Subway vehicle inflaming retarding finish paint and preparation method thereof

A technology for topcoat and vehicle, which is applied in the field of flame-retardant topcoat and its preparation, and achieves the effects of good weather resistance, maintenance cost saving, and good decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

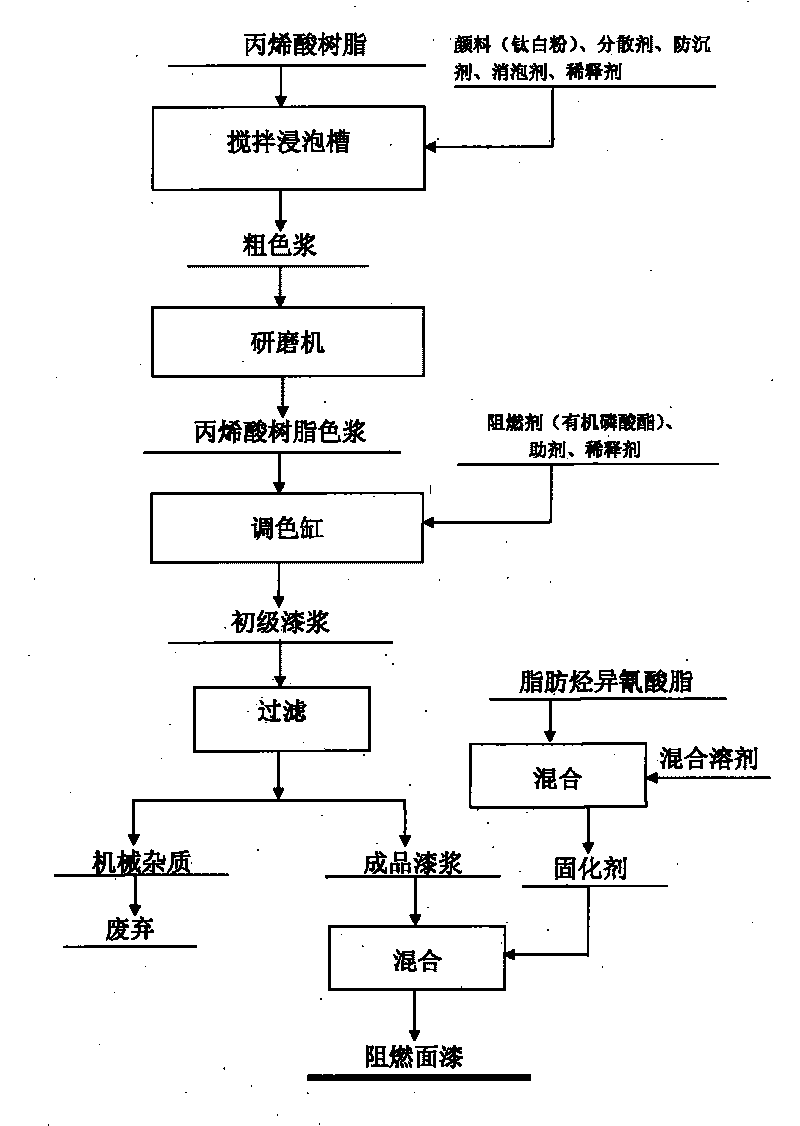

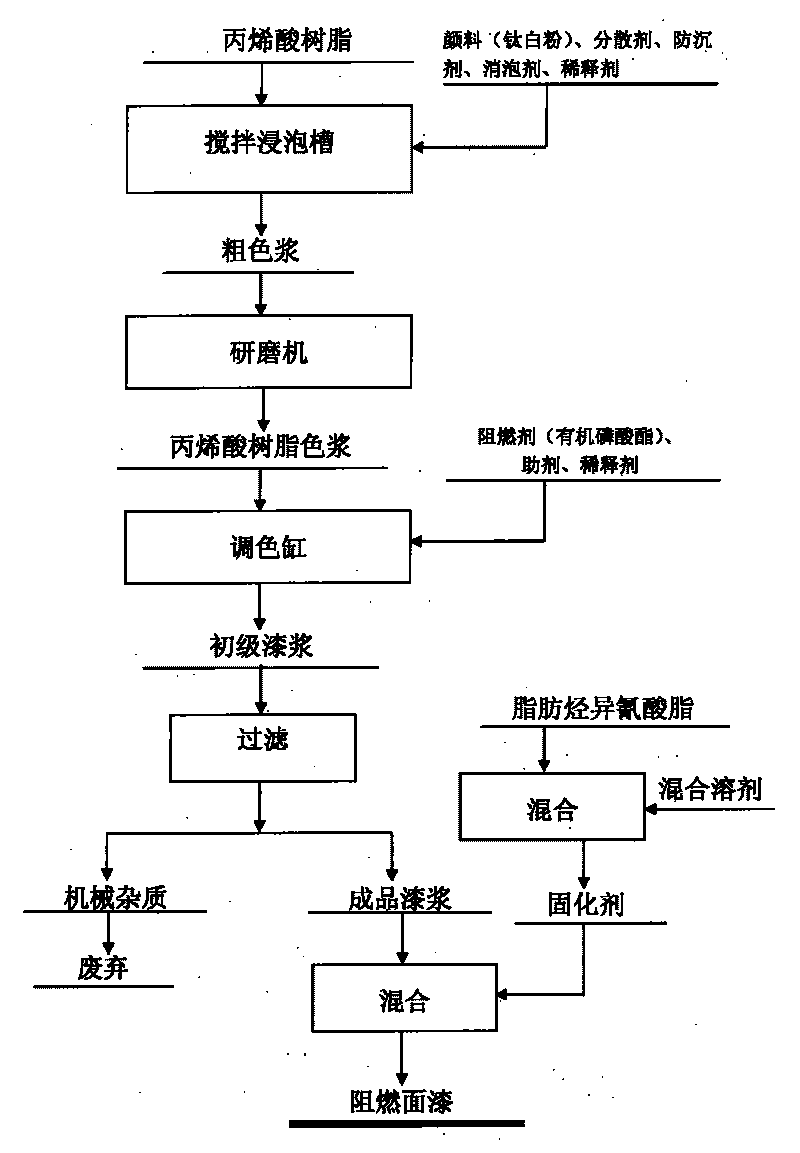

Method used

Image

Examples

preparation example Construction

[0051] C, the preparation of curing agent is that raw material (15)-(16) is placed in the container by above-mentioned ratio and stirs and mixes, and stirs evenly, output curing agent product, packs with iron drum, stand-by;

[0052] D. The preparation of the flame-retardant topcoat is to mix the finished paint base and the curing agent in a weight ratio of 1:0.3-0.5 during use, which is the flame-retardant topcoat of the present invention.

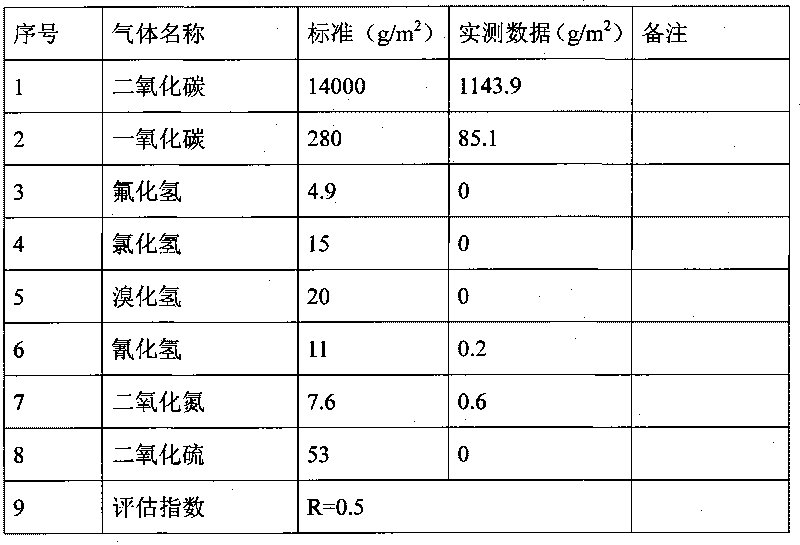

[0053] The flame-retardant topcoat for subway vehicles prepared by the method of the invention.

example 1

[0056] The production of color paste, with 39.5 parts of acrylic resin (produced by Bayer, Germany, solid content 70%, available domestically), as pigment titanium dioxide (produced by U.S. Dupont (Taiwan) Company, available in the territory, TiO 2 Minimum 93%, Al 2 o 3 Typical 2.5%, SiO 2 3.0%, specific gravity 4.0, average particle size 0.26μm) 24.5 parts, dispersant (polymer block copolymer solution containing pigment affinity groups, produced by BYK company in Germany, available in China) 0.3 parts, as anti-settling agent gas phase SiO 2 , (produced by German degussa company, available in China, specific surface area 110±20m 2 / g) 0.2 part, foam-breaking polymer and polysiloxane (produced by BYK company in Germany as defoamer, domestically available, solid content 40%) 0.2 part, xylene+butyl acetate as diluent + 3.3 parts of a mixture composed of propylene glycol methyl ether acetate (prepared by weight ratio 1:1:1, xylene, butyl acetate, and propylene glycol methyl et...

example 2

[0062] Production of color paste, 34.3 parts of acrylic resin, titanium dioxide (TiO 2 ) 19.5 parts, 0.2 parts of dispersant, 0.1 part of anti-sedimentation agent, 0.1 part of defoamer, 2.3 parts of diluent, placed in a soaking tank, stirred for 0.5 hours, stirring speed 800 rpm, then soaked for 24 hours, output The coarse color paste is pumped into the grinder with an air pump, and ground until the color paste particle size is less than 20 μm, and the acrylic resin color paste is produced;

[0063] For the production of paint base, 65 parts of acrylic resin color paste produced above, 0.3 part of fluorine-modified acrylate, 0.05 part of dibutyltin dilaurate, 0.6 part of benzotriazole, 0.5 part of hindered amine, and 0.2 part of defoamer parts, 0.4 parts of flame retardant, 1.2 parts of thinner,

[0064] The preparation of curing agent, 12 parts of aliphatic hydrocarbon isocyanate and 11 parts of mixed solvent are stirred and mixed to form a curing agent.

[0065] For the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com