Technique for efficiently removing iron from kaolin

A kaolin, high-efficiency technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of unsatisfactory magnetic separation iron removal effect, low iron removal efficiency, complicated operation process, etc., to achieve insignificant improvement effect and iron removal efficiency High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

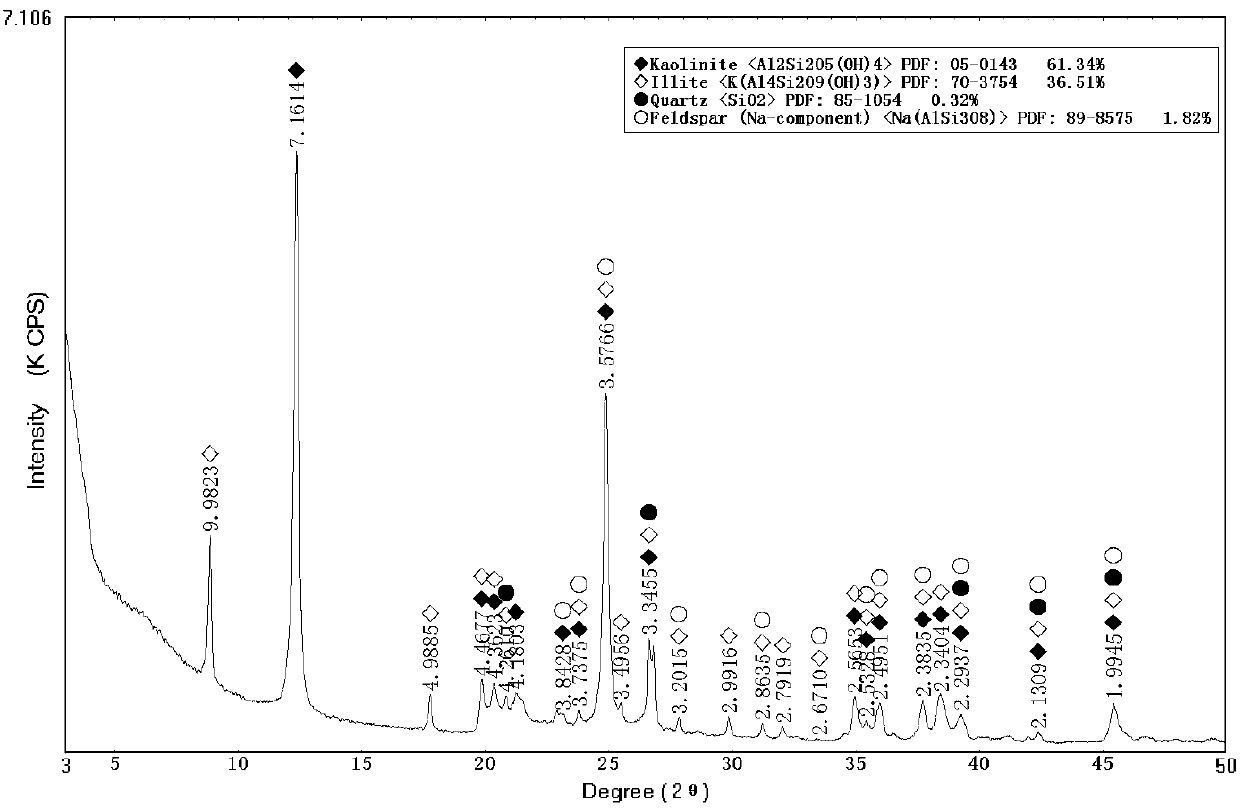

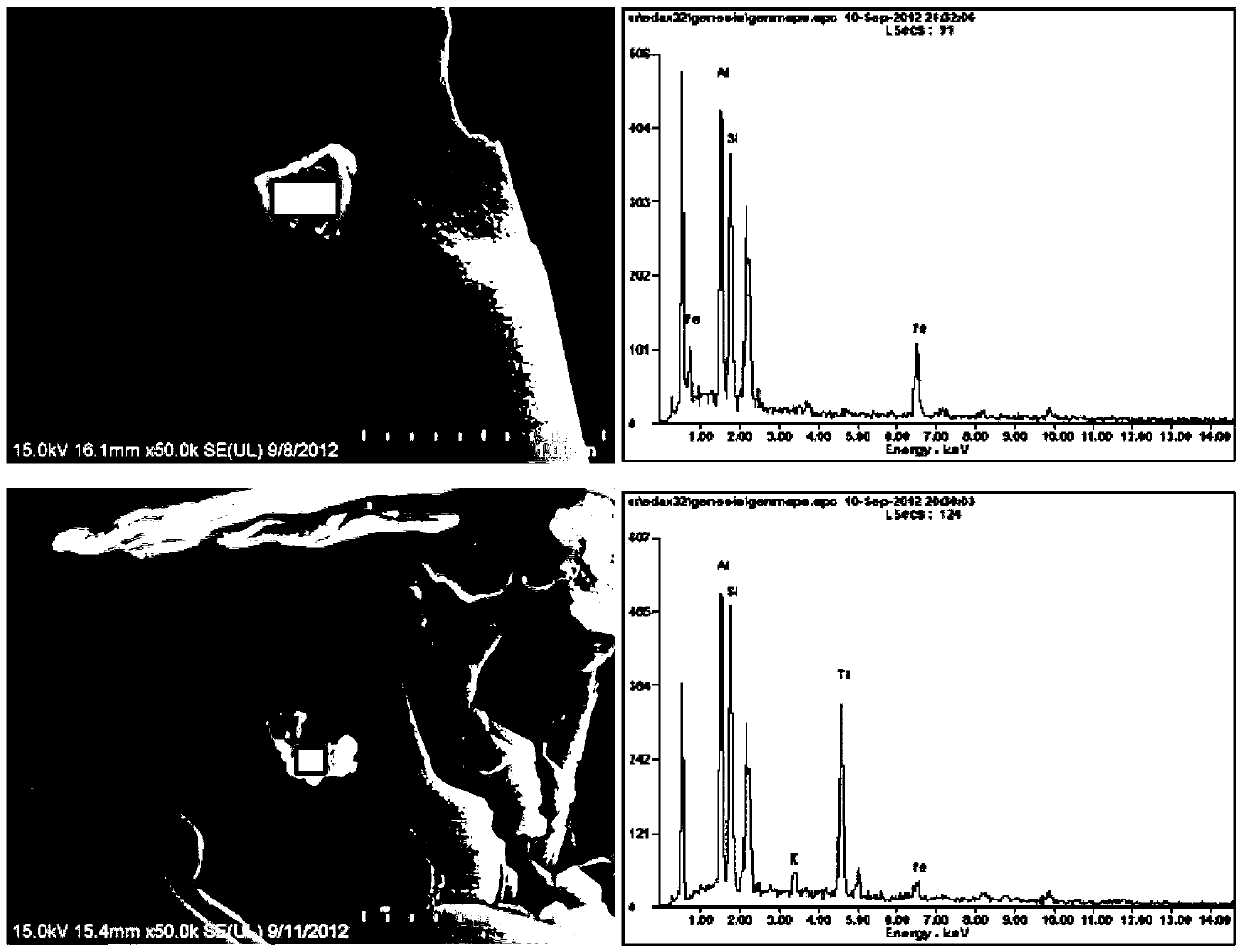

Problems solved by technology

Method used

Image

Examples

Embodiment 1

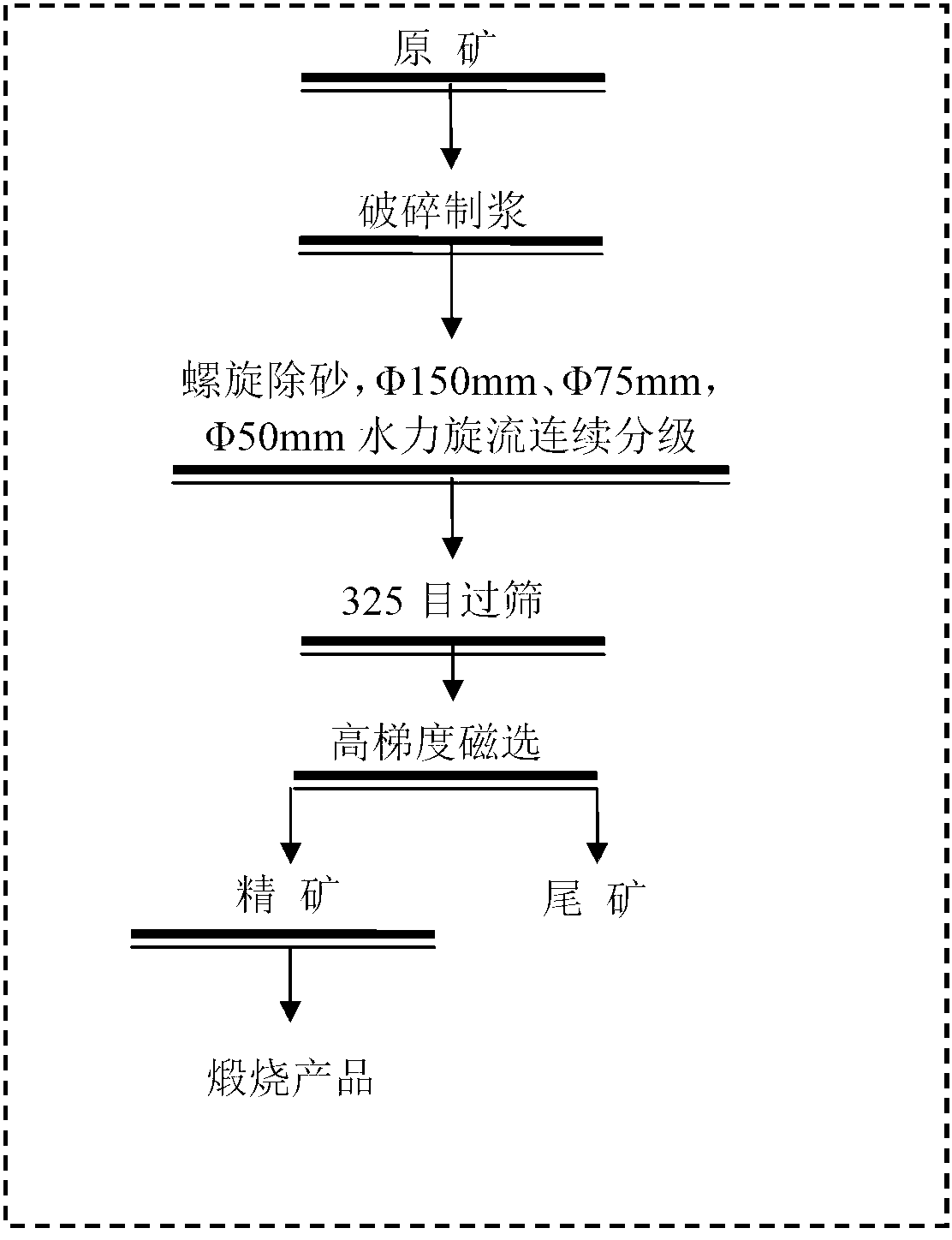

[0030] A high-efficiency iron removal process of kaolin, it comprises the steps:

[0031] (1) Simple purification of kaolin raw ore (as mentioned above) to obtain magnetic separation raw material (or purified kaolin);

[0032] (2) Add water to the magnetic separation raw material obtained in step (1) to prepare a mixed slurry with a solid content of 15wt%, then add sodium hexametaphosphate with a mass of 2 ‰ of the magnetic separation raw material, stir the slurry for 20 minutes, and pass through a 325-mesh wet sieve;

[0033] (3) The slurry under the 325-mesh sieve in step (2) is subjected to high-gradient magnetic separation, the magnetic field strength of the high-gradient magnetic separator is controlled to 1.0T, the slurry flow rate is 1.0cm / s, and the slurry is passed through the high-gradient magnetic separator. Separator for magnetic separation to obtain concentrate slurry;

[0034] (4) The amount of alum added is 6% of the mass of the concentrate slurry, and the conc...

Embodiment 2

[0038] A high-efficiency iron removal process of kaolin, it comprises the steps:

[0039] (1) Simple purification of kaolin raw ore to obtain magnetic separation raw material (or purified kaolin);

[0040] (2) Add water to the magnetic separation raw material obtained in step (1) to prepare a mixed slurry with a solid content of 15 wt%, then add sodium hexametaphosphate with a quality of 4 ‰ of the magnetic separation raw material, stir the slurry for 20 minutes, and pass through a 325-mesh wet sieve;

[0041] (3) The slurry under the 325-mesh sieve in step (2) is subjected to high-gradient magnetic separation, the magnetic field strength of the high-gradient magnetic separator is controlled to 1.4T, the flow rate of the slurry is 1.0cm / s, and the slurry is passed through the high-gradient magnetic separator. Separator for magnetic separation to obtain concentrate slurry;

[0042] (4) The amount of alum added is 1% of the mass of the concentrate slurry, and the concentrate sl...

Embodiment 3

[0046] A high-efficiency iron removal process of kaolin, it comprises the steps:

[0047] (1) Simple purification of kaolin raw ore to obtain magnetic separation raw material (or purified kaolin);

[0048] (2) Add water to the magnetic separation raw material obtained in step (1) to prepare a mixed slurry with a solid content of 15wt%, then add sodium hexametaphosphate with a quality of 6 ‰ of the magnetic separation raw material, stir the slurry for 20 minutes, and pass through a 325-mesh wet sieve;

[0049] (3) The slurry under the 325-mesh sieve in step (2) is subjected to high-gradient magnetic separation, the magnetic field strength of the high-gradient magnetic separator is controlled to 1.8T, the flow rate of the slurry is 1.0cm / s, and the slurry is passed through the high-gradient magnetic separator. Separator for magnetic separation to obtain concentrate slurry;

[0050] (4) The amount of alum added is 3% of the mass of the concentrate slurry, and the concentrate slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com