and a preparation method thereof, relating to the synthesis of flame-retardant polyalcohol. The preparation method of the phosphorus-nitrogen synergistic flame-retardant polyalcohol comprises the following steps: 1) with quaternary phosphorus salt as a raw material, adding alkali and stirring for reacting, filtering and separating the salt generated by reacting, then oxidizing with a hydrogen peroxide solution, and performing reduced-pressure distillation for removing moisture to obtain tris(hydroxymethyl)phosphine oxide; 2) performing an ether exchange reaction between hexakis(methoxymethyl)melamine and the tris(hydroxymethyl)phosphine oxide obtained in the step 1) at 50-100 DEG C in the presence of an acid catalyst, and reducing pressure for removing small-molecular methanol to obtain the phosphorus-nitrogen synergistic flame-retardant polyalcohol. The prepared phosphorus-nitrogen synergistic flame-retardant polyalcohol is formed by connecting phosphorus elements through phosphorus-carbon bonds, and the weakness that the phosphorus-carbon bonds (phosphorus-ester bonds) are hydrolyzed easily is avoided, thus the phosphorus-nitrogen synergistic flame-retardant polyalcohol has the characteristic of relatively high hydrolysis resistance.

Owner:XIAMEN UNIV

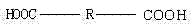

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Metallic ion modified polyphosphoric acid melamine salt and its preparation method

InactiveCN1733778AImprove thermal stabilityNo pollution in the processGroup 5/15 element organic compoundsMelamine phosphatePhosphate

The polyphosphoric cyanuric salt modified by metal ion comprises, oxygen 21~25wt%, carbon 15~18%, hydrogen 1~3%, phosphor 13~16%, nitrogen 37~42%, and metal ion 0.2~6%. The opposite preparation method comprises: dissolving or dispersing the metal hydroxides, oxide or carbonate into phosphoric acid solution with concentration as 80~90%; adding water, phosphoric acid solution with dihydric phosphate and melamine into kettle to react for two hours; heating the modified polyphosphoric cyanuric salt to 260~330Deg and taking polymerisation for 8~12h. The product has better thermallysis stability and flame retardant property to nylon. This method is simple, and has on-pollutant andhigh yield rate.

Owner:NORTHEAST FORESTRY UNIVERSITY

Halogen-free flame-retardant high-heat-resistance antibacterial polypropylene composite material and preparation method thereof

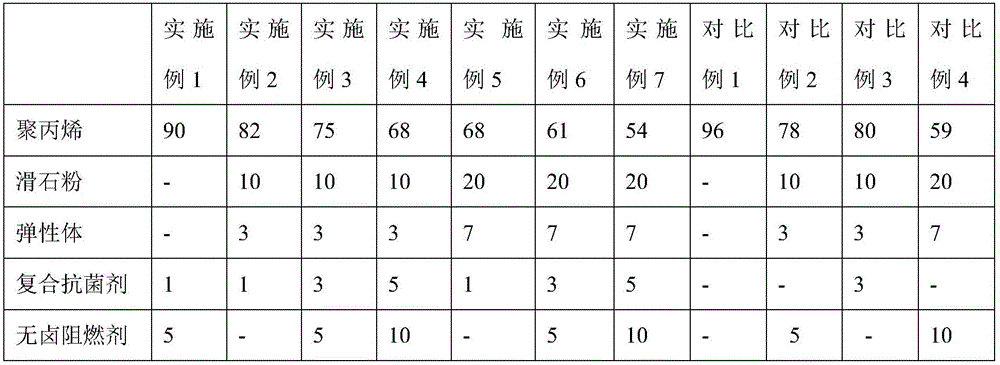

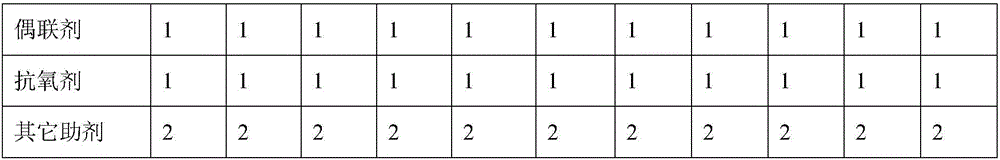

The invention discloses a halogen-free flame-retardant high-heat-resistance antibacterial polypropylene composite material and a preparation method thereof. The halogen-free flame-retardant high-heat-resistance antibacterial polypropylene composite material comprises the following raw materials in parts by weight: 54-96 parts of polypropylene, 0-20 parts of talcum powder, 0-7 parts of elastomer, 0-5 parts of composite antibacterial agent, 0-10 parts of halogen-free flame retardant, 0-2 parts of coupling agent, 0.1-2 parts of antioxidant and 0-2 parts of other aids. The novel organic-inorganic composite antibacterial agent is added on the basis of the formula of the polypropylene composite material; and the combination of the guanidine salt polymer and titanium dioxide can well perform the synergistic functions to enhance the antibacterial property and heat resistance of the polypropylene composite material. The novel silicon halogen-free flame retardant phosphorus silsesquioxane is also introduced into the polypropylene composite material system; and the added novel silicon halogen-free flame retardant phosphorus silsesquioxane has the advantages of low consumption and high flame-retardant efficiency, and can effectively enhance the flame retardancy of the composite material system.

Owner:SHANGHAI PRET COMPOSITES +4

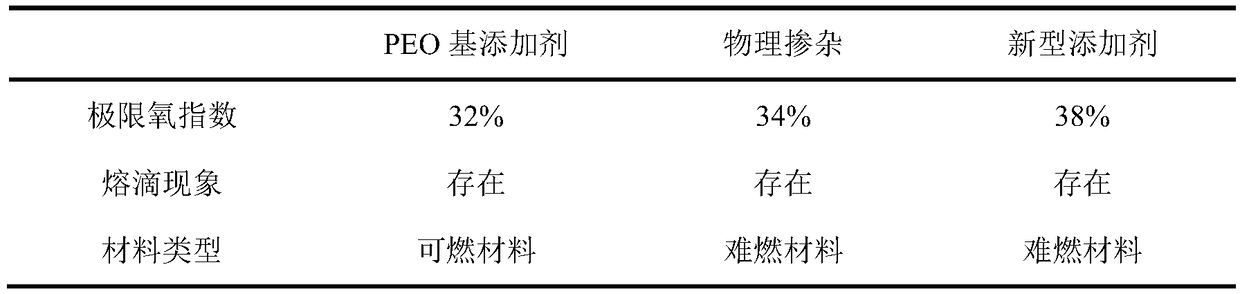

Preparation method of structural flame-retardant polyurethane soft foam

InactiveCN105199069AReduce manufacturing costHas structural flame retardant propertiesPolymer sciencePtru catalyst

The invention provides a preparation method of structural flame-retardant polyurethane soft foam, which comprises the following steps: reacting phenol and formaldehyde to obtain a liquid resol, reacting with melamine to obtain a hydroxymethylated melamine-phenolic resin, initiating the ring-opening polymerization between the hydroxymethylated melamine-phenolic resin and epoxy chloropropane by using a co-initiator to obtain a nitrogenous structural flame-retardant polyether glycol, mixing the nitrogenous structural flame-retardant polyether glycol and other polyether glycols to obtain a base resin, adding a catalyst, a foam stabilizer, a flame retardant and a foaming agent to form a component A, quickly mixing with a component B isocyanate uniformly, pouring into a mold, and foaming to obtain the structural flame-retardant polyurethane soft foam. The limited oxygen index of the obtained foam is 28.1-29.3%, the maximum horizontal combustion velocity is not greater than 70mm / minute, the horizontal combustion time is 75-85 seconds, the average combustion length is less than 50mm, and the apparent density is 35.2-40.3 kg / m<3>.

Owner:SHANGHAI INST OF TECH

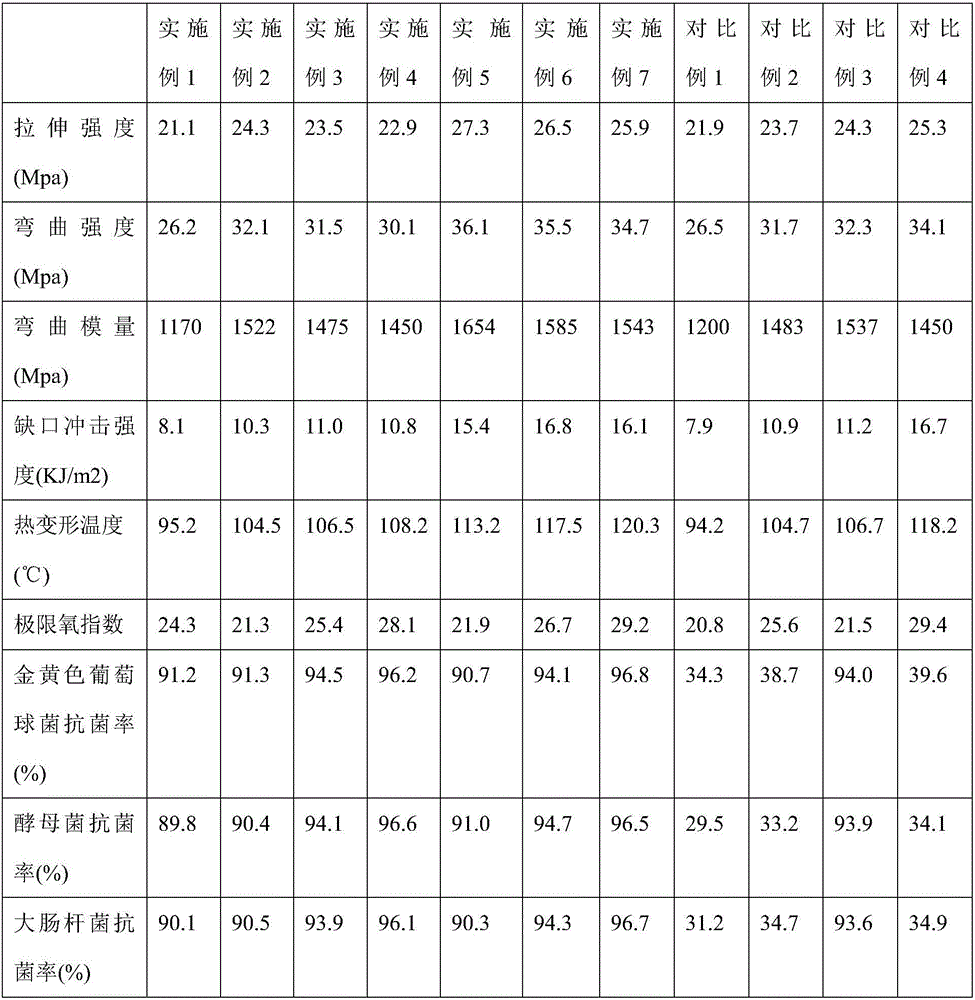

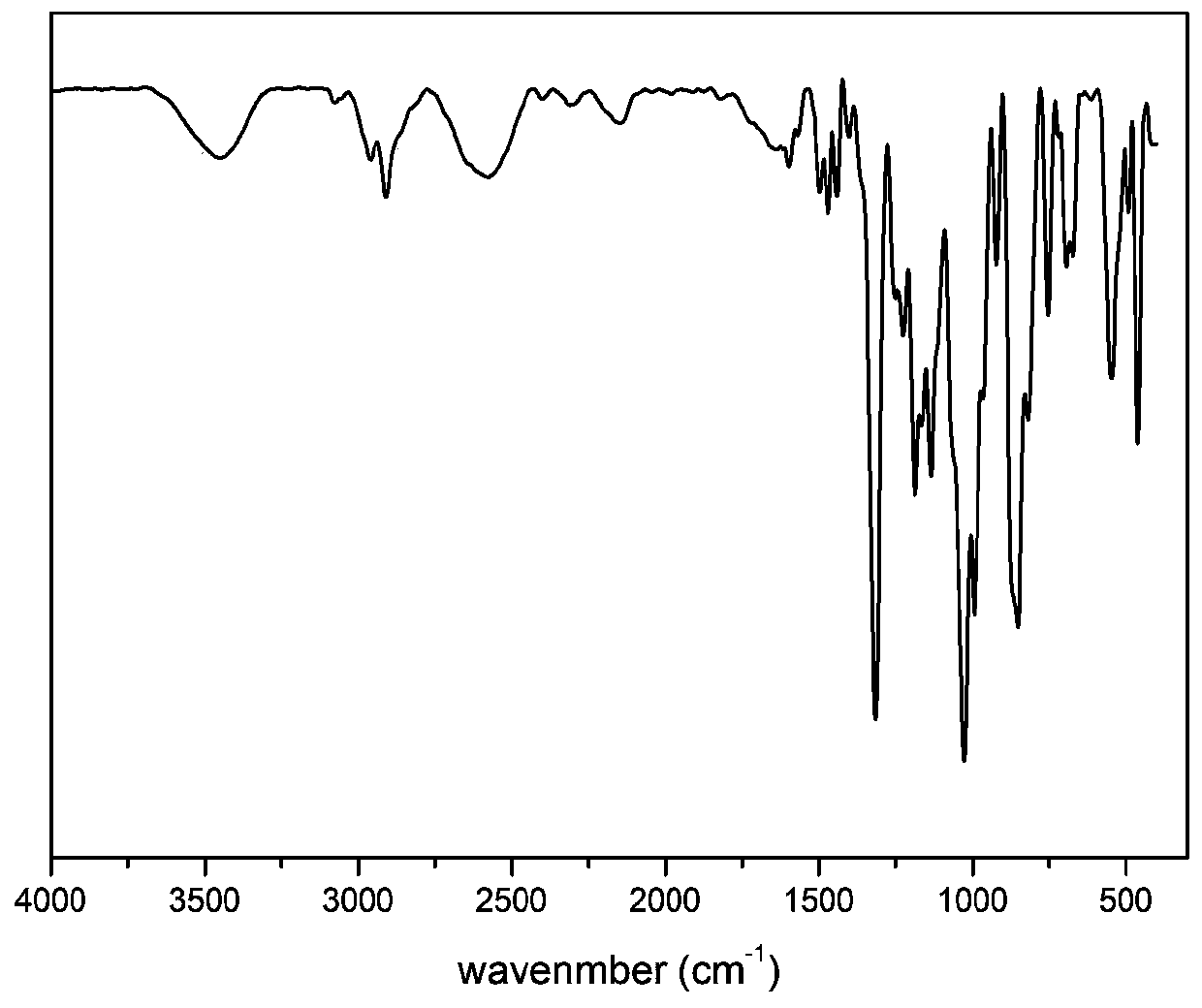

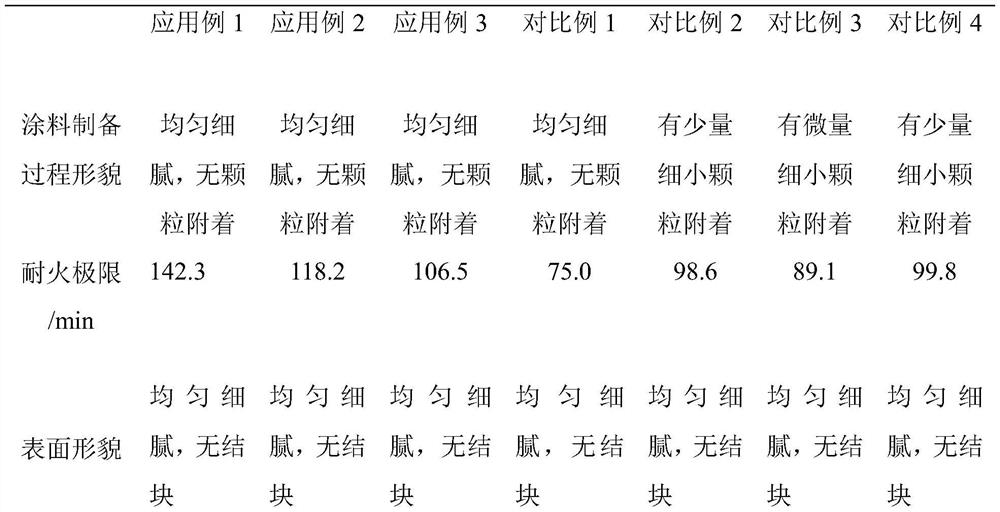

Water-based intumescent flame-retardant paint based on modified boron nitride and preparation method thereof

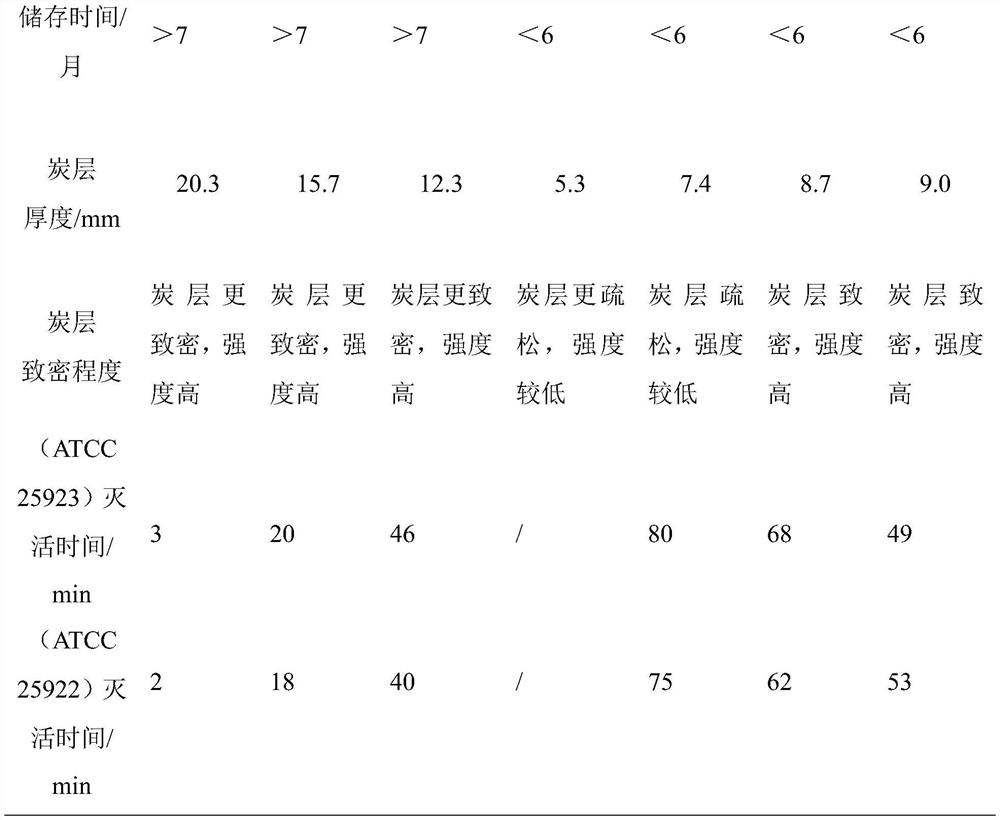

InactiveCN109401456ASmall sizeImprove flame retardant performanceFireproof paintsCarbon layerWater based

The invention relates to water-based intumescent flame-retardant paint based on modified boron nitride and a preparation method thereof. Firstly, by means of isopropanol liquid-phase mechanical ball milling and N,N-dimethylformamide assistant ultrasound, hexagonal boron nitride is exfoliated, and then the exfoliated boron nitride, water-based styrene-acrylic core-shell emulsion, ammonium polyphosphate, pentaerythritol, melamine, hydroxyethyl cellulose, a defoaming agent, a dispersion agent and water are prepared into the water-based intumescent flame-retardant paint according to a certain ratio. An intumescent carbon layer formed by the flame-retardant paint at high temperatures is compact and firm, the water-based intumescent flame-retardant paint based on the modified boron nitride has efficient flame-retardant performance, the preparation method thereof is simple, the film-forming performance is excellent, and water-based environment-friendliness is achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Novel halogen-free flame retardant composite material and preparation method thereof

The invention provides a novel halogen-free flame retardant composite material. The novel halogen-free flame retardant composite material comprises the following components in percentage by weight: 28% to 64.5% of polypropylene, 10% to 20% of thermoplastic polyurethane elastomer, 5% to 10% of bulking agent, 15% to 25% of halogen-free flame retardant agent, 5% to 15% of flame retardant synergist, and 0.5% to 2% of coupling agent, wherein the total percentage of the components by weight is 100%. The invention also aims at providing a preparation method of the novel halogen-free flame retardant composite material. The novel halogen-free flame retardant composite material has the advantages that the preparation technology is simple, the mechanical property is good, the high temperature-resistant property and flame-retardant property are realized, the efficiency is high, the clean and environment-friendly effects are realized, and the novel halogen-free flame retardant composite material can be widely applied to the fields of automobiles, household parts and accessories, wires and cables, and the like.

Owner:广州敬信高聚物科技有限公司

Thermoplastic resin composition with excellent flame retardancy and impact resistance

The invention discloses a thermoplastic resin compound with outstanding flame- proof and anti- vibration property. The component proportions are as follows: panlite 60- 90, polyacryl-nitrile- butadiene- polystyrene 10- 40, additional compatiable agent 1- 10, additional phosphate compound 5- 15, additional polyorganosilicon oxidant 1- 10, additional metal oxidant or inorganic acidic metal salt 1- 5. The product is characterized by environmental protection, high- efficiency flame proof and good mechanical property.

Owner:浙江荣泰塑胶有限公司 +1

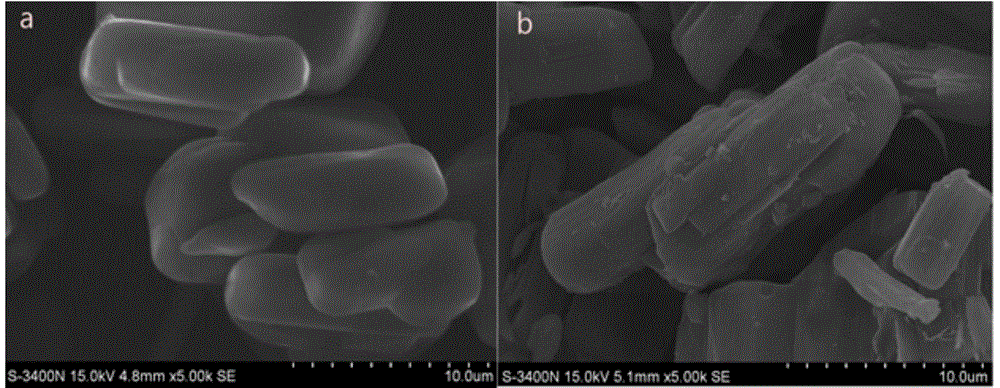

Flame retardant having reactivity and adopting core-shell structure as well as preparation method and application of flame retardant

ActiveCN104448394AGood compatibilityImprove the disadvantage of being easily soluble in waterPolyurethane elastomerPolymer science

The invention belongs to the field of materials, and discloses a flame retardant having reactivity and adopting a core-shell structure as well as a preparation method and an application of the flame retardant. The flame retardant takes APP (ammonium polyphosphate) as a capsule core and takes a methyl methacrylate and hydroxyethyl acrylate copolymer as a capsule material. The preparation method comprises the following steps: APP particles are added to a solvent at the room temperature, stirred and heated to 50-60 DEG C; a polymer monomer is added dropwise while stirred, the mixture is stirred for 10-20 min at the temperature of 50-60 DEG C and then heated to 70 DEG C, and a benzoyl peroxide solution is added dropwise; the mixture is heated to 75-85 DEG C, subjected to heat preservation and stirred for reacting for 4-8 h, and the flame retardant having reactivity and adopting the core-shell structure is obtained after extraction filtration, washing and drying. The surface of the flame retardant contains active reaction groups (hydroxyl) which can react with polymer such as rigid polyurethane foam, flexible polyurethane foam, polyurethane elastomer, polyurea and the like, so that the compatibility of the flame retardant in a substrate is improved, and the flame retardant is insoluble in water and has efficient flame retardancy.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Durable biomass polyphenol water-based flame retardant paint and preparation method and applications thereof

InactiveCN110467854AWide variety of sourcesLow priceFireproof paintsHeat resistant fibresWater basedPolyphenol

The invention provides durable biomass polyphenol water-based flame retardant paint and a preparation method and applications thereof. The water-based flame retardant paint is mainly composed of biomass polyphenol or a combination of the biomass polyphenol and a salt through a coordination bond or / and adsorption. The preparation method is to mix the biomass polyphenol with a certain amount of water or add a binder on the basis, or to mix the biomass polyphenol with a certain amount of water and drop a salt solution or add a binder on the basis. The preparation method of the biomass polyphenolwater-based flame retardant paint is low in energy consumption, environmentally friendly and safe. The prepared biomass polyphenol water-based flame retardant paint has the advantages of durability, high flame retardant efficiency, strong adhesion, environmental protection and safety, can be directly used as water-based flame retardant paint, and can also be used as surface treatment and additiveflame retardant agents for different polymer materials.

Owner:SICHUAN UNIV

Halogen-free compound flame retardant for glass fiber reinforced PBT (Polybutylene Terephthalate) material and preparation method thereof

The invention discloses a halogen-free compound flame retardant for a glass fiber reinforced PBT (Polybutylene Terephthalate) material and a preparation method thereof. The halogen-free compound flame retardant is prepared from the following components in percentage by weight: 20-80 percent of phenyl aluminum phenylphosphinate, 10-60 percent of melamine cyanurate, 1-20 percent of zinc borate, 1-10 percent of triphenyl phosphate and 1-5 percent of pentaerythrityl tetraisostearate. The halogen-free compound flame retardant provided by the invention has high-efficiency flame-retardant performance, favorable processing performance, excellent mechanical performance and color stability and is applied to the glass fiber reinforced PBT material so that the glass fiber reinforced PBT material reaches a flame-retardant level of UL94V0 and can keep favorable mechanical performance and electric performance.

Owner:广东省石油化工研究院

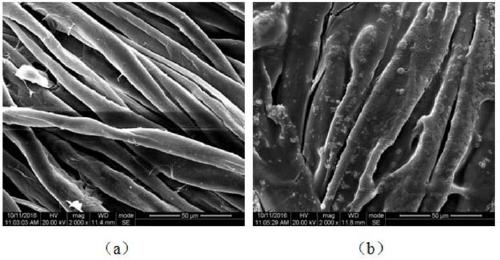

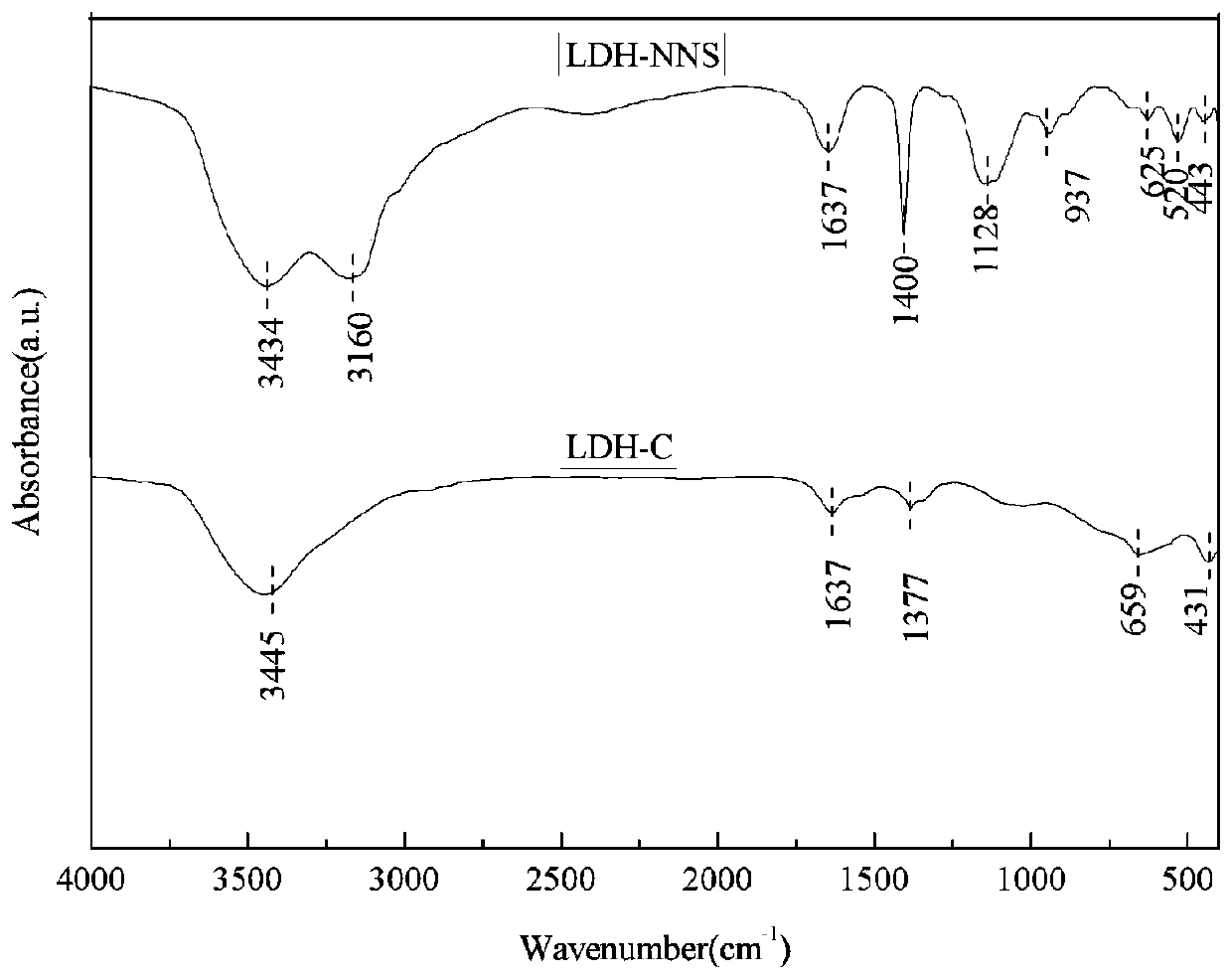

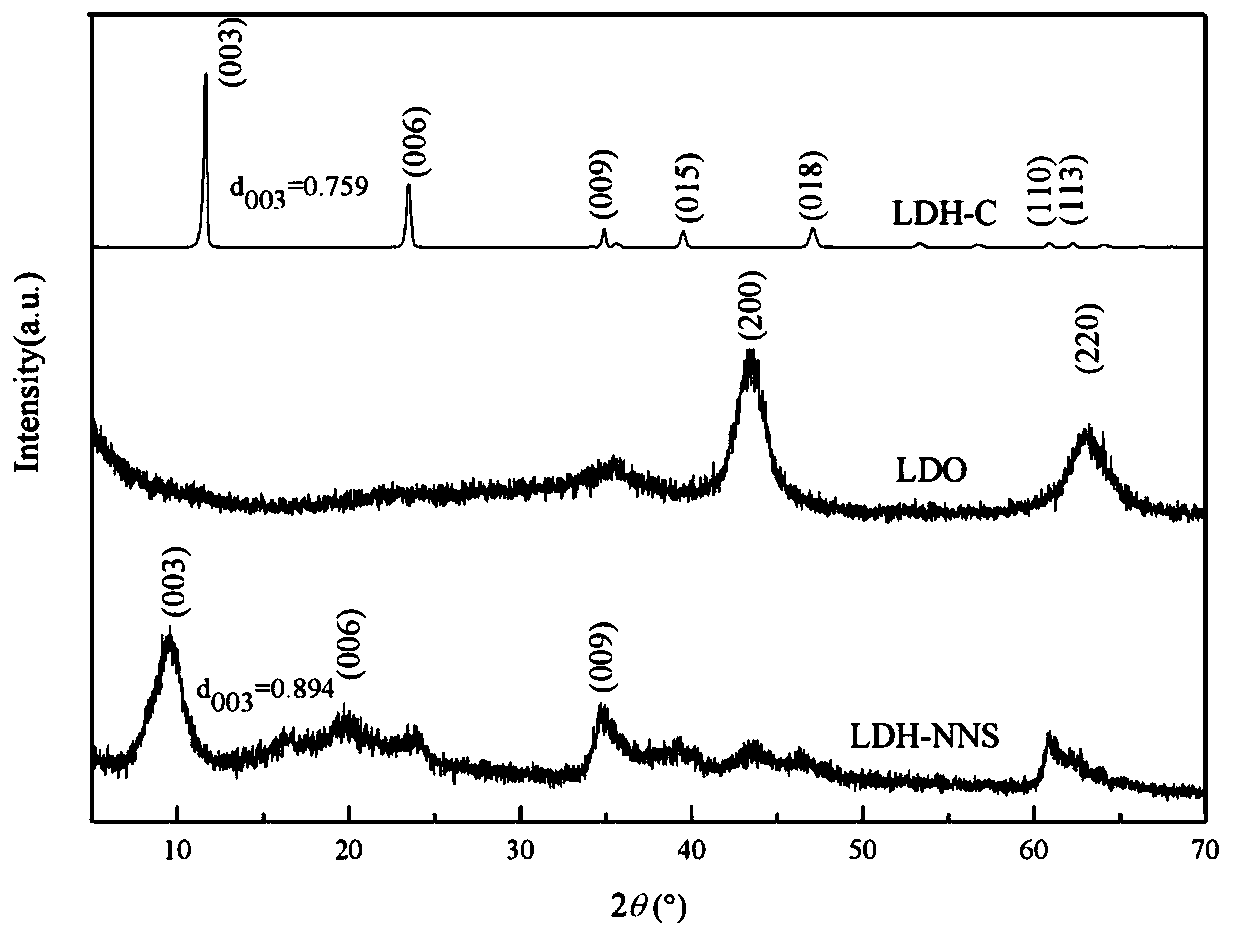

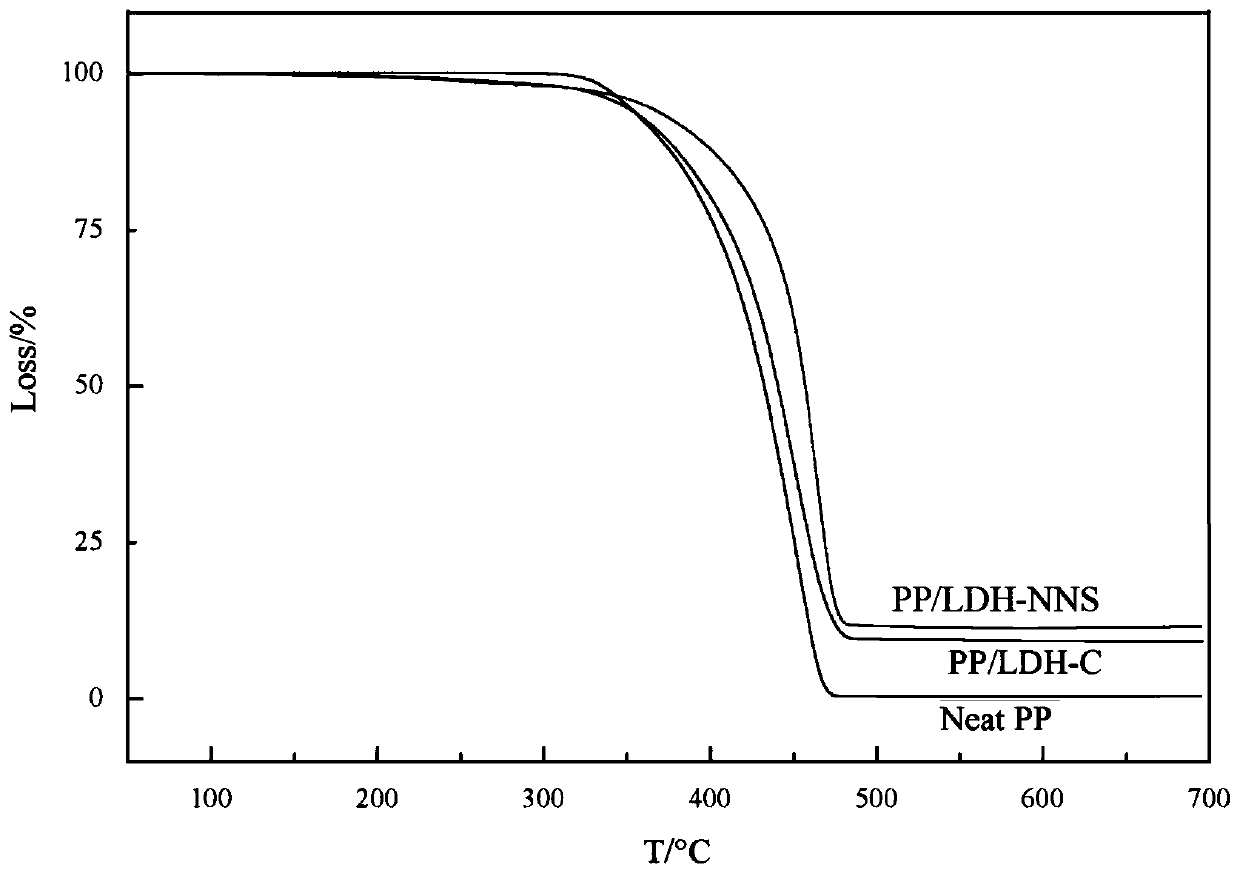

Synthesis of nitrogen and sulfur-containing synergistic flame retardant compound and preparation method of intercalated modified hydrotalcite thereof

ActiveCN110105298AEfficient Flame RetardancyEasy to manufactureOrganic chemistryPigment treatment with non-polymer organic compoundsPolyolefinPolymer science

The invention relates to synthesis of a nitrogen and sulfur-containing synergistic flame retardant compound and a preparation method of intercalated modified hydrotalcite thereof. By means of the "structure memory effect" of hydrotalcite, the compound is introduced into the interlayer of hydrotalcite, thus significantly improving the dispersion performance of a hydrotalcite-based flame retardant and enhancing flame retardance to a polymer matrix. Based on the flame-retardant mechanism and high-efficiency flame-retardant properties peculiar to nitrogen-sulfur compounds, the compound is introduced to the interlayer of hydrotalcite by self-assembly reconstruction to prepare a novel organic-inorganic hybrid flame retardant, thus enhancing the hydrophilic properties of the hydrotalcite surface,and also further enhancing the flame-retardant properties. The prepared nitrogen and sulfur-containing synergistic flame retardant compound intercalated hydrotalcite composite flame retardant can significantly improve the flame-retardant effect after filling in the polymer matrix, and has good application value in improving the flame retardance of polyolefins. The preparation of the nitrogen-sulfur synergistic flame retardant compound is simple and practicable, the reaction conditions are easy to control, and the flame retardant efficiency is high.

Owner:XIANGTAN UNIV

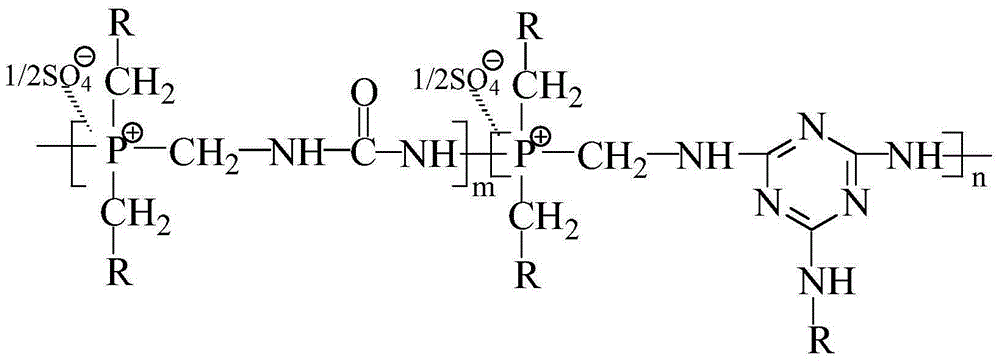

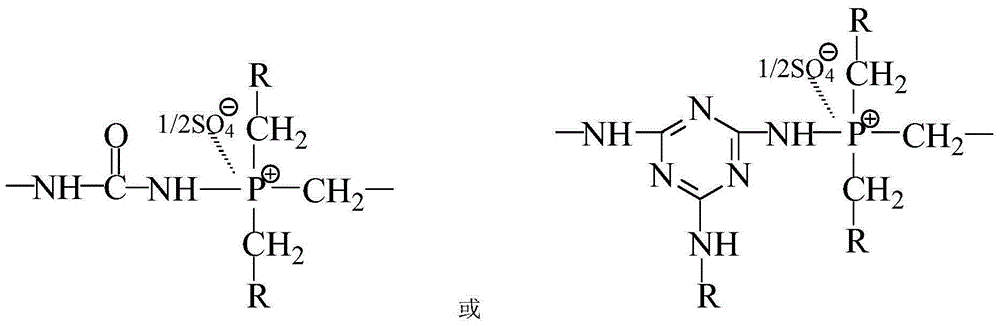

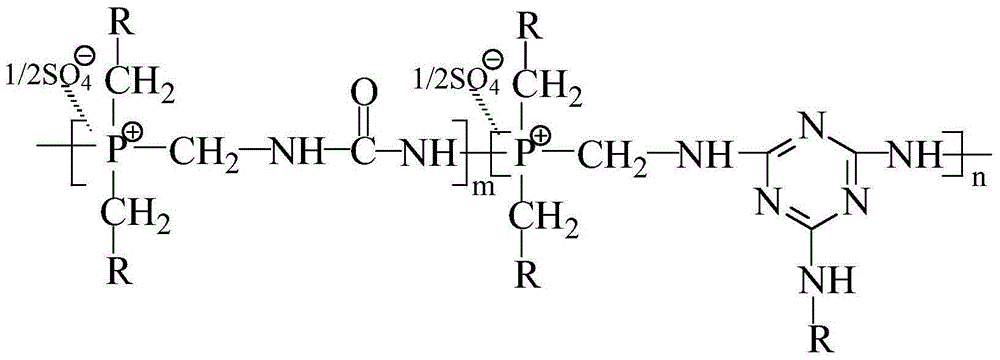

Cross-linked type insoluble halogen-free flame retardant and preparation method and application thereof

The invention discloses a cross-linked type insoluble halogen-free flame retardant and a preparation method and application thereof, and belongs to the technical field of flame retardants. The flame retardant is a cross-linked polymer formed when a methylol group of tetrakis hydroxymethyl phosphonium sulfate, difunctional amine compounds with amido groups and trifunctional melamine react under the effect of a catalyst hexamethylenetetramine, wherein the phosphorus content is larger than or equal to 10%, the nitrogen content is larger than or equal to 25%, the decomposition temperature is larger than or equal to 300 DEG C, solubility in water at the temperature of 25 DEG C is smaller than 0.01 g per 100 ml, the weight loss rate is smaller than 0.05 g per 100 ml after hot water at the temperature of 100 DEG C is boiled for 2 hours, and the flame retardant is not dissolved in conventional solvent such as ethyl alcohol, acetone, methylbenzene, petroleum ether and ethyl acetate at a temperature within the boiling point range. The flame retardant is used for superfine fiber synthetic leather and textile polyurethane coatings; the horizontal burning rate of the flame retardant is far lower than the flame retardance requirement of superfine fiber synthetic leather in the industry for the horizontal burning rate of smaller than 10 cm / min.

Owner:烟台蓝海博隆超纤新材料有限公司

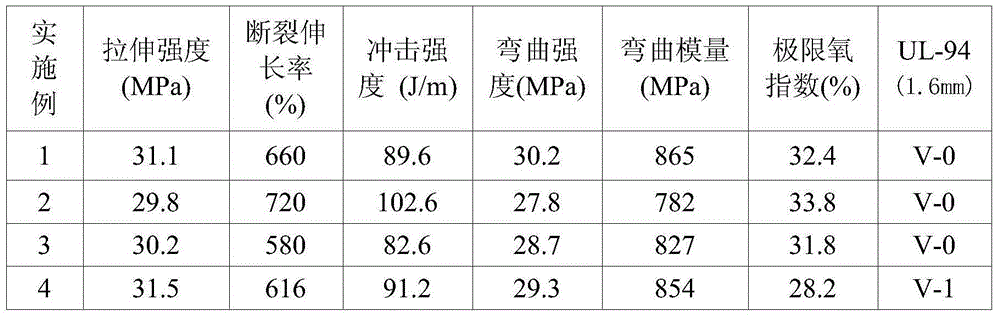

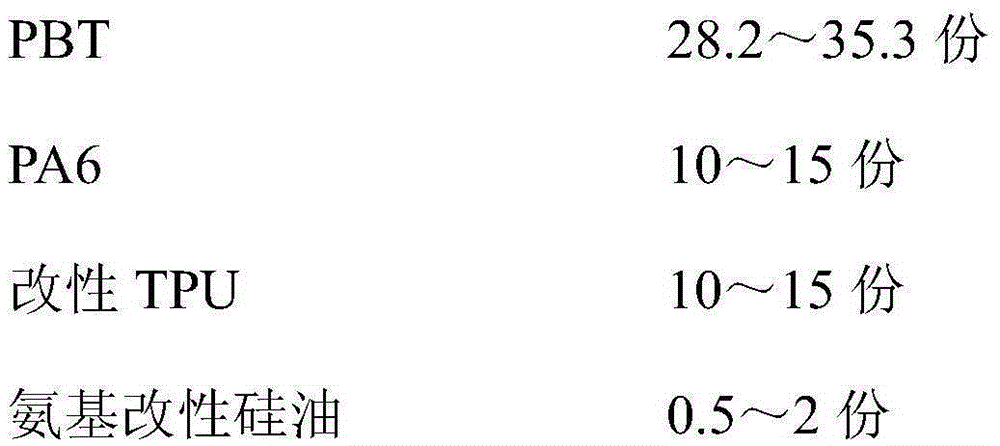

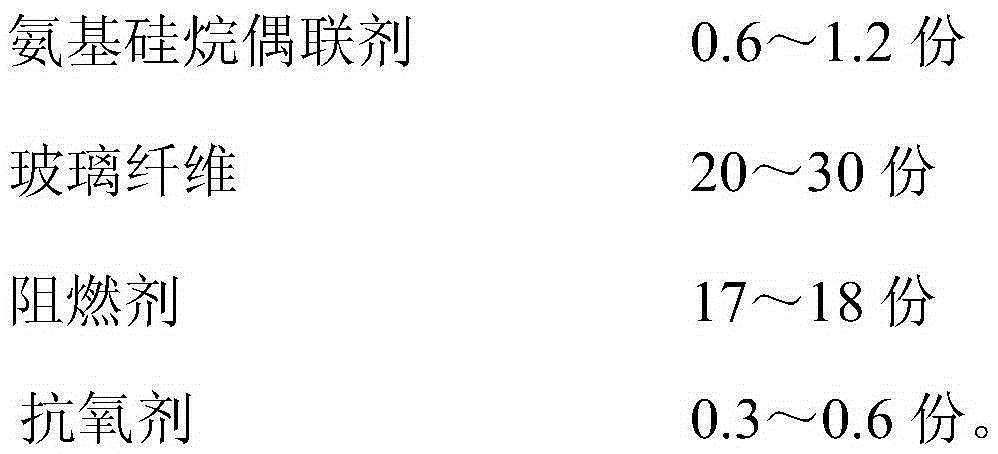

Reinforced flame-retardation PBT/PA6 composite material and preparation method thereof

A disclosed reinforced flame-retardation PBT / PA6 composite material comprises the following compositions in parts by mass: 28.2-35.3 parts by mass of PBT, 10-15 parts by mass of PA6 , 10-15 parts by mass of modified TPU, 0.5-2 parts by mass of amino-modified silicone oil, 0.6-1.2 parts by mass of an amino silane coupling agent, 20-30 parts by mass of glass fiber, 17-18 parts by mass of a composite fire retardant, and 0.3-0.6 parts by mass of an anti-oxidant. The invention also discloses a preparation method for the above reinforced flame-retardation PBT / PA6 composite material. According to the technical scheme, the compatibility of PBT with PA6, and PBT and PA6 with glass fiber is improved, and the composite material with relatively high mechanical properties and good flame retardation performance and processing property is obtained, is applied to automobile electrical appliance connectors, and is adaptable to relatively severer driving environment.

Owner:SOUTH CHINA UNIV OF TECH

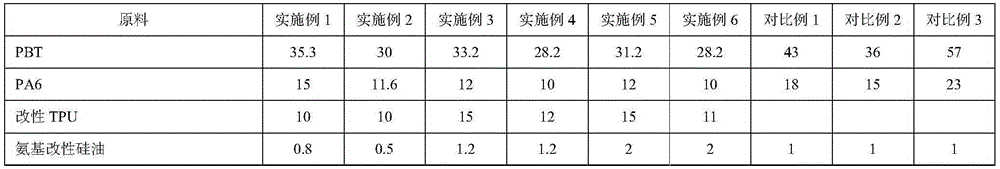

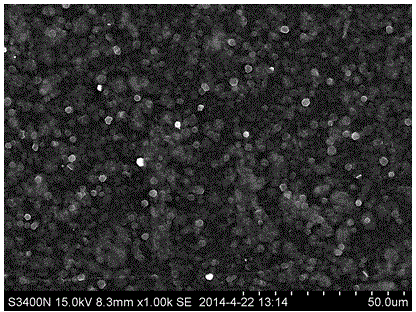

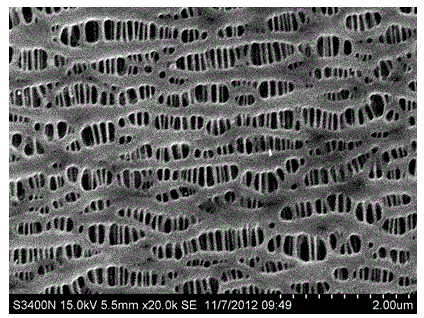

Preparation method of flame-retardant organic/inorganic composite membrane

ActiveCN104103793AImprove hydrophilic and electrophilic propertiesSimple processSecondary cellsCell component detailsPolyolefinFlame resistance

The invention discloses a preparation method of a flame-retardant organic / inorganic composite membrane. The method comprises the steps of preparing zirconium phosphate powder with a hexagonal structure by a time-temperature-concentration control method, organizing the prepared zirconium phosphate powder, stripping a multilayer structure to become a laminal filler as thin as possible, directly mixing an organized zirconium phosphate solution with a water-soluble binder solution, preparing coating pulp, coating the coating pulp on the surface of a polyolefin microporous membrane, drying the coating pulp, and obtaining the organic / inorganic composite membrane. The preparation method is used for preparing a membrane suitable for a high-power battery; the preparation method of the flame-retardant organic / inorganic composite membrane is simple in technology, low in equipment requirement, easy in condition control and low in cost, and is suitable for industrial production; the flame retardance of the membrane can be improved effectively by simple coating; an oxygen index is increased obviously; the flame-retardant grade reaches VTM-2; a demand of a battery membrane is met; and high performance of a common membrane is achieved.

Owner:GUANGDONG UNIV OF TECH

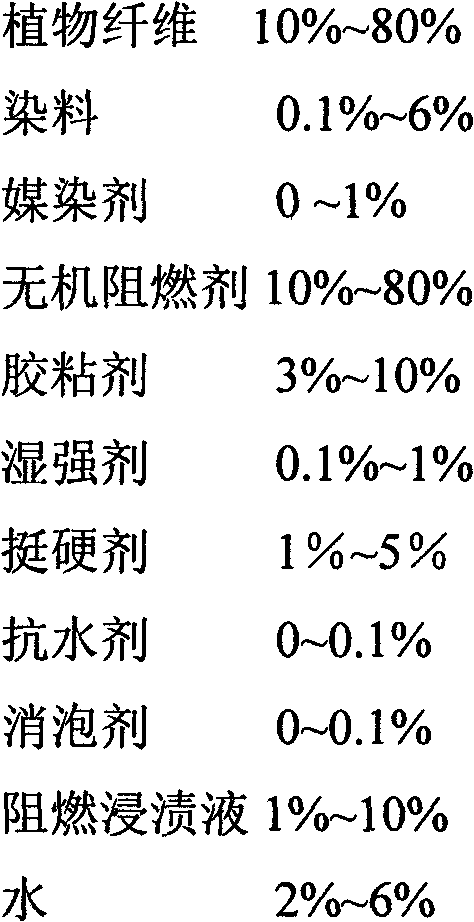

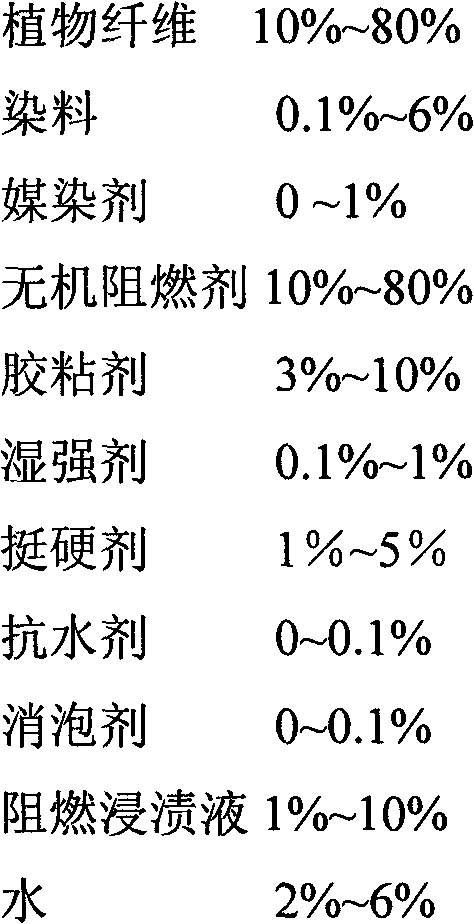

Colored flame-retardant insulation vulcanized fiber board and manufacturing technique thereof

ActiveCN103088697AImprove machinabilityCause secondary pollutionDefoamers additionReinforcing agents additionFiberCardboard

The invention relates to a colored flame-retardant insulation vulcanized fiber board and a manufacturing technique thereof. On the basis of paper making technology, the main raw material is pulped and dyed, and compounded with many flame retardants, and a production technique combining in-pulp addition and surface treatment is adopted to endow the vulcanized fiber paper with high efficiency, environmental protection and enduring flame retardancy. Meanwhile, the vulcanized fiber board has favorable machining properties (pressure resistance, impact resistance, cutting resistance, scratching resistance, no stratification or blowout under pressure, and the like), and favorable electric insulation properties. The colored flame-retardant insulation vulcanized fiber board is an excellent environment-friendly special-structure multifunctional material. The production technique comprises the following steps: adding flame retardants in the pulp, carrying primary molding, vacuum dehydration and high-temperature hot-press drying, and impregnating the flame retardants on the surface. The invention has the advantages of lower production cost, simple production technique, easy control, low energy consumption and less water and power consumption, can not produce secondary pollution on the environment, and can implement clean production.

Owner:GUANGDONG PAPER IND RES INST

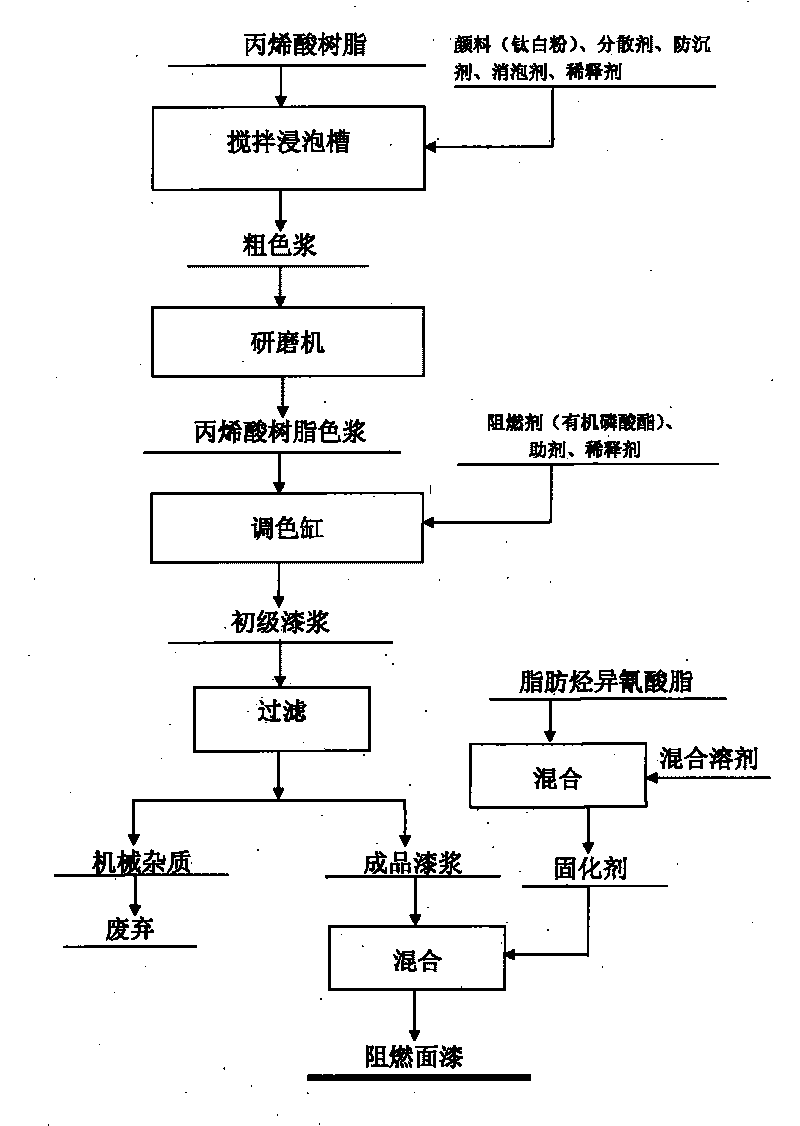

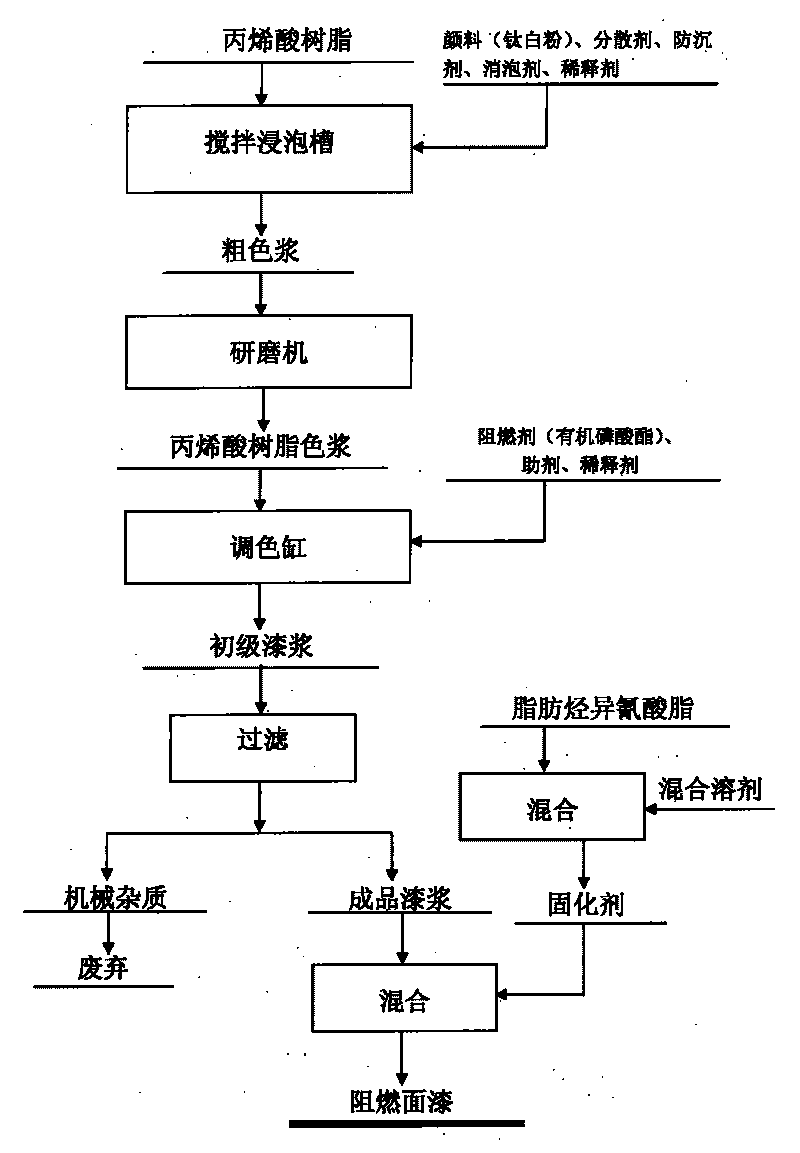

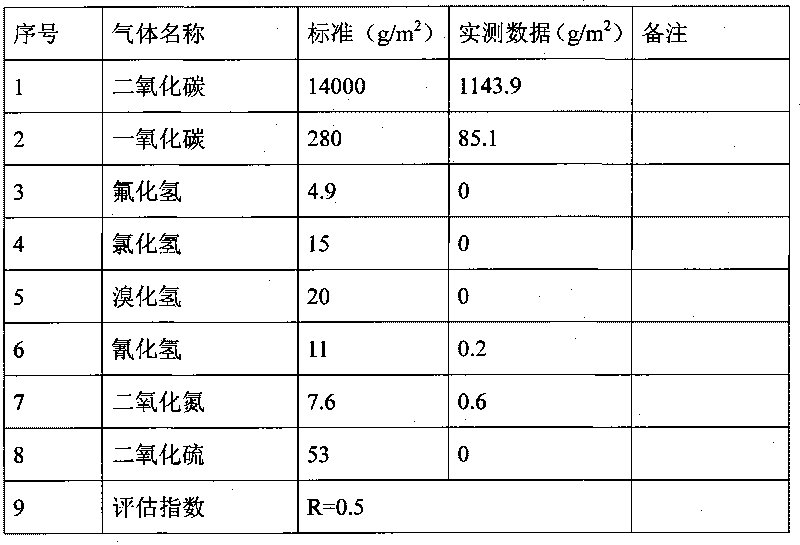

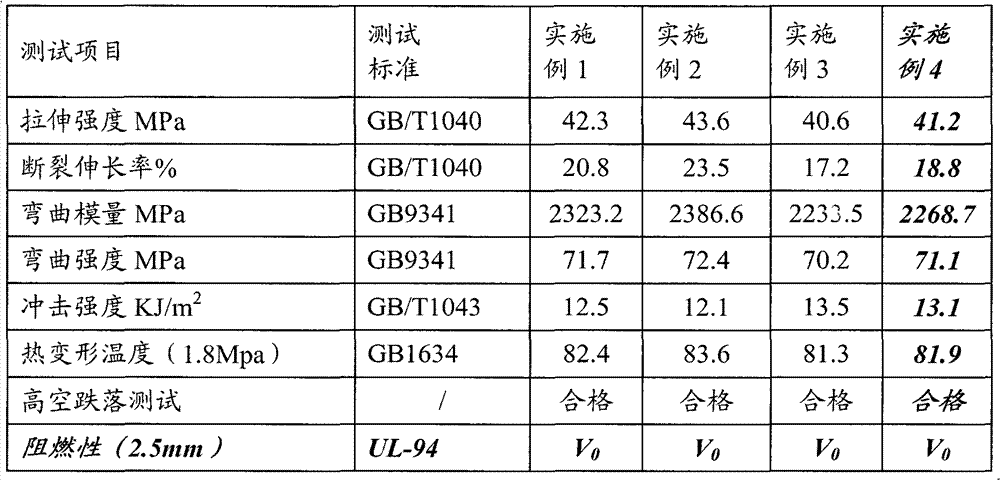

Subway vehicle inflaming retarding finish paint and preparation method thereof

The invention discloses a subway vehicle inflaming retarding finish paint and aims at providing an environmental-friendly inflaming retarding finish paint with efficient inflaming retarding, low toxicity and low smoke, which is prepared by the steps of soaking, grinding, toning, filtering and the like after mixing raw materials not containing halogen family elements, such as acrylic resin, titanium, dispersant, anti-settling agent, antifoaming agent, thinning agent, flatting agent, drier, ultraviolet absorber, hindered-amine, organic phosphate and isocyanates of aliphatic hydrocarbon. The invention is mainly used as the inflaming retarding finish paint of subway vehicles.

Owner:株洲市九华新材料涂装实业有限公司

High-toughness halogen-free flame-retardant reinforced PC (polycarbonate)/ASA (acrylonitrile styrene acrylate) alloy and preparation method thereof

The invention relates to high-toughness halogen-free flame-retardant reinforced PC (polycarbonate) / ASA (acrylonitrile styrene acrylate) alloy and a preparation method thereof. The alloy is prepared from the following raw materials in parts by mass: 55 to 65 parts of PC, 10 to 20 parts of ASA, 3 to 8 parts of compatilizer, 4 to 7 parts of toughening agent, 15 to 20 parts of halogen-free composite flame retardant, 0.5 to 1 part of anti-drop agent, 0.1 to 0.5 part of lubricant and 0.1 to 0.5 part of antioxidant. The preparation method comprises the steps of weighing the raw materials according to the proportion, evenly mixing, putting the raw materials into a feeding opening of a twin-screw extruder, setting a rotation speed of the twin-screw extruder as 100 to 300r / min and extruding and granulating to obtain the high-toughness halogen-free flame-retardant reinforced PC / ASA alloy. The alloy material disclosed by the invention has the advantages of very good comprehensive mechanical property and flame retardance and low heat release rate, further avoids generating a lot of molten drops and smog and is a high-efficiency flame-retardant environment-friendly practical alloy material.

Owner:WUHAN UNIV OF TECH

Anti-dropping flame-retardant ABS material and preparation method thereof

InactiveCN102850712AEfficient Flame RetardancyImprove mechanical propertiesMechanical propertyAnti oxidant

The invention discloses an anti-dropping flame-retardant ABS material, which comprises the following components by mass: 70-80% of ABS resin; 2-6% of a flexibilizer; 18-25% of a composite flame retardant; 0.2-0.6% of an anti-oxidant; 0.3-1% of a processing additive; and 0.1-0.3% of an anti-dropping agent. The invention also provides the preparation method of the anti-dropping flame-retardant ABS material. The anti-dropping flame-retardant ABS material provided by the invention not only has the advantages of good mechanical properties, high-efficient flame retardance, easy molding processability, and the like, but also has the advantage of no damage after high-altitude drop.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

Flame-retardant fabric

InactiveCN103556351AImprove flame retardant performanceEfficient Flame RetardancyWoven fabricsYarnYarnPolyester

The invention discloses a flame-retardant fabric which comprises warp yarns and weft yarns by interweaving, wherein the warp yarns are made of flame-retardant polyester fibers, and the weft yarns are polyphenylene sulfide fiber blended yarns. The flame-retardant fabric is comfortable, breathable, antibacterial and free of pungent smell, and has durable and efficient flame resistance.

Owner:SUZHOU WILDER IND & TRADE

Waterproof core-shell structure flame retardant and application of flame retardant to preparation of polyurethane composite

ActiveCN104817676AImprove the disadvantage of being easily soluble in waterEfficient Flame RetardancyMelamine formaldehydeFilter paper

The invention belongs to the field of materials and discloses a waterproof core-shell structure flame retardant and application of the flame retardant to preparation of a polyurethane composite. The flame retardant forms a core-shell structure by taking ammonium polyphosphate as a capsule core and taking a copolymer of melamine formaldehyde prepolymer and multiamino polyether as a capsule wall material. Since a shell of the system is hydrophobic resin, water resistance is highly improved as compared with that uncoated flame retardant particles, loss rate of ammonium polyphosphate particles sealed with filter paper reaches 98.0%, loss rate of the prepared waterproof flame retardant particles under the same conditions is lower than 8.50%, and the polyurethane composite prepared from the waterproof core-shell structure flame retardant has good flame retardant effect and can still keep efficient flame retardance under the condition of long-time water soaking.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Flame-retardant phase-change material film

The invention relates to the technical field of thermal management film materials, and particularly discloses a flame-retardant phase-change material film which comprises 3%-50% of a matrix, 30%-80% of phase-change microcapsules, 5%-20% of a flame retardant, 0.1%-0.5% of a wetting dispersant and 0.1%-1% of a defoaming agent. The invention provides the efficient environment-friendly halogen-free flame-retardant phase-change film, and the phase-change composite film meets the flame-retardant V0 grade in a space with the addition amount of the flame retardant being less than 20%. Therefore, a safer application environment can be guaranteed when the organic phase-change material with improved flame retardance is applied to electronic products.

Owner:STONEPLUS THERMAL MANAGEMENT TECH

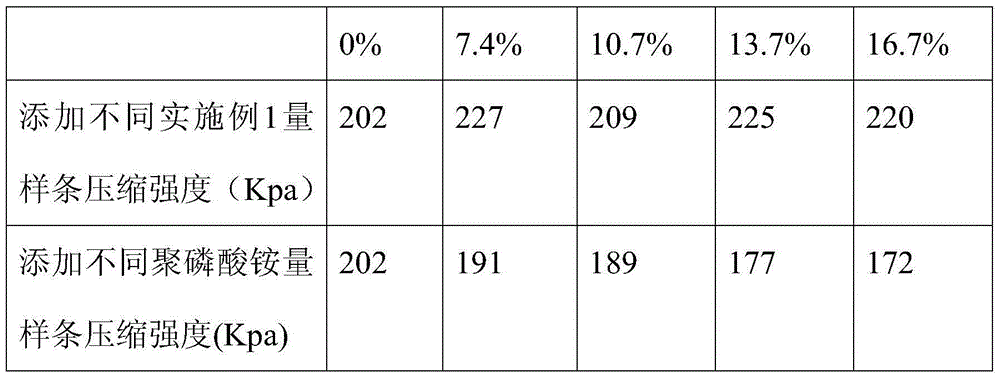

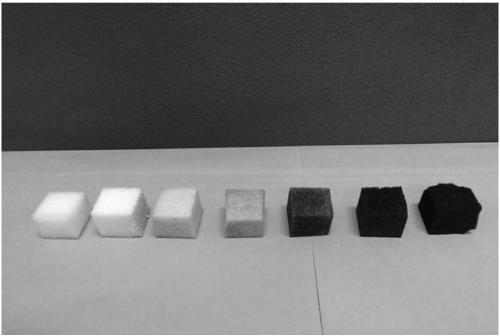

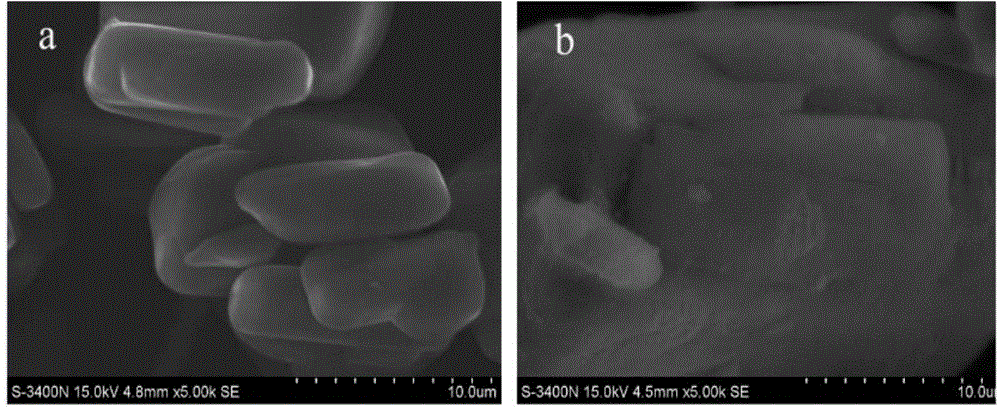

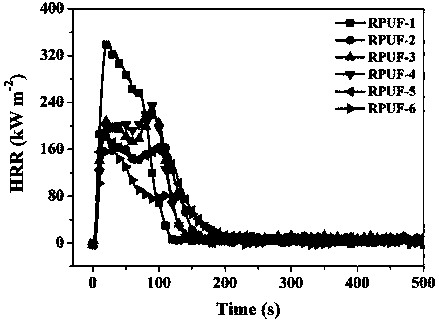

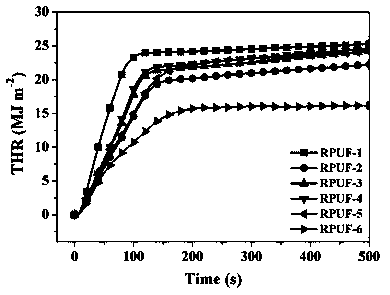

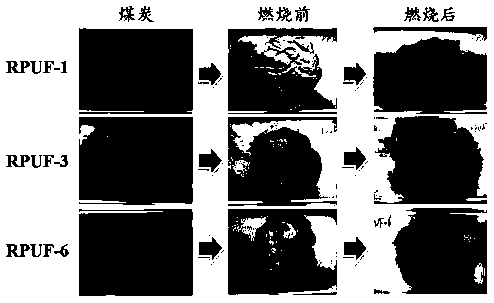

Flame-retardant rigid polyurethane foam material, and preparation method and application thereof

The invention belongs to the field of preparation of inhibition materials, and particularly relates to a flame-retardant rigid polyurethane foam material, and a preparation method and application thereof. The material comprises a mixture A and a mixture B, wherein the mixture A comprises the following components in parts by weight: 77.47-100 parts of a polyol, 0-22.53 parts of a glycol phosphinate, 1 part of an amine catalyst, 0.5 part of an organic tin catalyst, 2 parts of water, 2 parts of a foam stabilizer and 3 parts of triethanolamine; the mixture B is prepared from the following components in parts by weight: 149 to 152 parts of an isocyanate, 0 to 20.25 parts of expandable graphite, 0 to 20.25 parts of a phosphate and 0 to 7.5 parts of coal ash. The flame-retardant rigid polyurethane foam material possesses integrated condensed phase flame resistance, gas phase flame resistance and expanded graphite physical flame resistance, and the coal ash with synergistic flame resistance effect and excellent bonding performance is added, so that the rigid polyurethane foam material has excellent flame resistance, can not only be taken as a inhibition material for preventing and treatingspontaneous combustion of coal, and can also be taken as a sealing material and a thermal insulation material.

Owner:FUZHOU UNIV

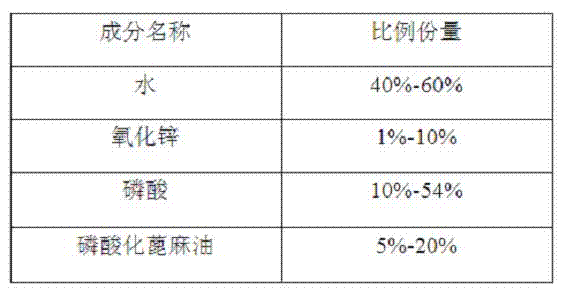

Fire retardant curtain

The invention provides a fire retardant curtain which is characterized in that fire retardant liquid for providing fire retardant process to the fire retardant curtain comprises the components by weight as follows: 40 to 60% of water, 1 to 10% of zinc oxide, 10 to 54% of phosphoric acid, and 5 to 20% of phosphorylation castor oil. The technical process of the fire retardant processing of a fire retardant door comprises: soaking, airing, spraying and parching; and the components of the fire retardant liquid of the fire retardant curtain are hard to volatilize, and have obvious effect of fire retarding.

Owner:SUZHOU CUIZHI NEW TECH DEV

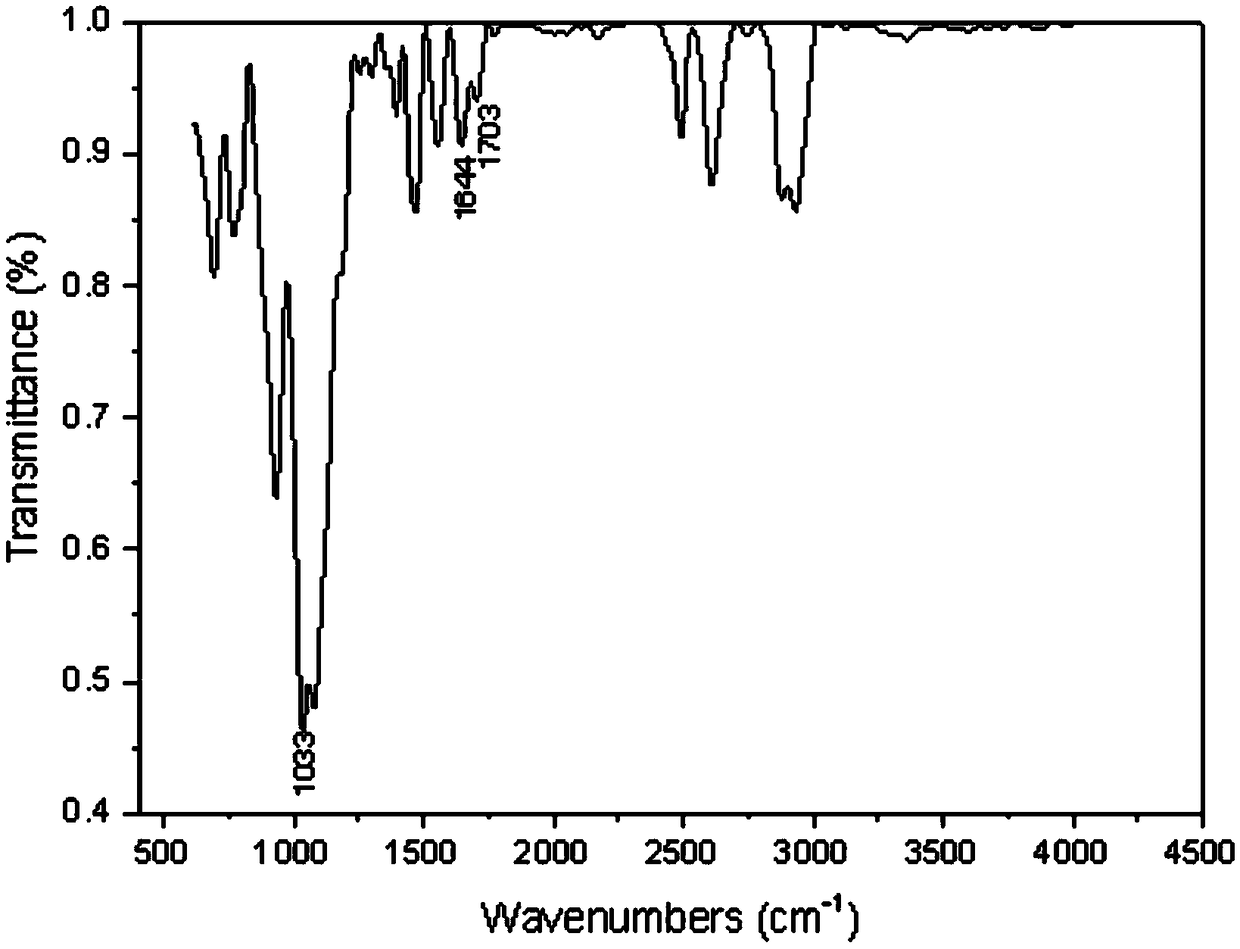

Lithium battery fire-extinguishing filling material additive preparation method

InactiveCN109054866AImprove flexibilityHigh physical and chemical stabilitySecondary cells servicing/maintenanceSolventChemistry

The invention discloses a lithium battery fire-extinguishing filling material additive preparation method. Preparation of a PEO-based fire-extinguishing additive comprises the steps that according toa mass ratio of 5 to 1, PEG and a silane coupling agent are accurately weighed, an appropriate amount of THF is used as a solvent for dissolving the PEG and the silane coupling agent, and after the PEG and the silane coupling agent are mixed, reaction is carried out under protection of nitrogen; a product, subjected to filtering treatment, of the last step is reacted with nano-silica hydrosol under protection of nitrogen, and a reaction product is subjected to centrifugation treatment; finally, the product of the last step is reacted with PPG. A product is observed through an electron microscope, a result shows that the product is good in reaction evenness, and both the dispersity and the mobility are up to standards; the novel high-flame retardation fire-extinguishing additive is easy tosynthesize, easy to use and low in waste, and a better choice is provided for replacing a toxic halogen-flame retardant.

Owner:浙江蓝盾电工新材料科技有限公司

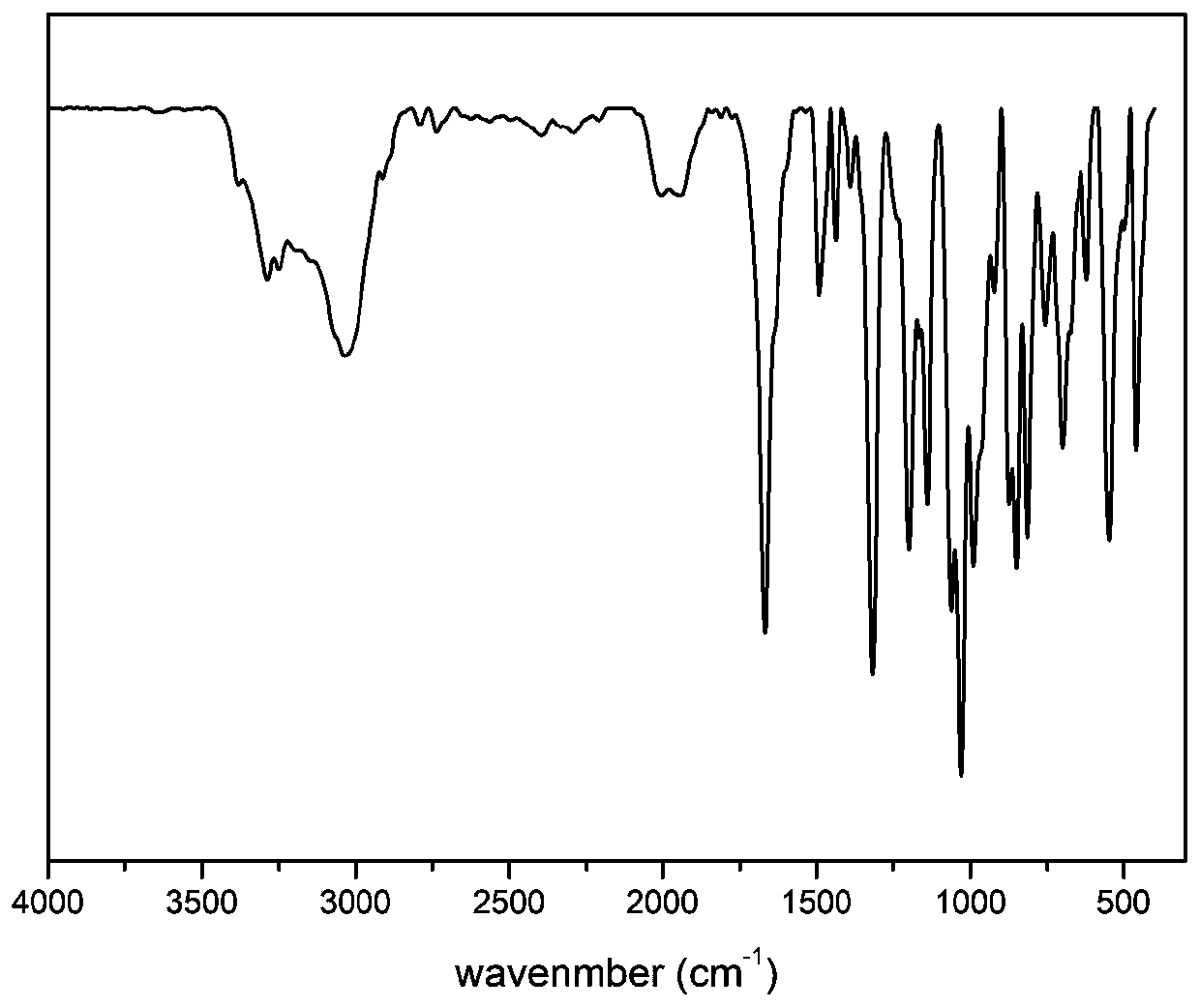

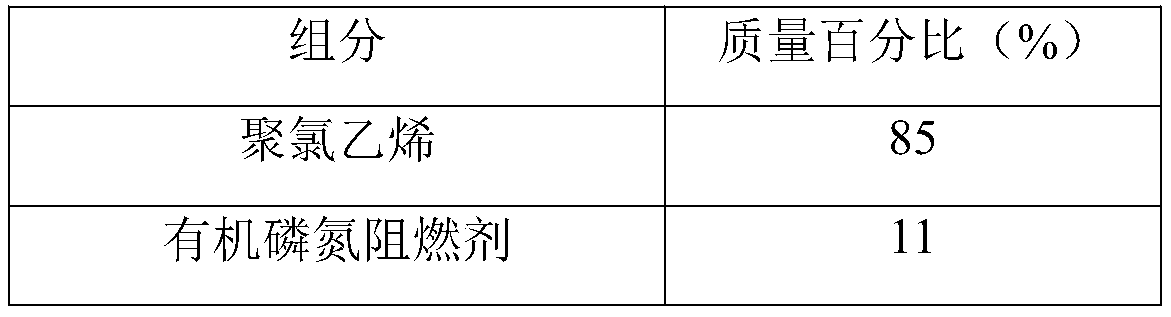

Flame-retardant polyolefin macromolecule composite material and preparation method thereof

The invention discloses a flame-retardant polyolefin macromolecule composite material. The material is prepared from 70-94 wt% of polyolefin, 5-25 wt% of an organic phosphorus-nitrogen flame retardantand 0.5-15 wt% of an inorganic flame retardant. The invention further discloses a preparation method of the flame-retardant polyolefin macromolecule composite material. The material has the advantages that the organic phosphorus-nitrogen flame retardant has a good cage-shaped structure, is free of halogen, low in toxicity and efficient in flame retardant property and can be used for replacing a halogen flame-retardant material; the organic phosphorus-nitrogen flame retardant is used for being compounded with the inorganic flame retardant, through a synergistic effect of the two kinds of flameretardants, the interaction of the polyolefin and the flame retardants is greatly improved, the overall flame retardance is improved, and the heat release speed is lowered by 60-80%; the limit oxygenindex is increased by 130-200%, and the material can be widely applied to home appliances and furniture such as cables and switches and other devices which need flame retardance.

Owner:KUNMING UNIV OF SCI & TECH

Nano zirconium phosphate-based flame-retardant bacteriostatic agent, and intumescent fireproof bacteriostatic coating prepared therefrom

ActiveCN113861794AEfficient Flame RetardancyGood char formationFireproof paintsAntifouling/underwater paintsPhosphoric acidFire retardant

The invention discloses a nano zirconium phosphate-based flame-retardant bacteriostatic agent. The nano zirconium phosphate-based flame-retardant bacteriostatic agent is prepared by performing intercalation stripping on zirconium phosphate and modifying the zirconium phosphate by using aminoimidazole and chloropropionaldehyde, so the problems that the zirconium phosphate is easy to agglomerate and the like are effectively solved, and the nano zirconium phosphate-based flame-retardant bacteriostatic agent can play a synergistic flame-retardant role with an intumescent flame-retardant system in a fireproof coating; the film-forming property, the fire resistance and the durability of the obtained fireproof coating can be obviously improved; and a Schiff base and imidazole loaded on the surface of a nano zirconium phosphate sheet layer can be more uniformly dispersed in coating components to play a role in barrier and bacteriostasis, and the Schiff base, nano zirconium phosphate and imidazole in the flame retardant can effectively improve the bacteriostasis performance of the fireproof coating. The flame retardant integrates the functions of flame retardance, smoke suppression, bacteriostasis and enhancement, and is halogen-free, low in cost, good in char forming property, environmentally friendly and wide in applicability, and the related preparation method is simple in process, simple in reaction condition and suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

High-effect flame retardant special for leather

InactiveCN104846132AEfficient Flame RetardancyNon-corrosiveLeather impregnationPolymer scienceActive agent

The invention relates to a high-effect flame retardant special for leather. The high-effect flame retardant is characterized by being prepared from the following raw materials in parts by weight: 3-5 parts of sodium lauryl sulfate, 2.5-4 parts of quaternary ammonium salt surface active agents, 2-5 parts of polyvinylpyrrolidone, 3-5 parts of melamine, 12-16 parts of zinc borate, 2-4 parts of ammonium polyphosphate, 6-12 parts of stearic acid, 4-6 parts of tributyl phosphate, 3-7 parts of aluminium trichloride, 8-16 parts of polyvinyl chloride resin, 3-6 parts of imide phthalate, 4-5 parts of calcium chloride, 3-6 parts of zinc cyanurate, 12-16 parts of chlorinated paraffin and 14-22 parts of propanetriol. The high-effect special flame retardant for the leather, which is disclosed by the invention, has the beneficial effects of high-effect flame retardance and non-toxic and non-corrosive characteristics without influencing the environment.

Owner:青岛百千川海洋生态科技有限公司

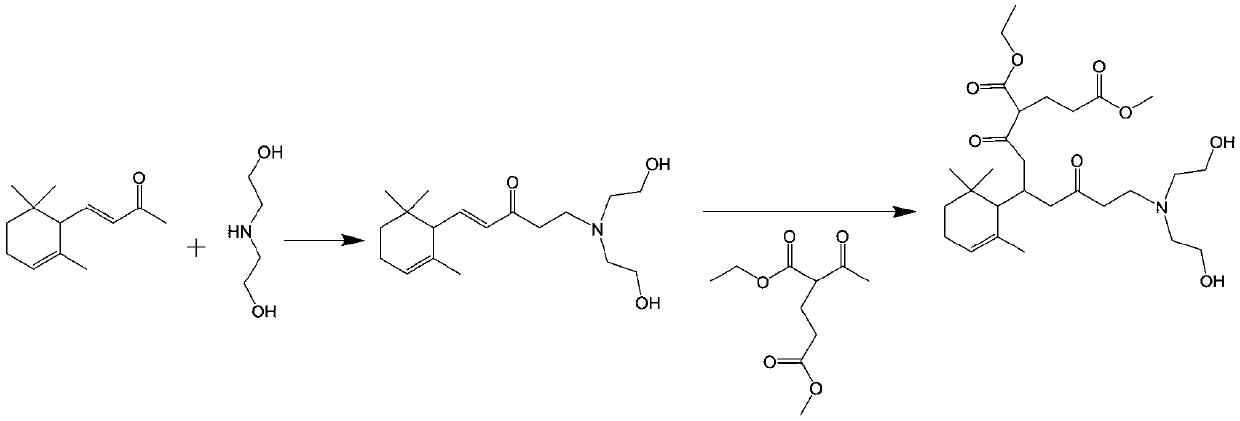

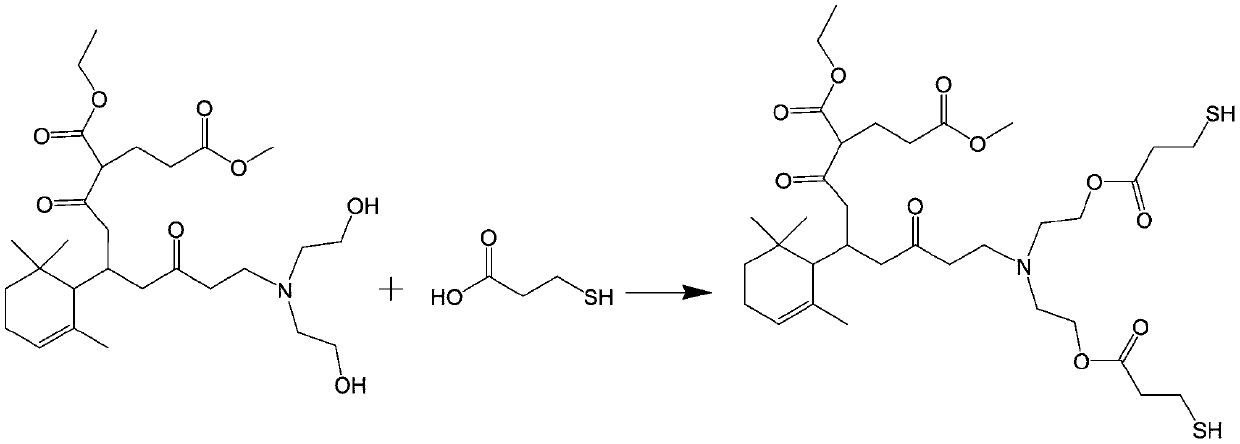

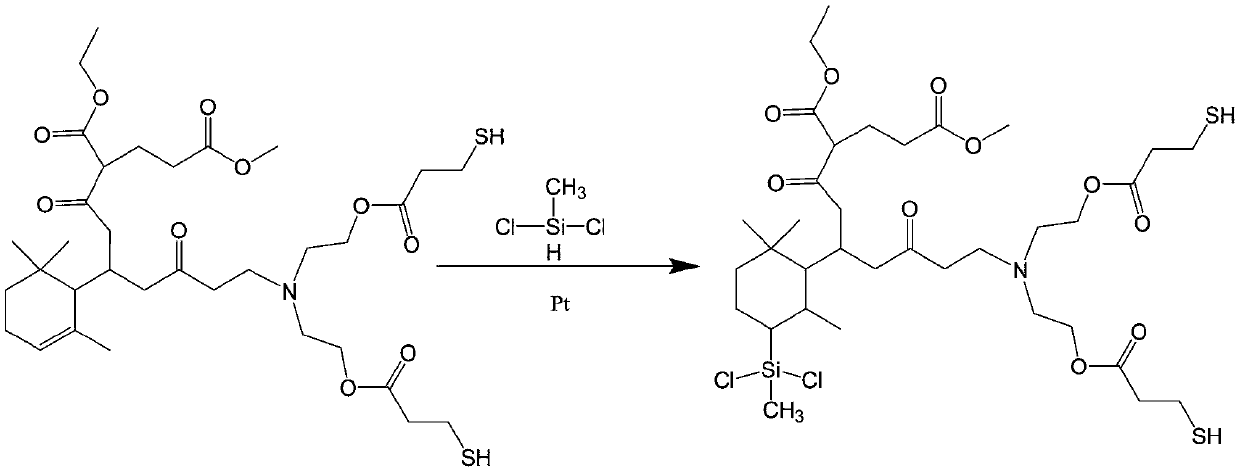

Preparation process of polyurethane-based thermal insulation type multi-layer composite waterproof coiled material

InactiveCN111574782AImprove insulation effectEfficient Flame RetardancyPolymer scienceTriphenylmethane triisocyanate

The invention discloses a preparation process of a polyurethane-based thermal insulation type multi-layer composite waterproof coiled material. The specific preparation process of the preparation process includes the following steps of: simultaneously adding polyphosphooxy polyamine, dibutyl dilaurate, diisopropanolamine and water into a stirring kettle; performing stirring and mixing, then addingtriphenylmethane triisocyanate into the stirring kettle; performing stirring and mixing, pouring an obtained mixture into a mold so as to subject the mixture to foaming and shaping; rolling obtainedpolyurethane foam for multiple times; and adhering a layer of polyvinyl chloride sheet to each of the upper surface and the lower surface of a polyurethane foam sheet to obtain the thermal insulationtype multi-layer composite waterproof coiled material. The toughening modifier prepared by the preparation method disclosed by the invention contains two sulfydryl groups which can react with chlorineatoms on a PVC chain, so that the toughening modifier can be introduced on the PVC chain; the toughening modifier contains a large amount of ester groups, so that Van der Waals' force among polyvinylchloride molecules can be weakened, the mobility of polyethylene molecular chains is improved, the crystallinity of the polymer molecular chains is reduced, the viscosity of the polymer is reduced, and flexibility is enhanced.

Owner:徐磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com