Environment-friendly water-based crack lacquer and application method thereof

A water-based crack paint and crack primer technology, applied in the coating and other directions, can solve the problems of peeling off the paint surface, no cracking on the crack surface, and quality degradation, and achieve the effect of simple spraying, high safety performance, and improved adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

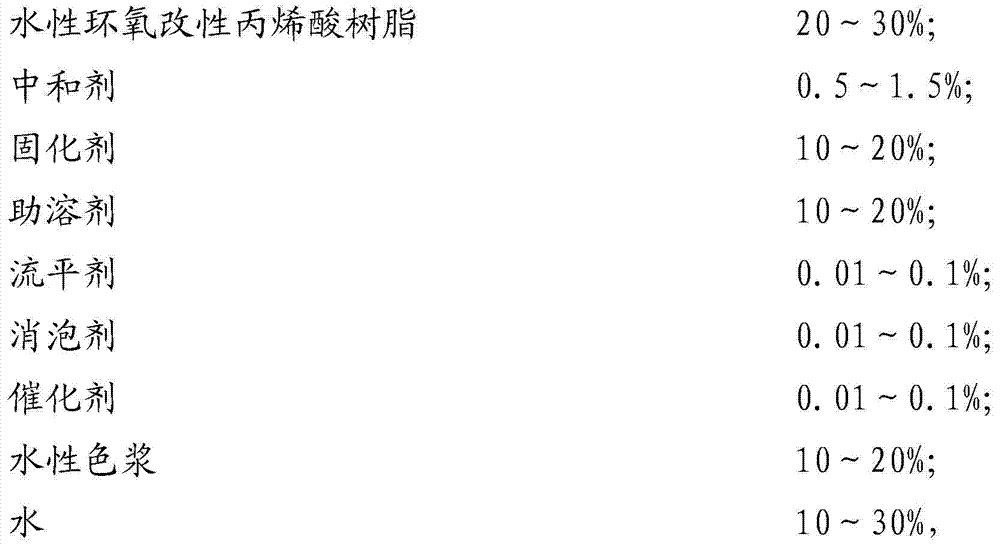

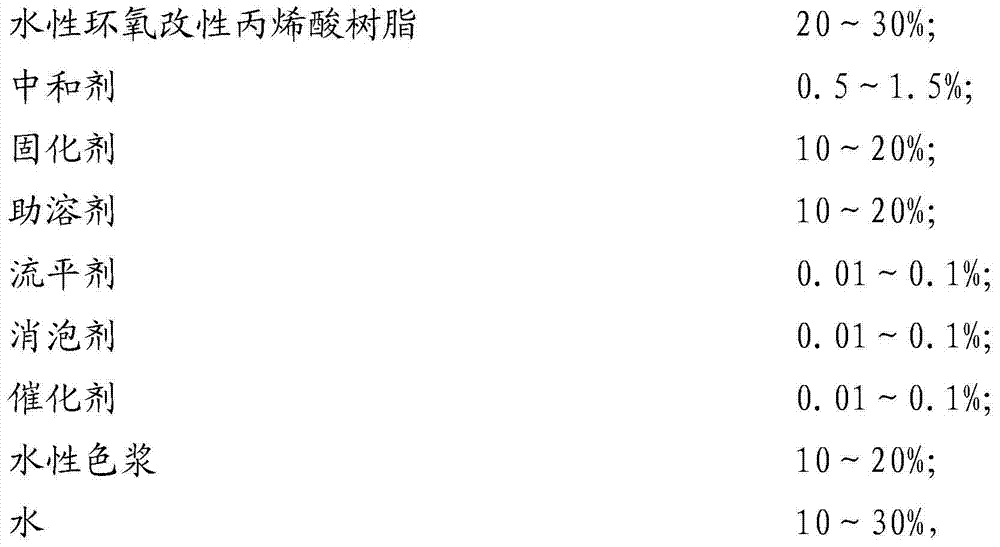

[0026] An environmentally friendly water-based crack paint, comprising a water-based crack primer and a water-based crack finish paint, the water-based crack primer includes: 20kg of water-based epoxy modified acrylic resin; 0.5kg of neutralizer; 20kg of curing agent; 20kg of cosolvent; leveling agent 0.01kg; defoamer 0.01kg; catalyst 0.01kg; water-based color paste 20kg; water 19.47kg, the water-based crack finish paint includes: styrene-acrylic emulsion 60kg; kg.

Embodiment 2

[0028] An environmentally friendly water-based crack paint, including water-based crack primer and water-based crack finish paint, the water-based crack primer includes: 22kg of water-based epoxy modified acrylic resin; 0.7kg of N,N-dimethylethanolamine; 18kg of amino resin; 18kg of alcohol; 0.03kg of leveling agent; 0.03kg of defoamer; 0.03kg of dibutyltin dilaurate; 18kg of water-based color paste; ; Water-based color paste 33.77kg; Water-based cracking agent 0.03kg.

Embodiment 3

[0030] An environmentally friendly water-based crack paint, comprising a water-based crack primer and a water-based crack finish paint, the water-based crack primer includes: 24kg of water-based epoxy-modified acrylic resin; 0.45kg of N,N-dimethylethanolamine, 0.45kg of diethanolamine; Blocked isocyanate 16kg; n-butanol 8kg, propylene glycol methyl ether 8kg; leveling agent 0.05kg; defoamer 0.05kg; dibutyltin dilaurate 0.02kg, dodecylbenzenesulfonic acid 0.03kg; 26.95kg of water, the water-based crack finish paint includes: 70kg of styrene-acrylic emulsion; 1.4kg of neutralizer; 28.55kg of water-based color paste; 0.05kg of water-based crack agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com