Composite potassium hydrogen persulfate disinfectant and its manufacturing process

A technology of potassium hydrogen persulfate and manufacturing process, applied in the directions of disinfectants, biocides, bactericides, etc., can solve the problems of inconvenient storage, dangerous use of peracetic acid disinfectants, polluting the environment, etc. The effect of inactivation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Composite potassium persulfate disinfectant of the present invention, according to mass percentage content, take potassium persulfate complex 60%, sodium chloride 1.8%, sulfamic acid 10%, sodium dodecylbenzene sulfonate 2% , sodium hexametaphosphate 10%, sodium citrate 5%, sodium tartrate 10.9%, fragrance agent 0.18% and pigment 0.12%, then each component after weighing is added in the mixing kettle, stirs, and fragrance agent is stirring During the process, use a small spray device to spray into the materials being mixed, stir thoroughly for 10 minutes, and discharge the materials for sub-packaging. Wherein, the stirring temperature is kept below 30 degrees Celsius.

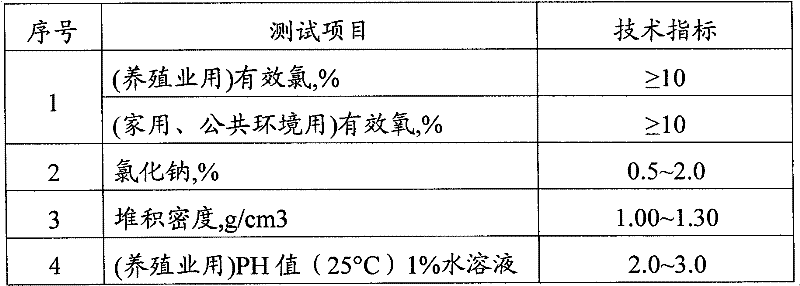

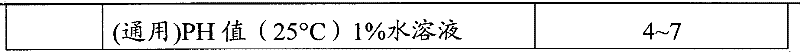

[0048] The compound potassium hydrogen persulfate disinfectant described in Example 1 has fully considered the different disinfection needs of medical, family and livestock and poultry breeding industries, and according to different users, the formulation is adjusted to the components to meet the needs of...

Embodiment 2

[0050] The compound potassium hydrogen persulfate disinfectant of the present invention, by mass percentage content, takes potassium hydrogen persulfate complex 65%, sodium chloride 1%, sulfamic acid 2%, sodium citrate 25%, sodium tartrate 6.8% and flavoring agent 0.2%, then add the weighed components into the mixing tank, and stir. During the stirring process, the flavoring agent is sprayed into the material being mixed with a small spray device, fully stirred for 10 minutes, and the material is discharged. Subpackaged. Wherein, the stirring temperature is kept below 30 degrees Celsius.

[0051] The compound potassium hydrogen persulfate disinfectant described in Example 2 has fully considered the different disinfection requirements of medical, household and livestock and poultry breeding industries, and according to different users, the formula is adjusted to the components to meet the needs of different users. It has a good killing effect on almost all bacteria, fungi, and...

Embodiment 3

[0053] Composite potassium persulfate disinfectant of the present invention, by mass percentage content, gets potassium persulfate complex 62%, sulfamic acid 8%, sodium dodecylbenzenesulfonate 1%, sodium hexametaphosphate 8% %, 20.88% of sodium citrate and 0.12% of pigment, and then add the weighed components into the mixing kettle, stir, fully stir for 10 minutes, and discharge for sub-packaging. Wherein, the stirring temperature is kept below 30 degrees Celsius.

[0054] The compound potassium hydrogen persulfate disinfectant described in Example 3 has fully considered the different disinfection needs of medical, family and livestock and poultry breeding industries, and according to different users, the formula is adjusted to the components to meet the needs of different users. It has a good killing effect on almost all bacteria, fungi, and viruses that are zoonotic, and at the same time has the characteristics of low toxicity and ultra-low toxicity. It is a perfect combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com