Patents

Literature

349 results about "Grossular" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grossular is a calcium-aluminium species of the garnet group of minerals. It has the chemical formula of Ca₃Al₂(SiO₄)₃ but the calcium may, in part, be replaced by ferrous iron and the aluminium by ferric iron. The name grossular is derived from the botanical name for the gooseberry, grossularia, in reference to the green garnet of this composition that is found in Siberia. Other shades include cinnamon brown (cinnamon stone variety), red, and yellow. Grossular is a gemstone.

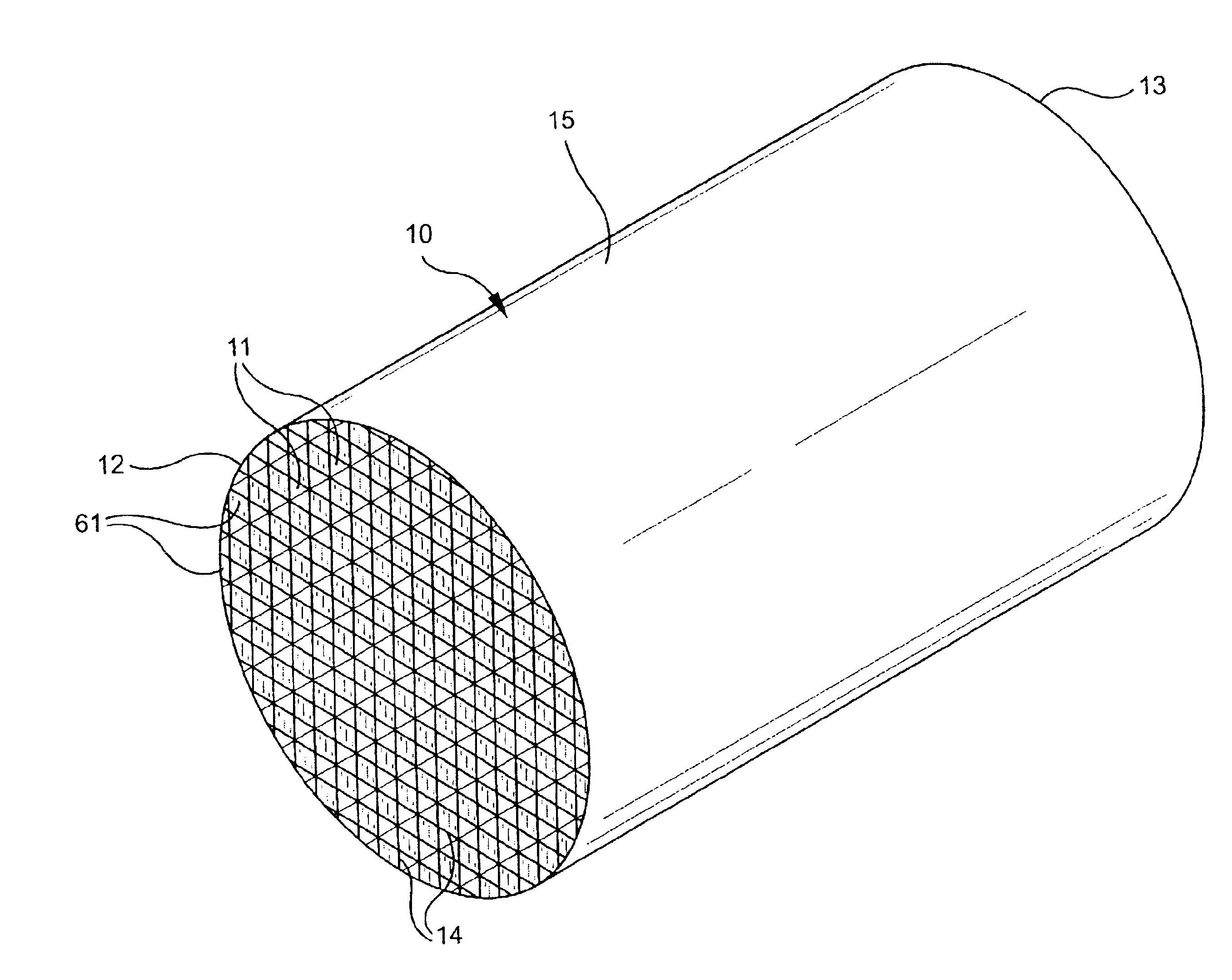

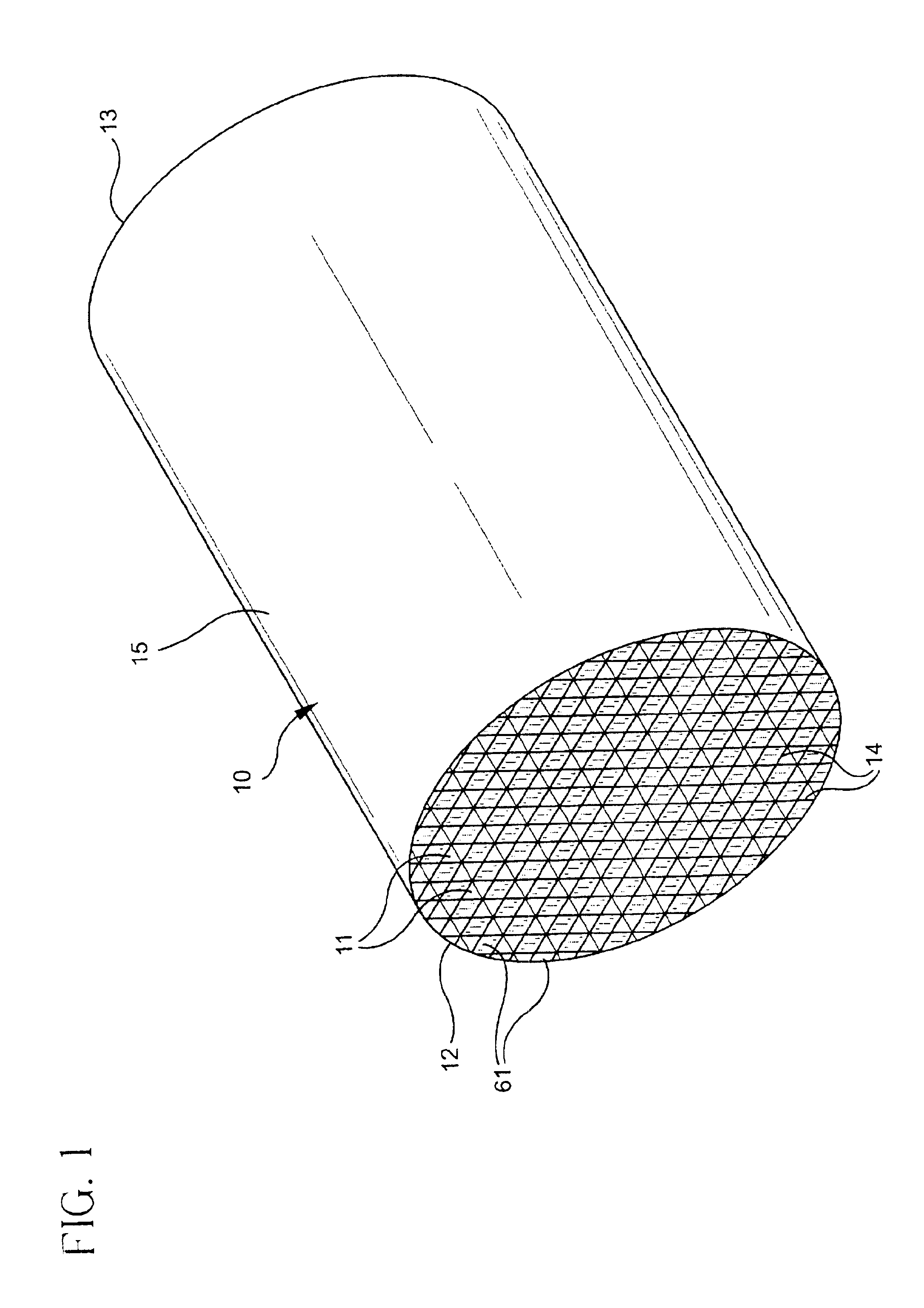

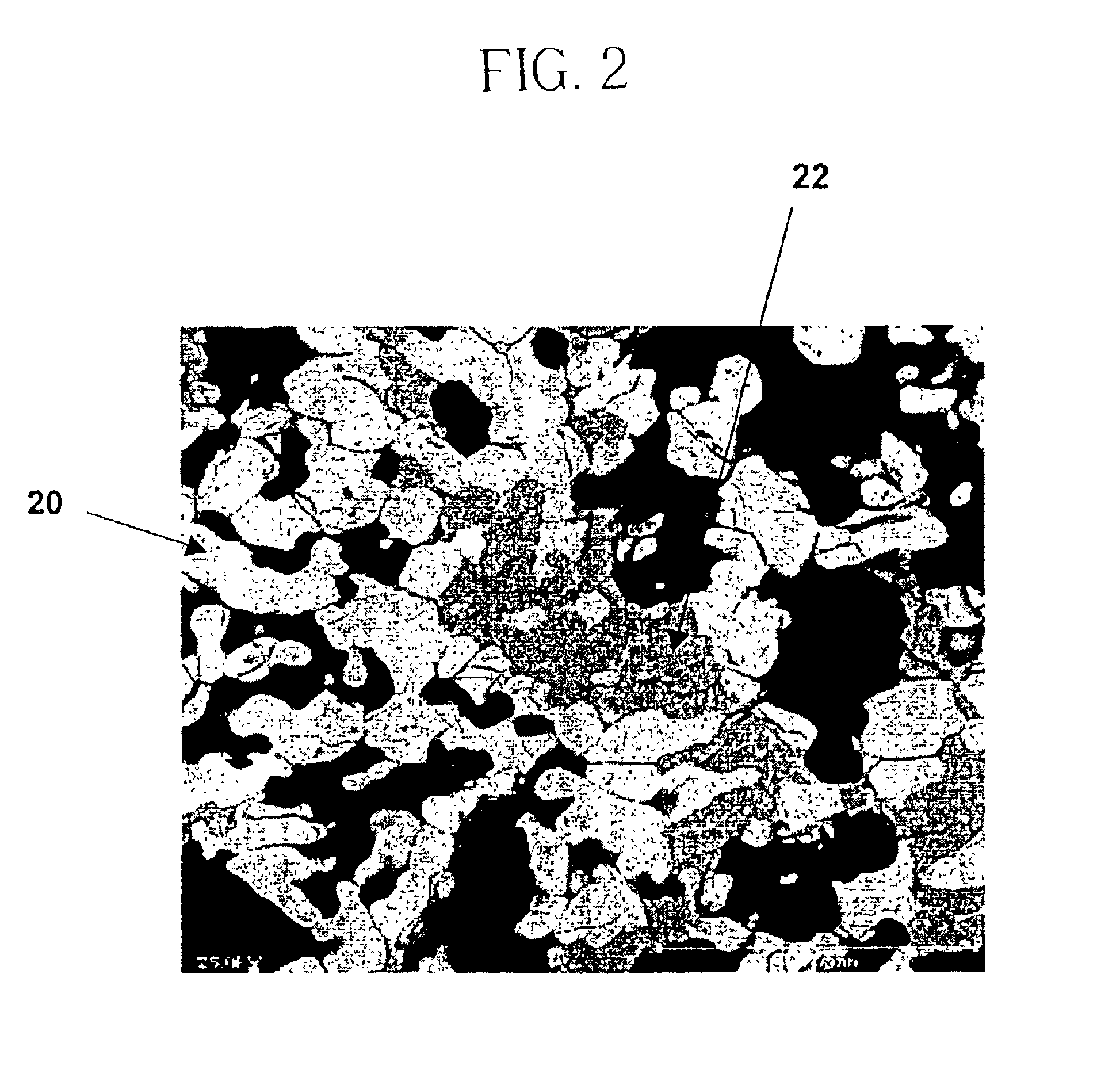

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

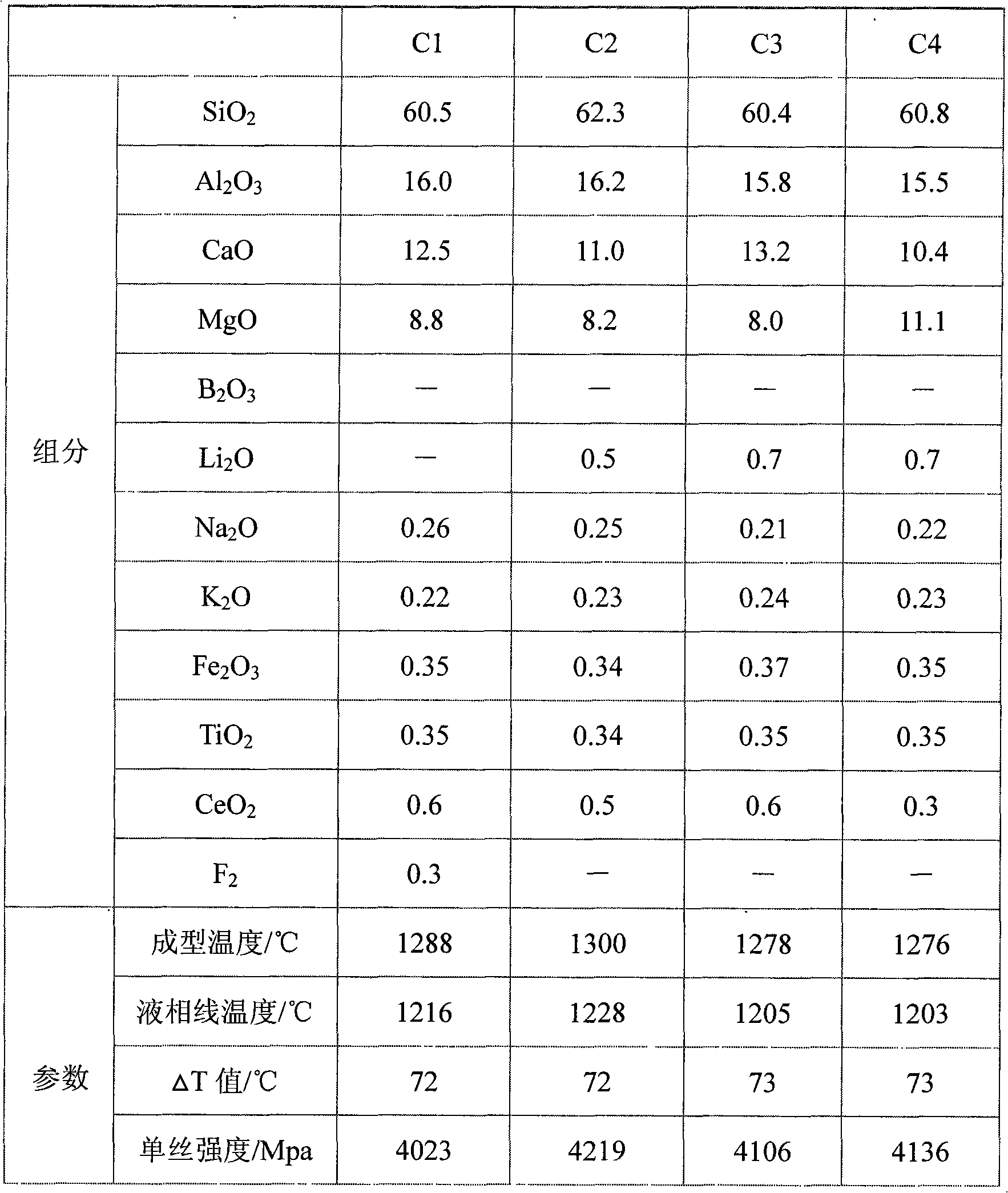

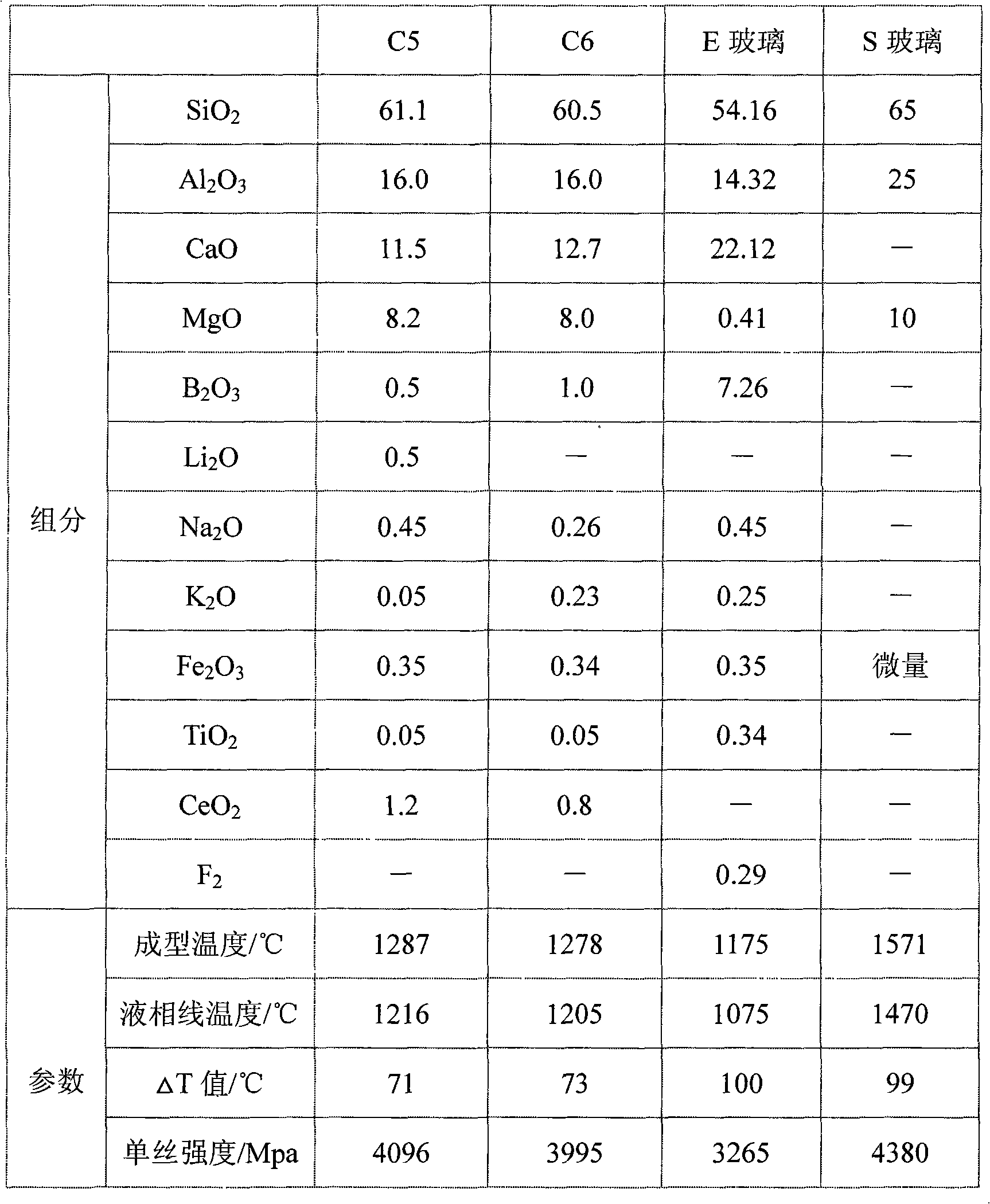

High strength glass fiber composition

The invention discloses a high strength glass fiber composition which comprises the components with the weight percentage: 58-65% of SiO2, 14-20% of Al2O3, 15-25% of CaO+MgO, 0.05-1% of K2O+Na2O, 0.05-1% of Fe2O3 and 0.1-2% of CeO2; wherein, the proportional relation of the components is that CaO / MgO is more than 0.7 and less than 2.2. By preference and combination of the components, the high strength glass fiber composition not only can fully utilize rich raw mineral materials of China, but also can reduce mold temperature, liquidus temperature and clarification temperature and has lower total cost and easy large scale commercial process under the premise of ensuring the high strength of glass fiber.

Owner:JUSHI GRP CO

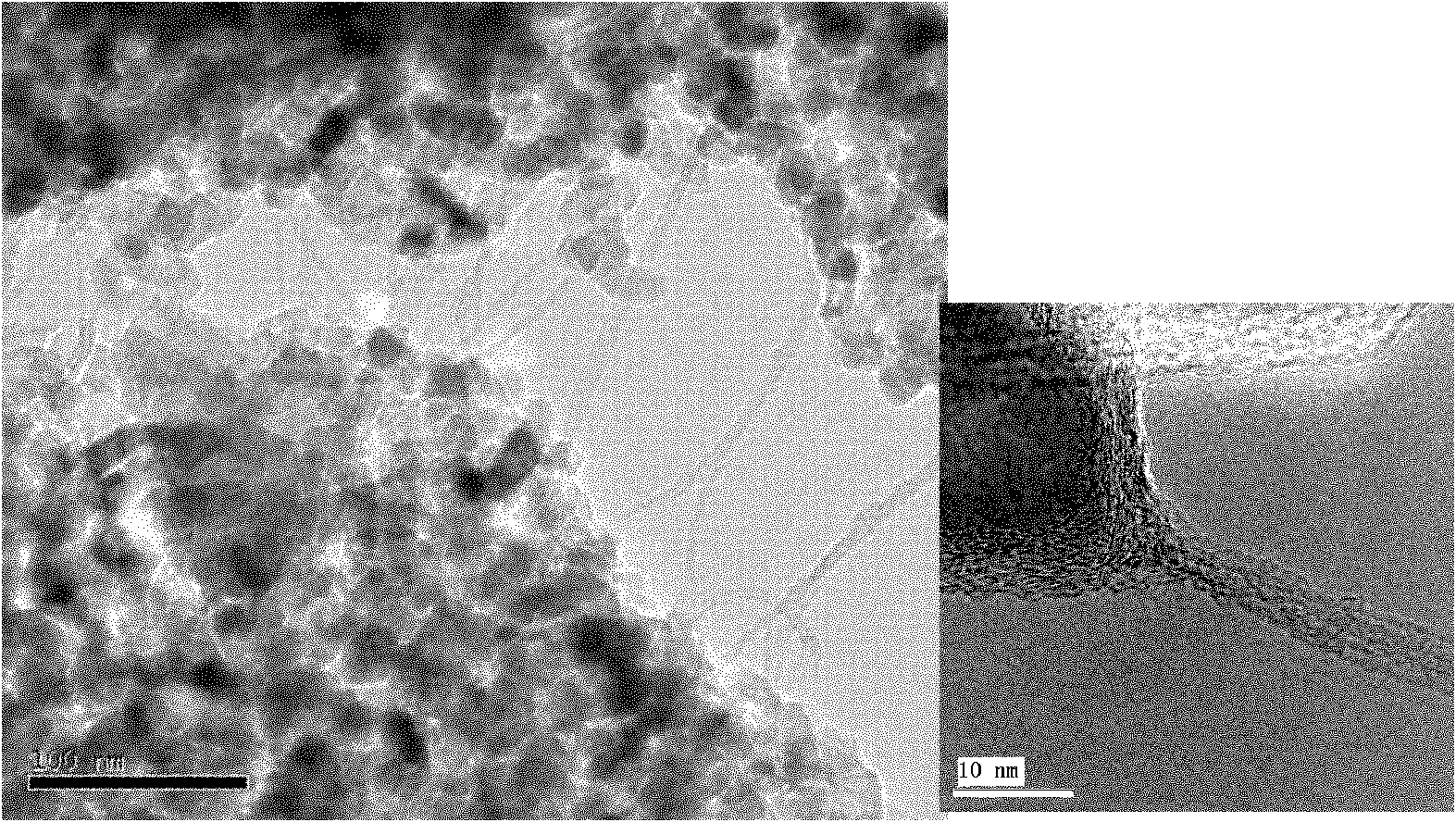

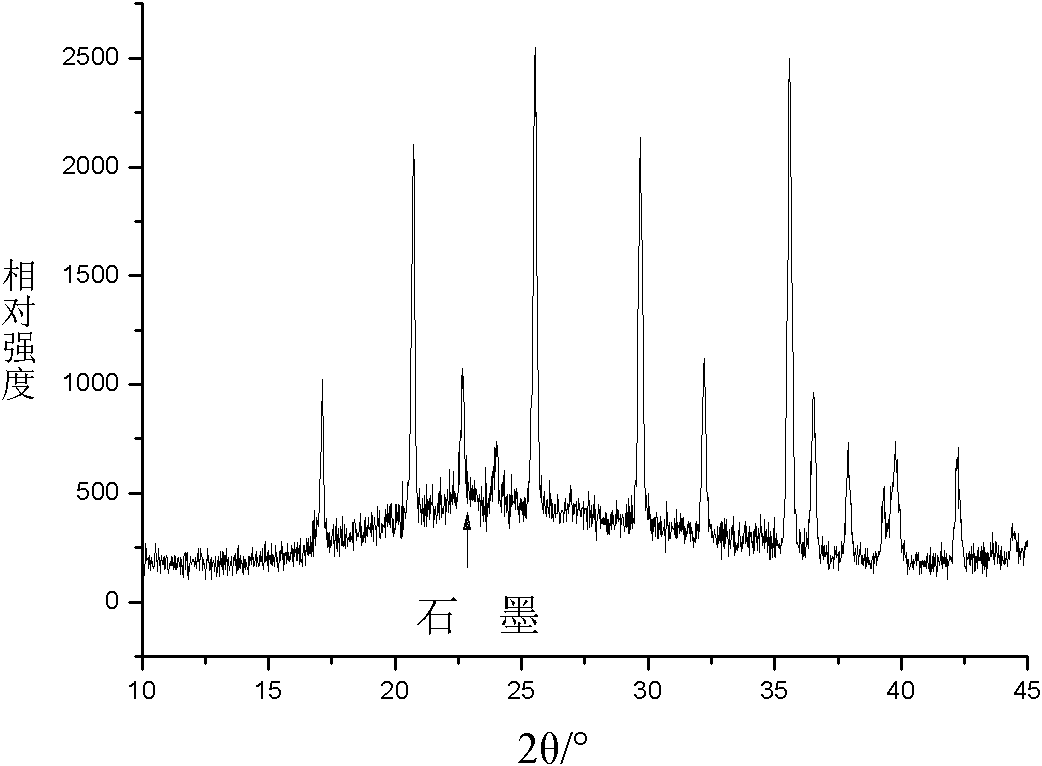

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

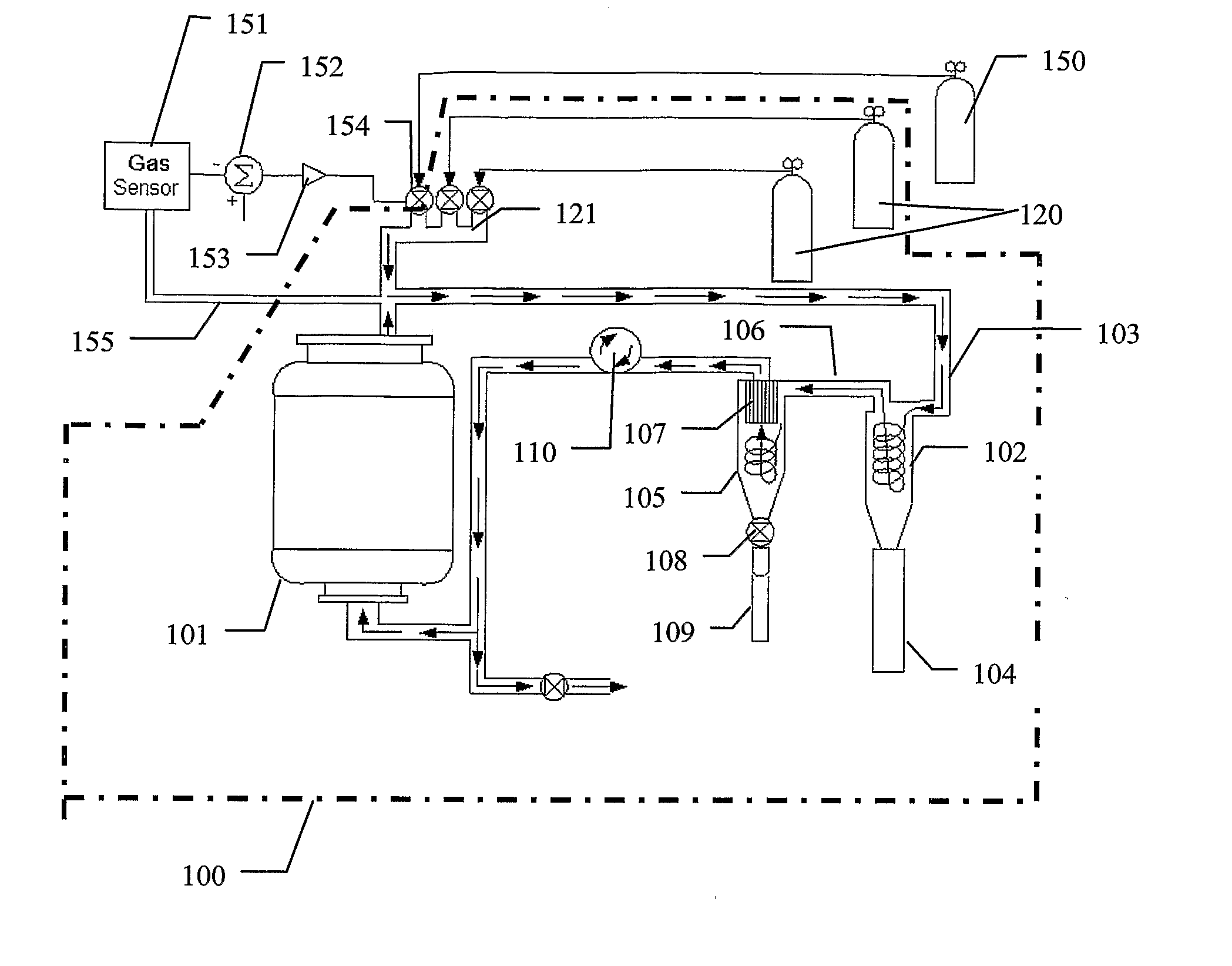

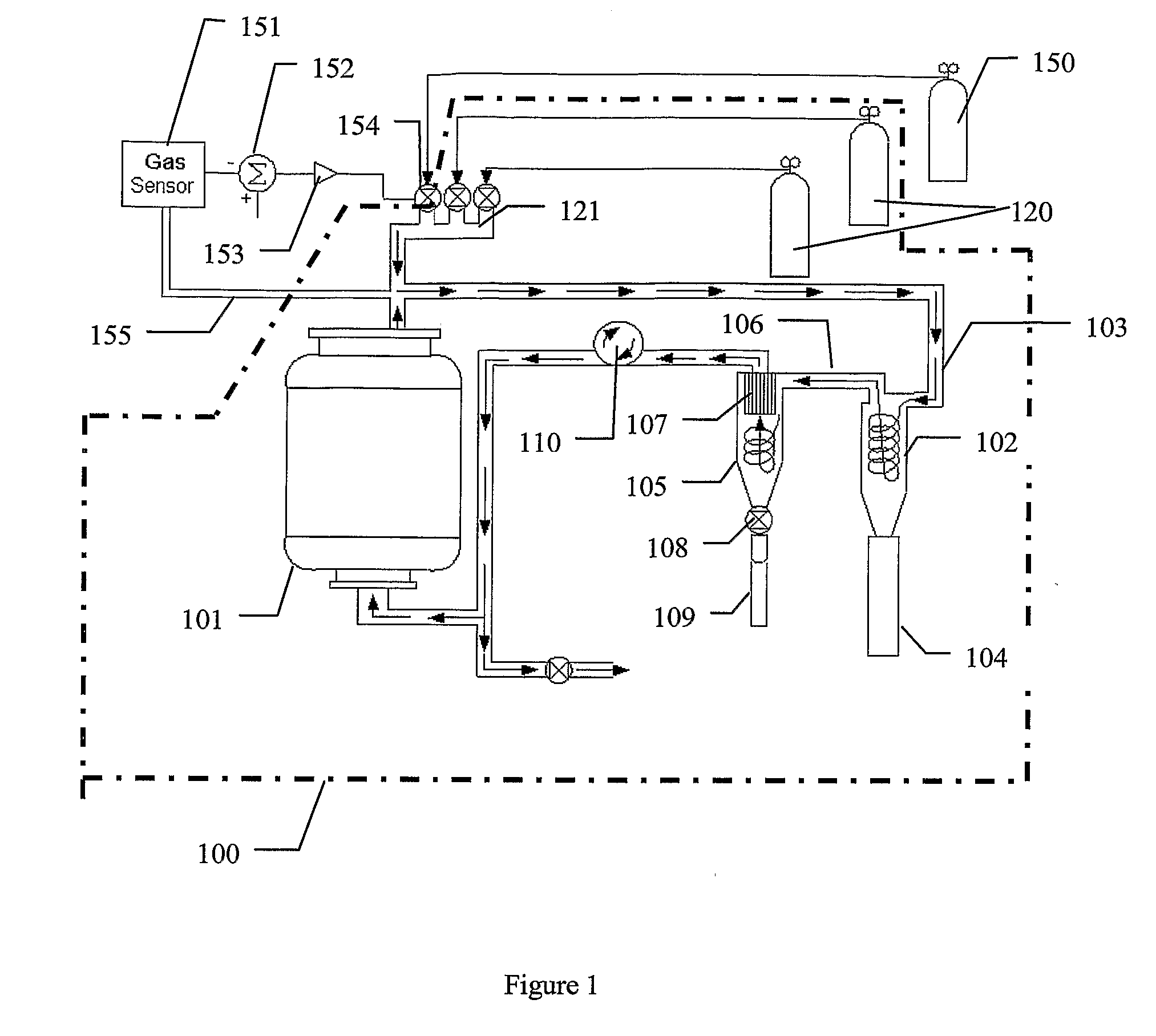

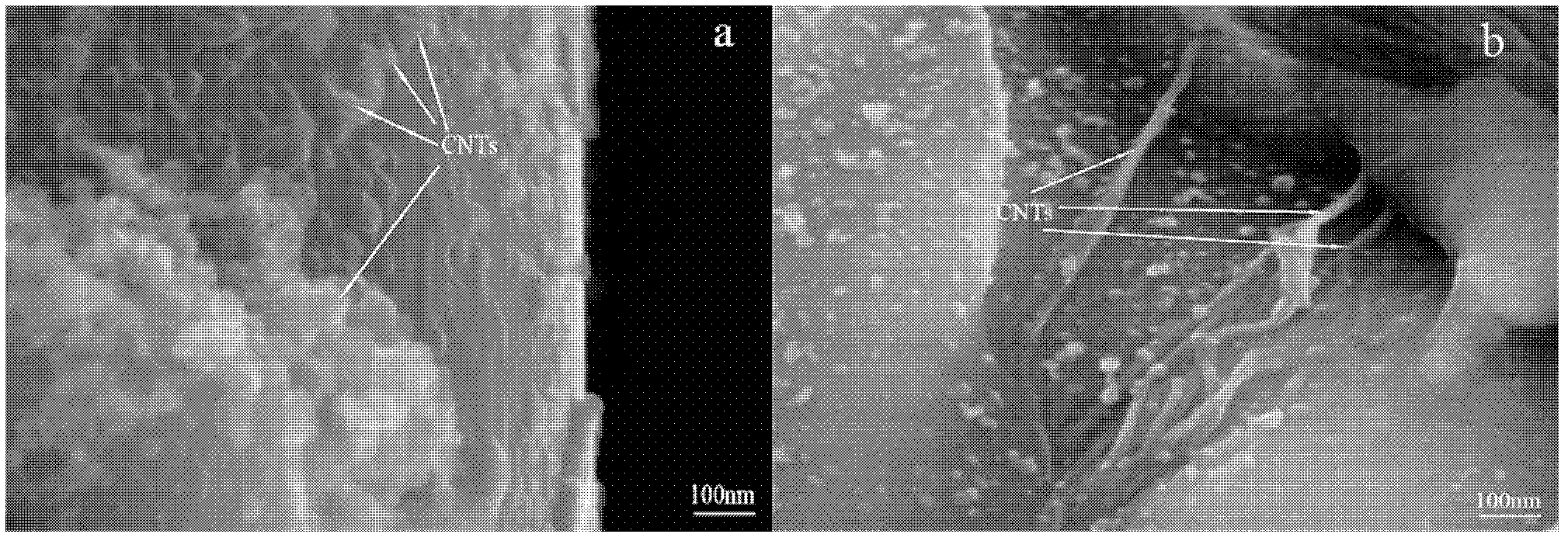

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

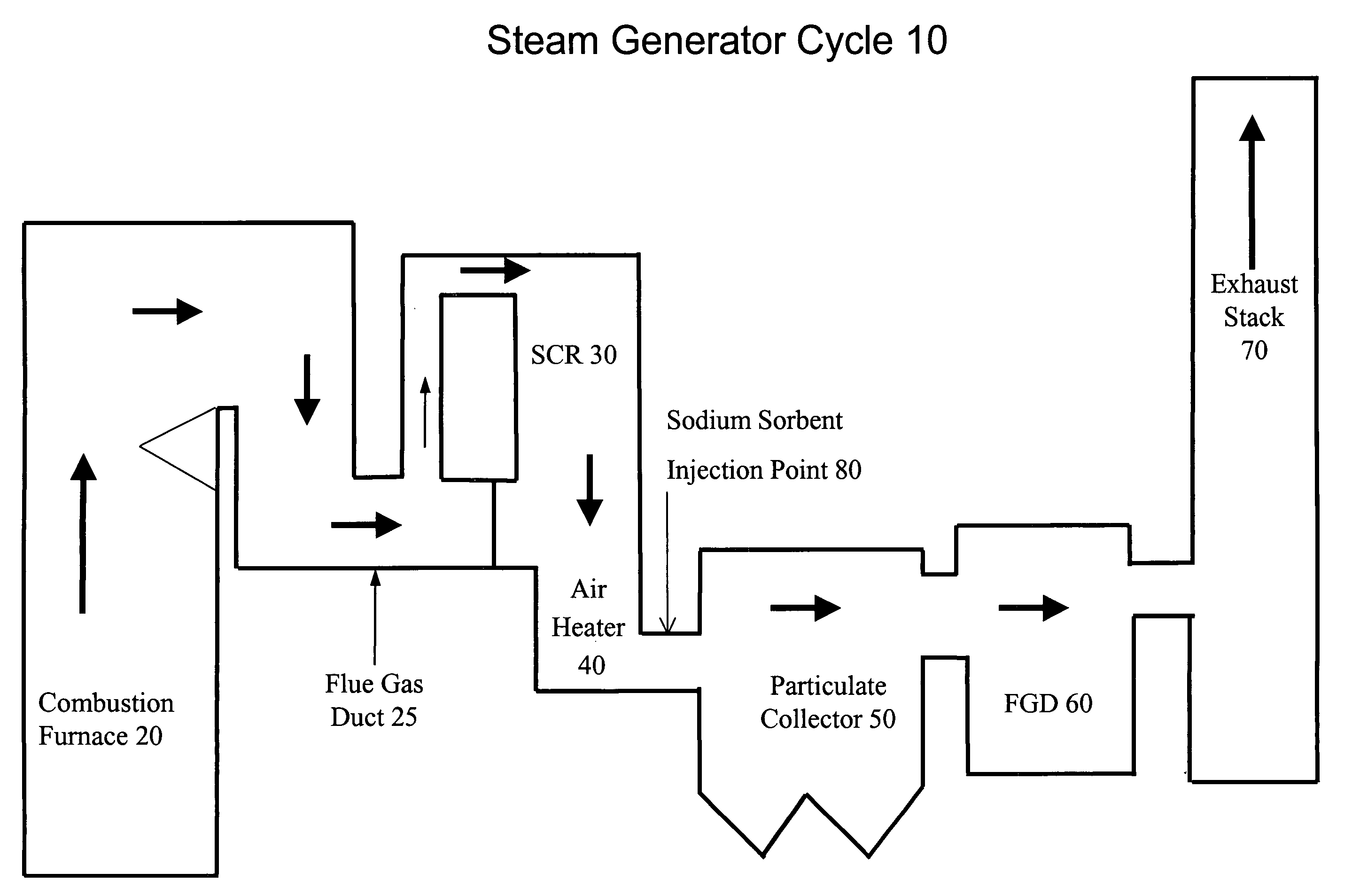

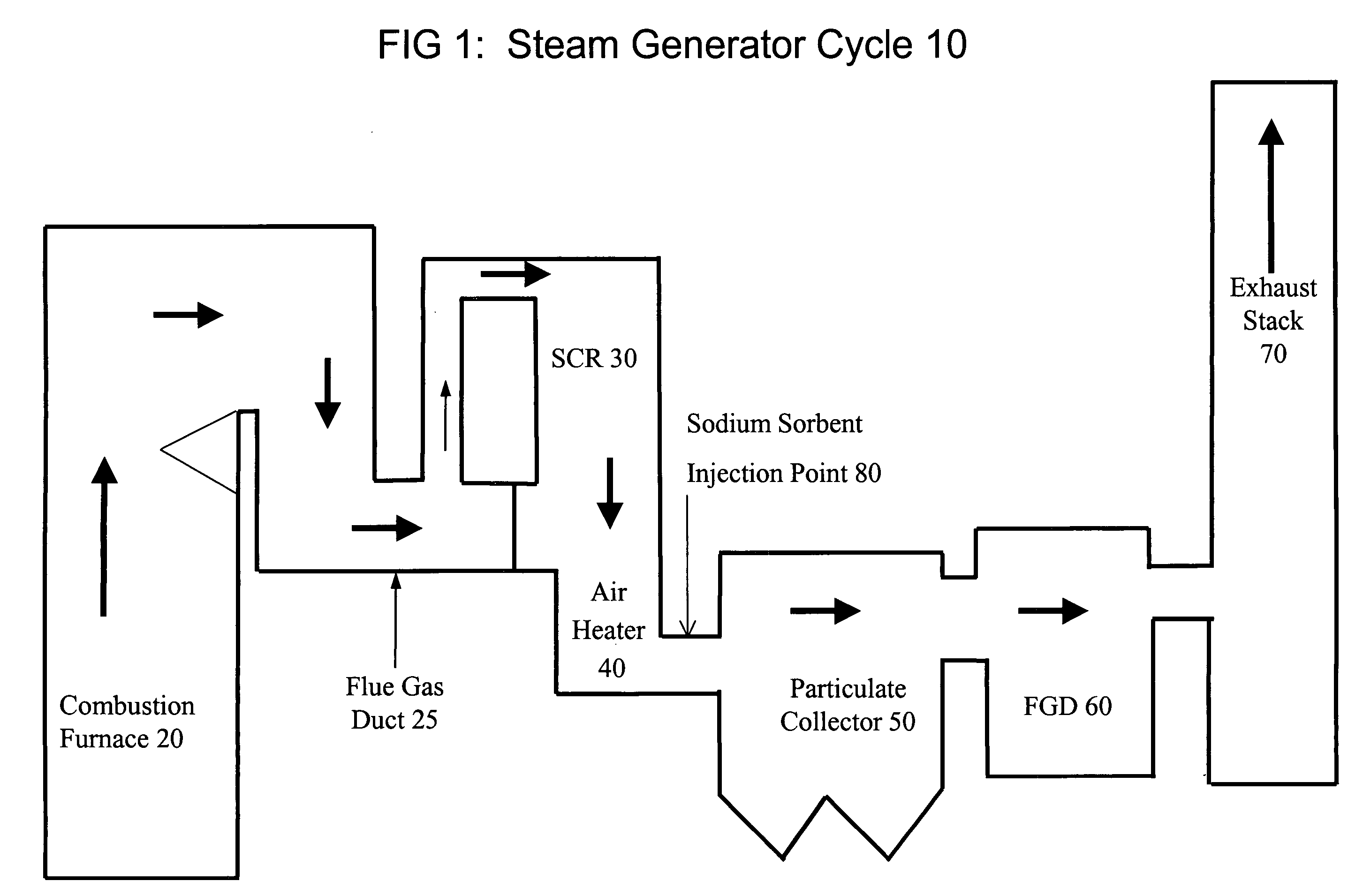

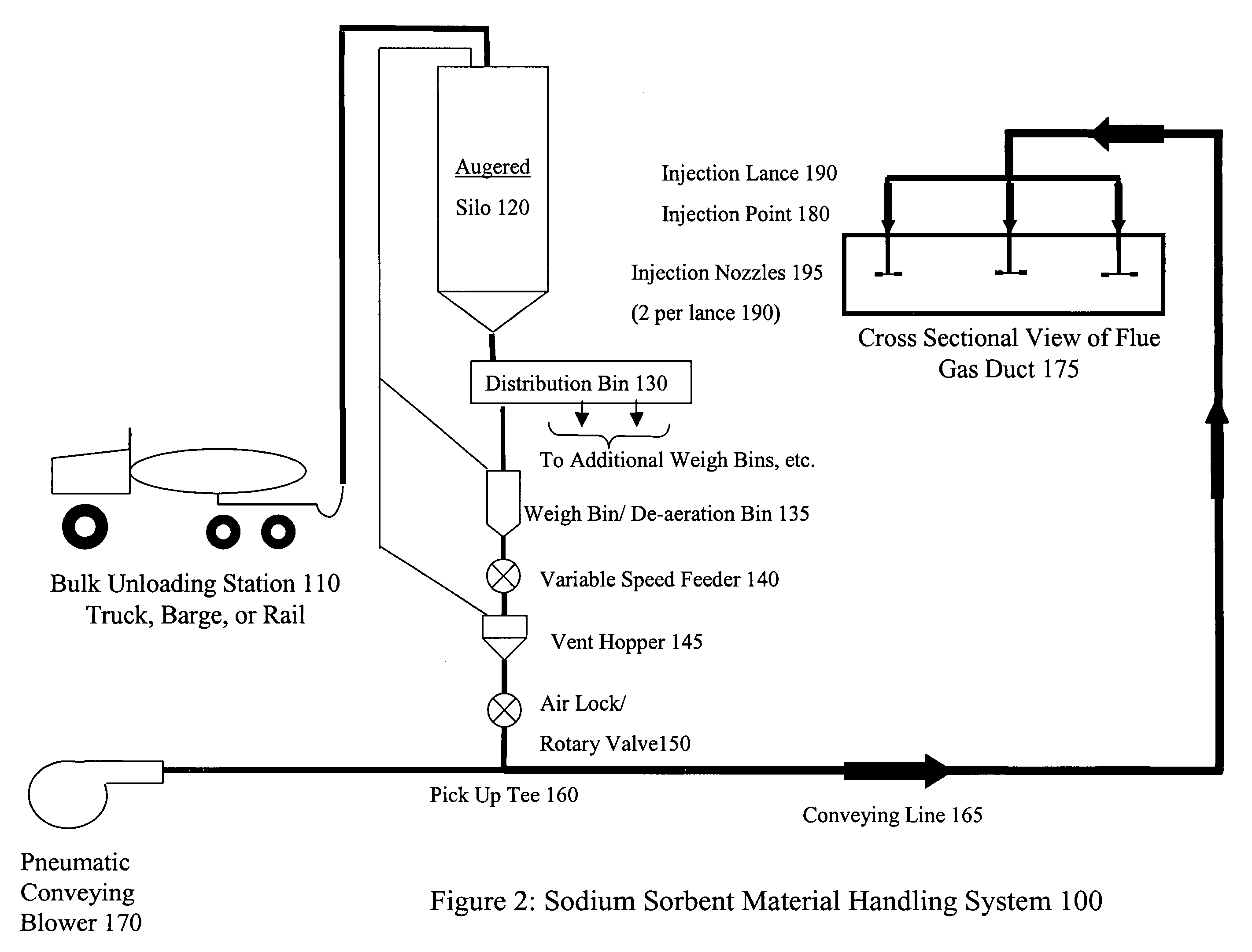

System and method for treating a flue gas stream

PendingUS20050201914A1Lower volume resistivityEfficient removalCombination devicesGas treatmentParticulatesDicarbonate

The present invention is a system and method for treating a flue gas stream to remove strong acid compounds selected from the group consisting of hydrofluoric acid (HF), hydrochloric acid (HCl), sulfuric acid (H2SO4), and sulfur trioxide (SO3) by injecting a sodium sorbent selected from the group consisting of sodium sesquicarbonate, sodium carbonate-bicarbonate, trona ore, mechanically refined trona ore, and trona into the flue gas stream, calcining substantially all of the sodium sorbent in the presence of the flue gas stream to form a soda ash, reducing the concentration of the at least one strong acid compound in the flue gas stream by reacting the at least one strong acid compound with the soda ash to form a sodium based by-product; and changing the chemistry of the flue gas stream to reduce the overall average resistivity of the particulate matter.

Owner:AMERICAN ELECTRIC POWER CO INC

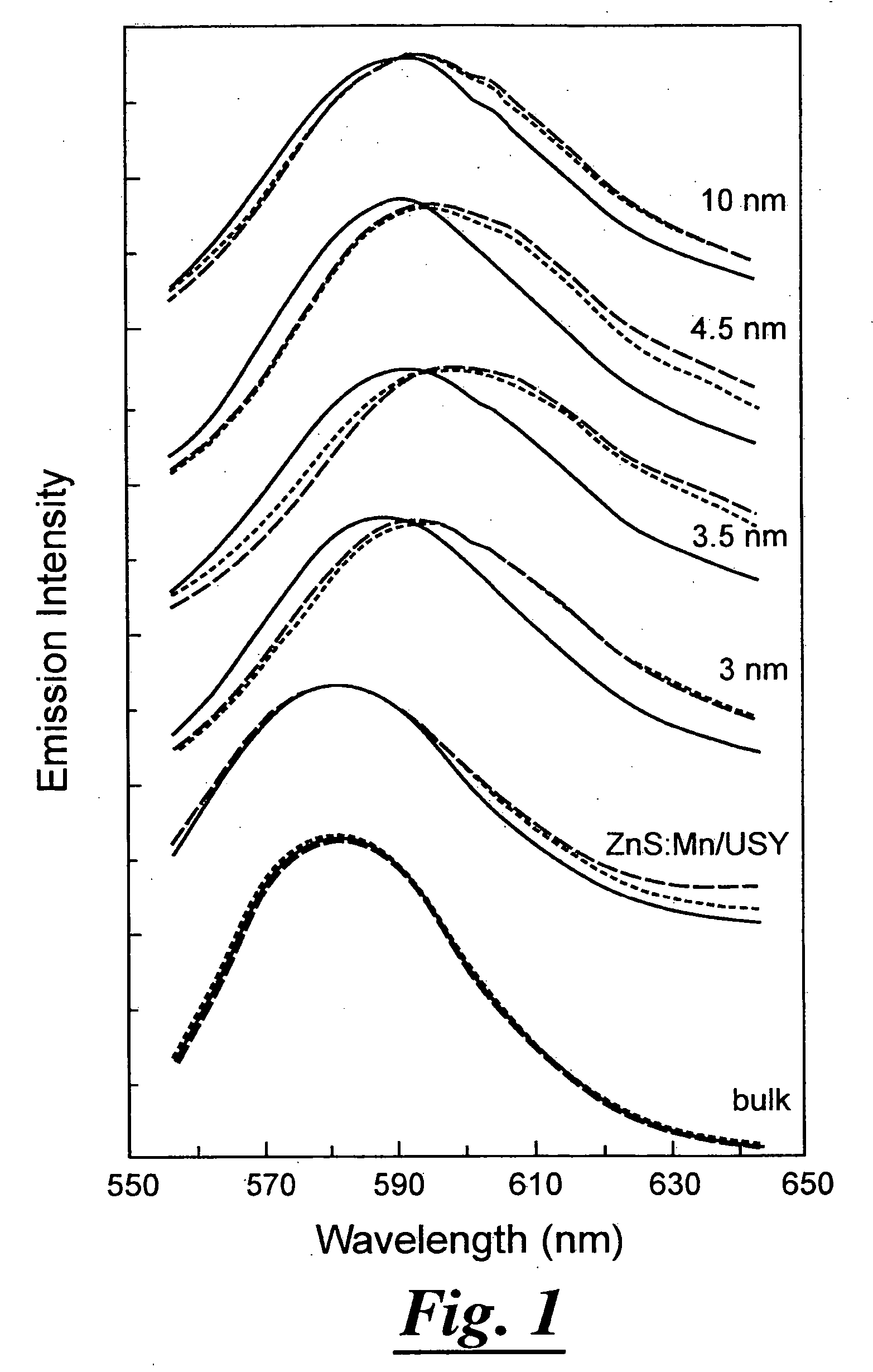

Manganese doped upconversion luminescence nanoparticles

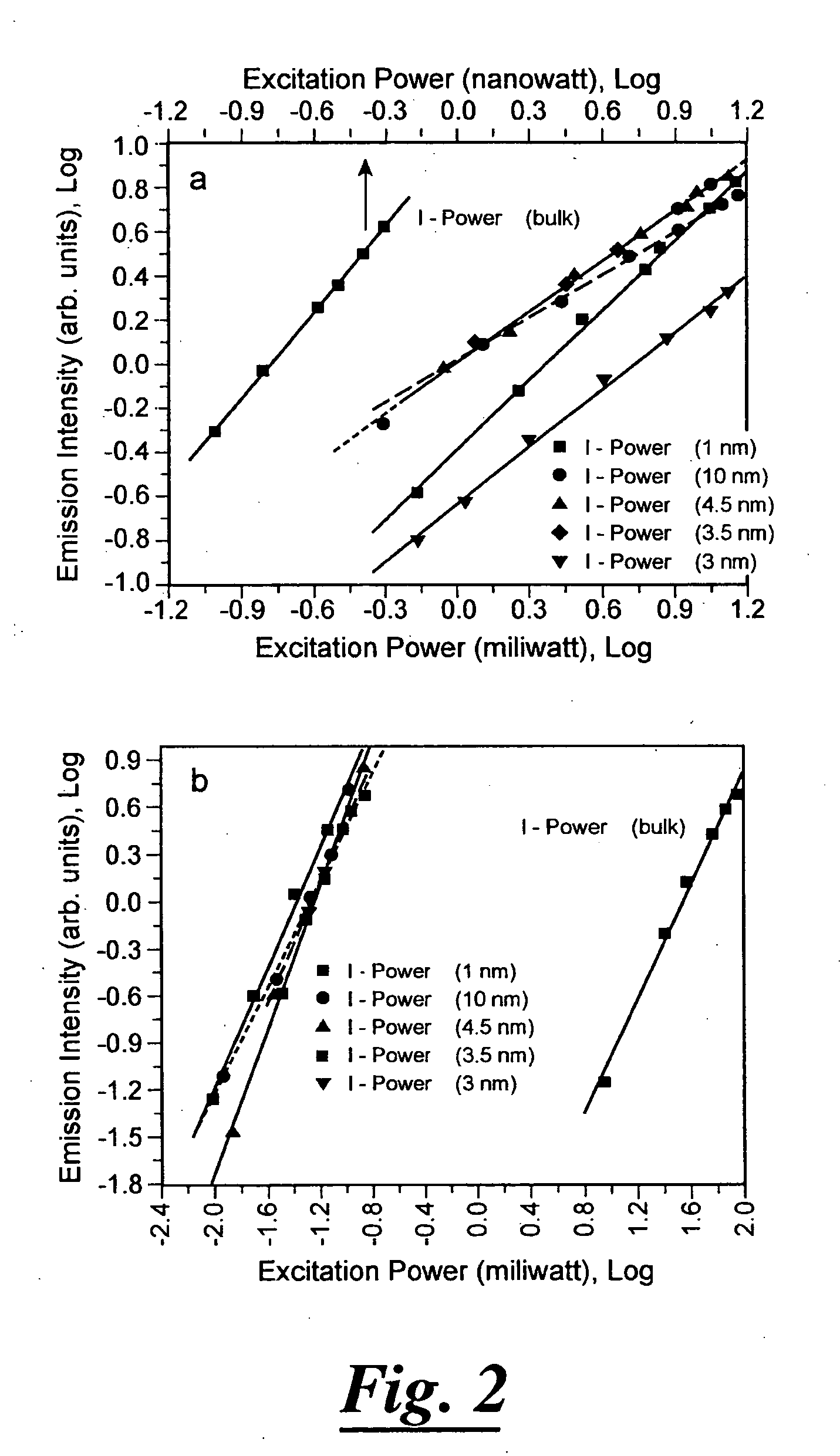

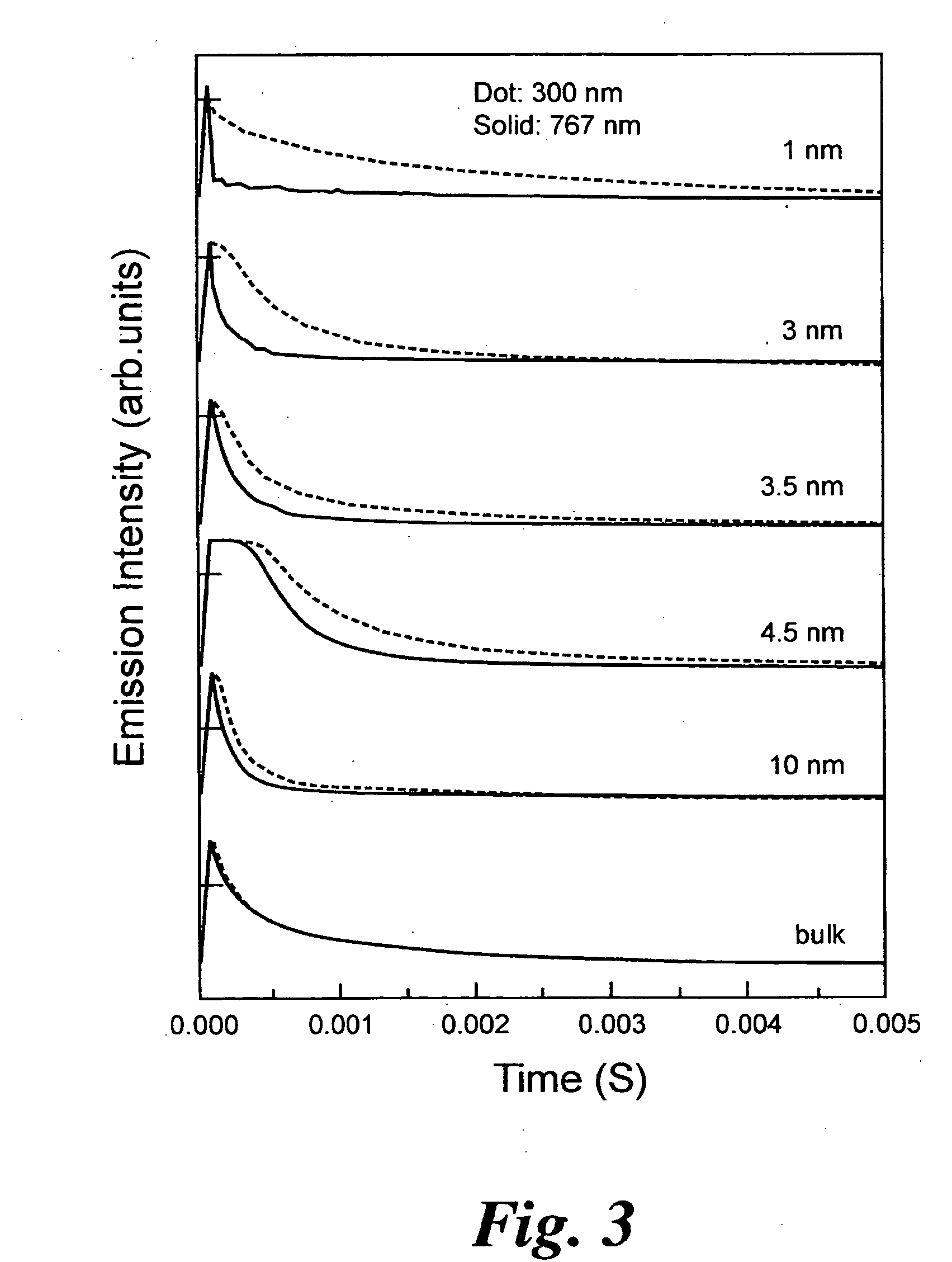

InactiveUS20060140240A1Reduce luminous intensityWeather/light/corrosion resistanceExcitation process/apparatusTwo-photon absorptionUpconversion luminescence

The present relates in general to upconversion luminescence (“UCL”) materials and methods of making and using same and more particularly, but not meant to be limiting, to Mn2+ doped semiconductor nanoparticles for use as UCL materials. The present invention also relates in general to upconversion luminescence including two-photon absorption upconversion, and potential applications using UCL materials, including light emitting diodes, upconversion lasers, infrared detectors, chemical sensors, temperature sensors and biological labels, all of which incorporate a UCL material.

Owner:FLIR DETECTION

Method for comprehensively extracting synephrine and hesperidine from immature bitter orange raw material

ActiveCN102050855AReduce manufacturing costEasy extractionSugar derivativesOrganic compound preparationOrganic solventSolvent

The invention discloses a method for comprehensively extracting synephrine and hesperidine from an immature bitter orange raw material, which overcomes the disadvantage of resource waste because two products cannot be comprehensively developed in the prior art, optimizes extraction steps, reduces production cost and improves operability. The method comprises the following steps of: after crushingthe raw material, extracting by adopting an alkaline organic solvent; combining the extract; concentrating to the specific gravity of 1.05; filtering, decoloring the filtrate; adjusting the filtrate to be neutral; filtering to obtain a hesperidine product, wherein the yield is 25 percent and the content is 95 percent; adjusting mother liquor obtained by filtering to be strongly alkaline; extracting by adopting a mixed organic solvent; and concentrating to a certain volume and adding a low-polarity solvent for crystallizing, wherein the product yield is 1.2 percent and the synephrine content is 98 percent. The method makes full use of the immature bitter orange raw material, designs a process for producing the two products, namely the synephrine and the hesperidine, at the same time, greatly reduces the production cost, optimizes an overall extraction process, shortens a process flow and saves the production cost.

Owner:三原润禾生物科技有限公司

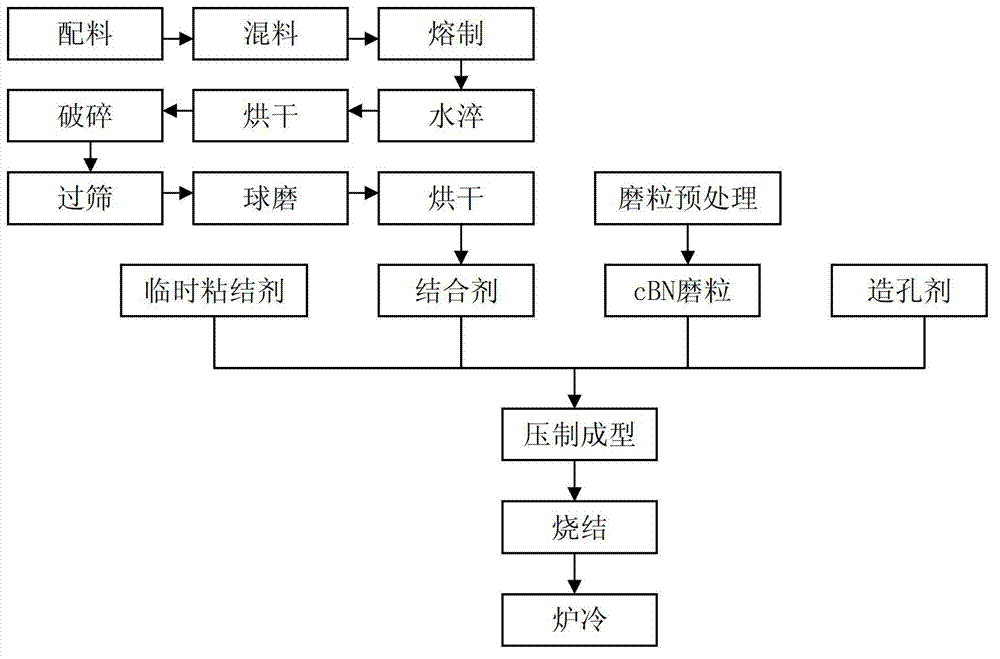

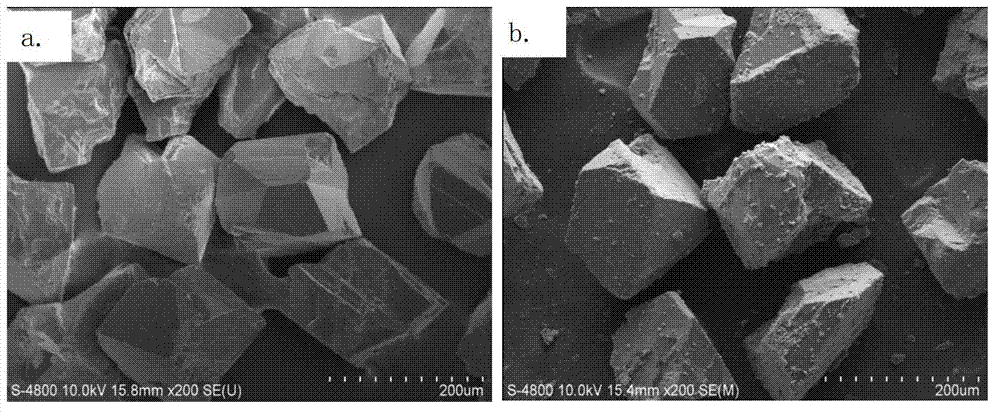

Ceramic bond cubic boron nitride abrasive tool and manufacturing method thereof

The invention discloses a ceramic bond cubic boron nitride abrasive tool and a manufacturing method of the ceramic bond cubic boron nitride abrasive tool. The method comprises preparing materials and mixing, placing mixed materials in an electric furnace for melting, conducting water quenching to prepare ceramic bond blocks, conducting smashing, ball-milling, sieving and drying on the ceramic bond blocks to prepare ceramic bond powder, conducting surface oxidation modified pretreatment on cubic boron nitride (cBN) grains, evenly mixing the ceramic bond powder, the cubic boron nitride (cBN) grains and a pore-forming agent NH4HCO3, obtaining a mixture, adding temporary binding agent polyethylene glycol in the mixture, evenly mixing to obtain abrasive tool raw materials, placing the abrasive tool raw materials in a die, conducting pressing shaping on a pressure machine to prepare an abrasive tool green body, placing the abrasive tool green body in a sintering furnace for sinter molding, and preparing the ceramic bond cubic boron nitride abrasive tool along with cooling of the furnace. The ceramic bond cubic boron nitride abrasive tool improves total strength of the abrasive tool, enables the abrasive tool to be not easy to break in using process, improves using safety of the abrasive tool, and prolongs service life of the abrasive tool.

Owner:XI AN JIAOTONG UNIV

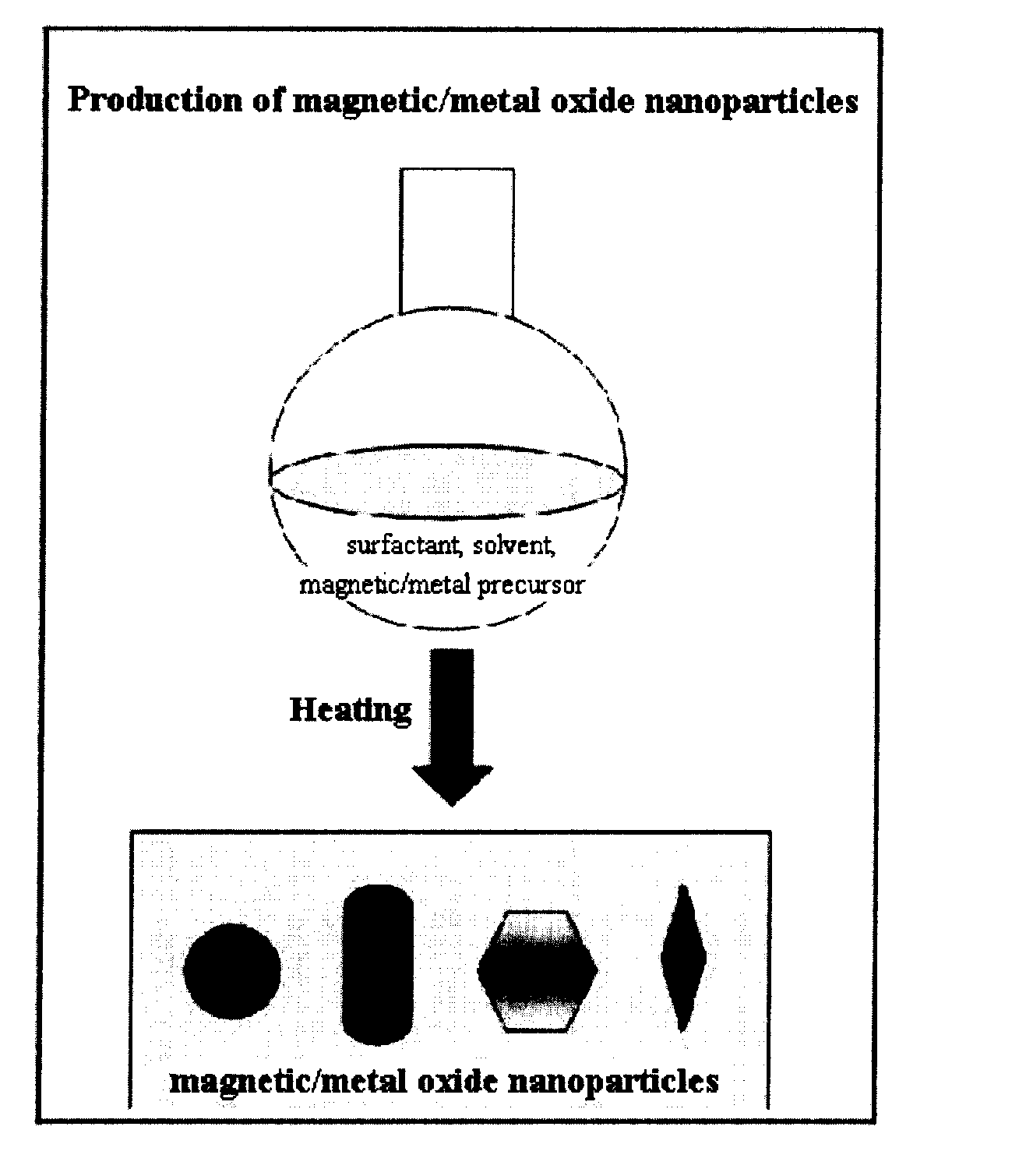

Preparation Method of Magnetic and Metal Oxide Nanoparticles

ActiveUS20080003159A1Efficient mass productionUniform shapeCopper oxides/halidesManganese oxides/hydroxidesMetal oxide nanoparticlesMagnetic oxide

This invention relates, in general, to a method of producing magnetic oxide nanoparticles or metal oxide nanoparticles and, more particularly, to a method of producing magnetic or metal oxide nanoparticles, which comprises (1) adding a magnetic or metal precursor to a surfactant or a solvent containing the surfactant to produce a mixed solution, (2) heating the mixed solution to 50-6001 C to decompose the magnetic or metal precursor by heating so as to form the magnetic or metal oxide nanoparticles, and (3) separating the magnetic or metal oxide nanoparticles. Since the method is achieved through a simple process without using an oxidizing agent or a reducing agent, it is possible to simply mass-produce uniform magnetic or metal oxide nanoparticles having desired sizes compared to the conventional method.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

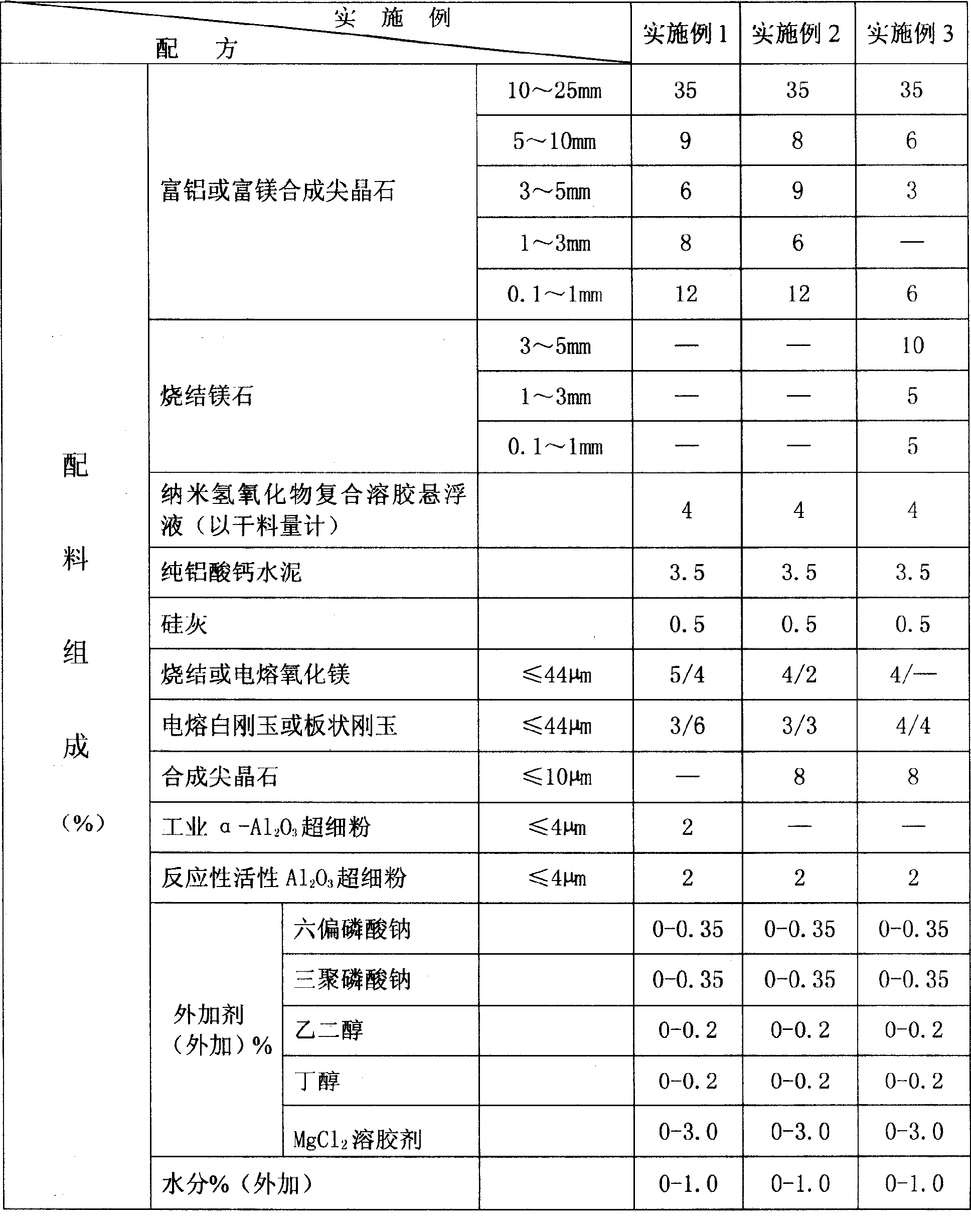

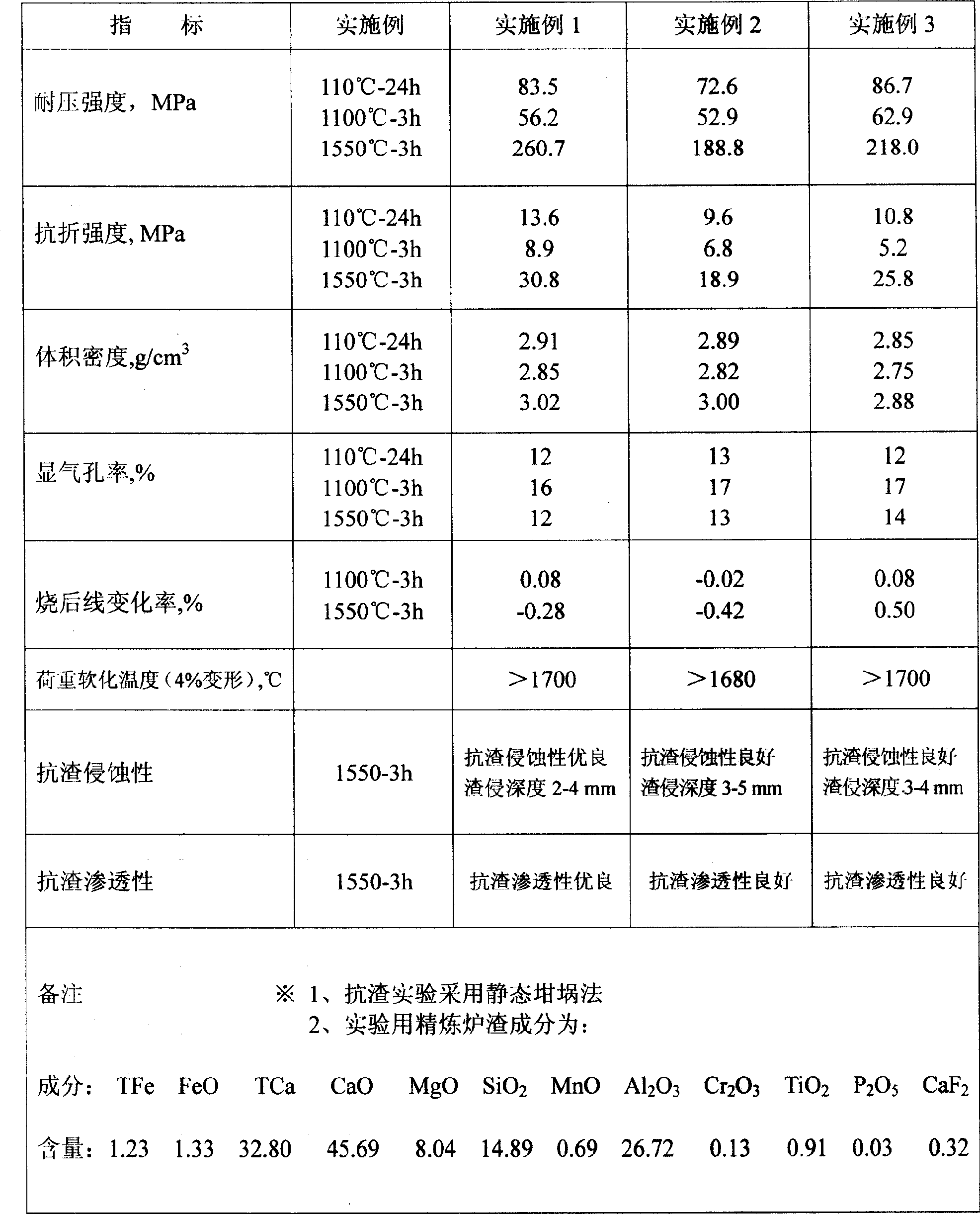

Nano Al2O3 and MgO composite ceramic bonded spinel-magnesia fireproof casting material and preparation method thereof

The invention relates to a nano Al2O3 and MgO composite oxide ceramic bonded spinel-magnesia fireproof casting material and a preparation method thereof. Al(OH)3 and Mg(OH)2 composite sol suspension is used as a nano ceramic bond, directly added into a mixture and subjected to in-situ synthesis reaction to form a nano structural matrix using spinel and magnesia as main components so as to form the nano spinel-magnesia fireproof casting material. The mixing materials of the casting material are characterized in that the spinel is used as aggregate or proper amount of sintered magnesia of less than or equal to 5 millimeters is added into the spinel aggregate to improve the total MgO content of the casting material; and the matrix material consists of a nano ceramic bond system, magnesia, little AlO3 with different properties and admixture, wherein after the synthesis reaction of the secondary spinel, the matrix material swells and is densified under constraint so as to cause the improvement of macrostructure and microstructure, improvement of performance and enhancement of durability and form the spinel-magnesia casting material with more excellent corrosion resistance and soakage resistance. The casting material is used in slag lines in integral secondary refining ladles, and obtains good using effect.

Owner:高树森

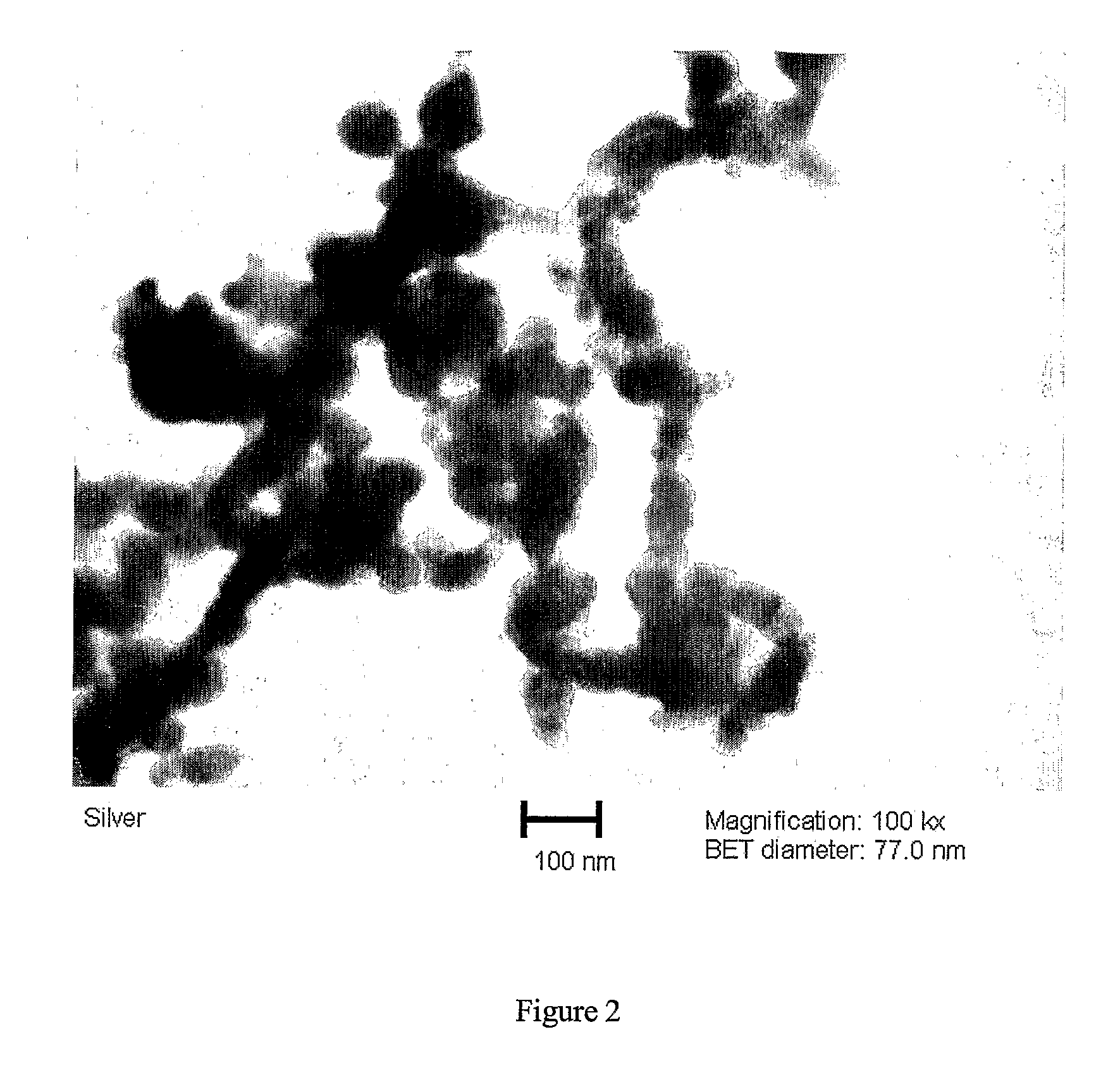

Carbon and Metal Nanomaterial Composition and Synthesis

InactiveUS20070272664A1High level and wide range of controlMaterial nanotechnologyPowder deliveryNanoparticleNanometre

The invention relates generally to nanopowder synthesis processes, and more particularly to the controlled use of a precursor material (such as a precursor gas) to assist in the formation of unagglomerated nanoparticles of the powder. It also relates to novel nanomaterials comprised of carbon and metals produced by the process along with the fundamental processes the novel nanomaterials enable.

Owner:NCC NANO LLC

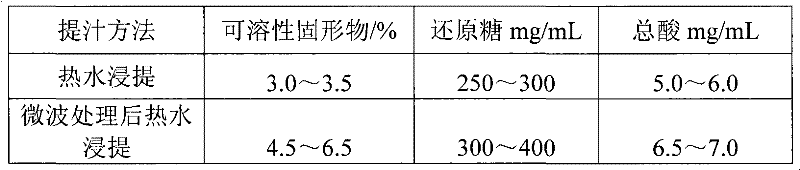

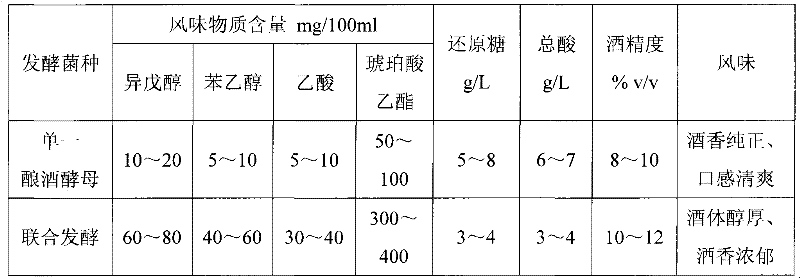

Brewing method of red date wine through multi-strain combined fermentation

InactiveCN102051310AImprove qualityGreat tasteAlcoholic beverage preparationMicroorganism based processesPichia pastorisFruit wine

The invention discloses multi-strain combined fermentation red date wine and a brewing method thereof, which belongs to the technical field of brewing. The red date wine is produced by taking red date as raw materials through such processes as pretreatment, digestion, enzymolysis, sterilization, fermentation, aging and clarification. The adopted Candida, Kloeckera, Hanseniaspora and Pichia pastoris move at the early stage of fruit wine fermentation generally, so that a great deal of aromatic substances and special flavor components can be generated, the quality of fruit wine is improved, and positive impact is generated on the total flavour of the red date wine. Non-brewing yeast and brewing yeast are accessed at different fermentation stages, the species and content of the flavor substances in the date wine can be increased through the combined fermentation of multiple strains, thereby improving the mouthfeel of the date wine and the quality of the date wine; the date wine has unique style, rich wine body, sweet and pure bouquet, fresh mouthfeel and typicality.

Owner:太原市汉波食品工业有限公司

Calcium treatment method for molten steel in steelmaking

The invention relates to a calcium treatment method for molten steel in steelmaking, which is the method for carrying out calcium treatment in two process steps in the steelmaking process route flow, and the steelmaking adopts the process route of pretreatment of molten iron plus smelting in a converter plus refining in an LF furnace plus RH refining plus continuous casting; the whole steelmaking process route adopts two times of calcium treatment; the first calcium treatment is to feed a calcium line into the molten steel to carry out the calcium treatment after finishing the LF treatment in the process step of refining in the LF furnace; and the second calcium treatment is to feed the calcium line into the molten steel to carry out the calcium treatment after finishing vacuum treatment in the process step of the RH refining. The application of the calcium treatment method for the molten steel in the steelmaking can respectively control the mass fractions of total oxygen and sulfur in a steel ball to be (5-20) multiplied by 106 and (2-30) multiplied by 106 respectively, most of inclusion in the steel ball is spherical, the equivalent diameter of the inclusion is (1-10) mu m, the qualified rate of the fault detection of a steel plate after rolling is larger than 99%, the B type inclusion grading is reduced as a whole, the proportion of the grade below grade 1 is 97%, and the control level of the inclusion is significantly improved.

Owner:NANJING IRON & STEEL CO LTD

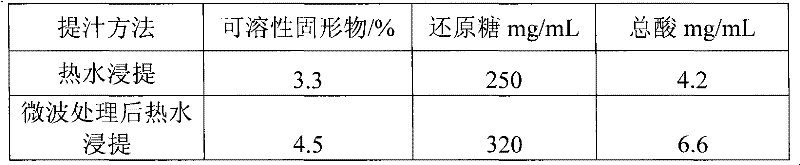

Brewing method of moso bamboo shoot wine

ActiveCN103409284AEfficient use ofHigh degreeAlcoholic beverage preparationMicroorganism based processesBamboo shootGeneral Appearance

The invention provides a brewing method of moso bamboo shoot wine. The brewing method comprises the following steps of (1) preparing materials and removing shells; (2) washing; (3) crushing; (4) distributing materials; (5) cooking; (6) saccharifying; (7) degrading cellulase and feeding sugar; (8) fermenting; (9) distilling; and (10) aging, mixing and packaging. The brewing method provided by the invention is simple in process and short in fermentation time; the general appearance of the brewed moso bamboo shoot wine is colorless, is bright and transparent and has no suspension matter and sediment; all tastes of the wine are coordinated and the wine is fragrant and pure, has a long-time sweet taste and is sweet and soft; the aftertaste is pure and cool.

Owner:HUNAN ACAD OF FORESTRY

Vibration molding-based method for design of mix proportion of graded broken stones

InactiveCN102021872AImprove compactionImprove road performanceIn situ pavingsCrushed stoneEngineering

The invention relates to a vibration molding-based method for design of mix proportion of graded broken stones, comprising the following steps: (1) selecting raw materials: selecting limestone as the base stone of the graded broken stones, adopting a reaction crusher to roll till the technical requirements are met; and selecting drinking water as added water for the mixture of the graded broken stones; (2) preparing optimized graded broken stones; (3) adding the drinking water into the graded broken stones in the step (2) according to 4-5% of water content to prepare a plurality of groups of mixtures of the graded broken stones; (4) carrying out vibrating compaction on the groups of mixtures of the graded broken stones obtained in the step (3), and determining the optimum water content and maximum dry density of the mixture of the graded broken stones under a vibrating compaction test mode; and (5) verifying the performances: under the conditions of the optimum water content and the maximum dry density determined by the step (4) and 98% of compaction degree, adopting a vibration molding test method to determine the California bearing ratio (CBR) of a test piece. The mixtures of the graded broken stones designed by adopting the method have the characteristics that the strength is high, the total quality is high, the construction is simple and convenient and the cost is low.

Owner:天津市市政工程研究院

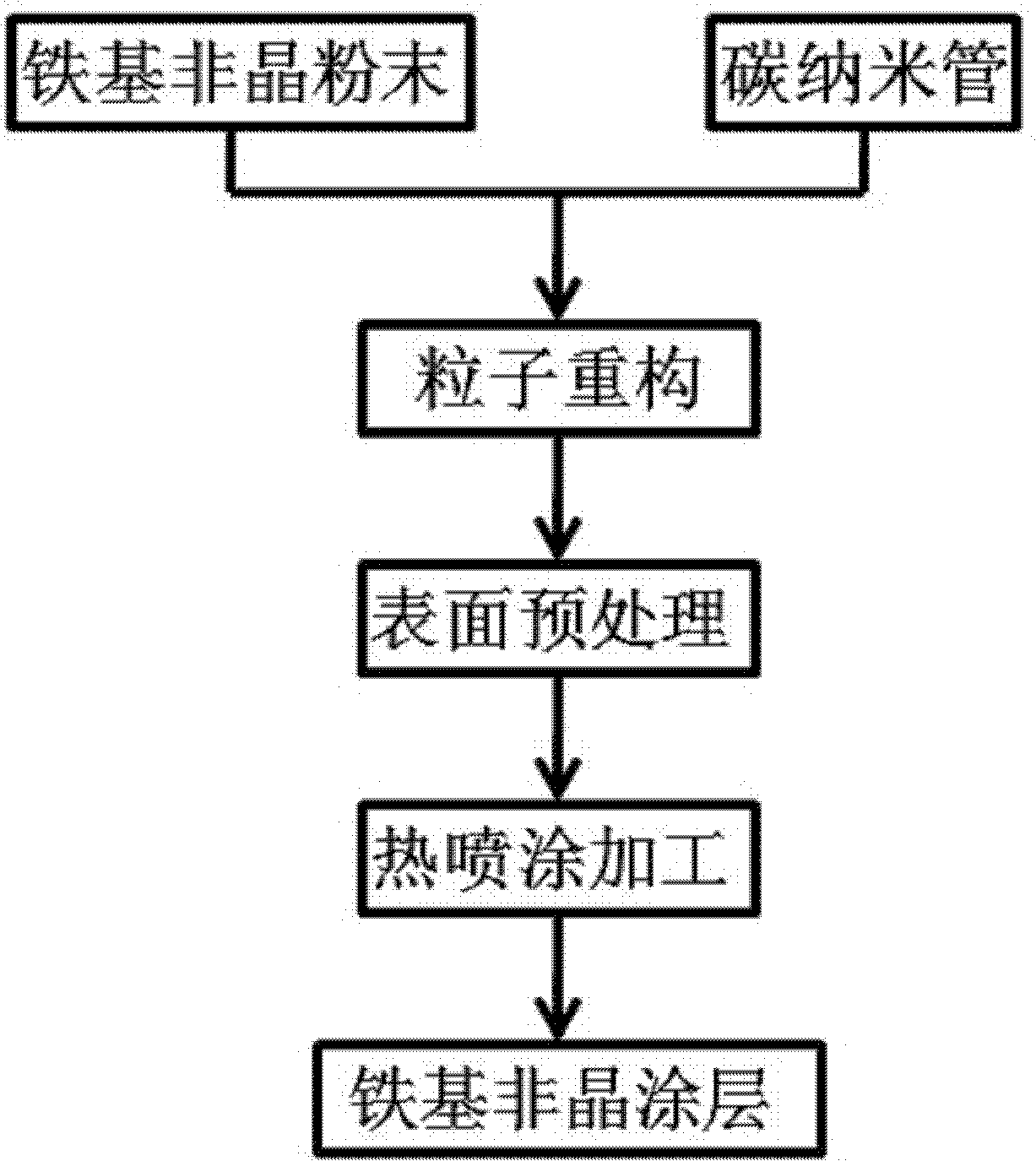

Production of carbon nanotube reinforced Fe-based amorphous alloy thermal spray coating and method

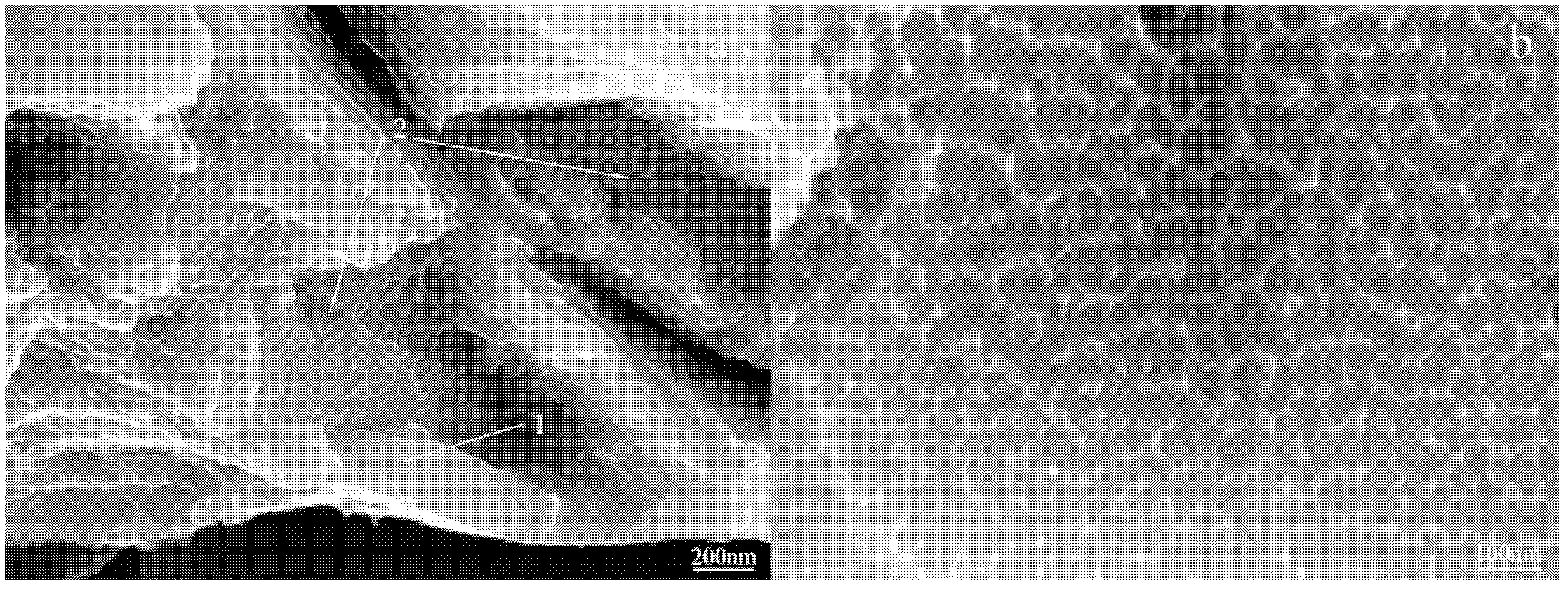

InactiveCN102650027AImprove toughnessPlay a reinforcing roleMolten spray coatingSpray GranulationThermal spraying

The invention provides the production of a carbon nanotube reinforced high tenacity Fe-based amorphous alloy thermal spray coating and a method. A mechanical ball-milling method or a spray granulation method is utilized to reconstruct Fe-based amorphous powder and a carbon nanotube to form Fe-based amorphous-carbon nanotube composite powder; a spraying material surface is pretreated; and the thermal spraying process is carried out, a plasma spraying technology is adopted to spray the Fe-based amorphous-carbon nanotube composite powder, so the high strength and tenacity Fe-based amorphous coating is produced. The Fe-based amorphous alloy powder comprises components of C, B, Ni, Si, Mo, Cr, W and Fe; and the granularity is 1-100mum. The carbon nanotube is a multi-wall carbon nanotube which has the purity larger than 95%, the external diameter of 8-70nm and the length of 100nm-20mum. The carbon nanotube and the Fe-based amorphous are well combined in the coating, so the reinforcing effect is obvious; and the coating fracture surface presents an appearance of total brittle fracture and local ductile fracture, both the tenacity and strength of the Fe-based amorphous are improved, so a practicable and feasible method for applying the Fe-based amorphous coating in a project is provided.

Owner:TIANJIN UNIV

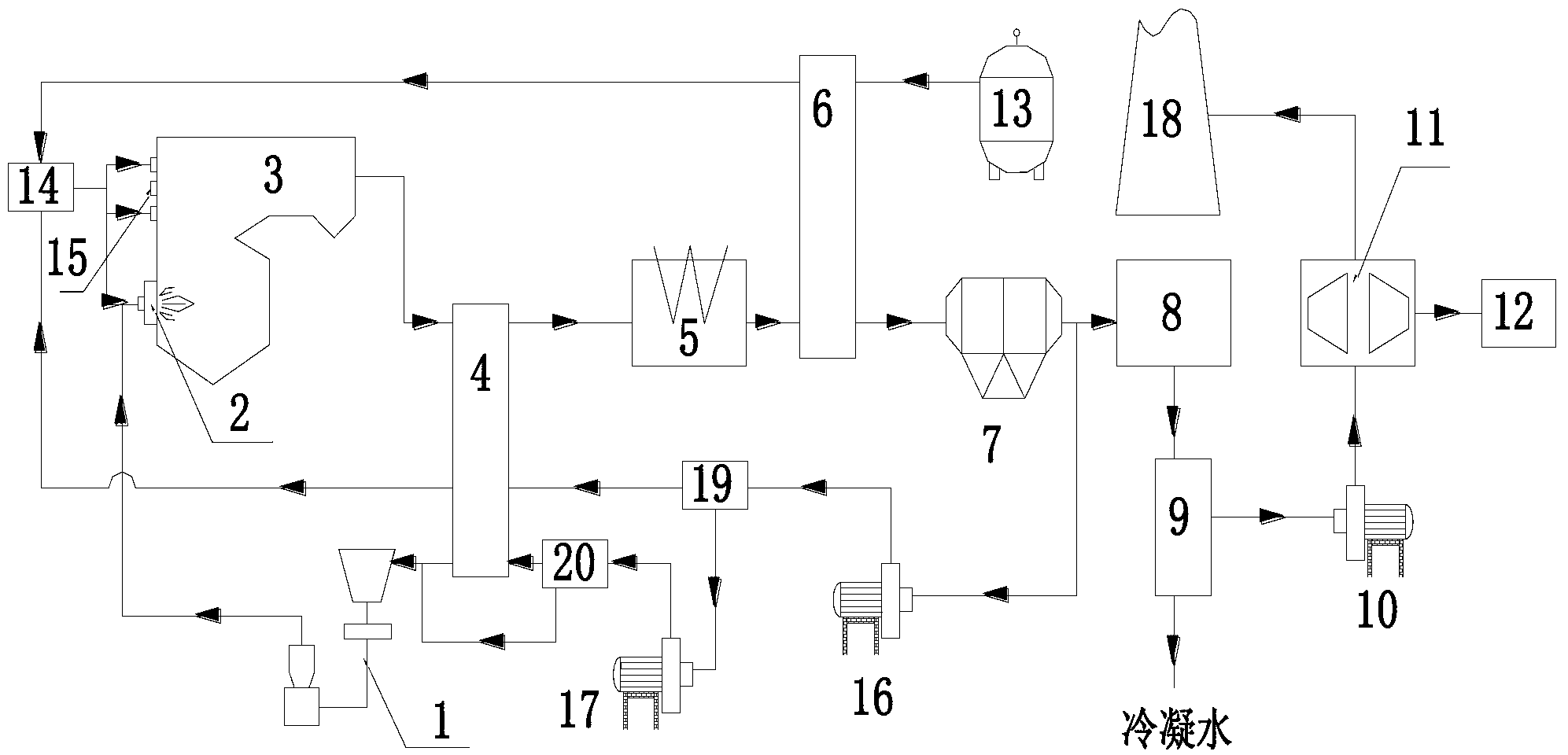

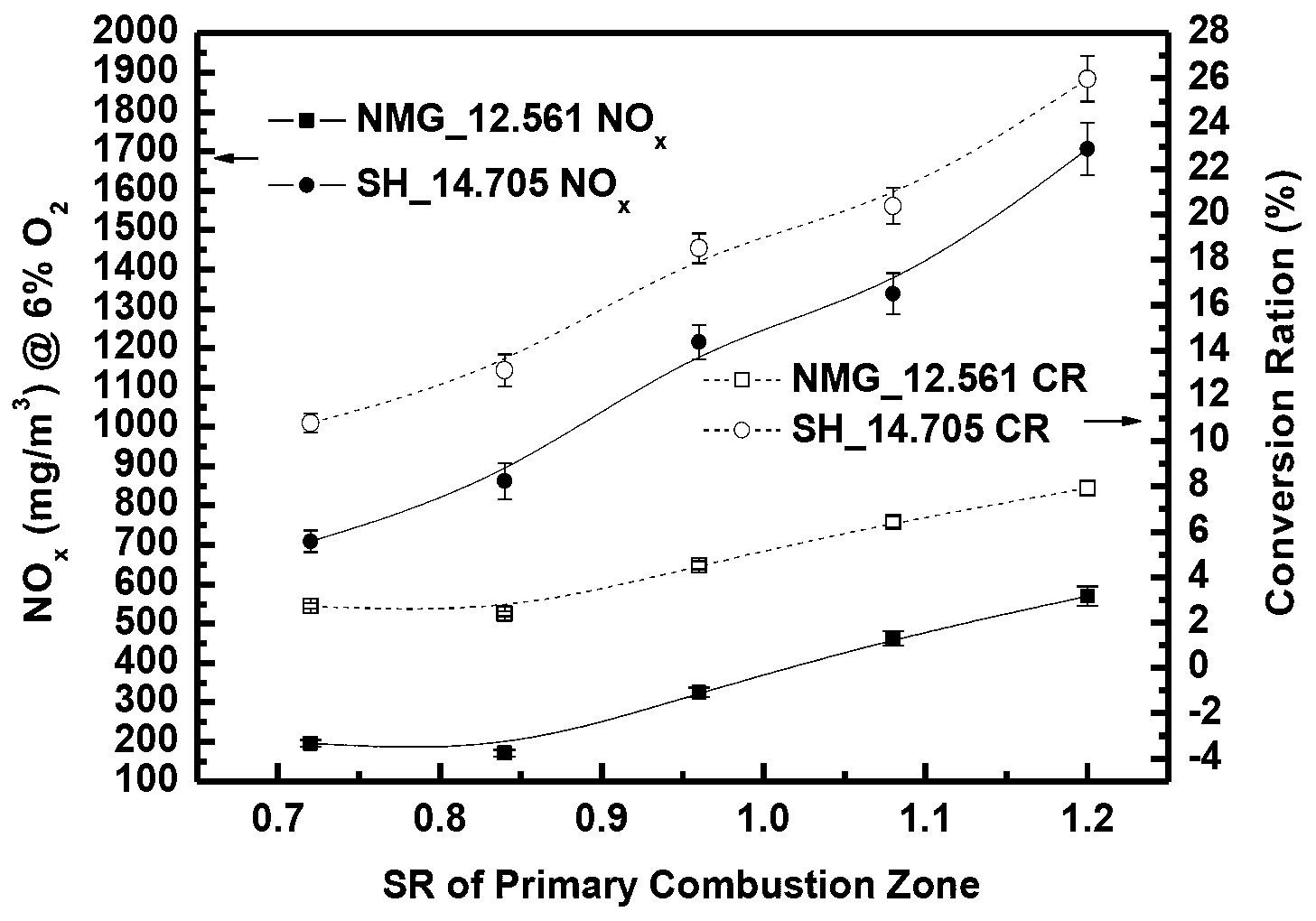

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

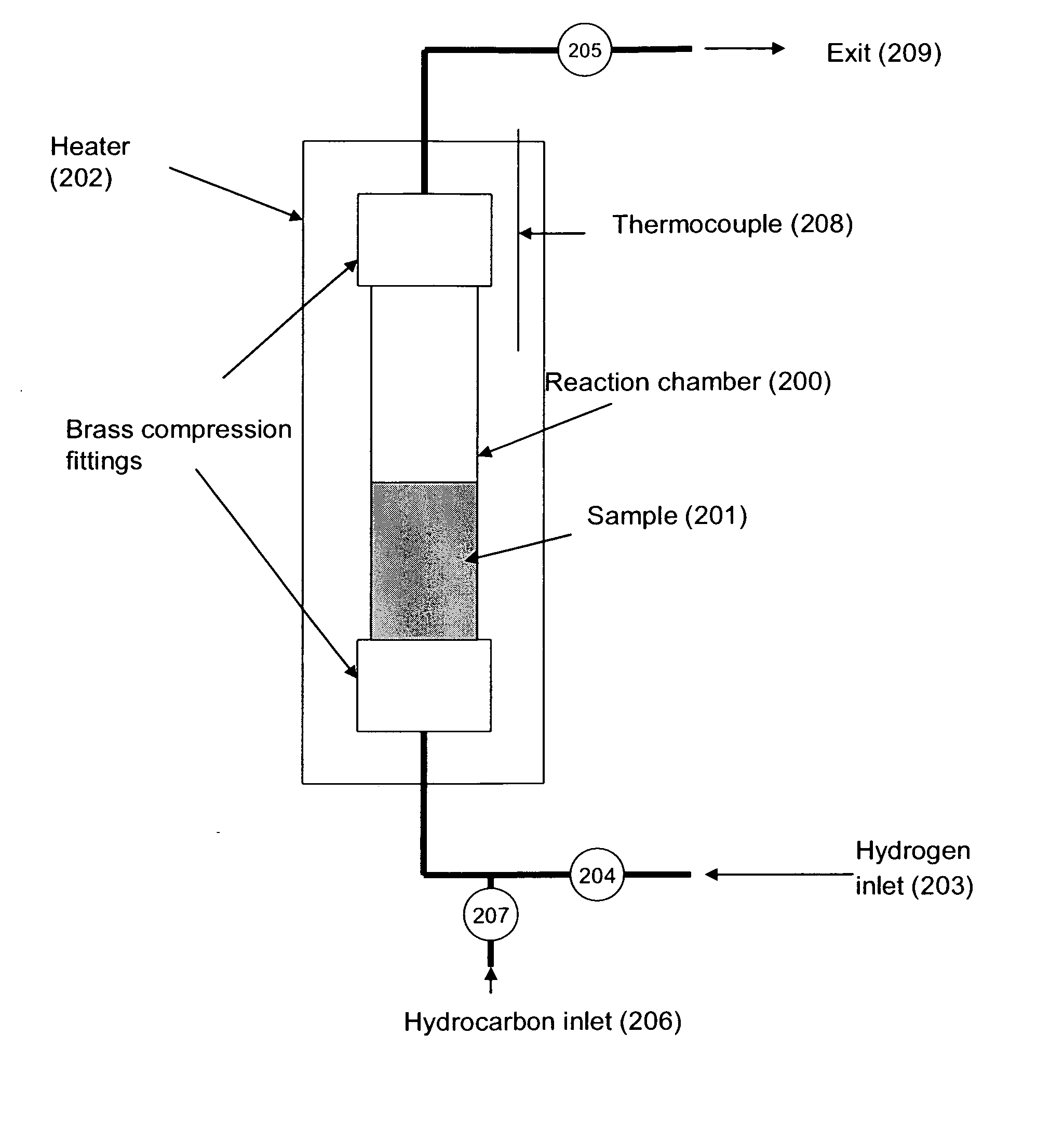

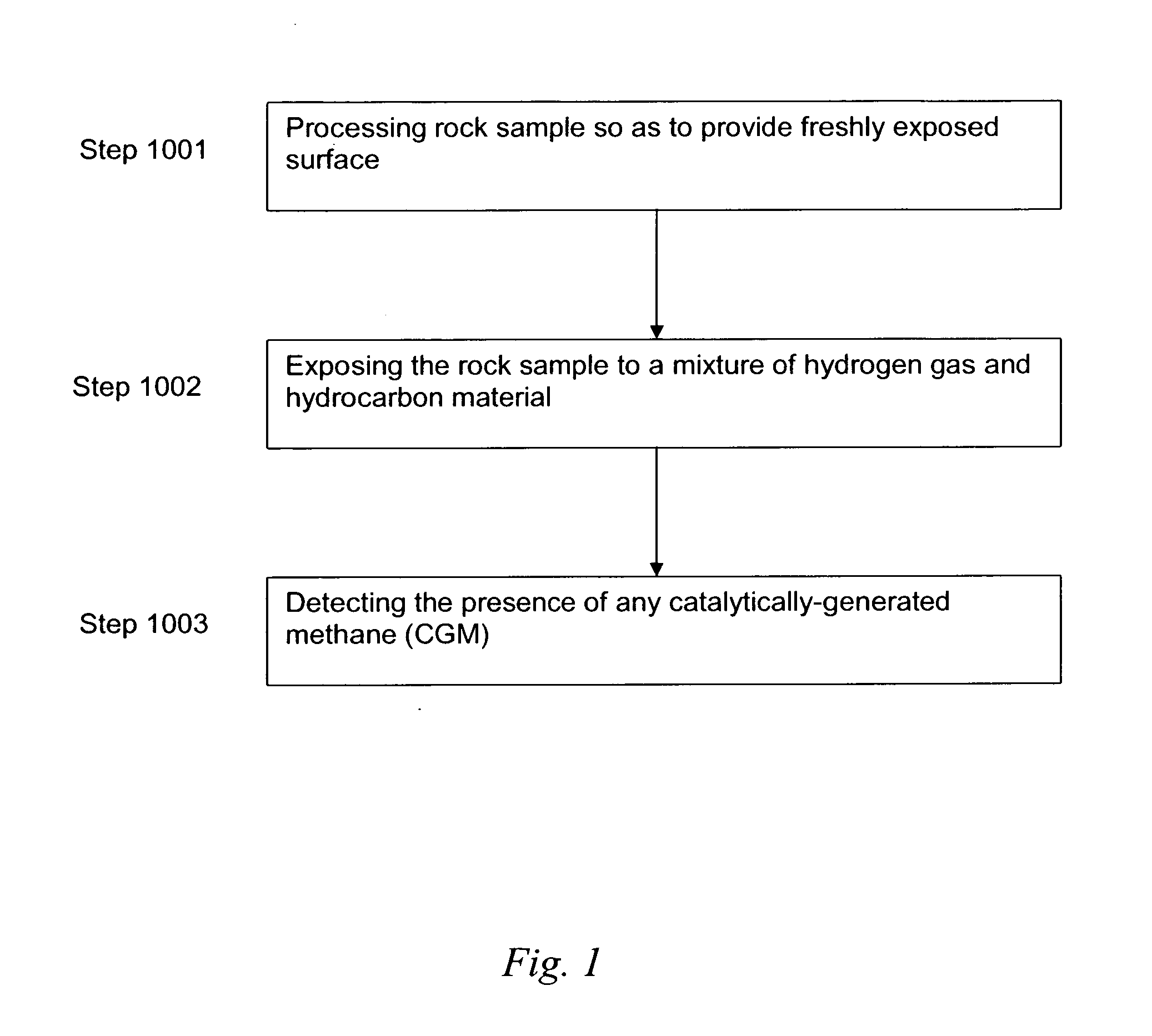

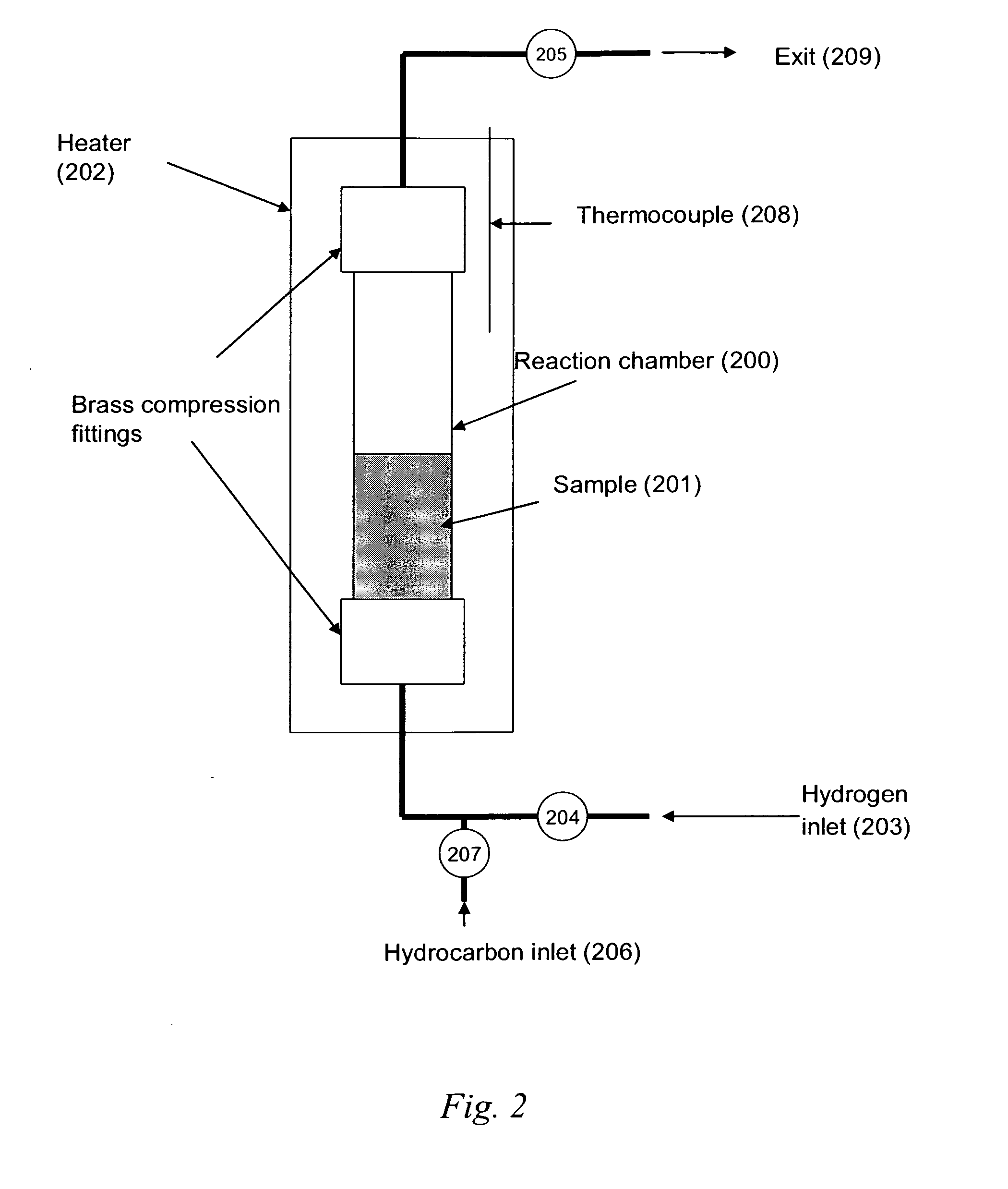

Novel well logging method for the determination of catalytic activity

InactiveUS20060117841A1Chemical analysis using catalysisEarth material testingWell loggingLinear relationship

The present invention relates to assays for ascribing catalytic activity to rock samples by virtue of zero-valent transition metals potentially being present within the sample. Embodiments of the present invention are generally directed to novel assays for measuring intrinsic paleocatalytic activities (k) of sedimentary rocks for converting oil to gas and projecting the activities to the subsurface based on the measured linear relationship between ln(k) and temperature (T).

Owner:PETROLEUM HABITATS LLC

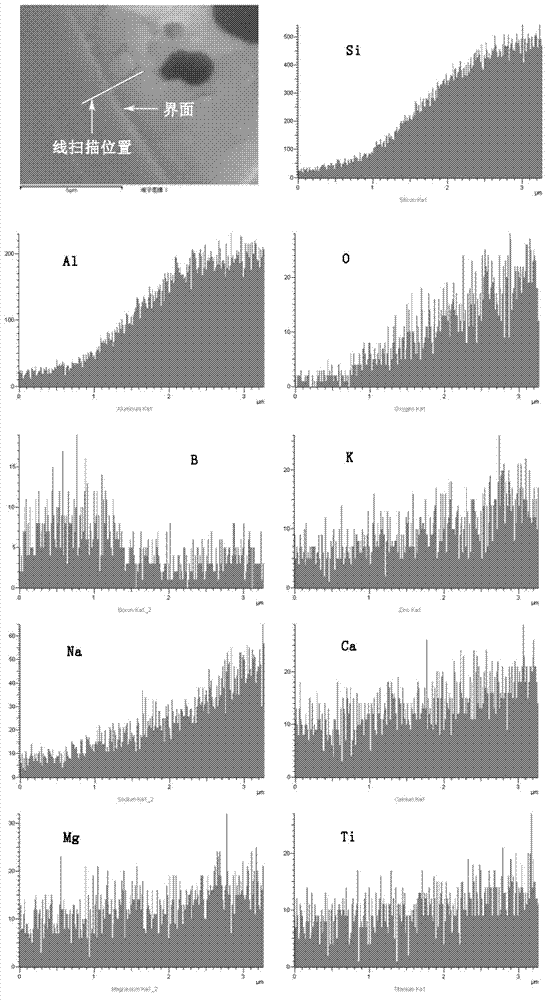

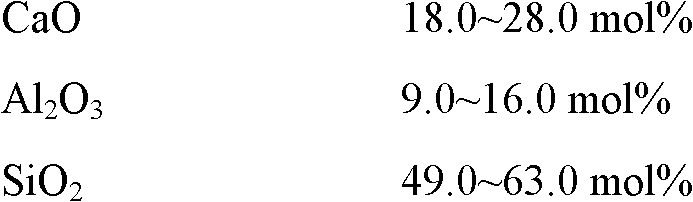

Calcium-aluminum-boron-silicon glass and fused quartz low-temperature co-fired ceramic material and preparation method thereof

The invention relates to a calcium-aluminum-boron-silicon glass and fused quartz low-temperature co-fired ceramic material and a preparation method thereof. In the ceramic material, the calcium-aluminum-boron-silicon low-melting-point glass phase accounts for 50-70% of the total material mass. The preparation method comprises the steps of: weighing raw materials according to the molar percentages of oxides required by the low-melting-point glass phase, maintaining the temperature at 1500-1600 DEG C for 3-5 hours, directly pouring the molten glass into deionized water to obtain glass slag, and ball-milling to obtain glass powder with average granularity of 1-3 mu m; ball-milling fused quartz to obtain fused quartz powder with average granularity of 3-5 mu m; uniformly mixing 50-70wt% of low-melting-point glass phase and high-melting-point ceramic filling phase, adding a polyvinyl alcohol adhesive accounting for 3wt% of the mixed material, granulating and carrying out dry pressing to obtain blank sheets; and sintering to obtain the low-temperature co-fired ceramic material. The obtained low-temperature co-fired ceramic material has low sintering temperature, and can be co-fired with gold, silver, copper and other conductor materials; the obtained material is high in densification degree, low porosity and lower in thermal expansion coefficient; and the process flow is simple and the cost is low.

Owner:TIANJIN UNIV

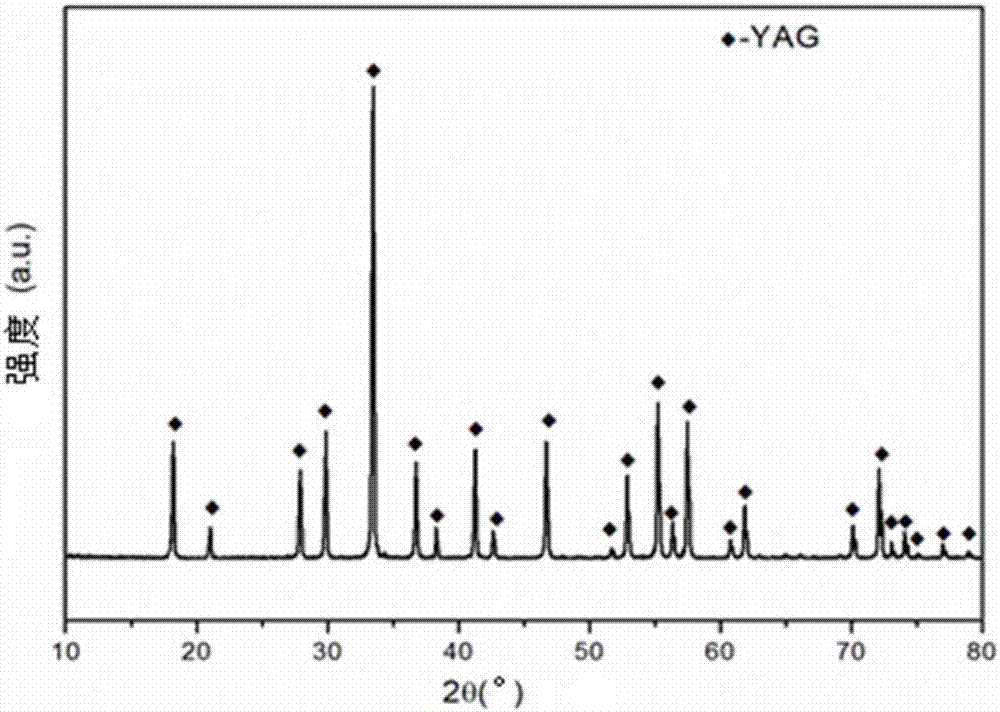

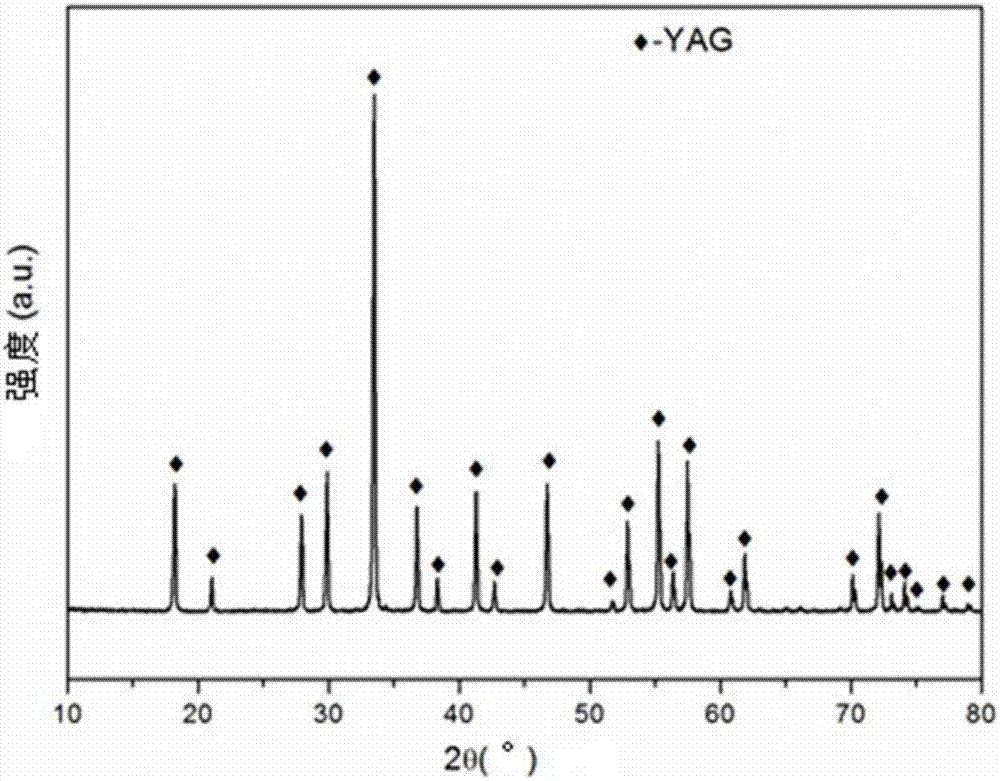

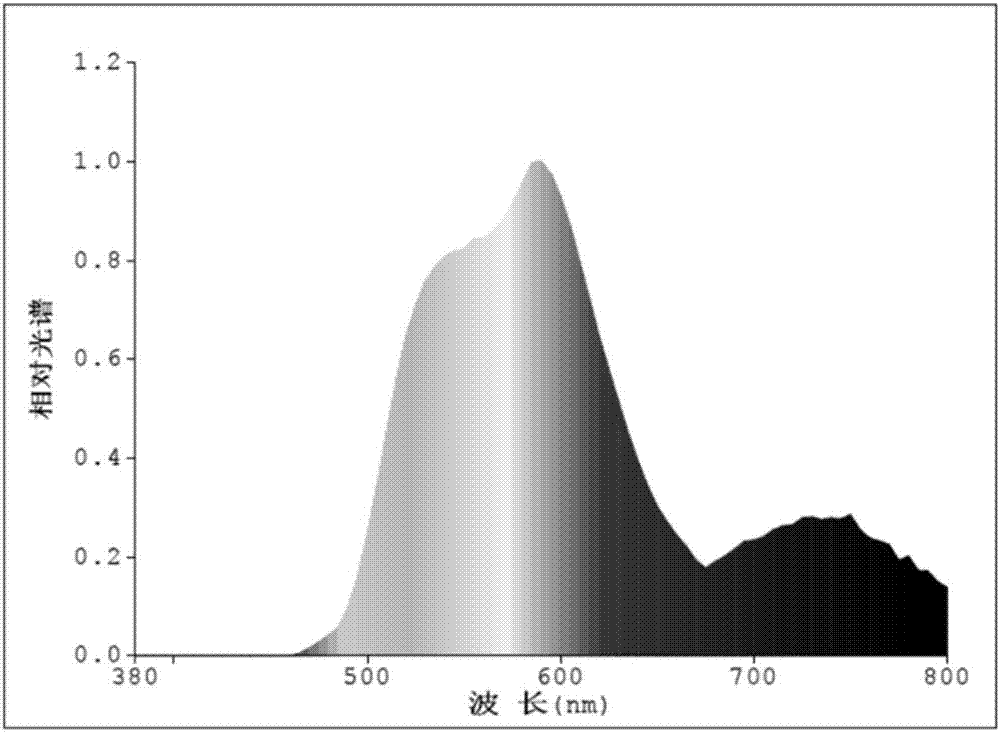

YAG (yttrium aluminum garnet)-type fluorescent powder, preparation method of YAG-type fluorescent powder, YAG-type transparent ceramic fluorescent body prepared from YAG-type fluorescent powder and application of YAG-type transparent ceramic fluorescent body

InactiveCN107384399AImprove low color rendering indexImprove the problem of high color temperatureEnergy efficient lightingLuminescent compositionsRare-earth elementOrganic solvent

The application discloses YAG (yttrium aluminum garnet)-type fluorescent powder and preparation method thereof. The YAG-type fluorescent powder comprises R(3-x)Al(5-2y)O12:xCe<3+>, yMn<2+> and yM<4+>, wherein R is selected from at least one of rare earth elements; M<4+> is a valence state compensation ion; x is equal to 0.005-0.2; and y is equal to 0.05-0.4. The preparation method comprises the following steps: mixing all the materials into an organic solvent; calcining in the reducing atmosphere, so as to obtain the YAG-type fluorescent powder. High-quality white light with soft color and high color rendering index can be generated by a YAG-type fluorescent transparent ceramic prepared from the YAG-type fluorescent powder instead of fluorescent powder and an organic resin or silica gel encapsulating material in the existing white light LED (light-emitting diode), and an encapsulating structure, the lighting effect and the stability of an LED light source can be globally optimized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of low-mercury compound catalyst for producing vinyl chloride

ActiveCN102500421AExtended service lifeGood dispersionPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsEvaporationChloride

The invention discloses a preparation method of a low-mercury compound catalyst for producing vinyl chloride, which relates to the catalyst which contains metallic mercury and nickel, and comprises the steps that: firstly a coaly carbon carrier is soaked in aqua regia, and simultaneously flows back in the aqueous solution of triethylamine, is stirred and pre-treated; then surfactant hexadecyltrimethylammonium chloride and additive nickel chloride are added by the mass ratio that hexadecyltrimethylammonium chloride: HgCl2 is 2.85 to 7.65: 4 to 6.5 and NiCl2: HgC12 is 4:4 to 6.5, and impregnated in a vacuum rotary evaporation way, wherein the prepared HgCl2 accounts for 4 percent to 6.5 percent of the total mass of the catalyst and NiCl2 accounts for 4 percent of the total mass of the catalyst, the hexadecyltrimethylammonium chlorid accounts for 2.85 percent to 7.65 percent of the total mass of the catalyst, and the balance is the low-mercury compound catalyst of C, so that the activity, stability and selectivity of the low-mercury compound catalyst are also significantly improved while the mercury content is reduced.

Owner:内蒙古海驰高科新材有限公司

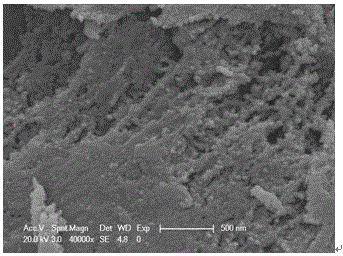

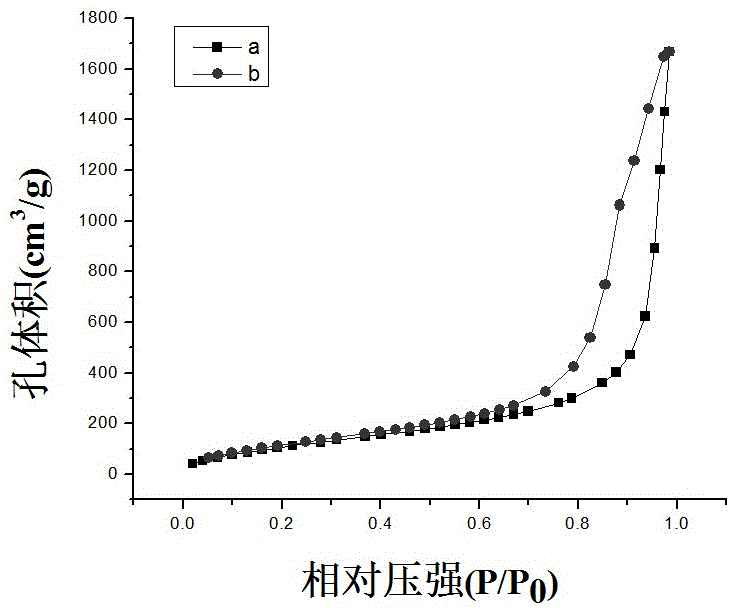

Preparation method of polyimide/silicon dioxide aerogel powder composite aerogel material

The invention relates to a preparation method of a polyimide / silicon dioxide aerogel powder composite aerogel material. Polyamide acid sol is synthesized from diamine and dianhydride monomers with a sol-gel method, common silicon dioxide aerogel particles and a polyamide acid solution are evenly mixed, composite gel is formed through a chemical imidization process, drying is performed with a supercritical drying technology, and the polyimide / silicon dioxide aerogel powder composite aerogel material is prepared. The method has the characteristics of wide application range, simple reaction process, low total cost and the like. High-temperature-resistant polymer polyimide plays roles in collecting and fixing silicon dioxide powder, and the nano-porous structure and excellent performance of the silicon dioxide aerogel are reserved. The introduction of inorganic silicon dioxide aerogel powder plays a role in inhibiting shrinking of organic polyimide. The material has excellent heat shielding performance and the heat conductivity is only 0.028-0.032 W / mK. The modulus of the composite aerogel is higher than that of pure silicon dioxide aerogel and is 0.8-11.8 MPa, and powder embedded in polyimide cannot fall off.

Owner:TONGJI UNIV

Low-density ceramic proppant and preparation method thereof

InactiveCN102516977AWide variety of sourcesEasy to purchaseFluid removalExpanded clay aggregateAlkali feldspar

The invention belongs to the technical field of solid proppants for oil and gas well fracturing technologies, and in particular, relates to a low-density ceramic proppant and a preparation method thereof. The proppant is prepared from the following raw materials: bauxite, clay, potassium feldspar, quartz, limestone and dolomite. The raw materials are wide in source, convenient to purchase and low in price; the production technology is simple, convenient and fast; and the cost of the ceramic proppant is generally reduced.

Owner:SANMENXIA FANGYUAN IND

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

Comprehensive utilization method of waste concrete

InactiveCN101665369AHigh activityReduce consumptionSolid waste managementBuilding componentsBrickSteam pressure

The invention discloses a comprehensive utilization method of waste concrete, which belongs to the technical field of building materials. The method comprises the following steps: calcining waste concrete at high temperature and then grinding and smashing the waste concrete; when the concrete reaches certain fineness, adding additive agents such as flyash, sand, a small amount of water, and the like to carry out semi-dry pressing; preparing load-bearing blocks by steam pressure curing; or adding additive agents such as the flyash, cement, aluminum powder paste, and the like, stirring and pouring the materials into moulds to mold and preparing aerated concrete blocks through steam pressure curing after foaming. The total additive amount of the waste concrete and the flyash is more than 90 percent, thereby greatly reducing the dependence on limited mineral resources, and moreover, the waste concrete is utilized 100 percent at a time without respective utilization in grades.

Owner:SHANDONG JIANZHU UNIV

Photocatalytic concrete material to which titanium dioxide/activated zeolite composite material is sprayed and preparation method of photocatalytic concrete material

ActiveCN105884396AImprove adsorption capacityImprove photocatalytic degradation efficiencyMolecular sieve catalystsCatalyst activation/preparationMolecular sievePhotocatalytic degradation

The invention provides a photocatalytic concrete material to which a titanium dioxide / activated zeolite composite material is sprayed and a preparation method of the photocatalytic concrete material. The photocatalytic concrete material to which a titanium dioxide / activated zeolite composite material is sprayed is prepared from, by weight, 0.1-20 parts of titanium dioxide, 0.1-20 parts of activated zeolite molecular sieve, 0.1-5 parts of dispersant, 0.05-2 parts of emulsifier, 0.05-2 parts of coupling agent, 40-90 parts of cement, 40-90 parts of fine sand and the balance water. The activated zeolite molecular sieve is suitable for serving as a carrier and can well load a titanium dioxide photocatalytic material, due to the large specific area (280.1 m<2) / g), gaseous pollutants in automobile exhaust can be easily adsorbed, photocatalytic degradation efficiency is improved accordingly, the photocatalytic degradation rate of the material can reach 92%, the advantages that the preparation process is simple, production raw materials are cheap, and the total preparation cost is low are achieved, and the photocatalytic concrete material is suitable for industrial production.

Owner:YANCHENG INST OF TECH

Porous composite biological material containing multiple active ions and preparation method thereof

InactiveCN103520779AImprove conductivityPromote formationCoatingsProsthesisPhosphateBiological materials

The invention discloses a porous composite biological material containing multiple active ions and a preparation method thereof, relating to the technical filed of production of medical materials. The porous composite biological material is a triple compound containing multiple active ions and calcium phosphate-silicate-calcium carbonate, and is composed of a porous ceramic structure main body containing active ions A and calcium phosphate-calcium carbonate and a phosphate-silicate cement coating, wherein both phosphate and silicate in the phosphate-silicate cement coating contain active ions B and calcium; and the phosphate-silicate cement coating accounts for 5-60% (mass percent) of the micropore structure main body. According to the invention, the exquisite three-dimensional intercommunication micropore structure of cuttlebone having extremely high porosity is kept, has excellent bone conductibility and favorable degradability, and can be subjected to stepped degradation; the release of the active ions and beneficial elements can be regulated and controlled; and the overall degradation rate of the material can be regulated according to different new bone formation requirements.

Owner:李亚屏

Medical wheat yellow wine yeast and making method thereof

InactiveCN101323824AQuality improvementGreat tasteAlcoholic beverage preparationBiotechnologyFermentation

The invention discloses a medicinal wheat yellow wine mold culture and a preparation method thereof. The material components of the mold culture (weight is calculated by kg) are as follows: wheat: 1000, golden cypress: 28 to 32, angelica: 8 to 12, combined spicebush: 37 to 43, tangerine peel: 8 to 10, marshmarigold to leaved beesia herb: 11 to 13, gardenia: 7 to 9, chrysanthemum: 10 to 14, contorta: 7 to 9, sagebrush: 9 to 11, carapace: 9 to 11, cinnamon: 7 to 9, almond: 5 to 7, small sweet herb: 10 to 12, anise tree: 7 to 9, Amomum tsao to ko: 8 to 10, Chinese prickly ash: 2 to 3, thorn seed: 75 to 85 and angelica root: 3 to 5; the integral process flow of the preparation method is raw materials-crushing-mixing-stirring-stepping-yeast production-fermenting-culture stage- ventilation stage-yeasting culture stage-taking out and storage. The medicinal wheat yellow wine mold culture of the invention integrates the advantages of the current wheat, wheat yeast and red rice, the preparation method causes the permeability of yeast base to be good and fermentation to be high active and complete, the yeast preparation process is easy to be controlled and the quality of finished yeast is stable. Yellow wine brewed by using the wheat yellow wine mold culture does not subside and has no suspended matters after a long period of storage, furthermore, the yellow wine tastes good and has stable quality and long quality guarantee period.

Owner:SHAANXI QINYANG CHANGSHENG WINERY

Preparation method of high-purity wind power fastener

InactiveCN109402320AEasy to useReduce H and O contentManufacturing convertersAlkalinitySmelting process

The invention discloses a preparation method of a high-purity wind power fastener. The preparation method of the high-purity wind power fastener comprises the following steps: (1) converter smelting:controlling the percentage by mass of C to be greater than or equal to 0.06% or controlling steel tapping TSO oxygen site to be less than or equal to 400 ppm at an end point, and enabling a steel tapping temperature to be greater than or equal to 1560 DEG C; (2) converter steel tapping: a, bottom stirring; and b, slag discharging; (3) deoxidization alloying: in the earlier stage of steel tapping,adding a carburant and carrying out preliminary deoxidation, sequentially adding alloy, a deoxidizing agent and slag, and maintaining argon blowing in the whole process in an alloying process; (4) LFtreatment: controlling the percentages of mass of inclusions in steel as follows: 50-60% of CaO and 15-25% of Al2O3, controlling the alkalinity of final slag to be 3-6, carrying out composite diffuseddeoxidation by using SiC, aluminum particles, silicon, aluminum and calcium and a deoxidizing slag former in a power supply smelting process, and ensuring the total mass percentage of TFe and MnO tobe less than or equal to 1%; (5) RH treatment: controlling vacuum degree to be 2.5 millibars or below, and maintaining for 0-5 min, enabling high vacuum maintaining time to be greater than or equal to8 min, carrying out calcium treatment after feeding an aluminum line for 1-2 min, and after calcium treatment, carrying out soft blowing for 10 min or above; and (6) carrying out continuous casting.

Owner:NANJING IRON & STEEL CO LTD

Process for producing dark green tea wine by using sugar fermentation brewing method

InactiveCN102978067ASimple processShorten the production cycleAlcoholic beverage preparationMicroorganism based processesWater bathsSucrose

The invention discloses a production process for producing dark green tea wine by using a sugar fermentation brewing method, relating to a technology for producing the dark green tea wine by using saccharomycetes and sugar. The production process comprises the following specific steps of: carrying out water-bath extraction on the raw-material dark green tea, filtering the extracted dark green tea, then adding cane sugar to mix to form an ingredient, carrying out high temperature sterilization on the ingredient, then adding activated saccharomycetes into the ingredient, fermenting at a certain temperature to form dark green wine fermentation liquor, then seasoning, filtering and clarifying the dark green tea wine fermentation liquor to form dark green tea wine liquor, carrying out high temperature sterilization on the dark green tea wine liquor, and then bottling and packaging to form the dark green tea wine. The dark green tea wine is bright reddish yellow in color, glittering and translucent in wine body, favorable in overall wine quality, soft and harmonized in taste, glittering and translucent in color and luster, free of impurities such as deposits, suspensions and the like, and has mellow flavors of dark green tea and wine; and according to the production process, used bacterial strains are simple, the raw materials do not contain grains, and no exhaust gas and wastewater emission exists in the production process.

Owner:张递霆 +1

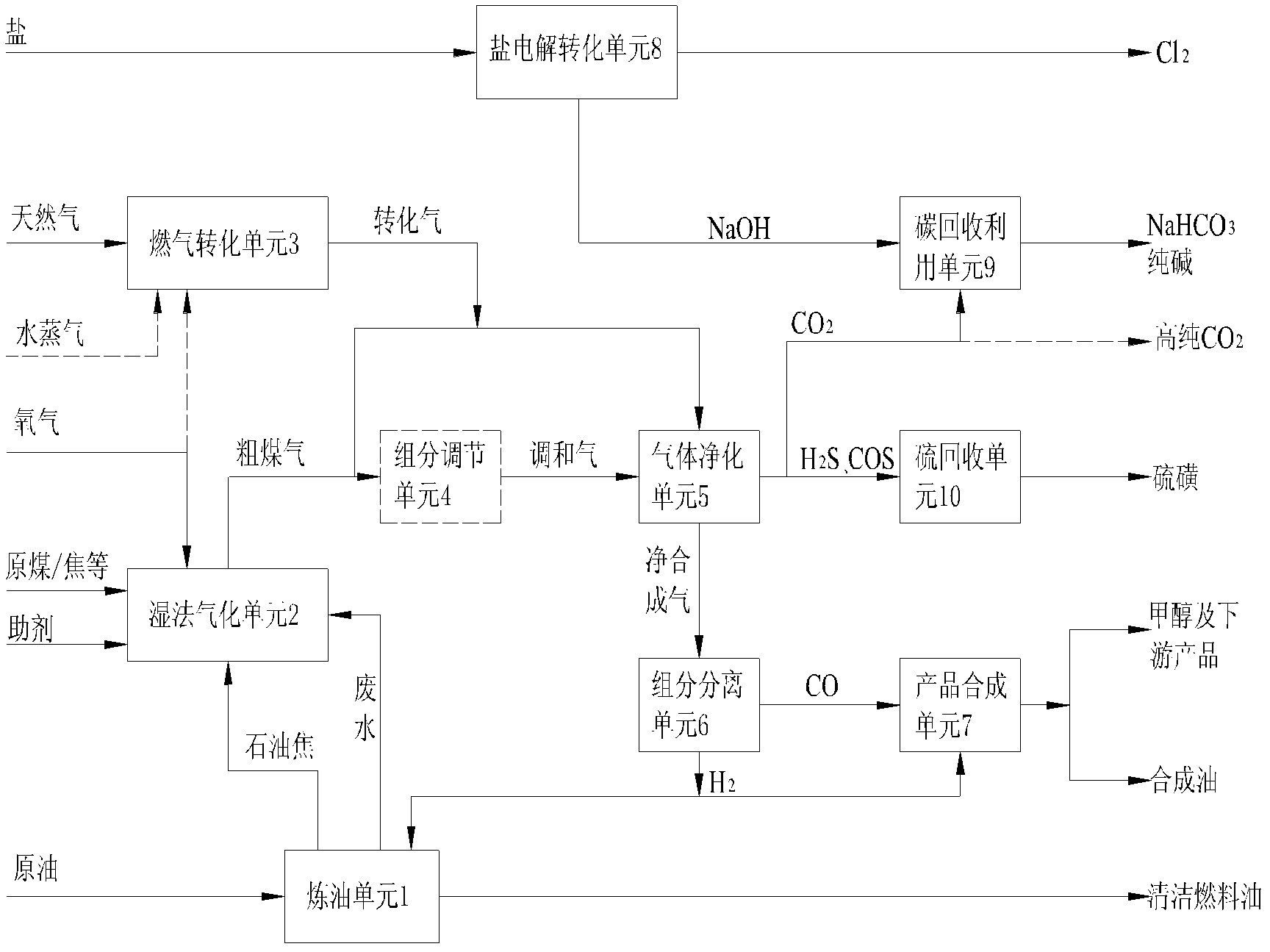

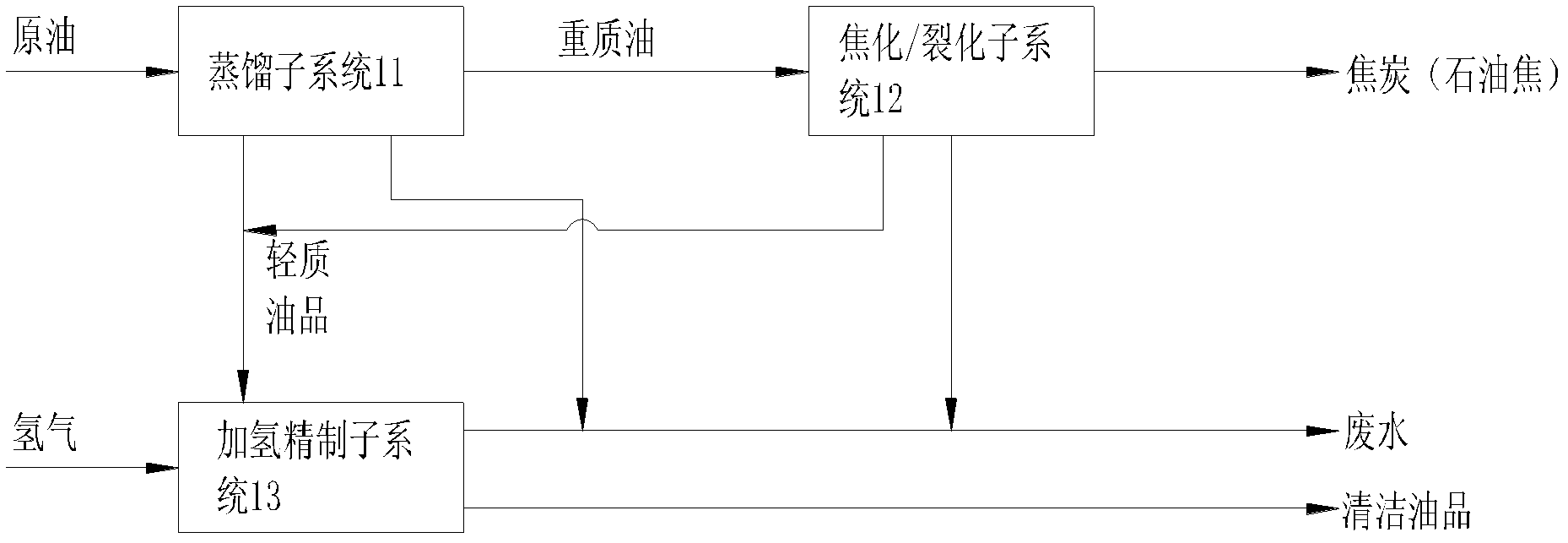

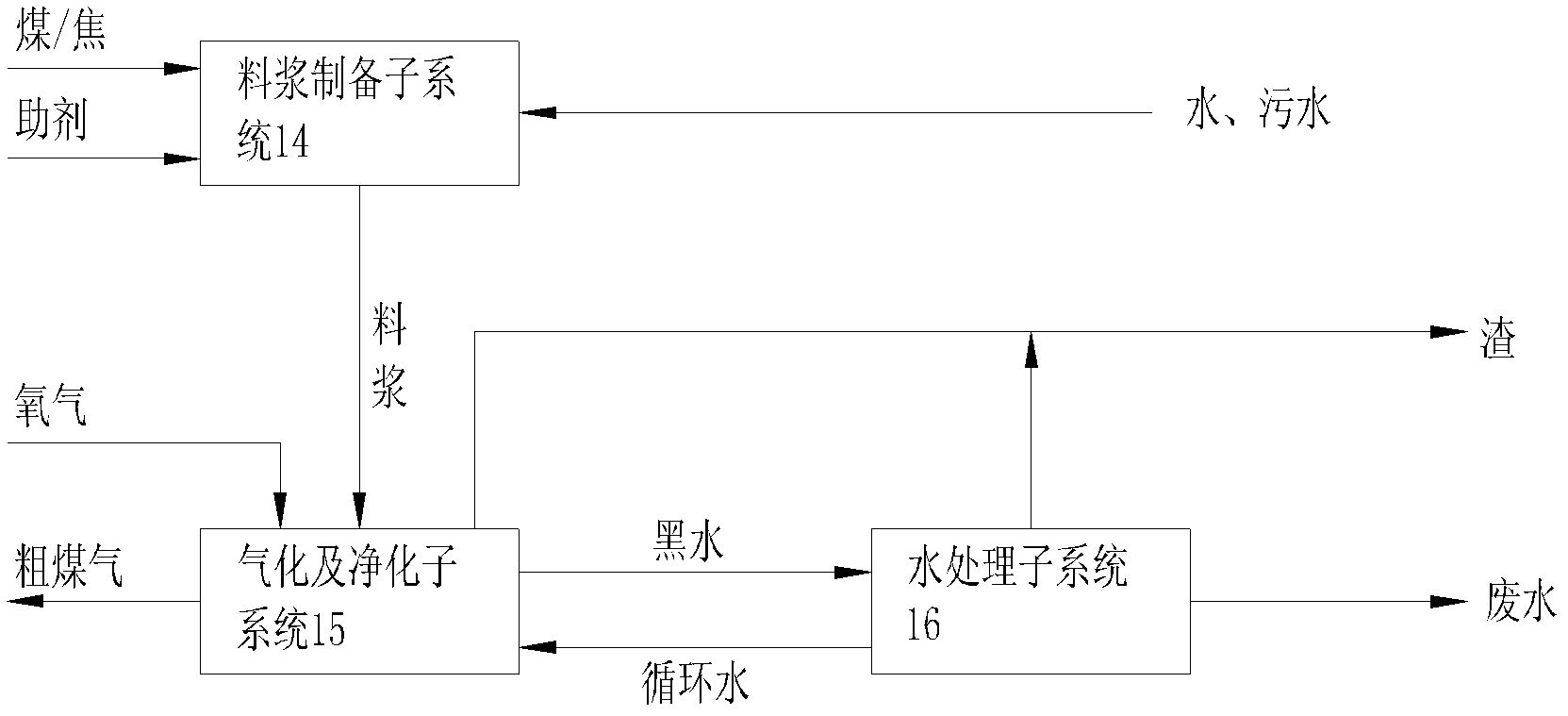

Method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials

ActiveCN102660330ASolve the problem of clean utilizationQuality improvementHydrogenOrganic compound preparationOil processingElectrolysis

The invention relates to a method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials. The method includes the steps of petroleum processing, slurry gasification, natural gas conversion, chemical product synthesis and salt electrolysis conversion. By reasonably using the coal, the petroleum, the natural gas and the salt resources, the energyand chemical overall goals of saving non-renewable resources and relieving environmental pollution can be achieved, and construction basis, solution and technical support are provided for Chinese large and super-huge energy industry base construction.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com