Patents

Literature

1788 results about "Sodium polymetaphosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hexametaphosphate (SHMP) is a hexamer of composition (NaPO3)6. Sodium hexametaphosphate of commerce is typically a mixture of polymeric metaphosphates, of which the hexamer is one, and is usually the compound referred to by this name. It is more correctly termed sodium polymetaphosphate.

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

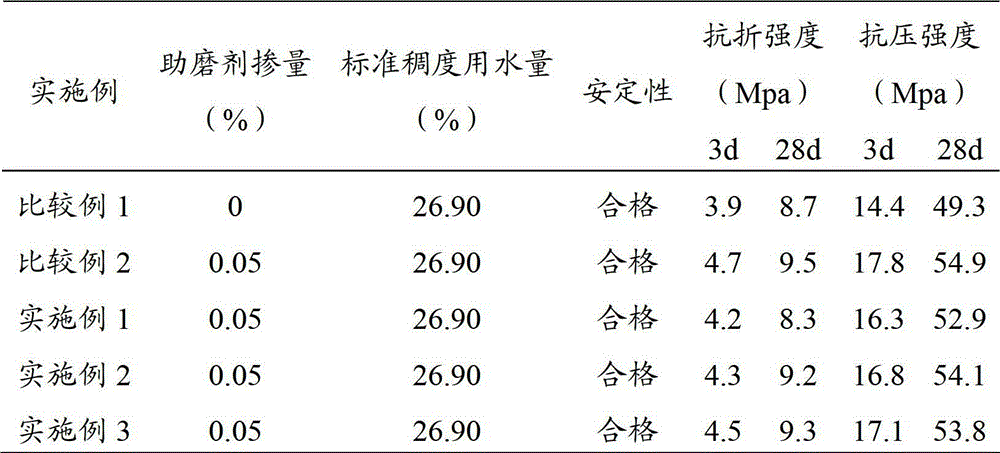

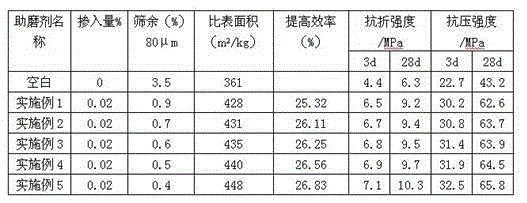

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

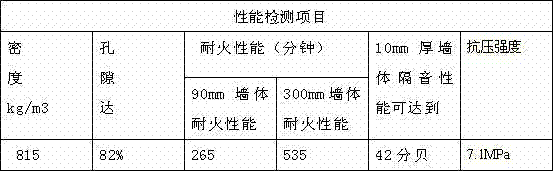

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

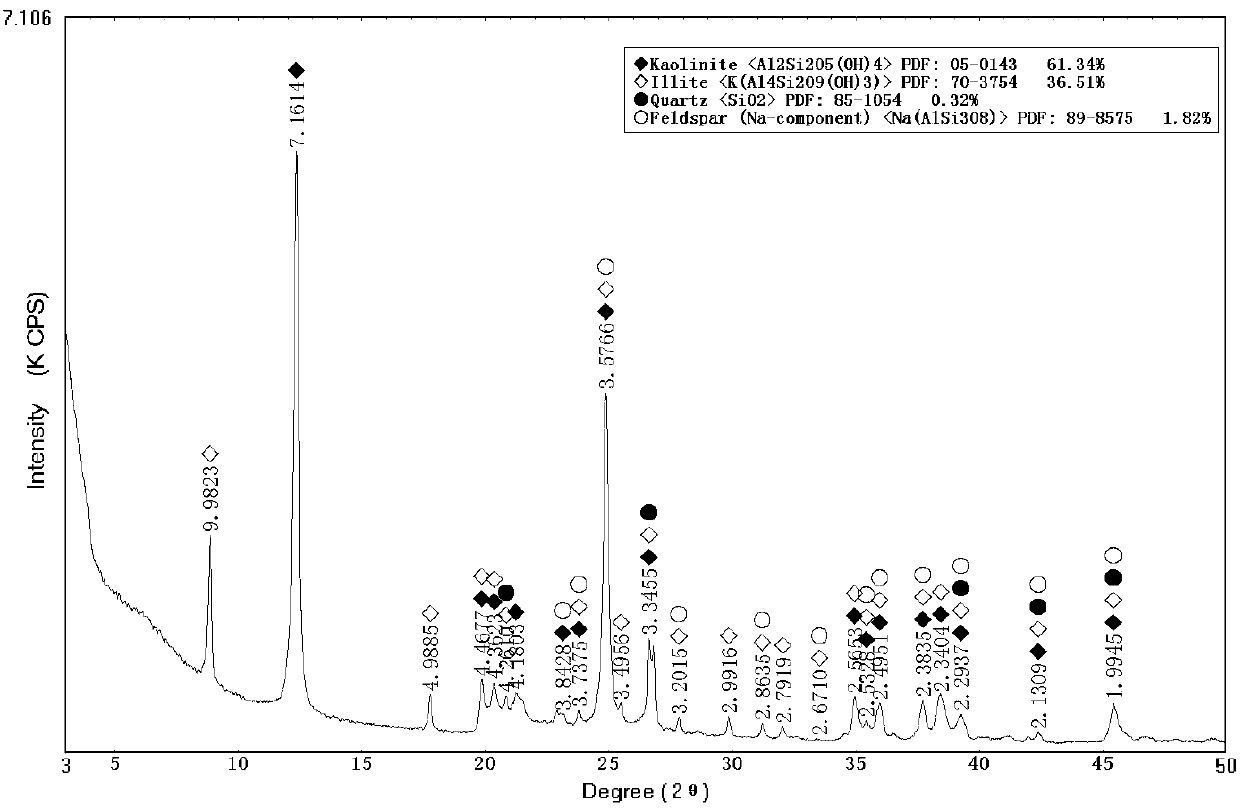

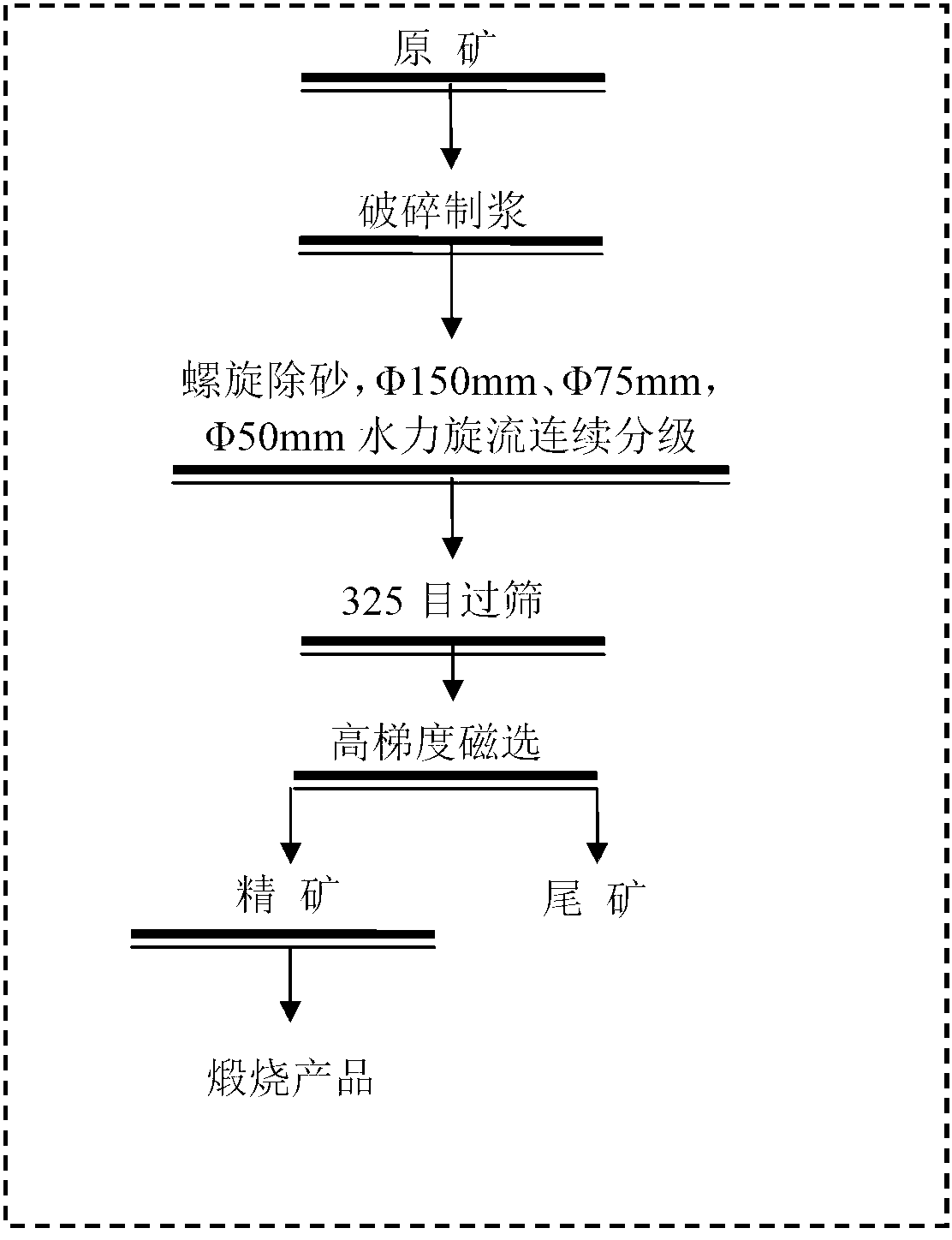

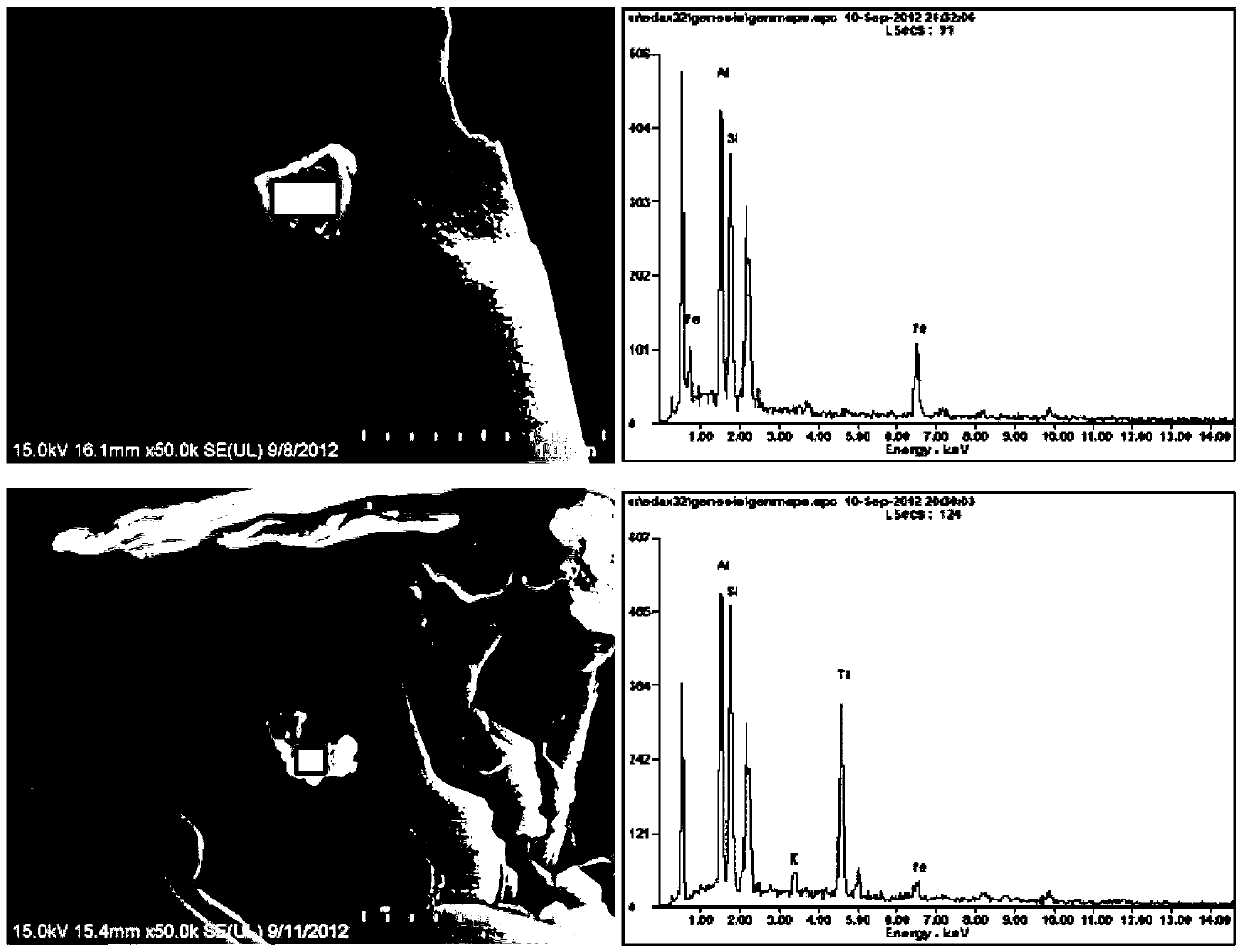

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

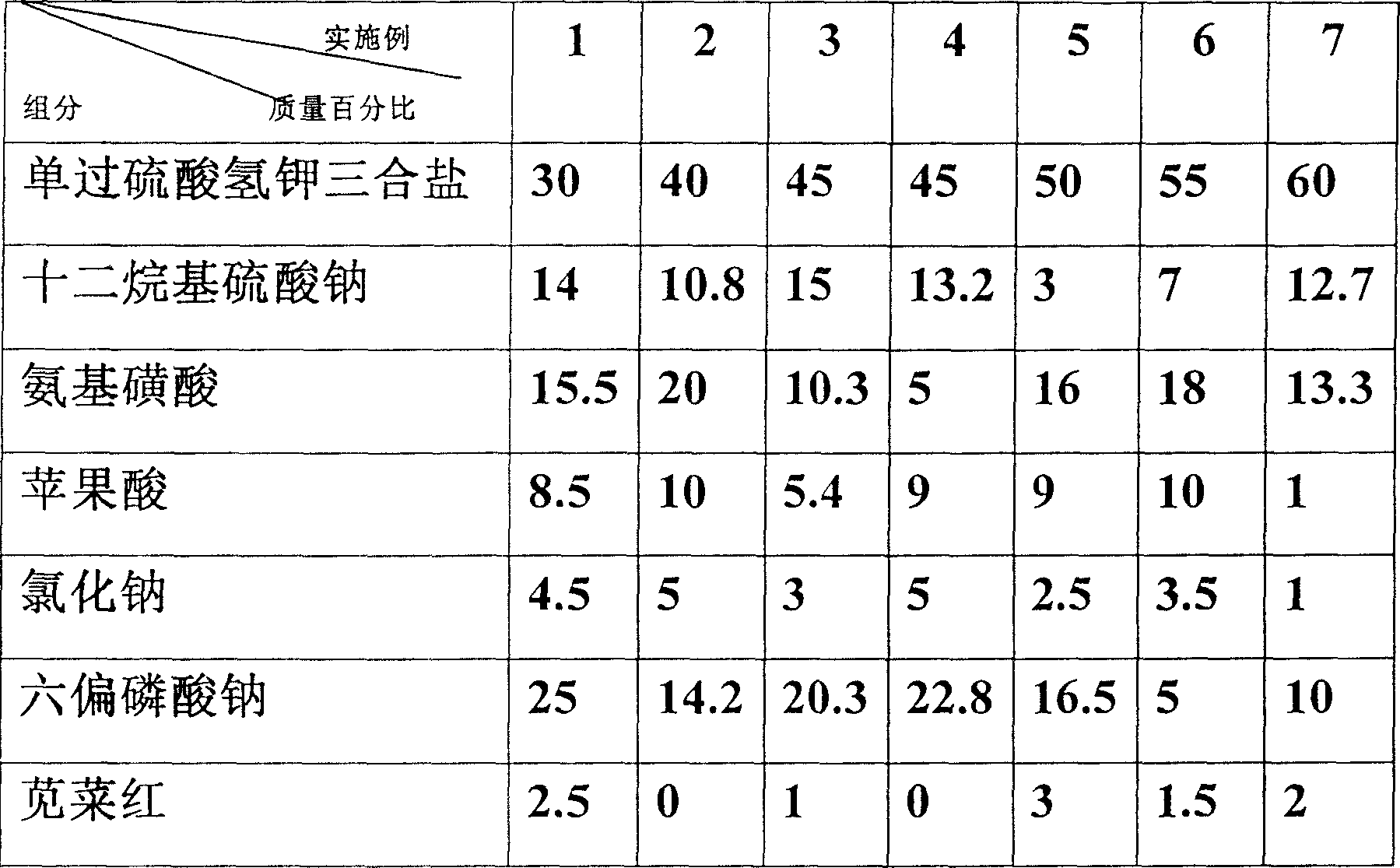

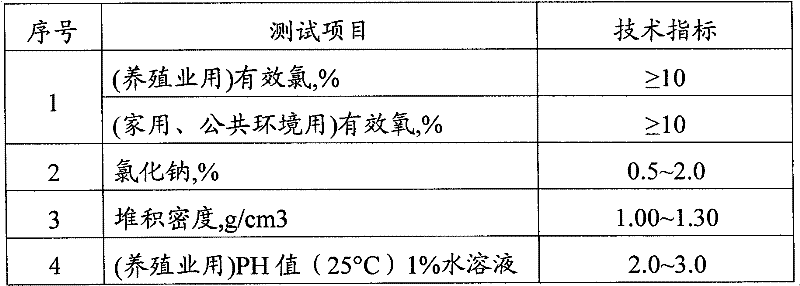

Sterilization powder, and preparation method.

InactiveCN101049107AImprove permeabilityImprove effectivenessBiocideDisinfectantsHydrogen SulfateNuclear chemistry

A disinfecting powder with high killing power to virus is proportionally prepared from the mixture of potassium hydrogen monosulfate, potassium hydrogen persulfate and potassium hydrogen sulfate, sodium laurylsulfate, sodium hexametaphosphate, aminosulfonic acid, malic acid and sodium chloride. Its preparing process is also disclosed.

Owner:CHENGDU ROSUN DISINFECTION PHARMA

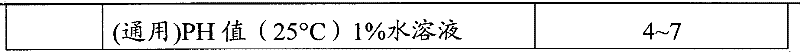

Composite potassium hydrogen persulfate disinfectant and its manufacturing process

ActiveCN102265904AMeet needsWith low toxicity and ultra-low toxicityBiocideFungicidesPotassium persulfateDisinfectant

The invention relates to a compound potassium hydrogen persulfate disinfectant and a manufacturing process thereof. The compound potassium hydrogen persulfate disinfectant comprises the following components in percentage by weight: 60-65% of potassium hydrogen persulfate complex, 0-1.8% of sodium chloride, 2-10% of aminosulfonic acid, 0-2% of sodium dodecyl benzene sulfonate, 0-10% of sodium hexametaphosphate, 0-25% of sodium citrate, 0-25% of sodium tartrate, 0-0.2% of flavoring agent and 0-0.12% of pigment. In the compound potassium hydrogen persulfate disinfectant provided by the invention, the different disinfection requirements of medical, family and livestock and poultry breeding industries are sufficiently considered and the contents of the components in the formula are adjusted according to different users, so that the compound potassium hydrogen persulfate disinfectant can meet the needs of different users; the compound potassium hydrogen persulfate disinfectant has good killing effects on almost all zoonotic bacteria, fungi and viruses, and simultaneously has the characteristics of low toxicity and ultra-low toxicity; and the wide application ranges and good stability and security are perfectly combined.

Owner:上海泰缘生物科技股份有限公司

Fluorite slag-containing aerated concrete block

The invention discloses a fluorite slag-containing aerated concrete block. The fluorite slag-containing aerated concrete block is prepared from the following raw materials by the conventional process for preparing the aerated concreted block: 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of volcanic rock powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.02 to 0.08 weight part of peregal, 0.03 to 0.08 weight part of oxyparaffin soap, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of bentonite, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium hexametaphosphate and an appropriate amount of water. Nano mineral powder is added, so that the volume weight of the brick, and the energy consumption are reduced; the aerated brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated concrete block, the fluorite slag-containing aerated concrete block has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:沛县铸本混凝土有限公司

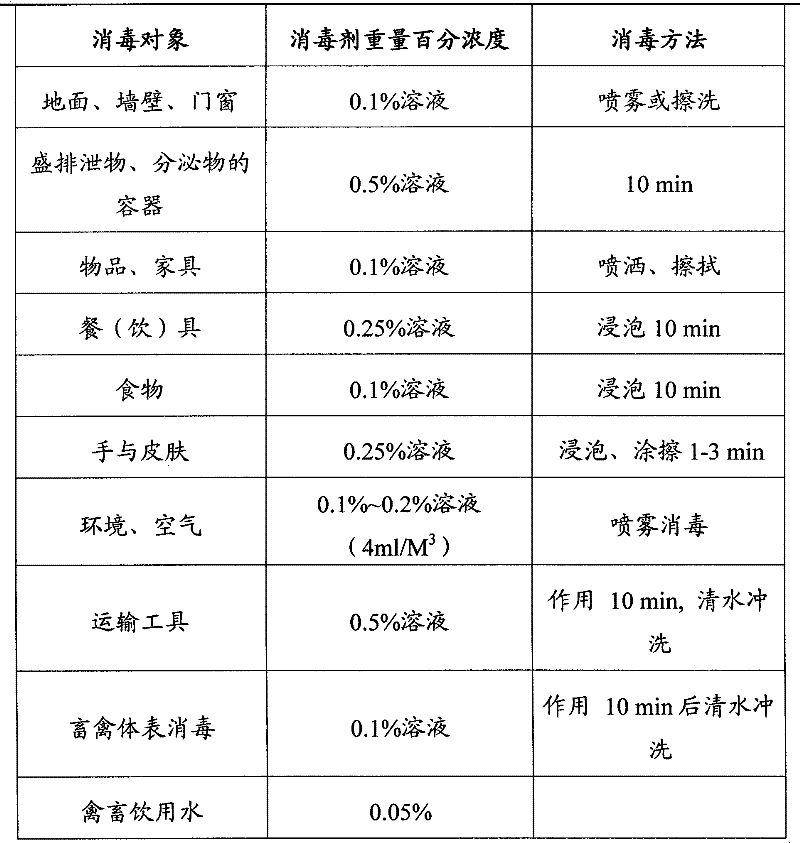

Method for preparing sintering-expanded haydite by taking red mud of Bayer process as main raw material

InactiveCN101538131AGood vitrificationUniform porositySolid waste managementSolid waste disposalCooking & bakingRed mud

The invention discloses a method for preparing a sintering-expanded haydite by taking red mud of Bayer process as a main raw material, comprising the following steps of by taking the red mud of Bayer process, fly ash, wasted glass, starch, carbon powder and sodium hexametaphosphate as raw materials, respectively grinding the red mud of Bayer process, the fly ash and the wasted glass by a sieve of 160 meshes; proportioning and uniformly mixing the sieved raw materials by the following mass ratio: (50-60):(20-25):(15-20):2:2;1 for Bayer process, fly ash, wasted glass, starch, carbon powder and sodium hexametaphosphate respectively; adding the water of 5-10% by mass in the raw material, mixing the mixture for 5-10min, decaying the mixture for 20-30min and forming balls; baking the formed balls in an oven for 2-5h at the temperature of 105 DEG C; drying the balls and preheating the balls in a muffle for 10-30min at the temperature of 600 DEG C; after preheating, quickly moving and baking the balls in a high-temperature Si-Mo furnace for 10-30min at the temperature of 1100-1200 DEG C; and after finishing baking, opening the furnace door, taking out the balls and forcibly cooling the balls. The sintering-expanded haydite prepared by the method has fine vitrification degree on the external surface and uniform internal aperture and takes closed holes as main ones.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

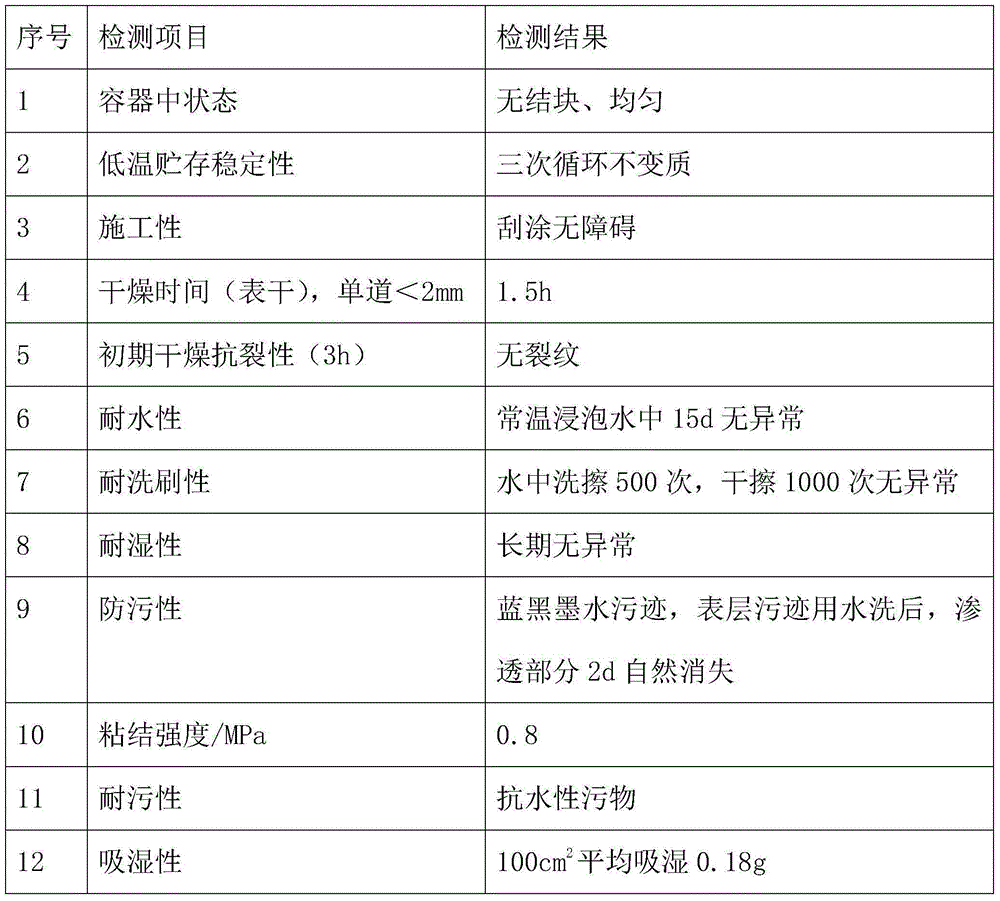

Putty powder used for walls in house

InactiveCN101705027AExcellent scratch coating construction performanceGuaranteed crack resistanceFilling pastesCalcium hydroxideSodium Bentonite

The invention provides putty powder used for walls in a house. The putty powder comprises the following ingredients: ground calcium carbonate, sodium-base bentonite, 1788 powder of polyving akohol, hydroxypropyl methyl cellulose and talcum powder, besides, white cement or / and calcium hydroxide powder is / are added therein as a reinforcing material, and also, sodium hexametaphosphate powder and / or tourmaline powder are / is added in the product. The putty powder has excellent scraping construction performance, long-acting mould-proof performance and excellent dense degree of the putty coating as well as the function of releasing negative ions for a long time, can effectively adsorb various harmful substances in the air and purify the air, and has excellent environment-friendly performance.

Owner:毕家新

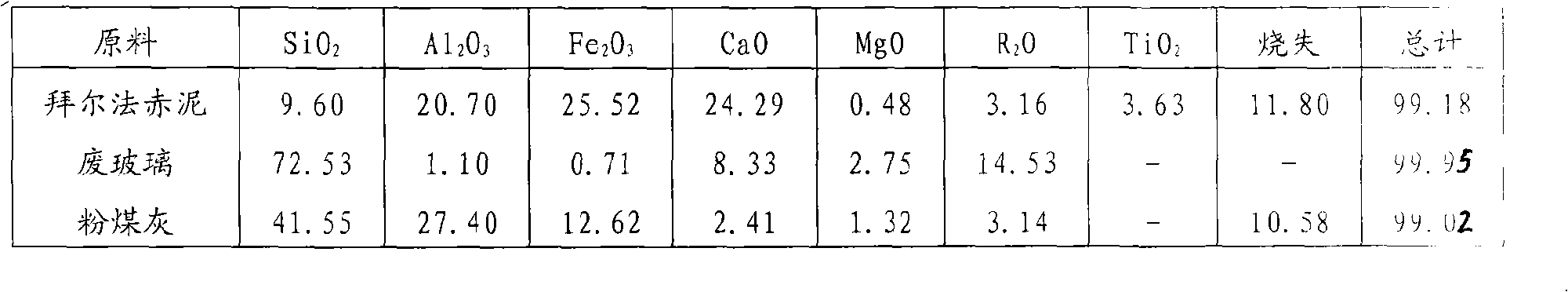

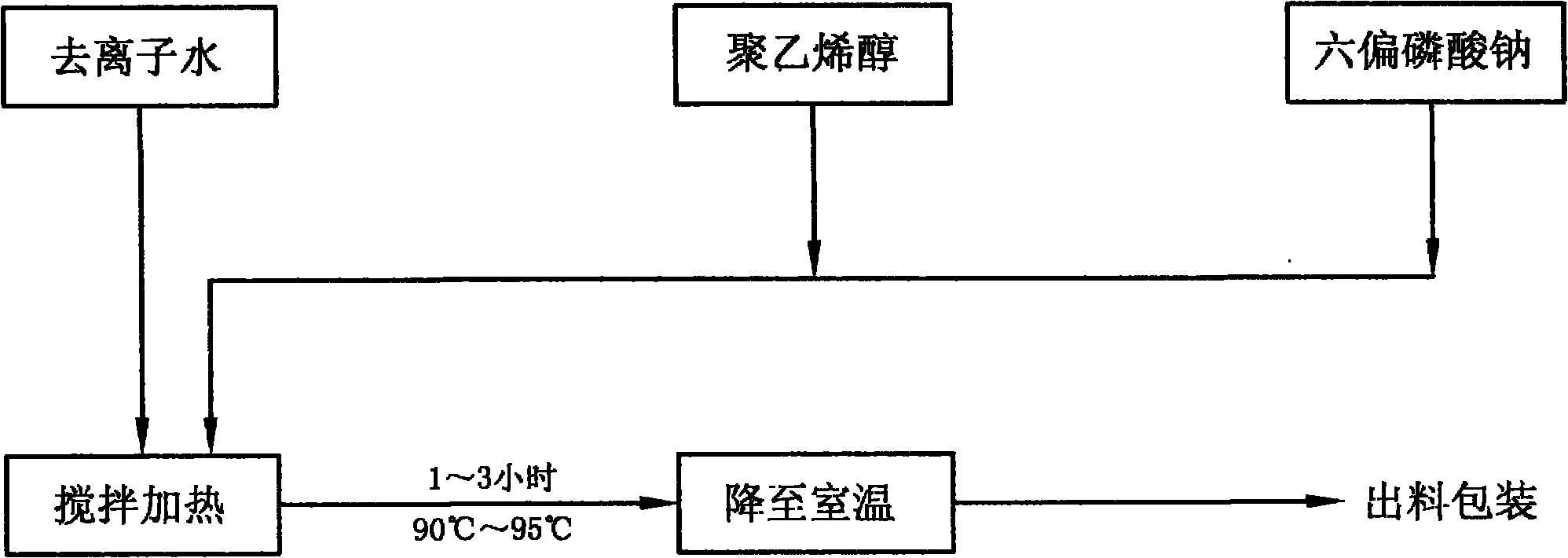

Method for preparing aluminum alloy anodic oxide film sealant

InactiveCN101812713AImprove pass rateImprove protectionSurface reaction electrolytic coatingSODIUM METAPHOSPHATEPolyvinyl alcohol

The invention discloses a method for preparing an aluminum alloy anodic oxide film sealant, which comprises the main processes of adding deionized water, zinc acetate, magnesium acetate, cerium acetate, surfactant, hydration promoter and sublimation preventing agent into a reaction kettle in turn, and mixing, stirring and heating the components to form the sealant. One of the important components of the sealant is sublimation preventing agent which is prepared by mixing the deionized water, polyvinyl alcohol and sodium hexametaphosphate together and then stirring and heating the mixture in the reaction kettle. The raw materials adopted by the preparation method do not contain nickel and fluorine elements, so the sealant is favorable for environmental protection; and the sealant reduces energy consumption during use, and improves the qualification rate of aluminum alloy products.

Owner:李继光

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Water quality purifying agent

ActiveCN105217802ASolve the suspension reuse problemSolve the problem of substrate hardeningBiological water/sewage treatmentSodium bicarbonateMicrobial agent

The invention discloses a water quality purifying agent. A formula of the water quality purifying agent comprises the following components in parts by weight: 15 to 55 parts of potassium hydrogen persulfate composite salt, 0 to 5 parts of sulfamic acid, 5 to 20 parts of citric acid, 1 to 12 parts of sodium carbonate, 0 to 10 parts of sodium bicarbonate, 0 to 0.5 part of magnesium carbonate, 0 to 9 parts of sodium hexametaphosphate, 15 to 30 parts of calcium peroxide, 0 to 1 part of sodium dodecyl benzene sulfonate, 0 to 2 parts of lauryl sodium sulfate, 0.05 to 0.1 part of polyethylene glycol, 5 to 15 parts of anhydrous sodium sulphate and 15 to 25 parts of composite microbial agent. In the formula of the water quality purifying agent, a composite potassium hydrogen persulfate product detoxifying technology and a sewage treatment technology beneficial for microorganisms to restore the micro-ecological balance are used for substituting the existing product capable of leading to the secondary pollution, the advantages such as fast onset of action and lasting effect can be realized, and the water quality purifying agent can take effect within half an hour; the water modification, detoxifying, bacteriostat and water purifying effect can last for 7 to 10 days, and the treatment on the water pollution and the restoration of the ecological balance can be realized in 7 days to 1 month.

Owner:上海泰缘生物科技股份有限公司

Phyllosilicate mineral depressor for sulfide ore floatation and preparation method thereof

The invention provides a phyllosilicate mineral depressor for sulfide ore floatation and a preparation method thereof. The phyllosilicate mineral depressor for the sulfide ore floatation is prepared from the following components in part by weight: 0 to 20 parts of modified corn starch, 8 to 30 parts of sodium alginate, 1 to 35 parts of carboxymethyl cellulose or polyanionic cellulose or methylenenapadisilate dinaphthalene sulfonate, and 5 to 55 parts of sodium hexametaphosphate. The preparation method comprises the following steps of: selecting the reagents according to types of depressed minerals; adding the reagents in a high-speed mixing granulator in the set ratio for granulation; and drying the obtained grains to obtain the phyllosilicate mineral depressor for the sulfide ore floatation. The product has the characteristics of small dosage, good depression selectivity, low toxicity, and the like. The specific depressor is mainly applied to depressing phyllosilicate minerals such as talcs, serpentines, chlorites, kaolinites and the like during the sulfide ore floatation, thus the specific depressor is favorable for improving floatation concentrate grade and metal recovery rate, and is particularly suitable for floating talc-containing molybdenites and nickel sulfide ores.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

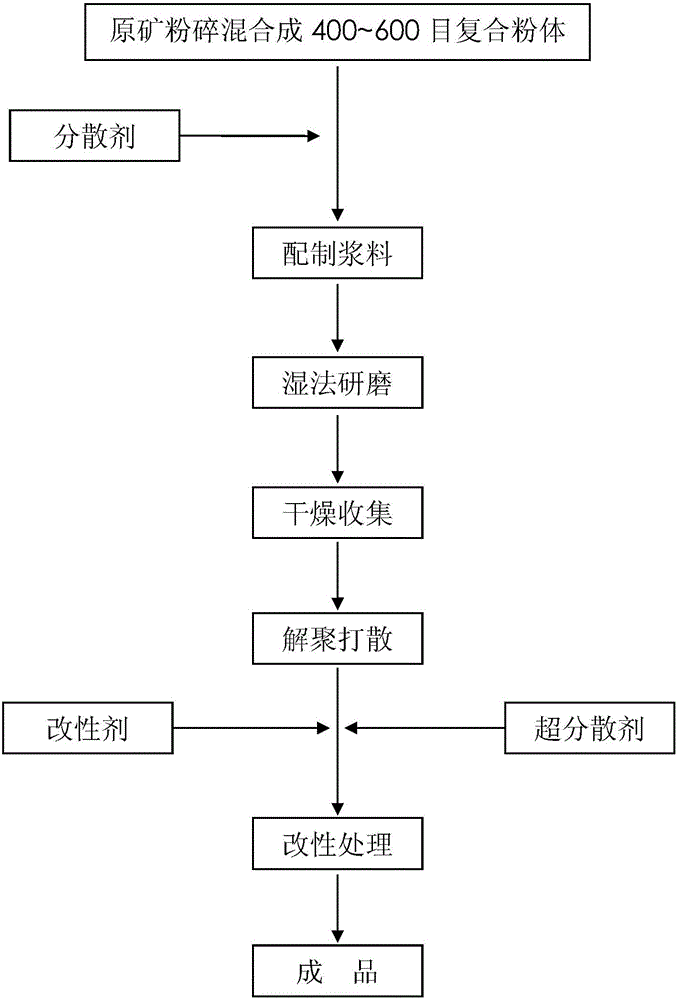

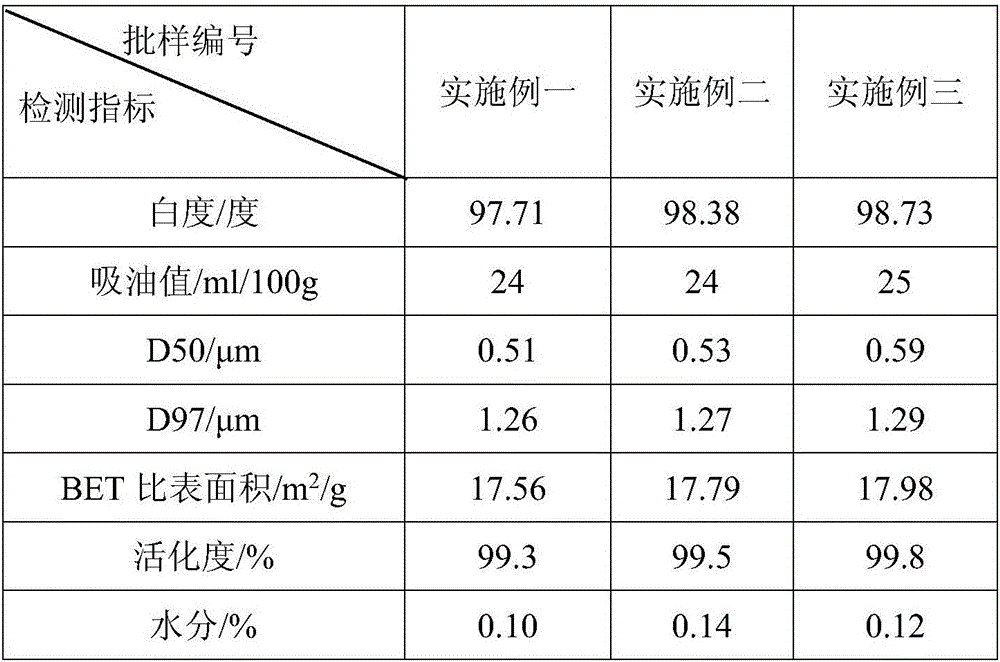

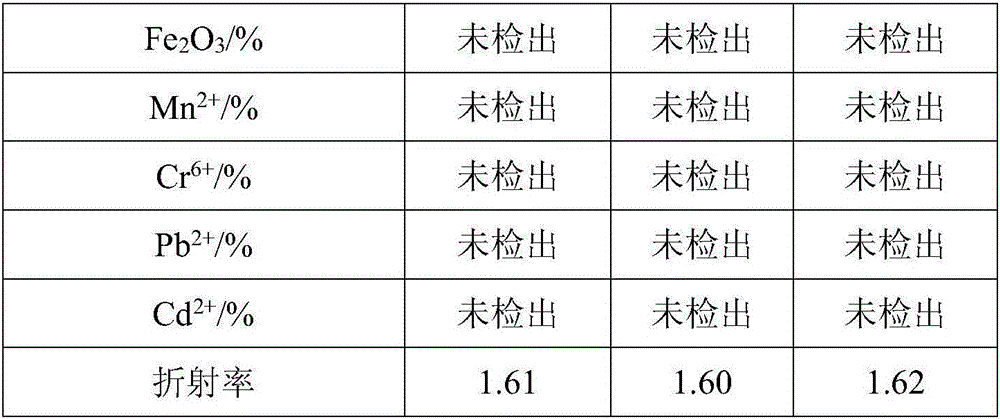

Preparation method of modified superfine calcium carbonate powder and product of preparation method

InactiveCN106433220AGood dispersionModified dispersion effect is goodPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolyesterDispersity

The invention provides a preparation method of modified superfine calcium carbonate powder. The preparation method comprises following steps: raw material mixing, slurry preparation, wet grinding, drying collection, depolymerization scattering and modified treatment, wherein a dispersing agent at least comprises ammonium polyacrylate salt, sodium hexametaphosphate and sodium polyacrylate salt; a modifying agent comprises one or more of octadecylamine, polymethyl methacrylate, a titanate coupling agent and a silane coupling agent; and a hyperdispersant comprises one or more of a polyester type hyperdispersant, a polyether type hyperdispersant, a polyacrylate hyperdispersant and a polyolefin hyperdispersant. By virtue of the preparation method, the dispersity of the powder can be improved, the dry-wet cover effects of building coatings can be improved, and the addition amount of titanium dioxide can be reduced.

Owner:JIANGXI GUANGYUAN CHEM

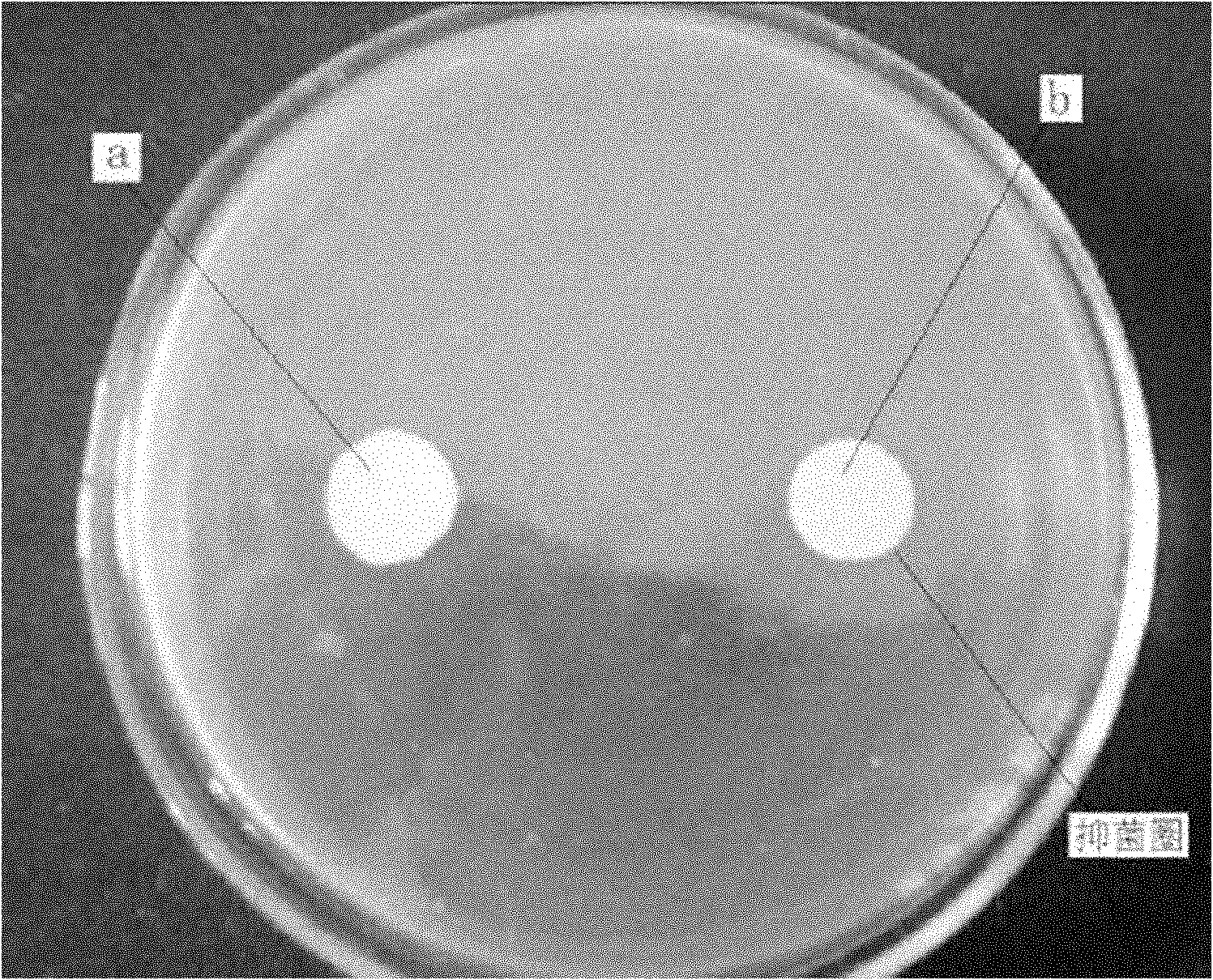

Nisin composite biological preservative and preparation method thereof

The invention discloses a Nisin composite biological preservative and a preparation method thereof. The preservative comprises the fermentation broth of lactic streptococci and components consisting of, on the basis of the weight of the fermentation broth of lactic streptococci, 0.2 to 0.6% of chitosan, 0.1 to 0.2% of antioxidant bamboo leaves, 1 to 5% of sodium hexametaphosphate, 0.5 to 1% of natamycin, 0.1 to 0.2% of garlicin, 0.05 to 0.1% of sodium ascorbate, 1 to 3% of maltodextrin and 0.5 to 2% of NaCl. The preservative provided by the invention does not contain any chemical preservative, overcomes the defects of a narrow antibacterial spectrum and low dependence on a pH value of pure Nisin, has the characteristics of high efficiency, a wide spectrum, good stability and high security, greatly improves the preservative effect and the application range of Nisin and produces high economic benefits and social benefits.

Owner:山东省蓝源生物工程有限公司

Silver-loaded nano-titanium dioxide/polrvinyl chloride membrane and preparation method thereof

InactiveCN102114389AImprove interception effectIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationDistilled water

The invention provides a silver-loaded nano-titanium dioxide / polrvinyl chloride membrane and a preparation method thereof. The method comprises the following steps of: dissolving polrvinyl chloride in an N-N-dimethylacetamide solvent; adding silver-loaded nano-titanium dioxide, and immediately adding a dispersant, namely sodium hexametaphosphate; adding a pore-forming agent, namely polyvinylpyrrolidone; standing at the temperature of between 20 and 30 DEG for 1 to 2 days for deaeration; casting deaerated casting solution to form a membrane at the temperature of between 15 and 30 DEG C under the humidity of between 40 and 80 percent; volatizing the casting solution in the air for 10 to 100 seconds after the membrane is cast, slowly placing into ethanol coagulation liquid at the concentration of between 10 and 50 percent and soaking for 12 to 24 hours; and taking the membrane out from the coagulation liquid and rinsing by using distilled water to obtain the silver-loaded nano-titanium dioxide modified polrvinyl chloride separation membrane. By the method, organic membranes are subjected to antibacterial modification, the disinfection and antipollution performance of the membranes can be improved, and the clear water filtration flux of the membranes can be improved.

Owner:HARBIN ENG UNIV

Light refractory castable material for heat insulation lining of cast steel plate (CPS) furnace roller

The invention discloses a light refractory castable material for a heat insulation lining of a cast steel plate (CPS) furnace roller. The light refractory castable material comprises the following components by weight percent: 40-50% of light mullite bone material, 5-8% of flint clay with a particle size of 0.1-1mm, 5-7% of kyanite powder, 6-9% of first-class bauxite chamotte with a particle sizeof less than or equal to 180 meshes, 7-9% of silicon micro powder, 5-8% of alpha-Al2O3 micro powder, 10-18% of bauxite cement, 1-4% of refractory fiber, 1-1.5% of spodumene, 0.05-0.154% of sodium hexametaphosphate, 0.05-0.15% of organic water reducing agent, 0.04-0.07% of organic silane coupling agent and 0.013-0.06% of defoaming agent. The refractory castable material has the characteristics of light volume weight, strong high temperature resistance, good mechanical property, good heat insulation property and excellent thermal shock stability performance.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

High iron pelitization wulfenite floatation method

The high iron slimed wulfenite floating process adopts sodium hexametaphosphate as dispersant, sodium hydroxide as ore pulp pH regulator, sodium sulfide for sulfurizing and deleading, copper sulfate as activator, kerosene as water repellent, isoamyl xanthate as wulfenite collector and 2# oil as foaming agent. The process can float to recover wulfenite with high iron content and serious sliming effectively. When the raw ore has Mo content of 0.5-0.76 %, Mo concentrate obtained through once coarse separation and four times of fine separation has Mo content of13-16.8 % and recovery rate up to 71-76 %.

Owner:GUANGXI UNIV

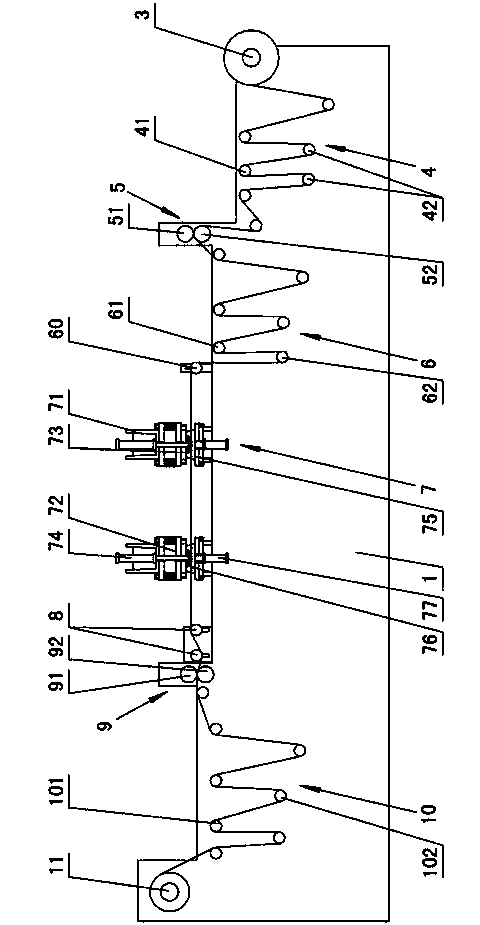

Preparation method of biodegradable mulching film

InactiveCN103819794AAvoid wrinklesRun in harmonyClimate change adaptationMetal working apparatusCross-linkStearate

A preparation method of a biodegradable mulching film is characterized in that: 1, according to the weight proportion, materials are prepared by taking the following components: 55-60 parts of polyethylene, 17-20 parts of cassava starch, 18-22 parts of corn starch, and 5-10 parts of a multielement biological degradation promoting agent; the polyethylene comprises the components by weight: 68-90 parts of 7050, and 10-32 parts of 1F7B; the multielement biological degradation promoting agent comprises the components by weight: 40-80 parts of a cross-linking agent, and 20-40 parts of a degradation accelerant; the cross-linking agent is an arbitrary combination of one or two of di(tert-butylperoxy isopropyl)benzene, sodium hexametaphosphate, sodium trimetaphosphate or sodium tripolyphosphate; the degradation accelerant is an arbitrary combination of one or two of a corn oil, a sunflower seed oil, an epoxidized soybean oil or manganese stearate; and 2, the preparation method comprises the following production steps: a, blending to obtain a degradation masterbatch; b, granulating the degradation masterbatch; c, carrying out blow molding to prepare a film; d, trepanning the biodegradable mulching film; and e, rolling up the biodegradable mulching film, carrying out seal package, and warehousing.

Owner:TAIZHOU HUANGYAN ALPHA PACKAGING FILM

Electrolytic manganese residue curing/stabilizing treatment method

ActiveCN104307849AGuaranteed curing/stabilizing effectReduce processing costsSolid waste disposalSODIUM METAPHOSPHATESodium phosphates

The invention discloses an electrolytic manganese residue curing / stabilizing treatment method. The method comprises the following steps: (1) adding electrolytic manganese residue into a mixer to mix, and adding water to the manganese residue; (2) adding alkaline medicament in the mixing process for several times, adding sodium hexametaphosphate after adding the alkaline medicament for the first time; (3) placing the mixed electrolytic manganese residue into a rotary releaser to perform ammonia gas continuous treatment, and unloading to obtain cured / stabilized electrolytic manganese residue. On the premise of guaranteeing the curing / stabilizing effect of the manganese residue, the solid waste pH requirement after treatment is satisfied by adding the alkaline medicament for several times, the lime additive amount is obviously reduced, and the manganese curing / stabilizing treatment cost is reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Forsterite bakie coating material and method for making same

InactiveCN101117464AImprove high temperature resistanceLow priceFireproof paintsMelt-holding vesselsFiberOlivine

The present invention relates to a refractory coating for forsterite tundish and the preparation method thereof. The technical scheme adopted is that: 20-50 wt percent of forsterite sand, 25-55 wt percent of forsterite clinker, 15-30 wt percent of magnesia powder, 5-15 wt percent of magnesia-calcium sand powder are mixed with 1-5 wt percent of clay, which are coupled with 0-0.5 wt percent of organic fiber of the above ingredients, 0.5-2.0 wt percent of sodium hexametaphosphate and 0.3-1.0 wt percent of sodium tripolyphosphate, and then the present invention is prepared through the mixing of a mixer; when the present invention is in use, the present invention is added with water and stirred. The present invention takes forsterite as base material, and the products prepared is characterized in good high-temperature resistance, low cost, no pollution to molten steel, good durability, no adverse effect to human body and convenient use.

Owner:WUHAN UNIV OF SCI & TECH

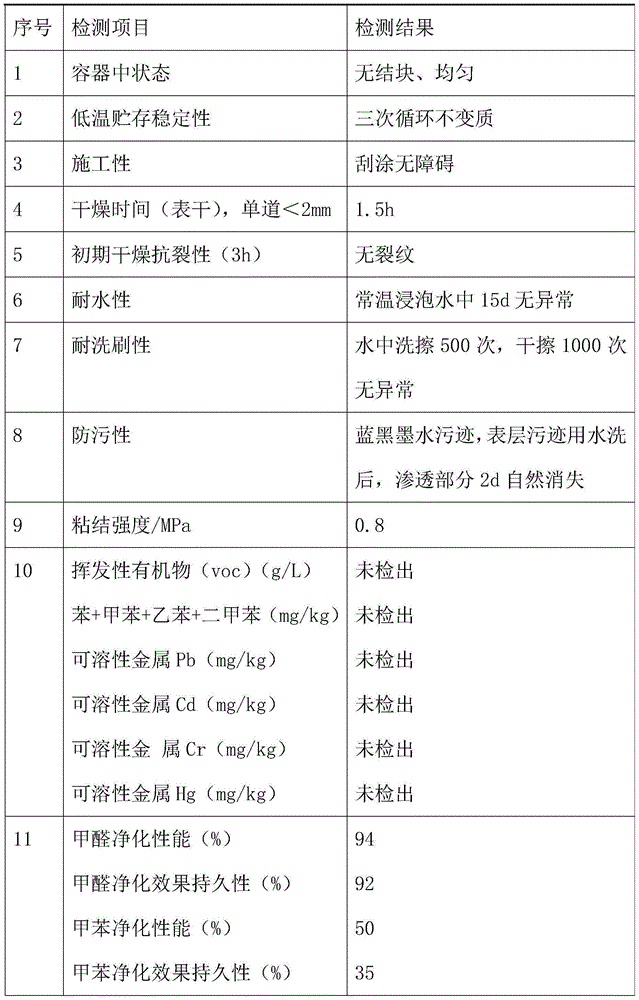

Multifunctional inner wall paint

InactiveCN105131774AGood scrub resistanceImprove rheologyCoatingsAcrylic resinHydroxyethyl cellulose

The invention discloses a multifunctional inner wall paint. The multifunctional inner wall paint comprises raw materials: modified acrylic resin emulsion, pure acrylic emulsion, light calcium carbonate, diatomite, lithopone, ultrafine talcum powder, water absorption composite materials, negative ion-anti-microbial additives, hydroxyethyl cellulose, a dispersant SN-5040, a wetting agent AP-680, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, propylene glycol monomethyl ether, an antifoaming agent TSP-01, sodium hexametaphosphate, a leveling agent L-150, a stain-resistant agent JZM-1, glycol, a multifunctional auxiliary agent AMP-95, mildew inhibitors and deionized water. The multifunctional inner wall paint has good scrubbing resistance, rheological property and brushing performance, can absorb harmful components in air indoors, adsorbs moisture, releases moisture, refreshes air, releases negative ions and is environmentally friendly and is helpful for health.

Owner:TIANCHANG YINHU PAINT

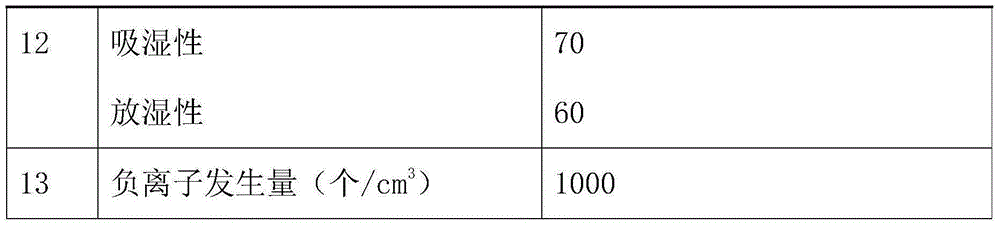

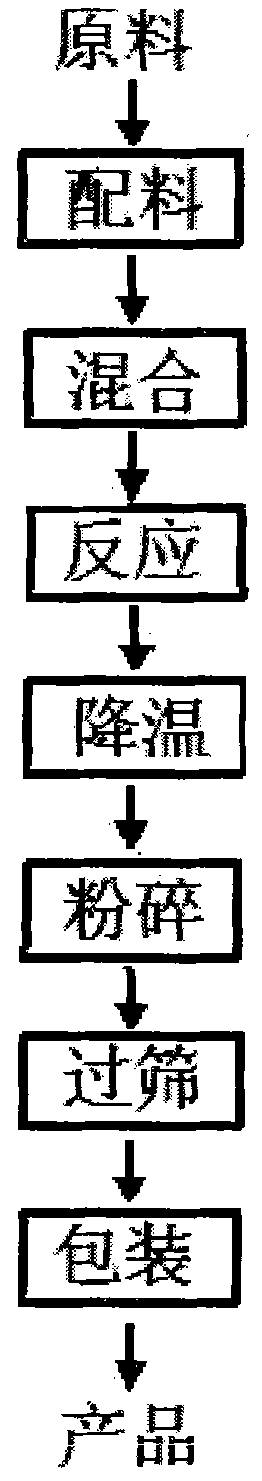

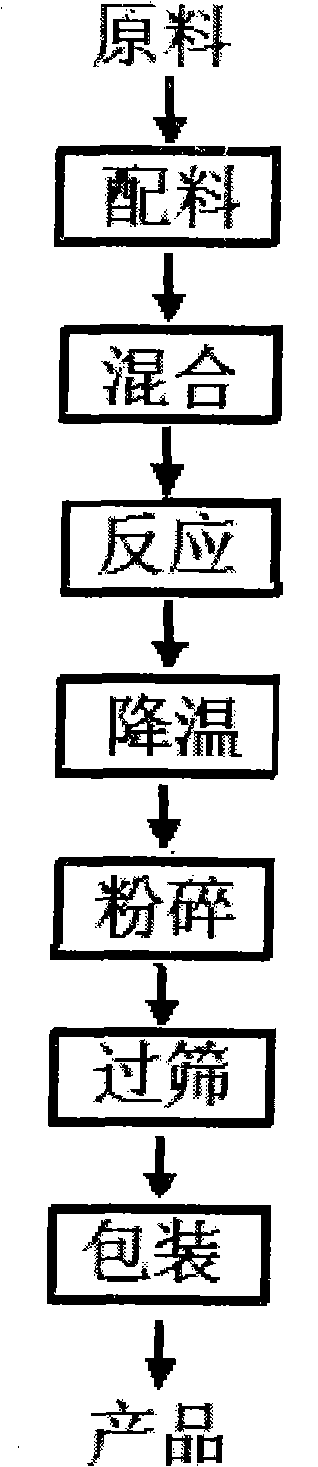

Mineral dressing additive for gold mine and preparation method thereof

The invention discloses a mineral dressing additive for a gold mine, which is prepared by taking inorganic substances as raw materials, and reacting at high temperature of 600-950 DEG C for 1-3 hours and pulverizing. The mineral dressing additive for a gold mine comprises the following components in parts by weight: 20-50 parts of urea, 5-10 parts of sodium hexametaphosphate, 5-10 parts of sodium sulfide, 0-10 parts of sodium bromide, 0-30 parts of sodium ferrocyanide, 20-50 parts of soda and 5-10 parts of sodium hydroxide. The product is free of virulent compounds, can not injure human and animals during production and use, can not cause significant pollution, and is environment-friendly. Proven by industrial trial, the product has the advantages of better mineral dressing effect, high recovery rate, simple production method, short process flow, easy technological operation, abundant and cheap raw materials for production, low production cost and better economic benefit and social benefit.

Owner:GUANGXI SENHE HIGH TECH CO LTD

High-activity biological nutrient solution fertilizer for spraying dripping irrigation, and preparation method thereof

InactiveCN101234920AEnvironmental protection is goodLow priceAnimal corpse fertilisersClimate change adaptationAdjuvantDrip irrigation

The invention provides highly active biological nutritional manure for drip irrigation. High-content amino acid leftover, high-protein animal dry matter, and rapeseed are crushed and mixed into 80 mesh to 350 mesh to obtain the high amino acid animal and plant powder; a certain amount of sugar, yellow humic acid, organic acid, poly peptide powder, microelement, effective adjuvant, sodium hexametaphosphate, and nitrogen, phosphor, and potassium fertilizers are added into the high amino acid animal and vegetable powder, and heated to 50 DEG C to 60 DEG C to carry out a complex reaction for 2 to 5 hours so as to prepare preparation A; urea is completely dissolved in water a temperature ranging from 35 DEG C to 40 DEG C to prepare preparation B; and then, the preparations A and B are mixed with each other and milled through a colloid mill to ensure that the floating granularity has a diameter of less than 120 microns. At last, the milled preparations are added with active microelement strain liquid, thoroughly mixed, and naturally fermented to obtain the product. The product has the advantages of high vegetable amino acid content and high biological activity, long effective period, obvious effect on growth increase, and simple technique.

Owner:师进

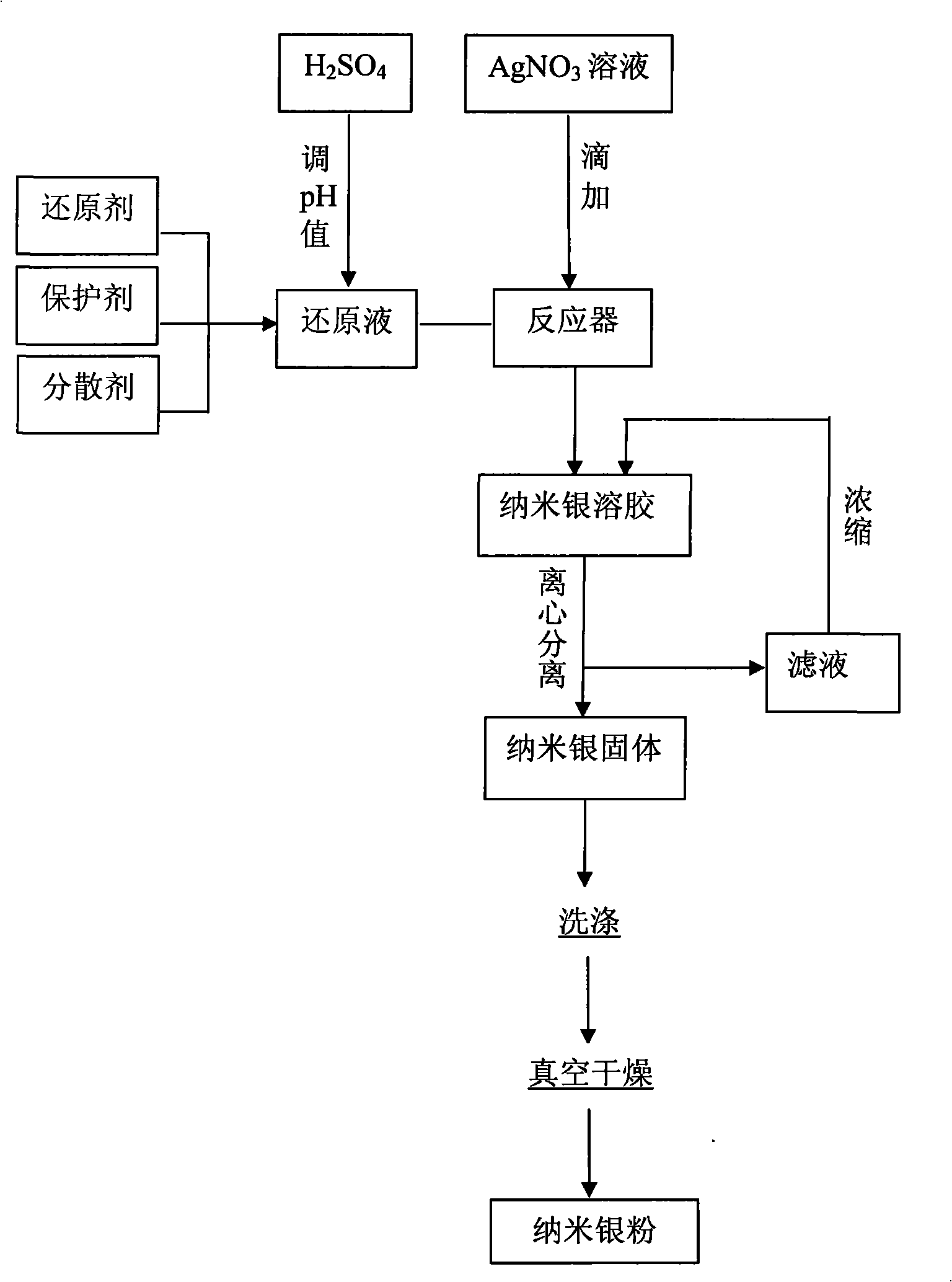

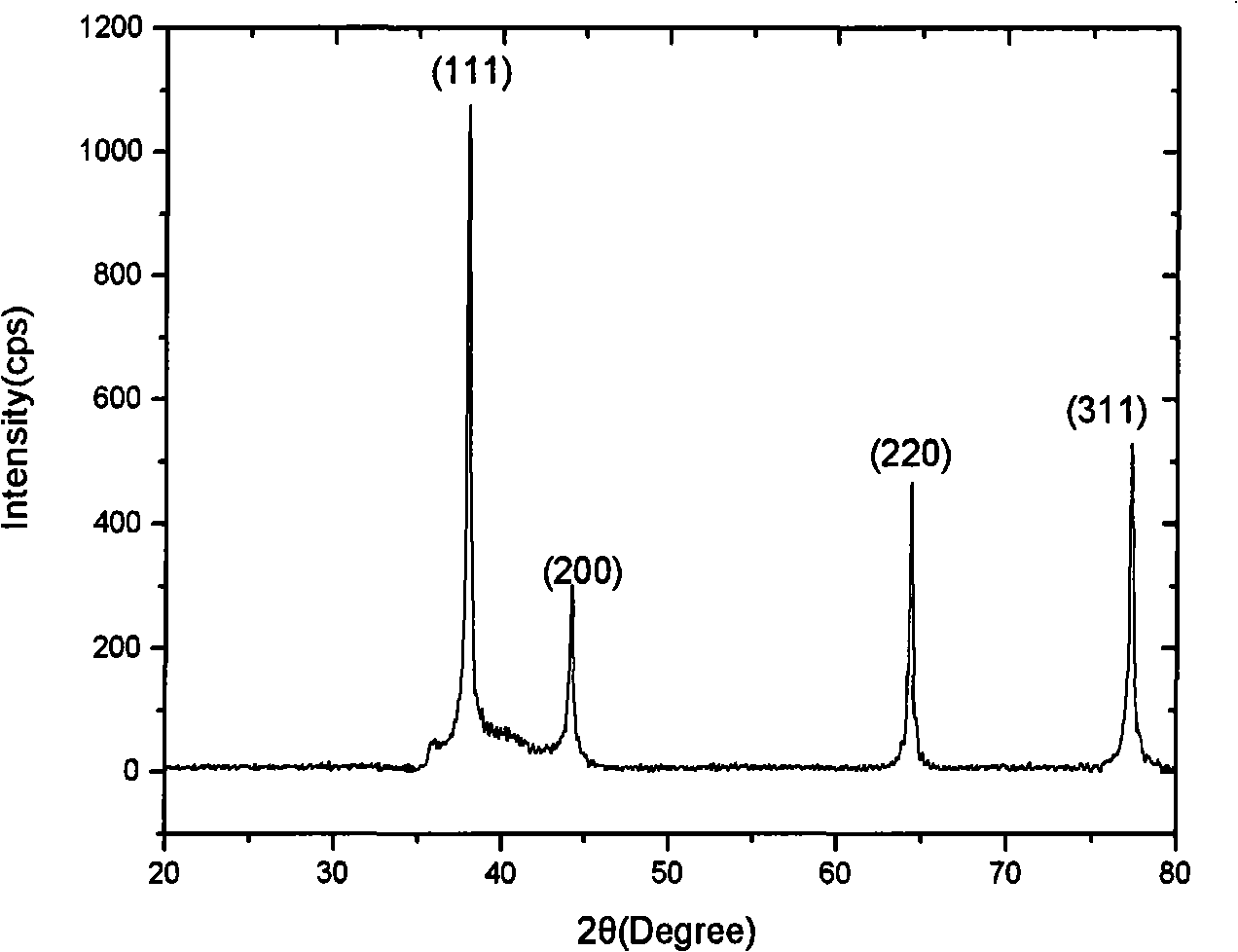

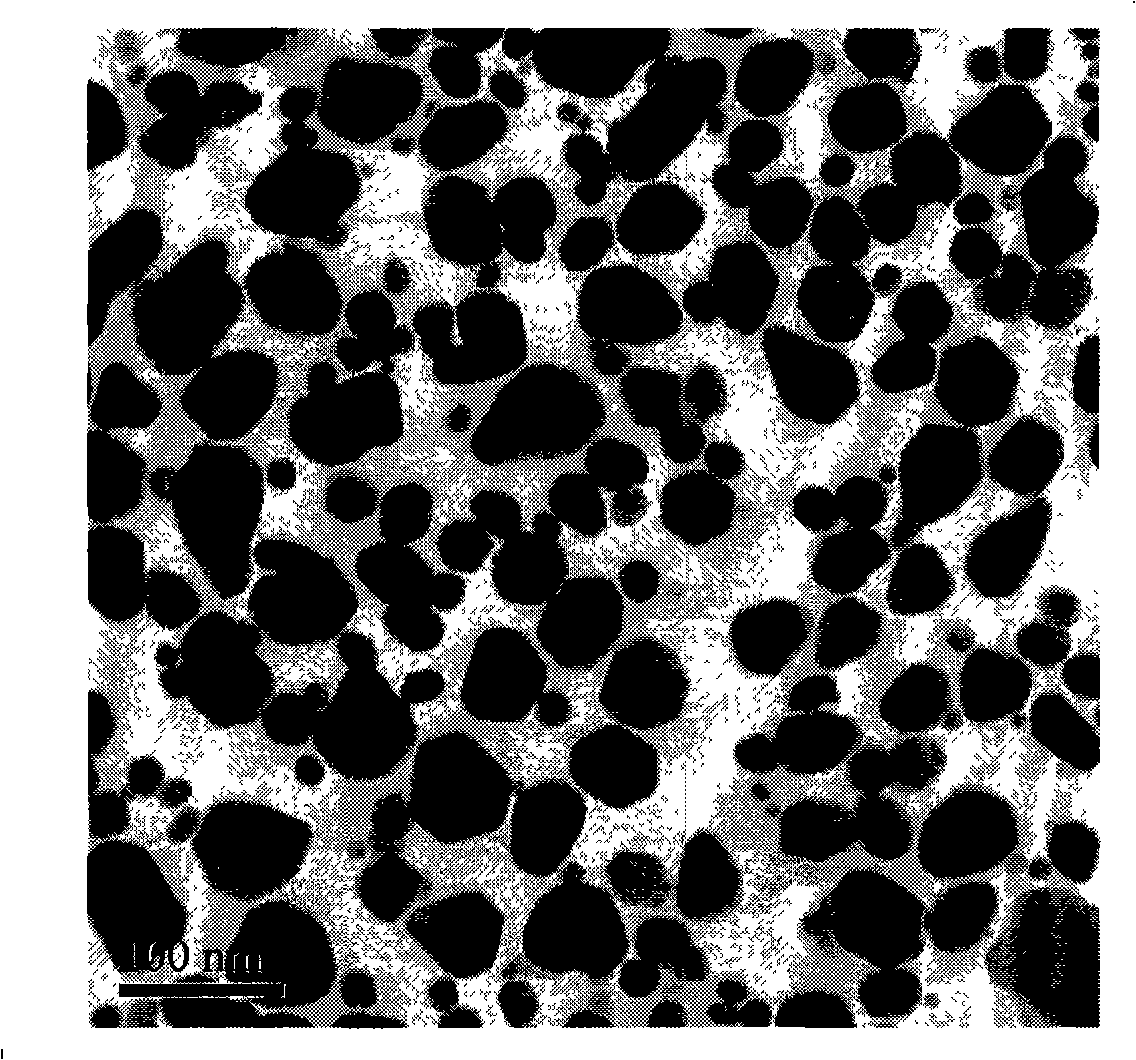

Preparation of nano aluminum powder for conducting resin and storage method

The invention relates to the preparation and storage method of silver nano-particles for conductive adhesive, in particular to a method for preparing silver nano-particles by reducing high-concentration silver nitrate by adopting a chemical liquid-phase method. The method comprises the following steps: mixing sodium hypophosphite, polyvinyl pyrrolidone and sodium hexametaphosphate to obtain reduction solution, adding sulfuric acid dropwise to adjust pH value, adding silver nitrate solution into the reduction solution under magnetically stirring to obtain silver colloid, standing, centrifugally separating, recovering filtrate, concentrating, centrifugally separating, washing the solid, vacuum-drying to obtain silver nano-particles, sealing and packaging, and storing at low temperature. The method adopts high-concentration silver nitrate solution, and has the advantages of simple process flow, high yield of silver powder, short production cycle and good safety. In the separation process, the filtrate can be recovered to improve the coefficient of recovery of silver powder. The silver nano-particle has spherical shape, uniform particle diameter, narrow distribution, high purity, good dispersibility, good storage stability and long storage time without oxidization, and can be used for conductive filler such as conductive adhesive.

Owner:CENT SOUTH UNIV

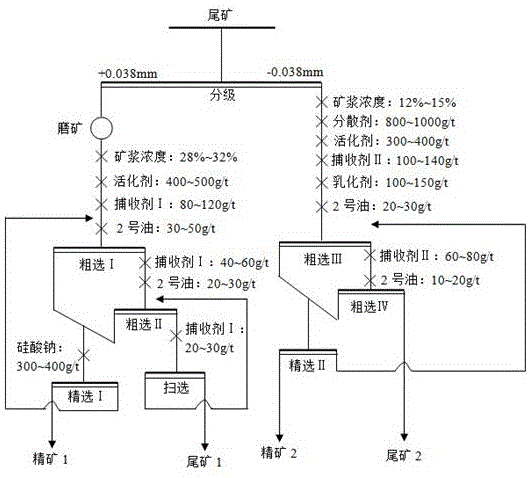

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

Andalusite self-flow castable

InactiveCN102503466AGood volume stability at high temperatureImproved thermal shock stabilityFiberVolume variation

The invention discloses an andalusite self-flow castable, comprising andalusite, fused mullite, silicon carbide, mullite hollow balls, pure calcium aluminate cement, aluminum oxide micro-powder, zirconium silicate, tripolycyanamide, and polycarboxylic acid FOX-8H. The castable further comprises nano calcium carbonate, sodium hexametaphosphate and anti-explosion fiber. According to the andalusite self-flow castable disclosed by the invention, raw materials, such as the high-quality andalusite, silicon carbide, various additives and the like are selected. The andalusite self-flow castable is formed by regulating according to repeated tests and feedback after being used by a manufacturer. As the andalusite is transformed to be the mullite at a high temperature, and the vast majority of residual SiO2 in the andalusite is located in mullite crystals. Under a high temperature state, the SiO2 softened in the mullite crystals can absorb the volume variation of the mullite, which is caused by the temperature variation, so that the structure of the mullite formed by the andalusite has better high-temperature volume stability and thermal shock stability.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Lightweight high-strength heat-insulation refractory castable

InactiveCN103396141AMake up for the lack of performance degradationAvoid missing gradesFiberDefoaming Agents

The invention discloses a lightweight high-strength heat-insulation refractory castable. The castable comprises the following raw materials by weight: 30 to 40% of lightweight mullite aggregate, 5 to 10% of an aluminum-rich spinel hollow sphere, 5 to 8% of andalusite, 6 to 9% of aluminum-rich spinel powder, 5 to 7% of kyanite powder, 5 to 8% of silicon powder, 5 to 10% of rho-Al2O3 micro powder, 12 to 18% of calcium aluminate cement, 3 to 6% of a refractory fiber, 0.05 to 0.15% of sodium hexametaphosphate, 0.05 to 0.15% of an organic water reducing agent, 0.04 to 0.07% of an organosilicon coupling agent and 0.01 to 0.02% of a defoaming agent. According to the invention, the heat insulation performance of the lightweight refractory castable is guaranteed, close bonding between aggregate and powder in the refractory castable is improved, mechanical strength, capacity of resisting mechanical and thermal shock damage, anti-permeability and comprehensive usage performance at high temperature of the refractory castable are enhanced, and cost for the refractory castable is reduced, thereby finally achieving the comprehensive targets of reduction of heat loss in cooling of furnace beams and columns, prolongation of the service life of a heat insulation lining, improvement of heating quality in a furnace, reduction of energy consumption and maintenance cost, etc.

Owner:武汉钢铁有限公司

Self-cleaning antifouling inter wall paint

InactiveCN105131772AImprove water resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionFluorocarbon

The invention discloses a self-cleaning antifouling inter wall paint. The inner wall paint comprises raw materials: modified fluorocarbon emulsion, pure acrylic emulsion, light calcium carbonate, calcined kaolin, diatomite powder, forsterite powder, nano-stannic oxide, magnesium sulfate, hydroxyethyl cellulose, a dispersant SN-5040, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent CF-16, negative ion-anti-microbial additives, sodium hexametaphosphate, a leveling agent L-150, a stain resistant agent JZM-1, glycol, mildew inhibitors, wetting agents and deionized water. The coating film of the inter wall paint is compact, and the inter wall paint is hydrophobic and oleophobic and has strong antifouling performance and self-cleaning capability. The coating effect is good and construction is convenient.

Owner:TIANCHANG YINHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com