Patents

Literature

232results about How to "Avoid pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

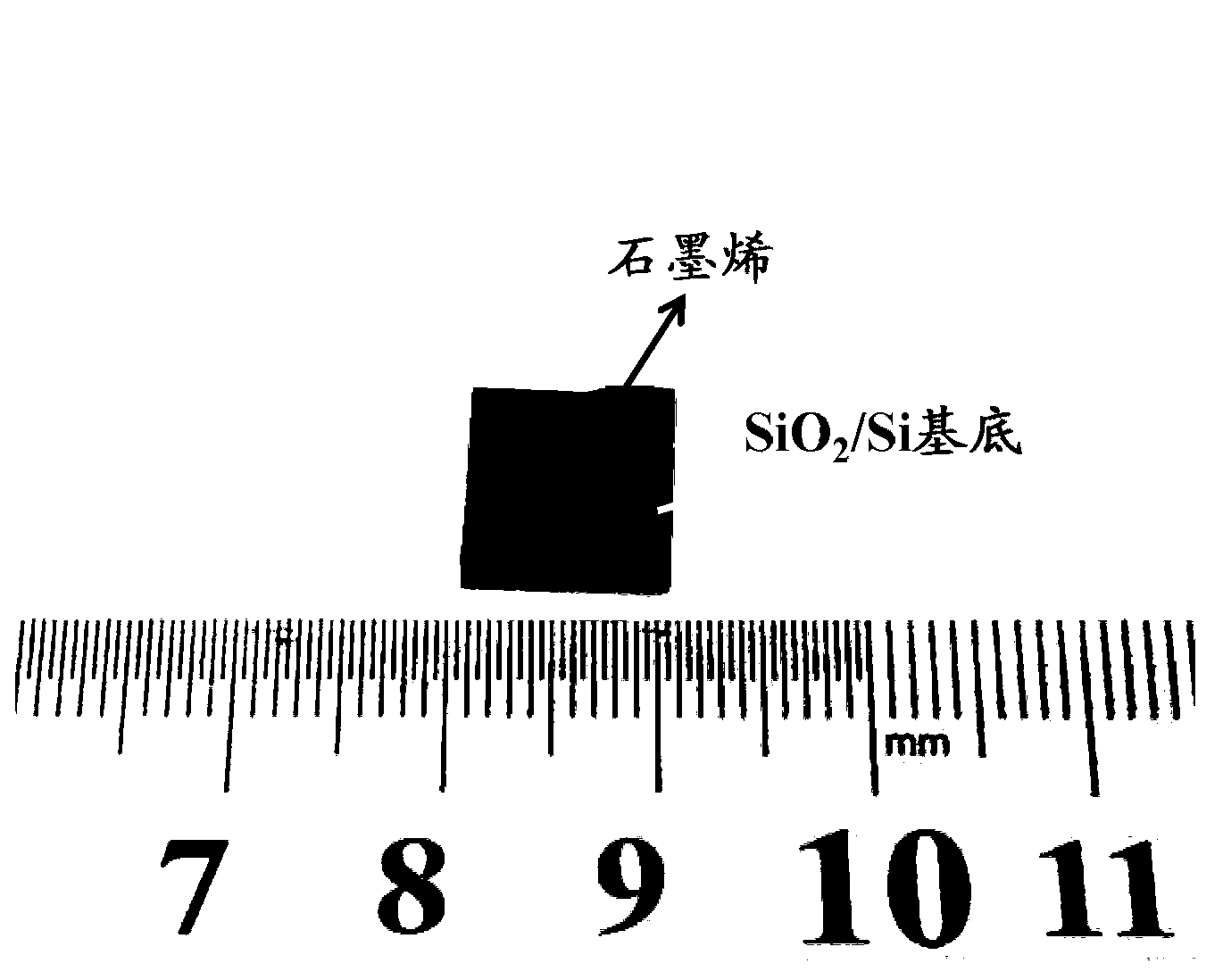

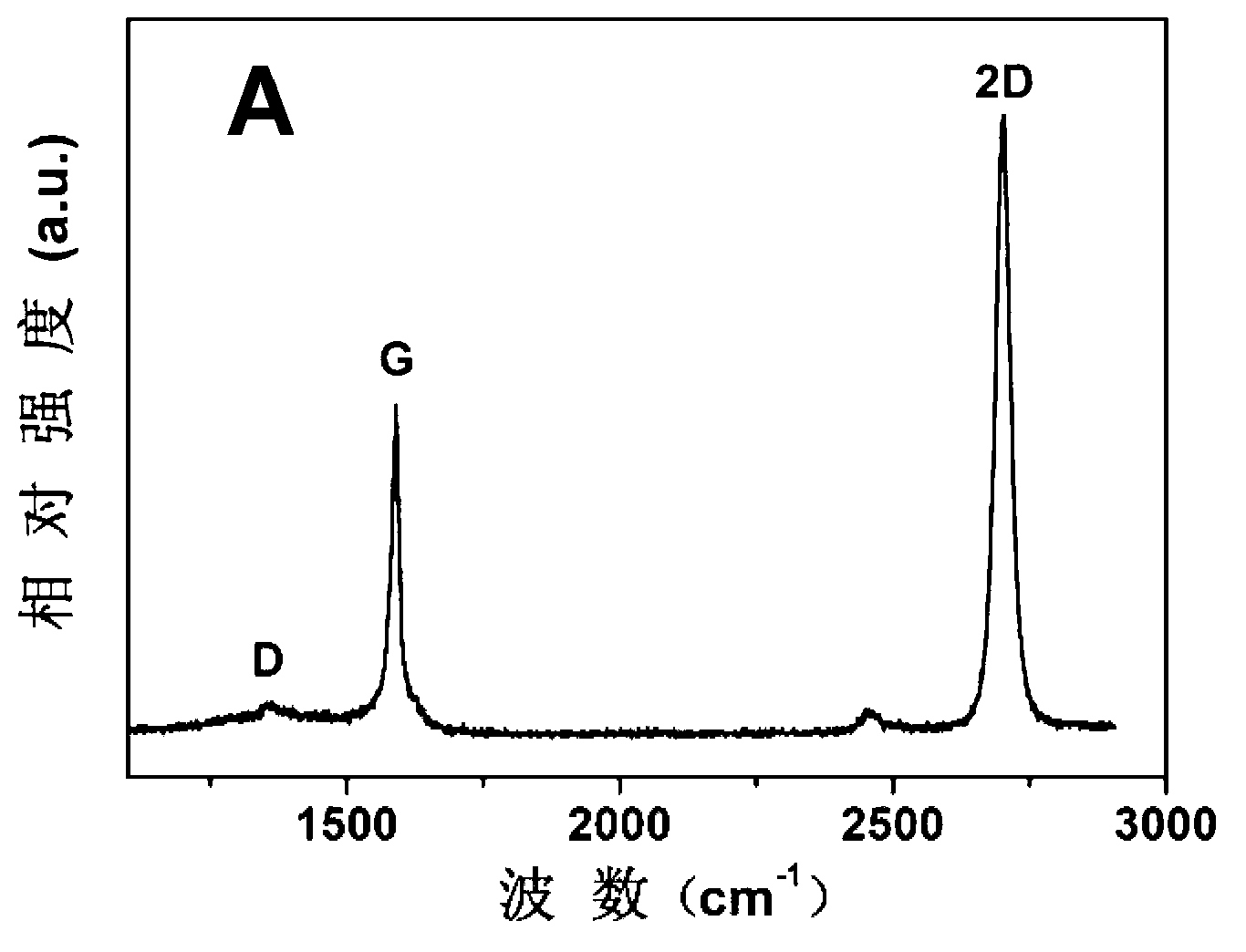

Method for low-temperature and efficient preparation of large-size graphene

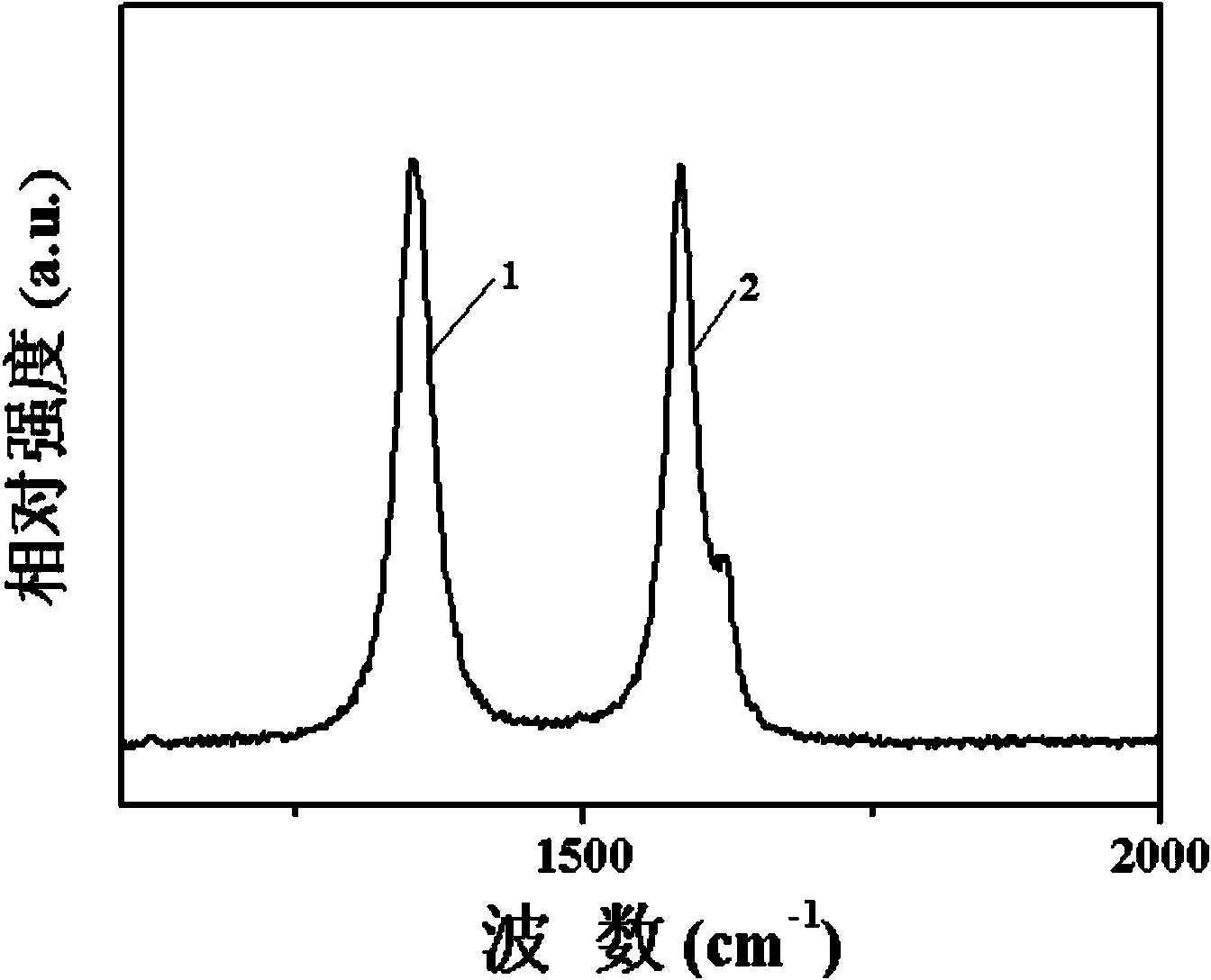

ActiveCN103183344AAvoid pyrolysisImprove decomposition efficiencyGrapheneShielding gasRoom temperature

The invention discloses a method for low-temperature and efficient preparation of large-size graphene, and relates to a method for preparing graphene, in order to solve the problems of conventional chemical vapor deposition (VDC) graphene preparation method which is high in preparation temperature, low in preparation duration and comparatively high in cost. The method comprises the following steps of: I, placing a metal substrate in plasmid enhanced chemical vapor deposition equipment, vacuumizing and filling H2, increasing temperature, preserving heat and implementing an annealing treatment; II, further filling Ar and CH4 gases, and depositing; and III, after depositing, turning off a radio frequency power supply and a heating power supply, stopping filling the CH4 gas, taking Ar and H2 as protective gases, and rapidly cooling to room temperature at 10 DEG C / s until graphene uniformly grows from the surface of the metal substrate, to finish. The method disclosed by the invention can finish growth of the graphene within a quite short duration, and can realize low-temperature and efficient preparation of the graphene material; and the method is simple, efficient, low in cost and convenient for industrial production, and the prepared graphene is large in size, high in quality and uniform in surface.

Owner:HARBIN INST OF TECH

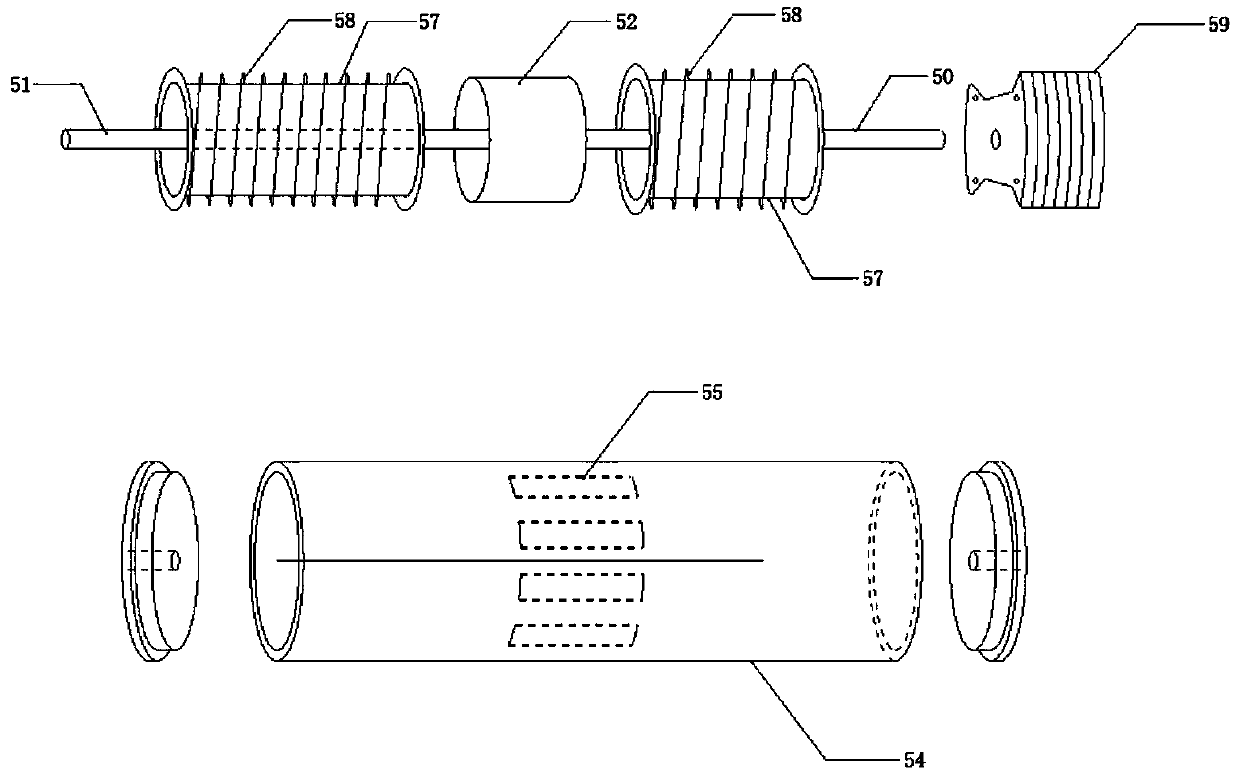

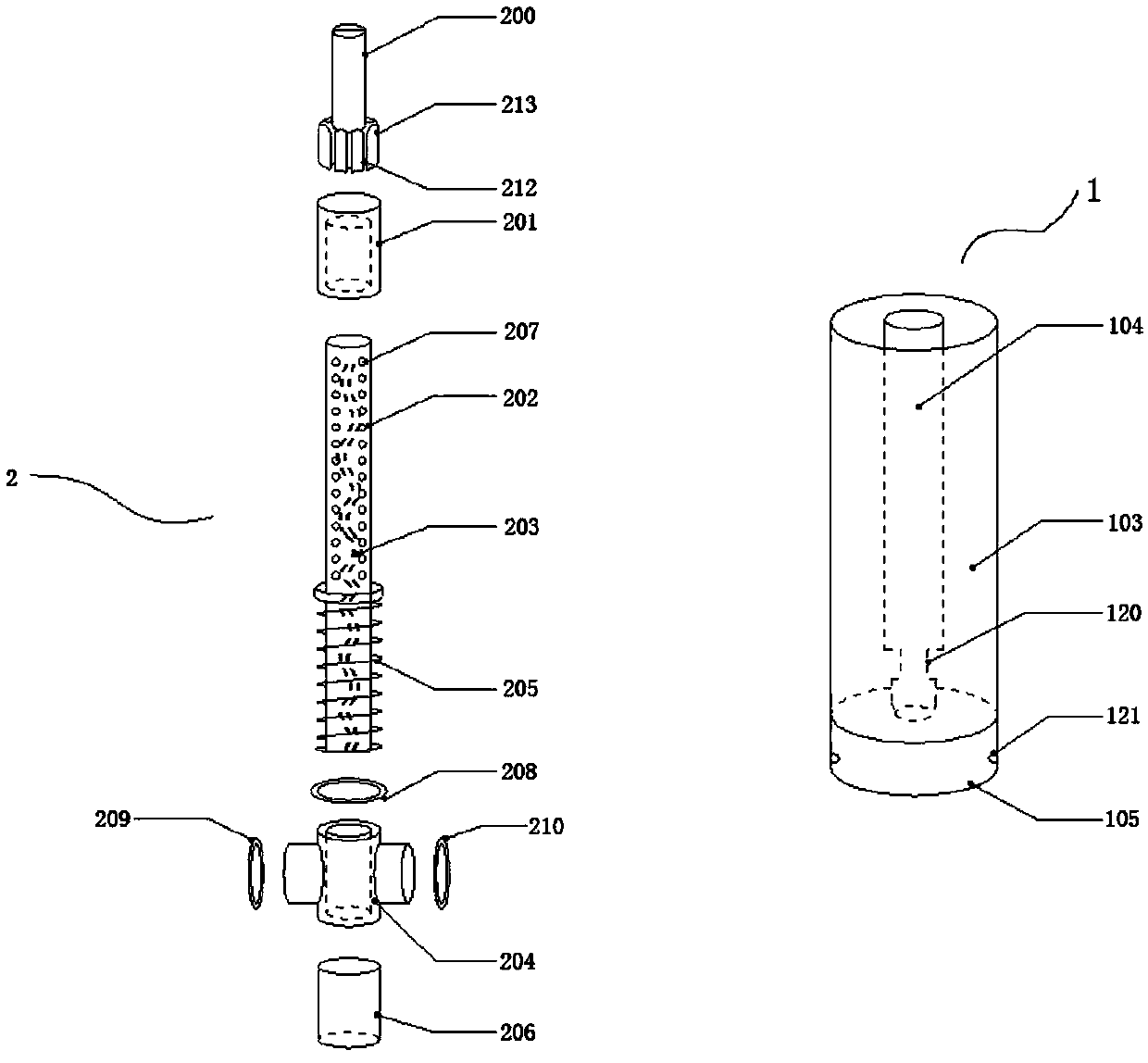

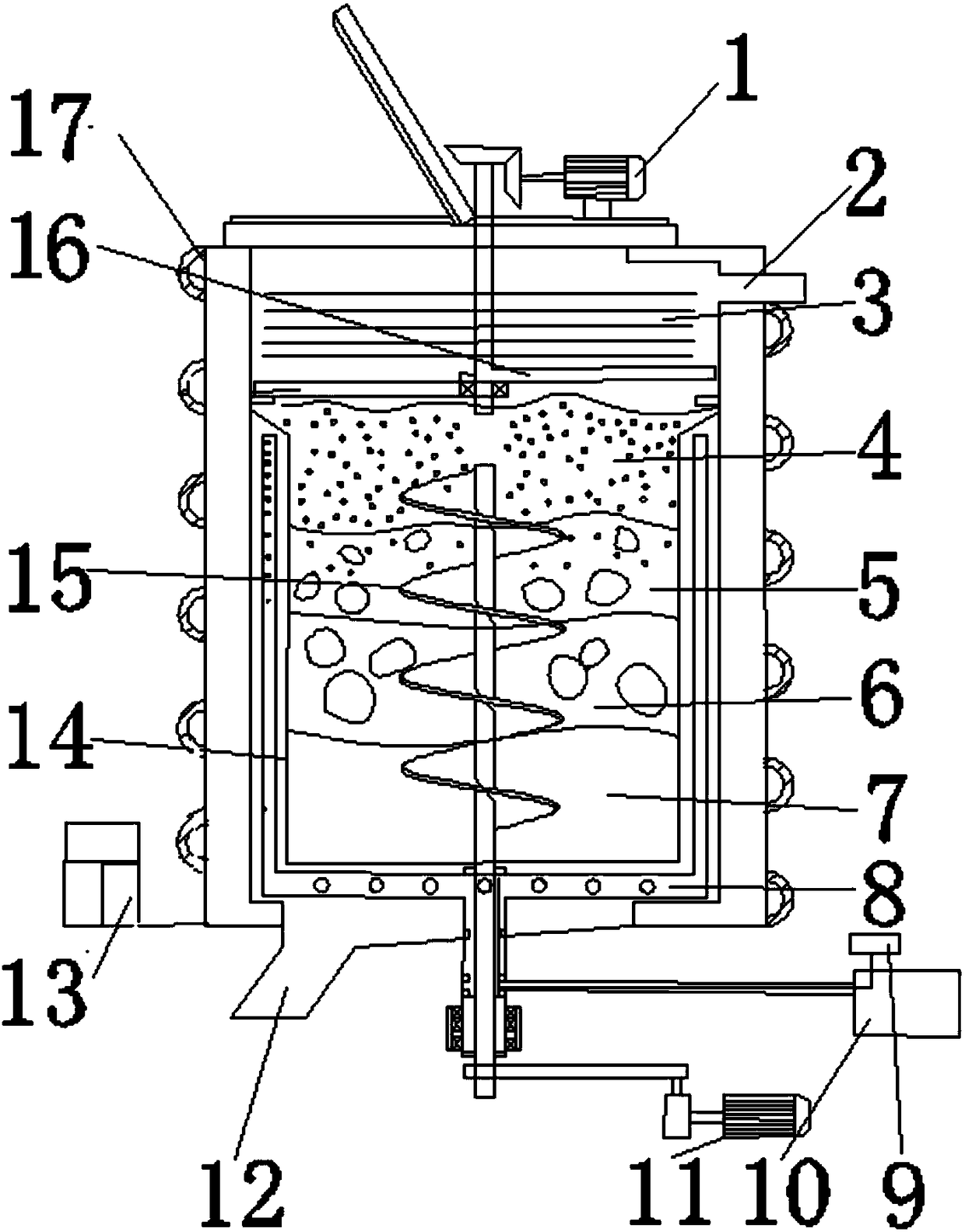

A type of oil storage atomizer with vibration

The invention discloses an accompanying vibration type oil storage atomize which comprises the following components: an oil storage element (1) and a porous vibration element (2), wherein the oil storage element (1) comprises a central passage (104) and an oil tank (103) surrounding the central passage; a base (105) is arranged at the bottom of the oil storage element (1); two inwards-raised oil inlets (120) are formed in the sidewall of the central passage (104); air inlets (121) are formed in the base (105), and are communicated with the central passage (104) through an airflow; the porous vibration element (2) is positioned in the central passage (104), and comprises a vibration cavity (202) and an oil guide element (203) positioned in the vibration cavity (202); a plurality of micropores (207) are formed in the sidewall of the vibration cavity (202); an upper end cover (201) is arranged at the upper part of the vibration cavity (202), and a lower end cover (204) and a vibration source connecting end (206) connected with the lower end cover (204) are arranged at the lower part; the vibration cavity (202) is sleeved with a spring (205).

Owner:CHINA TOBACCO YUNNAN IND

Manufacturing method of directionally organized ceramic matrix composite spare part

ActiveCN107032824AImprove production accuracyGood surface qualityCeramic shaping apparatusClay mixing apparatusSolventPyrolysis

The invention relates to a manufacturing method of a directionally organized ceramic matrix composite spare part. The manufacturing method includes steps of firstly manufacturing a spare part resin shell with two opened ends; preparing suspending slurry by monomer, crosslinking agent and ceramic powder, and pouring the suspending slurry in the spare part resin shell; cooling, solidifying and directionally crystalizing solvent in the suspending slurry along the direction of temperature gradient by arranging a temperate field; vacuum-freezing and drying the suspending slurry after being solidified completely, then preserving temperature at 900-1200 DEG; removing organic matters to obtain a ceramic spare part porous body; depositing a SiC interface on the inner fiber surface of the ceramic spare part porous body by a CVD / CVI method; applying precursor infiltration and pyrolysis to densify the ceramic spare part porous body deposited with the SiC interface to obtain the directionally organized ceramic matrix composite spare part. Through controlling solvent crystal under low temperature, and rapid shaping, fiber enhancement, precursor infiltration and pyrolysis and other technical steps, the directional organization is formed; the reinforcement and toughening can be realized effectively.

Owner:XI AN JIAOTONG UNIV

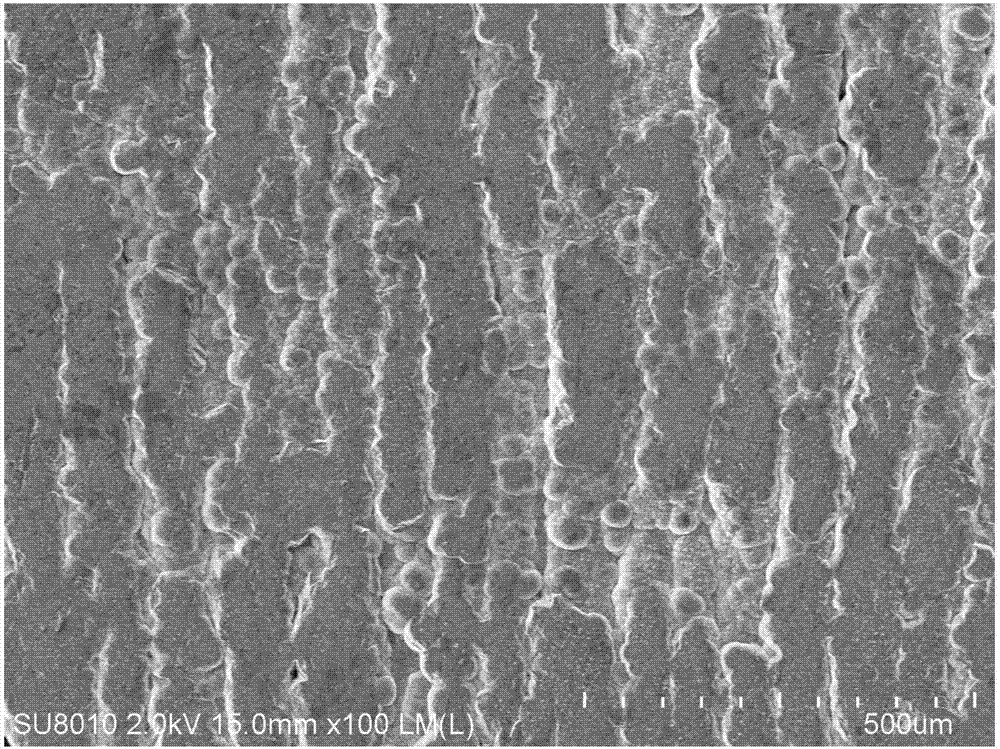

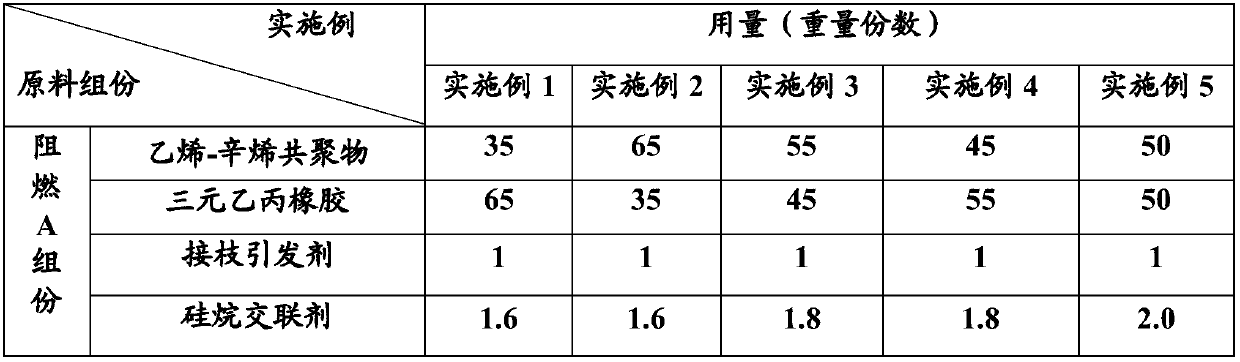

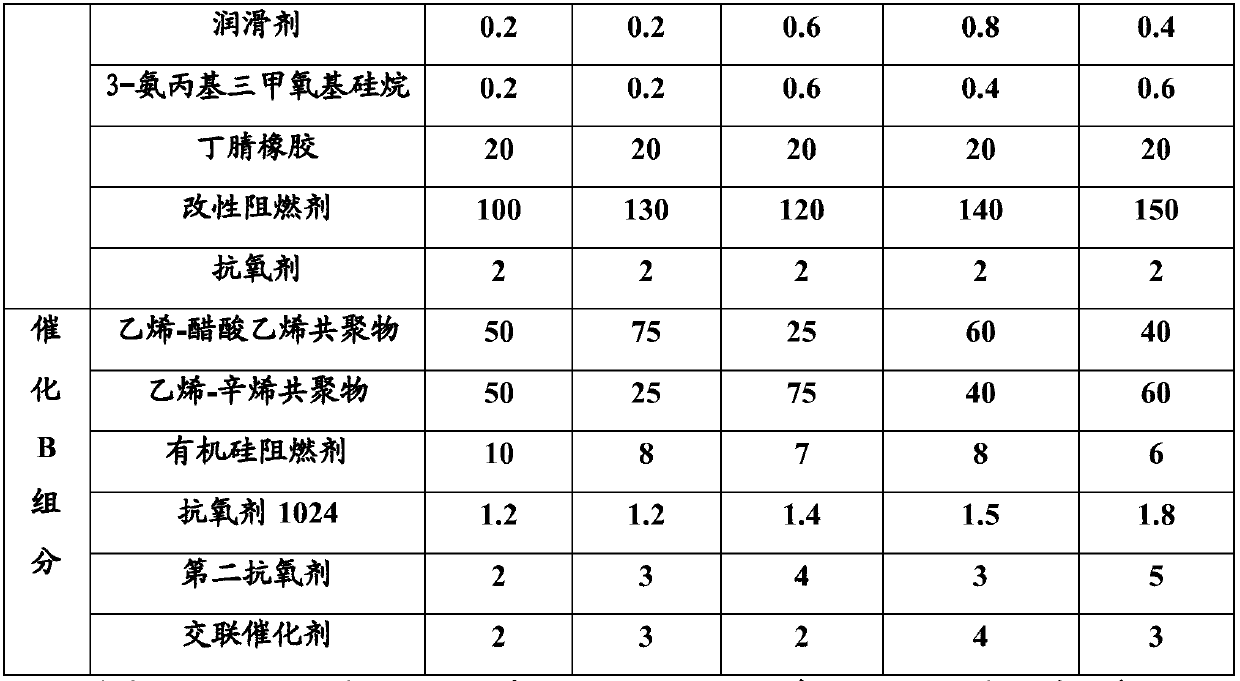

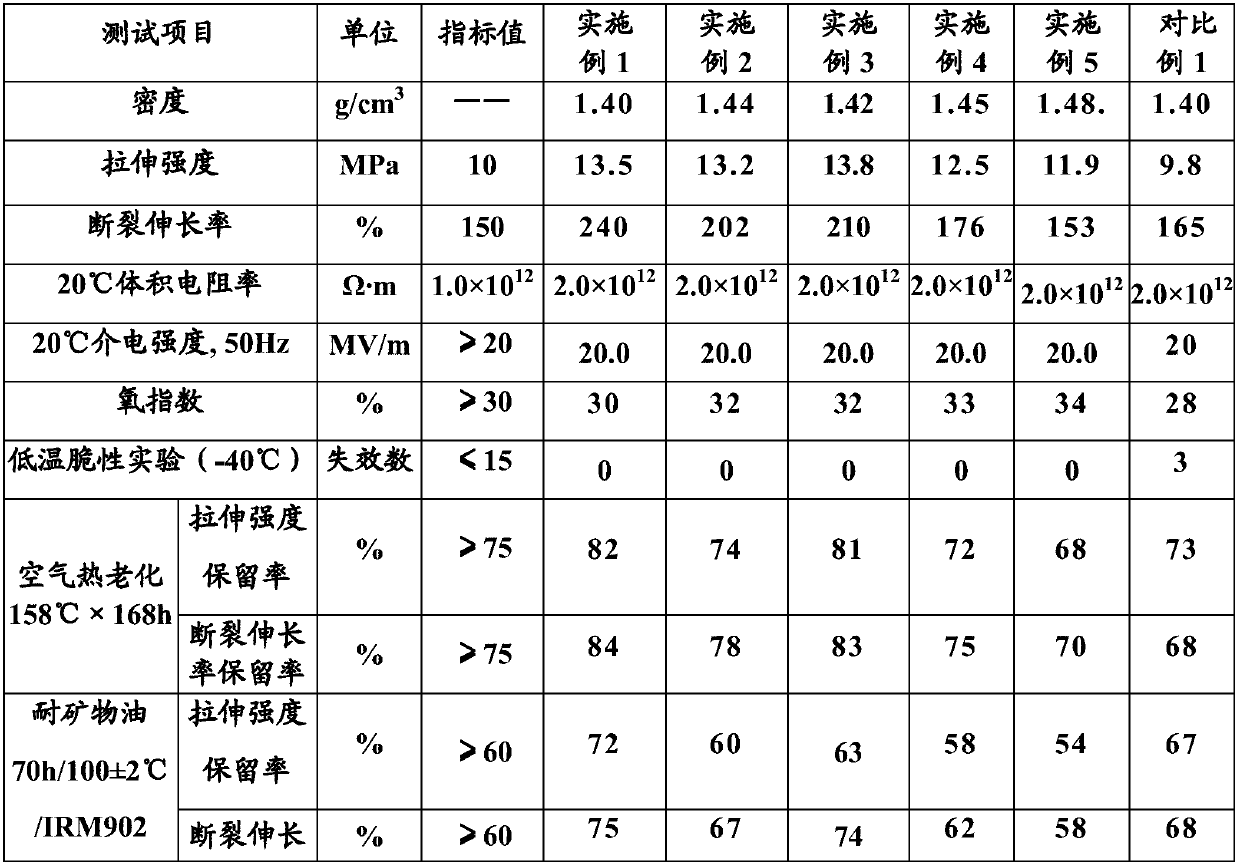

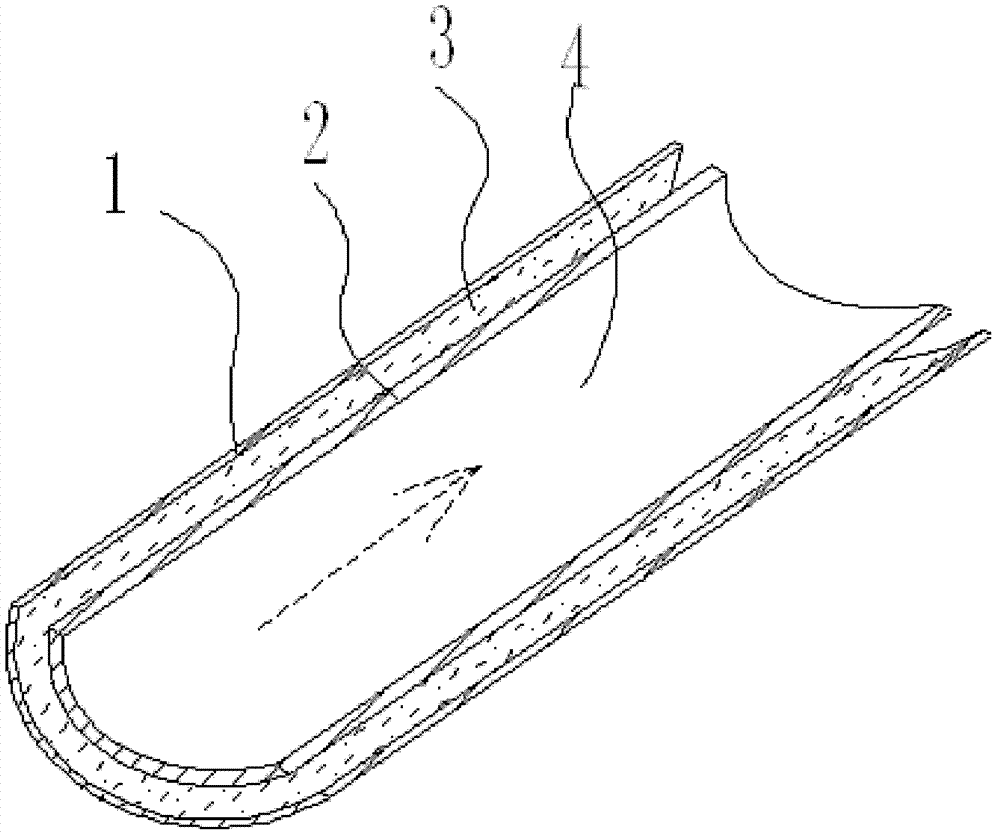

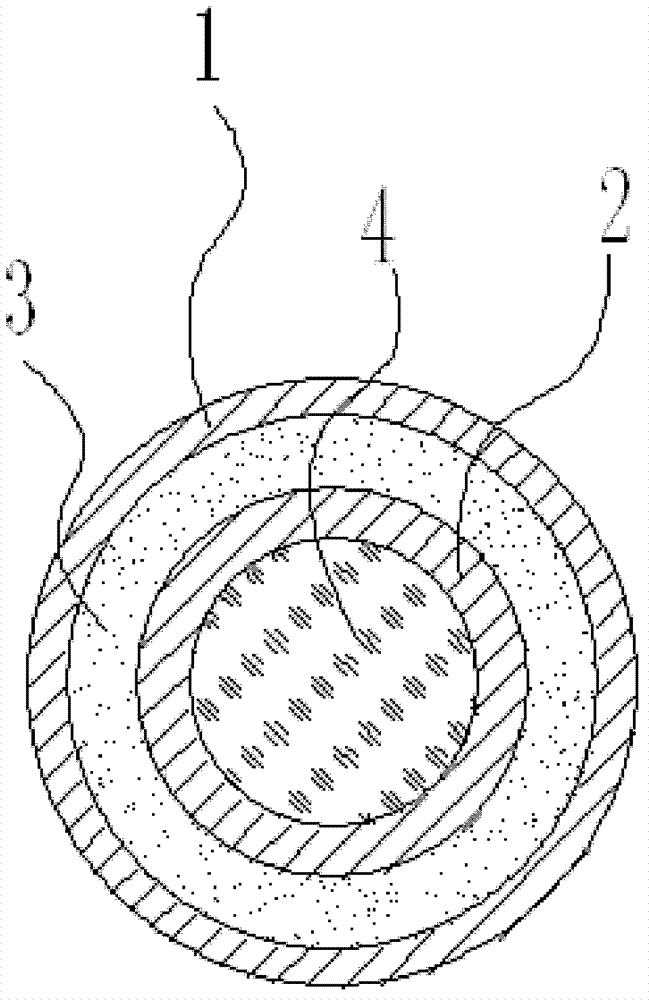

Silane self-crosslinking halogen-free low-smoke flame-retardant elastic material and preparation method thereof

ActiveCN102731917ASuperior elasticity and flame retardancyGood processing performanceInsulated cablesCable/conductor manufactureFlame resistanceSilanes

The invention relates to a silane self-crosslinking halogen-free low-smoke flame-retardant elastic material and a preparation method thereof. The elastic material comprises a flame-retardant component A and a catalysis component B with the weight proportion of 100:(4-6), wherein the flame-retardant component A comprises 30-70 parts of ethylene propylene diene monomer, 30-70 parts of ethylene-octylene copolymer, 15-25 parts of nitrile rubber, 1-6 parts of silane crosslinking agent, 0.3-1.5 parts of graft initiator, 0.1-5 parts of antioxygen, 0.2-2 parts of lubricant, 0.1-4 parts of 3-aminopropyl trimethoxy silane and 50-150 parts of modified flame retardant; and the catalysis component B comprises 100 parts of ethylene-vinyl acetate and / or ethylene-octylene copolymer, 3-50 parts of organosilicone flame retardant, 1-5 parts of first antioxygen, 1-10 parts of second antioxygen and 1-8 parts of crosslinking catalyst. The elastic material is a novel halogen-free low-smoke flame-retardant cable material, and has the advantages of excellent flame resistance and elasticity, low smoke, low toxicity, excellent processing performance and low cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

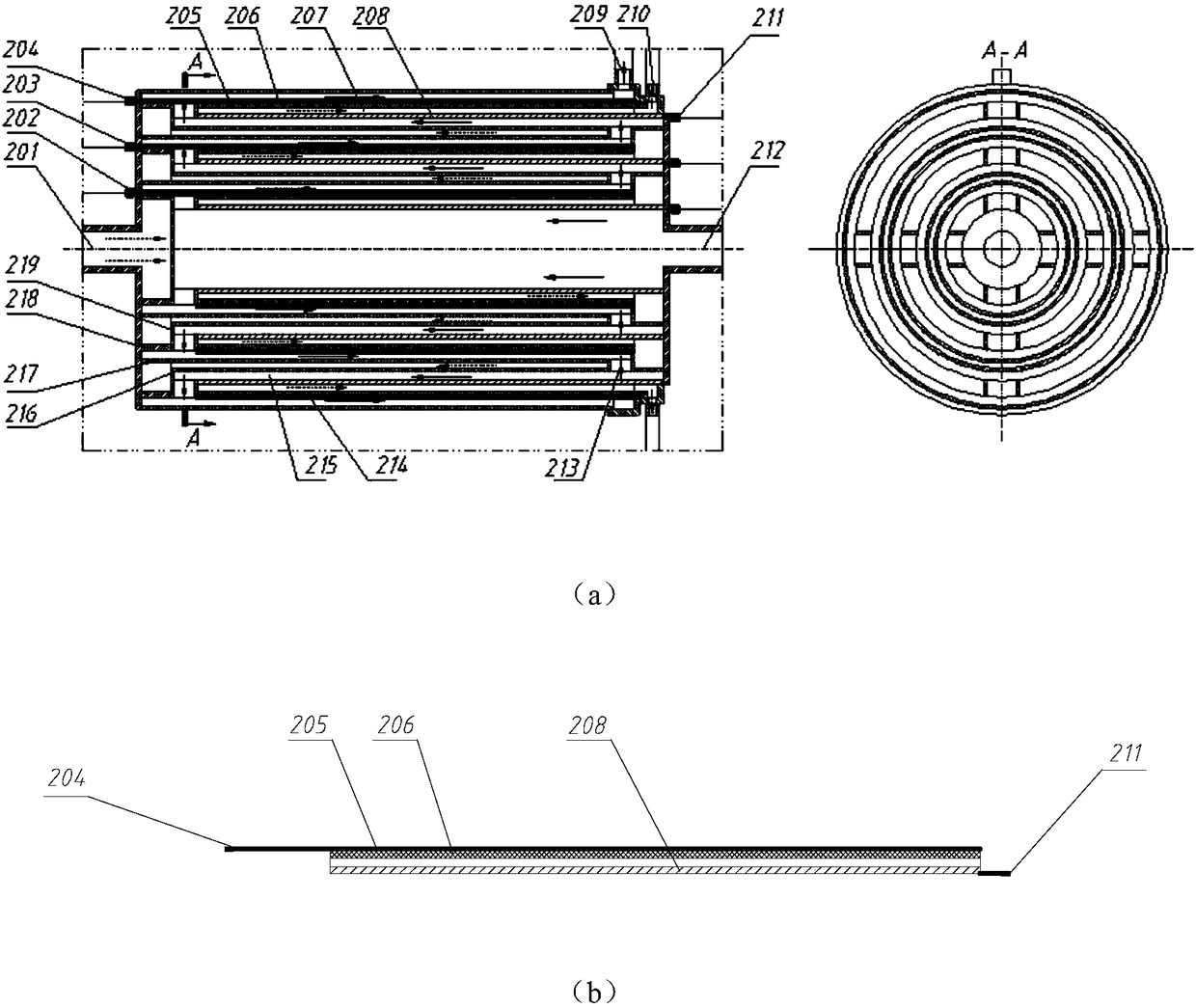

Heat capacity heat exchange device

InactiveCN103363690AAvoid overheating and deteriorationAvoid pyrolysisSolar heating energySolar heat devicesExternal energyEngineering

The invention provides a heat capacity heat exchange device which is composed of a first shell, a second shell, heat exchange media and heat capacity media. The first shell and the second shell are internally and externally arranged, the heat capacity media are filled in the full or partial space between the first shell and the second shell, the external energy is transmitted to the heat exchange media through the heat capacity media, and heat collection of the heat exchange device is completed. The heat capacity heat exchange device has the wide use range, can be applied to the solar energy utilized field of a groove type photo-heat heat collector or a fresnel array photo-heat heat collector or a disc type photo-heat heat collector or a tower type photo-heat heat collector, is particularly applied to a direct steam generation, conduction oil and melting salt system, can also be applied to boiler heating and the application field of the heat input and the heat output of a heat storage system, and well solves the technical problem which is hard to solve by a plurality of conventional technologies in the corresponding application field.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

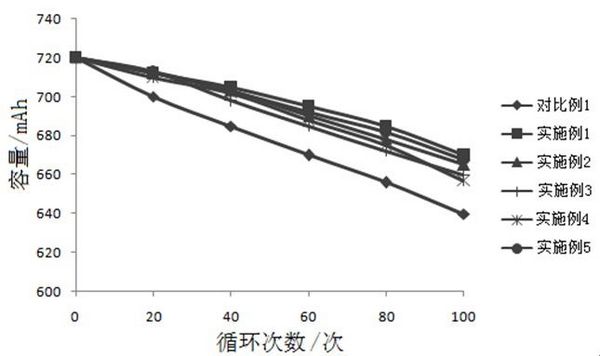

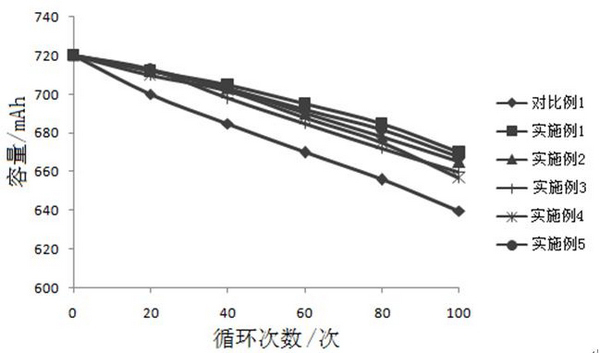

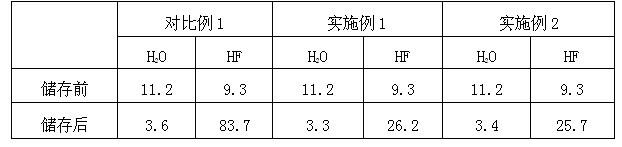

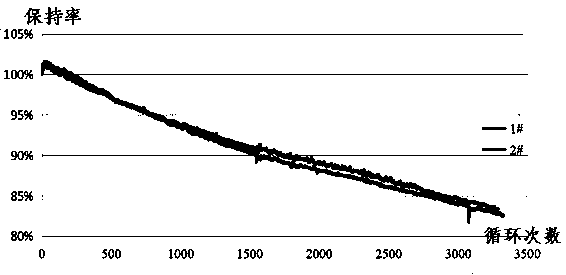

Lithium ion battery electrolyte and lithium ion battery

InactiveCN102324563AGood storage stabilityImprove thermal stabilitySecondary cellsElectrolytic agentOrganosolv

The invention relates to a lithium ion battery electrolyte and a lithium ion battery using the electrolyte. The electrolyte comprises the following ingredients: 10 weight portions of lithium salt, 55-80 weight portions of an organic solvent, and 0.4-2 weight portions of additive, wherein, the lithium salt is LiPF6, the organic solvent comprises ethylene carbonate and diethyl carbonate, and the additive comprises hexamethyldisilazane, preferred, the additive also comprises vinylene carbonate. Compared with the prior art, by adding hexamethyldisilazane, the electrolyte inhibits the hydrolysis and pyrolysis of LiPF6 in the electrolyte storage process, reduces the content of water and free acid in the electrolyte, improves the storage stability and thermal stability of the electrolyte, and improves the electrochemical performance and cycle performance of the lithium ion battery using the electrolyte.

Owner:SHANGHAI YAOYU INDAL

Preparation method of environment-friendly high-temperature-resistant water-based drilling fluid plugging anti-collapse agent

ActiveCN111138594ARestricted movementAvoid pyrolysisDrilling compositionHydrophilic monomerCross linker

The invention provides a preparation method of an environment-friendly high-temperature-resistant water-based drilling fluid plugging anti-collapse agent. The preparation method comprises the following steps: mixing and emulsifying a styrene monomer, an acrylic monomer and an emulsifier MS-1 aqueous solution to prepare a pre-polymerized emulsion; dispersing a hydrophilic monomer, a cationic monomer and an emulsifier MS-1 in water, adjusting the pH value to 6.5-8.5, then adding a mixed monomer of a styrene monomer and an acrylic monomer, and mixing and emulsifying to prepare a post-polymerization emulsion; adding a cross-linking agent 1 and an initiator 1 into the pre-polymerization emulsion, uniformly dispersing, and carrying out a reaction; adding the post-polymerization emulsion in a dropwise manner, adding a cross-linking agent 2 and an initiator 2, uniformly dispersing, continuously carrying out a reaction, drying, and crushing to obtain the plugging anti-collapse agent. The plugging anti-collapse agent prepared by the method is of a core-shell structure, is non-toxic and good in environmental protection performance, has excellent filtrate loss reduction, plugging and collapseprevention performances, has good temperature resistance, and can realize effective plugging and collapse prevention of a high-temperature stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

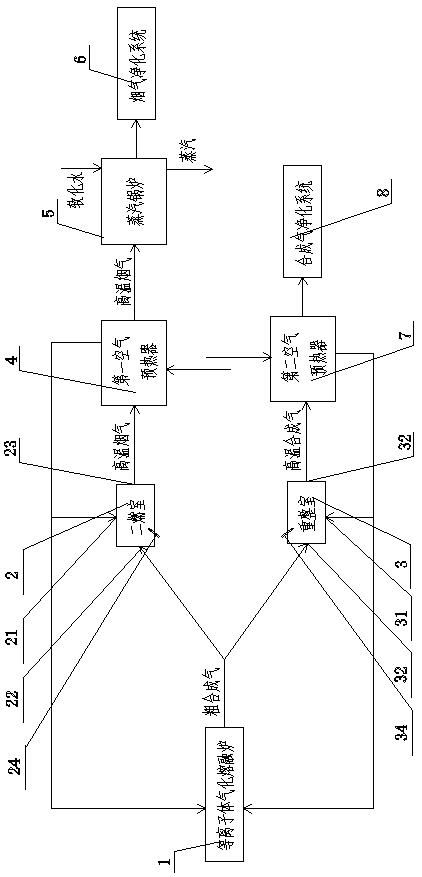

Plasma gasification and melting system for solid waste centralized processing

ActiveCN108097703AReduce the amount of dustPrevent regenerationWaste processingTransportation and packagingFuranCombustion chamber

The invention discloses a plasma gasification and melting system for solid waste centralized processing, and relates to the technical field of solid waste thermochemical treatment. The system comprises a plasma gasification and melting furnace, a synthesis gas outlet of the plasma gasification and melting furnace is connected with a secondary combustion chamber, a high-temperature smoke outlet ofthe secondary combustion chamber is sequentially connected with a waste heat recycling system and a smoke purifying system, and the synthesis gas outlet of the plasma gasification and melting furnaceis further connected with a reforming chamber, a high-temperature synthesis gas outlet of the reforming chamber is sequentially connected with a heat exchange system and a synthesis gas purifying system. The controlled oxygen combustion technology is adopted in the plasma gasification and melting furnace, the excessive air coefficient of primary air is about 0.3 to 0.5, the dust amount in rough synthesis gas can be effectively reduced, re-generation of toxic and harmful substances of dioxin and furan can be restrained, and the production of flying ash amount can be reduced.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

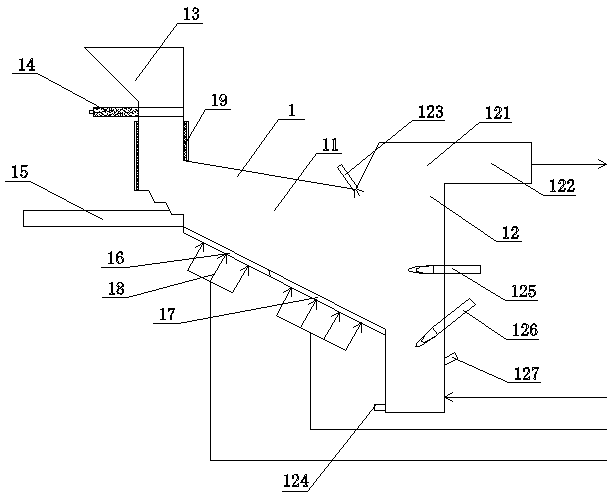

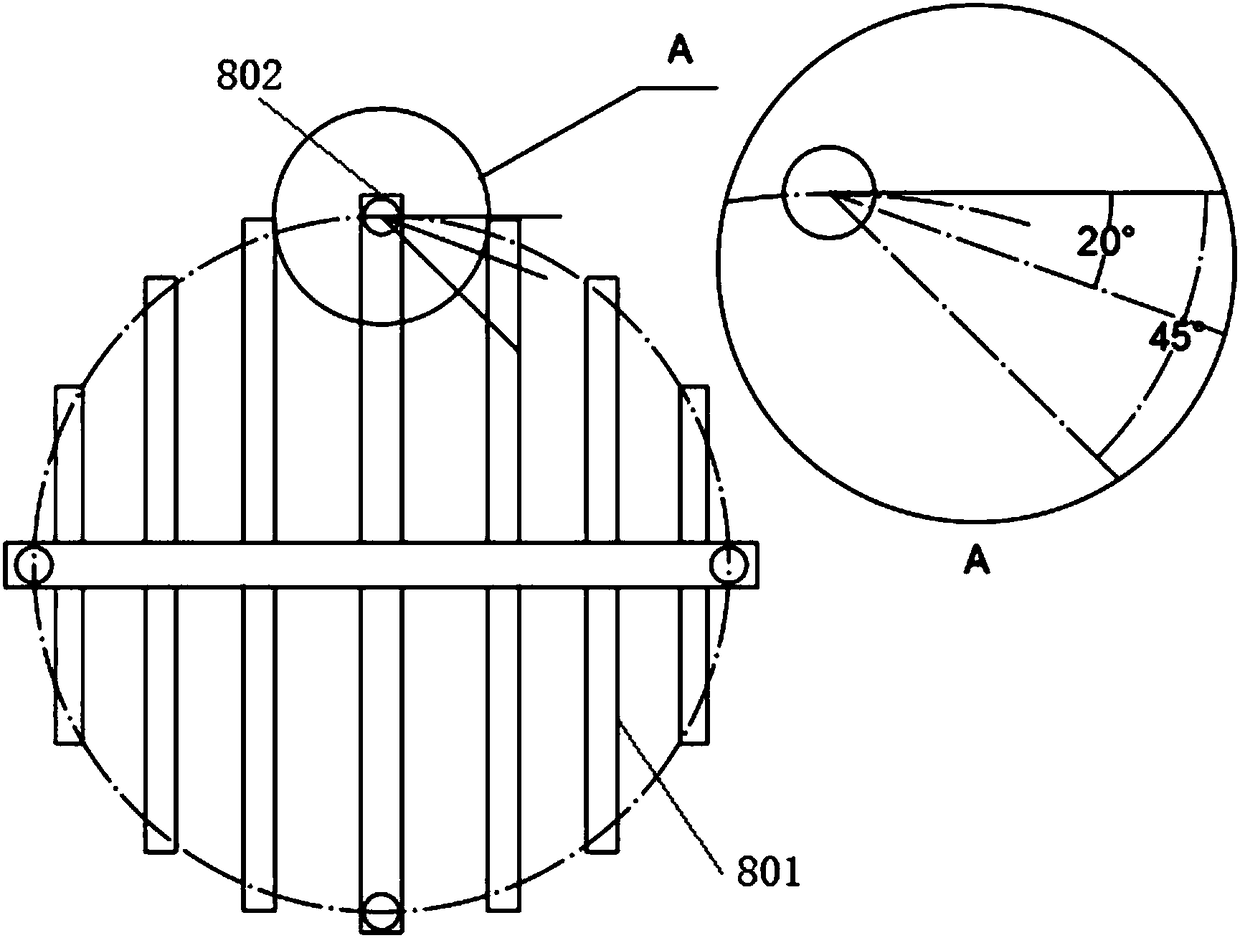

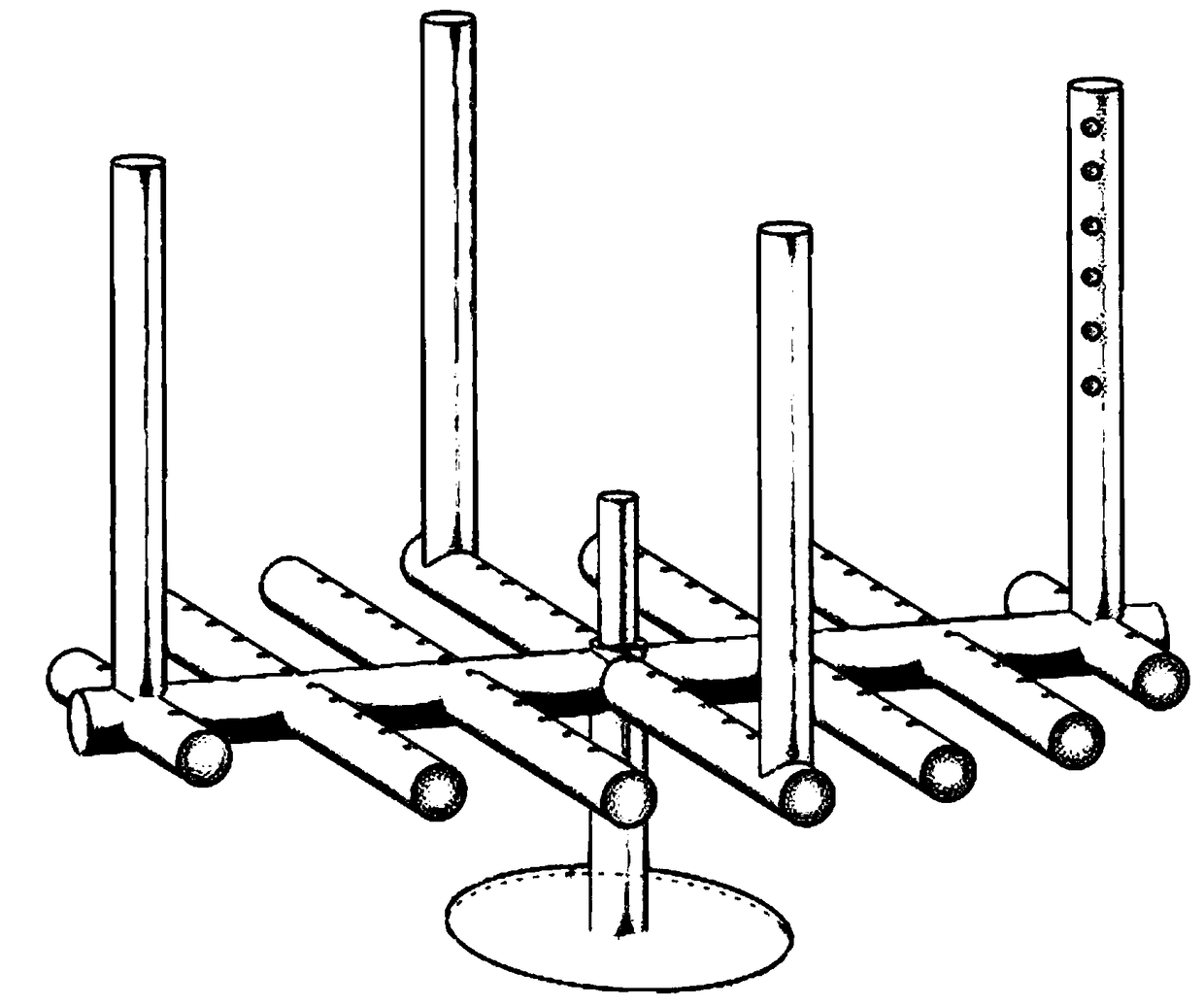

Wind power blade waste pyrolysis incinerator and control method thereof

The invention discloses a wind power blade waste pyrolysis incinerator and a control method thereof. The wind power blade waste pyrolysis incinerator comprises an incinerator body; a cooling pipe is arranged at the exterior of the incinerator body; an opening is formed in the top of the incinerator body; a smoke vent communicating with the outside is formed in the upper end of the incinerator body; an ash discharge chute furnace is arranged at the bottom of the incinerator body; a working cavity is formed in the incinerator body; an electric control feed door, a spiral agitator, a gas supply and distributing device and an isolation hood are arranged in the incinerator body; the electric control feed door and the spiral agitator are driven by motors correspondingly; the electric control feed door is arranged between a drying zone and a pyrolysis zone; a plurality of through holes are formed in the electric control feed door; the spiral agitator is located in the pyrolysis zone and the combustion zone; the gas supply and distributing device is arranged at the bottom of a combustion zone, is connected with a spiral bearing and can rotate in the incinerator body; and the isolation hoodis arranged on the inner side of the gas supply device and is used for isolating the gas supply device and a wind power blade material. Wind power blade waste can be pyrolyzed and burnt fully, and pollution is reduced.

Owner:上海博士高环保成套工程有限公司

Catalyst for catalyzing and dehydrating lactate and preparation and application thereof

InactiveCN101811059AEliminate acidityDepolarizationPhysical/chemical process catalystsOrganic compound preparationPhosphateSilica gel

The invention discloses a catalyst for catalyzing and dehydrating lactate and preparation and application thereof. The catalyst consists of alkali metal dihydric phosphate, grafted hydrophobic group and silica gel. The method for preparing the catalyst comprises the following steps of: grafting the hydrophobic group on the organosilane onto the surface of the silica gel by adopting a grafting method; impregnating the silica gel in aqueous solution of alkali metal dihydric phosphate; and preparing the hydrophobically modified silica-supportedalkali metal dihydric phosphate catalysts through roasting. The catalyst is used for catalyzing and dehydrating the lactate to prepare acrylic acid and acrylic ester. The catalyst makes the lactate highly selectively synthesize the acrylic ester, and can simplify process flow and reduce production cost and consumption of petroleum resources.

Owner:TAIYUAN UNIV OF TECH

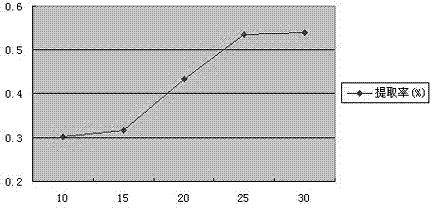

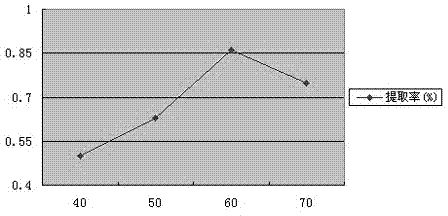

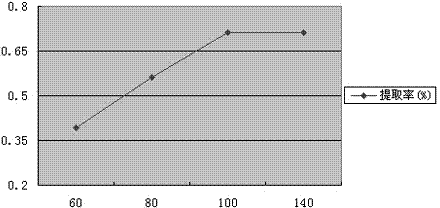

Process method for microwave assistant supercritical extraction of active ingredients of curcuma

InactiveCN102100875AIncrease polarityAvoid multi-stage extractionMetabolism disorderAntinoxious agentsFiltrationBULK ACTIVE INGREDIENT

The invention discloses a process method for microwave assistant supercritical extraction of active ingredients of curcuma. In the method, the active ingredients, namely curcumin and fat soluble curcuma oil, of curcuma are extracted by the synergistic action of the microwave technology and the supercritical technology. The process method mainly comprises the following steps of: performing microwave intermittent sudden heating and then carbon dioxide (CO2) supercritical extraction; separating CO2 and curcuma oil in an analyzing kettle; and adding water or ethanol into curcuma residue in a solid-to-liquid weight ratio of 1:7-14, and performing microwave action, twice soaking, filtration, condensation and spray drying to obtain the curcumin. The process method solves the problem that in the prior art, only single active ingredient can be extracted or the compositions of the extract are not balanced, and realizes the extraction of two main active ingredients, namely curcuma oil and curcumin, of the curcuma at the same time, and the yield is over 8 percent and 13 percent respectively. The process method is the physical method and has the advantages of no product pollution, high purity, low cost, simple process and easy mass production.

Owner:GUANGZHOU RZN BIOTECH CO LTD

Method for extracting ginseng volatile oil by supercritical CO2

InactiveCN102888281AHigh extraction rateHigh speedEssential-oils/perfumesPhysical chemistryProcess engineering

The invention relates to a method for extracting medicinal-edible isogenous plants, which namely relates to a method for extracting ginseng volatile oil by supercritical CO2, which comprises the following steps: adding ginseng powder to the containing bottle of an extracting kettle of a supercritical extracting device; filling the ginseng powder to the extracting kettle and sealing the extracting kettle; heating the extracting kettle, a separation kettle I and a separation kettle II respectively; when the temperature of the extracting kettle reaches to 40 degrees centigrade, slowly opening an extracting kettle valve; opening an air exhaust valve to discharge air when pressure in the extracting kettle is equal to the pressure of a storage tank; pressurizing a system through a high pressure system; controlling CO2 flow quantity within 20-50L / h when the extracting kettle, the separation kettle I and the separation kettle II reach to predetermined pressure; and starting to process circular extraction; after keeping an extracting temperature within 25-80 degrees centigrade, and keeping extracting time for 60-150min, and receiving extracted ginseng volatile oil from the discharging outlets of the separation kettle I and the separation kettle II. The method is characterized by high extraction rate, fast speed, no pollution, simple technology, good product quality, no solvent residue and the like and avoids oxidation and pyrolysis.

Owner:吉林人参研究院

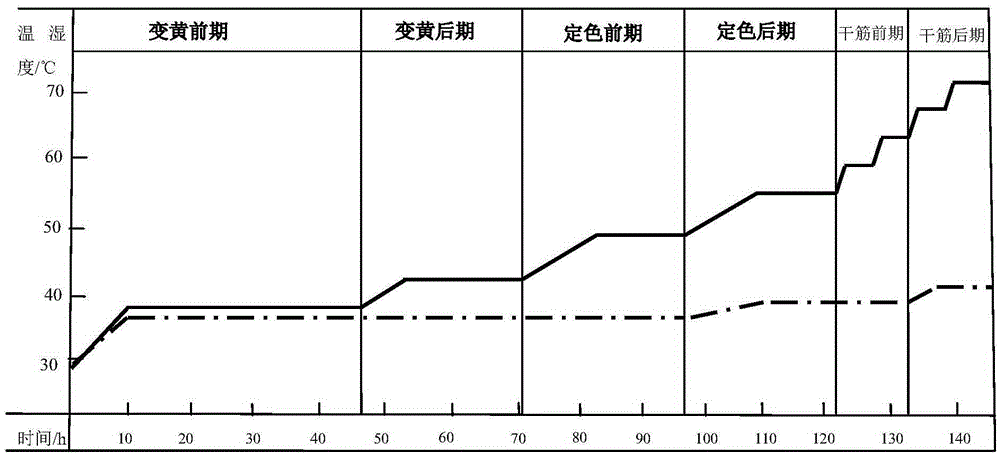

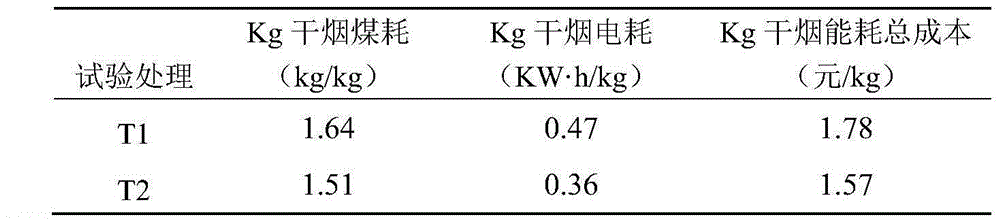

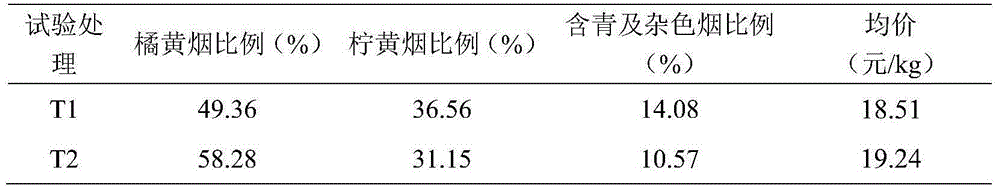

Starch-lowering aroma-improving baking process of flue-cured tobaccos

InactiveCN105192874AReduce starch contentImprove the quality of smokingTobacco preparationCooking & bakingHigh heat

The invention provides a starch-lowering aroma-improving baking process of flue-cured tobaccos. The starch-lowering aroma-improving baking process mainly comprises three baking phases including a high-temperature burning and low-temperature yellowing phase, an advanced dehumidifying and slow color fixing phase and a phased heating, aroma improving and drying phase. The starch-lowering aroma-improving baking process is characterized in that in a baking process, a circulating fan is intermittently run at the time with heat supplying and dehumidifying requirements in a whole yellowing period and a drying post-period; in the drying period, a heating manner of heating for four times and stopping for four times is adopted so that the staying time at a high-temperature period is shortened; three sections of humid ball temperature curves are set so that operation and control are facilitated. By virtue of adopting the baking process, about 15% of baking energy consumption can be saved; the ratio of badly baked tobaccos including green miscellaneous tobaccos, ash-containing tobaccos, steamed pieces and the like is obviously reduced, and the ratios of orange tobaccos and up first-class tobaccos are increased; baked tobacco leaves have much oil content, low starch content, coordinated chemical components, enough aroma and reduced irritation.

Owner:HUBEI TOBACCO SCI RES INST

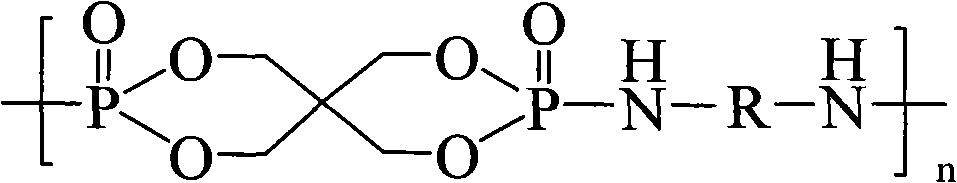

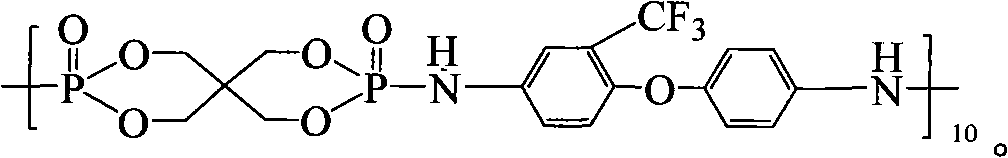

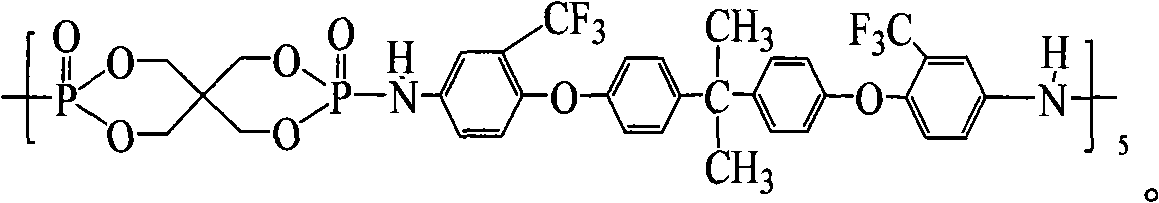

Expansible fire retardant containing fluorine-phosphorus-nitrogen oligomer and preparation method thereof

The invention relates to the technical field of fire retardants, particularly relating to an expansible fire retardant containing a fluorine-phosphorus-nitrogen oligomer and a preparation method thereof. The fire retardant is prepared by mixing pentaerythritoldiphosphatediphosphoryl chloride and diamine based on a molar ratio of 1:1-1.5 for reaction, filtering the obtained substance, washing and drying the filter residue. The method is simple and convenient. Meanwhile, the expansible fire retardant containing the fluorine-phosphorus-nitrogen oligomer prepared by the invention is an oligomer type molecule and has large molecular weight and good stability, and solves the problems of shift, precipitation or volatilization and the like which occur in processing and molding the fire retardants and polymer substrates; at the same time, the introduced functional fluorine element greatly improves the water resistance of the substrates; and the fire retardant integrates a carbon source, an acid source and a gas source into a whole, the charcoal yield is high, the carbon residue amount is about 58% at air atmosphere under the temperature of 800 DEG C, and the thermostability is favorable.

Owner:来安县亨通橡塑制品有限公司

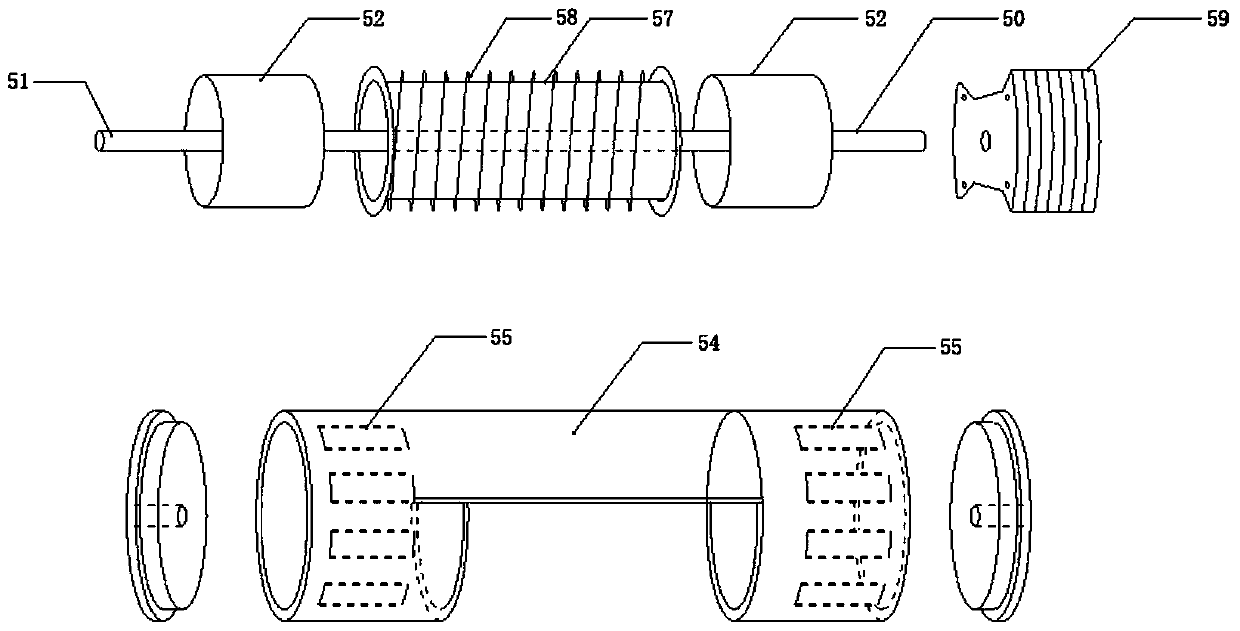

Method for preparing composite electrode material of carbon nano-tube-graphene supercapacitor

ActiveCN103824704AImprove conductivityLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureGas phaseCarbon nanotube

The invention relates to a method for preparing composite electrode materials, in particular to a method for preparing a composite electrode material of a carbon nano-tube-graphene supercapacitor. The method solves the problem that preparing temperature of graphene prepared through an existing CVD method is high, and the graphene of centimeter level cannot serve as the electrode material to be applied to the supercapacitor. The method comprises the steps of arranging a substrate material in a plasma enhanced chemical vapor deposition vacuum device, feeding argon, raising the temperature to 700 DEG C-900 DEG C, then feeding carbon source gas to adjust pressure intensity for deposition, after deposition is finished, stopping feeding the carbon source gas, the substrate material is cooled to below 100 DEG C, and the composite electrode material of the carbon nano-tube-graphene supercapacitor is obtained. The method is used for preparing the composite electrode material of the carbon nano-tube-graphene supercapacitor.

Owner:HARBIN INST OF TECH

Tin-bismuth composite alloy and preparation method thereof

The invention discloses a tin-bismuth composite alloy and a preparation method thereof. The method comprises the following steps: synthesizing conductive polymer nano fiber, and preparing a metal coating layer on the surface of the conductive polymer nano fiber; adding the conductive polymer nano fiber with the metal coating layer into an organic solvent, and dispersing; performing secondary doping treatment; preparing nano tin powder and nano bismuth powder respectively; adding the obtained nano tin powder and nano bismuth powder into the organic solvent, and performing acid pickling treatment; performing purification treatment to obtain pure nano composite powder; mixing the obtained conductive polymer nano fiber after the secondary doping treatment, the obtained nano composite powder and a soldering flux, and stirring to obtain uniform tin-bismuth composite powder; performing sintering treatment on the tin-bismuth composite powder to obtain the tin-bismuth composite alloy. Through the method, a low-temperature tin-bismuth composite alloy material with a low melting point and high toughness is obtained.

Owner:HOERSON ELECTRONICS TECH +1

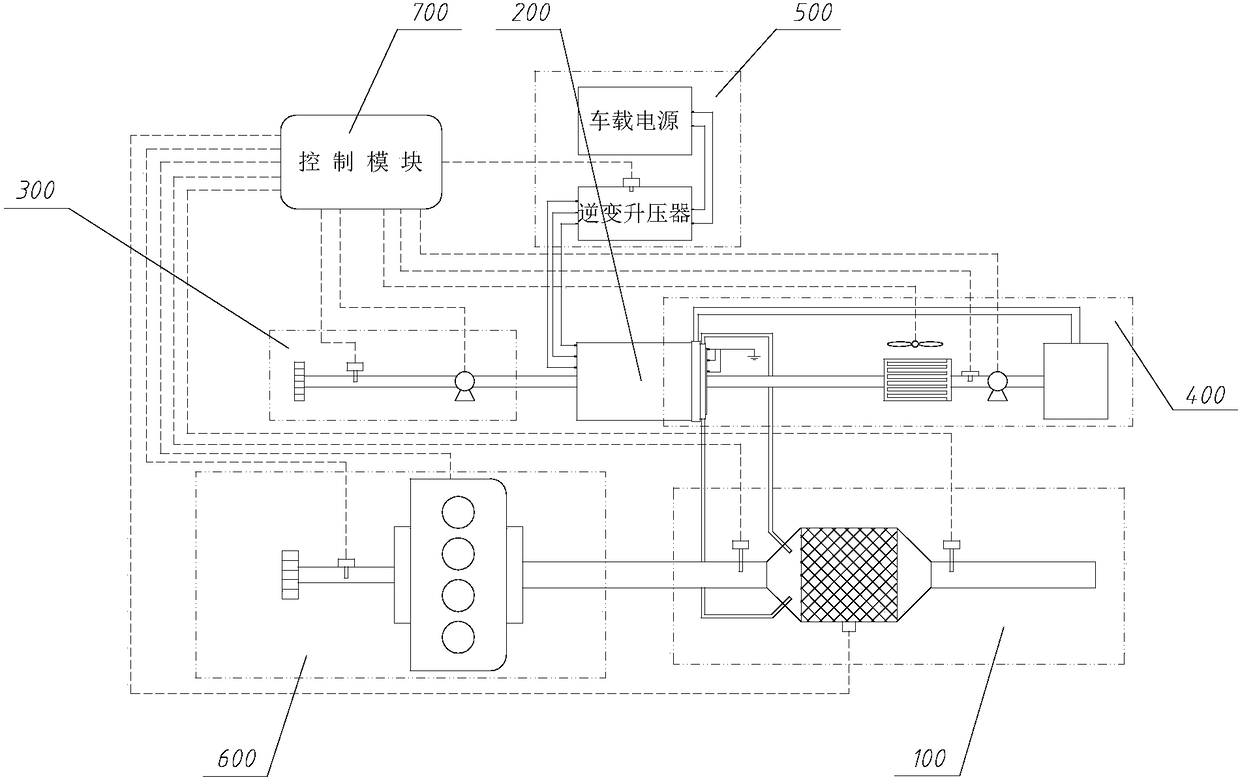

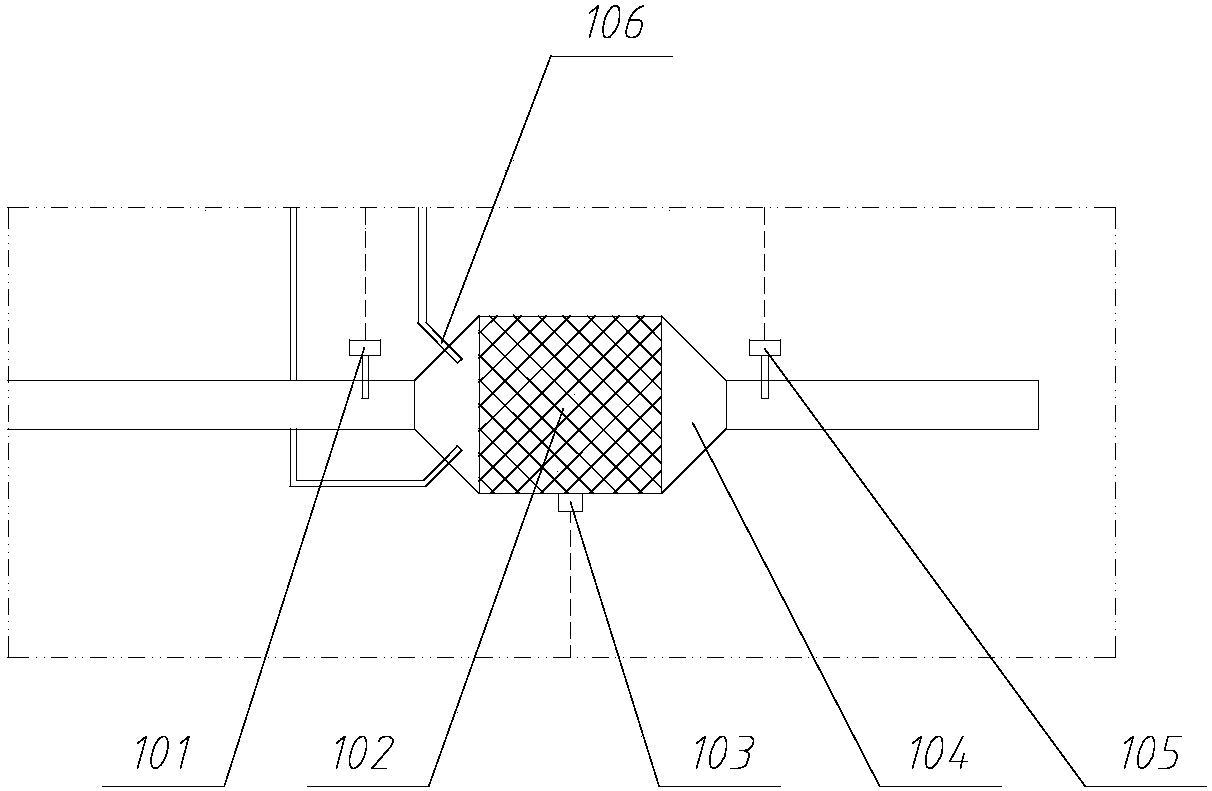

Vehicle-mounted DPF on-line regeneration system and control method

ActiveCN108533363AAvoid pyrolysisSlow down the flowInternal combustion piston enginesExhaust apparatusControl systemEngineering

The invention provides a vehicle-mounted DPF on-line regeneration system and a control method. The vehicle-mounted DPF on-line regeneration system mainly comprises a post-processing system, an NTP generation system, an NTP generator air inlet system, an NTP generator cooling system, a power supply device, a diesel engine system and a control module. The air inlet system is used for providing air for the NTP generation system, the system temperature is controlled by a cooling system, the NTP generation system is generated by discharging modules in the system and provides NTP active substances for the post-processing system through a NTP nozzle. The power supply device provides different voltages for each discharging module in the NTP generation system. The control module controls the wholesystem through various sensors and pumps. The diesel engine system can be coupled with the NTP system and the post-processing system in a regeneration mode to realize the control and optimization of the vehicle-mounted DPF on-line regeneration system. The vehicle-mounted DPF on-line regeneration system and the control method can effectively improve the efficiency of NTP generation system and the efficiency of DPF regeneration, can regenerate DPF in the running process of an engine, and is closer to the practical application.

Owner:JIANGSU UNIV

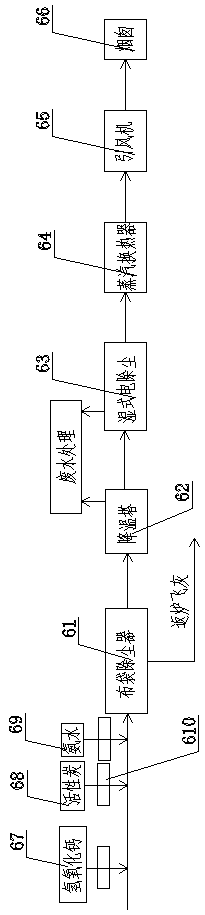

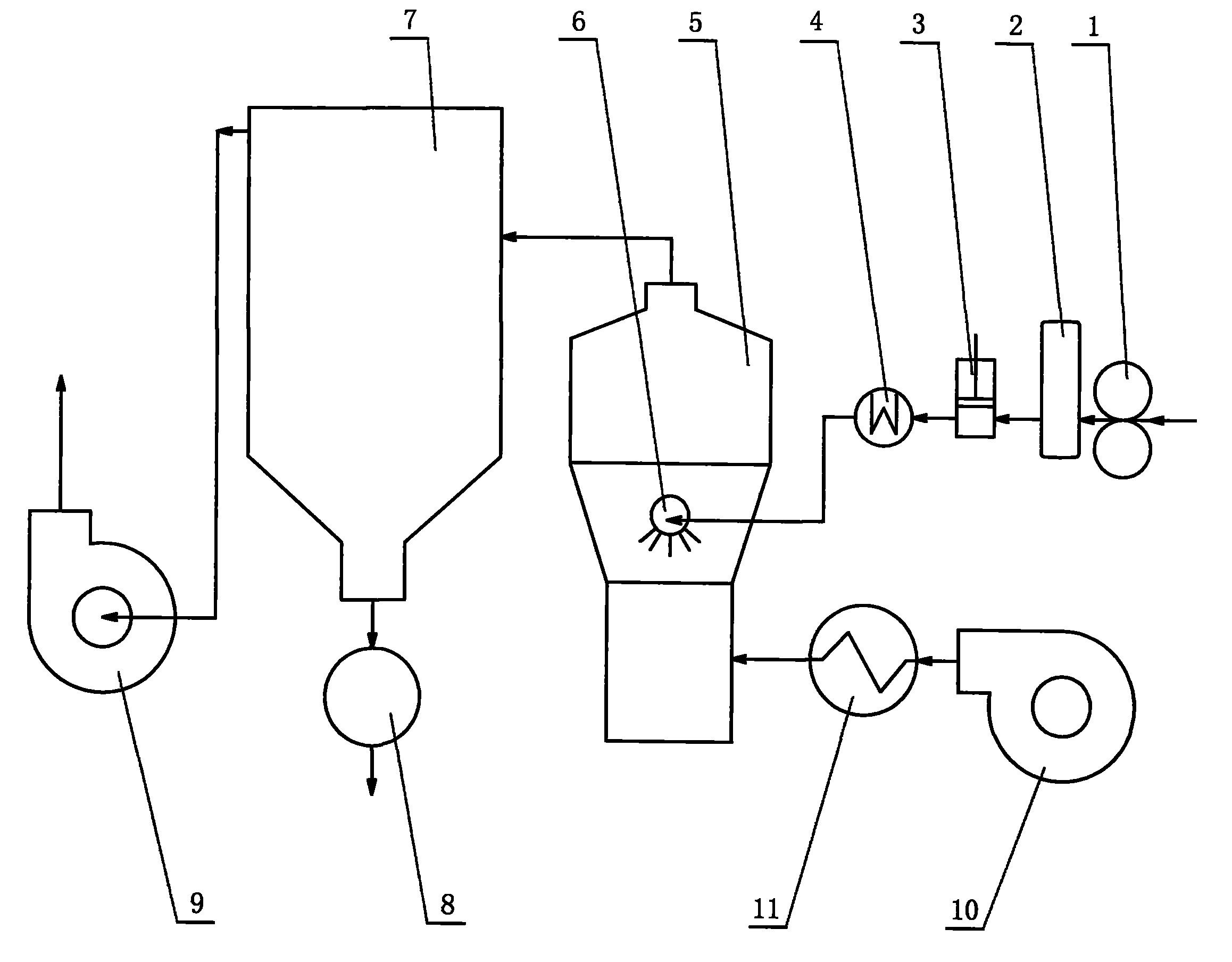

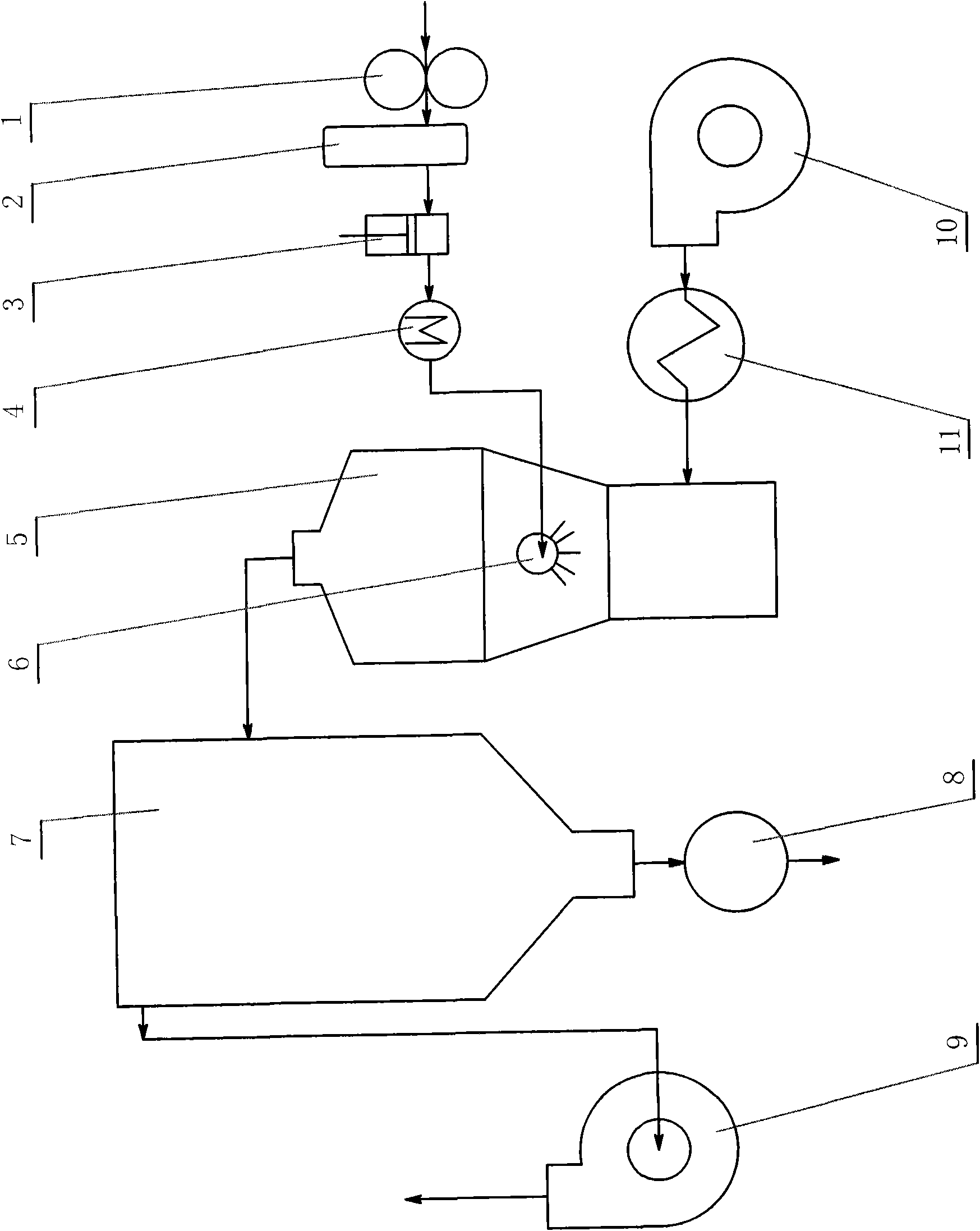

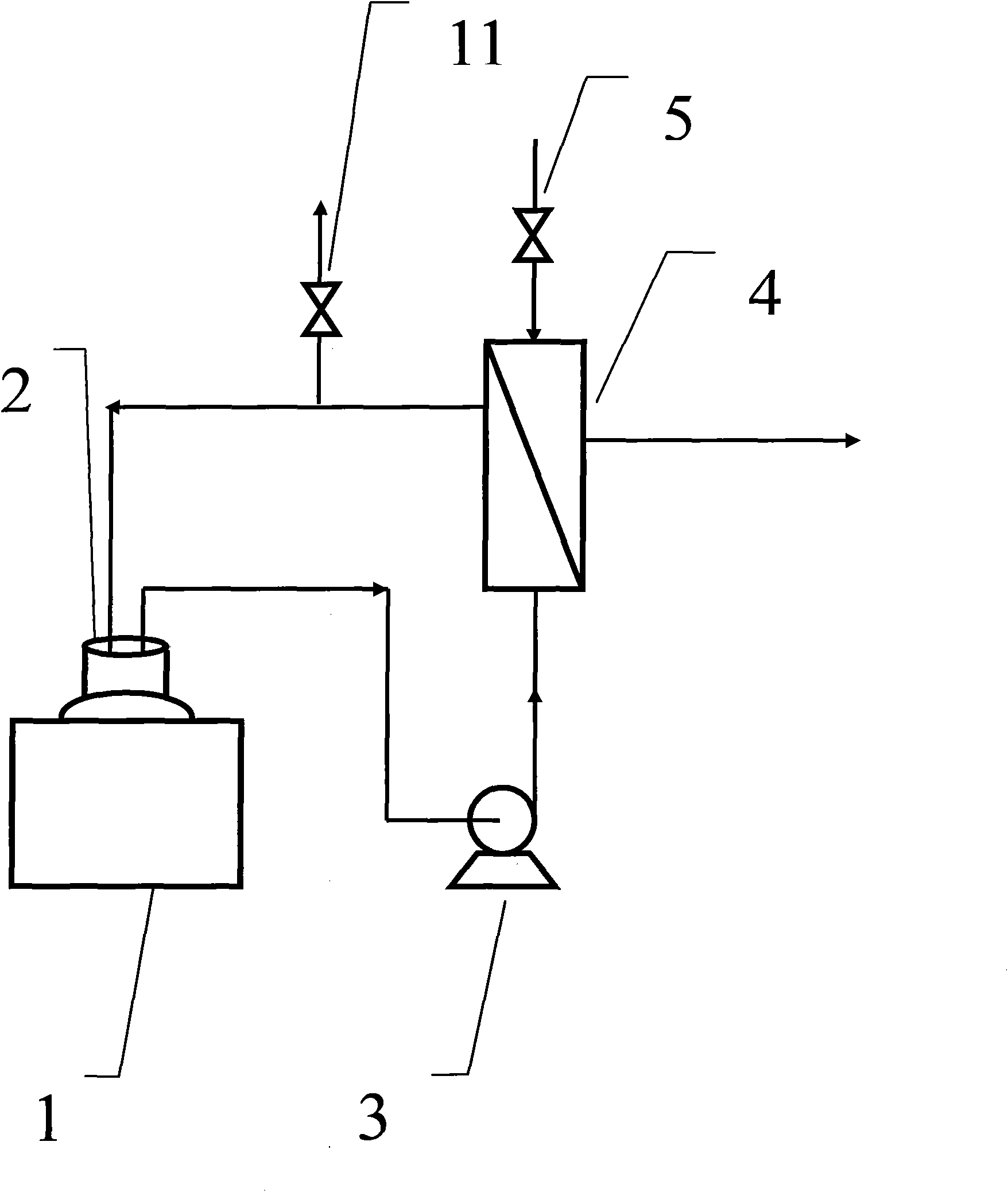

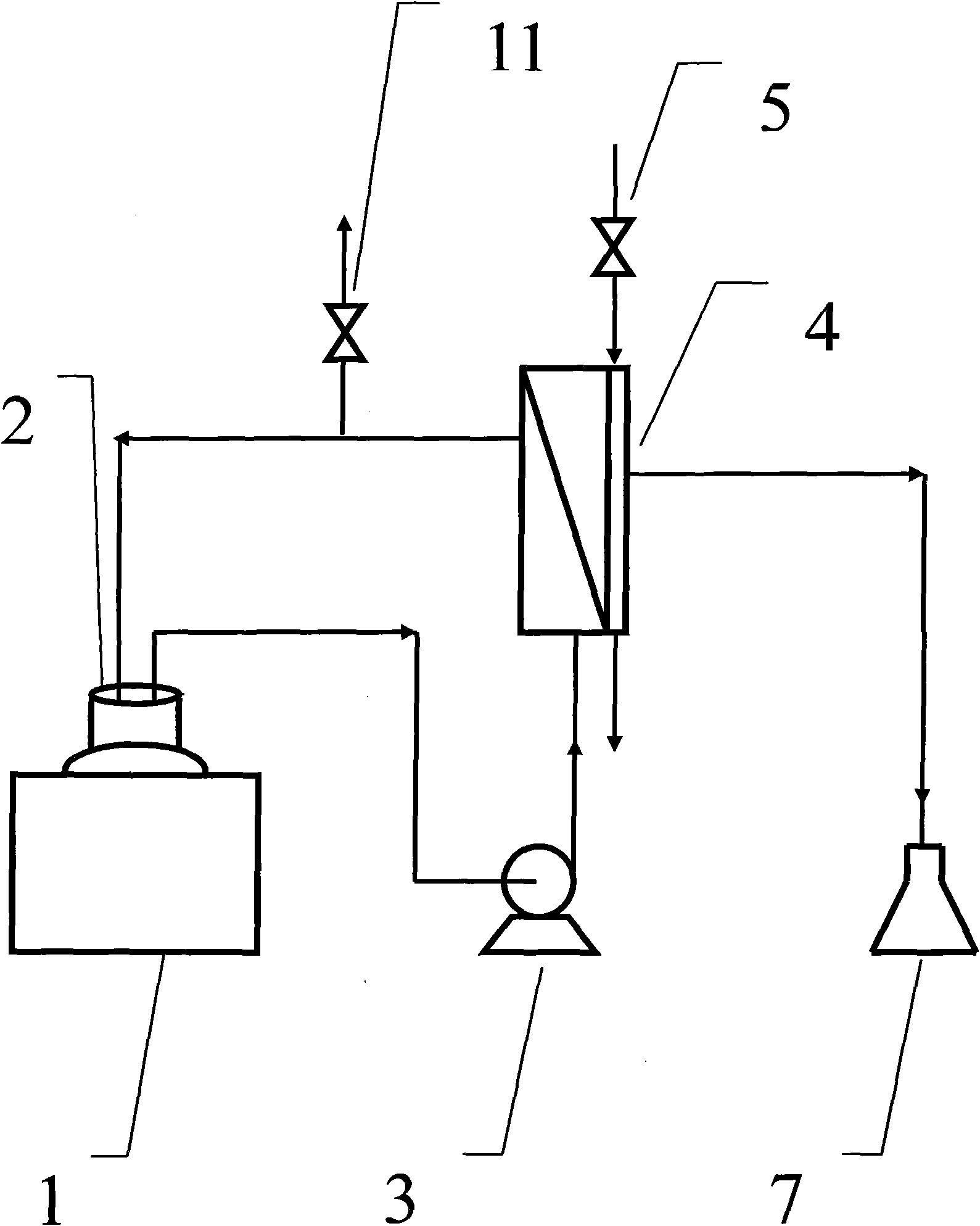

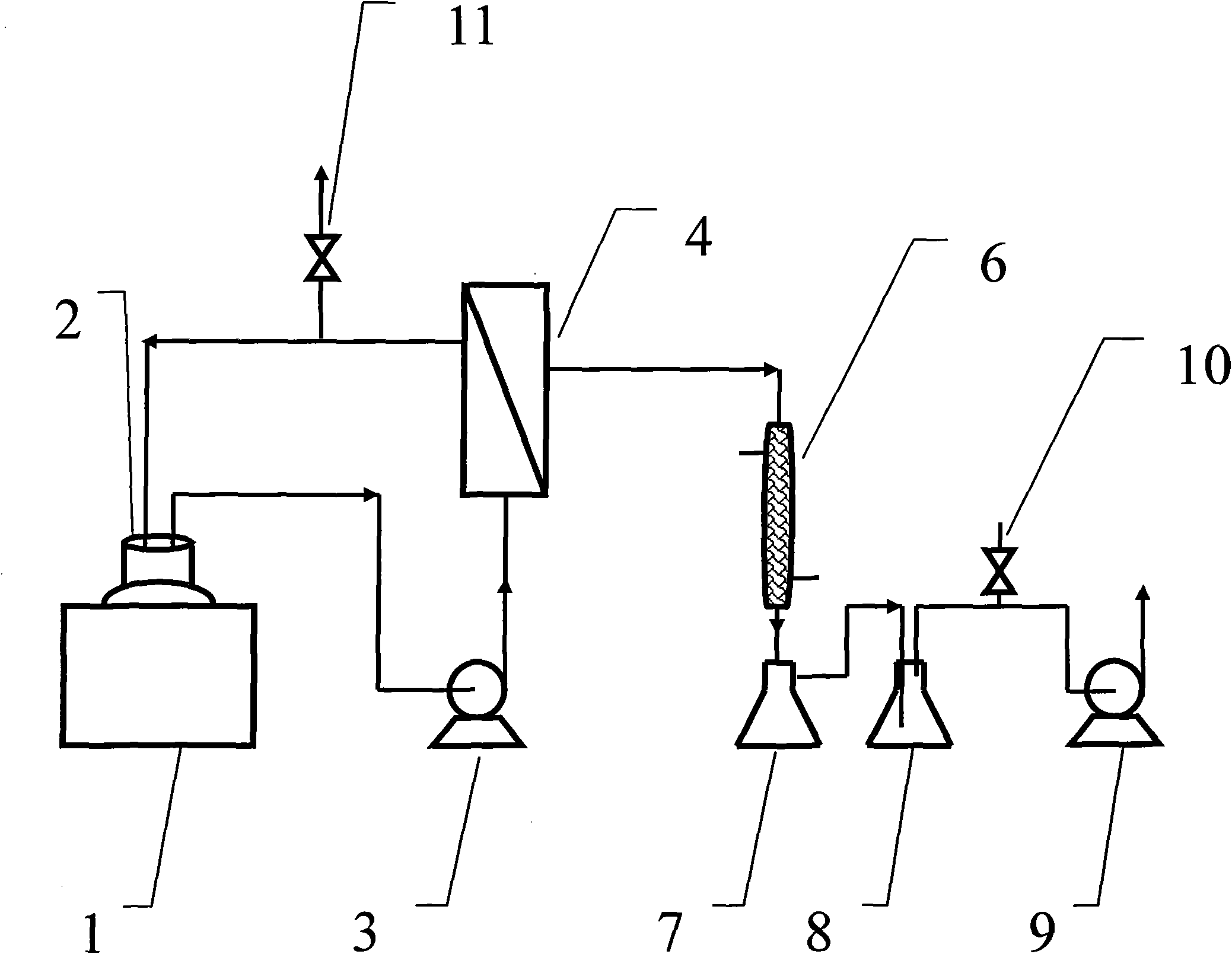

Method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry

InactiveCN101811994AAvoid the difficulty of continuous and stable atomizationEfficient dryingOrganic compound preparationTransportation and packagingFluidized bed dryingSulfate

The invention provides a method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry with easy continuous processing and low cost. The method comprises the following steps of: inputting airflow at the temperature of between 70 and 180 DEG C into a fluidized bed dryer (5) to ensure that inert particles in the dryer are fluidized; preheating the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry to the temperature of between 50 and 150 DEG C, and inputting the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry into the fluidized bed dryer (5) in a pulsating flow mode; allowing the slurry to pass through a mesh distribution screen (6); rupturing the slurry into short columns; ,making the slurry fall into a fluidized bed layer of the dryer; fluidizing the slurry and the inertia particles, and drying the fluidized slurry and the inertia particles to obtain the material; separating the dried material from surfaces of the inert particles to form fine powder; discharging the fine powder from the top of the fluidized bed dryer along with air flow, and allowing the fine powder to enter a bag separator (7); and exhausting tail gas from the top of the bag separator, and outputting the product of fine powder from the lower part of the bag separator. The method is suitable for drying a surface active agent.

Owner:SINOLIGHT CHEM

Method for preparing boron carbide coating through plasma spraying

ActiveCN103194714AReduce or even prevent churnAvoid churnMolten spray coatingDecompositionBoron carbide

The invention provides a method for preparing a boron carbide coating through plasma spraying. The method comprises the steps that: step (1), boron carbide powder and carbon powder are uniformly mixed; and the mixed powder is delivered into a plasma spraying device; step (2) the surface of a substrate requiring spraying is pretreated; step (3) plasma spraying is carried out on the surface of the substrate by using the plasma spraying device, such that the boron carbide coating is prepared. According to the invention, the coating is prepared through a carbon-doped B4C powder plasma spraying method. When jet flow is ejected, graphite powder take the priority to react with oxygen, such that B4C oxidation is avoided; with the addition of carbon, B4C high-temperature decomposition is inhibited, such that B4C loss under high temperature can be reduced or even prevented, and B4C coating with good performance can be obtained; with carbon doping, no impurity element is introduced into the coating, such that coating quality is ensured; also, with the addition of graphite powder, powder fluidity is increased, and spraying is facilitated.

Owner:SOI MICRO CO LTD

Ternary high-nickel electrolyte and high-nickel anode lithium ion battery containing same

InactiveCN109687010AReduced low temperature performanceGood low temperature performance, lowCell electrodesSecondary cellsHigh temperature storageSlurry

The invention provides ternary high-nickel electrolyte and a high-nickel anode lithium ion battery containing the electrolyte. The ternary high-nickel electrolyte is characterized by comprising, by weight, 13-15% of lithium salt, 80-85% of a non-aqueous organic solvent and 0.1-5% of an additive; wherein the additive comprises vinylene sulfate, vinylene carbonate, succinonitrile, tris (trimethyl silicon-based) phosphorus, lithium bifluroflavin imide and lithium dioxalate borate; the lithium salt is lithium hexafluorophosphate; the non-aqueous organic solvent comprises a cyclic carbonate compound, dimethyl carbonate and ethoxy pentafluoro tripolyphosphate; the high-nickel anode lithium ion battery containing the ternary high-nickel electrolyte adopts anode slurry prepared from high-nickel ternary anode powder, a conductive agent, a functional composite binder, a solvent N-methyl pyrrolidone to prepare the anode membrane, the high-nickel anode lithium ion battery has excellent normal-temperature cycle performance, high-temperature cycle performance and high-temperature storage service life, and can obviously reduce the gas yield in the high-temperature storage process.

Owner:湖北诺邦科技股份有限公司

Thermal-insulation extra-high voltage flame-retardant coating and preparation method thereof

ActiveCN105331207AImprove performanceLow heat resistanceFireproof paintsAnti-corrosive paintsThermal insulationPlasticizer

The invention provides a thermal-insulation extra-high voltage flame-retardant coating and a preparation method thereof. The coating comprises, in parts by weight, 50-65 parts of resin, 10-20 parts of borax, 5-8 parts of boric acid, 0.5-3.5 parts of natural camphor, 0.1-0.5 parts of a coupling agent, 12-18 parts of nanofiller, 30-40 parts of a solvent, 1-3 parts of a plasticizer, 1-3 parts of an anti-settling agent, 2-4 parts of a dispersing agent and 0.2-0.4 parts of a defoaming agent. The thermal-insulation extra-high voltage flame-retardant coating has the good flame retardance, the high mechanical properties and the good electrical insulating property, the preparation technology is simple, and raw materials are easy to obtain.

Owner:STATE GRID CORP OF CHINA +1

Processing technology for camellia oil

InactiveCN109593598AImprove shelling ratePure tasteFatty-oils/fats refiningFatty-oils/fats productionBranFood processing

The invention provides a processing technology for camellia oil and relates to the technical field of food processing. By taking camellia seeds, the oil content of which is 28-30%, as a raw material,the processing technology comprises the following steps: drying the camellia seeds and quick-freezing the camellia seeds; shelling the quick-frozen camellia seeds to obtain camellia seed kernels; mixing the micro-roasted camellia seed kernels with fresh bran coats uniformly, and carrying out low-temperature squeezing to obtain squeezed oil; and carrying out centrifugal filtration and distillationto obtain the camellia oil. The processing technology for camellia oil prevents generation of B(a)P in the processing course, is high in oil yield, and keeps the inherent smells and taste of the camellia oil. The camellia oil is pure in taste and natural nutritional components are kept intactly.

Owner:湖南泥头山油茶开发有限公司

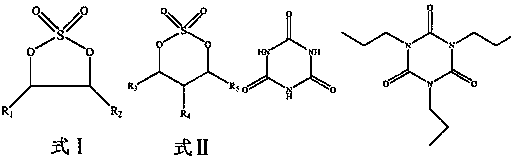

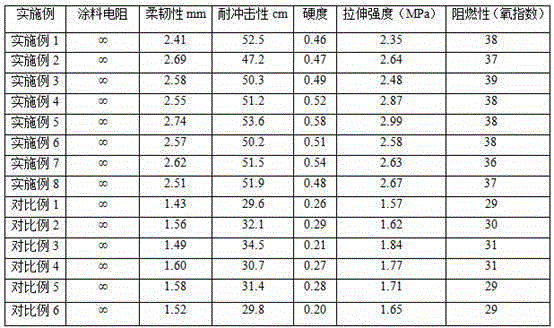

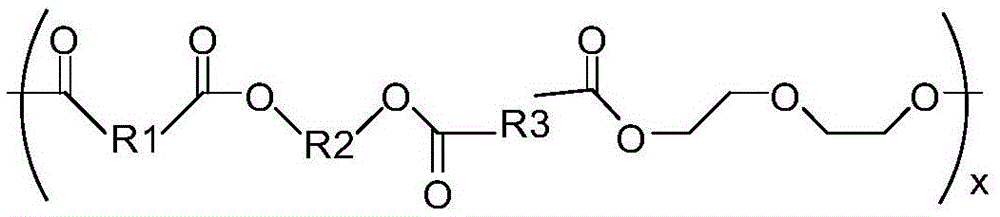

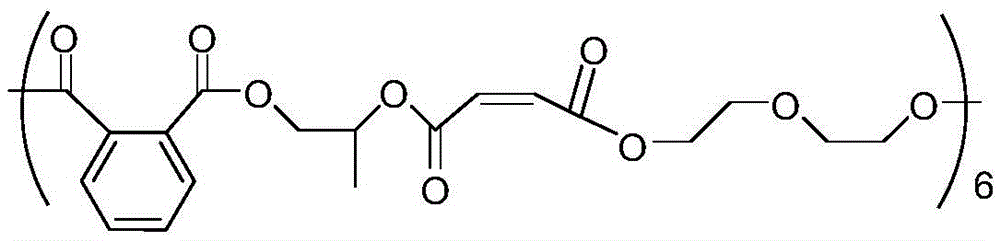

Diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin and preparation method thereof

ActiveCN105418904AImprove flame retardant performanceBarrier releaseDiethylene glycolUltimate tensile strength

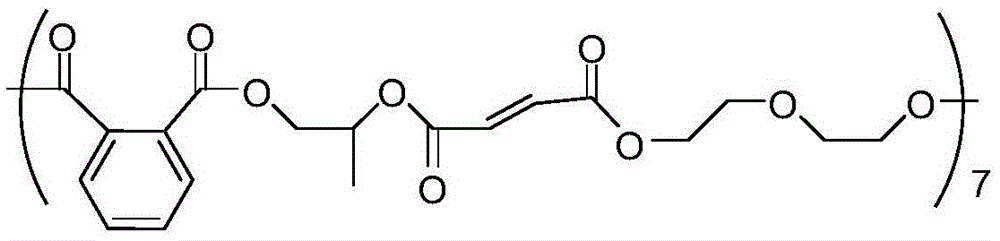

The invention discloses diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin and a preparation method thereof. The oxygen index measured value LOI of the diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin is increased to 26% from 20% compared with that of unsaturated polyester resin without a diethylene glycol component. The impact strength, bending strength and bending strength are all improved by 50% or above, wherein the impact strength can be improved by ten times. Diethylene glycol is used as a comonomer and well applied for improving the flame-retardant performance of the diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin. The structural general formula of a prepolymer of the diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin is shown as below (please see the specifications), wherein x is between 6 and 12, R1 is phenyl, R2 is alkyl and R3 is unsaturated alkyl.

Owner:南京新化原容和新材料有限公司

Sectional type non-combustion cigarette with self-heating material

The invention discloses a sectional type non-combustion cigarette with a self-heating material. The sectional type non-combustion cigarette with the self-heating material comprises a suction nozzle and a tobacco section, wherein the suction nozzle and the tobacco section are connected through rolling and connecting paper; the tobacco section is composed of the self-heating material, tobacco shreds and cigarette paper; the self-heating material is a cylinder the same as the tobacco shreds in diameter; the self-heating material is arranged at the front end of the tobacco shreds; the length of the self-heating material is 0.5- 2 times that of the tobacco shreds; airtight sealing layers are arranged outside the suction nozzle and the tobacco section. The sectional type non-combustion cigarette avoids high-temperature cracking of tobacco combustion, so that the release amount of harmful ingredients in main stream smoke is greatly reduced. Meanwhile, as the tobacco shreds are not combusted, the environment smoke is greatly reduced, the atomization and smoking effects of the tobacco shreds are good at a low temperature state, and satisfaction of customers is high.

Owner:HUBEI CHINA TOBACCO IND +1

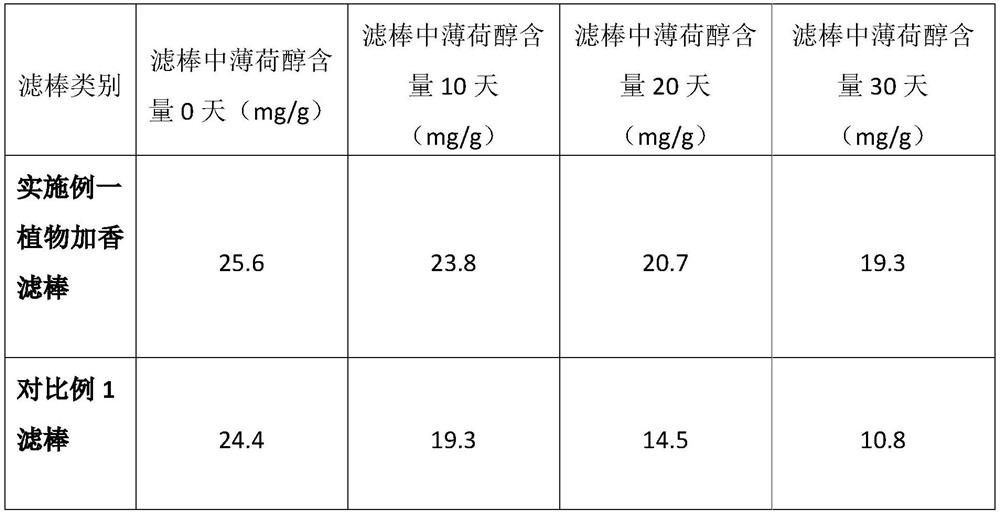

Tobacco product, plant perfumed filter stick thereof, and manufacturing method of filter stick

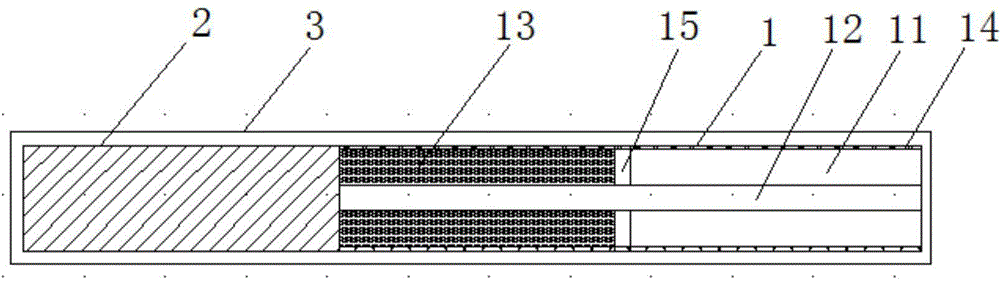

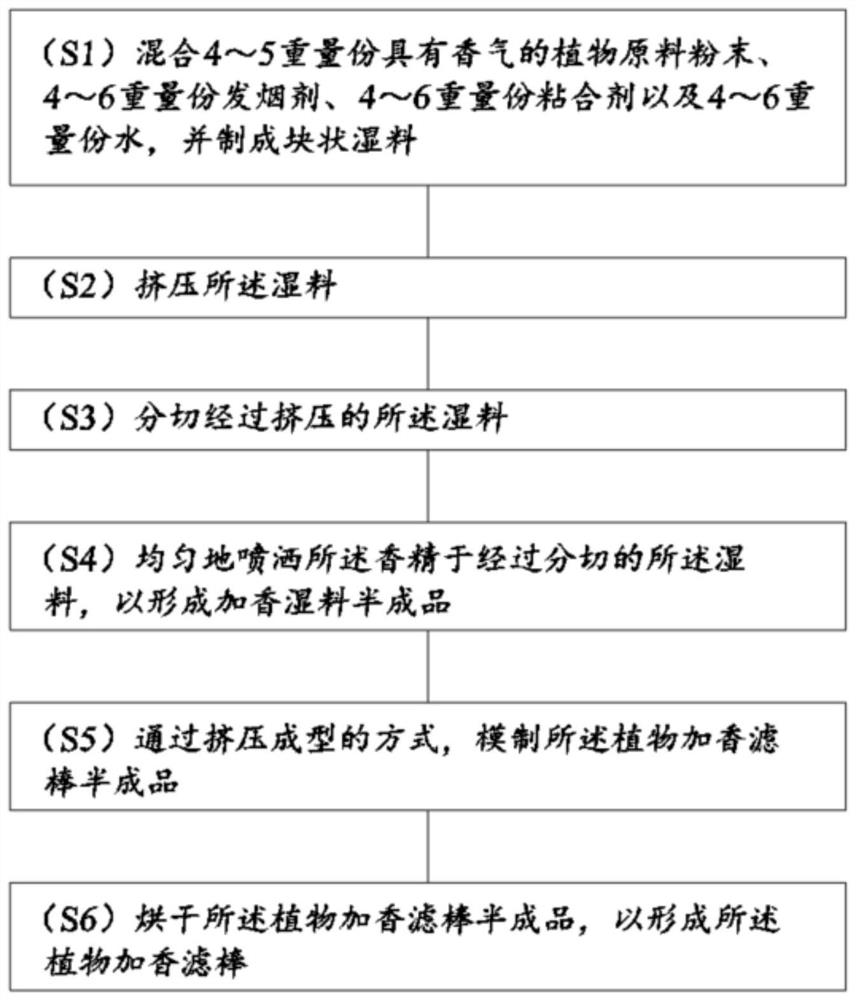

PendingCN112293790AFlavoring achievedAvoid lossCigar manufactureTobacco smoke filtersBiotechnologyNicotiana tabacum

The invention discloses a tobacco product, a plant perfumed filter stick thereof, and a manufacturing method of the plant perfumed filter stick. The plant perfumed filter stick is implemented to be provided with air holes penetrating through the two ends of a filter tip section, and the plant perfumed filter stick comprises, by weight, 4-5 parts of plant raw material powder with fragrance, 4-6 parts of a smoke agent, 4-6 parts of an adhesive, and 4-6 parts of water. The plant perfumed filter stick can achieve perfuming of tobacco products, and the plant perfumed filter stick achieves perfumingof the tobacco products through natural fragrance of the filter stick and fragrance emitted by the perfuming substance added to the filter stick. In addition, the plant perfumed filter stick can avoid loss and pyrolysis of aroma enhancement substances in the tobacco product storage and smoking process.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH +1

Method for extracting triterpenes from schisandra chinansis

ActiveCN101708215ANo pollution in the processAvoid pyrolysisAntiviralsImmunological disordersPollutionHigh heat

The invention relates to a method for extracting triterpenes from schisandra chinensis. The method comprises the steps of taking stems of the schisandra chinensis as main raw materials, firstly carrying out tissue breaking and cellulase and ultrasonic extraction for separating substances to be extracted from the raw materials, and then separating and extracting the triterpenes from the schisandra chinensis by utilizing the supercritical fluid extraction technology, selecting different composite entrainers and operation technological parameters and combining the high-speed countercurrent chromatography technology, thereby providing the effective method for separating and purifying the triterpenes from the schisandra chinensis. The method for extracting the triterpenes from the schisandra chinensis has the advantages of high extraction rate, simple operation process, low energy consumption, no pollution and high recovery rate, and can avoid the thermal pyrolysis of extracts at high temperature, protect the activity of physiological active substances and the like.

Owner:SANMARK CORP

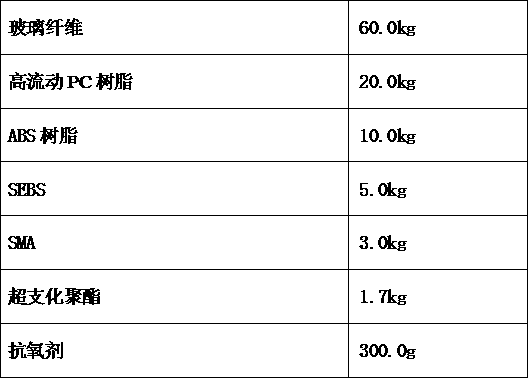

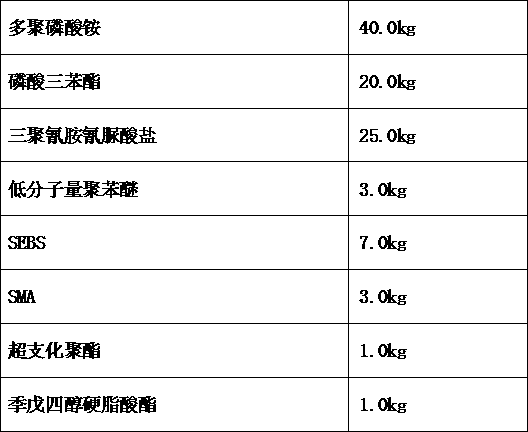

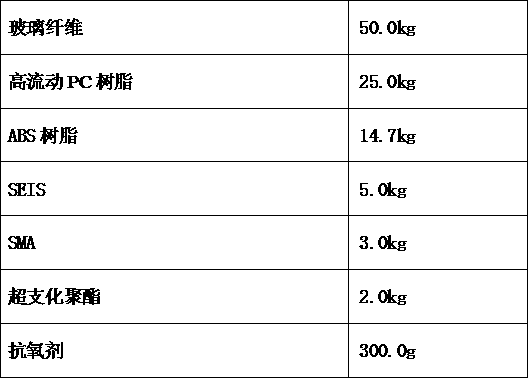

Efficient enhanced flame-retardant functional master batch for direct injection molding of PC-ABS alloy and preparation method of functional master batch

InactiveCN109517356ASolve the technical problem of mismatching processing temperatureGood dispersionElastomerGlass fiber

The invention belongs to the technical fields of modification and processing of plastics and particularly relates to an efficient enhanced flame-retardant functional master batch for direct injectionmolding of PC-ABS alloy and a preparation method of functional master batch. The functional master batch is formed by combing a master batch A with a master batch B, wherein the master batch A contains the following components in percentage by mass: 50.0wt%-60.0wt% of glass fibers, 20.0wt%-25.0wt% of high-flow PC resin, 10.0wt%-15.0wt% of ABS resin, 5.0wt%-10.0wt% of a thermoplastic styrene elastomer, 2.0wt%-3.0wt% of a styrene-maleic anhydride random copolymer, 1.0wt%-2.0wt% of hyperbranched polyester and 0.1wt%-0.3wt% of an antioxidant. Compared with a traditional plastic functional master batch, the functional master batch prepared by virtue of the preparation method has the advantages that, the problem that the modification effects are mutually damaged due to the mutual cutting wear between the glass fibers and a flame retardant in the machining process of an enhanced bromine-series flame-retardant PC / ABS alloy modified system is solved, and meanwhile, the problem that the machining temperatures of two modified systems are not matched is solved; and compared with a traditional enhanced bromine-series flame-retardant system, the modification effects of the two systems are remarkably improved.

Owner:江苏万纳普新材料科技有限公司

Compact low expansion cordierite honeycomb ceramics heat accumulator

The invention discloses a compact low expansion cordierite honeycomb ceramics heat accumulator, which is composed of 50-60% of cordierite powder, 0-10% of synthesized mullite powder, 5-25% of clay, 10-20% of feldspar powder and 5-15% of spodumene powder. The cordierite honeycomb ceramics heat accumulator has the advantages of small expansion coefficient and good thermal shock resistance performance, can increase the density, corrosion resistance, heat conduction coefficient and compression strength of the cordierite honeycomb ceramics heat accumulator, and has good comprehensive performance. The cordierite honeycomb ceramics heat accumulator can be widely used for a petroleum chemical process and various industries using an organic solvent, such as exhaust gas discharge processing devices-a regenerative thermal oxidizer in the industries of spraying, metal oil removing and degreasing, cementing agent, pharmacy, plastic, rubber processing and the like.

Owner:舒剑风 +1

Membrane distillation concentration method for hydrogen peroxide solution

InactiveCN101966981AMild operating conditionsAvoid pyrolysisPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOperating temperatureDecomposition

The invention discloses a membrane distillation concentration method for hydrogen peroxide solution, and belongs to the technical field of concentration of the hydrogen peroxide solution. The method is characterized in that a hydrophobic microporous membrane which is not soaked by the hydrogen peroxide solution is adopted, wherein a membrane distillation concentration device is selected for concentrating the hydrogen peroxide solution; the raw material side is the hydrogen peroxide solution which is heated at a constant temperature; the penetration side is in any form of cold fluid, air gap cooling plate, vacuum and carrier gas blowing; water in the aqueous solution of the hydrogen peroxide on the raw material side penetrates through membrane holes to the penetration side in the form of steam under the action of steam pressure difference on the two sides of the membrane; and water vapor on the penetration side is removed by condensation of the cold fluid, cooling of the air gap cooling plate, vacuuming or carrier gas blowing, so that the concentration of the hydrogen peroxide solution is realized. The method has the following advantages that: the operating conditions are mild by using the membrane distillation concentration method; the operating temperature is lower, so the decomposition of the hydrogen peroxide caused by high operating temperature is prevented; and the process has low energy consumption and simple flow, is easy to operate and saves the energy.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com