Novel phosphorous siliciferous flame retardant and preparation method thereof

A silicon flame retardant and a new technology are applied in the field of new phosphorus-containing silicon flame retardants and their preparation, which can solve the problems of low flame retardant efficiency, poor thermal deformation resistance, large filling amount, etc., and achieve excellent flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

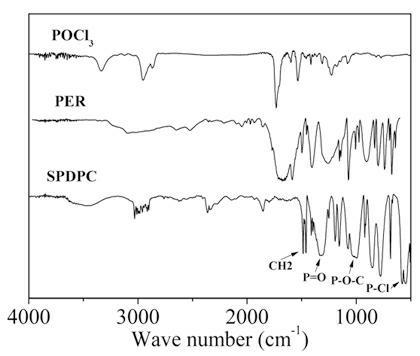

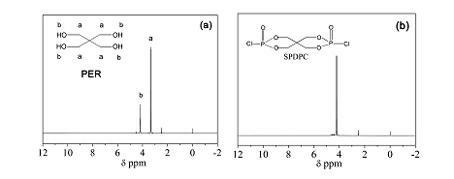

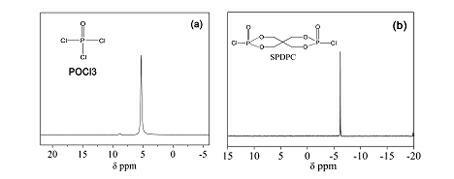

[0048] (1) Add pentaerythritol PER (68g, 0.5mol) in a 500ml three-neck round bottom flask, and add phosphorus oxychloride POCl dropwise while maintaining room temperature and stirring slowly 3 (460g, 3.0mol), stirred at 25°C for 1 hour; then slowly raised the temperature to 80°C, and stirred for about 8 hours until no hydrogen chloride gas was released. The mixture was filtered and washed with chloroform and acetone several times, then moved to a vacuum oven and dried at 60°C to constant weight to obtain a white powdery substance, namely double spiro ring SPDPC, with a measured melting point of 235.4-237.2°C. The rate is about 78%. figure 1 for POCl 3 , the infrared spectrogram (FTIR) of PER and SPDPC; figure 2 It is the comparison chart of the proton nuclear magnetic resonance spectrum (DMSO-d6) of PER (a) and SPDPC (b); image 3 for POCl 3 (a) and SPDPC (b) nuclear magnetic resonance phosphorus spectrum (DMSO-d6) comparison chart.

[0049](2) Add DOPO (108.0g, 0.5mol),...

Embodiment 2

[0058] (1) Add 1 mol of pentaerythritol PER to a three-neck round bottom flask, and add phosphorus oxychloride POCl dropwise while maintaining room temperature and stirring slowly 3 2mol, stirred at room temperature for 2 hours; then slowly warmed up to 100°C, and stirred for another 6 hours until no hydrogen chloride gas was released. After the mixture was filtered, it was washed three times with chloroform and acetone, and then moved to a vacuum oven at 50° C. to dry to constant weight to obtain a white powdery substance, namely double spiro ring SPDPC, with a yield of about 75%.

[0059] (2) Add DOPO 1mol, vinyldimethoxysilane VMDMS 1.5mol, solvent chloroform 5mol and initiator AIBN respectively in the three-necked round bottom flask, under the conditions of mechanical stirring and nitrogen protection, gradually warm up to the boiling point of chloroform (62 ℃), keep reflux for 10h; then add KOH (5%, wt) aqueous solution, continue to stir and react under nitrogen protectio...

Embodiment 3

[0062] (1) Add 1 mol of pentaerythritol PER to a three-neck round bottom flask, and add phosphorus oxychloride POCl dropwise while maintaining room temperature and stirring slowly 3 4mol, stirred at room temperature for 1.5 hours; then slowly warmed up to 90°C, and stirred for another 9 hours until no hydrogen chloride gas was released. After the mixture was filtered, it was washed four times with chloroform and acetone, and then moved to a vacuum oven at 55° C. to dry to constant weight to obtain a white powdery substance, namely double spiro ring SPDPC, with a yield of about 76%.

[0063] (2) Add DOPO 1mol, vinyldimethoxysilane VMDMS 1.2mol, solvent chloroform 6mol and initiator AIBN respectively in the three-necked round bottom flask, under the conditions of mechanical stirring and nitrogen protection, gradually warm up to the boiling point of chloroform (62 ℃), keep reflux for 13h; then add KOH (5%, wt) aqueous solution, continue to stir and react under nitrogen protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com