Patents

Literature

244results about How to "Low smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-impact polystyrene blend and preparation thereof

InactiveCN101372548AFlame-retardant high-impact polystyrene blend, environmentally friendlyEnvironmentally friendlyAntioxidantMechanical property

The invention relates to a synthetic material, in particular to a halogen-free flame retardant high impact polystyrene blend and a preparation method thereof. The high impact polystyrene blend comprises high impact polystyrene resin with the mass percent of 35-75%, an inorganic flame retardant with the mass percent of 7-45%, an intumescent flame retardant with the mass percent of 5-20%, a flame retardant synergist with the mass percent of 1-5%, a toughening agent with the mass percent of 10-20%, a coupling agent with the mass percent of 0.5-2.0%, a lubricant with the mass percent of 0.5-3.0% and an antioxidant with the mass percent of 0.2-3.0%. The halogen-free flame retardant high impact polystyrene blend is produced by high-speed premixing and extrusion prilling, and has the advantages of environmental protection, flame retardation, low smoke, weather resistance, good thermal stability and mechanical property, easy machine shaping, etc.

Owner:珠海市远康企业有限公司

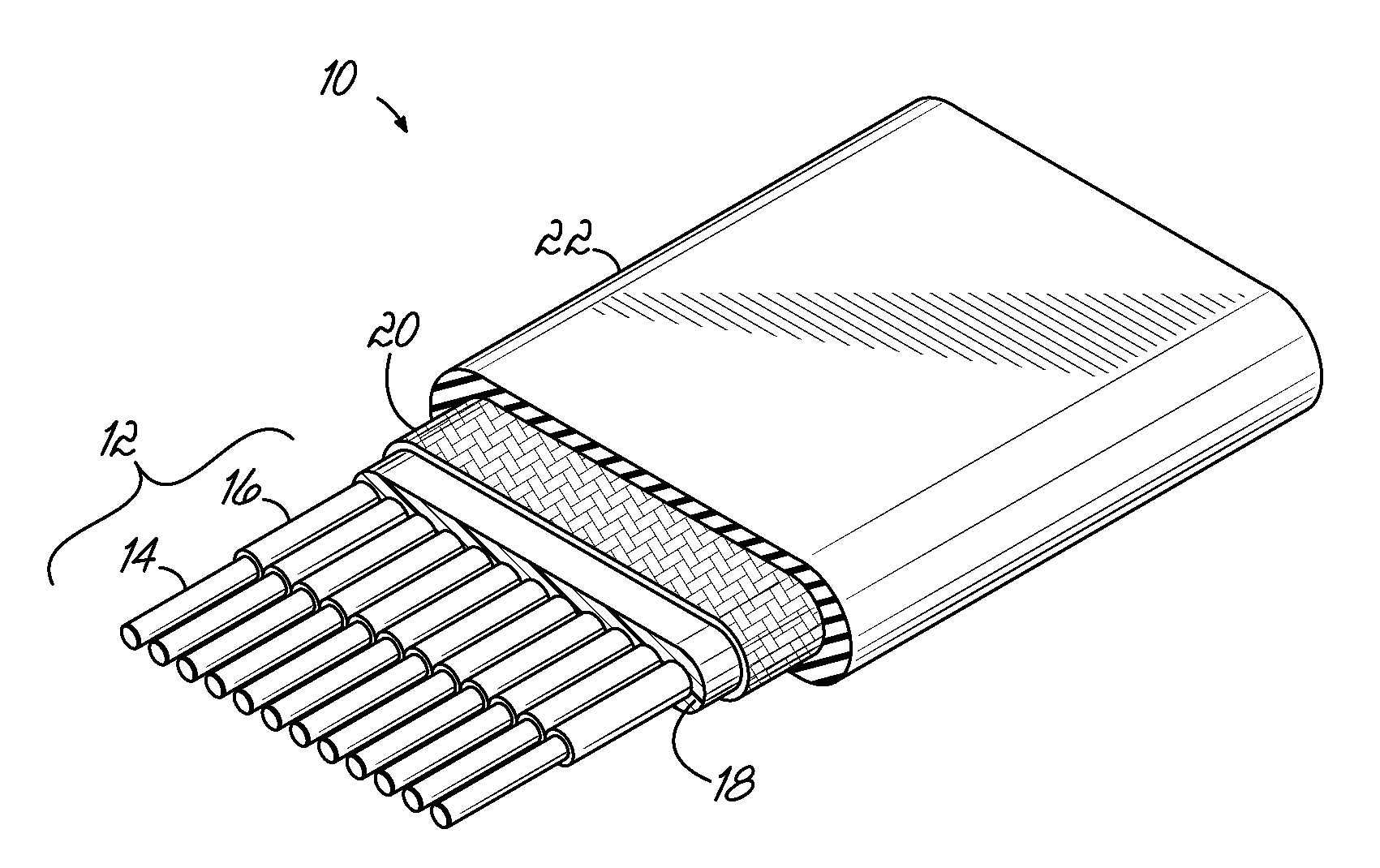

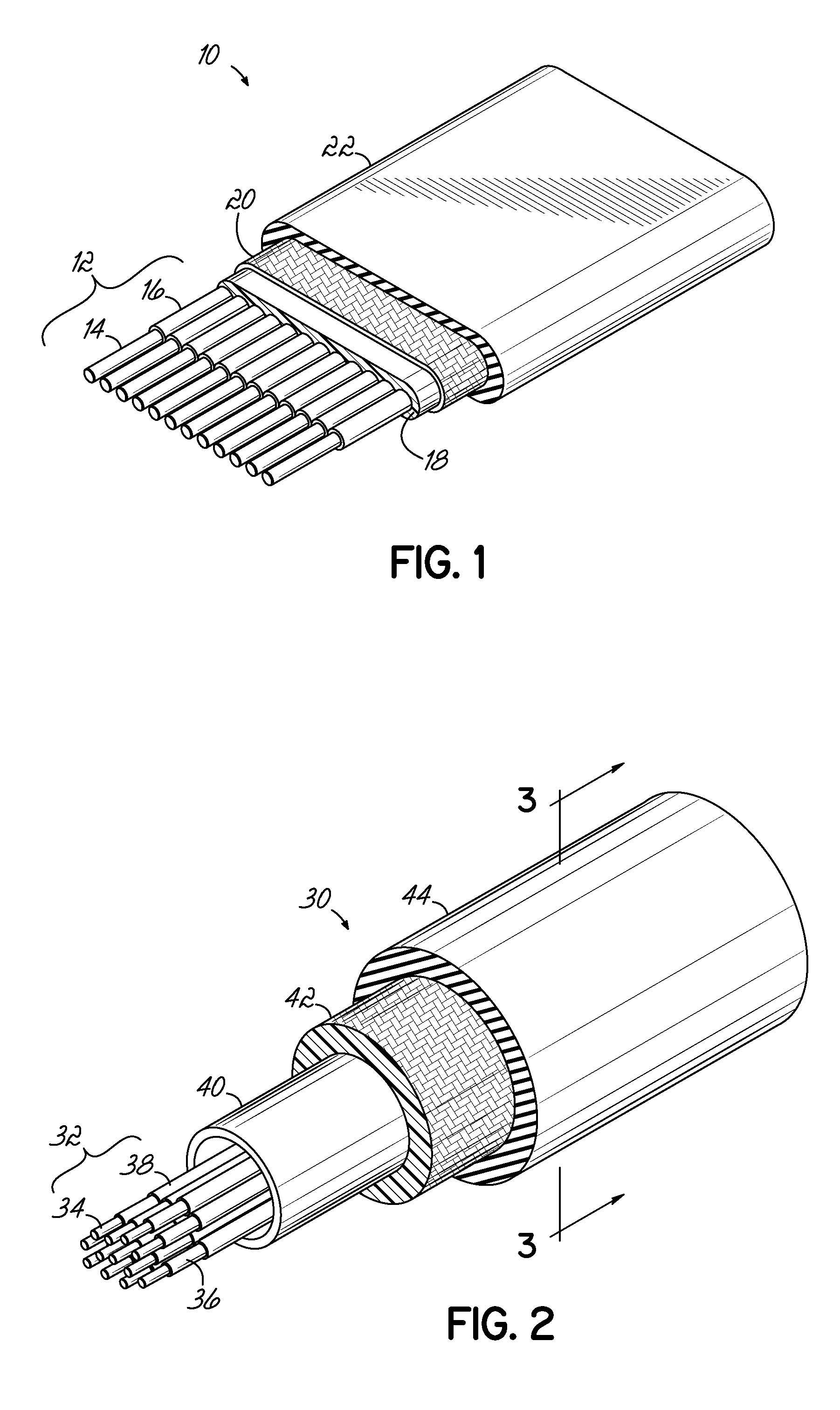

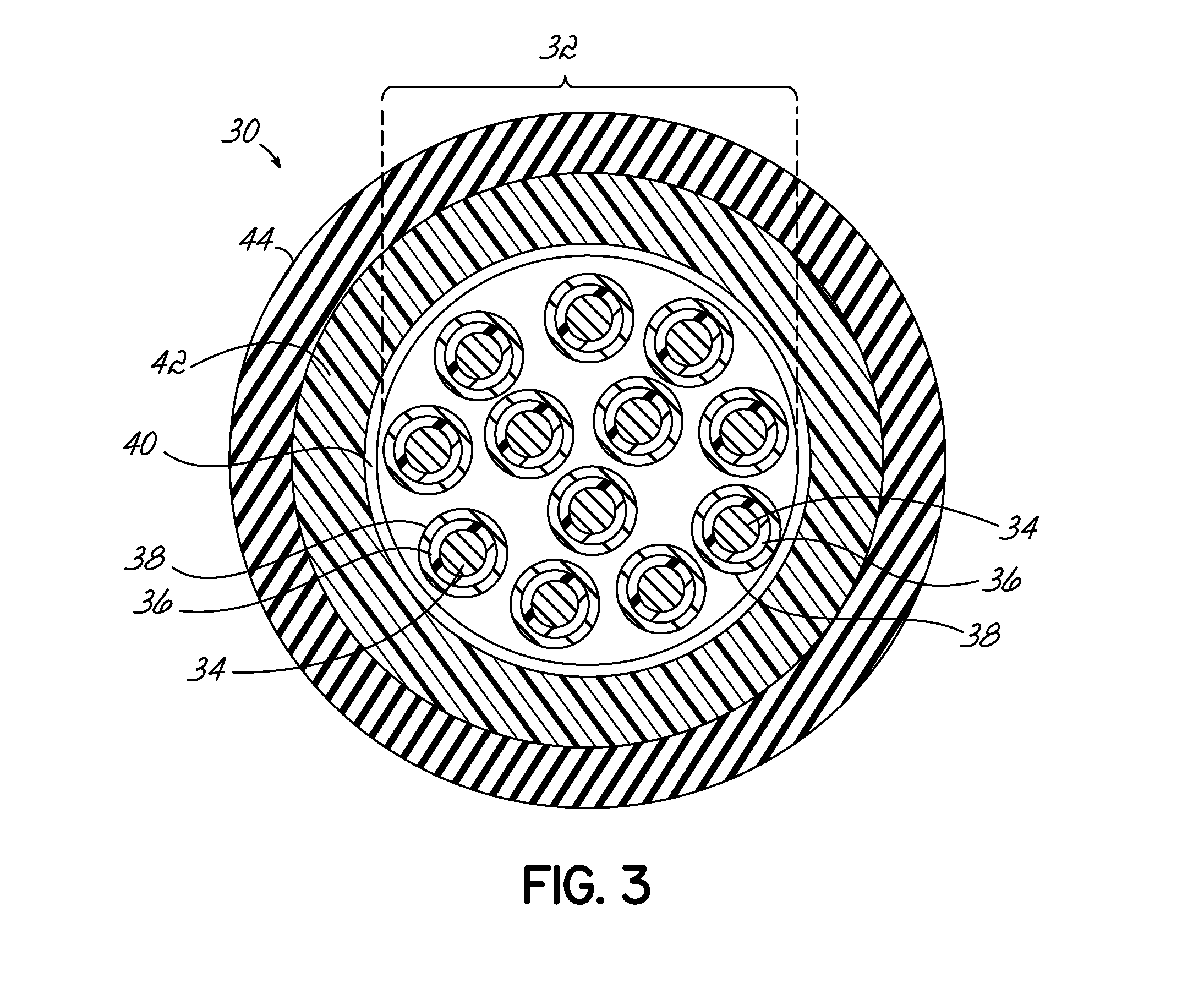

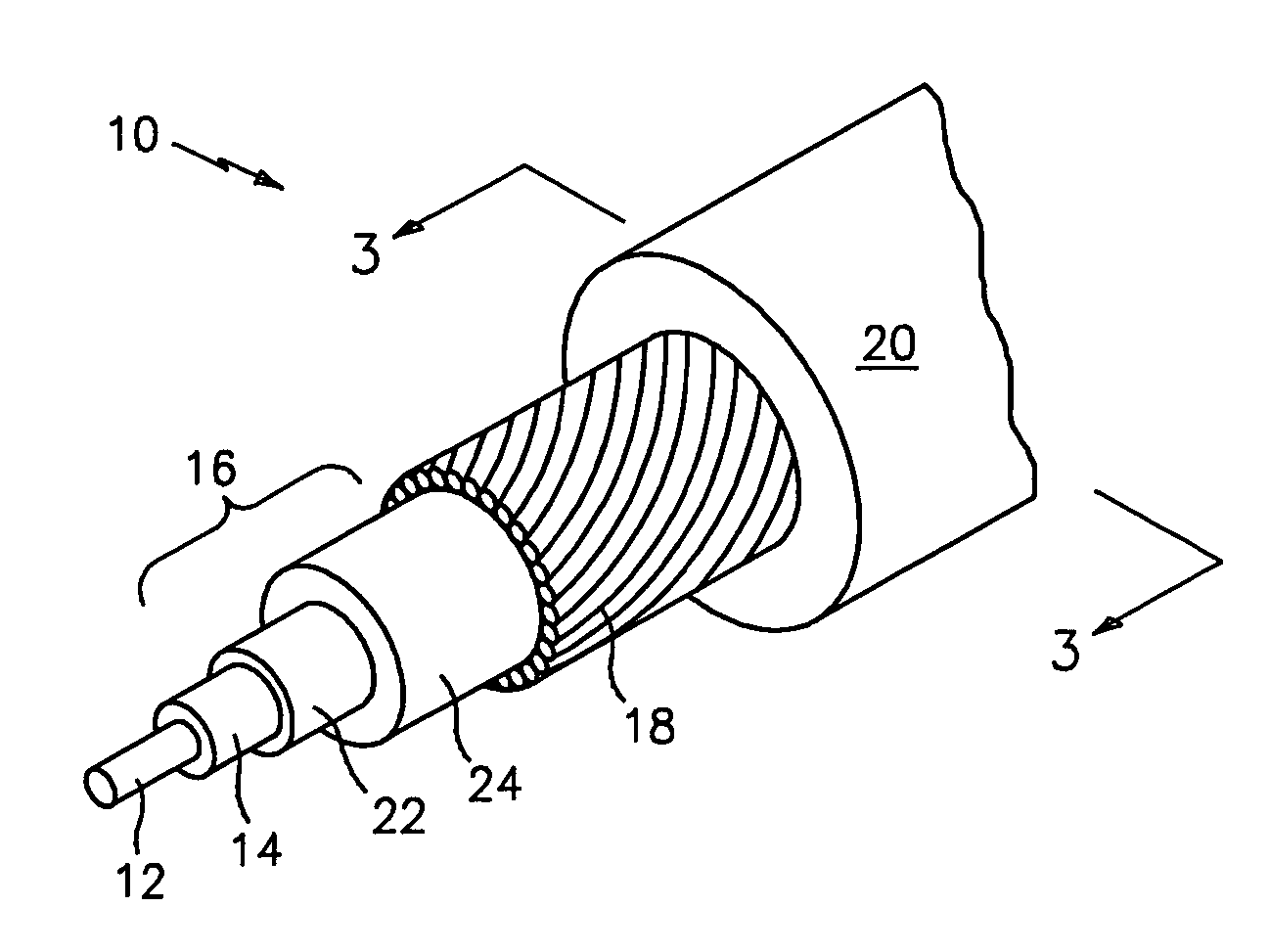

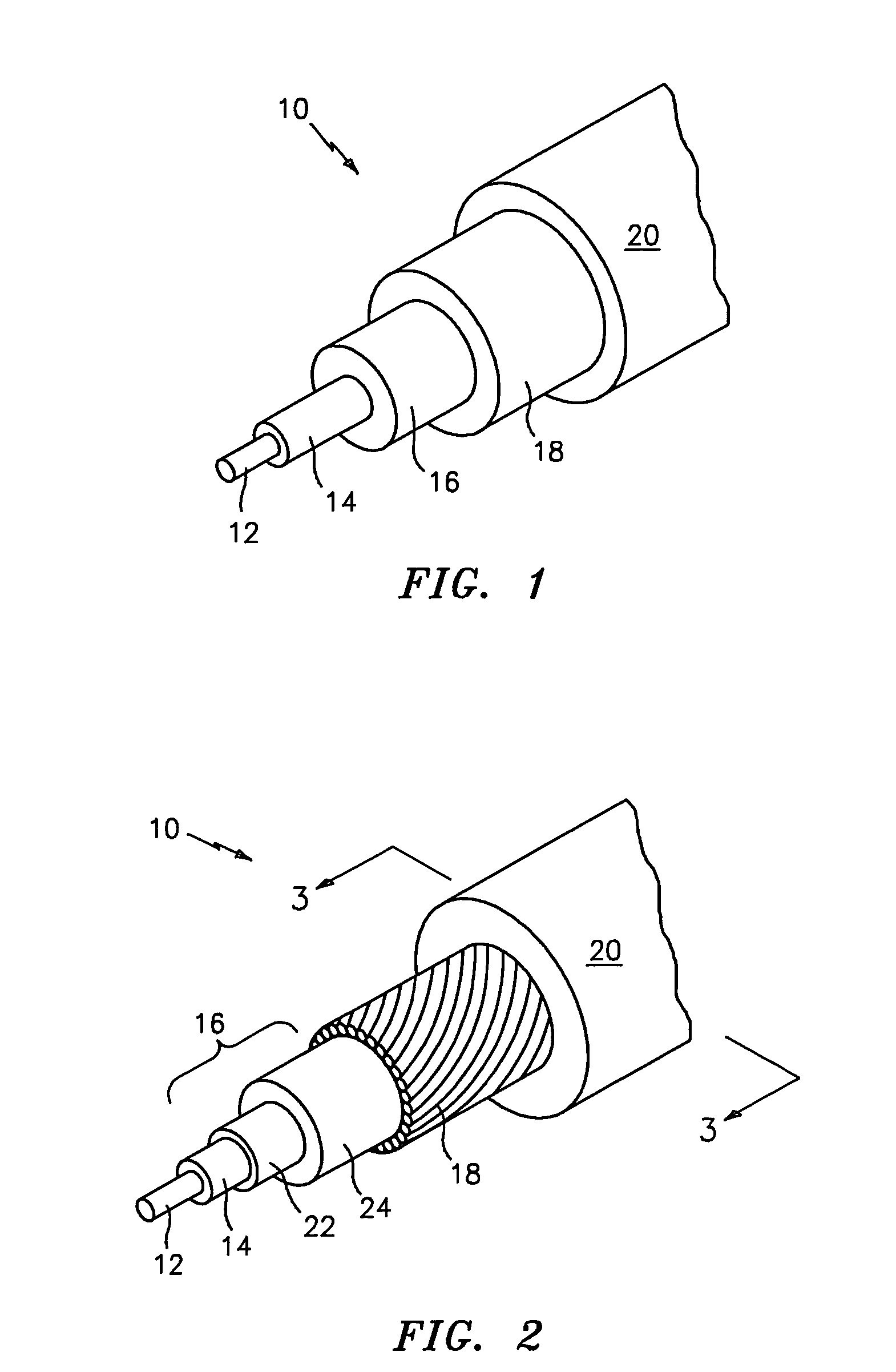

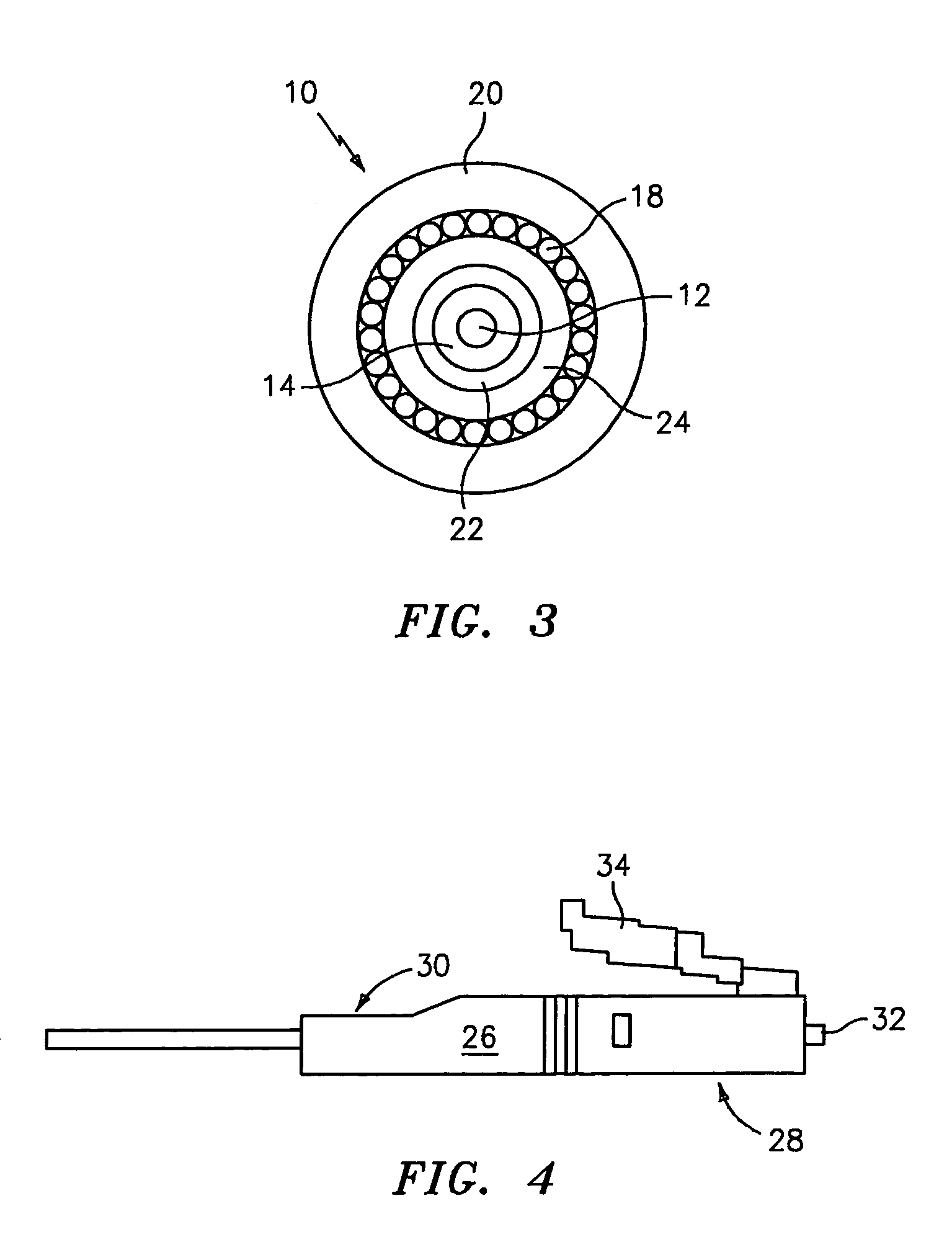

Fiber optic cable and method of manufacture

ActiveUS20120099825A1Low smokeHigh densityCladded optical fibreFibre mechanical structuresExtremes temperatureExtreme temperature

A fiber-optic cable for applications subject to extreme temperatures and high crushing and bending forces incorporating a loose fluoropolymer buffer material, a aramid / fiberglass strength member, and a fluoropolymer outer jacket compromising low smoke, low toxicity, and low flammability when exposed to flame.

Owner:CARLISLE INTERCONNECT TECH

Halon-free intumescent fire-retardant epoxy resin compound

A halogen-free expansion flame-retardant epoxy resin combination mainly includes the following components (in terms of weight portion) 45 to 85 portions of epoxy resin, 4 to 40 portions of ammonium polyphosphate, 2 to 30 portions of melamine or the derivatives, 1 to 20 portions of phosphonate ester, 1 to 13 portions of solidified agent, 0.1 to 8 portions of diluting agent and 0.1 to 4 portions of filling agent. The combination with no halogen, strong moisture resistance and good flame retardance can reach V-0 standard in UL-94; therefore, the combination is used as the substrate of manufacturing spare parts and fittings in the electronic and electric field.

Owner:SHANGHAI RES INST OF CHEM IND

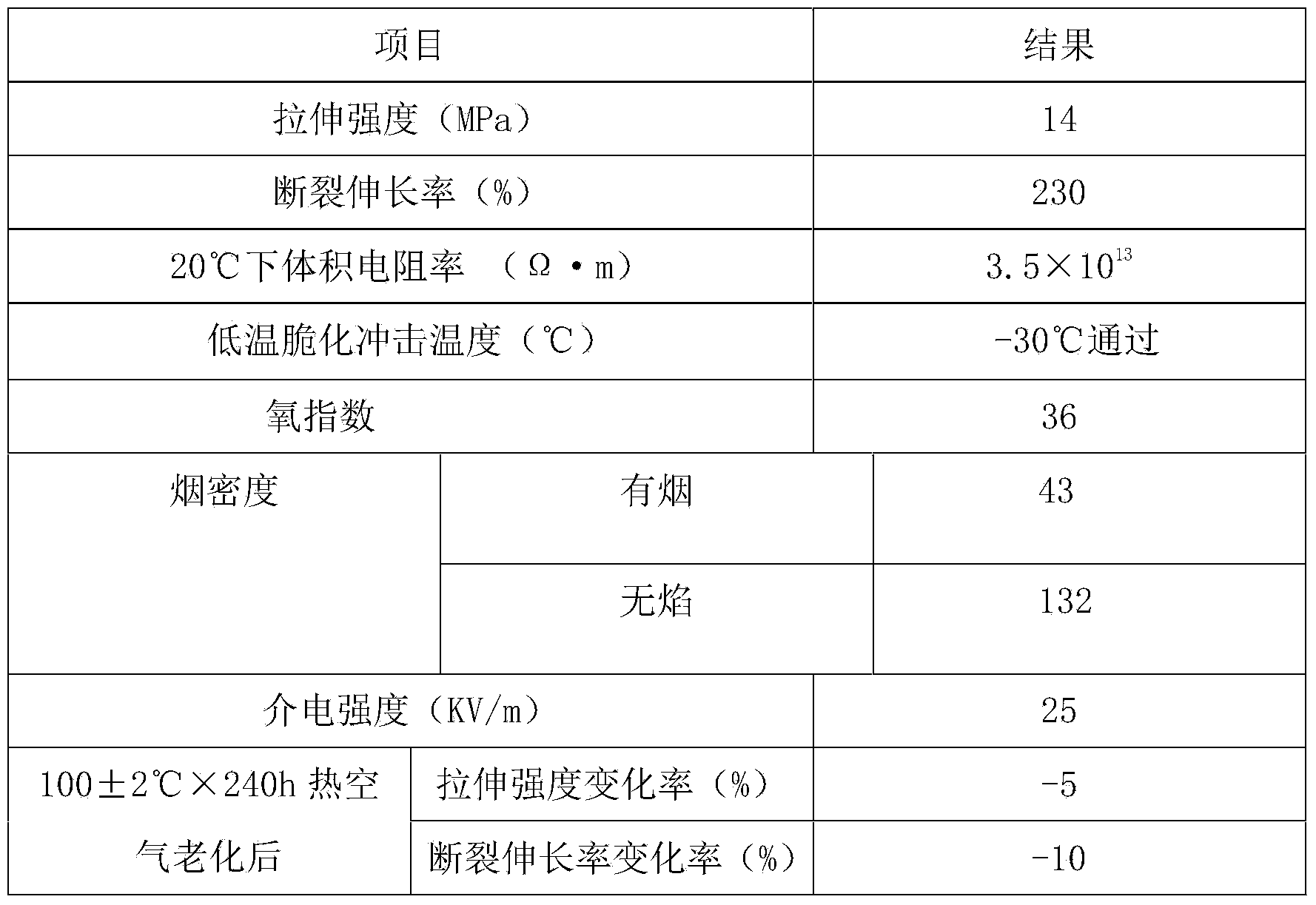

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

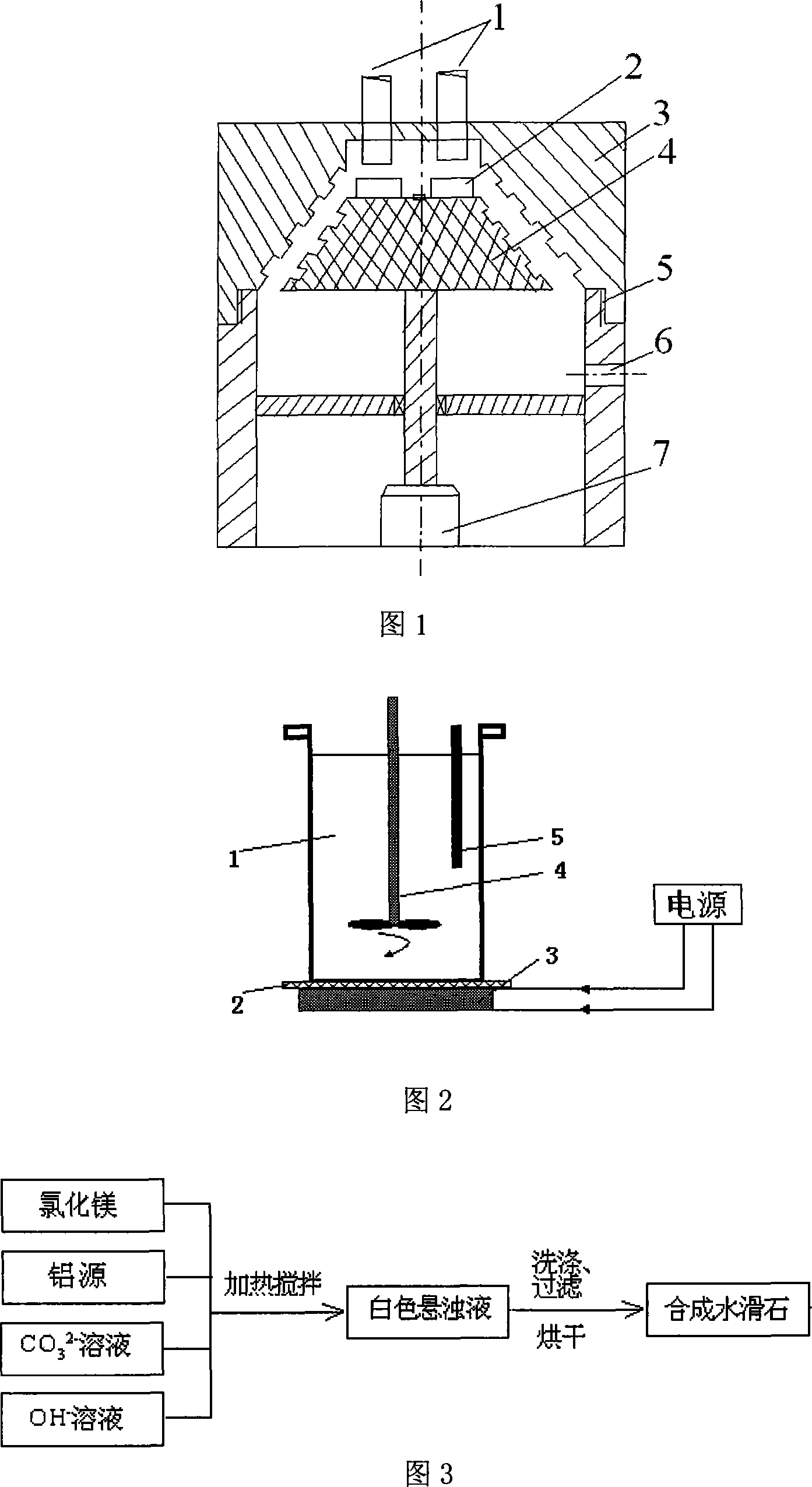

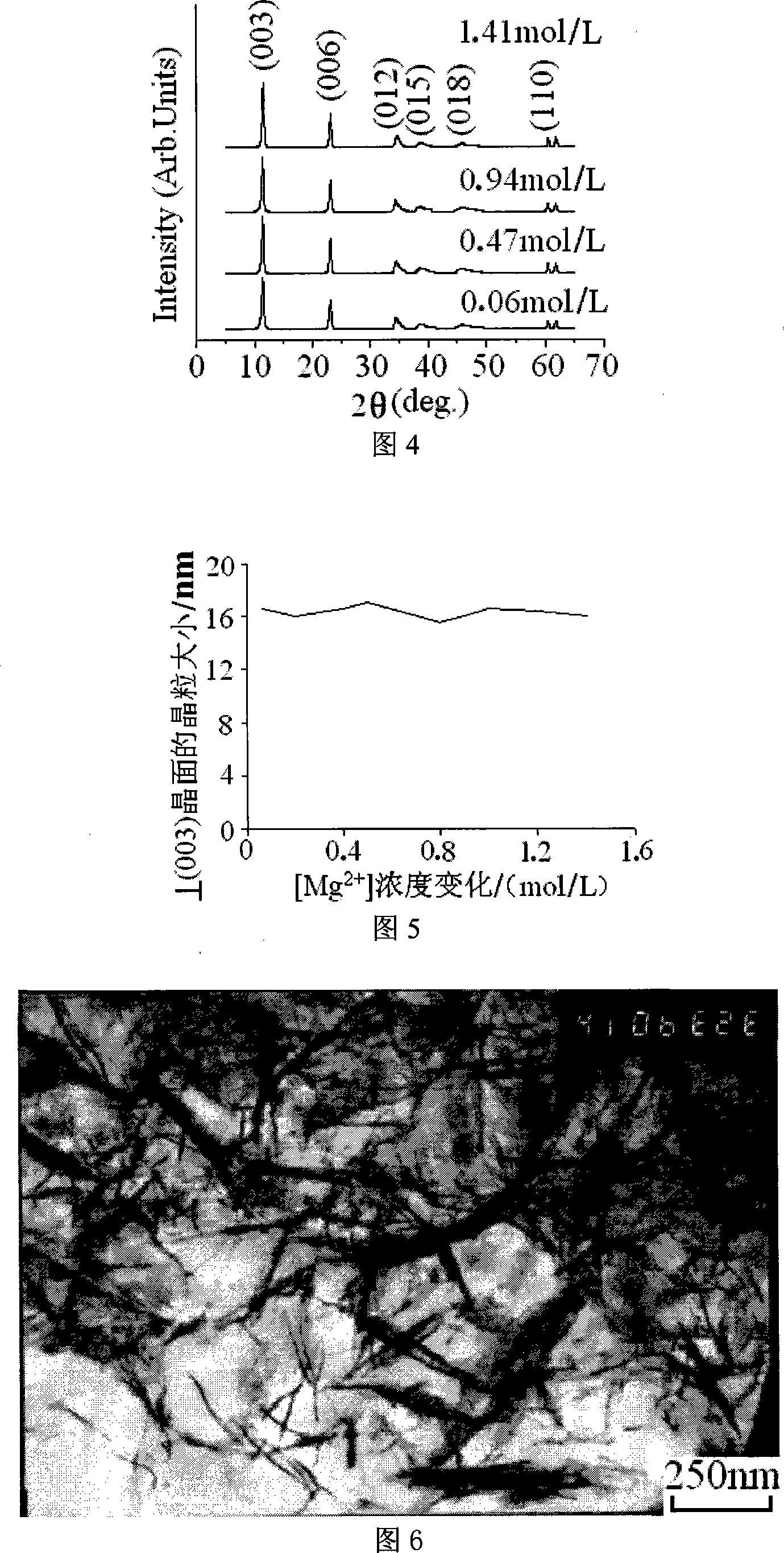

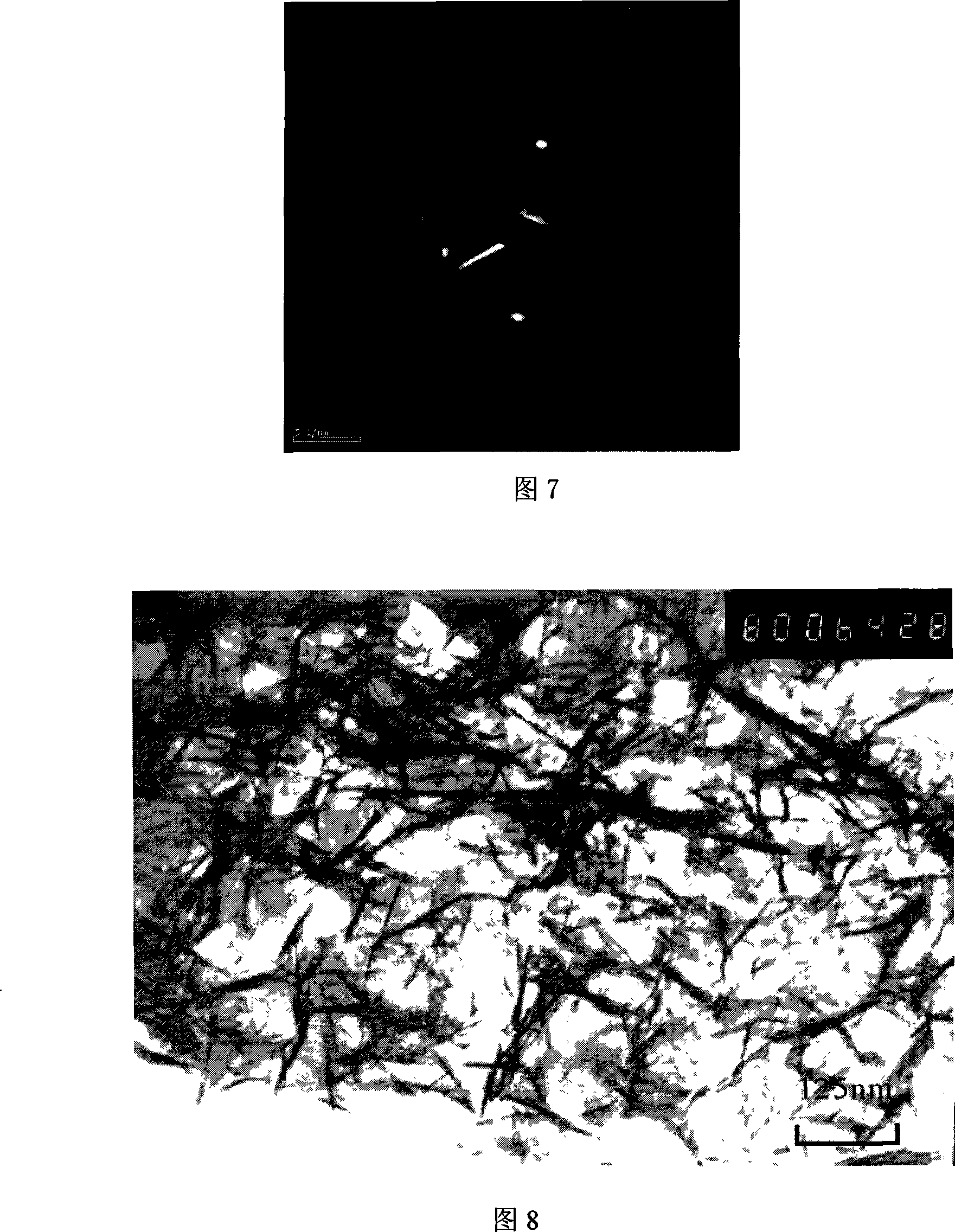

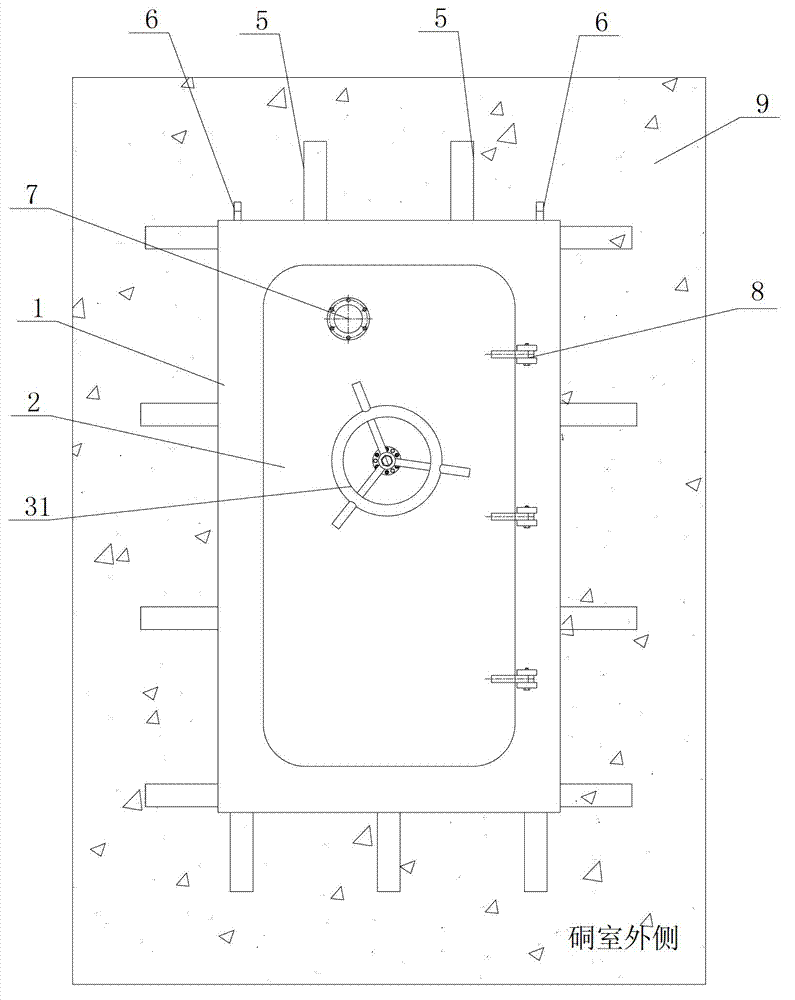

Needle, flake-shaped nano single crystal mg-al hydrotalcite Mg8Al2(OH)16CO3 4H2O preparation method

ActiveCN101187060AGood dispersionUniform sizePolycrystalline material growthSingle crystal growth detailsSingle crystalFire retardant

The invention discloses a process for preparing acicular, flake nano single crystal magnesia-alumina hydrotalcite Mg6Al2(OH)16C.4H2O, and the prepared Mg6Al2(OH)16CO3.4H2O is used as a flame retardant of power electronic devices. Acicular components comprise 0.06-1.41 mol / L crystal magnesium chloride, 0.02-0.47 mol / L aluminum salt, 0.3-4.5 mol / L sodium hydroxide and 0.094-1.368 mol / L sodium carbonate, and flake components are added with modifier basing on the above components. The invention has the process steps that the crystal magnesium chloride and the sodium hydroxide are firstly dissolved in deionized water and heated and stirred, and then the aluminum salt and sodium carbonate are added into the solution, the deionized water and the sodium hydroxide are added every 20 minutes during reaction, the time of reaction is 0.5-2 hours, and the solution is cooled until room temperature and is washed, filtered and dried. The crystal morphology of the prepared acicular nano single crystal magnesia-alumina hydrotalcite is that the diameter is 10-20 nanometer, the length is 60-130 nanometer, the diameter is 25-80 nanometer, and the length is 200-500 nanometer. The crystal morphology of the flake nano single crystal magnesia-alumina hydrotalcite is that the thickness is 10-20 nanometer, the diameter is 50-100 nanometer, the thickness is 20-30 nanometer, and the diameter is 60-200 nanometer. The process for preparation of the invention has short period and simple process, is prepared at atmospheric pressure, and is suitable for industrial production.

Owner:XIDIAN UNIV

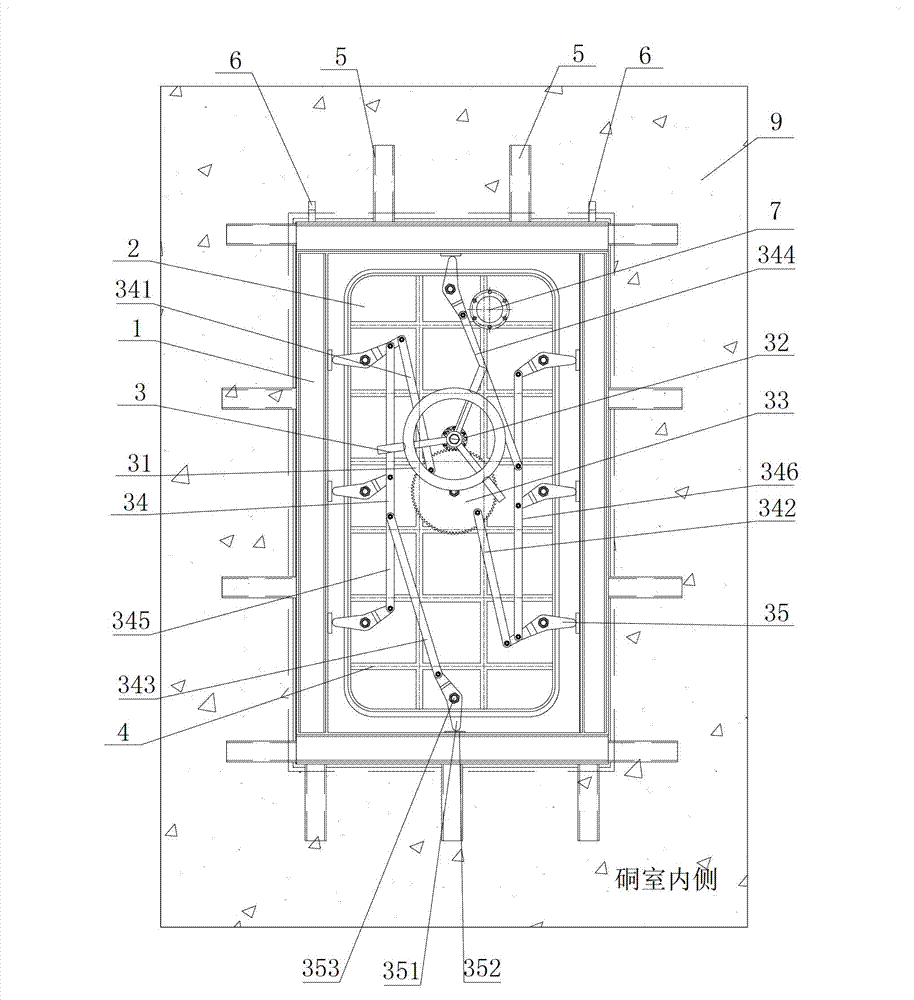

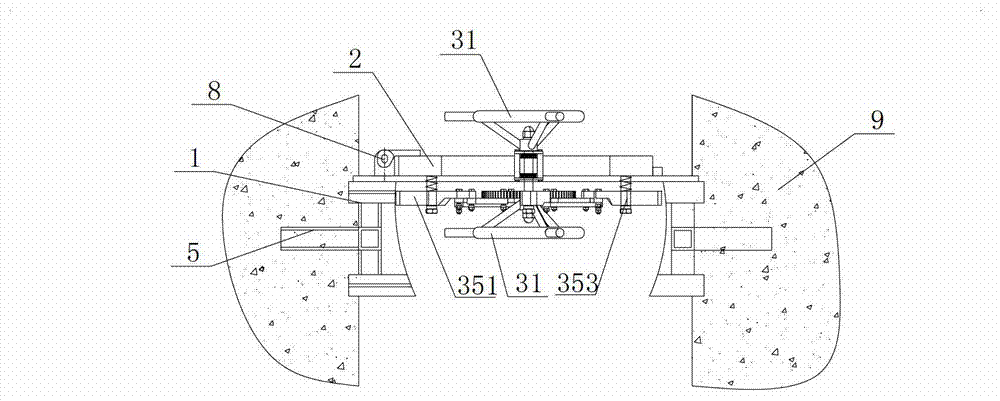

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

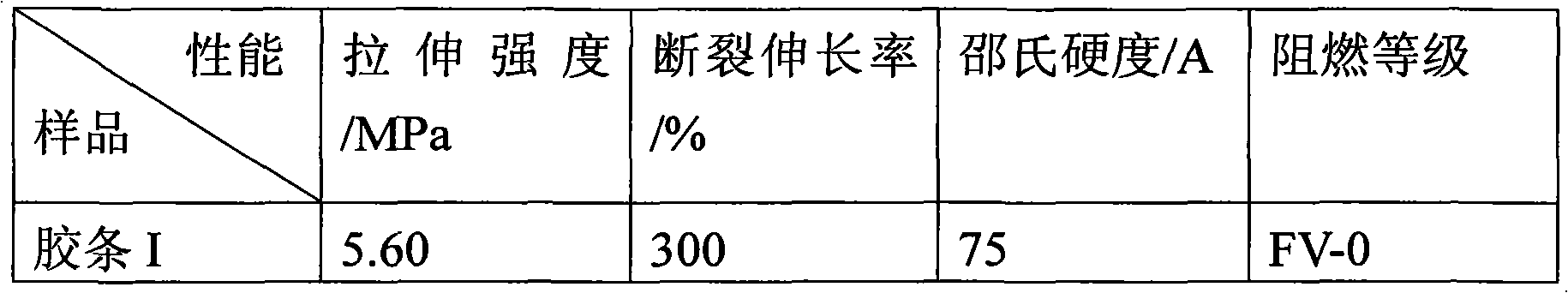

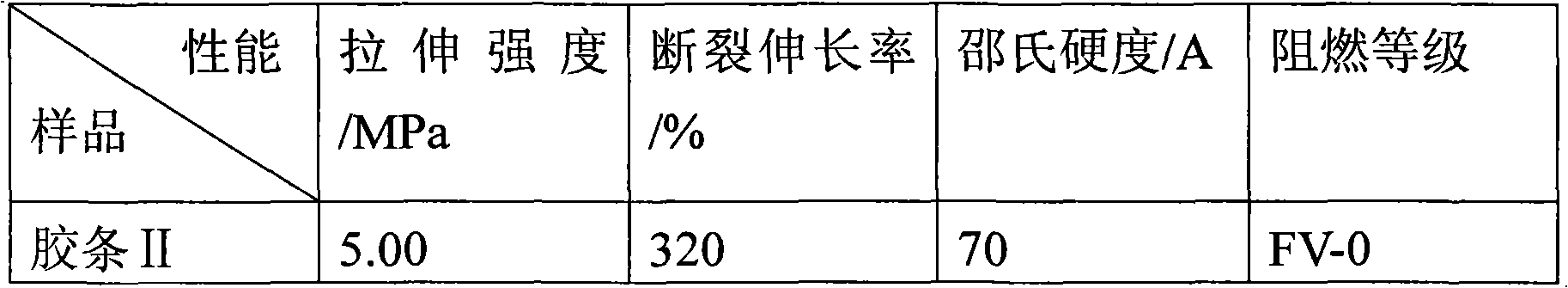

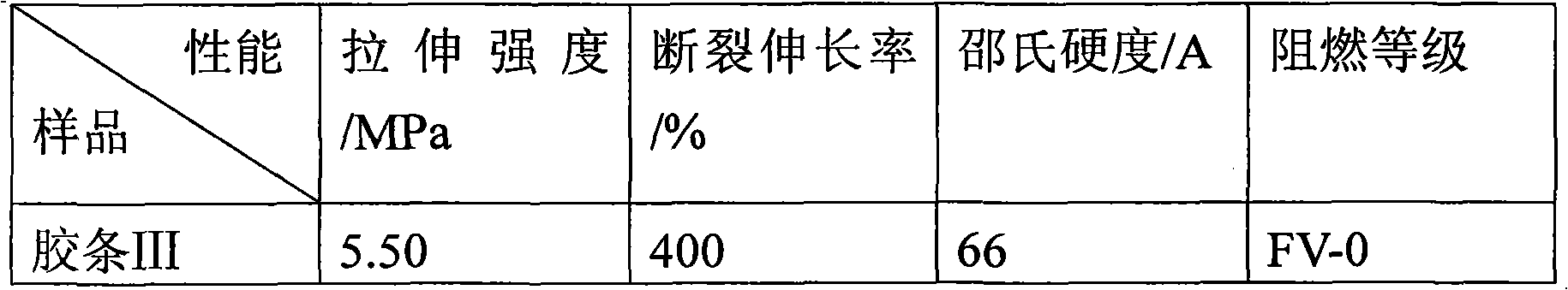

Flame-retardant high-temperature vulcanized silicone rubber strips for doors and windows of buildings and preparation method thereof

The invention discloses flame-retardant high-temperature vulcanized silicone rubber strips for doors and windows of buildings and a preparation method thereof. The method comprises the following steps: adding methyl vinyl silicone rubber, an inorganic flame retardant, fillers and a structural control agent into a kneading machine, dehydrating the mixture at the temperature of between 100 and 180 DEG C and the vacuum degree of between -0.06 and -0.10 MPa for 0.5 to 4 hours, and then cooling the mixture to produce compound rubber; thinning and milling masterbatch rubber, a vulcanizing agent and the compound rubber for 3 to 5 times at room temperature on a mill; cutting thinned compound rubber sheet into rubber strips with the width of between 4 and 6 centimeters and feeding the rubber strips to a screw extruder to extrude the rubber strips; and vulcanizing and forming the rubber strips through a high-temperature drying channel and finally performing a secondary vulcanization in a drying box to produce the flame-retardant high-temperature vulcanized silicone rubber strips for the doors and the windows of the buildings. The flame-retardant high-temperature vulcanized silicone rubber strips for the doors and the windows of the buildings overcome the defects of low hardness and difficult installation of common silicone rubber strips, have high flame-retardant performance and wide range of use temperature, and can be used under bad weather conditions.

Owner:浙江凌志新材料有限公司

Halogen-Free Flame-Retardant Polyolefin Composite Foam Material And Preparation Method Thereof

This present invention discloses a halogen-free flame retardant polyolefin foam composite, which is comprises: 80-125 parts by weight of ethylene / vinyl acetate copolymer (EVA), 8-13 parts by weight of high density polyethylene (HDPE) or low density polyethylene (LDPE), 15-25 parts by weight of polyolefin elastomer (POE), 60-77 parts by weight of acid source material, 17-22 parts by weight of carbon source material, 8-11 parts by weight of gas source material, 1-8 parts by weight of retardant synergist, 5.5-8 parts by weight of composite foaming agent, 0.7-1.0 parts by weight of crosslinking agent, 4.0-5.5 parts by weight of plasticizer, 0.5-1.6 parts by weight of surface treatment agent, 20-35 parts by weight of compatibility, 6-14 parts by weight of inorganic filler, and 1.6-4.6 parts by weight of additive. This halogen-free flame retardant polyolefin foam composite has the advantages of good softness, flexibility, impact resistance, low density, low compressibility and deformability, good shock absorbability, and so on.

Owner:FUZHOU UNIV

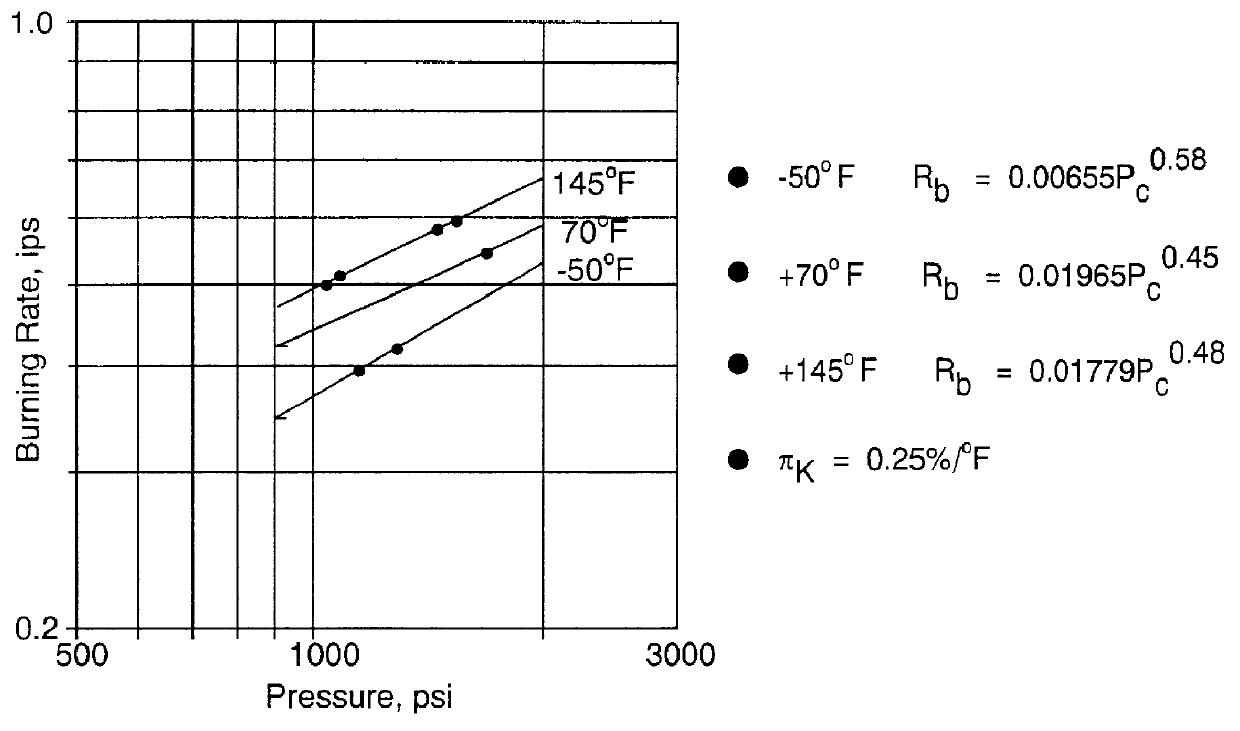

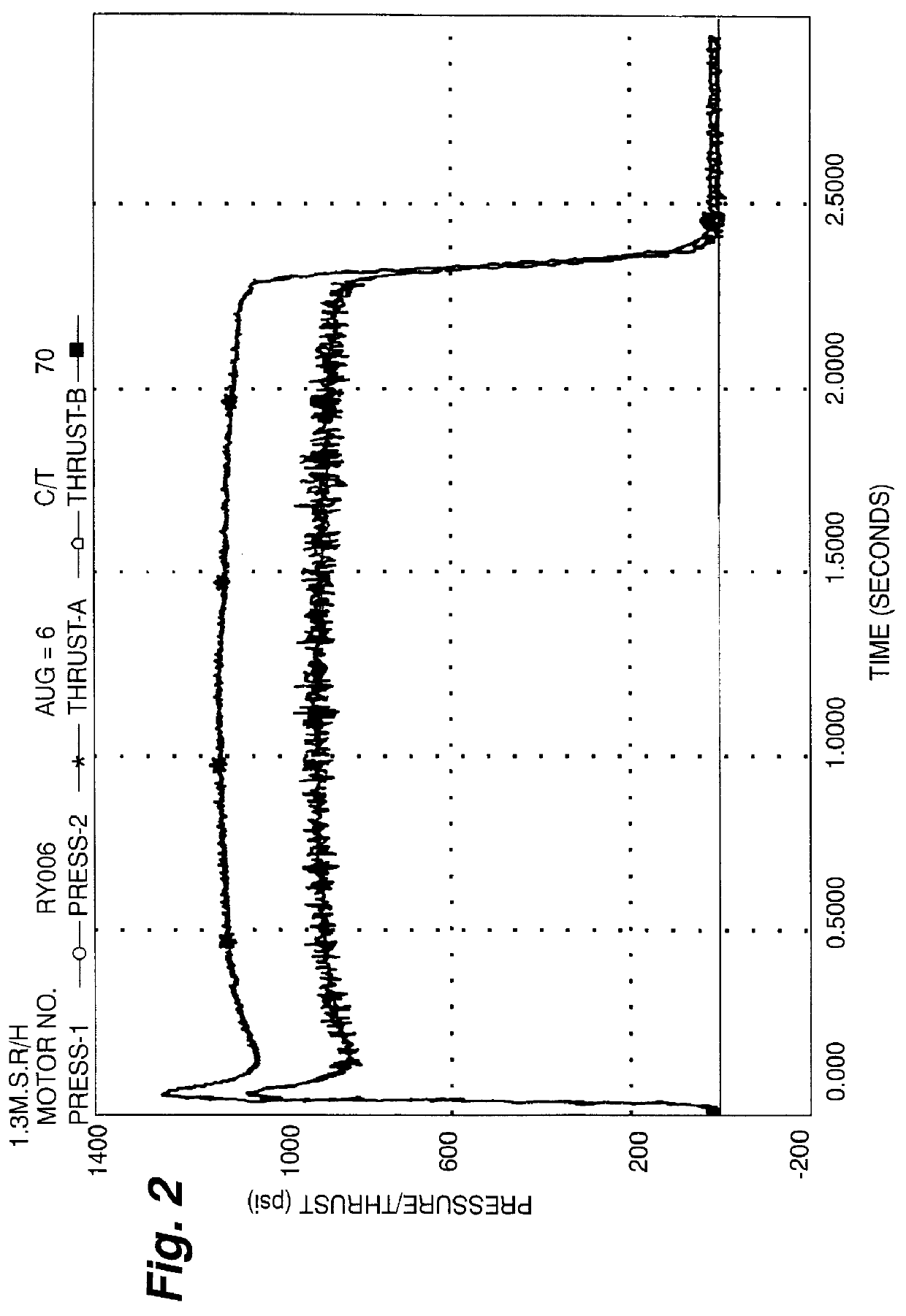

Castable double base solid rocket propellant containing ballistic modifier pasted in an inert polymer

InactiveUS6024810AHigh sensitivityLow smokeCosmonautic propulsion system apparatusNitrocellulose explosive compositionsDetonationBurn rate

Castable propellant formulations are provided including reduced toxicity ballistic modifiers that do not adversely increase the sensitivity of the propellant to shock detonation. Failure to adequately control the propellant burn rate often results in unacceptable performance of the propellant. Carbon can act as an effective ballistic, but not to the extent of metal compounds. It has been found that pasting a ballistic modifier, including ballistic modifiers containing lead, in an inert polymer modifies the burn rate of propellants while allowing the use of a reduced amount of modifier to achieve the same desired burn rate modification as the prior art, and therefore creating reduced shortcomings associated with the ballistic modifiers. Accordingly, the use of from about 1% to about 6% burn rate modifier wherein the burn rate modifier includes a ballistic modifier pasted in an inert polymer is taught as an effective burn rate modifier in a propellant, in order to provide reduced toxicity means for modifying the propellant burn rate without increasing the sensitivity of the propellant to shock detonation.

Owner:AEROJET ROCKETDYNE INC

Polyolefin flame retardant composition and synergists thereof

InactiveUS20150004343A1Low heat release rateLow smokeRubber insulatorsLayered productsPolymer sciencePolyolefin

There is provided herein a flame-retarded polyolefin composition comprising a thermoplastic polyolefin, an inorganic flame retardant filler and a metal phosphonate or metal phosphinate synergist of the general formula (A): where Me is a metal, R1 and R2 are the same or different linear or branched or cyclic alkyls having up to 6 carbon atoms, or benzyl, n is a metal valency and can be, 1, 2, 3 or 4, x is 1 for metal phosphonates and x is 0 for metal phosphinates. There is also provided a method for making a flame-retarded polyolefin composition comprising contacting at least one thermoplastic polyolefin polymer with at least one inorganic flame retardant filler and at least one metal phosphonate or metal phosphinate synergist and heating the mixture to above the melting temperature of the thermoplastic polyolefin.

Owner:ICL IP AMERICA INC

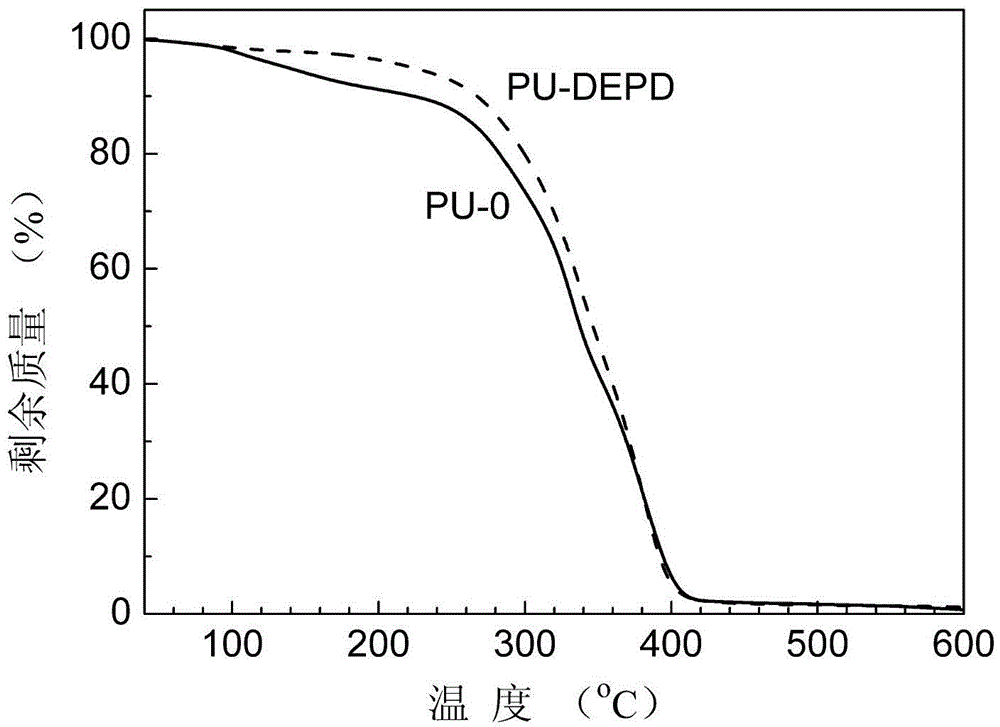

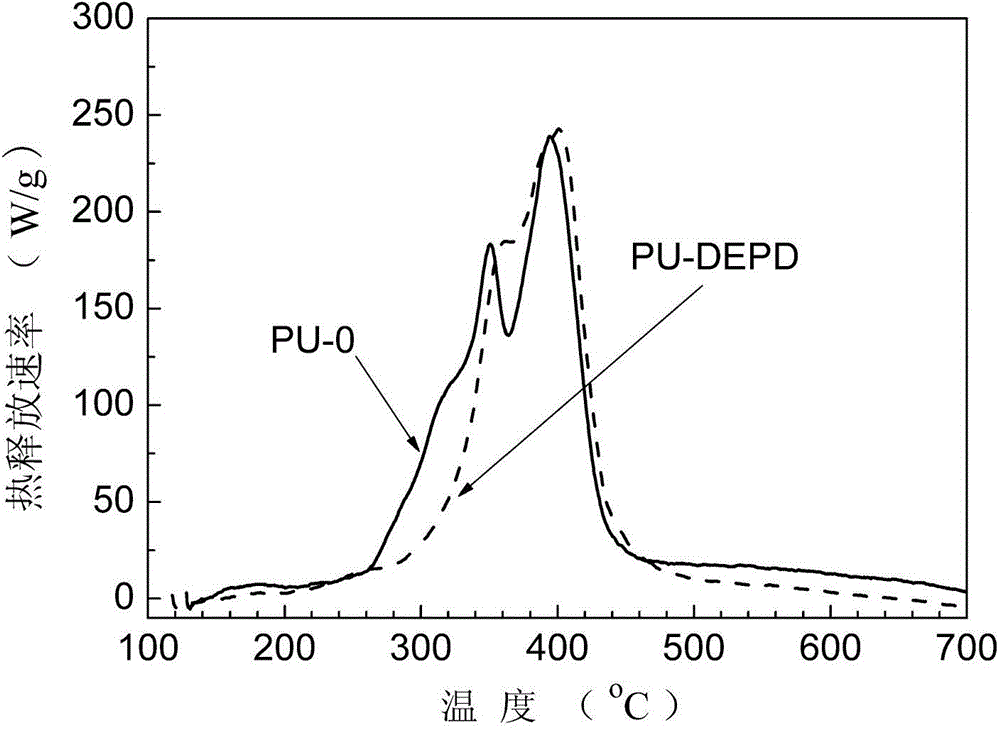

Halogen free phosphorous-nitrogen synergic antiflaming water-soluble polyurethane fabric coating agent and preparation method thereof

The invention relates to halogen free phosphorous-nitrogen synergic antiflaming water-soluble polyurethane fabric coating agent and a preparation method thereof, belonging to the technical field of light industry. The coating agent comprises diisocyanate, non-antiflaming polyalcohol, reactive type phosphorous-nitrogen series polyalcohol, hydrophilic chain extender and neutralizing agent. The diisocyanate, non-antiflaming polyalcohol, reactive type phosphorous-nitrogen series polyalcohol and hydrophilic chain extender are added into a kettle, and reaction is carried out, thus obtaining prepolymer; then the prepolymer is added into aqueous solution containing neutralizing agent, emulsification neutralization is carried out in high speed emulsification equipment, and then rotary evaporation is carried out to remove solvent, thus obtaining target product. The invention has the characteristics of environmental protection, no toxicity, low smoke, phosphorous-nitrogen synergic antiflaming and obvious antiflaming effect; the antiflaming water-soluble polyurethane fabric coating agent is adopted for finishing fabric, coating is transparent and unsticky, handfeel of fabric is not influenced, and soaping resistance can be realized, thus passing level B1 in GB / T5455-1997 textile-burning behaviour-vertical method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

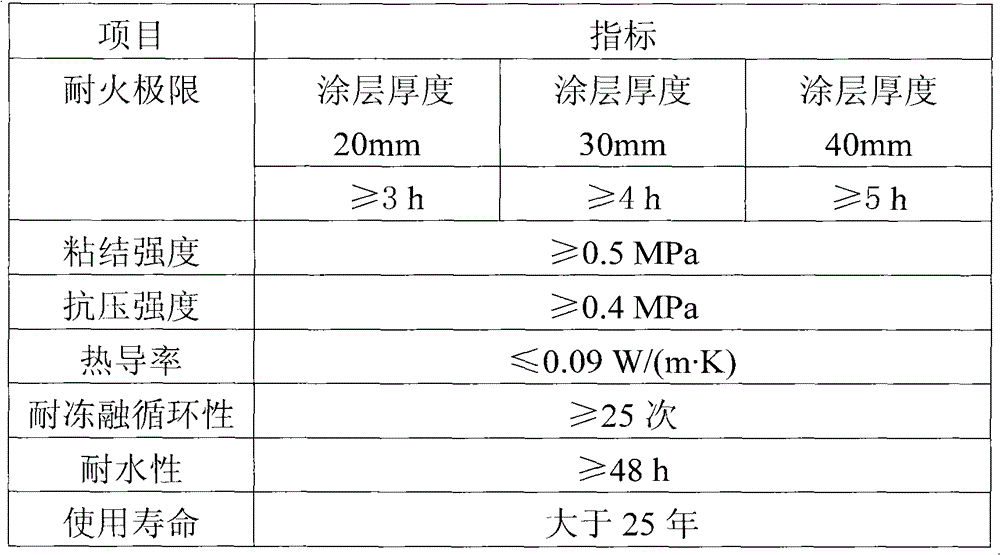

Steel structure fireproof paint by taking expanded and vitrified small ball as base material

The invention provides a preparation method of a steel structure fireproof paint by taking expanded and vitrified small ball as a base material, which is characterized in that on the basis of a traditional organic inorganic clad steel structure fireproof paint, and expanded and vitrified small ball and phenolic resin are used for obtaining the steel structure fireproof paint with excellent performance. According to the invention, expanded and vitrified small ball in the inorganic component replace a traditional lightweight aggregate, thereby the paint has the advantages of low density, high strength, stable physical and chemical performance, and has excellent performances of aging resistance and weatherability, heat insulation, fire resistance, sound insulation and insulation; phenolic resins can replace a traditional film forming agent in the organic component, no fire retardant is applied, so that the coating has the advantages of difficult combustion, good heat stability, low smoke, low toxicity, high mechanical strength, and strong anti-corrosion capability and weather resistance. The paint overcomes the disadvantages of poor flame resistance and toxic flue gas release due to thermal decomposition of the common organic resin.

Owner:BEIJING BUILDING TECH DEV

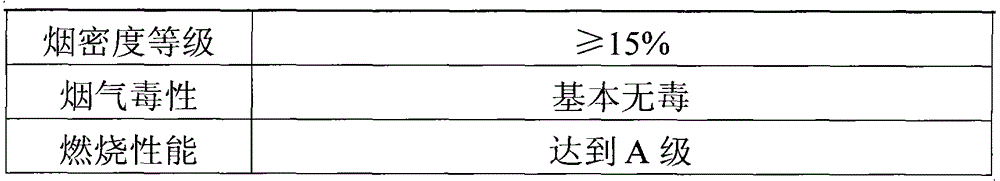

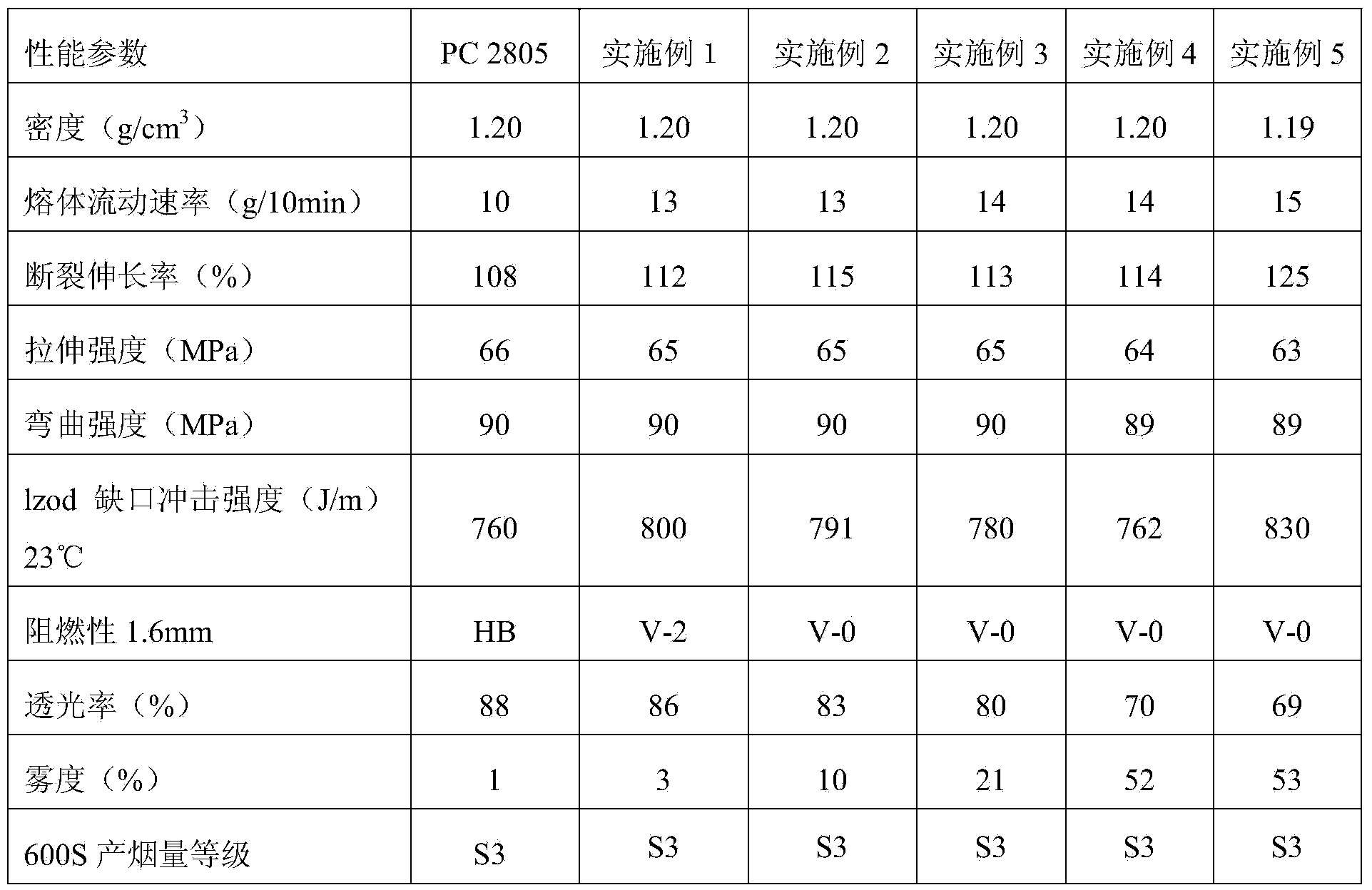

Transparent halogen-free low smoke antiflaming polycarbonate composite material and preparation method thereof

The invention discloses a transparent halogen-free low smoke antiflaming polycarbonate composite material and a preparation method thereof. The polycarbonate composite material comprises the following components in parts by weight: 900-980 parts of polycarbonate resin, 5-50 parts of polysiloxane fire retardant, 1-10 parts of sulfonate fire retardant, and 5-50 parts of additive. The preparation method comprises the following steps of mixing the polycarbonate resin, polysiloxane fire retardant, sulfonate fire retardant and additive in a highly mixing machine, then pelletizing through twin screw extrusion, drying and injection molding so as to obtain the transparent halogen-free low smoke antiflaming polycarbonate composite material. On one hand, the hazard that bromine antiflaming polycarbonate material generates carcinogen such as 4-bromo-dibenzdioxan and 4-bromo-dibenzofuran is avoided; on the other hand, the transparent halogen-free low smoke antiflaming polycarbonate composite material has excellent antiflaming performance, reaches the US standard of UL94V-0, also has high grade of transparency and excellent mechanical property, thermal property, low temperature performance and low smoke performance, and remarkably improves the processibility of the material.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

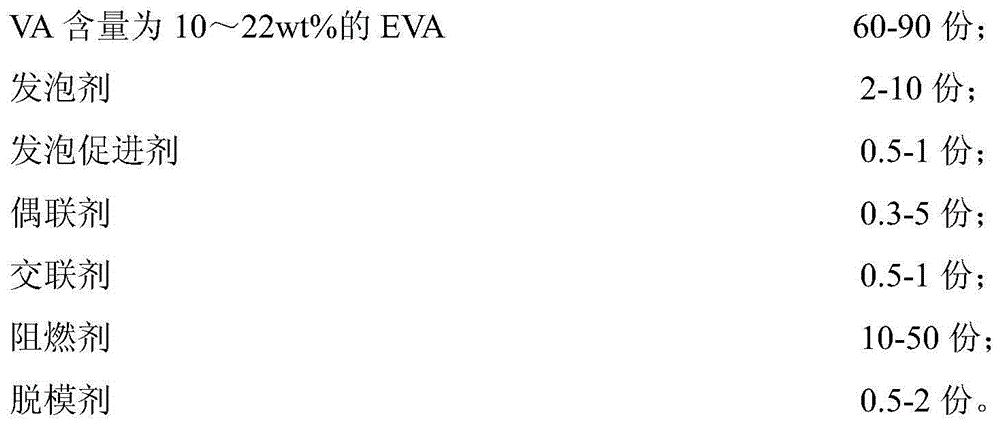

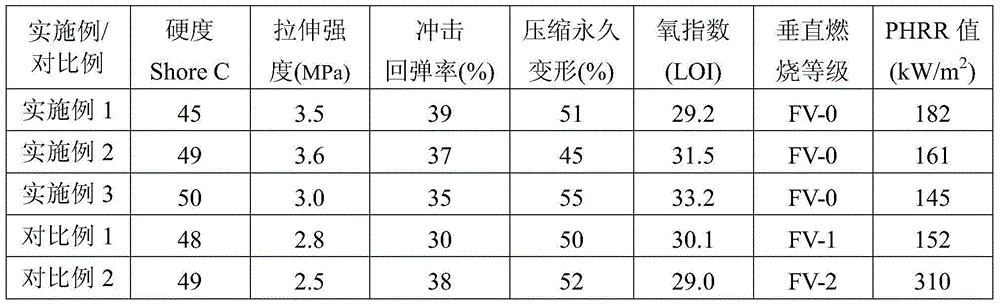

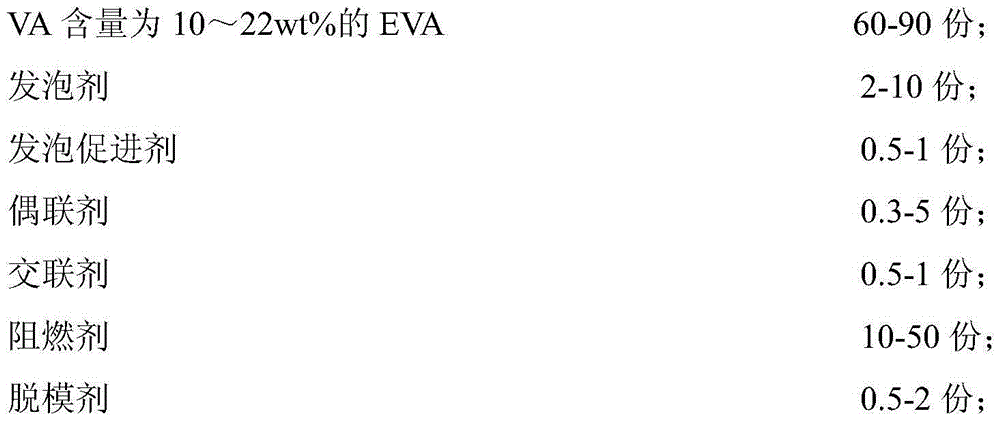

Nano-Mg-Al hydrotalcite fire-retardant EVA foaming material and preparation method thereof

InactiveCN105440420AImprove mechanical propertiesImprove flame retardant performanceCombustionFoaming agent

The present invention relates to a nano-Mg-Al hydrotalcite fire-retardant EVA foaming material comprising, by weight, 60-90 parts of an ethylene-vinyl acetate copolymer with 10-22wt% of VA, 2-10 parts of a foaming agent, 0.5-1 part of a foaming accelerator, 0.3-5 parts of a coupling agent, 0.5-1 part of a crosslinking agent, 10-50 parts of a flame retardant and 0.5-2 parts of a releasing agent, and the flame retardant is nano-Mg-Al hydrotalcite. Compared with traditional metal hydroxide flame retardants, the nano-Mg-Al hydrotalcite has great advantages in improvement of the limiting oxygen index, improvement of vertical combustion performances and reduction of heat release rate and other flame retardant aspects, and is better fire-retardant inhibitor. The present invention also provides a preparation method of the foaming material, and the method is simple to operate, the foaming process is not needed to be further modified or changed, production cost can be reduced, and energy can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

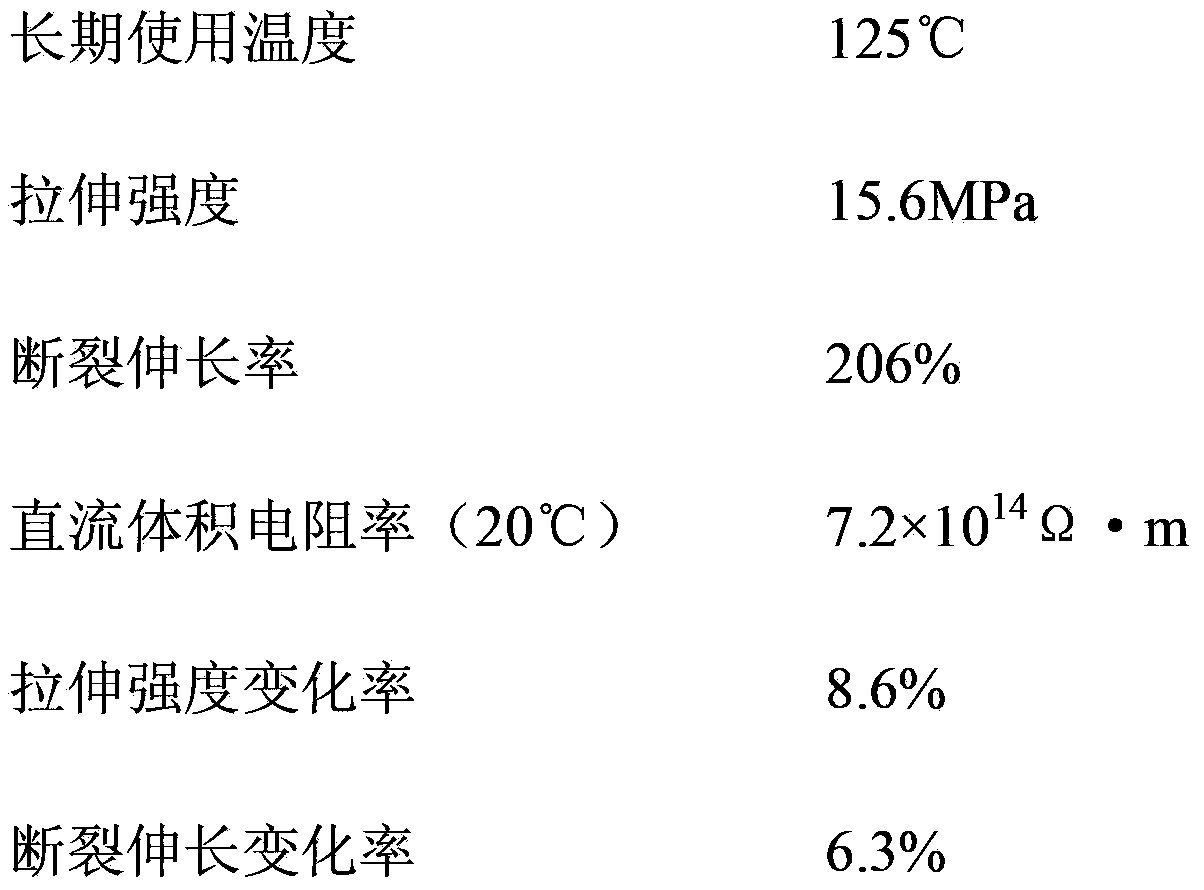

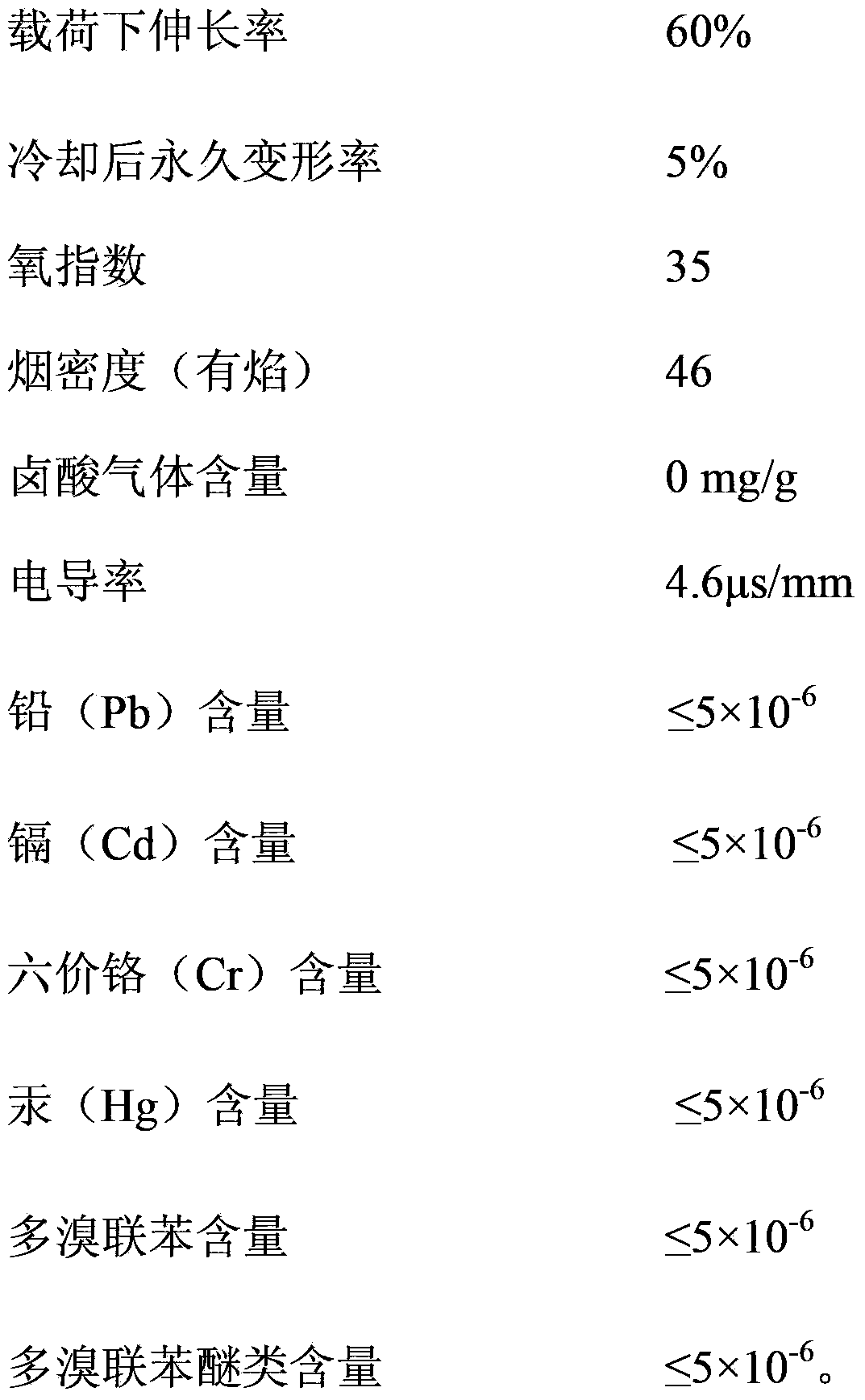

High-temperature resistant wear-resistant irradiation cross-linked regenerated-polyolefin/nano-magnesium-hydroxide halogen-free flame-retardant environmental-friendly cable material with high electric properties and production method of the cable material

ActiveCN103360712AIncrease added valueCreate pollutionPlastic/resin/waxes insulatorsCross-linkPolyolefin

The invention provides a high-temperature resistant wear-resistant irradiation cross-linked regenerated-polyolefin / nano-magnesium-hydroxide halogen-free flame-retardant environmental-friendly cable material with high electric properties. The cable material is used for products comprising power cables, mine cables, marine cables, electric equipment lines, locomotive and vehicle cables, and the like. The cable material is produced from following raw materials by weight: 30-40 parts of a regenerated polyolefin, 40-50 parts of a compatilizer, 15-20 parts of an ethylene-propylene-diene monomer (EPDM), 120-150 parts of a nano flame retardant, 3-5 parts of an antismoke agent, 3-3.5 parts of a sensitizer, 1-2 parts of a coupling agent, 1.0-1.5 parts of an antioxidant, 1.5-2 parts of a lubricant and 0.8-2.5 parts of a colorant. According to the cable material and the production method, waste and old plastics are used as the raw materials and an irradiation cross-linking technology and an nano new material are employed, and therefore the cable material has good comprehensive performances comprising high-temperature resistance, wear resistance, high electric properties, oil resistance, high strength, less smoke, no halogen, high flame retardance, good fluidity, etc., and the environmental performance of the cable material meets the requirements of electric wires and cables.

Owner:河南久通电缆有限公司 +1

Low smoke, low toxicity fiber optic cable

ActiveUS7187829B2Low smokeLow toxicityOptical fibre with multilayer core/claddingCoupling light guidesFiberEngineering

A low smoke, low toxicity fiber optic cable that provides an intermediate surface that facilitates bonding to optical connectors such as LC connectors, is provided. In a preferred embodiment, the inventive cable exhibits improved dimensional stability by minimizing or eliminating shrinkage stress on the optic fiber core.

Owner:JUDD WIRE

Flame-retardant polyethylene cable material capable of preventing mould

ActiveCN103509228AWith anti-mold functionWeather resistantInsulatorsZinc hydroxideLinear low-density polyethylene

The invention provides a flame-retardant polyethylene cable material capable of preventing mould. The flame-retardant polyethylene cable material is prepared with the following components and raw materials by weight: 50-60 parts of high-density polyethylene, 30-45 parts of linear low-density polyethylene, 10-15 parts of polyester resin, 8-10 parts of organic silicon resin, 2-3 parts of simethicone, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 1-2 parts of barium sulfate, 5-6 parts of dolomite, 6-8 parts of attapulgite, 4-6 parts of celestite, 10-12 parts of zinc hydroxide, 10-15 parts of triammonium phosphate, 10-12 parts of tricresyl phosphate (TCP), 6-8 parts of poly(1,2-propylene glycol adipate), 1-2 parts of sophora flavescens alcohol extract, 0.5-0.6 parts of zanthoxylum oil, 1-2 parts of OBPA (10,10'-oxybisphenoxarsine) mould inhibitor, 1-1.5 parts of PVC (polyvinyl chloride) processing agent ACR-401 (acrylate plastic modifier), and 10-15 parts of modified filler. The cable wire has good antibacterial property, and the characteristics of weather resistance, low smoke, ageing resistance, flame retardation and so on.

Owner:蚌埠尚维知识产权运营有限公司

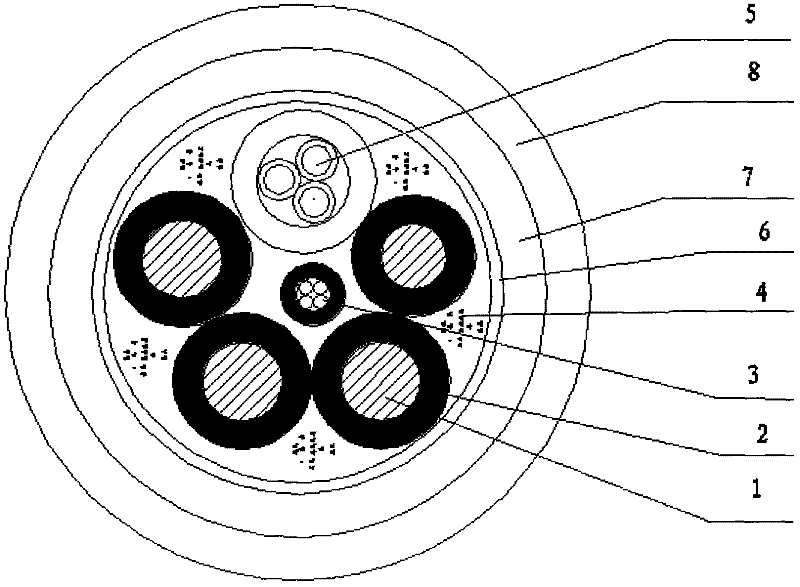

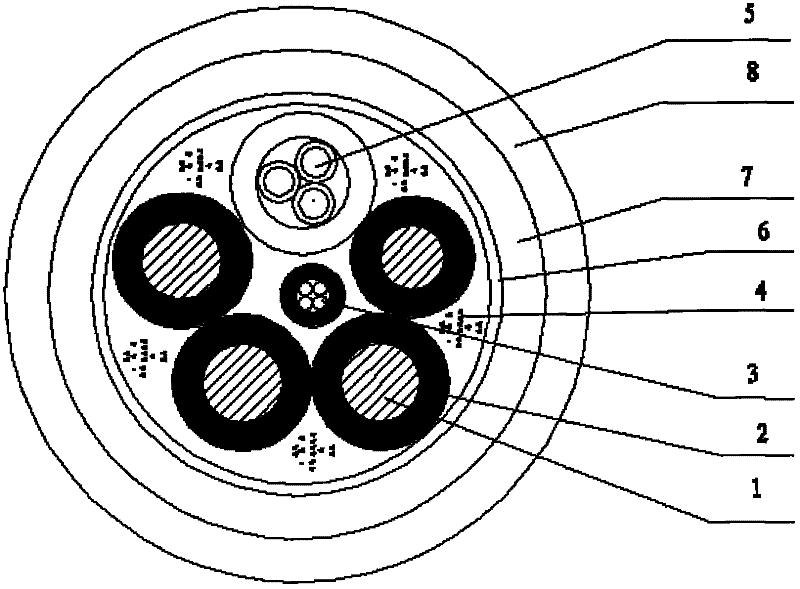

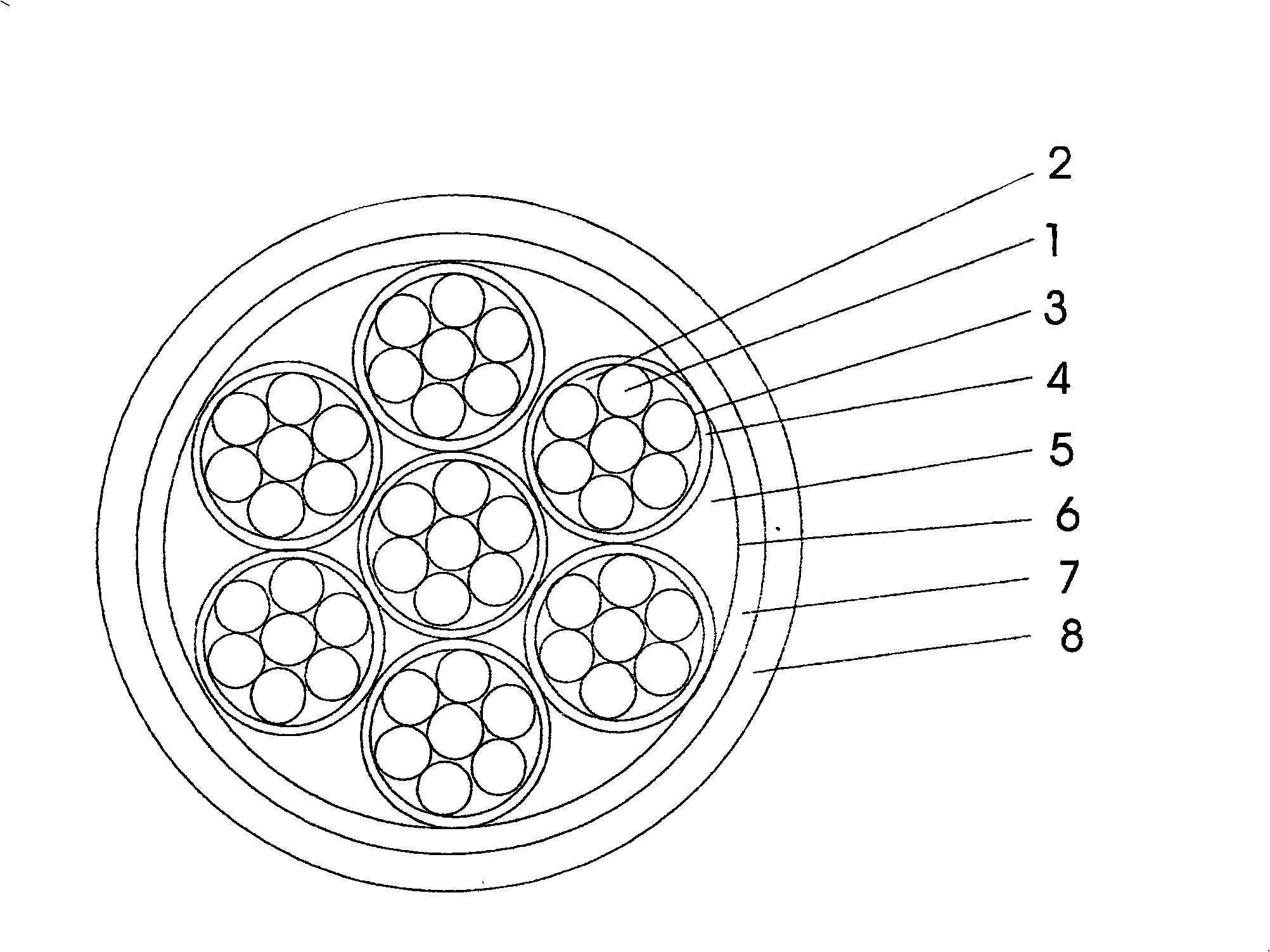

Optical fiber composite low-voltage smart cable for coal mine and preparation method thereof

InactiveCN102298993AReal-time understanding of the working surfaceReduce secondary wiring (control cables)Power cablesInsulating conductors/cablesFiberFire protection

The invention discloses an optical-fiber composite low-voltage intelligent cable used in coal mine. The optical-fiber composite low-voltage intelligent cable comprises: an insulation core, a fiber unit and a control cable unit. The cable is characterized in that: rubber strip fillers are filled in gaps between the insulation core, the fiber unit and the control cable unit; a taped covering, a fire protection layer and an over sheath are successively arranged out of the insulation core, the fiber unit, the control cable unit and the rubber strip fillers. The optical-fiber composite low-voltageintelligent cable of the invention has good fireproof performance, a mechanical property, an insulating property, a flame retardant property and an acid-resisting / alkali-resisting anticorrosion performance, and possesses low costs and a fiber communication function.

Owner:CHONGQING BAOFENG CABLE

Novel phosphorous siliciferous flame retardant and preparation method thereof

InactiveCN102492171AHalogen freeLow smokeFlame-proof filament manufactureGroup 5/15 element organic compoundsFiberPolymer science

The invention discloses a novel phosphorous siliciferous flame retardant comprising repeated structural units shown in a figure, wherein m ranges from 2 to 4, and n ranges from 5 to 8. The invention further discloses a preparation method for the novel phosphorous siliciferous flame retardant. The phosphorous siliciferous flame retardant disclosed by the invention contains a bis-spiral structure and a DOPO lateral group, can be used for polyolefin cable materials to endow the polyolefin cable materials with very excellent flame retardant property. Besides, compared with the traditional flame retardant, the novel phosphorous siliciferous flame retardant has the characteristics of zero halogen, low smoke, low toxicity, environmental friendliness and the like, and is suitable for polymer materials such as plastic, rubber, fiber and the like.

Owner:SHANGHAI JIAO TONG UNIV

Modified methanol synthesized lead-free gasoline with high cleanness

InactiveCN101643669AStrong antiknockIncrease motivationLiquid carbonaceous fuelsFuel additivesDioxyethylene EtherFatty alcohol

The invention discloses a modified methanol synthesized lead-free gasoline with high cleanness. The modified methanol synthesized lead-free gasoline with high cleanness is prepared by the following components by parts by weight: 30-60 parts of methanol, 30-40 parts of No. 60-No.70 crude gasoline, 0.8-1.5 parts of n-butanol, 1.0-10 parts of coking light oil, 0.3-0.5 part of dimethyl sulfoxide, 0.3-0.5 part of coconut oil polyoxyethylene ether-(20), 0.1-0.3 part of fatty alcohol polyoxyethylene ether-(40), 0.4-0.6 part of dioctyl phthalate, 0.4-0.6 part of dibutyl phthalate, 3-5 parts of dimethyl ether, 1-3 parts of trimethyl carbonate and 0-5 parts of No.6 solvent oil. The modified methanol synthesized lead-free gasoline with high cleanness has small polarity and weak corrosion, exhaust gasdoes not contain formaldehyde, and no atmospheric pollution is produced.

Owner:HEBEI ZHONGZHEN PETROCHEM TRADE

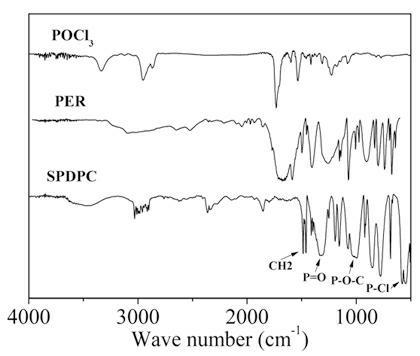

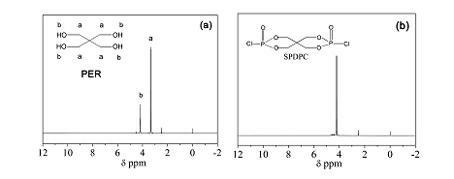

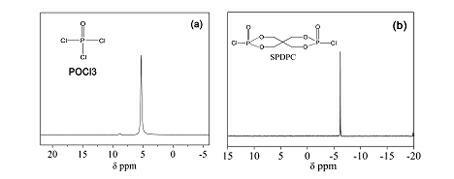

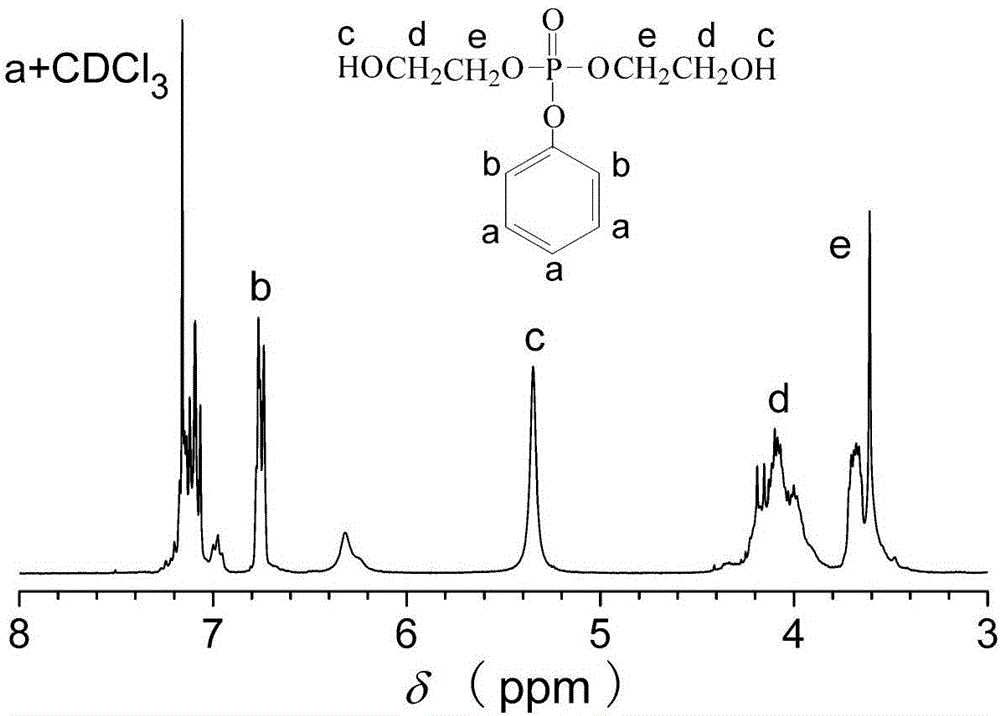

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

Production method of flame-retardant modified wood

InactiveCN104760101AImprove flame retardant performanceGood compatibilityWood treatment detailsPressure impregnationOxygenFire retardant

The invention discloses a production method of flame-retardant modified wood. The method comprises the following steps: 1, firstly, preparing a flame retardant and then adding the flame retardant into modified urea resin liquid to ensure that a mixture is completely dissolved to prepare wood impregnation liquid; 2, performing waiting treatment by using the wood impregnation liquid obtained in the step 1 by means of vacuum pressurization; and 3, drying to obtain the modified wood. The production process is simple, and the treating liquid can be recycled, so that the size stability of the wood subjected to the treatment is obviously improved, the physical and mechanical property can be obviously improved, the weight grain rate of the wood is 20-43 percent, the oxygen index can be improved by 30-70 percent, and the flame retardant performance of the wood can be kept for a long time.

Owner:广西宾阳县荣良农业科技有限公司

Adhesion-imparting agent and adhesion-imparting resin emulsion

InactiveCN101146884AImprove adhesionEasy to operateNatural resin chemical modificationRosin adhesivesEmulsionAdhesive

The present invention provides a tackifier that is a raw material of an adherence adhesive having good adhesion performance (in particular, holding power) for all members and can be used for various adherence adhesives, and a tackifier emulsion capable of being used for various aqueous adherence adhesives. The tackifier and the tackifier emulsion including a rosin resin wherein a ratio of the content of a component with a molecular weight of at most 300 comprised in the rosin resin to the softening point of the rosin resin (the content (% by weight) of a component with a molecular weight of at most 300 / softening point (K)) is at most 0.004; and the adherence adhesive composition including the tackifier; and the aqueous adherence adhesive composition including the tackifier emulsion.

Owner:ARAKAWA CHEM IND LTD

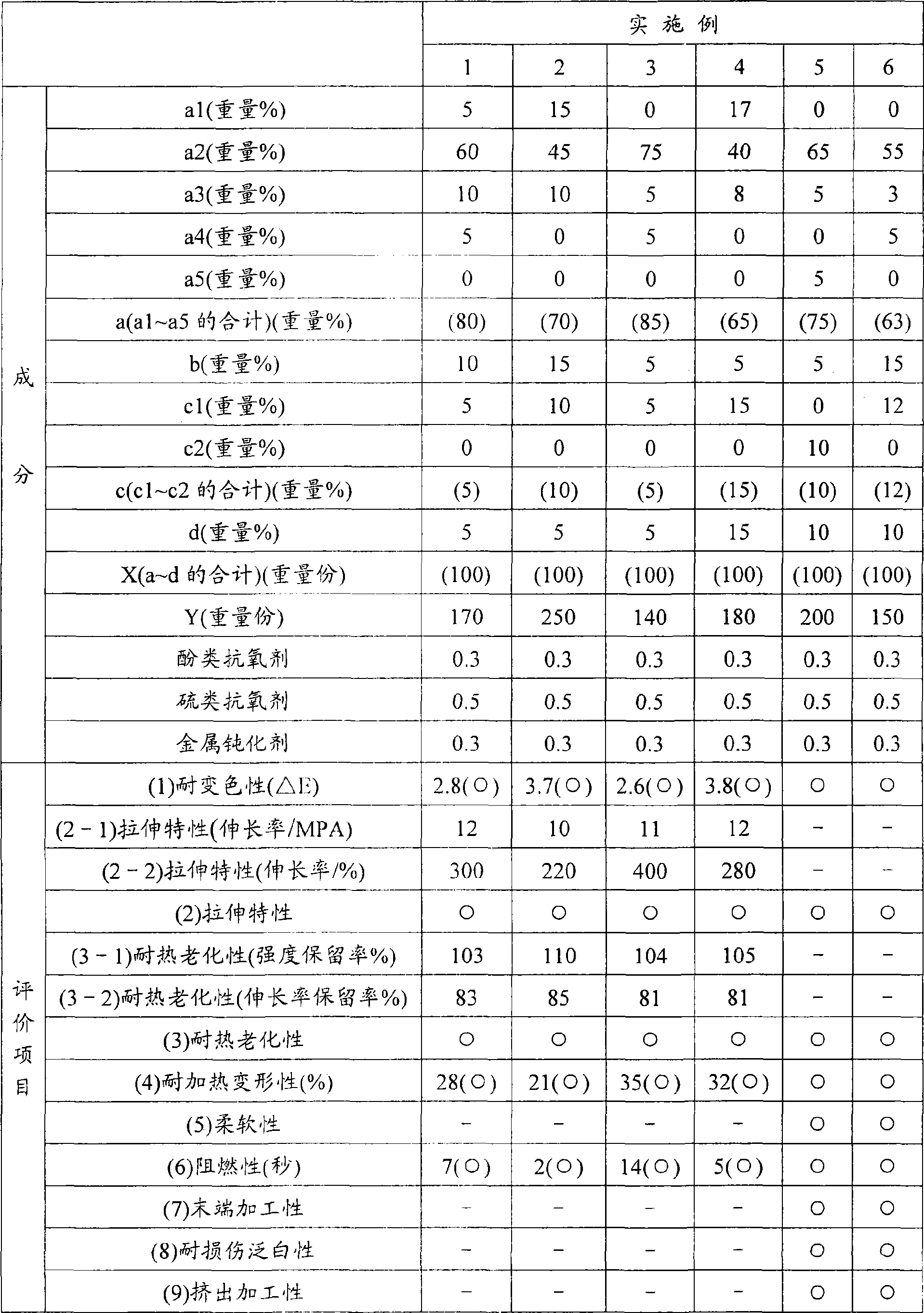

Flame-retardant thermoplastic resin composition

InactiveCN101522780AExcellent discoloration resistanceLow smokePlastic/resin/waxes insulatorsInsulated cablesHalogenThermoplastic elastomer

Disclosed is a flame-retardant thermoplastic resin composition which maintains high flame retardancy without containing a halogen, and is free from problems of conventional non-halogen flame-retardant thermoplastic resin compositions. This flame-retardant thermoplastic resin composition is flexible and highly heat-resistant, while having good terminal workability, scratch whitening resistance, mechanical strength, moldability and excellent discoloration resistance. Specifically disclosed is a flame-retardant thermoplastic resin composition which is obtained by blending 50-300 parts by weight of a metal hydroxide (Y) per 100 parts by weight of a thermoplastic resin composition (X) containing 25-90% by weight of a polyethylene resin (a), 1-20% by weight of a polypropylene resin (b), 5-39% by weight of a styrene thermoplastic elastomer (c) and 4-40% by weight of a mineral oil-based rubber softener (d). This flame-retardant thermoplastic resin composition is characterized in that at least a part of the polyethylene resin (a) is composed of an ethylene-vinyl acetate copolymer (EVA), and the ethylene-vinyl acetate copolymer content is 40-80% by weight relative to 100% by weight of the thermoplastic resin composition (X).

Owner:MITSUBISHI CHEM CORP

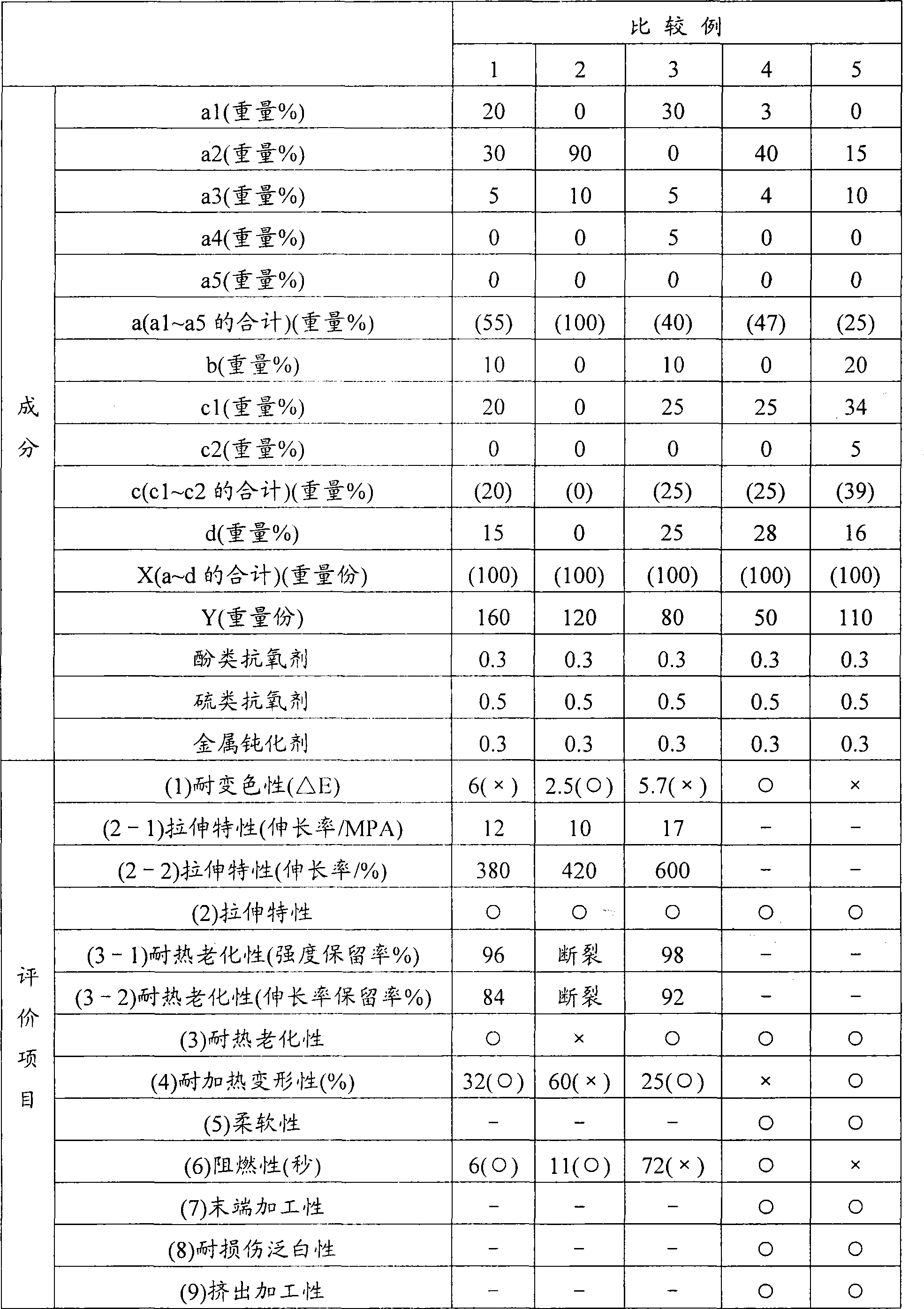

Preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg

The invention relates to a preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg. The solid content and the viscosity-temperature flow characteristic of phenolic resin are controlled with a reasonable synthesis process; solid phenolic resin and liquid epoxy resin are mixed uniformly according to formula design, and a resin system suitable for preparation of prepreg with a hot melt process is obtained; the gelation time of the resin is controlled to range from 140 s to 250 s, a hot melt resin adhesive film is prepared from the hot melt phenolic resin system, the coating temperature is controlled to range from 40 DEG C to 65 DEG C, the hot melt phenolic resin adhesive film and unidirectional fiber or fiber fabric are composited under heating and pressurizing conditions, and the hot melt prepreg is prepared. The hot prepreg with uniform texture and stable resin content can be obtained through resin synthesis, formula design and process design, and the hot melt prepreg and the composite have the characteristics of low smoke, no halogen, low smog toxin and flame retardancy and can meet requirements for use performance of interior trimming and structural composites for high-seed railways, aircrafts, steamships and other transportation tools.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Cable sheath material containing modified methyl vinyl silicone rubber and preparation method thereof

ActiveCN103289415AImprove mechanical propertiesHigh insulation resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolystyrene

The invention discloses a cable sheath material containing modified methyl vinyl silicone rubber and a preparation method thereof. The cable sheath material comprising raw materials of: the modified methyl vinyl silicone rubber, impact-resistant polystyrene, calcium carbonate, diatomite, aluminium nitride, accelerant DM, accelerant TMTD, Bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, calcium ricinoleate, diphenylamine, tributyl citrate and tritolyl phosphate. The cable sheath material containing the modified methyl vinyl silicone rubber and the preparation method thereof employ the modified methyl vinyl silicone rubber as a main material; the mechanical properties of the modified methyl vinyl silicone rubber are greatly modified by modifying the methyl vinyl silicone rubber; the cable sheath material has better mechanical properties, and has the characteristics of low smoke, being free of halogen and high insulation resistance; and calcium carbonate is used as a reinforcing agent in raw materials, and diatomite and aluminium nitride are used as filling materials.

Owner:HUBEI XINHAIHONG CHEM

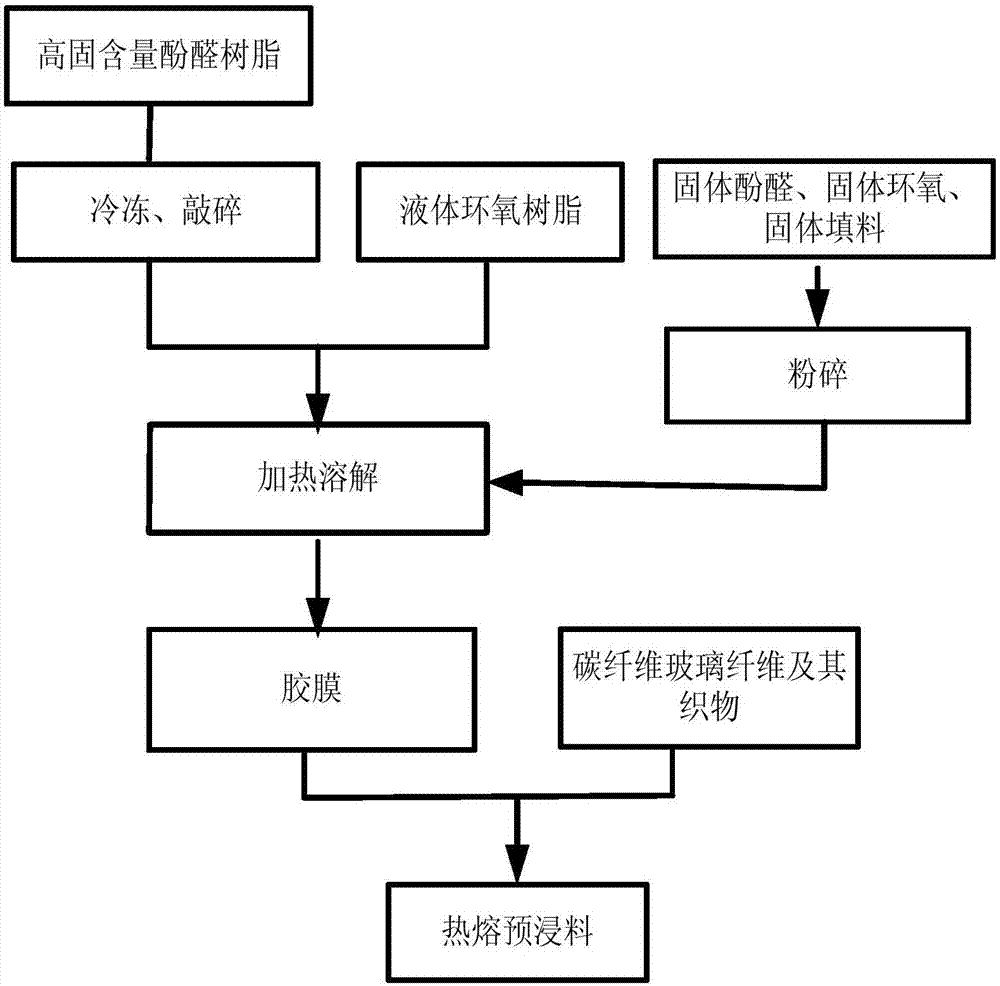

Ceramic fireproof fire-resistant silicon rubber wire and cable

InactiveCN103489510ASo as not to damageGuarantee unimpededInsulated cablesInsulated conductorsElectrical conductorFire - disasters

The invention relates to a ceramic fireproof fire-resistant silicon rubber wire and cable. The wire and cable comprise a plurality of conductors, each conductor is wrapped by a ceramic silicon rubber insulating layer in an extruding mode to form a wire core, multiple wire cores are wrapped by a wrapping tape layer to form a cable core, padding is arranged in the cable core, and a ceramic silicon rubber outer sheath is arranged outside the cable core. The ceramic fireproof fire-resistant silicon rubber wire and cable have characteristics batter than those of a common rubber cable and a flame retardant rubber cable and form a hard shell after being ablated by high-temperature flames to protect a burned article from being damaged, and the hard shell formed after ablation protects the wire and cable, so that unblocked electric power and communication are ensured, and precious time are won for personnel evacuation and rescue under the fire disaster condition.

Owner:江苏金枫达科技有限公司

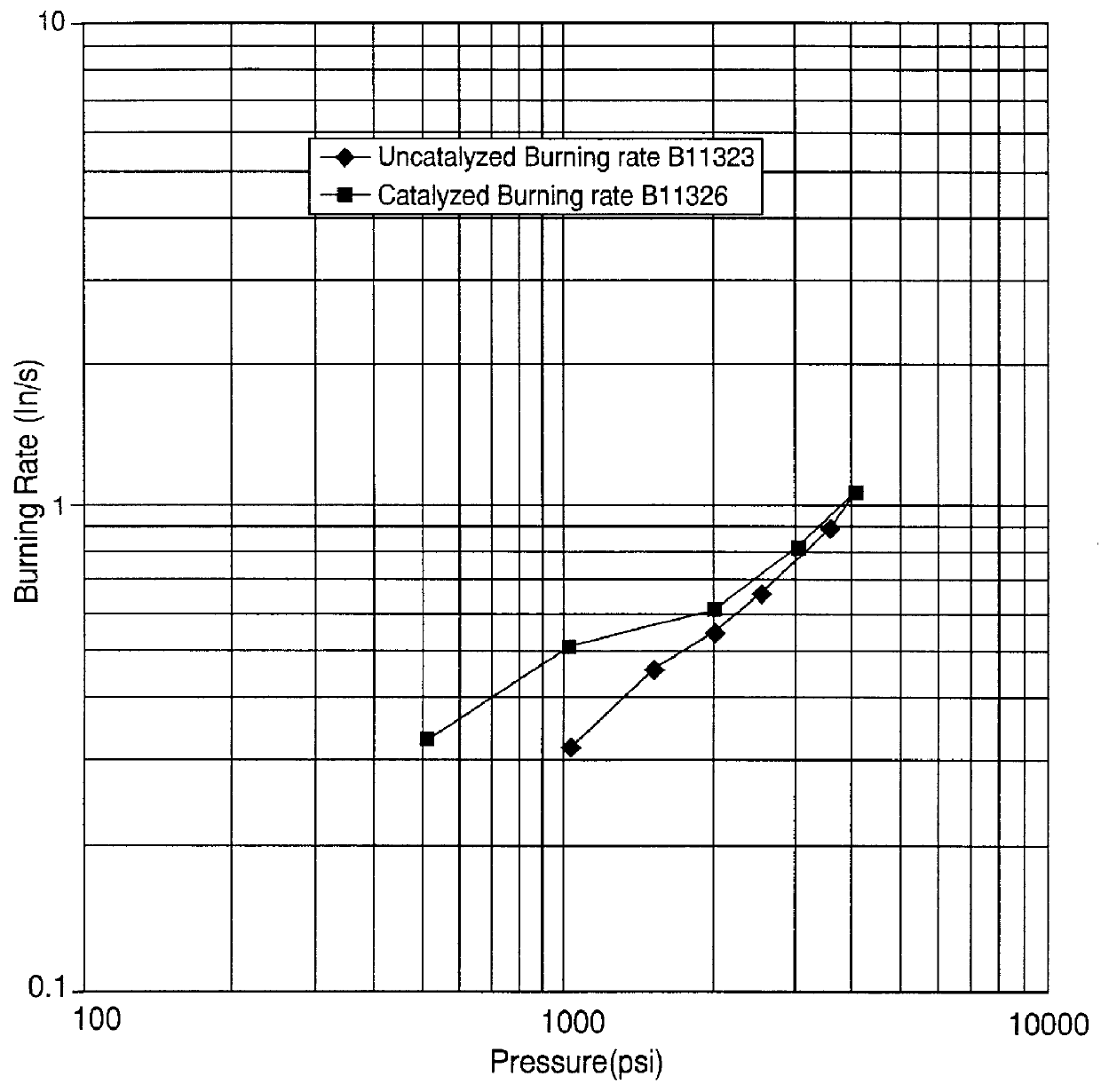

Low smoke rocket motor liner compositions

InactiveUS6051087AReduce smoke emissionsLow smokeNon-explosive/non-thermic compositionsPressure gas generationOxygenPolymer

A formulation is provided which is capable of performing as a liner layer between a rocket motor casing and the propellant grain disposed within the interior of the rocket motor casing. The composition produces relatively little smoke during the operation of the rocket motor and is capable of securely bonding a wide range of conventional propellants to a wide range of conventional casings. In one preferred formulation, the liner consists of from from about 50% to about 75% oxygen containing polymer; from about 3% to about 15% curing agent; from about 5% to about 50% filler and from about 0.01% to about 0.5% cure catalyst.

Owner:ORBITAL ATK INC

Deep-sea cable with long direction waterproof characteristic for ship

InactiveCN101299356ALow smokeLow toxicityClimate change adaptationSubmarine cablesCopper wireMarine engineering

The invention relates to a ship deep sea cable with the vertical watertight characteristic, which is provided with three to six conductors, each of which is composed of copper wires stranded with high conductivity, and the surface of each copper wire is coated with sealant. Each of the conductor is extruded with insulating layers. The sealant filled between the insulating layer and the periphery to compose the cable. An isolated area layer is wound at the periphery of the cable core; an outer sheath is extruded at the periphery of the isolated area layer, wherein the insulating layer is made of ethylene-propylene rubber materials. The sealant is the nonflowing sealing gluewater. The outer sheath is made of the chlorinated polyethylene materials. The invention provides a ship deep sea cable used in the deep water, particularly used in the sea with vertical watertight characteristic, and the sea water can not impregnate into the inner of the cable.

Owner:JIANGSUSNGSHANG CABLE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com