Patents

Literature

3249 results about "Dodecylbenzenesulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

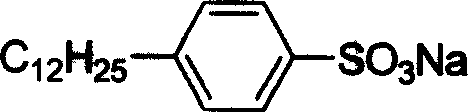

Dodecylbenzene Sulfonic Acid D2279 | 27176-87-0 Dodecylbenzene Sulfonic Acid, also known as Phenyldodecane, is a biodegradable surfactant intermediate that can be neutralized with a variety of inorganic bases and organic. Page.

Surface activating agent for oil-field thick-oil well

InactiveCN101024764AGood viscosity reduction effectImprove performanceTransportation and packagingMixingPhenolOleic Acid Triglyceride

The invention discloses a surface activator used in oil field thick oil well that is made up from water 1500kg, sheet alkali 330kg, alcohol 450kg, oleic acid 275kg, alkyl phenol polyoxyethylene (15) ether 200kg, sodium dodecyl benzene sulfonate 150kg. The invention could decrease interface tension, and under the emulsion effecting, the o / w or w / o would form flow state in normal state to be convenient to convey and pump. The invention has low cost and high effect.

Owner:图们市科兴石化技术开发有限公司

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

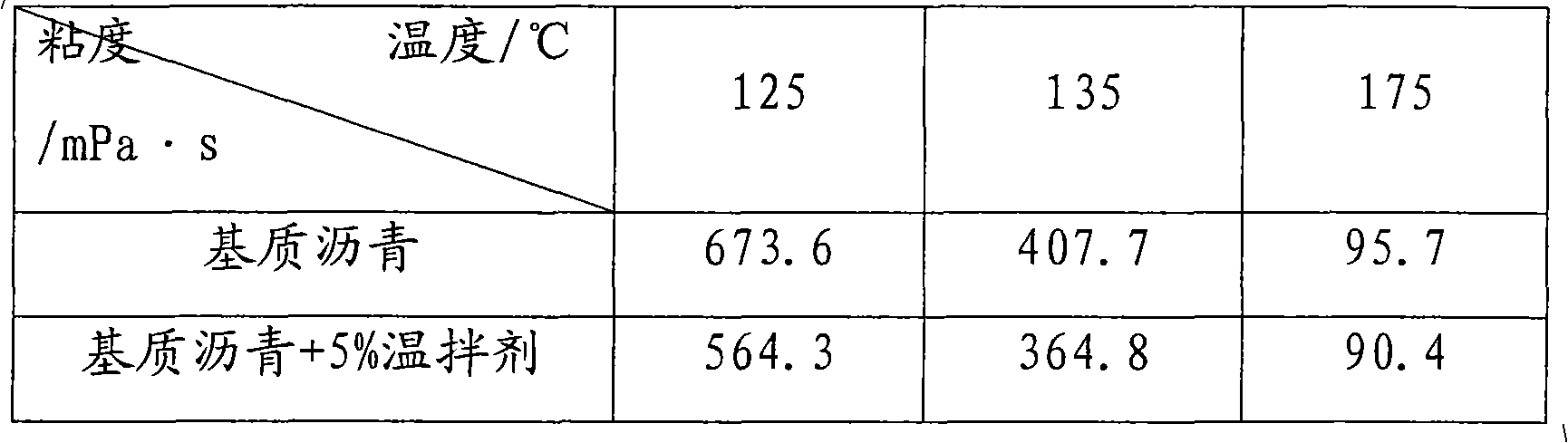

Rubber modified asphalt warm-mixing agent, preparation method and application

InactiveCN101831187ALow viscosityLow softening pointClimate change adaptationBuilding insulationsSurface-active agentsFatty alcohol

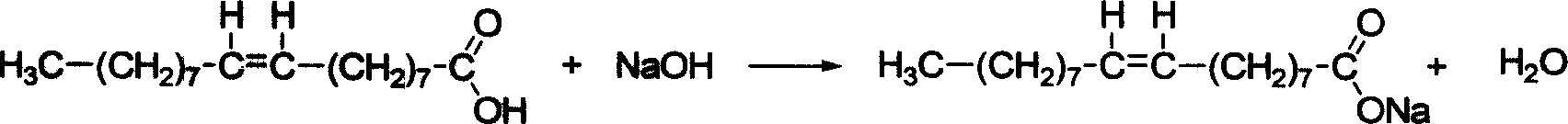

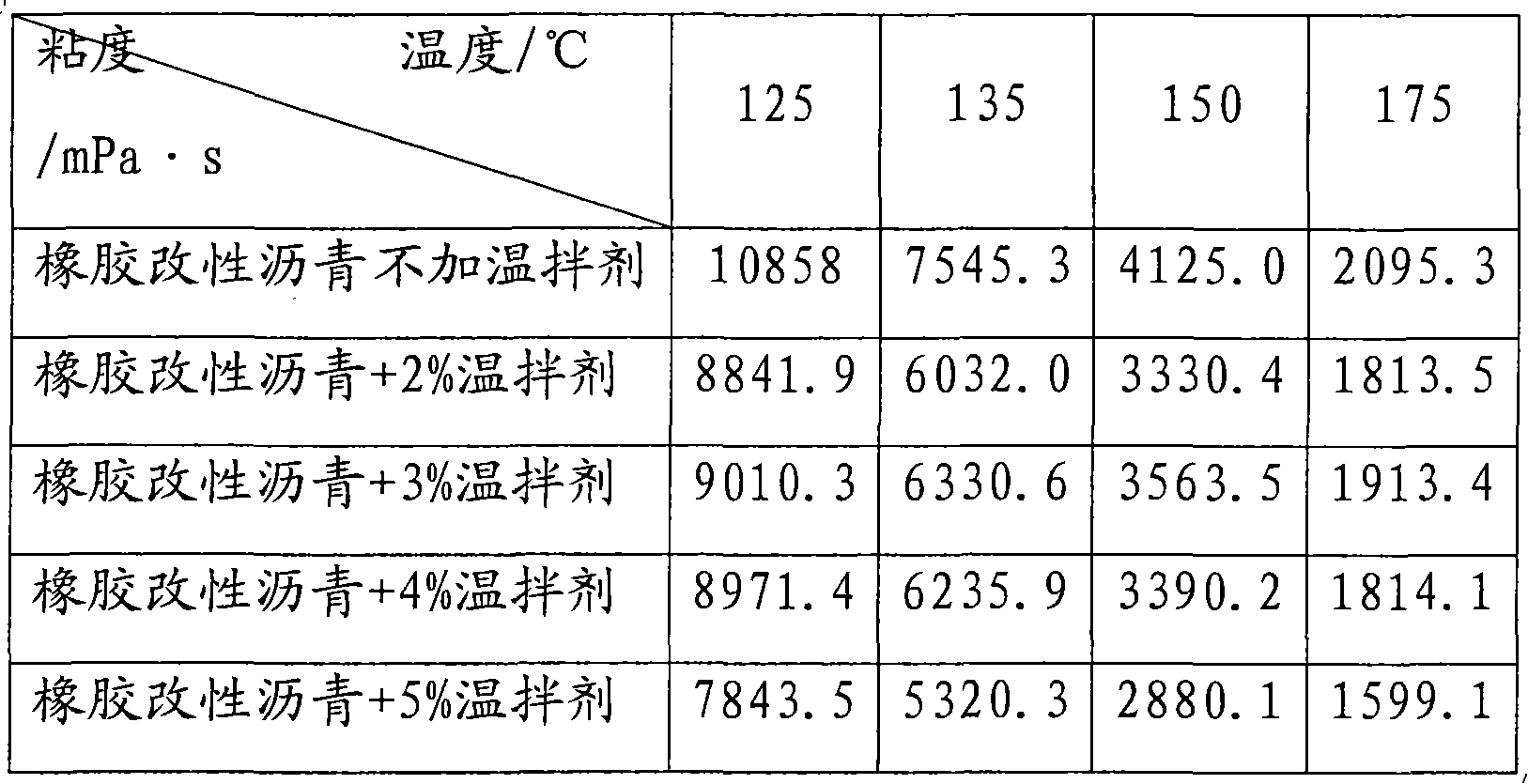

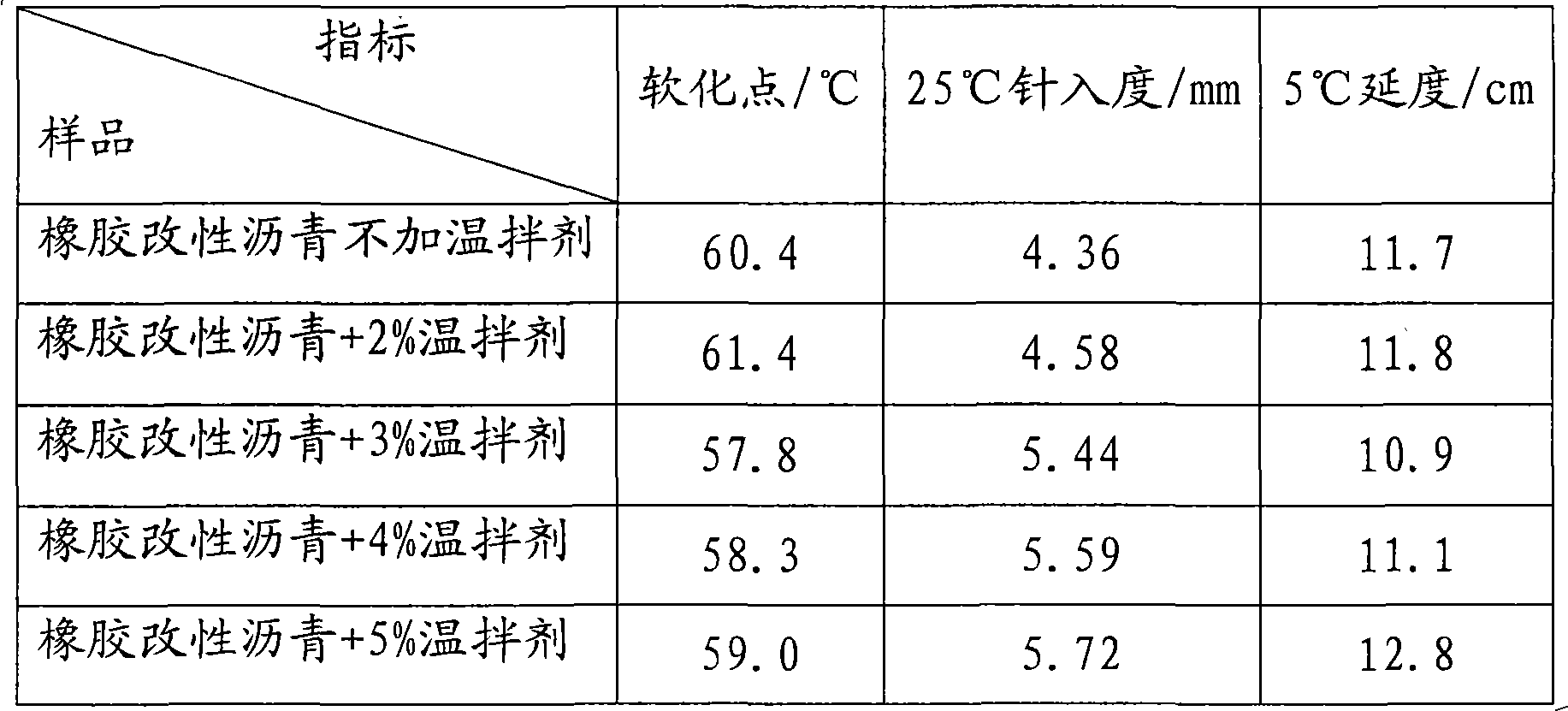

The invention discloses a rubber modified asphalt warm-mixing agent, a preparation method and application thereof. The warm-mixing agent comprises the following components in parts by weight: 100 parts of water, 5-30 parts of fatty alcohol sodium sulfate, 15-30 parts of palmitic acid, 5-30 parts of oleic acid, 1-20 parts of sodium dodecyl benzene sulfonate, 1-15 parts of cetyltrimethylammonium chloride and 10-30 parts of imidazoline-type cationic surface active agent ODD. The preparation method comprises the following steps of: adding the water in a container at the temperature of 65 DEG C, and then adding the following substances under the condition of stirring: the fatty alcohol sodium sulfate, the palmitic acid, the oleic acid, the sodium dodecyl benzene sulfonate, the cetyltrimethylammonium chloride and the imidazoline-type cationic surface active agent ODD, and stirring for 15 min to obtain the warm-mixing agent. The warm-mixing agent is directly applied to rubber asphalt or matrix asphalt to reduce the viscosity of the asphalt. The kinematic viscosity of the rubber powder asphalt added with the warm-mixing agent at the temperature of 150 DEG C can reach less than 3.0Pa.s of the kinematic viscosity at the temperature of 180 DEG C, and the production temperature can be reduced by about 30 DEG C, thereby not only preventing the rubber asphalt from being aged but also saving energy and reducing equipment loss.

Owner:BEIJING UNIV OF CHEM TECH

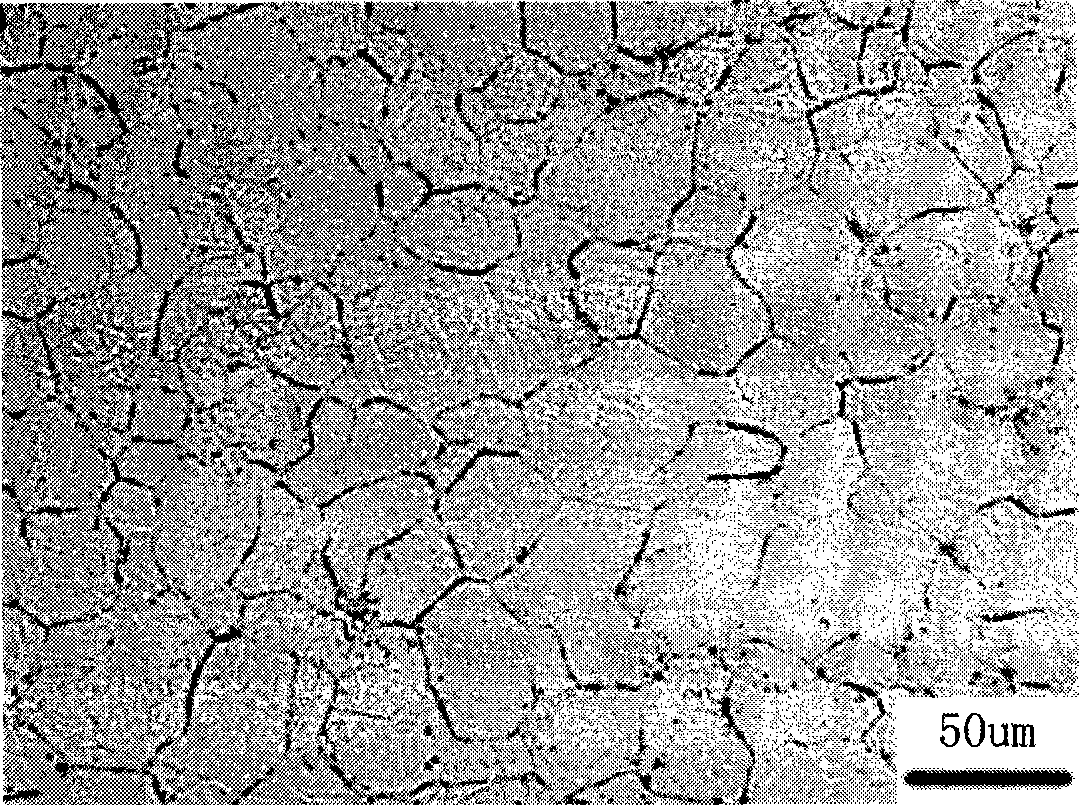

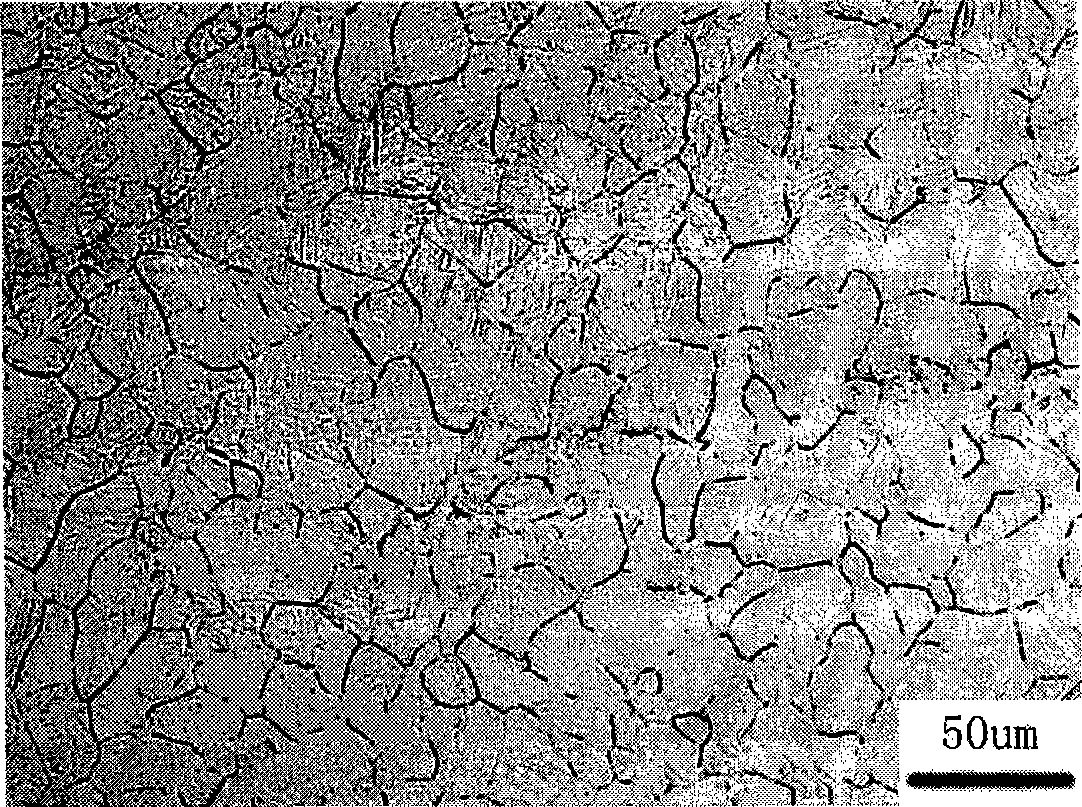

Method for displaying high-strength vessel slab original austenite crystal grain

ActiveCN101368889ADeep corrosionImprove solubilitySurface/boundary effectPreparing sample for investigationMaterials scienceDodecylbenzenesulfonic acid

The invention relates to a display method used for preparing high-intensity ship plate metallographic samples and the original austenite grains, belonging to the technical field of metallographic sample preparation. The invention has the following technological steps: coarse grinding, fine grinding, polishing and corrosion; the polished specimen is put in the etching solution at 70-80 DEG C; the formula of the etching solution comprises 100ml of distilled water, 5-7g of picric acid, 0.5-1.5ml of hydrochloric acid, 3-5g of SDBS, 5-15g of Seagull paste shampoo and 0.3-1ml of hydrogen peroxide; after being etched for 1-2 minutes, the surface of the specimen is dimmed, and the specimen is taken out, cleaned with alcohol and then dried; and the relatively clear original austenite structure can be observed under a microscope. The invention has the advantages of solving the problem of different display of the high-intensity ship plate austenite grains and clearly displaying the austenite structure; besides, the invention is easy and simple to implement.

Owner:NANTONG WANBAO IND

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

Quick-setting cationic aqueous emulsions using pre-treated rubber modified asphalt cement

Cationic aqueous emulsions of rubber modified asphalt cement (RMAC) useable for paving, seal coat, slurry seal, roofing, coating and other applications. First, a RMAC is prepared by combining 45 to 90% by weight asphalt with about 5% to about 55% by weight solid recycled rubber (e.g., crumb rubber from used vehicle tires) under conditions that cause at least a substantial portion of the solid rubber to become liquified or otherwise incorporated into the asphalt. The RMAC may be treated with dodecyl benzenesulfonic acid (DDBSA) which causes reaction(s) to occur and results in a lowering of the viscosity of the RMAC. The RMAC (or DDBSA-treated RMAC) may then be emulsified in an aqueous medium to provide an aqueous emulsion.

Owner:SABUR DIANA +1

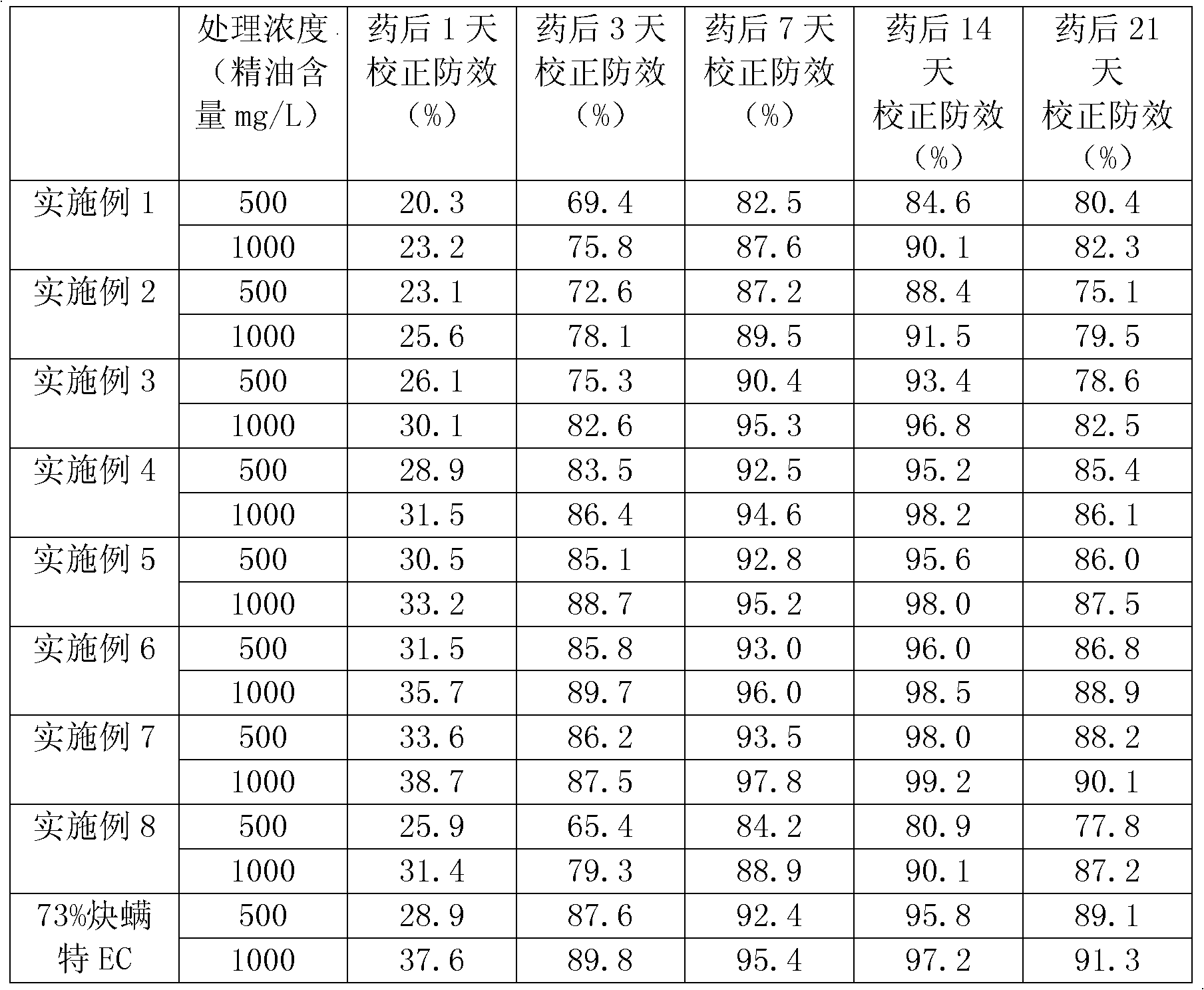

Agricultural pesticide with essential oil and application thereof

The invention relates to agricultural pesticide with essential oil and an application thereof. The agricultural pesticide comprises the following components: 5-90% of the essential oil with insecticidal active components, and 5-90% of solvent, 5-90% of pesticide adjuvant. The essential oil is one or mixture made one from wintergreen oil, camphor tree oil, clove oil, peppermint oil, eucalyptus oil, citronella oil or tea tree oil. The solvent is one or a mixture made of formic acid, acetic acid, propionic acid, methyl alcohol, ethyl alcohol or propyl alcohol. The pesticide adjuvant is one or mixture made of dodecyl benzenesulfonic acid, Tween-80, Span-80 (SPAN) or OP-10. The invention has low toxin for animals, safety for environment, efficiency for pests at each life stage and good effects for killing mites and pests. The agricultural pesticide has simple use method and low manufacturing cost, and is suitable for killing the mites and the pests in agriculture and forestry.

Owner:ZHEJIANG FORESTRY UNIVERSITY

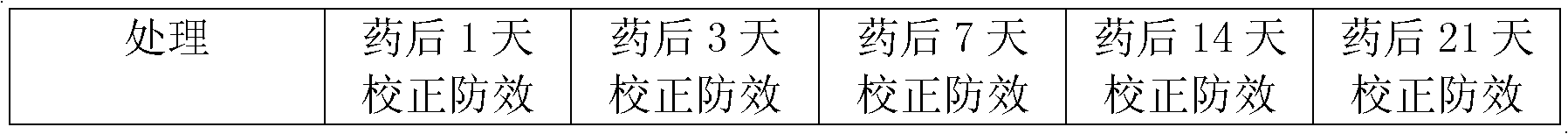

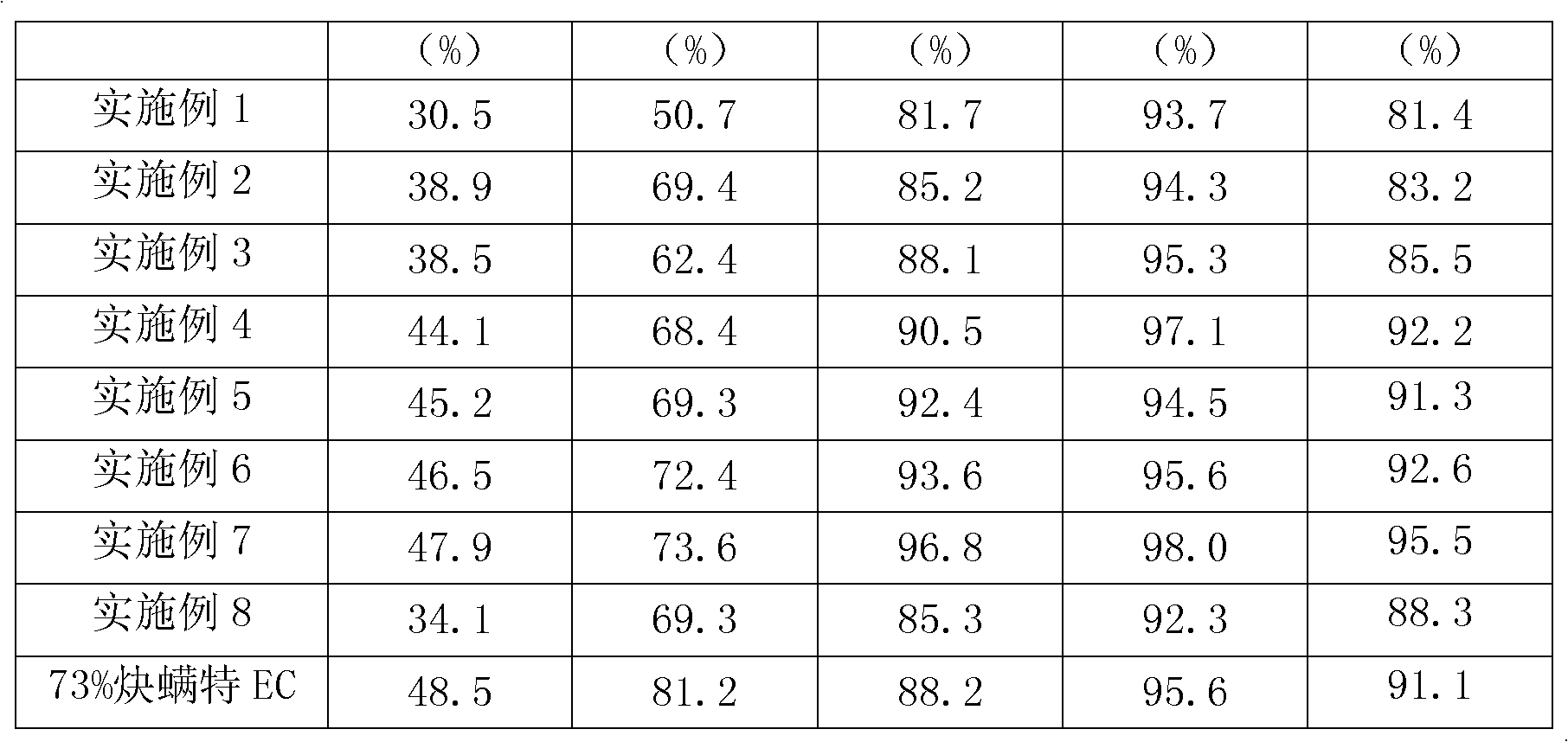

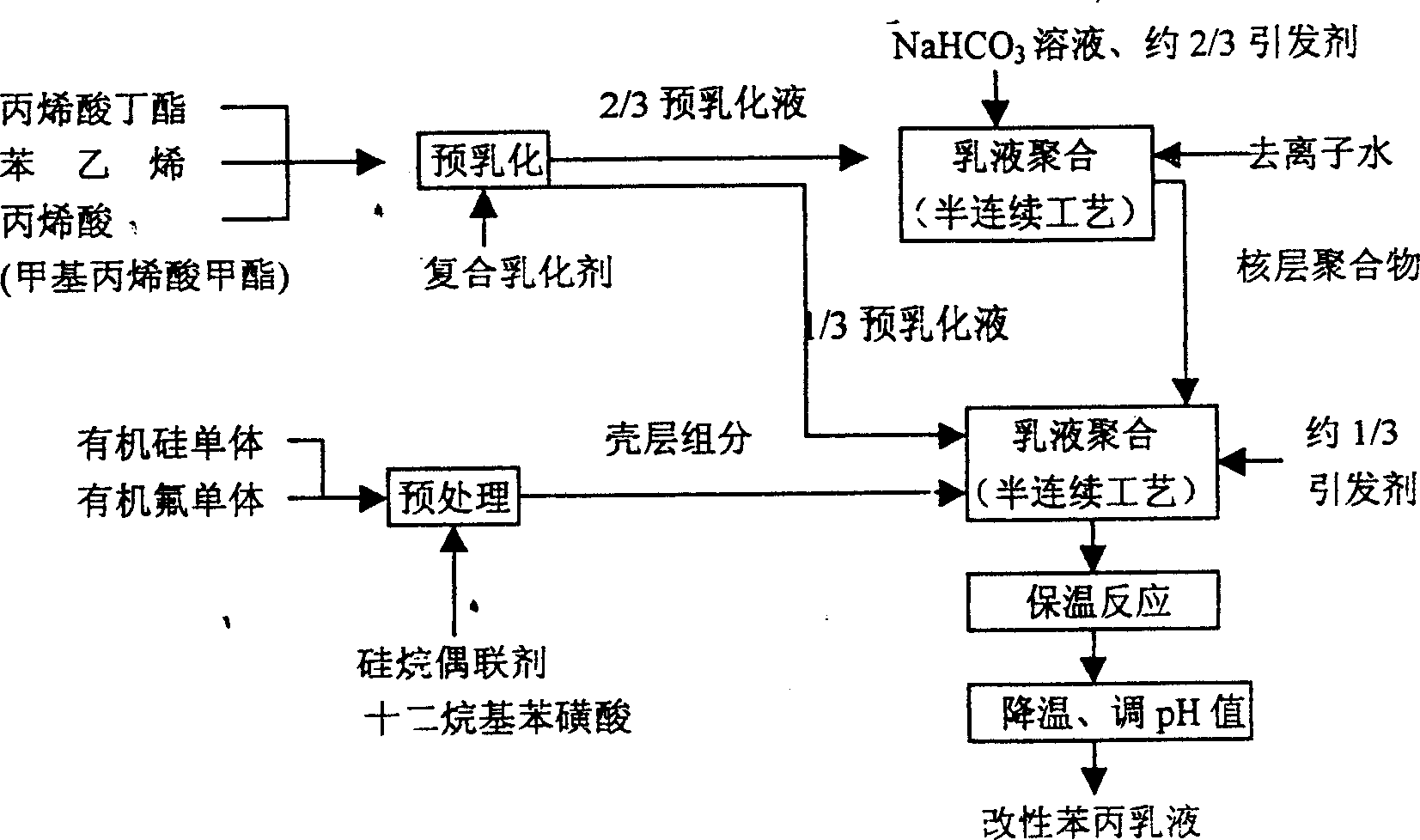

Prepn process of modified styrene-acrylic emulsion

The modified styrene-acrylic emulsion is prepared with styrene, propyl acrylate and acrylic acid as monomers for polymerization, organic fluoride as modifier, composite emulsifier, thermal decomposed initiator and silane crosslinking agent, dodecyl benzene sulfonic acid as catalyst and through core-shell polymerization process. The technological process is simple and easy to control, and has stable polymerizing system. The organosilicon modified styerne-acrylic emulsion may be used widely as base material in inner and outer wall paint with excellent adhesivity, waterproof perfomance, storage stability, good construction performance, good weather resistance, good antifouling performance and long service life.

Owner:JIANGHAN UNIVERSITY

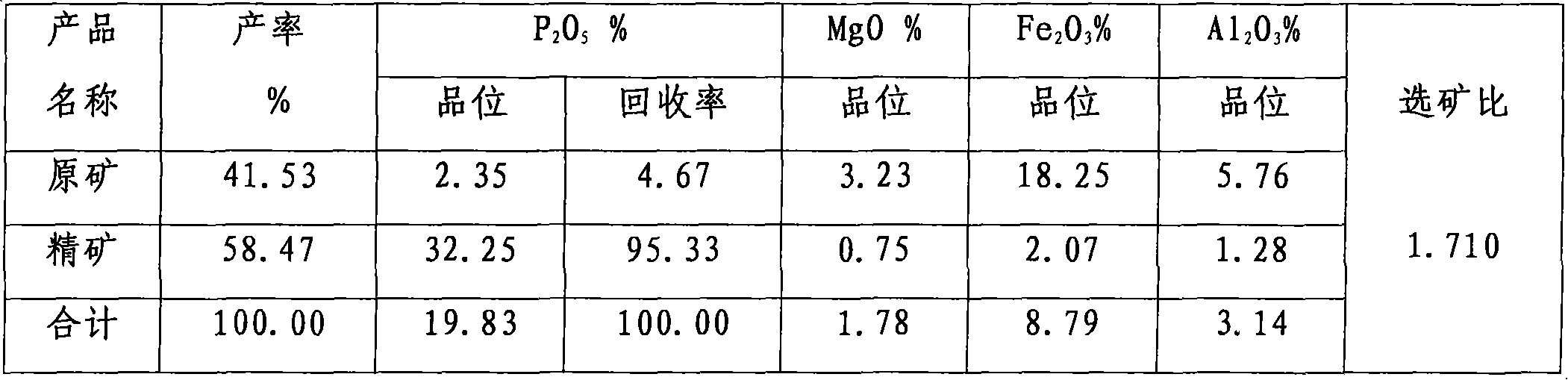

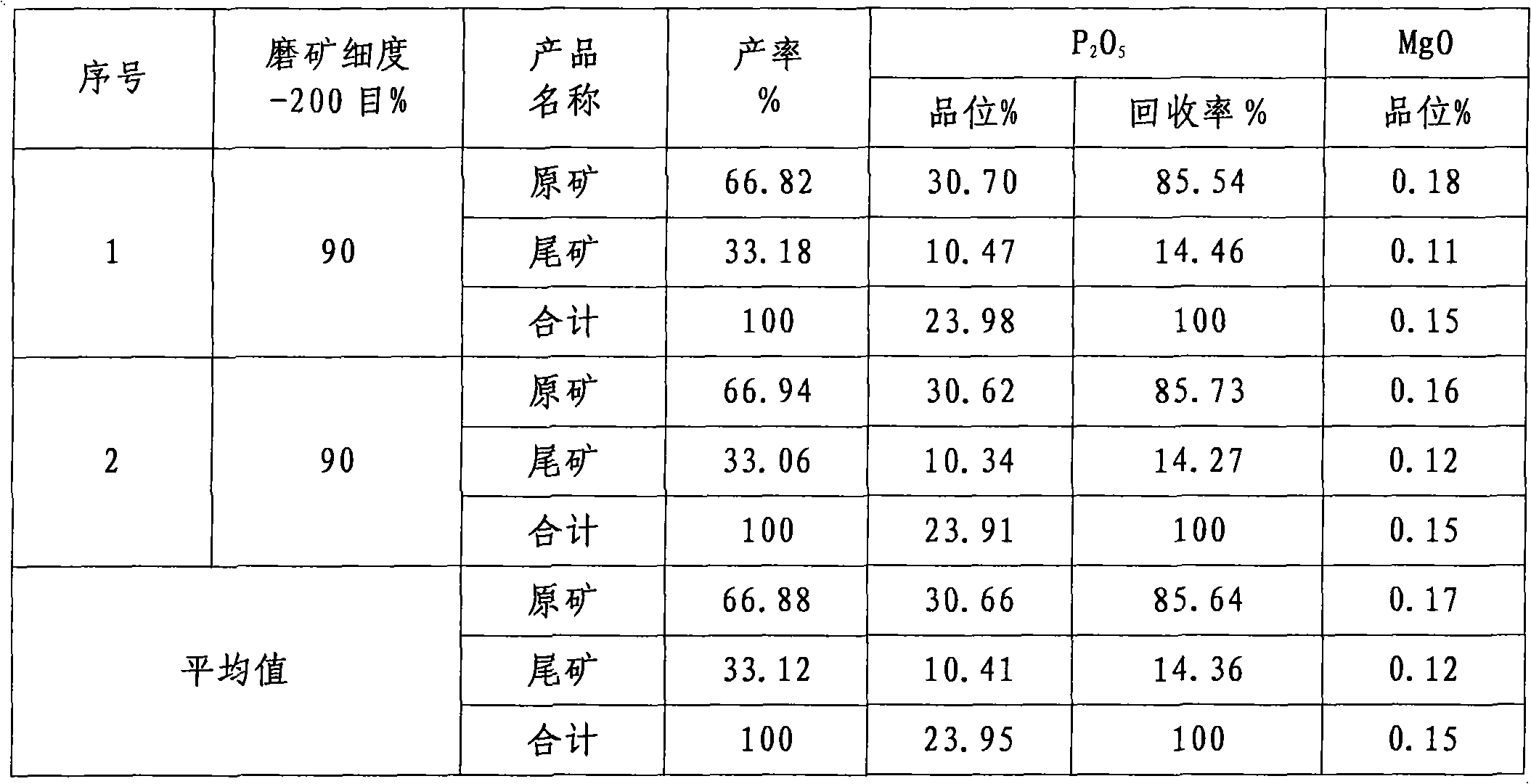

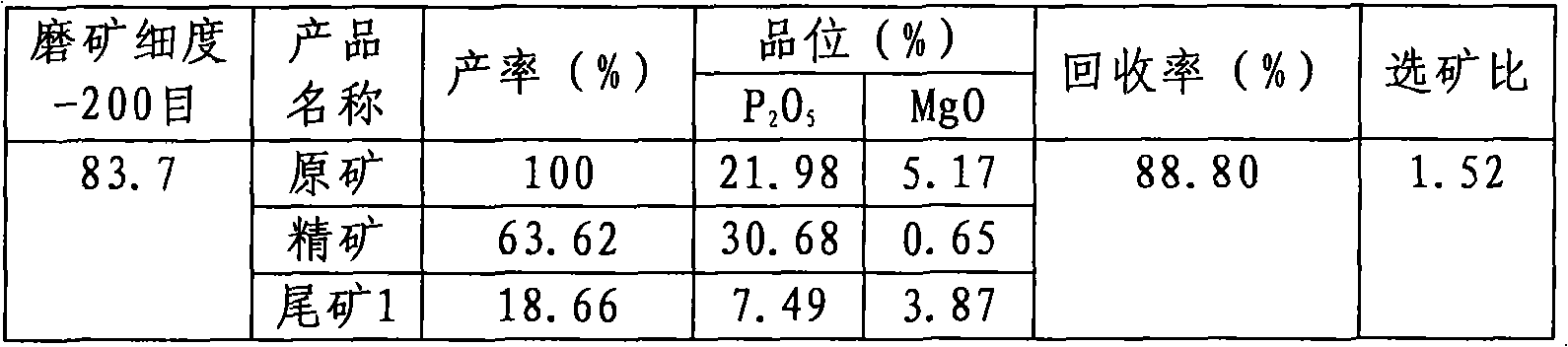

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

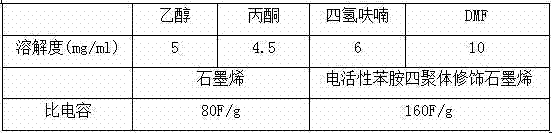

Preparation method for electroactive aniline oligomer-modified graphene

The invention relates to a preparation method for electroactive aniline oligomer-modified graphene. The preparation method comprises the following steps of: reducing graphite oxide by a reducing agent, cooling the reduced graphite oxide to the room temperature, centrifuging and drying the cooled graphite oxide to obtain the reduced graphene; ultrasonically dispersing the reduced graphene and the aniline oligomer into an organic solvent; adding dicyclohexyl carbodiimide and 4-dimethylamino-pyridine to the mixed solution; stirring and heating up the mixture for reacting; washing the mixture by a plurality of times by using acetone, alcohol and distilled water in sequence after the reaction is completed; and drying the mixture to obtain the aniline oligomer-modified graphene; doping the aniline oligomer-modified graphene by hydrochloric acid or dodecylbenzene sulfonic acid to obtain the electroactive aniline oligomer-modified graphene. The preparation method has the beneficial effects that the solubility in the organic solvent is improved and the specific capacitance reaches 160 F / g, so that the electroactive aniline oligomer-modified graphene has a broader application prospect in the fields such as super capacitors, solar cells and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Highly effective ferrous sulfide deactivation cleaning agent

ActiveCN101255383AWash thoroughlyAvoid spontaneous combustion accidentsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChlorine dioxideThiourea

A highly efficient inactivating detergent for ferrous sulfide is disclosed, which is characterized by that it comprises 0.1-10% of chlorine dioxide, 0.1-10% of surfactant, 0.1-5% of citric acid, 0.1-5% of EDTA, 0.1-5% of corrosion inhibitor and water. The surfactant is one or more from dodecyl sulphonate, dodecyl benzene sulfonate, condensate of alkyl phenol and epoxyethane and condensate of aliphatic alcohol and epoxyethane. The corrosion inhibitor is urotropine, dibutyl thiourea or alkyl pyridine. Using the inventive inactivating detergent in cleaning petroleum refining apparatus, ferrous can be thoroughly oxygenized, inactivated and sulfated on one aspect, to prevent occurrence of self-ignition accident, oil crust can be totally washed from the apparatus on the other aspect, which makes the invention has characteristics of high efficiency, secure and environmental protective.

Owner:CHINA PETROLEUM & CHEM CORP

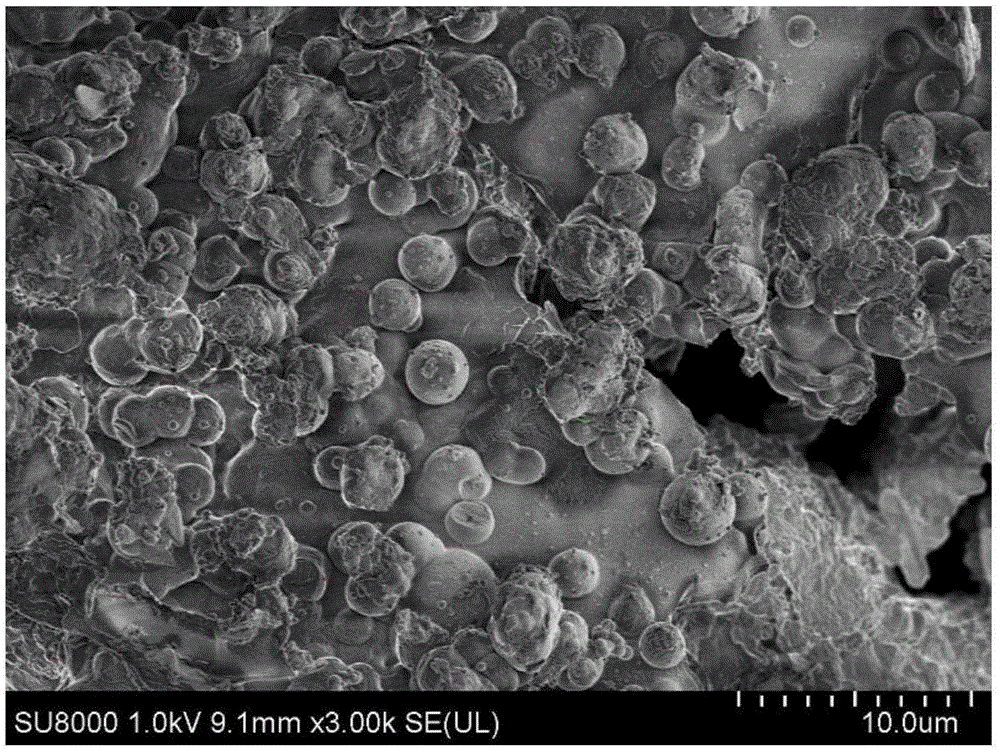

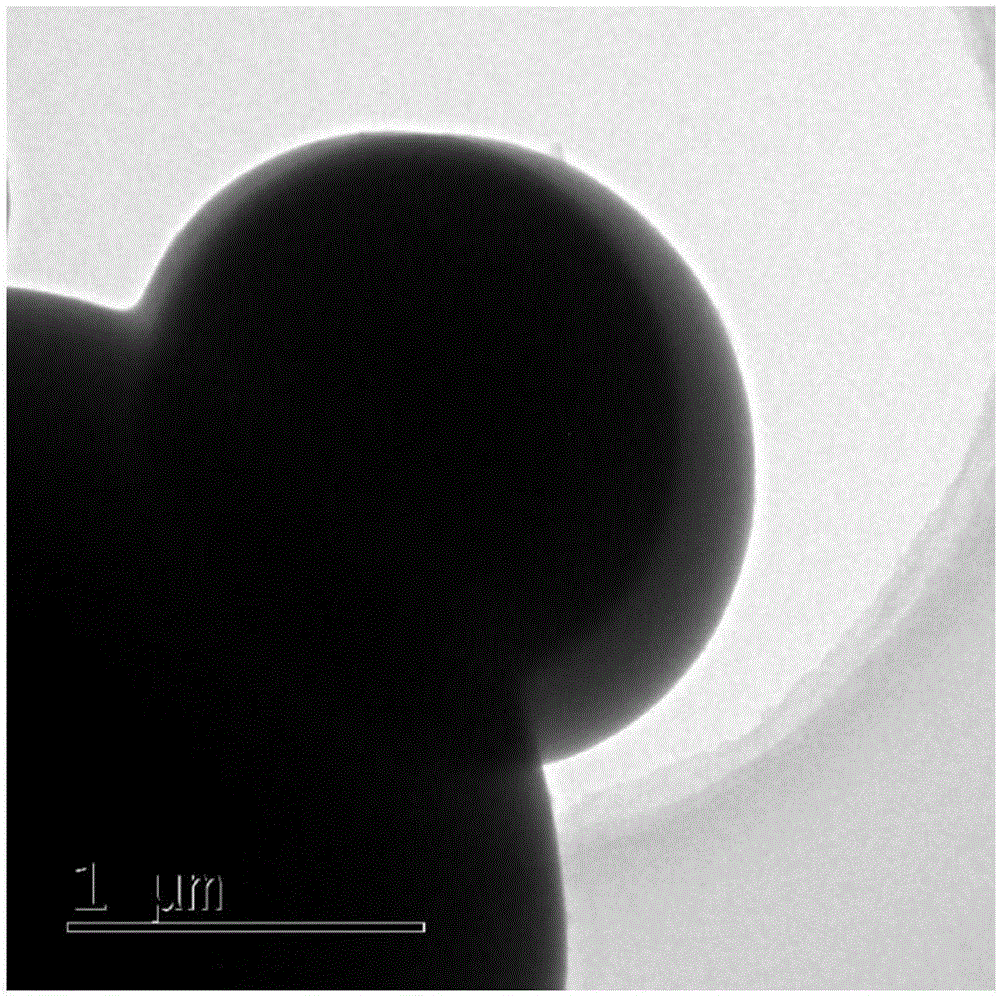

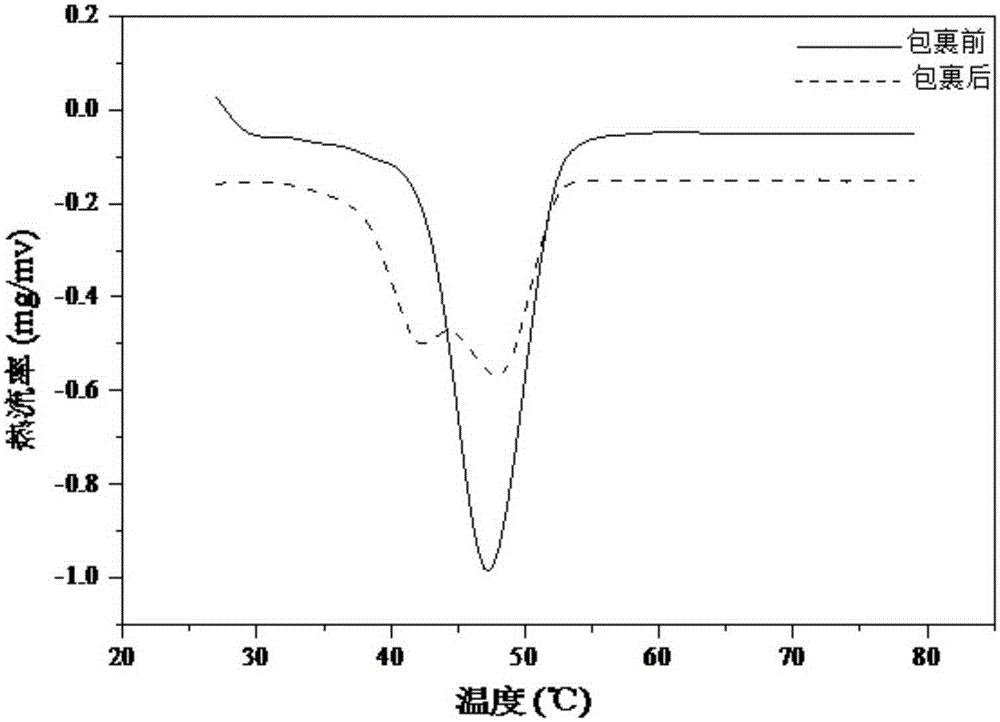

Paraffin wax phase change energy storage material and preparation method thereof

InactiveCN102127395ALow priceImprove surface propertiesSolid waste managementHeat storage plantsParaffin waxFilm coating

The invention provides a paraffin wax phase change energy storage material and a preparation method thereof. The paraffin wax phase change energy storage material comprises 48 to 56.7 percent of paraffin wax, 14.2 to 32 percent of high-density polyethylene, 4 to 5.7 percent of sodium dodecyl benzene sulfonate serving as a surfactant, 10.4 to 15.6 percent of sodium alginate serving as a film forming material and 5.6 to 7.8 percent of anhydrous calcium chloride serving as a crosslinking agent. The method for preparing paraffin wax phase change energy storage material comprises the following steps: preparing a microcapsule phase change material by using paraffin wax as a core material and high-density polyethylene as supporting material and by using a melting method; and preparing millimetercapsule phase change material by using a thin film coating technique. In the invention, the technical problems of low paraffin wax mixing amount, low storage performance, leakage, low stability and the like of the conventional microcapsule phase change material are solved.

Owner:SOUTHEAST UNIV

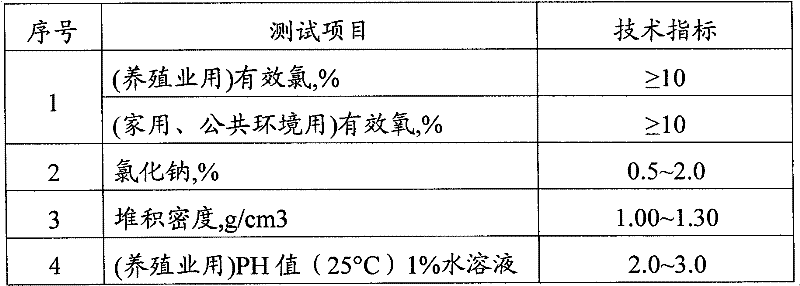

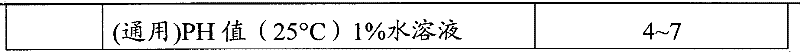

Composite potassium hydrogen persulfate disinfectant and its manufacturing process

ActiveCN102265904AMeet needsWith low toxicity and ultra-low toxicityBiocideFungicidesPotassium persulfateDisinfectant

The invention relates to a compound potassium hydrogen persulfate disinfectant and a manufacturing process thereof. The compound potassium hydrogen persulfate disinfectant comprises the following components in percentage by weight: 60-65% of potassium hydrogen persulfate complex, 0-1.8% of sodium chloride, 2-10% of aminosulfonic acid, 0-2% of sodium dodecyl benzene sulfonate, 0-10% of sodium hexametaphosphate, 0-25% of sodium citrate, 0-25% of sodium tartrate, 0-0.2% of flavoring agent and 0-0.12% of pigment. In the compound potassium hydrogen persulfate disinfectant provided by the invention, the different disinfection requirements of medical, family and livestock and poultry breeding industries are sufficiently considered and the contents of the components in the formula are adjusted according to different users, so that the compound potassium hydrogen persulfate disinfectant can meet the needs of different users; the compound potassium hydrogen persulfate disinfectant has good killing effects on almost all zoonotic bacteria, fungi and viruses, and simultaneously has the characteristics of low toxicity and ultra-low toxicity; and the wide application ranges and good stability and security are perfectly combined.

Owner:上海泰缘生物科技股份有限公司

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

Multi-effect biological pesticide aqueous solution agent and preparation method and application thereof

The invention relates to a multi-effect biological pesticide aqueous solution agent and a preparation method thereof. The multi-effect biological pesticide aqueous solution agent is characterized in that the agent contains 5-50 percent of pesticide active ingredient plant essence oil, 5-50 percent of simple organic carboxylic acid with a synergistic effect, 5-50 percent of pesticide assistant and 10-85 percent of water, wherein the plant essence oil is one or a mixture of wintergreen oil, camphor tree oil, clove oil, peppermint oil, eucalyptus oil, citionella oil, tea tree oil, lemongrass oil and cinnamon oil, the simple organic carboxylic acid with the synergistic effect is one or a mixture of formic acid, acetic acid and propionic acid, and the pesticide assistant is one or a mixture of dodecylbenzene sulfonic acid, Tween-80, Span-80 and OP-10. The agent can be used for insect killing, insect expelling, sterilization and antivirus in mosquito repelling, family agriculture, family flowering, organic agriculture and green agriculture.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Pesticide and fertilizer mixing particle agent for controlling soil insects and production method thereof

InactiveCN101717316AReduce dosageReduce pollutionFertiliser formsFertilizer mixturesChlorpyrifosVegetable oil

The invention relates to a pesticide and fertilizer mixing particle agent for controlling soil insects, which has the advantages of low cost, no pollution, no peculiar smell, strong absorption capability, good release effect, prevention of water and soil loss, control of underground insects, and enhancement of utilization rate of fertilizer efficiency, and is suitable for leek, corn, peanut and soybean. The mixing particle agent contains the following raw materials based on the total weight: 0.1%-10% of chlorpyrifos, 5%-20% of coating agent, 6%-15% of adhesive, 6%-10% of dispersant, and 45%-80% of NPK compound fertilizer, wherein the NPK compound fertilizer accounts for 25%-60% of the total weight of the medicine and fertilizer mixing particle agent; the coating agent is light-weight clay or low-grade diatomite; the dispersant is calcium dodecyl benzene sulfonate; and the adhesive is clay, dextrin or the mixture of the clay and the dextrin. The production method is characterized in that the adhesive, the dispersant and the NPK compound fertilizer are mixed and granulated by a granulator; the chlorpyrifos is dissolved in vegetable oil or organic solvent, diluted, uniformly sprayed to the surface of the prepared particle, coated by the coating agent, and sieved, and then the particle agent with the diameter of 1.0-4.75mm is prepared.

Owner:锦州硕丰农药集团有限公司

Flame-resistant and heat-resistant copper clad laminate preparation method

InactiveCN105172297AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMetal foilDimethyl phosphonate

The present invention relates to a flame-resistant and heat-resistant copper clad laminate preparation method, which comprises: adopting nanometer silica foam, dodecyl benzenesulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane and polyoxyethylene sorbitan monooleate as a raw materials to obtain a filler; adopting DOPO, a bisphenol A cyanate ester monomer, a phenol compound, a m-nitrobenzene sulfonic acid pyridine salt, 2,3-epoxy cyclopentyl cyclopentyl ether and dimethyl phosphonate as raw materials to obtain a resin prepolymer; adding the filler to o-phthalic acid diglycidyl este to obtain an active filler; mixing the resin prepolymer and an indole compound, and then adding the active filler and isomeric undecanol polyoxyethylene ether phosphate potassium salt to obtain a composite system; and carrying out hot pressing molding on the composite system, a reinforced material and metal foil to obtain the flame-resistant and heat-resistant copper clad laminate, wherein the flame-resistant and heat-resistant copper clad laminate has characteristics of excellent flame retardant property and excellent heat resistance, and meets the development applications of the flame-resistant and heat-resistant copper clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Foliage fertilizer special for kiwi berry with anti-cold effect

InactiveCN101391919AReasonable formulaImprove performanceOrganic fertilisersUrea compound fertilisersActinidiaSalicylic acid

The invention provides a foliar fertilizer specially used for Chinese gooseberries, which has the functions of cold resistance and consists of the following raw materials according to weight percentage: 0.1 to 8 percent of DMSO, 0.05 to 5 percent of trimethylene glycol, 0.05 to 5 percent of salicylic acid, 0.05 to 2 percent of compound ammonium nitrate, 1 to 15 percent of humic acid, 0.5 to 10 percent of chitosan, 1 to 10 percent of citric acid, 2 to 15 percent of urea, 1 to 10 percent of borax, 1 to 20 percent of zinc sulfate, 0.5 to 10 percent of ferrous sulfate, 0.05 to 5 percent of ammonium molybdate, 1 to 15 percent of manganese sulfate, 0.1 to 2 percent of SDBS and 35 to 80 percent of water. The foliar fertilizer has obvious effects of enhancing the cold resistance of the Chinese gooseberries, coordinating the nutrient balance in plant corpus, promoting the growth, increasing the output and improving the quality.

Owner:SICHUAN UNIV

Foaming agent and circulation microvesicle drilling fluids and drilling technique

InactiveCN101244372AGood leakage prevention and plugging effectImprove the lubrication effectTransportation and packagingMixingCelluloseMicrovesicle

The invention discloses a foaming agent and circulative micro-foam drilling fluid as well as well-drilling technological method; wherein, the foaming agent comprises 30% neopelex ABS, and 70% lauryl sodium sulfate SDS; the circulative micro-foam drilling fluid is produced through adding 0.1% sodium hydroxide, 0.2 to 0.3% xanthan gum XC, 0.2 to 0.3% medium viscosity flocculent cellulose CMC and 0.1 to 0.3% foaming agent; during well drilling construction, the circulative micro-foam drilling fluid is first to be prepared, and then is used to perform the wet drilling. With the foaming agent added to the circulative micro-foam drilling fluid, the formed micro-foam slurry has the advantages of good leakage proof and plugging effect, great lubrication performance, good rheology, obvious improved drilling quality and drilling efficiency.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Method for manufacturing oil solubility thick oil thinner for thick oil pipe-line transportation

InactiveCN101245240AMeet flowable viscosity requirementsImprove low temperature fluidityPipeline systemsDrilling compositionSolubilityMethacrylate

The invention relates to the preparation method of oil-solute viscosity reducer used for the transportation of heavy oil tubes, which is characterized by comprising the following steps, first the preparation of the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, second the preparation of acrylate high esters, third the preparation of oil-solute heavy oil viscosity reducer, according to the rate of the acrylate high esters : the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid equal to 1.0 to 4.5 ml : 1.0 to 7.5 ml, initiator ammonium persulfate, the mass fraction of which takes up 0.8 to 1.6 percent of the acrylate high esters and the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, is added, the reaction is kept for 6 to 8 hours with the temperature of 70 DEG C, then the oil-solute heavy oil viscosity reducer can be got, the method is characterized by the good viscosity reducing effect, the simple process and the low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Water quality purifying agent

ActiveCN105217802ASolve the suspension reuse problemSolve the problem of substrate hardeningBiological water/sewage treatmentSodium bicarbonateMicrobial agent

The invention discloses a water quality purifying agent. A formula of the water quality purifying agent comprises the following components in parts by weight: 15 to 55 parts of potassium hydrogen persulfate composite salt, 0 to 5 parts of sulfamic acid, 5 to 20 parts of citric acid, 1 to 12 parts of sodium carbonate, 0 to 10 parts of sodium bicarbonate, 0 to 0.5 part of magnesium carbonate, 0 to 9 parts of sodium hexametaphosphate, 15 to 30 parts of calcium peroxide, 0 to 1 part of sodium dodecyl benzene sulfonate, 0 to 2 parts of lauryl sodium sulfate, 0.05 to 0.1 part of polyethylene glycol, 5 to 15 parts of anhydrous sodium sulphate and 15 to 25 parts of composite microbial agent. In the formula of the water quality purifying agent, a composite potassium hydrogen persulfate product detoxifying technology and a sewage treatment technology beneficial for microorganisms to restore the micro-ecological balance are used for substituting the existing product capable of leading to the secondary pollution, the advantages such as fast onset of action and lasting effect can be realized, and the water quality purifying agent can take effect within half an hour; the water modification, detoxifying, bacteriostat and water purifying effect can last for 7 to 10 days, and the treatment on the water pollution and the restoration of the ecological balance can be realized in 7 days to 1 month.

Owner:上海泰缘生物科技股份有限公司

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Kiwi growth cold resistant agent

InactiveCN101390517AImprove stabilityRegulate water balancePlant growth regulatorsBiocideVegetable oilActinidia

The invention provides a kiwifruit growth cold-resistant agent, which is composed of the following materials based on weight percentage: 0.05-5% of 5-nitro guaiacol sodium, 0.3-5% of humic acid, 0.1-2% of paclobutrazol, 0.5-5% of chitosan, 0.1-5% of rosin, 0.1-5% of castor wax, 0-3% of paraffin, 0-5% of citric acid, 0-6% of calcium chloride, 0.5-10% of propylene glycol, 0.1-15% of salicylic acid, 0.5-8% of vegetable oil, 0.05-10% of dimethyl sulfoxide, 0.1-2% of sodium dodecyl benzene sulfonate, and 35-85% of water. The cold-resistant agent can effectively increase the membrane stability of kiwi branches, remove harmful free radicals, regulate in-vivo water balance of the plants, improve anti-freezing performance and ensure kiwifruit yield.

Owner:SICHUAN UNIV

Synthetic method for preparing colorless transparent alkyl polyglucoside

InactiveCN101696226AQuick responseGood emulsification and dispersionSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsGlycosideGlucose polymers

The invention relates to a synthetic method for preparing colorless transparent alkyl polyglucoside, which comprises the following steps: adding glucosum anhydricum or glucose containing one crystal water and aliphatic alcohol with 8 to 20 carbon atoms into a reaction kettle in the weight ratio of 1:2.8-6.5; adding a composite catalyst containing dodecyl benzene sulfonic acid under the agitation of an emulsifying agitator; after undergoing a reaction for 4 to 8 hours at a temperature of between 80 and 120 DEG C under the vacuum condition of between -0.093 and -0.098 MPa, reducing the temperature to between 70 and 80 DEG C; adding neutralizer alkaline hydroxide, adjusting the pH value between 6 and 8 to obtain a flaxen mixture of alkyl polyglucoside and the aliphatic alcohol; and performing dealcoholization and blanching on the mixture to obtain a product of the colorless transparent alkyl polyglucoside. The method has a simple process and convenient operations. The process of the method not only can use the glucosum anhydricum, but also can use the glucose containing one crystal water, has a low cost and good quality; and the method adopts the composite catalyst, has a mild temperature, smooth water yielding and no phenomenon of foam overflow.

Owner:石家庄金莫尔化学品有限公司

Reversible thermochromic microcapsule pigment preparation method

InactiveCN105170041AIncrease coverageImprove stabilityOrganic dyesTenebresent compositionsColor changesFORMALDEHYDE SOLUTION

The present invention discloses a reversible thermochromic microcapsule pigment preparation method, which comprises: weighing 0.08-0.1% by mass of crystal violet lactone, 0.4-0.5% by mass of bisphenol A, 3-6% by mass of hexadecanol, 2-4% by mass of melamine, 4.03-5% by mass of a formaldehyde solution, 0.4-0.6% by mass of sodium dodecyl benzene sulfonate, 0.09-0.11% by mass of sodium dodecyl sulfate ammonium, and 87-90% by mass of distilled water, preparing a complex A, preparing an O / W type emulsion and a melamine-formaldehyde pre-polymerization liquid, and carrying out a condensation polymerization reaction to prepare the pigment. According to the present invention, advantages of high color change sensitivity, low color change temperature and good color change stability are provided when the prepared monomer thermochromic material is adopted as the pigment, and the prepared reversible thermochromic microcapsule pigment can be widely used in the fields of anti-counterfeiting inks, temperature showing materials, and the like.

Owner:XIAN UNIV OF TECH

Phosphorite low-temperature foam flotation collector and preparation method thereof

ActiveCN101791591AStrong harvesting abilityHigh selectivityFlotationSesquioxideTemperature resistance

The invention relates to a phosphorite low-temperature foam flotation collector and a preparation method thereof. The collector consists of the following substances in part by weight: 0.7 to 0.9 part of cottonseed acidic oil, 0.1 to 0.3 part of fatty acid methyl ester, 0.01 to 0.05 part of sodium dodecyl benzene sulfonate, and 0.01 to 0.05 part of foaming agent. The preparation method comprises the following steps: mixing the 0.7 to 0.9 part of cottonseed acidic oil and the 0.1 to 0.3 part of fatty acid methyl ester; heating the mixture to the temperature of between 100 and 120 DEG C; adding alkali liquor into the mixture, stirring the mixture for saponification; controlling pH to be between 8 and 10; and adding the 0.01 to 0.05 part of sodium dodecyl benzene sulfonate and the 0.01 to 0.05 part of foaming agent into the mixture by using the saponified semi-finished product as a reference part to prepare the phosphorite low-temperature foam flotation collector. When the collector can be used in 'Haizhou type' phosphorite low-temperature direct flotation, the produced product still can achieve low sesquioxide concentrate and has higher recovery rate. Compared with the conventional 'Haizhou type' phsophorite low-temperature direct flotation collector, the collector has the characteristics of high collection capability, high selectivity, small using amount, low-temperature resistance, low mineral separation cost and the like.

Owner:HUBEI FORBON NEW MATERIAL CO LTD

Gray iron casting moulding sand and preparation method thereof

The invention discloses gray iron casting moulding sand which is prepared from the following raw materials in parts by weight: 250-280 parts by weight of quartz sand, 40-45 parts by weight of sepiolite, 160-170 parts by weight of loess, 30-35 parts by weight of shell powder, 20-25 parts by weight of titanium dioxide, 40-45 parts by weight of grass meal, 2-3 parts by weight of acrylic emulsion, 30-40 parts by weight of silicon carbide, 10-15 parts by weight of pulverized coal, 50-60 parts by weight of gypsum, 3-4 parts by weight of zinc stearate, 10-15 parts by weight of bentonite, 3-4 parts by weight of ammonium dihydrogen phosphate, 4-5 parts by weight of sodium bicarbonate, 2-3 parts by weight of sodium dodecyl benzene sulfonate, 4-6 parts by weight of urea, 10-12 parts by weight of flour, 40-45 parts by weight of wood-bamboo powder and a proper amount of water. The sepiolite, the loess, the bentonite and the like are calcined, thus the gray iron casting moulding sand has excellent plasticity and caking property; by using the shell powder, the grass meal, the wood-bamboo powder and the like, the air permeability is increased; by using the titanium dioxide, the dispersity is increased and the high-temperature collapsibility is good; by using the pulverized coal, the surface of a casting is bright. The yield of the casting is increased.

Owner:张志功

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

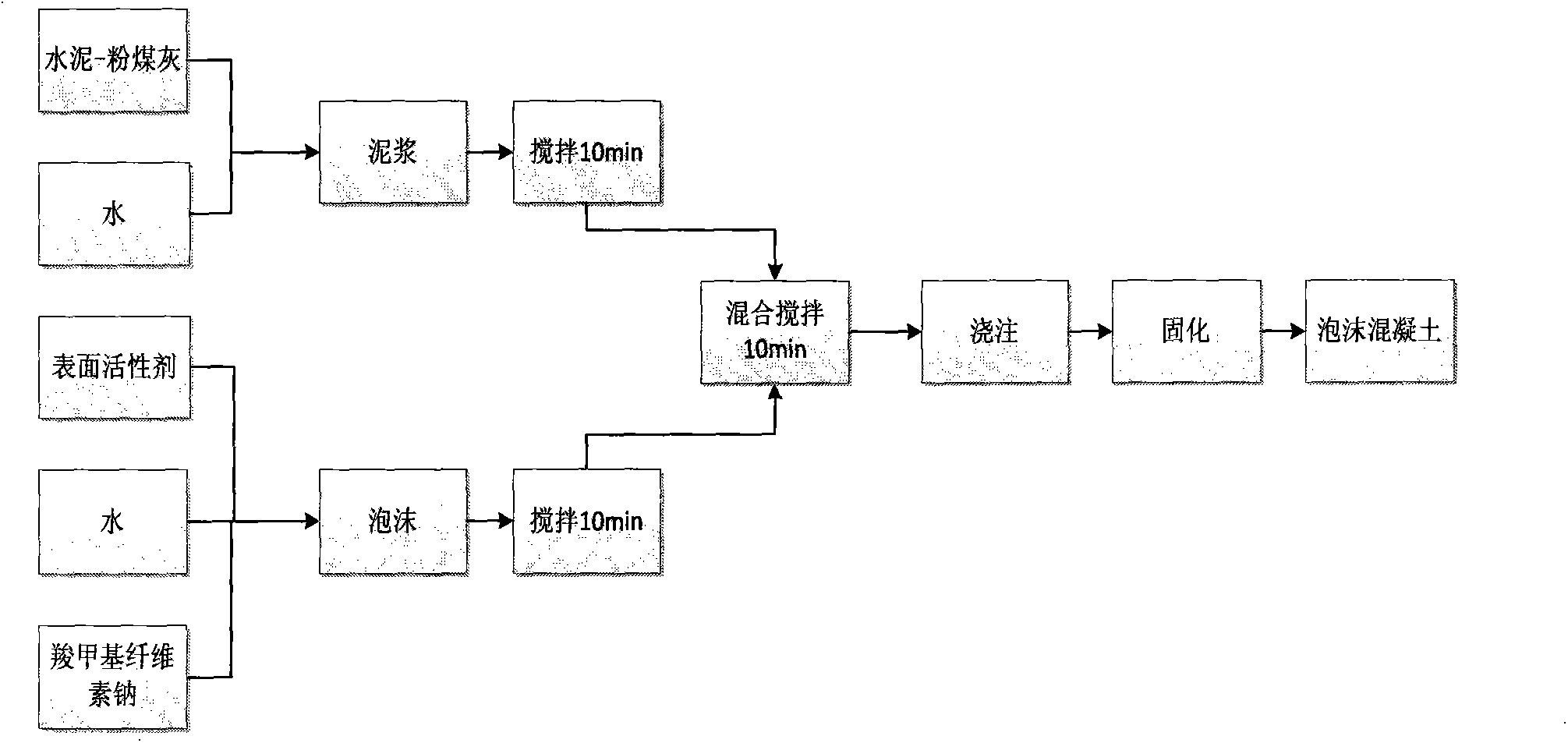

Pulverized fuel ash-cement foam material for controlling spontaneous combustion of coal and preparation method of pulverized fuel ash-cement foam material

ActiveCN103964766APrevent spontaneous combustionLow costCeramicwareSpontaneous combustionPulverized fuel ash

The invention discloses a pulverized fuel ash-cement foam material for controlling the spontaneous combustion of coal and a preparation method of the pulverized fuel ash-cement foam material. The pulverized fuel ash-cement foam material is prepared from the following components by weight: 10-40 % of sulfoaluminate superfine cement, 10-40 % of pulverized fuel ash, 0.5-0.9 % of carboxymethyl cellulose, 0.1-0.6 % of sodium fluoride, 0.2-0.6 % of melamine, 0.1-0.4 % of aluminum sulfate, 0.3-0.6 % of lauryl sodium sulfate, 0.4-0.6 % of sodium dodecyl benzene sulfonate, 0.5-0.8 % of saponin and the balance of water. The foam material is high in expansion rate of foam, long in stabilizing time, low in rate of water loss, good in plugging performance, and very suitable for extinguishment underground a coal mine. The pulverized fuel ash-cement foam material has the advantages of being low in cost, good in plugging performance, high in strength, simple to construct and the like.

Owner:胡相明

Preparation method for moisture-proof corrugated paper

InactiveCN104404816AWide variety of sourcesImprove waterproof and moisture-proof performanceLaminationLamination apparatusBenzeneWax

The invention discloses a preparation method for moisture-proof corrugated paper. The preparation method comprises the following steps: respectively weighing wood pulp and waste paper pulp; mixing the weighed wood pulp and the waste paper pulp till the mixture is uniform; removing impurities; adding water to soak the pulp mixture; carrying out scattering to obtain virgin pulp; adding a moisture-proof agent; carrying out paper making to obtain paper; conducting preheating and sizing on the paper; treating the preheated and sized paper with a single side machine to obtain corrugated paper; pasting a piece of wax-oil paper on the outermost layer of the corrugated paper; carrying out drying. The moisture-proof agent is prepared from the following raw materials in parts by weight: 25-30 parts of tapioca, 15-20 parts of allyl benzene, 13-18 parts of butenoic acid ester, 5-8 parts of paraffin, 2-5 parts of sodium dodecyl benzene sulfonate and 1-4 parts of silicon dioxide. The moisture-proof corrugated paper is wide in raw material resource and relative low in production cost. The preparation method has the advantages that the moisture-proof agent is added in the paper making process and the wax-oil paper is pasted on the outermost layer of the corrugated paper, so that the water-proof performance and moisture-proof performance of the corrugated paper are greatly improved.

Owner:柳州市柳江区联华纸制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com