UV (ultraviolet) curing ink and application thereof

An ink and resin technology, applied in UV-curable ink and its application fields, can solve the problems of high processing cost, adverse effects on human health and safe production, etc., and achieve the effect of good cutting fluid resistance, less environmental damage, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

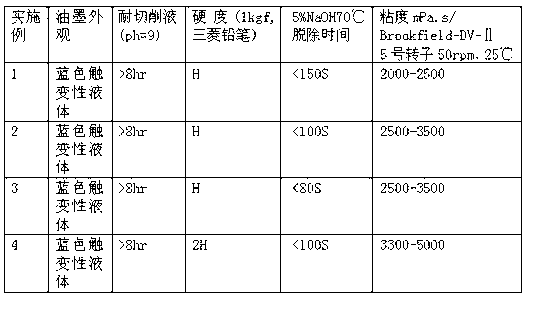

[0100] The present invention is further described in detail by the embodiments 1-4 shown in Table 1 as follows:

[0101] Table 1

[0102]

[0103] The components in any of the proportions of Examples 1 to 4 in the above Table 1 were added to the container according to the stated proportions, and the mixture was uniformly mixed under stirring conditions and constructed according to the following process and parameters.

[0104] Process sequence:

[0105] Substrate cleaning → printing → IR baking → UV curing → surface processing → 5% NaOH solution removal at 70 °C → clean water.

[0106] Process parameters:

[0107] Mesh: 200-300 mesh / inch (77-120 / cm);

[0108] Film thickness: 16-20um (Mitutoyo);

[0109] Cumulative UV energy 1500~2200mj / cm 2 (EIT UV Power Puck II);

[0110] Spectral range: 180~420nm;

[0111] UV lamp power: 80-120W / cm;

[0112] IR temperature: 100-110°C: 2-3min.

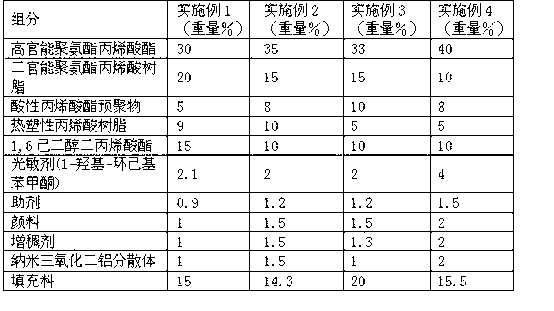

[0113] The properties of the ink layers obtained in Examples 1-4 on the glass surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com