Patents

Literature

55 results about "Industrial mineral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial resources (minerals) are geological materials which are mined for their commercial value, which are not fuel (fuel minerals or mineral fuels) and are not sources of metals (metallic minerals) but are used in the industries based on their physical and/or chemical properties. They are used in their natural state or after beneficiation either as raw materials or as additives in a wide range of applications.

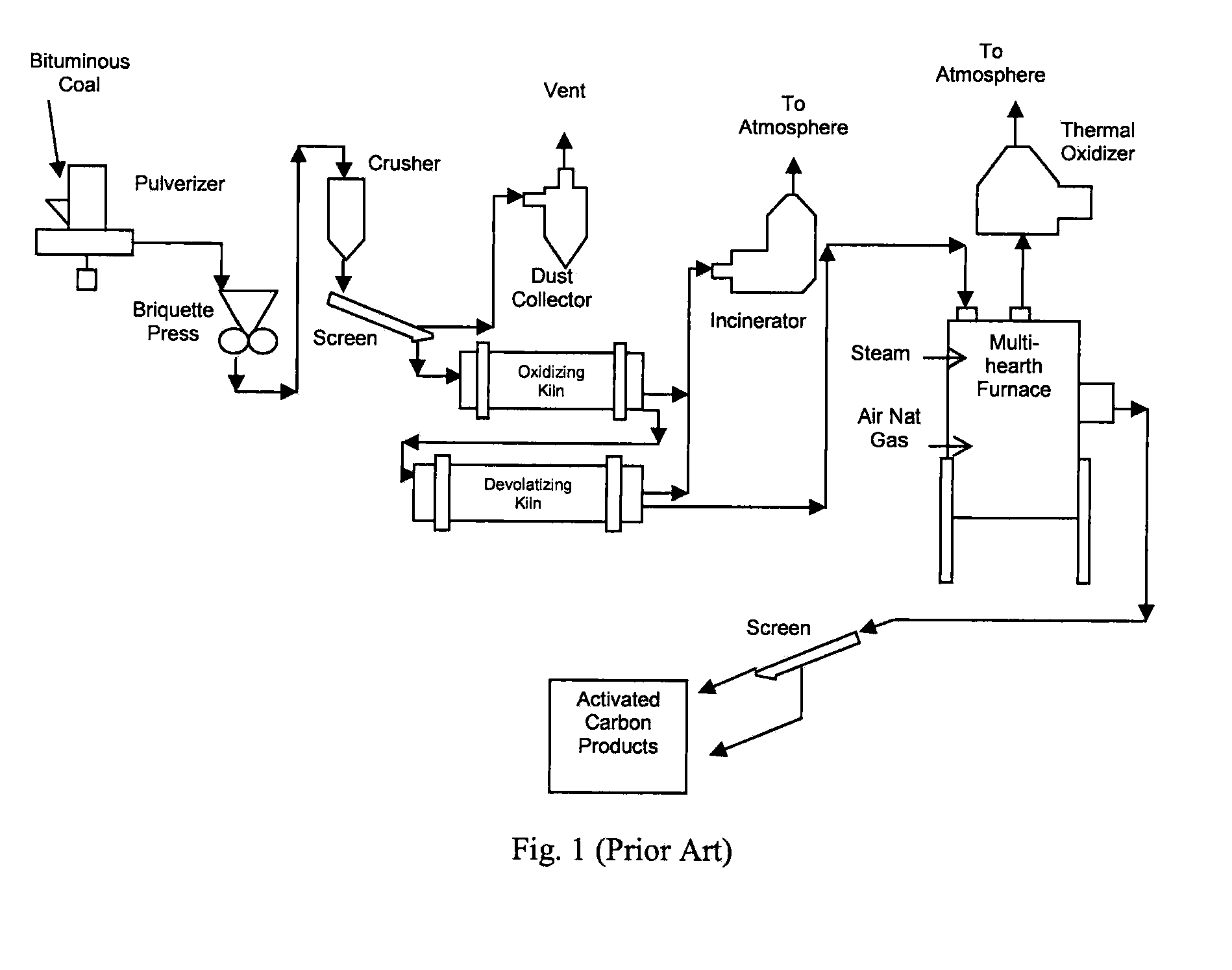

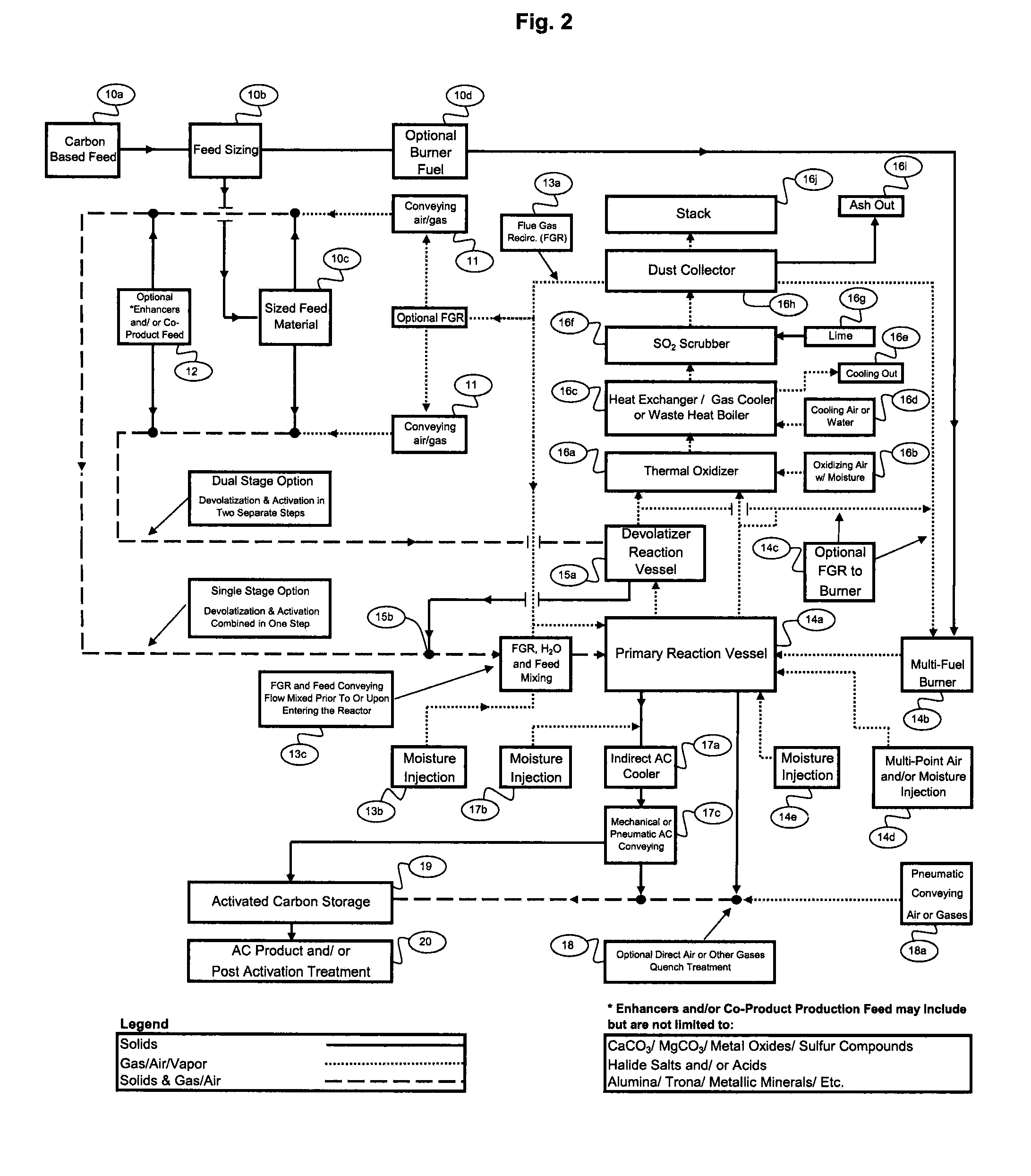

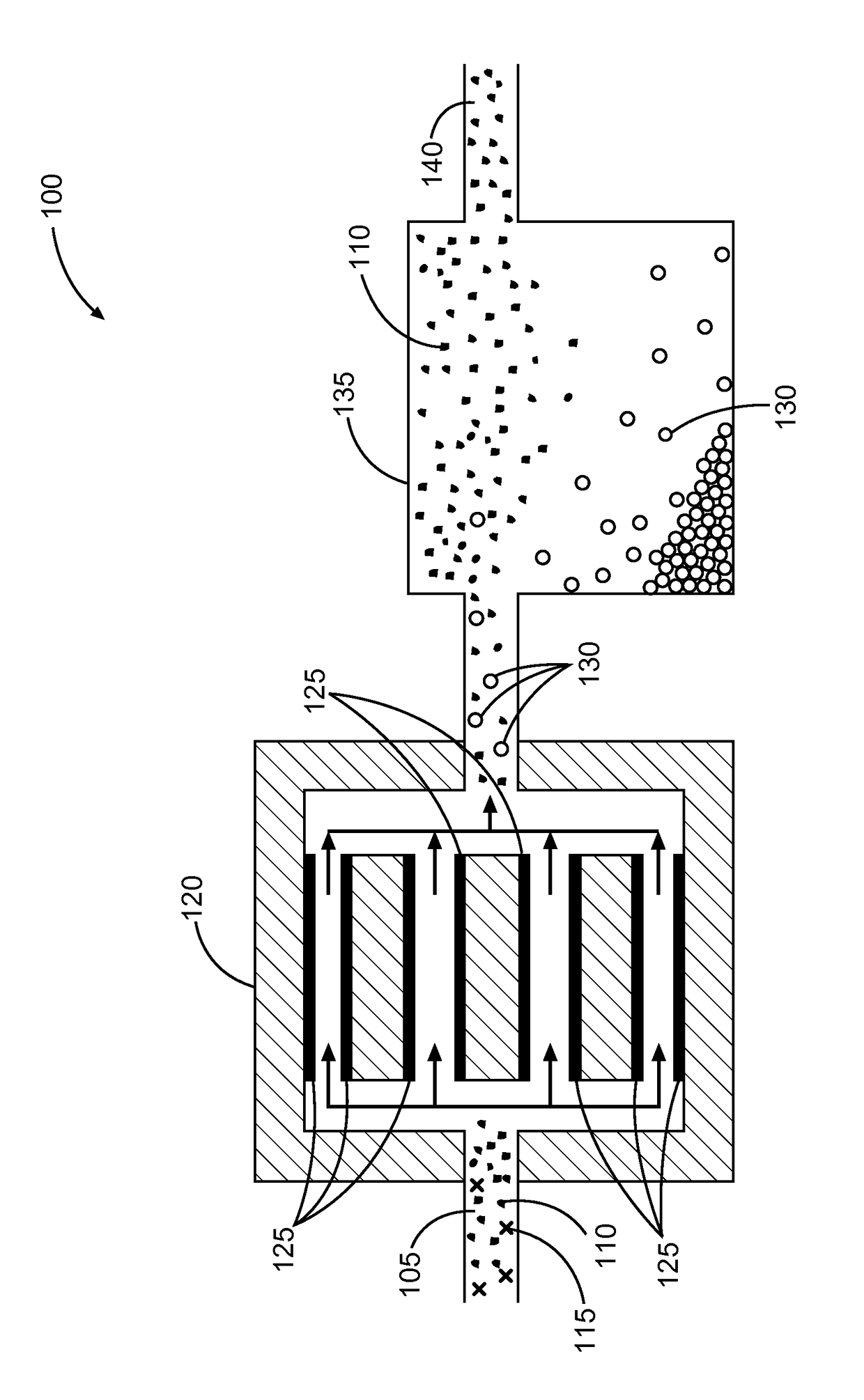

Carbon heat-treatment process

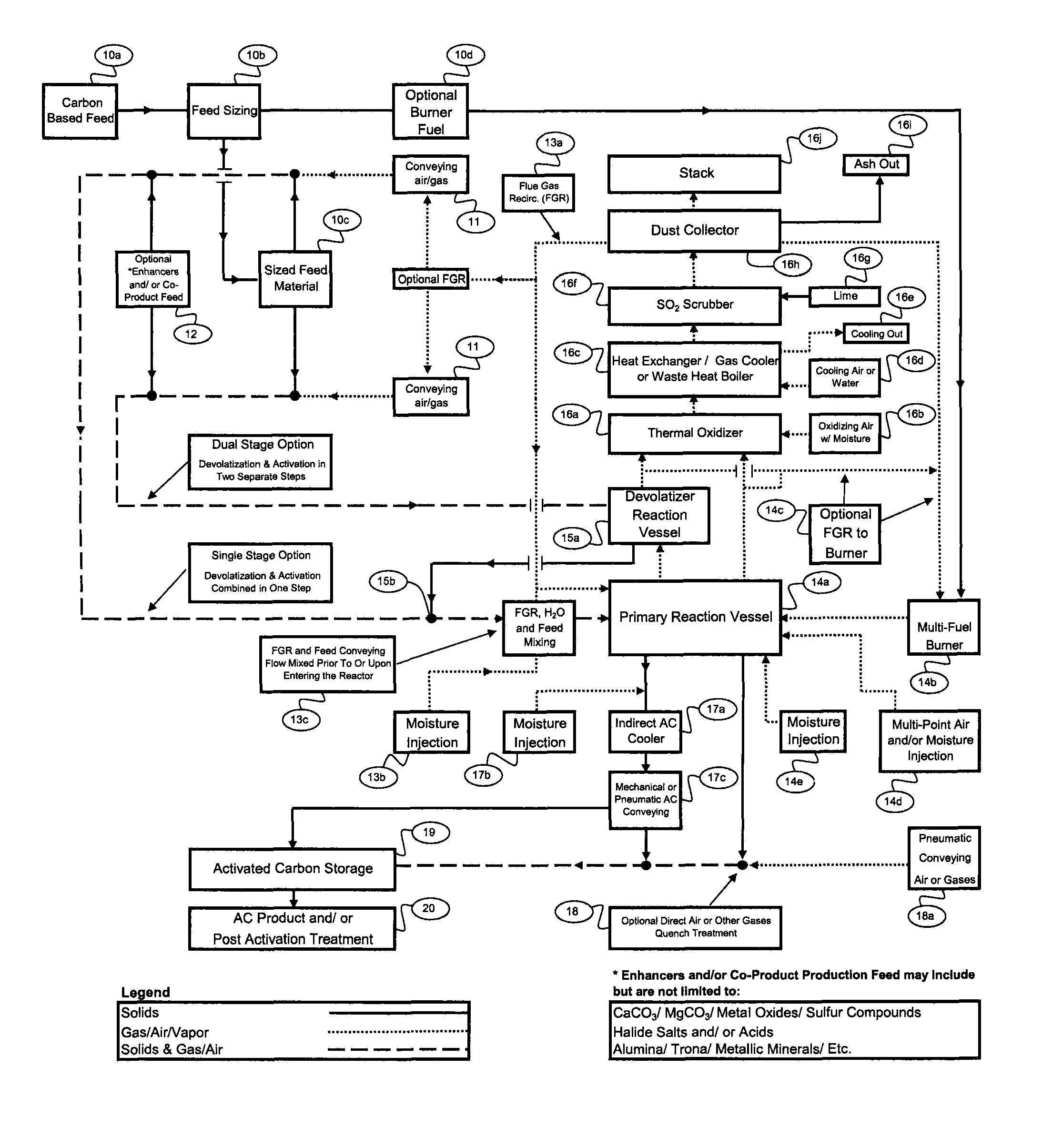

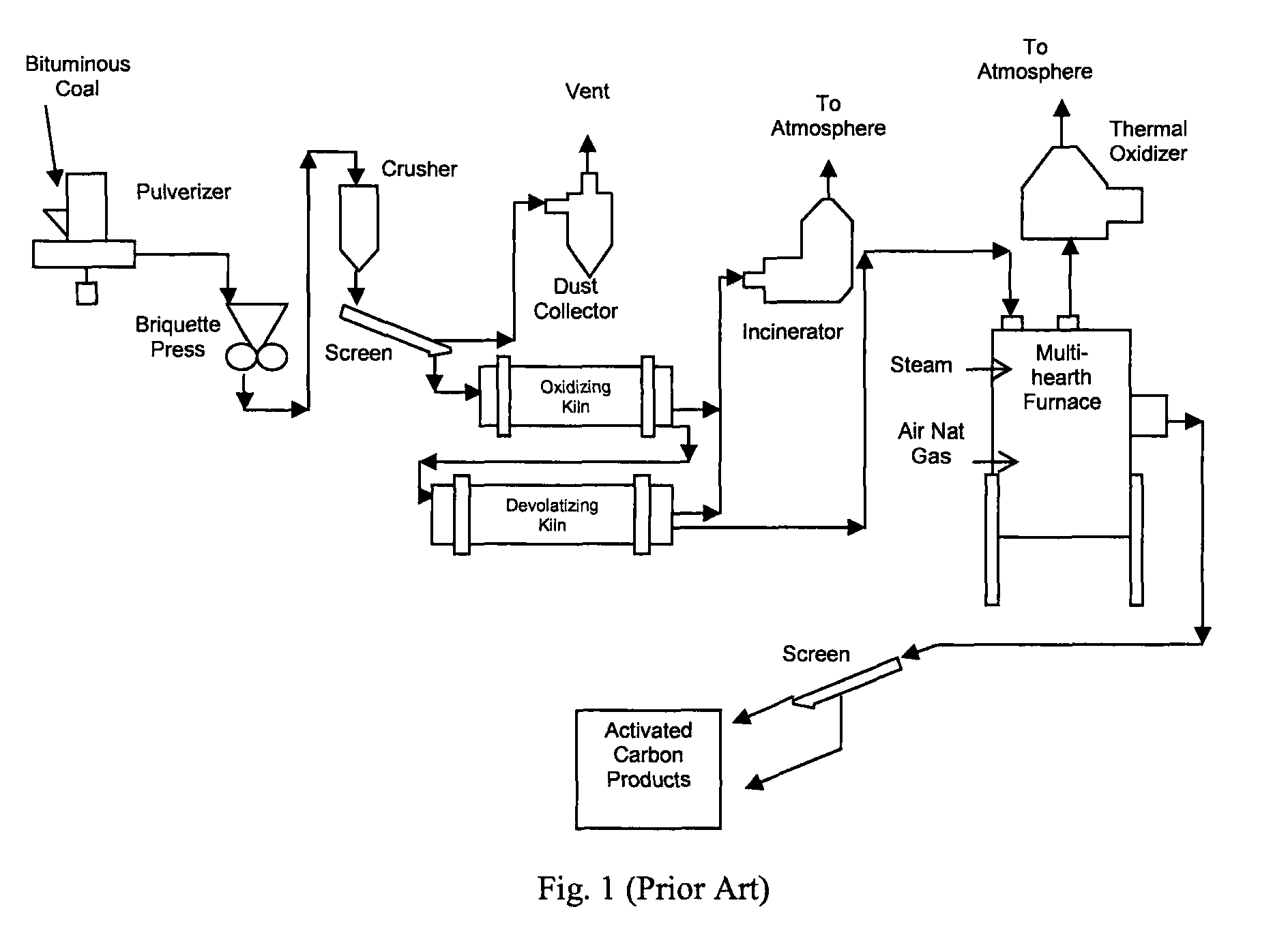

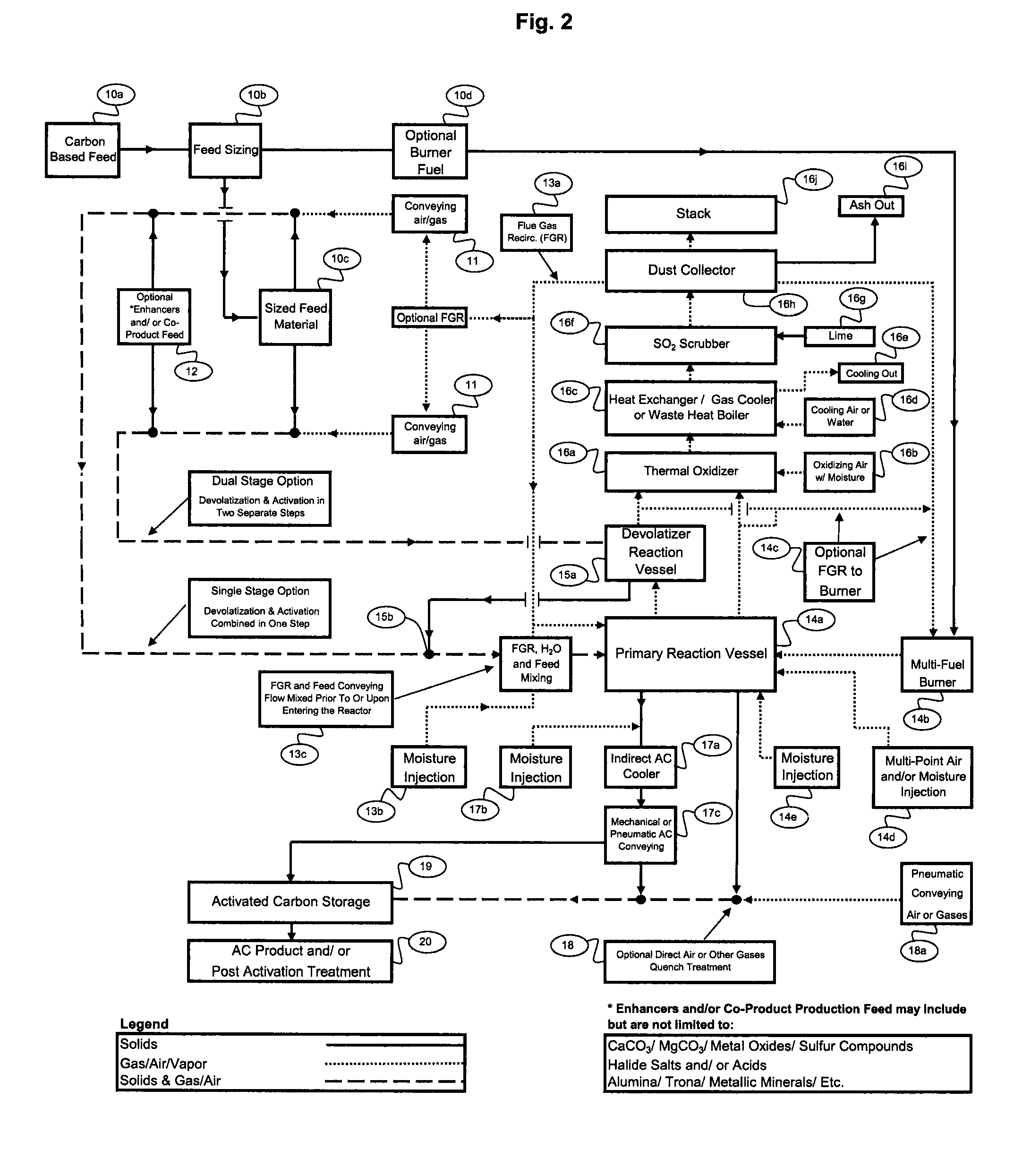

ActiveUS8309052B2Affecting structureAffecting yieldPigmenting treatmentCarbon compoundsActivated carbonCombustion

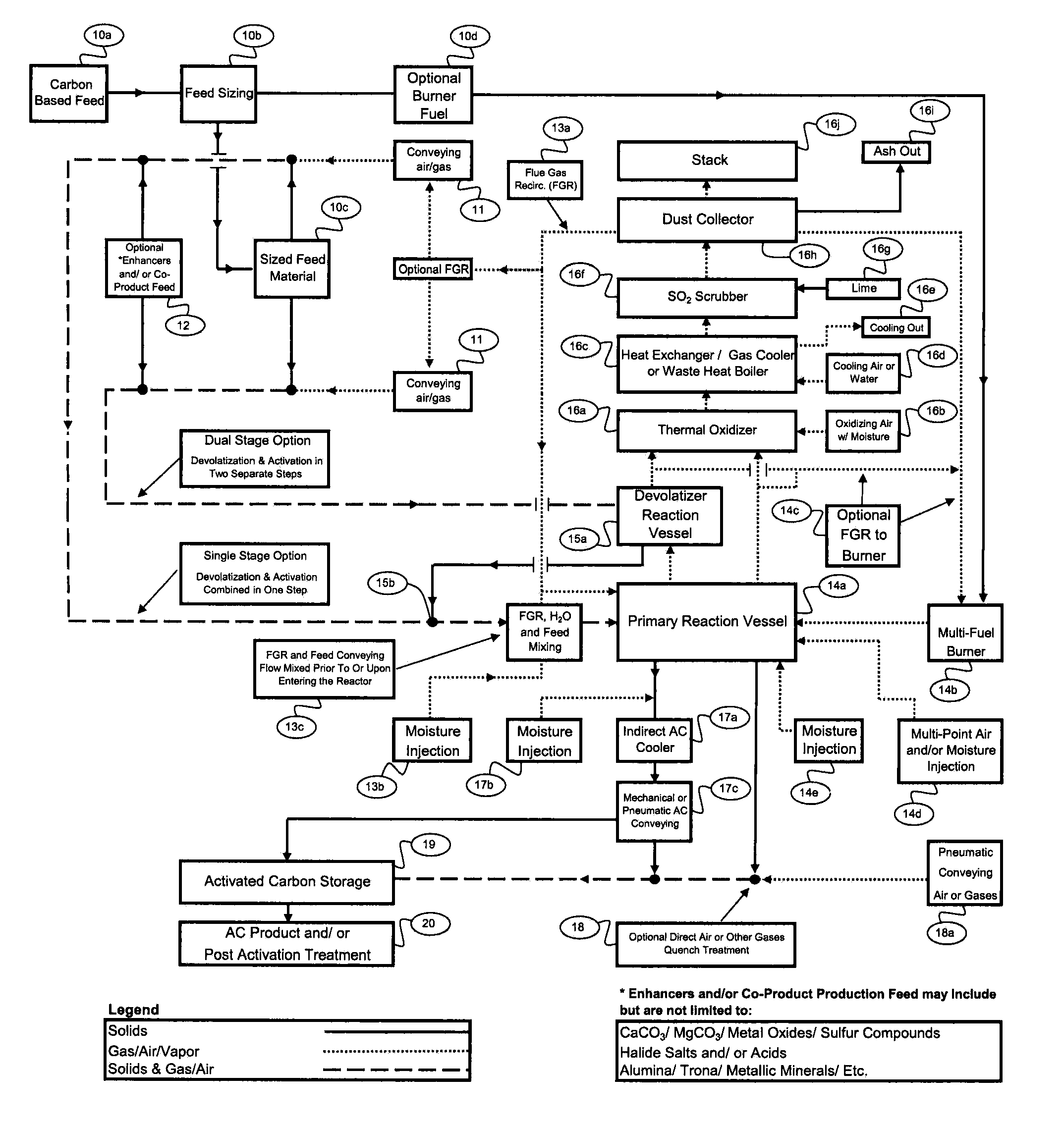

Methods for producing devolatilized and / or activated carbon in a reactor or reaction vessel of a heat treatment system from a suitable carbonaceous feedstock by introducing the feedstock into the reactor tangentially at a rotational velocity of at least 90 RPM. The methods include the steps of providing a combination of conveying means and a gas flow having various compositions and creating distinct carbonaceous feedstock material flow patterns and process conditions such that the feedstock is conveyed through the reactor or reaction vessel and heated via combustion, thereby producing activated carbon or other heat-treated carbons while concurrently avoiding adverse reaction conditions. Single and two-stage heat treatment systems may be used to heat a carbon feedstock, to which one or more industrial minerals may be added to co-produce compositions such as lime with the heat-treated carbon.

Owner:PNEUMATIC PROCESSING TECH

Rotary kilneye castable for treating industrial minerals and preparation method of castable

The invention relates in particular to a rotary kilneye castable for treating industrial minerals and a preparation method of the castable. The preparation method adopts the technical scheme that the preparation method comprises the steps that 40-60wt% of brown corundum particles or alumina particles, 20-40wt% of mullite particles, 6-20wt% of white corundum fine powder, 5-15wt% of silicon carbide fine powder, 1-5wt% of silicon oxide micro powder, 1-8wt% of activated alpha aluminium oxide micro powder and 2-8wt% of aluminate cement are taken as raw materials; 4-8wt% of water and 0.1-0.4 wt% of water reducing agent are added to the raw materials and mixed uniformly; casting and vibration molding is conducted; and a molded blank is naturally dried for 24h in air, and then dried for 24-48h at 110 DEG C. The rotary kilneye castable for treating the industrial minerals mainly comprises Al2O3 and SiC, has main crystalline phases of corundum, silicon carbide and mullite, has higher strength, and has the characteristics of good erosion resistance, thermal shock stability and wear resistance.

Owner:WUHAN UNIV OF SCI & TECH

Sand fixation method of green degradable inorganic sand fixation material

InactiveCN106753384AReduce the impactHold onOther chemical processesOrganic fertilisersCalcium silicateEcological environment

The invention relates to a sand fixation method of a green degradable inorganic sand fixation material, belonging to the field of environmental protection. The inorganic sand fixation material is prepared by mixing calcium silicate slag, fly ash, industrial mineral slag powder, gypsum, cement and solid aggregate used as main raw materials. The sand fixation material and water are mixed to prepare a sand fixation slurry; and the sand fixation slurry is sprayed or spread on sand soil to form a solidifying layer on the sand soil surface. The solidifying layer can satisfy the mechanical property requirements for fixing traveling dunes. After the sand fixation layer is laid, the sand fixation region is subjected to soil improvement and plant growth, so that the sand fixation layer can be degraded into substances which are nontoxic and harmless to the environment within 1-5 years, thereby obtaining the soil components and lowering the influence of artificial buildings on the desert ecological environment. After the sand fixation material reacts with water, no toxic component resides, and thus, the sand fixation material has the advantages of high safety and no secondary pollution. Besides, abundant industrial solid wastes are doped to lower the influence of solid waste piling on the environment; and the method has the advantages of low cost, simple construction technique and high practicality, and is applicable to related fields of desertification control and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Gypsum-based plastering mortar and preparation method thereof

The invention relates to the technical field of building materials, and particularly discloses gypsum-based plastering mortar and a preparation method thereof. The gypsum-based plastering mortar comprises the following components in parts by weight: 16.4% to 19.5% of gypsum, 5.9% to 7.8% of cement, 71.5% to 76.1% of sand and 1.3% to 1.7% of additive, wherein the sand is one or a multiple mixture of river sand, mountain sand, furnace slag and industrial mineral waste residues; the gypsum is one or a multiple mixture of desulphurization gypsum, phosphorus gypsum, electric gypsum, titanium gypsum and fluorine gypsum; and the additive comprises an emulsion and a stabilizer in a mass ratio of (4-6) to 1. The gypsum-based plastering mortar realizes the recycling of the waste gypsum, has the advantages of small usage amount of materials in unit area, low material volume ratio, flexibility, moderate hardness, small possibility of cracking, high bonding strength and the like, and ensures that the most convex position of a wall body can be shield by only utilizing the mortar of 3mm to 5mm.

Owner:CHANGSHA HAIHONG BUILDING MATERIALS

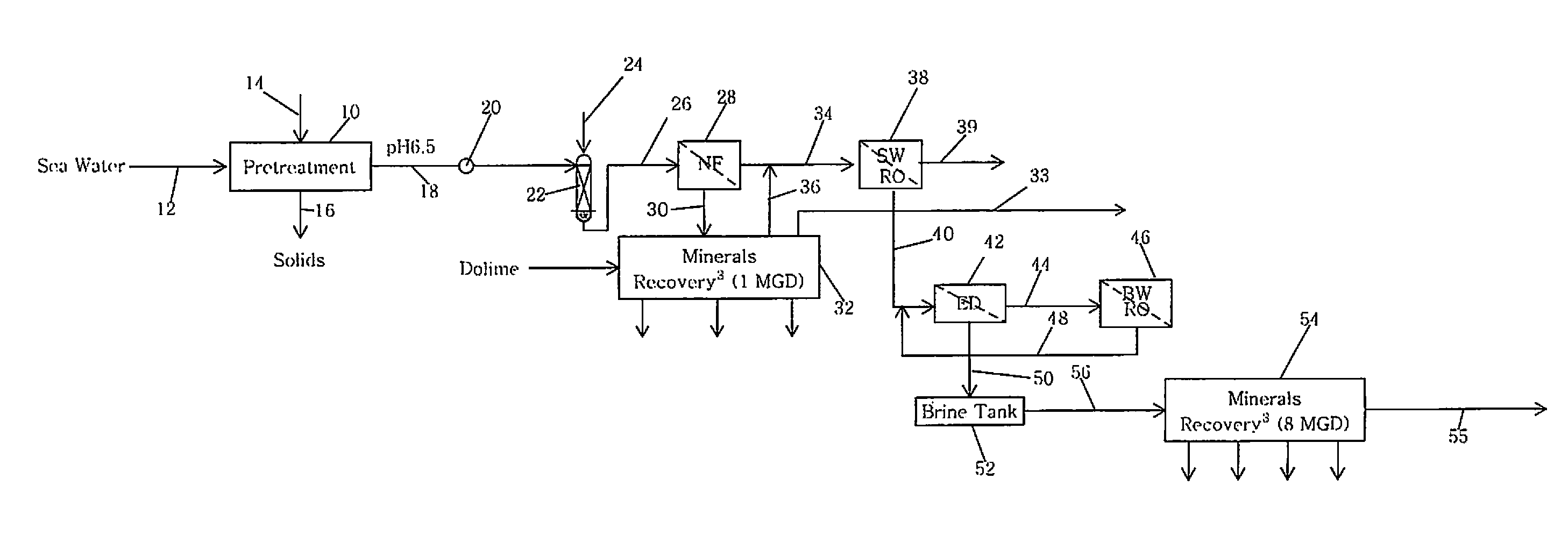

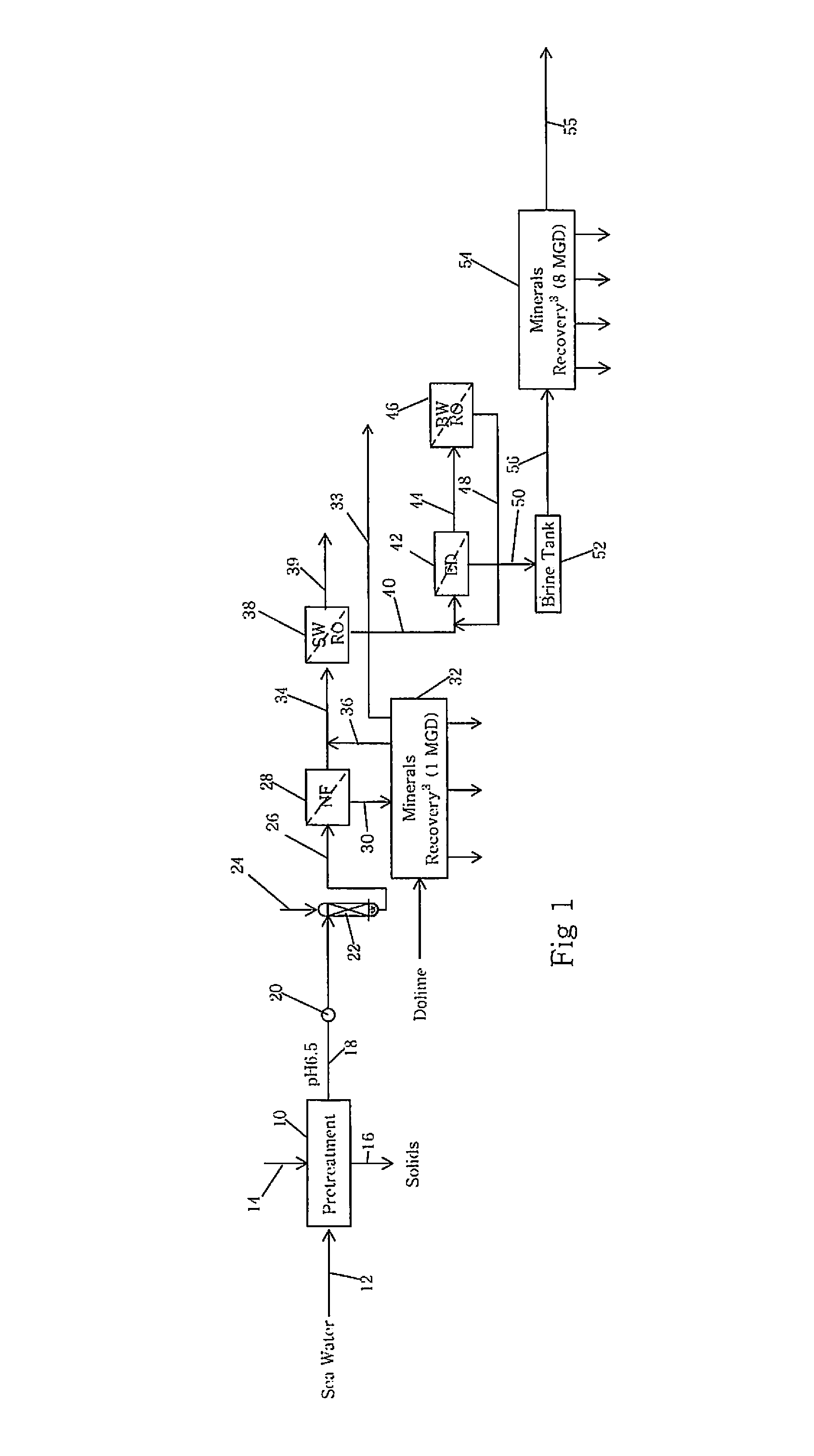

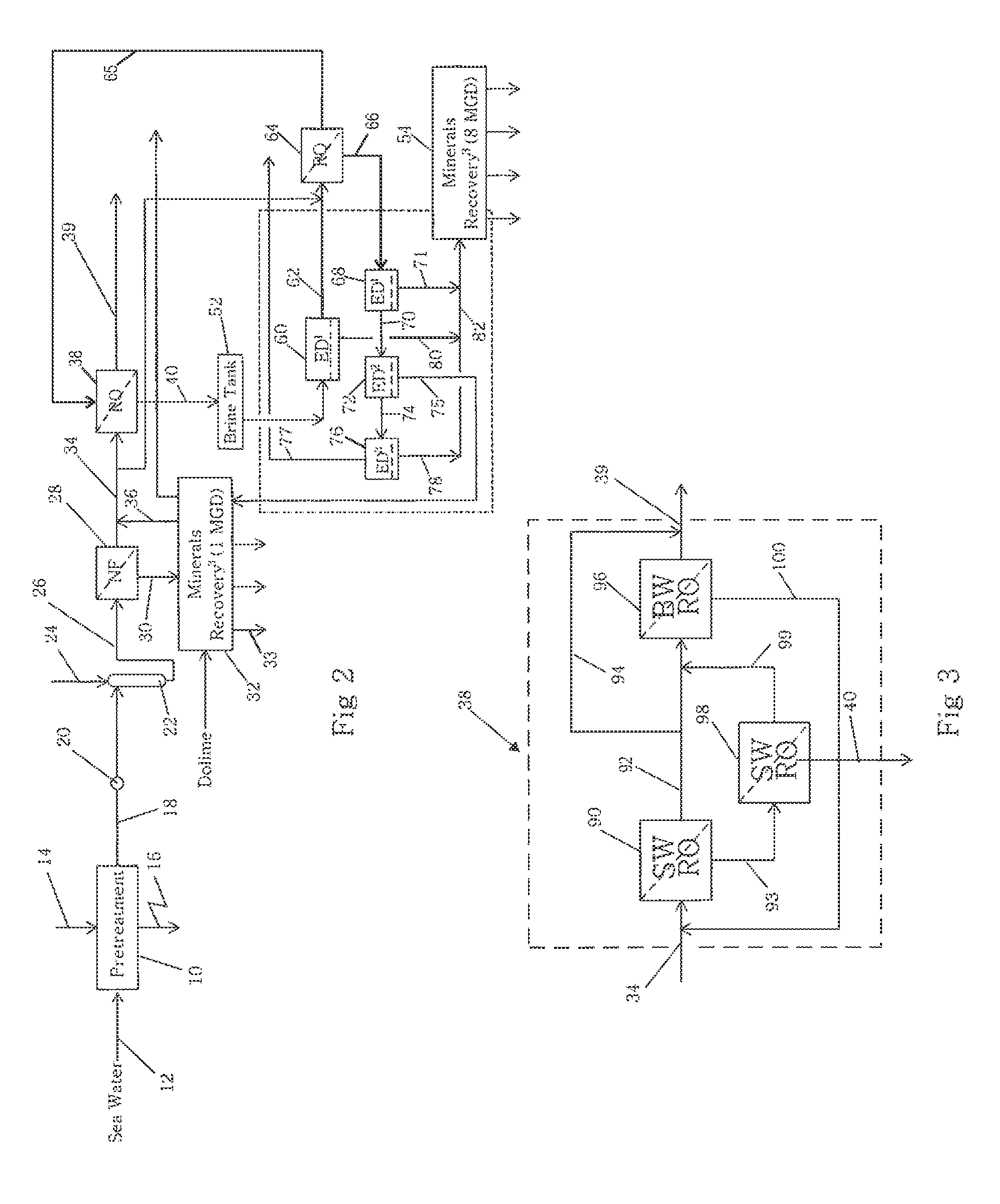

Membrane and electrodialysis based seawater desalination with salt, boron and gypsum recovery

ActiveUS8999171B2Low costLower overall pressure dropMembranesGeneral water supply conservationSeawaterElectrodialysis

A method of producing desalinated water and recovering minerals from the feedwater uses membrane separation and electrodialysis brine concentration. This process can recover all of the minerals as high purity industrial minerals, including capturing the calcium and sulfate as agricultural grade gypsum and boron as high purity boric acid. In addition the process allows the use of low cost lime or dolime to produce valuable magnesium hydroxide.

Owner:ENVIRO WATER MINERALS COMPANY

Flame-retardant type fuel plastic woven bag and preparation method thereof

InactiveCN105155031AConjugated synthetic polymer artificial filamentsArtifical filament manufactureLinear low-density polyethyleneTurpentine

The invention discloses a flame-retardant type fuel plastic woven bag and a preparation method thereof. The flame-retardant type fuel plastic woven bag comprises the following raw materials in parts by weight: 100 parts of polypropylene granules, 170-180 parts of nano calcium carbonate powder, 4-5 parts of paraffin, 3-4 parts of stearic acid, 3.5-4.5 parts of a coupling agent, 0.2-0.6 part of an antioxidant DLTP, 9-11 parts of polyoxymethylene, 20-24 parts of linear low-density polyethylene, 1.3-1.6 parts of polyethylene wax, 3.1-3.6 parts of an ethylene-methyl acrylate copolymer, 1.3-1.7 parts of tributyl citrate and 0.5-0.9 part of turpentine. Abnormities such as adhesion and melt marks are avoided after the flame-retardant type fuel plastic woven bag is tested under high temperature of 85 DEG C, and the flame retardancy meets the standard of the coal industry, so that the flame-retardant type fuel plastic woven bag can be widely applied to packaging of chemical engineering products, industrial minerals, chemical fertilizers, cement, fish meal, grains, feeds, fruits, vegetables and other agricultural and sideline products.

Owner:LIAONING CHENGWEI PLASTIC PROFILE

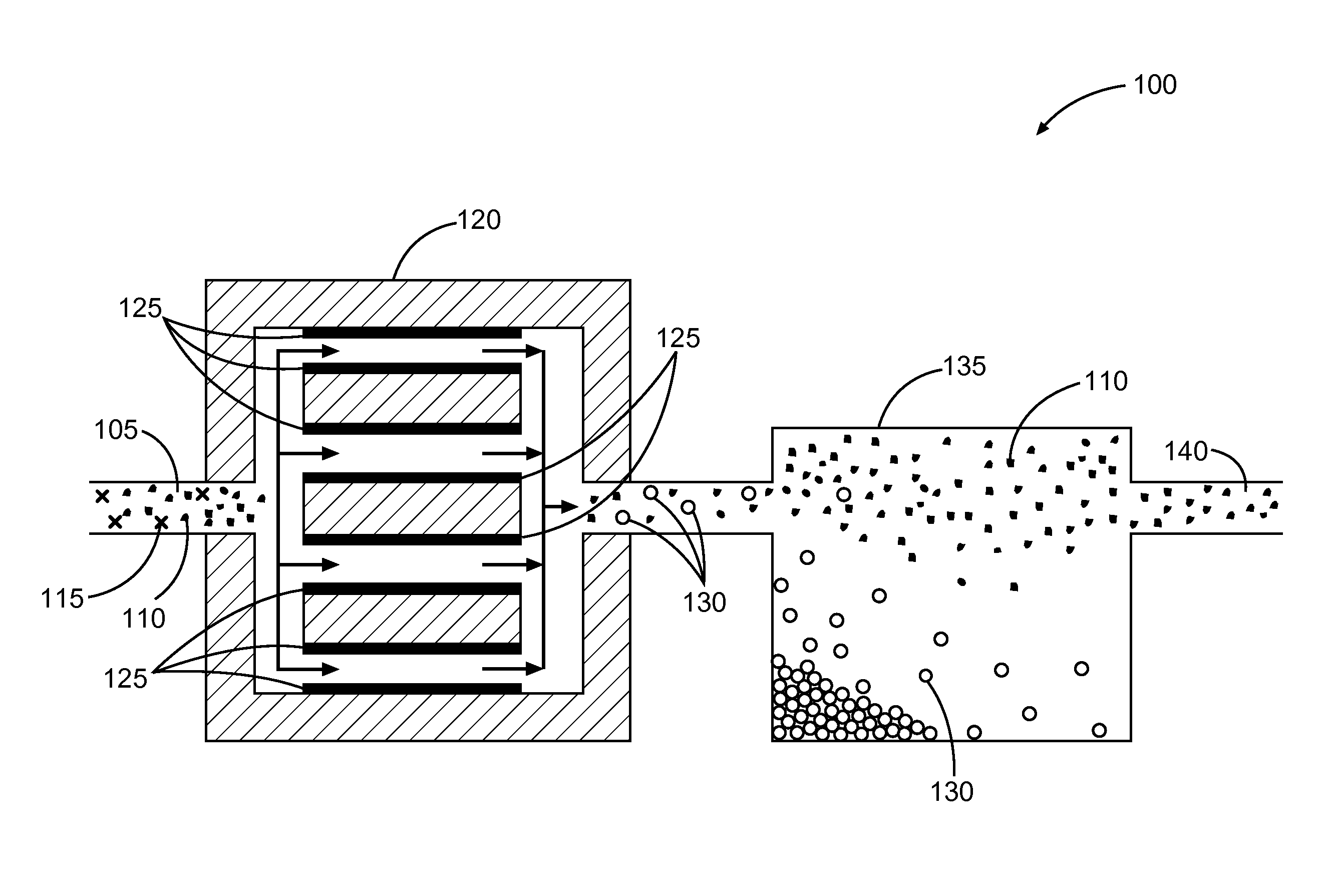

Methods of separating impurities from industrial minerals using electrocoagulation

ActiveUS20160194223A1Easy to separateIncrease volumeWaste water treatment from quariesPigmenting treatmentElectrocoagulationSlurry

Various embodiments disclosed relate to methods of separating impurities from industrial minerals using electrocoagulation and apparatuses for performing the same. In one embodiment, the present invention provides a method of purifying an industrial mineral composition. The method can include obtaining or providing an aqueous slurry comprising a mineral composition comprising one or more industrial minerals and one or more impurities. The method can include subjecting the aqueous slurry to an electrical current to form at least one coagulation comprising the one or more impurities. The method can include separating at least one of the coagulations from the one or more minerals, providing a purified mineral composition.

Owner:WATER TECTONICS +1

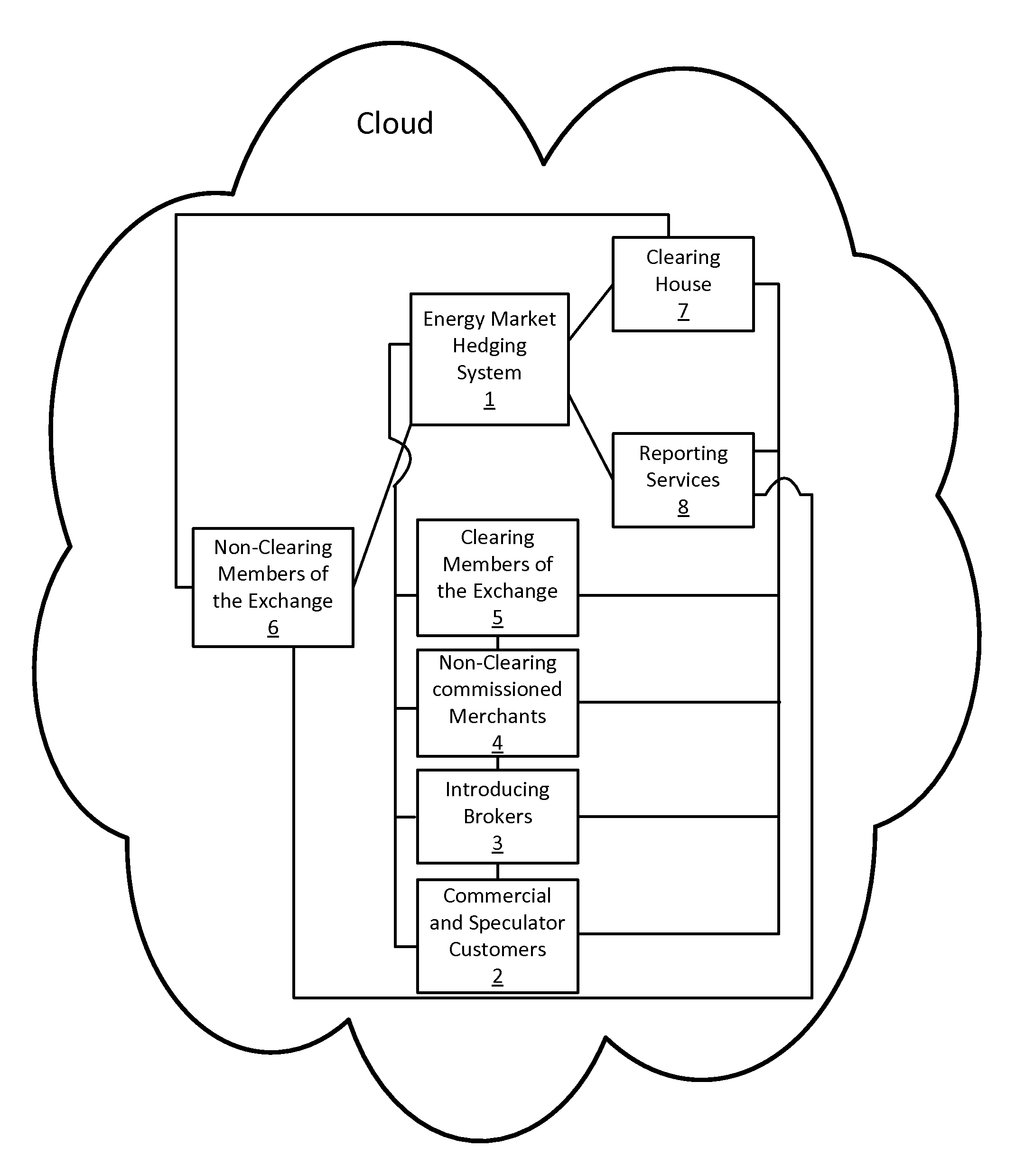

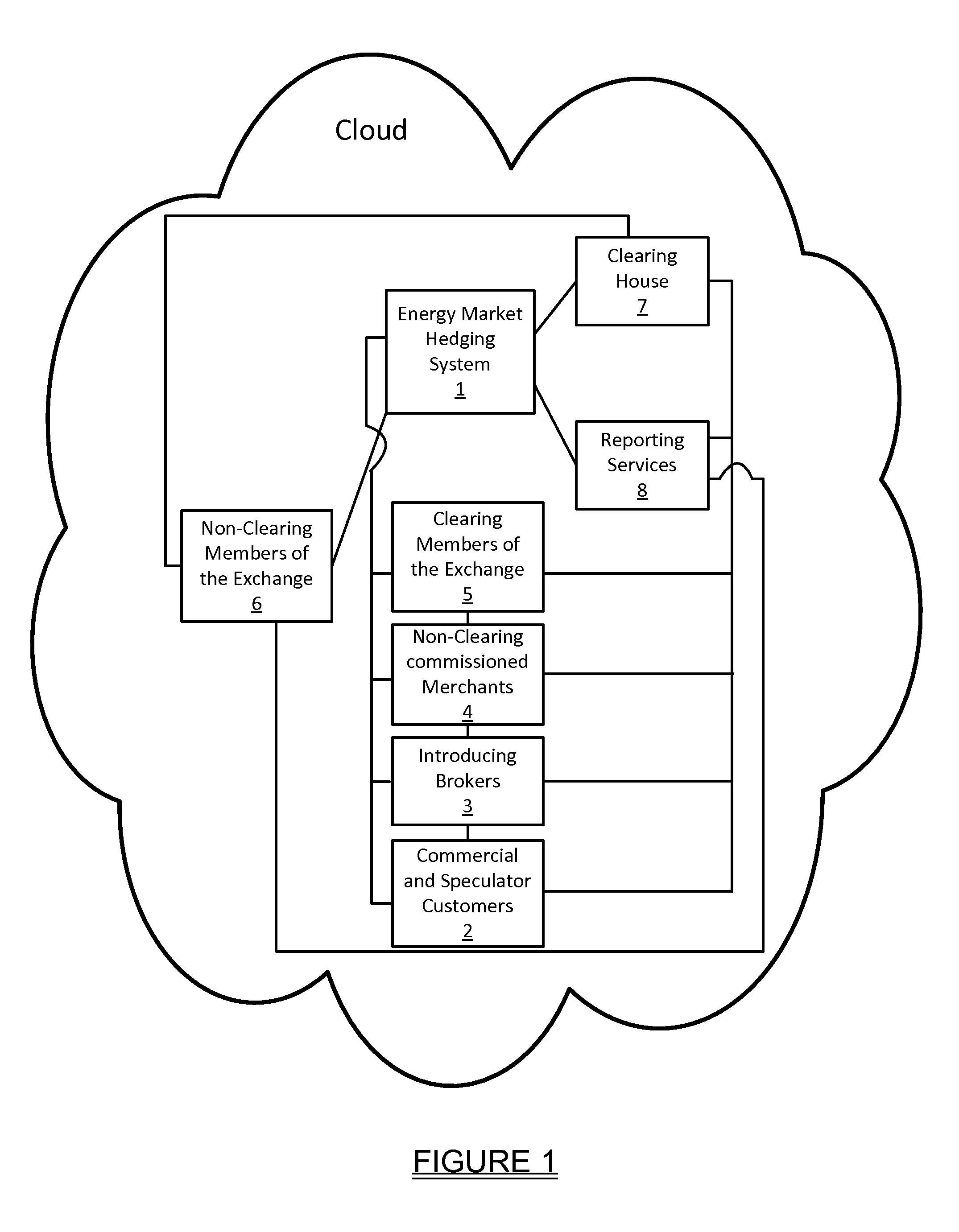

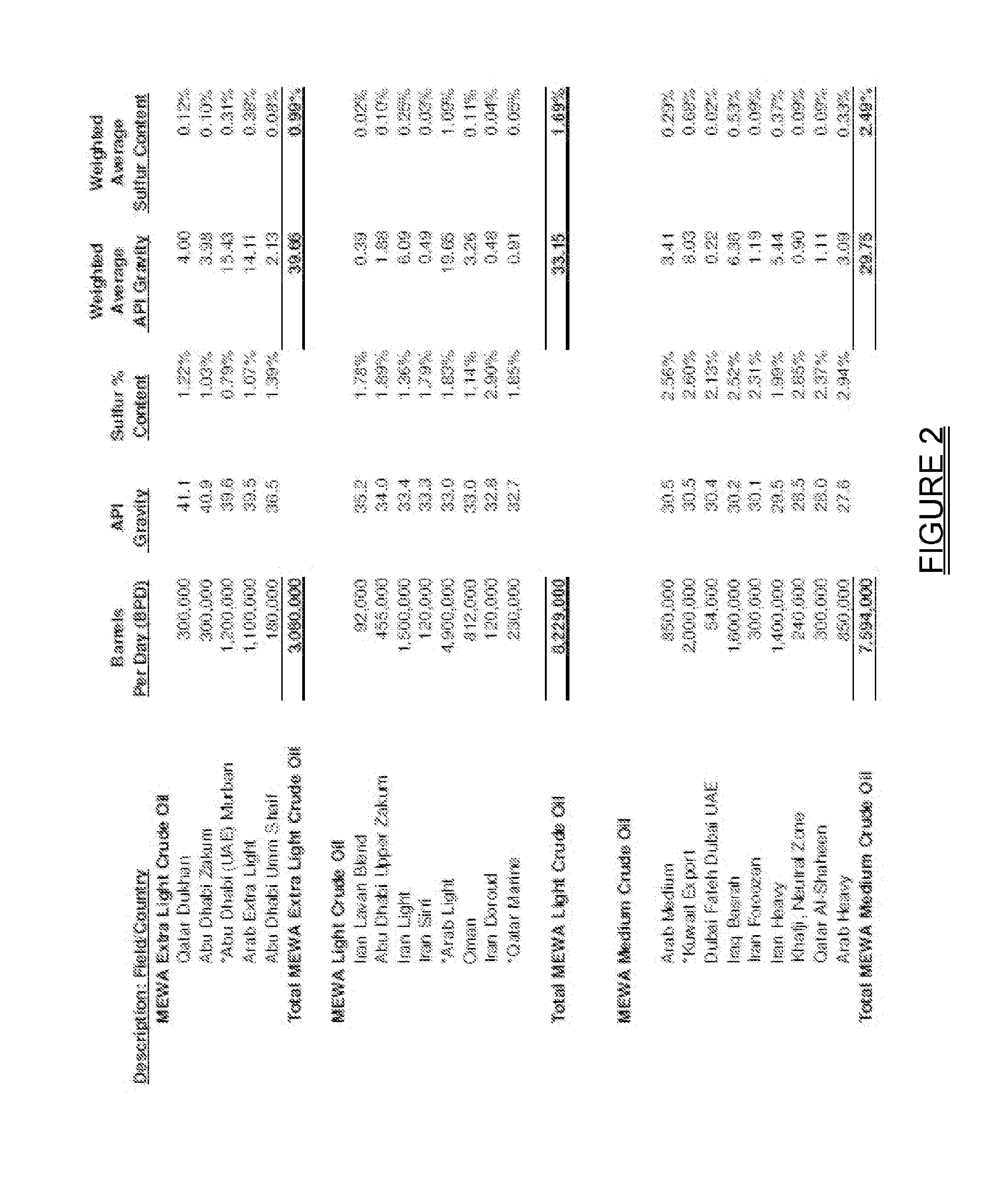

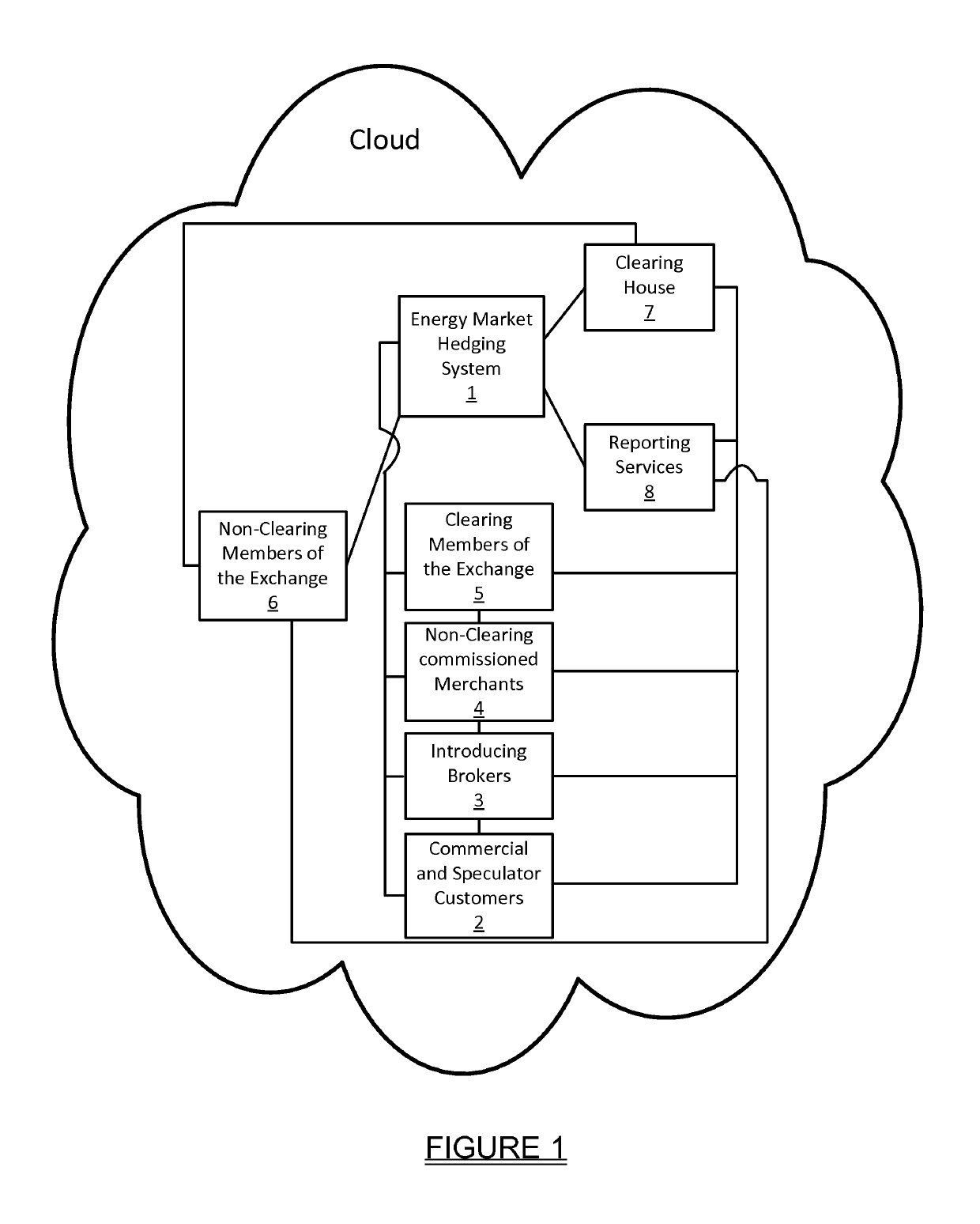

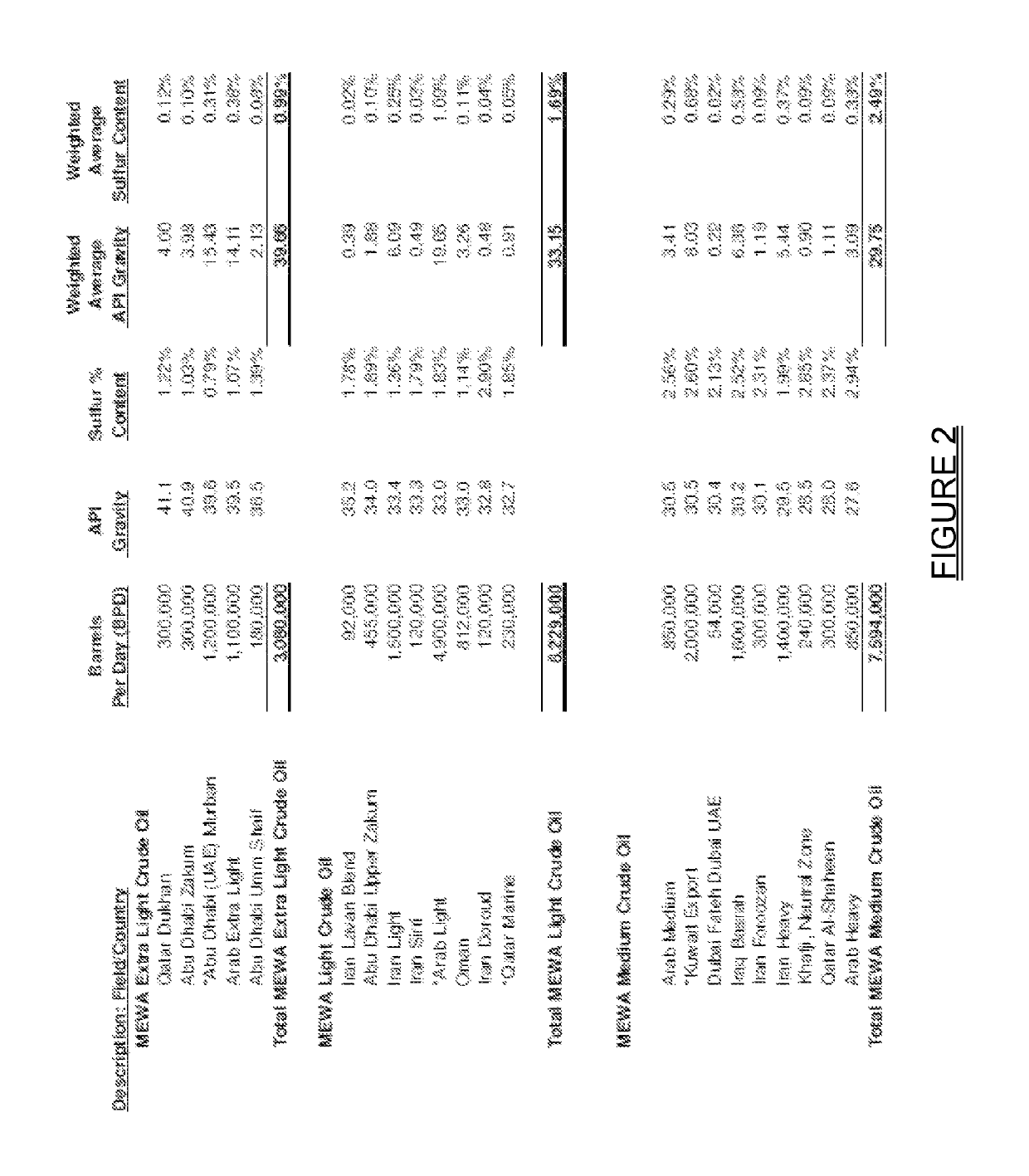

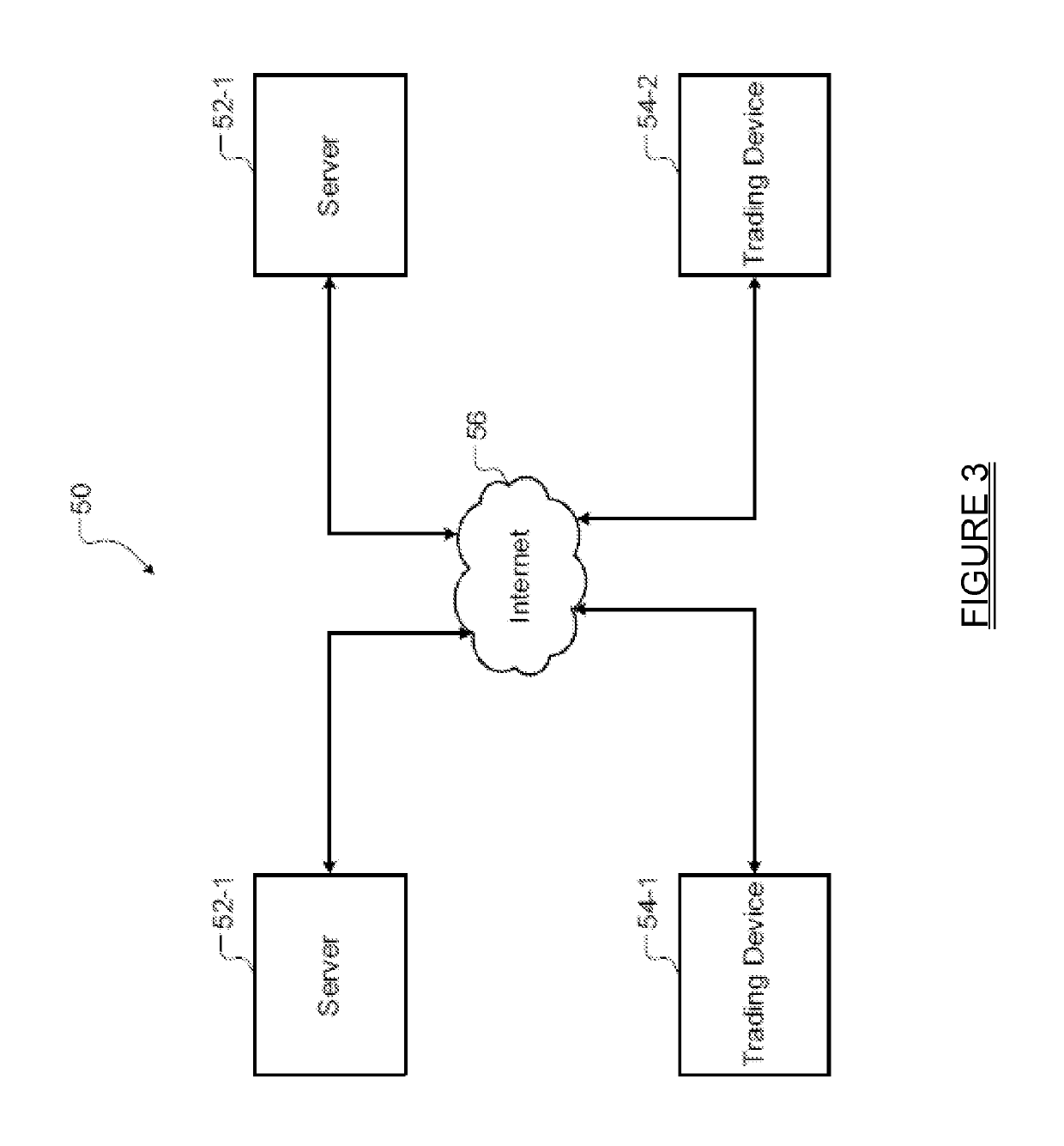

System and Method For Sharia-Based Energy Market Hedging And Related

ActiveUS20150221032A1Easily tradableIncrease flexibilityFinanceFinancial transactionComputer science

A tradable asset market trading and hedging system is disclosed. The tradable assets may include fuels or industrial minerals and rocks (IMRs). The system may include a conventional Exchange and its Islamic exchange affiliate or subsidiary (“IES”), a Sharia conversion module (both hardware and software), and a back-to-back order execution module (also both hardware and software). The IES makes use of a suitable cross-liquidity algorithm for the purpose of consolidating bids and offers from the Exchange and the IES in order to enhance IES liquidity. An entity that qualifies for Sharia-based trading with the IES may be issued a customized dongle to inter alia regulate and control who can access what data at any given time. The dongle interfaces with a computing device (e.g., laptop, desktop, tablet, etc.) used by an individual, institution or other qualified entity to access the IES. The dongle may include a customer position limits enforcement module and a high frequency trading order stuffing block module that are both in communication with a suitable processor. The system and method enables Sharia-compliant trades to be executed, including those trades that are attendant to Islamic-financed transactions.

Owner:DEARBORN FINANCIAL

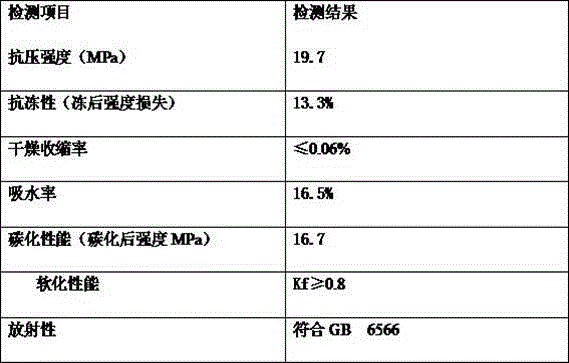

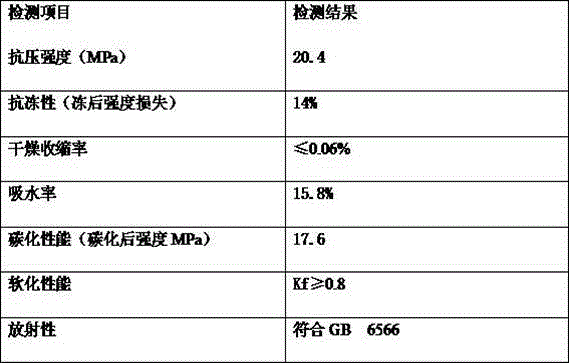

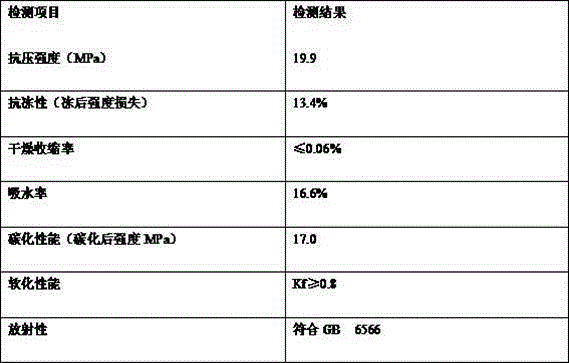

Non-fired and non-autoclavedtitanium gypsum brick and preparation method thereof

The invention discloses a non-fired and non-autoclavedtitanium gypsum brick and a preparation method thereof. The titanium gypsum brickcomprises components in percentage by mass as follows: 24.1%-32.3% of titanium gypsum, 52%-63.8% of aggregate, 11.2%-18.5% of cement / mineral powder and 0.8%-1.0 % of an additive, wherein the additive is a mixture of anhydrous sodium sulfate, alums and a curing agent; and the aggregate is one or more of industrial mineral slag, crushed stone and river sand. The preparation method of the titanium gypsum brick comprises steps as follows: S1, slurry type titanium gypsum is extruded and stirred to form hydraulic slurry; S2, the extruded and smashed titanium gypsum and the aggregate are mixed and stirred for 2-4 minutes; S3, a material prepared in S2 is mixed with the additive and the cement / mineral powder and stirred for 1-3 minutes; S4, extruding forming is performed, consistency of the water content in different positions of a hopper is kept through spraying and watering, and the mass ratio of water to the material prepared in the S3 is 1:(32:40). Raw materials are easy to prepare, main performance parameters meet the national standard, the preparation method is simple and easy to operate, the efficiency is high, energy consumption is reduced due to no need of firing and autoclaving, and environmental pollution is reduced.

Owner:CHANGSHA HAIHONG BUILDING MATERIALS

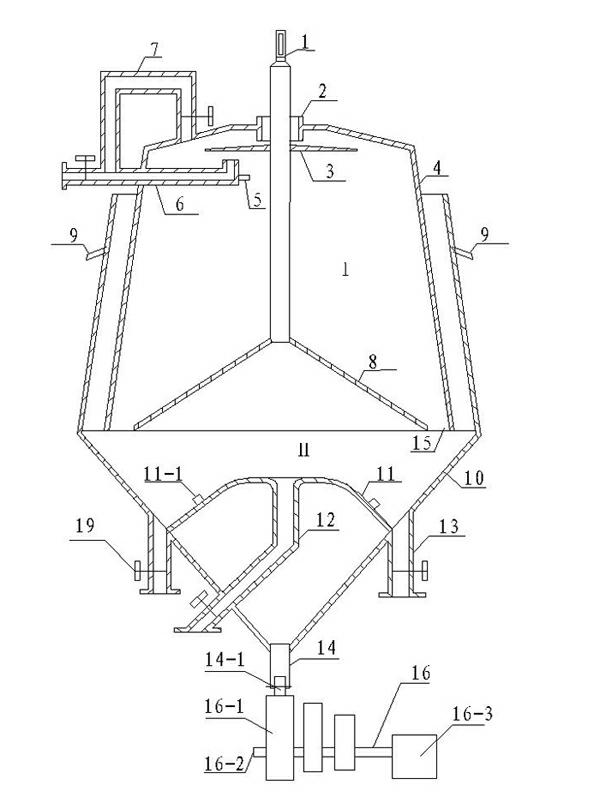

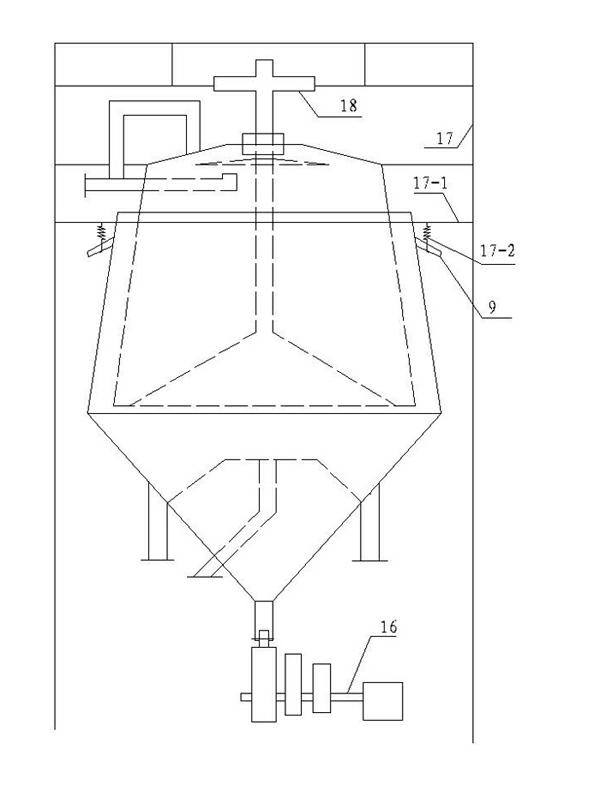

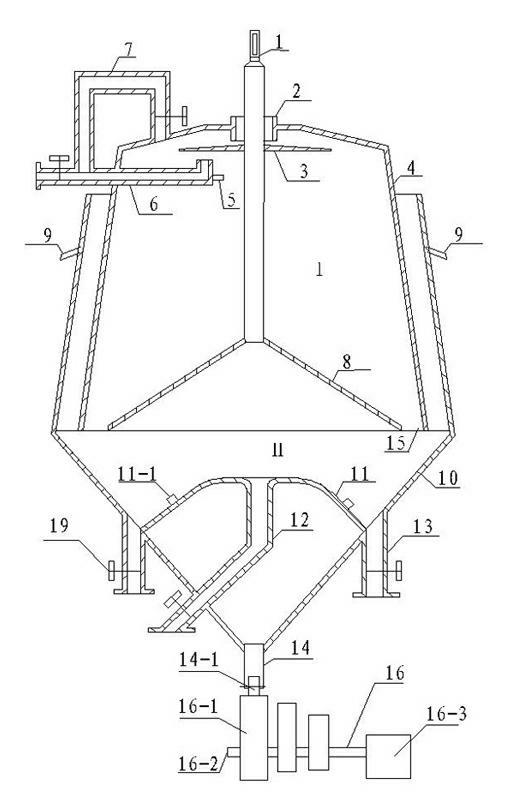

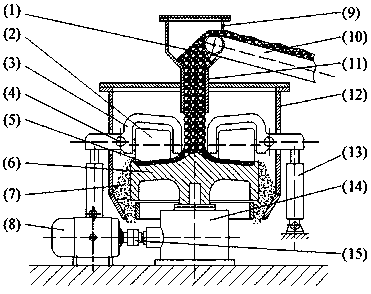

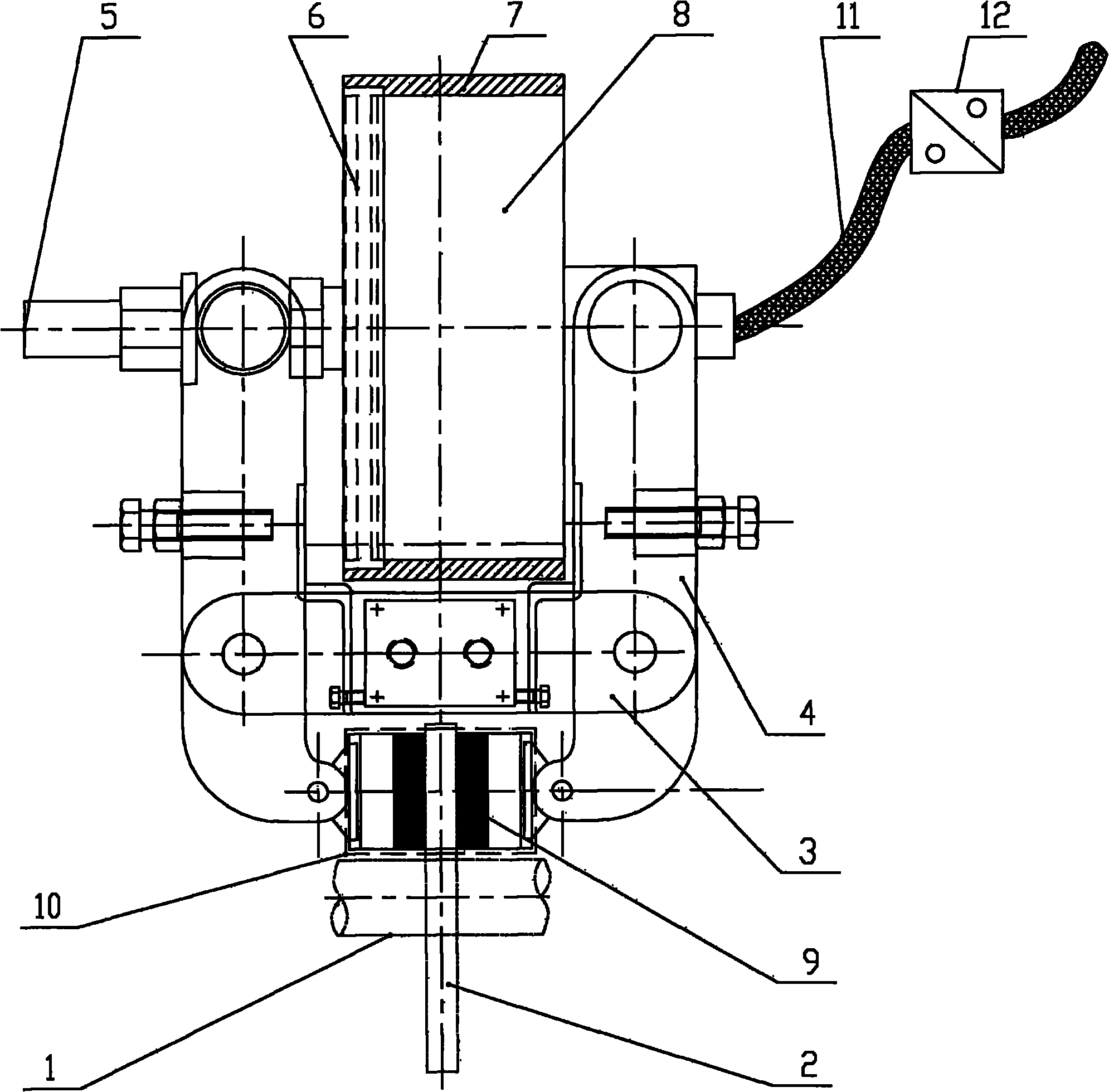

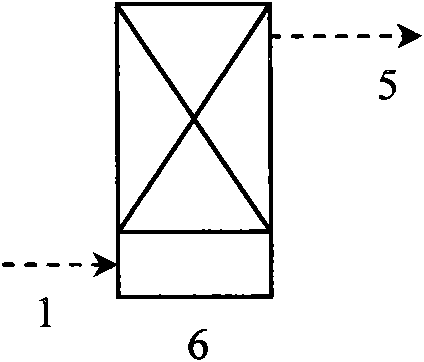

Method and equipment for processing mineral by jointly using gravity, centrifugal force and vibration force

InactiveCN102091669ASolving Intermittent Job ProblemsIncrease productivityWet separationEngineeringGravitational force

The invention disclose a method and equipment for processing mineral by jointly using gravity, centrifugal force and vibration force, belonging to the technical field of industrial mineral separation. The equipment comprises an upper conic cylinder and a lower conic cylinder which are perpendicular to each other; a rotating shaft is arranged in the upper conic cylinder along the center axis of the upper conic cylinder; the upper conic cylinder is fixed on a support; the lower conic cylinder is movably connected with the support; the lower part of the upper conic cylinder is sleeved in the upper part of the lower conic cylinder; the upper end of the rotating shaft can be rotationally fixed on the support; a stream guide disc is fixed on the middle part of the rotating shaft; a conic rotating disc is fixed on the lower end of the rotating shaft; a gap is left between the edge of the conic rotating disc and the inner wall of the upper conic cylinder to form a circular seam; the upper part of the upper conic cylinder is provided with an air intake pipe; the inlet of an upper tailing pipe is provided with a slurry measuring sensor; a vibration table is fixed in the lower conic cylinder; a material measuring sensor is arranged on the vibration table; a concentrate pipe is connected to the wall of the lower conic cylinder; a vibration joint is fixed on the lower end of the lower conic cylinder; and the vibration joint is connected with a vibration mechanism.

Owner:XUZHOU INST OF ARCHITECTURAL TECH

Biomass and mineral substance mixed type coal and manufacturing method thereof

The invention discloses a mixed type coal of biomass and mineral. The mixed type coal comprises the following compositions: 55 to 65 percent of biomass as a raw material, 3 to 7 percent of coke powder and 32 to 38 percent of coal slurry. The manufacturing method comprises the following steps: 1. straws of rice, wheat, soybean, corn and sorghum are crushed into sections; the branches of wood and bush are subjected to chipping and powder making; the relative humidity of the raw material is controlled to between 10 and 15 percent; 2. industrial coke slag is grinded to powders by a ball mill; 3. the coal slurry of industrial washery coal is dried; 4. the biomass material, the coke powder and the coal slurry are fully mixed according to the percentage; and 5. the mixed materials are extruded to be of a strip block shape to prepare a finished product. The mixed type coal has the characteristics that on the one hand, the coal can fully utilize the biomass material and industrial mineral waste and save energy; on the other hand, the coal can reduce the environmental pollution caused by the incineration of the biomass material or pure mineral fuel. The mixed type coal is in particular suitable for civil use; and the heat energy of the coal is basically equivalent to that of civil coal.

Owner:张广君

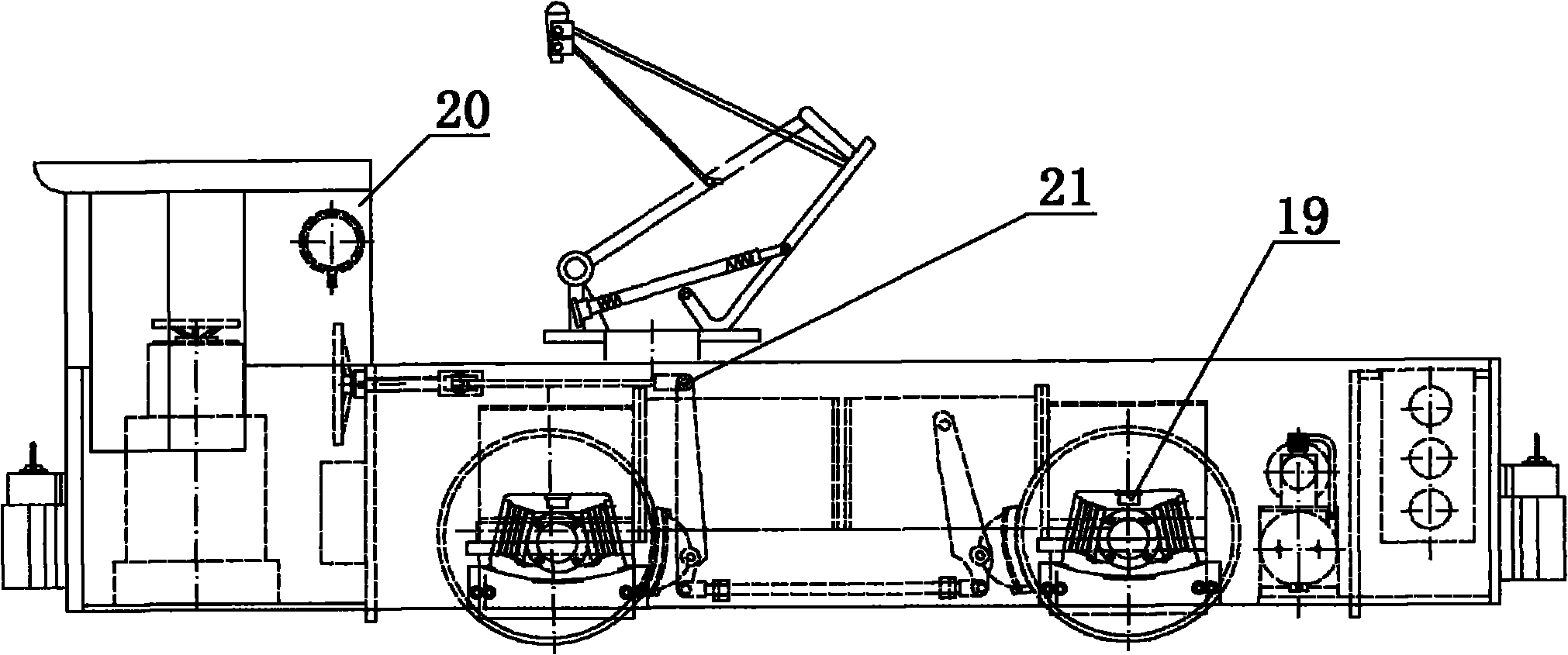

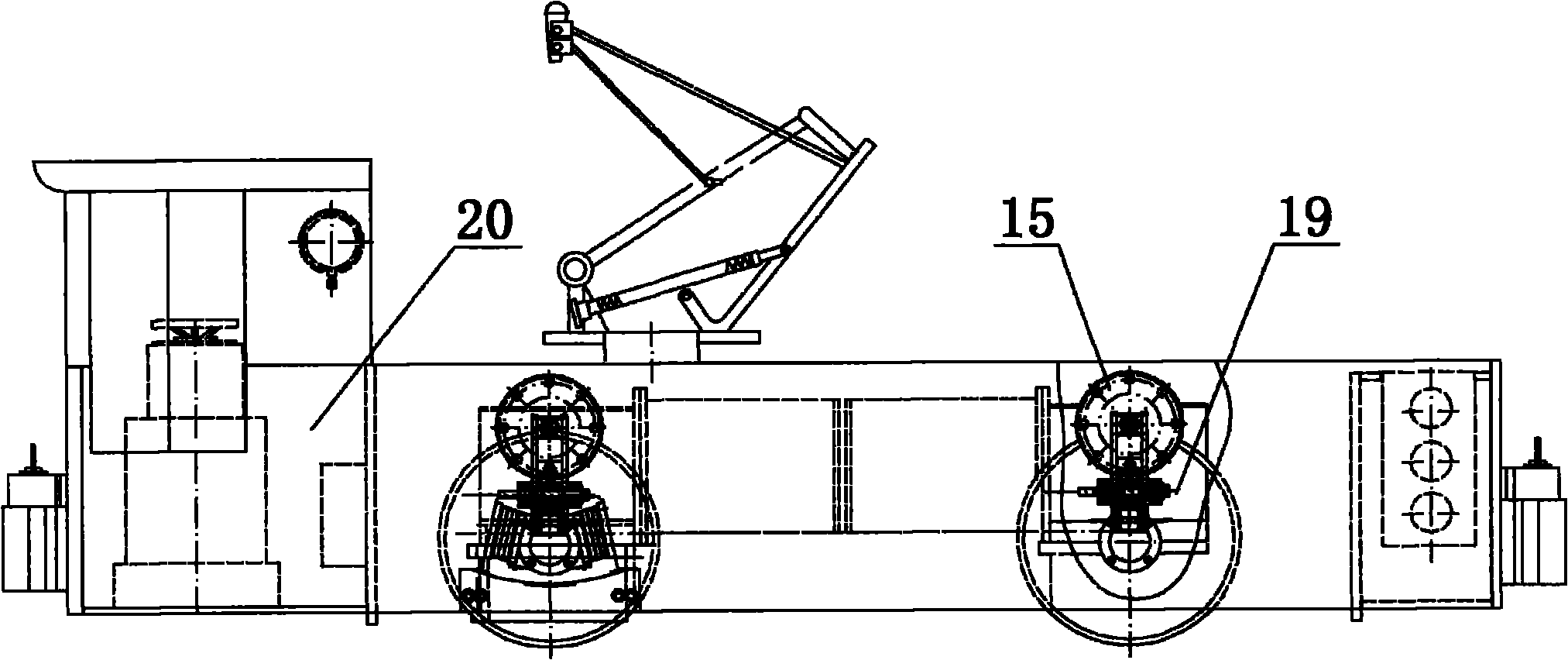

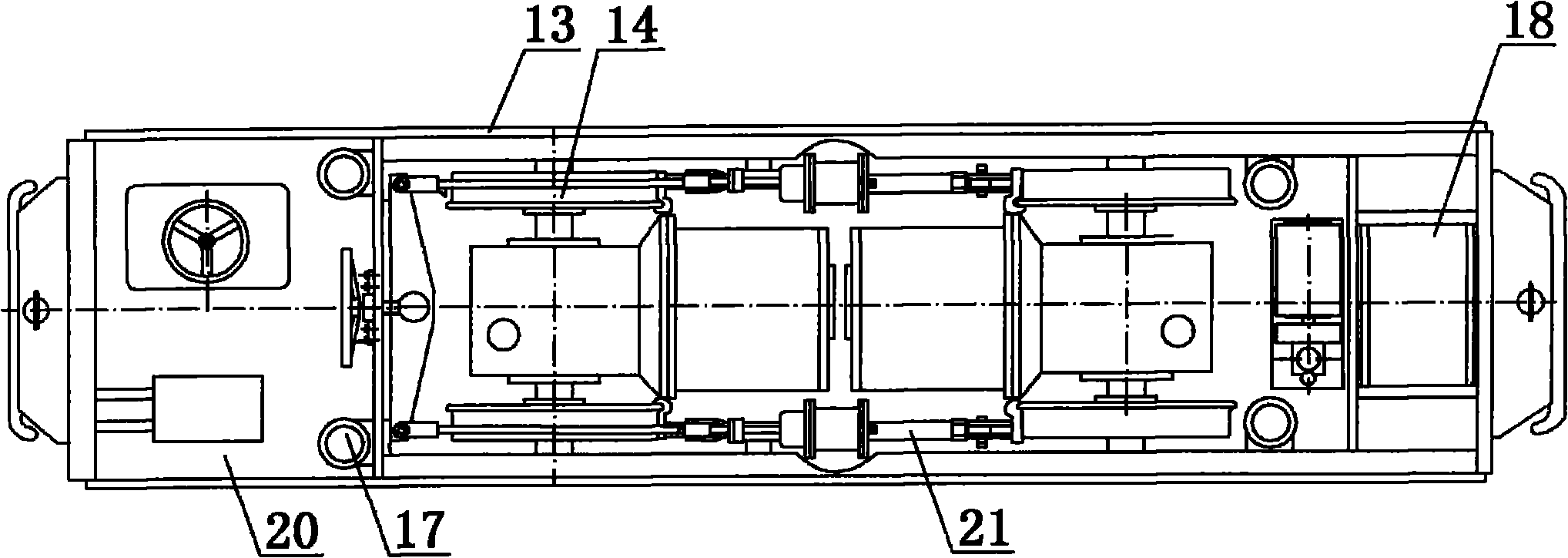

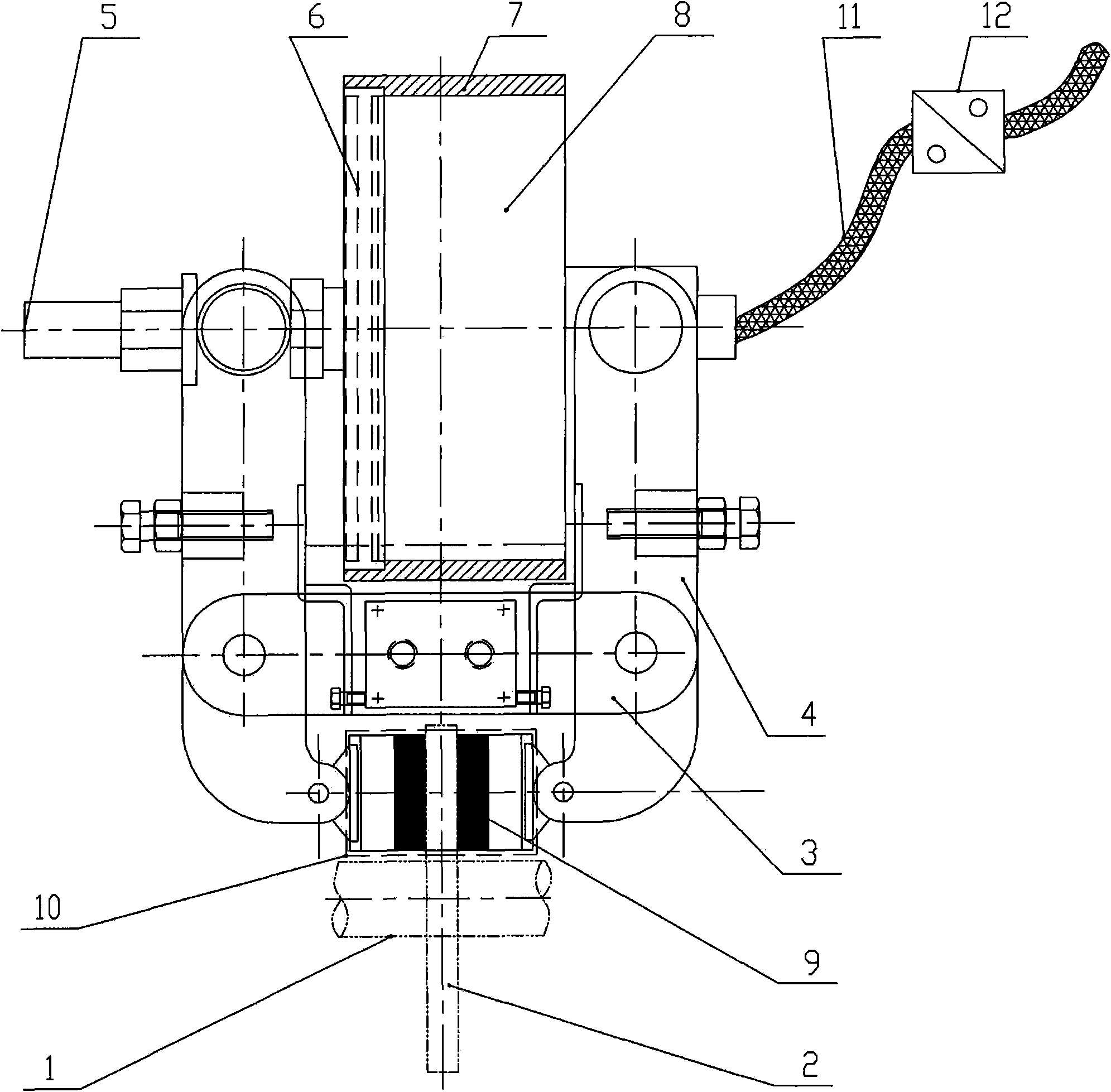

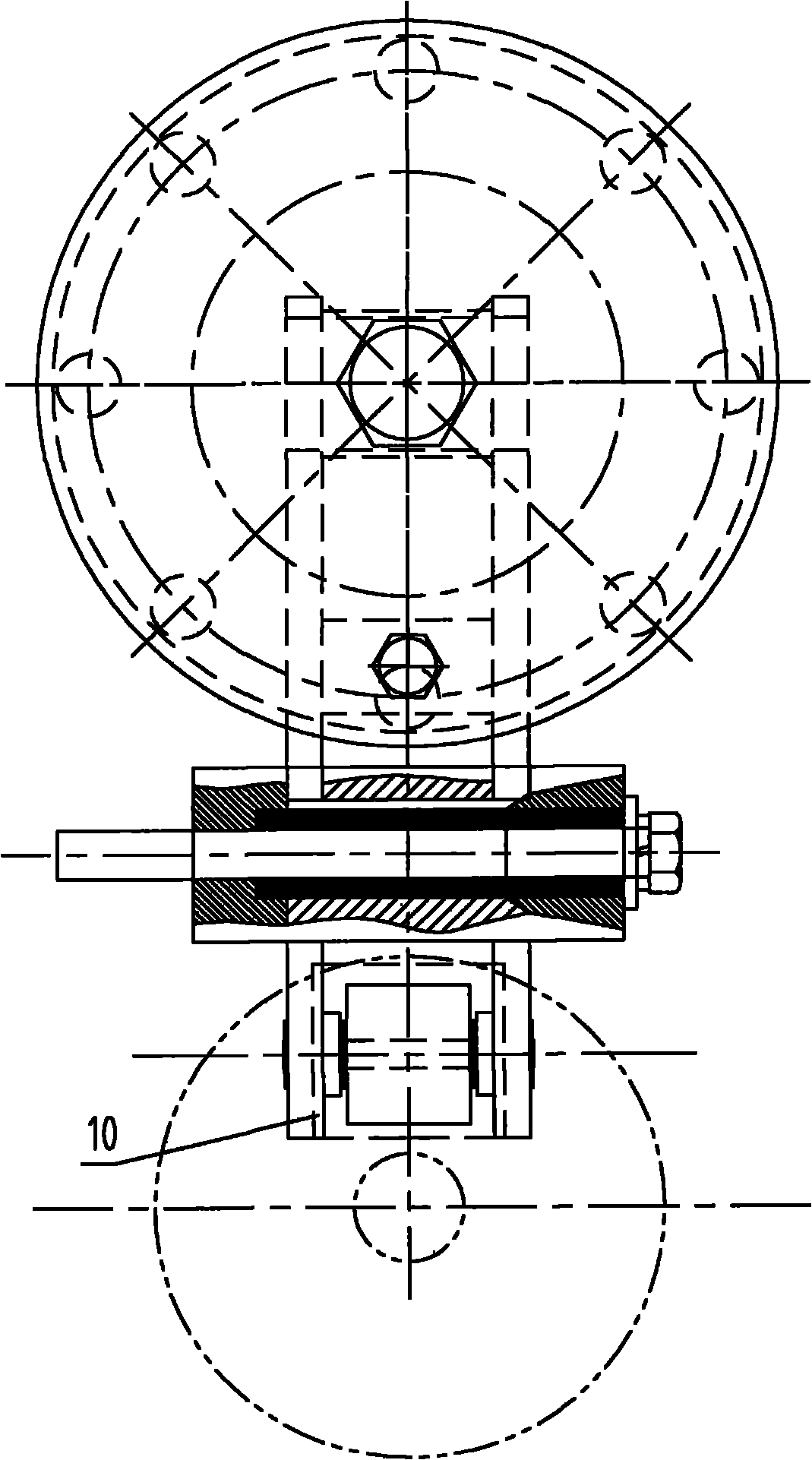

Electric trolley frequency conversion speed-regulating locomotive

InactiveCN101830230APrevent derailmentImprove securityElectric locomotivesBrake arrangement with pressed braking surfaceVehicle frameDerailment

The invention relates to an electric trolley frequency conversion speed-regulating locomotive. The device mainly overcomes the defects that as the existing pneumatic or handwheel mechanisms brake and respond slowly, the braking distance is long, the braking performance is poor, the brake block is easy to wear, etc. The device also solves the technical problems that owning to large braking force or mechanical reasons, the locomotive wheels lock so as to cause derailment phenomenon and the like. The keys of the technical scheme of the invention are as follows: the locomotive comprises a car frame assembly and a sanding device, wherein a cab assembly is arranged on the front end of the car frame assembly, a walking device and a frequency conversion speed-regulating electric control system are arranged on the car frame assembly, two anti-lock brake devices are separately arranged on the two sides of the walking device; and each anti-lock brake device adopts a normally closed electromagnetic time delay braking device, and the braking device mainly comprises a brake disc spring, a cylinder body, a cylinder column, an electromagnetic iron core, a brake lever, a clamping plate brake body, a brake disc, an electromagnetic pressure switch device and an electric trolley locomotive power-off anti-lock brake device. The electric trolley frequency conversion speed-regulating locomotive can adapt to various hauling operating conditions of the industrial-mineral electric locomotive and the technology of the invention can be used to modify old industrial-mineral electric locomotives.

Owner:湖南江麓冶金机械有限公司

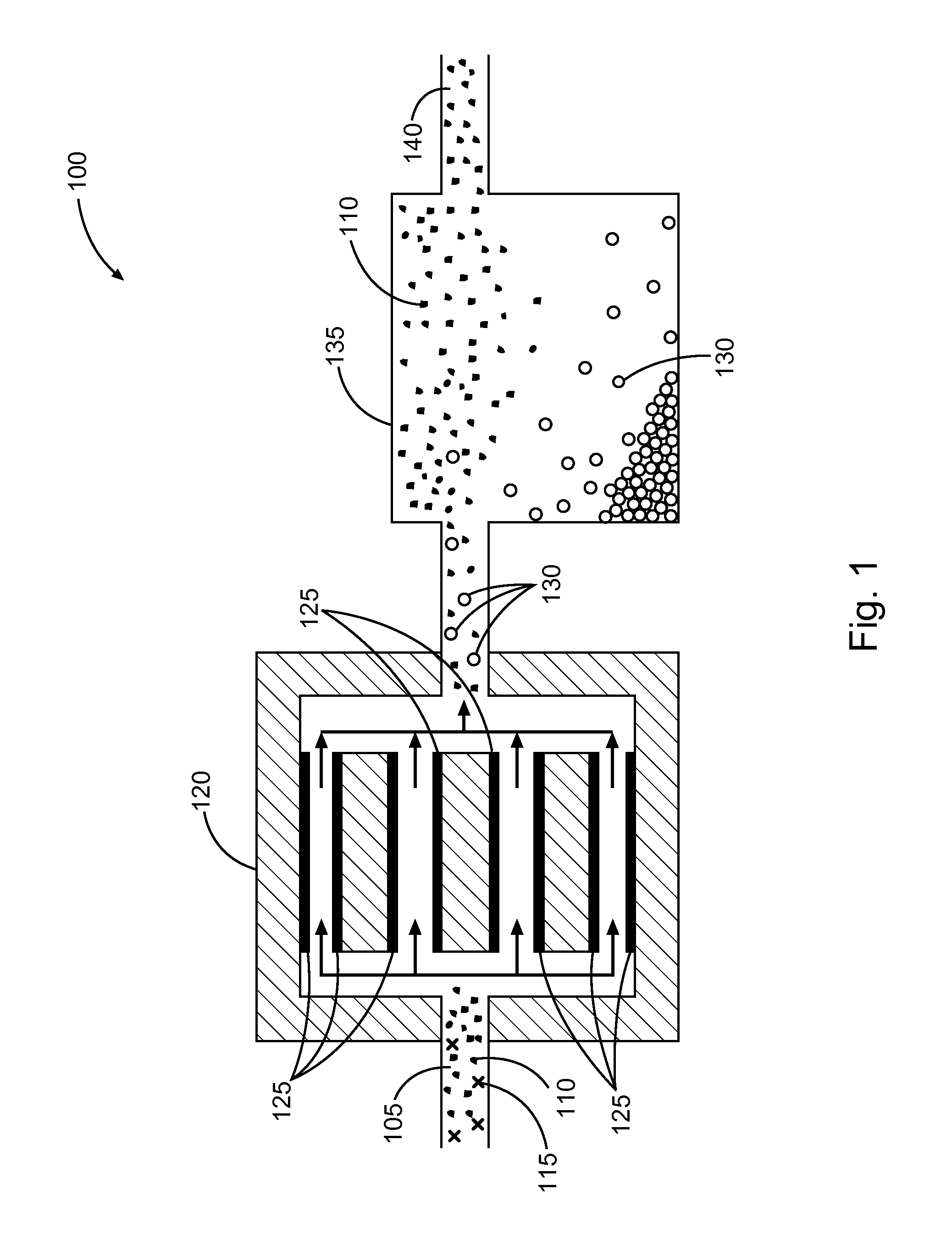

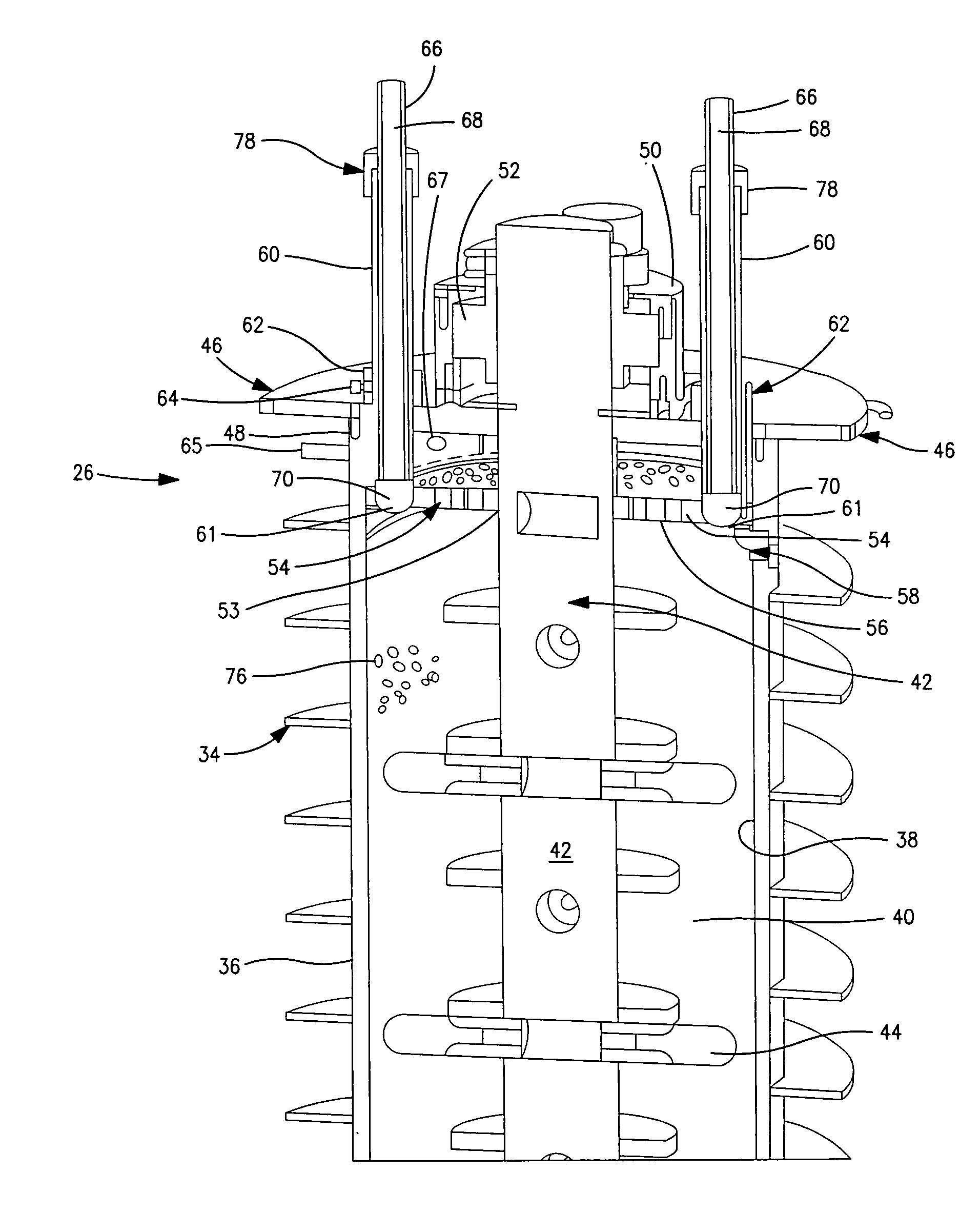

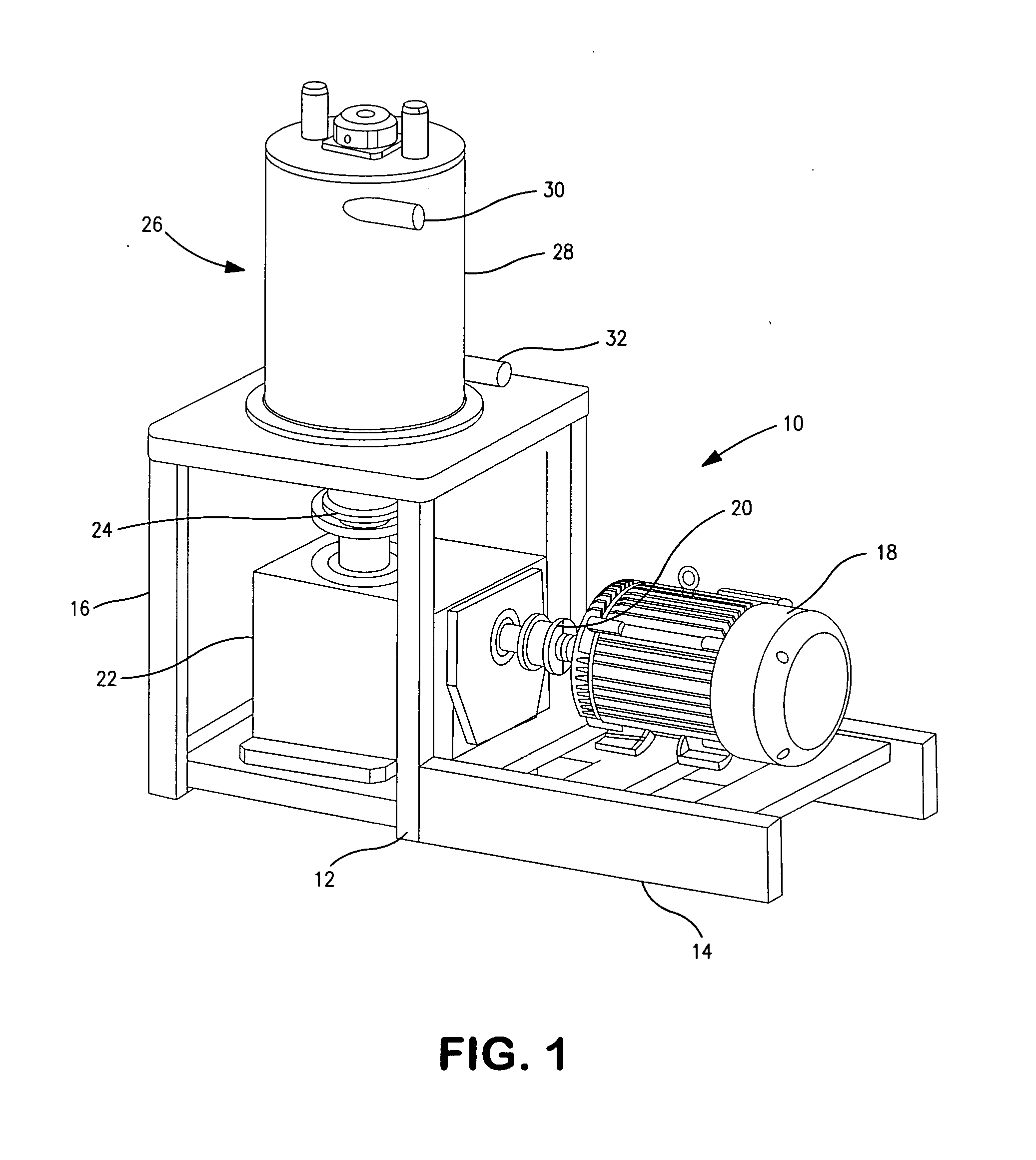

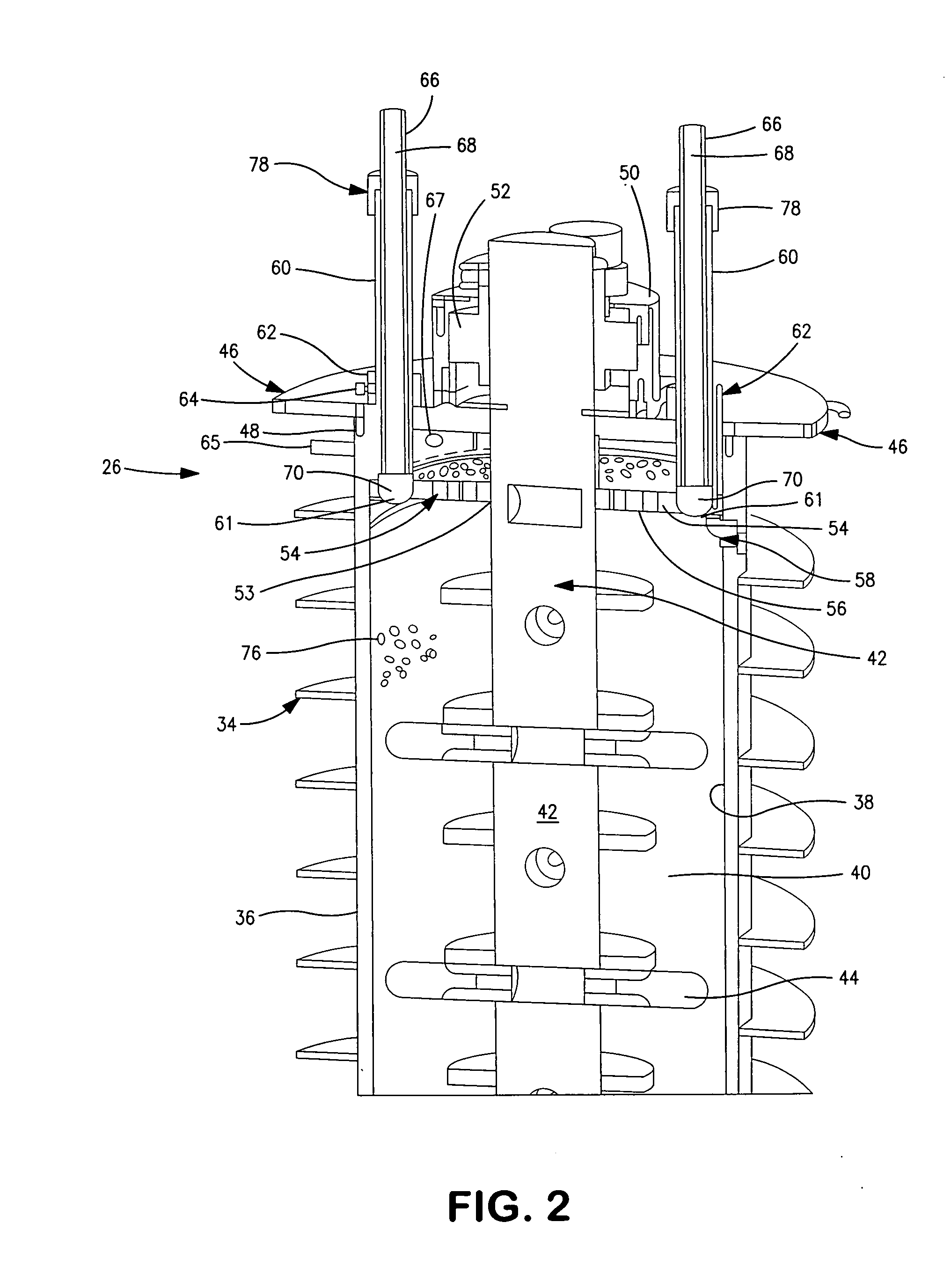

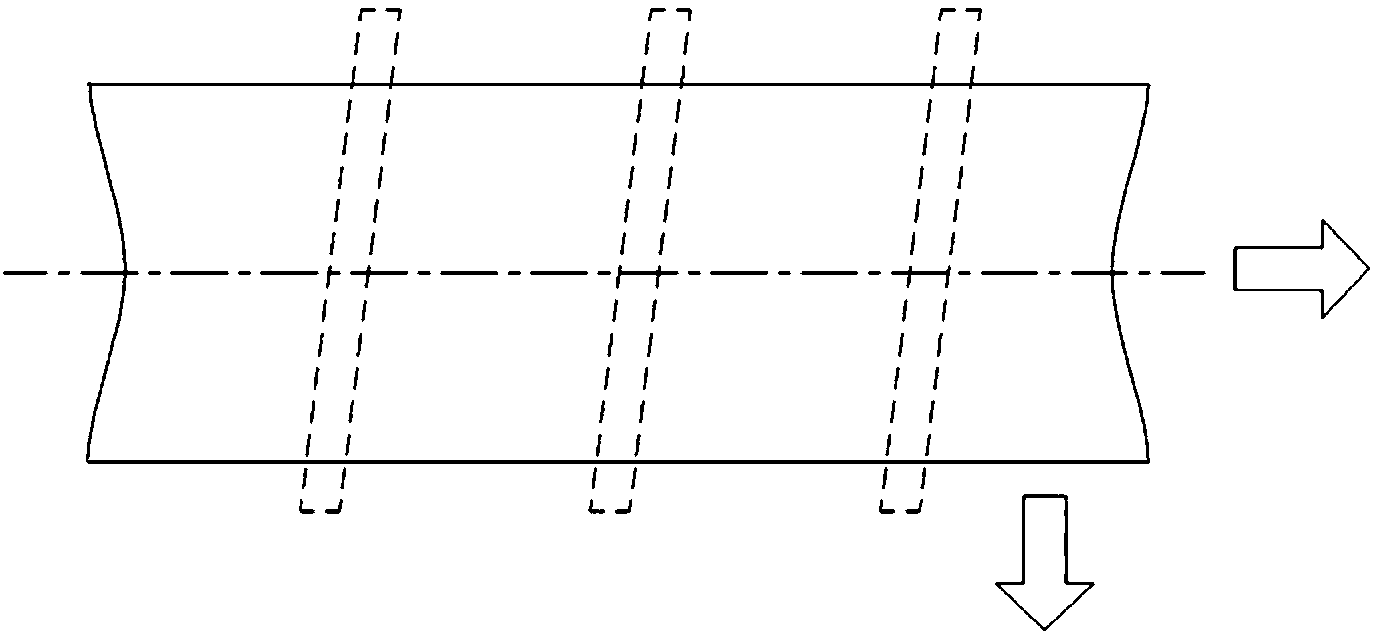

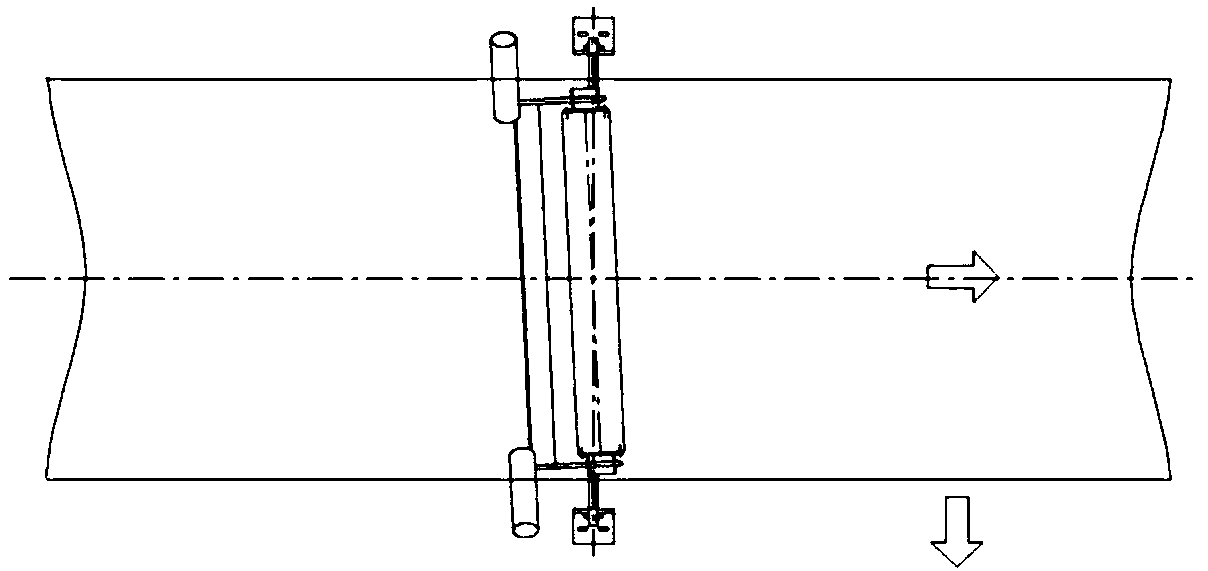

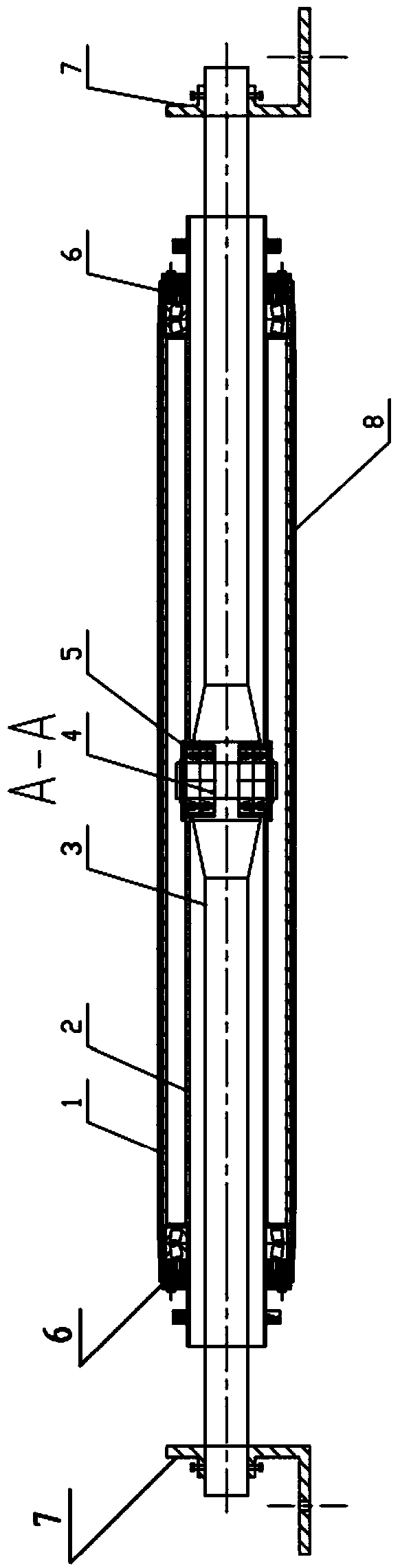

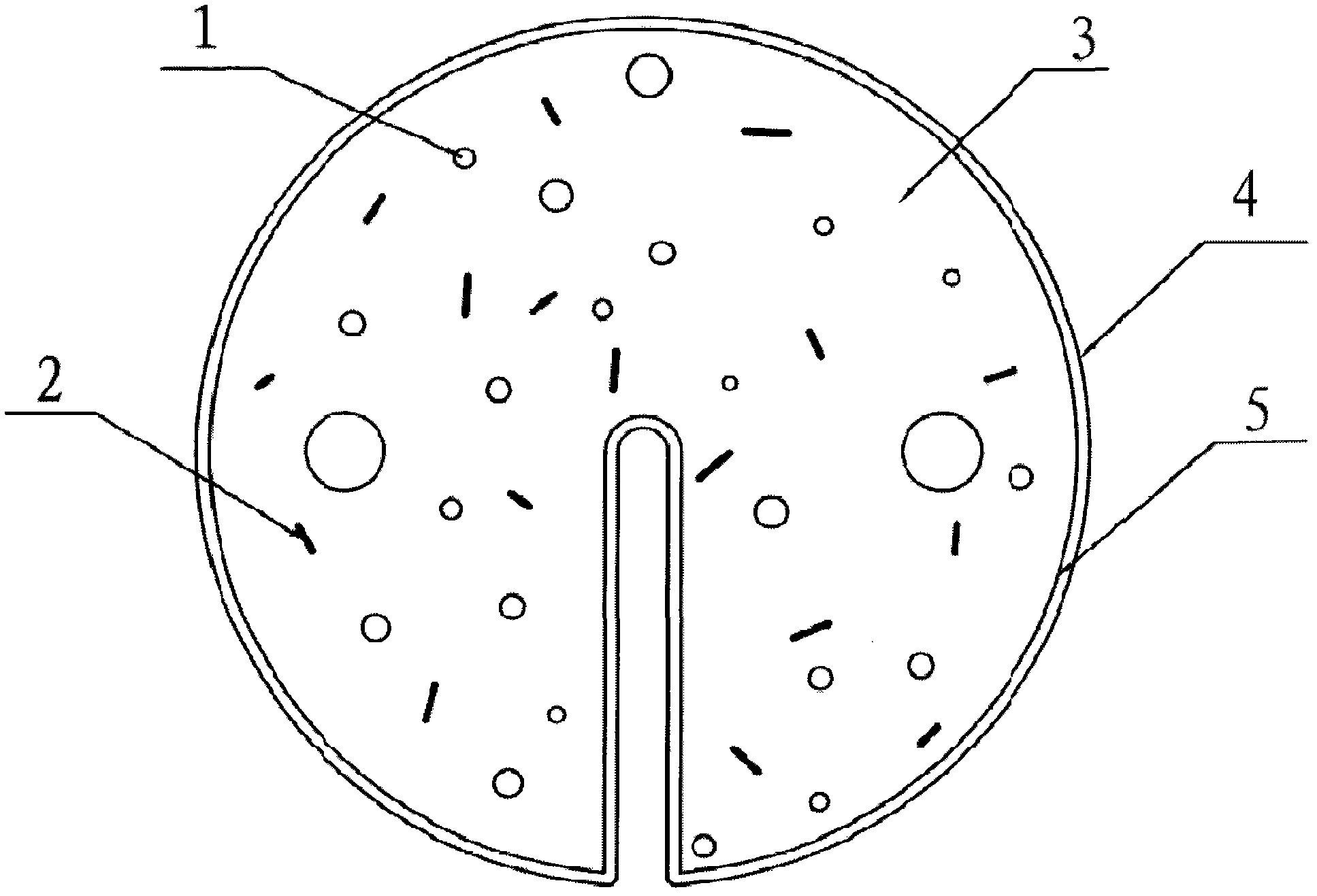

System and method for compressed bed grinding in a stirred media mill

InactiveUS20110226878A1Efficient dry grindingLow costSievingScreeningEngineeringMechanical engineering

A system and method are disclosed for the grinding of industrial minerals to fine powders. The system includes a grinding chamber having a generally vertically oriented agitator that is rotated to stir the grinding media intermixed with a feedstock. As the agitator stirs the grinding media and feedstock, there is a retaining plate that is also located within the grinding chamber and positioned atop of the grinding media to prevent the expansion of the grinding media when it is being stirred. The retaining plate has one or more openings to allow the finely ground feedstock to pass upwardly therethrough but to prevent any grinding media from passing through the retaining plate. Introduction of the feedstock may be through one or more hollow support rods that locate the retaining plate in the desired location within the grinding chamber. The support rods are locked into position when the retaining plate is properly located.

Owner:MARTIN CHRISTOPHER +2

Rectorite impurity removal purification mineral separation process, mineral separation system, rectorite concentrate and application of rectorite concentrate

PendingCN109248778ARaise the gradeLow impurity contentHigh gradient magnetic separationFlotationProduction lineLower grade

The invention discloses a rectorite impurity removal purification mineral separation process, a mineral separation system, a rectorite concentrate and an application of the rectorite concentrate, andrelates to the technical field of mineral separation. The rectorite impurity removal purification mineral separation process includes the steps: performing scrubbing dissociation and separation on crushed middle-low-grade primary or oxidation rectorite raw ores; performing stripping and grinding dissociation, mixing dispersion and roughing separation on dewatered separation materials; performing 1-4-section superfine grading and optionally high-gradient magnetic separation on roughing separation materials to obtain the rectorite concentrate. The rectorite impurity removal purification integrated industrial mineral separation method applicable to middle-low-grade primary or oxidation ores, a process method is economical and effective and can be flexibly adjusted and controlled according todifferent raw ore natures and different requirements for the rectorite concentrate, concentrates with multi-layer specifications and models are outputted on the same mineral separation production line, matched device parameters are suitably adjusted, requirements of process technical indexes can be met, and large-scale rectorite mineral separation industrial production can be easily achieved.

Owner:兰运堂

Carbon Heat-Treatment Process

ActiveUS20110002839A1Maintain good propertiesLower cost of capitalPigmenting treatmentCarbon compoundsActivated carbonCombustion

Methods for producing devolatilized and / or activated carbon in a reactor or reaction vessel of a heat treatment system from a suitable carbonaceous feedstock by introducing the feedstock into the reactor tangentially at a rotational velocity of at least 90 RPM. The methods include the steps of providing a combination of conveying means and a gas flow having various compositions and creating distinct carbonaceous feedstock material flow patterns and process conditions such that the feedstock is conveyed through the reactor or reaction vessel and heated via combustion, thereby producing activated carbon or other heat-treated carbons while concurrently avoiding adverse reaction conditions. Single and two-stage heat treatment systems may be used to heat a carbon feedstock, to which one or more industrial minerals may be added to co-produce compositions such as lime with the heat-treated carbon.

Owner:PNEUMATIC PROCESSING TECH

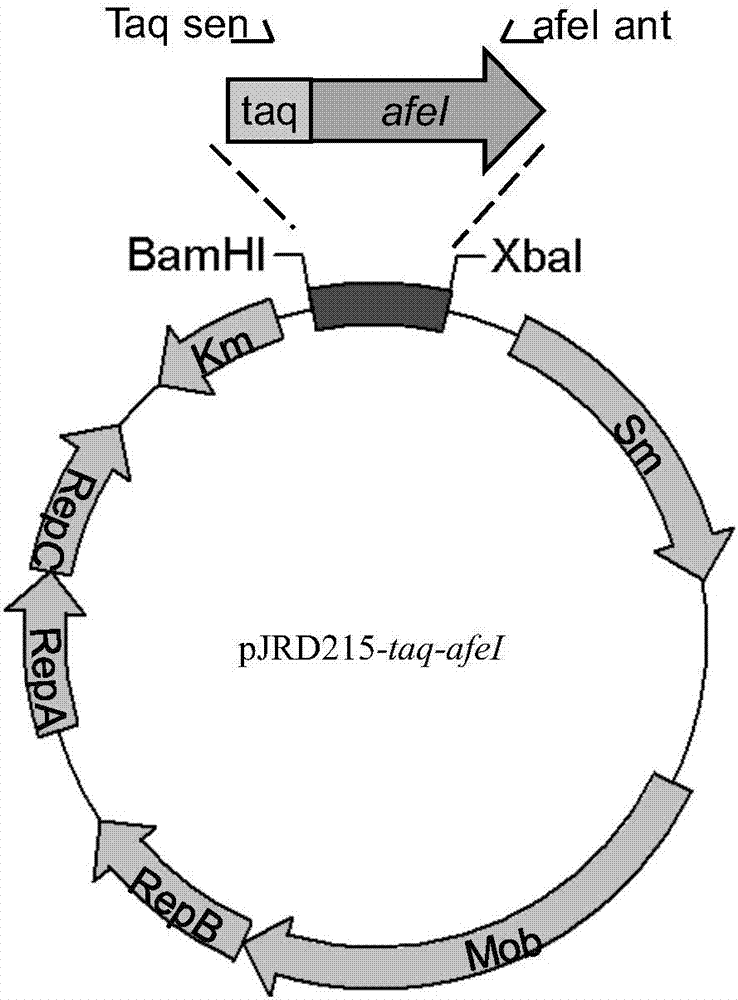

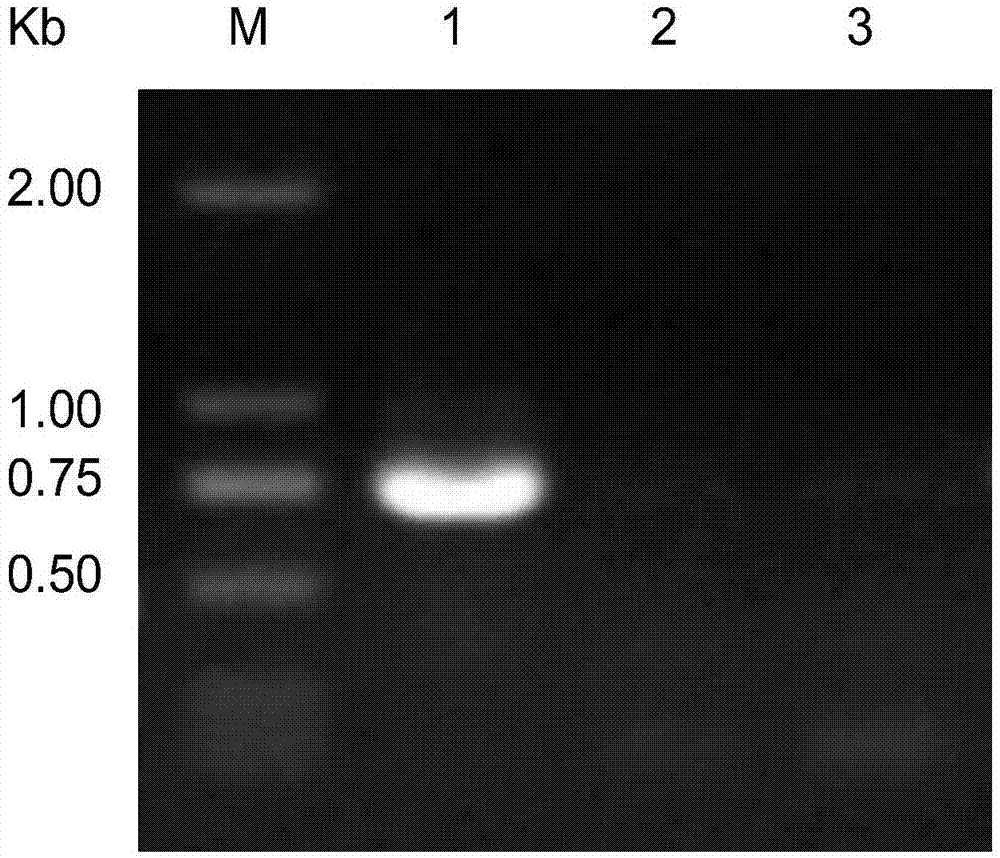

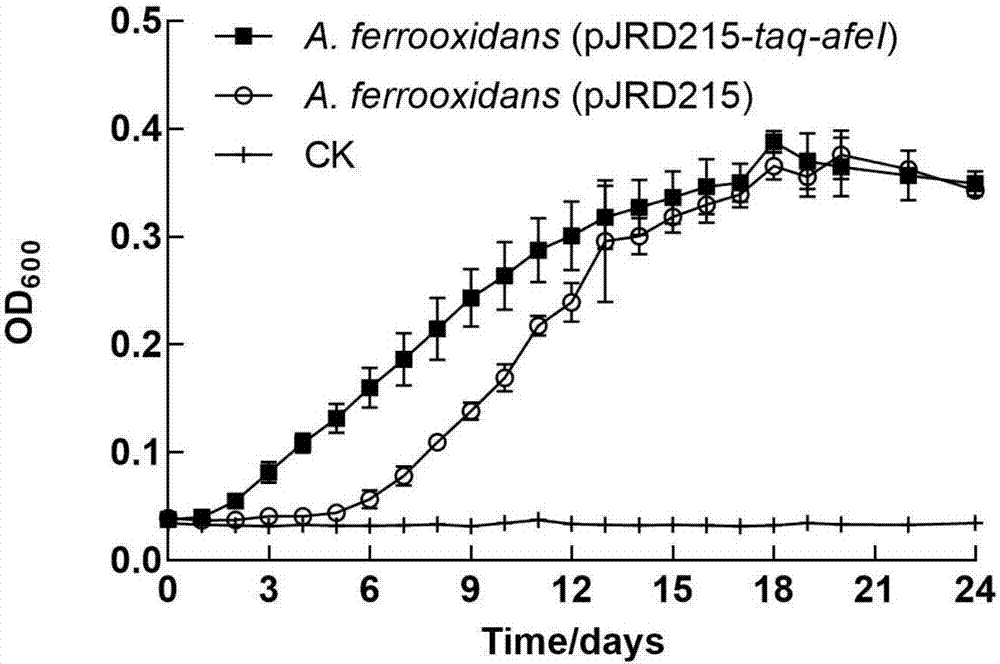

Method for effectively enhancing sulfur oxidation performance of acidithiobacillus ferrooxidans

InactiveCN107881189AImprove sulfur oxidation abilityImprove leaching efficiencyBacteriaMicroorganism based processesHomoserineSulfur

The invention discloses a method for effectively enhancing the sulfur oxidation performance of acidithiobacillus ferrooxidans. The method comprises the following steps: (1) constructing a recombinantbacterium A. ferrooxidans (pJRD215-taq-afeI), increasing the copy number of acyl homoserine lactone synthetase gene (afeI), by expressing afeI gene, increasing the content of acyl homoserine lactone (AHL) so as to enhance the sulfur oxidation performance of A. ferrooxidans; or (2) during the culture process of wild type A. ferrooxidans, adding exogenous acyl homoserine lactone (AHL) with a concentration of 5.4-10*10<3> mg / mL to enhance the sulfur oxidation performance of A. ferrooxidans through the increased content of AHL. The provided method has a wide application prospect in increasing theefficiency of industrial mineral leaching in the biological metallurgy field.

Owner:SHANDONG UNIV

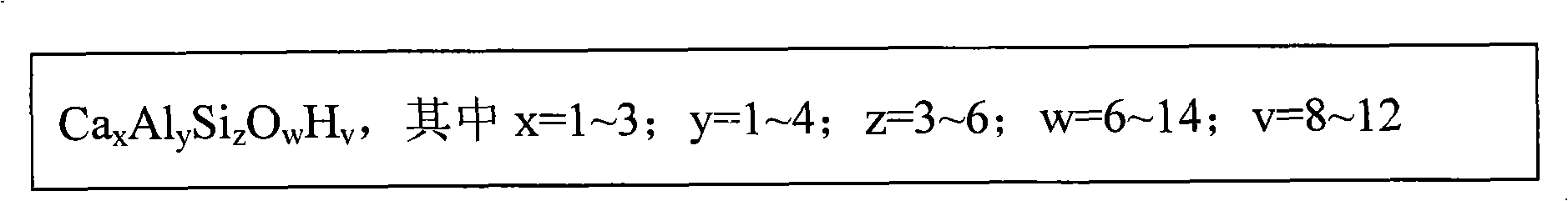

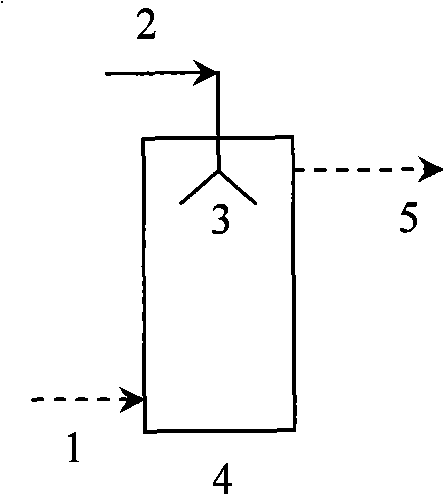

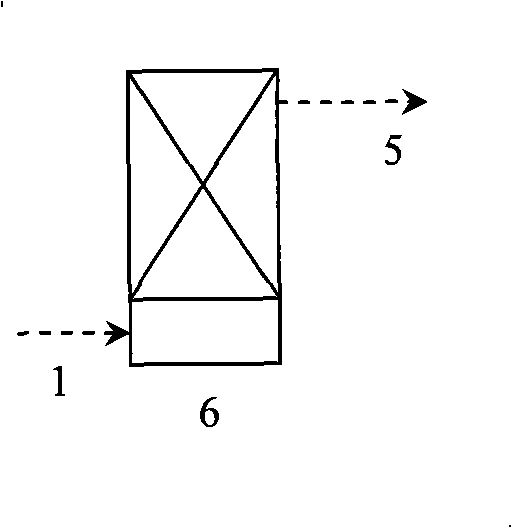

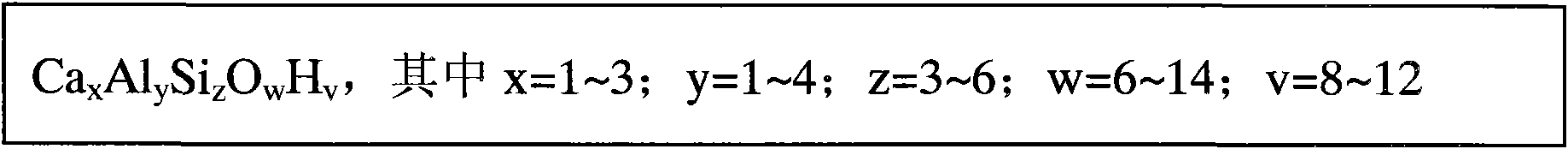

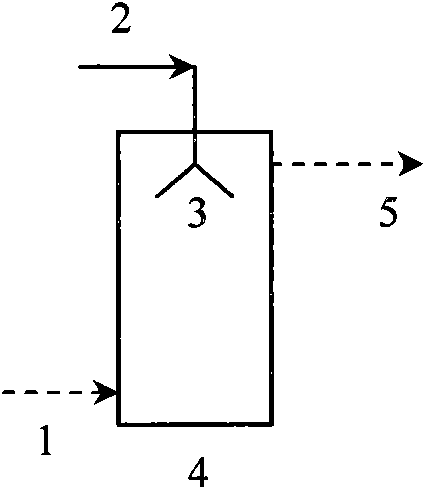

Purification technique for HCI gas in high temperature flue gas

InactiveCN101293171AEfficient removalSimple structureDispersed particle separationChemical reactionFixed bed

The present invention discloses a method, pertaining to the technical field of high-temperature flue-gas purification. The technical proposal includes: (1) alumina, silicon and lime are taken as the raw materials to obtain CaxALySizOwHv powder through chemical reaction by controlling the reaction conditions (wherein, x is equal to 1 to 3, y is equal to 1 to 4, z is equal to 3 to 6, w is equal to 6 to 14 and v is equal to 8 to 12); or (2) industrial mineral with abundant CaxAlySizOwHv is selected from the market as reactant (shortened as Ca-Al-Si reactant). The reactant can remove HCL gas from the high temperature (400 to 950 DEG C) flue gas and the efficiency is up to 90 to 99 percent. According to velocity and flux of the high-temperature flue-gas, the Ca-Al-Si reactant can be blown into the flue gas in the form of powder so as to ensure a certain reaction contact time; or the Ca-Al-Si reactant is processed into particles, blocks, etc. so as to be prepared into a form of a filler fixing bed reactor; when the high-temperature flue gas passes through the filler bed, HCL gas therein can be chemically purified, thus achieving the aim of flue-gas purification.

Owner:刘阳生 +1

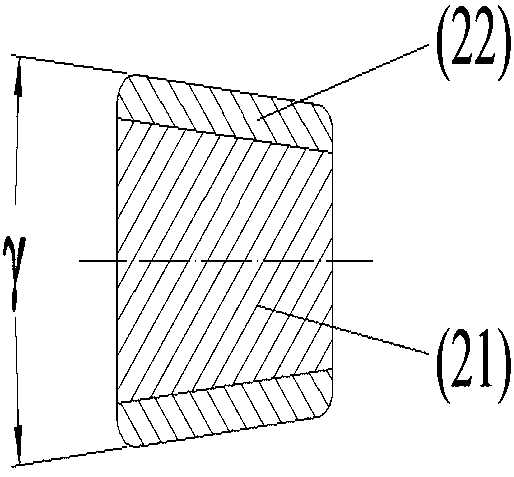

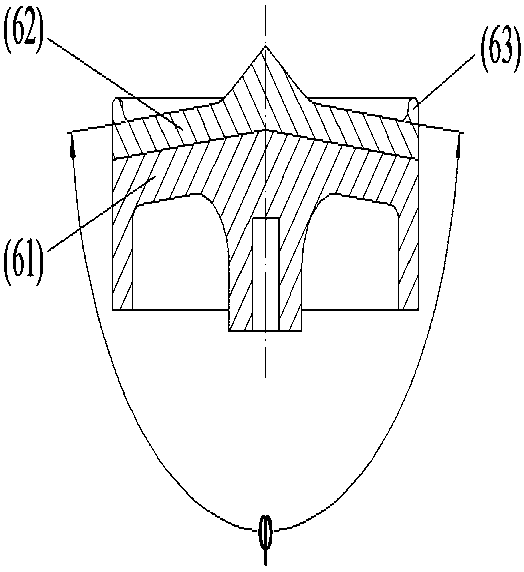

Roller disc grinding crusher

The invention relates to a roller disc grinding crusher for crushing of metal minerals, industrial minerals, chemical minerals and energy minerals. The roller disc grinding crusher mainly consists ofsuch parts as grinding rollers (2), a grinding roller frame (3), a pivot shaft (4), a grinding disc (6), a motor (8), a hydraulic cylinder (13) and a speed reducer (14). The surface of the grinding disc (6) is conical; the cone angle delta is 120-179 degrees; a projected flange (63) is arranged at the outer periphery; a material layer (5) is formed thereon; and one grinding disc is provided. The grinding rollers (2) are positioned above the grinding disc (6), are supported on the grinding roller frame (3) in a simple support beam support manner, are pressed on the grinding disc (6) by the hydraulic cylinder (13) through the grinding roller frame (3) with the pivot shaft (4) as a fulcrum, and are driven to rotate by the grinding disc (6). The grinding rollers (2) are conical; the cone angles gamma of the conical surfaces are 1-60 degrees; the ratios of the lengths to the large end diameters are larger than or equal to 1; and 1-10 grinding rollers are provided. The roller disc grinding crusher is higher in efficiency compared with a cylindrical grinder, and is simpler in structure and convenient to operate and maintain compared with a high-pressure roller grinder.

Owner:BEIJING HIGH MILL TECH CO LTD +2

System and method for Sharia-based energy market hedging and related

A tradable asset market trading and hedging system is disclosed. The tradable assets may include fuels or industrial minerals and rocks (IMRs). The system may include a conventional Exchange and its Islamic exchange affiliate or subsidiary (“IES”), a Sharia conversion module (both hardware and software), and a back-to-back order execution module (also both hardware and software). The IES makes use of a suitable cross-liquidity algorithm for the purpose of consolidating bids and offers from the Exchange and the IES in order to enhance IES liquidity. An entity that qualifies for Sharia-based trading with the IES may be issued a customized dongle to inter alia regulate and control who can access what data at any given time. The dongle interfaces with a computing device (e.g., laptop, desktop, tablet, etc.) used by an individual, institution or other qualified entity to access the IES. The dongle may include a customer position limits enforcement module and a high frequency trading order stuffing block module that are both in communication with a suitable processor. The system and method enables Sharia-compliant trades to be executed, including those trades that are attendant to Islamic-financed transactions.

Owner:DEARBORN FINANCIAL

Environment-friendly accelerator ZBEC pre-dispersed master batch and preparation method thereof

The invention discloses an environment-friendly accelerator ZBEC pre-dispersed master batch and a preparation method thereof. The environment-friendly accelerator ZEBC pre-dispersed master batch comprises, by weight, 69-72 parts of dibenzyldithiocarbamic acid, zinc salt, 14-20 parts of rubber matrix, 8-13 parts of industrial mineral oil and 2-5 parts of saturated fatty acid zinc salt. The preparation method of the environment-friendly accelerator ZBEC pre-dispersed master batch is simple and easy to operate; according to the preparation method, mixing time for subsequent procedures of preparing the master batch is reduced effectively, the accelerator ZBEC pre-dispersed master batch prepared by the method maintains original activity of ZBEC effectively and is free of caking at room temperature, is convenient to weigh and easy to blend for mixing and has good flow characteristic after being blended with rubber; feeding time is accelerated while dust flying is avoided and skin allergy to operators is avoided, and utilization rate of raw materials is high; the master batch disperses uniformly in rubber products after blending and mixing and thus production efficiency and quality of the rubber products are guaranteed. The environment-friendly accelerator ZBEC pre-dispersed master batch has great significance in promoting sustainable development of rubber manufacturing and has wide industrial prospect.

Owner:NINGBO ACTMIX POLYMER

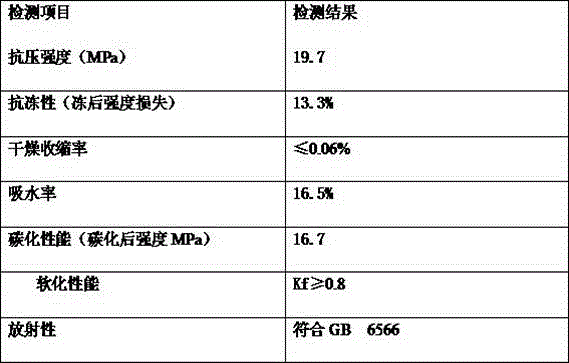

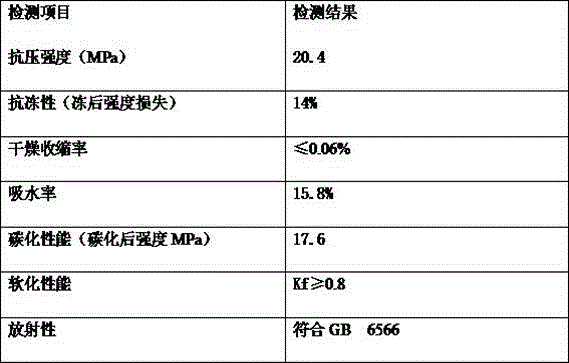

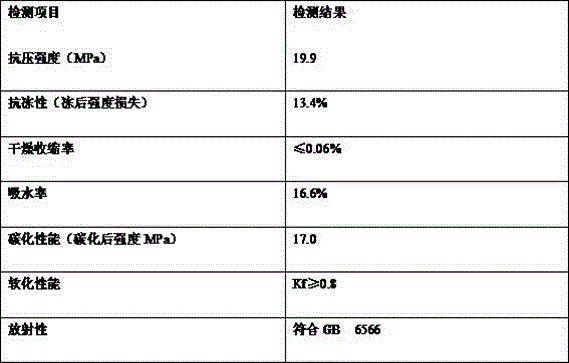

Method for preparing aerated concrete blocks by using andalusite mineral waste residues

ActiveCN103496911AReduce pollutionSave mineral resourcesSolid waste managementCeramicwareMineral SourcesResource utilization

The invention relates to a method for preparing aerated concrete blocks by using andalusite mineral waste residues. The method comprises the following steps: (1) preparing the following materials in parts by weight: 70-80 parts of andalusite mineral waste residues, 10-15 parts of quick lime, 2-5 parts of cement, 0.04-0.05 part of aluminium powder and 2-3 parts of coal ash; (2) mixing and stirring; (3) pouring and stilly curing; and (4) carrying out steam curing. The method has the beneficial effects that novel energy-saving building materials are prepared by the physical denaturation of the andalusite mineral waste residues, the pollution of the industrial mineral waste residues to environments is reduced, mineral resources are effectively saved, and the resource utilization rate is increased.

Owner:XINJIANG BAOAN NEW BUILDING MATERIAL

Foam dry-mixed mortar with high water permeability, high heat dissipation and thawing and freezing resistance and method for preparing foam dry-mixed mortar

The invention provides foam dry-mixed mortar with high water permeability, high heat dissipation and thawing and freezing resistance. The foam dry-mixed mortar with the high water permeability, the high heat dissipation and the thawing and freezing resistance comprises regenerated building aggregate, regenerated mineral aggregate, regenerated fiber materials, cement, water retaining agents, water reducing agents, adhesive and thickening agents. The regenerated building aggregate comprises building concrete and brick slag. The regenerated mineral aggregate comprises industrial mineral waste including silicon dioxide, aluminium sesquioxide, ferroferric oxide, titanium dioxide, magnesium oxide and calcium oxide. The regenerated fiber materials comprise industrial textile waste including natural fibers, chemical fibers and regenerated fibers. The foam dry-mixed mortar has the advantages that concrete prepared from the prepared foam dry-mixed mortar is made of different types of industrial building waste, is large in porosity, good in water permeability and heat dissipation, high in strength, easy to maintain and clean and wide in application range and has diversified colors.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Industrial-mineral electric locomotive anti-lock electromagnetic braking device

InactiveCN101830176APrevent derailmentImprove securityElectrodynamic brake systemsBraking systemsElectricityDerailment

The invention relates to an industrial-mineral electric locomotive anti-lock electromagnetic braking device. The device mainly overcomes the defects that as the existing pneumatic or handwheel mechanisms brake and respond slowly, the braking distance is long, the braking performance is poor, the brake block is easy to wear, etc. The device also solves the technical problems that owning to large braking force or mechanical reasons, the locomotive wheels lock so as to cause derailment phenomenon and the like. The keys of the technical scheme of the invention are as follows: a brake disc spring and an electromagnetic iron core are sleeved in a cylinder body, a brake pull rod penetrates through the brake disc spring and electromagnetic iron core in the cylinder body, brake levers are sleeved on the two ends of the brake pull rod, the lower ends of the brake levers are hinged with a braking device frame; clamping plate brake bodies are arranged on the two sides of a brake disc correspondingly, the clamping plate brake bodies are hinged on the two ends of the braking device frame and fit with the brake levers in a linkage manner; and a control cable is connected with the electromagnetic iron core, and an electromagnetic pressure switch is arranged on the control cable. The anti-lock electromagnetic braking device can be widely used for the brake control of the industrial and mineral electric locomotive.

Owner:湖南江麓冶金机械有限公司

Durable antistatic agent and preparing method thereof

InactiveCN109576995AImprove antistatic performanceEasy to prepareFibre treatmentPolyethylene glycolCarboxylic salt

The invention discloses a durable antistatic agent which is formed by combining an antistatic agent A and an antistatic agent B. The antistatic agent A is prepared from potassium acetate, industrial mineral oil, polypropylene, xylene, p-toluenesulfonic acid, triethanolamine, acetone, dimethyl terephthalate, a surfactant, an initiator, ethyl alcohol and deionized water by weight parts. The antistatic agent B is prepared from ethyl alcohol, deionized water, 2 pyrrolidone-4-carboxylate, polyethylene glycol, glycerinum and sodium alginate by weight parts. The preparing method is simple and easy toimplement, the prepared antistatic agent has a good antistatic effect and high stability.

Owner:宿迁广和新材料股份有限公司

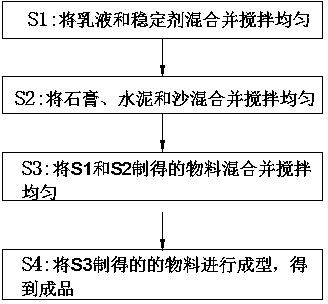

A non-burning and non-steaming titanium gypsum brick and its preparation method

The invention discloses a non-fired and non-autoclavedtitanium gypsum brick and a preparation method thereof. The titanium gypsum brickcomprises components in percentage by mass as follows: 24.1%-32.3% of titanium gypsum, 52%-63.8% of aggregate, 11.2%-18.5% of cement / mineral powder and 0.8%-1.0 % of an additive, wherein the additive is a mixture of anhydrous sodium sulfate, alums and a curing agent; and the aggregate is one or more of industrial mineral slag, crushed stone and river sand. The preparation method of the titanium gypsum brick comprises steps as follows: S1, slurry type titanium gypsum is extruded and stirred to form hydraulic slurry; S2, the extruded and smashed titanium gypsum and the aggregate are mixed and stirred for 2-4 minutes; S3, a material prepared in S2 is mixed with the additive and the cement / mineral powder and stirred for 1-3 minutes; S4, extruding forming is performed, consistency of the water content in different positions of a hopper is kept through spraying and watering, and the mass ratio of water to the material prepared in the S3 is 1:(32:40). Raw materials are easy to prepare, main performance parameters meet the national standard, the preparation method is simple and easy to operate, the efficiency is high, energy consumption is reduced due to no need of firing and autoclaving, and environmental pollution is reduced.

Owner:CHANGSHA HAIHONG BUILDING MATERIALS

Self-moving corrector

The invention relates to a self-moving corrector. The self-moving corrector comprises an outer correction cylinder, an inner correction cylinder, self-moving oscillating shafts, a self-moving revolving shaft, a revolving seal assembly, sleeve seal assemblies, support frames, outer cylinder rubber coating, side vertical rolls, side roll stands and inner correction cylinder supports, wherein the self-moving oscillating shafts are installed at the middle parts of left and right support frames; the outer correction cylinder is sheathed with the inner correction cylinder through the sleeve seal assemblies; the sleeve seal assemblies are sheathed at the two outer ends of the inner correction cylinder and inner correction cylinder supports are arranged at the two outer ends of the inner correction cylinder; the inner correction cylinder is sheathed with the self-moving oscillating shafts through the self-moving revolving shaft and the revolving seal assembly. The self-moving corrector has the advantages that the self-moving corrector is not influenced by industrial mineral dust, water and crushed material environments and the belt deviation can be automatically corrected. A belt deviation correction method mainly takes the measure of installing a deviation adjusting device on a belt rack.

Owner:洛阳广盈机械设备有限公司

Coated-type composite balance weight and manufacturing method thereof

The invention discloses a coated-type composite balance weight and a manufacturing method thereof. The coated-type composite balance weight is made of main materials as industrial mineral waste residue (1) and an inorganic bonding agents (3), wherein the weight of the industrial mineral waste residue accounts for 70-85% of the total weight; the weight of the inorganic bonding agents accounts for 7-25% of the total weight; the coated-type composite balance weight further comprises a reinforcing material (2) which can be short fibers or particulate fibers, and accounts for 0.5-3% of the whole weight; a layer of shell (4) is coated on the outer layer of the coated-type composite balance weight, and materials for preparing the shell can be materials such as rubber and epoxy resin. The coated-type composite balance weight provided by the invention can be compressed and molded once through using a mold, is stable in weight after forming, is high in pressure resistant intensity, is extremely low in moisture absorption rate, is a compound material, can prevent the possibility of being stolen, is good in freezing resistance, is good in durability, has long service life, and can avoid problems of cracking, corner falling, block falling and the like after being used for a long time, so that the quality of the balance weight and the safety of a contact net system can be ensured.

Owner:辽宁海澳科技有限公司

Metakaolin Production and Enhancement of Industrial Minerals

Methods for preparing metakaolin-enhanced industrial minerals. Mixing and heating kaolinite clay with an industrial mineral, such as activated carbon, that is between 750° F. and 1400° F. results in a metakaolin / activated carbon complex that provides good mercury sorbent qualities while producing a fly ash (after use as a sorbent in emissions applications) that has a lower foaming index.

Owner:PNEUMATIC PROCESSING TECH

Methods of separating impurities from industrial minerals using electrocoagulation

ActiveUS10189725B2Easy to separateIncrease volumeWaste water treatment from quariesPigmenting treatmentElectrocoagulationSlurry

Various embodiments disclosed relate to methods of separating impurities from industrial minerals using electrocoagulation and apparatuses for performing the same. In one embodiment, the present invention provides a method of purifying an industrial mineral composition. The method can include obtaining or providing an aqueous slurry comprising a mineral composition comprising one or more industrial minerals and one or more impurities. The method can include subjecting the aqueous slurry to an electrical current to form at least one coagulation comprising the one or more impurities. The method can include separating at least one of the coagulations from the one or more minerals, providing a purified mineral composition.

Owner:WATER TECTONICS +1

Chemical agent for purifying gaseous HC1 at high temperature as well as preparation method and application thereof

InactiveCN101816893AEfficient removalSimple structureDispersed particle separationChemical reactionFlue gas

The invention discloses a chemical agent for purifying gaseous HC1 at high temperature as well as a preparation method and application thereof. The chemical agent is a Ca-Al-Si reactant, and the molecular formula of the Ca-Al-Si reactant is CaxAlySizOwHv, wherein x is equal to 1-3, y is equal to 1-4, z is equal to 3-6, w is equal to 6-14, and v is equal to 8-12. The preparation method comprises the following steps of: by using alumina, silicon and lime as raw materials, preparing CaxAlySizOwHv powder through chemical reaction or selecting industrial minerals rich in CaxAlySizOwHv. The chemical agent is applied to removing HC1 gas in high-temperature flue gas of 400-950 DEG C and has the efficiency of 90%-99%, thereby being capable of effectively purifying the gaseous HC1 at the high temperature of 400-950 DEG C.

Owner:刘阳生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com