Patents

Literature

92results about How to "No heavy metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly antibacterial waterborne paint and preparation thereof

InactiveCN101486861AImprove adhesionFull paint filmAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention provides an environment-friendly antibacterial water paint and a preparation method thereof. The components include deionized water, germicide, assistant for film forming, defoaming agent, wetting agent, dispersant, nanometer TiO2, emulsion or water dispersoid resin, filler, anti-settling agent, flatting agent, thickener, pH regulator, scratch resistance agent or slipping agent, pigment or coloring agent, additive with special function and the like. The preparation method includes the steps of: A. preparing the water dispersoid; B. adding the water dispersoid obtained in the step A into the stirred emulsion, then adding the assistant for film forming, the flatting agent, the thickener, the anti-settling agent, and the pH regulator and uniformly stirring and dispersing the components; C. adding the pigment or the coloring agent; and D. charging water and adjusting the Stormer viscosity at the temperature of 25 DEG C to be 65-90KU, thus obtaining the water paint. The water paint provided in the invention has good adhesion to wood materials, full paint films with certain hardness, low VOC, no heavy metal, and the antibacterial and mildewproof functions, and belongs to the environment-friendly and safe children woodwork water paint.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

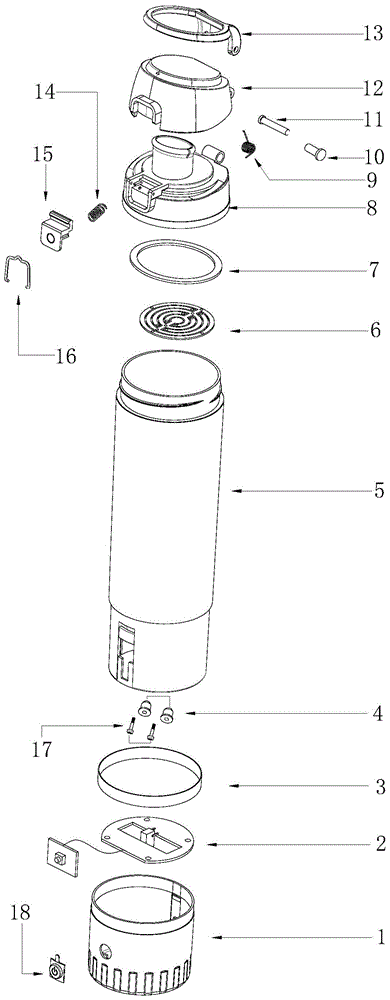

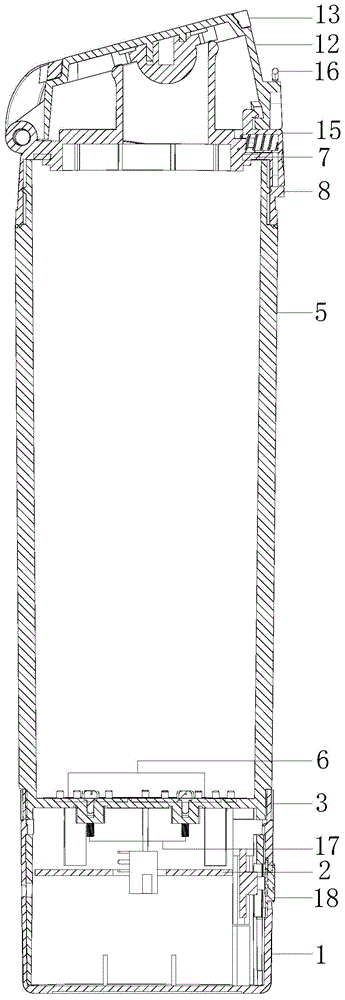

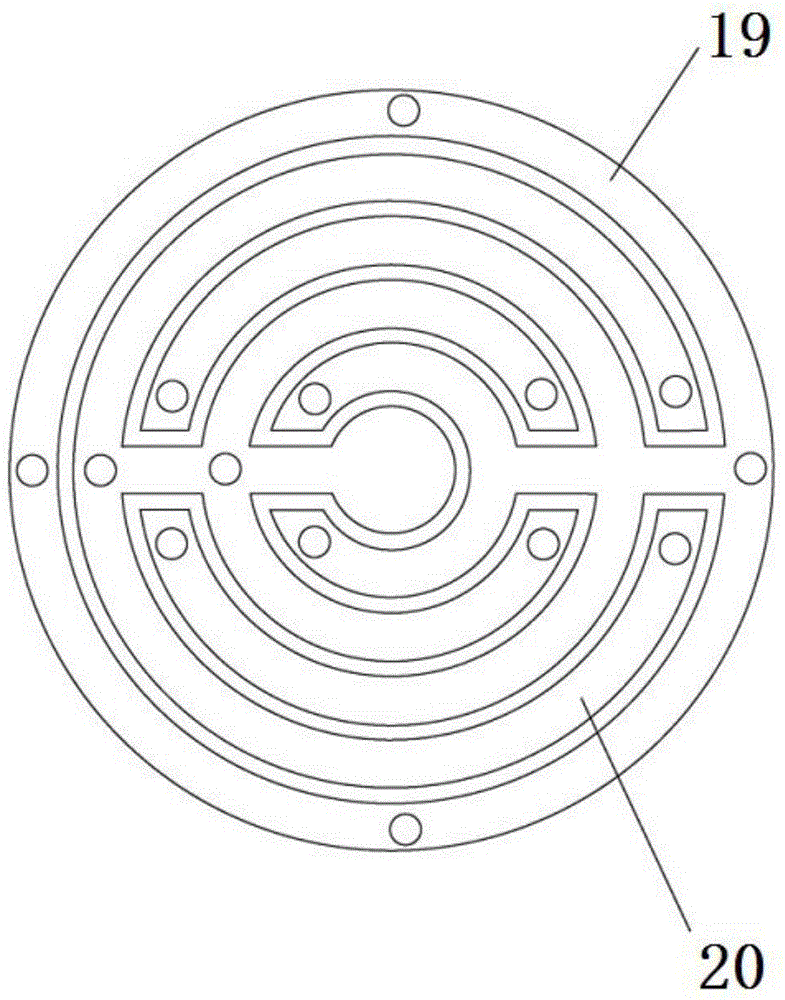

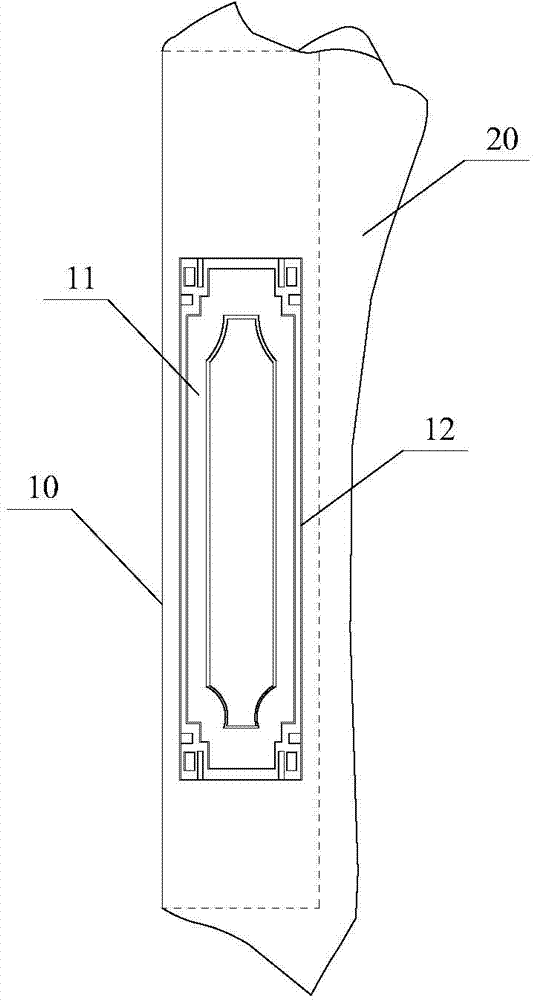

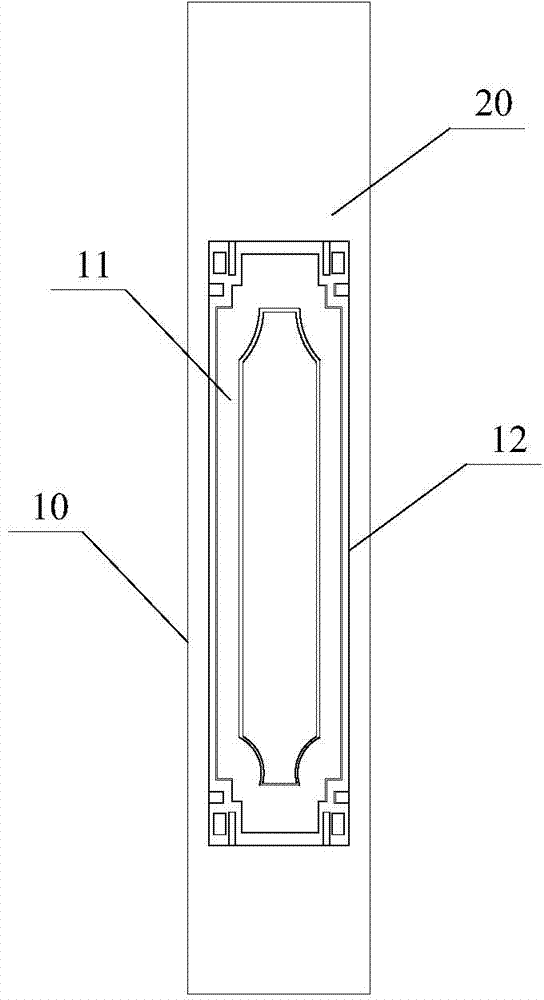

Electrolytic type hydrogen-rich health-care cup

ActiveCN104921549AHigh hydrogen contentNo heavy metalsWater/sewage treatment by substance additionDrinking vesselsHydrogenEngineering

The invention discloses an electrolytic type hydrogen-rich health-care cup comprising a bottom lid, a cup body and a cup lid main body. The bottom lid is connected to the cup body and is internally provided with a PCB, and the PCB is connected to a power switch button. The cup body is internally provided with an electrode plate comprising anodes and cathodes which are annularly arranged in sheet shapes, and the anodes and the cathodes are located on the same plane and are arranged at intervals. The upper portion of the cup body is in threaded connection with the cup lid main body, and is provided with a transparent cup lid. The upper portion of the transparent cup lid is provided with a cup lid handle. The cup lid main body is provided with a cup lid button, a pressure spring is arranged between the cup lid button and the cup lid main body, and a clamping spring used for buckling the transparent cup lid is arranged on the cup lid button. According to the invention, the PCB and the electrode plate is added to a conventional cup to form the health-care cup, and the drinking water is hydrolyzed by the use of the electrode plate so as to obtain the hydrogen-rich water, so that the cup has a health-care function.

Owner:广东氢时代健康产业科技有限公司

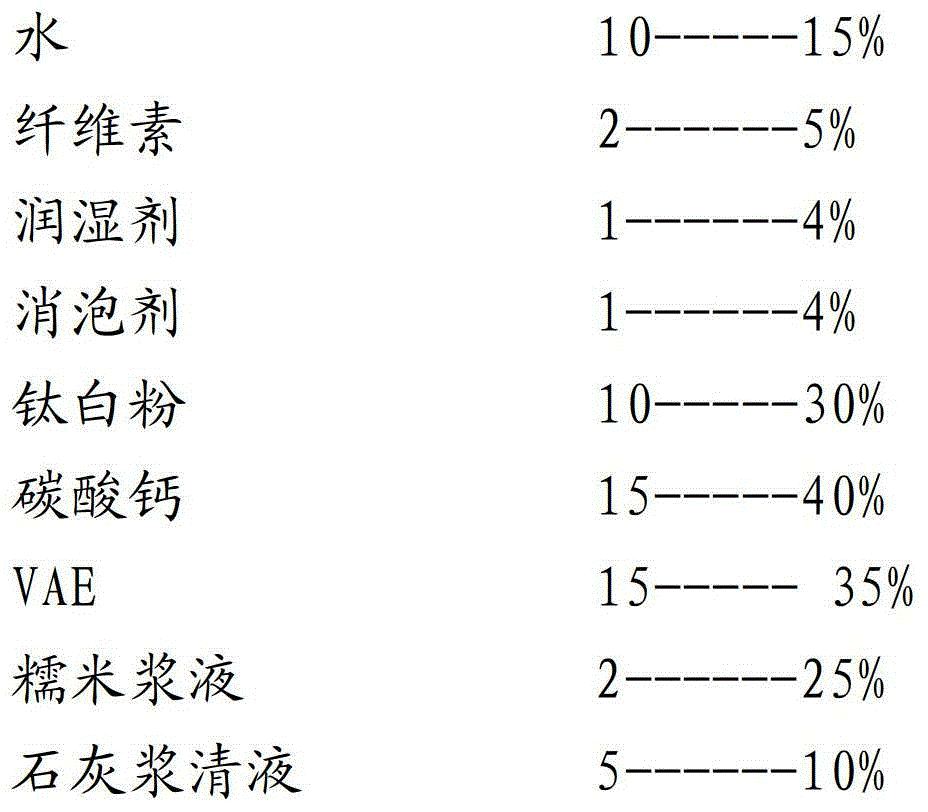

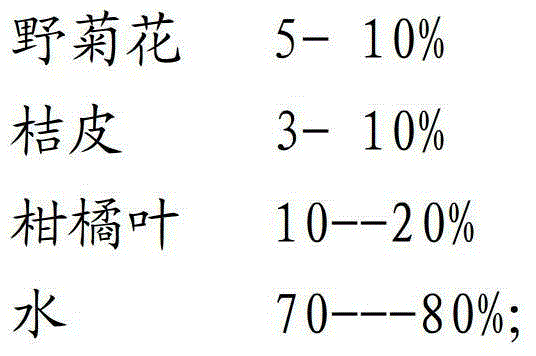

Multi-functional glutinous rice plant liquid coating

InactiveCN103333556AGood weather resistanceGood value for moneyCellulose coatingsCelluloseAdditive ingredient

The invention relates to a multi-functional glutinous rice plant liquid coating, and particularly relates to an environment-friendly, non-toxic and harmless biomass coating. The multi-functional glutinous rice plant liquid coating comprises, by mass, 10-15% of water, 2-5% of cellulose, 1-4% of a wetting agent, 1-4% of a defoaming agent, 10-30% of titanium dioxide, 15-40% of calcium carbonate, 15-35% of VAE, 2-25% of glutinous rice slurry, 5-10% of lime slurry supernatant, 0.5-1% of nano silver and 3-7% of plant extracts. With the above technical solution, the glutinous rice slurry, calcium carbonate and quicklime are mixedly used to produce an organic-inorganic composite material. The material is compact in structure, and has high mechanical strength, good toughness and a good sealing effect for matrix. Therefore, the obtained coating has excellent weather resistance and ageing resistance, and at the same time, by adding the plant extract, the coating is fresher and more natural. Besides, the obtained coating contains no harmful ingredient, is safe and environment-friendly and is simple in preparation.

Owner:东莞市康博士装饰材料有限公司

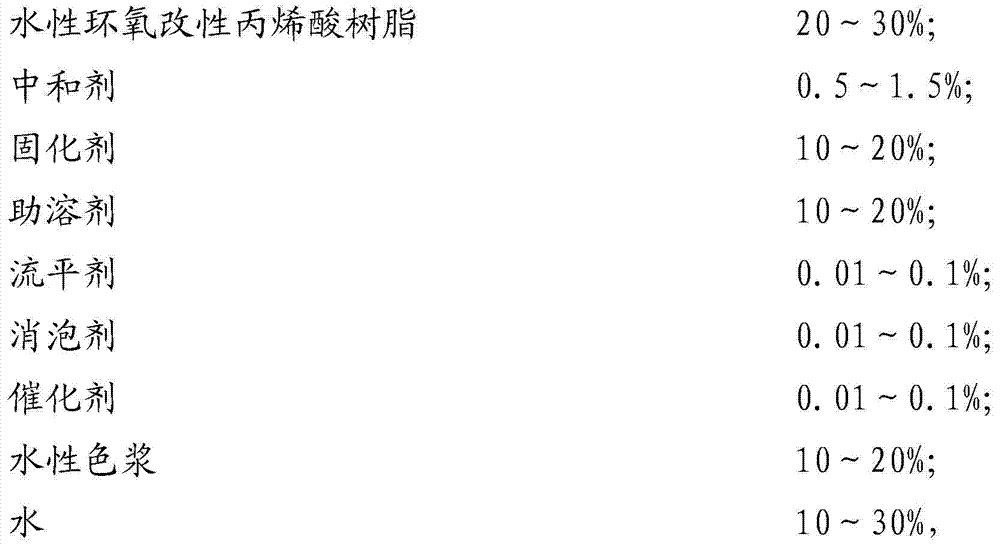

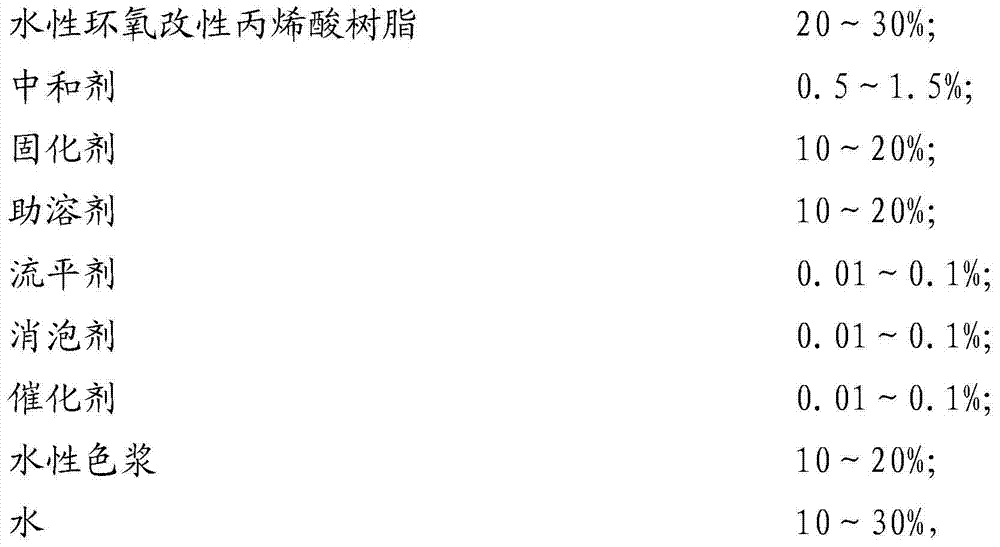

Environment-friendly water-based crack lacquer and application method thereof

The invention discloses an environment-friendly water-based crack lacquer and an application method thereof. The n environment-friendly water-based crack lacquer comprises a water-based crack primer and a water-based crack finishing coat; the water-based crack primer is prepared from such components in percentage by weight as 20-30% of water-based epoxy modified acrylic resin, 0.5-1.5% of neutralizer, 10-20% of curing agent, 10-20% of cosolvent, 0.01-0.1% of flatting agent, 0.01-0.1% of defoamer, 0.01-0.1% of catalyst, 10-20% of water-based color paste and 10-30% of water; the water-based crack finishing coat is prepared from such components in percentage by weight as 60-80% of styrene-acrylic emulsion, 1-2% of neutralizer, 15-40% of water-based color paste and 0.01-0.1% of water-based crack agent. Compared with the correlation techniques, the environment-friendly water-based crack lacquer has the beneficial effects of high environmental friendliness and safety performance, excellent decoration effect and strong adhesion.

Owner:湖南天氟新材料有限公司

Preparation method of reishi shell-broken spore powder at temperature difference ultrahigh pressure by wet process

ActiveCN104223038AImprove athletic performanceEffective absorptionFood preparationPlant ingredientsSporelingUltra Low Temperature Freezer

The invention discloses a preparation method of reishi shell-broken spore powder at temperature difference ultrahigh pressure by a wet process. The preparation method comprises the following steps: soaking fresh reishi spore powder so as to absorb water, putting into a centrifugal machine, centrifuging, airing, then putting into an ultralow-temperature refrigerator and liquid nitrogen sequentially, refrigerating so as to obtain the ultralow-temperature wet spore powder with cracked pore shells, then carrying out microwave unfreezing treatment so as to obtain dried shell-broken spore powder, and finally acquiring sterile spore powder with high shell breaking rate under ultrahigh pressure. The method provided by the invention can be used for solving the technical difficulties of low shell breaking rate, food pollution and difficulty in releasing polysaccharide in the processing course; the reishi shell-broken spore powder prepared by the invention has the characteristics of high spore powder shell breaking rate, no pollution source and easiness in absorption of functional inclusions.

Owner:SHANGHAI JIAO TONG UNIV

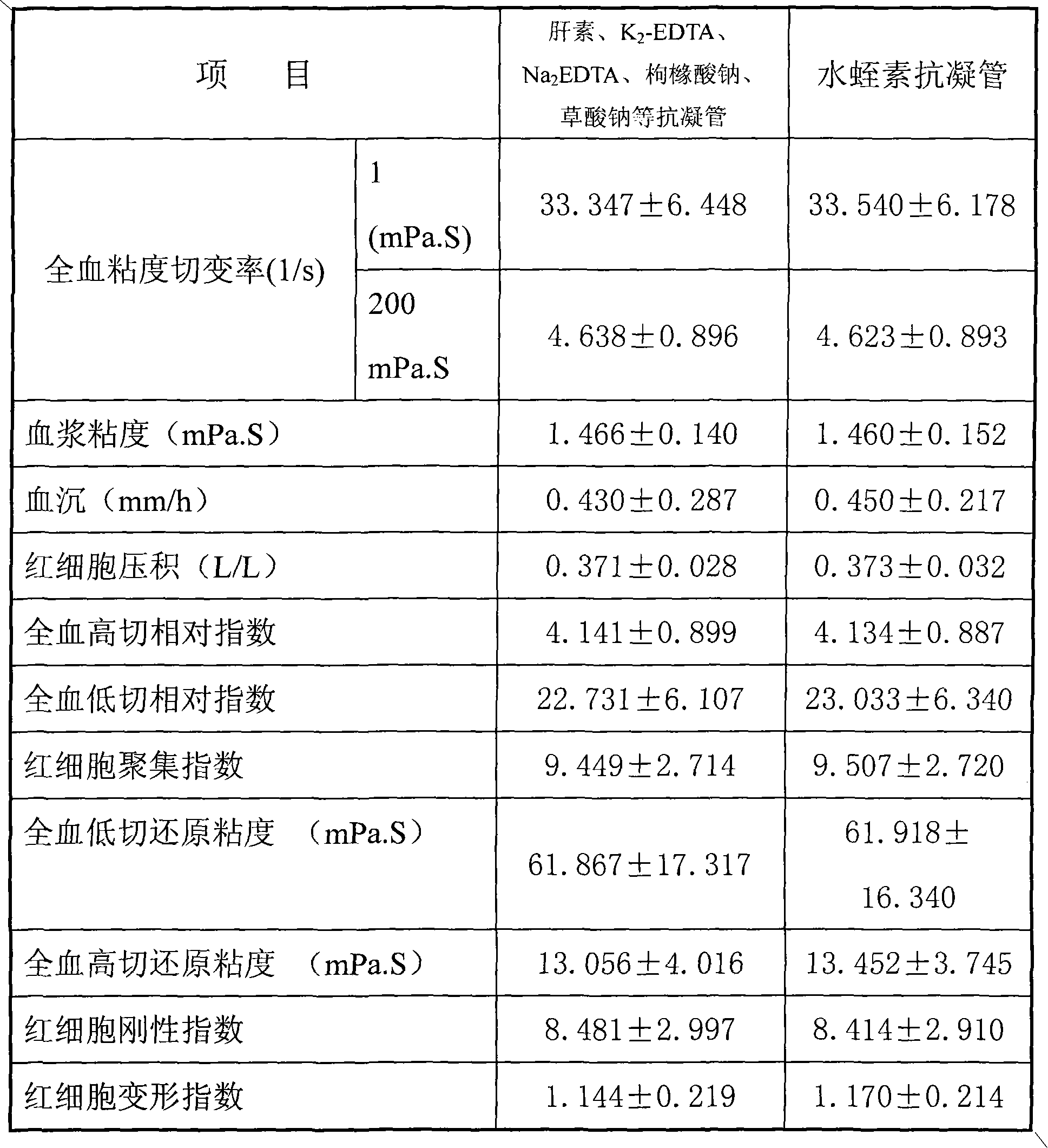

Hirudin vacuum blood collection tube

InactiveCN101779959AEasy to operateRelieve painPharmaceutical containersMedical packagingHirudinHeavy metals

The invention discloses a hirudin vacuum blood collection tube. A hirudin coating is coated on the inner wall of a tube body, wherein the hirudin content is 0.005 to 1 milligram per milliliter of blood. The tube has the advantages that: 1, the tube can replace an anticoagulant commonly used in clinic, save the trouble of ordering in blood collection, apply to various kinds of examination, facilitate the operation of doctors and relive pains in patients; 2, as the hirudin used in the tube is a biological reagent, so the examination result is reversible and once the clinic examination fails, examination can be performed again directly without drawing block again for test; 3, the anticoagulation time is as long as more than 7 days; 4, the interference with blood is zero so as not to cause hemolytic reaction; 5, impurities and heavy metals are avoided; 6, more than 300 examination items can be performed; and 7, the biological reagent is environmental-pollution free.

Owner:刘金雪 +1

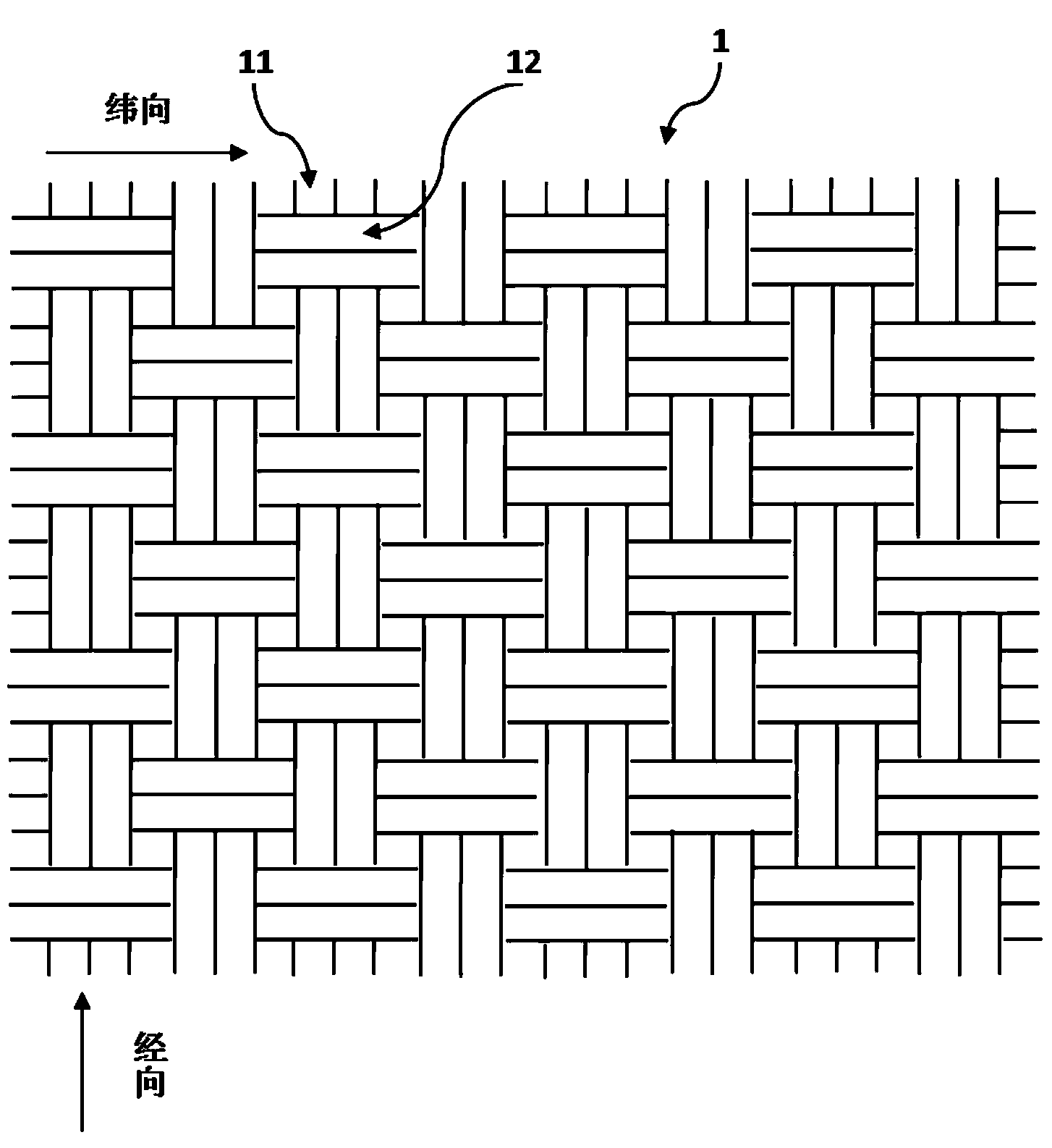

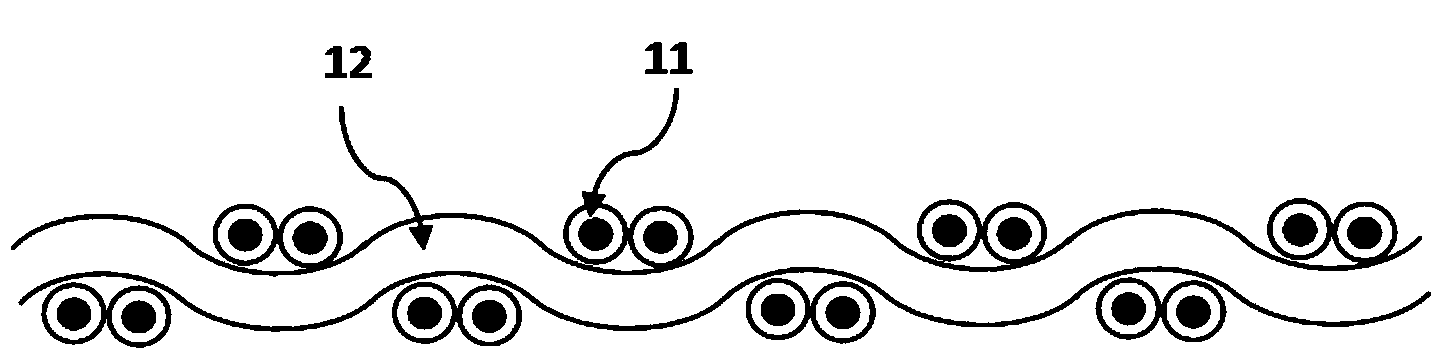

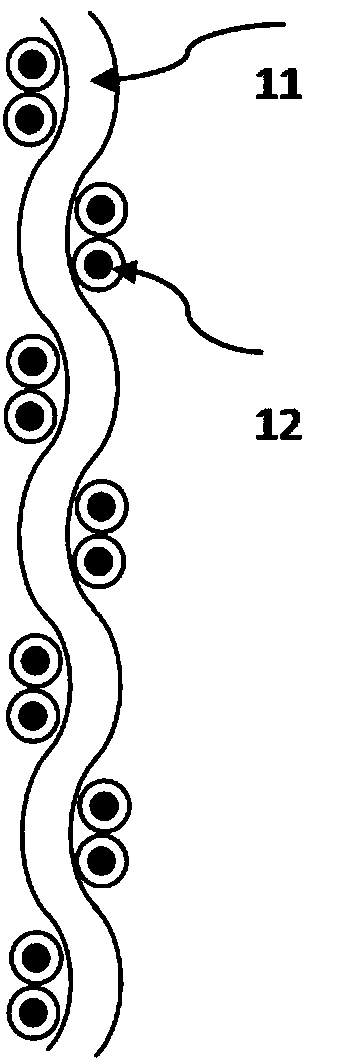

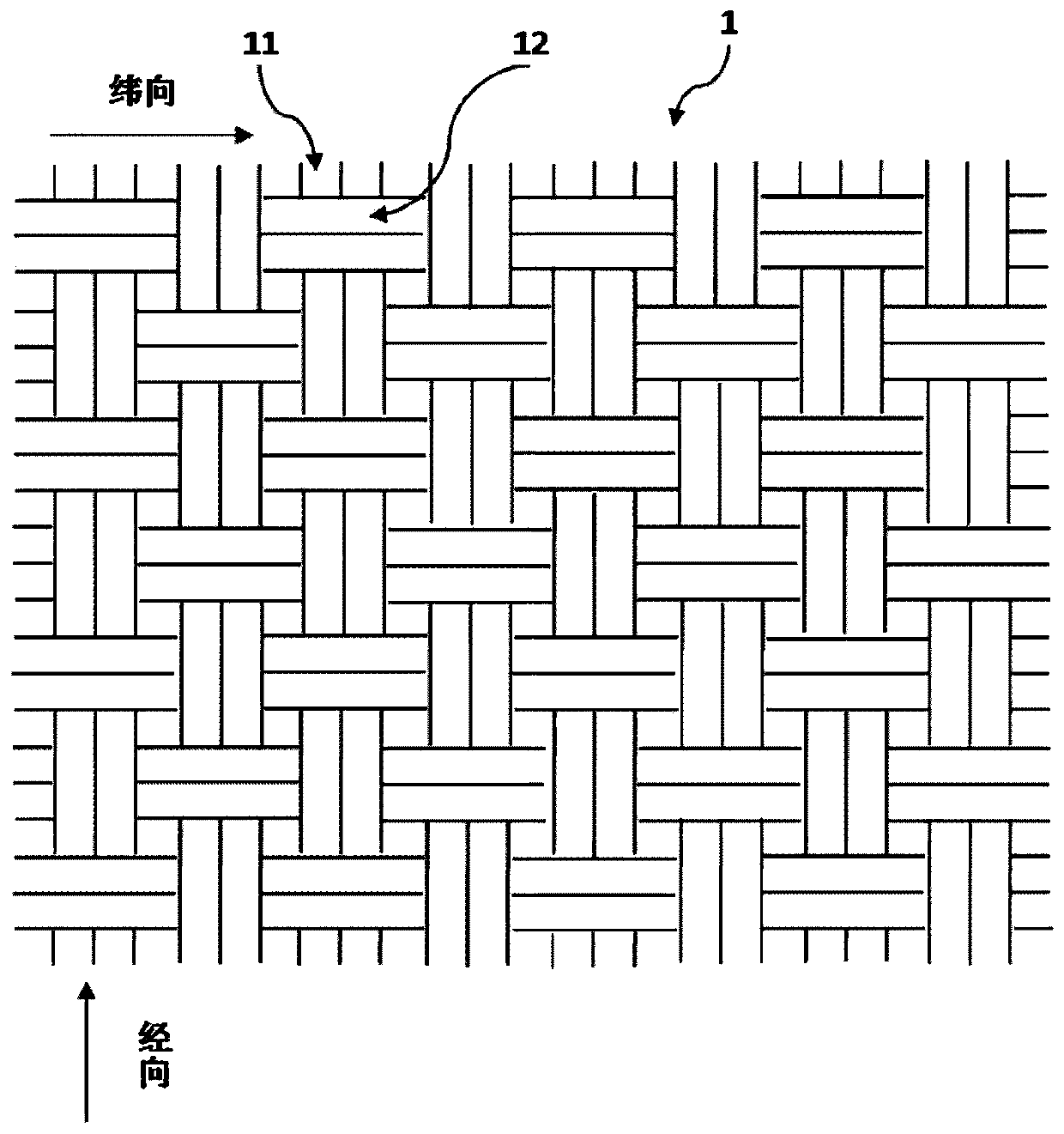

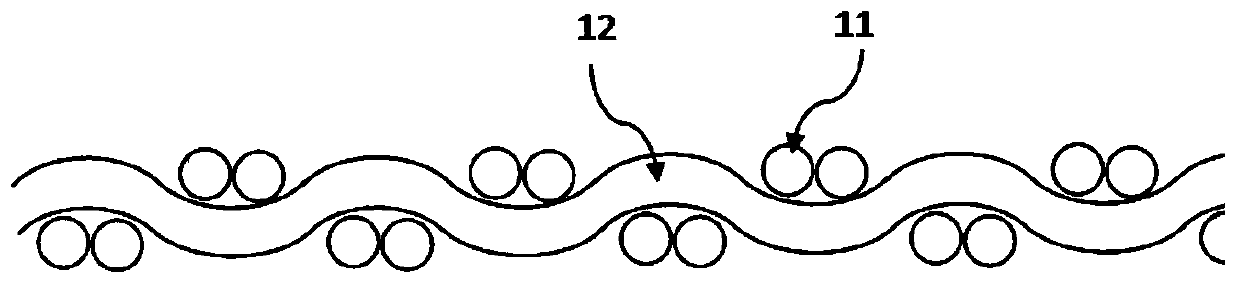

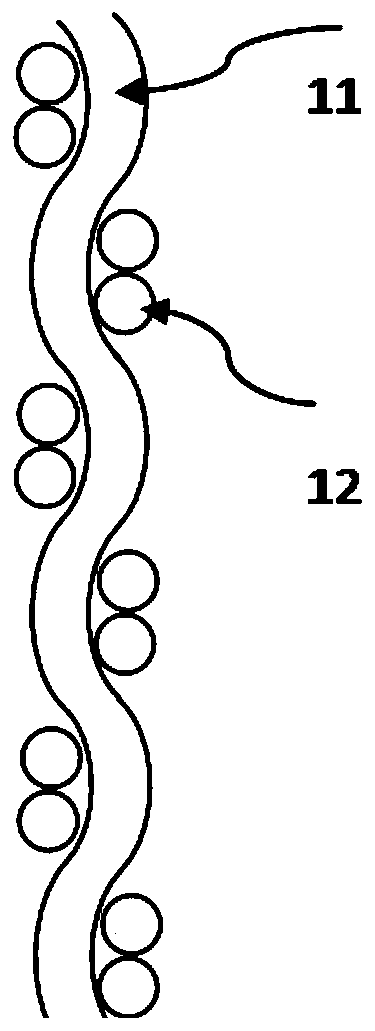

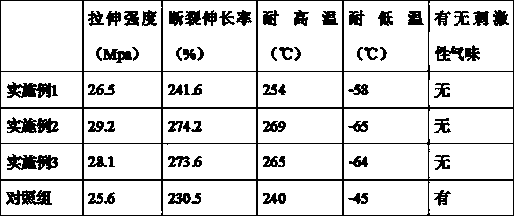

Halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and preparation method thereof

InactiveCN104233569AImprove breathabilityTranslucentHeating/cooling textile fabricsWoven fabricsPolyesterYarn

The invention relates to a halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and a preparation method thereof. The fabric is formed by weaving covered threads and has warp and weft structures; the covered threads comprise polyester fibers and halogen-free flame-retardant environment-friendly polyolefin composite materials covering the surfaces of the polyester fibers; the covered threads are 0.3-0.4 millimeter in diameter, rectangular or square gaps are reserved between the warp structures and the weft structures, and the aperture ratio is 2 to 10 percent; the halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric is 0.55-0.75mm in total thickness and 350-420g / m<2>. The invention also provides a preparation method for the fabric. The fabric has the characteristics of sunshading, ultraviolet resistance, flame retardancy, high color fastness and the like of similar PVC (polyvinyl chloride) substrate fabrics, and also has the advantages of no halogen, environment friendliness, low smoke density during combustion, high self-cleaning property, high chemical stability, light weight, high air permeability and the like.

Owner:NINGBO XIANFENG NEW MATERIAL

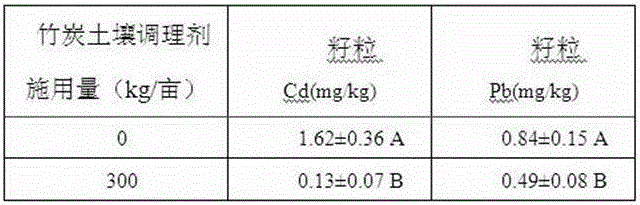

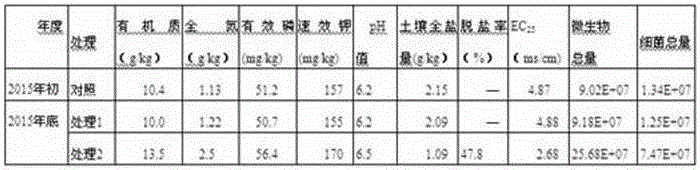

Soil conditioner with bamboo charcoal and method for preparing soil conditioner

InactiveCN106190141AIncrease acidityImprove breathabilityAgriculture tools and machinesOther chemical processesPesticide residuePotassium

The invention discloses a soil conditioner with bamboo charcoal and a method for preparing the soil conditioner. The soil conditioner comprises, by weight, 40-60% of bamboo charcoal powder, 10-30% of organic acid, 10-20% of quicklime powder, 5-10% of diatomaceous earth, 5-10% of urea and 0.5-2% of ferrous EDTA (ethylene diamine tetraacetic acid). The soil conditioner and the method have the advantages that the soil conditioner contains abundant stable-state organic carbon, accordingly, organic matters in soil can be effectively increased, emission of greenhouse gas N2O can be reduced, heavy metal and pesticide residues in the soil can be adsorbed and passivated, soil structures can be improved, and the microbial biomass and diversity of the soil can be improved; the potential of hydrogen of the soil can be regulated, the air permeability and the water retention of the soil can be improved, and phosphorus and potassium elements in the soil can be activated; the soil conditioner is low in usage and production cost and convenient to use and is green and environmentally friendly.

Owner:时科生物科技(上海)有限公司

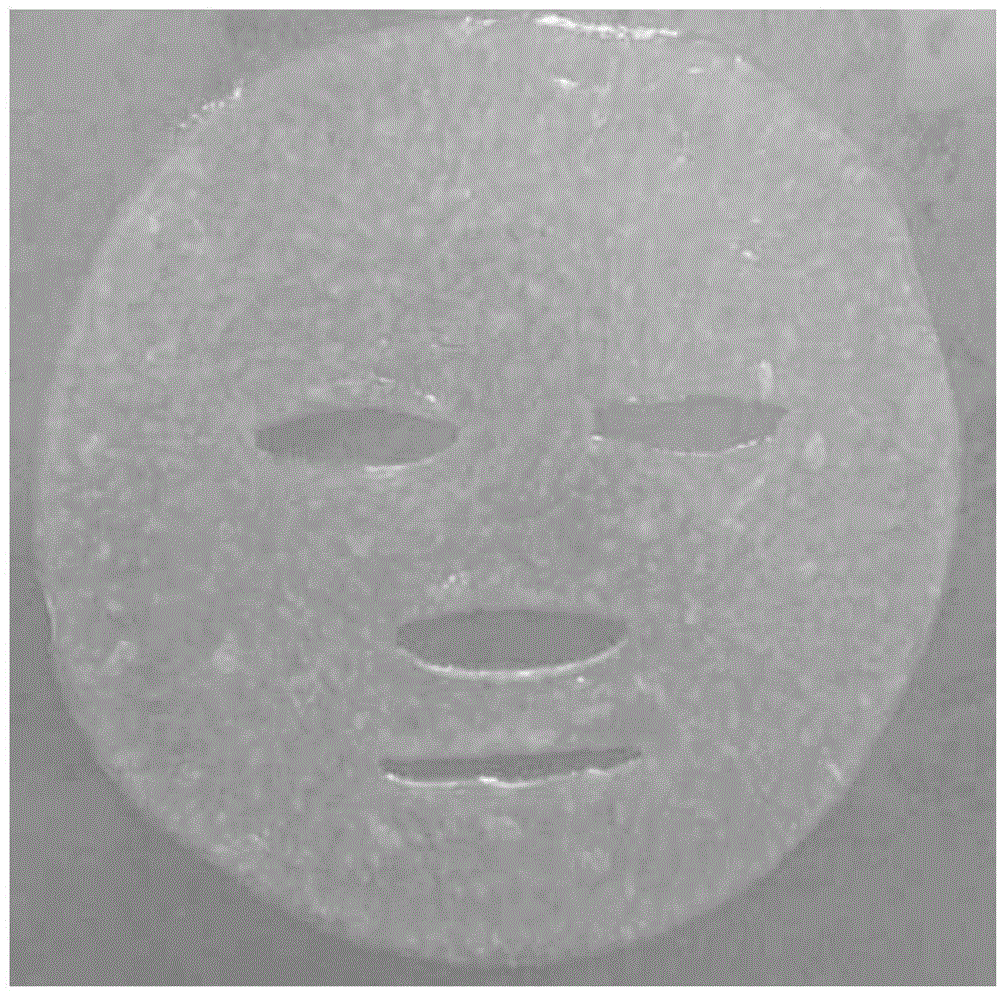

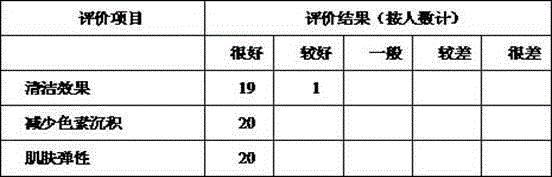

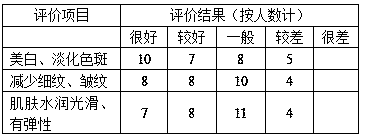

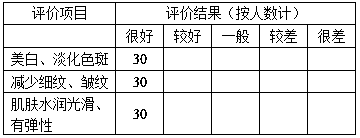

Biological fermentation primary liquid mask and preparation method and storing method thereof

InactiveCN104922050AGood air permeabilityGood flexibilityCosmetic preparationsToilet preparationsAir atmosphereDry skin

The invention provides a biological fermentation primary liquid mask and a preparation method and a storing method thereof and belongs to the field of cosmetics. The biological fermentation primary liquid mask is free of a carrier, is attached to the face and free of washing. The biological fermentation primary liquid mask is formed in the mode that blueberries, ginseng, roses, chamomile, soybean and tremella are decocted and fermented. The preparation method comprises the following steps that raw materials are screened, weighed and cleaned in sequence and then mixed, water is added, decocting is conducted, cooling and filtering are conducted, a product is poured into a mould containing original fungi, and then fermentation is conducted for 5-7 days at the temperature of 30-32 DEG C with the humidity being 40%-45% in an air atmosphere; in this way, the biological fermentation primary liquid mask is obtained, wherein the pH value is about 6.8. The storing method of the biological fermentation primary liquid mask comprises the steps that the mask is stored in storage liquid, sealed in vacuum and then stored in a shady, cool and dry place, wherein the storing liquid comprises lemon hydrosol, tea tree hydrosol, lavender hydrosol and mycose. The biological fermentation primary liquid mask achieves the purposes of whitening skin, removing beverage, redness, acne and wrinkles, shrinking pores, eliminating fat granules, improving dark and dry skin, removing dead skin and the like at a time.

Owner:哈尔滨瑞康源生物科技有限公司 +1

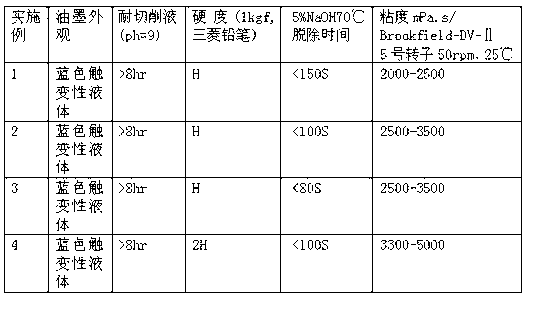

UV (ultraviolet) curing ink and application thereof

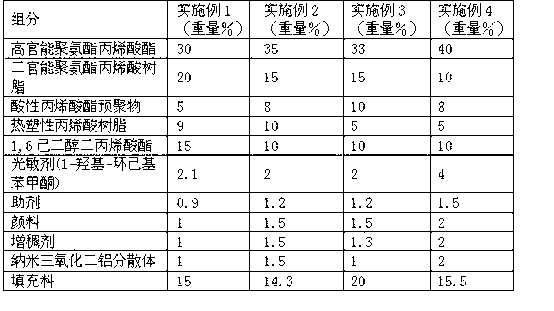

The invention discloses a UV (ultraviolet) curing ink and application thereof. The UV curing ink comprises the following components in percentage by weight:30-40% of high-functionality polyurethane acrylate, 10-20% of dual-functionality polyurethane acrylic resin, 5-10% acidic acrylate prepolymer, 5-10% of thermoplastic acrylic resin, 10-15% of 1,6-hexanediol diacrylate and 2-4% of photosensitizer. When being printed on a glass workpiece, the UV photocuring ink is used for temporary protection in the glass surface working process. After the UV photocuring ink is subjected to UV photocuring, a tough ink layer, which has the advantages of favorable adhesion to glass, high surface hardness, favorable scratch resistance and favorable cutting fluid resistance, can be formed on the glass surface, and can effectively ensure the glass not to be scratched in the surface working process. After finishing the glass working, alkaline water can quickly remove the UV photocuring ink layer, so that the glass can not be influenced.

Owner:深圳市美丽华科技股份有限公司

Anti-wrinkle cleansing lotion and preparation method thereof

ActiveCN105287331AStay hydratedGood skin affinityCosmetic preparationsToilet preparationsCellulosePunica

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle cleansing lotion and a preparation method thereof. The anti-wrinkle cleansing lotion consists of myristic acid, palmitic acid, stearic acid, glycerol, potassium hydroxide, sodium taurine laurate, sodium cocoyl glycinate, sodium lauroyl glutamate, C12-14 secondary-chain alkanol polyether-20, glycol distearate, propanediol, lactobacillus / punica granatum fruit fermentation product extract, arctic chlamydomonas essence, starfish essence, cortex acanthopanacis essence, a pearl extract, EDTA-Na2, hydroxypropyl methyl cellulose, methyl hydroxybenzoate, propyl hydroxybenzoate, methylisothiazolinone, essence and water. The anti-wrinkle cleansing lotion disclosed by the invention is gentle and skin-friendly, safe and non-irritant; and the cleansing lotion is capable of deeply cleansing skin, and meanwhile the cleansing lotion is capable of moisturizing and resisting wrinkles.

Owner:广州科玛生物科技股份有限公司

Feed functional package for producing pork rich in DHA and EPA, feed and application method thereof

InactiveCN106417958AHigh in DHANo fishy smellAnimal feeding stuffAccessory food factorsBiotechnologyFatty acid

The invention provides a feed functional package for producing pork rich in DHA and EPA, feed and an application method thereof. The feed functional package for producing the pork rich in DHA and EPA comprises the following components: seaweed powder and flaxseed. For optimizing and improving the edibility and functionality of the pork, algae and the flaxseed are applied to compounding and development of the feed for producing the pork rich in DHA and EPA, so that the content ratio of DHA to EPA in the produced pork is more scientific, the produced pork has no fishy taste or residues such as heavy metals, and the problems are solved; meanwhile, a feeding method of the feed functional package is optimized, so as to improve the composition of fatty acids of the pork; and the feed functional package provided by the invention has great significance on human body fatty acid equilibrium.

Owner:博智农贸易(深圳)有限公司

Method for making water-based matte scratch-resistant and flexible synthetic leather

The invention relates to the technical field of synthetic leather making and in particular relates to a method for making water-based matte scratch-resistant and flexible synthetic leather. The methodcomprises the following steps: a Beth making step, namely preparing a wet polyurethane coating, cleaning the base fabric, performing vacuum defoamation on the wet polyurethane coating, coating the wet polyurethane coating on the base fabric, entering a coagulating basin to be coagulated, washing, wiping, fixed-width expanding, performing secondary ironing and secondary drying, cooling, and rolling to make Beth; and a step of making a water-based matte treatment agent, namely preparing a mixed solution from a water-based PU resin, deionized water and a water-based plasticizer, and adding a curing agent, thereby obtaining the water-based treatment agent. The synthetic leather made by the method disclosed by the invention is soft in hand feeling, high in coating fullness, excellent in flexibility, wear-resistant, scratch-resistant, yellowing-resistant, permanent in elasticity, extremely low in odor, environmental-friendly and capable of realizing pure water environment friendliness, doesnot have free formaldehyde, and does not contain APEO (Alkylphenol Ethoxylates), potassium phthalate, isocyanates and other toxic and harmful component residues.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

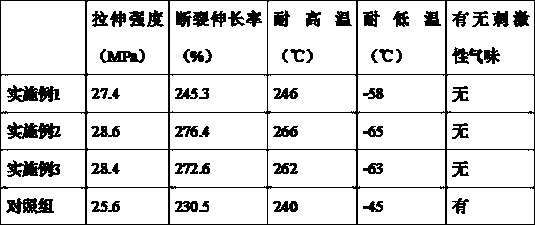

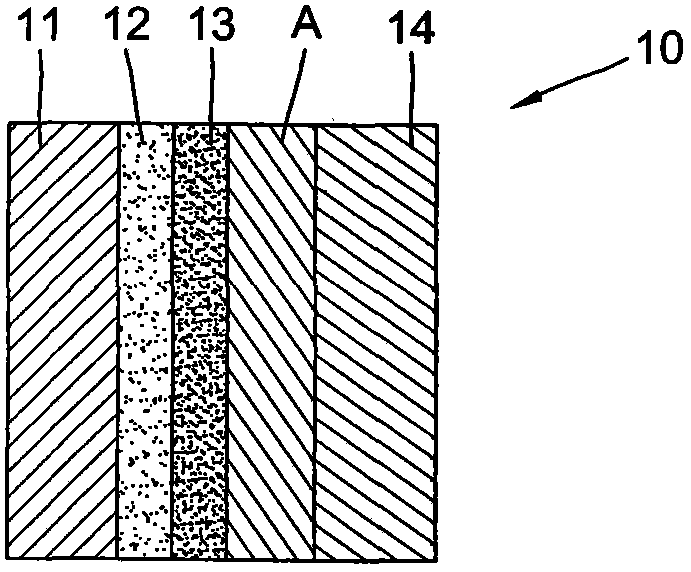

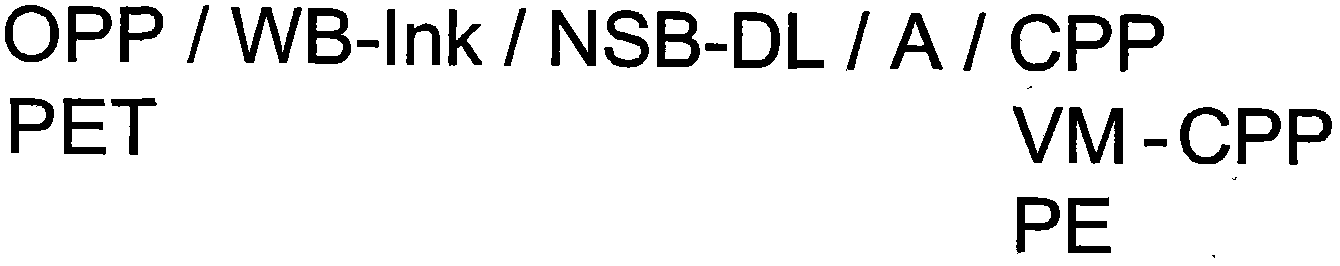

Food packing materials

ActiveCN103508074ADoes not affect healthNo pollution in the processFlexible coversWrappersNon solventAdhesive

The invention provides food packing materials. The food packing materials sequentially comprise an outer layer, parts formed after printing ink processing, non-solvent adhesives, parts formed after high-barrier processing and inner layers from top to bottom. The outer layer serves as a printing base material; patterns are printed on the inner face of the outer layer through printing ink; high-barrier processing is carried out, namely, space between the outer layer and the inner layers is coated with materials to form an isolation structure, and the outer layer is combined with one inner layer through the non-solvent adhesives. Hereby, the non-solvent adhesives will not lead to thermal expansion and pattern deformation (Pitch) of the food packing materials in the high-temperature drying and fitting process, fitting processing speed is three times the traditional speed, the non-solvent adhesives prevent residual solvents from polluting contents or generating foreign smells, and accordingly the packing materials which are free of pollution or toxicities and environmentally friendly are generated.

Owner:刘德成

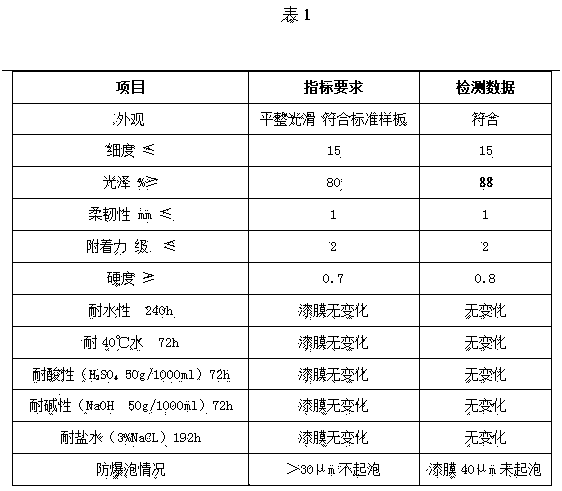

Waterborne acrylic resin and packaging container coating and preparation method

The invention discloses a waterborne acrylic resin and a packaging container coating and a preparation method. The packaging container coating is prepared to solve the problem that the existing waterborne stoving varnish is blistered in thickness and poor in fullness. The preparation method of the waterborne acrylic resin comprises the following steps: adjusting the monomer proportion; modifying through 1, 1-dimethyl-1-heptyl carboxyl glycidyl ester; neutralizing through 2-amino-2-methyl-1-propanol; salifying; and realizing waterborne property to prepare the waterborne acrylic resin which is low in viscosity and good in dispersity to pigments. The preparation method of the packaging container coating comprises the following steps: selecting amino resin; quickly curing without acid catalysis; and preparing a netty crosslinking coating with excellent performance by adopting various pigments and filler. The problem that the waterborne stoving varnish is blistered in thickness is effectively improved, the water resistance of the film is enhanced, the tensile strength is improved, and the fullness of the film is improved.

Owner:西北永新涂料有限公司

Method using plant oil after-cut fraction for production of green lubricating oil

ActiveCN104762121AFix stability issuesSettle the priceFatty-oils/fats separationBase-materialsVegetable oilThermal insulation

The present invention provides a method for using plant oil after-cut fraction for production of green lubricating oil, and the process comprises the following steps: various main components are separated by distillation of plant crude oil, after-cut fraction and a residue accounting for 6-15% of the total tower kettle substrate are heated to about 150 to 200 DEG C in a vacuum distillation tower device for thermal insulation distillation for more than 30-40 hours under the condition of maintaining the vacuum degree in-0.98mpa, wherein the vacuum distillation tower device has the tower height of 7-15m, and the plate number of more than 100, and use a 80-100 mesh stainless steel filler, kettle bottom residual liquid is discharged after cooling, the kettle bottom residual liquid is placed for cooling to 50 DEG C to 60 DEG C, and filter with a 150 mesh filter screen to obtain plant oil distillation kettle bottom polymer, the green lubricating oil is prepared by further addition of composite additives, and the green lubricating oil is similar with mineral base oil in density, viscosity, flash point, pour point and other indexes, and is good in thermal stability, biodegradable, low-cost, and environment friendly.

Owner:统一石油化工有限公司

Sun-shading fabric and preparation method thereof

ActiveCN110042528ANo plasticizerFormaldehyde freeFlame-proof filament manufactureProtective fabricsFiberLinear low-density polyethylene

The invention relates to a sun-shading fabric and a preparation method thereof, in particular to a halogen-free flame-retardant sun-shading fabric with a self-cleaning function and a preparation method of the sun-shading fabric, and belongs to the technical field of high polymer materials. The sun-shading fabric comprises fiber threads forming a double-warp and double-weft structure, the structurecomprises rectangular or square gaps, and the fiber threads are made from a halogen-free polyolefin composite material, wherein the halogen-free polyolefin composite material is prepared from, by weight, 50-70 parts of linear low-density polyethylene, 15-20 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of a halogen-free flame retardant, 3-5 parts of expansible graphite, 1-5 parts of aflame-retardant synergist, 10-20 parts of a flow modifier, 1-3 parts of polyvinylidene fluoride, 1-3 parts of nanometer titania, 3-8 parts of a compatilizer and 2-5 parts of other auxiliaries. The sun-shading fabric has highly flame-retardant and self-cleaning functions.

Owner:NINGBO XIANFENG NEW MATERIAL

Whitening and hydrating cleansing milk and method for manufacturing same

InactiveCN105267124AStay hydratedGood skin affinityCosmetic preparationsToilet preparationsBiotechnologyAsparagus cochinchinensis

The invention belongs to the technical field of cosmetics, and particularly relates to whitening and hydrating cleansing milk and a method for manufacturing the same. The whitening and hydrating cleansing milk comprises, by weight, 5-25 parts of surfactants, 15-35 parts of humectants, 5-25 parts of traditional Chinese medicine extract, 0.5-1.5 parts of thickeners, 30-40 parts of water, 0.05-0.25 part of vitamin E and 1-3 parts of propolis. The traditional Chinese medicine extract comprises eucommia ulmoides extract, aloe extract and mixed extract, the mixed extract comprises pearl barley and radix asparagi according to a weight ratio of 2-5:2-5. The whitening and hydrating cleansing milk and the method have the advantages that the whitening and hydrating cleansing milk is mild, skin friendly and safe and is free of irritation, the skins of users can be deeply cleansed, and obvious water supplementing and whitening effects can be realized.

Owner:陈洁娣

Water-based matt scratch-resistant soft synthetic leather

The invention relates to the field of manufacture of water-based synthetic leather, in particular to water-based matt scratch-resistant soft synthetic leather. The water-based matt scratch-resistant soft synthetic leather comprises a base cloth layer, a wet process polyurethane coating, a dry process polyurethane layer, a pearly luster layer, a matt treatment layer and a water-based matt treatmentlayer, wherein the wet process polyurethane coating is coated onto the base cloth; the dry process polyurethane layer is coated onto the wet process polyurethane coating; the pearly luster layer is printed onto the dry process polyurethane layer by high solid printing; the matt treatment layer is coated onto the pearly luster layer through template coating; the water-based matt treatment layer iscoated onto the matt treatment layer through template coating. Through study on the wet process polyurethane layer and the dry process polyurethane layer, the hand feeling of the synthetic leather issoft; the fullness degree of film coating is high; the toughness is very good; the wear resistance and scratch resistance are realized; through the arrangement of the water-based matt treatment layer, the hand feeling fullness and the texture fineness of the synthetic leather are better than those of a conventional solvent type product; the made synthetic leather has ultra-weak odor; the environment-friendly effect is achieved; the pure water-based performance and environment-friendly effects are achieved; no heavy metal and no free formaldehyde exist; APEO (alkylphenol ethoxylates) and potassium phthalate are not contained; no toxic and harmful ingredients such as isocyanate remains.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Leather pattern color forming process for engraving plate

The invention discloses a leather pattern color forming process for an engraving plate. The leather pattern color forming process comprises the following steps: selecting an engraving plate with a carving pattern on the front surface and leather, wherein the back surface of the leather is a base layer color coating, the front surface of the leather is a surface layer color coating arranged outside the base layer color coating; coating the front surface of the engraving plate with absorbing plastics, bonding the back surface of the leather on the engraving plate by the absorbing plastics, then placing the leather and the engraving plate in a vacuum plastic-absorbing machine integrally and heating for 0.5-1min, and performing vacuum plastic absorption at 120-190 DEG C, so as to enable the leather and the pattern layer of the engraving plate to be wholly fitted into one body; taking out the engraving plate for the water milling treatment, rubbing off the surface layer color coating of the leather except the pattern, and exposing the base layer color; and cutting off the excessive leather. According to the leather pattern color forming process for the engraving plate, the leather has anti-scratching and abrasion-resistant effects, has good handfeel, is flame retardant and high-low temperature resistant, has no foreign smell, has no formaldehyde and heavy metal, cannot be faded easily and has uniform quality, labor is saved, the working efficiency is improved and the large-scale volume production requirement can be met.

Owner:陈国岳

Circuit forming method of outer layer of circuit board

ActiveCN105338752AHigh hardnessImprove scratch resistanceInksConductive material chemical/electrolytical removalAcid etchingIrradiation

The invention relates to a circuit forming method of an outer layer of a circuit board. The method comprises: a circuit board with an outer layer circuit needing to be processed is provided; pouring and coating of deep-curing UV ink are carried out on a hole needing protection and / or a predetermined region needing protection at a circuit board surface on the circuit board; exposure is carried out on the condition of 100-300mJ / cm<2>; and development, etching, and membrane removing are carried out on the exposed circuit board to form an outer layer circuit of the circuit board. According to the invention, the deep-curing UV ink is used for manufacturing the circuit board and the inside of the hole and the region with the surface needing protection are coated with the ink; and deep curing can be realized after UV light source irradiation. Therefore, chemical impacts on a weak base developing solution with the pH being approximately equal to 10 and an acid etching solution with the pH being 2 to 3 and thus the anti-etching effect is realized.

Owner:深圳市乐建感光材料科技有限公司

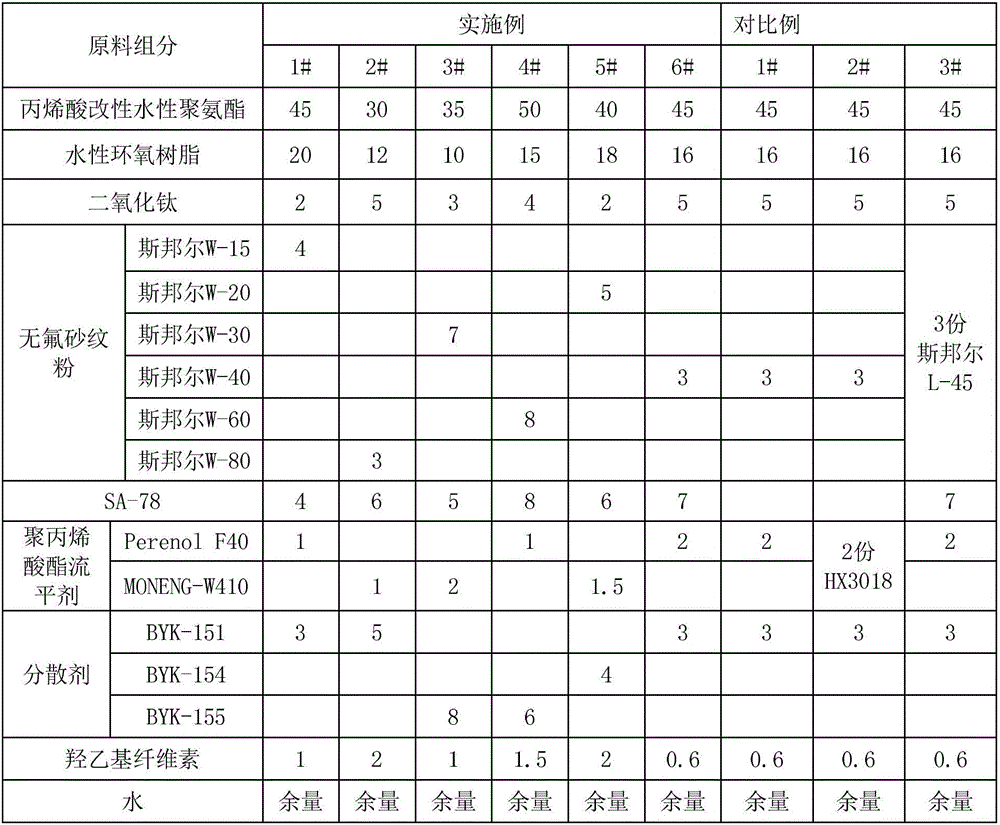

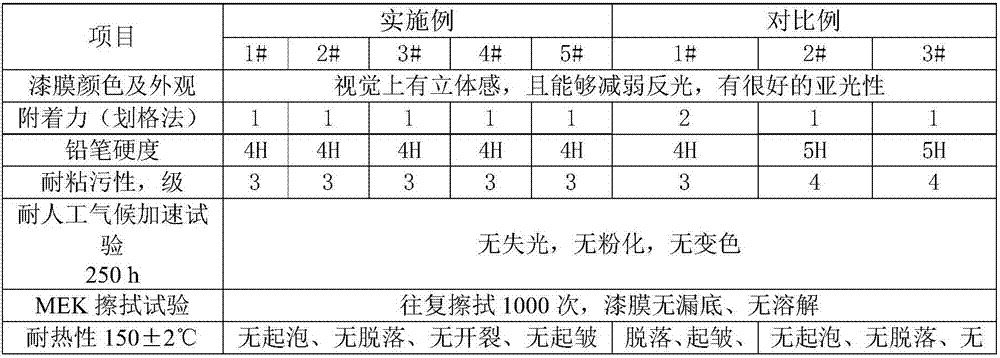

Water-based sand-textured paintand preparation method thereof

ActiveCN106634522AHigh hardnessExcellent heat and weather resistancePolyurea/polyurethane coatingsEpoxy resin coatingsWater basedEpoxy

The invention relates to the field of a water-based paint, and specifically relates to a water-based sand-textured paint. The water-based sand-textured paint comprises the following components in percent by weight: 30-50 percent of acrylic acid modified water-based polyurethane, 10-20 percent of water-based epoxy resin, 2-5 percent of pigments, 3-8 percent of non-fluorine sand-textured powder, 1-2 percent of a polyacrylate flatting agent, 4-8 percent of an adhesive-force accelerant, 3-8 percent of a dispensing agent, 1-2 percent of a thickening agent and the balance water. The water-based sand-textured paint disclosed by the invention has good adhesive force and compatibility, and helps to fully eliminate delamination phenomenon appearing between a new coating layer and a preceding sand-textured coating layer when the surface of the sand texture appears quality defects and needs to be coated again.

Owner:广东绿色大地化工有限公司

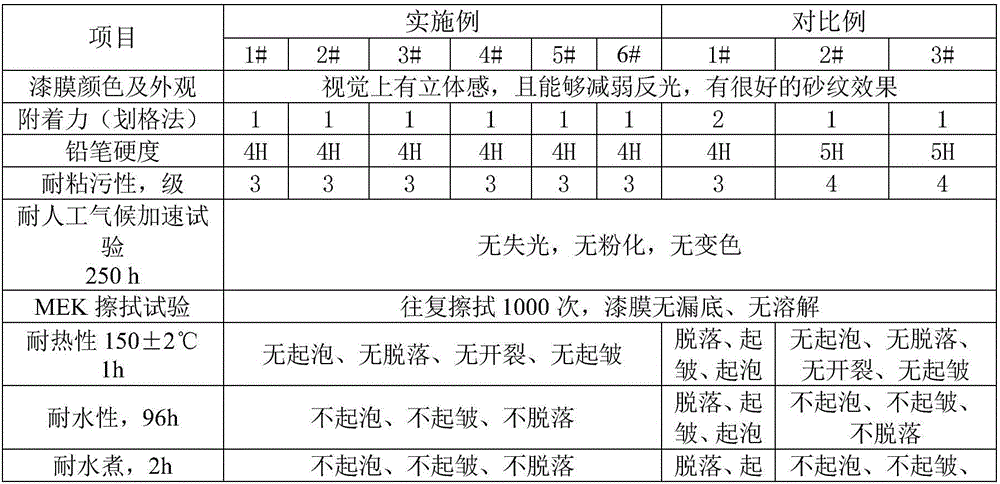

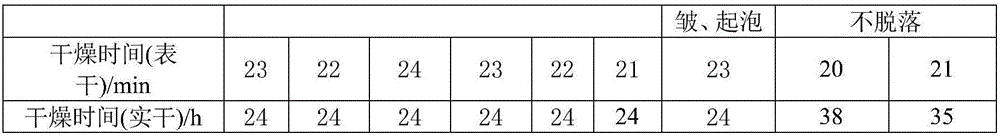

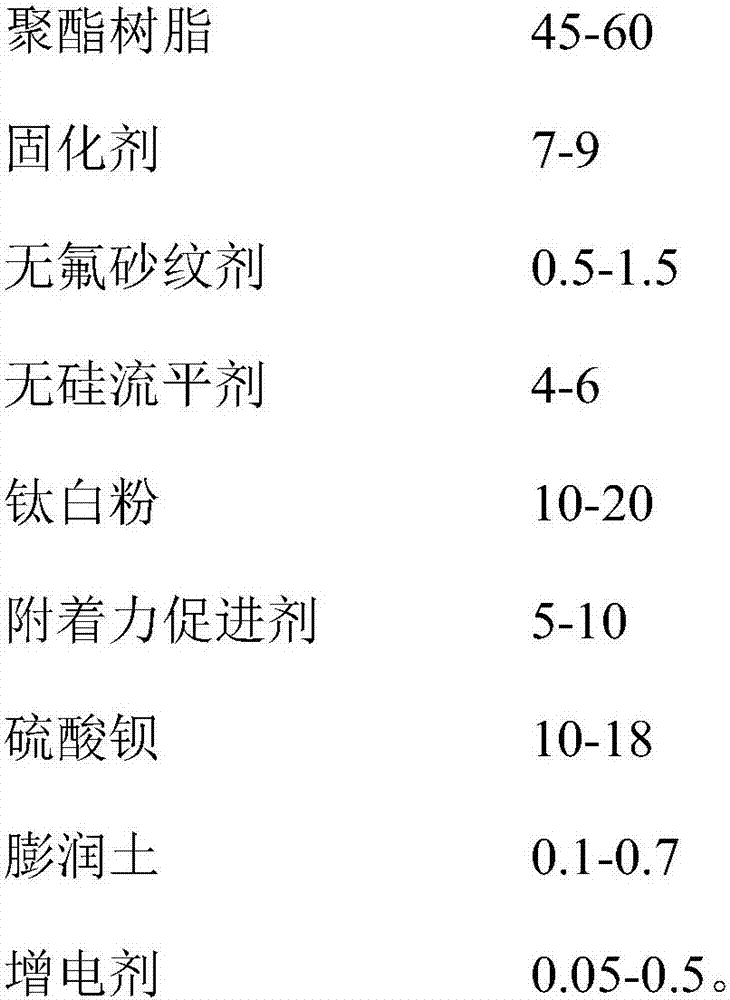

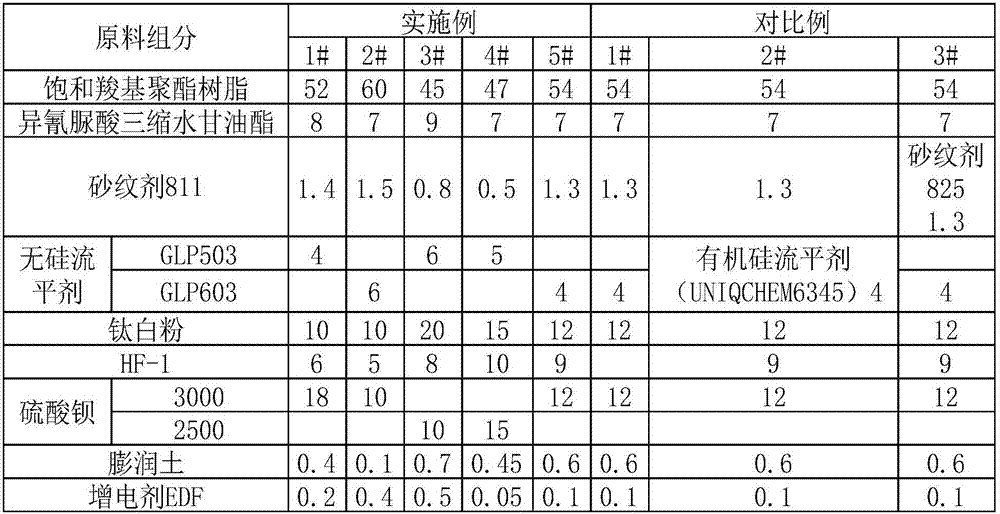

Powder spray-coating sand pattern paint

InactiveCN107325693AImprove adhesionStrong adhesionPowdery paintsPolyester coatingsPolyester resinFluorine containing

The invention relates to the field of coat spraying of powder, particularly to a powder spray-coating sand pattern paint, which comprises, by weight, 45-60 parts of a polyester resin, 7-9 parts of a curing agent, 0.5-1.5 parts of a fluorine-free sand pattern agent, 4-6 parts of a silicon-free leveling agent, 10-20 parts of titanium dioxide, 5-10 parts of an adhesion promoter, 10-18 parts of barium sulfate, 0.1-0.7 part of bentonite, and 0.05-0.5 part of an electric power increasing agent. According to the present invention, various components of the system are regulated, the fluorine-containing material, the silicon-containing material and other low surface energy aids are completely eliminated in the used components, the surface energy of the curing film is increased within the permissible range, and when the re-spraying is required due to the generation of the quality defect on the sand pattern surface, the combination of the sand pattern paint and the cured sand pattern surface is easily achieved.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

Ink for food packaging materials and preparation method and application of ink

The invention provides ink for food packaging materials and a preparation method and application of the ink. The ink is prepared from, in parts by weight, 20-30 parts of water-based acrylic resin, 20-30 parts of polyurethane emulsion, 10-15 parts of calcium carbonate, 5-10 parts of edible alcohol, 1-5 parts of defoamer, 30-40 parts of deionized water and 2-8 parts of food colorant. The water-basedacrylic resin is adopted as a connecting material, and due to low solid content in the ink, the ink has good dispersibility for the food colorant and good coloring polarity on OPP polypropylene plastic film, so that an ink layer has good printing adhesion, and printing is clear, does not fall off easily, and is resistant to hot water of 80 DEG C; in addition, environmental protection of the ink is achieved by adopting the deionized water; bubbles generated by grinding and stirring during preparation of pigment can be eliminated through the defoamer, so that even film of the ink is uniformly formed on packages, and the appearance of the formed film is good.

Owner:澧县津溥包装制品有限责任公司

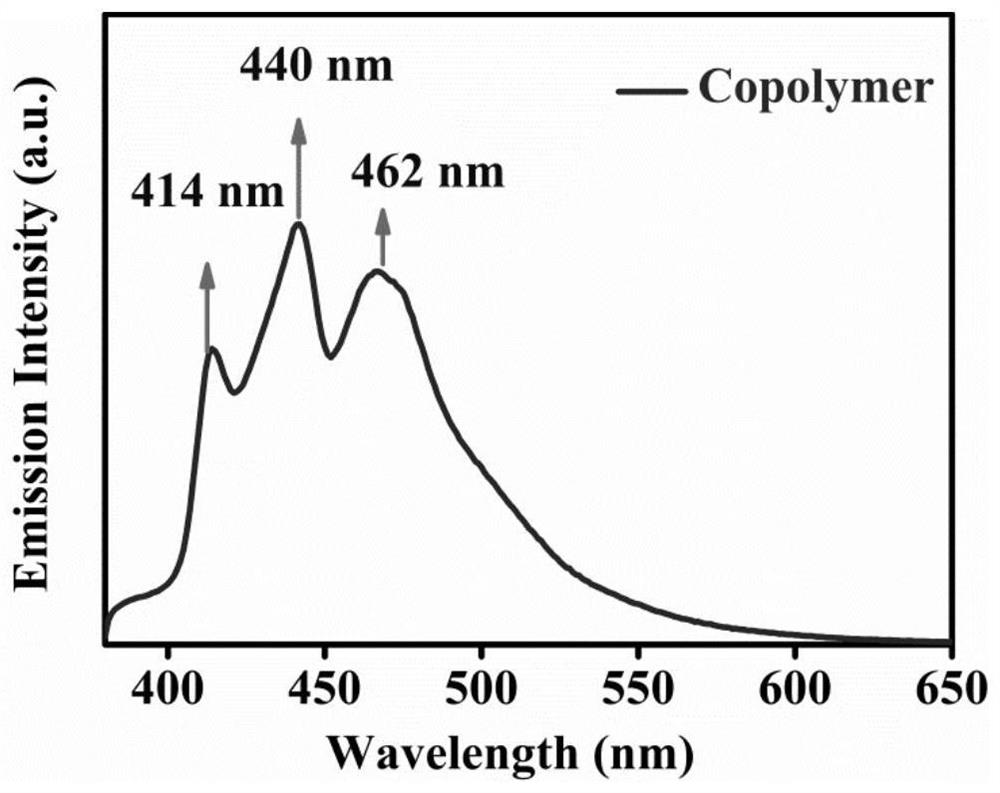

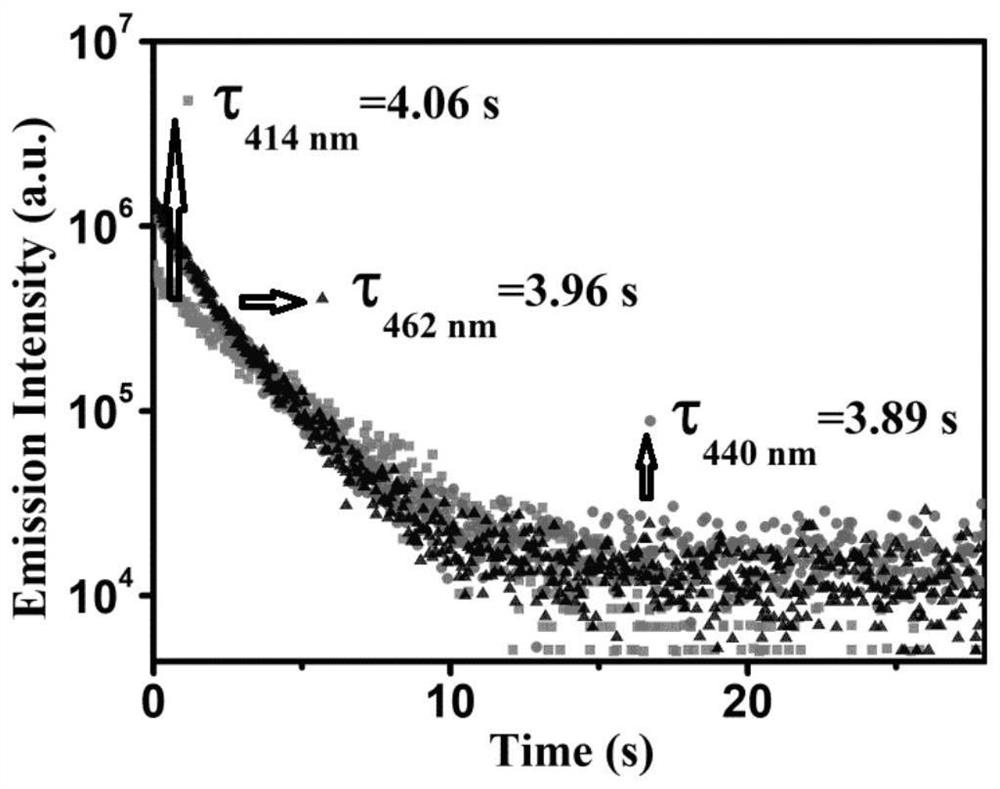

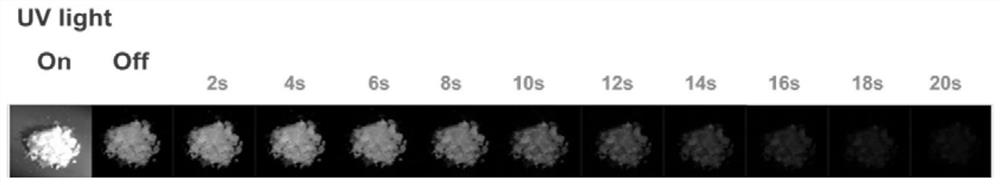

Method for synthesizing metal-free heavy-atom-free long-life room-temperature phosphorescent polymer through microwave radiation

ActiveCN112961275ANo pollution in the processHalogen freeLuminescent compositionsPolymer scienceVinyl carbazole

The invention relates to a method for synthesizing a metal-free heavy-atom-free long-life room-temperature phosphorescent polymer through microwave radiation. According to the method, the room-temperature phosphorescent polymer material with long service life is prepared from vinyl carbazole and an acrylamide monomer through free radical copolymerization under the action of microwaves, the phosphorescent service life is long at room temperature, meanwhile, the raw materials are easy to obtain, the preparation method is simple and convenient, the reaction time is short, and the product is non-toxic, pollution-free, heavy metal-free, halogen-free, good in water solubility and wide in application prospect.

Owner:FUJIAN NORMAL UNIV

Natural extraction compound with acne removing effect and preparation method and application thereof

InactiveCN113384642AGet rid of acneLighten acne marksCosmetic preparationsAntipyreticBiotechnologyOlive leaf

The invention belongs to the technical field of cosmetics, and discloses a natural extraction compound with an acne removing effect and a preparation method and application thereof. The natural extract compound is prepared from the following raw materials: broad-leaved epiphyllum, emblic leafflower fruit, golden camellia flower, golden camellia leaf, safflower, folium eriobotryae, centella asiatica, white willow bark, mangnolia officinalis, blue-ear grass, radix sophorae flavescentis, purslane, olive leaf and American mint leaf. The raw materials are organically combined, the formula is reasonable, the synergistic interaction effect is well exerted, and the effects of inhibiting bacteria, resisting inflammation, cleaning facial grease, removing acnes, fading acne marks and repairing damaged skin are jointly achieved. The natural extraction compound is safe and effective, has no irritation, hormone or heavy metal, and can prevent a user from being harmed by harmful substances.

Owner:忧立舒医药科技(广东)有限公司

A kind of whitening and anti-aging cleanser and preparation method thereof

ActiveCN105287290BReduce fine linesLighten dark spotsCosmetic preparationsToilet preparationsGinkgo Biloba Leaf ExtractGlycerol

The present invention belongs to the technical field of cosmetics, and particularly relates to a whitening and anti-aging face cleaner and a preparation method thereof, wherein the whitening and anti-aging face cleaner comprises lauric acid, glycerol, potassium hydroxide, squalane, sodium lauroyl glutamate, glyceryl monostearate, polyethylene glycol, a eucommia ulmoides extract, a horseradish tree leaf extract, a ophiopogon japonicus extract, a ginkgo biloba leaf extract, EDTA disodium, methylparaben, essence and water. The whitening and anti-aging face cleaner of the present invention has characteristics of mildness, good skin affinity, safety and no stimulating, and further has effects of deep skin cleaning, blood circulation promoting, moisturizing, whitening, and aging delaying.

Owner:杭州施莱生物科技有限公司

Composition with skin whitening function

InactiveCN102988220APromote cell metabolismIncrease skin whiteningCosmetic preparationsToilet preparationsSkin whiteningHeavy metals

The invention discloses a composition with a skin whitening function. The composition is prepared from the raw materials in parts by weight: 5-25 parts of grape seed extract, 4-16 parts of rose extract, 6-12 parts of trichosanthes aqueous extract, 8-24 parts of radix asparagi aqueous extract and 5-10 parts of white gourd juice. According to the composition with the skin whitening function, various components are preferentially proportioned according to a cell experiment, and the experimental result proves that the composition has the effects of promoting cell metabolism, reducing melanin pigmentation and whitening the skin, and the raw materials are natural products, do not contain heavy metals, do not have adverse impact on a human body and are wide in application range.

Owner:SUZHOU GULI BIOTECH

Waterproof decoration heat-insulation outdoor environment-friendly composite decoration plate and manufacturing method thereof

ActiveCN105601247AHigh strengthImprove insulation effectCovering/liningsFlooringEnvironmental resistanceInsulation layer

The invention relates to a waterproof decoration heat-insulation outdoor environment-friendly composite decoration plate, which consists of a molding face materiel and a heat insulation layer compounded into a whole with the molding face materiel, wherein the molding face materiel is prepared from the following materials in parts by weight: 100 parts of magnesia, 5 to 10 parts of diatom ooze, 10 to 20 parts of pulverized fuel ash, 2 to 4 parts of 3MM glass fiber, 0.2 to 0.4 parts of trisodium phosphate, 2 to 3 parts of ferric oxide, 0.2 to 0.4 parts of defoaming agents, 20 to 30 parts of magnesium sulfate, 30 to 40 parts of magnesium chloride and 30 to 50 parts of water; the heat insulation layer is prepared from the following materials in parts by weight through mixing: 60 to 70 parts of sucrose polyether polyol with the hydroxyl value being 500, 7 to 10 parts of amino polyether polyol with the hydroxyl value being 500, 20 to 30 parts of polyether polyol with the hydroxyl value being 360, 15 to 25 parts of physical foaming agent CFC-141B, 3 to 6 parts of water, 1 to 2 parts of cyclohexylamine, 0.3 to 0.5 parts of pentamethyl-diethylenetriamine, 3 to 5 parts of silicone oil, 20 to 30 parts of expansion graphite and 120 to 150 parts of coarse MDI. The composite decoration plate and a manufacturing method of the composite decoration plate have the advantages that by aiming at the vacancy of the existing market product or the limitation of the user perform, through the material formula development and the production processing mode improvement, the environment-friendly, fireproof and waterproof effects are really achieved; the heat function is realized; the appearance is exquisite; the color is lifelike; the installation is simple; the composite decoration plate can be used outdoors for a long time.

Owner:SHIJIAZHUANG JIANHENG HOUSEHOLD DECORATIONS CO LTD

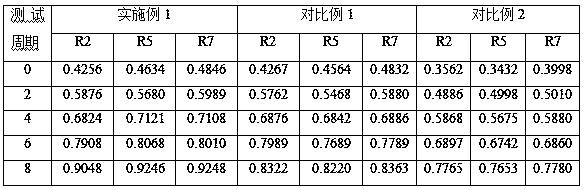

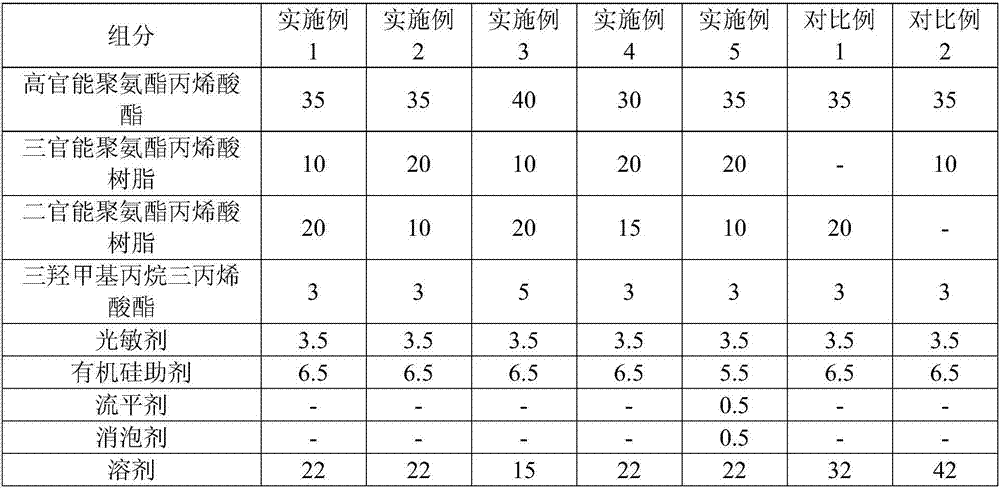

UV (Ultraviolet) curable coating as well as preparation method and application thereof

ActiveCN106957597AGuaranteed basic characteristicsGood flexibilityPolyurea/polyurethane coatingsPhotosensitizerPliability

The invention relates to a UV (Ultraviolet) curable coating as well as a preparation method and application thereof. The UV curable coating is prepared from the following components in percentage by weight: 30 to 40 percent of high-functionality polyurethane acrylate, 10 to 20 percent of trifunctional polyurethane acrylate, 10 to 20 percent of bifunctional polyurethane acrylate, 3 to 5 percent of trimethylolpropane triacrylate, 2 to 4 percent of photosensitizer and 10 to 15 percent of solvent. The UV curable coating disclosed by the invention is sprayed on the surface of single-fluid type colored paint, is used for glazing the single-fluid type colored paint surface, and can form a layer of tough coating film on the single-fluid type colored paint surface; the UV curable coating has the characteristics of good adhesion, good flexibility and good bending resistance for the single-fluid type colored paint and has no influence on the single-fluid type colored paint; a product is enabled not to be easy to bend and burst in the use process.

Owner:深圳市美丽华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com