Chemical agent for purifying gaseous HC1 at high temperature as well as preparation method and application thereof

A chemical agent and gaseous technology, which is applied to the chemical agent for purifying gaseous HC1 at high temperature and its preparation and application fields, can solve the problems of increasing the humidity of flue gas, serious secondary pollution, corroding downstream equipment, etc., and achieves a simple and efficient equipment structure. Removal, easy-to-run effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

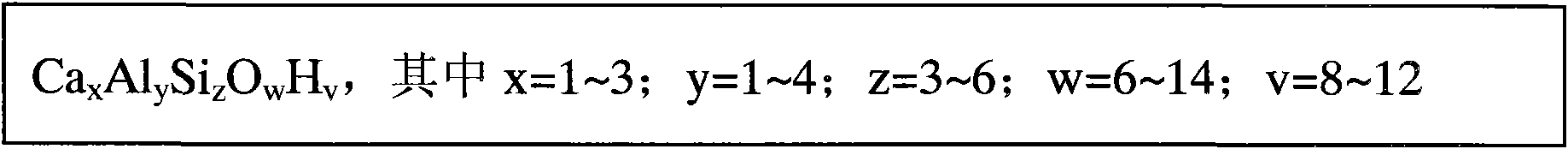

[0020] Using alumina, silicon oxide and lime as raw materials, the weight ratio of raw materials is 2:1:1, through chemical reaction, calcined at 800°C for 2 hours, and cooled to room temperature to prepare Ca x al y Si z o w h v Powder, wherein x=1~3; y=1~4; z=3~6; w=6~14; v=8~12.

Embodiment 2

[0022] Using alumina, silicon oxide and lime as raw materials, the weight ratio of raw materials is 2:1:1, through chemical reaction, calcined at 200°C for 5 hours, cooled to room temperature, to prepare Ca x al y Si z o w h v Powder, wherein x=1~3; y=1~4; z=3~6; w=6~14; v=8~12.

Embodiment 3

[0024] Select Ca-enriched x al y Si z o w h v The industrial mineral grossular garnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com